Sony TRV461E, TRV361, TRV460, TRV460E, DCR-TRV361 Service Manual

...

SERVICE MANUAL

DIGITAL VIDEO CAMERA RECORDER

LEVEL 2

Link

SERVICE NOTE

DISASSEMBLY

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

SPECIFICATIONS

SERVICE NOTE

DISASSEMBLY

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

SPECIFICATIONS

Link

Revision History

Revision History

M2000/M2200 MECHANISM

Ver 1.0 2003. 12

•For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987629351.pdf).

•For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL1 (987629341.pdf).

•For MECHANISM ADJUSTMENTS, refer to the “8mm Video MECHANICAL ADJUSTMENT MANUAL IX

M2000 MECHANISM ” (9-929-861-11).

• Reference No. search on printed wiring boards is available.

•Table for differences of function of each model.

•TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

• HELP: Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

DCR-TRV360

/

TRV361/TRV460/TRV460E/TRV461E

RMT-831

US Model

DCR-TRV360/TRV460

Canadian Model

DCR-TRV460

AEP Model

UK Model

East European Model

North European Model

Australian Model

DCR-TRV460E

E Model

DCR-TRV361/TRV460/TRV460E/TRV461E

On the VC-345 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the VC-345 board.

Therefore, schematic diagrams, printed wiring boards, mounted parts location and electrical parts list of the VC-345 board are

not shown.

The following pages are not shown.

Schematic diagrams ...........................Pages 4-9 to 4-44

Printed wiring boards ..........................Pages 4-59 to 4-62

Mounted parts location ..................

Pages 4-69 and 4-70

Electrical parts list......................... Pages 5-16 to 5-24

How to use

Acrobat Reader

How to use

Acrobat Reader

Photo: DCR-TRV460

— 2 —

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

SPECIFICATIONS

Video camera recorder

System

Video recording system

2 rotary heads, Helical scanning system

Still image recording s ystem

Exif Ver. 2.2*

1

*1Exif is a file format for still images,

established by the JEITA (Japan

Electronics and Information Tec hnology

Industries Association). Files in this format

can have additional information such as

your camcorder s setting information at the

time of recording.

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz, stereo 1,

stereo 2), 16 bits (Fs 48 kHz, stereo)

Video signal

NTSC

PAL color, CCIR standards

color, EIA standards

Usable cassette

8 mm video format cassette

Tape speed

SP: Approx. 28.67 mm/s

LP: Approx. 19.11 mm/s

Recording/play back time

SP: 60 min

LP: 90 min

Fast forward/rewind time

Approx. 5 min

Viewfinder

Electric viewfinder (monochrome)

Image device

3.0 mm (1/6 type) CCD (Charge Cou pl ed

Device)

Gross: Approx. 460 000 pixels

Effective (still): Approx. 350 000 pixels

Effective (movie): Approx. 350 000 pixels

Effective (still): Approx. 290 000 pixels

Effective (movie): Approx. 290 000 pixels

Lens

Combined power zoom lens

Filter diameter: 37 mm (1 7/16 in.)

20 × (Optical), 990 × (Digital)

F = 1.6 ~ 2.4

Focal length

2.5 - 50 mm (1/8 - 2 in.)

When converted to a 35 mm still camera

In CAMERA-TAPE:

42 - 840 mm (1 11/16 - 33 1/8 in.)

In CAMERA-MEMORY:

42 - 840 mm (1 11/16 - 33 1/8 in.)

Color temperature

Auto

Minimum illuminat i o n

4 lx (lux) (F 1.6)

0 lx (lux) (during the NightShot plus

function)*

2

*2Objects unable to be seen due to the dark can

be shot with infrared lighting.

Input/Output connectors

S video input/output

Luminance signal: 1 Vp-p, 75 Ω (ohms),

unbalanced

Chrominance signal:

75 Ω (ohms), unbalanced

4-pin mini DIN

Audio/Video input/output

AV MINIJACK

Video signal: 1 Vp-p, 75 Ω (ohms),

unbalanced, sync negative

Audio signal: 327 mV (at output impedance

more than 47 kΩ (kilohms)), Input impedance

more than 47 kΩ (kilohms), Output impedance

with less than 2.2 kΩ (kilohms)

Stereo minijack (φ 3.5mm)

DV input/output

4-pin connector

USB jack

mini-B

LCD screen

Picture

6.2 cm (2.5 type)

Total dot number

123 200 (560 × 220)

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor)

Average power consumption (when using the

battery pack)

During camera recordin g us ing the vie wfi n der

2.9 W

During camera recording using the LCD

3.8 W

Operating temperature

0° C to 40°C (32° F to 104° F)

Storage temperature

-20° C to + 60° C (-4°F to + 140° F)

Dimensions (approx.)

85 × 98 × 151 mm (3 3/8 × 3 7/8 × 6 in.)

(w/h/d)

Mass (Approx.)

800 g (1 lb 12 oz) main unit only

940 g (2 lb 1 oz) including the NP-FM30

rechargeable bat te r y pa ck, Hi8/Digital8

cassette, lens cap, and shoulder strap.

Supplied accessories

See page 7.

AC Adaptor AC-L15A/L15B

Power requirements

AC 100 - 240 V, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18 W

Output voltage

DC 8.4 V, 1.5 A

Operating temperature

0° C to 40°C (32° F to 104° F)

Storage temperature

-20° C to + 60° C (-4°F to + 140° F)

Dimensions (approx.)

56 × 31 × 100 mm (2 1/4 × 1 1/4 × 4 in.) (w/h/

d) excluding the pro jecting parts

Mass (approx.)

190 g (6.7 oz) excluding the power cord

Rechargeable battery pack (NP-FM30)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

5.0 Wh (700 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 1 3/16 × 2 1/4 in.) (w/h/d)

Mass (approx.)

65 g (2.3 oz)

Operating temperature

0° C to 40°C (32° F to 104° F)

Type

Lithium ion

Design and specifications are subject to change

without notice.

DCR-TRV360/TRV361/TRV460:

DCR-TRV360/TRV361/TRV460:

DCR-TRV460E/TRV461E:

SP: Approx. 28.70 mm/s

LP: Approx. 19.13 mm/s

DCR-TRV460E/TRV461E:

(using 120 min. Hi8/Digital8 video cassette)

DCR-TRV460E/TRV461E:

DCR-TRV360/TRV361/TRV460:

(using 90 min. Hi8/Digital8 video cassette)

(using 120 min. Hi8/Digital8 video cassette)

DCR-TRV460E/TRV461E:

DCR-TRV360/TRV361/TRV460:

(using 90 min. Hi8/Digital8 video cassette)

DCR-TRV360/TRV361/TRV460:

DCR-TRV460E/TRV461E:

Gross: Approx. 540 000 pixels

DCR-TRV460E/TRV461E: 0.3 Vp-p

DCR-TRV360/TRV361/TRV460: 0.286 Vp-p

Memory Stick 8MB (1)

AC Adaptor (1)

Power cord (1)

Lens cap (1)

Shoulder strap (1)

Wireless Remote commander RMT-831 (1)

A/V connecting cable (1)

USB cable (1)

Rechargeable battery pack NP-FM30 (1)

CD-ROM SPVD-012 USB Driver (1)

21-pin adaptor (1)

(AEP, UK, EE)

Camera Operations Guide (1)

Computer Applications Guide (1)

(DCR-TRV361/TRV461E)

SERIE

S

TM

— 3 —

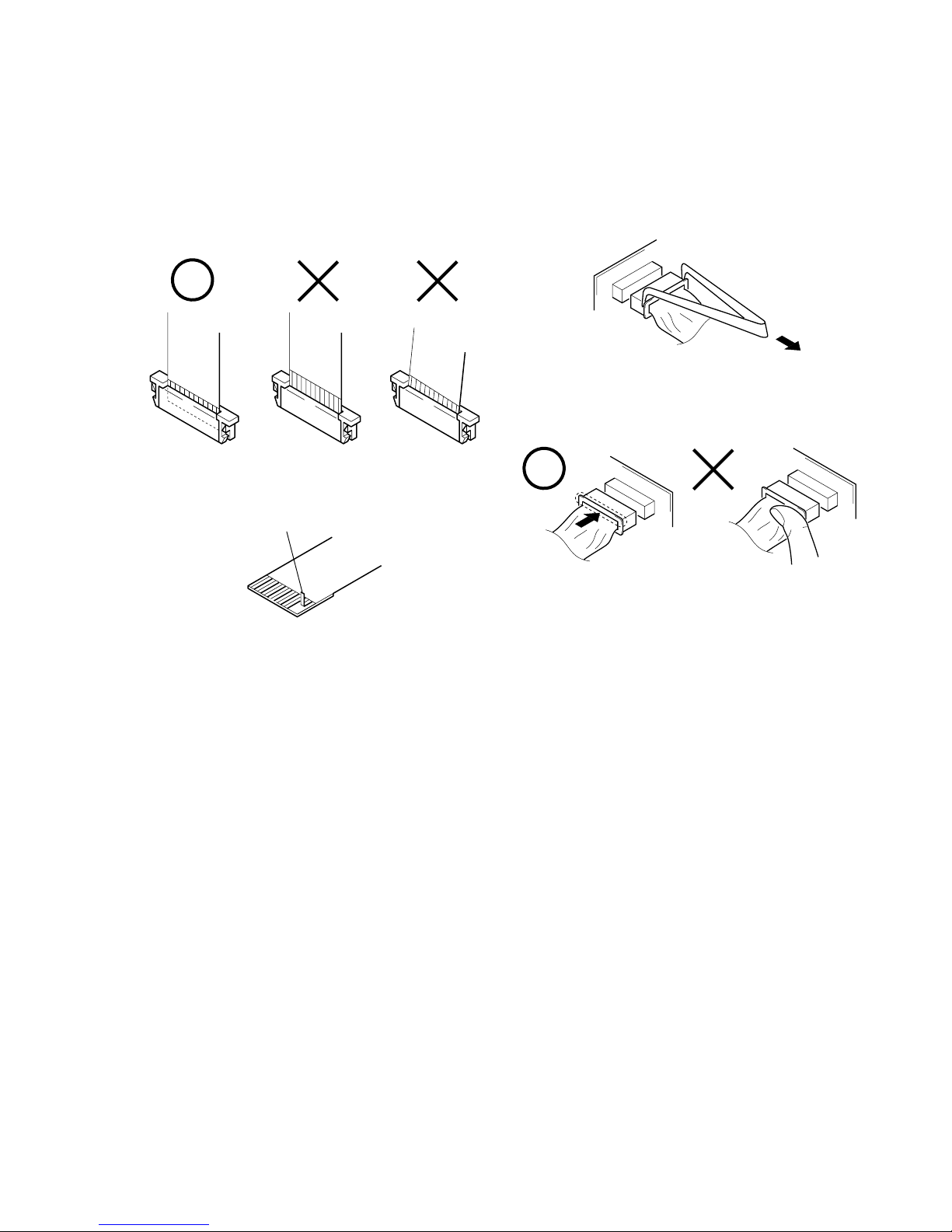

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flo w) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

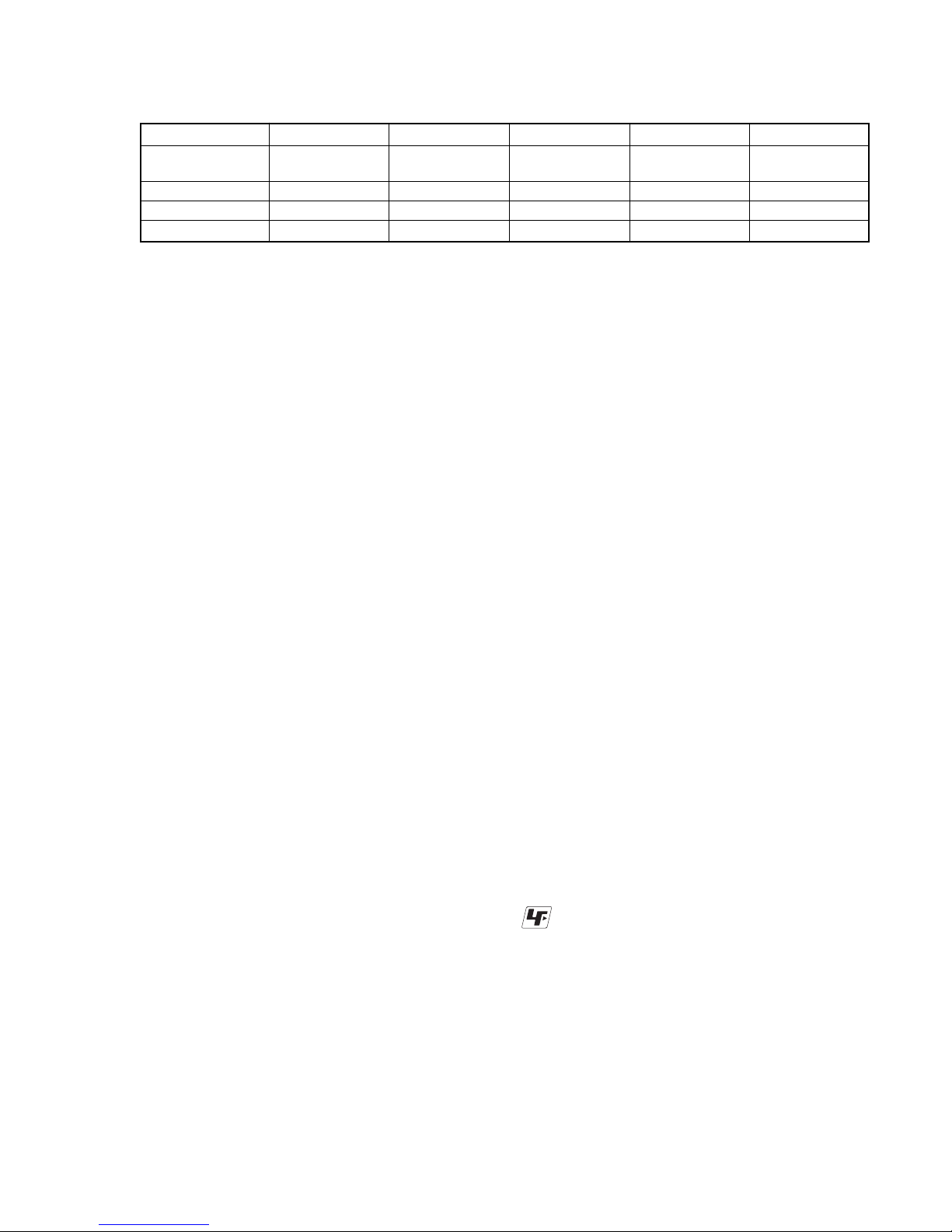

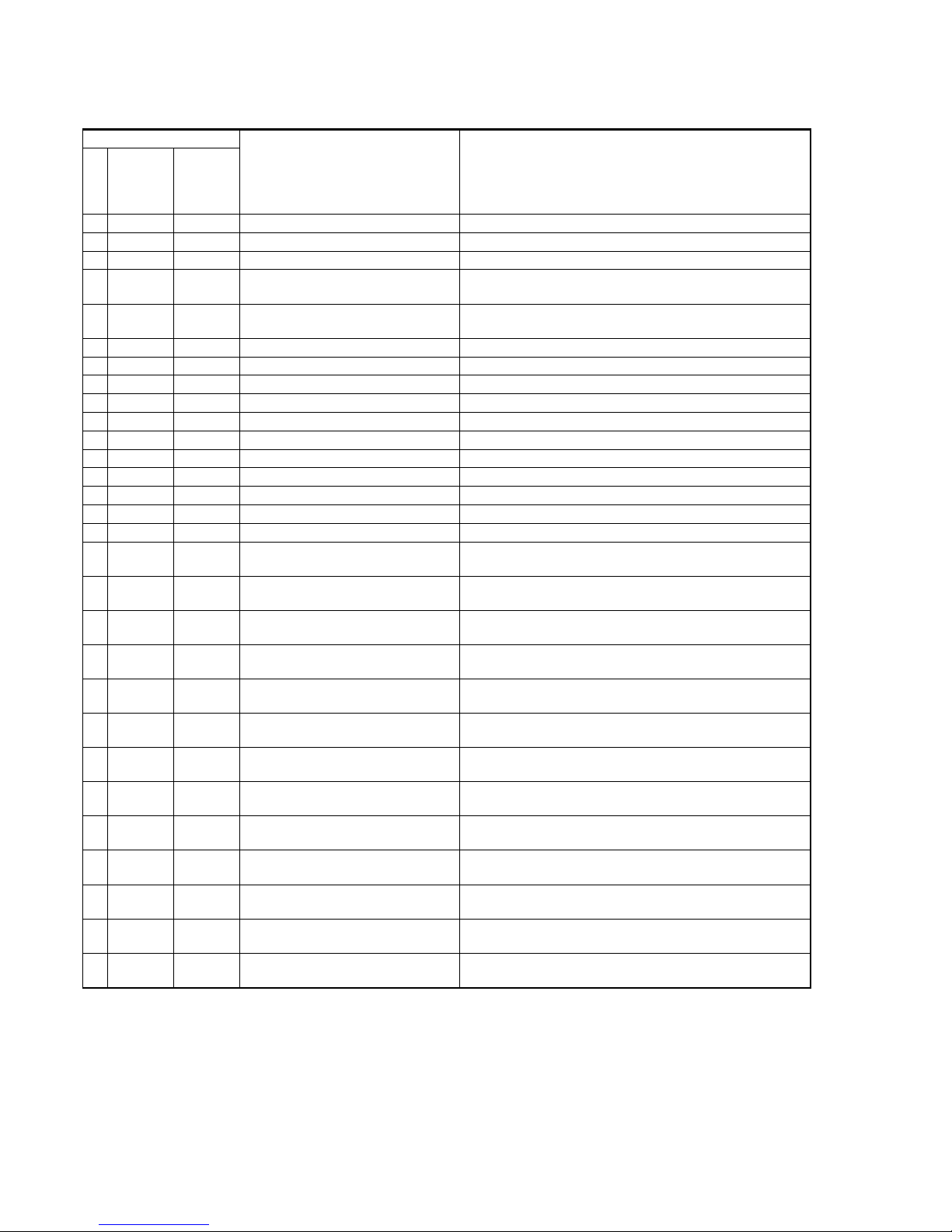

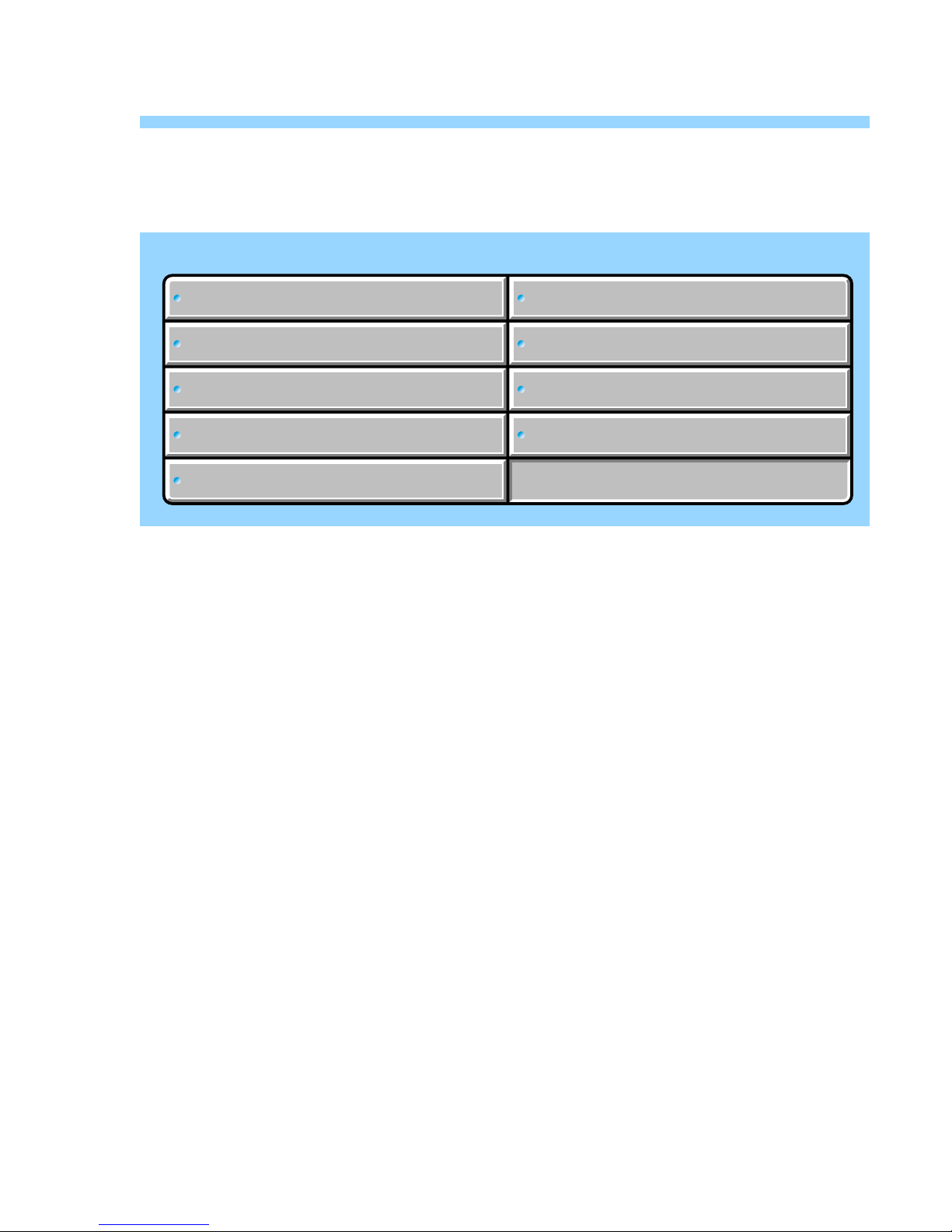

Table for differences of function

Model DCR-TRV360 DCR-TRV361 DCR-TRV460 DCR-TRV460E DCR-TRV461E

Destination US E US, CND, E

AEP, UK, EE

E

NE, E, AUS

Color system NTSC NTSC NTSC PAL PAL

Playback system Digital8 Digital8 Hi8/8/Digital8 Hi8/8/Digital8 Hi8/8/Digital8

Mechanism deck M2200 M2200 M2000 M2000 M2000

•Abbreviation

AUS: Australian model

CND: Canadian model

EE : East European model

NE : North European model

— 4 —

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. Note for Repair ································································1-1

1-2. Power Supply During Repairs ·········································1-1

1-3. To Take Out a Cassette when not Eject (Force Eject) ·····1-2

1-4. Self-diagnosis Function···················································1-3

1-4-1.Self-diagnosis Function···················································1-3

1-4-2.Self-diagnosis Display·····················································1-3

1-4-3.Self-diagnosis Code Table ···············································1-4

2. DISASSEMBLY

2-1. Flow Chart·······································································2-1

2-2. Mechanism Deck Service Position··································2-3

2-3. LCD Service Position ······················································2-5

2-4. Circuit Boards Location ·················································· 2-6

2-5. Flexible Boards Location ················································ 2-7

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/6)···········································3-1

3-2. Overall Block Diagram (2/6)···········································3-3

3-3. Overall Block Diagram (3/6)···········································3-5

3-4. Overall Block Diagram (4/6)···········································3-7

3-5. Overall Block Diagram (5/6)···········································3-9

3-6. Overall Block Diagram (6/6)·········································3-11

3-7. Power Block Diagram (1/3)··········································· 3-13

3-8. Power Block Diagram (2/3)··········································· 3-15

3-9. Power Block Diagram (3/3)··········································· 3-17

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams·············································4-1

4-2. Schematic Diagrams························································4-5

CD-472 (CCD IMAGER)················································4-7

PD-205 (LCD DRIVER, BACKLIGHT DRIVE)·········4-45

SI-041 (STEADYSHOT, JACK) ···································4-47

FP-792 FLEXIBLE ·······················································4-47

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ····································································4-49

SS-5100, PR-5100 (CONTROL KEY BLOCK) ···········4-50

CF-5100 (CONTROL KEY BLOCK)···························4-51

4-3. Printed Wiring Boards ··················································· 4-55

CD-472 ··········································································4-57

PD-205···········································································4-63

SI-041, FP-792 FLEXIBLE ··········································4-65

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ····································································4-67

4-5. Mounted Parts Location ················································ 4-71

Section Title Page Section Title Page

5. REPAIR PARTS LIST

5-1. Exploded V iews ····························································5-2

5-1-1. Overall Assembly··························································5-2

5-1-2. Front Panel Block ·························································5-3

5-1-3. Lens Block ····································································5-4

5-1-4. LCD Block ····································································5-5

5-1-5. Cabinet R Block ····························································5-6

5-1-6. EVF Block ····································································5-7

5-1-7. Battery Panel Block ······················································ 5-8

5-1-8. MD Frame Block ·························································· 5-9

5-1-9. Cassette Compartment Assembly, Drum Assembly ···5-10

5-1-10. LS Chassis Block Assembly ·······································5-11

5-1-11. Mechanical Chassis Block Assembly-1······················5-12

5-1-12. Mechanical Chassis Block Assembly-2······················5-13

5-2. Electrical Parts List ·····················································5-14

1-1

SECTION 1

SERVICE NOTE

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

1-1. NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

1-2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the po wer is shut of f so

that the unit cannot operate.

The following method is available to prevent this.

Method 1.

Use the AC power adaptor (AC-L10, AC-VQ800 etc.).

1-2

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

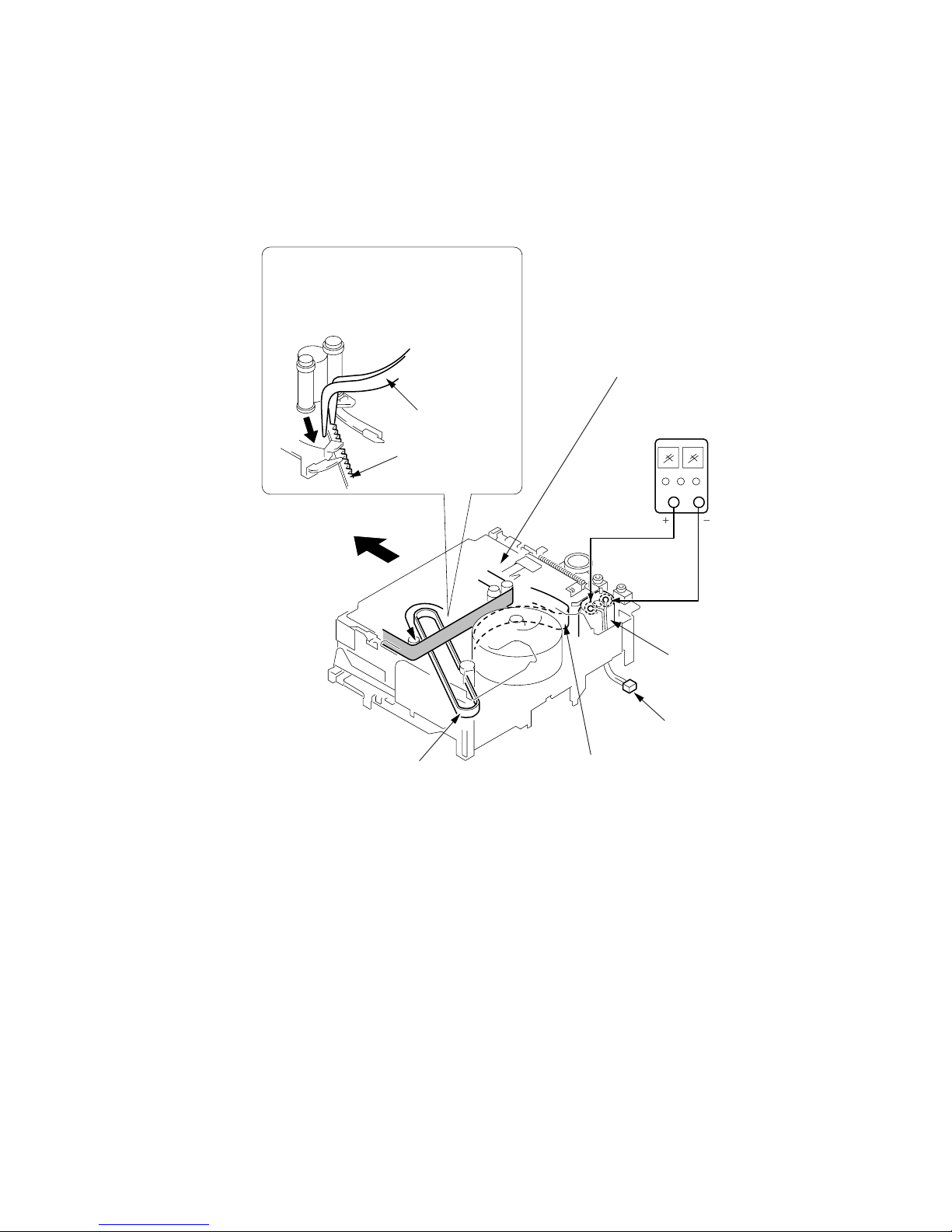

1-3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to “SECTION 2 DISASSEMBLY” to remove the mechanism deck block.

2 Disconnect CN2401 (2P) of VC-345 board.

3 Add +5V from the DC POWER SUPPLY and unload with a pressing the cassette compartment.

4 Pull the timing belt in the direction of

arrow A with a pincette while pressing

the cassette compartment (take care

not to damage) to adjust the bending

of a tape.

5 Let go your hold the cassette

compartment and rise the cassette

compartment to take out a cassette.

Pincette

Timing belt

Timing belt

Press the cassette compartment not to

rise the cassette compartment

[DC power supply]

(+5V)

Adjust the bending of a tape

Disconnect CN2401

of VC-345 board.

Loading motor

A

A

1-3

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

1-4. SELF-DIAGNOSIS FUNCTION

1-4-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD what

to do. This function consists of two display; self-diagnosis display

and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

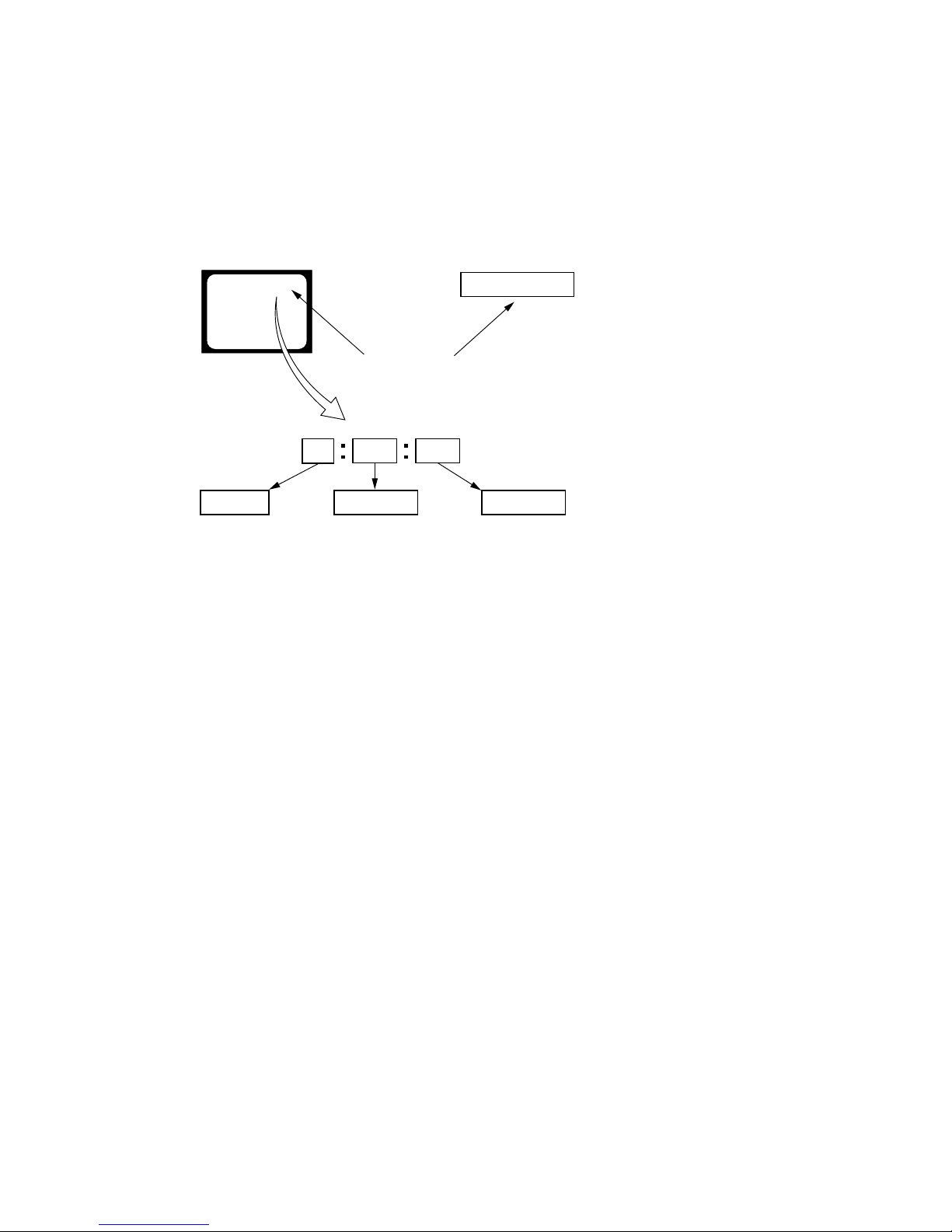

1-4-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD shows a 4-digit display consisting of an alphabet

and numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

1 1

3 1

C : 3 1 : 11

C

Repaired by:

Refer to 1-4-3. Self-diagnosis Code Table .

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

Block

Detailed Code

Blinks at 3.2Hz

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Viewfinder Display window

C : 3 1 : 1 1

1-4

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

1-4-3. Self-diagnosis Code Table

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

.

S reel

side tape slacking when unloading

.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum operations.

PG fault during normal drum operations.

Phase fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan

operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum

operations.

PG fault during normal drum

operations.

Phase fault during normal drum

operations.

Self-diagnosis Code

Repaired by:

Correction

Use the InfoLITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

1-5

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

E

E

E

E

Block

Function

61

61

62

62

Detailed

Code

00

10

00

01

Symptom/State

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Self-diagnosis Code

Repaired by:

Correction

Inspect the lens block focus reset sensor (Pin qs of CN1551 of

VC-345 board) when focusing is performed when the control dial

is rotated in the focus manual mode and the focus motor drive circuit

(IC1554 of VC-345 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin qg of CN1551 of

VC-345 board) when zooming is performed when the zoom switch

is operated and the zoom motor drive circuit (IC1554 of VC345board) when zooming is not performed.

Inspect pitch angular velocity sensor (SE752 of SI-041 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE751 of SI-041 board)

peripheral circuits.

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

“1-5. CHANGE OF IC4501” is not shown.

Pages 1-6 is not shown.

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

2-1 2-2

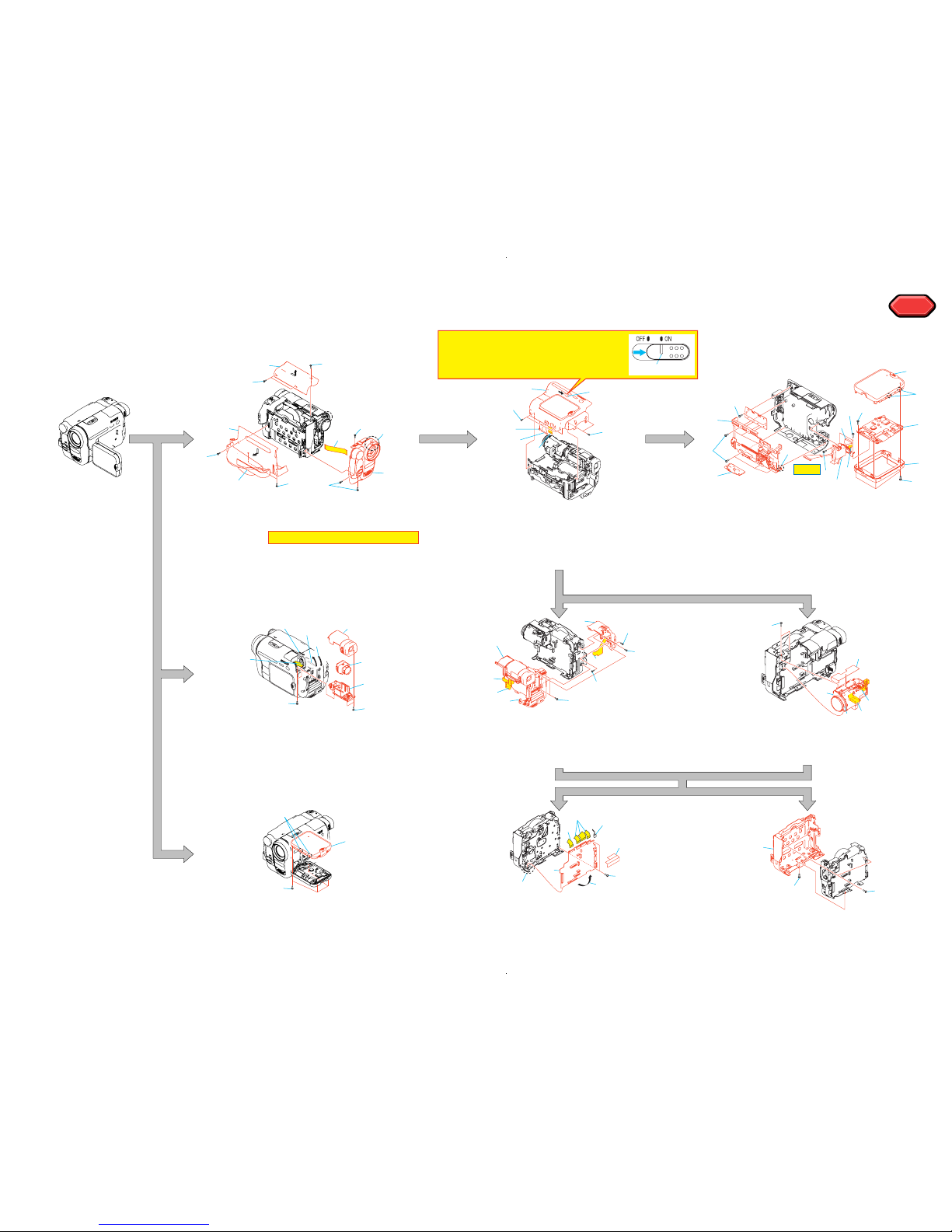

2-1. FLOW CHART

The following flow chart shows the disassembly procedure.

SECTION 2

DISASSEMBLY

HELP

HELP

HELP

NS knob

Note: When you remove Cabinet (R) Block,

or when you assembly, please slide

NS knob to the position of "ON".

Note: Flexible board is connected.

1 Lock ace

x3

2 Cabi (upper)

3 Grip belt

4 Lock ace

x3

5 Cabi (L)

1 Lock ace

x6

2 NS knob to the position of "ON".

3 Cabi (R)

4 VC-345: CN1007

5 VC-345: CN1003

6 VC-345: CN1008

1 Tripod Screw

2 Tapping P2

x2

3 Tapping P2

x6

4 Claw

5 CF-5100

6 Tapping P2

x4

7 Claw

x2

8 P Cabi (C)

9 Tapping P2

x2

q; Tapping P2

x1

qa P Cabi (M)

qs PD-205: CN6005

qd PD-205: CN6001

qf PD-205, LCD901, ND901

qg Tapping P2

x4

qh Hinge assy

6 Lock ace

x3

7 Claw

8 Front panel

9 FP-796: CN754, CN1001

1 Lift up the EVF.

2 Tapping P2

x4

3 Down the EVF.

4 EVF block

5 EVF Cabi (upper)

6 EVF Cabi (lower)

7 FP-797: LCD902

8 EVF lens

1 Tapping P2

x4

2 Claw

x2

3 P Cabi (C)

1 VC-345: CN1013

2 VC-345: CN1016

3 VC-345: CN4001

4 Lock ace

x3

5 EVF/Battely panel block

6 VC-345: CN1009

7 Tapping P2

x1

8 Lock ace

x1

9 SS-5100

1 VF blind sheet

2 VC-345: CN2403, CN2404, CN3201

3 VC-345: CN2401

4 Screw (M1.7)

x2

5 Claw

6 Open the VC-345.

7 VC-345: CN2402

8 VC-345

1 Screw (M1.7)

x3

2 CS frame

1 VC-345: CN1501

2 VC-345: CN1551

3 Lens sheet

4 Lock ace

x2

5 Boss

6 Lens LSV-820A

1

5

2

1

3

4

4

6

6

7

9

8

1

1

2

4

5

6

3

qd

qg

2

3

4

6

7

9

q;

qs

1

5

4

4

7

8

1

3

2

2

3

4

5

6

7

8

1

1

1

2

5

6

9

4

1

2

3

5

6

8

qa

qf

qh

1

2

2

3

4

7

5

6

2

1

3

8

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

A

B

Adjustment remote

commander (RM-95)

Info lithium battery

(L series)

I/F unit for LANC control

(J-6082-521-A)

CPC jig connector

(J-6082-539-A)

Cabinet R block

EVF block/

Battery panel block assembly

Mechanism deck

Control key block

(SS-5100)

VC-345 board

Front panel block

Lens block

Press the cassette compartment

in the direction of the arrow A

to move it up in the direction of

the arrow B.

How to move up the cassette

compartment manually

Contacting

surface

Eject switch

When exiting the "Forced Power ON" mode, connect the control

key block (SS-5100) to the CN1009 of VC-345 board. Or, when

ejecting the cassette, connect the control key block (SS-5100) to

the CN1009 of VC-345 board. and press the Eject switch.

Connection to Check the Mechanism deck

To check the mechanism deck, set the Camera or VTR to the "Forced power ON" mode. (Or, connect the control key

block (SS-5100) to the CN1009 of VC-345 board and set the power switch to the "CAMERA" or "PLAY/edit" position.)

Operate the Camera functions of the zoom and focus, the VTR function using the adjustment remote commander

(with the HOLD switch set in the OFF position).

Setting the "Forced Camera Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

Setting the "Forced VTR Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

Exiting the "Forced Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

AC adaptor

AC IN

1

5

2

1

3

4

4

6

6

7

9

8

1

1

2

4

5

6

3

4

4

7

8

1

3

2

2

3

4

5

6

7

8

1

1

1

2

5

6

9

4

1

2

3

5

6

2-3 2-4

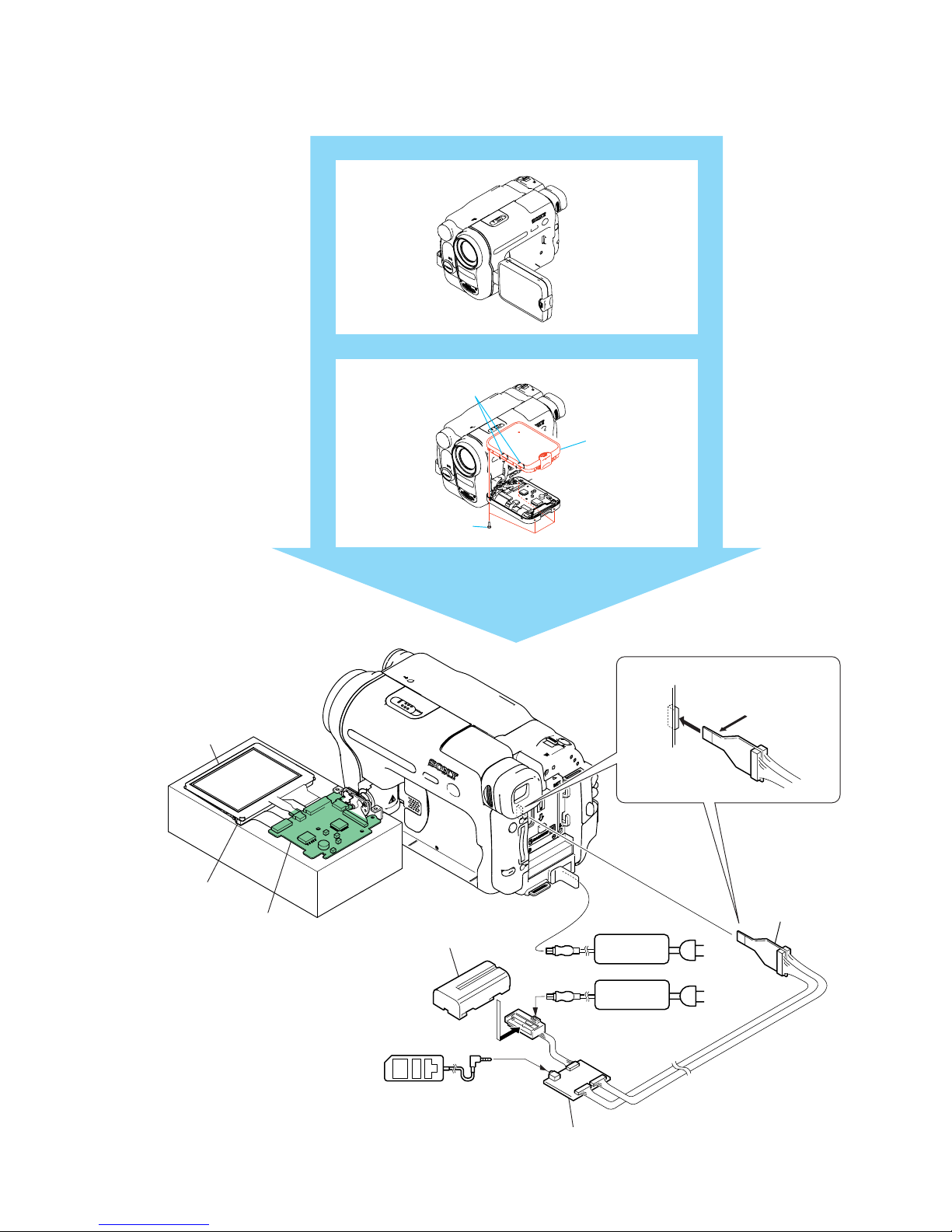

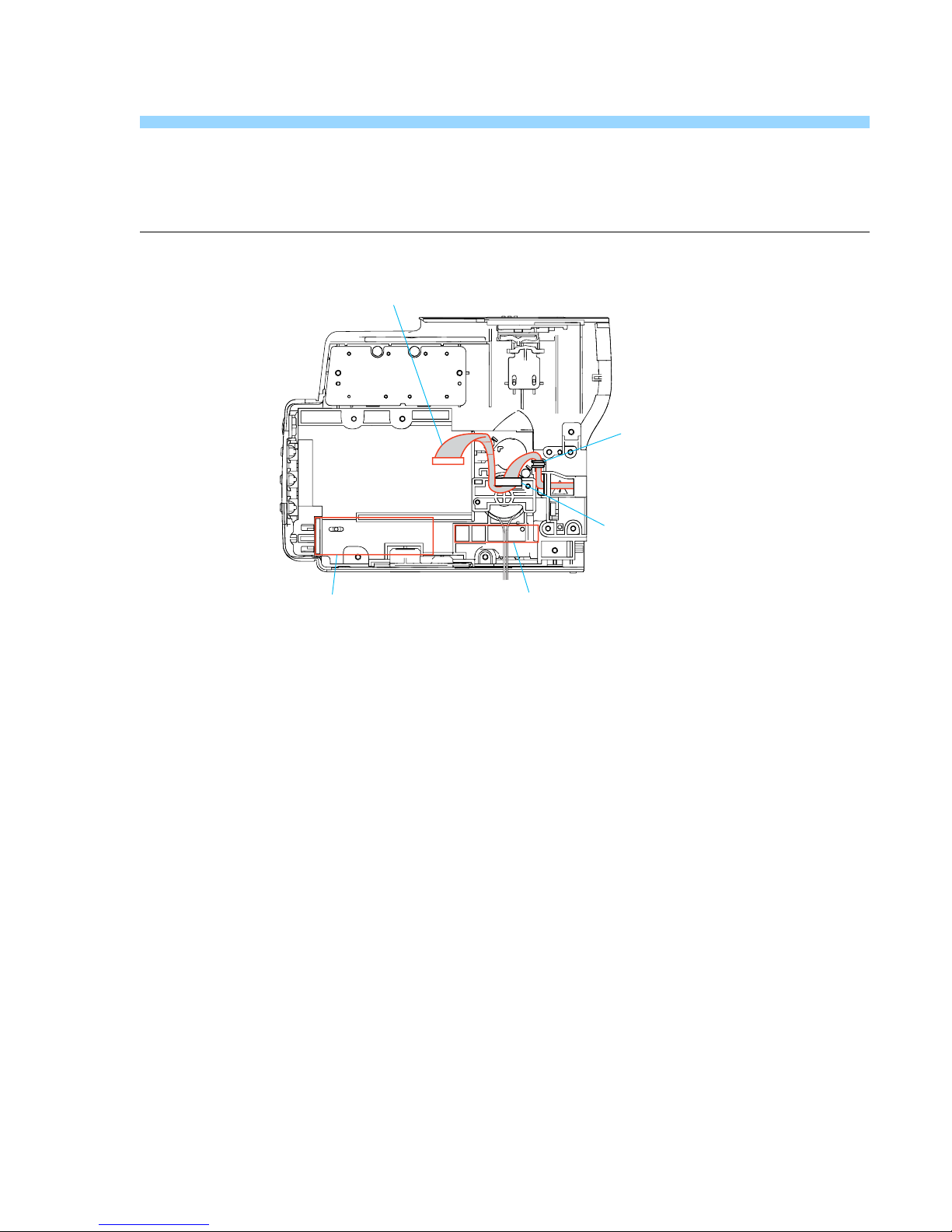

2-2. MECHANISM DECK SERVICE POSITION

2-5

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

2-3. LCD SERVICE POSITION

AC adaptor

AC IN

AC adaptor

I/F unit for LANC control

(J-6082-521-A)

CPC jig connector

(J-6082-539-A)

CPC jig connector

L serices Info

LITHIUM battery (7.2Vdc)

LCD panel

PD-205 board

Back light unit

Adjustment

remote commander (RM-95)

Conductor side

CN1011

1

16

LANC jack

AC IN

2

1

3

2-6

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

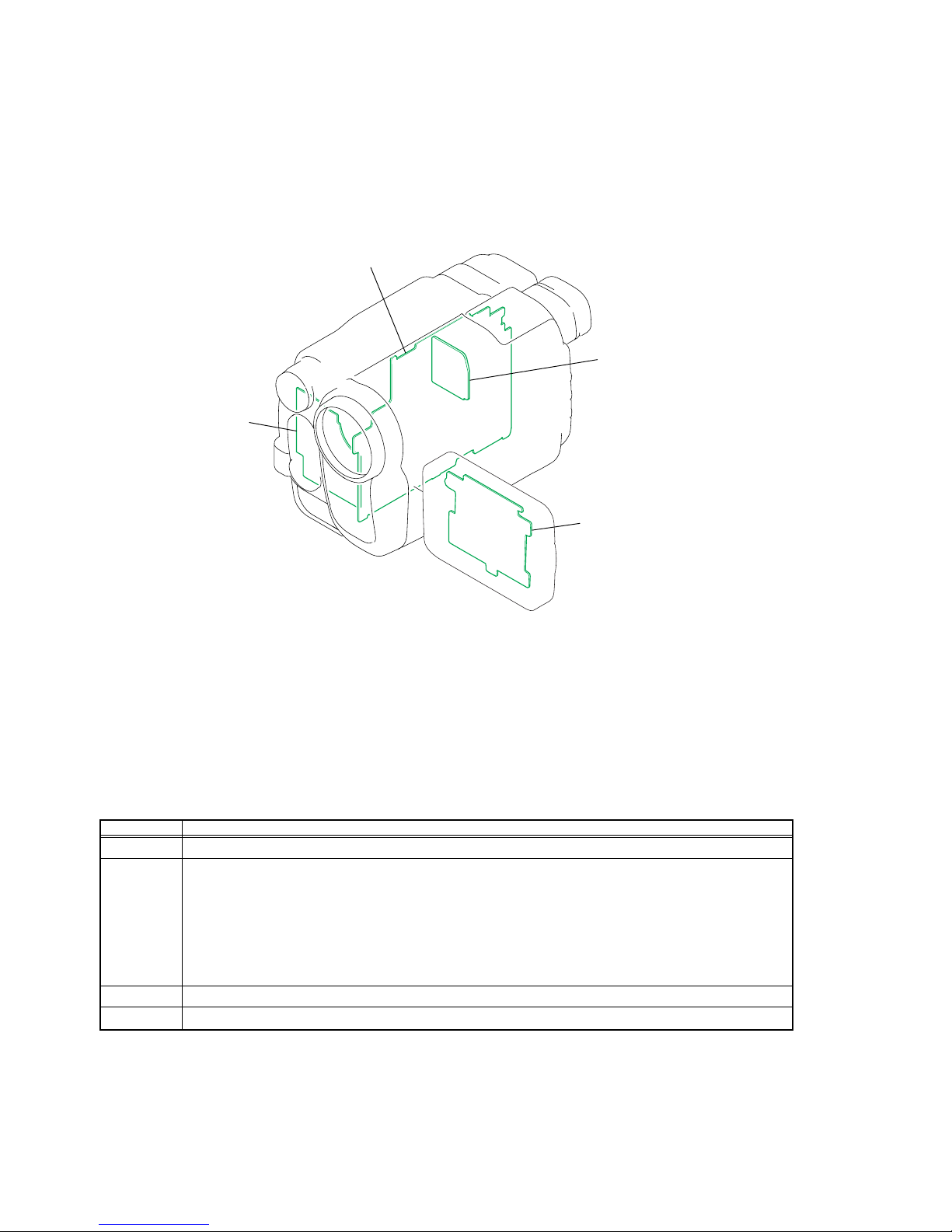

2-4. CIRCUIT BOARDS LOCATION

Board Name Function

CD-472 CCD IMAGER

VC-345 A/D CONVERTER, TIMING GENERATOR, VIDEO/AUDIO DSP,

LENS CONTROL, LENS DRIVE, Hi8/Std8 VTR PROCESS, VIDEO IN/OUT ,

DV SIGNAL PROCESS, REC/PB AMP, DV INTERFACE, STEADYSHOT,

Hi8/Std8 PB AMP, USB/MODE CONTROL, MS INTERFACE, MEMORY,

HI CONTROL, CAMERA/MECHA CONTROL, SERVO, AUDIO, DC CONTROL,

CONNECTOR

PD-205 LCD DRIVE, BACKLIGHT DRIVE

SI-041 STEADYSHOT, JACK

SI-041

VC-345

CD-472

PD-205

2-7E

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

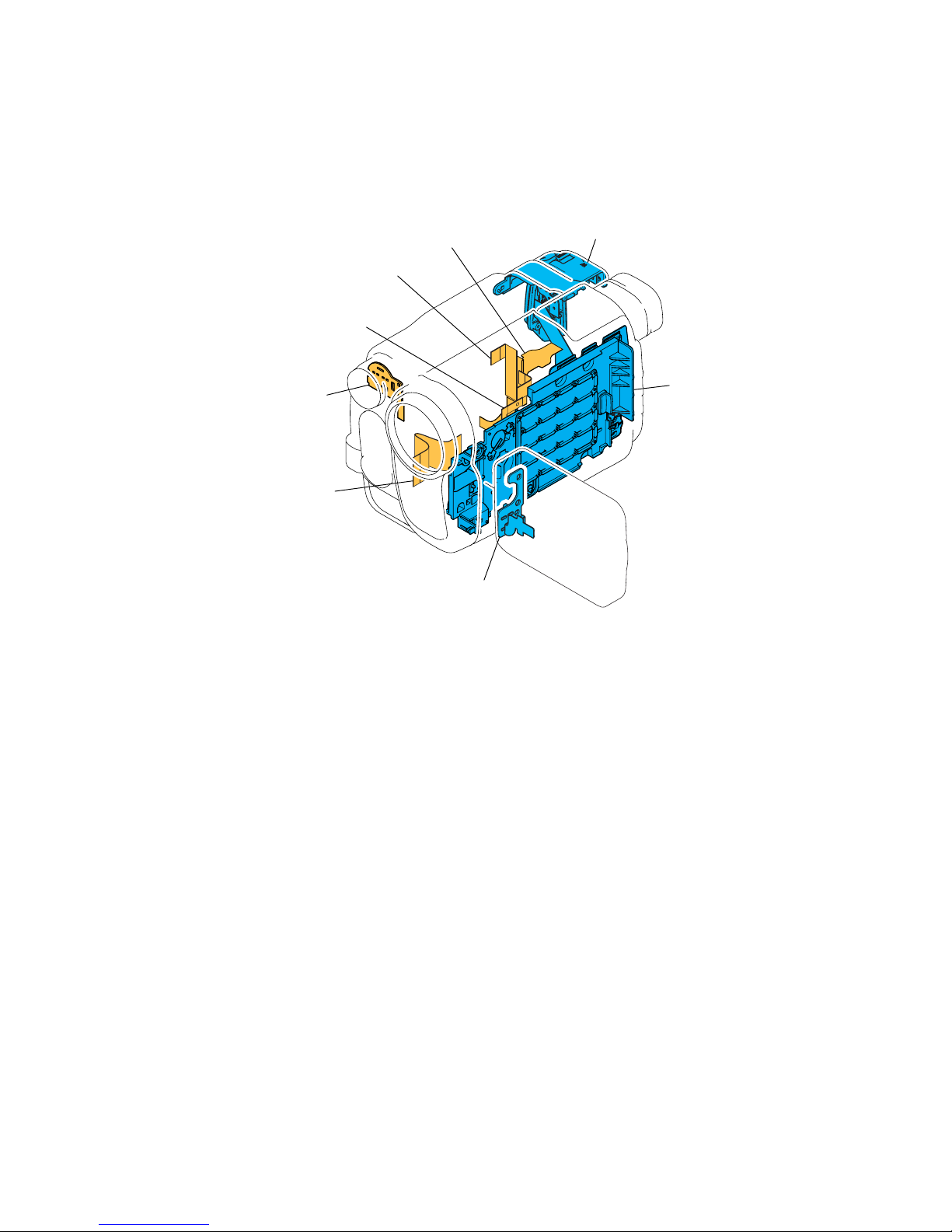

2-5. FLEXIBLE BOARDS LOCATION

FP-792

FP-799

FP-796

CF-5100

PR-5100

SS-5100

FP-797

FFC-005

HELP

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Note: Close the LCD panel, when you work.

Claw

Insulating sheet (CF)

Tape (CF)

(TRV360/TRV460/TRV460:E/TRV461E)

Claw

Harness (PD-124)

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

Link

Link

3. BLOCK DIAGRAMS

POWER BLOCK DIAGRAM (2/3)

OVERALL BLOCK DIAGRAM (2/6)

OVERALL BLOCK DIAGRAM (4/6)

OVERALL BLOCK DIAGRAM (3/6)

POWER BLOCK DIAGRAM (1/3)

OVERALL BLOCK DIAGRAM (6/6)

OVERALL BLOCK DIAGRAM (1/6)

OVERALL BLOCK DIAGRAM (5/6)

POWER BLOCK DIAGRAM (3/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (3/3)

OVERALL BLOCK DIAGRAM (2/6)

OVERALL BLOCK DIAGRAM (4/6)

OVERALL BLOCK DIAGRAM (5/6)

OVERALL BLOCK DIAGRAM (3/6)

POWER BLOCK DIAGRAM (1/3)

OVERALL BLOCK DIAGRAM (6/6)

OVERALL BLOCK DIAGRAM (1/6)

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

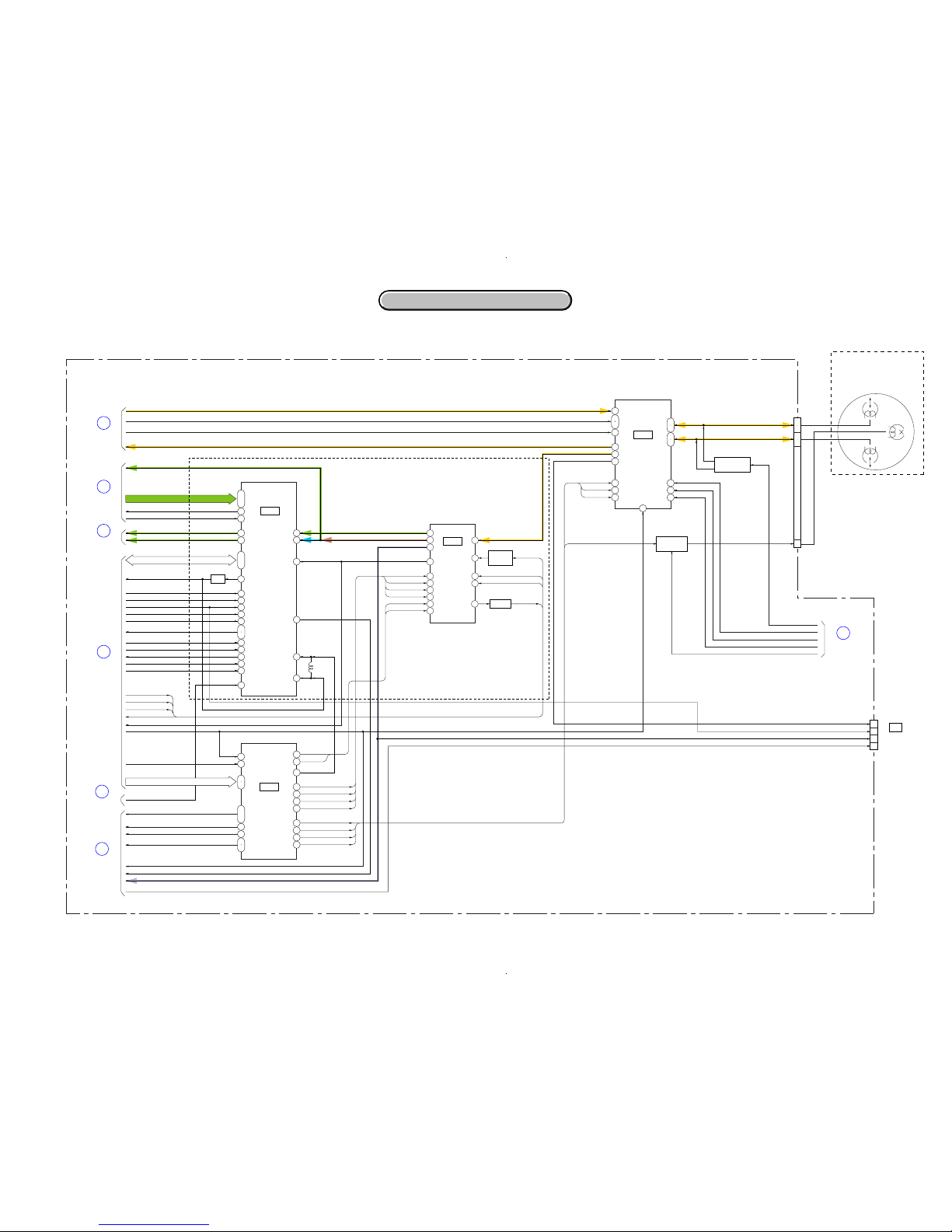

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

Hi8/Std8

Hi8/Std8

Hi8/Std8

Hi8/Std8, LINE

Hi8/Std8, LINE

Hi8/Std8

Hi8/Std8

ZOOM MOTOR

IR SWITCH

TEMPLENS TEMP AD

XNS SW

ZM SENS OUT

FOCUS MOTOR

IRIS

METER

12

10

14

8

13 – 16

5 7 17 19 2 4 21 23

(1/18)

FOCUS

MOTOR

DRIVE

IRIS

DRIVE

ZOOM

MOTOR

DRIVE

EN1, DIR1A,

DIR1B

HALL

GAIN

7

1 – 4 12 – 14

CCD

IMAGER

BUFFER

12

4

30

16

5

47

1

2

16

15

44

45

35

37

ı

39

TIMING

GENERATOR

46 4847

23

49

51

20 – 22

AUDIO

PROCESS

(16/18)

46

36

7

39

48

42

14

18

22

L

CN753

CN754 (1/4)

LIA 1

LIA 2

INT MIC L

INT MIC R

INT MIC L,R

XCS AU1

IC 8001 C OUT

34

IC 8001 Y OUT

ADCK27

IC 3701 C OUT

IC 3701

Y OUT

PB IN L, R

REC OUT L, R

SE751

SE752

SP+,–

SP+, –

TG HD, TG VD

CN1001

(1/4)

CN1008

HALL AD, LENS DET,

LENS TEMP AD, XNS SW

PITCH AD, YAW AD

YAW AD

PITCH AD

EN0,EN1, DIR0A,B, DIR1A,B,

FC RST, ZM RST

5 15 12 21 19

IRIS

10 – 7

FC SENS OUT

ZM RST

FC RST

EN0, DIR0A,

DIR0B

HALL

GAIN

IRIS PWM

ZOOM A,B,XA,XB

FOCUS A,B,XA,XB

IRIS HALL(–)

IRIS

DRIVE(–)

CN1551

LENS BLOCK

CN951 CN1501

CLPDM, PBLK,

XSHP, XSHD

CCD OUT

V1 – V4,RG,H1,H2

27 MHz

X1501

VCK

9

ADCK

VCK

ADCK

OVERALL (4/6)

(PAGE 3-7)

Q951

IRIS

DRIVE

Q1551

HALL GAIN

CONTROL

Q1554

SP901

SPEAKER

05

J752

CD-472 BOARD VC-345 BOARD (1/6)

MM MM

MM

IC1554

9 – 12

PITCH SENSOR

YAW SENSOR

SI-041 BOARD (1/4)

33

30

29

4

7

8

A/V

CONTROL KEY BLOCK (CF-5100) (1/2)

24

26

22

19

18

1 – 4

IC951

1

7

ı

9

11

ı

14

14

19

21

ı

23

36

34

2

ı

11

VCK

AV JACK IN, XS JACK IN

ACC-CONT, AGC-CONT, CLPVO

44

5

IC 2201 C OUT

IC 2201 Y OUT

IC 8001 C OUT

CPLVO

IC 8001 Y OUT

IC 2201 C OUT

ACC-CONT

IC 2201 Y OUT

OVERALL (3/6)

(PAGE 3-5)

VIDEO IN/OUT

(6/18)

S/H, AGC,

A/D CONVERTER

(1/18)

18

21

22

STEADYSHOT

(9/18)

8

12218

RG, H1, H2

1

ı

4

25

26

31

28

IRIS PWM

CK CONT

V1 – V4

OVERALL (2/6)

(PAGE 3-3)

S VIDEO

J751

1

2

11

9 10

XVIDEO IN

XCS IC 3701

LINE Y ON

2

5

HALL

AMP

HALL

BIAS

1

20

IRIS

BIAS(–)

H

2322

IRIS BIAS(+)

IRIS HALL(+)

6

HALL

OFFSET

73

HALL

REF

HALL AD

FOCUS

SENSOR

ZOOM

SENSOR

17

LENS

TEMP

SENSOR

(4/18)

FRQ TUNE

20

CLPOB

25

XS JACK IN

AV JACK IN

36

42

48

41

34

ZSG1, ZV1, TG ID

VGAT

ZSG1

ZV1

TG ID

VGAT

3

4

6

OVERALL (2/6)

(PAGE 3-3)

7

OVERALL (3/6)

(PAGE 3-5)

8

OVERALL (2/6)

(PAGE 3-4)

9

OVERALL (2/6)

(PAGE 3-3)

5

A : VIDEO SIGNAL

A : AUDIO SIGNAL

IC1552

(4/18)

IC1501

IC1502

CAM DD ON

4

5

7

8

2

3

15

16

AUDIO

A/D, D/A

CONVERTER

(16/18)

IC5402

DATA TO SFD

IC5401

MIC AMP

(16/18)

IC5801

MUTE

59

2

63

3

64

57

58

A/D

CONVERTER

(3/18)

IC8501

2

19

9

12

HALL OFFSET, HALL GAIN, HALL REF

Q5401, 5402

MUTE

DC LEVEL

DETECTOR

Q3701

VIDEO

BUFFER

Q8504

Q3702, 3703

IC3701

IC2001

1

3

32 5

20

SDC IN

40

43

XRST VTR

XRST VTR

PB C RF

IC 3701 Y OUT

OVERALL (4/6)

(PAGE 3-7)

2

OVERALL (3/6)

(PAGE 3-5)

1

46

14

24

26

OVERALL (2/6)

(PAGE 3-3)

10

BEEP

KASYAON

R

8

12

SFD BCK

DEM 0, 1,

XPWAD, XPWDA

DATA FROM SFD

9

11

SFD FCK

PB RF

AFM FSC

RF SWP

28

AU BPF

29

BPF MONI

1.7M DEV, 1.5M DEV

SFD LRCK

10

S Y I/O

S C I/O

S Y I/O

S C I/O

VIDEO I/O VIDEO I/O

AUDIO L I/O

AV JACK IN

XS JACK IN

AUDIO R I/O

AUDIO L,R I/O

MIC L,R

CH CS, CH SO, CH SCK

CH CS, CH SO, CH SCK

VSP SI, VSP SO, XVSP SCK

VD SO, VD SCK

VD SO, VD SCK

XCS IC 3701

CAM SI, CAM SO, CAM SCK, CAM CS

15

ı

24

AD0 C – AD9 C

17

18

5

1

14

AD0 – AD9

AD0 –AD9

8

ı

6

6

7

13

14

1

47

AGC-CONT

13

11

15

18

19

12

17

NIGHT

SHOT

PLUS

MIC901

MICROPHONE

R1510

R1507

TRV460/TRV460E

/TRV461E

TRV360/TRV361

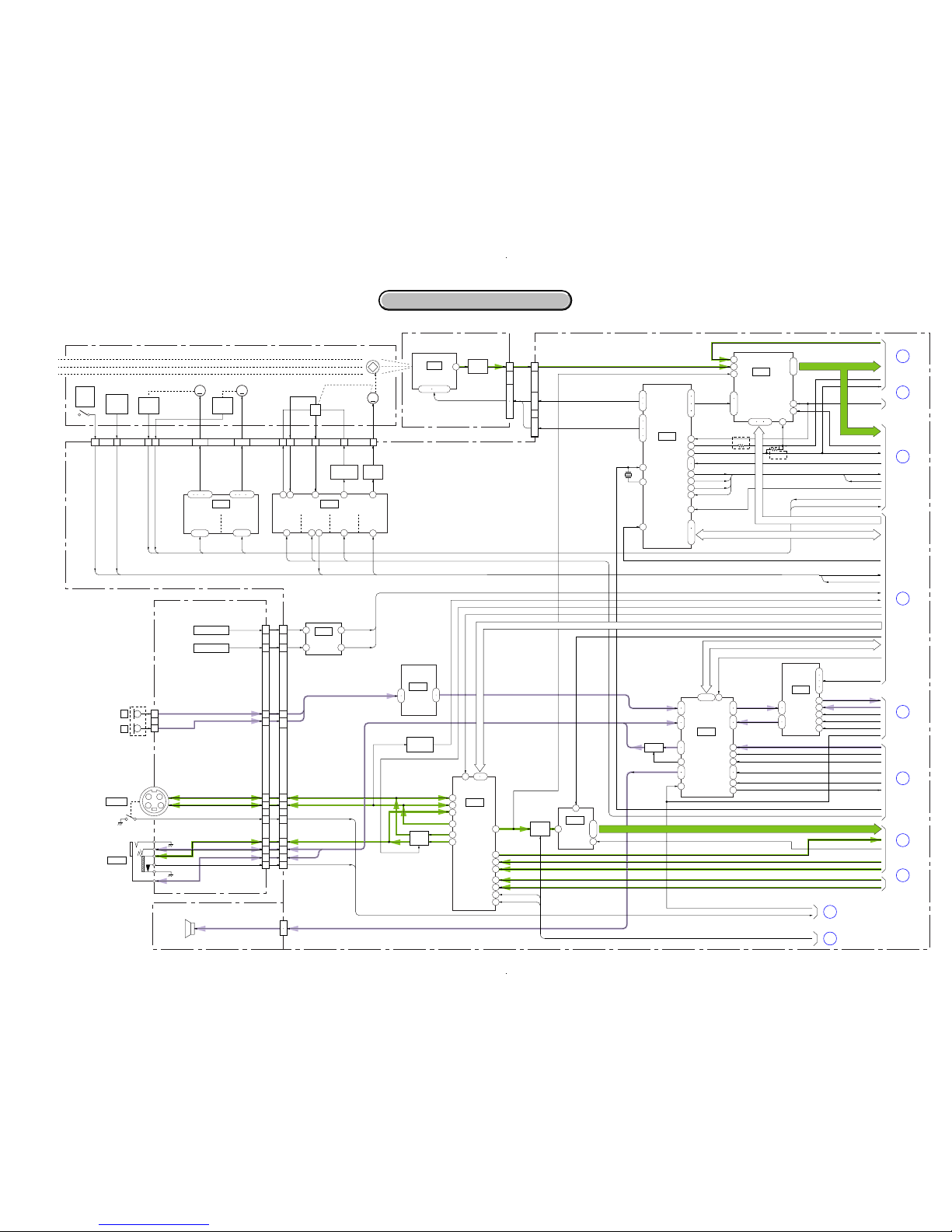

3-1. OVERALL BLOCK DIAGRAM (1/6)

3-1 3-2

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SECTION 3

BLOCK DIAGRAMS

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

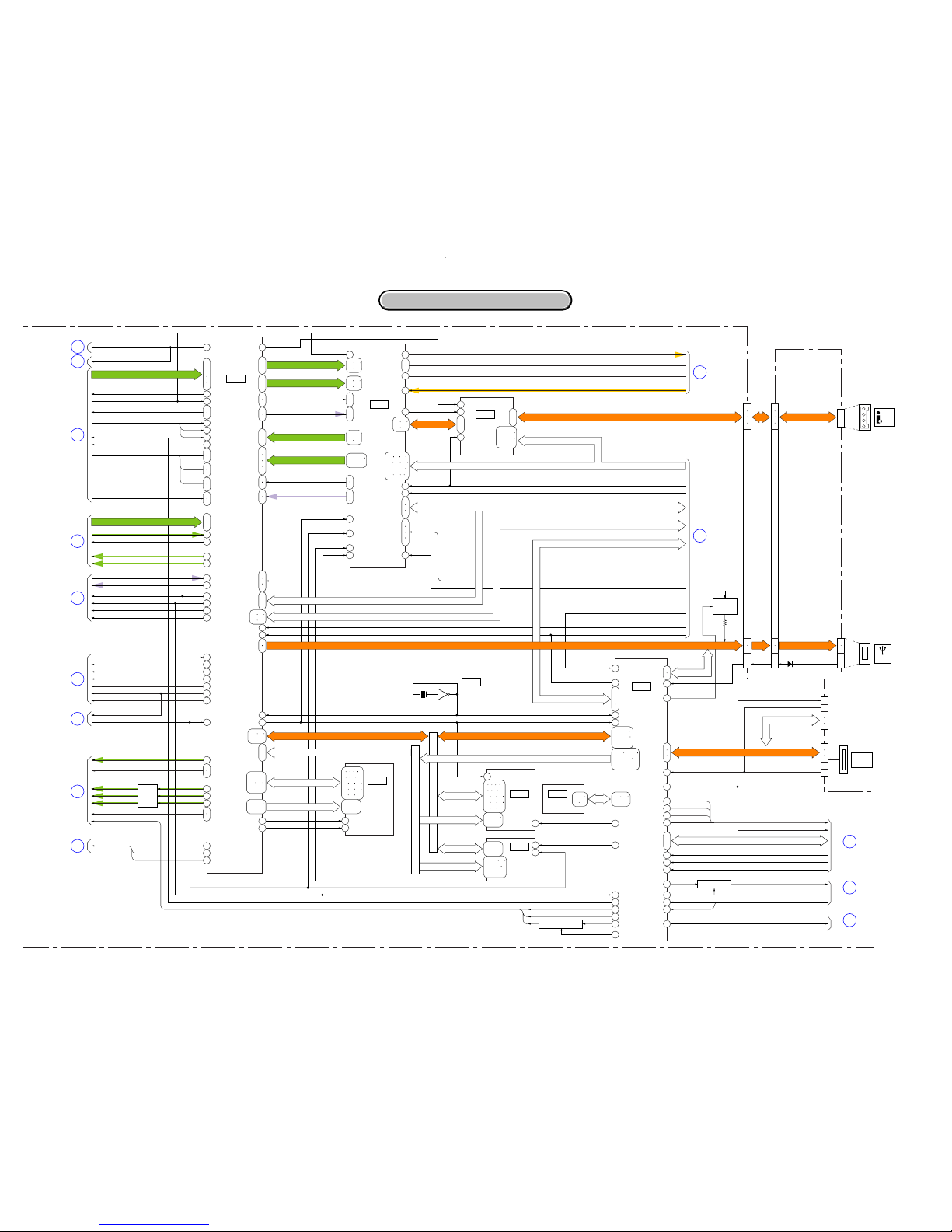

3-3 3-4

3-2. OVERALL BLOCK DIAGRAM (2/6)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

XCS IC8001

TRCKO

LCKO

LCKO

CN1001

(2/4)

CN754

(2/4)

PANEL R

PANEL HD, PANEL VD

05

PANEL B

PANEL G

VC-345 BOARD (2/6)

IC6001

DV SIGNAL

PROCESS

(7/18)

IC5701

USB CONTROL,

MEMORY STICK

INTERFACE,

MODE CONTROL

(11/18)

IC5703

XTAL OSC

(11/18)

EVF G/BW Y

42

ı

45

IC8002

16M

SDRAM

(3/18)

IC8301

DV INTERFACE

(9/18)

6

ı

9

SI-041 BOARD (2/4)

(USB)

92

93

EVF HD, EVF VD

95

96

104 47

79

41

45

139

143

40

46

39

45

21

78 60

TPX, TPY, TP SELE1

ACC-CONT, AGC-CONT,

CLPVO

OVERALL (3/6)

(PAGE 3-5)

16

OVERALL (1/6)

(PAGE 3-2)

9

OVERALL (5/6)

(PAGE 3-10)

19

OVERALL (5/6)

(PAGE 3-9)

18

OVERALL (4/6)

(PAGE 3-7)

17

CN751

DV

27

188

LINEOUT V

LINEOUT V

164

BIRDS VD

VFI OE

USB XEN

162

BIRDS FLD

163

VREF

165

ALIGN VD

161

160

80

1

CN752

36

VCK

VCK

BUFFER

Q8001

XCS IC 8301

XCS IC 8301

158

XCS IC 6001

47

48

224

ı

231

233

234

IC8001

VIDEO/AUDIO DSP,

D/A CONVERTER,

LENS CONTROL

(2/18)

150

ı

152

97

ı

99

237

98

ı

116

252

ı

261

157

SYS V

XCS IC 8001

REC PROOF

SYS V

USB CLK

24

MEMCK OUT

XSYS RST

141

216

ZSG1, ZV1, TG ID

33

IC 3701 C OUT Hi8/Std8, LINE

Hi8/Std8, LINE

245

ADCK27

217

236

ZSG1

ZV1

DIR0A,B

EN0,1

TG ID

DIR1A,B

222

VGAT

241

221

CLPOB

OVERALL (1/6)

(PAGE 3-2)

3

OVERALL (1/6)

(PAGE 3-2)

7

OVERALL (1/6)

(PAGE 3-2)

5

OVERALL (4/6)

(PAGE 3-8)

13

OVERALL (5/6)

(PAGE 3-9)

14

OVERALL (6/6)

(PAGE 3-11)

15

OVERALL (1/6)

(PAGE 3-2)

10

OVERALL (3/6)

(PAGE 3-5)

11

SPCK

OVERALL (4/6)

(PAGE 3-7)

12

SPCK

139

20

119 120

162 163

70 71

121 122

54 55 57

107 109 110

152 – 155

189 190 192

13 14

72 73

149 150

186 187

154 156

158 159

123 – 125

166

24 – 26

29 – 32

34 – 37

219

220

CAM DD ON

EN0,1, DIR0A,B, DIR1A,B

TG HD, TG VD

164

165

287

288

237

238

FC RST, ZM RST

127

168

301

302

126

167

298

299

239

248

246

247

250

251

AD0 C – AD9 C

268

ı

271

RYO0 – RYO3

264

ı

267

RYI0 – RYI3

HYO, HCO

ADATAIN0,1

ADATAOUT0,1

RECDT

RECA1,2

RECCK

RF IN

RECDT

RECA1,2

RECCK

RF IN

12

75

284

285

HYI, HCI

272

273

275

276

RCI0 – RCI3

279

ı

282

RCO0 – RCO3

AD0 – AD9

IC 8001 Y OUT

53

IC 8001 C OUT

60

DATA TO SFD

87

DATA FROM SFD

89

SFD BCK

82

SFD LRCK

SFD BCK

15

DSCK VM

DSCK VM

DSCK VM

XCS SDRAM VM

SFD LRCK

62

XSYS RST

83

SFD FCK

85

KASYAON

86

168

169

58

59

111

112

3

114

157

FRRV, TRRV, TRRT

FRRV, TRRV, TRRT, DRP

FRRV, TRRV, TRRT, DRP

SWP

91

Q5701, 5702

MODURATOR

LBUS0-3

TPA, NTPA, TPB, NTPBTPA+, –, TPB+, –

XCS IC 8301

XCS IC 6001

D24A00 – D31A07, DXXA08, DXXA09, ALE, WRX, RDX

28

29

D24A00 – D31A07, ALE, WRX, RDX

VSP SI, VSP SO, XVSP SCK VSP SI, VSP SO, XVSP SCK

VSP SI, VSP SO, XVSP SCK

DSCK VM

119 122

SFD LRCK

124

CAM DD ON

TP X

TP SEL1

TP Y

TP SEL2

131

137

249

138

250

239

USB CLK

X5703

48 MHz

177

SYS V

221

REC PROOF

234

168

256

196

CAM SI, CAM SO. CAM SCK. CAM CS

CAM SI, CAM SO. CAM SCK. CAM CS

121 122

124 – 137

2 3 5 6

8 9 11

12 39 40

42 43 45

46 48 49

19 – 24

27 – 32

198 – 205

207 208

210 – 215

D0 VM – D15 VM D0 VM – D15 VM

MDQ0 T – MDQ15 T

A1 VM – A19 VM

MA0 T – MA10 T, MA12 T

2

3

MEMORY

STICK

5

CN1016

2

4

6

2

5

CN1015

1

6

7

1

ı

4

D+, –

VCC

D755

USB D+

185

186

USB DET

USB D+ PULL UP

XS JACK IN

238

253

230

MELODY

MELODY ENV

274

AV JACK IN

BEEP

XVM MAD

86

XDS RESET

220

OSD V

AV JACK IN, XS JACK IN

80

MS XIN

MS LED ON

MS XIN

FOR JIG

MS XIN

MS LED ON

USB D+, USB D–

DATA BUS

ADDRESS BUS

IC5501

16M

SDRAM

(12/18)

2 3 5 6

8 9 11

12 39 40

42 43 45

46 48 49

19 – 24

27 – 32

D0 VM – D15 VM

IC 5001 RXD0, IC 5001 TXD0, IC 5001 SCK0, IC 5001 CS

XCS EEP,

EEP XRDY,

EEP RXD3,

EEP SCK3.

EEP TXD3

A1 VM – A11 VM, A13 VM

IC5502

32M

FLASH

(12/18)

IC5702

EEPROM

(11/18)

1 – 10 13

16 – 25

48

16 – 18

21 – 24

27 – 35

1 – 4 7 – 12

291 – 298

301 – 304

29 – 36

38 – 45

1 – 3

5 6

235 236

103 – 105

D0 VM – D15 VM

A1 VM – A22 VM

A1 VM – A22 VM

35

287

KEY AD 6

145

KEY AD 5

144

KEY AD 1

140

KEY AD 0

139

18 71

XCS FLASH

XSYS RST

26

12

69

35

MXCSO

190

18

MS DIO, MS BS, MS SCLK

MS DIO, MS BS, MS SCLK

149

USB D+, USB D–

USB D+, USB D–

HI SI, HI SO. XHI SCK. XCS MECHA

HI SI, HI SO. XHI SCK. XCS MECHA

28

29

31

32

35

34

1

9

8

6

5

2

3

USB

PULL UP

USB 3.1V

Q1007

78

81

85

KEY AD 0, 1, 5. 6

MS LED ON

93

ı

96

66

64

62

171 174

176 – 185

TP SELECT SWITCH

Q5703

IR ON

254

D24A00 – D31A07, DXXA08, DXXA09, ALE, WRX, RDX

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

DCR-TRV360/TRV361/TRV460/TRV460E/TRV461E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : SERVO SIGNAL

A : VIDEO/SERVO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

Q3202, 3204, 3205

FLYING

VIDEO HEAD

ERASE

CN3201

RF MON

ODD

ODD (SP1)

EVEN (SP2)

05

XFE ON

RF SWP

CN1011 (1/3)

EVEN

SW DIR

PB RF

IC3201

REC/PB AMP

(8/18)

5

2

BPF MONI

3

11

5

4

7

8

9

ERASE HAED

OSC

Q3206 – 3209

Hi8/Std8

PB ON SWITCH

187

ı

196

IC2201

IC3001

Hi8/Std8

VTR PROCESS

(5/18)

30

44

35

25

46

3

4

10

9

38

OVERALL (4/6)

(PAGE 3-8)

21

CPC

(FOR CHECK)

IC1601

EVR

(D/A CONVERTER)

(10/18)

FREQ TUNE

BPF MONI

HALL OFFSET, HALL GAIN, HALL REF

27

28

9

11

15

DA STRB

SPCK

16

RF SWP

RF SWP

4

3

23

20

5

24

22

AU BPF

1.7M DEV, 1.5M DEV

10

REC Y/MT CONT

REC L CONT

RP IR

MT Q

MT FO

OVERALL (1/6)

(PAGE 3-2)

6

OVERALL (2/6)

(PAGE 3-3)

11

37

SW PS

DRUM 8PB

ALL PS

VCK

198

IC 2201 Y OUT

4

IC 2201 C OUT

213

ADCK

185

43

13

XME/MP

SW PS

ALL PS

XME/MP

26

DOC DET

REC Y/MT CONT

RP POWER SAVE

AGC SLOW

REC L CONT

RP IR

DOC DET

MT FO

MT Q

12

21

8

AGC EVR

LPF FO

PB FBDP

6

XMP/ME

34

36

AGC EVR

LPF FO

PB FBDP

22

XMP/ME FE (X)

40

42

95

ı

97

17

ı

19

VD SI, VD SO, VD SCK

53

AFC F0

VCO

Q2207

83

JOG VD

84

X1/2 SWP

85

SWP DIR

87

ATF SAMPLE

88

SYS V

93

94

101

CK CONT

157

XTBC V RST

158

TBC VD

MECHA HD, MECHA VD

OVERALL (4/6)

(PAGE 3-7)

OVERALL (1/6)

(PAGE 3-2)

1

OVERALL (2/6)

(PAGE 3-4)

16

OVERALL (1/6)

(PAGE 3-2)

8

20

49

PB C RF

51

RF AGC OUT

PB C RF

98

XCS IC 2201

99

XRST IC 2201

AFC F0 ADJ

AFC F0 ADJ

PB RF

PB RF

AFM FSC

79

67

AFM FSC

SPCK

81

DOP

77

RECDT

RECA1,2

RECCK

RF IN

RECDT

RECA1,2

RECCK

RF IN

DV PB RF

RF MON

AD0 – AD9

VC-345 BOARD (3/6)

9

18

11

10

14

7

3

48

8

12

46

RP PB MODE

13

Hi8/Std8

PB AMP

(10/18)

CAM SO, CAM SCK

AGC

CONTROL

Q3001

RP POWER SAVE

AGC SLOW

RP PB MODE

RF ENV DET

DOP

Hi8/Std8

Hi8/Std8

Hi8/Std8

Hi8/Std8

66

15

19

RF ENV DET

5

Q3002

BUFFER

TRV460/TRV460E/TRV461E

M2000/M2200

MECHA DECK (1/2)

M2000: TRV460/TRV460E/TRV461E

M2200: TRV360/TRV361

3-5 3-6

3-3. OVERALL BLOCK DIAGRAM (3/6)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

Loading...

Loading...