Sony TCM-20DV, TCM-21DV, TCM-22DV, TCM-23DV Service Manual

TCM-20DV/21DV/

22DV/23DV

SERVICE MANUAL

Ver 1.1 2000. 11

With SUPPLEMENT-1

(9-927-668-81)

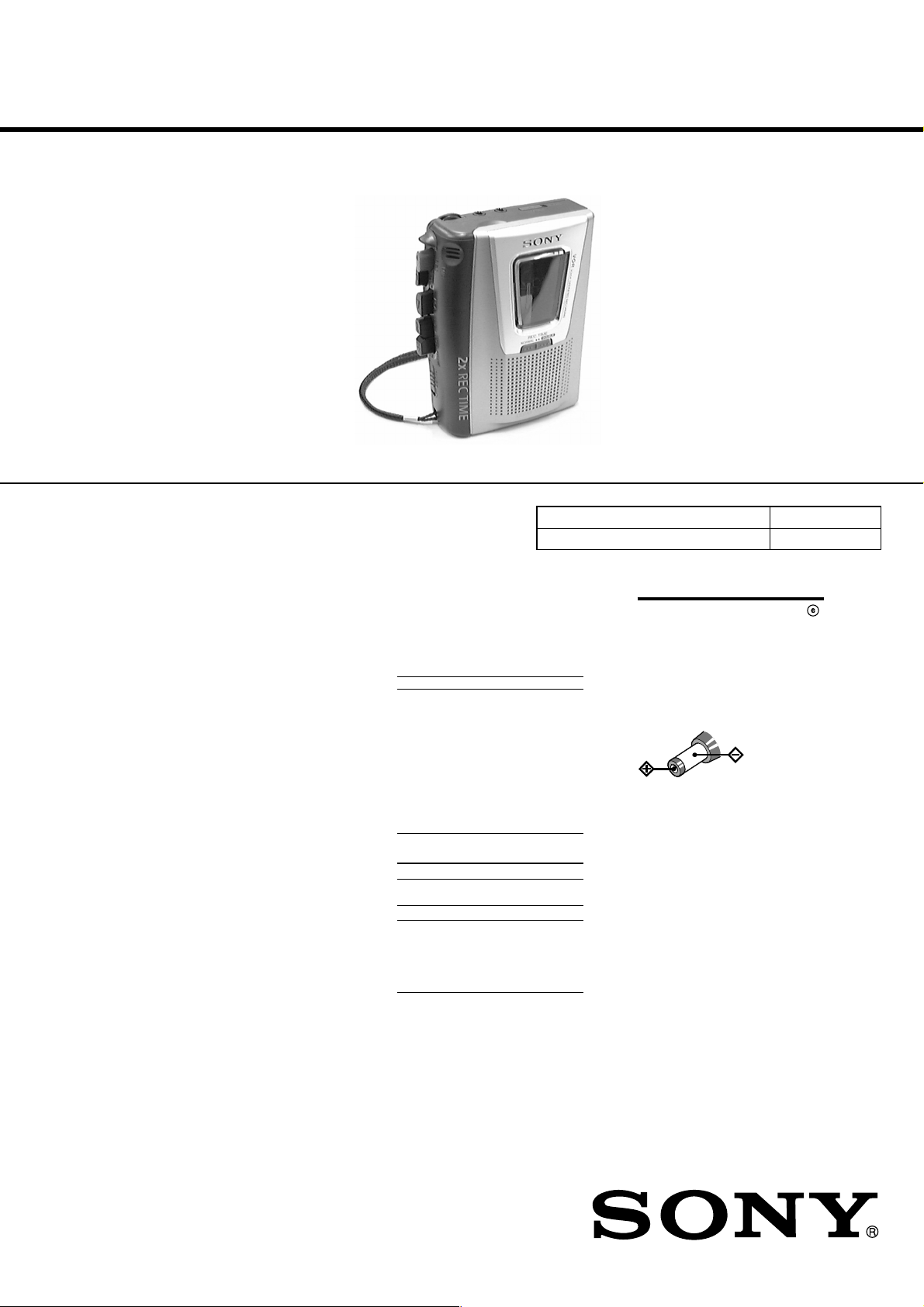

Photo: TCM-20DV

SPECIFICATIONS

Recording system

2-track 1 channel monaural

Tape speed

4.8 cm/s or 2.4 cm/s

Frequency range

250 - 6,300 Hz using nomal (TYPE

I) cassette (with REC TIME switch

at “NORMAL”)

Speaker

Approx. 3.6 cm (1

Power output

250 mW (at 10 % harmonic

distortion)

Input

Microphone input jack (minijack)

sensitivity 0.2 mV for 3 kilohms or

lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300

ohms earphone

Variable range of the tape speed

From approx. +30% to –15% (with

REC TIME switch at “NORMAL”)

Power requirements

3 V DC batteries R6 (AA) × 2/

External DC 3 V power sources

Dimensions (w/h/d) (incl. projecting

parts and controls)

Approx. 112 × 36.6 × 90.3 mm

1

⁄2 × 1 1⁄2 x 3 5⁄8 in.)

(4

Mass

Approx. 175 g (6.2 oz.)

7

/16 in.) dia.

Supplied accessories

The instructions in this manual are for

4 models.

The TCM-20DV is the model used for

illustration purposes.

TCM- 23DV 22DV 21DV 20DV

AC power adaptor (1)

Battery charger adaptor (1)

Rechargeable batteries (2)

(NC-AA, 1.2V, 700mAh,

Ni-Cd)

Cassette tape C-90 (1)

Battery LR6 (2)

Monaural microphone (1)

Super-directional

microphone (1)

Carrying pouch (1)

Hand strap (1)

(attached to the unit)

Battery life

Sony alkaline

LR6 (SG)

Sony R6P (SR) 3 3

Sony

rechargeable

battery

(NC-AA) fully

charged (TCM22DV only)

* Measured value by the standard of

EIAJ (Electronic Industries

Association of Japan). (Using a Sony

HF series cassette tape and playing

back with speakers)

Note

The battery life may shorten

depending on the operation of the

unit.

For maximum performance we

recommend that you use alkaline

batteries.

(Approx. hours) (EIAJ*)

Playback Recording

11 11

Model Name Using Similar Mechanism NEW

Tape Transpor t Mechanism Type MT-20DV-118

— a ——

— a ——

— a ——

——a —

——a —

——a —

a ———

——a —

aaaa

33

US Model

TCM-20DV/21DV/22DV/23DV

Canadian Model

TCM-20DV/22DV

AEP Model

TCM-20DV/21DV

E Model

TCM-20DV/23DV

Chinese Model

TCM-20DV

House Current

Connect the AC power adaptor to

DC IN 3V and to a wall outlet. The

AC power adaptor is supplied only

with the TCM-22DV. For other

models, use the AC-E30HG AC

power adaptor (not supplied). Do

not use any other AC power

adaptor.

Note

Specifications for AC-E30HG vary for

each area. Check your local voltage

and the shape of the plug before

purchasing.

Design and specifications are subject

to change without notice.

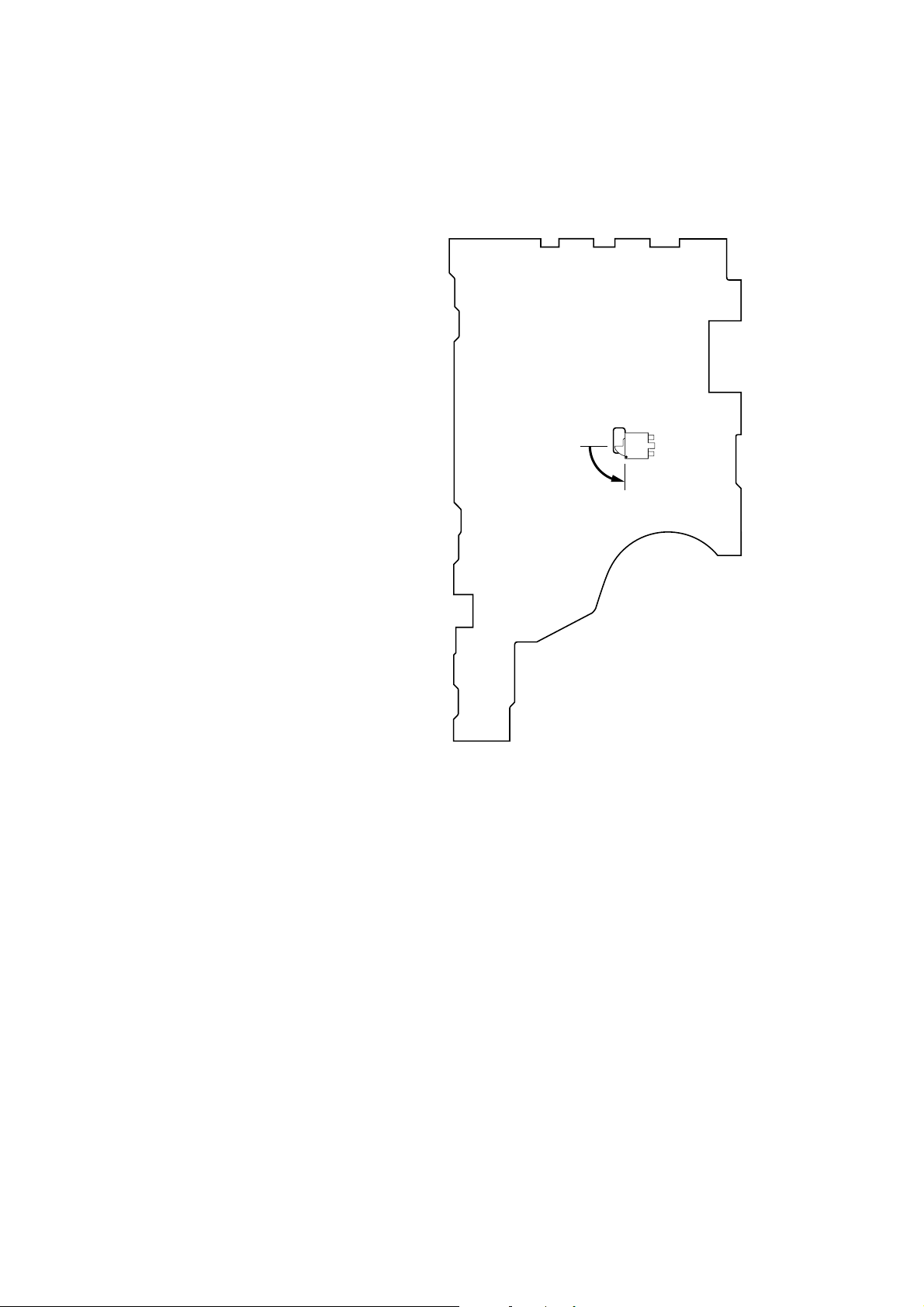

(see Fig. A- )

Polarity of

the plug

CASSETTE-CORDER

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 2

2. GENERAL ................................................................... 3

3. DISASSEMBLY ......................................................... 4

4. MECHANICAL ADJUSTMENTS....................... 7

5. ELECTRICAL ADJUSTMENTS......................... 8

6. DIAGRAMS

6-1. Block Diagram ................................................................ 9

6-2. Printed Wiring Board ...................................................... 11

6-3. Schematic Diagram ......................................................... 13

7. EXPLODED VIEWS ................................................ 16

8. ELECTRICAL PARTS LIST ............................... 19

In this set, the S102 (POWER) detects REC/PLAYBACK on.

It is mounted on the MAIN board, and therefore the REC/PLAYBACK on cannot be detected with the MAIN board removed.

When making an operation check and voltage check of mechanical deck with the MAIN board removed, fix the S102 at turn on.

– MAIN BOARD (Conductor Side) –

S102

on

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMA TIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

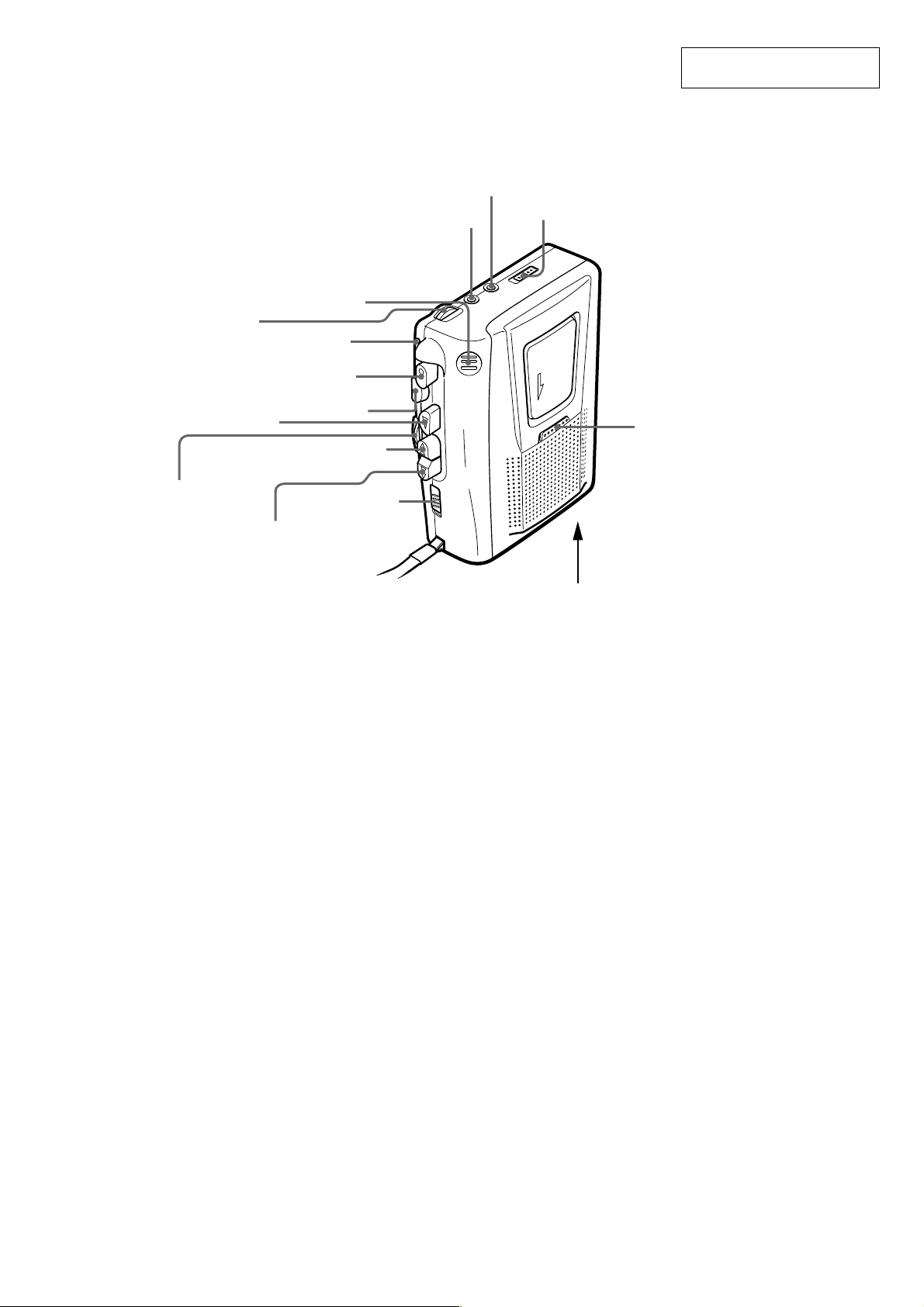

• Location of Controls

VOL

Built-in mic

BATT

z REC

SECTION 2

GENERAL

EAR

MIC

VOR

This section is extracted from

instruction manual.

B PLAY

SPEED CONTROL

M FF/CUE

x STOP

m REW/

REVIEW

PAUSE

.

REC TIME

DC IN 3 V

– 3 –

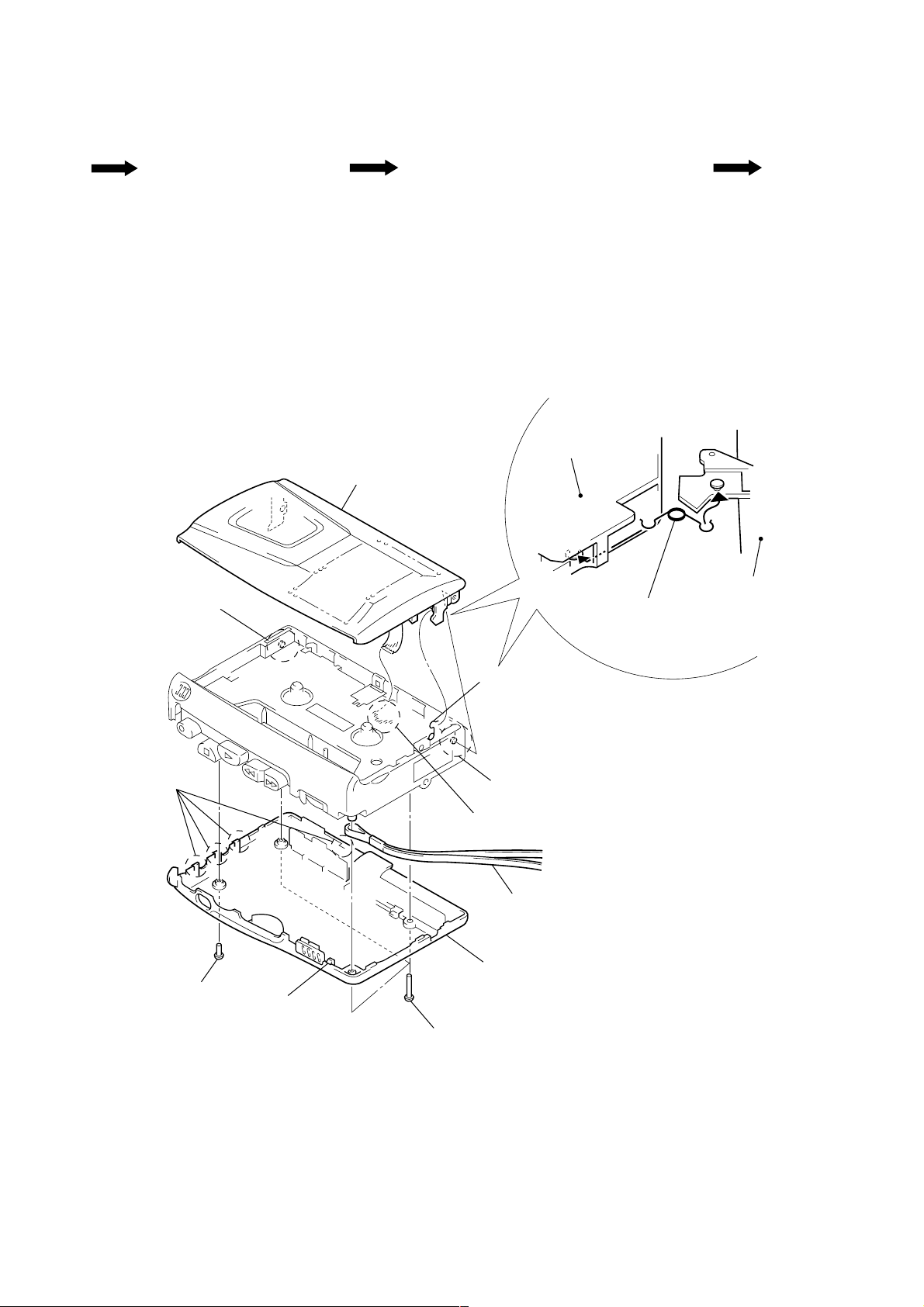

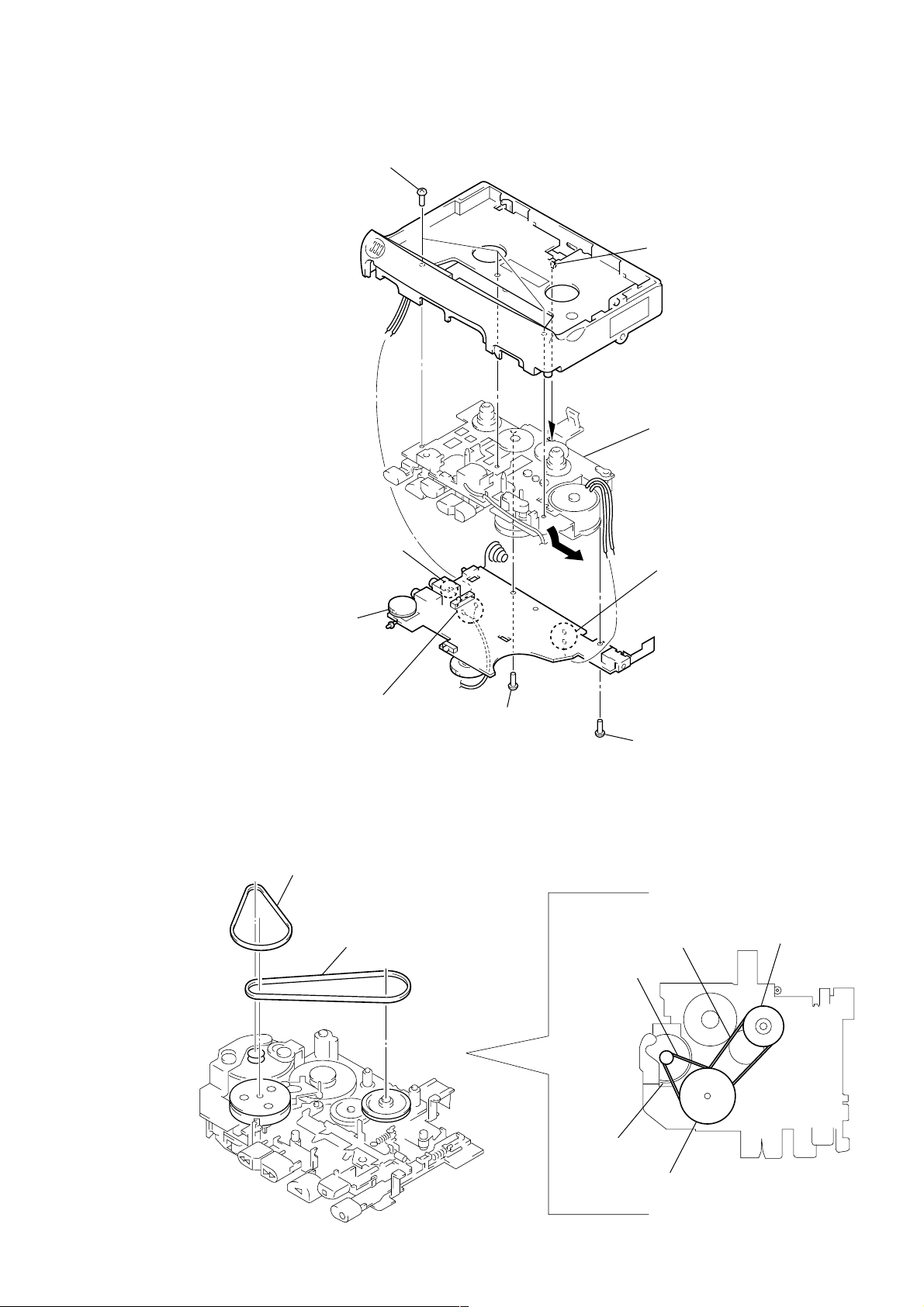

• This set can be disassembled in the order shown below.

T

G

SECTION 3

DISASSEMBLY

SET

Note: Follow the disassembly procedure in the numerical order given.

CABINET (REAR), CASSETTE LID

CABINET (REAR), CASSETTE LID

9 cassette lid

7 boss

MAIN BOARD, MECHANISM DECK (MT-20DV-118)

INSTALLATION CASSETTE SPRIN

cabinet front

cassette spring

BEL

cassette lid

3 four claws

2 screw

(IB lock)

7 boss

6 Remove the six solders.

5 hand strap

4 cabinet (rear)

3 claw

1 three screws

(B1.7 × 9)

– 4 –

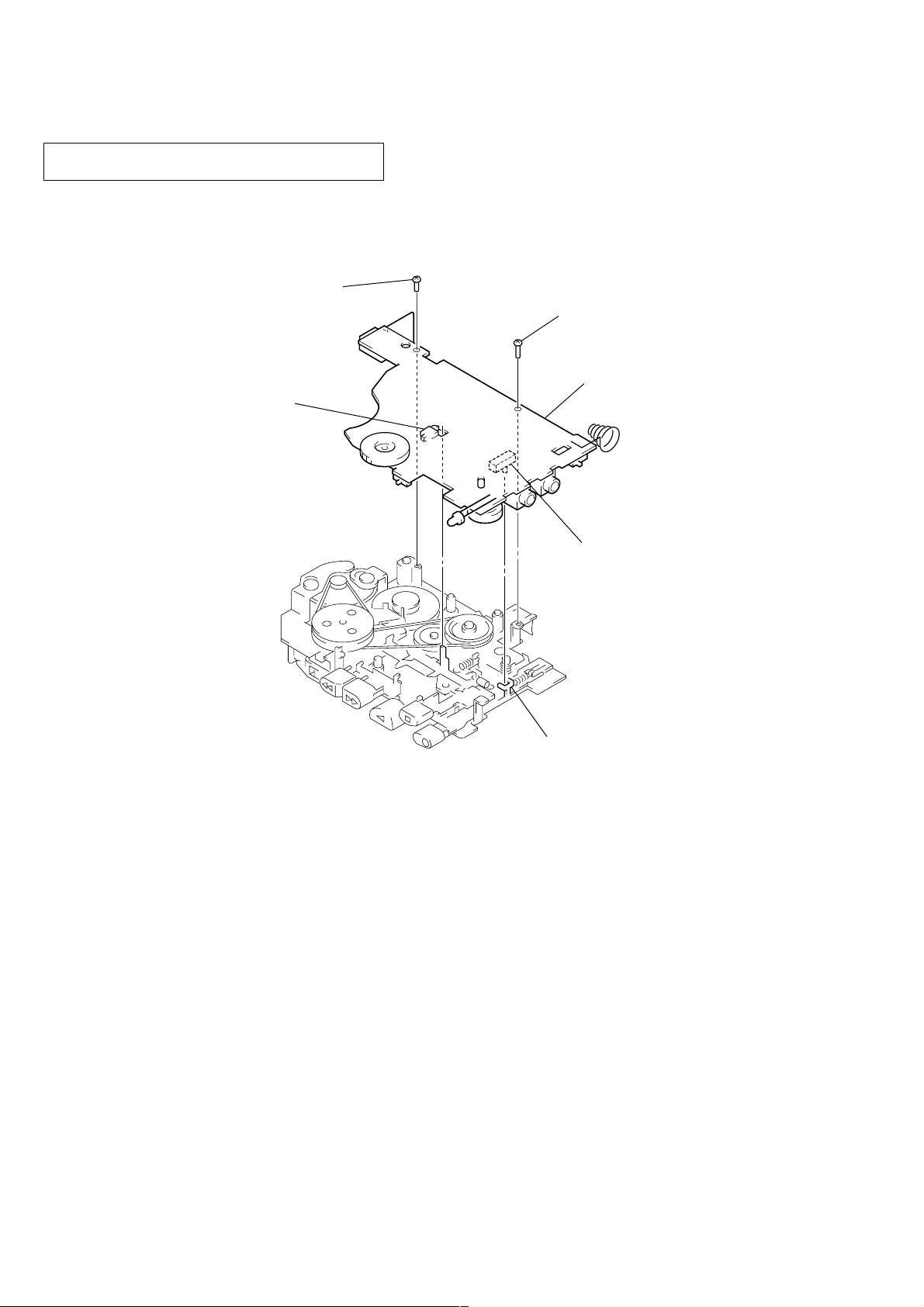

MAIN BOARD, MECHANISM DECK (MT-20DV-118)

5 three screws

(IB lock)

1 Remove the two solders

electret condenser microphone

(MIC101).

6 claw

7 mechanism deck

(MT-20DV-118)

1 Remove the two solders

motor (M901).

BELT

4 MAIN board

1 Remove the two solders

magnetic head (HRP901).

1 belt (capstan)

2 belt (FR)

3 screw

(M1.4)

2 screw

(1.7)

capstan belt

FR belt

pulley (FR) assy

– 5 –

motor DC

flywheel assy

INSTALLATION MAIN BOARD

On installation MAIN board, adjust to the S101 and

the S102.

screw

(1.7)

S102

(POWER)

screw

(M1.4)

MAIN board

S101 (REC/PB)

lever (REC)

– 6 –

SECTION 4

MECHANICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback head pinch roller

erase head rubber belt

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage (2.5 V) unless otherwise noted.

Torque Measurement

Mode Torque Meter Meter Reading

FWD

CQ-102C

FWD

Back Tension

FF

REW (more than 0.69 oz•inch)

CQ-201B (more than 50 g•cm)

2.16 - 4.7 mN•m

(22 - 48 g•cm)

(0.31 - 0.67 oz•inch)

0.05 - 0.29 mN•m

(0.5 - 3 g•cm)

(0.007 - 0.04 oz•inch)

4.90 mN•m

T ape Tension Measurement

Mode Torque Meter Meter Reading

FWD CQ-403C (more than 50 g)

4.90 mN•m

(more than 1.76 oz)

– 7 –

Loading...

Loading...