Sony WMFX-855 Service manual

WM-FX855

SERVICE MANUAL

Ver 1.3 2001.11

Photo: Black

Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation.

“ DOLBY ” and the double-D symbol a are trademarks of

Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

Tape player section and general

Frequency response (aNR switch off)

30–18,000 Hz

Output

Headphones (2 REMOTE jack)

Load impedance 8–300 ohms

Power output

3mW + 3mW at DC operation

Power requirements

1.5V DC

Rechargeable battery (NC-6WM), 1.2 V, 600mAh, Ni-Cd One R6

(size AA) battery

Battery life (Approx. hours)

Rechargeable NC-6WM

Fully charged

Playback 9

Radio/TV reception 9

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-WMEX655-125

Dimensions

Approx. 108.7 × 80.0 × 23.5 mm (w/h/d)

Weight

Approx. 150 g (Main unit)

Approx. 210 g (incl. Headphones with remote control, Rechargeable battery NC-6WM, Tape (C-60HF)

Radio section

Frequency range

Tourist model

FM : 76–90MHz

AM : 531–1,710kHz

TV : 1–12ch (Except Korean model.)

Korean model (Area setting : Eur)

FM : 87.5–108MHz

AM : 531–1,602kHz

Sony alkaline LR6 (WM)

Playback 36

Radio/TV reception 29

Sony R6P (SR)

Playback 10

Radio/TV reception 9

Rechargeable NC-6WM

Sony alkaline LR6 (WM)

Used together

Playback 45

Radio/TV reception 36

9-923-252-12 Sony Corporation

2001K0500-1 Personal Audio Company

C 2001.11 Published by Sony Engineering Corporation

Design and specifications are subject to change without notice.

– Continued on next page –

RADIO CASSETTE PLAYER

TABLE OF CONTENTS

1. SERVICE NOTE ....................................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY ......................................................... 6

4. MECHANICAL ADJUSTMENT.......................... 8

5. ELECTRICAL ADJUSTMENT............................ 8

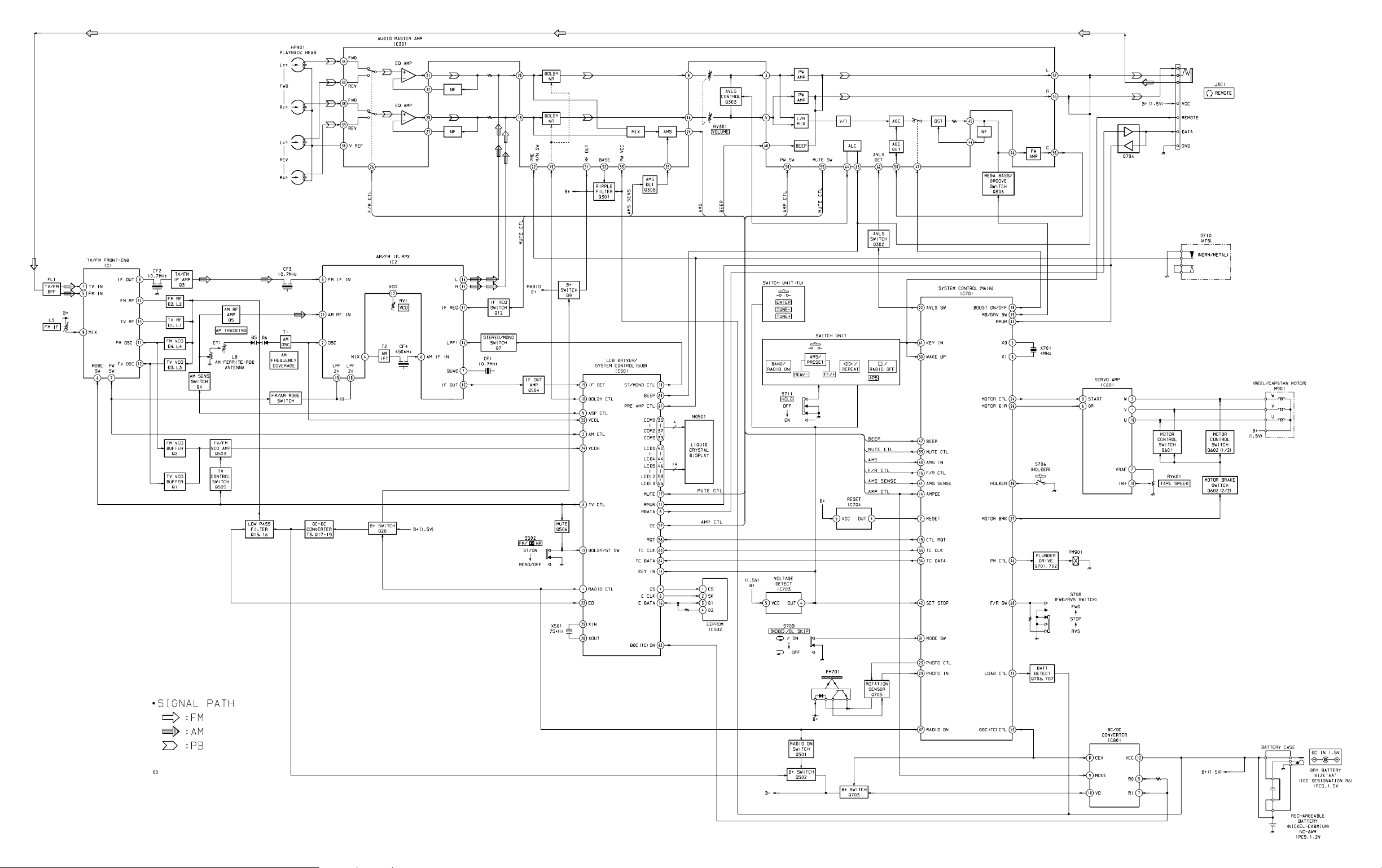

6. DIAGRAMS

6-1. Block Diagram ................................................................ 11

6-2. Printed Wiring Board

– AUDIO Section – ......................................................... 14

6-3. Schematic Diagram

– AUDIO Section – ......................................................... 17

6-4. Schematic Diagram

– TUNER Section – ........................................................ 22

6-5. Printed Wiring Board

– TUNER Section – ........................................................ 25

6-6. IC Pin Function Description ........................................... 30

7. EXPLODED VIEWS ................................................ 34

8. ELECTRICAL PARTS LIST ............................... 37

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

SERVICE NOTE

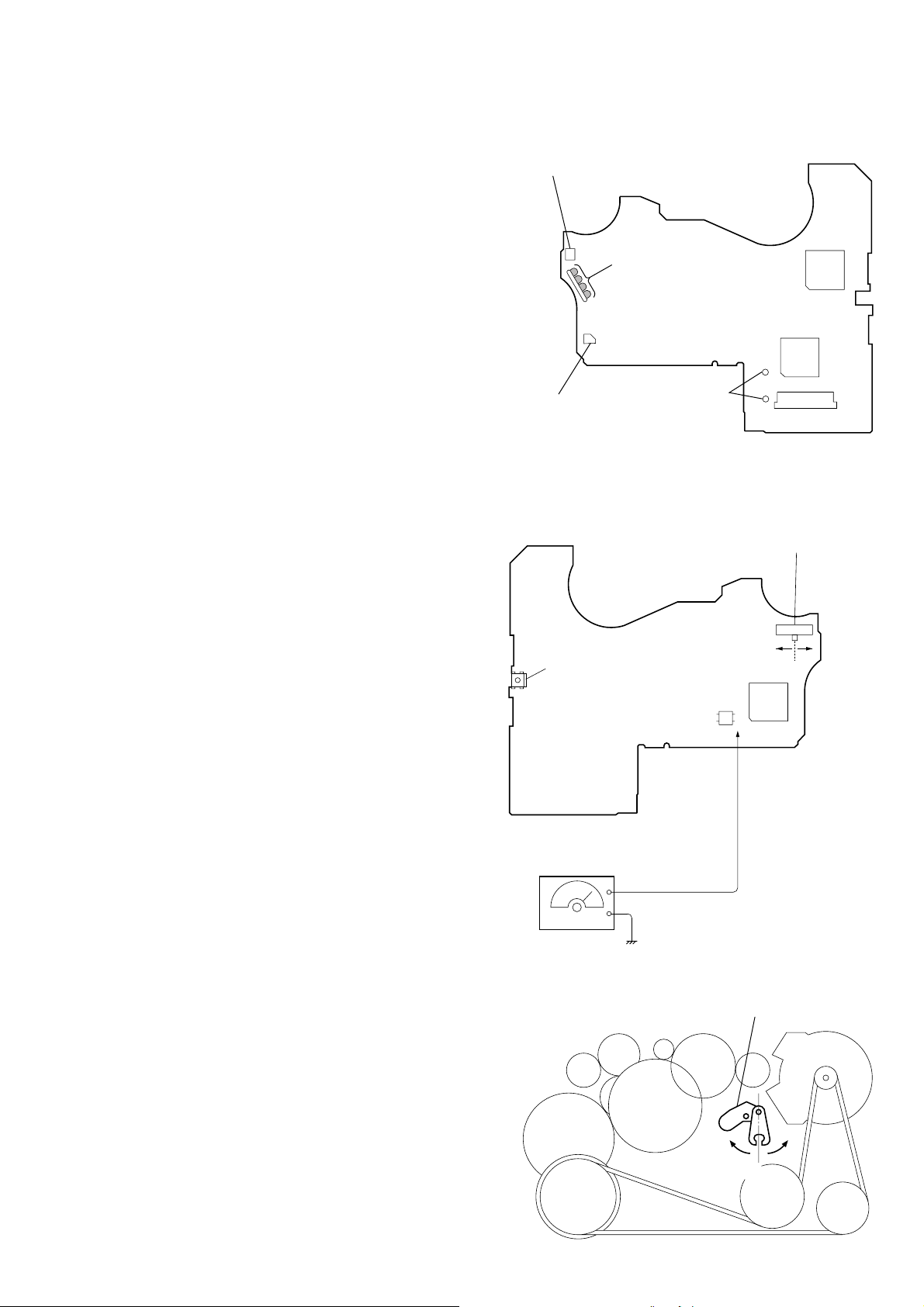

Service Mode

Mode for operating the mechanism section with the A UDIO board

opened.

1. Setting

1) Refer to “Disassembly”, and remov e the ca binet and open the

AUDIO board.

2) Connect the motor and plunger to the AUDIO board using

jumper wires. These can be connected easily with the use of

the extension tool (1-769-143-11) (ten in one set).

3) Turn ON the HOLDER switch (S706).

4) Input the square wave or sine wave to PH701. (See right figure.)

5) Supply 1.5 V to the ‘ and ’ terminals of the battery using a

regulated power supply.

2. Preset state

T o set the PLAY , FF, REW modes, the preset state must be set.

1) Check that the lever (FR SW) and FWD/RVS switch (S708)

are set to the center position. If not, set the preset state as follows.

2) Mo ve the FWD/RVS switch (S708) to the side which the lever

(FR SW) is facing.

3) The lever (FR SW) will move when the regulated power supply switch is set to OFF once and then set to ON. Move the

FWD/RVS switch (S708) according to this timing and set to

the center position.

Audio Board

— Side A –

Battery terminal (—)

Battery

terminal (+)

— Side B —

Connect to motor

Connect to plunger

IC501

CN501

S708

FWD/RVS Switch

(FWD

←

STOP → RVS)

IC301

3. FF, REW Modes

1) Check that the preset state is set and press the FF and REW

switches.

4. PLAY mode

1) Check that the preset state is set.

2) Pressing the ª · switc h will move the le ver (FR SW) once

towards the F side and then to the R side. Moving the FWD/

R VS switch (S708) according to this timing will set the PLAY

mode (R side). Pressing the ª · switch another time and

moving the FWD/RVS switch (S708) according to the movement of the lever (FR SW) will set the PLAY ( F side) mode.

Note 1: If the above fails, perform from preset again.

Note 2: Use the ª ·, π, FF, REW switches on the remote

commander as much as possible. If no remote commander,

do not touch the switches with your hands, but using a

stick with a round tip.

Note 3: When using headphones, the timing for moving the S708

can be determined from the beep sound.

S706

(HOLDER Switch)

AF OSCILLATOR

Lever (FR SW)

PH701

AK

Sguare wave

(Sine wave)

10 Hz —3.5 dB

side F side R

Center

IC701

CE

lever (FR SW)

– 3 –

side F

side R

center

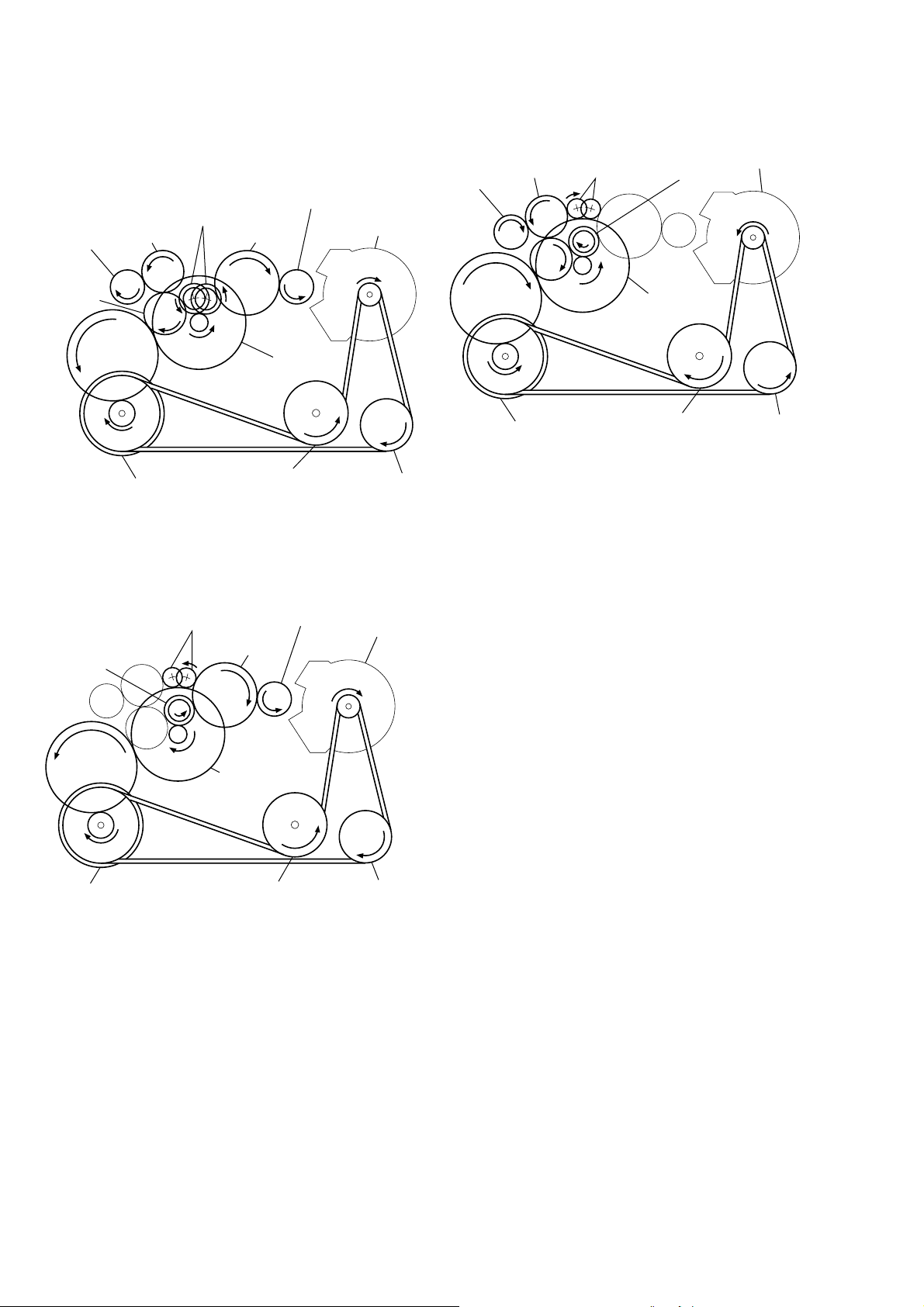

Rotation system

)

Rotation system during FF.

Rotation system during PLAY.

gear (NR)

(REW: right side/

FWD: left side)

gear (REEL)

(T side)

gear (TA)

gear (TB)

gear (Y)

flywheel (N) ass’y

flywheel (R) ass’y

Rotation system during REW.

gear (FR)

(REW: right side)

gear (S)

gear (NR)

gear (REEL)

(S side)

gear (S)

clutch ass’y (M)

gear (REEL)

(S side)

motor pulley

pulley (reverse)

motor pulley

gear (REEL)

(T side)

gear (Y)

gear (TB)

flywheel (N) ass’y

gear (FR)

(FF: left side)

gear (NR)

clutch ass’y (M)

flywheel (R) ass’y

motor pulley

pulley (reverse)

gear (Y)

flywheel (N) ass’y

clutch ass’y (M)

flywheel (R) ass’y

pulley (reverse

– 4 –

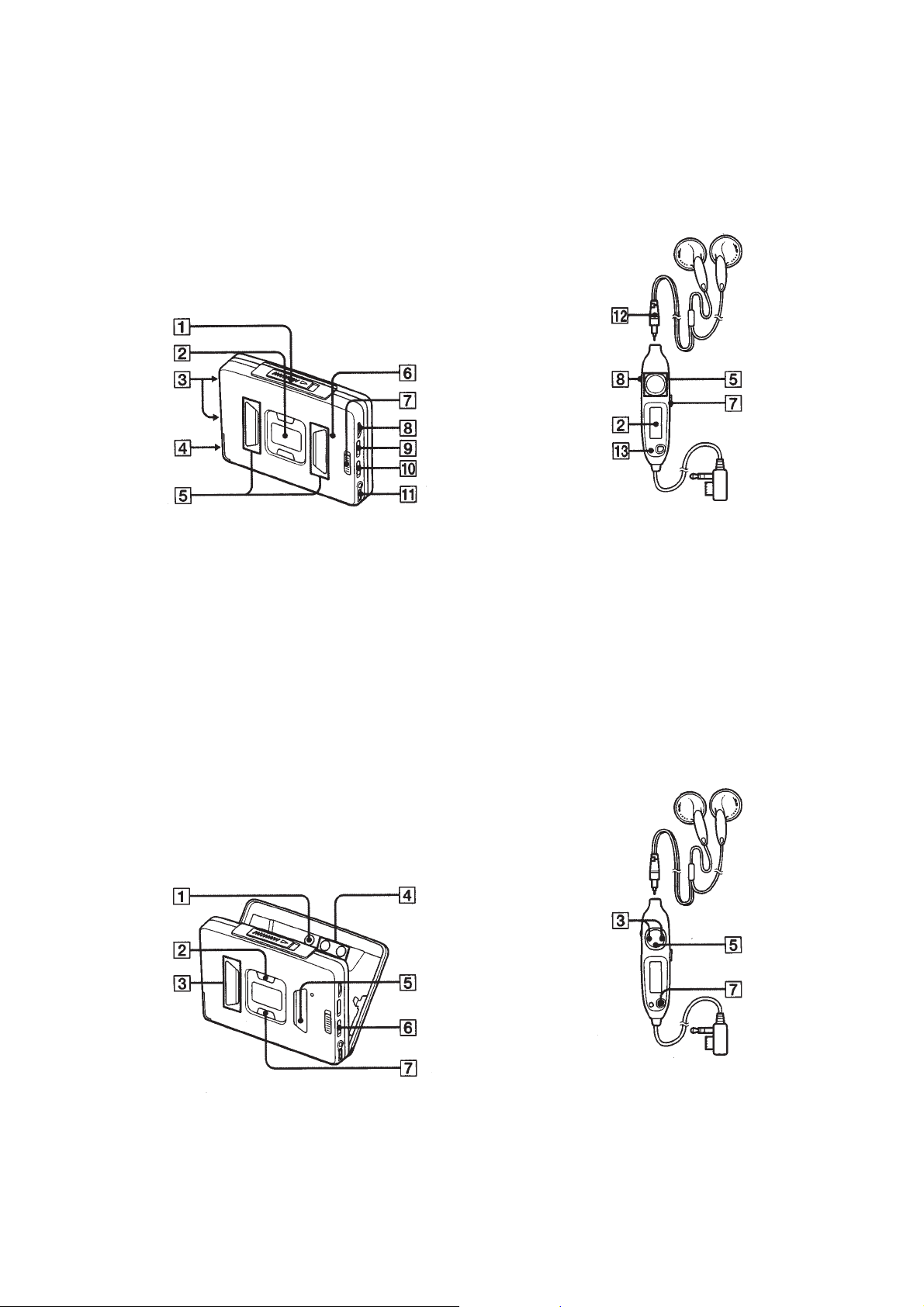

LOCATION AND FUNCTION OF CONTROLS

Tape player section and general

SECTION 2

GENERAL

• Main Unit

1 OPEN button

2 Information display

3 Contact for dry battery case

4 Rechargeable battery case

5 Tape operation buttons

6 BATT indicator

7 HOLD switch

• Headphones with Remote Control

Left Right

8 Main unit : VOLUME knob

Remote control : VOL knob

9 Åa (Tape direction),

BL SKIP (Blank skip) switch

!º a(DOLBY) NR switch

!¡ 2 REMOTE jack

!™ Micro plug

!£ SOUND/AVLS button

Radio section

• Main Unit

1 ENTER button

2 ASP (Auto Station Preset) button

3 PRESET +, – button

• Headphones with Remote Control

Left Right

4 TUNE +, – button

5 p, RADIO OFF button

6 FM ST/MONO switch

7 BAND, RADIO ON button

– 5 –

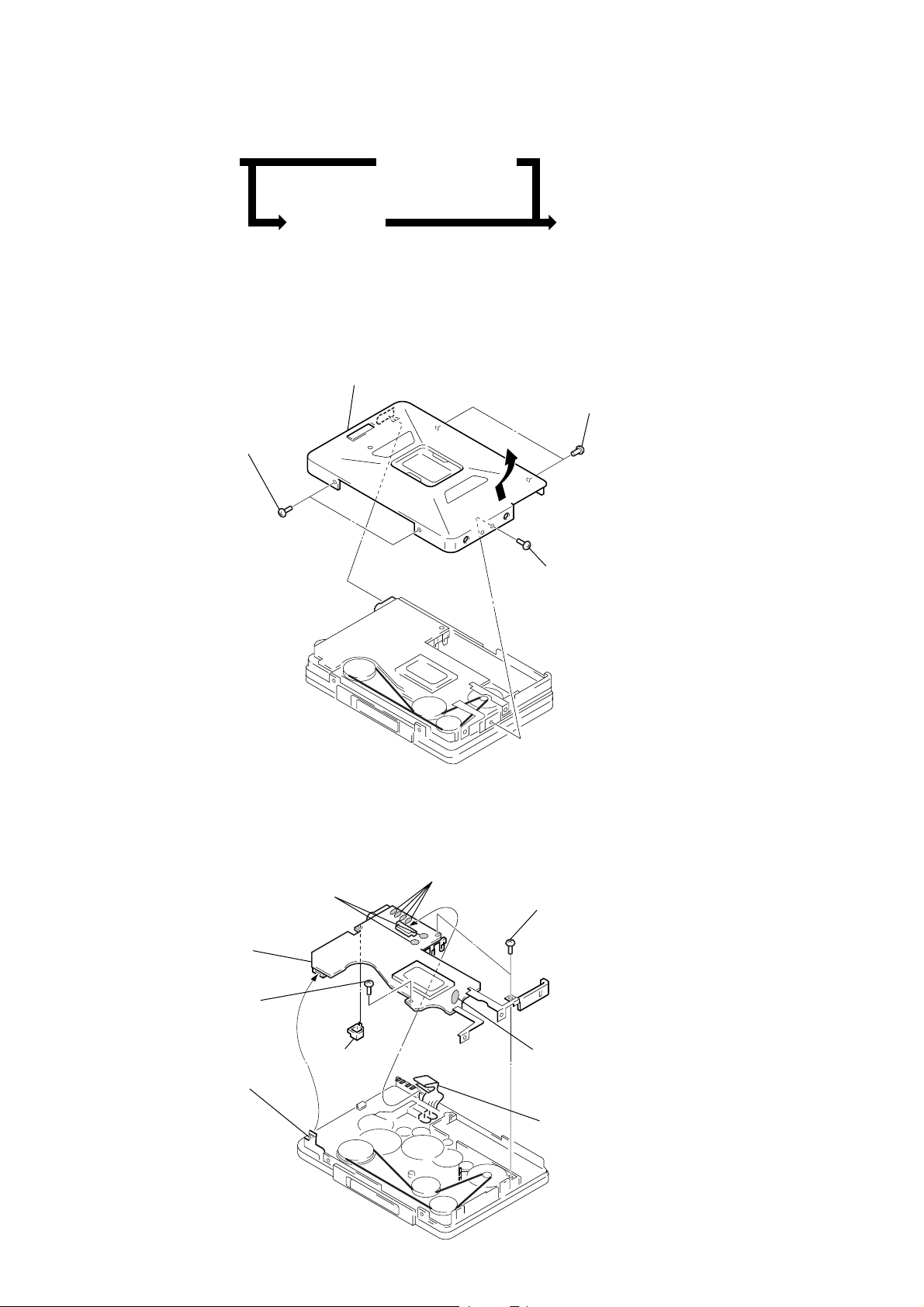

SECTION 3

K

DISASSEMBLY

• This set can be disassembled in the order shown below.

CASE ASS’Y

(page 6)

AUDIO BOARD

(page 6)

Note: Follow the disassembly procedure in the numerical order given.

LID ASS’Y CASSETTE

(page 7)

CASE ASS’Y

3

Remove the case ass’y

to direction of the arrow

1

two screws

(IB lock)

A

MECHANISM DEC

(page 7)

.

2

two screws

(IB lock)

2

screw (IB lock)

AUDIO BOARD

1

head flexible board

4

8

AUDIO board

Remove two solders.

7

screw

(IB lock)

9

sw cover

3

Remove four solders.

– 6 –

6

two screws

(M1.7

5

Remove four solders.

2

tuner flexible board

×

3.0)

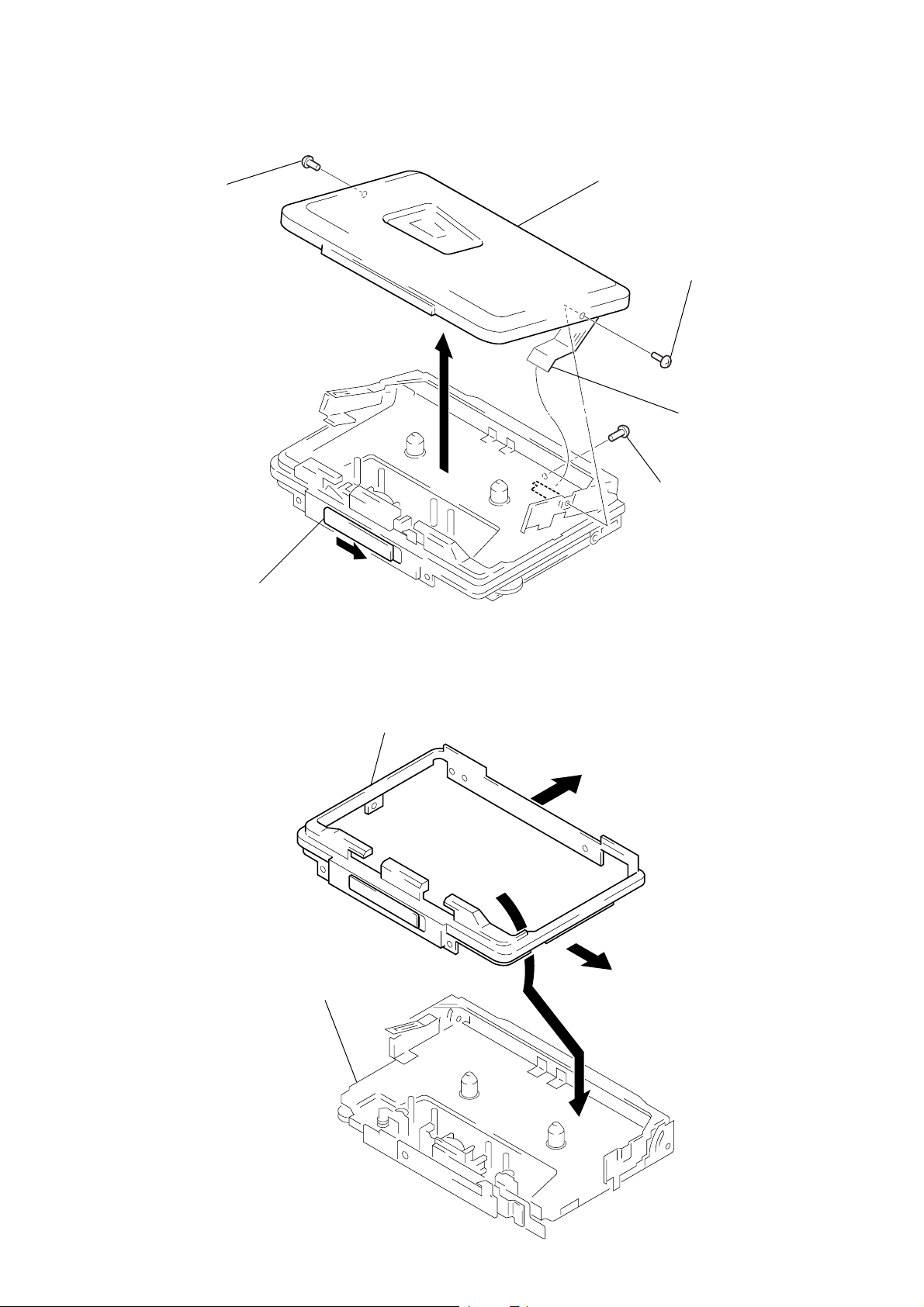

LID ASS’Y, CASSETTE

d

4

serrat (IB lock)

5

lid ass’y, cassette

3

4

serrat

(IB lock)

2

tuner flexible boar

screw

(IB lock)

1

Open the cassette lid.

MECHANISM DECK

ornament ass’y, reel

2

Remove the mechanism deck

to direction of the arrow

A

1

1

.

– 7 –

A

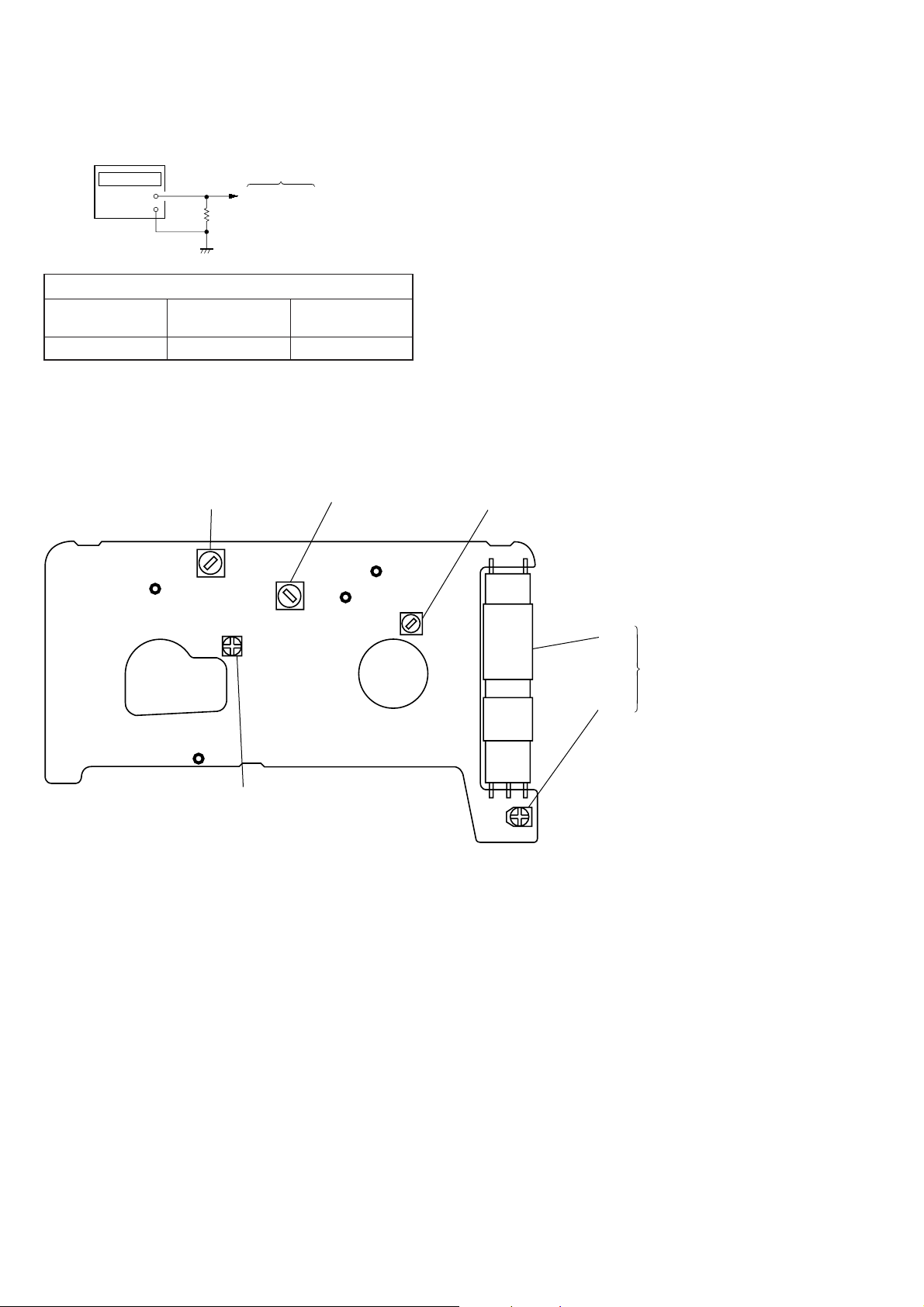

SECTION 4

Test tape

WS-48A

(3 kHz, 0 dB)

frequency counter

+

—

32

Ω

set

2

REOMTE jack

MECHANICAL ADJUSTMENTS

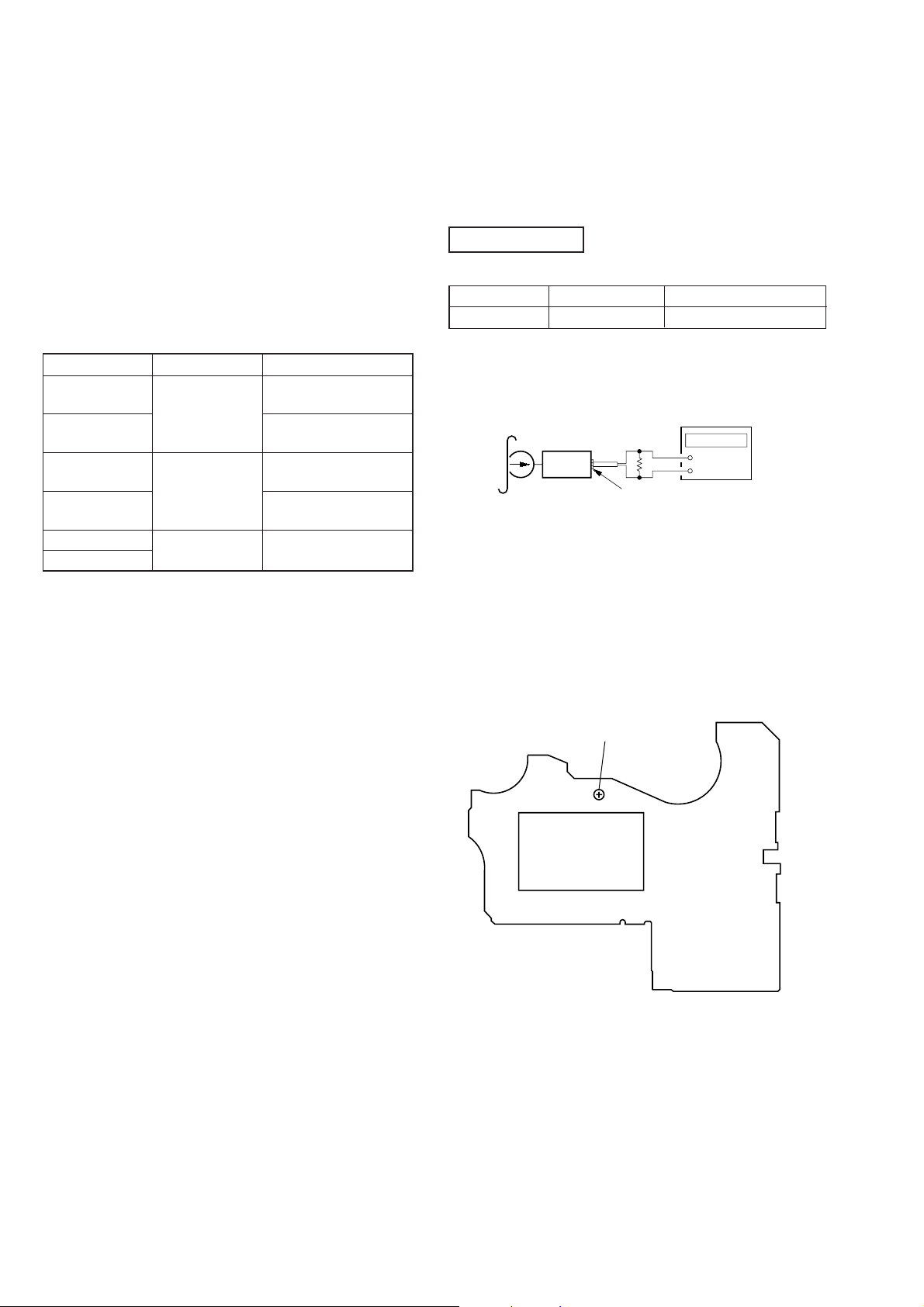

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belts capstan

2. Demagnetize the playback head with a head demagnetizer.

(Do not bring the head demagnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage (1.3 V) unless otherwise noted.

Torque Measurement:

Mode Torque meter Meter reading

FWD

FWD 0.7 – 2.0 g•cm

back tension (0.006 – 0.027 oz•inch)

REV

REV 0.7 – 2.0 g•cm

back tension (0.006 – 0.027 oz•inch)

FF

REW

CQ-102C

CQ-102RC

CQ-201B

18 – 30 g•cm

(0.25 – 0.41 oz•inch)

18 – 30 g•cm

(0.25 – 0.41 oz•inch)

more than 35g•cm

(more than 0.49 oz•inch)

PRECAUTION

1. Specified voltage : 1.3 V (DC)

2. Switch position

a NR switch : OFF

DIR MODE switch : a

TAPE SECTION

Test tape

Type Signal Used for

WS-48A 3 kHz, 0 dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure:

1. Playback WS-48A (tape center part) in the FWD state and adjust R V601 so that the frequency counter reading becomes 3,015

± 10 Hz.

2. Playback WS-48A (tape center) in the REV state.

Check that the frequency counter reading is within 2.5% of the

reading of step 1.

Adjutment Point:

AUDIO BOARD – Side A –

RV601

ND501

– 8 –

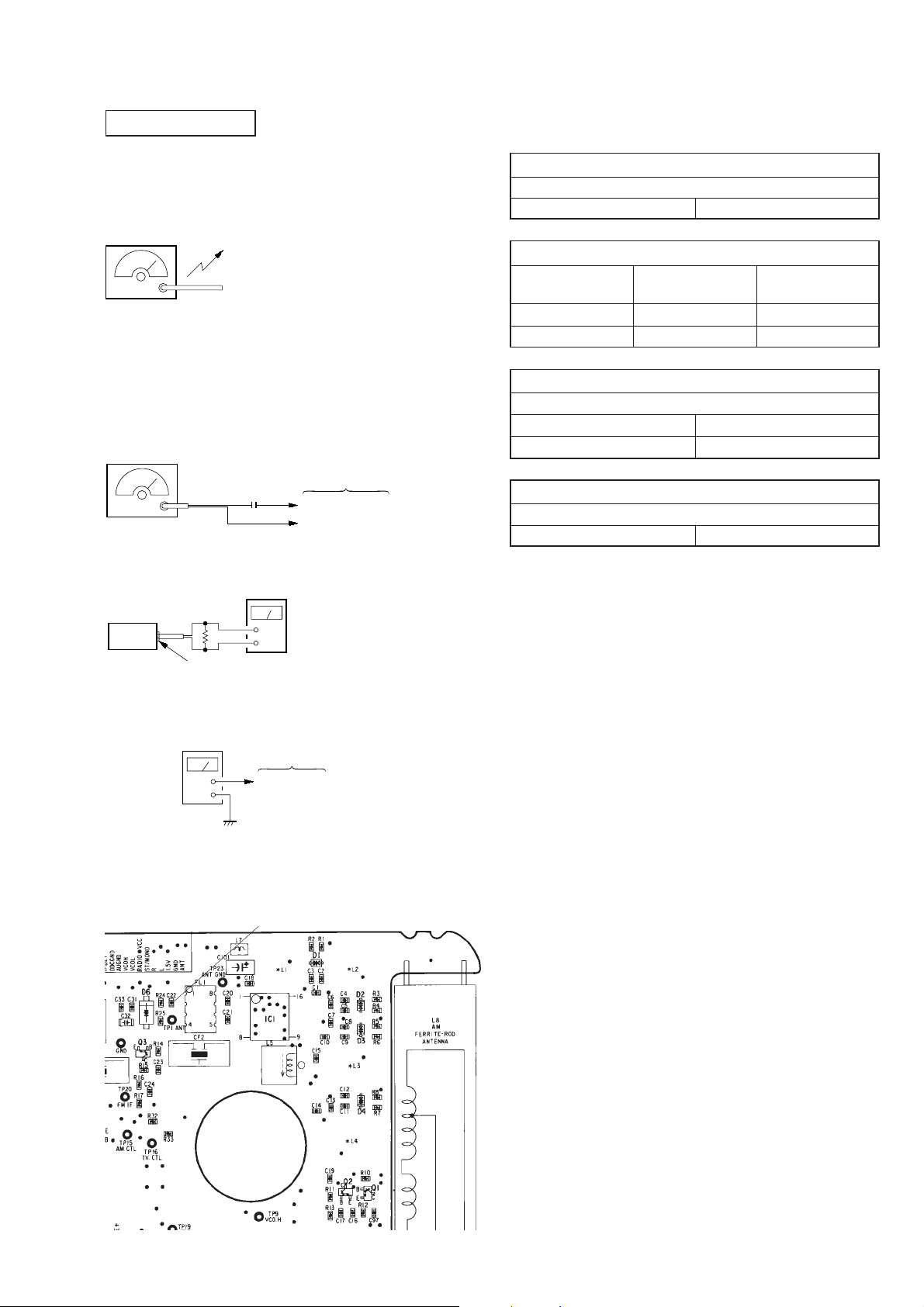

TUNER SECTION

)

r

AM SECTION

Setup:

BAND switch: AM

AM RF signal

generator

400 Hz 30 %

AM modulation

Output level: as low as possible

Put the lead-wire

antenna close to

the set.

• For the tracking adjustment, repeat is 2 or 3 times, then end

with adjustment of trimmer capacitor.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2 450 kHz

AM FREQUENCY COVERAGE ADJUSTMEN

Adjusting device Frequency display

Digital Voltmeter

reading

T1 531 kHz 1.3 ± 0.05 V

Confirm 1,710 kHz 7.95 ± 0.5 V

FM SECTION

Setup:

BAND switch: FM

FM RF signal

generator

µ

F

0.01

1 kHz 100 % FM modulation

frequency devition

Output level: as low as possible

set

±

75 kHz

level mete

32

Ω

2

REMOTE jack

Connection:

AM Frequency coveage adjustment

digital voltmeter

TUNER Board

—

+

TP21 (VT)

(see page10)

TUNER Board

TP1 (ANT)

TP23 (ANT GND

(see page 10)

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L8 621 kHz

CT1 1,404 kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

L5 10.7 MHz

Caution:

Before the FM measurement, remove a chip ceramic capacitor C22

in the ANT line. Reconnect it after measure ment.

[TUNER Board]

C22

– 9 –

VCO Adjustment

)

connection:

frequency counter

TUNER Board

+

—

150 k

Ω

VCO Adjustment

Adjusting device Frequency display

RV1 78.00 MHz 19.00 kHz ± 0.05 kHz

• Adjusting Location

TP25 (19 kHz

Frequency counter

reading

[TUNER Board]

AM IF Adjustment

TP25

(19 kHz)

TP21

(VT)

VCO Adjustment

T2

RV1

AM Frequency coverage

T1

Adjustment

TP23

(ANT GND)

TP1

(ANT)

L5

FM IF Adjustment

L8

AM

Tracking

Adjustment

CT1

– 10 –

Loading...

Loading...