Sony Trinitron KV-AR29T80C,Trinitron KV-AR29X80C Service Manual

HISTORY

When clicking an item, it’s detail is displayed.

Date SUPP./CORR. Description of SUP/COR

Change of

main text

2004.06 NEW –

Model Name: KV-AR29T80C/AR29X80C

SERVICE MANUAL

Part No. : 9-XXX-XXX-01

CHASSIS

SERVICE MANUAL

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

BY-1A

KV-AR29T80C RM-W104 China SCC-M35A-A

KV-AR29X80C RM-W104 China SCC-M35B-A

TRINITRON COLOR TV

R

RM-W104 KV-AR29T80C/AR29X80C

TV

1

2

3

4

6

7

8

9

0

5

MENU

PROG

A/B

RESET

– 2 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

– 3 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

Section Title Page

–––––– –––– ––––

Section Title Page

–––––– –––– ––––

6. DIAGRAMS

6-1. BLOCK DIAGRAM (1) ........................................... 21

BLOCK DIAGRAM (2) ........................................... 23

BLOCK DIAGRAM (3) ........................................... 25

BLOCK DIAGRAM (4) ........................................... 27

6-2. CIRCUIT BOARDS LOCATION ................................. 29

6-3. SCHEMATIC DIAGRAMS .......................................... 29

Schematic Diagram of A (1/3) Board ........................ 31

Schematic Diagram of A (2/3) Board ....................... 33

Schematic Diagram of A (3/3) Board ....................... 35

Schematic Diagram of C Board ................................ 37

Schematic Diagram of D3, H Board ........................ 39

Schematic Diagram of J Board ................................ 41

Schematic Diagram of U Board ............................... 43

6-4. PRINTED WIRING BOARD ........................................ 45

• A Board ................................................................... 45

• C Board ................................................................... 47

• D3 Board ................................................................. 48

• H Board ................................................................... 49

• J Boards .................................................................. 50

• U Board ................................................................... 51

6-5. WAVEFORMS ............................................................... 53

6-6. SEMICONDUCTORS ................................................... 54

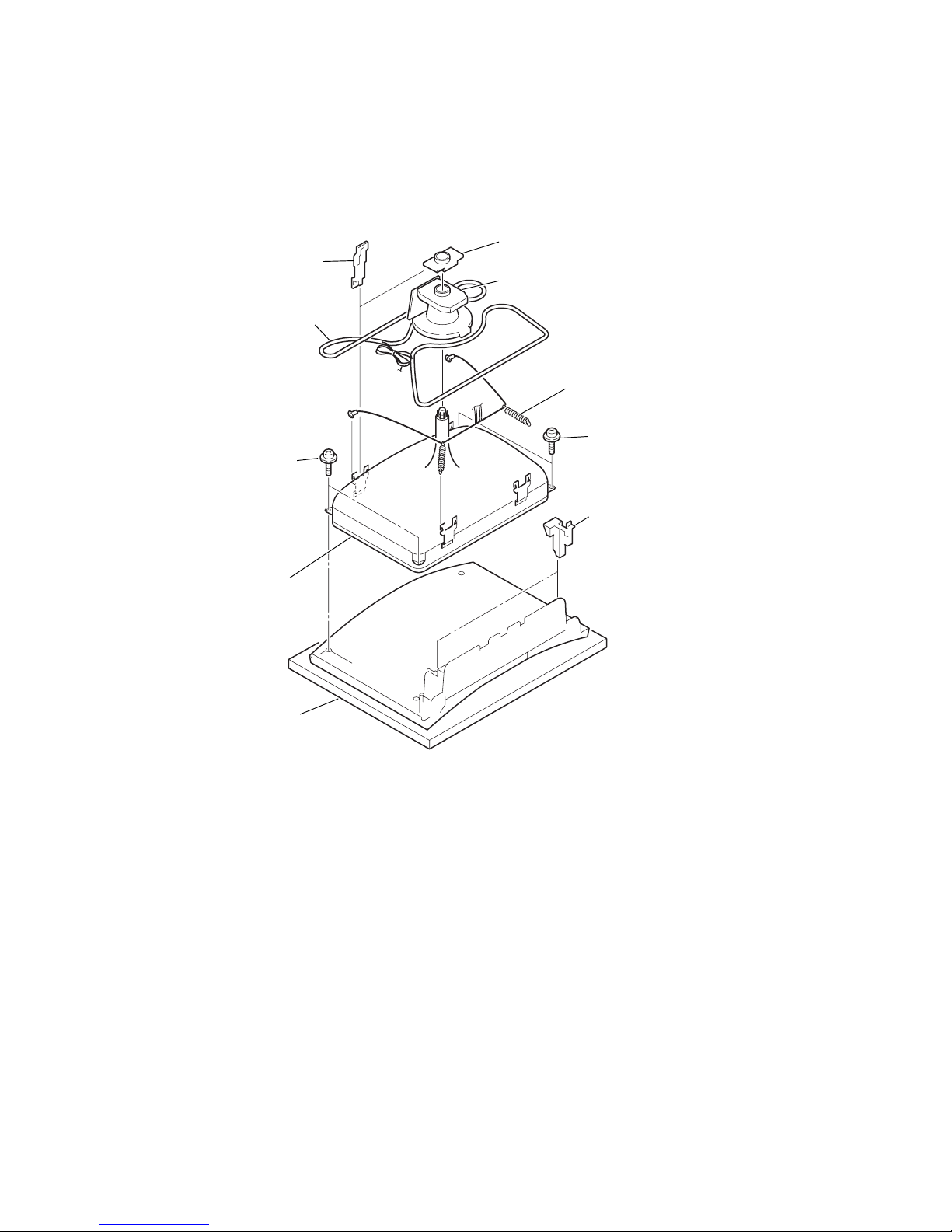

7. EXPLODED VIEWS

7-1. CHASSIS SECTION ................................................ 55

7-2. CRT SECTION ......................................................... 56

7-3. BEZEL SECTION ..................................................... 57

8. ELECTRICAL PARTS LIST.

• A Board ............................................................................... 58

• C Board ............................................................................... 63

• D3 Board ............................................................................. 64

• H Board ............................................................................... 64

• J Board ................................................................................ 64

• U Board ............................................................................... 64

TABLE OF CONTENTS

1. SPECIFICATIONS ............................................................. 4

2. DISASSEMBLY

2-1. REAR COVER............................................................ 5

2-2. SERVICE POSITION ................................................. 5

2-3. SPEAKER ................................................................... 6

2-4. D3 BOARD ................................................................. 6

2-5. H, J BOARDS ............................................................. 6

2-6. TERMINAL BRACKET ............................................. 7

2-7. A BOARD ................................................................... 7

2-8. U BOARD ................................................................... 8

2-9. C BOARD ................................................................... 8

2-10. HARNESS ARRANGEMENT ................................... 8

2-11. REMOVAL OF ANODE-CAP .................................... 9

2-12. CRT ........................................................................... 10

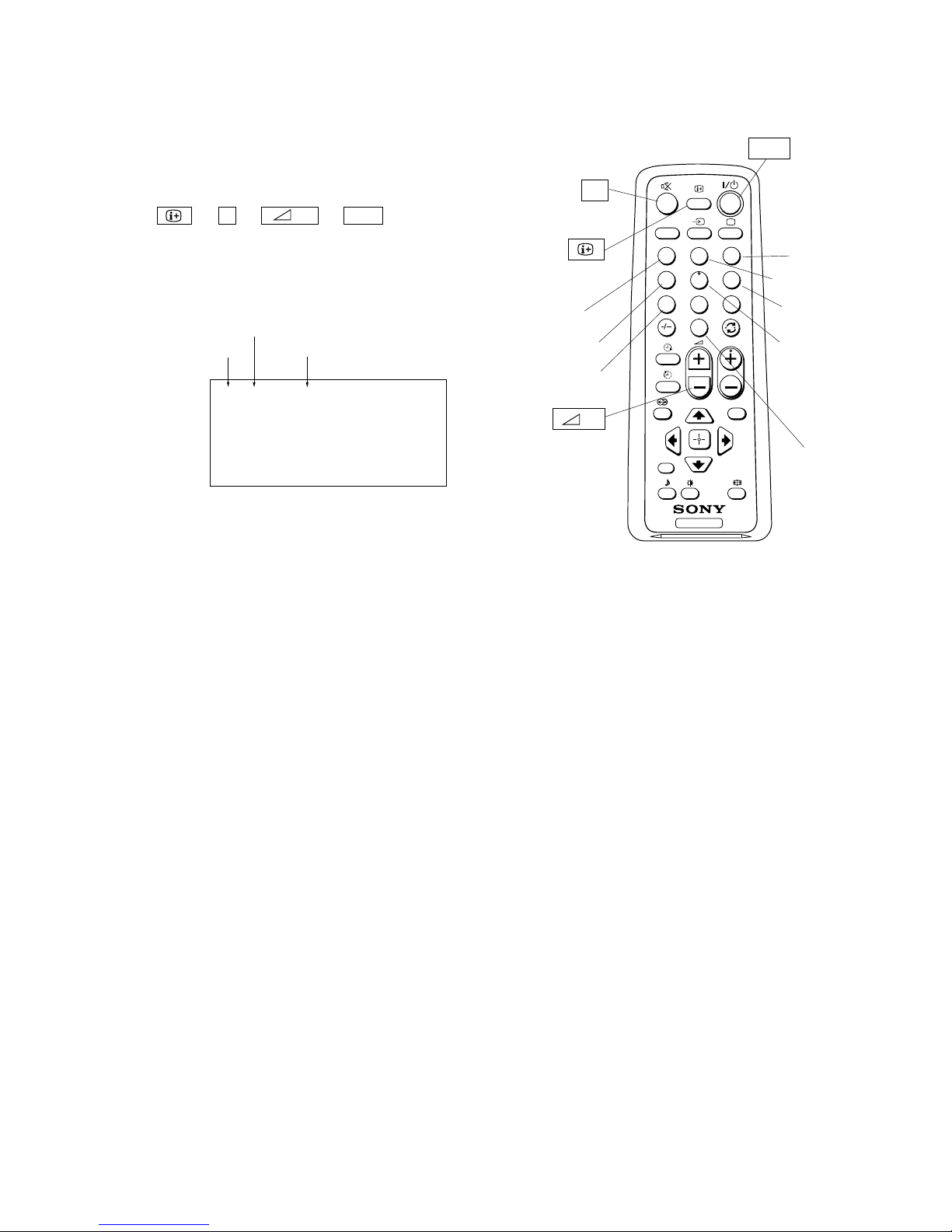

3. SERVICE MODE

3-1. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE ............................................ 11

3-2. SERVICE MODE ADJUSTMENT........................... 11

3-3. MEMORY WRITE CONFIRMATION METHOD .. 11

3-4. ADJUSTING BUTTONS AND INDICATOR ......... 11

3-5. SERVICE MODE LIST ............................................ 12

4. SET-UP ADJUSTMENTS

4-1. BEAM LANDING .................................................... 14

4-2. CONVERGENCE ADJUSTMENT .......................... 15

4-3. G2 (SCREEN) ADJUSTMENT ................................ 17

4-4. FOCUS ADJUSTMENT 1 ........................................ 17

4-5. NECK ASSY TWIST ADJUSTMENT ..................... 17

4-6. SFC COARSE ADJUSTMENT ................................ 17

4-7. SUB COLOR ADJUSTMENT ................................. 18

4-8. SUB HUE ADJUSTMENT....................................... 18

4-9. FOCUS ADJUSTMENT 2 ........................................ 18

5. SAFETY RELATED ADJUSTMENTS

5-1. CHECKING OCP OPERATION .............................. 19

5-2. CONFIRMATION OF V-PROTECTOR .................. 19

5-3. CHECKING POWER SUPPLY VOLTAGES .......... 19

– 4 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

KV-AR29T80C

Note

KV-AR29X80C

Power requirements 220 V AC, 50 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G, I, D/K, M

Color system PAL, NTSC3.58, NTSC4.43

Channel coverage

B/G VHF : E2 to E12

UHF : E21 to E69

CATV : S01 to S03, S1 to S41

I UHF : B21 to B68

CATV : S01 to S03, S1 to S41

D/K VHF : C1 to C12, R1 to R12

UHF : C13 to C57, R21 to R60

CATV : S01 to S03, S1 to S41, Z1 to Z39

M VHF : A2 to A13

UHF : A14 to A79

CATV : A-8 to A-2, A to W+4, W+6 to W+84

8(Antenna) 75-ohm external terminal

Audio output (Speaker) 7 W + 7 W (6 W + 6 W for 7% distortion)

Number of terminal

(Video) Input: 3 Output: 1 Phono jacks; 1 Vp-p, 75 ohms

(Audio) Input: 3 Output: 1 Phono jacks; 500 mVrms

(S Video) Input: 1 Y: 1 Vp-p, 75 ohms, unbalanced,

sync negative

C: 0.286 Vp-p, 75 ohms

(Component Input: 1 Phono jacks; Y: 1 Vp-p, 75 ohms,

Video) sync negative

C

B

: 0.7 Vp-p, 75 ohms

CR: 0.7 Vp-p, 75 ohms

Audio: 500 mVrms

Picture tube 29 type

Tube size (cm) 72 Measured diagonally

Screen size (cm) 68 Measured diagonally

Dimensions (w/h/d, mm) 765 x 578 x 502

Mass (kg) 48

Design and specifications are subject to change without notice.

SECTION 1

SPECIFICATIONS

– 5 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

SECTION 2

DISASSEMBLY

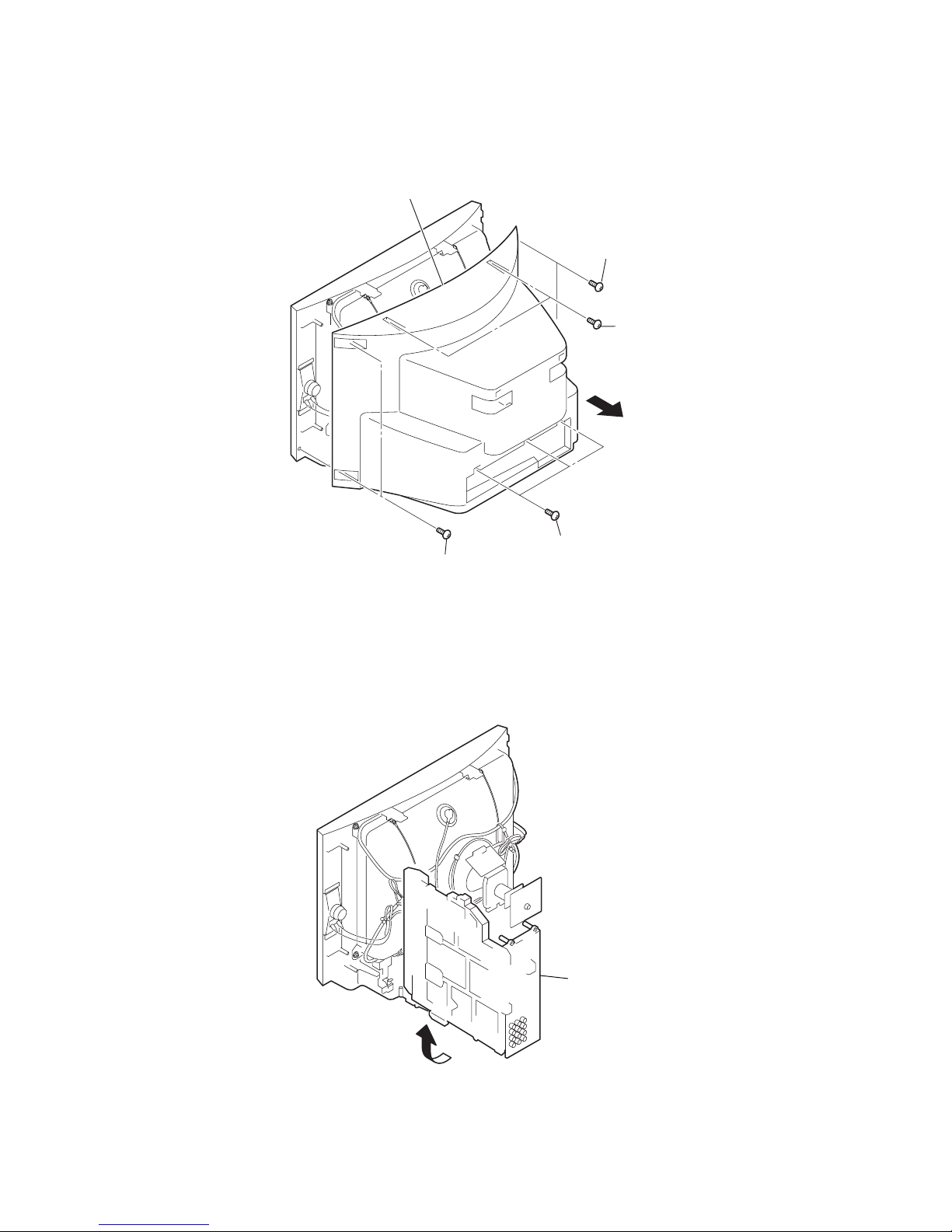

2-1. REAR COVER

2-2. SERVICE POSITION

1 Two screws

(+BVTP 4x16)

1 Two screws

(+BVTP 4x16)

3 Rear cover

2

1 Three screws

(+BVTP 4x16)

1 Two screws

(+BVTP 4x16)

Main bracket assembly

1

– 6 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

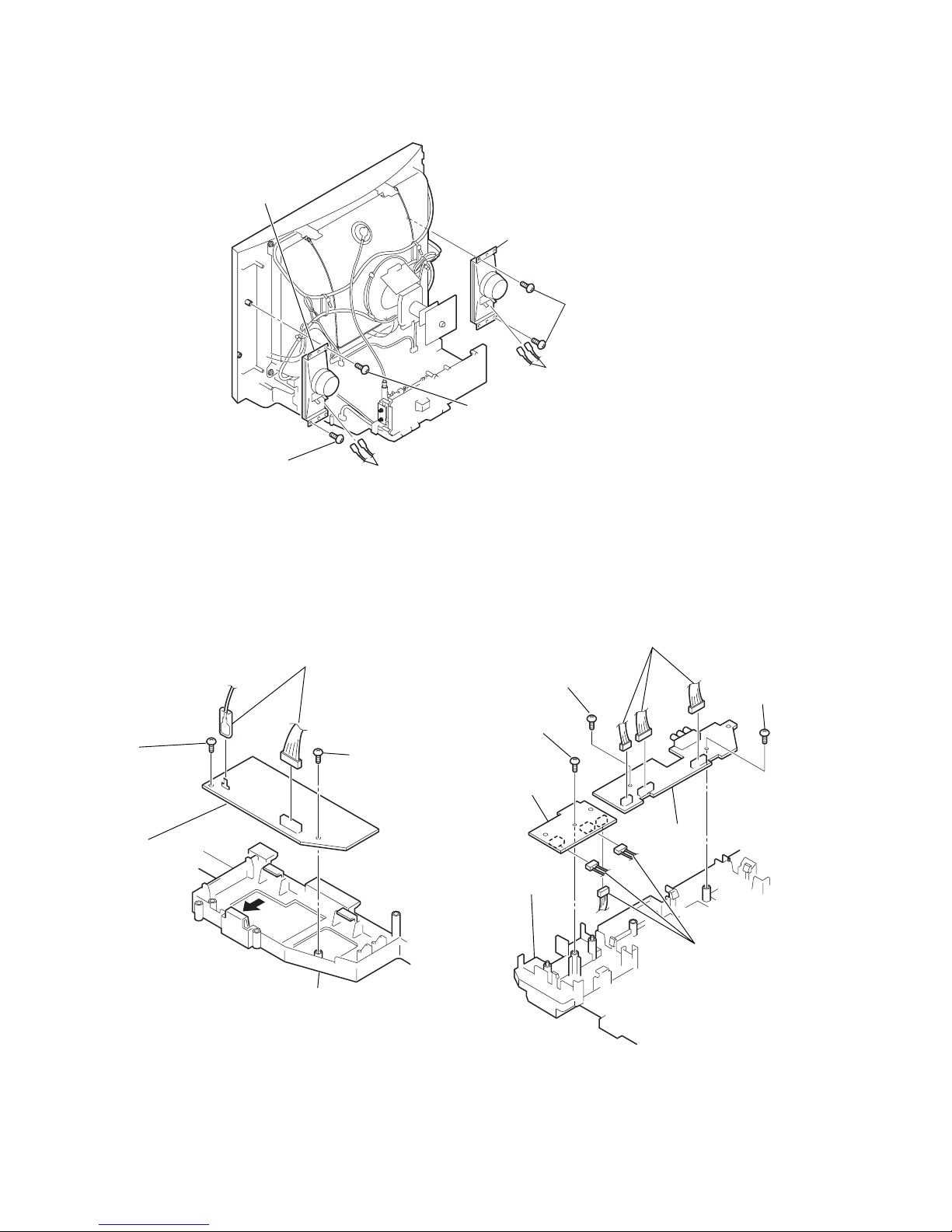

2-5. H, J BOARDS

2-3. SPEAKERS

2-4. D3 BOARD

2 Screw

(+BVTP 4x12)

3 Speaker

6 Speaker

2 Screw

(+BVTP 4x12)

5 Two screws

(+BVTP 4x12)

4 Cables

1 Cables

2 Screw

(+BVTP 3x12)

2 Screw

(+BVTP 3x12)

1 Two connectors

3 D3 board

Main bracket

2 Screw

(+BVTP 3x12)

5 Screw

(+BVTP 3x12)

2 Screw

(+BVTP 3x12)

1 Three connectors

4 Three connectors

6 J board

3 H board

Main bracket

– 7 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

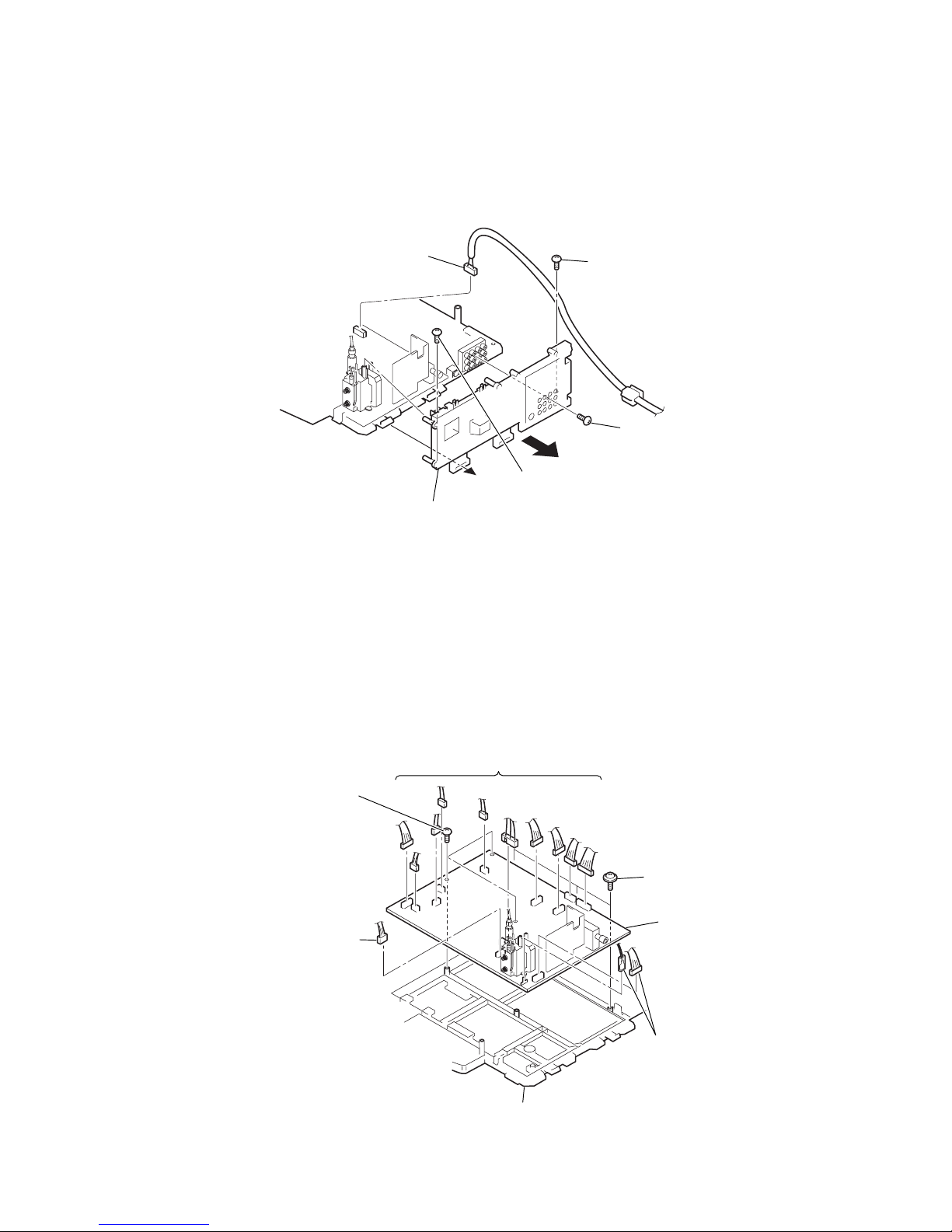

2-6. TERMINAL BRACKET

2-7. A BOARD

2 Screw

(+BVTP 3x12)

2 Screw

(+BVTP 3x12)

1 Connector

4 Ter minal bracket

3

2 Screw

(+BVTP 3x12)

2 Three screws

(+BVTP 3x12)

2 Three screws

(+PWH 3x12)

1 Connectors

1 Connector

1 Connector

3 A board

Main bracket

– 8 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

2-8. U BOARD

2-9. C BOARD

2 Screw

(+BVTP 3x12)

2 Screw

(+BVTP 3x12)

1 Two connectors

3 U board

Main bracket

1 Two connectors

3 C board

1 Connectors

2

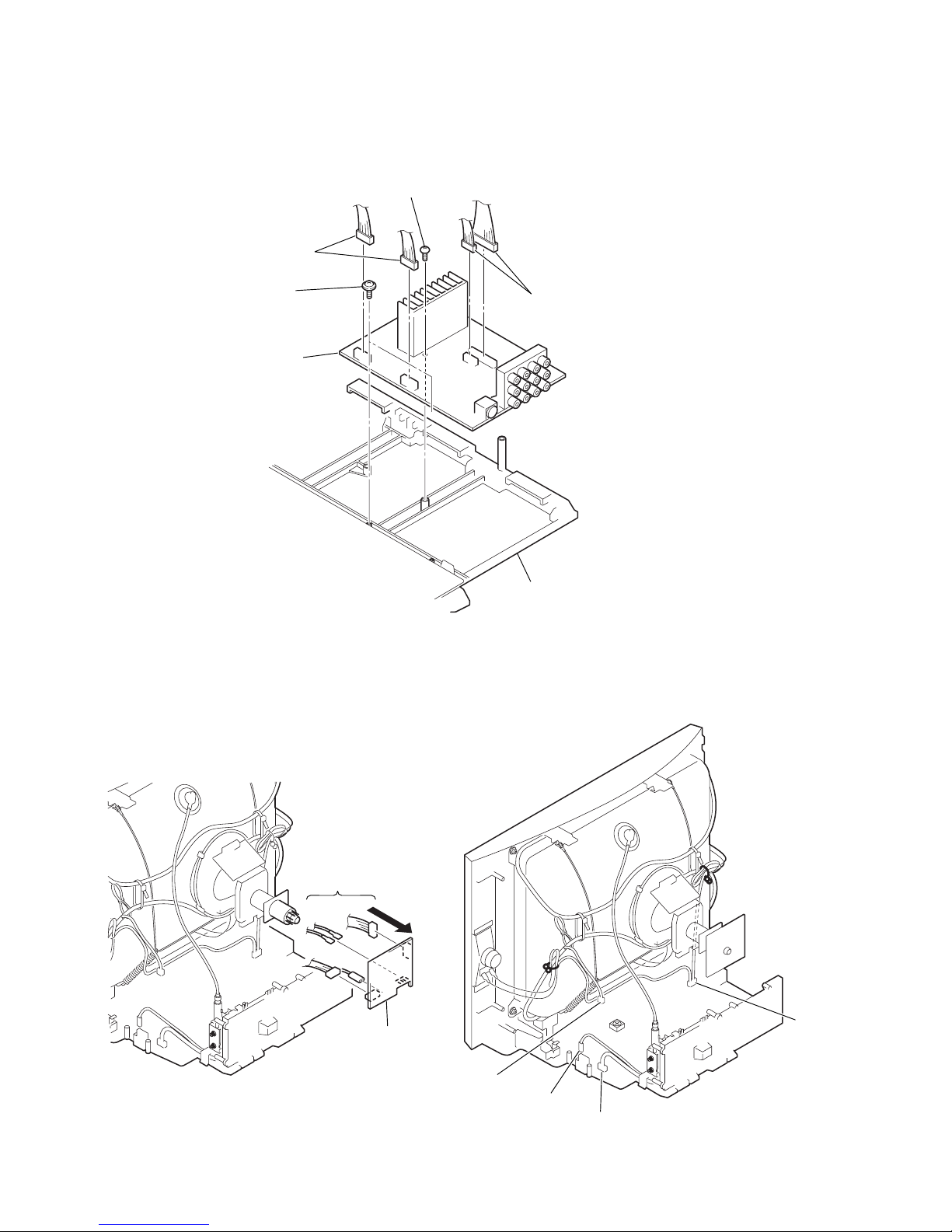

2-10. HARNESS ARRANGEMENT

CN2800

CN401

CN2803

CN603

– 9 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

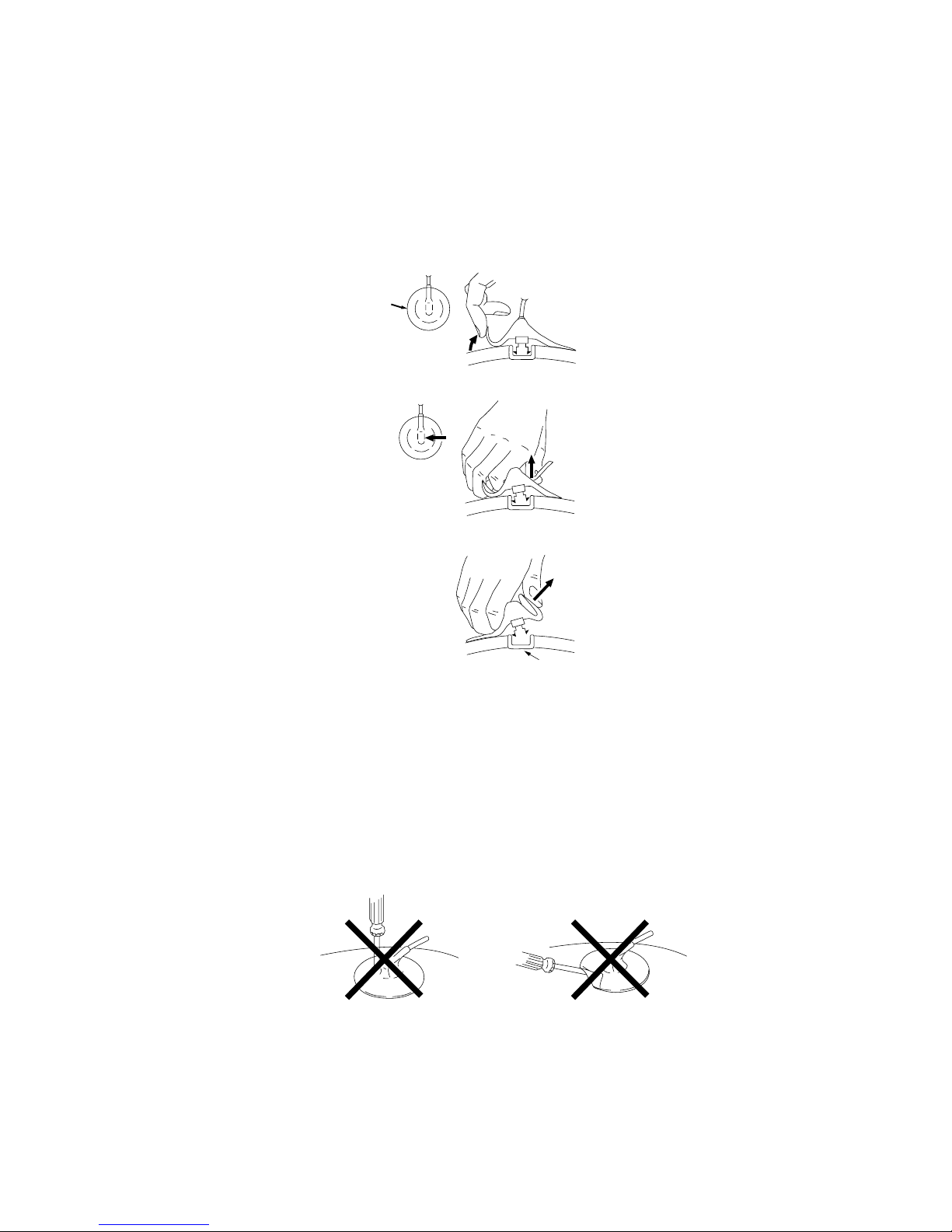

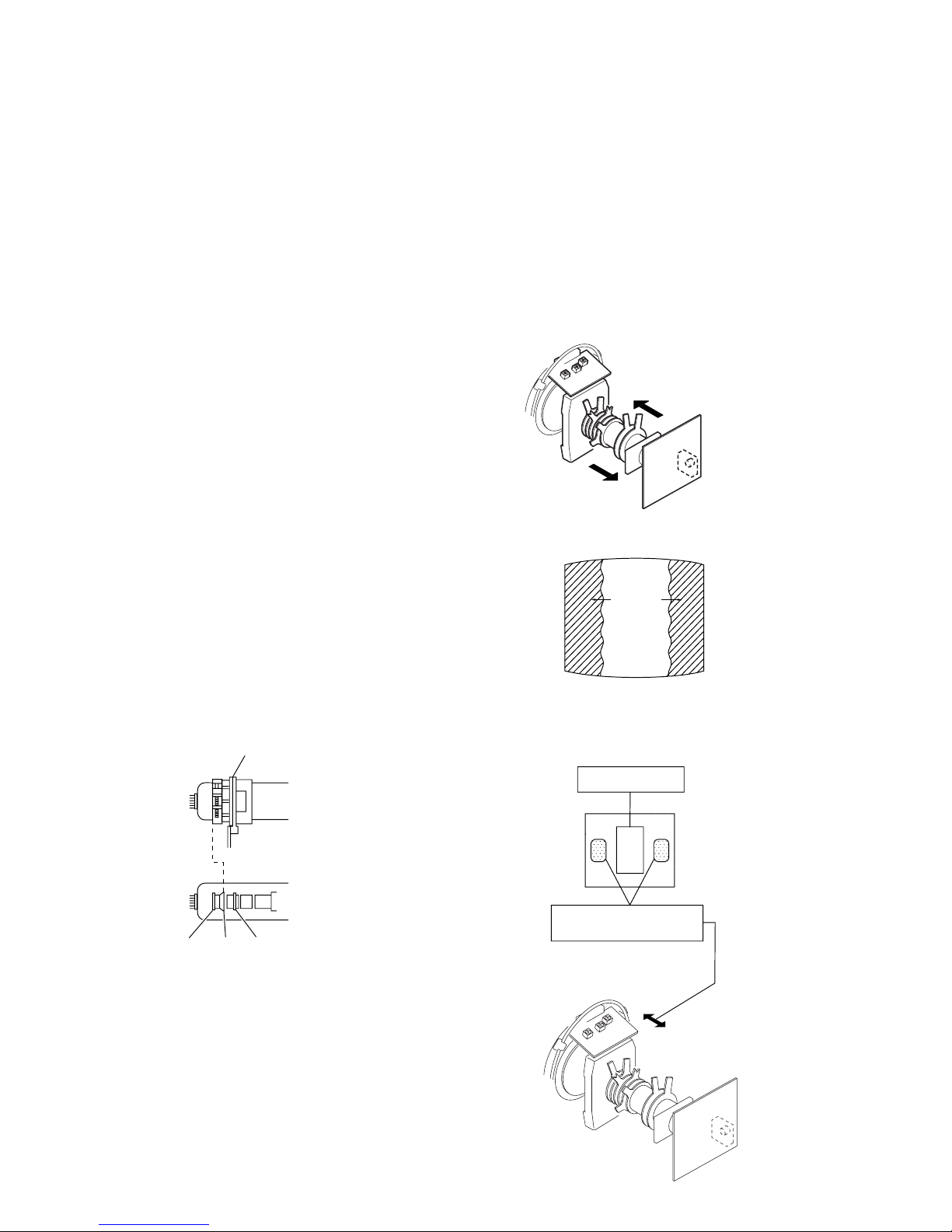

2-11. REMOVAL OF ANODE-CAP

NOTE : After removing the anode, short circuit the anode of the picture tube and

the anode cap to the metal chassis, CRT shield or carbon paint on the

CRT.

• REMOVING

PROCEDURES

1 Do not dama

ge the surface

of anode-caps with

sharp shaped objects.

2 Do not press

the rubber too hard

so as not to damage the inside of

anode-cap.

A metal fitting called

the shatter-hook terminal is built into

the rubber.

3 Do not turn

the foot of rubber over too hard.

The shatter-hook

terminal will stick out

or damage the rubber

.

• HOW TO HANDLE AN ANODE-CAP

3 When one side of the rubber cap is separated

from the anode b

utton, the anode-cap

can be removed by turning up the rubber cap and pulling it up in the direction of the

arrow

c.

2 Using a thumb pull up the rubber

cap firmly in the direction

indicated by the arrow b

.

1 Turn up one side of the rubber cap in the

direction indicated

by the arrow a.

a

a

b

b

c

– 10 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

2-12. CRT

NOTE: After removing the anode, short circuit the anode of the picture tube

and the anode cap to the metal chassis, CRT shield or carbon paint

on the CRT.

6 Two screws

tapping 7 +crown washer

6 Two screws

tapping 7 +crown washer

7 Two CRT supporters

Bezel assembly

3 Springs with ground wires

8 CRT

1 DGC clip

5 Deflection Yoke

4 Neck assembly

2 Degauss coil

– 11 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

TV

1

2

3

4

6

7

8

9

0

5

MENU

PROG

A/B

RESET

3. The SCREEN displays the item being adjusted.

4. Press 1 or 4 on the Remote Commander to select the

adjustment item.

5. Press 3 or 6 on the Remote Commander to change the data.

6. Press 2 or 5 on the Remote Commander to select the

category.

7. If you want to recover the latest values press 7 then - to read

the memory.

8. Press [ MUTING ] then - to write into memory.

9. Turn power off.

Note: Press 8 then - on the Remote Commander to initialize

or turn set off and on to exit.

3-3. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to Service Mode.

3. Call the adjusted items again and confirm they were adjusted.

3-1. METHOD OF SETTING THE SERVICE ADJUSTMENT

MODE

SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. n 5 n (+) n =/1

on the Remote Commander.

(Press each button within a second.)

3-2. SERVICE MODE ADJUSTMENT

3-4. ADJUSTING BUTTONS AND INDICATOR

RM-W104

Adjustment item up

Category up

Data up

Data down

Category down

Data

OSD 0 OSV 32 SERVICE 50 CH 1

Item NO.(register name)

Category

Adjustment item down

SECTION 3

SERVICE MODE

(+)

%

=/1

-

Read

– 12 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

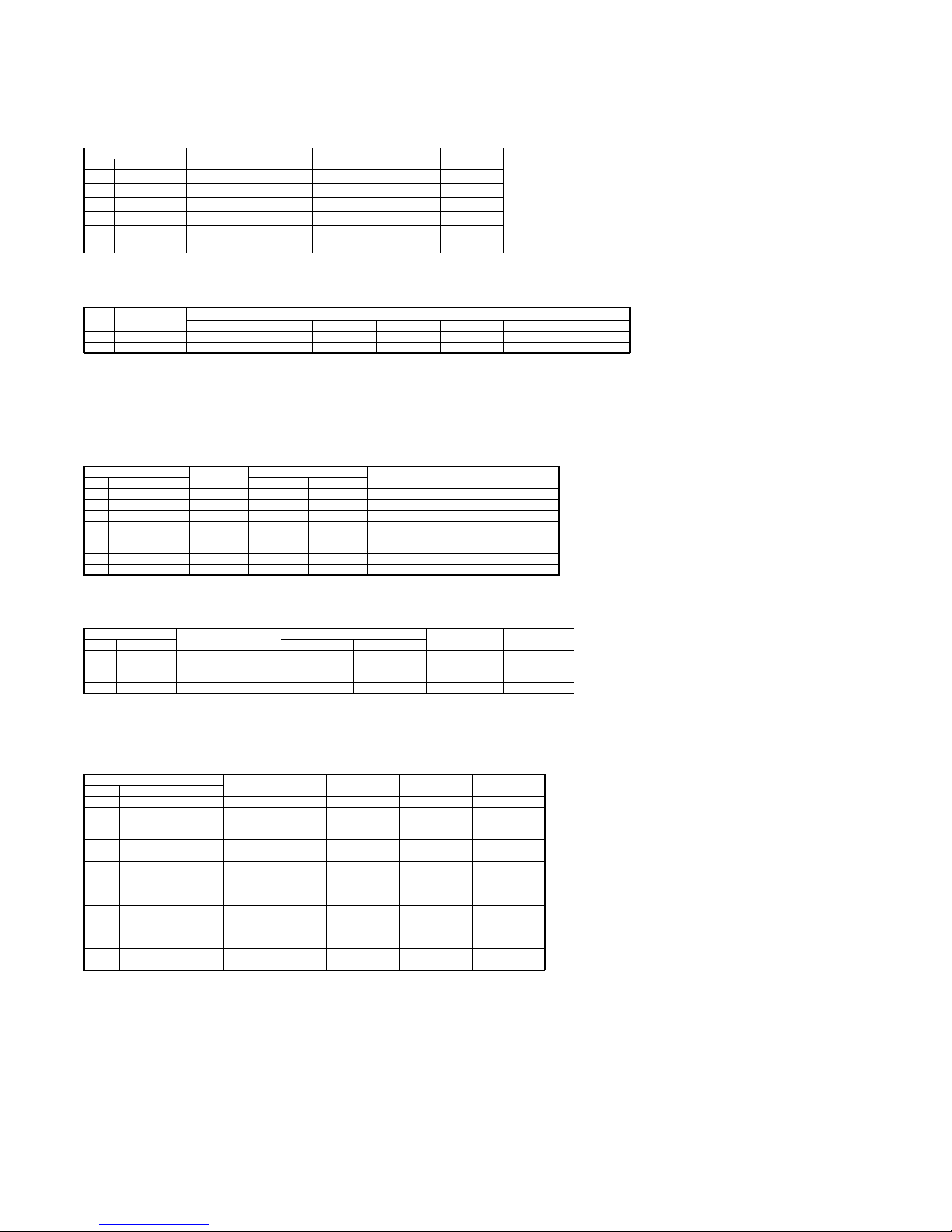

AP

No. Name

0SUBVS-OFF

0 - 3

02

1SUBVS-SIMU

0 - 3

02

2SUBVS-ON

0 - 3

00

3BASS

0 - 15

*1

4TREBLE

0 - 7

*1

5SURROUND 1 - 2 *1

Standards *1

PERSONAL TV-DYNAMIC TV-DRAMA TV-SOFT AV-DYNAMICE AV-DRAMA AV-SOFT

3BASS 7 12 10912109

4TREBLE 3654654

Sub volume surround on

Bass control

Treble control

Surround co ntrol

Funct ion Remar ksStandards

No. ITEM

Funct ionalit y

Range

Standards

Sub volume surround off

Sub volume stereo

3-5.SERVICE LIST

DEF1

No. Name 50Hz 60Hz

0H-PARALLEL 0 - 63 15 15 Horizontal parallelogram

1H-BOW 0-63 1B 1 9 Horizo ntal bow

2H-SHIFT 0-63 25 2C Horizontal shift

3H-WIDTH 0-63 2

A

2A EW width

4H-PARABOLA 0 - 63 15 18 EW parabola

5H-U.CORNER 0 - 63 19 1

F

EW uppercorner parabola

6H-L..CORNER 0-63 16 1D E W lower cor ner parabola

7H-TRAPE 0-63 28 29 EW trapezium

Remarks

Functionality Standards

Range Function

DEF2

No. Nam

e

50Hz 60Hz

0V-SLOPE 0-63 2B 2B Ver tical slope

1V-AMPL.. 0-63 38 3CVertical amplitud

2V-S.CORR 0-63 1C 24 Ver tical s correction

3V-SHIFT 0-63 20 20 Vertical shift

Remarks

Funct ionalit

y

Range

Standards

Function

OP0

No. Name

0FMWS0/1

1IFAGC SPEED

NORM / 0.7◊NORM /

3◊NORM / 6◊ NORM

83

2BlueSCREEN1/0 83

3FOAB

NORM/SLOW/SLOW

FAST/FAST

83

4FORFS

LAST FIELD

FREQUENCY/ATUO

50HZ IF NO SYNC/AUTO

60HZ IF NOSYNC/60HZ

83

5RP010

1:1.8/1:1/1: 1.25/1:1.5

BE

6EVG

OK/NO

BE

7DSK

DYNAMIC SKIN

OFF/DYNAMIC SKIN ON

0F

8HCO

EHT ONVERTICAL/EHT

ON VERT. AND HORI.

0F

Remarks

Funct ionalit y

Range Standar ds F unction

– 13 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

OP1

No. Name

0SOUND SYSTEM I DK / M I DK / BG I DK / M BG I DK 0F

1VIDEOMUTE YES/NO 0F

2SVM YES / NO 0F

3COMBFILTER YES/NO 0F

4 UOC VOLUME 0 - 63 33

Remarks

Funct ionalit y

Range St andards Funct ion

OP2

No. Name

0 NVM WRIGHT 0/1

1 AUTO-SHUTOFF OK/NO BE

2WOOFER OK/NO BE

3AVL ON/OFF BE

4 OVERSCAN TIME: 000MS - 310MS 00

Remarks

Functiona lity

Range Standar ds Functio n

VP

No. Name

0Y-DELAY 0-15 *1

1AGC-TAK 0-63 1F

2CATHODE 0 - 15 05

3SUB-COL -15 - +15 *2

4SUB-BRT -15-+15 *2

5SUB-HUE -15 - +15 *2

6SUB-SHP -15 - +15 *2

Standards *1

PAL NTSC 4.43NTSC3.58

0Y-DELAY 03 03 03 03

Standards *2

TV PAL TV NTSC AV PAL AV NTSC DVD PAL DVD NTSC

3SUB-COL 0A 09 09 07 08 0D

4SUB-BRT 0E 0E 11 11 10 10

5SUB-HUE 0F 0E 0F 0E 0F 0F

6SUB-SHP 05 05 17 17 17 17

Funct ionalit y

Range FunctionStandard s Remarks

Ydelay

AGC v oltag e adjustment

Catho de voltageadjustment

Sub color adjustment

Sub brightnessadjustment

Sub HUE adjustment

Sub sharpness adjustment

No. ITEM

Standards

No. ITEM

Standards

NON FRONT-END

WB

No. Name TV/AV DYAMIC DVD DYNAMIC T V/AV OTHER DVD OTHER

0RCT 0-63 1D 1 E 1E 1E Black level offset R

1GCT 0-63 1

A

1C 1C 15 Black level o ffset G

2RDR 0-63 21 2C 2C 26 Red

g

ain

3 GDR 0 - 63 21 28 28 23 Gr een gain

4BDR 0-64 28 25 25 1

F

Blue gain

5RGBOFF ON/OFF RGB on/off

Remarks

StandardsFunct ionalit y

Range Function

– 14 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

SECTION 4

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switches should be set as follows unless otherwise

noted:

PICTURE control ........................................................... normal

BRIGHTNESS control................................................... normal

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

...................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on the set’s

picture tube, face it east or west.

• Switch on the set’s power and degauss with the degausser.

4-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig4-1.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the purity control so that the green is at the center and the blue and

the red take up equally sized areas on each side.

(See Figures 4-1 through 4-3.)

5. Move the deflection yoke forward and adjust so that the

entire screen is green. (See Figure 4-2.)

6. Switch the raster signal to blue, then to green and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

normal

}

Neck assy

G2G1 G3

Behind the G2 edge

Fig. 4-1

Fig. 4-3

Red

Blue

Green

Fig. 4-4

Purity control

corrects this area.

Deflection yoke positioning

corrects these areas.

Fig. 4-2

– 15 –

KV-AR29T80C/AR29X80C

RM-W104 RM-W104

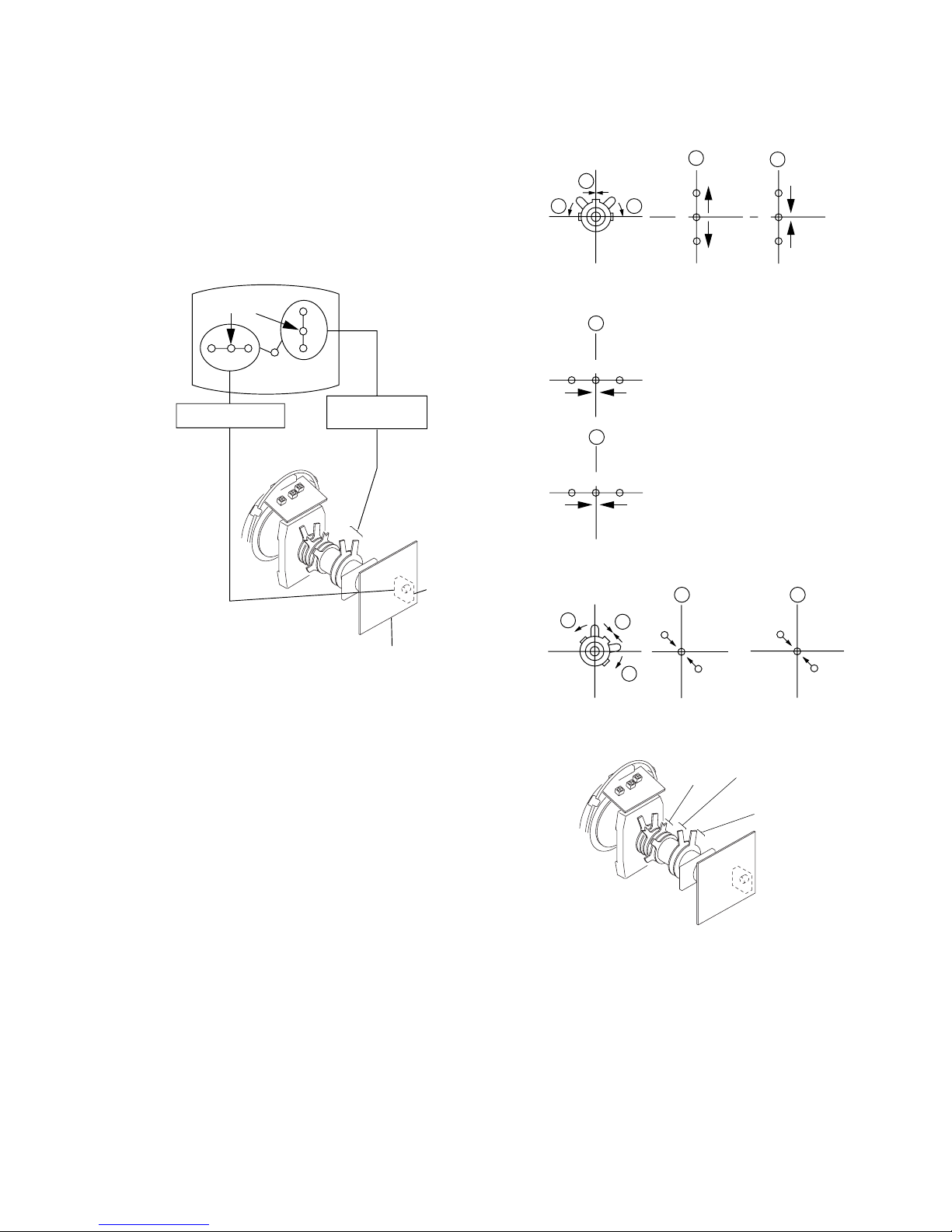

4-2. CONVERGENCE ADJUSTMENT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal

size and vertical size.

• Set the Picture Mode to “STANDARD”.

• Cross hatch / Dot pattern.

4-2-1. Horizontal and Vertical Static Convergence

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center

of the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the

red, green and blue dots are on top of each other at the center

of the screen.

3. If the H.STAT variable resistor cannot bring the red, green

and blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform adjustments while tracking.)

Center dot

R G B

R

G

B

H. STAT VR

V. S TAT

Magnet

RV702

H. STAT

C Board

1

V. STAT

2

H. STAT VR

R

R

G

G

B

B

a

a

b

b b

R

RGGBB

a

b

3

R

R

GG

B

B

a

a

b

b

b

V. STAT

Purity

BMC

Loading...

Loading...