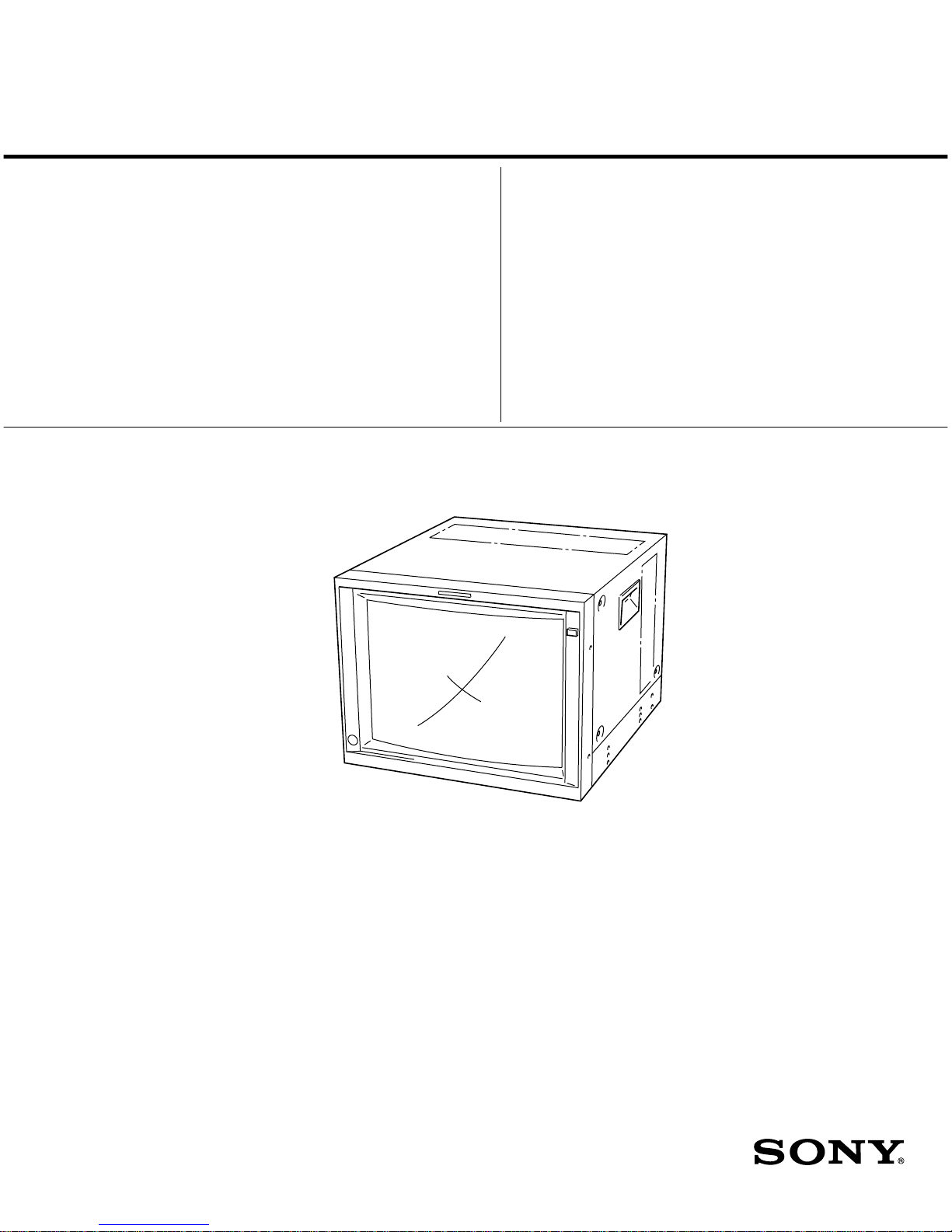

Sony TRINITRON PVM-14L5, TRINITRON PVM-20L5, TRINITRON PVM-D20L5A, TRINITRON PVM-D14L5A Service Manual

.............. ......... ....................

SERVICE MANUAL

.............. ......... ....................

MODEL

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PVM-14L5 US/CND SCC-G61K-A

PVM-20L5 US/CND SCC-G61L-A

PVM-D14L5A AUS SCC-H03D-A

PVM-D20L5A AUS SCC-H03E-A

TRINITRON® COLOR VIDEO MONITOR

REVISED-1

PVM-14L5/20L5/D14L5A/D20L5A

WARNING!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

!!

!!

! MARK ON THE SCHEMA TIC

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE P ART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY . CIRCUIT ADJUSTMENTS THAT ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS MANU AL.

FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

ATTENTION!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMA TEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNAGE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

!!

!!

! SUR

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT

MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS P AR SONY.

LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

1

PVM-14L5/20L5/D14L5A/D20L5A

Table of Contents

1. Service Informations

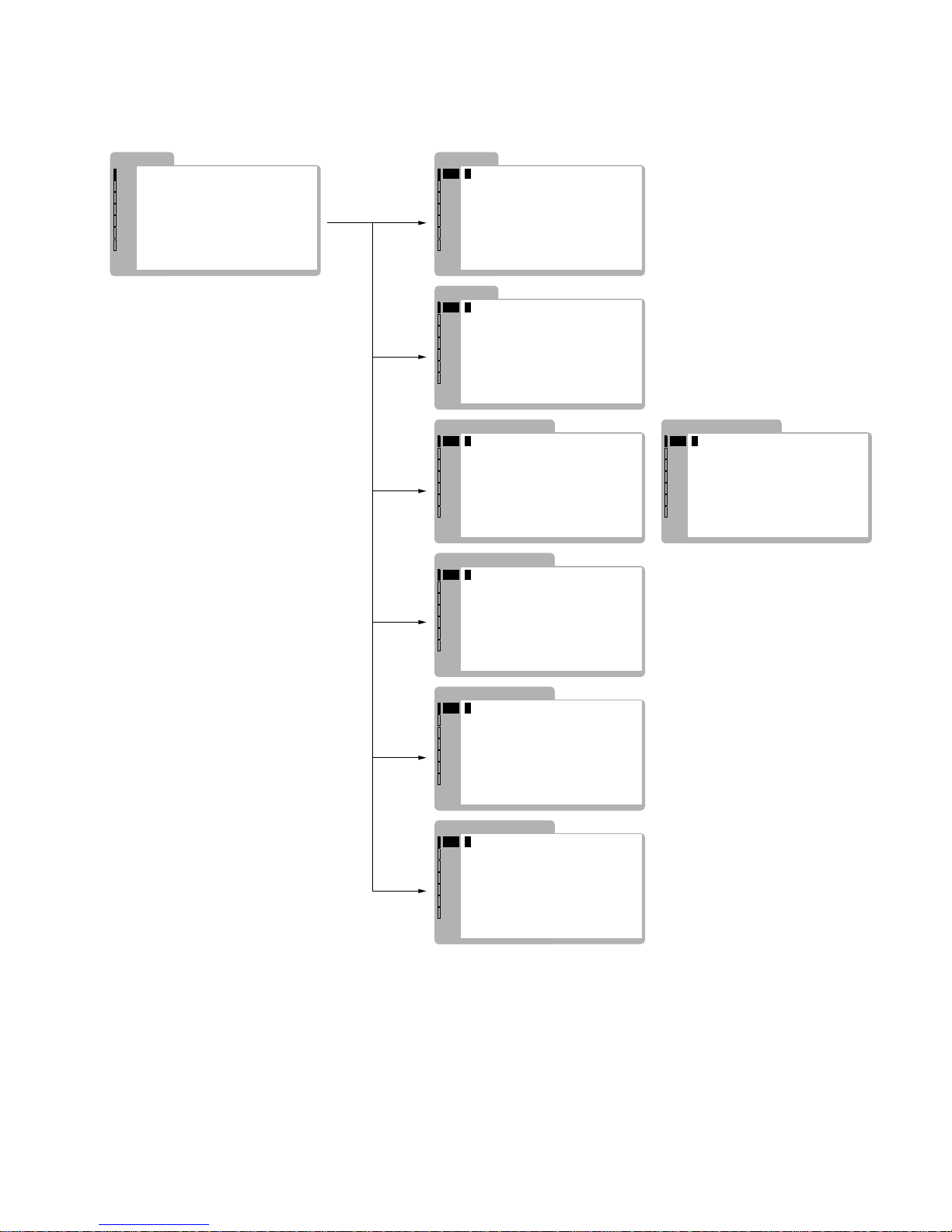

1-1. Board Layout (14 inch) ...............................................................................1-1

1-2. Disassembly (14 inch).................................................................................1-1

1-2-1. Top Cover Removal (14 inch)....................................................1-1

1-2-2. Bezel Assy Removal (14 inch)...................................................1-2

1-2-3. H1 Board Removal (14 inch) .....................................................1-2

1-2-4. H2 Board Removal (14 inch) .....................................................1-3

1-2-5. J , D1, D2 and D Boards Removal (14 inch) .............................1-3

1-2-6. C Board Removal (14 inch) .......................................................1-4

1-2-7. B Block Assy Removal (14 inch)...............................................1-4

1-2-8. K, T, B1, M and B Boards Removal (14 inch) ..........................1-5

1-2-9. Q Block Assy Removal (14 inch) ..............................................1-5

1-2-10. Removal of Anode Cap .............................................................. 1-6

1-2-11. G Board Removal (14 inch) .......................................................1-6

1-2-12. Picture Tube Removal (14 inch) ................................................1-7

1-2-13. Speaker Removal (14 inch) ........................................................ 1-8

1-2-14. Service Position (14 inch) ..........................................................1-8

1-3. Board Layout (20 inch) ...............................................................................1-9

1-4. Disassembly (20 inch)...............................................................................1-10

1-4-1. Top Cover Removal (20 inch)..................................................1-10

1-4-2. Bezel Assy Removal (20 inch).................................................1-10

1-4-3. HA Board Removal (20 inch) .................................................. 1-11

1-4-4. HB Board Removal (20 inch) ..................................................1-11

1-4-5. J, D1, D2 and D Boards Removal (20 inch) ............................1-12

1-4-6. C Board Removal (20 inch) .....................................................1-12

1-4-8. K, T, B1, M and B Boards Removal (20 inch) ........................1-13

1-4-7. B Block Removal (20 inch)......................................................1-13

1-4-9. Q Block Assy Removal (20 inch) ............................................1-14

1-4-10. Removal of Anode Cap ............................................................ 1-14

1-4-11. G Board Removal (20 inch) .....................................................1-15

1-4-12. Picture Tube Removal (20 inch) ..............................................1-15

1-4-13. Speaker Removal (20 inch) ...................................................... 1-16

1-4-14. Service Position (20 inch) ........................................................1-16

2. Set-up Adjustment

2-1. Equipment Required....................................................................................2-1

2-2. Preparations (1) ...........................................................................................2-1

2-3. Preparation (2). Initialization ...................................................................2-16

2-4. Writing Model Data .................................................................................. 2-17

2-5. Picture Output ........................................................................................... 2-17

2-6. Free-run Frequency Adjustment ...............................................................2-17

2

PVM-14L5/20L5/D14L5A/D20L5A

2-7. Landing Adjustment..................................................................................2-18

2-8. H Blanking Adjustment.............................................................................2-19

2-9. Linearity Adjustment ................................................................................2-20

2-10. Convergence Adjustment (1) .................................................................... 2-21

2-11. Deflection Yoke Neck Rotation Adjustment ............................................ 2-22

2-12. Convergence Adjustment (2) .................................................................... 2-22

2-13. G2 Adjustment ..........................................................................................2-23

2-14. White Balance Adjustment (15k)..............................................................2-23

2-15. White Balance Adjustment (33k)..............................................................2-24

2-16. SUB BRIGHT, SUB CONTRAST Adjustment (15 K) ............................ 2-24

2-17. SUB BRIGHT, SUB CONTRAST Adjustment (33 K) ............................ 2-25

2-18. White Balance Interference Correction Adjustment ................................. 2-25

2-18-1. NTSC Composite Adjustment..................................................2-25

2-18-2. PAL Composite Adjustment .................................................... 2-25

2-18-3. COMPONENT Adjustment ..................................................... 2-25

2-18-4. SDI Adjustment........................................................................2-25

2-18-5. HD and SDI Adjustments.........................................................2-26

2-19. Focus Adjustment......................................................................................2-26

3. Safety Related Adjustment

3-1. High Tension Regulator Confirmation........................................................3-2

3-2. Protection Circuit Confirmation..................................................................3-2

3-2-1. HV Protector Circuit Confirmation............................................3-2

3-2-2. 1K Protector Circuit Confirmation.............................................3-2

4. Electrical Adjustments

4-1. Equipment Required....................................................................................4-1

4-2. B Board Adjustments ..................................................................................4-2

4-2-1. Preparations ................................................................................ 4-2

4-2-2. 15k YPBPR SMPTE (601) Signal Adjustment..........................4-3

4.2-2-1. Black Level Adjustment.............................................................4-3

4-2-2-2. CHROMA Leak Adjustment......................................................4-4

4-2-2-3. MATRIX Adjustment ................................................................ 4-4

4-2-3. 15k YPBPR BETACAM SETUP 0 Signal Adjustment ............4-5

4-2-4. 15k YPBPR BETACAM SETUP 7.5 Signal Adjustment .........4-5

4-2-5. 33 k YPBPR SMPTE (709) Signal Adjustment.........................4-6

4-3. B1 Board Adjustments ................................................................................4-8

4-3-1. Preparation .................................................................................4-8

4-3-2. Y OUT Level Adjustment (BYPASS Mode) ............................. 4-9

4-3-3. Clamp Pulse Width Adjustment (NTSC) ...................................4-9

4-3-4. Burst Gate Pulse Width Adjustment (NTSC) ............................4-9

3

PVM-14L5/20L5/D14L5A/D20L5A

4-3-5. 3.58 f0 Adjustment (NTSC) ....................................................... 4-9

4-3-6. Phase Adjustment (NTSC) .........................................................4-9

4-3-7. Level Adjustment (NTSC) .......................................................4-10

4-3-8. Burst Gate Pulse Width Adjustment (PAL) .............................4-10

4-3-9. 4.43 f0 Adjustment (PAL)........................................................4-10

4-3-10. PAL B-Y PHASE Adjustment .................................................4-10

4-3-11. PAL PHASE Adjustment (Normal) .........................................4-11

4-3-12. Level Adjustment (PAL)..........................................................4-11

4-3-13. Level Adjustment (NTSC 443) ................................................4-11

4-3-14. Clamp Pulse Width Adjustment (SECAM) ............................. 4-12

4-3-15. H. Pulse Width Adjustment (SECAM) ....................................4-12

4-3-16. Level Adjustment (SECAM)....................................................4-12

5. Theory of Operation

5-1. B Board ....................................................................................................... 5-1

5-2. BI Board ......................................................................................................5-3

5-3. C Board ....................................................................................................... 5-4

5-4. Deflection Circuit and High Tension Circuit ..............................................5-5

5-7. Power Supply Circuit ..................................................................................5-7

6. Semiconductors................................................................................. 6-1

7. Spare Parts

7-1. Notes on Repair Parts..................................................................................7-1

7-2. Exploded Views ..........................................................................................7-2

7-3. Electrical Parts List ...................................................................................7-11

8. Block Diagrams

Overall (1/2) ................................................................................................8-1

Overall (2/2) ................................................................................................8-2

Q (1/2), B (1/5), T (1/2), K..........................................................................8-3

B (2/5) ......................................................................................................... 8-4

B (3/5) ......................................................................................................... 8-5

Q (2/2), B (4/5, 5/5), M, T (2/2), H1 (14L)/HA (20L), H2 (14L)/HB (20L) ...

8-6

B1 ................................................................................................................8-7

C, D, D1, D2, DY........................................................................................8-8

G, J .............................................................................................................. 8-9

4

PVM-14L5/20L5/D14L5A/D20L5A

9. Diagrams

9-1. Frame Schematic Diagram .......................................................................... 9-3

Frame...........................................................................................................9-3

9-2. Schematic Diagrams and Printed Wiring Boards........................................9-4

Schematic Diagrams

Q (1/2) .........................................................................................................9-5

Q (2/2) .........................................................................................................9-6

T .................................................................................................................. 9-8

B (1/5) ....................................................................................................... 9-11

B (2/5) ....................................................................................................... 9-12

B (3/5) ....................................................................................................... 9-13

B (4/5) ....................................................................................................... 9-14

B (5/5) ....................................................................................................... 9-15

B1 (1/2) .....................................................................................................9-21

B1 (2/2) .....................................................................................................9-22

M ............................................................................................................... 9-24

H1 .............................................................................................................. 9-25

H2 .............................................................................................................. 9-27

HA .............................................................................................................9-29

HB .............................................................................................................9-30

K ................................................................................................................ 9-31

C ................................................................................................................9-33

X ................................................................................................................ 9-34

J ................................................................................................................. 9-35

D ................................................................................................................ 9-37

D2 .............................................................................................................. 9-37

D1 .............................................................................................................. 9-39

G (1/2) .......................................................................................................9-42

G (2/2) .......................................................................................................9-43

Printed Wiring Boards

Q .................................................................................................................. 9-4

T .................................................................................................................. 9-7

B ................................................................................................................9-16

B1 ..............................................................................................................9-20

M ............................................................................................................... 9-23

H1 .............................................................................................................. 9-23

H2 .............................................................................................................. 9-26

HA .............................................................................................................9-28

HB .............................................................................................................9-28

K ................................................................................................................ 9-31

C ................................................................................................................9-32

X ................................................................................................................ 9-34

J ................................................................................................................. 9-35

D2 .............................................................................................................. 9-35

D ................................................................................................................ 9-36

D1 .............................................................................................................. 9-38

G ................................................................................................................ 9-40

1-1

PVM-14L5/20L5/D14L5A/D20L5A

Section 1

Service Informations

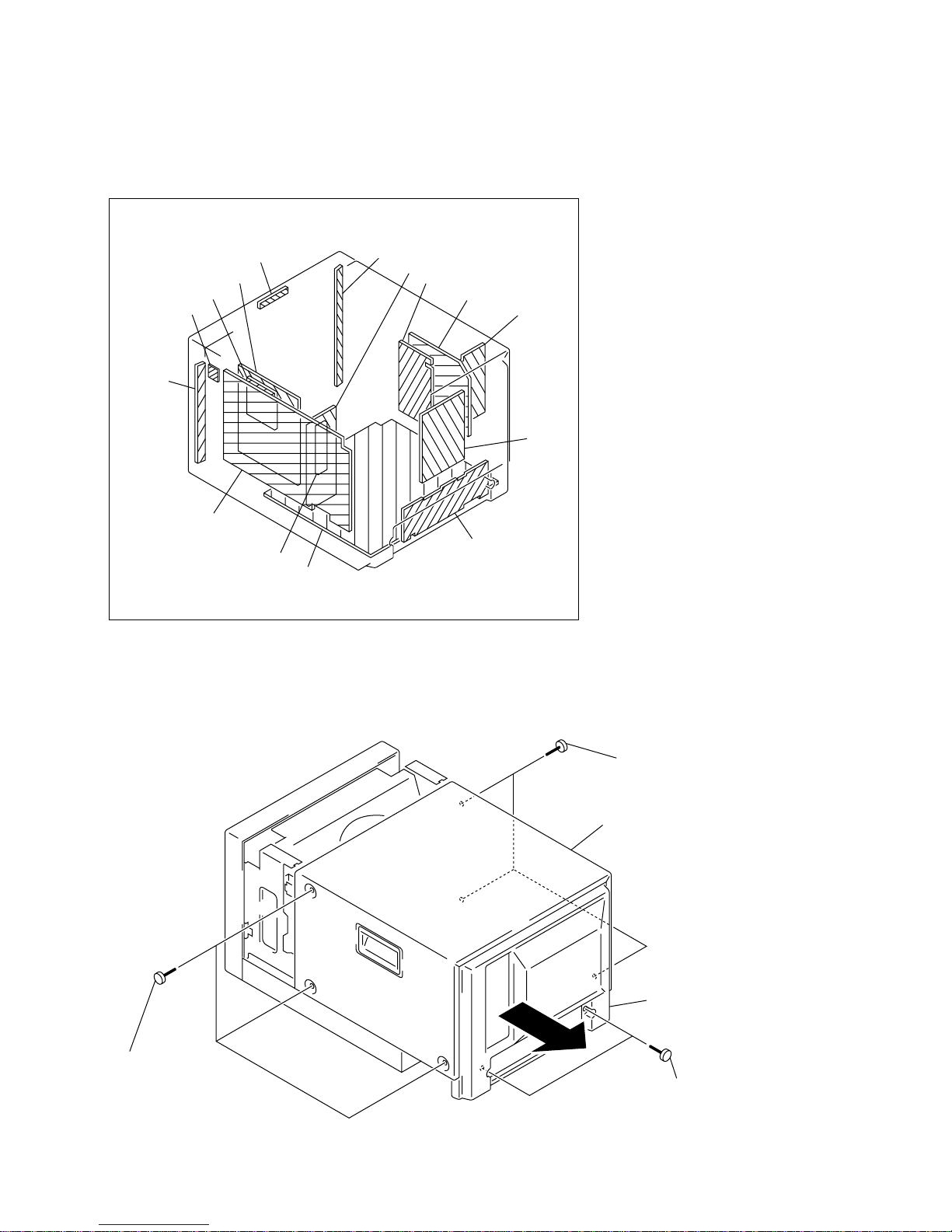

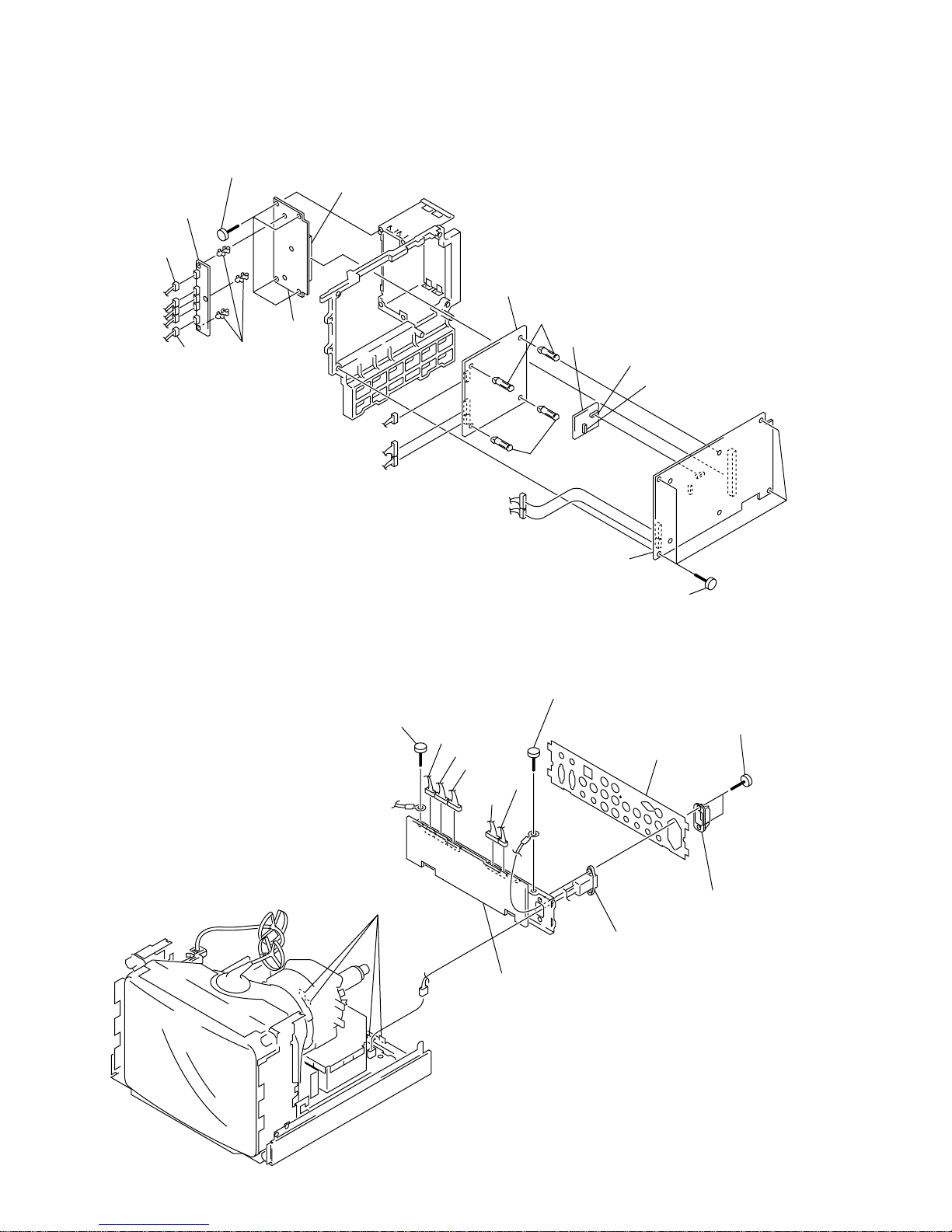

1-1. Board Layout (14 inch)

M

X

D1

B1

B

D

C

Q

G

H1

H2

J

K

D2

T

1-2. Disassembly (14 inch)

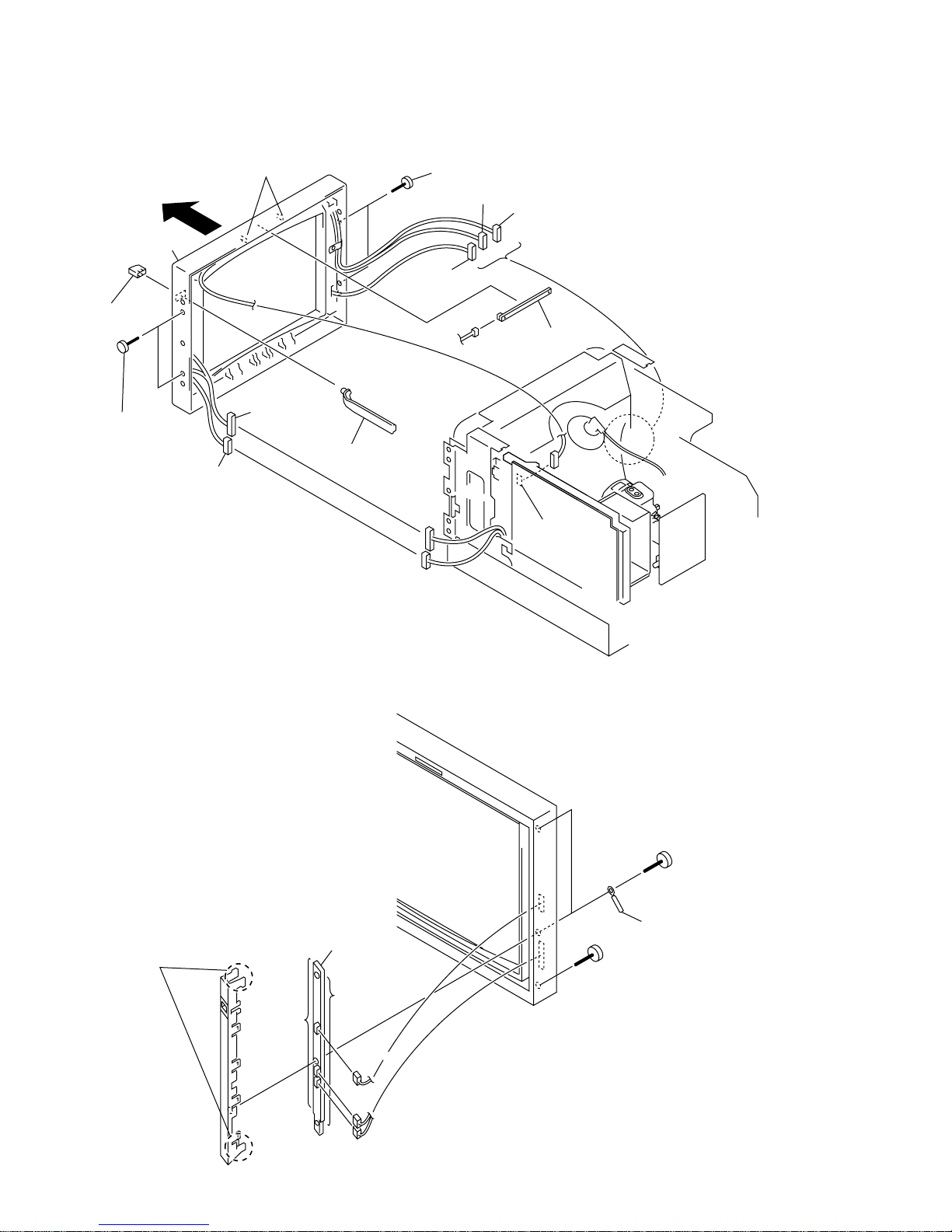

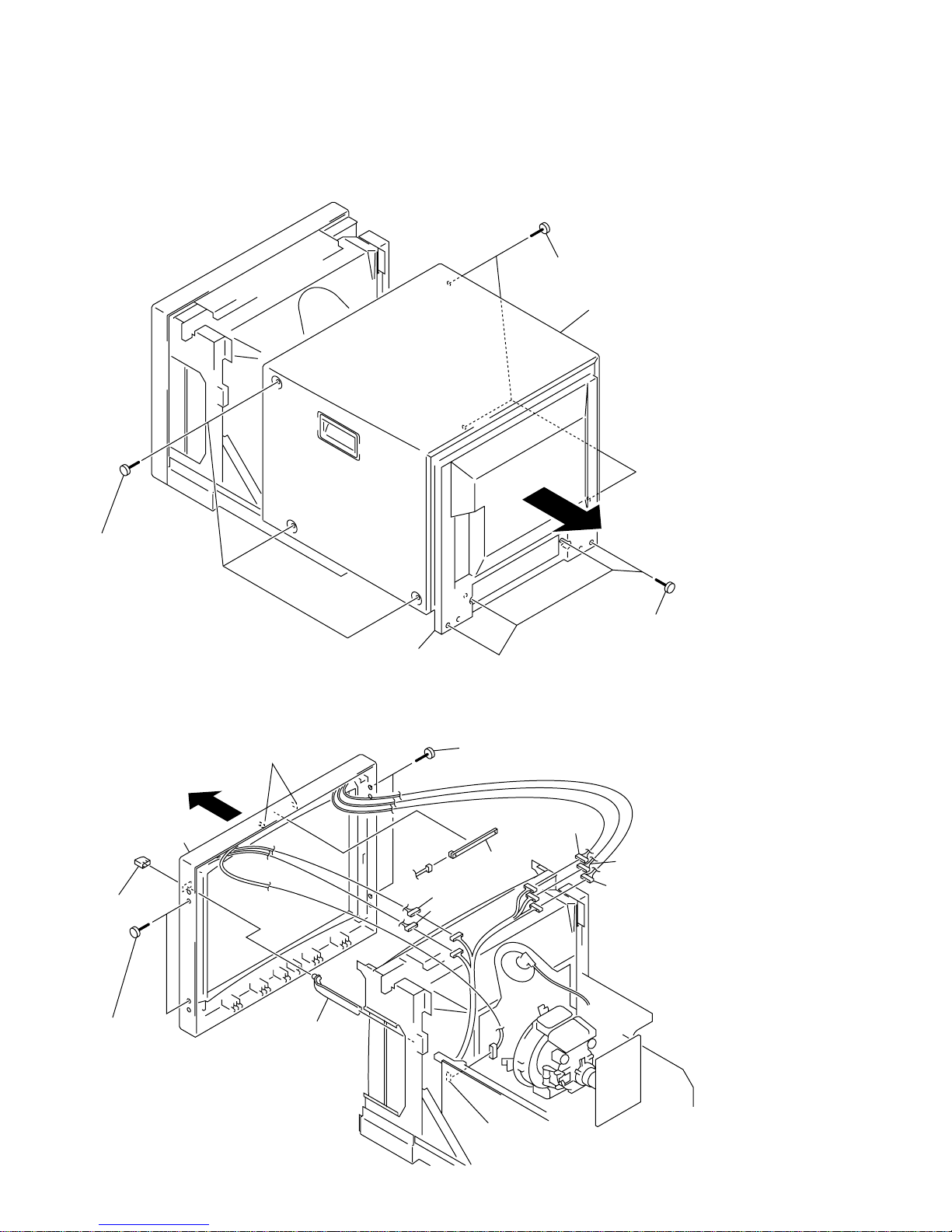

1-2-1. Top Cover Removal (14 inch)

1 Three screws

(claw case screw (OS))

2 Three screws

(claw case screw (OS))

Top cover

Rear cover

4

3 T wo screws

(+BVTT 4 x 8)

1-2

PVM-14L5/20L5/D14L5A/D20L5A

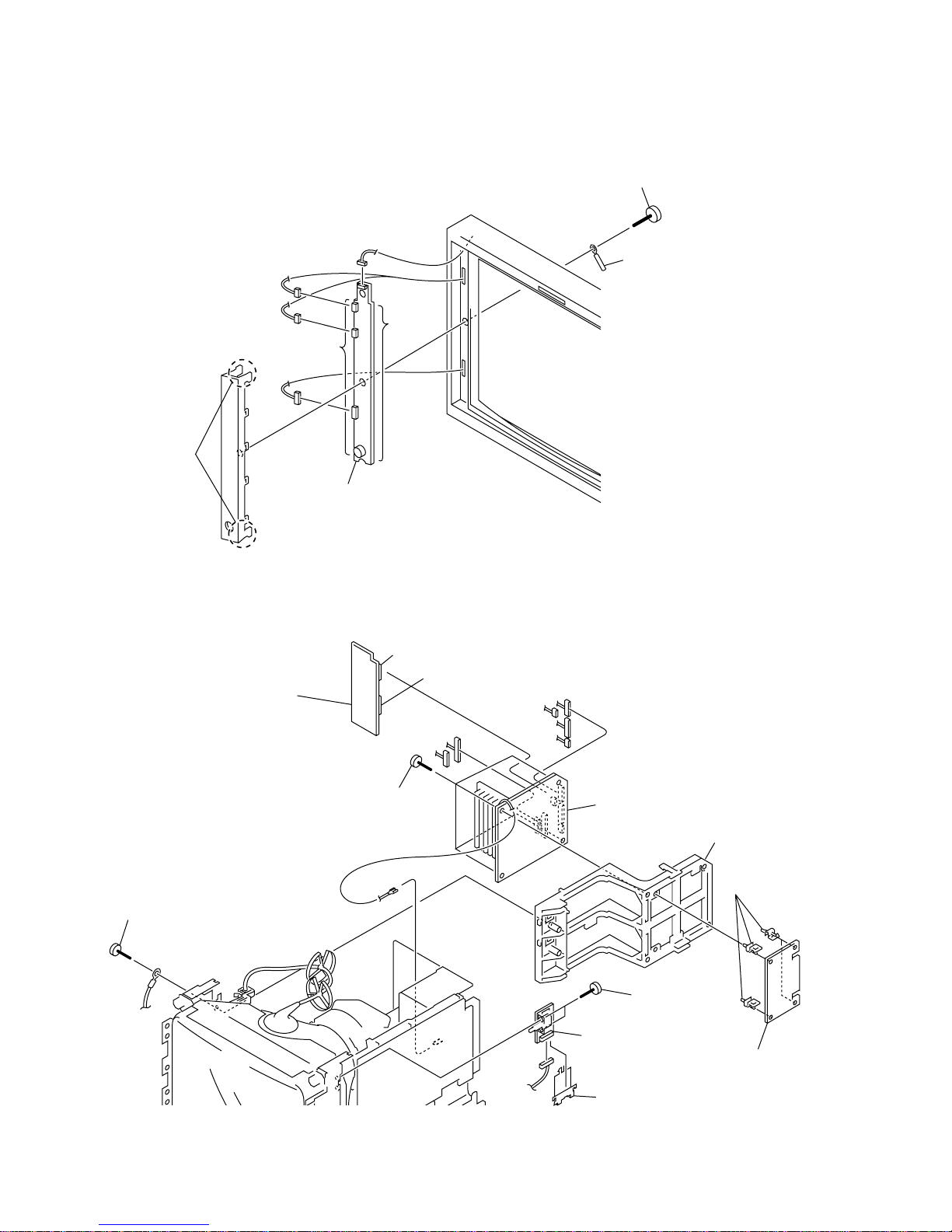

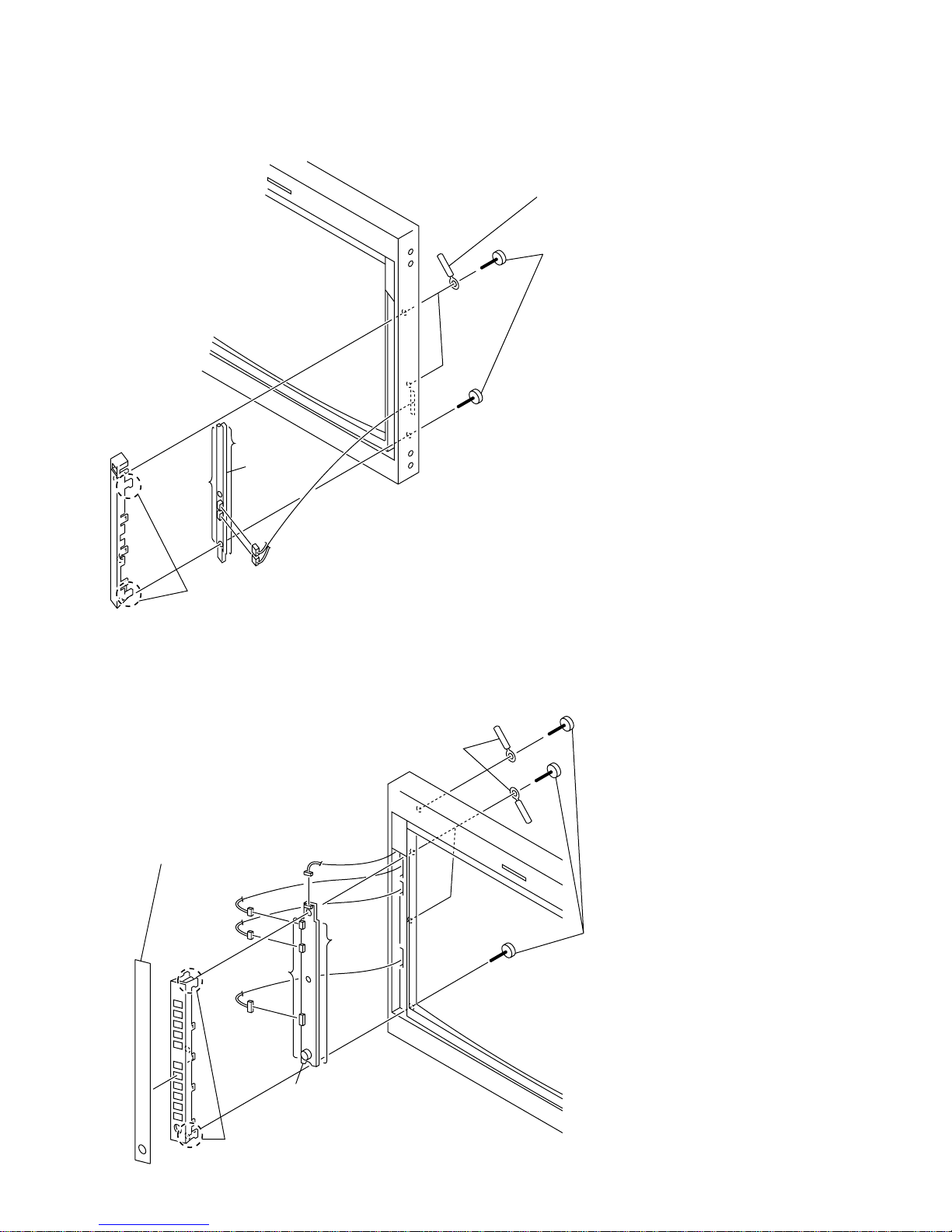

1-2-2. Bezel Assy Removal (14 inch)

3 Two screws (+B 3 x 8)

6 Two claws

5 Shaft switch

4

2 Two screws

(+B 3 x 8)

10 pin

X board

9 pin

7 pin

9 pin

5 pin

CN105

CN900

Bezel assy

1 Power button

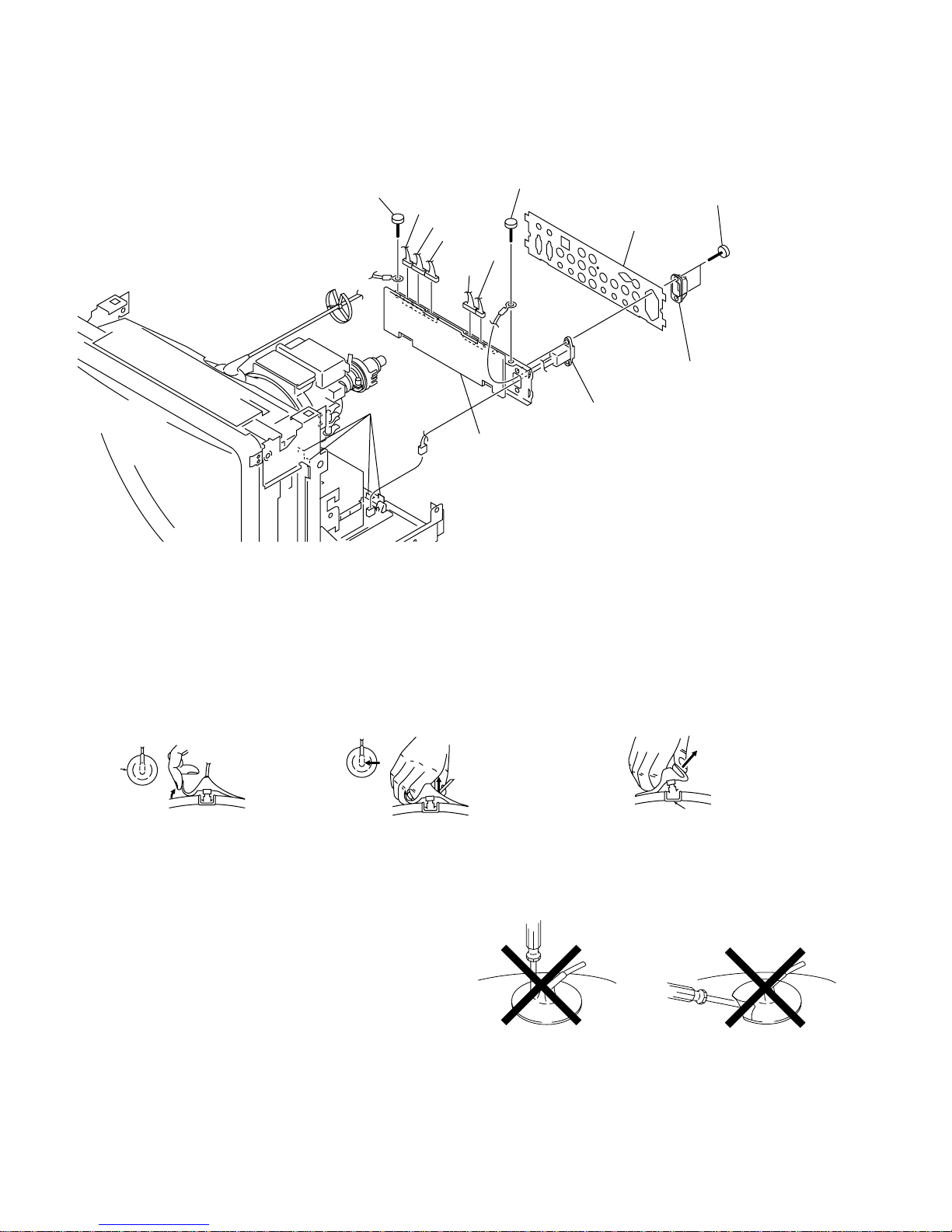

1-2-3. H1 Board Removal (14 inch)

4 Four claws

5 Three

claws

6 Four claws

1 Two screws

(+BVTP 3 x 12)

3 Screw (+BVTP 3 x 12)

2 Two wire holders

CN2903

CN2902

CN2901

H1 board

1-3

PVM-14L5/20L5/D14L5A/D20L5A

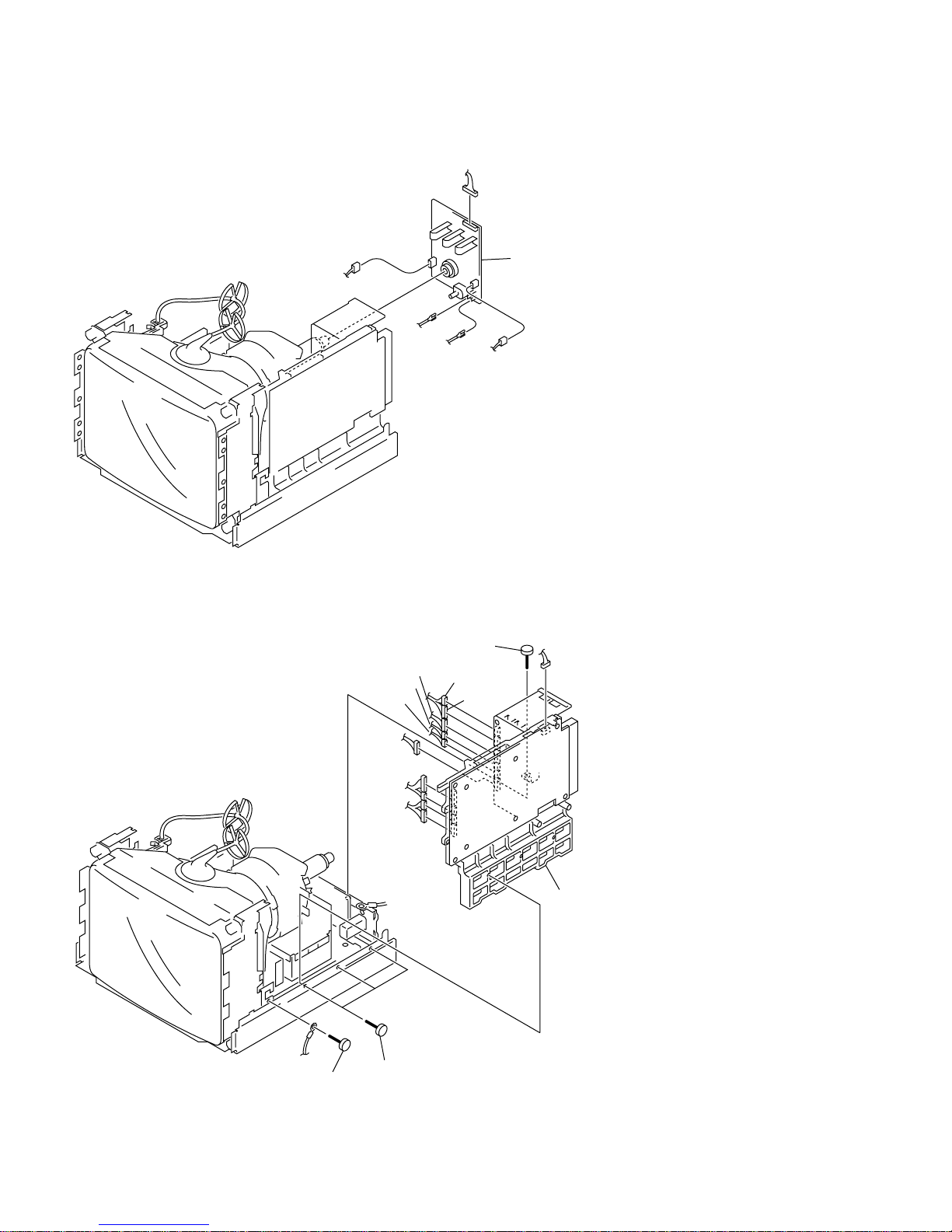

1-2-4. H2 Board Removal (14 inch)

3 Four claws

4 Four claws

5 Four

claws

1 Screw (+BVTP 3 x 12)

CN5005

CN5002

CN5001

CN5004

H2 board

2 Wire holder

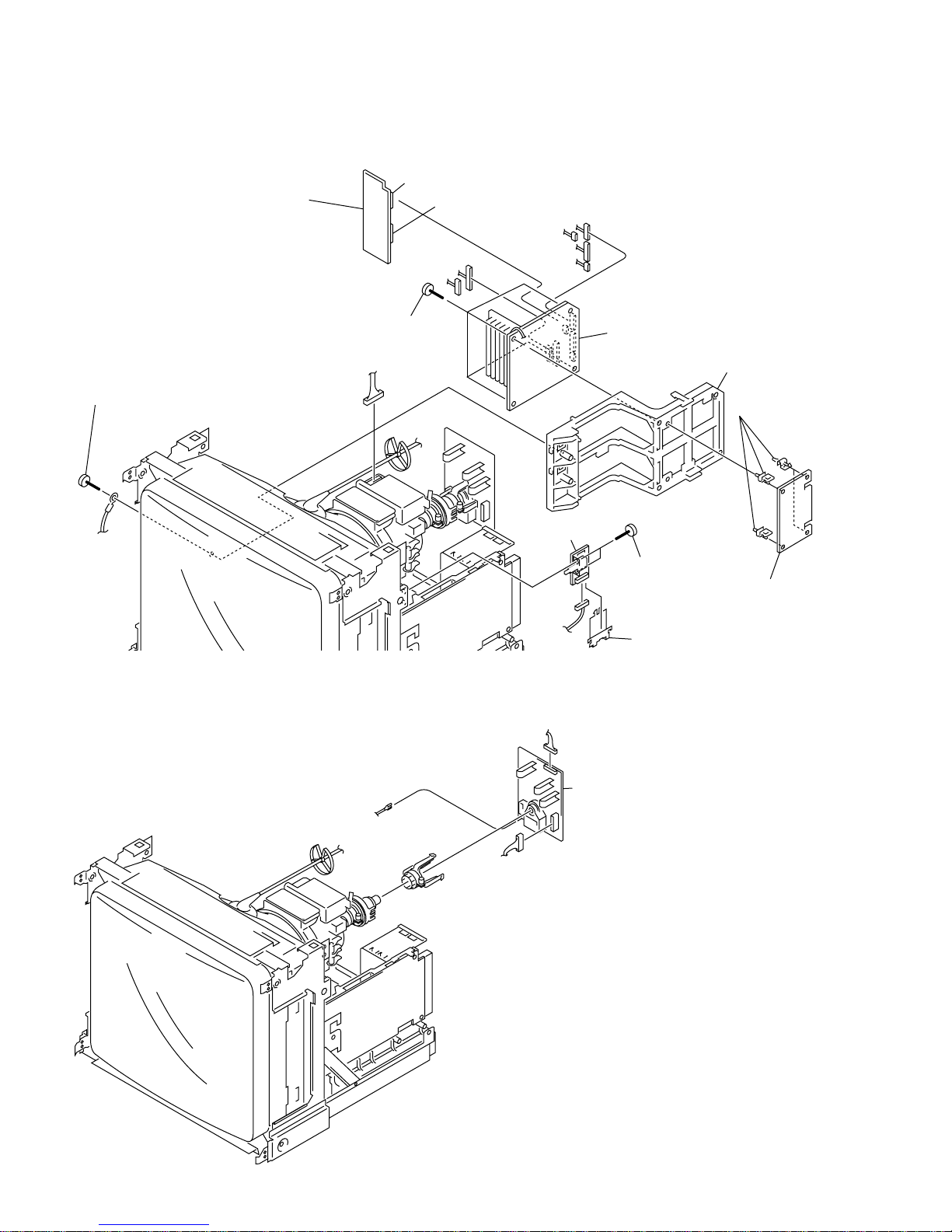

1-2-5. J , D1, D2 and D Boards Removal (14 inch)

CN1501

CN706

CN1508

CN1506

CN1507

CN1502

CN1503

6 Four screws

(+BVTP 3 x 12)

D board

5 Screw (+BVTT 4 x 8)

CN2502 (board to board)

4 D1 board

CN2501 (board to board)

1 Two screws

(+PSW 3 x 8)

2 Insulator (J PWB)

3 J board

CN951

9 Bracket D

8 D2 board

7 Four card edge

spacers

1-4

PVM-14L5/20L5/D14L5A/D20L5A

1-2-6. C Board Removal (14 inch)

CN705

CN704

CN702

CN701

CN703

C board

1-2-7. B Block Assy Removal (14 inch)

CN101

CN1906

CN1908

B block assy

CN2401

CN1905

CN1904

CN1903

CN1907

CN102

CN103

CN104

3 Screw (+PSW 4 x 8)

2 Three screws (+BVTP 3 x 12)

1 Screw (+BVTP 3 x 8)

1-5

PVM-14L5/20L5/D14L5A/D20L5A

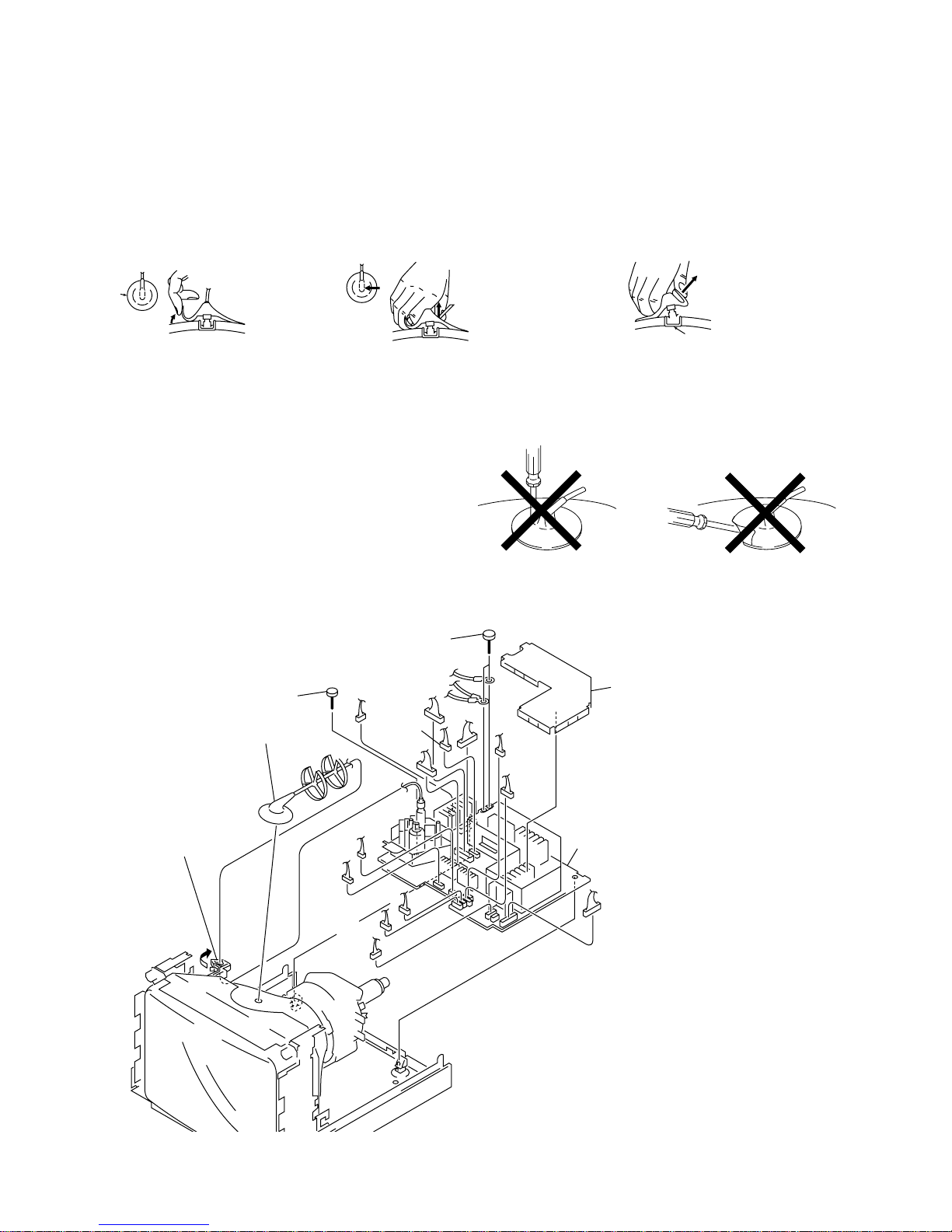

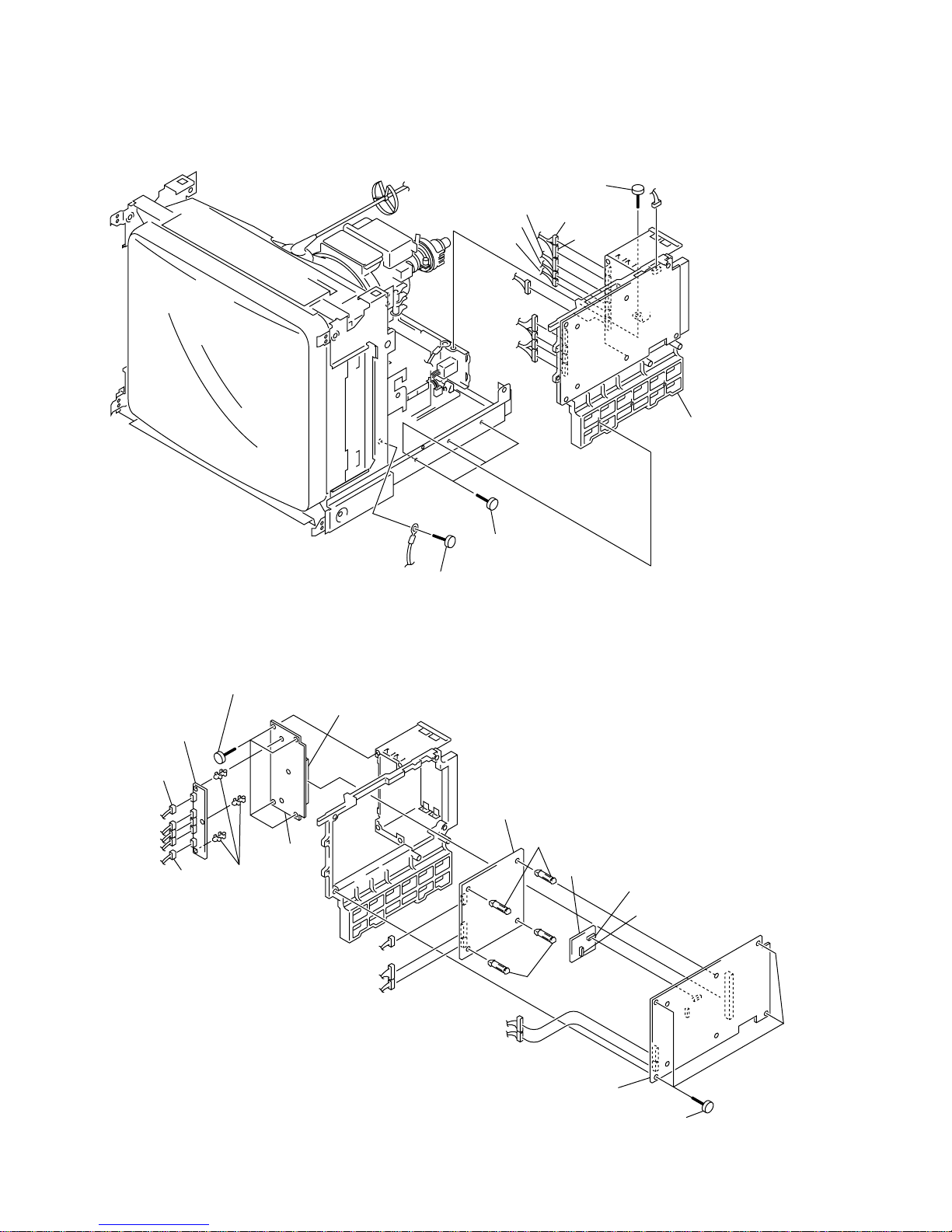

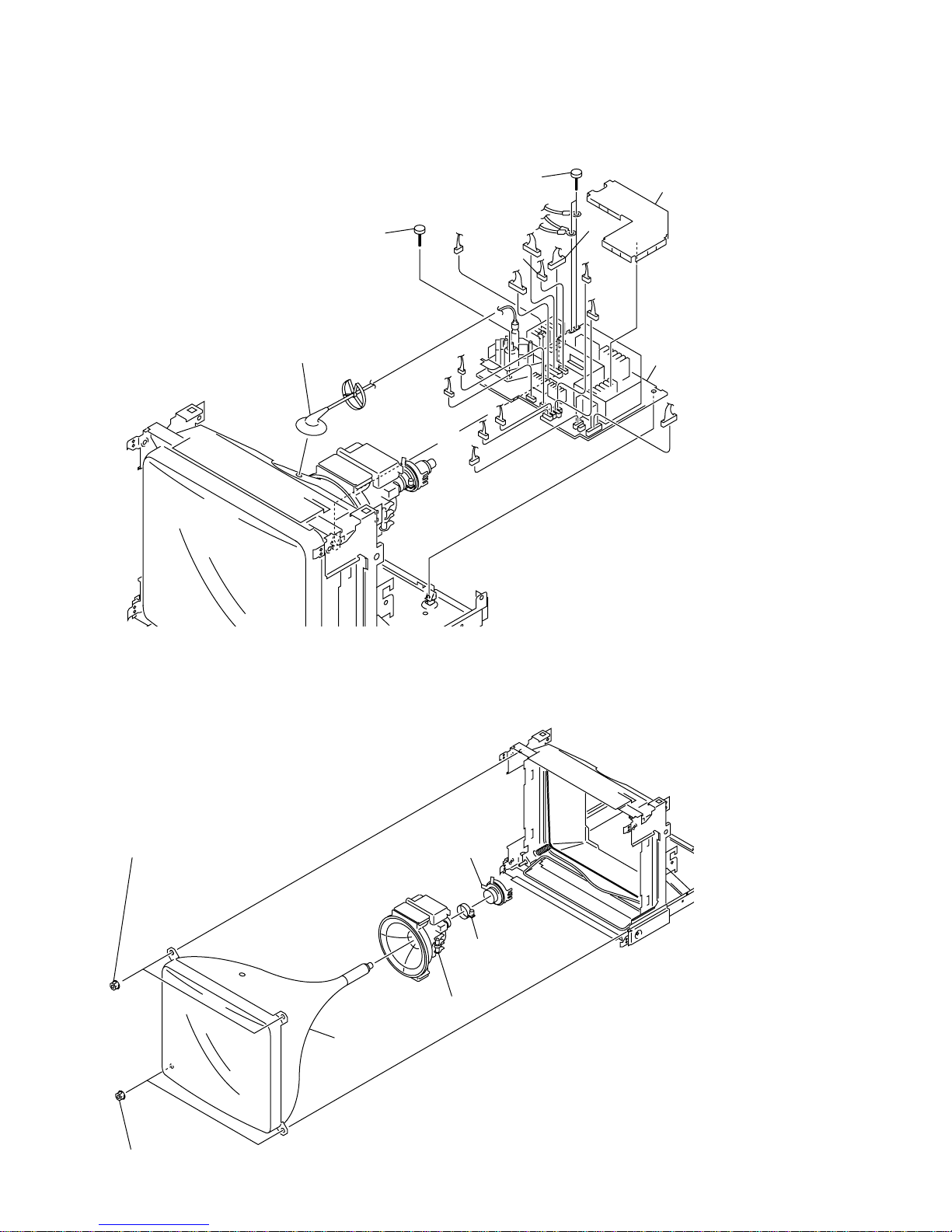

1-2-8. K, T, B1, M and B Boards Removal (14 inch)

CN801

CN113

CN107 (board to board)

CN108 (board to board)

CN201

CN3802

CN3801

9 Four screws (+BVTT 3 x 8)

T board

1 Three PWB

holders

2 K board

7 Four screws

(+BVTP 3 x 12)

4 Two PWB

holders

3 Two PWB holders

5 B1 board

6 M board

8 B board

CN1901 (board to board)

CN3504

CN3505

CN3503

CN3502

CN3501

1-2-9. Q Block Assy Removal (14 inch)

CN2704

CN601

CN2706

CN2705

CN2707

CN2710

4 Two screws

(+PSW 3 x 12)

2 Four claws

1 Screw (+PSW 4 x 8)

3 Screw (+PSW 4 x 8)

6 Connector label

5 Plug holder (A)

7 AC inlet 3p (with noise filter)

8 Q block assy

1-6

PVM-14L5/20L5/D14L5A/D20L5A

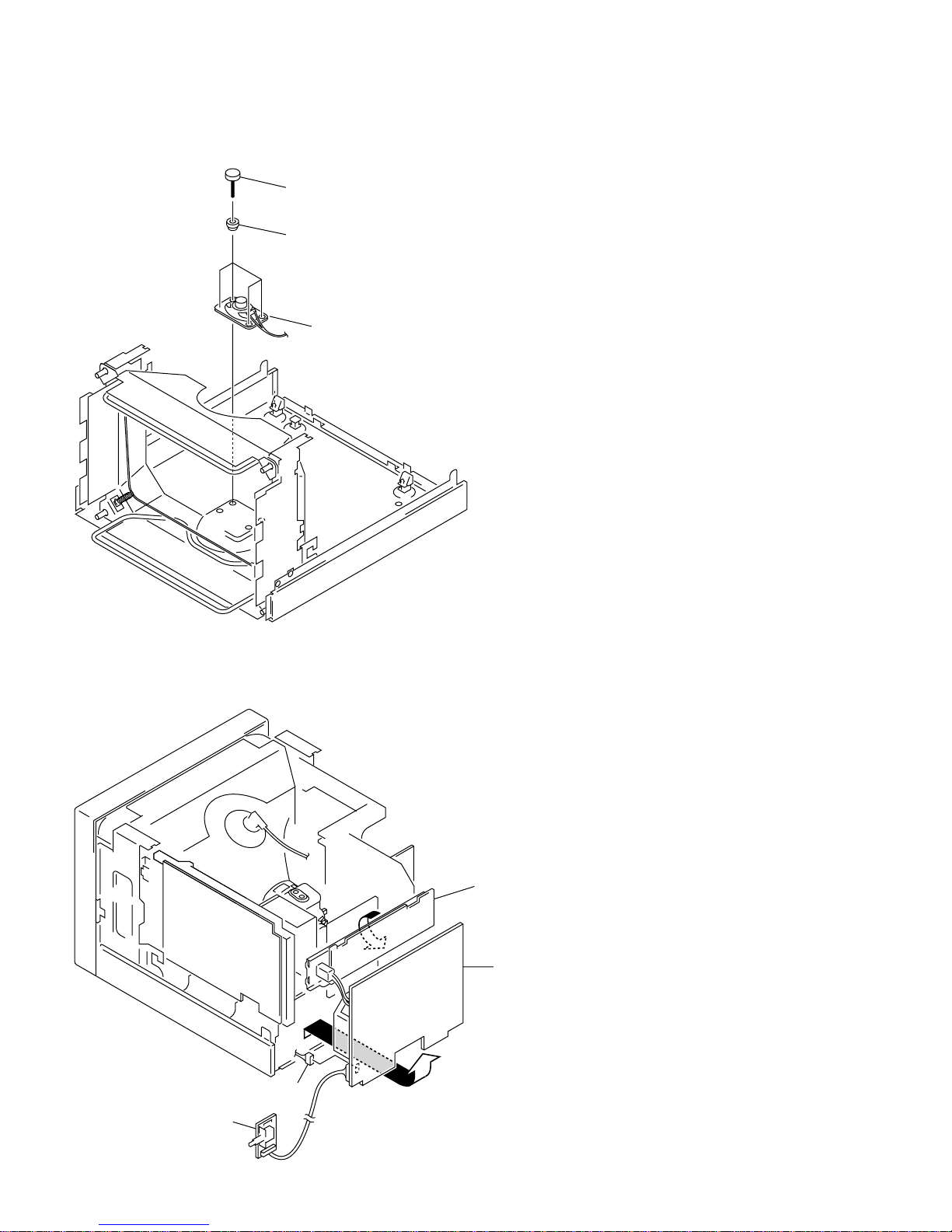

1-2-11.G Board Removal (14 inch)

4 Two screws (+PSW 4 x 8)

6 G shield

5 G board

CN602

CN603

CN610

CN609

CN604

CN608

CN608

CN607

CN503

CN606

CN607

CN508

CN505

1 Anode cap

2 Open the lead holder in the

direction of the arrow.

3

Screw (+BVTP 3 x 16)

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

1-2-10.Removal of Anode Cap

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

..

. Removal Procedure

..

..

. Handling Precautions

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

a

a

b

b

c

Anode button

1-7

PVM-14L5/20L5/D14L5A/D20L5A

1-2-12. Picture Tube Removal (14 inch)

4 Two nuts (flange nut (B) M5)

6 Two nuts (flange nut (B) M5)

5 Two washers

(CRT position washer)

1 Fastening band assy

2 DY shield

7 Picture tube

3 Deflection yoke

1-8

PVM-14L5/20L5/D14L5A/D20L5A

1-2-13.Speaker Removal (14 inch)

2 Four speaker cushions

3 Speaker

1 Four screws (step screw M3 x 4)

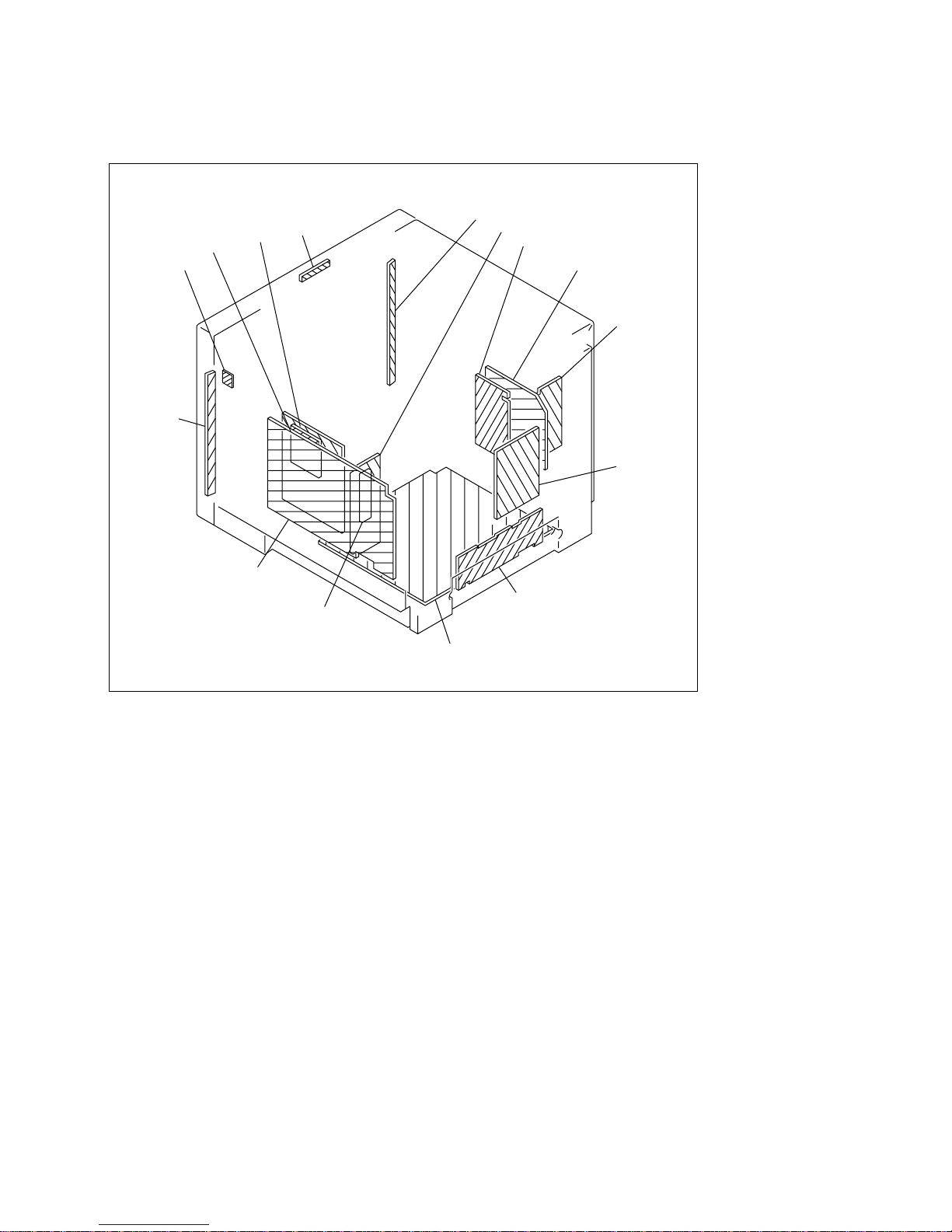

1-2-14.Service Position (14 inch)

CN603

G board

J board

Q board

*Because there exist the portions that have the high tension voltage,

be careful that the printed boards must not touch each other

nor must not touch with the chassis.

1-9

PVM-14L5/20L5/D14L5A/D20L5A

1-3. Board Layout (20 inch)

M

X

D1

B1

B

D

C

Q

G

T

HA

HB

K

J

D2

1-10

PVM-14L5/20L5/D14L5A/D20L5A

1-4. Disassembly (20 inch)

1-4-1. Top Cover Removal (20 inch)

4

1 Three screws

(claw case screw (OS))

2 Three screws

(claw case screw (OS))

3 Four screws

(+BVTT 4 x 8)

Top cover

Rear cover

1-4-2. Bezel Assy Removal (20 inch)

10 pin

10 pin

5 pin

9 pin

7 pin

2 Two screws

(+B 3 x 8)

3 Two screws (+B 3 x 8)

5 Shaft switch

1 Power button

6 Two claws

4

CN900

CN105

X board

Bezel assy

1-11

PVM-14L5/20L5/D14L5A/D20L5A

1-4-3. HA Board Removal (20 inch)

1 Three screws

(+BVTP 3 x 12)

2 Two wire holders

CN2902

CN2901

3 Four claws

4 Three

claws

5 Four claws

HA board

1-4-4. HB Board Removal (20 inch)

3 Control label (L)

CN5005

CN5002

CN5001

CN5004

4 Four claws

5 Four

claws

6 Four

claws

1 Four screws

(+BVTP 3 x 12)

HB board

2 Three wire holders

1-12

PVM-14L5/20L5/D14L5A/D20L5A

1-4-6. C Board Removal (20 inch)

CN702

CN701

CN704

C board

1-4-5. J, D1, D2 and D Boards Removal (20 inch)

CN1501

CN1508

CN1506

CN1507

CN1502

CN1503

CN2502 (board to board)

CN2501 (board to board)

CN951

6 Four screws

(+BVTP 3 x 12)

D board

5 Screw

(+BVTT 4 x 8)

4 D1 board

1 Two screws

(+PSW 3 x 8)

2 Insulator (J PWB)

3 J board

9 pin

9 Bracket D

8 D2 board

7 Four card edge

spacers

1-13

PVM-14L5/20L5/D14L5A/D20L5A

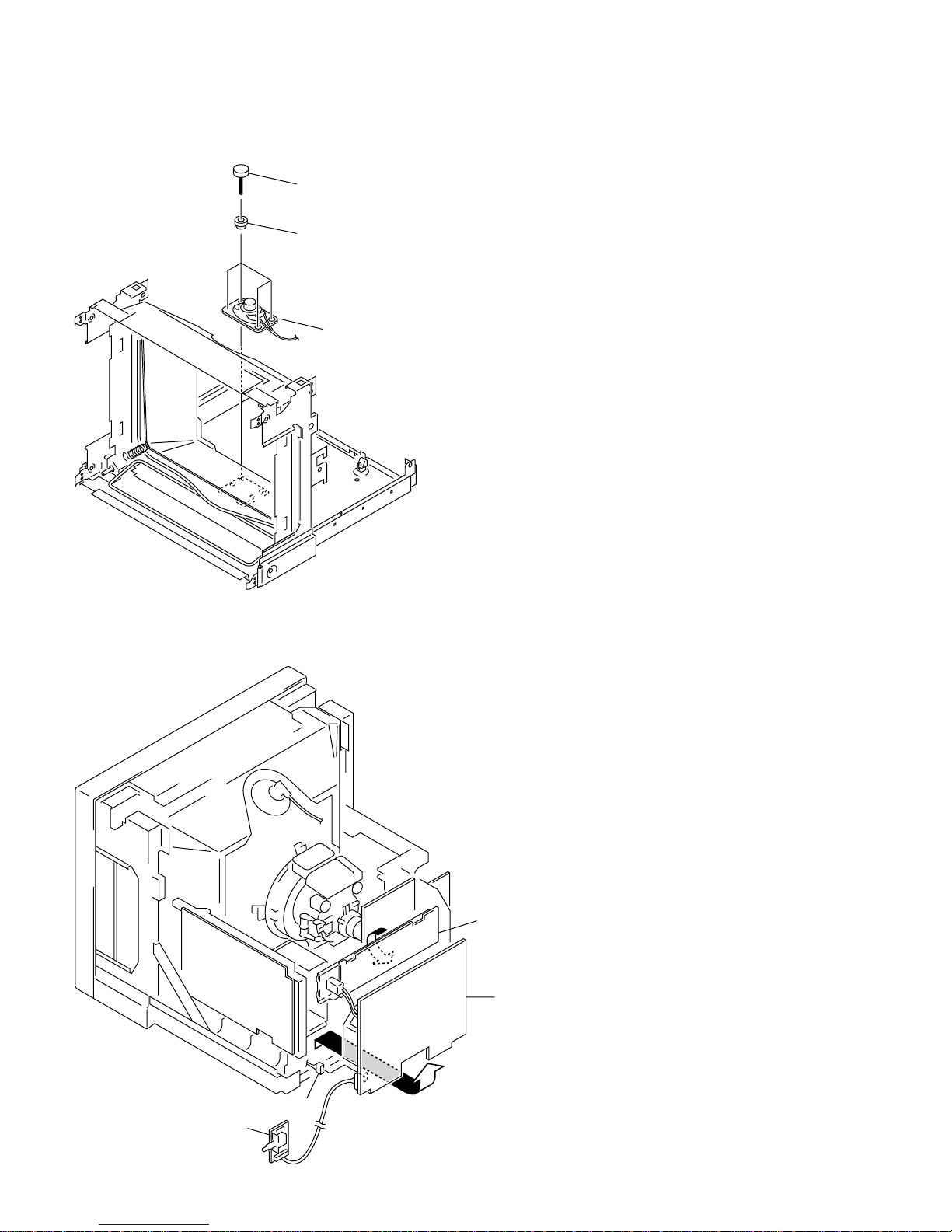

1-4-7. B Block Assy Removal (20 inch)

CN101

CN1906

CN1908

CN2401

CN1905

CN1904

CN1903

CN1907

CN102

CN103

CN104

3 Screw (+PSW 4 x 8)

2 Three screws

(+BVTP 3 x 12)

B block assy

1 Screw (+BVTT 4 x 8)

CN801

CN113

CN107 (board to board)

CN108 (board to board)

CN201

CN3802

CN3801

9 Four screws (+BVTT 3 x 8)

T board

1 Three PWB

holders

2 K board

7 Four screws

(+BVTP 3 x 12)

4 Two PWB

holders

3 Two PWB holders

5 B1 board

6 M board

8 B board

CN1901 (board to board)

CN3504

CN3505

CN3503

CN3502

CN3501

1-4-8. K, T, B1, M and B Boards Removal (20 inch)

1-14

PVM-14L5/20L5/D14L5A/D20L5A

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

1-4-10.Removal of Anode Cap

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

..

. Removal Procedure

..

..

. Handling Precautions

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

a

a

b

b

c

Anode button

1-4-9. Q Block Assy Removal (20 inch)

CN2704

CN601

CN2706

CN2705

CN2707

CN2710

4 Two screws

(+PSW 3 x 12)

2 Four claws

1 Screw (+PSW 4 x 8)

3 Screw (+PSW 4 x 8)

6 Connector label

5 Plug holder (A)

7 AC inlet 3p (with noise filter)

8 Q block assy

1-15

PVM-14L5/20L5/D14L5A/D20L5A

1-4-11.G Board Removal (20 inch)

3 Two screws (+PSW 4 x 8)

5 G shield

1 Anode cap

4 G board

2 Screw (+BVTP 3 x 16)

CN602

CN603

CN610

CN609

CN604

CN608

CN608

CN607

CN606

CN503

CN505

CN607

CN508

4 Two nuts (flange nut (B) M5)

5 Two nuts (flange nut (B) M5)

2 Neck assy

6 Picture tube

3 Deflection yoke

1 Fastening band

assy

1-4-12.Picture Tube Removal (20 inch)

1-16

PVM-14L5/20L5/D14L5A/D20L5A

1-4-14.Service Position (20 inch)

CN603

G board

J board

Q board

*Because there exist the portions that have the high tension voltage,

be careful that the printed boards must not touch each other

nor must not touch with the chassis.

1-4-13.Speaker Removal (20 inch)

2 Four speaker cushions

3 Speaker

1 Four screws (step screw M3 x 4)

2-1

PVM-14L5/20L5/D14L5A/D20L5A

Section 2

Set-up Adjustment

2-1. Equipment Required

. Oscilloscope

Sony Tektronix 2465 or equivalent (with bandwidth of

350 MHz)

. NTSC/PAL/SECAM component signal generator

Sony Tektronix TG2000 +AVG1 (option module)

+AWVG2 (option module) or equivalent

. SDI signal generator

Sony Tektronix TSG-422

. Monoscope signal generator

ShibaSoku TP22AX or equivalent

. VG (programmable video signal generator)

. VG814 or equivalent

. Frequency counter

Advantest TR5821AK or equivalent

. Digital VOM

Advantest TR6845 or equivalent

. Slide induction transformer

. High tension voltmeter

. DC power supply

. Ammeter

. Luminance meter

Minolta CA-110 or equivalent.

If the Minolta CA-110 is not available, perform the

measurement by visual inspection by comparing the

monitor that has already been adjusted earlier with the

monitor that you want to adjust.

n

Start the following adjustments after 5 minutes have

passed after the main power is turned on.

* In this chapter, [||||||] indicates the control items in the

service mode.

Example : [60|H-FREQ]

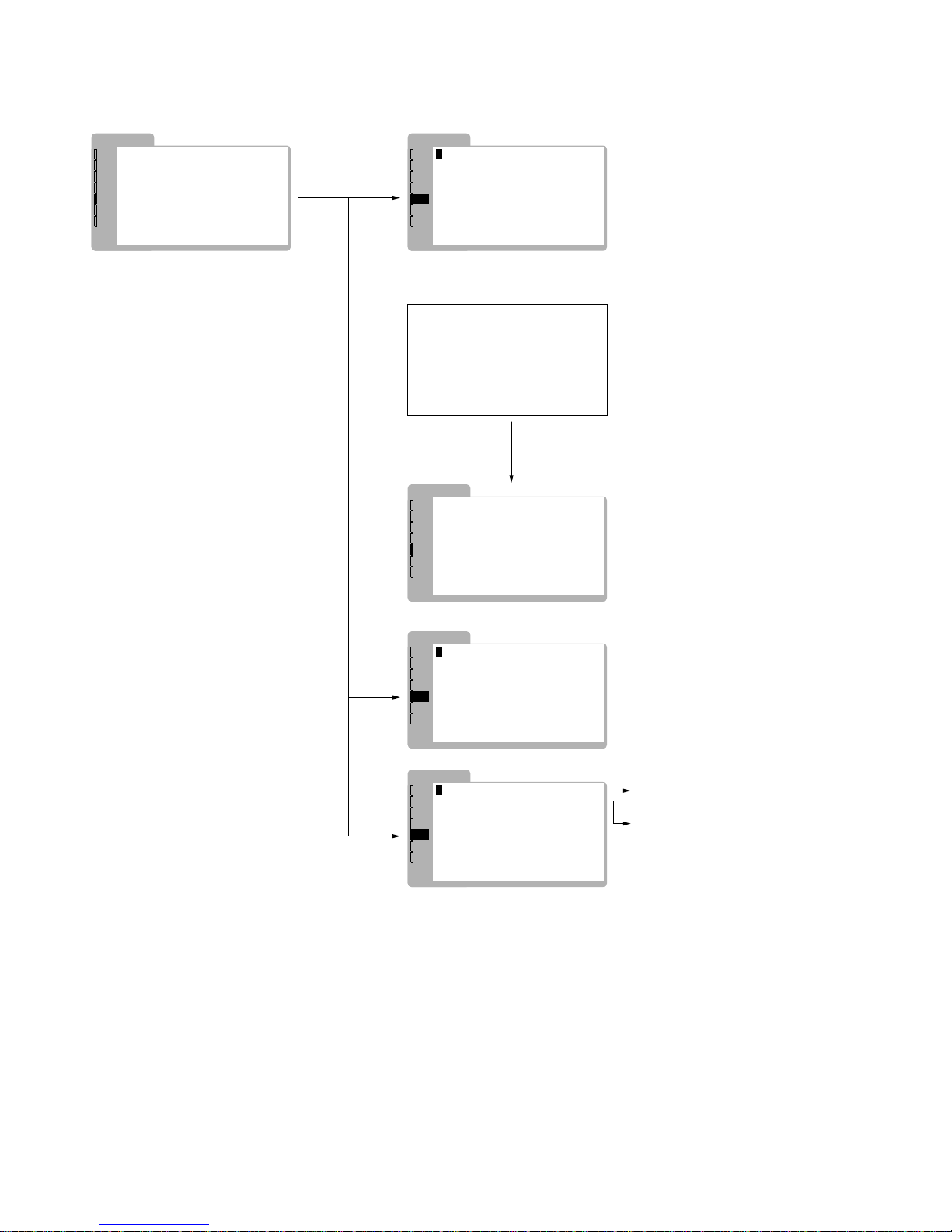

2-2. Preparations (1)

Service Mode

This set is provided with a switch for service on the front

panel that can be used to make various adjustments. The

operation method of this switch is explained in detail below.

1. Entering the service mode

Simultaneously press the [ENTER] key and the

[DEGAUSS] key shown on the display of the menu.

2. Operating the Service Mode

Select the desired service item with the [UP],

[DOWN] key and press the [ENTER] key to enter the

adjustment mode.

Press the [UP] key to increase the adjustment value.

Press the [DOWN] key to decrease the adjustment

value.

Press the [ENTER] key to save the adjustment value.

Press the [MENU] key to cancel the entry.

3. Finishing the service mode

Simultaneously press the [ENTER] key and the

[DEGAUSS] key shown on the display of the menu.

4. Easy ON/OFF of the service mode

If once entering the service mode after having turned

on the power, easy ON/OFF is possible by once more

pressing the LINE-A, LINE-B, RGB/COMP, OPT-A

or OPT-B switch on the front panel (the LED lights) as

long as the power is not turned off or as long as the

service mode is not finished.

SIGNAL

SIG

• LEVEL-1...

• LEVEL-2...

• WHITE BALANCE...

• DECODER COLOR...

• DECODER LEVEL...

• DETECTION...

DEF

OPT

REM

SYS

STA

ENG

2-2

PVM-14L5/20L5/D14L5A/D20L5A

5. Executing FACTROY LOAD

If the adjustment data is damaged or lost by some

reasons, you can restore the default factory adjustment

data by executing FACTROY LOAD as described

below.

Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [FACTROY...] →

[LOAD...] to read the default factory data. If the

default factory data is damaged or the ROM is replaced without executing FACTORY SAVE as

described in the following paragraph, you cannot

execute FACTROY LOAD.

6. Executing FACTORY SAVE

This operation is to write the FACTROY LOAD data

into the factory data area in the memory.

Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MAINTENANCE ID]

and type 111. Then select the following submenus

from the Service Menu in the order of : [ENGINEER]

→ [FACTROY SAVE] to write the factory data in the

memory. FACTORY SAVE is protected from misoperation so that FACTORY SAVE cannot be executed unless MAINTENANCE ID is set.

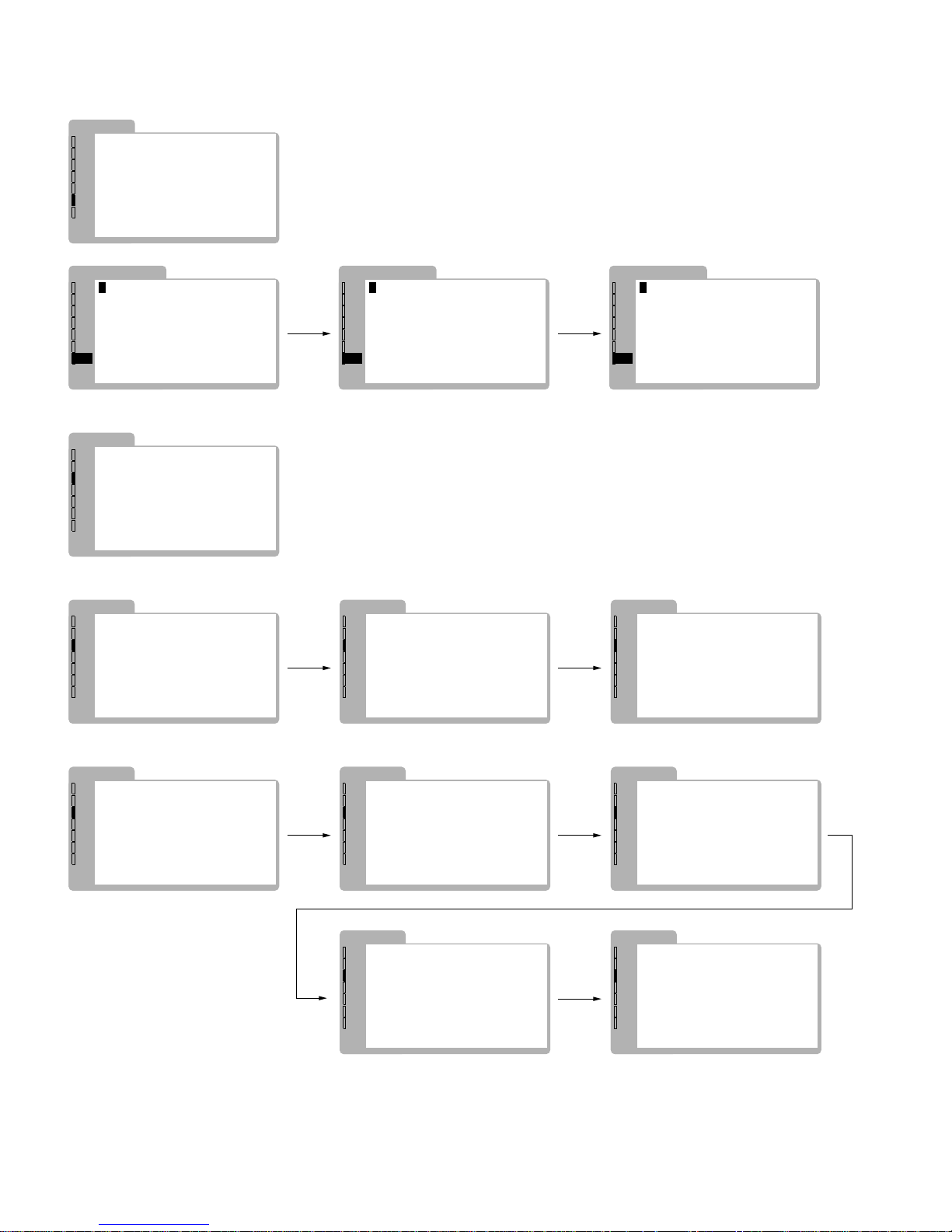

FACTORY SET

If the following circuit board is replaced or the following

NVRAM on the respective board is replaced, perform the

following settings.

B board : IC104, IC108, IC109

B1 board: IC4804

1. Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MAINTENANCE ID]

and type 111.

2. Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MODEL GRADE] →

[MODEL TYPE] and write the model data of each

model in the [MODEL TYPE] referring to table 2-4.

3. If the NVRAM on the B board is replaced, select the

following submenus from the Service Menu : [ENGINEER] → [CLEAR NVM ON B] and write data.

4. If the NVRAM on the B1 board is replaced, select the

following submenus from the Service Menu : [ENGINEER] → [CLEAR NVM ON B1] and write data.

5. If any IC on the B board is replaced, perform all

adjustment items of the [SIGNAL] menu and of the

[DEFLECTION] menu.

If any IC on the B1 board is replaced, perform the

adjustment items of the [SIGNAL] → [DECODER

COLOR] and of [DECODER LEVEL] menus.

6. Upon completion of adjustment, select the menus

[ENGINEER] → [FACTORY SAVE] to save the

adjustment data.

2-3

PVM-14L5/20L5/D14L5A/D20L5A

SIGNAL

SIG

• LEVEL-1...

• LEVEL-2...

• WHITE BALANCE...

• DECODER COLOR...

• DECODER LEVEL...

• DETECTION...

DEF

OPT

REM

SYS

STA

ENG

LEVEL-1

SIG

• Y BLACK

• PB BLACK

• PR BLACK

• CHROMA PB

• CHROMA PR

• Y LEVEL

DEF

OPT

REM

SYS

STA

ENG

LEVEL-2

SIG

• G-Y/B LEVEL

• G-Y/R LEVEL

• PB LEVEL

• PR LEVEL

DEF

OPT

REM

SYS

STA

ENG

47

84

70

74

228

182

214

140

WHITE BALANCE

SIG

• SUB CONTRAST

• SUB BRIGHT

• COLOR TEMP

• MANUAL/AUTO

DEF

OPT

REM

SYS

STA

ENG

131

35

D65

AUTO

• START...

• X 313

• Y 329

• REF VALUE D65

WHITE BALANCE

SIG

• SUB CONTRAST

• SUB BRIGHT

• COLOR TEMP

• MANUAL/AUTO

DEF

OPT

REM

SYS

STA

ENG

131

35

D65

MANUAL

• ADJUST GAIN...

• ADJUST BIAS...

• ADJUST FINE...

DECODER COLOR

SIG

• HP

• CLP

• BURST GATE PLS

• XTAL F0

DEF

OPT

REM

SYS

STA

ENG

20

216

83

81

76

• SUB PHASE

• ACC PHASE 128

• R-Y PHASE 113

DECODER LEVEL

SIG

• DEC Y LEVEL

• DEC B-Y LEVEL

• DEC R-Y LEVEL

• ACC LEVEL

DEF

OPT

REM

SYS

STA

ENG

138

171

196

128

SIGNAL/DETECTION

SIG

• MACROVISION

DEF

OPT

REM

SYS

STA

ENG

ON

54

92

• CLP P DLY 225

Service Mode screen display

2-4

PVM-14L5/20L5/D14L5A/D20L5A

DEFLECTION

SIG

• FOCUS...

• RASTER H...

• RASTER V...

• GEOMETRY...

DEF

OPT

REM

SYS

STA

ENG

REMOTE

SIG

SERIAL

• BAUDRATE

• STOPBIT

• PARITY

38400

2BIT

EVEN

DEF

OPT

REM

SYS

STA

ENG

DEFLECTION

SIG

• H DUTY

• HFV SENSE

• HFV CONTROL

• H DF PHASE

• H DF PARA

• LANDING

• H PLL

25

62

250

34

18

128

LOCK

DEF

OPT

REM

SYS

STA

ENG

FOCUS

DEFLECTION

SIG

• H SIZE

• H CENTER

• H BLK LEFT

• H BLK RIGHT

• H BLK R FINE

• H POSITION

• MARKER SUB L

• MARKER SUB R

85

107

215

128

11

121

84

59

DEF

OPT

REM

SYS

STA

ENG

RASTER H

DEFLECTION

SIG

• V S LIN

• V C LIN

• TRAPEZOID

• SIDE PIN

• SIDE PIN W

• SIDE PIN BAL

• PARA CONTROL

• SIDE PIN S

13

24

28

36

32

16

16

24

DEF

OPT

REM

SYS

STA

ENG

GEOMETRY

DEFLECTION

SIG

• V SIZE

• V CENTER

• V BLK TOP

• V BLK BOTTOM

• OSD TIMING

84

142

82

196

0

DEF

OPT

REM

SYS

STA

ENG

RASTER V

H BLK R FINE is adjustable only

in 1080/60I and 1035/60I.

It is the fixed value in other modes.

2-5

PVM-14L5/20L5/D14L5A/D20L5A

SYSTEM

SIG

VERSION

• MODEL GRADE

• MODEL TYPE

• W/B DESCRIPTION...

• AGING MODE

• FACTORY...

• SIGNAL...

• MAINTENANCE ID

1.3

L4/L3

E14

0

DEF

OPT

REM

SYS

STA

ENG

SYSTEM

SIG

VERSION

• MODEL GRADE

• MODEL TYPE

• W/B DESCRIPTION...

• AGING MODE

• FACTORY...

• SIGNAL...

• MAINTENANCE ID

1.3

L4/L3

E14

0

DEF

OPT

REM

SYS

STA

ENG

SYSTEM

SIG

• COL2

• COL1 65

93

DEF

OPT

REM

SYS

STA

ENG

W/B DESCRIPTION

SYSTEM

SIG

• STANDARD...

• LOAD...

DEF

OPT

REM

SYS

STA

ENG

FACTORY

SYSTEM

SIG

• 720/50P

• 1080/48I

OFF

OFF

When OFF, 1080/48I is identified

as NO SYNC.

When OFF, 720/50P is identified

as NO SYNC.

LOAD cannot be selected and remains

in the blue display unless the NVM data is valid.

In such a case, clear the NVM and

make the NVM data valid first.

However, if the default factory data is damaged,

or if the FACTORY SET process is not executed

after ROM is replaced, LOAD cannot be executed.

STANDARD returns the various setups

of the user menu to the default factory setting.

DEF

OPT

REM

SYS

STA

ENG

SIGNAL

AGING MODE

All white screen

To return to the original screen,

press the button of the input selector

illuminating in orange.

2-6

PVM-14L5/20L5/D14L5A/D20L5A

STATUS

SIG

ADJUST ERROR

ABNORMAL I2C

NVM BOARD B

NVM BOARD B1

0

0

OK

OK

DEF

OPT

REM

SYS

STA

ENG

ENGINEER 1/3

SIG

• AUSP SAMPLE POS

• OE

• P SAVE

• DISPLAY

• D A

• D B

• H BLK1

1

0

1

0

1

0

• FACTORY SAVE...

• CLEAR NVM ON B...

• CLEAR NVM ON B1...

OFF

DEF

OPT

REM

SYS

STA

ENG

OPTION

SIG

BKM-129X

DEF

OPT

REM

SYS

STA

ENG

OPTION

SIG

BKM-120D (1/3)

DEF

OPT

REM

SYS

STA

ENG

• CCP P

• DA FV

• DB FV

• Y LEVEL

• PB LEVEL

• PR LEVEL

137

84

109

82

71

74

OPTION

SIG

BKM-120D (2/3)

DEF

OPT

REM

SYS

STA

ENG

• YB2

• YW0

• YW1

0

0

0

OPTION

SIG

BKM-120D (3/3)

DEF

OPT

REM

SYS

STA

ENG

ENGINEER 2/3

SIG

• DATA REFRESH

• SREM RAW DATA

• OSDLIMIT

• AWB ANA VALUE

• INTERNAL SIGNAL

ON

OFF

OFF

• 4:3MARKER LIMIT OFF

OFF

0

DEF

OPT

REM

SYS

STA

ENG

ENGINEER 3/3

SIG

• H SYNC COUNT

• MENU DOTCLOCK

• MENU H POS

• BLK H POS

• OPTION BOARD ID

HIDE

231

14

• BLK DOTCLOCK 231

8

255

DEF

OPT

REM

SYS

STA

ENG

OPTION (BKM-120D)

• 1125/60I SYS

• OE

• P SAVE

• DISPLAY

• IN1

• IN2

AUTO

1

0

0

0

0

OPTION

SIG

BKM-142HD 1/5

DEF

OPT

REM

SYS

STA

ENG

• YPBPR

• H BLK1

• H SUB

• Y LEVEL

• PB LEVEL

• PR LEVEL

1

240

128

120

22

28

OPTION

SIG

BKM-142HD 2/5

DEF

OPT

REM

SYS

STA

ENG

• SYSTA0

• SYSTA1

• P0

• P1

• P2

• P3

0

1

1

1

0

1

OPTION

SIG

BKM-142HD 3/5

DEF

OPT

REM

SYS

STA

ENG

• STRB

• SYCS1

• SYCS2

• SYIF0

• SYIF1

• SYIF2

1

1

0

1

1

1

OPTION

SIG

BKM-142HD 4/5

DEF

OPT

REM

SYS

STA

ENG

• SYIF3

• SYIF4

• SYIF5

• SYIF6

• SYIF7

1

0

0

0

0

OPTION

SIG

BKM-142HD 5/5

DEF

OPT

REM

SYS

STA

ENG

OPTION (BKM-142HD)

OPTION (BKM-129X)

2-7

PVM-14L5/20L5/D14L5A/D20L5A

• OE

• P SAVE

• DISPLAY

• D A

• D B

• H BLK1

0

0

1

0

1

0

OPTION

SIG

BKM-150CP (1/4)

DEF

OPT

REM

SYS

STA

ENG

• CCP P

• DA FV

• DB FV

• Y LEVEL

• PB LEVEL

• PR LEVEL

110

80

80

85

110

105

OPTION

SIG

BKM-150CP (2/4)

DEF

OPT

REM

SYS

STA

ENG

• SDTI SW

• TC MODE 0

• TC MODE 1

• TC MODE 2

• AUDIO MUTE

0

0

0

0

0

OPTION

SIG

BKM-150CP (3/4)

DEF

OPT

REM

SYS

STA

ENG

• AUDIO GRP 0

• AUDIO GRP 1

• AUDIO CH 0

• AUDIO CH 1

• AUDIO MIX

• AUDIO MONO L

1

1

0

1

1

0

• AUDIO MONO R 1

OPTION

SIG

BKM-150CP (4/4)

DEF

OPT

REM

SYS

STA

ENG

OPTION (BKM-150CP)

• OE

• V B

• V C

• BYPASS SW

• COMB SW

• ACC SW

0

1

1

OFF

ON

ON

OPTION

SIG

BKM-126M (1/4)

DEF

OPT

REM

SYS

STA

ENG

• PAL S SW

• APT SW

• PCD SW

• PAL SW

• KILLER

S

OFF

OFF

ON

0

OPTION

SIG

BKM-126M (2/4)

DEF

OPT

REM

SYS

STA

ENG

• Y LEVEL

• PB LEVEL

• PR LEVEL

• PHASE

• SUB PHASE

127

127

127

127

127

• BGP W 127

• ACC LEVEL 127

OPTION

SIG

BKM-126M (3/4)

DEF

OPT

REM

SYS

STA

ENG

• APT LEVEL

• CLP W

• R-Y PHASE

• ACC PHASE

• F0

127

127

127

127

127

OPTION

SIG

BKM-126M (4/4)

DEF

OPT

REM

SYS

STA

ENG

OPTION (BKM-126M)

2-8

PVM-14L5/20L5/D14L5A/D20L5A

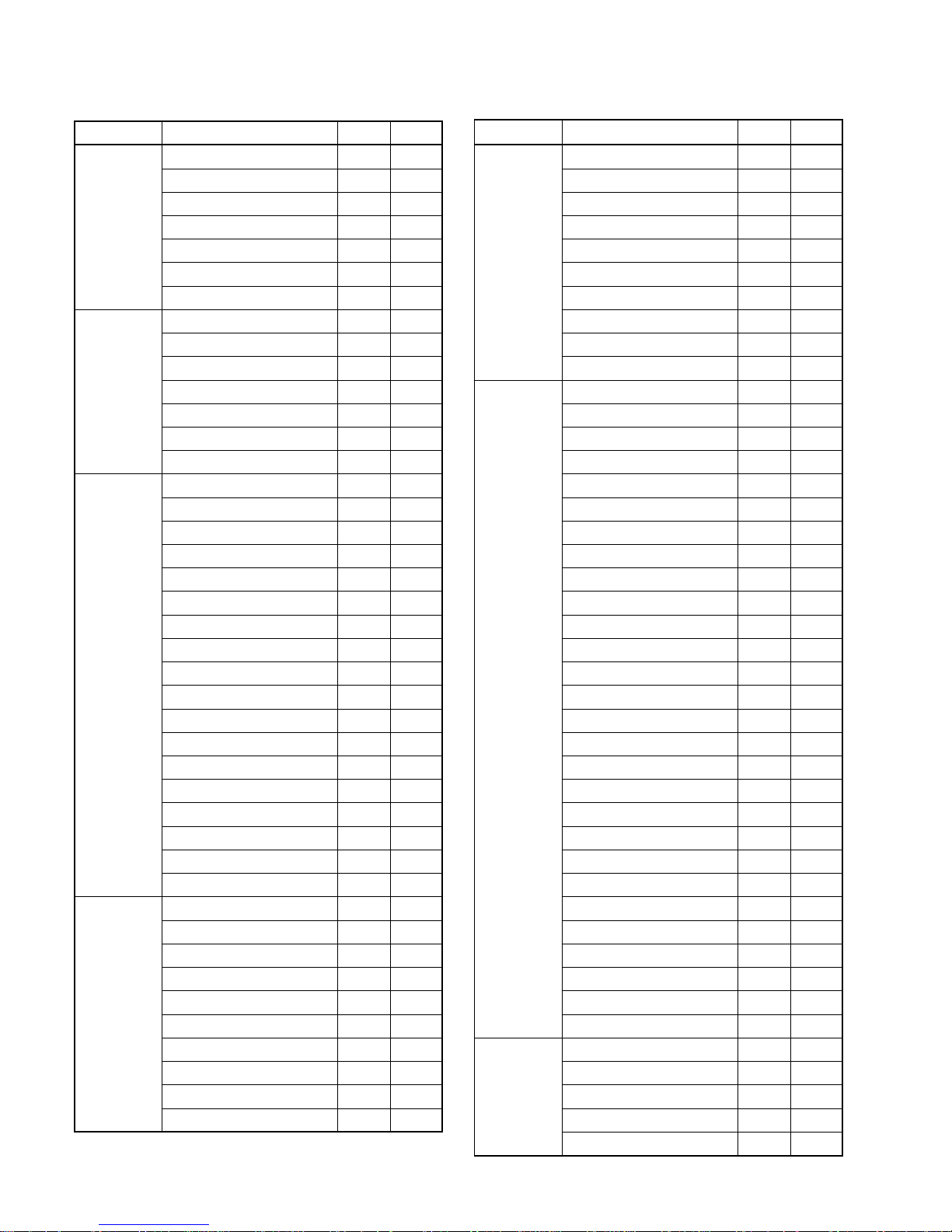

Name Description Inch20 Inch14

HFV_SENS Horizontal frequency 15K 27 42

Horizontal frequency 27K 37 25

Horizontal frequency 28K 37 25

Horizontal frequency 31K 36 33

Horizontal frequency 33K 4 26

Horizontal frequency 37K 26 16

Horizontal frequency 45K 26 17

HFV_CONTROL Horizontal frequency 15K 249 250

Horizontal frequency 27K 200 200

Horizontal frequency 28K 200 200

Horizontal frequency 31K 180 188

Horizontal frequency 33K 177 177

Horizontal frequency 37K 160 160

Horizontal frequency 45K 128 128

H_SIZE 480/60I NORMAL 74 95

480/60I UNDER 49 71

575/50I NORMAL 78 102

575/50I UNDER 56 79

1080/48I NORMAL 77 106

1080/48I UNDER 55 82

1080/50I NORMAL 77 106

1080/50I UNDER 55 82

480/60P NORMAL 46 74

480/60P UNDER 32 50

576/50P NORMAL 54 81

576/50P UNDER 34 56

1080/60I 1035/60I NORMAL 41 64

1080/60I 1035/60I UNDER 21 44

720/50P NORMAL 41 64

720/50P UNDER 21 44

720/60P NORMAL 53 75

720/60P UNDER 30 51

H_CENT 480/60I 100 107

575/50I 100 107

1080/48I 100 107

1080/50I 100 107

480/60P 100 107

576/50P 100 107

1080/60I 1035/60I NORMAL 100 107

1080/60I 1035/60I UNDER 100 107

720/50P 100 107

720/60P 100 107

Name Description Inch20 Inch14

H_POSITION 480/60I 82 85

575/50I 74 77

1080/48I 64 70

1080/50I 64 70

480/60P 83 89

576/50P 80 85

1080/60I 1035/60I NORMAL 92 101

1080/60I 1035/60I UNDER 92 101

720/50P 79 86

720/60P 79 86

SIDE_PINBAL 480/60I 4:3 NORMAL 18 19

480/60I 4:3 UNDER 18 23

480/60I 16:9 NORMAL 14 18

480/60I 16:9 UNDER 18 19

575/50I 4:3 NORMAL 14 15

575/50I 4:3 UNDER 16 15

575/50I 16:9 NORMAL 16 15

575/50I 16:9 UNDER 16 17

1080/48I NORMAL 16 17

1080/48I UNDER 16 14

1080/50I NORMAL 16 17

1080/50I UNDER 16 14

480/60P 4:3 NORMAL 15 13

480/60P 4:3 UNDER 16 16

480/60P 16:9 NORMAL 15 14

480/60P 16:9 UNDER 16 14

575/50P 4:3 NORMAL 15 16

575/50P 4:3 UNDER 15 15

575/50P 16:9 NORMAL 16 14

575/50P 16:9 UNDER 15 16

1035/60I NORMAL 14 15

1035/60I UNDER 16 14

1080/60I NORMAL 14 15

1080/60I UNDER 16 14

720/50P NORMAL 15 14

720/50P UNDER 15 15

720/60P NORMAL 15 14

720/60P UNDER 15 15

PARA_CONTROL 480/60I 4:3 NORMAL 13 14

480/60I 4:3 UNDER 14 15

480/60I 16:9 NORMAL 14 15

480/60I 16:9 UNDER 14 15

575/50I 4:3 NORMAL 11 16

Loading...

Loading...