Sony XCL-CG510, XCL-CG510C Technical Manual

Digital Video

Camera Module

C-629-100-11 (1)

Technical Manual

XCL-CG510/CG510C

© 2017 Sony Corporation

Table of Contents

Overview

Features....................................................................3

Phenomena Specific to Image Sensors ..................4

System Components................................................5

Connection...............................................................6

Location and Function of Parts and Operation ...7

Front/Top/Bottom ................................................7

Using a tripod ......................................................7

Rear......................................................................8

Connecting the cables..........................................9

Controlling the camera from the host device.......9

When mounting the camera...............................10

Connections

Communication Setting .......................................11

Camera link output settings ................................12

Data Order.............................................................13

1tap ....................................................................13

2tap ....................................................................13

3tap ....................................................................14

Port assignment..................................................14

Color pixel array................................................14

Trigger Signal Input .............................................15

Trigger signal polarity .......................................15

GPIO Connector ...................................................16

Functions

Partial Scan ..........................................................17

Binning...................................................................18

Output Bit Length.................................................18

Image flip ..............................................................18

Gain .......................................................................18

Manual gain .......................................................18

Auto gain (AGC) ...............................................18

Area gain............................................................19

Shutter (Exposure)................................................19

Configuring the setting ......................................19

Auto exposure (AE)...........................................19

Combination of Continuous AGC and Continuous

AE...........................................................................19

Trigger Control .....................................................20

Free run/trigger mode ........................................20

Special trigger....................................................21

Burst trigger.......................................................22

Trigger source....................................................23

Trigger inhibition ...............................................24

Trigger delay......................................................24

Trigger counter ..................................................24

Frame counter ....................................................24

Trigger range limit .............................................25

Image sensor Fast trigger mode .........................25

Frame Rate ........................................................... 25

Auto frame rate .................................................25

Specifying frame rate ........................................ 26

Displaying frame rate........................................ 26

Fastest frame rate for partial scanning .............. 26

White Balance....................................................... 27

LUT........................................................................ 27

Binarization....................................................... 27

5-point interpolation.......................................... 27

Arbitrary setting ................................................ 27

3 × 3 filter .............................................................. 28

Test Chart Output ................................................ 28

GPIO...................................................................... 29

GPI .................................................................... 29

GPO................................................................... 29

Sensor Readout (Sensor Output)....................... 31

Pulse Train Generator ......................................... 31

Status LED ........................................................... 31

Temperature Readout Function.......................... 32

Defect Correction ................................................. 32

Shading Correction ..............................................33

User Set.................................................................. 35

User set name .................................................... 35

User set memory ............................................... 35

Free Memory......................................................... 35

User ID................................................................... 35

Saving and Startup............................................... 35

Initializing .............................................................36

Camera Information ............................................ 36

Help Command..................................................... 36

Echo off.................................................................. 36

Restart ................................................................... 36

Error information acquisition ............................. 36

Camera Control Commands

Command Form ................................................... 37

Command Input and Response........................... 37

Command List ...................................................... 38

Specifications

Specifications ........................................................ 43

Timing Chart ........................................................ 44

Horizontal timing .............................................. 44

Vertical timing...................................................44

Trigger latency/Exporure time .......................... 45

Spectral Sensitivity Characteristics (Typical

Values) ................................................................... 46

Dimensions ............................................................ 47

2

Overview

This unit is a digital video camera module that achieves

image output with LVDS signal via DIGITAL Interface

connector.

This operating instructions of digital video camera

module covered:

• XCL-CG510 (monochrome models)

• XCL-CG510C (color models)

Body fixing

The screw holes to install the camera module are located

under the front panel (the image sensor reference plane).

Installing the camera module on the front panel

minimizes deviation of the optical axis.

LUT (Look Up Table)

You can switch to OFF or ON. When set to ON, you can

select from five preset values, such as inversion,

binarization, any of five-point approximation, etc.

In this document, we refer to “Digital Video Camera

Module” as “the unit”, “XCL-CG510” as “Monochrome

camera”, and “XCL-CG510C” as “Color camera”.

Features

DIGITAL Interface connector

Equipped with a Camera Link standard mini connector.

The unit can output a detailed and high speed digital

image.

High image quality

2/3 type 5.07 Megapixel CMOS image sensors with a

global shutter function (Monochrome/Color)

Various settings

Sending a command from the host device allows various

settings, including the following.

•Gain

•Shutter

• Partial scan

• Trigger control

• LUT (Look Up Table)

• Output: 8/10/12-bit

• Defect correction

• Shading correction

Switching an Output Bit Length

You can select 8-bit output, 10-bit output or 12-bit

output.

Binning (XCL-CG510 only)

Sensitivity can be doubled approximately by combining

two pixels aligned vertically or horizontally. You can set

horizontal and vertical binning at the same time.

Defect correction

The unit includes a function to reduce sensor defects,

and can be set to ON or OFF.

Shading correction

The unit includes a function to correct shading, resulting

from a light source or a particular lens, and can be set to

ON or OFF.

Area gain function

You can set the individual digital gain to 16 optional

rectangular areas. In the case that multiple rectangular

areas overlap, the gain value with the smaller area

number will have priority.

Electronic shutter function

Set anywhere from 1/100,000 sec to 60 sec in 1 µs

increments.

External trigger shutter function

By synchronizing with an external trigger signal, any

shutter timing can be used.

Partial scan

The camera module can limit the number of video

output lines to achieve high frame rates, enabling highspeed image processing.

3

Phenomena Specific to Image Sensors

Note

The following phenomena that may occur in images are

specific to image sensors.

They do not indicate a malfunction.

White flecks

Although the image sensors are produced with highprecision technologies, fine white flecks may be

generated on the screen in rare cases, caused by cosmic

rays, etc.

This is related to the principle of image sensors and is

not a malfunction.

The white flecks especially tend to be seen in the

following cases:

• when operating at a high environmental temperature

• when you have raised the gain (sensitivity)

• when using the slow shutter

Aliasing

When fine patterns, stripes, or lines are shot, they may

appear jagged or flicker.

4

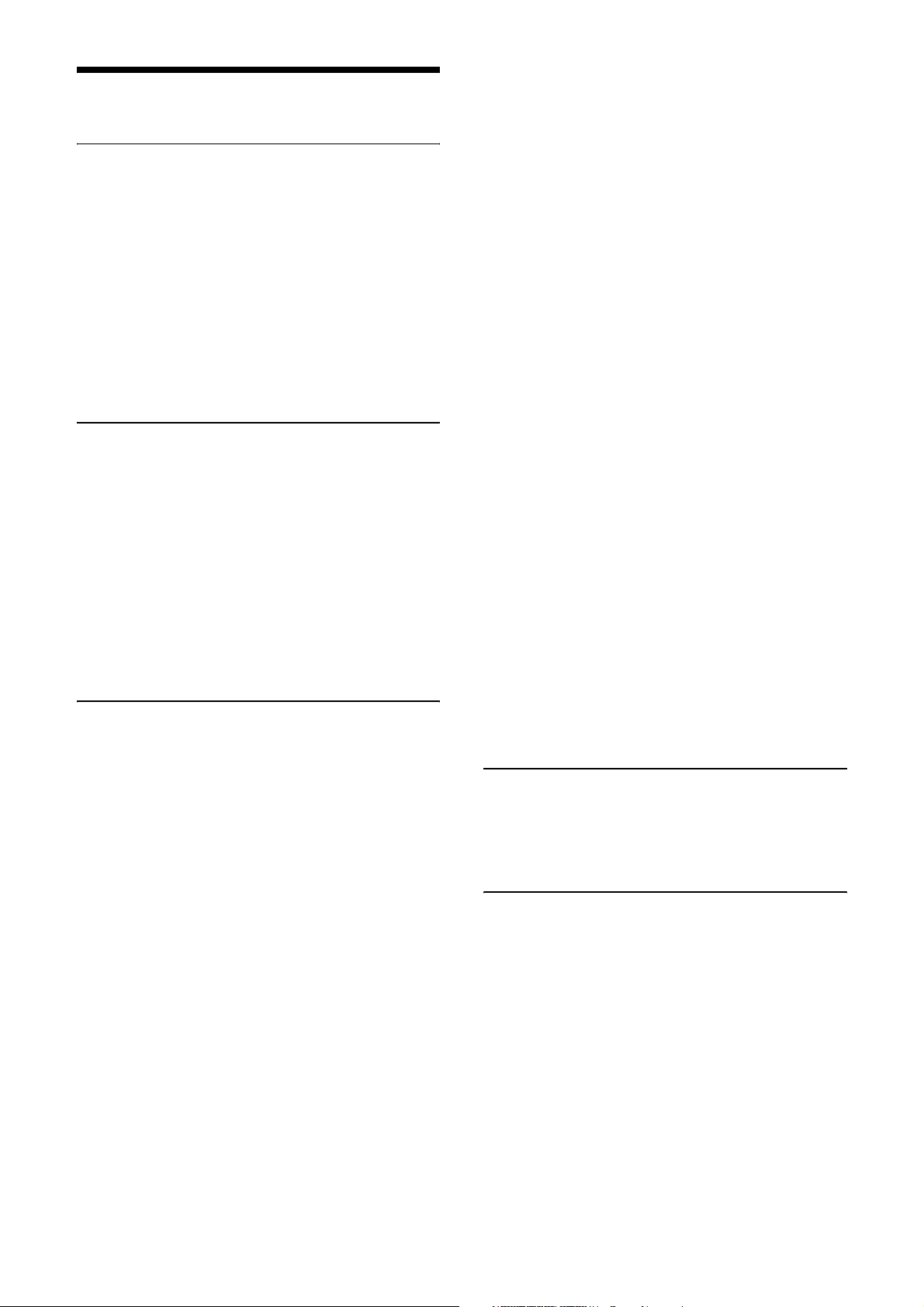

System Components

Video Camera Module Camera cable

Camera module interface

board

Camera Link cable

(Sony Camera-compatible)

CCXC-12P02N (2 m, 6.6 ft)

CCXC-12P05N (5 m, 16.4 ft)

CCXC-12P10N (10 m, 32.8 ft)

CCXC-12P25N (25 m, 82 ft)

Install the board in a PCI/PCI-Express slot in devices such as a computer. Select a

commercially available interface board compatible with the Camera Link feature. You can use

either a board that supports PoCL, or one that does not.

Due to the performance of the board, the frame rate may become low according to lack of

processing capacity. To have this product output frames at the highest speed, use a board

corresponding to PCI-Express.

Performance may also be dependent on the host device (e.g., Computer), so consult the

dealer if images are not displayed properly.

This cable connects to the DIGITAL Interface connector on the rear panel of the camera

module. Image/control signals are transmitted via this cable.

If there is support for PoCL, power is also supplied at the same time.

If you use a camera module interface board with support for PoCL, be sure to use a camera

link cable with support for PoCL.

Spotted noise may appear in a specific brightness in the window according to the attribute of

the cable. If this noise is an obstacle, use a shorter cable.

C-mount lens

Use a lens appropriate

for the pixel count of

the camera.

Camera adaptor

DC-700/700CE

Tripod adaptor

VCT-333I (Insulated type)

5

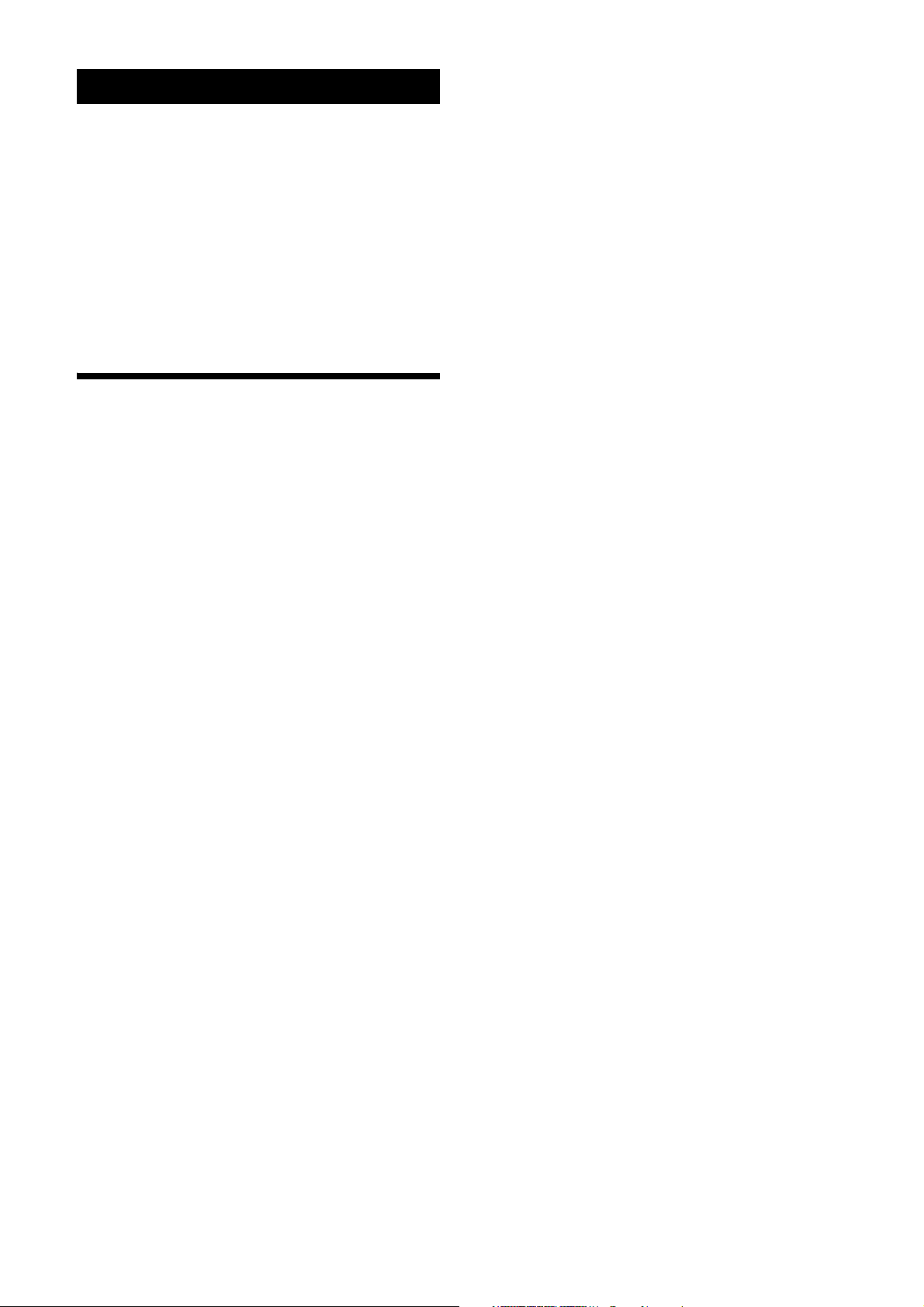

Connection

Camera Link cable

Camera module

C-mount lens

Camera cable

CCXC-12P02N

Tripod adaptor

VCT-333I

Power supply

You can supply power to the camera module using the following methods.

Using the DIGITAL Interface connector

This unit supports the PoCL (Power over Camera Link) standard. By connecting a PoCL-compatible camera link cable to a PoCLcompatible camera module interface board, you can power, control, and output images from the camera using a single cable.

Heat dissipation is required depending on the usage environment.

CCXC-12P05N

CCXC-12P10N

CCXC-12P25N

* If the camera module interface board for the camera supports PoCL, the

camera can be operated even if the items within the dashed line are not

connected.

Camera module interface board

Camera adaptor

DC-700/700CE

AC

TRIG

Internal signal

output

Using the DC power input connector

You can supply power via the DC power input connector using the power adapter.

Use DC-700/700CE which is the stable power source free from ripple or noise.

Heat dissipation

For heat dissipation, refer to When mounting the camera (see page 10).

6

Location and Function of Parts and Operation

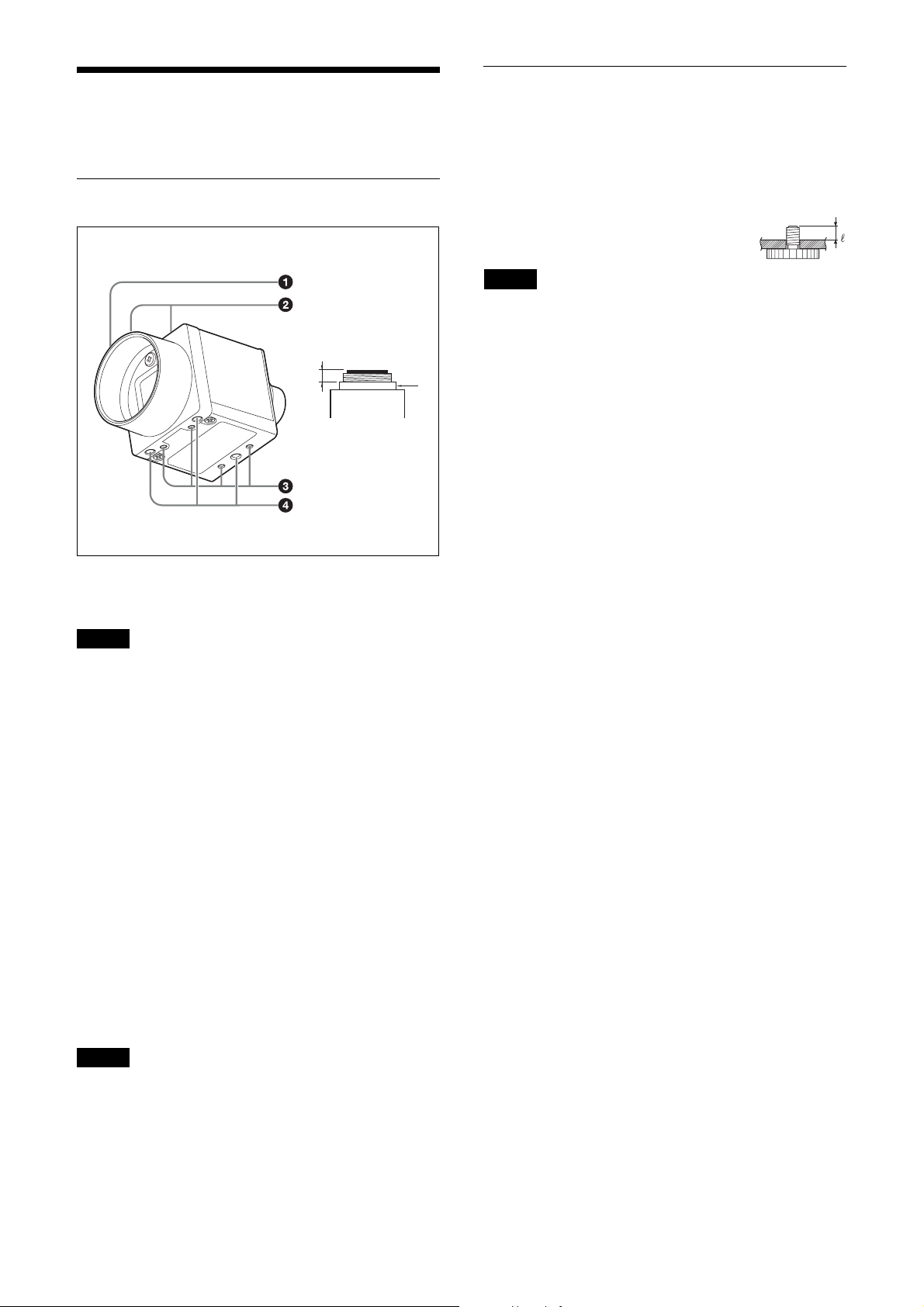

Front/Top/Bottom

Using a tripod

To use the tripod, install the tripod adaptor VCT-333I

(not supplied) on the camera module.

Use a tripod screw with a protrusion (4) extending from

the installation surface, as follows, and tighten it, using

a screwdriver. Be sure that the protrusion (4) does not

exceed 5.5 mm in length.

Length 4.5 to 5.5 mm

Note

If you install a tripod adapter (not supplied), use the

screws provided.

a

a Lens mount (C-mount)

Attach any C-mount lens or other optical equipment.

Note

Use a C-mount lens with a protrusion (a) extending from

the lens mount face (b) of 10 mm or less.

When you use the camera with the lens attached, the

resolution of the image output from the camera may

differ according to the performance of the lens. Note it

when you select a lens.

The performance of a lens may change according to the

aperture level.

If the resolution is not enough, adjust the aperture level.

b

b Guide screw holes (Top)

c Guide screw holes / Tripod screw holes (Bottom)

When using a tripod, use these four screw holes to attach

a VCT-333I tripod adaptor.

d Reference screw holes (Bottom)

These precision screw holes are for locking the camera

module. Locking the camera module into these holes

secures the optical axis alignment.

Note

Refer to the outer dimensions on page 47 about the

guide hole and the position and size of standard hole.

7

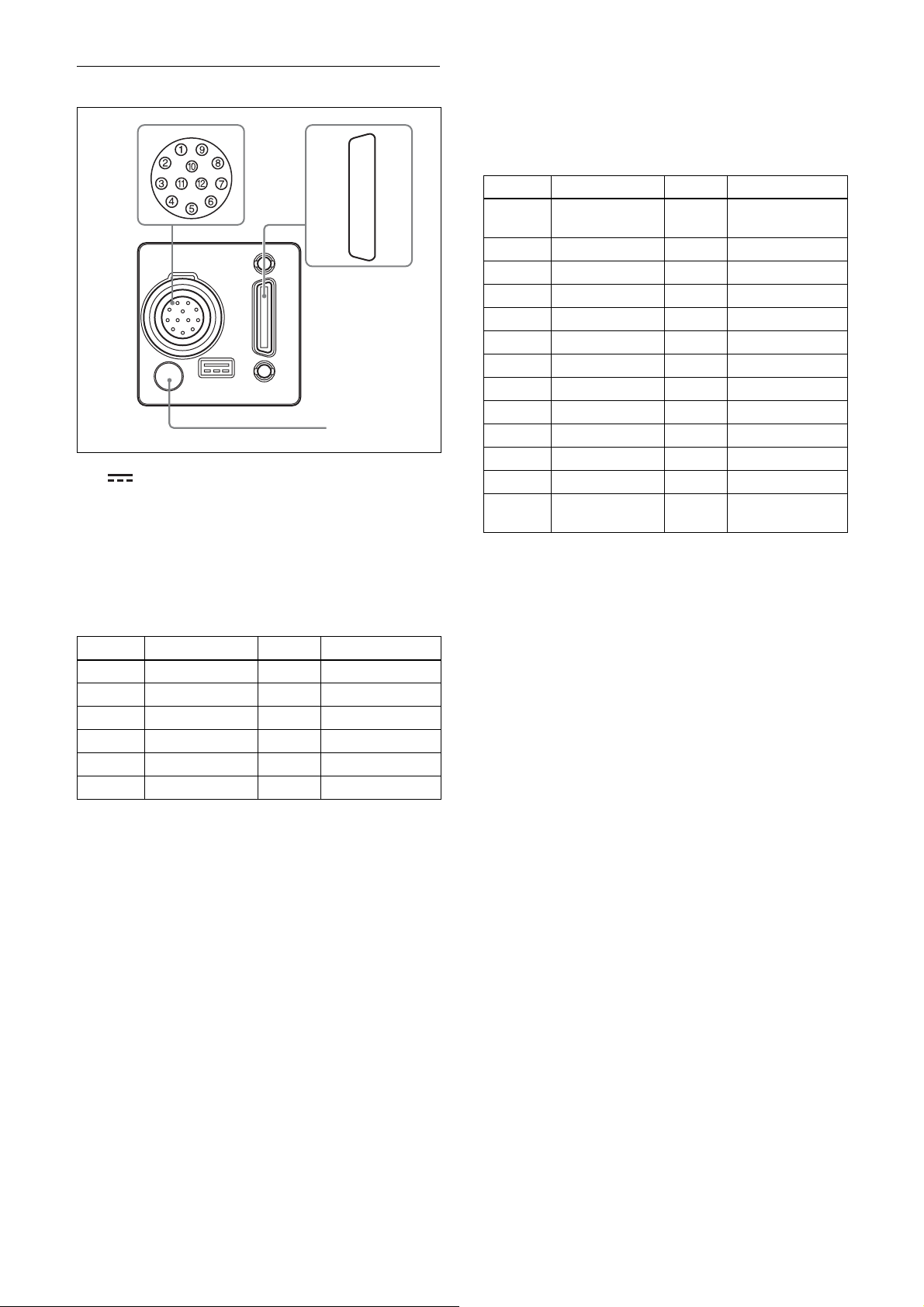

Rear

5

e (DC power input) connector (12-pin)

You can connect a camera cable CCXC-12P05N etc. to

input the 12 V DC power supply. The pin configuration

of this connector is as follows. You can operate the

camera without using this connector when using a

PoCL-compatible camera module interface board.

For details on the pin arrangement, see the following

table.

Pin No. Signal Pin No. Signal

1 Ground 7 GPI3

2 DC 12 V 8 Ground

3 Ground 9 GPI3

4GPO1

5 Ground 11 GPI1

6GPO2

*1

*1

6

26 13

25 12

15 2

14 1

7

*2

*1

10 GPI2

12 Ground

*2

*2

Interface connector and operate a camera module in the

external trigger mode.

The following table shows the relation between the pin

numbers of the DIGITAL Interface connector and the

input/output signals and the like.

Pin No. Signal Pin No. Signal

1 Power supply or

14 Ground

Ground*

2 X0– 15 X0+

3 X1– 16 X1+

4 X2– 17 X2+

5XCLK– 18XCLK+

6 X3– 19 X3+

7 SerTC+ 20 SerTC–

8SerTFG– 21SerTFG+

9 CC1– 22 CC1+

10 CC2+ 23 CC2–

11 CC3– 24 CC3+

12 CC4+ 25 CC4–

13 Ground 26 Power supply or

Ground*

* About the 1st pin and 26th pin of the DIGITAL

Interface connector

The connection differs depending on the type of

camera module interface board you use.

In the case of PoCL support: Both the 1st pin and 26th

pin are Power supply

In the case of non-PoCL support: Both the 1st pin and

26th pin are Ground

g Status LED (Green)

Indicates the status of the Camera.

For details, refer to “Status LED” (page 31).

*1

Signal output from pin 4, 6, 9 (GPO1/2/3) of DC

power input connector

This setting allows you to select from exposure

signal, strobe control signal, Hi/Low fixed value, etc.

The initial values of GPO1/2/3 are all Hi fixed.

*2

Signal output from pin 7, 10, 11 (GPI3/2/1) of DC

power input connector

Function as GPI input or trigger input. The initial

setting is GPI1 for trigger input and GPI2/3 for GPI

input.

f DIGITAL Interface connector (26-pin mini

conector)

Camera Link Base Configuration:

You can connect a Camera Link cable to this connector

to control a camera module from a host device utilizing

the serial communication protocol while outputting a

video signal from the camera module. If you use a

camera module interface board with support for PoCL,

you can also supply power from this connecter. You can

input the external trigger signal via the DIGITAL

8

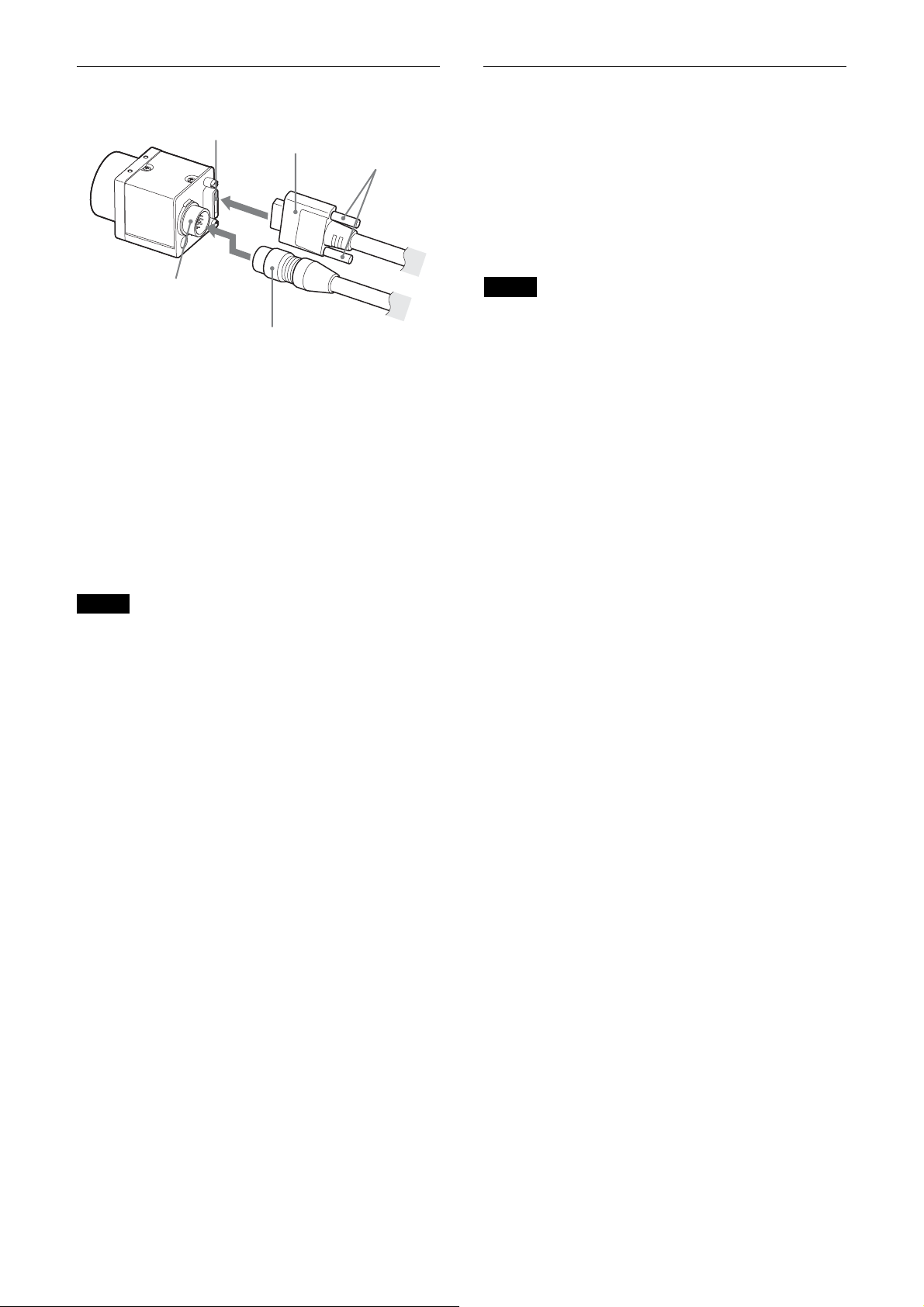

Connecting the cables

2

4

5

Controlling the camera from the host device

You can control the camera from host device such as a

computer.

You can send a command corresponding to the control

items, with parameters for the desired settings, if

necessary, from the host device to control the camera.

Refer to “Camera Control Commands” on page 37 for

details on how to send a command and its parameter.

1

3

Connect the camera cable (c) to the DC power input

connector (a) and the Camera Link cable (d) to the

DIGITAL Interface connector (b) respectively. If you

use a camera module interface board with support for

PoCL, you can operate the camera even if you do not

connect the camera cable to the DC power input

connector. When you connect the Camera Link cable,

turn the two fastening screws (e) on the connector to

secure the cable tightly.

Connect the other end of the camera cable to the DC700/700CE and the other end of the Camera Link cable

to the camera module interface board.

Note

Please be careful with the points below, as they may be

the cause of camera or camera image input board failure.

– Connect or disconnect camera cables or camera link

cables while the power is not supplied.

– Supply power after confirming each cable is firmly

connected.

– Do not supply power from both camera cable and

camera link cable simultaneously.

– If you use the camera with PoCL connection, make

sure to connect a cable that supports PoCL.

Note

Make sure to supply power to the camera module and

confirm that the camera module is operating before

inputting a trigger signal. If you input trigger signal to a

camera module without the power supplied, this may

cause a malfunction of the camera module.

9

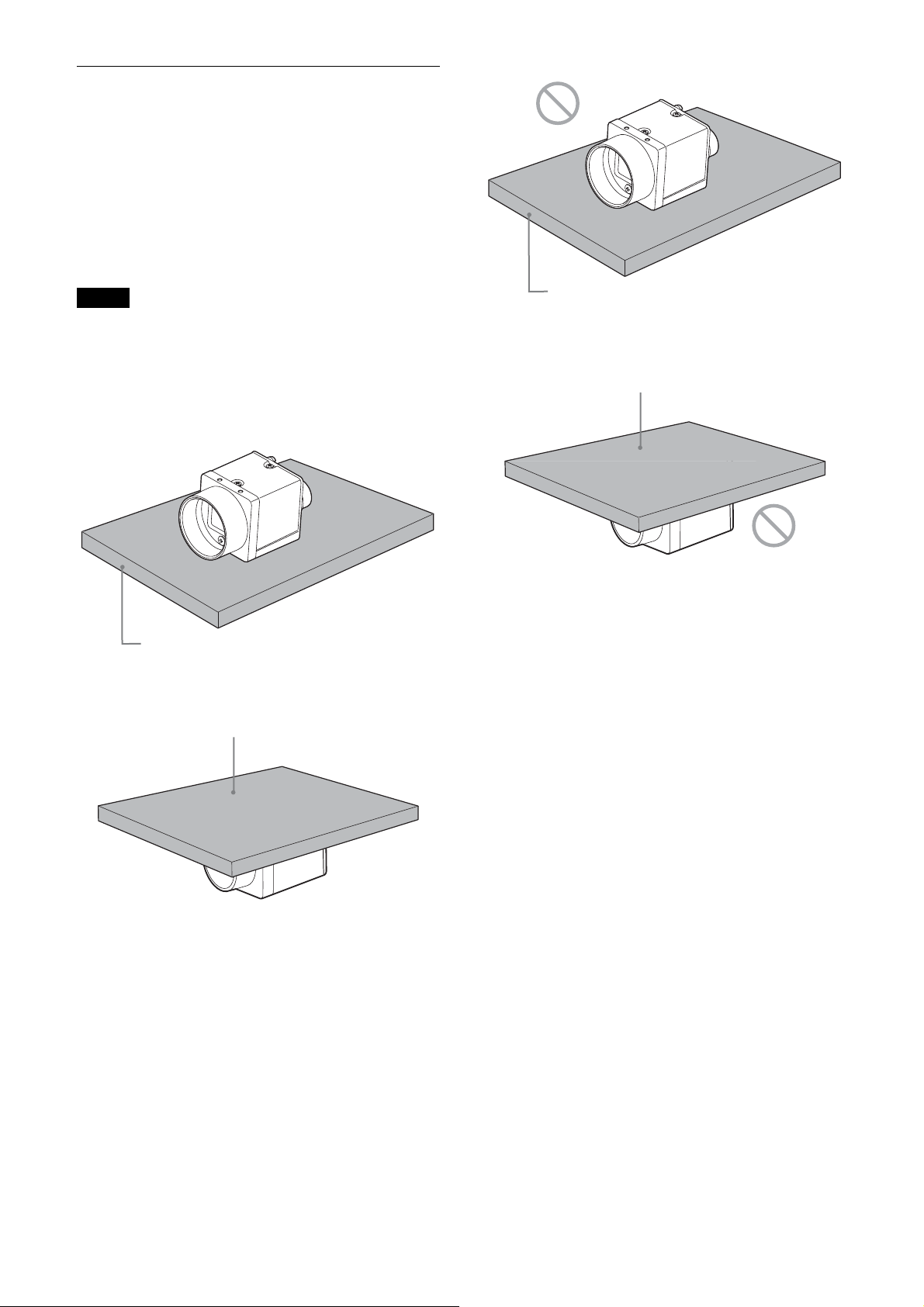

When mounting the camera

When the value read from the temperature sensor is

above 75 °C (167 °F), heat dissipation is required.

For more information about reading from the

temperature sensor, see “Temperature Readout

Function” (page 32).

To promote heat dissipation from the unit and maintain

the performance, mount the camera to a metallic base to

fix.

Notes

• When mounting the camera to the fixing base, secure

the camera tightly by using the reference screw holes

(see page 7) and screws.

• Do not mount the camera to a plate made of a material

such as wood or resin that prevents heat dissipation.

Metallic fixing base

Metallic fixing base

Plate that prevents heat dissipation

(made of wood, resin, etc.)

Plate that prevents heat dissipation

(made of wood, resin, etc.)

10

Connections

Communication Setting

Use the serial port assigned to the image input board for the camera. Communication settings are shown in the table

below. Echo back is performed for input commands.

Echo back can be set OFF to accelerate command responses. Commands are not case sensitive.

Baud rate 921600/460800/230400/115200/57600/38400/19200/14400/9600

Data bit 8

Parity None

Stop bit 1

Flow control None

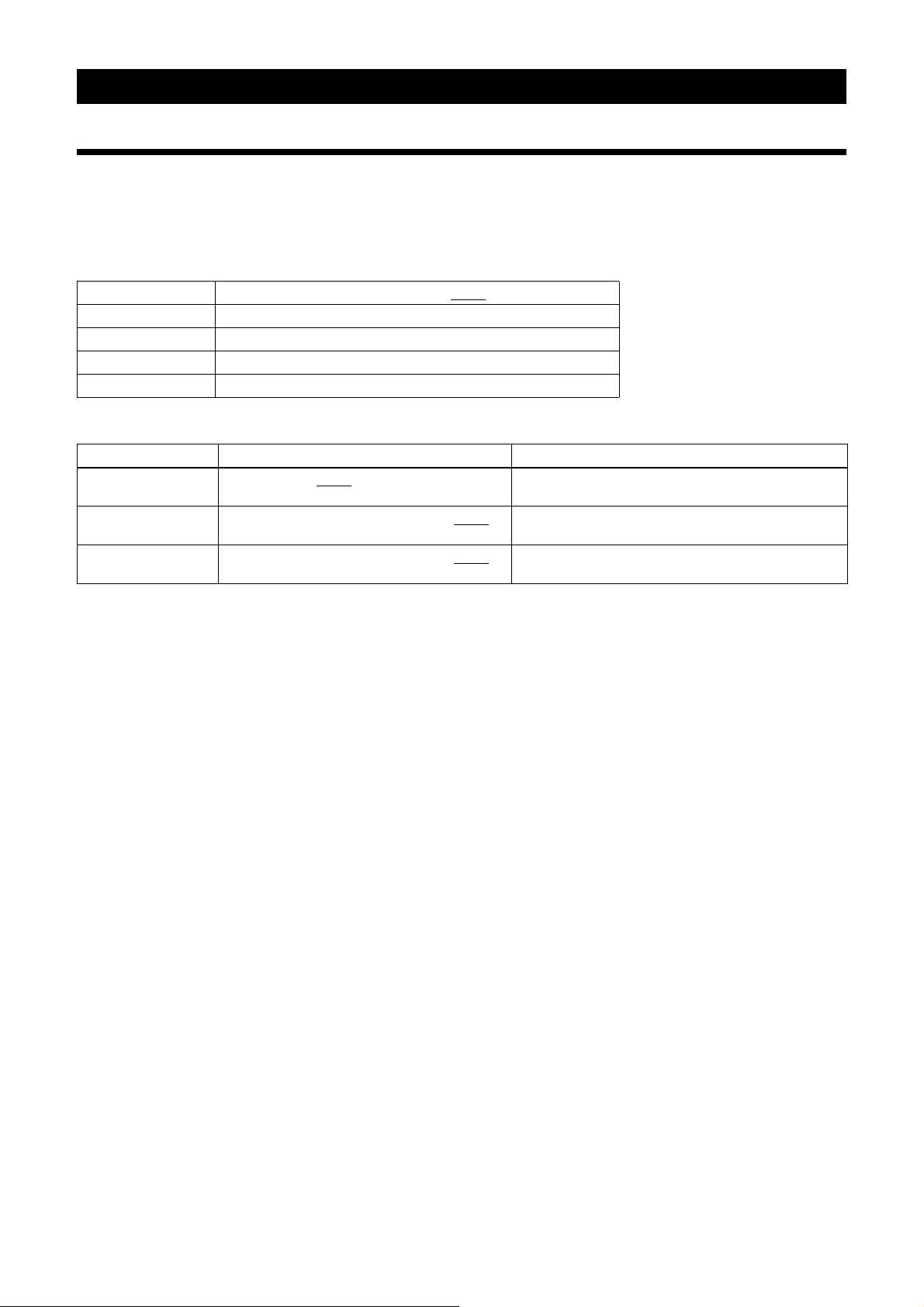

Default values are underlined. (same applies hereinafter)

Command Parameter

BAUDRATE 115200/57600/38400

BAUDRATE-TMP 921600/460800/230400/115200/57600/38400

19200/14400/9600

BAUDRATE-SAVE 921600/460800/230400/115200/57600/38400

19200/14400/9600

/19200/14400/9600 Settings are saved in the camera and will be enabled

after restart.

/

Settings will be implemented immediately, but not

saved in the camera.

/

Settings are saved in the camera and will be enabled

after restart.

When you increase the baud rate, save them using the BAUDRATE-SAVE command after changing the settings

temporarily using the BAUDRATE-TMP command and confirming the communication between PC is enabled.

11

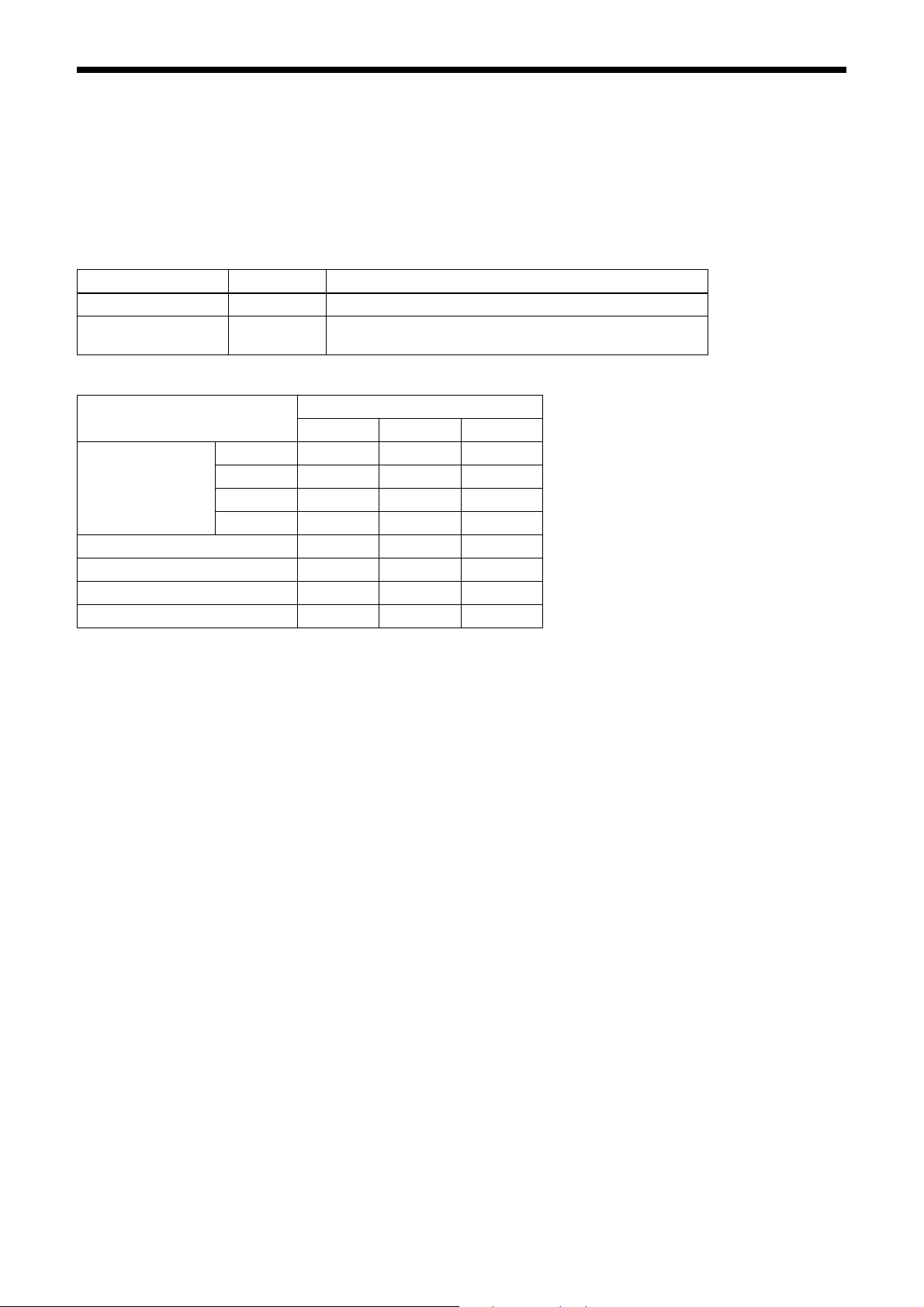

Camera link output settings

Camera link tap can be selected from 1, 2 or 3.

Camera link clock frequency can be selected from 45 MHz or 75 MHz.

By turning down the clock frequency, the length of the camera link cable can be extended because of durability

improvement against the attenuation of image signals.

Camera link tap and Camera link clock settings will be saved on the flash memory automatically and enabled after

restart.

You don’t have to set each time when launching the application.

Command Parameter

CAMERALINK-TAP 1/2/3 Sets the Camera link tap.

BASE-CLOCK 45/75 Specifies the Camera link clock frequency [MHz].

Combinations of camera link taps and output bit lengths.

Output Bit Length 8 zzz

10 zz –

12 zz –

24* z ––

Defect detection function z ––

Defect offset function zzz

Shading detection function z ––

Shading offset function zzz

z Usable function – Not usable function

* XCL-CG510C only

Setting other than provided in left will not work.

CAMERALINK-TAP

123

12

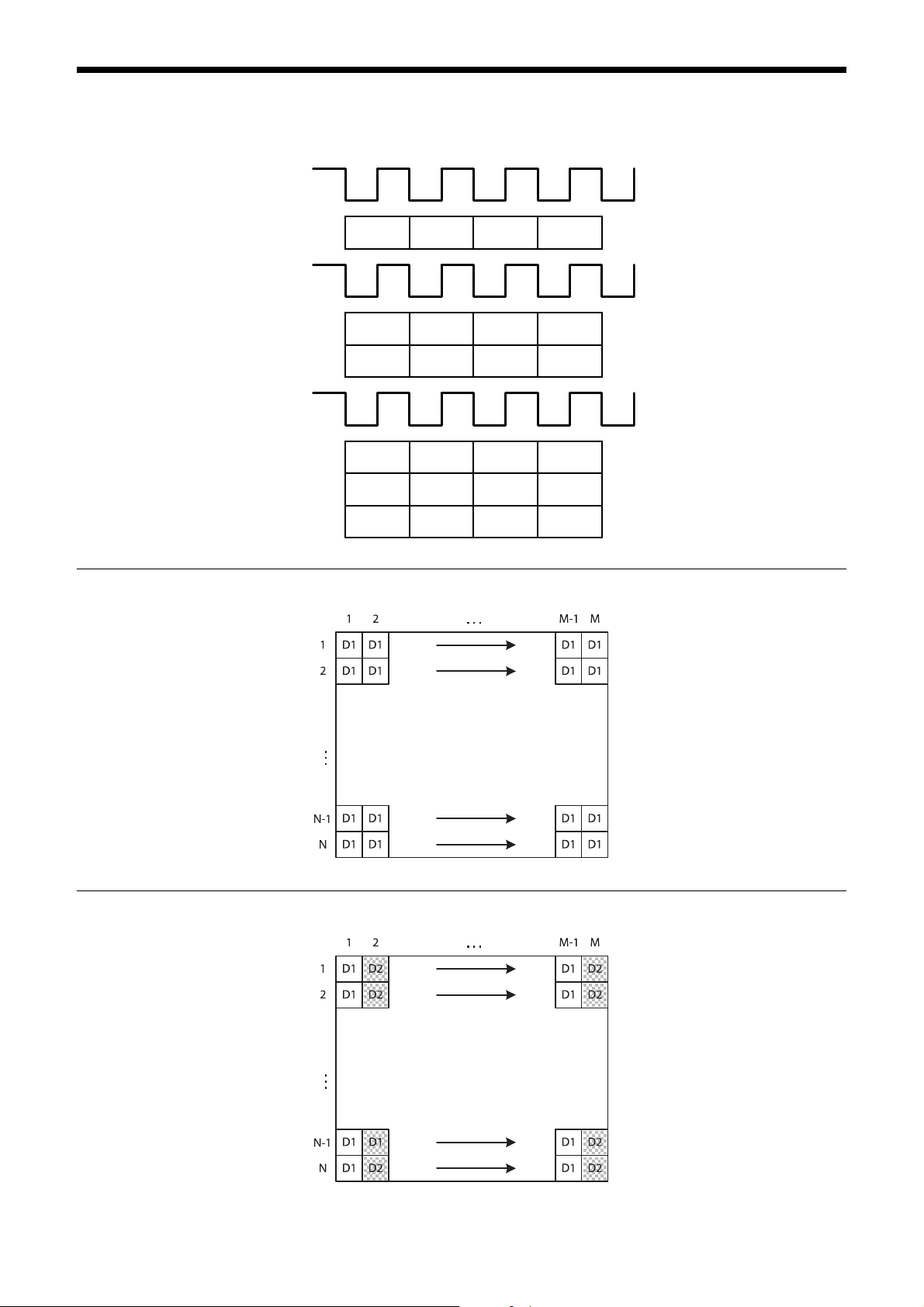

Data Order

Figures below show the data order when an image of M × N pixels is transmitted in 1tap/2tap/3tap.

STROBE

1tap

1tap

2tap

3tap

Video output

STROBE

Video output

STROBE

Video output

D1

D1 D1 D1 D1

D2 D2 D2 D2

D1 D1 D1 D1

D2 D2 D2 D2

D3 D3 D3 D3

D1 D1 D1

2tap

M × N pixels

M × N pixels

13

3tap

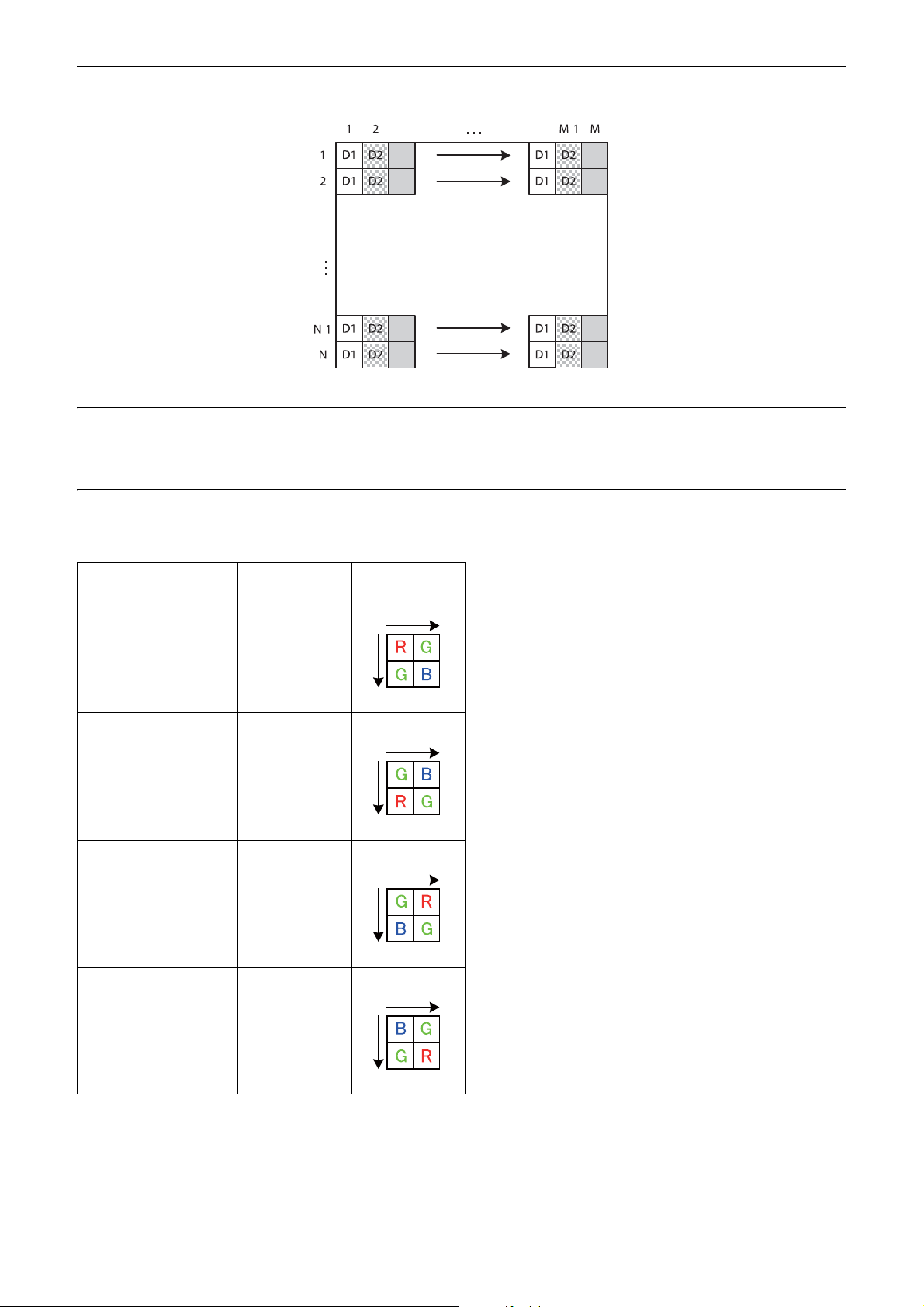

D3

D3

M-23

D3

D3

M × N pixels

D3

D3

D3

D3

Port assignment

Camera link port allocation to image signal output data of this unit complies with Camera Link V2.0 specifications.

Color pixel array

Signals of all pixels are output sequentially according to the Bayer Array corresponding to the settings of image grip.

Reverse X Reverse Y Location

00

01

10

11

14

Trigger Signal Input

Trigger signals can be input via the 7th, 10th, 11th pins of the DC power input connector, the CC1, CC2, CC3, CC4 pins

of the DIGITAL Interface connector, or the software command. Switchover of the trigger signal can be changed via the

TRG-SRC command.

Command Parameter Trigger signal assigned pin

TRG-SRC 7 DC power input connector 7th pin (GPI3)

10 DC power input connector 10th pin (GPI2)

11

101 DIGITAL Interface connector 22nd [+]/9th [-] (CC1)

102 DIGITAL Interface connector 10th [+]/23rd [-] (CC2)

103 DIGITAL Interface connector 24th [+]/11th [-] (CC3)

104 DIGITAL Interface connector 12th [+]/25th [-] (CC4)

0 Software command (TRG-SOFT)

20 OR of GPI1/GPI2/GPI3

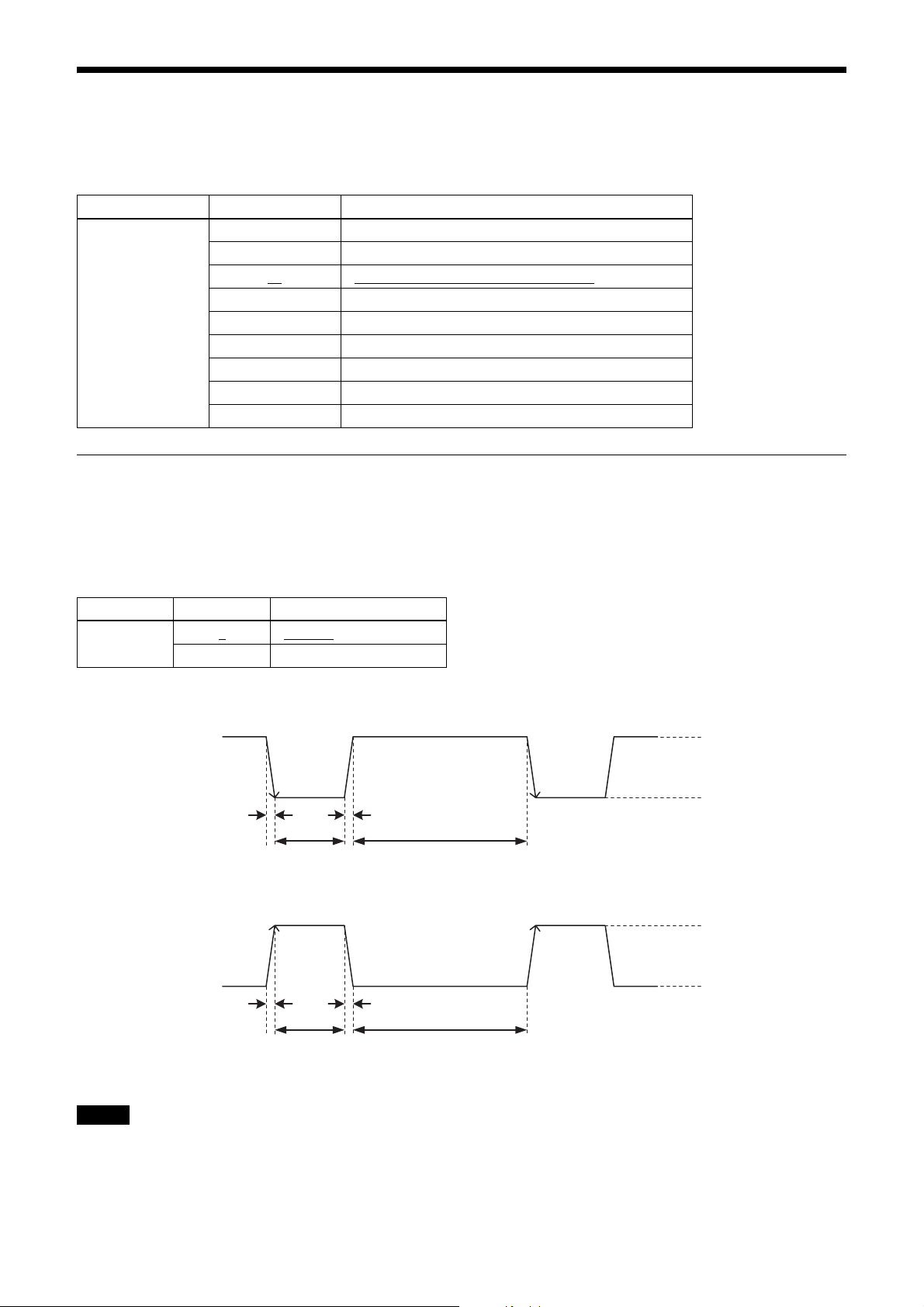

Trigger signal polarity

Positive refers to a trigger signal polarity activated while rising from Low to Hi, or during the Hi interval. Negative refers

to a trigger signal polarity activated while falling from Hi to Low, or during the Low interval. The default value of a

camera is Negative. The GPI connectors 1, 2, and 3 are pulled up on the camera side. When a connector is open, the

trigger signal is at the high level and is logically inactive. Note that when Positive of GPI1, 2 or 3 is selected as a trigger

input, when the terminal is open, the trigger will be activated.

DC power input connector 11th pin (GPI1)

Command Parameter Trigger signal polarity

TRG-POL 0

1 Positive

Negative

DC power input connector specifications

2.0 µs or less

10 µs to 2 s

2.0 µs or less

10 µs to 2 s

2.0 µs or less

1 frame hour or more

Trigger input polarity = Negative

2.0 µs or less

1 frame hour or more

2 to 24 V

0 to 0.4 V

2 to 24 V

0 to 0.4 V

Trigger input polarity = Positive

Note

When inputting a trigger signal to the camera using the DC-700/700CE, use DC 5 V or less at the logical high level.

15

Loading...

Loading...