Sony TCI-200 Training Manual

S®

Projection

T elevision

Training Manual

Circuit Description and Troubleshooting

Course: TCI-200

Course Description

and Troubleshooting:

RA-4 Chassis

Prepared by: National Training Department

Sony Service Company

A Division of Sony Electronics Inc.

Course presented by______________________________________

Date___________________________________________________

Student Name ___________________________________________

Sony Service Company

A Division of Sony Electronics Inc ©1998

All Rights Reserved

Printed in U.S.A.

Sony and Trinitron are registered trademarks of Sony.

Table of Contents

Features 1

Overview 1

Picture 1

Audio 1

Self-Diagnostics 3

Board Descriptions 5

Power Supply Block 7

AC Input 7

Power ON 7

Converter 7

Regulation 7

Protection 7

AC Input and Switching B+ 9

Overview 9

AC Input 9

B+ Rectifier 9

Standby Power Supply 1 1

Overview 11

Standby Switching supply 11

Vcc Switch (Power On) 13

Overview 13

Power ON 13

DC Protect 13

AC Protect 13

Soft Start 15

Overview 15

Soft Start - Power ON 15

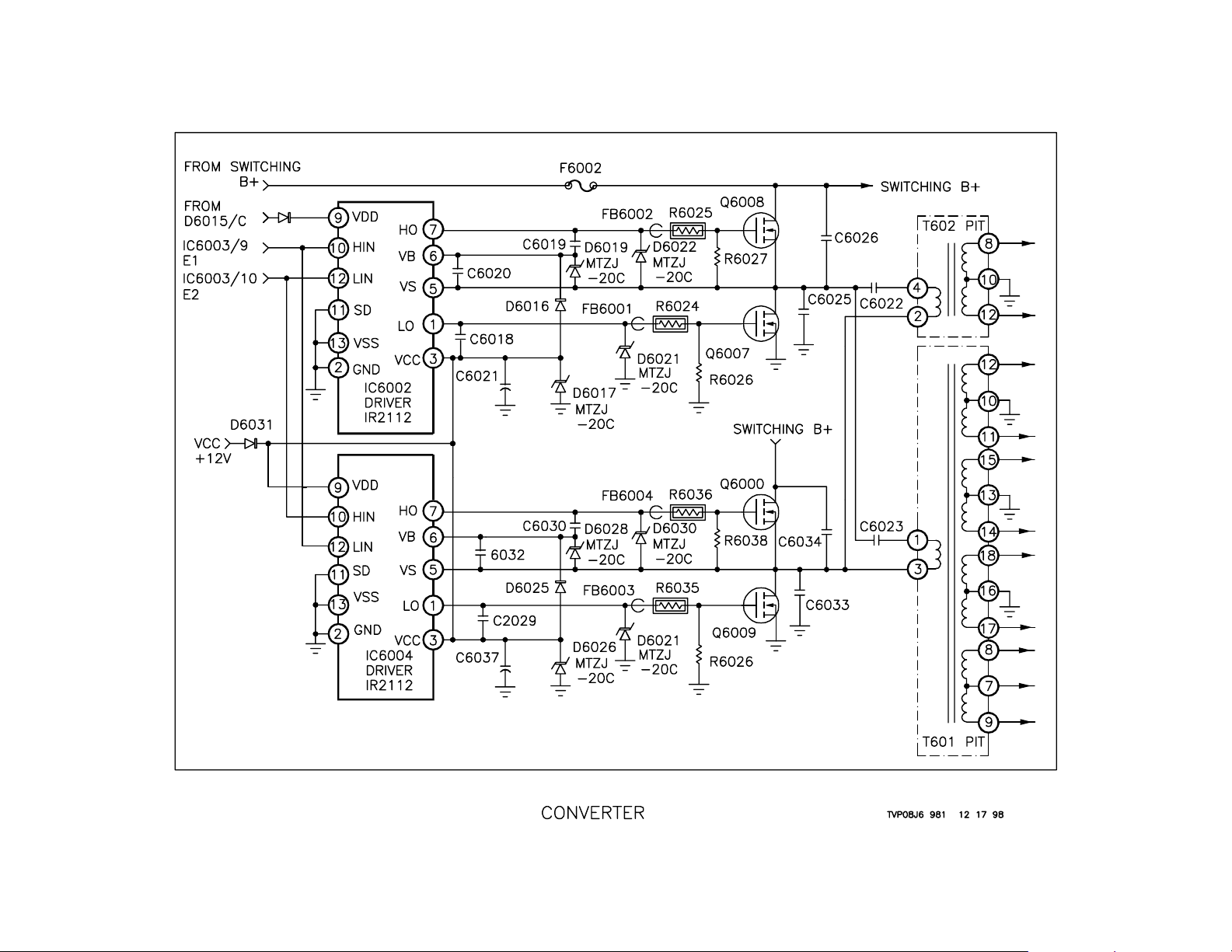

Converter 17

Overview 17

Operation 17

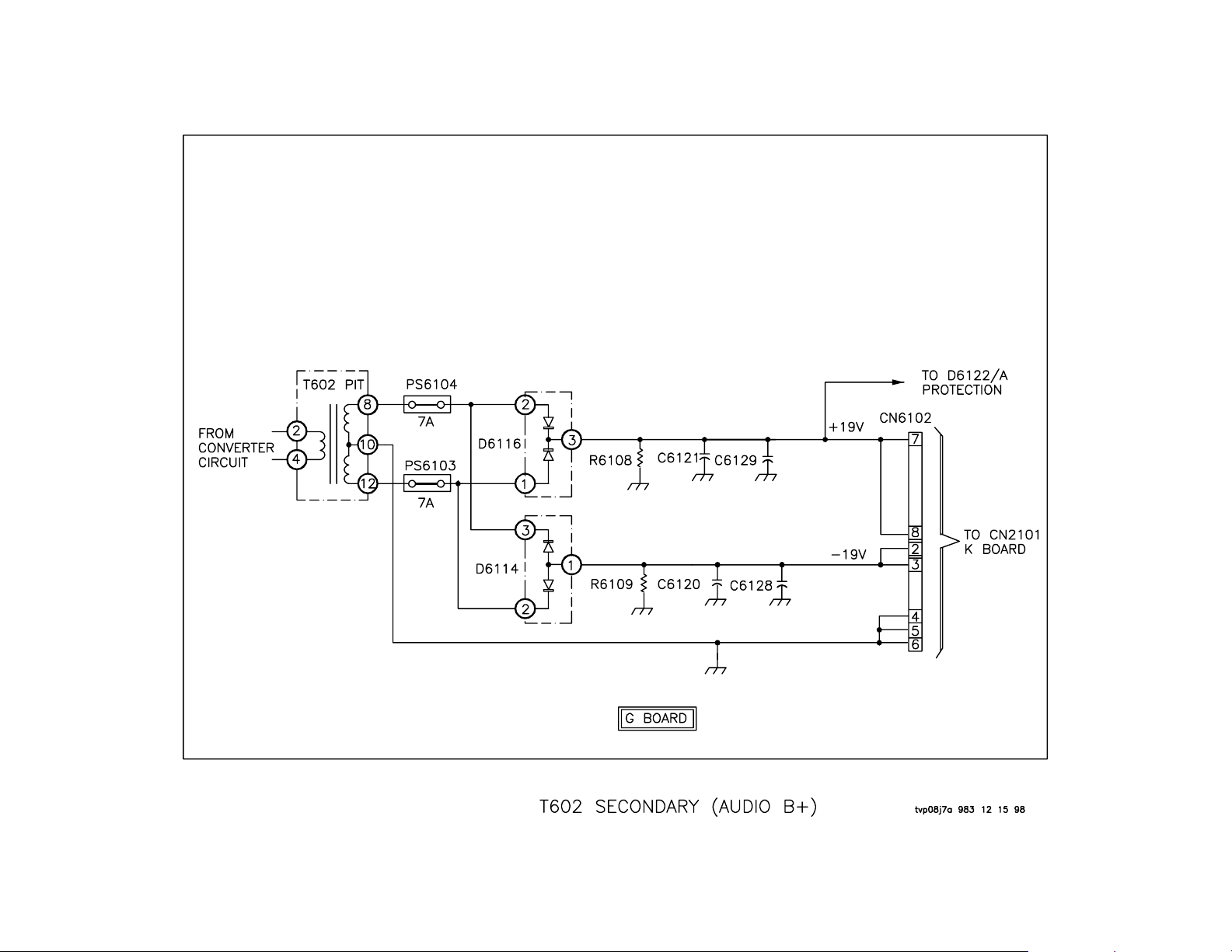

T602 Secondary (Audio B+) 19

Overview 19

Operation 19

T601 Secondary-1 21

Overview 21

+/- 15 Volts 21

+ 11 Volts 21

+/- 22 Volts 21

Distribution 21

T601 Secondary-2 23

+7 Volts 23

+135 Volts 23

-135 Volts 23

+33 Volts 23

Distribution 23

M (Main) Bus 37

Regulation 25

Overview 25

Operation 25

DC Protection 27

Overview 27

Shut Down 27

+135 Volt Over Voltage 27

+135 Volt Over Current Protection 27

+19, +22, +7 Volt LVP 27

PS Troubleshooting 29

Overview 29

Troubleshooting 29

Protection Block 31

Overview 31

P (Auto Registration) Bus 37

MID Bus 37

Video Path Block 39

Inputs 39

Main Video 39

Sub-Video 39

IC511 Video Processor 39

Input Switching 41

Overview 41

Inputs 41

Outputs 41

Main Y and C Buffers 43

Overview 43

Y Buffer 43

Diagnostic Indication 31

Circuit Description 33

Reset 35

Overview 35

Initial Reset 35

Power ON Reset 35

System Block Diagram 37

Overview 37

B (Standby) Bus 37

Sync Separator 43

C Buffer 43

3D Comb Filter 45

Overview 45

What is a 3D Comb Filter? 45

Circuit Description 45

Main Chroma Decoder 49

Overview 49

C Processing 49

Y Processing 49

Sync Processing 6 5

H and V Sync 49

3.58 MHz 49

Main YUV Switch 51

Overview 51

Inputs 51

Output Selection 51

DRC - Digital Reality Creation 53

DRC Block 57

Overview 57

Inputs 57

DRC Processing 57

Outputs 57

Troubleshooting 57

MID - Multi Image Driver 59

IK/AKB 69

Overview 69

Video Drive 69

IK 69

Troubleshooting 69

Sync Paths 71

Overview 71

Sync Paths 71

Deflection Block 73

Overview 73

Vertical 73

Horizontal 73

High Voltage 73

Convergence 73

MID Block 63

Overview 63

MID Inputs 63

MID Processing 63

MID Outputs 6 3

MID Troubleshooting 63

Video Processor 65

Overview 65

Video Processing 65

Horizontal Deflection Block 75

Horizontal Jungle 77

Overview 77

H Drive 77

H Out 79

Overview 79

H Drive 79

H Out 79

Horizontal Centering 7 9

Pin Amp 81

Overview 95

Overview 81

Pin Amp 81

H Protect/HP 83

Overview 83

HP 83

H Protect 83

Vertical Deflection Block 85

H BLK Delay and 1/2 H + Odd/Even 87

Overview 87

H BLK Delay 87

1/2 H and Odd/Even 87

VDSP 89

Overview 89

VCO 89

HV Drive 95

Peak Drive 95

HV Regulation Control 99

Overview 99

Regulation Control 99

+12 High Voltage LVP 99

HV Regulation PWM 101

Overview 101

Sawtooth Generator 101

PWM 101

HV Stop 2 103

Overview 103

ABL 103

Hold Down 103

CDP 89

DSP 89

DAC 89

V Out 91

Overview 91

V Out 91

V Protect 91

High Voltage Block 93

HV Drive 95

HV Stop 1 105

Overview 105

ABL 105

High Voltage Block Tap 105

+125 Volt OVP 105

Convergence Block 107

Overview 107

Convergence 107

Auto Focus (Auto Registration) 107

Sensor Amp 109

Overview 109

Auto Focus 109

Circuit Description 113

BD Input 115

Overview 11 5

Digital Convergence 115

BD Output 117

Overview 11 7

IC1707 Regi Correction 117

Convergence Out 119

Overview 11 9

Regi Mute 119

Convergence Amp 119

Service Mode 121

Overview 121

Normal Service Mode 121

PJED Mode 121

Protection Block 127

Overview 127

Diagnostic Indication 127

Circuit Description 129

Features

Overview

The models covered by this manual are the new KP53XBR200 and the

KP61XBR200. These two models are electrically identical. The differences have to do with screen size. Therefore they use different cabinets,

screens, mirrors and tubes. These sets also have a Self Diagnostic system.

Picture

The two models share the following picture features:

··

· Advanced Pro-Optic System – Sony technology that allows full cor-

··

ner to corner focusing.

··

· New Extended Definition CRT – Allows corner to corner focusing to

··

be increased by 25% over last year’s model.

··

· MICROFOCUS Lens System

··

··

· Digital Reality Creation (DRC) – DRC uses line doubling and pat-

··

tern recognition algorithms to take the NTSC signal to a near HDTV

equivalent. This will be discussed in more detail later.

··

· Double Scan Technology

··

··

· Auto Focus Full Digital Convergence – Allows the setting of V and

··

H center and skew by the customer. This convergence system can

produce a sharper picture and is less susceptible to drift due to aging

or shipment.

··

· High Performance Video Processor

··

··

· 3D Digital Comb Filter

··

··

· Brightview Dual Component Screen – The screen contains a Thin

··

Film Fresnel that brightens and sharpens the picture, and a Fine Pitch

Lenticular screen that achieves higher resolution by using black stripes

to increase contrast.

··

· Built-in High Contrast Screen

··

1

··

· First Surface Mirror – Unlike most mirrors, the reflective surface is

··

on the front of the mirror glass. This improves brightness and contrast, and eliminates ghosting caused by the reflected light passing

through the glass.

··

· Advanced Velocity Modulation

··

··

· Advanced High Voltage Regulation – Eliminates distortion and fo-

··

cus fluctuations that occur when changes in brightness levels cause

changes in the high voltage.

··

· Noise Reduction

··

··

· Shading Compensation – Eliminates color shift and hot spots that

··

can occur due to the angle of the picture tubes to the mirror.

··

· Wideband Video Amplifier

··

··

· Multi Image Driver – Digital-editing technology that provides versatil-

··

ity in controlling on-screen images. Used in Picture and Picture and

Channel Index modes.

··

· Twin View Picture-in-Picture – Allows for viewing two pictures si-

··

multaneously and the ability to expand either image up to double its

normal size.

··

· Free Layout Picture-in-Picture – Allows the PIP window to be placed

··

anywhere on the screen.

··

· XDS (Extended Data Service) – Receives data information services

··

that some stations may broadcast. This data includes time, station

call letters, etc.

Audio

The two models share the following audio features:

··

· MTS Stereo with dbx NR

··

··

· Dolby Pro Logic Surround Sound

··

··

· Front Left/Right Audio Power - 20Wx2

··

··

· Center Audio Power – 20W

··

··

· Surround Audio Power – 15Wx2

··

··

· Center speaker input for use with a separate Dolby Pro Logic A/

··

V Reciever

NOTES

2

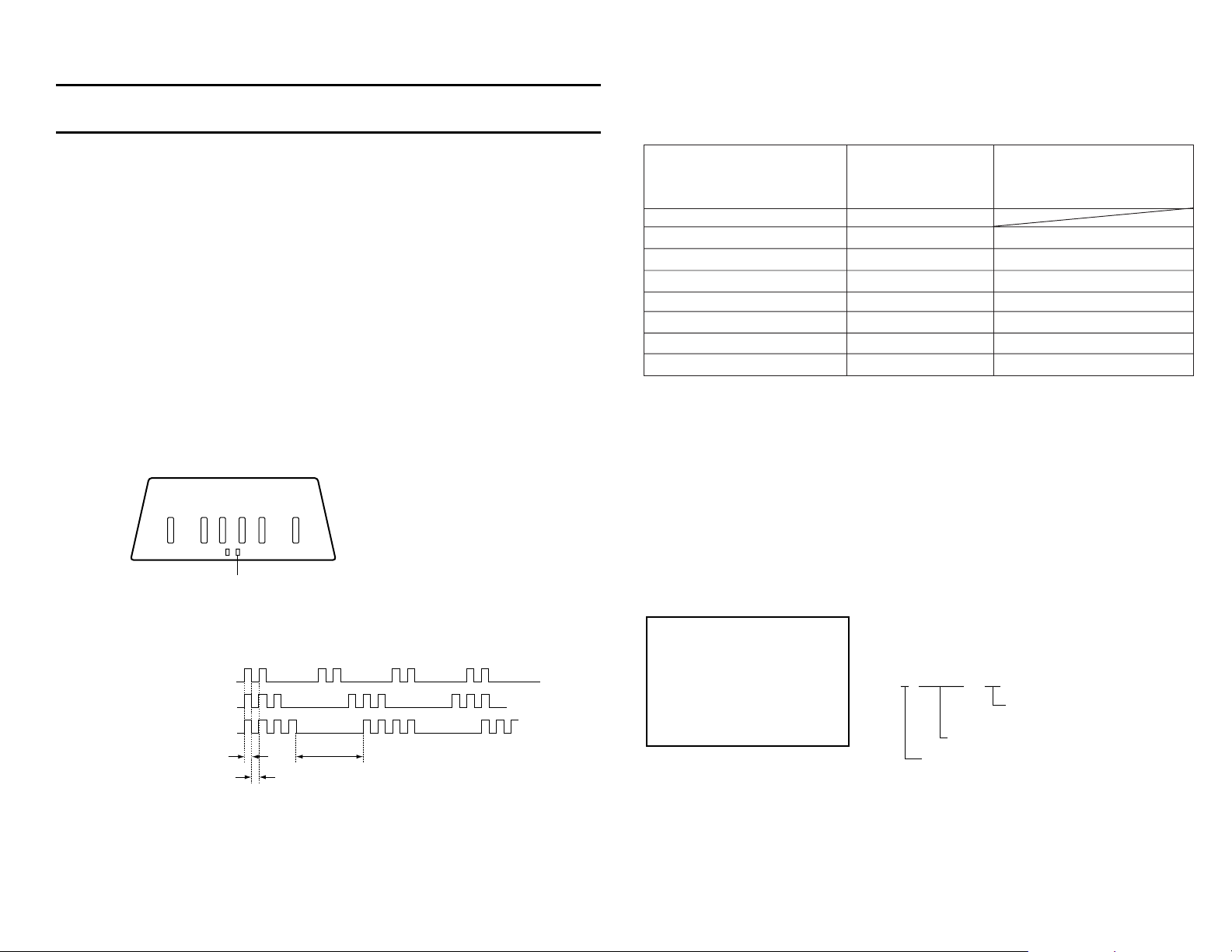

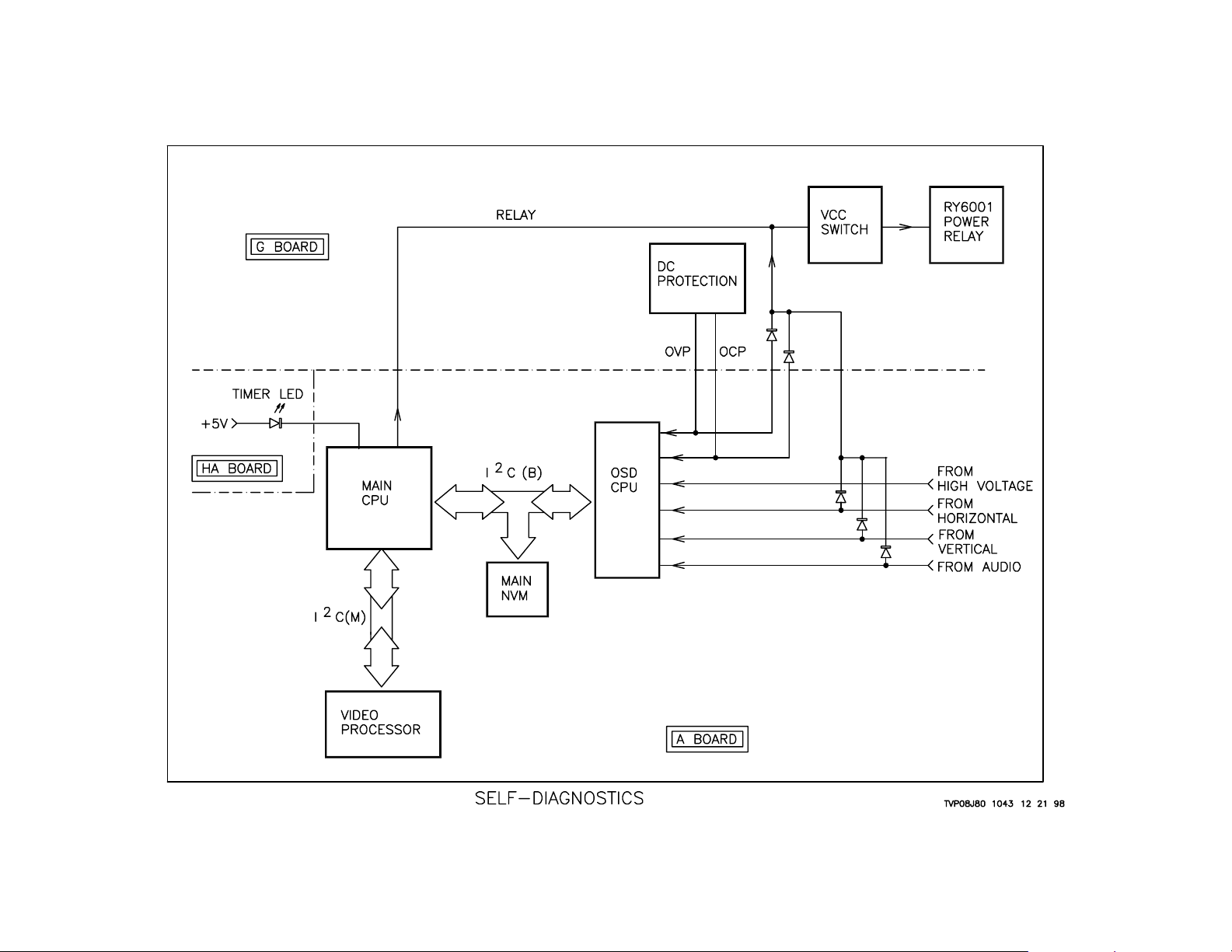

Self-Diagnostics

3

The number of times the LED blinks may correspond to that shown in the

following table:

Overview

The RA-4 chassis employs a Self-Diagnostic system that uses the Timer

LED and an on screen menu to help indicate where the problem with the

set has occurred. You will generally have to use the flashing LEDs since

the set will be shut down. AC power must be disconnected in order to turn

the set off once shutdown has occurred.

When a failure occurs, all of the circuits covered by the Self-Diagnostics,

except AKB, send a signal to the OSD CPU. The OSD CPU sends data

to the Main CPU that indicates how many times the Timer LED will flash.

The AKB circuit located in the Video Processor IC sends data over the

I2C bus directly to the Main CPU. In addition, each circuit, except AKB

and High Voltage, send a signal to the latch circuit to shut the set down

when failure occurs.

< FRONT PANEL >

TIMER/STANDBY indicator

•EXAMPLE

<Diagnosis Items>

• +B overcurrent

• +B overvoltage

• Vertical deflection stop

Diagnosis item Standby/ Self-diagnosis

sleep lamp, screen display,

Number of blinks Diagnosis item: Results

• Power not ON Not lit

+B OCP detection LED blinks 2 times 2 : +B OCP XX

+B OVP detection LED blinks 3 times 3 : +B OVP XX

V detection LED blinks 4 times 4 : V STOP XX

AKB detection LED blinks 5 times 5 : AKB XX

H detection LED blinks 6 times 6 : H STOP XX

HV abnormality detection LED blinks 7 times 7 : HV XX

Audio abnormality detection LED blinks 8 times 8 : AUDIO XX

: XX the range of values for number of operations is 00-99. For 99 or higher there is no count up

*

and the number remains at 99.

If the problem is intermittent and you can get the set to operate, you can

display a menu showing the number of times failures have occurred. This

is done by pressing the following sequence of buttons on the remote.

Display Channel 5 Vol - Enter

The display will look as follows.

<Number of Blinks>

2 times

3 times

4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

Lamp OFF :

3.0 seconds

SELF CHECK

2 : +B OCP XX

3 : +B OVP XX

4 : V STOP XX

5 : AKB XX

6 : H STOP XX

7 : HV XX

8 : AUDIO XX

9 : WDT XX

2 : +B OCP XX

Diagnosis

Results

XX the range of values for number of

operations is 00-99.

For 99 or higher there is no count up

and the numberremainsat 99.

4

5

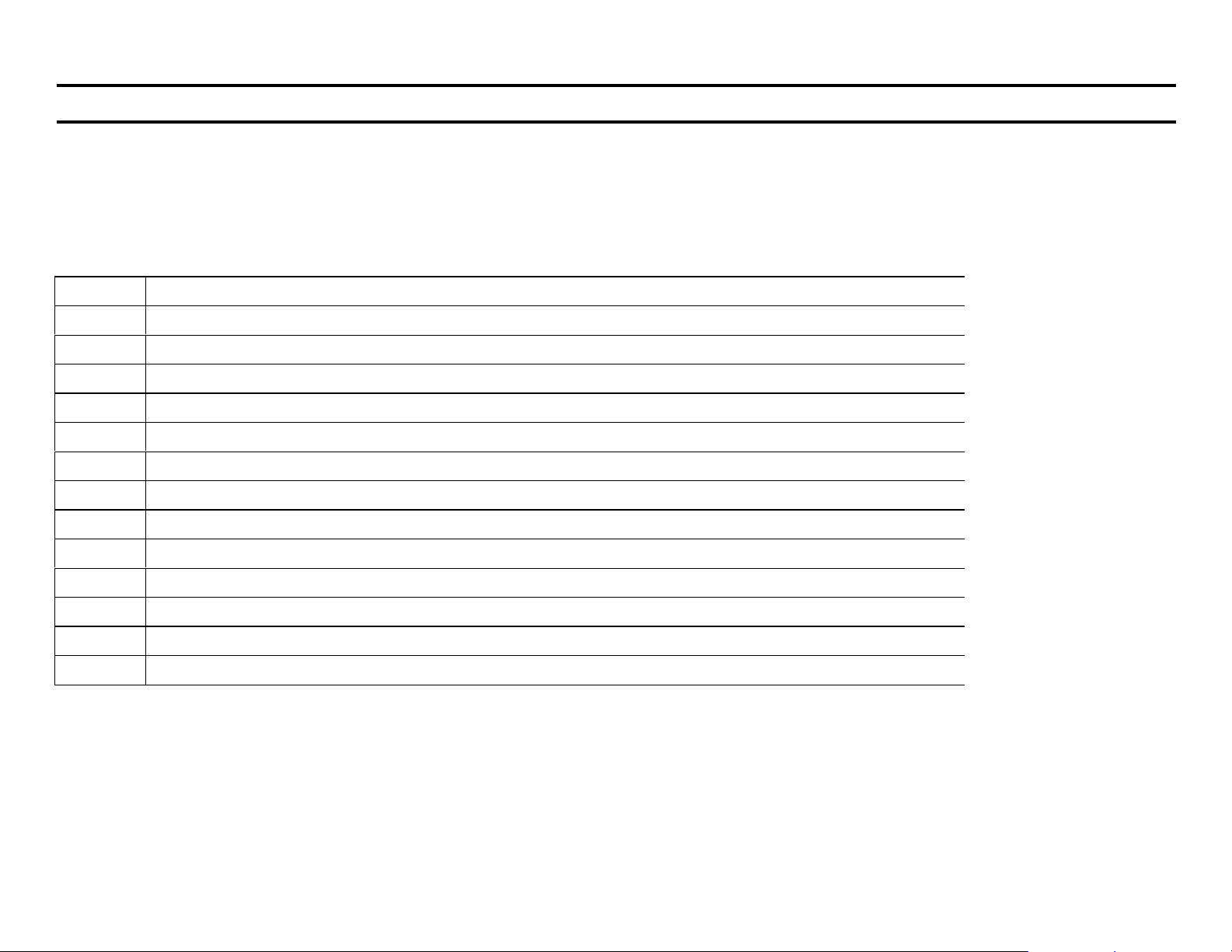

Board Descriptions

Overview

The models covered by this manual are the new KP53XBR200 and the KP61XBR200. These two models are electrically identical. The differences

have to do with screen size. The table below shows which circuits are present on each of the boards. This will help if you are doing board level (SA YS)

or component level repair.

Name Circuits contained

A Tuners, A/V switching, RGB processing, H Jungle, VDSP, Syscon

BD Auto r e gistration (Digital Convergence)

BM MID (Multi Image Driver)

BR DRC (Digital Reality Creation)

CR,CB,CG CRT drive and IK feedback.

D H and V deflection, Sub-deflection, HV, HV Regulation

G Power supply

HA Front panel controls, Power and Timer LEDs

HB Front video inputs, Auto Focus and Setup buttons

HC Remote sensor

K Audio Processing and Audio Outputs

U S Link Input/Output

ZR,ZG,ZB Hor. and Vert. deflection and sub-deflection coils, VM

CG

ZB

CB

ZG

HC

ZR

HA

CR

HB

K

U

A

G

BM

BD

D

6

BR

7

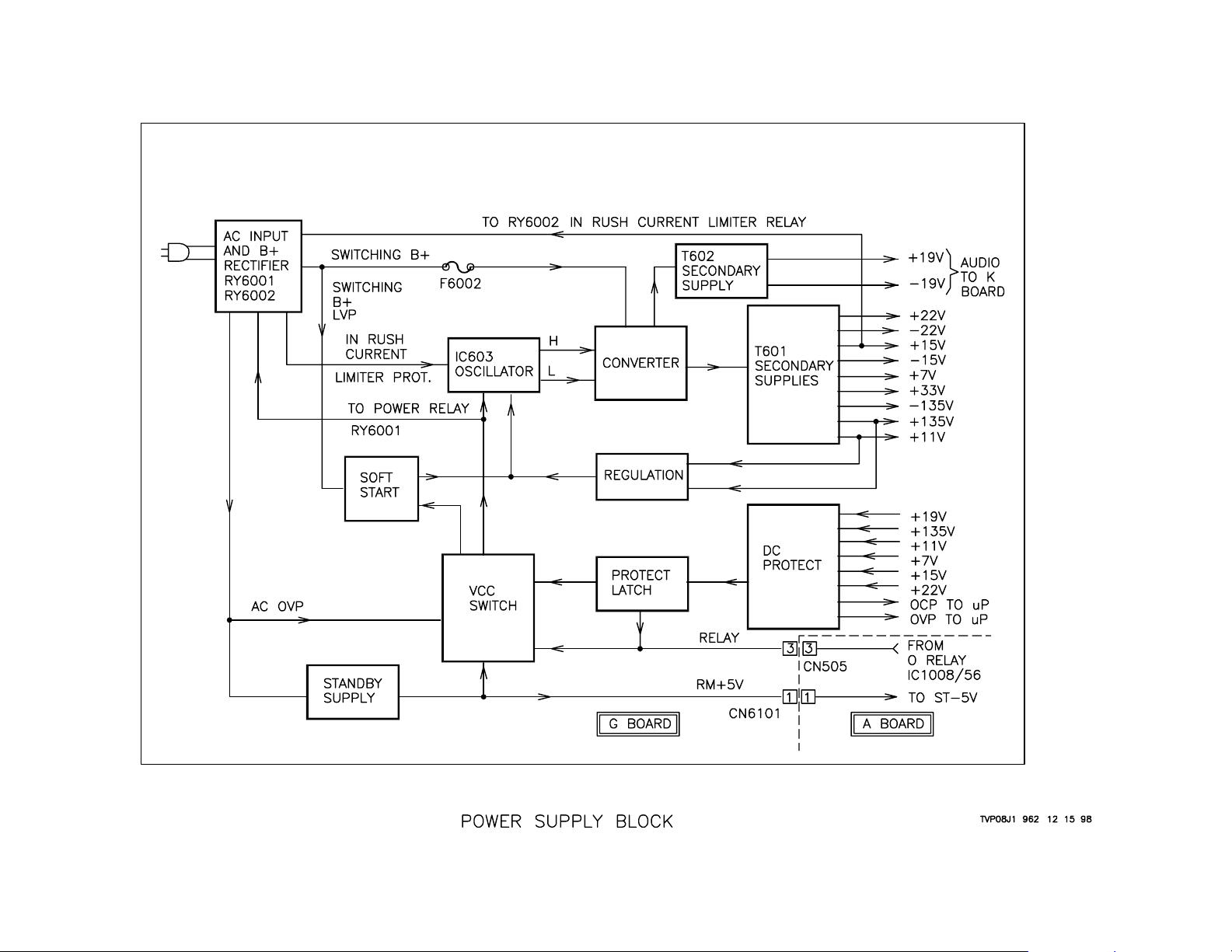

Power Supply Block

AC Input

When the unit is first plugged in, AC power passes through two line filters

and is applied to the Standby Power Supply. This is a switching power

supply that produces the Vcc source voltage and the standby +5V (RM+5V)

for System Control. When the set is turned ON, the AC input is applied

through RY6001 Power Relay to the switching B+ rectifier , which supplies

power to the Converter circuit. The switching B+ rectifier is monitored at

each of its outputs. The negative side of the switching B+ rectifier is monitored to ensure that RY6002 is activated. RY6002 is closed to bypass the

In-Rush Current Limiter Resistor when the set is turned ON. When RY6002

is closed, it shunts In-Rush Current Limiter Resistor so that the negative

side of the bridge is connected to ground. If the relay is not closed, a

voltage will be developed to shut down the set. The positive side of the

switching B+ rectifier is monitored to hold the secondary voltages down if

the AC voltage should be too low. This is performed by monitoring the

switching B+ voltage and applying that voltage to the soft start circuit. This

is done because of the excessive current draw when the switching B+ is

low.

Power ON

When Power ON is selected using the remote or the front panel switch, a

signal is sent from IC1008 Main-CPU to the Vcc switch section on the G

board. The Vcc circuit sends voltage from the Standby supply to the Oscillator and Soft Start circuits. When this voltage reaches IC6003 Oscillator, it begins oscillating. The Soft Start circuit is activated at the same

time. This circuit keeps the oscillator at a certain frequency (175KHz) for

a specified period of time. This keeps the initial start up voltage low and

prevents excessive back EMF from destroying the converter transistors.

When regulation begins, the normal operating frequency is around 73KHz.

Converter

When the Oscillator circuit begins oscillating, it outputs two signals that

are 180 degrees out of phase. These signals are applied to the converter

circuit. The converter circuit contains two Driver ICs that drive two push

pull transistor circuits. These circuits drive two transformers that create

the AC voltages, which are rectified by the two secondary supply circuits

to power the rest of the set.

Regulation

Once the secondary supplies begin to generate DC voltages we can begin to regulate their output. This is done using the +1 1 volt and +135 volt

lines. The +11 volt line is used to power the regulation circuit while the

+135 volt line is monitored to regulate the supplies. The +135 volt line is

sent to the regulation circuit to produce an error voltage that is fed back to

the oscillator circuit. This voltage controls the pulse width and frequency

of the oscillator. Changes in the frequency cause changes in ef ficiency of

the transformers, which in turn cause the voltage to become lower or higher .

Protection

In addition to the three protection circuits on the AC side of the supply,

there are additional circuits on the DC side. The +135V line is checked for

OVP and OCP. If one of these conditions occurs, a voltage is sent to the

protect latch to turn it ON. The latch shuts down the set by turning OFF

the Vcc switch. A voltage is also sent to the System Control circuit for the

self-diagnostic system. In addition, the 11V line is compared to the +19,

+22 and +7 volt lines. If these voltages fall below a specified level, the

protect latch will be activated and the set will shut down. There is no

indication in the self-diagnostic menu that this circuit has been activated.

8

9

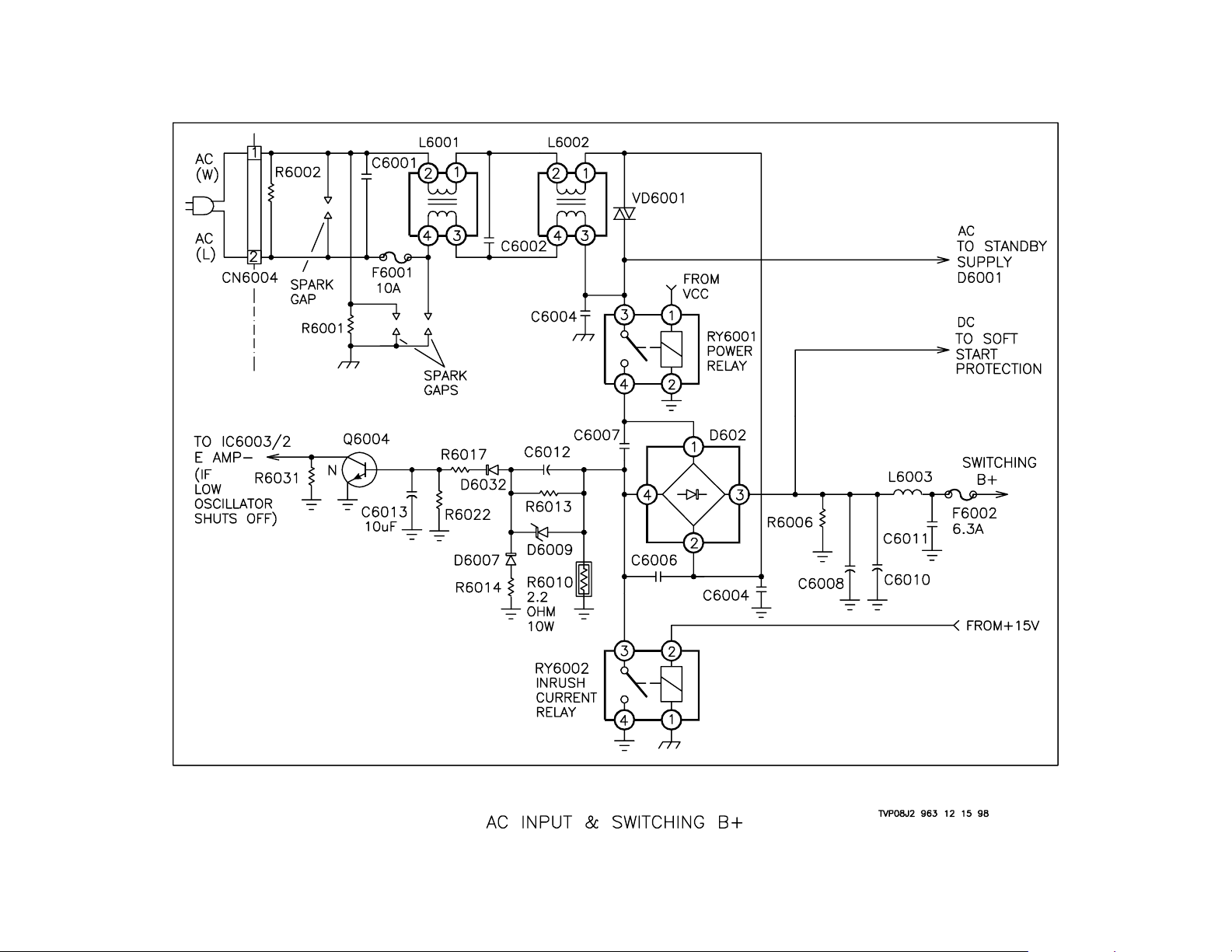

AC Input and Switching B+

Overview

The AC Input and Switching B+ circuit is used to filter the AC line voltage

and generate the DC voltage necessaary to run the switching supply.

AC Input

AC enters the G board at CN6004 when the unit is plugged in. It then

passes through F6001 and L6001 and L6002 Line Filters. L6002/3 is

the High side of the AC line and splits off to two places. It is used to

power the Standby +5V supply and is connected to one of the contacts

of RY6001 Power Relay.

There are a few protection components in place in addition to F6001

Fuse. There are two spark gaps across the AC line at CN6004 AC Input.

There is also one across the AC line after F6001 Fuse. Two capacitors,

C6001 and C6002, are present on either side of L6001 Line Filter. VD6001

is a VDR across the L6002/1 and 3 for spike protection.

Troubleshooting

Problems in this area are usually the result of line spikes or lightning. If

you have a dead set and suspect lightning damage, you should remove

the G board by removing one screw and pulling it out. A quick visual

check can be performed by looking on both sides of the board for burnt

traces or components. If F6001 is open, be sure to check for any burnt

components. If everything looks OK, then check the voltage across

VD6001. If the line voltage is not present there, continue to work your

way back checking across the AC line until you find an open component.

B+ Rectifier

When power is turned ON, the AC line voltage is applied across D602

Bridge Rectifier because RY6001 Power Relay is closed. D602/3 + outputs 130 volts which is filtered by C6008, C6010 and L6003. This voltage is used as the B+ for the switching power supply converter circuit

and is fused by F6002. D602/4 is connected to ground through R6010

In-Rush Current Limiter at initial power ON. When the secondary supplies begin to run, RY6002 will be closed which connects D602/4 - to Hot

ground.

Switching B+ Low Voltage Protect

Both outputs of the D602 Bridge Rectifier are monitored to cause shutdown of the set. D602/3 + has a sample voltage sent to the Soft Start

circuit to monitor for under voltage. If the voltage at this point is too low,

the Soft Start circuit will raise the frequency of the switching supply , thereby

lowering the secondary output voltages and disabling regulation. The

lowering of the secondary voltages will also cause RY6002 to open or

may shut the set down. Due to the fact that the power supply voltages

will be lowered, the set will indicate an AKB shutdown by flashing the

Timer LED five times, pausing, and then repeating. This action will be

discussed in greater detail in the Soft Start section.

In-Rush Current Limiter Protect

D602/4 is monitored to ensure that the R6010 In-Rush Current Limiter

has been switched out of the circuit by RY6002. If it has not, a voltage

will be developed across it that is rectified and sent to the base of Q6004

AC Protect. If Q6004 AC Protect is turned on, IC6003 Oscillator will be

shut down. This will cause no output from the switching supply. Keep in

mind that there will be 150 volts present at F6002 since the power relay

is still turned ON. In addition, the Timer LED will flash twice, pause and

repeat. You will not be able to shut the set OFF using the remote or the

front panel switch. The set will have to be unplugged to attempt to restart the set.

10

11

Standby Power Supply

Overview

The Standby Power Supply is used to develop the voltages that are required by the set in order for it to turn ON. One of these voltages is used

to supply power to the System Control ICs. This voltage is a regulated 5

volts and is called RM+5. The other voltage is used as the source voltage for Vcc, which is the low voltage supply for the switching power

supply . The AC input to the standby supply is monitored for overvoltage.

It will shut the Vcc switch OFF if there is a problem.

Standby Switching Supply

The line AC from L6002/3 is rectified by D6001 and D6003 and filtered

by C6009. This voltage is monitored for overvoltage via D6035 and is

used to power the standby supply. This voltage then passes through

fusible resistor R6012, then to T603 SRT. IC6001 is connected to T6003/

1 and begins switching when the voltage arrives. IC6001 PWMSW is a

self-starting N-channel MOSFET switching device with a self contained

oscillator and error loop amplifier used for regulation.

RM+5

As IC6001 PWMSW voltages are induced in the secondary windings of

T6003 SRT, one of these voltages is used to develop the RM+5 line. The

signal from T6003/7 is rectified by D6120 and filtered by C6137, C6138

and L6113. This voltage is input to IC6104/1. IC6104 5-Volt Regulator

outputs 5 volts from pin 2. This is the RM+5 line on the G board. It is

called ST-5V on the A board.

Regulation

The secondary winding at pins 3 and 4 of T6003 SRT develops a voltage

that is rectified by D6015. This voltage is used for two purposes. It is the

source voltage for the Vcc switch and the feedback voltage for regulation. This voltage passes through D6012, D6011 and R6021, and is

input to IC6001/4. Pin 4 is the regulation input for IC6001 PWMSW.

12

13

Vcc Switch (Power On)

Overview

When Power On is selected, IC1008 Main CPU sends a signal to the G

board to turn ON the Vcc switch. The Vcc voltage powers the Soft Start,

Oscillator and Driver circuits. There is a connection from the latch circuit

to shut OFF the set if there is a problem on the DC side of the power

supply. In addition, there is a connection from the Standby Source Voltage that will shut down the supply if the AC line voltage becomes to high.

Power ON

When Power ON is selected using either the remote or the front panel

switch, 5 volts is output from IC1008/56 O Relay. This voltage travels

from CN505/3 on the A board to CN6101/3 on the G board. It then goes

through R6112, R6121 and D6112, placing .6V at Q6104/B. This turns

Q6104 ON and causes Q6104/C to pull IC6104/2 to ground. This turns

the phototransistor inside IC6104 Vcc Switch ON. When this occurs,

current flows through the B-E junction of Q6001. When Q6001 turns

ON, it causes Q6011 VccSW to turn ON. This switches the Standby

voltage through Q601 1 VccSW where it is called Vcc. Vcc turns R Y6001

Power Relay ON, as well as powering the Soft Start, Oscillator and Driver

circuits.

DC Protect

The DC protection latch circuit is connected through D6111 to the power

ON line at the junction of R6112 and R6121. When the protection latch

is activated, it pulls the O Relay line LOW and turns power OFF by turning and holding Q6014 OFF.

AC Protect

The Standby Source voltage is monitored in case there is an overvoltage

problem on that line. If the voltage from the Standby Source voltage

goes too high, it will cause the voltage at the cathode of D6035 to rise

above 12.6 volts. The voltage at Q6013/B will be enough to turn it ON.

When this occurs, Q6013 conducts, causing Q6012 to conduct. This

action causes the Q6001 to turn OFF, thereby shutting down the set.

14

15

Soft Start

Overview

A Soft Start circuit is necessary to keep the oscillator that drives the switching circuit above the normal operating frequency of the tuned circuit that

is in the switching supply circuit. If this frequency is not above the normal

operating frequency at start up, the voltage at the secondary could become too high and cause damage to the set. The soft start circuit causes

the oscillator to start at a frequency high above the normal operating frequency by holding the regulating voltage down at initial turn ON of the set.

This circuit is also activated if the Switching B+ voltage falls below a certain level.

Soft Start – Power ON

When Power ON is selected, the Vcc switch supplies voltage to IC6003

Oscillator. This oscillator is connected to the regulation line that begins to

develop voltage. This voltage is held LOW at Q6006/E while C6016 is

charging. Once C6016 is charged, the regulation line is controlled by

IC6005/4.

Q6005 provides a discharge path for C6016 when the set is turned OFF.

This is important because if C6016 is not completely discharged, the oscillator may output the normal operating frequency during Power ON. The

discharge path would be through Q6005/C-E junction. Q6005 is OFF

during the set’s operation because of the voltage applied to it from IC601 1/

3. Be careful when measuring voltages at Q6005/B as this circuit is easily

loaded by a meter or a scope. It is best measured using a scope and a

10X probe.

Soft Start - LVP

The soft start circuit can also be activated if the voltage from D602/3

Switching B+ goes too low. When the voltage across R6007 drops below

12.6 volts, it will cause Q6002 to turn OFF. This causes Q6003 to turn

ON. When Q6003 is ON, the cathode of D6014 will be held at ground

potential. This is the same condition that occurs at turn ON, therefore the

oscillator will oscillate at a high frequency and this will reduce the output

voltages from the secondary supplies. If this occurs while the set is operating, it will shutdown. The set will act as if there was an AKB failure, the

Timer LED will flash five times, pause and then repeat.

16

Converter

Overview

Simply put, the converter circuit switches the DC Switching Supply B+ ON

and OFF to create an AC signal. The converter in this set consists of two

Driver ICs that drive two sets of N-channel MOSFET transistors. The

drivers use the output signal from the oscillator to switch the transistors.

These transistors are switched 180 degrees out of phase and are parallel

with the two Power Input Transformers.

Operation

Two signals 180 degrees out of phase are applied to the Hi and Lo side

inputs. The Hi side input of IC6002/10 is the same phase as the Lo side

input at IC6004/12. The Low side input at IC6002/12 is the same phase

as the Hi side input at IC6004/10. These signals are amplified and output

in phase with their inputs.

The Hi side of each of these drivers has a floating power supply that

boosts the output level of the signal. The input to this supply is at IC6002/

6 and IC6004/6. The return is at pin 5 of IC6002 and IC6004. This floating supply allows a 130 Vpp signal to be output for each Hi side driver.

17

If IC6002/7 is outputting a High signal, then Q6008 turns ON. When

Q6008 is ON, it allows the 130-volt Switching B+ to be present at Q6008/

S. This voltage is applied to IC6002/6, the floating supply input, and also

to C6022 and C6023. The signal seeks ground through Q6009, which is

always ON when Q6008 is ON. Current flows through the transformers

T602 and T601 while C6022 and C6023 are charging. At the same time,

the signal outside of IC6002/1 Lo side output is Low. When the signal at

Q6008/G goes Low, the signal at Q6007/G goes High. This causes C6022

and C6023 to be connected to ground. At the same time, Q6010 is turned

ON and Q6009 is turned OFF. This causes current to flow through the

transformers T601 and T602 and capacitors C6022 and C6023. This

cycle continues while the set is running and causes sine waves to be

seen at T601/1 and T602/4. This signal is induced into the secondary of

the transformers to produce the power supply output.

18

T602 Secondary (Audio B+)

Overview

The secondary winding of T602 PIT is used to develop two voltages - +/19 volts. These voltages are used to power the K board, which contains

all of the audio circuits.

Operation

The voltage induced into the secondary winding of T602 is used to develop +/- 19 volts. This voltage is used to supply the Audio section (K

board) and is fused with PS6103 and PS6104.

This voltage is rectified by D6116 and filtered by C6121 and C6129 to

create the +19 volt supply. It is also rectified by D6114 and filtered by

C6120 and C6128 to create the –19 volts. The +19 volt supply is output

at CN6102/7 and 8. It also goes to D6122/A, which is part of the protection circuitry. The –19 volt supply is output at CN6102/2 and 3.

19

Troubleshooting

If the rest of the power supply is working, but there is a problem with these

supplies, you should suspect a problem on the K board. The set can be

run with CN6102 unplugged. If the correct voltages are measured at

CN6102, then the problem is on the K board. If PS6104 and PS6103 are

open, it would be a good idea to power the unit without CN6102 disconnected. If everything appears to be OK, check the K board for shorts on

the +/- 19 volt lines. If none are found, then plug CN6102 in and power up

the unit.

20

21

T601 Secondary-1

Overview

There are four secondary windings on T601 PIT. The voltages induced in

these windings are used to power everything in the set, except for the

audio section. The voltages developed here are +/- 15 volts, +/- 22 volts,

+11 volts, +7 volts, +/- 135 volts and +33 volts.

+/- 15 Volts

The voltage from the winding of T601/1 1 and 12 is applied across D6105

Bridge Rectifier. C6119, C6132 and L6108 filter the positive output of

D6105/3. This output is used for three things. First, it is applied to Q6106/

E, which turns Q6106 ON and allows current to flow through its E-C junction. It passes through R6141 to RY6002 In Rush Current Limiter Relay.

It turns the relay ON when the voltage is sufficient. If the voltage does not

rise to a sufficient level or there is a problem with Q6106, the set will shut

down. Next it is sent to D6126/A, which is part of the protection circuitry .

Lastly it is sent to CN6105/3, CN6106/5 and CN6104/2 where it is sent to

the D and A boards.

The negative output from D6105/3 goes through R6122, R6123 and R6124,

which are parallel. C61 18, C6131 and L6109 then filter this voltage. It is

then output from CN6105/4 and CN6106/6, both of which go to the D

board.

These lines are used to produce other voltages on the D board. These

voltages are +/- 12 volts and +/- 5 volts.

+ 11 Volts

The voltage from the winding of T601/1 1 and 12 is applied across D6102

through L6103 and L6104. C6122, C6133 and L6110 filter the rectified

voltage. This voltage is used on the G board by the regulation and protection circuits and it exits the G board at CN6104/11 to the A board.

+/- 22 Volts

The voltage from the winding of T601/14 and 15 is applied across D6108

through PS6105 and PS6106. C6125, C6135 and L6112 filter the rectified voltage. The voltage is used on the G board by the protection circuit

and it exits the G board at CN6105/1.

The winding of T601/14 and 15 is applied across D61 17 through PS6105

and PS6106. C6124, C6134 and L6111 filter the rectified voltage which

leaves the G board at CN6105/6.

The +/- 22volt lines are used to power only the Convergence amplifiers on

the D board.

Distribution

The table below shows the circuits powered by the voltages previously

discussed:

Supply Circuits

+15

-15

+12(D)

+12V(A)

-12

+5

-5

+11

+9

+22

-22

Vertical Out IC5004, 12 Volt regulator IC5002 (D board), IC502 12

Volt regulator (A board)

Vertical Out IC5004, -12 Volt regulator IC5001

V, H, B+, HV, and IK protection circuits, Shading, HV control, PWM,

H Saw, Auto Registration sense and switching, 5 Volt regulator

IC8004

H Jungle IC507, VM and IK buffers

Shading, HV control, H Saw, H pulse shaper,-5 Volt regulator IC8003

BD board (Auto Registration)

BD board (Auto Registration)

Off Mute Q547, 9 Volt regulator IC505

TU501, TU502 Video Processing, AVU switch

Convergence Amplifiers IC5005 and IC5006

Convergence Amplifiers IC5005 and IC5006

The +1 1 volt supply is used on the A board to produce the +9 volt supply.

22

Loading...

Loading...