Sony WM-EX500, WM-EX505 Service Manual

WM-EX500/EX505

SERVICE MANUAL

Ver 1.2 2002. 01

Photo: WM-EX505

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

AEP Model

WM-EX500/EX505

E Model

WM-EX505

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism T ype MT-WMEX505-162

• Frequency response (Dolby NR off (WM-EX505))

Playback: 30 - 18,000 Hz

• Output

Headphones (i jack)

Load impedance 8 - 300 ohms

• Power requirements

1.5 V

One R6 (size AA) battery

• Dimensions (w/h/d)

Approx. 78.7 x 109.7 x 28.1 mm, incl. projecting parts and

controls

• Mass

Approx. 145 g

Approx. 200 g (incl. a battery and a cassette)

• Supplied accessories

Stereo headphones or earphones with remote control (1)

Stereo headphones or earphones (1) (WM-EX500)

Design and specifications are subject to change without notice.

(WM-EX505)

Battery life (Approx. hours) (EIAJ*)

Tape playback 35

* Measured value by the standard of EIAJ (Electronic

Industries Association of Japan). (Using a Sony HF series

cassette tape)

Note

• The battery life may shorten depending on the

operation of the unit.

Sony alkaline LR6 (SG)

9-927-634-12 Sony Corporation

2002A0500-1 Personal Audio Company

C 2002.1 Published by Sony Engineering Corporation

CASSETTE PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY ......................................................... 6

4. MECHANICAL ADJUSTMENTS....................... 12

5. ELECTRICAL ADJUSTMENTS......................... 12

6. DIAGRAMS

6-1. Block Diagram ................................................................ 13

6-2. Printed Wiring Board ...................................................... 15

6-3. Schematic Diagram ......................................................... 17

6-4. IC Pin Function Description ........................................... 22

7. EXPLODED VIEWS ................................................ 24

8. ELECTRICAL PARTS LIST ............................... 26

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

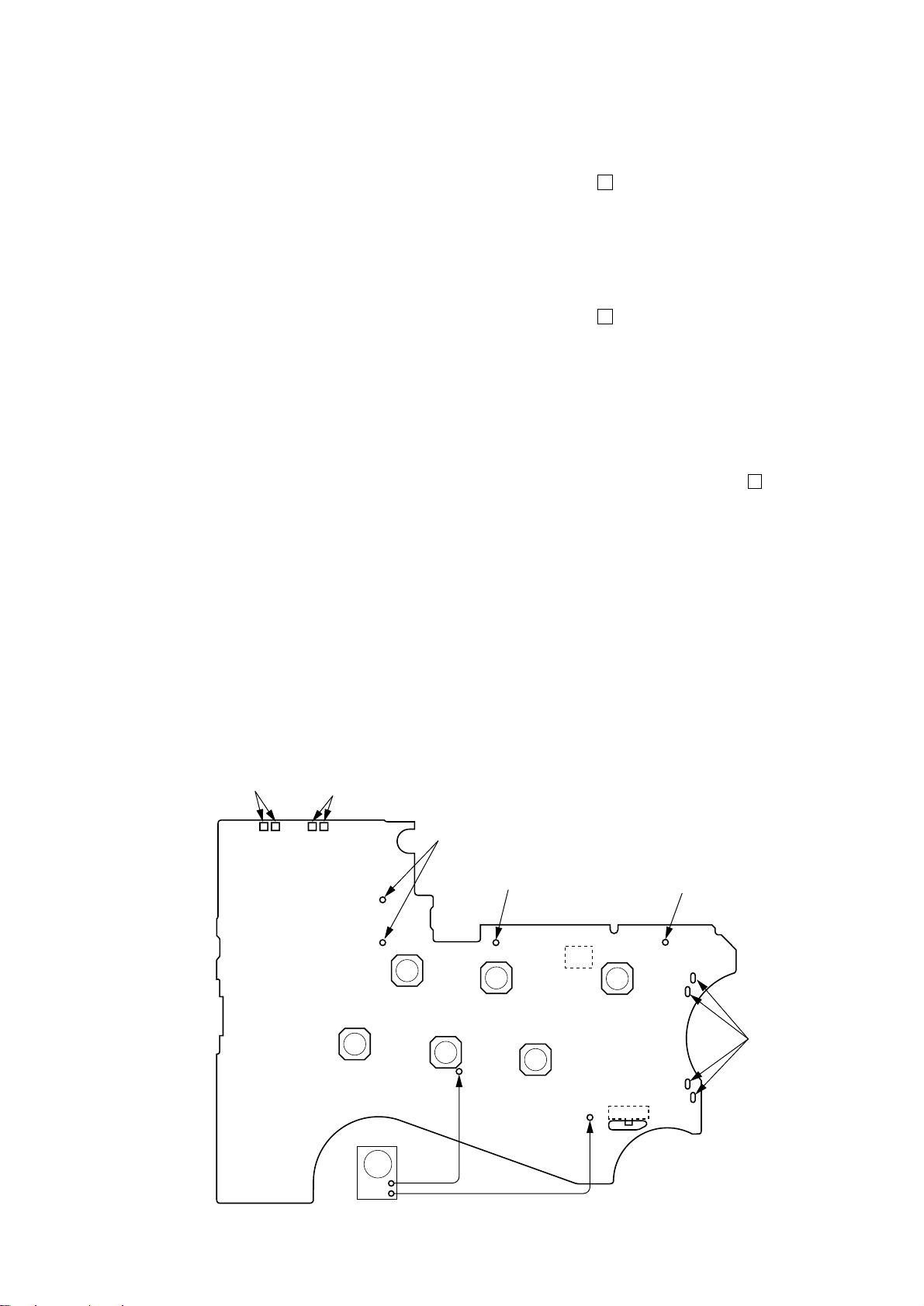

SECTION 1

e

SERVICING NOTES

This set detects the rotation of the idler gear (A) (side S) using the

PH701 (photo reflector). The PH701 is mounted on the MAIN

board, therefore the idler gear (A) (side S) cannot be detected with

the MAIN board removed. As a r esult, the motor (M901) cannot

be controlled, causing malfunction.

Further, the DIRECTION switch (S701) is also mounted on the

MAIN board, and with the board removed, the mechanism position cannot be detected and the operation is not changed over.

Therefor, when the voltage check is e xecuted with the MAIN board

removed, follow the procedure provided below.

1. Setting

(1) Refer to “3. DISASSEMBLY”, and remove the MAIN board.

(2) Connect the MAIN board to the motor (M901) and the

plunger (PM901) using jumper wires. These can be connected

easily with the use of the extension tool (Part No. 1-769143-11) (ten in one set).

(3) Short the TAPE DETECT switch (S901-1) terminals and the

ATS switch (S901-2) terminals.

(4) Connect the AF oscillator to the TP36 (PHOTO IN) and the

TP46 (GND).

(5) Supply 1.3 V to the battery terminals using the regulated

power supply.

2. Preset state

T o set the PLAY , FF, REW modes, the preset state must be set.

(1) Check that the slider (NR) and the DIRECTION switch

(S701) are set to the center position. If not, set the preset

state as follow.

(2) Move the DIRECTION switch (S701) to the side, which the

slider (NR) is facing.

(3) The slider (NR) will move when the regulated power supply

switch is set to OFF once and then set to ON. Move the DIRECTION switch (S701) according to this timing and set to

the center position.

3. FF, REW modes

(1) Check that the preset state is set.

(2) Input the square wave or sine wave to the TP36 (PHO TO IN)

and the TP46 (GND).

(3) Press the x button (S702) to set the STOP mode.

(4) Press the [FF AMS] button (S704) or the [REW AMS] but-

ton (S705).

4. PLAY mode

(1) Check that the preset state is set.

(2) Input the square wave or sine wave to the TP36 (PHO TO IN)

and the TP46 (GND).

(3) Press the x button (S702) to set the STOP mode.

(4) Press the [ REPEAT] button (S703) will move the

n N

slider (NR) once towards the side R and then to the side F.

Move the DIRECTION switch (S701) according to this

timing will set the PLAY mode (side F). Press the

n N

[ REPEAT] button (S703) another time and move the

DIRECTION switch (S701) according to the movement of

the slider (NR) will set the PLAY (R mode).

Note 1: If the above fails, perform from preset again.

Note 2: Use the [ REPEAT] (S703), x (S702), [FF AMS]

Note 3: When using headphones, the timing for move the DIRECTION

n N

(S704), and [REW AMS] (S705) buttons on the remote controller as much as possible. If no remote controller, do not touch the

buttons with your hands, but using a stick with a round tip.

switch (S701) can be determined from the beep sound.

– MAIN Board (Side B) –

TAPE DETECT

switch

(S901-1)

ATS switch

(S901-2)

YREPEAT

FF AMS

(S704)

(S703)

AF oscillator

connect to the plunger

(PM901)

battery

terminal 3

x

(S702)

REW AMS

(S705)

FUNCTION

(S708)

TP36

(PHOTO IN)

PH701

SOUND

(S706)

S701

DIRECTION

FWDTCENTERtREV

TP46

(GND)

battery

terminal #

connect to th

motor (M901)

+

–

square wave

(sine wave)

10 Hz, – 3.5 dB

– 3 –

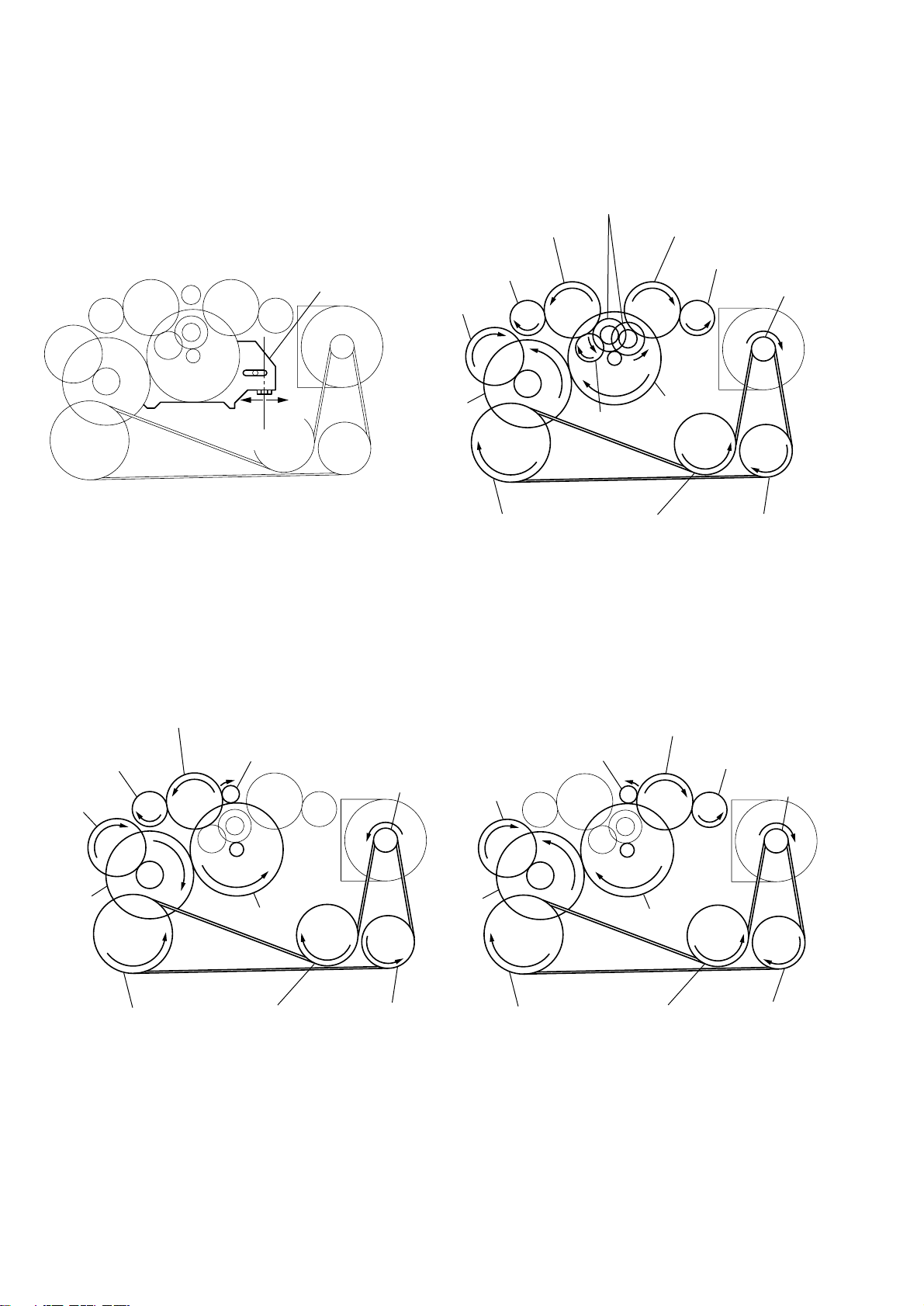

SLIDER (NRA) Rotation system

g

y

Rotation system during PLAY

idler (A) gear (T side)

gear (NR)

(FWD: left side

REW: right side)

idler (A) gear (S side)

gear (REEL) (T side)

cam gear

gear (Y)

insert flywheel (N)

idler (B) gear

insert flywheel (R)

side F

slider (NRA)

side R

center

Rotation system during FF Rotation system during REW

gear (REEL) (S side)

motor pulle

clutch assy (F)

reverse pulley

gear (REEL)

(T side)

cam gear

ear (Y)

idler (A) gear (T side)

insert flywheel (N)

gear (FR)

(FF: left side)

clutch assy (F)

insert flywheel (R)

motor pulley

reverse pulley

cam gear

gear (Y)

gear (FR)

(REW: right side)

insert flywheel (N)

idler (A) gear (S side)

gear (REEL) (S side)

clutch assy (F)

insert flywheel (R)

motor pulley

reverse pulley

– 4 –

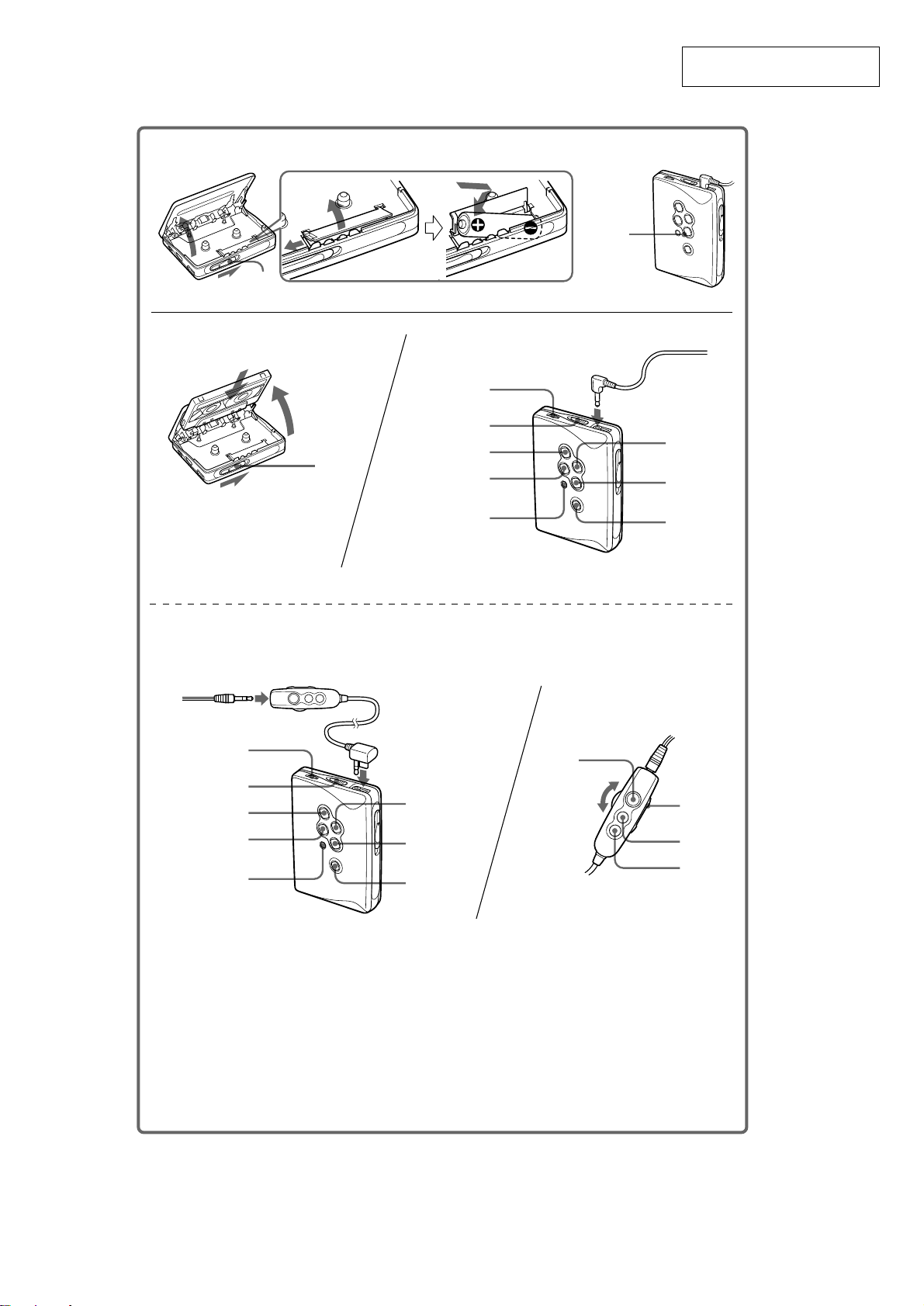

SECTION 2

GENERAL

This section is extracted from

instruction manual.

A

OPEN

OPEN

(WM-EX500)

VOL

HOLD

Y•REPEAT

REW(AMS•AVLS)

FUNCTION

B

BATT

FF (AMS•

BL SKIP/s)

x

SOUND

(WM-EX505)

VOL

HOLD

Y•REPEAT

REW (AMS•AVLS)

FUNCTION

Plug in firmly.

Branchez fermement.

FF (AMS•

BL SKIP/s)

x•;NR

SOUND

Y•x

VOL

HOLD

FF

REW

– 5 –

)

Ver 1.2

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

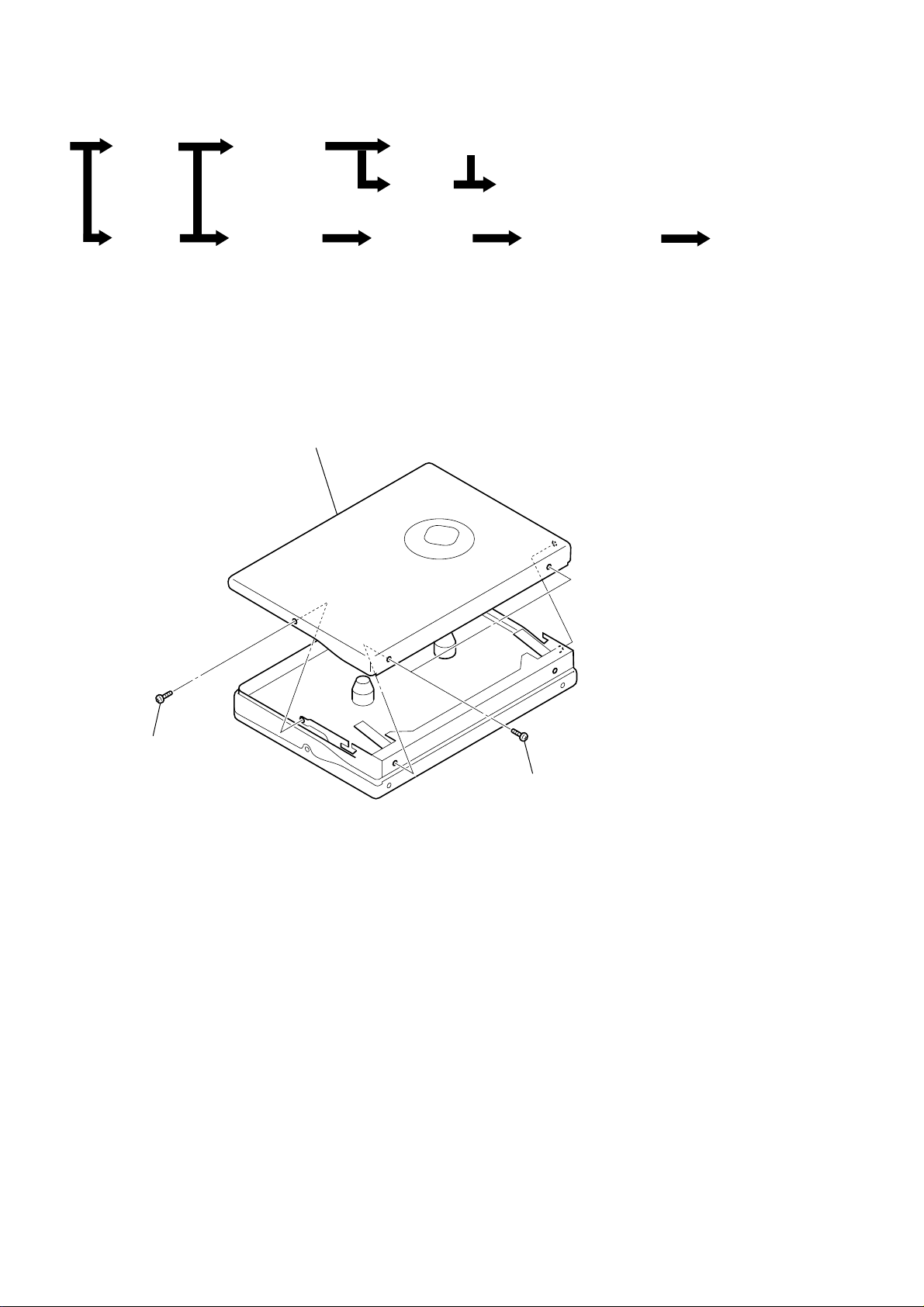

Case Assy

Lid Assy,

Cassette

Holder, Battery

Ornament Assy

Holder (FS) Assy

CASE ASSY

2

case assy

Main Board/Note for Installation

Belt Motor (Capstan/Reel) (M901)

Lever (N/R) Assy, Pinch

Head, Magnetic

(HP901)

1

screw

(M1.4

×

2.0)

1

two screws

(M1.4

×

2.0

– 6 –

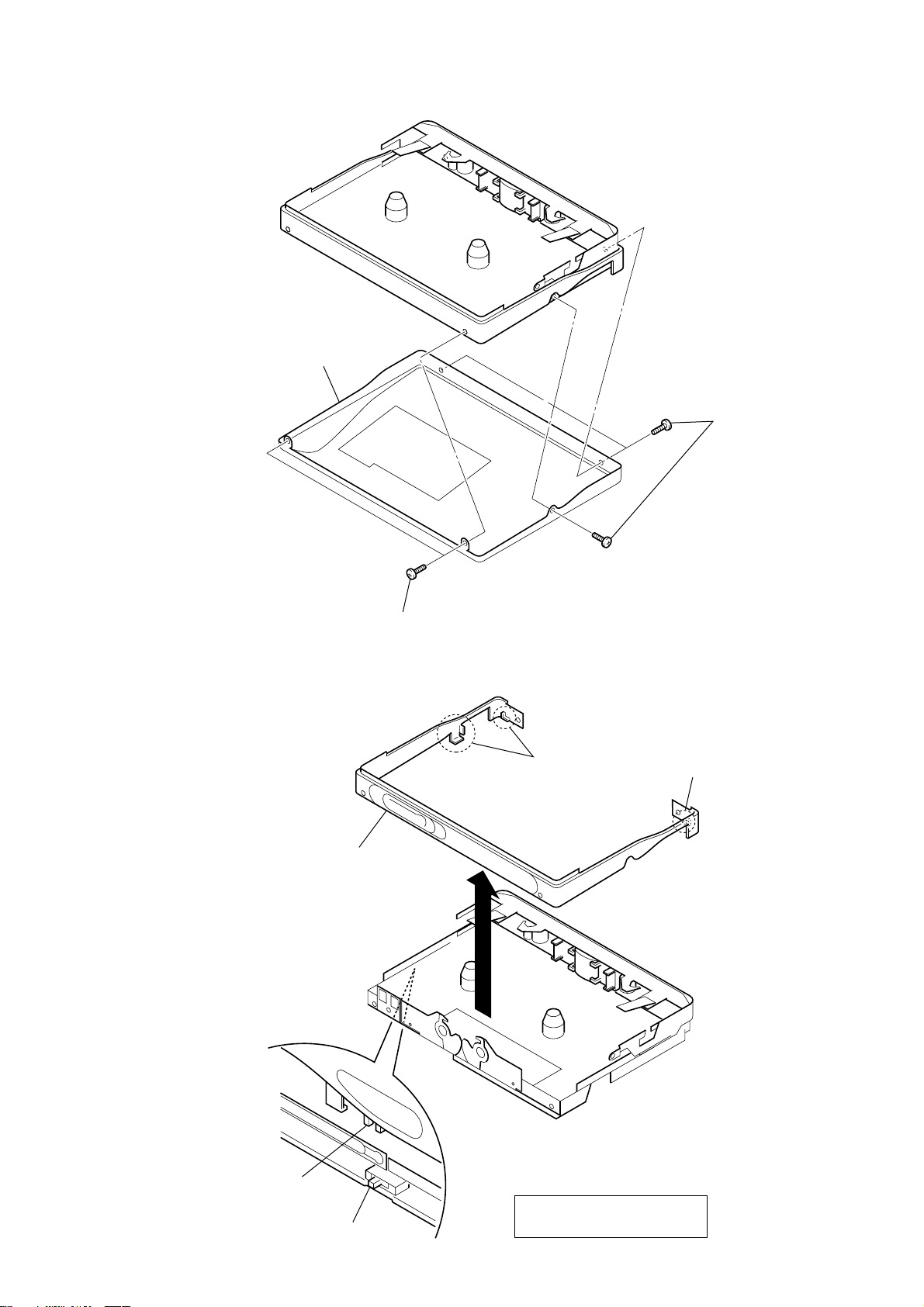

LID ASSY, CASSETTE

2

lid assy, cassette

1

three screws

(M1.4 × 3.0)

Ver 1.2

ORNAMENT ASSY

2 ornament assy

1

two screws

(M1.4 × 3.0)

1 two claws

1 claw

knob (hold)

S707

On installation reel ornament,

adjust the S707 and knob (hold).

– 7 –

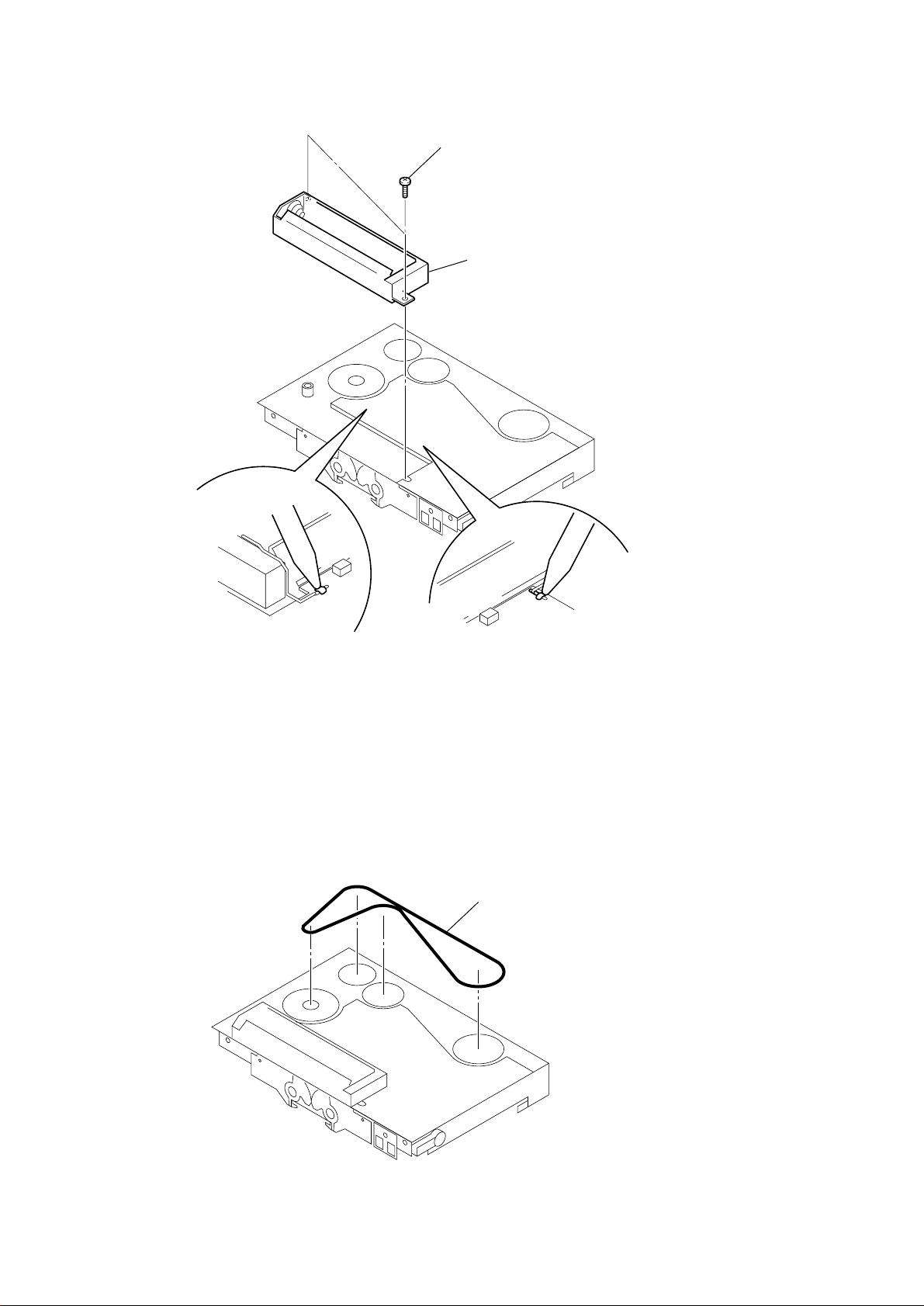

HOLDER, BATTERY

2 two screws

(M1.7 × 4.5)

3 battery holder

BELT

1 Break the soldering

of battery terminal (–).

1 Break the soldering

of battery terminal (+).

1 belt (See page 4)

– 8 –

Loading...

Loading...