Page 1

SCD-CE595

SERVICE MANUAL

Ver. 1.3 2006.08

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM79C-DVBU51

Optical Pick-up Name DBU-3

When a Super Audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 40 kHz (–3 dB)

Dynamic range 100 dB or more

Total harmonic distort ion r at e

Wow and flutter Value of measurable limit

When a CD is played

Frequency response 2 Hz to 20 kHz

Dynamic range 96 dB or more

Total harmonic distort ion r at e

Wow and flutter Value of measurable limit

Output connector

Jack type Output

ANALOG

5.1CH OUT

DIGITAL

(CD) OUT

OPTICAL*

*Output only the audio signals of the CD

Phono

jacks

Square

optical

output

connector

0.0035 % or less

(±0.001 % W. PEAK) or

less

0.0039 % or less

(±0.001 % W. PEAK) or

less

level

2 Vrms (at

50 kilohms)

–18 dBm (Light

Load

impedance

Over 10

kilohms

emitting

wave length:

660 nm)

General

Laser Semiconductor laser

Power requirements

US, Canadian:

AEP, UK:

Power consumption 15 W

Dimensions (w/h/d) 430 110 420 mm incl.

Mass (approx.) 5.5 kg

Supplied accessories

Audio connecting cord Red and White 2 (1)

Remote commanderRM-SX800 (1)

Battery R6 (size-AA) (2)

Design and specifications are subject to change

without notice.

(Super Audio CD: λ = 650

nm) (CD: λ = 780 nm)

Emission duration:

continuous

1

20 V AC, 60 Hz

230 V AC, 50/60 Hz

××

projecting parts

×

9-879-006-04

2006H16-1

© 2006.08

SUPER AUDIO CD PLAYER

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

Page 2

SCD-CE595

TABLE OF CONTENTS

1. SERVICING NOTES ........................................... 3

2. GENERAL ............................................................ 4

3. TEST MODE......................................................... 6

4. DIAGRAMS

4-1. Block Diagram ................................................................ 8

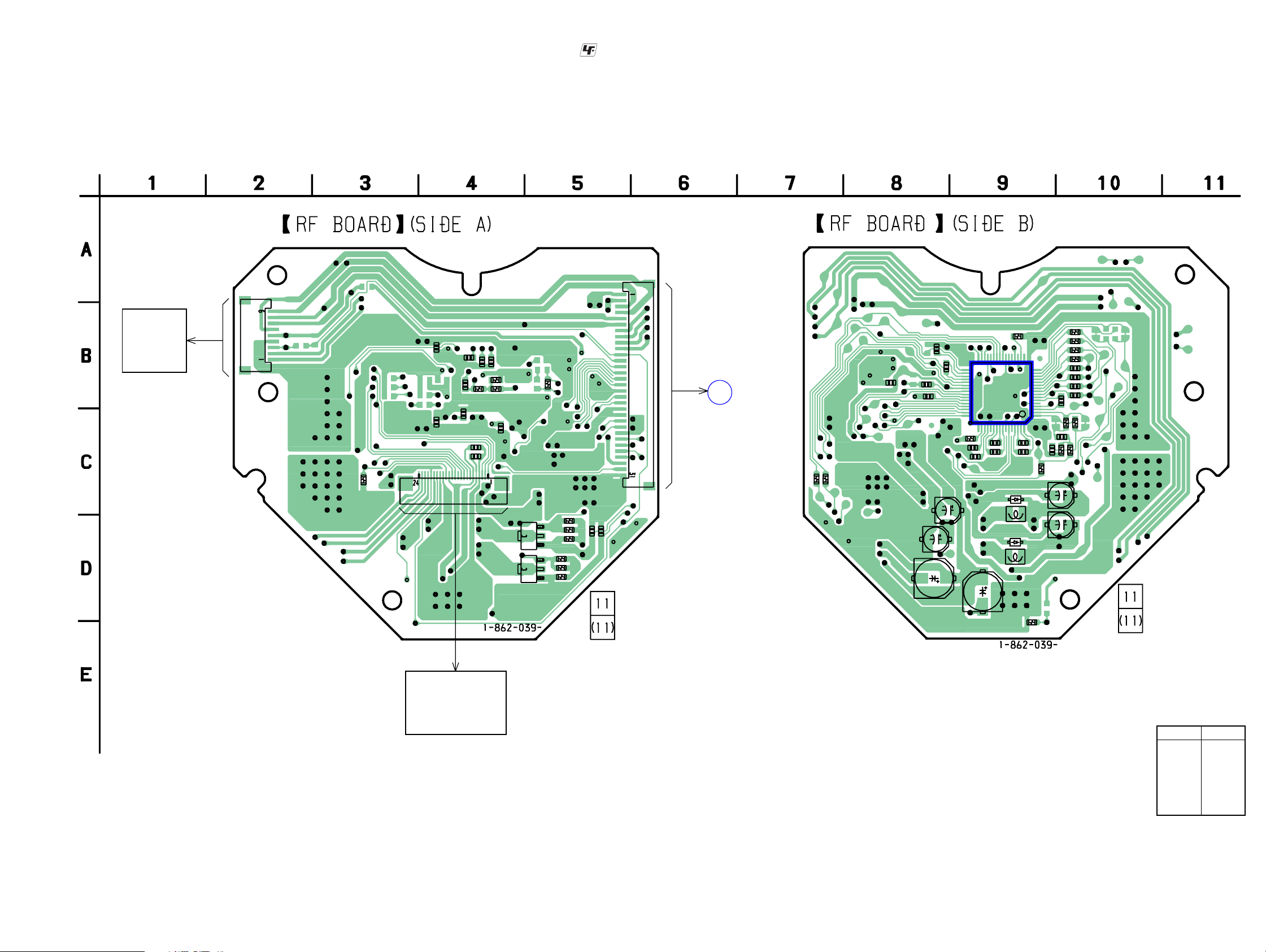

4-2. Printed Wiring Board — RF Section — ......................... 9

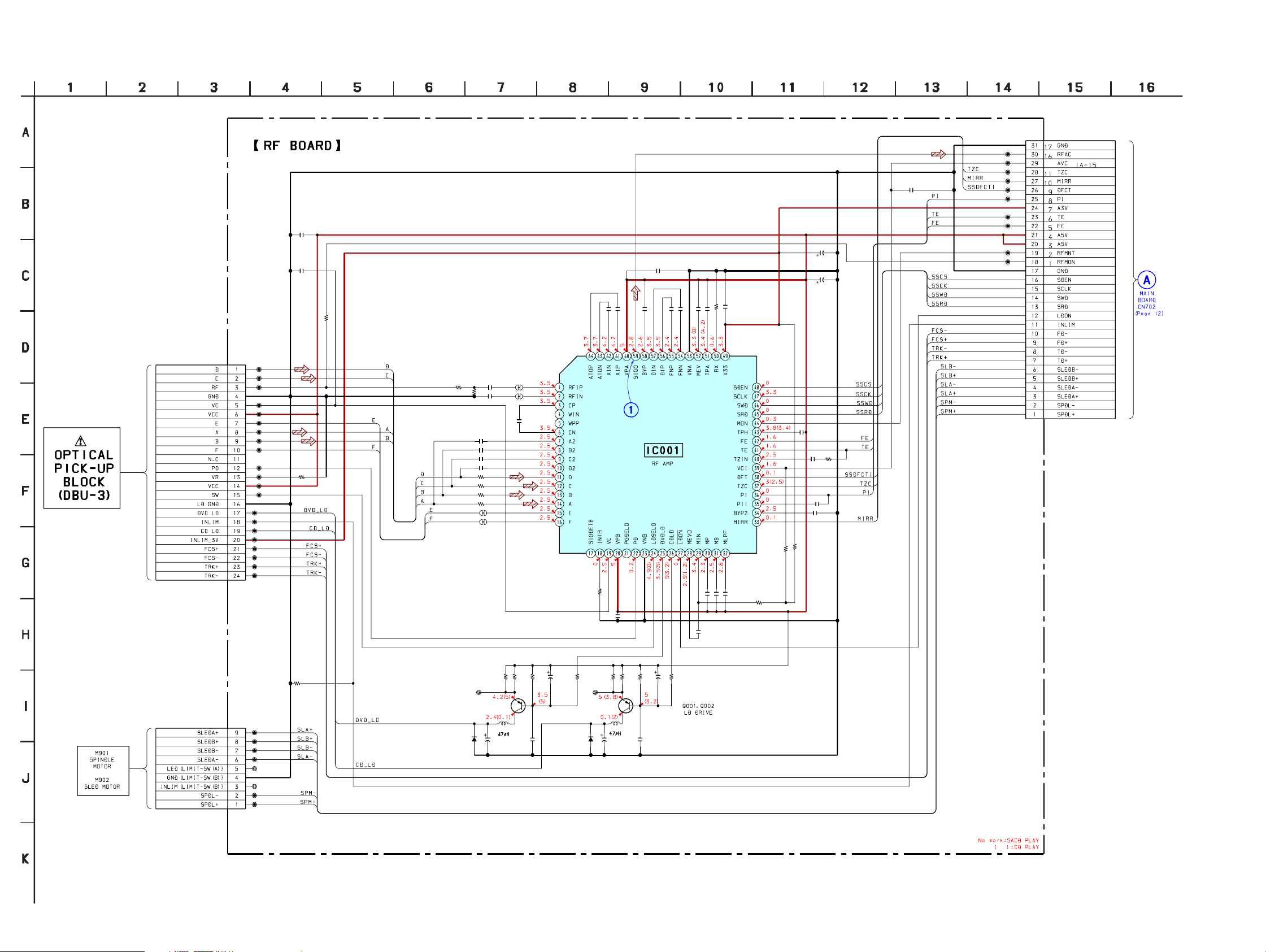

4-3. Schematic Diagram — RF Section — ........................... 10

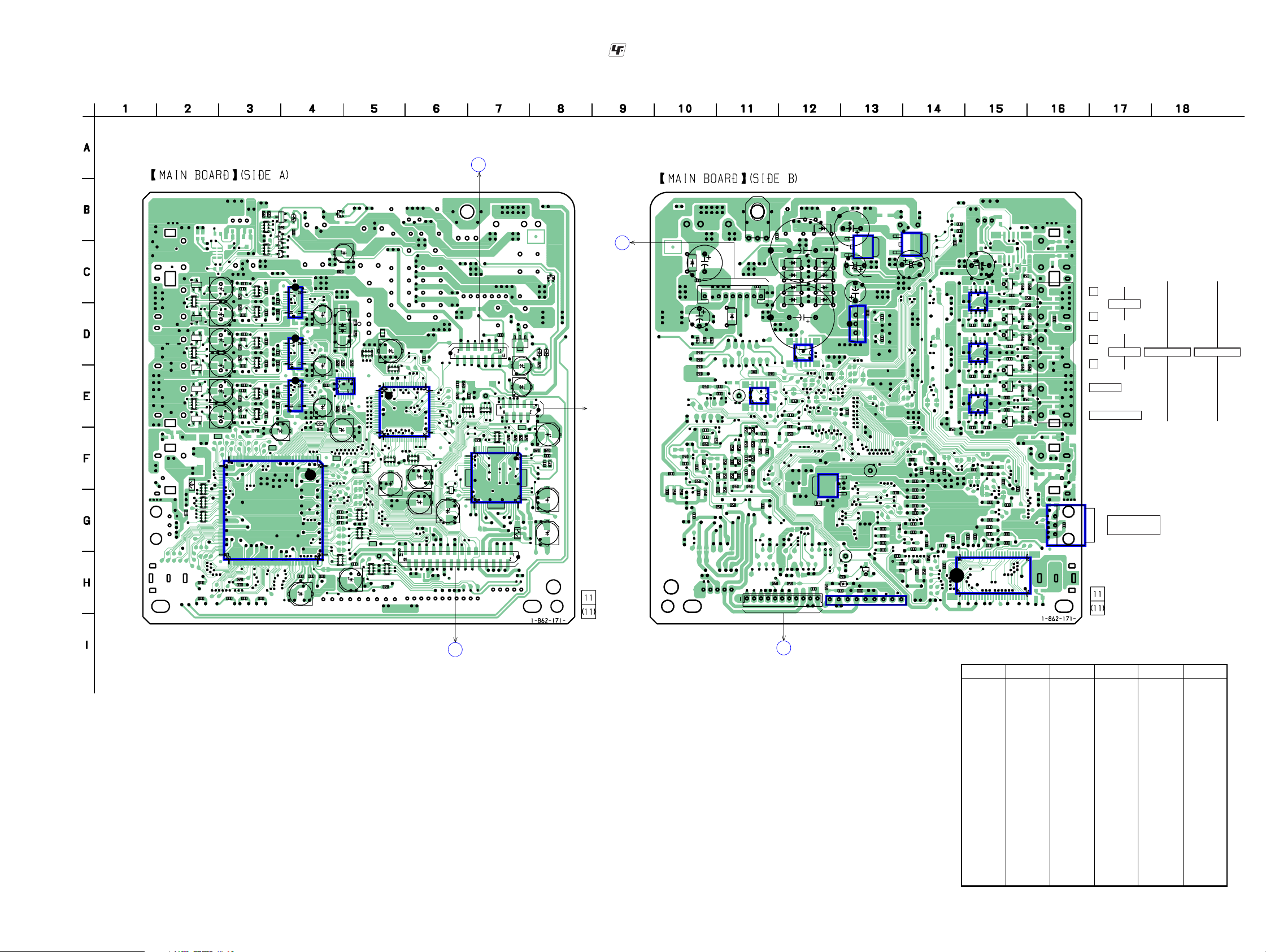

4-4. Printed Wiring Board — MAIN Section — ................... 11

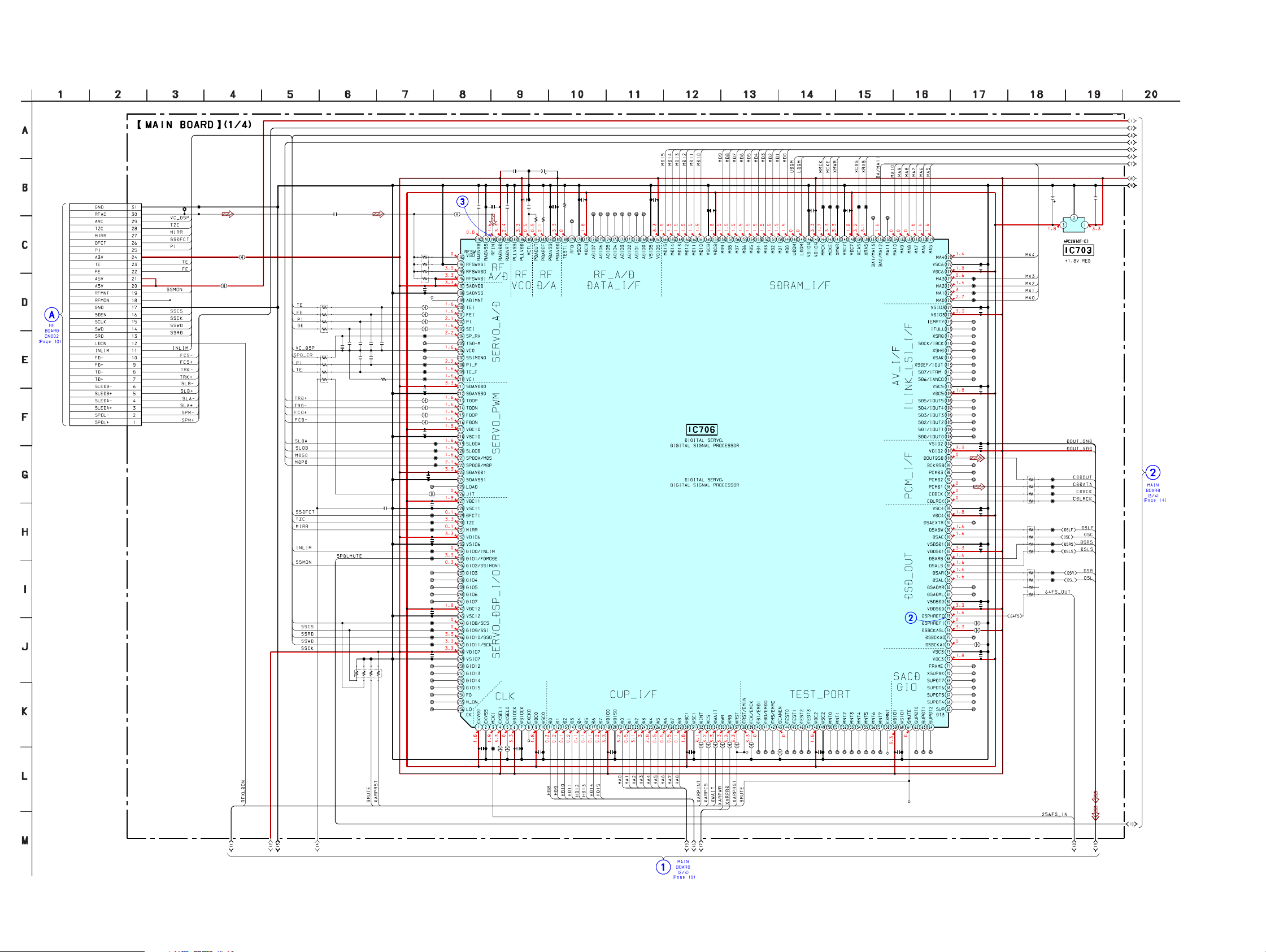

4-5. Schematic Diagram — MAIN Section (1/4) — ............ 12

4-6. Schematic Diagram — MAIN Section (2/4) — ............ 13

4-7. Schematic Diagram — MAIN Section (3/4) — ............ 14

4-8. Schematic Diagram — MAIN Section (4/4) — ............ 15

4-9. Printed Wiring Board — DISPLAY Section — ............ 16

4-10. Schematic Diagram — DISPLAY Section — ................ 17

4-11. Printed Wiring Board — MD-94 Board Section — ...... 18

4-12. Schematic Diagram — MD-94 Board Section — .......... 19

5. EXPLODED VIEWS

5-1. Main Section.................................................................... 22

5-2. Front Panel Section ......................................................... 23

5-3. Chassis Section ................................................................ 24

5-4. CD Mechanism Section (1) (CDM79C-DVBU51) ......... 25

5-5. CD Mechanism Section (2) (CDM79C-DVBU51) ......... 26

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is

classified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

6. ELECTRICAL PARTS LIST ............................ 27

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

Page 3

SECTION 1

tapering driver

1

2

r

SERVICING NOTES

SCD-CE595

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

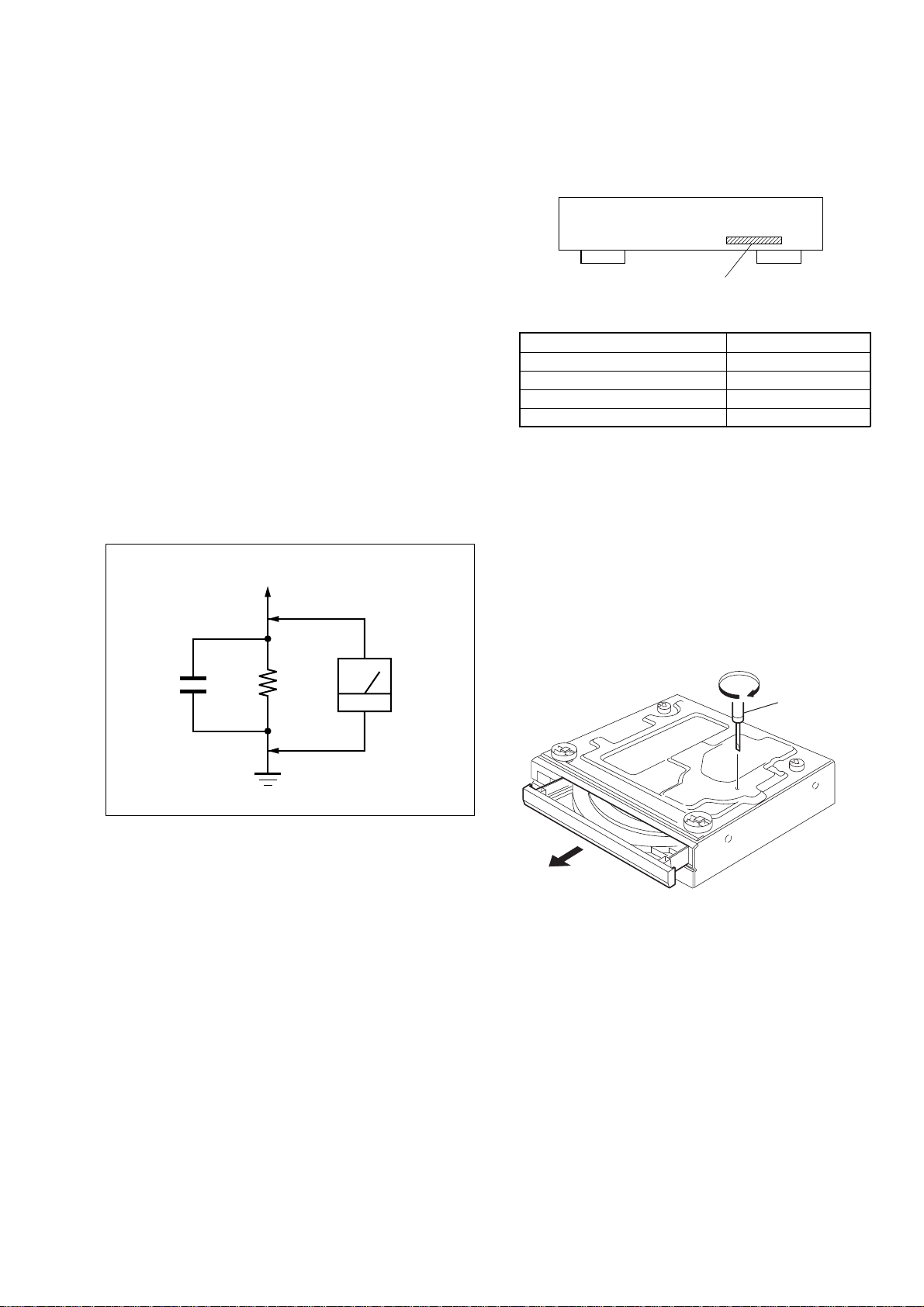

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufactur ers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must hav e an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

MODEL IDENTIFICATION

– Back Panel –

Parts No.

MODEL Part No.

US Model 4-255-250-0[ ]

Canadian Model 4-255-250-1[ ]

AEP Model 4-255-250-2[ ]

UK Model 4-255-250-3[ ]

HOW TO OPEN THE DISC TRAY WHEN POWER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and turn

in the direction of arrow.

Use a flat (-) head screwdriver to open the disc tray by manual

operation. (Flat head screwdriver with nominal blade length of

3mm.)

* To close the disc table, turn the driver in the reverse direction.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

3

Page 4

SCD-CE595

q

q

q

q

q

q

q

q

q

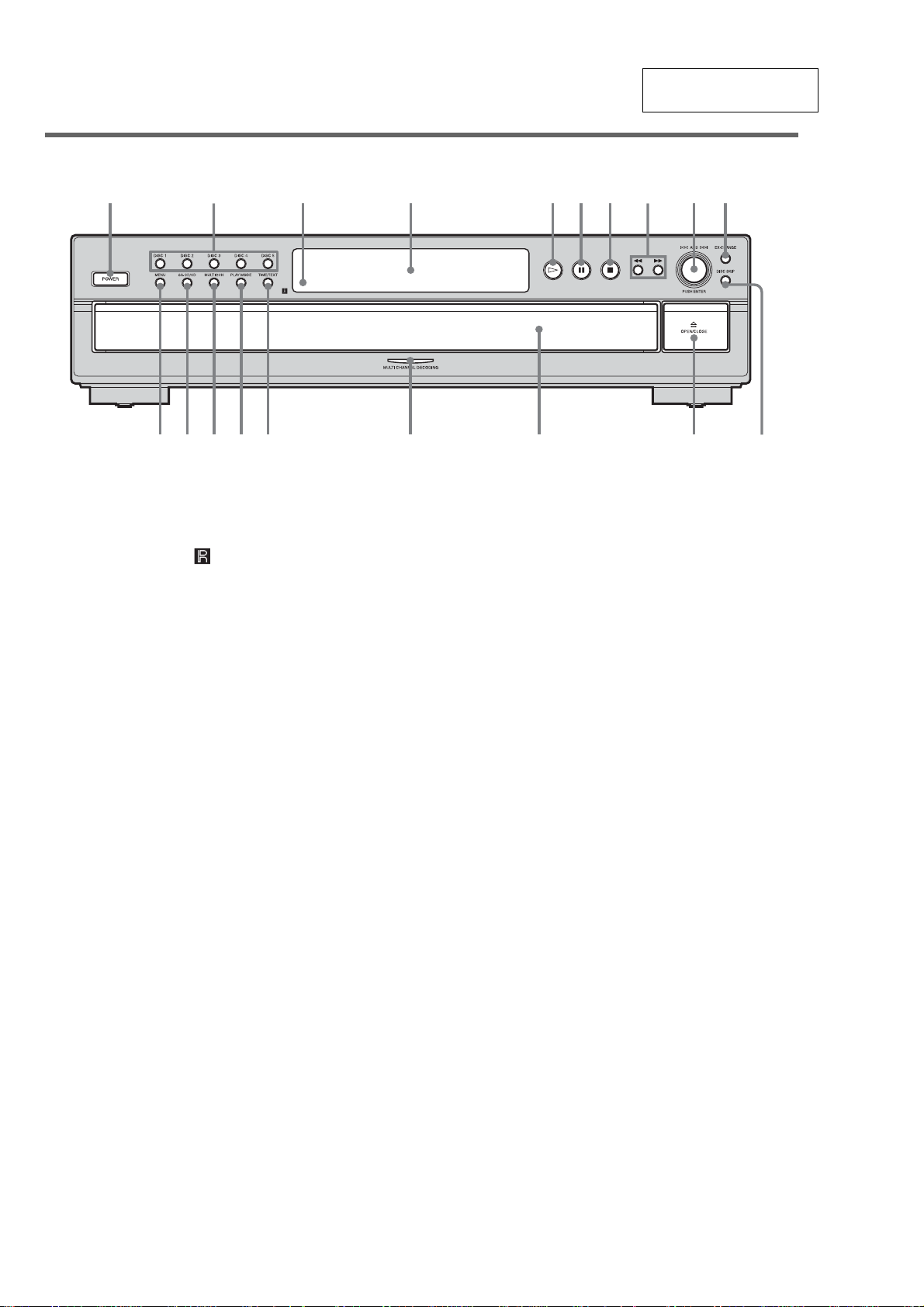

Front Panel

123 4 56789q;

SECTION 2

GENERAL

This section is extracted

from instruction manual.

g

h

j

k

l

A POWER switch (9)

B DISC 1-5 buttons (9, 14)

Press to select the disc directly.

C Remote sensor (6)

D Display window (10)

E H button (9, 13, 14)

F X button (9)

G x button (9, 15)

H m/M buttons (13)

I l AMS L dial

(AMS: Automatic Music Sensor) (8, 9, 10,

12, 13, 14, 16, 17, 19)

J EX-CHANGE button (12)

Press to replace discs while playing a disc.

K DISC SKIP button (9, 12, 14)

Press to select the disc.

L A OPEN/CLOSE button (9)

M Disc tray (9)

N MULTI CHANNEL DECODING indicator

Turns on when you turn on the player, or when the

Multi-channel Super Audio CD is loaded and

select the multi-channel playback area by pressing

MULTI/2CH.

f

O TIME/TEXT button (11)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appears in the display.

P PLAY MODE button (9, 14)

Press to select the play mo de.

Q MULTI/2CH button (5, 10)

Press to select the playback area when a disc with

the 2 channel area and the multi-channel area

(page 5) is loaded.

R SA-CD/CD button (5, 9)

Each time you press the button while playing back

a hybrid dis c, the layer to be played b ack switches

between the SA-CD layer and the CD layer.

S MENU button (8, 9, 10, 12, 16, 17, 19)

Press to enter the menu.

Press to exit from the menu and return to the

normal display.

d

s

a

4

Page 5

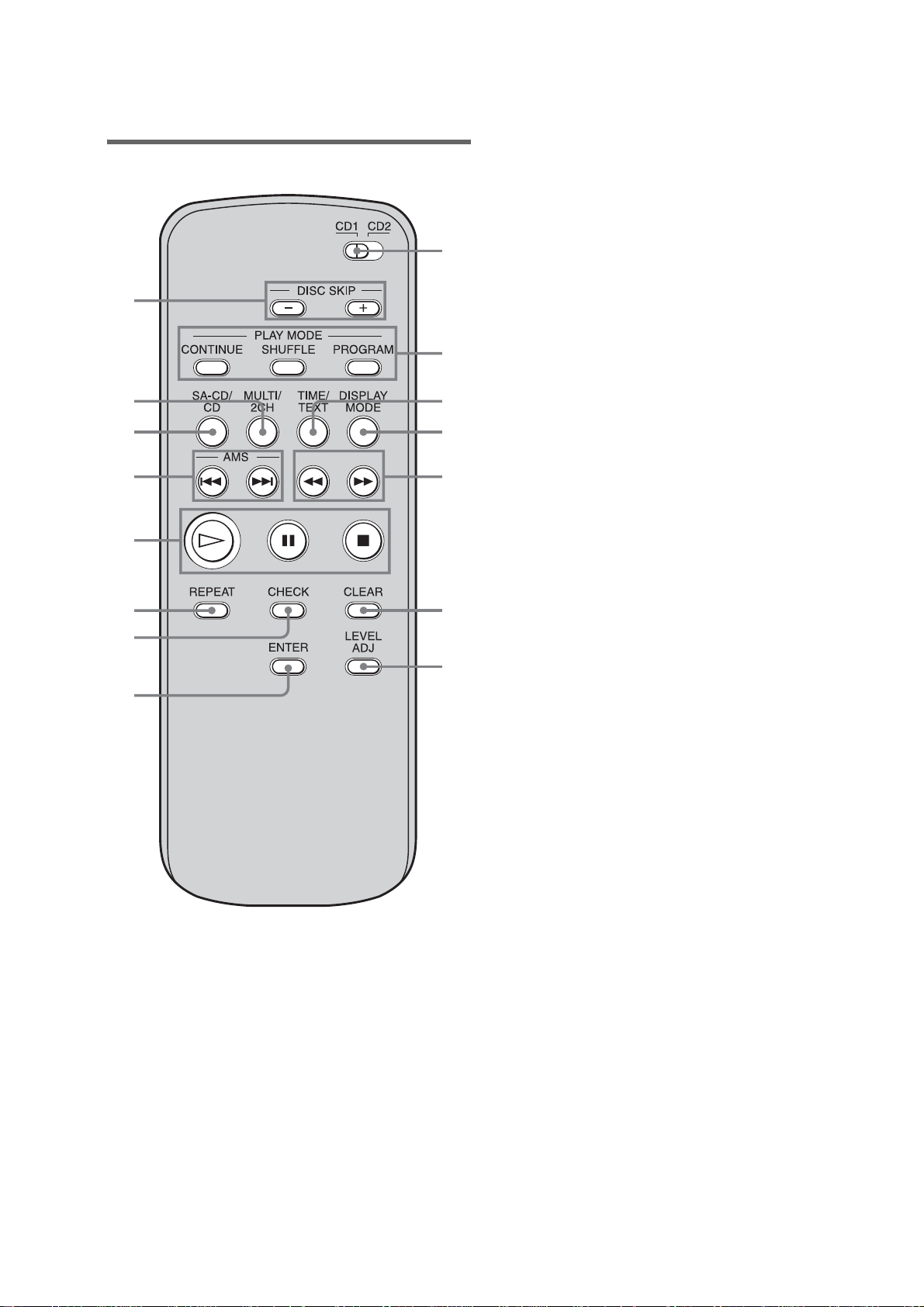

Remote

qg

qf

qd

qs

qa

q;

9

8

1

2

3

4

5

6

7

SCD-CE595

A CD1/2 (command mode) switch (8)

Select the command mo d e.

B CONTINUE button (9, 14)

Press to resume Continuous Play from Shuffle Play

or Program Play.

SHUFFLE button (14)

PROGRAM button (14)

C TIME/TEXT button (11)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appears in the display.

D DISPLAY MODE button (12)

Press to turn the display information off or on.

E m/M buttons (13)

F CLEAR button (14, 15)

Press to delete a progra me d tr a c k nu mber.

G LEVEL ADJ button (17)

Press to adjust the output level balanc e for the

Multi-channel management function (page 15).

H ENTER button (8, 10, 12, 14, 16, 18, 19)

I CHECK button (15)

Press to check the programed order.

J REPEAT button (13)

K H button (9, 13, 14)

X button (9)

x button (9, 15)

L AMS ./> buttons

(AMS: Automatic Music Sensor) (8, 9, 10,

12, 13, 14, 16, 18, 19)

M SA-CD/CD button (5, 9)

Each time you press the button while playing back

a hybrid disc, the layer to be played back switches

between the SA-CD layer and the CD layer.

N MULTI/2CH button (5, 10)

Press to select the playback area when a disc with

the 2 channel area and the multi-channel area

(page 5) is loaded.

O DISC SKIP +/– buttons (9, 12, 14)

Press to select the disc .

5

Page 6

SCD-CE595

SECTION 3

TEST MODE

1. Setting Methed of Test Mode

Press three buttons m , [PUSH ENTER] and [POWER] simulta-

neously, The test mode becomes active. Then all segments of the

fluorecent indicator tube are turned on.

2. FL Tube Grid, Segments Check

Procedure:

1. Grid of all segments lights up sequentially starting from 1G to

16G.

2. The vertical line (total 5 lines) of all grids lights up sequentially

in the range of 5G to 16 G starting from the left.

3. The horizontal line of (total 7 lines) of all grids lights up

sequentially in the range of 5G to 16G starting from the top.

3. Sircs Receive Check

Procedure:

1. The message “SIRCS CHECK” is displayed on the fluorecent

indicator tube.

2. With the machine in the status that is set in step 2, press any

on the remote commander. The machine enters the ke y check

standby state. (When the H key or the x key is pressed,

the reception check is canceled.)

4. Key Check

Procedure:

1. In the key check mode, the fluorecent indicator displays “KEY

CHECK**”. Each time a button is pressed, “**” value.

However, once a button is pressed, it is no longer taken into

account.

2. To exit from this mode, the message “JOG CHECK” is

displayed.

5. Jog Check

Procedure:

1. After the key check is completed, turn JOG clockwise to tur n

on the calendar segments sequentially . When the segment “15”

is confirmed, turn JOG counter-clockwise that turns off the

calendar segment. When the segment “1” is conf irmed, this is

the end of check.

6. Releasing Meted of Test Mode

1. After all the checks are completed, confirm to see that the

display “TEST-END” appears. The message indicates that

the check is ended normally.

2. Press the [POWER] button to turn off the main power and

disconnect the power plug from the wall outlet.

6

Page 7

SECTION 4

d

DIAGRAMS

SCD-CE595

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

• f : internal component.

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

These are omitted.

Note Schematic Diagrams.

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note:

The components identified by mark 0 or dotted line with mark 0 are

critical for safety.

Replace only with part

number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark: SACD PLAY

( ) : CD PLAY

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage v ariations ma y be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage v ariations ma y be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : CD DIGITAL OUT (OPTICAL)

4

W or less unless otherwise

Note:

Les composants identifiés

par une marque 0 sont critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

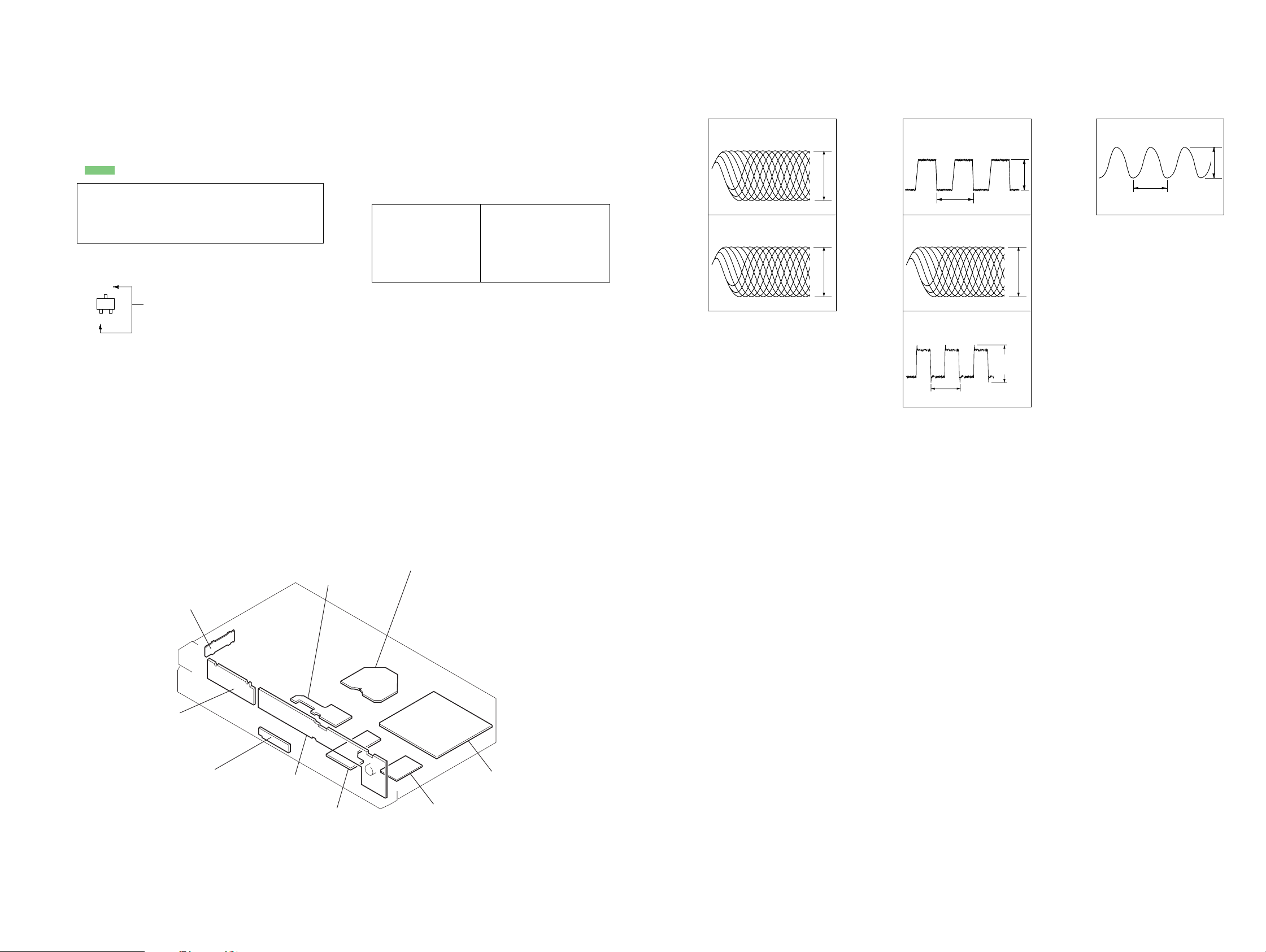

•Waveforms

– RF Board – – MAIN Board – – DISPLAY Board –

5

1

IC001 tl SIGO (CD)

200 ns/DIV

1

IC001 tl SIGO (SACD)

40 ns/DIV

1.4 Vp-p

1.4 Vp-p

2

IC706 uk DSPHREFO

354 ns

3

4

<z./ RF IN (SACD)

IC706

40 ns/DIV

1.4 Vp-p

IC320 2,4,6,q;,qs

88.6 ns

3.5 Vp-p

3.3 to 3.5

Vp-p

IC801 3 X1

200 ns

3.1 Vp-p

1 V/DIV, 200 ns/DIV

• Circuit Boards Location

POWER SW board

KEY board

LED board

SE-130 board

DISPLAY board

MD-94 board

RF board

MAIN boar

PT board

SCD-CE595

77

Page 8

SCD-CE595

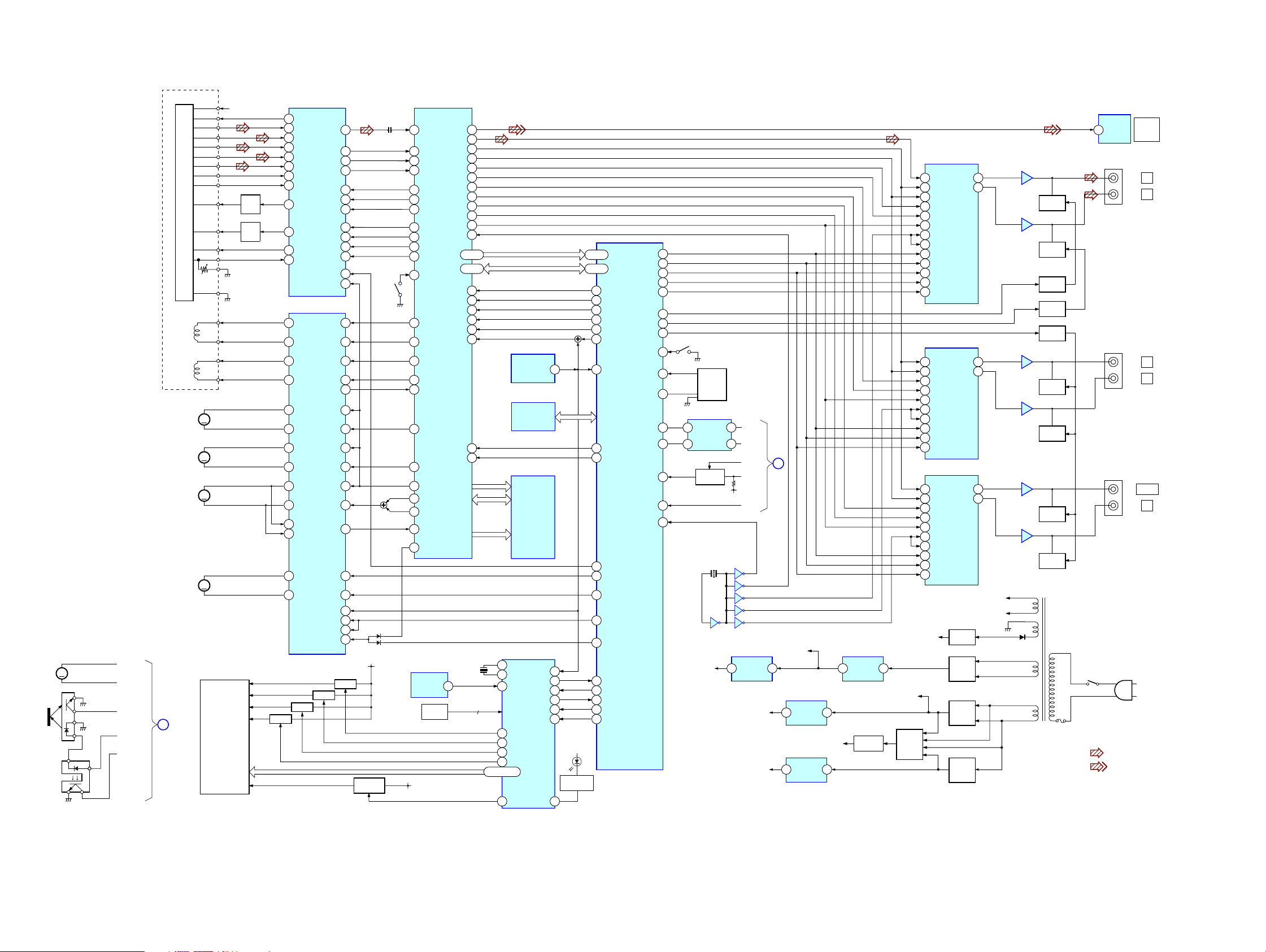

4-1. BLOCK DIAGRAMS

TURN TABLE

MOTOR

PH101

PH102

OPTICAL PICK-UP BLOCK

IC001

19

VC

1

RFIP

14

A

13

B

12

C

11

D

15

E

16

F

25

DVDLD

26

CDLD

24

LDSELO

2

PD

MOTOR/COIL DRIVER

37

DO1+

36

DO1-

35

DO2+

34

DO2-

32

DO3+

31

DO3-

30

DO4+

29

DO4-

28

DO5+

27

DO5-

46

OPIN1-

47

OPIN1+

25

DO6+

24

DO6-

Q822-Q825

FLDRIVER

Q823

Q822

RF AMP

IC712

41TE

42FE

PI

36

33MIRR

TZC

37

DFT

38

45SRD 245

46SWD 246

47SCLK 247

48SDEN 244

LDON

27

VCI

39

SWITCH

IN1+

48

IN1-

1

IN2+

3

4

IN2-

5

OUT2

IN3+

6

IN3-

7 SLDB

IN4+

9

IN4-

10 SLDA

12

IN5+

IN5-

13

45

OPOUT1

1716REV

FWD

PS

39

MUTE12

19

20

21

Q825

D509

+3.3V

FLDRIVER

Q821

MUTE34

MUTE5

Q824

LIMIT

IN

S841-845,

S851-853,855,

S875-871

VCC

6,14

5

3

8

9

2

1

7

10

DVDLD

17

19

15

12

4

FOCUS

COIL

TRACKING

COIL

SLED B

MOTOR

SLED A

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

M

4

3

2

1

2

3

4

TM-

TM+

DSENS

1

SENSOR

LED

TSENS

1

A5V

VC

RF

A

B

C

D

E

F

CDLD

SW

PD

VR

GND

FCS+

FCS-

TR+

TR-

SLB+

M

SLB-

SLA+

M

SLA-

SPM-

M

SPM+

LOADP

M

LOADN

INDICATION TUBE

FL801

Q001

LD

DRIVE

Q002

LD

DRIVE

5

6

7

8

9-20,32-48

49

IC706

DIGITAL SERVO,

DIGITAL SIGNAL PROCESSOR

DOUT958

19059SIGO

RFAC

200

TEI

201

FEI

202

PI

MIRR

231

TZC

230

DFCTI

229

SSI

SSO

SCK

SCS

234 INLIM

215

FDOP

216

FDON

213

TDOP

214

TDON

203

SEI

220

219

VCO

206

221

MDS0

222

MDP0

204

SP RV

235

FGMODE

IC802

SIRCS

29

+3.3V

RM

KEY

100

PCMD1

96

CDBCK

95

CDLRCK

94

DSAL

83

DSAR

84

DSALS

85

DSARS

86

DSAC

89

DSASW

90

DSPHREFO

78

MCKI

3

21-29 13,15-22A0-8 CA0-8

11-18 4-11D0-7 CD0-7

XINT

32

XCS

33

XWAIT

34

XWR

35

XRD

36

XRST

37

JIT

226

SMUTE

61

MA0-10,BA A0-10,BA

MD0-15 DQ0-15

XRAS,

XCAS,

XMWR,

MCKE,

MMCK,

LDQM,

UDQM

X801

5MHz

1

12

16

7

4

22-19

76-61,58-46

9

8

IC701

RESET

OUT

IC702

EEPROM

IC708

16M SDRAM

RAS,

CAS,

WE,

CKE,

CLK,

LDQM,

UDQM

IC801

DISPLAY CONTROLLER

3X1

4X2

17 SIRCS

ANI0-3

80 FIP0

79 FIP1

78 FIP2

77 FIP3

FIP4-32

45 FIP33

D511

6

6RESET

D801

LED DRIVER

11P23

Q826

MASTER CONTROL

92

XINT0

87

XCS

73

XWAIT

71

XWR

70

XRD

72

XWRST

59

XRST

EPR/B,

XEPCS,

XEWC,

EEPSO,

EEPSI,

EEPSCK

52

JIT

74

SMUTE

38

XLDON

TRAY OUT33

30

TRAY IN

DRV ON

35

36

SP ON

849 IFSISO1

838 IFSOSI1

9112 XIFINTACK

857 IFSCSCK1

9615 XIFCSINTP0

IC705

3SLATR DAC

2SCLK DAC

1SDATA DAC

94MZR

95MZL

L MUTE

98

97R MUTE

100M/2

S001 (TRY POSITION DETECT SWITCH)

25LOAD S0

27LOAD S1

26LOAD S2

39TRMP

40TRMM 2OUT2

29DSENS

30TSENS TSENS

EXTAL

65

ROTARY

ENCODER

IC710

TURN TABULE MOTOR DRIVER

9

RIN

7

FIN

INVERTER

Q701

9812

+1.8V

4OUT1

3.3V

X321

11.2896MHz

56

34

11 10

13 12

IC320

INVERTER

3 1

TM-

TM+

DSENS

SENSOR

LED

IC703

+1.8V REG

+5V

AU+

1

+3.3V

IC950

+5V REG

3 1

IC985

AU+ REG

3 1

3 1

MUTE

IC920

+3.3V REG

MUTE REG

Q961

+12V

RECT

D960,961

4

PDATA

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

14 ZEROR

13 ZEROL

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

VFL

IC200

DAC

VOUTL

VOUTR

IC230

DAC

VOUTL 9

VOUTR

IC260

DAC

VOUTL

VOUTR

VFL REG

Q971

RECT

D921-924

RECT

D931-934

RECT

D936,937

IC330

OPTICAL OUT

D OUT

1

IC400(1/2)

AMP

IC400(2/2)

IC430(1/2)

SL

SR

IC430(2/2)

CENTER

SW

IC460(2/2)

VF2

VF1

67

MUTE

Q401,402

AMP

21

MUTE

Q501,502

L MUTE

Q303

R MUTE

Q305

MUTE

Q301

AMP

67

MUTE

Q431,432

AMP

21

MUTE

Q531,532

IC460(1/2)

AMP

67

MUTE

Q462,463

AMP

21

MUTE

Q562,563

T101

POWER TRANSFORMER

D971

9

10

10

9

10

S891

POWER

• Signal Path

J351(1/3)

J351(2/3)

J351(3/3)

DIGITAL

OUT

OPTICAL

L

R

SL

SR

CENTER

SW

: CD

: CD DIGITAL OUT (OPTICAL)

SCD-CE595

88

Page 9

SCD-CE595

4-2. PRINTED WIRING BOARD — RF SECTION —

OPTICAL

PICK-UP

BLOCK

CN003

(DBU-3)

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

C026

C036

C034

R038

C038

C040

R005

R006

R004

CN002

MAIN BOARD

C039

Q001

Q002

R007

R008

R010

R020

R023

R025

C018

(Page 11)

C024

R003

C027

CN001

C028

C001

C002

A

CN702

R011

R029

C011

C004

C047

C043

C017

C046

C044

C048

C035

R037

C033

IC001

C031

C032

D001

L001

C023

R018

D004

C022

C025

L002

R002

R055

R054

R053

R052

C008

C016

C009

C021

C019

C005

R050

C015

R009

R051

R045

C007

C006

SCD-CE595

M901

SPINDLE MOTOR

M902

SLED MOTOR

R013

• Semiconductor

Location

Ref. No.

D001 C-9

D004 D-9

IC001 C-9

Q001 D-5

Q002 D-5

Location

99

Page 10

SCD-CE595

4-3. SCHEMATIC DIAGRAM — RF SECTION —

CN001

24P

JL003

JL004

JL005

JL006

JL007

JL008

JL009

JL010

JL011

JL012

JL013

JL014

JL015

JL016

JL017

JL018

JL019

JL020

JL021

JL022

JL023

• See page 7 for Waveforms.

C001

0.01

C002

0.01

100

R002

R003

100

C011

0.01

C004

22

R005

100k

6.3V

C044

10

16V

C043

0.1

R004

0

C047

0.1

C048

0.01

C046

0.01

CN002

31PIN

C027

0.01

0.1

0.001

IC001

0.1

C031

0.1

C032

C033

0.1

C025

0.1

C028

SP3726A

0.1

C022

C015

R009

R045

820

220

C016

C005

C006

C007

C008

R052

R053

R054

R055

0.0047

0.0022

0.0022

0.0022

0.0022

0

0

0

JW003

JW004

0.0047

0

JW001

JW002

C019

560p

R018

10k

0.047

C036

C035

12k

R037

0.047

C038

C039

0.01

C040

150p

R038

2.2M

R006

27k

SCD-CE595

CN003

C026

0.01

C017

R008

R007

33

D001

JL001

Q001

2SB1132-T100-QR

C009

L001

10

16V

R013

10k

9P

JL024

JL025

JL026

JL027

JL028

JL031

JL029

JL030

1SS355TE-17

C018

0.001

R010

33

47k

100

6.3V

2SB1132-T100-QR

D004

1SS355TE-17

R011

100

JL002

Q002

R020

R023

33

33

L002

C021

R025

47k

6.3V

C023

100

C024

0.001

10

16V

R029

C034

0.022

100

1010

Page 11

SCD-CE595

4-4. PRINTED WIRING BOARD — MAIN SECTION —

Q961

D963

R962

R963

R961

C962

Q303

RB302 RB301

Q301 Q305

Q502

RB410

Q402

Q532

RB442

Q432

Q563

RB441

Q463

L341

RB616

L342

C775

C772

TP730

RB617 RB615

C536

C436

C566

C466

C506

C406

C776

R791

C777

R534

R434

C463

R504R404

R564

R464

C504

C503

C534

C433

C564

C563

C403

C533

Q502

C506

C406

C503

R201

IC706

IC200

C502

RB502

C206C208

C402

RB402

IC230

C532

RB532

C236

C432

C238

RB432

C562

RB562

C268 C266

C462

RB462

IC260

C202

TP715

C753

C781C779

C754

C788

L320

C789

C242

C212

C324

D321

C726

C729

C722

C272

TP714

D960

C961

FB201

X321

R330

R328

IC320

R324

R326

C325

RB604

C791

C733

R322

R321

R323

RB602

RB611

RB603

TP713

RB608

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

DISPLAY BOARD

CN801

(Page 16)

B

PT BOARD

CN102

(Page 16)

C

D961

R702

RB601

C705

CN703

R899

RB607

IC712

C970

RB609

R895

Q971

CN701

TP733

R894

C972

C973

R893

R806

R879

R892

D973

C783

C785

C795

R975

C809

D972

R853

C813

R846

not used

C804

C819

C822

R871

RB613

RB606

R851

FL606

C713

RB605

IC705

RB610

C714

C716

C709

C703

C701

R703

D511

RB612

D509

C796

CN702

R857

R872

C901

R976

R977

R978

R979

C830

R880

C820

C787

C794

D937

R701

C829

R886

R874

R973

R804

C971

R972

R820

C702

C704

C821

C828

R971

C935

R888

R889

R876

R885

R866

CN901

STP703

R865

C816

R870

R819

R852

D971

FB710

R869

C832

C817

ETP910

C920

IC701

R861

R878

C825

C815

R860

R877

R897

C800

R831

C793

R858

C814

C932

R818

C808

STP702

D703

C748

C954

C924

STP701

C799

IC950

C953

IC920

C322

C923

C321

C723

C727

C730

C731

Q701

C745

D933

D923

D924

D934

C921

C931

D936

D932

D931

D921

D922

C910

IC702

FB703

R708

C711

C721

R734

C715

C712

C706

IC703

R848

CN704

C806

R815

R828

C749

C734

R752

C746

C750

C934

C742

C743

C736

C739

C740

C741

C737

C738

IC985

C757

C751

C744

C755

C756

C752

R782

C933

R781

R783

C305

C303

C302

IC400

IC430

IC460

R202

C758

C782

C759

C464

C762

C434

C760

C201

C761

C362C404

C364

C366

C763

C764

C767

C768

C769

C771

C780

IC708

C535

C435

C465

C770

C565

C766

C778

C505

C405

C765

Q462

R467

Q401

Q501

Q531

Q431

Q562

R567

R468

R509

R409

R437

R537

R507

C281

R407

R568

R508

R408

R538

R438

R569

R511

R411

R539

R439

R469

C351

C331

IC330

J351

L

FRONT

R

L

SURR 5.1CH OUT ANALOG

R

CENTER

SUB WOOFER

OPTICAL OUT

(DIGITAL CD)

IC710

SCD-CE595

A

RF BOARD

CN002

(Page 9)

D

MD-94 BOARD

CN001

(Page 18)

• Semiconductor Location

Ref. No.

D321 E-4

D509 G-6

D511 E-6

D703 H-13

D921 C-12

D922 C-12

D923 C-12

D924 C-12

D931 C-12

D932 C-12

D933 C-12

D934 C-12

D936 B-12

D937 C-10

D960 B-4

D961 C-8

D963 B-4

D971 D-11

D972 D-8

Location

Ref. No.

IC200 C-4

IC230 D-4

IC260 E-4

IC320 S-5

IC330 G-16

IC400 D-15

IC430 D-15

IC460 E-15

IC701 E-11

IC702 D-12

IC703 F-12

IC705 E-5

IC706 G-3

IC708 H-15

IC710 H-13

IC712 F-7

IC920 D-13

IC950 B-13

IC985 B-14

Location

Ref. No.

Location

Q301 C-3

Q303 C-3

Q305 C-3

Q401 C-15

Q402 D-2

Q431 D-15

Q432 E-2

Q462 E-15

Q463 E-2

Q501 C-15

Q502 C-2

Q531 D-15

Q532 D-2

Q562 E-15

Q563 E-2

Q701 H-13

Q961 B-3

Q971 D-7

D973 D-8

1111

Page 12

SCD-CE595

4-5. SCHEMATIC DIAGRAM — MAIN SECTION (1/4) —

CN702

31P

CL721

STP702

CL724

XX

CL723

SL897

SL896

• See page 7 for Waveforms.

C733

0.047

RB604

4.7k

C736

RB603

RB602

470

1

C730

C723

C727

0.0047

0.0047

C729

0.001

0.1

C726

C722

0.001

R752

RB613

0

C734

0.1

10k

1k

TP713

SL774

SL773

SL772

SL771

CL830

C731

0.0047

CL829

CL828

CL754

CL753

CL752

CL751

C743

SL778

SL777

SL776

SL775

C742

CL834

CL833

CL832

CL831

0.1

C741

CL767

SL770

0.1

C740

CL827

CL826

CL825

0.1

C739

CL824

CL823

CL766

CL765

CL764

CL763

CL762

0.1

C738

CL822

CL821

CL820

CL819

0.1

C737

CL761

CL760

CL759

CL758

CL757

CL756

CL755

C754

C789

220

0.1

4V

RB617

RB616

RB615

C714

220

4V

470

CL873

CL872

CL871

CL870

470

CL869

CL867

CL866

CL865

CL864

470

C746

0.1

0.1

C745

0.1

SL798

0.1

0.1

0.1

C751

0.1

100p

1k

C788

C749

47k

R781

R782

C755

0.1

0.1

R783

10k

C753

CL835

CL836

CL837

CL838

CL839

CL840

CL841

C757

0.1

CL842

CL843

IC706

CXD2754Q

256-QFP(0.4)

0.1

C759

0.1

C761

CL844

CL845

CL846

0.1

CL771

CL770

CL848

CL847

C762

0.1

C771

CL877

CL876

CL875

CL874

C770

0.1

CL804

CL803

CL802

CL801

CL800

CL799

CL798

CL797

C769

0.1

CL796

CL795

CL794

CL793

CL792

CL791

C768

0.1

CL790

CL789

CL788

CL787

CL786

C767

0.1

0.1

C766

CL785

C765

CL784

0.1

SL871

SL875

CL782

SL872

C764

0.1

CL781

CL780

CL779

CL778

CL777

CL776

CL775

C706

0.1

IC703

SCD-CE595

1

0.1

C750

CL737

SL799

SL800

TP714

C752

C744

1

0.1

C756

0.1

C758

SL837

SL839

SL840

SL841

SL843

TP715

SL845

SL848

CL849

CL850

CL851

SL856

CL852

CL853

CL854

CL855

0.1

C760

CL856

CL857

CL858

CL859

CL860

CL861

CL862

CL863

TP729

0.1

CL774

CL773

CL772

C763

TP730

XX

1212

Page 13

SCD-CE595

4-6. SCHEMATIC DIAGRAM — MAIN SECTION (2/4) —

CN703

13P

FB703

0UH

FB710

0UH

17

15

• See page 20 for IC Block Diagrams. • See page 20 for IC Pin Function Description.

12

RB612

RB606

10k

10k

RB601 RB607

10k 10k

FL606

0UH

C713

100 16V

C715

C721

0.1

40

7

L

0.1

C

8

87

L

C

46

L7

C

2

3

0

1

8

8

8

79

88

8

8

8

8

L

L

L

L

L

C

C

C

C

C

48

7

L

C

R734

R708

CN701

9P

15

100

D511

DAP202UT106

C704

STP703

R707

1k

C705

0.1

R701

0

3

L7

C

R703

C703

0.1

0.1

CL708

1k

C702

1

IC701

M51957BFP-600C

10k

CL710

C701

0.1

R702

10k

10k

CL734

CL731

C712

0.1

C711

0.1

CL891

CL890

CL889

CL888

CL733

CL732

CL743

5

9

73

73

L

L

5

6

C

2

73

L7

L

C

9

0

7

L

C

C

2

8

C

9

3

8

7

0

L

L

32

3

C

C

7

7

L

L

S

S

HD6432238RN51TEV

4

3

9

89

L8

L

C

C

IC705

2

5

1

7

4

4

4

4

7

7

7

L

L

L7

L

C

C

C

C

1

53

2

4

L7

S

5

9

7

7

46

L

L

7

74

S

S

L

SL

S

RB611

10k

2

0

9

57

79

79

75

7

L

L

L

L

S

S

S

S

CL769

CL768

C748

0.1

15

SCD-CE595

IC702

BR9040F-WE2

CL722

CL726

RB605

10k

1313

Page 14

SCD-CE595

4-7. SCHEMATIC DIAGRAM — MAIN SECTION (3/4) —

CL712

CL727

CL713

GND

BA6956AN

FIN

9.3

9.3

C799

0.1

CL711

IC710

VCC

C791

STP701

XX

TABLE_GND

VREF

OUT2

RMF

OUT1

VIN

123456789

5

0

0

0

C808

0.01

47

25V

C806

0.1

TABLE_+12V

R848

R851

2.2K

1K

D703

UDZSTE-175.1B

15

C716

C709

100

220

16V

4V

CL728

CL729

RIN

00 0

R860

0.0015

R878

470k

C825

R877

470k680k

R861

270k

C815

0.015

R858C814

120k0.22

CN704

C796

C793

100

0.1

16V

D509

DAP202UT106

CL818

0.1

12

C775

0.1

CL805

47

R791

CL806

C777

10p

C778

0.1

C780

0.1

C782

0.1

IC708

MSM56V16160F- 8TK7R1

C772

C776

0.1

10

R806

C779

0.1

C781

0.1

CL815

CL814

SL895

SL894

SL893

SL892

SL891

SL898

C795

C794

100

0.1

16V

R880

100k

R820

150k

R819

150k

TP733

XX

R831

10k

R840

100k

C800

0.1

IC712

FAN8035L

C787

0.1

R804

330

R872

10k

1

C785

220

10k

R871

C819

4V

C804

0.1

R852

33k

R897

470k

C832

0.0047

R899

220k

C817

0.001

R870

33k

R869

56k

C816

0.001

R866

33k

R865

56k

R876

R885

C828

15k

82k

C821

100p

C820 R893

220p 120k

C809

C783

100

16V

R853

56k

0.033

R846

56k

33k

R857

C813

0.033

C822

0.068

R874

33k

0.068

C829

82k

R886

220p

RB609

10k

R889

0

R895

56k

R894

56k

R892

120k

15k

C830

100p

R888

TRMP

TRMM

Q701

DTC143TKA

-T146

DSENS

TSENS

RB608

R815

R818

0

0

CL810

CL811

CL809

CL808

CL807

CL816

CL817

47K

CL812

CL813

100

100

0

R828

220

RB618

RB618

47K

47K

11P

S0

S1

S2

SOND

SENSOR LED

TSENS

DSENS

LMLM+

TM+

TM-

1

2

3

4

5

6

7

8

9

10

11

D

MD-94 BOARD

CN001

(Page 19)

SCD-CE595

13

1414

Page 15

SCD-CE595

4-8. SCHEMATIC DIAGRAM — MAIN SECTION (4/4) —

14

C325

100

6.3V

C324

D321

1SS357-TPH3

IC320

SN74LVU04APWR

13

13

SL215

SL216

SL217

SL220

SL201

SL231

SL261

SL262

CL201

R324

100

IC260

DSD1751DBQR

1

22

R326

IC200

DSD1751DBQR

IC230

DSD1751DBQR

CL868

22

R330

22

R328

R323

1k

R321

1M

R322

C322

15p

C321

15p

X321

11.2896M

C212

10

50V

1

1

C208

C206

C242

10

50V

CL244

CL245

1

1

C238

C236

C272

10

50V

CL275

CL274

C268

C266

1

1

• See page 7 for Waveforms.

0

C281

2200p

C404

1

C201

1000

6.3V

FB201

R201

1

C504

0UH

10k

R202

33k

1

C434

1

C534

1

C464

C564

IC985

BA12FP-E2

C934

C933

470

0.1

16V

C953

C954

470

0.1

10V

IC950

BA50BC0FP-

E2

C921

C924

0.1

470

10V

C923

Q305

UN5116-TX

Q303

2SC3624A-

Q531

2SC3624A-

T1L15L16

2SC3624AT1L15L16

2SC3624A-

T1L15L16

Q501

T1L15L16

2SC3624A-

T1L15L16

Q462

Q562

2SC3624A-

T1L15L16

UN5116-TX

2SC3624A-T

1L15L16

Q502

2SC3624A-T

1L15L16

Q432

2SC3624A-

T1L15L16

Q532

2SC3624A-

T1L15L16

Q463

2SC3624A-T

1L15L16

Q563

2SC3624A-T

1L15L16

C305

0.1

R411

100

Q402

RB410

2.2k

RB442

2.2k

C303

0.1

CL302

R409

220

Q401

R509

220

R439

220

Q431

RB441

2.2k

R539

220330

R469

220

R569

220

CL301

C302

0.1

Q301

UN5116-TX

RB301

4.7k

IC400(2/2)

NJM4565M(T

E2)

RB402

C403

6.8k

150p

C402

0.001

C502

0.001

RB502

6.8k

C202

47

IC430(2/2)

6.3V

NJM4565M(T

RB432

C432

6.8k

0.001

C532

RB532

0.001

6.8k

IC430(1/2)

NJM4565M(T

E2)

IC460(2/2)

NJM4565M(T

E2)

C462

RB462

0.001

6.8k

C562

RB562

0.001

6.8k

1

C362

0.1

C503

150p

IC400(1/2)

NJM4565M(T

E2)

E2)

150p

C433

C364

0.1

C533

150p

C366

0.1

150p

C463

C563

150p

IC460(1/2)

NJM4565M(T

E2)

RB302

220k

C406

47 25V

R408

330

C405

0.1

R407

100k

R404

3.3k

R507R504

100k3.3k

C505

0.1

R508 R511

C506

330 100

47 25V

C436

R438

47

25V

330

C435

0.1

R437

R434

100k

3.3k

R537

R534

100k

3.3k

C535

0.1

R538

C536

47

25V

C466

R468

3304725V

C465

0.1

R464

R467

3.3k

100k

R564

R567

3.3k

100k

C565

0.1

R568

C566

330

47

25V

IC920

BA33BC0T

10000

Q961

DTC143TKA-

10V

T146

R963

1k

R962

1k

C962

D960

DAN202UT106

C931

10000

16V

C961

10

50V

1k

D963

UDZSTE -173.0B

R961

0.1

C331

0.1

C932

1SR154-400TE25

470

35V

1SR154-400TE25

1SR154-400TE25

D936

D931

D932

C910

1SR154-400TE25

1SR154-400TE25

C971

47

63V

1SR154-400TE25

1SR154-400TE25

D961

DAN202UT106

0.001

ETP910

EARTH PLATE

D921

D922

1SR154-400TE25

D971

1SR154-400TE25

R972

10k

R971

10k

D937

D933

1SR154-400TE25

D934

1SR154-400TE25

D924

R973

3.3k

UDZSTE-17-33B

C935

1000

16V

C901

0.01

D923

C920

0.01

CN901

8P

17

C970

0.01

13

Q971

2SB1260

D972

R976

R977

D973

UDZSTE-179.1B

C972

10

50V

R975

33k

R978

100

100

22k

C973

R979

22

10k

16V

J351

6P

C351

0.1

CL202

IC330

IC TOTX141L

SCD-CE595

1515

Page 16

SCD-CE595

4-9. PRINTED WIRING BOARD — DISPLAY SECTION —

CN102

LP5

LP6

AMS

.>

PUSH ENTER

S845

R845

M

JW826

LP856

JW830

S852

EX-CHANGE

R852

S853

C

MAIN BOARD

CN901

(Page 11)

R853 R854

DISC SKIP

S855

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

LP4

C101

CN101

LP3

JW820

C827

JW821

R841

R842

S842

H

JW825

FB801

Q826

R856

R857

R858

JW824

C816

JW823

JW822

S844

m

T101

R844

S841

S843

R843

X

x

Q825

C825

R825

JW819

JW817

JW818

C824

Q824

C817

C818

R824

Q823

C823

R817

R818

POWER

R823

R822

JW815

JW816

S891

C822

C813

Q822

C812

C811

C801

R805

C803

CN892

X801

C802

JW814

C891

FL801

JW812

JW813

CN891

IC801

C804

C820

C819

JW806

Q821

R819

R820

R821

R826

JW811

LP2

LP1

JW804

JW810

R821

C805

JW805

JW809

JW808

C806

C821

JW807

R831

C829

C831

C866

JW803

AC IN

JW802

IC802

JW801

C832

R832

CN805

• Semiconductor

Location

Ref. No.

IC801 G-14

IC802 G-18

Q821 G-15

Q822 F-13

Q823 F-12

Q824 F-12

Q825 F-11

Q826 G-10

Location

B

MAIN BOARD

CN703

(Page 11)

CN801

CN804

JW833

JW832

JW831

JW829

JW828

R851

S851

JW827

A

MULTI CHANNEL DECODING

CN814

C833

R834

D801

S875

R874

R873

S874

S873

R872

S872 R871

TIME/TEXT PLAY MODE MULTI/2CH SA-SD/CD MENU

R864

CN813

S864S865

R863

S863

R862

S862

R871

R861

DISC 1DISC 2DISC 3DISC 4DISC 5

S861

SCD-CE595

1616

Page 17

SCD-CE595

4-10. SCHEMATIC DIAGRAM — DISPLAY SECTION —

R871R872R873R874

1k2.2k2.2k4.7k

S875

S8774

S873

S872

S871

DISK5 DISK4 DISK3 DISK2 DISK1

S865

S864

S863

R861R862R863R864

1k2.2k2.2k4.7k

S862

S861

CN813

2P

KEY 0

3

• See page 7 for Waveforms.

KEY 0

3

CN805

2P

IC802

NJL73H400A

C820

0.01 25V

R832

100

C831

47

C832

6.3V

0.01

R831

47

TP126

C804

0.1

R826

10k

TP26

R820

10k

1.6

-30.8

-33

-33

-33

Q821

DTC114EKA-T146

-20

-28

-28

-32

-24

-22

-30

-29

-28

-26.5

C805

-30

0.1

C806

0.1

-31

-31

-33

-22.3

-28.7

-30

IC801

8BT-A

3.3

0.5

3.3

3.3

-31

-31

-31

-31

-31

-31

-31

-31

-31

-31

-31

-30

DTC114EKA-T146

R821 R822 R823 R824 R825

100k 100k 100k 100k 100k

C821

0.001

C829

0.1

C819

0.01

R841

R819

10k

k

k

0

1

10

7

8

1

8

81

R

R

1

.1

0

0.0

0.01

3

8

80

81

817

C

C

C

C816

0.001

C812

0

0.001

Q822

0.001

C813

C811

0.001

R856

FB801

10k

FB

TP5

X801

5MHz

R805

10k

Q823

DTC114EKA

-T146

C822

0.001

S841 S842 S843 S844 S845

S851

Q826

2SC3624A- T1L15L16

C802

0.1

Q824

DTC114EKA

-T146

C823

0.001

R842 R843

1k1k2.2k 2.2k

R851

C824

0.001

*

*

R844

4.7k

R852 R853

2.2k 2.2k

S853

S852

**

R858

82

R857

10k

C801

100

6.3V

Q825

DTC114EKA

-T146

C825

0.001

S852

EXCHANGE

S853

DISCSKIP

R845

10k

C827

0.1

R854

4.7k

S855

ENCORDER

CN804

2P

13

CN801

13P

SCD-CE595

FL801

T101

CN814

2P

C101

0.0022 250V

CN101

C833

R834

D801

SEL5E20C-STP15

S891

C891

0.0022

250V

CN892

2P

2P

CN891

2P

BLUE

0.1 10k

15

CN102

8P

1717

Page 18

SCD-CE595

4-11. PRINTED WIRING BOARD — MD-94 BOARD SECTION —

SE-130 BOARD

PH101

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

M001

TURN TABLE

M

MOTOR

CN102

PH102

MD-94 BOARD

D

CN001

MAIN BOARD

CN704

(Page 11)

CN101

13

(13)

SCD-CE595

ROTARY

ENCODER

LOADING

MOTOR

M

CN003CN004

CN002

13

S001

(13)

1818

Page 19

4-12. SCHEMATIC DIAGRAM — MD-94 BOARD SECTION —

CN001

11P

CN003

3P

SCD-CE595

D

3/4

CN704

14

S001

CN004

2P

CN002

6P

SCD-CE595

CN101

6P

CN102

PH101

RPR-220C1N

PH102

RPI-392

2P

M001

1919

Page 20

SCD-CE595

• IC Block Diagrams

– MAIN Board –

IC701 M51957BFP-600C

NC

8

1

NC

VCC

7

–

+

1.25V

2

IN

• IC Pin Function Description

• MAIN BOARD IC705 HD6432238RN51TEV (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Description

IC702 BR9040F-WF2

1SDATA DAC O Data output to the DAC (IC200)

2 SCLK DAC O Clock output to the DAC (IC200)

OUT

6

C

5

WC

8 7 6 5

GND

DO

DI

3 SLATR DAC O Latch (R-ch) output to the DAC (IC200)

4 to 11 CD0 to 7 I/0 Data Bus to the Digital Servo Processor (IC706)

4096bit

EEPROM ARRAY

8bit

ADDRESS

DECODER

3

4

NC

GND

8bit

ADDRESS

BUFFER

16bit

R/W

AMP

16bit

DATA

REGISTER

HIGH VOLTAGE

GENERATOR

COMMAND

REGISTER

WRITE

DISABLE

POWER

SUPPLY

VOLTAGE

DETECTOR

COMMAND DECODE

CONTROL CLOCK

GENERATION

12 CVCC — Power supply terminal (+3.3V)

13 CA0 O Address Bus to the Digital Servo Processor (IC706)

14 VSS — Ground terminal

15 to 22 CA1 to 8 O Address Bus to the Digital Servo Processor (IC706)

23 PB1 — Not used (open)

24 PB2 — Not used (open)

25 LOAD S0 I DISK cyacking select (SO)

26 LOAD S1 I TRAY (S2:OPEN)

27 LOAD S2 I TRAY (S1:TURN)

28 TSENS I T sens signal input

29 DSENS I DISK sens signal input

1 2 3 4

R/B

VCC

CS

SK

30 TRAY IN O TRAY in control output to the Motor Driver (IC712)

31 RS232CTX O PC serial signal

32 RS232CRX I PC serial signal

33 TRAY OUT O TRAY out control output to the Motor Driver (IC712)

34 P10 — Not used (open)

35 DRV ON O Driver mute output to the Motor Driver (IC712)

36 SP ON O Spindle mute output to the Motor Driver (IC712)

37 P13 — Not used (open)

38 XLDON O LD ON/OFF output to the Motor Driver (IC712)

39 TRMP O Table control (+Clockwise) output to the TMD (IC710)

40 TRMM O Table control (-Counterclock) output to the TMD (IC710)

41 P17 — Not used (open)

42 AVSS — Ground terminal

43 DIAO I Test Mode input

44 P96 — Ground terminal

45 to 50 P47 to P42 — Ground terminal

51 MODEL I Model check (L:1Hi,Mi:5Es,H:5 Hi)

52 JIT I Waltz jetter select

53 VREF I Reference voltage

54 AVCC — Power supply terminal (+3.3V)

55 MD0 I Muving mode control 0

56 MD1 I Muving mode control 1

57 OSC2 — Not used (open)

58 OSC1 — Ground terminal

59 XRST O System reset

60 XNMI I NMI input (fixed at “H”)

61 XSTBY I Standby input (fixed at “H”)

62 VCC — Power supply terminal (+3.3V)

63 XTAL — Not used (open)

64 VSS1 — Ground terminal

65 EXTAL I External clock input

SCD-CE595

2020

Page 21

Pin No. Pin Name I/O Description

66 FEW I Flash writing Enable

67 MD2 I Muving mode control 2

68 PF7 — Not used (open)

69 AS — Not used (open)

70 XDR O Reed sycle signal

71 XWR O Write sycle signal

72 XWRST O Waltz reset signal output

73 XWAIT I Bus sycle wait signal input

74 SMUTE O Waltz smute signal output

75 EPR/B I Read/Busy signal input from the EEPROM (IC702)

76 XEPCE O XCS signal output to the EEPROM (IC702)

77 XEWC O XWC signal output to the EEPROM (IC702)

78 P32 O Not used (open)

79 EEPS0 O Communication signal to the EEPROM (IC702)

80 EEPS1 I Communication signal from the EEPROM (IC702)

81 EEPSC O Communication signal to the EEPROM (IC702)

82 P36 — Not used (open)

83 IFS0 O Communication signal to the IS CON (IC801)

84 IFS1 I Communication signal from the IS CON (IC801)

85 IFSCK O Communication signal to the IS CON (IC801)

86 P74 — Not used (open)

87 XCS O WALTZ chip select

88 P72 — Not used (open)

89 P71 — Not used (open)

90 P70 — Not used (open)

91 XIFINT I ACK input signal from the IS CON (IC801)

92 XINTO I WALTZ input from the Digital Servo Processor (IC706)

93 PG2 — Ground terminal

94 MZR I ZEROR input signal from DAC (IC200)

95 MZL I ZEROL input signal from DAC (IC200)

96 XIFCS O Chip select to the IS CON (IC801)

97 R MUTE O Rch mute signal output

98 L MUTE O Lch mute signal output

99 INIT DAC O DAC int output

100 M/2 O Mch mute control output (surr/Cntr/Sw)

SCD-CE595

21

Page 22

SCD-CE595

Ver. 1.3

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

5-1. MAIN SECTION

SECTION 5

EXPLODED VIEWS

• The mechanical parts with no reference

number in the exploded views are not supplied.

•Abbreviation

CND : Canadian model

2

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque 0

sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant le

numéro spécifié.

4

front panel section

1

5

2

chassis section

#1

Ref. No. Part No. Description Remark

1 X-4956-436-1 PANEL ASSY, LOADING

2 3-363-099-02 SCREW (CASE 3 TP2)

22

Ref. No. Part No. Description Remark

4 4-951-620-01 SCREW (2.6X8), +BVTP

5 3-073-127-22 CASE, UPPER

#1 7-685-872-09 SCREW +BVTT 3X8

Page 23

5-2. FRONT PANEL SECTION

3

SCD-CE595

not supplied

54

#3

not supplied

52

53

#3

not supplied

#

55

56

#3

51

not supplied

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 X-4956-434-1 PANEL ASSY, FRONT (US,CND)

51 X-4956-435-1 PANEL ASSY, FRONT (AEP,UK)

52 3-354-981-11 SPRING (SUS), RING

53 4-232-622-01 KNOB (AMS)

54 4-255-244-01 BUTTON, POWER

55 A-4752-651-A DISPLAY BOARD, COMPLETE

56 1-828-334-11 WIRE (FLAT TYPE) (13 CORE)

#3 7-685-646-79 SCREW +BVTP 3X8 TYPE2 IT-3

23

Page 24

SCD-CE595

5-3. CHASSIS SECTION

#1

#1

104

103

105

CD mechanism section

(CDM79C-DVBU51)

not supplied

#2

101

102

107

#4

not supplied

106

T101

#6

#6

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 X-2022-049-1 FOOT ASSY

102 4-977-358-01 CUSHION

* 103 3-703-244-00 BUSHING (2104), CORD

0 104 1-777-071-43 CORD, POWER (AEP,UK)

0 104 1-783-531-32 CORD, POWER (US,CND)

105 3-704-515-32 SCREW (BV/RING)

106 A-4752-598-A MAIN BOARD, COMPLETE

107 4-951-620-01 SCREW (2.6X8), +BVTP

0 T101 1-443-286-11 TRANSFORMER, POWER (US,CND)

0 T101 1-443-287-11 TRANSFORMER, POWER (AEP,UK)

#1 7-685-872-09 SCREW +BVTT 3X8

#2 7-685-535-19 SCREW +BTP 2.6X10 TYPE2 N-S

#4 7-682-544-04 SCREW +P 3X3

#6 7-685-534-19 SCREW +BTP 2.6X8 TYPE2 N-S

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

24

Page 25

5-4. CD MECHANISM SECTION (1)

)

(CDM79C-DVBU51)

SCD-CE595

Ver. 1.2

157

156

153

155

#4

not

supplied

#6

#6

not

supplied

152

154

not

supplied

#6

#6

151

158

151

CD mechanism section (2

(CDM79C-DVBU51)

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 3-074-737-01 PLATE (GUIDE)

152 A-6060-642-A SE-130 BOARD, COMPLETE

153 3-074-716-01 TABLE

154 A-6060-640-A UNIT ASSY, TD

155 3-074-725-01 BELT, TD

156 3-074-717-01 TRAY

157 4-218-252-52 SCREW (+PTPWH M2.6), FLOATING

158 1-823-921-11 FMS-18

#4 7-682-544-04 SCREW +P 3X3

#6 7-685-534-19 SCREW +BTP 2.6X8 TYPE2 N-S

25

Page 26

SCD-CE595

5-5. CD MECHANISM SECTION (2)

(CDM79C-DVBU51)

210

209

208

RE901

211

212

201

214

215

216

not

supplied

217

#2

not

supplied

204

not supplied

M901

205

206

213

218

not supplied

219

220

#8

207

not supplied

203

202

#7

201

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 4-218-252-52 SCREW (+PTPWH M2.6), FLOATING

202 3-074-744-01 GEAR (LOADING A)

203 3-074-745-01 BELT (LOADING)

204 3-074-742-01 GEAR (SHAFT)

205 4-951-619-01 CUSHION (A)

206 3-074-735-01 GEAR (IDOLER)

207 1-829-172-11 WIRE (FLAT TYPE) (31 CORE)

208 3-074-741-01 GEAR (LOADING B)

209 3-074-738-01 GEAR (SWING)

210 3-074-739-01 COLLAR (SWING)

211 3-016-533-01 WASHER (FR), STOPPER

212 3-074-740-01 GEAR (LOADING C)

213 3-074-736-01 GEAR (CHUCK)

#8

214 4-981-923-01 SCREW (M), STEP

215 3-053-847-31 INSULATOR

0 216 A-1067-676-A DEVICE, OPTICAL (DBU-3)

217 A-4736-882-A CHUCK ASSY

218 1-824-106-12 CABLE, FLEXIBLE FLAT (24 CORE)

219 X-4955-252-3 HOLDER (BU) ASSY

220 A-4750-527-A RF BOARD, COMPLETE

M901 1-541-632-12 MOTOR, DC

RE901 1-418-746-11 ENCODER, ROTARY

#2 7-685-535-19 SCREW +BTP 2.6X10 TYPE2 N-S

#7 7-621-259-25 SCREW +P 2.6X4

#8 7-685-534-19 SCREW +BTP 2.6X8 TYPE2 N-S

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

26

Page 27

SCD-CE595

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

• CAPACITORS

uF: µF

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-4752-651-A DISPLAY BOARD, COMPLETE

************************

4-949-935-41 CUSHION (FL)

< CAPACITOR >

C801 1-124-584-00 ELECT 100uF 20% 6.3V

C802 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C803 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C804 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C805 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C806 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C811 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C812 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C813 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C816 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C817 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C818 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C819 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C820 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C821 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C822 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C823 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C824 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C825 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C827 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C829 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C831 1-124-589-11 ELECT 47uF 20% 6.3V

C832 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

< CONNECTOR >

CN801 1-779-281-11 CONNECTOR, FFC (LIF (NON-ZIF)) 13P

< FERRITE BEAD >

FB801 1-414-595-11 INDUCTOR, FERRITE BEAD

< FLUORESCENT INDICATOR TUBE >

FL801 1-518-992-11 INDICATOR TUBE, FLUORESCENT

< IC >

IC801 6-804-318-01 IC uPD780232GC-706-8BT-A

IC802 8-759-826-33 IC NJL73H400A ( )

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

• COILS

uH: µH

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

•Abbreviation

CND : Canadian model

Q821 8-729-027-43 TRANSISTOR DTC114EKA-T146

Q822 8-729-027-43 TRANSISTOR DTC114EKA-T146

Q823 8-729-027-43 TRANSISTOR DTC114EKA-T146

Q824 8-729-027-43 TRANSISTOR DTC114EKA-T146

Q825 8-729-027-43 TRANSISTOR DTC114EKA-T146

Q826 8-729-141-73 TRANSISTOR 2SC3624A-T1L15L16

R805 1-216-833-11 METAL CHIP 10K 5% 1/10W

R817 1-216-833-11 METAL CHIP 10K 5% 1/10W

R818 1-216-833-11 METAL CHIP 10K 5% 1/10W

R819 1-216-833-11 METAL CHIP 10K 5% 1/10W

R820 1-216-833-11 METAL CHIP 10K 5% 1/10W

R821 1-216-845-11 METAL CHIP 100K 5% 1/10W

R822 1-216-845-11 METAL CHIP 100K 5% 1/10W

R823 1-216-845-11 METAL CHIP 100K 5% 1/10W

R824 1-216-845-11 METAL CHIP 100K 5% 1/10W

R825 1-216-845-11 METAL CHIP 100K 5% 1/10W

R826 1-216-833-11 METAL CHIP 10K 5% 1/10W

R831 1-216-805-11 METAL CHIP 47 5% 1/10W

R832 1-216-809-11 METAL CHIP 100 5% 1/10W

R841 1-216-821-11 METAL CHIP 1K 5% 1/10W

R842 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R843 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R844 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R845 1-216-833-11 METAL CHIP 10K 5% 1/10W

R851 1-216-821-11 METAL CHIP 1K 5% 1/10W

R852 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R853 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R854 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R856 1-216-833-11 METAL CHIP 10K 5% 1/10W

R857 1-216-833-11 METAL CHIP 10K 5% 1/10W

R858 1-216-808-11 METAL CHIP 82 5% 1/10W

S841 1-762-875-21 SWITCH, KEYBOARD (x)

S842 1-762-875-21 SWITCH, KEYBOARD (H)

S843 1-762-875-21 SWITCH, KEYBOARD (X)

S844 1-762-875-21 SWITCH, KEYBOARD (m)

S845 1-762-875-21 SWITCH, KEYBOARD (M)

S851 1-762-875-21 SWITCH, KEYBOARD (A)

S852 1-762-875-21 SWITCH, KEYBOARD (EX-CHANGE)

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque 0

sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant le

numéro spécifié.

• Accessories are given in the last of this parts

list.

< TRANSISTOR >

< RESISTOR >

< SWITCH >

DISPLAY

27

Page 28

SCD-CE595

DISPLAY MAINKEY LED

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

S853 1-762-875-21 SWITCH, KEYBOARD (DISC SKIP)

S855 1-478-268-11 ENCODER, ROTARY

(. AMS >)(PUSH ENTER)

< VIBRATOR >

X801 1-795-058-21 VIBRATOR, CERAMIC 5MHz

************************************************************

1-862-173-11 KEY BOARD

**********

< CONNECTOR >

CN813 1-506-468-11 PIN, CONNECTOR 3P

< RESISTOR >

R861 1-216-821-11 METAL CHIP 1K 5% 1/10W

R862 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R863 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R864 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R871 1-216-821-11 METAL CHIP 1K 5% 1/10W

R872 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R873 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R874 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

< SWITCH >

S861 1-762-875-21 SWITCH, KEYBOARD (MENU)

S862 1-762-875-21 SWITCH, KEYBOARD (SA-CD/CD)

S863 1-762-875-21 SWITCH, KEYBOARD (MULITI/2CH)

S864 1-762-875-21 SWITCH, KEYBOARD (PLAY MODE)

S865 1-762-875-21 SWITCH, KEYBOARD (TIME/TEXT)

S871 1-762-875-21 SWITCH, KEYBOARD (DISC 1)

S872 1-762-875-21 SWITCH, KEYBOARD (DISC 2)

S873 1-762-875-21 SWITCH, KEYBOARD (DISC 3)

S874 1-762-875-21 SWITCH, KEYBOARD (DISC 4)

S875 1-762-875-21 SWITCH, KEYBOARD (DISC 5)

************************************************************

1-862-174-11 LED BOARD

**********

< CAPACITOR >

C833 1-164-156-11 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

CN814 1-506-481-11 PIN, CONNECTOR 2P

< DIODE >

D801 6-500-647-01 DIODE SEL5E20C-STP15

< RESISTOR >

R834 1-216-833-11 METAL CHIP 10K 5% 1/10W

************************************************************

A-4752-598-A MAIN BOARD, COMPLETE

*********************

< CAPACITOR >

C201 1-126-916-11 ELECT 1000uF 20% 6.3V

C202 1-126-205-11 ELECT CHIP 47uF 20% 6.3V

C206 1-115-156-11 CERAMIC CHIP 1uF 10V

C208 1-115-156-11 CERAMIC CHIP 1uF 10V

C212 1-128-991-21 ELECT CHIP 10uF 20% 50V

C236 1-115-156-11 CERAMIC CHIP 1uF 10V

C238 1-115-156-11 CERAMIC CHIP 1uF 10V

C242 1-128-991-21 ELECT CHIP 10uF 20% 50V

C266 1-115-156-11 CERAMIC CHIP 1uF 10V

C268 1-115-156-11 CERAMIC CHIP 1uF 10V

C272 1-128-991-21 ELECT CHIP 10uF 20% 50V

C281 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C302 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C303 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C305 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C321 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

C322 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

C324 1-115-156-11 CERAMIC CHIP 1uF 10V

C325 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C331 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C351 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C362 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C364 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C366 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C402 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C403 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C404 1-115-156-11 CERAMIC CHIP 1uF 10V

C405 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C406 1-128-992-21 ELECT CHIP 47uF 20% 25V

C432 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C433 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C434 1-115-156-11 CERAMIC CHIP 1uF 10V

C435 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C436 1-128-992-21 ELECT CHIP 47uF 20% 25V

C462 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C463 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C464 1-115-156-11 CERAMIC CHIP 1uF 10V

C465 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C466 1-128-992-21 ELECT CHIP 47uF 20% 25V

C502 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C503 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C504 1-115-156-11 CERAMIC CHIP 1uF 10V

C505 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C506 1-128-992-21 ELECT CHIP 47uF 20% 25V

C532 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C533 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C534 1-115-156-11 CERAMIC CHIP 1uF 10V

C535 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C536 1-128-992-21 ELECT CHIP 47uF 20% 25V

C562 1-115-416-11 CERAMIC CHIP 0.001uF 5% 25V

C563 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C564 1-115-156-11 CERAMIC CHIP 1uF 10V

C565 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C566 1-128-992-21 ELECT CHIP 47uF 20% 25V

C701 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C702 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C703 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C704 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C705 1-164-156-11 CERAMIC CHIP 0.1uF 25V

28

Page 29

SCD-CE595

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C706 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C709 1-126-246-11 ELECT CHIP 220uF 20% 4V

C711 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C712 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C713 1-117-681-11 ELECT CHIP 100uF 20% 16V

C714 1-126-246-11 ELECT CHIP 220uF 20% 4V

C715 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C716 1-117-681-11 ELECT CHIP 100uF 20% 16V

C721 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C722 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C723 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C726 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C727 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C729 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C730 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C731 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C733 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C734 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C736 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C737 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C738 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C739 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C740 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C741 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C742 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C743 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C744 1-115-156-11 CERAMIC CHIP 1uF 10V

C745 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C746 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C748 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C749 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C750 1-115-156-11 CERAMIC CHIP 1uF 10V

C751 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C752 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C753 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C754 1-126-246-11 ELECT CHIP 220uF 20% 4V

C755 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C756 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C757 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C758 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C759 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C760 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C761 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C762 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C763 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C764 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C765 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C766 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C767 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C768 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C769 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C770 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C771 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C772 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C775 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C776 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C777 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C778 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C779 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C780 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C781 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C782 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C783 1-117-681-11 ELECT CHIP 100uF 20% 16V

C785 1-126-246-11 ELECT CHIP 220uF 20% 4V

C787 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C788 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C789 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C791 1-128-992-21 ELECT CHIP 47uF 20% 25V

C793 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C794 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C795 1-117-681-11 ELECT CHIP 100uF 20% 16V

C796 1-117-681-11 ELECT CHIP 100uF 20% 16V

C799 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C800 1-164-156-11 CERAMIC CHIP 0.1uF 25V