Sony WM-EX510 Service Manual

Q

Q

3

7

6

3

1

WM-FX822

5

1

5

0

8

9

2

4

9

8

2

9

9

SERVICE MANUAL

Ver 1.1 2002. 01

TEL 13942296513 QQ 376315150 892498299

Model Name Using Similar Mechanism WM-EX510

Tape Transport Mechanism Type MT-WMEX510-112

SPECIFICATIONS

Radio section

Frequency range

TEL

Tape player section and general

Frequency response

Output

Power output

Power requirements

Battery life (Approx. hours)

Rechargeable NC-6WM

fully charged

Playback 5

Radio/TV reception 7.5

Sony alkaline LR6 (WM)

Playback 16

Radio/TV reception 24

13942296513

FM (stereo) : 76.0 - 90 MHz

AM (mono) : 531 - 1,710 kHz

TV (mono): 1 -12 ch

(a NR off)

20 - 18,000 Hz (EIAJ*)

Headphones (2/REMOTE jack)

load impedance 8 - 300 Ω

4 mW + 4 mW (EIAJ, 16 Ω)

DC1.5V

Rechargeable battery (NC-6WM)

One R6 (size AA) battery

Dimensions

Mass

7

3

Q

Q

Design and specifications subject to change without notice.

Using AC power

Remove the rechargeable battery if inserted and attach the battery

case and connect the AC power adaptor (AC-E15L or ACE15HG) not supplied) to the DC IN 1.5V of the battery case and

to the wall outlet. Do not use any other AC power adaptor.

Dolby noise reduction manufactured under licence from Dolby

Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol 8 are trademarks of Dolby

Laboratories Licensing Corporation.

6

3

Tourist Model

Approx. 108.5 x 78.6 x 23.0 mm (w/h/d)

incl. projecting parts and controls (EIAJ)

Main unit Approx. 145 g

5

1

5

1

For use Appox. 240 g (incl. Stereo

earphone with remote controller,

rechargeable battery NC-6WM, tape C60HF)

0

8

9

2

4

Polarity of

the plug

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

Sony R6P (SR)

Playback 3.5

Radio/TV reception 7

9-960-416-12

w

w

2002A1600-1

© 2002.1

w

Sony Corporation

.

Personal Audio Company

Published by Sony Engineering Corporation

xia

*(EIAJ) Electric Industries Association of Japan

o

y

u

1

6

— 1 —

— Continued on next page —

RADIO CASSETTE PLAYER

3

.

c

o

m

7

Q

Q

Receiving Stations Outside Japan

1 Press BAND•RADIO ON to turn on the radio.

2 Press ENTER. The frequency digits, “PRESET” and a preset

number flash in the display.

3 Press BAND•RADIO ON for more than 2 seconds. “AREA

1” flashes in the display.

4 While “AREA 1” is flashing, press PRESET+/– repeatedly to

select either area “USA” (USA and Canada) or “Eur”

(Europe and other countries) and then press ENTER.

5 Press ASP to store the radio stations (both AM and FM)

automatically.

TEL 13942296513 QQ 376315150 892498299

The Walkman starts searching and storing stations.

6 Press BAND•RADIO ON to select the desired band and

press PRESET+/– to select a station.

3

6

3

1

5

1

5

0

Section Title Page

SECTION 1. GENERAL .......................................... 3

SECTION 2. SERVICE NOTE ................................. 4

SECTION 3. DISASSEMBLY

3-1. Bracket assembly and Cassette Holder assembly .............. 6

3-2. Audio Board ....................................................................... 6

3-3. Tuner Board ....................................................................... 7

SECTION 4. ADJUSTMENTS

4-1. Mechanical Adjustments .................................................... 8

4-2. Electrical adjustments ........................................................ 8

SECTION 5. DIAGRAMS

5-1. Printed Wiring Board — Tuner Section —.....................11

5-2. Schematic Diagram — Tuner Section —........................ 13

5-3. Schematic Diagram — Audio Section — ....................... 17

5-4. Printed Wiring Board — Audio Section — .................... 21

5-5. IC Pin Functions

IC701 MSM63120B System Control .............................. 25

IC702 SMC62L3A LCD Driver ...................................... 26

4

2

9

8

TABLE OF CONTENTS

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

13942296513

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

w

.

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

xia

PUBLISHED BY SONY.

o

y

u

SECTION 6. EXPLODED VIEWS

Q

Q

6-1. Case and Tuner Board Section ........................................ 28

6-2. Audio Board Section........................................................ 29

6-3. Mechanism Section (WM-EX510-112) ........................... 30

SECTION 7. ELECTRICAL PARTS LIST ............. 31

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when

soldering or unsoldering.

1

6

3

6

7

3

3

.

1

5

c

1

0

5

o

9

8

m

2

4

9

8

2

9

9

— 2 —

SECTION 1

GENERAL

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

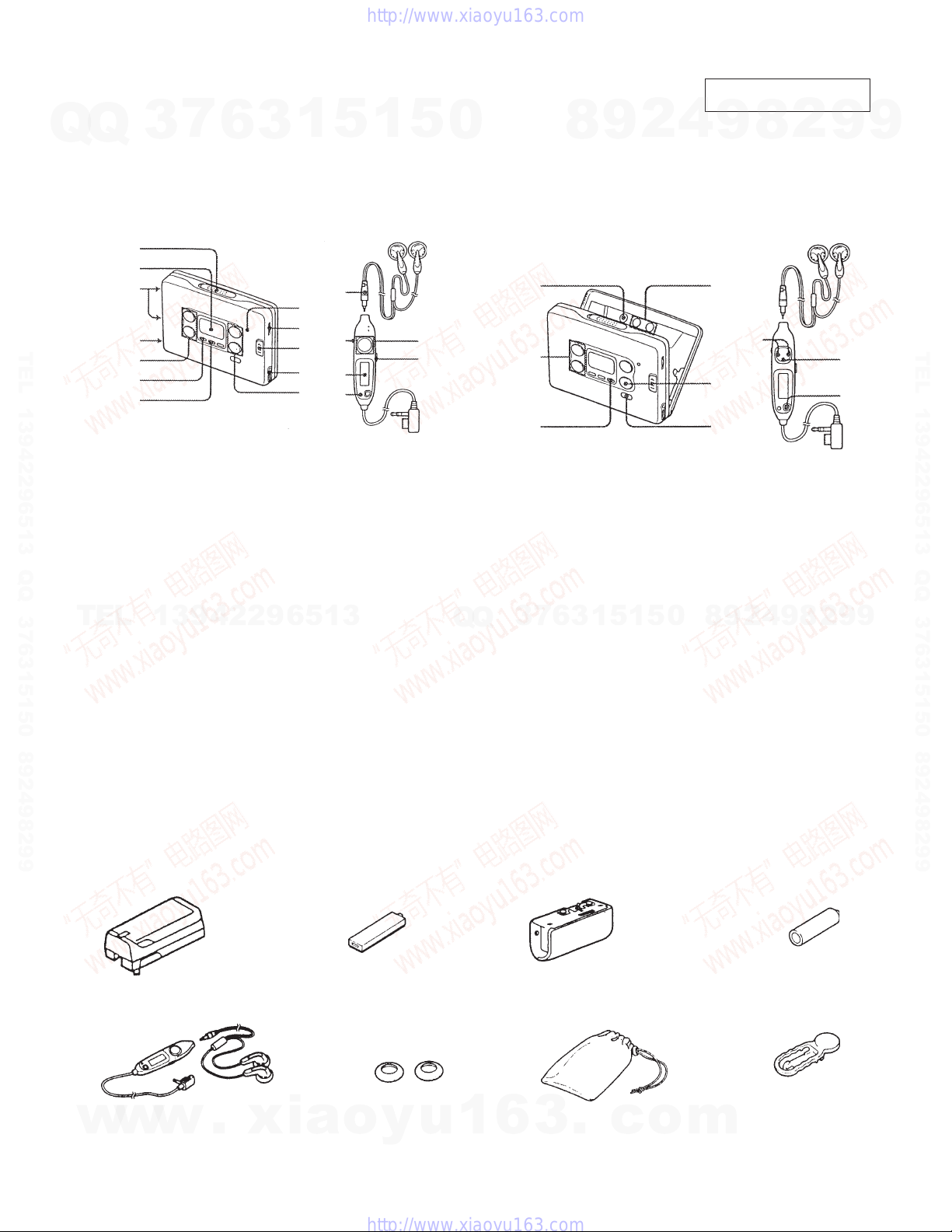

PARTS IDENTIFICATION

Tape Player and General section Radio section

1

2

3

4

5

6

7

1 OPEN knob

2 Display window

3 Terminal for a dry battery case

4 Battery compartment lid

(for the rechargeable battery)

5 Tape operation buttons

6 MENU (function select) botton

7 SET (function change) botton

8 BATT (battery) indicator

9 Main unit : VOLUME knob

0 Main unit : Hold cover

!¡ 2 REMOTE (Headphone with remote control unit)

!™ Micro plug

!£ DBB (dynamic bass boost)/ALARM botton

13942296513

Remote controller : VOL knob

Remote controller : HOLD switch

jack

6

3

1

8

9

0

!¡

!™

5

!™

9

2

!£

1

L

5

R

5

0

0

Q

Q

1

2

3

1 ENTTER (input) button

2 PRESET +, – button

3 ASP (Automatic Station Preset) button

4 TUNE (tuning) +/– switch

5 p • RADIO OFF (stop/radio off) button

6 BAND (FM/AM/TV band select) • RADIO ON

7

3

8

button

3

6

9

1

5

1

2

5

4

0

This section is extracted

from instruction manual.

2

8

9

L

4

2

5

6

2

8

9

4

2

9

8

9

R

5

6

9

9

TEL 13942296513 QQ 376315150 892498299

9

Accessories supplied

• Battery charger • Rechageable battery • Battery case • Sony alkaline battery AM3 (SR)

• Stereo earphone • Ear adaptors(2) • Carrying case • Clip

(with Remote Controller) (If the earphones do not fit your

• Plug adaptor

w

w

• Instruction manual

w

• Leaf lets

• Warranty card

.

xia

NC-6WM

ears, attach the ear adaptors.)

o

y

u

1

6

— 3 —

3

.

c

o

m

SECTION 2

SERVICE NOTE

7

Q

Q

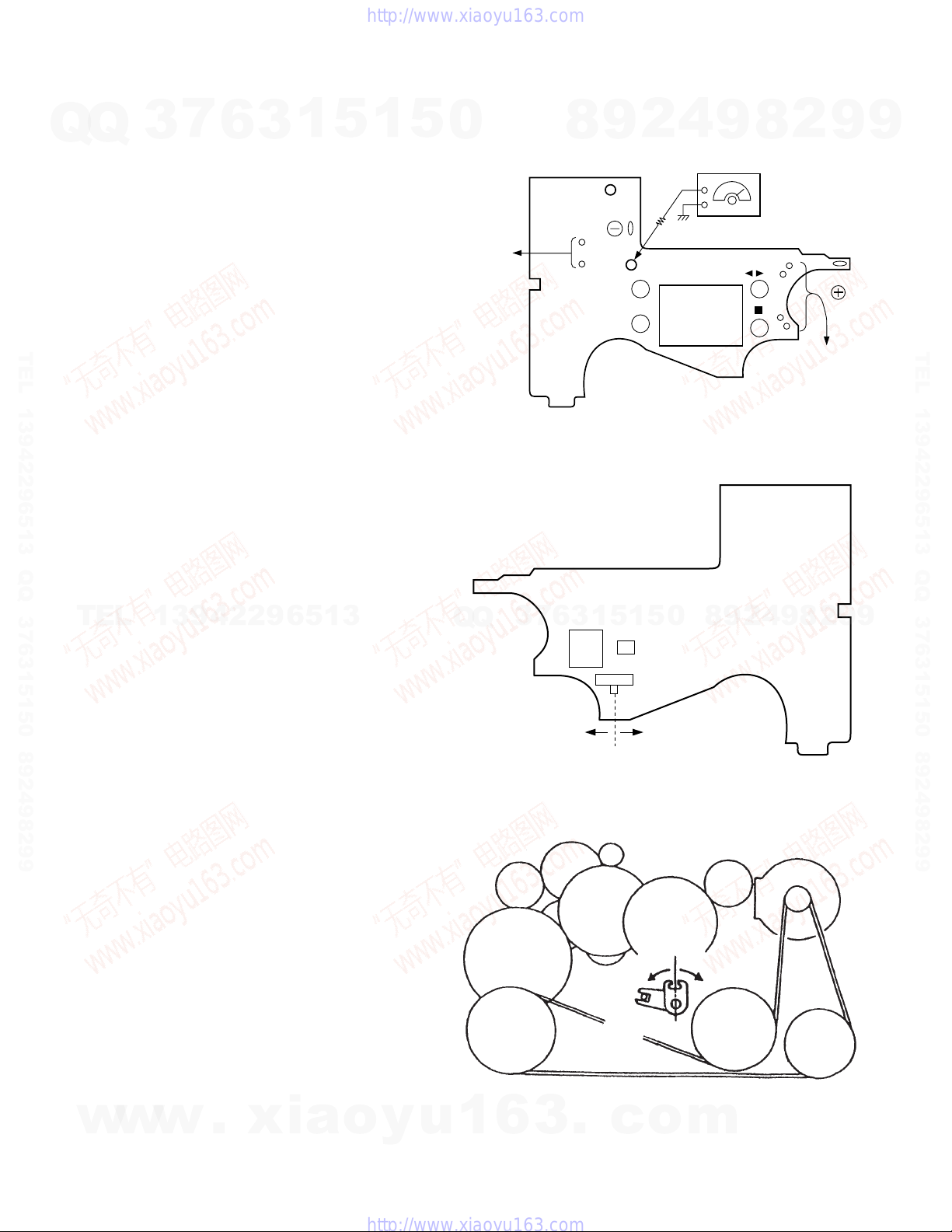

[Service Mode]

Mode which enables the mechanism to be operated with the

MAIN board opened.

1. Setting

1) Refer to “Disassembly” and remove the cabinet and open the

MAIN board.

2) Connect the MAIN board to the motor and plunger using a

jumper wire. Use “Extension tool (1-769-143-11) (one set 10

tools)” to make connection simple.

3) Short-circuit theTP52 and GND by soldering.

TEL 13942296513 QQ 376315150 892498299

4) Turn OFF the BL SKIP switch.

5) Apply a square wave signal or a sine wave signal to TP52.

(see the right figure)

6) Supply 1.3V to the battery terminals (+) and (–) using a

stabilized power supply.

3

6

3

1

5

1

5

0

[MAIN Board]

TO

PLUNGER

8

TP50

9

BATT

FF

REW

2

50KΩ

TP52

4

AF oscillator

ND701

9

+

–

8

SQUARE

WAVE

(SINE WAVE)

10Hz, –3.5dB

2

MOTOR

BATT

TO

9

9

TEL 13942296513 QQ 376315150 892498299

2. Preset State

This state must be set to set the PLAY, FF, and REW modes.

1) Check that the lever (NR SW) is at the center and F/R switch

(S701) is at the center. If not, set the preset state as follows.

2) Move the N/R switch (S701) according to the side faced by

the lever (NR SW).

3) Turn OFF the stabilized power supply switch once and then

turn it ON again so that the lever (NR SW) can be moved.

Move the N/R switch (S701) according to this timing and set

TEL

to the center.

3. FF REW Mode

1) Check the “2. Preset State” and press the FF switch and

REW switch.

4. PLAY Mode

1) Check the “2. Preset State”.

2) Press the œ switch. The lever (NR SW) will move to the F

side once and then to the R side. Move the N/R switch

(S701) according to this timing to set the PLAY (R side)

mode. Press the œ switch another time and move the N/R

switch (S701) according to the movement of the lever (NR

SW) to set the PLAY (N side) mode.

13942296513

— Side A —

— Side B —

7

3

Q

Q

[Lever (NR SW)]

IC702

5

1

3

6

S701

N SIDE R SIDE

CENTER

1

PH701

5

0

8

9

2

4

9

8

2

9

9

Note 1: If the above cannot be performed, start again from preset.

Note 2: Use the remote control œ, p , FF, and REW switches as

much as possible. If the remote control is not available, do

not touch switch with the hand and use something with a

round tip to press them.

Note 3: By using a headphone, the timing for moving S701 can be

known by the beep.

w

w

w

.

xia

o

y

u

1

— 4 —

6

3

.

R side

Lever

(NR SW)

c

Center

o

F side

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

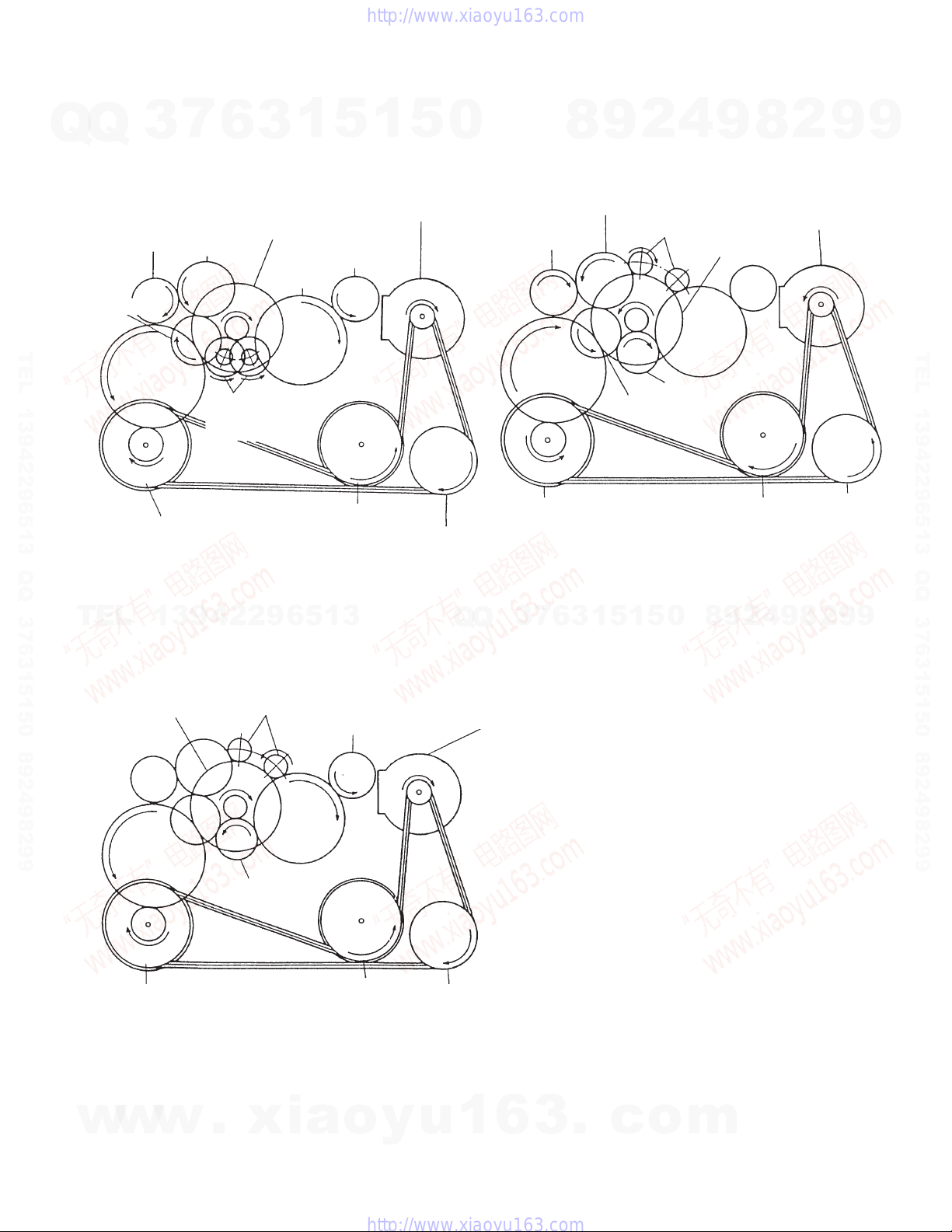

[Rotation system]

Rotation system during PLAY.

Reel table

(T side)

Gear (A)

Gear (K)

Capstan wheel (N)

assembly

6

Clutch assembly

Gear (B)

Gear (NR)

(REW : Left side/

FWD : Right side)

1

3

Reel table

(S side)

Gear (C)

Capstan wheel (R)

assembly

5

1

5

Motor pully

0

Rotation system during REW.

Reel table

(T side)

Gear (K)

Capstan wheel (N)

assembly

Pulley

(REVERSE)

8

Gear (B)

9

Gear (A)

4

2

Gear (FR)

(REW : Left side)

9

Clutch assembly

Gear (NR)

Capstan wheel (R)

assembly

8

2

9

Motor pully

Pulley

(REVERSE)

9

TEL 13942296513 QQ 376315150 892498299

TEL

Rotation system during FF.

Capstan wheel (N)

assembly

13942296513

Clutch assembly

Gear (K)

Gear (NR)

Gear (FR)

(FF : Right side)

Gear (C)

Capstan wheel (R)

assembly

Reel table

(S side)

Q

Q

Motor pully

Pulley

(REVERSE)

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

— 5 —

3

.

c

o

m

SECTION 3

DISASSEMBLY

7

Q

Q

Note : Follow the disassembly procedure in the numerical order given.

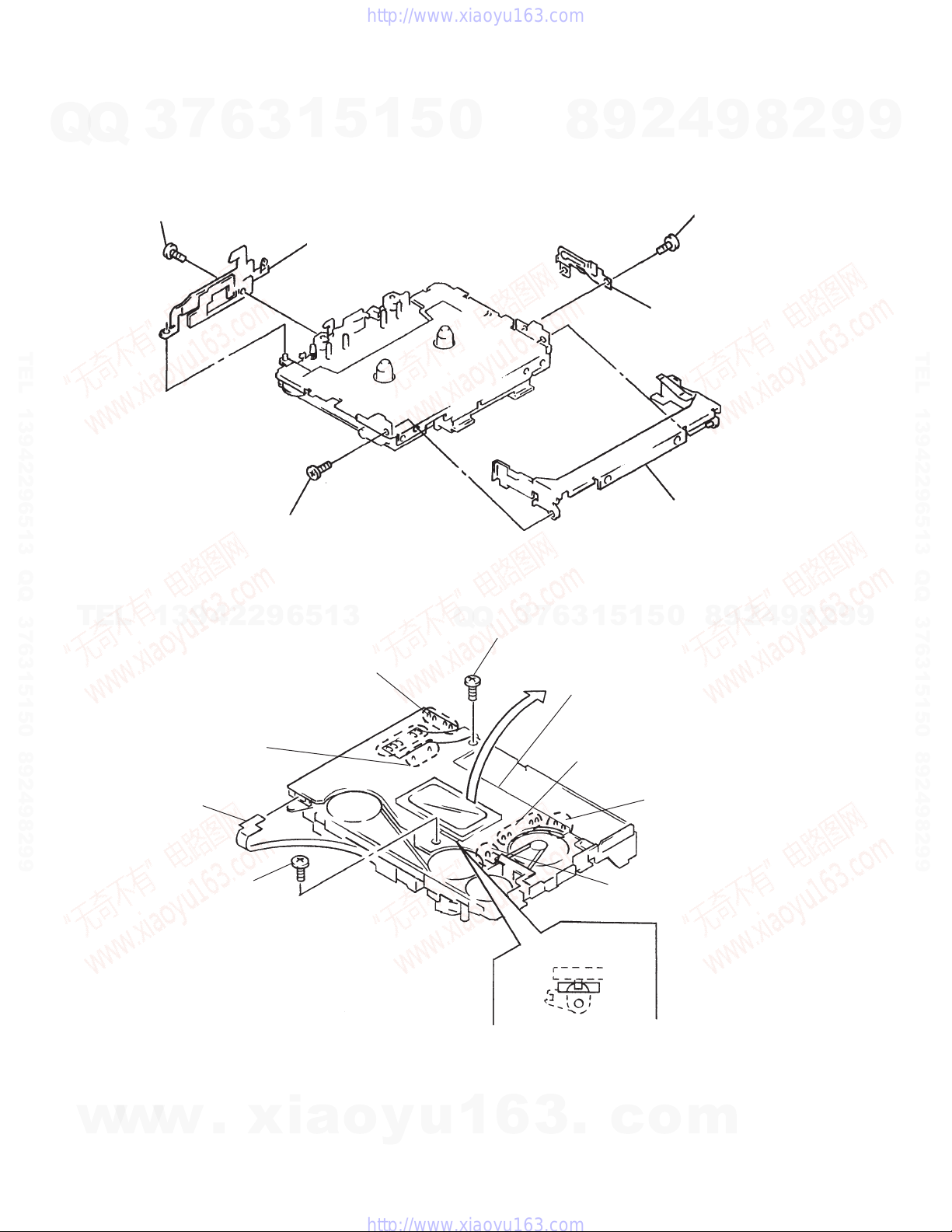

3-1. BRACKET ASSEMBLY AND CASSETTE HOLDER ASSEMBLY

3

1

Screw (M1.4)

6

3

1

5

2

Bracket assembly

1

5

0

8

9

4

2

4

Lever (B), Lock

3

9

Screw

(M1.4)

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

5

Screw (M1.4)

3-2. AUDIO BOARD

TEL

6

7

13942296513

4

5

Remove the solder

of the flexible board.

Remove the solder of

the plunger solenoid.

Flexible board

(Head)

Remove the solder of

the switch (S901).

Q

Q

9

7

3

Screw (M1.4)

6

Cassette holder assembly

5

1

5

1

3

6

0

Remove the Audio board

direction of arrow.

2

Remove the solder

of the motor.

3

4

2

9

8

0

Remove the solder of

the battery terminal.

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

8

Screw (M1.4x2.0)

w

.

xia

Note: Confirm if the switch lever

o

y

u

1

6

— 6 —

1

Remove the solder of the

battery terminal.

S701

Lever (NR SW)

installs itself in the groove of

a lever (NR SW) for

assembling.

3

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

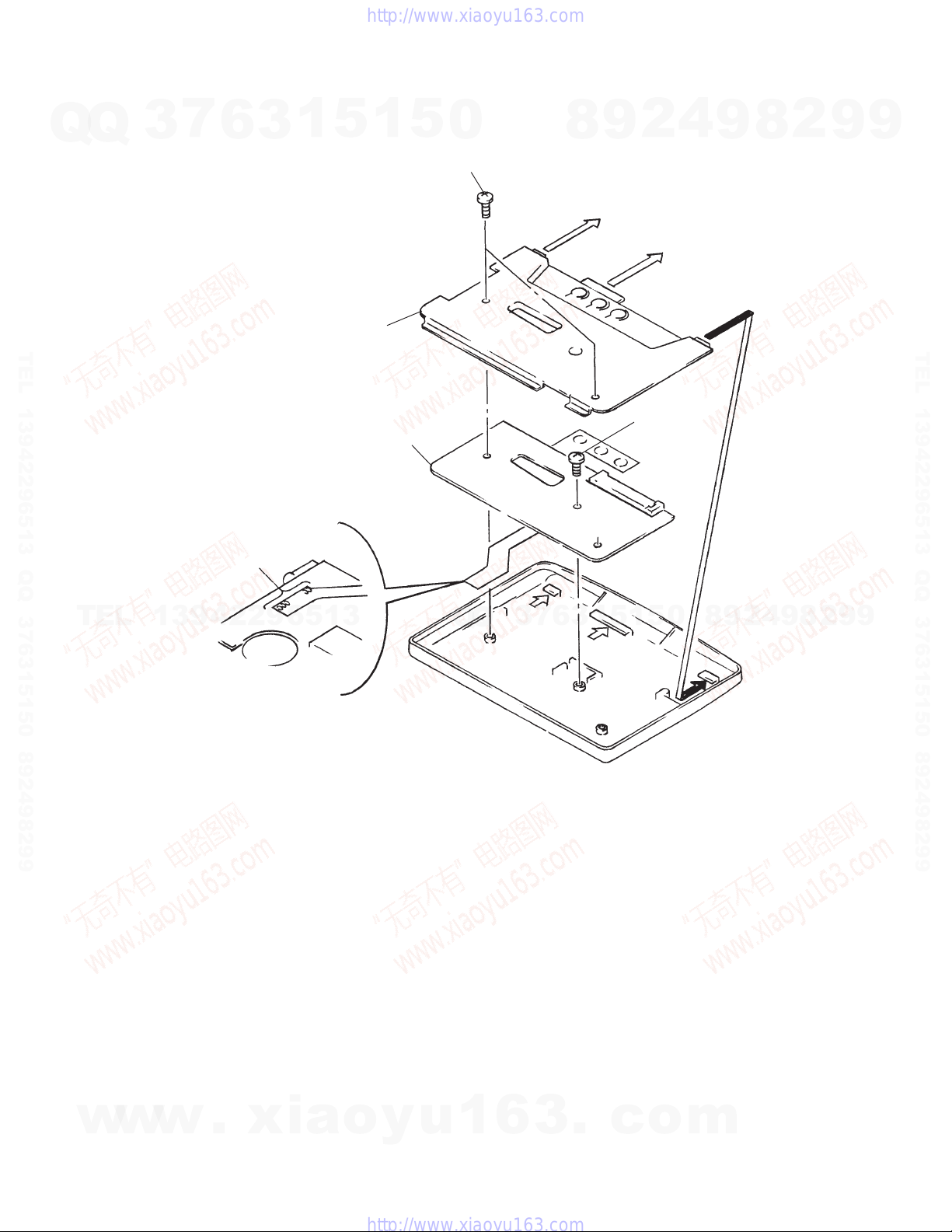

3-3. TUNER BOARD

1

Remove the solder of

the flexible board.

6

3

1

3

5

TU cover

5

1

5

Tuner board

0

2

Screw (M1.7x2.5)

8

9

2

4

Screw

(M1.7x2.5)

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

— 7 —

3

.

c

o

m

SECTION 4

ADJUSTMENTS

7

Q

Q

4-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

TEL 13942296513 QQ 376315150 892498299

supply voltage (1.3V) unless otherwise noted.

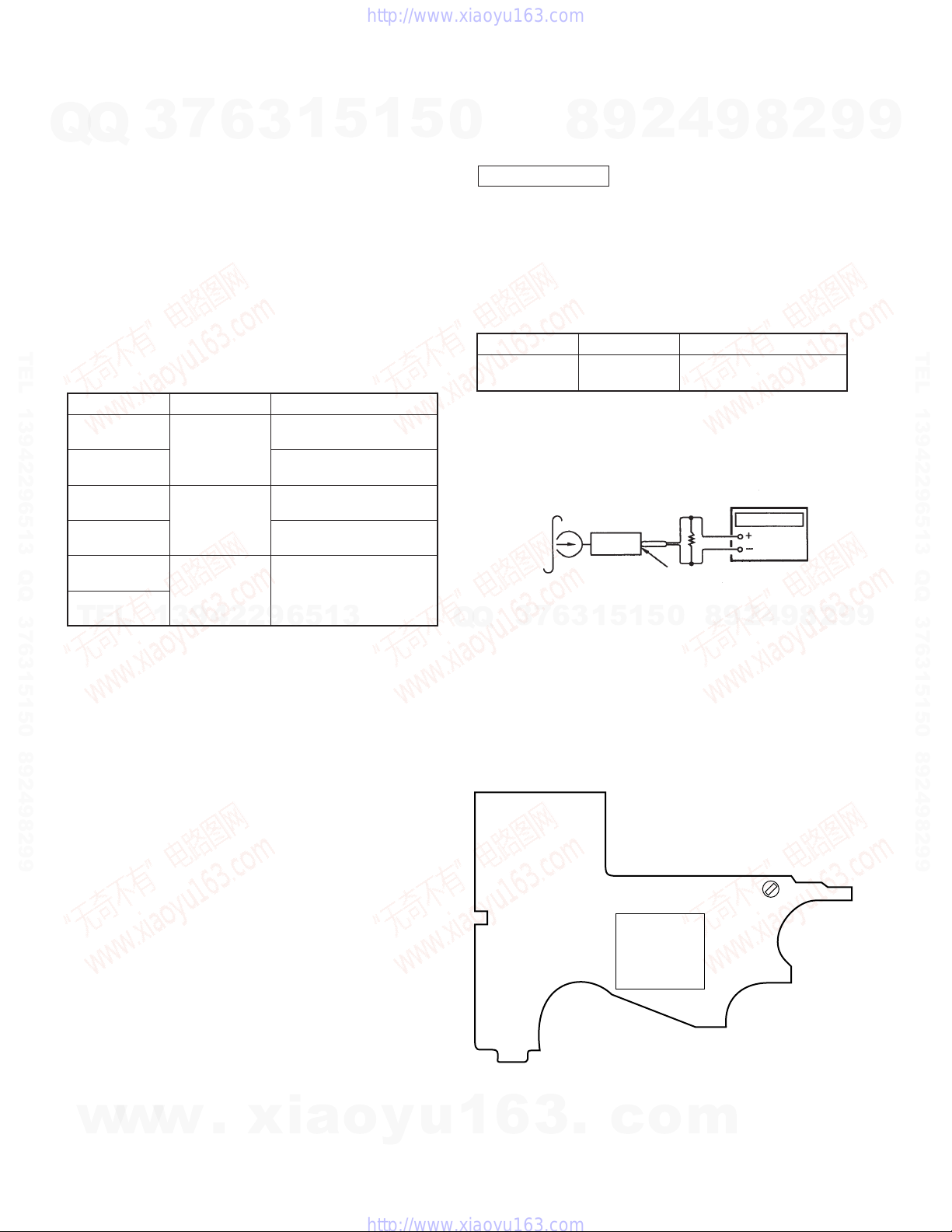

Torque Measurement

FWD

FWD

Back Tension

REV

REV

Back Tension

3

playback head rubber belts

capstan pinch roller

Mode Torque Meter

6

CQ-102C

CQ-102RC

3

1

5

Meter Reading

18 — 33 g • cm

0.5 — 3 g • cm

18 — 33 g • cm

0.5 — 3 g • cm

1

5

0

4-2. ELECTRICAL ADJUSTMENTS

TAPE SECTION

PRECAUTION

1. Power supply voltage : 1.3V.

2. Switch position

DOLBY NR switch : OFF

EX DBB switch : NORM

Test Tape

Type

WS-48A

TAPE SPEED ADJUSTMENT

Procedure :

Test Tape

WS-48A

(3kHz, 0dB)

8

2

9

Signal

3 kHz, 0 dB

set

4

Tape Speed Adjustment

16

9

Used for

frequency

counter

8

+

–

2

9

9

TEL 13942296513 QQ 376315150 892498299

FF

REW

TEL

CQ-201B

more than 60 g • cm

13942296513

REMOTE jack

1. Play back WS-48A (tape center portion) in FWD mode.

Adjust the RV601 so that the frequency counter reads 3,000 ±

Q

Q

30 Hz.

2. Play back WS-48A (tape center portion) in REV mode.

Confirm that the reading of frequency counter is within 2.5%

from the reading in step 1.

Adjustment Part Location Diagram :

[MAIN BOARD] (SIDE A)

3

7

6

3

1

5

1

ND701

5

0

8

9

RV601

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

— 8 —

3

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

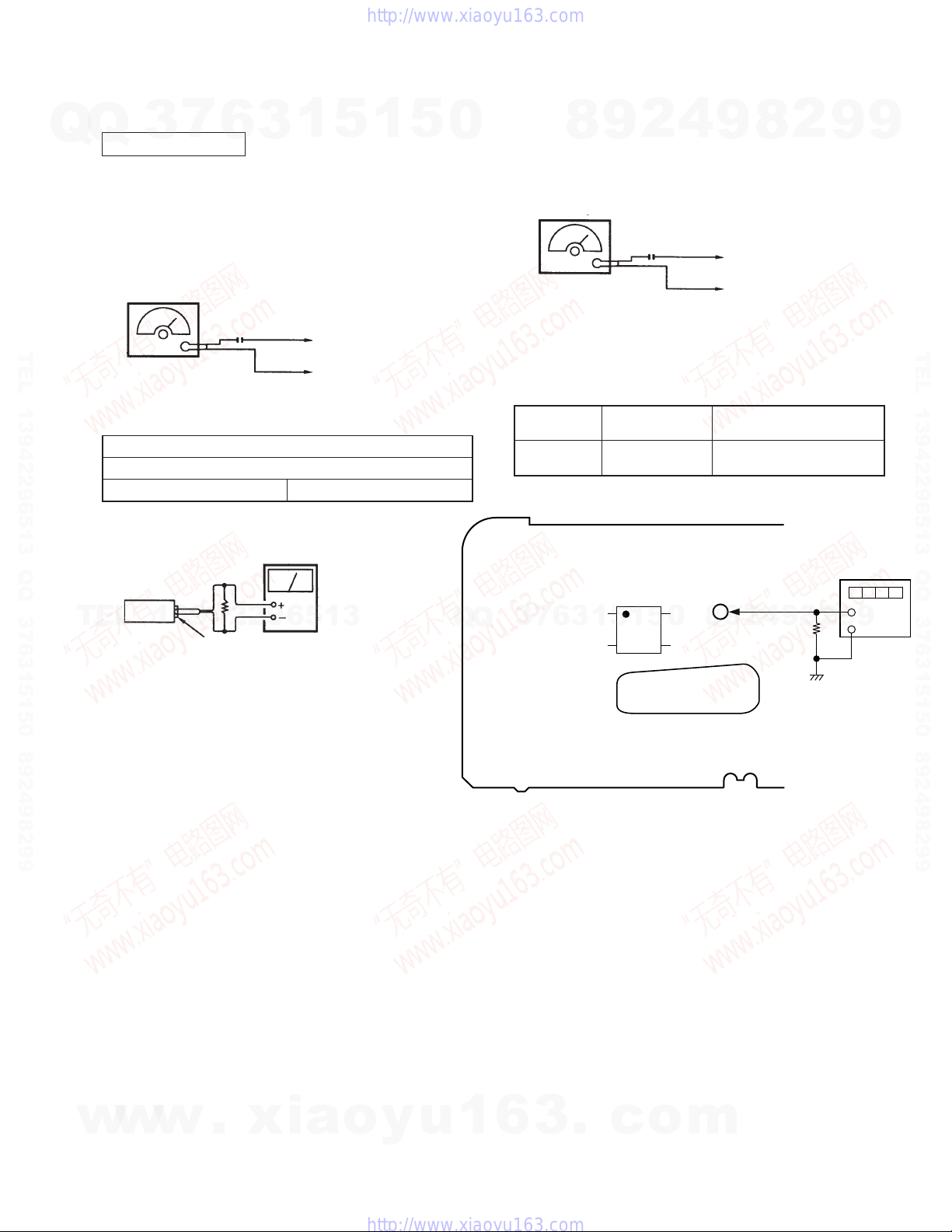

TUNER SECTION

FM SECTION

Setting:

FUNCTION switch : RADIO

BAND switch : FM

FM RF SSG

Modulation : 400 Hz, 22.5 kHz dev. (30%)

Output level: as low as possible.

6

0.01µF

FM IF ADJUSTMENT

Adjust for a maximum reading on VTVM.

L5 76.00 MHz

(AC : 0.5–5V range)

16

3

VTVM

1

TP (ANT)

TP (GND)

5

1

5

0

VCO ADJUSTMENT

Carrier frequency : 78.00 MHz

Modulation : no-modulation

Output level : 55 dB (562 µV)

[TUNER BOARD]

Adjustment

Element

8

FM RF SSG

RV1

4

2

9

0.01µF

Frequency

Display

78.00 MHz 19.00 kHz ± 0.05 kHz

9

TP (ANT)

TP (GND)

Frequency counter

8

Reading

2

9

frequency

counter

9

TEL 13942296513 QQ 376315150 892498299

TEL

set

13942296513

REMOTE jack

Q

Q

3

7

6

3

1

5

1

IC3

5

0

9

8

TP

(VCO)

2

4

150kΩ

9

8

2

9

+

9

–

w

w

w

.

xia

o

y

u

1

6

— 9 —

3

.

c

o

m

Loading...

Loading...