Sony STRW-77 Service manual

STR-W77

SERVICE MANUAL

STR-W77 is RECEIVER section in

MHC-W77AV.

SPECIFICATIONS

With 6 ohm loads, both channels driven, fr om 40–20, 000 Hz; rated 100 watts

per channel minimum RMS power, with no more than 0.9 % total harmonic

distortion from 250 milliwatts to rated output. (US model)

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range EXCEPT Tourist model :

87.5–108.0 MHz

Tourist model :

76.0–108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range US, Canadian, E2, Argentine, Australian,

Thailand model :

AM : 530–1,710kHz (10kHz)

531–1,710kHz (9kHz)

E3, Saudi Arabia, Hong Kong, Singapore,

Malaysia, Tourist model :

MW : 531–1,602kHz (9kHz)

SW : 5.95–17.90MHz (9kHz)

Antenna AM loop antenna, External antenna terminals

Intermediate frequency 450 kHz

Amplifier section

Continuous RMS power output

US model :

(FRONT)

100 W + 100 W

(6 ohms at 40–20,000 Hz, 0.9% THD)

120 W + 120 W

(6 ohms at 1 kHz, 5% THD)

(CENTER)

30 W (8 ohms at 1 kHz, 5% THD)

US Model

Canadian Model

E Model

Austr alian Model

Tourist Model

(REAR)

15 W + 15 W

(8 ohms at 1 kHz, 5% THD)

EXCEPT US model :

(FRONT)

120 W + 120 W

(6 ohms at 1 kHz, 5% THD)

(CENTER)

30 W (8 ohms at 1 kHz, 5% THD)

(REAR)

15 W + 15 W

(8 ohms at 1 kHz, 5% THD)

Inputs VIDEO/MD IN (phono jacks) :

voltage 250 mV/450 mV

impedance 47 kilohms

MIX MIC (phono jacks) :

sensitivity 1 mV/450 mV

impedance 10 kilohms

Outputs VIDEO/MD OUT (phono jacks) :

voltage 250 mV

impedance 1 kilohms

PHONES (stereo phono jacks) :

accepts headphones of 8 ohms or more

FRONT SPEAKER :

accepts impedance of 6 to 16 ohms

CENTER SPEAKER :

accepts impedance of 8 to 16 ohms

REAR SPEAKER :

accepts impedance of 8 to 16 ohms

SUPER WOOFER :

voltage 250 mV impedance 1 kilohms

– Continued on page 2 –

FM STEREO/FM-AM RECEIVER

MICROFILM

General

Power requirements US, Canadian model : 120 V AC, 60 Hz

Australian model : 240 V AC, 50/60Hz

Thailand model : 220 V AC, 50/60Hz

Other models :

110-120 V/220-240 V AC adjustable, 50/60 Hz

Power consumption EXCEPT Canadian model : 260 watts

Canadian model : 350 VA

Dimensions Approx. 280 x 205 x 345 mm (11x

81/16 x 139/16 in.) (w/h/d)

Mass Approx. 6.4 kg (14 lb 2 oz)

TABLE OF CONTENTS

Section Title Page

Specifications ................................................................................. 1

1. GENERAL .............................................................................. 4

2. TEST MODE .......................................................................... 5

3. ELECTRICAL ADJUSTMENTS ......................................... 6

Design and specifications are subject to change without notice.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

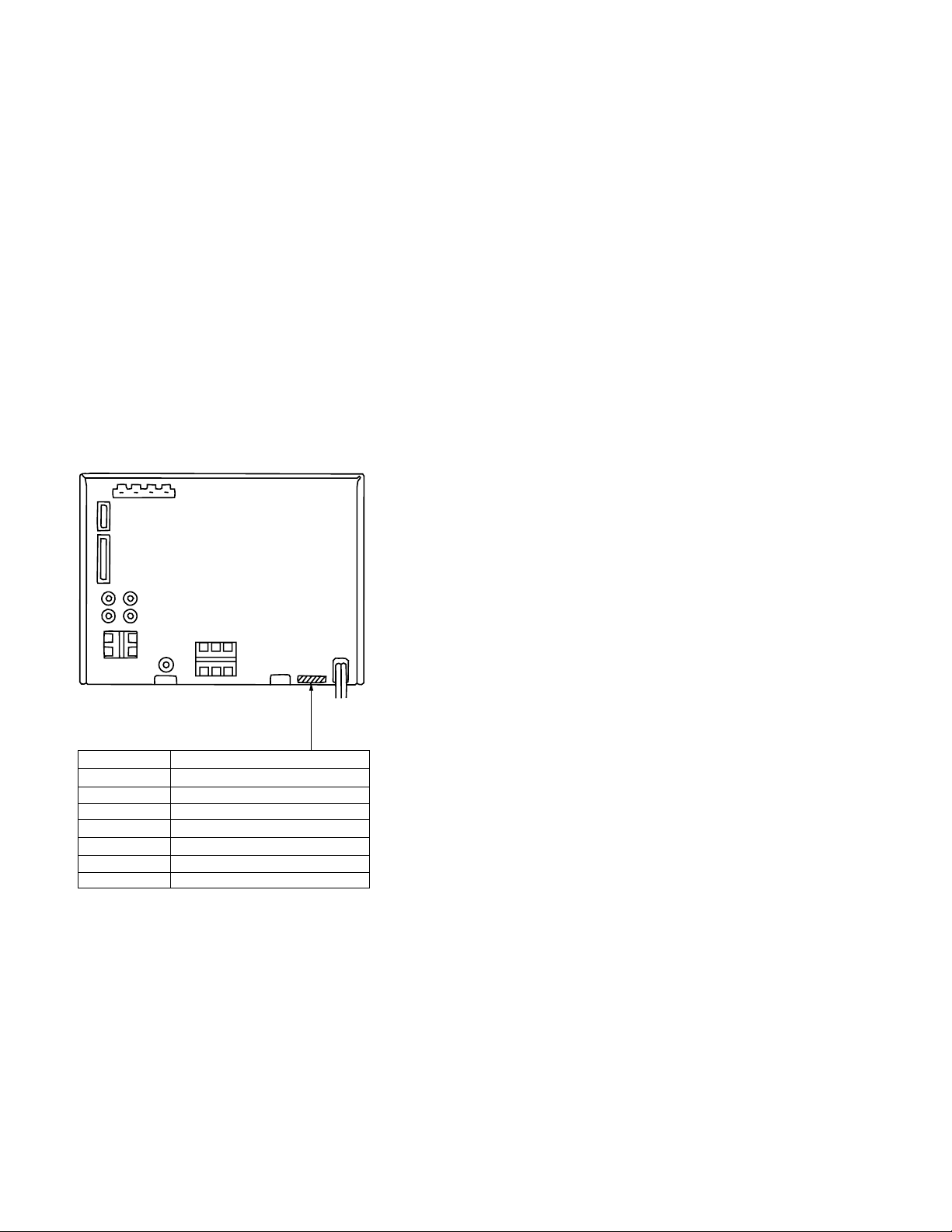

MODEL INDENTIFICATION

– BACK PANEL –

Parts No. Model

4-980-659-0π US

4-980-659-1π Canadian

4-980-659-2π E, Saudi Arabia, Argentine, Torist

4-980-659-3π Australian

4-980-659-4π Hong Kong

4-980-659-5π Malaysia, Singapore

4-980-659-7π Thailand

4. EXPLANATION OF IC TERMINALS.................................. 8

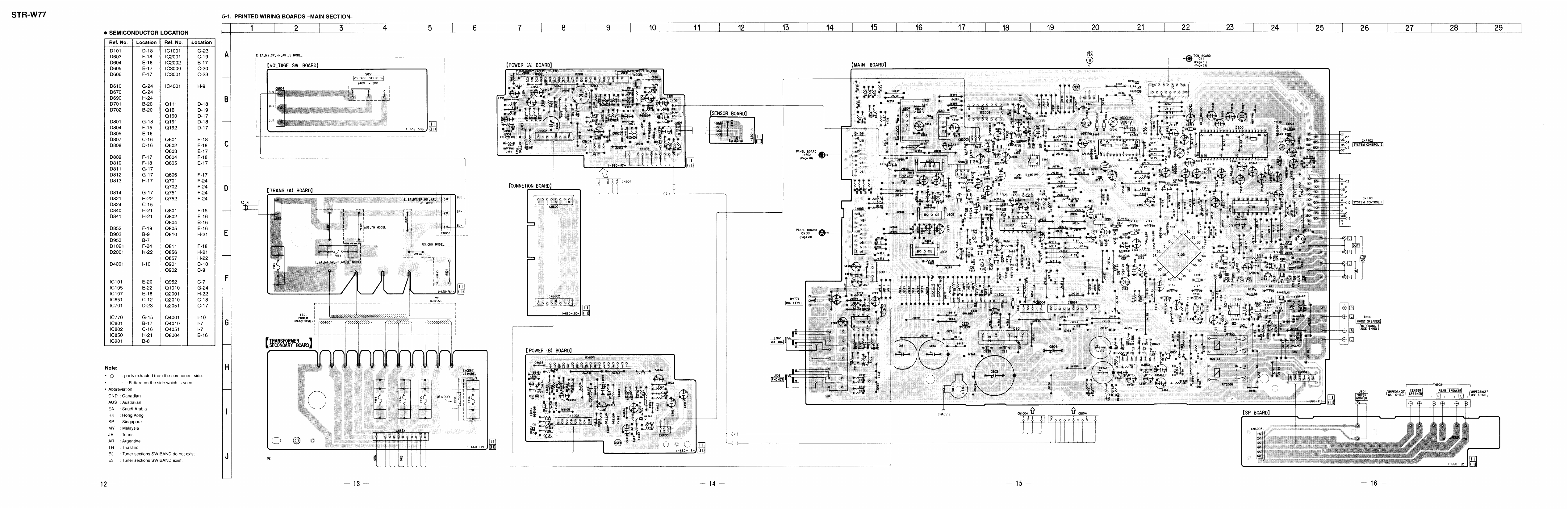

5. DIAGRAMS

5-1. Printed Wiring Boards – Main Section–......................... 12

5-2. Schematic Diagram – Main Section– ............................. 17

5-3. Schematic Diagram – Panel Section–............................. 23

5-4. Printed Wiring Boards – Panel Section– ........................ 27

5-5. Schematic Diagram – TCB Section–

(US, CND, E2, AR, AUS, TH model) ............................ 29

5-6. Printed Wiring Boards – TCB Section–

(US, CND, E2, AR, AUS, TH model) ............................ 31

5-7. Printed Wiring Boards – TCB Section–

(E3, EA, MY, SP, HK, JE model) ................................... 32

5-8. Schematic Diagram – TCB Section–

(E3, EA, MY, SP, HK, JE model) ................................... 33

6. EXPLODED VIEWS

6-1. Chassis Section ............................................................... 35

6-2. Front Panel Section......................................................... 37

7. ELECTRICAL PARTS LIST .............................................. 38

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMA TIC DIA GRAMS AND IN THE PARTS LIST

ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P AR TS WHOSE P ART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

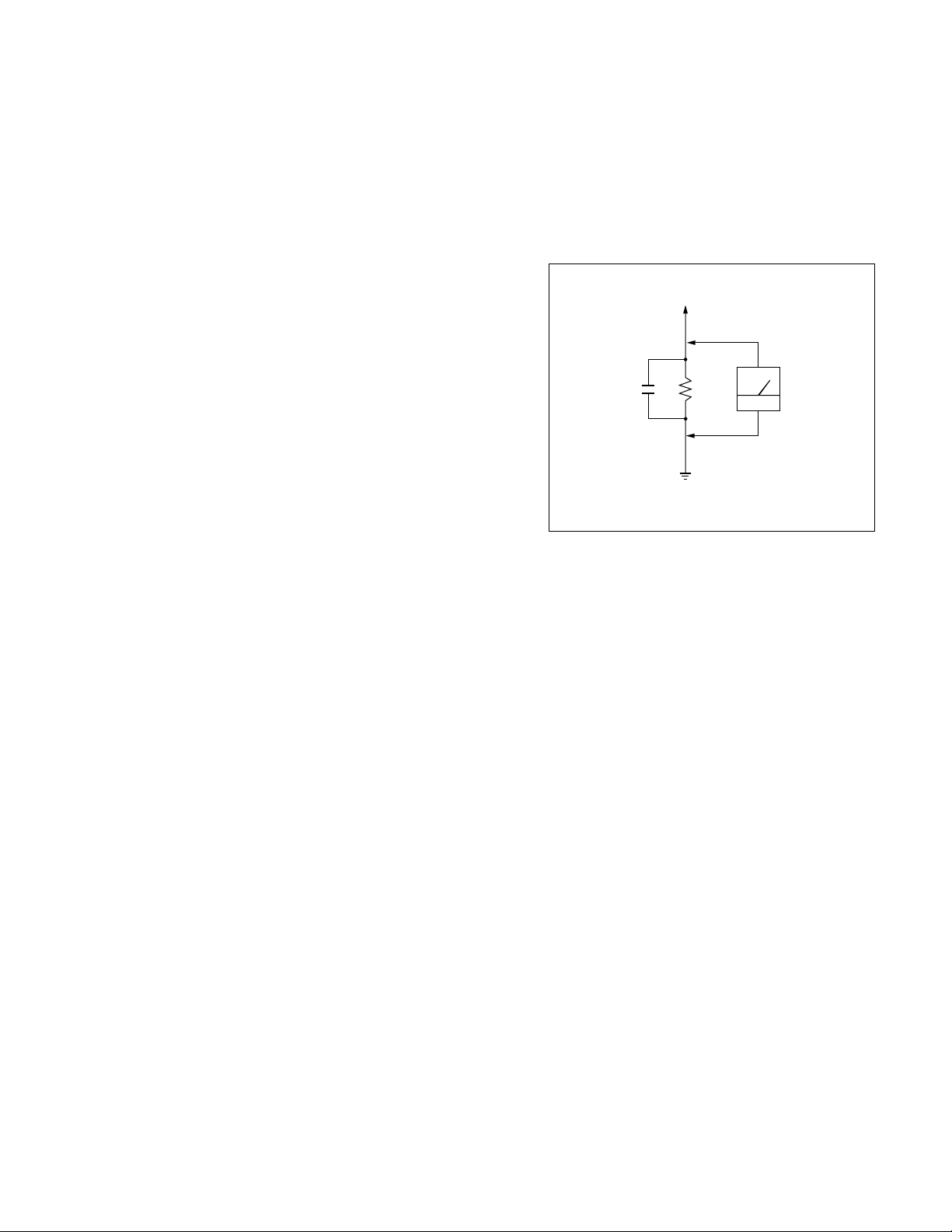

SAFETY CHECK-OUT

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

AC

Voltmeter

(0.75V)

0.15 F

µ

1.5k

Ω

To Exposed Metal

Parts on Set

After correcting the original service problem, perform the following

safety check before releasing the set to the customer :

Check the antenna terminals, metal trim, "metallized" knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C voltmeter . The “limit” indication is 0.75V,

so analog meters must have an accurate low-voltage scale. The

Simpson 250 and Sanwa SH-63Trd are examples of a passi ve V OM

that is suitable. Nearly all battery operated digital multimeters that

have a 2V AC range are suitable. (See Fig. A)

– 3 –

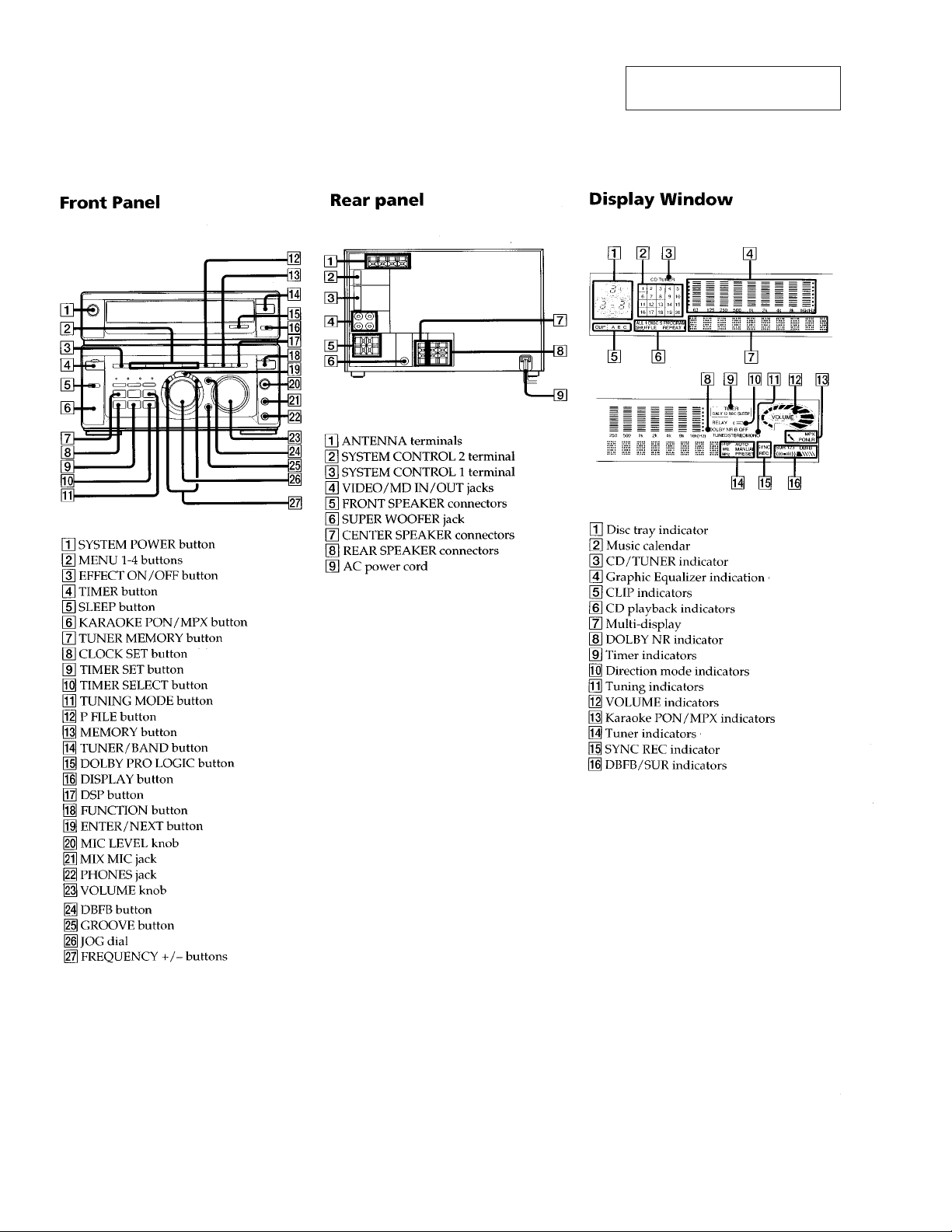

INDEX TO PARTS AND CONTROLS

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 4 –

SECTION 2

TEST MODE

DISPLAY / KEY TEST MODE

Press the ENTER/NEXT and FUNCTION buttons simultaneously.

Then press the MENU 1 button with the following 4 seconds to set the Test Mode.

1. The message “W3 NA (destination) ” appears on the screen and a 32 cycle square wa ve of the subcrystal oscillator is output from Pin 24

(AUB. OUT).

2. Press any key to rotate JOG and all FL indicators light up.

When you rotate JOG at this point, the display changes as follows.

N all FL indicators on Nn FL pattern 1 Nn FL pattern 2 n

The changes and all LED indicators light up.

3. Again press any key to set the key count check. The following display appears.

000

The numbers in order from left to right show ; the number of keys pressed, the JOG count (1 click per 4 counts), and the VOL count.

(1 cycle is a count of 96.)

4. Press the Power button to reset to the factory settings.

AMP TEST MODE

Press the ENTER/NEXT and FUNCTION buttons simultaneously.

Then press the MENU 2 button with the following 4 seconds to set the Test Mode.

1. The message “AMP TEST” appears on the screen. Press the MENU button to call up the Equalizer Curve for the Amp Test.

However when the function is set to the tuner, use the MENU button to call up each tuner preset from 1 through 5.

2. Press the Power button to reset to the factory settings.

MICROCOMPUTER COLD START

Press the ENTER/NEXT and FUNCTION buttons simultaneously.

Then press the MENU 3 button with the following 4 seconds to reset the microcomputer to the factory settings.

SUBCRYST AL TEST MODE

Press the ENTER/NEXT and FUNCTION buttons simultaneously.

Then press the MENU 4 button with the following 4 seconds.

The message “XT AL TEST ” appears on the screen and a 32 cycle square w ave of the subcrystal oscillator is output from Pin 24 (A UB.OUT).

In addition, a square wave of the same frequency as the subcrystal oscillator, is output from 4PIN (POWER. ON/OFF).

Press the Power button to reset to the factory settings.

– 5 –

SECTION 3

ELECTRICAL ADJUSTMENTS

Precautions in Repairing

Note. 1 : The adjustment should be performed in the publication.

(MW n FM n SW)

Note. 2 : As a front-end (FE1) is difficult to repair if faulty, replace

it with new one.

r

Abbreviation

AUS : Australian AR : Argentine

EA : Saudi Arabia HK : Hong Kong

SP : Singapore JE : Tourist

MY : Malaysia TH : Thailand

CND : Canadian

E2 : Tuner sections SW BAND do not exist.

E3 : Tuner sections SW BAND exist.

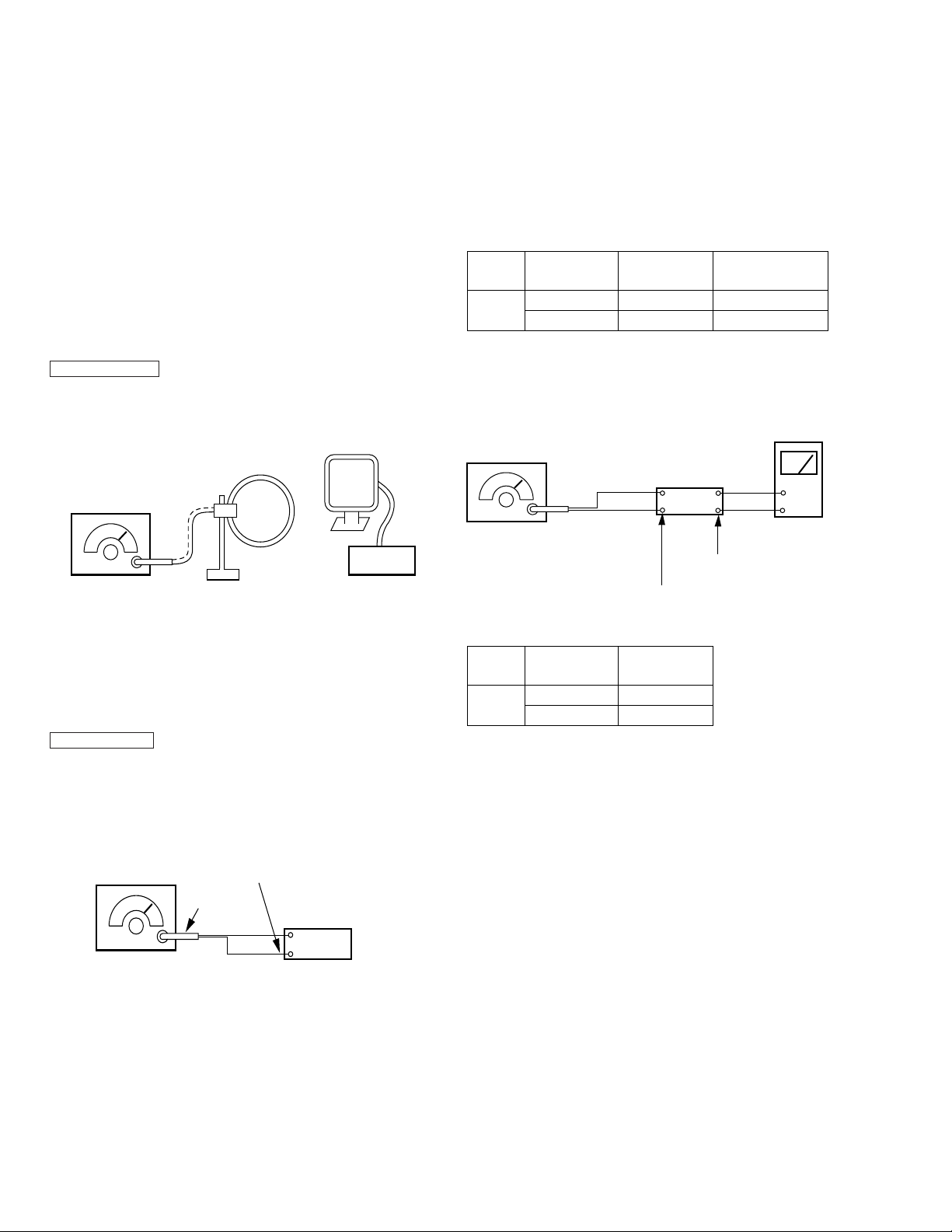

MW SECTION

MW Tuned Indication Lighting Level

Setting :

Band : MW

loop antenna A

AM RF signal

generator

loop antenna B

set

SW Control Voltage Adjustment

(Frequency Coverge Adjustment)

(E3, EA, MY, SP, HK, JE model)

Setting :

Band : SW

Procedure :

1. Connect digital Voltmeter to diode D1 center lead and ground.

2. Adjust for a following value reading on digital Voltmeter.

SW

Set frequency

5.95MHz T2 1.2Vdc

17.9MHz CV2 8.5Vdc

Adjustment

part

Reading on digital

voltmeter

SW T racking Adjustment

(E3, EA, MY, SP, HK, JE model)

Setting :

Band : SW

AM RF signal

generator

Modulation : 400Hz

30% modulation

set

SPEAKER terminal

VTVM

+

–

Carrier frequency : 999kHz (at 9kHz step)

1,050kHz (at 10kHz step)

Procedure :

1. Set loop antenna A so that the loop antenna B input lev el becomes

55dBµ/m (0.6mV/m)

2. Tune the set to 999kHz or 1,050kHz.

3. Adjust RV41 so that the TUNED indicatior goes on.

FM SECTION

FM Tuned Indication Lighting Level

Note : Always make the tuning level adjustment first.

(Since it affects the FM tuning level.)

Setting :

Band : FW

FM RF stereo signal

generator

75

Carrier frequency : 98MHz

Modulation : OFF

Output level : 0.018mV (25dB )

Procedure :

1. Tune the set to 98MHz.

2. Adjust RV42 so that the TUNED indicator goes on.

FM ANTENNA terminal

Ω

coaxial

µ

set

AM ANTENNA terminal

Procedure :

Adjust for maximum reading on VTVM.

Set frequency

SW

r

Repeat the procedures is each adjustment several times, and the

7MHz T1

17MHz CV1

Adjustment

part

frequency coverage and tracking adjustment should be finally done

by the trimmer capacitors.

Adjustment Location : TCB board

– 6 –

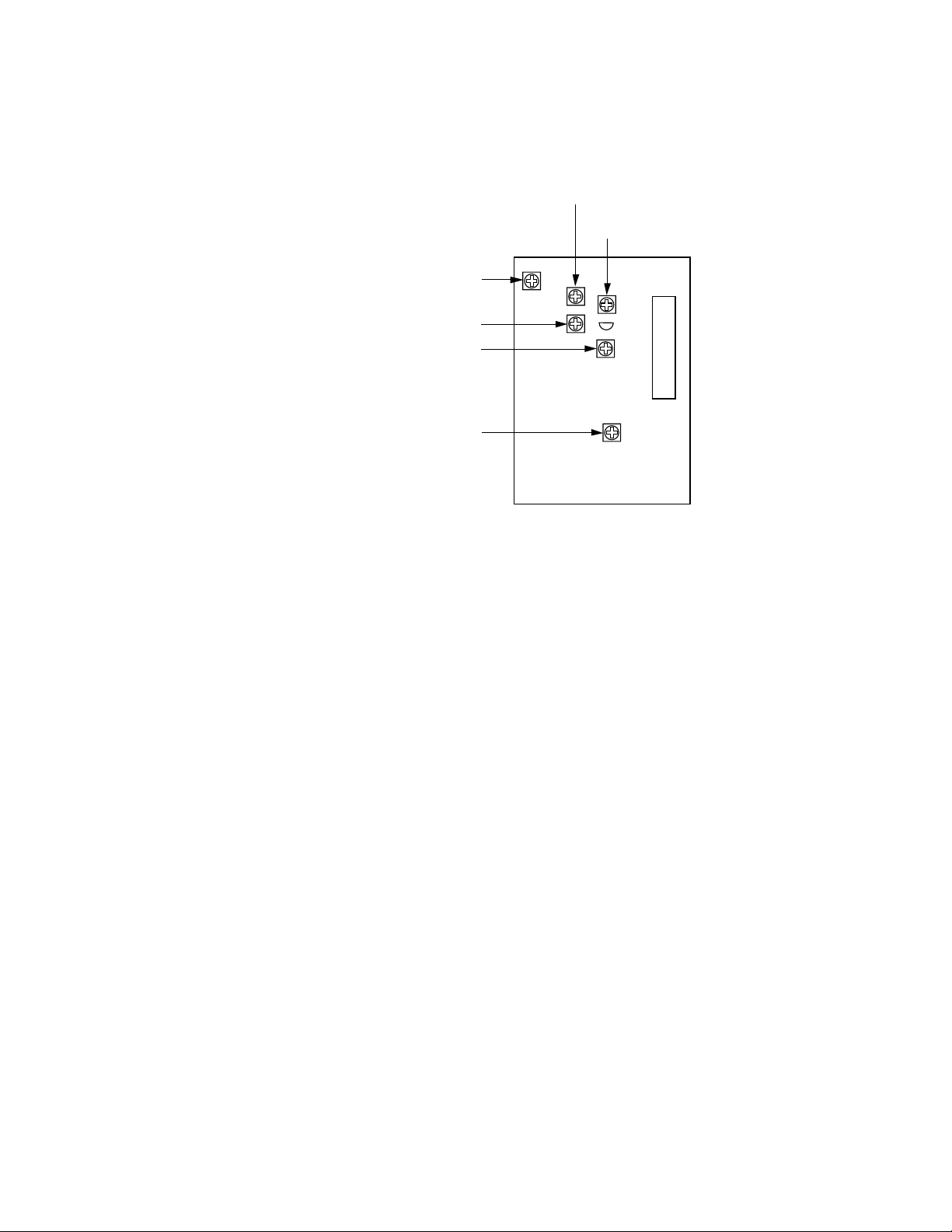

Adjustment Location

[TCB BOARD] – Component side –

RV41 : MW Tuned indication Lighting Level

CV1 : SW Tracking Adjustment

T1 : SW Tracking Adjustment

CV2 : SW Control Voltage Adjustment

T2 : SW Control Voltage Adjustment

RV42 : FW Tuned indication Lighting Level

D1

FE1

– 7 –

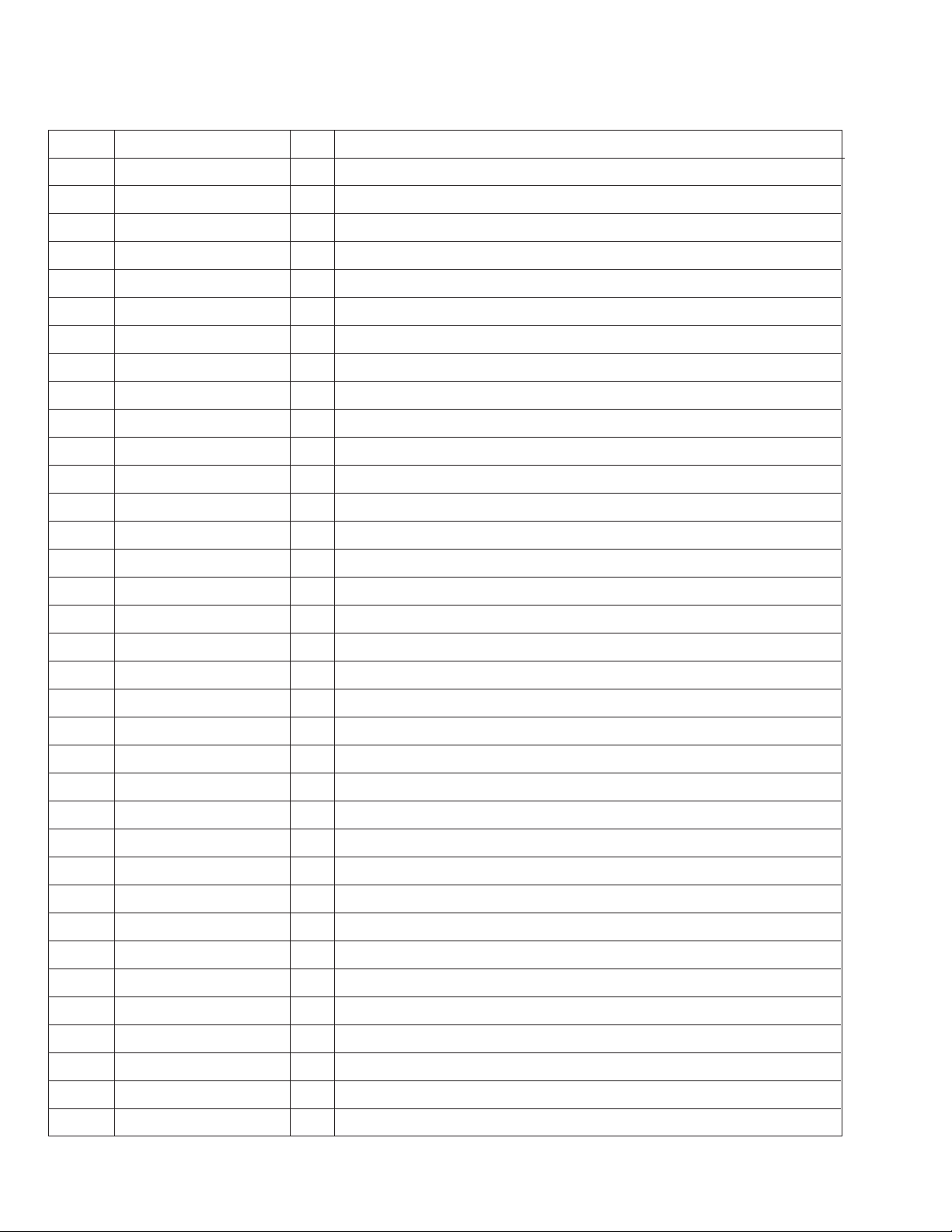

SECTION 4

EXPLANATION OF IC TERMINALS

IC501 ASD0205GF-015-3BA (SYSTEM CONTOROL)

Pin No. Pin name I/O Description

1 VDD – Power supply.

2 CLK OUT O Direct output for communications with HCD-W55.

3 RDY IN I/O Direct input / output for communications with HCD-W55.

4 POWER ON / OFF O L : Relay ON

5 MUTE O Mute output to transistor. L : Mute ON

6 PROLOGIC LATCH O Latch output to IC3001 (LA2785).

7 VOL. LATCH O Latch output to IC2002 (TC9210P).

8 427LAT O Latch output to IC105 (M62427FP).

9 LED LAT O Latch output to IC504 (M66313FP-200C).

10 RESET I Reset terminal.

11 X2 – Oscillator connection terminal. (5MHz)

12 X1 – Oscillator connection terminal. (5MHz)

13 IC – Ground connection.

14 XT2 – Oscillator connection terminal. (32MHz)

15 XT1 – Oscillator connection terminal. (32MHz)

16 VDD – Power supply.

17 BACK UP I AC Power supply OFF.

18 COM CLK O Transfer clock output serial data.

19 COM DATA O Serial data output.

20 ST DATA IN I Serial data input from IC 1.

21 ST CE O Chip enable output to IC 1.

22 STEREO I Stereo signal input.

23 TUNED I Tuned signal input.

24 AUB OUT O Audio bus output.

25 AVSS – Ground.

26 PROLOGIC. RY O Rear and center speaker relay ON/OFF control.

27 SUFFIX I Input for model select.

28 SPE I Spectrum analyzer signal input.

29 SPE I Spectrum analyzer signal input.

30 SPE I Spectrum analyzer signal input.

31 SPE I Spectrum analyzer signal input.

32 KYE 1 I Key data input (A/D converter).

33 KYE 2 I Key data input (A/D converter).

34 AVDD – Power supply for anlog.

35 AV REF – Reference voltage for A/D converter.

– 8 –

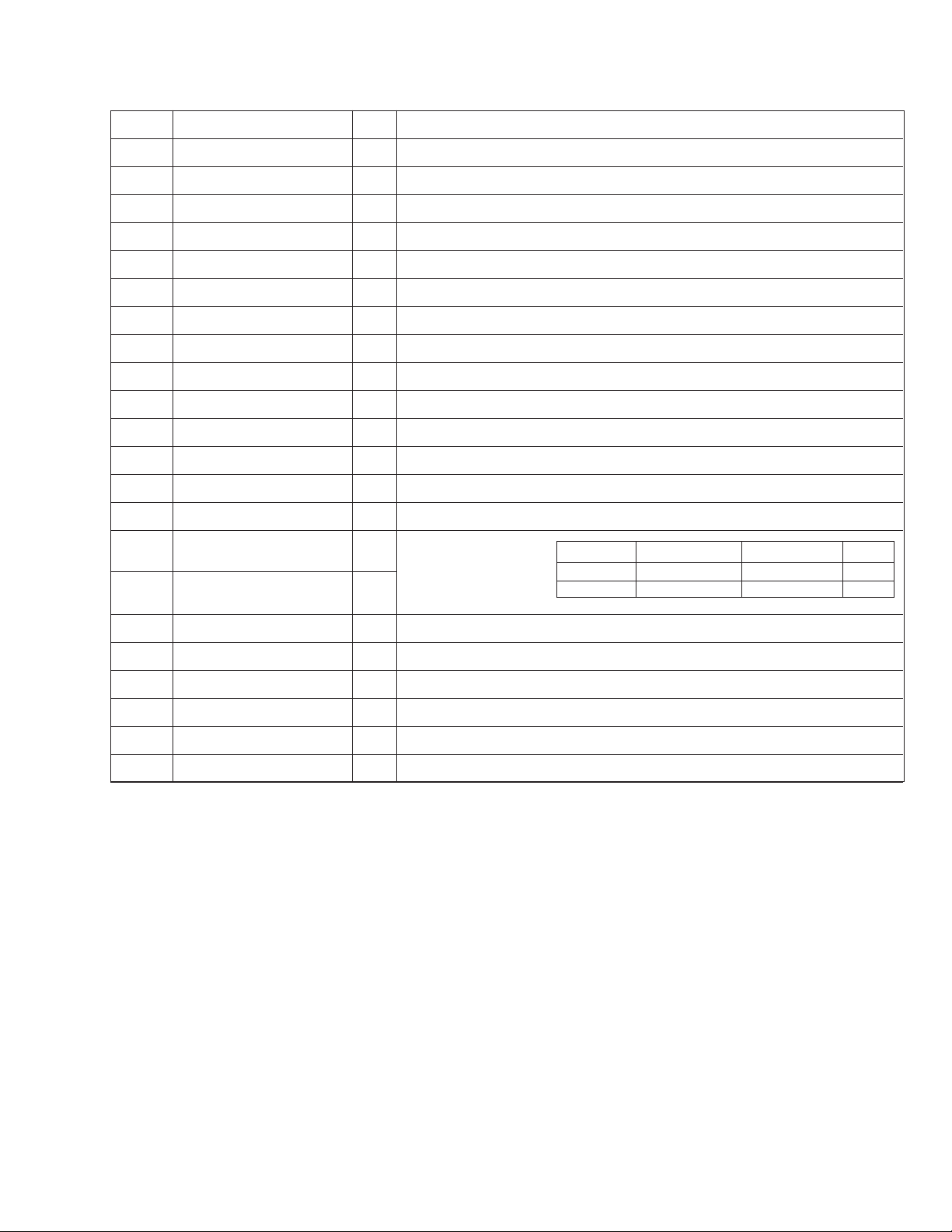

Pin No. Pin name I/O Description

36 VOL IN A I Volume encoder input.

37 JOG IN A I JOG dial encoder input.

38 RDS CLK I Not uset.

39 AUB IN I Audio bus output.

40 VSS – Ground.

41 RDS DATA I Not uset.

42 D 3 I/O System control data signal input / output.

43 D 2 I/O System control data signal input / output.

44 D 1 I/O System control data signal input / output.

45 D 0 I/O System control data signal input / output.

46 VDD – Power supply +5V.

47 SIRCS IN I SIRCS signal input.

48 VOL IN B I Volume encoder input.

49 JOG IN B I JOG dial encoder input.

50 ST FM O

BAND select output.

51 ST MUTE O

52 EMG OUT O Urgent signal standby output. “H” : standby

53 EMG IN I Urgent signal start input. “H” n “L” : start

57 – 78 P 32 – P 8 O Segment output to FL501.

79 VG – Power supply for fluorescent indicator tube.

80 – 86 P 7 – P 1 O Segment output to FL501.

87 – 100 14 G – 1 G O Grid output for FL501.

%º pin H L H

%¡ pin L L H

FM Receiving AM Receiving MUTE

– 9 –

– 10 –

– 11 –

Loading...

Loading...