Sony Trinitron PVM-1353, Trinitron PVM-1453MD Service Manual

PVM· 1353MD/1453MD

SERVICE MANUAL

CJ

/

/

__ ,

US Model

Canadian Model

PVM-1353MD

Chassis No. SCC-H31 B-A

AEPModel

PVM-1453MO

Chassis No. SCC-H29C-A

SPECIFICATIONS (PVM-1353MD)

Video signal

Color system

Resolution

Aperture correction

Frequency response

Synchronization

NTSC. PAL

600 TV lines

0 dB-+6.0 dB

LINE 9.0 MHz (-3 dB)

RGB 10.0 MHz (-3 dB)

AFC time constant 1.0 msec.

Picture performance

Overscan

Normal scan

Underscan

Linearity

Convergence

20% overscan of CRT effective

screen area

7% overscan of CRT effective screen

area

5% underscan of CRT effective

screen area

Horizontal: Less than 4% (typical)

Vertical: Less than 4% (typical)

Central area

0.6 mm (typical)

Peripheral area

0.8 mm (typical)

Raster size stability

H 1.0%, V 1.5%

High voltage regulation

CRT

Color temperature

Inputs

Y/CIN

VIDEO IN

3.5'k

SMPTE-C phosphor

6500K/5600K/USER (3200K

-

10000K, factory setting is 6500K)

4-pin mini DIN connector

See the pin assignmem on the

page 2.

BNC connector I Vp-p ±6 dB, sync

negative

AUDIO IN phono jack, -5 dBu, more than 47k

ohms

R/R-Y IN, G/Y IN, B/B-Y IN

R, G, B channels

Sync on green

BNC connector

0.7 Vp-p ±6 dB

1.0 Vp-p Sync negative, 75 ohms

terminated

- Continued on next page:-

TRINITRON® COLOR VIDEO MONITOR

MICROFILM

SONY:

PVM-1353MD/1453MD

R-Y, B-Y channels

Y channel

EXT SYNC IN

Outputs

Y/C OUT

0.7 Vp-p ±6 dB

1.0 Vp-p±6dB

(Standard color bar signal of 75%

chrominance)

BNC connector composite sync

4 Vp-p ±6 dB, negative

4-pin mini DIN connector. 75 ohms

terminated

VIDEO OUT BNC

connector. 75 ohms terminated

AUDIO OUT phono jack

R/R-Y OUT. G/Y OUT.

BIB-Y OUT

EXT SYNC OUT

DC OUT

Speaker output

Remote input

REMOTE

I

RS-232C

General

BNC connector, 75 ohms terminated

BNC connector, 75 ohms terminated

5 V/1 A

Output level 0.8 W

8-pin mini DIN

See

the pin assig11111c111 011 1hc

page 2.

9-pin D-sub

See the pin

assignment 011 the

page 2.

Power requirements 120 V AC. 50/60 Hz

1.3A

Capable of JOO to 240V operation

Operating temperature range

0-35°C

Storage temperature range

-I0-+40°C

Humidity

O - 90%

Dimensions Approx. 346 x 340 x 411.5 mm

(w/h/d)

Mass

(13

5

/8 x 131/2 x 161/4 inches)

not incl. projecting

pans and controls

Approx. 16.7 kg (36 lb 14 oz)

Accessory supplied AC power cord

(I)

0 dBu = 0.775 Vr.111.s.

AC plug holder (I)

Splash proof covers (2)

Control panel cover (I)

Panel hinges (2)

Remote Control Connector

8-pin mini DIN (I)

Operating Instructions ( I)

Interface Manual for Programmers (I)

Quick Reference Card (I)

Double-sided adhesive tapes (4)

Design and specifications are subject to change without

notice.

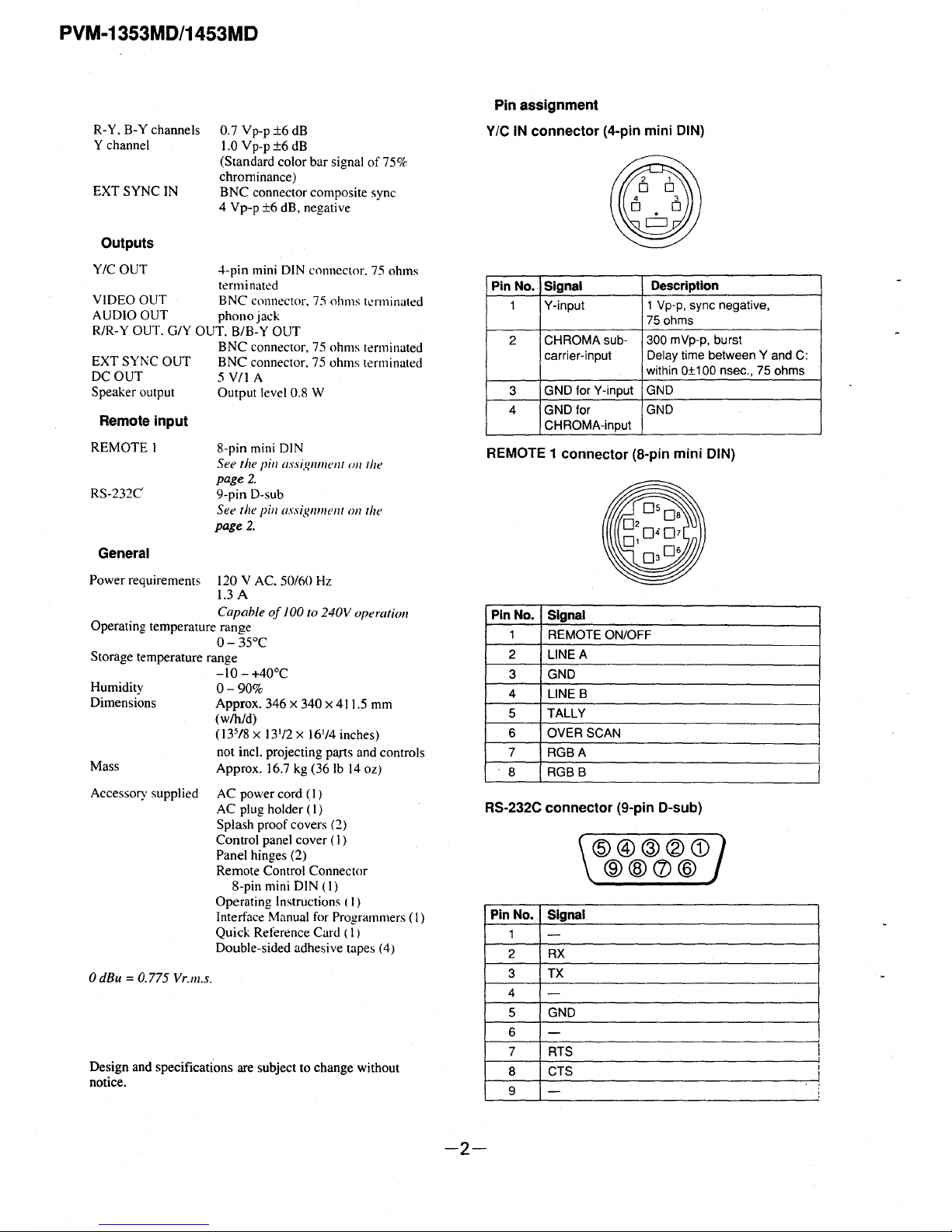

Pin assignment

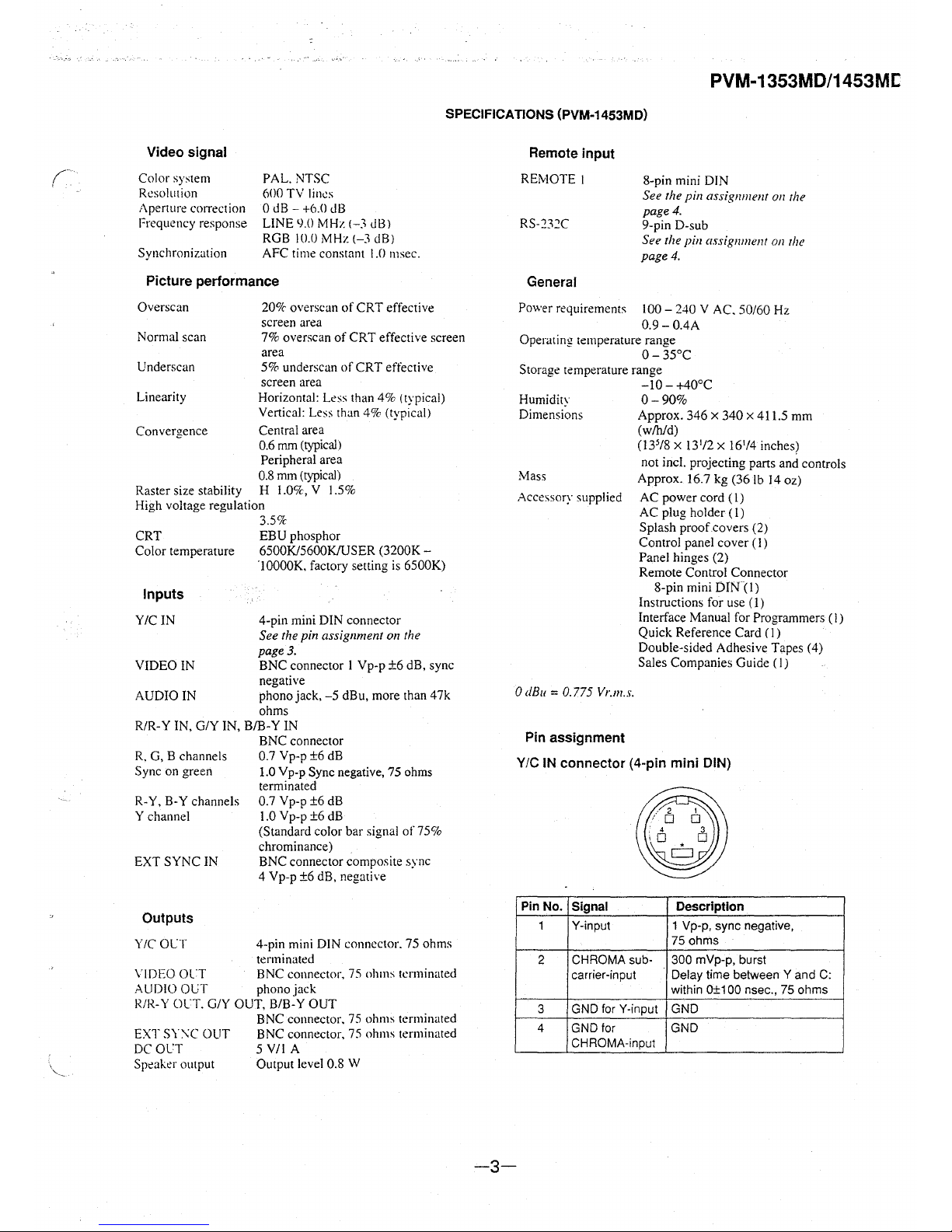

V/C IN connector (4-pin mini DIN)

Pin No. Signal

Description

1 Y-input

1 Vp-p, sync negative,

75 ohms

2

CHROMA sub-

300 mVp-p, burst

carrier-input

Delay time between Y and C:

within 0±100 nsec., 75 ohms

3

GND for Y-input GND

4 GND for

GND

CHROMA-input

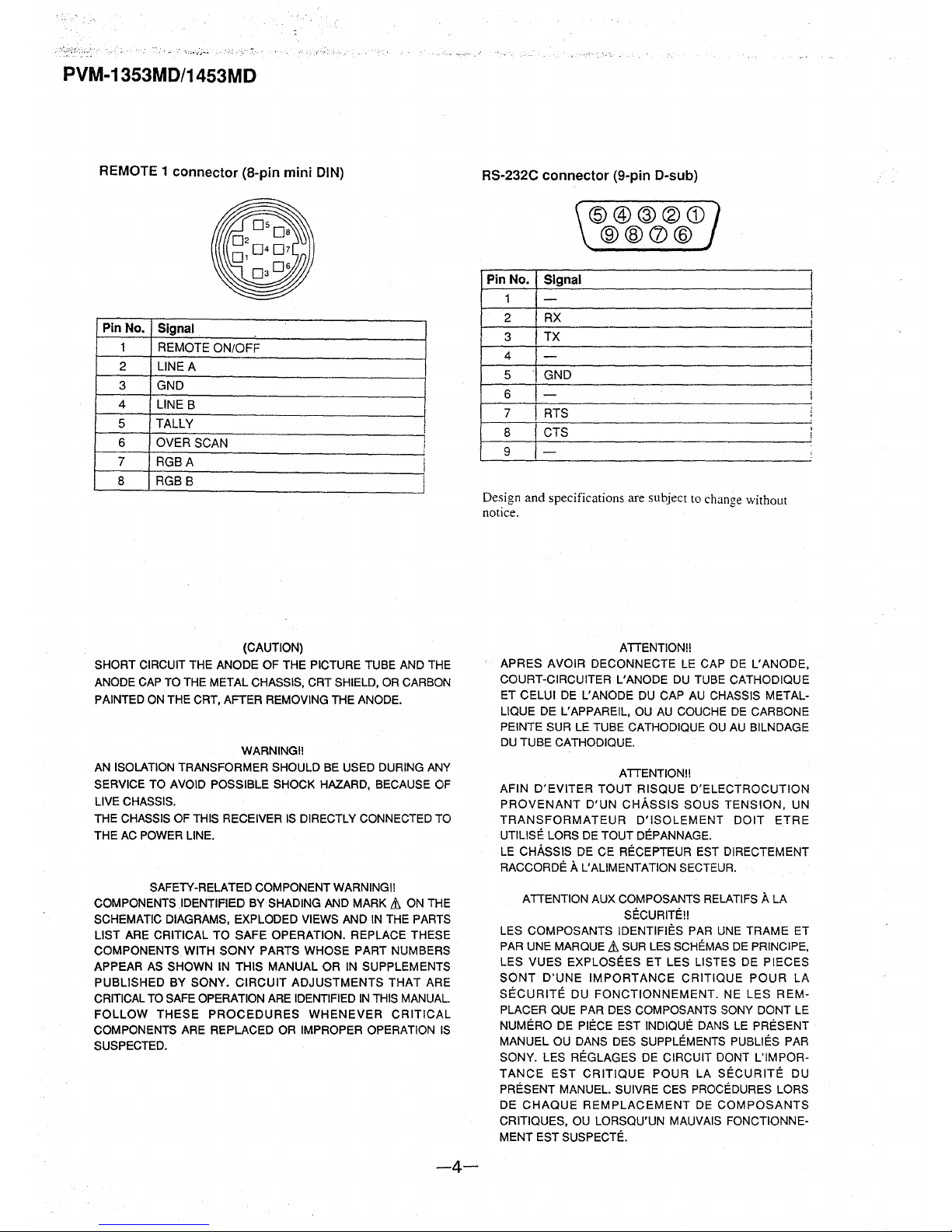

REMOTE 1 connector (8-pin mini DIN)

Pin No. Signal

1 REMOTE ON/OFF

2

LINEA

3 GND

4

LINE B

5 TALLY

6

OVER SCAN

7 RGBA

8 RGBB

RS-232C connector (9-pin D-sub)

Pin No.

1

2

3

4

5

6

7

8

9

-2-

Signal

-

RX

TX

-

GND

-

RTS

CTS

-

@@@®G)

®@CD@

PVM· 1353MD/1453MD

SONY.'.'..

SERVICE MANUAL

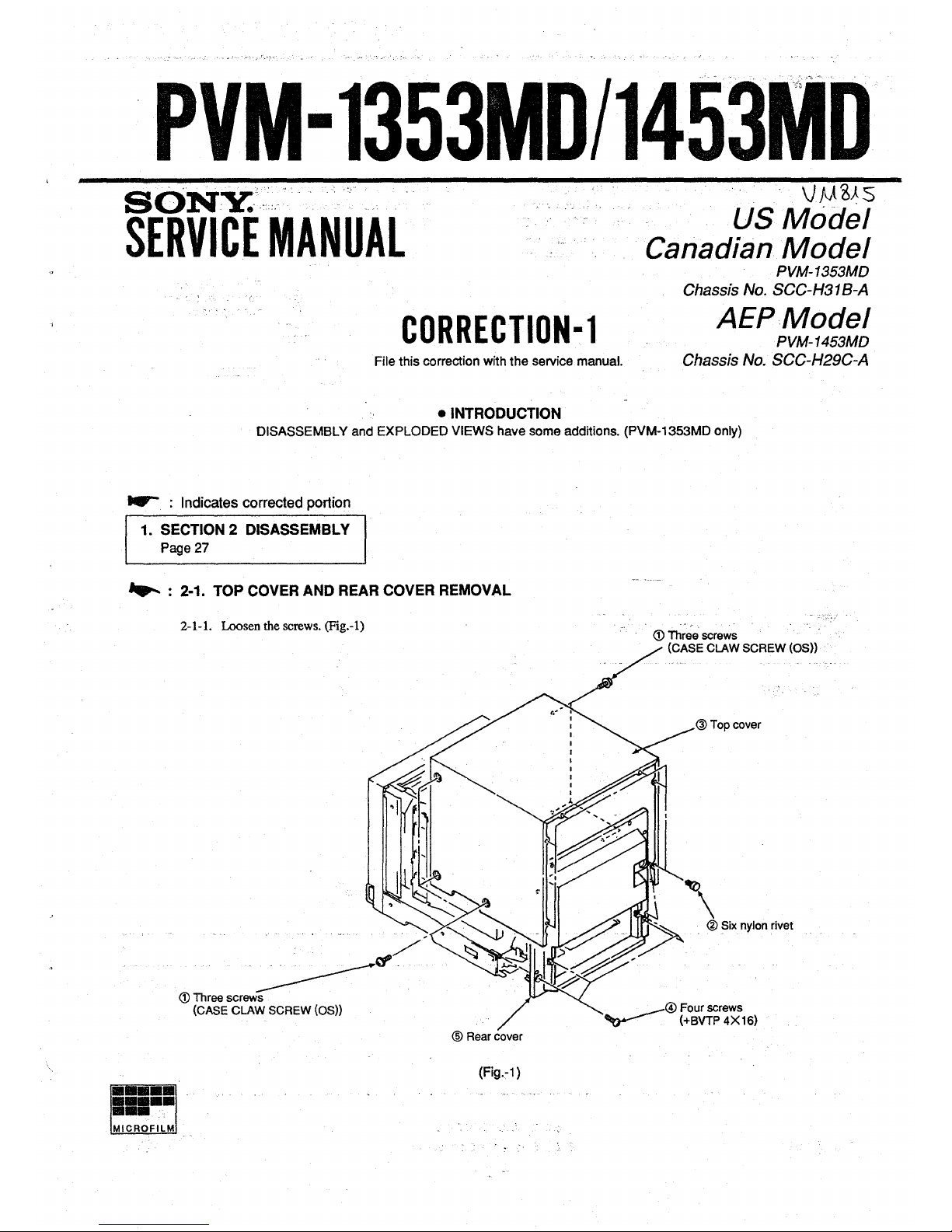

CORRECTION· 1

File this correction with the service manual.

• INTRODUCTION

VM '8ts

US Model

Canadian Model

PVM-1353MD

Chassis No. SCC-H31B-A

AEPModel

PVM-1453MD

Chassis No. SCC-H29C-A

DISASSEMBLY and EXPLODED VIEWS have some additions. (PVM-1353MD only)

-- : Indicates corrected portion

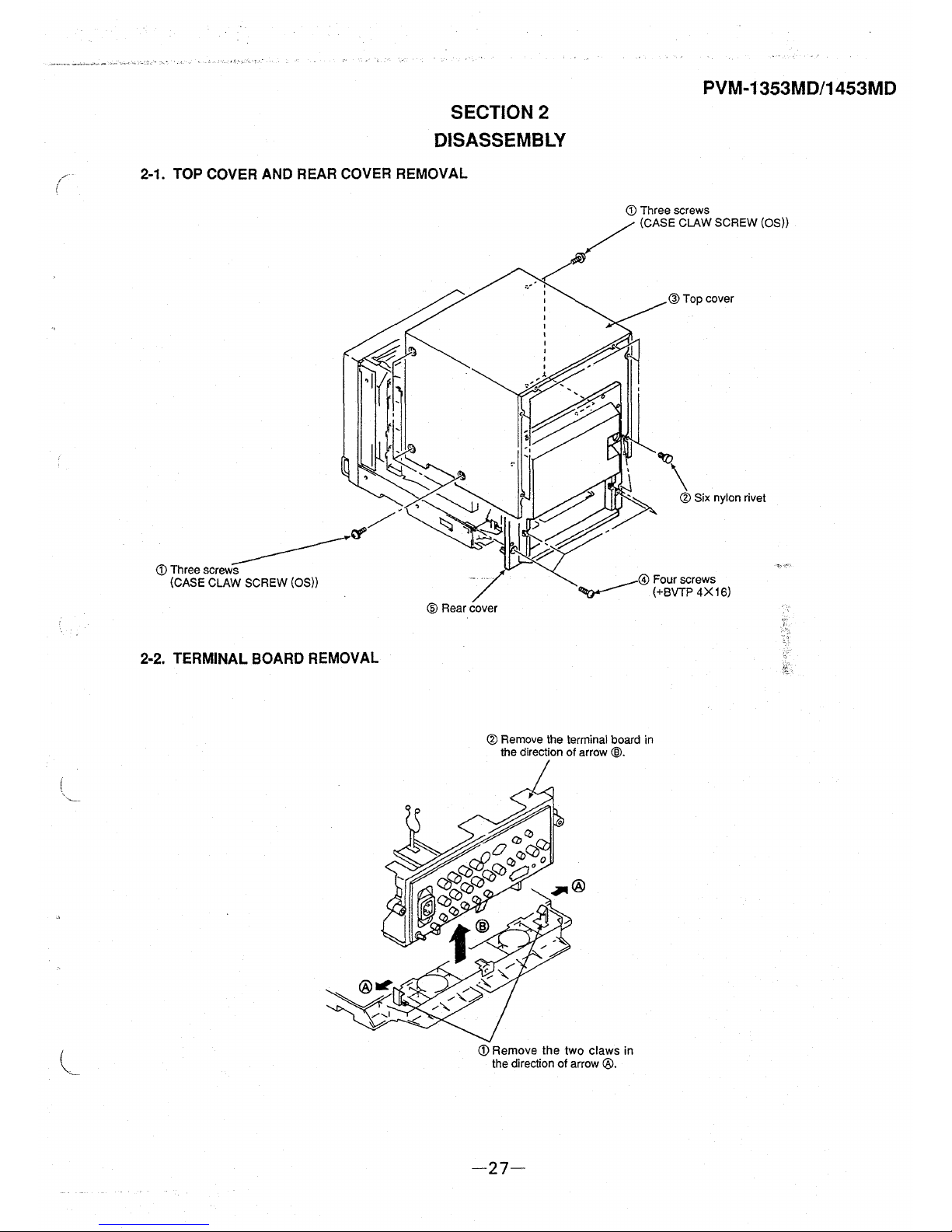

1. SECTION 2 DISASSEMBLY

Page 27

...... : 2-1. TOP COVER AND REAR COVER REMOVAL

2-1-1. Loosen the screws. (Fig.-1)

® Rear cover

(Fig.~1)

., , ..

<D Three screws

(CASE CLAW SCREW (OS))

@Top cover

2-1~2 .. Pult'o~1>:rop COVER toba~kward0slightly. (Fig.'~2) .·.

Caution: At this time, must not pull out to backward so

· , considerably because the lead wire of TOP COVER

breaks. Only the lead wire exchanging is not able when

the lead wire has broken but COVER COMPLETE

ASSY, TOP exchanging is able.

~II out slightly.

(Fig.-2)

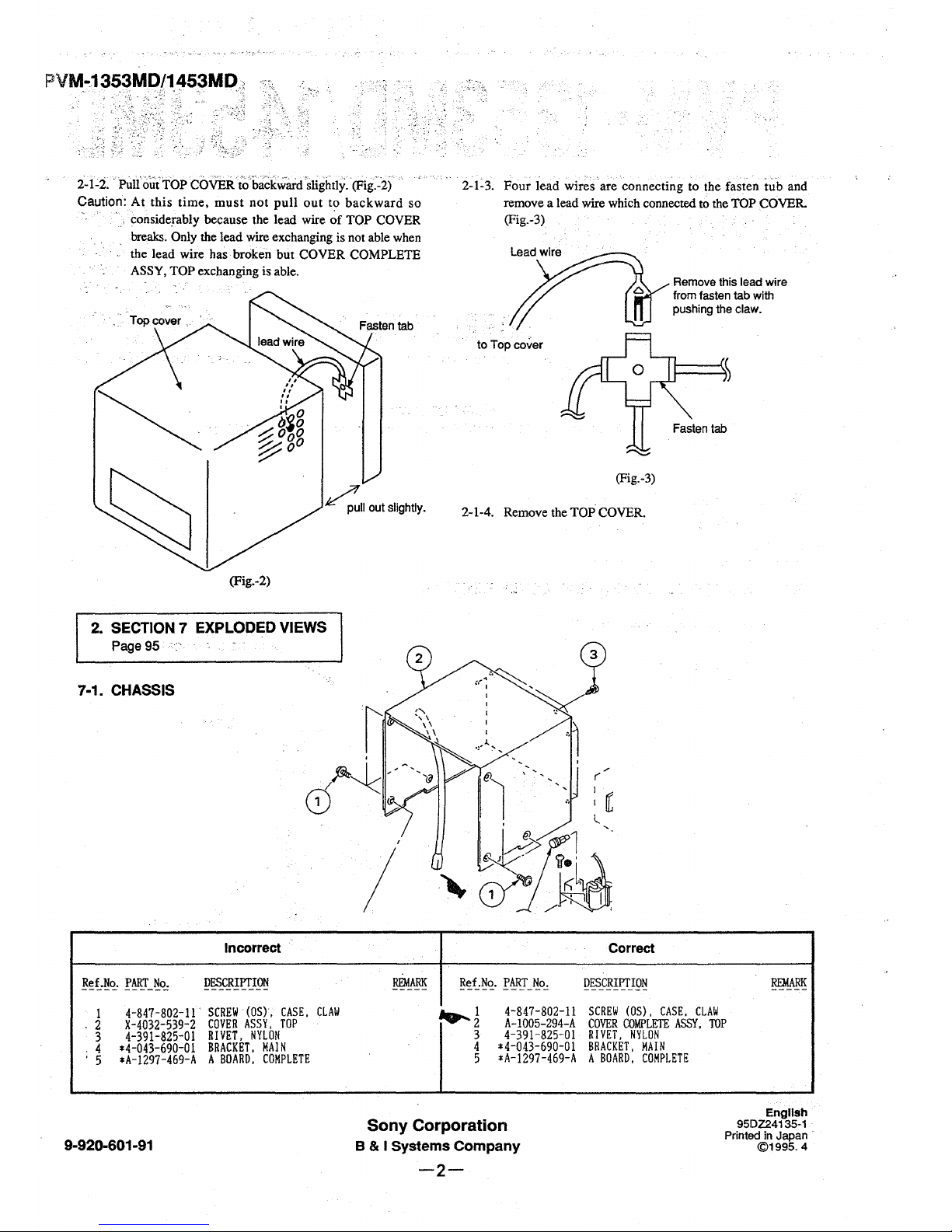

2. SECTION 7 EXPLODED VIEWS

Page 95

7-1. CHASSIS

I

Incorrect

Ref.No. PART No.

DESCRIPTION

REMARK

1

4-847-802-11. SCREW (OS), CASE.

CLAW

. 2

X-4032-539-2 COVER ASSY, TOP

3

4-391-825-01

RIVET, NYLON

4

*4-043-690-01

BRACKET,

MAIN

' 5

*A-1297-469-A

A BOARD, COMPLETE

2-1~3. Four lead wir~s are connecting to the fasten tub and

remove a lead wire which connected to the TOP COVER.

(Fig.-3)

to Top cover

(Fig.-3)

Remove this lead wire

from fasten tab with

pushing the claw.

Fasten tab

2-1-4. Remove the TOP COVER.

Correct

Ref.No. PART No.

DESCRIPTION

~

~J

4-847-802-11

SCREW (OS), CASE, CLAW

A-1005-294-A COVER COMPLETE ASSY,

TOP

3

4-391-825-01

RIVET, NYLON

4 *4-043-690-01

BRACKET, HAIN

5

*A-1297-469-A

A BOARD, COMPLETE

Sony Corporation

English

95DZ24135-1

Printed in Japan

©1995.4

9-920-601-91

B & I Systems Company

-2-

PVM-1353MD/1453MC

SPECIFICATIONS (PVM-1453MD)

Video signal

Color system

Resolution

Aperture correction

Frequency response

Synchronization

PAL. NTSC

600 TV lines

0 dB

- +6.0 dB

LINE

9.0 MHz (-3 dB)

RGB

IO.O MHz (-3 dB)

AFC time constant

1.0 111sec.

Picture performance

Overscan

Normal scan

Underscan

Linearity

20% overscan of CRT effective

screen area

7% overscan of CRT effective screen

area

5% underscan of CRT effective

screen area

Horizontal:

Less than 4% (typical)

Vertical: Less than 4% (typical)

Convergence Central area

0.6

mm (typical)

Peripheral area

0.8 mm (typical)

Raster size stability

H I .O<x, V I .5%

High voltage regulation

3.5%

CRT EBU phosphor

Color temperature 6500K/5600K/USER (3200K

-

·10000K, factory setting is 6500K)

Inputs

Y/CIN

VIDEO IN

AUDIO IN

4-pin mini DIN connector

See the pin assignment on the

page 3.

BNC connector I Vp-p ±6 dB, sync

negative

phono jack, -5 dBu, more than 47k

ohms

R/R-Y IN, G/Y IN, B/B-Y IN

R. G, B channels

Sync on green

BNC connector

0.7 Vp-p ±6 dB

1.0 Yp-p Sync negative, 75 ohms

terminated

R-Y, B-Y channels 0.7 Vp-p ±6 dB

Y channel 1.0 V p-p ±6 dB

EXT SYNC IN

Outputs

Y/C OLT

(Standard color bar signal of 75%

chrominance)

BNC connector composite sync

4 Vp-p ±6 dB, negative

4-pin mini DIN connector. 75 ohms

terminated

VIDEO OL'.T BNC connector, 75 ohms terminated

AUDIO Ol;T phonojack

R/R-Y m·T. G/Y OUT. BIB-Y OUT

EXT

SY:\C OUT

DC OCT

Speaker output

BNC connector. 75 ohms terminated

BNC connector, 75 ohms terminated

5 V/1 A

Output level 0.8 W

Remote input

REMOTE I

RS-232C

General

8-pin mini DIN

See the pin assignment on the

page 4.

9-pin D-sub

See the pin assignment on the

page 4.

Power requirements 100 - 240 V AC. 50/60 Hz

0.9-0.4A

Operating temperature range

0-35°C

Storage temperature range

-I0-+40°C

Humidity

O - 90%

Dimensions Approx. 346 x 340 x 4 I 1.5 mm

(w/h/d)

(13

5

/8 x 131/2 x 161/4 inches)

not incl. projecting parts and controls

Mass Approx. 16.7 kg (36 lb 14 oz)

Accessory supplied AC power cord

(I)

AC plug holder (I)

Splash proof.covers (2)

Control panel cover

(I)

Panel hinges (2)

Remote Control Connector

8-pin mini

DfN(l)

Instructions for use ( 1)

Interface Manual for Programmers (I)

Quick Reference Card (I)

Double-sided Adhesive Tapes (4)

Sales Companies Guide (

1)

0 dB11 = 0. 775 Vr.111.s.

Pin assignment

Y/C IN connector (4-pin mini DIN)

Pin No.

Signal Description

1 Y-input 1 Vp-p, sync negative,

75 ohms

2

CHROMA sub- 300 mVp-p, burst

carrier-input Delay time between Y and C:

within 0±100 nsec., 75 ohms

3 GND for Y-input GND

4 GND for GND

CHROMA-input

-3-

PVM-1353MD/1453MD

REMOTE 1 connector (8-pin mini DIN)

Pin No.

Signal

1

REMOTE ON/OFF

2

LINE A

3 GND

4

LINE B

5 TALLY

6

OVER SCAN

I

;

7

RGBA

I

8 RGB B

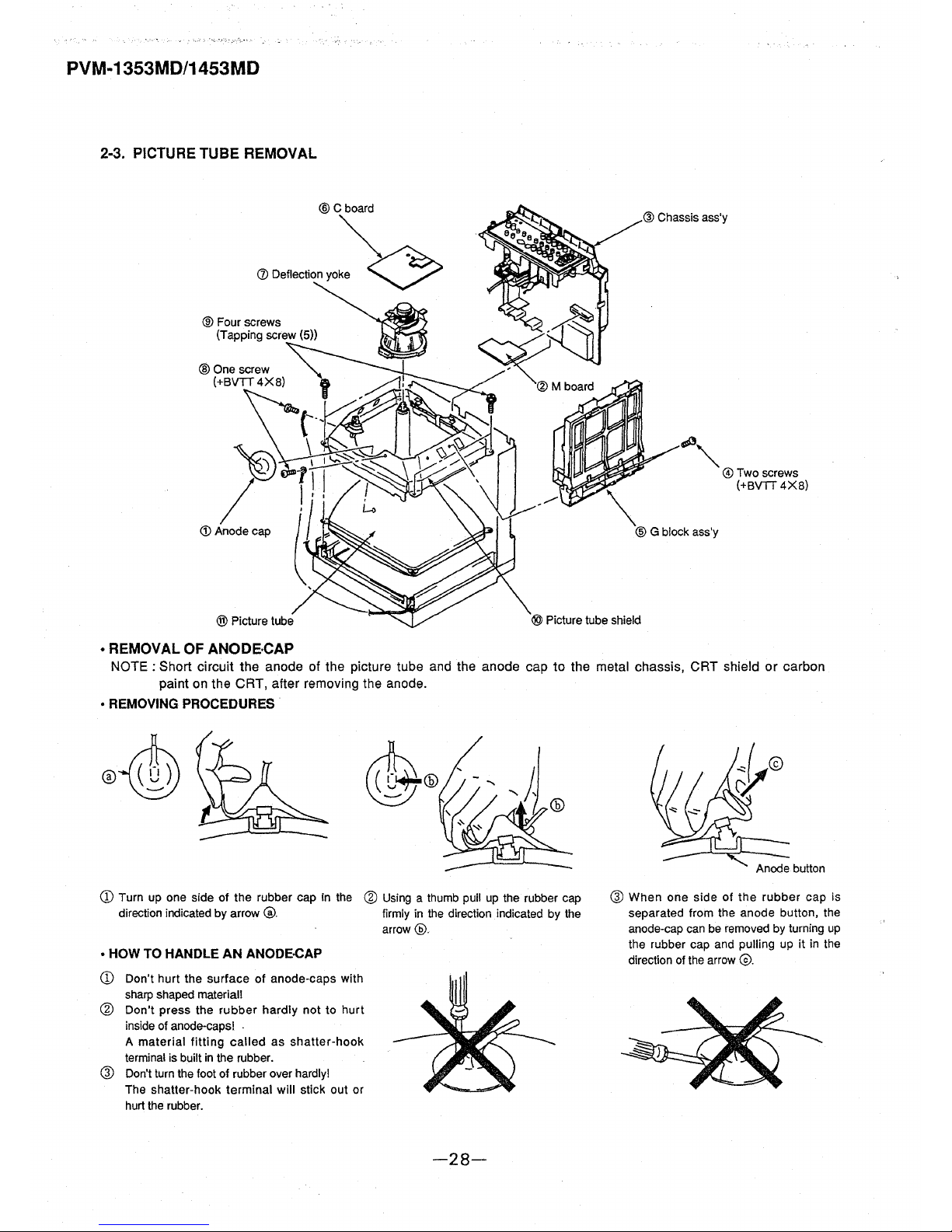

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON

PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNINGII

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF

LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED TO

THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS .IDENTIFIED BY SHADING AND MARK

& ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS MANUAL

FOLLOW THESE PROCEDURES WHENEVER CRITICAL

COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

-4-

RS-232C connector (9-pin D-sub)

Pin No.

1

2

3

4

5

6

7

8

9

Signal

-

RX

TX

-

GND

-

I ATS

CTS

-

@@@®CD

®@CV@

Design and specifications are subject to chanl!e without

notice.

~

ATTENTION!!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE,

COURT-CIRCUITER L'ANODE DU TUBE CATHODIQUE

ET CELUI DE L'ANODE DU CAP AU CHASSIS METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE

PEINTE SUR LE TUBE CATHODIQUE OU AU BILNDAGE

DU TUBE CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RISQUE D'ELECTROCUTION

PROVENANT D'UN CHASSIS SOUS TENSION, UN

TRANSFORMATEUR D'ISOLEMENT DOIT ETRE

UTILISE LORS DE TOUT DEPANNAGE.

LE CHASSIS DE CE RECEPTEUR EST DIRECTEMENT

RACCORDE

A L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS

A LA

SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET

PAR UNE MARQUE

& SUR LES SCHEMAS DE PRINCIPE,

LES VUES EXPLOSEES ET LES LISTES DE PIECES

SONT D'UNE IMPORTANCE CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMERO DE

PIECE EST INDIQUE DANS LE PRESENT

MANUEL OU DANS DES SUPPLEMENTS PUBLIES PAR

SONY. LES REGLAGES DE CIRCUIT DONT L'IMPOR-

TANCE EST CRITIQUE POUR LA

SECURITE DU

PRESENT MANUEL. SUIVRE CES PROCEDURES LORS

DE CHAQUE REMPLACEMENT DE COMPOSANTS

CRITIQUES, OU LORSQU'UN MAUVAIS FONCTIONNEMENT EST SUSPECTE.

!

I

I

I

i

I

I

I

i

'

I

!

PVM-1353MD/1453MD

SAFETY CHECK-OUT

(US Model only)

After correcting the original service problem,

perform the following safety checks before releasing

the set to the customer:

1. Check the area of your repair for unsoldered or

poorly-soldered connections. Check the entire

board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no

wires are "pinched" or contact high-wattage

resistors.

3, Check that all control knobs, shields, covers,

ground straps, and mounting hardware have

been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, par-

ticularly transistors, that were installed during

a previous repair. Point them out to the cus-

tomer and recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out

to the customer and recommend their replace-

ment.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line

cord to the customer.

7. Check the B+ and HV to see if they are at the

values specified. Make sure your instruments

are accurate; be suspicious of your HV meter if

sets always have low HY.

8. Check the metal trim, metallized knobs,

screws, and all other exposed metal parts

for AC leakage.

Check leakage as described below.

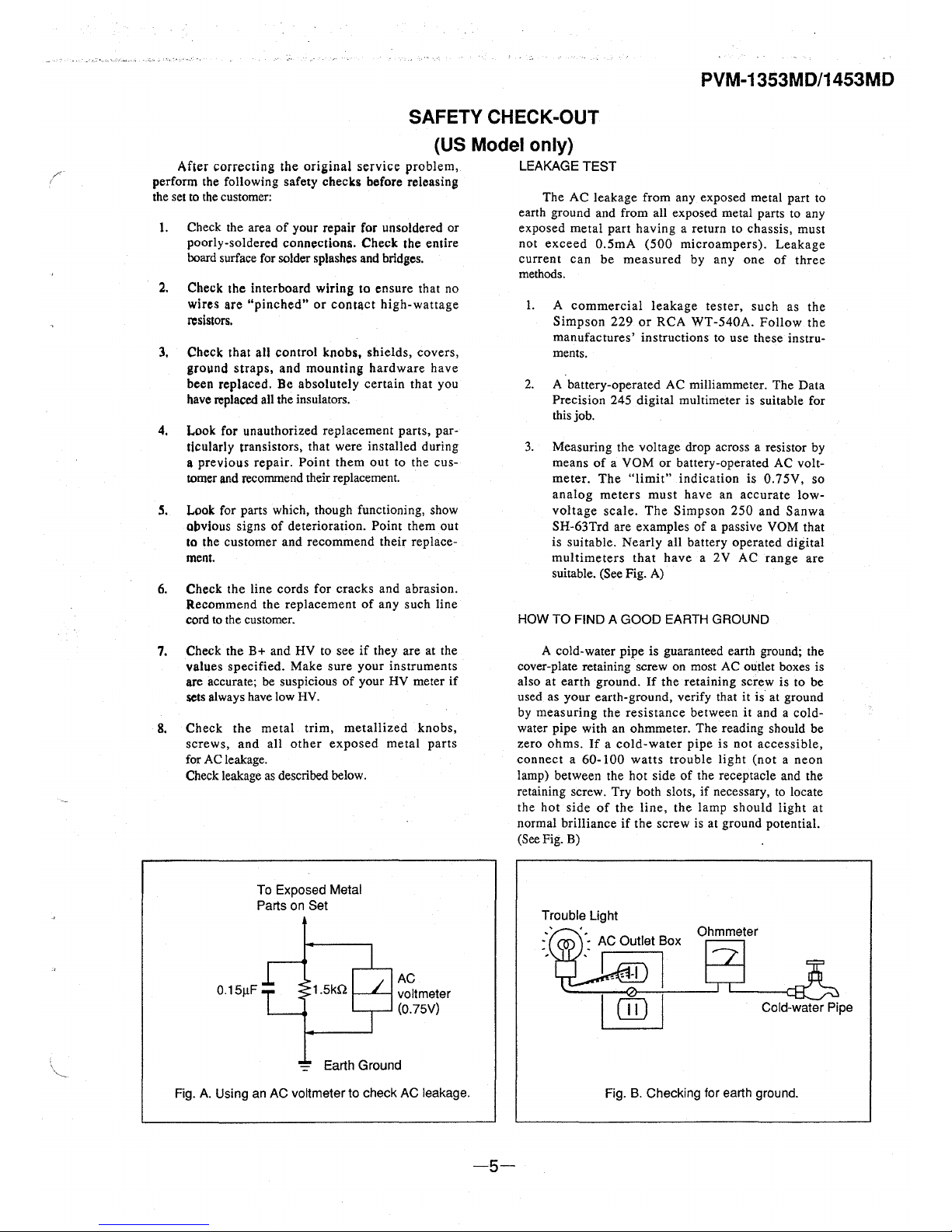

To Exposed Metal

Parts on Set

0.15µF

1.5kQ

AC

voltmeter

(0.75V)

-= Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

-5-

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to any

exposed metal part having a return to chassis, must

not exceed 0.5mA (500 microampers). Leakage

current can be measured by any one of three

methods.

I. A commercial leakage tester, such as the

Simpson 229 or RCA WT-540A. Follow the

manufactures' instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data

Precision 245 digital multimeter is suitable for

this job.

3. Measuring the voltage drop across a resistor by

means of a VOM or battery-operated AC voltmeter. The "limit" indication is 0.75V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM that

is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are

suitable. (See Fig. A)

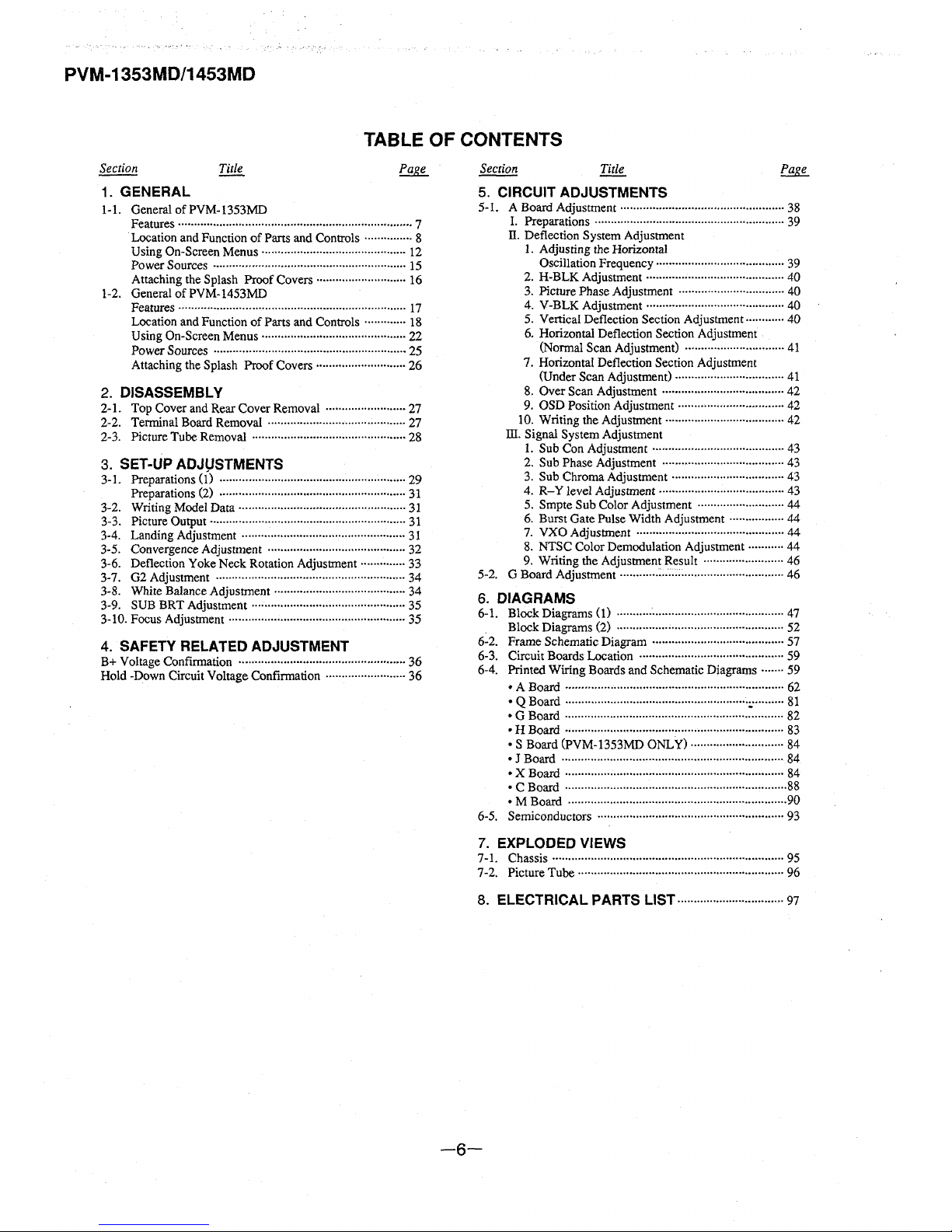

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground; the

cover-plate retaining screw on most AC outlet boxes is

also at earth ground.

If the retaining screw is to be

used as your earth-ground, verify that it is at ground

by measuring the resistance between it and a cold-

water pipe with an ohmmeter. The reading should be

zero ohms.

If a cold-water pipe is not accessible,

connect a 60-100 watts trouble light (not a neon

lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate

the hot side of the line, the lamp should light at

normal brilliance if the screw is at ground potential.

(See Fig. B)

Trouble Light

Ohmmeter

Cold-water Pipe

Fig. B. Checking for earth ground.

PVM-1353MD/1453MD

TABLE OF CONTENTS

1. GENERAL

1-1. General of PVM-1353MD

Features········································································· 7

· Location and Function of Parts and Controls ··············· 8

Using On-Screen Menus ............................................. 12

Power Sources ............................................................ 15

Attaching the Splash Proof Covers ............................ 16

1-2. General of PVM-1453MD

Features ......... ············ ········ ·········· ·················· ······ ·· ······ 17

Location and Function of Parts and Controls ............. 18

Using On-Screen Menus············································· 22

Power Sources ············ ······ ······················ .................... 25

Attaching the Splash Proof Covers ···························· 26

2. DISASSEMBLY

2-1. Top Cover and Rear Cover Removal ························· 27

2-2. Terminal Board Removal ··········································· 27

2-3. Picture Tube Removal ················································ 28

3. SET-UP ADJUSTMENTS

3-1. Preparations (1) ·························································· 29

Preparations (2) ...... ···· .................................. ·············· 31

3-2. Writing Model Data ···················································· 31

3-3. Picture Output····························································· 31

3-4. Landing Adjustment ·· ··················· ·· ···· ······ ·············· .... 31

3-5. Convergence Adjustment ........................................... 32

3-6. Deflection Yoke Neck Rotation Adjustment·············· 33

3-7. 02 Adjustment ........................................................... 34

3-8. White Balance Adjustment ········································· 34

3-9. SUB BRT Adjustment ................................................ 35

3-10. Focus Adjustment ··························· .................. ······ .... 35

4. SAFETY RELATED ADJUSTMENT

B+ Voltage Confirmation ················ ···· ···· ............................ 36

Hold -Down Circuit Voltage Confirmation ························· 36

5. CIRCUIT ADJUSTMENTS

5-1. A Board Adjustment ··· ···· .............................. ···· .. ···· ···· 38

I. Preparations · ········ ···· ········ ·· ···· ·················· ·· ............ 39

II. Deflection System Adjustment

1. Adjusting the Horizontal

Oscillation Frequency ········································ 39

2. H-BLK Adjustment ··········································· 40

3. Picture Phase Adjustment ································· 40

4. V-BLK Adjustment ........................................... 40

5. Vertical Deflection Section Adjustment············ 40

6. Horizontal Deflection Section Adjustment

(Normal Scan Adjustment) ............................... 41

7. Horizontal Deflection Section Adjustment

(Under Scan Adjustment)·································· 41

8. Over Scan Adjustment ······································ 42

9. OSD Position Adjustment ................................. 42

10. Writing the Adjustment ..................................... 42

ill. Signal System Adjustment

1. Sub Con Adjustment ......................................... 43

2. Sub Phase Adjustment ······································ 43

3. Sub Chroma Adjustment ................................... 43

4. R-Y level Adjustment ....................................... 43

5. Smpte Sub Color Adjustment ...........................

44

6. Burst Gate Pulse Width Adjustment ................. 44

7. VXO Adjustment .............................................. 44

8. NTSC Color Demodulation Adjustment ........... 44

9. Writing the Adjustment Result ......................... 46

5-2. G Board Adjustment ............ : .. : ................................... 46

6. DIAGRAMS

6-1. Block Diagrams (1) ···················································· 47

Block Diagrams (2) ···················································· 52

6-2. Frame Schematic Diagram ......................................... 57

6-3. Circuit Boards Location ············································· 59

6-4. Printed Wiring Boards and Schematic Diagrams ······· 59

• A Board···································································· 62

:

~

:~:1 :::::::::::::::::::::::::::::::::::::::::::::::::::::::::~::::::::::

~~

•HBoard ···································································· 83

• S Board (PVM-1353MD ONLY) ····························· 84

• J Board ..................................................................... 84

•X Board .................................................................... 84

• C Board ..................................................................... 88

• M Board .................................................................... 90

6-5. Semiconductors .......................................................... 93

7. EXPLODED VIEWS

7-1. Chassis ........................................................................ 95

7-2. Picture Tube································································ 96

8. ELECTRICAL PARTS LIST································· 97

-6-

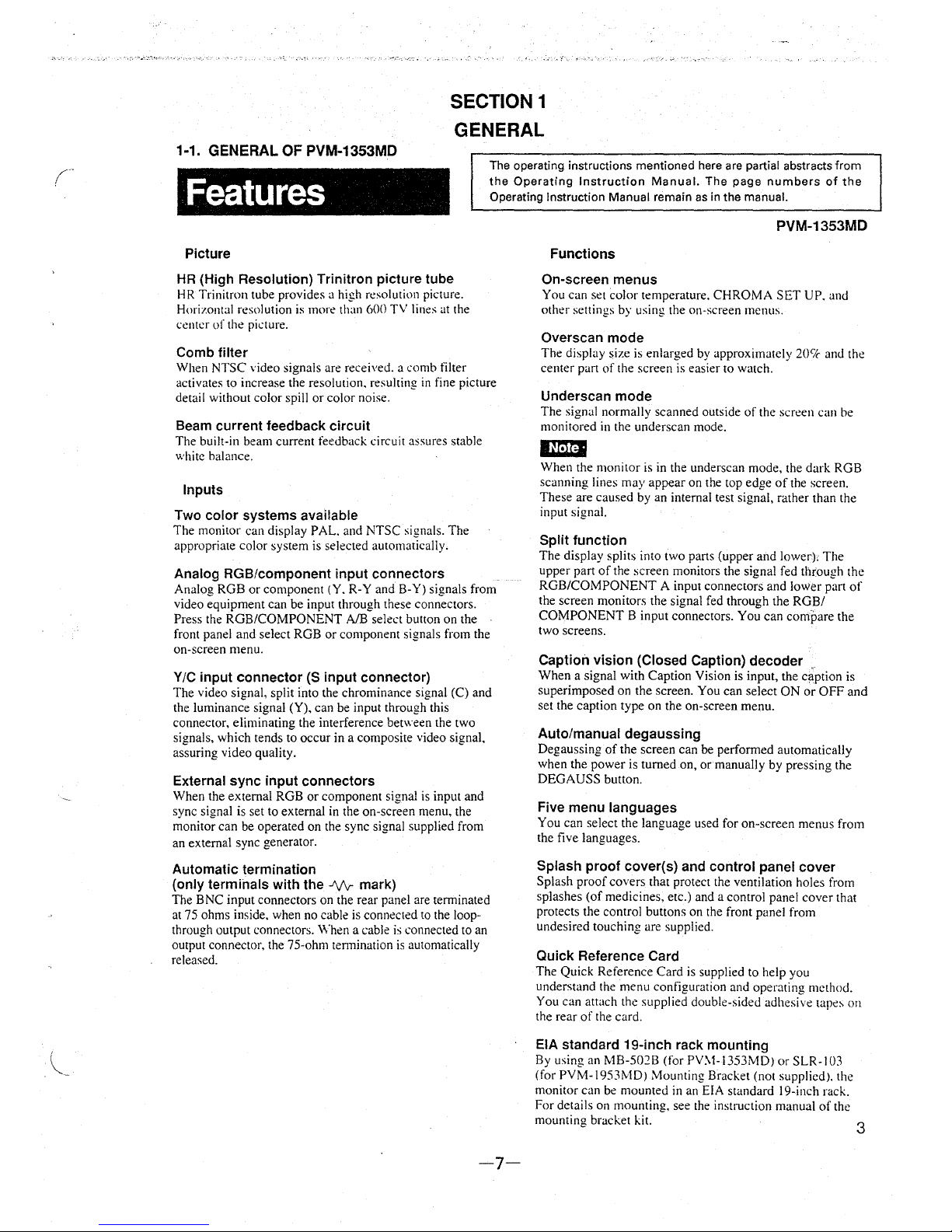

SECTION 1

GENERAL

1-1. GENERAL OF PVM-1353MD

Features

The operating instructions mentioned here are partial abstracts from

the Operating Instruction Manual. The page numbers of the

Operating Instruction Manual remain as in the manual.

Picture

HR (High Resolution) Trinitron picture tube

HR Trinitron tube provides a high resolution picture.

Horizontal resolution is more than 600 TV

lines at the

center of the picture.

Comb filter

When NTSC video signals are received. a comb filter

activates to increase the resolution. resulting in fine picture

detail without color spill or color noise.

Beam current feedback circuit

The built-in beam current feedback circuit assures stable

white balance.

Inputs

Two color systems available

The monitor can display PAL. and NTSC signals. The

appropriate color system is selected automatically.

Analog RGB/component input connectors

Analog RGB or component (Y. R-Y and B-Y) signals from

video equipment can be input through these connectors.

Press the ROB/COMPONENT

A/B select button on the

front panel and select RGB or component signals from the

on-screen menu.

Y/C input connector (S input connector)

The video signal, split into the chrominance signal (C) and

the luminance signal (Y), can be input through this

connector, eliminating the interference

between the two

signals, which tends to occur in a composite video signal,

assuring video quality.

External sync input connectors

When the external RGB or component signal is input and

sync signal is set to external in the on-screen menu, the

monitor can be operated on the sync signal supplied from

an external sync generator.

Automatic termination

(only terminals with the

..1\./v-mark)

The BNC input connectors on the rear panel are terminated

at 75 ohms inside, when no cable is connected to the loopthrough output connectors.

When a cable is connected to an

output connector, the 75-ohm termination is automatically

released.

-7-

PVM-1353MD

Functions

On-screen menus

You can set color temperature. CHROMA SET UP. and

other settings

by using the on-screen menus.

Overscan mode

The display size is enlarged by approximately 20C/c and the

center part of the screen is easier to watch.

Underscan mode

The signal normally scanned outside of the screen can be

monitored in the underscan mode.

IU:Jrl

When the monitor is in the underscan mode, the dark RGB

scanning lines may appear on the top edge of the screen.

These are caused by an internal test signal, rather than the

input signal.

Split function

The display splits into two parts (upper and lower), The

upper part of the screen monitors the signal fed through the

RGB/COMPONENT A input connectors and

lower part of

the screen monitors the signal fed through the RGB/

COMPONENT B input connectors. You can compare the

two screens.

Caption vision (Closed Caption) decoder

When a signal with Caption Vision is input, the ciption is

superimposed on the screen. You can select ON or OFF and

set the caption type on the on-screen menu.

Auto/manual degaussing

Degaussing of the screen can be performed automatically

when the power is turned on, or manually by pressing the

DEGAUSS button.

Five menu languages

You can select the language used for on-screen menus from

the five languages.

Splash proof cover(s) and control panel cover

Splash proof covers that protect the ventilation holes from

splashes (of medicines, etc.) and a control panel cover that

protects the control buttons on the front panel from

undesired touching are supplied.

Quick Reference Card

The Quick Reference Card is supplied to help you

understand the menu configuration and operating method.

You can attach the supplied double-sided adhesive

tape~ on

the rear of the card.

EIA standard 19-inch rack mounting

By using an MB-502B (for PV:.1-l353MDJ or SLR-103

(for PVM-1953~10) Mounting Bracket (not supplied). the

monitor can be mounted in an EIA standard

19-inch rack.

For details on mounting, see the instruction manual of the

mounting bracket kit.

3

·:,/.·-·.•.»."· . .;"

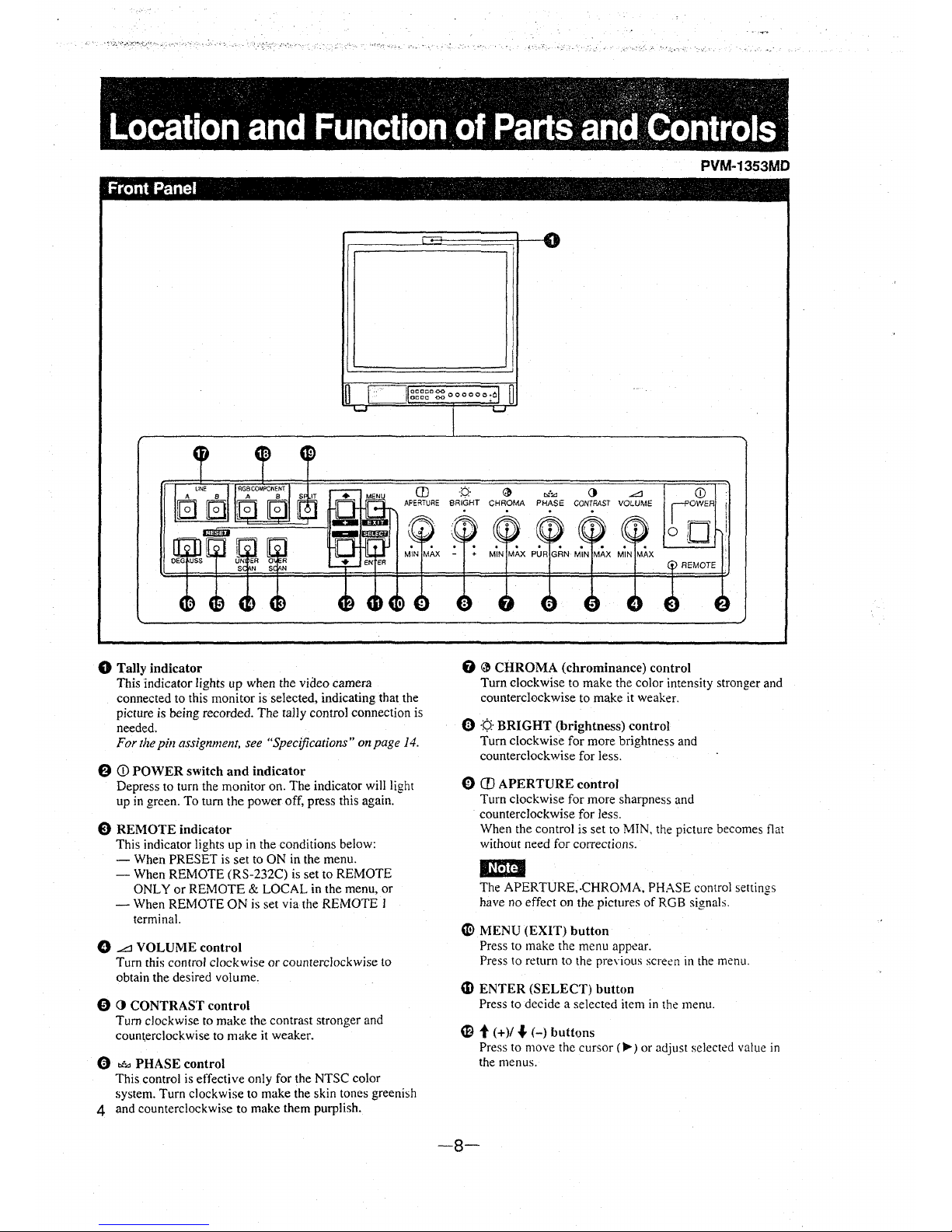

Location and Function of Part~ anti ~~ntrols ·

. ,,.

~ ~

PVM-1353MD

Front Panel . . .

~

00000

.00 000000 o n

L.___Joc~c -co : LJ

0 Tally indicator

This indicator lights up when the video camera

connected to this monitor is selected, indicating that the

picture is being recorded. The tally control connection is

needed.

For the

pin assignment, see "Specifications" on page 14.

8 CD POWER switch and indicator

Depress to turn the monitor on. The indicator will light

up in green. To turn the power off, press this again.

E) REMOTE indicator

This indicator lights up in the conditions below:

- When PRESET is set to ON in the menu.

- When REMOTE (RS-232C) is set to REMOTE

ONLY or REMOTE

& LOCAL in the menu, or

- When REMOTE ON is set via the REMOTE l

terminal.

0 A VOLUME control

Turn this control clockwise or counterclockwise to

obtain the desired volume.

0 0 CONTRAST control

Turn clockwise to make the contrast stronger and

counterclockwise to make it weaker.

0 .,.,,, PHASE control

This control is effective only for the NTSC color

system. Turn clockwise to make the skin tones greenish

4 and counterclockwise to make them purplish.

-b·

~

,,,:,,, 0 .Ll

SRiciHT CHROMA PHASE CONTRAST VOLUME

REMOTE

0

~

CHROMA (chrominance) control

Turn clockwise to make the color intensity stronger and

counterclockwise to make it weaker.

(l) ·¢.· BRIGHT (brightness) control

Turn clockwise for more brightness and

counterclockwise for less.

0 CD APERTURE control

Turn clockwise for more sharpness and

counterclockwise for Jess.

When the control is set to

MIN. the picture becomes flat

without need for corrections.

,~ma

The APERTURE,-CHROMA, PHASE control settings

have no effect on the pictures of RGB

signals.

~

CI!) MENU (EXIT) button

Press to make the menu appear.

Press to return to the

preYious sere.en in the menu.

~

ENTER (SELECT) button

Press to decide a selected item in the menu.

et(+)/ ,f. (-) buttons

Press to move the cursor (,...) or adjust selected value in

the menus.

-8-

.;,.•.-.~,.,.,: .• · .. , ... •., ;, c•.:•·,·,~··, .• •' •·,.,, ·,·~, ~.·,;•c,··,~.,, ..

4B OVERSCAN button

Press (light on) for overscanning. The display size is

extended by approximately

20'7c so that the center of

screen is easier to watch. By pressing the button again,

the display returns to the normal size (light oft).

~

UNDERSCAN button

Press (light on) for underscanning. The display size is

reduced by approximately 5% so that four corners of the

raster are visible. By pressing the button again, the

display returns to the normal size {light off).

'9 RESET button

During menu adjustments, press to reset the setting in

the menu.

CD DEGAUSS button

Press this button momentarily. The screen will be

demagnetized.

Wait for IO minutes or more before activating this

button again.

Em?I

The picture rolls vertically while the screen is being

demagnetized.

CD LINE A/B select buttons

Press to select a signal (light on).

A: Press to monitor the signal fed through the LINE A

input connectors.

B: Press to monitor the signal fed through the LINE B

input connectors.

G) RGB/COMPONENT A/B select buttons

Press to select a signal (light on).

A: Press to monitor the signal fed through the RGB/

COMPONENT A input connectors.

B: Press to monitor the signal fed through the RGB/

COMPONENT B input connectors.

~

SPLIT button

When you select RGB signals fed through the RGB/

COMPONENT A and RGB/COMPONENT B input

connectors, press this button (light on) to split the

display into two parts (upper and lower), and monitor

the both RGB signals simultaneously.

mD

Make sure the signals fed through the RGB/

COMPONENT A and RGB/CO.\IPONENT B input

connectors are synchronized.

-9-

PVM-1353MD

5

' '

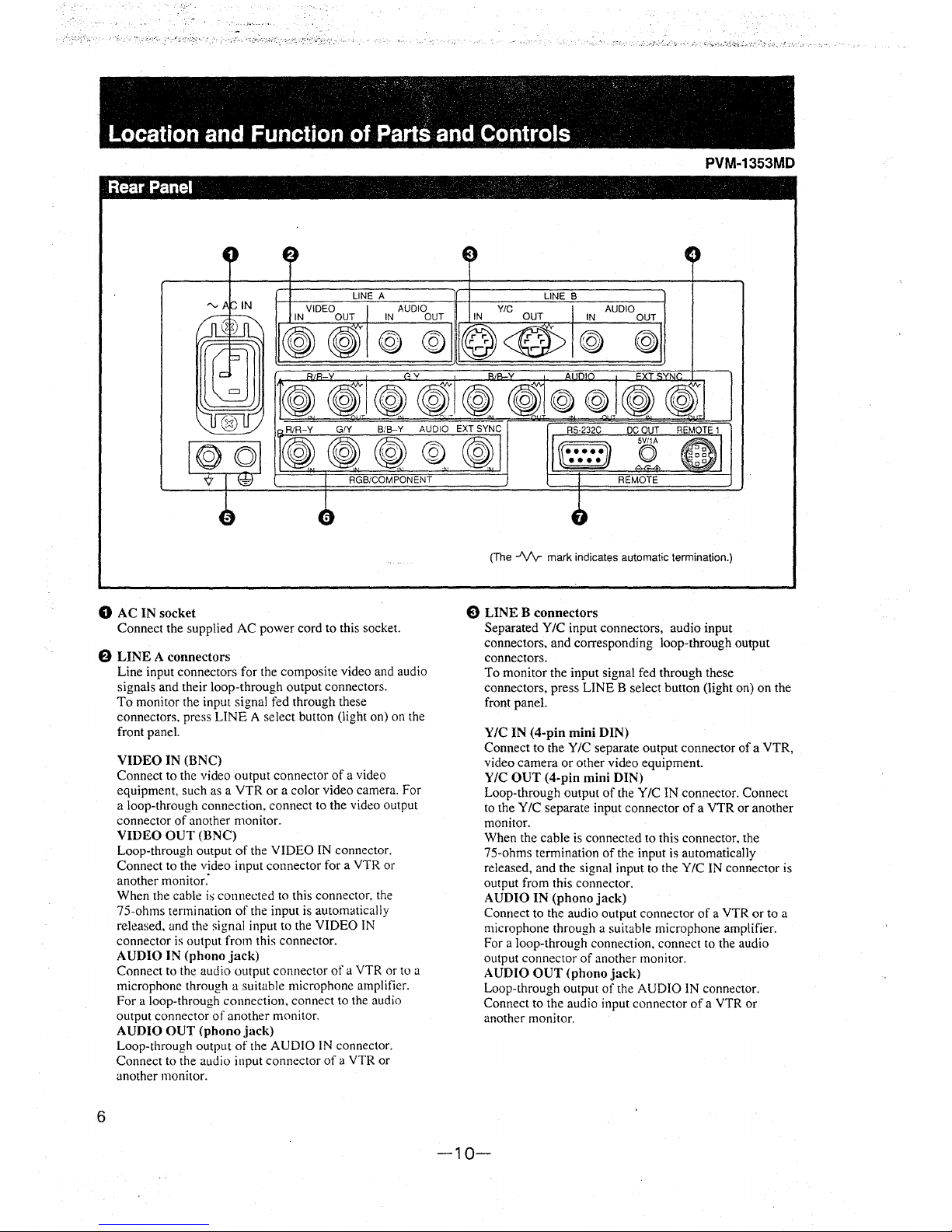

Location and Function of Parts and Controls

PVM-1353MD

Rear Panel

LINE A

LINE B

VIDEO AUDIO Y/C AUDIO

,--l.!.:IN_,___..;0:::.U:::.T:,.,...l-...:.1:.:,N __ O;::,U;::,T;_, IN OUT IN OUT

©) @@<@)@ @)

(The -VV mark indicates automatic termination.)

0 AC IN socket

8 LINE B connectors

Connect the supplied AC power cord to this socket.

8 LINE A connectors

6

Line input connectors for the composite video and audio

signals and their loop-through output connectors.

To monitor the input signal fed through these

connectors. press LINE A select button (light on) on the

front paneL

VIDEO IN (BNC)

Connect to the video output connector of a video

equipment, such as a VTR or a color video

camera. For

a loop-through connection, connect to the video output

connector of another

monitor.

VIDEO OUT (BNC)

Loop-through output of the VIDEO IN connector.

Connect to the video input connector for a VTR or

another monitor:

When the cable is connected to this connector, the

75-ohms termination of the input is automatically

released, and the signal input to the VIDEO IN

connector is output from this

connector.

AUDIO IN (phono jack)

Connect to the audio output connector of a VTR or to a

microphone through a suitable microphone

amplifier.

For

a loop-through connection. connect to the audio

output connector of another

monitor.

AUDIO OUT (phonojack)

Loop-through output of the AUDIO IN connector.

Connect to the audio input connector of a VTR or

another monitor.

Separated Y

IC input connectors, audio input

connectors, and corresponding loop-through output

connectors,

To monitor the input signal fed through these

connectors, press LINE B select button (light on) on the

front

panel.

Y/C IN (4-pin mini DIN)

Connect to the Y/C separate output connector of a VTR,

video camera or other video equipment.

Y/C OUT (4-pin mini DIN)

Loop-through output of the Y/C IN connector. Connect

to the Y /C separate input connector of a VTR or another

monitor.

When the cable is connected to this connector. the

75-ohms termination of the input is automatically

released, and the signal input to the

Y/C IN connector is

output from this connector.

AUDIO IN (phono jack)

Connect to the audio output connector of a VTR or to a

microphone through a suitable microphone amplifier.

For a loop-through connection, connect to the audio

output connector of another

monitor.

AUDIO OUT (phono jack)

Loop-through output of the AUDIO IN connector.

Connect to the audio input connector of a VTR or

another

monitor.

-10-

• ~' -

~

~IV , • • • :, ' '

~~

. . .

" ca" •' • ,- ' •

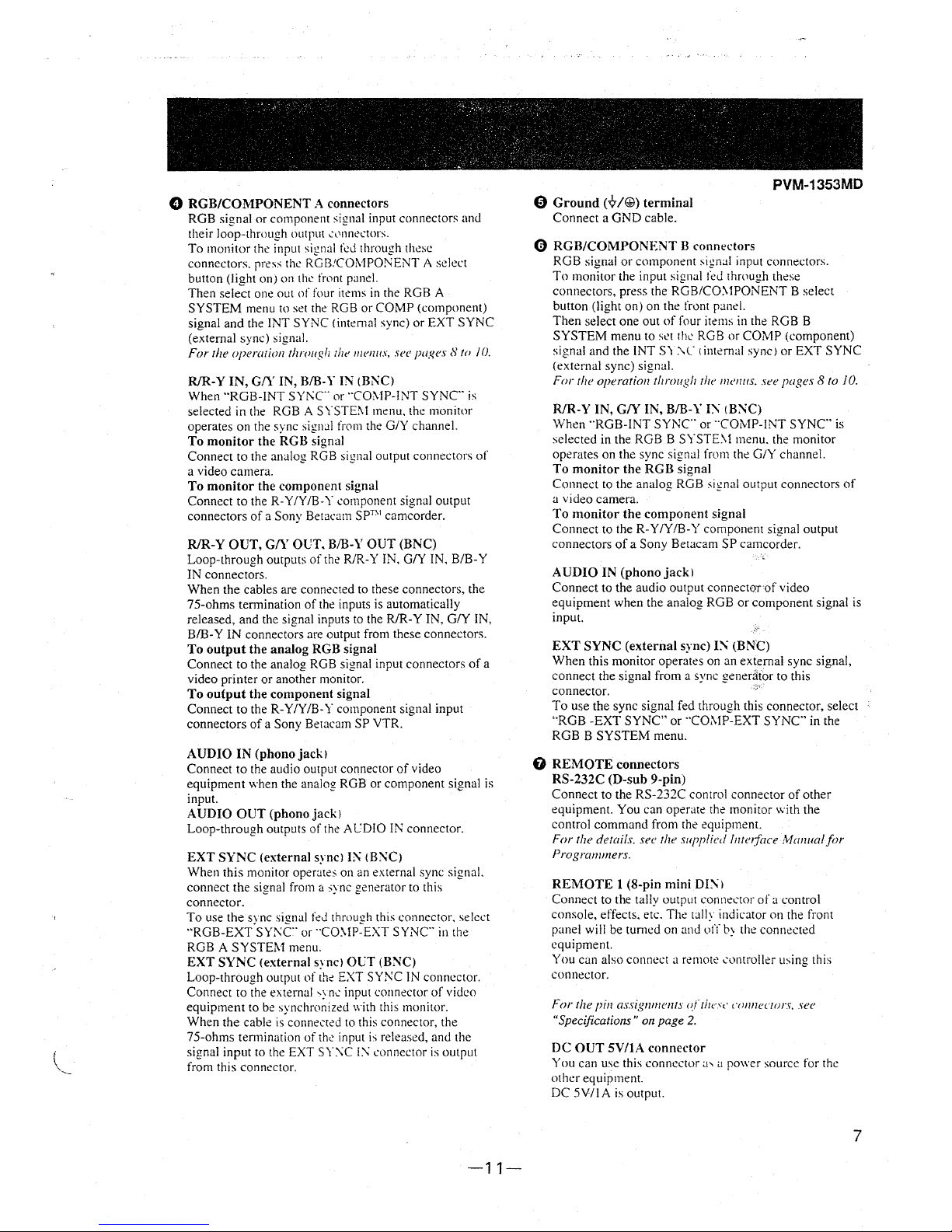

0 RGB/COMPONENT A connectors

RGB signal or component signal input connectors and

their loop-through output ,,,nncctors.

To monitor the input signal fod through these

connectors. press

the RGB!COtv!POJ\iENT A select

button (light on) on the fwnt panel.

Then select one out

of four items in the RGB A

SYSTEM menu to set the RGB or COMP (component)

signal and the INT SYNC (internal sync) or EXT SYNC

(external sync)

signal.

For the operation throuph 1he 111e1111s, Sff pages 8 to /0.

R/R-Y IN, G/Y IN, B/B-Y IN (B;-..;C)

When "ROB-INT SYNC or "CO'.\IP-INT SYNC is

selected

in the RGB A SYSTE'.\I menu. the monitor

operates on the sync

signal from the G/Y channel.

To monitor the RGB signal

Connect to the analog RGB signal output connectors of

a video camera.

To monitor the component signal

Connect to the R-Y /Y /B-Y component signal output

connectors of a Sony

Betacam sprn camcorder.

R/R-Y OUT, G/Y OCT. B/B-Y OUT (BNC)

Loop-through outputs of the R/R-Y IN, G/Y IN, B/B-Y

IN connectors.

When the cables are connected to these connectors, the

75-ohms termination of the inputs is automatically

released, and the signal inputs to the R/R-Y IN, G/Y IN,

BIB-Y IN connectors are output from these connectors.

To output the analog RGB signal

Connect to the analog RGB signal input connectors of a

video printer or another monitor.

To output the component signal

Connect to the R-Y /Y /B-Y component signal input

connectors of a Sony Betacam SP VTR.

AUDIO IN (phonojackJ

Connect to the audio output connector of video

equipment when the analog RGB or component signal is

input.

AUDIO OUT (phonojackJ

Loop-through outputs of the ACDIO IN connector.

EXT SYNC (external sync) I" (B:\'C)

When this monitor operates on an external sync signal.

connect the signal from

a ,ync generator to this

connector.

To use the sync signal fcJ through this connector. select

"RGB-EXT SY;\'C or "CO'.\!P-EXT SYNC in the

RGB A SYSTEM menu.

EXT SYNC (external syncJ OCT (BNC)

Loop-through output of the EXT SY;\'C IN connector.

Connect to the external

,::, nc input connector of video

equipment to be

svnchronized \1·ith this monitor.

When the cable

is' connected to this connector, the

75-ohms ten11i11ation of

the input is released, and the

signal input to the EXT

SY:'\C I.\' connector is output

from this connector.

-11-

PVM-1353MD

0 Ground ('Q'/@) terminal

Connect a GND cable.

0 RGB/COMPONENT B connectors

RGB signal or component

sign.ii input connectors.

To monitor the input signal

fed through these

connectors, press the

RGB/CO'.\IPONENT B select

button (light on) on the front

p.inel.

Then select one out of four items in the ROB B

SYSTEM menu to

st?t the RGB or COMP (component)

sign.ii and the INT SY\C I intern.ii sync) or EXT SYNC

(external sync)

sign.ii.

For the operation through 1he 111e1111s. see pages 8 to JO.

R/R-Y IN, G/Y IN, B/B-Y I:\ (BNC)

When ··RGB-INT SYNC or "COMP-INT SYNC" is

selected in the RGB B

SYSTE'.\I menu. the monitor

operates on the sync signal from the G/Y channel.

To monitor the RGB signal

Connect to the analog RGB signal output connectors of

a video camera.

To monitor the component signal

Connect to the R-Y /Y /B-Y component signal output

connectors of a Sony Betacam SP camcorder.

AUDIO IN (phonojackl

Connect to the audio output connector of video

equipment when the analog RGB or component signal is

input.

EXT SYNC (external sync) IN (BNC)

When this monitor operates on an external sync signal,

connect the signal from a sync

genertlior to this

connector.

To use the sync signal fed through this connector, select

"RGB -EXT SYNC" or "C0:-.1P-EXT SYNC in the

RGB B SYSTEM menu.

0 REMOTE connectors

RS-232C (D-sub 9-pin)

Connect to the RS-232C control connector of other

equipment. You can

operate the monitor with the

control command from the equipment.

For the details. see the supplied lntuface :'v!anua! for

Programmers.

REMOTE 1 (8-pin mini DI:\l

Connect to the tally output connector of a control

console, effects. etc.

The tally indicator 011 the front

panel will be turned on and

off b:-the connected

equipment.

You can also connect

a remote controller using this

connector.

For the pin assig11111enTs <f Thc·s,· n,nneuors, see

"Specifications" on page 2.

DC OUT SV/IA connector

You can use this connector .i, .i power source for the

other equipment.

DC 5V/IA is output.

7

PVM-1353MD

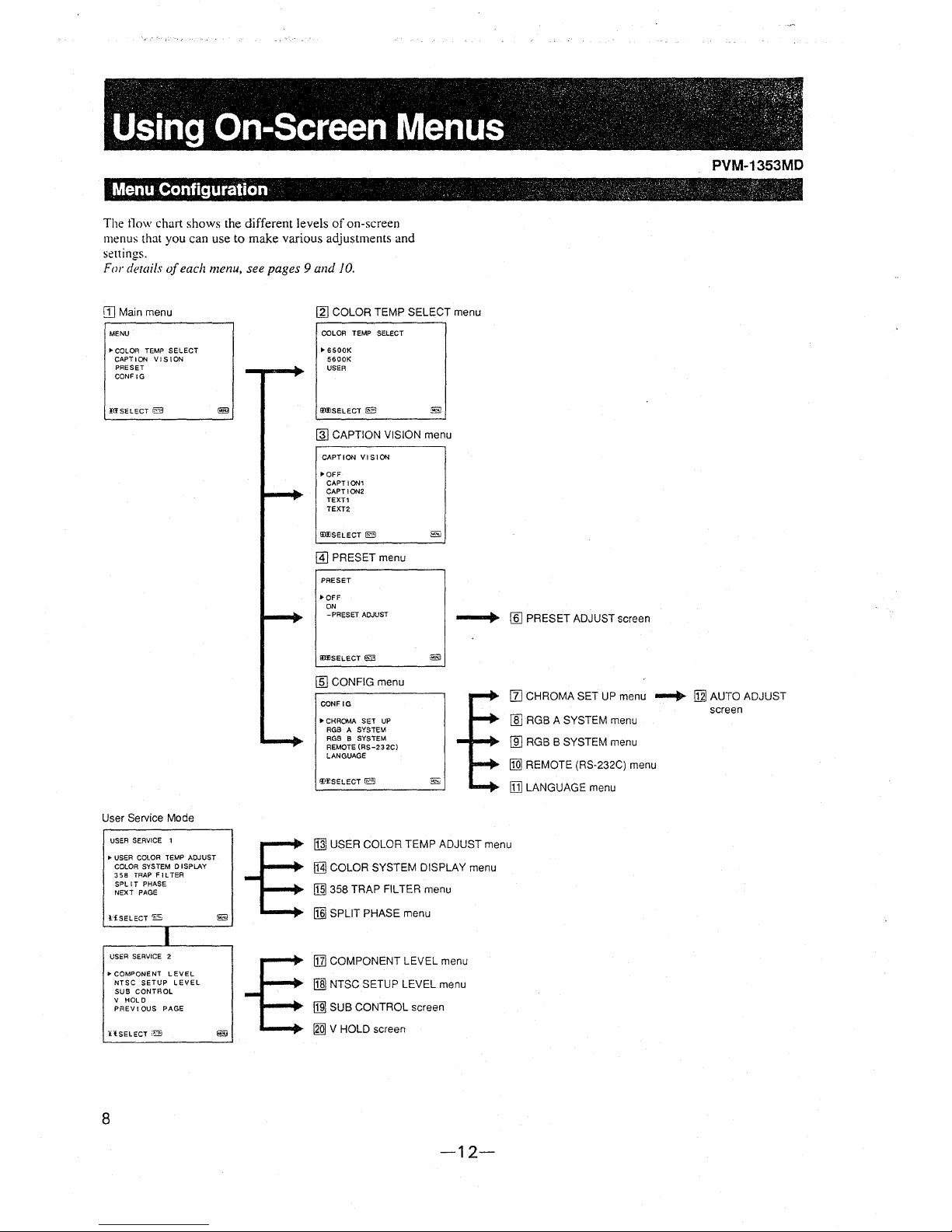

Menu Configuration ,. · · -, "· -. , · , ., '\ · - -. _ -:" ,, :'

The flow chart shows the different levels of on-screen

menus

that you can use to make various adjustments and

settings.

For details of each menu, see pages 9 and JO.

[] Main menu [g) COLOR TEMP SELECT menu

MENU

"'COLOR TEMP SELECT

CAPTI0/'11 VISION

PRESET

CONF

IG

IIISELECT iB

COLOR TEMP SELECT

"'6500K

5600K

USER

!I(f)SELECT fE3

@l CAPTION VISION menu

CAPTION VISION

J>QFF

CAPTION1

CAPTION2

TEXT1

TEXT2

!m!SELECT 0

@] PRESET menu

PRESET

•OFF

ON

- PRESET ADJUST

IIHJSELECT @I

[ID CONFIG menu

--+ [§] PRESET ADJUST screen

CONF IG

II] CHROMA SET UP menu ...... fill AUTO ADJUST

User Service Mode

USER SERVICE 1

"'USER COLOR TEMP ADJUST

COLOR SYSTEM DI SPLAY

358

TRAP FILTER

SPLIT PHASE

NEXT PAGE

l:fSELECT 'ES

I

USER SERVICE 2

"'COMPONENT LEVEL

NTSC SETUP LEVEL

SUB CONTROL

V

HOLD

PREVIOUS PAGE

llSELECT §

8

~

@

• CHROMA SET UP

RGB

A SYSTEM

RGB 8 SYSTEM

REMOTE (AS-23 2C)

LANGUAGE

f!!TSELECT 0

ffiJ RGB A SYSTEM menu

[[] RGB B SYSTEM menu

[Q] REMOTE (RS-232C) menu

ID] LANGUAGE menu

~

USER COLOR TEMP ADJUST menu

MJ COLOR SYSTEM DISPLAY menu

[§I 358 TRAP FILTER menu

[§j SPLIT PHASE menu

[ZJ COMPONENT LEVEL menu

11]] NTSC SETUP LEVEL menu

jill SUB CONTROL screen

[gQ] V HOLD screen

-12-

screen

, .. \?-r., ·'·-!F~>_. . .. · . · .. t,/·· .. - .

:

~

, :,,'

~

"' /." < ·,. • '

~

. -

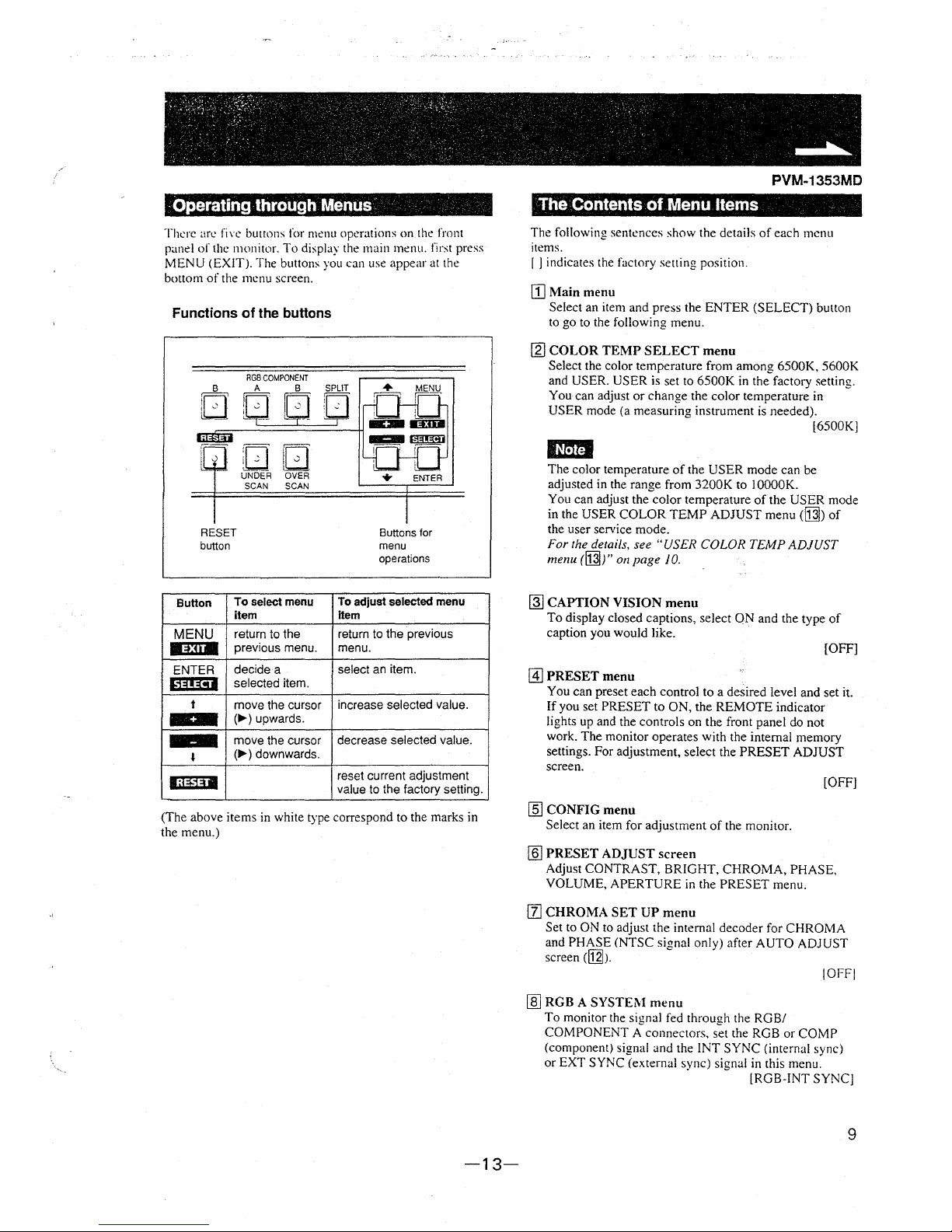

· Operating through Menus·

There are fin: buttons for menu operations on the front

panel of the monitor. To display the main menu. first press

MENU (EXIT). The buttons you can use appear at the

bottom of the menu screen.

Functions of the buttons

RGB COMPONENT

B A B SPLIT

nu GD

lLJ L_7___ =r--;_

DD

UNDER OVER

SCAN SCAN

RESET

button

Button

To select menu

item

MENU

return to the

11~:1111

previous menu.

ENTER

decide a

l1~!!~1

selected item.

t

move the cursor

(..,._) upwards.

move the cursor

•

(..,._) downwards .

liiil~I

Buttons for

menu

operations

To adjust selected menu

Item

return to the previous

menu.

select an item.

increase selected value.

decrease selected value.

reset current adjustment

value to the factory setting.

(The above items in white type correspond to the marks in

the menu.)

-13-

PVM-1353MD

The Contents of Menu Items

The following sentences show the details of each menu

items.

r J indicates the factory setting position.

[]Main menu

Select an item and press the ENTER (SELECT) button

to go to the following menu.

[g:j COLOR TEMP SELECT menu

Select the color temperature from among 6500K, 5600K

and USER. USER is set to 6500K in the factory setting.

You can adjust or change the color temperature in

USER mode (a measuring instrument is needed).

[6500K]

IMUI

The color temperature of the USER mode can be

adjusted in the range from

3200K to I OOOOK.

You can adjust the color temperature of the USER mode

in the USER COLOR TEMP ADJUST menu

(M) of

the user service mode.

For the details, see "USER COLOR TEMP ADJUST

menu (M)" on page 10.

~

CAPTION VISION menu

To display closed captions, select ON and the type of

caption you would like.

[OFF]

@] PRESET menu

You can preset each control to a desired level and set it.

If you set PRESET to ON, the REMOTE indicator

lights up and the controls on the front panel do not

work. The monitor operates with the internal memory

settings. For adjustment, select the PRESET ADJUST

screen.

[OFF]

[§] CONFIG menu

Select an item for adjustment of the monitor.

[§] PRESET ADJUST screen

Adjust CONTRAST, BRIGHT, CHROMA, PHASE,

VOLUME, APERTURE in the PRESET menu.

[I] CHROMA SET UP menu

Set to ON to adjust the internal decoder for CHROMA

and PHASE (NTSC signal only) after AUTO ADJUST

screen

([j]J.

!OFFJ

ffi] RGB A SYSTEl\I menu

To monitor the signal fed through the RGB/

COMPONENT A connectors. set the RGB or COMP

(component) signal and the INT SYNC (internal sync)

or EXT SYNC (external sync) signal in this menu.

[RGB-lNT SYNC]

9

. :i . . ,{,,: . .. t:t~rt ; ;,, s)f;,

Using On-Screen ·Menus _; __ .-._:·:·. ·· --: :: · ..

[ill RGB B SYSTEM menu

To monitor the signal fed through the RGB/

COMPONENT B connectors, set

the RGB or COMP

(component) signal and

the INT SYNC (internal sync)

or EXT SYNC (external sync) signal in this menu.

IRGB-INT SYNC!

[ill REMOTE (RS-232C) menu

Select one out of following three modes.

REMOTE OFF:

You can adjust settings and controls by the buttons and

controls on the front panel.

RS-232C connector does not function.

REMOTE ONLY:

You can adjust settings and controls through the

RS-232C connector.

Buttons and controls on the front panel. except the

menu operation ones, do not function.

REMOTE & LOCAL:

You can adjust settings and controls both through the

RS-232C connector and the front panel buttons.

Controls on the front panel do not function.

[REMOTE OFF]

B] LANGUAGE menu

You can select the language used for on-screen menus

from the following five languages (English,

German,

French, Italian, Spanish).

[ENGLISH]

[gj AUTO ADJUST screen

Select the color bar signal (full, SMPTE, EIA) and press

the ENTER (SELECT) button to start automatic

adjustment.for CHROMA and PHASE. For these

adjustments

io be valid, you must select ON in

CHROMA SET UP menu

([I]).

User Service Mode

The user service mode is useful when adjusting the settings

and controls except for the above.

To enter the user service mode, press and hold the MENU

(EXIT) button until the following USER SERVICE I

appears.

To move to the second page of the mode. select

''NEXT

PAGE"

and to return to the first page of the menu, select

"PREVIOUS

PAGE".

10

USER SERVICE 1

,. USER COLOR TEMP ADJUST

COLOR SYSTEM O I SPLAY

358 TRAP FILTER

SPLIT PHASE

NEXT PAGE

!if SELECT@

USER SERVICE 2

i,, COMPONENT LEVEL

NTSC SETUP LEVEL

SUB CONTROL

V HOLD

PREVIOUS PAGE

:u SELECT '::::·:

PVM-1353MD

~

USER COLOR TEMP ADJUST menu

The value of adjustment in this menu works only when

"USER" is selected in the COLOR TDIP SELECT

menu ([1] ).

ADJUST GAIN:

Adjusts

the color balance (gain) of the USER mode.

ADJUST BIAS:

Adjusts the color balance (bias) of the USER mode.

COLOR TEMP RANGE:

When you adjust the color temperature in the USER

mode. select a color temperature range before

adjusting ADJUST GAIN

and ADJUST BIAS. If the

adjusted color temperature is between 3200K and

5000K. select

"3200K-5000K." If the adju,ted color

temperature is between 5000K and lOOOOK.

select

"5000K-IOOOOK." [5000K-10000K]

[11 COLOR SYSTEM DISPLAY menu

Select the color system display mode. In Al'TO. the

kind of color system being used appears on the screen

each time you change the signal input. [AUTO]

!1]1358 TRAP FILTER menu

Color spill or color noise may be eliminated if you

select ON (NTSC signal only). Normally set it to OFF.

[OFF]

[§I SPLIT PHASE menu

When the SPLIT function is activated, if the lower side

picture (the signal fed through the RGB/COMPONENT

B input connectors) has some discrepancy of location

with the upper side picture, adjust the SPLIT PHASE

menu.

Each time you press the

t( +) button. the lower side

picture moves left.

IUMI

When the adjustment is made in the menu. the skew

error will occur on the top of the lower side picture.

Bl] COMPONENT LEVEL menu

Select the component level from among three modes.

NIO/SMPTE: for 100/0/100/0 signal

BETA 7.5: for 100/7.5/75/7.5 signal

BET A 0: for l 00/0/75/0 signal (BETA 7.5]

[j]J NTSC SETUP LEVEL menu

Select the NTSC setup level from two modes. The 7.5

setup level is mainly used in north America. The O setup

level is mainly used in Japan. [7.5)

G]J SUB CONTROL screen

You can finely adjust the controls on the front panel.

CONTRAST. PHASE,

CHR01'-IA and BRIGHT

controls

have clicks at the center of their adju,tment

range. You can adjust the setting of the click

po~ition

with this feature.

[gQ] V HOLD screen

Adjust the vertical hold if the picture rolls \enically.

IUtitl

If the rolling of the picture prevents you from watching

the screen. select an input that has nothing connected.

-14-

(

. ' '- . . ',- ': ' . '~" ·:,.

~

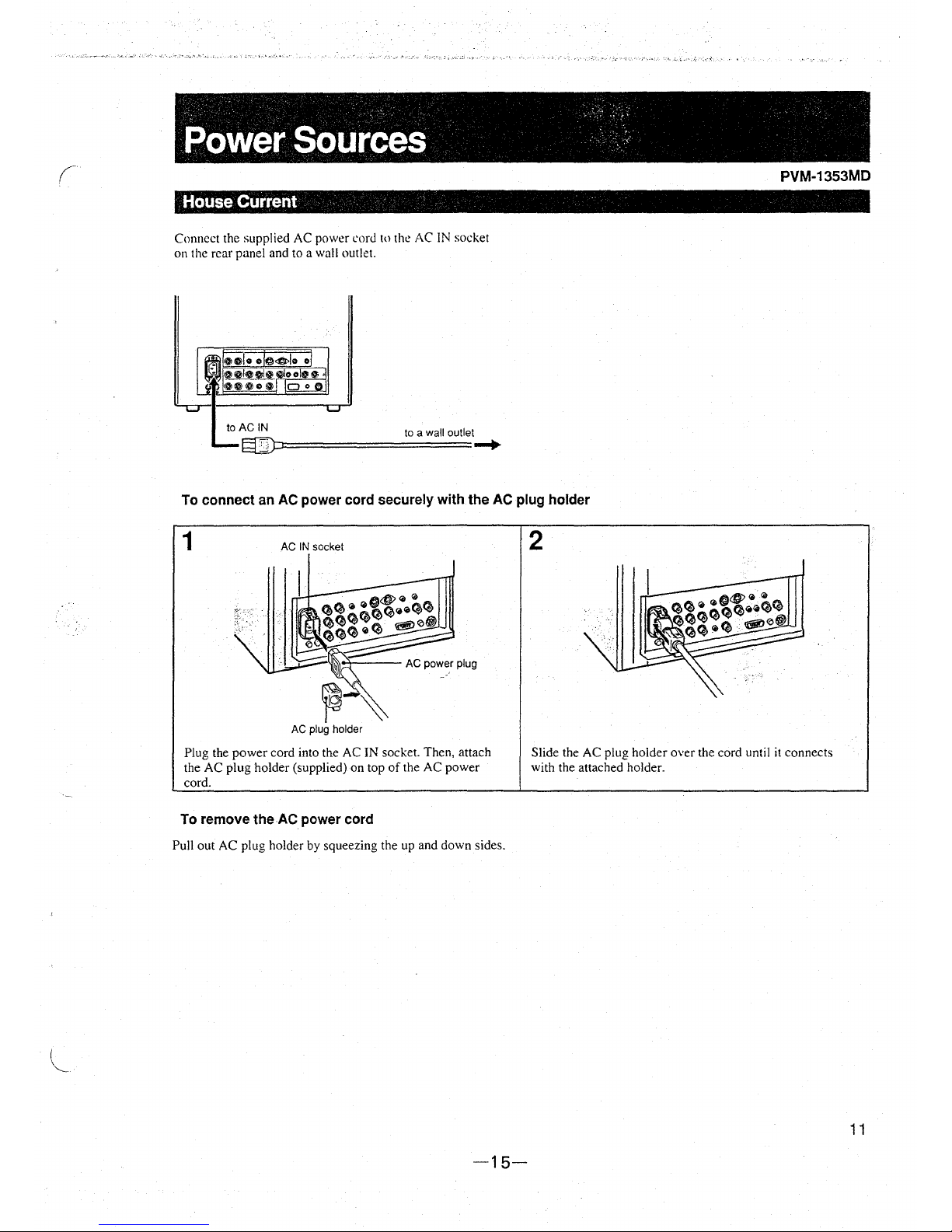

Power Sources -·, -->

PVM-1353MD

House Current ·

Connect the supplied AC power cord to the AC IN socket

on

the rear panel and to a wall outlet.

to a wall outlet

========= ....

To connect an AC power cord securely with the AC plug holder

1 AC IN socket

Plug the power cord into the AC IN socket. Then, attach

the AC plug holder (supplied) on top of the AC power

cord.

To remove the AC power cord

Pull out AC plug holder by squeezing the up and down sides.

-15-

2

Slide the AC plug holder over the cord until it connects

with the attached

holder.

11

' ' '~ • - • >; :- ' '> ~: :-~·,._ >

~

<

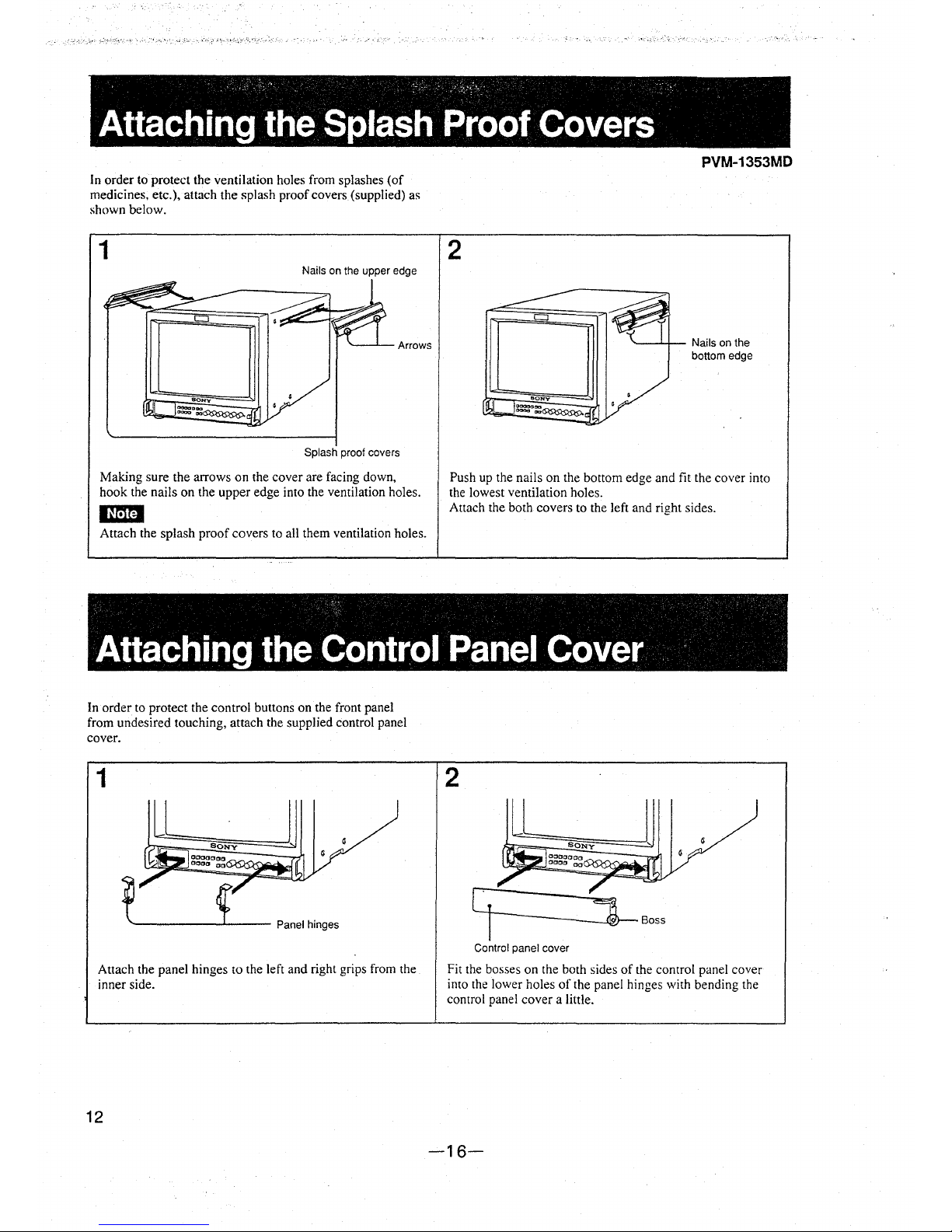

Attaching the Splash Proof Covers

In order to protect the ventilation holes from splashes (of

medicines, etc.), attach the splash proof covers (supplied) as

shown below.

1

Nails on the upper edge

Splash proof covers

Making sure the arrows on the cover are facing down,

hook the nails on the upper edge into the ventilation holes.

Em

Attach the splash proof covers to all them ventilation holes.

2

PVM-1353MD

"----'-+-- Nails on the

bottom edge

Push up the nails on the bottom edge and fit the cover into

the lowest ventilation holes.

Attach the both covers to the left and right sides.

Attaching the Control Panel Cover ·

In order to protect the control buttons on the front panel

from undesired touching, attach the supplied control panel

cover.

1

~---------'---- Panel hinges

Attach the panel hinges to the left and right grips from the

inner side.

12

2

Control panel cover

Fit the bosses on the both sides of the control panel cover

into the lower holes of the panel hinges with bending the

control panel cover a little.

-16-

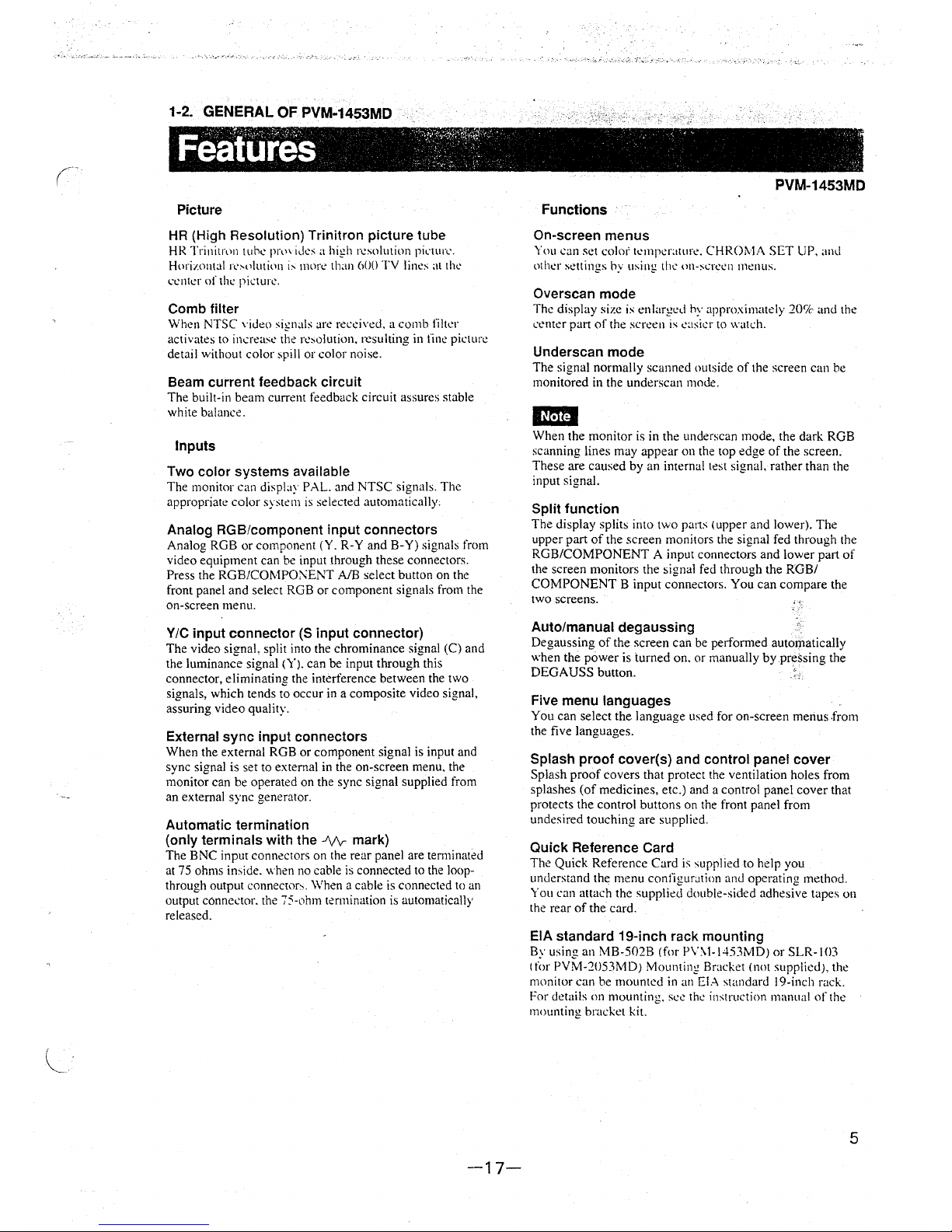

1-2. GENERAL OF PVM-1453MD

Picture

HR (High Resolution) Trinitron picture tube

HR Trinitrt>n tub.: pr,n id.:s a high r.:solution piL·wrc.

Horimntal I\',,>luti,,n i, rnon: than 600

TV lin.:s al th.:

c.:nll:r of

the picturl'.

Comb filter

When NTSC \·ideo sirnals arc rect:i\'ed. a comb filter

activates to increase tl1e re,olution. resulting in fine picture

detail without color spill or color noise.

Beam current feedback circuit

The built-in beam current feedback circuit assures stable

white balance.

Inputs

Two color systems available

The monitor can display PAL. and NTSC signals. The

appropriate color system is selected automatically.

Analog RGB/component input connectors

Analog RGB or component (Y. R-Y and B-Y) signals from

video equipment can be input through these connectors.

Press the RGB/COMPO:\ENT

AIB select button on the

front panel and select RGB or component signals from the

on-screen menu.

Y/C input connector (S input connector)

The video signal, split into the chrominance signal (C) and

the luminance signal

(Y). can be input through this

connector, eliminating the interference between the two

signals, which tends to occur in a composite video signal,

assuring video quality.

External sync input connectors

When the external RGB or component signal is input and

sync signal is set to external in the on-screen menu, the

monitor can be operated on the sync signal supplied from

an external sync generator.

Automatic termination

(only terminals with the

-'Vv-mark)

The BNC input connectors on the rear panel are tem1inated

at 75 ohms in,ide.

when no cable is connected to the loop-

through output

connecwr,. When a cable is connected to an

output connector. the

75-ohm termination is automatically

released.

-17-

PVM-1453MD

Functions

On-screen menus

You can set colo1' t.:rnperatur<:. CHROMA SET UP, and

oth,:r

settings hy using till' on-scr.:.:11 menus.

Overscan mode

Th.: display size is enlarged by approximately 20'7c and the

L'Cnter pal1 of the scr.:en is .:asit:r to watch.

Underscan mode

The signal normally scanned outside of the screen can be

monitored in the underscan mode.

'*"'

When the monitor is in the underscan mode, the dark RGB

scanning lines may appear on the top edge of the screen.

These are caused by an internal test signal. rather than the

input signal.

Split function

The display splits into two pans (upper and lower). The

upper part of the screen monitors the signal fed through the

RGB/COMPONENT A input connectors and lower part of

the screen monitors the signal fed through the RGB/

COMPONENT B input connectors. You can compare the

two screens.

Auto/manual degaussing

Degaussing of the screen can be performed auto1J1atically

when the power is turned on. or manually by pressing the

DEGAUSS button.

Five menu languages .

You can select the language used for on-screen menus .from

the five languages.

Splash proof cover(s) and control panel cover

Splash proof covers that protect the ventilation holes from

splashes (of medicines, etc.) and a control panel cover that

protects the control buttons on the front panel from

undesired touching are supplied.

Quick Reference Card

The Quick Reference Card is supplied to help you

understand the menu configuration

and operating method.

You can attach the supplied double-sided adhesive tapes on

the rear of the card.

.

EIA standard 19-inch rack mounting

By using an MB-502B (for P\'\l-1453MD) or SLR-103

t for PVM-2053MD) Mounting Bracket (not supplied), the

monitor can be mounted in

an El..\ standard 19-inch rack.

For details on mounting. see th.: instruction manual of the

mounting

bracket kit.

5

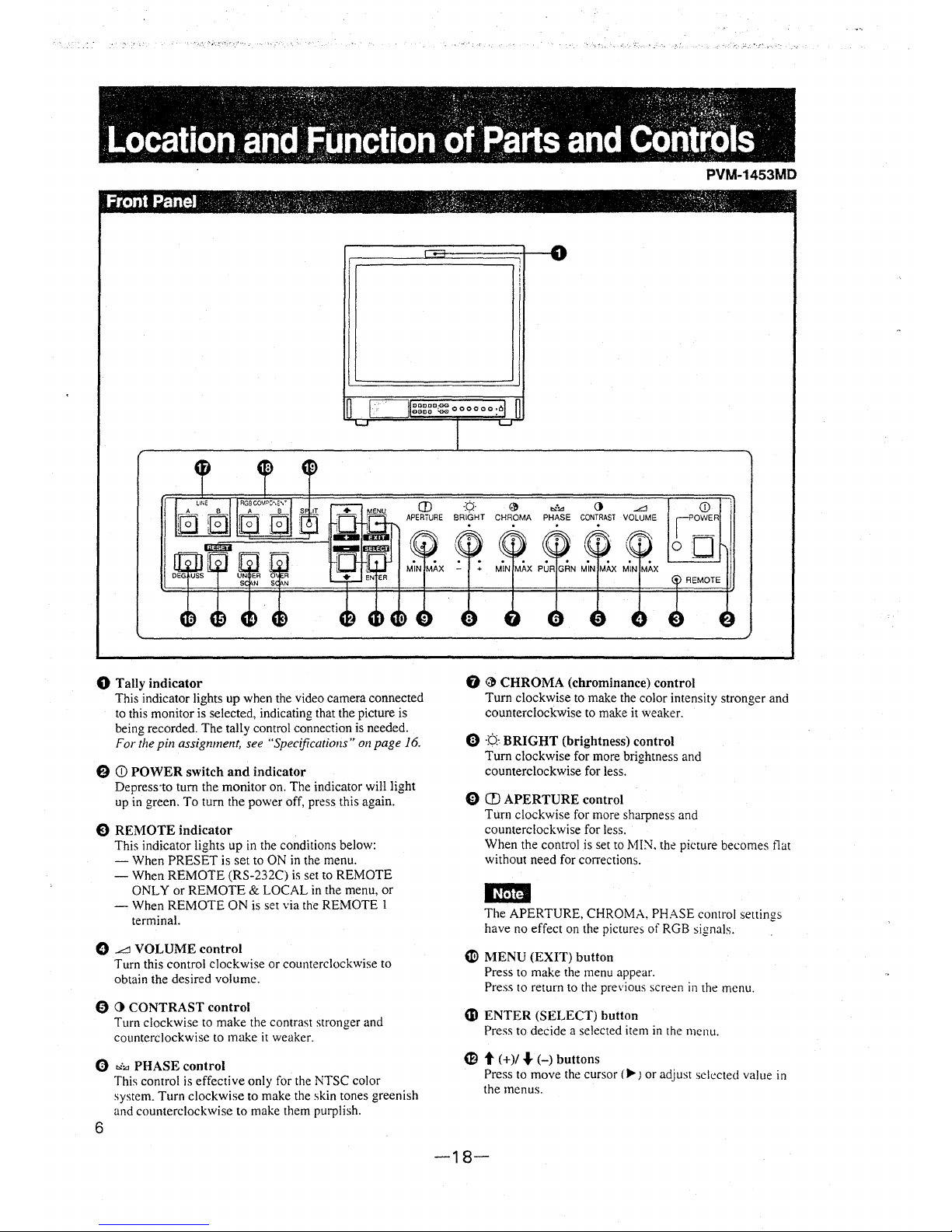

PVM-1453MD

~

00000

;00000000 o n

~0000 '00 : u

0 Tally indicator

This indicator lights up when the video camera connected

to this monitor is selected, indicating that the picture is

being recorded. The tally control connection is needed.

For the pin assignment, see "Specifications" on page 16.

8 CD POWER switch and indicator

Depress·to tum the monitor on. The indicator will light

up in green. To turn the power off, press this again.

E) REMOTE indicator

This indicator lights up in the conditions below:

- When PRESET is set to ON in the menu.

- When REMOTE (RS-232C) is set to REMOTE

ONLY or REMOTE

& LOCAL in the menu, or

- When REMOTE ON is set via the REMOTE I

terminal.

0 L'.l VOLUME control

Turn this control clockwise or counterclockwise to

obtain the desired volume.

0 (} CONTRAST control

Turn clockwise to make the contrast stronger and

counterclockwise to make it weaker.

0 ""."' PHASE control

6

This control is effective only for the NTSC color

system. Turn clockwise to make the skin tones greenish

and counterclockwise to make them purplish.

0 "'"' 0 .L:J

CHROMA PHASE CONTRAST VOLUME

REMOTE

G

~

CHROMA (chrominance) control

Turn clockwise to make the color intensity stronger and

counterclockwise to make it weaker.

8 ·¢.· BRIGHT (brightness) control

Turn clockwise for more brightness and

counterclockwise for less.

0 CD APERTURE control

Turn clockwise for more sharpness and

counterclockwise for less.

When the control is set to

MIN. the picture becomes flat

without need for corrections.

IHfiti

The APERTURE, CHROMA. PHASE control settirnis

have no effect on the pictures of RGB signals.

~

e MENU (EXIT) button

Press to make the menu appear.

Press to return to the previous screen in the menu.

(D ENTER (SELECT) button

Press to decide a selected item in the menu.

CB t (+)/ ... (-)buttons

Press to move the cursor (Iii-J or adjust selected value in

the menus.

-18-

;

I

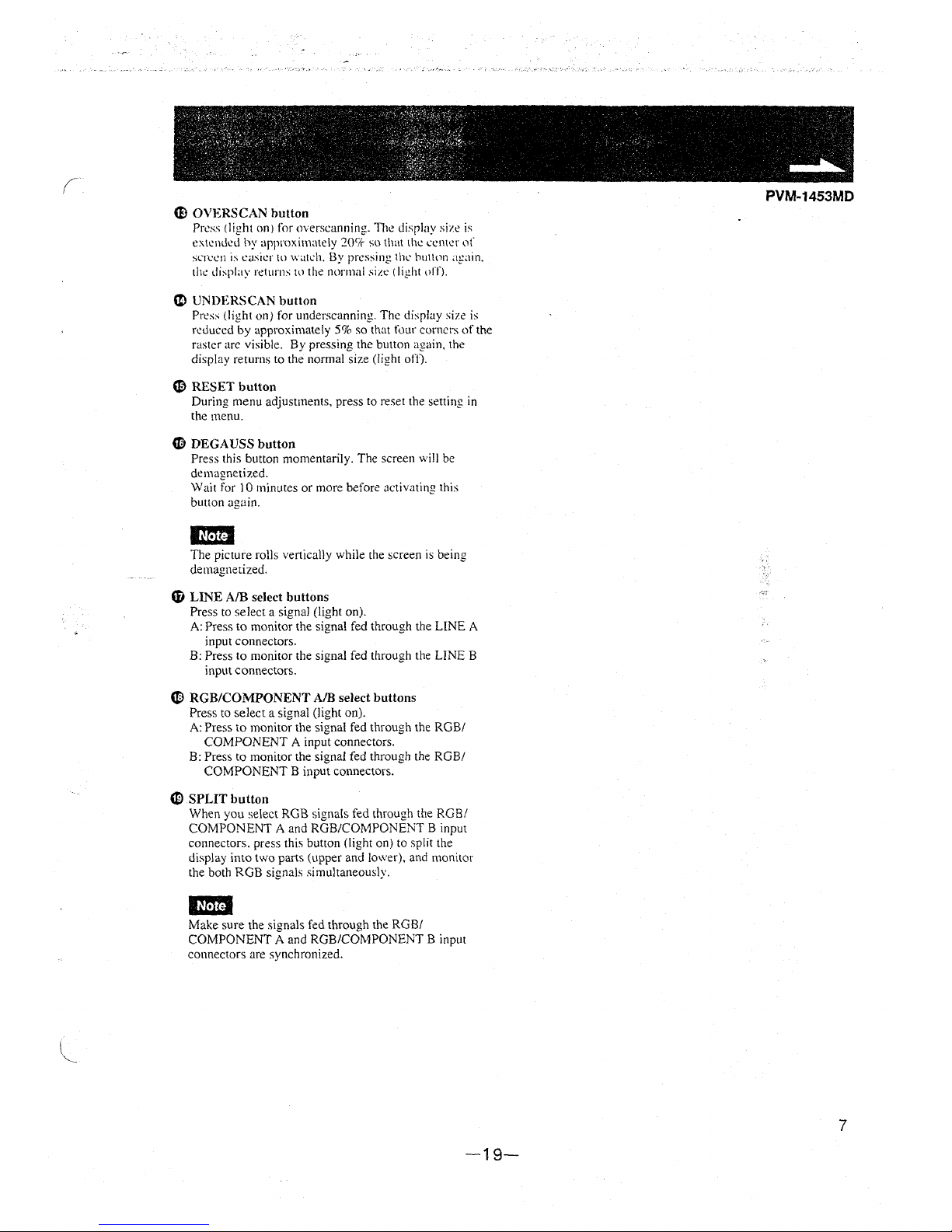

CF) OVERSCAN button

Press (light on) for overscanning. The disrlay size is

extemkd by approximately 2oc1c so that th<.: cel1\n ,)f

screen is easier to w,itch. By pressing the' bullon af,lin.

the display returns Ill the normal size ( light \lff}.

CI) UNDERSCAN button

Press {light on} for underscanning. The display size is

reduced by approximately 5% so that four corners of the

raster arc visible.

By pressing the button again, the

display returns to the normal size (light

off).

C9 RESET button

During menu adjustments, press to reset the setting in

the menu.

CB DEGAUSS button

Press this button momentarily. The screen will be

demagnetized.

Wait for 10 minutes or more before

activating this

button again.

en

The picture rolls vertically while the screen is being

demagnetized.

G) LINE A/B select buttons

Press to select a signal (light on).

A: Press to monitor the signal fed through the LINE A

input connectors.

B: Press to monitor the signal fed through the LINE B

input connectors.

(Ill RGB/COMPONENT A/B select buttons

Press to select a signal (light on).

A: Press to monitor the signal fed through the RGB/

COMPONENT A input connectors.

B: Press to monitor the signal fed through the RGB/

COMPONENT B input connectors.

'1J) SPLIT button

When you select RGB signals fed through the RGB/

COMPONENT A and RGB/COMPONENT B input

connectors. press this button (light on) to split the

display into two parts (upper and lower), and monitor

the both RGB signals simultaneously.

m

Make sure the signals fed through the RGB/

COMPONENT A and RGB/COMPONENT B input

connectors are synchronized.

-19-

PVM-1453MD

7

e

0

I

PVM-1453MD

l-l-----'L='-1:..:NE=-:.A.:.__A_U_D_IO--r~~ C LINE B

AUDIO

OUT

IN OUT IN

OUT

I

0

Im

Before connecting the video equipment. see ·'Important

safeguards/notices for use in the medical environments"

on

page 3.

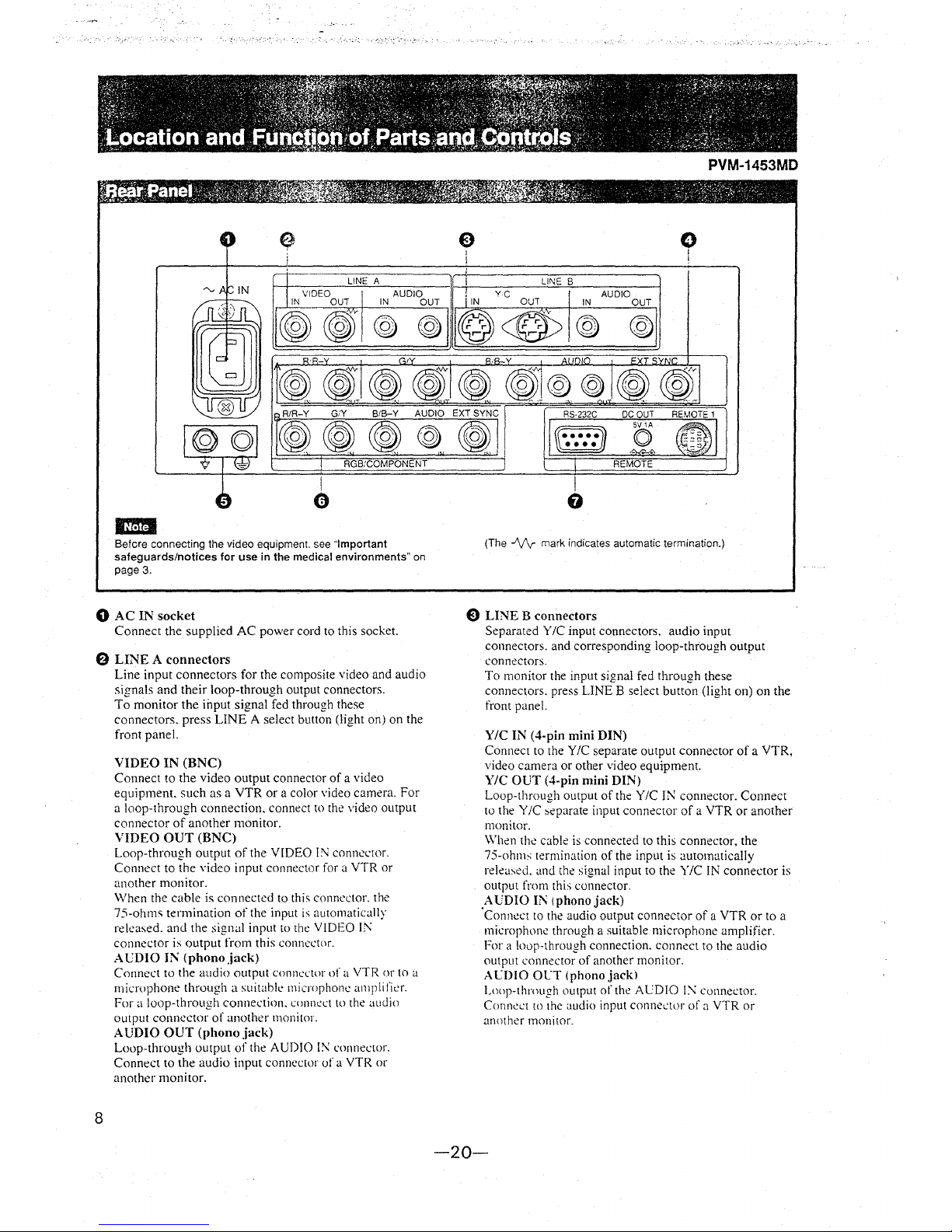

0 AC IN socket

Connect the supplied AC power cord to this socket.

8 LINE A connectors

8

Line input connectors for the composite video and audio

signals and their loop-through output connectors.

To monitor the

input signal fed through these

connectors. press

LINE A select button (light on) on the

front panel.

VIDEO IN (BNC)

Connect to the video output connector of a video

equipment. such as a VTR or a color

video camera. For

a loop-through connection. connect to the video output

connector of another monitor.

VIDEO OUT (BNC)

Loop-through output of the VIDEO l:\l connector.

Connect to the video input connector for a VTR or

another monitor.

When the cable is connected to this connector. the

75-ohms termination of the input is automatically

released. and the signal input to the VIDEO Ii\

connector is output from this connector.

ACDIO IN (phonojack)

Connect to the audio output connector of a VTR or to a

microphone through a

suitable microphone amplifier.

For a loop-through connection. connect to the audio

output connector of another monitor.

AUDIO OUT (phonojack)

Loop-through output of the AUDIO 1:\: connector.

Connect to the audio input

conncctlll' of a VTR or

another monitor.

@<@)

0

(The -'V\r mark indicates automatic termination.)

0 LINE B connectors

Separated Y /C input connectors, audio input

connectors. and corresponding loop-through output

connectors.

To monitor the input signal fed through these

connectors. press

LINE B select button (light on) on the

front panel.

Y/C IN (4-pin mini DIN)

Connect to the Y/C separate output connector of a VTR.

video camera or other video equipment.

Y/C OUT (4-pin mini DIN)

Loop-through output of the Y /C IN connector. Connect

to the Y/C separate input connector of a VTR or another

monitor.

When

the cable is connected to this connector, the

75-ohrns termination of the input is automatically

relea\ed. and the signal input to the Y/C IN connector is

output from this connector.

AUDIO Il\ (phonojack)

·connect to the audio output connector of a VTR or to a

microphone through a suitable microphone amplifier.

For a loop-through connection. connect to the audio

output connector of another monitor.

ACDIO OLT (phono jack)

Lollp-through output of the ALDIO l:'\ connector.

Connect

w the audio input connector of a VTR or

another monitor.

-20-

(

""-·

0 RGB/COMPONENT A connectors

RGB signal or component signal input connectors and

their loop-through output connectors.

To monitor the input signal fed through these

connectors. press

the RGB/COMPONE;-,iT A select

button (light on) on the front panel.

Then

select one out of four items in the RGB A

SYSTEM menu to set the RGB or COMP (component)

signal and the INT SYNC (internal sync) or EXT SYNC

(external sync) signal.

For the operation through the menus. see pages 10 to

12.

R/R-Y IN, G/Y IN, B/B-Y IN (BNC)

When .. RGB-INT SYNC or .. COMP-INT SYNC" is

selected in the RGB

A SYSTEM menu, the monitor

operates on the sync signal from the G/Y channel.

To monitor the RGB signal

Connect to the analog RGB signal output connectors of

a video camera.

To monitor the component signal

Connect to the R-Y /Y /B- Y component signal output

connectors of a Sony Betacam

SPTM camcorder.

R/R-Y OUT, G/Y OUT, B/B-Y OUT (BNC)

Loop-through outputs of the R/R-Y IN, G/Y IN, B/B-Y

IN connectors.

When the cables are connected to these connectors, the

75-ohms termination of the inputs is automatically

released, and the signal inputs to the R/R-Y

IN, G/Y IN,

BIB-Y IN connectors are output from these connectors.

To output the analog RGB signal

Connect to the analog RGB signal input connectors of a

video printer or another monitor.

To output the component signal

Connect to the R-Y /Y /B- Y component signal input

connectors of a Sony Betacam SP VTR.

AUDIO IN (phono jack)

Connect to the audio output connector of video

equipment

when the analog RGB or component signal is

input.

AUDIO OUT (phono jack)

Loop-through outputs of the AUDIO I~ connector.

EXT SYNC (external sync! IN (BNCJ

When this monitor operates on an external sync signal,

connect the signal from a

sync generator to this

connector.

To use the sync signal fed through this connector, select

.. RGB-EXT SYNC or .. CO'.\IP-EXT SYNC in the

RGB

A SYSTEM menu.

EXT SYNC (external sync) OUT (B:\C)

Loop-through output of the EXT

SYNC IN connector.

Connect to the external sync input connector of video

equipment to be synchronized

with this monitor.

When the cable is connected to this connector, the

75-ohms

termination of the input is released. and the

signal input to the EXT SY'.\C IN connector is output

from this connector.

-21-

PVM-1453MD

0 Ground ('17/@) terminal

Connect a GND cable.

0 RGB/COMPONENT B connectors

RGB signal or component

signal input connectors.

To monitor the input signal

fed through these

connectors, press the RGB/COMPONENT B select

button

(I ight on) on the front panel.

Then select one out of four items in the RGB B

SYSTEM menu to set the RGB or COMP (component)

signal and the INT SYNC (internal sync) or EXT SYNC

(external sync) signal.

For the operation through the menus, see pages JO to

12.

R/R-Y IN, G/Y IN, B/B-Y IN (BNC)

When "RGB-INT SYNC" or "COMP-INT SYNC" is

selected in the RGB B SYSTEM menu, the monitor

operates on the sync signal from the

G/Y channel.

To monitor the RGB signal

Connect to the analog RGB signal output connectors of

a video camera.

To monitor the component signal

Connect to the R-Y /Y /B-Y component signal output

connectors of a Sony Betacam SP car11corder.

AUDIO IN (phono jack)

Connect to the audio output connector of video

equipment when the analog RGB or component signal is

input.

EXT SYNC (external sync) IN (BNC)

When this monitor operates on an external sync signal,

connect the signal from a sync generator to this

connector.

To use the sync signal fed through this connector, select

"RGB -EXT SYNC" or "COMP-EXT SYNC" in the

RGB B SYSTEM menu.

0 REMOTE connectors

RS-232C (D-sub 9-pin)

Connect to the RS-232C control connector of other

equipment. You can operate the monitor with the

control command from the equipment.

For the details, see the supplied lnte1face Manual for

Programmers.

REMOTE 1 (8-pin mini DIN)

Connect to the tally output connector of a control

console. effects, etc. The tally indicator on the

fro~t

panel will be turned on and off by the connected

equipment.

You can also connect a remote controller using this

connector.

For the pin assig11111ellts of these co1111ectors. see

"Specifications" on page 4.

DC OUT SV /lA connector

You can use this connector as a power source for the

other equipment.

DC 5V

/I A is output.

9

. ,,_

-~.,;.:/ .·. _·, '~ ' . ' ., .. -~::··,\. ',:•,/>.~-<\. r • ', '· •.' • • ,:,S', 1 . _,' . :, ·\','N-'3:\:'.·'· ;' _,,;·' .,:·~:,;;~;~~;_?• y:r;,;

'.~o·sing· On~Screen'"·M.en·us· ,,.;.. . .. ... . ~,,J,,,,w.,h·, .• , .• ---~·~Jt ·· -?~'./~i

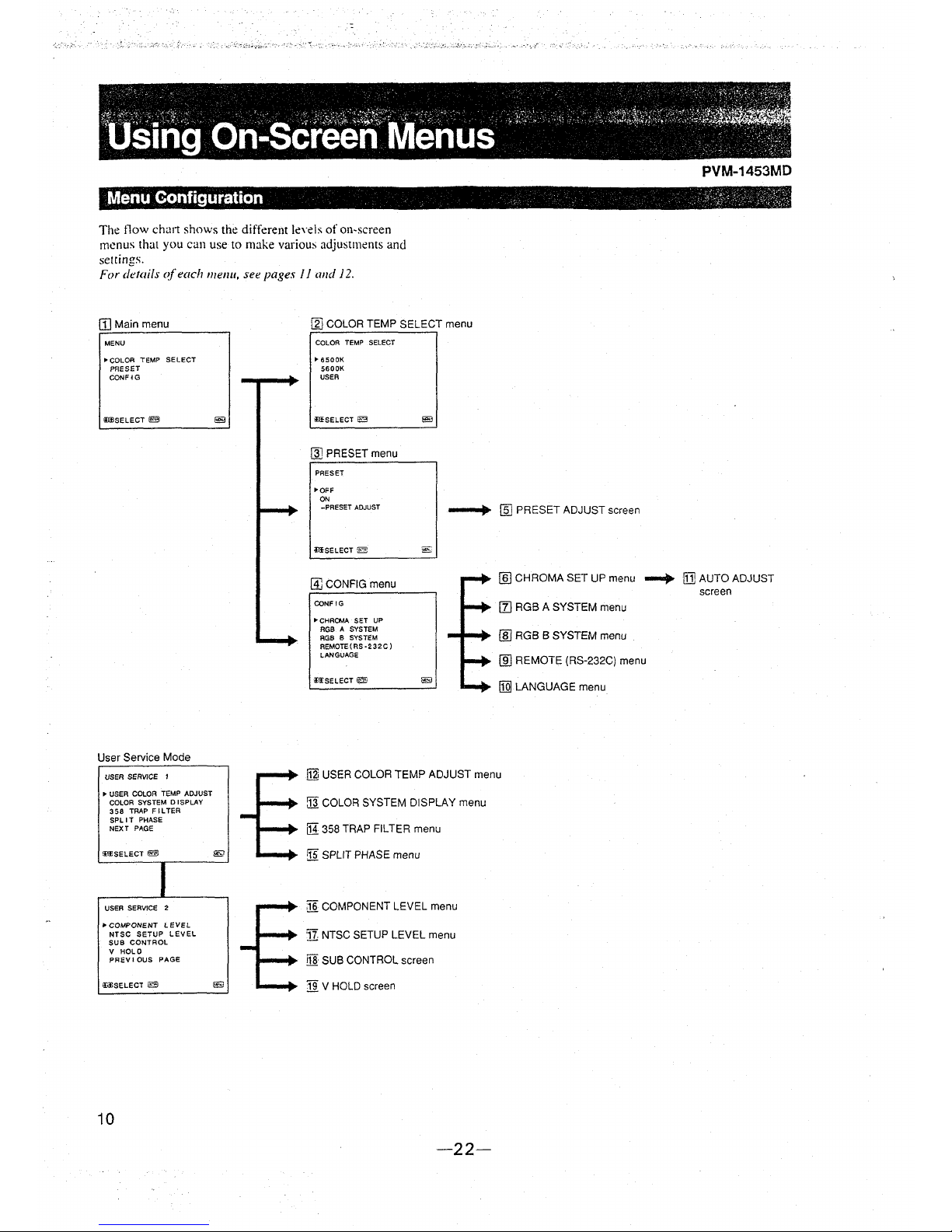

The flow cha11 shows the different Je,·els of on-screen

menus that you can use to make various

adjustments and

settings.

For details <!leach 111e1111, see pages J J and J 2.

[j] Main menu

~

COLOR TEMP SELECT menu

MENU

• COLOR TEMP SELECT

PRESET

CONFlG

(IJJ)SELECT

~

COLOR TEMP SELECT

"'6500K

5600K

USER

ilJ.fSELECT :§1

@] PRESET menu

PRESET

•OFF

ON

-PRESET ADJUST

msELECT 2

@] CONFIG menu

CONF IG

"'CHRCMA SET UP

RGB A SYSTEM

RGB B SYSTEM

REMOTE( RS

·232C)

~

[fil PRESET ADJUST screen

~

[§] CHROMA SET UP menu

[z] RGB A SYSTEM menu

(ID RGB B SYSTEM menu

....

LANGUAGE

(ID REMOTE (RS-232C) menu

User Service Mode

USER SERVICE

'

• USER COLOR TEMP ADJUST

COLOR SYSTEM DI SPLAY

358 TRAP FILTER

SPLIT PHASE

NEXT PAGE

!l1ESELECT

~

I

USER SERVICE 2

• COMPONENT LEVEL

NTSC SETUP LEVEL

SUB CONTROL

V HOLD

PREVIOUS PAGE

iL11SELECT iel

10

@

@

fi:SELECT

~

~

[Q] LANGUAGE menu

fil] USER COLOR TEMP ADJUST menu

:J1 COLOR SYSTEM DISPLAY menu

[H 358 TRAP FIL TEA menu

!Ji SPLIT PHASE menu

]1 COMPONENT LEVEL menu

Jl NTSC SETUP LEVEL menu

!li! SUB CONTROL screen

19 V HOLD screen

-22-

PVM-1453MD

ITIJ AUTO ADJUST

screen

i,;;,,,.:;1,;,,:,-,~~~~,t,::'.,!Wi!i>:S(>l--,iL, :., i ;, ' ' ' ,;f:ft ' ' ' ,,,

... , ........._

. . "" -

. -

' ~' ' • ~ '_t ' < •

~

' '

:operating-through~Nlenus. >- , :-_ '.'

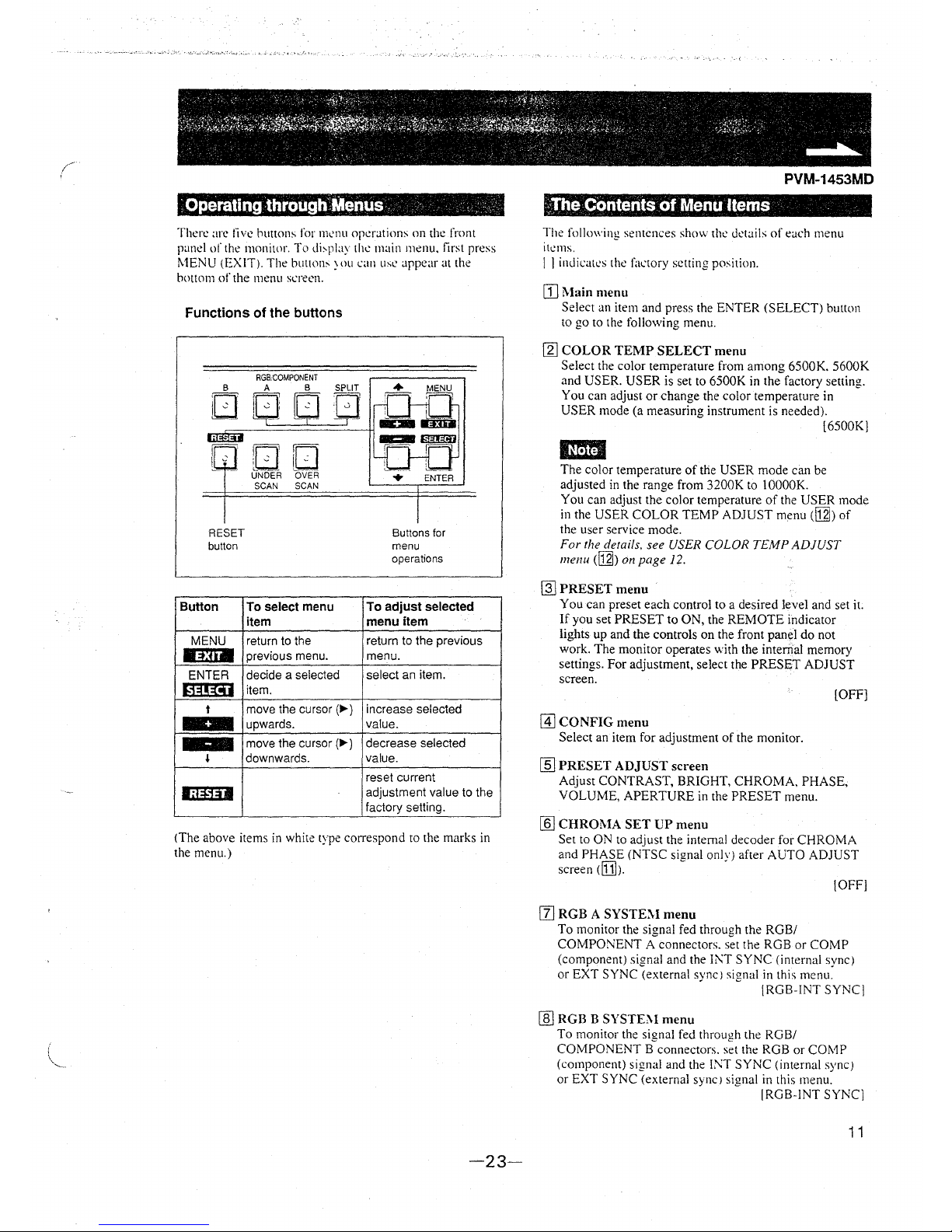

There arc five huttons for menu operations on the front

panel of the monitor_ To di~play the main menu. first press

MENU (EXIT). The hutton, ::,m1 can use appear at the

hottom

of the menu screen.

Functions of the buttons

B

iO

=--

RESET

button

Button

MENU

.!3i11

ENTER

(1~!~!ii

t

'

lili131

RGRCOMPONENT

A B SPLIT

[JD

=o·

I , , , . , ,_

j V i '- V

~- ·r- -1

~

DO

UNDER OVER

SCAN SCAN

To select menu

item

return to the

previous menu.

decide a selected

item.

move the cursor (,._)

upwards.

move the cursor(,..)

downwards.

+ ENTER

Buttons for

menu

operations

To adjust selected

menu item

return to the previous

menu.

select an item.

increase selected

value.

decrease selected

value.

reset current

adjustment value to the

factory setting.

(The above items in white type correspond to the marks in

the menu.)

-23-

PVM-1453MD

},l'he Contents of Menu Items

The following sentences show the details of each menu

items.

I I indicates the factory setting position.

[TI Main menu

Select an item and press the ENTER (SELECT) button

to go to the following menu.

[gJ COLOR TEMP SELECT menu

Select the color temperature from among 6500K. 5600K

and USER. USER is set to 6500K in the factory setting.

You can adjust or change the color temperature in

USER mode (a measuring instrument is needed).

[6500K]

IUfttl

The color temperature of the USER mode can be

adjusted in the range from

3200K to 10000K.

You can adjust the color temperature of the USER mode

in the USER COLOR TEMP ADJUST menu

([gj) of

the user service mode.

For the details, see USER COLOR TEMP ADJUST

menu

([gj) on page 12.

~

PRESET menu

You can preset each control to a desired level and set it.

If you set PRESET to ON, the REMOTE indicator

lights up and the controls on the front panel do not

work. The monitor operates with the

internal memory

settings. For adjustment, select the PRESET ADJUST

screen.

[OFF]

@J CONFIG menu

Select an item for adjustment of the monitor.

[ID PRESET ADJUST screen

Adjust CONTRAST, BRIGHT, CHROMA, PHASE,

VOLUME, APERTURE in the PRESET menu.

lli] CHROMA SET UP menu

Set to ON to adjust the internal decoder for CHROMA

and PHASE (NTSC signal only) after AUTO ADJUST

screen

dU]J.

!OFF]

[zJ RGB A SYSTE'.\1 menu

To monitor the signal fed through the RGB/

COMPONENT A connectors, set the RGB or COMP

(component) signal and the 11\T SYNC (internal sync)

or EXT SYNC (external sync l signal in this menu.

IRGB-INT SYNC]

[ill RGB B SYSTE:\1 menu

To monitor the signal fed through the RGB/

COMPONENT B connectors. set the RGB or COMP

(component) signal and the

INT SYNC (internal sync)

or EXT SYNC (external sync) signal in this menu.

IRGB-INT SYNC]

11

..

~;, ..,.", ~: ... i·f·' . >:, ,,,_:~./ • ... ~.;-",.,,: '>' l

~

" ~ ' • ' > • • •

isillg 6n-Screen Menus .. · .••.. . ·. · •

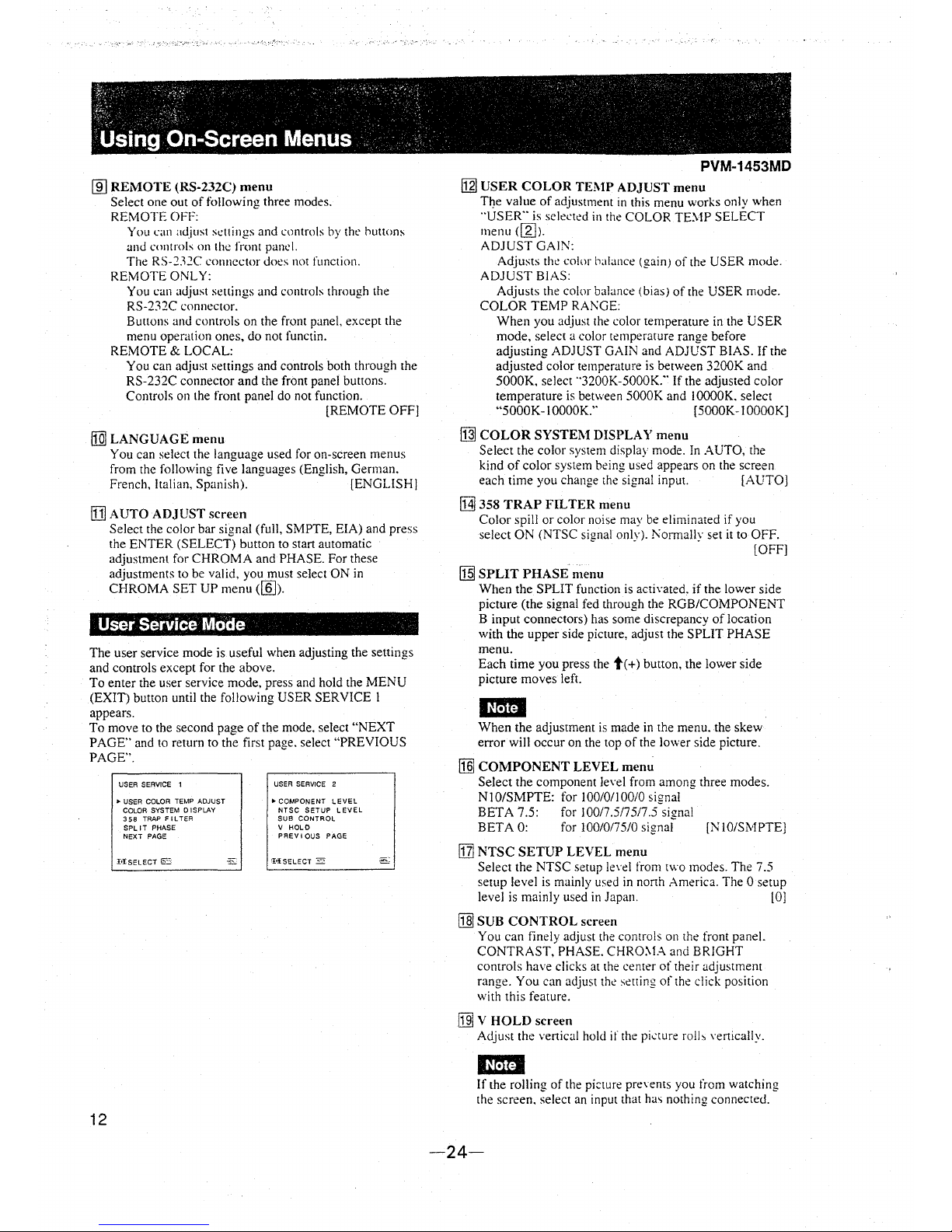

(ID REMOTE (RS-232C) menu

Select one out of following three modes.

REMOTE OFF:

You

can adjust settings and controls by the buttons

and controls on

the front panel.

The RS-232C connector does not function.

REMOTE ONLY:

You

can adjust settings and controls through the

RS-2:12C connector.

Buttons and controls on the front panel, except the

menu operation ones, do not functin.

REMOTE & LOCAL:

You can adjust settings and controls both through the

RS-232C connector and the front panel buttons.

Controls on the front panel do not function.

[REMOTE OFF]

[ill LANGUAGE menu

You can select the language used for on-screen menus

from the following five languages (English, German.

French, Italian, Spanish). [ENGLISH!

\TI] AUTO ADJUST screen

Select the color bar signal (full, SMPTE, EIA) and press

the ENTER (SELECT) button to start automatic

adjustment for CHROMA and PHASE. For these

adjustments to be valid, you must select ON in

CHROMA SET UP menu

([ill).

User Service Mocle

The user service mode is useful when adjusting the settings

and controls except

for the above.

To enter the user service mode, press and hold the MENU

(EXIT) button

until the following USER SERVICE I

appears.

To

move to the second page of the mode. select "NEXT

PAGE" and to return to the first page. select "PREVIOUS

PAGE".

12

USER SERVICE 1

., USER COLOR TEMP ADJUST

COLOR SYSTEM O 1SPLAY

358 TRAP FILTER

SPLIT PHASE

NEXT PAGE

USER SERVICE 2

• COMPONENT LEVEL

NTSC SETUP LEVEL

SUB CONTROL

V HOLD

PAEV I OUS PAGE

'I

1

1SELECT 2

El

I

PVM-1453MD

[gj USER COLOR TEl\tP ADJUST menu

T~e value of adjustment in this menu works only when

"'USER" is selected in the COLOR TE'.vlP SELECT

menu

([g]).

ADJUST GAIN:

Adjusts

the color balance (gain) of the USER mode.

ADJUST BIAS:

Adjusts the color balance (bias) of the USER mode.

COLOR TEMP

RANGE:

When you adjust the color temperature in the USER

mode, select a color temperature range before

adjusting ADJUST GAIN and ADJUST BIAS. If the

adjusted color temperature is between 3200K and

5000K, select

.. 3200K-5000K:· If the adjusted color

temperature is between 5000K and l OOOOK. select

"5000K-IOOOOK.'' [5000K-IOOOOK]

~

COLOR SYSTEM DISPLAY menu

Select the color system display mode. In AUTO, the

kind of color system being used appears on the screen

each time you change the signal input. [AUTO]

M 358 TRAP FILTER menu

Color spill or color noise may be eliminated if you

select ON (NTSC signal only).

l'\ormally set it to OFF.

[OFF)

[§I SPLIT PHASE n1enu

When the SPLIT function is acti\'ated. if the lower side

picture (the signal fed through the RGB/COMPONENT

B input connectors) has some discrepancy of location

with the upper side picture, adjust the SPLIT PHASE

menu.

Each time you press the

t( +) button, the lower side

picture moves left.

l~Mti

When the adjustment is made in the menu. the skew

error will occur on the top of the lower side picture.

[§] COMPONENT LEVEL menu

Select the component Je\·el from among three modes.

NIO/SMPTE: for I00/0/100/0 signal

BETA 7.5: for I00/7.5/75/7.5 signal

BETA 0: for 100/0/75/0 signal

[N 10/Sivf PTEJ

[Z] NTSC SETUP LEVEL menu

Select the NTSC setup le\·el from two modes. The 7.5

setup level is mainly used in north America. The O setup

level is mainly used in Japan. l OJ

G]J SUB CONTROL screen

You can finely adjust the controls on the front panel.

CONTRAST, PHASE.

CHRO:-lA and BRIGHT

controls

have clicks at the center of their adjustment

range. You can adjust

the setting of the click position

with this feature.

[ill V HOLD screen

Adjust the vertical hold if the pi..:ture rolb Yertically.

l~Mti

If the rolling of the pi::ture preYents you from watching

the screen, select an input that

ha, nothing connected.

-24-

;,;::1('' . . ">,,,,, ·'~f·::'. .

Power so·~~ces · . '.·:.~:·~

. '

PVM-1453MD

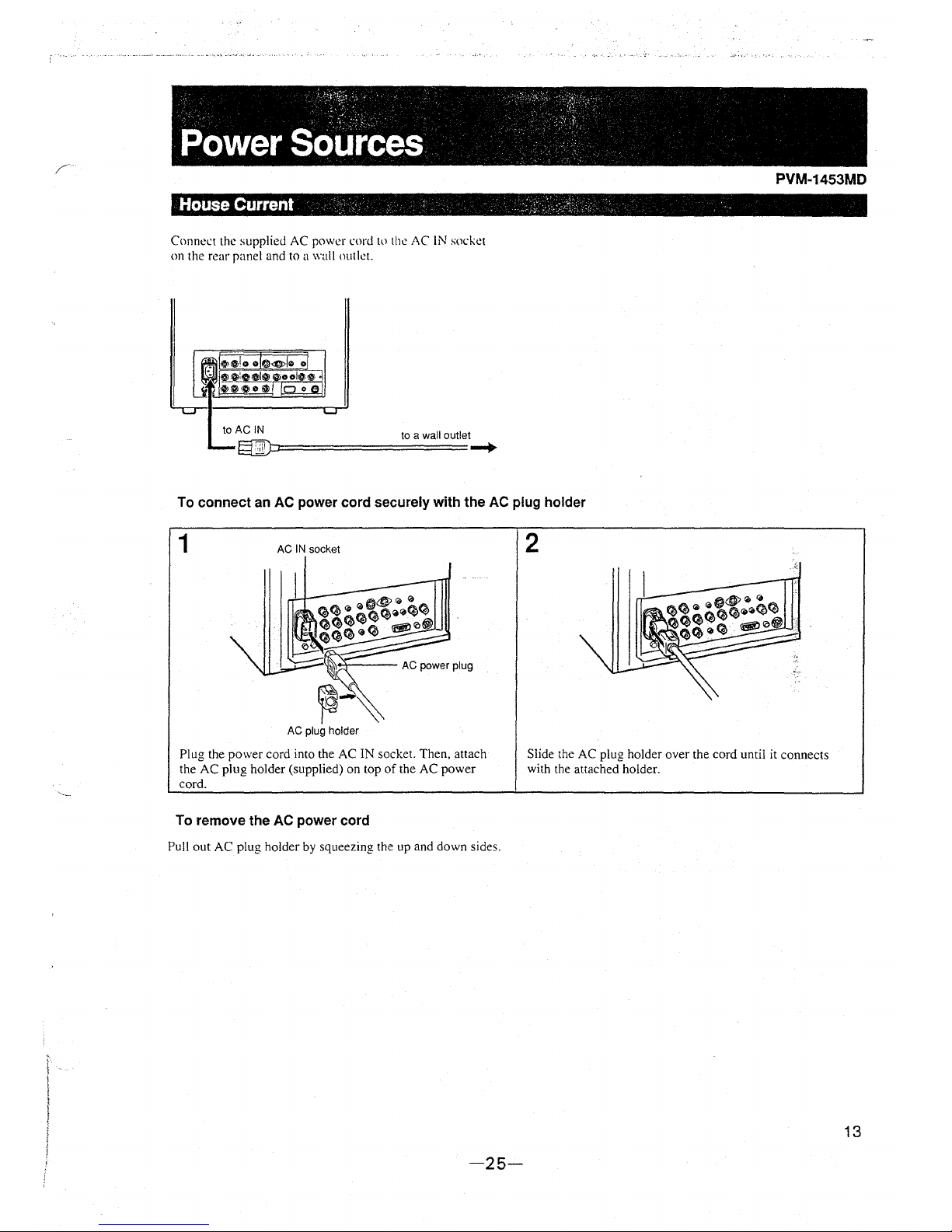

Connect the supplied AC power cord tn the AC IN socket

on the rear panel and to a wall outlet.

to a wall outlet

==========-+

To connect an AC power cord securely with the AC plug holder

1 AC IN socket

,-~

AC plug holder

Plug the power cord into the AC IN socket. Then, attach

the AC plug holder (supplied) on top of the AC power

cord.

To remove the AC power cord

Pull out AC plug holder by squeezing the up and down sides.

-25-

2

Slide the AC plug holder over the cord umil it connects

with the attached holder.

13

,t. '·>_ tt' .. · ' . . - · ... /\ :: ' ,-:··". ·:,:··::;:~;~::\\:;., ... >.~-~\.·:·_;;'.:\ .. :,-.· :····::·:-,·~~')(

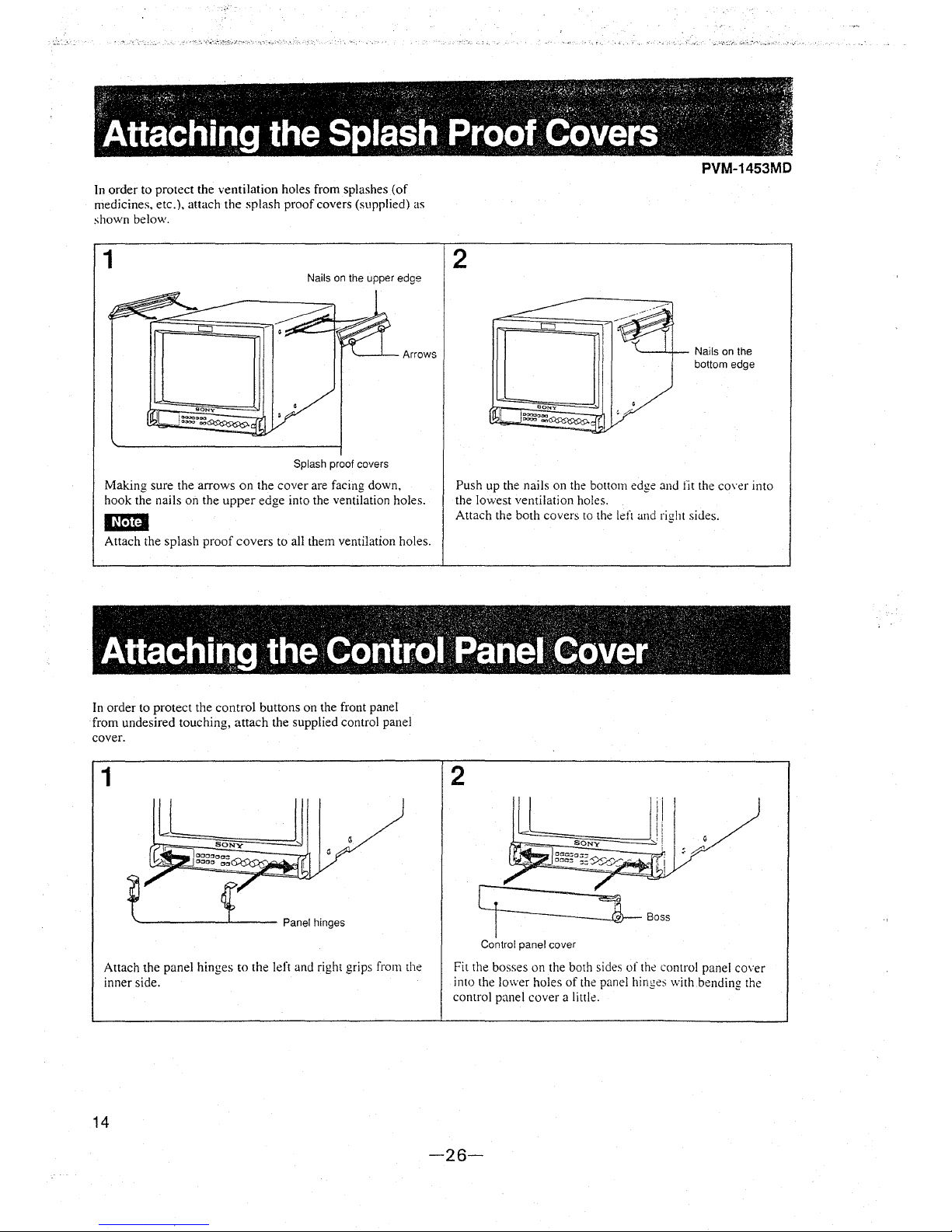

·Attaching the Splash Proof-Coliers :· · · · ·.,_!

In order to protect the ventilation holes from splashes (of