Sony TC-WE625, TС-WE725, TС-WE825S Service Manual

TC-WE625/WE725/

WE825S

SERVICE MANUAL

Photo: TC-WE825S

Dolby noise reduction extension manufactured under license

from Dolby Laboratories Licensing Corporation.

HX Pro originated by Bang & Olufsen. “DOLBY”, the double-D

symbol a and “HX PRO” are trademarks of Dolby Laboratories

Licensing Corporation.

US Model

TC-WE625/WE825S

Canadian Model

TC-WE625

AEP Model

UK Model

TC-WE725/WE825S

E Model

Australian Model

Chinese Model

TC-WE625

Model Name Using Similar

Mechanism

DECK A TC-WE725/WE825S :

Tape Transport TCM-190RB13C

Mechanism Type TC-WE625 : TCM-190RB12CL

DECK B TC-WE725/WE825S :

TC-WE505/WE605S/WE705S

TC-WE625 :TCM-190RB12CL

TCM-190RB11C

System

Recording system

4-track 2-channel stereo

Fast-winding time (approx.)

90 sec. (with Sony C-60 cassette)

High-speed fast-winding time (approx.) (TC-WE825S and TC-WE725

only)

45 sec. (with Sony C-60 cassette)

Bias

AC bias

Signal-to-noise ratio (at peak level and weighted with Dolby NR off)

Type I tape, Sony Type I (NORMAL): 55 dB

Type II tape, Sony Type II (HIGH): 57 dB

Type IV tape, Sony Type IV (METAL): 58 dB

S/N ratio improvement (approximate values)

With Dolby B NR on: 5 dB at 1 kHz, 10 dB at 5 kHz

With Dolby C NR on: 15 dB at 500 Hz, 20 dB at 1 kHz

With Dolby S NR on (TC-WE825S only): 10 dB at 100 Hz,

24 dB at 1 kHz

SPECIFICATIONS

Harmonic distortion

0.4% (with Type I tape, Sony Type I (NORMAL):

160 nWb/m 315 Hz, 3rd H.D.)

1.8% (with Type IV tape, Sony Type IV (METAL):

250 nWb/m 315 Hz, 3rd H.D.)

Frequency response (Dolby NR off)

Tape type

Type I tape, Sony Type I 30-16,000 Hz (±3 dB, IEC),

(NORMAL) 20-17,000 Hz (±6 dB)

Type II tape, Sony Type II 30-17,000 Hz (±3 dB, IEC),

(HIGH) 20-18,000 Hz (±6 dB)

Type IV tape, Sony Type IV 30-19,000 Hz (±3 dB, IEC),

(METAL) 20-20,000 Hz (±6 dB),

30-13,000 Hz (±3 dB, –4 dB

recording)

– Continued on next page –

MICROFILM

STEREO CASSETTE DECK

– 1 –

Wow and flutter

± 0.13% W. Peak (IEC)

0.07% W. RMS (NAB)

± 0.18% W. Peak (DIN)

Variable pitch range (approx.)

–30 to +30%

Inputs

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Line inputs (phono jacks)

Sensitivity : 0.16 V

Input impedance : 47 kilohms

Outputs

Line outputs (phono jacks)

Rated output level : 0.5 V at a load impedance of

47 kilohms

Load impedance : Over 10 kilohms

Headphones (stereo phono jack)

Output level : 0.25 mW at a load impedance of

32 ohms

General

Power requirements

Where purchased Power requirements

US, Canadian 120 V AC, 60 Hz

AEP, UK, Chinese 220 - 230 V AC, 50/60 Hz

Australian 240 V AC, 50/60 Hz

Singapore, Malaysia 120/220/230 - 240 V AC, 50/60 Hz

Power consumption

30 W

Dimensions (approx.) (w/h/d)

Model for UK and Australian :

430 × 120 × 310 mm (w/h/d)

(17 × 4 3/4 × 12 1/4 in.)

Model for other countries :

430 × 120 × 290 mm (w/h/d)

including projecting parts and controls

Mass (approx.)

4.3 kg (9 lbs 8 oz)

Supplied accessories

Audio connecting cords (2 phono plugs - 2 phono

plugs) (2)

CONTROL A1 cord (supplied for Canadian models

only) (1)

Design and specifications are subject to change without

notice.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

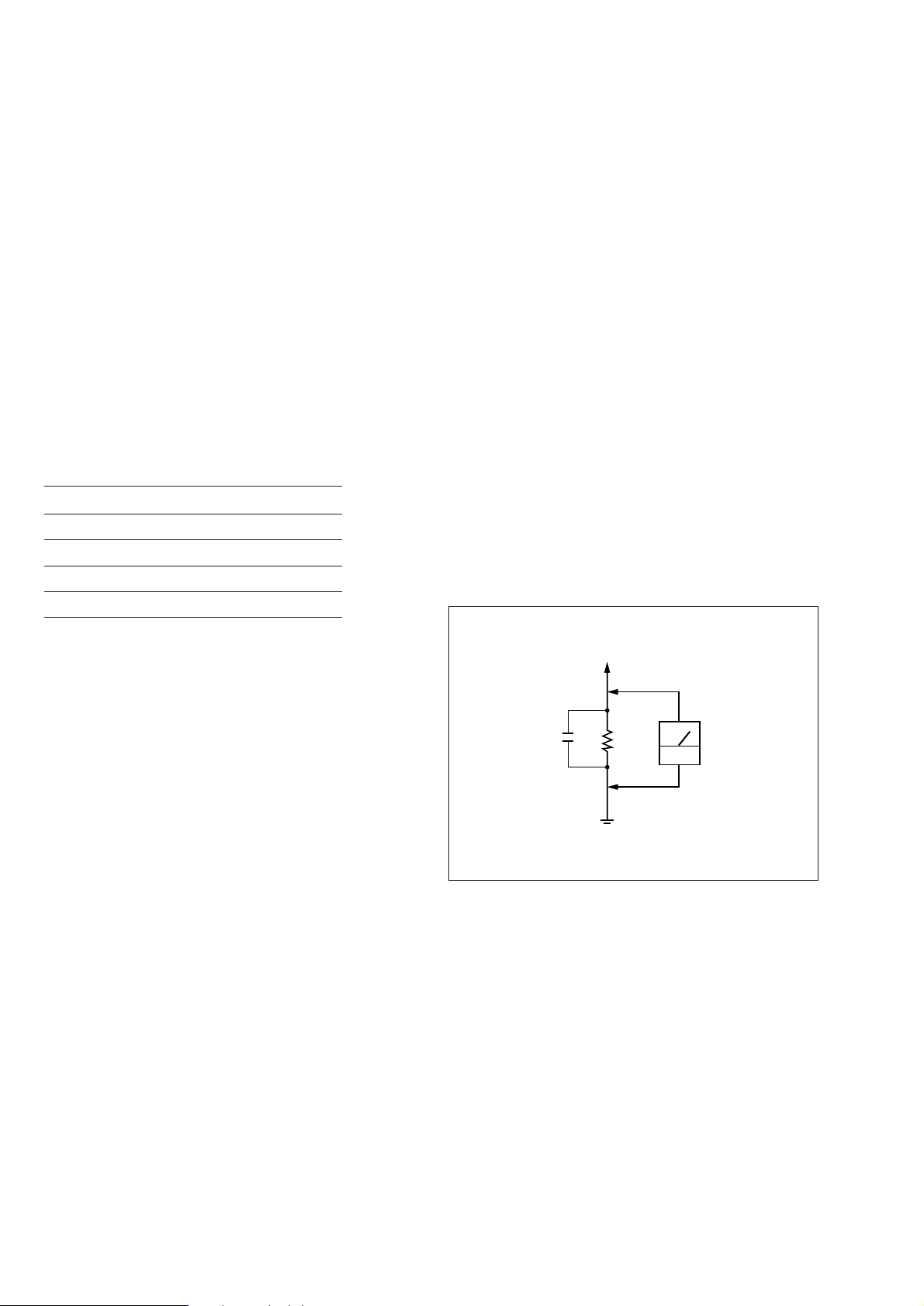

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15

µ

F

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P AR TS WHOSE

P AR T NUMBERS APPEAR AS SHO WN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

MODEL IDENTIFICATION

TABLE OF CONTENTS

–Back panel–

Part No. Model

3-021-228-0π TC-WE625 : US model

3-021-228-1π TC-WE625 : CND model

3-021-228-2π TC-WE625 : AUS model

3-021-228-3π TC-WE625 : SP, MY model

3-021-228-4π TC-WE625 : CH model

3-021-242-0π TC-WE725 : AEP model

3-021-242-1π TC-WE725 : UK model

3-021-243-0π TC-WE825S : AEP model

3-021-243-1π TC-WE825S : UK model

3-021-243-3π TC-WE825S : US model

• Abbreviation

CND : Canadian model

AUS : Austrarian model

SP : Singapore model

MY : Malaysia model

CH : Chinese model

Part No.

1. GENERAL

1-1. Location of Controls ........................................................... 4

2. DISASSEMBLY

2-1. Front Panel Assy .................................................................5

2-2. Mechanism Deck................................................................. 5

2-3. Fitting Base ......................................................................... 6

2-4. Capstan Motor, Reel Motor.................................................6

2-5. Head Deck Assy .................................................................. 7

3. MECHANICAL ADJUSTMENTS................................. 8

4. ELECTRICAL ADJUSTMENTS...................................8

5. DIAGRAMS

5-1. IC Pin Description............................................................. 12

5-2. Circuit Boards Location .................................................... 14

5-3. Printed Wiring Boards –Main Section– ............................ 15

5-4. Schematic Diagram –Main Section (1/4)– ........................ 17

5-5. Schematic Diagram –Main Section (2/4)– ........................ 19

5-6. Schematic Diagram –Main Section (3/4)– ........................ 21

5-7. Schematic Diagram –Main Section (4/4)– ........................ 23

5-8. Printed Wiring Boards –Power Section–...........................25

5-9. Schematic Diagram –Power Section– ............................... 26

5-10. Printed Wiring Boards –Panel Section– ............................ 27

5-11. Schematic Diagram –Panel Section– ................................ 29

5-12. Printed Wiring Boards –Deck A Section–......................... 31

5-13. Schematic Diagram –Deck A Section– .............................32

5-14. Printed Wiring Boards –Deck B Section–......................... 33

5-15. Schematic Diagram –Deck B Section– .............................34

5-16. Printed Wiring Board

–DOLBY-S Section (TC-WE825S only)–........................ 35

5-17. Schematic Diagram

–DOLBY-S Section (TC-WE825S only)–........................ 35

6. EXPLODED VIEWS

6-1. Case Section ......................................................................38

6-2. Chassis Section ................................................................. 39

6-3. Cassette Holder Section .................................................... 40

6-4. Front Panel Section ........................................................... 41

6-5. Tape Mechanism Section 1 ............................................... 42

6-6. Tape Mechanism Section 2 ............................................... 43

7. ELECTRICAL PARTS LIST ........................................ 44

– 3 –

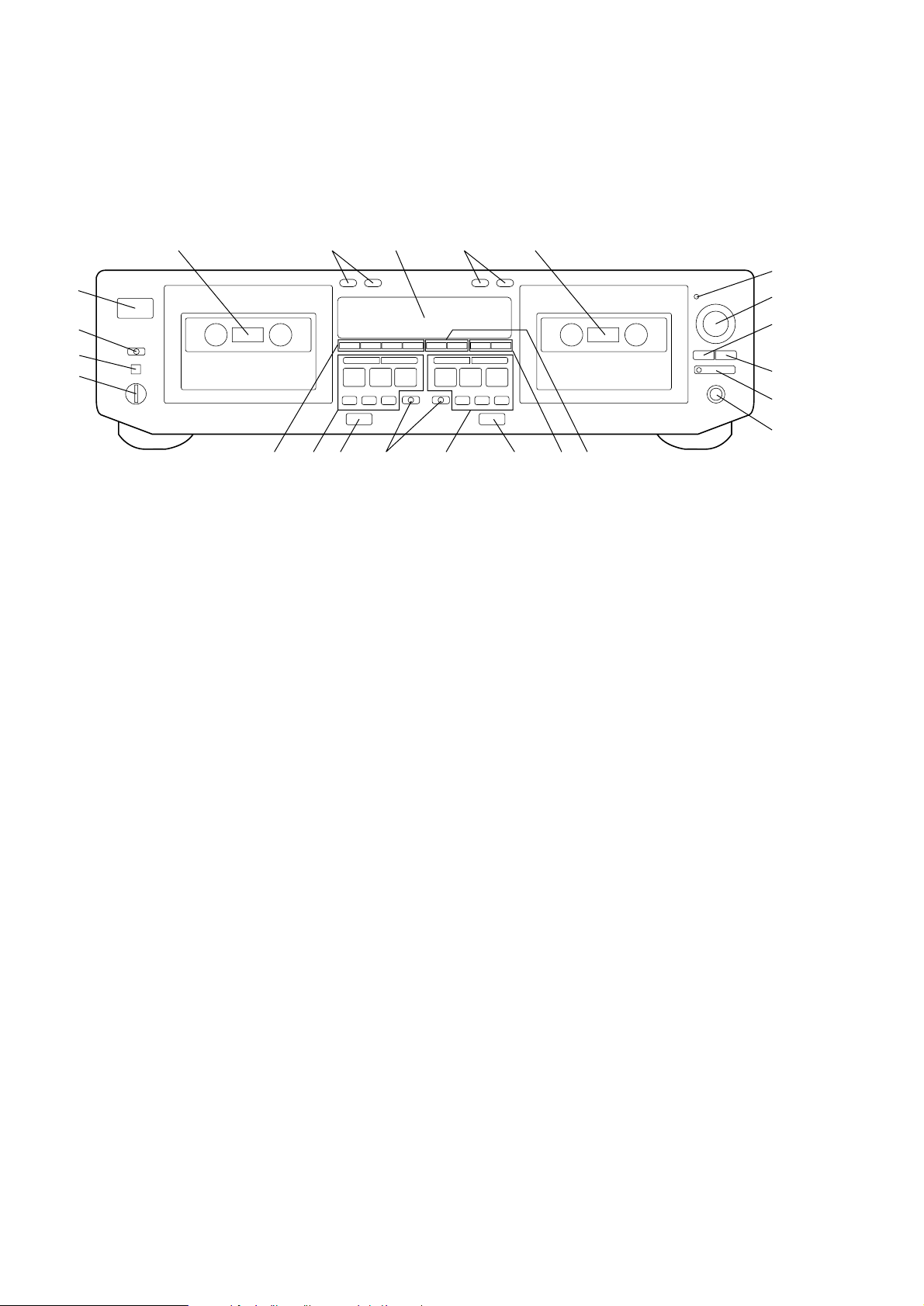

1-1. LOCATION OF CONTROLS

SECTION 1

GENERAL

56

1

2

3

4

10

11 1412 13 15 16 17

1. 1/u (Power) button (US, Canadian)

U (Power) button (EXCEPT US, Canadian)

2. DIRECTION MODE switch

3. PITCH CONTROL (Ø ON/ø OFF) switch

(TC-WE725/WE825S)

4. PITCH CONTROL knob (TC-WE725/WE825S)

5. Cassette holder (Deck A)

6. COUNTER A buttons (Deck A)

RESET button

MEMORY button

7. Display window

8. COUNTER B buttons (Deck B)

RESET button

MEMORY button

9. Cassette holder (Deck B)

10. RMS buttons

RMS/START button

SET button

CHECK button

DISPLAY button

11. Tape operation buttons (Deck A)

0 (AMS), RMS - button

) (AMS), RMS + button

p CLEAR (Stop) button

ª BACK (Reverse play) button

· FRONT (Foward play) button

P PAUSE button

R REC MUTING button

r REC button

7

98

23

22

21

20

19

18

12. § (Eject) button (Deck A)

13. DOLBY NR switches

ON, OFF, FILTER switch

B, C, S switch (“S” use for TC-WE825S)

14. Tape operation buttons (Deck B)

0 (AMS) button

) (AMS) button

p (Stop) button

ª (Reverse play) button

· (Foward play) button

P PAUSE button

R REC MUTING button

r REC button

15. § (Eject) button (Deck B)

16. START (DECK B P) buttons

A+B REC button

HIGH/NORMAL, DUBBING AnB button

17. AUTO CAL (START P) buttons

DECK A button

DECK B button

18. PHONES jack

19. SYNCHRO button and indicator

20. ARL button

21. FADER button

22. REC LEVEL knob

23. AUTO indicator

– 4 –

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

CASE

Unscrew the five case attachment screws M3 × 8 and remove

the case.

2-1. FRONT PANEL ASSY

POWER VOLTAGE SELECTOR 1 - 2 (Singapore, Malaysia)

FRONT PANEL ASSY 1 - !¶

!§

CN501, 502

!¢

claw

8

CN51

0

CN002

!¡

CNP73

(WE725/WE825S)

2

power voltage selector

3

CNA807

1

BVTP 3x8

4

CNS802

5

CNA801 (US, Canadian)

6

CNA803

1

BVTP 3x8

2

lug plate

!•

front panel assy

!£

2-2. MECHANISM DECK

1 Press the EJECT button.

2

claws

BVTP 3x8

3

cassette lid

9

CN51

!™

BVTP 3x6

!¶

CN503, 504

6

mechanism deck

!∞

claw

7

CNA806

– 5 –

4

BVTP 2.6x8

5

BVTP 2.6x8

2-3. FITTING BASE

6

fitting base

5

claws

4

PTPWH 2x23

3

connector

2

Pull the square belt

and put around claws.

7

gear (trigger)

2-4. CAPSTAN MOTOR, REEL MOTOR

8

capstan motor

7

B 2.6x3

9

P 2.6x2.8

1

Pull the capstan belt

and put around claws.

3

connector

0

!¡

ground plate

4

reel motor

claw

5

claws

2

connector

6

AUDIO board

1

square belt

– 6 –

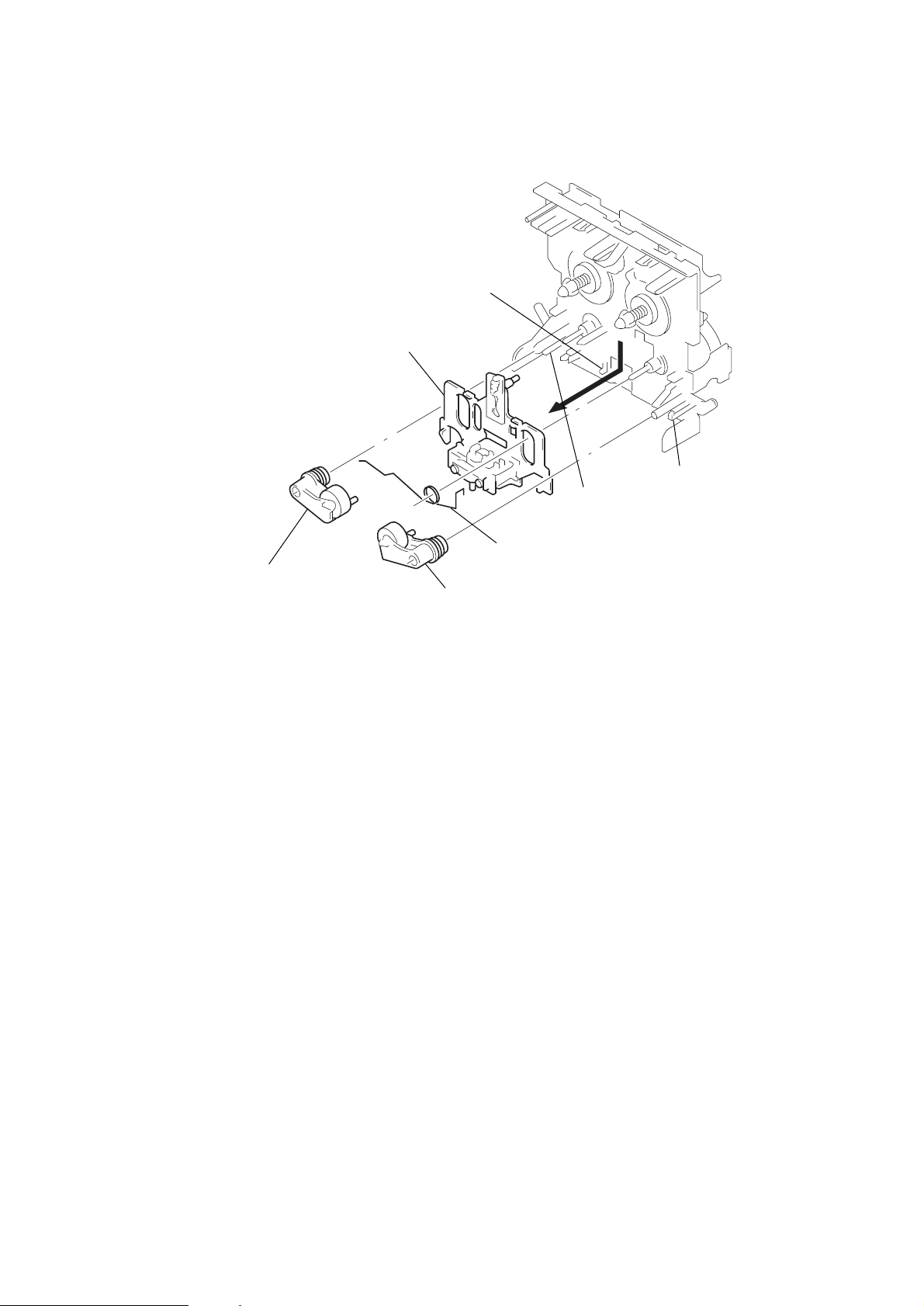

2-5. HEAD DECK ASSY

4

7

lever (pinch R) assy

head deck assy

2

lever (pinch F) assy

6

claw

5

torsion spring

3

claw

1

claw

– 7 –

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab :

record/playback/erase head pinch roller

rubber belts capstan

idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustment.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

Forward CQ-102C

Forward (0.014 to 0.083 oz • inch)

back CQ-102C

tension DECK B : 2 to 9 g • cm

Reverse CQ-102RC

Reverse

back CQ-102RC

tension

FF/REW CQ-201B

30 to 65 g • cm

(0.42 to 0.90 oz • inch)

DECK A : 1 to 6 g • cm

(0.028 to 0.125 oz • inch)

30 to 65 g • cm

(0.42 to 0.90 oz • inch)

1 to 6 g • cm

(0.014 to 0.083 oz • inch)

70 to 120 g • cm

(0.97 to 1.67 oz • inch)

PRECAUTION

1. The adjustment should be performed in the publication.

(Be sure to male playback adjustment at first.)

2. The adjustments and measurement should be performed for both

L-CH and R-CH.

• Switch position

DOLBY NR switch : OFF

DIRECTION MODE switch : A

• Standard record position :

Deliver the standard input signal level to input jack and set

the REC LEVEL control to obtain the standard output signal

level as follows.

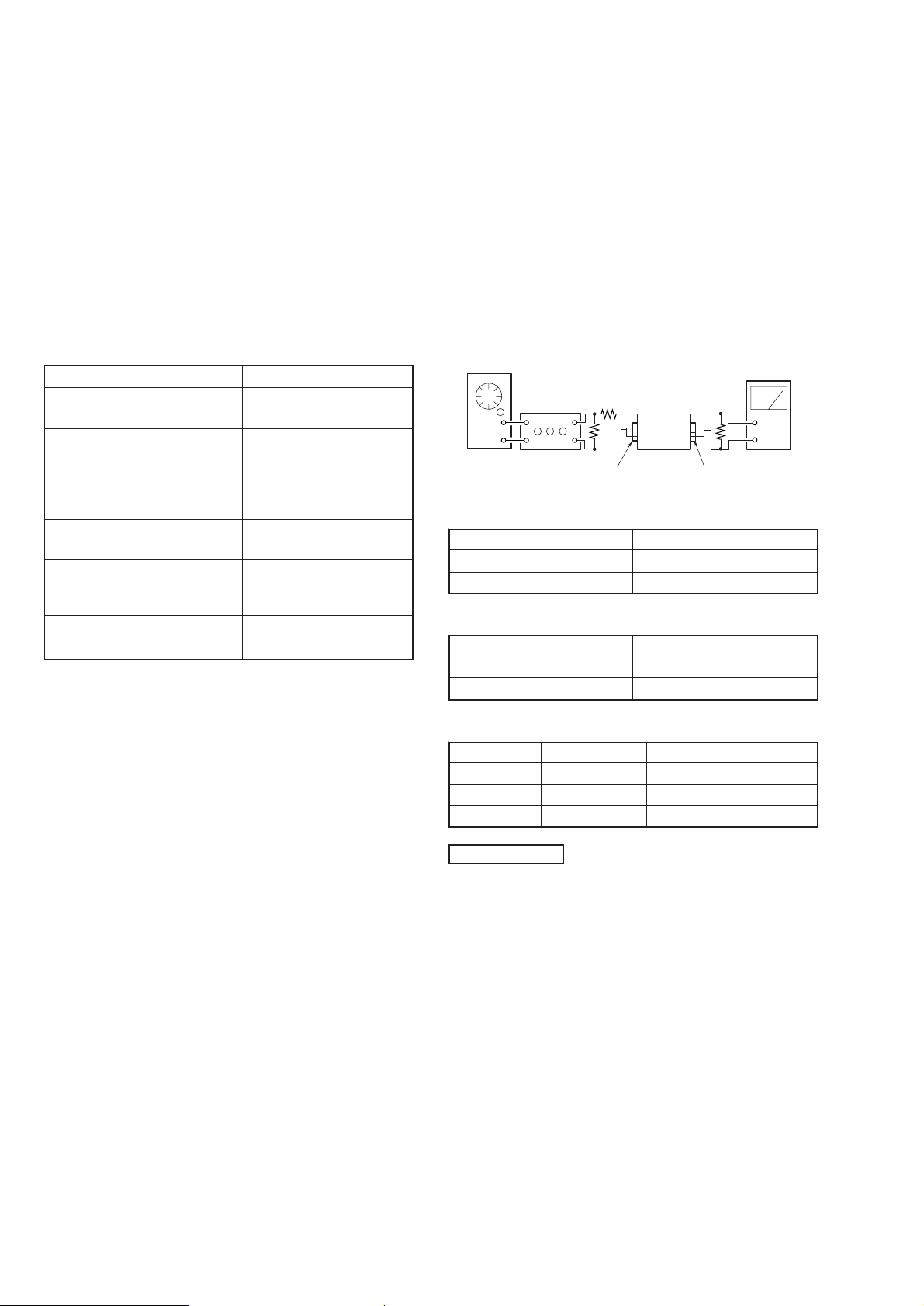

– Record Mode–

AF OSC

10 k

600

Ω

LINE IN

Ω

set

attenuator

Standard Input Level

Input terminal LINE IN

source impedance 10 kΩ

input signal level 0.5 V (–3.8 dB)

Standard Output Level

Output terminal LINE OUT

load impedance 47 kΩ

output signal level 0.5 V (–3.8 dB)

level meter

47 k

Ω

LINE OUT

+

–

Test Tape

T ape Contents Use

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB PB Level Adjustment

0 dB = 0.775 V

Test Mode

1. Turn ON power switch pressing “REC MUTING” switch of deck

A and B at the same time.

At first, all the fluorescent indicator light up, then the system

returns to normal display. (Ho we ver, “0. 00” is not displayed on

the counter.)

2. To release the test mode, turn OFF the power switch.

– 8 –

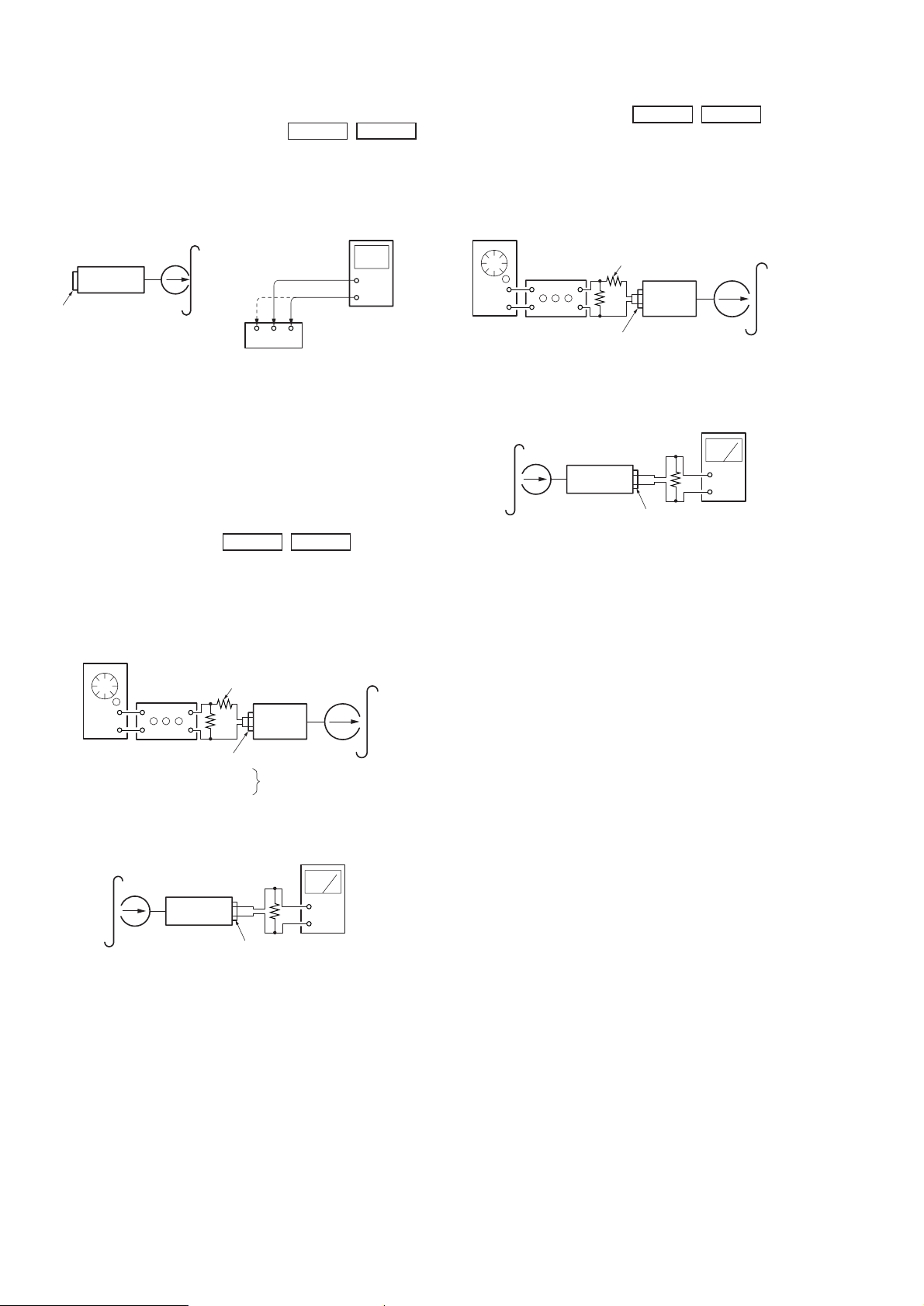

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Procedure:

1. Forward Playback Mode

test tape

P-4-A100

(10 kHz, –10 dB)

set

LINE OUT

47 k

level meter

Ω

+

–

2. Turn the adjustment screw for the maximum output levels. If

these levels do not match, turn the adjustment screw until both

of output levels match together within 1 dB.

L-CH

peak

screw

position

R-CH

peak

output

level

1 dB

L-CH

peak

R-CH

peak

within

1 dB

screw position

within

3. Playback Mode

test tape

P-4-A100

(10 kHz, –10 dB)

In phase 45˚ 90˚ 135˚ 180˚

L-CH

set

R-CH

Screen Pattern

good wrong

47 k

47 k

LINE OUT

Ω

Ω

oscilloscope

VH

+

–+–

T ape Speed Adjustment DECK A DECK B

Procedure:

–Forward Playback Mode–

test tape

WS-48B

(3 kHz, 0 dB)

set

LINE OUT

frequency counter

47 k

Ω

+

–

(High speed adjustment)

1. Set to test mode. (Refer to page 8.)

2. Set to FWD playback mode.

3. Twice pressing the HIGH/NORMAL switch.

4. Adjust RV72 so that the frequency counter reading becomes

6,000 ± 20 Hz.

5. Release test mode after adjustment is completed.

(Normal speed adjustment)

1. Set to FWD playback mode.

2. Adjust RV71 so that the frequency counter reading becomes

3,000 ± 10 Hz.

(Pitch control adjustment) (TC-WE725/WE825S only)

1. Push the PITCH CONTROL switch.

2. Set RV902 to mechanical center.

3. Set to FWD playback mode.

4. Adjust RV601 so that the frequency counter reading becomes

3,000 ± 10 Hz.

Frequency difference between the beginning and the end of the tape

should be within ± 3%.

Frequency difference between the deck A and deck B the beginning

of the tape should be within ± 1.5%.

Adjustment Location: AUDIO board, MAIN board

(See page 11.)

Playback Level Adjustment DECK A DECK B

Procedure:

–Forward Playback Mode–

test tape

P-4-L300

(315 Hz, 0 dB)

set

47 k

level meter

Ω

+

–

4. Change the reverse playback mode and repeat the steps 1 to 3.

5. After the adjustment, lock the adjustment screws with suitable

locking compound.

Adjustment Location: –record/playback head–

forward side

adjustment screws

reverse side

LINE OUT

Adjust R V11 (L-CH) and RV21 (R-CH) so the lev el meter r eading

becomes the adjustment limits below.

Adjustment V alue:

LINE OUT level : –7.7 ± 0.5 dB (0.301 to 0.338 V)

Level difference between channels : within 0.5 dB

Confirm that the LINE OUT level does not change in playback mode

while changing the mode from playback to stop several times.

Adjustment Location: AUDIO board (See page 11.)

– 9 –

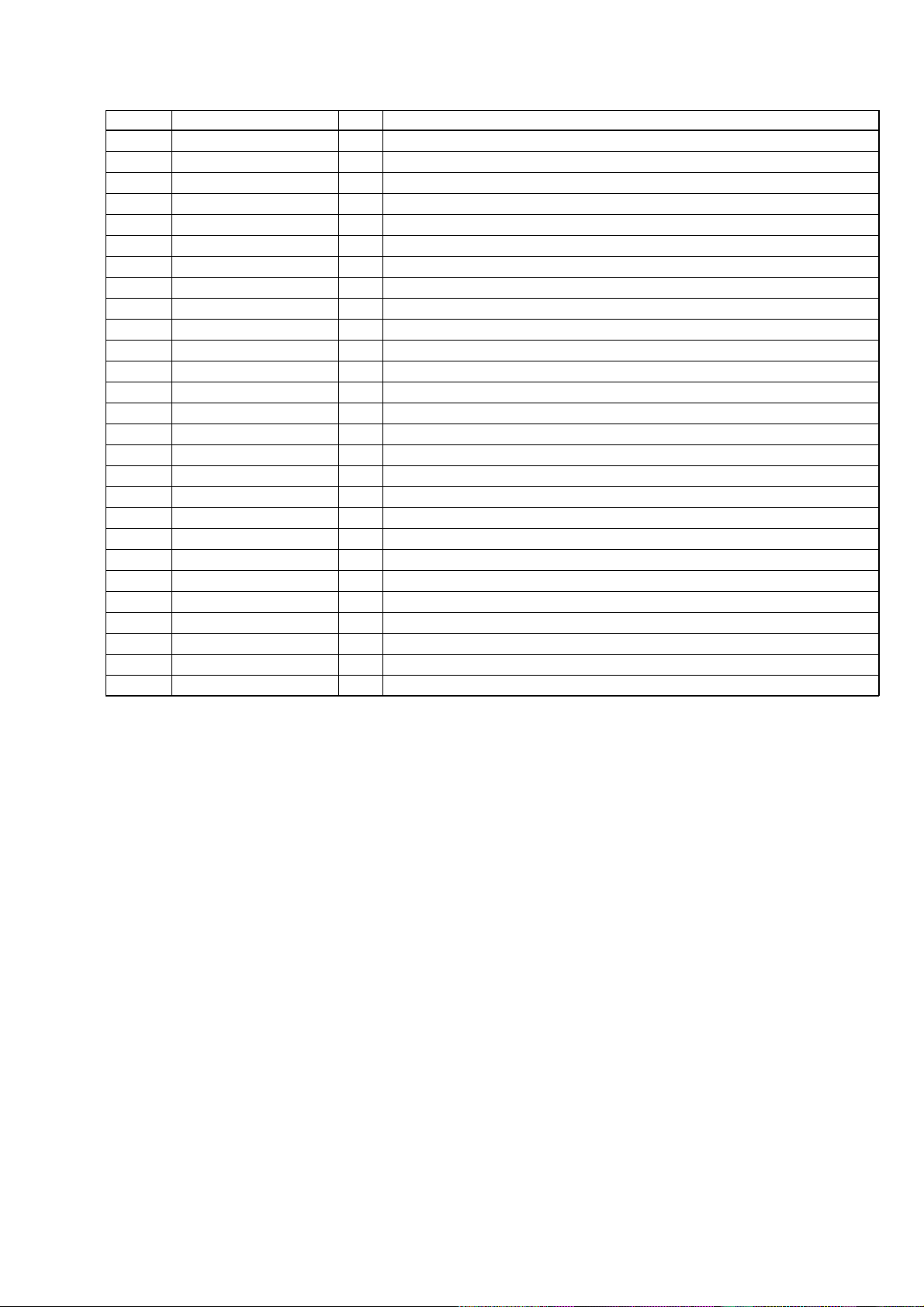

Bias Consumption Current Adjustment

DECK A DECK B

This adjustment should be performed when replacing the head assy

or the bias oscillator transformer (T81, T91).

Procedure:

digital

voltmeter

+

–

TP81

LINE IN

no signal

blank tape

CS-413

set

L-CHR-CH

123

1. Connect the digital voltmeter to test point TP81.

2. Set RV81 (L-CH), RV91 (R-CH) to mechanical center.

3. Set to FWD record mode.

4. Adjust T81 (L-CH), T91 (R-CH) so that the digital voltmeter

reading becomes minimum.

Record Level Adjustment DECK A DECK B

Setting:

REC LEVEL control : standard record position (See page 8.)

Procedure:

1. Record Mode

AF OSC

attenuator

10 k

Ω

set

600

Ω

LINE IN

315 Hz, 38.8 mV (–26 dB)

blank tape

CS-123

2. Playback Mode

recorded

portion

47 k

level meter

Ω

Adjustment V alue: Maximum 220 mV

Adjustment Location: AUDIO board (See page 11.)

Record Bias Adjustment DECK A DECK B

Setting:

REC LEVEL control : standard record position (See page 8.)

Procedure:

1. Record Mode

AF OSC

attenuator

10 k

600

Ω

LINE IN

1) 315 Hz

2) 10 kHz

Ω

set

38.8 mV (–26 dB)

blank tape

CS-123

2. Playback Mode

recorded

portion

set

47 k

level meter

Ω

+

–

set

LINE OUT

+

–

Confirm playback the tape recorded become adjustment level as

follows.

If necessary, adjust Deck A : RV102 (L-CH), RV202 (R-CH) and

Deck B : R V101 (L-CH), R V201 (R-CH) and repeat the steps 1 and

2.

Adjustment V alue:

LINE OUT level : –26 ± 0.5 dB (36.7 to 41.1 mV)

Adjustment Location: MAIN board (See page 11.)

LINE OUT

Confirm that the 10 kHz playback output is 0 ± 0.5 dB relative to

the 315 Hz output. If necessary, adjust RV81 (L-CH), RV91 (RCH) and repeat the steps given above.

Adjustment Location: AUDIO board (See page 11.)

– 10 –

Adjustment Location:

–audio board (component side)–

RECORD BIAS ADJ

CONSUMPTION

BIAS

CURRENT

ADJ

RV91

(R)

T81 (L)

T91 (R)

RV81

(L)

RV72 (HIGH)

RV71 (NORMAL)

TP81

TAPE SPEED ADJ

RV21 (R)

RV11 (L)

PLAYBACK

LEVEL

ADJ

–main board (component side)–

RECORD LEVEL ADJ

(DECK A)

(R)

RV102

(L)

RV601

TAPE SPEED ADJ

(PITCH CONTROL)

RV202

RECORD LEVEL ADJ

(DECK B)

RV201

RV101

(L)

(R)

– 11 –

SECTION 5

DIAGRAMS

5-1. IC PIN DESCRIPTION

• IC801 CXP82432A-006Q (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Pin Description

1 T-REEL (A) I Take-up reel rotation detection input (DECK A)

2 S-REEL (B) I Supply reel rotation detection input (DECK B)

3 T-REEL (B) I Take-up reel rotation detection input (DECK B)

4 SIRCS IN I Sircs signal input

5 POWER IN I Power-off detection input

6 VOL OUT O Record level control output (PWM)

7 A/B SEL I Playback A/B selector input “L” : A, “H” : B

8 CONTROL-A IN I Control A signal input

9 CONTRL-A OUT O Control A signal output

10 REC MUTE (A) O Recording mute output (DECK A) “L” : Mute ON

11 REC CAL 0 (A) O Recording CAL-0 output for auto calibration. (DECK A)

12 REC CAL 1 (A) O Recording CAL-1 output for auto calibration. (DECK A)

13 GP CAL 0 (A) O GEQ CAL-0 output for auto calibration. (DECK A)

14 GP CAL 1 (A) O GEQ CAL-1 output for auto calibration. (DECK A)

15 REC/PB O Record/playback dolby NR mode selector output “L” : Playback

16 REC MUTE (B) O Recording mute output (DECK B) “L” : Mute ON

17 AMS IN I AMS signal input “L” : Music present

18 CAL/OFF/S O Audio selector “H” : CAL, “Open” : Dolby off, “L” : Dolby S

19 C/B/OFF O Dolby selector “H” : C, “Open” : B, “L” : Dolby off

20 REC CAL 0 (B) O Recording CAL-0 output for auto calibration. (DECK B)

21 REC CAL 1 (B) O Recording CAL-1 output for auto calibration. (DECK B)

22 GP CAL 0 (B) O GEQ CAL-0 output for auto calibration. (DECK B)

23 GP CAL 1 (B) O GEQ CAL-1 output for auto calibration. (DECK B)

24 POWER OUT O Power hold output

25 RECEQ HIGH/NORM O REC EQ high/normal select output “L” : Normal

26 PASS/MUTE/DOLBY O Audio selector “H” : Pass, “Open” : Mute, “L” : Dolby

27 BS/AMS/OFF O AMS amp selector “H” : BS, “Open” : AMS, “L” : OFF

28 EX IN 0 I Expander control input (0)

29 EX IN 1 I Expander control input (1)

30 EXP CTRL 0 O Expander control output (0)

31 EXP CTRL 1 O Expander control output (1)

32 A/D IN 0 I Expander A/D input (0)

33 A/D IN 1 I Expander A/D input (1)

34 KEY 5 I Key 5 input (A/D converter)

35 VOL IN I Record volume input (A/D converter)

36 TEST/PITCH/VER I Test mode/pitch control/version input

37 CD SYNC LED O CD SYNCHRO LED driver “L” : ON

38 RESET I System reset input

39 EXTAL I System clock oscillator input (10 MHz)

40 XTAL O System clock oscillator output (10 MHz)

41 VSS — Ground

42 TX — Connected to ground.

43 TEX — Connected to ground.

44 ARL LED O ARL LED driver “H” : ON

45 PITCH ON/OFF O Pitch control ON/OFF output “L” : ON

46 AVREF I Reference voltage input for A/D converter.

47 AVSS — Ground for A/D converter.

48 LINE MUTE O Line mute ON/OFF control output “L” : Mute ON

49 OSC H/L O OSC frequency H/L select output for auto calibration.

50 OSC ON/OFF O OSC ON/OFF select output for auto calibration.

51 BIAS CAL 0 (B) O EQ bias CAL-0 output for auto calibration. (DECK B)

– 12 –

Pin No. Pin Name I/O Pin Description

52 BIAS CAL 1 (B) O EQ bias CAL-1 output for auto calibration. (DECK B)

53 BIAS CAL 2 (B) O EQ bias CAL-2 output for auto calibration. (DECK B)

54 BIAS CAL 3 (B) O EQ bias CAL-3 output for auto calibration. (DECK B)

55 BIAS CAL 0 (A) O EQ bias CAL-0 output for auto calibration. (DECK A)

56 BIAS CAL 1 (A) O EQ bias CAL-1 output for auto calibration. (DECK A)

57 BIAS CAL 2 (A) O EQ bias CAL-2 output for auto calibration. (DECK A)

58 BIAS CAL 3 (A) O EQ bias CAL-3 output for auto calibration. (DECK A)

59 CAP.M (B) O Capstan motor driver output (DECK B) “H” : ON

60 CAP.M (A) O Capstan motor driver output (DECK A) “H” : ON

61 CAP.M H/L O Capstan motor high/normal select output “L” : ON

62 – 77 P16 – P1 O Fluorescent indicator tube segment driver

78 – 85 G1 – G8 O Fluorescent indicator tube grid driver

86 G6,G7 O Fluorescent indicator tube grid driver

87 G7,G8 O Fluorescent indicator tube grid driver

88 VFDP — Fluorescent indicator tube power supply (-28 V)

89 VDD — Power supply (+5 V)

90 N.C — Connected to power supply.

91 VSS — Ground

92 REEL (A) + O Reel motor (+) output (DECK A)

93 REEL (A) - O Reel motor (-) output (DECK A)

94 REEL (B) + O Reel motor (+) output (DECK B)

95 REEL (B) - O Reel motor (-) output (DECK B)

96 BIAS (A) O Bias ON/OFF output (DECK A) “H”:ON

97 RELAY (A) O Relay record/playback selector output (DECK A) “L” : Record

98 BIAS (B) O Bias ON/OFF output (DECK B) “H” : ON

99 RELAY (B) O Relay record/playback selector output (DECK B) “L” : Record

100 S-REEL (A) I Supply reel rotation detection input (DECK A)

– 13 –

Loading...

Loading...