Page 1

STR-NX5MD

g

SERVICE MANUAL

STR-NX5MD is the

Tuner and Amplifier

Section in DHC-NX5MD.

SPECIFICATIONS

Amplifier section

European model

DIN power output (rated) 80 + 80 watts

Continuous RMS power output (reference)

Music power output (reference)

Other models

DIN power output (rated) 90 + 90 watts

Continuous RMS power output (reference)

Inputs

VIDEO IN: voltage 250 mV

(phono jacks) impedance 47 kilohms

TAPE IN: voltage 250 mV

(phono jacks) impedance 47 kilohms

Outputs

TAPE OUT: voltage 250 mV

(phono jacks) impedance 1 kilohms

PHONES: accepts headphones of 8 ohms or

(stereo mini jack) more

FRONT SPEAKER: accepts impedance of 6 to 16 ohms

REAR SPEAKER: accepts impedance of 16 ohms

SUPER WOOFER: volta

(6 ohms at 1 kHz, DIN)

100 + 100 watts

(6 ohms at 1 kHz, 10% THD)

160 + 160 watts

(6 ohms at 1 kHz, 10% THD)

(6 ohms at 1 kHz, DIN)

110 + 110 watts

(6 ohms at 1 kHz, 10% THD)

e 1 V, impedance 1 kilohms

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

Tourist model: 76.0 – 108.0 MHz

Other models: 87.5 – 108.0 MHz

Aerial FM lead aerial

Aerial terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

European models: 531 – 1,602 kHz

(with the interval set at 9 kHz)

Other models: 531 – 1,602 kHz

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

Aerial AM loop aerial

Aerial terminals External aerial terminal

Intermediate frequency 450 kHz

AEP Model

UK Model

E Model

General

Power requirements

European models: 230 V AC, 50/60 Hz

Other models: 120 V, 220 V or 230 – 240 V AC,

Power consumption

European models: 190 watts

Other models: 220 watts

Dimensions (w/h/d) Approx. 225 × 202 × 356 mm

Mass

European models: Approx. 7.8 kg

Other models: Approx. 7.6 kg

Supplied accessories: AM loop aerial (1)

Design and specifications are subject to change

without notice.

50/60 Hz Adjustable with voltage

selector

Remote Commander (1)

Batteries (2)

FM lead aerial (1)

Speaker cords (2)

Front speaker pads (8)

TUNER/AMPLIFIER

1

Page 2

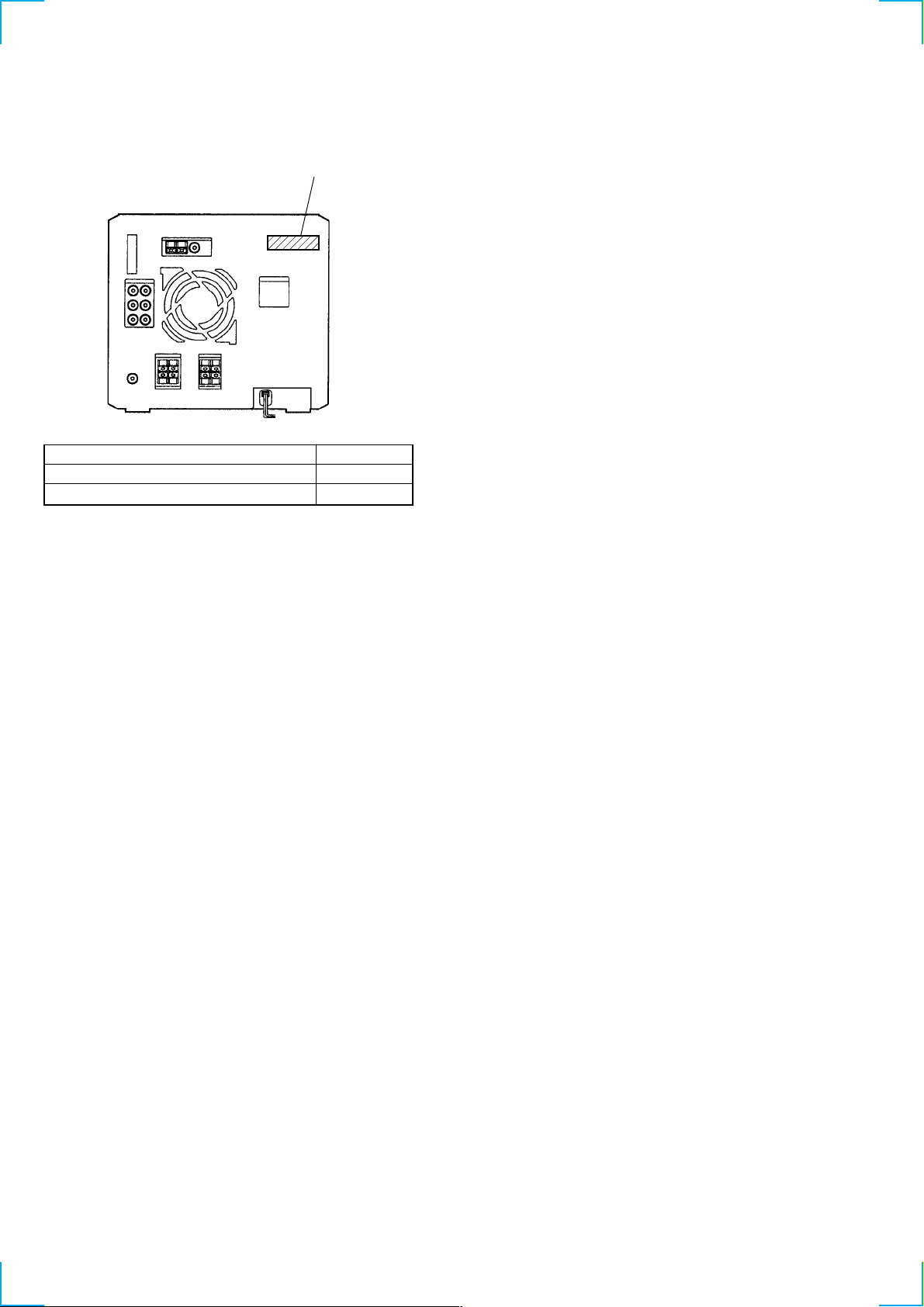

• MODEL IDENTIFICATION

– Rear Panel –

PART No.

MODEL PART No.

AEP, UK, G, AED and CIS models 4-221-391-8[]

Malaysia and Singapore models 4-221-391-9[]

• Abbreviation

G : German model

AED : North European model

TABLE OF CONTENTS

1. GENERAL .......................................................................... 3

2. DISASSEMBLY

2-1. Case ....................................................................................... 5

2-2. Front Panel Assy ................................................................... 5

2-3. Back Panel Assy .................................................................... 6

2-4. Main Board ........................................................................... 6

3. TEST MODE ........................................................................ 7

4. DIAGRAMS

4-1. Notes for Printed Wiring Boards and Schematic Diagrams.. 9

4-2. Schematic Diagram – Main Board (1/3) – .......................... 10

4-3. Schematic Diagram – Main Board (2/3) – .......................... 11

4-4. Schematic Diagram – Main Board (3/3) – .......................... 12

4-5. Printed Wiring Board – Main Board – ................................ 13

4-6. Printed Wiring Board – PA Board – .................................... 14

4-7. Schematic Diagram – PA Board – ...................................... 15

4-8. Printed Wiring Board – Panel Section – ............................. 16

4-9. Schematic Diagram – Panel Section – ................................ 17

4-10. Printed Wiring Board – Transformer Section – ................. 18

4-11. Schematic Diagram – Transformer Section – ................... 19

4-12. IC Pin Function Description ............................................. 20

5. EXPLODED VIEW

5-1. General Section ................................................................... 22

5-2. Front Panel Section ............................................................. 23

5-3. Chassis Section ................................................................... 24

6. ELECTRICAL PARTS LIST ........................................ 25

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

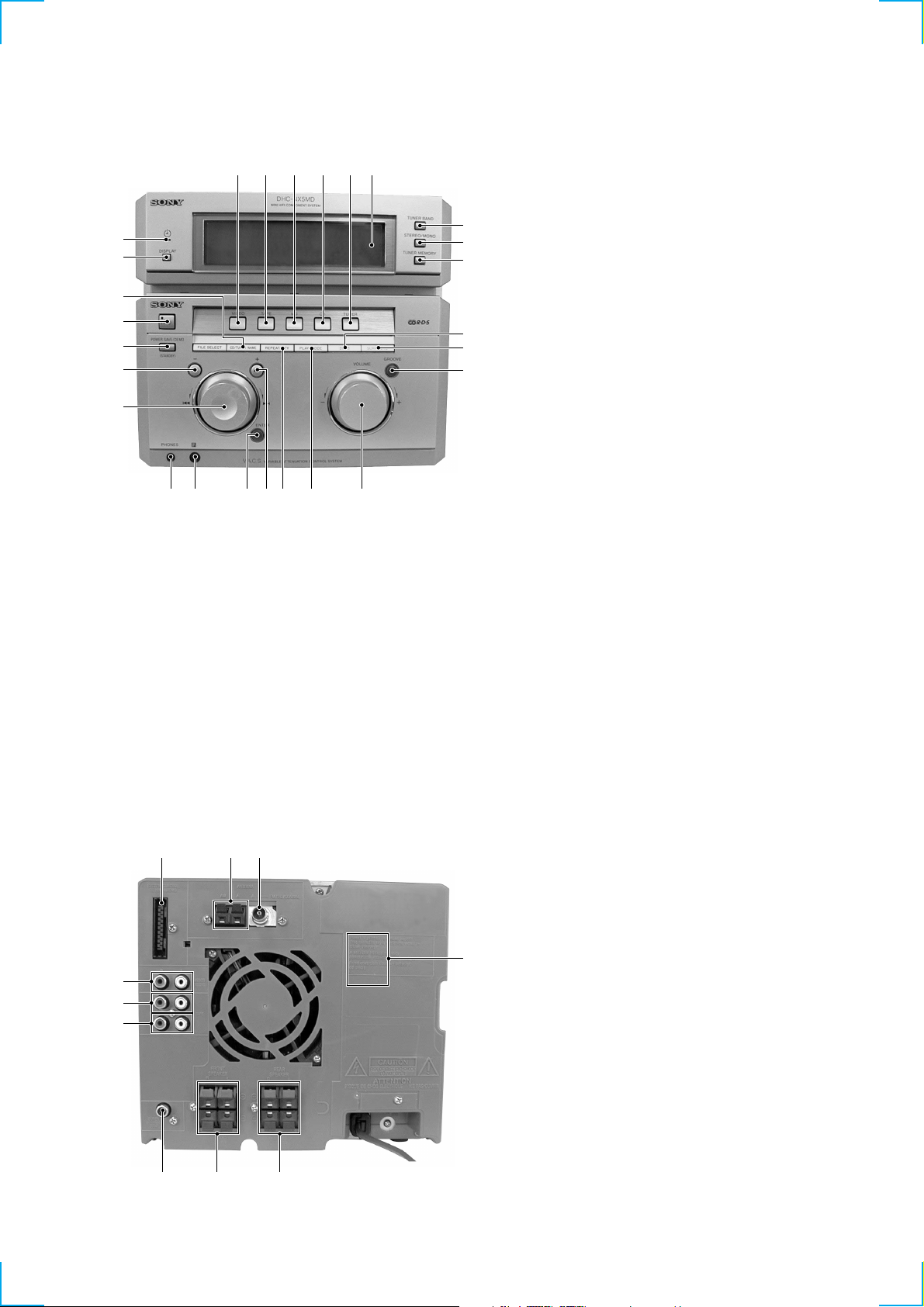

• LOCATION OF CONTROLS

1 2 3

5 6 7 8 9 0

– Front Panel –

4

3

2

1

wh

wg

wf

SECTION 1

GENERAL

1 ?/1 (Power) button and indicator

2 CD/TUNER NAME button

qa

qs

qd

qf

qg

qh

qkqlwswd w;wa

qj

3 DISPLAY button

4 TIMER indicator

(AEP, UK, German, AED and CIS models)

5 VIDEO button

6 TAPE button

7 MD button

8 CD button

9 TUNER button

q; Display window

qa TUNER BAND button

qs STEREO/MONO button

qd TUNER MEMORY button

qf DBFB button

qg SURROUND button

qh GROOVE button and indicator

qj VOLUME knob

qk PLAY MODE button

ql REPEAT/PTY button

w; + M button

wa ENTER button and indicator

ws Remote sensor

wd PHONES jack

wf Jog dial

wg – m button

wh POWER SAVE/DEMO (STANDBY) button

wj FILE SELECT button

– Rear Panel –

0

9

8

6 57

Photo: AEP model

4

1 SYSTEM CONTROL terminals

2 AM ANTENNA terminals

3 FM ANTENNA terminal

4 VOLTAGE SELECTOR switch

(Malaysia and Singapore models)

5 REAR SPEAKER terminals

6 CENTER SPEAKER terminals

7 SUPER WOOFER OUT jack

8 MD OUT jacks

9 MD IN jacks

q; VIDEO (AUDIO) jacks

• Abbreviation

AED : North European model

3

Page 4

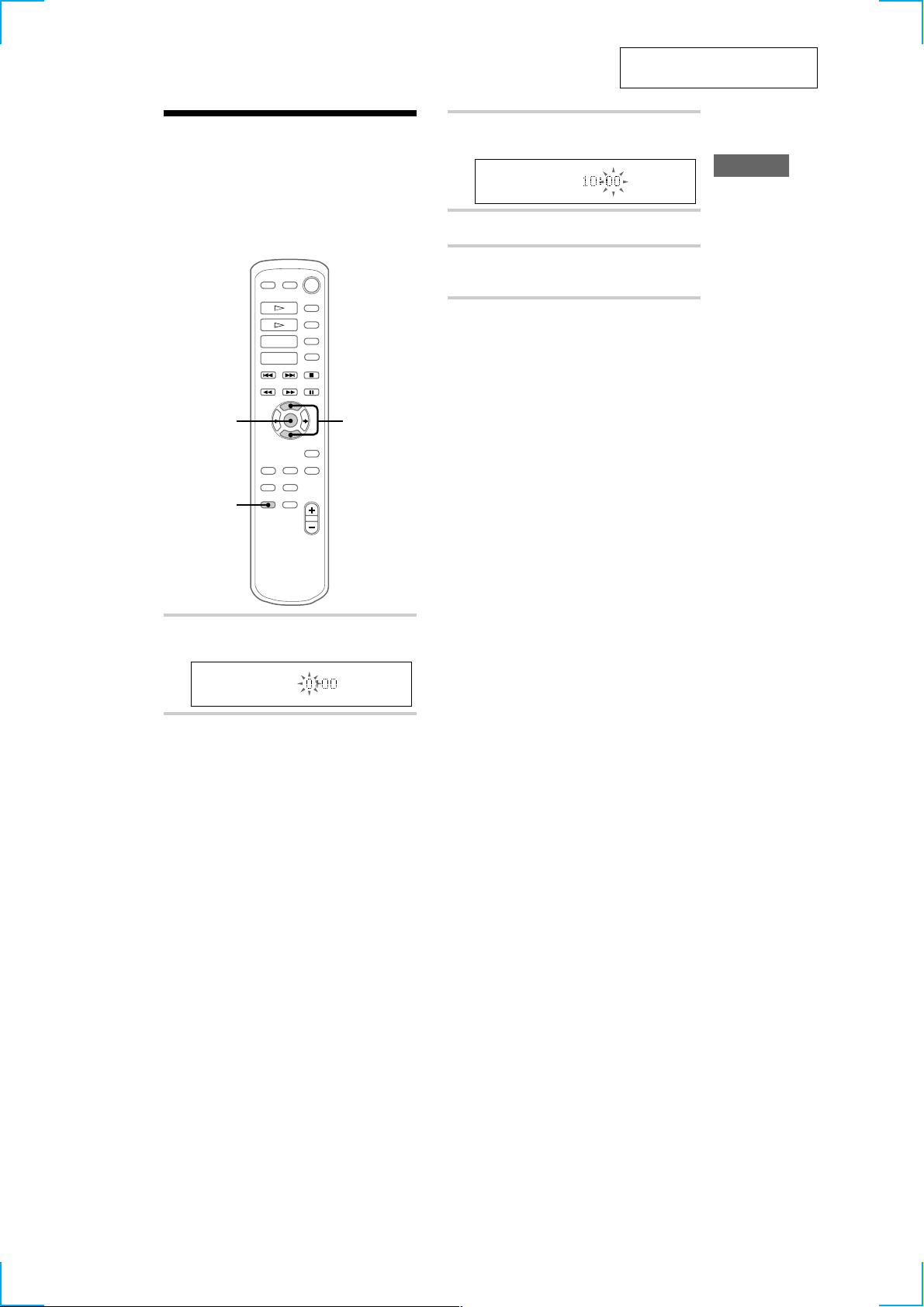

Step 2: Setting the time

You must set the time beforehand to use the timer

functions.

The clock is on a 24-hour system for the European

model, and a 12-hour system for other models.

The 24-hour system is used for illustration

purposes.

3,5 2,4

1

This section is extracted from

instruction manual.

3

Press ENTER.

The minute indication flashes.

4

Press V or v to set the minute.

5

Press ENTER.

The clock starts.

Tips

• If you’ve made a mistake, start over from step 1.

• Setting the time deactivates the demo mode.

If you want to display the demo mode, press

DISPLAY (European model) or DEMO

(STANDBY) (other models) when the power is off.

To change the time

The previous explanation shows you how to set

the time while the power is off. To change the

time while the power is on, do the following:

1 Press CLOCK/TIMER SET.

2 Press V or v to select the SET CLOCK.

3 Press ENTER.

4 Perform steps 2 through 5 above.

Note

The clock settings are cancelled when you disconnect

the mains lead or if a power failure occurs.

Getting Started

1

Press CLOCK/TIMER SET.

The hour indication flashes.

2

Press V or v to set the hour.

7

4

Page 5

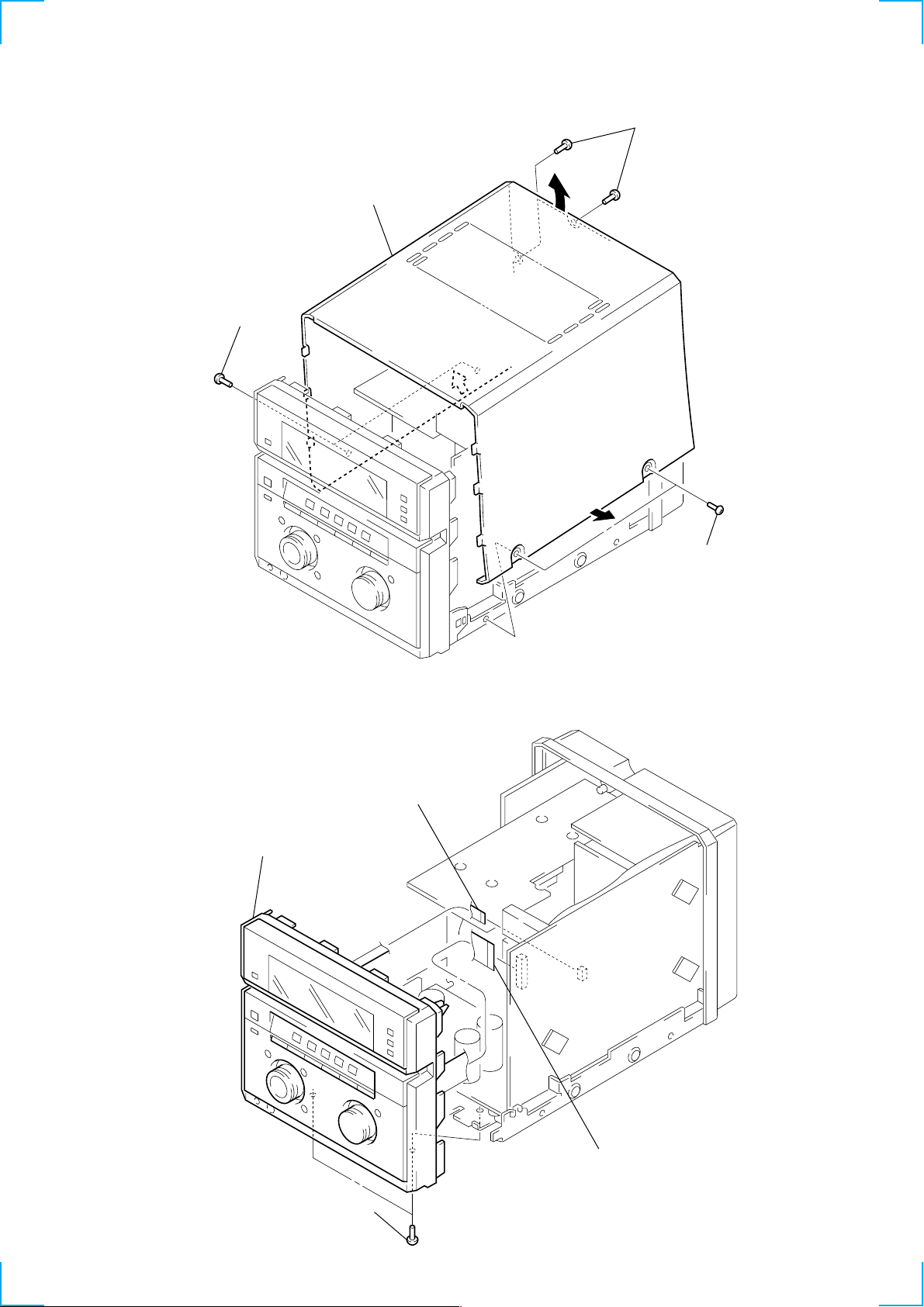

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. CASE

3 case

1 two screws

(case 3 TP2)

2 two screws

(BVTP3 × 10)

1 two screws

(case 3 TP2)

2-2. FRONT PANEL ASSY

4 front panel assy

1 flat cable (7 core)

(CN132)

2 flat cable (25 core)

(CN131)

3 two screws

(BVTT3 × 6)

5

Page 6

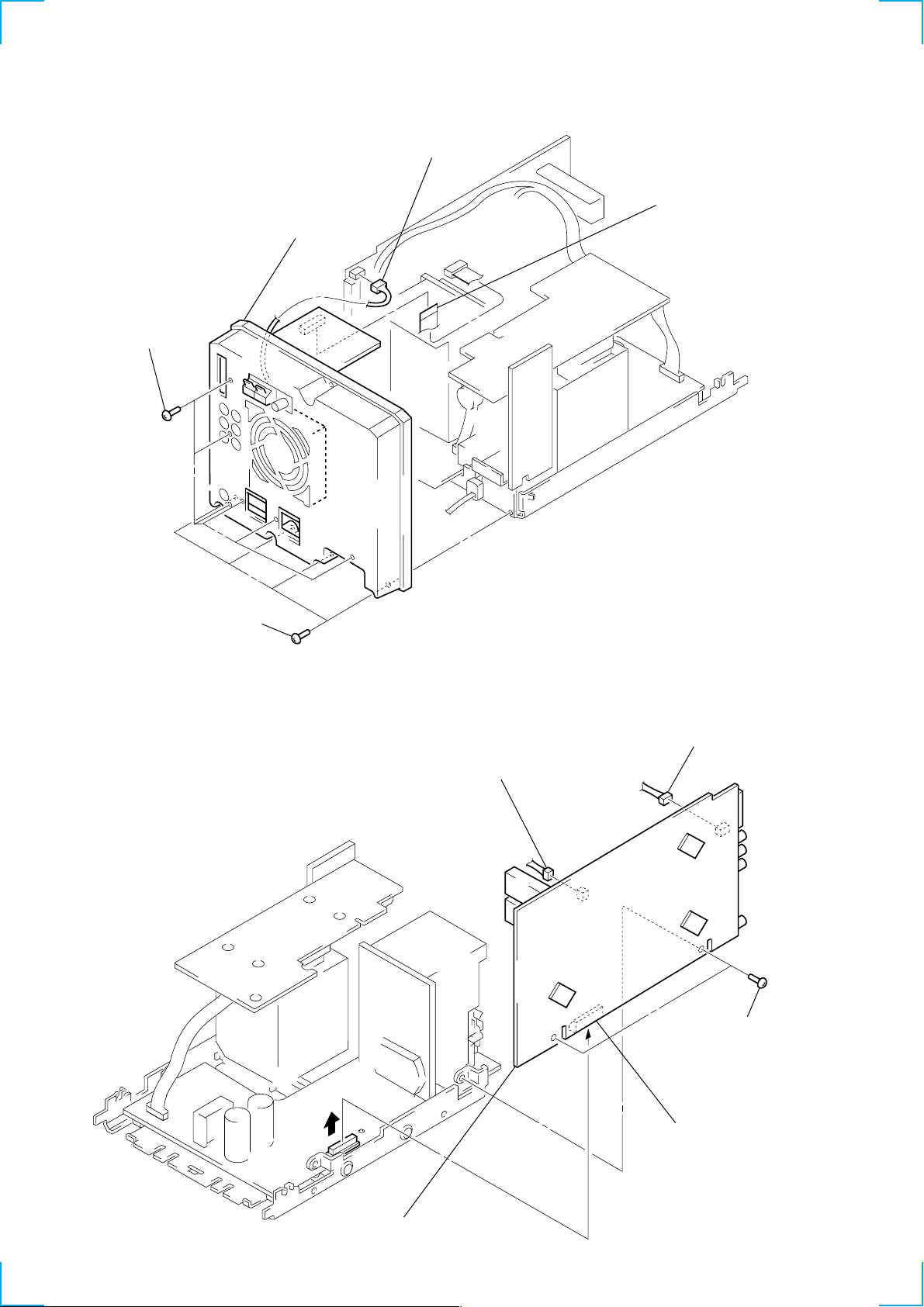

2-3. BACK PANEL ASSY

)

3 six screws

(BVTP3 × 10)

4 back panel assy

2 connector

(CN173)

1 flat cable (13 core)

(CN1)

2-4. MAIN BOARD

3 four screws

(BVTP3 × 10)

2 connector (CN111)

1 connector

(CN181)

3 two screws

(BVTP3 × 10)

4 connector (CN152

5 main board

6

Page 7

SECTION 3

TEST MODE

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the [ENTER] and ?/1 buttons simultaneously.

3. A message “LOCK” is displayed on the liquid crystal display,

and the CD delivery mode is set.

[Change-over the MW Tuning Interval]

• The MW tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the [TUNER] button to select the function “TUNER”,

and press the [TUNER BAND] button to select the BAND “MW”.

3. Press the ?/1 button to turn the power OFF.

4. Press the [TUNER MEMORY] and ?/1 buttons simultaneously,

and the display on the liquid crystal display changes to “MW

9 k STEP” or “MW 10 k STEP”, and thus the tuning interval

is changed over.

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press the [GROOVE] and ?/1 buttons simultaneously.

3. The set is reset, and displays “COLD RESET”, then becomes

DEMO mode.

[Amplifier Test Mode]

Procedure:

1. Press the

2. Press three buttons of [ENTER] , [DISPLAY] , and

?/1 button to turn the power ON.

[TUNER BAND] simultaneously.

3. “ALC OFF” is displayed, then the function which was set be-

fore the test mode became active is displayed.

[LED and Liquid Crystal Display All Lit, Software Version Display, Key Check, VACS Level Display Mode]

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of [ENTER] , [DISPLAY] , and

[STEREO/MONO] simultaneously.

3. LEDs and liquid crystal display are all turned on.

Rotating the JOG dial changes over the check patterns of liquid crystal display.

4. Successively, the following three modes can be activated.

(1) Press the [VIDEO] button, and the software version is displayed

on the liquid crystal display.

(2) Press the [MD] button, and the key check mode is activated.

In the key check mode, the liquid crystal display displays “K

0 J0 V0”. Each time a button is pressed, “K” value increases.

However, once a button is pressed, it is no longer taken into

account.

“J” value increases like 1, 2, 3 ... if turn the JOG dial clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial counterclockwise.

“V” value increases like 1, 2, 3 ... if turn the [VOLUME] dial

clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial

counterclockwise.

(3) Press the [TAPE] button, and the VACS level is displayed on

the liquid crystal display.

5. To release from these mode, press three buttons in the same

manner as step 2, or remove the power cord.

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of

[ENTER] , [DISPLAY] , and

[TUNER MEMORY] simultaneously.

3. The set is reset, and becomes standby state.

[Change-over of VACS ON/OFF]

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of [ENTER] , [DISPLAY] , and [GROOVE]

simultaneously, and the display on the liquid crystal display

changes to “VACS ON” or “VACS OFF”, and thus the VACS

ON/OFF is changed over.

[VIDEO input, Record and CD play in CD function]

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of [ENTER] , [DISPLAY] , and

- m simultaneously.

3. “DVD 5.1CH” is displayed on liquid crystal display, and at

the same time, CD is played and the deck B is placed in the

record status.

[CD Service Mode]

• This mode can run the CD sled motor optionally. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the

3. Press three buttons of [ENTER] , [POWER SAVE/DEMO

(

STANDBY) , and [STEREO/MONO] simultaneously.

4. Set to the Sled Servo mode.

5. With the CD in stop status, turn the JOG dial clockwise to

move the optical pick-up to outside track, or turn it counterclockwise to inside track.

6. To release from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Remove the power cord.

Notes: • Always move the optical pick-up to most inside track when

[CD] button to select the function “CD”.

releasing from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

7

Page 8

[Aging Mode]

This mode can be used for operation check of CD section and tape

deck section.

CD section and tape deck section work in parallel.

• If an error occurred:

The aging operation stops only an error occurred sections and

display then status.

• If no error occurs:

The aging operation continues repeatedly.

Procedure:

1. Set disc in DISC5 tray.

2. Load the tapes into the decks A and B respectively.

3. Press the [PLAY MODE] button to set the “ALL DISCS” mode,

and press the [REPEAT/PTY] button to “REPEAT” off.

4. Press the [CD] button to select the function “CD”.

5. Press three buttons of [ENTER] , [POWER SAVE/DEMO

(

STANDBY) , and [TUNER BAND] simultaneously.

6. The aging mode is activated, if the indicator of disc tray num-

ber on the liquid crystal display is blinking.

7. To release from the aging mode, press the ?/1 button to turn

the power OFF and operate the cold reset. (Refer to the “MC

Cold Reset”)

• Display at an error occurred

1) Display of the error count

(1) Press three buttons of [ENTER] , [POWER SAVE/DEMO

(

STANDBY)

, and [GROOVE] simultaneously.

(2) Display of the error count following as below.

Display

EMC**EDC

Notes:

EMC**: The number of mechanical error.

EDC**: The number of no disc error after chucking the disc.

**

2) Display of mechanical error

Display

E**M##$$&&

1. Display at the Aging Mode

• Display operating state of CD section and tape deck section alternately.

• If an error occurred, stop display which that section.

2. CD Section

• Display at the aging mode is the same as the normal operation.

• The sequence during the aging mode is following as below.

Aging mode sequence (CD section) :

Open the disc1 tray

Disc5 chucking

Disc5 TOC read

Disc5 play track1 for 2 seconds

Disc5 play last track for 2 seconds

Notes:

: The number of mechanical error.(“00” is latest one)

**

(Press the [PLAY MODE] button to changes next error display)

## : Not used.

$$ : Loading error. (Second figure is not used)

D : The error in the midst of close at the except mechanical trouble.

E : The error in the midst of open at the except mechanical trouble.

C : The error in the midst of chuck up at the except mechanical

trouble.

F : The error in the midst of EX-open at the except mechanical

trouble.

&&: Loading error. (Second figure in not used)

1:The error in the midst of chuck up.

2:The error in the midst of chuck down.

3:Time up of EX-open

4:Time up of EX-close.

3) Display of no disc error

Display

E**D##$$&&

Notes:

: The number of mechanical error.(“00” is latest one)

**

(Press the [REPEAT] button to changes next error display)

##:

01:Focus error

02:GFS error

03:Set up error

$$:

00:No disc error when does not chucking retry.

02:No disc error when chucking retry to completion.

&&: The state when judged no disc error. (Second figure is not used)

1:Stop

2:Set up

3:TOC read

4:Access

5:Play

6:Pause

7:Manual search (Play)

8:Manual search (Pause)

8

Page 9

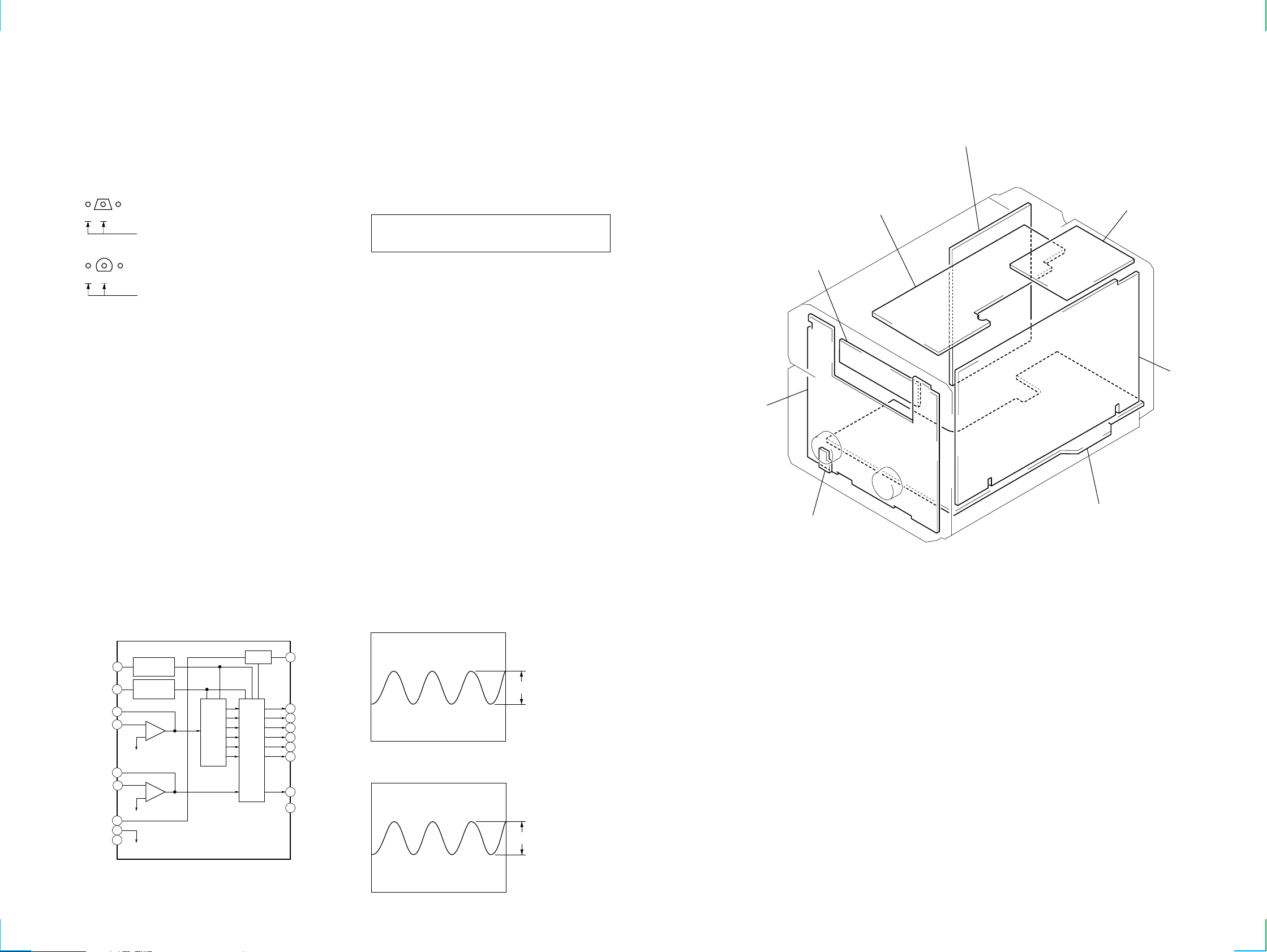

SECTION 4

SUB TRANS board

(AEP, UK, G, AED, CIS)

TRANS board

BACK LIGHT board

PANEL board

R board

PA board

MAIN board

TUNER pack

DIAGRAMS

4-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• x : parts mounted on the conductor side.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated)

• Indication of transistor.

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

: internal component.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• V : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM)

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

E : MD PLAY

J : CD PLAY

j : MD REC

• Abbreviation

MY : Malaysia model

SP : Singapore model

G : German model

AED : North European model

4

W or less unless otherwise

• Circuit Boards Location

• IC Block Diagram

– MAIN Board –

1

2

3

4

5

6

7

8

9

REFERENCE

REFERENCE

IC401 BA3830F

R02

R01

LINE NF

LINE IN

REC NF

REC IN

RESET C

BIAS C

GND

CURRENT

CURRENT

–

+

–

+

BAND

PASS

FILTER

RESET

DET

18

17

16

15

14

13

12

11

10

RESET

F01

F02

F03

F04

F05

F06

REC LEVEL

VCC

• Waveforms

– MAIN Board –

1 IC501 qa (XCOUT)

32.768 kHz

2 IC501 qd (XOUT)

3 Vp-p

2.8 Vp-p

16.025 MHz

99

Page 10

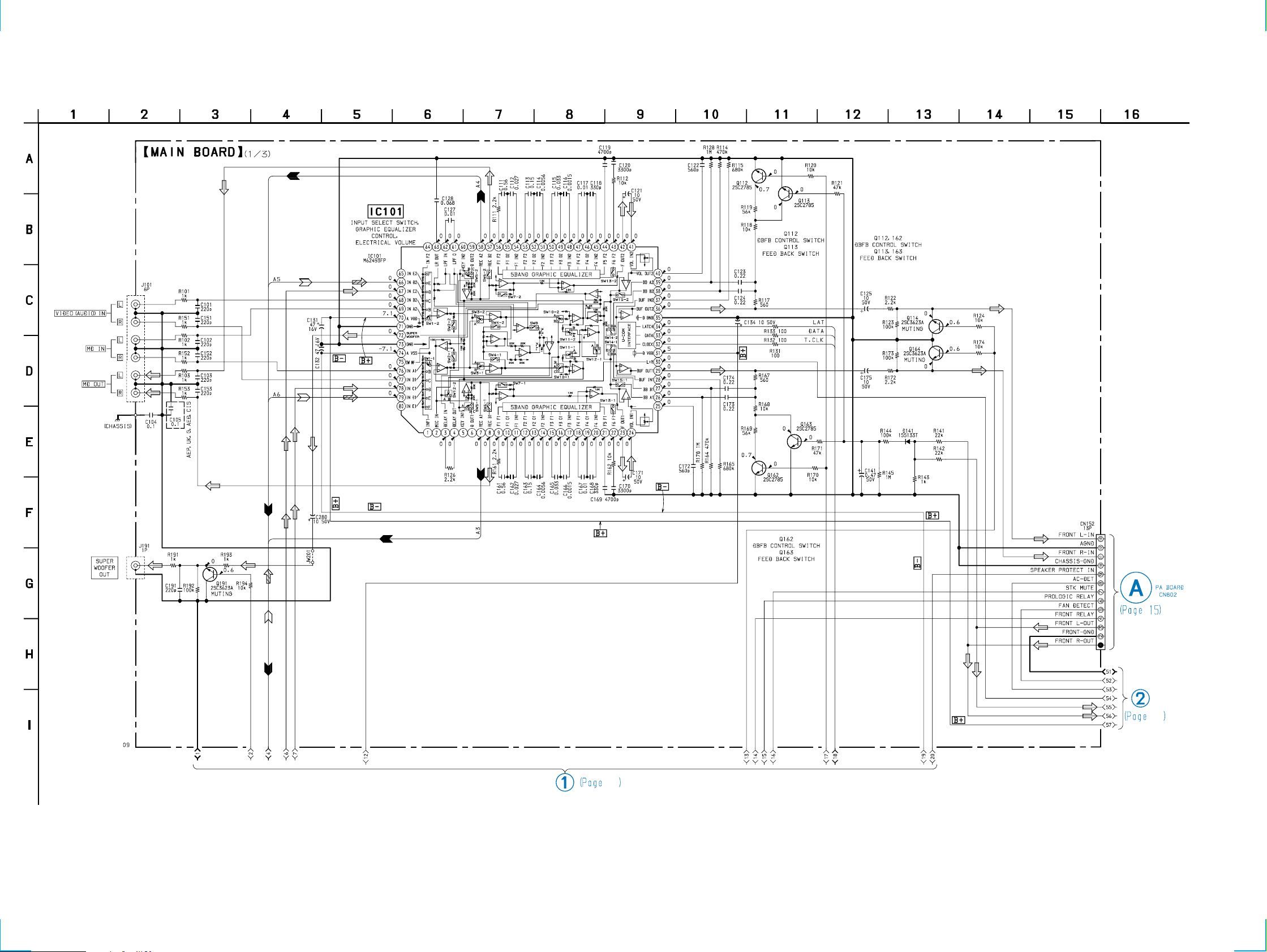

STR-NX5MD

4-2. SCHEMATIC DIAGRAM – MAIN Board (1/3) – • See page 13 for Printed Wiring Board.

11

10 10

12

Page 11

4-3. SCHEMATIC DIAGRAM – MAIN Board (2/3) – • See page 9 for Waveforms. • See page 13 for Printed Wiring Board.

10

STR-NX5MD

PIN FUNCTION

12

11 11

Page 12

STR-NX5MD

4-4. SCHEMATIC DIAGRAM – MAIN Board (3/3) – • See page 9 for IC Block Diagram.

10

• Semiconductor Location

Ref. No. LocationRef. No. Location

D141 A-8

D501 B-2

D502 D-1

D503 D-1

D504 E-1

D505 E-1

D506 E-1

D507 F-1

D508 E-2

D510 C-1

D901 B-5

D902 B-5

D903 B-5

D904 B-4

D905 A-6

D906 A-6

D914 A-3

D915 B-3

D920 B-4

D921 B-3

D925 B-4

D931 A-4

D932 A-4

IC101 B-9

IC401 E-5

IC501 E-3

IC502 E-1

IC901 A-2

IC921 C-2

Q112 A-8

Q113 A-8

Q114 G-6

Q162 A-9

Q163 A-9

Q164 G-6

Q191 G-11

Q411 D-5

Q421 C-3

Q431 E-6

Q432 D-6

Q461 D-5

Q501 F-1

Q502 F-1

Q503 F-1

Q901 A-6

Q902 A-6

Q903 A-6

Q904 A-3

Q905 A-3

Q906 B-3

Q907 B-4

Q921 B-3

Q926 B-3

Q927 B-3

Q951 B-6

Q952 B-6

Q953 B-6

11

12 12

Page 13

4-5. PRINTED WIRING BOARD – MAIN Board – • See page 9 for Circuit Boards Location.

(Page 18)

STR-NX5MD

(Page 18)

(Page 16)

(Page 16)

(Page 18)

(Page 14)

There are a few cases that the part isn’t mounted in

model is printed on diagram.

13 13

Page 14

STR-NX5MD

4-6. PRINTED WIRING BOARD – PA Board – • See page 9 for Circuit Boards Location.

MAIN

BOARD

CN152

(Page 13)

(AEP, UK, AED, CIS)

(AEP, UK,

AED, CIS)

(MY, SP)

(MY, SP)

TRANS

BOARD

CN952

(Page 18)

14 14

• Semiconductor Location

Ref. No. LocationRef. No. Location

D802 B-5

D821 E-4

D831 C-6

D852 C-5

D871 B-10

D881 E-2

D883 A-11

D884 C-11

D885 F-10

There are a few cases that the part isn’t mounted in

model is printed on diagram.

IC801 C-8

Q801 B-5

Q821 D-7

Q822 D-7

Q823 C-7

Q824 C-7

Q825 H-4

Q826 H-4

Ref. No. Location

Q827 H-4

Q828 G-4

Q829 G-4

Q830 G-4

Q831 C-7

Q851 C-5

Q881 B-10

Q882 B-9

Page 15

4-7. SCHEMATIC DIAGRAM – PA Board –

STR-NX5MD

15 15

Page 16

STR-NX5MD

4-8. PRINTED WIRING BOARDS – PANEL Section – • See page 9 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D631 E-2

D636 G-5

D637 A-8

D638 D-8

D643 C-6

D644 C-7

D645 C-4

D646 C-5

D647 C-2

D648 C-3

(Page 13)

Q631 E-1

Q636 F-5

Q637 B-7

Q638 D-8

Q641 D-7

Q642 D-7

Q643 D-7

16 16

(Page 13)

There are a few cases that the part isn’t mounted in

model is printed on diagram.

Page 17

4-9. SCHEMATIC DIAGRAM – PANEL Section –

STR-NX5MD

17 17

Page 18

STR-NX5MD

4-10. PRINTED WIRING BOARDS – TRANSFORMER Section – • See page 9 for Circuit Boards Location.

(AEP, UK, G,

AED, CIS)

1

(AEP, UK, G,

AED, CIS)

(MY, SP)

(MY, SP)

JW953

(MY, SP)

CN952

MAIN

BOARD

(Page 13)

(Page 13)

(Page 14)

10

CN111

MAIN

BOARD

CN181

PA

BOARD

CN808

09

(Page 13)

18 18

There are a few cases that the part isn’t mounted in

model is printed on diagram.

Page 19

4-11. SCHEMATIC DIAGRAM – TRANSFORMER Section –

STR-NX5MD

19 19

Page 20

4-12. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC501 M30622MAA-A39FP (SYSTEM CONTROLLER )

Pin No. Pin Name I/O Descriptions

1 L+R I

2 BPF SL I

3 F RELAY O Speaker protect relay drive signal output for the front side speaker “H”: relay on

4 R RELAY O Speaker protect relay drive signal output for the rear side speaker “H”: relay on

5 SIRCS I Remote control signal input from the remote control receiver (IC601)

6 LINE MUTE O Line muting on/off control signal output terminal “L”: muting on

7 DBFB O

8 BYTE I External data bus line byte selection signal input terminal Fixed at “L” in this set

9 CNVSS — Ground terminal

10 XCIN I Sub system clock input terminal (32.768 kHz)

11 XCOUT O Sub system clock output terminal (32.768 kHz)

12 RESET I

13 XOUT O Main system clock output terminal (16 MHz)

14 VSS — Ground terminal

15 XIN I Main system clock input terminal (16 MHz)

16 VCC — Power supply terminal (+5V)

17 NMI I Non-maskable interrupt input terminal Fixed at “H” in this set

18 WAKE UP O Wakeup control signal output to the CPU on the HMC-NX5MD “H” active

19 PHONES MUTE O Muting on/off control signal output terminal “L”: muting on Not used (open)

20 RDS INT I

21 RDS DATA I

22 AC CUT I AC off detection signal input from the reset signal generator (IC502) “L”: AC cut checked

23 PL CLK O Not used (open)

24 PL DATA O Not used (open)

25 PL LAT O Not used (open)

26 STK POWER O Power amplifier on/off selection signal output terminal “L”: standby mode, “H”: on

27 SPEAKER PROTECT I

28 SOFT-TEST O Output terminal for the software test Not used (open)

29 IIC CLK I/O

30 IIC DATA I/O Communication data bus with the CPU on the HMC-NX5MD

31 TXD1 O Not used (open)

32 RXD1 I Not used (fixed at “L”)

33 CLK1 I Not used (fixed at “L”)

34 RTS1 O Not used (open)

35 LCD DAT A O Serial data output to the liquid crystal display unit (LCD601)

36 RXD0 I Not used (fixed at “L”)

37 LCD CLK O Serial data transfer clock signal output to the liquid crystal display unit (LCD601)

38 493 LT O Serial data latch pulse output to the M62493FP (IC101)

39 CLOCK OUT O Output terminal for the clock signal check Not used (open)

40 VC L+R/L–R O Virtual cinema L+R/L–R selection signal output terminal Not used (open)

Spectrum analyzer drive signal input from the spectrum analyzer band-pass filter (IC401)

(for VACS, non-stop signal)

Spectrum analyzer drive (super low frequency) signal input from the spectrum analyzer

band-pass filter (IC401) (for 40 Hz)

DBFB normal/high selection signal output to the M62493FP (IC101)

“L”: DBFB high, “H”: DBFB low/off

System reset signal input from the reset signal generator (IC502) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

RDS serial data transfer clock signal input from the tuner pack

(Used for the AEP, UK, G*, AED* and CIS models only)

RDS serial data input from the tuner pack

(Used for the AEP, UK, G*, AED* and CIS models only)

Protect on/off detection signal input from the speaker protect circuit

“L”: protect on, “H”: protect off

Communication data reading clock signal input or transfer clock signal output with the CPU

on the HMC-NX5MD

Pin No. Pin Name I/O

41 XHOLD I Not used (fixed at “L”)

42 LCD SW O

43 STBY RELAY O

44 BASS FREQ O

45 OPT SEL O Not used (open)

46 XWR I Not used (fixed at “H”)

47 493 DATA O Serial data output to the M62493FP (IC101)

48 493 CLK O Serial data transfer clock signal output to the M62493FP (IC101)

49 ST MUTE O Tuner muting control signal output to the tuner pack “H”: muting on

50 STEREO I FM stereo detection signal input from the tuner pack “L”: stereo

51 TUNED I Tuning detection signal input from the tuner pack “L”: tuned

52 ST CE O PLL chip enable signal output to the tuner pack

53 ST DOUT O PLL serial data output to the tuner pack

54 ST DIN I PLL serial data input from the tuner pack

55 ST CLK O PLL serial data transfer clock signal output to the tuner pack

56 VC BYPASS O Virtual cinema bypass control signal output terminal Not used (open)

57 PHONES DETECT I

58 LCD LAT O Serial data latch pulse output to the liquid crystal display unit (LCD601)

59 LCD A0 O Address signal output to the liquid crystal display unit (LCD601)

60 LCD RESET O Reset signal output to the liquid crystal display unit (LCD601) “L”: reset

61 NC O Not used (open)

62 VCC — Power supply terminal (+5V)

63 NC O Not used (open)

64 VSS — Ground terminal

65 to 67 NC O Not used (open)

68 TUNER MUTE O TUNER 5V ON/OFF SW

69 JOG B I Jog dial pulse input from the rotary encoder (S652 JOG) (B phase input)

70 JOG A I Jog dial pulse input from the rotary encoder (S652 JOG) (A phase input)

71 VOL B I Jog dial pulse input from the rotary encoder (S651 VOLUME) (B phase input)

72 VOL A I Jog dial pulse input from the rotary encoder (S651 VOLUME) (A phase input)

73 to 75 NC O Not used (open)

76 HMC POWER O HMC POWER detection

77, 78 NC O Not used (open)

79 LED FUNCTION O LED drive signal output of the key illumination indicator (D643 to D648) “H”: LED on

80 LED POWER O LED drive signal output of the I/1 indicator (D638) “H”: LED on

81 LED TIMER O

82 LED LCD O

83 LED ENTER O LED drive signal output of the ENTER indicator (D636) “H”: LED on

84 LED JOG O LED drive signal output terminal Not used (open)

85 LED CINEMA O LED drive signal output terminal Not used (open)

86 LED DOLBY O

Liquid crystal display on/off selection signal output terminal “L”: on, “H”: off

Not used (open)

Main power on/off control signal output terminal “L”: standby mode, “H”: power on

(Used for the AEP, UK, G*, AED* and CIS models only)

Sync bass frequency normal/high selection signal output to the M62493FP (IC101)

“L”: sync bass off (normal), “H”: sync bass high Not used (open)

Connection detect signal input of the headphone jack (J701)

“L”: no connected, “H”: headphone connected

LED drive signal output of the TIMER indicator (D637) “H”: LED on

(Used for the AEP, UK, G*, AED* and CIS models only)

LED drive signal output of the liquid crystal display back light indicator (D639 to D642)

“H”: LED on

LED drive signal output of the PRO LOGIC indicator (D633) “H”: LED on

Not used (open)

Descriptions

20 20

Page 21

Pin No. Pin Name I/O

87 LED 5.1CH O

88 LED GROOVE O LED drive signal output of the GROOVE indicator (D631) “H”: LED on

89 BPF 1 I

90 BPF 2 I

91 BPF 3 I

92 BPF 4 I

93 KEY1 I

94 KEY0 I

95 MODEL-IN I Destination setting terminal

96 AVSS — Ground terminal (for A/D conversion)

97 SPEC-IN I Setting terminal for the version

98 VREF I Reference voltage (+5V) input terminal (for A/D conversion)

99 AVCC — Power supply terminal (+5V) (for A/D conversion)

100 POWER O Power on/off control signal output terminal “L”: standby mode, “H”: power on

LED drive signal output of the DVD 5.1CH indicator (D632) “H”: LED on

Not used (open)

Spectrum analyzer drive (low frequency) signal input from the spectrum analyzer band-pass

filter (IC401) (for 100 Hz)

Spectrum analyzer drive (low and middle frequency) signal input from the spectrum

analyzer band-pass filter (IC401) (for 400 Hz)

Spectrum analyzer drive (middle and high frequency) signal input from the spectrum

analyzer band-pass filter (IC401) (for 2 kHz)

Spectrum analyzer drive (high frequency) signal input from the spectrum analyzer band-

pass filter (IC401) (for 6 kHz)

Key input terminal (A/D input)

S615 to S617, S619 to S622 (TUNER BAND, STEREO/MONO, TUNER MEMORY,

GROOVE, + M, – m) keys input

Key input terminal (A/D input)

S601 to S614 (I/1, DISPLAY, POWER SAVE/DEMO (STANDBY), VIDEO/DVD, MD,

TAPE, CD, TUNER, DSB, DBFB, PLAY MODE, REPEAT, EDIT, FILE SELECT) keys

input

Descriptions

* Abbreviation

G : German model

AED : North European model

21

Page 22

SECTION 5

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

• Abbreviation

MY : Malaysia model

SP : Singapore model

G : German model

AED : North European model

5-1. GENERAL SECTION

2

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list is given in the last of

the electrical parts list.

M401

#1

#1

6

#1

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

#1

#1

1

Front panel assy

#4

#1

#1

#1

4

1

3

5

Ref. No. Part No. Description Remark

1 3-363-099-11 SCREW(CASE 3 TP2)

2 4-221-365-11 CASE

3 X-4952-909-1 PANEL ASSY, BACK(MY,SP)

3 X-4952-910-1 PANEL ASSY, BACK(AEP,UK,G,AED,CIS)

4 1-751-688-11 WIRE(FLAT TYPE) (13 CORE)(MY,SP)

22

Ref. No. Part No. Description Remark

4 1-773-011-11 WIRE(FLAT TYPE) (15 CORE)

(AEP,UK,G,AED,CIS)

5 4-965-822-01 FOOT

6 1-693-482-11 TUNER(FM/AM)(MY,SP)

6 1-693-490-11 TUNER(FM/AM)(AEP,UK,G,AED,CIS)

M401 1-763-478-11 FAN, DC

Page 23

5-2. FRONT PANEL SECTION

57

55

53

58

not

supplied

56

LCD601

60

#1

59

57

61

57

66

65

57

62

57

63

54

supplied

with S652

52

supplied

with S651

51

Ref. No. Part No. Description Remark

51 X-4951-814-2 KNOB(VOL) ASSY

52 X-4951-831-2 KNOB(JOG) ASSY

53 X-4952-907-1 PANEL ASSY, FRONT(AEP,UK,G,AED,CIS)

53 X-4952-908-1 PANEL ASSY, FRONT(MY,SP)

54 4-221-378-01 RING

55 4-221-380-31 PANEL (ST)(AEP,UK,G,AED,CIS)

55 4-221-380-61 PANEL (ST)(MY,SP)

56 X-4952-249-1 WINDOW (STR) ASSY

57 4-951-620-01 SCREW (2.6X8), +BVTP

58 4-221-377-21 PLATE (TA-HL), ORNAMENTAL

59 4-221-370-01 SHEET, DIFFUSION

67

64

not

supplied

Ref. No. Part No. Description Remark

60 4-221-369-01 HOLDER (LCD)

61 1-674-798-11 BACKLIGHT BOARD

62 1-769-908-11 WIRE(FLAT TYPE) (9 CORE)

63 1-675-197-11 R BOARD

64 1-773-213-11 WIRE(FLAT TYPE) (25 CORE)

65 A-4473-303-A PANEL BOARD, COMPLETE

(AEP,UK,G,AED,CIS)

65 A-4473-312-A PANEL BOARD, COMPLETE(MY,SP)

66 1-568-441-11 SOCKET, CONNECTOR 9P

67 1-769-885-11 WIRE(FLAT TYPE) (7 CORE)

LCD601 1-803-738-11 DISPLAY PANEL, LIQUID CRYSTAL

23

Page 24

5-3. CHASSIS SECTION

109

101

T951

AEP, UK, G, AED, CIS

108

not supplied

#5

#3

#5

#3

not

supplied

not supplied

104

B

AEP, UK, MY, SP

#5

not supplied

107

107

102

#2

106

105

B

#5

#1

UKMY, SP

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

101 1-674-803-11 TRANS BOARD

102 A-4473-309-A PA BOARD, COMPLETE(AEP,UK,G,AED,CIS)

102 A-4473-318-A PA BOARD, COMPLETE(MY,SP)

0 104 1-777-071-51 CORD, POWER(MY,SP)

0 104 1-777-071-61 CORD, POWER(AEP,UK,G,AED,CIS)

* 105 3-703-244-00 BUSHING (2104), CORD

106 A-4473-305-A MAIN BOARD, COMPLETE(AEP,UK,G,AED,CIS)

24

Ref. No. Part No. Description Remark

106 A-4473-314-A MAIN BOARD, COMPLETE(MY,SP)

0 107 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P(UK)

0 107 1-569-008-21 ADAPTOR, CONVERSION(MY,SP)

108 1-674-801-11 SUBTRANS BOARD(AEP,UK,G,AED,CIS)

109 4-900-386-01 SCREW

0 T951 1-435-566-11 TRANSFORMER, POWER(AEP,UK,G,AED,CIS)

0 T951 1-435-567-11 TRANSFORMER, POWER(MY,SP)

Page 25

SECTION 6

ELECTRICAL PARTS LIST

BACK LIGHT MAIN

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

• Abbreviation

MY : Malaysia model

SP : Singapore model

G : German model

AED : North European model

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1-674-798-11 BACK LIGHT BOARD

*****************

< CONNECTOR >

CN605 1-785-329-11 PIN, CONNECTOR (LIGHT ANGLE)3P

< DIODE >

D639 8-719-076-15 DIODE SELS6B14C-TP6 (LCD BACK LIGHT)

D640 8-719-076-15 DIODE SELS6B14C-TP6 (LCD BACK LIGHT)

D641 8-719-076-15 DIODE SELS6B14C-TP6 (LCD BACK LIGHT)

D642 8-719-076-15 DIODE SELS6B14C-TP6 (LCD BACK LIGHT)

< TRANSISTOR >

Q639 8-729-900-36 TRANSISTOR BA1F4M-TP

Q640 8-729-900-36 TRANSISTOR BA1F4M-TP

< RESISTOR >

R639 1-249-403-11 CARBON 68 5% 1/4W F

R640 1-249-403-11 CARBON 68 5% 1/4W F

R670 1-247-807-31 CARBON 100 5% 1/4W

**************************************************************

A-4473-305-A MAIN BOARD, COMPLETE (AEP,UK,G,AED,CIS)

*********************

A-4473-314-A MAIN BOARD, COMPLETE (MY,SP)

*********************

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

< CAPACITOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

C119 1-137-368-11 MYLAR 0.0047uF 5.00% 50V

C120 1-137-367-11 MYLAR 0.0033uF 5.00% 50V

C121 1-126-964-11 ELECT 10uF 20.00% 50V

C122 1-162-291-31 CERAMIC 560PF 10.00% 50V

C123 1-136-169-00 FILM 0.22uF 5.00% 50V

C124 1-136-169-00 FILM 0.22uF 5.00% 50V

C125 1-126-964-11 ELECT 10uF 20.00% 50V

C127 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C128 1-136-495-11 FILM 0.068uF 5.00% 50V

C131 1-104-664-11 ELECT 47uF 20.00% 16V

C132 1-104-664-11 ELECT 47uF 20.00% 16V

C134 1-126-964-11 ELECT 10uF 20.00% 50V

C141 1-126-959-11 ELECT 0.47uF 20.00% 50V

C151 1-162-286-31 CERAMIC 220PF 10% 50V

C152 1-162-286-31 CERAMIC 220PF 10% 50V

C153 1-162-286-31 CERAMIC 220PF 10% 50V

C161 1-137-195-11 FILM 0.56uF 5.00% 50V

C162 1-136-158-00 FILM 0.027uF 5.00% 50V

C163 1-136-167-00 FILM 0.15uF 5.00% 50V

C164 1-137-437-11 MYLAR 0.0056uF 5.00% 50V

C165 1-136-159-00 FILM 0.033uF 5.00% 50V

C166 1-137-365-11 MYLAR 0.0015uF 5.00% 50V

C167 1-136-153-00 FILM 0.01uF 5% 50V

C168 1-162-288-31 CERAMIC 330PF 10% 50V

C169 1-137-368-11 MYLAR 0.0047uF 5.00% 50V

C170 1-137-367-11 MYLAR 0.0033uF 5.00% 50V

C171 1-126-964-11 ELECT 10uF 20.00% 50V

C172 1-162-291-31 CERAMIC 560PF 10.00% 50V

C173 1-136-169-00 FILM 0.22uF 5.00% 50V

C174 1-136-169-00 FILM 0.22uF 5.00% 50V

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

C101 1-162-286-31 CERAMIC 220PF 10% 50V

C102 1-162-286-31 CERAMIC 220PF 10% 50V

C103 1-162-286-31 CERAMIC 220PF 10% 50V

C104 1-164-159-11 CERAMIC 0.1uF 50V

C105 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,AED,CIS)

C111 1-137-195-11 FILM 0.56uF 5.00% 50V

C112 1-136-158-00 FILM 0.027uF 5.00% 50V

C113 1-136-167-00 FILM 0.15uF 5.00% 50V

C114 1-137-437-11 MYLAR 0.0056uF 5.00% 50V

C115 1-136-159-00 FILM 0.033uF 5.00% 50V

C116 1-137-365-11 MYLAR 0.0015uF 5.00% 50V

C117 1-136-153-00 FILM 0.01uF 5% 50V

C118 1-162-288-31 CERAMIC 330PF 10% 50V

C175 1-126-964-11 ELECT 10uF 20.00% 50V

C191 1-162-286-31 CERAMIC 220PF 10% 50V

C280 1-126-964-11 ELECT 10uF 20.00% 50V

C420 1-110-518-91 ELECT 10uF 20.00% 100V

C421 1-107-717-11 ELECT 47uF 20.00% 50V

C431 1-164-159-11 CERAMIC 0.1uF 50V

C432 1-126-963-11 ELECT 4.7uF 20.00% 50V

C437 1-126-964-11 ELECT 10uF 20.00% 50V

C438 1-162-303-11 CERAMIC 0.0033uF 30.00% 16V

C439 1-126-964-11 ELECT 10uF 20.00% 50V

C440 1-126-964-11 ELECT 10uF 20.00% 50V

C441 1-126-963-11 ELECT 4.7uF 20.00% 50V

C470 1-110-518-91 ELECT 10uF 20.00% 100V

C501 1-126-964-11 ELECT 10uF 20.00% 50V

25

Page 26

MAIN

Ref. No. Part No. Description Remark

C502 1-164-159-11 CERAMIC 0.1uF 50V

C503 1-136-165-00 FILM 0.1uF 5.00% 50V

C505 1-126-916-11 ELECT 1000uF 20.00% 6.3V

C506 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C507 1-107-713-11 ELECT 4.7uF 20.00% 35V

C511 1-162-205-31 CERAMIC 18PF 5% 50V

C512 1-162-203-31 CERAMIC 15PF 5.00% 50V

C513 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C514 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C515 1-104-665-11 ELECT 100uF 20.00% 10V

C521 1-104-665-11 ELECT 100uF 20.00% 10V

C522 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C523 1-126-961-11 ELECT 2.2uF 20.00% 50V

(AEP,UK,G,AED,CIS)

C523 1-126-964-11 ELECT 10uF 20.00% 50V

(MY,SP)

C901 1-136-165-00 FILM 0.1uF 5.00% 50V

C902 1-126-936-11 ELECT 3300uF 20.00% 16V

C903 1-126-934-11 ELECT 220uF 20.00% 16V

C904 1-126-924-11 ELECT 330uF 20.00% 10V

C905 1-104-664-11 ELECT 47uF 20.00% 16V

C908 1-126-964-11 ELECT 10uF 20.00% 50V

C909 1-126-916-11 ELECT 1000uF 20.00% 6.3V

C920 1-126-767-11 ELECT 1000uF 20.00% 16V

C921 1-126-941-11 ELECT 470uF 20.00% 25V

C922 1-126-952-11 ELECT 1000uF 20.00% 35V

C923 1-164-159-11 CERAMIC 0.1uF 50V

C924 1-126-786-11 ELECT 47uF 20.00% 16V

C926 1-126-916-11 ELECT 1000uF 20.00% 6.3V

C927 1-126-933-11 ELECT 100uF 20.00% 16V

C931 1-126-961-11 ELECT 2.2uF 20.00% 50V

C941 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,AED,CIS)

Ref. No. Part No. Description Remark

D508 8-719-911-19 DIODE 1SS133T-72

D510 8-719-911-19 DIODE 1SS133T-72 (AEP,UK,G,AED,CIS)

D901 8-719-024-99 DIODE 11ES2-NTA2B

D902 8-719-024-99 DIODE 11ES2-NTA2B

D903 8-719-024-99 DIODE 11ES2-NTA2B

D904 8-719-024-99 DIODE 11ES2-NTA2B

D905 8-719-911-19 DIODE 1SS133T-72

D906 8-719-921-48 DIODE MTZJ-T-72-5.6C

D914 8-719-911-19 DIODE 1SS133T-72 (MY,SP)

D915 8-719-024-99 DIODE 11ES2-NTA2B (MY,SP)

D920 8-719-024-99 DIODE 11ES2-NTA2B

D921 8-719-110-23 DIODE MTZJ-T-72-11C

D925 8-719-024-99 DIODE 11ES2-NTA2B

D931 8-719-911-19 DIODE 1SS133T-72

D932 8-719-911-19 DIODE 1SS133T-72

< EARTH TERMINAL >

* EP901 1-537-738-21 TERMINAL, EARTH

* EP902 1-537-738-21 TERMINAL, EARTH

< IC >

IC101 8-759-571-54 IC M62493FP

IC401 8-759-083-77 IC BA3830F

IC501 8-759-668-66 IC M30622MAA-A39FP

IC502 8-759-635-63 IC M51943BSL-TP

IC901 8-759-231-53 IC M5F7805L

IC921 8-759-231-58 IC M5F7812L

< JACK >

J101 1-784-275-11 JACK, PIN 6P (VIDEO (AUDIO) IN/MD IN/MD

OUT)

J191 1-774-785-11 JACK, PIN 1P (SUPER WOOFER OUT)

C951 1-136-165-00 FILM 0.1uF 5.00% 50V

C952 1-126-768-11 ELECT 2200uF 20.00% 16V

C953 1-126-934-11 ELECT 220uF 20.00% 16V

C954 1-126-924-11 ELECT 330uF 20.00% 10V

< CONNECTOR >

CN101 1-793-351-11 SOCKET, CONNECTOR 19P

* CN111 1-564-506-11 PLUG, CONNECTOR 3P

CN121 1-784-774-11 CONNECTOR, FFC 13P(MY,SP)

CN121 1-784-776-11 CONNECTOR, FFC 15P(AEP,UK,G,AED,CIS)

CN131 1-784-786-11 CONNECTOR, FFC 25P

CN132 1-568-826-11 CONNECTOR, FFC 7P

CN141 1-506-468-11 PIN, CONNECTOR 3P(AEP,UK,G,AED,CIS)

CN152 1-778-982-21 CONNECTOR, BOARD TO BOARD 13P

* CN173 1-564-506-11 PLUG, CONNECTOR 3P

* CN181 1-564-506-11 PLUG, CONNECTOR 3P

< DIODE >

D141 8-719-911-19 DIODE 1SS133T-72

D501 8-719-911-19 DIODE 1SS133T-72

D502 8-719-911-19 DIODE 1SS133T-72

D503 8-719-911-19 DIODE 1SS133T-72

D504 8-719-911-19 DIODE 1SS133T-72

D505 8-719-911-19 DIODE 1SS133T-72

D506 8-719-911-19 DIODE 1SS133T-72

D507 8-719-911-19 DIODE 1SS133T-72

< COIL >

L436 1-410-517-11 INDUCTOR 47uH

L501 1-410-509-11 INDUCTOR 10uH

< TRANSISTOR >

Q112 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q113 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q114 8-729-141-30 TRANSISTOR 2SC3623ATP-LK

Q162 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q163 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q164 8-729-141-30 TRANSISTOR 2SC3623ATP-LK

Q191 8-729-141-30 TRANSISTOR 2SC3623ATP-LK

Q411 8-729-141-30 TRANSISTOR 2SC3623ATP-LK

Q421 8-729-900-63 TRANSISTOR BN1F4M-TP

Q431 8-729-111-29 TRANSISTOR 2SD1616-TP-LK

Q432 8-729-119-76 TRANSISTOR 2SA1175TP-HFE

Q461 8-729-141-30 TRANSISTOR 2SC3623ATP-LK

Q501 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q502 8-729-900-63 TRANSISTOR BN1F4M-TP

Q503 8-729-900-63 TRANSISTOR BN1F4M-TP

Q901 8-729-018-60 TRANSISTOR 2SD2012-LC

Q902 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q903 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q904 8-729-900-36 TRANSISTOR BA1F4M-TP

Q905 8-729-900-36 TRANSISTOR BA1F4M-TP

26

Page 27

MAIN

Ref. No. Part No. Description Remark

Q906 8-729-040-20 TRANSISTOR RT1P137L-TP

Q907 8-729-900-36 TRANSISTOR BA1F4M-TP

Q921 8-729-026-68 TRANSISTOR 2SD2525(TP)

Q926 8-729-040-20 TRANSISTOR RT1P137L-TP

(AEP,UK,G,AED,CIS)

Q927 8-729-900-36 TRANSISTOR BA1F4M-TP(AEP,UK,G,AED,CIS)

Q951 8-729-018-59 TRANSISTOR 2SB1375(LB-SONY)

Q952 8-729-119-76 TRANSISTOR 2SA1175TP-HFE

Q953 8-729-119-76 TRANSISTOR 2SA1175TP-HFE

< RESISTOR >

R101 1-249-417-11 CARBON 1K 5% 1/4W F

R102 1-249-417-11 CARBON 1K 5% 1/4W F

R103 1-249-417-11 CARBON 1K 5% 1/4W F

R105 1-247-807-31 CARBON 100 5% 1/4W

R106 1-247-807-31 CARBON 100 5% 1/4W

R111 1-249-421-11 CARBON 2.2K 5% 1/4W F

R112 1-249-429-11 CARBON 10K 5% 1/4W

R114 1-247-895-00 CARBON 470K 5% 1/4W

R115 1-247-899-11 CARBON 680K 5% 1/4W

R117 1-249-414-11 CARBON 560 5% 1/4W F

R118 1-249-429-11 CARBON 10K 5% 1/4W

R119 1-249-438-11 CARBON 56K 5% 1/4W

R120 1-249-429-11 CARBON 10K 5% 1/4W

R121 1-249-437-11 CARBON 47K 5% 1/4W

R122 1-249-421-11 CARBON 2.2K 5% 1/4W F

Ref. No. Part No. Description Remark

R193 1-249-417-11 CARBON 1K 5% 1/4W F

R194 1-249-429-11 CARBON 10K 5% 1/4W

R411 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R411 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R412 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R412 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R413 1-260-084-11 CARBON 56 5% 1/2W

R414 1-249-417-11 CARBON 1K 5% 1/4W F

R415 1-249-429-11 CARBON 10K 5% 1/4W

R416 1-249-437-11 CARBON 47K 5% 1/4W

R417 1-249-417-11 CARBON 1K 5% 1/4W F

R418 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R418 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R431 1-249-421-11 CARBON 2.2K 5% 1/4W F

R432 1-249-425-11 CARBON 4.7K 5% 1/4W F

R433 1-249-441-11 CARBON 100K 5% 1/4W

R436 1-247-893-11 CARBON 390K 5% 1/4W

R437 1-247-893-11 CARBON 390K 5% 1/4W

R438 1-249-441-11 CARBON 100K 5% 1/4W

R440 1-249-437-11 CARBON 47K 5% 1/4W

R441 1-249-441-11 CARBON 100K 5% 1/4W

R123 1-249-441-11 CARBON 100K 5% 1/4W

R124 1-249-425-11 CARBON 4.7K 5% 1/4W

R126 1-249-421-11 CARBON 2.2K 5% 1/4W F

R128 1-247-903-00 CARBON 1M 5% 1/4W

R131 1-247-807-31 CARBON 100 5% 1/4W

R132 1-247-807-31 CARBON 100 5% 1/4W

R133 1-247-807-31 CARBON 100 5% 1/4W

R141 1-249-433-11 CARBON 22K 5% 1/4W

R142 1-249-433-11 CARBON 22K 5% 1/4W

R143 1-249-417-11 CARBON 1K 5% 1/4W F

R144 1-249-441-11 CARBON 100K 5% 1/4W

R145 1-247-903-00 CARBON 1M 5% 1/4W

R151 1-249-417-11 CARBON 1K 5% 1/4W F

R152 1-249-417-11 CARBON 1K 5% 1/4W F

R153 1-249-417-11 CARBON 1K 5% 1/4W F

R155 1-247-807-31 CARBON 100 5% 1/4W

R156 1-247-807-31 CARBON 100 5% 1/4W

R161 1-249-421-11 CARBON 2.2K 5% 1/4W F

R162 1-249-429-11 CARBON 10K 5% 1/4W

R164 1-247-895-00 CARBON 470K 5% 1/4W

R165 1-247-899-11 CARBON 680K 5% 1/4W

R167 1-249-414-11 CARBON 560 5% 1/4W F

R168 1-249-429-11 CARBON 10K 5% 1/4W

R169 1-249-438-11 CARBON 56K 5% 1/4W

R170 1-249-429-11 CARBON 10K 5% 1/4W

R442 1-249-440-11 CARBON 82K 5% 1/4W

R443 1-249-420-11 CARBON 1.8K 5% 1/4W F

R444 1-249-429-11 CARBON 10K 5% 1/4W

R447 1-249-435-11 CARBON 33K 5% 1/4W

R448 1-247-895-00 CARBON 470K 5% 1/4W

R461 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R461 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R462 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R462 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R463 1-260-084-11 CARBON 56 5% 1/2W

R464 1-249-417-11 CARBON 1K 5% 1/4W F

R468 1-260-089-11 CARBON 150 5% 1/2W

(AEP,UK,G,AED,CIS)

R468 1-260-319-51 CARBON 180 5% 1/2W

(MY,SP)

R501 1-249-413-11 CARBON 470 5% 1/4W F

R502 1-249-425-11 CARBON 4.7K 5% 1/4W F

R503 1-249-437-11 CARBON 47K 5% 1/4W

R504 1-249-437-11 CARBON 47K 5% 1/4W

R505 1-249-429-11 CARBON 10K 5% 1/4W

R506 1-249-409-11 CARBON 220 5% 1/4W F

R507 1-249-441-11 CARBON 100K 5% 1/4W

R171 1-249-437-11 CARBON 47K 5% 1/4W

R172 1-249-421-11 CARBON 2.2K 5% 1/4W F

R173 1-249-441-11 CARBON 100K 5% 1/4W

R174 1-249-425-11 CARBON 4.7K 5% 1/4W

R178 1-247-903-00 CARBON 1M 5% 1/4W

R191 1-249-417-11 CARBON 1K 5% 1/4W F

R192 1-249-441-11 CARBON 100K 5% 1/4W

R510 1-249-429-11 CARBON 10K 5% 1/4W

R511 1-247-891-00 CARBON 330K 5% 1/4W

R513 1-249-429-11 CARBON 10K 5% 1/4W

R514 1-247-807-31 CARBON 100 5% 1/4W

R515 1-249-425-11 CARBON 4.7K 5% 1/4W F

R516 1-249-429-11 CARBON 10K 5% 1/4W

R517 1-247-807-31 CARBON 100 5% 1/4W

27

Page 28

MAIN PA

Ref. No. Part No. Description Remark

R518 1-249-425-11 CARBON 4.7K 5% 1/4W F

R519 1-249-425-11 CARBON 4.7K 5% 1/4W F

R520 1-247-807-31 CARBON 100 5% 1/4W

R521 1-247-807-31 CARBON 100 5% 1/4W

R527 1-247-807-31 CARBON 100 5% 1/4W

R528 1-247-807-31 CARBON 100 5% 1/4W

R530 1-247-807-31 CARBON 100 5% 1/4W

R531 1-247-807-31 CARBON 100 5% 1/4W

R532 1-249-429-11 CARBON 10K 5% 1/4W

R534 1-247-807-31 CARBON 100 5% 1/4W

(AEP,UK,G,AED,CIS)

R535 1-249-429-11 CARBON 10K 5% 1/4W

R536 1-249-417-11 CARBON 1K 5% 1/4W F

R537 1-249-429-11 CARBON 10K 5% 1/4W

R538 1-247-807-31 CARBON 100 5% 1/4W

R539 1-247-843-11 CARBON 3.3K 5% 1/4W

R543 1-249-429-11 CARBON 10K 5% 1/4W

R544 1-249-429-11 CARBON 10K 5% 1/4W

R546 1-247-807-31 CARBON 100 5% 1/4W

R547 1-247-807-31 CARBON 100 5% 1/4W

R548 1-247-807-31 CARBON 100 5% 1/4W

R549 1-247-807-31 CARBON 100 5% 1/4W

R550 1-247-807-31 CARBON 100 5% 1/4W

R551 1-247-807-31 CARBON 100 5% 1/4W

R552 1-249-429-11 CARBON 10K 5% 1/4W

R553 1-247-807-31 CARBON 100 5% 1/4W

Ref. No. Part No. Description Remark

R588 1-247-807-31 CARBON 100 5% 1/4W

(AEP,UK,G,AED,CIS)

R589 1-247-807-31 CARBON 100 5% 1/4W

(AEP,UK,G,AED,CIS)

R901 1-247-843-11 CARBON 3.3K 5% 1/4W

R902 1-249-415-11 CARBON 680 5% 1/4W F

R903 1-249-383-11 CARBON 1.5 5% 1/6W F

R905 1-249-419-11 CARBON 1.5K 5% 1/4W F

R906 1-249-414-11 CARBON 560 5% 1/4W F

R907 1-249-425-11 CARBON 4.7K 5% 1/4W F

R908 1-249-429-11 CARBON 10K 5% 1/4W

R909 1-249-430-11 CARBON 12K 5% 1/4W

R910 1-249-429-11 CARBON 10K 5% 1/4W

R920 1-249-417-11 CARBON 1K 5% 1/4W F

R921 1-249-409-11 CARBON 220 5% 1/4W F

R931 1-249-425-11 CARBON 4.7K 5% 1/4W F

R932 1-249-425-11 CARBON 4.7K 5% 1/4W F

R933 1-249-433-11 CARBON 22K 5% 1/4W

R951 1-247-843-11 CARBON 3.3K 5% 1/4W

R952 1-249-415-11 CARBON 680 5% 1/4W F

R953 1-249-383-11 CARBON 1.5 5% 1/6W F

< VIBRATOR >

X511 1-567-098-41 VIBRATOR, CRYSTAL (32.768kHz)

X512 1-781-107-21 VIBRATOR, SERAMIC (16MHz)

**************************************************************

R554 1-247-807-31 CARBON 100 5% 1/4W

R555 1-247-807-31 CARBON 100 5% 1/4W

R556 1-247-807-31 CARBON 100 5% 1/4W

R557 1-247-807-31 CARBON 100 5% 1/4W

R558 1-247-807-31 CARBON 100 5% 1/4W

R559 1-247-807-31 CARBON 100 5% 1/4W

R560 1-249-429-11 CARBON 10K 5% 1/4W

R561 1-247-807-31 CARBON 100 5% 1/4W

R562 1-247-807-31 CARBON 100 5% 1/4W

R563 1-247-807-31 CARBON 100 5% 1/4W

R566 1-247-807-31 CARBON 100 5% 1/4W

R567 1-247-807-31 CARBON 100 5% 1/4W

R568 1-247-807-31 CARBON 100 5% 1/4W

R570 1-247-807-31 CARBON 100 5% 1/4W

R571 1-247-807-31 CARBON 100 5% 1/4W

R572 1-247-807-31 CARBON 100 5% 1/4W

R573 1-247-807-31 CARBON 100 5% 1/4W

R574 1-249-429-11 CARBON 10K 5% 1/4W

R575 1-249-429-11 CARBON 10K 5% 1/4W

R581 1-249-425-11 CARBON 4.7K 5% 1/4W F

R582 1-249-419-11 CARBON 1.5K 5% 1/4W F

R583 1-249-415-11 CARBON 680 5% 1/4W F

(AEP,UK,G,AED,CIS)

R583 1-249-425-11 CARBON 4.7K 5% 1/4W F

(MY,SP)

R584 1-249-411-11 CARBON 330 5% 1/4W

(MY,SP)

R584 1-249-425-11 CARBON 4.7K 5% 1/4W F

(AEP,UK,G,AED,CIS)

R585 1-247-807-31 CARBON 100 5% 1/4W

R586 1-247-807-31 CARBON 100 5% 1/4W

R587 1-247-807-31 CARBON 100 5% 1/4W

A-4473-309-A PA BOARD, COMPLETE (AEP,UK,G,AED,CIS)

*******************

A-4473-318-A PA BOARD, COMPLETE (MY,SP)

*******************

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

< CAPACITOR >

C801 1-128-582-11 ELECT 10uF 20.00% 100V

C802 1-162-292-31 CERAMIC 680PF 10% 50V

C803 1-162-286-31 CERAMIC 220PF 10% 50V

C804 1-126-967-11 ELECT 47uF 20.00% 50V

C806 1-128-560-11 ELECT 22uF 20.00% 100V

C807 1-128-582-11 ELECT 10uF 20.00% 100V

C808 1-136-495-11 FILM 0.068uF 5.00% 50V

C809 1-136-495-11 FILM 0.068uF 5.00% 50V

C810 1-136-165-00 FILM 0.1uF 5.00% 50V

(AEP,UK,G,AED,CIS)

C811 1-136-165-00 FILM 0.1uF 5.00% 50V

(AEP,UK,G,AED,CIS)

C812 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,AED,CIS)

C821 1-128-562-11 ELECT 47uF 20.00% 100V

C822 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C823 1-162-294-31 CERAMIC 0.001uF 10% 50V

C825 1-104-665-11 ELECT 100uF 20.00% 10V

C826 1-126-961-11 ELECT 2.2uF 20.00% 50V

C827 1-104-665-11 ELECT 100uF 20.00% 10V

C831 1-126-968-11 ELECT 100uF 20.00% 50V

C851 1-128-582-11 ELECT 10uF 20.00% 100V

C852 1-162-292-31 CERAMIC 680PF 10% 50V

C853 1-162-286-31 CERAMIC 220PF 10% 50V

28

Page 29

PA

Ref. No. Part No. Description Remark

C854 1-126-967-11 ELECT 47uF 20.00% 50V

C856 1-128-560-11 ELECT 22uF 20.00% 100V

C857 1-128-582-11 ELECT 10uF 20.00% 100V

C858 1-136-495-11 FILM 0.068uF 5.00% 50V

C859 1-136-495-11 FILM 0.068uF 5.00% 50V

C860 1-136-165-00 FILM 0.1uF 5.00% 50V

(AEP,UK,G,AED,CIS)

C861 1-136-165-00 FILM 0.1uF 5.00% 50V

(AEP,UK,G,AED,CIS)

C862 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,AED,CIS)

C880 1-126-163-11 ELECT 4.7uF 20% 50V

C883 1-127-752-11 ELECT 3300uF 20% 63V

(AEP,UK,G,AED,CIS)

C883 1-127-813-11 ELECT 3300uF 20% 71V

(MY,SP)

C884 1-127-752-11 ELECT 3300uF 20% 63V

(AEP,UK,G,AED,CIS)

C884 1-127-813-11 ELECT 3300uF 20% 71V

(MY,SP)

C887 1-130-777-00 MYLAR 0.1uF 10.00% 100V

C888 1-130-777-00 MYLAR 0.1uF 10.00% 100V

C889 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

< CONNECTOR >

CN802 1-778-981-21 CONNECTOR, BOARD TO BOARD 13P

CN808 1-691-766-11 PLUG (MICRO CONNECTOR) 4P

< DIODE >

D802 8-719-911-19 DIODE 1SS133T-72

D821 8-719-911-19 DIODE 1SS133T-72

D831 8-719-911-19 DIODE 1SS133T-72

D852 8-719-911-19 DIODE 1SS133T-72

D871 8-719-911-19 DIODE 1SS133T-72

D881 8-719-510-68 DIODE D5SBA204101

D883 8-719-911-19 DIODE 1SS133T-72

< EARTH TERMINAL >

* EP802 1-537-738-21 TERMINAL, EARTH

* EP803 1-537-738-21 TERMINAL, EARTH (AEP,UK,G,AED,CIS)

< IC >

Ref. No. Part No. Description Remark

Q829 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q830 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q831 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q851 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q881 8-729-140-82 TRANSISTOR 2SA988TP-PAFAEA

Q882 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

< RESISTOR >

R801 1-249-417-11 CARBON 1K 5% 1/4W F

R802 1-249-438-11 CARBON 56K 5% 1/4W

R803 1-249-414-11 CARBON 560 5% 1/4W F

R804 1-249-438-11 CARBON 56K 5% 1/4W

0 R805 1-212-881-11 FUSIBLE 100 5% 1/4W

0 R807 1-217-156-00 METAL 0.22 10% 5W

R808 1-249-417-11 CARBON 1K 5% 1/4W F

R809 1-249-431-11 CARBON 15K 5% 1/4W

R810 1-249-441-11 CARBON 100K 5% 1/4W

R811 1-260-076-11 CARBON 10 5% 1/2W

R812 1-260-076-11 CARBON 10 5% 1/2W

(AEP,UK,G,AED,CIS)

R813 1-260-076-11 CARBON 10 5% 1/2W

(AEP,UK,G,AED,CIS)

R814 1-249-437-11 CARBON 47K 5% 1/4W

R821 1-249-435-11 CARBON 33K 5% 1/4W

R822 1-249-435-11 CARBON 33K 5% 1/4W

R823 1-249-439-11 CARBON 68K 5% 1/4W

R824 1-249-421-11 CARBON 2.2K 5% 1/4W F

R825 1-249-433-11 CARBON 22K 5% 1/4W

R826 1-249-429-11 CARBON 10K 5% 1/4W

R827 1-249-433-11 CARBON 22K 5% 1/4W

0 R828 1-202-972-61 FUSIBLE 1 5% 1/4W

R829 1-249-441-11 CARBON 100K 5% 1/4W

R830 1-249-441-11 CARBON 100K 5% 1/4W

R831 1-249-429-11 CARBON 10K 5% 1/4W

(AEP,UK,G,AED,CIS)

R831 1-249-430-11 CARBON 12K 5% 1/4W

(MY,SP)

R832 1-249-431-11 CARBON 15K 5% 1/4W

R833 1-249-435-11 CARBON 33K 5% 1/4W

R836 1-249-425-11 CARBON 4.7K 5% 1/4W F

R837 1-249-433-11 CARBON 22K 5% 1/4W

R838 1-249-435-11 CARBON 33K 5% 1/4W

IC801 8-749-015-39 IC STK407-120E

< COIL >

L801 1-420-872-00 COIL, AIR-CORE (AEP,UK,G,AED,CIS)

L851 1-420-872-00 COIL, AIR-CORE (AEP,UK,G,AED,CIS)

< TRANSISTOR >

Q801 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q821 8-729-140-82 TRANSISTOR 2SA988TP-PAFAEA

Q822 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q823 8-729-140-84 TRANSISTOR 2SC1841TP-PAFAEA

Q824 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q825 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q826 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q827 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

Q828 8-729-140-82 TRANSISTOR 2SA988TP-PAFAEA

R839 1-249-429-11 CARBON 10K 5% 1/4W

R840 1-249-429-11 CARBON 10K 5% 1/4W

R841 1-249-437-11 CARBON 47K 5% 1/4W

R842 1-249-438-11 CARBON 56K 5% 1/4W

0 R850 1-202-972-61 FUSIBLE 1 5% 1/4W

R851 1-249-417-11 CARBON 1K 5% 1/4W F

R852 1-249-438-11 CARBON 56K 5% 1/4W

R853 1-249-414-11 CARBON 560 5% 1/4W F

R854 1-249-438-11 CARBON 56K 5% 1/4W

0 R855 1-212-881-11 FUSIBLE 100 5% 1/4W

0 R857 1-217-156-00 METAL 0.22 10% 5W

R858 1-249-417-11 CARBON 1K 5% 1/4W F

R859 1-249-431-11 CARBON 15K 5% 1/4W

R860 1-249-441-11 CARBON 100K 5% 1/4W

R861 1-260-076-11 CARBON 10 5% 1/2W

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

29

Page 30

PA PANEL

Ref. No. Part No. Description Remark

R862 1-260-076-11 CARBON 10 5% 1/2W

(AEP,UK,G,AED,CIS)

R863 1-260-076-11 CARBON 10 5% 1/2W

(AEP,UK,G,AED,CIS)

R864 1-249-437-11 CARBON 47K 5% 1/4W

R881 1-249-429-11 CARBON 10K 5% 1/4W

R882 1-249-437-11 CARBON 47K 5% 1/4W

R883 1-249-429-11 CARBON 10K 5% 1/4W

R884 1-249-441-11 CARBON 100K 5% 1/4W

0 R885 1-216-481-11 METAL OXIDE 1.2K 5% 3W

< RELAY >

RY881 1-755-168-11 RELAY

< TERMINAL >

TM801 1-537-240-11 TERMINAL BOARD (CHECKER PIN)

TM802 1-537-240-11 TERMINAL BOARD (CHECKER PIN)

**************************************************************

A-4473-303-A PANEL BOARD, COMPLETE

(AEP,UK,G,AED,CIS)

**********************

A-4473-312-A PANEL BOARD, COMPLETE (MY,SP)

**********************

Ref. No. Part No. Description Remark

D647 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

D648 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

< EARTH TERMINAL >

* EPT601 1-537-738-21 TERMINAL, EARTH

* EPT602 1-537-738-21 TERMINAL, EARTH

< JACK >

J701 1-785-569-11 JACK (SMALL TYPE) (PHONES)

< COIL >

L601 1-410-509-11 INDUCTOR 10uH

< TRANSISTOR >

Q631 8-729-900-36 TRANSISTOR BA1F4M-TP

Q636 8-729-900-36 TRANSISTOR BA1F4M-TP

Q637 8-729-900-36 TRANSISTOR BA1F4M-TP (AEP,UK,G,AED,CIS)

Q638 8-729-900-36 TRANSISTOR BA1F4M-TP

Q641 8-729-900-36 TRANSISTOR BA1F4M-TP

Q642 8-729-900-36 TRANSISTOR BA1F4M-TP

Q643 8-729-900-36 TRANSISTOR BA1F4M-TP

< RESISTOR >

< CAPACITOR >

C601 1-164-159-11 CERAMIC 0.1uF 50V

C651 1-164-159-11 CERAMIC 0.1uF 50V

C652 1-104-664-11 ELECT 47uF 20.00% 16V

C653 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C654 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C655 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C656 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C657 1-104-664-11 ELECT 47uF 20.00% 16V

C658 1-104-664-11 ELECT 47uF 20.00% 16V

C659 1-104-664-11 ELECT 47uF 20.00% 16V

C660 1-164-159-11 CERAMIC 0.1uF 50V

C701 1-162-294-31 CERAMIC 0.001uF 10% 50V

C702 1-162-294-31 CERAMIC 0.001uF 10% 50V

C703 1-164-159-11 CERAMIC 0.1uF 50V

C741 1-164-159-11 CERAMIC 0.1uF 50V

< CONNECTOR >

CN601 1-784-731-11 CONNECTOR, FFC 9P

CN602 1-784-747-11 CONNECTOR, FFC 25P

CN603 1-568-850-11 CONNECTOR, FFC 7P

* CN606 1-560-666-00 PIN, CONNECTOR 3P

CN608 1-564-718-11 PIN, CONNECTOR (SMALL TYPE) 2P

< DIODE >

D631 8-719-076-21 DIODE SEL5255S-TP15 (GROOVE)

D636 8-719-076-21 DIODE SEL5255S-TP15 (ENTER)

D637 8-719-076-21 DIODE SEL5255S-TP15 (TIMER)

(AEP,UK,G,AED,CIS)

D638 8-719-076-21 DIODE SEL5255S-TP15 (`/1)

D643 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

R602 1-249-411-11 CARBON 330 5% 1/4W

R603 1-249-413-11 CARBON 470 5% 1/4W F

R604 1-249-414-11 CARBON 560 5% 1/4W F

R605 1-249-415-11 CARBON 680 5% 1/4W F

R606 1-249-417-11 CARBON 1K 5% 1/4W F

R607 1-249-418-11 CARBON 1.2K 5% 1/4W F

R608 1-249-420-11 CARBON 1.8K 5% 1/4W F

R609 1-249-422-11 CARBON 2.7K 5% 1/4W F

R610 1-247-843-11 CARBON 3.3K 5% 1/4W

R611 1-249-425-11 CARBON 4.7K 5% 1/4W F

R612 1-249-427-11 CARBON 6.8K 5% 1/4W F

R613 1-249-429-11 CARBON 10K 5% 1/4W

R614 1-249-431-11 CARBON 15K 5% 1/4W

R616 1-249-411-11 CARBON 330 5% 1/4W

R617 1-249-413-11 CARBON 470 5% 1/4W F

R618 1-249-414-11 CARBON 560 5% 1/4W F

R619 1-249-415-11 CARBON 680 5% 1/4W F

R620 1-249-417-11 CARBON 1K 5% 1/4W F

R621 1-249-418-11 CARBON 1.2K 5% 1/4W F

R622 1-249-420-11 CARBON 1.8K 5% 1/4W F

R626 1-249-410-11 CARBON 270 5% 1/4W F

R627 1-249-410-11 CARBON 270 5% 1/4W F

R631 1-249-411-11 CARBON 330 5% 1/4W

R636 1-249-411-11 CARBON 330 5% 1/4W

R637 1-249-411-11 CARBON 330 5% 1/4W

(AEP,UK,G,AED,CIS)

R638 1-249-411-11 CARBON 330 5% 1/4W

R641 1-249-403-11 CARBON 68 5% 1/4W F

R642 1-249-403-11 CARBON 68 5% 1/4W F

R643 1-249-403-11 CARBON 68 5% 1/4W F

R651 1-249-401-11 CARBON 47 5% 1/4W F

D644 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

D645 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

D646 8-719-076-15 DIODE SELS6B14C-TP6 (KEY ILLUMINATION)

30

R652 1-249-429-11 CARBON 10K 5% 1/4W

R653 1-249-429-11 CARBON 10K 5% 1/4W

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Page 31

PANEL R SUB TRANS TRANS

Ref. No. Part No. Description Remark

R654 1-249-429-11 CARBON 10K 5% 1/4W

R655 1-249-429-11 CARBON 10K 5% 1/4W

R656 1-249-417-11 CARBON 1K 5% 1/4W F

R657 1-249-417-11 CARBON 1K 5% 1/4W F

R661 1-247-807-31 CARBON 100 5% 1/4W

R666 1-247-807-31 CARBON 100 5% 1/4W

R667 1-247-807-31 CARBON 100 5% 1/4W

(AEP,UK,G,AED,CIS)

R668 1-247-807-31 CARBON 100 5% 1/4W

R669 1-247-807-31 CARBON 100 5% 1/4W

< SWITCH >

S601 1-762-875-21 SWITCH, KEYBOARD (`/1)

S602 1-762-875-21 SWITCH, KEYBOARD (DISPLAY)

S603 1-762-875-21 SWITCH, KEYBOARD (POWER SAVE/DEMO

(STANDBY))

S604 1-762-875-21 SWITCH, KEYBOARD (VIDEO)

S605 1-762-875-21 SWITCH, KEYBOARD (MD)

S606 1-762-875-21 SWITCH, KEYBOARD (TAPE)

S607 1-762-875-21 SWITCH, KEYBOARD (CD)

S608 1-762-875-21 SWITCH, KEYBOARD (TUNER)

S609 1-762-875-21 SWITCH, KEYBOARD (SURROUND)

S610 1-762-875-21 SWITCH, KEYBOARD (DBFB)

S611 1-762-875-21 SWITCH, KEYBOARD (PLAY MODE)

S612 1-762-875-21 SWITCH, KEYBOARD (REPEAT/PTY)

S613 1-762-875-21 SWITCH, KEYBOARD (CD/TUNER NAME)

S614 1-762-875-21 SWITCH, KEYBOARD (FILE SELECT)

S615 1-762-875-21 SWITCH, KEYBOARD (TUNER BAND)

S616 1-762-875-21 SWITCH, KEYBOARD (STEREO/MONO)

S617 1-762-875-21 SWITCH, KEYBOARD (TUNER MEMORY)

S619 1-762-875-21 SWITCH, KEYBOARD (GROOVE)

S620 1-762-875-21 SWITCH, KEYBOARD (+ M)

S621 1-762-875-21 SWITCH, KEYBOARD (– m)

Ref. No. Part No. Description Remark

0 C991 1-113-925-11 CERAMIC 0.01uF 20.00% 250V

(AEP,UK,G,AED,CIS)

< CONNECTOR >

* CN901 1-580-230-11 PIN, CONNECTOR (PC BOARD) 2P

(AEP,UK,G,AED,CIS)

CN902 1-564-321-00 PIN, CONNECTOR 2P (AEP,UK,G,AED,CIS)

< DIODE >

D952 8-719-024-99 DIODE 11ES2-NTA2B (AEP,UK,G,AED,CIS)

D953 8-719-024-99 DIODE 11ES2-NTA2B (AEP,UK,G,AED,CIS)

D954 8-719-024-99 DIODE 11ES2-NTA2B (AEP,UK,G,AED,CIS)

D955 8-719-024-99 DIODE 11ES2-NTA2B (AEP,UK,G,AED,CIS)

D956 8-719-911-19 DIODE 1SS133T-72 (AEP,UK,G,AED,CIS)

D957 8-719-911-19 DIODE 1SS133T-72 (AEP,UK,G,AED,CIS)

< IC >

IC991 8-759-450-47 IC BA05T (AEP,UK,G,AED,CIS)

< TRANSISTOR >

Q991 8-729-119-78 TRANSISTOR 2SC2785TP-HFE

(AEP,UK,G,AED,CIS)

< RESISTOR >

R991 1-249-441-11 CARBON 100K 5% 1/4W

(AEP,UK,G,AED,CIS)

R992 1-249-429-11 CARBON 10K 5% 1/4W

(AEP,UK,G,AED,CIS)

< RELAY >

0 RY901 1-755-276-11 RELAY, POWER (AEP,UK,G,AED,CIS)

S622 1-762-875-21 SWITCH, KEYBOARD (ENTER)

S651 1-473-392-11 ENCODER, ROTARY (VOLUME)

S652 1-473-534-11 ENCODER, ROTARY (JOG DIAL)

**************************************************************

1-675-197-11 R BOARD

********

< CONNECTOR >

* CN607 1-565-835-11 SOCKET, CONNECTOR 3P

< IC >

IC601 8-749-011-05 IC GP1U28X (REMOTE CONTROL RECIEVER)

**************************************************************

1-674-801-11 SUB TRANS BOARD (AEP,UK,G,AED,CIS)

****************

< CAPACITOR >

C932 1-126-768-11 ELECT 2200uF 20.00% 16V

(AEP,UK,G,AED,CIS)

C933 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,AED,CIS)

C934 1-126-933-11 ELECT 100uF 20.00% 16V

(AEP,UK,G,AED,CIS)

C935 1-126-964-11 ELECT 10uF 20.00% 50V

(AEP,UK,G,AED,CIS)

< TRANSFORMER >

0 T901 1-433-999-11 TRANSFORMER, POWER (AEP,UK,G,AED,CIS)

**************************************************************

1-674-803-11 TRANS BOARD

************

1-533-293-11 FUSE HOLDER

< CAPACITOR >

C951 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C952 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C953 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

< CONNECTOR >

CN951 1-564-321-00 PIN, CONNECTOR 2P (MY,SP)

< FUSE >

0 F951 1-532-505-31 FUSE (TIME LUG) T5AL/250 V(MY,SP)

0 F961 1-533-949-31 FUSE, CYLINDRICAL (TIME LUG) T8AL/250V

0 F962 1-533-949-31 FUSE, CYLINDRICAL (TIME LUG) T8AL/250V

0 F965 1-532-504-31 FUSE (TIME LUG) T4AL/250V

0 F966 1-532-504-31 FUSE (TIME LUG) T4AL/250V

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

31

Page 32

STR-NX5MD

TRANS

Ref. No. Part No. Description Remark

< RESISTOR >

0 R951 1-219-120-11 FUSIBLE 0.15 5% 1/4W

0 R952 1-219-120-11 FUSIBLE 0.15 5% 1/4W

< SWITCH >

0 S951 1-771-291-11 SWITCH, POWER (VOLTAGE SELECTOR)

< TRANSFORMER >

0 T951 1-435-566-11 TRANSFORMER, POWER (AEP,UK,G,AED,CIS)

0 T951 1-435-567-11 TRANSFORMER, POWER (MY,SP)

**************************************************************

MISCELLANEOUS

***************

4 1-751-688-11 WIRE (FLAT TYPE) (13 CORE) (MY,SP)

4 1-773-011-11 WIRE (FLAT TYPE) (15 CORE)

(AEP,UK,G,AED,CIS)

6 1-693-482-11 TUNER (FM/AM) (MY,SP)

6 1-693-490-11 TUNER (FM/AM) (AEP,UK,G,AED,CIS)

62 1-769-908-11 WIRE (FLAT TYPE) (9 CORE)

64 1-773-213-11 WIRE (FLAT TYPE) (25 CORE)

66 1-568-441-11 SOCKET, CONNECTOR 9P

67 1-769-885-11 WIRE (FLAT TYPE) (7 CORE)

0 104 1-777-071-51 CORD, POWER (MY,SP)

0 104 1-777-071-61 CORD, POWER (AEP,UK,G,AED,CIS)

0 107 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P (UK)

0 107 1-569-008-21 ADAPTOR, CONVERSION (MY,SP)

LCD601 1-803-738-11 DISPLAY PANEL, LIQUID CRYSTAL

M401 1-763-478-11 FAN, DC

0 T951 1-435-566-11 TRANSFORMER, POWER (AEP,UK,G,AED,CIS)

(MY,SP)

0 T951 1-435-567-11 TRANSFORMER, POWER (MY,SP)

**************************************************************

**************

HARDWARE LIST

**************

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-650-79 SCREW +BVTP 3X16 TYPE2 IT-3

#3 7-685-872-09 SCREW +BVTT 3X8 (S)

#4 7-685-871-01 SCREW +BVTT 3X6 (S)

#5 7-685-646-79 SCREW +BVTT 3X8 TYPE2 N-S

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

9-929-520-11

32

Sony Corporation

Audio Entertainment Group

Printed in Hungary © 2000. 8

2000H097551-1

Published by HA Quality Assurance Dept.

Loading...

Loading...