Sony SST-100, SAVA-700 Service manual

SA VA-700/SS-T100

SERVICE MANUAL

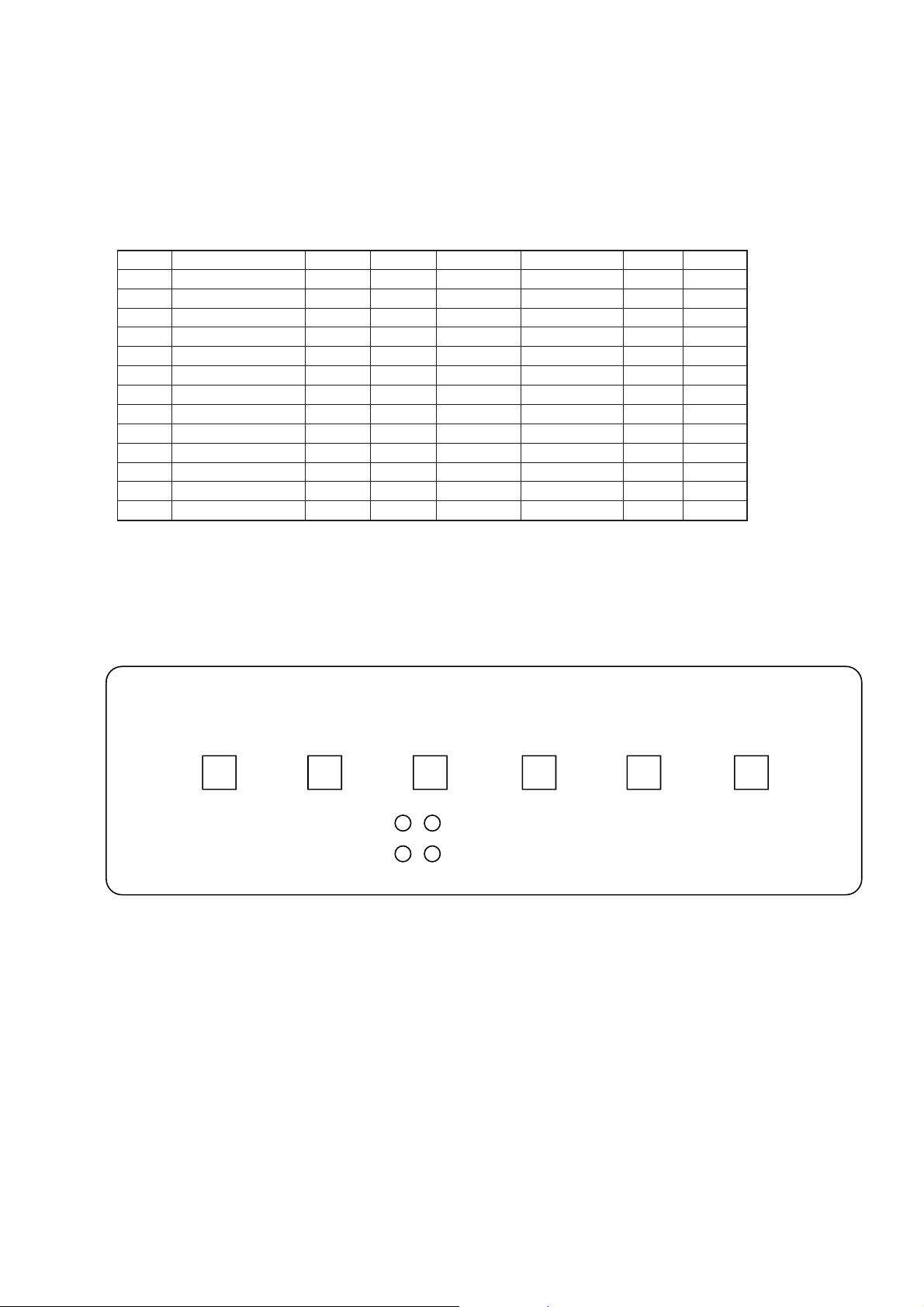

The SAVA-700 composed of the following table.

Front Speaker Main Unit

Center/Rear Speaker SS-T100

SPECIFICATIONS

US Model

AEP Model

UK Model

E Model

(L-ch) (R-ch)

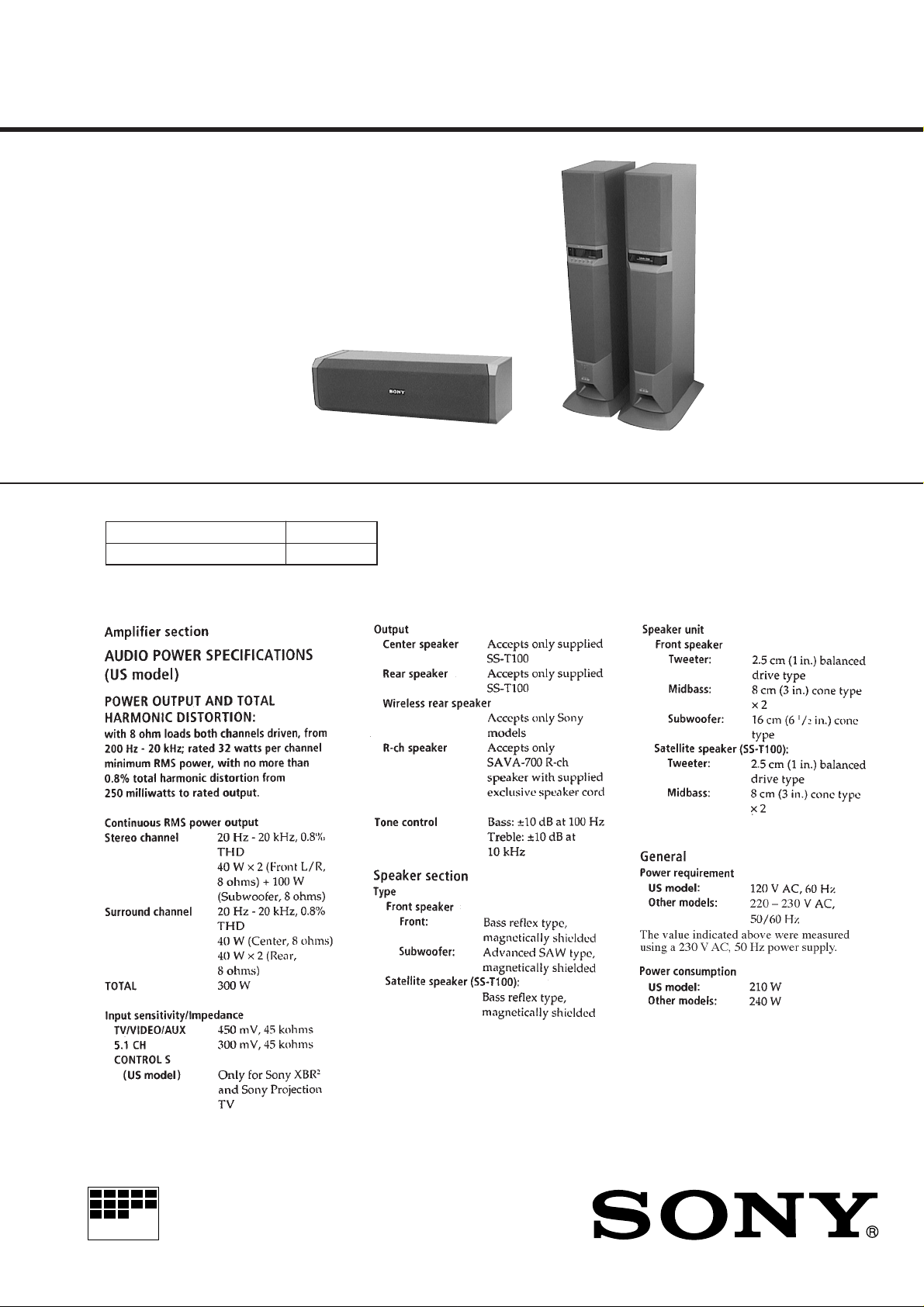

Photo: Main UnitPhoto: SS-T100

MICROFILM

– Continued on next page –

HOME THEATER ACTIVE SPEAKER SYSTEM

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 5

4. TEST MODE.............................................................. 8

5. DIAGRAMS

5-1. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 11

5-2. Printed Wiring Board – Main Board– ........................... 12

5-3. Schematic Diagram – Main Board (1/3) – .................... 13

5-4. Schematic Diagram – Main Board (2/3) – .................... 14

5-5. Schematic Diagram – Main Board (3/3) – .................... 15

5-6. Printed Wiring Boards – FILTER/THERMO/REG/

T2/T1/STANDBY/AC-SW Board – ............................... 16

5-7. Schematic Diagram – FILTER/THERMO/REG/

T2/T1/STANDBY/AC-SW Board – ............................... 17

5-8. Printed Wiring Board – AMP Board – .......................... 18

5-9. Schematic Diagram – AMP Board – ............................. 19

5-10. Printed Wiring Boards

– DISPLAY/LED/KEY Board – ..................................... 20

5-11. Schematic Diagram

– DISPLAY/LED/KEY Board – ..................................... 21

5-12. IC Pin Function Description ........................................... 24

6. EXPLODED VIEWS ................................................ 26

7. ELECTRICAL PARTS LIST ............................... 30

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

SERVICING NOTES

MODEL IDENTIFICATION

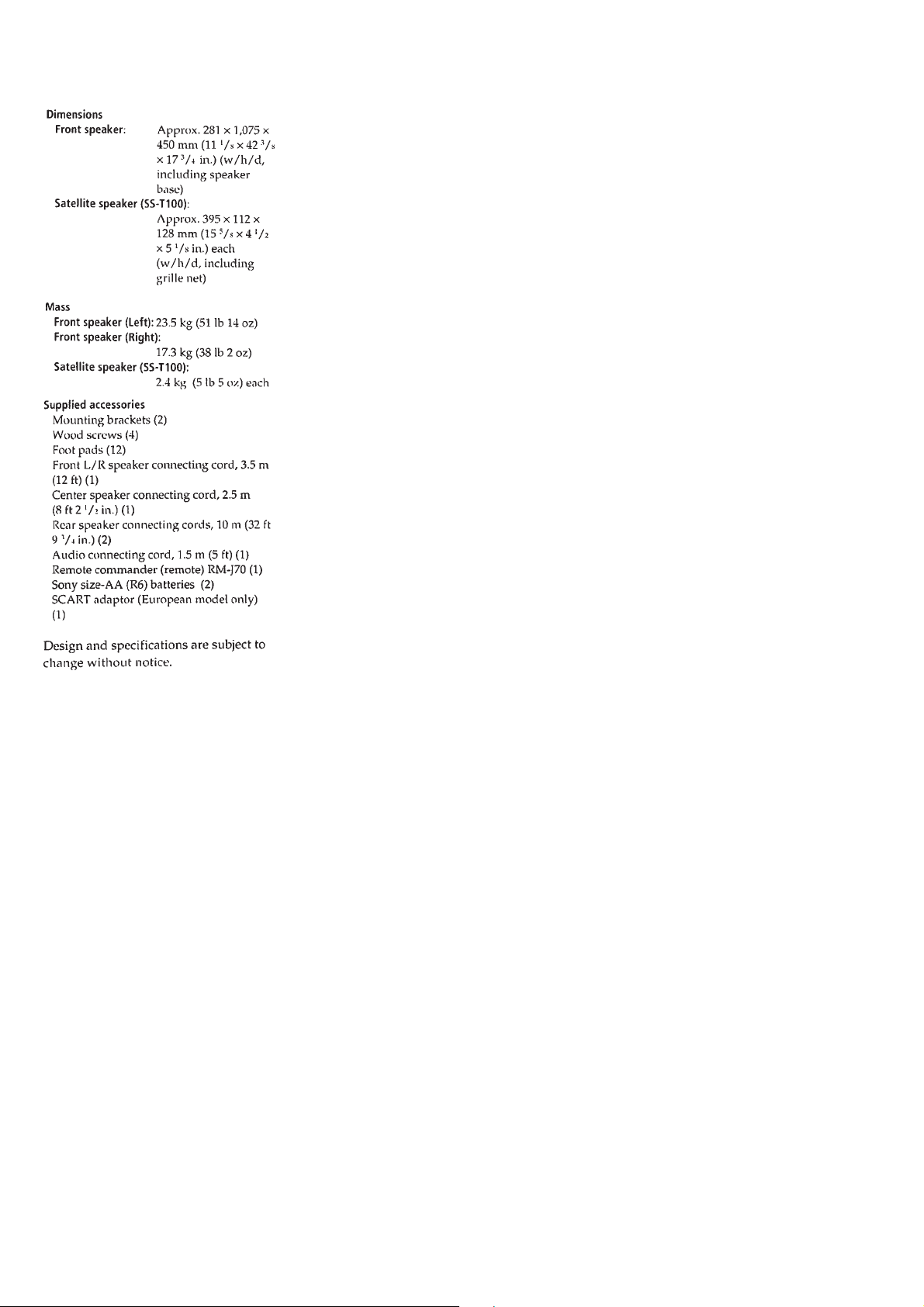

– Rear view –

PART No.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The A C leaka ge from an y e xposed metal part to earth g round and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are e xamples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

MODEL PART No.

US model 4-217-252-0

EXCEPT US models 4-217-252-2

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

3

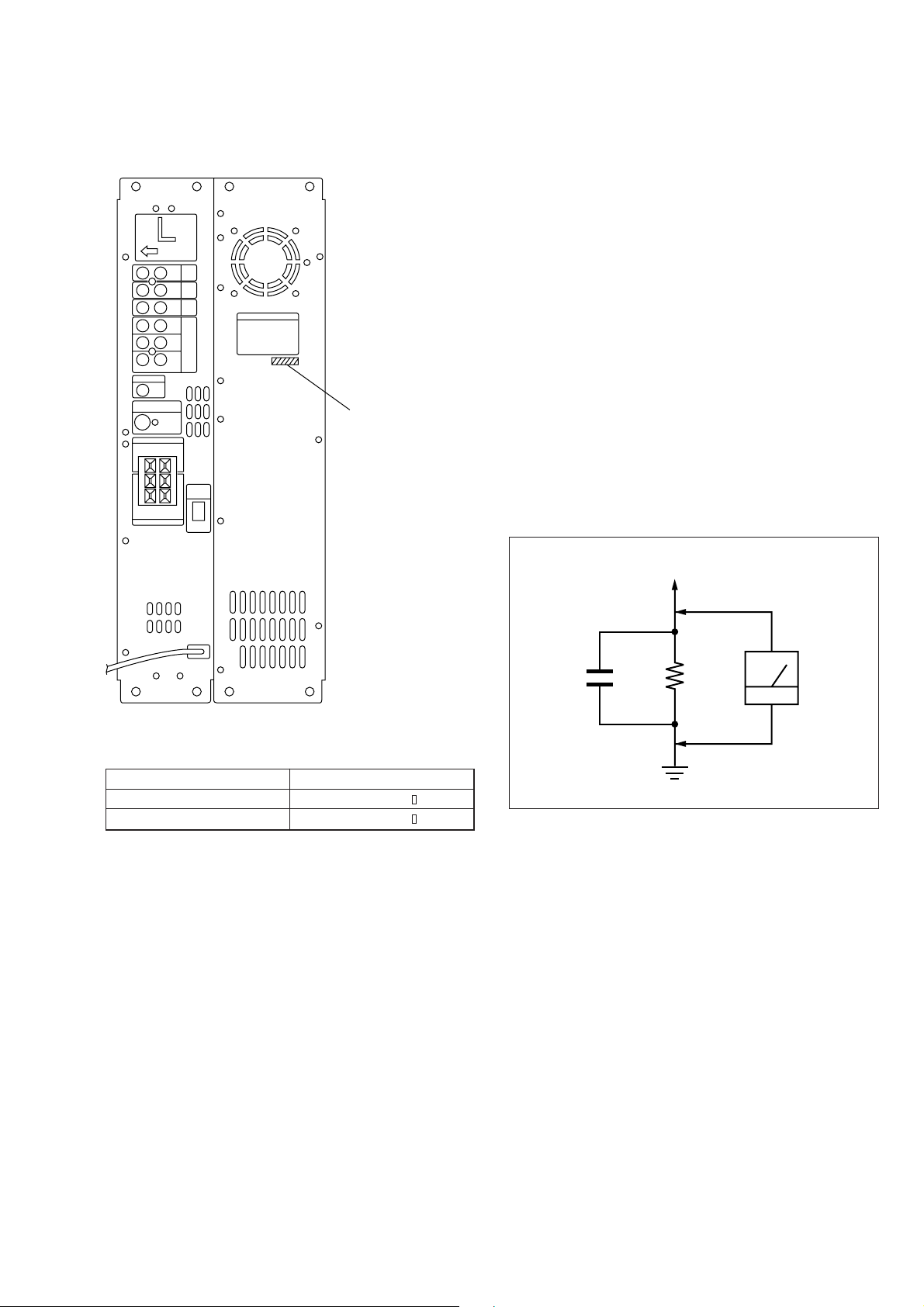

• LOCATION OF CONTROLS

Main Unit (L-ch)

– Front View –

32

1

5

6

7

4

SECTION 2

GENERAL

1 INPUT button

2 SURROUND button

3 CENTER MODE button

4 S. WOOFER button

5 MASTER VOL +/– buttons

6 STANDBY, ON, READY indicators

7 U button

– Rear View –

1

2

3

4

5

6

7

8

9

1 TV IN jack

2 VIDEO IN jack

3 AUX IN jack

4 5.1CH INPUT (FRONT, REAR, WOOFER, CENTER) jack

5 CONTROL S, TV IN jack (US model)

6 WIRELESS REAR SPEAKER jack

7 CENTER SPEAKER terminal

8 REAR SPEAKERS terminal

9 R-ch SPEAKER OUTPUT connector

4

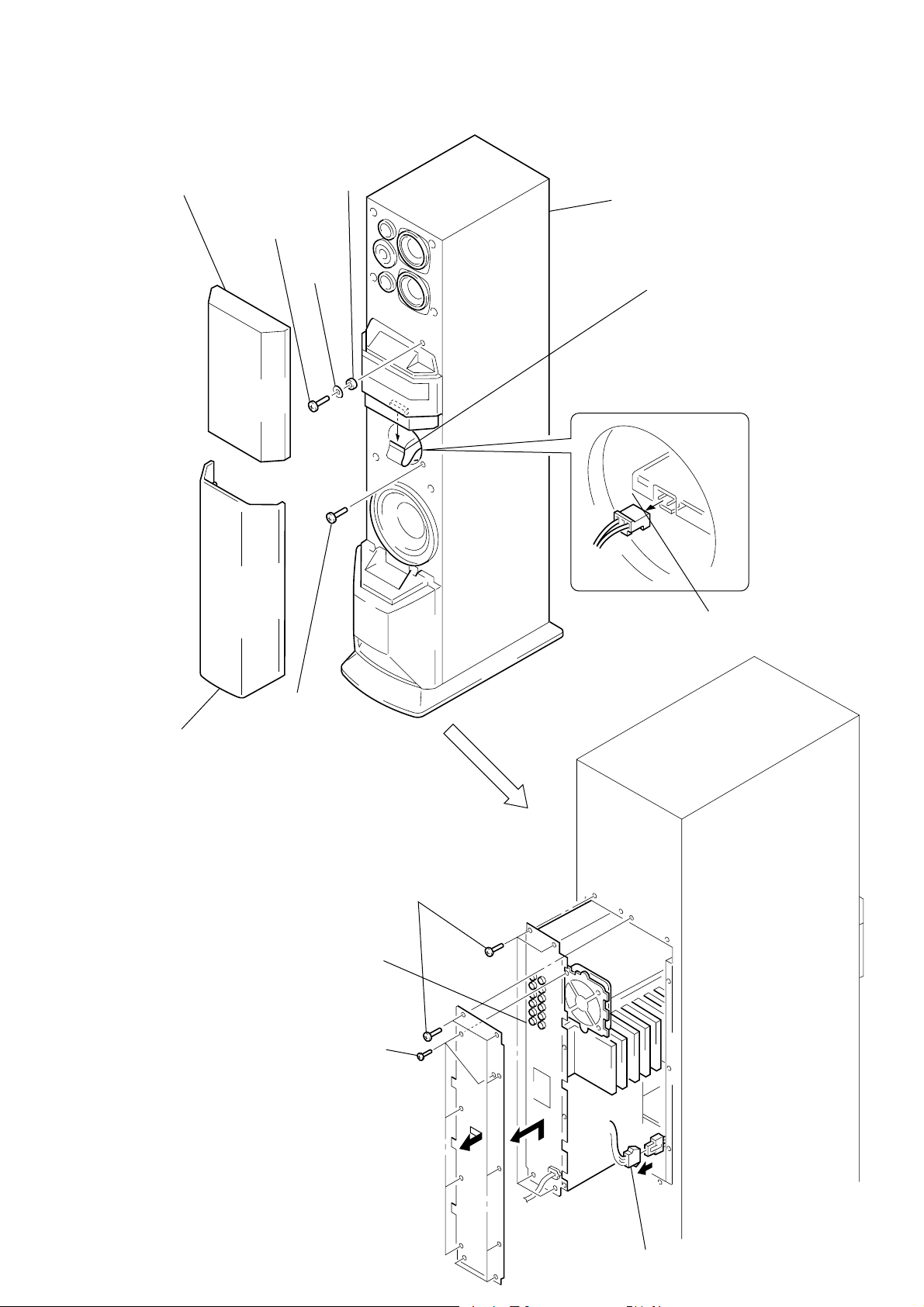

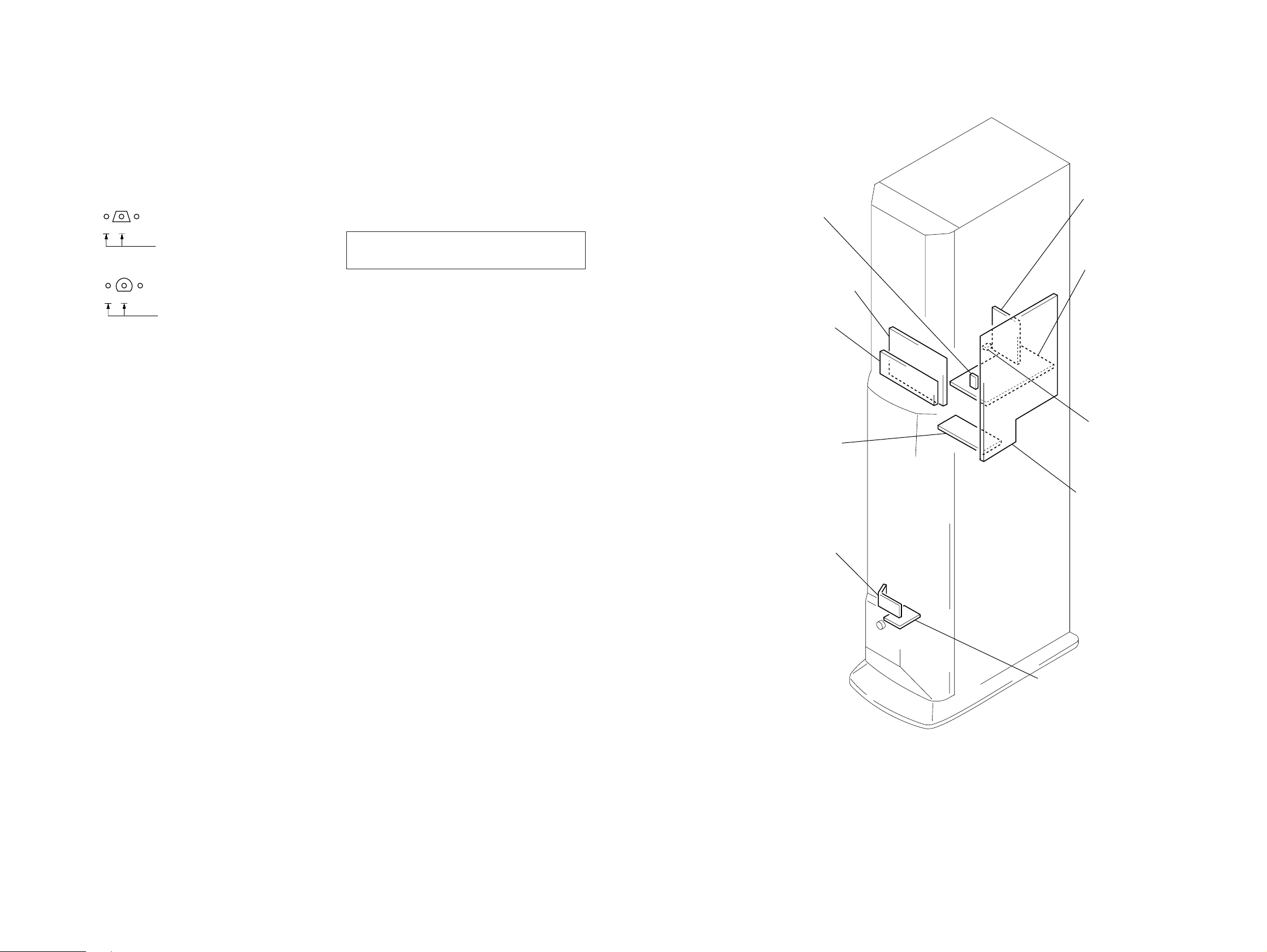

SECTION 3

r

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

AMPLIFIER SECTION

2

grille frame (A)

ass’y

3

screw

(BVTT4

5 washer

×

25)

4 washer

(BF)

(S)

L-ch speaker section

7

flat wire

(CN503)

1

grille frame (B) ass’y

6

screw

(BVTT4

!£

Remove the amplifier

section in arrow

direction.

!º

five screws

(BVTP3

×

25)

9

eleven screws

(4

×

20)

B

×

8)

8

connecto

(CN907)

!¡

Remove the panel (L/B)

in arrow

A

direction.

A

B

!™

connector

5

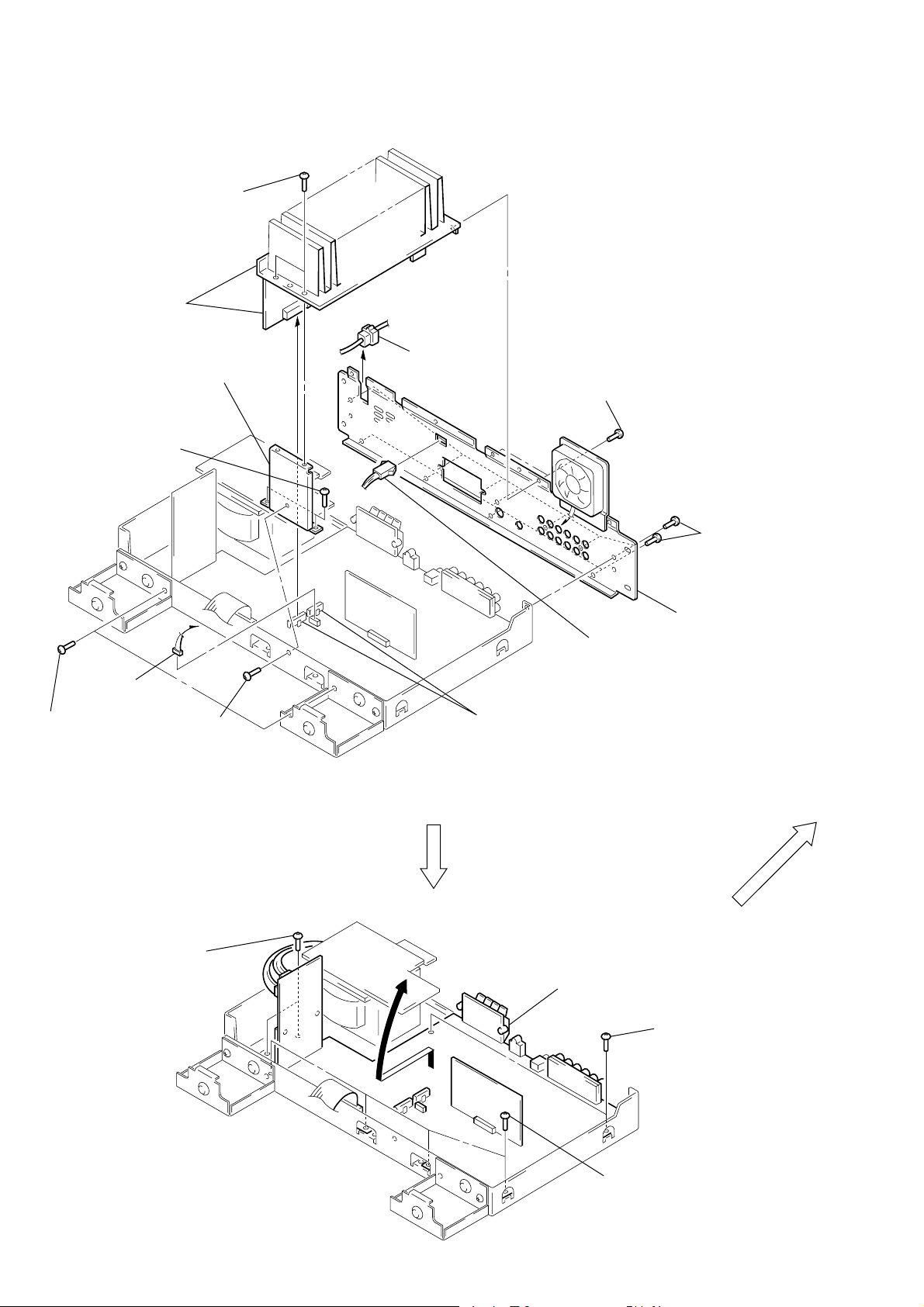

SERVICE POSITION

s

)

1

Remove the amplifier section. (Refer to page 5)

2

two screws

(transistor)

5

heatsink and

AMP board

7

bracket

6

two screws

(BVTP3 × 8)

9

cord bushing

3

two screws

(BVTP3 × 8)

!¡

eleven screw

(BVTP3 × 8)

!£

two screws

(BVTP3 × 8)

8

connector

6

!¢

two screws

(BVTP3

screw

(BVTP3 × 8)

×

8)

A

4

two connectors

(CN601, 603)

!º

connector

Erect the Main board

!∞

in arrow

A

direction.

!™

!¢

two screws

(BVTP3

back panel (L/A)

×

8

!¢

four screws

(BVTP3

×

8)

6

MAIN board

chassis

!§

Insert an insulation sheet

between chassis and

MAIN board.

bracket

!¶

!ª

Connect the fan motor lead wire

to MAIN board connector (CN301).

Attach the bracket

to the heatsink

with two screws.

heatsink

!•

Insert two connectors

(CN601, 603) into

the connectors

(CN301, 911) on

the MAIN board.

@º

Connect the power SW

lead wire to STANDBY

board connector (CN907).

@¡

Connect the flat wire to

DISPLAY board connector (CN503).

@£

Push the power SW.

@™

Connect the MAIN board

and chassis with

two clip wires.

7

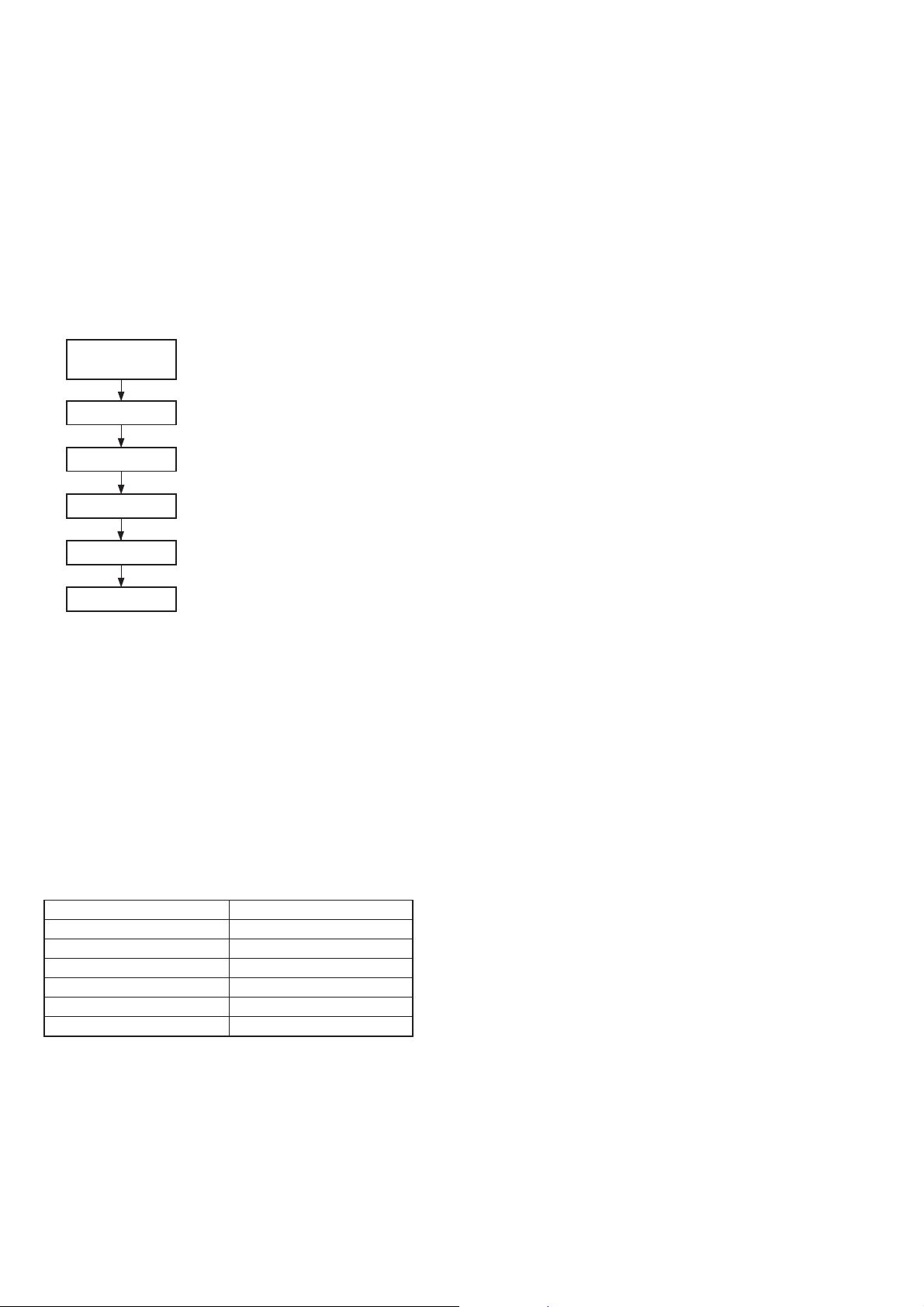

SECTION 4

TEST MODE

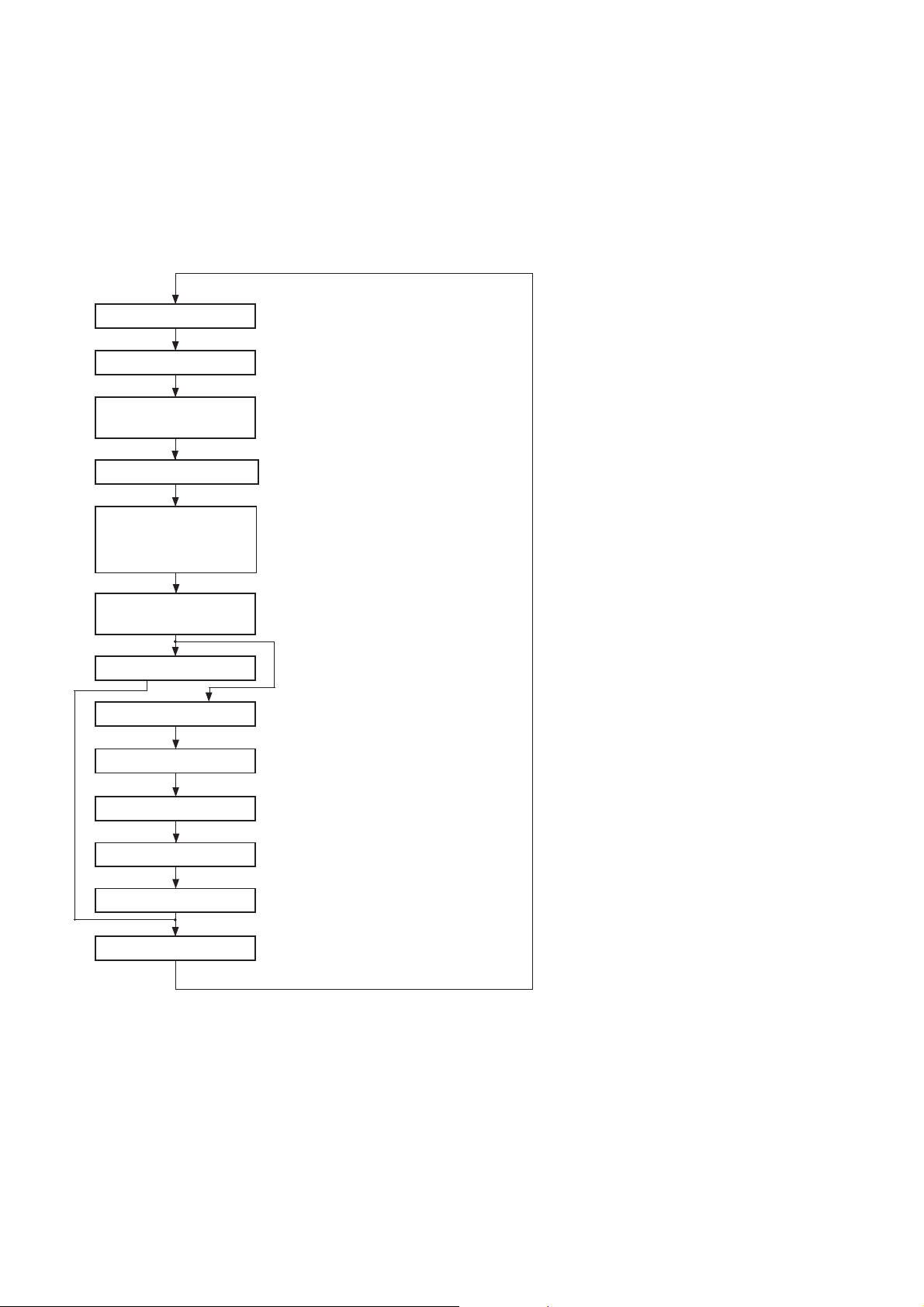

This set provides four test modes as follows.

1. INPUT CHECK MODE

2. KEY CHECK MODE

3. AMP CHECK MODE

4. DEMONSTRATION MODE

The following describes each test mode in detail.

4-1. INPUT CHECK MODE

Procedure:

1. While pressing the both [S.WOOFER] and [MASTERVOL+] buttons, turn the power ON.

2. Fluorescent indicator tube display “SAVA-700”, after the all lights up, and enter the input check mode.

3. Pressing the [INPUT] button varies the display as follows.

SAVA-700

*********

S.WOOFER *1 S.WOOFER check mode (5.1CH INPUT check mode)

AUX AUX input (SURROUND OFF) check mode

VIDEO VIDEO input (SURROUND OFF) check mode

TV TV input (SURROUND OFF) check mode

AUTO POWER AUTO POWER ON/OFF check mode

*1 Pressing the

maximum, or

Note: In each mode, the volume is muted except for the channels that can be checked.

4. To release the test mode, push back [] button.

[SURROUND] button makes the S.WOOFER level minimum, or the [S.WOOFER] button makes the S.WOOFER level

[CENTERMODE] button returns default.

U

4-2. KEY CHECK MODE

Procedure:

1. Push back [] button to turn the power OFF.

2. Connect the lead wire to TP3 and TP4 on the KEY board.

3. Push [] button to power ON.

4. Let the lead wire short TP3 and TP4.

5. Fluorescent indicator tube display “KEY CHK 700” , and enter the key check mode.

6. Pressing any buttons, the number of button will be displayed on the fluorescent indicator tube.

7. Pressing the f irst button turns on the [READY] LED (red), and the second b utton turns on the [ON] LED (green). T hus, two LEDs light

up alternately each time the buttons are pressed.

INPUT

SURROUND

CENTER MODE

WOOFER

MASTER VOL –

MASTER VOL +

U

U

Button

Button Number

1

2

3

4

5

6

8. After all b uttons are pressed, it will be in the ST ANDBY mode.

Note: If a check failed, the set does not go in STANDBY mode, and you cannot exit from the test mode. In this case, quit the test mode by pushing back

[] button.

U

8

4-3. AMP CHECK MODE

Procedure:

1. Push back [] button to turn the power OFF.

2. Connect the lead wire to TP1 and TP2 on the KEY board.

3. Push [] button to power ON.

4. Let the lead wire connected TP1 and TP2.

5. Fluorescent indicator tube display “AMP CHK 700”, and enter the amp check mode.

6. The check step advances in order as TP1 and TP2 are shorted.

STEP

0

1

2

3

4

5

6

7

8

9

10

11

12

*

*1 The step 12 is the AUTO POWER ON/OFF check.

*2 The step 12 is automatically turned the power OFF in one second, ON when a signal is entered to TV input, and OFF when a signal

input stops.

*3 After the step 12 finished, return the parameters to default values, then turn the power OFF.

7. To release the test mode, push back [] button.

U

U

AMP CHK 700

AMP CHK 1

AMP CHK 2

AMP CHK 3

AMP CHK 4

AMP CHK 5

AMP CHK 6

AMP CHK 7

AMP CHK 8

AMP CHK 9

AMP CHK 10

AMP CHK 11

AMP CHK 12

INPUT

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

AUX

AUX

5.1

5.1

5.1

5.1

TV

U

VOL

MIN

MAX

MAX

MAX

MAX

MAX

MIN

MAX

MAX

MIN

MAX

MAX

MAX

SW MODE

1

OFF

OFF

OFF

1

2

1

1

1

1

1

1

1

SUR MODE

PRO LOGIC

OFF

PRO LOGIC

GAME

OFF

OFF

PRO LOGIC

PRO LOGIC

–

–

–

–

PRO LOGIC

BASS

0

0

0

0

0

0

0

0

0

0

–5

+5

0

TREBLE

0

0

0

0

0

0

0

0

0

0

–5

+5

0

• Checking Location

– KEY Board (Conductor Side) –

S505 S506 S502

S504 S503 S501

TP3 TP2

TP4TP1

9

4-4. DEMONSTRATION MODE

1. Entering the demonstration mode

• Press the [INPUT] and [MASTERVOL+] buttons simultaneously to start demonstration mode.

• When the set goes in demonstration mode, the [ON] LED (green) blinks, and the [STANDBY] and [READY] LEDs (red) light up.

• The sequence during the demonstration mode is following as bellow.

Notes:1. In the demonstration mode, only the [INPUT], [MASTERVOL], and [S.WOOFER] buttons are active.

2. The operation with remote commander is disabled.

Demonstration mode sequence:

@@@@@@@@@

@ H E L L O @

WELCOME TO SAVA *1

SOUND SYSTEM

I AM SAVA-700 *1

MY FEATURES ARE 4

INPUTS AND 5 *1

SURROUND MODE

LISTEN TO *1

MY SOUND

5.1 INPUT

5.1 CH IN OTHER INPUT

PRO LOGIC *2

C.STUDIO *2

*1 First seven characters are dis-

played, then eighth and subsequent characters are displayed.

HALL *2

(Characters run on the display)

*2 Displayed for 5 seconds.

STUDIUM *2

GAME *2

THANK YOU *2

Note: 1 The demonstration mode operates with the input, and volume position selected last.

2 The input and volume are variable even during demonstration mode.

2. Releasing the demonstration mode

• To release the demonstration mode, push back [] button.

U

10

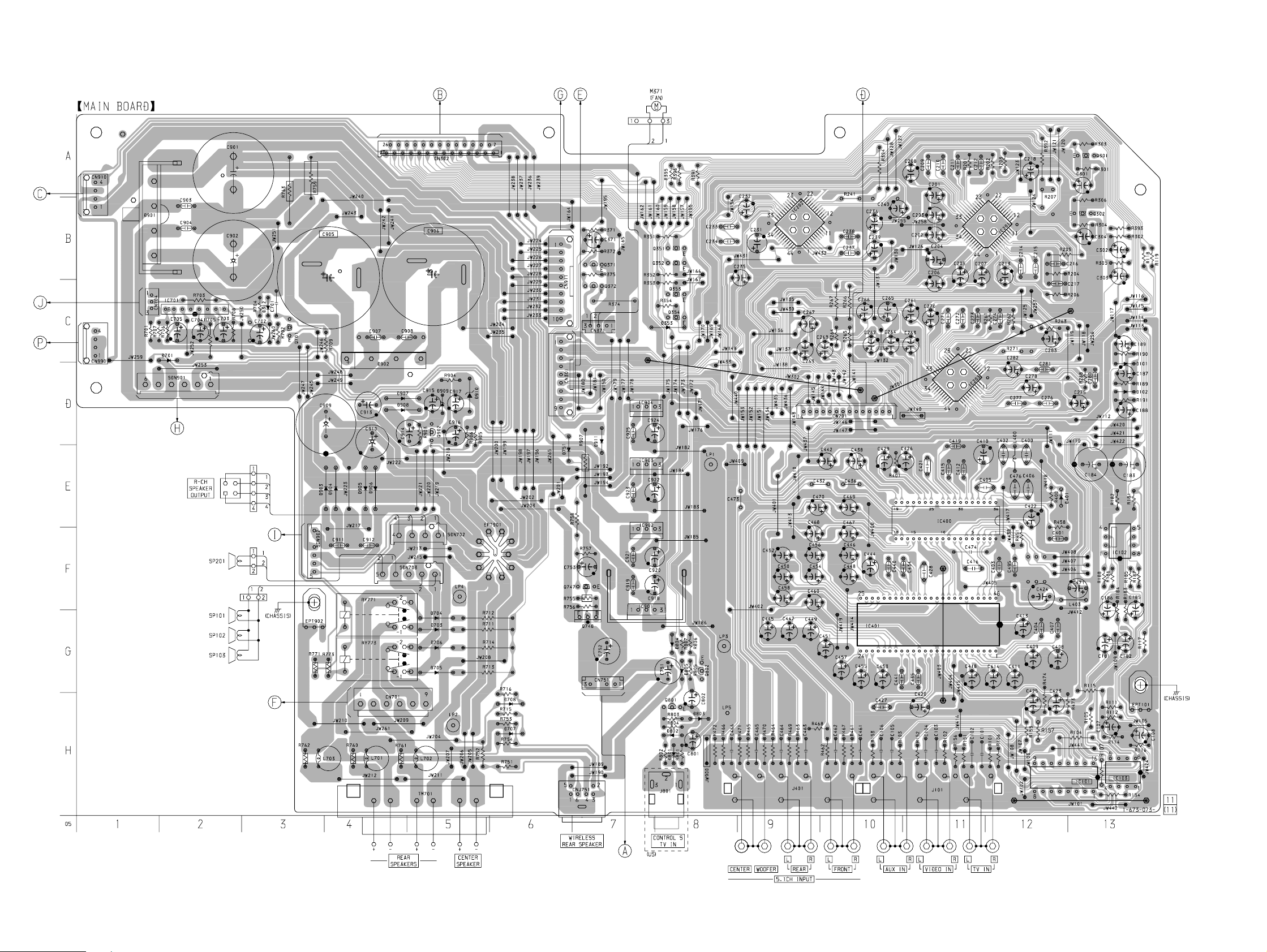

SECTION 5

DIAGRAMS

5-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• p : parts mounted on the conductor side.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Indication of transistor.

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark ! or dotted line

• U : B+ Line.

• V : B– Line.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark ! are critical for safety.

Replace only with part number specified.

under no-signal conditions.

no mark : AUDIO

Voltage var iations may be noted due to normal production tolerances.

Voltage var iations may be noted due to normal production tolerances.

F : AUDIO

4

W or less unless otherwise

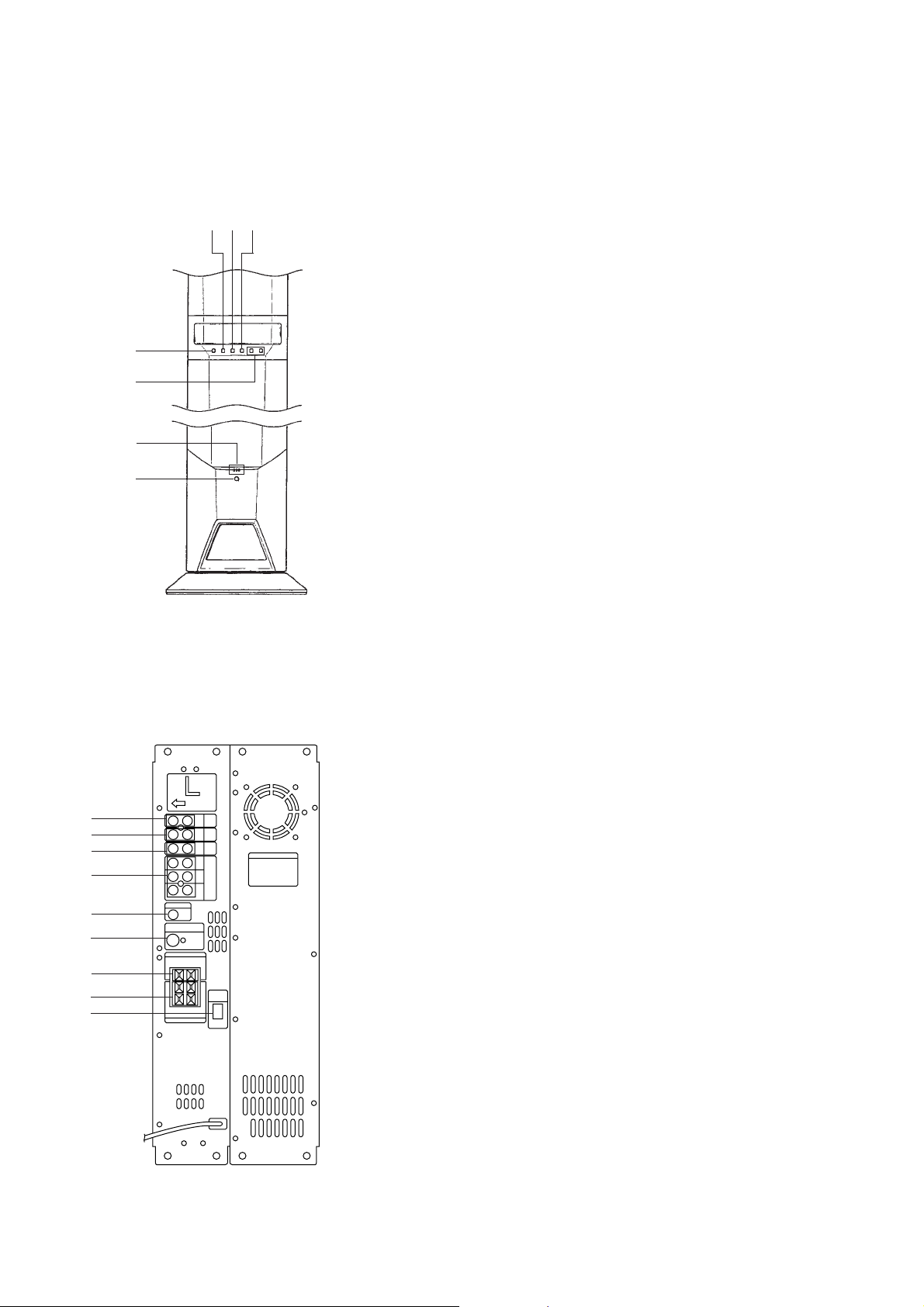

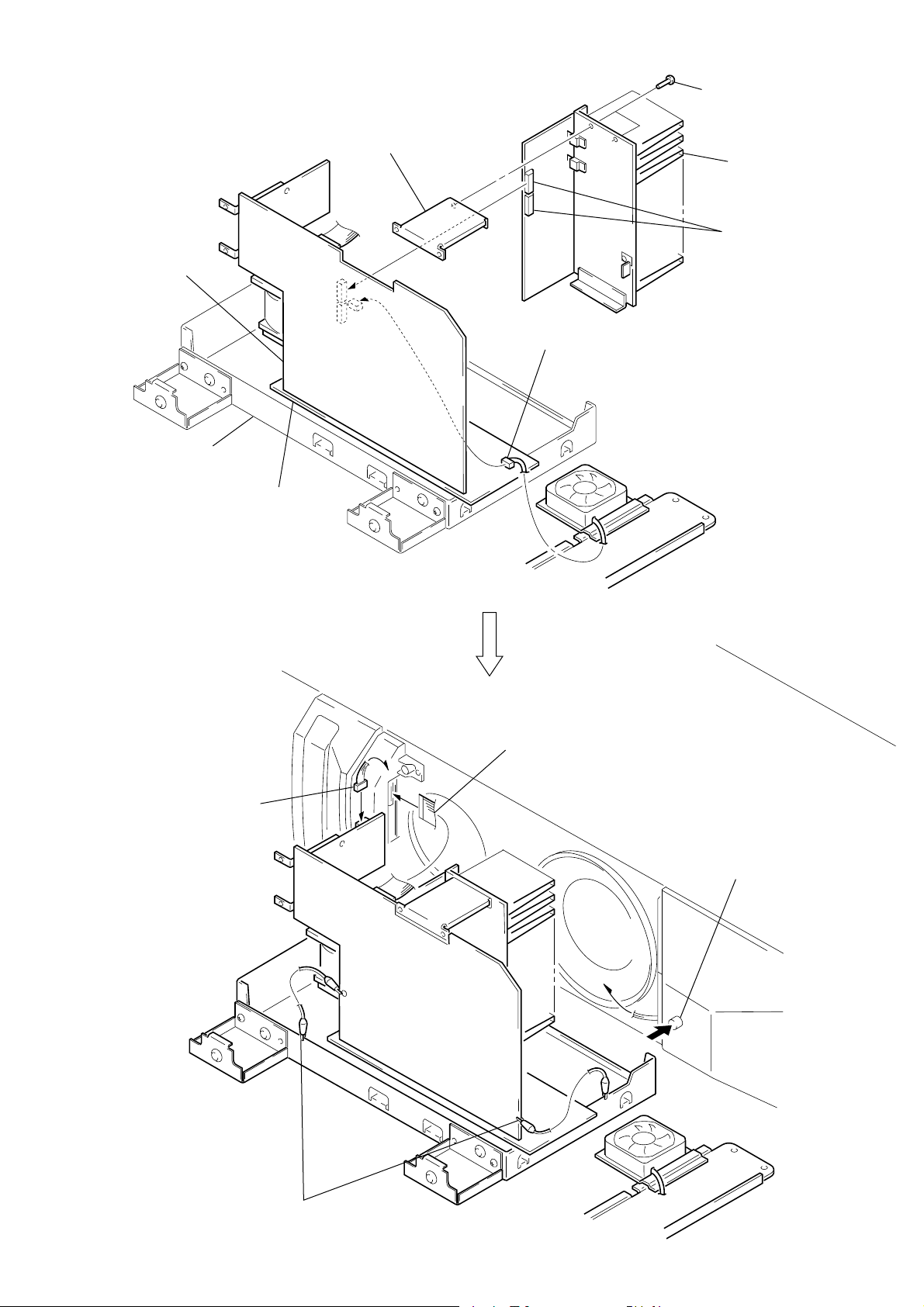

• Circuit Boards Location

FILTER board

REG board

AMP board

DISPLAY board

KEY board

THERMO board

STANDBY board

LED board

MAIN board

AC-SW board

– L-ch speaker section –

1111

SAV A-700/SS-T100

5-2. PRINTED WIRING BOARD – MAIN Board – • See page 11 for Circuit Boards Location.

(Page 16)

(Page 16)

(Page 16)

(Page 20)

(Page 18)

(Page 18)

(Page 16)

(Page 16)

(Page 16)

(Page 18)

(Page 16)

1212

Loading...

Loading...