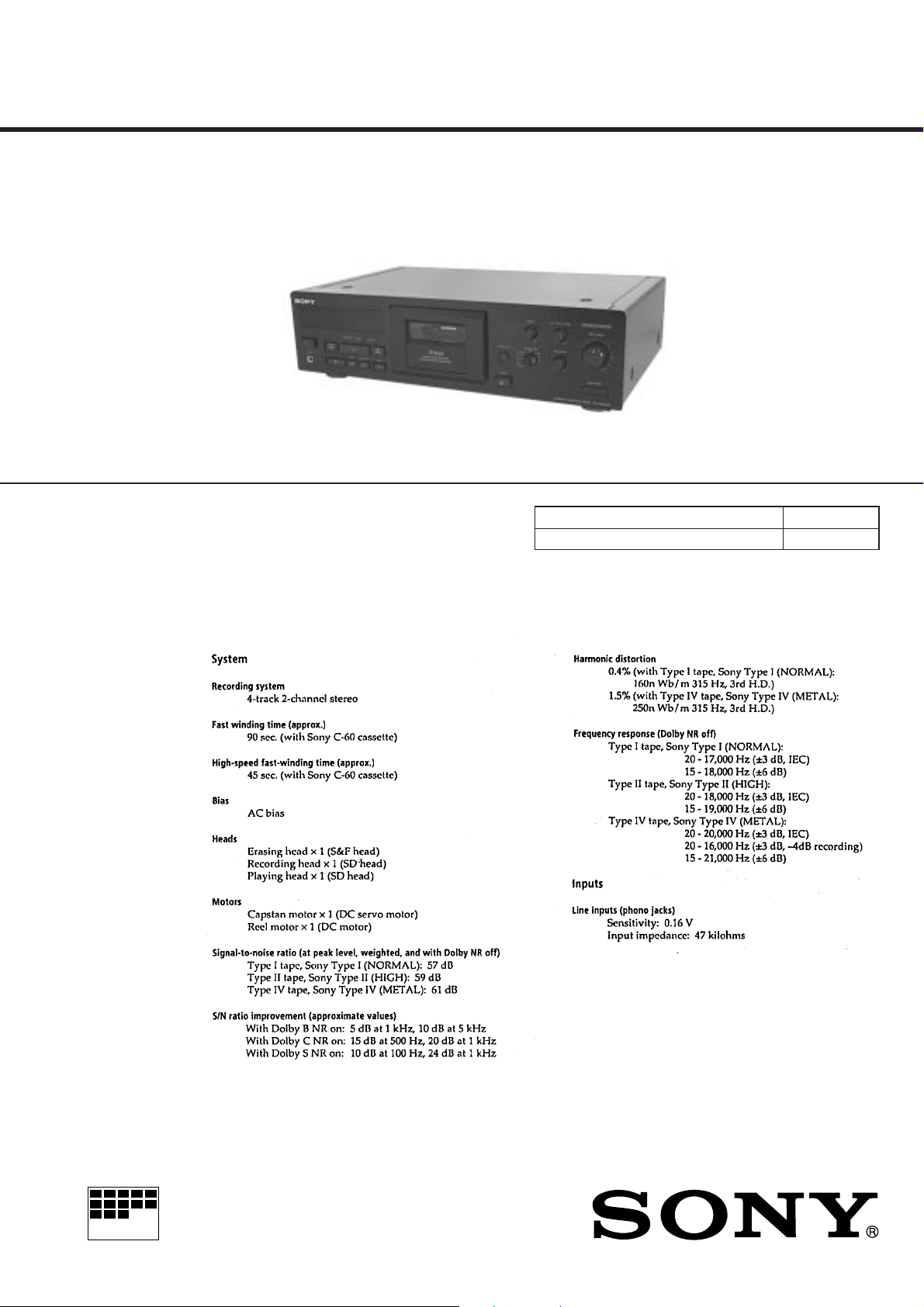

Sony TCKB-920-S Service manual

TC-KB920S

SERVICE MANUAL

Dolby noise reduction and HX Pro headroom extension manufactured under license from Dolby

Laboratories Licensing Corporation. HX Pro originated by Bang & Olufsen.

“DOLBY”, the double-D symbol a, and “HX PRO”

are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICA TIONS

AEP Model

E Model

Australian Model

Model Name Using Similar Mechanism TC-KE500S

T ape Transport Mechanism Type TCM-190VB14

MICROFILM

– Continued on next page –

STEREO CASSETTE DECK

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

MODEL IDENTIFICATION

– BACK PANEL –

3-020-984-

AEP Model : 0

Australian Model : 2

Malaysia, Singapore Model: 3

π

π

π

– 2 –

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

1. GENERAL ................................................................... 4

2. DISASSEMBLY ......................................................... 5

3. MECHANICAL ADJUSTMENTS....................... 9

4. ELECTRICAL ADJUSTMENTS......................... 10

5. DIAGRAMS

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 14

5-2. Printed Wiring Boards – MD Section –......................... 15

5-3. Schematic Diagram – MD Section – .............................. 17

5-4. Printed Wiring Board – MAIN Section –...................... 19

5-5. Schematic Diagram – MAIN Section – (1/2)................. 21

5-6. Schematic Diagram – MAIN Section – (2/2)................. 23

5-7. Printed Wiring Board – DOLBY-S Section – ............... 25

5-8. Schematic Diagram – DOLBY-S Section – .................. 25

5-9. Printed Wiring Boards – POWER Section – ................. 27

5-10. Schematic Diagram – POWER Section – ...................... 28

5-11. Printed Wiring Boards – PANEL Section – .................. 29

5-12. Schematic Diagram – PANEL Section –........................ 31

5-13. IC Pin Function Description ........................................... 33

6. EXPLODED VIEWS ................................................ 35

7. ELECTRICAL PARTS LIST ............................... 40

– 3 –

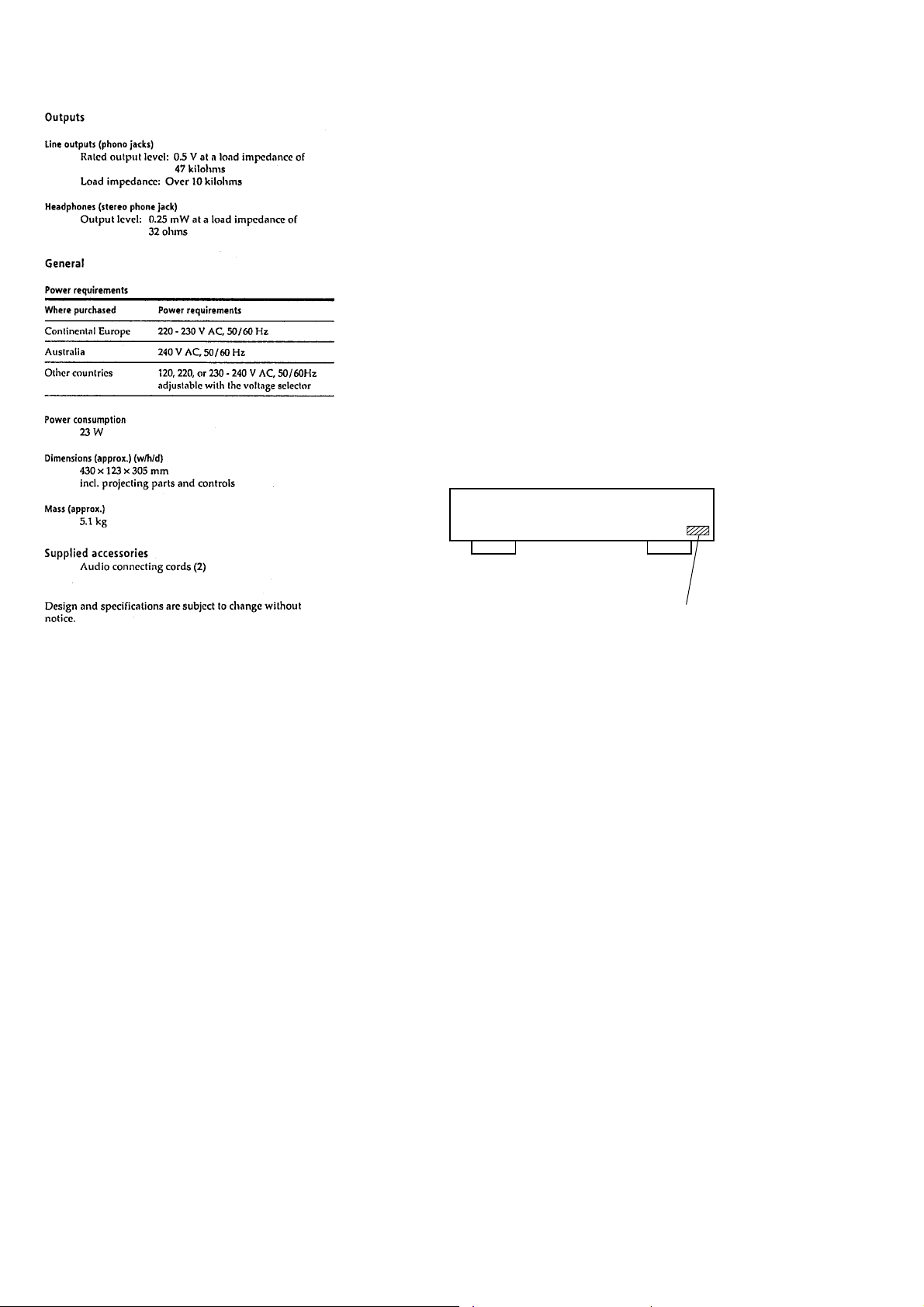

LOCATION OF CONTROLS

SECTION 1

GENERAL

1 I/O (Power) button

2 Remote control sensor

3 PHONES jack

4 Display panel

5 Tape operation buttons

AMS* 0 button

· button

AMS* ) button

p button

P PAUSE button

R REC MUTING button

r REC button

6 Tape counter

7 Counter buttons

RESET button

MEMORY button

8 Cassette holder

9 § EJECT button

!º AUTO CAL button

!¡ DOLBY NR switch

!™ BIAS control

!£ BALANCE control

!¢ CAL REC LEVEL control

!∞ MONITOR button

!§ REC LEVEL control

* AMS is an abbreviation for Automatic Music Sensor.

– 4 –

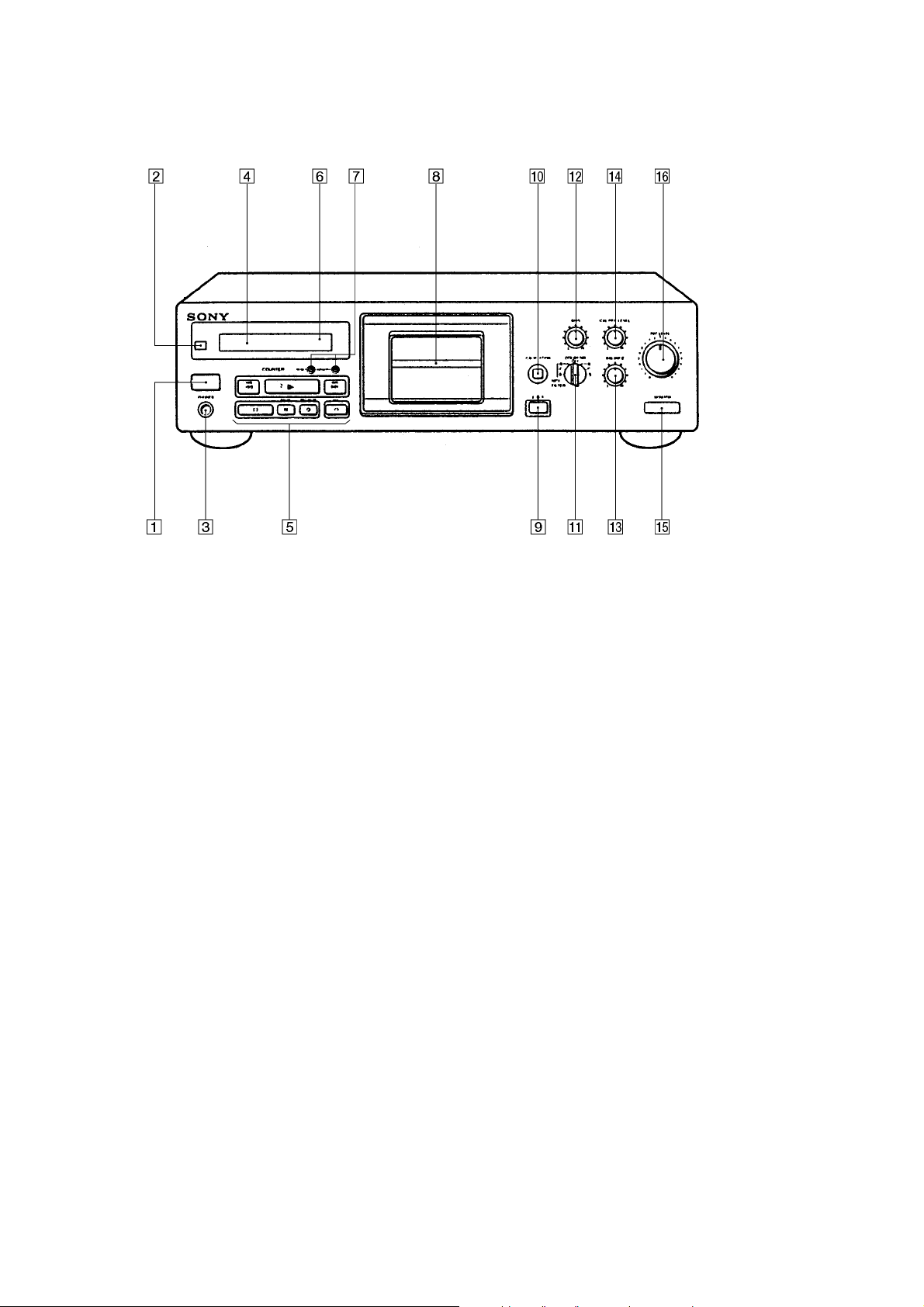

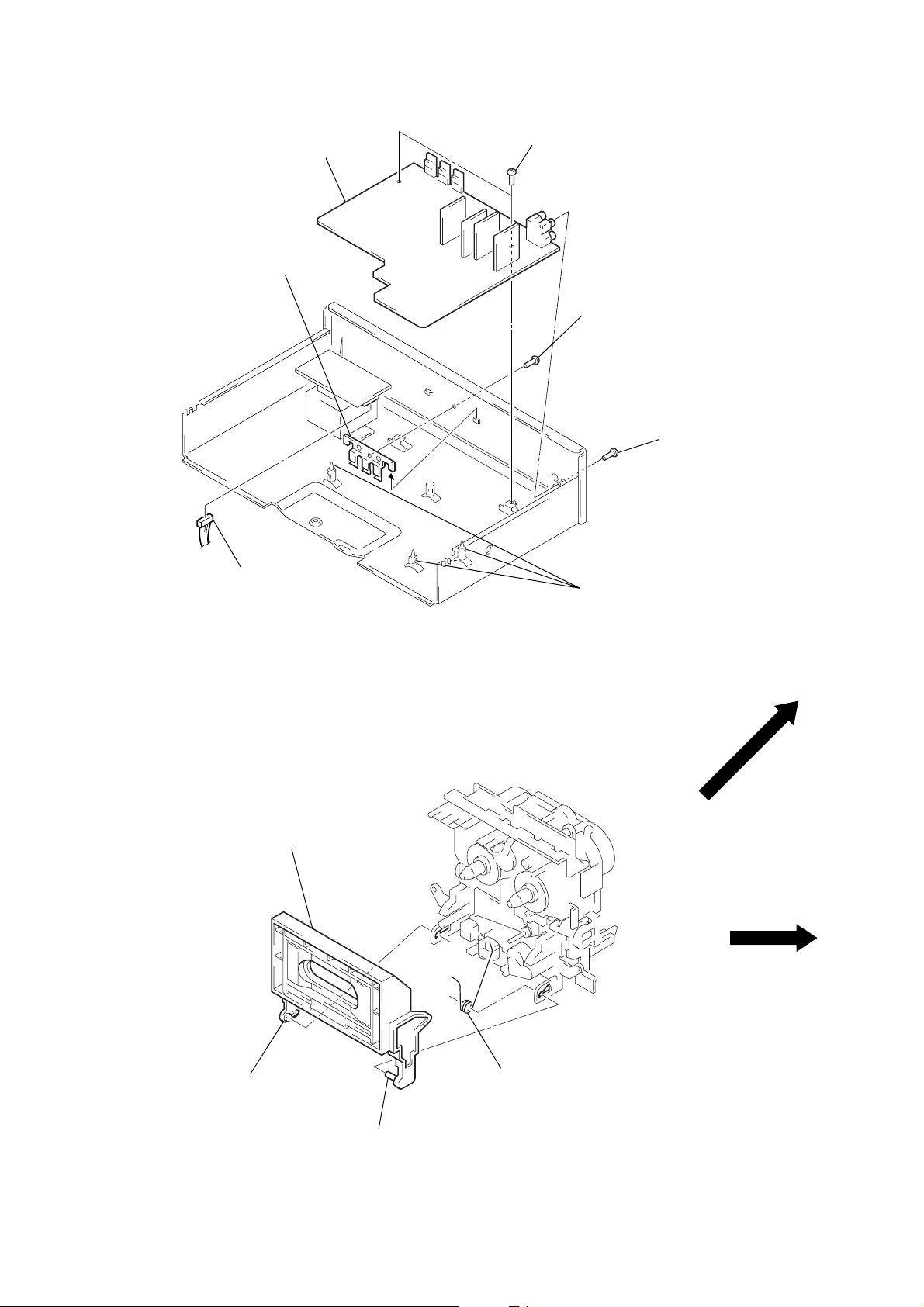

SECTION 2

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

Unscrew the four case attachment seven tapping screws and

remove the case.

FRONT PANEL SECTION

1

three flat cables

(CN803 – 805)

2

connector

(CN704)

4

claw

2

five connectors

(CNP301 – 303, 305, 306)

3

four screws

(BVTP3

×

8)

MD ASS’Y SECTION

2

two

claws

4

two screws

(BVTT2.6

5

front panel

section

×

8)

A

4

claw

3

screw

(BVTP3

×

8)

6

Remove the MD ass’y section

to direction of arrow

2

two connectors

(CNP304, CN801

A

5

two screws

(BVTP2.6

.

×

8)

3

cassette lid

ass’y

2

two claws

1

Push the eject button.

– 5 –

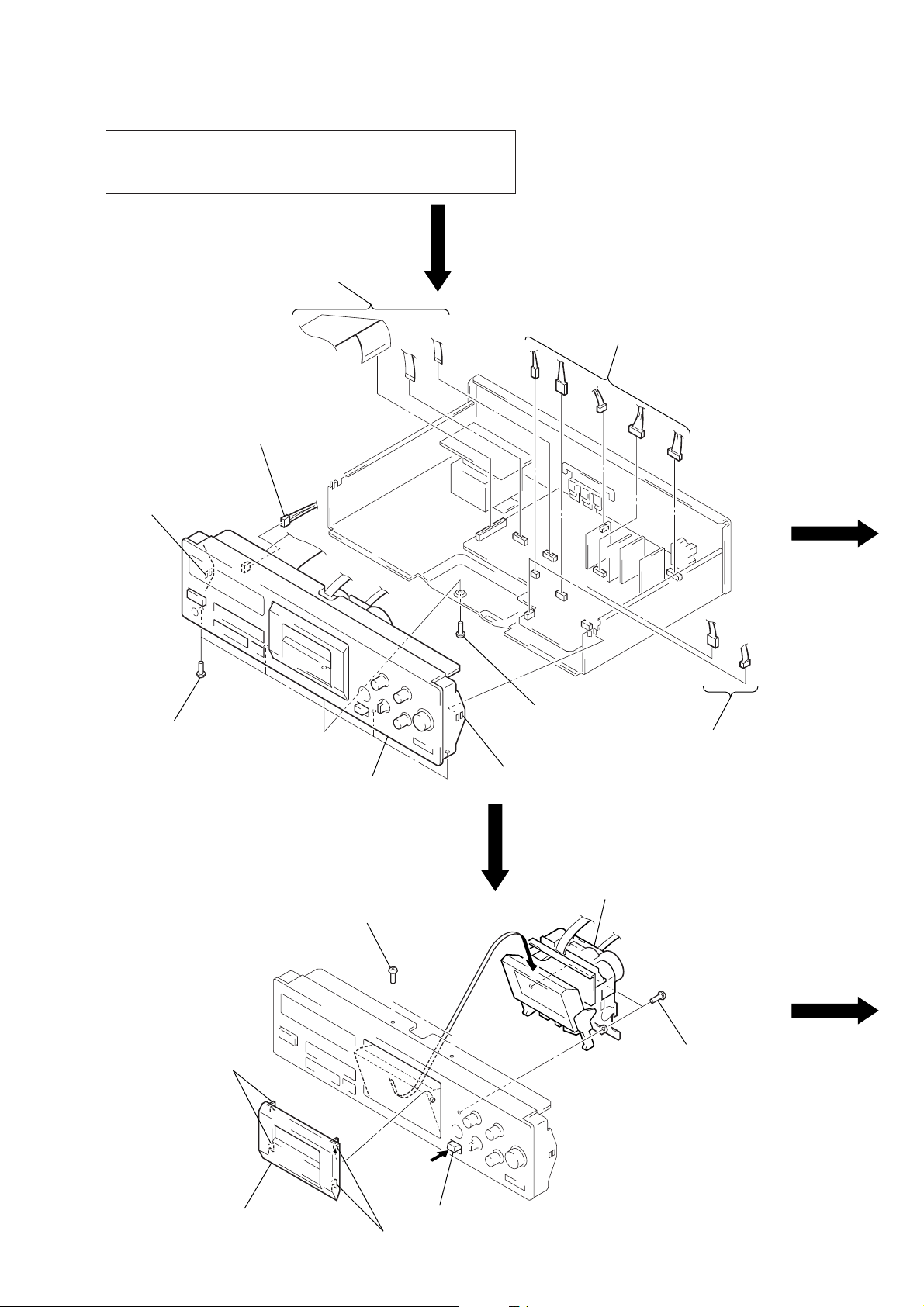

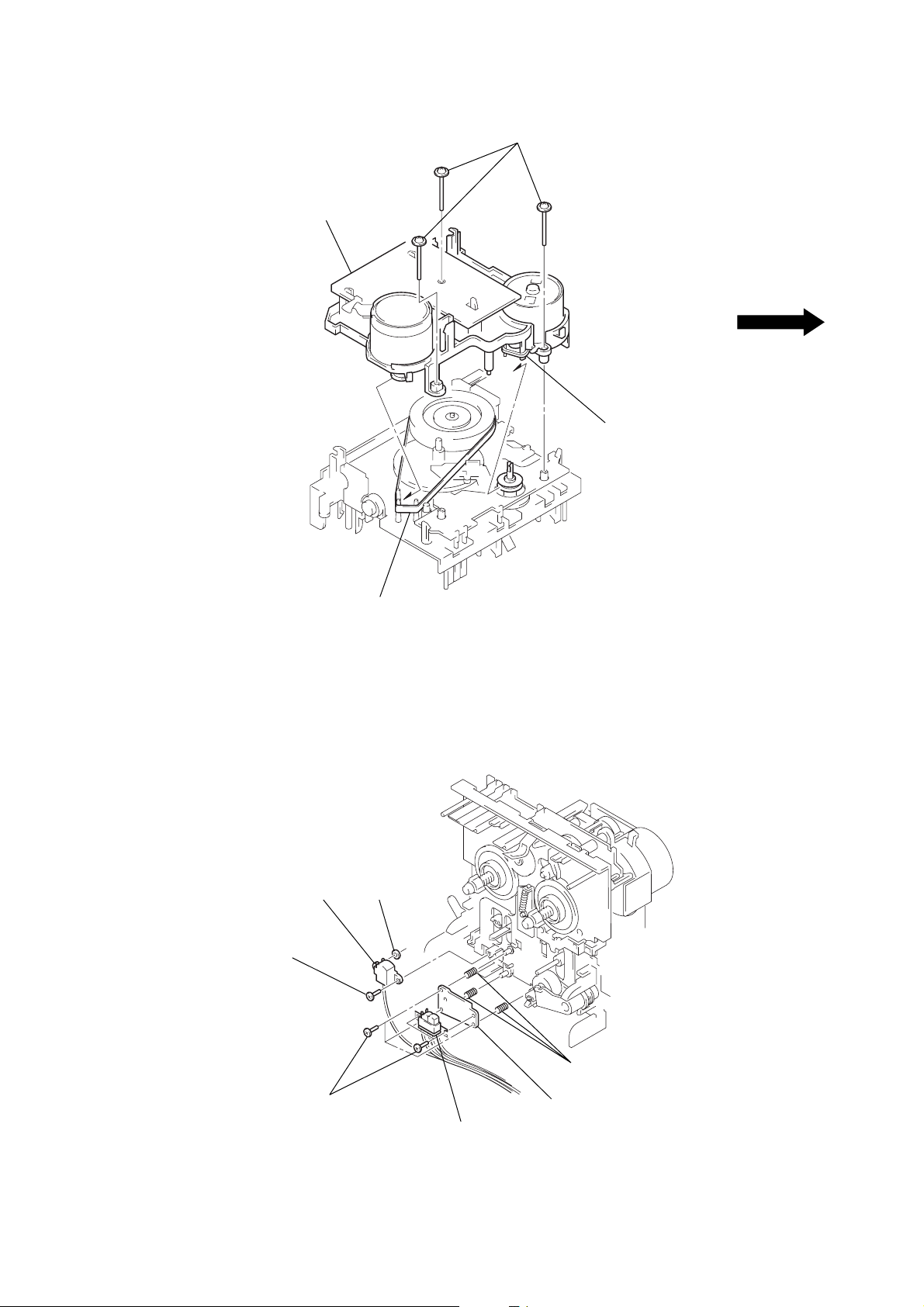

MAIN BOARD

)

3

bracket (TR)

6

MAIN board

4

two screws

(BVTP3

×

2

screw

(BV/ring)

8)

4

screw

(BV/ring

1

connector

(CN701)

CASSETTE HOLDER (R) ASS’Y

4

cassette holder (R)

ass’y

5

three PC board

holders

2

boss

3

shaft

– 6 –

1

torsion spring

FITTING BASE BLOCK

s

2

fitting base block

1

three screws

(PTPWH2

×

23)

Note:

When installing,

pull the FR belt

and put around the

claws as shown below.

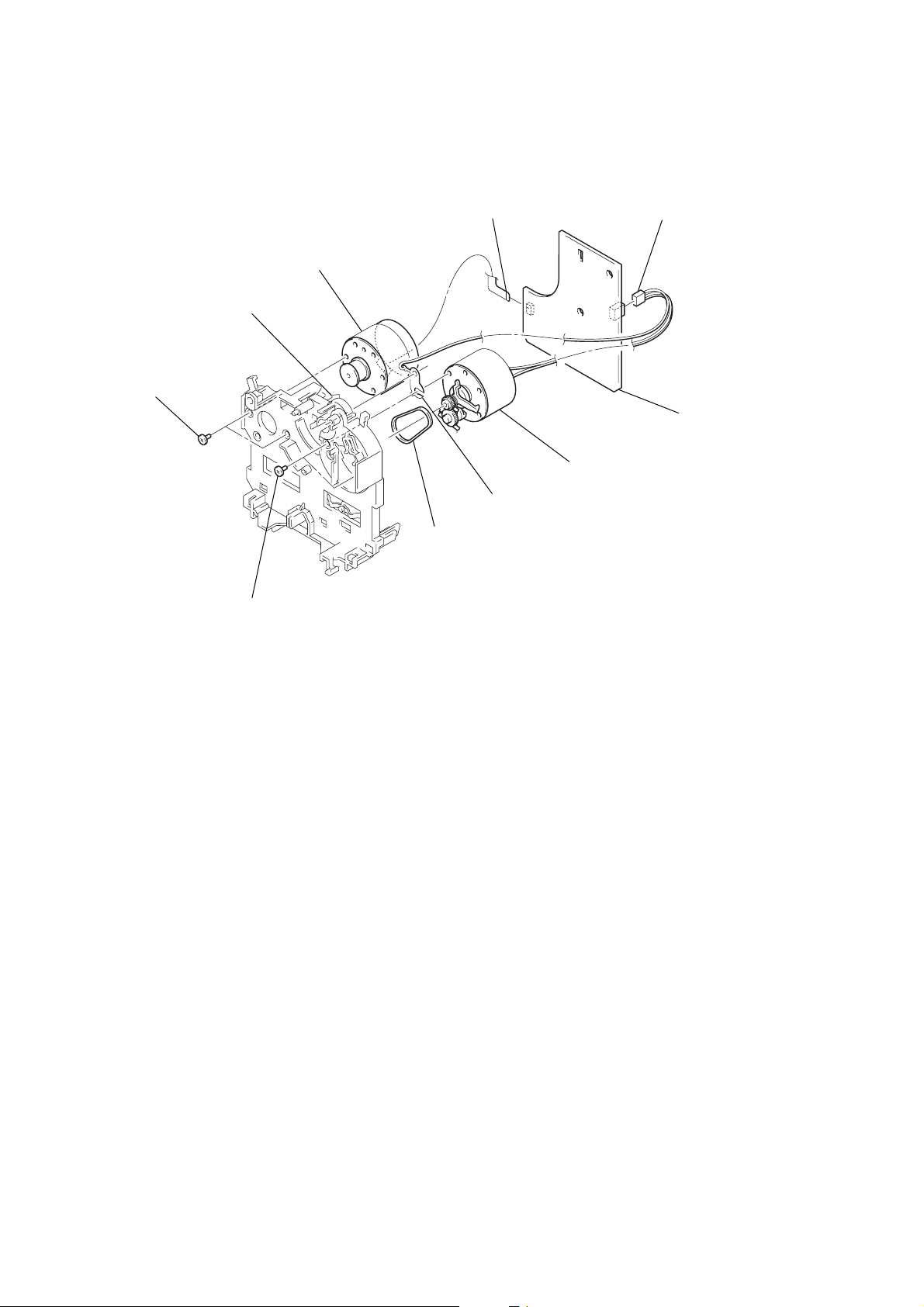

HEAD

1

screw

(B2

Note:

When installing, pull the capstan belt

and put around the claws as shown below.

2

erase

head

×

4)

3

washer

4

five screws

(B2

7

three RPH spring

6

×

4)

5

record/

playback

head

head blacket

– 7 –

AUDIO BOARD AND MOTOR

d

3

claw

5

two screws

(B2.6

×

3)

6

capstan motor

9

belt (FR)

2

flexible board

(CNP72)

0

ground plate

8

reel motor

1

connector

(CNP71)

4

audio boar

7

two screws

(P2.6

×

2.8)

– 8 –

SECTION 3

)

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback/erase head pinch roller

rubber belts capstan

idler

2. Demagnetize the record/playback head with a head demagne-

tizer.

(Head demagnetizer do not approach for the erase head.)

3. Do not use a magnetized screwdriver for the adjustment.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

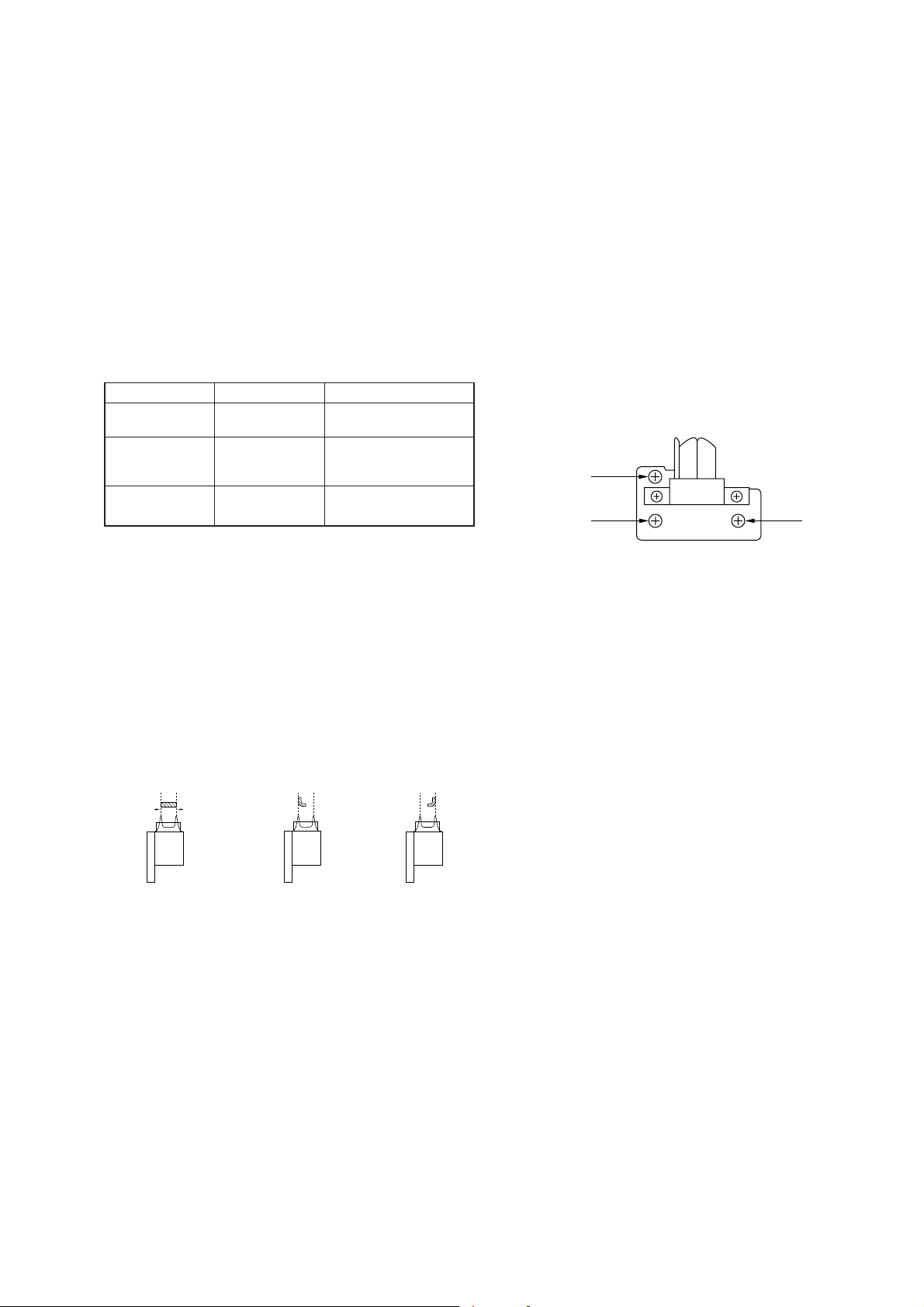

• T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

back CQ-102C

tension

FF/REW CQ-201B

Record/Playback Head Height/Declination Adjustment

Procedures:

1. Test cassette: CQ-009C

2. Insert the mirror cassette and put the unit in record/Playback

mode.

1) Height Adjustment:

Check to see if the tape is curling at the tape guide of the head.

If it is curling, tighten screws A, B and C, respectively by

the same angle, moving the head so that it remains at the same

angle throughout the procedure. If it curls on the bottom side

of the mirror cassette (actually the inner side), tighten all the

screws equally; but loosen them if the tape begins to curl on

the top side. (outer side.)

30 to 65 g•cm

(0.42 to 0.90 oz•inch)

1 to 6 g•cm

(0.014 to 0.08 oz•inch)

70 to 120 g•cm

(0.98 to 1.66 oz•inch)

2) Dec lination Adjustment:

While in the record/playback position, set the back tension to

0 (wind the supply reel with something thin like a pencil in a

counterclockwise direction) and make sure there is no curling

or shifting (shifting up/shifting down) at the guide of the

record/playback head.

Because shifting can only occur due to a difference in the width

of the tape and that of the tape guides (curling will otherwise

occur), it is necessary to pay close attention since it can be

easily overlooked.

When there is a shift, tighten screws B and C equally and

change the declination of the head. If the tape is shifting up,

tighten the screws, and if it is shifting down, loosen them.

Repeat the adjustments in steps 1) to 2) and fine adjust the

height and the declination.

Adjustment Location: – record/playback head –

A

BC

inside

Normal

(Record/playback head

as seen from the side of

the erasehead.

outside

Curling on the inner

side

Tighten screws

and C.

A, B

Curling on

the outer side

Loosen screws

B

and C.

A

,

– 9 –

SECTION 4

r

e

Adjustment screw

ELECTRICAL ADJUSTMENTS

Note: The adjustment should be performed in the order given in the ser-

vice manual. As a rule, adjustments about playback should be performed before those about recording.

The adjustments should be performed before for both L-CH and RCH.

• Switches and controls should be set as follows unless otherwise

specified.

DOLBY NR, MPX FILTER switch: OFF

MONITOR switch: Tape

• Standard Record:

Deliver the standard input signal level to the input jack and set

the REC LEVEL control to obtain the standard output signal

level.

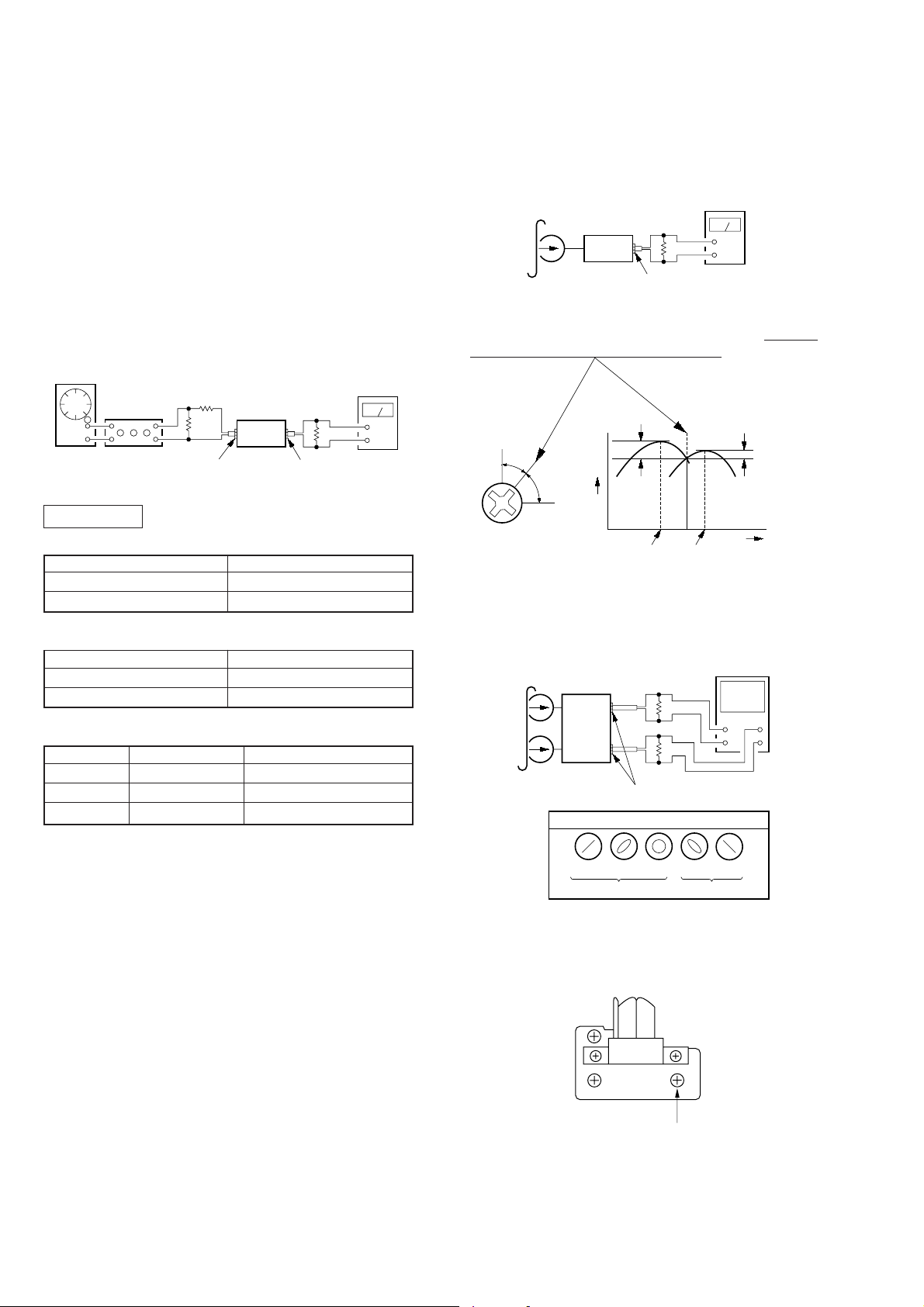

– Record Mode –

AF OSC

attenuator

10 k

600

Ω

Ω

LINE IN

47 k

set

LINE OUT

level meter

Ω

+

–

0 dB=0.775 V

Standard Input Level

input terminal LINE IN

source impedance 10 kΩ

input signal level 0.5 V (–3.8 dB)

Standard Output Level

output terminal LINE OUT

load impedance 47 kΩ

output signal level 0.5 V (–3.8 dB)

Test T ape

Type Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

P-4-L300 315 Hz, 0 dB Playback Level Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

Record/Playback Head Azimuth Adjustment

Procedure:

1. Mode: FWD playback

Test tape

P-4-A100

(10 kHz, –10 dB)

47 k

set

level mete

Ω

+

–

LINE OUT

2. Turn the adjustment screw for the maximum output levels. If

these levels do not match, turn the adjustment screw until both

of output levels match together within 1 dB.

output

level

within

1dB

L-CH peak

within

1dB

angl

R-CH peak

L-CH

peak

Screw

position

R-CH

peak

3. Phase Check

Mode: playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

set

R-CH

47 k

47 k

LINE OUT

Screen pattern

Ω

Ω

oscilloscope

H

V

+

+

–

–

in phase 45

°90°

Good Wrong

135°180

°

4. After the adjustment, lock the screw with locking compound.

Adjustment Location: Record/Playback head

– 10 –

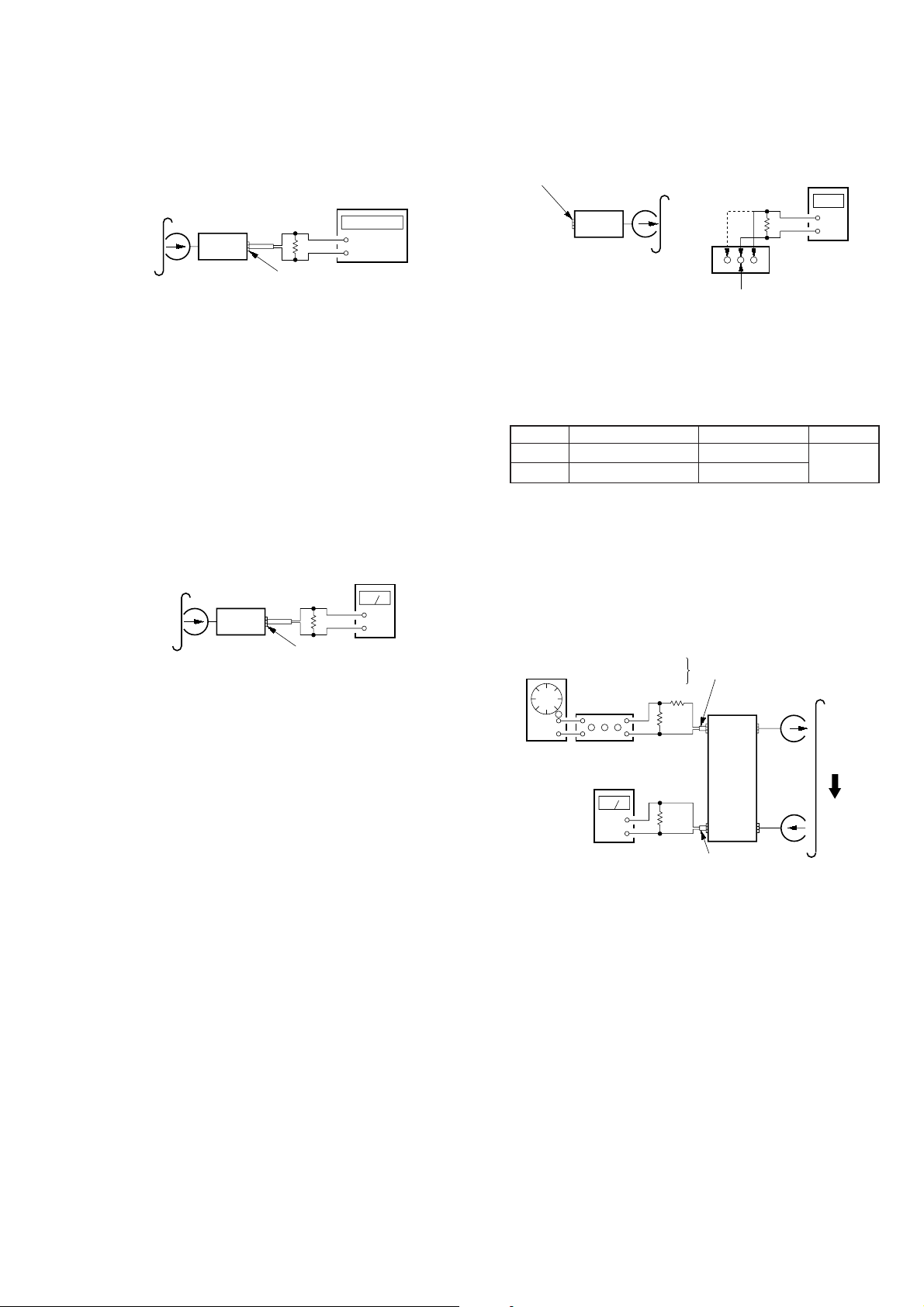

Tape Speed Adjustment

r

r

r

Procedure:

Mode: playback

test tape

WS-48B

(3 kHz, 0 dB)

set

47 k

Ω

LINE OUT

frequency counte

+

–

1. Set to FWD playback mode.

2. Adjust RV71 so that the frequency counter reading becomes

3,000±90 Hz.

3. Frequency difference between the beginning and the end of

the tape should be within 3%.

Adjustment Location: AUDIO board (See page 12.)

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

Playback Level Adjustment

Procedure:

Mode: playback

test tape

P-4-L300

(315 Hz, 0 dB)

set

Ω

47 k

LINE OUT

level mete

+

–

Adjust RV121 (L-CH) and RV221 (R-CH) so that the reading on

level meter meets the adjustment limits below.

Adjustment Limits:

LINE OUT level: –7.7±0.5 dB (0.301 to 0.338 V)

Level difference between channels: within 0.5 dB

Check that the LINE OUT level does not change even if Playback

and Stop operation is repeated several times.

Adjustment Location: MAIN board (See page 12.)

Bias Consumption Current Adjustment

Procedure:

LINE IN

(no signal)

CS-413 blank tape

set

TP321

L-CH

2

3

1

B+ (+7.5 V)

47 k

R-CH

digital voltmete

Ω

–

+

1. Set RV103 (L-CH) and RV203 (R-CH) to mechanical center

and turn the set recording mode.

2. Connect digital voltmeter as shown by the following table.

3. Adjust the following transformers for the minimum readings

on the digital voltmeter.

Measurement Point Adjustment Part Value

L-CH 2 and 3, TP321 T101

R-CH 1 and 2, TP321 T201

minimum

Adjustment Location: MAIN board (See page 12.)

Record Bias Adjustment

Setting:

REC LEVEL control: Standard Record (See page 10.)

Procedure:

1. Mode: record and playback

LINE IN

+

–

315 Hz

10 kHz

10 k

600

47 k

50 mV (–23.8 dB)

Ω

Ω

set

Ω

LINE OUT

CS-123

blank tape

AF OSC

Attenuator

level meter

2. Adjust RV103 (L-CH) and RV203 (R-CH) so that 10 kHz playback output is 0±0.3 dB relative to the 315 Hz output.

Adjustment Location: MAIN board (See page 12.)

– 11 –

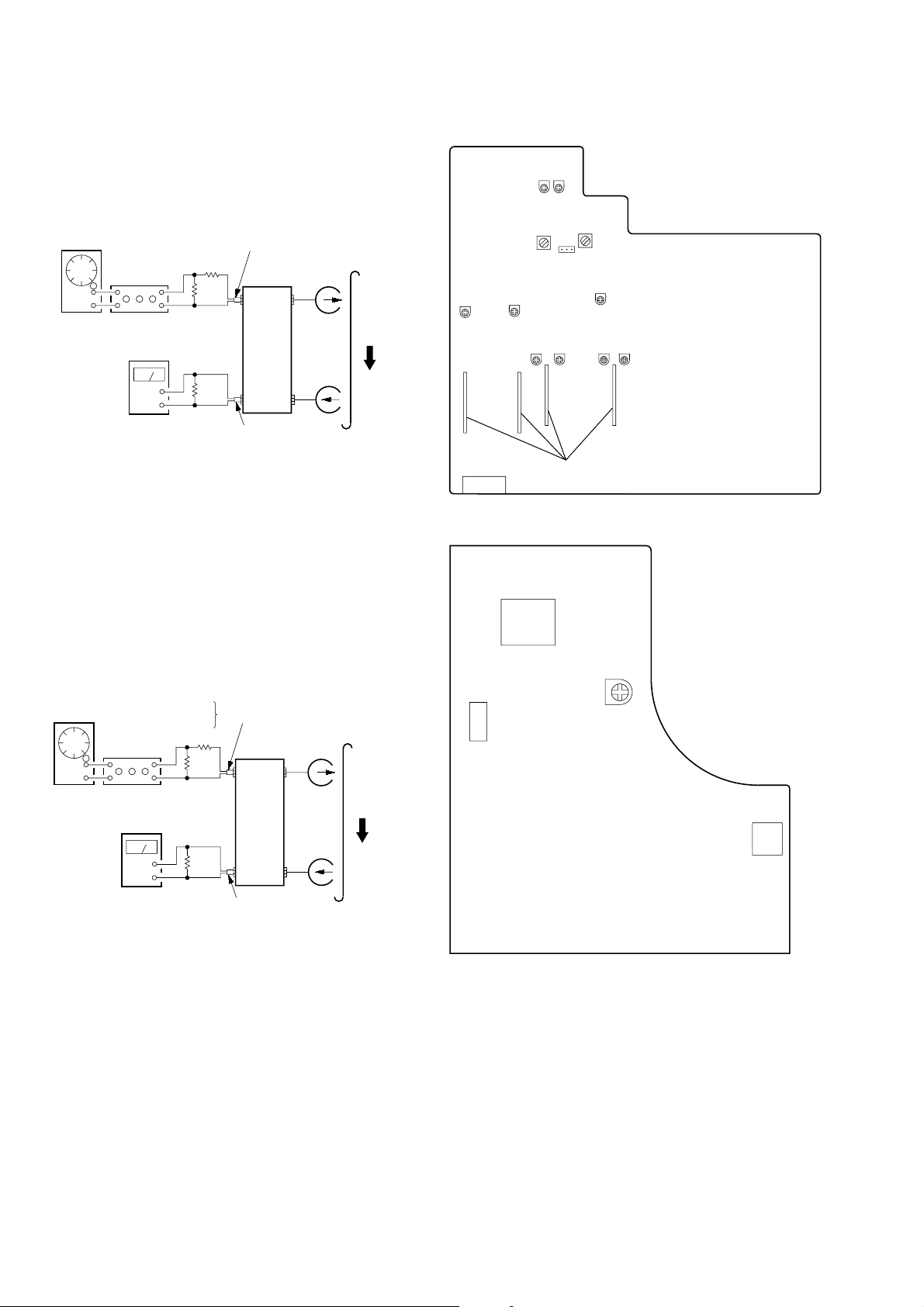

Record Level Adjustment

Setting:

REC LEVEL control: Standard Record (See page 10.)

Procedure:

1. Mode: record and playback

LINE IN

AF OSC

Attenuator

315 Hz, 50 mV (–23.8 dB)

10 k

Ω

600

Ω

CS-123

blank tape

Adjustment Location:

[MAIN BOARD] – COMPONENT SIDE –

RV103

RV203

T101

13

TP301

RV306

RV221

T201

RV121

level meter

+

–

47 k

Ω

set

LINE OUT

2. Adjust R V101 (L-CH) and RV201 (R-CH) so that the reading

on level meter meets the adjustment limits below.

Adjustment Limits: –23.8±0.5 dB (47.2 to 53 mV)

Adjustment Location: MAIN board

Record EQ (IV) Adjustment

Setting:

REC LEVEL control: Standard Record (See page 10.)

Procedure:

1. Mode: record and playback

LINE IN

AF OSC

Attenuator

level meter

315 Hz

10 kHz

10 k

600

47 k

50 mV (–23.8 dB)

Ω

Ω

set

Ω

CS-123

blank tape

RV201

RV202

J301

[AUDIO BOARD] – COMPONENT SIDE –

CNP73

CNP71

RV101

DOLBY-S

BOARD

RV102

RV71

CNP72

+

–

LINE OUT

2. Adjust RV102 and RV202 so that they become maximum.

3. Adjust RV102 (L-CH) and RV202 (R-CH) so that the difference between R-CH and L-CH at 10 kHz is within 1 dB.

4. Adjust RV306 so that the R-CH meet the specification.

Adjustment Limits:

10 kHz level difference against 315 Hz reference.

0±1.0 dB

Adjustment Location: MAIN board

– 12 –

Loading...

Loading...