Page 1

SERVICE MANUALSERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Magellan IIMagellan II

Magellan II

Magellan IIMagellan II

CHASSISCHASSIS

CHASSIS

CHASSISCHASSIS

MODEL

VTX-D800UVTX-D800U

VTX-D800U

VTX-D800UVTX-D800U

VTX-D800NVTX-D800N

VTX-D800N

VTX-D800NVTX-D800N

VTX-D800EVTX-D800E

VTX-D800E

VTX-D800EVTX-D800E

COMMANDER DEST

RM-X800 UK

RM-X800 FINLAND/SWEDEN

RM-X800 ESP

DIGITAL RECEIVER

Service Manual

- 1 -

Page 2

TABLE OF CONTENTS

Safety Warning. .................... 3

Tools Required. .................... 3

1 Dissassembly .................... 4

1.1 Cover Removal. .................... 4

1.2 Front Panel Removal. .................... 4

1.3 B Board Removal. .................... 5

1.4 Chassis Removal. .................... 5

2 Service Mode [TT Mode] .................... 6

2.1 Special Key Sequence .................... 6

2.2 Special Remote Commander Data Code .................... 6

2.3 Exiting TT Mode .................... 6

3 Entering the TT Command Number .................... 7

3.1 Cancelling a Command Entry .................... 7

3.2 Example .................... 7

4 List of TT Commands .................... 8

5 Power Supply .................... 11

5.1 Power Supply Detailed Description .................... 12

6 Technical Specifications . .................... 15

7 Device descriptions. .................... 19

8 Diagrams

8.1 Block Diagram. .................... 21

8.2 B board PWB layout. .................... 22

8.3 B board circuit diagram.

8.3.1 Multimedia Processor & Clock Generator .................... 23

8.3.2 Front Panel & Reset .................... 24

8.3.3 Power Supply .................... 25

8.3.4 Audio DAC & Smartlink Switch .................... 26

8.3.5 AV Switch & SCART .................... 27

8.3.6 Tuner NIM .................... 28

9 Exploded View . .................... 29

10 Electrical Parts List. .................... 30

Service Manual

- 2 -

Page 3

Safety Warning

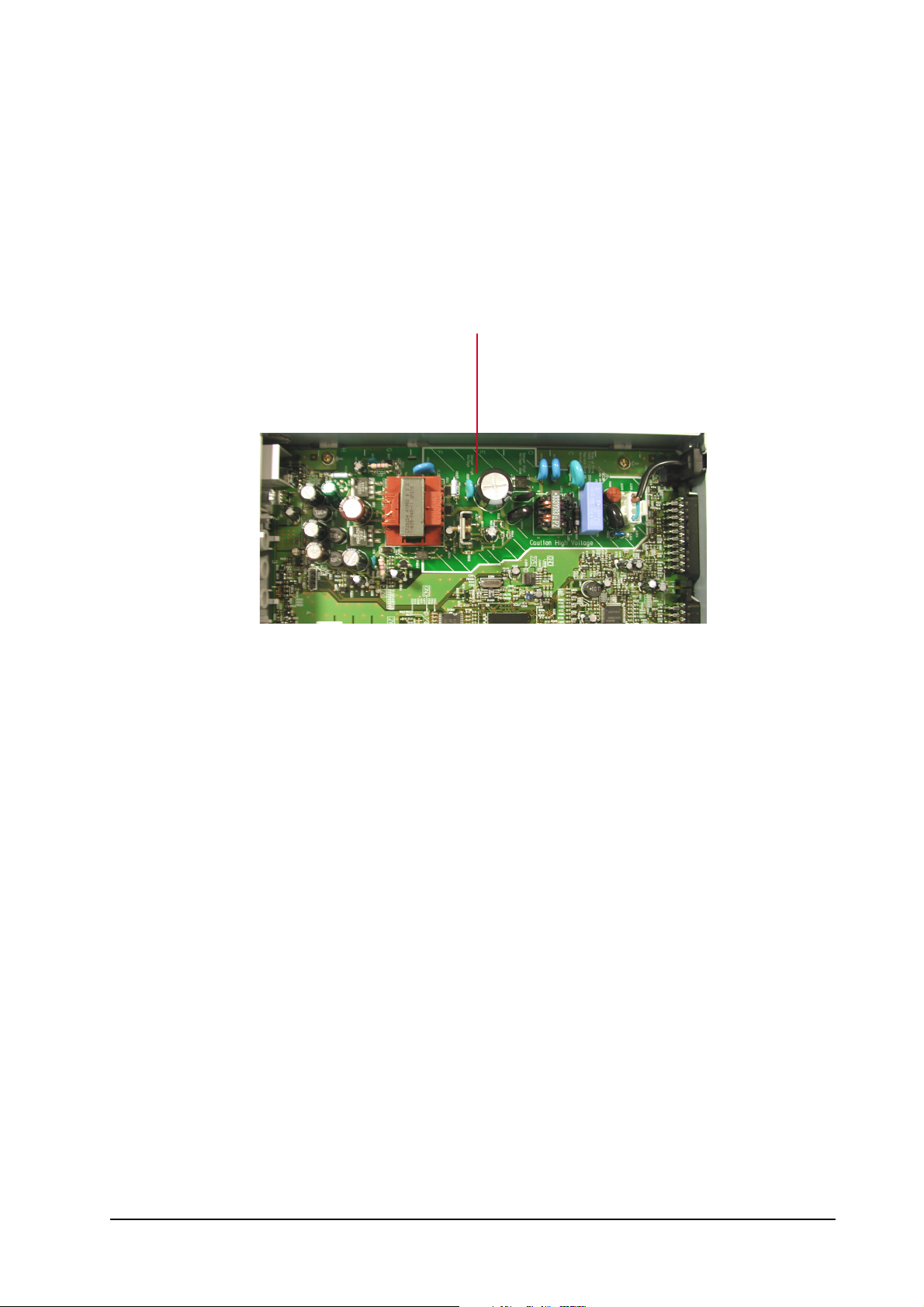

Dangerously high voltages exist on the Power Supply Unit (PSU) PWB (See Fig 1).

FOR THIS REASON, THE RECEIVER MUST ALWAYS BE DISCONNECTED FROM THE MAINS SUPPLY

BEFORE ANY WORK DETAILED IN THIS MANUAL IS CARRIED OUT.

Caution High Voltage

Fig. 1

CAUTION !!!

Anti-static precautions should be taken when handling the PWB. Once removed from its fixings, the PWB can

become flexible. Care should be taken to avoid damage to the PWB or components.

All fixings must be replaced correctly for correct performance and continued safety compliance.

Tools Required

Philips Screwdriver

Service Manual

- 3 -

Page 4

1 Dissassembly

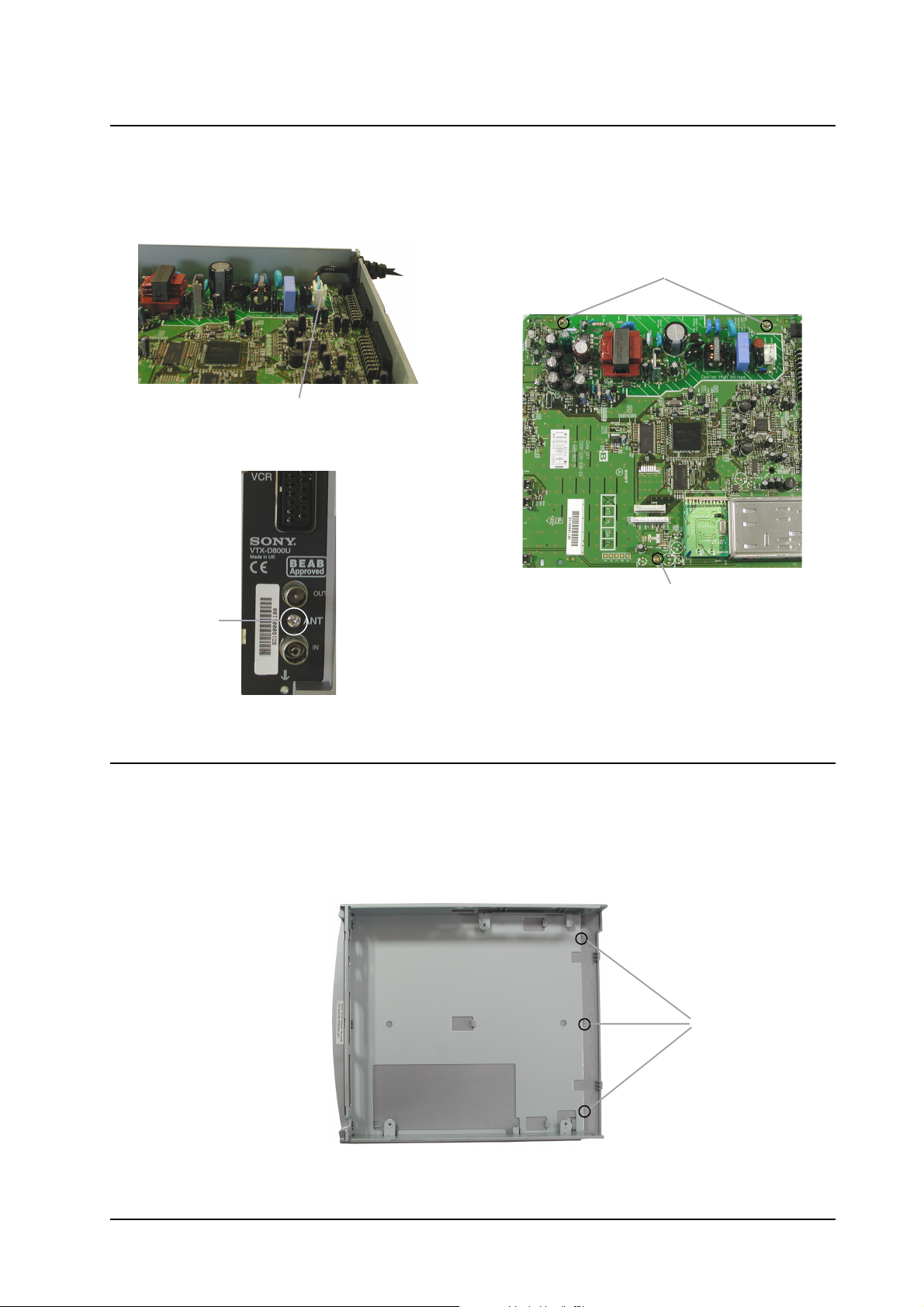

1.1 Cover Removal

Remove the foot by releasing the clips circled and easing the foot carefully away from the unit. Remove the 2

screws located at the rear of the unit (shown arrowed). Lift the front of the cover slightly and slide towards the rear

of the unit until it is clear. Reassembly is the reversal of removal.

==>

Lift cover

gently at this

point.

==>

==>

1.2 Front Panel Removal

Remove the cover as indicated above. Carefully unhook the front panel locating clips from the chassis, pull the

front panel gently forward and lift clear.

Service Manual

Clip located

on both sides

of Front panel

- 4 -

Page 5

[ 1.3 ] B Board Removal

Remove the cover and front panel as indicated in [1-1] and [1-2]. Disconnect CN600 power cord and remove from

unit. Remove the 1 Philips screw from the rear panel. Remove the 3 Philips screws from the circuit booard. The B

board can then be lifted clear of the chassis.

Screw

CN600

==>

==>

==>

Screws

==>

Screw

[ 1.4 ] Chassis Removal

To remove, lift the front of the chassis slightly to clear the stops and slide forward out of the bottom cover.

Stops

Service Manual

- 5 -

Page 6

2 Service Mode [TT mode]

There are 2 possible mechanisms for starting TT mode on Sony cook STB’s…

2.1 Special key sequence

The following key sequence entered via the standard remote commander for a particular STB can enable TT

mode. This sequence must be entered…

(1) In full, with no deviation from the sequence from first to last.

(2) With the STB in Standby mode at the start of the sequence.

=>

Should the STB be in active standby at any time (i.e. during software upgrade) it shall not be possible to enter

TT mode.

=>

2.2 Special remote commander data code

It is considered that the sequence described in section 2.1 above is too complex for automated machinery to

enter reliably without the possibility to confuse the state of the STB, therefore in order to aid manufacture the

SIRCS standard defines that in each remote control category the data code ‘1111111’ (0x7f) shall be reserved

and can be used to enter test mode.

For Cook STB products this SIRCS code shall enter TT mode and is valid in the following conditions…

(1) If the unit is in standby. At which point the STB will come out of standby

(2) When the unit is not is standby and there is no menu displayed

(3) When the unit is not tuning (automatically or manual)

(4) Then the unit is not displaying interactive services

The category code is different between each equipment type (DTT, etc) and the correct category code

must be received according to the equipment type.

The test code shall not be made available on any consumer remote commander equipment.

2.3 Exiting TT mode

Sequence number Key

1 DIGIT 1

2 DIGIT 9

3 LEFT CURSOR

4 BLUE

=>

TT mode can be exited using one of the following mechanisms…

(1) Removing the power to the STB

(2) Placing the STB into Standby mode

(3) Entering the command ‘0’

After TT mode is exited any changes to the state of the box will still be effective. It is better to force a box

reset post-TT mode.

Service Manual

- 6 -

4

Page 7

3 Entering the TT command number

The TT number is entered using the standard digit keys using the category defined for the STB type. Category

codes for equipment types other than this STB’s type must be rejected.

Depending on the type of equipment the number of digits available for commands will vary. Leading zero can

be omitted. If the full compliment of digits is not entered a 3 second time -out period will be required to elapse

before the command is activated. Automated entry mechanisms such as those used during manufacturing

should enter the full compliment of digits in order to avoid the STB and controller getting out of sync.

The following are defined digit lengths for current planned models…

Model Number of digits

VTX-D800U 3

VTX-D800E 3

VTX-D800N 3

3.1 Cancelling a command entry

Entering a ‘0’ digit after any other digit entry (thus making the command a multiple of 10) will immediately

reset the display and perform no action.

3.2 Example

VTX-D800U requires 3 digits. Therefore the following sequences would be valid to issue a test command…

Sequence Result

0 ⇒ 1 ⇒ 4

1 ⇒ 4 ⇒ Timeout after 3 seconds

1 ⇒ 0

0 ⇒ Timeout after 3 seconds

0 ⇒ 0 ⇒ 0

Executes command 14

Executes command 14

Does not execute any command (cancels input)

Cancels TT mode

Cancels TT mode

Service Manual

- 7 -

Page 8

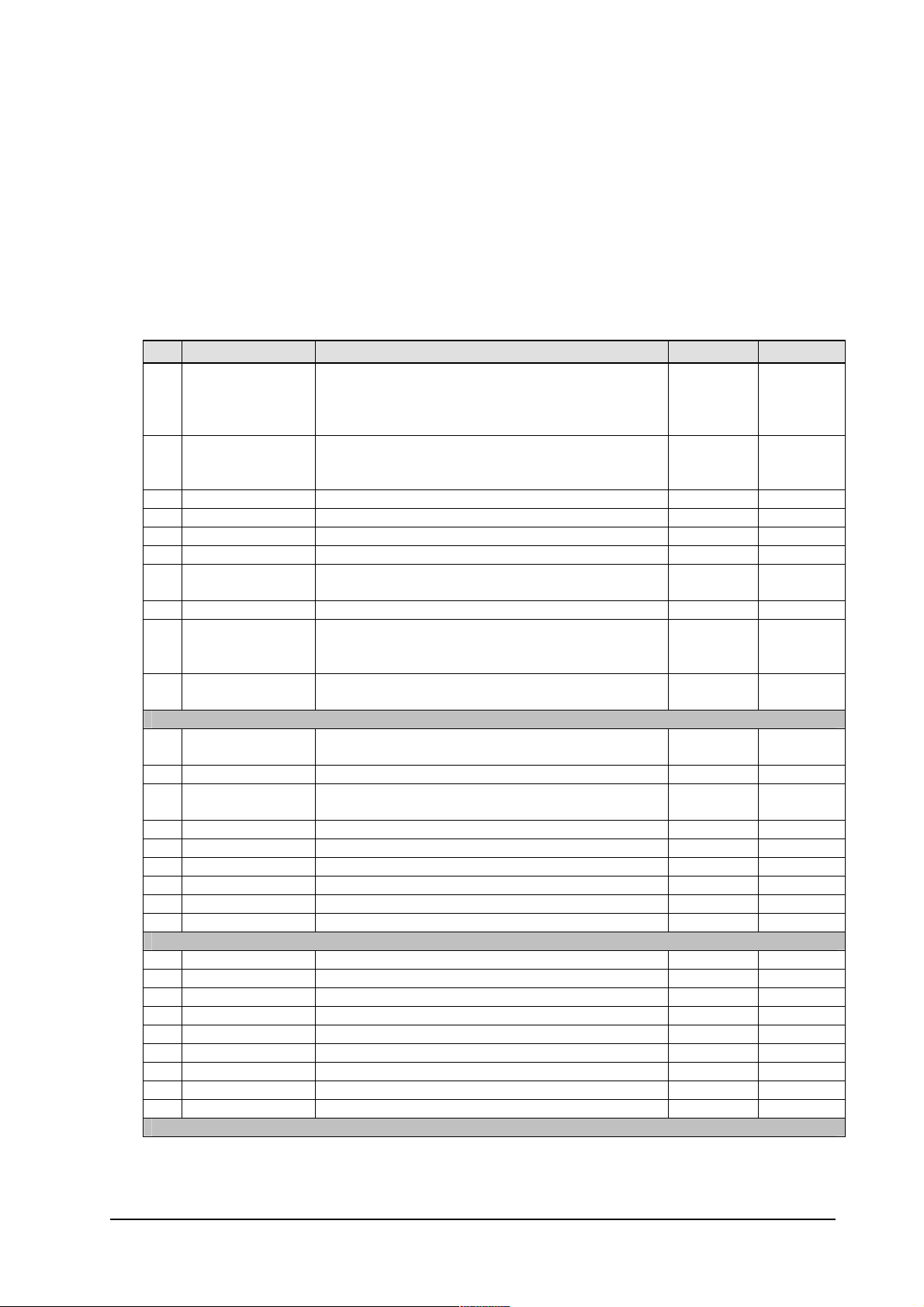

4 List of TT commands

Depending on the STB model the number of digits which are capable of being entered will vary, therefore any

leading zero have been omitted from the TT number defined in the list. Entries should be made according to

the description in section 3.

All commands ending in zero (ie. 0, 10, 20, 30, 40) etc reset the display, cancelling partially entered

commands.

All settings, except those marked “Permanent”, are reset after a power cycle.

TT Name Description Permanent Supported

0 Revert to normal Stops TT mode and returns the STB to normal active

mode.

It does not necessarily revert to the mode of

operation prior to TT mode being entered.

1 STB reset Force the box to reset

This resets the state of the box to just powered on.

STB will power on in standby mode.

2

3

4

5

6 Factory reset &

reboot

7 Factory reset Reset all settings to defaults (shipping) Yes

8 Shipping default

& reboot

9 Shipping default Set the box to shipping condition

SCART/AV

11 Colour bar ON Enable colour bar output on TV & VCR SCART

12 Colour bar OFF Disable colour bar output on TV & VCR SCARTS

13 Smart link test Sends a sequence of commands to the AV link bus.

14 Scart control off Sets pin 8 on all SCART sockets to 0V No

15 Scart control 16:9 Sets pin 8 on all SCART sockets to 16:9 level No

16 Scart control 4:3 Sets pin 8 on all SCART sockets to 4:3 level No

17

18

19

21

22

23

24

25

26

27

28

29

Common interface

Reset all settings to defaults (shipping)

Reboot

Set the box to shipping condition

Tune database is cleared

Reboot - Start-up menu will be activated

Tune database is cleared

When colour bar is enabled the OSD cannot be seen.

Appendix A shows the sequence sent.

Yes

Yes

Yes

No

Service Manual

- 8 -

Page 9

31 Slot 0 bypass Transport stream is set to bypass slot 0.

This command is effective only when there is no CAM

inserted into slot 0.

32 Slot 0 pass thru Transport stream is set to pass out/in slot 0.

This command is effective only when there is no DVB

compliant CAM inserted into slot 0.

If there is no output/input device then the demux will

not receive a valid transport stream.

33 Slot 1 bypass Transport stream is set to bypass slot 1.

This command is effective only when there is no CAM

inserted into slot 1.

34 Slot 1 pass thru Transport stream is set to pass out/in slot 1.

This command is effective only when there is no DVB

compliant CAM inserted into slot 1.

If there is no output/input device then the demux will

not receive a valid transport stream.

35

36

37

38

39

Software upgrade

41 Upgrade Serial Forces a software upgrade from the serial port

STB will reset after loading & TT mode will be

cancelled

Yes

42 Upgrade Ethernet Forces a software upgrade from the Ethernet port (if

available)

STB will reset after loading & TT mode will be

cancelled

Yes No

43 Upgrade off-air Forces a software upgrade from the current service

A change of service, satellite, etc will be done as

required.

STB will reset after loading & TT mode will be

cancelled

Yes

44 Upgrade Memory

stick

Forces a software upgrade from the Memory stick (if

available)

STB will reset after loading & TT mode will be

cancelled

Yes

45

46

47

48

49 Allow downgrade On next SW update, update the software even if the

version is older than, or the same as, the current

version

Yes

Screen control

51

52

53

54

55

56

57

58

59

I/O

61 LED OFF Sets all LED’s Off

Service Manual

- 9 -

Page 10

62 LED ON 1 Sets all LED’s as Colour 1 (Red)

If bicolour LED and Colour 2 ON, it will be Orange

63 LED ON 2 Sets all LED’s as Colour 2 (Green)

If bicolour LED and Colour 1 ON, it will be Orange

64

65

66

67

68

69

Tuner

71 Show tuner status Shows the tuner status display on the OSD

72 Clear tune info Erase the tune database

Sets all channels to an un-tuned state

Yes

73

74

75

76

77

78

79

81

82

83

84

85

86

87

88

89

91

92

93

94

95

96

97

98

99

Service Manual

- 10 -

Page 11

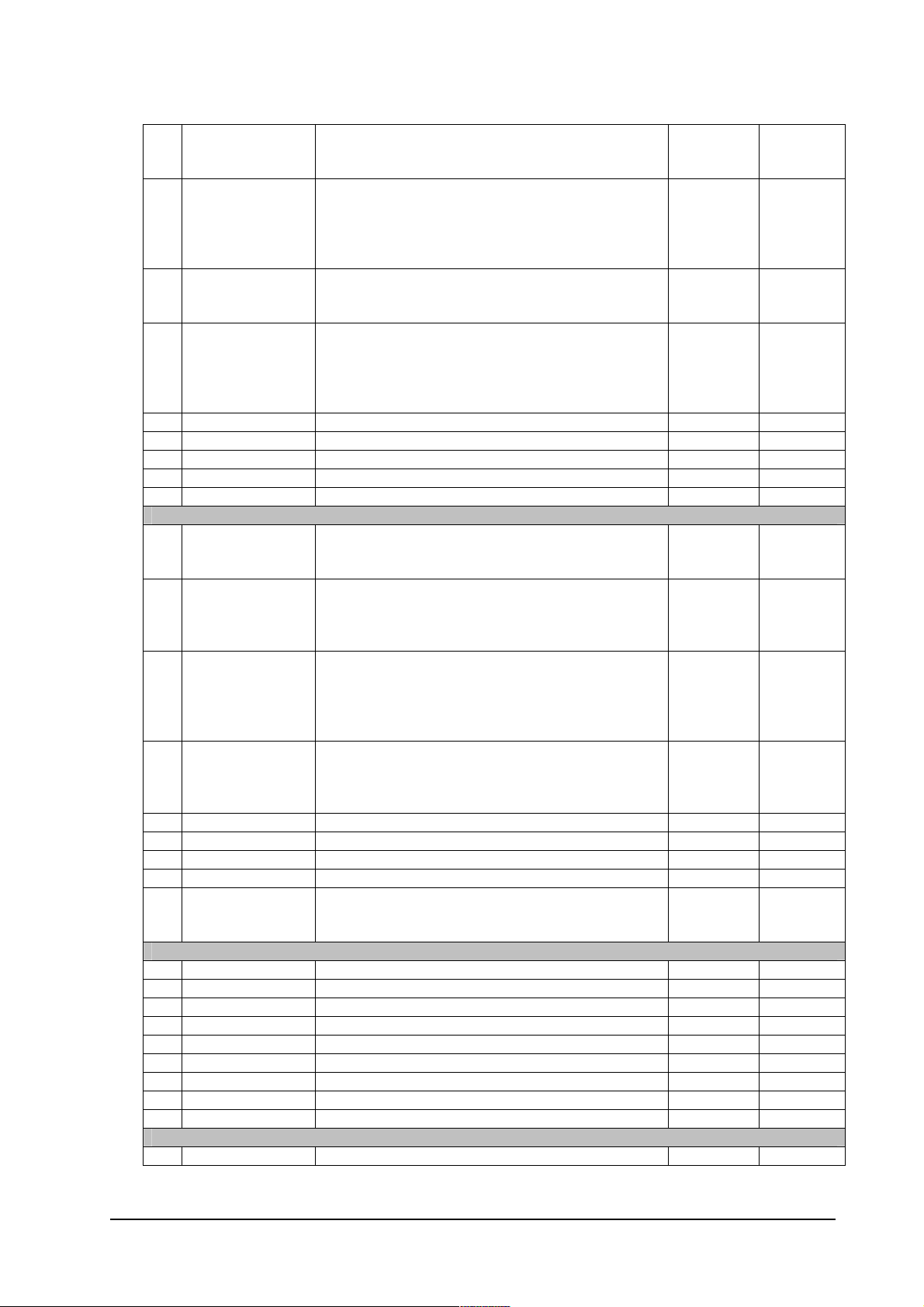

5.0: Power supply

A

The power supply in an integrated part of the Main PWB, and contains the following functional blocks: -

The main components are:-

1. Mains Plug, Lead and input filter

2. Primary and PWM Controller

3. Transformer and outputs

4. Feedback Circuit

5. Post Regulation Circuits.

Input

Filter

Primary &

Transformer

32.5V Output

Controller

+5V

udio

Feedback Circuit

21V Output

5V Output

3.3V Output

+12V

2V5

1V5

The output of this power supply can be measured at the following positions on the PWB, and should be within the

tolerances for each of the supply rails (marked on the PWB):-

Label / Rail JL Position Vnom Vmin Vmax

33v J1 33 30 35

12v G3 12 11.4 12.6

5v J2 5 4.75 5.25

3v3 J3 3.3 3.14 3.46

2v5 F4 2.5 2.3 2.7

1v5 D3 1.5 1.43 1.57

Service Manual

- 11 -

Page 12

5.1: Power Supply Detailed Description

The most common failures will be fixed by replacing the following components.

PRIMARY BLAST KIT:- F600, D600, D602 D601, IC600, PH600, IC602, D604.

The components detailed below have the following functions:

Fuse, F600. T1.25A 250V

Always replace the fuse, with the same type and ratings as the one removed.

The fuse will fail if the following occurs:

1. A Primary component fails

2. The input circuit was over stressed

3. or both.

When the fuse fails check the following components: VDR600, C600, L602, D600, D602 D601, IC600.

If all the components look and measure OK, then replace the fuse and apply power, most probable cause is that the

VDR clamped a mains surge and caused the fuse to fail.

If any of the components have failed, then replace as necessary.

VDR600, 620V Metal Oxide Varistor

If this component has failed then the unit has seen a massive mains voltage surge, probably from Lightening or

similar phenomenon. Replace the following components:-

F600

VDR600

C600

L602

If the primary circuit has been damaged in any other way, replace the components as necessary.

If the unit is exposed to a massive mains surge then the feedback components may have been damaged. Also

Check PH600, IC602, D604.

D600 Bridge Rectifier

It is common for bridge rectifier to fail under repetitive mains surge conditions. Check the value of the TH601, if

it is lower than 10 Ohms replace it. TH601 is there to protect the bridge rectifier.

Before you apply power after changing D600 check the other primary parts, if D600 failed F600 should be open

and often the primary blast kit will need to be changed.

IC600 Primary Controller

This IC houses the primary MOSFET and the PWM controller. Check the DRAIN SOURCE characteristic to see if

it’s failed. Often when IC600 fails there are signs of damage to the package. In most cases this will fail short. In

some rare cases the part will fail open. If IC600 fails the primary blast kit needs to be replaced.

D601 Flyback Diode

This diode catches the transformers flyback voltage, and pushes the energy into the snubber circuit. This circuit

will often fail as a result of IC600 failing.

If damaged primary replace the blast kit.

Service Manual

- 12 -

Page 13

D602 Catch Diode

The catch diode is in place to help limit the excess voltage to the MOSFET to guarantee the parts ratings. If the

STB is victim to high mains this part is the first to fail trying to protect IC600.

If damaged primary replace the blast kit.

Healthy Drain Voltage on IC600

On a normal scope, it is normal to see a 4KHz jitter on the drain waveform. This is a feature of the PWM IC for

reducing EMI.

Service Manual

- 13 -

Page 14

Secondary Operation

The secondary outputs from the transformer will all rise at the same time, 3.3V reach its regulation point first

followed by 5.0V, +21V and 32V.

If the LED is flashing about once every second then a transformer output is shorted to GND or overloaded.

Remove FB610 (33V)

Remove FB607 (+5V)

Remove FB605 (+3V3)

Remove FB608 (+21V)

Once the FB’s are removed check to see if the PSU is stable. The primary waveform will not look ideal as the

previous figure, because the PSU is lightly loaded.

However, the output voltages should be there and stable, if not, check the Feedback loop and primary again.

Service Manual

- 14 -

Page 15

6. Technical Specifications for the SONY Cook (FTA DTT) IRD

• Receiver Type DVB Terrestrial Receiver Decoder

• Inputs

RF input 1 x RF input from customer antenna 75Ω

termination

Modulation DVB-T (OFDM)

Input Frequency 470 MHz - 862MHz (CH 21 to 69)

Bandwidth 8 MHz

Symbol Rate <1.5 to 15 Msymbol / Sec

Input Level (BER) QPSK = 2/3 –91.7dBm

VTX-D800U QAM 16/64 -82.8 dBm

VTX-D800E, VTX-D800N QAM 8/16/64 -82.8 dBm

Return Loss > 8dB

Loop-through Loss +3dB power On /StBy

( Loop through is not supported in Power off state)

• Outputs

Video Outputs 2 x SCART Sockets (EN50049-1)

TV - RGB/YC/CVBS + Stereo/Mono

Audio + Slow & Fast Blanking out.

(CVBS + Stereo Audio in)

SmartLink supported on this SCART only

VCR - CVBS + Stereo/Mono Audio out.

(CVBS + Stereo Audio

+ Slow Blanking in)

(CVBS = 1Vpk/pk @75Ohm, Audio In =

500mV @>10Kohm)

Audio Output (Analogue) 1 x Line level output <O/P of VCR

Service Manual

Scart> (1Vrms, < 470 Ohm) – supplied through

Standard 3 pin Jack connector (3.5mm combination

Connector).

-15 -

Page 16

Audio Output (Digital) Optical output :- (Digital PCM output) (Complies

with IEC958 Consumer Mode )

1 x (3.5mm Jack type) – as part of 3.5mm

Combination Connector.

RF Outputs 1 x RF Male Connector, (looped through

DTT Tuner )

Maximum RF loss = < 9dBm

• Signal Processing

Descrambler DVB Common Scrambling

Demultiplexer MPEG2, ISO / IEC 13818-1

Video Decoder MPEG2 MP@ML up to 15Mbps / ETR154

Audio Decoder MPEG1 Layer 1&2 (32, 44.1, 48 KHz Sampling)

ETR154

• CPU/Memory Configuration (expandable as option)

Multimedia CPU DTV Processor / Decoder, NEC EMMA2(Light)

Family (UPD 61120F1-100-JN1) non Macro Vision

MM CPU Main Memory 1x 128Mbit DDR SDRAM (option for 256Mbit)

1 x 64Mbit NAND Flash (option for 128 Mbit)

• Graphics Capability

Bitmap ARGB 8888

Resolution 720 x 576

• Software

Operating System Nucleus +

Service Manual

-16 -

Page 17

User interface Physical (located on the front panel) :-

2 x Channel buttons (Tactile µSwitches)

1 x Standby / On (Tactile µSwitch)

1 x Standby / On Indicator LED (Red / Green)

Software :-

Sony design GUI, based on Sony IDTV#2 DLI

• Remote IR control Sony SIRCs system :-

Commander CAT code = 0x1B7

• PSU Specifications Requirements :-

Input supply = 176 to 264 VAC @ 48 to 52Hz

Output supply :-

33V

12V

5V

3.3V

2.5V

Tuner

AV-Switch

Tuner

AV-Switch

Tuner

Emma2L

Flash

LED & IR

Spdiff

Clock Circuit

Audio DAC

Siel Tuner

SDRAM

Emma2L

Vmin Vnom Vmax I-Mi n I-Nom Imax

30 33 35 1 1.5

11.4 12 12.6 30 55

4.75 5 5.25 200 300

4.75 5 5.25 60 85

3.15 3.3 3.45 70 200

3.14 3.3 3.46 22 100

3.15 3.3 3.45 30 90

3.15 3.3 3.45 30 40

3.15 3.3 3.45 8 12

3.15 3.3 3.45 7 12

33.35.5 22 30

2.3 2.5 2.7 210 300

2.3 2.5 2.7 130 263

2.3 2.5 2.7 12 50

1.5V

Service Manual

Emma2L

1.43 1.5 1.57 560 900

-17 -

Page 18

Accessories 1 x User Manual – English

1 x SCART Lead

1 x RF loop through Cable

1 x Remote Control Unit (RM-X800)

2 x Batteries (AA)

4 x Unit rubber feet

• Dimensions (Unit ) 215 x 48 x 240 mm

• Dimensions (Carton Box) 401 x 295 x 188 mm

• Weight 4Kg (Boxed), Unit = ~1.5Kg

• Mains Power 176V to 264VAC/48 to 52Hz, 10 W Max

(Fused 1.25Amp on board)

Service Manual

-18 -

Page 19

7. Device Descriptions

TU1000 - BTD-DU606Z

The Front End DTT (digital terrestrial) NIM module receives an off air UHF signal, and converts the digital

content into a parallel transport stream, to be fed into the MPEG decoder IC. This device is I2C controlled.

IC600 -TOP244Y

The TOP244Y is the Main PSU, PWM control IC. Supplied with a rectified AC source, this device produces

a Programmed PWM signal to control the Switch Mode PSU.

IC800 - CXA7002R-T6

The CXA7002R-T6 is an Audio/Video switch. It provides Audio and Video routing from the Digital decoder

source to the TV and VCR SCART connectors CN800 / 801. This device is I2C controlled.

IC700 - XWM8729ED/R

The XWM8729ED/R is a high performance DAC. It supports data input word lengths from 16 to 24 bits and

sampling rates up to 192 KHz. This device is I2C controlled.

IC200 - FS6128-04

This is a monolithic CMOS clock generator, with circuitry that implements a VCXO when an external

resonator is attached. 13.5MHz Xtal is attached - X200.

IC201 - UPD61120F1-100-JN1

The Multimedia microprocessor has the following functions, running main software application, MPEG

transport stream decoding + analogue video output ( internal video DENC ), Master I2C control, digital

audio output ( external Audio DAC required ).

IC300 / IC304 - TC58V64BFTEL, Y

These IC’s are single mount options. Both IC’s are Flash Memory IC’s, IC300 is a 128Mbit part ( 16M x 8

bits ) and IC304 is a 64Mbit part.

IC302 - MT46V8M16TG-75

This device is a high speed CMOS, dynamic random-access memory containing 134,217,728 bits. It is

internally configured as a quad-bank DRAM.

IC604 - PQ015EZ01ZP

This is a fixed 1.5V regulator, its main function is to supply the PWB with a 1.5V supply.

Service Manual

-19 -

Page 20

IC601 - PQ025EZ01ZP

This is a fixed 2.5V regulator, its main function is to supply the PWB with a 2.5V supply.

IC701- LM317LMX

This is a variable voltage regulator, its main function is to supply IC700 with a 5V supply.

List of Specification Sheets included on Service Manual CD

TU1000 - BTD-DU606Z

IC600 -TOP244Y

IC800 - CXA7002R-T6

IC700 - XWM8729ED/R

IC200 - FS6128-04

IC201 - UPD61120F1-100-JN1

IC300 / IC304 - TC58V64BFTEL, Y

IC302 - MT46V8M16TG-75

IC604 - PQ015EZ01ZP

IC601 - PQ025EZ01ZP

IC701- LM317LMX

Service Manual

-20 -

Page 21

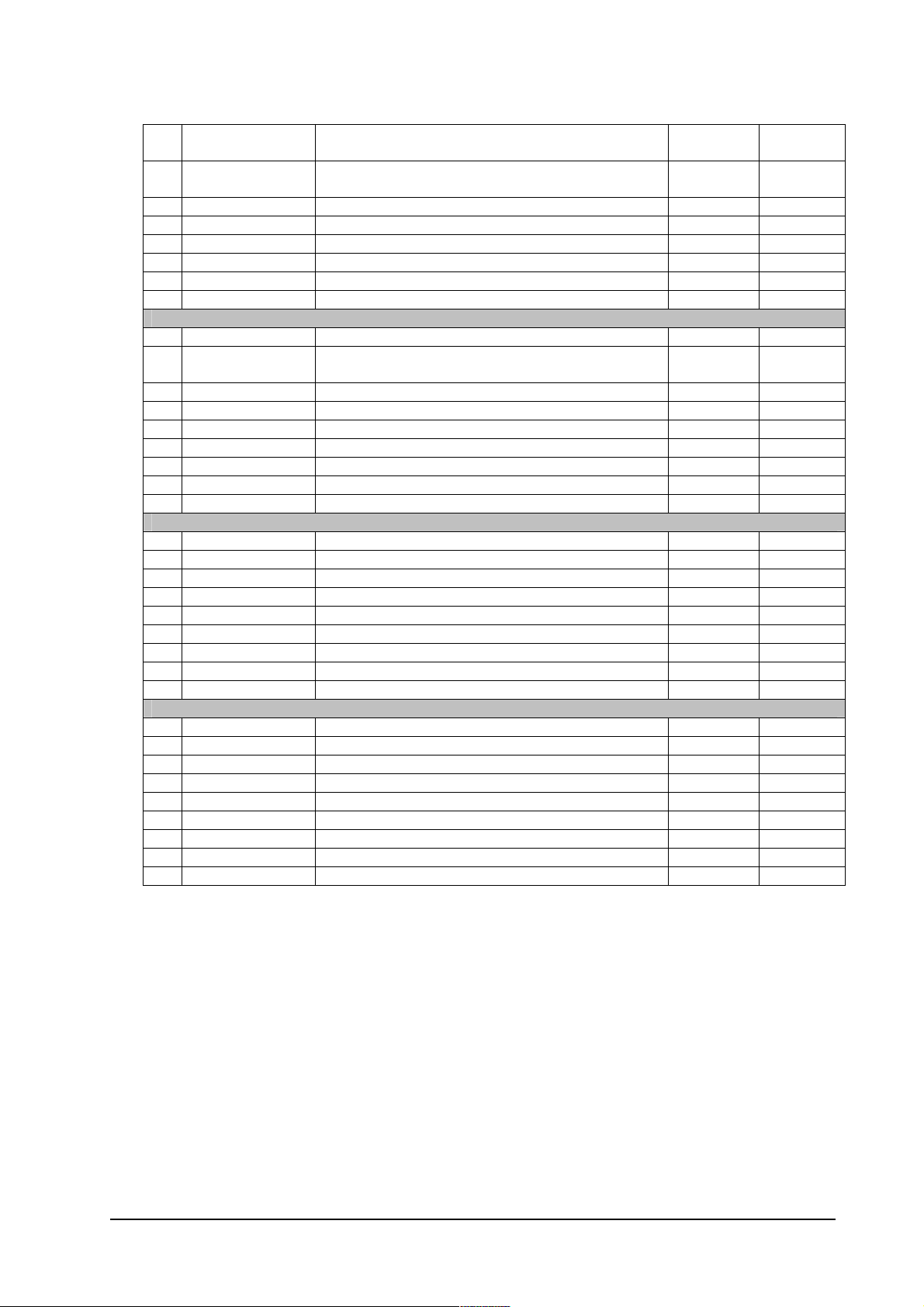

8.1 BLOCK DIAGRAM

PSU

+32V

+12V

+5V0

+3V3

+2V5

+1V5

TV SCART

CN801

RGB

YC, CVBS

Audio L, R

AV Switch

IC800

VCR SCART

CN800

RGB

YC, CVBS

Audio DAC

IC7 0 0

MultiFunction

Connector

J800

+3V 3

Audio L, R

+12V

+5V

Audio

SPDIF

Audio

+5V

Smart Link

C Bus

2

I

DDR SDRAM

16 or 32 MBytes

IC3 0 2

+2V 5

NAND Fla s h

8 or 16 MBytes

IC304/300

+3V 3

TS (parallel)

DTT Tuner

TU1000

16 bit

8 bit

+32V

+5V

+3V3

I2C Bus

Video RGB / YC / CVBS

DDR S DRAM

Inte rface

Bus s peed =

133MHz

+2V 5

ROM

Inte rface

Bus bur st

speed =

20.75MHz

+3V3

TS

SYSTEM

27MHz

VCXO

IC2 0 0

I2S

2

SDENC

I

GPIO SPDIF

Main Processor

NEC EMM A2L

+3V 3

+2V 5

+1V 5

EJT A G RES ET

Reset

IC500

+3V3+3V 3

FUART1

UA RT2 /3

2

C

I

IR IN

GPIO

I2C Bus

IR Re ceiv e r

IC502

FP Buttons

and LEDs

Service Serial

Int erface

CN202

+3V3

+3V3

+3V3

13.5MHz

- 21 -

Page 22

ABCDE F

1

2

3

4

G

HI JKLMN

5

6

7

8

9

10

11

8.2 B Board PWB Layout

- 22 -

Page 23

10

1

2

3

4

5

6

7

8

9

ABCDE F

B..-VTX-D800

+3V3

C264

0.1

C265

C209

0.1

16V

+2V5

C210

0.1

16V

+1V5

C249

4.7

10V

JTAG CONFIGURATION

FOR NORMAL JTAG:-

FIT R256, R257, R258, R259, R202.

NO-FIT R260, R261, R262, R263, R203.

FOR EJTAG:-

FIT R260, R261, R262, R263, R203

NO-FIT R256, R257, R258, R259, R202.

+3V3

L200

C208

100uH

4.7

10V

ALRCK,ADO,ABCK,AMCK

27MHz CLOCK GENERATION

R273

R274

0

0

R275

8765

X2

X200

X1

C204

0.1

1000p

XX

C203

0.1

16V

VCC

GND

VCC

GND 27M

AIN

4321

C260

0.1

16V

C200

XX

13.5MHz

XXC201

+3V3

FB200

0uH

C202

16V

C260 TO BE PLACED CLOSE

TO PIN 2, IC200

PLACE R200 AND R273 -> R275 CLOSE

TO PINS 5 & 6 RESPECTIVELY

R273 -> R275 ARE PROVIDED AS LINK

OPTIONS FOR THE ICS3721

C259

4.7

10V

0.1

C266

C267

C268

C211

16V

JTRST

C263

FS6128-04

0.1

100

10V

IC200

0.1

0.1

0.1

R200

1/10W

Ground stiching for

3.3V Close to Power

0.1C270

Plane

For Front and Side of PCB

STP0_CLK,STP0_DAT[0-7],STP0_EN

0.1C269

NALE

SDA_0

RSTSWB

JEDINT

VACOMP

NRBB

RXD_1B

RSTOUT

JTDI

VAR

NCLE

SCL_0

JTDO

SDA_1

SCL_1

JTMS

STP0_CLK,STP0_DAT[0-7],STP0_EN

STP0_EN

RDATA[11]

RDATA[5]

RDATA[12]

STP0_DAT[4]

STP0_DAT[6]

NALE

STP0_DAT[1]

RDATA[4]

NCLE

STP0_DAT[0]

STP0_DAT[3]

STP0_DAT[5]

TMODE2

R242

4.7k

10kR204

4.7kR205

+3V3

R264

47

4.7kR241

RDATA[3]

NRBB

STP0_CLK

STP0_DAT[2]

TMODE0

TMODE1

RSTOUT

C222

C207

C246

0.1

1

16V

C213

C244

C247

0.1

0.1

4.7

16V

16V

10V

C214

0.1

16V

C248

4.7

10V

C215

C224

0.1

0.1

16V

16V

R261

R260

XX

XX

6.3V

C220

C245

0.1

1

6.3V

16V

C230

C227

0.1

1

6.3V

16V

R262

XX

R202

R263

XX

C219

C206

0.1

16V

C223

0.1

16V

C251

1

6.3V

0.1

1

16V

6.3V

C254

C255

C252

0.1

1

0.1

16V

6.3V

16V

10k

SPDIF

1/10W

C250

4.7

10V

ALRCK

ABCK

ADO

AMCK

10k

R257

10k

1/10W

1/10W

C212

1

6.3V

PLACE CLOSE TO IC201

R265

47

1/10W

R266

47

1/10W

R267

47

1/10W

R268

47

1/10W

R203

10k

10k

XX

C217

C218

0.1

0.01

16V

25V

TXD_1B

NMI

R259

R258

R256

PWM_OUT

33

CLK27M

VAG

VAB

R201

10k

PWM_OUT

C216

0.1

16V

DADD[0-12]

DQ[0-15]

RDATA[0-15]

RDATA[0-15]

DBA0,DBA1,DCASB,DCLK,DCLKB,DCSB,DQM0,DQM1,DQS0,DQS1,DRASB,DVREF,DWEB

R206

4.7k

SCL_1

G

HI JKLMN

+3V3

RSTSWB

FB205

0uH

Q201

JIG_MODE

+3V3

+3V3

4.7k

R269

1/10W

RSTSW

DTC114YUA-T106

GND

C242

0.1

16V

CTS_1B

RTS_1B

RXD_1B

TXD_1B

R253

10k

1/10W

4.7k

R270

1/10W

RSTSW

IR_IN_0

IR_IN_0

Q202

GND

+1V5

+3V3

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

VCC

VCC

JIG_MODE

CTS

RTS

RXD

TXD

GND

3V3_EMMA

DEBUG CONNECTOR

CN202

8P

WHT

CN203

7P

GND

E_RX_2

E_RX_3

E_TX_3

E_TX_2

PPORT35

R278

1/10W

R281

R282

10k

10k

R280

R240

R279

10k

10k

10k

1/10W

1/10W

1/10W

RXD_2B

RXD_3B

+3V3

TXD_3B

TXD_2B

100

JTCLK

RDATA [ 7 ]

RDATA[14]

STP0_DAT[7]

VAY

STBY_SW

RDATA [ 6 ]

RDATA[13]

RDATA[15]

CTS_1B

CHANNEL_DOWN_SW

FOEB

VAC

RTS_1B

CHANNEL_UP_SW

TUNER_RESETB

USB_INT

R272

XX

FWEB

RSTSWB

DTC114YUA-T106

IR_IN_0B

FOEB

IR_IN_0B

FWEB

C238

0.1

137

GND

GND

GND

GND

VDD1

PPORT22/MMDOUT/DSR0B

MMCLK/DTR0B

RADD1

PPORT36

RADD0

PPORT37

139 138140147159 146158 155 143145160 144157 151 150152154 148156 142 141153 149

VDD3

FEWB

AGND1_16

RADD20

AVDD1_16

AVSYSCLKIN

PPORT23/SMRST0

GND

GND

GND

GND

GND

VDD1

RADD22

RADD16

RADD21

EVCK

SYSCLKIN

AVDD1_162

VDD1

VDD1

VDD1

VDD1

VDD2

VDD1

RADD12

RADD23

RADD15

AGND1_162

CLK27IN

AVDD1_266

VDD3

FCSB0

RADD25

RADD7

RADD24

MCLKIN

AGND1_266

AGND1_6

GND

VDD3

RADD5

PPORT28

RADD6

VRCLKIN

AVDD1_6

SDIN

VDD1

GND

GRDYB

RADD4

PPORT31/OFF1

PPORT35

FCSB1

PPORT40

IRIN0

PPORT33/SMDAT1

RADD2

PPORT32/SMCLK1

RADD3

STPERRB

PPORT42

PPORT41

DWEB

GND2

VDD2

GND2

RXD3B/PPORT51

VDD3

GND2

VDD2

66 67 68

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

DQ1

75

DQ3

74

DQ5

73

DQ7

DWEB

72

71

70

69

GRDYB

DQ[1]

DQ[3]

DQ[5]

DQ[7]

C261

0.1

16V

C239

C262

0.1

16V

C240

1000p

C241

4.7

50V

10

0.1

16V

CLK27M

+3V3

R252

10k

1/10W

FCS1B

AVS_INTB

IR_IN_0

JIG_MODE

R276

XX

SCART_GPO_2

SMARTLINK_TX

MEMORY STICK INTERFACE

JL PIN SIGNAL

MS INSERTED

MSINS

JL219

SERIAL CLOCK

MSSCLK

JL220

POWER ON

MSPON

JL221

BUS STATE

MSBS

JL215

DATA IO

MSDIO

JL222

161162163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204

VAC

RDATA13

DCLK

RDATA 6

DQM0

MMRINGB/PPORT12

DQS1

CBPF

VDD2

AGND5

DQ9

VAY

DQ11

SMCLK0

DQ13

RADD10

DQ15

GND

VDD1

206

GND

207

GND

0.1

C232

C233

C234

208

CBPC

0.1

209

0.1

210

211

212

213

214

215

216

217

218

219

220

221

222

100R208

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

100R209

244

245

246

247

C235

248

0.1

249

250

251

252

253

254

255

256

257

258

259

260

261

262

100

R243

263

100R244

264

265

266

267

0.1C236

268

269

270

271

272

STP_DAT7 / PMSDIO

CBPD

CBPE

AGND4

STP_EN / PMSINS

RDATA11

RDATA 5

RDATA12

NAND_ALE

ATX

ADO

STP_DAT1

STP_DAT4 / PMSSCLK

STP_DAT6 / PMSPON

TEST

SDA0

JTDI

JTRST

RSTSWB

VAR

AVDD1

AGND2

AVDD3

AVDD4

AVDD5

OFF0/PPORT25

RDATA 4

NAND_CLE

TXD1B

ALRCK

ABCK

STP_DAT0

STP_DAT3

STP_DAT5/PMSBS

TMODE2

EDINT

SCL0

JTDO

NMI

EIVHS

AGND1

CBPB

AVDD0

VACOMP

AVDD2

RDATA 3

NAND_R/BB

GCSB1

RXD1B

PWMOUT

AMCK

STP_CLK

STP_DAT2

TMODE0

TMODE1

SDA1

SCL1

JTMS

RSTOUT

EIVVS

CBPA

AGND0

VAG

AGND3

VAB

CMDVCC0

PPORT34

RXD2B/PPORT53

PPORT49

1 2 3 4 5 6 7 8 9 1011121314151617181920212223242526272829303132333435363738394041424344454647484950515253545556575859606162636465

1k

1/10W

R277

DADD4

DADD5

DADD7

RDATA14

NAND_SEB

DADD8

DADD11

RDATA 7

DRASB

GND

GND

GND

JTCK

VDD3

VDD1

205

RDATA15

GND2

GCSB0

CTS0B/PPORT46

CTS1B

MMBCLK

RDATA 9

RDATA 2

GND

FOEB

VDD1

RADD11

PPORT27/SMDAT0

RDATA10

TXD4B/PPORT52

PPORT48/TXD0B

DADD2

DADD6

DADD10

PPORT18/MMHCO

DADD9

VDD3

VDD3

PPORT11/MMFS

PPORT10/RTS1B

IC201

UPD61120F1-100-JN1

DADD12

DCASB

DQM1

DVREF

PPORT30/CMDVCC1

VDD2

RADD9

DQ8

PPORT16/MMDIN

PPORT29/SMRST1

MMPWRCNT/DCD0B

PPORT13/MMOFFHOOK

DQ10

DQ12

DQ14

GND2

VDD3

PPORT45/RTS0B

GND

RADD8

ACLKIN

RADD17

RADD13

RDATA 0

RDATA 8

RDATA 1

TXD3B/PPORT54

STP_STRT

GND

GND

VDD1

PPORT17/MMRST

PPORT19/MMMUTEB/RI0B

DADD3

DADD1

DADD0

DBA1

DBA0

GND

DCSB

GND

DCLKB

VDD1

DQS0

RADD19

DQ6

RADD14

DQ4

RADD18

DQ2

AVDD1_18

AGND1_18

DQ0

PPORT44

GND

RXD0BP/PPORT47

RXD_2B

DADD[4]

DADD[5]

DADD[7]

DADD[8]

DADD[11]

DRASB

DCLK

DQM0

DQS1

DQ[9]

DQ[11]

DQ[13]

DQ[15]

DCASB

DADD[12]

DADD[2]

DADD[10]

DADD[6]

RDATA [ 2 ]

RDATA [ 9 ]

RDATA[10]

DADD[9]

DQM1

DVREF

DQ[8]

DQ[10]

DQ[12]

DQ[14]

STP0_STRT

RDATA [ 0 ]

DADD[1]

DADD[3]

RDATA [ 1 ]

RDATA [ 8 ]

DADD[0]

DBA1

DBA0

DCSB

DCLKB

DQS0

DQ[6]

DQ[4]

DQ[2]

DQ[0]

STBY_LED_2

SCART_GPO_1

B

1/6

TXD_3B

TXD_2B

R271

1/10W

10k

SMARTLINK_RX

STBY_LED_2

STBY_LED_1

RXD_3B

GND

11

~ B Board Schematic Diagram [ Multimedia Processor & Clock Generator ] Page 1/6 ~

- 23 -

Page 24

ABCDE F

G

HI JKLMN

B..-VTX-D800

1

FULL HARDWARE RESET CIRCUIT (STANDBY BUTTON FOR AT LEAST 5s)

+3V3

RESET SIGNAL GENERATION

2

D506

DAN202K-T-146

R533

220k

R510

100

3

SIGNAL FROM FRONT

PANEL STANDBY BUTTON

STBY_SW

Q504

DTC144EKA

1/10W

NOTE Leakage

May dictate

A change of

Dielectric

1/10W

R511

220k

1/10W

C505

6.3V

1

R531

18k

1/10W

R532

3.3k

1/10W

Q513

2SA1037AK-T146-QR

Q506

2SC2412K-T-146-R

Q512

2SA1037AK-T146-QR

R534

100k

1/10W

R513

10k

1/10W

Q511

2SA1037AK-T146-QR

R512

22k

1/10W

R514

22k

1/10W

R537

100k

1/10W

R536

100k

1/10W

R535

10k

1/10W

R538

22k

1/10W

R539

47k

1/10W

GEN_RSTB

Q505

2SC2412K-T-146-R

4

RESET PULSE STRETCHER

RSTOUT

R549

1k

1/10W

2SC2412K-T-146-R

Q514

C509

6.3V

+3V3

R552

10k

1/10W

R550

1k

1/10W

R551

100

1/10W

2SC2412K-T-146-R

GND

Q515

R554

470

1/10W

R553

1k

1/10W

1

JL502

SWITCHES AND LEDS

D502

SPR-325MVW

+3V3

Q509

2SA1037AK-T146-QR

R529

120

1/10W

G

R

STANDBY LED

Q510

2SA1037AK-T146-QR

R530

180

1/10W

R546

1k

1/10W

STANDBY CHANNEL UP CHANNEL DOWN

S500

R547

1k

1/10W

S501

R548

1k

1/10W

S502

D505

BZA456A

RESET CIRCUIT

+3V3

DAN202K-T-146

R500

1k

12

C500

0.1

16V

D500

IC500

PST575IMT-T1

GND

VCC

OUT

CD

C501

XX

43

R501

22k

1/10W

C502

10

16V

RSTSWB

GEN_RSTB

4PCN503

GND

RSTB

NMI

GND

4 PIN RESET HEADER

NO MOUNT IN PRODUCTION

R527

100

1/10W

1

2

3

4

NOTE: NMI IS FOR EJTAG ONLY

RSTSWB

NMI

Q500

DTC144EKA

5

R540

10k

R544

10k

1/10W

1/10W

R541

10k

1/10W

STBY_LED_1

STBY_LED_2

6

7

CHANNEL_DOWN_SW

CHANNEL_UP_SW

STBY_SW

R543

10k

1/10W

10

11

8

IR RECEIVER

9

+3V3

C508

0.1

16V

C503

100

10V

R555

1/10W

VCC

4.7k

GND

OUT

IC502

RPM7240-H5

IR_IN_0B

B

2/6

~ B Board Schematic Diagram [ Front Panel & Reset ] Page 2/6 ~

- 24 -

Page 25

ABCDE F

G

HI JKLMN

1

B..-VTX-D800

2

NOTE: THE TOPSWITCH DESCRIPTION IS WRONG FOR THIS SYMBOL !!

CORRECT DESCRIPTION SHOULD BE TOP244Y (SYMBOL DUE TO BE UPDATED).

THE P/N AND MACRO ARE CORRECT THOUGH.

R646

47

1/4W

D606MBRB760

C651

XX

C613

2200

10V

3

1

2

TL431CLP-Z20

R620

4.7k

IC602

I_LIMIT

R607

6.8

1/10W

C608

47

50V

0.1C607

VLINK

D602

BZG03-C180/T1

C605

1000p

2kV

VDRAIN

10kR606

1/8W

16V

DAN202K-T-146

VBIAS

VBIAS_RECT

R611

C609

50V

R602

47k

1W

RS

D601

RS1J

D604

0

1

WRONG PN.

CORRECT MACRO

FOR SA20-FER28

PC123ZY2

PH600

C645

2200p

250V

T600

18

11

10

14

15

16

12

17

13

9

3

4

1

7

VLINK

R604

R605

2.7M

1M

1/8W

1/8W

R603

1M

1/8W

PRI_GND

NOTE: DO NOT CONNECT HEATSINK TO ANY

SIGNALS. IT MUST REMAIN FLOATING.

IC600

IC600

TOP224Y

TOP244Y

406642611

A600

Mount Mecha

D

F

S

X

L

C

12345 7

C604

450V

R643

1.2M

1/8W

R644

1.2M

1/8W

33

3

SIDE A SIDE B

F600

CN600

4P

4

1

L-N 3.2MM

4

AC_NEUTRAL

SIDE A SIDE B

ADD TEETH

ADD TEETH

FB600

0uH

VDR600

180383031

FB601

0uH

SPARK_GAP

C646

4700p

250V

E

ALL LIVE TRACKS 2.5MM

INCORRECT PART

SHOULD BE SUFFIX 51

C600

R600

0.22

1M

1/2W

275V

NEUTRAL

SPARK GAP

3.2MM FROM

USE TEETH

SEC - SPARK GAP

3.2MM

L600

L-N 3.2MM

EMI

EMI

NEUTRAL_EMI

L601

LIVE_EMI

L602

LIVE_FILTER

4

23

1

NEUTRAL_FILTER

C601

2200p

250V

VDR601

PRI - SEC

3.2MM

TH601

NEUTRAL_INRUSH

C602

2200p

250V

D600

S1NB60-4062

5

6

C644

C615

R618

100p

4.7k

1W

1kV

D607

RS1J

C616

22

50V

D609

ES2G

C618

1W

100p

1kV

C650

R647

XX

220

UGB8BT

D612

R648

220

1/10W

C621

1000

10V

R614

1k

1/10W

C610

10

50V

1

6.3V

L603

3.3uH

R627

100

1/10W

R682

470

1/10W

R617

10k

1/10W

C619

L605

3.3uH

C614

R616

4.7k

1/10W

R680

CHIP

470

35V

1000

10V

0

R619

680

1W

D608

UDZS-TE17-33B

L604

3.3uH

C622

1000

10V

R637

XX

R641

47k

R681

0

R640

XX

R642

150k

1/10W

C617

10

50V

C640

220

35V

FB607

R622

2.2k

D610

MA111-TX

+33V_CLEAN

Q602

2SD2150-T100QRS

R624

100k

D611

PDZ12B-115

PS601

1A

FB610

0uH

C638

0.1

50V

0uH

C635

16V

FB605

0uH

0.1

C633

16V

0.1

C620

50V

FB608

10

+33V_CLEAN

F/E

+12V

AV_OUT

0uH

C636

0.1

25V

+5V

AV_OUT

+3V3

NAND

VCXO

E2L

RESET

10

GND

7

8

9

THIS CIRCUIT IS TO BE PLACED CLOSE TO EMMA

VINVCVO

C649

16V

0.1

12345

+3V3

+2V5

GND

R601

1/10W

R649

XX

+3V3

C647

C648

0.1

0.1

16V

16V

GND

1k

PQ015EZ01ZPH

IC604

670492301

R635

XX

R639

XX

R636

XX

VADJ

GND

+1V5

C627

0.1

16V

C628

10V

100

C630

16V

0.1

GND

THIS CIRCUIT IS TO BE PLACED CLOSE TO SDRAM AND EMMA

+3V3

+3V3

GND

C603

16V

R633

R650

IC601

PQ025EZ01ZP

C606

0.1

0.1

16V

GND

1k

XX

C611

0.1

16V

VINVCVO

12345

R610

XX

R613

XX

R615

XX

VADJ

GND

+2V5

C639

C637

C612

16V

0.1

0.1

100

10V

16V

GND

B

3/6

11

~ B Board Schematic Diagram [ Power Supply ] Page 3/6 ~

- 25 -

Page 26

ABCDE F

G

HI JKLMN

1

B..-VTX-D800

VIDEO

B

2

3

4

4/6

VAR

VAG

VAB

VACOMP

VAY

VAC

NOTE THE USE OF

0.5% RESISTORS

R721

180

1/10W

CHIP

R722

180

1/10W

CHIP

R723

180

1/10W

CHIP

R724

180

1/10W

CHIP

R725

180

1/10W

CHIP

R726

100

1/10W

CHIP

RED

GREEN

BLUE

CVBS

LUMA

CHROMA

RED

GREEN

BLUE

CVBS

LUMA

CHROMA

C713

4.7

16V

+12V

AUDIO DAC SUPPLY OPTION

R756

220

1/10W

C715

R757

4.7

16V

680

1/10W

VIN

VOUT

VOUT

4321

ADJ NC

VOUT

VOUT

NC

IC701

LM317LM

876

5

5

GND

SMARTLINK

+5V

6

R751

4.7k

1/10W

R742

22k

1/10W

FB701

0uH

D704

DAN202K-T-146

R738

220

1/10W

7

SCART_SMART

NOTES:

8

FB701 SHOULD BE PLACED VERY CLOSE TO THE TV AND VCR SCARTS

9

+3V3

R735

100k

1/10W

Q707

2SC2412K-T-146-R

Q710

2SC2412K-T-146-R

GND

R731

10k

1/10W

R732

10k

1/10W

R739

10k

1/10W

2SA1037AK-T146-QR

Q708

2SC2412K-T-146-R

C711

0.047

16V

Q706

Q709

2SC2412K-T-146-R

R733

4.7k

1/10W

R734

1/10W

AUDIO DAC

+5V

RSTSWB

DAC_AVDD

DAC_L

DAC_R

L700

XX

GND

C710

XX

SMARTLINK_RX

DAC_DVDD

FB700

R730

1k

10k

1/10W

R741

4.7k

R752

22k

1/10W

1/10W

R750

4.7k

1/10W

SMARTLINK_TX

RSTSW

ALRCK,ADO,ABCK,AMCK

C700

0.1

16V

0uH

GND

ALRCK,ADO,ABCK,AMCK

ALRCK

ADO

ABCK

AMCK

C702

16V

0.1

IC700

XWM8729ED/R

LRCIN

DIN

BCKIN

MCLK

DGND

DVDD

VOUTR

87654321

AGND

FORMAT

DEM

MUTEB

VREFP

VREFN

VMID

VOUTL

AVDD

16 15 14 13 12 11 10 9

C704

0.1

16V

C703

4.7

16V

C706

0.1

16V

C707

C712

XX

NOTE: C712 IS ONLY FITTED WHEN

L700 IS FITTED

R755

0

CHIP

R754

XX

4.7

16V

10

11

~ B Board Schematic Diagram [ Audio DAC & Smartlink Switch ] Page 4/6 ~

- 26 -

Page 27

ABCDE F

G

HI JKLMN

B..-VTX-D800

+3V3

C837

0.1

1

2

3

4

R_OUT_VCR

R_IN_VCR

L_OUT_VCR

5

6

7

GND

GND

L_IN_VCR

B_VCR

SLB_VCR

GND

SMARTLINK

G_VCR

N/C

GND

GND

R/C_VCR

FB_VCR

GND

GND

V_OUT_VCR

V_IN_VCR

GND

R_OUT_TV

R_IN_TV

L_OUT_TV

GND

GND

L_IN_TV

B_TV

SLB_TV

GND

SMARTLINK

G_TV

N/C

GND

GND

R_TV

FB_TV

GND

GND

V_OUT_TV

V_IN_TV

GND

8

9

16V

C845

XX

SCART_SMART

R_TV_SCART

FB_TV_SCART

V_OUT_TV_SCART

XXR820

XXR821

1

2

3

1

D800

BZA408B-115

R800

XX

R801

XX

R802

XX

R803

XX

R804

XX

R805

XX

R807

XX

R809

R810

XX

R894

XX

R817

XX

R818

XX

R819

XX

R888

R887

6

XX

XX

5

1 1

4

1

BZA408B-115

1

2

3

1

GND

1

D807

PZM-13NB2A

2

3

1

R823

75

1/10W

1

GND

R806

XX

XXR808

XX

R811

XX

XXR812

XXR814

CHIPXX R816

VIN

VCC

GND

J800

GP1FC300TP-MULTI FUNCTION CONNECTOR

1

SPDIF

VCR

21P

CN800

SCART_SMART

C858

C857

100p

100p

50V

50V

1

GND

TV

21P

CN801

C859

C860

100p

100p

50V

50V

1

GND

R824

1/10W

R825

470

1/10W

D801

D802

BZA408B-115

D808

BZA456A

BZA456A

C800

16V

470

D804

0.1

C839

6

5

4

1

GND

6

5

4

1

R893

XX

D803

PZM-13NB2A

2

D809

BZA456A

10

50V

C840

10

50V

R/C_VCR

1

1/10W

R827

1/10W

R828

1/10W

R829

1/10W

R830

1/10W

R831

1/10W

+5V

C850

C849

C815

0.1

0.1

16V

16V

C816

L802

47

100uH

SCL_5V

CVBS

16V

C817

0.1

16V

R854

100

CHIP

SDA_5V

33343536373839404142434445464748

SCL

SDA

GND

ROUT1

LOUT1

VCC_AUD

GND_AUD

-5V_GNDA

MONO

PHONO_R

PHONO_L

+5/+12V_VCCA

-5V_GNDA

AUD_BIAS

GND_DIG

+5V_DIG

FBLK_IN2

FNC_VCR

TV_FBLK

FBLK_IN1

HW_MUTE

FNC_TV

VIN8

Y

+12V

VIN9

GND

-5V_GNDA

LOGIC

LTV

RTV

1

1

R852

68k

C804

R839

10k

1/10W

1/10W

R889

XX

R890

XX

1

GND

R891

XX

1

GND

R892

XX

1

R833

R832

R815

75

75

75

3

1/10W

1/10W

1/10W

1

R840

1/10W

1

6.3V

1

GND

C805

10k

1

6.3V

1

GND

R841

C806

10k

1

1/10W

6.3V

1

GND

1

GND

R842

10k

1/10W

1

GND

R836

470

1/10W

R837

470

C844

10

50V

R838

470

1/10W

R843

XX

11

R835

C807

1

6.3V

C841

10

50V

C842

10

50V

R880

75

C802

0.1

16V

C803

0.1

16V

C843

470

10

50V

EXTRA DE-COUPLING CAPACITORS FOR 5V

C811

1

16V

R_TV_IC

0.1

0.1

C854

16V

16V

C856

C855

0.1C846

R879

1k

1

GND

0.1

16V

C853

1

GND

C808

0.1

16V

V_OUT_TV_IC

R844

XX

0.1

22

25V

2

1

GND

49

RIN4

50

LIN4

51

VIN7

52

VIN10

53

VIN4

54

VIN2

55

VIN13

56

VIN12

0.1

C847

57

VIN11

58

+5V_VID

C810

0.1

59

GND_VID

60

VOUT5

61

VOUT6

62

VOUT4

63

VOUT3

64

C809

0.1

16V

+5V_VOUT

1/10W

R853

100

CHIP

DAC_R

DAC_L

INTERRUPT

LIN1

LIN2

LIN3

RIN3

VOUT2

VOUT1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

AUD_BIAS

VOUT7

TRAP

RIN2

SYNC_ID

VID_BIAS

VIN1

B

RIN1

IC800

CXA7002R-T6

VIN3

VIN5

GRC

INTERRUPT

VIN6

VCR SCART CHROMA OUTPUT SELECTION

R851

R860

XX

Q805

2SC2412K-T-146-R

R861

C848

XX

XX

Q804

2SC2412K-T-146-R

1

R855

0

CHIP

R862

0

CHIP

1

D805

BZA456A

1

GND

R826

75

75

75

75

75

75

R869

Q806

XX

XX

SCART_GPO_2

Q807

2SC2412K-T-146-R

R899

XX

1

R834

75

1/10W

C801

0.1

16V

1

1kR845

1kR846

1k

R847

1k

R848

R849

1k

1k

R850

1

XX

L800

XX

C812

XX

1

C813

0.1

16V

16V

1

C820

0.1

16V

1

GND

32

31

30

29

28

27

26

25

22C838

25V

24

23

22

21

20

19

18

17

1

C823

0.1

16V

C852

C851

0.1

0.1

0.1

16V

16V

1

C821

XX

FB_TV_IC

R859

470

R857

1/10W

XX

R856

XX

R867

XX

Q800

XX

R863

XX

R858

XX

R898

XX

1

1

R866

XX

R868

470

1/10W

R864

XX

R896

XX

R895

XX

Q801

XX

1

+3V3

10k

R878

CHIP

1/10W

C828

4.7

10

R873

C829

4.7

R875

10

NOTE 0.5% TOLERANCE RESISTORS

+12V

+5V

C826

0.1

L804

16V

1

12uH

C822

0.1

16V

C824

4.7

16V

R865

10k

1/10W

L803

100uH

1

C825

47

16V

C836

1

0.1

16V

C827

0.1

16V

1

VCR SCART SLOW BLANKING DIRECTION CONTROL (SYNCRO RECORD)

C830

0.1

C831

0.1

C832

0.1

C833

0.1

C834

0.1

C835

0.1

R882

R881

1k

1

GND

SCL_0

SDA_0

DAC_L

DAC_R

DAC_L

DAC_R

AVS_INTB

LUMA

CVBS

CHROMA

RED

GREEN

BLUE

1.5kR872

1

10k

1.5kR874

1

10k

LUMA

CVBS

CHROMA

RED

GREEN

BLUE

R883

R884

1k

1k

R886

R885

1k

1k

1k

NOTE 0.5% TOLERANCE RESISTORS REQUIRED

10

11

TV SCART CHROMA IN ENABLE

SCART_GPO_1

R813

XX

SCART_GPO_1

2SC2412K-T-146-R

R822

470

Q802

1

GND

Q803

2SC2412K-T-146-R

B

5/6

1

GND

~ B Board Schematic Diagram [ AV Switch & SCART ] Page 5/6 ~

- 27 -

Page 28

ABCDE F

B..VTX-D800

1

B

6/6

G

HI JKLMN

SIEL NIM

THIS CIRCUIT IS TO BE PLACED CLOSE TO TU1000

2

3

NO FIT FOR SONY BARCELONA NIM

+3V3

C1035

C1034

XX

XX

IC1001

C1037

XX

XX

VINVCVO

12345

R1019

XX

R1032

XX

R1005

R1008

XX

VADJ

GND

+2V5_TU

XX

R1011

XX

C1038

XX

C1064

XX

C1040

XX

4

+2V5_TU

5

+2V5_TU

6

SCL_1

SDA_1

R1015

100

7

R1016

100

8

+3V3

+3V3

C1027

C1026

XX

+2V5_TU

C1028

R1013

XX

R1014

XX

STP0_CLK,STP0_DAT[0-7],STP0_EN

+3V3

XX

C1036

XX

XX

TUNER_RESETB

+5V

+5V

FB1000

XX

C1062

XX

L1001

XX

FB1001

XX

C1001

XX

C1002

C1003

XX

STP0_DAT[7]

C1005

XX

STP0_DAT[6]

STP0_DAT[5]

STP0_DAT[4]

STP0_DAT[3]

STP0_DAT[2]

STP0_DAT[1]

STP0_DAT[0]

STP0_EN

STP0_CLK

TUNER_RESET_1

STP0_CLK,STP0_DAT[0-7],STP0_EN

C1007

XX

C1004

XX

XX

R1017

100

FB1002

C1029

XX

XX

C1030

XX

R1020

R1021

R1022

R1023

R1024

R1025

R1026

R1027

R1028

R1029

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

R1031

XX

GND

GND

+2V5

+3V3

TS 7

TS 6

TS 5

TS 4

TS 3

TS 2

TS 1

TS 0

TS SYNC

TS VALID

TS CLOCK

NOT RESET

SCL

SDA

GND

GND

+5V

+33V

GND

GND

GND

TU1000

XX

BCN NIM

+5V

+12V

1608

C1018

XX

C1016

0.1

16V

C1012

XX

FB1005

0uH

IC1000

XX

IO

G

+33V_CLEAN

+5V

+3V3

C1054

XX

C1063

16V

FB1008

0uH

C1060

C1052

0.1

33

50V

L1000

100uH

C1053

C1045

0.1

0.1

33

16V

50V

C1022

C1023

33

0.1

50V

50V

C1021

C1020

0.1

100

16V

16V

FB1009

0uH

FB1006

0uH

FB1004

0uH

C1048

16V

0.1

C1049

0.1

16V

C1009

C1011

4.7

10V

C1050

1000p

50V

+5V_BCN_B1_FILT

C1051

1000p

50V

BCN_NIM_+33V_FILT

C1013

1000p

0.1

50V

50V

C1015

1000p

50V

STP0_CLK,STP0_DAT[0-7],STP0_EN

R1030

10k

1/10W

C1042

0.1

16V

STP0_DAT[0]

STP0_DAT[1]

STP0_DAT[2]

STP0_DAT[3]

STP0_DAT[4]

STP0_DAT[5]

STP0_DAT[6]

STP0_DAT[7]

STP0_CLK

STP0_EN

NC

+5V

SPLITTER

NC

B1 +5V

VC +32V

AGC MONI

PRESET

(+1.8V)

+3.3V

SDA

SCL

AS

GND

TU1001

PD0/

(PDSERIAL)

PD1

PD2

PD3

PD4

PD5

PD6

PD7

PDOCLK

PDOVAL

PDOERR/

(RSLOCK)

PDSYNC

CASE WILL HAVE GROUND CONNECTION

10

11

+33V_CLEAN

+33V_CLEAN

C1032

FB1003

XX

C1031

XX

XX

C1044

XX

C1008

XX

9

GND

~ B Board Schematic Diagram [ Tuner NIM ] Page 6/6 ~

- 28 -

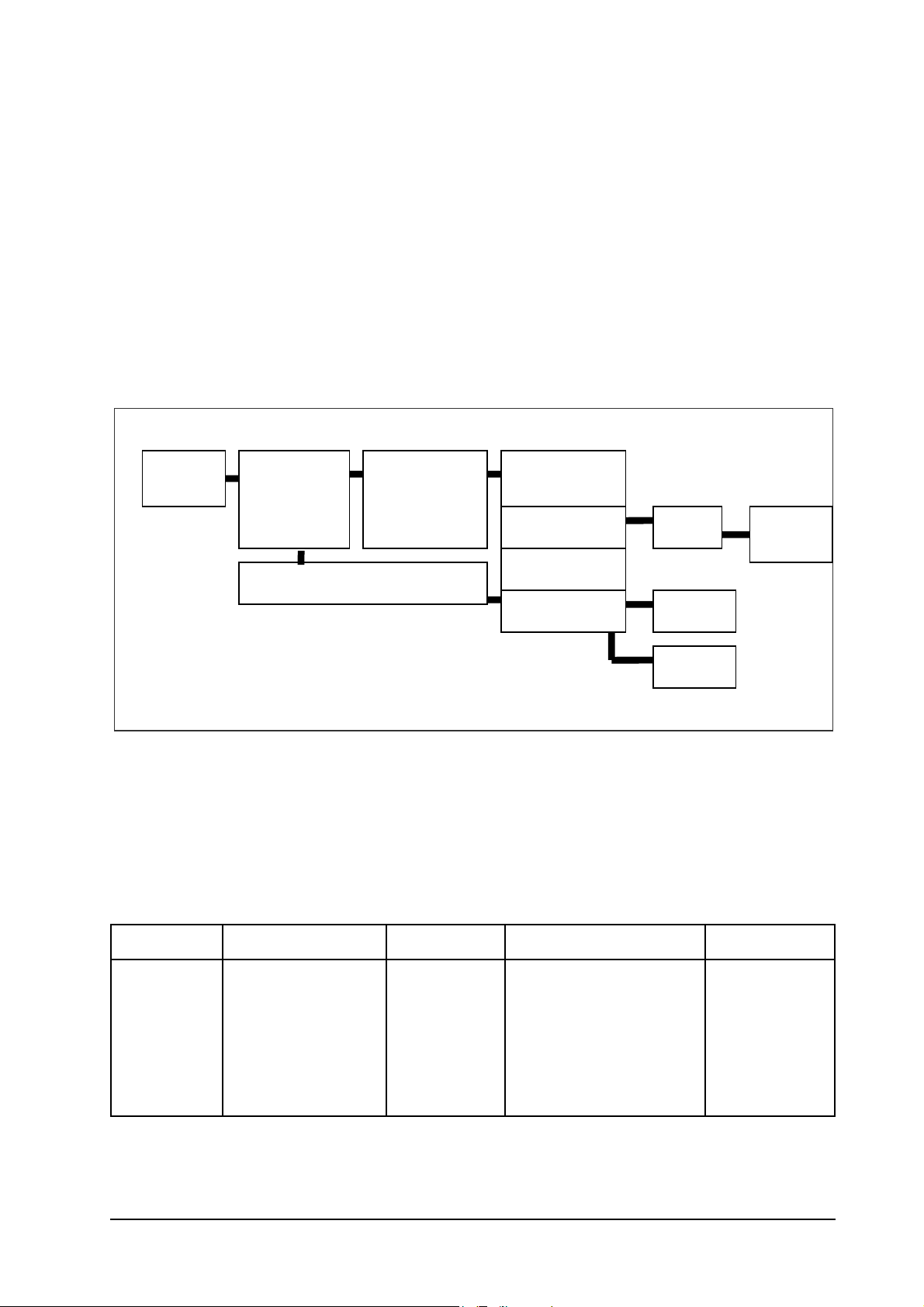

Page 29

REF.NO.

PART.NO

DESCRIPTION

REMARK

SECTION 9

The construction parts of an assembled part are

indicated with a collation number in the remarks

column.

Items marked “*” are not stocked

routine service. Some delay should

be anticipated when ordering these

items.

- 29

-

ONLY

3

5

8

6

SCREW +BVTP

2

6

7

10

10

10

9

11

11

£ 1-827-469-11 CORD, POWER SUPPLY (VTX-D800N/

VTX-D800E)

2 4-099-730-01 SCREW + BVTP 3X12 TYPE 2 TT(B)

X-4042-575-1

COVER, BOTTOM ASSY

5 7-682-546-04 SCREW +B 3X5

Page 30

- 30

-

PARTS LISTING TABLE OF CONTENTS

Items marked “*” are not stocked since they are seldom required for routine service. Some delay should

be anticipated when ordering these items.

ACCESSORIES AND PACKAGING MATERIALS :

Page 31

- 31

*A-1302-374-A COMPLETE PC BOARD, B

4-382-854-01

SCREW (M3X8), P, SW (+)

< CAPACITOR >

C202

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C203

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C204

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C206

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C207

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C208

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C209

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C210

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C211

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C212

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C213

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C214

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C215

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C216

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C217

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C218

1-162-970-11

CERAMIC CHIP 0.01UF 10.00% 25V

C219

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C220

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C222

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C223

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C224

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C227

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C230

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C232

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C233

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C234

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C235

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C236

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C238

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C239

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C240

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C241

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C242

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C244

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C245

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C246

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C247

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C248

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C249

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C250

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C251

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C252

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C254

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C255

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C259

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C260

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C261

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C262

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C263

1-165-722-31

ELECT 100UF 20% 10V

C264

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C265

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C266

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C267

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C268

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C269

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C270

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C300

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C301

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C302

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C303

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C304

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C305

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C306

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C307

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C308

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C309

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C310

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C311

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C312

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C320

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C324

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C325

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C327

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C328

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C329

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C330

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C331

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C332

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C333

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C334

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C335

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C336

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C500

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C502

1-124-779-00

ELECT CHIP 10UF 20.00% 16V

C503

1-104-665-11

ELECT 100UF 20.00% 25V

C505

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C508

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C509

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C600

£ 1-165-437-11

FILM 0.22UF 275V

C601

£ 1-113-907-51

CERAMIC 0.0022UF 20.00% 250V

C602

£ 1-113-907-51

CERAMIC 0.0022UF 20.00% 250V

C603

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C604

1-107-681-41

ELECT 33UF 20.00% 450V

C605

1-161-754-00

CERAMIC 0.001UF 10.00% 2KV

C606

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

Page 32

- 32

C807

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C808

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C809

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C810

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C811

1-128-551-11

ELECT 22UF 20.00% 63V

C813

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C815

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C816

1-126-947-11

ELECT 47UF 20.00% 35V

C817

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C820

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C822

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C823

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C824

1-164-506-11

CERAMIC CHIP 4.7UF 16V

C825

1-126-947-11

ELECT 47UF 20.00% 35V

C826

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C827

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C828

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C829

1-115-566-11

CERAMIC CHIP 4.7UF 10.00% 10V

C830

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C831

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C832

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C833

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C834

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C835

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C836

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C837

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C838

1-128-551-11

ELECT 22UF 20.00% 63V

C839

1-126-964-11

ELECT 10UF 20.00% 50V

C840

1-126-964-11

ELECT 10UF 20.00% 50V

C841

1-126-964-11

ELECT 10UF 20.00% 50V

C842

1-126-964-11

ELECT 10UF 20.00% 50V

C843

1-126-964-11

ELECT 10UF 20.00% 50V

C844

1-126-964-11

ELECT 10UF 20.00% 50V

C846

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C847

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C849

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C850

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C851

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C852

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C853

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C854

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C855

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C856

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C857

1-162-927-11

CERAMIC CHIP 100PF 5.00% 50V

C858

1-162-927-11

CERAMIC CHIP 100PF 5.00% 50V

C859

1-162-927-11

CERAMIC CHIP 100PF 5.00% 50V

C860

1-162-927-11

CERAMIC CHIP 100PF 5.00% 50V

C1009

1-115-339-11

CERAMIC CHIP 0.1UF 10.00% 50V

C1011

1-117-720-11

CERAMIC CHIP 4.7UF 10V

C1013

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C607

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C608

1-126-967-11

ELECT 47UF 20.00% 50V

C609

1-126-960-11

ELECT 1UF 20.00% 50V

C610

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C611

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C612

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C613

1-128-946-31

ELECT 2200UF 20% 10V

C614

1-128-945-31

ELECT 1000UF 20% 10V

C615

1-107-792-11

CERAMIC 100PF 5.00% 1KV

C616

1-126-965-91

ELECT 22UF 20.00% 50V

C617

1-126-964-11

ELECT 10UF 20.00% 50V

C618

1-107-792-11

CERAMIC 100PF 5.00% 1KV

C619

1-128-958-31

ELECT 470UF 20% 35V

C620

1-126-964-11

ELECT 10UF 20.00% 50V

C621

1-128-945-31

ELECT 1000UF 20% 10V

C622

1-128-945-31

ELECT 1000UF 20% 10V

C627

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C628

1-165-722-31

ELECT 100UF 20% 10V

C630

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C633

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C635

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C636

1-164-004-11

CERAMIC CHIP 0.1UF 10.00% 25V

C637

1-165-722-31

ELECT 100UF 20% 10V

C638

1-115-339-11

CERAMIC CHIP 0.1UF 10.00% 50V

C639

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C640

1-117-342-91

ELECT 220UF 20.00% 35V

C644

1-126-964-11

ELECT 10UF 20.00% 50V

C645

1-113-907-51

CERAMIC 0.0022UF 20.00% 250V

C646

£ 1-117-703-51

CERAMIC 0.0047UF 99% 250V

C647

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C648

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C649

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C650

1-100-152-91

CERAMIC CHIP 100PF 5% 100V

C651

1-100-152-91

CERAMIC CHIP 100PF 5% 100V

C700

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C702

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C703

1-164-506-11

CERAMIC CHIP 4.7UF 16V

C704

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C706

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C707

1-164-506-11

CERAMIC CHIP 4.7UF 16V

C711

1-165-176-11

CERAMIC CHIP 0.047UF 10.00% 16V

C713

1-164-506-11

CERAMIC CHIP 4.7UF 16V

C715

1-164-506-11

CERAMIC CHIP 4.7UF 16V

C800

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C801

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C802

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C803

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C804

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C805

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

C806

1-125-837-91

CERAMIC CHIP 1UF 10% 6.3V

Page 33

- 33

C1015

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C1016

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1020

1-126-933-11

ELECT 100UF 20.00% 16V

C1021

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1022

1-126-966-11

ELECT 33UF 20.00% 50V

C1023

1-115-339-11

CERAMIC CHIP 0.1UF 10.00% 50V

C1042

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1045

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1048

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1049

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1050

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C1051

1-162-964-11

CERAMIC CHIP 0.001UF 10.00% 50V

C1052

1-126-966-11

ELECT 33UF 20.00% 50V

C1053

1-126-966-11

ELECT 33UF 20.00% 50V

C1060

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

C1063

1-107-826-11

CERAMIC CHIP 0.1UF 10.00% 16V

< CONNECTOR >

CN202

1-766-281-11

PIN, CONNECTOR (PC BOARD) 8P

CN600

£*1-580-689-11

PIN, CONNECTOR (PC BOARD) 4P

CN800

*1-817-725-11

CONNECTOR (SQUARE TYPE) 21P

CN801

*1-817-725-11

CONNECTOR (SQUARE TYPE) 21P

< DIODE >

D500

8-719-914-43

DIODE DAN202K

D502

8-719-064-11

DIODE SPR-325MVW

D505

8-719-073-11

DIODE BZA456A

D506

8-719-914-43

DIODE DAN202K

D600

£ 8-719-064-12

DIODE S1NB60-4062

D601

8-719-077-02

DIODE RS1J

D602

8-719-077-03

DIODE BZG03-C180/T1

D604

6-500-807-01

DIODE BAS19/T1

D606

8-719-076-14

DIODE MBRB760-31

D607

8-719-077-02

DIODE RS1J

D608

8-719-083-87

DIODE UDZS-TE17-33B

D609

8-719-076-39

DIODE ES2G

D610

8-719-404-50

DIODE MA111-TX

D611

8-719-158-49

DIODE RD12SB2

D612

8-719-076-73

DIODE UGB8BT-31

D704

8-719-914-43

DIODE DAN202K

D800

8-719-071-50

DIODE BZA408B-115

D801