Page 1

B/W DIGITAL CAMERA MODULE

XCD-U100

XCD-SX90

XCD-V60

COLOR DIGITAL CAMERA MODULE

XCD-U100CR

XCD-SX90CR

XCD-V60CR

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! A VERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 3

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 3

Related manuals ........................................................................... 3

1. Service Overview

1-1. Board Location ...............................................................1-1

1-2. Removing/Installing the Cabinet ....................................1-1

1-2-1. Upper case/Lower case..........................................1-1

1-2-2. Rear Panel Assembly ............................................1-2

1-2-3. Front Panel Assembly ...........................................1-2

1-3. Removing/Installing the Board ....................................... 1-3

1-3-1. BI-217/218/219 Board...........................................1-3

1-3-2. FM-96 Board .........................................................1-3

1-3-3. DC-DC Converter .................................................1-4

1-3-4. IF-1068 Board ....................................................... 1-4

1-3-5. CN-3020 Board ..................................................... 1-5

1-4. Lens Mount Cap, Filter Bracket, Optical Dust Cover

(XCD-V60/SX90/U100), Infrared Cut Filter (XCD-

V60CR/SX90CR/U100CR), Sealing Rubber .................1-6

1-5. Round Type Connector (12-Pin) .................................... 1-7

1-6. Matching Connectors and Cables ...................................1-7

1-7. Signal Inputs and Outputs...............................................1-7

1-8. Unleaded Solder..............................................................1-8

3. Circuit Description

3-1. BI-217, BI-218, and BI-219 Boards ...............................3-1

3-2. FM-96 Board ..................................................................3-1

3-3. IF-1068 Board.................................................................3-1

3-4. CN-3020 Board...............................................................3-1

4. Spare Parts

4-1. Notes on Repair Parts .....................................................4-1

4-2. Exploded Views .............................................................. 4-2

4-3. Packing Materials & Supplied Accessories ....................4-4

5. Block Diagram

Overall ............................................................................5-1

6. Frame Wiring

Frame Wiring .................................................................. 6-1

2. Adjustment

2-1. Writing of Serial Number and Node Unique ID.............2-1

2-2. Camera Adjustment ........................................................2-2

2-2-1. Black and White (B/W) Camera

(XCD-U100/SX90/V60) .......................................2-3

2-2-2. Color Camera

(XCD-U100CR/SX90CR/V60CR) .......................2-4

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

1

Page 4

Page 5

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual of the B/W Digital Camera Module XCD-U100/

SX90/V60 and Color Digital Camera Module XCD-U100CR/SX90CR/V60CR.

This manual contains the service overview, adjustment, circuit description, spare

parts, block diagrams, and frame wiring.

The service of this unit is basically performed by the replacement of board.

Therefore, the schematic diagram, board layout and electrical parts list are not

contained.

In addition to this Service Manual the following manual is provided.

..

. “Operating Instructions” (supplied with this unit)

..

Part No.: 3-287-508-0X (Japanese, English)

3-287-508-1X (Korean)

This manual is necessary for application and operation of this unit.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

This manual contains a complete list of semiconductors and their ID Nos., and

thus should be used together with the CD-ROM.

Part number: 9-968-546-06

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

3

Page 6

Page 7

Section 1

Upper case

PM2 x 4

PM2 x 4

PM2 x 4

PM2 x 4

Lower case

Service Overview

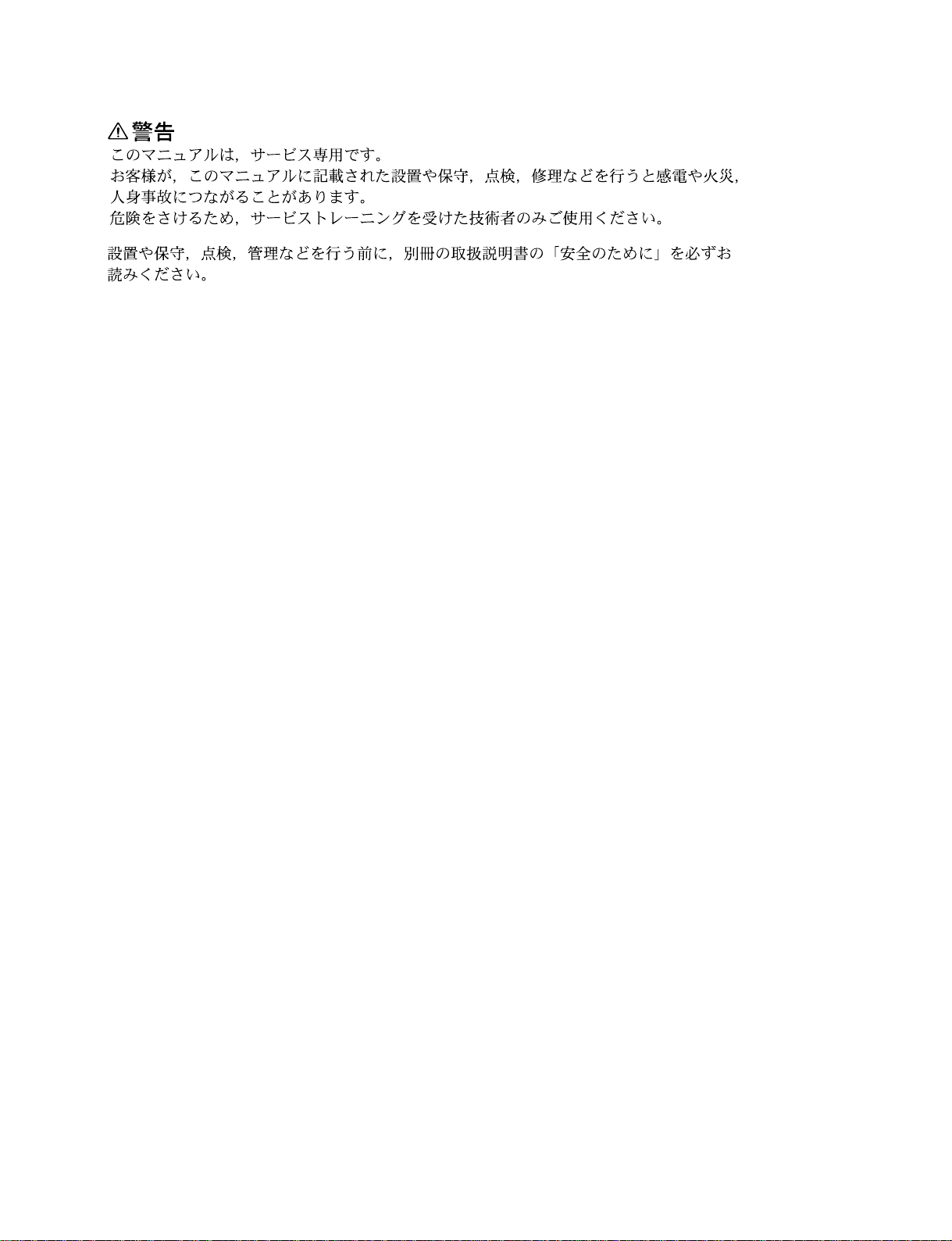

1-1. Board Location

FM-96 board

Board name Model name

BI-217 board XCD-V60

BI-218 board XCD-SX90

BI-219 board XCD-U100

CN-3020 board Common

DC-DC converter XCD-V60/V60CR/U100/U100CR

FM-96 board Refer to “Section 4 Spare Parts”

IF-1068 board Common

CN-3020 board

DC-DC converter

IF-1068 board

BI-217/218/219 board

XCD-V60CR

XCD-SX90CR

XCD-U100CR

XCD-SX90/SX90CR

1-2. Removing/Installing the Cabinet

1-2-1. Upper case/Lower case

1. Remove the seven screws, then remove the upper case

and lower case.

2. Attach the upper case and lower case in the reverse

order of step 1.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

1-1

Page 8

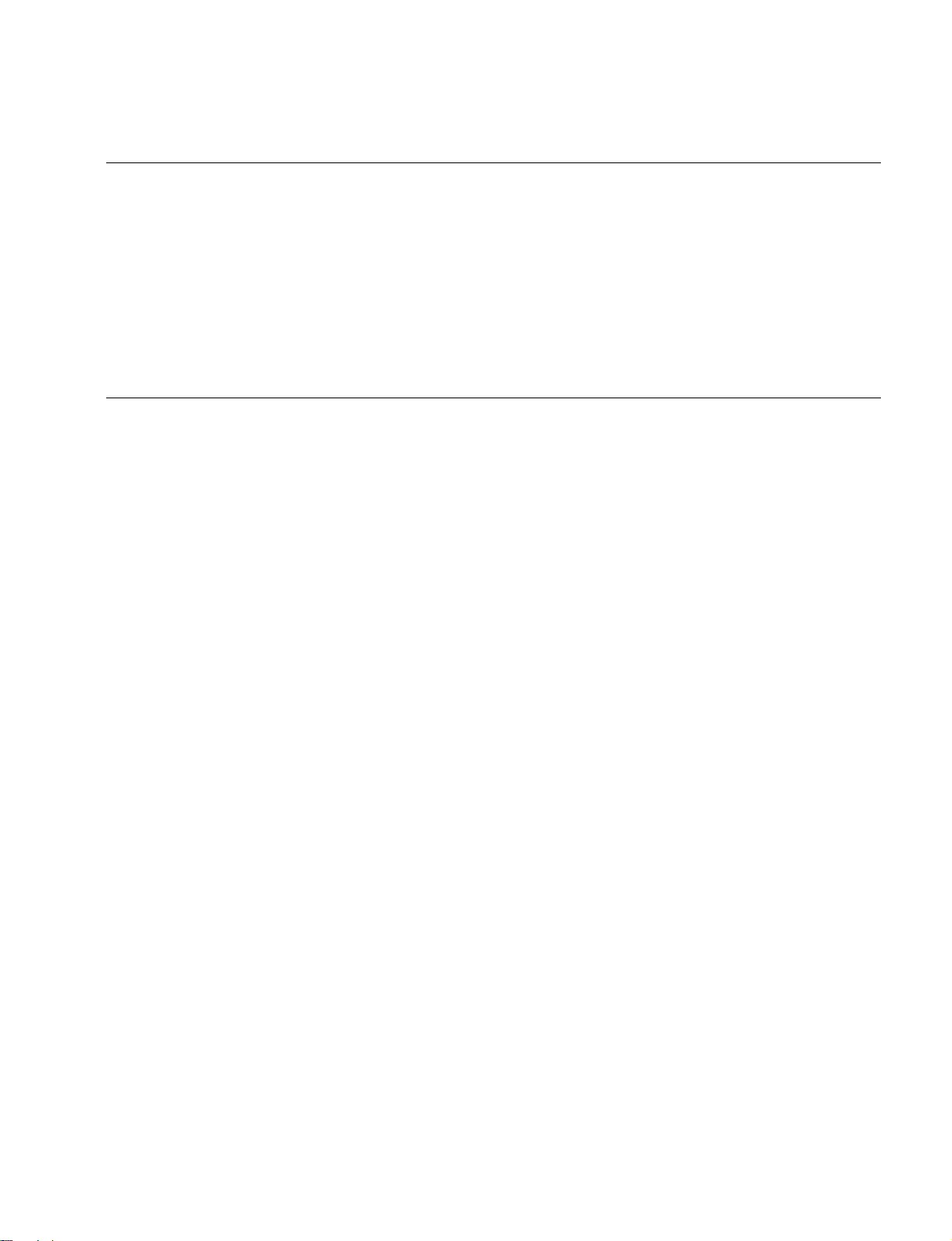

1-2-2. Rear Panel Assembly

1-2-3. Front Panel Assembly

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the two screws, then pull out the rear panel

assembly.

3. Disconnect the flexible flat cable from the connector

(CN900) on the CN-3020 board.

CN-3020 board

CN900

Flexible flat cable

PM2 x 4

Rear panel assembly

PM2 x 4

4. Attach the rear panel assembly in the reverse order of

steps 1 to 3.

n

When attaching the rear panel assembly, securely

attach it while pushing it against the chassis.

n

When replacing the front panel assembly, perform the

writing the serial number and Node Unique ID and camera

adjustment. For details, refer to Sections 2-1 and 2-2.

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the two screws, then pull out the front panel

assembly.

3. Disconnect the flexible flat cable from the connector

(CN101) on the BI-217/218/219 board.

Flexible flat

cable

CN101

Front panel assembly

PM2 x 4

PM2 x 4

BI-217/218/219 board

This illustration is for XCD-SX90/SX90CR.

Rear panel assemblyChassis

4. Attach the front panel assembly in the reverse order of

steps 1 to 3.

n

ChassisFront panel assembly

When attaching the front panel assembly, securely

attach it while pushing it against the chassis.

1-2

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 9

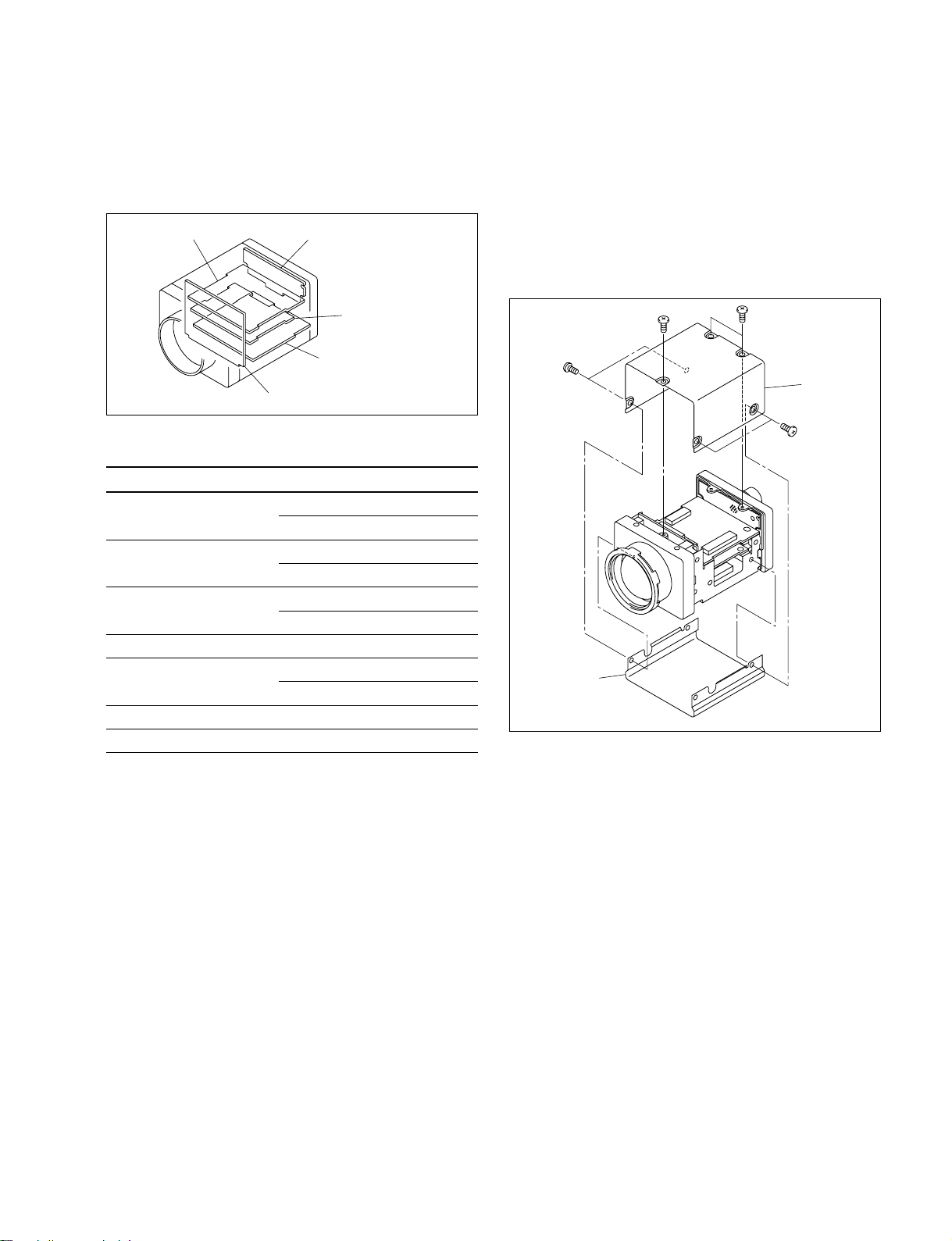

1-3. Removing/Installing the Board

PM2 x 4

CN200

CN700

XCD-SX90/SX90CR

CN400

Flexible flat

cables

Shield sheet

Flexible flat cable

FM-96 board

1-3-2. FM-96 Board

1-3-1. BI-217/218/219 Board

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the front panel assembly.

(Refer to Section 1-2-3.)

3. Remove the two screws.

4. Remove the solders of CCD, then remove the BI-217/

218/219 board.

. BI-217 board: 16 solders

. BI-218 board: 24 solders

. BI-219 board: 20 solders

Front panel assembly

CCD

BI-217/218/219 board

Solders

PM2 x 4

n

When replacing the FM-96 board, perform the writing of

the serial number and Node Unique ID. For details, refer to

Section 2-1.

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the rear panel assembly.

(Refer to Section 1-2-2.)

3. Remove the front panel assembly.

(Refer to Section 1-2-3.)

4. Disconnect the three flexible flat cables from the

connectors (CN200, CN400 and CN700) on the FM-96

board.

5. XCD-SX90/SX90CR:

Remove the three screws, then remove the shield sheet

and FM-96 board.

XCD-V60/V60CR/U100/U100CR:

Remove the three screws, then remove the FM-96

board.

This illustration is for XCD-V60/V60CR.

5. Install the BI-217/218/219 board in the order of steps

3, 4, 2 and 1.

6. Install the FM-96 board in the reverse order of steps 1

to 5.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

1-3

Page 10

1-3-3. DC-DC Converter

1-3-4. IF-1068 Board

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the rear panel assembly.

(Refer to Section 1-2-2.)

3. Remove the front panel assembly.

(Refer to Section 1-2-3.)

4. Remove the FM-96 board. (Refer to Section 1-3-2.)

5. Disconnect the two flexible flat cables from the

connectors (CN001 and CN002) on the DC-DC

converter.

6. Remove the three screws 1, then remove the DC-DC

converter in the direction of the arrow.

7. Remove the two screws 2, then remove the board

support.

Screws 2

(PM2 x 4)

CN001

CN002

Flexible flat cable

Screw 1

(PM2 x 4)

DC-DC

converter

Board support

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the rear panel assembly.

(Refer to Section 1-2-2.)

3. Remove the front panel assembly.

(Refer to Section 1-2-3.)

4. Remove the FM-96 board. (Refer to Section 1-3-2.)

5. Remove the DC-DC converter.

(Refer to Section 1-3-3.)

6. Disconnect the three flexible flat cables from the

connectors (CN800, CN801 and CN802) on the IF1068 board.

7. Remove the three screws, then remove the IF-1068

board in the direction of the arrow.

8. Remove the two shield plates (connector).

Flexible flat cable

CN800

PM2 x 4

CN802

Flexible flat cable

Shield plates

(connector)

IF-1068 board

Screw 1

(PM2 x 4)

Flexible flat cable

Screw 1

(PM2 x 4)

8. Attach the DC-DC converter in the reverse order of

steps 1 to 7.

CN801

Flexible flat cable

9. Install the IF-1068 board in the reverse order of steps 1

to 8.

1-4

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 11

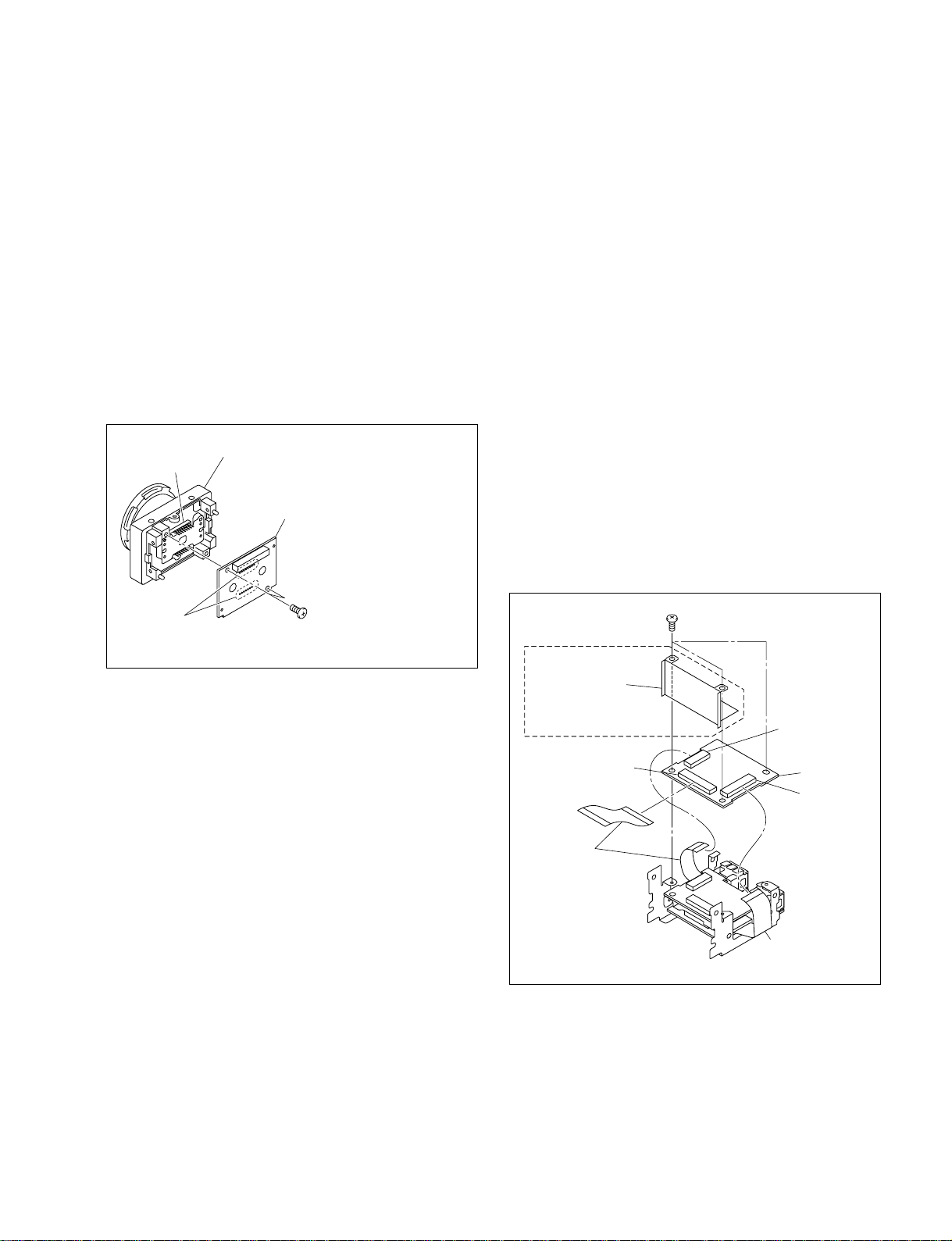

1-3-5. CN-3020 Board

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the rear panel assembly.

(Refer to Section 1-2-2.)

3. Remove the twelve solders of the connector from the

CN-3020 board.

4. Remove the screw, then remove the CN-3020 board.

Rear panel assembly

Solders

PM2 x 4

CN-3020 board

5. Install the CN-3020 board in the reverse order of steps

1 to 4.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

1-5

Page 12

1-4. Lens Mount Cap, Filter Bracket, Optical Dust Cover (XCD-V60/SX90/

U100), Infrared Cut Filter (XCD-V60CR/SX90CR/U100CR), Sealing Rubber

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the front panel assembly. (Refer to Section 1-2-3.)

3. Remove the lens mount cap.

4. XCD-V60/SX90/U100:

Remove the two screws (M1.7 x 4), then remove the

filter bracket and optical dust cover.

XCD-V60CR/SX90CR/U100CR:

Remove the two screws (M1.7 x 4), then remove the

filter bracket and infrared cut filter.

5. Remove the two screws (M1.7 x 4).

n

When attaching the screws, attach the screw 1 first

and then 2.

6. Remove the two screws (PM2 x 4), then remove the

BI-217/218/219 board and spacers.

n

When attaching the spacers, be sure to attach them

back to the original positions.

7. Remove the sealing rubber.

BI-217/218/219 board

2

M1.7 x 4

PM2 x 4

8. Attach the lens mount cap, filter bracket, optical dust

cover, infrared cut filter and sealing rubber in the

reverse order of steps 1 to 7.

Note for attaching the infrared cut filter

(XCD-V60CR/SX90CR/U100CR)

Attach the infrared cut filter so that its evaporation surface

is placed on the side of BI-217/218/219 board.

Evaporation surface checking method

When you put the cotton-tipped swab on the surface of the

infrared cut filter, the image of the cotton-tipped swab is

reflected as if the tips contact each other (state being

reflected in a mirror) if it is the evaporation surface.

Image that is reflected as

Evaporation

surface

Image of

cotton-tipped

swab

if the tips contact each other

Cotton-tipped

swab

Spacers

Sealing rubber

XCD-V60/SX90/U100

Lens mount cap

Optical dust cover

Filter bracket

M1.7 x 4

XCD-V60CR/SX90CR/U100CR

Lens mount cap

Infrared cut filter

Filter bracket

M1.7 x 4

Spacers

Evaporation

surface

Boss

Front panel

Front panel

Infrared cut filter

1

M1.7 x 4

Note for attaching the sealing rubber

Attach the sealing rubber to the boss side with its chamfered portion placed upward.

(Refer to the illustration on the left.)

1-6

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 13

1-5. Round Type Connector (12-Pin)

1-7. Signal Inputs and Outputs

1. Remove the upper case and lower case.

(Refer to Section 1-2-1.)

2. Remove the rear panel assembly.

(Refer to Section 1-2-2.)

3. Remove the CN-3020 board. (Refer to Section 1-3-5.)

4. Remove the nut and washer, then remove the round

type connector (12-pin).

Rear panel

Washer

Nut

Round type

connector (12-pin )

5. Attach the round type connector (12-pin) in the reverse

order of steps 1 to 4.

1-6. Matching Connectors and Cables

When external cables are connected to the connector of

each unit, the hardware listed below (or equivalents) must

be used.

Connector Matching connector/cable

IEEE1394b IEEE1394b cable (9P-9P)

DC IN Camera cable

(Commercially available products)

IEEE1394b cable (9P-6P)

(Commercially available products)

CCXC12P02N (2 m)

CCXC12P02N (5 m)

CCXC12P02N (10 m)

CCXC12P02N (25 m)

2

1

11

1 IEEE1394b connector

11

. IEEE1394b-2002

59

41

— External view —

Pin No. Signal name Remarks

1 TPB (_) Twisted pair B (_)

2 TPB (+) Twisted pair B (+)

3 TPA (_) Twisted pair A (_)

4 TPA (+) Twisted pair A (+)

5 TPA (R) Twisted pair A (Ground reference)

6 VG Power ground

7 N.C.

8 VP Power voltage input

9 TPB (R) Twisted pair B (Ground reference)

22

2 DC IN: 12-pin (male)

22

19

28

!/

!=

7

3!-

46

5

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

— External view —

Pin No. Signal Pin No. Signal

1 POWER_GND 7 GPIO_IN2

2 POWER_IN 8 GPIO_OUT2_

3 ISO_GND 9 GPIO_OUT2+

4 STROBE_OUT 10 GPIO_IN1

5 GPIO_OUT1_ 11 TRIGGER_IN

6 GPIO_OUT1+ 12 ISO_GND

1-7

Page 14

1-8. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no

lead.(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

1-8

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 15

Section 2

xxxxxxxx

xxxxxxxx

xx

Type the serial number.

Type the Node Unique ID.

[Write] button

Adjustment

2-1. Writing of Serial Number and Node

Unique ID

n

Perform the writing when replacing the FM-96 board or

front panel assembly.

Required equipment

. Personal computer (PC)

. IEEE1394.b board

. IEEE1394b cable (Commercially available products)

. IIDC_CAM**** software: J-7120-410-A

(**** represents the version number.)

Connection

Camera

IEEE1394b

2. Click the “Adjust” tab and “Enter Adjust mode” tab.

The unit enters the adjustment mode.

Adjust tab

xxxxxxxx

xxxxxxxx

xx

3. Check the model nameplate on the bottom of this unit.

Type the Node Unique ID in the Node Unique ID box

and type the serial number in the Serial Number box.

Lens side

Serial

number

No.

Model nameplate affixed

to the bottom of this unit

Personal computer

IEEE1394b

cable

Preparation

1. Connect each device as shown in the above illustration.

2. Install the IIDC control software in an arbitrary place

of PC.

Procedure

1. Start the IIDC_CAM****software.

The IIDC control window is displayed.

Node Unique ID

Rear side

4. Click the [Write] button.

Node Unique ID

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

xxxxxxxx xxxxxxxx

xx

2-1

Page 16

5. Click the “Flash” tab.

6. Click the [Restart|the|Camera] button to restart.

Flash tab

[Restart|the|Camera] button

7. Check if the serial number and Node Unique ID on the

model nameplate correspond to each number in the

IIDC control window. If not, perform the procedure

from step 1 again.

2-2. Camera Adjustment

n

Perform the adjustment when replacing the front panel

assembly.

Required equipment

. Personal computer (PC)

. IEEE1394b cable(Commercially available products)

. IIDC_CAM**** software: J-7120-410-A

(**** represents the version number.)

. Pattern box PTB-700: J-6431-850-A

. Clear chart (manufactured by Kenko): J-6080-621-A

. C-mount lens VF2509 (Canon) or equivalent

Connection

Clear chart

Camera

IEEE1394b

IEEE1394b

cable

Pattern box

PTB-700

C-mount

lens

Personal computer

Preparation

1. Connect each device as shown in the above illustra-

tion.

2. Install the IIDC_CAM**** software in an arbitrary

place of PC.

2-2

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 17

Exposure tab

2-2-1. Black and White (B/W) Camera

xxxxxxxx

xxxxxxxx

xx

[Write] button

[Gain0dB] button

(XCD-U100/SX90/V60)

1. Shoot the pattern box in the center of the window

through the clear chart at the wide end.

2. Start the IIDC_CAM**** software.

3. Click WFM (Waveform Monitor) in the menu.

The waveform is displayed.

WFM

6. Click the Exposure tab and adjust the shutter in the

window so that the Green level reaches close to 100%

(does not exceed 100% (236)) in the WFMwindow.

The shutter value (reference value) at which the Green

level reaches close to 100% on WFM is as follows.

XCD-V60: 13

XCD-SX90: 19

XCD-U100: 19

Green level

4. Start the IIDC_CAM**** software.

The IIDC control window is displayed.

xxxxxxxx xxxxxxxx

xx

5. Set the lens iris to F1.4. (Zoom at the full angle of

field)

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

7. Click the “Adjust” tab in the IIDC control window.

8. Click the [Gain0dB] button.

The Gain 0dB adjustment is performed.

9. Check that the adjustment level (Y) satisfies the

specification A.

A = 235 ±1 step

n

If the specification A is not satisfied, perform the

procedure from step 1 again.

10. After the adjustment is completed, click the [Write]

button and write the adjustment value.

2-3

Page 18

2-2-2. Color Camera

[Write]

(XCD-U100CR/SX90CR/V60CR)

1. Shoot the pattern box in the center of the window

through the clear chart at the wide end.

2. Start the IIDC_CAM**** software.

3. Click WFM (Waveform Monitor) in the menu.

The waveform is displayed.

WFM

Green level

7. Click the “Adjust” tab in the IIDC control window.

4. Start the IIDC_CAM**** software.

The IIDC control window is displayed.

xxxxxxxx xxxxxxxx

xx

5. Set the lens iris to F1.4. (Zoom at the Tele end)

6. Click the Exposure tab and adjust the shutter in the

window so that the Green level reaches close to 100%

(does not exceed 100% (236)) in the WFM window.

The shutter value (reference value) at which the Green

level reaches close to 100% on WFM is as follows.

XCD-V60CR: 28

XCD-SX90CR: 41

XCD-U100CR: 36

Exposure tab

button

[Gain0dB] button

[AdjustWB] button

xxxxxxxx

xx

xxxxxxxx

8. Click the [AdjustWB] button to adjust the color.

9. Click the [Gain0dB] button.

The Gain 0dB adjustment is performed.

10. Check that the adjustment level satisfies the specification A.

A = 235 ±1 step

n

If the specification A is not satisfied, perform the

procedure from step 1 again.

11. After the adjustment is completed, click the [Write]

button and write the adjustment value.

12. Click the [AdjustWB] button.

The WB adjustment is performed.

13. Check that the adjustment level satisfies the specification B.

B = 235 ±1 step

n

If the specification B is not satisfied, perform the

procedure from step 1 again.

14. After the adjustment is completed, click the [Write]

button and write the adjustment value.

2-4

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 19

Section 3

Circuit Description

3-1. BI-217, BI-218, and BI-219 Boards

These boards consist of CCD (IC101) and ADC (BI-217:

IC105), BI-218: IC102), and BI-219: IC105) that are used

for VGA color/black & white (BI-217), SXGA color/black

& white (BI-218), and UXGA color/black & white (BI-

219).

CCD is driven using the power, communication

(AD_SCK/SL/SDATA), sync signal (AD_CLK/HD/VD),

and CCD vertical drive pulses sent from the FM-96 board

and using the CCD horizontal drive pulse generated by an

analog-to-digital converter (ADC). CCD analog data is

input to ADC and output to FPGA on the FM-96 board as

digital data so as to produce an LVDS signal through CDS/

GAIN/CLAMP/AD conversion in ADC

3-2. FM-96 Board

This board consists of an oscillator (X200), FPGA (IC201:

TG/DSP/CPU/SDRAM controller incorporating an

IEEE1394LINK, a, b-compatible layer), SDRAM (IC301)

for image saving, SDRAM (IC502) for CPU execution,

EEPROM (IC402) for camera parameter saving, a V driver

(IC200), flash (IC503) for FPGA data saving, and an

FPGA write connector (CN500). A power pulse is input

from a DC-DC converter through the flexible wiring board

of connector CN101.

The image data of an LVDS signal is input from CN200 to

FPGA as a flow of image data, passed through DSP and

image SDRAM, and converted into a 1394 packet using a

1394LINK layer. The converted data is output through

CN801 to the 1394PHY layer on the IF-1068 board.

Two-way communication is done in the block related to a

1394 system. Image data is not only output, but also the

control data from the host is input. The control data is

saved in the register of a LINK layer. Internal CPU

interprets instructions and sets them to the internal module

of FPGA.

CN801 is also used as the interface of the external input/

output signal from CN901 on the CN-3020 board.

3-3. IF-1068 Board

This board consist of an oscillator (X800), an

IEEE1394PHY layer (IC803), 1394 connectors (CN803

and CN804), and an external input signal isolation circuit

(consisting of PH800, PH801, and PH802).

A power signal is input from a DC-DC converter through

the flexible wiring board of CN802. It also plays the part

for transferring the original power to the DC-DC converter.

Image data is input from the LINK layer of the FM-96

board to the PHY layer and output to the connected

connectors (CN803 and CN804) as a differential signal of

800/400 MHz. The control data from host PC is input

from a 1394 connector as a differential signal, and simultaneously, power is also supplied from the 1394 connector.

The external input signal input from the CN-3020 board is

passed through an external input signal isolation circuit

and sent to FPGA on the FM-96 board.

X800 is sent to the PHY and FM-96 board because it is

used as the clock of a 1394 system and used in the CPU/

1394 module inside FPGA.

3-4. CN-3020 Board

This board consists of a 12-pin connector (CN901) for an

external input/output signal and external power, and an

external output signal isolation circuit (PH901 and

PH902).

External power is used to compensate for the insufficient

power supply on the host side during multiple daisy-chain

connections.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

3-1

Page 20

Page 21

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

Section 4

Spare Parts

4. Harness

Harnesses with no part number are not registered as

spare parts.

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

4-1

Page 22

Overall Block

4-2. Exploded Views

22

22

22

C

A

22

23

14

22

F900

12

2

10

F

25

12

17

22

22

7

9

22

16

E

13

8

F800

22

4

E

3

11

D

G

B

24

22

F

H

22

18

1

C

15

A

20

G

D

6

21

18

19

5

XCD-V60

XCD-SX90

H

B

6

XCD-U100

XCD-V60CR

XCD-SX90CR

XCD-U100CR

4-2

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 23

No. Part No. SP Description

1 A-1441-025-A s MOUNTED CIRCUIT BOARD, BI-217

(FOR XCD-V60/V60CR)

A-1441-026-A s MOUNTED CIRCUIT BOARD, BI-218

(FOR XCD-SX90/SX90CR)

A-1441-027-A s MOUNTED CIRCUIT BOARD, BI-219

(FOR XCD-U100/U100CR)

2 A-1441-028-A s MOUNTED CIRCUIT BOARD, FM-96 V60

(FOR XCD-V60)

A-1441-030-A s MOUNTED CIRCUIT BOARD, FM-96 SX90

(FOR XCD-SX90)

A-1441-031-A s MOUNTED CIRCUIT BOARD, FM-96 SX90CR

(FOR XCD-SX90CR)

A-1441-032-A s MOUNTED CIRCUIT BOARD, FM-96 U100

(FOR XCD-U100)

A-1441-033-A s MOUNTED CIRCUIT BOARD, FM-96 U100CR

(FOR XCD-U100CR)

A-1466-674-A s MOUNTED CIRCUIT BOARD, FM-96 V60CR

(FOR XCD-V60CR)

3 A-1441-034-A s MOUNTED CIRCUIT BOARD, IF-1068

4 A-1441-035-A s MOUNTED CIRCUIT BOARD, CN-3020

5 A-1466-663-A s PANEL ASSY (RP), FRONT (FOR XCD-V60)

A-1466-746-A s PANEL ASSY (RP), FRONT (FOR XCD-V60CR)

A-1466-748-A s PANEL ASSY (RP), FRONT (FOR XCD-SX90)

A-1466-768-A s PANEL ASSY (RP), FRONT (FOR XCD-SX90CR)

A-1466-769-A s PANEL ASSY (RP), FRONT (FOR XCD-U100)

A-1466-771-A s PANEL ASSY (RP), FRONT (FOR XCD-U100CR)

6 1-251-887-11 s COVER, OPTICAL DUST

(FOR XCD-V60/SX90/U100)

1-547-185-51 o FILTER, INFRARED CUT

(FOR XCD-V60CR/SX90CR/U100CR)

7 1-480-424-11 s CONVERTER, DC-DC

(FOR XCD-V60/V60CR/U100/U100CR)

1-480-424-21 s CONVERTER, DC-DC (FOR XCD-SX90/SX90CR)

8 1-691-410-31 s CONNECTOR, ROUND TYPE 12P

9 1-831-171-11 s CABLE, FLEXIBLE FLAT (14 CORE)

10 1-834-991-11 s CABLE, FLEXIBLE FLAT (40 CORE)

Overall Block

11 1-834-992-11 s CABLE, FLEXIBLE FLAT (30 CORE)

12 1-834-993-11 s CABLE, FLEXIBLE FLAT (20 CORE)

13 3-287-055-01 s PANEL, REAR

14 3-287-057-01 s CASE, UPPER

15 3-287-058-01 s CASE, LOWER

16 3-287-629-01 s PLATE,SHIELD (CONNECTOR)

17 3-287-630-01 s SHEET, PROTECTION

18 3-303-809-81 s SCREW (M1.7X4), SPECIAL HEAD

19 3-622-446-01 s CAP,LENS MOUNT(FOR C MOUNT)

20 3-863-430-01 s RUBBER,SEAL

(FOR XCD-SX90/SX90CR/U100/U100CR)

3-992-901-01 s RUBBER,SEAL (FOR XCD-V60/V60CR)

21 3-863-431-01 s BRACKET,FILTER

22 3-968-729-71 s SCREW (M2), LOCK ACE, P2

23 3-398-173-01 s SHIELD SHEET (FOR XCD-SX90/SX90CR)

24 3-398-174-01 s MG SHEET A (FOR XCD-SX90/SX90CR)

25 3-398-175-01 s MG SHEET A (FOR XCD-SX90/SX90CR)

F800 ! 1-533-998-21 s FUSE, (SMD) (1A/125V)

F900 ! 1-533-998-21 s FUSE, (SMD) (1A/125V)

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

4-3

Page 24

4-3. Packing Materials & Supplied

Accessories

---------------------------------------PACKING MATERIALS & SUPPLIED ACCESSORIES

--------------------------------------- Ref. No.

or Q'ty Part No. SP Description

1pc ! 3-287-508-01 s MANUAL, INSTRUCTION

(JAPANESE,ENGLISH)

1pc ! 3-287-508-11 s MANUAL, INSTRUCTION

(KOREAN)

4-4

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

Page 25

Section 5

Block Diagram

OverallOverall

BI-217 BOARD (VGA)

BI-218 BOARD (SXGA)

BI-219 BOARD (UXGA)

IC101

CCD

IC102 (BI-218 BOARD)

IC105 (BI-217/219 BOARD)

14-BIT CCD

SIGNAL

PROCESSOR

FM-96 BOARD

DOUT0N

DOUT0P

DOUT1N

DOUT1P

CLK_P

CLK_N

AD_HD

AD_VD

SCK

SDATA

SL

V_TO1-TO6

V_BO1-BO4

6

5

IC200

VERTICAL

DRIVER FOR

CCD SENSORS

IC201

18

6

FPGA

1810

32

SD_D0-D31

16

P_D0-D15

SDRAM

(4MB x32)

SDRAM

(16MB)

IC301

IC502

PHY-IF

GPIO

+3.3V_IF

+1.95V_IF

+ISO_5V

IC803

THREE-PORT

CABLE

TRANSCEIVER/

ARBITER

X800

98.301MHz

IC800-IC802

PH800-PH803

PHOTO-

COUPLER

4

6

1394

1394

S800

S800

DC IN

PH901, PH902

PHOTO-

COUPLER

CN-3020

BOARD

IF-1068 BOARD

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

+3.3V_FM

+1.95V_BI

+5V/+3.6V_BI

+15V_BI

_7.5V/_8.5V_BI

X200

36.000MHz

(XCD-U100/U100CR,

XCD-V60/V60CR)

49.302MHz

(XCD-SX90/SX90CR)

IC402

EEPROM

(256kBIT)

16

P_D0-D15

+3.3V_FM

+15V_BI

_7.5V/_8.5V_BI

+1.3V_FM

+1.95V_BI

+5V/+3.6V_BI

FLASH MEMORY

5-1 5-1

IC503

(2MB)

+3.3V_IF

+1.95V_IF

+ISO_5V

+3.3V_FM

+15V_BI

_7.5V/_8.5V_BI

+1.3V_FM

+1.95V_BI

+5V/+3.6V_BI

DC-DC CONVERTER

Overall

Page 26

Page 27

Section 6

Frame Wiring

Frame WiringFrame Wiring

LENS

CN101

BI-217 (XCD-V60/V60CR)

BI-218 (XCD-SX90/SX90CR)

BI-219 (XCD-U100/U100CR)

FLEXIBLE

FLAT

CABLE

CN200

CN500

JTAG

CN002

CN400

CN700 CN900

FM-96 CN-3020

FLEXIBLE

FLAT

CABLE

CN001

FLEXIBLE

FLAT

CABLE

FLEXIBLE

FLAT

CABLE

CN901

DC IN

IF-1068

DC-DC CONVERTER

FLEXIBLE

FLAT

CABLE

CN801

CN802

CN800

CN803

IEEE1394b

CN804

IEEE1394b

Frame Wiring

XCD-U100/SX90/V60

XCD-U100CR/SX90CR/V60CR

6-1 6-1

Page 28

Page 29

Page 30

XCD-U100 (SY)

XCD-U100CR (SY)

XCD-SX90 (SY)

XCD-SX90CR (SY)

XCD-V60 (SY)

XCD-V60CR (SY) E

9-968-402-01

Printed in Japan

Sony Corporation 2007. 12 22

©2007

Loading...

Loading...