Page 1

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

SERVICE MANUAL

Ver 1.2 2002. 11

SPECIFICATIONS

Main unit

Time display

12-hour system

Auto power down function

OFF/60 min/120 min/180 min

Output

LINE OUT jack (ø 3.5 mm stereo minijack)

Power requirements

6 V DC, DC IN 6V jack

Dimensions

Incl. projecting parts and controls:

Main unit:

Approx. 105 × 40 × 120 mm (w/h/d)

(Approx. 4

When the main unit is installed in the car cradle with the car stand:

Approx. 105 × 68 × 128 mm (w/h/d)

(Approx. 4

When the main unit is installed in the home cradle with the home

stand:

Approx. 105 × 55 × 128 mm (w/h/d)

(Approx. 4

Not incl. projecting parts and controls:

Main unit:

Approx. 102 × 38 × 120 mm (w/h/d)

(Approx. 4

When the main unit is installed in the car cradle with the car stand:

Approx. 102 × 66 × 128 mm (w/h/d)

(Approx. 4

When the main unit is installed in the home cradle with the home

stand:

Approx. 102 × 53 × 128 mm (w/h/d)

(Approx. 4

Mass

Main unit:

Approx. 220 g (7.8 oz)

When the main unit is installed in the car cradle with the car stand:

Approx. 380 g (13.4 oz)

When the main unit is installed in the home cradle with the home

stand:

Approx. 300 g (10.6 oz)

1

/4 × 1 5/8 × 4 3/4 inches)

1

/4 × 2 3/4 × 5 1/8 inches)

1

/4 × 2 1/4 × 5 1/8 inches)

1

/8 × 1 1/2 × 4 3/4 inches)

1

/8 × 2 5/8 × 5 1/8 inches)

1

/8 × 2 1/8 × 5 1/8 inches)

US Model

Remote commander

Power requirements

3V DC, one CR2025 lithium battery

Dimensions

Approx. 52 × 89 × 12 mm (w/h/d)

(Approx. 2

incl. projecting parts and controls

Mass

Approx. 30 g (1.1 oz) incl. lithium battery

Accessories supplied

XM antenna (1)

Remote commander (1)

For DRN-XM01C/XM01CK/XM01R:

For DRN-XM01C/XM01CK only:

For DRN-XM01R only:

For DRN-XM01H/XM01HK:

Design and specifications are subject to change without notice.

1

/8 × 3 5/8 × 1/2 inches)

Car cradle (1)

Car stand (1)

Screw (5)

Cover (1)

Water proof cushion (1)

Cable guide (3)

Cord clamp (4)

Cushion with the double-sided adhesive tape (1)

Seal (1)

Car battery cord (1)

Car connecting pack (1)

RF modulator (1)

Home cradle (1)

Home stand (1)

Audio cord (1)

AC power adaptor (1)

9-873-268-03

2002K1600-1

© 2002.11

DIGITAL AUDIO RECEIVER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

TABLE OF CONTENTS

1. SERVICING NOTES ················································· 3

2. GENERAL ·································································· 5

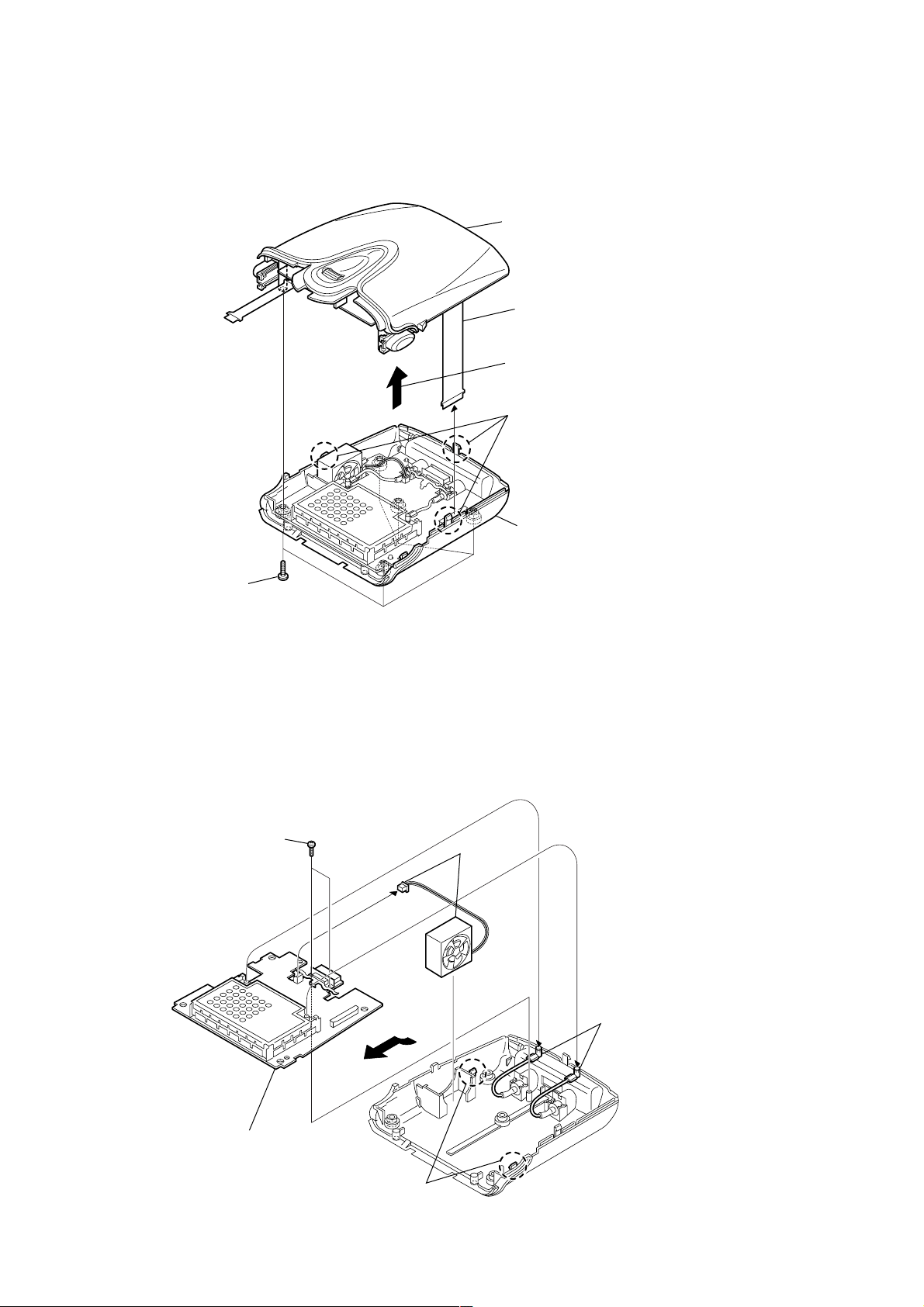

3. DISASSEMBLY ························································· 7

3-1. Front Panel Assy ·························································· 7

3-2. LCD Board ··································································· 7

3-3. Lower Cabinet Assembly,

Upper Cabinet Assembly ············································· 8

3-4. BB Board, DC FAN ····················································· 8

3-5. CPU Board, USB Board··············································· 9

4. TEST MODE ···························································· 10

4-1. Test Mode ··································································· 10

4-2. Diagnostic Mode ························································ 11

4-3. System Error List ······················································· 11

5. SERVICE TOOL

5-1. Installing USB Driver················································· 12

5-2. Installing DRN-XM01 Service Tool ·························· 19

5.3. How To Use DRN-XM01 Service Tool ····················· 22

6. DIAGRAMS ······························································ 26

6-1. Block Diagram – Tuner Section –······························ 27

– Control Section – ···················································· 28

6-2. Printed Wiring Boards – CPU Board – ······················ 29

6-3. Schematic Diagram – CPU Board (1/2) – ·················· 30

6-4. Schematic Diagram – CPU Board (2/2) – ·················· 31

6-5. Printed Wiring Boards – BB Board –························· 32

6-6. Schematic Diagram – BB Board (1/3) – ···················· 33

6-7. Schematic Diagram – BB Board (2/3) – ···················· 34

6-8. Schematic Diagram – BB Board (3/3) – ···················· 35

6-9. Printed Wiring Boards – Panel Section – ··················· 36

6-10. Schematic Diagram – Panel Section – ······················· 37

6-11. IC Block Diagrams····················································· 38

6-12. IC Pin Function Description ······································ 40

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit Board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

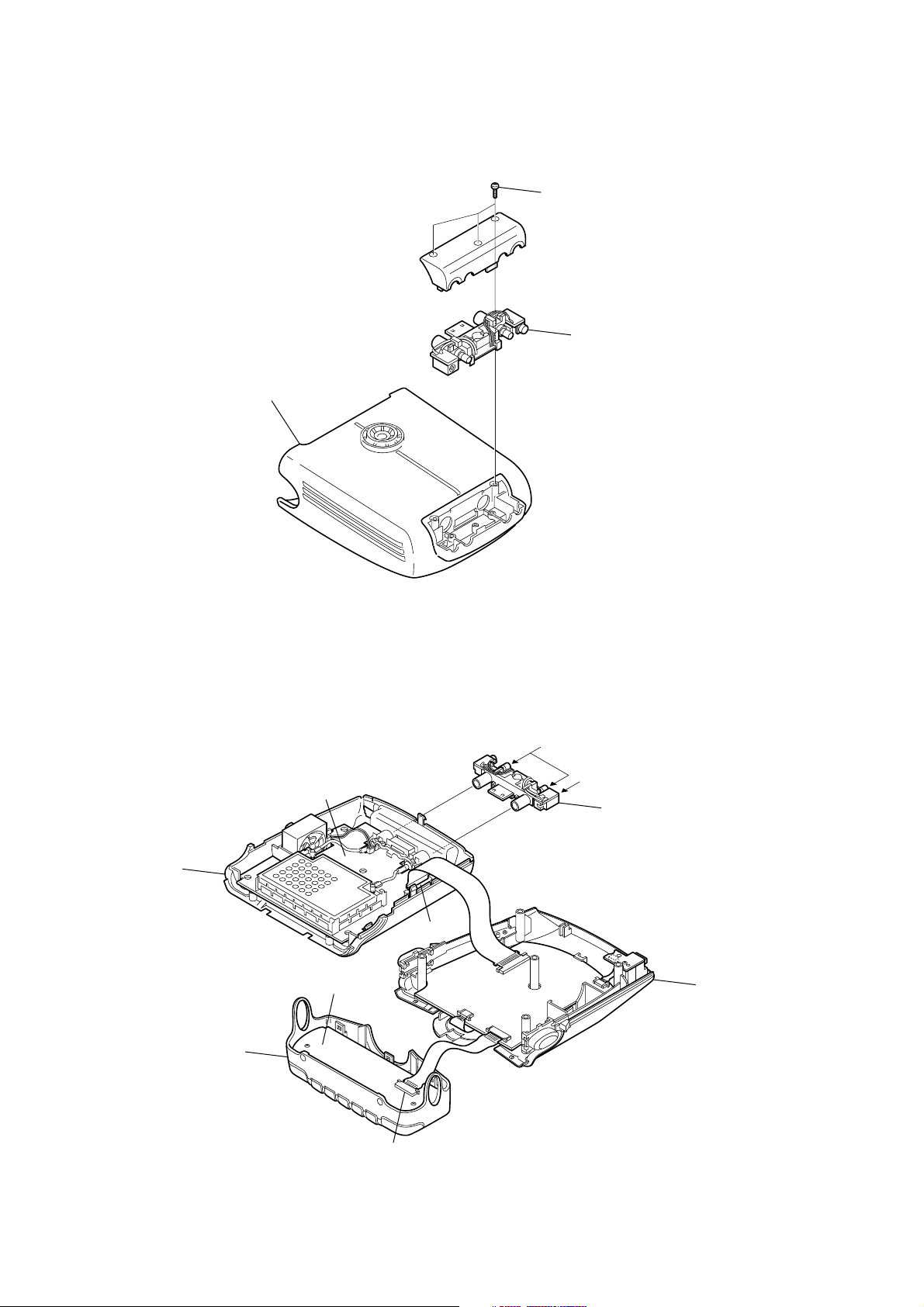

7. EXPLODED VIEWS

7-1. Front Panel Assembly,

Lower Panel Assembly ··············································· 42

7-2. Upper Cabinet Assembly ··········································· 43

8. ELECTRICAL PARTS LIST ·································· 44

2

Page 3

DRN-XM01C/XM01R/XM01H/

SECTION 1

XM01CK/XM01HK

SERVICING NOTES

What to do when memory or the BB board or the unit is replaced?

The DRN-XM01 Service Tool is simply referred to as “the dedicated software” in this document.

• When IC504 (flash memory) is replaced

Connect the DRN-XM01 to a PC with the USB cable and enter the serial number in the dedicated software. Then

write the newest program in the flash memory.

(Contents of the user setup are automatically cleared.)

•When IC509 (EEPROM) is replaced

Connect the DRN-XM01 to a PC with the USB cable and enter the serial number in the dedicated software. Then

write the newest program in the flash memory.

(Contents of the user setup are automatically cleared.)

•When failed in writing the flash memory

Connect again the DRN-XM01 to the PC with the USB cable and enter the serial number in the dedicated software.

Then write the newest program in the flash memory.

(Contents of the user setup are automatically cleared.)

•When IC102 (STA450) and/or IC103 (ST19AF08) is damaged

Replace the BB board. (Use the tuner module from old board.)

Connect again the DRN-XM01 to the PC with the USB cable and enter the serial number in the dedicated software.

Then write the newest program in the flash memory.

(Contents of the user setup are automatically cleared.)

Turn on the power of the DRN-XM01. Write the radio ID that is displayed on the CH0 into the label.

Then attach the label to the DRN-XM01.

Ver 1.2 2002.11

After that, update the contract with the XM Radio Inc. Ltd., accordingly.

• When the BB board is replaced

Connect the DRN-XM01 to a PC with the USB cable and write the newest program in the flash memory using the

dedicated software.

(Contents of the user setup are automatically cleared.)

Turn on the power of the DRN-XM01. Write the radio ID that is displayed on the CH0 into the label.

Then attach the label to the DRN-XM01.

After that, update the contract with the XM Radio Inc. Ltd., accordingly.

• When the CPU board is replaced

Connect the DRN-XM01 to a PC with the USB cable and write the newest program in the flash memory using the

dedicated software.

(Contents of the user setup are automatically cleared.)

• When the DRN-XM01 is replaced

Perform the “activate” work (see Note 2). Update the contract with the XM Radio Inc. Ltd., accordingly.

Note 1 : CAP : IC103 ST19AF08 (Conditional Access Processor)

Note 2 : “activate” work: The procedure of visiting the XM Radio Inc., Ltd., Web site or contacting the XM Radio

Inc., Ltd., over telephone to tell them the credit card number and radio ID (XM Radio Hardware ID) to

enable reception of pay radio.

3

Page 4

DRN-XM01C/XM01R/XM01H/

s

y

XM01CK/XM01HK

SERVICE POSITION

• Disassemble and remove A from the cradle.

Cradle

Three screw

A

• Connect A to the set as shown below.

Then connect XM antenna and power supply.

BB board

Lower cabinet assembly

Front panel assy

LCD board

XM Antenna

DC IN (6V)

A

CN102

CN501

CPU board

CN502

Upper cabinet assembl

CN301

4

Page 5

SECTION 2

GENERAL

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

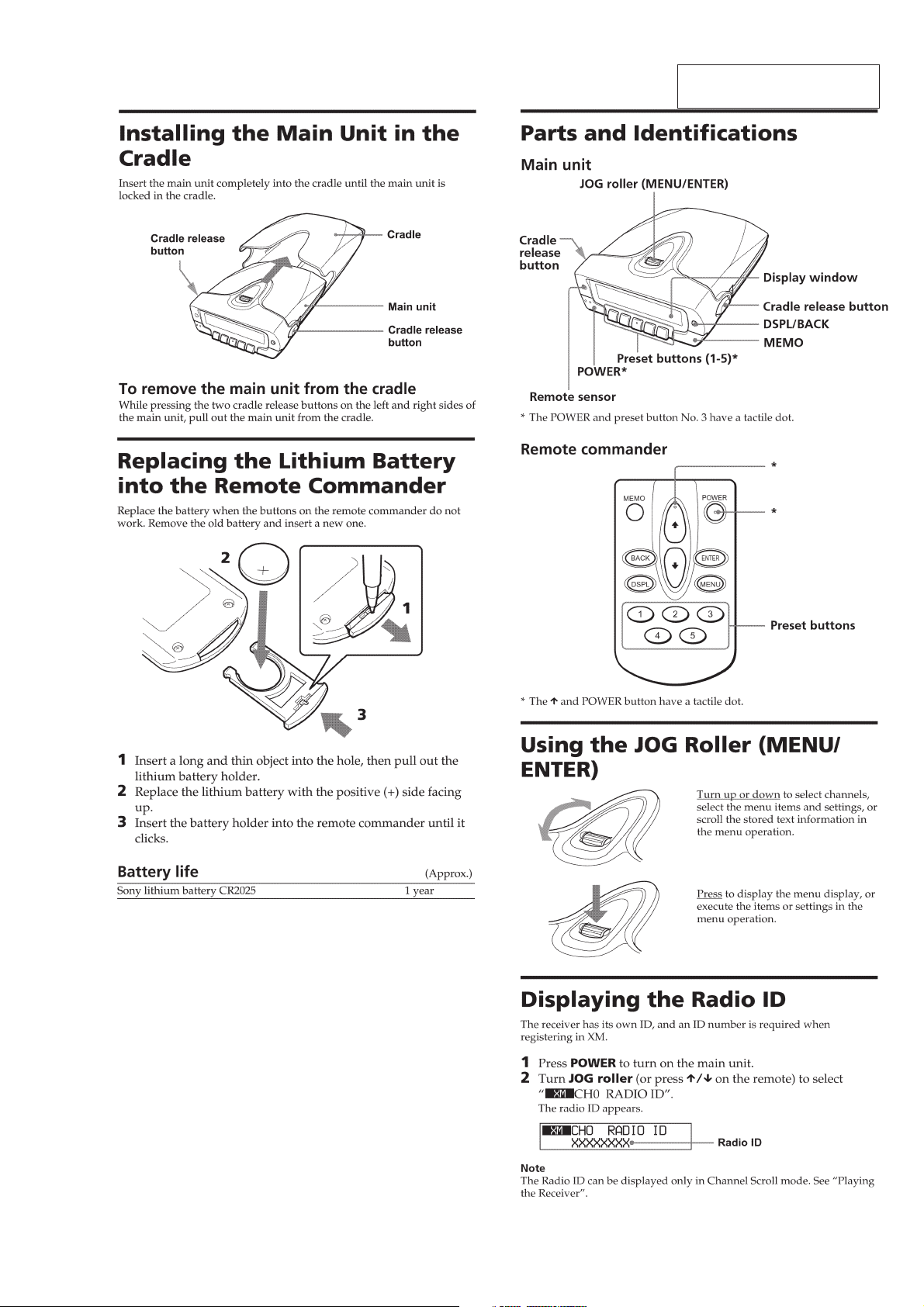

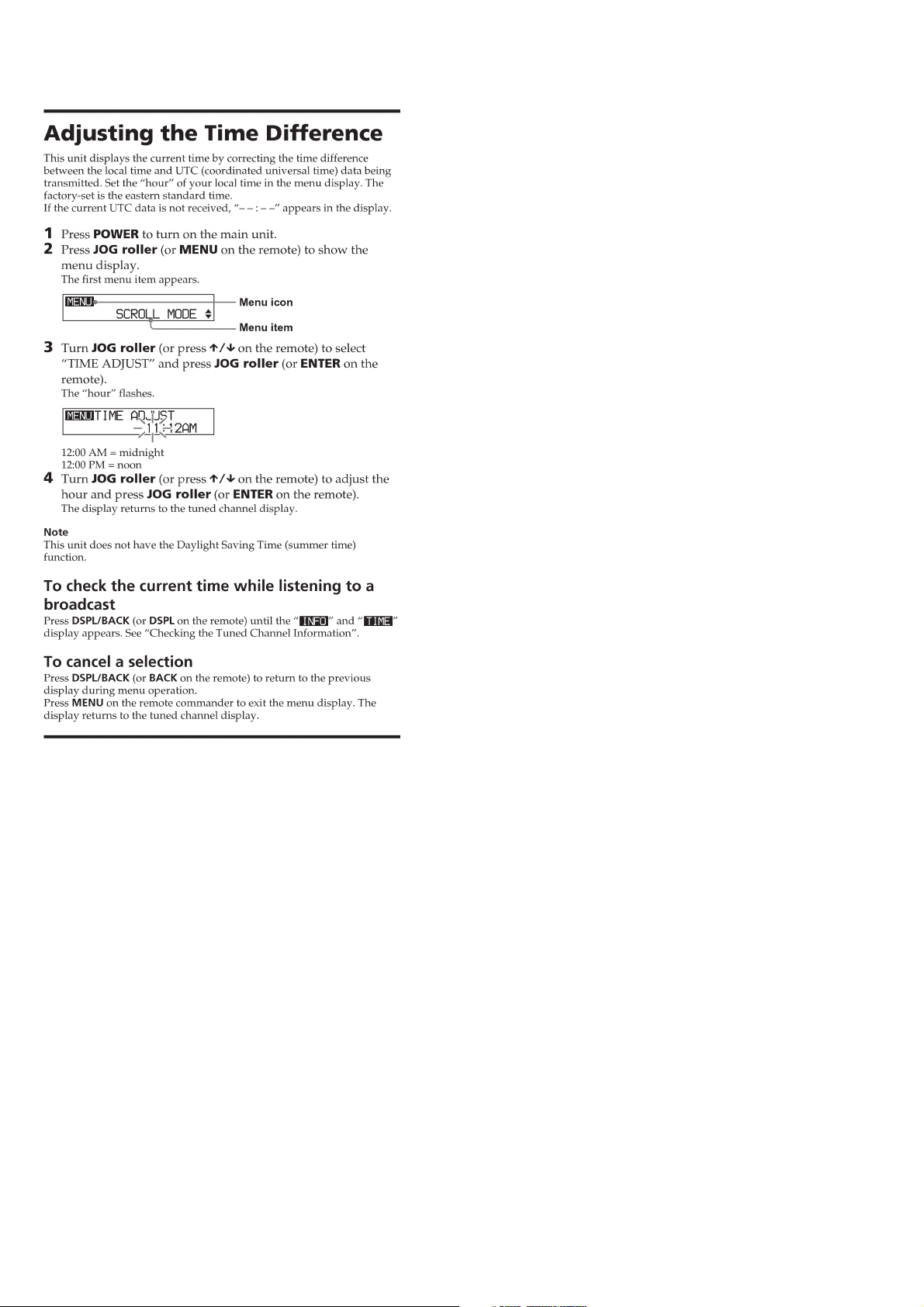

This section is extracted from

instruction manual.

5

Page 6

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6

Page 7

r

D

Disassemble the unit in the order as shown below.

SECTION 3

DISASSEMBLY

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

FRONT PANEL ASSY

LOWER CABINET ASSEMBLY,

UPPER CABINET ASSEMBLY

LCD BOARD

Note : Follow the disassembly procedure in the numerical order given.

3-1. FRONT PANEL ASSY

A

Button (release L)

4 Flexible board

(20P) (CN301)

2 Three claws

C

5 Front panel assy

BB BOARD, DC FAN

CPU BOARD, USB BOAR

Button (release R)

B

3 While pushing the button (release L)

and the button (release R) in the

direction of the arrow A and B,

remove the front panel assy in the

direction of the arrow C.

3-2. LCD BOARD

1 Two screws (M1.7)

1 Two screws

(M1.7 × 6)

3 LCD board

4 DSPL button

2 Two claws

7

Page 8

DRN-XM01C/XM01R/XM01H/

)

XM01CK/XM01HK

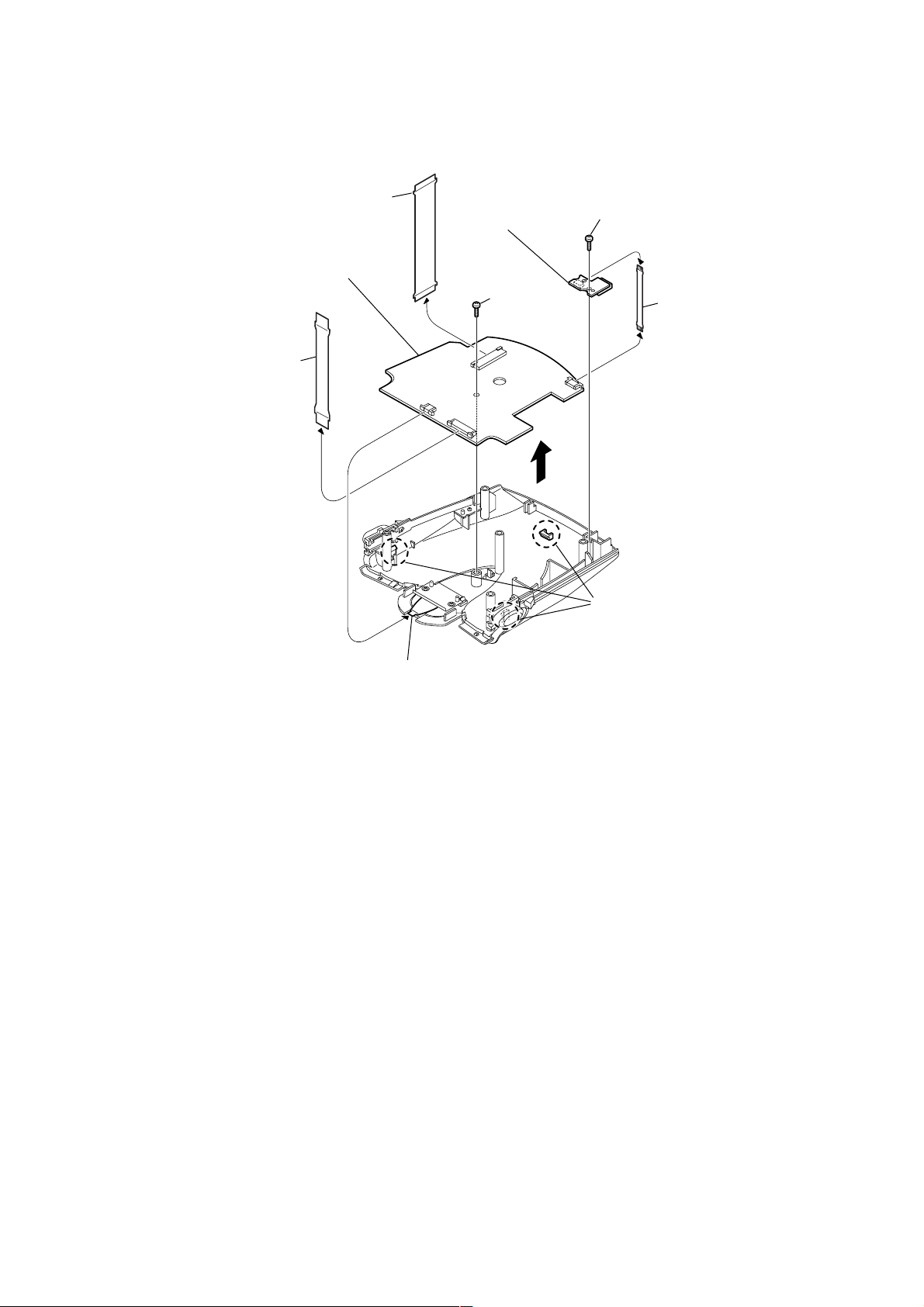

3-3. LOWER CABINET ASSMBLY,

UPPER CABINET ASSEMBLY

5 Upper cabinet assembly

3 Flexible board

(30P) (CN102 )

Remove the upper cabinet assembly

in the direction of the arrow.

2 Three claws

1 Five screws

(+BTP 2.6 × 10)

3-4. BB BOARD, DC FAN

3 Two screws

(M1.7 × 6)

4 Lower cabinet assembly

1 DC fan

(CN104)

2 Two cables

(with connector

5 Remove the BB board

in the direction of the arrow.

4 Two claws

8

Page 9

3-5. CPU BOARD, USB BOARD

1 Flexible board

(30P) (CN501)

9 Remove the CPU board in

the direction of the arrow.

6 USB board

7 Screw

(M1.7 × 6)

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

4 Screw

(M1.7 × 6)

(CN2)

5 Flexible board (USB)

2 Flexible board

(20P) (CN502 )

(CN504)

8 Three claws

3 Flexible board

(JOG) (CN503)

9

Page 10

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

SECTION 4

TEST MODE

4-1. TEST MODE

4-1-1. SETTING THE TEST MODE

The following is the method of entering the test mode under the

condition of power-off.

Procedure:

1. Press the JOG roller and the preset button 2 simultaneously for

three seconds.

2. Press the preset button 1 .

3. Press the preset button 3 .

4. Press the preset button 5 .

5. The menu screen is displayed.

4-1-2. EXITING THE TEST MODE

Press the POWER button excluding LCD/KEY/BACKLIGHT Test

Mode.

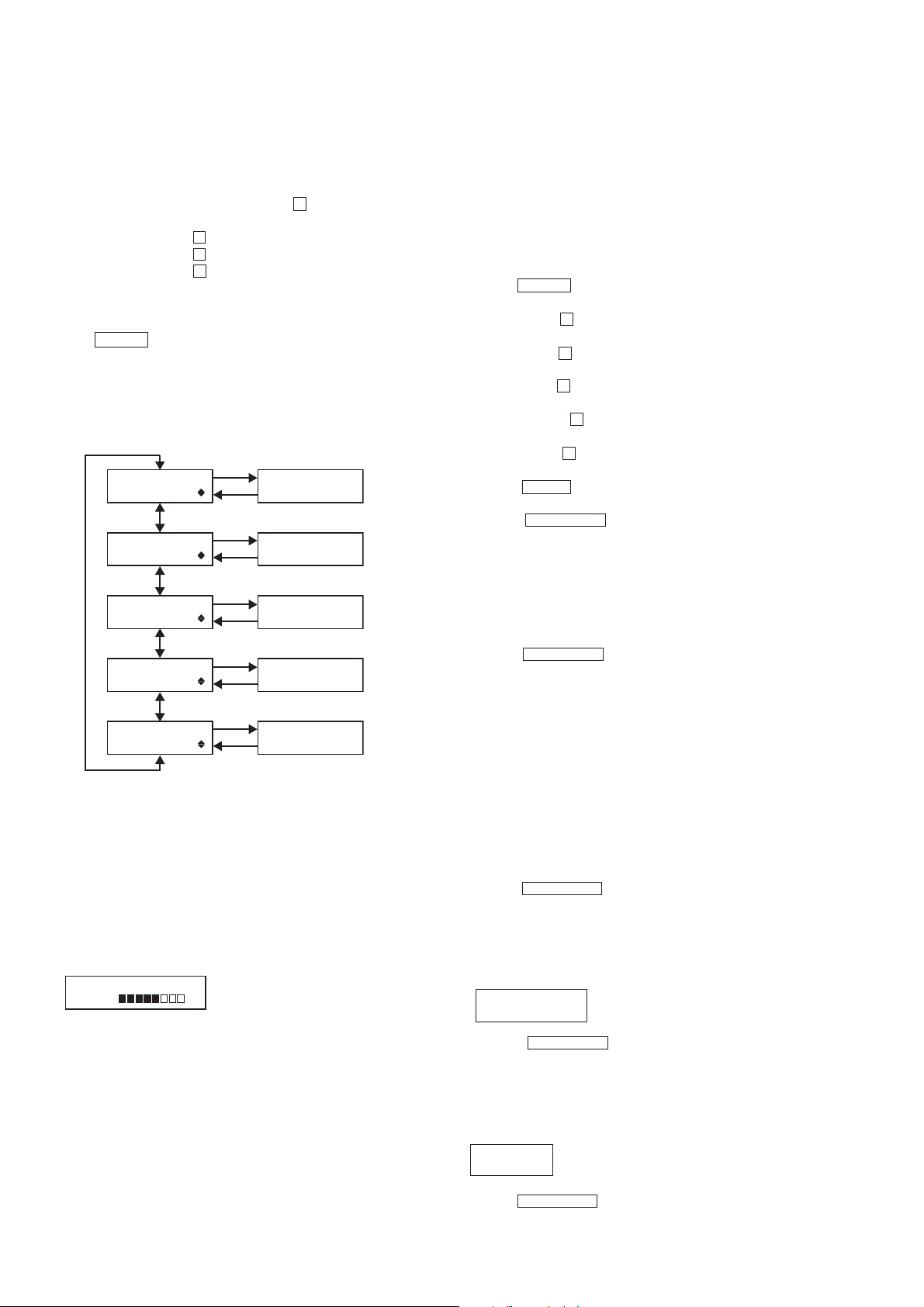

4-1-3. TEST MODE MENU

Select the menu and press the JOG roller.

(MENU) (MODE)

JOG roller

TEST MENU

LCD ADJUST

TEST MENU

LCD/KEY/BKLIGHT

TEST MENU

EEP INIT.

TEST MENU

SOFT VERSION

TEST MENU

SERIAL NO.

JOG PUSH

DSPL/BACK

LCD

Adjustment Mode

LCD/KEY/BACKLIGHT

Check Mode

EEPROM

Initialization Mode

SOFT VERSION

Display Mode

SERIAL NO.

Display Mode

4-1-4. OPERATION OF THE TEST MODE

[LCD Adjustment Mode]

* This mode is used to adjust the contrast of LCD to the medium

value.

This adjustment is different from user's adjustment of the contrast

in 8 levels.

Procedure:

1. Select the MENU LCD ADJUST and press the JOG roller.

2. The following screen is displayed.

LCD ADJUST XX

L H

XX : LCD Contrast Value (00 to 31)

4-1-5. OPERATION OF THE TEST MODE

[LCD/KEY/BACKLIGHT Check Mode]

* This mode is used to check the operation of LCD, Keys, the JOG

roller, the backlight and the power LED.

Procedure:

1. Select the MENU LCD/KEY/BKLIGHT and press the JOG roller.

The test is excuted by pressing buttons correctly in the following

order.

2. All segments of LCD and the power LED are turnd on and the

backlight is lit brightly.

3. Press the POWER button. segments of LCD changes to checkers

and the backlight keeps bright.

4. Press the preset 1 button. LCD displays reverse checkers and

the backlight is bright.

5. Press the preset 2 button. LCD displays lateral stripes and the

backlight is bright.

6. Press the preset 3 button. LCD displays vertical stripes and the

backlight is bright.

7. Press the preset 4 button. LCD displays chekers and the

backlight is dim.

8. Press the preset 5 button. LCD displays reverse chekers and

the backlight is dim.

9. Press the MEMO button. LCD displays lateral stripes and the

backlight is dim.

10. Press the DSPL/BACK button. LCD displays vertical stripes

and the backlight is dim.

11.

Rotate the JOG roller down. The message “JOG TEST COUNT : :

00” is displayed. Rotate the JOG roller down to “COUNT : : 08”.

12. Rotate the JOG roller up. The value “JOG TEST COUNT : : 08”

decreases to “COUNT : : 00”.

13. Press the JOG roller. LCD, the backlight and the power LED

are turned out.

14. Press the DSPL/BACK button to return to the TEST MENU.

[EEPROM Initialization Mode]

* This mode is used to initialize the values of EEPROM without

LCD factory adjustment value and the serial number.

Note: When this mode is activated, all of the information that has

been preset by customer is cleared. Before activating this mode,

take a note of the information that has been preset by customer.

After Test mode is completed, set the saved information to

recover the original setup.

Procedure:

1. Select the MENU EEP INIT. and press the JOG roller. Then

initialization is executed.

2. The message “EEP INT. COMPLETE” is displayed.

3. Press the DSPL/BACK button to return to the TEST MENU.

[SOFT VERSION Display Mode]

Procedure:

1. Select the MENU SOFT VERSION and press the JOG roller.

2. The following message is displayed,

SOFT VERSION R : ROM

R : 01.00 F : 01.00 F : Flash

3. Adjust the LCD to the center contrast in 32 levels by rotating

the JOG roller up or down.

4. Press the JOG roller to set the value.

5. The display returns to the TEST MENU.

10

3. Press the DSPL/BACK button to return to the TEST MENU.

[SERIAL NO. Display Mode]

Procedure:

1. Select the MENU SERIAL NO. and press the JOG roller.

2. The following message is displayed.

SERIAL NO.

XXXXXX XXXXXX : Serial No. (6 digits)

3. Press the DSPL/BACK button to return to the TEST MENU.

Page 11

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

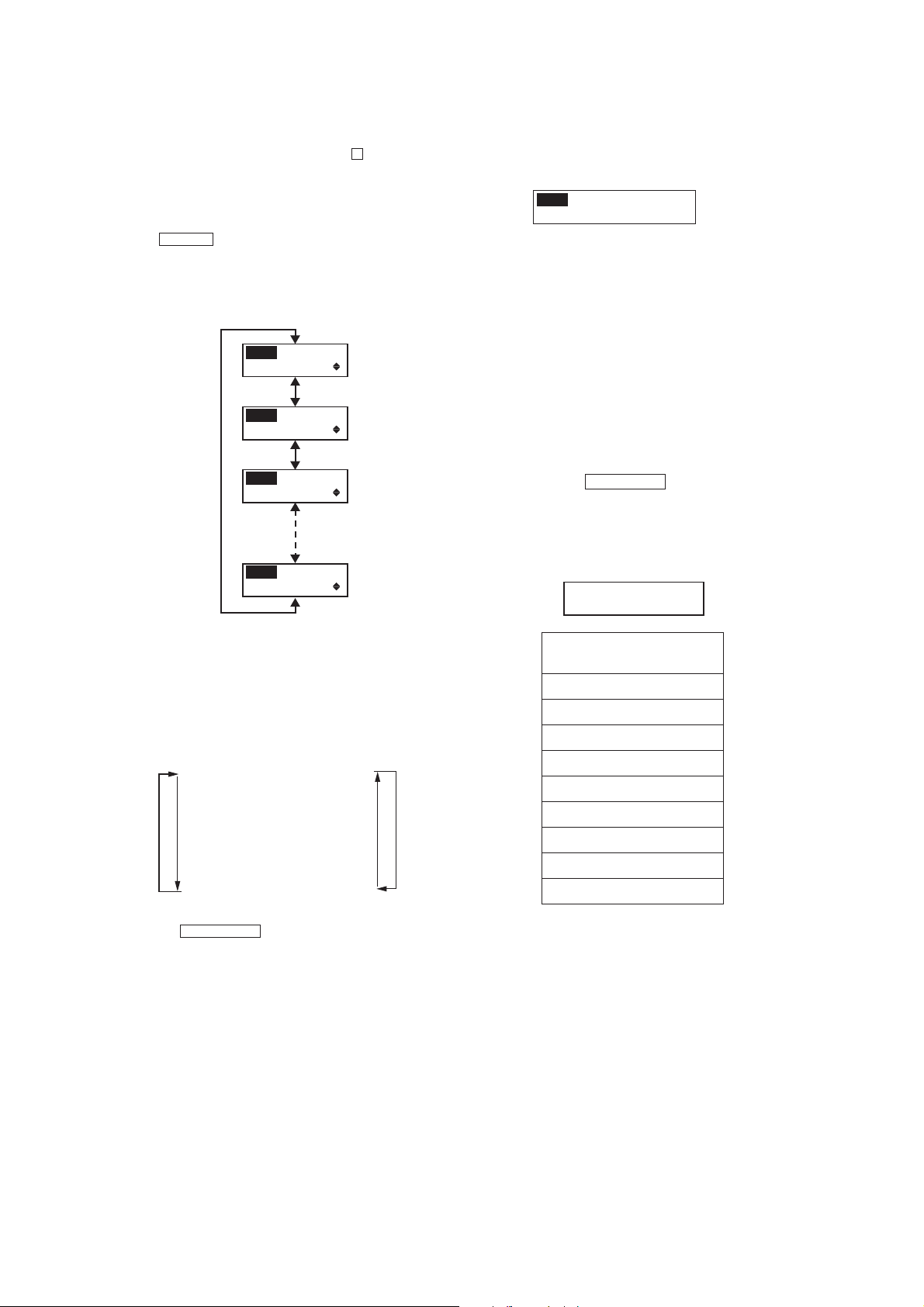

4-2. DIAGNOSTIC MODE

4-2-1. SETTING THE DIAGNOSTIC MODE

Press the JOG roller and the preset button 5 simultaneously for

three seconds under the condition of power-off.

Press the JOG roller when the set is powered on.

4-2-2. EXITING THE DIAGNOSTIC MODE

Press the POWER button to exit from this mode.

4-2-3. MENU

Select the menu and press the JOG roller.

JOG roller

MENU

DIAG. MODE

MENU

BER

MENU

SCROLL MODE

MENU

LINE OUT LEVEL

[BER Display Mode]

Procedure:

1. Select the MENU BER and press the JOG roller.

2. The following message is displayed.

MENU

XXX1 XXX2 XXX3

XXX4 XXX5 X6 X7

XXX1 : SAT1 BER

(4 digits Hex data)

XXX2 : SAT2 BER

(4 digits Hex data)

XXX3 : TERR BER

(4 digits Hex data)

XXX4 : RS Error Byte

(4 digits Hex data)

XXX5 : RS Error Block

(4 digits Hex data)

X6 : SAT AGC

(2 digits Hex data)

X7 : TER AGC

(2 digits Hex data)

3. Press the DSPL/BACK button to return the DIAG. MENU.

4-3. SYSTEM ERROR LIST

If system error is happened, the message of system error is displayed

and the set sounds beep.

SYSTEM ERROR xx

XXXXXXXXXXXXXXXXXXXX

xx : Error information per bit

4-2-4. OPERATION

[Diagnostic Mode]

Procedure:

1. Select the MENU DIAG. MODE and press the JOG roller.

2. The message “STATE1 QOS Test” is displayed.

3. Select the message(menu) by rotating the JOG roller up or down

as following order.

STATE1 QOS Test

STATE2 Terr Err

STATE3 Sat1 Err

STATE4 Sat2 Err

STATE5 Tuner Stat

STATE6 Audio Err

STATE7 Gen Err

STATE8 Ext Err0

STATE9 Ext Err1

4. Press the DSPL/BACK button to return the DIAG. MENU.

UpDown

INFORMATION OF ERROR

(XXXXXXXXXXXXXXXXXXXX)

TUNER UNLOCKED

DSP NO RESPOND

DSP INCORRECT RESP.

UNSUPPORTED DSPSW

CDEC NO RESPOND

I2C BUS ERROR

CAP ERROR

EEPROM ERROR

EEPROM FORMAT ERROR

11

Page 12

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

SECTION 5

SERVICE TOOL

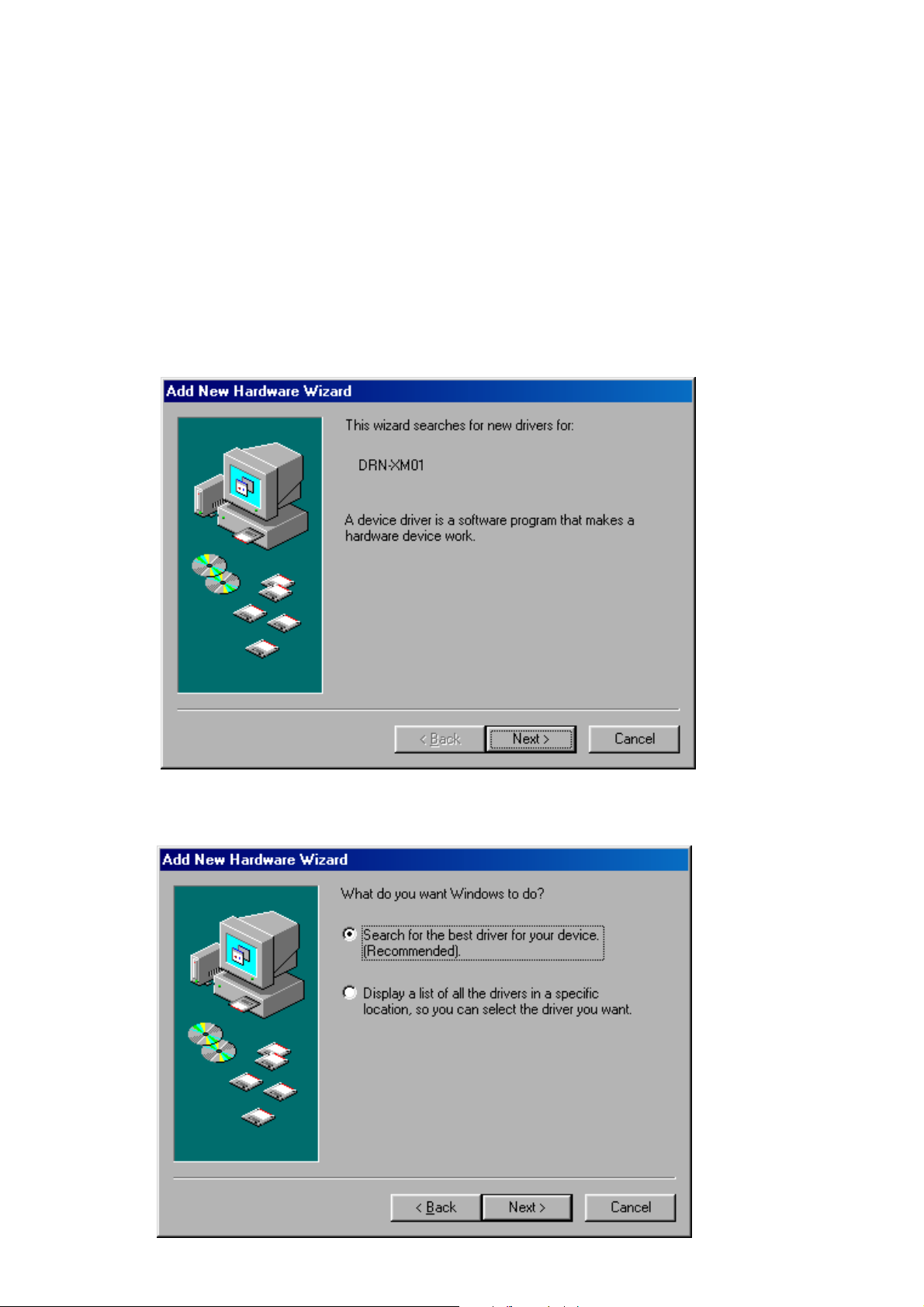

5-1. Installing USB Driver

This section describes how to install USB driver for DRN-XM01.

Operating environment

Operating environments of a PC to which the driver software is installed are as follows.

* Applicable OSs are Windows98SE, Windows 2000 and Windows ME.

* USB can be connected.

Installation

For Windows 98SE

1. Insert the driver software program CD into the PC.

2. Connect the PC and DRN-XM01 with USB cable.

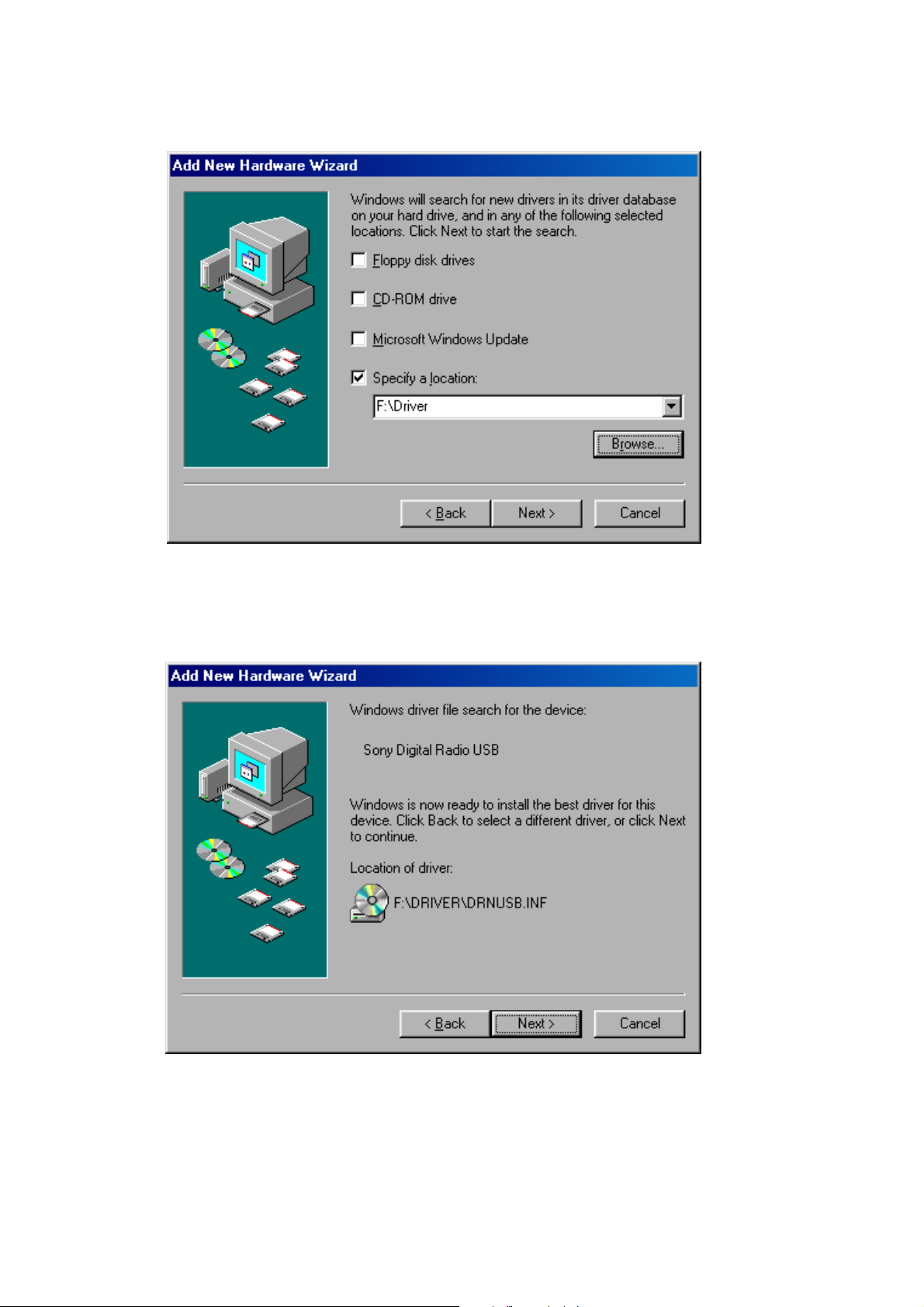

3. After a while, the following dialog box appears. Press the Next button.

4. Then the following dialog box appears. Select ”Search for the best driver for your device (Recommended).” and press the NEXT button.

12

Page 13

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

5. Then the following dialog box appears. Click on the check box ”Specify a location:” and press the Browse…button.

6. The following file selector dialog box appears. Select ”(CD drive):\Driver”(CD drive is F in this sample picture) and press the OK button.

13

Page 14

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

7. Confirm the path and press the NEXT button.

8. After a while, the following dialog box appears. Press the NEXT button.

14

Page 15

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

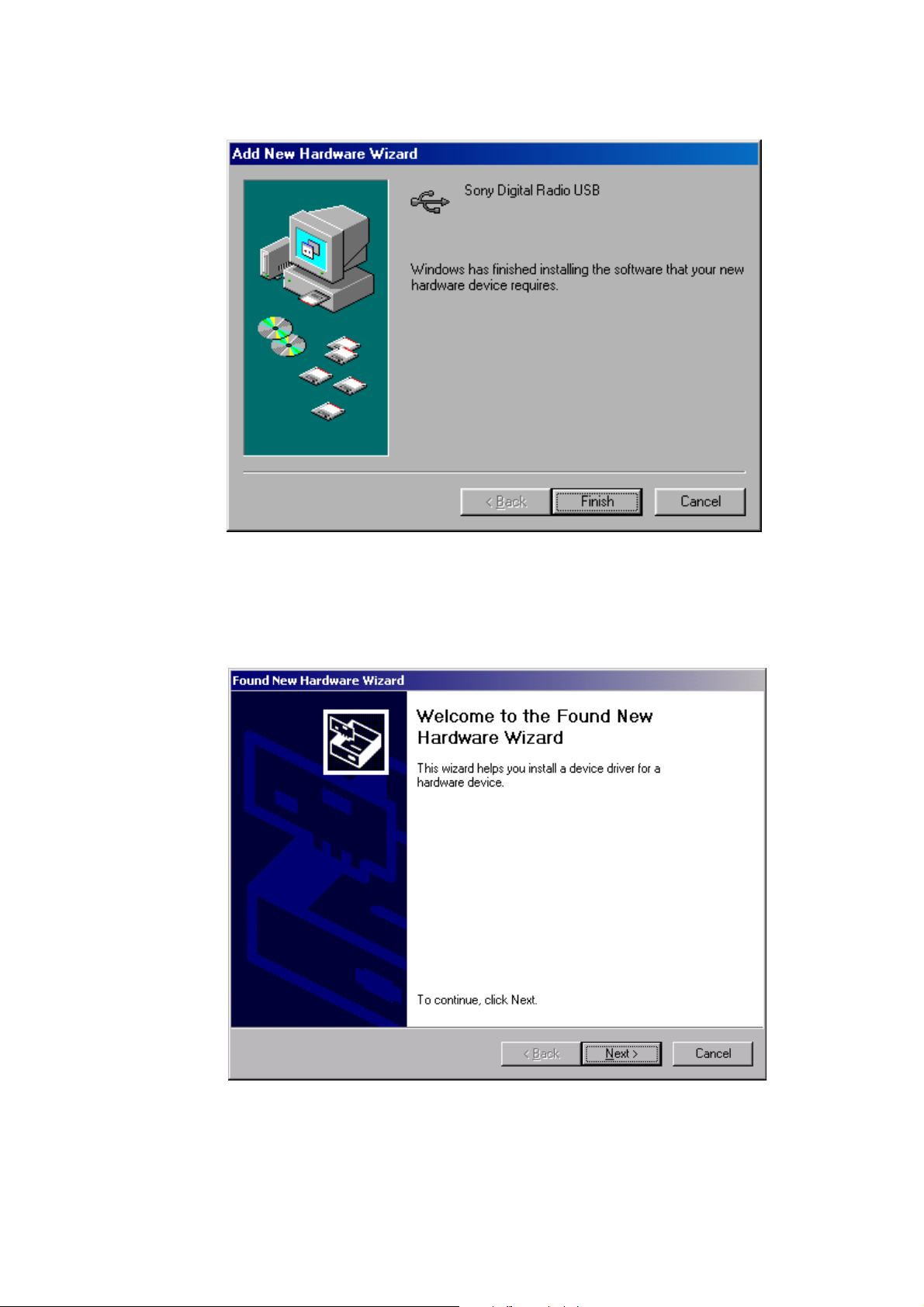

9. After a while, installation is completed and the following dialog box appears. Press the Finish button to terminate the installation program.

For Windows 2000

1. Insert the driver software program CD into the PC.

2. Connect the PC and DRN-XM01 with USB cable.

3. After a while, the following dialog box appears. Press the NEXT button.

15

Page 16

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

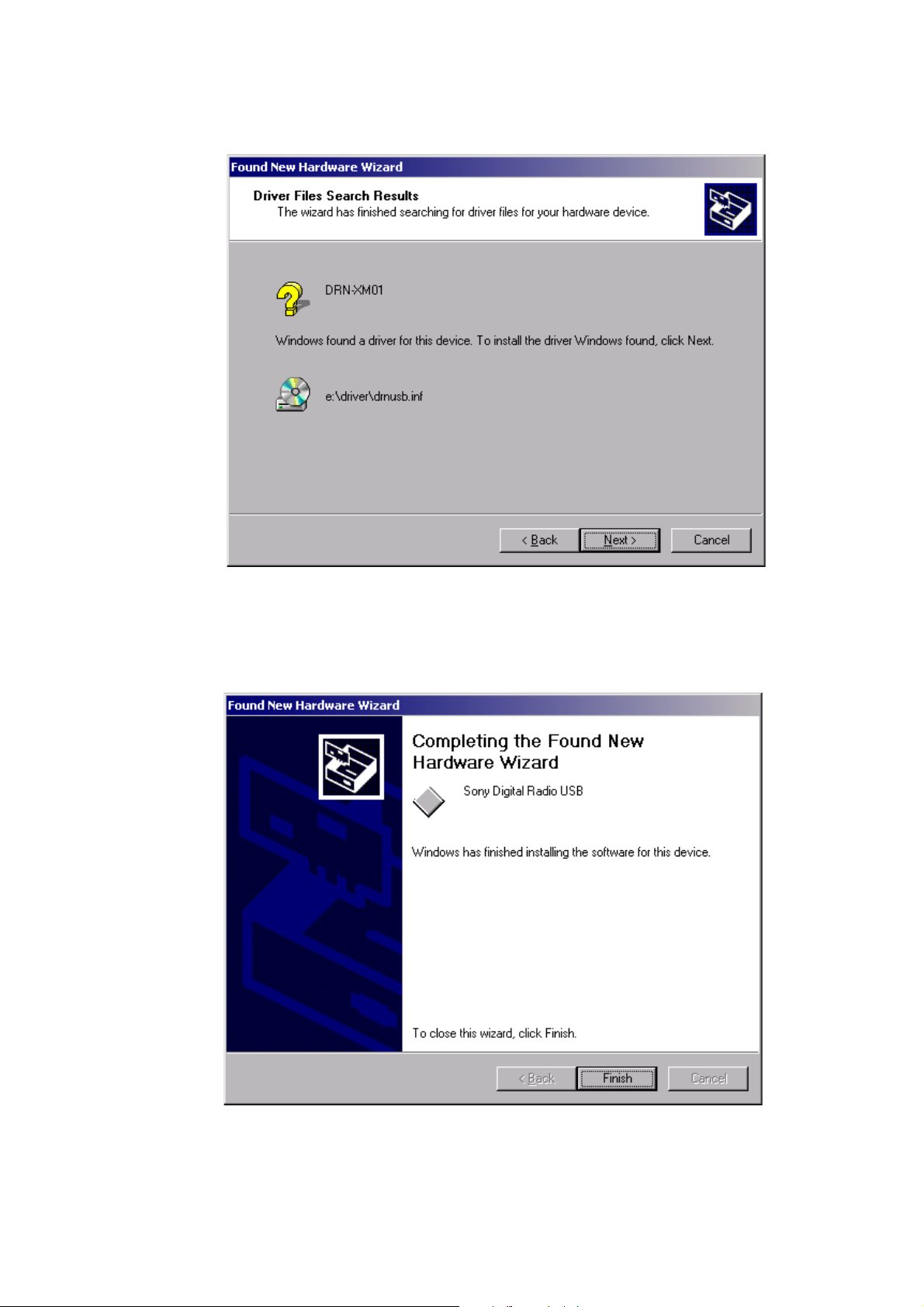

4. Then the following dialog box appears. Select ”Search for suitable driver for my device(recommended)” and press the NEXT button.

5. Then the following dialog box appears. Select ”CD-ROM drives” and press the NEXT button.

16

Page 17

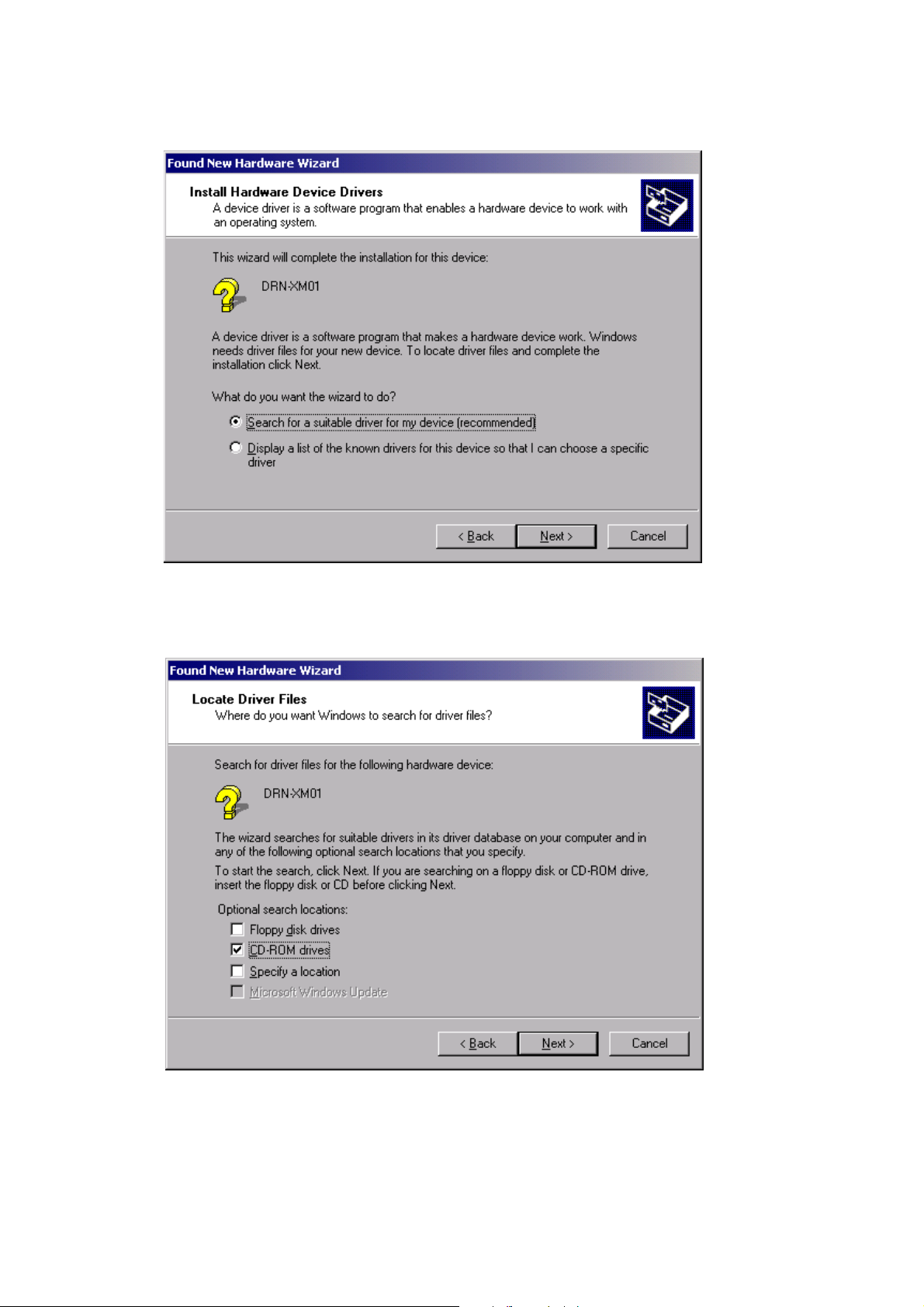

6. After a while, the following dialog box appears. Press the Next button.

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

7. After a while, installation is completed and the following dialog box appears. Press the Finish button to terminate the installation program.

17

Page 18

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

For Windows ME

1. Insert the driver software program CD into the PC.

2. Connect the PC and DRN-XM01 with USB cable.

3. After a while, the following dialog box appears. Click the check box ”Automatic search for a better driver(Recommended)” and press the

NEXT button.

4. After a while, installation is completed and the following display appears. Press the Finish button to terminate the installation program.

18

Page 19

DRN-XM01C/XM01R/XM01H/

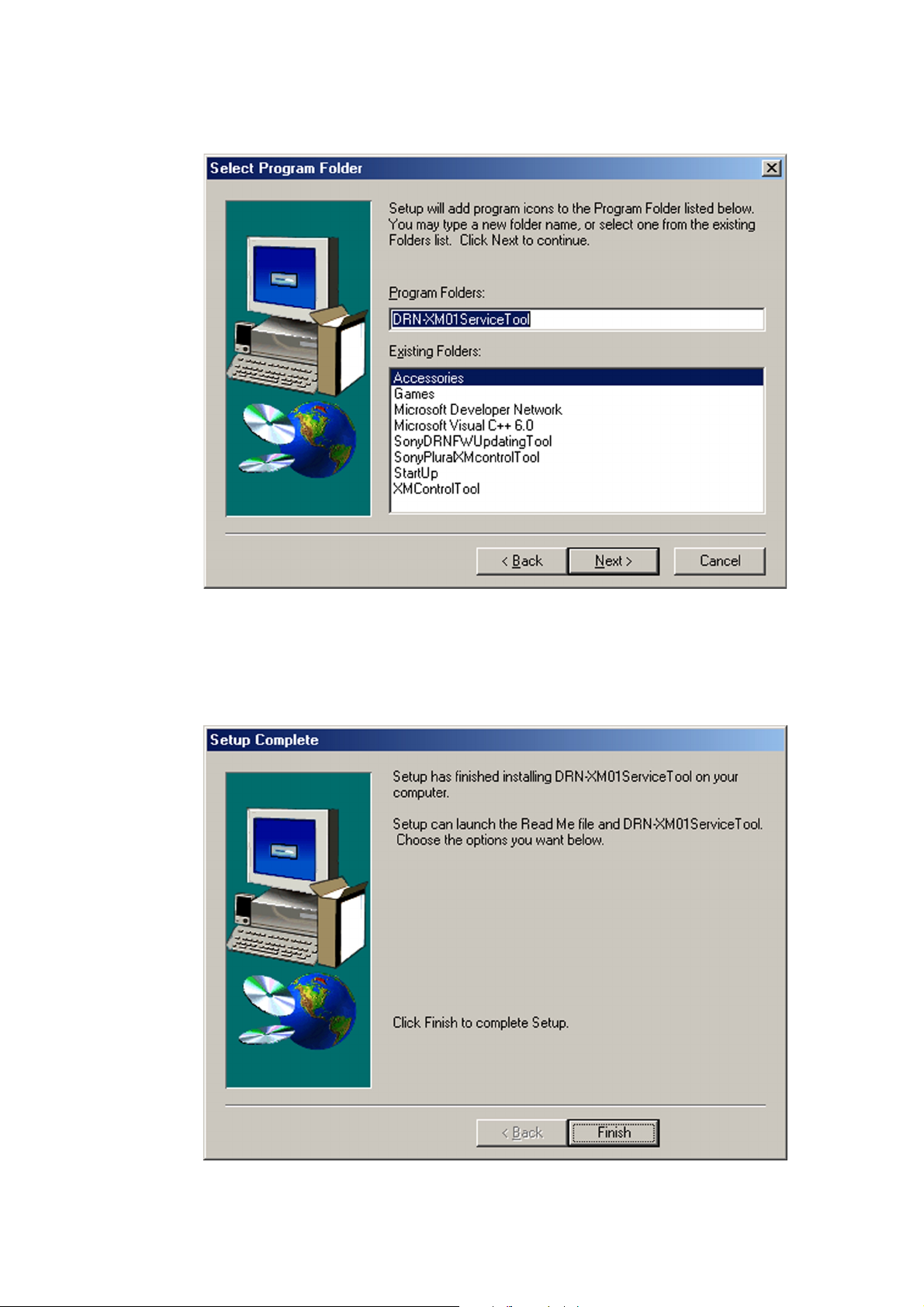

5-2. Installing DRN-XM01 Service Tool

This section describes how to use DRN-XM01 Service Tool.

Operating environment

Operating environments of a PC to which DRN-XM01 Service Tool is installed are as follows.

• Applicable OSs are Windows98SE, Windows 2000 and Windows ME.

• USB can be connected.

• USB driver for DRN-XM01 is installed.

Installation

1. Insert DRN-XM01 Service Tool CD into the PC.

2. Open ”DRN-XM01 Service Tool” in the CD drive with Explorer or the like and double-click Setup. exe.

XM01CK/XM01HK

Ver 1.1 2001.12

19

Page 20

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

3. The following dialog box appears after a while. Press the Next button.

4. The following dialog box appears. Select an appropriate folder by pressing the [Browse…] button as desired. Press the Next button.

20

Page 21

5. The following dialog box appears. Change if required and press the Next button.

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

6. The following dialog box appears after a while. Press the Finish button to terminate the installation program.

21

Page 22

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

5-3. How to use DRN-XM01 Service Tool

Note: When the Write Firmware program is executed, all of the information that has been preset by customer is cleared. Before executing

the Write Firmware program, take a note of the information that has been preset by customer. After execution of the Write Firmware

program is completed, set the saved information to recover the original setup.

1. Connect the DRN-XM01 power cord to the wall outlet and connect the DRN-XN01 to a PC with the USB cable.

Note: Even if the power of the DRN-XM01 is not turned on, the DRN-XM01 Service Tool firmware can be activated but an error occurs

during sequence of the execution. So, be sure to turn on the power of the DRN-XM01. Because DRN-XM01 Service Tool firmware

cannot be updated if the power of the DRN-XM01 is not turned on.

2. Select Start t Program t DRN-XM01ServiceTool to start up the tool.

3. When DRN-XM01ServiceTool starts up, the following dialog box appears prompting you to confirm that the characters "DRN-XM01" is

displayed in the Product Name (1), the present version in the Device Version (2) and the present serial number in the Serial No text boxes.

(When the serial number is not written due to replacement of CPU board or others, the characters "------" appear.)

22

Page 23

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

4. When File t Open is selected on the menu bar, the file selection dialog box appears. Select the firmware update file (extension .rom) for

the DRN-XM01 and confirm the file version that appears in File Version (4) text box. When the characters "------" are displayed in the

Serial No text box, input the serial number that is printed on the label on the back of the machine, into the Serial No text box.

5. When Firmware t Write Firmware is selected, the following progress dialog box appears.

23

Page 24

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

6. When writing of the firmware is completed, the pop-up menu appears as shown below. Confirm that the writing of the firmware has

completed with normal end.

7. When the OK button is pressed in step 6, Radio ID appears in the Radio ID (5) text box.

24

Page 25

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

Log function

When View t Log File is selected, "Notepad" appears enabling you to view the firmware logs saved by this software up to present.

If this file is cleared by mistake or the contents are re-written or the tool is uninstalled, the logs will disappear.

25

Page 26

DRN-XM01C/XM01R/XM01H/

1

IC101 es (XTO)

1.3 Vp-p

42 ns

500mV/div 20ns/div

4

IC505 qd (XOUT)

3.8 Vp-p

83 ns

1V/div 40ns/div

2

IC501 wh (X2)

3.3 Vp-p

16 ns

1V/div 100ns/div

3

IC501 es (XT2)

2 Vp-p

31 ns

500mV/div 20µs/div

d

XM01CK/XM01HK

SECTION 6

DIAGRAMS

Note on Printed Wiring Boards

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

C

Q

These are omitte

EB

Note on Schematic Diagram

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

f

•

• C : panel designation.

.

Note: The components identified by mark 0 or dotted

: internal component

line with mark 0 are critical for safety.

Replace only with part number specified.

1

4

/

W or less unless otherwise

r

WAVEFORMS

• : B+ Line.

• Power voltage is dc 6.0V and fed with regulated dc power

supply from cradle.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : SAT

f : TER

26

Page 27

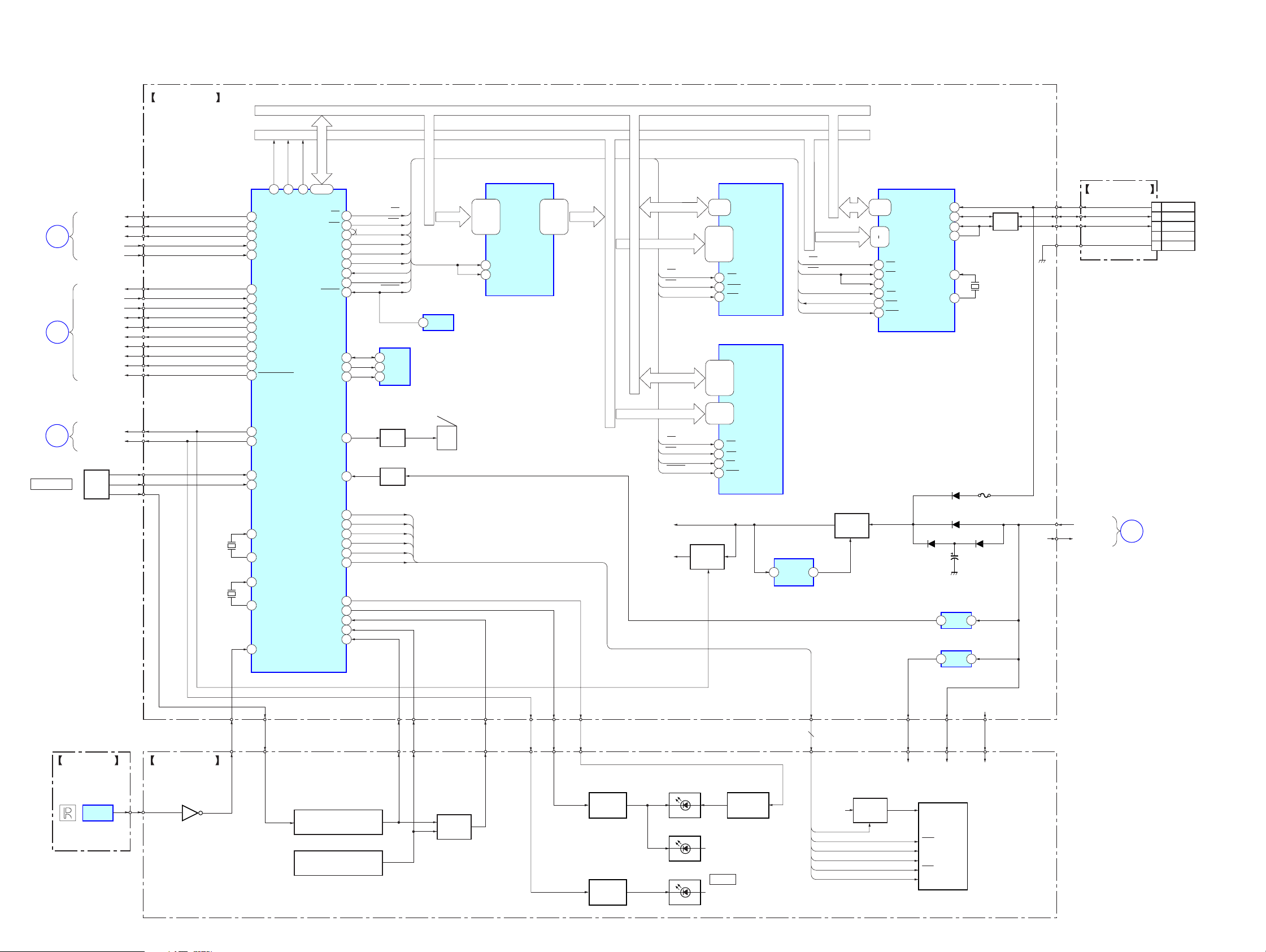

6-1. BLOCK DIAGRAM – TUNER SECTION –

BB BOARD

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

FROM

CRADLE

(XM ANTENNA)

CPU

BOARD

CRADLE

CPU

BOARD

IC106

DAC

DIN

5

4

LRCIN

6

BCKIN

1

XTI

16

MD/DM0

17

MC/DM1

18

ML/MUTE

15

RSTB

IC50

SWITCHING REG

FB EXT

5 1

CE

IC51

SWITCHING REG

FB EXT

5 1

CE

IC52

+5V REG

VOUT VDD

1 3

CE

IC107(1/2)

7

VOUTL

12

VOUTR

9

Q51

POWER

SWITCH

4

POWER_DIG

Q52

POWER

SWITCH

4

TUNER_EN

4

LPF

LPF

6

IC107(2/2)

2

LF103

FILTER

MUTE

Q101-103

MUTE

CONTROL

LINE

1

Q105

Q104

MUTE

Q106,109

FAN

DRIVER

FU3

DEC_3.3V

AUDIO_L

AUDIO_R

Signal path

FAN1

DC 6V

POWER_DIG

TUNER_EN

DC 6V

DEC_3.3V

: SAT

: TER

FROM

CRADLE

TO

CRADLE

C

D

CPU

BOARD

CPU

BOARD

IF2TA_P

IF2TA_N

IF2SA_N

IF2SA_P

TAGC

SAGC

XTI/MCLK

MAO2

MAO1

MAI1

MRESET

INTR

SDA

SCL

IC101

CDEC

MADD0-11

83

PCSD1

85

PCDC1

82

PCFS1

108

MFP_CLK

MCLKO

35 5

IC104

SDRAM

MDQ0-7

MBS0

MBS1

MCKE

MCS0

MDQM

MWE

MCLKON

RAS

CAS

120

127

95-100

103-106

109,110

111

112

113

117

119

130

131

132

36

2,5,8,10

44,47

50,53

23-26

29-34

22,35

20

21

37

19

39

18

17

16

38

BA0

BA1

CKE

CS

DQM

RAS

CAS

WE

CLK

DQ0-7

A0-11

DEC_RESET

SDEC_INT

I2C_DATA

I2C_CLK

34

33

39

29

55

56

60

59

A/D_2.5V

TUNER_3.3V

TU101

TUNER UNIT

IC701

DIFFERENTIAL

DRIVER

8

1

4

2

5

14

D102

ANT_5V

I2C_CLK

10

11

12

13

6

8

TER_IN

SAT_IN

SPI_CLK

SPI_DATA

SPI_LE

CDEC_CLK_OUT

LOCK_DET

T_AUX

S_AUX

TER_IF2_OUT

SAT_IF2_OUT

TER_AGC_IN

SAT_AGC_IN

TER IN

SAT IN

TUNER_CLK

TUNER_DATA

TUNER_LE

A

TUNER_LOCK

ANT_DET

MOBILE_A

TO

MOBILE_B

MOBILE_OUT

DEC_RESET

CDEC_INT

SDEC_INT

I2C_DATA

I2C_CLK

Q108

AMP

DEC_RESET

CDEC_INT

SDEC_INT

I2C_DATA

5

1

4

SINGLE

TO

DIFFERENTIAL

DEC_RESET

CDEC_INT

I2C_DATA

I2C_CLK

14

15

20

21

29

30

33

88

87

92

28

53

70

69

B

DAC_DATA

DAC_CLK

DAC_LE

DAC_RESET

MUTE

DAC_DATA

DAC_CLK

DAC_LE

DAC_RESET

MUTE

IC102

SDEC

PCSD

PCDC

PCFS1(FIT_2)

PLL_SYNC(FIT_5)

CLK_IN

RESET_N

EVENT_IRQ

SDA

SCL

SDO

LRCKT

SCKT

OCLK

SDA_M

SCL_M

CAP_RST

IC54

+2.5V REG

VOUT VDD

1 3

IC53

+3.3V REG

VOUT EXT

3 4

73

72

74

75

14

13

8

CE

CE

IC103

CAP

PA0

17

PA1

5

RST

6

CLK

4

DEC_ 2.5V

4

5

Q53

DRIVER

DAC_DATA

DAC_CLK

DAC_LE

DAC_RESET

MUTE

FU4

Q55

ANT_5V

4V

2727

Page 28

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

– CONTROL SECTION –

CPU BOARD

TUNER_CLK

BB

BOARD

BB

BOARD

BB

BOARD

MENU/ENTER

TUNER_DATA

A

B

C

TUNER_LE

TUNER_LOCK

ANT_DET

DEC_RESET

CDEC_INT

SDEC_INT

I2C_DATA

I2C_CLK

DAC_DATA

DAC_CLK

DAC_LE

DAC_RESET

MUTE

POWER_DIG

TUNER_EN

JOG

ROLLER

JOG A

JOG B

SW1

A18

A18 A17 A16

90

TUNER_CLK

70

TUNER_DATA

4

TUNER_LE

96

AN4(TUNER_LOCK)

94

AN2(ANT_DET)

DEC_RESET

8

CDEC_INT

14

SDEC_INT

10

84

SDA(CDEC,SDEC)

85

SCL(CDEC,SDEC)

42

DAC_DATA

40

DAC_CLK

39

DAC_LE

41

DAC_RESET

73

HWR(MUTE)

6

POWER_DIG

7

TUNER_POWER_EN

JOG_A INT2

36

99

AN7(JOG_B)

A17

6165 60

IC501

CPU

AD0-15

A16

44-59

AD0-15

WR

ALE

SRAMCS

FLASHCS

USBCS

USBINT4

USB_RESET

RESET

EEPROM-SDA

EEPROM-SCK

EEPROM-WP

BUZZER

VDET DC-IN

DATA BUS AD0 - 15

ADDRESS BUS A0 - 18

IC502

ADDR_LATCH

47,46,44

43,41,40

38-35

33,32,30

29,27,26

48

25

1LE

2LE

1D1-8,

2D1-8

RD

71

72

43

80

81

79

38

9

30

69

68

67

5

86

WR

ALE

SRAMCS

FLASHCS

USBCS

USB INT4

USB_RESET

RESET

IC509

EEPROM

SDA

5

SCL

6

7

WP

Q501

BUZZER

DRIVER

Q502

BUF

RD

AD0-15 A0-15

ALE

IC4

RESET

1

BZ501

1Q1-8,

2Q1-8

2,3,5

6,8,9

11-14

16,17,19

20,22,23

AD0-7 AD0-15

A0-16

RD

WR

SRAMCS

AD0-15

A1-18

RD

WR

FLASHCS

RESET

21-23

25-29

20-13

3,2

31,1,12

4,11

7,10

32

5

30

29,31,33

38,40,42

44,30,32

34,36,39

41,43,45

25-18

8-1

48,17

28

11

26

12

OE

R/W

CE1

OE

WE

CE

RST

IC503

SRAM

D1-8

A0-16

IC504

FLASH

D0-15

A0-17

A1-6

RD

WR

USBCS

USB INT4

USB_RESET

23-34

37-40

17

22

43

44

41

45

42

46

D0-15

A1-6

RD

WR

TEST2

CS

INT

RST

IC505

USB_MICOM

VBUS

TRON

XIN

XOUT

USB BOARD

X503

12MHz

FU1

LF501

LINE

FILTER

5

D-

3

D+

4

6

14

13

D2,9

CN1

1

VBUS

2

D-

3

D+

NC(ID)

4

5

DGND

IR BOARD

IC301

REMOTE

SENSOR

6.144MHz

LCD BOARD

Q301

X501

X502

32kHz

IR_INT

28

26

31

32

37

X1

X2

TX1

TX2

IR INT3

JOG_PUSH

LCD_RESET

LCD_CLK

LCD_SI

LCD_CS

LCD_A0

LCD_POWER

BACKLIGHT2

SCK(BACKLIGHT)

KEY INT1

AN0(KEY-A/D1)

AN1(KEY-A/D2)

S301-303

FUNCTION

SWITCH

S304-308

FUNCTION

SWITCH

19

20

18

16

17

13

74

83

35

92

93

LCD_RESET

LCD_CLK

LCD_SI

LCD_CS

LCD_A0

LCD_POWER

BACKLIGHT2

BACKLIGHT1

KEY INT

KEY-A/D1

KEY-A/D2

KEY-A/D2

KEY-A/D1

Q303,304

KEY

DET

KEY INT

TUNER_EN

BACKLIGHT1

BACKLIGHT2

Q302

LED

DRIVER

Q305

LED

DRIVER

CPU_3.3V

DEC_3.3V

POWER_DIG

(BACK LIGHT)

D304,305,S301-308

(KEY BACK LIGHT)

D301,302

Q2,3

B+

SWITCH

POWER

D303

Q307,308

BRIGHTNESS

CONTROL

IC3

SWITCHING REG

FB EXT

5 1

6

CPU_3.3V

LCD_POWER

LCD_RESET

LCD_CLK

LCD_SI

LCD_CS

LCD_A0

Q1

POWER

SWITCH

Q300,306

B+

SWITCH

D3

D4 D1

IC1

DC-IN

DET

VDD

RES

SCL

SI

CS1

A0

LED_6V

LCD301

IC11

+5V

REG

LED_6V

IR_5V

IR_5V

LIQUID CRYSTAL DISPLAY

C9

21

23

CPU_3.3V

CPU_3.3V

DC 6V

DEC_3.3VDEC_3.3V

BB

D

BOARD

2828

Page 29

6-2. PRINTED WIRING BOARDS – CPU BOARD –

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

A

B

C

D

12

CPU BOARD (SIDE A)

3456789101112

CPU BOARD (SIDE B)

USB BOARD

CN1

TP1

E

CN2

11

(11)

A

TO

BB BOARD

CN102

(Page 32)

IC1

1

5

4

3

IC3

5

4

IC4

1

3

1-682-676-

E

F

G

E

• Semiconductor Location

Ref. No. Location

D1 C-9

D2 C-9

D3 C-9

D4 C-9

D5 C-10

D6 D-9

D7 C-10

D9 C-9

D501 E-1

D504 F-9

D505 F-9

D506 F-9

D507 F-9

Ref. No. Location

IC1 C-8

IC3 C-10

IC4 D-10

IC11 F-10

IC501 E-10

IC502 E-8

IC503 E-8

IC504 E-7

IC505 D-8

IC509 E-3

Q1 C-10

Q2 D-10

Q3 D-10

Q501 E-1

Q502 F-10

1

4

IC509

IC505

IC504

5

4

13

IC501

E

1-682-676-

11

(11)

8

5

IC503

IC502

IC11

11

1-682-676-

(11)

TO

JOG ROLLER

MENU/ENTER

B

TO

LCD BOARD

CN301

(Page 36)

2929

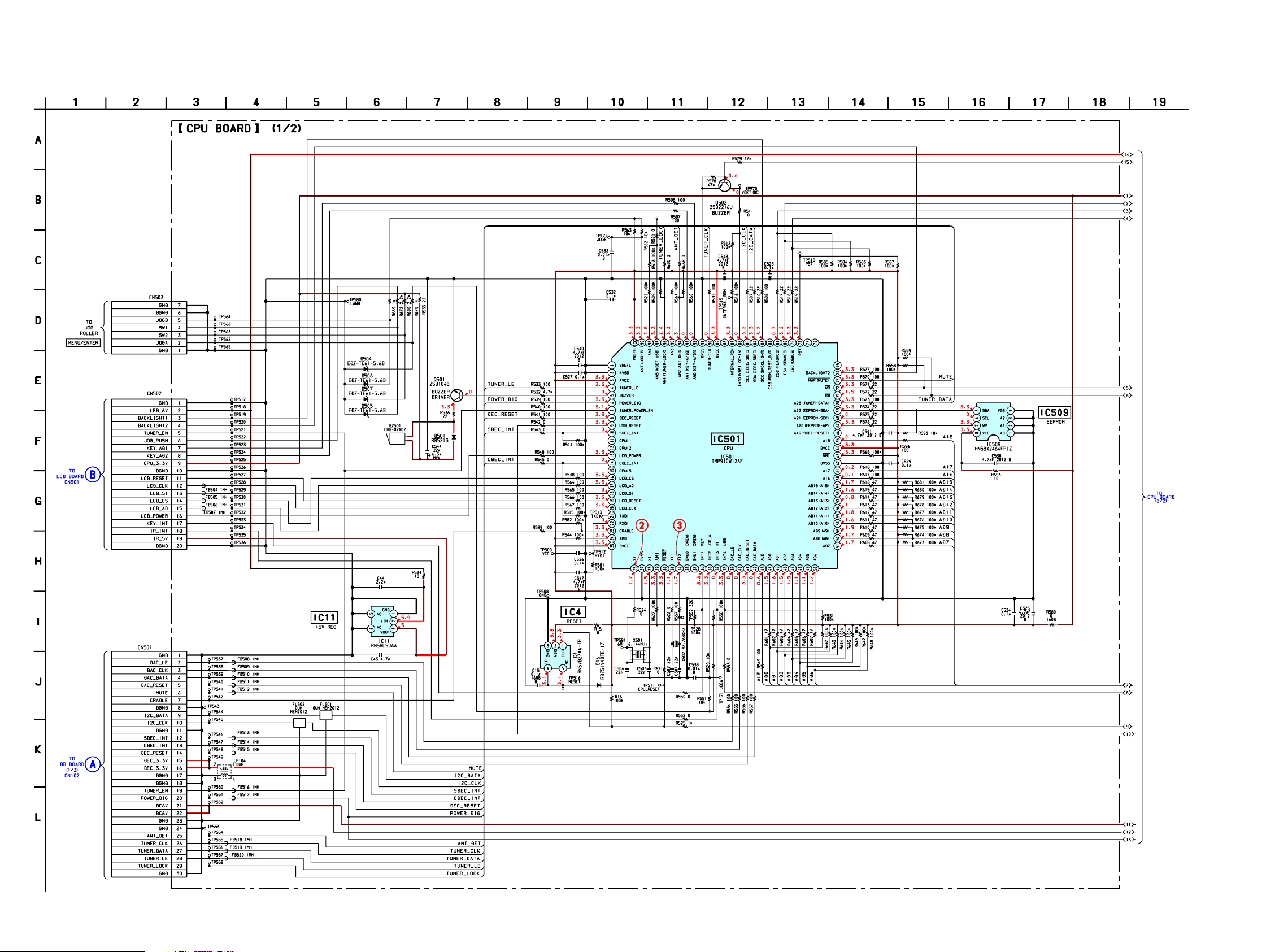

Page 30

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-3. SCHEMATIC DIAGRAM – CPU BOARD (1/2) –

• See page 26 for Wavefoms. • See page 40 for IC Pin Function Description.

(Page 37)

(Page 33)

3030

Page 31

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-4. SCHEMATIC DIAGRAM – CPU BOARD (2/2) –

• See page 39 for IC Block Diagram. • See page 26 for Wavefom.

IC B/D

3131

Page 32

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-5. PRINTED WIRING BOARDS – BB BOARD –

A

B

C

12

34567891011

BB BOARD (SIDE A) BB BOARD (SIDE B)

TO

FAN1

IC106

IC51

IC107

IC53

IC50

E

E

E

IC102

TO

CRADLE

A

TO

CPU BOARD

CN501

(Page 29)

D

IC52

E

F

• Semiconductor Location

G

Ref. No. Location

D51 D-2

D52 B-2

D53 C-3

D54 E-2

D55 C-2

D56 C-2

D57 F-5

D101 C-7

D102 D-2

D106 B-3

D111 B-3

D112 B-4

D113 B-7

D114 B-7

D115 B-3

D116 B-3

IC104

Ref. No. Location

D117 B-3

D118 B-7

D119 B-3

D120 B-7

D121 C-3

D122 B-7

D123 B-7

D124 B-7

D125 D-1

D126 B-7

D151 E-3

D152 B-3

D153 B-3

D154 B-3

D155 B-3

IC101

IC701

Ref. No. Location Ref. No. Location

IC50 C-2

IC51 B-2

IC52 E-1

IC53 C-2

IC54 F-5

IC101 E-4

IC102 C-8

IC103 E-5

IC104 E-2

IC106 B-5

IC107 B-5

IC701 F-3

Q51 C-2

Q52 B-2

Q53 C-2

Q55 C-2

Q101 C-7

Q102 C-7

Q103 C-7

Q104 C-5

Q105 C-5

Q106 C-3

Q108 D-1

Q109 C-2

IC54

FOR

CAP-BINDING

IC103

TO

XM ANTENNA

(TER)

3232

1-682-677-

11

(11)

TO

XM ANTENNA

(SAT)

Page 33

6-6. SCHEMATIC DIAGRAM – BB BOARD (1/3) –

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.1 2001.12

330k

220k

(Page 30)

3333

Page 34

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-7. SCHEMATIC DIAGRAM – BB BOARD (2/3) –

• See page 38 for IC Block Diagram. • See page 26 for Wavefom.

IC B/D

3434

Page 35

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-8. SCHEMATIC DIAGRAM – BB BOARD (3/3) –

FOR

CAP-BINDING

• See page 38, 39 for IC Block Diagrams.

IC B/D

IC B/D

3535

Page 36

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-9. PRINTED WIRING BOARDS – PANEL SECTION –

A

B

C

12

LCD BOARD (SIDE A)

IR BOARD (SIDE A)

3456789

DSPL/

BACK

(LIQUID CRYSTAL DISPLAY)

1-682-675-

54321

MEMOPOWER

(11)

11

D

E

F

G

H

IC301

1-682-679-

g

(11)

11

LCD BOARD (SIDE B)

IR BOARD (SIDE B)

11

(11)

1-682-679-

B

TO

CPU BOARD

CN502

(Page 29)

1-682-675-

(11)

• Semiconductor

Location

Ref. No. Location

D301 B-2

D302 B-7

D303 C-2

11

D304 C-2

D305 C-7

D311 F-6

D312 F-3

D313 E-5

D314 E-5

IC301 D-2

Q300 F-6

Q301 F-7

Q302 E-5

Q303 E-4

Q304 E-4

Q305 F-5

Q306 F-5

Q307 F-6

Q308 E-5

3636

Page 37

6-10. SCHEMATIC DIAGRAM – PANEL SECTION –

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

(Page 30)

3737

Page 38

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-11. IC BLOCK DIAGRAMS

IC101 STA400 IC102 STA450

VSS

PCDC1

PCBS1

MAO1

MAO2

NC

VSS

VDD

MAI1

NC

NC

MADD0

MADD1

MADD2

MADD3

MADD4

MADD5

VSS

VDD3

MADD6

MADD7

MADD8

MADD9

VSS

MFP CLK

MADD10

MADD11

MBS0

MBS1

MCKE

113

112

111

110

106

107

108109

102

103104105

97

99100101

98

9596

9293

90

94

91

878889

84

86

85

VSS

VDD

VDD3

MCS0

MCS1

MDQM

MDQ0

MDQ1

MDQ2

MDQ3

MDQ4

MDQ5

MDQ6

MDQ7

VSS

VDD

RAS

CAS

MWE

FTESTOUT0

FTESTOUT1

FTESTOUT2

FTESTOUT3

FTESTOUT4

VSS

VDD3

FTESTOUT5

FTESTOUT6

FTESTOUT7

FTESTOUT8

FTESTOUT9

FTESTOUT10

FTESTOUT11

FTESTOUT12

FTESTOUT13

FTESTOUT14

FTESTOUT15

VDD

VDD3

VSS

TREFM

114

115

116

117

118

119

120

122

123

124

125

126

127

129

130

131

132

133

135

136

137

138

139

140

141

142

143

144

121

128

134

83

PCSD1

82

PCFS1

81

868583 82 79

DEPUNCYURING

WEIGHTING AND

8 bit

AGC

14 15

VITERBI

DECODER

RS

DECODER

SAT/SAT

COMBINING

TERR. FIFO

FIFO FIFO FIFO

SAL1 TDM

SYNCH. AND

DESCRAMBLING

SATELLITE 1

QPSK

DEMODULATOR

TDM

DEMUX

SAL1 AND SAL2

TERR/SAT.

COMBINING

WEIGHTING

FACTOR

CALCULATION

20

8 bit

AGC

FEC

SAL2 TDM

SYNCH. AND

DESCRAMBLING

SATELLITE 2

DEMODULATOR

19,22-25

21

PORT #1

BITSTREAM

INTERFACE #1

QPSK

PC

PC

CONTROLLER

TDM MANAGEMENT

INTERFACE #2

PRC

DEMUX

TDM DECODING

BER MEAS.

TERR. FIFO

EXTEMAL

MEMORY

CONTROLLER

FIFO

88

87

TERR. TDM

SYNCH. AND

DESCRAMBING

92

1

2

3

4

5

6

7

8

9

10

TERRESTRIAL

MULTI CARRIER

DEMODULATOR

TERR

AGC

78

77

76

PC

PORT #2

PC

BITSTREAM

TERR

AGC

74

75

TEST

INTERFACE

INTERFACE

MICROPROCESSOR

CLOCK

DISTRIBUTION

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

VSS

NC

PCTS EF1

PCBS2

PCDC2

PCSD2

PCFS2

PCTS EF2

BIST EM

SCAN WN

TEST EN

SDA

SCL

VSS

VDD

VDD3

IF2SD0

IF2SD1

IF2SD2

IF2SD3

IF2SD4

IF2SD5

IF2SD6

IF2SD7

LOCK M

CLKD

VDD

VSS

INTR

FTESTEN

IF2TD0

IF2TD1

IF2TD2

IF2TD3

IF2TD4

IF2TD5

IF2TD6

IF2TD7

IF2TD8

IF2TD9

VSS

RFU

GND1

VDD1

TEST0

CLK IN

RFU

TESTB

CAP RST

GND2

VDD2

VDD IO1

CLK OUT

SCL-M

SDA-M

GND3

VDD3

RFU

SCAN

MODE

APLL

GND

APLL

VDD

VDD12

I958 OUT

INPUT

BUFFER

GND4

77

AUDIO PLL

24

VDD4

GND12

76

I2C MASTER

(CAP I/F)

25

CLK M126CLK M0

RS232 TX

RS232 RX

78

79

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

33

34

13

14

PC BITSTREAM

INTERFACE

(USSIO O)

INPUT

SYSTEM AND AUDIO CLOCKS

SYS PLL

22

21

23

FLT 1

FILT 0

OCLK

75

CDO

SCKT

74

73

I2 SLAVE

(SYSCON I/F)

SERVICE

LAYER DEMUX

DSP BASED

27

RFU28RFU

72

59

29

PLL

LRCKT

60

SYNC

VDD IO4

71

30

GND5

VDD11

70

596164

GPIO

INTERFACE

DECRYPTION

31

VDD5

GND11

69

32

VDD IO2

DP CLK

67

68

80

65

DECODER

33

PCDC34PCSD

DP DATA

RS232

AYDIO

DP EN

66

79

35

RFU36RFU

RFU

65

RFU

64

63

EXETERNAL

INTTERRUPT

37

38

GND6

VDD10

39 29

OUTPUT

BUFFER

VDD6

62

39

GND10

PCFS

61

40

RFU

FIT 1

SPDIFF

OUTPUT

AUDIO PORT

OUTPUT

INTERFACE

(PCM I/F)

DATA PORT

OUTPUT

INTERFACE

(USSIO 3)

SDA

60

SCL

59

VDD9

58

GND9

57

EVENT

56

IRQ

RESET N

78

73

74

72

75

68

67

66

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

TEST1

DATA EN

VDD IO3

VDD8

GND8

DATA REQ

EXAUD

SCLK IN

EXAUD

DATA IN

RFU

VDD7

GND7

EXAUD

SCLK OUT

EXAUD

DATA OUT

RFU

11 12 13

TREFP

TADCREF

TINCM

14

15

IF2TA P

16

17 18 19 20 21 22 23 24 252627 28 29 30 31 32 33 34

TAGC

IF2TA N

TVCMO

AVDD

AGND

SVCMO

IF2SA N

IF2SA P

SINCM

SREFP

SADCREF

SREFM

AVDD

AGND

MRESET

SAGC

VSS

XTO

ADCSEL

XTI/MCLK

35

MCLKO

36

MCLKON

37 38

LOCK S1

39 40

LOCK S2

VDD3

VDD

3838

Page 39

IC106 PCM1717E-ST2

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

MODE

RSTB

MC/DM0

MD/DM1

ML/MUTE

CLKO

XTO

MULTI-LEVEL

SERIAL

14

15

16

17

18

19

20

INPUT

I/F

MODE

CONTROL

I/F

RESET

1 2 3

XTI

8X OVERSAMPLING

DIGITAL FILTER WITH

MULTI FUNCTION

CONTROL

CLOCK/OSC MANAGER

GND

VDD

DELTA-SIGMA

MODULATOR

MULTI-LEVEL

DELTA-SIGMA

MODULATOR

4

LRCIN

BPZ-CONT.

5 6

DIN

DAC

DAC

POWER SUPPLY

BCKIN

OUTPUT AMP

AND

LOW-PASS

FILTER

OUTPUT AMP

AND

LOW-PASS

FILTER

13

D/C L

VOUT L

12

11

VCC

AGND

10

9

VOUT R

8

D/C R

ZERO

7

IC505 M66291GP

VCC

GND

D-

D+

VBUS

TRON

TEST1

TRST/DREQ2

TCK/DACK2

TMS/HWR/SEL

TDI/A0

TDO/INT2/SOF

DACK

48

1

2

3

4

5

6

7

8

9

10

11

12

5

6

4

3

14

13

I/O BLOCK

OSCILLATION

BUFFER

/48MHzPLL

VBUS

INPUT CIRCUIT

D+ PIN PULLUP

CIRCUIT

USB

TRANSCEIVER

46

47

USB-IP

WR

CS

45

INTERRUPT CONTROLLER

TRANSFER

CONTROLLER

SERIAL

INTERFACE

ENGINE

(SIE)

RD

4344

TEST2

INT

42

ENDPOINT

CONTROLLER

FIFO MEMORY CONTROLLER

D15

40

41

FIFO MEMORY

D13

D14

39

D12

3738

BUS

INTERFACE

UNIT

(BIU)

8-10

36

GND

VCC

35

34

D11

D10

33

32

D9

31

D8

D7

30

29

D6

D5

28

D4

27

26

D3

11

D2

25

RST

DREQ

13 14 15 16 17 18 19

A1

XOUT

XIN

GND

VCC

A2

20

21 22 23 24

A3

A4

A5

A6

D0

D1

39

Page 40

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

6-12. IC PIN FUNCTION DESCRIPTION

• IC501 TMP91CW12AF-SR7501 (CPU)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44 to 59

60

61

62

63

64

65

Pin Name

VREFL

AVSS

AVCC

TUNER_LE

BUZZER

POWER_DIG

TUNER_POWER_EN

DEC_RESET

USB_RESET

SDEC_INT

CPU11

CPU12

LCD_POWER

CDEC_INT

CPU15

LCD_CS

LCD_A0

LCD_SI

LCD_RESET

LCD_CLK

TXD1

RXD1

CRADLE

AM0

DVCC

X2

DVSS

X1

AM1

RESET

XT1

XT2

EMU0

EMU1

KEY INT1

JOG_A INT2

IR INT3

USB INT4

DAC_LE

DAC_CLK

DAC_RESET

DAC_DATA

ALE

AD0 - 15

A16

A17

DVSS

NMI

DVCC

A18

I/O

–

Analog reference voltage (ground)

–

Analog ground

–

Analog power supply

O

Tuner LE signal output

O

Buzzer control signal output

O

Power control signal output(CDEC,SDEC,ANT)(H:active)

O

Tuner power enable signal output (H:active)

O

CDEC and SDEC reset signal output

O

USB micom reset signal output

I

SDEC interrupt signal input

O

Not used (open)

O

Not used (open)

O

LCD power control signal output (L:off,H:on)

I

CDEC interrupt signal input

O

Not used (open)

O

LCD chip select signal output

O

LCD A0 signal output

O

LCD data signal output

O

LCD reset signal output

O

LCD clock signal output

O

For writing internal flash memory (open)

I

For writing internal flash memory (pull-down)

I

Not used

–

Operation mode setting input (pull-up)

–

Power supply

–

Connection for a crystal resonator (Main system clock)

–

Ground

–

Connection for a crystal resonator (Main system clock)

–

Operation mode setting input (pull-up)

I

System reset input

–

Connection for a crystal resonator (sub clock)

–

Connection for a crystal resonator (sub clock)

–

Not used (open)

–

Not used (open)

I

Key interrupt signal input

I

JOG A interrupt signal input

I

IR interrupt signal input

I

USB interrupt signal input from the USB micom

O

Strobe clock signal output to the DAC

O

Mode control signal output for BCKIN

O

DAC reset signal output

O

Mode control signal output for data

O

Address latch enable signal output

I/O

Address/data bus

O

Address bus

O

Address bus

–

Ground

I

Non-maskable interrupt input (pull-up)

–

Power supply

O

Address bus

Description

40

Page 41

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Pin No.

66

67

68

69

70

71

72

73

74

75 to 77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

A19

EEPROM-WP

EEPROM-SCK

EEPROM-SDA

TUNER-DATA

RD

WR

HWR(MUTE)

BACKLIGHT2

P34 - 36

P37

CS0(USBCS)

CS1(SRAMCS)

CS2(FLASHCS)

CS3(ROM_TEST_OUT)

SCK(BACKLIGHT)

SDA(CDEC,SDEC)

SCL(CDEC,SDEC)

INT0(VDET DC-IN)

INTERNAL_ROM

P65

DVCC

TUNER-CLK

DVSS

AN0(KEY-A/D1)

AN1(KEY-A/D2)

AN2(ANT_DET)

AN3

AN4(TUNER-LOCK)

AN5(VDET USB)

AN6

AN7(JOG-B)

VREFH

I/O

O

Address bus (Not used)

O

EEPROM write protect signal output

O

EEPROM serial clock signal output

I/O

EEPROM serial data signal input or output

O

Tuner data signal output

O

Read memory signal output

O

Write memory signal output

O

Muting control signal output

O

Backlight control signal output (H:bright,L:dim)

O

Not used (open)

O

Flash BOOT terminal (pull-up)

O

USB chip select signal output

O

SRAM chip select signal output

O

Flash memory chip select signal output

O

Internal ROM test out (Firmware update)

O

Backlight control signal output (H:active)

I/O

IIC data signal input or output

O

IIC clock signal output

I

Voltage detect signal input

I

Terminal for forced internal ROM mode (L:active)

O

Not used (open)

–

Power supply

O

Tuner clock signal output

–

Ground

I

Key input signal from the function key

I

Key input signal from the function key

I

Antenna signal detect input

I

Not used (pull-up)

I

Tuner lock detect signal input

I

VBUS voltage detect signal input (not used)

I

Not used (pull-up)

I

JOG B signal input

–

Analog reference voltage (connected to Vcc)

Description

41

Page 42

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

7-1. FRONT PANEL ASSEMBLY, LOWER PANEL ASSEMBLY

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

12

13

a

14

15

TU101

not

supplied

15

not

supplied

b

10

17

LCD301

d

9

11

16

c

20

21

19

9

18

8

7

6

5

FAN1

4

3

a

2

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-233-501-01 CABINET (LOWER)

2 1-823-236-11 CABLE (WITH CONNECTOR)

3 3-234-360-01 RING, FIXED

* 4 3-592-351-01 PAPER, VIBRATION PROOF (B)

5 3-235-910-01 PLATE (A), SHIELD

6 A-3021-590-A BB BOARD, COMPLETE

7 3-233-504-01 SHEET, INSULATION

8 3-235-911-01 TERMINAL, CONTACT

9 3-318-203-11 SCREW (1.7X6), TAPPING

10 3-363-895-11 SCREW (M1.7)

b

1

#1

d

UPPER CABINET ASSEMBLY

13 3-234-123-01 SHEET, ADHESIVE

14 X-3380-987-1 PANEL ASSY, FRONT

15 3-233-559-01 SPRING, COMPRESSION

16 3-233-488-01 BUTTON (DSPL)

17 1-682-679-11 IR BOARD

* 18 A-3062-637-A LCD BOARD, COMPLETE

* 19 3-009-156-01 SHEET, ADHESIVE

20 3-234-124-01 SHEET, REFLECTION

21 3-233-496-01 PLATE, LIGHT GUIDE

#1 7-685-535-14 SCREW +BTP 2.6X10 TYPE2 N-S

c

11 1-682-681-11 PWB, FLEXIBLE (30P)

12 3-233-486-01 PLATE, TRANSPARENT

42

FAN1 1-763-733-11 FAN, DC

LCD301 1-804-505-11 DISPLAY PANEL, LIQUID CRYSTAL

TU101 1-693-561-11 TUNER (XM SATELLITE RADIO)

Page 43

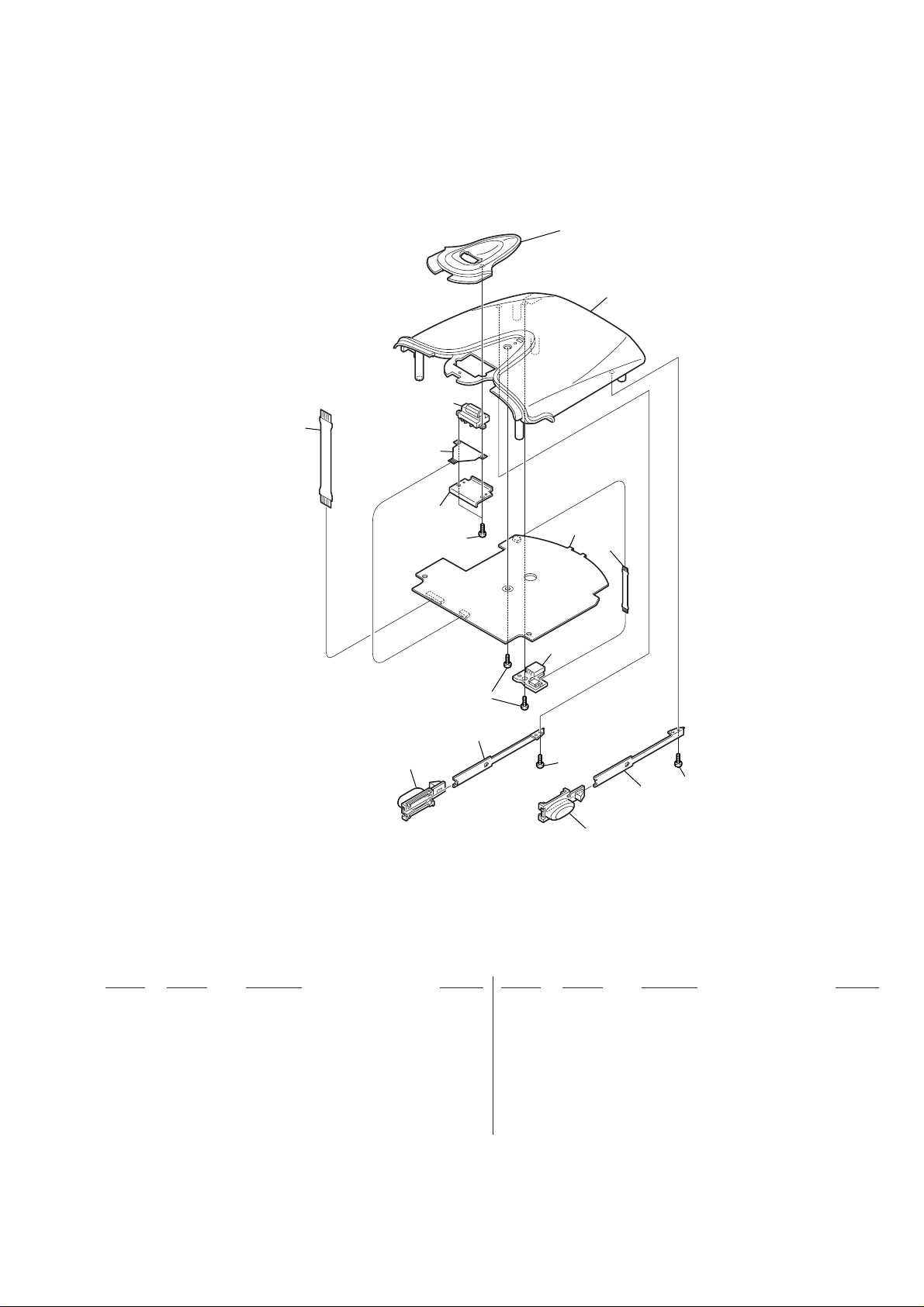

7-2. UPPER CABINET ASSEMBLY

63

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

65

64

62

61

52

60

55

56

54

57

55

59

51

58

53

55

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-233-498-01 BUTTON (RELEASE R)

52 3-233-497-01 BUTTON (RELEASE L)

53 3-233-567-01 SPRING (RELEASE R), LEAF

54 3-233-566-01 SPRING (RELEASE L), LEAF

55 3-309-597-31 SCREW (1.4), TAPPING,PRECISION

56 3-318-203-11 SCREW (1.7X6), TAPPING

* 57 1-682-678-11 USB BOARD

58 1-682-683-11 PWB, FLEXIBLE (USB)

59 A-3021-589-A CPU BOARD, COMPLETE

60 3-233-560-01 BRACKET (JOG)

61 1-682-682-11 PWB, FLEXIBLE (JOG)

62 1-476-762-41 ENCODER (ROTARY)

63 1-682-680-11 PWB, FLEXIBLE (20P)

64 3-233-500-01 CABINET (UPPER)

65 3-233-499-01 PANEL (JOG)

43

Page 44

DRN-XM01C/XM01R/

XM01H/XM01CK/XM01HK

BB

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

A-3021-590-A BB BOARD, COMPLETE

*******************

3-233-565-01 WASHER, SLIT

3-235-910-01 PLATE (A), SHIELD

ELECTRICAL PARTS LIST

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

SECTION 8

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

C120 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C121 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C122 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C123 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C124 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

< CAPACITOR >

C51 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C52 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C53 1-135-346-11 ELECT 39uF 20% 16V

C56 1-164-862-11 CERAMIC CHIP 33PF 5.00% 16V

C58 1-135-595-11 ELECT 100uF 20% 6.3V

C59 1-127-772-11 CERAMIC CHIP 33000PF 10% 10V

C61 1-135-346-11 ELECT 39uF 20% 16V

C63 1-164-862-11 CERAMIC CHIP 33PF 5.00% 16V

C65 1-135-595-11 ELECT 100uF 20% 6.3V

C66 1-127-772-11 CERAMIC CHIP 33000PF 10% 10V

C67 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C68 1-135-595-11 ELECT 100uF 20% 6.3V

C70 1-128-934-11 CERAMIC CHIP 0.33uF 20% 10V

C71 1-127-573-11 CERAMIC CHIP 1uF 10% 16V

C72 1-126-396-11 ELECT CHIP 47uF 20.00% 16V

C73 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C74 1-126-396-11 ELECT CHIP 47uF 20.00% 16V

C75 1-127-772-11 CERAMIC CHIP 33000PF 10% 10V

C76 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C77 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C78 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C79 1-127-772-11 CERAMIC CHIP 33000PF 10% 10V

C80 1-135-346-11 ELECT 39uF 20% 16V

C83 1-127-573-11 CERAMIC CHIP 1uF 10% 16V

C85 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C102 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C104 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C105 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C106 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C107 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C108 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C110 1-164-866-11 CERAMIC CHIP 47PF 5.00% 16V

C112 1-164-860-11 CERAMIC CHIP 27PF 5.00% 16V

C113 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C114 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C115 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C116 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C117 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C118 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C119 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C125 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C126 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C128 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C129 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C130 1-164-935-11 CERAMIC CHIP 470PF 10.00% 16V

C131 1-164-935-11 CERAMIC CHIP 470PF 10.00% 16V

C132 1-164-941-11 CERAMIC CHIP 0.0047uF 10.00% 16V

C133 1-162-977-11 CERAMIC CHIP 0.0018uF 10.00% 50V

C134 1-162-977-11 CERAMIC CHIP 0.0018uF 10.00% 50V

C135 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C136 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C137 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C138 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C139 1-164-866-11 CERAMIC CHIP 47PF 5.00% 16V

C141 1-164-866-11 CERAMIC CHIP 47PF 5.00% 16V

C143 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C144 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C145 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C146 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C148 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C149 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C150 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C151 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C152 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C153 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C154 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C155 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C156 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C157 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C158 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C159 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C160 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C161 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C162 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C163 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C164 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C165 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C166 1-126-412-11 ELECT CHIP 220uF 20.00% 4V

C167 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C168 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

44

Page 45

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

BB

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C169 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C170 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C171 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C172 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C173 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C229 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C230 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C231 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C232 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C233 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C174 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C175 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C176 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C177 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C178 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C179 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C180 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C181 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C182 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C183 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C184 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C185 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C186 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C187 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C188 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C189 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C190 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C191 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C192 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C193 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C194 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C195 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C196 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C197 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C198 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C234 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C235 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C236 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C237 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C238 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C239 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C240 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C241 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C242 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C265 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C266 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C267 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C268 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C272 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C273 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C274 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C275 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C276 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C277 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C278 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C279 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C280 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C281 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C282 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C283 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C199 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C200 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C201 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C202 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C203 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C204 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C205 1-164-943-11 CERAMIC CHIP 0.01uF 10.00% 16V

C206 1-164-874-11 CERAMIC CHIP 100PF 5.00% 16V

C207 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C208 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C209 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C210 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C211 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C212 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C213 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C214 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C215 1-164-866-11 CERAMIC CHIP 47PF 5.00% 16V

C216 1-164-866-11 CERAMIC CHIP 47PF 5.00% 16V

C217 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C218 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C219 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C220 1-164-937-11 CERAMIC CHIP 0.001uF 10.00% 16V

C221 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C222 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C223 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C224 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C225 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C226 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C227 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C228 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

C701 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C702 1-164-858-11 CERAMIC CHIP 22PF 5.00% 16V

C703 1-164-858-11 CERAMIC CHIP 22PF 5.00% 16V

C704 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C705 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C706 1-125-777-11 CERAMIC CHIP 0.1uF 10.00% 10V

C707 1-127-760-11 CERAMIC CHIP 4.7uF 10% 6.3V

< CONNECTOR >

CN101 1-815-863-11 CONNECTOR (FEMALE)

CN102 1-778-544-11 CONNECTOR, FFC/FPC (ZIF) 30P

* CN104 1-565-135-11 PIN, CONNECTOR (STRAIGHT) 2P

< DIODE >

D51 8-719-066-33 DIODE RB081L-20TE25

D52 8-719-066-16 DIODE RB491D-T146

D53 8-719-071-34 DIODE RB521S-30-TE61

D54 8-719-071-34 DIODE RB521S-30-TE61

D55 8-719-071-34 DIODE RB521S-30-TE61

D56 8-719-071-34 DIODE RB521S-30-TE61

D57 8-719-071-34 DIODE RB521S-30-TE61

D101 8-719-421-27 DIODE MA728-TX

D102 8-719-066-16 DIODE RB491D-T146

D106 8-719-056-61 DIODE MAZS082008SO

D111 8-719-056-61 DIODE MAZS082008SO

D112 8-719-056-61 DIODE MAZS082008SO

D113 8-719-421-27 DIODE MA728-TX

D114 8-719-074-67 DIODE EDZ-TE61-5.6B

D115 8-719-074-67 DIODE EDZ-TE61-5.6B

45

Page 46

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

Ver 1.2 2002.11

BB

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

D116 8-719-074-67 DIODE EDZ-TE61-5.6B

D117 8-71 9-074-67 DIODE EDZ-TE61-5.6B

D118 8-719-074-67 DIODE EDZ-TE61-5.6B

D119 8-719-074-67 DIODE EDZ-TE61-5.6B

D120 8-719-074-67 DIODE EDZ-TE61-5.6B

LF103 1-411-957-11 FILTER, COMMON MODE

< LINE FILTER >

< TRANSISTOR >

D121 8-719-074-67 DIODE EDZ-TE61-5.6B

D122 8-719-074-67 DIODE EDZ-TE61-5.6B

D123 8-719-074-67 DIODE EDZ-TE61-5.6B

D124 8-719-074-67 DIODE EDZ-TE61-5.6B

D125 8-719-056-61 DIODE MAZS082008SO

D126 8-719-421-27 DIODE MA728-TX

D151 8-719-074-67 DIODE EDZ-TE61-5.6B

D152 8-719-074-67 DIODE EDZ-TE61-5.6B

D153 8-719-074-67 DIODE EDZ-TE61-5.6B

D154 8-719-074-67 DIODE EDZ-TE61-5.6B

D155 8-719-074-67 DIODE EDZ-TE61-5.6B

< FERRITE BEAD >

FB101 1-469-084-21 FERRITE 1MH

FB102 1-469-084-21 FERRITE 1MH

FB108 1-469-084-21 FERRITE 1MH

FB109 1-469-084-21 FERRITE 1MH

FB110 1-469-084-21 FERRITE 1MH

< IC RINK >

FU3 1-533-397-11 RINK, CHIP IC

FU4 1-533-808-11 RINK, CHIP IC

< IC >

Q51 8-729-051-47 TRANSISTOR XP162A12A6PR

Q52 8-729-051-47 TRANSISTOR XP162A12A6PR

Q53 8-729-807-34 TRANSISTOR 2SB766A-R-TX

Q55 8-729-037-52 TRANSISTOR 2SD2216J-QR(TX).SO

Q101 8-729-230-60 TRANSISTOR 2SA1586YG-TE85L

Q102 8-729-037-74 TRANSISTOR UN9213J-(TX).SO

Q103 8-729-037-61 TRANSISTOR UN9113J-(TX).SO

Q104 8-729-013-37 TRANSISTOR 2SC4213-AB-TE85L

Q105 8-729-013-37 TRANSISTOR 2SC4213-AB-TE85L

Q106 8-729-807-34 TRANSISTOR 2SB766A-R-TX

Q108 8-729-037-52 TRANSISTOR 2SD2216J-QR(TX).SO

Q109 8-729-037-52 TRANSISTOR 2SD2216J-QR(TX).SO

< RESISTOR >

R52 1-208-947-11 METAL CHIP 330K 0.5% 1/16W

R53 1-208-943-11 METAL CHIP 220K 0.5% 1/16W

R54 1-218-985-11 RES-CHIP 470K 5% 1/16W

R55 1-218-989-11 RES-CHIP 1M 5% 1/16W

R56 1-208-670-11 METAL CHIP 300K 0.5% 1/16W

R57 1-208-935-11 METAL CHIP 100K 0.5% 1/16W

R58 1-218-983-11 RES-CHIP 330K 5% 1/16W

R59 1-218-989-11 RES-CHIP 1M 5% 1/16W

R60 1-218-965-11 RES-CHIP 10K 5% 1/16W

R61 1-218-990-11 SHORT 0

IC50 8-759-578-53 IC XC6365D103MR

IC51 8-759-578-53 IC XC6365D103MR

IC52 8-759-598-20 IC R1121N501B-TR

IC53 8-759-574-57 IC RN5RF33AA-TR

IC54 8-759-598-17 IC R1121N251B-TR

IC101 6-700-974-01 IC STA400

✩ IC102 ---------------- IC STA450

✩ IC103 ---------------- IC ST19AF08BR20QMAA

IC104 6-700-840-01 IC uPD45128841G5-A80-9JF

IC106 8-759-464-81 IC PCM1717E-ST2

IC107 8-759-662-11 IC TLV2362IPWR

IC701 6-700-838-01 IC AD8131ARM-REEL7

< COIL >

L51 1-416-669-11 INDUCTOR 22uH

L52 1-416-670-11 INDUCTOR 33uH

L53 1-414-398-11 INDUCTOR 10uH

L54 1-414-392-21 INDUCTOR 1uH

L55 1-414-398-11 INDUCTOR 10uH

L57 1-414-398-11 INDUCTOR 10uH

L59 1-414-398-11 INDUCTOR 10uH

L101 1-414-398-11 INDUCTOR 10uH

L102 1-414-398-11 INDUCTOR 10uH

L103 1-414-392-21 INDUCTOR 1uH

L104 1-414-392-21 INDUCTOR 1uH

L105 1-414-398-11 INDUCTOR 10uH

L108 1-414-392-21 INDUCTOR 1uH

✩ When IC102 and/or IC103 is damaged,

replace the BB board.

R62 1-218-989-11 RES-CHIP 1M 5% 1/16W

R63 1-218-977-11 RES-CHIP 100K 5% 1/16W

R64 1-218-977-11 RES-CHIP 100K 5% 1/16W

R67 1-218-977-11 RES-CHIP 100K 5% 1/16W

R101 1-218-953-11 RES-CHIP 1K 5% 1/16W

R102 1-218-953-11 RES-CHIP 1K 5% 1/16W

R103 1-218-953-11 RES-CHIP 1K 5% 1/16W

R104 1-218-953-11 RES-CHIP 1K 5% 1/16W

R107 1-218-935-11 RES-CHIP 33 5% 1/16W

R108 1-218-935-11 RES-CHIP 33 5% 1/16W

R109 1-218-953-11 RES-CHIP 1K 5% 1/16W

R110 1-218-953-11 RES-CHIP 1K 5% 1/16W

R111 1-220-212-11 RES-CHIP 300K 5% 1/16W

R112 1-220-212-11 RES-CHIP 300K 5% 1/16W

R113 1-218-959-11 RES-CHIP 3.3K 5% 1/16W

R114 1-218-962-11 RES-CHIP 5.6K 5% 1/16W

R115 1-218-959-11 RES-CHIP 3.3K 5% 1/16W

R116 1-218-962-11 RES-CHIP 5.6K 5% 1/16W

R117 1-218-969-11 RES-CHIP 22K 5% 1/16W

R118 1-218-969-11 RES-CHIP 22K 5% 1/16W

R119 1-208-643-11 RES-CHIP 22 5% 1/16W

R121 1-218-941-11 RES-CHIP 100 5% 1/16W

R124 1-218-953-11 RES-CHIP 1K 5% 1/16W

R125 1-218-953-11 RES-CHIP 1K 5% 1/16W

R126 1-218-990-11 SHORT 0

R127 1-218-990-11 SHORT 0

R128 1-218-990-11 SHORT 0

R131 1-208-643-11 RES-CHIP 22 5% 1/16W

R135 1-218-977-11 RES-CHIP 100K 5% 1/16W

R136 1-208-643-11 RES-CHIP 22 5% 1/16W

46

Page 47

DRN-XM01C/XM01R/XM01H/

XM01CK/XM01HK

BB

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R137 1-208-643-11 RES-CHIP 22 5% 1/16W

R138 1-218-965-11 RES-CHIP 10K 5% 1/16W

R139 1-218-965-11 RES-CHIP 10K 5% 1/16W

R140 1-218-965-11 RES-CHIP 10K 5% 1/16W

R141 1-208-643-11 RES-CHIP 22 5% 1/16W

R198 1-218-937-11 RES-CHIP 47 5% 1/16W

R201 1-218-941-11 RES-CHIP 100 5% 1/16W

R202 1-218-941-11 RES-CHIP 100 5% 1/16W

R203 1-218-941-11 RES-CHIP 100 5% 1/16W

R204 1-218-941-11 RES-CHIP 100 5% 1/16W