Sony SCD-XB780,SCD-XB790 Service Manual

SERVICE MANUAL

SUPER AUDIO CD PLAYER

AEP Model

UK Model

Korean Model

SCD-XB780

Ver 1.3 2002.11

SPECIFICATIONS

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM66B-DVBU6B

Base Unit Name DVBU-6B

Optical Pick-up Name KHM-234AMA

9-873-930-04 Sony Corporation

2002K0500-1 Home Audio Company

C 2002.11 Published by Sony Engineering Corporation

2

SCD-XB780

This appliance is classified as a CLASS 1

LASER product.

This label is located on the rear exterior.

The following caution label is located

inside the unit.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Case ................................................................................. 9

3-3. Front Panel Section ......................................................... 9

3-4. AUDIO Board, MAIN Board.......................................... 10

3-5. Mechanism Deck (CDM66B-DVBU6B) ....................... 10

3-6. Base Unit (DVBU-6B).................................................... 11

4. TEST MODE.............................................................. 12

5. DIAGRAMS

5-1. Block Diagram – RF/SERVO Section – ........................ 20

5-2. Block Diagram – SERVO Section – .............................. 21

5-3. Block Diagram – MAIN Section – ................................ 22

5-4. Block Diagram – AUDIO Section – .............................. 23

5-5. Block Diagram – DISPLAY/KEY CONTROL/

POWER SUPPLY Section – ........................................... 24

5-6. Notes for Printed Wiring Boards and

Schematic Diagrams ....................................................... 25

5-7. Schematic Diagram – RF Board – ................................. 26

5-8. Printed Wiring Boards

– RF/LOADING Boards – .............................................. 27

5-9. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 28

5-10. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 29

5-11. Schematic Diagram

– MAIN (1/5)/ LOADING Boards – ............................. 30

5-12. Schematic Diagram – MAIN Board (2/5) –.................. 31

5-13. Schematic Diagram – MAIN Board (3/5) –.................. 32

5-14. Schematic Diagram – MAIN Board (4/5) –.................. 33

5-15. Schematic Diagram – MAIN Board (5/5) –.................. 34

5-16. Schematic Diagram – AUDIO/HP Boards – ................. 35

5-17. Printed Wiring Board

– AUDIO Board (Component Side) – ............................ 36

5-18. Printed Wiring Boards

– AUDIO (Conductor Side)/HP Boards – ..................... 37

5-19. Printed Wiring Boards – DISPLAY/KEY Boards –...... 38

5-20. Schematic Diagram – DISPLAY/KEY Boards – .......... 39

5-21. Printed Wiring Boards

– POWER/POWER SW/PT Boards – ............................ 40

5-22. Schematic Diagram

– POWER/POWER SW/PT Boards – ............................ 41

5-23. IC Pin Function Description........................................... 49

6. EXPLODED VIEWS

6-1. Case Section .................................................................... 61

6-2. Front Panel Section ......................................................... 62

6-3. Chassis Section ............................................................... 63

6-4. Mechanism Deck Section (CDM66B-DVBU6B) .......... 64

6-5. Base Unit Section (DVBU-6B)....................................... 65

7. ELECTRICAL PARTS LIST ............................... 66

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3

SCD-XB780

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

CLEANING OF OPTICAL PICK-UP LENS

In cleaning the lens of optical pick-up, use the air blower.

Never use a cotton swab for cleaning the lens of optical pick-up,

which otherwise causes a trouble.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

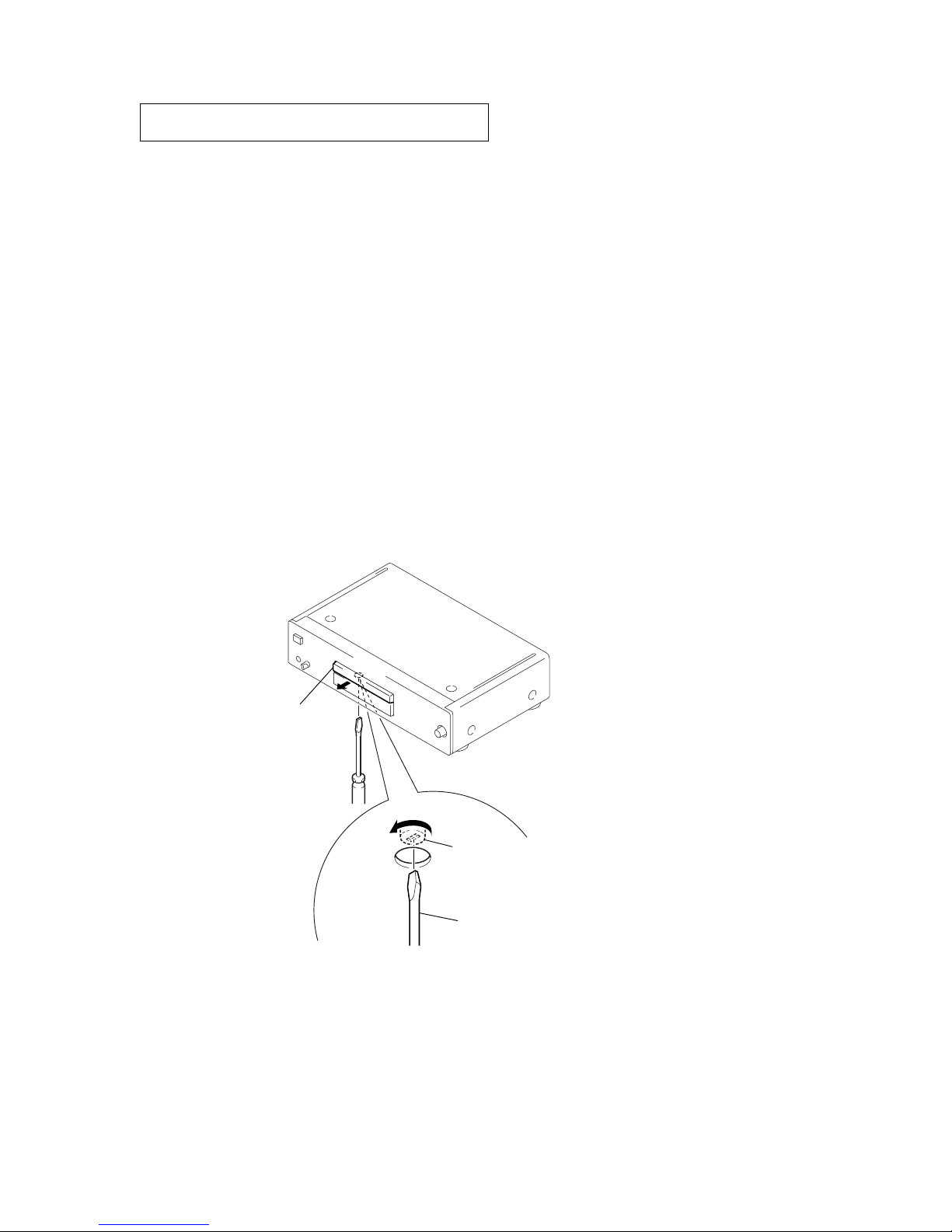

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURNS OFF

tray

tapering driver

cam (66)

1

Insert a tapering driver (3 mm in diameter)

in the hole at the bottom of the unit,

turn the cam (66) fully in the direction of arrow A.

A

SECTION 1

SERVICING NOTES

4

SCD-XB780

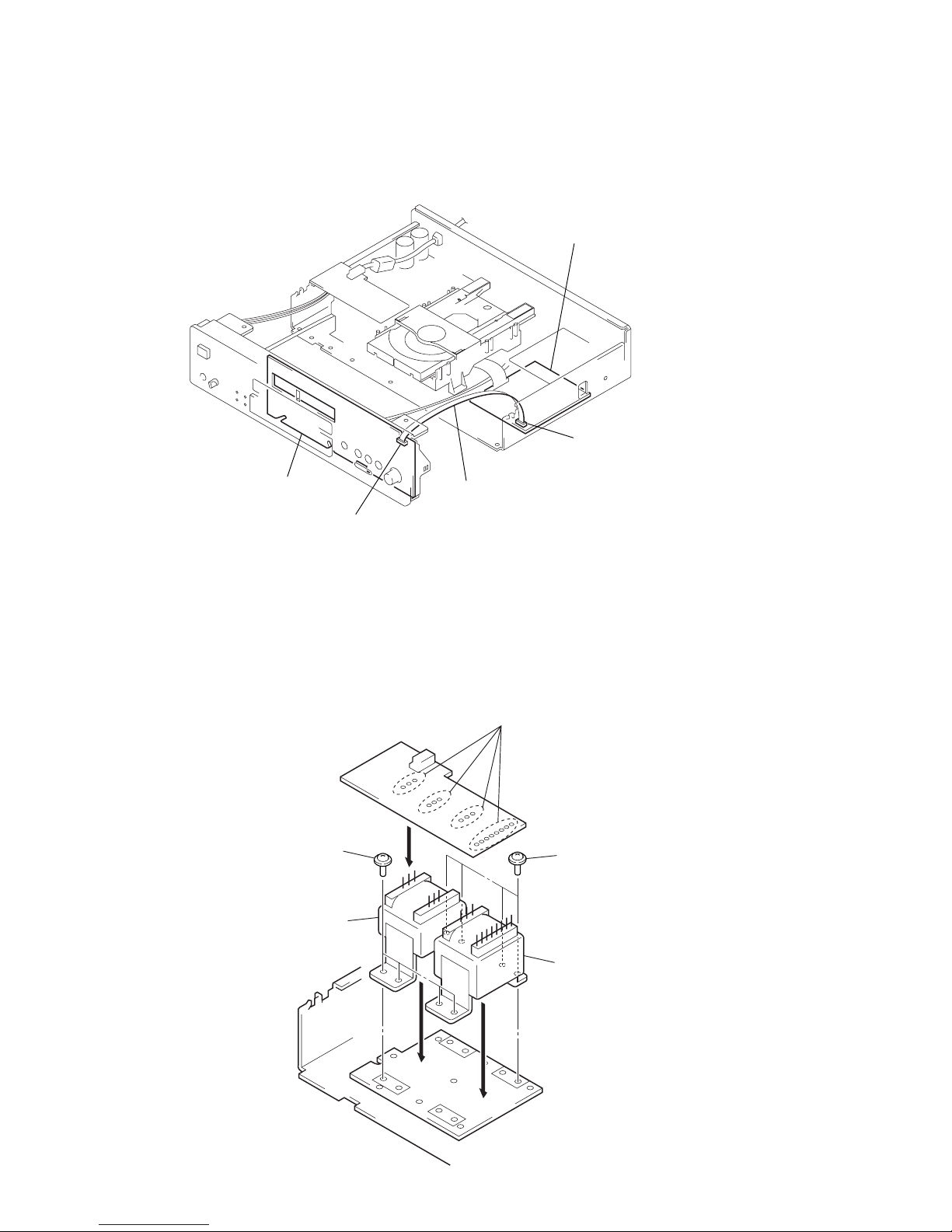

DISPLAY BOARD SERVICE POSITION

In checking the DISPLAY board, prepare jig (extension cable J-2501-200-A : 1.00 mm Pitch, 11 cores, Length 300 mm.)

MAIN board

DISPLAY board

CN801

Connect jig (extension cable J-2501-200-A)

to the DISPLAY board (CN801) and

MAIN board (CN706).

CN706

Note: Follow the assembly procedure in the numerical order given.

INSTALLATION OF THE TRANS BOARD

3

four screws

(PTTWH3

×

6)

2

power transformer

(T902)

4

3

four screws

(PTTWH3

×

6)

1

power transformer

(T901)

5

Solder seventeen portions.

Note : Solder the TRANS board after installing power transformers (T901, T902)

to the chassis.

(To prevent the TRANS board from being cracked.)

5

SCD-XB780

RESETTING OPERATION AT POWER ON

If the power is turned on with a disc loaded in the set, a sequence of operation as shown below will be performed.

(The operation varies depending on the type of disc) Condition: continue mode

(1) CD

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for CD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle ser vo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Stop

(2) SACD (single layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle ser vo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Stop

(3) SACD (dual layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on (layer 0)

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment (layer 0)

12. Tracking & sled servo on (layer 0)

13. Focus bias auto adjustment (layer 0)

14. Focus servo gain auto adjustment (layer 0)

15. Tracking servo gain auto adjustment (layer 0)

16. Jump to lead-in area

17. Read TOC

18. Focus jump (layer 0tlayer 1)

19. E-F balance auto adjustment (layer 1)

20. Tracking & sled servo on (layer 1)

21. Focus bias auto adjustment (layer 1)

22. Focus servo gain auto adjustment (layer 1)

23. Tracking servo gain auto adjustment (layer 1)

24. Focus Jump (layer 1tlayer 0)

25. Stop

6

SCD-XB780

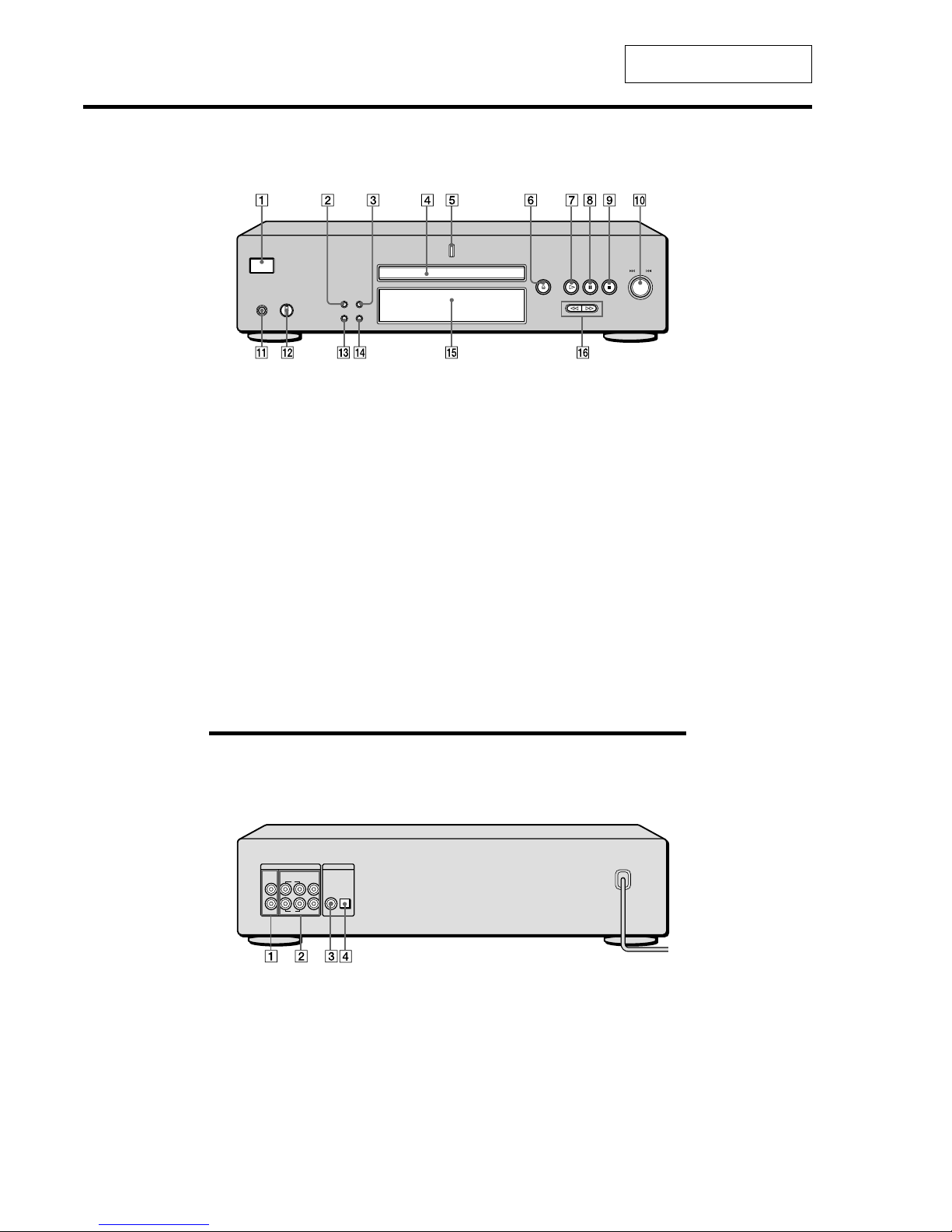

Front Panel Parts

Descriptions

Rear Panel Parts Descriptions

ANALOG

L

L

R

R

2CH OUT 5.1CH OUT OUT

FRONT COAXIAL OPTICALSURR CENTER

SUB

WOOFER

DIGITAL(CD)

1 ANALOG 2CH OUT L/R jacks

Connect to an audio component (stereo/2 channel)

using the audio connecting cord.

2 ANALOG 5.1CH OUT jacks

Connect to an amplifier equipped with the 5.1CH

input jacks (Multi-channel amplifier, AV amplifier,

etc.) using the audio connecting cords.

3 DIGITAL (CD) OUT COAXIAL connector

Connect to an audio component using the coaxial

digital cable.

4 DIGITAL (CD) OUT OPTICAL connector

Connect to an audio component using an optical

digital cable.

Note

Only the audio signals of the CD can be output from the

DIGITAL (CD) OUT connectors shown in 3 and 4. Those of the

Super Audio CD cannot be output through DIGITAL (CD) OUT.

SECTION 2

GENERAL

This section is extracted from

instruction manual.

PHONES

POWER

PHONE LEVEL

MIN MAX

PUSH ENTER

AMS

TIME/TEXT SACD/CD

MENU MULTI/2CH

OPEN CLOSE

1 POWER switch

Press to turn on the player.

2 TIME/TEXT button

Each time you press the button, the playing time of the

track, the total remaining time on the disc, or TEXT

information appears in the display.

3 SACD/CD button

Each time you press the button while playing back a

hybrid disc, the layer to be played back switches

between the HD (Super Audio CD) layer and the CD

layer.

4 Disc tray

Press A OPEN/CLOSE to open/close the disc tray.

5 Multi-channel indicator

Turns on when you turn on the player, or when the

Multi-channel Super Audio CD is loaded and select

the Multi-channel playback area by pressing MULTI/

2CH.

6 A OPEN/CLOSE button

Press to open the disc tray.

7 H button

Press to start play.

8 X button

Press to pause play.

9 x button

Press to stop play.

0 l AMS L dial (AMS: Automatic Music Sensor)

When you turn the l AMS L dial

counterclockwise by one click, you go back to the

preceding track; when you turn the l AMS L

dial clockwise by one click, you go to the succeeding

track.

qa PHONES

Connect the headphones.

During playback of a Multi-channel Super Audio CD,

the same signal that is output from the ANALOG

5.1CH FRONT L/R jacks is output from the PHONES

jack.

qs PHONE LEVEL

Adjust the headphones volume.

qd MENU

Press to enter the menu.

Press to exit from the menu and return to the normal

display.

qf MULTI/2CH button

Press to select the playback area when the 2 channel +

Multi-channel Super Audio CD is loaded.

qg Display window

Shows various information.

qh m/M buttons

Press to locate a portion you want to play within a

track.

7

SCD-XB780

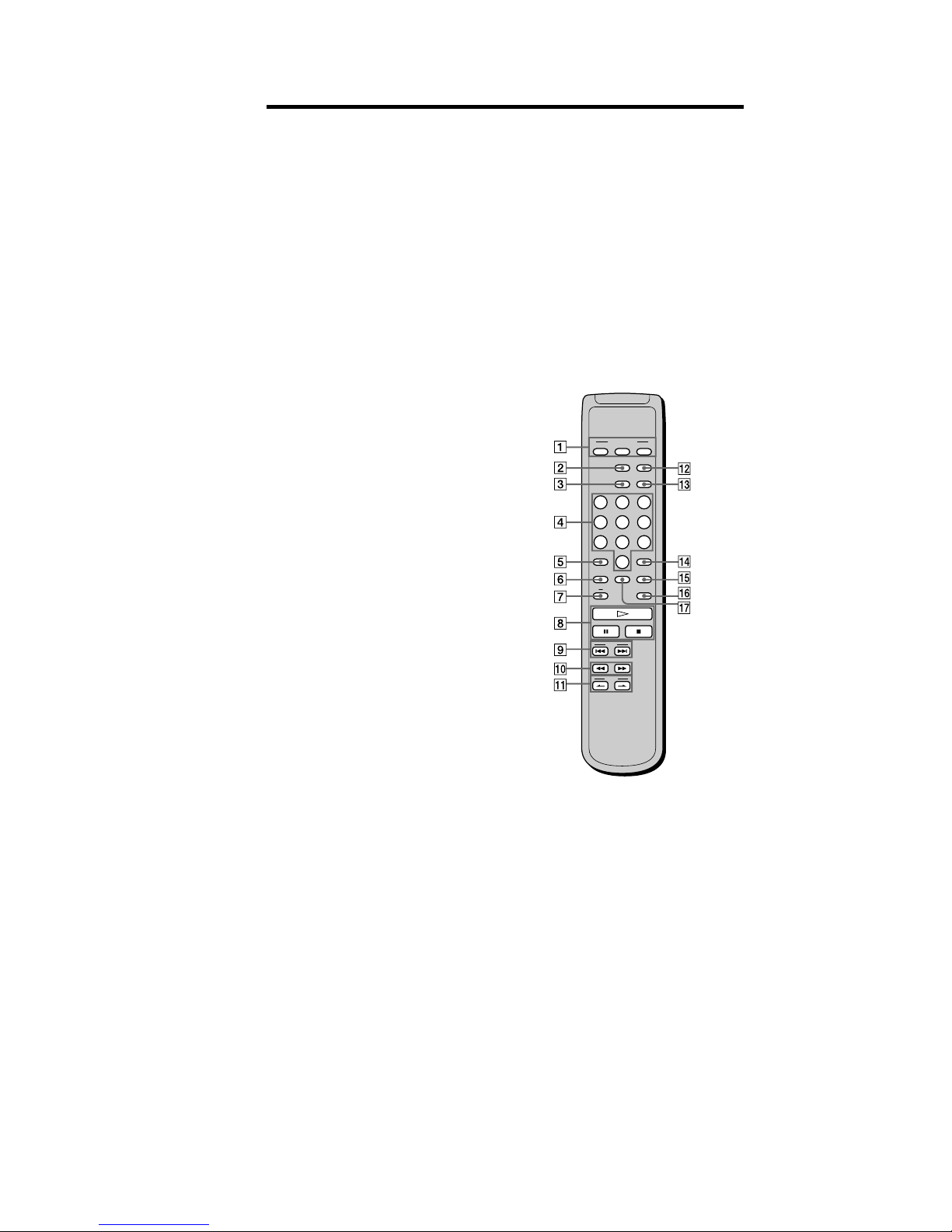

Remote Parts Descriptions

CONTINUE SHUFFLE

PLAY MODE

PROGRAM

SACD/CD

123

456

78

10/0

9

TIME/TEXT

REPEAT

AMS

BA

CLEAR

>10 ENTER

MODE

DISPLAY/

MULTI/2CH

INDEX

LEVEL

ADJ

CHECK

1 CONTINUE button

Press to resume normal play from Shuffle Play or

Programme Play.

SHUFFLE button

Press to select Shuffle Play.

PROGRAM button

Press to select Programme Play.

2 DISPLAY MODE button

Press to turn off the information.

3 TIME/TEXT button

Each time you press the button, the playing time of the

track, the total remaining time on the disc, or TEXT

information appears in the display.

4 Number buttons

Press to enter the track numbers.

5

i

10 button

Press to locate a track numbered over 10.

6 REPEAT button

Press repeatedly to play all tracks or only one track on

the disc.

7 A yB button

Press to select Repeat A-B Play.

8 H button

Press to start play.

X button

Press to pause play.

x button

Press to stop play.

9 AMS ./> (AMS: Automatic Music Sensor)

buttons

Press to locate a specific track.

0 m /M buttons

Press to locate a portion you want to play within a

track.

qa INDEX >/. buttons

Press to locate a specific point marked with an index

signal when you play a disc that has index signals.

qs SACD/CD button

Each time you press the button while playing back a

hybrid disc, the layer to be played back switches

between the HD (Super Audio CD) layer and the CD

layer.

qd MULTI/2CH button

Press to select the playback area when the 2 channel +

Multi-channel Super Audio CD is loaded.

qf ENTER button

Press to decide the selection.

qg CLEAR button

Press to delete a programmed track number.

qh LEVEL ADJ button

Press to adjust the output level balance for the Multichannel management function.

qj CHECK button

Press to check the programmed order.

SCD-XB780

8

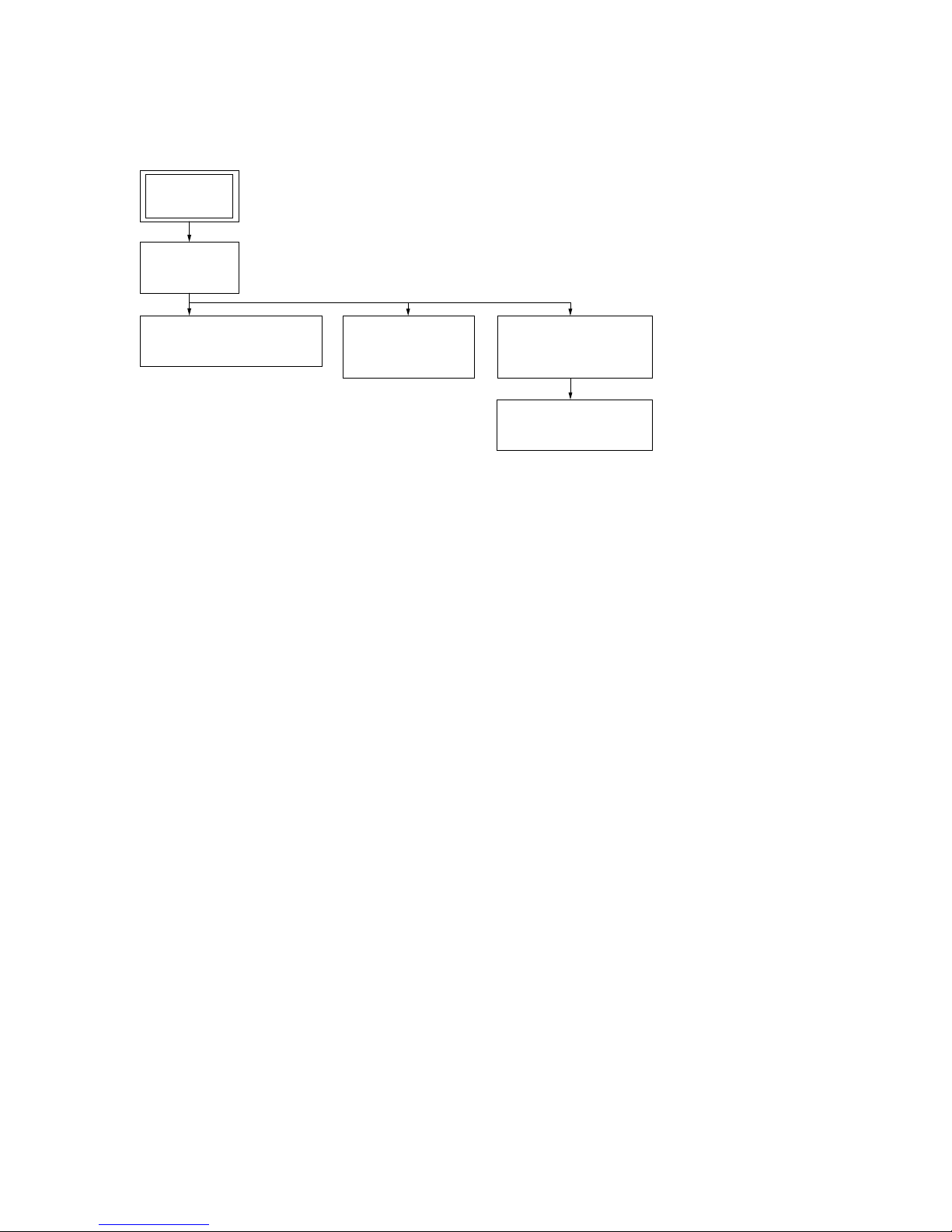

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SECTION 3

DISASSEMBLY

3-2. CASE

(Page 9)

3-3. FRONT PANEL SECTION

(Page 9)

3-6. BASE UNIT

(DVBU-6B)

(Page 11)

3-5. MECHANISM DECK

(CDM66B-DVBU6B)

(Page 10)

3-4. AUDIO BOARD,

MAIN BOARD

(Page 10)

SET

SCD-XB780

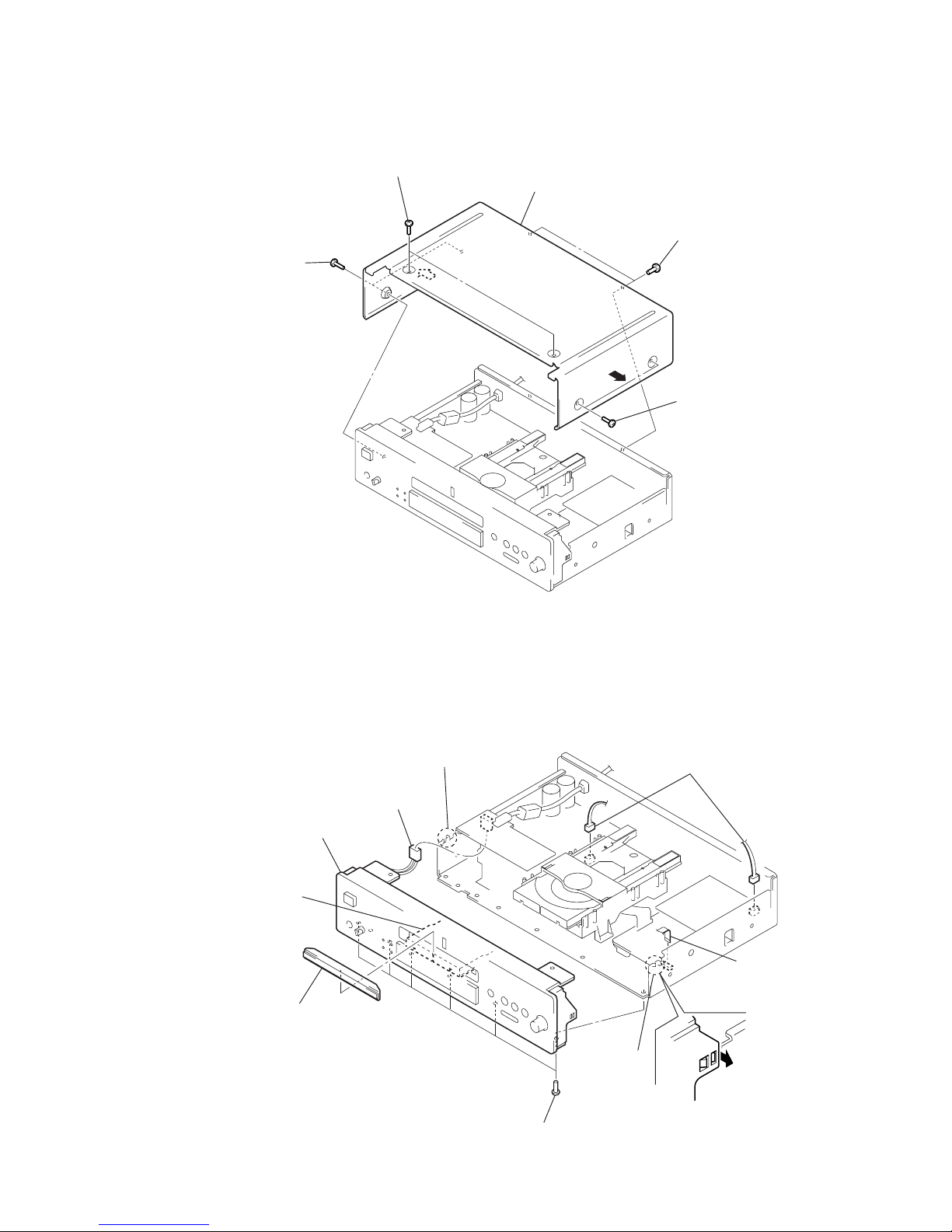

9

3-3. FRONT PANEL SECTION

Note: Follow the disassembly procedure in the numerical order given.

3-2. CASE

1

two screws

3

case

2

two flat head screws (TP)

2

two flat head screws (TP)

2

two flat head screws (TP

)

2

loading panel assy

1

Pull out the tray.

(Refer to page 3, HOW TO

OPEN THE TRA Y WHEN

POWER SWITCH TURNS

OFF.)

6

two claws

4

connector

(CN992)

7

front panel section

4

two connector

(CN305, 905)

3

wire (flat type)

(11 core)

(CN706)

6

two claws

5

six screws

(BV/RING)

SCD-XB780

10

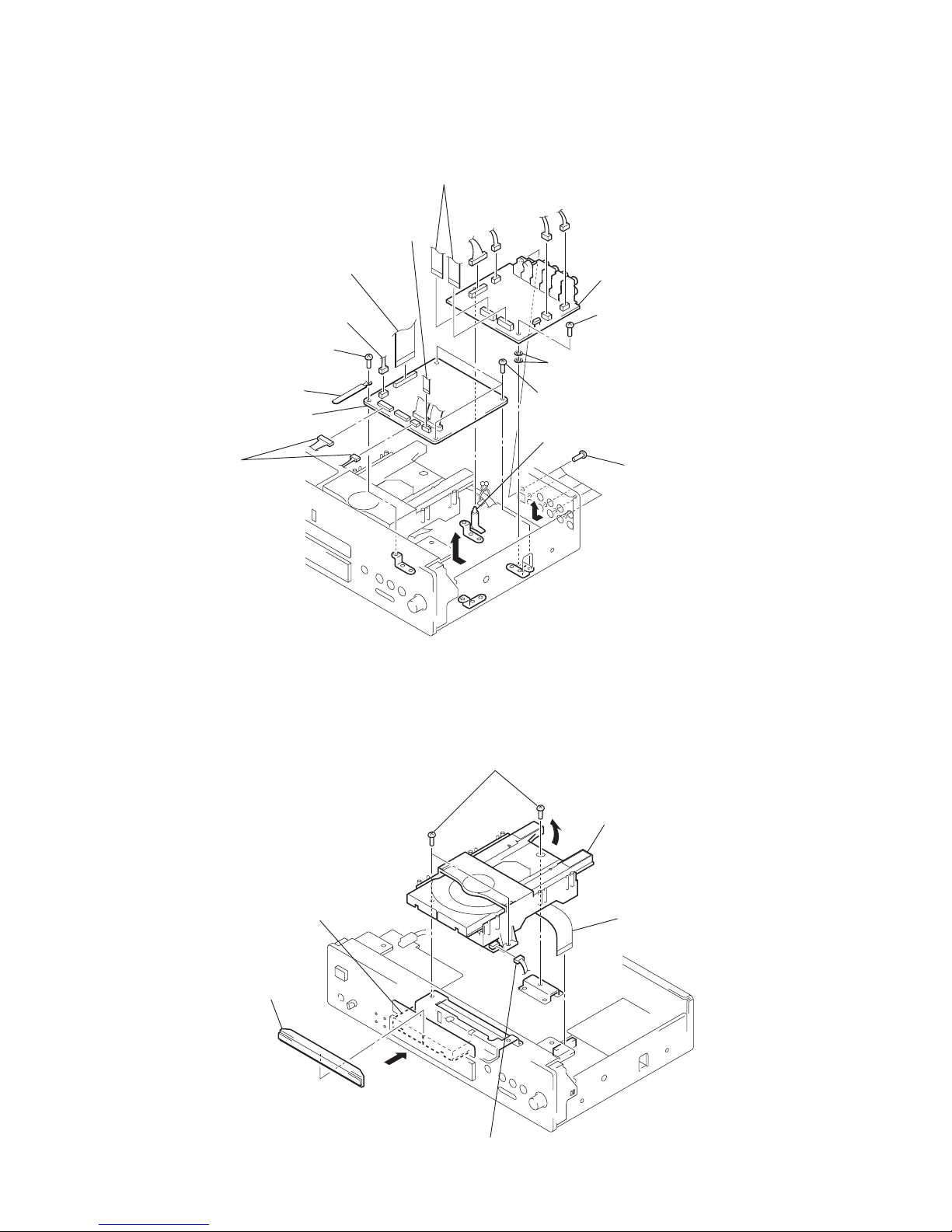

3-4. AUDIO BOARD, MAIN BOARD

3-5. MECHANISM DECK (CDM66B-DVBU6B)

3

five screws

(BVT/RING)

2

four connectors

(CN301, 304, 305, 306)

1

two wires

(flat type) (19 core)

(CN302, 303)

7

AUDIO board

4

screw

(BVTT3

×

6)

5

two washers (DIA. 3.6)

0

three screws

(BVTT3

×

6)

6

PC board holder

8

wire (flat type)

(11 core) (CN706)

9

connector

(CN703)

0

screw

(BVTT3

×

6)

qs

MAIN board

qa

wiring stopper

9

two connectors

(CN704, 707)

8

wire (flat type)

(30 core) (CN708)

6

three screws

(BVTT3

×

8)

4

wire (flat type) (30 core

)

(CN708)

7

mechanism deck

(CDM66B-DVBU6B)

2

loading panel assy

5

connector (CN151)

1

Pull out the tray.

(Refer to page 3, HOW TO OPEN THE TRAY

WHEN POWER SWITCH TURNS OFF.)

3

Push

the tray.

SCD-XB780

11

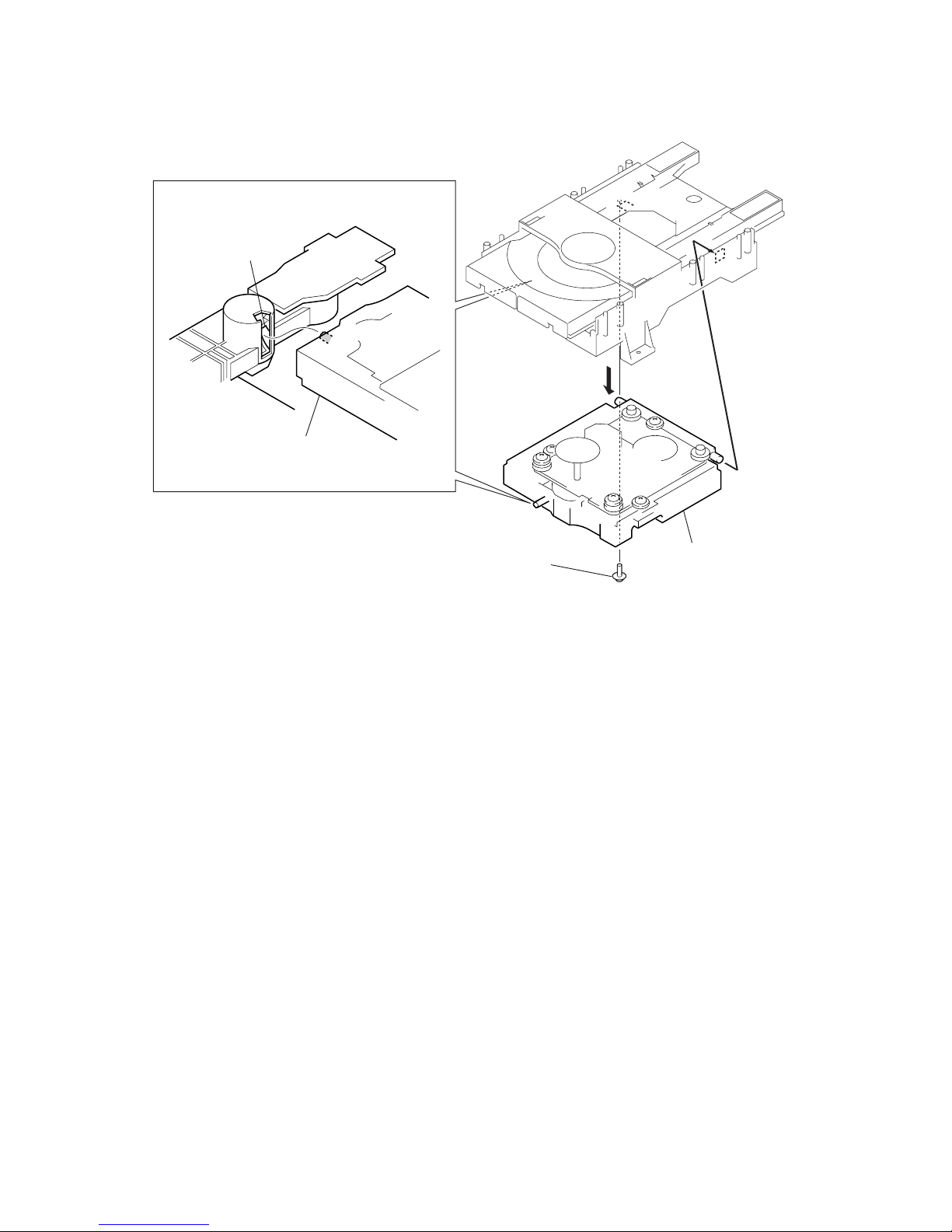

3-6. BASE UNIT (DVBU-6B)

1

screw (DIA. 12), floating

2

– BOTTOM VIEW –

3

base unit (DVBU-6B

)

base unit (DVBU-6B)

cam (66)

12

SCD-XB780

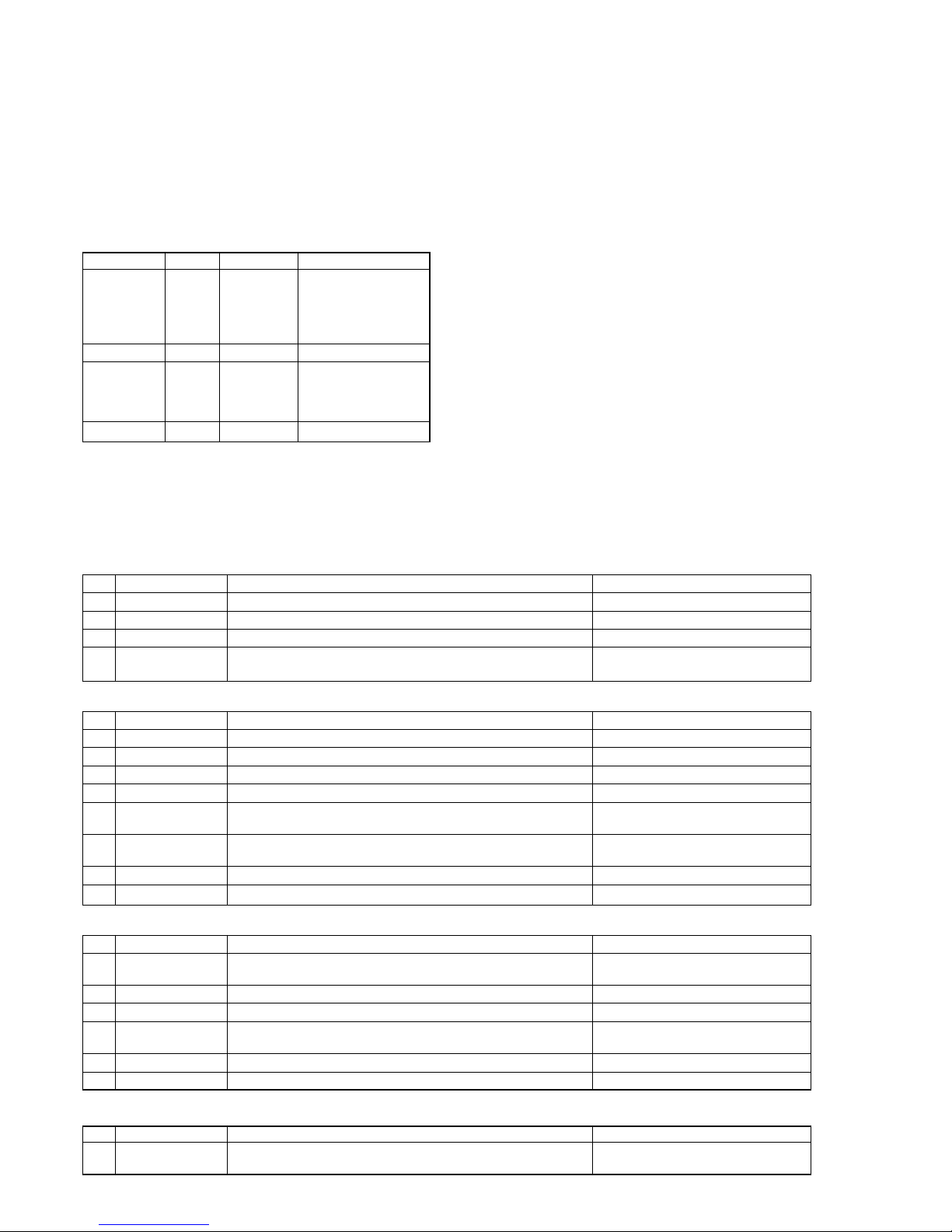

Test Mode Command List

The contents of test mode are as follows.

Note: Wrong operation in the test mode causes a trouble, thus requiring extreme care.

LINE command (0X): Use mainly for a manufacturing line.

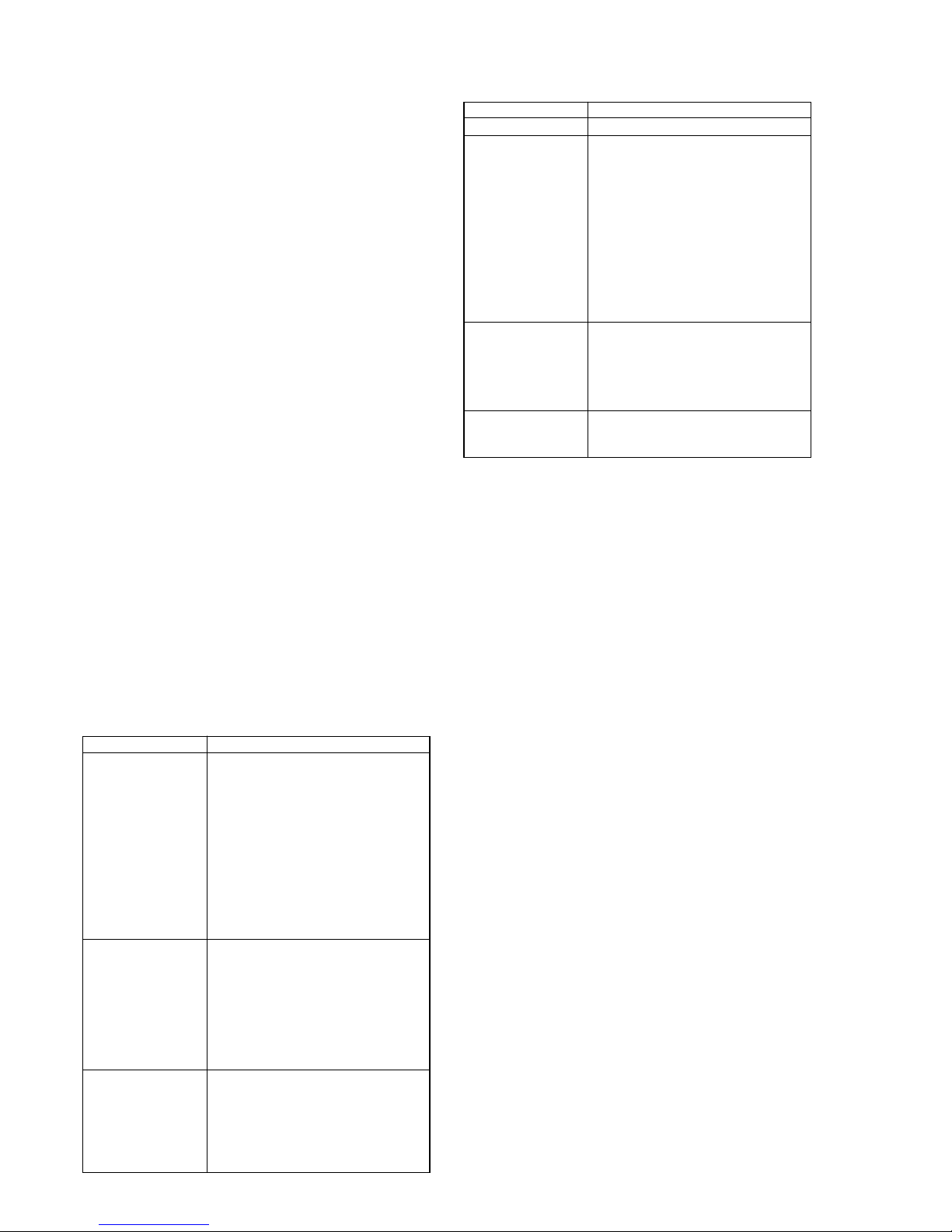

No. Name Description Remarks

00 RFAmp Read Each register set value of the IC001 (RF AMP) is displayed via RS-232C Not used for the servicing

05 DSP MON1 XUGF, XPCK, C2PO outputted from IC509 (CD DSP) Not used for the servicing

06 DSP MON2 MNT0, MNT1, MNT2, MNT3 outputted from IC509 (CD DSP) Not used for the servicing

07 DSP MON3 RFCK, XPCK, XROF, GTOP outputted from IC509 (CD DSP)

Electrical measurement,

CD CLV jitter measurement

STANDARD command (1X): Use when the servo is applied by manual operation.

No. Name Description Remarks

12 LD ON/OFF The laser diode is turned on or off On or off are switched alternately

13 SPIN ON/OFF The spindle motor is rotated with the regulated voltage On or off are switched alternately

14 FSRV ON/OFF The focus servo is turned on or off On or off are switched alternately

15 TSRV ON/OFF The tracking servo is turned on or off On or off are switched alternately

16 CLV ON/OFF

The spindle SLV servo is turned on or off

On or off are switched alternately

Focus and tracking servos must be already turned on

17 SSRV ON/OFF

The sled servo is turned on or off

On or off are switched alternately

Focus, tracking and spindle servos must be already turned on

18 ALL SRV ON All servos are turned on

19 ALL SRV OFF All servos are turned off Stop command in the test mode

FOCUS command (2X): Focus related. (All servos must be already turned on (except command 21))

No. Name Description Remarks

21 FSRCH ON/OFF

The continuous vertical motion of the optical pick-up lens is turned on or Avoid a long-time use

off On or off are switched alternately

22 F-BIAS UP Increase focus bias Focus bias value

23 F-BIAS DOWN Decrease focus bias Focus bias value

24 ADJ FCSBIAS

The focus bias is adjusted automatically

Both + and - directions are searched to search for best jitter point

25 FGAIN UP/DW The focus servo gain is switched between normal and down Normal or down are switched alternately

27 FOCUS AGC The focus servo gain is adjusted automatically

OFFSET (PI, FE, TE) command (3X): Adjusts the offset of PI, FE and TE signals.

No. Name Description Remarks

31 PI/FE OFSET

Adjusts the offset of PI, FE and TE signals TE offset adjustment is executed for the CD

This adjustment must be executed after 61 DISC DETECT only

SECTION 4

TEST MODE

In this set, various checks are automatically performed by executing

the commands in the test mode.

Note: This set makes adjustment e very optical pick-up and stores its result

in the EEPROM (IC903) on the MAIN board. Accordingly, if a

combination of optical pick-up and EEPROM is changed, be sure

to perform 4-3. SET CHECK. Also, perform 4-1. IC INTERFACE

CHECK, 4-2. DISPLA Y CHECK, and 4-6. WA VEFORMS CHECK.

Disc for Test Mode

Various checks of this set r equire the following discs.

Model Type *1 Category Application

MODEL

SATD-S5

12 cm disc

Adjusted value check,

(J-2501-215-A) SL

Reference disc

Operation check,

SATD-S4 Optical waveform check

(J-2501-184-A)

Not specified DL 12 cm disc Operation check

PATD-012

Adjusted value check,

(4-225-203-01)

CD

12 cm disc

Operation check,

YEDS-18 Reference disc

Optical waveform check

(3-702-101-01)

Not specified HYBRID 12 cm disc Operation check

*1 SL: Single Layer

DL: Dual Layer

Setting Method of Test Mode

Turn the

[POWER] button on while pressing the [ AMS ]

dial and the [MENU] button. Release the [MENU] button and the

[ AMS ] dial in this order when “DIAG MODE” is displayed

on the fluorescent indicator tube.

Releasing Method of Test Mode

To release the test mode, turn the [POWER] switch off.

Selection/Entry of Test Mode

To select and enter the “DIAG MODE”, operate as follows.

1. Rotate the [ AMS ] dial to select the menu, and press

the [ AMS ] dial to enter.

2. The test is switched on or off alternately each time the

[ AMS ] dial is pressed.

3. To return to the previous step, rotate the [ AMS ] dial

to select the desired item, and press the [ AMS ] dial

to enter.

lL

lL

lL

lL

lL

lL

l

L

13

SCD-XB780

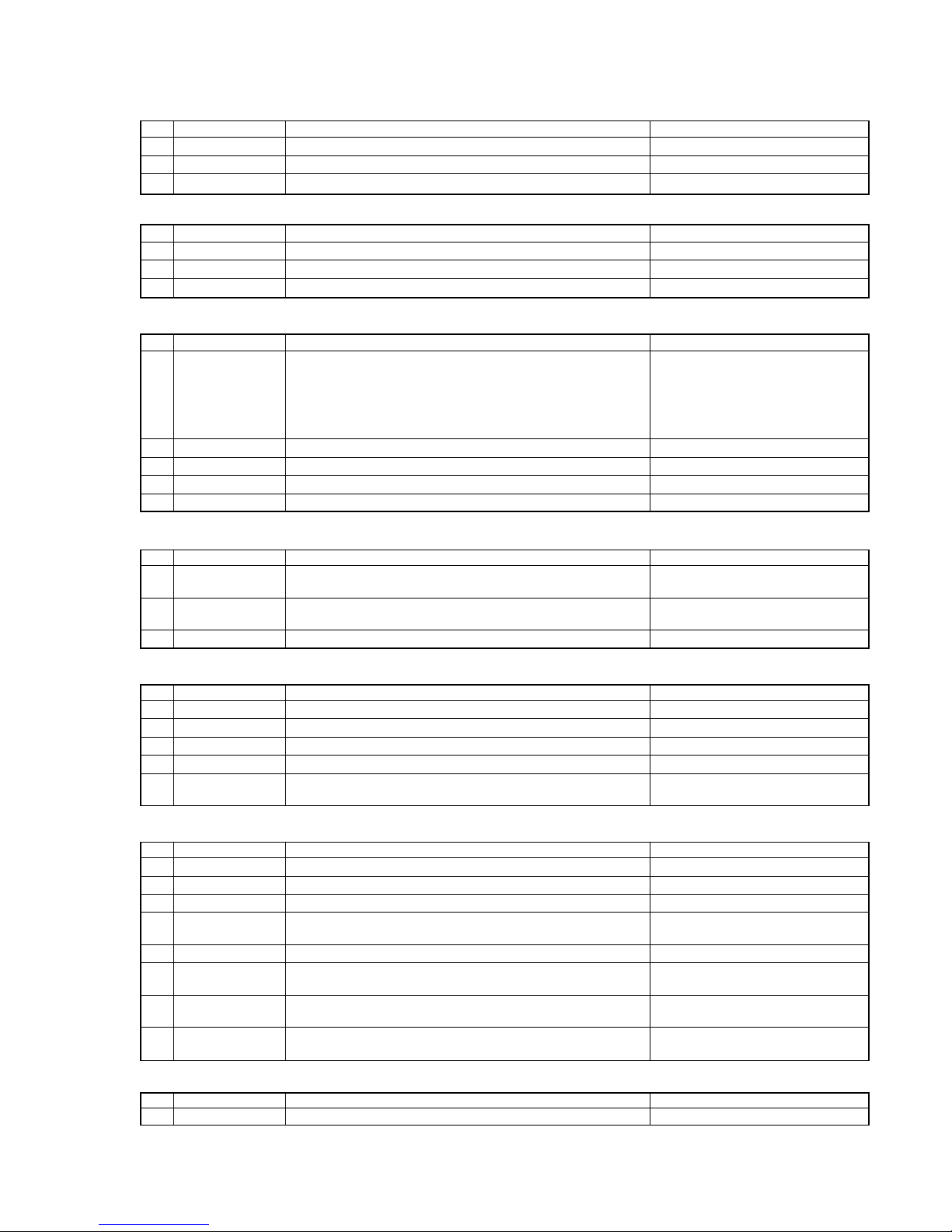

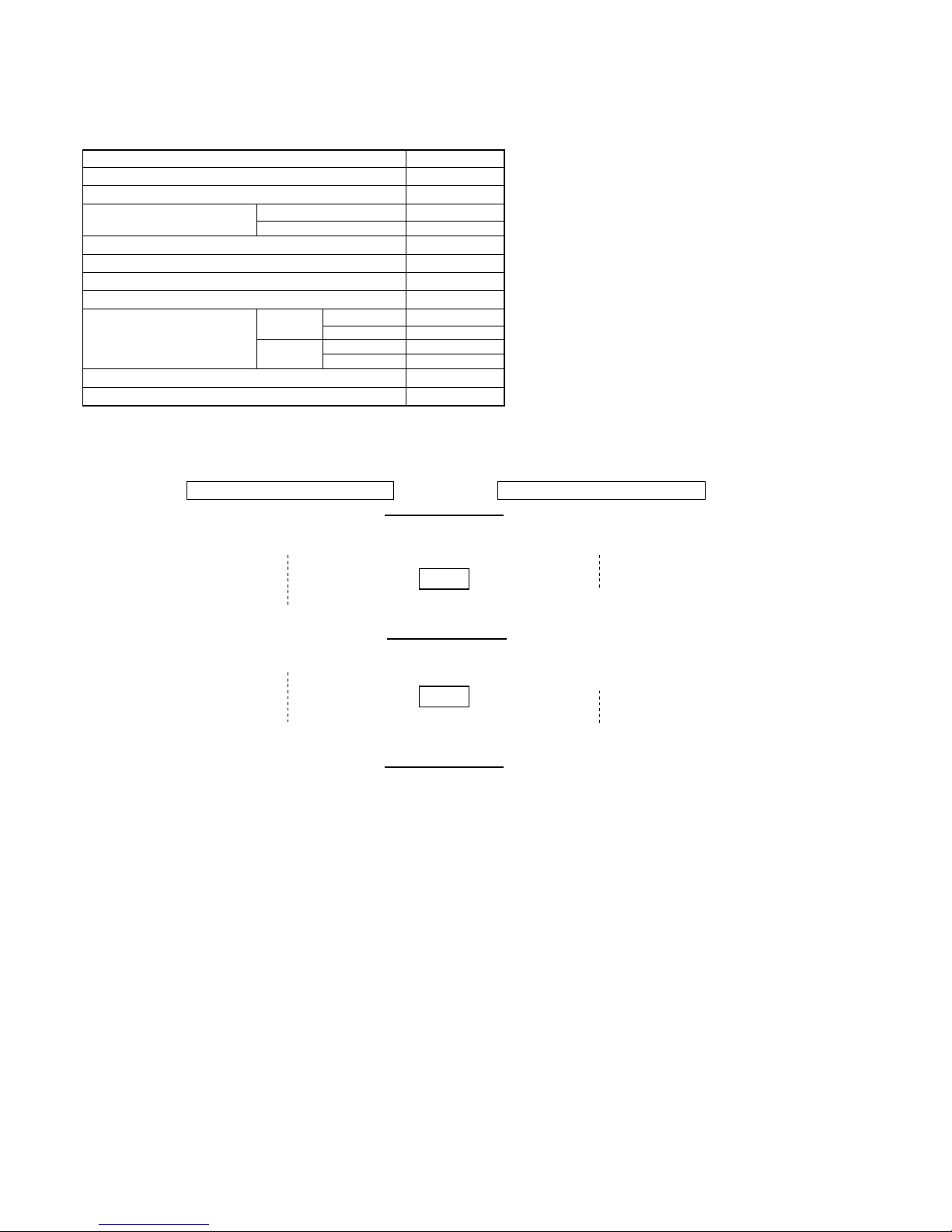

TRACKING command (4X): Tracking servo related.

No. Name Description Remarks

41 TGAIN NM/UP The tracking servo gain is switched between normal and up Normal or up are switched alternately

44 ADJ TRK DSP The traverse AGC and E-F balance adjustment is performed

45 TRACKING AGC The tracking servo gain is adjusted automatically

SEARCH command (5X): Track search related. (Nos. 51 through 53 are not used for the servicing.)

No. Name Description Remarks

51 1-TRCK JUMP One-track jump is performed

52 FINE SEARCH Fine search is performed

53 M-TRCK MOVE M-track movement is performed

DISC DETECT command (6X): Disc type check related.

No. Name Description Remarks

Disc type check is executed

Display after judgment

61 DISC DETECT

DSKMOD CD: Judged as CD Refer to how to apply servo by manual

DSKMOD SL: Judged as SACD (SL) operation (See page 14)

DSKMOD DL: Judged as SACD (DL)

DSKMOD HYB: Judged as HYBRID

62 CD SETTING Enter disc type CD setting CD forced setting

63 SL SETTING Enter disc type SL setting SL forced setting

64 DL SETTING Enter disc type DL setting DL forced setting

6F Download Not used for the servicing

LASER command (7X): Laser of optical pick-up related.

No. Name Description Remarks

7A ADDTIME CD

Cumulative light emission time of the laser for CD is displayed

(Initialized by 8D command)

7B ADDTIME HD

Cumulative light emission time of the laser for SACD is displayed

(Initialized by 8D command)

7C FJUMP TEST Not used for the servicing

TOOLS command (8X): Performs aging, reads adjusting parameters, etc.

No. Name Description Remarks

81 VERSION Firmware version is displayed Example: Ver 1.00

83 TRAY AGING Tray open-close aging is performed Not used for the servicing

87 DISP ADJ DT Automatic adjusting parameters are displayed via RS-232C Not used for the servicing

8A FL CHECK Display of fluorescent indicator tube and keys are checked

8D SETUP MODE

Set to factory shipping mode Set when repair completed

PLAY MODE, etc. are initialized Refer to 4-5. SHIPPING MODE (See page 17)

QA command (9X)

No. Name Description Remarks

91 FJUMP CHECK The focus jump is checked Not used for the servicing

92 SET CHECK The set is checked Refer to 4-3. SET CHECK (See page 15)

93 WATER MARK Not used for the servicing

94 SET AGING

The set aging is performed

Not used for the servicing

Repeat by the specified number of times or until an error occurred

95 FJMP CHK BU The focus jump is checked (for jig) Not used for the servicing

9C BU DENCHO

The S curve waveform, traverse waveform, and RF waveform can be Refer to 4-6.WAVEFORMS CHECK

checked successively (See page 17)

9D PLAY&RFD ON

SACD playback, RFD output

Not used for the servicing

SACD jitter measuring mode

9E RFD ON/OFF

RFD output is turned on or off

Not used for the servicing

SACD jitter measuring mode

IC command (AX)

No. Name Description Remarks

A0 IC SELF CHK Each IC and its communication are checked Normal or up are switched alternately

14

SCD-XB780

How to Apply Servo by Manual Operation

In analyzing failures of the set, the servo may be applied by manual

operation. To apply servo in the test mode, use the following

method.

1. After setting the test mode, rotate the [ AMS ] dial to

select a command, and press the [ AMS ] dial to enter.

2. “61 DISC DETECT” (Disc type check)t“18 ALL SRV ON”

(All servos on + auto adjustment)

3. If applying servo while checking the condition one by one,

“61 DISC DETECT” (Disc type check)t“31 PI/FE OFSET”

(Offset automatic adjustment)t“14 FSRV ON/OFF” (Focus

servo on)t“16 CLV ON/OFF” (CLV servo on)t“44 ADJ

TRK DSP ” (E-F balance adjustment)t“15 TSRV ON/OFF”

(Tracking servo on)t“17 SSRV ON/OFF” (Sled servo

on)t“24 ADJ FCSBIAS” (Focus bias adjustment)t“27

FOCUS AGC” (Focus auto gain adjustment)t “45

TRACKING AGC” (Tracking auto gain adjustment).

Note: 1. On and off are alternately switched in the same command.

2. For a stop, select “19 ALL SR V OFF” and press the [ AMS ]

dial.

4-1. IC INTERFACE CHECK

The communication between microcomputer and main ICs is

checked.

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “A0. IC SELF CHECK” and press the [ AMS ]

dial to enter.

2. A checking will start automatically. (Checking time is about 3

seconds)

3. At successful completion of check, “IC CHECK OK” is displayed. In this case, no error exists in the IC interface.

Note: The check mentioned above tests the communication from micro-

computer to main ICs. Even if the check successfully finished, the

IC to be checked is not always normal. Consider it for reference

only.

4. In case of an IC communication error, the following display

will be given during the checking. Possible causes of error are

as listed below.

Error display Causes (typical example)

DVD DEC. ERROR 1. IC701 (SACD decoder) is faulty

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin ts (XDIS IO) does not go “H”

• IC904 (PLD) is faulty

3. 768fs (33.8688 MHz) is not present to

IC701 pin <znm (XTAL)

• IC811 (3-multiplying circuit) is faulty

• Clock signal 256fs is not sent from

AUDIO board (CN701 pin qg)

• CN702 pin 6 (GND) and pin 7

(+3.3V-D) are open or shorted

• CN701, 702 and FFC connection is loose,

or FFC is disconnected

DVD DRAM ERR 1. IC706 (D-RAM) is faulty

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin ts (XDIS IO) does not go “H”

• IC904 (PLD) is faulty

3. Faulty communication line between

IC701 and IC706

•Data line, address line, WE, etc.

4. D903 (1SS367) is faulty

D+3.3V is not present to IC706

CD DSP ERROR 1. IC509 (CD DSP) is faulty

2. 768fs (33.8688 MHz) is not present to

IC509 pin ua (XTAL)

Same as cause 3 of DVD DEC. ERROR

3. IC509 pin 2 (XRST) does not go “H”

• IC901 pin ts (XDIS IO) does not go “H”

• IC904 (PLD) is faulty

Error display Causes (typical example)

EEPROM ERROR 1. IC903 (EEPROM) is faulty

SAMBA DRAM ERR 1. IC808 (D-RAM) is faulty

(DSD decoder is also 2. IC801 (DSD decoder) is faulty

checked) 3. 768fs (33.8688 MHz) is not present to

IC801 pin qa (MCKI)

Same as cause 3 of DVD DEC. ERROR

4. IC801 pin 9 (XRST) does not go “H”

• IC901 pin ts (XDIS IO) does not go “H”

• IC904 (PLD) is faulty

5. Faulty communication line between

IC801 and IC808

•Data line, address line, WE, etc.

6. D904 (1SS367) is faulty

D+3.3V is not present to IC808

RF AMP ERROR 1. IC001 (RF AMP) is faulty

2. Loose connection between CN708 on

MAIN board and CN005 on RF board,

or FFC disconnection

CN708 pin qj (CLK RF), pin qh (DATA

RF) and pin qg (SDEN) must be checked

SD BUS ERROR 1. IC701 SD bus and IC801 AV decoder

interface is faulty

2. IC812 to 814 are faulty

Causes Common to Each IC:

1. Faulty communication line between microcomputer and each

IC.

Disconnected patterns, floating series resistors, bridge, etc.

2. Faulty IC supply voltage.

Particularly, check D+3.3V voltage.

3. Faulty microcomputer communication port to each IC

Note: In case of more than two errors, the error display is switched over

one after another, thus making the reading difficult.

In such a case, press again the [ AMS ] dial to make a

recheck for error reading.

4-2. DISPLAY CHECK

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “8A. FL CHECK” and press the [ AMS ] dial to

enter.

2. Respective segments of fluorescent indicator tube will

automatically light up in order, and therefore check that there

is no chipped character.

3. The “INPUT REMOCON” will be displayed after the segment

check finished successfully, and then press a proper key on

the remote commander.

4. After “JOG CHECK” is displayed, the numbers of calendar

will be displayed from 1 to 15 each time the [ AMS ]

dial is rotated clockwise.

5. After display up to 15, the numbers of calendar will

disappear in order each time the [ AMS ] dial is

rotated counterclockwise.

6. “TTX-1514?” will be displayed when all are cleared, and then

press the [ AMS ] dial.

7. Upon display of “KEY CHECK”, if a key on the display is

pressed, the corresponding segment of fluorescent indicator

tube will light up.

8. “FL TEST END” will be displayed if all keys are pressed.

Note: The keys include the [ AMS ] dial. If the segment that

corresponds to the pressed key does not light up, that key is faulty.

9. The test mode selection display will be back, if the [ AMS ]

dial is pressed.

lL

lL

lL

lL

lL

lL

lL

lL

lL

lL

lL

l

L

lL

15

SCD-XB780

4-3. SET CHECK (AUTOMATIC VARIOUS MEASUREMENTS)

The operational stability of the set is checked. The check and OK/NG judgment are performed automatically.

Note: In the set check using the CD, besides a checking, the MIRR time used for the disc check is measured every optical pick-up, and from the measured

result, the threshold value is calculated and it is stored in the EEPROM (IC903) on the MAIN board. Accordingly, if a combination of optical pickup and EEPROM is changed (for example, the optical pick-up or MAIN board is replaced), be sure to perform the set check using the following CD.

As the data stored in the EEPROM are overwritten every set check, retry if failed. For the set check using the SACD, only checking is made.

Set Check

CD and SACD (SL) Disc Operation Check

Checking method:

1. After setting the test mode, rotate the [ AMS ] dial to select “SET CHECK” and press the [ AMS ] dial to enter.

2. Upon display of “AUTO CHECK SP?”, further press the [ AMS ] dial.

3. The tray will open automatically, and then set the test disc*1 of CD or SACD.

4. With the “DISC IN&JOG ON” displayed, press the [ AMS ] dial, and the check will be executed automatically.

5. “SPEC OK!” will be displayed if the measured result is within the specification. Faulty item name and the measured result will be

displayed if any measured item is NG.

6. After that, “A UT O CHECK SP?” will be again displayed, and then rotate the [ AMS ] dial to select “CHECK END?”. Further,

press the [ AMS ] dial, and the test mode selection display will be back, and then press the [OPEN/CLOSE ] button and take

the test disc out.

*1 Use PATD-012 or YEDS-18 for CD, and SATD-S5 or SATD-S4 for SACD (SL). Using another disc will result in a checking failure.

Measured Items:

Items Description Remarks

Offset values before RF (PI), VC, FE, TE signal offset adjustment At offset 0

RF/VC/FE/TE (ORG) RF (8 bit data in hex notation) RF: A0h

VC, FE, TE (9 bit data in hex notation) VC, FE, TE: 00h

Offset values after RF (PI), VC, FE, TE signal offset adjustment VC offset is not adjusted

RF/VC/FE/TE (ADJ)

(Less than ORG value if offset correction is normal) (Measurement only)

RF (8 bit data in hex notation) Also, for SACD, the TE offset is

VC, FE, TE (9 bit data in hex notation) not measured and adjusted

PI (ORG): PI value at disc type check (decimal data) PI level conversion

PI (ADJ): PI value after PI offset adjustment Read value × 12.9mV

(read value at microcomputer A/D) (decimal data)

PI/TRVS PP (ORG/ADJ) TRVS PP (ORG): Traverse level before level correction (AGC) Traverse level conversion

(decimal data) Read value × 12.9mV

TRVS PP (ADJ):Traverse level after level correction (AGC)

(decimal data) 12.9mV=3.3V ÷ 256 (8 bit)

PIOR: Set value of PI offset coarse adjusting register Registers in RF amplifier

PIOR/CCR/TRCR CCR: Set value of FE offset coarse adjusting register

TRCR: Set value of TE offset coarse adjusting register

FOCUS/TRK GAIN

Auto gain adjusted values of focus and tracking servos

(8 bit data in hex notation)

FBIAS: Focus bias set value (9 bit data in hex notation)

TRCR2 adjusts the E-F gain

TRVSC: Traverse center value (9 bit data in hex notation)

balance and used for CD only

FBIAS/TRVSC/TRCR2/CFR

TRCR2: Set value of E-F balance coarse adjusting register

(Fixed to 06 for SACD)

CFR: Set value of traverse level adjusting register

TRCR2 and CFR are registers in

RF amplifier

PSP AMPLITUDE SACD only

1-LAST TRK SEEK (msec) Average seek time from first track to last track of disc

Error rate measurement

For the CD, Measure for 7 sec at track

ERROR RATE For CD: Average value/Maximum value of C1 and C2

No.5

For SACD: Average value/Maximum value of PO, PI1 and PI2

For the SACD, calculation from 100-

block data at track No.5

lL

A

92. SET CHECK AUTO CHECK SP?

AUTO CHECK?

DISP RESULT S?

CHECH END?

DISP RESULT F?

The set check is executed to judge OK or NG.

(For the CD, the threshold value is stored in the EEPROM)

The measured result is displayed on the fluorescent indicator tube.

The set check of measurement only is executed.

The measured result is displayed via RS-232C.

The set check is finished.

lL

lL

lL

lL

lL

16

SCD-XB780

Measured Items Specified value

RF AVRG (ADJ) 8Ch to ABh

VC AVRG (ADJ) 1F7h to09h

FE AVRG (ADJ)

(1) CD 1EEh to 12h

(2) SACD 1F1h to 0Fh

TE AVRG (ADJ) 1E2h to 1Eh

TRVS PP (ADJ) 45h to 73h

FCS GAIN 10h to 60h

TRK GAIN 10h to 60h

(1) CD

C1 20 or less

ERROR RATE C2 0

(2) SACD

PI1 NUM 100 or less

PI1 FRAME 5 or less

PSP AMPLITUDE (SACD only) 1000 to 4000

1-LAST TRK SEK 3500 or less

Hexadecimal (hex) display 9 bit data

FF 011111111 (+255)

FE 011111110 (+254)

(+) Side

(-) Side

MAX

01 000000001 (+1)

00 000000000 (0)

1FF 111111111 (-1)

101 100000001 (-255)

100 100000000 (-256)

Hexadecimal (hex) display 8 bit data

7F 01111111 (+127)

7E 01111110 (+126)

01 00000001 (+1)

00 00000000 (0)

02 00000010 (+2)

FF 11111111 (-1)

FE 11111110 (-2)

81 10000001 (-127)

80 10000000 (-128)

MIN

0

Specified Value:

Specified value used for OK/NG judgment when executing 92. SET CHECKtAUTO CHECK SP?

Note: The specified values attached with “h” are hexadecimal n umbers, and others are decimal numbers.

RF, VC, FE, and TE measured values are hexadecimal data with positive and negative signs. When comparing the measured

value with the specified value, refer to the following.

17

SCD-XB780

4-4. SACD (DL) DISC OPERATION CHECK

(• Perform as necessary)

This checking performs the focus jump using a DL disc, which is

a dual-layer HD disc, to verify the stability of the set.

A set of layer 0 most-outside track access (only once)tone-second

tracetfocus jump (layer 0t1)tone-second tracetfocus jump

(layer 1t0) are repeated 5 times.

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “91 FJUMP CHECK” and press the [ AMS ] dial

to enter.

2. The tray will open automatically, and then set the DL disc.

3. With “DISC IN&JOG ON” displayed, press the [ AMS ]

dial.

4. The tray will be loaded in automatically, and then the test will

start.

5. During the test, “NOW TESTiiii” is displayed.

6. Upon successful completion of the check, “OK!” will be

displayed and the tray will open automatically. (In case of

NG, “NG! ERR FJ-UP” or “NG! ERR FJ-DWN” is displayed)

7. Take the DL disc out and press the [OPEN/CLOSE ] button,

and the test mode selection display will be back

4-5. SHIPPING MODE

The repaired set must be initialized, and for this purpose the set

should be set to the shipping mode.

Setting Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “8D SETUP MODE” and press the [ AMS ] dial

to enter.

2. “INITIAL OK” is displayed and the test mode selection display

will be back immediately.

“8D 000000000 00” will be displayed, and if the scroll starts in

the left direction, the set initialization has completed

3. Press the

[POWER] button to turn the power off.

The following setups are established in the shipping mode

1. Initialization of EEPROM (IC903)

• PLAY MODE CONTINUE

• LAYER SELECT SACD

• M/2CH SELECT MULTI

• 2ch SPK MODE 2ch DIRECT

• Mch SPK MODE Mch DIRECT

• Resetting the cumulative light emission time of the laser

Note: Even if the shipment mode setting mentioned above is made, the

disc check threshold value attained in the 3. SET CHECK is not

cleared.

2. The optical pick-up moves to the home position (most-inside

track)

Error List

Display Description

Toc Error * Error during the time from auto adjustment to TOC

reading, Different type of disc (Such as a DVD disc),

Disc is dirty

Toc Error **** Illegal SACD (Such as a pirated version)

4-6. WAVEFORMS CHECK

BU Electrical Adjustment Mode

The BU electrical adjustment mode is used to check the S curve

waveform, traverse waveform, RF wav eform, and CL V jitter . After

a disc is placed on the tray, each time the [ AMS ] dial is

pressed, the check mode is switched in order for S curve

waveformt tra verse wav eformtRF waveformtCLV jitter (for

the CD).

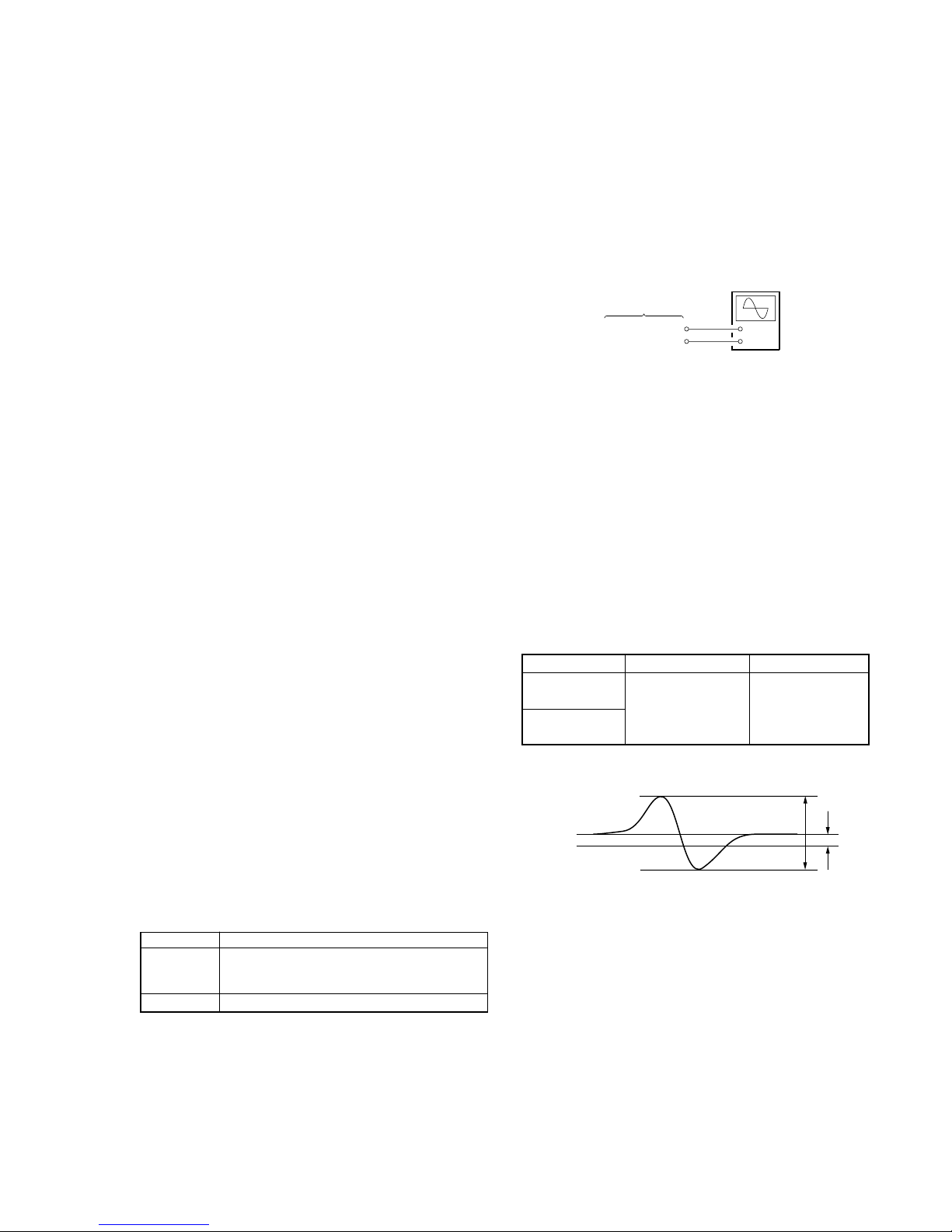

S Curve Check

Connection:

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “9C. BU DENCHO” and press the [OPEN/CLOSE ]

button. Place the test disc (PATD-012 or YEDS-18 or SATDS5 or SATD-S4) on the tray and close the tray, then press

the [ AMS ] dial.

2. At the completion of disc type check, “CD DETECT” will be

displayed (for PATD-012 or YEDS-18).

Note: For the SATD-S5 or SATD-S4, “SL DETECT” is displayed.

3. Press again the [ AMS ] dial, and the S curve waveform

check mode will become active and “S-CURVE MODE” will

be displayed.

4. Connect an oscilloscope to the TP506 (FE) and TP504 (AVC)

on the MAIN board.

5. Check that the level A and B of wa veform on the oscilloscope

satisfy the specification.

Specified Value:

Disc AB

SATD-S5 or

SATD-S4

PATD-012 or

0.7 to 1.7 Vp-p –0.1 to +0.1V

YEDS-18

Note: For easier observation of this waveform, extend the sweep time

and raise the brightness.

Checking and Connecting Location : See page 19.

MAIN board

TP506 (FE)

TP504 (AVC)

+

–

oscilloscop

e

A

B

S curve waveform

VC

lL

l

L

lL

lL

lL

lL

A

A

lL

lL

lL

18

SCD-XB780

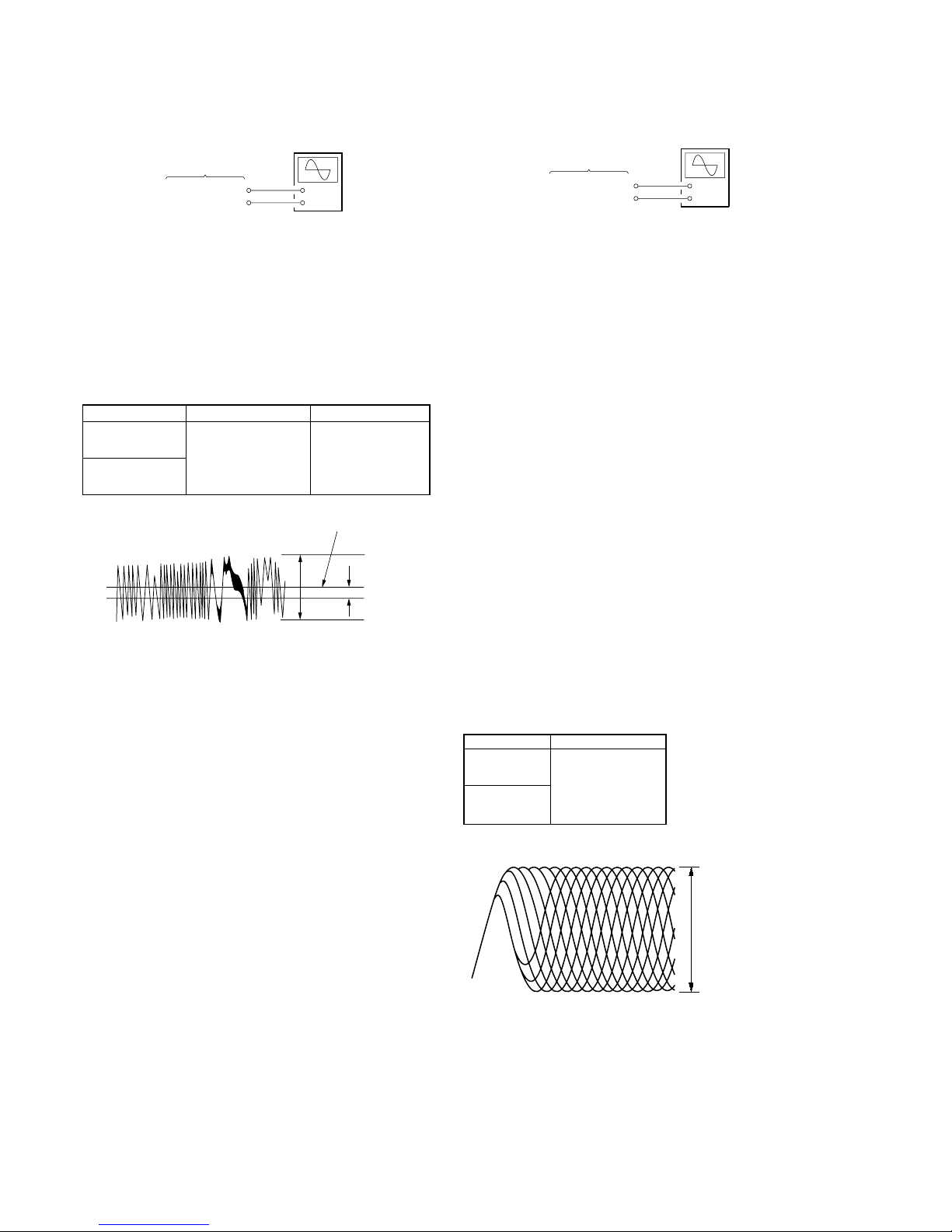

RF Level Check

Connection:

Checking Method:

1. Under the condition of traverse waveform check mode in step

4, press the [ AMS ] dial.

2. Connect an oscilloscope to the TP703 (RFAC) and TP704

(AGND) on the MAIN board.

3. After “W AIT” is displayed, the RF waveform check mode will

become active and “PLAY 5th TRACK” (for the SA CD, “RF

MODE ON”) will be displayed, and the 5th music on the disc

will be played.

4. Check that the RF waveform is clear and the level satisfies the

specification.

5. Press the [ AMS ] dial (for the SACD, “RF JITTER

(5th)” will be displayed, and further press the AMS dial), and

“OUTSIDE TRACK” will be displayed and the outward track

of the disc will be played.

6. Check that the RF waveform is clear and the level satisfies the

specification.

7. Press the [ AMS ] dial, and “INSIDE TRACK” will be

displayed and the inward track of the disc will be played.

8. Check that the RF waveform is clear and the level satisfies the

specification.

9. After checking, press the [ AMS ] dial, and the test is

over when “BU MEASURE” is displayed.

10. Press the [OPEN/CLOSE ] button to open the tray, and remove the test disc.

11. Using each type of disc, repeat from step 1 of S curve waveform check up to step 10 of RF level check.

12. When the check is over, press the

[POWER] button to turn the

power off.

Note: Take care not to leave the test disc in the set.

Specified Value:

Disc A

SATD-S5 or

SATD-S4

PATD-012 or

0.9 to 1.4 Vp-p

YEDS-18

Note: Clear RF waveform refers to the wav eform where ◊ shapes should

be distinctively observed in the center.

Checking and Connecting Location : See page 19.

MAIN board

TP703 (RFAC)

TP704 (AGND)

+

–

oscilloscope

VOLT/DIV: 200 m

V

TIME/DIV: 500 ns

RF signal waveform

A

lL

lL

lL

lL

A

Traverse Check

Connection:

Checking Method:

1. Under the condition of S curve waveform check mode in step

5, press the [ AMS ] dial.

2. After “W AIT” is displayed, the traverse wa veform check mode

will become active and “TRV MODE ON” will be displayed.

3. Connect an oscilloscope to the TP513 (TE) and TP504 (AVC)

on the MAIN board.

4. Check that the level A and B of waveform on the oscillo-

scope satisfy the specification.

Specified Value:

Disc AB

SATD-S5 or

SATD-S4

PATD-012 or

0.9 to 1.4 Vp-p –0.1 to +0.1V

YEDS-18

Checking and Connecting Location : See page 19.

MAIN board

TP513 (TE)

TP504 (AVC)

+

–

oscilloscope

A

B

VC

Center fo the waveform

Traverse waveform

lL

SCD-XB780

1919

– MAIN Board (Component Side) –

TP506

(FE)

TP513

(TE)

TP504

(AVC)

TP704

(AGND)

TP703

(RFAC)

TP514

(RFCK)

TP517

(WFCK)

TP808 (DG)

IC703

IC701

IC509

IC801

CLV Jitter Check (CD only)

Connection:

Checking Method:

Under the condition of RF level check mode in step 3, connect the

oscilloscope to the TP516 (RFCK) (CH1), TP517 (WFCK) (CH2),

and the TP808 (DG) (GND) on the MAIN board to check that the

value A of the waveform satisfies the specification.

Note: Take care not to leave the test disc in the set.

Specified Value:

Disc A

PATD-012 or

35 µsec or less

YEDS-18

Checking and Connecting Location:

A

CLV jitter waveform

MAIN board

TP516 (RFCK)

TP517(WFCK)

TP808 (DG)

+

+

–

oscilloscop

e

(CH2)

(CH1)

SCD-XB780

2020

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAM – RF/SERVO Section –

MUTE LOAD

DETECTOR

1

63

3

4

5

6

9

10

11

12

14

15

16

13

18

17

61

62

535254

55

59

60

DVDRFP

RFSIN

A2

B2

C2

D2

CD E

CD F

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

CD A

CD B

CD C

CD D

DVDLD

CDPD

CDLD

DVDPD

DVDPDSW

MUX ATT

ATON

ATOP

FNP

FNN

INPUT

BIAS,

AGC

PROGRAMMABLE

EQ FILTER

DIFFERENTIATOR

AIP

AIN

DIP

DIN

SUMMING AMP

IC004 (1/4)

SUMMING AMP

IC004 (2/4)

GCA

MUX

DUAL

APC

GCA,

EQ

GCA

L. P. F.

+

–

PHASE

DETECTOR

COMPARATOR MUX

+

–

+

–

+

+

+

+

+

+

+

–

CLAMP&

ENVELOPE

LEVEL DAC

GCA

SUB GCA

SEL

L. P. F.

OFFSET

CANCEL

MUX

BOTTOM

ENVELOPE

INPUT

BUFFER

PEAK/

BOTTOM

HOLD

SERIAL

PORT

REGISTER

57

27

31

32

39

47

46

48

FULL WAVE

RECTIFER

AGC

CHARGE PUMP

AVC BUFFER

IC004 (4/4)

AVC

(+1.65V)

A+3.3V

WAVRB BUFFER

IC503 (1/2)

WAVRB

D+5V

VC

(+2.5V)

VC

AGCO

SACD/CD RF AMP,

FOCUS/TRACKING ERROR AMP

IC001

OPTICAL PICK-UP

BLOCK

(KHM-234AMA)

MODULE

CIRCUIT

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

21

22

23

12 5

11 6

9

AUTOMATIC POWER

CONTROL (FOR CD)

Q003

AUTOMATIC POWER

CONTROL (FOR SACD)

Q001

FOCUS COIL

DRIVE

14 2

13 3

TRACKING COIL

DRIVE

17 24

18 23

33

34

20

22

21

19

8

40 41 39 43

31

32

29

30

20

SLED MOTOR

DRIVE

FOCUS/TRACKING COIL DRIVE,

SLED MOTOR DRIVE

IC502

M

M2

(SLED)

8

9

SPINDLE MOTOR

DRIVE

MM

M3

(SPINDLE)

6

5

LOADING MOTOR

DRIVE

MM

M151

(LOADING)

16 17

13

FOCUS/TRACKING/SLED

PWM GENERATOR

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

A/D

CONVERTER

FOCUS

TRACKING/SLED

SERVO DSP

DFCT, FOK

DETECTOR

26

SE

TE

FE

RFDC

TE

FE

PI

26

DIGITAL SERVO

PROCESSOR

IC509 (1/2)

TO CPU INTERFACE

D+3.3V

S1

(LIMIT)

MIRR

FOK

DFCT

COUT

SCLK

SSTP

STBY1

STBY2

RF

A

B

C

D

E

F

G

H

DVD LD

CD LD

DVD/CD PD

DVD VR

FCS+

FCS–

TRK+

TRK–

D

CBA

AGCO

RFAC

MIRR

MIN

MEVO

PI

FE

TE TE

SDATA

SCLK

SDEN

LDON

LOAD OUT

LOAD IN

MUTE 2D

SPDA

F JMP1

F JMP2

• SIGNAL PATH

: SACD PLAY

: CD PLAY

2

RFAC

(Page 21)

3

TE, FE, PI

(Page 22)

4

SDATA, SCLK, SDEN

(Page 22)

5

LDON

(Page 21)

DVDPDSW, CDPDSW

(Page 22)

10

SPDA, F JMP1/2

(Page 21)

11

SPIN

(Page 21)

12

MUTE 2D, SP ON, MUTE LOAD

(Page 22)

13

LOAD IN/OUT

(Page 22)

8

FOK, MIRR,

COUT, SCLK

(Page 22)

TRKSW

(Page 22)

DRVC BUFFER

IC503 (2/2)

DRVC

(+2.5V)

D+5V

SPINDLE MOTOR

DRIVE

42MNTR

FE

PI

PIFETE

SDATA

SCLK

SDEN

MIRR

FOK

COUT

SCLK

9

(Page 22)

LIM SW

BUFFER

BUFFER

2

SP ON

MUTE2

MUTE1

SPINDLE/LOADING MOTOR DRIVE

IC512

21

22

24

15

23

L. P. F.

GCA

OFFSET

CANCEL

40

L. P. F.

OFFSET

CANCEL

38

PI ERROR AMP

IC004 (3/4)

24

PHOTO DIODE

CONTROL SWITCH

(FOR SACD)

Q005

CD VR

PHOTO DIODE

CONTROL SWITCH

(FOR CD)

Q004

TRACKING COIL DRIVE

CONTROL SWITCH

IC501

1 241 2

CDPDSW

7

6

TRACKING COIL DRIVE

CONTROL SWITCH

IC505

27

26

1

(Page 21)

SP ERR

25

4

SCD-XB780

2121

53 55 52 54 12

50

49

48

24

75

100

25 4 6 5 7 15 79 80 76 77 10 11 13

34 35 36 9 26 33 37 71

3

2

138

68

64

17

14

65

67

66

71

72

6916

43 44 64 58 85 84 12 22 23

117

111

7 8

89 – 96 14 – 21

A0 – A7 D0 – D7

142

144

140

135

147148150151137 153 146 155 163 158 160 164

26

46

51

54

62

63

49

48

53

23

162

29

44, 41, 39, 35,

32, 30, 27, 24

31, 34, 37,

40, 43, 45

59, 56, 60

157159939294767895

3334

170

171835

21 – 24, 27 – 32

79, 80, 82 – 87,

89, 91

41 – 44, 46 – 49

96, 97, 99, 101,

102, 104 – 106

2 – 5, 7 – 10

5, 7, 9 – 14 172 – 176, 1, 2, 4

66 – 69, 71,

73 – 75

169167

109

107

16

21

20

19

18

17

113 114 115

2

FILTER

ASYMMETRY

CORRECTOR

EFM

DEMODULATOR

32K

RAM

D/A

DIGITAL

INTERFACE

CLOCK

GENERATOR

ERROR

CORRECTOR

DIGITAL

OUT

SUBCODE

PROCESSOR

DIGITAL CLV

PROCESSOR

CPU INTERFACE

DIGITAL PLL

INTERNAL BUS

C4M

XTSL

DIGITAL SIGNAL

PROCESSOR

IC509 (2/2)

RFAC

RFAC

ASYI

ASYO

FILO

PCO

XPCK

FILI

CLTV

D+3.3V

XTAO

XTAI

PCMD

WDCK

DOUT

XRST

C2PO

LRCK

BCK

MDAT

LRCK

BCLK

XRST DVD

WAVE SHAPER

Q302

OPTICAL

TRANSCEIVER

IC309

18

17

19

20

DIGITAL (CD)

OUT OPTICAL

DIGITAL (CD)

OUT COAXIAL

J303

(Page 22)

(Page 22)

(Page 23)

(Page 22)

21

(Page 22)

SD0 – SD7

SDEF

22

(Page 22)

23

(Page 22)

24

(Page 22)

25

(Page 22)

RFAC

768FS (33.8688MHz)

MDAT, BCLK, LRCK

XRST CD, MUTE CD, XRST DVD

HOST INTERFACE

DLRC

DDAT

MA10/MNT1

XMOE

XCAS

MA0 – MA9

MDB8, MDB9,

MDBA – MDBF

MDB0 – MDB7

DASYO

DASYI

ASF1

ASF2

XRAS

XMWR

MA11/MNT2

DBCK

XSAK,

XSHD,

XDCK,

XSRQ

WPK

XTAL

HDB0 –

HDB7

HDB8

HDB9

HDBA –

HDBF

HA0 –

HA2

XSAK

XHRS

XSRQ

XDCK

XSHD

HCS1

HCS0

HINT

REDY

• SIGNAL PATH

: SACD PLAY

: CD PLAY (ANALOG)

: CD PLAY (DIGITAL OUT)

ATAPI

PACKET FIFO

ATAPI

REGISTER

DMA

FIFO

DAC

INTERFACE

CD ESP

OE

UCAS

WE

RAS

LCAS

A0 – A9I/O8 – I/O15I/O0 – I/O7

D-RAM

IC706

AUTHENTICATION

CPU

INTERFACE,

DMA

CONTROLLER

XTL1

XTL2

XTAL

APEO

GFS

XWAIT

XRD

XWR

XCS

XINT0

XINT1

DATA BUS

ADDRESS BUS

DATA BUS

ADDRESS BUS

INTEGRATOR

IC703 (1/2)

16

(Page 22)

15

(Page 22)

14

(Page 22)

10

(Page 20)

5

(Page 20)

XHRD, XHWR

A0

D0 – D7

SPDA, F JMP1/2

LDON

11

(Page 20)

SPIN

F JMP1

SPDA

F JMP2

TO SERVO AUTO

SEQUENCER

LOCK

MDP

DATA

SQCK

WFCK

EMPH

MUTE

GFS

RFCK

SQSO

EXCK

SBSO

SCOR

SENS

XLAT

CLOK

LOCK CD

DATA CD

CLOK CD

XLAT CD

SENS CD

SCOR CD

SQSO CD

SQCK CD

GFS CD

3

DOCTRL

LD ON

SPDA

APDO

JITTER

GFS DVD

XRD

XWR

XCS DVD

INIT0 DVD

INIT1 DVD

XHRD

XHWR

XCS

XINT0

XINT1

FCS JMP1

FCS JMP2

SPINDLE MOTOR DRIVE

IC708 (2/2)

SYNC

CONTROL

SUBCODE

DEINTERLEAVE & ECC

DESCRAMBLE

BUFFER

IC708 (1/2)

FFM

DEMODULATOR

RF

ASSYMMETRY

PLL

FILTER

ANALOG

MIXER

SPINDLE

CONRTOL

CD DSP INTERFACE

MDSOUT

MDIN1

MDPOUT

CLVS

SPO

MDIN2

WFCK

SCOR

SBIN

EXCK

XRCI

GSCOR

C2PO

LRCK

BCLK

MDAT

XRST

WFCK

SCOR

SBSO

EXCK

A0 – A7

D0 – D7

SACD DECODER

IC701

RFIN

CPU

IC901 (1/3)

63

MD2

MAIN DATA ECC & EDC

DVD-ROM CD-ROM

59

1

(Page 20)

SP ERR

SP ERR

DMA CONTROLLER

(PRIORITY RESOLVE & SEQUENCER)

(Page 20)

XRST CD

MUTE CD

XHRD

XHWR

XCS

XINT0

XINT1

XSAK

XSRQ

XDCK

XSHD

DVC BUFFER

IC703 (2/2)

DVC

(+1.65V)

A+3.3V

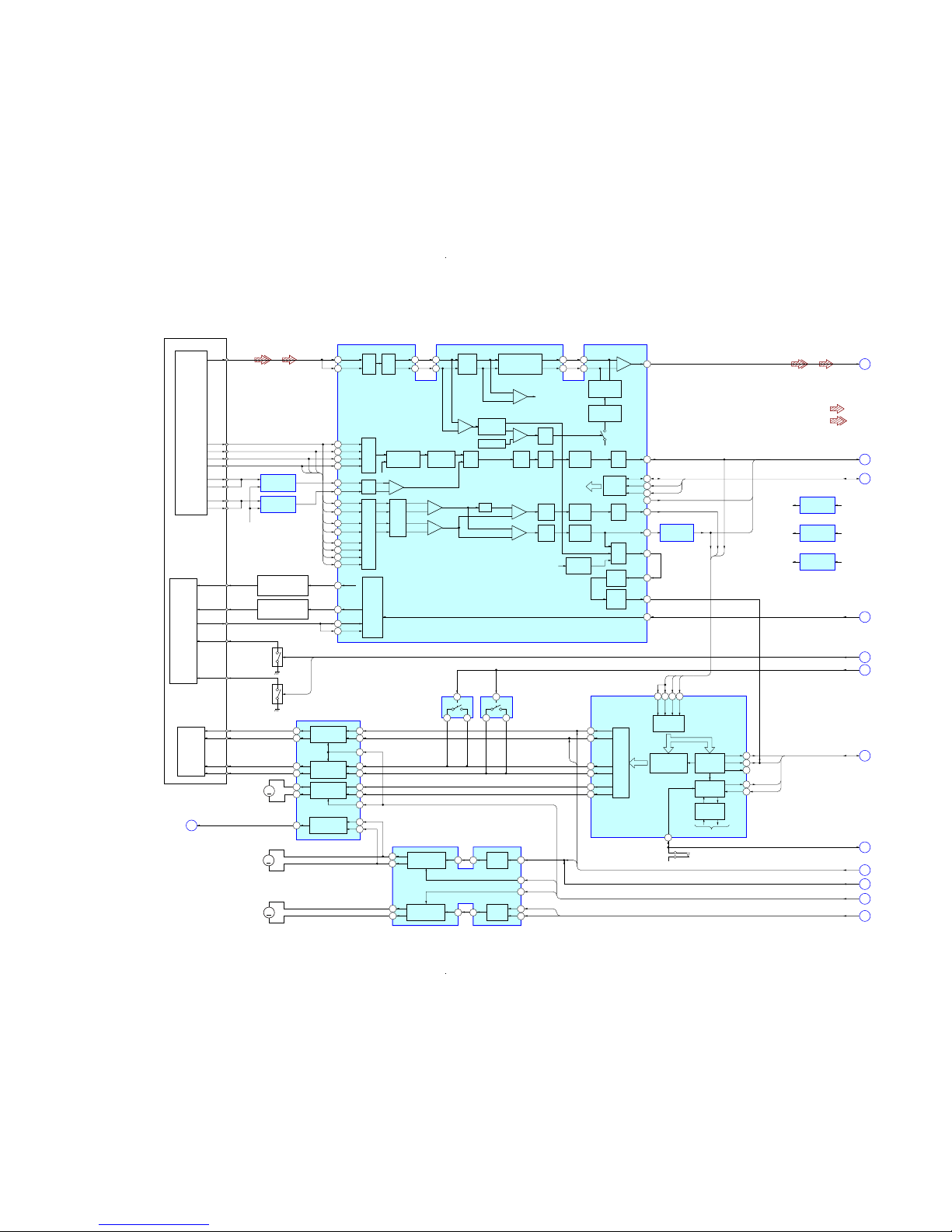

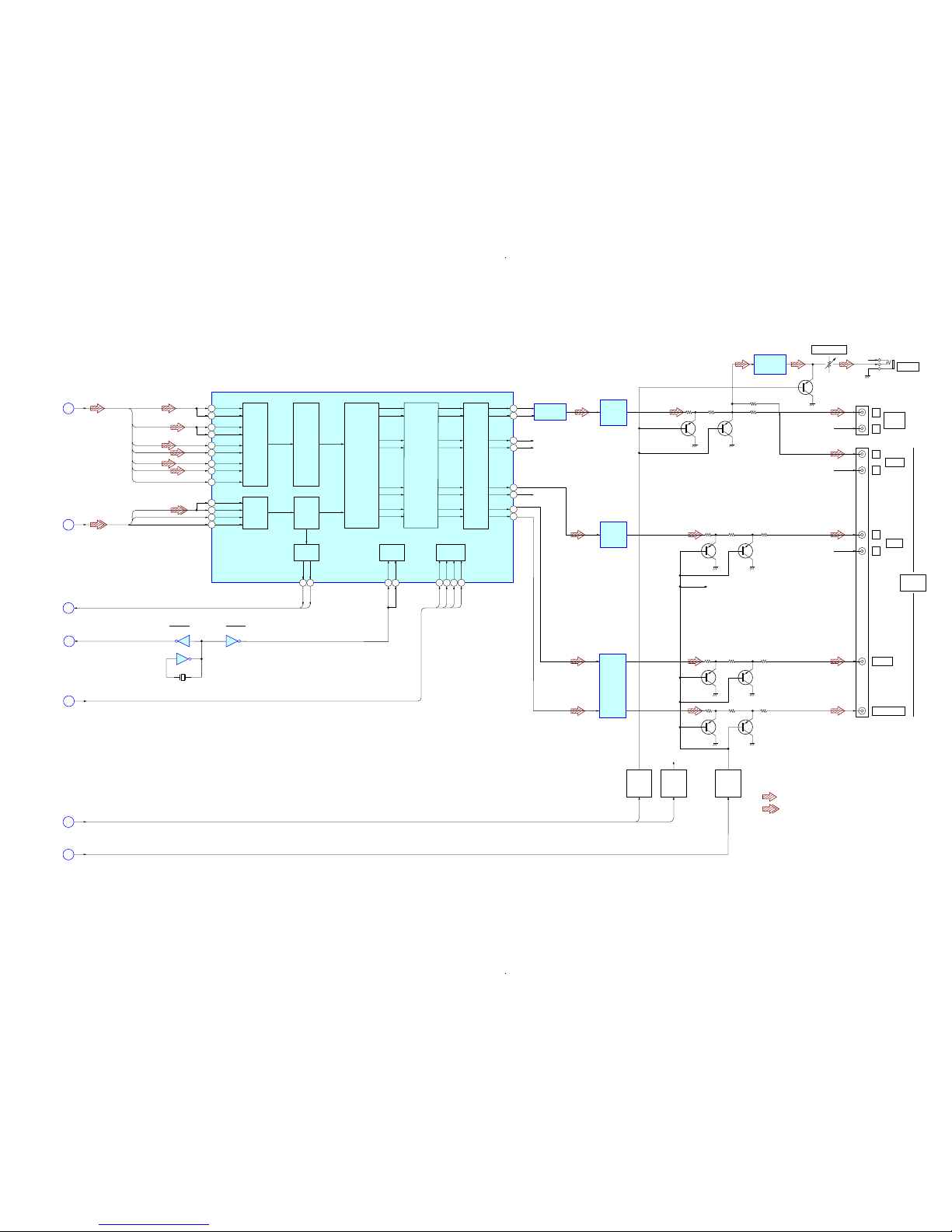

5-2. BLOCK DIAGRAM – SERVO Section –

SCD-XB780

2222

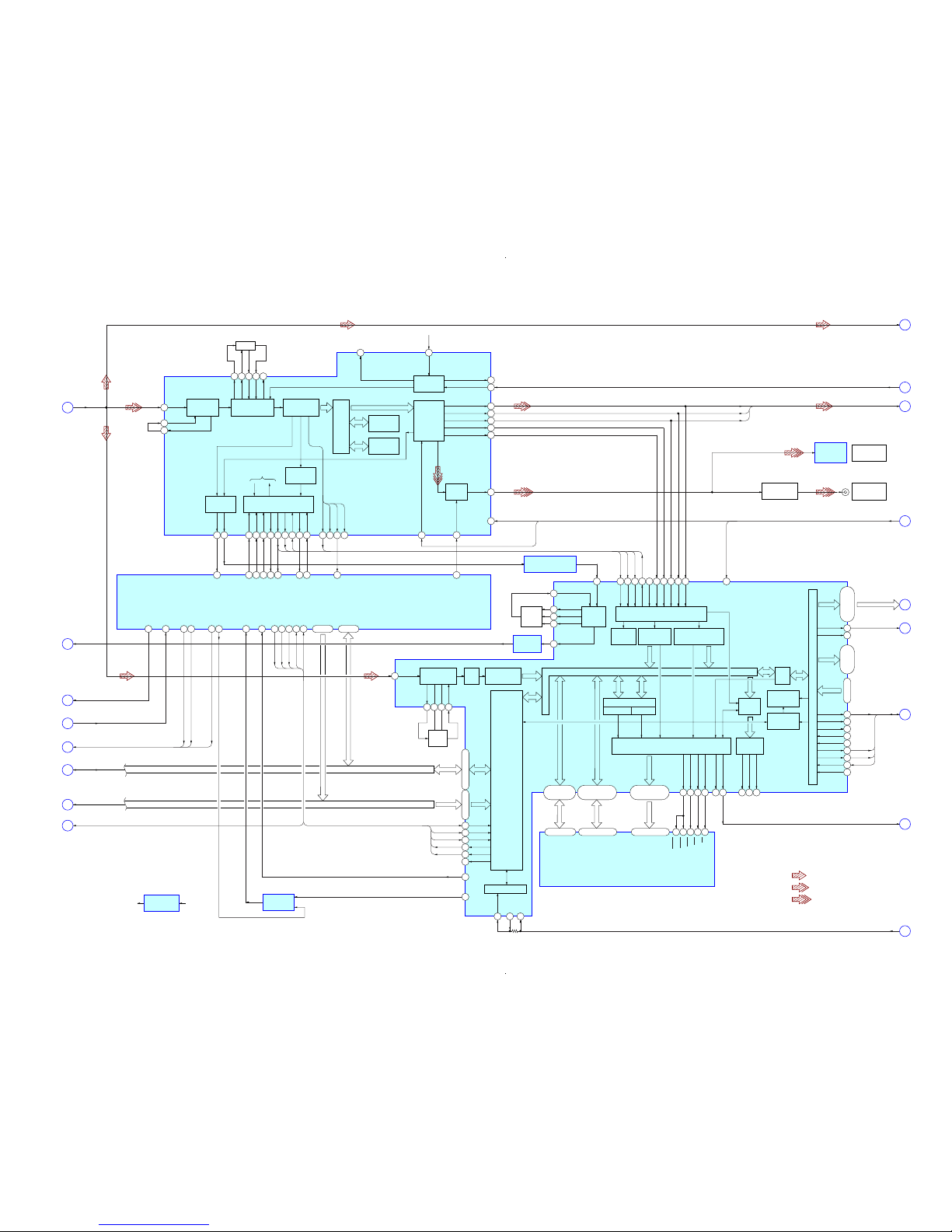

5-3. BLOCK DIAGRAM – MAIN Section –

11 – 18

DQ0 – DQ7

169 – 176

2 – 9

B1 –

B8

A1 –

A8

2 18

3 17

4

5 15

16

64

LEVEL SHIFT

IC814

164

11 12

11

2

13 1

3

16

17

15

34

D-RAM

IC808

LEVEL SHIFT

IC813

LEVEL SHIFT

IC812

DSD DECODER

IC801

3-MULTIPLYING

IC811

21

(Page 21)

3

(Page 20)

8

(Page 20)

4

(Page 20)

22

(Page 21)

23

(Page 21)

24

(Page 21)

17

(Page 21)

25

(Page 21)

18

(Page 21)

20

(Page 21)

74

83

77

74

25

29

72

65

67

SDATA

SDEN

SCLK

FOK

MIRR

COUT

SCLK

TE

FE

10 4

9 5

8

6

6

4

3

2

10

7

48

49

50

47

51

27

11

52

35

78

79

38

EEPROM

IC903

5

6

SDA

SCL

RESET SIGNAL

GENERATOR

IC905

9

10

11

24

25

31

32

768FS (33.8688MHz)

XTAL

XSAK

XSHD

XDCK

XSRQ

SDEF

SD0 – SD7

SDATA, SCLK, SDEN

FOK, MIRR, COUT, SCLK

TE, FE, PI

XRST CD, MUTE CD, XRST DVD

12 – 16, 19 – 21

DATA BUS

27

(Page 23)

14

(Page 21)

15

(Page 21)

16

(Page 21)

45

46

13

(Page 20)

• SIGNAL PATH

: SACD PLAY

A1

A2

A3

B1

B2

B3

A4

B4

A0 – A11

CAS

RAS

WE

CKE

DQ0 – DQ7A0 – A11

SD0 – SD7

SDCK

SDEF

XSAK

XSHD

XSRQ

WCK

XCAS

XRAS

XWE

DCKE

DSAL

MCKI

DSALS

MSDATO

MSDATI

MSCK

XMSLAT

SMUTE

MSREADY

SDATAL

SDATALS

DATA RF

CLK RF

FOK CD

MIRR RF

COUT CD

SCLK CD

TE

FE

SIN DSD

SOUT DSD

SCK DSD

XLAT DSD

MUTE DSD

RDY DSD

CPU

IC901 (2/3)

XCS IO

XDIS IO

EEPSIO

EEPSCL

XRST

SDEN

XCS

RST

RST DSD

RST DVD

RST CD

XRD

XWR

D0 – D7

LOAD IN

LOAD OUT

PROGRAMMABLE

LOGIC DEVICE

IC904

XRST CD

SDATAL, SDATAR, SDATALS, SDATARS,

SDATAC, SDATALF, 64FS

D0 – D7

A0

XHRD, XHWR

LOAD IN/OUT

66PIPI

98

97

LATCH DF

INIT DF

22A

166

165

167

168

XASK, XSHD,

XDCK, XSRQ

126 WARFI

REAC

WPK

2, 3, 5, 6,

8, 9, 11, 12

139 – 136,

134 – 131

21 – 24, 27 – 32,

20, 19

162 – 159, 157 – 154,

152, 151, 149, 148

144

145

143

142

35CLK DCLK

141

66DSAR

SDATAR

76DSARS

SDATARS

69DSAC

SDATAC

71DSASW

SDATALF

61PHREFI

64FS

59BCKAI

128FS

26

(Page 23)

34MULTI

30

(Page 23)

3

4

FS64

FS128

5YO

64FS

128FS

XHRD

XHWR

2

41

28

(Page 23)

ZEROL

ZEROR

ZEROL, ZEROR

ZEROL

ZEROR

38

37

29

(Page 23)

LMUTE

RMUTE

LMUTE, RMUTE

LMUTE

RMUTE

33

23

6

(Page 20)

DVDPDSW

CDPDSW

DVDPDSW, CDPDSW

DVDPDSW

CDPDSW

LOAD IN

LOAD OUT

40 XTAL

41 EXTAL

X901

20MHz

DATA

CLK

LATCH

INIT

32

(Page 23)

DATA, CLK,

LATCH, INIT

26

31

(Page 24)

RST DP

XRST DP

36 ISBTEST

12

(Page 20)

MUTE 2D, SP ON, MUTE LOAD

115

TEST1

XRST

9

43 ZDFR

42 ZDFL

63

ZDFL

ZDFR

65

XRST DVD

123

MULTI

1TRKSW

7

(Page 20)

TRKSW

44LIM SW

9

(Page 20)

LIMSW

256FS

30

31

S152

(LOADING IN)

S151

(LOADING OUT)

IN SW

OUT SW

4

MUT 2D6SP ON1MUT LOAD

MUTE 2D

73

MUTE CD

MUTE CD

SP ON

MUTE LOAD

SCD-XB780

2323

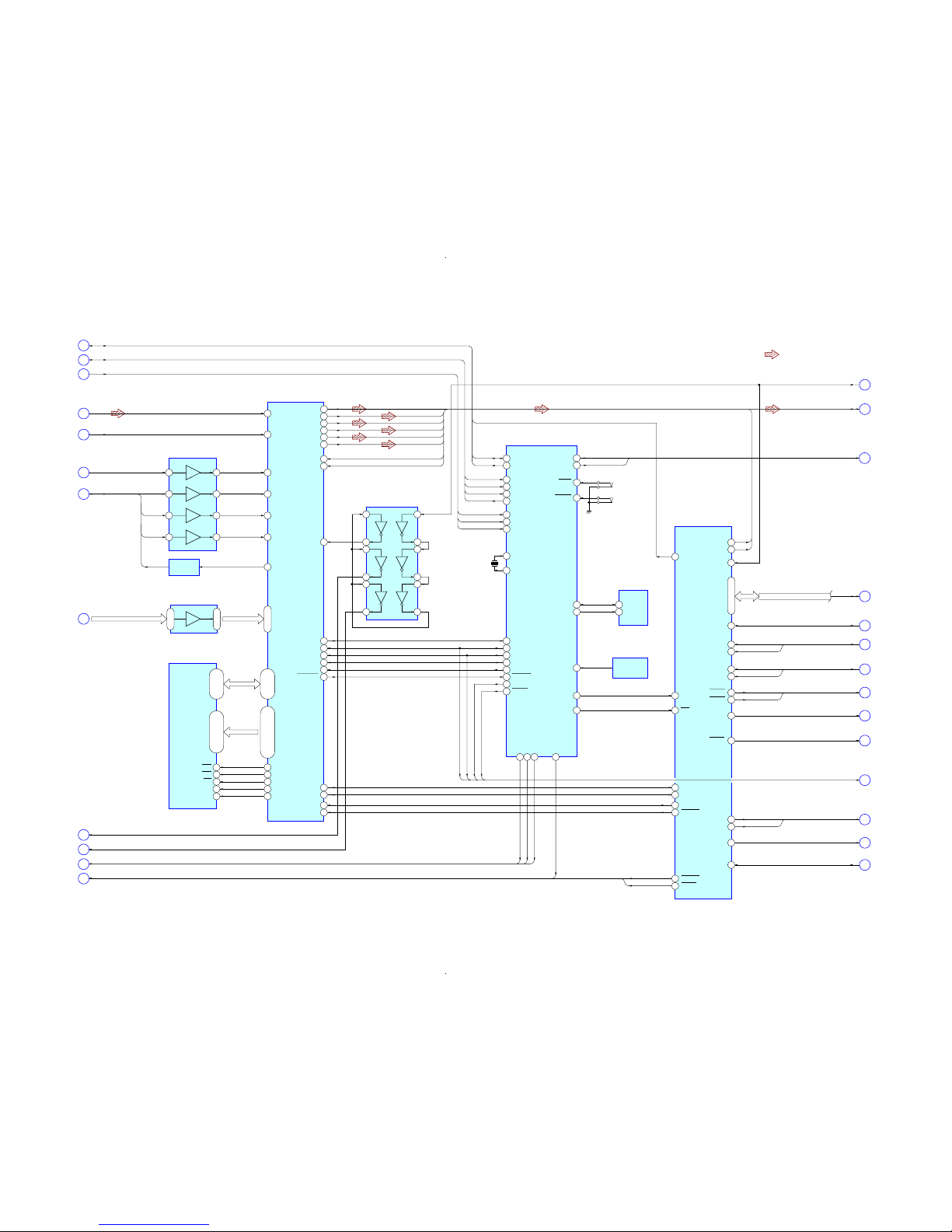

5-4. BLOCK DIAGRAM – AUDIO Section –

DSD1

DSD2

DSD5

DSD6

DSD7

DSD8

DBCK

SDATAL

SDATAR

SDATALS

SDATARS

SDATAC

SDATALF

64FS

DSD3

27

(Page 22)

SDATAL, SDATR,

SDATALS, SDATARS,

SDATAC, SDATALF,

64FS

PBCK

PLRCK

PDATA2

BCLK

LRCK

MDAT

19

(Page 21)

MDAT,

LRCK,

BCLK

26

(Page 22)

256FS

• SIGNAL PATH

: SACD PLAY

: CD PLAY (ANALOG)

• R-ch is omitted due to same as L-ch.

65 3

4

12

CLOCK BUFFER

IC304

X301

11.2896MHz

28

(Page 22)

ZEROL,

ZEROR

ZEROL

ZEROR

DIGITAL FILTER,

D/A CONVERTER,

LOW-PASS FILTER

IC301

32

(Page 22)

DATA, CLK, LATCH, INIT

30

(Page 22)

MULTI

R-CH

R-CH

R-CH

MUTING

Q401

MUTING

Q402

MUTING

Q403

R-CH

MUTING

Q421

MUTING

Q422

MUTING

Q441

MUTING

Q442

29

(Page 22)

LMUTE, RMUTE

MUTING

Q541

MUTING

Q542

ANALOG

LOW-PASS

FILTER

IC307

MUTING

CONTROL

SWITCH

Q303

R-CH

PHONE LEVEL

RV601

PHONES

J601

HEADPHONE

AMP

IC308 (1/2)

L

R

ANALOG

2CH OUT

J301

L

R

J302

FRONT

SUB WOOFER

CENTER

L

R

ANALOG

5.1CH OUT

R-CH

R-CH

R-CH

SURR

ANALOG

LOW-PASS

FILTER

IC305 (2/2)

ANALOG

LOW-PASS

FILTER

IC306 (2/2)

DSD

INTERFACE

DSD

FILTER

PCM

INTERFACE

ENHANCED

MULTI LEVEL

DELTA-SIGMA

MODULATOR

FUNCTION

CONTROL

MDIMCMS

10

VOUT3

VOUT1

9

VOUT4

11

VOUT2

31

VOUT5

30

VOUT6

29

VOUT7

28

VOUT8

XRST

DATA

CLK

INIT

LATCH

OUTPUT

AMP &

LOW-PASS

FILTER

DSD4

38

39

42

43

44

45

37

40

PDATA1

46

41

50

51

47

PCM

FILTER

ZERO

DETECT

MIX AMP

IC315 (2/2)

6

ZERO17ZERO2

SYSTEM

CLOCK

33

PSCK34DSCK

12

2 4 3 36

D/A

CONVERTER

R-CH

LMUTE

RMUTE

MUTING

CONTROL

SWITCH

Q304

MUTING

CONTROL

SWITCH

Q301

SCD-XB780

2424

5-5. BLOCK DIAGRAM – DISPLAY/KEY CONTROL/POWER SUPPLY Section –

S810 – 813

AMS

Ll

S801 – 806

PUSH ENTER

S830

ROTARY

ENCODER

REMOTE

CONTROL

RECEIVER

IC802

60KEY0

61KEY1

62KEY2

82RM

57LED DRV

53FLOUT

54FLCLK

56FLCS

55 FL. DATA (DI)

54 FL. CLK (CL)

53 FLT (CE)

OSC

C815,

R801

50 OSC0

51 OSC1

52

FLRST

31

(Page 22)

XRST DP

31S35

61 – 64, 1 – 3045 – 3246, 47

3G – 16G1G, 2G S1 – S34

CPU

IC901 (3/3)

FLUORESCENT INDICATOR TUBE DRIVER

IC801

SEGMENT

DRIVE

Q803

D803

(MULTI-CHANNEL)

LED

DRIVE

Q701, 702

GRID

DRIVE

Q801, 802

FL801

FLUORESCENT

INDICATOR

TUBE

F1

F2

RECT

D905, 906

+3.3V

DAC+5V

+3.3V

REGULATOR

IC302

+5V

REGULATOR

IC903

A+7V

+7V

REGULATOR

IC901

A+UR

RECT

D901, 902

A–7V

–7V

REGULATOR

IC902

RECT

D903, 904

A–UR

VFL–33V

FLUORESCENT INDICATOR

TUBE DRIVER

(IC801)

–33V

REGULATOR

Q921

RECT

D917 – 920

T901

POWER

TRANSFORMER

R954

D302D301

T902

POWER

TRANSFORMER

F1

F2

D922

D+3.3V

+3.3V

REGULATOR

IC904

RECT

D909 – 912

A+3.3V

+2.5V

REGULATOR

IC702

+2.5V

+5V

REGULATOR

IC906

D+5V

A+5V

M+12V

(MOTOR DRIVE (IC512))

+12V

REGULATOR

IC905

RECT

D913 – 916

+5V

REGULATOR

IC504

+5V

(COIL/MOTOR DRIVE (IC502))

S991

POWER

LINE

FILTER

L901

(AC IN)

SCD-XB780

2525

5-6. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Main board is multi-layer printed board.

However, the patterns of intermediate-layer have not been

included in diagram.

• Indication of transistor

C

B

These are omitted.

E

Q

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

4

W or less unless otherwise

specified.

•f: internal component.

• 5 : fusible resistor.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : SACD PLAY

(): CD PLAY

∗

: Impossible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : SACD PLAY

c : CD PLAY (ANALOG)

I : CD PLAY (DIGITAL OUT)

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

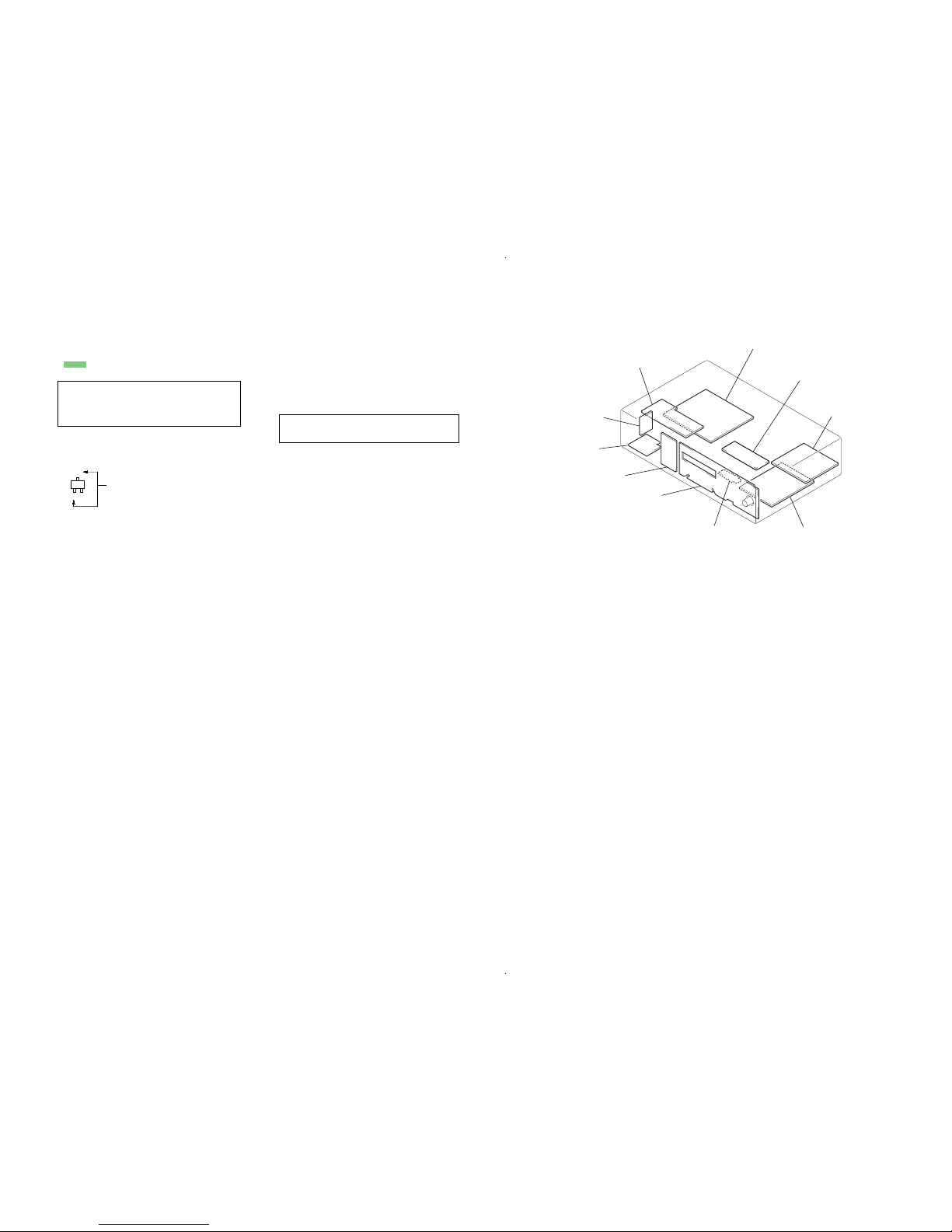

• Circuit Boards Location

PT board

POWER board

RF board

AUDIO boar

d

MAIN board

DISPLAY board

LOADING board

HP board

POWER SW board

KEY board

SCD-XB780

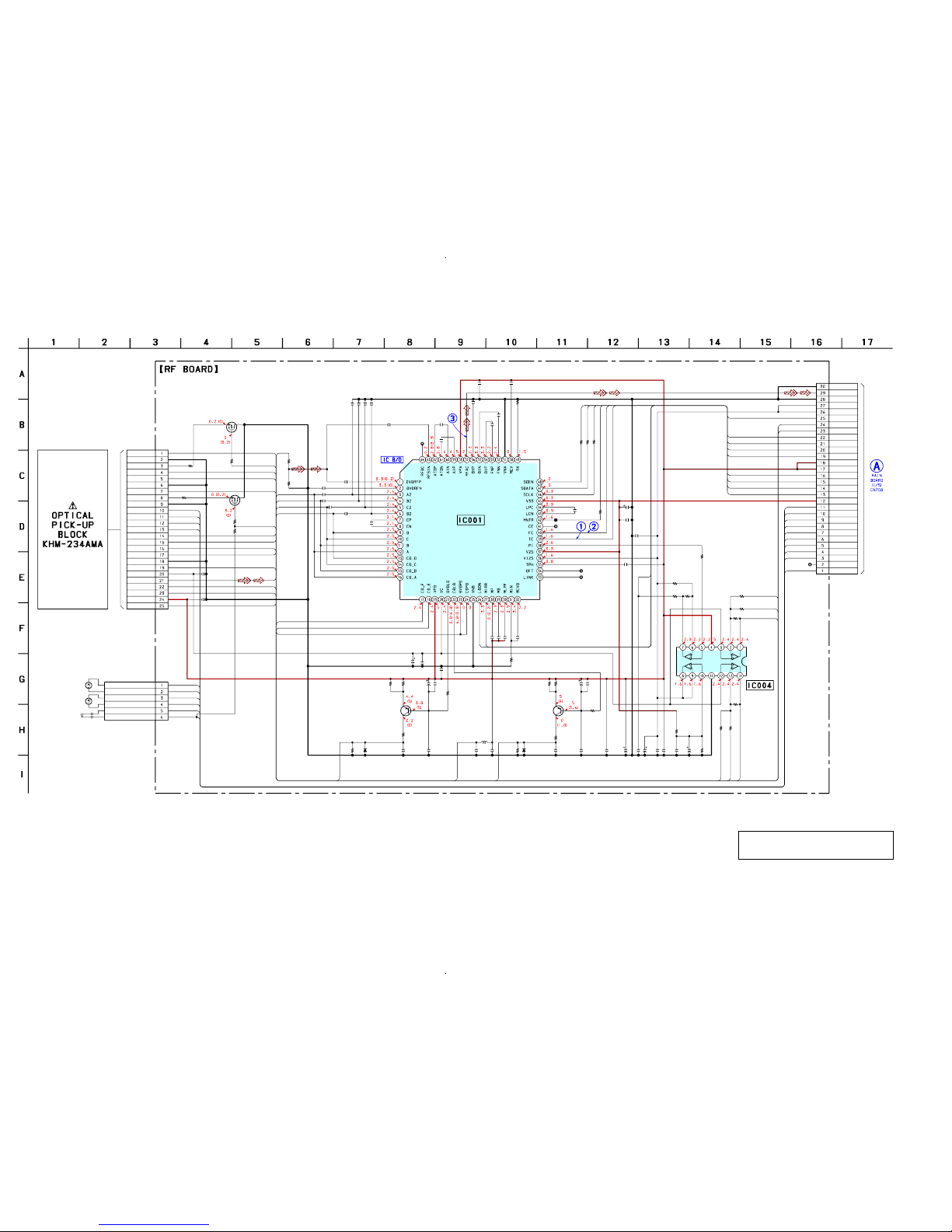

2626

5-7. SCHEMATIC DIAGRAM – RF Board – • See page 42 for Waveforms. • See page 45 for IC Block Diagram.

R020

R006

R007

C040

JL051

R083

R082

R084

R087

R086R085

R066C094C064C095

C060

R065

R029

R046 R036

R044

R025

R024

R023

C055

C052

C051

C048

JL003

R035

C047

JL002

JL001

C050

C003

C028

C090

C002C038

C037C029

L001

R019 R094

R021

C046

R022

C045

C041

C036

C039

C032

C031

JL081

R017

C025C027

C030

C001C023R015

C022

R093

C016

C008

C026

C021C017

C018

C020

C006

R004

CN002

IC001

R001

Q004

R005

Q005

R092

C015D001R097

Q001 Q003

R090

D002C014C007 R003

M3

S1

M2

CN003

CN005

C012

C011

C010

C009

C013

R008

C004

R002

C044

C043

C042

JL006

IC004

470

220

820

0.01

10k

10k

10k

10k

10k10k

10k22

10V

0.10.1

0.1

10k

47k

100 10k

8.2k

0

0

0

47

6.3V

0.1

0.1

0.047

0

0.1

22

10V

0.1

47

6.3V1

2200p100

6.3V

1000p10

47µH

33 33

10M

0.47

12k

1000p

0.01

0.1

0.1

0.1

0.1

470

0.10.1

22

10V

2200p100

6.3V

33

1000p

33

180p

2200p

0.01

22p22p

22p

22p

0.1

47k

6P

CXD1881AR-1

0

2SK3018

47k

2SK3018

0

101SS352-TPH333k

2SB1121-ST-TD 2SB1121-ST-TD

0

1SS352-TPH31010 33k

25P

30P

5600p

2200p

2200p

2200p

5600p

2.2k

0.1

100

330p

0.033

0.033

NJM3403AV(TE2)

RFPCD_LD

SP+

SP-

LIM_SW

SD-

SD+

SP-

SP+

LIM_SW

SD+

SD-

TD-

TD+

A

B

C

D

VMOD

FD-

FD+

FD-

FD+

TD-

TD+

C

D

_

E

L

D

O

N

M

IR

R

D3V

D3V

S

D

E

N

D

A

T

A

_

R

F

C

L

K

_

R

F

F

E

/P

I

F

E

E

F

PI

MIRR

FE/PI

TE

PI

SDEN

DATA_RF

CLK_RF

LDON

FE

T

E

D

V

D

_

L

D

V

M

O

D

C

D

_

L

D

B

RFP

C

D

A

DVD_CD_PD

DVD_LD

CDPDSW

DVDPDSW

DVD_CD_PD

DVDPDSW

CDPDSW

H

G

CD_F

E

H

F

G

CD_F

CD_E

TRK+

TRK-

FCS-

FCS+

MIRR

PI

TE

FE

SDEN

RFAC

D3V

D3V

CLK_RF

DATA_RF

A5V

A5V

AGND

AGND

LIM_SW

A3V

LIM_SW

SP+

SP-

SP+

SP-

LDON

TD-

TD+

FD-

FD+

SD-

SD+

SD+

SD-

CD_LD

CD_LDGND

A

D

E

C

GND

H

VC

RF

F

G

VCC

B

AVC

AVC

FE/PI

DVDPDSW

VMOD

CDPDSW

NC

CD_VR

DVD_CD_PD

LD_GND

DVD_LD

DVD_LDGND

DVD_VR

SUMMING AMP,

PI ERROR AMP,

AVC BUFFER

SACD/CD RF AMP

FOCUS/TRACKING ERROR AMP

PHOTO DIODE

CONTROL SWITCH

(FOR CD)

S

S

PHOTO DIODE

CONTROL SWITCH

(FOR SACD)

(FOR SACD)

AUTOMATIC

POWER CONTROL

AUTOMATIC

POWER CONTROL

(FOR CD)

(LIMIT)

(SLED)

(SPINDLE)

VCC

VEE

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

(Page 30)

Loading...

Loading...