WM-GX780/GX788

SERVICE MANUAL

Ver 1.1 2003. 10

Photo: WM-GX788

US Model

AEP Model

WM-GX788

E Model

Chinese Model

WM-GX780/GX788

Tourist Model

WM-GX788

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism T ype MF-WMGX788-162

SPECIFICATIONS

Radio section

Frequency range

FM:

87.5 - 108 MHz

530 - 1 710 kHz (North, Central,

AM:

and South America)

531 - 1 602 kHz (other

countries/regions)

Tape section

Frequency response

Playback: 40 - 15 000 Hz

Recording/playback: 100 - 8 000 Hz

Output

Headphones (i) jack

Load impedance 8 - 300 Ω

Input

Microphone (MIC) jack

General

Power requirements

1.5 V

Rechargeable battery

One R6 (size AA) battery

Dimensions (w/h/d)

Approx. 77.1 × 108.0 × 22.5 mm

1

(3

⁄8 × 43⁄8 × 29⁄32 inches) excl. projecting

parts and controls

Mass

Approx. 152 g (5.4 oz) (main unit only)

Supplied accessories

AC power adaptor (1)

Battery case (1)

Stereo headphones or earphones with

remote control (1)

Charging stand (1)

AC plug adaptor (1) (Saudi Arabian

model only)

Rechargeable battery (NH-14WM(A),

1.2 V, 1 350 mAh (min), Ni-MH) (1)

Rechargeable battery carrying case (1)

Carrying pouch (1)

Stereo microphone (1)

Design and specifications are subject to

change without notice.

9-877-201-02

2003J16-1

© 2003.10

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

WM-GX780/GX788

TABLE OF CONTENTS

1. SERVICE NOTE······························································· 3

2. GENERAL ··········································································5

3. DISASSEMBLY

3-1. Case Block Assy ····························································· 6

3-2. Button Rec, Button Assy················································· 7

3-3. Cassette Lid Assy···························································· 7

3-4. Ornament Block Assy Reel, Flexible Retainer ··············· 8

3-5. MAIN Board, Belt (F0) ·················································· 8

3-6. Motor (M901) ·································································9

3-7. Bracket (cassette) Assy, Holder (FA) Assy ····················· 9

3-8. Pinch Lever (RA) Assy, Pinch Lever (NA) Assy ·········· 10

3-9. Magnetic Head (HP901) ··············································· 10

4. MECHANICAL ADJUSTMENT ································ 11

5. ELECTRICAL ADJUSTMENT ··································11

6. DIAGRAMS······································································12

6-1. Block Diagram ······························································ 13

6-2. Printed Wiring Board (Side A) ······································ 14

6-3. Printed Wiring Board (Side B)······································ 15

6-4. Schematic Diagram (1/2) ·············································· 16

6-5. Schematic Diagram (2/2) ·············································· 17

6-6. IC Block Diagrams ······················································· 18

6-7. IC Pin Function Discription ·········································· 19

7. EXPLODED VIEWS

7-1. Case Section·································································· 21

7-2. Main Section ································································· 22

7-3. Mechanism Deck Section (MF-WMGX788-162) ········ 23

8. ELECTRICAL PARTS LIST ······································· 24

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C .

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

SECTION 1

SERVICE NOTE

[Service Mode]

The service mode enables to operate the mechanism of WM-GX780/

GX788 while the MAIN board is opened.

Rotation of the idler gear (A) (S side) is detected using the photoreflector (PH701) in the WM-GX780/GX788. PH701 is located on

the MAIN board, therefore the rotation of the idler gear (A) (S side)

cannot be detected by PH701 when the MAIN board is removed.

As a result, the motor cannot be controlled and cannot run correctly .

To repair the machine after the MAIN board is removed while the

main power is turned on, follow the procedures as described below.

1. Setting

1) Remove the cabinets referring to section “3. DISASSEMBL Y”.

Open the MAIN board.

2) Connect the motor (M601) and the plunger solenoid (PM901)

to the MAIN board using the jumper wires. When the extension

jig (1-769-143-11) (10 wires as a set) is used, they can be

connected easily.

3) Short the TAPE DETECT switch (S303), REV TUME switch

(S503), FWD TUME switch (S502) and ATS switch (S302).

4) Connect an AF oscillator to resistor (R712).

5) Connect DC 1.3 V from external re gulated power supply to ‘

and ’ terminals of the battery.

2. PRE-SET status

The PLA Y, FF and REW modes can be entered only from the PRESET status.

1) Check that the slider (NR) is in the center position (S801), and

the FWD/REV switch is also in the center position. When

these switches are not in the center position, set them to the

PRE-SET status as follows.

2) Move the FWD/REV switch (S801) to the same position as the

slider (NR) is set.

3) The slider (NR) can be moved when the main power of the

regulated power supply is turned OFF once then back ON.

Move the FWD/REV switch (S801) to the center position in

synchronism with the timing when the slider (NR) is moved.

WM-GX780/GX788

3. FF, REW modes

1) Check that the PRE-SET status is set.

2) Connect square wave or sine wave to resistor (R712). (See

illustration below.)

3) Press the x switch (S703) to enter the STOP mode.

4) Press the FF PRESET+ switch (S708) and the REW PRESET–

switch (S707).

4. PLAY mode

1) Check that the PRE-SET status is set.

2) Connect square wave or sine wave to resistor (R712). (See

illustration below.)

3) Press the x switch (S703) to enter the STOP mode.

4) When the nNREPEAT switch (S709) of the MAIN board

is pressed, the slider (NR) moves once to the F side then moves

to the R side. When the FWD/REV switch (S801) is pressed

in the synchronism with the above timing, the machine can

enter the PLAY (R side) mode. Press the nNREPEAT

switch (S709) again, and move the FWD/REV switch (S801)

in the synchronism with the motion of slider (NR). It enables

the machine to enter into the PLAY (F side) mode.

Note 1: When you fail to enter the PLAY mode, re-start from step

1) PRE-SET status.

Note 2: Regarding the nNREPEAT (S709), x (S703),

FF PRESET+ (S708), and REW PRESET– (S707)

switches, use these switches of the remote control unit as

much as possible.

Note 3: If a headphones are used, the beep sound shows the timing

of the FWD/REV switch (S801).

REV TUME

SWITCH

(S503)

Short

TAPE DETECT

SWITCH

(S303)

Battery terminal

ENTER

(S702)

SET

(S705)

MENU

(S706)

– MAIN BOARD (SIDE B) —

Plunger (PM901)

#

REC

(S710)

RADIO ON/

BAND

(S704)

R710

(Side A)

Y

REPEAT

(S709)

REW/PRESET–

(S801)

FWD

←

STOP→REV

(S707)

OSC

Sine wave

10 Hz, -3.5 dB

FF/PRESET+

(S708)

ATS

SWITCH

(S302)

FWD TUME

SWITCH

(S502)

Battery terminal

x

RADIO OFF

(S703)

Short

M

3

M601

3

WM-GX780/GX788

y

[ Slider (NR) ] [ Tape drive mechanism ]

Tape drive mechanism in PLAY mode

Gear (NR)

(FWD : Left side

REV : Right side)

Idler Gear

(A)(T side)

Gear

Idler Gear(B)

F side

Center

Slider (NR)

(REEL)(T side)

Cam Gear

R side

Gear (Y)

Idler Gear (A)(S side)

Gear (REEL)(S side)

Motor Pulley

Clutch Assy(F)

Tape drive mechanism in FF mode

Idler Gear

(A)(T side)

Gear

(REEL)(T side)

Cam Gear

Gear (Y)

Gear (FR)

(FF : Left side)

Clutch Assy(F)

Motor Pulle

Insert Flywheel (N)

Insert Flywheel (R)

Tape drive mechanism in REW mode

Gear (FR)

(REW : Right side)

Cam Gear

Gear (Y)

Idler Gear

(A)(S side)

Clutch Assy(F)

Pulley (Reverse)

Gear

(REEL)(S side)

Motor Pulley

Insert Flywheel (N)

4

Pulley (Reverse)

Insert Flywheel (R)

Pulley (Reverse)

Insert Flywheel (N)

Insert Flywheel (R)

• LOCATION OF CONTROLS

FF/CUE

REW/REVIEW

Y•REPEAT**

VOL*

SET

MENU

HOLD

WM-GX780/GX788

SECTION 2

GENERAL

Plug in firmly.

i

x

ISS

MIC**

HOLD

VOL

REW –

FF +

Y•x

This section is extracted

from instruction manual.

ENTER

SET

MENU

RADIO ON/BAND

TUNE/PRESET –/+

RADIO OFF

MENU

SET

REC

x

FF +

REW –

RADIO ON/BAND

OFF

SPEED

CONTROL

MENU

SET

COUNTER RESET

ENTER/

HOLD

Tape counter

HOLD SOUND

MODE

5

WM-GX780/GX788

DISASSEMBLY

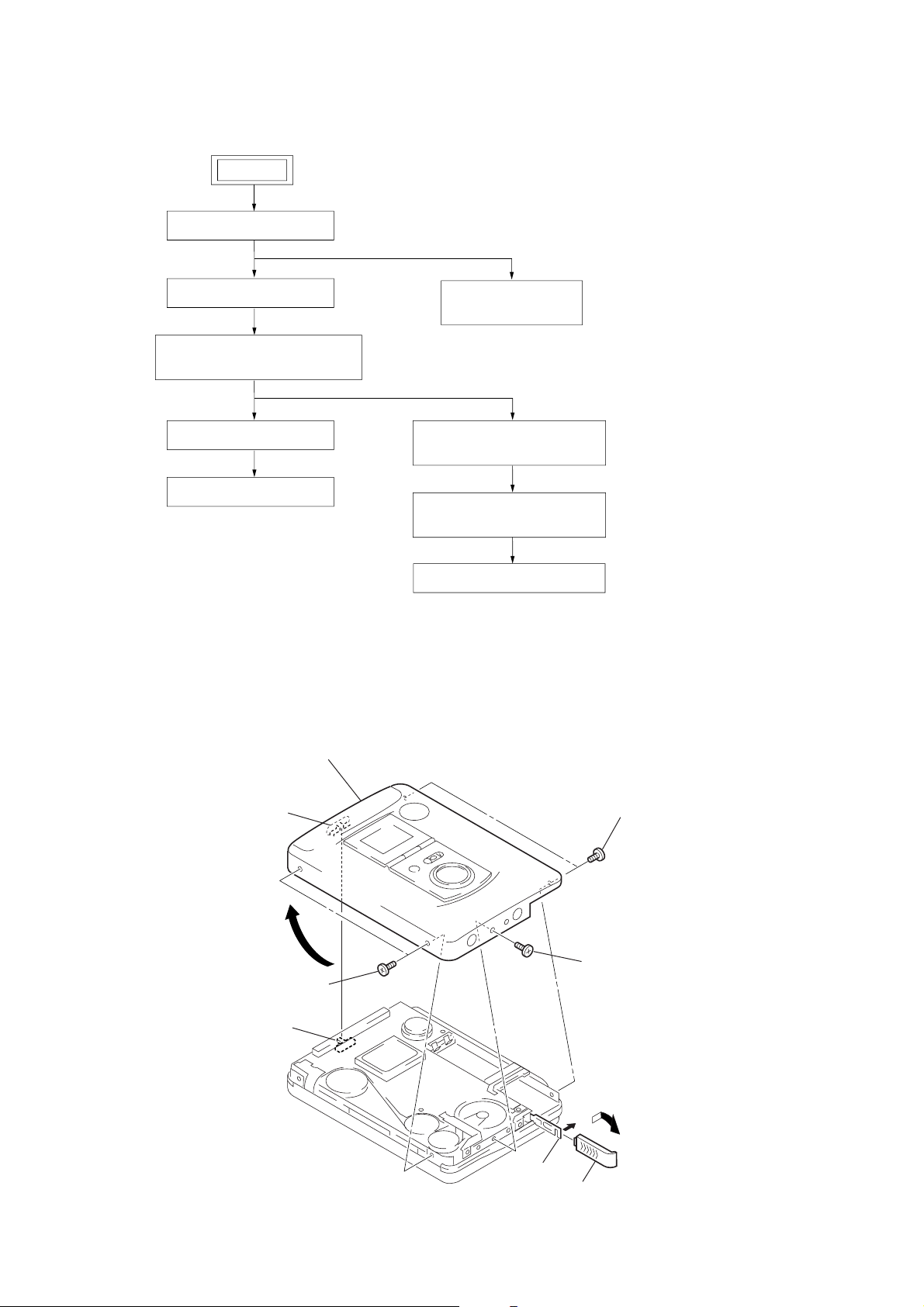

Note : Disassemble the unit in the order as shown below.

SET

CASE BLOCK ASSY

SECTION 3

CASSETTE LID ASSY

ORNAMENT BLOCK ASSY REEL,

FLEXIBLE RETAINER

MAIN BOARD, BELT (F0)

MOTOR (M901)

BRACKET (CASSETTE) ASSY,

HOLDER (FA) ASSY

PINCH LEVER (RA) ASSY,

PINCH LEVER (NA) ASSY

MAGNETIC HEAD (HP901)

Note : Follow the disassembly procedure in the numerical order given.

3-1. Case Block Assy

7

Remove the case block assy

in the direction of the arrow.

BUTTON REC,

BUTTON ASSY

knob (iss)

4

two screws

(M1.4)(EG)

S501

Note: On installation case block assy

adjust the S501 and knob (iss).

2

claw

5

3

battery lid

6

two screws

(M1.4)(EG)

screw

(M1.4)(EG)

1

Open the battery lid.

6

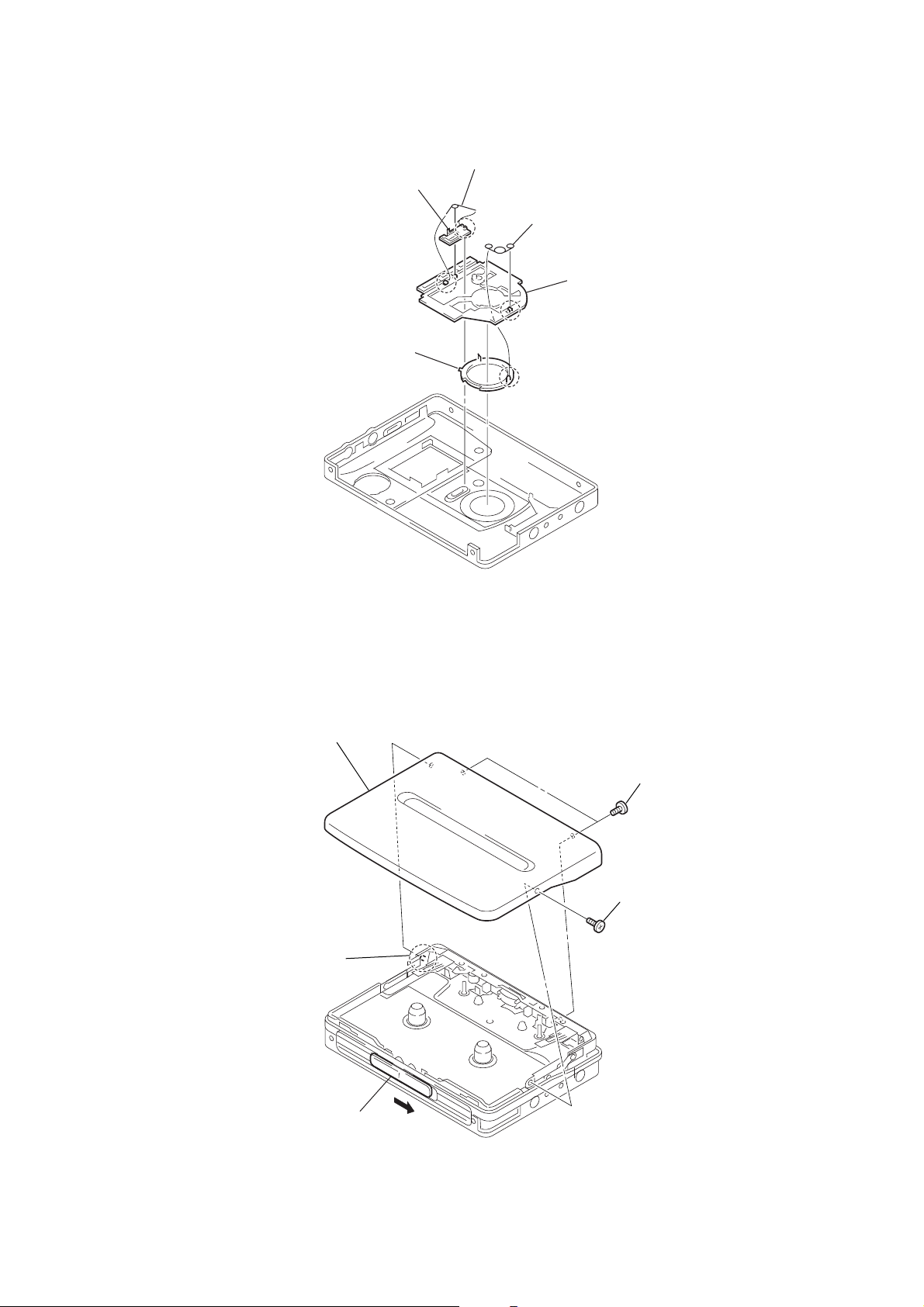

3-2. Button Rec, Button Assy

)

)

2

5

knob (hold)

button rec

1

rec spring

3

torion spring (hold

4

button assy

WM-GX780/GX788

3-3. Cassette Lid Assy

5

cassette lid assy

3

Slide the knob (open)

in the direction of the arrow.

4

shaft

2

two screws

(M1.4)(EG)

1

screw (M1.4)(EG

7

WM-GX780/GX788

f

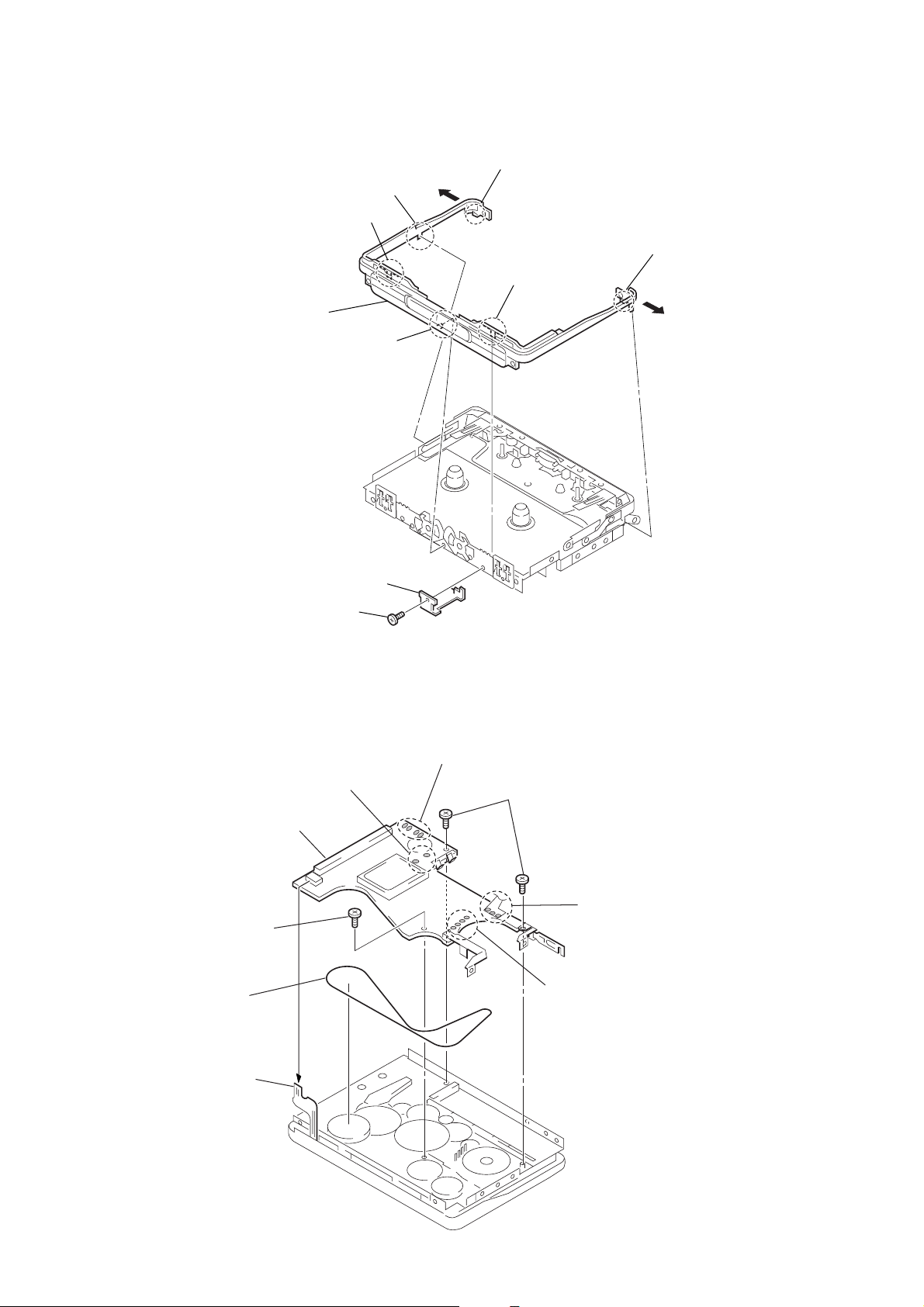

3-4. Ornament Block Assy Reel, Flexible Retainer

2

claw

3

claw

5

ornament block assy reel

4

boss

1

claw

3

claw

1

claw

3-5. MAIN Board, Belt (F0)

8

6

screw (M1.4)

9

belt (F0)

7

flexible retainer

6

screw (M1.4)

3

Remove two solders

of plunger solenoid.

MAIN board

4

Remove four solders

of leaf switch.

5

two screws

2

Remove three solders o

ATS flexible board.

1

Remove four solders of motor.

7

flexible board (head)

8

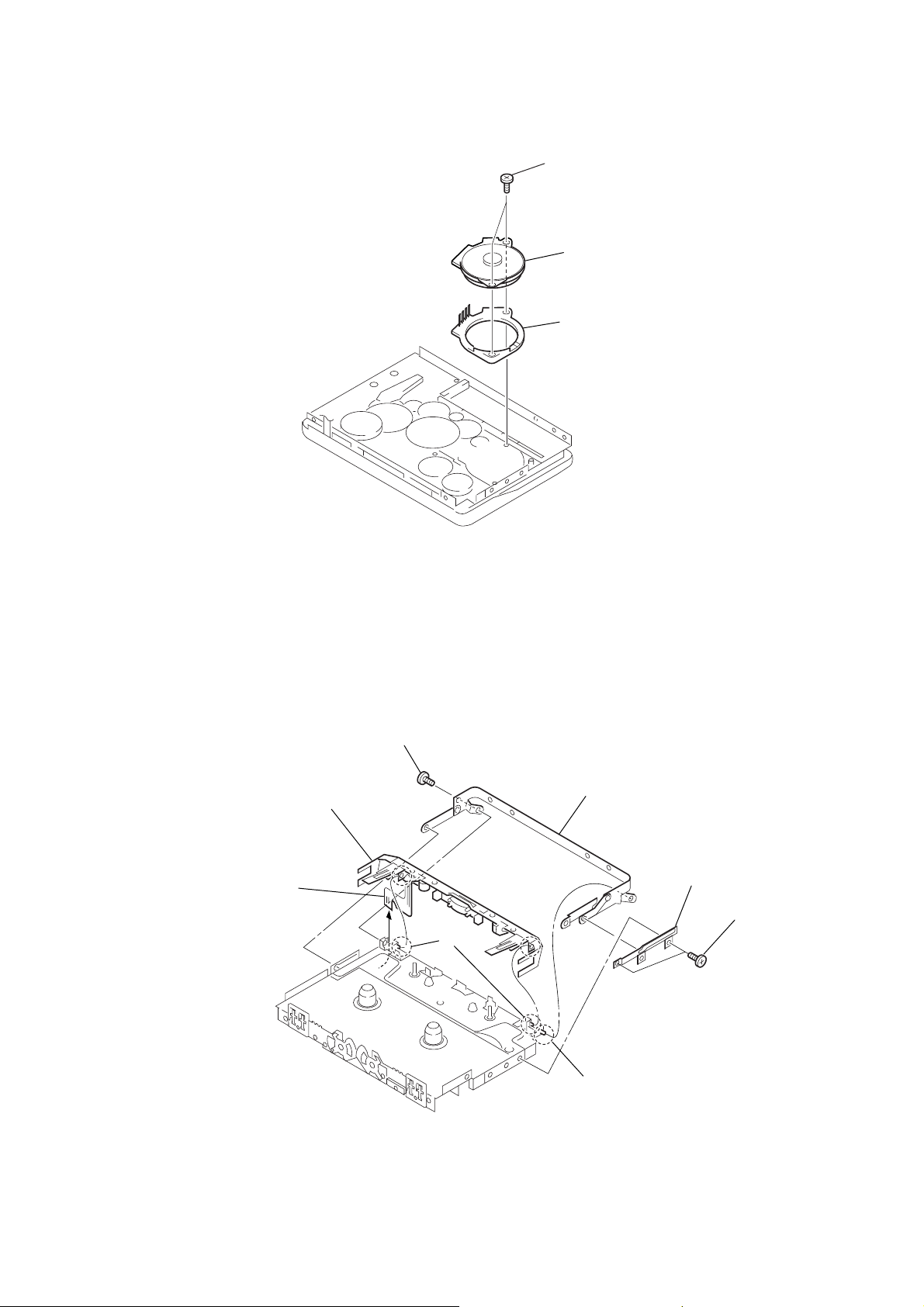

3-6. Motor (M901)

)

1

two screws (M1.4)

2

motor (M901)

3

motor retainer (F1

WM-GX780/GX788

3-7. Bracket (cassette) Assy, Holder (FA) Assy

3

screw (M1.4)

8

holder (FA) assy

6

flexible board (head)

7

shaft

5

bracket (cassette) assy

4

shaft

2

lock lever (B)

1

two screws

(M1.4

×

1.6)

9

WM-GX780/GX788

w

3-8. Pinch Lever (RA) Assy, Pinch Lever (NA) Assy

1

claw

2

Remove the pinch lever (RA) assy

in the dereciton of the arrow.

4

Remove the pinch lever (NA) assy

in the direction of the arrow.

3

cla

3-9. Magnetic Head (HP901)

1

claw

2

Remove the magnetic head (HP901)

in the direction of the arrow.

10

SECTION 4

)

r

MECHANICAL ADJUSTMENT

WM-GX780/GX788

SECTION 5

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback/erase head with a head

demagnetizer. (Do not bring a head demagnetizer close to the

erase head.)

3. The adjustments should be performed with the r ated power

supply voltage unless otherwise noted.

• T orque Measurement

Mode

Torque Meter

Meter Reading

1.47 to 2.45 mN•m

FWD

CQ-102C

(15 to 25 g•cm)

(0.21 to 0.34 oz•inch)

FWD

Back Tension

CQ-102C

Less than 0.20 mN•m

(Less than 2.0g•cm)

(Less than 0.028 oz•inch)

1.47 to 2.45 mN•m

REV

CQ-102RC

(15 to 25 g•cm)

(0.21 to 0.34 oz•inch)

REV

Back Tension

CQ-102RC

Less than 0.20 mN•m

(Less than 2.0g•cm)

(Less than 0.028 oz•inch)

More than 4.90 mN•m

FF, REW

CQ-201B

(More than 50 g•cm)

(More than 0.69 oz•inch)

Adjustment Parts Location :

PRECAUTION

1. Specified voltage : 1.3 V (DC)

2. Switch and control position

MENU switch

HOLD : OFF

VOL : MAX

ISS : 1

TAPE SECTION

Tape

WS-48A (4.8cm/s)

WS-24CC (2.4cm/s)

Signal

3 kHz, 0 dB

3 kHz, 0 dB

Tape Speed Adjustment

Procedure:

Test tape

WS-48A/24CC

(3kHz, 0dB)

Set

i REMOTE jack (J301)

1. Enter the FWD playback mode.

2. Confirm RV602 at center value. (mechanical center)

3. Adjust R V601 so that the value of the frequenc y counter reading

becomes 3,000 Hz.

Specification value:

Frequency counter

2,955 Hz – 3,045 Hz

4. Check that the frequency deviation at the be ginning and ending

of a tape is within 1.5 % (45 Hz).

5. Select switch to 2X (2.4 cm/s), then depress play button in and

adjust RV603 (2,955 Hz–3,045 Hz) at tape center.

Used for

Tape Speed Adjustment

Tape Speed Adjustment

Frequency counter

16 Ω

+

–

TUNER SECTION

0dB=1µV

[AM]

BAND switch : AM

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

Put the lead-wire

antenna close to

the set.

[FM]

BAND : FM

FM RF signal

generator

0.01µF

to ANT

22.5kHz frequency deviation by 400Hz signal.

Output level : as low as possible

level mete

16Ω

set

i REMOTE jack (J301)

+

–

•Repeat the procedures in each adjustment several times.

[MAIN BOARD] — SIDE A —

J501

J301

[MAIN BOARD] — SIDE B —

L5

L1

CT1

CT1 : AM frequency coverage

adjustment

L5 : AM frequency coverage

adjustment

L1 : FM frequency coverage

adjustment

RV603 RV601

WS-48A (4.8 cm/s

adjustment

WS-24CC (24 cm/s)

adjustment

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

620 kHz (US)

L5

621 kHz (Except US)

1400 kHz (US)

CT1

1395 kHz (Except US)

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 76 MHz

Confirmation 108 MHz

1111

WM-GX780/GX788

SECTION 6

DIAGRAMS

Note for Printed Wiring Board and Schematic Diagrams

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• H : adjustment for repair.

•Power voltage is dc 1.5 V and fed with regulated dc power

•Voltages and waveforms are dc with respect to ground

: internal component.

supply from battery terminal.

under no-signal (detuned) conditions.

∗ : impossible to measure

Main board (1/2)

no mark : FM/AM, TAPE STOP

(): FM

[]: AM

<>: TAPE PB

Main board (2/2)

no mark : REC / PB

(): REC

[]: PB

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage var iations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage var iations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

E : PB

a : REC

F : FM

4

W or less unless otherwise

Note on Printed Wiring Board:

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side A) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Side B) the parts face are indicated.

•Abbreviation

CH : Chinese model.

EA : Soudi Arabia model.

JE : Tourist model.

HK : Hong Kong model.

KR : Korea model.

• Wavef orm

1

T401 DD CON OUT

9MHz

IC701 ua XOUT 5µsec/div

2

0.5V/div

75kHz

100nsec/div

5V/div

1212

6-1. Block Diagram

FWD REC/PB HEAD

REV REC/PB HEAD

D1(1/2)

D1(2/2)

FWD

ERACE HEAD

REV

D3

CT1

AM FREQUENCY

L

R

L

R

L5,CT1

COVERAGE

L2D2

TV FREQUENCY

L1D4

FM FREQUENCY

L3

L5

L4

BIAS

Q509

FL1

HPF

FL2

BPF

L2

COVERAGE

L1

COVERAGE

L3

FM/TV

OSC

L5

AM

OSC

Q504

REV/FWD

R-CH

R-CH

SW

1

2

30

29

24

25

27

28

SW

Q506

FWD/REV

SW

Q507,508

BIAS

SELECT

S501

1-2-3

T501

Q511-515,505

FWD/REV

SW

1/2

FM/TV

MIX

TV

OSC

FM

OSC

AM

OSC

AM

MIX

VCCRF

• R-CH is omitted due to same as L-CH.

: FM

: PB

: REC

IC501

REC AMP

44

41

15

REG

6 7 8

REG

IC1

DET

LEVEL

DET

DET

1/16

ALC

FWD/REV

+1.5V

FM

AM

1/8

Q404,407

VT

DET

16

27 CONT D

28 CONT C

REC BIAS

5

Q502

BIAS

OSC

CF1

BPF

4 8 12 13

5 10

CF2

BPF

REC BIAS

Q510

FM/TV/AM TUNER

46

21

23

32REC/PLAY

33

34MIC/RADIO

Q503

SW

RADIO+1.5V

FM/AM/TV

PW SW

IC501-VCC2

VCCRF

IC1-VCC

IC301(1/3)

1

5

15 40

16

FM

MPX

15 R-CH

14 23 MONO/STEREO

19

SW

20

22

23 49 OSC IN

Q501

SW

Q517

SW

Q1

SW

+2.5V

AMS

DET

PRE

AMP

Q2

BUFF

Q702

IC301(3/3)

FILTER

FILTER

RIPLE

RIPLE

Q302

7

1214

191817

Q3

CONT

+1.5V

PRE

44 43 42

45 41

R-CH

S701

S702-710

KEY

REV-STOP-FWD

SW

46

Q305

S801

CUE

REVIEW

IC702

EEPROM

HOLD

ATS SW

Q306

AVLS

1 37 E2P CS

2 39 E2P CLK

3

4

X701

75kHz

S302

RV301

VOL

SYSTEM CONTROL

46 AMS IN

62 AVLS CTL

30 CUE REVIEW

55 PRE CTRL

38 E2P DATA

40 REC CTRL

54 F/R CONT

51 LOCAL/DX

71 X OUT

72 X IN

42 HOLD

58 MAIN KEY

69 MD SW(REV)

68 MD SW(STOP)

67 MD SW(FWD)

45 IF IN

56 MUTE CTL

32 BAND 121

33 BAND 2

52 D0

63 BST CTL

34 AMP CTRL

66 MIC/RADIO

Q303

MB/GRV

IC701

MOTOR BRAKE

+2.5V

IC301(2/3)

AGC

39

RV602

IC401

VOUT

1

Q401-403

DC-DC

CONV

T401

POWER

AMP-L

POWER

AMP-C

LCD701

LCD

3DRSTART

18

RV603

IC901

BATT

2 3

DET

5

28

R-CH

32 21

BEEP

SW

64MB/GRV CTL

36BEEP

65RV CONT

61REMOTE KEY

57R DATA I/O

COM1

1

|

|

COM4

4

5

S1

|

|

22

S18

29PM CTRL

45PHOTO IN

33PHOTO CTRL

59TAPE SW

27

24MOTOR START

28MOTOR DIR

25SPEED CTRL 1

26SPEED CTRL 2

SPEED CONTROL

70RESET

60BATT DET

2

RADIO+1.5V

AGC

DET

Q703,704

PLUNGER

DRIVER

Q701

BUFFER

S303,502,503

TAPE

SW

IC601

MOTOR DRIVER

8

SPEED

CONT

RV602

Q405

Q406

20

29

3533

RV601

SW

SW

Q605-607

+2.5V

IN+VREF

10

1

Q304

RV

SW

SENSER

PH701

W

U

V

IC703

RESET

+1.5V

ANT

REMOTE

24

1

2

R-CH

Q601-604

MOTOR

BRAKE

DATA

R-CH

1.5V

M601

M

WM-GX780/GX788

J301

J501

MIC

NI-MH

1.2V

1313

WM-GX780/GX788

6-2. Printed Wiring Board (Side A)

12

A

B

C

D

E

F

G

:Uses unleaded solder.

34567891011121314

• Semiconductor

Location

Ref. No. Location

D1 C-10

D5 E-11

D101 D-10

D201 D-10

D302 D-11

D303 B-11

D304 B-11

D305 B-10

D401 D-2

IC501 E-8

IC601 E-5

IC703 G-5

IC901 G-6

PH701 D-6

Q305 F-10

Q306 F-10

Q404 G-7

Q405 D-4

Q407 G-7

Q502 D-8

Q504 H-10

Q505 E-8

Q506 G-10

Q507 D-7

Q508 D-7

Q509 H-11

Q510 D-8

Q514 H-10

Q515 H-11

Q516 H-11

Q601 D-4

Q602 E-4

Q603 D-4

Q701 D-6

Q702 G-7

IC601

REV STOP FWD

IC703

IC501

J301

REMOTE

R

L

J501

MIC

(PLUG IN POWER)

S501

ISS

3

2

1

RV301

VOL

H

IC901

I

1414

WM-GX780/GX788

6-3. Printed Wiring Board (Side B)

12

A

S503 S303

REVE TUME TAPE SW

B

C

D

E

L5

AM FERRITE-ROD

F

ANTENNA

:Uses unleaded solder.

34567891011121314

• Semiconductor

Location

Ref. No. Location

D2 E-2

D3 D-3

D4 D-2

D402 D-9

D403 D-8

D404 D-8

D701 D-4

IC1 E-3

IC301 F-4

IC401 D-10

IC701 G-6

IC702 G-5

Q1 F-3

Q2 G-3

Q3 H-2

Q302 G-4

Q303 E-5

Q304 F-5

Q401 D-8

Q402 E-9

Q403 E-8

Q406 D-7

Q501 D-5

Q503 E-4

Q511 I-3

Q512 H-3

Q513 H-3

Q517 E-5

Q604 E-9

Q605 E-8

Q606 E-8

Q607 F-8

Q703 D-4

Q704 D-4

IC1

IC301

SPEED CONTROL

PM901

(PLUNGER)

MENU

ENTER

REC

RADIO ON/

BAND

IC701

REPEAT

S701

HOLD

FF/PRESET+

BATTERY PACK

(Ni-Cd)

NC-6WM 1.2V

S302 S502

RADIO

OFF

FWD TUMEATS SW

IC401

(CAPSTAN/REEL MOTOR)

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

1PC 1.5V

(BATTERY CASE)

M601

U

V

W

G

H

IC702

FLEXIBLE

1

2

3

4

5

6

7

8

9

HP901

L CH

REV

R CH

R CH

FWD

L CH

I

REV

FWD

1515

WM-GX780/GX788

6-4. Schematic Diagram (1/2)

C701

0.047 0B

C702

0.1 0B

C703

0.1 0B

C709

0.1 0B

C704

0.1 0B

C708

10 6.3V P

C705

10p CH

C706

10p CH

470k

S-80808ANNP-E7Y

R901

100k

0.5%

0B

0B

0.0022

0.0022

C809

C810

R704

IC703

RESET IC

R705

C712

0.0022

220k

11B

R902

100k

0.5%

C811

0B

X701

75 KHz

TP34

0.5%

22k

0.5%

47k

R702

R703

R706

220k

220k

R708

R709

220k

F/R SW

S801

• See page 12 for Waveforms. • See page 18 for IC Block Diagram.

LCD701

IC701

IC901

XC62RP1602MR

TP36

R710

220k

XP4315

TC9328AF-118

1B

4V

C707

22

C711

0.47

R735

22k

TP13

TP70

TP37

TP25

R737

4.7k

R711

2.2k

R712

Q701

470k

PH701

PR-20

R741

100k

R707

47k

R714

10k

L701

R701

10k

R739

470k

220k

R738

TP69

TP67

TP68

S302

S303

S503

10k

R724

TP702

TP701

S701

HOLD OFF-ON

TP38

R716

1M

R736

220k

0B

C716

0.047

TP66

S502

10k 0.5%

1M

R740

100k 0.5%

R718

R720

10k

470

0.5%

0.5%

R719

R721

1.5k

100k

0.5%

0.5%

10k

0.5%

R725

220

0.5%

470

0.5%

R733

15k

0.5%

R742

15k

0.5%

C714

11B

TP7

TP8

TP35

IC702

R717

1k

R745

R743

470 0.5%

R744

R746

1.5k 0.5%

TP45

C715

0.047 0B

S703

R722R723

2.2k

S708

0.5%

R726

1k

S707

0.5%

R728

S706

5.6k

0.5%

R729

3.3k

S705

0.5%

R730

3.3k

S704

0.5%

R731R732

4.7k

S709

0.5%

R734

15k

S702

0.5%

S710

AK93C41AV-E2

TP21

D1

C23

SVC347

CT1

10p

TP40

IC401

TP60

C31

0.022 0B

R410

220k

R401

L4

TP6

R408

470k

L401

0.022 0B

BAR ANTENNA

CF1

FM IF

TP2

1k

TP1

0.1 1B

R8

470k

C24

0.022 0B

C19

0.01 0B

C16

0.01 0B

R4

2.2k

C15

TP41

X1

FM-DISCR

CF2

AM IF

TA

4V

C9

47

R414

47k 0.5%

R415

22k 0.5%

10k

C414

470p 0B

R412

R413

4.7k

C415

0.5%

0.47 1B

0B

0B

Q407

2SC4617TL-Q

220p

0.01

Q404

C416

C409

2SC4617TL-Q

TP23

R10

100k

C35

0.0022

*

FL1

COIL,FM RF

MA2S357

C34

0.0022 0B

D4

C6

TP63

4.7

6.3V

P

Q405

UMZ8NTR

R409

4.7k

XC6383C251ML

D401

ISS367

TA

0B

4V

C417

C412

0.1

22

TP59

3p

C20

0.0022 0B

CH

C39

220p

R12

*

*

D5

C1

0.001

0B

1B

1

C710

*

R11

TP61

BP1

L1

C33

C38

0.001

0B

C17

0.01 0B

IC1

TA2154FN

TUNER IC

C3

0.001

0B

C30

470p CH

R7

L5

10k

AM OSC

CH

R9

470k

TP3

C4

0.1 0B

C2

4.7

6.3V

P

1k

C7

R1

470p

0B

1B

0.47

C8

R411

R402

47k

4.7k

0.5%

F

0B

16V

0.022

C402

C401

CH

10p

10p

C29

C37

TP4

0B

0B

0B

0.01

0.022

0.047

C11

C5

C10

0B

0.01

C12

R403

470

0B

0.022

MAZS130

C404

D402

1B

1

C403

0.047 0B

C46

0.047 0B

C14

0.022

L402

1B

1

C406

2p

C40

C13

0.022

XP1215-TXE

XP4501

C45

R22

10k

R21

10k

2.2k

R2

2.2k

R3

R26

TP5

0B

0B

0.01

0.01

C44

C43

D403

MA2S111

D404

MA2SD1000L

P

6.3V

Q401

2SD1048

10

C407

L3

R25

0

FM-OSC

22nH

0

Q2

0.0022 0B

Q3

R404

47

Q403

12A02S-TL

DC/DC

100k

R6

C28

100p

C21

T401

C408

0.01

0B

D3

MA2S357

R19

10k

12A02S-TL

Q402

2SC4617TL-Q

CH

100p

C36

R18

10k

1k

R24

R23

100k

Q1

Q406

12A02S-TL

1B

1

680

C413

R405

Q704

12A02S-TL

W1

TP39

TP62

Q703

UN9216

W2

MA111

D701

W3

R17

4.7k

R13

4.7k

TP65

TP64

L403

47k

R407

P

1k

R406

1B

6.3V

1

10

C411

C410

1616

WM-GX780/GX788

6-5. Schematic Diagram (2/2)

Q601

12A02S-TL

CN3

TP55

TP56

TP57

M601

TP51

CB301

680P (SL)

C102

22 4V TA

R109

220

R108

22k

R102

R202

R208

22k

R209

220

C202

22 4V TA

D304

FB1

MA8051

0UH

FB2

0UH

FB3

0UH

FB4

0UH

J301

7P

CN1

• See page 18 for IC Block Diagrams.

TP33

TP32

Q604

UN5216QRS-(TX)

47k

TP601

470

470

R607

R608

Q602

Q603

12A02S-TL

12A02S-TL

R620 R621

470k 470k

TP30

R118

470

R110

R114

22k

10k

C104

C204

R214

10k

L301

L101

L201

1k

1k

0.047 0B

0.047 0B

R218

470

R112

C103

220k

0.022

0B

R111

R211

C203

0.022

R212

0B

220k

R210

22k

R203

22k

C319

0.1

R615

470

R614

470k

R616

Q607

XP1115

R617

470k

TP27

47

2.5V

C302

1B

2.2

C303

1k

1k

22k

C317

22k

0.0047

0B

R103

0B

F701

0.25A

R303

R304

47k

R302

C304

220k

0.1 0B

TP42

R113

*1

R610

220k

R609

220k

R611

C609

0.047

0B

Q605

TP58

HNIKO2FU

R603

0

IC301

TA2123AF

IC301: Impossible to measure

C305

22 4V

0.47

C105

22k

22

2.2

R305

C306

R104

TP44

220k

TH601

R213

100

*1

C608

0.0047 0B

C604

LB11675V-TLM

1B

0.22

C605

TP18

4.7

R306

0.001

C323

TP43

F

0.22

IC601

4.7k

RV602

0.47

C205

2.2

R204

R604

RV601

MA8051

4.7k

15k

MA8051

MA8051

D201

0

R613

R622

4.7k

C308

12A02S-TL

C309

4.7

6.3V

D305

MA8051

D303

D302

D101

MA8051

0B

C606

0.0047 0B

C607

0.0047

C603

1B

1B

100k

0.047

R601

C601

47k

R516

10k

R605

22k

RV603

Q606

HNIKO2FU

1B

220

R602

R619

2.2k

P

4.7

6.3V

Q302

C602

1B

1

C314

C311

0.1 0B

470k

R307

R301

2.2 4V

C312

0.22 1B

C316

C106

C206

2.2k

C315

0.047

1B

11B

R106

2.2k

R116

4.7k

R206

2.2k

R105

1B

1k

R205

1B

1k

XP1115

Q303

UN9116

Q304

Q306

XP1116

TP19

TP20

1B

*2

*2

R107

R215

1B

C107

C207

RV301

RES, VAR

30K/30K

C310

C318

0.1

C313

0.22 1B

C320

0.022

0B

R216

4.7k

C322

0.022

0B

C201

C101

0.001

0.001

0B

0B

Q305

XP1215

100k

R524

1B

1

C529

4.7 6.3V

100k

C537

R517

R526

1B

1

C540

220

R115

470

C536

4.7 6.3V

470

R510

F

F

1

1

C527

C528

R523

1.0M

R522

470k

Q501

XP4315

Q517

1SA02S-TL

TP54

220

R207

IC501

LA3235W

C523

4V

22

C524

Q510

12A02S-TL

2.5V

4V

R528

47

22

4.7k

C514

C535

C509

R508

0.0047

0.0022

Q503

DTC143TETL

Q504

C513

2.2 4V B

C515

C516

C517

C518

C519

CH

100p

TP53

10k

0B

C511

0B

1B

C521

0.22

B

F

1

6.3V

C520

1

C522

2.2

4V

Q508

XP1215

22

R505

C504

Q502

2SD596

L501

C534 C533

220p CH 220p CH

T501

11B

1F

1F

1F

1F

C503

2200p

SL

R513

10k

0.0022 0B

C507

R511

10k

0.0022 0B

C508

R520

10k

0.0022 0B

C506

R512

10k

C538

10k

R525

C541

10k

R527

TP48TP52

C531 C532

470p 0B 470p 0B

S501

1-2-3

11B

11B

XP1215

R509

10k

C505

0.0022

0B

Q507

XP1115

Q512

2SJ344

Q511

2SK2009

R507

10k

R519

470

C510

1 6.3V B

C512

1 6.3V B

Q506

XP1115

R506

R504

10k

10k

R518

470

Q509

XN4404

Q505

DTC144TETL

*3

R514

Q513 Q515Q516

2SK2009 2SK20092SK2009

FB502

0UH

TP31

FB503

0UH

TP46

FB501

TP47

P

6.3V

4.7k

10

R503

C502

R521

470

TP29

TP49

Q514

2SJ344

R529

470k

R515

0UH

R502

C525

4.7k

0.001

0B

C526

0.001

0B

TP28

TP26

TP22

TP50

TP24

2.2M

CN301

J501

3P

9P

1717

WM-GX780/GX788

6-6. IC Block Diagrams

IC1 TA2154FN(EL) IC301 TA2123AF(EL)

CONT B

CONT C

N.C.

REC MUTE

MIC/RADIO

FWD/REV

REC/PLAY

CONT F

CONT A

3536 34 33 32 31 30 29 28 27 26 25

CONT D

CONT E

N.C.

IC501 LA3235W

AGC DET

AGC IN

BST NF

BST OUT

IN-C

LPF

EQ R

NF-R

IN-R

IN-L

PW NF-L

36 35 34 33 32 31 30 29 28 27 26 25

EQ-L

V REF

GND

REV REC L

REV REC R

FWD REC R

FWD REC L

VCC2

MONITOR L

MONITOR R

IC601 LB11675V-TLM

N.C.

REF

N.C.

37

38

V REF

39

40

41

42

43

44

45

46

47

48

SYSTEM CONTROL

REV

REC

AMP

FWD

REC

AMP

MONITOR

AMP

MIC

REGULATOR

123456789101112

N.C.

MIC REG

MIC REG REF

VCC2

( ):REC

REC BIAS REGULATOR

OSC

REC BIAS REG

REC BIAS REG REF

(FWD)

PLAY(REV)

BASE

(REV)

PLAY(FWD)

VCC1

(REV)

(REV)

PLAY(FWD)

DET

VCCRF

PLAY

PLAY(FWD)

ALC

GND

REC

ALC

AMP

ALC

AMP

L

R

N.C.

24

23

22

21

20

19

18

17

16

15

14

13

GND

MIC IN L

NF L

RADIO IN L

MIC IN R

NF R

RADIO IN R

MIC OUT R

MIC OUT L

REC IN L

REC IN R

N.C.

CAMP SW

MT TC

BEEP

AMS OUT

MT SW

PW SW

BST SW

F/R SW

PRE SW

M/N SW

PRE GND

VREF IN

AGC

DET

37

38

39

BEEP

40

41

42

SW

43

44

45

46

47

48

VREF

–

BST

+

RF IN

24

PW GND

23

–

PWC

PWB

+

+

PWA

–

OUT L

22

OUT C

21

OUT R

20

+

VCC

TOMP

–

RIPPLE

FILTER

PREA

+

–

PREB

+

–

MIX

+

–

19

18

17

16

15

14

13

BASE

RF OUT

GND

AMS

AMS

AMS

MTL DRV

W OUT NC NC PGND COM FC

24

23 22 21 20 19 18 17 16 15 14 13

STARTING

DETECTION

VCC

POWER

SUPPLY

BIAS

VCC

10K

PREDRIVER

DR

REF

VOLTAGE

OSC

CIRCUIT

PV

PU

SOFT SW

SPEED

DETECTION

PW TC2 TC1

STARTING LOGIC

COMMUNICATION/

CURRENT

DETECTION

12111098765321 4

IN

IN

REF OUT

IN

IN

NF

OUT

MTL

MTL

OUT

NF

AMS IN

1

V OUT V OUT START PGND GND VCCI

1818

2 3 4 5 6 7 8 9 10 11 12

OSC

V REF

VSP

IN + OUT RI

6-7. IC Pin Function Description

• IC701 TC9328AF-118

WM-GX780/GX788

Pin No.

1 to 4

5 to 22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Pin Name

COM 1 to

COM 4

S1 to S18

MONO/

STEREO

MOTOR

START

SPEED CTRL1

SPEED CTRL2

MOTOR

BREAK

MOTOR DIR

PM CTRL

CUE REVIEW

VDD

BAND1

BAND2

AMP CTRL

PHOTO CTRL

BEEP

E2P CS

E2P DATA

E2P CK

REC CTRL

TEST

HOLD

E2P WRITE IN

PHOTO IN

IF IN

AMS IN

GND

NC

OSC IN

VDD

I/O

O

Common terminal.

O

Segment output terminal.

O

Stereo/Mono select terminal (H :STEREO / L:MONO)

O

Motor start terminal (H-Imp:Motor Off/ L:Motor ON.)

O

Refer Speed Ctrl List (page 20)

O

Refer Speed Ctrl List (page 20)

O

Motor break terminal (H:Motor Break/ L:Motor Break Off)

O

Motor direction terminal (H:CCW/ L:CW)

O

PL control terminal. (H:PL ON/ L:Normal)

O

H : Cue/Review/ L:Normal

—

Power supply voltage.

O

H: AM/TV(H) L: STOP/FM/TV(L)

O

H: FM,TV(L),TV(H) L: STOP/AM

O

H:AMP ON / L:AMP OFF

O

H:On / L:Off

O

BEEP terminal.

O

EEPROM chip select

I/O

EEPROM DATA output

O

EEPROM clock terminal.

O

Recording control terminal. (H:Normal/ L:Rec)

—

TEST terminal

I

Hold control input. (H:HOLD OFF / L:HOLD ON)

I

H:NORMAL / L:E2P Write in mode

I

Photo input terminal.

I

IF input.

I

Tape sound existing or not-exiting detect (L: Music exists: H: Music does not exist).

—

Power supply Ground terminal.

—

Non connection terminal.

I

OSC input terminal

—

Power supply voltage.

Description

19

WM-GX780/GX788

Pin No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Pin Name

LOCAL//DX

DO

VREG

F/R CTRL

PRE CTL

MUTE CTL/

IF REQ

R DATA I/O

MAIN KEY

TAPE SW

BATT DET

REMOTE KEY

AVLS CTL

BST CTL

MB/GRV CTL

RV CTL

MIC/RADIO

MD SW (FWD)

MD SW(STOP)

MD SW (REV)

RESET

XOUT

XIN

GND

VDB

C1

C2

VEE

C3

C4

VLCD

I/O

O

TUNER sensitivity select terminal (H: LOCAL, L: DX).

O

Phase comparator output.

—

Power supply voltage.

O

HEAD select terminal (L: FWD, H: REW).

O

PRE AMP control terminal.(H :AMP OFF / L :AMP ON)

O

H : MUTE OFF / L:MUTE ON (IF Req ON)

I/O

Remote data I/O terminal.

I

Main Set key in.

I

Tape switch, Fwd Tsume, Rvs Tsume.

I

Voltage detect input.

I

Remote control key in.

O

Terminal for controlling AVLS (when ON=H).

O

Tone control terminal (L: normal, Hi-imp: MEGA BASS).

O

Tone control terminal (L: GRV, H: MB).

O

Revive control terminal.

O

Rec input select terminal.(L : RADIO ON, H : MIC)

I

Mecha Position switch

I

Mecha Position switch

I

Mecha Position switch

I

RESET terminal (H during operation).

O

Terminal to which external oscillator is connected.

I

—

Power supply Ground terminal.

—

Terminal to which external oscillator is connected.

—

Terminal to step-up power supply voltage for LCD drive.

—

—

Terminal for 1.5V constant voltage power supply of LCD drive.

—

Terminal to step-up power supply voltage for LCD drive.

—

—

Terminal to step-up power supply voltage for LCD drive. (3V)

Description

SPEED CTL LIST

ACTION

PLAY

FF/REW , AMS+/AMS-, REC

1/2PLAY

1/2REC, CUE/REVIEW

20

SPEED CTL1

H

H

L

L

SPEED CTL2

H-Imp

L

H-Imp

L

TAPE SPEED

NORMAL

NORMAL

1/2

1/2

SPEED CTL

OK

NON

OK

NON

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference number

in the exploded views are not supplied.

7-1. Case Section

SECTION 7

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet’s Color

8

9

WM-GX780/GX788

• Accessories are given in the last of electrical

parts list.

•Abbreviation

CH : Chinese model.

EA : Soudi Arabia model.

JE : Tourist model.

HK : Hong Kong model.

KR : Korea model.

10

7

17

18

12

13

14

15

4

5

6

16

3

16

19

16

2

1

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-245-675-01 WINDOW, LCD (SILVER) (GX788)

1 3-245-675-11 WINDOW, LCD (BLUE) (GX788)

1 3-245-675-21 WINDOW, LCD (GX780)

2 3-245-678-01 KNOB (REC)

3 3-245-673-01 CASE (SILVER)

3 3-245-673-11 CASE (BLUE) (GX788)

4 3-034-066-02 KNOB (ISS)

5 3-254-488-01 KNOB (OPEN)

6 3-029-220-11 SPRING, TENSION

7 3-233-968-01 ORNAMENT, REEL

8 3-245-674-01 PLATE, COVER (SILVER)

8 3-245-674-11 PLATE, COVER (BLUE) (GX788)

9 A-3608-446-A BUTTON ASSY (GX788)

9 A-3608-550-A BUTTON ASSY (GX780)

10 3-222-892-01 SPRING (HOLD), TORSION

12 3-245-677-01 KNOB (HOLD)

13 3-248-891-01 SPRING, REC

14 3-245-679-01 BUTTON REC

15 3-245-680-01 ORNAMENT PLATE TERMINAL

16 3-225-996-11 SCREW (M1.4)(EG),PRECISION PAN

(FOR SILVER)

16 3-225-996-12 SCREW (M1.4)(EG),PRECISION PAN

(FOR BLUE)

17 3-248-889-01 ADHESIVE, COVER PLATE

18 3-248-887-01 ADHESIVE, BUTTON OPERATE

19 3-248-890-01 ADHESIVE, WINDOW LCD

21

WM-GX780/GX788

Ver 1.1 2003.10

7-2. Main Section

MF-WMGX788-162

69

S303,

S503

69

57

60

62

64

73

63

74

73

75

65

72

66

67

59

71

70

56

58

5570

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-034-068-51 LID, BATTERY (FOR SILVER)

51 3-034-068-91 LID, BATTERY (FOR BLUE)

52 X-3383-152-1 TERMINAL BOARD ASSY, BATT /G

53 3-038-057-01 TERMINAL BOARD, BATTERY

54 3-031-460-01 SHEET (BT)

55 3-034-074-11 RETAINER, FLEXIBLE

56 3-375-114-71 SCREW

57 3-038-056-01 TERMINAL BOARD (MINUS) (/M)

58 3-248-885-01 KNOB SPEED CONTROL

* 59 A-3608-404-A MAIN BOARD, COMPLETE (E,KR,HK,JE)

* 59 A-3608-474-A MAIN BOARD, COMPLETE (US)

* 59 A-3608-536-A MAIN BOARD, COMPLETE (CH,EA)

* 59 A-3608-544-A MAIN BOARD, COMPLETE (AEP)

60 X-3377-717-2 BRACKET ASSY (/M)

62 3-035-199-01 SHEET (GR3)

63 3-246-486-11 MD COVER

64 X-3383-281-1 LID ASSY, CASSETTE (BLUE) (GX788:E)

64 X-3383-298-1 LID ASSY, CASSETTE (SILVER)

64 X-3383-317-1 LID ASSY, CASSETTE (BLUE)

68

S302,

S502

54

69

51

(GX780/GX788:US,CH,KR,HK,EA,JE)

(GX780/GX788:US,CH,KR,HK,EA,JE)

53

52

56

64 X-3383-309-1 LID ASSY, CASSETTE (BLUE) (GX788:AEP)

65 3-245-282-01 WINDOW (CASSETTE)

66 X-3377-719-1 BRACKET (CASSETTE) ASSY (/M)

67 3-038-054-01 LEVER (B) (/M), LOCK

68 1-672-579-11 PWB, ATS FLEXIBLE

69 3-366-890-02 SCREW (M1.4)

70 3-704-197-01 SCREW (M1.4X1.6), LOCKING

71 3-345-648-71 SCREW (M1.4), TOOTHED LOCK

72 3-365-630-41 SCREW (M1.4)

73 3-225-996-09 SCREW (M1.4)(EG),PRECISION PAN

(FOR SILVER)

73 3-225-996-10 SCREW (M1.4)(EG),PRECISION PAN

(FOR BLUE)

74 3-039-616-01 SHEET (GR9)

75 3-029-225-11 SHEET (CASSETTE WINDOW)

S302 1-692-100-11 SWITCH, LEAF (ATS)

S303 1-692-101-11 SWITCH, LEAF (TAPE DETECT)

S502 1-692-100-11 SWITCH, LEAF (FWD TUME)

S503 1-692-101-11 SWITCH, LEAF (REV TUME)

22

7-3. Mechanism Deck Section (MF-WMGX788-162)

114

113

110

109

WM-GX780/GX788

117

M901

125

123

124

132

126

107

112

PM901

108

122

104

111

127

121

103

116

128

106

105

115

HP901

129

130

133

118

119

129

127

120

131

122

121

101

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 X-3377-589-3 HOLDER (FA) ASSY /M

102 X-3377-228-1 LEVER (RA) ASSY, PINCH

103 3-046-789-01 SPRING (HDA)

104 X-3377-227-1 LEVER (NA) ASSY, PINCH

105 3-029-276-02 WASHER (STOPPER R)

106 3-029-289-01 WASHER

107 3-029-275-01 WASHER (STOPPER N)

108 3-029-278-01 WASHER

109 X-3376-813-1 CLUTCH ASSY (FM)

110 3-932-724-21 WASHER

111 3-040-897-04 SPRING (TGA), TORSION

112 3-386-694-01 WASHER

113 X-3379-420-1 FLYWHEEL (N), INSERT

114 3-221-357-01 BELT (F0)

115 X-3379-421-1 FLYWHEEL (R), INSERT

116 3-007-428-01 WASHER (R)

117 3-029-765-01 SCREW (M1.4), TOOTHED LOCK

118 3-029-883-01 RETAINER (F1), MOTOR

102

119 3-007-433-12 SHEET (N), REFLECTION

120 X-3377-584-5 CHASSIS ASSY (FA)

121 3-010-274-02 TABLE, REEL

122 3-010-954-01 SPRING (BT), COMPRESSION

123 3-029-282-12 GEAR (Y)

124 3-029-285-02 GEAR, CAM

125 3-029-284-13 LEVER, TRIGGER

126 3-029-281-01 GEAR, IDLER (B)

127 3-010-273-02 GEAR (REEL)

128 3-029-273-01 GEAR (FR)

129 3-029-283-02 GEAR, IDLER (A)

130 3-029-286-01 GEAR (NR)

131 3-029-288-11 PULLEY, REVERSE

132 3-033-757-01 SHEET (H)

133 3-032-575-11 LEVER, HEAD

M901 1-787-000-11 MOTOR

HP901 1-500-355-22 HEAD, MAGNETIC (REC/PB/ERASE)

PM901 1-454-674-32 SOLENOID, PLUNGER

23

WM-GX780/GX788

SECTION 8

MAIN

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• Accessories and packing materials are given in

the last of this parts list.

• CAPACITORS:

uF: µF

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-3608-536-A MAIN BOARD, COMPLETE (CH,EA)

*********************

* A-3608-404-A MAIN BOARD, COMPLETE (E,KR,HK,JE)

*********************

ELECTRICAL PARTS LIST

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

•Abbreviation

CH : Chinese model.

EA : Soudi Arabia model.

JE : Tourist model.

HK : Hong Kong model.

KR : Korea model.

C37 1-164-850-11 CERAMIC CHIP 10PF 0.50PF 50V

C38 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C39 1-164-882-11 CERAMIC CHIP 220PF 5.00% 16V

C40 1-164-842-11 CERAMIC CHIP 2PF 0.25PF 50V

C43 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

* A-3608-474-A MAIN BOARD, COMPLETE (US)

*********************

* A-3608-544-A MAIN BOARD, COMPLETE (AEP)

*********************

1-126-236-11 ELECT 330uF 20.00% 2V

3-245-681-01 HOLDER, LCD

3-245-683-01 RUBBER, CONDUCTIVE

< CAPACITOR >

C1 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C2 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C3 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C4 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C5 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C6 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C7 1-164-935-11 CERAMIC CHIP 470PF 10.00% 50V

C8 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C9 1-131-862-91 TANTAL. CHIP 47uF 20% 4V

C10 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C11 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C12 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C13 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C14 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C15 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C44 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C45 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C46 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C101 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C102 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C103 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C104 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C105 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C106 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C107 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C201 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C202 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C203 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C204 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C205 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C206 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C207 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C302 1-119-663-11 TANTAL. CHIP 47uF 20.00% 2.5V

C303 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C304 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C305 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C306 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C308 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C309 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C310 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C16 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C17 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C19 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C20 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C21 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C23 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C24 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C28 1-164-874-11 CERAMIC CHIP 100PF 5.00% 50V

C29 1-164-850-11 CERAMIC CHIP 10PF 0.50PF 50V

C30 1-164-315-11 CERAMIC CHIP 470PF 5.00% 50V

C31 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C33 1-164-843-11 CERAMIC CHIP 3PF 0.25PF 50V

C34 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C35 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C36 1-164-874-11 CERAMIC CHIP 100PF 5.00% 50V

24

C311 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C312 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C313 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C314 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C315 1-165-176-11 CERAMIC CHIP 0.047uF 10.00% 16V

C316 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C317 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C318 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C319 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C320 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C322 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C323 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C401 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C402 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C403 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

WM-GX780/GX788

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C404 1-107-819-11 CERAMIC CHIP 0.022uF 10.00% 16V

C406 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C407 1-117-919-11 TANTAL. CHIP 10uF 20.00% 6.3V

C408 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C409 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C701 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C702 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C703 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C704 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C705 1-164-850-11 CERAMIC CHIP 10PF 0.50PF 50V

C410 1-117-919-11 TANTAL. CHIP 10uF 20.00% 6.3V

C411 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C412 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C413 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C414 1-164-935-11 CERAMIC CHIP 470PF 10.00% 50V

C415 1-125-891-11 CERAMIC CHIP 0.47uF 10.00% 10V

C416 1-164-933-11 CERAMIC CHIP 220PF 10.00% 50V

C417 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C502 1-117-919-11 TANTAL. CHIP 10uF 20.00% 6.3V

C503 1-164-676-11 CERAMIC CHIP 2200PF 5.00% 16V

C504 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C505 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C506 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C507 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C508 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C509 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C510 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C511 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C512 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C513 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C514 1-119-663-11 TANTAL. CHIP 47uF 20.00% 2.5V

C515 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C516 1-115-156-11 CERAMIC CHIP 1uF 10V

C517 1-115-156-11 CERAMIC CHIP 1uF 10V

C518 1-115-156-11 CERAMIC CHIP 1uF 10V

C519 1-115-156-11 CERAMIC CHIP 1uF 10V

C520 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C521 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C522 1-115-156-11 CERAMIC CHIP 1uF 10V

C523 1-164-874-11 CERAMIC CHIP 100PF 5.00% 50V

C524 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C525 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C526 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 50V

C527 1-115-156-11 CERAMIC CHIP 1uF 10V

C528 1-115-156-11 CERAMIC CHIP 1uF 10V

C529 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C531 1-164-935-11 CERAMIC CHIP 470PF 10.00% 50V

C532 1-164-935-11 CERAMIC CHIP 470PF 10.00% 50V

C533 1-164-882-11 CERAMIC CHIP 220PF 5.00% 16V

C534 1-164-882-11 CERAMIC CHIP 220PF 5.00% 16V

C535 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C536 1-125-926-91 TANTAL. CHIP 4.7uF 20% 6.3V

C537 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C538 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C540 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C541 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C601 1-165-176-11 CERAMIC CHIP 0.047uF 10.00% 16V

C602 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C603 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C604 1-165-128-11 CERAMIC CHIP 0.22uF 16V

C605 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C606 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C607 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C608 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C609 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C706 1-164-850-11 CERAMIC CHIP 10PF 0.50PF 50V

C707 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C708 1-117-919-11 TANTAL. CHIP 10uF 20.00% 6.3V

C709 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C710 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C711 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C712 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C714 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C715 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C716 1-119-923-81 CERAMIC CHIP 0.047uF 10.00% 10V

C809 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C810 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

C811 1-164-939-11 CERAMIC CHIP 0.0022uF 10.00% 50V

< CAPACITOR BLOCK >

CB301 1-117-968-41 CAP, CHIP CERAMIC 680PF SL

< FILTER >

CF1 1-767-362-11 FILTER, CERAMIC

CF2 1-767-480-11 FILTER, CERAMIC (AM)

< CONNECTOR >

CN301 1-766-620-21 CONNECTOR, FFC/FPC 9P

< TRIMMER >

CT1 1-141-313-11 CAP, CHIP TYPE TRIMMER 10PF

< DIODE >

D1 8-719-072-60 DIODE SVC347T-TL

D3 8-719-080-77 DIODE MA2S357(E)-(TX).SO

D4 8-719-080-77 DIODE MA2S357(E)-(TX).SO

D5 1-216-864-11 METAL CHIP 0 5% 1/16W

(GX780:CH/GX788:AEP,CH,EA)

D5 6-500-174-01 DIODE MA2SP0100LSO

(GX780:KR/GX788:US,E,KR,HK,JE)

D101 8-719-422-37 DIODE MA8051-TX

D201 8-719-422-37 DIODE MA8051-TX

D302 8-719-422-37 DIODE MA8051-TX

D303 8-719-422-37 DIODE MA8051-TX

D304 8-719-422-37 DIODE MA8051-TX

D305 8-719-422-37 DIODE MA8051-TX

D401 8-719-049-09 DIODE 1SS367-T3SONY

D402 8-719-056-60 DIODE MAZS130008SO

D403 8-719-046-91 DIODE MA2S111-TX

D404 8-719-074-07 DIODE MA2SD10001S0

D701 8-719-404-50 DIODE MA111-TX

< FUSE >

0F701 1-576-439-21 FUSE (SMD) 0.25A 125V

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

25

WM-GX780/GX788

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< FERRITE BEAD >

FB1 1-414-760-21 FERRITE 0uH

FB2 1-414-760-21 FERRITE 0uH

FB3 1-414-760-21 FERRITE 0uH

FB4 1-414-760-21 FERRITE 0uH

FB501 1-414-760-21 FERRITE 0uH

FB502 1-414-760-21 FERRITE 0uH

FB503 1-414-760-21 FERRITE 0uH

Q305 8-729-426-36 TRANSISTOR XP1215-TXE

Q306 8-729-425-94 TRANSISTOR XP1116-TXE

Q401 8-729-800-37 TRANSISTOR 2SD1048X6-TB

Q402 8-729-927-99 TRANSISTOR 2SC4617TL-Q

Q403 6-550-623-01 TRANSISTOR 12A02S-TL

Q404 8-729-927-99 TRANSISTOR 2SC4617TL-Q

Q405 6-550-075-01 TRANSISTOR UMZ8NTR

Q406 6-550-623-01 TRANSISTOR 12A02S-TL

Q407 8-729-927-99 TRANSISTOR 2SC4617TL-Q

< FILTER >

FL1 1-239-015-21 FILTER, BAND PASS

< IC >

IC1 6-701-310-01 IC TA2154FN(EL)

IC301 8-759-579-12 IC TA2123AF(EL)

IC401 8-759-553-28 IC XC6383C251ML

IC501 8-759-428-23 IC LA3235W

IC601 6-704-202-01 IC LB11675V-TLM

IC701 6-802-988-01 IC TC9328AF-118

IC702 6-704-077-01 IC AK93C41A

IC703 8-759-572-21 IC S-80808ANNP-E7Y-T2

IC901 8-759-457-70 IC XC62RP1602MR

< JACK >

J301 1-779-867-81 JACK(REMOTE)

J501 1-766-907-43 JACK 3P(MIC)

< COIL >

L1 1-428-919-21 COIL, FM RF

L3 1-469-916-21 INDUCTOR 22NH

L4 1-456-357-11 BAR ANTENNA

L5 1-406-404-11 COIL (MW OSCILATION)

L101 1-414-760-21 FERRITE 0uH

Q501 8-729-425-46 TRANSISTOR XP4315-TXE

Q502 8-729-141-75 TRANSISTOR 2SD596-T1DV4

Q503 8-729-929-23 TRANSISTOR DTC143TE-TL

Q504 8-729-425-89 TRANSISTOR XP1115-TXE

Q505 8-729-929-32 TRANSISTOR DTC144TE-TL

Q506 8-729-425-89 TRANSISTOR XP1115-TXE

Q507 8-729-426-36 TRANSISTOR XP1215-TXE

Q508 8-729-426-36 TRANSISTOR XP1215-TXE

Q509 8-729-422-39 TRANSISTOR XN4404-TX

Q510 6-550-623-01 TRANSISTOR 12A02S-TL

Q511 8-729-028-27 TRANSISTOR 2SK2009(TE85L)

Q512 8-729-028-23 TRANSISTOR 2SJ344(TE85L)

Q513 8-729-028-27 TRANSISTOR 2SK2009(TE85L)

Q514 8-729-028-23 TRANSISTOR 2SJ344(TE85L)

Q515 8-729-028-27 TRANSISTOR 2SK2009(TE85L)

Q516 8-729-028-27 TRANSISTOR 2SK2009(TE85L)

Q517 8-729-037-64 TRANSISTOR UN9116J-(TX).SO

Q601 6-550-623-01 TRANSISTOR 12A02S-TL

Q602 6-550-623-01 TRANSISTOR 12A02S-TL

Q603 6-550-623-01 TRANSISTOR 12A02S-TL

Q604 8-729-421-26 TRANSISTOR UN5216QRS-TX

Q605 8-729-038-06 TRANSISTOR HN1K02FU(TE85L)

Q606 8-729-038-06 TRANSISTOR HN1K02FU(TE85L)

Q607 8-729-425-89 TRANSISTOR XP1115-TXE

Q701 8-729-425-46 TRANSISTOR XP4315-TXE

L201 1-414-760-21 FERRITE 0uH

L301 1-414-760-21 FERRITE 0uH

L401 1-412-033-11 INDUCTOR CHIP 220uH

L402 1-412-010-41 INDUCTOR 22uH

L403 1-412-010-41 INDUCTOR 22uH

L501 1-412-010-41 INDUCTOR 22uH

L701 1-412-010-41 INDUCTOR 22uH

< LIQUID CRYSTAL DISPLAY >

LCD701 1-804-966-11 LCD

< PHOTO INTERRUPTER >

PH701 8-749-014-43 PHOTO REFLECTOR PR-20-T

< TRANSISTOR >

Q1 6-550-623-01 TRANSISTOR 12A02S-TL

Q2 8-729-427-72 TRANSISTOR XP4501-TXE

Q3 8-729-426-36 TRANSISTOR XP1215-TXE

Q302 6-550-623-01 TRANSISTOR 12A02S-TL

Q303 8-729-037-64 TRANSISTOR UN9116J-(TX).SO

Q304 8-729-425-89 TRANSISTOR XP1115-TXE

Q703 8-729-013-60 TRANSISTOR UN9216J-(TX).SO

Q704 6-550-623-01 TRANSISTOR 12A02S-TL

< RESISTOR >

R1 1-218-953-11 RES-CHIP 1K 5% 1/16W

R2 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R3 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R4 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R6 1-218-977-11 RES-CHIP 100K 5% 1/16W

R7 1-218-965-11 RES-CHIP 10K 5% 1/16W

R8 1-218-985-11 RES-CHIP 470K 5% 1/16W

R9 1-218-985-11 RES-CHIP 470K 5% 1/16W

R10 1-218-977-11 RES-CHIP 100K 5% 1/16W

R11 1-218-953-11 RES-CHIP 1K 5% 1/16W

(GX780:KR/GX788:US,E,KR,HK,JE)

R12 1-218-953-11 RES-CHIP 1K 5% 1/16W

(GX780:KR/GX788:US,E,KR,HK,JE)

R13 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R17 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R18 1-218-965-11 RES-CHIP 10K 5% 1/16W

R19 1-218-965-11 RES-CHIP 10K 5% 1/16W

R21 1-218-965-11 RES-CHIP 10K 5% 1/16W

R22 1-218-965-11 RES-CHIP 10K 5% 1/16W

26

WM-GX780/GX788

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R23 1-218-977-11 RES-CHIP 100K 5% 1/16W

R24 1-218-953-11 RES-CHIP 1K 5% 1/16W

R25 1-218-990-11 SHORT CHIP 0

R26 1-218-990-11 SHORT CHIP 0

R408 1-218-953-11 RES-CHIP 1K 5% 1/16W

R409 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R410 1-218-981-11 RES-CHIP 220K 5% 1/16W

R411 1-208-927-11 METAL CHIP 47K 0.5% 1/16W

R102 1-218-953-11 RES-CHIP 1K 5% 1/16W

R103 1-218-969-11 RES-CHIP 22K 5% 1/16W

R104 1-244-161-81 RES-CHIP 2.2 5% 1/16W

R105 1-218-953-11 RES-CHIP 1K 5% 1/16W

R106 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R107 1-208-635-11 RES-CHIP 10 5% 1/16W

(GX780/GX788:US,E,CH,KR,HK,EA,JE)

R107 1-218-945-11 RES-CHIP 220 5% 1/16W

(GX788:AEP)

R108 1-218-969-11 RES-CHIP 22K 5% 1/16W

R109 1-218-945-11 RES-CHIP 220 5% 1/16W

R110 1-218-969-11 RES-CHIP 22K 5% 1/16W

R111 1-218-953-11 RES-CHIP 1K 5% 1/16W

R112 1-218-981-11 RES-CHIP 220K 5% 1/16W

R113 1-218-990-11 SHORT CHIP 0

(GX780/GX788:US,E,CH,KR,HK,EA,JE)

R113 1-218-941-81 RES-CHIP 100 5% 1/16W

(GX788:AEP)

R114 1-218-965-11 RES-CHIP 10K 5% 1/16W

R115 1-218-945-11 RES-CHIP 220 5% 1/16W

R116 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R118 1-218-949-11 RES-CHIP 470 5% 1/16W

R202 1-218-953-11 RES-CHIP 1K 5% 1/16W

R203 1-218-969-11 RES-CHIP 22K 5% 1/16W

R204 1-244-161-81 RES-CHIP 2.2 5% 1/16W

R205 1-218-953-11 RES-CHIP 1K 5% 1/16W

R206 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R207 1-218-945-11 RES-CHIP 220 5% 1/16W

R208 1-218-969-11 RES-CHIP 22K 5% 1/16W

R209 1-218-945-11 RES-CHIP 220 5% 1/16W

R210 1-218-969-11 RES-CHIP 22K 5% 1/16W

R211 1-218-953-11 RES-CHIP 1K 5% 1/16W

R212 1-218-981-11 RES-CHIP 220K 5% 1/16W

R213 1-218-990-11 SHORT CHIP 0

(GX780/GX788:US,E,CH,KR,HK,EA,JE)

R213 1-218-941-81 RES-CHIP 100 5% 1/16W

(GX788:AEP)

R214 1-218-965-11 RES-CHIP 10K 5% 1/16W

R215 1-208-635-11 RES-CHIP 10 5% 1/16W

(GX780/GX788:US,E,CH,KR,HK,EA,JE)

R215 1-218-945-11 RES-CHIP 220 5% 1/16W

(GX788:AEP)

R216 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R218 1-218-949-11 RES-CHIP 470 5% 1/16W

R301 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R302 1-218-981-11 RES-CHIP 220K 5% 1/16W

R303 1-218-969-11 RES-CHIP 22K 5% 1/16W

R412 1-208-699-11 METAL CHIP 4.7K 0.5% 1/16W

R413 1-218-965-11 RES-CHIP 10K 5% 1/16W

R414 1-208-927-11 METAL CHIP 47K 0.5% 1/16W

R415 1-208-715-11 METAL CHIP 22K 0.5% 1/16W

R502 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R503 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R504 1-218-965-11 RES-CHIP 10K 5% 1/16W

R505 1-244-161-81 RES-CHIP 2.2 5% 1/16W

R506 1-218-965-11 RES-CHIP 10K 5% 1/16W

R507 1-218-965-11 RES-CHIP 10K 5% 1/16W

R508 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R509 1-218-965-11 RES-CHIP 10K 5% 1/16W

R510 1-218-949-11 RES-CHIP 470 5% 1/16W

R511 1-218-965-11 RES-CHIP 10K 5% 1/16W

R512 1-218-965-11 RES-CHIP 10K 5% 1/16W

R513 1-218-965-11 RES-CHIP 10K 5% 1/16W

R514 1-216-861-11 METAL CHIP 2.2M 5% 1/16W

(GX780/GX788:AEP,E,CH,KR,HK,EA,JE)

R514 1-218-861-11 METAL CHIP 3.9K 0.5% 1/10W

(GX788:US)

R515 1-216-861-11 METAL CHIP 2.2M 5% 1/16W

R516 1-218-973-11 RES-CHIP 47K 5% 1/16W

R517 1-218-949-11 RES-CHIP 470 5% 1/16W

R518 1-218-949-11 RES-CHIP 470 5% 1/16W

R519 1-218-949-11 RES-CHIP 470 5% 1/16W

R520 1-218-965-11 RES-CHIP 10K 5% 1/16W

R521 1-218-949-11 RES-CHIP 470 5% 1/16W

R522 1-218-985-11 RES-CHIP 470K 5% 1/16W

R523 1-218-989-11 RES-CHIP 1M 5% 1/16W

R524 1-218-977-11 RES-CHIP 100K 5% 1/16W

R525 1-218-965-11 RES-CHIP 10K 5% 1/16W

R526 1-218-977-11 RES-CHIP 100K 5% 1/16W

R527 1-218-965-11 RES-CHIP 10K 5% 1/16W

R528 1-218-965-11 RES-CHIP 10K 5% 1/16W

R529 1-218-985-11 RES-CHIP 470K 5% 1/16W

R601 1-218-977-11 RES-CHIP 100K 5% 1/16W

R602 1-218-945-11 RES-CHIP 220 5% 1/16W

R603 1-218-990-11 SHORT CHIP 0

R604 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R605 1-218-965-11 RES-CHIP 10K 5% 1/16W

R607 1-218-949-11 RES-CHIP 470 5% 1/16W

R608 1-218-949-11 RES-CHIP 470 5% 1/16W

R609 1-218-981-11 RES-CHIP 220K 5% 1/16W

R610 1-218-981-11 RES-CHIP 220K 5% 1/16W

R611 1-218-981-11 RES-CHIP 220K 5% 1/16W

R304 1-218-973-11 RES-CHIP 47K 5% 1/16W

R305 1-218-969-11 RES-CHIP 22K 5% 1/16W

R306 1-220-803-81 RES-CHIP 4.7 5% 1/16W

R307 1-218-985-11 RES-CHIP 470K 5% 1/16W

R401 1-218-985-11 RES-CHIP 470K 5% 1/16W

R402 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R403 1-218-949-11 RES-CHIP 470 5% 1/16W

R404 1-218-937-11 RES-CHIP 47 5% 1/16W

R405 1-218-951-11 RES-CHIP 680 5% 1/16W

R406 1-218-953-11 RES-CHIP 1K 5% 1/16W

R407 1-218-973-11 RES-CHIP 47K 5% 1/16W

R613 1-218-990-11 SHORT CHIP 0

R614 1-218-949-11 RES-CHIP 470 5% 1/16W

R615 1-218-973-11 RES-CHIP 47K 5% 1/16W

R616 1-218-985-11 RES-CHIP 470K 5% 1/16W

R617 1-218-985-11 RES-CHIP 470K 5% 1/16W

R619 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R620 1-218-985-11 RES-CHIP 470K 5% 1/16W

R621 1-218-985-11 RES-CHIP 470K 5% 1/16W

R622 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R701 1-218-965-11 RES-CHIP 10K 5% 1/16W

R702 1-208-715-11 METAL CHIP 22K 0.5% 1/16W

27

WM-GX780/GX788

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R703 1-208-927-11 METAL CHIP 47K 0.5% 1/16W

R704 1-218-985-11 RES-CHIP 470K 5% 1/16W

R705 1-218-981-11 RES-CHIP 220K 5% 1/16W

R706 1-218-981-11 RES-CHIP 220K 5% 1/16W

R707 1-218-973-11 RES-CHIP 47K 5% 1/16W

R708 1-218-981-11 RES-CHIP 220K 5% 1/16W

R709 1-218-981-11 RES-CHIP 220K 5% 1/16W

R710 1-218-981-11 RES-CHIP 220K 5% 1/16W

R711 1-218-957-11 RES-CHIP 2.2K 5% 1/16W

R712 1-218-985-11 RES-CHIP 470K 5% 1/16W

R714 1-218-965-11 RES-CHIP 10K 5% 1/16W

R716 1-218-989-11 RES-CHIP 1M 5% 1/16W

R717 1-218-953-11 RES-CHIP 1K 5% 1/16W

R718 1-208-707-11 METAL CHIP 10K 0.5% 1/16W

R719 1-208-935-11 METAL CHIP 100K 0.5% 1/16W

R720 1-208-675-11 METAL CHIP 470 0.5% 1/16W

R721 1-208-687-11 METAL CHIP 1.5K 0.5% 1/16W

R722 1-208-691-11 METAL CHIP 2.2K 0.5% 1/16W

R723 1-208-707-11 METAL CHIP 10K 0.5% 1/16W

S707 1-786-515-21 SWITCH, TACTILE(REW PRESET-)

S708 1-786-515-21 SWITCH, TACTILE(FF PRESET+)

S709 1-786-515-21 SWITCH, TACTILE(REPEAT)

* S710 1-786-079-21 SWITCH, PUSH (1 KEY)(REC)

S801 1-771-475-21 SWITCH, SLIDE

< TRANSFORMER >

T401 1-423-745-11 TRANSFORMER, DC-DC CONVERTER

T501 1-423-744-11 TRANSFORMER, BIAS OSCILLATION

< THERMISTOR >

TH601 1-803-120-21 THERMISTOR, NTC (1608)

< VIBRATOR >

X1 1-795-410-21 FILTER, CERAMIC (10.7MHz)

X701 1-767-790-11 VIBRATOR, CRYSTAL(75kHz)

************************************************************

R724 1-218-965-11 RES-CHIP 10K 5% 1/16W

R725 1-218-945-11 METAL CHIP 220 0.5% 1/16W

R726 1-208-683-11 METAL CHIP 1K 0.5% 1/16W

R728 1-218-865-11 METAL CHIP 5.6K 0.5% 1/10W

R729 1-208-695-11 METAL CHIP 3.3K 0.5% 1/16W

R730 1-208-695-11 METAL CHIP 3.3K 0.5% 1/16W

R731 1-208-699-11 METAL CHIP 4.7K 0.5% 1/16W

R732 1-208-675-11 METAL CHIP 470 0.5% 1/16W

R733 1-208-711-11 METAL CHIP 15K 0.5% 1/16W

R734 1-208-711-11 METAL CHIP 15K 0.5% 1/16W

R735 1-218-969-11 RES-CHIP 22K 5% 1/16W

R736 1-216-849-11 METAL CHIP 220K 5% 1/16W

R737 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R738 1-216-849-11 METAL CHIP 220K 5% 1/16W

R739 1-218-985-11 RES-CHIP 470K 5% 1/16W

R740 1-216-857-11 METAL CHIP 1M 5% 1/16W

R741 1-218-977-11 RES-CHIP 100K 5% 1/16W

R742 1-208-711-11 METAL CHIP 15K 0.5% 1/16W

R743 1-208-707-11 METAL CHIP 10K 0.5% 1/16W

R744 1-208-935-11 METAL CHIP 100K 0.5% 1/16W

R745 1-208-675-11 METAL CHIP 470 0.5% 1/16W

R746 1-208-687-11 METAL CHIP 1.5K 0.5% 1/16W

R901 1-208-935-11 METAL CHIP 100K 0.5% 1/16W

R902 1-208-935-11 METAL CHIP 100K 0.5% 1/16W

< VARIABLE RESISTOR >

RV301 1-225-684-21 RES, VAR, CARBON 30K/30K(VOL)