Sony WMEX-660 Service manual

WM-EX660/EX662

SERVICE MANUAL

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

AEP Model

UK Model

WM-EX660/EX662

E Model

WM-EX662

Model Name Using Similar Mechanism WM-EX650/EX652/EX654

Tape Transport Mechanism Type MT-WMEX550-125

MICROFILM

CASSETTE PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY ......................................................... 8

4. MECHANICAL ADJUSTMENTS....................... 13

5. ELECTRICAL ADJUSTMENTS......................... 13

6. DIAGRAMS

6-1. Block Diagram ................................................................ 14

6-2. Printed Wiring Board ...................................................... 16

6-3. Schematic Diagram ......................................................... 19

6-4. IC Pin Function Description ........................................... 25

7. EXPLODED VIEWS ................................................ 27

8. ELECTRICAL PARTS LIST ............................... 30

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

SECTION 1

SERVICING NOTES

This set detects the rotation of GEAR (PH) using the PH701 (photo

reflector). The PH701 is mounted on the MAIN board, and therefore the GEAR cannot be detected with the MAIN board removed.

As a result, the motor cannot be controlled, causing malfunction.

Further, the S702 (FWD/REV switch) is also mounted on the MAIN

board, and with the board removed, the mechanism position

cannnot be detected and the operation is not changed over.

Therefore, when the voltage check is executed with the MAIN

board removed, follow the procedure provided below.

Note : Do not move the S702 swithc position when removing the MAIN

board.

If it is moved, the set will not be changed over to the selected mode.

In this case, reconnect the MAIN board to the set and retry the

work from the beginning.

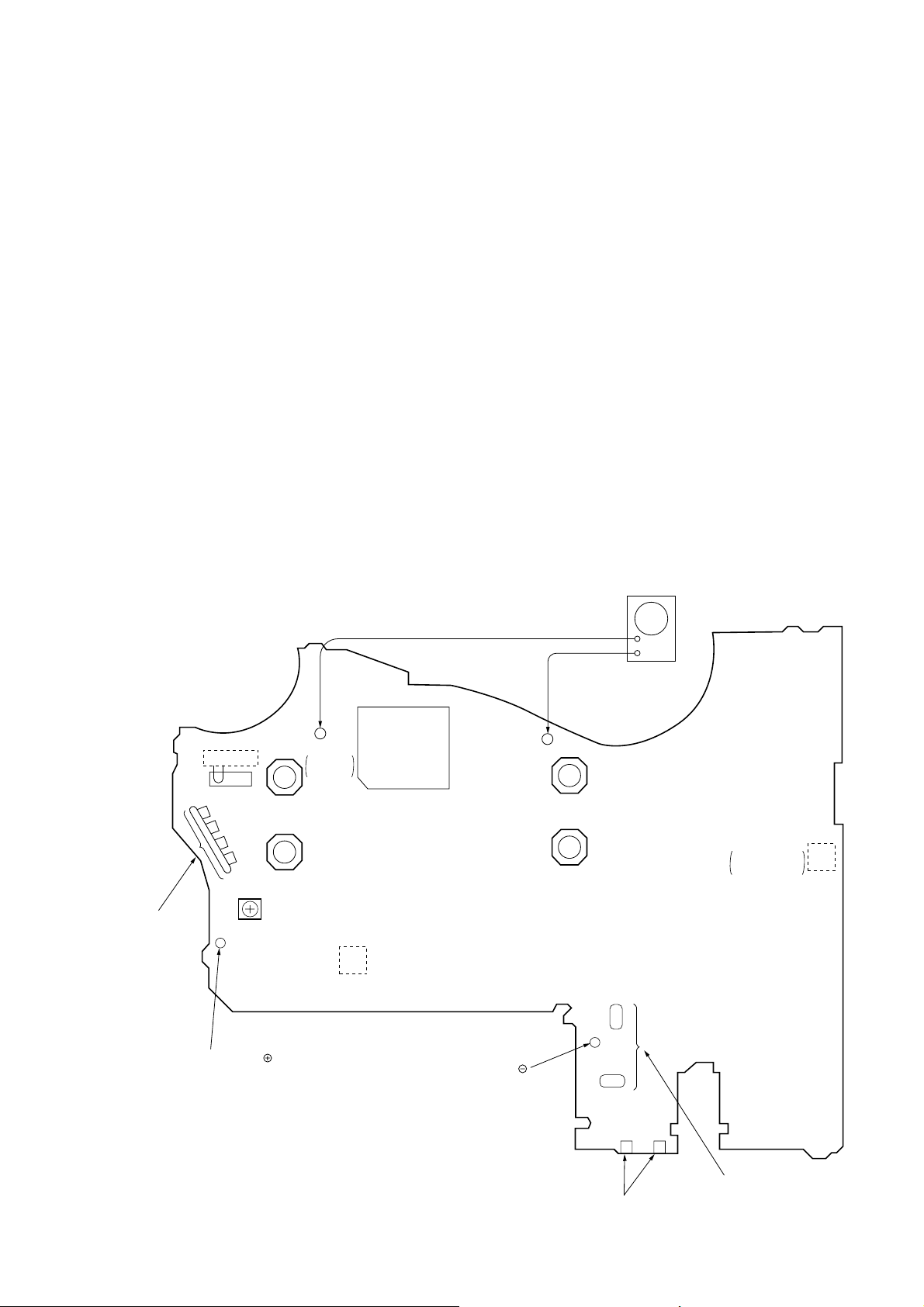

— MAIN BOARD (SIDE B) —

square wave

10 Hz, – 3.5 dB

1. Setting

1) Refer to “3. DISASSEMBLY”, and remove the cabinet and

open the MAIN board.

2) Connect the MAIN board to the M901 (motor) and PM901

(plunger) using jumper wires.

3) Short the ATS terminals.

4) Press and fixed the S701 (CASSETTE HOLDER).

5) Supply 1.5V to the battery terminals ‘ and ’ using a stabilized power supply.

2. FF, REW Modes

1) Input a square wave to the TP35 (PHOTO IN) and TP23

(GND). (See figure below)

2) Press the S704 (STOP) for selecting STOP mode.

3) Press the S706 (FF) or S707 (REW).

3. PLAY mode

1) Input a square wave to the TP35 (PHOTO IN) and TP23

(GND). (See figure below)

2) Press the S704 (STOP) for selecting STOP mode.

3) Press the S705 (PLAY). (Each time the switch is pressed, the

mode is changed over.)

AF

oscillator

+

–

connect to

M901 (motor)

battery terminal

S702

FWD

→

REV

S706 (FF)

S707 (REW)

RV601

TP35

PHOTO

IN

PH701

IC701

battery terminal

TP23

(GND)

S705 (PLAY)

S704 (STOP)

S701

CASSETTE

HOLDER

– 3 –

ATS terminals

(to S901)

connect to

PM901 (plunger)

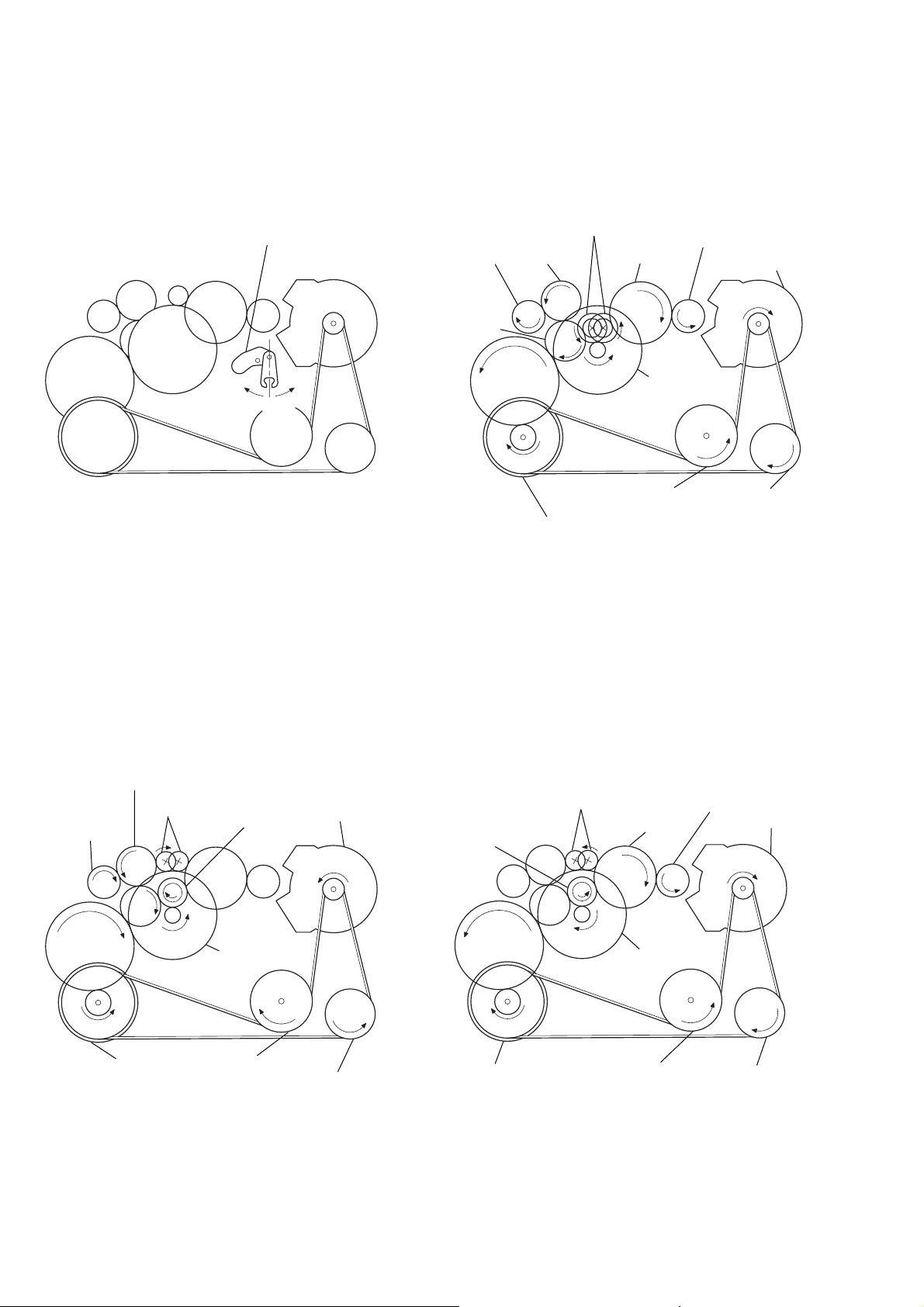

Lever (SW) Rotation system

y

Rotation system during PLAY.

lever (SW)

gear (REEL)

(T side)

gear (TA)

gear (TB)

gear (NR)

(REV: right side/

FWD: left side)

gear (S)

gear (REEL)

(S side)

motor pulle

Rotation system during FF.

gear (TB)

gear (FR)

gear (REEL)

(T side)

(FF: left side)

side R

side F

senter

gear (NR)

motor pulley

gear (Y)

flywheel (N) ass’y

Rotation system during REW.

gear (FR)

(REW: right side)

gear (NR)

clutch ass’y (M)

gear (S)

Pulley (reverse)flywheel (R) ass’y

gear (REEL)

(S side)

motor pulley

gear (Y)

flywheel (N) ass’y

clutch ass’y (M)

flywheel (R) ass’y

pulley (reverse)

gear (Y)

clutch ass’y (M)

flywheel (N) ass’y

flywheel (R) ass’y

pulley (reverse)

– 4 –

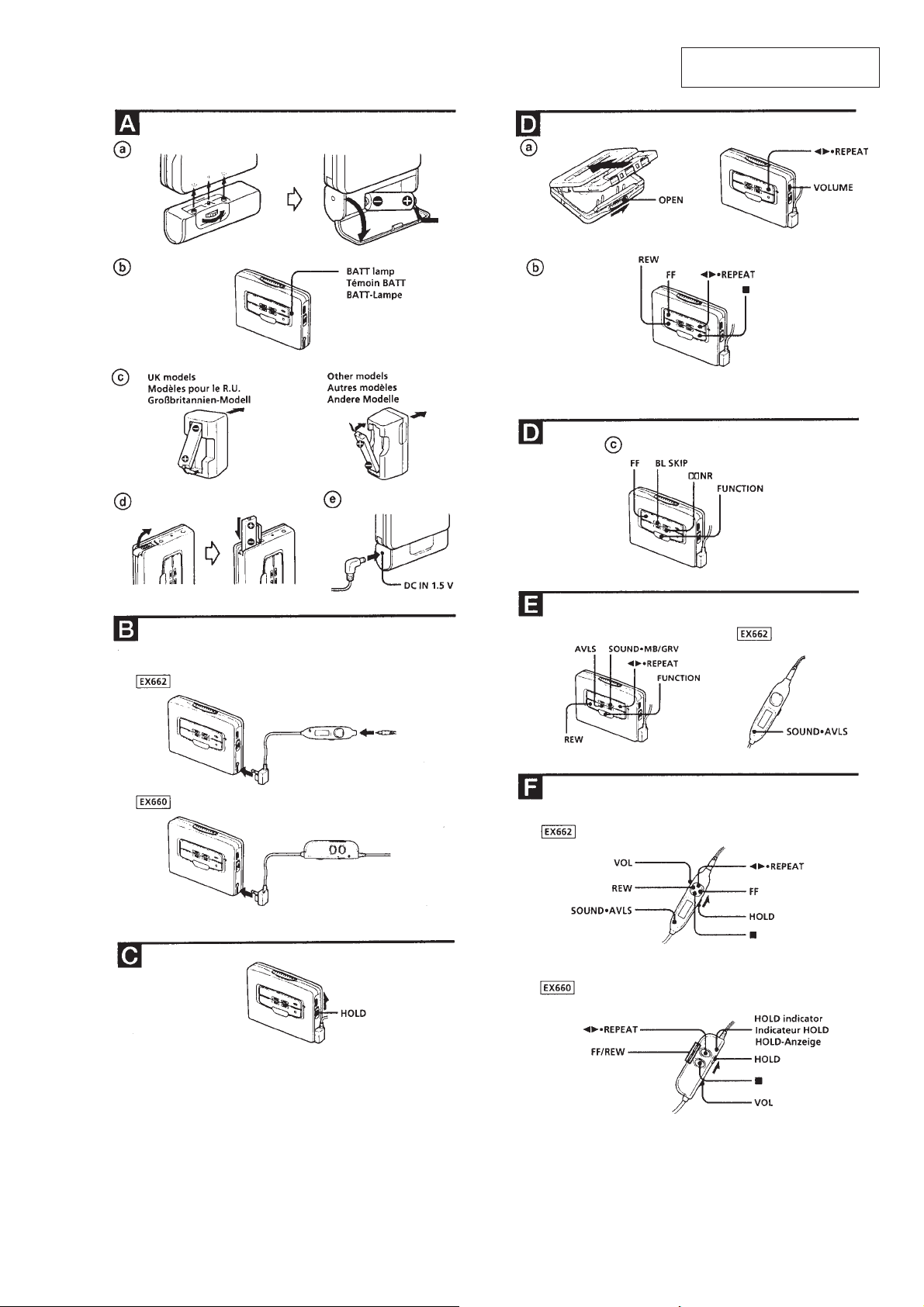

SECTION 2

GENERAL

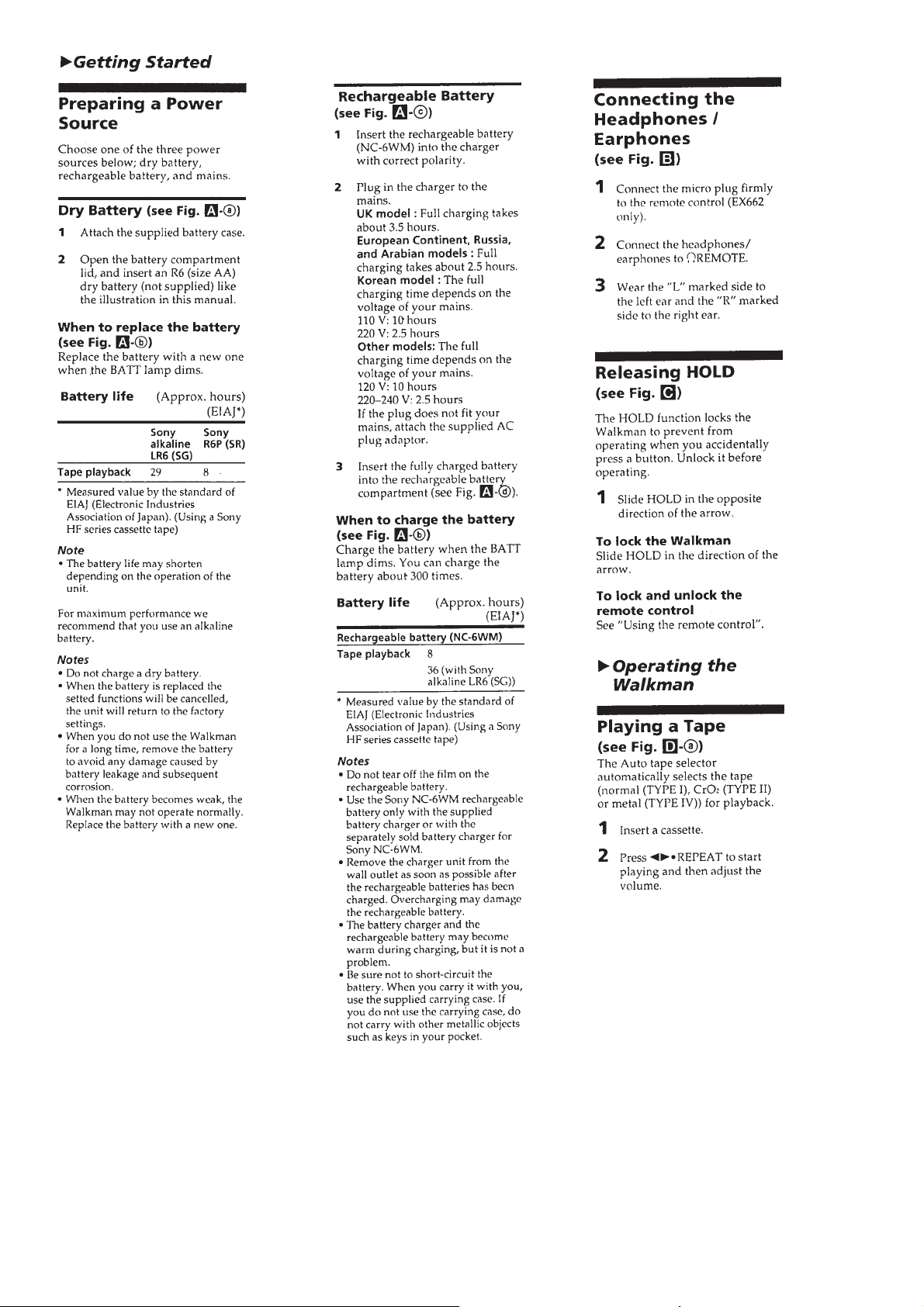

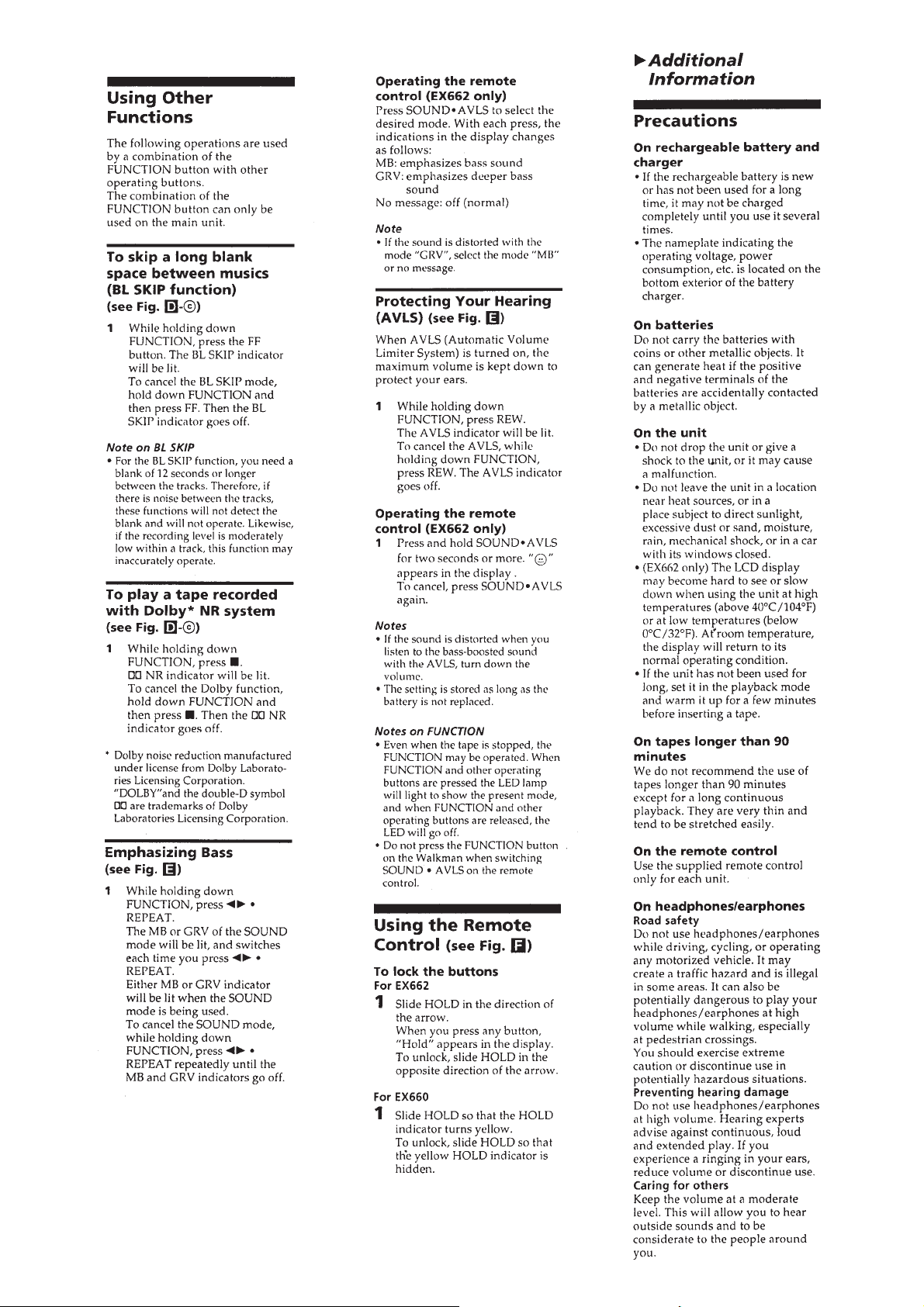

This section is extracted from

instruction manual.

– 5 –

– 6 –

– 7 –

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

SET

Note: Follow the disassembly procedure in the numerical order given.

CASSETTE

LID ASS’Y

CASE (N) ASS’Y REEL ORNAMENT MAIN BOARD

CASSETTE LID ASS’Y

3

Remove the cassette lid ass’y to

direction of the arrow

A

.

NOTE FOR INSTALLATON

BELT

MAGNETIC HEAD (HP901)

2

screw (1.4 × 2)

MOTOR (M901)

1

Open the cassette lid ass’y.

2

screw (IB lock)

A

– 8 –

Loading...

Loading...