Sony WMFQ-01 Service manual

WM-FQ01

SERVICE MANUAL

SPECIFICATIONS

Radio

US, Canadian model :

FM : 87.6 – 108MHz

AM : 530 – 1,710kHz

AEP model :

FM : 87.6 – 107.9MHz

AM : 531 – 1,602kHz

US Model

Canadian Model

AEP Model

Model Name Using Similar Mechanism WM-FX321

Tape Transport Mechanism Type MF-WMFX305-43

Power Requirements

Battery life

(approximate hours) (EIAJ*)

* Measured value by the standard of EIAJ (Electronic Industries

Dimensions

Mass

Supplied accessories

Design and specifications are subject to change without notice.

• 3V DC Batteries R6 (AA) x 2

• External DC 3V power sources

Sony Alkaline LR6 (SG) Sony R6P (SR)

16 hours. (playback) 4.5 hours. (playback)

48 hours. (radio) 16 hours. (radio)

Association of Japan). (Using Sony HF series cassette tape)

118.8 x 89.5 x 34.1 mm (4 3/4 x 3 5/8 x 1 3/8in)

(w/h/d) incl. projecting parts

205g (7.3 oz) incl. batteries

• Stereo headphones (1)

• Belt clip (1)

• Protecter (1)

RADIO CASSETTE PLAYER

MICROFILM

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Location and Function of Controls .................................... 2

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

2. DISASSEMBLY

2-1. Cabinet (Rear) Removal ............................................. 3

2-2. Cabinet (Front) Removal ............................................ 3

2-3. Main Board, Mechanism Deck Removal ................... 3

2-4. Cassette Holder Sub Assy Removal ........................... 4

2-5. Dial Pointer Setting .................................................... 4

3. ADJUSTMENTS

3-1. Mechanical Adjustment .............................................. 5

3-2. Electrical Adjustment ................................................. 5

4. DIAGRAMS

4-1. Block Diagram............................................................ 7

4-2. Printed Wiring Boards ................................................ 9

4-3. Schematic Diagram....................................................11

5. EXPLODED VIEWS

5-1. Cabinet and Board Section ....................................... 15

5-2. Mechanism Deck Section ......................................... 16

6. ELECTRICAL PARTS LIST ................................17

SECTION 1

GENERAL

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

• HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF2 and X2.

Y ou must used same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must changed two pieces together

since it's supply two pieces in one package as a spare parts

mark

CF2

mark

X2

Mark Center Frequency

red 10.70MHz

blue 10.67MHz

orange 10.73MHz

black 10.64MHz

white 10.76MHz

This section is extracted from

instruction manual.

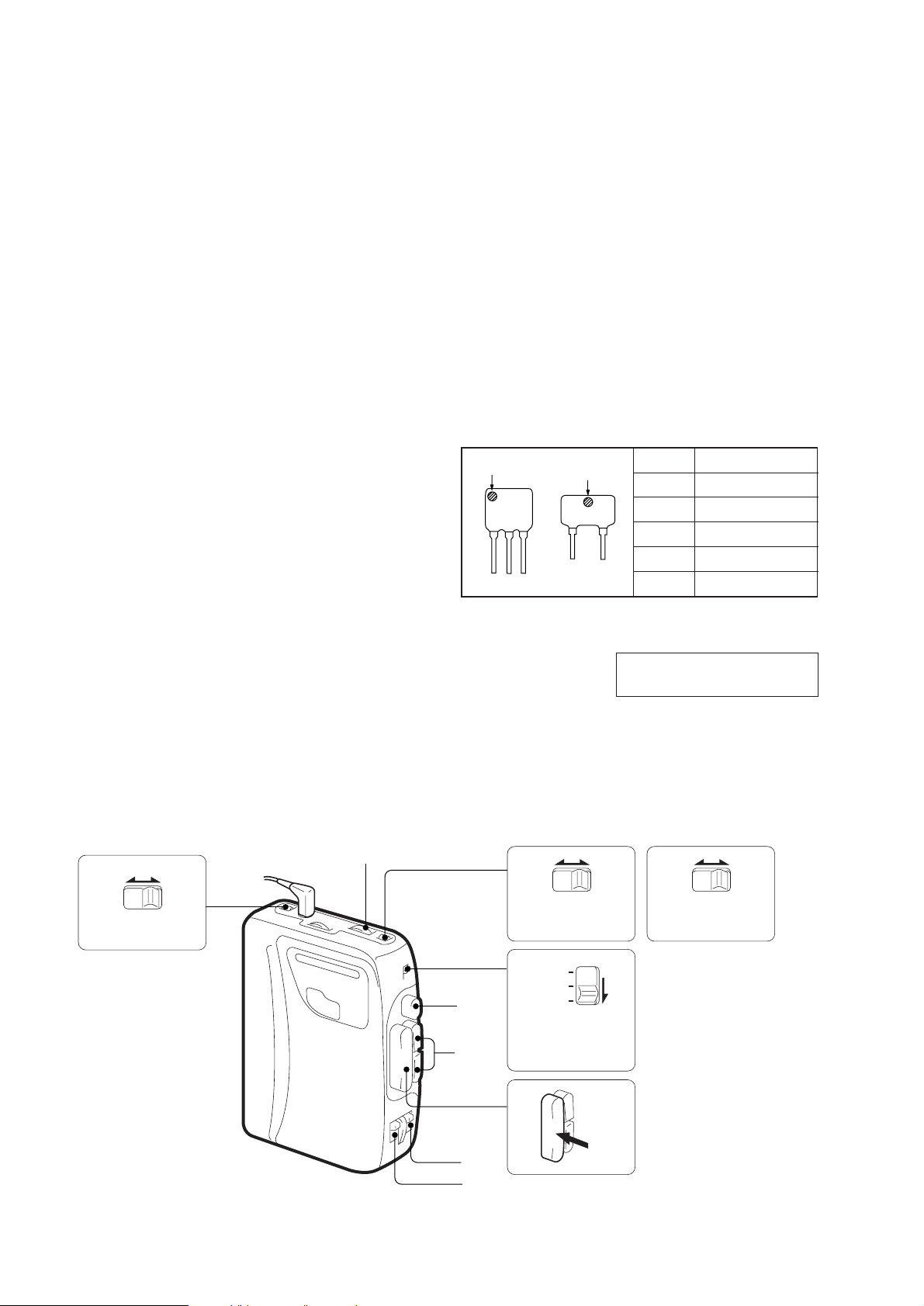

LOCATION AND FUNCTION OF CONTROLS

VOLUME

••

NORM LIMIT

AVLS

p

0 )

MODE

DIR

US, Canadian model AEP model

••

NORM CrO

METAL

DX LOCAL

FM AM TAPE

(RADIO OFF)

2/

PLAY

••

NORM CrO2/

METAL

ST MONO

– 2 –

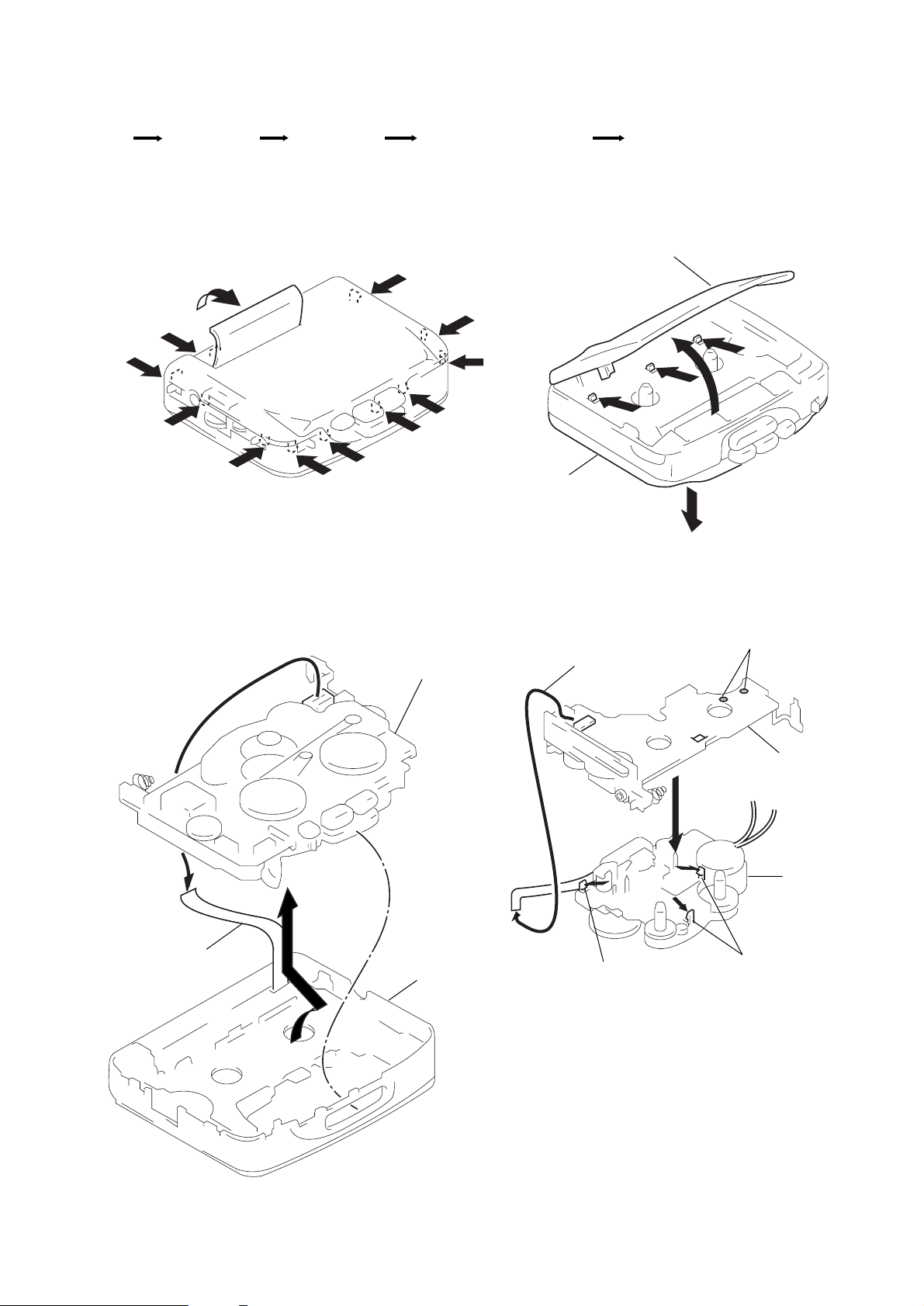

SECTION 2

k

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Set

Cabinet (Rear)

Cabinet (Front)

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR) REMOVAL

1

Main board, Mechanism deck

4

Cassette holder sub assy

Cassette holder sub assy

2

2

3

3

7

2-2. CABINET (FRONT) REMOVAL

7

7

Main board and

Mechanism deck

4

7

7

6

6

Cabinet (Rear)

8

6

5

2-3. MAIN BOARD, MECHANISM DECK REMOVAL

1

Remove solder

2

Head flexible board

Main board

1

Flexible board

2

4

Mechanism dec

3

3

Cabinet (Front)

Claw

Claws

– 3 –

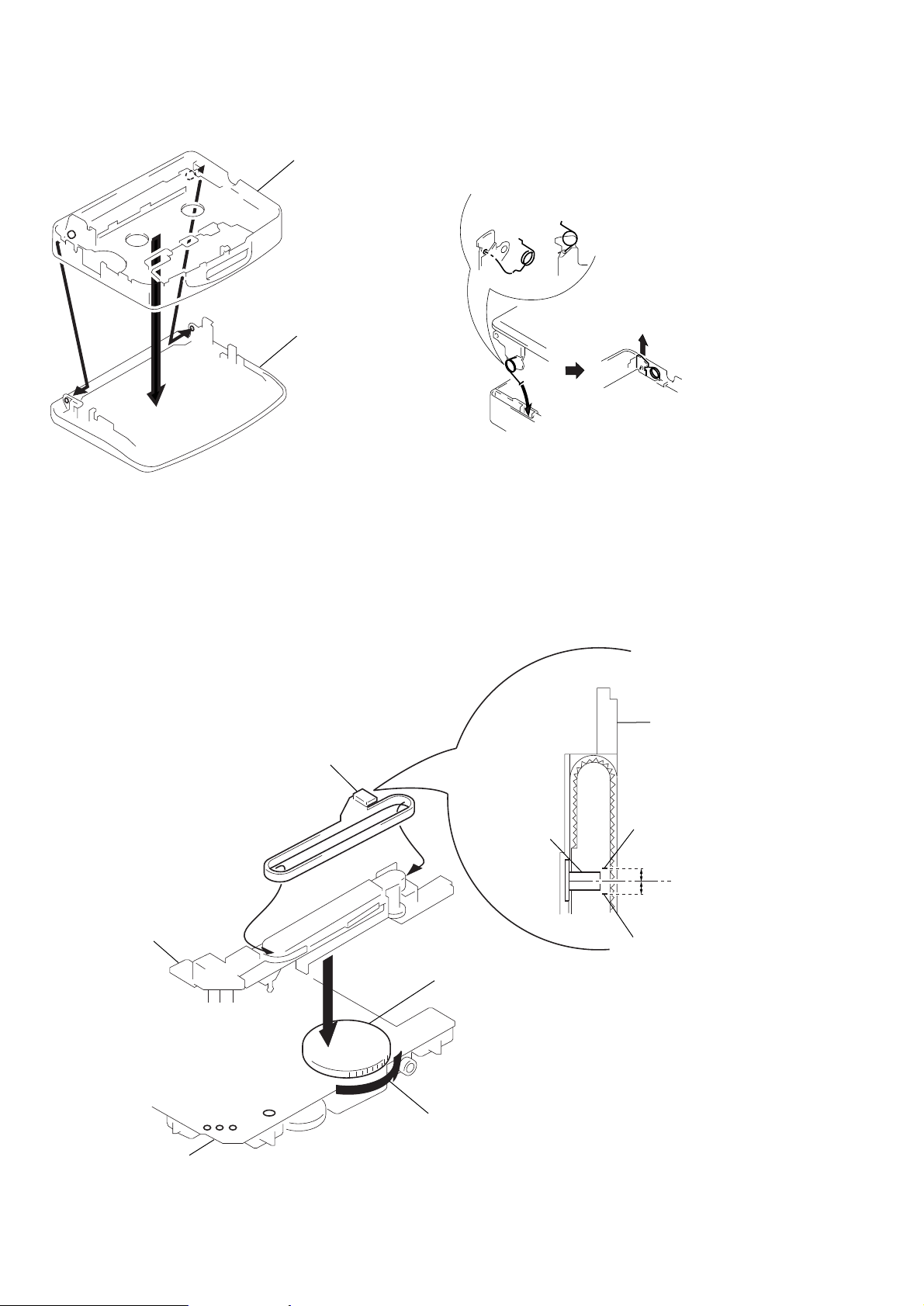

2-4. CASSETTE HOLDER SUB ASSY REMOVAL

y

y

Cabinet (Front)

NOTE FOR INSTALLATION

The torsion spring will be removed together with the cassette lid that

preform the following for installation.

r

TORSION SPRING

1

Attach the torsion spring

as shown in the figure

2

3

1

2-5. DIAL POINTER SETTING

Cassette holder sub ass

Pointer

2

Insert the torsion spring

in the hole as shown in the figure.

2

Align pointer with arrow marked

side as shown in Fig. 1 and then

fit to groove in the order of

3

Lift the torsion spring in

the arrow direction and

hook it properly

a

and b.

Ferrite-rod antenna sub ass

Ferrite-rod antenna sub assy

Main board

a

3

b

Pointer

Fig. 1

Knob (tune)

1

Rotate tune knob fully to arrow direction.

Align point

A

(A=B)

B

Align point

– 4 –

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch roller

capstan rubber belt

2. Demagnetize the playback head using a head demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage (2.5V) unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

FWD

FWD less than 2 g • cm

back tension (less than 0.03 oz• inch)

REV

REV less than 2 g • cm

back tension (less than 0.03 oz• inch)

FF, REW CQ-201B

Tape Pulling Force Measurement

Mode Torque Meter Meter Reading

FWD CQ-403A more than 40 g

REV CQ-403R (more than 1.42 oz)

CQ-102C (0.28 – 0.58 oz• inch)

CQ-102RC (0.28 – 0.58 oz• inch)

20 – 42 g • cm

20 – 42 g • cm

more than 60g • cm

(more than 0.83 oz• inch)

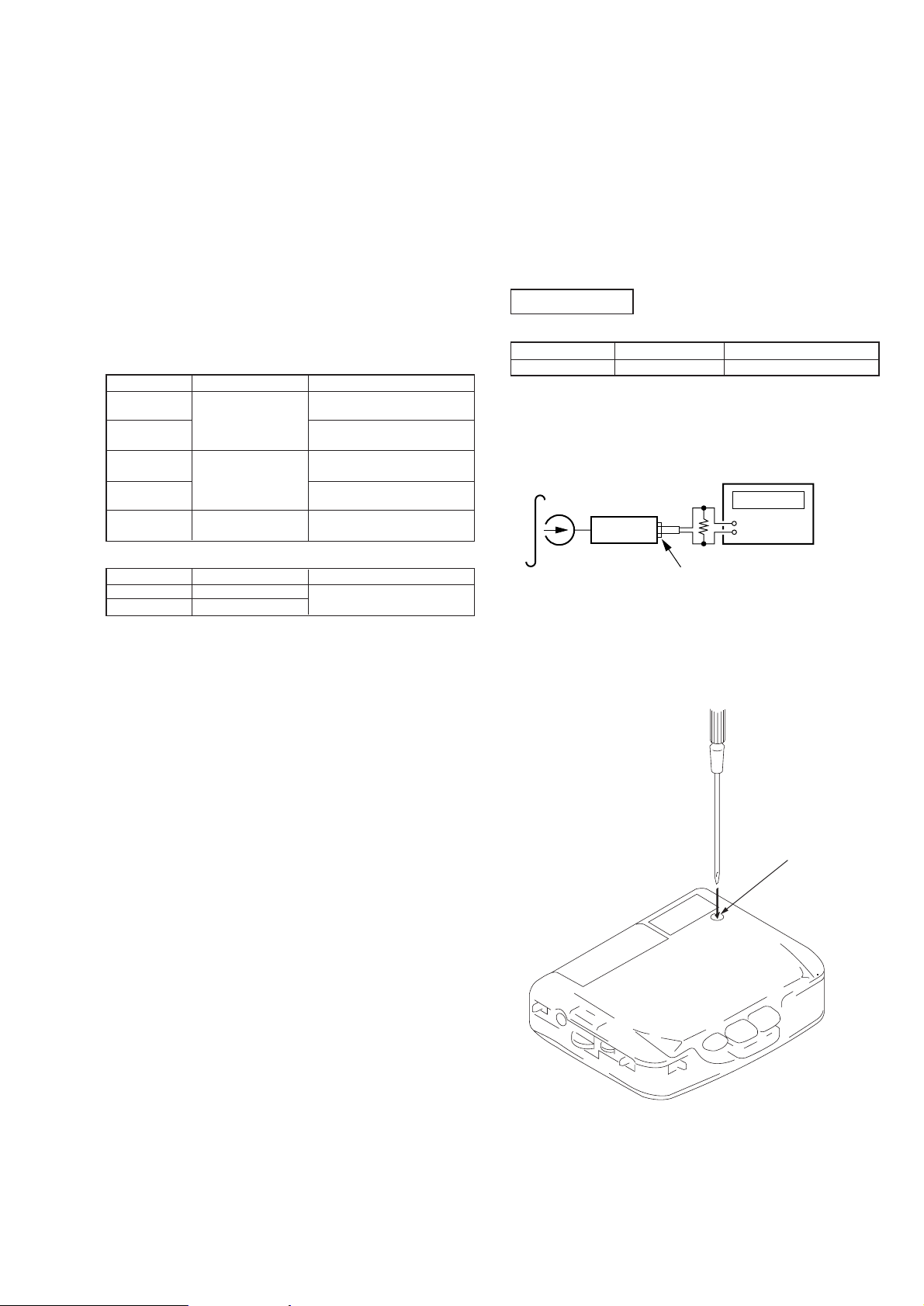

3-2. ELECTRICAL ADJUSTMENTS

PRECAUTION

• Specified voltage : 2.5V.

• Switch and control position

TAPE switch : NORM

VOLUME control : maximum

AVLS switch : NORM

Function switch : TAPE

T APE SECTION

Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure :

test tape

WS-48A

(3kHz, 0dB)

set

Play back WS-48A (tape center part) and adjust RV601 so that the

frequency counter reading becomes 2,985 – 3,015Hz.

Frequency difference the beginning and the end of the tape should

be within 1.5%.

frequency counter

16

Ω

J302 (phones)

+

–

Adjustment Location :

RV601

– 5 –

Loading...

Loading...