Sony trinitron PVM-1450QM,trinitron PVM-1454QM Service Manual

· SERVICE MANUAL

AEP Model

PVM-1450QM:

Chassis No. SCC-G62C-A

D

PVM-1454QM:

Chassis No. SCC-G628-A

PVM-1450QM

PVM-1454QM

SPECIFICATIONS (PVM-1450QM)

Video signal

Color system

Resolution

Aperture correction

Frequency response

PAL, SECAM, NTSC, NTSCw

450TV lines

0dB-+6.0dB

LINE 9.0 MHz (-3 dB)

RGB 10.0 MHz (-3 dB)

Synchronization AFC time constant 1.0 msec.

Pidure performance

Normal scan 7% over scan of CRT effective screen

area

H. linearity Less than 8.0% (typical)

V. linearity Less than 7.0% (typical)

Raster size stability H: 1.0%, V: 1.5%

High voltage regulation

3.5%

CRT P22 phosphor

Color temperature 6,SOOK

Inputs and Outputs

Inputs

Y IC IN: 4-pin mini DIN connector

(See the pin assignment.)

VIDEO IN: BNC connector

1Vp-p ±6 dB, sync negative

AUDIO IN: phono jack, -5 dBs, more

than 47k ohms

R, G, BIN: BNC connector

0.7 Vp,p, ±6 dB

Sync on green: 0.3 Vp-p, negative,

75 ohms terminated

RGB SYNC IN: BNC connector

Composite sync 4 Vp-p, ±6 dB,

negative

Loop-through outputs Y /C OUT: 4-pin mini DIN connector

VIDEO OUT: BNC connector,

75 ohms terminated

AUDIO OUT: phono jack

Speaker output Output level 0.8 W

General

Power consumption 90 Wh

Power requirements 100- 240 V AC, 50/60 Hz

Operating temperature range

0-35°C

Storage temperature range

-10-+40°C

Humidity 0 - 90%

Dimensions Approx. 346 x 340 x 411.5 mm

(w/h/d)

(13

5

/s x 131h x 16 ¼ inches)

not incl. projecting parts and controls

Mass Approx. 16.7 kg (36 lb 14 oz)

Accessory supplied AC power cord (1)

AC plug holder (1)

- Continued on page 2 -

TRINITRON@ COLOR VIDEO MONITOR

SO:NY:

PVM-1450QM/1454QM

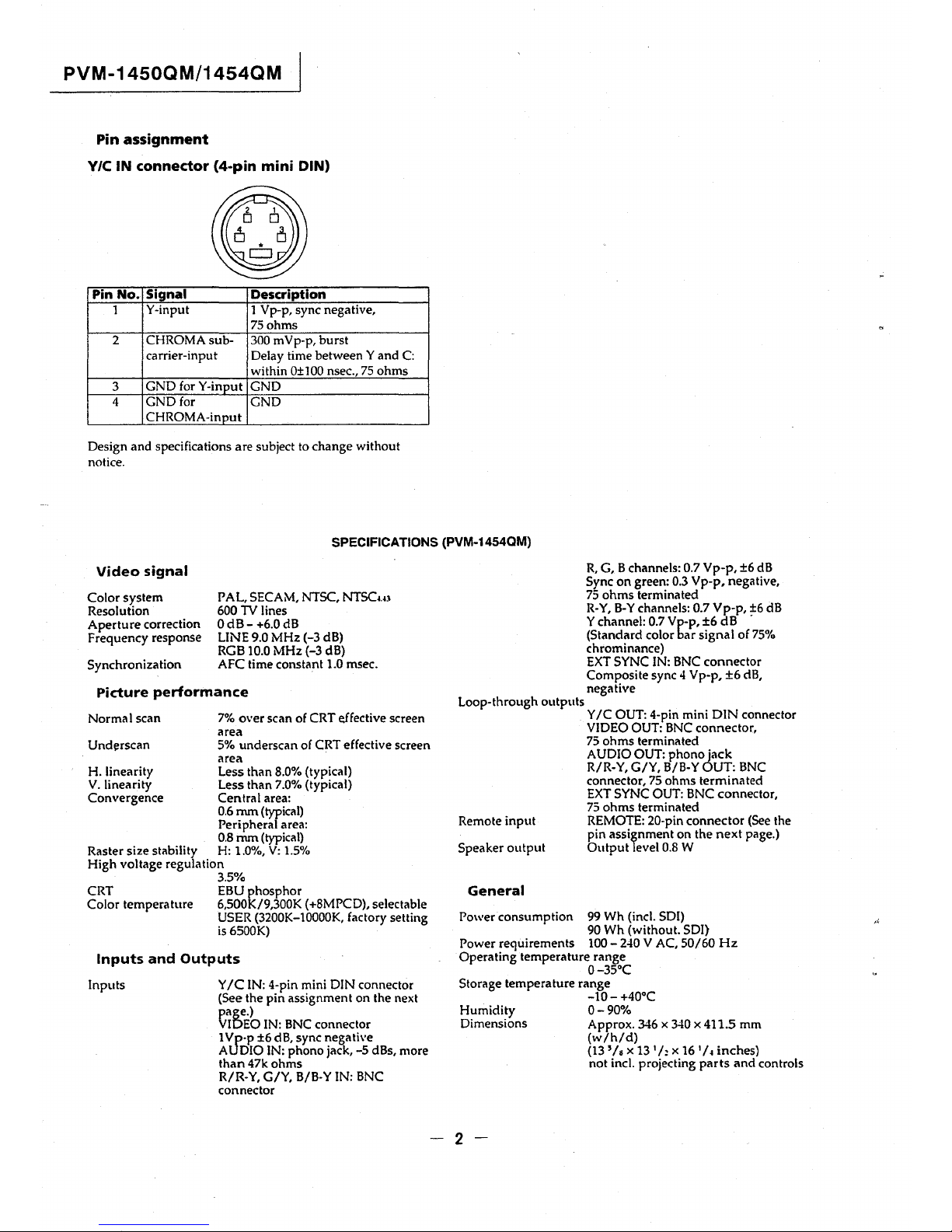

Pin assignment

V/C IN connector (4-pin mini DIN)

Pin No. Signal Description

1

Y-input 1 Vp-p, sync negative,

75 ohms

2 CHROMA sub- 300 mVp-p, burst

carrier-input Delay time between Y and C:

within 0+100 nsec., 75 ohms

3

GND for Y-inout

GND

4

GND for

GND

CHROMA-in out

Design and specifications are subject to change without

notice.

SPECIFICATIONS (PVM-1454QM)

Video signal

Color system

Resolution

Aperture correction

Frequency response

Synchronization

PAL, SECAM, NTSC, NTSCw

600 TV lines

OdB-+6.0dB

LINE 9.0 MHz (-3 dB)

RGB 10.0 MHz (-3 dB)

AFC time constant 1.0 msec.

Picture performance

7% over scan of CRT effective screen

area

Loop-through outputs

R, G, B channels: 0.7 Vp-p, ±6 dB

Sync on green: 0.3 Vp-p, negative,

75 ohms terminated

R-Y, B-Y channels: 0.7 Vp-p, ~6 dB

Y channel: 0.7 Vp-p, ±6 dB

(Standard color bar signal of 75%

chrominance)

EXT SYNC IN: BNC connector

Composite sync 4 Vp-p, ±6 dB,

negative

Y IC OUT: 4-pin mini DIN connector

VIDEO OUT: BNC connector,

Normal scan

Und!!rscan

5% underscan of CRT effective screen

75 ohms terminated

AUDIO OUT: phono jack

H. linearity

V. linearity

Convergence

area

Less than 8.0% (typical)

Less than 7.0% (typical)

Central area:

0.6 mm (typical)

Peripheraf area:

0.8 mm (typical)

Raster size stability H: 1.0%, V: 1.5%

High voltage regulation

CRT

Color temperature

3.5%

EBU phosphor

6,500K/9,300K (+8MPCD), selectable

USER (3200K-10000K, factory setting

is 6500K)

Inputs and Outputs

Inputs Y IC IN: 4-pin mini DIN connector

(See the pin assignment on the next

page.)

VIDEO IN: BNC connector

1 Vp·p ±6 dB, sync negative

AUDIO IN: phono jack, -5 dBs, more

than 47k ohms

R/R-Y, G/Y, B/B-Y IN: BNC

connector

R/R-Y, G/Y, B/B-Y OUT: BNC

connector, 75 ohms terminated

EXT SYNC OUT: BNC connector,

75 ohms terminated

Remote input REMOTE: 20-pin connector (See the

pin assignment on the next page.)

Speaker output Output level 0.8 W

General

Power consumption 99 Wh (incl. SDI)

90 Wh (without. SDI)

Power requirements 100- 240 V AC, 50/60 Hz

Operating temperature range

0-35°C

Storage temperature range

-10-+40°C

Humidity O - 90%

Dimensions Approx. 346 x 340 x 411.5 mm

(w/h/d)

(13 '/ • x 13

1

h x 16

1

/

~

inches)

not incl. projecting parts and controls

-2-

Mass

Approx. 16.7 kg (36 lb 14 oz)

PVM-2054QM

Accessory supplied

AC power cord (1)

AC plug holder (1)

Tally label (1)

Cable with a 20-pin connector (1)

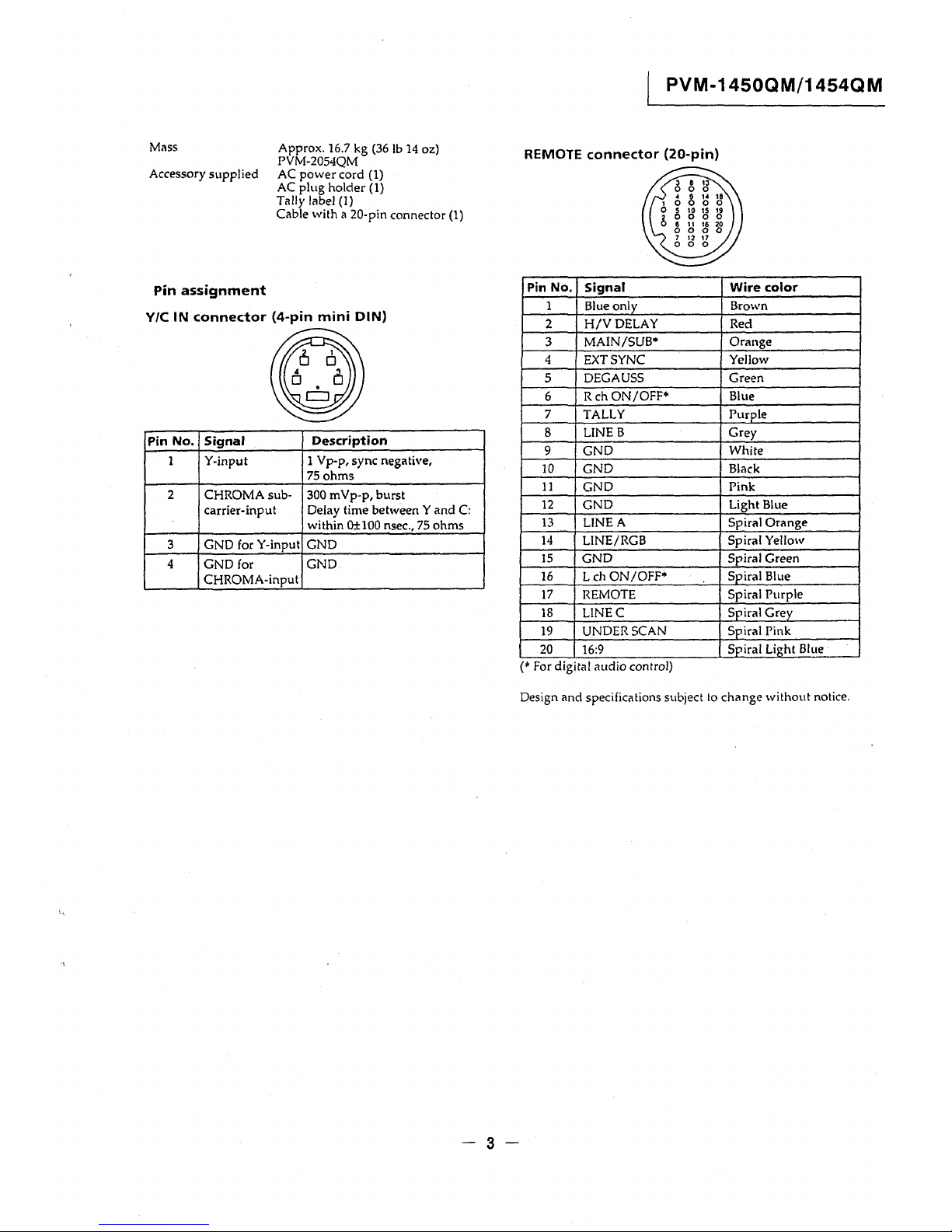

Pin assignment

Y/C IN connector (4-pin mini DIN)

Pin No. Signal

Description

1

Y-input

l Vp-p, sync negative,

75ohms

2

CHROMA sub- 300 mVp-p, burst

carrier-input

Delay time between Y and C:

within 0±100 nsec., 75 ohms

3

GND for Y-input

GND

4

GND for GND

CHROMA-input

-3-

PVM-1450QM/1454QM

REMOTE connector (20-pin)

Pin No.

Signal

Wire color

1 Blue only Brown

2 H/VDELAY Red

3

MAIN/SUB• Orange

4 EXT SYNC Yellow

5

DEGAUSS Green

6

Reh ON/OFF• Blue

7 TALLY Purple

8

LINE B

Grey

9 GND

White

10 GND

Black

11

GND

Pink

12

GND

Light Blue

13 LINEA Spiral Orange

14 LINE/RGB

Spiral Yellow

15

GND

Spiral Green

16 Leh ON/OFF*

Spiral Blue

17

REMOTE

Spiral Purple

18 LINEC

Spiral Grey

19 UNDER SCAN

Spiral Pink

20 16:9

Spiral Light Blue

(* For digital audio control)

Design and specifications subject to change without notice.

PVM-1450QM/1454QM

TABLE OF CONTENTS

1. GENERAL 5. CIRCUIT ADJUSTMENTS

1-1. General of PVM-1450QM ...................................... 5

5-1. A Board Adjustments······ .................................... 31

I-2. General of PVM-1454QM · · · · · · · · · · · · · · · · · · · .. · · · · · · · · · · · · · · · l l

5-2. G Board Adjustment ........................................... 41

2. DISASSEMBLY

6. DIAGRAMS

2-I. Top Cover and Rear Cover Removal · · · · · · · · · · · · · · · .. · · · · · · 19

2-2. Terminal Board Removal····································· 19

2-3. Picture Tube Removal········································· 20

6-1. Block Diagrams (1) ............................................ 43

Block Diagrams (2) · ·· · · · · · · ·· ·· ·· .. ··· · · · · · .. · · · · · ·· · · ·· · · · · · · 48

6-2. Frame Schematic Diagram············· ....................... 53

6-3. Circuit Boards Location········· .. ···························· 55

3. SET-UP ADJUSTMENTS

6-4. Printed Wiring Boards and Schematic Diagrams ......... 55

3-1. Preparations (1)····························· .. ··················21

• A Board ( 1/3) ......... · ......... ·· ...... · ... · .... · · ·· .. · · · · .... 63

Preparations (2) · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· ·· .. · · · .. · · · · · · · · · · · 23

3-2. Writing Model Data ............................................ 23

3-3. Picture Output ... , ... ········ .... ······· .. ························ 23

3-4. Landing Adjustment · · · .................. ·· ·· ................. · 23

3-5. Convergence Adjustment .. ···· · · · ...... ·· .................... 24

3-6. Deflection Yoke Neck Rotation Adjustment ........... ··· 25

3-7. G2 Adjustment······"·········································· 26

3-8. White Balance Adjustment ·· · ............ ·· ·· ........ ······ · · 26

3-9. Blue-Only White Balance Adjustment ··· ·· · ·········· ··· · · 27

3-IO.Sub Brt Adjustment · · · · · · · .. · · · · · · · · · ·· · · · · · · · · · · · · · · · · · · · .. · · · 27

• A Board (2/3)--......... · .. · ....................... ·· ·· ........ 68

• A Board (3/3) .................................................. 73

• Q Board .................. ; ...................................... 78

• G Board ......................................................... 80

• J Board .......................................................... 82

• X Board ......................................................... 82

• H Board····· .. ·· .. ·· .... ····· .. ·· .... · .... ····· .. · .... · · .... · · · · 82

• C Boa1d······· .................................................. 83

6-5. Semiconductons .. · .. · · · · · · · · · ·· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · · 89

3-1 I.Focus Adjustment ........................................... , ... 27

7. EXPLODED VIEWS

7-1. Chassis ............................................................ 91

7-2. Picture Tube····················································· 92

4. SAFETY RELATED ADJUSTMENT ..... ·· .... ···· · · · ·· · · · · · 29

8. ELECTRICAL PARTS LIST····································· 93

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON

PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF

LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED TO

THE AC POWER LINE.

SAF.ETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK Lt ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL TO SAFE OPERATION ARE IDENTIFIED INTHIS MANUAL.

FOLLOW THESE PROCEDURES WHENEVER CRITICAL

COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

-4-

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from

the Operating Instruction Manual. The page numbers of the

Operating Instruction Manual remein as in the manual.

1-1. GENERAL OF PVM-1450QM

Features

Fine Pitch Trinitron picture tube

Fine Pitch Trinitron tube provides a high resolution picture.

Horizontal resolution is more than 450 TV lines at the center

of the picture.

Four color systems available

The monitor can display PAL, SECAM, NTSC and

NTSCH3* signals. The appropriate color system is selected

automatically.

* A signal of NTSCw is used for playing back NTSC

recorded video cassettes with a video tape recorder/

player especially designed for use with this system.

Analog RGB input connectors

Analog RGB signals from video equipment can be input

through these connectors.

Y/C input connectors

The video signal, split into the chrominance signal (C) and

the luminance signal (Y), can be input through this

connector, eliminating the interference between the two

signals, which tends to occur in a composite video signal,

assuring video quality.

Beam current feedback circuit

The built-in beam current feedback circuit assures stable

white balance.

Comb filter

When NTSC video signals are received, a comb filter

activates to increase the resolution, resulting in fine picture

detail without color spill or color noise.

Automatic termination

(connector with 1\/v-mark only)

The input connector is terminated at 75 ohms inside when

no cable is connected to the loop-through output

connectors. When a cable is connected to an output

connector, the 75-ohms termination is automatically

released.

Blue only mode

In the blue only mode, an apparent monochrome display is

obtained with all three cathodes driven with a blue signal.

This facilitates color saturation and phase adjustments and

observation of VCR noise.

Auto/manual degaussing

Degaussing of the screen can be performed automatically

when the power is turned on, or manually by pressing the

DEGAUSS button.

On-screen menus

You can set CHROMA SET UP and other settings by using

the on-screen menus.

Five menu languages

You can select the menu language from among the five

languages on the menu.

EIA standard 19-inch rack mounting

By using an MB-502B mounting bracket (not supplied), the

monitor can be mounted in an EIA standard 19-inch rack.

For details on mounting, see the instruction manual of the

mounting bracket kit.

-5-

1

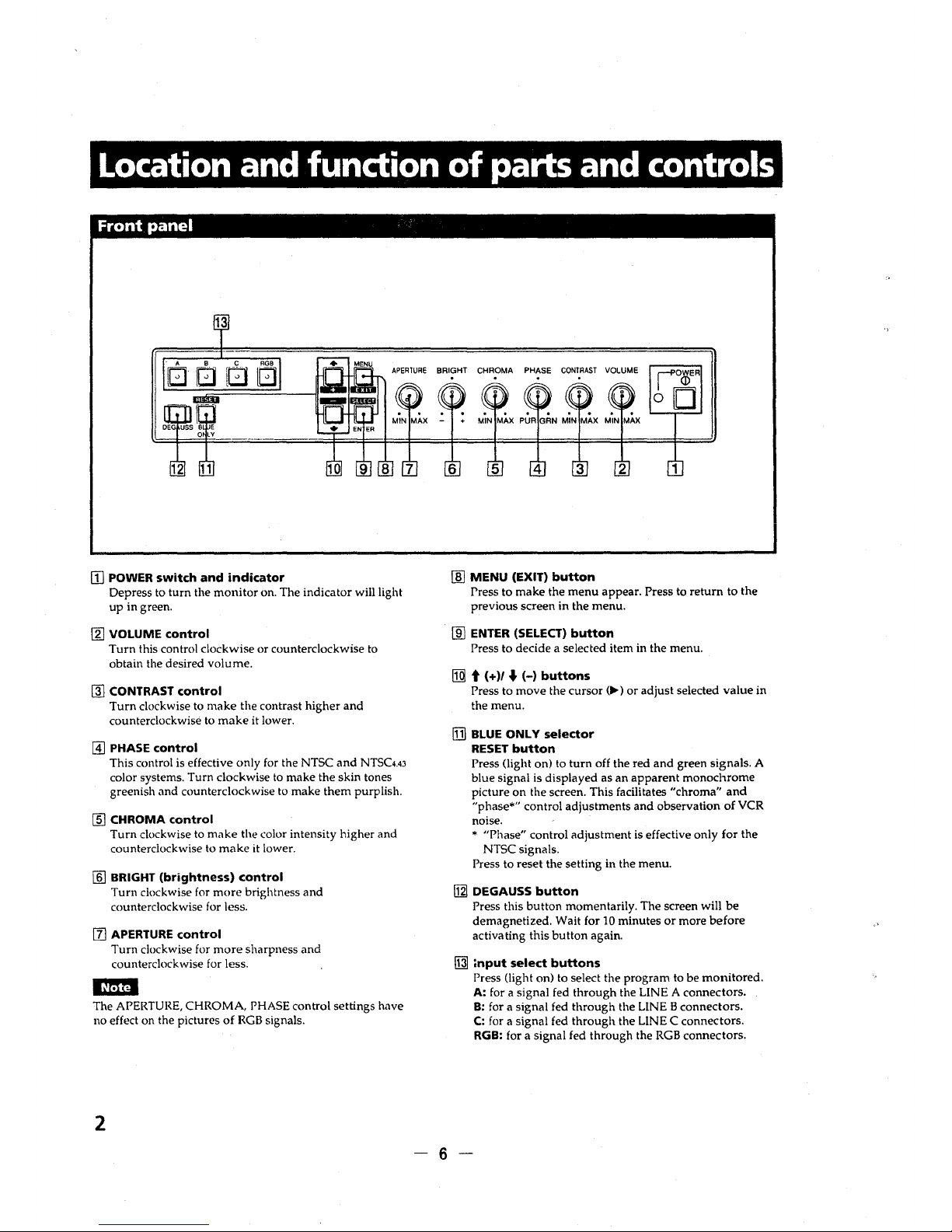

Location and function of parts and controls

Front panel

[I] POWER switch and indicator

Depress to turn the monitor on. The indicator will light

up in green.

(g] VOLUME control

Turn this control clockwise or counterclockwise to

obtain the desired volume.

m) CONTRAST control

Turn clockwise to make the contrast higher and

counterclockwise to make it lower.

@] PHASE control

This control is effective only for the NTSC and NTSC4.43

color systems. Turn clockwise to make the skin tones

greenish and counterclockwise to make them purplish.

(ID CHROMA control

Turn clockwise to make the color intensity higher and

counterclockwise to make it lower.

[ID BRIGHT (brightness) control

Turn clockwise for more brightness and

counterclockwise for less.

[I] APERTURE control

Turn clockwise for more sharpness and

counterclockwise for less.

l~Mtl

The APERTURE, CHROMA, PHASE control settings have

no effect on the pictures of RGB signals.

2

BRIGHT CHROMA PHASE CONTRAST VOLUME

1

[ID MENU (EXIT) button

Press to make the menu appear. Press to return to the

previous screen in the menu.

[ID ENTER (SELECT) button

Press to decide a selected item in the menu.

[IQl t ( + )/ .J (-) buttons

Press to move the cursor (Iii-) or adjust selected value in

the menu.

[DJ BLUE ONLY selector

RESET button

Press (light on) to turn off the red and green signals. A

blue signal is displayed as an apparent monochrome

picture on the screen. This facilitates "chroma" and

"phase*" control adjustments and observation of VCR

noise.

* "Phase" control adjustment is effective only for the

NTSC signals.

Press to reset the setting in the menu.

[gj DEGAUSS button

Press this button momentarily. The screen will be

demagnetized. Wait for 10 minutes or more before

activating this button again.

~

,nput select buttons

Press (light on) to select the program to be monitored.

A: for a signal fed through the LINE A connectors.

-6-

B: for a signal fed through the LINE B connectors.

C: for a signal fed through the LINE C connectors.

RGB: for a signal fed through the RGB connectors.

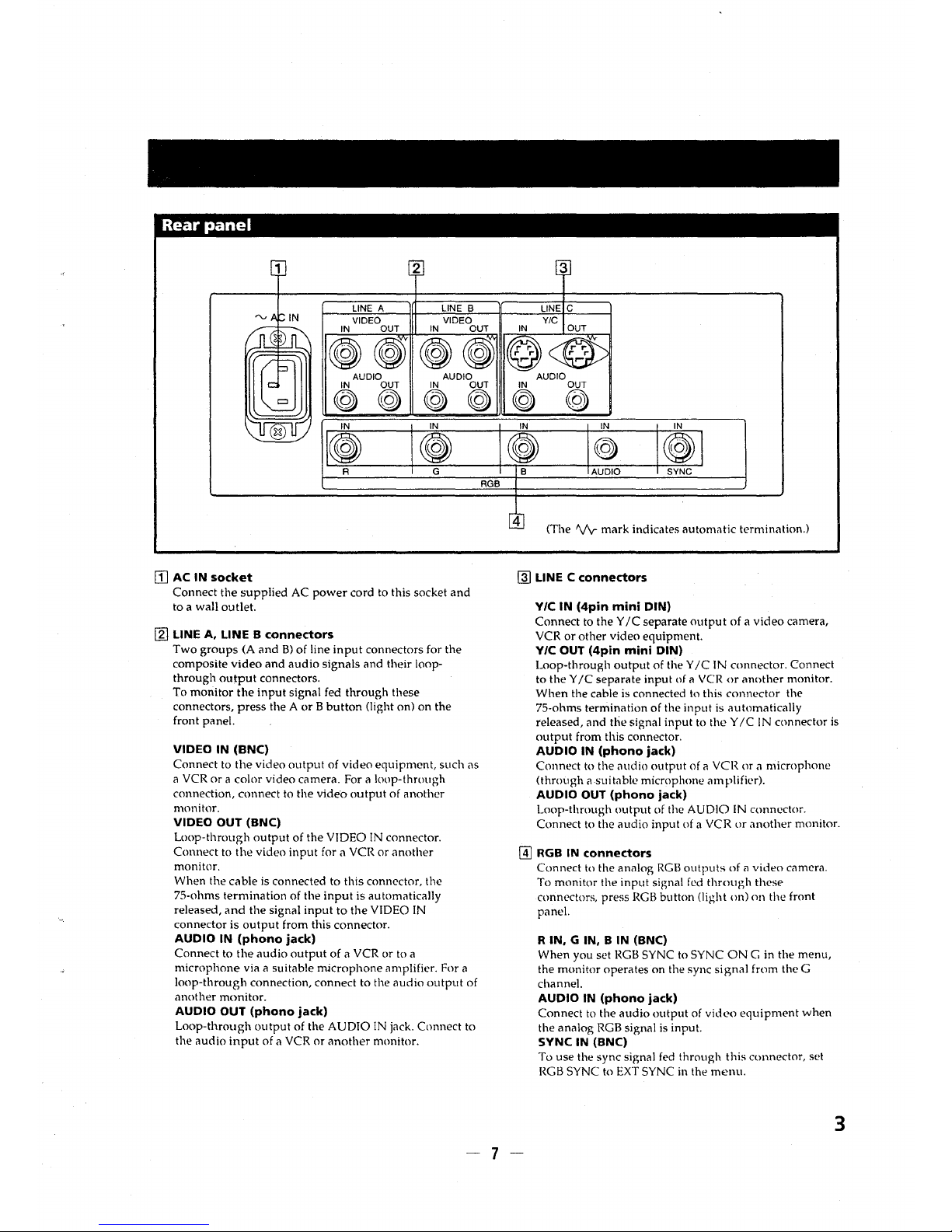

Rear panel

1

2

LINE A

LINE B

'v p.

CIN

VIDEO

VIDEO

~

D .fl

IN

OUT

IN OUT

e:

~

~

~~

AUDIO

AUDIO

IN OUT

IN OUT

@) ©) ©)

@)

ll@LI,

IN

IN

I~

~

R G

[I] AC IN socket

Connect the supplied AC power cord to this socket and

to a wall outlet.

[g) LINE A, LINE B connectors

Two groups (A and B) of line input connectors for the

composite video and audio signals and their loopthrough output connectors.

To monitor the input signal fed through these

connectors, press the A or B button (light on) on the

front panel.

VIDEO IN (BNC)

Connect to the video output of video equipment, such as

a VCR or a color video camera. For a loop-through

connection, connect to the video output of another

monitor.

VIDEO OUT (BNC)

Loop-through output of the VIDEO IN connector.

Connect to the video input for a VCR or another

monitor.

When the cable is connected to this connector, the

75-ohms termination of the input is automatically

released, and the signal input to the VIDEO IN

connector is output from this connector.

AUDIO IN (phono jack)

Connect to the audio output of a VCR or to a

microphone via a suitable microphone amplifier. For a

loop-through connection, connect to the audio output of

another monitor.

AUDIO OUT (phono jack)

Loop-through output of the AUDIO IN jack. Connect to

the audio input of a VCR or another monitor.

RGB

3

LINE C

YIC

IN OUT

@<@>

.- .- r ,..

,... ,...

AUDIO

IN OUT

©) @

IN

IN IN

~

©>

~I

B AUDIO SYNC

4

(The 'V\r mark indicates autom;it1c termination.)

~

LINE C connectors

VIC IN (4pin mini DIN)

Connect to the Y JC separate output of a video camera,

VCR or other video equipment.

VIC OUT (4pin mini DIN)

Loop-through output of the Y JC IN connector. Connect

to the Y JC separate input of ii VCR or another monitor.

When the cable is connected to this connector the

75-ohms termination of the input is ilUtomatirnlly

released, and the signal input to the Y JC IN connector is

output from this connector.

AUDIO IN (phono jack)

Connect to the audio output of ct VCR or a microphone

(through ii-suitable microphone mnplifier).

AUDIO OUT (phono jack)

Loop-through output of the AUDIO IN connector.

Connect to the audio input of a VCR or another monitor.

@] RGB IN connectors

Connect to the analog RGB outputs of a video camera.

To monitor the input signal fed through these

connectors, press RGB button (light on) nn the front

panel.

R IN, G IN, B IN (BNC)

When you set RGB SYNC to SYNC ONG in the menu,

the monitor operates on the sync signal from the G

channel.

AUDIO IN (phono jack)

Connect to the audio output of video equipment when

the anil!og RGB signal is input.

SYNC IN (BNC)

To use the sync signal fed through this connector, set

RGB SYNC to EXT SYNC in the menu.

3

-7-

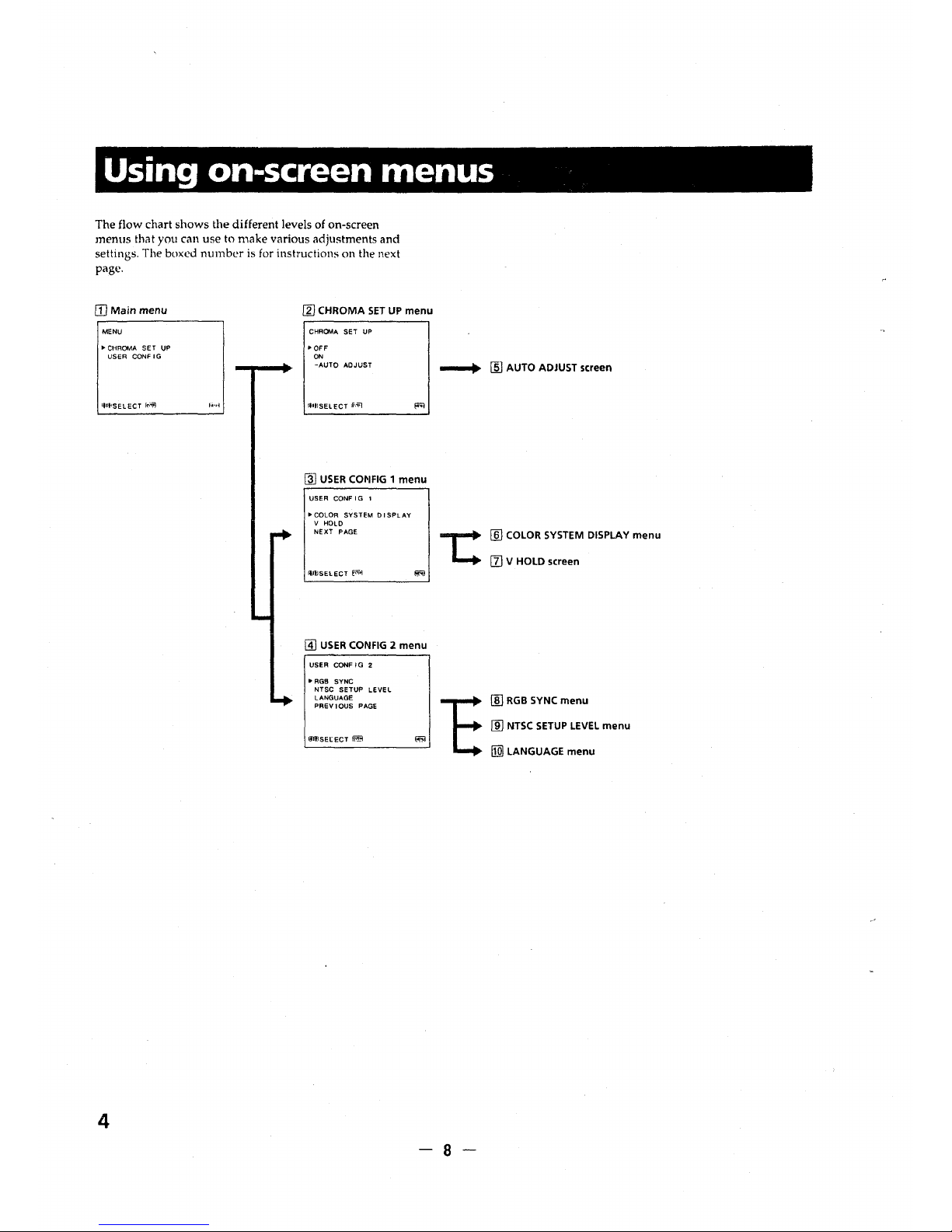

Using on-screen menus

The flow chart shows the different levels of on-screen

menus that you can use to make various adjustments and

settings. The boxed number is for instructions on the next

page.

[D Main menu

MENU

.. CHROMA SET UP

USER CONFIG

lflf

1

SELECT [r."iii)

4

[gJ CHROMA SET UP menu

CHROMA SET UP

•OFF

ON

-AUTO ADJUST

lflflSELECT ii"...,.;i

[ID USER COMFIG 1 menu

USER CONF I G 1

"'COLOR SYSTEM O I SPLAY

V HOLD

NEXT PAGE

flWSELECT [-,iol

@] USER CONFIG 2 menu

USER CONF I G 2

• RGB SYNC

NTSC SETUP LEVEL

LANGUAGE

PREVIOUS PAGE

IJJfJSEl:ECT

~

_.,. [fil AUTO ADJUST screen

,:

[ID COLOR SYSTEM DISPLAY menu

[I] V HOLD screen

!ID RGB SYNC menu

[ID NTSC SETUP LEVEL menu

[IQ) LANGUAGE menu

-8-

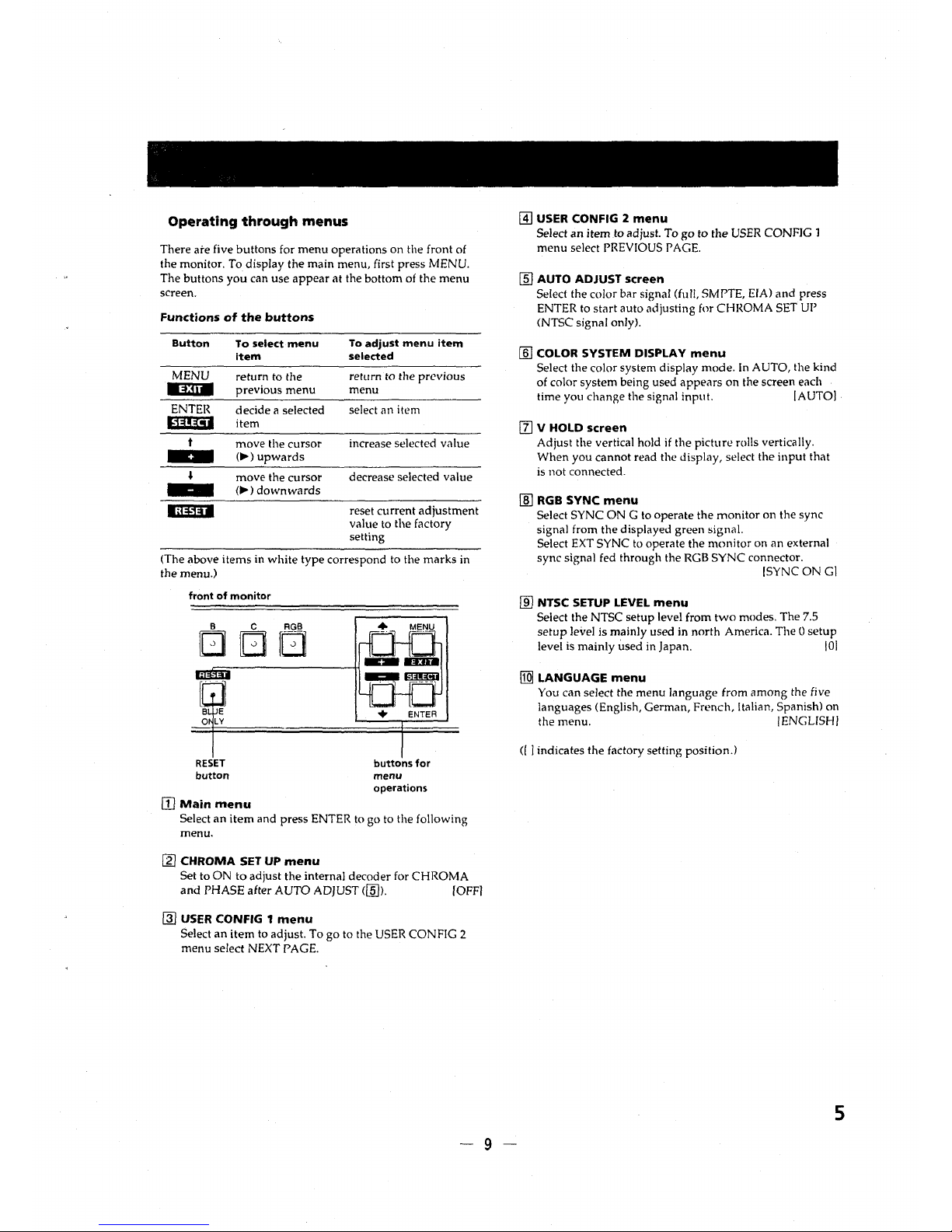

Operating through menus

There are five buttons for menu operations on the front of

the monitor. To display the main menu, first press MENU.

The buttons you can use appear at the bottom of the menu

screen.

Functions of the buttons

Button

To select menu

To adjust menu item

Item selected

MENU

return to the

return to the previous

lli:HII

previous menu

menu

ENTER

decide a selected

select an item

E:~!!!:11

item

t

move the cursor

increase selected value

-

(..,.) upwards

•

move the cursor

decrease selected value

(..,.) downwards

ldi1il

reset current adjustment

value to the factory

setting

(The above items in white type correspond to the marks in

the menu.)

front of monitor

RESET

button

[IJ Main menu

buttons for

menu

operations

Select an item and press ENTER to go to the following

menu.

[g) CHROMA SET UP menu

Set to ON to adjust the internal decoder for CHROMA

and PHASE after AUTO ADJUST([§]). IOFFI

@] USER CONFIG 1 menu

Select an item to adjust. To go to the USER CONFIG 2

menu select NEXT PAGE.

-9-

@] USER CONFIG 2 menu

Select an item to adjust. To go to the USER CONFIG 1

menu select PREVIOUS PAGE.

[§] AUTO ADJUST screen

Select the color bar signal (full, SMPTE, EIA) and press

ENTER to start auto adjusting for CHROMA SET UP

(NTSC signal only).

[ID COLOR SYSTEM DISPLAY menu

Select the color system display mode. In AUTO, the kind

of color system being used appears on the screen each

time you change the signal input. [AUTO[

II] V HOLD screen

Adjust the vertical hold if the picture rolls vertically.

When you cannot read the display, select the input that

is not connected .

[ill RGB SYNC menu

Select SYNC ON G to operate the monitor on the sync

signal from the displayed green signal.

Select EXT SYNC to operate the monitor on an external

sync signal fed through the RGB SYNC connector.

[SYNC ON Gl

[ID NTSC SETUP LEVEL menu

Select the NTSC setup level from two modes. The 7.5

setup level is mainly used in north America. The O setup

level is mainly used in Japan. IOI

[Q] LANGUAGE menu

You can select the menu language from among the five

languages (English, German, French, Italian, Spanish) on

the menu. I ENGLISH I

([ ] indicates the factory setting position.)

5

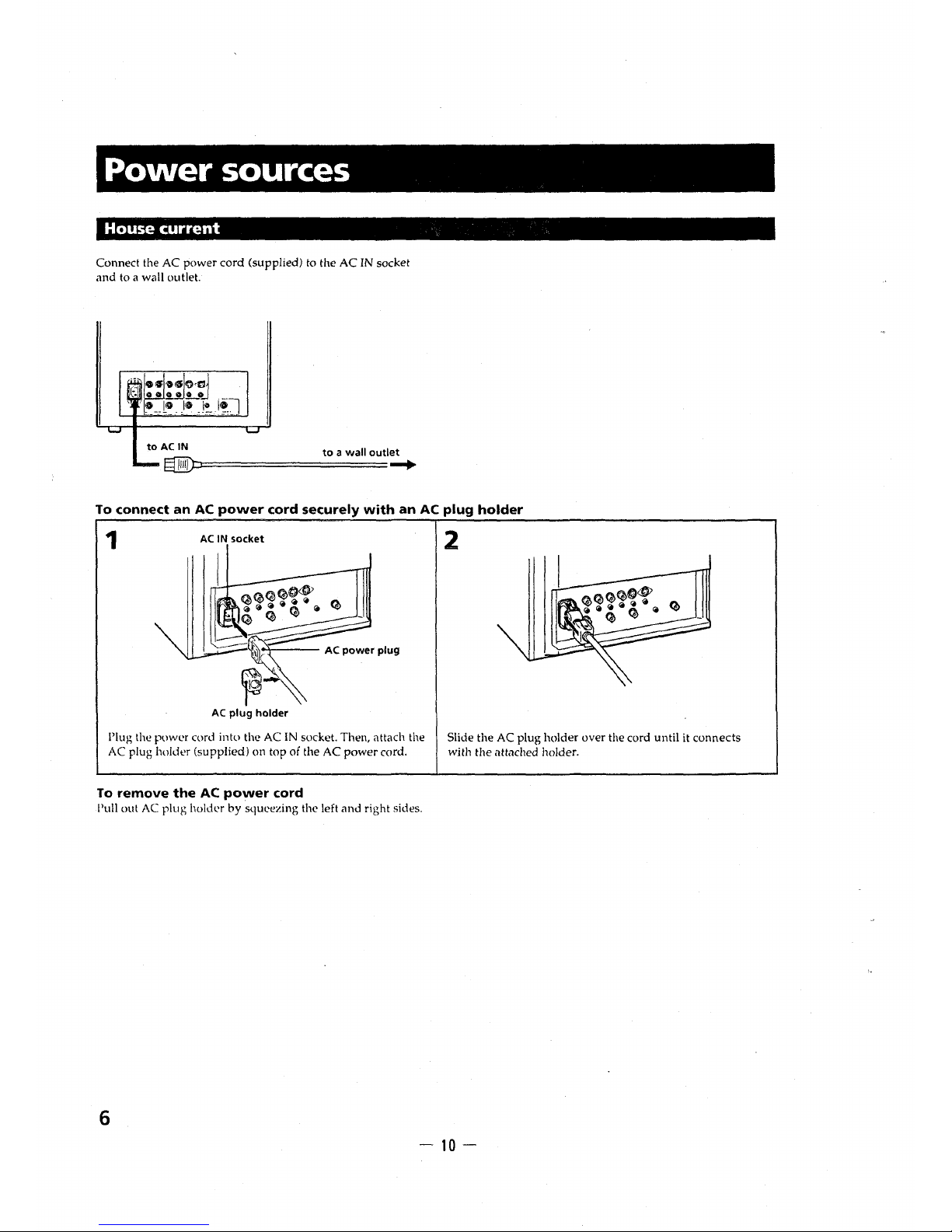

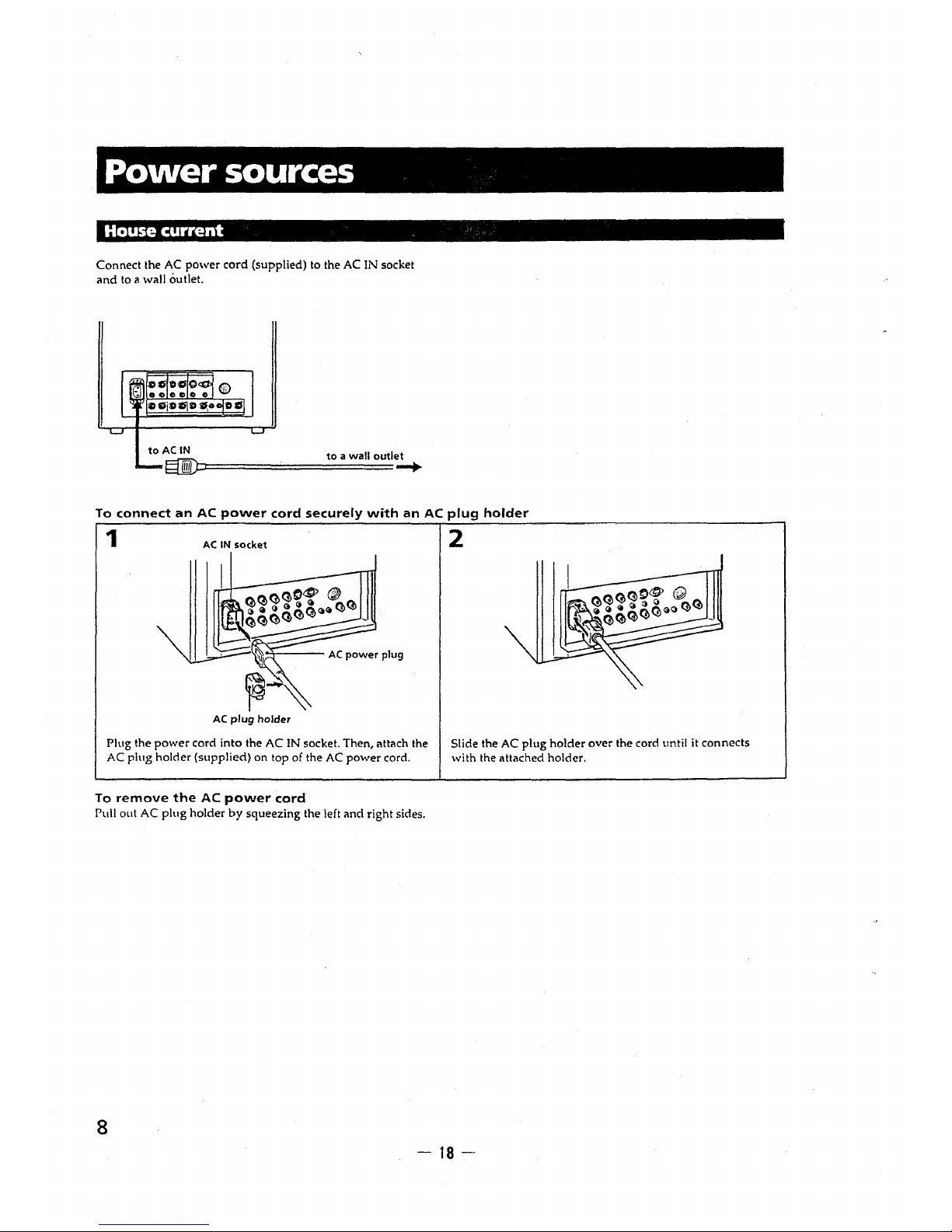

Power sources

House current

Connect the AC power cord (supplied) to the AC IN socket

and to a wall outlet.

to AC IN to a wall outlet

~i:::========= ...

To connect an AC power cord securely with an AC plug holder

1

AC IN socket

AC plug holder

!'lug the power cord into the AC IN socket. Then, attach the

AC plug holder (supplied) on top of the AC power cord.

To remove the AC power cord

Pull out AC plug hokk•r by squeezing the left and right sides.

6

2

Slide the AC plug holder over the cord until it connects

with the attached holder.

- 10 -

1-2. GENERAL OF PVM-14540M

Features

HR (High Resolution) Trinitron picture tube

HR Trinitron tube provides a high resolution picture ..

Horizontal resolution is more than 600 TV lines at the center

of the picture.

Four color systems available

The monitor can display PAL, SECAM, NTSC and NTSCu)•

signals. The appropriate color system is selected

automatically.

• A signal of NTSCw is used for playing back NTSC

recorded video cassettes with a video tape recorder/

player especially designed for use with this system.

Blue only mode

In the blue only mode, an apparent monochrome display is

obtained with all three cathodes driven with a blue signal.

This facilitates color saturation and phase adjustments and

observation of VCR noise.

Analog RGB/component input connectors

Analog RGB or component (Y, R-Y and B-Y) signals from

video equipment can be input through these connectors.

Y/C input connectors

The video signal, split into the chrominance signal (C) and

the luminance signal (Y), can be input through this

connector, eliminating the interference between the two

signals, which tends to occur in a composite video signal,

assuring video quality.

Beam current feedback circuit

The built-in beam current feedback circuit assures stable

white balance.

Comb filter

When NTSC video signals are received, a comb filter

activates to increase the resolution, resulting in fine picture

detail without color spill or color noise.

Automatic termination

(connector with V'v mark only)

The input connector is terminated at 75 ohms inside when no

cable is co1inected to the loop-through output connectors.

When a cable is connected to an output co1mector, the

75-ohms termination is automatically released.

Underscan mode

The sign.ii normally sc.inned outside of the screen can be

monitored in the undersc.in mode.

,~mrw

When the monitor is in the underscan mode, the dark RGB

scanning lines may appear on th~ top edge of the screen.

These are mused by an internal test signal, rather th.in the

input sign.ii.

Horizontal/vertical delay mode

The horizontal and vertical sync signals can be checked

simultaneously in the H/V delav mode.

External sync input

When the EXT SYNC selector is in the on position, the

monitor can be operated on the sync signal supplied from

an external sync generator.

Auto/manual degaussing

Degaussing of the screen can be performed automatically

when the power is turned on, or manually by pressing the

DEGAUSS button.

On-screen menus

You can set color temperature, CHROMA SET UP, .ind

other settings by using the on-screen menus.

Five menu languages

You can select the menu language from among the five

languages on the menu.

EIA standard 19-inch rack mounting

By using an MB-502B (for PVM-1454QM) or SLR-103 (for

PVM-2054QM) mounting bracket (not supplied), the

monitor can be mounted in an EIA standard 19-inch rack.

For details on mounting, see the instruction manual of the

mounting bracket kit.

SDI (Serial Digital Interface) kit

By using SDI kit, the monitor can display SMPTE 259M 4:2:2

serial digital signal from a digital VTR. (ex. Sony 4:2:2 VTR)

SDI kit: 4:2:2 digital video board

Digital audio board

1

- 11 -

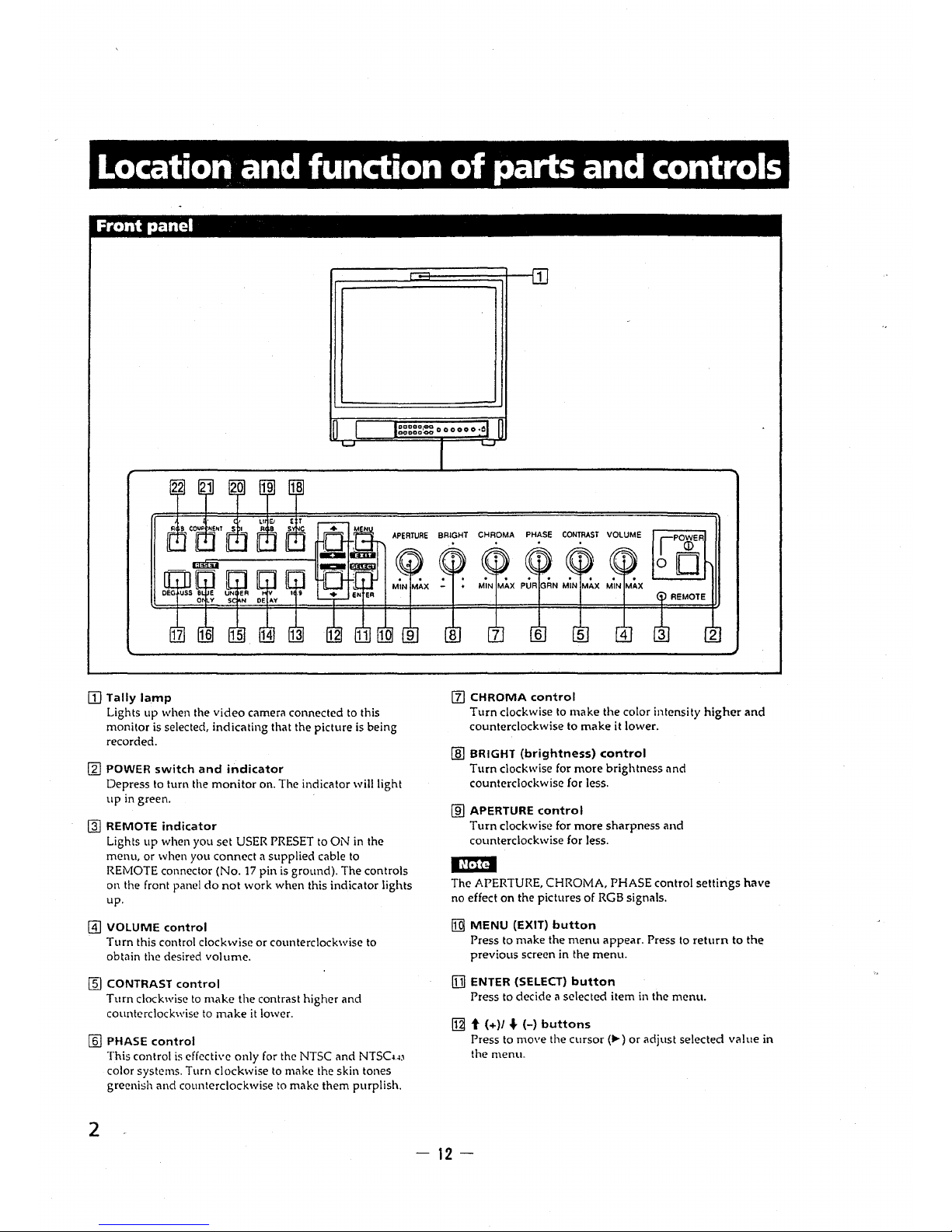

Location and function of parts and controls

Front panel

[Il Tally lamp

Lights up when the video camera connected to this

monitor is selected, indicating that the picture is being

recorded.

~

POWER switch and indicator

Depress to tum the monitor on. The indicator will light

up in green.

~

REMOTE indicator

Lights up when you set USER PRESET to ON in the

menu, or when you connect a supplied cable to

REMOTE connector (No. 17 pin is ground). The controls

on the front panel do not work when this indicator lights

up.

@] VOLUME control

Turn this control clockwise or counterclockwise to

obtain the desired volume.

[fil CONTRAST control

Turn clockwise to make the contrast higher and

counterclockwise to make it lower.

[ID PHASE control

2

This control is effective only for the NTSC and NTSCw

color systems. Turn clockwise to make the skin tones

greenish and counterclockwise to make them purplish.

1

[z) CHROMA control

Turn clockwise to make the color intensity higher and

counterclockwise to make it lower.

[ID BRIGHT {brightness) control

Turn clockwise for more brightness and

counterclockwise for less.

(ID APERTURE control

Turn clockwise for more sharpness and

counterclockwise for less.

,~ma

The APERTURE, CHROMA, PHASE control settings have

no effect on the pictures of RGB signals.

[gj MENU {EXIT) button

Press to make the menu appear. Press to return to the

previous screen in the menu.

[11 ENTER {SELECT) button

Press to decide a selected item in the menu.

[gj t (+)/ .f. H buttons

Press to move the cursor(..,.) or adjust selected value in

the menu.

- 12 -

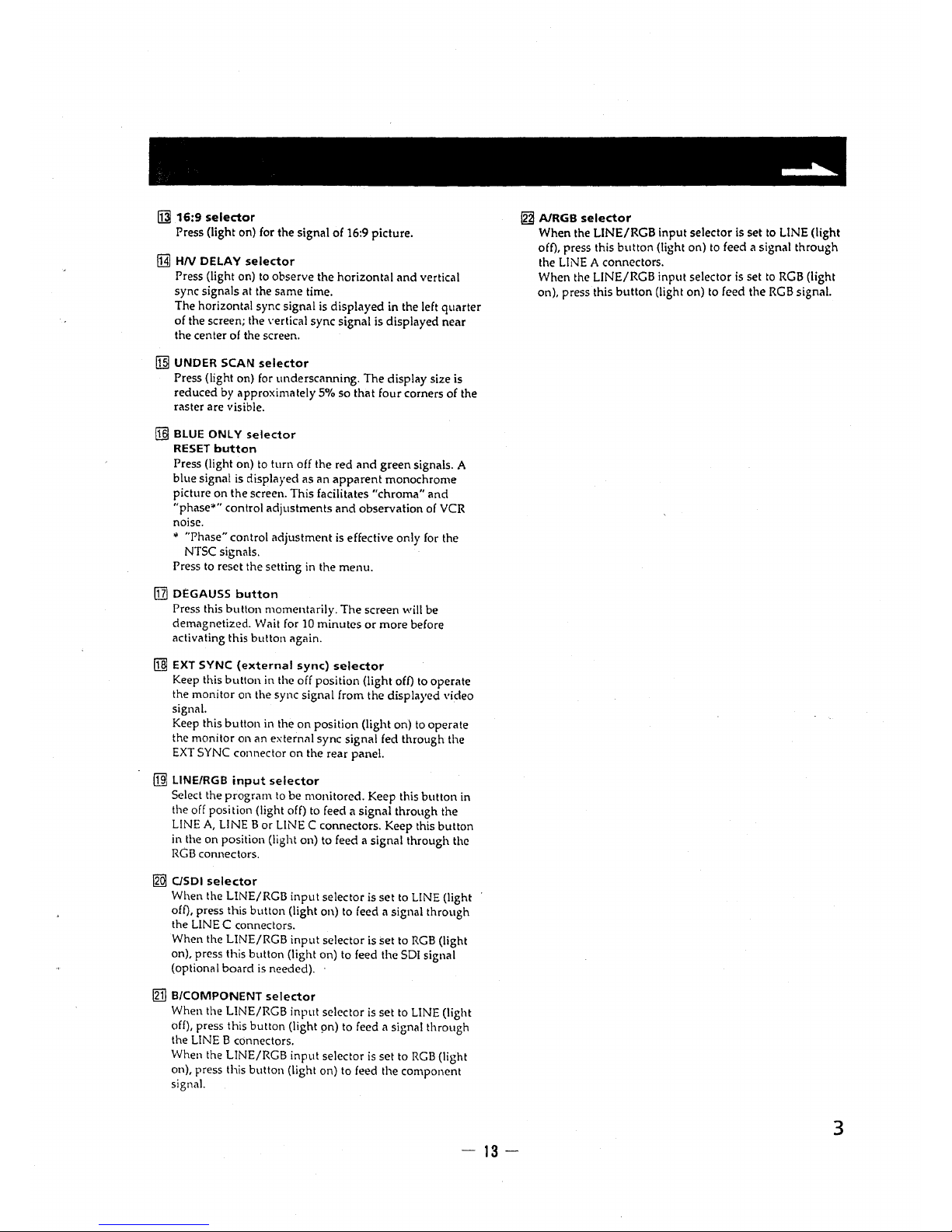

~

16:9 selector

Press (light on) for the signal of 16:9 picture.

~

HN DELAY selector

Press (light on) to observe the horizontal and vertical

sync signals at the same time.

The horizontal sync signal is displayed in the left quarter

of the screen; the ,·ertical sync signal is displayed near

the center of the screen.

[§I UNDER SCAN selector

Press (light on) for underscanning. The display size is

reduced by approximately 5% so that four comers of the

raster are visible.

ff§] BLUE ONLY selector

RESET button

Press (light on) to turn off the red and green signals. A

blue signal is displayed as an apparent monochrome

picture on the screen. This facilitates "chroma" and

"phase*" control adjustments and observation of VCR

noise.

* "Phase" control adjustment is effective only for the

NTSC signals.

Press to reset the setting in the menu.

[Uj DEGAUSS button

Press this button momentarily. The screen will be

demagnetized. Wait for 10 minutes or more before

activating this button again.

[ill EXT SYNC (external sync) selector

Keep this button in the off position (light off) to operate

the monitor on the sync signal from the displayed video

signal.

Keep this button in the on position (light on) to operate

the monitor on an extem11l sync signal fed through the

EXT SYNC connector on the rear panel.

~

LINE/RGB input selector

Select the program to be monitored. Keep this button in

the off position (light off) to feed a signal through the

LINE A, LINE B or LINE C connectors. Keep this button

in the on position (light on) to feed a signal through the

RGB connectors.

~

C/SDI selector

When the LINE/RGB input selector is set to LINE (light

off), press this button (light on) to feed a signal through

the LINE C connectors.

When the LINE/RGB input selector is set to RGB (light

on), press this button (light on) to feed the SD! signal

(optional board is needed).

~

B/COMPONENT selector

When the LINE/RGB input selector is set to LINE (light

off), press this button (light im) to feed a signal through

the LINE B connectors.

When the LINE/RGB input selector is set to RGB (light

on), press this button (light on) to feed the component

signal.

- 13-

~

A/RGB selector

When the LINE/RGB input selector is set to LINE (light

off), press this button (light on) to feed a signal through

the LINE A connectors.

When the LINE/RGB input selector is set to RGB (light

on), press this button (light on) to feed the RGB signal.

3

Location and function of parts and controls

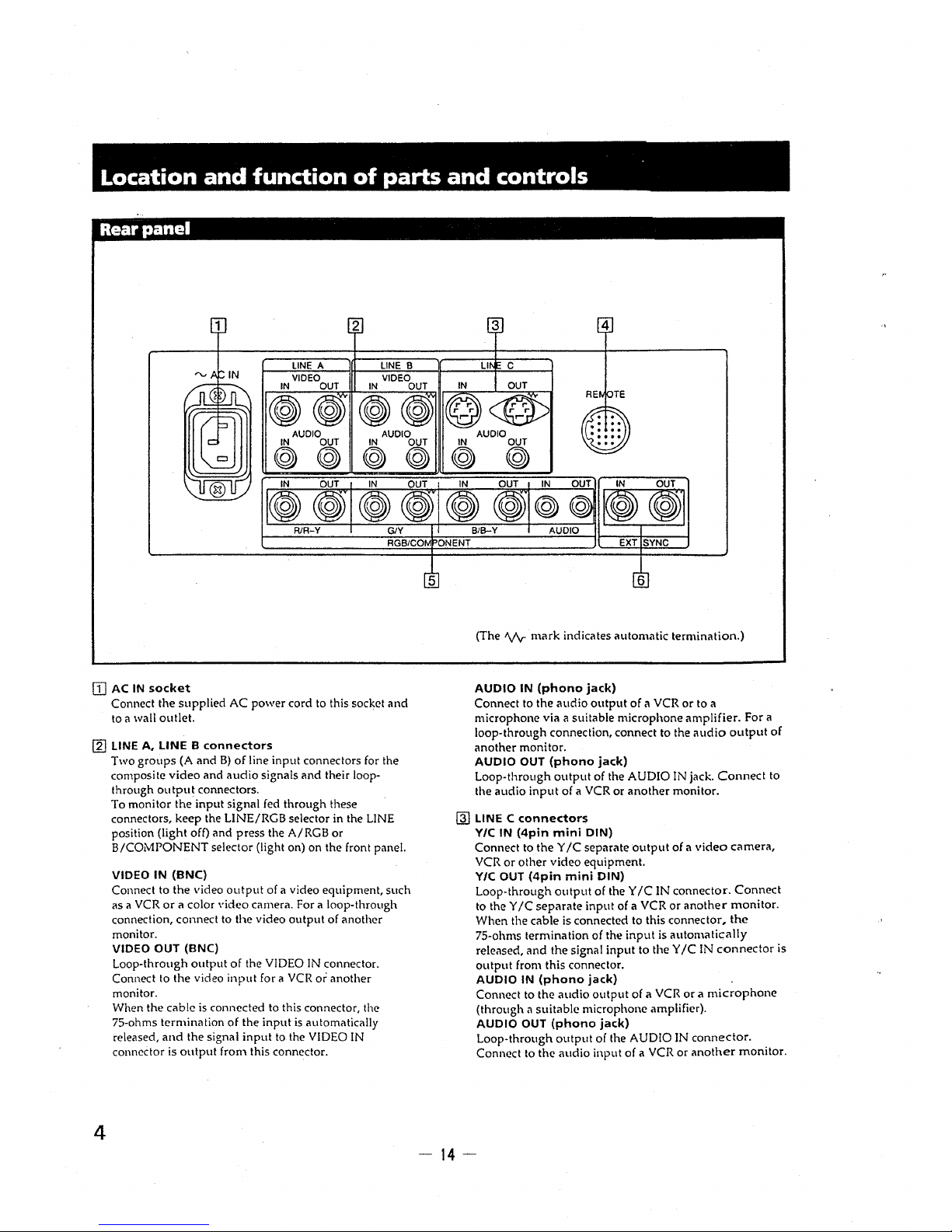

Rear panel

LINE A

LINE B

VIDEO VIDEO

IN OUT IN OUT

AUDIO AUDIO

IN OUT

IN OUT

©) ©) ©) ©)

IN

@

3

LI C

AUDIO

OUT

©)

IN OUT IN OUT IN OUT IN

R/A-Y G/Y BIB-Y

RGBICOM ONENT

5

(The Vv- mark indicates automatic termination.)

II] AC IN socket AUDIO IN (phono jack)

Connect the supplied AC power cord to this socket and

to a wall outlet.

[g] LINE A, LINE B connectors

4

Two groups (A and B) of line input connectors for the

composite video and audio signals and their loop-

through output connectors.

To monitor the input signal fed through these

connectors, keep the LINEIRGB selector in the LINE

position (light off) and press the AIRGB or

BICOMPONENT selector (light on) on the front panel.

VIDEO IN (BNC)

Connect to the video output of a video equipment, such

as a VCR or a color video camera. For a loop-through

connection, connect to the video output of another

monitor.

VIDEO OUT (BNC)

Loop-through output of the VIDEO IN connector.

Connect to the video input for a VCR or another

monitor.

When the cable is connected to this connector, the

75-ohms termination of the input is automatically

released, and the signal input to the VIDEO IN

connector is output from this connector.

Connect to the audio output of a VCR or to a

microphone via a suitable microphone amplifier. For a

loop-through connection, connect to the audio output of

another monitor.

AUDIO OUT (phono jack)

Loop-through output of the AUDIO IN jack. Connect to

the audio input of a VCR or another monitor.

@I LINE C connectors

Y/C IN (4pin mini DIN)

Connect to the Y IC separate output of a video camera,

VCR or other video equipment.

Y/C OUT (4pin mini DIN)

Loop-through output of the Y IC IN connector. Connect

to the Y IC separate input of a VCR or another monitor.

When the cable is connected to this connector, the

75-ohms termination of the input is automatically

released, and the signal input to the Y IC IN connector is

output from this connector.

AUDIO IN (phono jack)

Connect to the audio output of a VCR or a microphone

(through a suitable microphone amplifier).

-14-

AUDIO OUT (phono jack)

Loop-through output of the AUDIO IN connector.

Connect to the audio input of a VCR or another monitor.

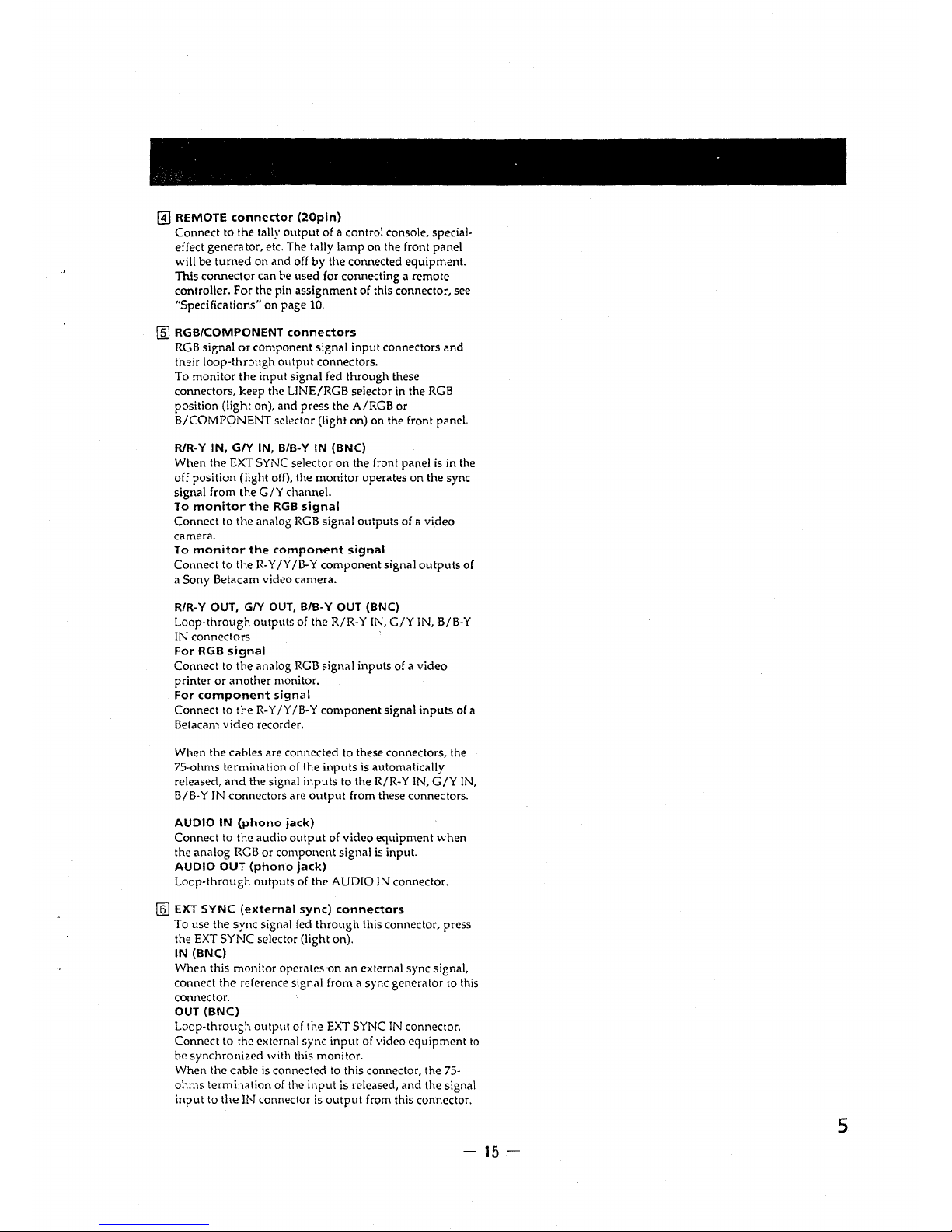

@] REMOTE connector (20pin)

Connect to the tally output of a control console, specialeffect generator, etc. The tally lamp on the front panel

will be turned on and off by the connected equipment.

This connector can be used for connecting a remote

controller. For the pin assignment of this connector, see

"Specifications" on page 10.

[§) RGB/COMPONENT connectors

RGB signal or component signal input connectors and

their loop-through output connectors.

To monitor the input signal fed through these

connectors, keep the LINE/RGB selector in the RGB

position (light on), and press the A/RGB or

B/COMPONENT selector (light on) on the front panel.

R/R-Y IN, G/Y IN, B/B-Y IN {BNC)

When the EXT SYNC selector on the front panel is in the

off position (light off), the monitor operates on the sync

signal from the G/Y channel.

To monitor the RGB signal

Connect to the analog RGB signal outputs of a video

camera.

To monitor the component signal

Connect to the R-Y /Y /B-Y component signal outputs of

a Sony Betacam video camera.

R/R-Y OUT, GfY OUT, B/B-Y OUT {BNC)

Loop-through outputs of the R/R-Y IN, G/Y IN, B/B-Y

IN connectors '

For RGB signal

Connect to the analog RGB signal inputs of a video

printer or another monitor.

For component signal

Connect to the R-Y /Y /B-Y component signal inputs of a

Betacam video recorder.

When the cables are connected to these connectors, the

75-ohms termination of the inputs is automatically

released, nnd the signal inputs to the R/R-Y IN, G/Y IN,

B/B-Y IN connectors are output from these connectors.

AUDIO IN (phone jack)

Connect to the audio output of video equipment when

the analog RGB or component signal is input.

AUDIO OUT (phone jack)

Loop-through outputs of the AUDIO IN connector.

[§] EXT SYNC (external sync) connectors

To use the sync signnl fed through this connector, press

the EXT SYNC selector (light on).

IN (BNC)

When this monitor operates-on an external sync signal,

connect the reference signal from a sync generator to this

connector.

OUT (BNC)

Loop-through output of the EXT SYNC IN connector.

Connect to the external sync input of video equipment to

be synchronized with this monitor.

When the cable is connected to this connector, the 75-

ohms termination of the input is released, and the signal

input to the IN connector is output from this connector.

- 15 -

5

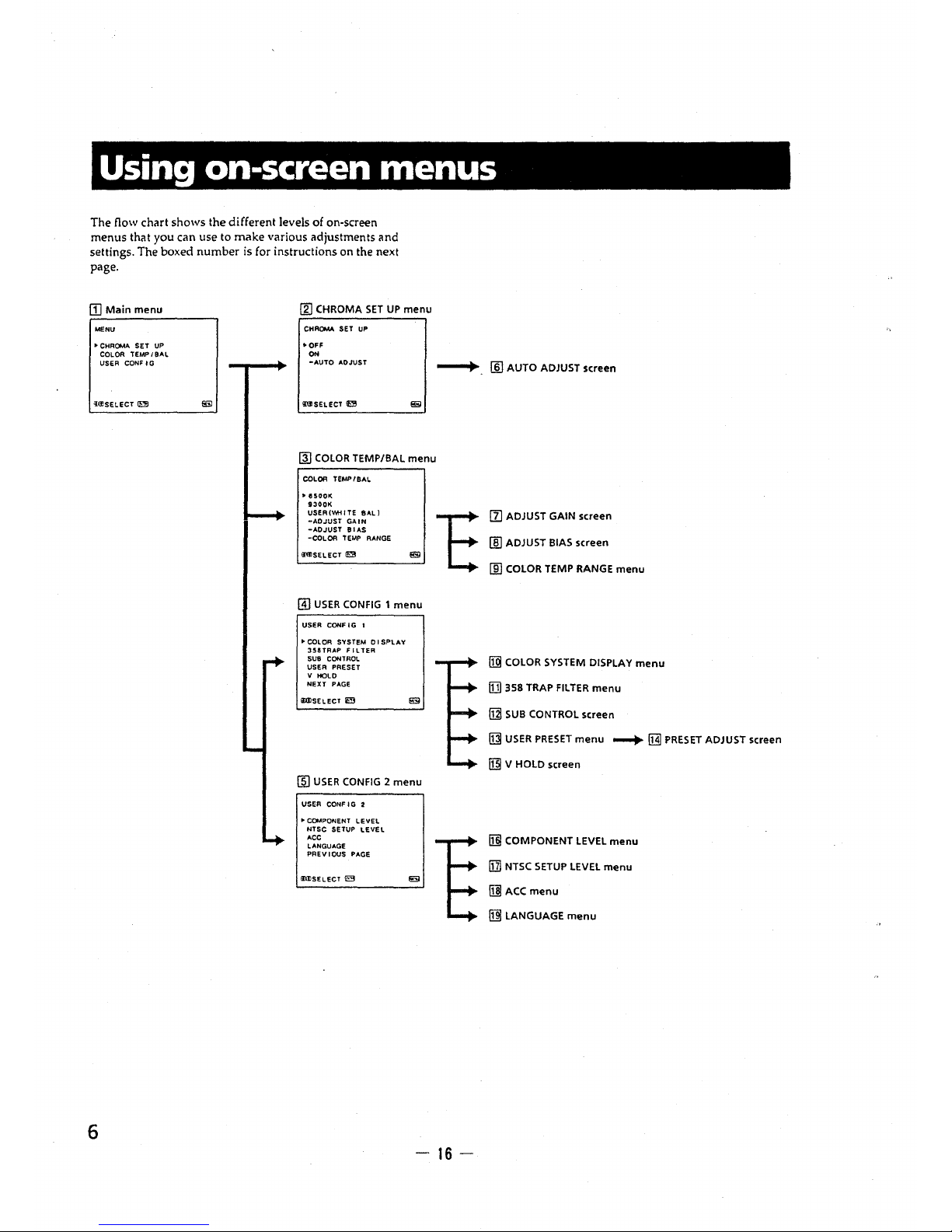

Using on-screen menus

The flow chart shows the different levels of on-screen

menus that you can use to make various adjustments and

settings. The boxed number is for instructions on the next

page.

(I] Main menu

MENU

(2] CHROMA SET UP menu

CHROMA SET UP

•OFF

°"

to CHROMA SET UP

COLOR TEMP/BAL

USER CONF IG

-AUTO ADJUST

~- [ID AUTO ADJUST screen

i(J)SELECT

~

6

msELECT !Ira

~

COLOR TEMP/BAL menu

COLOR TEMP I BAL

,. esoot<.

9300K

USER(.,,.ITE BAL)

-ADJUST GAIN

-AO JUST BI AS

-COL OR TEMP RANGE

111])SELECT IE[l

@) USER CONFIG 1 menu

USER CONF I G 1

• COLOR SYSTEM O I SP'LAY

358TFtAP FILTER

SUB CONTROi.

USER PRESET

V HOLD

NEXT PAGE

lllllSELECT IE;j

(ID USER CONFIG 2 menu

USER CONF I G 2

,. COMPONENT LEVEL

NTSC SETUP LEVEL

ACC

LANGUAGE

PREVIOUS PAGE

IDI'SELECT

~

t

E

-16-

[z) ADJUST GAIN screen

[ID ADJUST BIAS screen

(ID COLOR TEMP RANGE menu

[j] COLOR SYSTEM DISPLAY menu

fl] 358 TRAP FILTER menu

[ill SUB CONTROL screen

~

USER PRESET menu --+ [j]] PRESET ADJUST screen

[i]l V HOLD screen

[i] COMPONENT LEVEL menu

[ii NTSC SETUP LEVEL menu

[i] ACC menu

Ii]] LANGUAGE menu

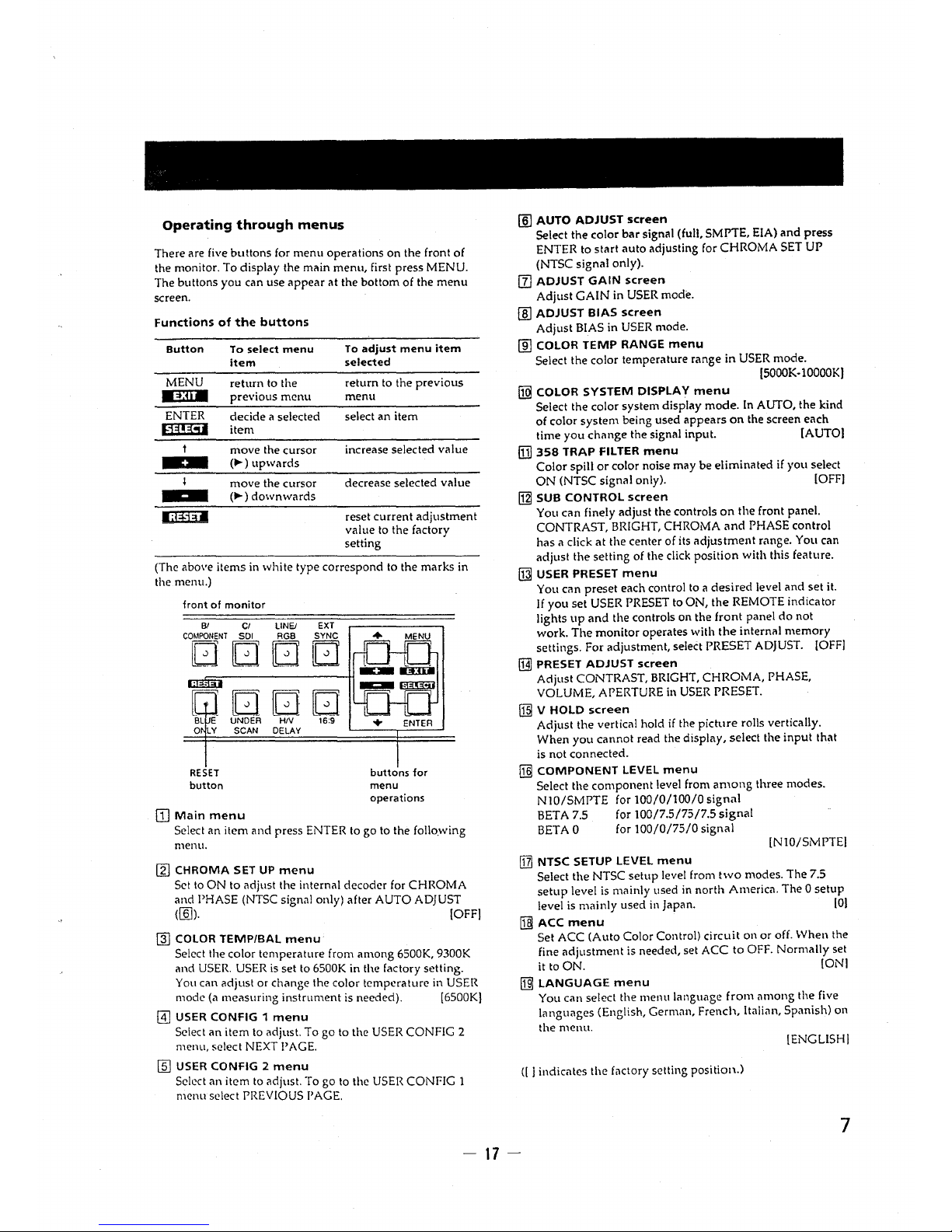

Operating through menus

There are five buttons for menu operations on the front of

the monitor. To display the main menu, first press MENU.

The buttons you can use appear at the bottom of the menu

screen.

Functions of the buttons

Button

To select menu

To adjust menu item

item

selected

MENU

return to the

return to the previous

.:i:li•

previous menu

menu

ENTER

decide a selected

select an item

lja!~:51

item

move the cursor

increase selected value

--

(.,..) upwards

move the cursor

decrease selected value

(.,..) downwards

ligilll

reset current adjustment

value to the factory

setting

(The above items in white type correspond to the marks in

the menu.)

front of monitor

Bl Ci LINE/ EXT

COMPONENT SDI AGB SYNC

D D G [CJ

..

w D Q D

BL E UNDER HIV 16:9

0 LY SCAN DELAY

RESET

button

[Il Main menu

buttons for

menu

operations

Select an item and press ENTER to go to the folio.wing

menu.

~

CHROMA SET UP menu

Set to ON to adjust the internal decoder for CHROMA

and PHASE (NTSC signal only) after AUTO ADJUST

(ffi]). (OFF)

@) COLOR TEMP/BAL menu

Select the color temperature from among 6500K, 9300K

and USER. USER is set to 6500K in the factory setting.

You can adjust or change the color temperature in USER

mode (a measuring instrument is needed). (6500K)

@] USER CONFIG 1 menu

Select an item to adjust. To go to the USER CONFIG 2

menu, select NEXT I' AGE.

ffi) USER CONFIG 2 menu

Select an item to adjust. To go to the USER CONr-IG 1

menu select PREVIOUS PAGE.

[ID AUTO ADJUST screen

Select the color bar signal (full, SMPTE, EIA) and press

ENTER to start auto adjusting for CHROMA SET UP

(NTSC signal only).

(l] ADJUST GAIN screen

Adjust GAIN in USER mode.

(ID ADJUST BIAS screen

Adjust BIAS in USER mode.

(ID COLOR TEMP RANGE menu

Select the color temperature range in USER mode.

[S0OOK-lOO00K)

[ill COLOR SYSTEM DISPLAY menu

Select the color system display mode. In AUTO, the kind

of color system being used appears on the screen each

time you change the signal input. (AUTO)

[TI] 358 TRAP Fil TER menu

Color spill or color noise may be eliminated if you select

ON (NTSC signal only). !OFF!

[gj SUB CONTROL screen

You can finely adjust the controls on the front panel.

CONTRAST, BRIGHT, CHROMA and PHASE control

has a click at the center of its adjustment range. You can

adjust the setting of the click position with this feature.

~

USER PRESET menu

You can preset each control to a desired level and set it.

If you set USER PRESET to ON, the REMOTE indicator

lights up and the controls on the front panel do not

work. The monitor operates with the internal memory

settings. For adjustment, select PRESET ADJUST. [OFF!

~

PRESET ADJUST screen

Adjust CONTRAST, BRIGHT, CHROMA, PHASE,

VOLUME, APERTURE in USER PRESET.

[ill V HOLD screen

Adjust the vertical hold if the picture rolls vertically.

When you cannot read the display, select the input that

is not connected.

[j]] COMPONENT LEVEL menu

Select the component level from among three modes.

N10/SMPTE for 100/0/100/0 sign.ii

BETA 7.5 for 100/7.5/75/7.5 signal

BET AO for 100/0/75/0 signal

[N10/SMPTEI

[TI] NTSC SETUP LEVEL menu

Select the NTSC setup level from two modes. The 7.5

setup level is mainly used in north America. The 0 setup

level is mainly used in Japan. [OJ

5]I ACC menu

Set ACC (Auto Color Control) circuit on or off. When the

fine adjustment is needed, set ACC to OFF. Normally set

it to ON. [ONI

~

LANGUAGE menu

You can select the menu language from among the five

languages (English, German, French, Italian, Spanish) on

the menu.

[ENGLISH!

(I I indicates the foctory setting position.)

7

- 17 -

Power sources

House current

Connect the AC power cord (supplied) to the AC IN socket

and to a wall outlet.

to AC IN to a wall outlet

efilD::=========--+-

To connect an AC power cord securely with an AC plug holder

1

AC IN socket

AC plug holder

Plug the power cord into the AC IN socket. Then, attach the

AC plug holder (supplied) on top of the AC power cord.

To remove the AC power cord

Pull out AC plug holder by squeezing the left and right sides.

8

2

Slide the AC plug holder over the cord until it connects

with the attached holder.

- 18 -

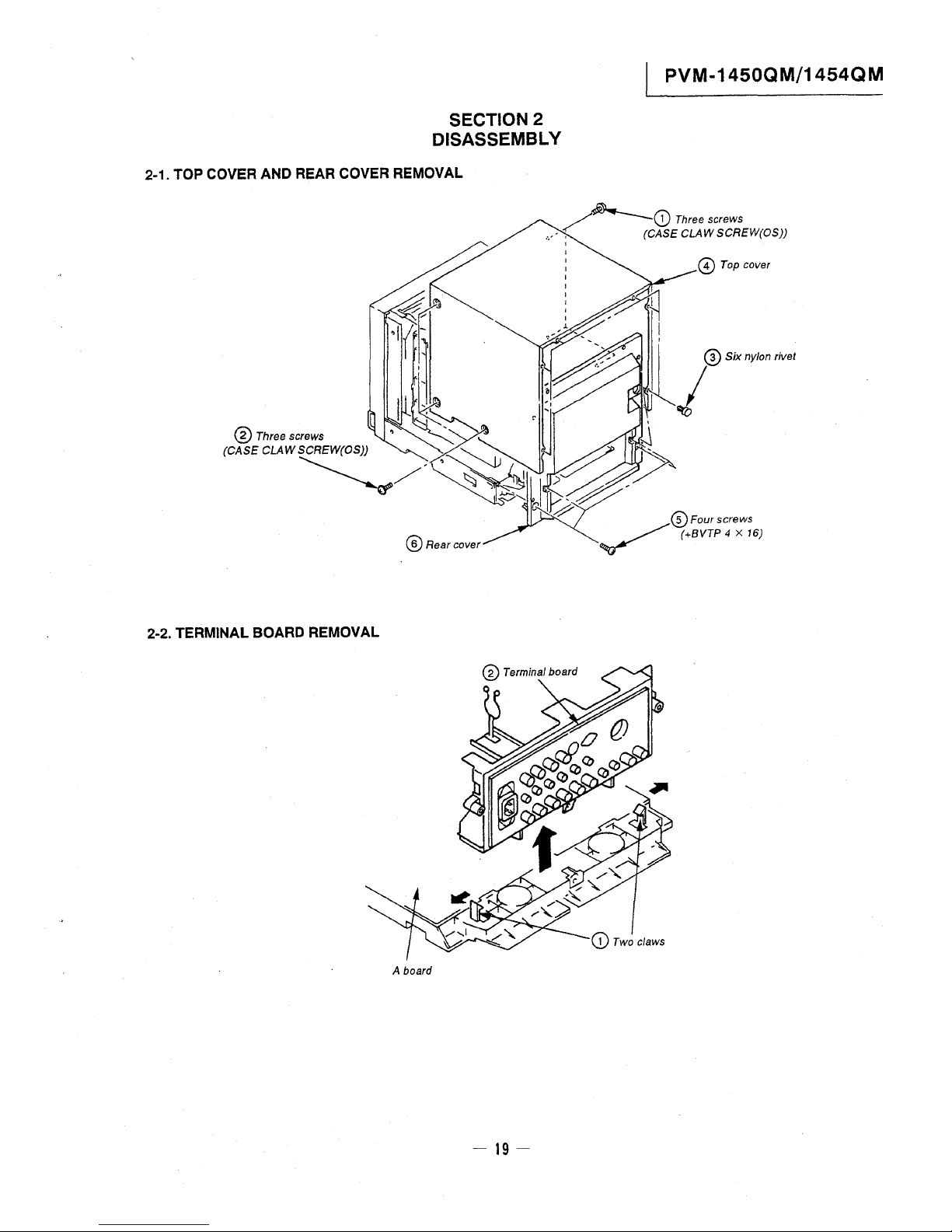

SECTION 2

DISASSEMBLY

2-1. TOP COVER AND REAR COVER REMOVAL

PVM-1450QM/1454QM

~G) Three screws

.,-- , (CASE CLAW SCREW(OS))

@ Rear cover

2-2. TERMINAL BOARD REMOVAL

A board

- 19-

I

I

© Top cover

PVM-1450QM/1454QM

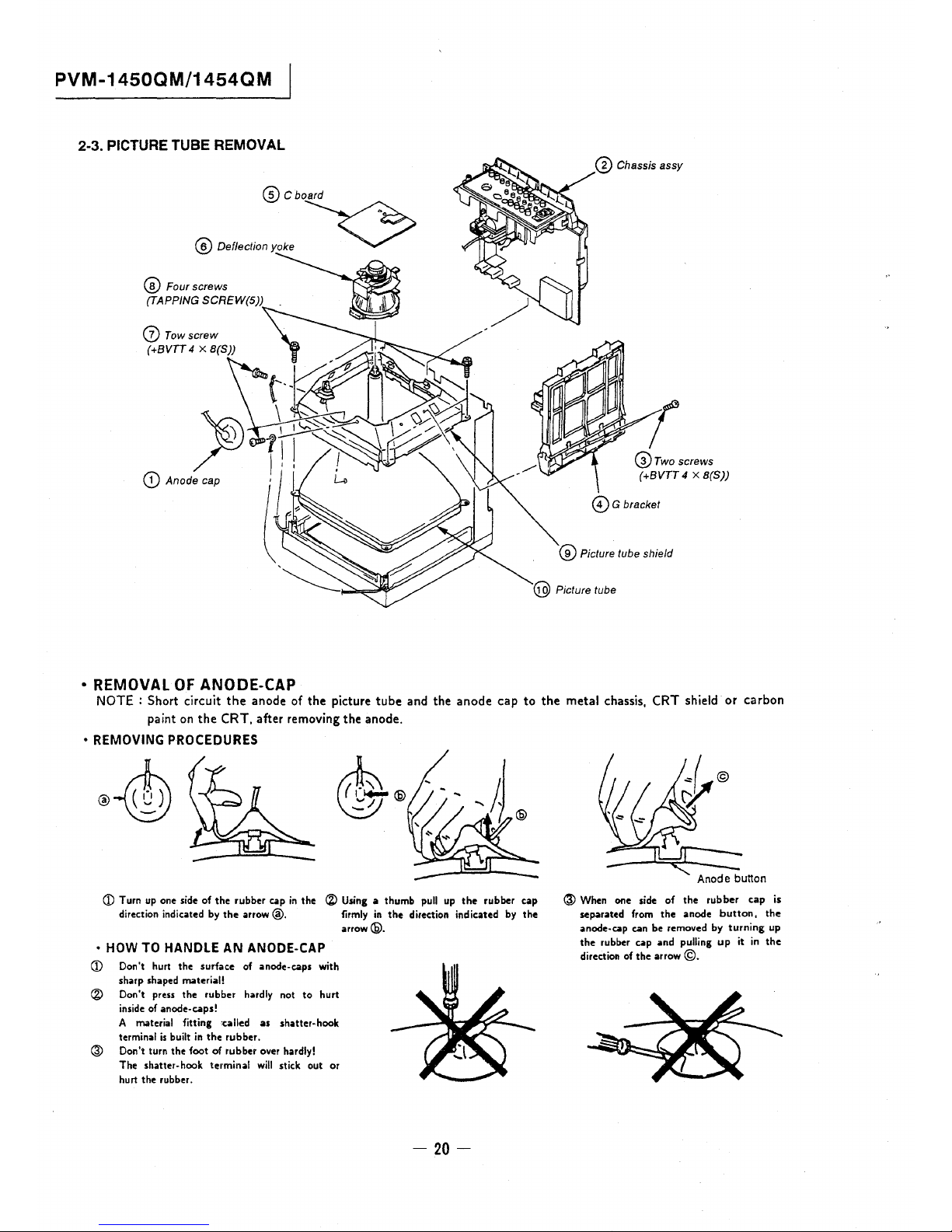

2-3. PICTURE TUBE REMOVAL

@ Cboard

@ Delledfo, yoke

~

@ Four screws

(TAPPING SCREW(5))

(z) Tow screw

(+BVTT 4 X B(S))

•REMOVALOFANOD~CAP

@ Chassis assy

1

@rwoscrews

(+BVTT 4 x B(S))

©G bracket

@ Picture tube shield

NOTE : Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon

paint on the CRT, after removing the anode.

• REMOVING PROCEDURES

~@

~

CD Turn up one side of the rubber cap in the ® Using a thumb pull up the rubber cap

direction indicated by the arrow@. firmly in the direction indicated by the

arrow@.

• HOW TO HANDLE AN ANODE-CAP

CD Don't hurt the surface of anode-caps with

sharp shaped material!

® Don't press the rubber hardly not to hurt

inside of anode-caps!

A material fitting :called as shatter-hook

terminal is built in the rubber.

@ Don't turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or

hurt the rubber.

- 20 -

@ When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning up

the rubber cap and pulling up it in the

direction of the arrow ©.

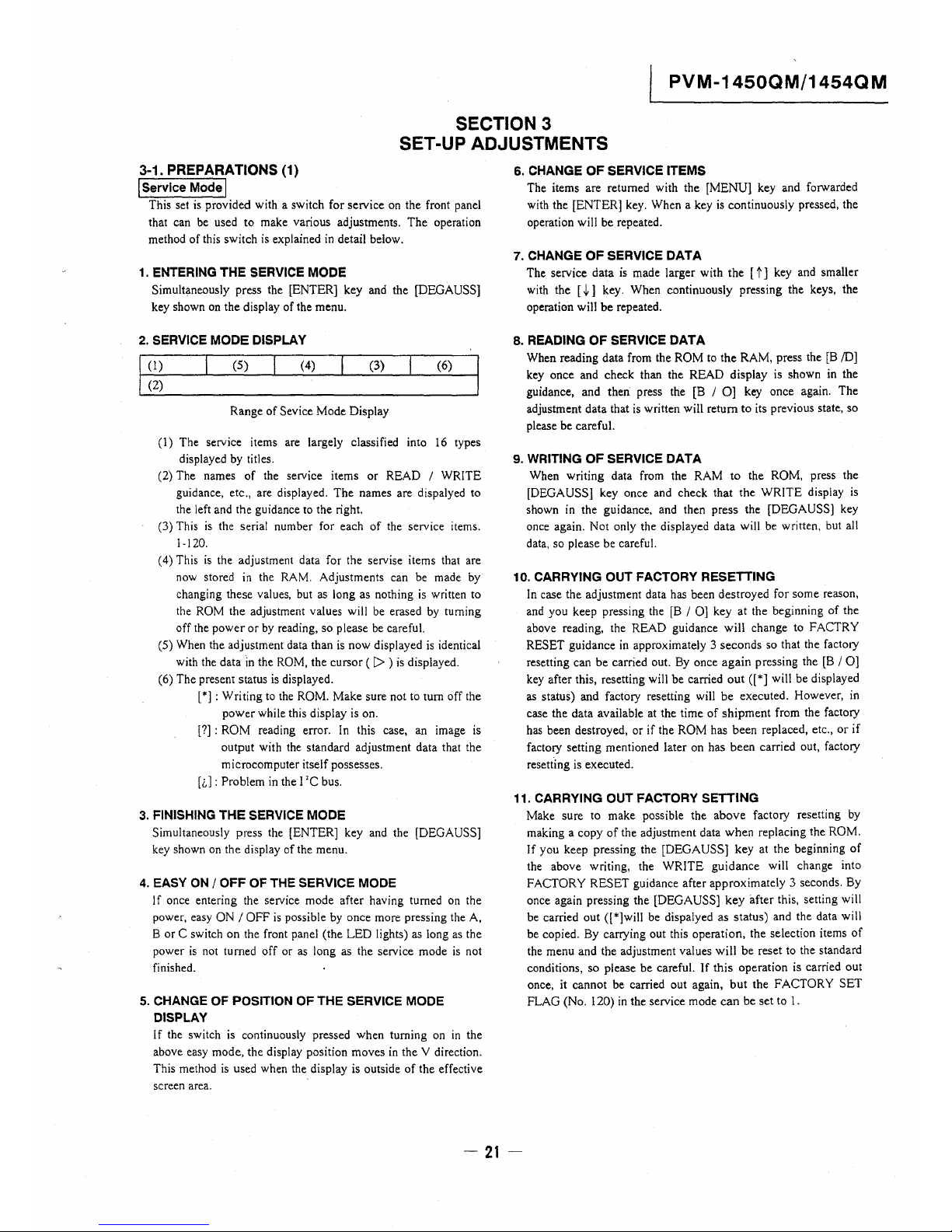

PVM-1450QM/1454QM

SECTION 3

SET-UP ADJUSTMENTS

3-1. PREPARATIONS (1)

I Service Mode I

This set is provided with a switch for service on the front panel

that can be used to make various adjustments. The operation

method of this switch is explained in detail below.

1. ENTERING THE SERVICE MODE

Simultaneously press the [ENTER] key and the [DEGAUSS]

key shown on the display of the menu.

2. SERVICE MODE DISPLAY

(I)

(5)

(4)

(3)

(6)

(2)

Range of Sevice Mode Display

(1) The service items are largely classified into 16 types

displayed by titles.

(2) The names of the service items or READ / WRITE

guidance, etc., are displayed. The names are dispalyed to

the left and the guidance to the right.

(3) This is the serial number for each of the service items.

1-120.

( 4) This is the adjustment data for the servise items that are

now stored in the RAM. Adjustments can be made by

changing these values, but as long as nothing is written to

the ROM the adjustment values will be erased by turning

off the power or by reading, so please be careful.

(5) When the adjustment data than is now displayed is identical

with the data in the ROM, the cursor ( I> ) is displayed.

(6) The present status is displayed.

[*] : Writing to the ROM. Make sure not to tum off the

power while this display is on.

[?] : ROM reading error. In this case, an image is

output with the standard adjustment data that the

microcomputer itself possesses.

[i,): Problem in the I 'C bus.

3. FINISHING THE SERVICE MODE

Simultaneously press the [ENTER] key and the [DEGAUSS]

key shown on the display of the menu.

4. EASY ON / OFF OF THE SERVICE MODE

If once entering the service mode after having turned on the

power, easy ON / OFF is possible by once more pressing the A,

B or C switch on the front panel (the LED lights) as long as the

power is not turned off or as long as the service mode is not

finished.

5. CHANGE OF POSITION OF THE SERVICE MODE

DISPLAY

If the switch is continuously pressed when turning on in the

above easy mode, the display position moves in the V direction.

This method is used when the display is outside of the effective

screen area.

6. CHANGE OF SERVICE ITEMS

The items are returned with the [MENU] key and forwarded

with the [ENTER] key. When a key is continuously pressed, the

operation will be repeated.

7. CHANGE OF SERVICE DATA

The service data is made larger with the [ t] key and smaller

with the [ i] key. When continuously pressing the keys, the

operation will be repeated.

8. READING OF SERVICE DATA

When reading data from the ROM to the RAM, press the [B /DJ

key once and check than the READ display is shown in the

guidance, and then press the [B / OJ key once again. The

adjustment data that is written will return to its previous state, so

please be careful.

9. WRITING OF SERVICE DATA

When writing data from the RAM to the ROM, press the

[DEGAUSS] key once and check that the WRITE display is

shown in the guidance, and then press the [DEGAUSS] key

once again. Not only the displayed data will be written, but all

data, so please be careful.

10. CARRYING OUT FACTORY RESETTING

In case the adjustment data has been destroyed for some reason,

and you keep pressing the [B / OJ key at the beginning of the

above reading, the READ guidance will change to FACTRY

RESET guidance in approximately 3 seconds so that the factory

resetting can be carried out. By once again pressing the [B / OJ

key after this, resetting will be carried out ([*] will be displayed

as status) and factory resetting will be executed. However, in

case the data available at the time of shipment from the factory

has been destroyed, or if the ROM has been replaced, etc., or if

factory setting mentioned later on has been carried out, factory

resetting is executed.

11. CARRYING OUT FACTORY SETTING

Make sure to make possible the above factory resetting by

making a copy of the adjustment data when replacing the ROM.

If you keep pressing the [DEGAUSS] key at the beginning of

the above writing, the WRITE guidance will change into

FACTORY RESET guidance after approximately 3 seconds. By

once again pressing the [DEGAUSS] key after this, setting will

be carried out ([*]will be dispalyed as status) and the data will

be copied. By carrying out this operation, the selection items of

the menu and the adjustment values will be reset to the standard

conditions, so please be careful. If this operation is carried out

once, it cannot be carried out again, but the FACTORY SET

FLAG (No. 120) in the service mode can be set to I.

-21-

PVM-1450QM/1454QM

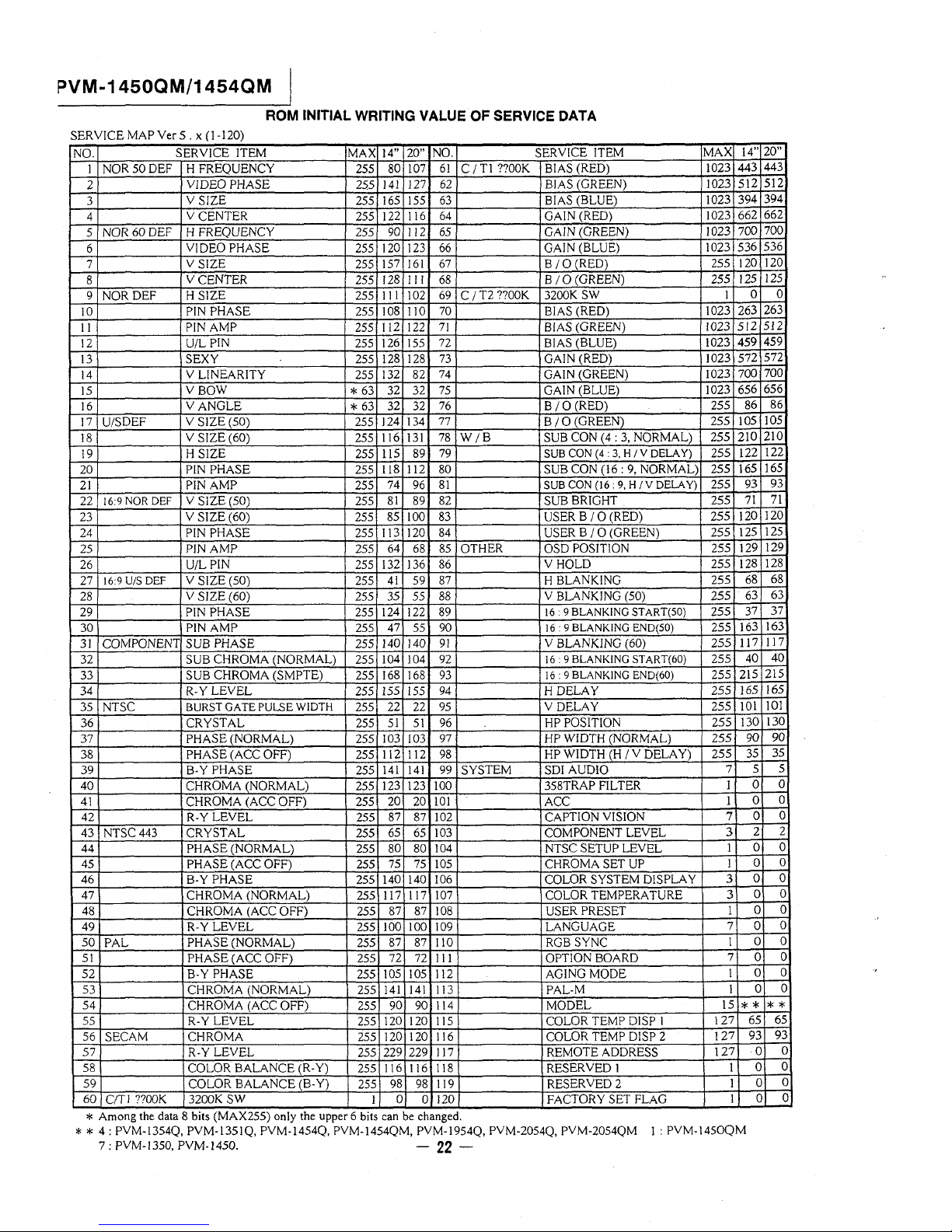

ROM INITIAL WRITING VALUE OF SERVICE DAT A

SERVICE MAP Ver 5. x (J-120)

NO.

SERVICE ITEM

MAX

14" 20" NO. SERVICE ITEM

I

NOR 50DEF H FREQUENCY

255

80

107 61 C /Tl ??OOK BIAS (RED)

2

VIDEO PHASE

255

141 127 62

BIAS (GREEN)

3

V SIZE

255

165 155 63

BIAS (BLUE)

4

VCENTER

255

I22

116 64 GAIN (RED)

5

NOR 60 DEF

H FREQUENCY

255

90 112 65 GAIN (GREEN)

6

VIDEO PHASE

255

120 123 66

GAIN (BLUE)

7

VSJZE

255

157 161

67

B / 0 (RED)

8

VCENTER

255

128

11 l

68

B /O(GREEN)

9

NOR DEF

HSIZE

255

111

102

69 C !T2 ??OOK 3200K SW

10 PIN PHASE 255

108 l 10

70

BIAS (RED)

11

PIN AMP

255

I 12 122

71 BIAS (GREEN)

12 U/L PIN 255

126 155 72

BIAS (BLUE)

13 SEXY 255

128 128

73

GAIN (RED)

14

V LINEARITY

255

132

82

74

GAIN (GREEN)

15

VBOW

* 63

32

32

75 GAIN (BLUE)

16 V ANGLE

* 63

32

32

76

8 /0 (RED)

17

U/SDEF

V SIZE (50)

255

124 134

77

8 /0 (GREEN)

18

V SIZE (60)

255

I 16 131

78

W /8

SUB CON (4: 3, NORMAL)

19 H SIZE 255

115 89

79

SUB CON (4: 3. H /V DELAY)

20 PIN PHASE 255

118 112 80

SUB CON (16: 9, NORMAL)

21

PIN AMP

255

74

96

81

SUB CON (16: 9, H / V DELAY)

22

16:9 NOR DEF V SIZE (50)

255

81

89 82 SUB BRIGHT

23

V SIZE (60)

255

85 100 83 USER B / 0 (RED)

24 PIN PHASE 255

113

120

84 USER B / 0 (GREEN)

25 PIN AMP 255

64

68 85 OTHER OSD POSlTION

26 U/L PIN 255

132 136 86

VHOLD

27 16:9 U/S DEF V SIZE (50)

255

41 59

87

H BLANKING

28

V SIZE (60)

255

35

55

88 V BLANKING (50)

29 PlN PHASE 255

124

122 89

16 · 9 BLANKING START(S0)

30 PIN AMP 255

47 55 90

16 · 9 BLANKING END(S0)

31 COMPONENT SUB PHASE

255

140 140 91 V BLANKJNG (60)

32

SUB CHROMA (NORMAL)

255

104

]04

92

16: 9 BLANKING START(60)

33

SUB CHROMA (SMPTE)

255

168 168 93

16: 9 BLANKING END(60)

34 R-Y LEVEL

255

155

155

94 H DELAY

35 NTSC

BURST GATE PULSE WIDTH

255

22

22

95 V DELAY

36 CRYSTAL

255

51 51 96

HP POSITION

37 PHASE (NORMAL)

255

103 l03

97

HP WIDTH (NORMAL)

38 PHASE (ACC OFF)

255

I 12 112 98

HP WIDTH (H / V DELAY)

39 B-Y PHASE

255

141

141 99 SYSTEM SDI AUDIO

40 CHROMA (NORMAL)

255

123

123 100

358TRAP FILTER

41 CHROMA (ACC OFF)

255 20

20 IOI

ACC

42 R-Y LEVEL

255

87 87

102

CAPTION VISION

43 NTSC 443 CRYSTAL

255

65

65 103 COMPONENT LEVEL

44

PHASE (NORMAL)

255

80

80

104 NTSC SETUP LEVEL

45 PHASE (ACC OFF)

255

75 75

105 CHROMA SET UP

46 B-Y PHASE

255

140 140 106 COLOR SYSTEM D!SPLA Y

47

CHROMA (NORMAL) 255

117 117 107 COLOR TEMPERATURE

48 CHROMA (ACC OFF) 255

87 87

108 USER PRESET

49

R-Y LEVEL

255

JOO 100 109 LANGUAGE

50

PAL

PHASE (NORMAL)

255

87 87

110 RGB SYNC

51

PHASE (ACC OFF) 255

72

72 III

OPTION BOARD

52 B-Y PHASE

255

105 105 112 AGING MODE

53

CHROMA (NORMAL) 255

141 141 I 13 PAL-M

54

CHROMA (ACC OFF)

255

90 90

I 14

MODEL

55 R-Y LEVEL

255

120

120 I 15 COLOR TEMP DISP I

56

SECAM CHROMA 255

120 120 116 COLOR TEMP DISP 2

57

R-Y LEVEL

255

229 229 117 REMOTE ADDRESS

58 COLOR BALANCE (R-Y)

255

I 16

I 16 I 18

RESERVED I

59 COLOR BALANCE (B-Y)

255

98

98

I 19 RESERVED2

60

C/Tl ??OOK 3200K SW

1

0 0 120 FACTORY SET FLAG

* Among the data 8 bits (MAX255) only the upper 6 bits can be changed.

MAX

14"

1023

443

1023 512

1023

394

1023

662

1023

700

1023 536

255 120

255

125

l

0

1023 263

1023 512

1023

459

1023 572

1023 700

1023 656

255

86

255 105

255 210

255 122

255 165

255

93

255

71

255 120

255

125

255

129

255 128

255

68

255

63

255

37

255

163

255 117

255

40

255 215

255

165

255

IOI

255

130

255 90

255

35

7 5

I

0

I

0

7

0

3

2

1

0

I

0

3

0

3

0

1

0

7 0

I

0

7

0

I

0

I

0

15

**

127

65

127

93

127

0

I

0

1

0

I

0

* * 4: PVM-l354Q, PYM-1351Q, PVM-1454Q, PVM-1454QM, PVM-1954Q, PVM-2054Q, PVM-2054QM I: PVM-1450QM

7: PVM-1350, PVM-1450. - 22 -

20"

443

512

394

662

700

536

120

125

0

263

512

459

572

700

656

86

105

210

122

165

93

71

120

125

129

128

68

63

37

163

l l 7

40

215

165

101

130

90

35

5

0

0

0

2

0

0

0

0

0

0

0

0

0

0

**

65

93

0

0

0

0

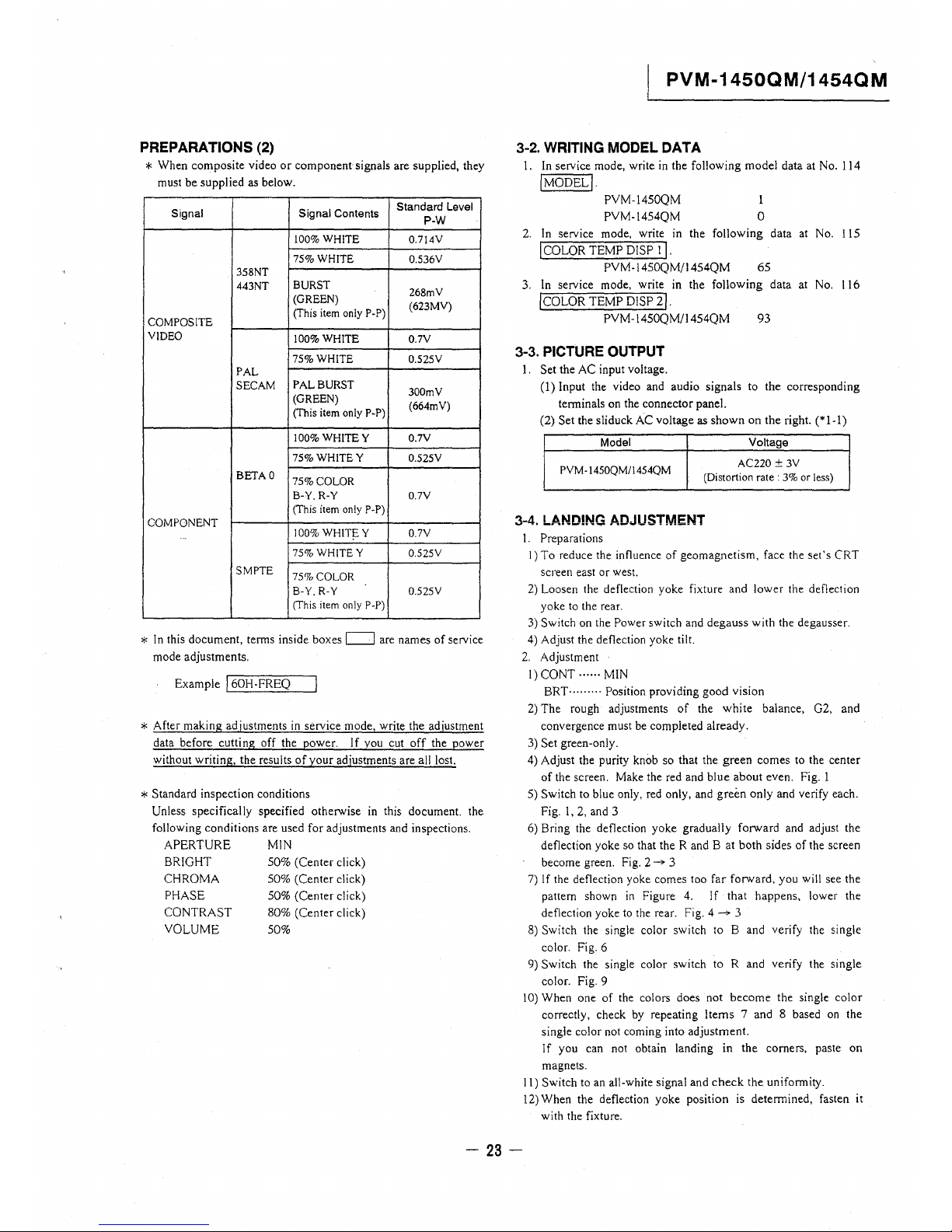

PREPARATIONS (2)

* When composite video or component signals are supplied, they

must be supplied as below.

Signal Signal Contents

Standard Level

P-W

100%WHITE 0.714V

75%WHITE

0.536V

358NT

443NT

BURST

268mV

(GREEN)

(623MV)

COMPOSITE

(This item only P-P)

VIDEO

100%WHITE

0.7V

75%WHITE

0.525V

PAL

SECAM

PAL BURST

300mV

(GREEN)

(664mV)

(This item only P-P)

100%WHITEY 0.7V

75%WHITEY

0.525V

BETAO

75%COLOR

B-Y. R-Y 0.7V

(This item only P-P)

COMPONENT

JOO% WHIT!: Y 0.7V

75% WHITEY

0.525V

SMPTE

75%COLOR

B-Y.R-Y 0.525V

(This item only P-P)

* In this document, terms inside boxes c:=J are names of service

mode adjustments.

Example I 60H-FREQ

* After making adjustments in service mode, write the adjustment

data before cutting off the power. If you cut off the power

without writing, the results of your adjustments are all lost.

* Standard inspection conditions

Unless specifically specified otherwise in this document. the

following conditions are used for adjustments and inspections.

APERTURE MIN

BRIGHT

CHROMA

PHASE

CONTRAST

VOLUME

50% (Center click)

50% (Center click)

50% (Center click)

80% (Center click)

50%

PVM-1450QM/1454QM

3-2. WRITING MODEL DATA

I. In service mode, write in the following model data at No. 114

!MODEL!.

PVM-1450QM

PVM-1454QM

l

0

2. In service mode, write in the following data at No. 115

I COLOR TEMP DISP I , .

PVM-1450QM/1454QM 65

3. In service mode, write in the following data at No. 116

!COLOR TEMP DISP 21.

PVM-1450QM/1454QM 93

3-3. PICTURE OUTPUT

l. Set the AC input voltage.

(l) Input the video and audio signals to the corresponding

terminals on the connector panel.

(2) Set the sliduck AC voltage as shown on the right. (*l-1)

Model

PVM-!450QM/1454QM

Voltage

AC220 ± 3V

(Distortion rate: 3% or less)

3-4. LANDING ADJUSTMENT

I. Preparations

I) To reduce the influence of geomagnetism, face the set's CRT

screen east or west.

2) Loosen the deflection yoke fixture and lower the deflection

yoke to the rear.

3) Switch on the Power switch and degauss with the degausser.

4) Adjust the deflection yoke tilt.

2. Adjustment

I) CONT······ MIN

BRT ......... Position providing good vision

2) The rough adjustments of the white balance, G2, and

convergence must be completed already.

3) Set green-only.

4) Adjust the purity knob so that the green comes to the center

of the screen. Make the red and blue about even. Fig. I

5) Switch to blue only, red only, and green only and verify each.

Fig. !, 2, and 3

6) Bring the deflection yoke gradually forward and adjust the

deflection yoke so that the R and B at both sides of the screen

become green. Fig. 2-" 3

7) If the deflection yoke comes too far forward, you will see the

pattern shown in Figure 4. If that happens, lower the

deflection yoke to the rear. Fig. 4 --;. 3

8) Switch the single color switch to B and verify the single

color. Fig. 6

9) Switch the single color switch to R and verify the single

color. Fig. 9

10) When one of the colors does not become the single color

correctly, check by repeating Items 7 and 8 based on the

single color not coming into adjustment.

If you can not obtain landing in the corners, paste on

magnets.

11) Switch to an all-white signal and check the uniformity.

12) When the deflection yoke position is determined, fasten it

with the fixture.

- 23 -

PVM-1450QM/1454QM

purity control

\https://manualmachine.com/

purity

deflection yoke

R G B

A'=A

A

A'

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

GHJ-D-~

Fig. 8 Fig. 9 Fig. 10

3-5. CONVERGENCE ADJUSTMENT

I. Input a dot pattern signal.

CONT ..... · Position providing good vision

BRT .... , .... MJN

2. Align the horizontal R, G, and B dots at the center of the

screen with the H-STAT VR. (*I)

*I: If the H-CENTER adjustment was after the H-STAT

adjustment, re-adjust the H-ST AT.

(The H-CENT VR changes the H-STAT too.)

3. Align the R, G, and B at the center of the screen with the

V-STAT magnets. (*2)

*2 : After the V -ST AT adjustment, paint on the knobs to

lock them.

y

Good example

V-ST AT magnet knobs

While keeping the angles for A

and B equal (!=I'), align the

vertical convergence.

y

Bad example

If the A and B knobs are not

symmetrical (I ,;cc]'), this has

bad effects. The focus may

deteriorate and beam striking

may occur.

4. For HMC, use the 6-pole magnet to adjust the R and B dots to

be symmetrical left and right about the G dot. (*I)

*I :

6-pofe magnet

The HMC adjustment

changes the opening of the

6-pole magnet.

- 24 -

R

G

B

Adjust the 6-pole magnet so

that A=A'. You must maintain

the relationship I* [' while

moving the magnet.

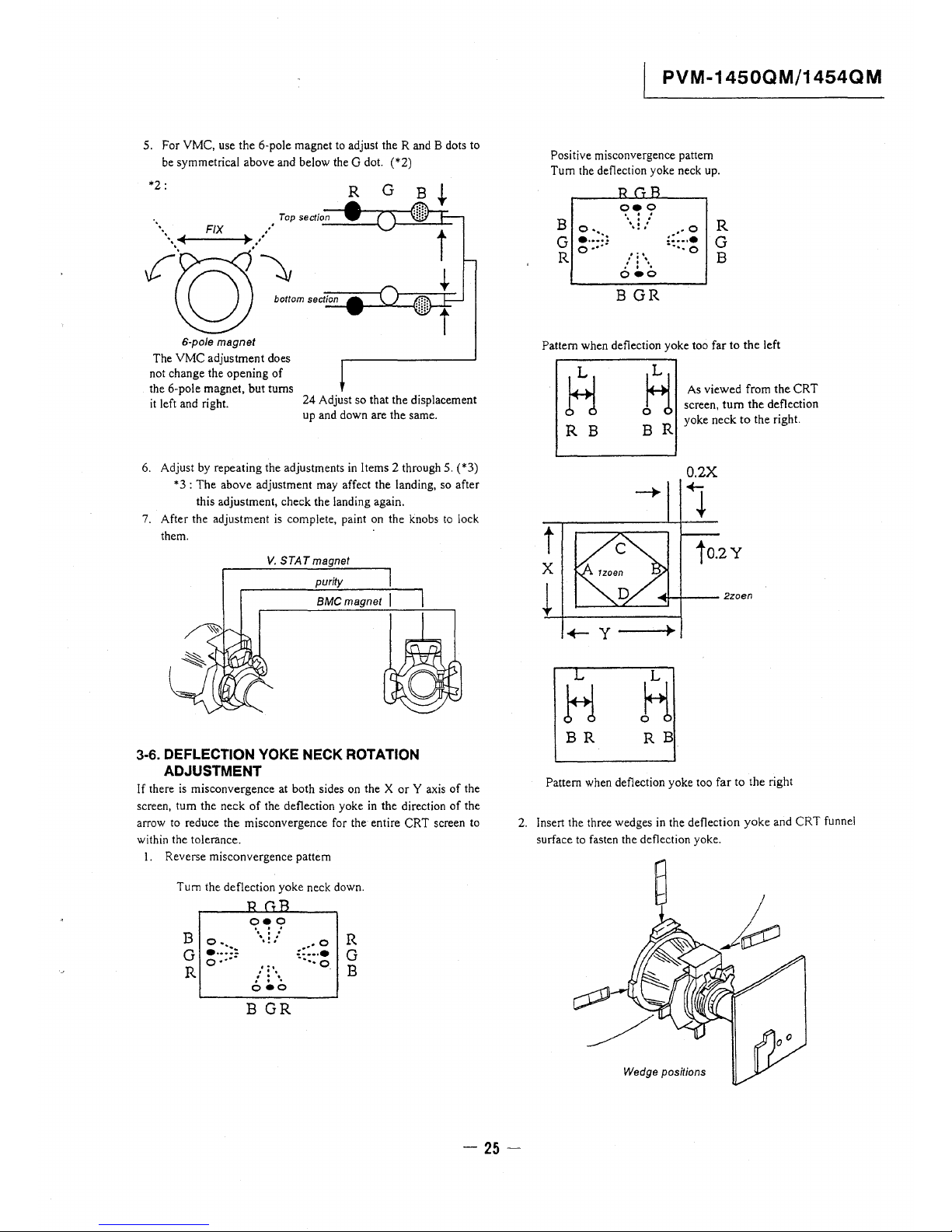

5. For VMC, use the 6-pole magnet to adjust the Rand B dots to

be symmetrical above and below the G dot. (*2)

*2:

R

G

B

Top section

•••• FIX ,• -----1.

;tos··~,m ,oci-ion --,

6-pole magnet

The VMC adjustment does

not change the opening of

the 6-pole magnet, but turns

it left and right.

24 Adjust so that the displacement

up and down are the same.

6. Adjust by repeating the adjustments in Items 2 through 5. (*3)

*3: The above adjustment may affect the landing, so after

this adjustment, check the landing again.

7. After the adjustment is complete, paint on the knobs to lock

them.

V. STAT magnet

purity

BMC magnet

3-6. DEFLECTION YOKE NECK ROTATION

ADJUSTMENT

If there is misconvergence at both sides on the X or Y axis of the

screen, tum the neck of the deflection yoke in the direction of the

arrow to reduce the misconvergence for the entire CRT screen to

within the tolerance.

I. Reverse misconvergence pattern

Turn the deflection yoke neck down.

B o ..

G

•... :::.

o ····

R

'?~9

...

...

...

...

...

. . .

o•o

B GR

R

G

B

PVM-1450QM/1454QM

Positive misconvergence pattern

Turn the defiection yoke neck up.

B o ..

G ~·:;::

R

oeo

...

...

...

...

...

. . .

. . .

. . .

oeo

B GR

R

G

B

Pattern when deflection yoke too far to the left

R

H

As viewed from the CRT

screen, tum the defiection

R B

BR

yoke neck to the right.

t

X

L

2zoen

..,_y

~

L

L

H

H

BR RB

Pattern when defiection yoke too far to the right

2. Insert the three wedges in the deflection yoke and CRT funnel

surface to fasten the deflection yoke.

Wedge positions

- 25 -

PVM-1450QM/1454QM

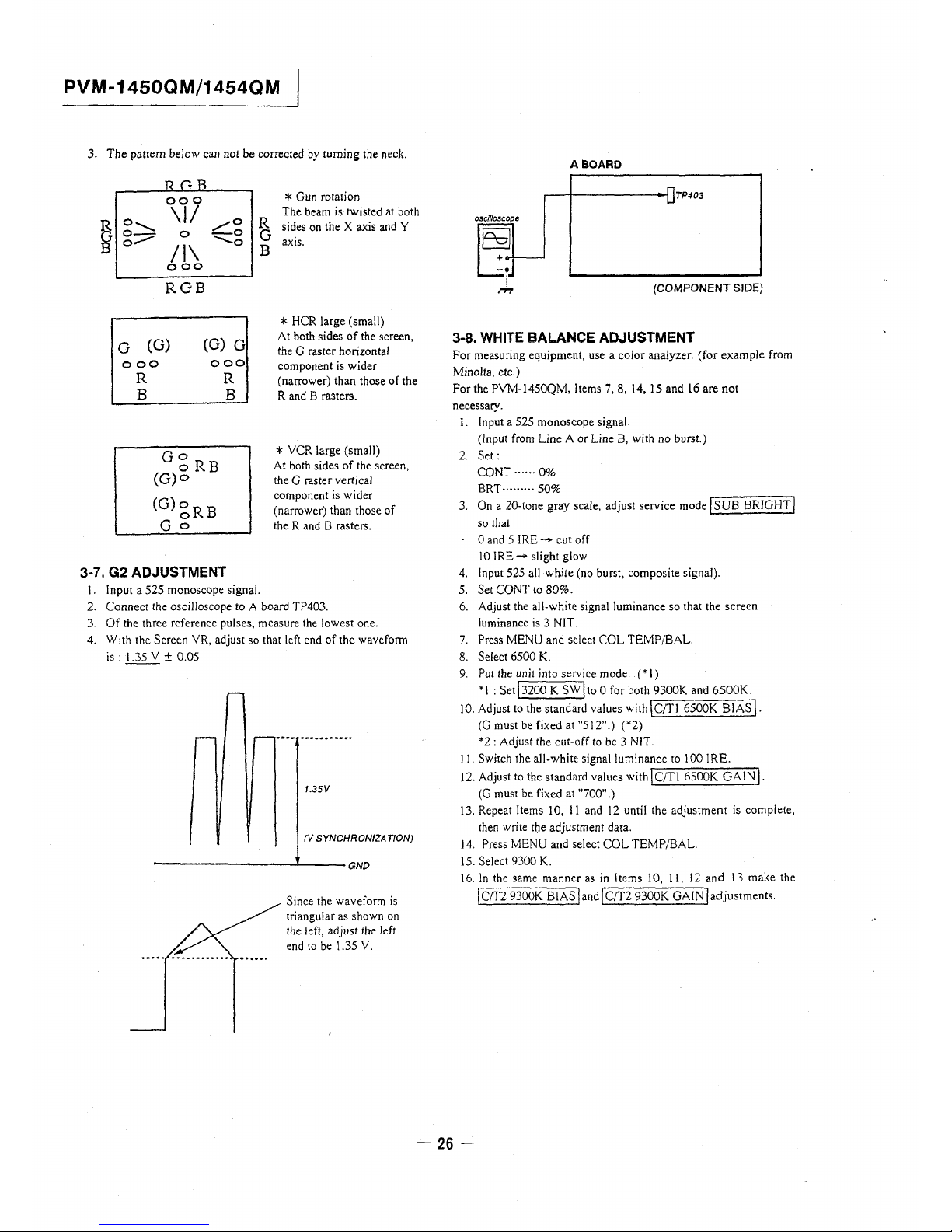

3. The pattern below can not be corrected by turning the neck.

~

000

\II

o........._

/0

g..-

0

-0

/I\

....._o

coo

RGB

G (G)

(G) G

000

000

R

B

og RB

(G)o

(G)gRB

Go

R

B

3-7. G2 ADJUSTMENT

R

G

B

1. Input a 525 monoscope signal.

* Gun rotation

The beam is twisted at both

sides on the X axis and Y

axis.

* HCR large (small)

At both sides of the screen,

the G raster horizontal

component is wider

(narrower) than those of the

R and B rasters.

* VCR large (small)

At both sides of the screen,

the G raster vertical

component is wider

( narrower) than those of

the R and B rasters.

2. Connect the oscilloscope to A board TP403.

3. Of the three reference pulses, measure the lowest one.

4. With the Screen VR, adjust so that left end of the waveform

is : 1.35 Y ± 0.05

1.35V

(V SYNCHRONIZA T/ON)

----------'----GND

Since the wavefom1 is

triangular as shown on

the left, adjust the left

end to be 1.35 Y.

ABOARD

TP403

(COMPONENT SIDE)

3-8. WHITE BALANCE ADJUSTMENT

For measuring equipment, use a color analyzer. (for example from

Minolta, etc.)

For the PVM-1450QM, !terns 7, 8, 14, 15 and 16 are not

necessary.

l. Input a 525 monoscope signal.

(Input from Line A or Line B, with no burst.)

2. Set:

CONT .. ···· 0%

BRT ......... 50%

3. On a 20-tone gray scale, adjust service modelSUB BRIGHT/

so that

0 and 5 IRE___,. cut off

10 IRE__,. slight glow

4. Input 525 all-wh.ite (no burst, composite signal).

5. Set CONT to 80%.

6. Adjust the all-white signal luminance so that the screen

luminance is 3 NIT.

7. Press MENU and select COL TEMP/BAL.

8. Select 6500 K.

9. Put the unit into service mode. (*I)

* l : Set j 3200 K SW I to 0 for both 9300K and 6500K.

IO. Adjust to the standard values with \CIT! 6500K BIAS\.

(G must be fixed at "512".) ( *2)

*2 : Adjust the cut-off to be 3 NIT.

11. Switch the all-white signal luminance to I 00 I RE.

12. Adjust to the standard values with \CIT! 6500K GAIN\.

(G must be fixed at "700" .)

13. Repeat Items 10, 11 and 12 until the adjustment is complete,

then write t]:le adjustment data.

14. Press MENU and select COL TEMP/BAL.

15. Select 9300 K.

16. In the same manner as in Items 10, 11, 12 and 13 make the

/C!T2 9300K BIAS /and /C!T2 9300K GAIN /adjustments.

- 26 -

3-9. BLUE-ONLY WHITE-BALANCE ADJUSTMENT

For the PVM-l 450QM, Items 3, 4, 5, 6, 7 and 8 are not necessary.

I. Switch the user control SW Blue Only On (to set blue-only

mode).

2. Input an all-white signal (no burst composite signal). (*!)

The luminance of the all-white signal must be 100 IRE.

CONT ...... 80%

BRT··· ...... 50%

3. Select COL TEMP/BAL.

4. Select 6500 K.

5. Adjust to the standard values with jcrn 6500K B/O (RED)j

and IC/Tl 6500K 8/0 (GREEN) J.

6. Select COL TEMP/BAL.

7. Select 9300 K.

8. Adjust to the standard values with IC/TI 9300K 8/0 (RED) J

andjC!Tl 9300K B/O (GREEN)j.

9. Check that the white balance is obtained when the all-white

signal luminance is adjusted and the screen luminance is 8

NIT.

~10SUBBRTADJUSTMENT

I. Input a 525 monoscope signal.

2. CONT ...... MIN

Bfn ......... CENTER (SO%)

3. Put the unit into service mode and select I SUB BRIGHT I.

4. AdjustjSUt3 BRIGHT/so that 10 IRE gives a slight glow and

IO I RE gives cut off.

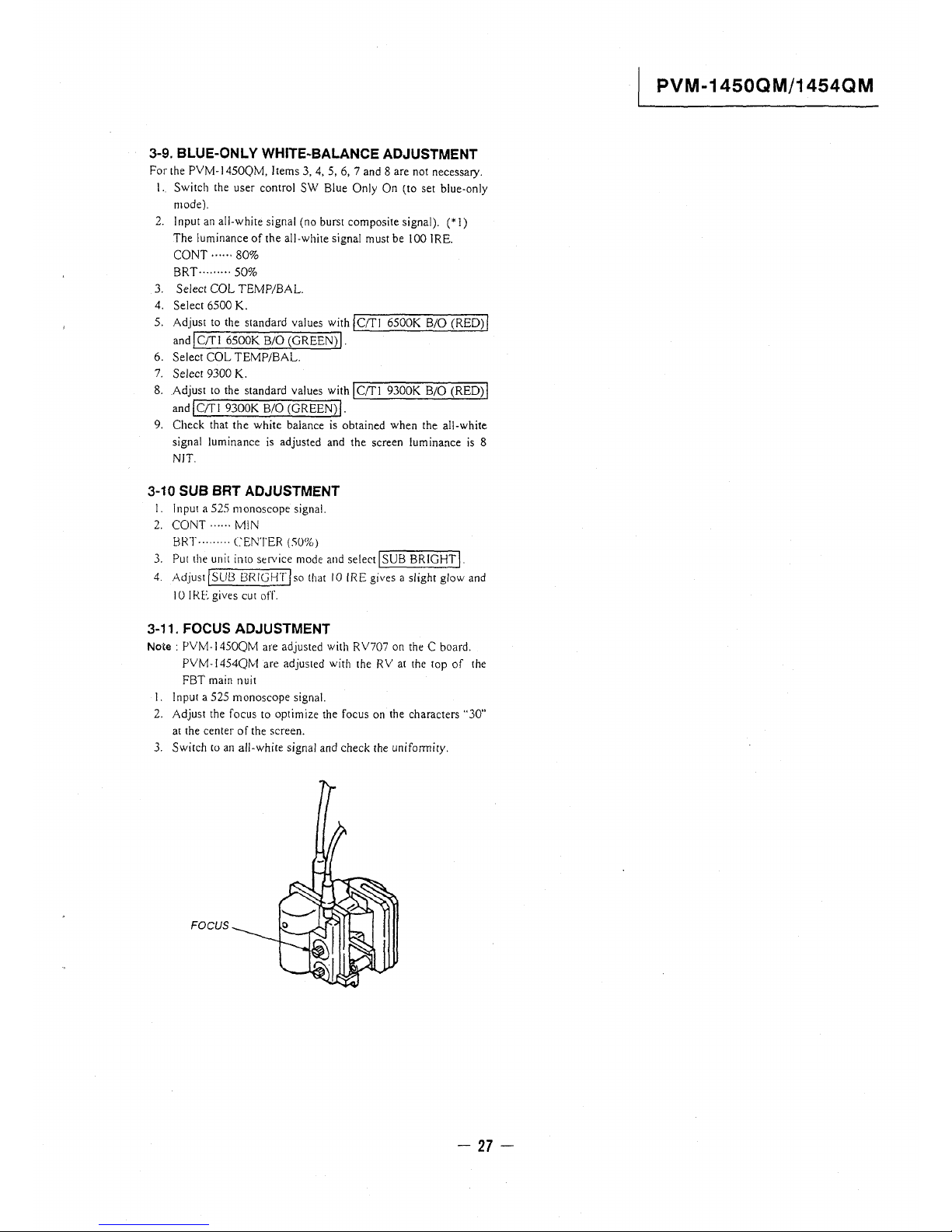

3-11. FOCUS ADJUSTMENT

Note: PVM-14SOQM are adjusted with RV707 on the C board.

PVM- I 454QM are adjusted with the RV at the top of the

FBT main nuit

I. Input a 525 monoscope signal.

2. Adjust the focus to optimize the focus on the characters "30"

at the center of the screen.

3. Switch to an all-white signal and check the uniformity.

FOCUS

- 27 -

PVM-1450QM/1454QM

=>VM-1450QM/1454QM

MEMO

- 28-

PVM-1450QM/1454QM

SECTION 4

SAFETY RELATED ADJUSTMENT

The following adjustments should always be performed when

replacing the following components (marked with B, [;ii on the

schematic diagram).

+B detection ........................... B R1535

Tertiary coil detection ............... B Rl536

Part replosed( [;ii)

Hold Down Circuit.. ....... [;ii A board ICSOO, D533, R1537, C592,

Rl536, C523, Rl560, R551,

C549, R518, C506, C512,

D501, R506, R519, TSO!,

IC507

Beam Current Protector

Circuit ........................ [;ii A board R508, R515, R516, RS! 7,

C513, QSOO, QSll

B+ Regulator Circuit...... [;ii A board Rl535

[;ii G board C603,IC602

I B+ MAX VOLTAGE CONFIRMATION (RV601) I

Standard: 115.0-117.0 VDC

Check Condition: Input voltage: 130-132 VAC

Note : Use NF Power Supply or make sure that

distortion factor is 3% or less.

Input signal : ALL White

Controls : BRT & CONT ~ Minimum

I HOLD-DOWN CIRCUIT VOLTAGE CONFIRMATION I

Check Condition : Input voltage : 130-132 V AC

Input signal : monoscope signal

Controls : BRT & PIC ~ initial reset

B+ voltage : Less than 117.0 V

R690

(1) Hold down circuit (+B Actuation)

a) When IABL = 600 ± 50 µ A, raster goes out at less

than 130.5 V of +B voltage (TP502) by adjusting

1::-, R690 and RV601.

Input signal : ALL white

1::-, R690 : 470-5.6k 1/4 W RN

b) When IABL = 120 ± 20 µ A, raster goes out at less than

134Vof +B voltage(TP502)by adjusting 1::-, R690 and RV601.

Input signal : Dot

(2) Hold down circuit (Tertiary coil detectiol\ voltage)

Confirmatory item : 110.0 V voltage should be applied to

the (11) pin of ICS00.

a) When IABL = 600 ± 50 µ A, raster goes out when

applying less than DC 146.7 V voltage to the (11)

pin (TP503) of ICSOO from outside.

Input signal : ALL white

b) When IABL = 40 ± 20 µ A, raster goes out when

applying less than DC 147.0 V voltage to the (11)

pin (TP503) of ICS00 from outside.

Input signal : Dot

..d!lll!ll!ll! ....

(CONDUCTOR SIDE)

- 29-

PVM-1450QM/1454QM

(COMPONENT SIDE)

'

ABOARD

~03

digital multimeter

'------'-EJ

i

I

(COND~CTOR SIDE)

I

~

30-

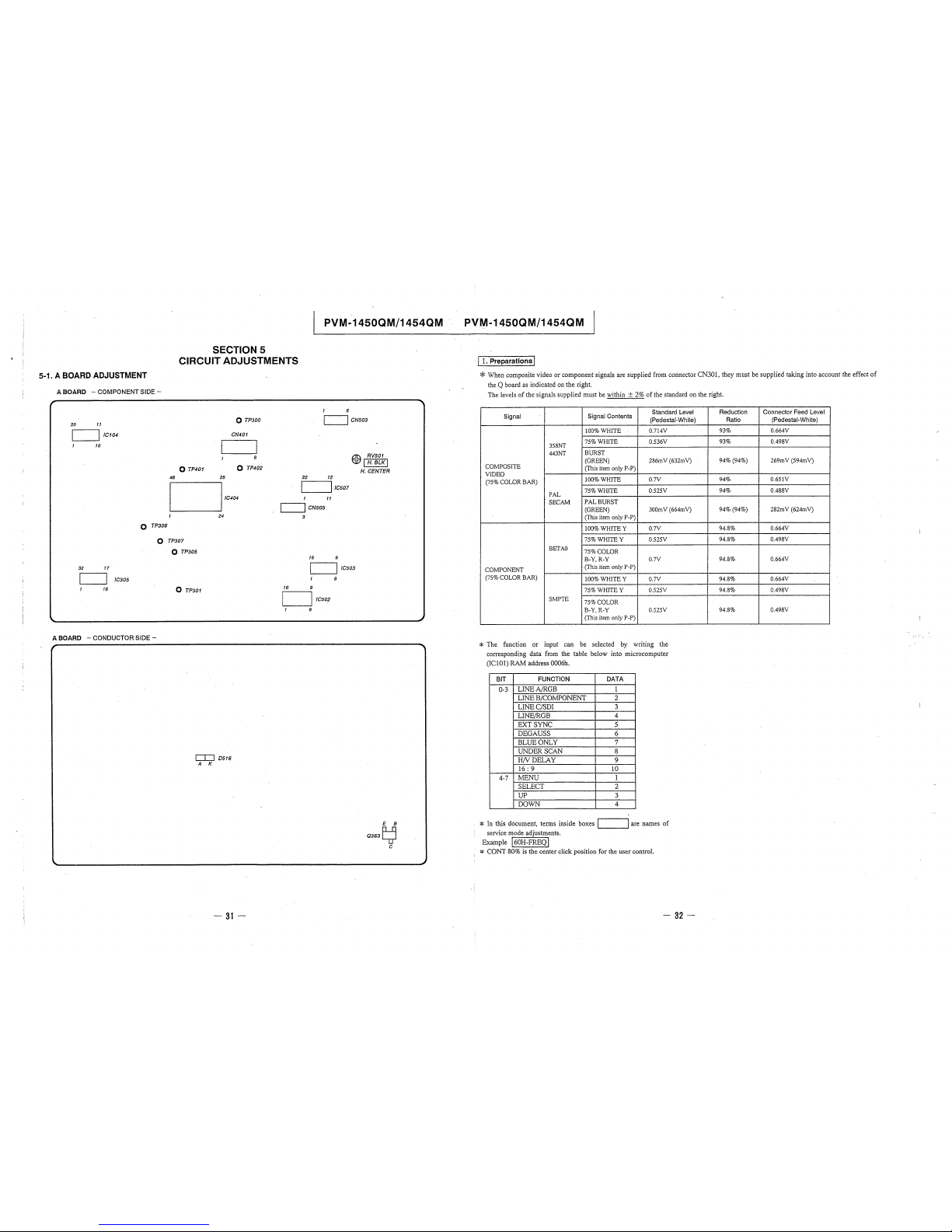

5-1. A BOARD ADJUSTMENT

A BOARD - COMPONENT SIDE -

20 11

.__ _ __.I /Cl 04

10

0 TP306

48

SECTION 5

CIRCUIT ADJUSTMENTS

0 TP401

25

0 TP300

CN401

8

0 TP402

PVM-1450QM/1454QM

1 6

C:=JcN503

22 12

'-----'' /C507

11

~

RV501

'1l7 I H. BLK I

H. CENTER

24

'----'' CN505

3

0 TP307

32 17

/C305

16

A BOARD - CONDUCTOR SIDE -

,

0 TP305

0 TP301

C[J D516

A K

-31-

16

16

9

LJ,cso?

1 8

9

I /C503

8

E B

Q363~

C

PVM-1450QM/1454QM

· I I. Preparations I

* When composite video or component signals are supplied from connector CN301, they must be supplied taking into account the effect of

the Q board as indicated on the right.

The levels of the signals supplied must be within + 2% of the standard on the right.

Signal

Signal Contents

Standard Level

(Pedestal-White)

100%WHITE

0.714V

358NT

75%WHITE

0.536V

443NT

BURST

COMPOSITE

(GREEN)

286mV (632mV)

(This item only P-P)

VIDEO

(75% COWR BAR)

!00%WHITE

0.7V

PAL

75%WHITE 0.525V

SECAM

PAL BURST

(GREEN)

300mV (664mV)

(This item only P-P)

100%WHITEY

0.7V

75%WHITEY

0.525V

BETA0

75%COLOR

B-Y,R-Y

0.7V

COMPONENT

(This item only P-P)

(75% COLOR BAR)

100%WHITEY

0.7V

75%WHITEY 0.525V

SMPTE

75%COLOR

B-Y,R-Y

0.525V

(This item only P-P)

* The function or input can be selected by writing the

corresponding data from the table below into microcomputer

(ICl0l) RAM address 0006h.

BIT

FUNCTION DATA

0-3

LINEA/RGB

1

LINE B/COMPONENT 2

LINEC/SDI 3

LINE/RGB 4

EXT SYNC 5

DEGAUSS 6

BLUEONLY

7

UNDER SCAN 8

HNDELAY 9

16: 9 10

4-7

MENU 1

SELECT 2

UP 3

DOWN 4

* In this document, terms inside boxes ._I __ __.I are names of

service mode adjustments.

Example j60H-FREQI

* CONT 80% is the center click position for the user control.

- 32-

Reduction

Ratio

93%

93%

94% (94%)

94%

94%

94% (94%)

94.8%

94.8%

94.8%

94.8%

94.8%

94.8%

Connector Feed Level

(Pedestal-White)

0.664V

0.498V

269mV (594mV)

0.651V

0.488V

282mV (624mV)

0.664V

0.498V

0.664V

0.664V

0.498V

0.498V

Loading...

Loading...