Sony SPP-S2720 Service manual

SPP-S2720

SERVICE MANUAL

Ver 1.0 2001.06

SPECIFICATIONS

General

Spread method

Direct-Sequence Spread-Spectrum

Access method

FDMA-TDD

Frequency band

2.4075 - 2.4720 GHz

Operating channel

40 channels

Dial signal

Tone, 10 PPS (pulse) selectable

Supplied accessories

AC power adaptor (AC-T46)

Telephone line cord

Rechargeable battery pack (BP-T38)

Cordless handset

Power source

Rechargeable battery pack BP-T38

Battery life

Standby: Approx. 6 days

Talk: Approx. 5 hours

Battery charging time

Approx. 12 hours

Dimensions

Approx. 2

antenna excluded

(approx. 58 x 166 x 48 mm)

Antenna: Approx. 2

(approx. 72 mm)

Mass

Approx. 8.1 oz

(approx. 230 g), battery included

3

⁄8 x 6 5⁄8 x 1 15⁄16 inches (w/h/d),

7

⁄8 inches

US Model

Canadian Model

Base unit

Power source

DC 9V from AC power adaptor

AC-T46

Dimensions

Approx. 6 1⁄8 x 2 5⁄8 x 6 inches (w/h/d),

antenna excluded

(approx. 154 x 65 x 151 mm)

Antenna: Approx. 4 3⁄ 8 inches

(approx. 108 mm)

Mass

Approx. 9.4 oz

(approx. 265 g)

Design and specifications are subject to

change without notice.

9-873-166-01 Sony Corporation

2001F0500-1 Personal Audio Company

C 2001.6 Shinagawa Tec Service Manual Production Group

CORDLESS TELEPHONE

SPP-S2720

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL

Identifying the Parts ........................................................ 4

Registering additional cordless handsets........................ 8

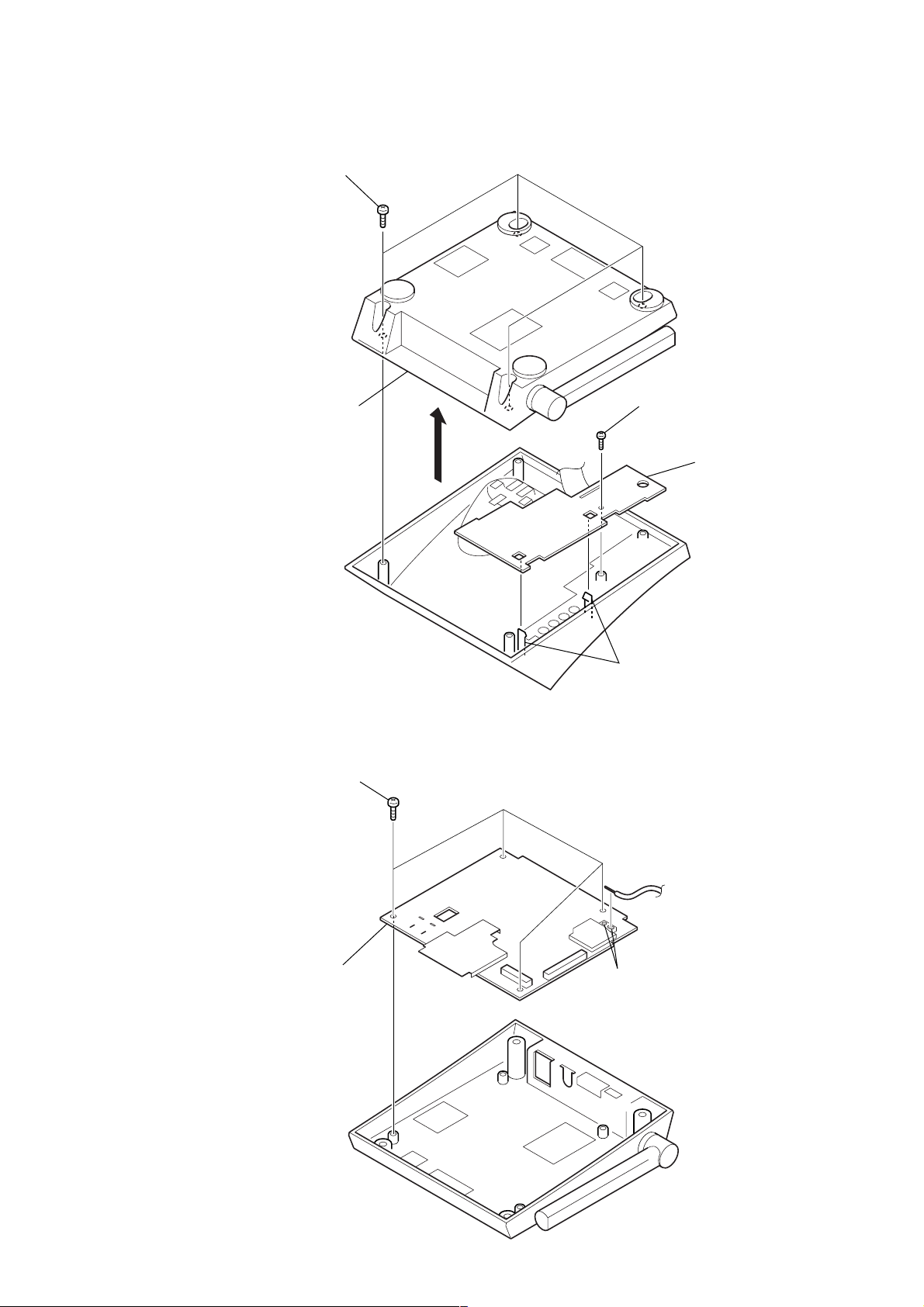

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 10

3-2. Cabinet (Rear) ................................................................. 10

3-3. Hand Main Board ............................................................ 10

3-4. Base Cabinet (Lower) Assy, Key Main Board ............... 11

3-5. Base Main Board............................................................. 11

4. TEST MODE

Base Unit ......................................................................... 12

Handset ............................................................................ 14

5. ELECTRICAL ADJUSTMENTS

Base Unit ......................................................................... 16

Handset ............................................................................ 18

6. DIAGRAMS

6-1. Block Diagram – BASE UNIT Section –...................... 21

6-2. Block Diagram – HANDSET Section –........................ 22

6-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 23

6-4. Printed Wiring Board

– BASE MAIN Board (Component Side)– .................... 24

6-5. Printed Wiring Boards – BASE MAIN

(Conductor Side)/KEY MAIN Boards – ........................ 25

6-6. Schematic Diagram

– BASE MAIN (1/3)/KEY MAIN Boards – .................. 26

6-7. Schematic Diagram – BASE MAIN Board (2/3) –....... 27

6-8. Schematic Diagram – BASE MAIN Board (3/3) –....... 28

6-9. Printed Wiring Board – HAND MAIN Board – ........... 30

6-10. Schematic Diagram – HAND MAIN Board (1/2) – ..... 31

6-11. Schematic Diagram – HAND MAIN Board (2/2) – ..... 32

6-12. IC Pin Function Description ........................................... 33

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

NOTE FOR REPLACEMENT OF THE CRYSTAL VIBRATOR ON THE HAND MAIN BOARD

There are two types of crystal vibrators used on the HAND MAIN

board. Accordingly, when replacing the crystal vibrator, replace

the following reference number parts together. Similarly, when

the following reference number parts are replaced, check which

type of crystal vibrator is used and use the same type.

Crystal

vibrator

X31 C12 18PF 22PF

[How to identify the TYPE A or B of crystal vibrator]

The type A or B can be identified from the initial character of a

character staring indicated on the top surface of the parts.

TYPE A: Starting with a numeric value

TYPE B: Staring with alphabet D

Ref. No. TYPE A TYPE B

C11 18PF 33PF

R40 1.5kΩ 1kΩ

7. EXPLODED VIEWS

7-1. Hand Set .......................................................................... 39

7-2. Base Set ........................................................................... 40

8. ELECTRICAL PARTS LIST ............................... 41

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

SECTION 1

SERVICING NOTES

IF AN ERROR MESSAGE IS DISPLAYED (Handset)

If the following error message is displayed after the power was turned on, check the items where “1” is indicated.

SPP-S2720

ERROR=[]000

• Note on Replacing The EEPROM

After the EEPROM was replaced, write var ious parameters in the “TEST MODE E” (see page 15). (For the ID, see “Writing ID Numbers”

described below)

Note: Replacing the EEPROM causes all data such as customer registered telephone directory to be cleared.

[][]

00

EEPROM (IC122) data error t Write correct data to the EEPROM.

ID error t Write correct ID data.

EEPROM

(IC122) error t Check the EEPROM and its peripheral circuits.

NOTE ON CONNECTING THE PANEL FOR SPP-A2780 FOR TEST MODE (Base Unit)

Some items in the test mode and electrical adjustments of this set require 12 keys for data writing, but this set does not provide 12 keys.

Accordingly, the panel (B ASE CABINET (UPPER) ASSY) for the SPP-A2780 is connected for these items, but the connector CN302 for

panel connection is not mounted on the BASE MAIN board in this set.

Therefore, in performing the test mode and electrical adjustments, the connector CN302 must be additionally mounted, and it need not be

removed after use, as the patterns of the board could be damaged when removing the connector. However, note that it may be a little

difficult to close the cabinet with the CN302 left mounted because of a narrow internal space.

Further, additional mounting of the CN301 for the SPP-2780 panel connection besides the CN302 enables the LCD display. Also, in this

case, the CN301 need not be removed after repair.

RE-REGISTERING ALREADY REGISTERED SET

Initialize the registered information on base unit and all handsets, and then register again all handsets starting with handset 1 by the

method given below. When re-registering the handset, refer to “Registering additional cordless handsets” in the instruction manual. (see

page 8)

– Base unit –

1. Turn the power on.

2. Press three keys of [1], [EZ ACCESS], and [INTERCOM] simultaneously to set the test mode.

– Handset –

1. Turn the power on.

2. Press three keys of [1], [EZ ACCESS], and [INTERCOM] simultaneously.

WRITING ID NUMBERS (for additional handsets)

The ID numbers are given in decimal notation on the bottom of base unit. If handsets are added, ID can be written in the TEST mode, but

the TEST mode handles ID numbers in hexadecimal notation, thus requiring decimal numbers to be con verted into he xadecimal numbers.

Accordingly, when adding the handsets, refer to “Registering additional cordless handsets” in the instruction manual. (see page 8)

However, if the EEPROM was replaced, the handsets cannot be registered by the method mentioned above. In such a case, enter various

parameters except ID numbers in the “TEST MODE E”, and then register the handsets by the method given in the instruction manual.

Also, the ID numbers can be written in the “TEST MODE B”(decimal number) (base unit: see page 13, handset: see page 15).

3

SPP-S2720

SECTION 2

GENERAL

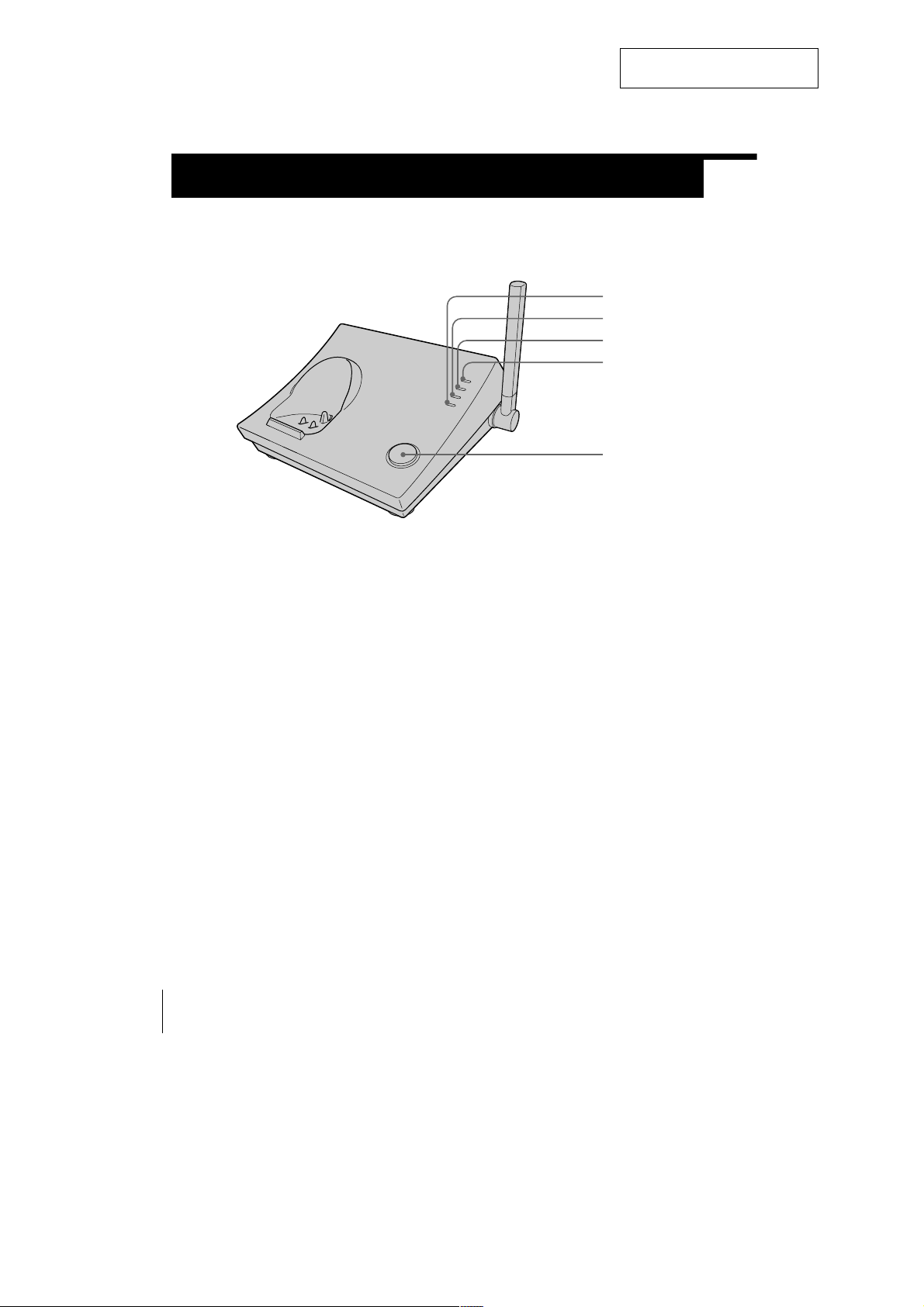

Identifying the parts

Refer to the pages indicated in parentheses for details.

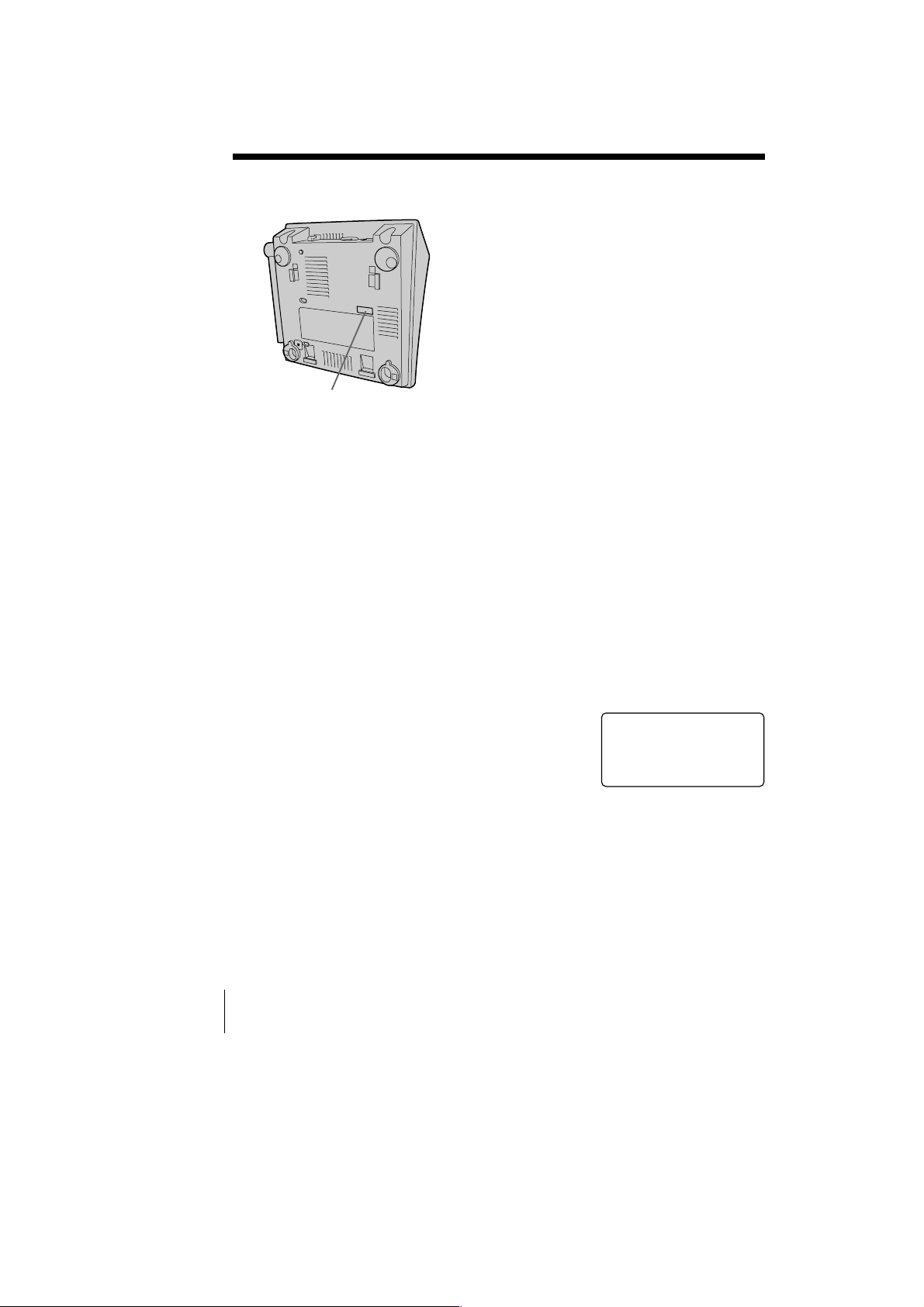

Base unit

This section is extracted from

instruction manual.

1

2

3

4

5

1 VOICE MAIL lamp (p. 59)

Flashes, noticing that you have

messages waiting for you to retrieve

in voice mail service.

2 NEW CALL lamp (p. 51)

Flashes when there is a “NEW”

data in the Caller ID list.

3 IN USE lamp (p. 30)

Lights when the handset is in use.

US

Getting Started

26

4 CHARGE lamp (p. 14)

Lights while the battery is being

charged.

5 HANDSET LOCATOR button

(p. 46)

Allows you to page the handset.

4

SPP-S2720

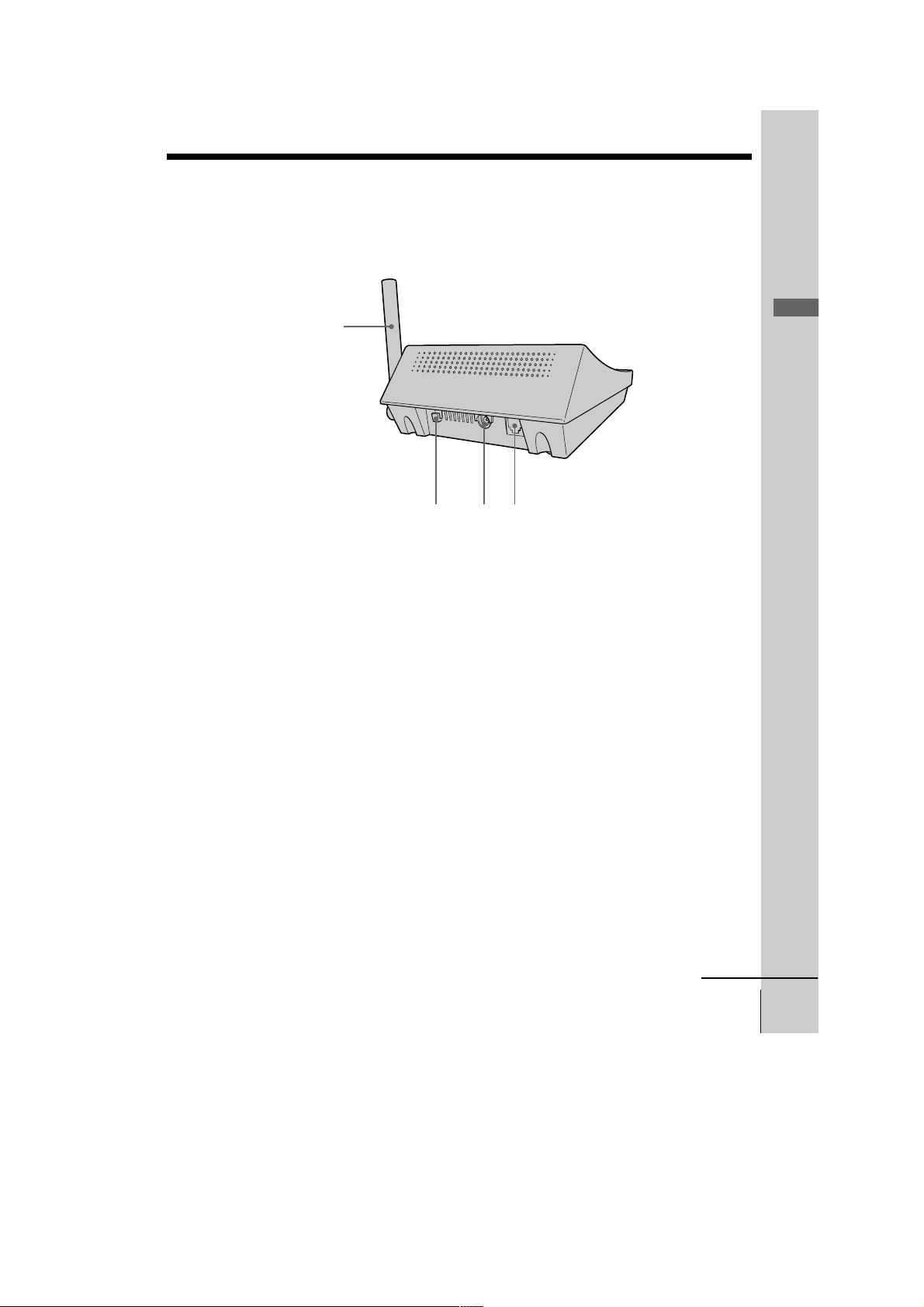

6

6 Antenna (p. 12)

7 Hook for AC power adaptor

cord (p. 12)

8 DC IN 9V jack (p. 12)

9 LINE (telephone line) jack

(p. 12)

Getting Started

87 9

continued

Getting Started

27

US

5

SPP-S2720

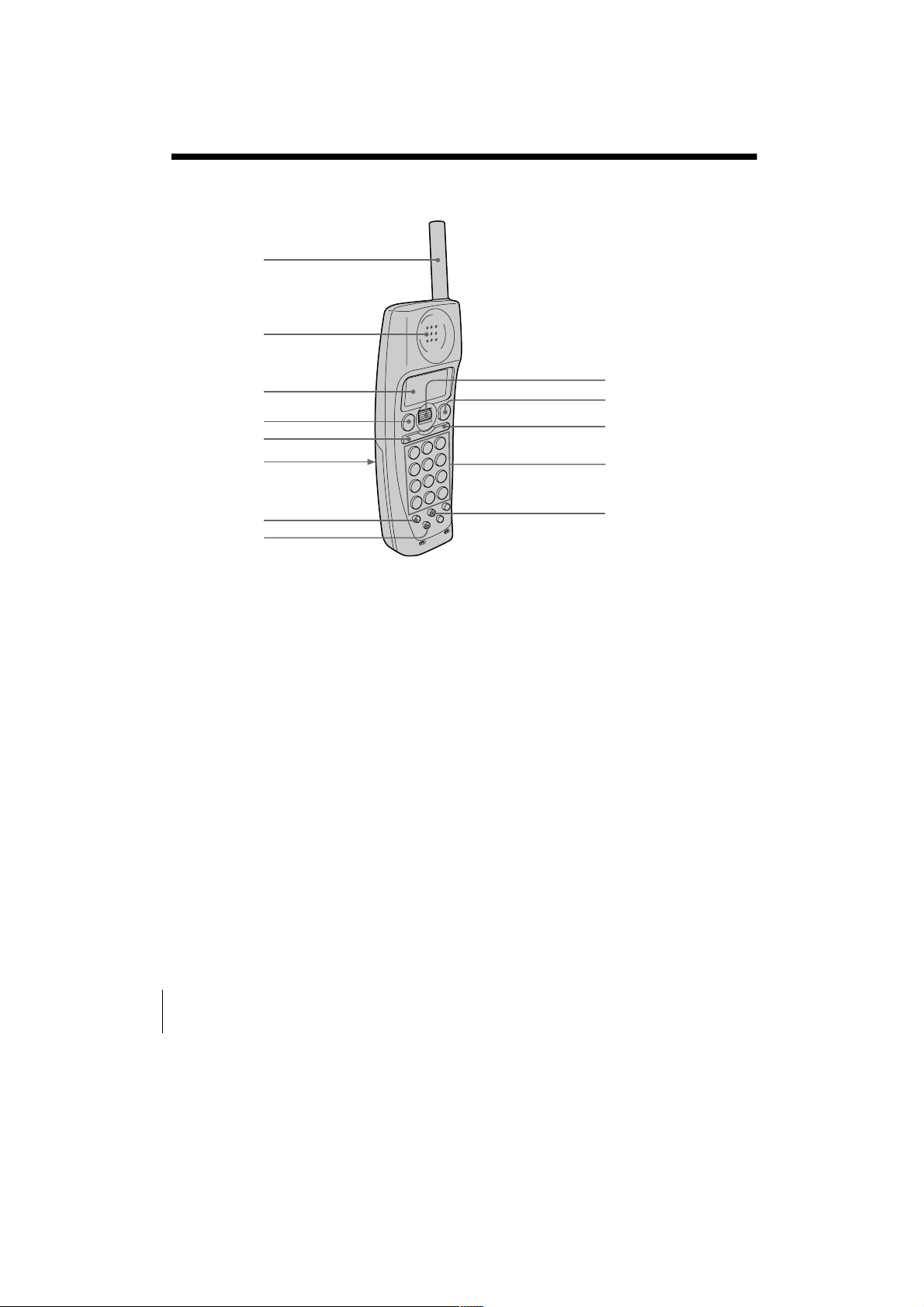

Identifying the parts (continued)

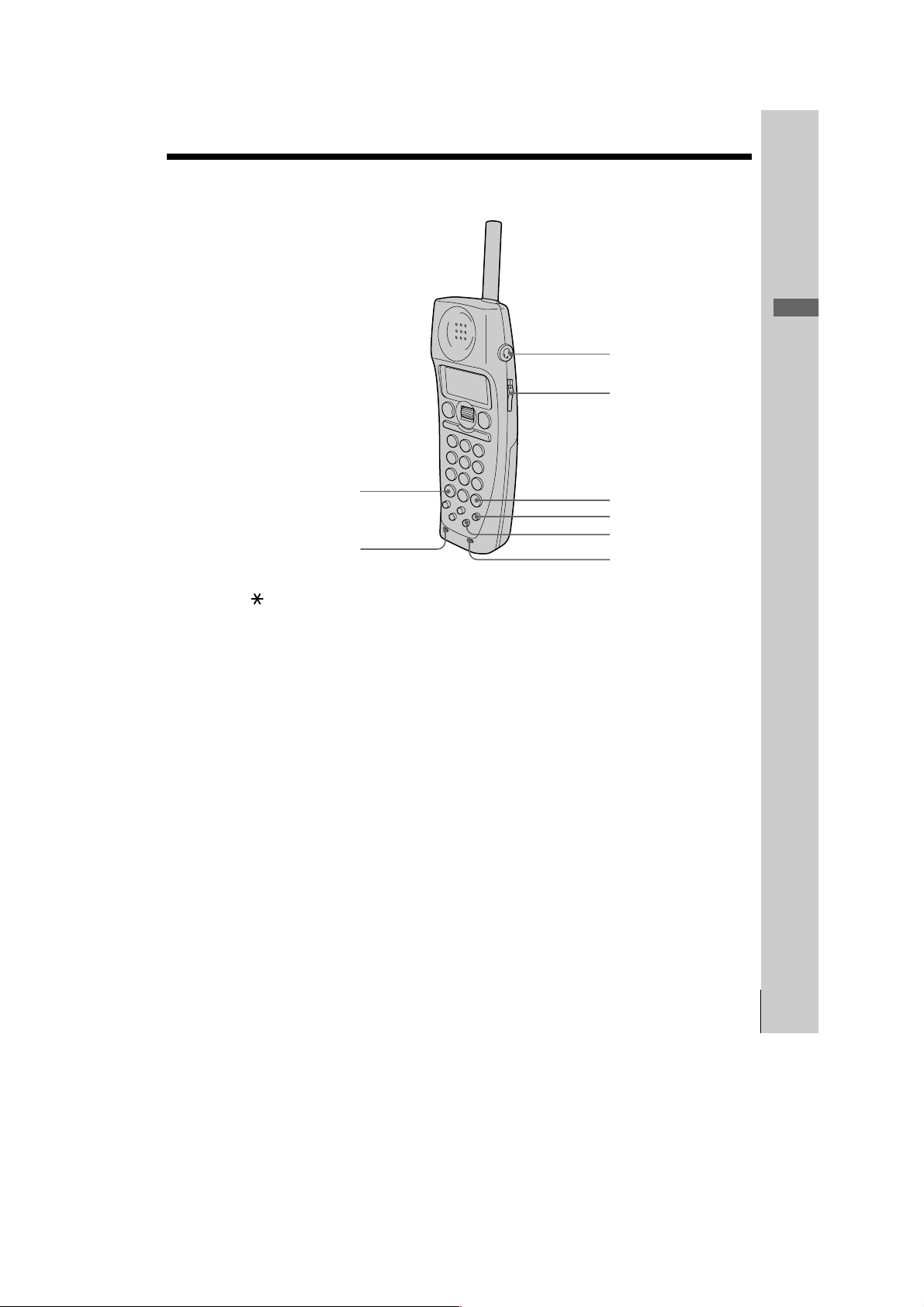

Cordless handset

1

2

3

4

5

6

7

8

1 Antenna

2 Speaker

3 Display window (p. 30, 50)

4 TALK button (p. 30)

Lets you make or receive a call.

5 HOLD button (p. 31)

Puts a call on hold.

6 Battery compartment (p. 14)

7 CALL WAITING/FLASH button

(p. 31, 58)

Switches to a second call if you

have “call waiting” service, or lets

you make a new call.

9

0

qa

qs

qd

9 Jog Dial (p. 17, 37, 51)

0 OFF button (p. 30, 36)

Allows you to disconnect the call.

qa INTERCOM button (p. 48, 49)

Lets you talk between the cordless

handsets (when the system has any

other additional cordless handsets).

qs Dialing keys (p. 30)

qd ERASE button (p. 18, 39)

8 EZ ACCESS button (p. 21, 31)

Lets you make a call with the

registered access number.

US

Getting Started

28

6

qh

qj

SPP-S2720

Getting Started

qf

qg

qf TONE button (p. 31)

Allows you to switch temporarily to

tone dialing.

qg RINGER

qh I (HEADSET) jack (p. 31, 35, 61)

qj VOL (volume) switch (p. 31)

Adjust the cordless handset

volume.

qk # button (p. 56)

Used to change the number of digits

of the phone number in the Caller

ID list.

qk

ql

w;

wa

ql PGM (program) button

(p. 17, 37)

w; REDIAL/PAUSE button

(p. 22, 33)

Redials one of the last five numbers

called/inserts a pause in the dialing

sequence.

wa MIC (Microphone)

Getting Started

29

US

7

SPP-S2720

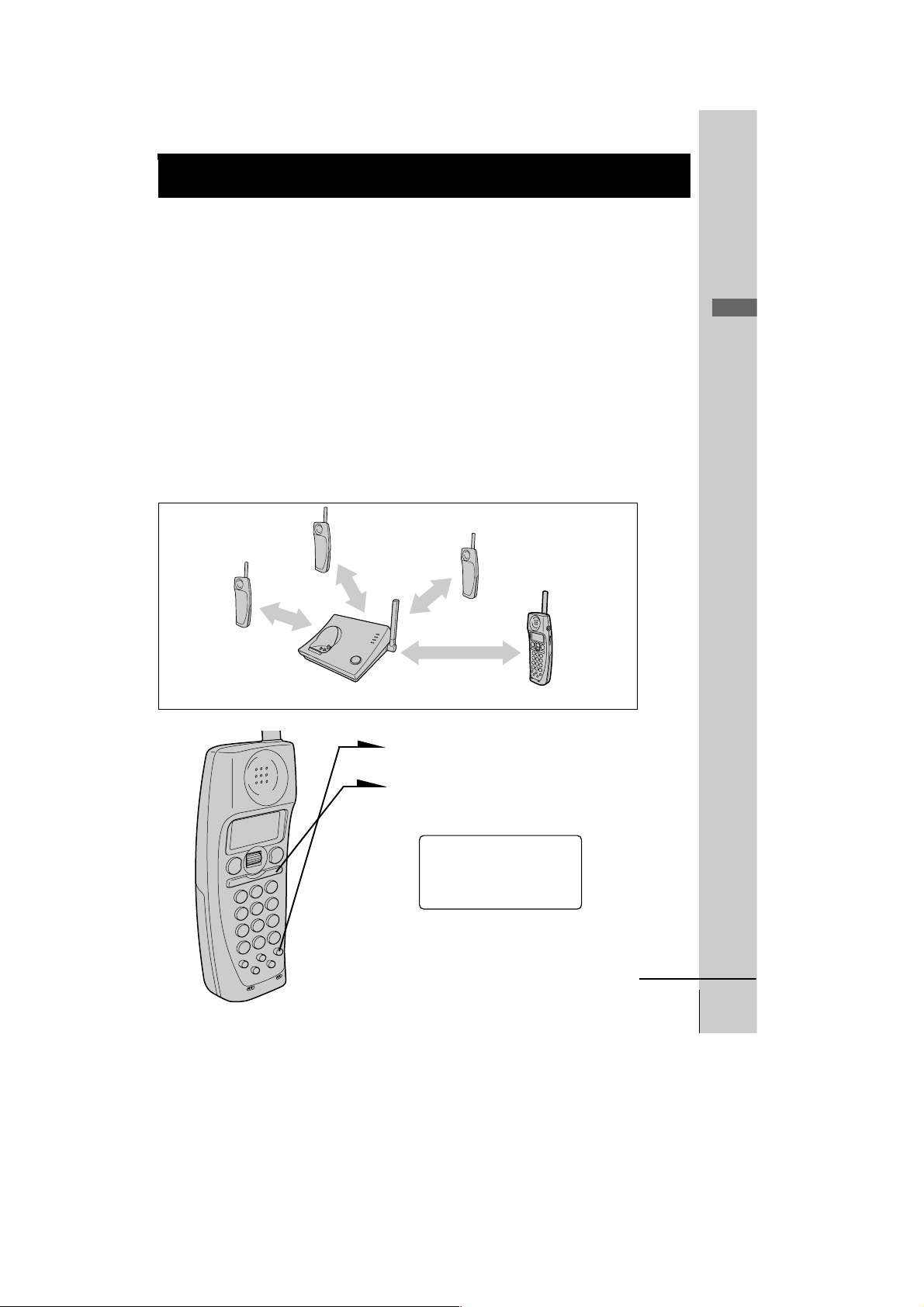

Registering additional cordless handsets

The phone system includes a cordless handset. You can expand the

system including a total of four cordless handsets. Be sure to register

the ID number of the additional cordless handset called “station

number” to the base unit before using the additional cordless handset.

The station number of the cordless handset (supplied with the base

unit) is set to 1 at the factory. The station number of the cordless

telephone newly added to the system will be one of the number 2

through 4 in the order of registration.

Before you start registering, set all the unit of the system in standby

mode and place them close to each other (within a distance of 12

inches). Then do the following procedure only on the additional

cordless handsets one bye one.

Caution

Do not register two or three cordless handsets at the same time.

Doing so may result in more than one cordless handsets having an

identical station number.

Getting Started

Base unit

within 12 inches

cordless handset

1

Press (PGM).

2

Press (INTERCOM).

You hear a confirmation beep.

ENTER SYSTEM ID

_

RING OFFMASSAGEOLDNEW

continued

Getting Started

23

US

8

Registering additional cordless handsets (continued)

3

Enter the 10 digits system ID by

pressing the dialing keys.

The system ID is shown on a sticker

affixed to the bottom of the base unit.

4

Press (PGM).

You hear a long confirmation beep and

the assigned station number is

displayed.

System ID

Notes

• Do not allow more than 60 seconds to elapse during the operation procedure.

• Once you add a cordless handset to the base unit system, you cannot change the

station numbers, or cancel the additional registrations.

• When you press any button other than (PGM) to use an unregistered cordless

handset, the message “PLEASE REGISTER THIS HANDSET” will appear on the

display, and five short error beeps will be heard. You must first register the cordless

handset you want to add to the system.

• If you try to register a cordless handset which you have already added to the system,

the five short error beeps will be heard and the registration will be canceled.

• If the registration is unsuccessful, “ERROR” will appear on the display, and five short

error beeps will be heard after (PGM) is pressed in step 4. Move all the cordless

handsets closer to the base unit, and then start over the procedure.

SPP-S2720

To check the station number assigned to the additional

cordless handset

The station number of the cordless handset appears on

the display of the cordless handset while it is seated on

the charger. You can also utilize the supplied sticker of

the station number and attaching on the cordless

handset. (For details, see Operating Instructions of

SPP-H273.)

US

Getting Started

24

HANDSET 2

RING OFFMASSAGEOLDNEW

9

SPP-S2720

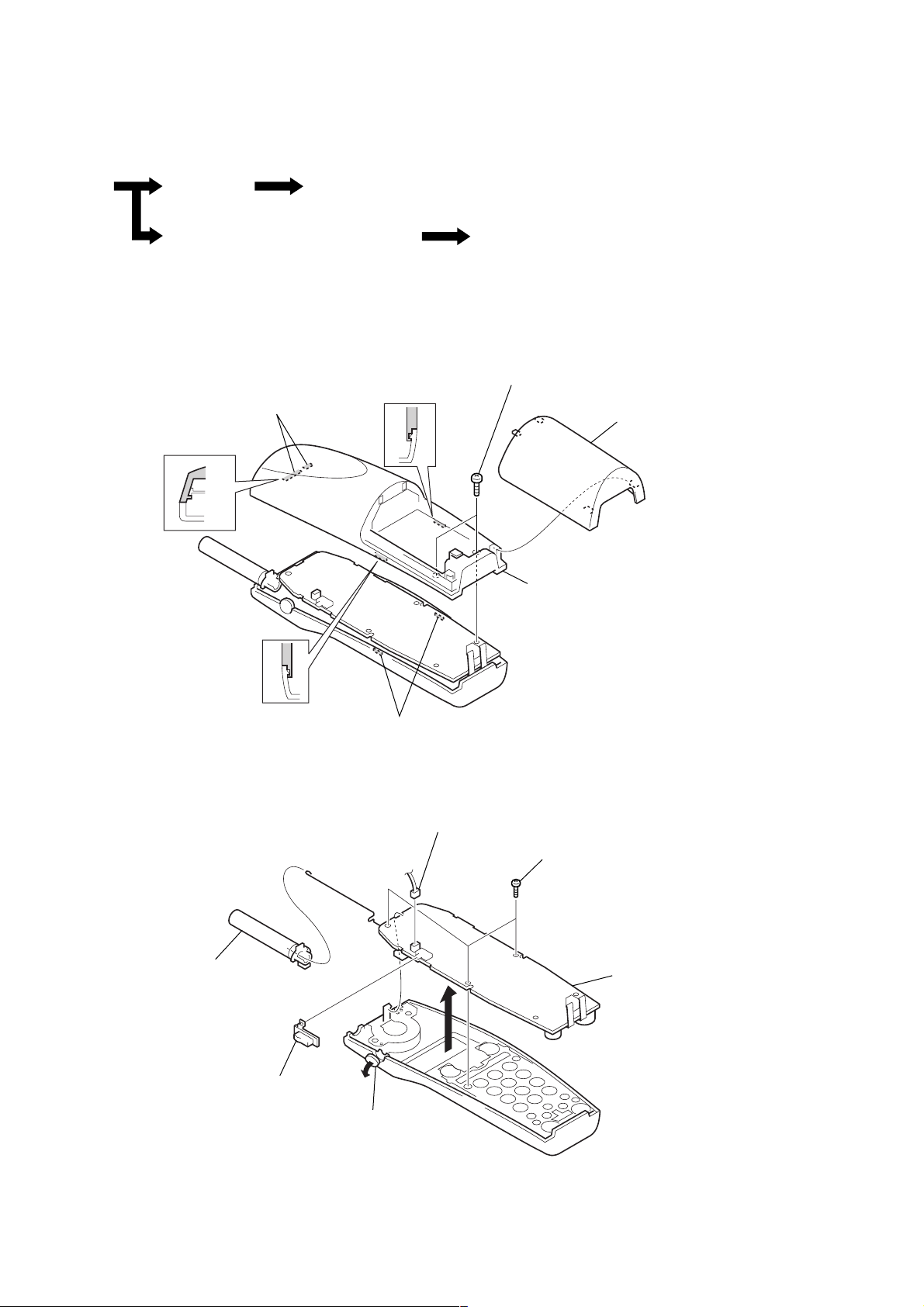

d

d

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

Cabinet (rear) Hand Main Board

Base Cabinet (lower) Assy, Key Main Board Base Main Boar

3-2. CABINET (REAR)

4

two claws

2

two screws (BTP2.6 × 12)

1

5

cabinet (rear)

lid, battery case

3-3. HAND MAIN BOARD

5

cover (antenna. H)

6

button (VOL. H)

3

two claws

3

cover (head set jack)

1

4

connector

(CN1)

2

three screws

(BTP2.6

×

8)

7

HAND MAIN boar

10

3-4. BASE CABINET (LOWER) ASSY, KEY MAIN BOARD

d

1

four screws

×

10)

(BTP3

6

base cabinet (lower) assy

3

screws

(BTP2.6

SPP-S2720

×

8)

3-5. BASE MAIN BOARD

2

four screws

(BTP2.6

2

4

two claws

×

8)

5

KEY MAIN boar

3

BASE MAIN board

1

Remove two solders.

11

SPP-S2720

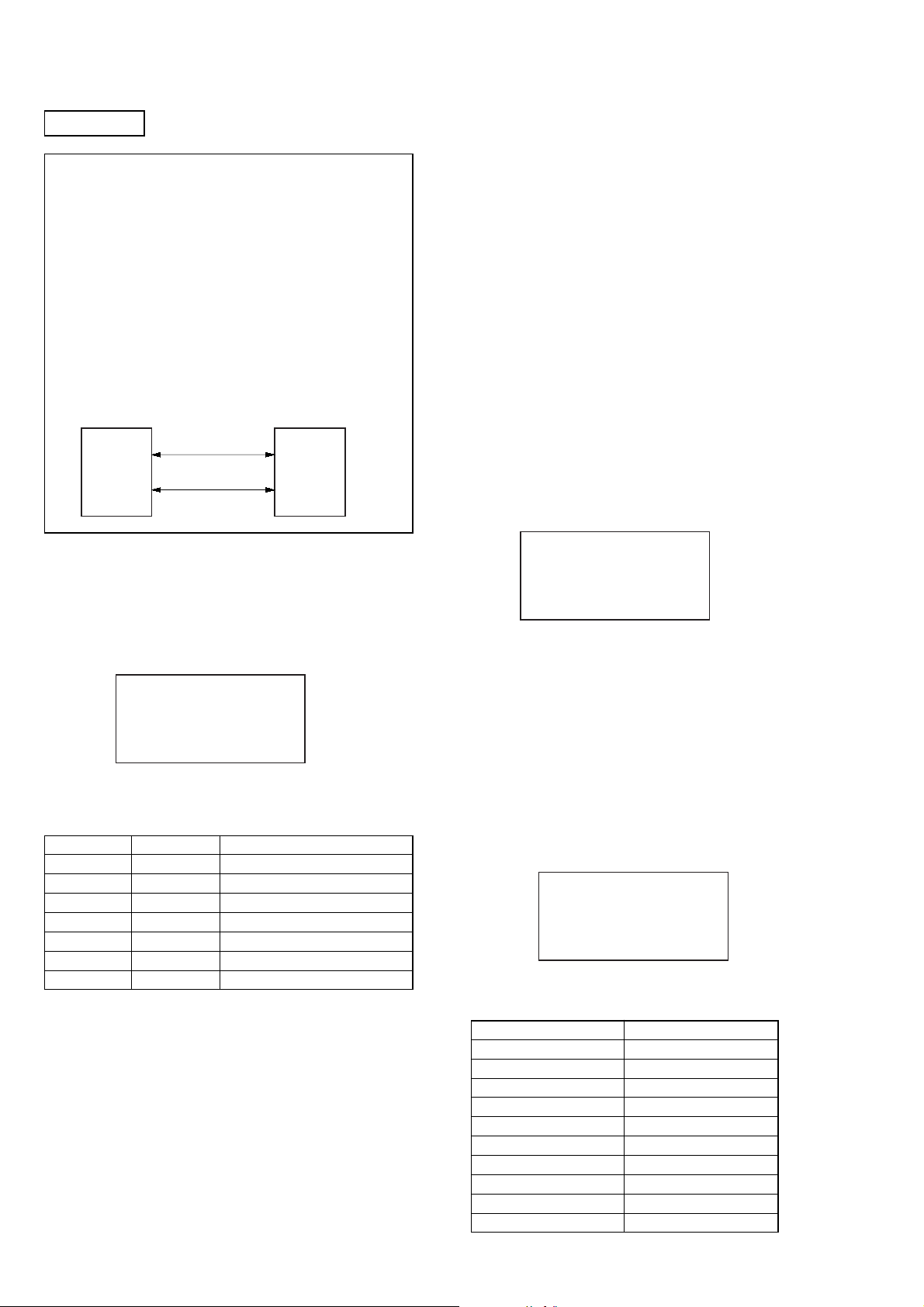

SECTION 4

TEST MODE

BASE UNIT

Note:

To perform the test mode, prepare the panel (BASE CABINET (UPPER) ASSY) for SPP-A2780, and use it connecting the panel for SPPA2780.

But the connector CN302 for panel connection is not mounted on the

BASE MAIN board in this set.

Therefore, in performing the test mode the connector CN302 must be

additionally mounted, and it need not be removed after use, as the

patterns of the board could be damaged when removing the connector.

However, note that it may be a little difficult to close the cabinet with

the CN302 left mounted because of a narrow internal space.

Further, additional mounting of the CN301 for the SPP-2780 panel

connection besides the CN302 enables the LCD display. Also, in this

case, the CN301 need not be removed after repair.

SPP-S2720

BASE MAIN board

CN301

CN302

SPP-A2780 BASE KEY board

(in the panel)

15 pin

11 pin

CN702

CN703

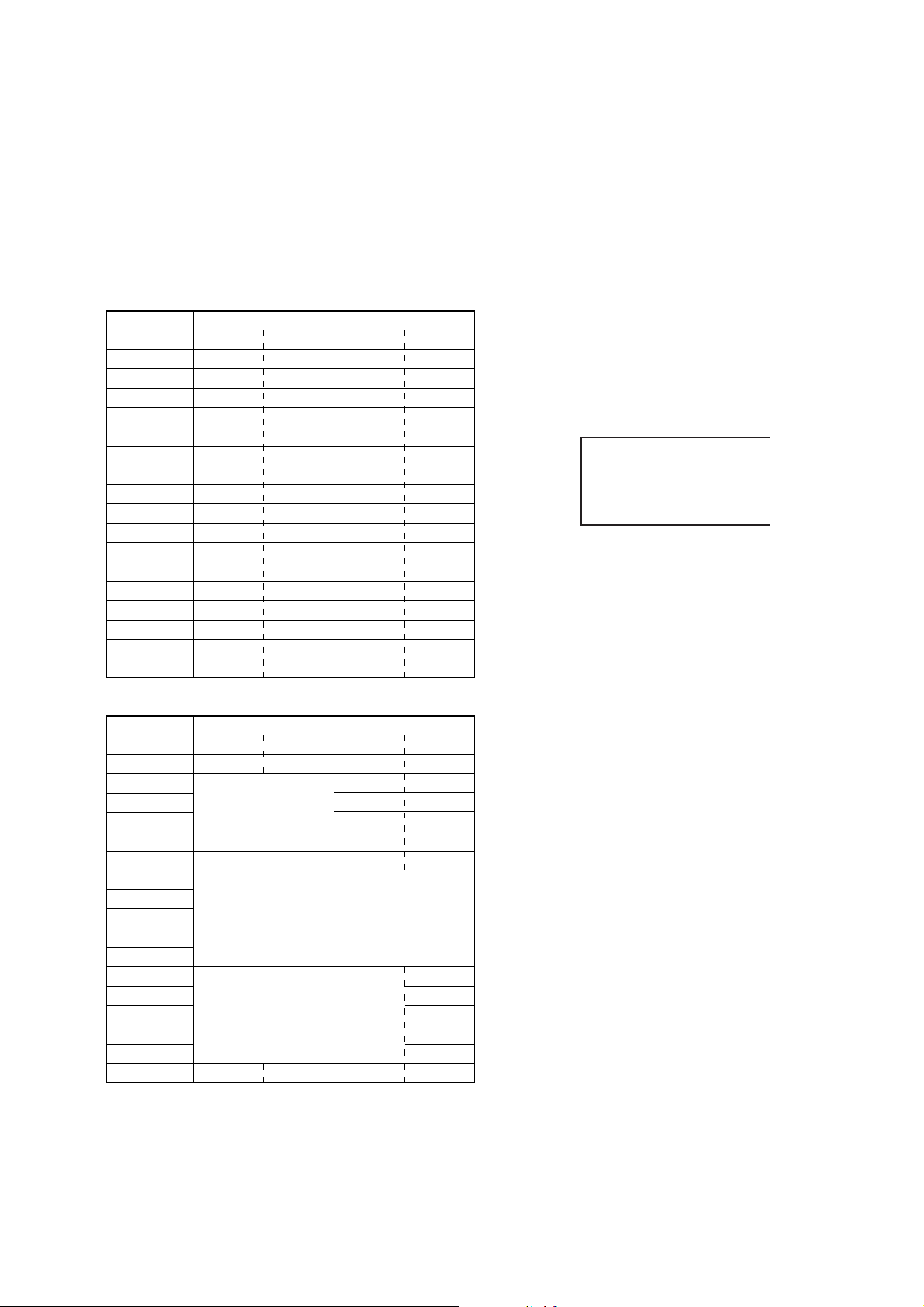

[ENTERING THE TEST MODE]

1. Turn the power on.

2. Press three keys of [2], [6], and [ERASE] simultaneously.

3. When the test mode becomes active, the LCD displays as below. (Idling status of test mode)

2. TEST MODE C (TX Power Measurement Mode)

In the test mode idling status, press the [3] key to active this mode

and display “TEST C”.

1. In the “TEST C” status, press the [1] key to active the TX

power measurement mode and transmit the single carrier continuously.

2. In this status, setting can be changed by entering the following

keys (not displayed).

[1] : Select main antenna

[3] : Select sub antenna

[7] : Select channel 5

[8] : Select channel 28

[9] : Select channel 50

3. TEST MODE D (RF Control Mode)

In the test mode idling status, press the [4] key to active this mode

and display “TEST D”.

In this mode, TX power lev el, TX pow er on/off, bit error late (fixed

at OF), channel number, LQ, mode, RSSI and RXST are displayed

on the LCD as below . Each setting can be changed by entering the

following keys. (default: TX on, master mode)

display example

PW=Hi TXON BR=OF

CH=15 LQM=3F Mst

RSSI=3F STS=1100

display example

JK DSP=V3 0425to

FONT=NEW

S2720

4. Pressing either key in the following table causes the mode associated with the pressed key to be activated.

Key Mode Items

[1] TEST A Manufacturing mode

[3] TEST C Electrical adjustment mode

[4] TEST D RF control mode

[5] TEST E EEPROM read/write mode

[6] TEST F DSP control mode

[7] TEST B Writing the ID numbers

[ERASE] Erase Initialize the EEPROM

5. To return the idling status, press the [VOL --] key.

[RELEASING THE TEST MODE]

Disconnect the power.

[DETAIL OF EACH MODE]

1. TEST MODE A (Manufacturing mode)

In the test mode idling status, press the [1] key to activ e this mode

and display “TEST A”.

LED Test

In the “TEST A” status, press the [3] key to active the LED test

and [IN USE]/[VOICE MAIL] LEDs on this set and [NEW CALL]

LED on this set blink alternately.

[1] : Lowers the channel

[3] : Raises the channel

[4] : Turns on/off the TX

[6] : Switches the mode to master/slave

[7] : Switches the TX power to Lo/ML/MH/Hi

[9] : Switches the antenna to main/sub (not displayed)

4. TEST MODE E (EEPROM Read/Write Mode)

In the test mode idling status, press the [5] key to active this mode

and display as below.

display example

EEPROM ADRS=

Read Dt=

WriteDt=

[][][]

[][][][][][][][]

[][][][][][][][]

[]: hexadecimal number (initial values are all blank)

Refer to following table for key assignment.

Key Assignment

[0] to [9] input 0 to 9

[EZ ACCESS] input A

[REDIAL/PAUSE] input B

[CALL WAITING/FLASH] input C

[INTERCOM] input D

[HOLD] input E

[SPEAKERPHONE] input F

[PROGRAM] check sum

[#] enter

[*] reset

12

SPP-S2720

Enter the data associated with each address by referring to the

“EEPROM data” in the following table.

Writing procedure:

1. Input the address number (3 digit) of EEPROM.

2. Press the [#] key to enter the address number and display read

data (8 digit=4 byte).

3. If rewrite the data, input the rewriting data (8 digit=4 byte).

4. Press the [#] key to enter the rewriting data.

5. To release this mode, press the [VOL --] key.

EEPROM data:

Address Data (hexadecimal)

(hexadecimal) 1st byte 2nd byte 3rd byte 4th byte

754 (ID1) (ID2) F6 (C-sum)

714 81 01 00 (C-sum)

718 03 05 0C (C-sum)

71C C2 C0 00 (C-sum)

720 A9 3D 1C (C-sum)

724 48 C7 04 (C-sum)

728 50 03 51 08

72C 52 08 54 0D

730 5A 06 5D 02

734 60 0B 66 0F

738 70 07 FF 83

73C FF FF FF (C-sum)

740 FF FF FF (C-sum)

744 FF FF FF (C-sum)

690 90 E8 2A (C-sum)

694 6A AA 01 (C-sum)

794 01 00 00 (C-sum)

Contents of EEPROM data:

Address Data (hexadecimal)

(hexadecimal) 1st byte 2nd byte 3rd byte 4th byte

754 ID1 ID2 RF parameter C-sum

714 reserved C-sum

718 audio parameter RF parameter C-sum

71C reserved C-sum

720 RF parameter C-sum

724 audio parameter C-sum

728

72C

730 RF parameter

734

738

73C C-sum

740 reserved C-sum

744 C-sum

690

694 C-sum

794 H-No. reserved C-sum

audio parameter

C-sum

5. TEST MODE F (DSP Control Mode)

In the test mode idling status, press the [6] key to activ e this mode

and display “TEST F”.

CPT detection

When detect stutter tone, it lights up the [IN USE] LED.

6. TEST MODE B (Writing the ID number)

Note: Though the “TEST MODE E” handles the ID numbers as hexa-

decimal numbers, the “TEST MODE B” handles them as decimal

numbers. Both are different in numerical notation format only, and

net values are same.

The ID numbers written on the bottom of base unit are decimal

numbers, and accordingly use the “TEST MODE B” when entering the ID numbers.

In the test mode idling status, press the [7] key to activ e this mode

and display as below.

display example

TEST B 224******

ID=224

*: Already registered ID number

[]: Inputted ID number (initial values are all blank)

IF a wrong ID number was entered by mistake, press the [VOL--]

key to return to the test mode idling status, then re-enter correct

ID number.

7. INITIALIZE THE EEPROM

In the test mode idling status, EEPROM (IC303) and Flash memory

(IC403) are all cleared except VP setting v alue when the [ERASE]

key is pressed.

When execute this operation, it erases stored data (phone dictionary, caller ID, message data).

[][][][][][]

Note:

ID1, ID2 : ID numbers in hexadecimal notation (refer to “6. TEST MODE

B”)

C-sum : Check sum value (After entering the data up to 3 bytes, press

the [PROGRAM] key to start automatic calculation.)

H-No. : Number of registered handset

13

SPP-S2720

HANDSET

[ENTERING THE TEST MODE]

1. Connect the power.

2. Press three keys of [2], [6], and [ERASE] simultaneously.

3. When the test mode becomes active, the LCD displays as below along with an acknowledged tone. (Idling status of test

mode)

display example

JK 0425to

FONT=NEW

S2720

4. Pressing either key in the following table causes the mode associated with the pressed key to be activated.

Key Mode Items

[1] TEST A Manufacturing mode

[3] TEST C Electrical adjustment mode

[4] TEST D RF control mode

[5] TEST E EEPROM read/write mode

[7] TEST B Writing the ID numbers

[ERASE] Erase Initialize the EEPROM

1-2. Jog T est

1. In the “TEST A” status, press the [2] key to active the jog test

and display as below.

display example

TEST A JOG

UP

2. In this test mode, rotate the jog dial up/down or press the jog

dial to respective status will be displayed on the LCD as follows.

Up the jog dial : “UP” is displayed on the second line.

Down the jog dial : “DN” is displayed on the second line.

Press the jog dial : “P” is displayed on the second line.

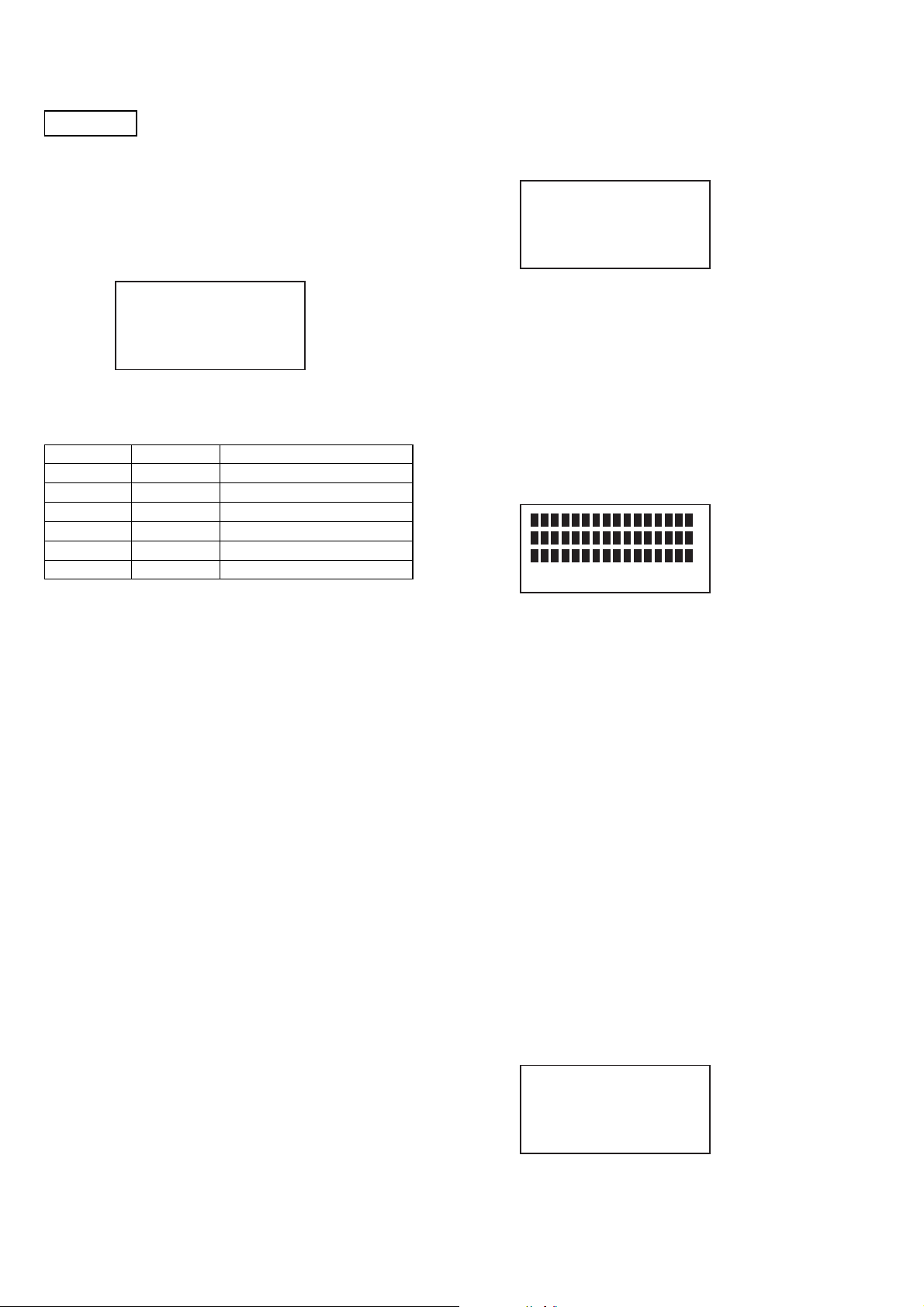

1-3. LCD and LED Test

In the “TEST A” status, press the [3] key to active the LCD and

LED test and display as below along with the LCD back light and

key illumination LED blink alternately.

display

[NEW][OLD][MESSAGE][RING OFF]

5. To return the idling status, press the [OFF] key.

[RELEASING THE TEST MODE]

Disconnect the power.

[DETAIL OF EACH MODE]

1. TEST MODE A (Manufacturing mode)

In the test mode idling status, press the [1] key to activ e this mode

and display “TEST A”.

1-1. Key T est

1. In the “TEST A” status, press the [1] key to active the ke y test

and display “TEST A KEY”.

2. Press the key following order.

[TALK]t[OFF]t[HOLD]t[INTERCOM]t[1]t[2]t

[3]t[4]t[5]t[6]t[7]t[8]t[9]t[*]t[0]t[#]t

[CALL WAITING/FLASH]t [EZ ACCESS]t [ERASE]t

[REDIAL/PAUSE]t[PGM]

3. When this test finished, a completion tone is generated and

the base unit returns to the initial test mode “TEST A” and

waits for a command.

Also, pressing the keys in wrong order causes the set to be

returned to the initial status.

Note: “NEW”/“MESSAGE” and “OLD”/“RING OFF” blink alternately

2. TEST MODE C (TX Power Measurement Mode)

In the test mode idling status, press the [3] key to active this mode

and display “TEST C”.

1. In the “TEST C” status, press the [1] key to active the TX

power measurement mode and transmit the single carrier continuously.

2. In this status, setting can be changed by entering the following

keys (not displayed).

[1] : Set TX power to middle/low

[3] : Set TX power to high

[7] : Select channel 5

[8] : Select channel 28

[9] : Select channel 50

3. TEST MODE D (RF Control Mode)

In the test mode idling status, press the [4] key to active this mode

and display “TEST D”.

In this mode, TX power lev el, TX pow er on/off, bit error late (fixed

at OF), channel number, LQ, mode, RSSI and RXST are displayed

on the LCD as below . Each setting can be changed by entering the

following keys. (default: TX on, slave mode)

display example

14

PW=Hi TXON BR=OF

CH=15 LQM=3F Slv

RSSI=3F STS=1100

[1] : Lowers the channel

[3] : Raises the channel

[4] : Turns on/off the TX

[6] : Switches the mode to master/slave

[7] : Switches the TX power to Lo/ML/MH/Hi

SPP-S2720

4. TEST MODE E (EEPROM Read/Write Mode)

In the test mode idling status, press the [5] key to activ e this mode

and display as below.

display example

EEPROM ADRS=

Read Dt=

WriteDt=

[][][]

[][][][][][][][]

[][][][][][][][]

[]: hexadecimal number (initial values are all blank)

Refer to following table for key assignment.

Key Assignment

[0] to [9] input 0 to 9

[HOLD] input A

[INTERCOM] input B

[CALL WAITING/FLASH] input C

[EZ ACCESS] input D

[ERASE] input E

[REDIAL/PAUSE] input F

[PGM] check sum

[#] enter

[*] reset

Enter the data associated with each address by referring to the

“EEPROM data” in the following table.

Writing procedure:

1. Input the address number (3 digit) of EEPROM.

2. Press the

data (8 digit=4 byte).

3. If rewrite the data, input the rewriting data (8 digit=4 byte).

4. Press the [#] key to enter the rewriting data.

5. To release this mode, press the [OFF] key.

EEPROM data:

Address Data (hexadecimal)

(hexadecimal) 1st byte 2nd byte 3rd byte 4th byte

[#] key to enter the address number and display read

004 (ID1) (ID2) F6 (C-sum)

0E0 A9 3D 1C FD

008 50 03 51 08

00C 52 08 54 0D

010 5A 06 5D 02

014 60 0B 66 0F

018 70 07 FF 83

01C FF FF FF FF

020 FF FF FF FF

024 FF FF FF FF

0D8 01 01 00 (C-sum)

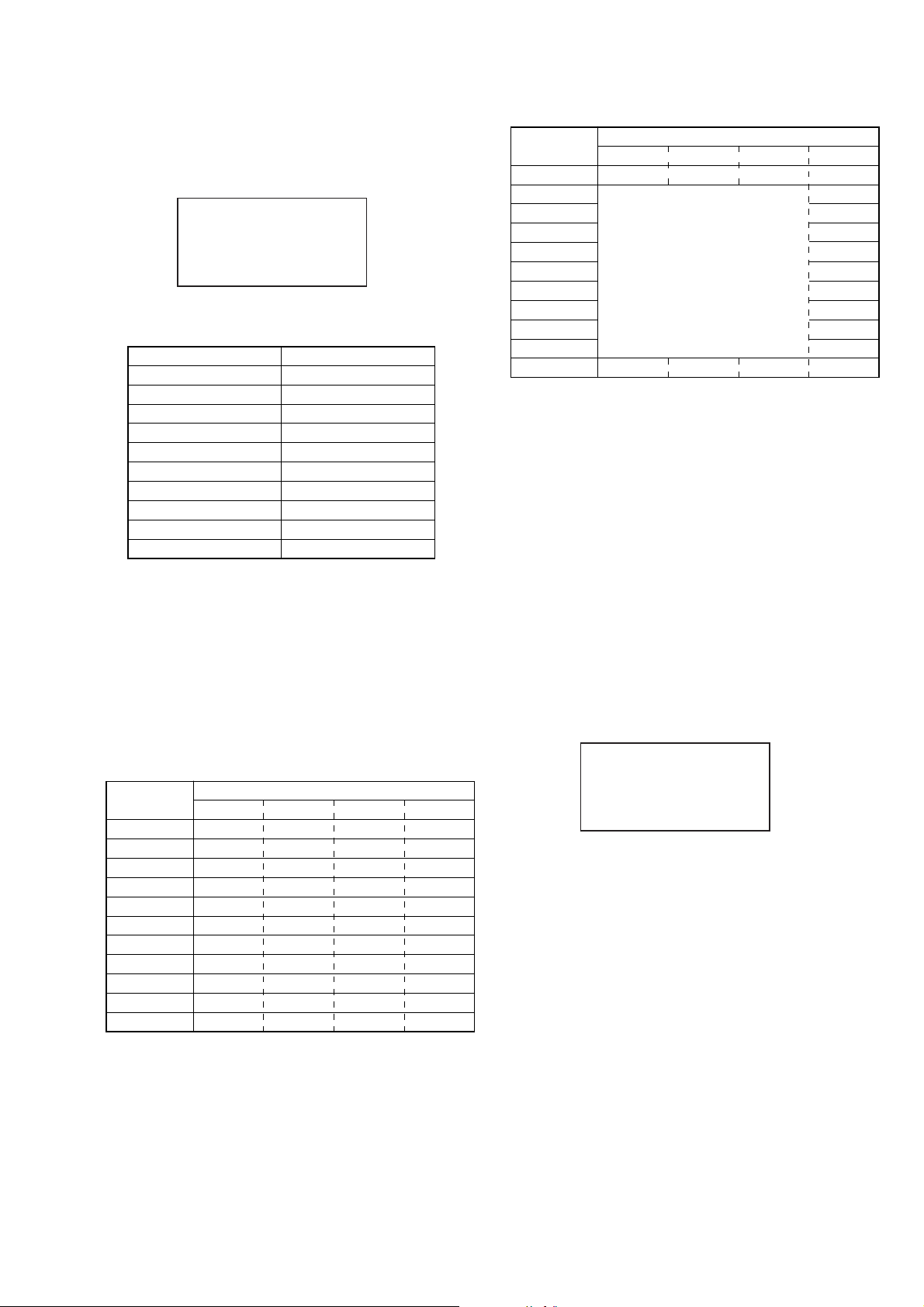

Contents of EEPROM data:

Address Data (hexadecimal)

(hexadecimal) 1st byte 2nd byte 3rd byte 4th byte

004 ID1 ID2 RF parameter C-sum

0E0 C-sum

008 C-sum

00C C-sum

010 C-sum

014 RF parameter C-sum

018 C-sum

01C C-sum

020 C-sum

024 C-sum

0D8 OWN-No. H-No. M-No. C-sum

Note:

ID1, ID2 :ID numbers in hexadecimal notation (refer to “5. TEST MODE

C-sum : Check sum value (After entering the data up to 3 bytes, press

OWN-No.: Self number of handset

H-No. : Number of registered handset

M-No. : Number of model destination (SPP-S2720: 00h)

B”)

the [PROGRAM] key to start automatic calculation)

5. TEST MODE B (Writing the ID number)

Note: Though the “TEST MODE E” handles the ID numbers as hexa-

decimal numbers, the “TEST MODE B” handles them as decimal

numbers. Both are different in numerical notation format only, and

net values are same.

The ID numbers written on the bottom of base unit are decimal

numbers, and accordingly use the “TEST MODE B” when entering the ID numbers.

In the test mode idling status, press the [7] key to activ e this mode

and display as below.

display example

TEST B 224******

ID=224

*: Already registered ID number

[]: Inputted ID number (initial values are all blank)

IF a wrong ID number was entered by mistake, press the [OFF]

key to return to the test mode idling status, then re-enter correct

ID number.

6. INITIALIZE THE EEPROM

In the test mode idling status, EEPROM (IC122) is all cleared

except VP setting value when the [ERASE] key is pressed.

When execute this operation, it erases stored data (phone dictionary, caller ID, message data).

[][][][][][]

15

Loading...

Loading...