Page 1

UNIVERSAL CONTROL PANEL

UCP-8060

MAINTENANCE MANUAL

1st Edition

Serial No. 10001 and Higher

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! A VERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

UCP-8060

Page 3

For the U.S.A

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

WARNING

This unit has no power switch.

When installing the unit, incorporate a readily

accessible disconnect device in the fixed wiring, or

connect the power cord to a socket-outlet which must

be provided near the unit and easily accessible, so that

the user can turn off the power in case a fault should

occur.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the rear of

the unit 10 cm (4 inches) or more away from walls

in order to obtain proper exhaust and radiation of

heat.

WARNUNG

Dieses Gerät hat keinen Netzschalter.

Beim Einbau des Geräts ist daher im Festkabel ein

leicht zugänglicher Unterbrecher einzufügen, oder das

ß

Netzkabel mu

mit einer in der Nähe des Geräts

befindlichen, leicht zugänglichen Wandsteckdose

verbunden werden, damit sich bei einer

Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

When using a LAN cable:

For safety,do not connect to the connector for

peripheral device wiring that might have excessive

voltage.

UCP-8060

1 (P)

Page 4

Page 5

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Related manuals................................................................................................... 3 (E)

Contents ............................................................................................................... 4 (E)

Trademarks .......................................................................................................... 4 (E)

1. Service Overview

1-1. Removing the Upper Panel ...................................................................1-1 (E)

1-2. Main Parts Location ..............................................................................1-1 (E)

1-3. System Indicator and Status Indicator...................................................1-2 (E)

1-3-1. System Indicator...................................................................1-2 (E)

1-3-2. Status Indicator.....................................................................1-2 (E)

1-4. Troubleshooting ....................................................................................1-3 (E)

1-5. Replacing the Board ..............................................................................1-8 (E)

1-5-1. MB-978 Board .....................................................................1-8 (E)

1-5-2. CPU-352 Board ....................................................................1-9 (E)

1-5-3. TouchEngine Board .............................................................1-9 (E)

1-6. Replacing the Main Parts ....................................................................1-10 (E)

1-6-1. Switching Regulator ...........................................................1-10 (E)

1-6-2. Rotary Encoder...................................................................1-11 (E)

1-6-3. Inverter Unit .......................................................................1-12 (E)

1-6-4. LCD Panel ..........................................................................1-13 (E)

1-6-5. Back Light ..........................................................................1-14 (E)

1-6-6. Touch Panel........................................................................1-14 (E)

1-7. Replacing the Fuse/IC Link ................................................................1-15 (E)

1-8. Initializing System Setting Value........................................................1-15 (E)

1-9. System File Recovery .........................................................................1-16 (E)

UCP-8060

2. Spare Parts

2-1. Notes on Repair Parts.................................................................................. 2-1

2-2. Exploded Views .......................................................................................... 2-2

2-3. Electrical Parts List ..................................................................................... 2-5

2-4. Supplied Accessories List .........................................................................2-10

2-5. Power Cords List....................................................................................... 2-10

2-6. Optional Fixtures List ...............................................................................2-10

1 (E)

Page 6

3. Semiconductor Pin Assignments

4. Circuit Description and Overall Block Diagram

4-1. Circuit Description ................................................................................4-1 (E)

4-2. Overall Block Diagram ............................................................................... 4-2

5. Schematic Diagrams

CN-2284....................................................................................................5-1

CPU-352 ...................................................................................................5-2

KY-537 ....................................................................................................5-5

LED-397 ...................................................................................................5-6

MB-978 ....................................................................................................5-7

PS-635 ..................................................................................................5-12

SW-1098 ................................................................................................. 5-13

SW-1099 ................................................................................................. 5-13

VR-282 .................................................................................................. 5-14

Frame Wiring ..........................................................................................5-15

6. Board Layouts

CN-2284....................................................................................................6-1

CPU-352 ...................................................................................................6-1

KY-537 ....................................................................................................6-2

LED-397 ...................................................................................................6-2

SW-1099 ................................................................................................... 6-2

VR-282 .................................................................................................... 6-2

MB-978 ....................................................................................................6-3

PS-635 ....................................................................................................6-4

2 (E)

UCP-8060

Page 7

Purpose of this manual

Related manuals

Manual Structure

This manual is the maintenance manual of Universal Control Panel UCP-8060.

This manual is intended for use by trained system and service engineers, and

describes the information for maintenance and detailed service.

The following manuals are prepared for UCP-8060.

..

. Operation Manual (Supplied with UCP-8060)

..

This manual describes the notes on operating, the locations and functions of parts,

and controls of UCP-8060.

..

. Installation Manual (Supplied with UCP-8060)

..

This manual describes the information on installing the UCP-8060.

..

. User’s Guide (Available on request)

..

This manual describes the operations of the operation software.

If this manual is required, please contact your local Sony Sales Office/Service

Center.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

service manual for the corresponding unit. The service manual contains a complete list of all semiconductors and their ID Nos., and thus should be used together

with the CD-ROM.

Part number: 9-968-546-XX

UCP-8060

3 (E)

Page 8

Contents

This manual is organized by following sections.

Section 1 Service Overview

This section explains the information and procedure required for service such as

functions and operations of system indicator and status indicator, causes and

remedies of the troubles, and replacement of main parts.

Section 2 Spare Parts

This section describes the spare parts.

Section 3 Semiconductor Pin Assignments

This section contains information on semiconductors used for unit.

It includes a complete list of the semiconductors and their ID Nos. for retrieving

information on “Semiconductor Pin Assignments” CD-ROM, which is available

separately.

Please refer to this section together with the “Semiconductor Pin Assignments” CDROM.

Information on the semiconductors not contained in the CD-ROM at the time of

issue of this manual, if any, is given in this section as well.

Section 4 Circuit Description and Overall Block Diagram

This section describes the circuit description and overall block diagram.

Trademarks

Section 5 Schematic Diagrams

This section describes the schematic diagrams of each board, and frame wiring.

Section 6 Board Layouts

This section describes the board layouts and locatious of components.

Trademarks and registered trademarks used in this manual are follows.

. Java is a registered trademark of Sun Microsystems, Inc..

. Memory Stick is a trademark of Sony Corporation.

. MultiMediaCard is a trademark of Infineon Technologies AG.

. TouchEngine is a trademark of Sony Corporation.

Other system names, product names, and company names appearing in this manual

are trademarks or registered trademarks of their respective holders.

4 (E)

UCP-8060

Page 9

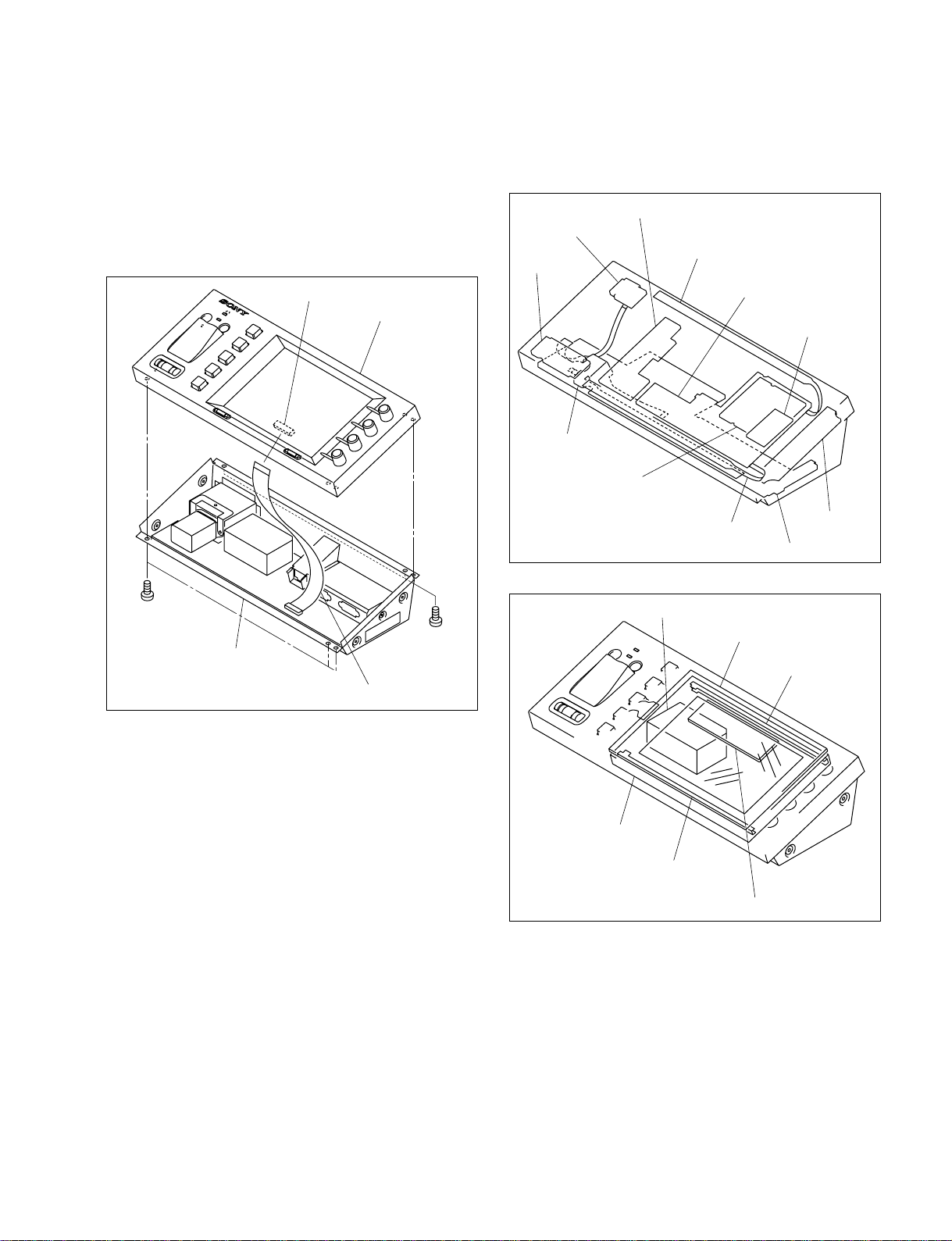

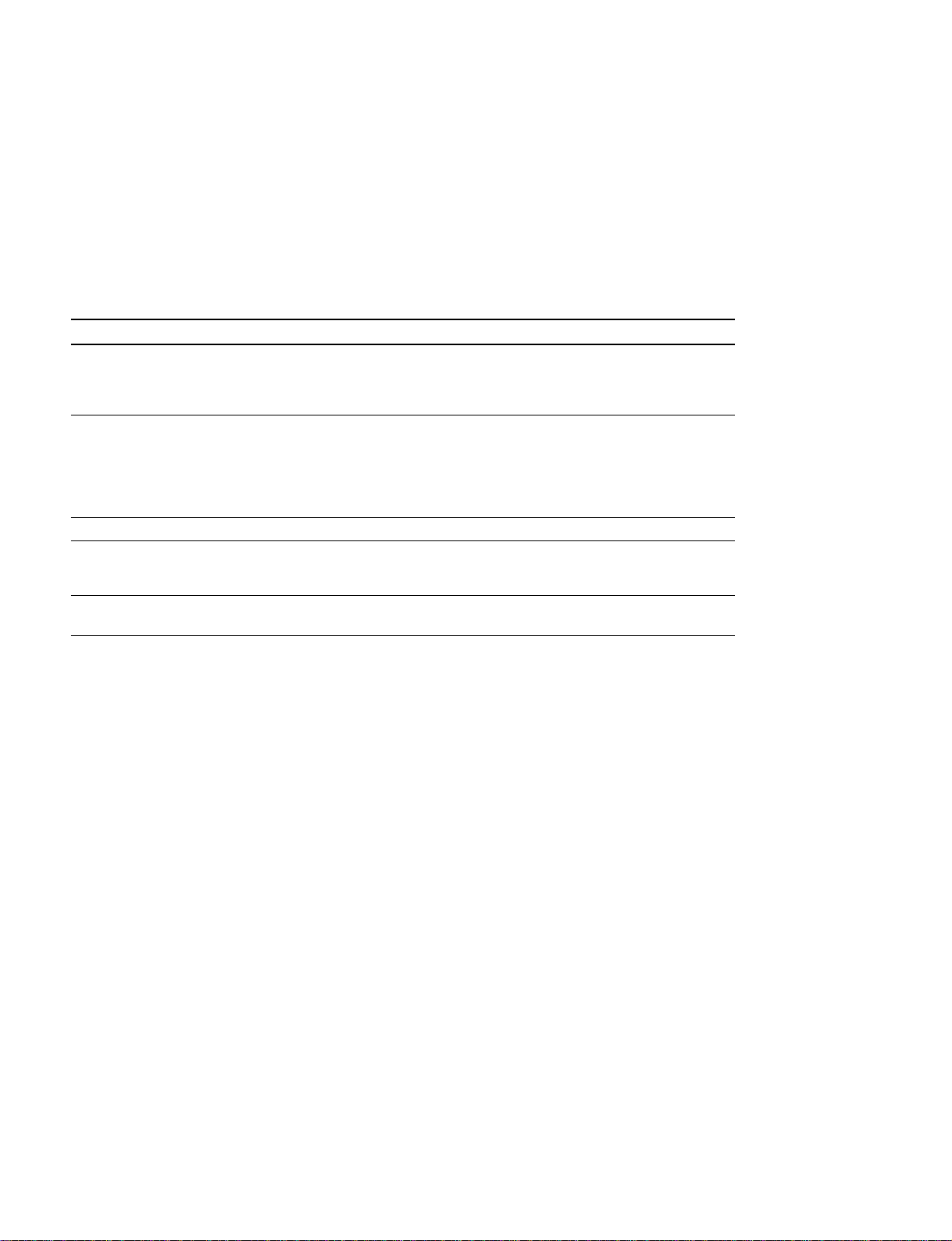

Section 1

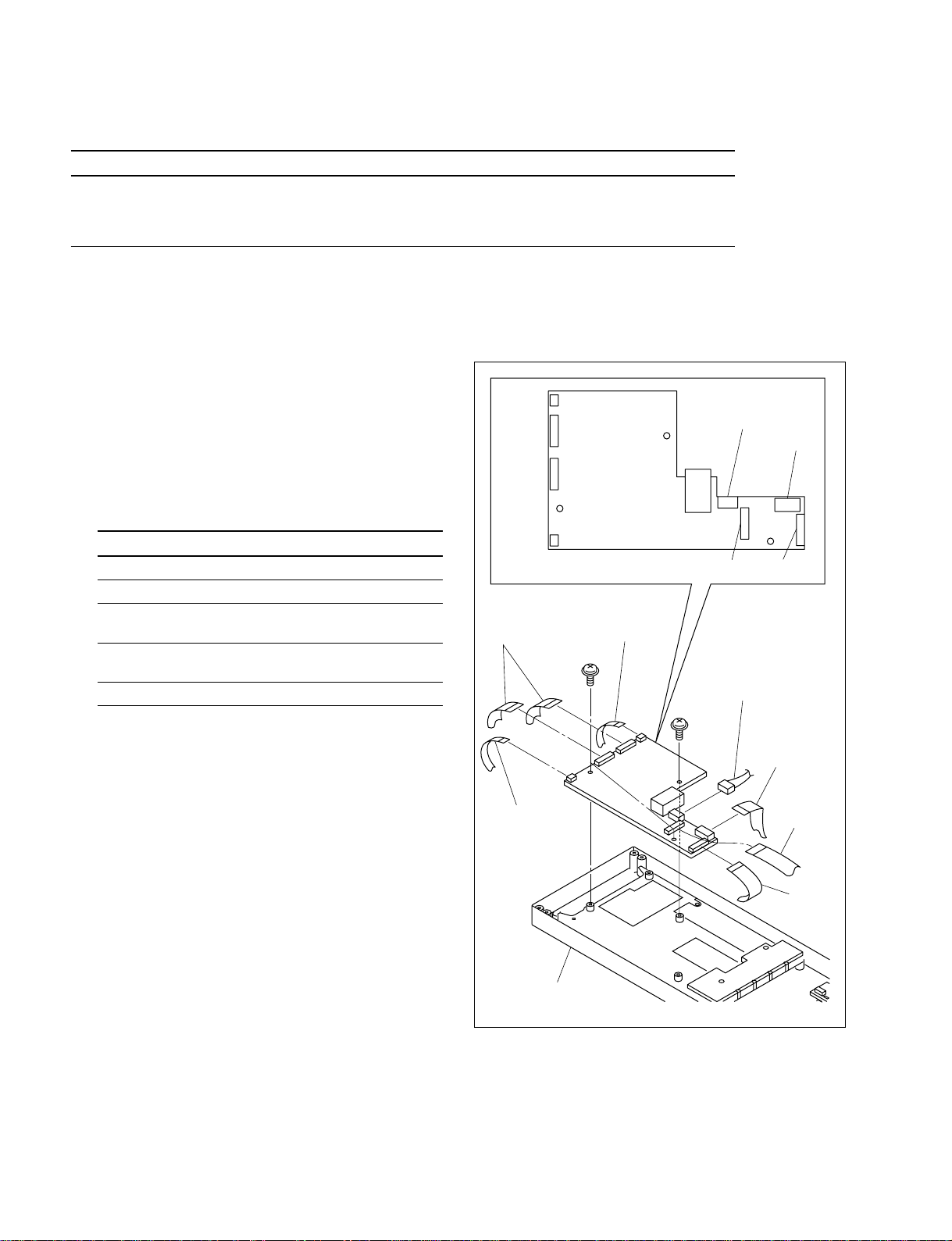

LED-397 board

CPU-352 board

VR-282 board

CN-2284 board

TouchEngine board

TouchEngine board

SW-1098 board

PS-635 board

SW-1099

board

KY-537 board

MB-978 board

Touch panel

Switching regulator

LCD panel

Back light

Inverter unit

Back light

Service Overview

1-1. Removing the Upper Panel

1. Remove the six screws, then remove the upper panel.

2. Disconnect one flexible flat cable from the connector

(CN101) on the MB-978 board.

CN101

Upper panel

B 3x5

B 3x5

Lower panel

1-2. Main Parts Location

Flexible flat cable

UCP-8060

1-1 (E)

Page 10

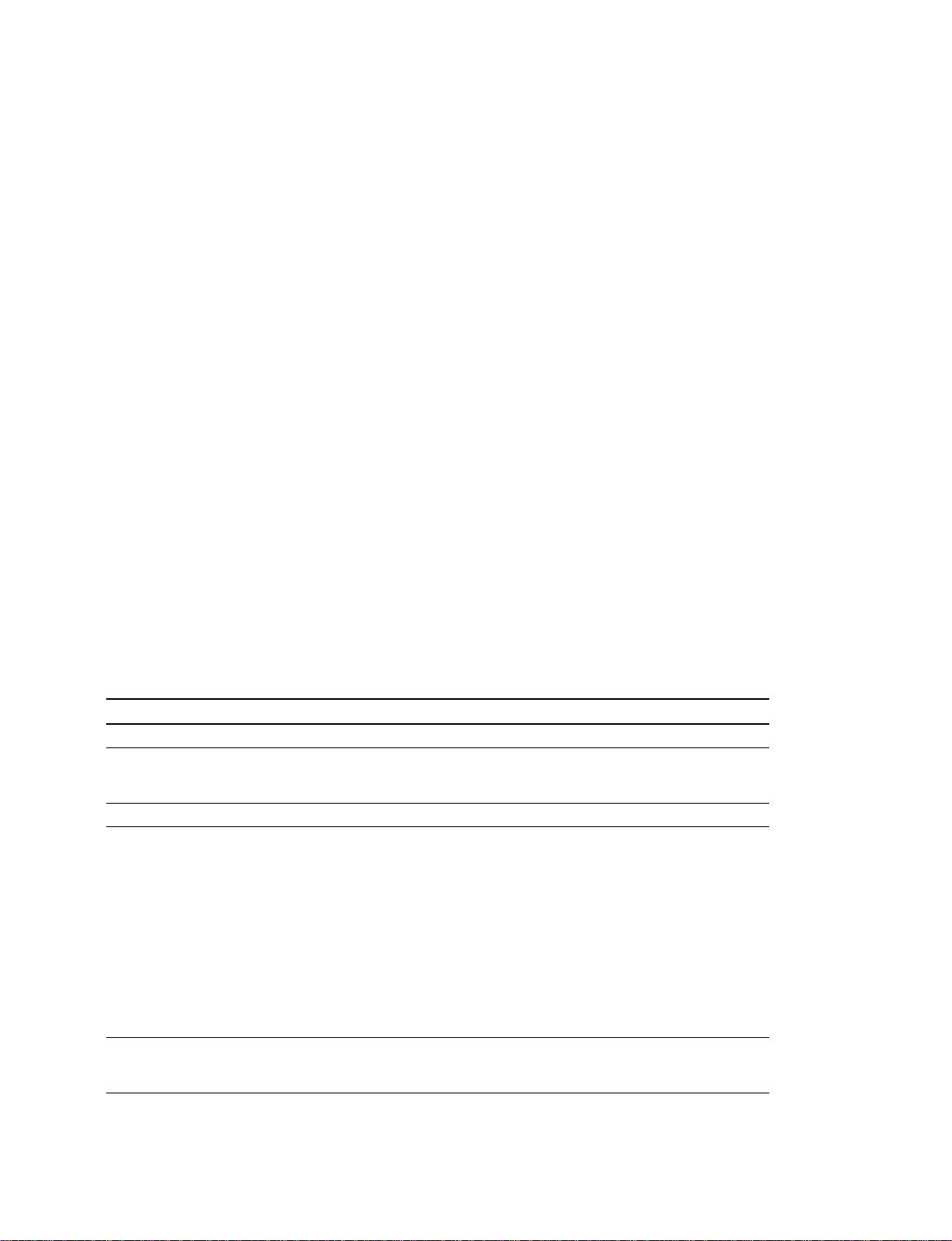

1-3. System Indicator and Status Indicator

1-3. System Indicator and Status Indicator

1-3-1. System Indicator

The system indicator mainly indicates the operation status of the hardware.

The system indicator lights in red when the power is turned on. Generally it changes to amber soon, and

then to green when the system normally starts. If not, the indicator blinks in green or amber. In this case,

the system file needs to be reinstalled using the boot-up MMC (MultiMediaCard). (Refer to Section 1-9.)

Color of light Functions of indicator System operation/status

Red (lights) Lights on immediately after startup. Resetting hardware, etc.

Amber (lights) Indicates that the CPU started. Downloading Configuration data to FPGA

Green (lights) Indicates that the operation software started. Startup screen is displayed.

Green (blinks) Indicates that although the download of

Amber (blinks) Indicates that the download of Configuration data is

The indicator stays lit in red if there is no boot

program such as the case that nothing is written

in the flash memory.

The indicator changes to green when the (approx. 7 seconds)

download of Configuration data to FPGA is

completed. In case that the indicator stays lit in

amber, it means that a configuration error

(Configuration file is not normal, etc.) has occurred.

Configuration data is completed, an error was

detected in the initial check of FPGA.

failed and the UCP-8060 cannot start due to an error.

1-3-2. Status Indicator

The functions of status indicator at the power-on/restart are different from those when the Memory Stick

is used.

At the power-on/restart

The UCP-8060 checks the file of operation software installed and indicates the results with the status indicator.

..

. Amber (blinks)

..

Indicates that the status error related to the software is detected.

The status indicator blinks in amber when the UCP-8060 cannot start in such case that the system file is

damaged although the CPU is not damaged. At the same time, the system indicator lights in red or amber,

or blinks in amber.

The number of blinking varies depending on the type of error. In any case, install the system file again.

(Refer to the operation manual.)

n

The system file is checked before FPGA starts. Therefore the indication at the power-on /restart is not

mixed up with the status indication when the Memory Stick is used.

..

. Amber (Continuously blinks)

..

Indicates that FPGA is not normal. The system indicator blinks in amber at the same time.

If FPGA is not normal, the LCD module cannot be controlled. Therefore the system cannot start. In this

case, the system automatically tries to start the BIOS UTILITY after continuously blinking in amber for

ten times. If the BIOS UTILITY can be started, the communication via RS-232C is enabled.

1-2 (E)

UCP-8060

Page 11

When Memory Stick is used

Green (lights): Indicates that the data is read to the Memory Stick

Red (lights): Indicates that the data is written in the Memory Stick

Amber (lights): Indicates that the system is in other operation

1-4. Troubleshooting

Index

. Power cannot be turned on.

. Back light does not light.

. Buzzer does not sound.

. Function switch cannot be operated, or does not light.

. Control knobs cannot be operated.

. Jog roller or jog L or R button cannot be operated.

. Select L or R button cannot be operated.

. Data in the Memory Stick cannot be read.

. Although the back light is lit, nothing is displayed on the LCD panel.

. The UCP-8060 cannot communicate via RS-232C.

. The UCP-8060 cannot communicate via LAN.

. Touch panel does not operate.

. TouchEngine does not operate.

. TouchEngine is weak. (Sensitivity of the touch panel feels weak.)

. Clock does not operate.

. Back light is dark.

1-3. System Indicator and Status Indicator

1-4. Troubleshooting

Power cannot be turned on.

Status and possible cause Remedy

Power cord is disconnected. Check if the power cord is connected.

The UCP-8060 is starting up. Wait for a while.

(System indicator lights in amber) The system indicator changes to green in about 15 seconds

and the UCP-8060 starts up when it is in normal operation.

Fuse is blown. Replace the fuse (F101).

Power supply of 5 V, 3.3 V and 2.5 V are not Check if each power supply is normally output.

normally output. . 5 V : TP102, TP101/PS-635 board

System indicator lights in red. Replace the CPU (IC202) on the CPU-352 board. If the

. 3.3 V : TP102/MB-978 board

. 2.5 V : TP103/MB-978 board

5 V is not output.

Replace the AC/DC converter (CP101) on the PS-635 board.

If 5 V is not still output, replace the AC inlet (CN105).

5 V is output, but 3.3 V and 2.5 V are not output.

Check the connection of the harness between the PS-635

board and the MB-978 board.

If the power supply is not output although the connection is

correct, replace the corresponding regulator IC (IC101 or

IC102).

system indicator still lights in red, replace the flash ROM

(IC203).

UCP-8060

1-3 (E)

Page 12

1-4. Troubleshooting

Back light does not light.

Status and possible cause Remedy

Power is not turned on. Check if the power cord is connected.

Back light is broken. If the system indicator lights in green, replace the back light. If

the back light does not light after replacing the back light,

replace the inverter unit.

System indicator lights in red or amber. Replace the CPU (IC202) on the CPU-352 board.

Buzzer does not sound.

Status and possible cause Remedy

Sound Level is set to 0 in the Device Control Set the Sound Level to the level other than 0.

menu of the SYSTEM SETUP UTILITY.

(Refer to the operation manual.)

Buzzer is broken. If the buzzer does not sound although the Sound Level is set

to the level other than 0, replace the buzzer (BZ101).

Function switch cannot be operated, or does not light.

Status and possible cause Remedy

The connection between the KY-537 board and Check the operation in the Self Diagnosis menu of the

the MB-978 board is not correct. SYSTEM SETUP UTILITY. If the results of the Self Diagnosis

Function switch is broken.

It results from the specifications or setting of Check that the function switch lights in green → red → amber

operation software. (It is not failure.) sequentially every time it is pressed in the Self Diagnosis

are not normal, check the connection of the harness between

the KY-537 board and the MB-978 board. If the connection is

correct, replacethe corresponding function switch (S301S305/KY-537 board).

menu of the SYSTEM SETUP UTILITY. If the switch lights

sequentially, refer to the user’s guide of each operation

software and check the setting.

Control knob cannot be operated.

Status and possible cause Remedy

The connection between the VR-282 board and Check the operation in the Self Diagnosis menu of the

the MB-978 board is not correct. SYSTEM SETUP UTILITY. If the results of the Self

Rotary encoder is broken.

It results from the specifications or setting of Check the operation in the Self Diagnosis menu of the

operation software. (It is not failure.) SYSTEM SETUP UTILITY. If the control knob operates, refer

Diagnosis are not normal, check the connection of the

harness between the VR-282 board and the MB-978 board.

If the connection is correct, replace the corresponding rotary

encoder (EN201-EN204).

to the user’s guide of each operation software and check the

setting.

1-4 (E)

UCP-8060

Page 13

Jog roller, jog L button, or jog R button cannot be operated.

Status and possible cause Remedy

The connection between the SW-1099 board and Check the operation in the Self Diagnosis menu of the

the SW-1098 board is not correct. SYSTEM SETUP UTILITY. If the results of the Self Diagnosis

Jog roller is broken.

Jog L button or Jog R button is broken.

It results from the specifications or setting of Check the operation of the jog roller and jog L and R buttons

operation software. (It is not failure.) in the Self Diagnosis menu of the SYSTEM SETUP UTILITY.

are not normal, check the following.

Check the connection of the harness between the SW-

1098 board and the SW-1099 board.

If the connection is correct, the system indicator is lit and the

jog L and R buttons operate normally, replace the jog roller

(EN701).

Check the connection of the harness between the SW-

1098 board and the MB-978 board.

If the connection is correct and the system indicator is lit, but

the jog L or R button does not operate normally, replace the

jog L or R button (S701 or S702).

If they operate, refer to the user’s guide of each operation

software and check the setting.

Select L button or select R button cannot be operated.

1-4. Troubleshooting

Status and possible cause Remedy

The connection between the SW-1098 board and Check the operation in the Self Diagnosis menu of the

the MB-978 board is not correct. SYSTEM SETUP UTILITY. If the results of the Self Diagnosis

Select L or R button is broken.

It results from the specifications or setting of Check the operation of the Select L and R buttons in the Self

operation software. (It is not failure.) Diagnosis menu of the SYSTEM SETUP UTILITY. If they

are not normal, check the connection of the harness

between the SW-1098 board and the MB-978 board. If the

connection is correct, replace the select L or R button (S1 or

S2).

operate, refer to the user’s guide of each operation software

and check the setting.

Data in the Memory Stick cannot be read.

Status and possible cause Remedy

The connection between Memory Stick connector Check the connection of the harness between the Memory

and the SW-1098 board is not correct. Stick connector and theSW-1098 board.

Although the back light is lit, nothing is displayed on the LCD panel.

Status and possible cause Remedy

LCD module and the CN-2284 board are not Check the connection of the harnesses if the LCD module and

correctly connected to the MB-978 board. the CN-2284 board are correctly connected to the MB-978

IC on the MB-978 board is broken.

LCD module is broken.

board. If the connection is correct, replace IC202 on the MB-

978 board. If nothing is displayed after replacing IC202,

replace the LCD module.

UCP-8060

1-5 (E)

Page 14

1-4. Troubleshooting

The UCP-8060 cannot communicate via RS-232C.

Status and possible cause Remedy

Matching cable is not used. Check if the cross cable is used.

Cross cable is broken. Check the cross cable.

Communication conditions of PC are not correct. Correct the communication conditions of PC.

RS-232C connector or communication IC is Check the communication status in the following procedure.

broken. 1. Connect the personal computer (referred to as PC hereafter) to

the RS-232C connector on the UCP-8060 with the RS-232C

cross cable.

2. Turn on the power of the PC and start the terminal software.

3. Set the communication conditions as follows;

Baud rate 9600

Data 8 bit

Parity None

Stop 1 bit

Flow control None

4. Start the BIOS UTILITY of the UCP-8060. (For startup

procedure, refer to the “Basic Operations” (Confirming of the

Basic Information) in the operation manual.)

Check of transmission

If the following message appears on the terminal screen, the

transmission is being performed.

# Welcome to BIOS SETUP UTILITY for UCP-8060 vx.xx

>

Check of reception

Type any letter with the keyboard.

If the typed letter appears on the screen, the reception is being

performed.

BIOS UTILITY

version

Replace the corresponding component (CN102 or IC101/PS-635

board) based on the results of communication check.

The UCP-8060 cannot communicate via LAN.

Status and possible cause Remedy

LAN cable is broken. If the indicator (amber) of the DATA LAN connector neither lights

IP address is not correct. Set the IP address correctly.

nor blinks, check the LAN cable.

If the communication cannot be done although the IP address

setting is correct, replace the DATA LAN connector (CN401). If

the communication cannot be done after replacing the DATA LAN

connector (CN401), replace the PHY chip IC (IC401).

1-6 (E)

UCP-8060

Page 15

Touch panel does not operate.

Status and possible cause Remedy

The connection between the MB-978 board Check the connection of the harness between the touch panel and

and touch panel is not correct. the MB-978 board. If the connection is correct, replace the touch

panel.

Touch panel or touch panel drive circuit is Replace FPGA (IC202) on the MB-978 board. If the touch panel

broken. does not operate after replacing FPGA (IC202), replace the A/D

converter IC (IC304). If the touch panel does not operate after

replacing the A/D converter IC (IC304), replace the touch panel.

It results from the specifications or setting of If the calibration can be set in the Calibrate Touch Panel menu of

operation software. (It is not failure.) the SYSTEM SETUP UTILITY and any line can be drawn in the

Scribble Test menu, refer to the user’s guide of each operation

software and check the setting.

TouchEngine does not operate.

Status and possible cause Remedy

Operation setting of TouchEngine is set to OFF. Set the Touch Engine Force to the setting other than OFF in the

Device Control menu of the SYSTEM SETUP UTILITY.

The connection between the TouchEngine Check the connection of the harness between the TouchEngine

board and the MB-978 board is not correct. board and the MB-978 board.

20 V is not output from the MB-978 board. Measure the voltage of TP501 on the MB-978 board. It is no

problem if the voltage is between 19.0 V and 20.0 V.

If 20 V is output, replace the piezoelectric actuator. If 20 V is not

output, replace the corresponding component of the step-up

circuit (Q505, IC502, etc.).

1-4. Troubleshooting

TouchEngine is weak. (Sensitivity of the touch panel feels weak.)

Status and possible cause Remedy

Operation setting of the TouchEngine is set Set the Touch Engine Force to MID or HARD in the Device

to SOFT. Control menu of the SYSTEM SETUP UTILITY. If you still feel the

TouchEngine weak although the Touch Engine Force is set to

MID or HARD, replace the TouchEngine board.

Clock does not operate.

Status and possible cause Remedy

Backup power is not supplied. Measure the voltage of TP201 on the CPU-352 board. If the

Crystal Oscillator for clock is not operating. Check if the crystal oscillator (X201) on the CPU-352 board is

voltage is 2.8 V or less, perform charging. If the clock does not

operate after charging, replace the corresponding component of

the backup power supply circuit (Q101, Q102, C101, etc.).

operating. If it is not oscillating at 32.768 kHz (±20 ppm), replace

the crystal oscillator (X201). If the clock does not operate although

the crystal oscillator is operating, replace the CPU (IC202).

UCP-8060

1-7 (E)

Page 16

1-4. Troubleshooting

1-5. Replacing the Board

Back light is dark.

Status and possible cause Remedy

Brightness level of the back light is low. Check the brightness of LCD in the Device Control menu of the

SYSTEM SETUP UTILITY and set to the level higher than the

current level. If the back light is dark although the level is set to

the maximum value (level 7), replace the back light.

1-5. Replacing the Board

1-5-1. MB-978 Board

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Disconnect the flexible boards, cables, and harness

from the connectors on the MB-978 board.

Connector Quantity Cable

CN301, CN304, CN306 3 Flexible flat cable

CN501, CN502 2 TouchEngine board

CN303 1 SW-1098 flexible

board

CN305 1 Touch panel flexible

board

CN302 1 Harness

3. Remove the three screws, then remove the MB-978

board.

4. Remove the CPU-352 board. (Refer to Section 1-5-2.)

CN501

CN306

CN304

CN502

Flexible flat

cables

MB-978 board (Side B)

TouchEngine

board

PSW

3x6

CN302

CN303 CN301

Harness

PSW

3x6

Touch panel

flexible board

CN305

1-8 (E)

SW-1098

TouchEngine

board

Upper panel

flexible

board

Flexible

flat cable

5. Install the new MB-978 board in the reverse order of

steps 1 to 4.

UCP-8060

Page 17

1-5. Replacing the Board

CN501

CN303 CN305

CN502

MB-978 board (Side B)

CN306

LCD panel

assembly

MB-978 board

TouchEngine boards

Flexible flat

cable

Touch panel

flexible board

SW-1098

flexible board

PSW

3x6

PSW

3x6

1-5-2. CPU-352 Board

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the MB-978 board. (Refer to Section 1-5-1.)

3. Open the two hooks of the connector (CN102) on the

MB-978 board in the direction of the arrow A, then

remove the CPU-352 board in the direction of the

arrow B.

CPU-352 board

CN102

MB-978 board

A

Hook

1-5-3. TouchEngine Board

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the two TouchEngine boards from the

connectors (CN501 and CN502), one flexible flat

cable from the connector (CN306), one touch panel

flexible board from the connector (CN305), and one

SW-1098 flexible board from the connector (CN303)

on the MB-978 board.

3. Remove the four screws, then remove the LCD panel

assembly.

A

Hook

B

4. Install a new CPU-352 board in the reverse order of

steps 1 to 3.

UCP-8060

1-9 (E)

Page 18

1-5. Replacing the Board

1-6. Replacing the Main Parts

4. Remove the two TouchEngine boards from the four

bosses.

Install the TouchEngine board with the

piezoelectric actuator side up.

TouchEngine board

TouchEngine board

Upper panel

Bosses

1-6. Replacing the Main Parts

1-6-1. Switching Regulator

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

n

Do not disassemble the switching regulator.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the two screws (B 3x6), then remove the heat

conducting plate.

3. Remove the two screws (M 3x8) and one screw (B

3x5), then remove the plate nut.

4. Remove the four screws (PSW 3x6), then remove the

PS-635 board.

Heat conducting plate

B

Boss

TouchEngine board

Boss

5. Install new TouchEngine boards in the reverse order of

steps 1 to 4.

m

. When installing the TouchEngine boards, make sure

to install them with the piezoelectric actuator side

up.

. Before attaching the LCD panel assembly, make

sure that the dust is not adhered to the surface of the

LCD panel and the backside of the touch panel.

Plate nut

A

B 3x5

A

PSW

3x6

M 3x8

B

PS-635

board

B 3x6

1-10 (E)

UCP-8060

Page 19

1-6. Replacing the Main Parts

VR-282 board

PSW 3x6

Volume knob assemblies

MB-978 board

CN306

Flexible flat cable

5. Remove the five solders fixing the switching regulator.

6. Remove the switching regulator from the PS-635

board.

Switching regulator

PS-635 board

Solders

7. Attach a new switching regulator in the reverse order

of steps 1 to 6.

1-6-2. Rotary Encoder

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the four volume knob assemblies.

n

Do not pull the volume knob assemblies by force.

Otherwise, it may damage the rotary encoders.

3. Disconnect one flexible flat cable from the connector

(CN306) on the MB-978 board.

4. Remove the two screws, then remove the VR-282

board.

UCP-8060

1-11 (E)

Page 20

1-6. Replacing the Main Parts

5. Remove the four nuts and four washers, then remove

the VR mounting plate.

6. Remove the solder from the VR-282 board, then

remove the rotary encoder.

VR mounting plate

Nut

Washer

Rotary encoders

Solder

VR-282 board

1-6-3. Inverter Unit

w

. Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

. Do not start the replacement within 30 minutes after

turning off the power to avoid the electric shock or

injury.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Disconnect the two harnesses from the connectors

(CN2 and CN3) on the inverter unit.

3. Remove the two screws, then remove the inverter unit.

4. Disconnect one harness from the inverter unit.

PSW

3x6

Harness

CN2

Inverter unit

CN3

7. Attach a new rotary encoders in the reverse order of

steps 1 to 6.

n

When attaching the rotary encoders, be sure to

temporarily secure them to the VR mounting plate

with nuts and washers before soldering to the VR-282

board.

Harnesses

MB-978 board

5. Attach a new inverter unit in the reverse order of steps

1 to 4.

1-12 (E)

UCP-8060

Page 21

1-6. Replacing the Main Parts

1-6-4. LCD Panel

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the LCD panel assembly. (Refer to steps 1 to

3 of “1-5-3. TouchEngine Board”)

3. Disconnect one flexible flat cable from the connector

(CN301) on the MB-978 board.

4. Remove the three screws, then raise the MB-978

board.

5. Raise the two wire holders, then disconnect the two

harnesses from the connectors (CN2 and CN3) on the

inverter unit.

PSW

3x6

PSW

3x6

MB-978 board

CN301

Flexible

flat cable

6. Remove the four screws, then remove the LCD panel.

7. Remove the CN-2284 board from the LCD panel.

B 3x6

LCD panel

B 3x6

CN-2284

board

MB-978 board

Inverter unit

LCD panel assembly

Wire holder

Wire holder

CN2

CN3

Harnesses

8. Attach a new LCD panel in the reverse order of steps 1

to 7.

n

Before attaching the LCD panel assembly, make sure

that the dust is not adhered to the surface of the LCD

panel and the backside of the touch panel.

UCP-8060

1-13 (E)

Page 22

1-6. Replacing the Main Parts

1-6-5. Back Light

w

. Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

. Do not start the replacement within 30 minutes after

turning off the power to avoid the electric shock or

injury.

n

When replacing, replace the two back lights at the same

time.

1. Perform steps 1 to 5 of Section 1-6-4.

2. Pull out the two back lights while pushing the two

stoppers of the LCD panel in the direction of the arrow

A.

1-6-6. Touch Panel

w

Before starting the replacement, be sure to pull out the

power plug from the wall outlet.

1. Remove the upper panel. (Refer to Section 1-1.)

2. Remove the LCD panel assembly and TouchEngine

board. (Refer to Section 1-5-3.)

3. Remove the touch panel.

Touch panel

Tape side

Guides

Guides

A

Stopper

A

LCD panel

Stopper

Back light

Back light

3. Attach new back lights in the reverse procedure.

n

Before attaching the LCD panel assembly, make sure

that the dust is not adhered to the surface of the LCD

panel and the backside of the touch panel.

Upper panel

4. Attach a new touch panel in the reverse order of steps

1 to 3.

m

. Make sure to attach the touch panel with the tape

(affixed to the touch panel flexible board) side up.

. Attach the touch panel along the guides of the upper panel

and make sure that the touch panel is securely attached.

. After installing the touch panel flexible board to the

connector (CN305) on the MB-978 board, put a crease in

the board.

(Refer to Fig. 1.)

. Before attaching the LCD panel assembly, make sure

that the dust is not adhered to the surface of the LCD

panel and the backside of the touch panel.

1-14 (E)

UCP-8060

Page 23

1-6. Replacing the Main Parts

# Welcome to BIOS SETUP UTILITY for UCP-8060 vx.xx

>

BIOS

UTILITY of

version

1-7. Replacing the Fuse/IC Link

1-8. Initializing System Setting Value

Fig. 1

CN305

MB-978 board

Put a crease.

2-4 mm

Touch panel

flexible board

1-7. Replacing the Fuse/IC Link

w

A fuse and IC link are critical parts to safe operation.

Replace this component with Sony parts whose part

numbers appear in this manual published by Sony.

If not, this may cause a fire or electric shock.

Be sure to use the specified component in this manual.

The fuses and IC links are mounted on the boards below.

Be sure to replace with the specified fuse and IC link as

shown below after removing the foreign substances that

may cause the shorts.

PS-635 board

1-8. Initializing System Setting Value

Following are the items to be initialized.

. Calibration data of touch panel

n

The unit always enters the calibration input mode at the

first startup after the initialization of system setting

value. This is because of the specification of operation

software and is not a problem.

. DEVICE CONTROL DATA file (brightness of LCD

back light, brightness of function switch, buzzer sound

volume, TouchEngine sensitivity and touch buzzer

sound off/on)

. TCP/IP setting value

Perform this initialization also when the MAC address

written in the flash memory (IC203/CPU-352 board) is

damaged, it is automatically restored based on the data

backed up in EEPROM (IC204/CPU-352 board).

Required equipment

. PC (with terminal software installed)

. RS-232C cross cable

Procedure

1. Connect the PC and the RS-232C connector of the

UCP-8060 using the RS-232C cross cable.

2. Turn on the power of the PC to start the terminal

software.

3. Set the communication conditions as follows;

Ref No. (Address) Description Parts No.

F101 (B-2) H.B.C. Fuse !1-576-228-11

PS101 (F-2) Circuit Protector !1-533-282-21

IC link 2 A

UCP-8060

Baud rate 9600

Data 8 bit

Parity None

Stop 1 bit

Flow control None

4. Start the BIOS UTILITY of the UCP-8060. (For

startup procedure, refer to the “Basic Operations”

(Confirmation of the basic information) in the

operation manual.)

Following message appears on the terminal screen.

1-15 (E)

Page 24

1-8. Initializing System Setting Value

1-9. System File Recovery

5. Type “factory” from the keyboard of the PC.

6. Press the Enter key.

The initialization starts. When it is completed, the

following message is displayed on the terminal screen.

Remove setup files for factory mode... OK

7. Terminate the terminal software.

1-9. System File Recovery

Required equipment

. PC that can copy files to the Memory Stick

. Boot-up MultiMediaCard (MMC)

For the procedure to make the boot-up MMC, refer to

Section 2-5 of the installation manual.

. Memory Stick (with nothing is written)

. System file

. Operation software (to be reinstalled after system file

recovery)

To obtain the system file and operation software, contact

your local Sony Sales Office/Service Center.

Memory Stick slot

Function button 2

Select L button

Select R button

Preparation

1. Format the Memory Stick. (Refer to the operation

manual.)

2. Turn on the power of the PC.

3. Copy the system file to any place of the PC.

4. Double-click the system file to uncompress it.

The uncompressed data is stored in the following

directory.

MSSONY/PRO/UCP

5. Insert the Memory Stick formatted in step 1 into the

PC.

6. Copy the folder including the data uncompressed in

step 4 to the Memory Stick.

7. Pull out the Memory Stick from the PC.

1-16 (E)

UCP-8060

Page 25

Installation (Update)

1. Remove the six screws, then open the upper panel.

n

Do not disconnect the flexible flat cable connecting the

PS-635 board and the MB-978 board.

2. Check that S201 (D-1) on the MB-798 board is set to

ON.

3. Insert the boot-up MMC to the CN201 (D-1) on the

MB-978 board.

4. Close the upper panel. (Securing with screws is not

required.)

5. Turn on the power of the UCP-8060.

6. While pressing the function button 2, press the select L

and R buttons simultaneously for more than three

seconds.

When the function button 2 lights on, release all

buttons.

7. Insert the Memory Stick in which the system file is

written into the Memory Stick slot of the UCP-8060.

8. Press the select R button according to the instruction

on the screen.

Updating of the system file starts.

9. Check that the message to indicate the completion of

updating is displayed on the screen.

10. Pull out the Memory Stick from the Memory Stick

slot.

11. Turn off the power of the UCP-8060.

12. Open the upper panel and pull out the boot-up MMC.

13. Close the upper panel.

1-9. System File Recovery

Operation check

1. Turn on the power of the UCP-8060.

2. Check that the Main screen is displayed.

If the Main screen is displayed, it means that the

system file is recovered.

n

In case that the Main screen is not displayed, the

hardware may be damaged.

Refer to “Although the back light is lit, nothing is

displayed on the liquid crystal panel” in “1-4.

Troubleshooting”.

3. Attach the upper panel with the six screws.

4. Install the operation software as required. (Refer to the

operation manual.)

UCP-8060

1-17 (E)

Page 26

Page 27

Section 2

Spare Parts

2-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Harness

Harnesses with no part number are not registered as

spare parts.

In need of repair, get components shown in the list and

repair using them.

2-1.

UCP-8060

2-1

Page 28

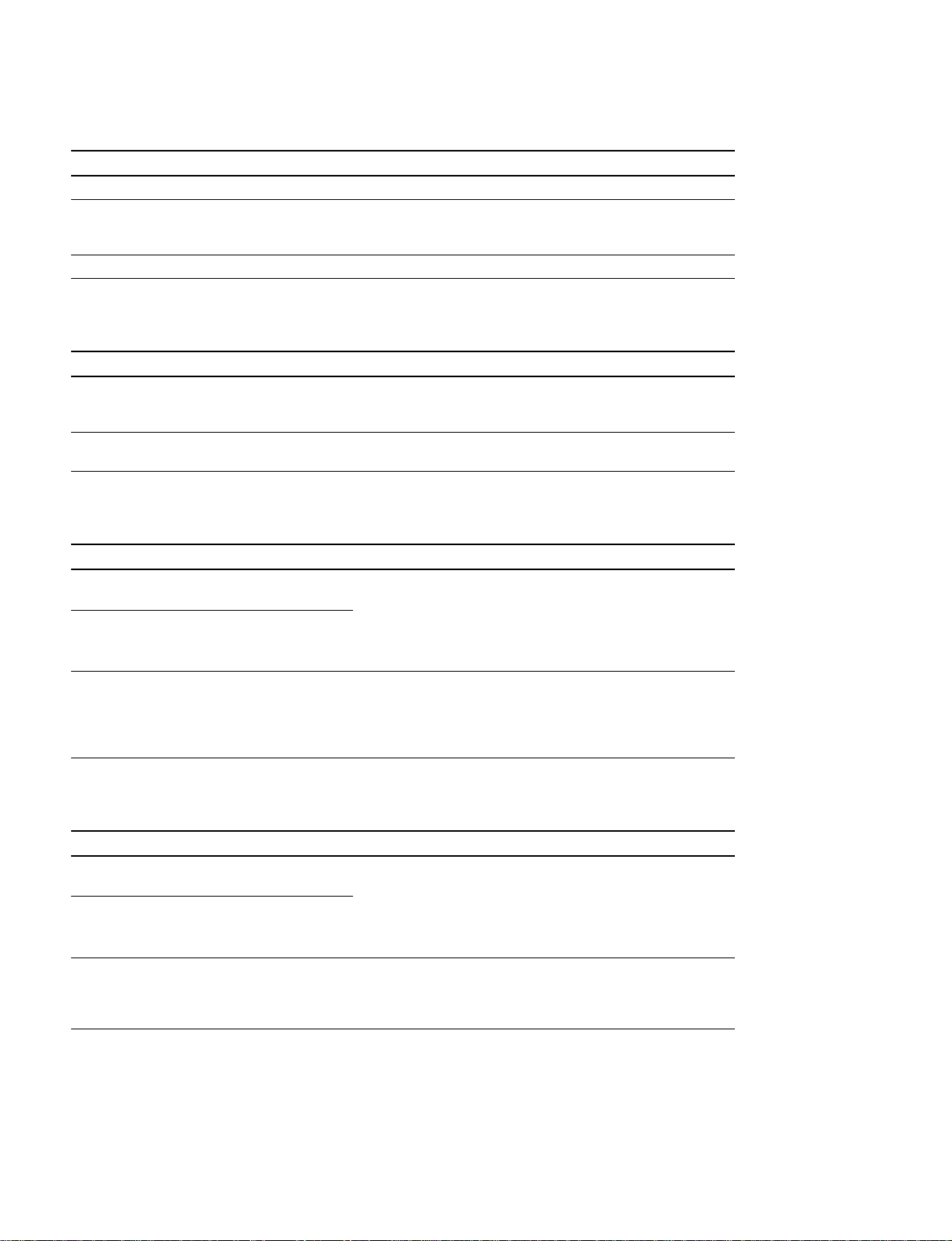

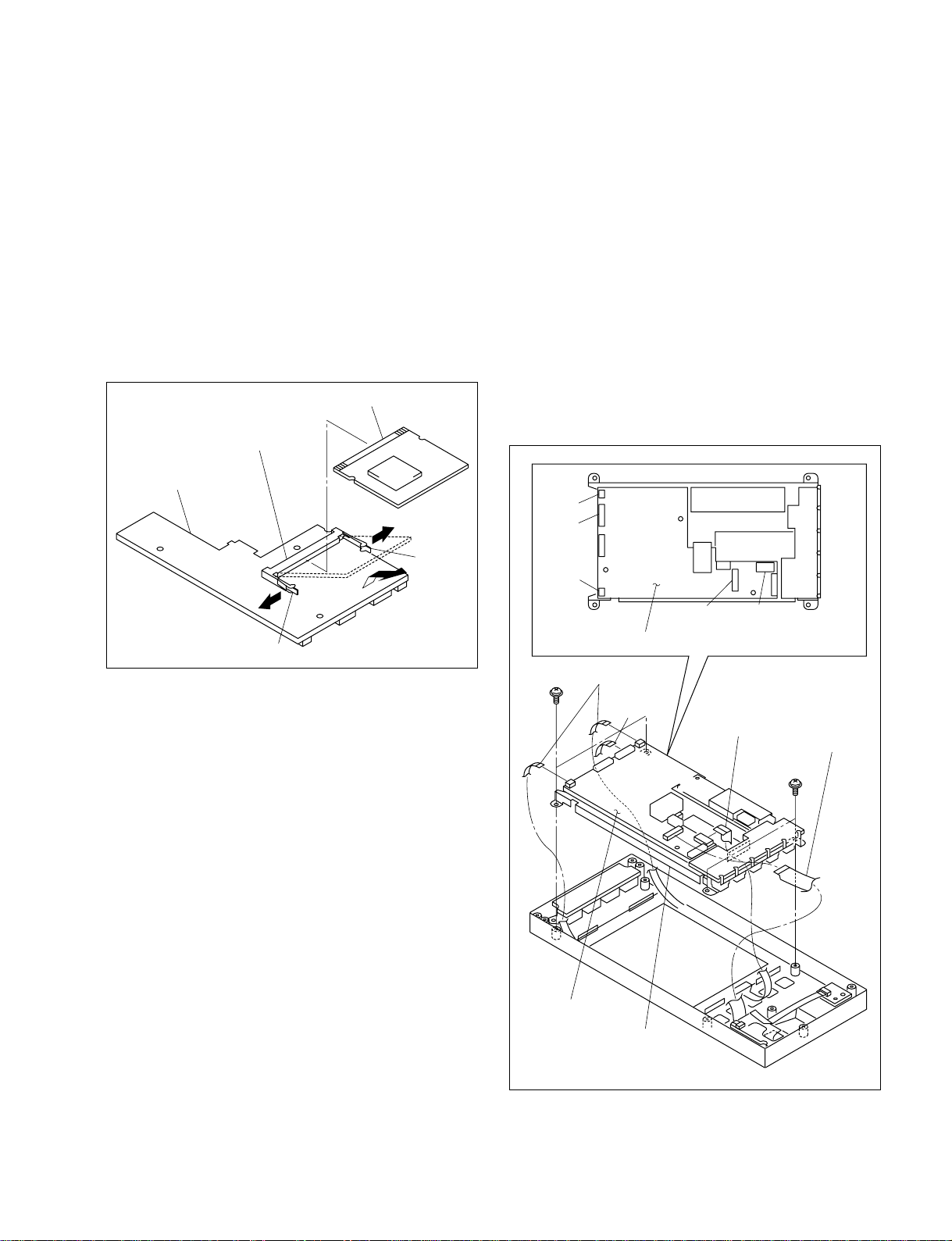

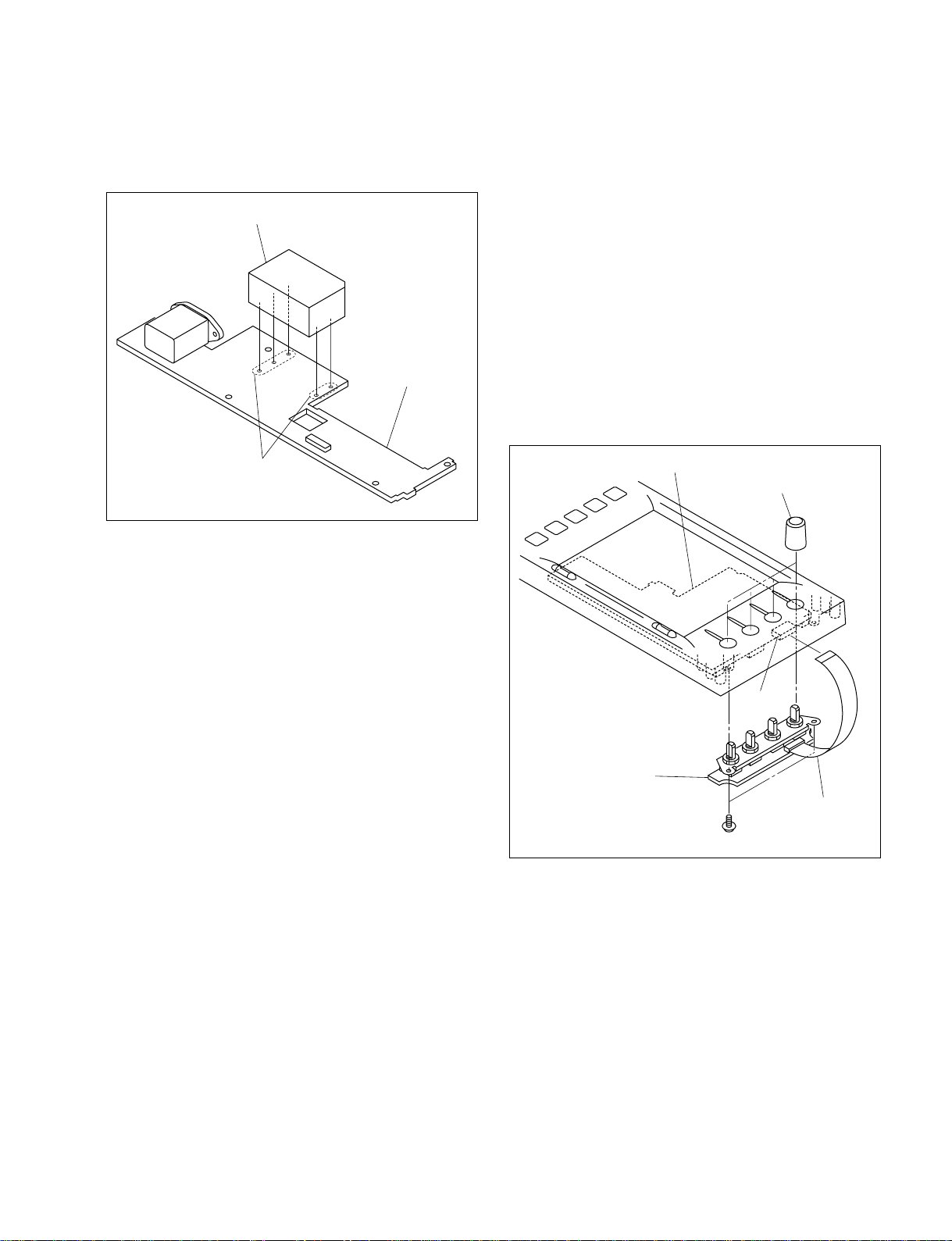

Lower Panel Block

2-2. Exploded Views

3

B

A

6

1

4

PSW 3x6

2

PS-635

Board

B 4x6

A

B

B 3x5

No. Part No. SP Description

B 3x5

1 ! 1-468-486-11 s REGULATOR, SWITCHING (KWS15-5)

2 1-757-644-11 s CABLE, FLEXIBLE FLAT (30 CORE)

3 ! 1-794-141-11 s INLET (WITH NOISE FILTER)

4 3-364-990-01 s SCREW (M3X8)

5 3-370-475-01 s SCREW (+B) (3X6),NYLOCK

6 3-629-592-02 o RUBBER (PR), RADIATION

7-682-546-09 s SCREW +B3X5

7-682-560-09 s SCREW +B4X6

7-682-947-01 s SCREW +PSW 3X6

2-2

5

B 3x5

B 4x6

UCP-8060

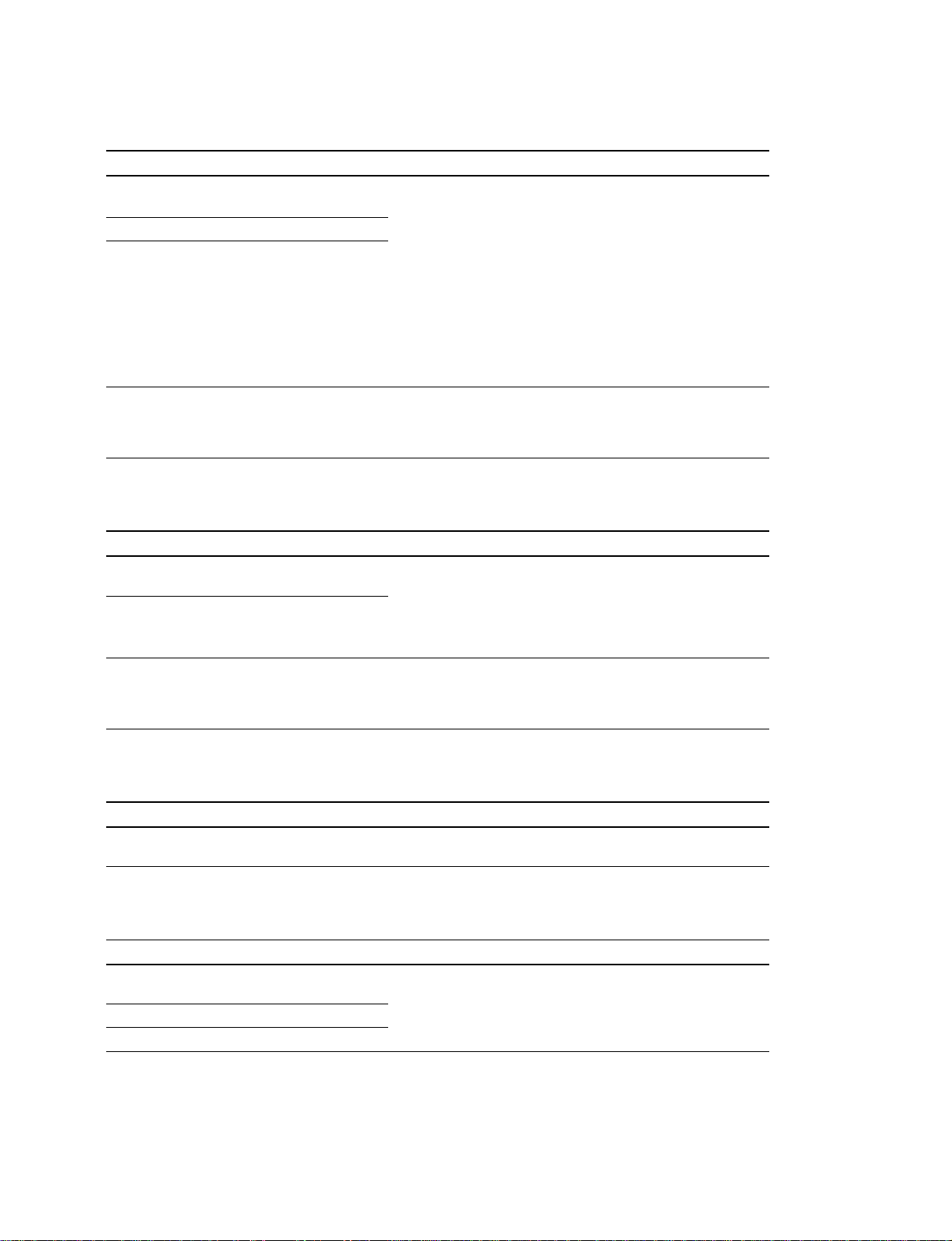

Page 29

LED-397

Board

Front Panel Block

PSW 3x6

SW-1099

Board

104

A

SW-1098

Board

PSW 3x6

102

101

104

B

PSW

3x6

103

PSW 3x6

A

PSW 3x6

No. Part No. SP Description

101 X-3608-487-1 s ASSY,VOLUME KNOB

102 1-417-337-11 s PANEL, TOUCH

103 1-477-701-11 s ENCODER TYPE, OPTICS

104 1-761-651-11 s PWB, MOUNTED

105 1-823-558-11 s CABLE, FLEXIBLE FLAT (30CORE)

7-682-947-01 s SCREW +PSW 3X6

B

PSW 3x6

VR-282

Board

105

UCP-8060

2-3

Page 30

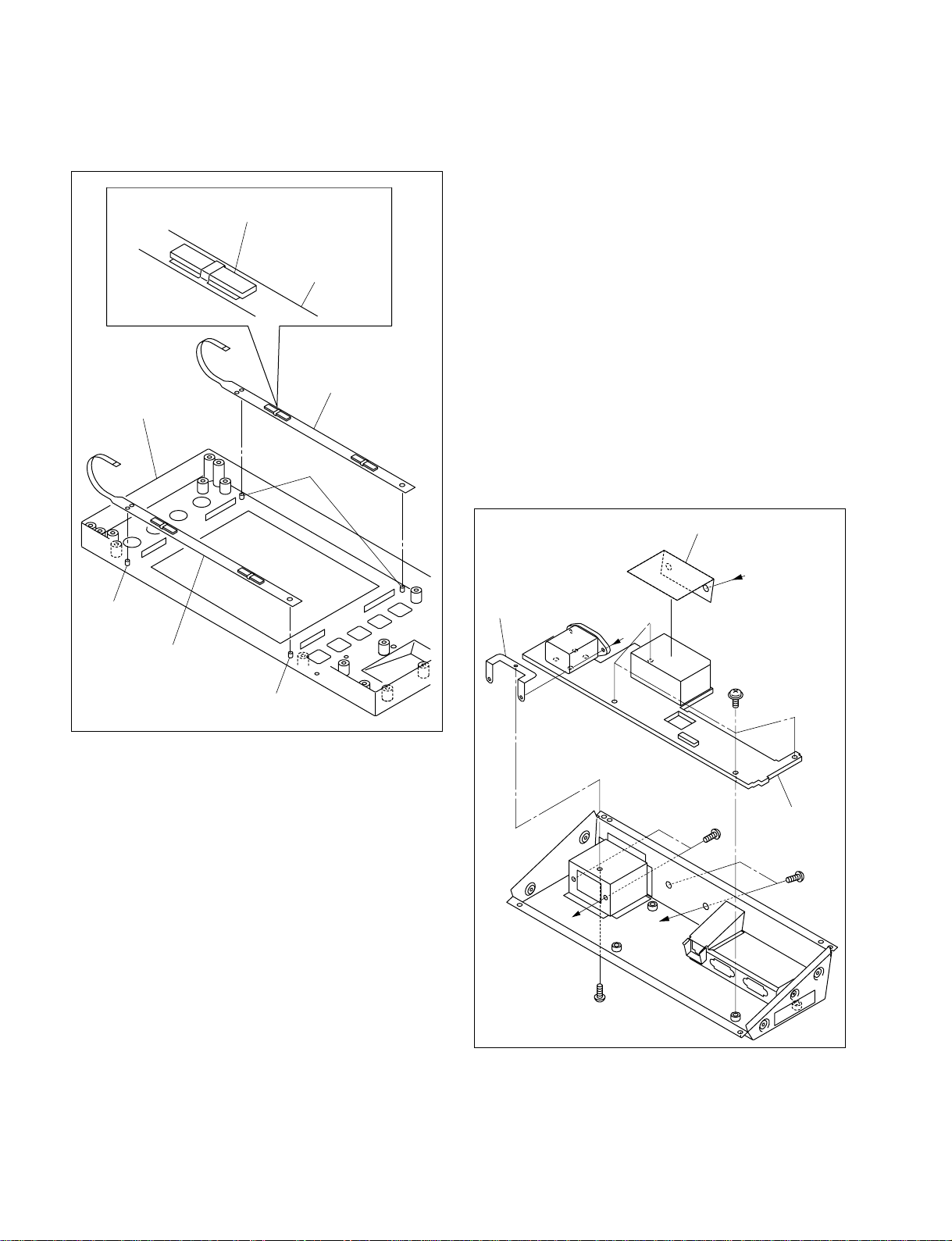

LCD Block

209

PSW 3x6

203

207

B 3x6

205

PSW

3x6

207

B 3x6

208

CN-2284

Board

PSW 3x6

KY-537

Board

PSW 3x6

204

PSW 3x6

202

No. Part No. SP Description

201 A-8345-525-A s MOUNTED CIRCUIT BOARD, CPU-352

202 A-8345-526-A s MOUNTED CIRCUIT BOARD, MB-978

203 ! 1-477-607-11 s INVERTER UNIT (LCD MODULE)

204 1-757-273-11 s CABLE, FLEXIBLE FLAT (30 CORE)

205 1-805-059-11 s LCD MODULE

206 1-823-558-11 s CABLE, FLEXIBLE FLAT (30CORE)

207 3-701-822-00 s HOLDER, WIRE

208 4-908-723-11 o SPACER (1)

209 9-885-028-72 s BACK LIGHT

201

206

7-682-547-04 s SCREW +B3X6

7-682-947-01 s SCREW +PSW 3X6

2-4

UCP-8060

Page 31

2-3. Electrical Parts List

------------CN-2284 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

CN304 1-573-370-21 s CONNECTOR, FFC/FPC 30P

------------CPU-352 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

1pc A-8345-525-A s MOUNTED CIRCUIT BOARD, CPU-352

CN801 1-779-396-11 o CONNECTOR, BOARD TO BOARD 31P

C201 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C202 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C203 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C205 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C206 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C207 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C208 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C210 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C211 1-162-919-11 s CAPACITOR,CERAMIC 22PF/50V CH

C212 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C214 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C215 1-162-919-11 s CAPACITOR,CERAMIC 22PF/50V CH

C216 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C217 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C218 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C219 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C220 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C221 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C222 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C223 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C224 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C225 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C227 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C228 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C229 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C230 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C231 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C232 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C233 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C234 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C235 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C236 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C301 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C302 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C303 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C304 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C305 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C306 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C307 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C308 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C309 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C310 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C311 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C312 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C313 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C314 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C315 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C316 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C317 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C318 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C319 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C320 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C321 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C322 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C323 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

UCP-8060

C324 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

2-5

Page 32

(CPU-352 BOARD)

Ref. No.

or Q'ty Part No. SP Description

-----------KY-537 BOARD

----------- Ref. No.

or Q'ty Part No. SP Description

IC201 8-759-584-62 s IC RQ5RW28BA-TR

CN301 1-573-370-21 s CONNECTOR, FFC/FPC 30P

IC202 6-703-172-01 s IC IM100-TQ144C

IC203 6-703-134-01 s IC AT45DB321B-TI

IC204 8-759-678-06 s IC CAT24WC02JI-TE13

IC205 8-759-699-62 s IC MT4LC4M16R6TG-5TR

Q301 8-729-014-45 s TRANSISTOR RN1905-TE85R

Q302 8-729-014-45 s TRANSISTOR RN1905-TE85R

Q303 8-729-014-45 s TRANSISTOR RN1905-TE85R

Q304 8-729-014-45 s TRANSISTOR RN1905-TE85R

IC206 8-759-699-62 s IC MT4LC4M16R6TG-5TR

Q305 8-729-014-45 s TRANSISTOR RN1905-TE85R

IC301 6-702-658-01 s IC XC2S150-5PQ208C1

IC302 8-759-548-95 s IC SN74LV00APWR

R301 1-211-969-11 s RESISTOR,CHIP 10 1/10W (1608)

R302 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

L201 1-414-170-41 s INDUCTOR, CHIP 100UH (2012)

R303 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R304 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R203 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R305 1-211-969-11 s RESISTOR,CHIP 10 1/10W (1608)

R204 1-216-857-11 s RESISTOR,CHIP 1M 1/10W(1608)

R205 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R206 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R207 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R306 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R307 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R308 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R309 1-211-969-11 s RESISTOR,CHIP 10 1/10W (1608)

R209 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R310 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R210 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R211 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R212 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R213 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R311 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R312 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R313 1-211-969-11 s RESISTOR,CHIP 10 1/10W (1608)

R314 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R308 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R315 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R309 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R310 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R311 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R316 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R317 1-211-969-11 s RESISTOR,CHIP 10 1/10W (1608)

R318 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

X201 1-760-622-21 s VIBRATOR, CRYSTAL

X202 1-781-204-11 s VIBRATOR, CRYSTAL

R319 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R320 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

S301 1-786-251-11 s SWITCH, TACTILE

S302 1-786-251-11 s SWITCH, TACTILE

S303 1-786-251-11 s SWITCH, TACTILE

S304 1-786-251-11 s SWITCH, TACTILE

S305 1-786-251-11 s SWITCH, TACTILE

2-6

-------------

LED-397 BOARD

-------------

Ref. No.

or Q'ty Part No. SP Description

CN601 1-691-346-11 s CONNECTOR, FFC/FPC 8P

D601 8-719-073-33 s DIODE CL-165HR/YG-D-T

D602 8-719-073-33 s DIODE CL-165HR/YG-D-T

UCP-8060

Page 33

-----------MB-978 BOARD

----------- Ref. No.

or Q'ty Part No. SP Description

(MB-978 BOARD)

Ref. No.

or Q'ty Part No. SP Description

1pc A-8345-526-A s MOUNTED CIRCUIT BOARD, MB-978

C305 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C306 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C101 1-165-603-11 s CAPACITOR DOUBLE LAYERS 1.5F

C103 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C105 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C307 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C308 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C309 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C106 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C107 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C310 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C311 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C108 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C109 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C110 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C312 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C313 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C314 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C111 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C112 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C315 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C401 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C113 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C114 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C115 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C402 1-162-919-11 s CAPACITOR,CERAMIC 22PF/50V CH

C403 1-162-919-11 s CAPACITOR,CERAMIC 22PF/50V CH

C404 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C116 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C117 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C405 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C406 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C118 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C119 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C120 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C407 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C408 1-164-230-11 s CAPACITOR,CERAMIC 220PF/50V

C409 1-164-230-11 s CAPACITOR,CERAMIC 220PF/50V

C201 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C203 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C410 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C411 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C204 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C205 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C206 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C412 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C413 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C414 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C207 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C208 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C415 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C501 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C209 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C210 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C211 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C502 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C503 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C504 1-165-872-11 s CAPACITOR,SOLID ELECT 47MF

C212 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C213 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C506 1-107-420-11 s CAPACITOR,ELECT 47MF/35V(105C)

C507 1-107-420-11 s CAPACITOR,ELECT 47MF/35V(105C)

C214 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C215 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C216 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C508 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C509 1-162-923-11 s CAPACITOR,CERAMIC 47PF/50V CH

C511 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C217 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C218 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C512 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C513 1-165-872-11 s CAPACITOR,SOLID ELECT 47MF

C219 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C220 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C221 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C222 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C223 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

CN101 1-573-370-21 s CONNECTOR, FFC/FPC 30P

CN102 1-785-948-12 s HINGE LEFT 14G-NI

CN301 1-573-370-21 s CONNECTOR, FFC/FPC 30P

CN302 1-580-789-21 o PIN,CONNECTOR (SMD) 6P

CN303 1-573-370-21 s CONNECTOR, FFC/FPC 30P

C224 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C225 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C226 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C227 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C228 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

CN304 1-573-370-21 s CONNECTOR, FFC/FPC 30P

CN305 1-793-708-21 s CONNECTOR, FLEXIBLE 8P

CN306 1-573-370-21 s CONNECTOR, FFC/FPC 30P

CN401 1-817-173-11 s JACK, MODULAR (WITH LED, PT)8P

CN402 1-778-551-11 o PIN, CONNECTOR 20P

C229 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C230 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C231 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

CN501 1-691-346-11 s CONNECTOR, FFC/FPC 8P

CN502 1-691-346-11 s CONNECTOR, FFC/FPC 8P

C232 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C233 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

D102 8-719-036-80 s DIODE RD3.9SB

D201 8-719-064-52 s DIODE CL-191YG-CD-T

C234 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C236 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C237 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

D202 8-719-071-10 s DIODE CL-191HR-CD-T

D301 8-719-989-00 s DIODE DA221

D302 8-719-420-90 s DIODE MA8051-M

C301 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C302 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

D303 8-719-420-90 s DIODE MA8051-M

D304 8-719-420-90 s DIODE MA8051-M

C303 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C304 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

D305 8-719-420-90 s DIODE MA8051-M

D306 8-719-420-90 s DIODE MA8051-M

UCP-8060

2-7

Page 34

(MB-978 BOARD)

(MB-978 BOARD)

Ref. No.

or Q'ty Part No. SP Description

D307 8-719-420-90 s DIODE MA8051-M

D308 8-719-420-90 s DIODE MA8051-M

D309 8-719-420-90 s DIODE MA8051-M

D501 8-719-048-98 s DIODE RB160L-40TE25

Ref. No.

or Q'ty Part No. SP Description

R305 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R306 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R307 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R308 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R309 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

FB301 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

FB302 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

FB303 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

FB304 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

FB401 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

R310 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R311 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R312 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R313 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R314 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

FB402 1-414-444-11 s MICRO INDUCTOR (CHIP TYPE)

R315 1-218-887-11 s RESISTOR,CHIP 47K 1/10W (1608)

IC101 8-759-460-72 s IC BA033FP

IC102 6-700-394-01 s IC BA25BC0FP-TE2

IC201 8-759-523-84 s IC TC74VHC14FT (EL)

IC202 6-702-658-01 s IC XC2S150-5PQ208C1

R316 1-218-887-11 s RESISTOR,CHIP 47K 1/10W (1608)

R317 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R318 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R319 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

IC203 8-759-557-51 s IC RN5VD30AA-TL

R320 1-218-831-11 s RESISTOR, CHIP 220 1/10W(1608)

IC204 8-759-091-93 s IC TLC555CPS

IC301 8-759-337-40 s IC NJM2904V(TE2)

IC302 8-759-549-22 s IC SN74LV574APWR

IC303 8-759-549-22 s IC SN74LV574APWR

R321 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R323 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R324 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R325 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

IC304 8-759-248-78 s IC MB88102PFV-G-BND-ER

R326 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

IC305 8-759-548-95 s IC SN74LV00APWR

IC401 6-703-185-01 s IC LXT971ALC

IC501 8-759-245-52 s IC TA7291F

IC502 8-759-455-17 s IC MAX1771CSA-TP

R327 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R328 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R329 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R330 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

L501 1-416-345-11 s COIL, CHOKE 22UH

R331 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R332 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

Q101 8-729-928-19 s TRANSISTOR 2SA1774R

Q102 8-729-929-08 s TRANSISTOR DTC123JE

Q201 8-729-928-54 s TRANSISTOR DTA123JE

R333 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R334 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R335 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

Q301 8-729-929-08 s TRANSISTOR DTC123JE

Q302 8-729-928-54 s TRANSISTOR DTA123JE

R336 1-218-879-11 s RESISTOR,CHIP 22K 1/10W (1608)

R337 1-218-879-11 s RESISTOR,CHIP 22K 1/10W (1608)

Q501 8-729-044-58 s TRANSISTOR SI2304DS-T1

Q502 8-729-044-58 s TRANSISTOR SI2304DS-T1

Q503 8-729-928-54 s TRANSISTOR DTA123JE

R401 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R402 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R403 1-216-857-11 s RESISTOR,CHIP 1M 1/10W(1608)

Q504 8-729-928-54 s TRANSISTOR DTA123JE

Q505 8-729-044-58 s TRANSISTOR SI2304DS-T1

R404 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R405 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

Q506 8-729-929-08 s TRANSISTOR DTC123JE

R406 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R407 1-218-879-11 s RESISTOR,CHIP 22K 1/10W (1608)

R101 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R409 1-211-985-11 s RESISTOR,CHIP 47 1/10W (1608)

R103 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R201 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R202 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

R203 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R410 1-211-985-11 s RESISTOR,CHIP 47 1/10W (1608)

R411 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R412 1-218-823-11 s RESISTOR,CHIP 100 1/10W (1608)

R413 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R204 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R414 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R211 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R212 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R213 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R214 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R415 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R416 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R417 1-211-977-11 s RESISTOR,CHIP 22 1/10W (1608)

R501 1-218-887-11 s RESISTOR,CHIP 47K 1/10W (1608)

R215 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R502 1-218-911-11 s RESISTOR,CHIP 470K 1/10W(1608)

R216 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R217 1-218-911-11 s RESISTOR,CHIP 470K 1/10W(1608)

R218 1-218-911-11 s RESISTOR,CHIP 470K 1/10W(1608)

R219 1-218-903-11 s RESISTOR,CHIP 220K 1/10W(1608)

R503 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R505 1-219-611-21 s RESISTOR, CHIP 0.047 1W

R507 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

R508 1-218-879-11 s RESISTOR,CHIP 22K 1/10W (1608)

R220 1-218-903-11 s RESISTOR,CHIP 220K 1/10W(1608)

R510 1-218-903-11 s RESISTOR,CHIP 220K 1/10W(1608)

R301 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R302 1-218-847-11 s RESISTOR, CHIP 1K 1/10W (1608)

R303 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R516 1-218-911-11 s RESISTOR,CHIP 470K 1/10W(1608)

R517 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

R304 1-218-863-11 s RESISTOR,CHIP 4.7K 1/10W(1608)

RB201 1-236-908-11 s RESISTOR,NETWORK 10K (3216)

2-8

UCP-8060

Page 35

(MB-978 BOARD)

Ref. No.

or Q'ty Part No. SP Description

-----------PS-635 BOARD

----------- Ref. No.

or Q'ty Part No. SP Description

RB202 1-236-908-11 s RESISTOR,NETWORK 10K (3216)

RB301 1-233-576-11 s RESISTOR,CHIP NETWORK 100

RB402 1-233-412-11 s RESISTOR,CHIP NETWORK 1K

2pcs 1-533-189-11 s HOLDER, FUSE

2pcs 7-623-422-07 s WASHER LW 3 (TYPE 3)

2pcs 7-682-547-04 s SCREW +B3X6

RB403 1-233-412-11 s RESISTOR,CHIP NETWORK 1K

RB404 1-233-412-11 s RESISTOR,CHIP NETWORK 1K

RB405 1-233-412-11 s RESISTOR,CHIP NETWORK 1K

RB406 1-233-576-11 s RESISTOR,CHIP NETWORK 100

RB407 1-233-576-11 s RESISTOR,CHIP NETWORK 100

RB408 1-233-576-11 s RESISTOR,CHIP NETWORK 100

BZ101 1-544-886-11 s BUZZER, PIEZOELECTRIC

C101 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C102 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C103 1-165-870-21 s CAPACITOR, ELECT 100MF(6.3X6)

C104 1-165-870-21 s CAPACITOR, ELECT 100MF(6.3X6)

C105 1-165-870-21 s CAPACITOR, ELECT 100MF(6.3X6)

RY301 1-755-380-21 s RELAY

C106 1-165-870-21 s CAPACITOR, ELECT 100MF(6.3X6)

S201 1-771-709-31 s SWITCH, SLIDE

S202 1-572-474-11 s SWITCH, TACTILE

C107 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C108 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C109 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

X401 1-781-518-21 s VIBRATOR, CRYSTAL

C110 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C111 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C112 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C113 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C114 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

CN101 1-573-370-21 s CONNECTOR, FFC/FPC 30P

CN102 1-779-059-11 o PIN, CONNECTOR (PC BOARD) 9P

CN103 1-779-195-11 s CONNECTOR, D SUB 9P

CN104 1-817-051-11 s CONNECTOR, BOARD TO BOARD 20P

CN105 ! 1-794-141-11 s INLET (WITH NOISE FILTER)

CP101 ! 1-468-486-11 s REGULATOR, SWITCHING (KWS15-5)

F101 ! 1-576-228-11 s FUSE (H.B.C)

IC101 8-759-252-59 s IC MAX202CSE

IC102 8-759-396-99 s IC MAX489CSD-TE2

L101 1-416-948-21 s COIL, CHOKE (SMD)

L102 1-416-948-21 s COIL, CHOKE (SMD)

PS101 ! 1-533-282-21 s CIRCUIT PROTECTOR 2A (3225)

R101 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R102 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R103 1-218-871-11 s RESISTOR,CHIP 10K 1/10W (1608)

R104 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R105 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R106 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R107 1-218-839-11 s RESISTOR,CHIP 470 1/10W (1608)

R108 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R109 1-218-855-11 s RESISTOR,CHIP 2.2K 1/10W(1608)

R110 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

R111 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

R112 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

R113 1-218-895-11 s RESISTOR,CHIP 100K 1/10W(1608)

S101 1-771-709-31 s SWITCH, SLIDE

UCP-8060

2-9

Page 36

------------SW-1098 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

----FRAME

---- Ref. No.

or Q'ty Part No. SP Description

S1 1-572-474-11 s SWITCH, TACTILE

S2 1-572-474-11 s SWITCH, TACTILE

------------SW-1099 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

C701 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C702 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C705 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

CN701 1-691-346-11 s CONNECTOR, FFC/FPC 8P

EN701 1-418-498-31 s ENCODER, ENCODER

IC701 8-759-523-84 s IC TC74VHC14FT (EL)

RB701 1-236-908-11 s RESISTOR,NETWORK 10K (3216)

RB702 1-236-908-11 s RESISTOR,NETWORK 10K (3216)

S701 1-572-474-11 s SWITCH, TACTILE

S702 1-572-474-11 s SWITCH, TACTILE

1pc 1-417-337-11 s PANEL, TOUCH

1pc ! 1-477-607-11 s INVERTER UNIT (LCD MODULE)

1pc 1-757-273-11 s CABLE, FLEXIBLE FLAT (30 CORE)

1pc 1-757-644-11 s CABLE, FLEXIBLE FLAT (30 CORE)

2pcs 1-761-651-11 s PWB, MOUNTED

1pc 1-805-059-11 s LCD MODULE

2pcs 1-823-558-11 s CABLE, FLEXIBLE FLAT (30CORE)

2pcs 9-885-028-72 s BACK LIGHT

CN105 ! 1-794-141-11 s INLET (WITH NOISE FILTER)

CP101 ! 1-468-486-11 s REGULATOR, SWITCHING (KWS15-5)

2-4. Supplied Accessories List

Ref. No.

or Q'ty Part No. SP Description

1pc 3-704-736-01 s MANUAL, INSTALLATION

1pc 3-704-876-01 s OPERATION MANUAL

2-5. Power Cords List

-----------VR-282 BOARD

----------- Ref. No.

or Q'ty Part No. SP Description

C201 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C202 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C203 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C204 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

Ref. No.

or Q'ty Part No. SP Description

<For customers in Japan>

1pc ! 1-791-041-31 s CORD SET, POWER

1pc ! 1-793-461-11 s CONNECTOR, CONVERSION (3P-2P)

<For customers in the U.S.A. and Canada>

1pc ! 1-557-377-11 s CORD, AC POWER

CN306 1-573-370-21 s CONNECTOR, FFC/FPC 30P

EN201 1-477-701-11 s ENCODER TYPE, OPTICS

EN202 1-477-701-11 s ENCODER TYPE, OPTICS

EN203 1-477-701-11 s ENCODER TYPE, OPTICS

EN204 1-477-701-11 s ENCODER TYPE, OPTICS

Q201 8-729-928-54 s TRANSISTOR DTA123JE

Q202 8-729-928-54 s TRANSISTOR DTA123JE

2-10

<For customers in all European countries>

1pc ! 1-782-929-11 s CORD, AC POWER

2-6. Optional Fixtures List

Part No. SP Description

3-179-054-01 o TOOL, CAP PULL

UCP-8060

Page 37

Section 3

Semiconductor Pin Assignments

The following describes the semiconductor types used in

this unit.

For semiconductors marked with page numbers in the

index, refer to the corresponding pages in this section.

However, in some cases incompatible types are also listed,

therefore, when a part is to be replaced, also refer to the

Spare Parts section.

In addition, for semiconductors with ID Nos., refer to the

separate CD-ROM titled “Semiconductor Pin Assignments”

(Sony Part No. 9-968-546-xx) that allows searching for

parts by semiconductor type or ID No.

The semiconductors in the manual or on the CD-ROM are

listed by equivalent types. Thus the external view or the

index mark indication may differ from the actual type.

Pin assignments and block diagrams are based on the IC

manufacturer’s data book.

Index

DIODE Page or ID No.

02DZ5.1-TPH3 .................................................................DC008-04

DA221 ..............................................................................DC001-01

DA221-TL......................................................................... DC001-01

MA8051-M .......................................................................DC008-04

RB160L-40TE25 .............................................................. DC007-01

RD3.9SB ..........................................................................DC008-04

RD3.9SB-T1..................................................................... DC008-04

LED Page or ID No.

CL-165HR/YG-D-T........................................................... LC009-04

CL-191HR-CD-T .............................................................. LC004-02

CL-191YG-CD-T .............................................................. LC004-01

TRANSISTOR Page or ID No.

2SA1774R........................................................................ TC001-01

2SA1774TL-QR ............................................................... TC001-01

DTA123JE........................................................................ TC001-04

DTA123JE-TL .................................................................. TC001-04

DTC123JE ....................................................................... TC001-03

DTC123JE-TL .................................................................. TC001-03

RN1905-TE85R ............................................................... TC005-14

SI2304DS-T1 ................................................................... TC001-07

IC Page or ID No.

AT45DB321B-TI.......................................................................... 3-2

BA033FP..................................................................... L78M05T-FA

BA033FP-E2 ............................................................... L78M05T-FA

BA25BC0FP-E2 ..................................................... BA18BC0FP-E2

BA25BC0FP-TE2 ................................................... BA18BC0FP-E2

CAT24WC02J-TE13 ....................................................X24C02S-30

IM100-TQ144C ........................................................................... 3-2

LXT971ALC ................................................................................ 3-3

MAX1771CSA-TP ....................................................................... 3-4

MAX202CSE ............................................................... MAX202CSE

MAX202CSE-T ........................................................... MAX202CSE

MAX489CSD-TE2.......................................................... LTC491CS

MB88102PFV-G-BND-ER....................... MB88102PFV-G-BND-ER