Sony SLV-UY, SLV-E220AE, SLV-VP1, SLV-VP2, SLV-E270CP Service Manual

...

MICROFILM

SERVICE

MANUAL

J VIDEO CASSETTE RECORDER

Photo : SLV-E280UX

AEP Model

SLV-E120AE/E220AE/VP1/VP2/E270CP/VC1/VC2/E280CP/VC1/VC2

UK Model

SLV-E220UY/E280UX

SPECIFICATIONS

System (SLV-E220UY/E280UX)

Channel coverage

PAL (I) :

UHF B21 - B69

RF output signal

UHF I21 - 69 CH

Aerial out

75-ohm asymmetrical aerial socket

System (EXCEPT SLV-E220UY/E280UX)

Channel coverage

PAL (B, G) :

VHF E2 - E12

(comprese channel C)

(A - H only For Italy)

UHF E21 - E69

CATV S01 - S03, S1 - S20

HYPER BAND S21 - S41

Intermediate frequency

F1 - 1 Video 38.9MHz

F2 - 1 Audio 33.4MHz

RF output signal

UHF G22 - 69

Aerial out

75-ohm asymmetrical aerial socket

Inputs/outputs

ÚEURO-AV1

21-pin

Video input : pin 20

Audio input : pins 2 and 6

Video output : pin 19

Audio output : pins 1 and 3

J EURO-AV2 (2nd Scart)

21-pin

(Except SLV-E120AE/E220 Series)

Video input : pin 20

Audio input : pins 2 and 6

Front Line In (SLV-E280 Series)

VIDEO IN, Phono jack (1)

Input signal : 0.5 –1.5 Vp-p

75 ohms, unbalanced, sync negative

AUDIO IN, Phone jack (1)

Input level : –8 dBs

(0 dBs = 0.755 Vrms)

Input impedance : more than

47 kilohoms

General

Power requirements

220 – 240 V AC, 50 Hz

Power consumption

17 W

5W (standby)(SLV-E120AE/E220 Series)

6W (standby)(Except SLV-E120AE/E220 Series)

Operating temperature

5°C to 40°C

Storage temperature

–20°C to 60°C

Dimensions

Approx. 360 x 97 x 298 mm (w/h/d)

including projecting parts and controls

Mass

Approx. 3.7 kg

Supplied accessories

Remote commander (1)

R6 (size AA) batteries (2)

Aerial cable (1)

Mains lead (1)

Design and specifications are subject to change without notice.

SLV-E120AE/E220AE/UY/VP1/VP2/E270CP/VC1/VC2/

E280CP/UX/VC1/VC2

RMT-V206C/V206D/V207C/V207D/V207E/V207G/V207H

– 2 –

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIA GRAMS AND

IN THE P ARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer :

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

– 3 –

1. GENERAL

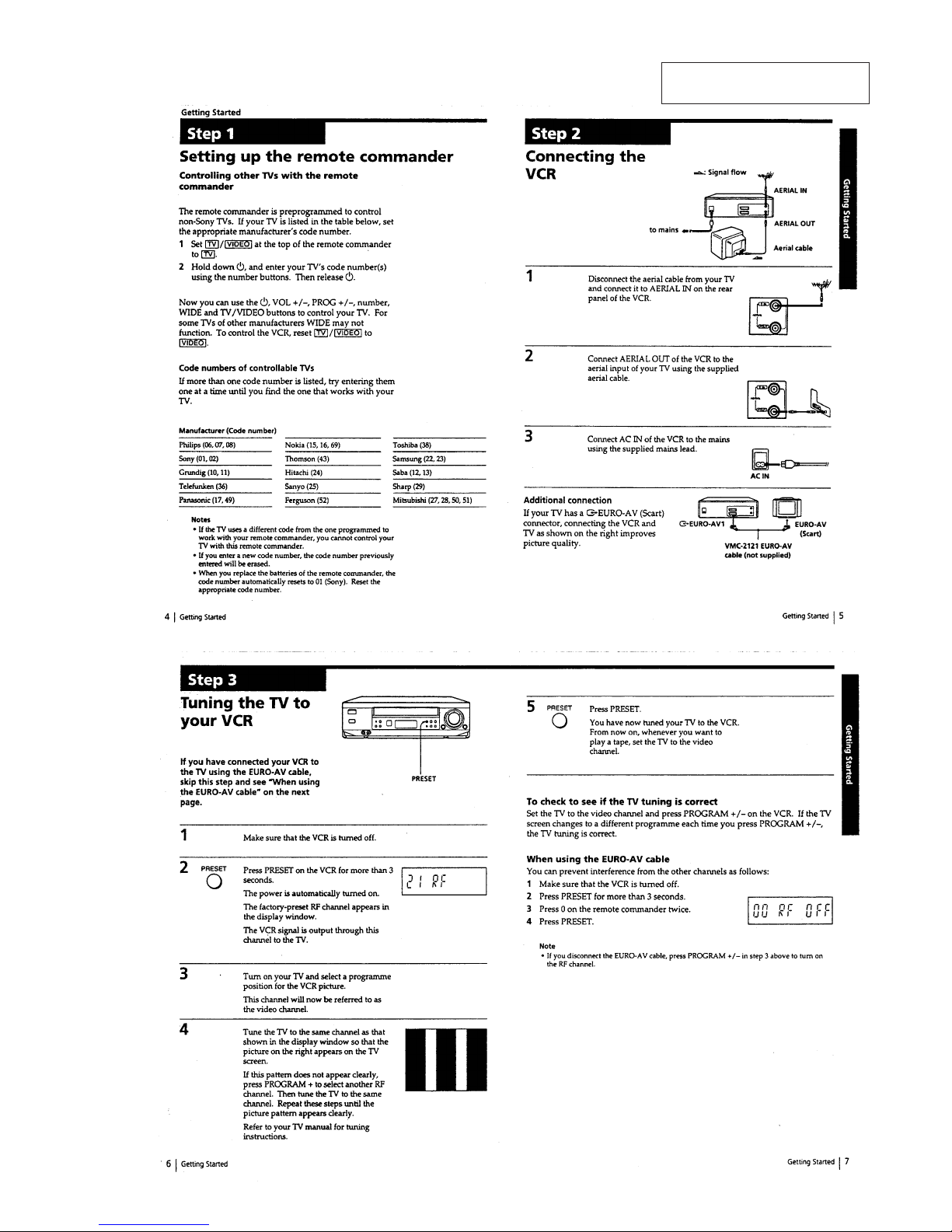

Step 1 Setting up the remote commander ..................... 1-1

Step 2 Connecting the VCR .......................................... 1-1

Step 3 Tuning the TV to your VCR............................... 1-1

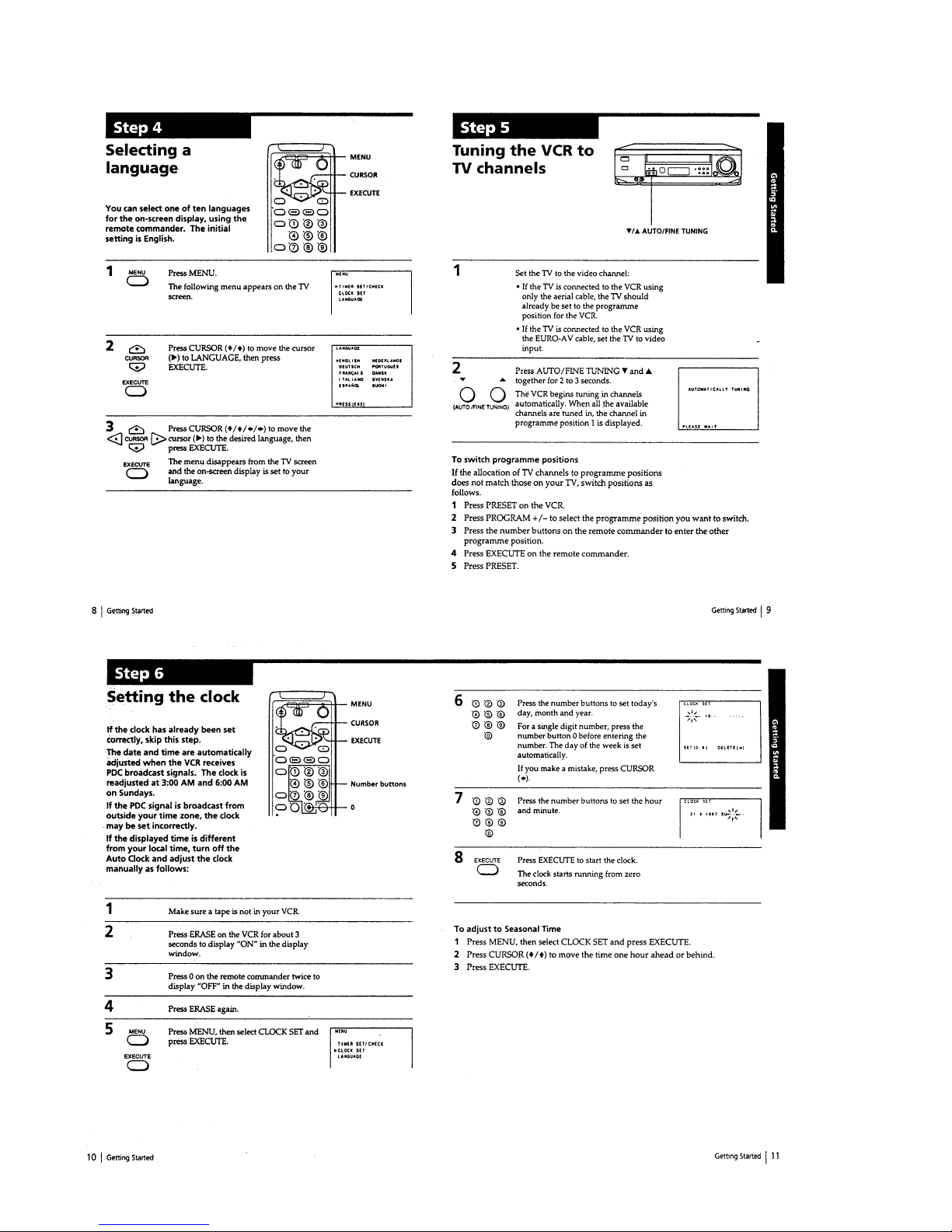

Step 4 Selecting a language........................................... 1-2

Step 5 Tuning the VCR to TV Channels ....................... 1-2

Step 6 Setting the Clock ................................................ 1-2

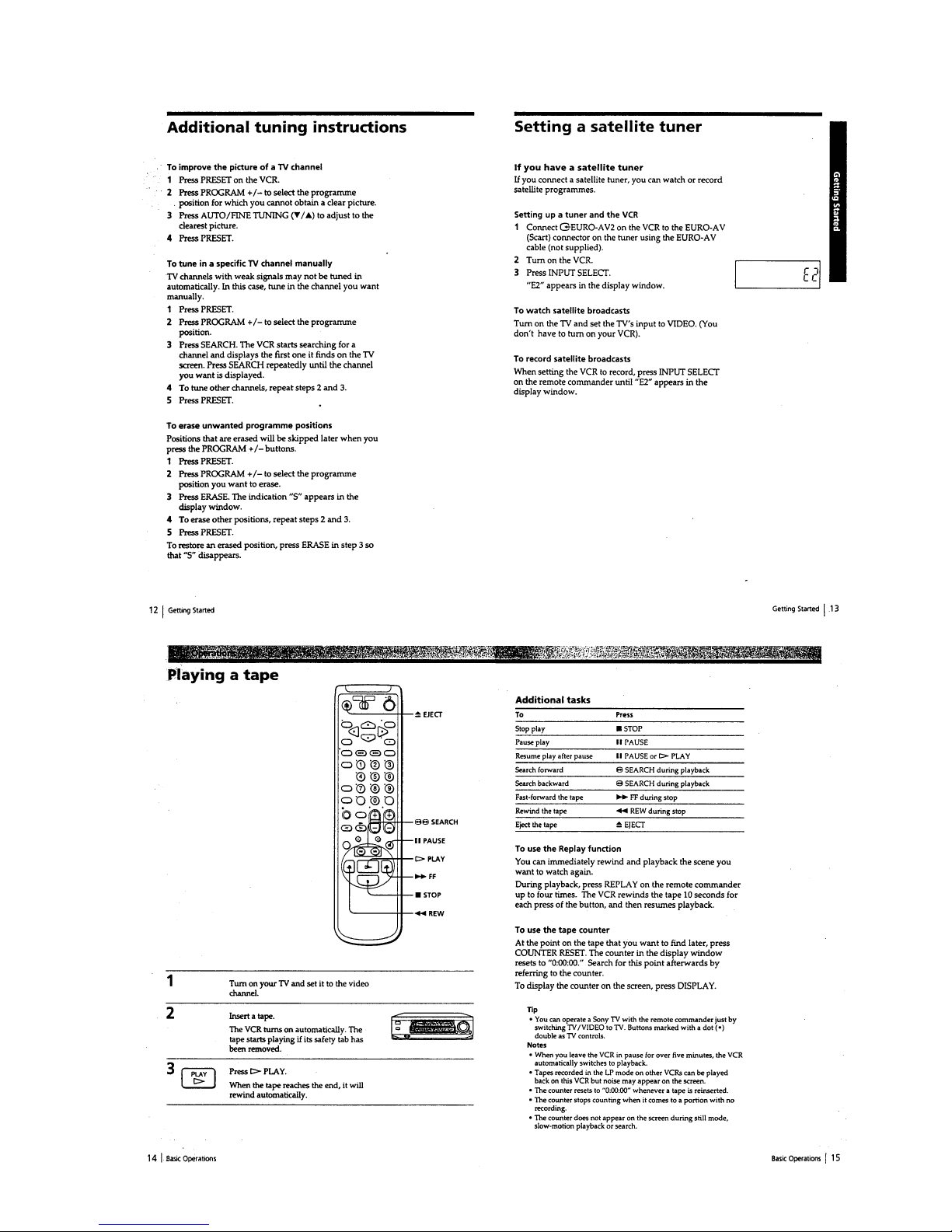

Additional Tuning Instructions ..................................... 1-3

Setting a Satellite Tuner ................................................ 1-3

Playing a Tape ............................................................... 1-3

Recording TV Programmes........................................... 1-4

Recording TV Programmes using Video Plus + ........... 1-4

Playing/Searching at Various Speeds ............................ 1-5

Setting the Timer Manually........................................... 1-5

Recording TV Programmes using the Quick Timer...... 1-6

Checking/Cancelling Timer Settings............................. 1-6

Searching using the index function ............................... 1-6

Editing with another VCR............................................. 1-7E

Adjusting the Picture..................................................... 1-7E

Visual index................................................................... 1-7E

2. DISASSEMBLY

1-1. Removal of Cabinet, Mechanism Unit and Main

Board ..................................................................... 2-1

Removing the Cabinet Parts .................................. 2-1

Removing the Mechanism Main Unit and the

CP-1 PWB Assembly............................................. 2-1

l-2. Temporarily Setting Up and Connecting

CP-1 PWB Assembly............................................. 2-3E

1-3. Installation of the Front Panel................................ 2-3E

3. DIAGRAMS

Circuit Boards Location ................................................ 3-1

Overall wiring Diagram ................................................ 3-3

Mechanism Connection Diagram.................................. 3-5

Video Circuit Diagram .................................................. 3-6

System Control & Servo Circuit Diagram ................... 3-9

Audio Circuit Diagram.................................................. 3-12

Terminal & Input/ Output Selector Circuit Diagram

(SLV-E270 & E280 Series) ........................................... 3-14E

4. SCHEMATIC DIAGRAMS AND PRINTED

WIRING BOARDS

CP-1 Board (PW-A) Power Supply Circuit Diagram .... 4-1

CP-1 Board (AD-A) Terminal & Selector

(SLV-E270 & E280 Series) ........................................... 4-3

CP-1 Board (AD-A) Terminal Circuit Diagram

(SLV-E120AE/E220 Series).......................................... 4-5

CP-1 Board (VA-A) Video & Audio Circuit Diagram

(SLV-E270 Series/E280CP/VC1/VC2)......................... 4-7

CP-1 Board (VA-A) Video & Audio Circuit Diagram

(SLV-E120AE & E220 Series)...................................... 4-9

CP-1 Board (VA-A) Video & Audio Circuit Diagram

(SLV-E280UX).............................................................. 4-11

Video Circuit Waveforms.............................................. 4-13

VP-1 Board Video Pre-Amp circuit Diagram ............... 4-14

CP-1 Board (SV-A) Servo Circuit Diagram.................. 4-16

Servo Circuit Waveforms .............................................. 4-18

CP-1 Board (SY-A) System Control, Timer & Tuner

Circuit Diagram (Except SLV-E220UY/E280UX) ....... 4-19

IC 301 System Control, Timer & Tuning Control MPU Pin

Functions Ta ble ............................................................. 4-20

CP-1 Board (SY-A) System Control, Timer & Tuner

Circuit Diagram (SLV-E220UY/E280UX) ................... 4-21

TM-1 Board Operation Key Circuit Diagram ............... 4-27

TABLE OF CONTENTS

Section Title Page

______ ____ ____

Section Title Page

______ ____ ____

TM-2 Board Circuit Diagram........................................ 4-29

A7101 Display (FLD) Grid/Anode Assignment

Drawing & Table ........................................................... 4-30

TM-9 Board PDC/VPS (SLV-E220VP1/E270 &

E280 Series) .................................................................. 4-31E

5. ADJUSTMENTS

1. Maintaining and Checking the Mechanism............... 5-1

l -1. Regular Checks and Maintenance Items............... 5-1

1-1-1. Regular Checks................................................ 5-1

1-1-2. Cleaning............................................................ 5-1

1-2 Service Tools ........................................................... 5-2

1-2-1. Service Tools ................................................... 5-2

1-2-2. Using the Relay Cable (VHJ-0106).................. 5-3

2. An Overview of the Mechanism ................................ 5-3

2-1. Names of the Main Parts........................................ 5-3

2-1-1. Cassette Mechanism Assembly ........................ 5-3

2-1-2. Top View .......................................................... 5-4

2-1-3. Under Side ........................................................ 5-4

2-2. An Overview of the Mechanism Modes ................ 5-5

2-2-1. Mechanism Mode Switching Table .................. 5-5

2-2-2. Movement Check List for the Main Parts of the

Mechanism........................................................ 5-6

2-2-3. How to Check the Mechanism

Mode Position................................................... 5-6

2-2-4. Self-Diagnosis Display ..................................... 5-6

3. Disassembling the Main Parts of the Mechanism ..... 5-7

3-1. How to Make the Mechanism Move...................... 5-7

3-1-1. How to Operate the Loading Motor Using

A DC Voltage Supply ....................................... 5-7

3-1-2. Operating the Loading Motor

by the Manual Method...................................... 5-7

3-1-3. Making the Mechanism Move

Using the Manual Method ................................ 5-7

3-2. Mechanism Unit..................................................... 5-8

3-3. Cassette Drive Mechanism..................................... 5-8

3-3-1. Cassette Mechanism Assembly ........................ 5-8

3-3-2. Cassette Drive Gear .......................................... 5-9

3-3-3. Door opener, Under Frame and Stand L........... 5-9

3-3-4. Start Rack Gear and Front Rack Gear .............. 5-10

3-4. Cleaner Roller Assembly ....................................... 5-10

3-5. Cylinder (DRUM).................................................. 5-11

3-5-1. Upper Cylinder Assembly (UPPER DRUM) ... 5-11

3-5-2. Cylinder Motor (ROTOR and STATOR) .......... 5-12

3-5-3. Cylinder Assembly ........................................... 5-12

3-6. FE Head and ACE Head......................................... 5-13

3-6-1. Audio R/P Head Assembly (ACE HEAD)........ 5-13

3-6-2. Full Erase Head ................................................ 5-13

3-7. Capstan Motor........................................................ 5-14

3-7-1. Capstan Motor .................................................. 5-14

3-7-2. Capstan Brake Assembly.................................. 5-14

3-8. Loading Motor Assembly and

Worm Gear Assembly............................................ 5-15

3-9. Pinch Roller Pressure Mechanism ......................... 5-15

3-9-1. Pinch Roller Lever Assembly ........................... 5-15

3-9-2. Pinch Lift Cam and Pinch Cam Gear ............... 5-16

3-10. L Guide Lever Assembly and

Load Lever Assembly .......................................... 5-17

3-11. BT Lever Assembly ............................................. 5-17

3-12. Reel Drive Mechanism......................................... 5-18

3-12-1. Reel belt, Reel Pulley, Friction Gear

Assembly and Clutch Change Lever............... 5-18

3-12-2. Clutch Mounting Assembly............................ 5-18

3-12-3. S Soft Lever, Supply Reel Assembly

and S Reel Gear .............................................. 5-18

– 4 –

Section Title Page

______ ____ ____

3-12-4. T Soft Brake Assembly, Take Up Reel

Assembly, T Reel Gear ................................... 5-19

3-13. Brakes .................................................................. 5-19

3-13-1. S Brake Assembly, T Brake

Assembly, T Brake ACT Slide ........................ 5-19

3-13-2. Brake Control Lever and Brake ACT Lever

Assembly ........................................................ 5-20

3-13-3. S Brake ACT Slide and BT Spring Lever

Assembly ........................................................ 5-20

3-14. Guides .................................................................. 5-21

3-14-1. Guide Roller Assembly................................... 5-21

3-14-2. S and T Incline Mounting Assemblies............ 5-21

3-15. Wheel Gear 2, Main Cam and Mode Switch ....... 5-22

3-16. Crescent Slide ...................................................... 5-23

3-17. S Load Gear, T Load Gear, S Load Lever

Assembly and T Load Lever Assembly ............... 5-24

3-18. Tape Sensors, Reel Sensor and EP SW Lever...... 5-25

3-18-1. Tape Top Sensor and Tape End Sensor ........... 5-25

3-18-2. Reel Sensor ..................................................... 5-25

3-18-3. EP Switch Lever ............................................. 5-25

4. Mechanism Checks and Adjustments........................ 5-26

4-1. Reel Table Torque Check ....................................... 5-26

4-2. Adjusting the BT Lever Assembly Position and

Checking the Back Tension Torque in Play Mode. 5-26

4-2-1. BT Lever Pole Position Adjustment ................. 5-26

4-2-2. Checking the Back Tension Torque

Play Mode......................................................... 5-26

4-3. Tape Path Adjustment ............................................ 5-27

4-3-1. Adjustment Procedure ...................................... 5-27

4-3-2. Load Lever Assembly Height Adjustment........ 5-27

4-3-3. Guide Roller Height Adjustment...................... 5-28

4-3-4. Audio R/P Head (ACE HEAD) Height

Adjustment, Azimuth Adjustment and

Horizontal Position Adjustment........................ 5-29

4-3-5. Checking After Adjustment .............................. 5-30E

6. ELECTRICAL ADJUSTMENTS

Circuit Boards Location ................................................ 6-1

Self -Diagnosis Display................................................. 6-2

1. Self-Diagnosis Contents and Mechanism Mode

Display ...................................................................... 6-2

2. Electrical Adjustment ................................................ 6-4

2-1. Servo Circuit Adjustment....................................... 6-4

2-1-1. Test Equipment and Standards Required .......... 6-4

2-1-2. Location of Adjustment Points ......................... 6-4

2-1-3. Switching Position Adjustment ........................ 6-5

2-2. Video Circuit Relay Jig .......................................... 6-6

2-2-1. Test Equipment and Standards Required .......... 6-6

2-3. IF Circuit Adjustment ............................................ 6-7E

2-3-1. Test Equipment and Standard Required ........... 6-7E

2-3-2. Location of Adjustment Point........................... 6-7E

2-3-3. RF AGC Adjustment........................................ 6-7E

3. Test Points for Tape Path Adjustment ....................... 6-7E

7. EXPLODED VIEWS

7-1. Cabinet & Chassis Parts......................................... 7-1

7-2. Mechanism Parts-1 ................................................ 7-3

7-3. Mechanism Parts-2................................................. 7-5E

8. ELECTRICAL PARTS LIST ................................. 8-1

Hardware List................................................................ 8-10E

1-1

SECTION 1

GENERAL

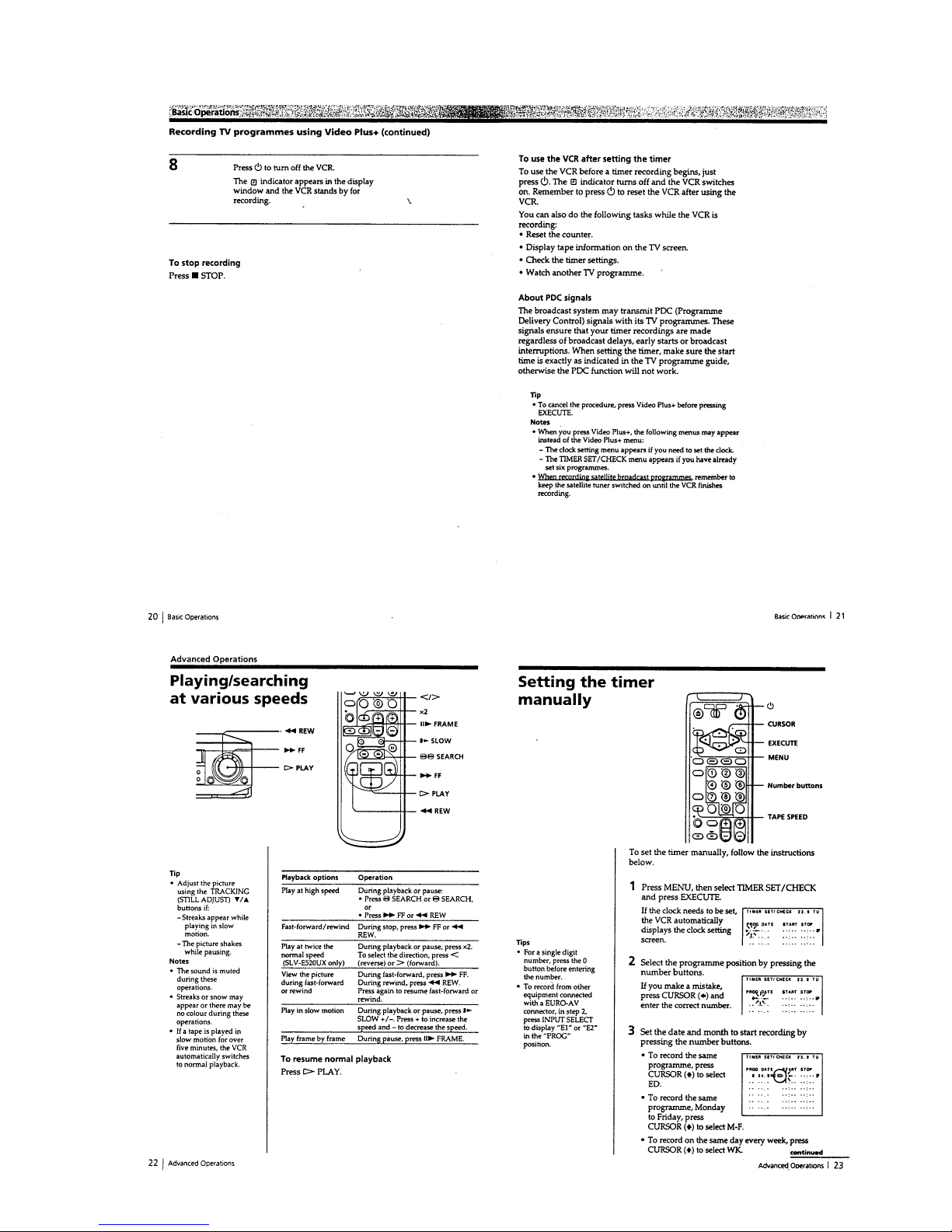

This section is extracted from

SLV-E280UX instruction manual.

SLV-E120AE/E220AE/UY/VP1/VP2/E270CP/VC1/VC2/E280CP/UX/VC1/VC2

1-2

1-3

1-4

1-5

1-6

1-7 E

2-1

SECTION 2

DISASSEMBLY

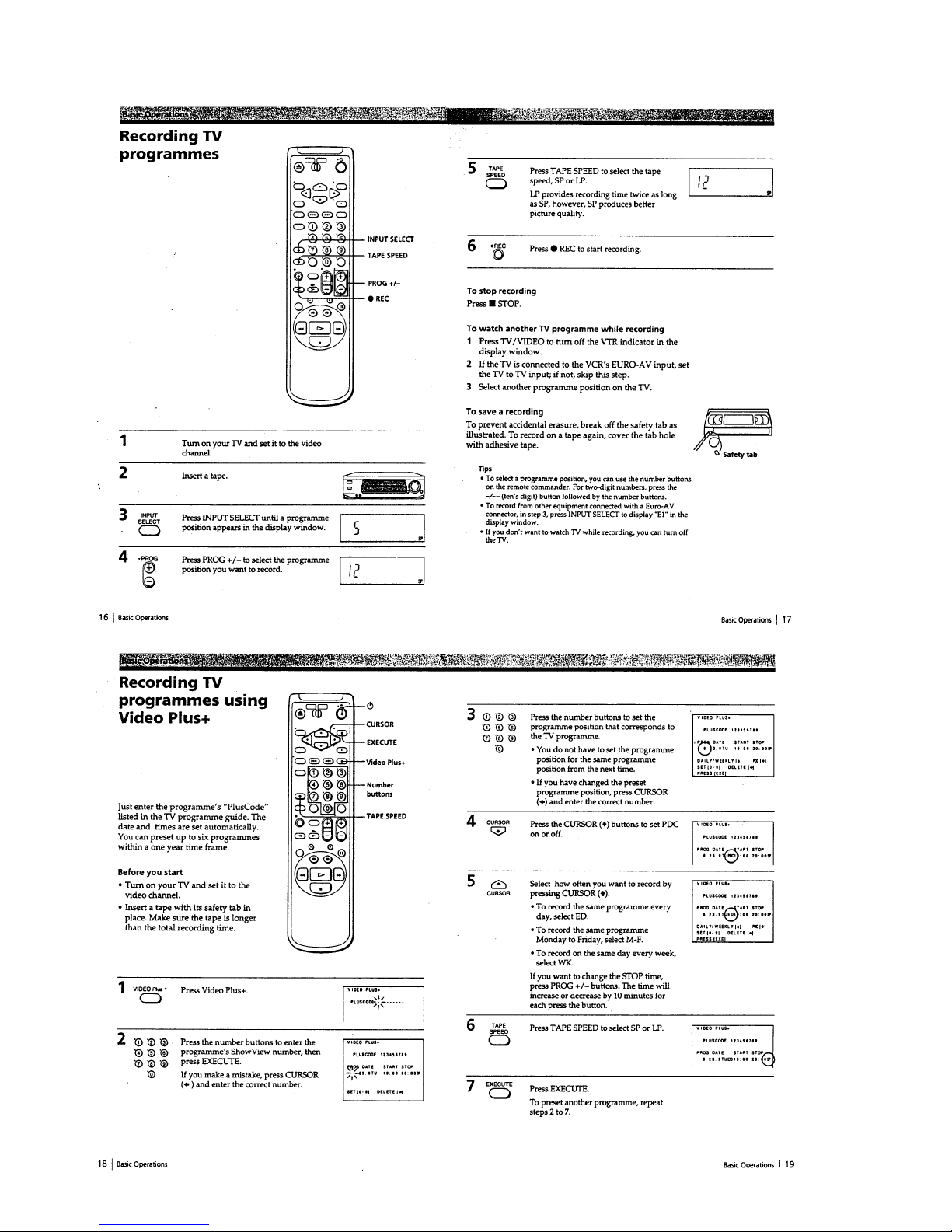

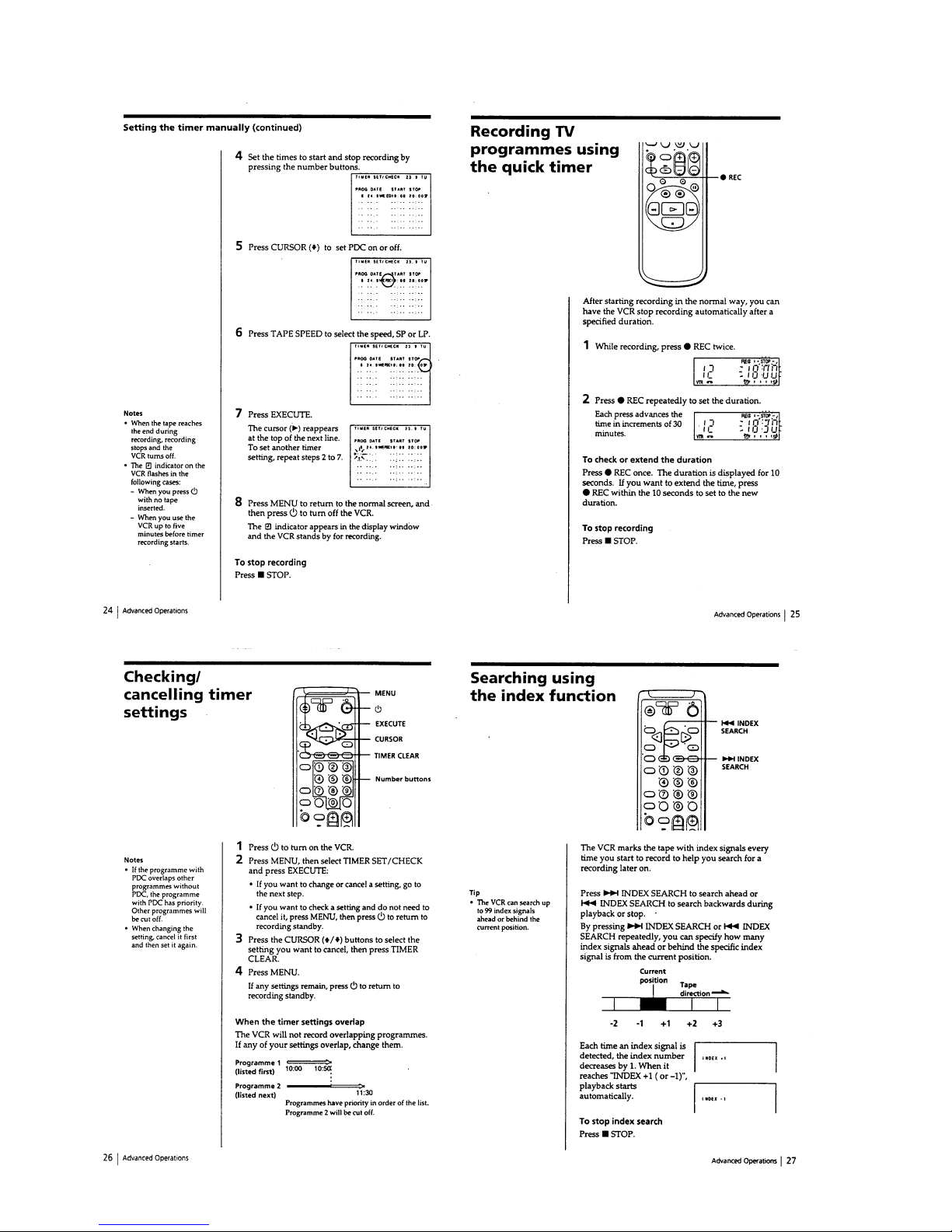

1-1. REMOVAL OF CABINET, MECHANISM UNIT, AND MAIN BOARD

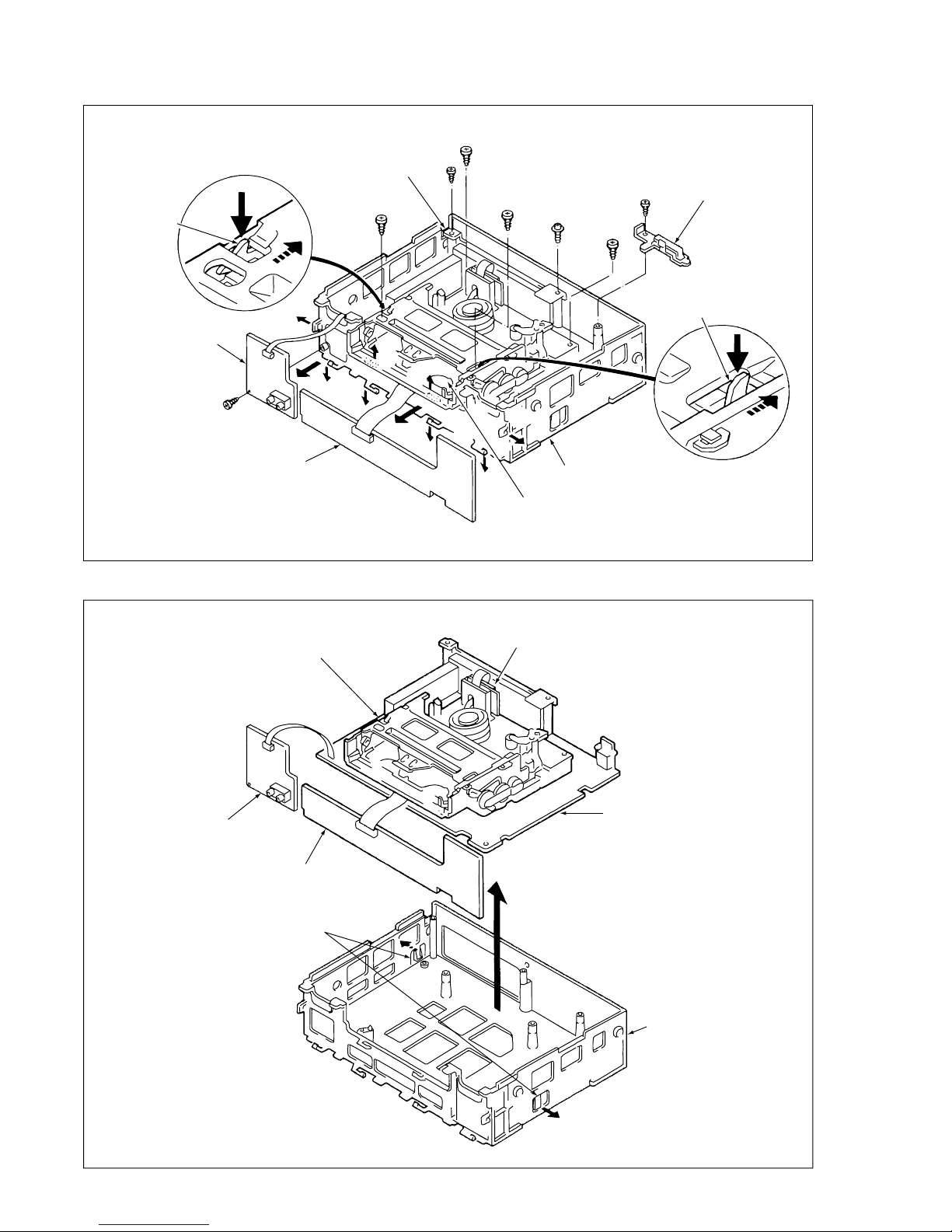

REMOVING THE CABINET PARTS (Fig. 1-1-1 )

1. Remove the cabinet and bottom cover by removing the

four screws 1 and four screws 2 .

2. Pull out the shuttle knob by fingers together with the

button assembly, and remove the front panel by removing the locks of the clamps (A) using a screwdriver. etc.,

and slightly rotating the bottom part in the direction of

the arrow.

Notes: • Electrical adjustments for the this model can be

performed with only the cabinet removed.

• When replacing the bottom cover, do not tighten

the screws 2 too much. Excess tightness may

damage the screw taps on the chassis.

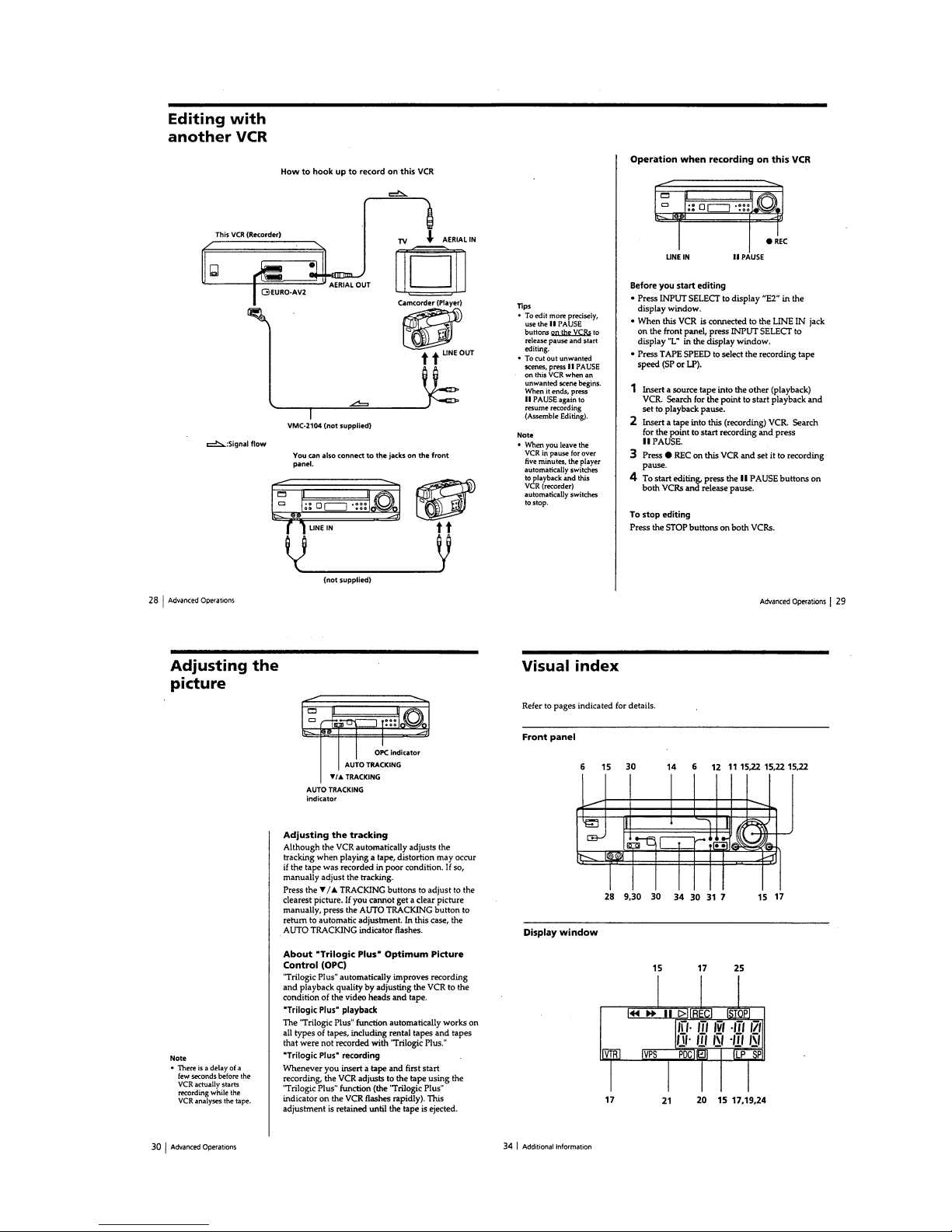

REMOVING THE MECHANISM MAIN UNIT AND

THE CP-1 PWB ASSEMBLV (Fig.1-1-2 and 1-1-3)

After removing the cabinet parts, remove the mechanism

unit and the CP-1 PWB assembly connected as follows.

1. First, remove the red screw 3 of the TB-1 PWB, spread

out lock clamps (B) and (C) in the arrow direction

slightly and remove TM-1 PWB and TM-2 PWB as

shown in Fig. 1-1-2.

2. Remove the screw 4 at the back of the chassis.

3. Remove the red screw 5 in the chassis, remove the red

screw 6, and remove the holder in this order.

4. Remove the two screws 7 and two screws 8 of the

mechanism unit. The two screws 8 of the cassette tray

can be removed easily by pushing the tray lock lever in

the arrow direction to remove the lock as shown in the

enlarge view A and by pushing the lid opener lever in

the arrow direction to remove the lock as shown in the

enlarge view B.

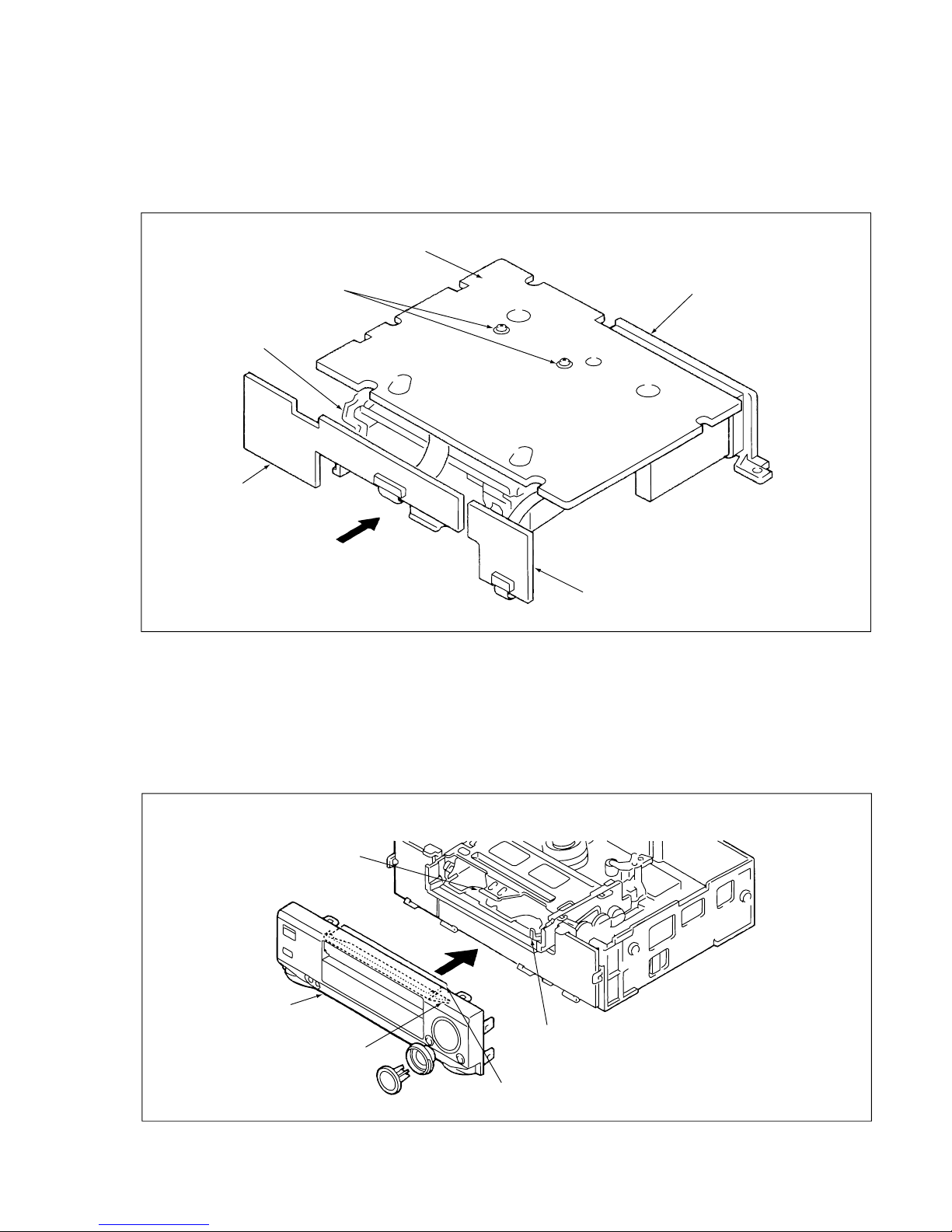

5. Lift up the whole mechanism unit and main board (CP-1

PWB assembly), and as shown in Fig. 1-1-3. push the

two lock clamps (D) of the chassis i n the arrow direction so that they can be removed from the chassis.

1

1

1

1

2

2

2

2

Clamps (A)

Front Panel

Button Assembly

Shuttle Knob

Main Unit

Bottom Cover

Cabinet

Fig. 1-1-1

SLV-E120AE/E220AE/UY/VP1/VP2/E270CP/VC1/VC2/E280CP/UX/VC1/VC2

2-2

3

8

5

7

8

4

7

6

Cassette Tray

Chassis

Lid Opener Lever

Holder

Terminal Board

(B)

(B)

(C)

(C)

(C)

(C)

(C)

(C)

Tray Lock Lever

TM-1 PWB

TM-2 PWB

Fig. 1-1-2

A

B

Chassis

TM-1 PWB

TM-2 PWB

VP-1 PWB Assembly

Mechanism Main Unit

Clamps (D)

CP-1 PWB Assembly

Fig. 1-1-3

2-3

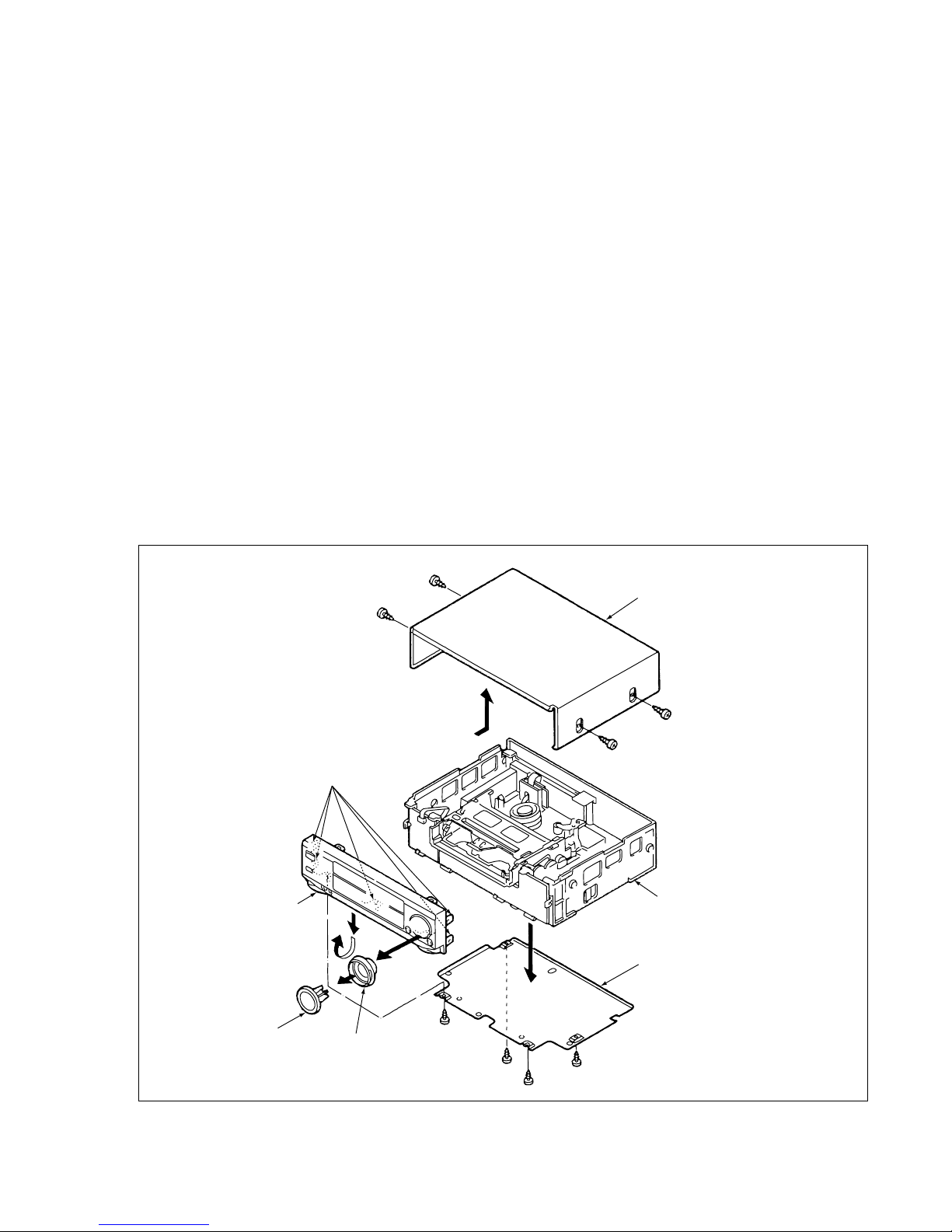

1-2. TEMPORARILY SETTING UP AND CONNECTING CP-1 PWB ASSEMBLY

The following is an example of how to place and connect the main board without a jig, when repairing the CP-1 PWB

assembly.

1. Place the mechanism unit and main board up side down

as a whole on a flat surface with the foil side of the main

board facing up.

2. Operate the unit using the buttons on TM-1 PWB or the

remote control.

Mechanism Main Unit

Screws

9

CP-1 PWB Assembly (Foil side)

Terminal Board

Cassette Compartment

TM-1 PWB

TM-2 PWB

Fig. 1-1-4

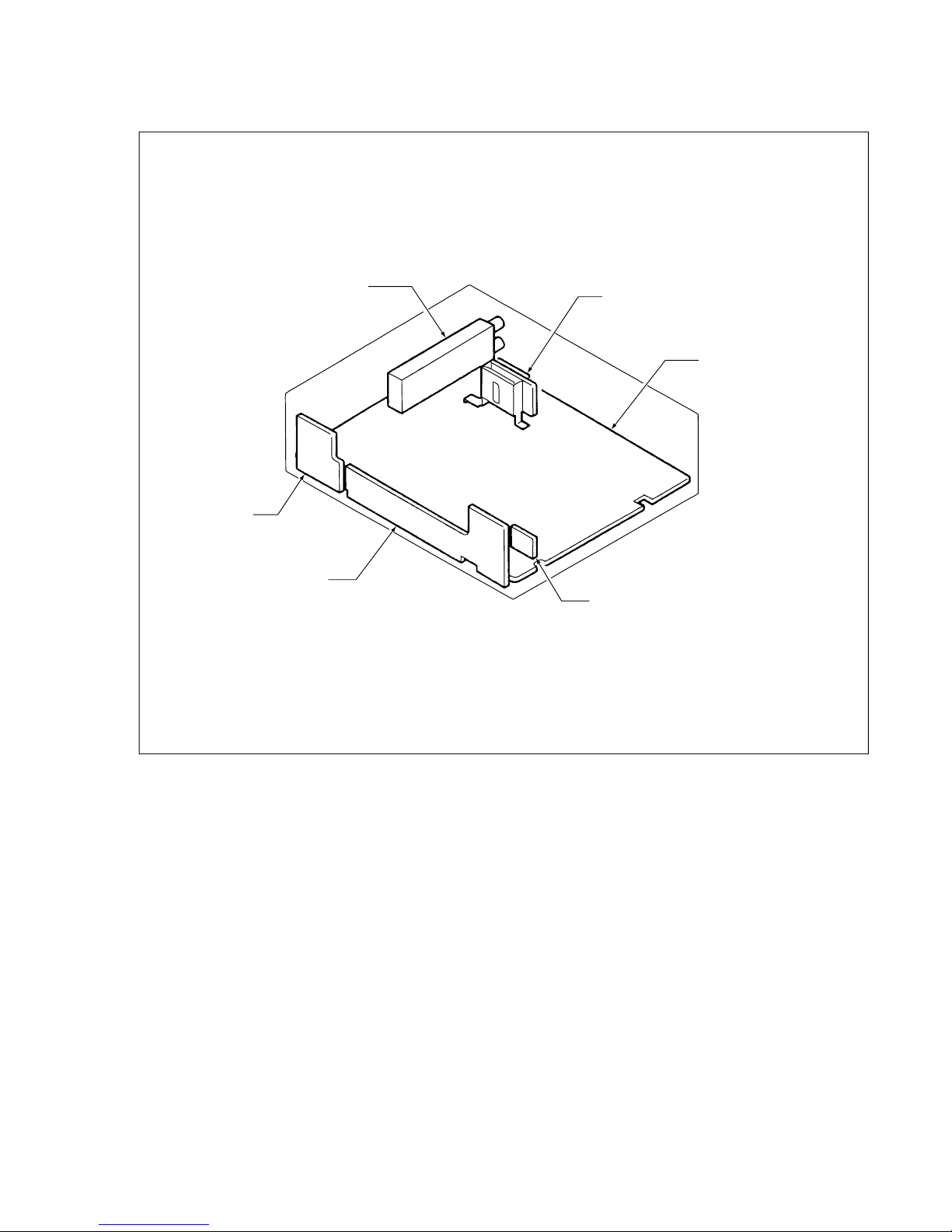

1-3. INSTALLATION OF THE FRONT PANEL

When installing the front panel to the chassis after repaires and adjustments.

1.Pressing down the door opener lever of the mechanism

main unit.

2. Set the cassette door to half-opened state as shown in

Fig. 1-1-5, and install the front panel to the chassis.

Note: Opened cassette door position does not install the

front panel to the chassis.

Jutted part of

Cassette Holder

Cassette Door

(Position A)

Cassette Door

(Position B)

Door Opener Lever

Front Panel

Fig. 1-1-5

E

3-1

SECTION 3

DIAGRAMS

CIRCUIT BOARDS LOCATION

CP-1 PWB Assembly

VP-1 PWB Assembly

3 in 1 Tuner

(Tuner / RF Conv.)

TM-1 PWB

TM-9 PWB

TM-2 PWB

SLV-E120AE/E220AE/UY/VP1/VP2/E270CP/VC1/VC2/E280CP/UX/VC1/VC2

5-1

1-1. REGULAR CHECKS AND

MAINTENANCE ITEMS

To obtain full function and maximum performance from

the set, and to stop it getting dirty or scratched, we

recommend that you carry out the following maintenance

procedures and regular checks. The maintenance checks

described in the following section should also be carried

out without fail after carrying out any repairs to the set.

1-1-1. REGULAR CHECKS

1. MAINTAINING AND CHECKING THE MECHANISM

NOTE: OIL AND GREASE

• Always use the specified brands of oil and grease. If you

use a grease with the wrong viscosity, for example, this

can lead to all sorts of problems. Be careful to keep the

oil and grease free of dust and foreign bodies.

• A “drop” of oil is the amount of oil remaining on the tip of

a rod with a diameter of 1.5mm after it is dipped in oil to

a depth of 1cm and then taken out.

Fig.1-1-1

SECTION 5

ADJUSTMENTS

Clean Check Oil

Hours of use (H)

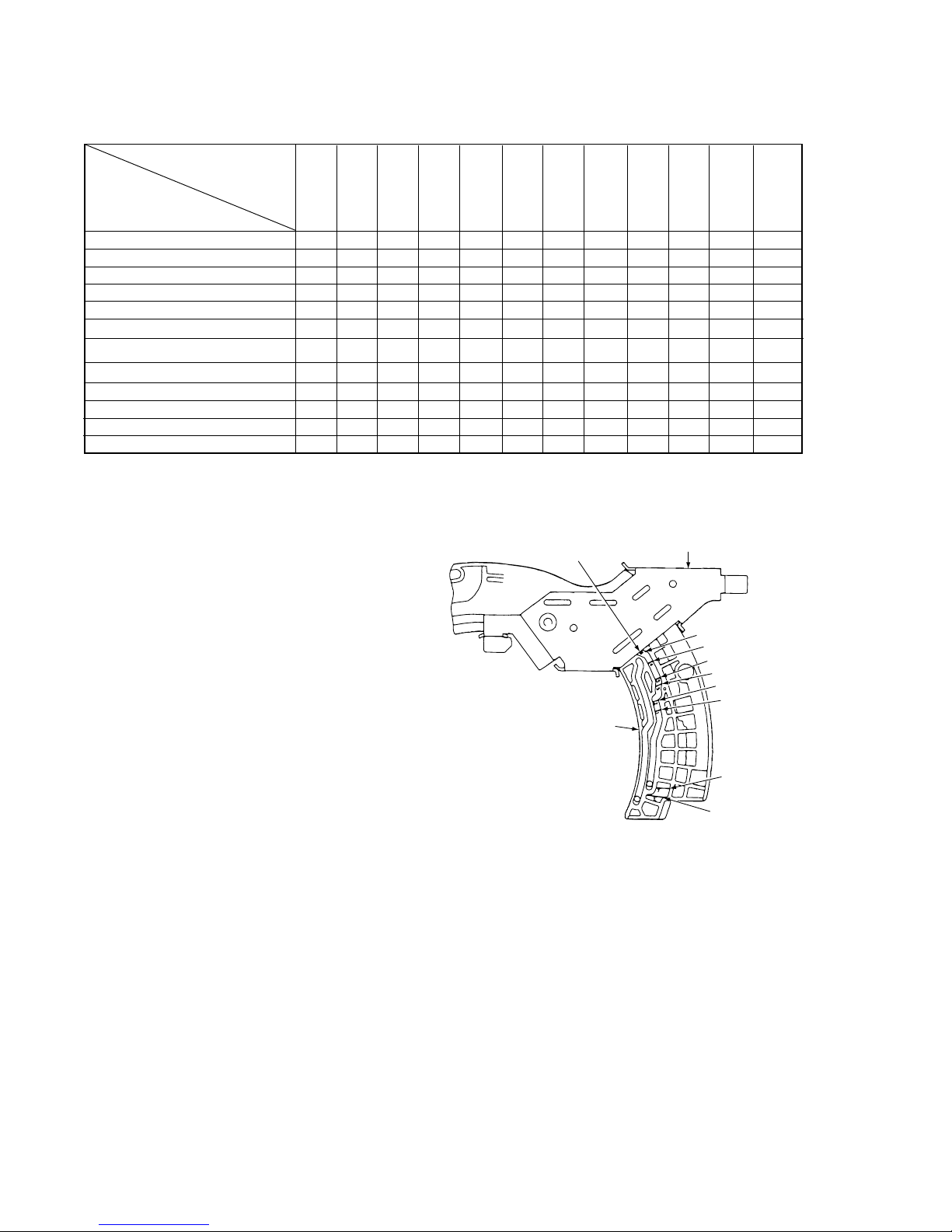

Part maintained 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 Remarks

Tape guide

ACE head, full erase head

Tape path

Cylinder (drum)

system

Cleaner roller assembly

Pinch roller

Reel table

Drive Reel belt

system

Relay gear, Pulley shaft, Gear shaft

Loading motor

Back tension

Perform- Brake system

ance

checks FWD, REW, PLAY torque,

REV torque

( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( )

The life of parts varies

enormously, depending

on the environment in

which the part is used.

Playback tension torque:

30 to 50g/cm

FWD: 600g/cm or over

REW: 600g/cm or over

PLAY (SP mode):

80 to I 40g/cm

REV: 120 to 220g/cm

1-1-2. CLEANING

1. Cylinder (Drum) (See Fig.1-1-1 )

Moisten a chamois with methyl alcohol and clean the video

head (including the Hi-Fi audio head) and the tape path

surface of the cylinder. Be sure to wipe horizontally in

relation to the video head. If you wipe vertically, or use

excessive force, you can damage the video head.

2. Tape Path System / Reel Drive System

Clean the pinch roller, the capstan shaft, the tape guides,

the FE head, the ACE head, the reel table, the pulley and

the reel belt with a soft cloth, or chamois, moistened with

methyl alcohol.

Tape path surface

Video head

Cylinder

(Drum)

SLV-E120AE/E220AE/UY/VP1/VP2/E270CP/VC1/VC2/E280CP/UX/VC1/VC2

5-2

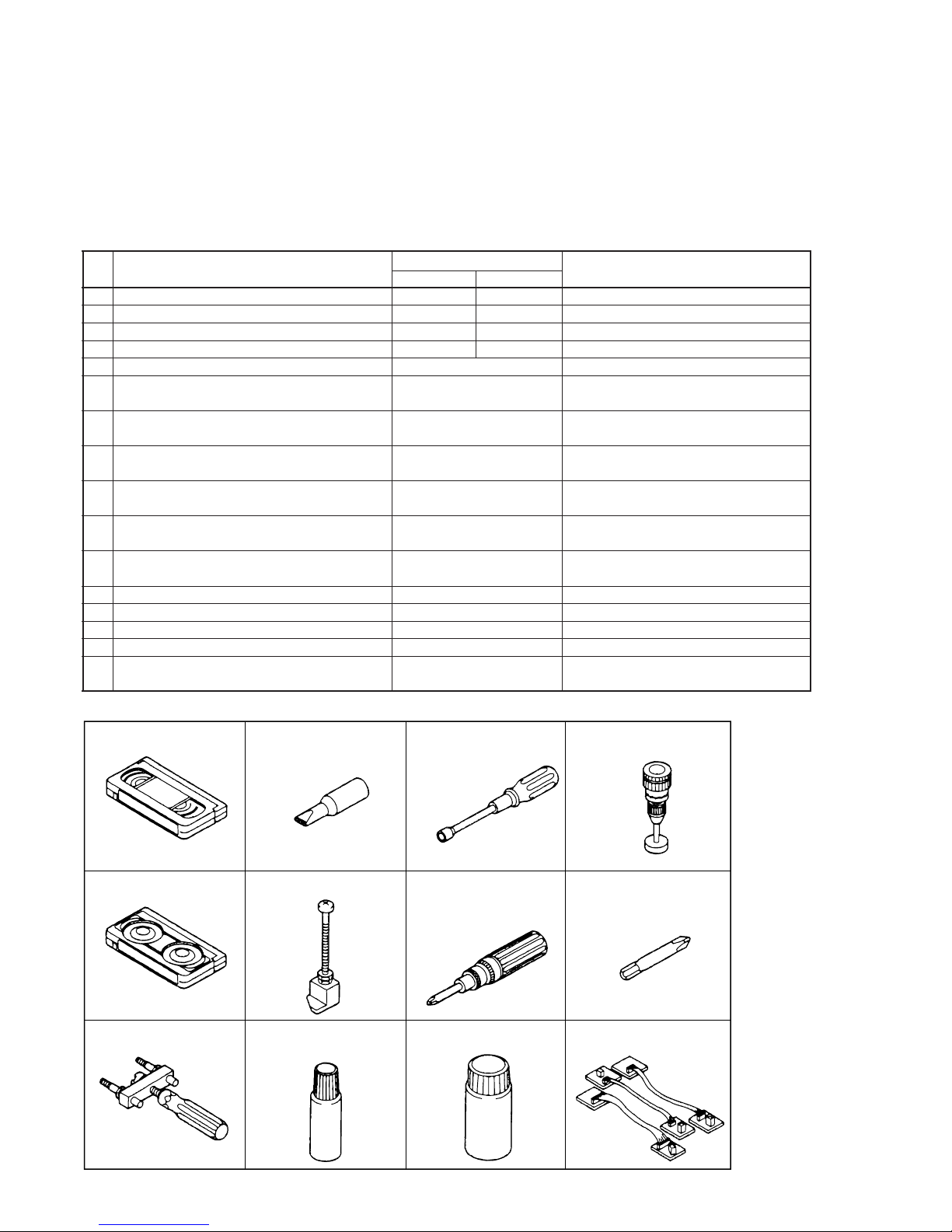

1-2. SERVICE TOOLS

1-2-1. SERVICE TOOLS

NOTES ON ALIGNMENT TAPES

Select a PAL or NTSC alignment tape from the list below, according to the transmission system of the VCR you are

repairing.

PAL: For models with 625 scanning lines and a field frequency of 50Hz

NTSC: For models with 525 scanning lines and a field frequency of 60Hz

VHJ-0005, VHJ-0006, VHJ-0007

VHJ-0003

VHJ-0102

VHJ-0048

VHJ-0014

VHJ-0100, VHJ-0101

VHJ-0045

VHJ-0016

VHJ-0099

No. 1, 2, 3, 4

No. 5

No. 6 No. 7

No. 8

No. 9

No. 10 No. 11

No. 12

No. 13

No. 14, 15 No. 16

VHJ-0106

VHJ-0041

VHJ-0004

Fig.1-2-1

No. Tool

Tool No.

Remarks

NTSC PAL

1 Alignment tape VHJ-0005 VHJ-0008 SP colour bar 1kHz (normal)

2 Alignment tape VHJ-0006 VHJ-0009 SP monoscope 7kHz (normal)

3 Alignment tape VHJ-0007 –––––––– EP monoscope

4 Alignment tape –––––––– VHJ-0052 LP monoscope

5 Eccentric screw driver VHJ-0003 Used to adjust the tape path

6 Nut box VHJ-0048

Used to adjust the height of the

lever load assembly

7 Torque dial gauge VHJ-0004

Used to measure reel winding

torque

8 Cassette torque meter VHJ-0016

Used to measure back tension

torque

9 Load lever assembly height adjustment tool VHJ-0102

Used to adjust the height of the

load lever assembly

10 Torque gauge screwdriver VHJ-0014

Used to adjust the tightening torque

of screws

11 3 mm dia. bit for torque screwdriver VHJ-0045

Used to replace the bit of the torque

gauge screwdriver

12 Video head removing tool VHJ-0041 Used to remove the upper cylinder

13 Oil VHJ-0099

14 Grease VHJ-0100

15 Grease VHJ-0101

16 Relay cables VHJ-0106

Relay cables of mechanism and

CP-1 PWB assembly

5-3

1-2-2. Using the Relay Cable (VHJ-0106)

The mechanism can be repaired without using the relay

cable (VHJ-0106). As shown in Fig. 1-3-1, the relay cable

(VHJ-0106) is a tool used for relay between the CP-1 PWB

assembly and mechanism unit.

When connecting it, take note of the pin number of the

connector.

NOTE 1: Do not place the mechanism upright as shown

in Fig. 1-3-1 when inserting/ejecting the cassette.

NOTE 2: For NTSC models, be sure to connect the VM-1

PWB assembly and CP-1 PWB assembly.

Mechanism unit

CP-1 PWB assembly

VM-1 (VP-1) PWB

assembly

Relay cable:

VHJ-0106

Fig. 1-2-2

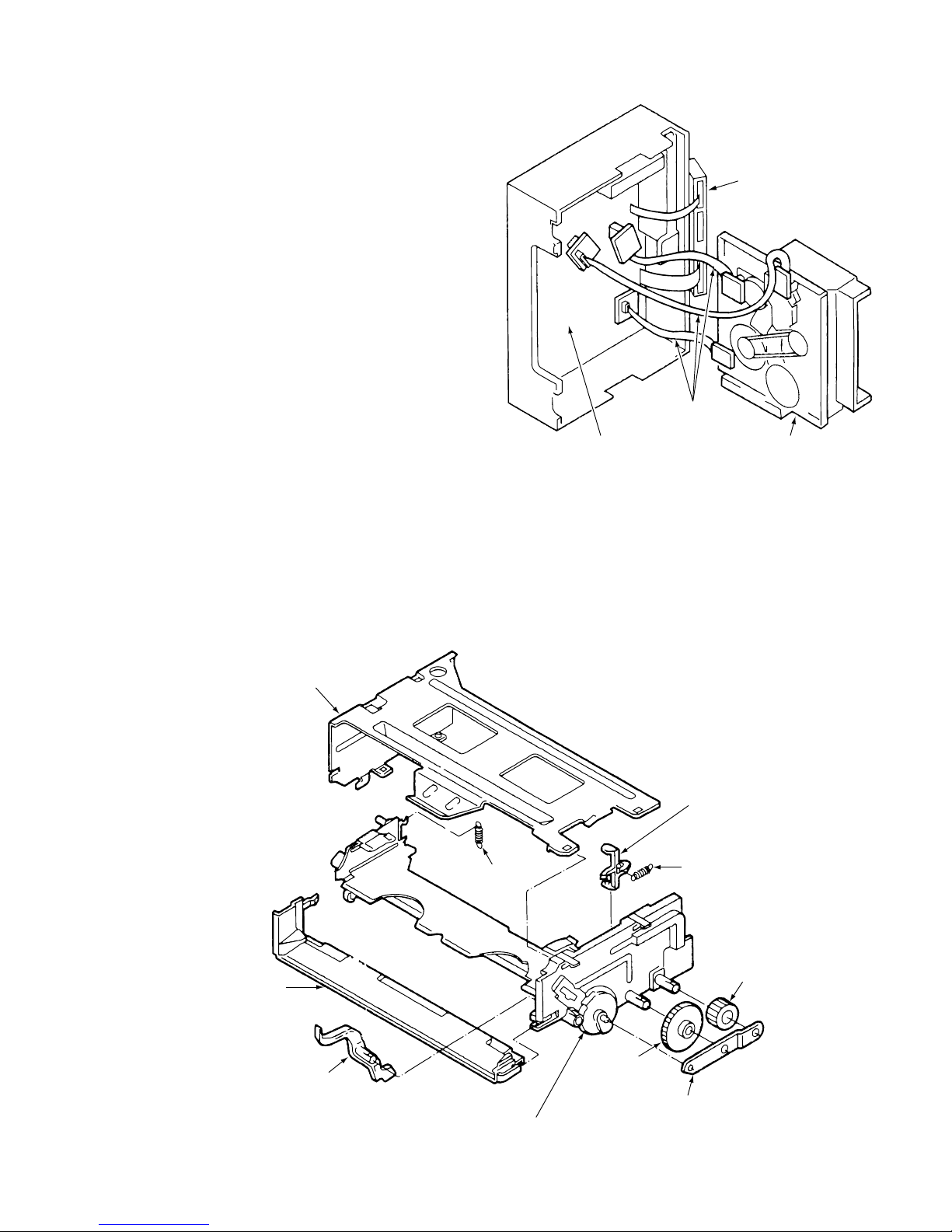

Fig. 2-1-1

2. AN OVERVIEW OF THE MECHANISM

2-1. NAMES OF THE MAIN PARTS

2-1-1. CASSETTE MECHANISM ASSEMBLY

Under frame

Stand L

Release lever

Lid opener spring

Pinion gear

Lock gear

Gear holder

Drive gear

Tray lock

spring

Door opener

lever

5-4

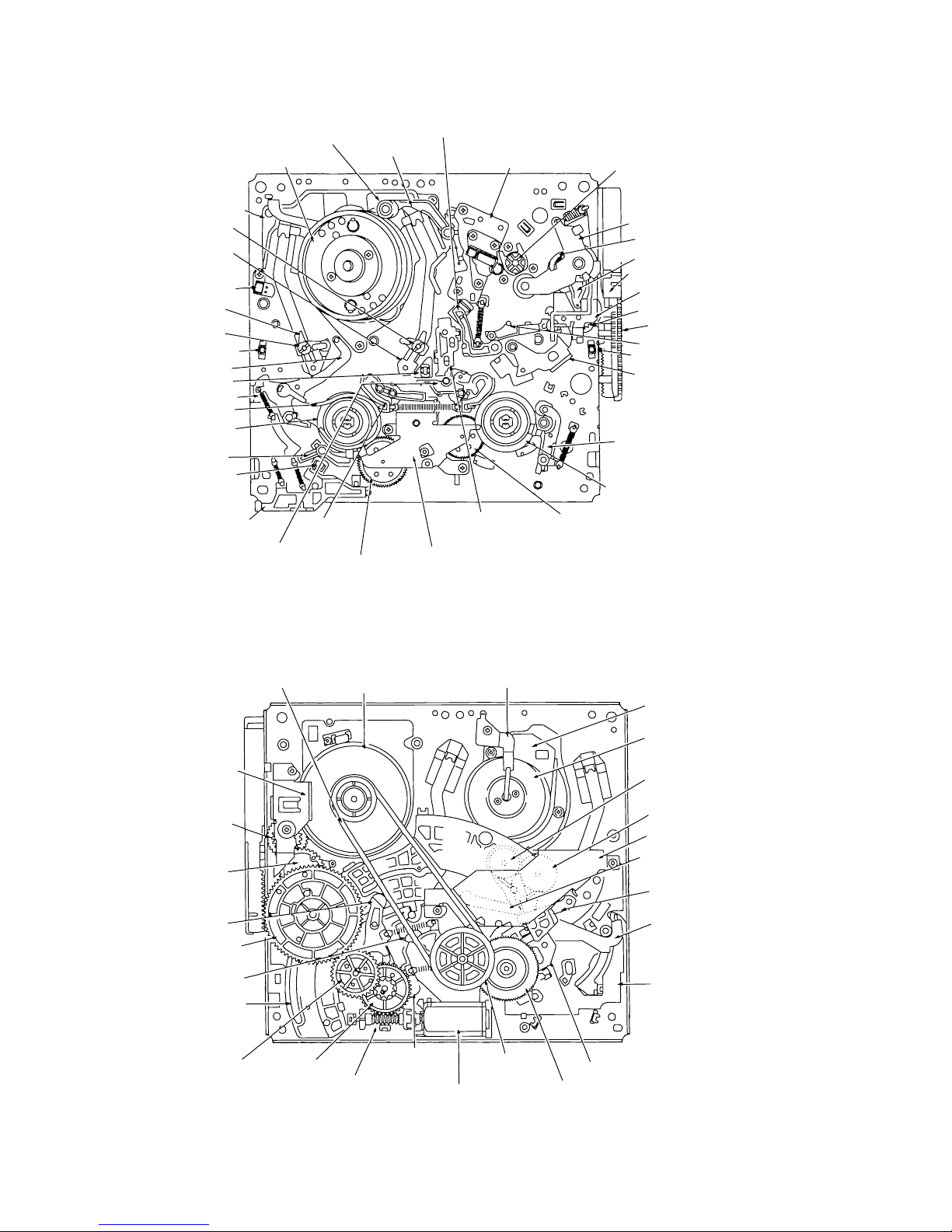

2-1-2. T OPVIEW

2-1-3. UNDERSIDE

Capstan motor

Pinch roller lever assembly

Pinch lift cam

Pinch lift mounting

Front rack gear

Opener mounting

Pinch cam gear

Start rack gear

Load lever assembly

Tape top sensor

L guide act lever assembly

T soft brake assembly

Take-up reel assembly

T reel gear

Cylinder (Drum)

Cleaner lever

Cleaner roller assembly

Capstan brake assembly

Audio R/P head assembly

(ACE head)

T brake act slide

Clutch mounting assembly

S reel gear

S brake

assembly

T brake assembly

EP sw lever

EP switch

S soft lever

Supply reel assembly

Band brake assembly

BT spring

Tape sensor LED

BT lever assembly

Tape end sensor

Guide roller assembly

S incline mounting assembly

Full erase head

T incline mounting assembly

Guide roller assembly

Cylinder mounting

Fig. 2-1-2

Fig. 2-1-3

Stator

Rotor

T load gear

S load gear

Crescent mounting

T load lever assembly

S load lever assembly

BT spring lever assembly

MC-1 PWB assembly

Reel belt

Capstan motor

Loading motor assembly

Reel pulley

Friction gear assembly

S brake act slide

Wheel gear 2 Wheel gear 1

Worm gear assembly

Cylinder earth

assembly

Brake act lever

assembly

Harness mounting

Pinch cam gear

Mode switch (S8001)

Brake control lever

Main cam

Clutch change lever

Crescent slide

5-5

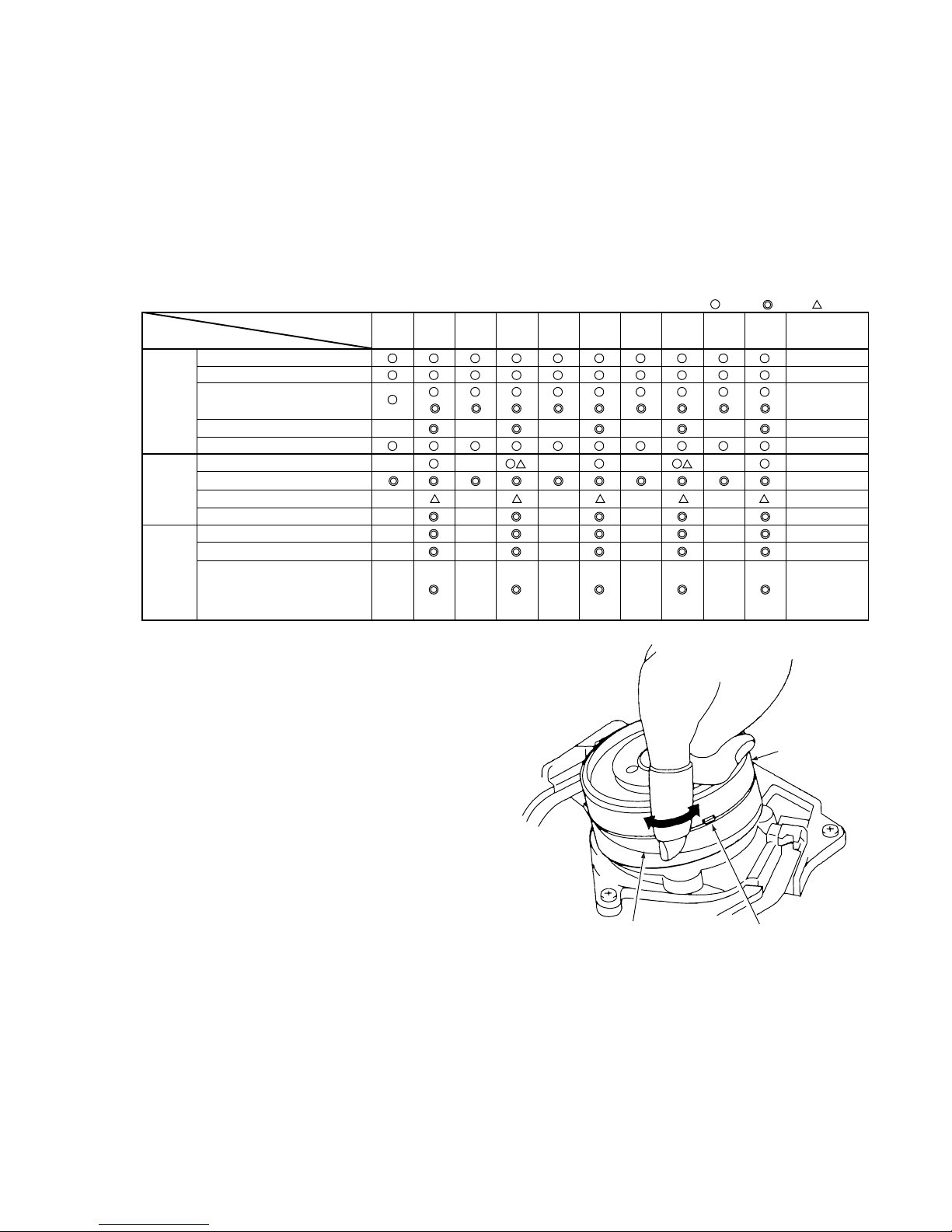

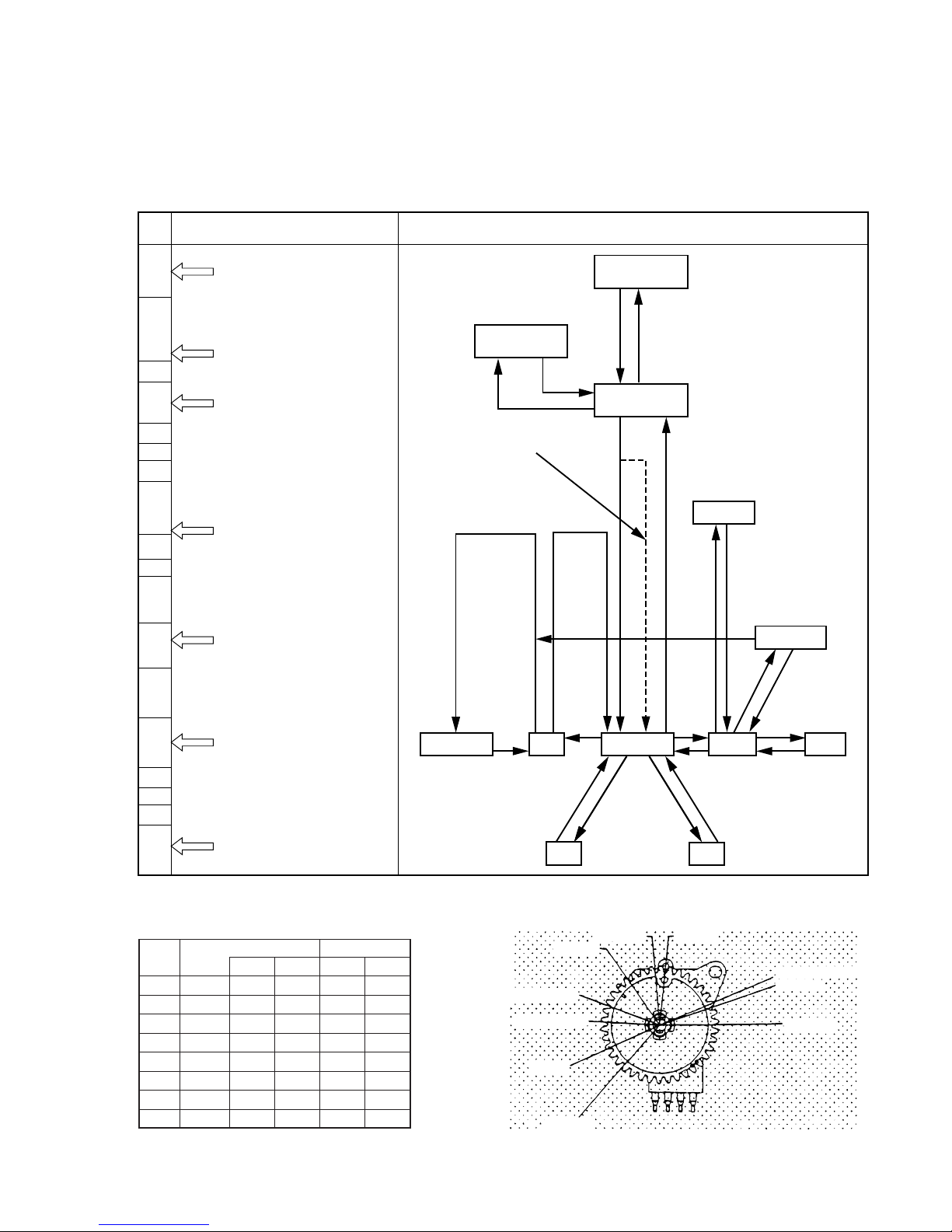

2-2. AN OVERVIEW OF THE MECHANISM MODES

2-2-1 . MECHANISM MODE SWITCHING TABLE

NOTE: The letters and figures enclosed in circles in the mechanism mode column are the codes on the crescent slide.

FF/REW EJECT

CASSETTE IN

IN REW

INITIAL

REVIEW

IDLER

STILL/SLOW

PLAY/STOP

BRAKE

Fig. 2-2-1

6

2

0

7

0

1

0

1

0

2

0

3

0

5

0

4

0

6

EJECT E

Distinguished by whether the

EP switch is ON or OFF.

Horizontal shift section.

Vertical shift section.

IN REW R

INITIAL 7

Cleaner roller assembly: ON

S/T mounting incline assembly

pressure begins.

S/T mounting incline assembly

pressure ends.

REVIEW 1

IDLER pos. 2

(Pinch roller OFF)

STILL/SLOW 3

PLAY/STOP 5

BRAKE pos. 4

FF/REW 6

CASSETTE OUT

(EJECT)

IN REW

(SHORT REW)

INITIAL

(POWER OFF)

The principal mode-switching states of the mechanism

Mechanism mode

HEX

DATA

When loading is carried out starting at

the CASSETTE IN position

REVIEW

STILL/SLOW

REC PAUSE REC STOP P LAY CUE

REW

FF

APPEARANCE OF MODE SWITCH AND

RELATIONSHIP BETWEEN MODE POSITIONS

MODE SWITCH OUTPUT TABLE

HEX SW DATA SW DATA 2

DATA 1 X Y Z

0 5.0V H H H 5V

1 5.0V H H L 0V

2 2.5V H L H 5V

3 2.5V H L L 0V

4 3.4V L H H 5V

5 3.4V L H L 0V

6 2.0V L L H 5V

7 2.0V L L L 0V

5-6

2-2-2. MOVEMENT CHECK LIST FOR THE MAIN PARTS OF THE MECHANISM

2-2-3. HOW TO CHECK THE MECHANISM MODE

POSITION

You can tell which mode the mechanism is currently in by

looking at the codes and marking-lines on the crescent

slide on the underside of the mechanism chassis. The

edge of the crescent mounting is used as the reference

line, as shown in Fig.2-2-2, and the marking-lines and

symbols indicating the mechanism modes are displayed

on the crescent slide, which slides against the edge of the

crescent mounting. The mechanism mode is read off from

the marking-line on the slide crescent which is aligned

with the reference-line on the crescent mounting.

Example: In Fig.2-2-2, marking-line 6 is aligned with the

reference-line on the crescent mounting , so the mechanism is seen to be in FF/REW mode.

2-2-4. SELF-DIAGNOSIS DISPLAY

Some models are equipped with the SELF-DIAGNOSIS

DISPLAYS function.

Use it as a means of finding out the symptoms and cause

of the error before performing repairs.

For details, refer to the separate service manual for the

respective models.

6: FF/REW

4: BRAKE

5: PLAY/STOP

3: STILL/SLOW

2: IDLER

1: REVIEW

7: INITIAL

(POWER OFF)

E: EJECT

Crescent slide

Crescent mounting

The edge of the

crescent mounting

is the reference-line

Fig. 2-2-2

(S): Strength (W): Weakness

T brake assembly OFF OFF ON ON ON OFF OFF OFF OFF ON

ON/OFF

S brake assembly OFF OFF OFF OFF OFF OFF OFF OFF OFF ON

ON/OFF

T soft brake assembly OFF OFF OFF ON ON ON ON OFF OFF OFF OFF

S soft lever ON ON ON ON ON OFF OFF OFF OFF OFF OFF

BT lever assembly OFF OFF OFF OFF OFF ON ON ON ON ON ON

BT spring OFF OFF OFF OFF OFF

ON(W) ON(W) ON(S) ON(S) ON(S) ON(W)

Pinch roller lever assembly UP UP UP

UP/ DOWN/

ON OFF ON ON OFF OFF

DOWN UP

Clutch mounting assembly PLAY PLAY PLAY PLAY PLAY PLAY PLAY PLAY PLAY PLAY FF

Load lever assembly UNLO UNLO UNLO LO LO LO LO LO L LO LO

Capstan brake assembly OFF OFF OFF OFF OFF OFF OFF ON OFF OFF OFF

S and T incline mounting assembly LO UNLO

Cleaner roller assembly OFF OFF OFF (ON) (ON) OFF OFF OFF OFF OFF OFF

Principal parts

Mechanism mode

EJECT

IN REW

INITIAL

(POWER OFF)

(LOADING)

(UNLOADING)

REV

IDLER

STILL/SLOW

PLAY/STOP

BRAKE

FF/REW

Loading...

Loading...