Sony SCDC-222-ES Service manual

SCD-C222ES

SERVICE MANUAL

Ver 1.0 2001.07

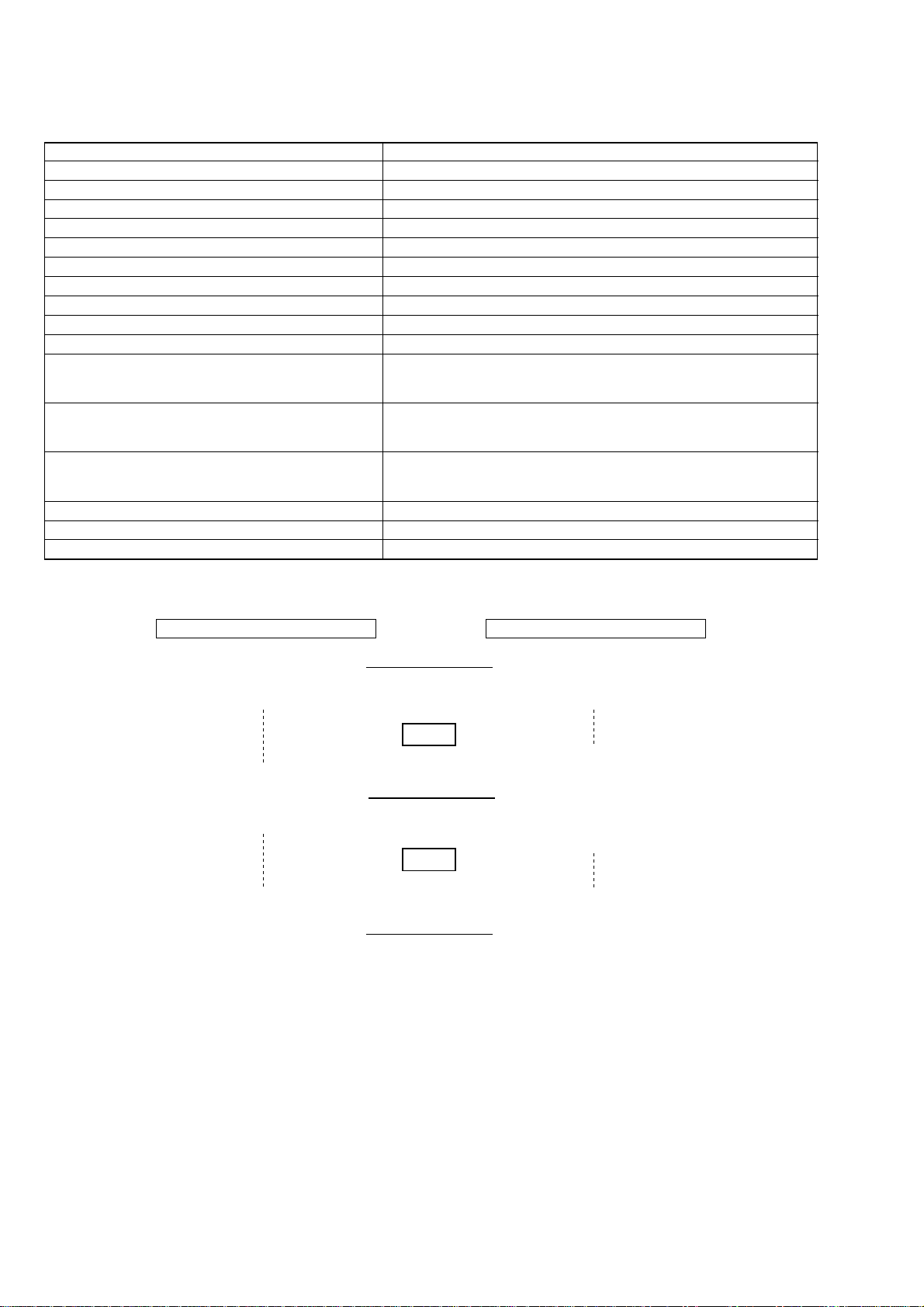

SPECIFICATIONS

When a super audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 50 kHz (–3 dB)

Dynamic range 104 dB or more

Total harmonic distortion rate

Wow and flutter Value of measurable limit (±0.001 %

When a CD is played

Frequency response 2 Hz to 20 kHz

Dynamic range 99 dB or more

Total harmonic distortion rate

Wow and flutter Value of measurable limit (±0.001 %

Output connector

Jack type Output level Load impedance

ANALOG OUT Phono 2 Vrms Over 10 kilohms

DIGITAL (CD) Square –18 dBm

OUT OPTICAL* optical

DIGITAL (CD) Coaxial 0.5 Vp-p 75 ohms

OUT COAXIAL* output

PHONES Stereo 10 mW 32 ohms

*Output only the audio signals of the CD

output

connector

connector

phone jack

0.0018 % or less

W. PEAK) or less

0.0020 % or less

W. PEAK) or less

jacks (at 50 kilohms)

Light emitting

wave length:

( )

660 nm

US Model

Canadian Model

Model Name Using Similar Mechanism SCD-CE775

CD Mechanism Type CDM59A-DVBU5A

Base Unit Name DVBU5A

Optical Pick-up Name KHM-230AAA

General

Laser Semiconductor laser

Power requirements 120 V AC, 60 Hz

Power consumption 26 W

Dimensions (w/h/d) 430 × 135 × 400 mm

Mass (approx.) 7.5 kg (16 lbs 9 oz.)

Supplied accessories

• Audio connecting cord

phono jack × 2 (Red and White) y phono jack × 2 (Red

and White) (2)

and White) (2)

phono jack × 1 (Black) y phono jack × 1 (Black) (2)

• Monaural (2P) mini-plug cord (1) (Connecting cord for

CONTROL A1

• Remote commander (remote) RM-SC500 (1)

• R6 (size-AA) batteries (2)

Design and specifications are subject to change without notice.

(SACD: λ = 650 nm)

(CD: λ = 780 nm)

Emission duration: continuous

(17 × 4 1/4 × 15 3/4 in.)

incl. projecting parts

)

SUPER AUDIO CD PLAYER

9-873-158-01 Sony Corporation

2001G0500-1 Home Audio Company

C 2001.7 Shinagawa Tec Service Manual Production Group

SCD-C222ES

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 4

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Case ................................................................................. 9

3-3. Front Panel Section ......................................................... 9

3-4. CD Mechanism Deck (CDM59A-DVBU5A) ................ 10

3-5. AUDIO Board ................................................................. 10

3-6. POWER Board ................................................................ 11

3-7. MAIN Board ................................................................... 11

3-8. Base Unit (DVBU5A)..................................................... 12

3-9. T able Assy ....................................................................... 12

3-10. SENSOR Board ............................................................... 13

3-11. LOADING MOTOR Board ............................................ 13

4. ASSEMBLY................................................................. 14

5. TEST MODE.............................................................. 15

6. DIAGRAMS

6-1. Block Diagram – RF/SERVO Section – ........................ 30

6-2. Block Diagram – SERVO Section – .............................. 31

6-3. Block Diagram – MAIN Section – ................................ 32

6-4. Block Diagram – AUDIO Section – .............................. 33

6-5. Block Diagram – DISPLAY/KEY CONTROL/

POWER SUPPLY Section – ........................................... 34

6-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 35

6-7. Printed Wir ing Board – RF Board – .............................. 36

6-8. Schematic Diagram – RF Board –................................. 37

6-9. Printed W iring Boards

– MOTOR/SENSOR Section –....................................... 38

6-10. Schematic Diag ram – MOTOR/SENSOR Section – .... 39

6-11. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 40

6-12. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 41

6-13. Schematic Diagram – MAIN Board (1/5) – ................. 42

6-14. Schematic Diagram – MAIN Board (2/5) – .................. 43

6-15. Schematic Diagram – MAIN Board (3/5) – .................. 44

6-16. Schematic Diagram – MAIN Board (4/5) – .................. 45

6-17. Schematic Diagram – MAIN Board (5/5) – .................. 46

6-18. Schematic Diagram

– AUDIO/HEADPHONE Boards – ................................ 47

6-19. Printed Wiring Board

– AUDIO Board (Component Side) – ............................ 48

6-20. Printed Wiring Boards – AUDIO (Conductor Side)/

HEADPHONE Boards – ................................................. 49

6-21. Printed Wiring Boards

– DISPLAY/KEY/LED/RM Boards – ............................ 50

6-22. Schematic Diagram

– DISPLAY/KEY/LED/RM Boards – ............................ 51

6-23. Printed Wiring Boards – POWER/REG Boards –......... 52

6-24. Printed Wiring Boards – POWER SW/PT Boards –..... 53

6-25. Schematic Diagram

– POWER/POWER SW/PT/REG Boards –................... 54

6-26. IC Pin Function Description ........................................... 63

7. EXPLODED VIEWS

7-1. Case Section .................................................................... 79

7-2. Front Panel Section ......................................................... 80

7-3. Chassis Section ............................................................... 81

7-4. CD Mechanism Deck Section-1

(CDM59A-DVBU5A)..................................................... 82

7-5. CD Mechanism Deck Section-2

(CDM59A-DVBU5A)..................................................... 83

7-6. Base Unit Section (DVBU5A) ........................................ 84

8. ELECTRICAL PARTS LIST ............................... 85

2

SCD-C222ES

r

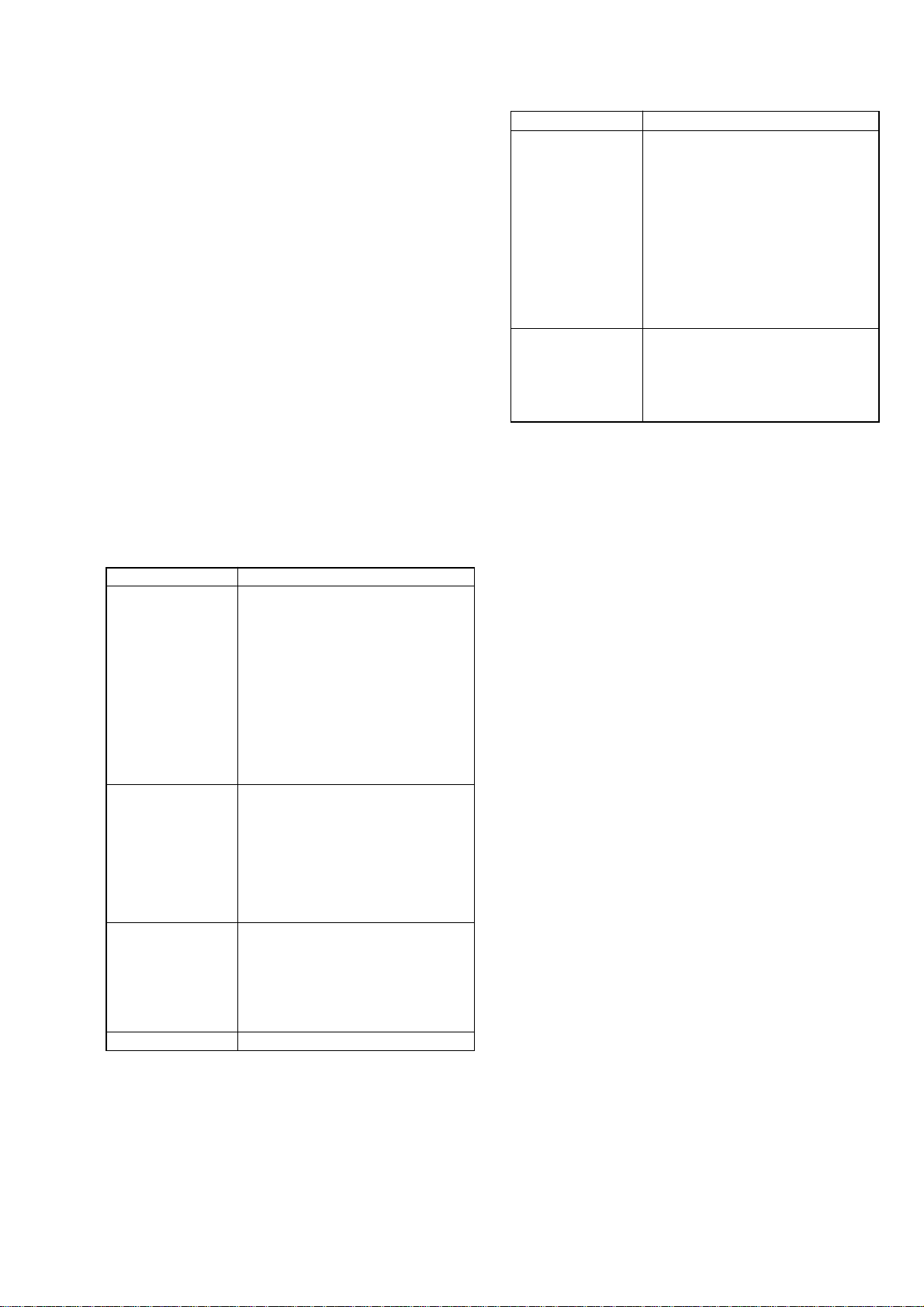

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

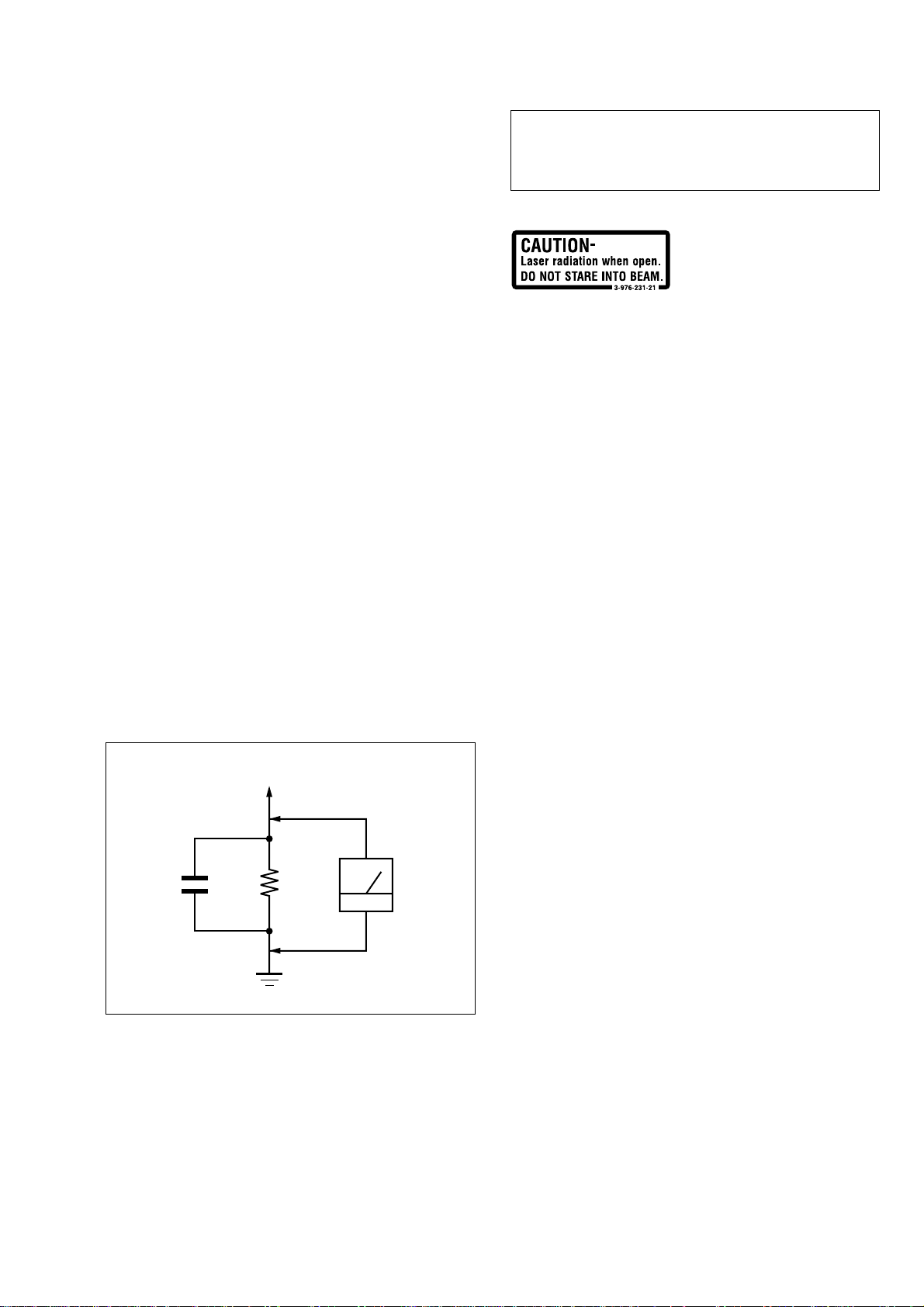

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This label is located on the LEFT exterior.

To Exposed Metal

Parts on Set

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

AC

voltmete

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQ UE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

SCD-C222ES

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

CLEANING OF OPTICAL PICK-UP LENS

In cleaning the lens of optical pick-up, use the air blower.

Never use a cotton swab for cleaning the lens of optical pick-up,

which otherwise causes a trouble.

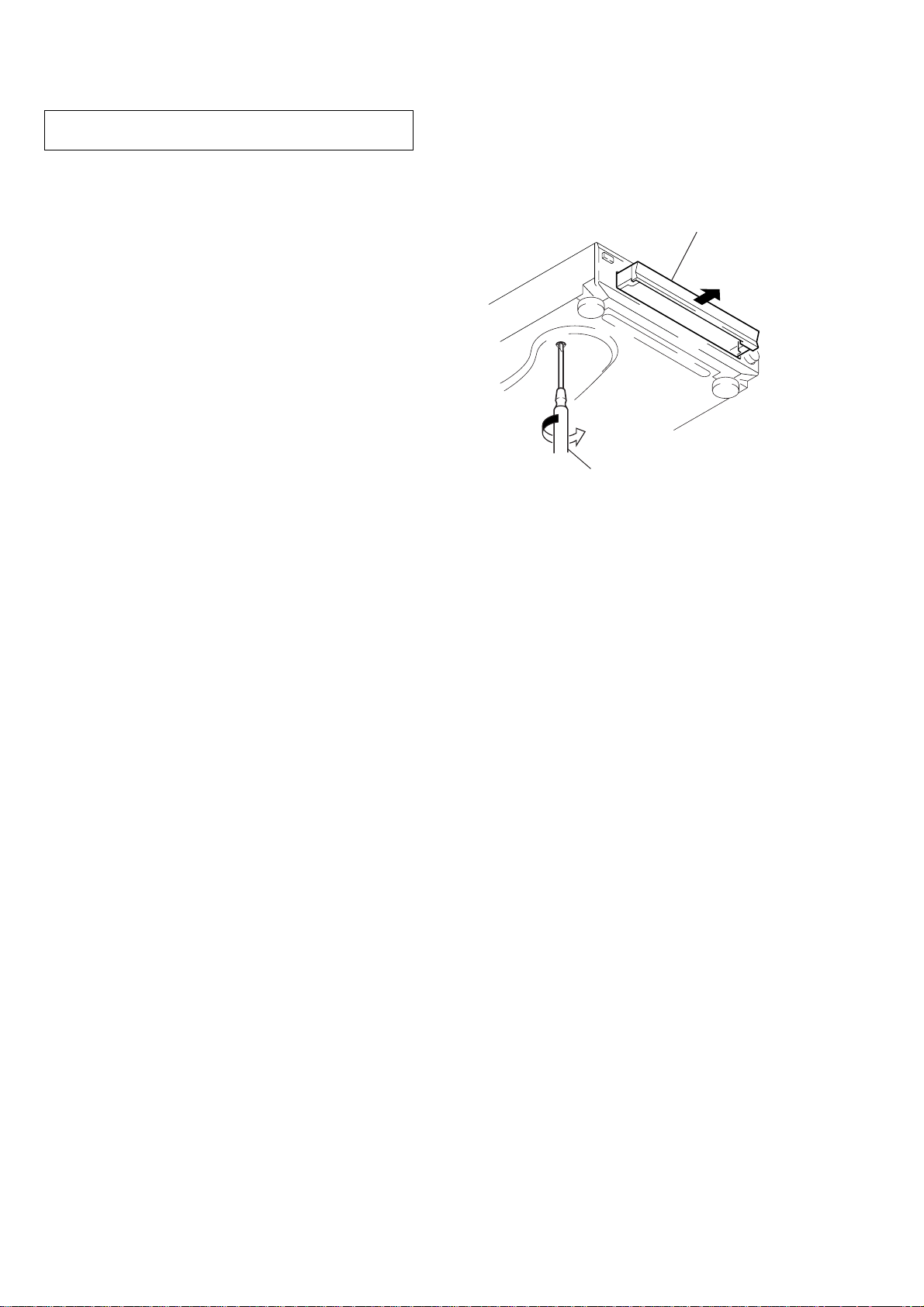

HOW TO OPEN THE DISC TABLE WHEN PO WER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and

turn it in the direction of the arrow (to OUT direction).

table

tapering driver

*

To close the disc table, turn the tapering

driver in the reverse direction (to IN direction).

CHECKING SIGNALS OF CD SECTION

Efficiency to check each signal of CD section is increased when

the test points on the MAIN board are used.

Refer to 5-8. WAVEFORMS CHECK (page 27)

4

RESETTING OPERATION AT POWER ON

If the power is turned on with a disc loaded in the set, a sequence of operation as shown below will be performed.

(The operation varies depending on the type of disc) Condition: continue mode

SCD-C222ES

(1) CD

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for CD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Stop

(2) SACD (single layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Stop

(3) SACD (dual layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on (layer 0)

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment (layer 0)

12. Tracking & sled servo on (layer 0)

13. Focus bias auto adjustment (layer 0)

14. Focus servo gain auto adjustment (layer 0)

15. Tracking servo gain auto adjustment (layer 0)

16. Jump to lead-in area

17. Read TOC

18. Focus jump (layer 0tlayer 1)

19. E-F balance auto adjustment (layer 1)

20. Tracking & sled servo on (layer 1)

21. Focus bias auto adjustment (layer 1)

22. Focus servo gain auto adjustment (layer 1)

23. Tracking servo gain auto adjustment (layer 1)

24. Focus Jump (layer 1tlayer 0)

25. Stop

5

SCD-C222ES

SECTION 2

GENERAL

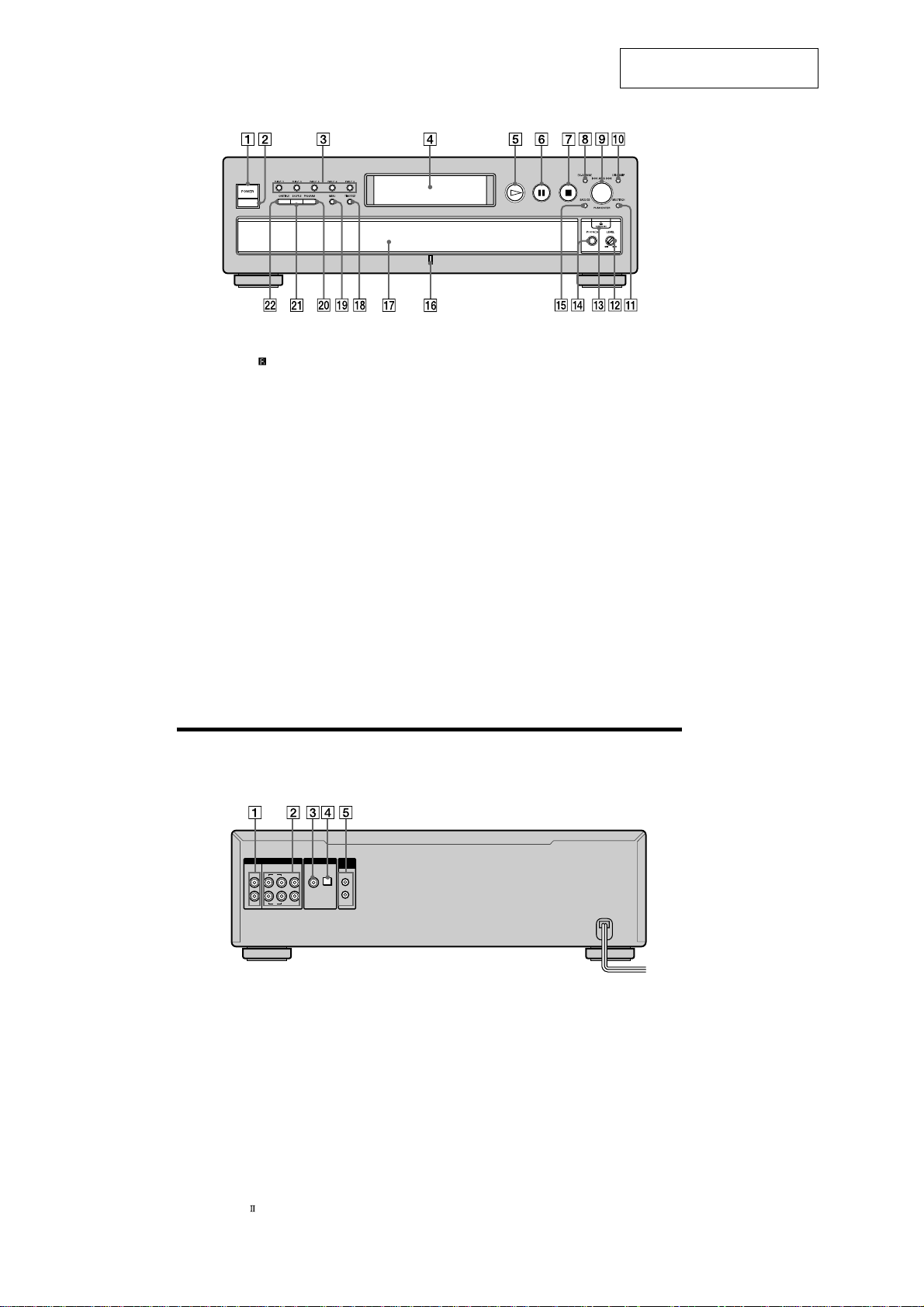

Front Panel Parts Descriptions

This section is extracted from

instruction manual.

1 POWER switch (11)

Press to turn on/off the player.

2 Remote sensor

3 DISC 1–5 button (12)

Press to select the disc.

4 Display window (12)

Shows various information.

5 N button (12)

Press to start play.

6 X button (12)

Press to pause play.

7 x button (12)

Press to stop play.

8 EX-CHANGE button (15)

Press to replace discs while playing a disc.

9 lAMSL dial (AMS: Automatic Music Sensor)

(6, 12)

When you turn the lAMSL dial

counterclockwise by one click, you go back to the

preceding track; when you turn the lAMSL dial

clockwise by one click, you go to the succeeding track.

0 DISC SKIP button (11)

Press to select the disc.

qa MULTI/2CH button (with an LED) (12)

Press to select the playback area when the 2 channel +

Multi-channel Super Audio CD is loaded. When you

select the Multi-channel playback area (page 11), the

LED turns on.

qs PHONES LEVEL control

Adjust the headphones volume.

qd A OPEN/CLOSE button (11)

Press to open/close the disc tray.

(4)

Rear Panel Parts Descriptions

qf PHONES jack

Connect the headphones.

During playback of a Multi-channel Super Audio CD,

the same signal that is output from the ANALOG

5.1CH FRONT L/R jacks is output from the PHONES

jack.

qg SACD/CD button (with an LED) (12)

Each time you press the button while the Hybrid disc

(page 10) is loaded, the layer changes between an HD

(SACD) layer (the LED turns on) and CD layer (the

LED turns off).

qh MULTI CHANNEL DECODING indicator

Turns on when you turn on the player, or when the

Multi-channel Super Audio CD is loaded and select

the Multi-channel playback area by pressing MULTI/

2CH.

qj Disc tray (11)

Press A OPEN/CLOSE to open/close the disc tray.

qk TIME/TEXT button (13)

Each time you press the button, the playing time of the

track, the total remaining time on the disc, or TEXT

information appears in the display.

ql MENU button (6)

Press to enter the menu.

w; PROGRAM button (20)

Press to select Program Play.

wa SHUFFLE button (19)

Press to select Shuffle Play.

ws CONTINUE button (11)

Press to resume normal play from Shuffle Play or

Program Play.

ANALOG

DIGITAL (CD)

CONTROL

OUT

COAXIAL OPTICAL

A1ΙΙ

Note

Only the audio signals of the CD can be output from the

DIGITAL (CD) OUT connectors shown in 3. Those of the Super

Audio CD cannot be output through DIGITAL (CD) OUT.

5.1CH OUT

2CH OUT

SURRFRONT

CENTER

L

L

R

SUB

R

WOOFER

1 ANALOG 2CH OUT L/R jacks (5)

Connect to an audio component (stereo/2 channel)

using the audio connecting cord.

2 ANALOG 5.1CH OUT jacks (4)

Connect to an amplifier equipped with the 5.1CH

input jacks (Multi-channel amplifier, AV amplifier,

etc.) using the audio connecting cords.

3 DIGITAL (CD) OUT COAXIAL connector (6)

Connect to an audio component using an coaxial

digital cable.

4 DIGITAL (CD) OUT OPTICAL connector (6)

Connect to an audio component using an optical

digital cable.

5 CONTROL A1

Connect to a Sony audio component using the

monaural (2P) mini-plug cord.

jacks (6, 26)

6

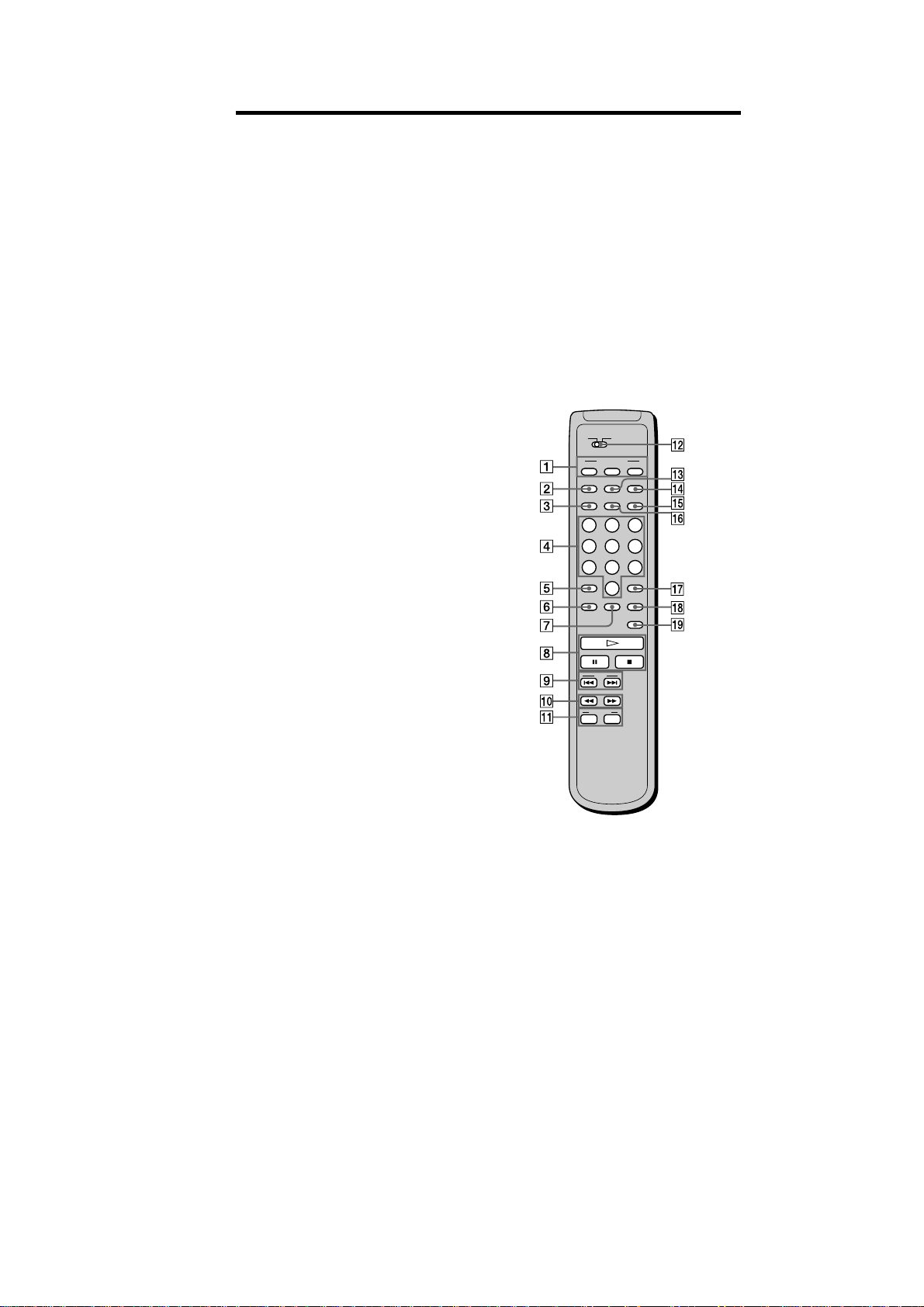

Remote Parts Descriptions

SCD-C222ES

1 CONTINUE button (11)

Press to resume normal play from Shuffle Play or

Program Play.

SHUFFLE button (19)

Press to select Shuffle Play.

PROGRAM button (20)

Press to select Program Play.

2 NAME INPUT button (25)

Press to enter the name input mode.

3 DISC/CAPS button (16, 25)

Press to select the disc.

Press to select the capital letter in name input mode.

4 Number buttons (16)

Press to enter the track numbers.

5

i

10 button (16)

Press to locate a track numbered over 10.

6 REPEAT button (18)

Press repeatedly to play all tracks or only one track on

the disc.

7 CHECK button (20)

Press to check the programmed order.

8 H button (12)

Press to start play.

X button (12)

Press to pause play.

x button (12)

Press to stop play.

9 AMS ./> (AMS: Automatic Music Sensor)

buttons (16)

Press to locate a specific track.

0 m/M buttons (17)

Press to locate a portion you want to play within a

track.

qa DISC SKIP +/– buttons (16)

Press to select the disc.

qs CD1/2 (COMMAND MODE) switch (6)

Select the command mode.

qd DISPLAY MODE button (13)

Press to turn off the information.

qf SACD/CD button (12)

Each time you press the button while the Hybrid disc

(page 10) is loaded, the layer changes between an HD

layer (the SACD/CD LED turns on) and CD layer (the

SACD/CD LED turns off).

qg MULTI/2CH button (12)

Press to select the playback area when the 2 channel +

Multi-channel Super Audio CD is loaded. When you

select the Multi-channel playback area (page 11), the

MULTI/2CH LED turns on.

qh TIME/TEXT/SPACE button (13, 25)

Each time you press the button, the playing time of

the track, the total remaining time on the disc, or

TEXT information appears in the display.

Press to insert a space in name input mode.

qj ENTER button (25)

Press to decide the selection.

qk CLEAR button (20)

Press to delete a programmed track number.

ql LEVEL ADJ button (23)

Press to adjust the output level balance for the Multichannel management function (page 21).

CD1

CD2

PLAY MODE

CONTINUE SHUFFLE

PROGRAM

DISPLAY

NAME

SACD/CD

MODE

INPUT

TIME/TEXT

DISC

MULTI/2CH

SPACE

CAPS

ABC DEF&!?

123

JKL MNOGHI

456

TUV WXYZPQRS

78

9

>10 ENTER

10/0

REPEAT CHECK

AMS

DISC SKIP

—+

CLEAR

LEVEL

ADJ

7

SCD-C222ES

SECTION 3

DISASSEMBLY

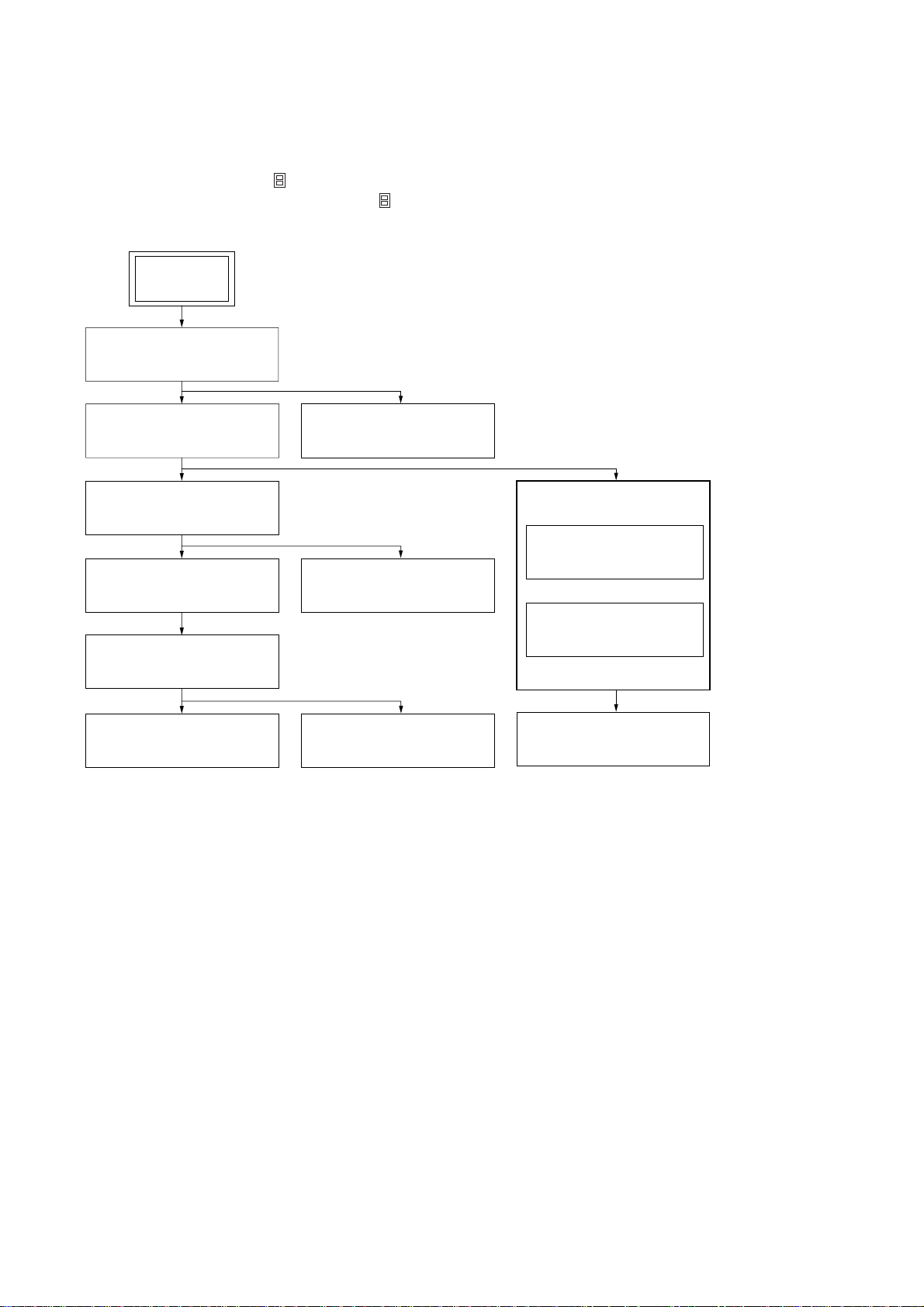

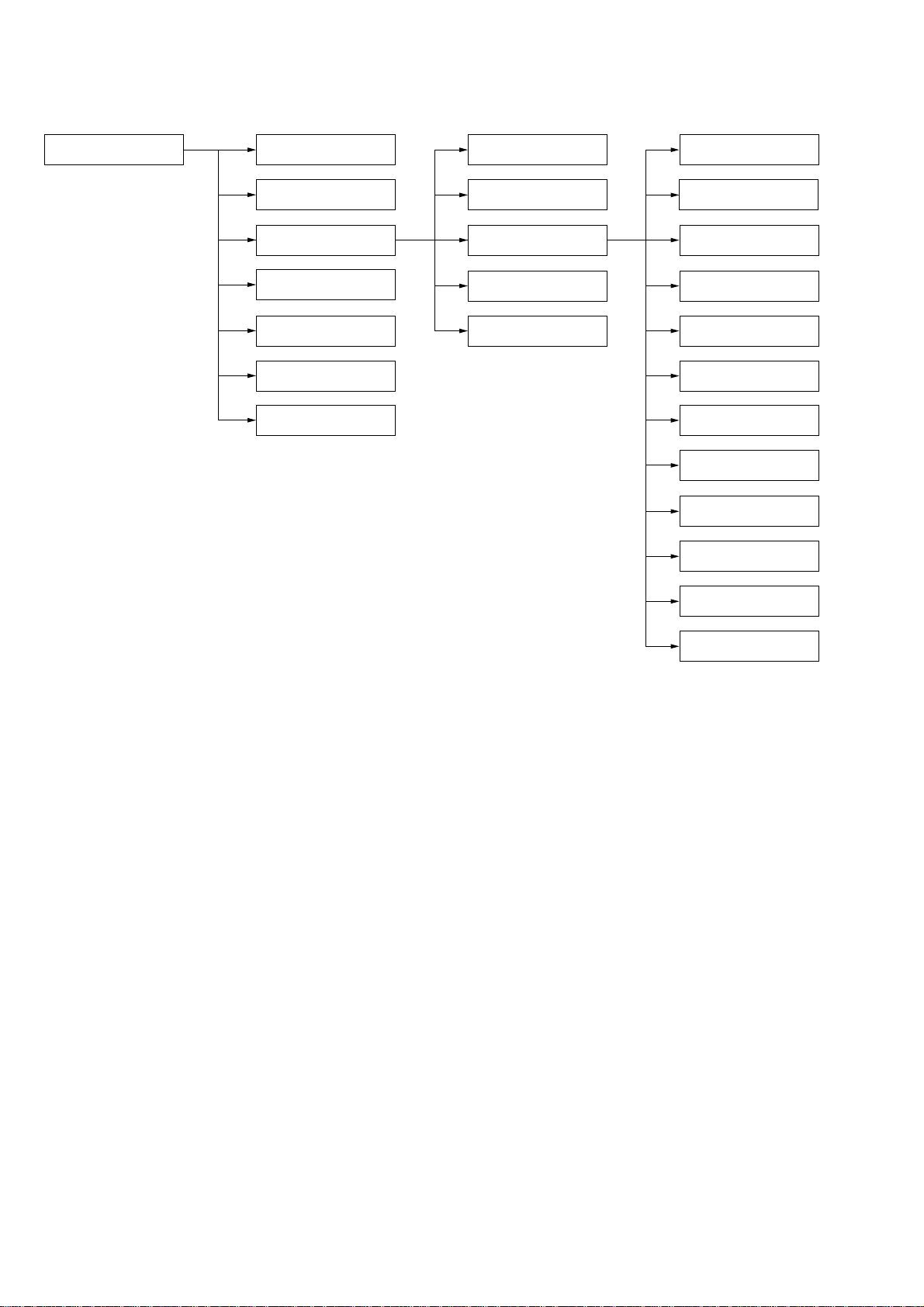

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Illustration of disassembly is omitted.

SET

3-2. CASE

(Page 9)

3-3. FRONT PANEL SECTION

(Page 9)

3-4. CD MECHANISM DECK

(CDM59A-DVBU5A)

(Page 10)

3-8. BASE UNIT (DVBU5A)

(Page 12)

3-9. TABLE ASSY

(Page 12)

3-10.SENSOR BOARD

(Page 13)

3-5. AUDIO BOARD

(Page 10)

3-6. POWER BOARD

(Page 11)

3-11.LOADING MOTOR BOARD

(Page 13)

3-4. CD MECHANISM DECK

(CDM59A-DVBU5A)

(Page 10)

3-5. AUDIO BOARD

(Page 10)

3-7. MAIN BOARD

(Page 11)

8

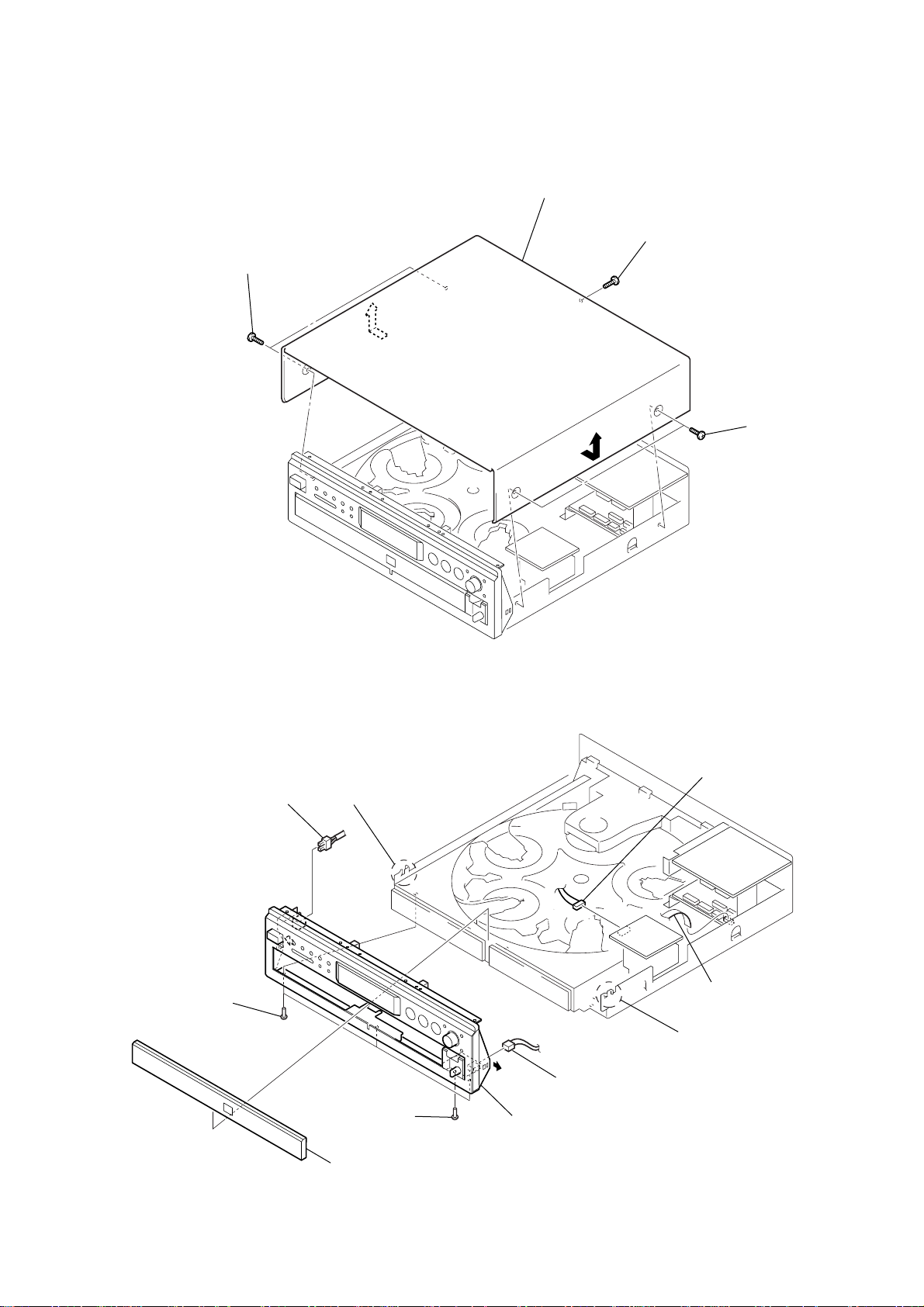

Note: Follow the disassembly procedure in the numerical order given.

s

3-2. CASE

1

two screws

(flat head)

3

case

2

screw

(flat head)

SCD-C222ES

1

two screw

(flat head)

3-3. FRONT PANEL SECTION

5

7

three screws

×

8)

(3

connector

(CN601)

8

6

claw

screw

(BVTP3

3

connector

(CN104)

2

wire (flat type) (12 core)

(CN706)

8

claw

4

connector

(CN881)

×

8)

9

front panel section

1

loading panel assy

Note: When removing the loading panel,

refer to "Section 1. Servicing Notes" on page 4.

9

SCD-C222ES

)

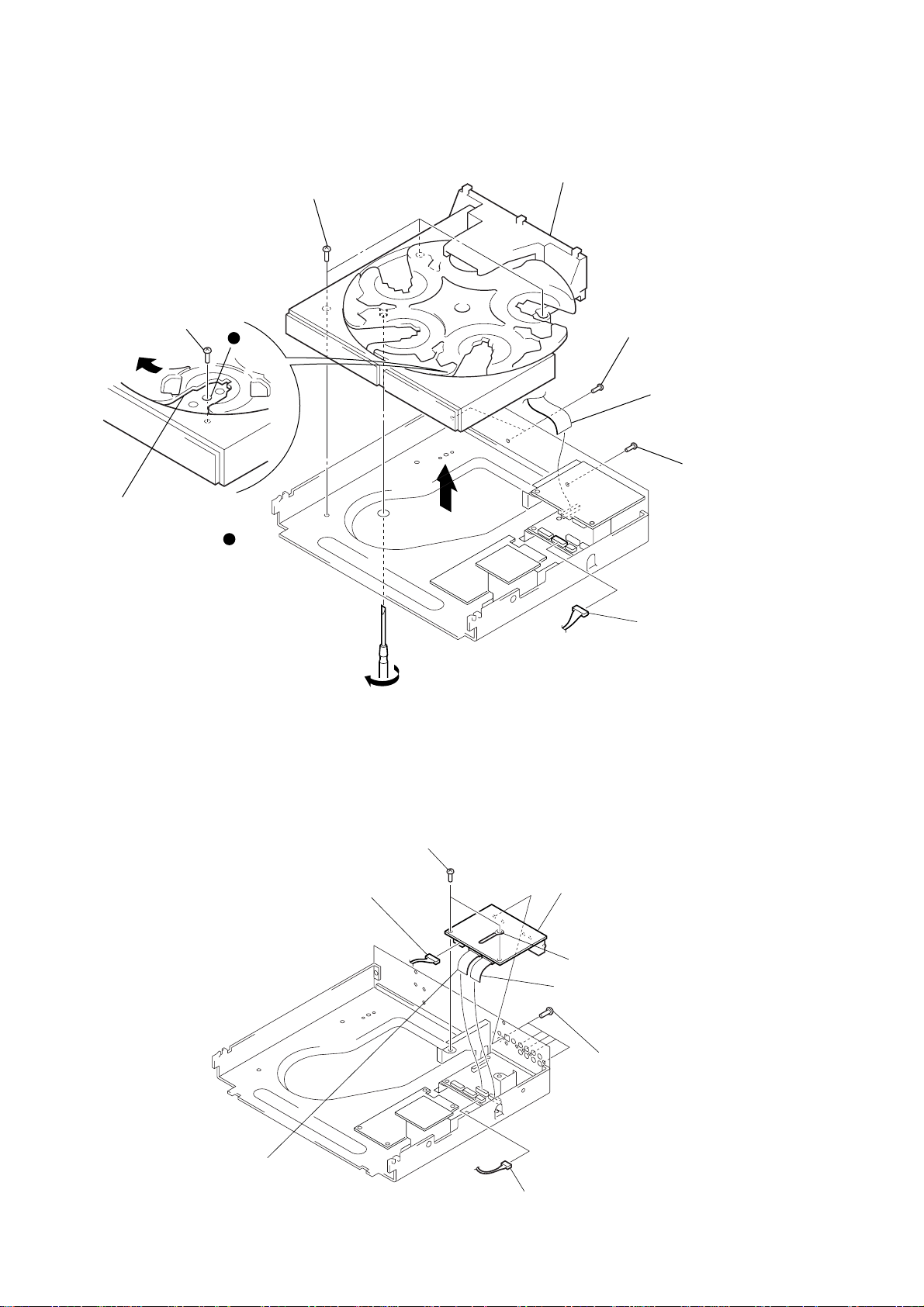

3-4. CD MECHANISM DECK

(CDM59A-DVBU5A)

4

screw

(BVTP3

3

Slide the tray until the screw

that fixes the table assy can be

seen through around hole

in the table assy.

×

8)

a

a

6

three screws

(BVTP3

9

CD mechanism deck

×

8)

7

(CDM59A-DVBU5A)

5

two screws

(BVTP3

8

wire (flat type) (30 core)

(CN708)

5

×

8)

screw

(BVTP3

×

8)

3-5. AUDIO BOARD

2

connector

(CN301)

5

two screws

(BVTP3 × 8)

1

connector

(CN705)

2

Insert a tapering driver from the bottom of the chassis,

and turn it in the direction of the arrow until the base unit

goes down to the lowest position.

7

AUDIO board

6

clamp

1

wire (flat type) (19 core

(CN702)

4

five screws

(BVTP3 × 8)

10

1

wire (flat type) (19 core)

(CN701)

3

connector (CN704)

3-6. POWER BOARD

r

4

6

POWER board

7

four washers

four screws

(BVTP3 × 8)

5

two clamps

3

connector

(CN707)

2

SCD-C222ES

connector

(CN301)

3-7. MAIN BOARD

1

2

3

clamp

connector

(CN707)

1

connector

(CN105)

four screws

(BVTP3

×

8)

1

connector

(CN151)

4

MAIN board

3

connecto

(CN705)

1

connector

(CN705)

11

SCD-C222ES

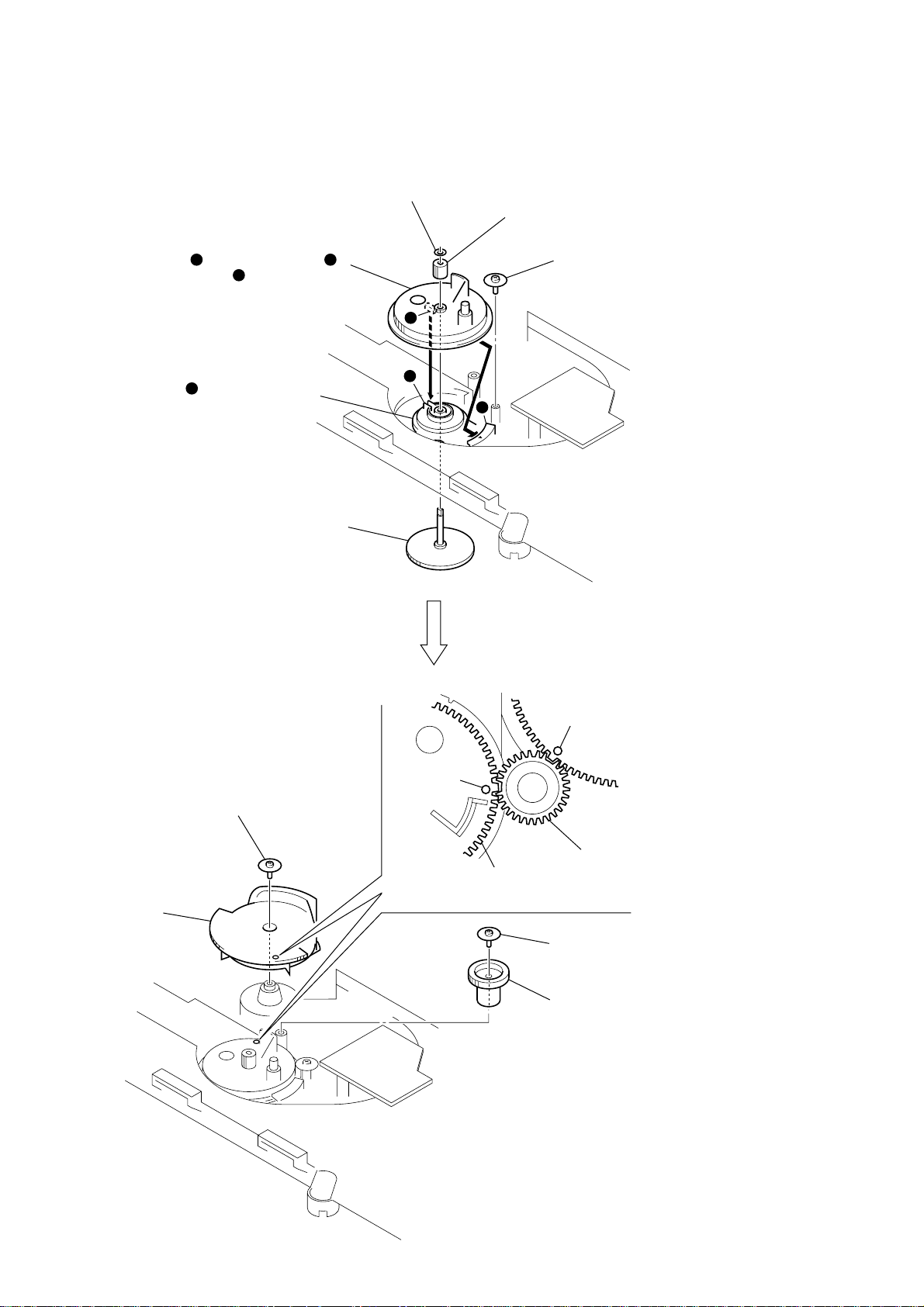

)

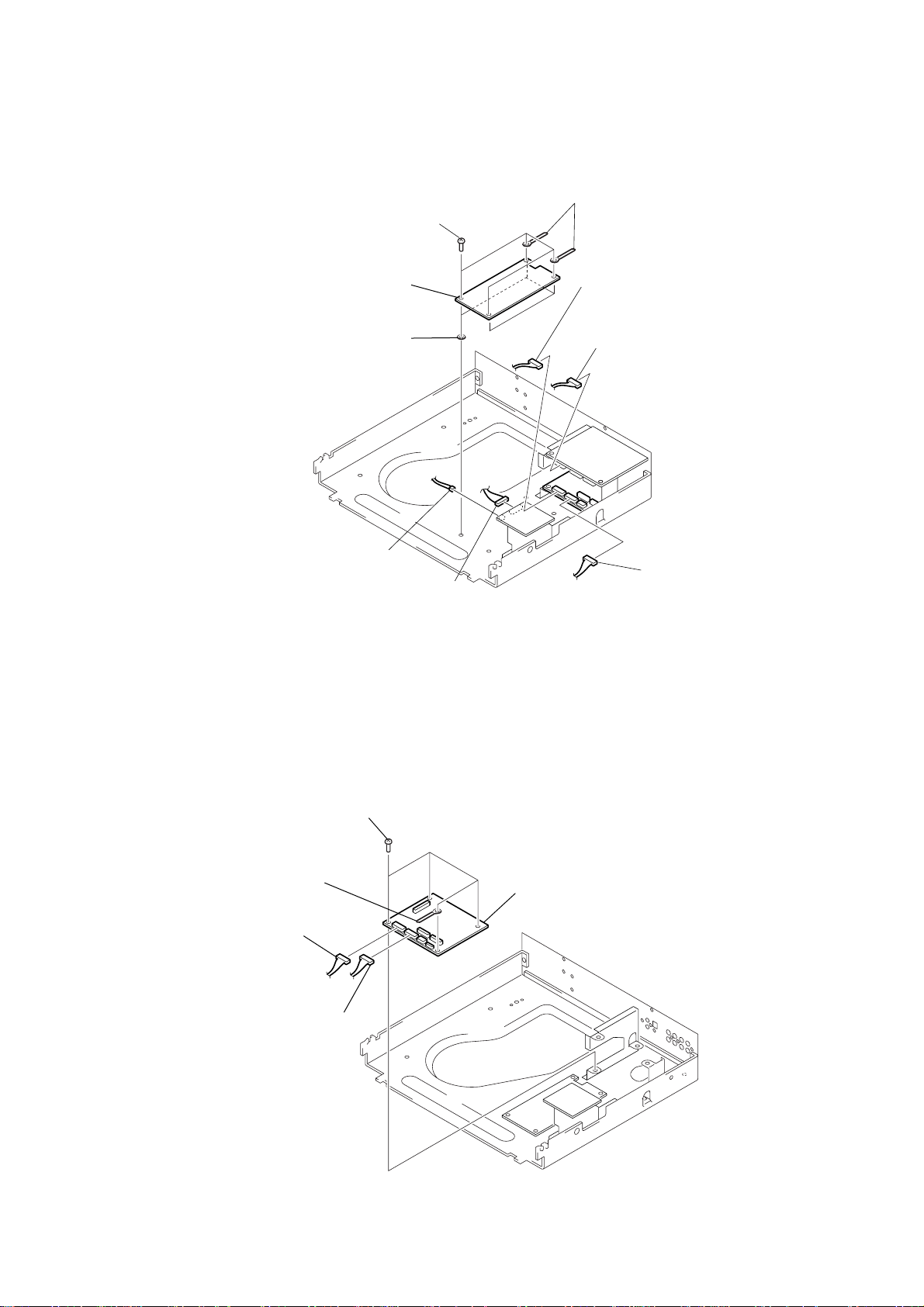

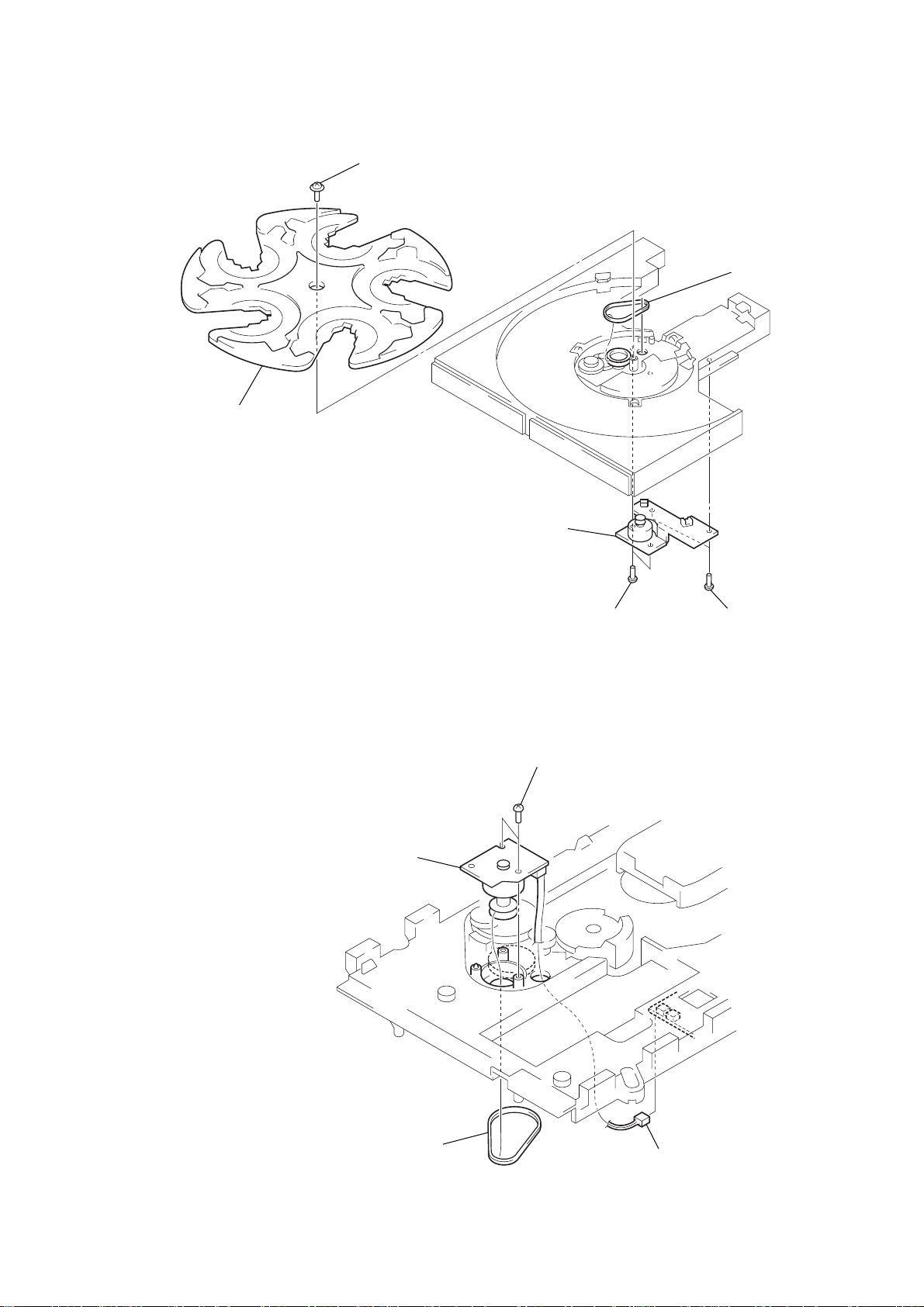

3-8. BASE UNIT (DVBU5A)

Note: When installing the BU

on the chassis, set the

lever (lifter) in free

position, the gear (U/D)

in UP position, and insert

the shaft into the

groove of gear (U/D).

b

3-9. TABLE ASSY

gear (U/D)

9

three screws

(BTTP M2.6)

e

BU section

b

q;

3

base unit (DVBU5A)

clamp

qa

bracket (guide)

gear

(loading C)

1

wire (flat type) (25 core

(CN003)

2

two screws

(PTPWH M2.6), floating

7

two screws

(BTTP M2.6)

8

bracket (guide 2)

4

wire (flat type)

(6 core) (CN15)

qs

table assy

Note: When installing the table assy

on the chassis assy, engage

the gear (loading C) with the groove

by looking into the gear through

a hole in the table assy.

e

12

3

5

screw

(BTTP M2.6)

2

two screws

(BTTP M2.6)

1

d

c

6

bracket (guide)

Slide the tray until the screw

that fixes the bracket (guide)

can be seen through a round

c

hole , in the table assy.

d

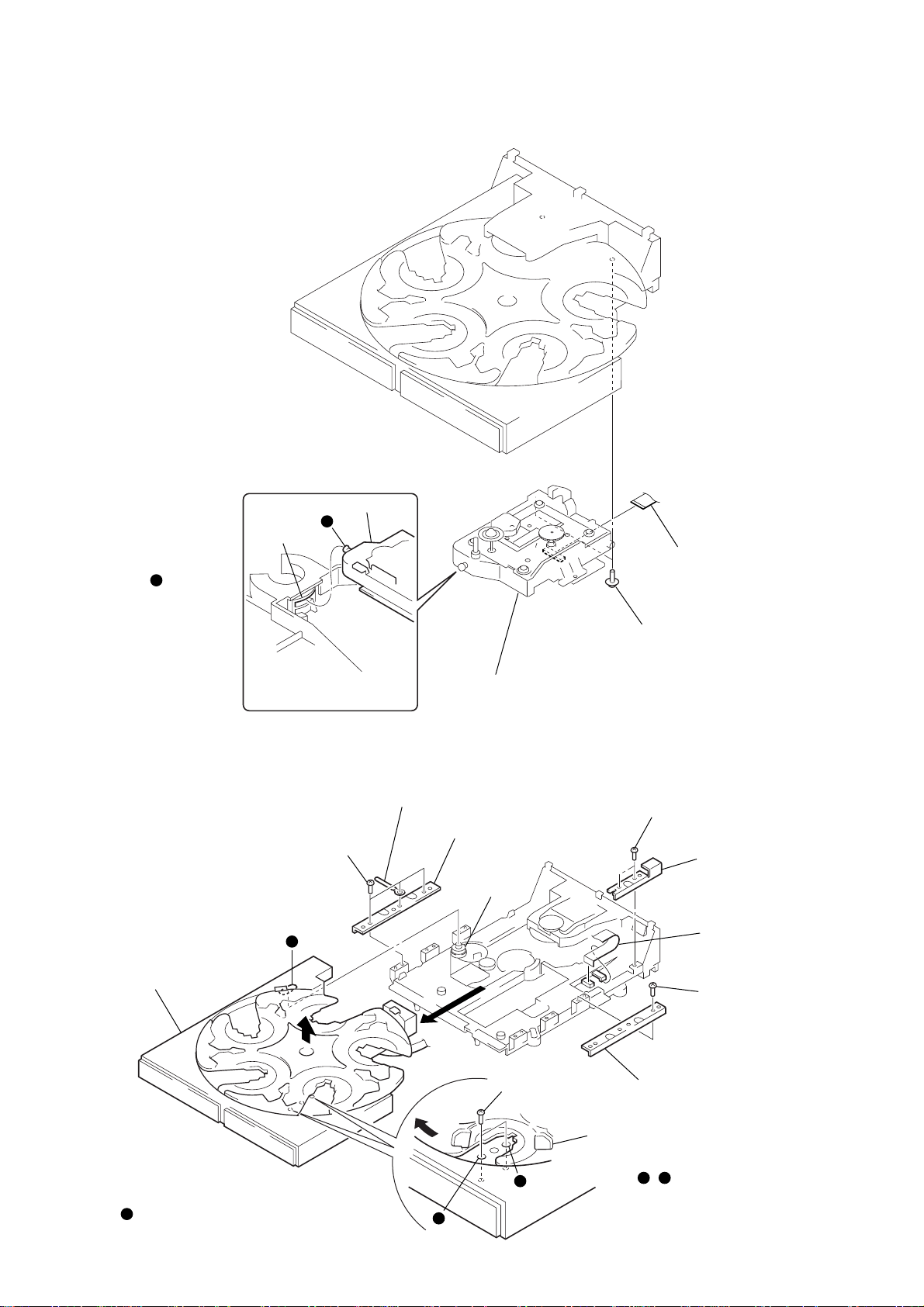

3-10. SENSOR BOARD

2

tray

1

screw

(PTPWH M2.6)

SCD-C222ES

3

belt (rotary)

3-11. LOADING MOTOR BOARD

4

LOADING MOTOR board

5

SENSOR board

4

3

two screws

(BTTP M2.6)

two screws

(BTTP M2.6)

4

two screws

(BTTP M2.6)

1

belt (loading)

2

connector

(CN13)

13

SCD-C222ES

SECTION 4

ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

ADJUSTING PHASE OF SWING GEAR AND GEAR (U/D)

5 stopper washer (FR)

3 Let the swing gear through under the

chassis and engage its dowel

with the groove of rotary encoder.

h

f

g

g

4 Push fully the shaft of shaft gear and

align the hole shape of gear (loading B).

6 screw

(PTPWH M2.6)

2 Install the rotary encoder so that

its groove comes to the position

shown in the figure.

f

1 Insert the shaft gear up to the

position where its shaft comes

out by 5 mm.

8 screw

(PTPWH M2.6)

f

h

circle mark

circle mark

14

7 gear (U/D)

gear (RV)

swing gear

Fig. A

q; screw

(PTPWH M2.6)

9 gear (RV)

Note: Align swing gear, a circle mark

on the gear (U/D), and the teeth

of gear (RV) to the position

showing in the Fig. A.

SECTION 5

TEST MODE

SCD-C222ES

This set automatically executes self-diagnosis and various checks

by entering the test mode.

Note: This set automatically makes various adjustments according to the

type of disc, thereby not requiring adjustment of the set when parts

were replaced. However, be sure to execute 5-1. IC AND FLUORESCENT DISPLAY TUBE CHECK, 5-2. AUTO CHECK and 5-

8. WAVEFORMS CHECK.

Disc for Test Mode

Various checks of this set require the following discs.

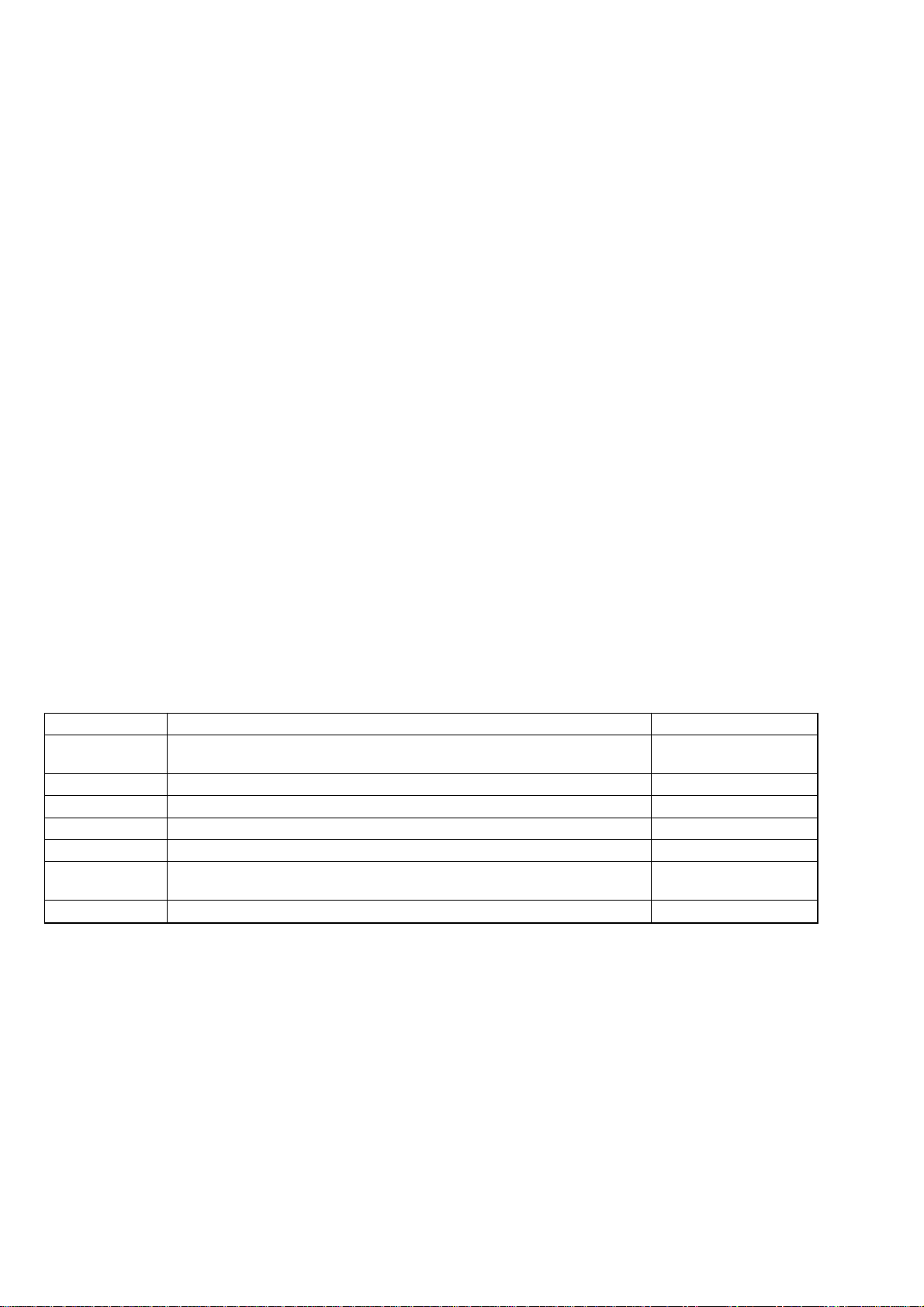

Model Type *1 Category Application

MODEL

SATD-S5

(J-2501-215-A) SL

SATD-S4 Optical waveform check

(J-2501-184-A)

Not specified DL 12 cm disc Operation check

PATD-012

(4-225-203-01)

YEDS-18 Reference disc

(3-702-101-01)

Not specified HYBRID 12 cm disc Operation check

CD

12 cm disc

Reference disc

12 cm disc

Adjusted value check,

Operation check,

Adjusted value check,

Operation check,

Optical waveform check

*1 SL: Single Layer

DL: Dual Layer

Setting Method of Test Mode

Turn the [POWER] switch on while pressing the [ AMS ]

lL

dial and the [MENU] button. Release the [MENU] button and the

lL

[ AMS ] dial in this order when “Test Mode Menu” is

displayed on the fluorescent indicator tube. (If the [ A MS ]

lL

dial is released first, the test mode becomes active b ut “T est Mode

Menu” is not displayed)

[ OPEN/CLOSE] Key in the Test Mode.

A

A

The [ OPEN/CLOSE] key is disabled immediately after setting

the test mode. Be sure to turn the [ AMS ] dial to select 59

T able Init and push [ AMS ] once. When initialization of the

lL

lL

table is completed, the message “INIT AIL OK” appears sev eral seconds on the fluorescent indicator tube. After this, the [ OPEN/

A

CLOSE] key is enabled and disc can be inserted and ejected.

When the command 59 T able Init is ex ecuted, the same operations

of the POWER ON to the disc chucking in the normal operations

as described below are performed. However, it presumes that the

door and the tray are closed depending on the stop status.

59 Table Init t BU DOWN (disc unchucking) t Table rotates

(disc search) t BU UP (disc chucking) at the disc that is found

first of all.

When there are no discs, BU UP is executed at the DISC1 position.

Releasing Method of Test Mode

To release the test mode, turn the [POWER] switch off.

Selection/Entry of Test Mode

To select and enter the “Test Mode Menu”, operate as follows.

1. Rotate the [ AMS ] dial to select the menu, and press

the [ AMS ] dial to enter.

2. The test is switched on or off alternately each time the

lL

[ AMS ] dial is pressed.

3. To return to the previous step, rotate the [ AMS ] dial

to select the desired item, and press the [ AMS ] dial

to enter.

lL

lL

lL

lL

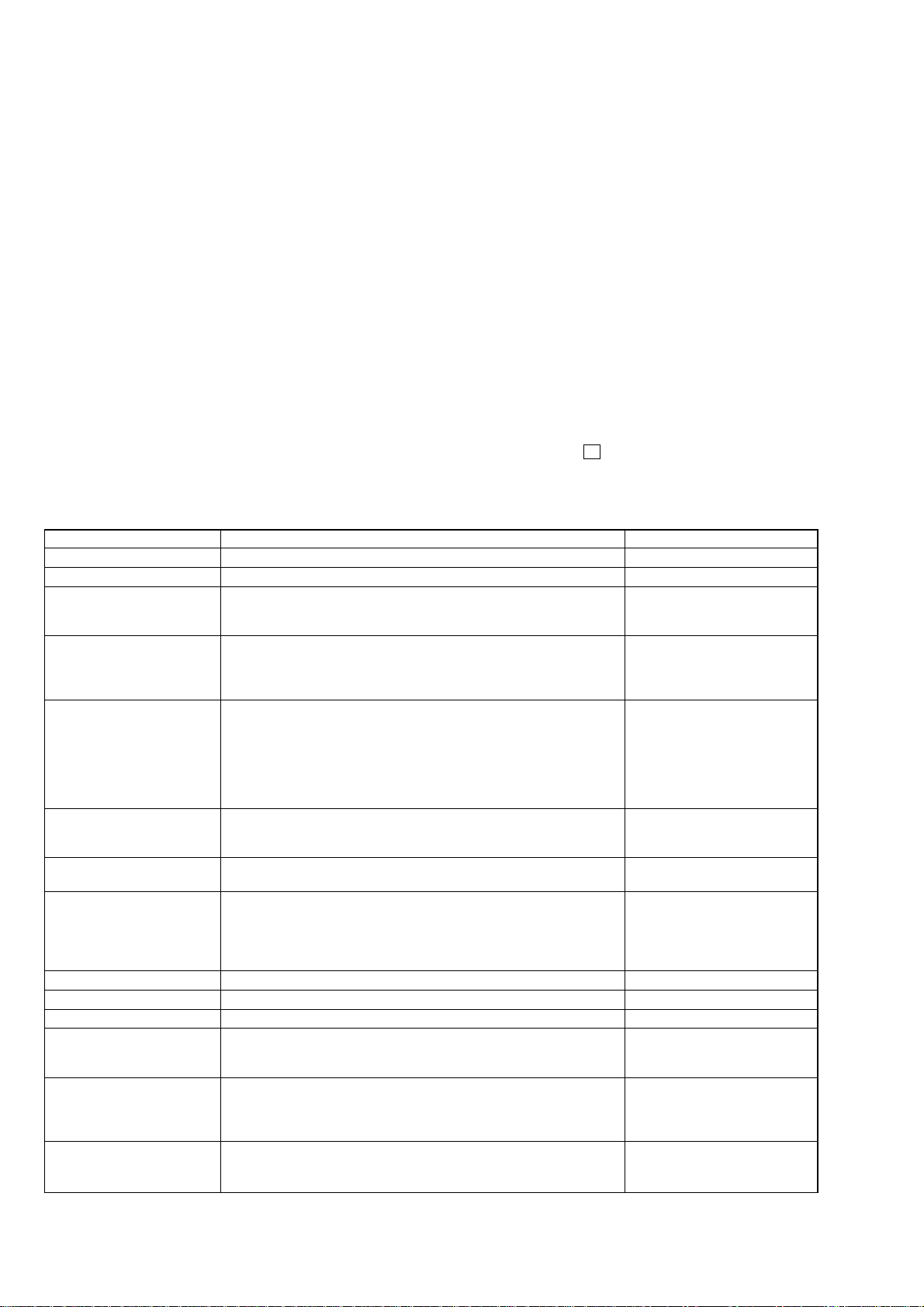

Test Mode Command List

The contents of test mode are as follows.

Note: Wrong operation in the test mode causes a trouble, thus requiring extreme care.

LINE command (1X): Use mainly for a manufacturing line.

No. Name Description Remarks

05 DSP MON1 XUGF, XPCK, C2PO outputted from IC509 (CD DSP) Not used for the servicing

06 DSP MON2 MNT0, MNT1, MNT2, MNT3 outputted from IC509 (CD DSP) Not used for the servicing

07 DSP MON3 RFCK, XPCK, XROF, GTOP outputted from IC509 (CD DSP) Electrical measurement,

CD CLV jitter measurement

STANDARD command (1X): Use when the servo is applied by manual operation.

No. Name Description Remarks

12 LD ON/OFF The laser diode is turned on or off On or off are switched alternately

13 SPIN ON/OFF The spindle motor is rota ted with the regulated voltage On or off are switched alternately

14 FSRV ON/OFF The focus servo is turned on or off On or off are switched alternately

15 TSRV ON/OFF The tracking servo is turned on or off On or off are switched alternately

16 CLV ON/OFF The spindle SLV servo is turned on or off On or off are switched alternately

17 SSRV ON/OFF The sled servo is turned on or off On or off are switched alternately

18 ALL SRV ON All servos are turned on

19 ALL SRV OFF All servos are turned off Stop command in the test mode

Focus and tracking servos must be already turned on

Focus, tracking and spindle servos must be already turned on

15

SCD-C222ES

FOCUS command (2X): Focus related. (All servos must be already turned on (except command 21))

No. Name Description Remarks

21 FSRCH ON/OFF The continuous vertical motion of the optical pick-up lens is turned on or Avoid a long-time use

22 F-BIAS UP Increase focus bias Focus bias value

23 F-BIAS DOWN Decrease focus bias Focus bias value

24 ADJ FCSBIAS The focus bias is adjusted automatically

25 FGAIN UP/DW The focus servo gain is switched between normal and down Normal or down are switched alternately

26 FJMP UP/DWN Focus jump is executed Valid only for DL

27 FOCUS AGC The focus servo gain is adjusted automatically

28 DISP FBdata The focus bias adjusted value is displayed Hexadecimal display 9 bit data

Note: On or off and up or down are switched alternately

OFFSET (PI, FE, TE) command (3X): Adjusts the offset of PI, FE and TE signals.

No. Name Description Remarks

31 PI/FE OFSET Adjusts the offset of PI, FE and TE signals TE offset adjustment is executed for the CD

TRACKING command (4X): Tracking servo related.

No. Name Description Remarks

41 TGAIN NM/UP The tracking servo gain is switched between normal and up Normal or up are switched alternately

44 ADJ TRK DSP The traverse AGC and E-F balance adjustment is performed

45 TRACKING AGC The tracking servo gain is adjusted automatically

off

Both + and - directions are searched to search for best jitter point

UP: layer 0t1, DOWN: layer 1t0

This adjustment must be executed after 61 DISC DETECT only

SEARCH command (5X): Track search related. (Nos. 51 through 53 are not used for the servicing.)

No. Name Description Remarks

51 1-TRCK JUMP One-track jump is performed

52 M-TRCK MOVE M-track movement is performed

53 FINE SEARCH Fine search is performed

58 CDM Check Measurement of table rotation hours, tray open/close hours and panel door

59 Table Init Initializes the table. After this command, the [ OPEN/CLOSE]

open close hours

A

key is enabled.

DISC DETECT command (6X): Disc type check related.

No. Name Description Remarks

61 DISC DETECT Disc type check is executed Refer to how to apply servo by manual

62 SetDiscMode Enter disc type CD setting CD forced setting

63 Enter disc type SL setting SL forced setting

64 Enter disc type DD setting DD forced setting

65 Enter disc type HYBRID HD setting HD forced setting

66 Enter disc type HYBRID CD setting CD forced setting

6F Download Not used for the servicing

Display after judgment operation (page 17)

DSKMOD CD: Judged as CD

DSKMOD SL: Judged as SACD (SL)

DSKMOD DL: Judged as SACD (DL)

DSKMOD HLHD: Judged as HYBRID HD

DSKMOD CDRW: Judged as CD-RW

16

SCD-C222ES

TOOLS command (8X): Performs aging, reads adjusting parameters, etc.

No. Name Description Remarks

81 VERSION Firmware version is displayed Example: Ver 1.00

83 TRAY AGING Tray open-close aging is performed Number of times and eccentricity

Not used for the servicing measurement Not used in this set.

84 JITTER Jitter measurement Not used for the servicing

85 ERROR RATE Error rate measurement Error rate

86 ALL SRV ON Apply all servos Use when applying the servo by

87 DISP ADJ DT Automatic adjusting parameters are displayed Refer to auto check items (page 20)

8A FL TEST Not used for the servicing

8d Set Up Init Set to factory shipping mode Set when repair completed

8F 49 TRCK JIT Used for jitter measurement of 49th music on SACD-S4 For manufacturing line

QA command (9X)

No. Name Description Remarks

91 F.JMP CHECK Not used for the servicing

92 SET CHECK The set is checked Refer to 5-2. AUTO CHECK (page 20)

93 WATER MARK Not used for the servicing

94 SET AGING The set aging is performed Refer to 5-6. AGING MODE (page 25)

95 DISP ERROR The content of error recorded to the set is read and displayed Refer to Error Display list (page 26)

96 D-OUT OnOff Digital out of CD is turned on or off Not used in this set.

98 APDD JITTER Not used for the servicing

9C BU DENCHO The content of error recorded to the set is read, and then the S curve Refer to 5-8.WAVEFORMS CHECK

9D P-ON HOUR Approximate cumulative power supplying time is displayed In unit of 1 hour

9E RFD OUT RFD output is turned on or off Not used for the servicing

CD: C1, C2 Not used for the servicing

SACD: PO, PI1, PI2

Full automatic measurement including PI, FE and TE offset adjustment is manual operation

performed Refer to STANDARD command (page 15)

The offset adjusted values are scroll-displayed in order of RF, VC, FE and

TE Refer to auto check items (page 20)

PLAY, REPEAT, DIGIFIL, etc. are initialized Refer to 5-7. SHIPPING MODE (page 25)

Not used for the servicing

Repeat by the specified number of times or until an error occurred

(Error recording) Only one item is recorded

waveform, traverse waveform, and RF waveform can be checked (page 27)

successively

(Initialized by 8d command)

SACD jitter measuring mode

How to Apply Servo by Manual Operation

In analyzing failures of the set, the servo may be applied by manual operation. To apply servo in the test mode, use the following method.

1. After setting the test mode, rota te the [ AMS ] dial to select a command, and press the [ AMS ] dial to enter.

lL lL

2. “61 DISC DETECT” (Disc type check)t “86 ALL SRV ON” (All servos on + auto adjustment)

3. If applying servo while checking the condition one by one, “61 DISC DETECT” (Disc type check)t“31 PI/FE OFSET” (Offset

automatic adjustment)t“14 FSRV ON/OFF” (Focus servo on)t“16 CLV ON/OFF” (CLV servo on)t“44 ADJ TRK DSP ” (E-F

balance adjustment)t“15 TSRV ON/OFF” (Tracking servo on)t“17 SSRV ON/OFF” (Sled servo on)t“24 ADJ FCSBIAS” (Focus bias adjustment)t“27 FOCUS AGC” (Focus auto gain adjustment)t“45 TRACKING AGC” (Tracking auto gain adjustment).

Note: 1. On and off are alternately switched in the same command.

2. For a stop, select “19 ALL SRV OFF” and press the [ AMS ] dial.

lL

17

SCD-C222ES

Set Check

92. SET CHECK SET TEST START 10. TOTAL CHECK 120. MANUAL CHK

0. IC&FL CHECK ? 11. AUTO CHECK ?

1. TOTAL CHECK ? 12. MANUAL CHK ? 122. SPIN UP ?

2. F.JUMP CHECK ?

3.HYB CHECK ? TOTAL CHK END ? 124.

4. DISP ERROR ? 125. 1/3 SEEK ?

END ?? 126. 1-M SEEK ?

13. DISP RSLT ? 123. PARAMETER ?

121. LOAD IN ?

(Not used)

READ TOC & PSP ?

127. ERR RATE ?

128. HENSHIN ?

129. SPIN DOWN ?

12A. LOAD OUT ?

(Not used)

MAN. CHK END?

Press the [ AMS ] dial when No.sssss sssss*1 is displayed, and a checking for that display will start or the lower layer

will be selected. For the selection on the same layer, rotate the [ AMS ] dial. It is looped on the same layer, and when “END?” is

displayed, press the [ AMS ] dial to return to the upper layer.

lL

lL

l

L

*1 s denotes a displayed character.

Manual Check Method

In the “12. MANUAL CHK”, individual checks (121. LOAD IN to 12A. LOAD OUT) are possible.

Example: If 124. READ TOC & PSP of 12. MANUAL CHECK is to be checked.

Setting Method:

1. After setting the test mode, rotate the [ AMS ] dial to select “92. SET CHECK” and press the [ AMS ] dial to enter.

l

2. When “SET TEST START” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “1. TOTAL CHECK?”

and press the [ AMS ] dial to enter.

lL

3. When “10. TOTAL CHECK” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “12. MANUAL CHK?" and

press the [ AMS ] dial to enter.

lL

4. When “120. MANUAL CHK” is displayed, rotate the [ AMS ] dial clockwise by 4 clicks to select “124. READ TOC & PSP?”

and press the [ AMS ] dial to enter.

lL

L

lL

lL

l

L

lL

5. A checking will start automatically.

Note: In making a check, the disc must be loaded. Immediately when a check started, the tray is drawn into the set. Also, the tray can be opened/closed

even during the set check mode.

18

SCD-C222ES

5-1. IC AND FLUORESCENT DISPLAY TUBE CHECK

(SELF-DIAGNOSIS)

The communication between microcomputer and main ICs (selfdiagnosis) and the fluorescent display tube all lit are checked.

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “92. SET CHECK” and press the [ AMS ] dial

lL

l

L

to enter.

2. When “SET TEST START” is displayed, rotate the

lL

[ AMS ] dial clockwise by 1 click to select “0. IC&FL

CHECK?” and press the [ AMS ] dial to enter.

lL

3. A checking will start automatically, and “0. IC&FL CHECK”

will be displayed. (Checking time is about 3 seconds)

4. After IC communication check, all segments of fluorescent

display tube will be lit. At this time, check visually for a skipped

character.

5. At successful completion of check, “0. IC CHECK OK” is

displayed. In this case, no error exists in the IC interface. Proceed to 5-2. AUTO CHECK.

Note: The check mentioned above tests the communication from micro-

computer to main ICs. Even if the check successfully finished, the

IC to be checked is not always normal. Consider it for reference

only.

6. In case of an IC communica tion error, the following display

will be given during the checking. Possible causes of error are

as listed below.

Error display Causes (typical example)

DVD DEC. ERROR 1. IC701 (SACD decoder) is faulty

DVD DRAM ERR 1. IC706 (D-RAM) is faulty

CD DSP ERROR 1. IC509 (CD DSP) is faulty

EEPROM ERROR 1. IC903 (EEPROM) is faulty

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin ts (XDIS) does not go “H”

• IC902 (expander) is faulty

3. 768fs (33.86688 MHz) is not present to

IC701 pin <znm (XTAL)

• IC811 (3-multiplying circuit) is faulty

• Clock signal 256fs is not sent from

AUDIO board (CN702 pin 0)

• CN701 pin 3 (GND) and pin 2

(+3.3V-D) are open or shorted

• CN701, 702 and FFC connection is loose,

or FFC is disconnected

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin ts (XDIS) does not go “H”

• IC902 (expander) is faulty

3. Faulty communication line between

IC701 and IC706

• Data line, address line, WE, etc.

4. D903 (1SS367) is faulty

D+3.3V is not present to IC706

2. 768fs (33.86688 MHz) is not present to

IC509 pin ua (XTAL)

Same as cause 3 of DVD DEC. ERROR

3. IC509 pin 2 (XRST) does not go “H”

• IC901 pin ts (XDIS) does not go “H”

• IC902 (expander) is faulty

Error display Causes (typical example)

PRAWN DRAM ERR 1. IC808 (D-RAM) is faulty

*1 2. IC801 (DSD decoder) is faulty

RF AMP ERROR 1. IC001 (RF AMP) is faulty

3. 768fs (33.86688 MHz) is not present to

IC801 pin qa (MCKI)

Same as cause 3 of DVD DEC. ERROR

4. IC801 pin 9 (XRST) does not go “H”

• IC901 pin ts (XDIS) does not go “H”

• IC902 (expander) is faulty

5. Faulty communication line between

IC801 and IC808

• Data line, address line, WE, etc.

6. D904 (1SS367) is faulty

D+3.3V is not present to IC808

2. Loose connection between CN708 on

MAIN board and CN005 on RF board,

or FFC disconnection

CN708 pin qj (CLK RF), pin qh (DATA

RF) and pin qg (SDEN) must be checked

*1 DSD decoder is also checked.

Causes Common to Each IC:

1. Faulty communication line between microcomputer and each

IC.

Disconnected patterns, floating series resistors, bridge, etc.

2. Faulty IC supply voltage.

Particularly, check D+3.3V voltage. (D+5V for display microcomputer)

3. Faulty microcomputer communication port to each IC

Note: In case of more than two errors, the error display is switched over

one after another, thus making the reading difficult.

In such a case, press again the [ AMS ] dial to make a

recheck for error reading.

lL

19

SCD-C222ES

5-2. AUTO CHECK (AUTOMATIC VARIOUS MEASUREMENTS)

The auto check is performed to check if the set operates stably. Though a checking is made automatically, whether the measured data are

within the specification is evaluated by the service person. The auto check results in NG immediately, if the check itself causes an error.

Setting Method of Auto Check Mode:

1. After setting the test mode, rotate the [ AMS ] dial to select “92. SET CHECK” and press the [ AMS ] dial to enter.

2. When “SET TEST START” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “1. TOTAL CHECK?”

and press the [ AMS ] dial to enter.

lL

3. When “10. TOTAL CHECK” is displayed, rotate the [ AMS ] dial clockwise by 1 click to select “11. AUTO CHECK?”.

lL

lL

lL

CD and SACD (SL) Disc Operation Check

Checking method:

1. Press the [ OPEN/CLOSE] button to open the tray and place the test disc *1. The [ OPEN/CLOSE] key is disabled immediately

A A

after setting the test mode. Be sure to initialize the table.

2. Press the [ AMS ] dial, and the following check will be performed automatically.

lL

3. Finally, the test disc will be ejected and the auto check will finish.

4. “AUTO CHECK OK” will be displayed at successful completion of auto check.

5. Recheck is enabled if the [ AMS ] dial is pressed in step 4. (Also, use this operation when exchanging the test disc)

lL

6. In case of an error during the checking, the check is interrupted automatically and the error is displayed. (Error display example:

“DISC DETECT ERROR”) After error display, “CONT?STOP (J/S)” is displayed. In this case, if the [ AMS ] dial is pressed,

the check where the error occurred is skipped and you can proceed to the next check. Also, x if button is pressed, the check finishes

and “AUTO CHECK NG” is displayed when even one NG item exists.

*1 Use PATD-012 or YEDS-18 for CD, and SATD-S5 or SATD-S4 for SACD (SL). Using another disc will result in a checking failure.

lL

lL

Check Items:

Items Description Remarks

LOAD IN TIME (msec) Time until a disc is chucked from the state where loading tray is out Loading in switch HtL

SPIN UP TIME (msec) Time from spindle kick to PLL lock Lock signal LtH

RF/VC/FE/TE (ORG) Offset values before RF (PI), VC, FE, TE signal offset adjustment At offset 0

RF/VC/FE/TE (ADJ) Offset values after RF (PI), VC, FE, TE signal offset adjustment VC offset is not adjusted

PI/TRVS PP (ORG/ADJ) PI (ORG): PI value at disc type check (decimal data) PI level conversion

PIOR/CCR/TRCR PIOR: Set value of PI offset coarse adjusting register Registers in RF amplifier

FOCUS/TRK GAIN Auto gain adjusted values of focus and tracking servos Reference: 30h

FBIAS/TRVSC/TRCR2/CFR FBIAS: Focus bias set value (9 bit data in hex notation) TRCR2 adjusts the E-F gain

MIN JITTER AT F.BIAS Minimum jitter value in focus bias adjustment (CD only) Correlative with RF jitter

READ TOC TIME (msec) Time required for TOC reading

PSP AMPLITUDE SACD only

1/3 SEEK TIME Seek time between 1/3LBA and 2/3LBA of the disc LBA: Absolute address

F) A VE/MIN/MAX (msec): 1/3LBAt2/3LBA average/minimum/maximum

R) AVE/MIN/MAX (msec): 2/3LBAt1/3LBA average/minimum/maximum

1-MAX TRK SEEK Seek time between most inward track (0LBA) and most outward track max

F) A VE/MIN/MAX (msec): most inwardtmost outward average/minimum/maximum

R) AVE/MIN/MAX (msec): most outwartmost inward average/minimum/maximum

ERROR RATE Error rate measurement Measure for 10 sec at track No.5

RF (8 bit data in hex notation) RF: A0h

VC, FE, TE (9 bit data in hex notation) VC, FE, TE: 00h

(Less than ORG value if offset correction is normal) (Measurement only)

RF (8 bit data in hex notation) Also, for SACD, the TE offset is

VC, FE, TE (9 bit data in hex notation) not measured and adjusted

PI (ADJ): PI value after PI offset adjustment Read value × 12.9mV

(read value at microcomputer A/D) (decimal data)

TRVS PP (ORG):Traverse level before level correction (AGC) Traverse level conversion

(decimal data) Read value × 12.9mV

TRVS PP (ADJ):Traverse level after level correction (AGC)

(decimal data) 12.9mV=3.3V ÷ 256 (8 bit)

CCR: Set value of FE offset coarse adjusting register

TRCR: Set value of TE offset coarse adjusting register

(8 bit data in hex notation)

TRVSC: Traverse center value (9 bit data in hex notation) balance and used for CD only

TRCR2: Set value of E-F balance coarse adjusting register (Fixed to 06 for SACD)

CFR: Set value of traverse level adjusting register TRCR2 and CFR are registers in

RF amplifier

LBA

For CD: Average value/Maximum value of C1 and C2 For the SACD, 160 block data

For SACD: Average value/Maximum value of PO, PI1 and PI2 except the data under tracking jump

20

SCD-C222ES

Items Description Remarks

HENSHIN RYOU Eccentricity measurement For the CD only are measured

SPIN DOWN TIME (msec) Time from spindle brake application to rotation stop FG (IC901 pin ys) monitoring

LOAD OUT TIME (msec) Time until loading table comes out from the state where a disc is in chuck Loading out switch HtL

Measured Data Reading Method:

To judge the check result, the measured data must be read.

1. When “AUTO CHECK OK” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks.

2. When “13. DISP RSLT?” is displayed, press the [ AMS ] dial to enter.

3. “PLEASE WAIT” will be displayed and in several seconds, “13. DISP RESULT” will be displayed.

4. Rotate the [ AMS ] dial clockwise by 1 click, and the “LOAD IN” will be displayed.

5. Press the [ AMS ] dial to enter.

lL

lL

6. Compare the displayed value with the following specified value.

7. Hence , repeat step 4 to 6 (display is variable) and read the measured data respectively.

8. Compare the measured da ta with the specified value to check for NG item.

Note: Blank display of measured value means that an error occurred during the checking or no measurement was taken place.

Specified V alue:

(1) SACD (Use the test disc SATD-S5 or SATD-S4)

Note: Measured values in check items are typical ones.

LOAD IN TIME (msec) : Not displayed in this set.

SPIN UP TIME (msec) : 1993 1800 to 2450

PF/VC/FE/TE AVRG (ORG) : 8E, E, 1E2, 12 RF: 91-C8, VC: 1F8-8, FE: 1D1-30, TE: 198-75

PF/VC/FE/TE AVRG (ADJ) : 9D, E, 6, 2 RF: 91-AF, VC : 1F8-8, FE: 1EE-12, TE: 1EA-16

PI/TRVS PP (ORG/ADJ) : 80, 129, 100, 90 PI ORG: 80-100, PI ADJ: 80-95, TRVS ORG: 53-118, TRVS ADJ: 45-132

PIOR/CCR/TRCR : 1B, 31, 1F No specified value given

FOCUS/TRK GAIN : 29, 35 FOCUS: 1E-35, TRK: F-40

FBIAS/TRVSC/TRCR2 : 2FE, 14, 6 F.BIAS: 1E2-3A, TRVSC: 1E4-4D TRCR2: no specified value given

READ TOC TIME (msec) : 1098 1350 to 2050

PSP AMPLITUDE : 2387 1450 to 2150

1/3 SEEK TIME : 2268581, 625121, <_>, 1446850

F) AVE/MIN/MAX (msec) : 926, 909, 938 AVE: 1150 msec or less, MAX: 1300 msec or less

R) AVE/MIN/MAX (msec) : 919, 901, 937 AVE: 1150 msec or less, MAX: 1300 msec or less

1/MAX SEEK TIME : 2268581, 0, <_>, 2268581

F) AVE/MIN/MAX (msec) : 1846, 1819, 1879 AVE: 2250 msec or less, MAX: 2500 msec or less

R) AVE/MIN/MAX (msec) : 1837, 1829, 1849 AVE: 2250 msec or less, MAX: 2500 msec or less

ERROR RATE

PO MAX/AVE FRAME : 0, 0 MAX: 0, AVE: 0

PO MAX/AVE NUM : 480, 28 MAX: 1500 or less, AVE: 200 or less

PI1 MAX/AVE FRAME : 0, 0 MAX: 0, AVE: 0

PI1 MAX/AVE NUM : 320, 11 MAX: 1500 or less, AVE: 200 or less

PI2 MAX/AVE FRAME : 0, 0 MAX: 0, AVE: 0

PI2 MAX/AVE NUM : 41, 0 MAX: 1500 or less, AVE: 200 or less

SPIN DOWN TIME (msec) : 1312 1300 to 2100

LOAD OUT TIME (msec) Not displayed in this set.

Eccentricity (actual eccentric amount) of disc, disc pulley total • Read by dividing by 10

• 0 may be displayed if eccentricity

is small (10um or less) (Due to

measurement reason)

lL

lL

Check items Specified value

* Items are not used in the

SATD-S5.

21

SCD-C222ES

(2) CD (Use the test disc PATD-012 or YEDS-18)

Note: Measured values in check items are typical ones.

Check items Specified value

LOAD IN TIME (msec) : Not displayed in this set.

SPIN UP TIME (msec) : 1354 1300 to 1600

RF/VC/FE/TE AVRG (ORG) : 8E, D, 1E3, 12 RF: 91-C8, VC: 1F8-8, FE: 1D1-30, TE: 198-75

RF/VC/FE/TE AVRG (ADJ) : 9C, C, 6, 2 RF: 91-AF, VC: 1F8-8, FE: 1EE-12, TE: 1EA-16

PI/TRVS PP(ORG/ADJ) : 84, 128, 100, 90 PI ORG: 80-100, PI ADJ: 80-95, TRVS ORG: 55-155, TRVS-ADJ: 50-120

PIOR/CCR/TRCR : 1B, 11, 1E No specified value given

FOCUS/TRK GAIN : 33, 28 FOCUS: 24-53, TRK: 1A-4E

FBIAS/TRVSC/TRCR2 : 10, 0, 5 F.BIAS: 1D9-2A, TRVSC: 1E2-19 TRCR2: no specified value given

MIN JITTER AT F.BIAS : 147 700 or less

READ TOC TIME (msec) : 827 1150 to 3150

1/3 SEEK TIME : 311660, 103786, <_>, 207722

F) AVE/MIN/MAX (msec) : 794, 699, 908 AVE: 1200 msec or less, MAX: 1300 msec or less

R) AVE/MIN/MAX (msec) : 824, 661, 920 AVE: 1200 msec or less, MAX: 1300 msec or less

1/MAX SEEK TIME : 311660, 0, <_>, 311660

F) AVE/MIN/MAX (msec) : 1991, 1964, 2015 AVE: 2200 msec or less, MAX: 2500 msec or less

R) AVE/MIN/MAX (msec) : 1711, 1701, 1726 AVE: 2200 msec or less, MAX: 2500 msec or less

ERROR RATE

C1 MAX/AVE : 3, 0 C1 MAX: 15 or less

C2 MAX/AVE : 0, 0 C2 MAX: 0

HENSHIN RYOU (1/10um) : 168 800 or less (100 um or less)

SPIN DOWN TIME (msec) : 1342 450 to 1500

LOAD OUT TIME (msec) Not displayed in this set.

Note: RF, VC, FE, TE, FBIAS and TRVSC measured values are hexadecimal data with positive and negative signs. When comparing the measured

value with the specified value, refer to the following.

Hexadecimal (hex) display 9 bit data

FF 011111111 (+255)

FE 011111110 (+254)

01 000000001 (+1)

00 000000000 (0)

1FF 111111111 (-1)

101 100000001 (-255)

100 100000000 (-256)

MAX

(+) Side

0

(-) Side

MIN

Hexadecimal (hex) display 8 bit data

7F 01111111 (+127)

7E 01111110 (+126)

02 00000010 (+2)

01 00000001 (+1)

00 00000000 (0)

FF 11111111 (-1)

FE 11111110 (-2)

81 10000001 (-127)

80 10000000 (-128)

22

SCD-C222ES

5-3. SACD (DL) DISC OPERATION CHECK

(• Perform as necessary)

The stability of the set can be checked by repeating the combined

operation of focus jump (layer 0t1, layer 1t0) and access to

the most inward trackymost outward track by the set number of

times or until an error occurs using the dual layer HD disc, DL

disc.

A set of operation including an access to the layer 0 (most inward

track)tlayer 0 (most outward track)t focus jump (layer

0t1)tlayer 1 (most outward track)t layer 1 (most inward

track)tfocus jump (layer 1t0) is carried out repeatedly by the

set number of times.

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “92. SET CHECK” and press the [ AMS ] dial

lL

l

L

to enter.

2. When “SET TEST START” is displayed, rotate the

lL

[ AMS ] dial clockwise by 3 clicks to display “2.

F.JMP CHECK?”.

3. Press the [ OPEN/CLOSE] b utton to open the tray , and place

A

the DL disc.

4. Press the [ AMS ] dial to load the tray into the set.

lL

5. “NOW SET UP” will be displayed and the DL disc setup will

start. (It takes about ten and several seconds to set up the disc

as two layers of layer 0 and layer 1 are adjusted)

6. At the completion of setup, “F.JUMP TIMES” will be displayed.

7. Rotate the [ AMS ] dial clockwise by 5 clicks to display

lL

“5”. (If 5 sets of operation is executed *1)

8. Press the [ AMS ] dial, and the check will start.

lL

9. Immediately when the check finished, “UP MAX

ssss”t“UP A VE ssss”t“DW MAX

ssss”t“DW AVE ssss”t“F.JMP OK

[TIMES]”

will be displayed repeatedly. (s denotes the measured value

in msec)

UP MAX: Max time required for layer 0 (most inward

track)tlayer 0 (most outward track)tfocus jump

(layer 0t1)

UP AVE: Average time required for layer 0 (most inward

track)tlayer 0 (most outward track)tfocus jump

(layer 0t1)

DW MAX:Max time required for layer 1 (most outward

track)tlayer 1 (most inward track)tfocus jump

(layer 1t0)

DW AVE: Average time required for layer 1 (most outward

track)tlayer 1 (most inward track)tfocus jump

(layer 1t0)

Specified value: 7000 msec or less (if no error occurred)

If an error occurred due to defocusing during the checking,

refer to the following error list. (page 25)

10. Press the [ OPEN/CLOSE] button, and the disc will be ejected

and the check will finish. Also, if the [ AMS ] dial is

A

lL

pressed in step 9, “2. F.JUMP CHK OK” will be displayed.

Then, if the [ AMS ] dial is again pressed, “2. F.JMP

lL

CHECK” will be displayed instantaneously and a recheck is

enabled from the step 5 in the same manner.

*1 Setting arbitrary number of times instead of 5 allows the check-

ing to be repeated by the set number of times. Also, setting 0

(zero) allows the aging check to be repeated until an error occurs.

5-4. HYBRID DISC OPERATION CHECK

(• Perform as necessary)

This test checks the auto adjustment time required when the disc

is switched between HD (SACD) layer and CD layer. This test is

conducted to check the stability in switching from CD to SACD,

or SACD to CD in the HYBRID disc.

A set of operation including CD layer stop statetHD layer auto

adjustmenttHD layer TOC readingtHD layer stop statetCD

layer auto adjustmenttCD layer TOC readingtCD layer stop

state is repeated by the set number of times.

Checking Method:

1. After setting the test mode, rotate the

select “92. SET CHECK” and press the [ AMS ] dial

lL

[ AMS ] dial to

lL

to enter.

2. When “SET TEST START” is displayed, rotate the

lL

[ AMS ] dial clockwise by 4 clicks to display “3.

HYB CHECK?”.

3. Press the [ OPEN/CLOSE] b utton to open the tray , and place

A

the HYBRID disc.

4. Press the [ AMS ] dial to load the tray into the set.

lL

5. “NOW SET UP” will be displayed and the HYBRID disc setup

will start. (It takes about several seconds to set up the disc *1)

6. At the completion of setup, “CHANGE TIMES?” will be displayed.

7. Rotate the [ AMS ] dial clockwise by 5 clicks to display

l

L

“5” (if 5 sets of operation is executed *2)

8. Press the [ AMS ] dial, and “ST AR T” will be displayed

lL

and the check will start. During the check, the following will

be displayed.

“CD—>HD” display: Time from switching from CD layer to

HD layer up to start of play is measured.

“HD—>CD” display: Time from switching from HD layer to

CD layer up to start of play is measured.

9. Immediately when the check finished, “CD MAX

ssss”t“CD A VE ssss”t“HD MAX

ssss”t“HD AVE ssss” will be displayed

repeatedly. (s denotes the measured value in msec)

Specified value: 10000 msec or less (if no error occurred)

If an error occurred due to defocusing during the checking,

refer to the following error list. (page 25)

[ OPEN/CLOSE] button, and the disc will be ejected

10. Press the

and the check will finish. Also, if the [ AMS ] dial is

A

lL

pressed in step 9, “HYB CHK OK” will be displayed. Then, if

lL

the [ AMS ] dial is again pressed, “HYBRID CHECK”

will be displayed instantaneously and a recheck is enabled from

the step 5 in the same manner.

*1 “NOW SET UP” display may continue for several minutes

and an error may be displayed depending on the discs. In this

case, press the [ AMS ] dial again.

lL

*2 Setting arbitrary number of times instead of 5 allows the check-

ing to be repeated by the set number of times. Also, setting 0

(zero) allows the aging check to be repeated until an error occurs

23

SCD-C222ES

5-5. CDM59 AND THE DOOR CHECK

Measurement of table rotation hours, tray open/close hours and

panel door open close hours can be executed together with CDM59.

Procedure

1. Set the test mode. Turn the [ AMS ] dial and select

59 Ta ble Init. Press [ AMS ] once (that enables the

A

[ OPEN/CLOSE] key.)

2. When the message INITIAL OK appears, press the [ OPEN/

CLOSE] key to eject the tray. Place a disc in the DISC1 of the

table. (Be sure to place a disc in DISC1. If a disc is placed in

any locations other than DISC1, the correct measurement cannot be executed. Therefore, be sure to place a disc in DISC by

using the [DISC SKIP] key.)

3. Select 58 CDM Check by turning [ AMS ] and press

lL

[ AMS ] once.

4. Measurement starts automatically.

5. When the measurement is completed, the message DOOR OP

ss.s (s is a decimal number) appears on the fluorescent

indicator tube.

6. Result of measurement can be check by turning [ AMS ].

If any measurement item does not meet specification, a message “ng” is displayed next to the measurement value.

7. When you want to repeat the test, press [ AMS ] again.

8. Press the [ OPEN/CLOSE] key to terminate the test and remove the disc.

* 1.The measurement can be performed without placing a disc.

* 2.When the machine enters this mode once, it cannot return

A

However , the B U chucking time and unchucking time will

be slightly different from the actual values.

to the normal test mode. If any other tests are desired, turn

off the main power once and then back on again to enter

the test mode.

lL

lL

l

lL

A

L

lL

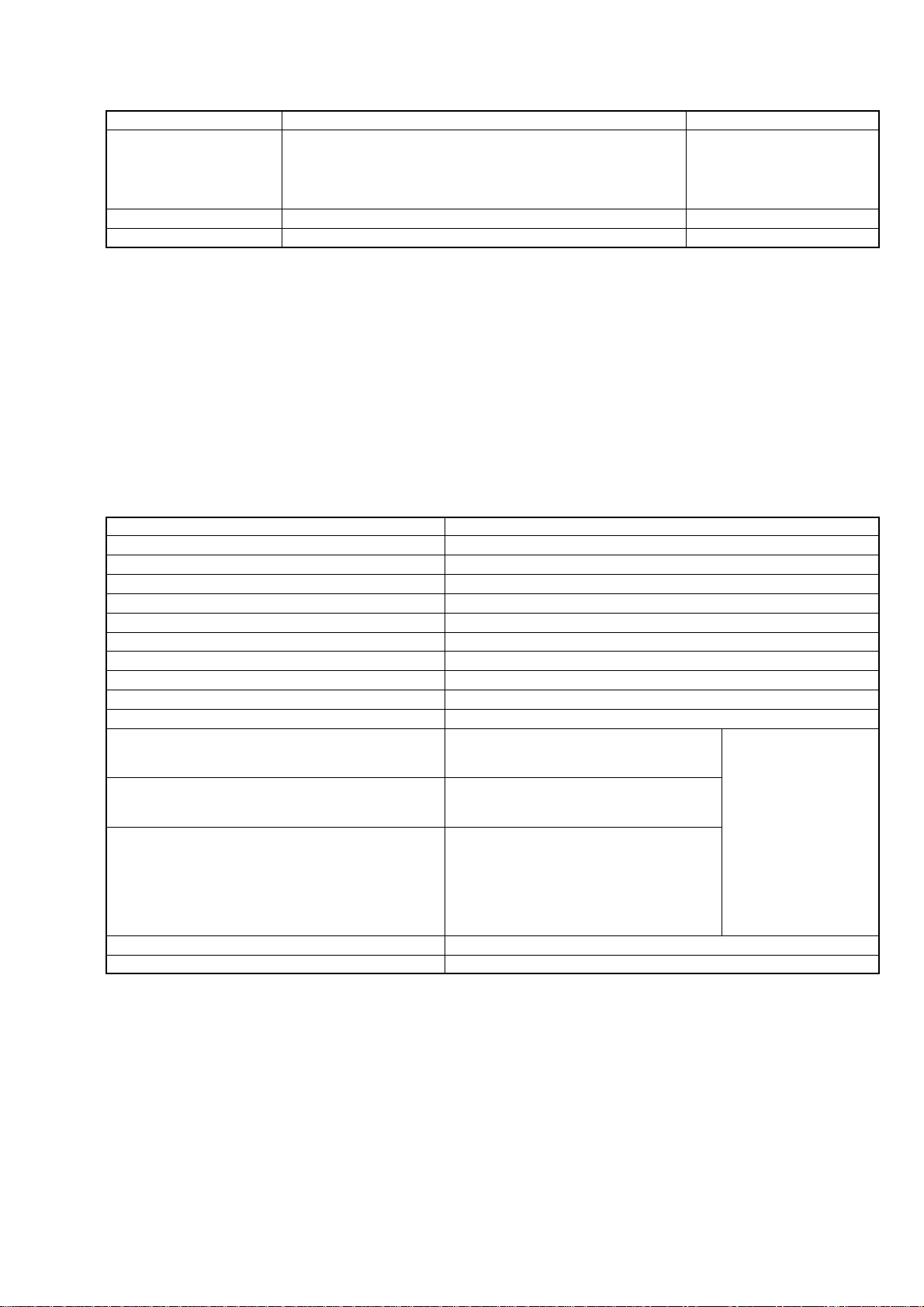

Measurement items and specifications

Measurement item Description Specifications (unit: second)

RL Time required for the table to make one complete rotation. 6.0 to 7.5

(R: Clockwise rotation. L: Counter-clockwise rotation)

CLOSE Time required to close the tray. <3.7

BU UP Time required for the BU block to perform chucking from the DOWN position <1.4

EXOPEN The XCHANGE OPEN time <2.6

EXCLOSE The EXCHANGE CLOSE time <3.8

BU DOWN Time required for the BU block to perform unchucking and going to the DOWN <2.7

position

OPEN Time required to open the tray <3.2

24

SCD-C222ES

5-6 . AGING MODE

(• Perform as necessary)

5-6-1. The aging can be performed to the set in the test

mode.

The aging can be continued by the set number of times or until an

error occurs.

In the aging, the following operations are repeated.

Table turntDisc chuckingt Disc detecttServo ontAuto

adjustmenttTOC readingtPlay of first track for 5 secondtPlay

of last track for 5 secondtPlay of first track for 5 secondtDisc

unchucking

Setting Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “94. SET AGING” and press the [ AMS ] dial

lL

lL

to enter.

2. When “A GING TIMES” is displayed, rotate the [ AMS ]

lL

dial to set the number of aging times. (For the number of times,

every 10 times can be set. Setting 0 (zero) eliminates the count

limitation where the aging is repeated until an error occurs)

Note: Do not perform unmanned overnight aging..

3. Press the [ AMS ] dial, and “AGING START” will be

lL

displayed instantaneously, then “DISC IN & JOG ON” will be

displayed and the tray will come out automatically.

4. Place a disc (CD or the SACD SL disc) on the tray. In the case

of SCD-C222ES, the multiple discs can be placed. Even when

the discs (CD or the SACD SL disc) of different types are

mixed, the aging test can be performed. Use the [DISC SKIP]

key when placing a disc. When discs are placed in positions,

turn the [ AMS ] dial.

lL

5. The aging test starts.

6. At the completion of aging by the set number of times, the

tray will come out automatically and the check will stop.

Typical time required for aging About 1 hour/100 times

“AGING SUCCESS!” will be displayed if no error occurred

in the aging, or the error will be displayed if an error occurred.

(Refer to the following error list)

5-6-2. Aging Mode of the Panel Door Independently

1. Start up the unit in the normal operation mode.

2. While press the

[ ] key, turn the [ AM S ] dial and then

x

lL

press the [CONTINUE] key. (The pro gram does not advance

if these keys are not pressed in the above sequence.)

3. The panel door repeats opening and closing.

4. The messages “AP-B 000000” (during open) t “AP-C

000000” (during close) are repeated on the FL display. Number of times of open/close are displayed in decimal number in

“000000” with OPEN/CLOSE as a set.

5. Press the [ ] key to terminate the aging mode and to return to

x

the normal mode.

5-7. SHIPPING MODE

The repaired set must be initialized, and for this purpose the set

should be set to the shipping mode.

Setting Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “8d Set Up Init” and press the [ AMS ] dial to

lL

lL

enter.

2. “8D 000000000 00” will be displayed, and if the scroll starts

in the left direction, the set initialization has completed

3. Press the [POWER] button to turn the power off.

Note: Take care not to leave the test disc in the set.

The following setups are established in the SHIPPING MODE

1. Initializa tion of EEPROM (IC903)

• PLAY MODE ALL DISCS, CONTINUE

• COMMAND MODE CD1

• LAYER SELECT SACD

• M/2CH SELECT MULTI

• DIGITAL FILTER STD

• 2ch SPK MODE 2ch DIRECT

• Mch SPK MODEMch DIRECT

• Resetting the accumulated hours meter.

2. Chucking at the DISC1 position.

Error List

An error occurring during the check in the aging mode of the test mode is displayed automatically (scroll display) immediately when the

error occurred.

< How to view the error history >

1. Select “95 DISP ERROR” with the [ AMS ] key, and press the [ AMS ] key once.

lL lL

2. The error that has occurred lastly in the set and the signal status (H = 1, L = 0) at that time are displayed on the FL display by scrolling.

(Types of the errors and the signal status that can be checked, are the same as the error display of the aging mode.)

3. Press the [ AMS ] key once again to show the error history repeatedly.

lL

4. When the error history is displayed with scrolling once, the mode returns to the normal test mode.

25

SCD-C222ES

Error display is as follows.

Error name, Disc type, IN SW (Sled in switch state), FOK (FOK signal state), LOCK (LOCK signal state), From (Displayed if effective),

To (Displayed if effective), Aging times (Displayed in aging mode only)

Display example

ACCESS MOVE ERROR : SACDSL : IN SW 1 FOK 0 LOCK 0 : FROM 205663 : TO 2461601 : TIMES 5

(Error name) (Disc type) (Sled in switch, FOK, LOCK signal state) (Relative address) (Relative address)(Aging times)

Display Items List:

Display items Description Remarks

Error name tRefer to the error display list

IN SW Sled in switch state when an error occurred

FOK FOK signal state when an error occurred

LOCK LOCK signal state when an error occurred.

From Displayed if effective in the error item Disc PSN (relative address) is

To Displayed if effective in the error item Disc PSN (relative address) is

0: switch off Not limit in

1: switch on Limit in (Optical pick-up is at most inward track)

FOK signal Is focus on?

0: FOK L (Focus off), 1: FOK H (Focus on)

LOCK signal Is PLL lock?

0: LOCK L Not lock, 1: LOCK H Lock

tRefer to the error display list displayed in case of access error

tRefer to the error display list displayed in case of access error

Error Display List:

Error display Error description Main causes of errors

DISC DETECT ERROR Disc type error Optical pick-up, RF amplifier or CD

OFFSET ADJUST ERROR Offset adjustment error Optical pick-up, RF amplifier or CD

FCS SRV ON ERROR Focus servo error From:1 means focus search failed

CLV SRV ON ERROR CLV servo error Defocusing

E-F BALANCE ERROR E-F balance adjustment error Defocusing

TRK SRV ON ERROR Tracking servo error Tracking servo on time out

SLD SRV ON ERROR Sled servo error Sled servo on time out

FOCUS BIAS ERROR Focus bias adjustment failed Defocusing during adjustment

FCS AGC ERROR Error at focus gain automatic adjustment Defocusing during adjustment

TRK AGC ERROR Error at tracking gain automatic adjustment Defocusing during adjustment

ACCESS 1TJ ERROR Access Error at one-track jump Access failed

ACCESS FINE ERROR Access Error at fine search Access failed

ACCESS MOVE ERROR Access Error at M-track MOVE Access failed

WHILE PLAYING ERROR Error during disc playing Defocusing

FCS JUMP ERROR Time out error at focus jump Defocusing

MIRR measured time is displayed in From: DSP IC is faulty

DSP IC is faulty

An error code is displayed in From: From:2 means defocusing

Optical pick-up, RF amplifier or CD

DSP IC is faulty

An error code is displayed in From: Description of display

An error code is displayed in From

From:1 means retry failed 3 times

From:2 means abnormal value

Optical pick-up, RF amplifier or CD

DSP IC is faulty

Optical pick-up, RF amplifier or CD

DSP IC is faulty

Optical pick-up, RF amplifier or CD

DSP IC is faulty

Effective addresses (PSN) are displayed in From: and To: Defocusing at access, etc

Effective addresses (PSN) are displayed in From: and To: Defocusing at access, etc

Effective addresses (PSN) are displayed in From: and To: Defocusing at access, etc

Focusing retry failed

Focusing retry failed

System errors are as follows.

Note: This error is not saved in the set.

Display Description

Toc Error * Error during the time from auto adjustment to TOC reading, Different type of disc (Such as a DVD disc), Disc is dirty

Toc Error **** Illegal SACD (Such as a pirated version)

Read Error Music data read error (Error during disc playing)

26

SCD-C222ES

e

A

B

VC

Center fo the waveform

Traverse waveform

5-8. WAVEFORMS CHECK

This set performs automatic adjustment for each disc, and therefore the set need not be adjusted when parts are replaced, but it

requires checking following the description in this section, 5-1.

IC AND FLUORESCENT DISPLAY TUBE CHECK and 5-2.

AUTO CHECK.

For the check, the test mode is used. Wrong setting causes a trouble,

thus requiring extreme care.

BU Electrical Adjustment Mode

The BU electrical adjustment mode is used to check the S curve

waveform, traverse waveform and RF waveform. After a disc is

lL

placed on the tray, each time the

[ AMS ] dial is pressed,

the check mode is switched in order for S curve waveformt

traverse waveformtRF waveform.

Setting Method:

After setting the test mode, rotate the [ AMS ] dial to select

“9C BU DENCHO” and press the [ AMS ] dial to enter.

lL

lL

“BU MEASURE” will be displayed if the BU electrical adjustment mode becomes active.

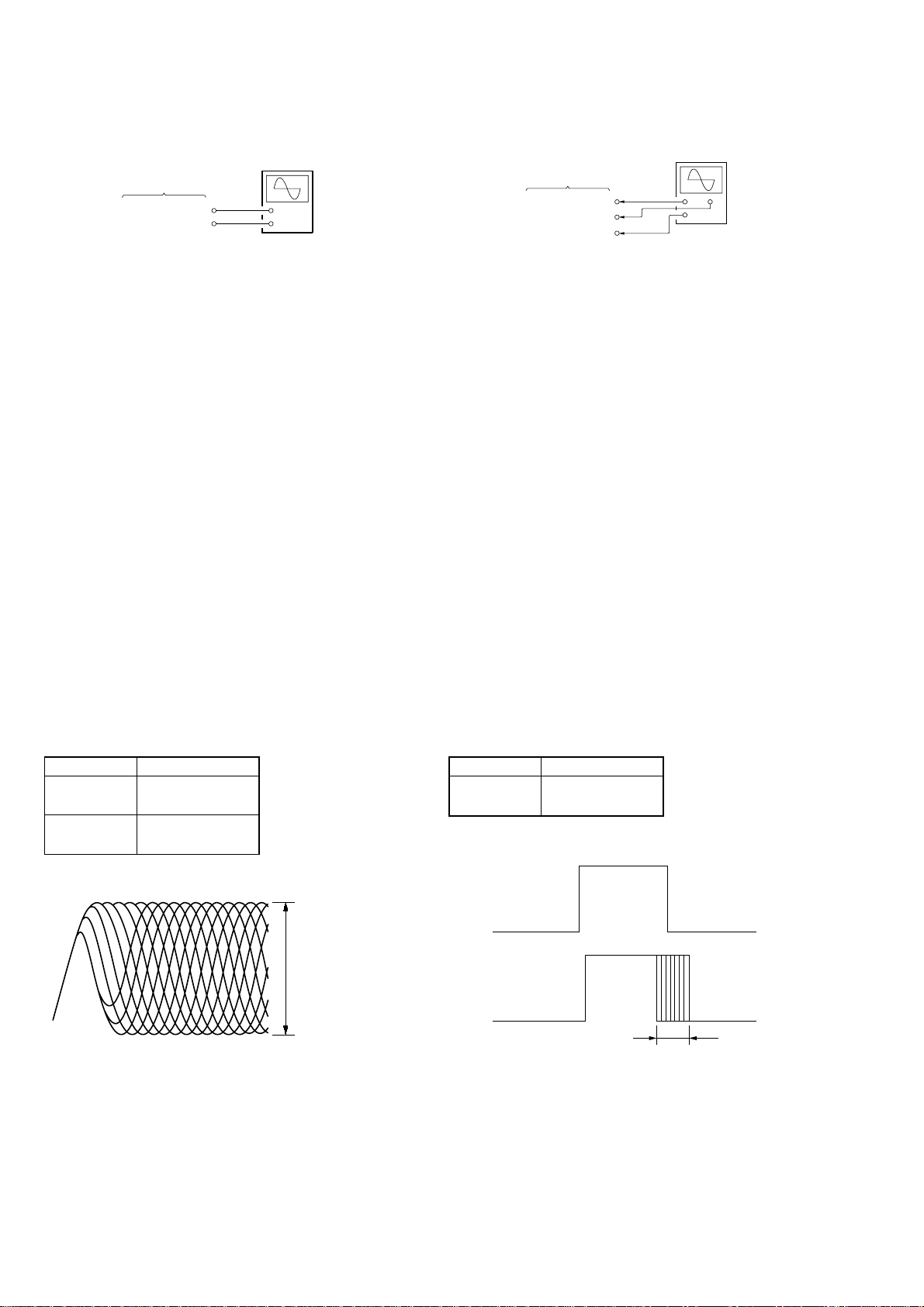

S Curve Check

Connection:

oscilloscop

MAIN board

TP506 (FE)

TP504 (AVC)

+

–

Traverse Check

Connection:

oscilloscope

MAIN board

TP513 (TE)

TP504 (AVC)

+

–

Checking Method:

1. Under the condition of S curve wav eform check mode in step

5, press the [ AMS ] dial.

lL

2. After “WAIT” is displayed, the trav erse wav eform check mode

will become active and “TRAVERSE MODE” will be displayed.

3. Connect an oscilloscope to the TP513 (TE) and TP504 (AVC)

on the MAIN board.

4. Chec k that the level A and B of waveform on the oscilloscope satisfy the specification.

Specified Value:

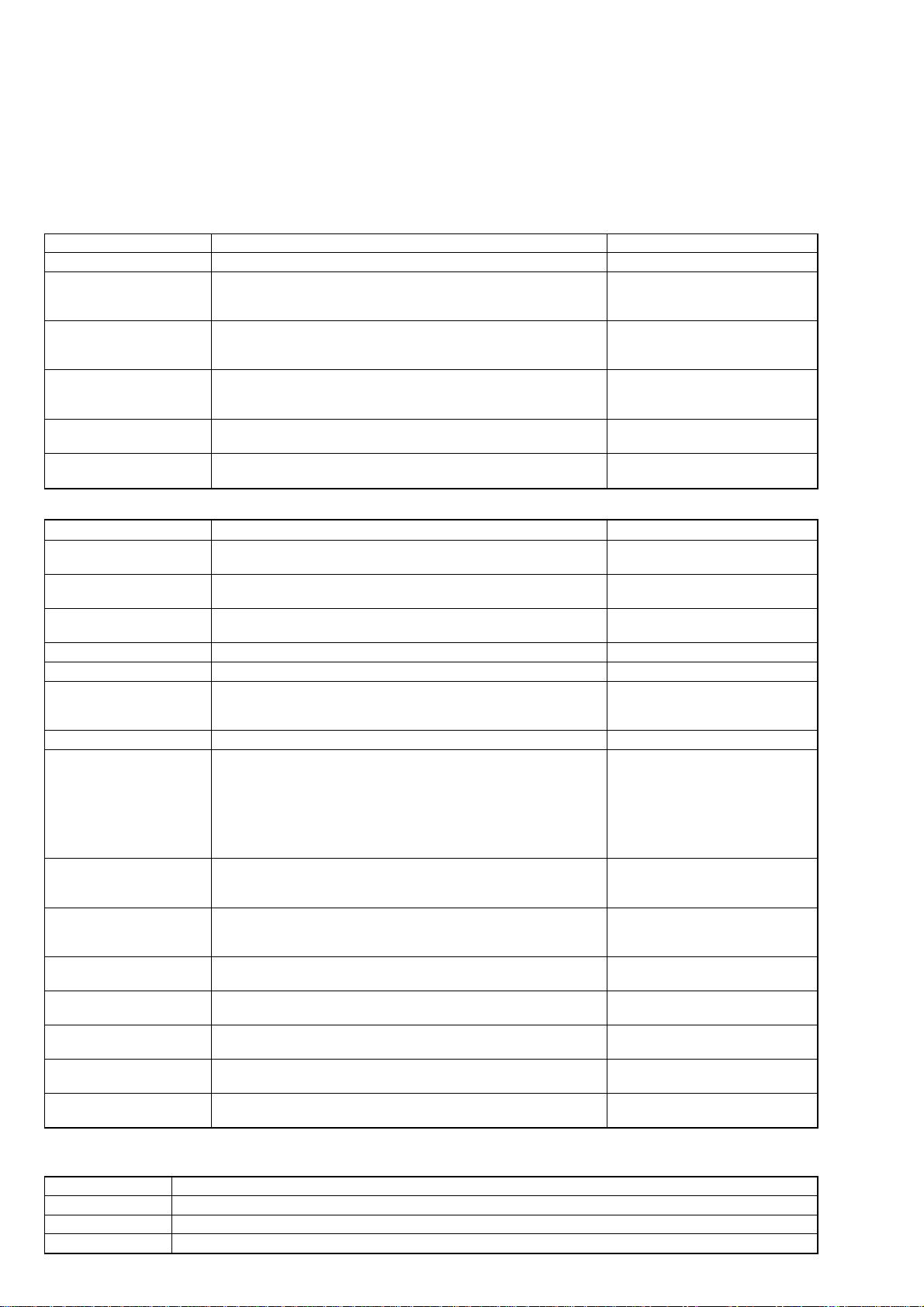

Disc AB

SATD-S5 or

SATD-S4

PATD-012 or

YEDS-18

0.6 to 1.6 Vp-p

–0.1 to +0.1V

0.5 to 1.3 Vp-p

Checking Method:

1. After setting the BU electrical adjustment, place the test disc

(PATD-012 or SATD-S5 or SATD-S4) on the tray and close

[ AMS ] dial.

the tray, then press the

lL

2. At the completion of disc type check, “CD DETECT” will be

displayed (for PATD-012 or YEDS-18).

Note: For the SA TD-S5 or SATD-S4, “SACD DETECT“ is displayed.

3. Press again the [ AMS ] dial, and the S curve waveform

l

L

check mode will become active and “S-CURVE MODE” will

be displayed.

4. Connect an oscilloscope to the TP506 (FE) and TP504 (AVC)

on the MAIN board.

5. Check that the level A and B of waveform on the oscilloscope

satisfy the specification.

Specified V alue:

Disc AB

SATD-S5 or

SATD-S4

PATD-012 or

YEDS-18

S curve waveform

VC

0.7 to 1.7 Vp-p –0.1 to +0.1V

A

B

Checking and Connecting Location : See page 29.

Note: For easier observation of this waveform, extend the sweep time

and raise the brightness.

Checking and Connecting Location : See page 29.

27

SCD-C222ES

V

e

RF Level Check

Connection:

oscilloscope

MAIN board

TP703 (RFAC)

TP704 (AGND)

+

–

Checking Method:

1. Under the condition of traverse waveform check mode in step

4, press the [ AMS ] dial.

lL

2. Connect an oscilloscope to the TP703 (RFAC) and TP704

(AGND) on the MAIN board.

3. After “WAIT” is displayed, the RF wa veform check mode will

become active and “PLAY 5th TRACK” will be displayed,

and the 5th music on the disc will be played.

4. Check that the RF waveform is clear and the level satisfies the

specification.

5. Press the [ AMS ] dial, and “OUTSIDE TRACK” will be

lL

displayed and the outward track of the disc will be played.

6. Check that the RF waveform is clear and the level satisfies the

specification.

7. Press the [ AMS ] dial, and “INSIDE TRACK” will be

lL

displayed and the inward track of the disc will be played.

8. Check that the RF waveform is clear and the level satisfies the

specification.

9. After checking, press the [ AMS ] dial, and the test is

lL

over when “BU MEASURE” is displayed.

10. Press the [ OPEN/CLOSE] button to open the tray, and re-

A

move the test disc.

11. Using each type of disc, repeat from step 1 of S curve waveform check up to step 10 of RF level check.

12. When the check is over, press the

[POWER] button to turn the

power off.

Note: Take care not to leave the test disc in the set.

CLV Jitter Check (CD only)

Connection:

oscilloscop

MAIN board

TP516 (RFCK)

TP517(WFCK)

TP808 (DG)

(CH1)

(CH2)

+

+

–

Checking Method:

1. Set the test mode.

2. Connect an oscilloscope to the TP516 (RFCK) (CH1), TP517

(WFCK) (CH2) and TP808 (DG) (GND) on the MAIN board.

3. Place the test disc PATD-012 or YEDS-18 on the tray, and

close the tray.

4. Rotate the [ AMS ] dial to select “61 DISC DETECT”,

and press the [ AMS ] dial to enter. Then, the disc type

lL

lL

will be judged.

5. Check that the disc type has been judged.

(For the P ATD-012, “DSKMOD CD” will be displayed. Refer

to the test mode, DISC DETECT command (page 16))

6. Rotate the [ AMS ] dial to select “86 ALL SRV ON”,

and press the [ AMS ] dial. Then, the disc will rotate,

lL

lL

automatic adjustment will be carried out, and all servos will

be turned on.

7. Rotate the [ AMS ] dial to select “07 DSP MON3”, and

press the [ AMS ] dial to enter.

l

lL

L

8. Check that the value A of waveform on the oscilloscope satisfies the specification.

9. Rotate the [ AMS ] dial to select “19 ALL SRV OFF”,

and press the [ AMS ] dial. Then, all servos will be

lL

lL

turned off and the disc rotation will stop.

[ OPEN/CLOSE] button to open the tray, and re-

10. Press the

A

move the test disc.

11. Press the [POWER] button to turn the power off.

Note: Take care not to leave the test disc in the set.

Specified Value:

Disc A

SATD-S5 or

SATD-S4

PATD-012 or

YEDS-18

RF signal waveform

Note: Clear RF waveform refers to the waveform where ◊ shapes should

be distinctively observed in the center.

0.65 to 1.1 Vp-p

0.45 to 0.95 Vp-p

VOLT/DIV: 200 m

TIME/DIV: 500 ns

A

Checking and Connecting Location : See page 29.

Specified Value:

Disc A

PATD-012 or

YEDS-18

CLV jitter waveform

35 µsec or less

A

Checking and Connecting Location : See page 29.

28

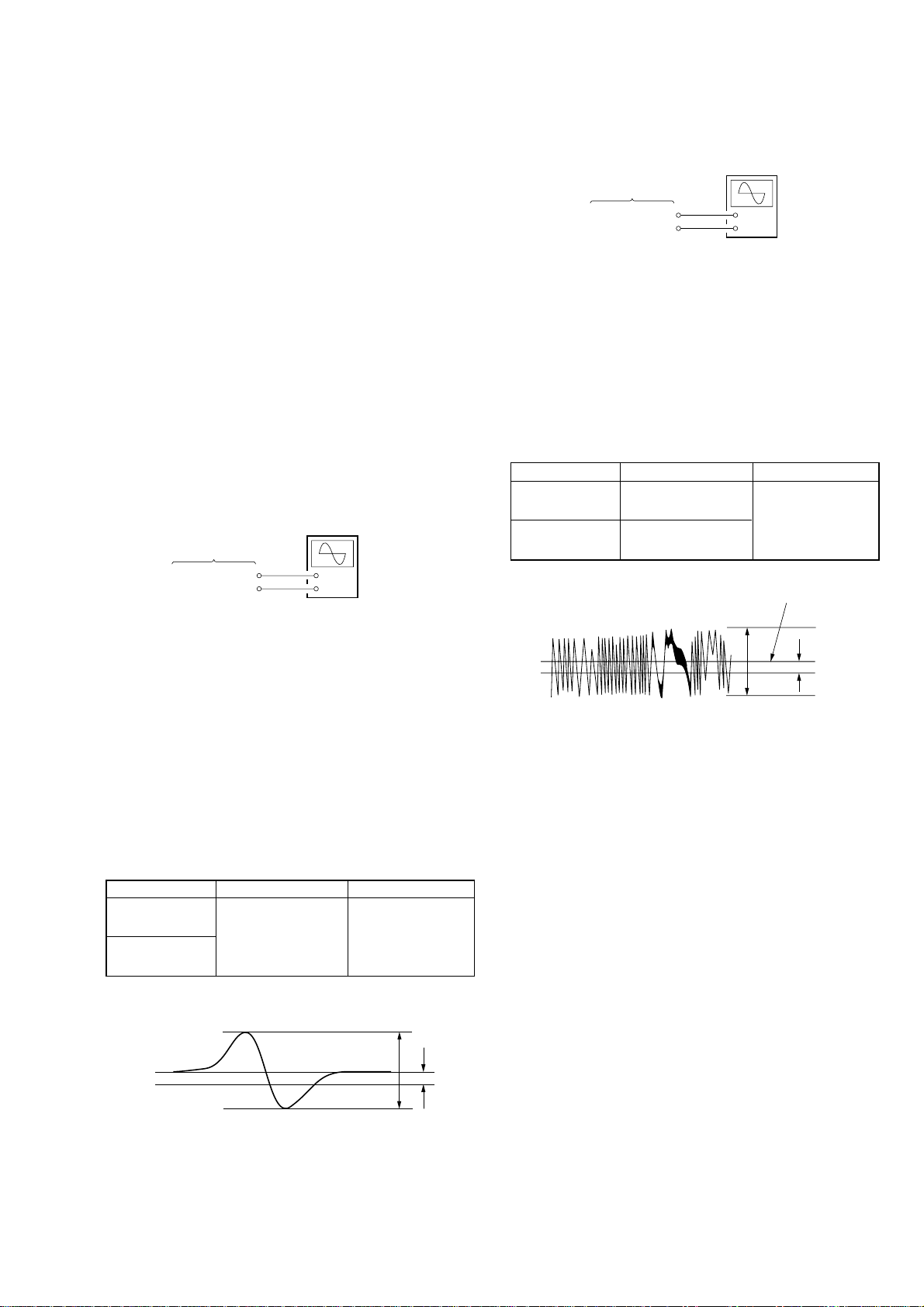

Checking and Connecting Location:

– MAIN Board (Component Side) –

TP704

TP506

(FE)

TP513

(TE)

TP504

(AVC)

IC509

(AGND)

TP516

(RFCK)

TP703

(RFAC)

SCD-C222ES

IC703

TP808

(DG)

TP517

(WFCK)

IC701

IC801

2929

SCD-C222ES

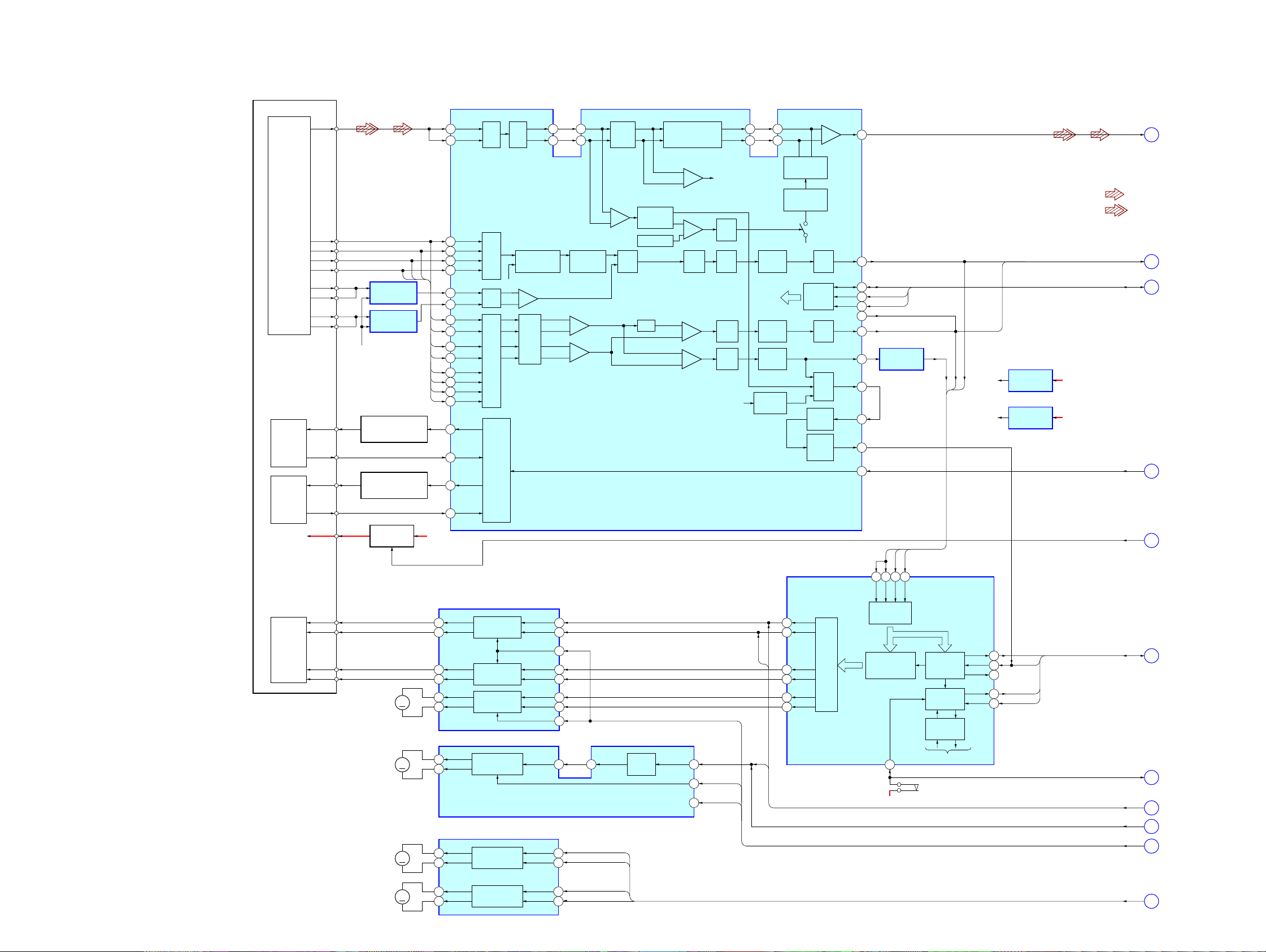

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – RF/SERVO Section –

DETECTOR

OPTICAL PICK-UP

BLOCK

(KHM-230AAA)

LASER

DIODE

(FOR CD)

LASER

DIODE

(FOR SACD)

MODULE

CIRCUIT B+

CD LD

CD PD

DVD LD

DVD PD

VMOD

RF

A

B

C

D

E

F

G

H