Sony TC-PB10 Service Manual

CASSETTE PLAYER

Playback

System:

Fast-forward

and

Rewind

Time:

Playback

Signal-to-

noise

Ratio:

SPECIFICATIONS

4-track

2-channel

stereo

Approx.

90

sec.

(with

C-60 cassette)

.With

TYPE lV

cassette

(Sony

METALLIC)

60 dB at

peak

level . . . US model

60 dB at

peak

level

(NAB)

I

60 dB

(DtN)

J

AtY' È' uK model

.With

TYPE lV

cassettF

(Sony

METALLIC)

20 - 18,000

Hz

30 - 16,000

Hz

(t

3 dB)

.With

TYPE

I

cassette

(Sony

HFX)

. . .

US

model

Power

Output:

US

model

12W

+

12 W

(70

Hz

-

20,O00 Hz,

1 % harmonic

distortion)

AEP, UK,

E model

25W+25W(Music)

50W+50W(peakmusic)

14W

+

14 W

(1

kHz,

1 % harmonic

distortion)

Harmonic

Distortion:

O.OSo/"

14

W

+

4 W)

lnputs;

Microphone

input

(phone

iack)

Sensitivity

O.435

mV

(-65

dB)

For

a low-impedance

microphone

AUX IN

Sensitivity

435

mV

(-S

dB)

Input

impedance

5

kf,ù

Outputs:

Line

outputs

Output

level

250 mV

(*10

dB)

at

toad

impedance

50 kf,ù

Load

impedance

over 1O k,fl

Headphone

output

Output level

380

mV

(-16

dB)

at a toad

impedance

of 8 f,l with

the volume

level

maximum

-

Continued

on

page

2

-

Frequency

Response:

(Sony

BHF)

. . .

AEP,

UK,

E model

20 - 1t,ooo Hz

30 - 15.000 Hz

(t

3

dB)

Wow

and

Flutter:

0.05 % WRMS . . .

US model

i3:.i#Hi,(NAB)

IAEP,

uK, E

model

Tape Transport Mechanism

Type

I

TCM-1 10V5

il====l

rrr

I

MICROFILM

I

SERIJICE

MANUAL

TC-PB I O

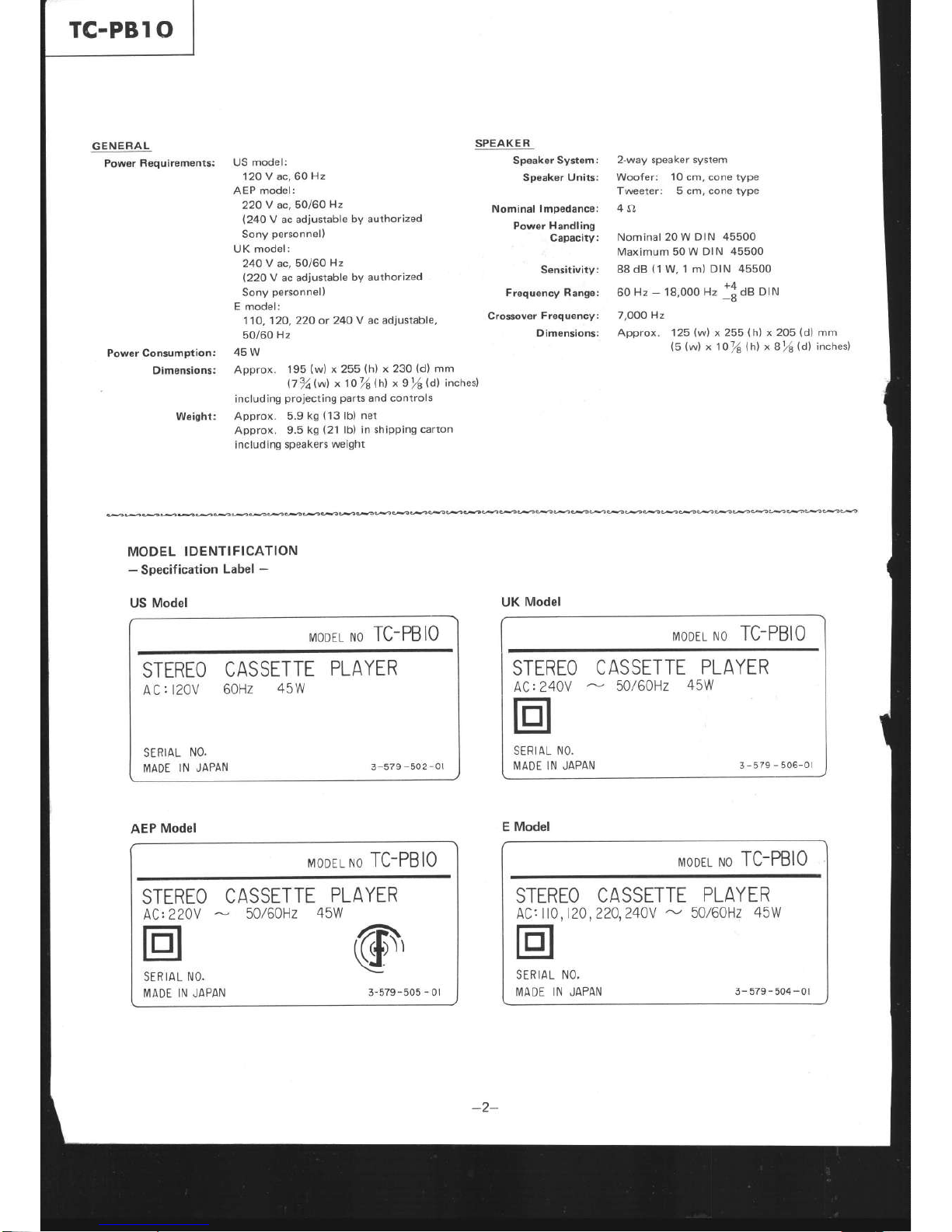

GENERAL

Power

Requirements:

Power Consumption:

Dimensions:

US model:

12OV

ac,60Hz

AEP model:

22OV

ac,50/60

Hz

(24OV

ac adjustable

by

authorized

Sony

personnel)

UK model:

24OY

ac,50/60

Hz

(22OV

ac adiustable

by authorized

Sony

personnel)

E

model:

110,12O,22O or

24O V ac adjustable,

50/60

Hz

45W

Approx.

195

(w)

x

255

(h)

x

230

(d)

mm

07afu1

x1o78hl

x9%(d) inches)

including

proiecting

parts

and controls

Approx.

5.9

kg

(13lb)

net

Approx. 9.5

kg

(21

lb) in shipping

carton

including speakers

weight

SPEAKER

Speaker

System:

Speaker

Units:

Nominal lmpedance:

Power Handling

Capacity:

Sensitivity:

Frequency Range:

Crossover

Frequency:

Dimensions:

2-way speaker system

Woofer:

1O cm,

cone

type

Tweeter: 5 cm, cone type

4{t

Nominal 20 W

DIN 45500

Maximum 50

W DIN 45500

88 dB

(1

W, 1 m)

DIN 45500

+^

60

Hz

-

'l

8,000

Hz

d

dB

DIN

7,OO0

Hz

Approx. 125

(w)

x 255

(h)

x 2O5

(d)

mm

(5 (w)

x 1o/8

lhl

x I

%

(d)

inches)

Weight:

MODEL

IDENTIFICATION

-

Specification

Label

-

666ûâ

US

Model

MODEL

NO

TC-PBIO

STEREO

CASSETTE

PLAYER

AC

r

l20V

60Hz

45W

SERIAL

NO.

MADE

lN JAPAN

3-57e-5o2-or

UK

Model

MODEL NO TC-PBIO

STEREO

CASSETTE

PLAYER

AC:

240V

-

50/60H2

45W

t:l

SERIAL NO.

MADE lN JAPAN

3-s7s-506-ol

AEP

Model

MODEL NO

TC-PBIO

STEREO

CASSETTE

PLAYER

ACt220V

50/60H2

45W

@'

SERIAL

NO.

MADE

IN JAPAN

3-579-505

-

0l

E Model

MODEL NO

TC-PBIO

STEREO CASSETTE

PLAYER

AC: Il0,

120,220,240V

-

50/60H2

45W

SERIAL

NO,

IVIADÊ

lN

JAPAN

3-5?e-504-ol

z

a

û!-0/

SECTION

1

OUTLINE

1.1. BLOCK

DIAGRAM

+t

@@

+++

@@æ

G.

Y

U

z

-

È

-o

o<

tsU

z

)

@

L

=

È

U

=

L

L

=

U

z

o

-

F

=

E

=

U

z

o

F

ô

z

U

J

o

É

3

æ

F

z

o

È

=

=

Y

=

ô

z

)

o

ù

=

É

U

=

æ

F

=

z

J

r

z

F

L

=

z

J

0

=

ox

==

o

=

r

no

51"

o

=

L

nÔ

uo

È

uo

=

o

É

o

F

-

bL"

b+;=

I

I

È

=

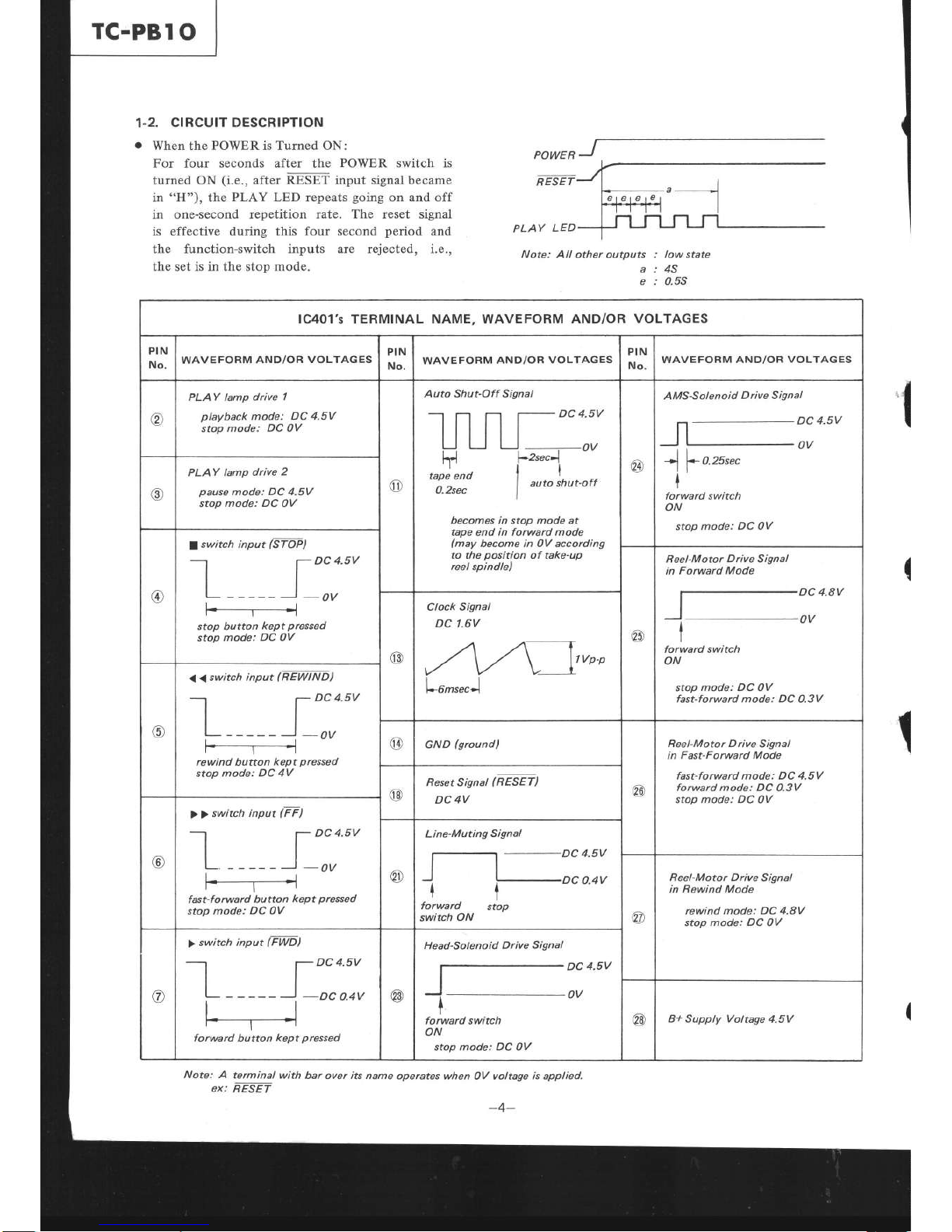

1-2.

CIRCUIT DESCRIPTION

o

When the

POWER

is Turned ON:

For

four

seconds after

the

POWER

switch is

turned ON

(i.e.,

after RESET input signal became

in

"H"),

the

PLAY LED repeats

going

on and

off

in one-second repetition rate.

The

reset signal

is effective during this

four second

period

and

the function-switch inputs are rejected,

i.e.,

the

set

is in the stop mode.

Note: All

other outputs

: low state

a:45

e : 0.55

1C401's TERMINAL NAME, WAVEFORM

AND/OR

VOLTAGES

PIN

No.

WAVEFORM

AND/OR

VOLTAGES

PIN

No.

WAVE

FORM AND/OR

VOLTAGES

PIN

No.

WAVEFORM

AND/OR

VOLTAGES

@

PLAY lamp

drive

1

playback

mode:

DC 4.5V

stop

mode: DC OV

@

Auto Shut-Off Signal

DC 4.5V

ts

tape end

O.2sec

OV

auto

shut-off

becomes in stop mode at

tape end in forward mode

(may

become in 0V according

to the

position

of

take-up

reel spindle)

@

AMS-S ol enoid

D rive S

ignal

rl

I

f

o.zssec

I

forward switch

ON

stop

mode:

DC OV

@

PLAY lamp

drive

2

pause

mode:

DC 4.5V

stop

mode: DC

OV

@

a

switch input

(STOP)

-l

7

DC

a.sv

tt

tl

L _____

'

_OV

F___r_D1

stop button

kept

pressed

stop

mode:

DC

0V

6À

R eel-M otor

D rive S ignal

in

Forward Mode

DC 4.8V

OV

forward switch

ON

stop

mode: DC

0V

fast-forward mode: DC

0.3V

@

Clock

Signal

DC't.6V

l*6msec-l

o

< <

switch input

(

R EWINDt

---.1

l-

DC 4.5V

tl

tl

i_______,_0V

r.-----Tr----

rewind button

kept

pressed

stop

mode: DC 4V

@

GND

(groundl

€e

R eel-M oto r D

rive

S ign al

in

Fast-Forward Mode

fast-forward mode: DC 4.5V

forward mode: DC

O.sV

stop

mode:

DC OV

@

Reset Signal

(RESET)

DC

4V

@

> >

switch input

(FF)

I 7

Dca.sv

tl

L- -----)-ov

@

Line-Muting

Signal

DC

O.4V

I

forward

switch

ON

I

stop

@

R eel-M

oto

r D rive

S ign al

in

Rewind Mode

rewind mode: DC 4.8V

stop mode:

DC

OV

@

forward

button

kept

pressed

>

switch input

IFWD)

f-

DC 4.5V

tl

tt

L------J

-Dco.4v

@

Head-Solenoid

Drive

Signal

DC

4.5V

OV

I

forward switch

ON

stop mode: DC 0V

@

B+ Supply Voltage

4.5V

Note: A

terminal

with bar

over

iB

name operates

when OV voltage

is

applied.

I

ex:

RESET

TC-PBI

O

I

-246-515-00

I

-210 -814-00

l

-210-815{0

1

-210-816-00

l

-210

-817-00

1

-210-818-00

I

-210-8r9{0

i

-210-820-00

I

-210-821

{0

t-244-?5440

I

-214-755

{0

I

-244-756-00

r-244-757

40

l

-244-758-00

r-214-75940

I

-214-760-00

t-214-76140

t-244-76240

l

-246-521

-00

t-246-52240

I

-246-523-00

t-216-52440

L-246-525{0

t-246-52640

t-246-52'l40

I

-246-528{0

l

-216-529{0

1

-246-530{0

I

-246-531

-00

1

-246-532-00

I

-246-533-00

I

-246-531

{0

l

-246-535-00

l

-246-536-00

I

-246-537

-00

1 246-538-00

I

-246

-539-00

I

-246-510{0

I

-216

-541

-00

r-246-51240

1

-246-543-00

1

-246-544{0

1.0M

1.lM

l.2M

l.6M

l.8M

2.7M

3.0M

3.3M

4.3M

4.7M

I

-216-49?

{0

l

-246-498-00

1-246-199{0

I

246-500-00

I

-246-501

{0

t-246-50240

I

-246-503-00

1

-246

-504-00

l

-246-505

{0

I

-246-506

-00

l

-246-507

{0

I

-246-508-00

1

-246-509-00

I

246

510{0

l 216-51r{0

t-246-512{0

1

-216-513-00

1

-246

-511-00

I

-246-51

5

-00

l

-246-516

{0

I

-246

-517

{0

I

-246-518

{0

t

-246-519-00

I

-246

-520-00

t00k

110k

l20k

130k

l50k

160k

180k

200k

220k

240k

270k

300k

330k

360k

390k

430k

470k

5l0k

560k

620k

680k

750k

820k

9l0k

|

-246-473-00

t-246-47

4-00

1-246-17540

t-246-476-00

t-246-477

-00

t-246-478-00

L-246-47940

1 246-480-00

l-246-481

00

r-246-482{0

I

-246-483-00

I

-246-484-00

I

-246-485-00

1

-246

-486-00

L-246-487

-00

I

-246-488-00

I

246

489-00

1

-246-190{0

1-246-491

00

t-246-492-00

I

-246

-493-00

1

-246-494

-00

I

-246-495{0

I

-246

-496-00

l0k

tlK

12k

l3k

IJK

l6k

18k

20k

22k

24k

27k

30k

33k

36k

39k

43k

47k

Jlk

56k

62k

68k

,JK

82k

91k

1 .0k

l.lk

l.2k

1 .3k

r .5k

I .6k

I .8k

2.0k

2.2k

2.4k

2.7k

3.0k

3.3k

3.6k

3.9k

4.3k

4.7k

5.

lk

5.6k

6.2k

6.8k

7 .5k

8. 2k

9. 1k

100

110

120

130

150

160

180

200

220

240

270

300

330

360

390

130

470

510

560

620

680

l-246

449

00

1

-246-450{0

l

-246-151

-00

1-246

452-00

I

-246-453-00

1-246-454

{0

I

-246-455

{0

1-216

456-00

1-246-457

40

r

-246-458-00

1

-246-459-00

I

246-460-00

1

246-461-00

1

-246-462-00

I

246

463

00

1

-246-464-00

I

-246-465-00

l

-246-466-00

I 246-467-00

1

-246-468-00

I

-246-469-00

1 246

470{,0

t-216-471{,0

t-246-47240

l0

I

1-246

425-00

ll I

l-246-426{0

t2

|

r-246

42?Ao

13

I

l-246-428

00

15

1-216

42940

16

l

-246-430{0

18

|

l 246

431

00

20 |

l-246

43240

22 I

l-246

433{0

24

1

1-246-434-00

27

I

1-246-435-00

30 |

I

246

436

00

33

I

l-246

437

oo

36

I

-246-438-00

39

I

l-246

439-00

13

J

1-246

440{0

47 |

l-246-44140

5t

I

L-246-44240

s6 I

1-246

443-00

62

I

1-246-444-00

68

L

1-246-445

00

75 I

l-246

446{0

82

|

t-246-447

00

9l

I

l-246-448-00

I

-216

-101

-00

t-246-402{0

I

-246-403-00

I

-246-404

-00

1-246

405

00

I

-246-106{0

1-246-407

00

I

-246-408{0

I

-246-109-00

l

-246

-410-00

I

246-411-00

L-246-412.{0

1

-216-413

-00

1

-216-114

-00

l-246-415

00

l

-246

-416-00

L

246-117

40

I 216-418{0

I-246-419

00

t-246

420-00

L

246-42140

1-246

42240

t-246-42340

L-246-42440

1.0

l.l

1.2

1.3

1.5

1.6

1.8

2.0

2.2

2.7

3.0

3.6

3.9

1.3

4.7

5.1

5.6

6.2

6.8

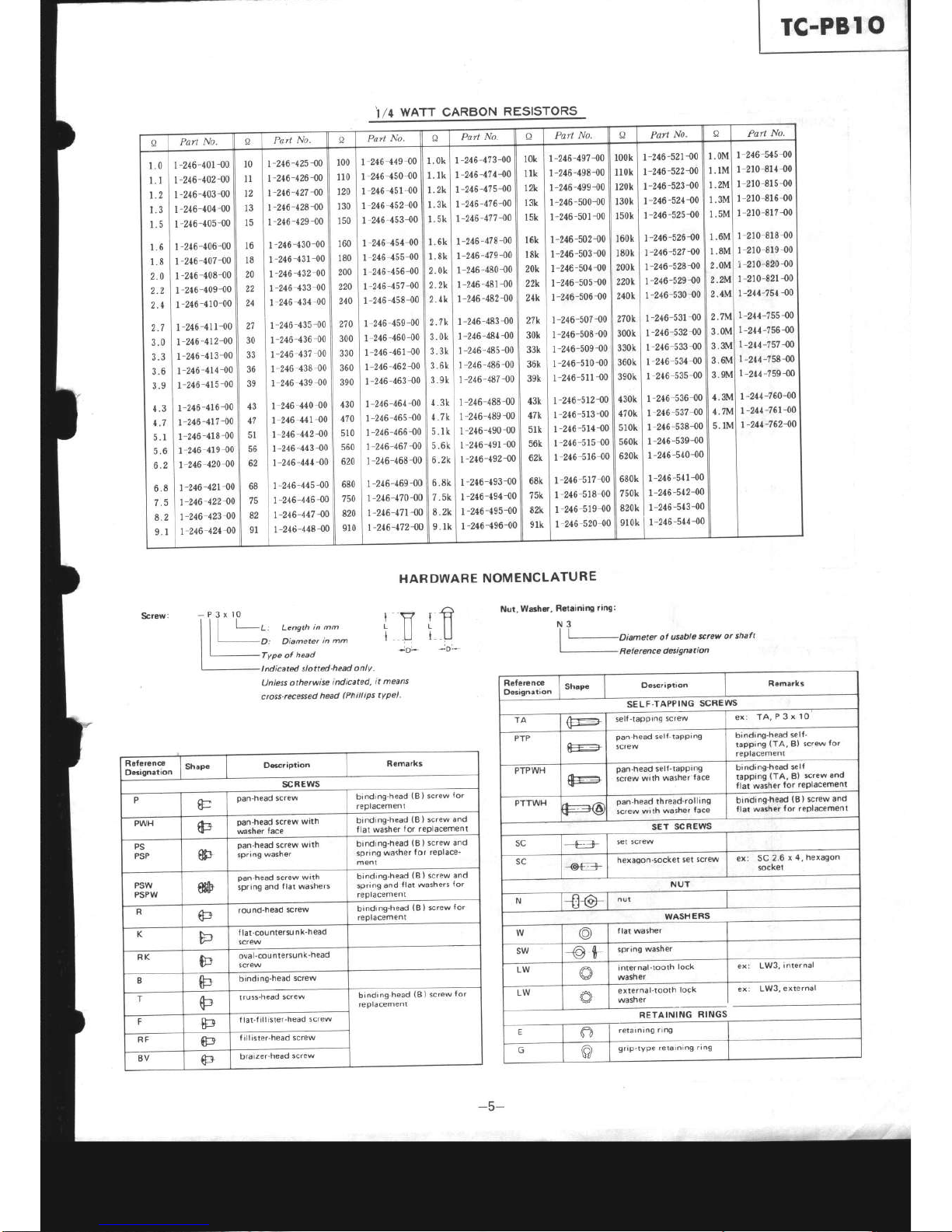

t/4

WATT CARBON

RE€!9r989

I{ARDWARE

NOMENCLATURE

Nui,

Warhw,

RGlsining

ring:

10

3x

N3

|

|

Di"-eter

ol

ueble

ærew

or shaft

I

I

Refercnce

detigBtion

I

'

a,

Lensth

in mm

>

D: Diameter

in mm

r1

iU

-O'-

Type of

head

t nd

icated slotted

-head

o nl

y

l)nless othe.wise

indicated,

it means

cross-ræ6sed

hæd

(Phillips

tYpe).

IF

ÏU

-oL

R6{€rsn@

06ignation

Shape

Dæription

Remarks

scREws

P

û-

pan-head

screw

binding-head

(B)

screw

for

replacement

PWH (t+

pan-head screw

with

msher

lace

binding-head

(8

I

screw

and

tlat washer

tor rePlacement

PS

PSP

I

pan-heôd

screw

wllh

spring

washer

binding-head

(8)

screw and

spriôg

washer

tor rePlace'

ment

PSW

PSPW

fiù

oan-heâd

screw

wrth

sprinq

aôd

tlal

washers

bind;ng-head

(B)

screw and

spring

and

tlat washers

tor

replacement

round-head

screw

biôding-head

(8)

screw

for

replacemenl

K

F

llat-countersu

nk-head

screw

RK

F

oval-cou

ntersunk'head

screw

B

F

binding'head

screw

T

F

truss-head

screw

binding-head

(B)

screw

tor

reglacement

tlal-f iil ister-head

screw

a-l

lrllister-head

screw

8V

ka

braizer-head

screw

Rgfer€næ

D6ignôlion

Shape

Oescriplion

Remarks

SELF.TAPPING

SCREWS

TA

\F-'--.'_

selt-lapprng

Screw

ex:

TA,P3x10

PTP

tlli:

pan-head

self-taPPiôg

screw

binding-head

self'

tapping

(TA,

Bl

screw

for

replacement

PTPWH

F

oan'head

self-taPPing

screw

with

washer

tace

bindinE-head

ælf

tapping

(TA,

B)

screw

ând

llat washer

for replacement

PTTWH

oan-head

thread'rolling

screw

wilh

washer

face

binding-head

SET

SCREWS

sc

-

€f-

set

screw

sc

-oæ

hexagon-socket

set screw

ex:

SC

2.6

x 4,

hexagon

sockel

NUT

N

-ft@ nut

WASHERS

lâr

v

flat washer

SW

-o$

spriôg

washel

LW

qJ

internal-1o01h

lock

washer

ex:

L!V3,

internal

LW

i-fJ-rern"t--ottt

toct

I

ex:

LW3,

external

I Aj I

washe,

I

tr

RETAINING

RINGS

E

e

retarnrng

rln9

o

griP-tYPe

retarnrng

rlng

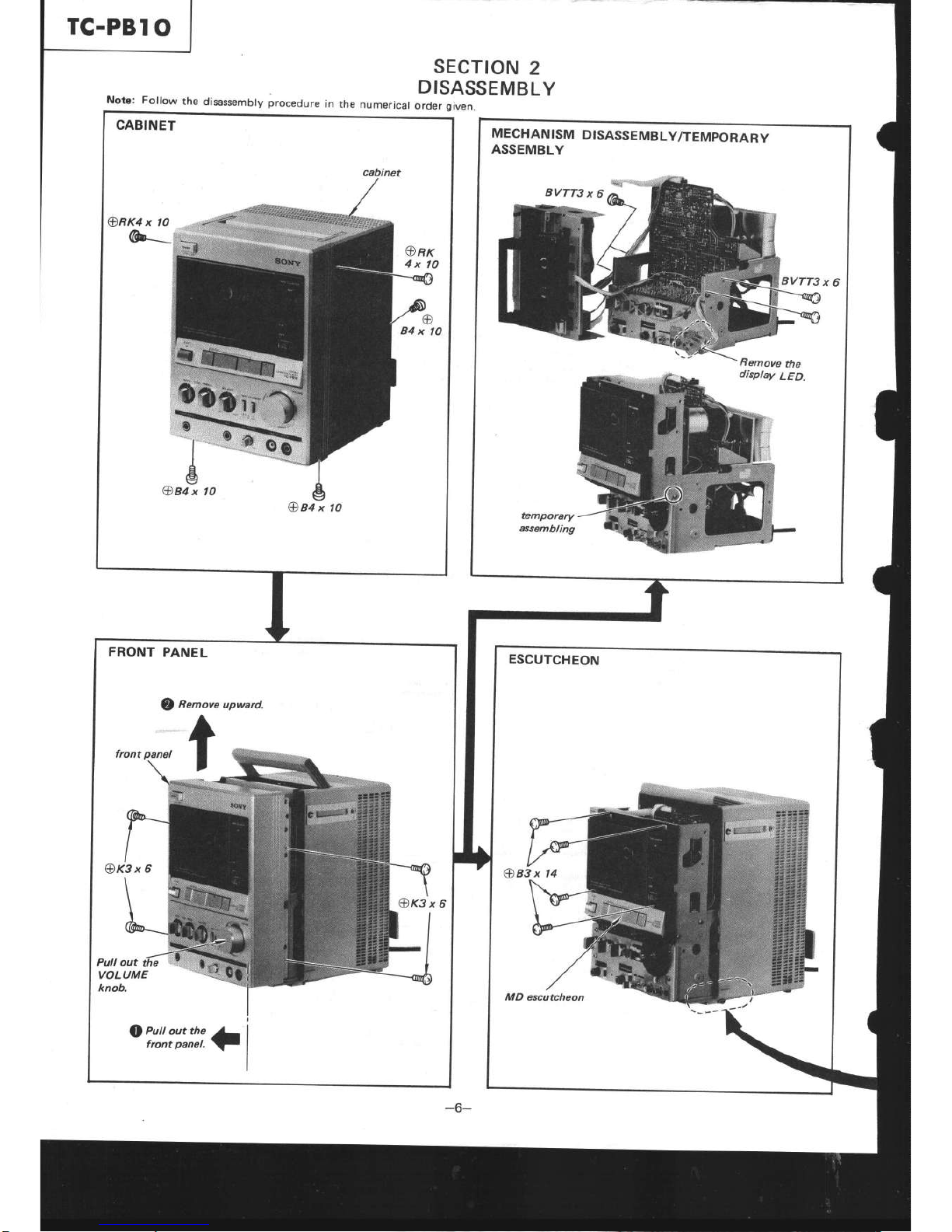

TC.PB

I

O

SECTION

2

Note: Fottow

rhe

disassembry procedure

in

the numeric.

-Or:rtâ:tEMBLY

cabinet

@

MECHANISM

DISASSEMBLY/TEMPORARY

ASSEMBLY

oi:!,i",:ili.1

-6-

TC-PBI

O

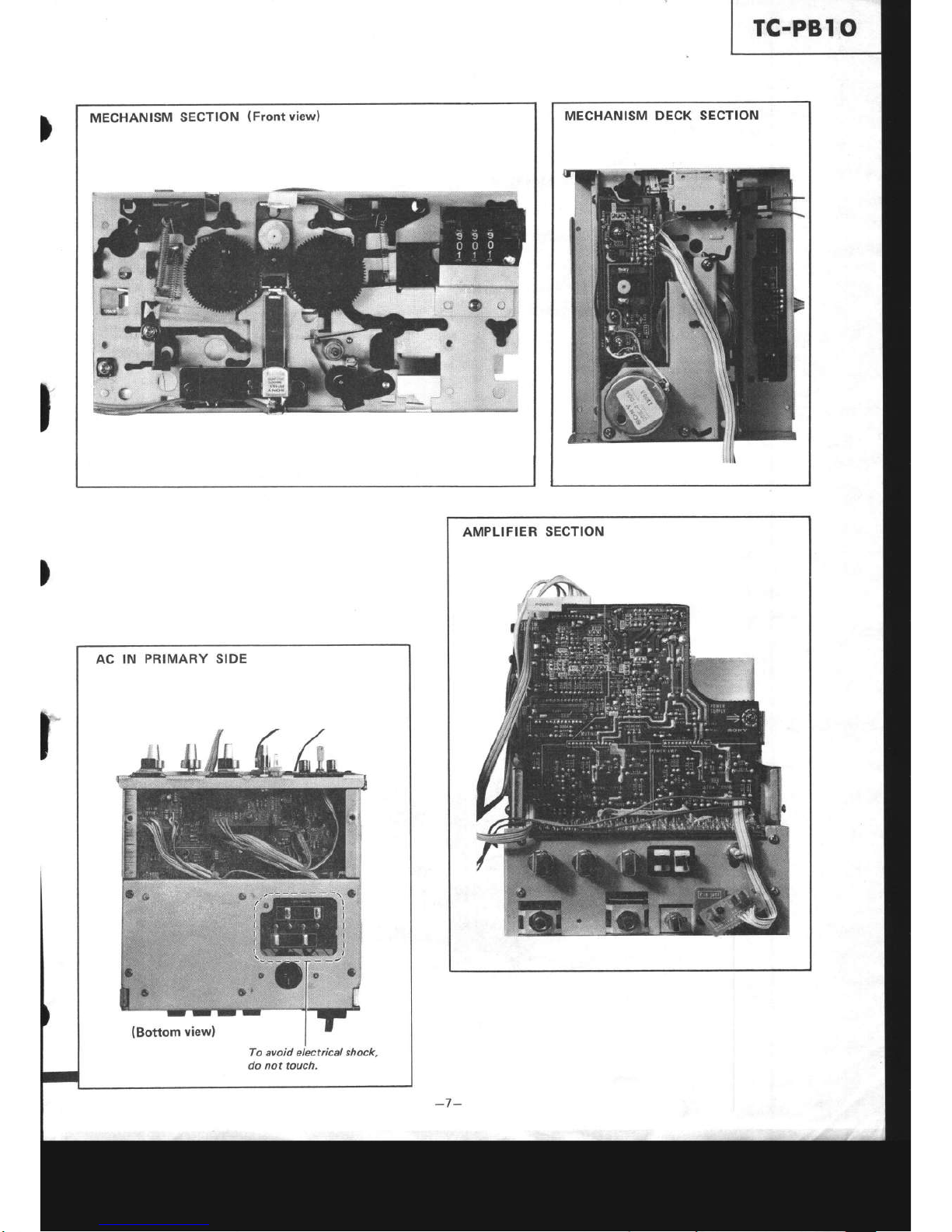

AC IN

PRIMARY SIDE

To avoid electrical shock,

do not touch.

MECHANISM

SECTION

(Front

view) MECHANISM

DECK SECTION

AMPLIFIER

SECTION

TC.PBI

O

l.

SECTION

3

ADJUSTM

ENTS

3.1.

MECHANICAL

ADJUSTMENTS

PRECAUTION

Clean

the

following parts

alcohol-moistened

swab

record/playback

head

erase

head

capstan

Demagnetize

the

playback

demagnetizer.

.Do

not

use

a magnetized

screwdriver

for

the

adiust

ments.

After the

adjustments,

apply suitable locking

compound

to the

parts

adjusted.

The

adjustments should

be

performed

with

the

rated

power

supply voltage

unless

otherwise

noted.

(

z.

with

a denatured-

pinch

roller

rubber

belts

id lers

head with

a head

5.

I

I

Torgue Measurement

and Back Tension

2.

If the specified

tained,

change

spring.

back-tension

torque is

not

the hooking

position

of

supply-reel

spindle

back-tension

lever

weaker

<+

stronger

Change

the

hooking

Position.

(

lgcm

per

one slide.)

Torque

Torque

meter Meter

reading

Forward

cQ-102C

30-60

g.cm

(0.42*0.83

oz.inch)

Fast

forward,

Rewind

cQ-201A

110-165

g.cm

(1.53-2.2

oz.inch)

Back tension cQ-102c

2.5-4.5

g.cm

(0.04-0.06

oz.inch)

TC-PBI

O

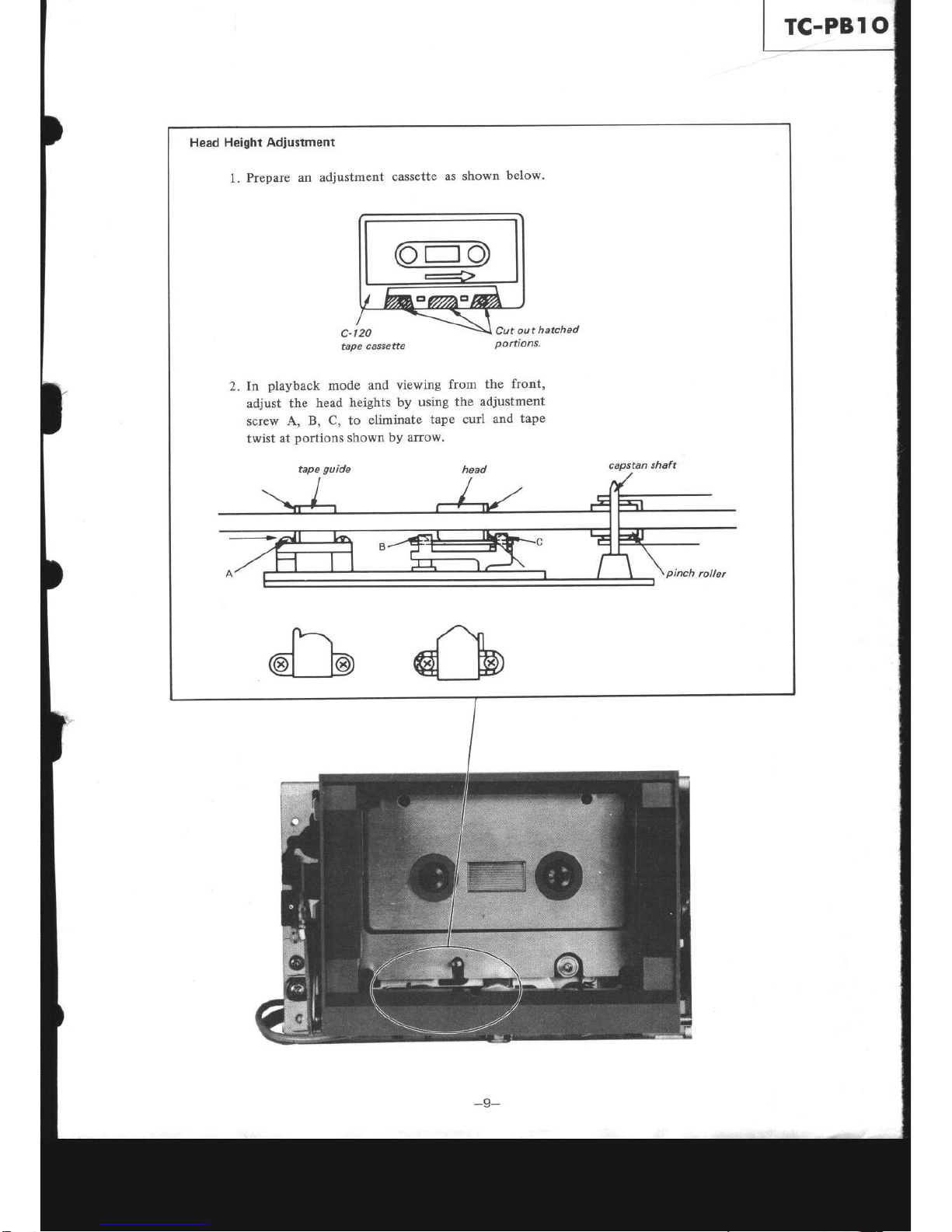

Head

Height Adjustment

l.

Prepare

an adjustment

cassette

as shown

below.

Cut

out

hatched

portions.

2. In

playback

mode

and

viewing

from

the

front,

adjust

the

head

heights

by

using the

adjustment

screw

A, B,

C, to

eliminate

tape

curl

and

tape

twist

at

portions

shown

bY arrow.

capstan

shaft

c-|20

tape

cassette

Loading...

Loading...