Sony WMGX-510, WMGX-512 Service manual

WM-GX510/GX512

SERVICE MANUAL

Ver 1.1 2002. 01

Photo : WM-GX512

SPECIFICATIONS

AEP Model

WM-GX510

E Model

WM-GX510/GX512

Tourist Model

WM-GX512

Model Name Using Similar Mechanism WM-GX614

Tape Transport Mechanism Type MF-WMGX614-112

9-960-475-12

2002A1600-1

© 2002.1

530-1.710 kHz (For “USA” indication)

– Continued on next page –

RADIO CASSETTE CODER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

— 1 —

Dry Battery

TABLE OF CONTENTS

Section Title Page

SECTION 1. GENERAL ...............................................3

SECTION 2. SERVICE NOTE .....................................4

SECTION 3. DISASSEMBLY

3-1. Cassette Lid ASSY and Case ASSY .................................6

3-2. Bracket ASSY and Cassette Holder ASSY ....................... 6

3-3. Tuner Board ....................................................................... 7

3-4. Main Board.........................................................................7

SECTION 4. MECHANICAL ADJUSTMENT ...........8

SECTION 5. ELECTRICAL ADJUSTMENT .............8

SECTION 6. DIAGRAMS

6-1. Printed Wiring Board — Tuner Section —.....................11

6-2. Schematic Diagram — Tuner Section —........................ 13

6-3. Schematic Diagram — Main Section — ......................... 17

6-4. Printed Wiring Board — Main Section —...................... 21

6-5. IC Pin Functions

IC501 BA3641FV REC AMP ......................................... 25

IC701 MSM63120B System Control .............................. 25

IC702 SMC62L3A LCD Drive ....................................... 27

SECTION 7. EXPLODED VIEWS

7-1. Case Section ..................................................................... 28

7-2. Main Board Section ......................................................... 29

7-3. Mechanism Section (MF-WMGX614-112)..................... 30

SECTION 8. ELECTRICAL PARTS LIST ..............31

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

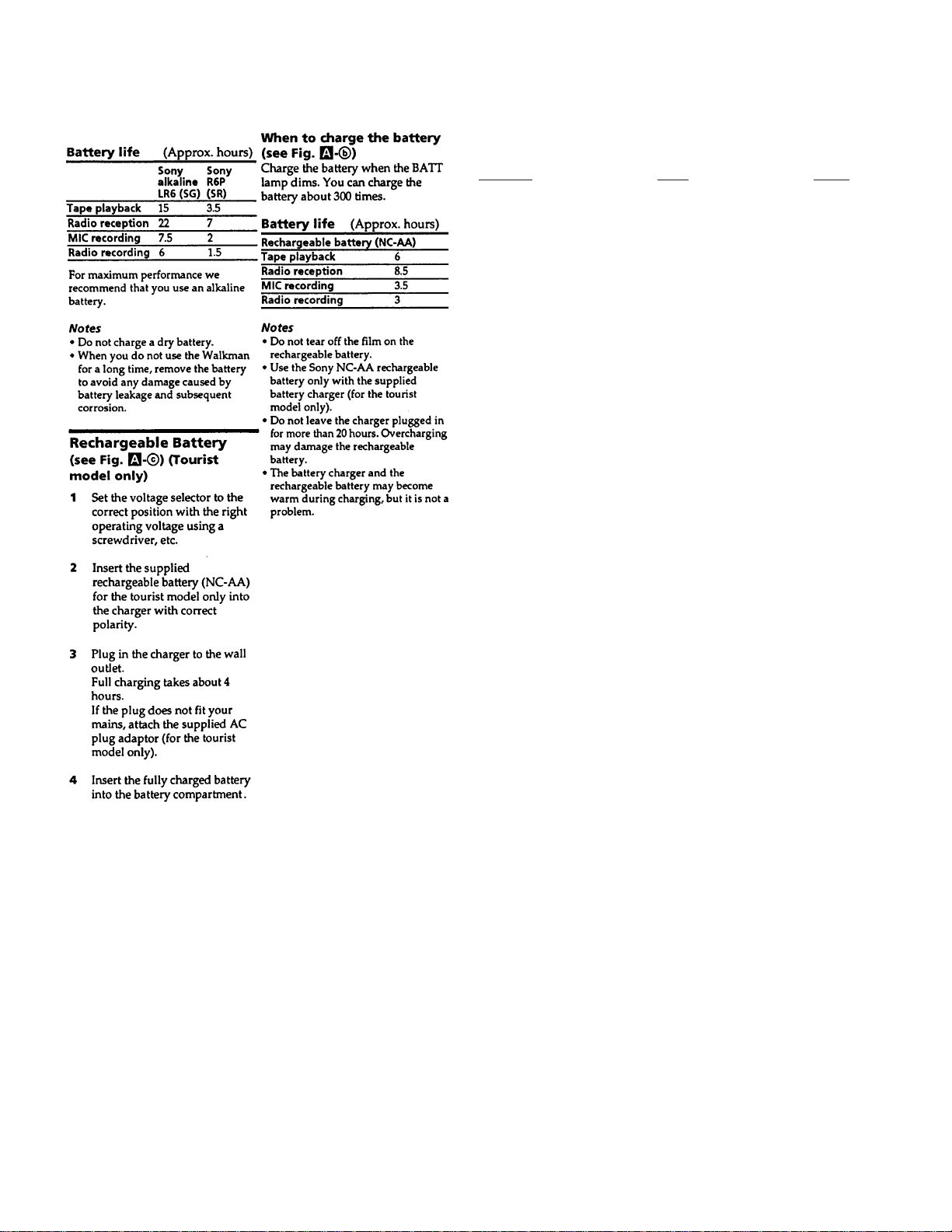

FUNCTION OF CONTROL

!•

2

1

!¶

!§

!∞

!¢

SECTION 1

GENERAL

!£

!™

!¡

0

1Display Window

2PRESET + • AMS • FF button

3PRESET –•AMS • REW button

4MENU button

5cREC switch

6SET button

7p RADIO OFF button

8ISS switch

9ENTER button

02REMOTE (GX512), 2(GX510) jack

!¡MIC (PLUG IN POWER) jack

!™CHOLD button

!£ VOLUME knob

!¢RADIO ON•BAND button

!∞TUNIG + button

!§TUNIG – button

!¶œ button

!•BATT indicater

3

5

6

4

This section is extracted

from instruction manual.

7

8

• ILLUST LATION:WM-GX512 MODEL

9

— 3 —

SECTION 2

SERVICE NOTE

[Service Mode]

Mode which enables the mechanism to be operated with the

MAIN board opened.

Photo sensor PH701 mounted on the MAIN board is used to

detect rotaion of the reels. Because it is mounted on the MAIN

board, when the MAIN board is being removed, rotation of the

reels cannot be detected and the auto-off/tape-end detector

circuit does not operate correctly.

F/R switch (S701) is also mounted on the MAIN board.

Therefore, without the MAIN board, the head cannnot be

placed in playback position, and power cannot be supplied to

the circuitry of the playback system.

When the MAIN board is being removed, follow the

procedures below, in order to check operation of the

mechanisms of the tape deck and to check voltages supplied to

each circuit.

1. Setting

1) Refer to “Disassembly” and remove the cabinet and open

the MAIN board.

2) Connect the MAIN board to the motor and plunger using a

jumper wire. Use “Extension tool (1-769-143-11)) (one set

10 tools)” to make connection simple.

3) Short-circuit the service mode land (4 points) by soldering.

4) Apply a square wave signal to TP20. (See the figure on the

right.)

5) Supply 1.5V to the battery terminals (+) and (–) using a

DC power supply.

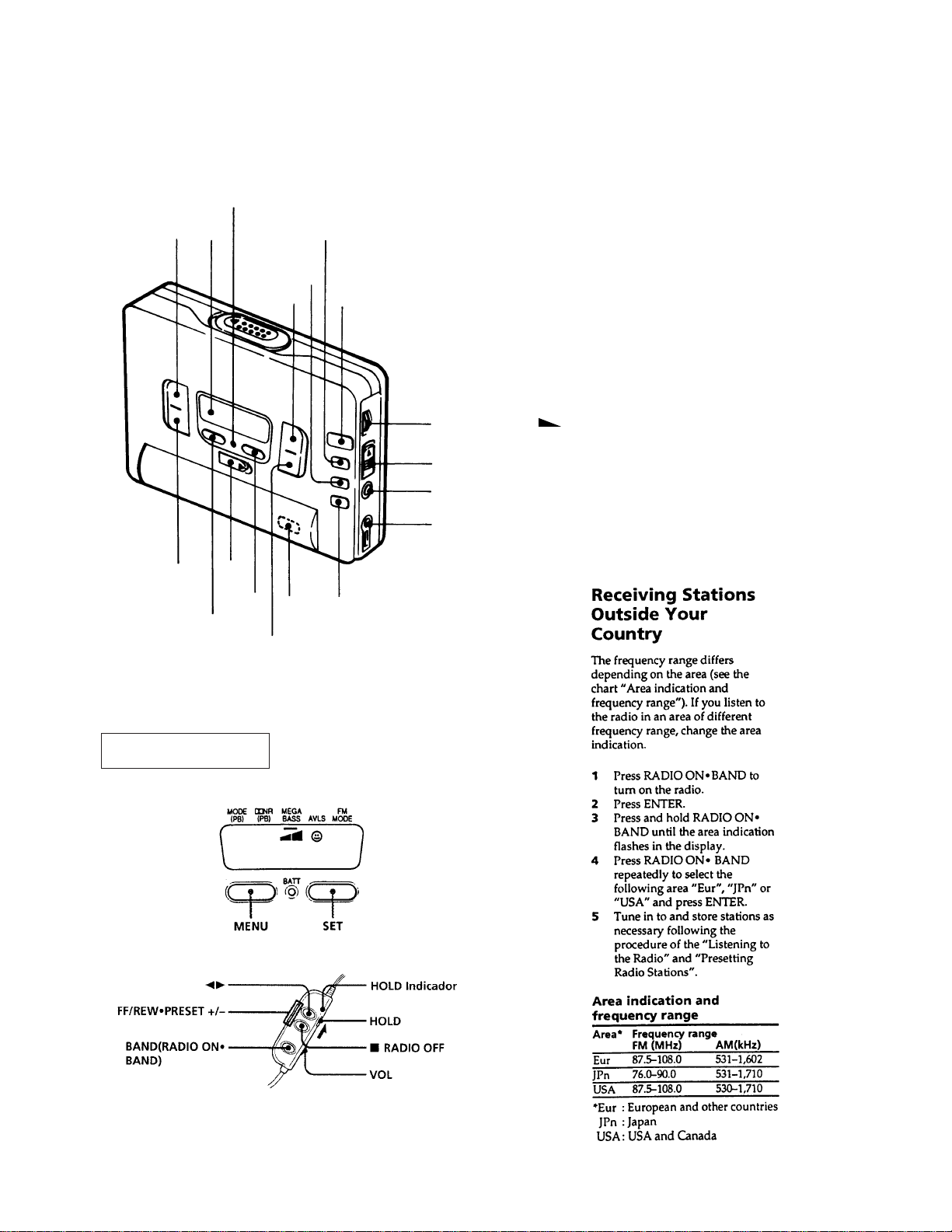

[MAIN Board]

— Side A —

AF OSCILLATOR

Connect to

plunger

S713

(ENTER)

S712

(TUNING –)

S704

S711

(TUNING +)

S707

(RADIO ON

BAND)

— Side B —

(REPEAT œ)

Battery Terminal (–)

S703

(RADIO OFF p)

SQUARE WAVE (SINE WAVE)

10Hz

3.5 dB (1.5V)

Service mode land

S709

(SET)

Service

mode land

S710

(MENU)

(AMS REW

PRESET –)

S705

(AMS FF

PRESET +)

S706

TP20

Battery

Terminal (+)

Connect to

motor

2. Preset State

This state must be set to set the PLAY, FF, and REW

modes.

1) Check that the lever (NR SW) is at the center and F/R

switch (S701) is at the center. If not, set the preset state as

follows.

2) Move the F/R switch (S701) according to the side faced by

the lever (NR SW).

3) Turn OFF the DC power supply switch once and then turn

it ON again so that the lever (NR SW) can be moved.

Move the F/R switch (S701) according to this timing and

set to the center.

3. FF REW Mode

1) Set the preset state and press the FF switch and REW

switch.

4. PLAY Mode

1) Set the preset state.

2) Press the œ switch. The lever (NR SW) will move to the

F side once and then to the R side. Move the F/R switch

(S701) according to this timing to set the PLAY (R side)

mode. Press the œ switch another time and move the F/

R switch (S701) according to the movement of the lever

(NR SW) to set the PLAY (F side) mode.

Note 1 : If the above cannot be performed, start again from

preset.

Note 2 : Use the remote control œ , p , FF, and REW

switches as much as possible. If the remote control is

not available, do not touch S703 to S706 with the

hand and use something with a round tip to press

them.

F side

[Lever (FR SW)]

PH701

S701 F/R SWITCH

(FWD N STOP n REV)

R side

Center

R side

Lever (NR SW)

Center

F side

S702

(HOLDER

SWITCH)

S714

(C HOLD)

C

HOLD

— 4 —

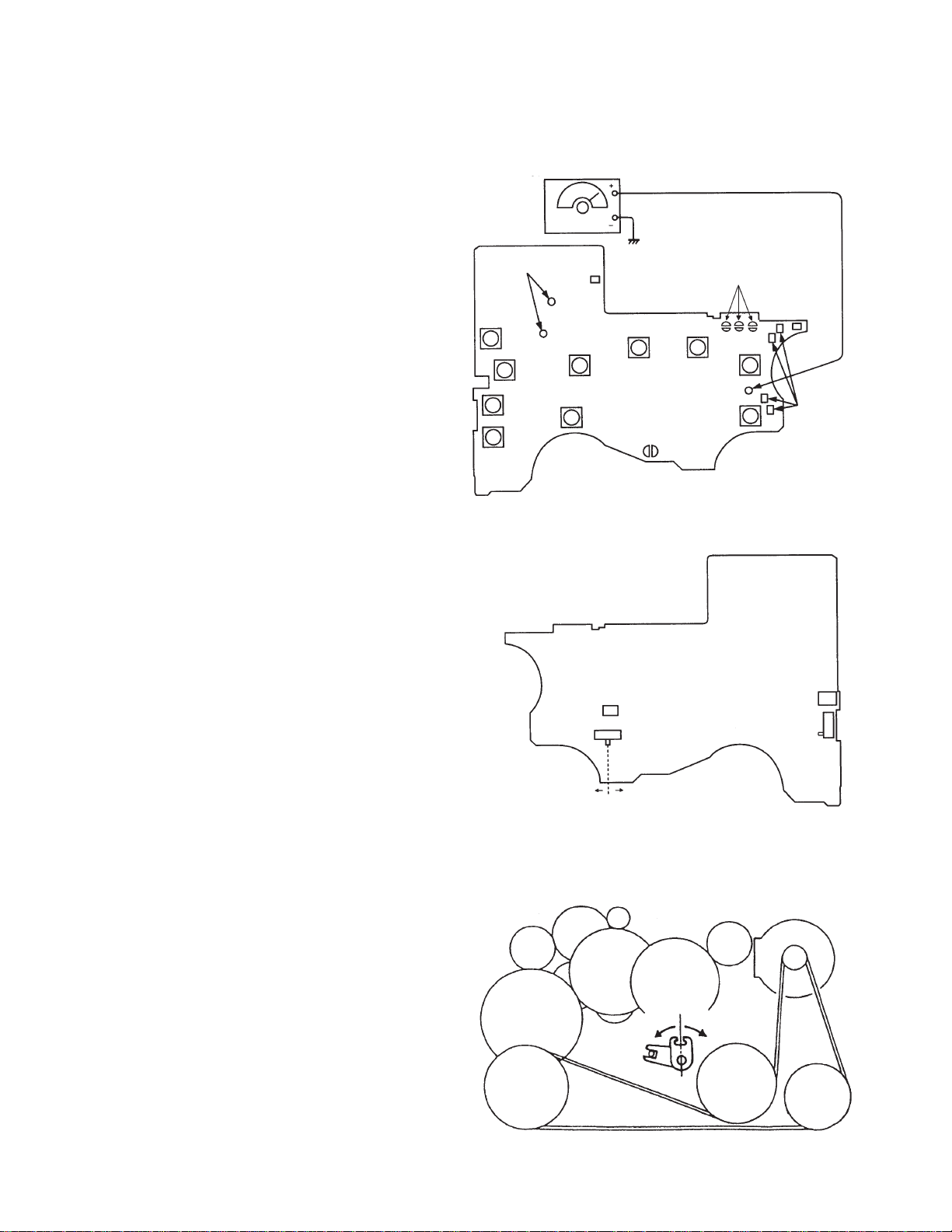

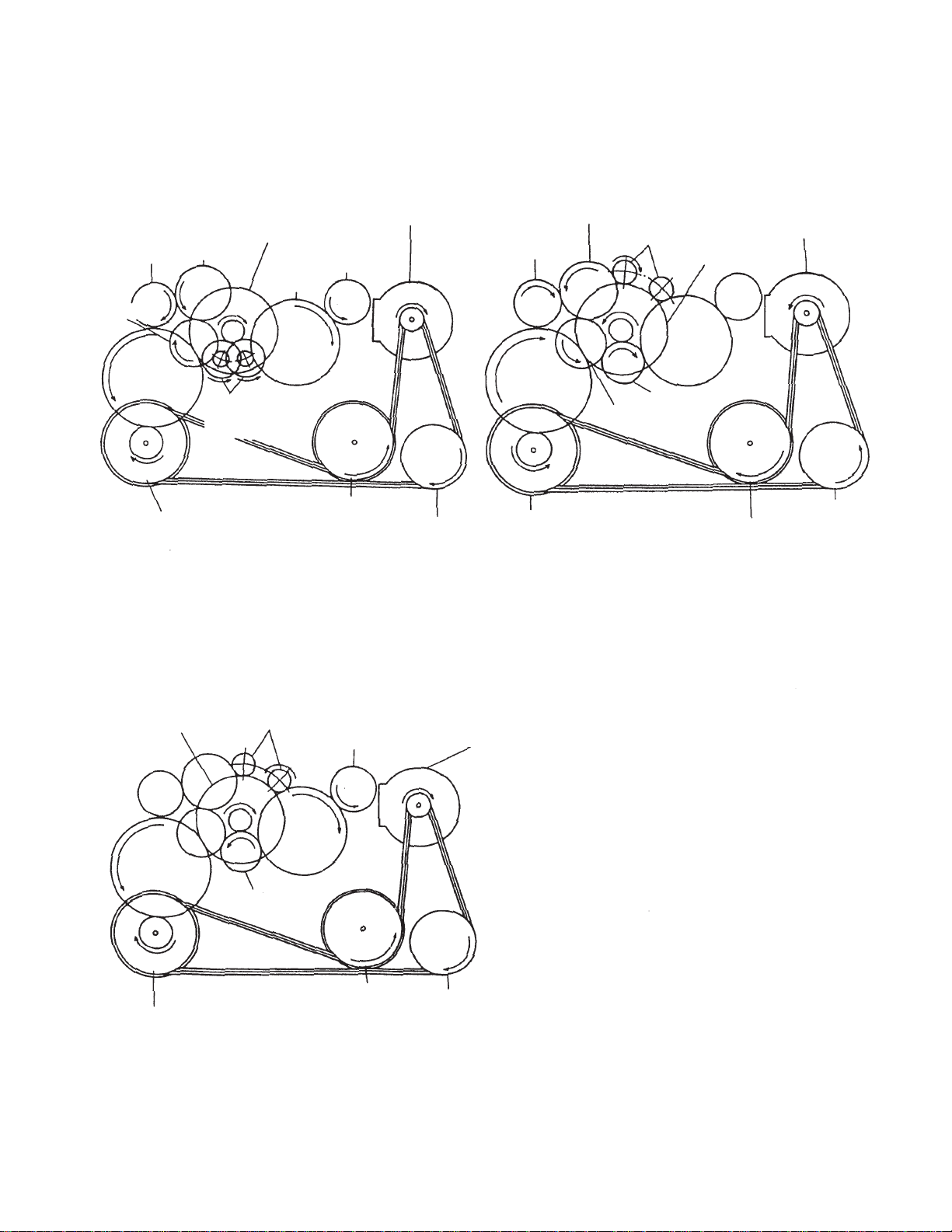

[Rotation system]

Rotation system during PLAY.

Reel table

(T side)

Gear (A)

Gear (K)

Capstan wheel (N)

assembly

Clutch assembly

Gear (B)

Gear (C)

Gear (NR)

(REV : Left side/

FWD : Right side)

Capstan wheel (R)

assembly

Reel table

(S side)

Motor pully

Pulley

(REVERSE)

Rotation system during REW.

Gear (B)

Reel table

(T side)

Gear (K)

Capstan wheel (N)

assembly

Gear (NR)

(REW : Left side)

Gear (NR)

Gear (A)

Capstan wheel (R)

assembly

Motor pully

Clutch assembly

Pulley

(REVERSE)

Rotation system during FF.

Gear (FR)

Clutch assembly

Gear (K)

Capstan wheel (N)

assembly

(FF : Right side)

Gear (NR)

Reel table

(S side)

Gear (C)

Capstan wheel (R)

assembly

Motor pully

Pulley

(REVERSE)

— 5 —

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

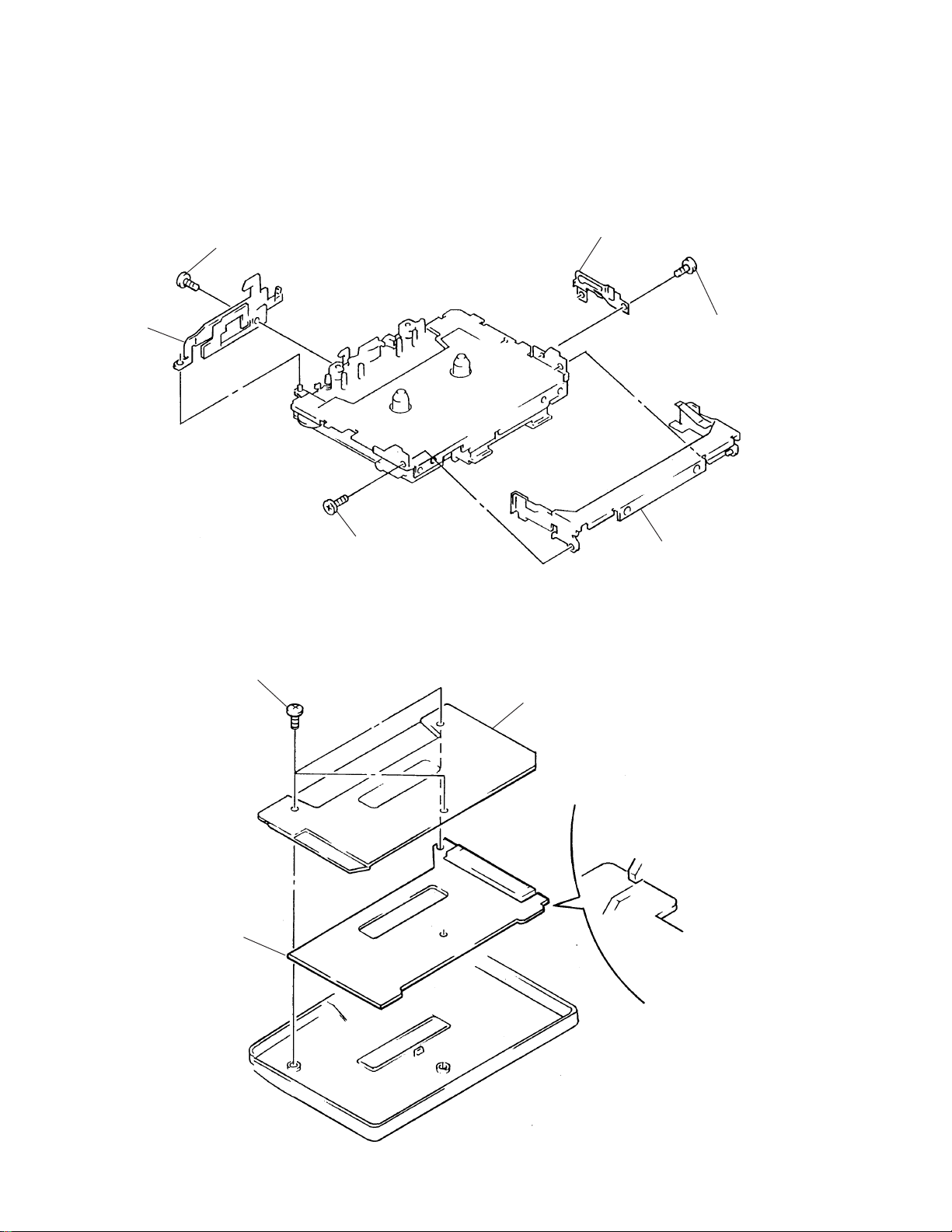

3-1. BRACKET ASSEMBLY AND CASSETTE HOLDER ASSEMBLY

1

Screw (M1.4x1.1)

2

Bracket assembly

4

Lock lever (B)

3

Screw (M1.4x1.1)

3-2. TUNER BOARD

3

Tuner board

5

Screw (M1.4x1.1)

1

Three screws (1.7x2.5)

(tapping)

2

TU cover

6

Cassette holder assembly

Note for installation

— 6 —

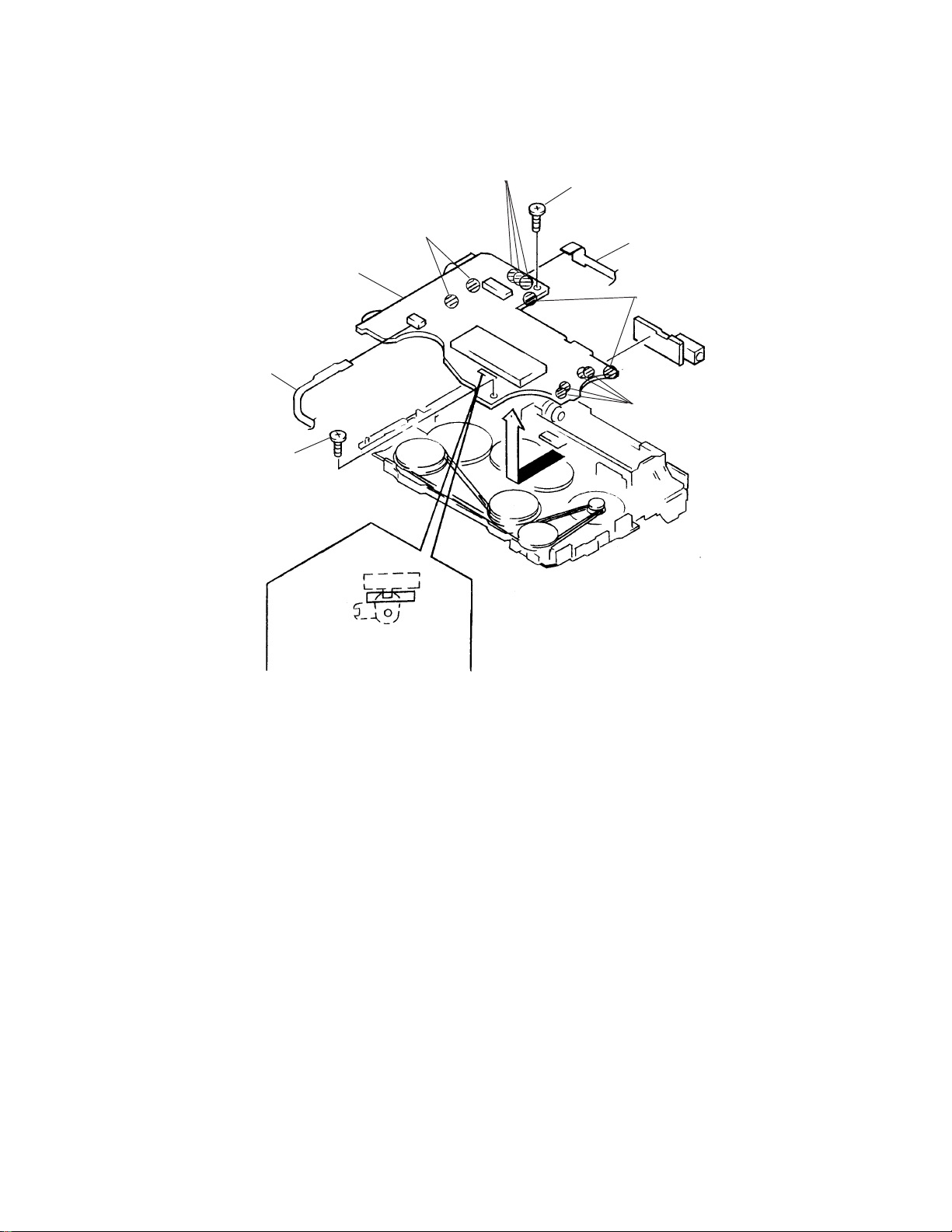

3-3. MAIN BOARD AND SUB BOARD

2

Remove the solder of the

plunger solenoid.

8

Remove the Main board

direction of arrow.

1

Flexible board

(Head)

7

Screw (M1.4x2.0)

S701

3

Remove the solder of the

ATS flexible board.

6

Tapping screw

ATS flexible board

4

5

Battery terminal

Remove the solder of the

motor.

Lever (NR switch)

Note : Confirm if the switch lever

installs it self in the groove

of a lever (NR switch) for

assembling.

— 7 —

SECTION 4

SECTION 5

MECHANICAL ADJUSTMENT

PRECAUTION

1. Before adjusting, clean the following parts with a piece of

cotton moistened with alcohol.

REC/PB head pinch roller

rubber belt capstan

2. Demagnetize the playback head using a head

demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (1.3V)

to perform the adjustments.

[Torque Measurement]

Mode

FWD

FWD

Back tension

REV

REV

Back tension

FF

REW

Torque Meter Meter Reading

18 — 33 g • cm

CQ-102C

0.5 — 3.0 g • cm

18 — 33 g • cm

CQ-102RC

0.5 — 3 g • cm

CQ-201B

More than 40 g • cm

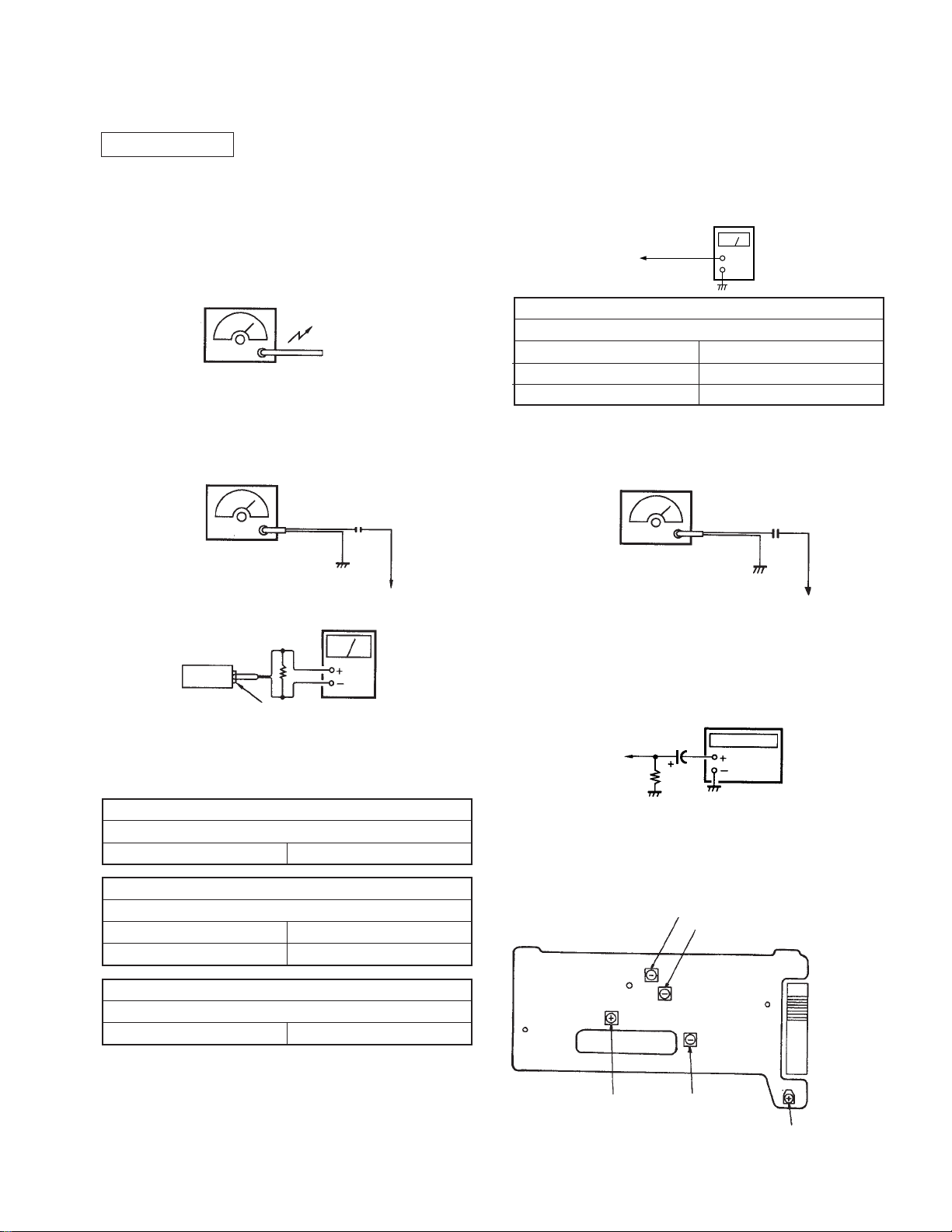

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Specified voltage : 1.3V.

2. Switch position

DOLBY NR switch : OFF

MEGA BASS switch: NORM

AVLS : OFF

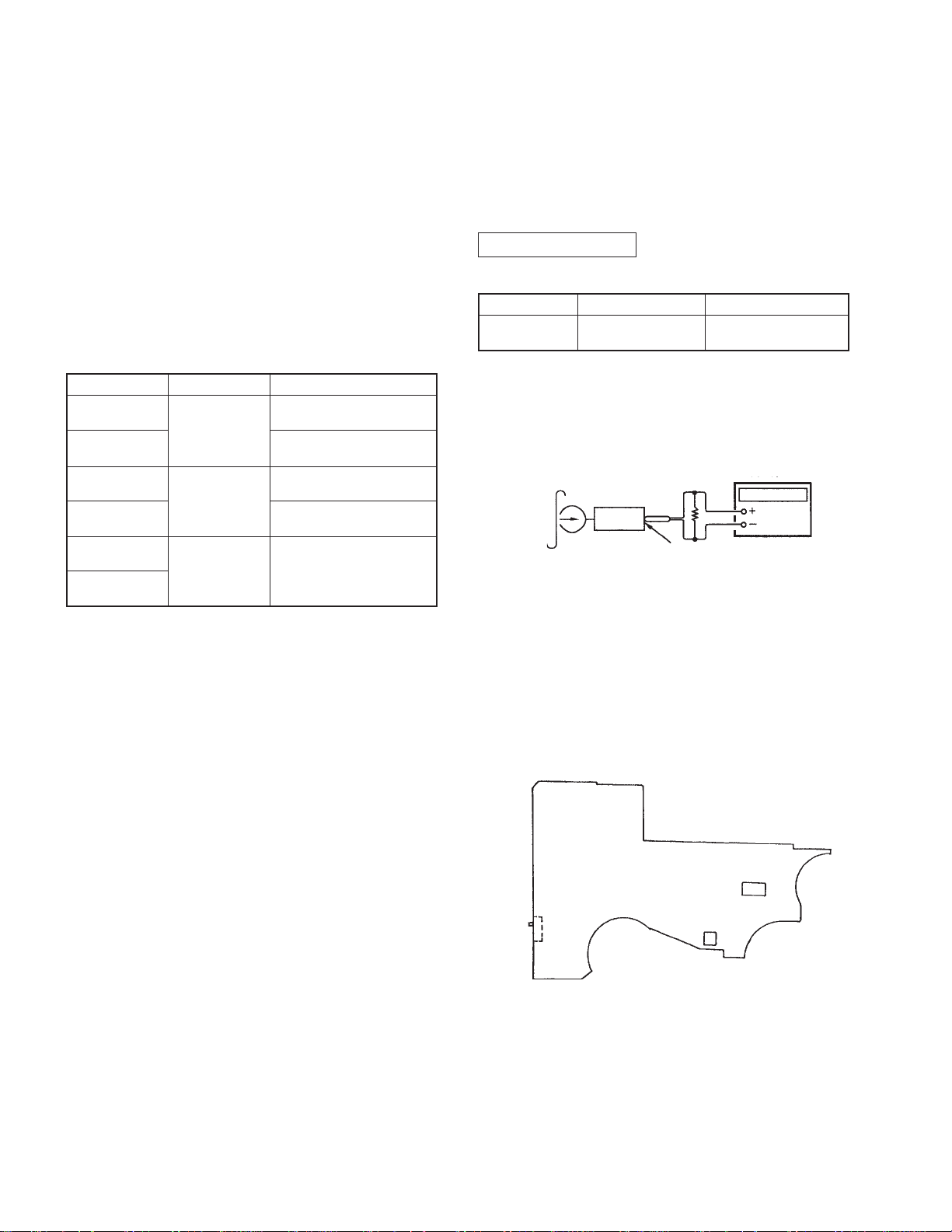

CASSETTE SECTION

Test tape

Type

[Tape Speed Adjustment]

Procedure :

Test tape

WS-48A

(3kHz, 0dB)

1. Playback WS-48A (tape center part) in the FWD state and

adjust RV601 so that the frequency counter reading

becomes 3000 ± 10 Hz.

2. Playback WS-48A (tape center) in the REV state.

Check that the frequency counter reading is within 2.5%

of the reading of step 1.

Signal Used for

16

Tape Speed AdjustmentWS-48A

frequency

counter

3 kHz, 0 dB

set

PHONES jack

Adjustment Point :

[MAIN BOARD] — Side A —

S714

(HOLD)

IC601

RV601

— 8 —

TUNER SECTION

[AM]

BAND switch : AM

NOTE: The adjustment should be performed setting the area indication

to “Eur”. (Refer to “Receiving Stations Outside Your Country”

on page 3.)

After the adjustment, reset the area indication as it was.

AM RF SSG

30% amplitude modulation by

400Hz signal

output level : as low as possible

Put the lead-wire

antenna close to

the set.

[FM]

BAND switch : FM

FM RF SSG

0.01µF

22.5kHz frequency deviation

by 400Hz signal.

output level : as low as possible

32

set

PHONES

to ANT (TP1)

VTVM

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM VT VOLTAGE ADJSTMENT

BAND switch : AM

TP22

(VT)

AM VT VOLTAGE ADJUSTMENT

Adjust for following values on digital voltmeter.

Display indication

Digital voltmeter reading 1.5V

Adjustment part

digital

voltmeter

+

–

AM531 kHz

T1

[FM VCO Adjustment]

Procedure :

Carrier frequency : 98MHz

Modulation : no modulation

output level : 0.1V (100dB)

FM RF SSG

0.01µF

to ANT (TP1)

1. Connect frequency counter to the positions shown below.

2. Tune the to 98 MHz.

3. Adjust RV1 for 19 kHz ± 100Hz reading on the frequency

counter.

frequency

counter

TP23

(IC2 Pin !™)

1µF

100k

AM IF ADJUSTMENT

Adjust for a maximum reading on VTVM.

T2 450 kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on VTVM.

L5

CT1

FM IF ADJUSTMENT

Adjust for a maximum reading on VTVM.

L3 10.7 MHz

621 kHz

1,395 kHz

— 9 —

(IC2 Pin 9)

• Adjustment Parts Location

[TUNER BOARD] — Component side —

T2 : AM IF

T1 : AM VT

TP23

TP22

RV1 : VCO

L3 : FM IF

TP1

CT1 : AM TRACKING

L5 :

AM

TRACKING

Loading...

Loading...