Sony SPP-801, SPP-811, SPP-851, SPP-861 Service Manual

SPP-801/811/851/861

MICROFILM

SERVICE MANUAL

Ver 1.1 2000. 11

With SUPPLEMENT-1

(9-927-610-81)

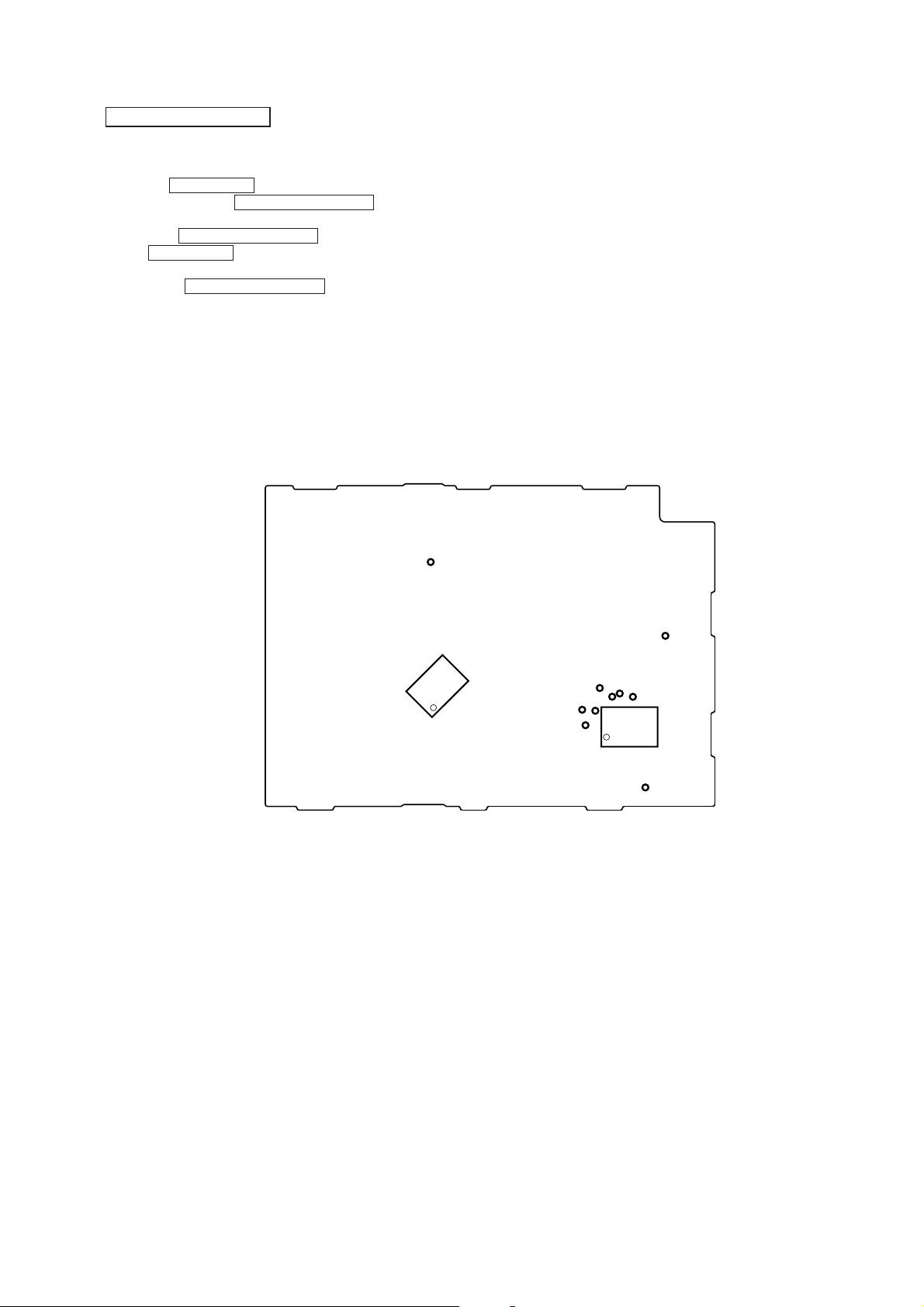

Photo: SPP-851

SPECIFICATIONS

General

Frequency control Crystal-controlled PLL

Operation mode FM, duplex

Operation channel 10 channels

Supplied accessories AC power adaptor AC-T56 (1)

Telephone line cord (1)

Rechargeable battery pack BP-T16 (1)

Screws (2)

Directories (2 sheets)

Taiwan Model

Handset

Power source Rechargeable battery pack BP-T16

Battery life Standby: Approx. 14 days

Dimensions Approx. 58 × 194 × 47

Mass Approx. 220 g, battery included

Base unit

Power source DC 9V from AC power adaptor

Battery charging time Approx. 12 hours

Dimensions Approx. 132 × 56 × 220 mm (w/h/d), antenna

Mass Approx. 310 g

Design and specifications are subject to change without notice.

Talk: Approx. 6 hours

excluded

Antenna: Approx. 110 mm

excluded

Antenna: Approx. 310 mm

mm (w/h/d), antenna

CORDLESS TELEPHONE

– 1 –

TABLE OF CONTENTS

1. GENERAL ........................................................................... 3

2. DISASSEMBLY

2-1. Cabinet (Lower) (Base Unit)............................................... 6

2-2. Cabinet (Rear) (Handset) ....................................................6

3. TEST MODE

Base Unit Section ....................................................................7

Handset Section ....................................................................... 9

4. ELECTRICAL ADJUSTMENTS

Base Unit Section ..................................................................12

Handset Section ..................................................................... 14

5. DIAGRAMS

5-1. IC Pin Descriptions ...........................................................16

5-2. Block Diagram –Base Unit Section– ................................19

5-3. Block Diagram –Handset Section– ................................... 21

5-4. Printed Wiring Board –Base Unit Section– ......................23

5-5. Schematic Diagram –Base Unit Section– .........................25

5-6. Printed Wiring Board –Handset Section– ......................... 27

5-7. Schematic Diagram –Handset Section– ............................ 29

6. EXPLODED VIEWS

6-1. Base Unit Section .............................................................. 32

6-2. Handset Section................................................................. 33

7. ELECTRICAL PARTS LIST ........................................ 34

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P AR T NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

GENERAL

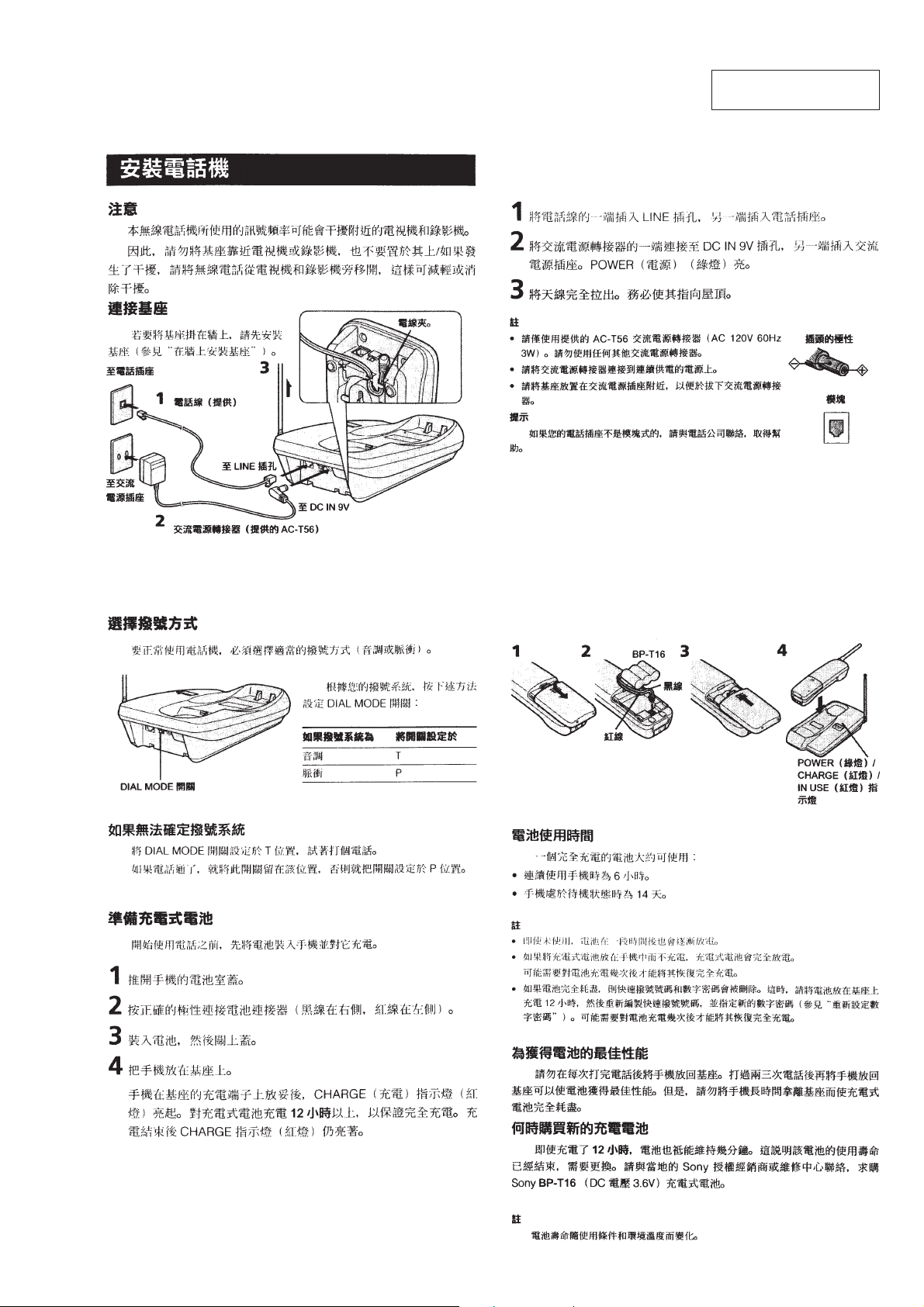

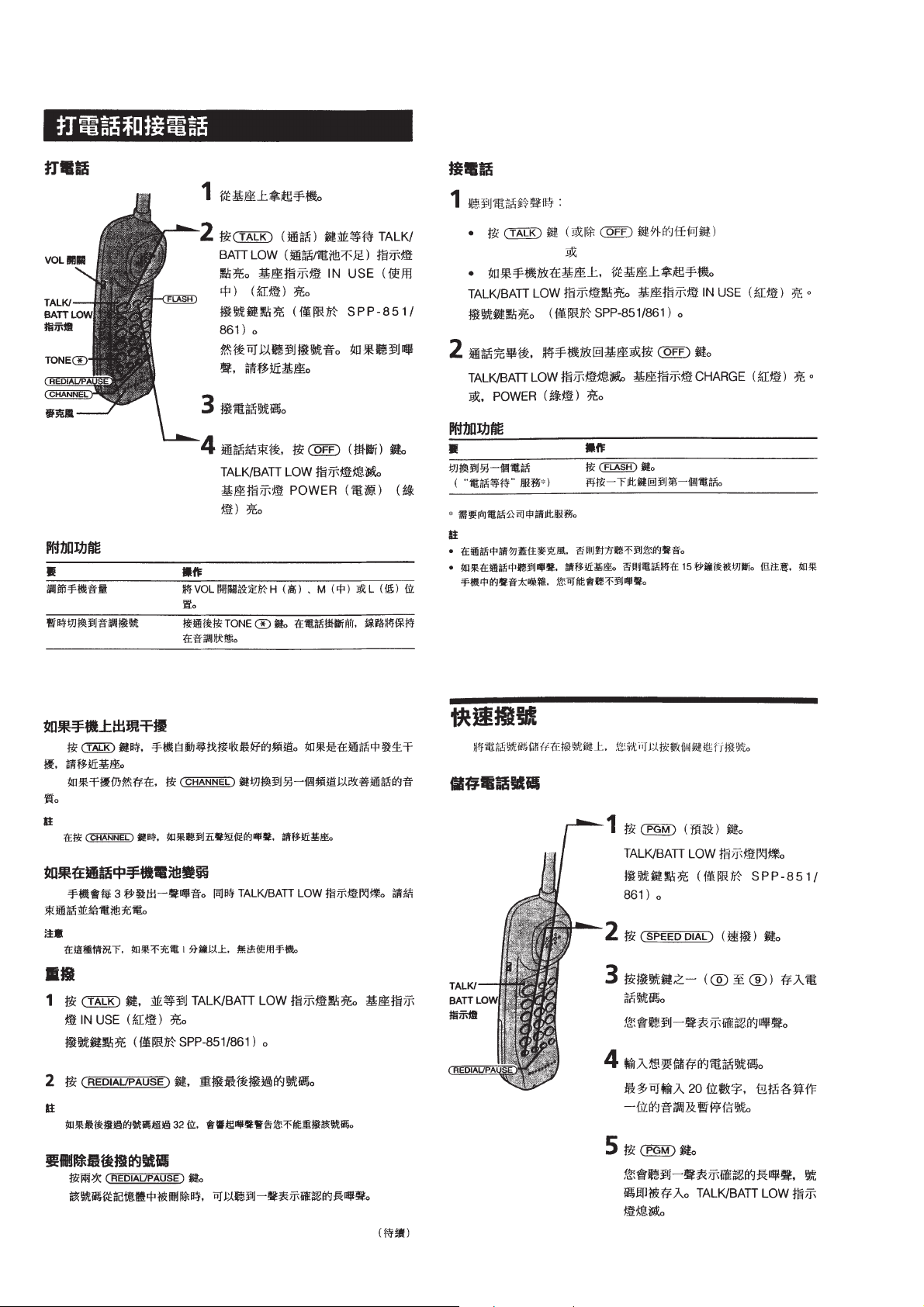

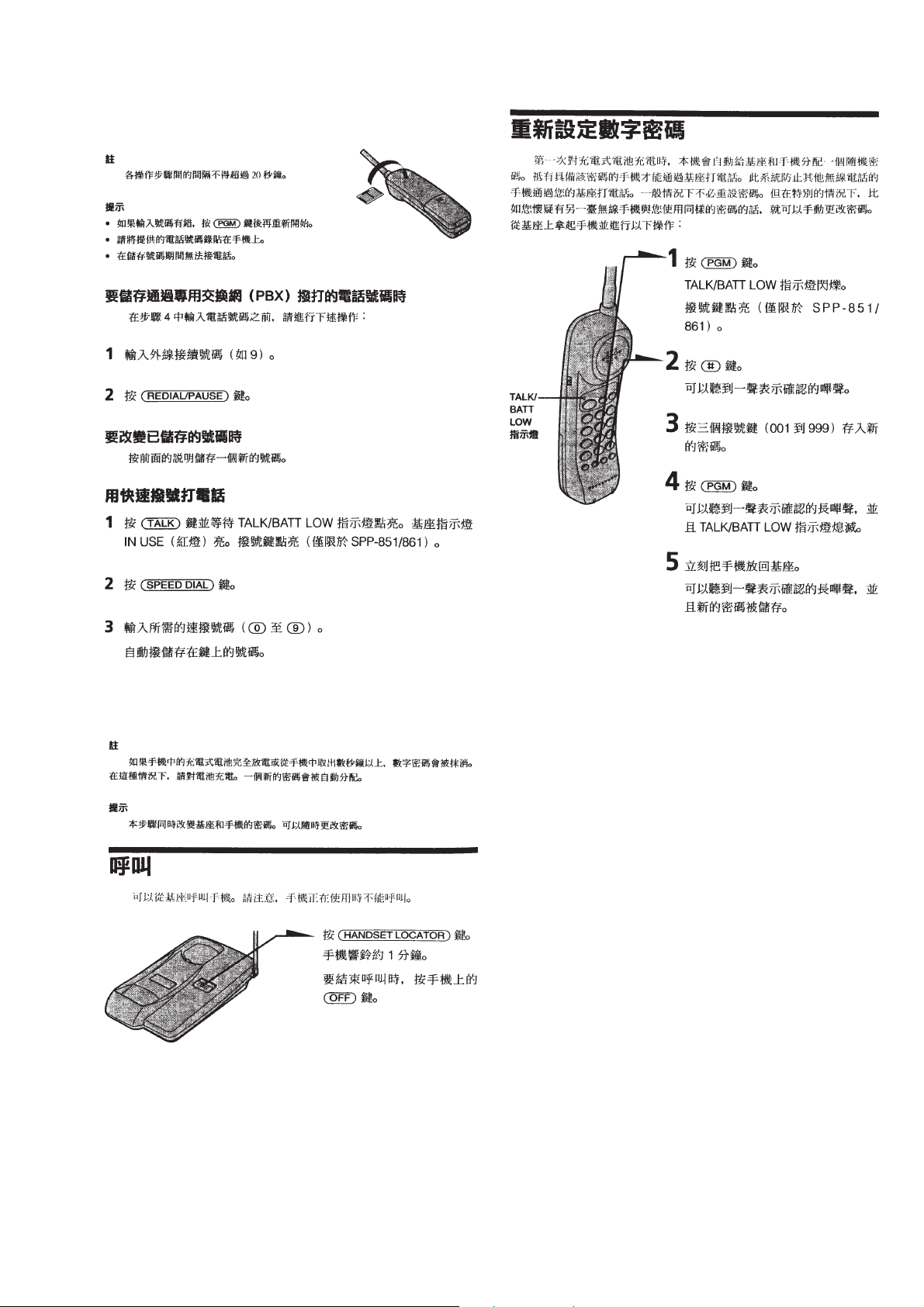

This section is extracted

from instruction manual.

– 3 –

– 4 –

– 5 –

)

)

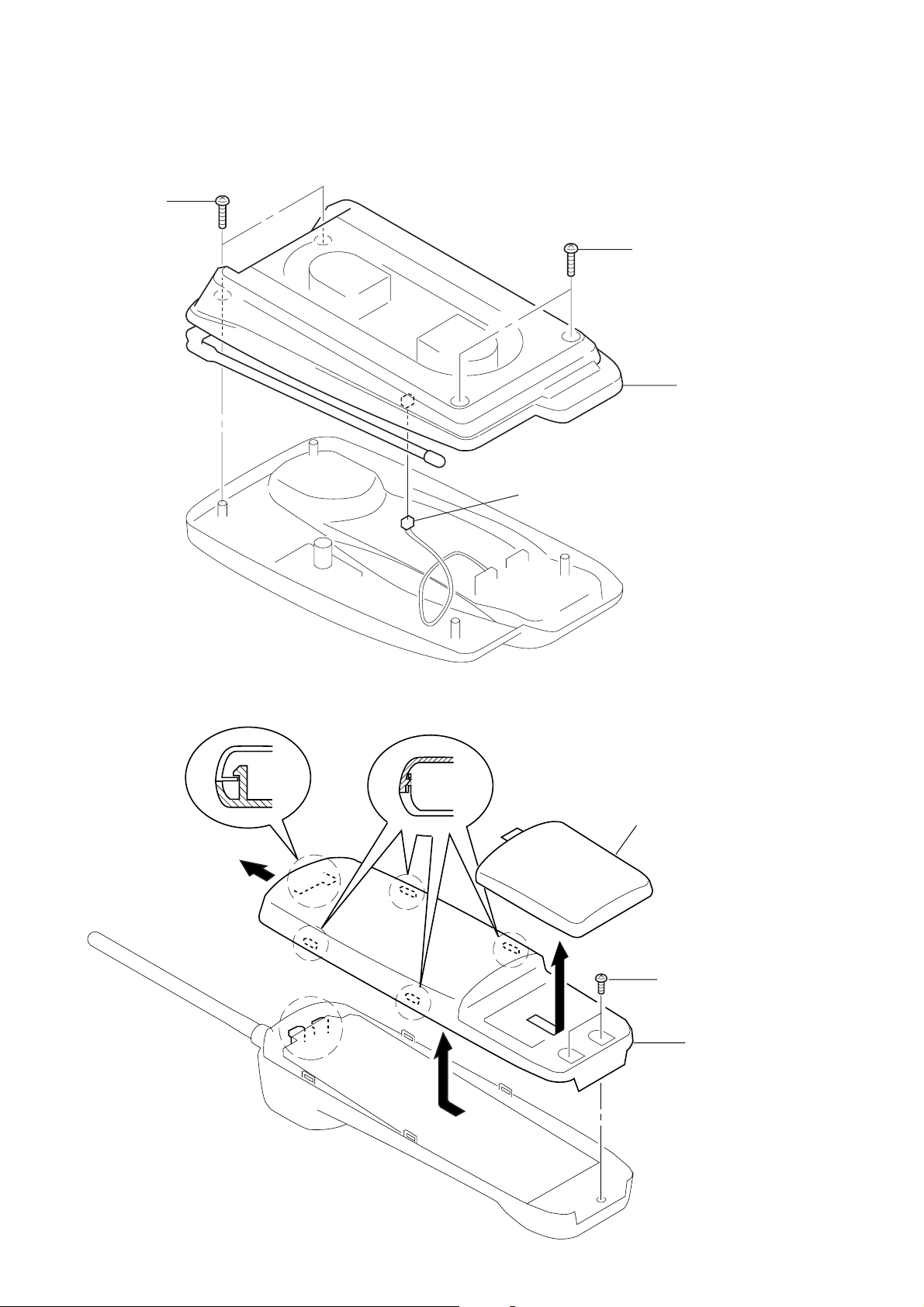

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (LOWER) (BASE UNIT)

1

P 3x10

3

connector (CN301)

2

P 3x10

4

cabinet (lower

2-2. CABINET (REAR) (HANDSET)

4

claw

3

claws

1

battery case lid assy

2

BTP 2.6x10

5

cabinet (rear

– 6 –

SECTION 3

TEST MODE

BASE UNIT SECTION

MANUAL TEST MODE

Set the Test Mode:

1. Set the DIAL MODE switch to “P” (pulse).

2. While pressing the HANDSET LOCATOR key, insert the AC

adaptor (Reset start).

3. With the HANDSET LOCATOR key, still held down, switch

the DIAL MODE switch “P” (pulse) n “T” (tone) n

“P” (pulse).

4. When the HANDSET LOCATOR key is released, test mode

starts.

5. Firstly, “0” will be dialled out at 10 pps. Then “1”, “4”, “8”

and “#” will be sent out by DTMF.

6. Set to TX ON. Goes to external line state in 1 CH.

Release the Test Mode:

1. Pull out the AC adaptor or turn off the power.

– base main board (conductor side) –

TP46

MACHINE TEST MODE

Set the Test Mode:

1. With one of the CH setting terminals in “H” input state,cause

Reset of Power ON. Equipment enters machine test mode.

2. Setting of CH according to logic input with CH setting

terminal.

3. ON/OFF of TX is according to the input logic of the DIAL

MODE terminal.

Release the Test Mode:

1. Pull out the AC adaptor or turn off the power.

2. Remove the short plug and turn on the power again.

IC101

TP65

TP64

TP66

TP63

TP47

TP62

TP61

TP67

IC501

TP106

– 7 –

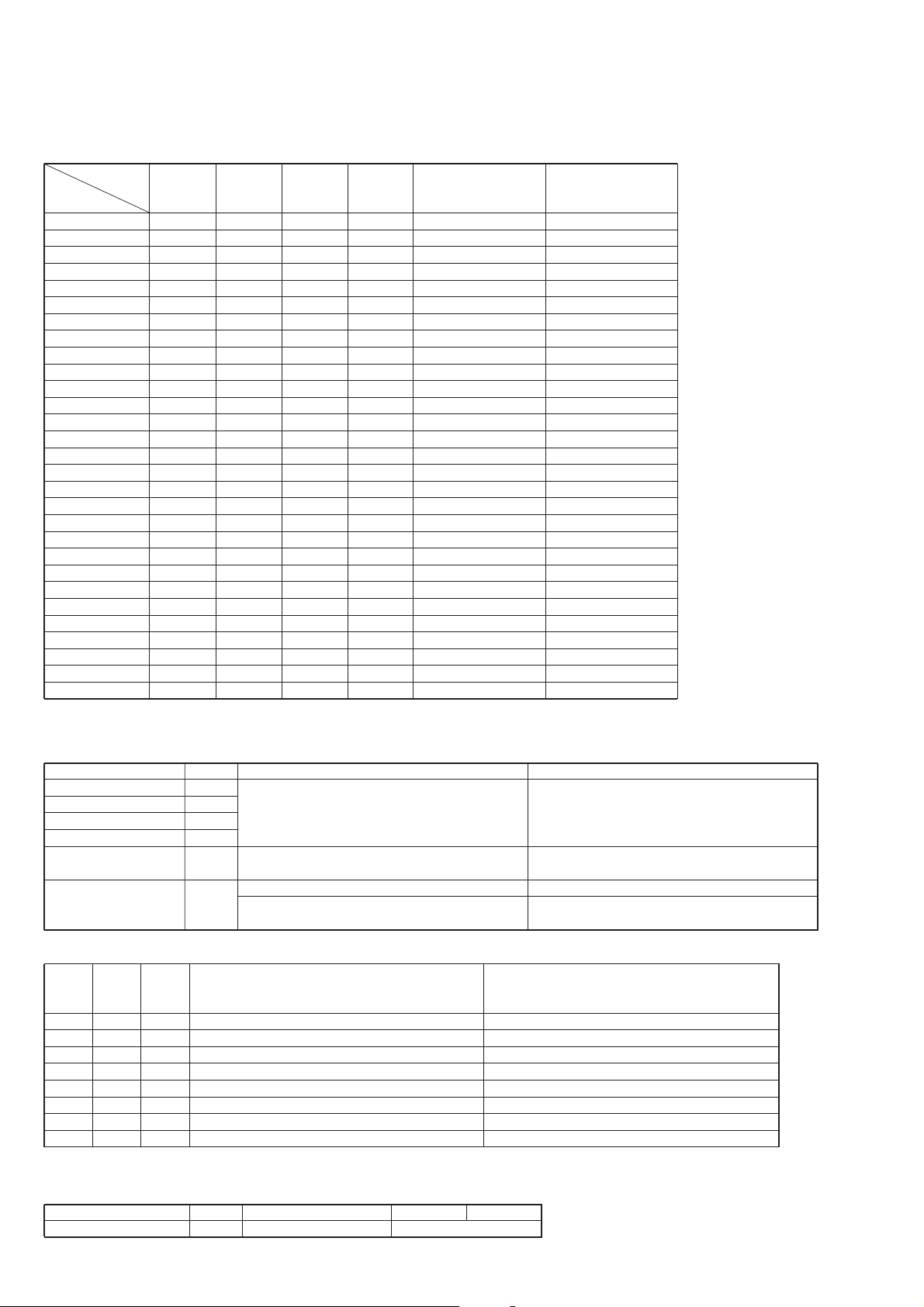

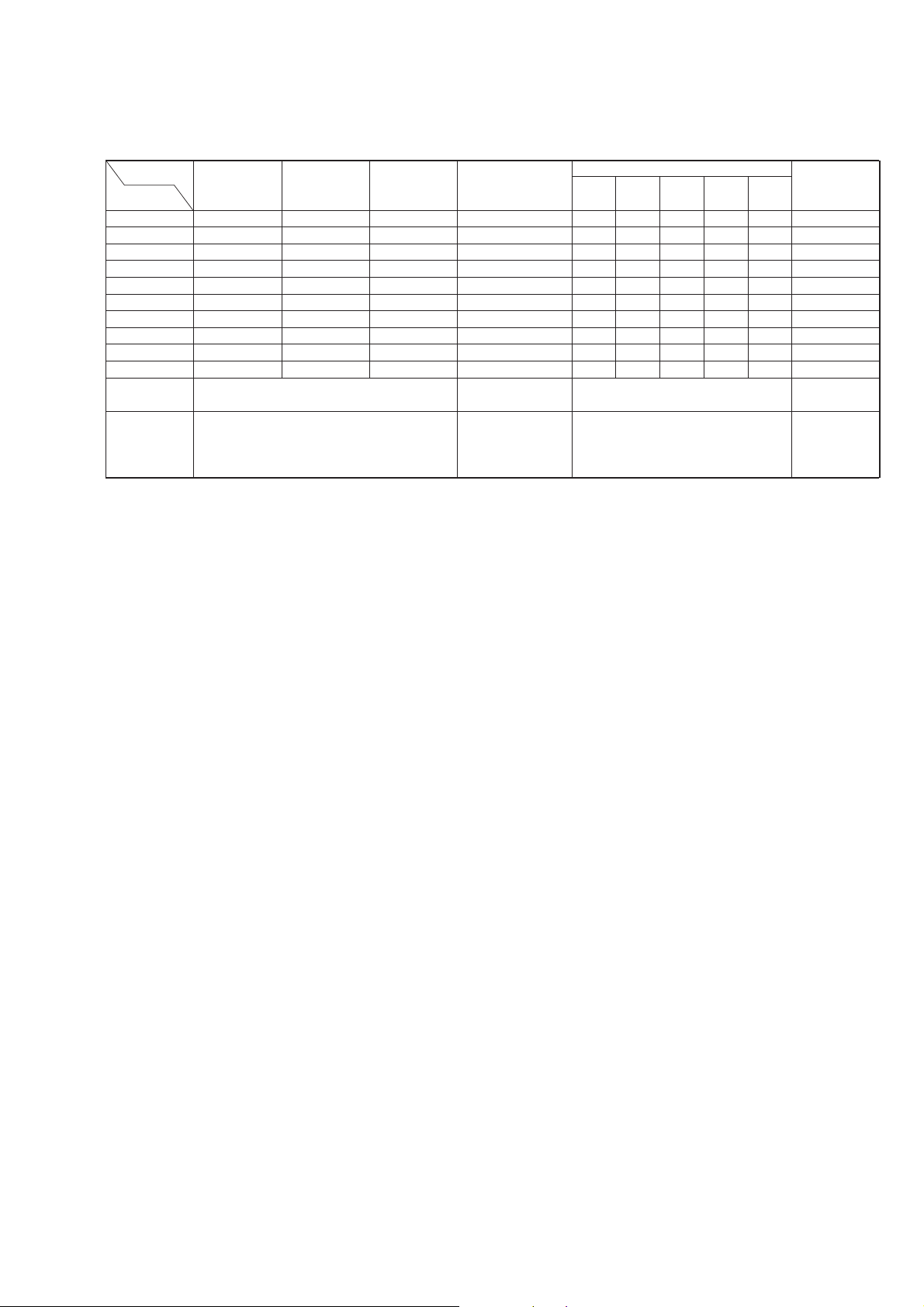

Channel Setting:

During startup in machine test mode, make the following channel

settings by loading the terminal input data.

Pin No.

Channel

CH1 H L L L 43.720 48.760

CH2 L H L L 43.740 48.840

CH3 H H L L 43.820 48.860

CH4 L L H L 43.840 48.920

CH5 43.920 49.020

CH6 43.960 49.080

CH7 44.120 49.100

CH8 44.160 49.160

CH9 44.180 49.200

CH10 44.200 49.240

CH11 44.320 49.280

CH12 44.360 49.360

CH13 44.400 49.400

CH14 H L H L 44.460 49.460

CH15 L H H L 44.480 49.500

CH16 H H H L 46.610 49.670

CH17 L L L H 46.630 49.845

CH18 46.670 49.860

CH19 46.710 49.770

CH20 46.730 49.875

CH21 46.770 49.830

CH22 46.830 49.890

CH23 H L L H 46.870 49.930

CH24 L H L H 46.930 49.990

CH25 H H L H 46.970 49.970

TEST1 L L H H 43.780 48.800

TEST2 H L H H 43.890 48.970

TEST3 L H H H 46.800 49.910

TEST4 H H H H 46.900 49.950

23 24 25 26

M1 M2 M3 M4

(TP61) (TP62) (TP63) (TP64)

TX frequency RX frequency

(MHz) (MHz)

Machine Test Mode Input / Output:

1. Input (Input ports for other than main tasks)

Pin Name Pin No. Function Logic

M1 (TP61) 23

M2 (TP62) 24

M3 (TP63) 25

M4 (TP64) 26

DIAL MODE

(TP47)

HANDSET LOCATOR

(TP46)

29 28 27

TEST1 TEST2 TEST3 Operation with CHARGE LED Operation with TX ON

(TP67) (TP66) (TP65)

L L L If RSSI (H) is detected : Light ON If RSSI (H) is detected : Light ON

L L H If RSSI (L) is detected : Light ON If RSSI (L) is detected : Light ON

L H L If TX LOCK is detected : Light OFF If TX LOCK is detected : Light OFF

L H H If RX LOCK is detected : Light OFF If RX LOCK is detected : Light OFF

H L L BEEP output

H L H ID CODE output

H H L If RING is detected : Light ON If RING is detected : Light ON

H H H If HANDSET LOCATOR key is input : Light ON If HANDSET LOCATOR key is input : Light ON

Setting the CH (channel) Refer to channel setting

17 Setting the TX ON/OFF TONE : open, PULSE : short

Manual : Channel increment Incrementing of channels in order from 1 to 10.

16 Machine : Dial data “5” is output to Key input with “L” input.

DTMF/DP exchange The first time there is output of “5” with DTMF.

2. Output (Output ports for other than main tasks)

Pin Name Pin No. Function H Logic L Logic

CHARGE DET (TP21) 18 State in section 1. Input Refer to section 1. Input

– 8 –

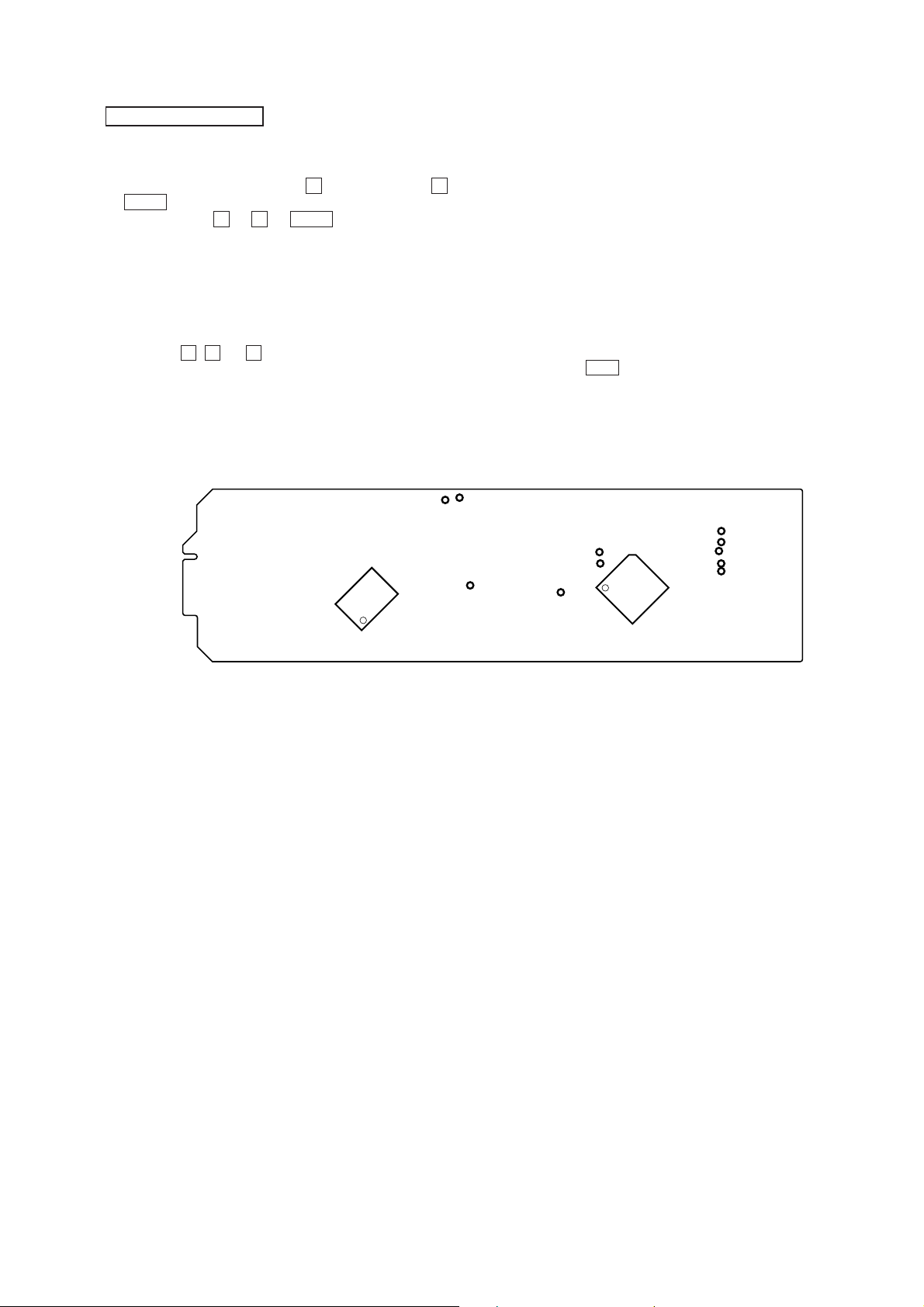

HANDSET SECTION

MANUAL TEST MODE

Set the Test Mode:

1. Enter the test mode by pressing 0 key while pressing 1 and

TALK keys when in idle condition.

(Key operation 0 n 1 n TALK )

2. The RINGER will ring for 500 msec. when the test mode is

started.

3. Measurement mode of consumption current. (42# state)

4. Use key input to carry out the various settings.

5. Use port inputs to set output from LED terminals.

Release the Test Mode:

1. Press the 0 , 0 and # keys.

2. Turn off the power. (Remove the battery and replace them.)

– hand main board (side B) –

TP35

TP55

IC101

MACHINE TEST MODE

Set the Test Mode:

1. When power on reset is applied while a “H” (high) is input the

TEST SW (TP43) terminal (IC501 $º pin), the RING (Level

H, 500 msec) sounds.

2. Following that, at timing in which the TEST SW terminal has

“H” (high) input, there is output of “L” (low) by the CH

(channel) setting control terminal. Then there is PLL setting to

the CH which was read to with the CH setting terminal

according to that “L” (low) output.

3. Set the TX setting to TX OFF.

4. The channel is set by voice not by data.

5. Use port inputs to set output from LED terminals.

Release the Test Mode:

1. Press the OFF key.

2. Remove the short plug and turn on the power.

TP36

TP13

TP43

TP44

TP33

IC501

TP14

TP16

TP15

TP17

– 9 –

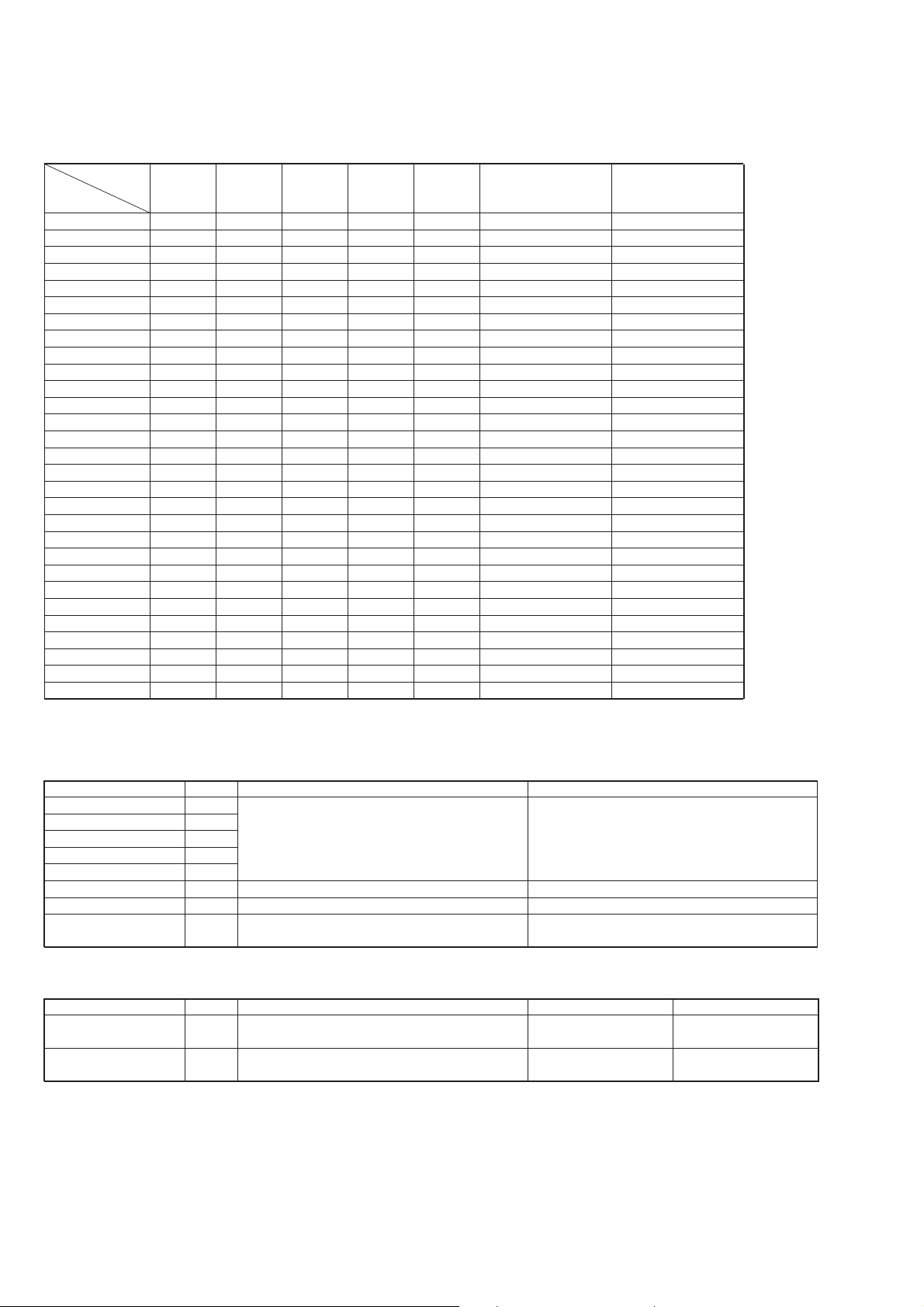

Channel Setting:

During startup in machine test mode, make the following channel

settings by loading the terminal input data.

Pin No.

Channel

CH1 H L L L L 48.760 43.720

CH2 H L L L H 48.840 43.740

CH3 H L L H L 48.860 43.820

CH4 H L L H H 48.920 43.840

CH5 H L H L L 49.020 43.920

CH6 H L H L H 49.080 43.960

CH7 H L H H L 49.100 44.120

CH8 H L H H H 49.160 44.160

CH9 H H L L L 49.200 44.180

CH10 H H L L H 49.240 44.200

CH11 H H L H L 49.280 44.320

CH12 H H L H H 49.360 44.360

CH13 H H H L L 49.400 44.400

CH14 H H H L H 49.460 44.460

CH15 H H H H L 49.500 44.480

CH16 L L H H L 49.670 46.610

CH17 L L H H H 49.845 46.630

CH18 L H L L L 49.860 46.670

CH19 L H L L H 49.770 46.710

CH20 L H L H L 49.875 46.730

CH21 L H L H H 49.830 46.770

CH22 L H H L L 49.890 46.830

CH23 L H H L H 49.930 46.870

CH24 L H H H L 49.990 46.930

CH25 L H H H H 49.970 46.970

TEST1 L L L H L 48.800 43.780

TEST2 L L L H H 48.970 43.890

TEST3 L L H L L 49.910 46.800

TEST4 L L H L H 49.950 46.900

34 33 32 31 29

ROW5 ROW4 ROW3 ROW2 ROW1

(TP13) (TP14) (TP15) (TP16) (TP17)

TX frequency RX frequency

(MHz) (MHz)

Machine Test Mode Input / Output:

1. Input (Input ports for other than main tasks)

Pin Name Pin No. Function Logic

ROW1 (TP17) 29

ROW2 (TP16) 31

ROW3 (TP15) 32 Setting the CH (channel) Refer to channel setting

ROW4 (TP14) 33

ROW5 (TP13) 34

TEST CH (TP33) 1 Control terminal for setting the CH (channel) H : OFF, L : ON

TEST SW (TP43) 40 Start up of the test mode H : Start, L : Not start

TEST ACK (TP44) 44

2. Output (Output ports for other than main tasks)

Pin Name Pin No. Function H Logic L Logic

T ALK LED (TP35) 48

KEY LED (TP55) 2

During the test mode, causes start of intermittent

operation with external input.

Various input/output monitor output

(default : RSSI (H) detection).

During test mode : All light lit. However, does

not include measurment of consumption current.

H : Intermittent start

No detection Detection

No light Light

– 10 –

Key Processing (Setting the Manual Test Mode) :

1. (Upper position) (Lower position) Set with #.

2. 3X# can be substituted with X .

Upper position

Lower position

0 QUIT 10 ch 20 ch Batt Alarm H A L T G KEY TEST

1 1 ch 11 ch 21 ch CHARGE DET GgGGG

2 2 ch 12 ch 22 ch GggGG

3 3 ch 13 ch 23 ch ggGGG

4 4 ch 14 ch 24 ch RX LOCK gggGG

5 5 ch 15 ch 25 ch TX LOCK ggggG

6 6 ch 16 ch T1 ch RSSI (H) ggggg

7 7 ch 17 ch T2 ch RSSI (L) —————

8 8 ch 18 ch T3 ch DATA TX —————

9 9 ch 19 ch T4 ch —————

Purpose CH setting only SIGOUT control

Application

• By pressing the CH key there is increment of the channel.

However, this does not include the test channel.

• Control of the power source during 38# DATA TX is (TX & RX

RF & RX AF=ON) in 44# state.

• Control of the power source during the 70# key check mode is

41# state (TX OFF).

• For CH setting, SIGOUT control and power source control (with

the exception of above-mentioned 38# state) the state can be set

independently.

Example : In 15 ch, the order for carrying out TX modulation

level and RSSI (H) sensitivity setting is as follows :

The following are possible :15# n 44# n 36#

012 3TXRX RX

The standard is external communication

state.

State for standard electrical adjustment

process.

*

36# n 15# n 44#

44# n 36# n 15#

Condition

surveillance with

T ALK LED.

4

RF AF

Measurement mode of

consumption current.

g : ON, G : OFF

MIC Lk

7

General

operation

– 11 –

)

)

SECTION 4

ELECTRICAL ADJUSTMENTS

BASE UNIT SECTION

Note:

• Apply 9V dc from regurated DC power supply.

• Perform the adjustment at TEST3CH (28CH: 49.910 MHz) as a

rule.

• Set to base unit manual test mode. (Refer to page 7)

• Switch position :

S302 (DIAL MODE) : P (pulse)

TX SECTION ADJUSTMENT

• The electrolytic capacitor (10 µF/10 V) connected TP23 (DET

OUT) to TP19 (GND). (Only TX section adjustment)

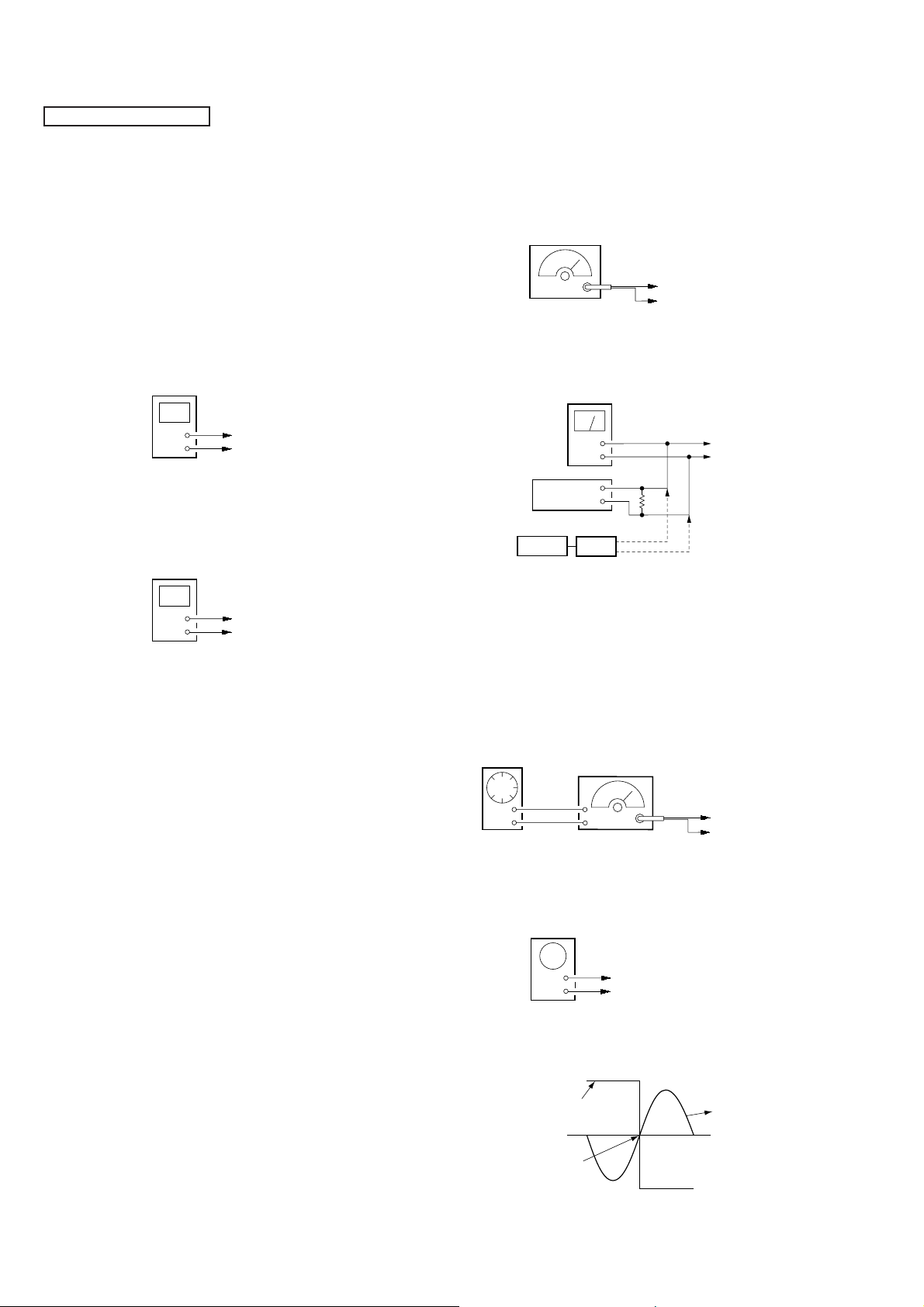

TX VT Adjustment

Setting :

Procedure :

1. The digital voltmeter connected TP6 (TX VT) to TP19 (GND).

2. Adjust the L52 for 2.2 ± 0.05 V reading on the digital voltmeter.

RX VT Adjustment

Setting :

Procedure :

1. The digital voltmeter connected TP5 (RX VT) to TP3

(RX GND).

2. Adjust the L101 for 2.4 ± 0.05 V reading on the digital voltmeter .

digital voltmeter

+

–

digital voltmeter

+

–

TP6 (TX VT)

TP19 (GND)

TP5 (RX VT)

TP3 (RX GND)

RX SECTION ADJUSTMENT

RX LEVEL Adjustment

Note:

• Perform the adjustment at TEST3CH (28CH: 49.910 MHz) as a

rule.

Setting :

FM RF

signal generator

TP2

TP3 (RX GND

Carrier frequency : 49.910 MHz

Modulation : 1 kHz

Deviation : FM 3 kHz

Output level : 60 dBµV (1 mV) (EMF)

level meter

PBX tester

DC 48V

+

–

Ω

600

or

F.B.

TP105

TP104

Procedure :

1. Adjust the FL101 for the maximam reading on the level meter.

Also check that the output level is the specified values.

Specified V alue : –1.4 to –9.6 dBV

RSSI Hi Adjustment

Note:

• Perform the adjustment at TEST3CH (28CH: 49.910 MHz) as a

rule.

Setting :

AF oscillator

FM RF

signal generator

TP2

Output: 20 Hz

oscilloscope

(DC range)

Carrier frequency : 49.910 MHz

Modulation : 20 Hz (EXT)

Deviation : AM 50%

Output level : 17 dBµV (7.1 µV) (EMF)

+

–

TP9 (SIG OUT)

TP19 (GND)

TP3 (RX GND

Procedure :

1. Use the oscilloscope to confirm the FM RF signal generator

input (AF) signal waveform and RSSI signal, and use the R V101

so that they are synchronized (duty is synchronized).

RSSI output waveform

0 V

Adjust so that they

synchronize at 0 V.

RSSI WAVEFORM

AF oscillator

EXT signal

20 Hz

Adjustment Location : base main board (See page 13)

– 12 –

Loading...

Loading...