SCD-C2000ES

SERVICE MANUAL

Ver. 1.2 2005.10

SPECIFICATIONS

US Model

Canadian Model

Model Name Using Similar Mechanism SCD-CE595

CD Mechanism Type CDM79C-DVBU51

Optical Pick-up Name DBU-3

When a Super Audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 40 kHz (–3 dB)

Dynamic range 101 dB or more

Total harmonic distortion rate

0.003 % or less

Wow and flutter Value of measurable limit

(±0.001 % W. PEAK) or

less

When a CD is played

Frequency response 2 Hz to 20 kHz

Dynamic range 97 dB or more

Total harmonic distortion rate

0.0032 % or less

Wow and flutter Value of measurable limit

(±0.001 % W. PEAK) or

less

Output connector

ANALOG OUT (phono jacks):

Output level 2 Vrms (at 50 kilohms)

Load impedance Over 10 kilohms

DIGITAL (CD) OUT OPTICAL*

(square optical output conne c tor) :

Output level –18 dBm

DIGITAL (CD) OUT COAXIAL*

(coaxial output connector):

Output level 0.5 Vp-p

Load impedance 75 ohms

PHONES (stereo phone jack):

Output level 10 mW

Load impedance 32 ohms

*Output only the audio signals of the CD

General

Laser Semiconductor laser

(Super Audio CD: λ = 650

nm) (CD: λ = 780 nm)

Emission duration:

continuous

Power requirements 120 V AC, 60 Hz

Power consumption 15 W

Dimensions (w/h/d) 430 × 115 × 420 mm incl .

projecting parts

Mass (approx.) 5.8 kg

Supplied accessories

Audio connecting cord Red and White × 2 (2)

Black × 2 (2)

Remote commander RM-SC505 (1)

Battery R6 (size-AA) (2)

Design and specifications are subject to change

without notice.

9-879-094-03

2005J16-1

© 2005.10

SUPER AUDIO CD PLAYER

Sony Corporation

Home Audio Division

Published by Sony Engineering Corporation

SCD-C2000ES

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Upper Case ...................................................................... 8

3-3. Loading Panel.................................................................. 8

3-4. Front Panel Section ......................................................... 9

3-5. CD Mechanism Deck (CDM79C-DVBU51) .................. 9

3-6. KEY Board, LED Board, DISPLAY Board .................... 10

3-7. T able Assy ....................................................................... 10

3-8. SE-130 Board, Td Unit Assy........................................... 11

3-9. DC Motor (M901) ........................................................... 11

3-10. Pick-up Unit Section ....................................................... 12

3-11. RF Board, Pick-up Unit................................................... 12

4. DIAGRAMS

4-1. Block Diagram ................................................................ 14

4-2. Printed Wiring Board — RF Section — ......................... 15

4-3. Schematic Diagram — RF Section — ........................... 16

4-4. Printed Wiring Board — MAIN Section — ................... 17

4-5. Schematic Diagram — MAIN Section (1/4) — ............ 18

4-6. Schematic Diagram — MAIN Section (2/4) — ............ 19

4-7. Schematic Diagram — MAIN Section (3/4) — ............ 20

4-8. Schematic Diagram — MAIN Section (4/4) — ............ 21

4-9. Printed Wiring Board — DISPLAY Section — ............ 22

4-10. Schematic Diagram — DISPLAY Section —................23

4-11. Printed Wiring Board — MD-94 Board Section — ...... 24

4-12. Schematic Diagram — MD-94 Board Section — ......... 25

5. TEST MODE ............................................................... 28

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

6. EXPLODED VIEWS

6-1. Main Section.................................................................... 29

6-2. Front Panel Section ......................................................... 30

6-3. Chassis Section................................................................ 31

6-4. CD Mechanism Section (1) (CDM79C-DVBU51) ......... 32

6-5. CD Mechanism Section (2) (CDM79C-DVBU51) ......... 33

7. ELECTRICAL PARTS LIST................................ 34

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

2

SECTION 1

tapering driver

1

2

r

SERVICING NOTES

SCD-C2000ES

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leaka ge from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufactur ers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

HOW TO OPEN THE DISC TRAY WHEN POWER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and turn

in the direction of arrow.

Use a flat (-) head screwdriver to open the disc tray by manual

operation. (Flat head screwdriver with nominal blade length of

3mm.)

* To close the disc table, turn the driver in the reverse direction.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

3

SCD-C2000ES

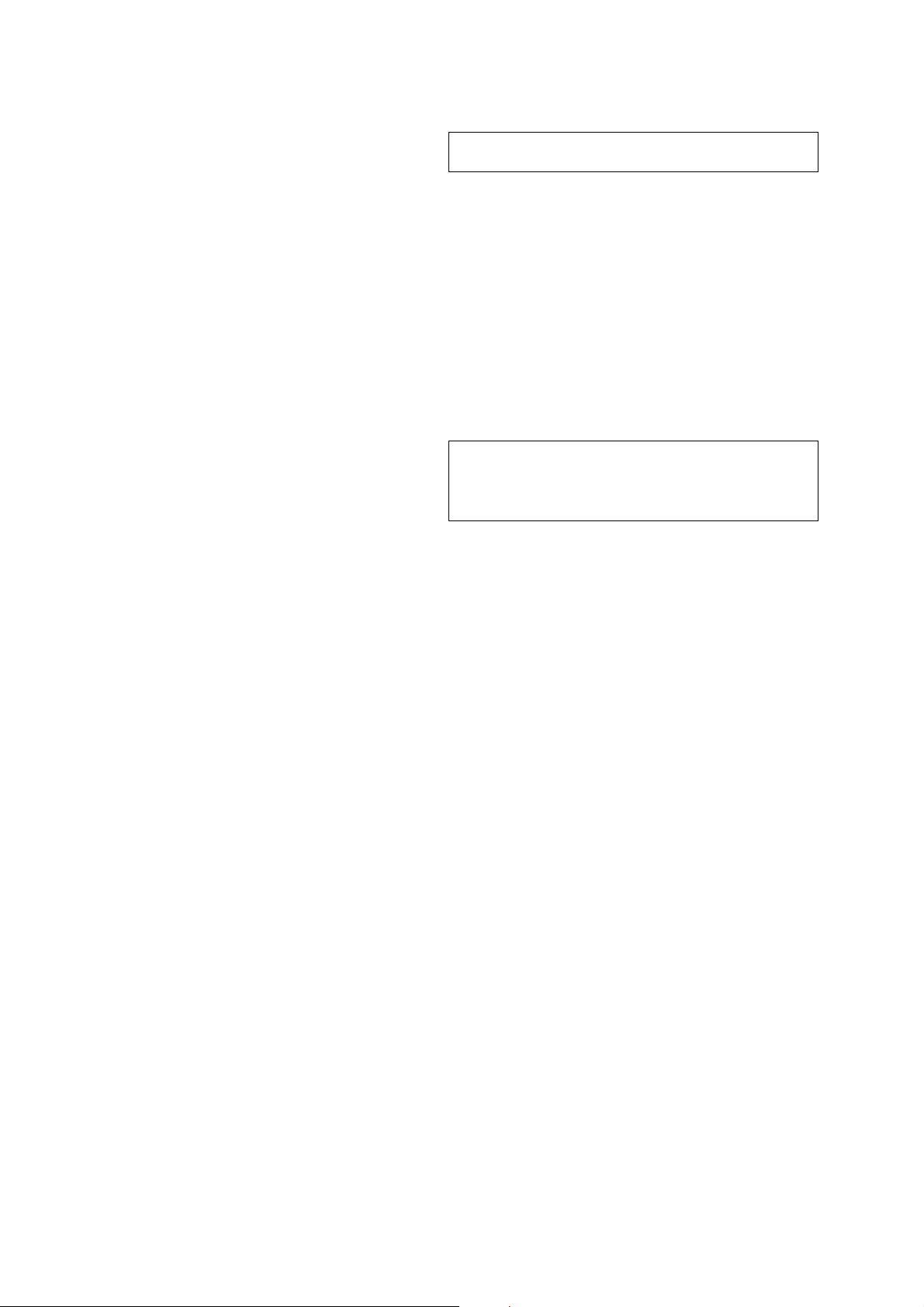

Front Panel

SECTION 2

GENERAL

This section is extracted

from instruction manual.

A POWER swit ch (9, 22)

B DISC 1-5 buttons (10, 15)

Press to select the disc directly.

C Remote sensor (6)

D Display window (11)

E N button (10, 14, 15)

F X button (10)

G x button (10, 16, 22)

H m/M buttons (1 4 , 21 )

I l AMS L dial

(AMS: Automatic Music Sensor) (9, 10, 13,

14, 15, 17, 18, 20, 21)

J EX-CHANGE button (13)

Press to replace disc s whil e playing a disc.

K DISC SKIP button (9, 13)

Press to select the disc.

L A OPEN/CLOSE button (9)

M LEVEL control

Adjust the headphones volum e.

N PHONES jack

Connect the headphones.

During playback of a Multi-chann el Sup er Audi o

CD, the same signal that is output from the

ANALOG 5.1CH OUT FRONT L/R jacks is

output from the PHON ES ja c k.

O Disc tray (9)

P MULTI CHANNEL DECODING indicator

Turns on when you turn on the player, or when the

Multi-channel Super Audio CD is loa ded and

select the m ulti-c hanne l play back area by pr essin g

MULTI/2CH.

Q TIME/TEXT button (12)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appears in the display.

In name input mode, pr ess to select the char acter

type.

R PLAY MODE button (9, 15)

Press to select the play mode.

S MULTI/2CH button (5, 10)

Press to select the playback area when a disc with

the 2 channel area and the multi-c ha nnel area is

loaded.

T SA-CD/CD button (5, 10)

Each time you press the button while playing back

a hybrid disc, the layer to be played back switches

between the SA-CD la ye r and the CD layer.

U MENU button (9, 10, 13, 17, 1 8, 20, 21)

Press to enter the menu .

Press to exit from th e menu and return to the

normal display.

4

SCD-C2000ES

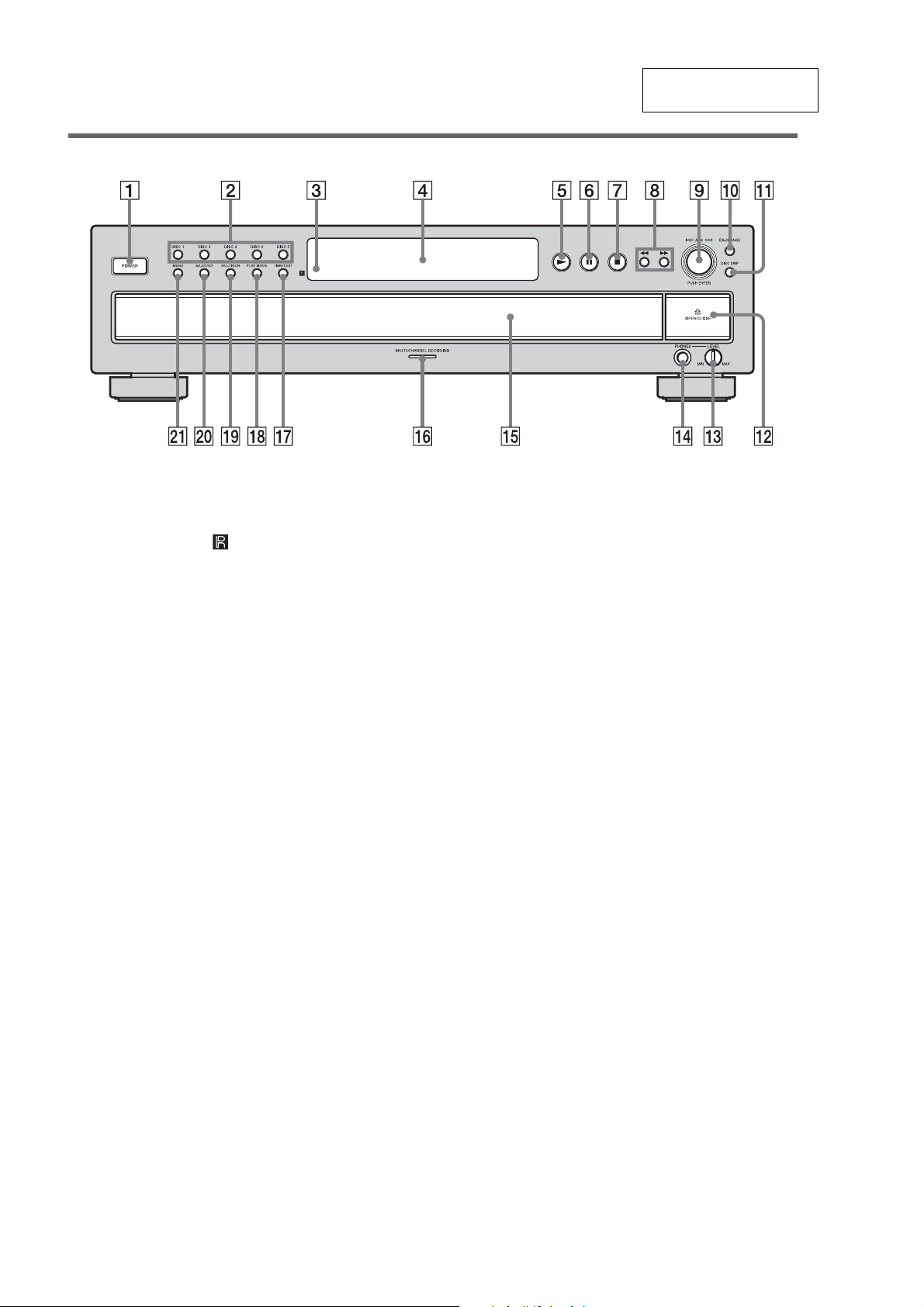

Rear Panel

A ANALOG 2CH OUT jacks (7)

B ANALOG 5.1CH OUT jacks (6)

C DIGITAL (CD) OUT COAXIAL connector (8)

D DIGITAL (CD) OUT OPTICAL connector (8)

E IR REMOTE IR IN jack

Connect to a component equipped with the IR

output jack.

5.1CH OUT2CH OUT

OPTICALCOAXIAL

SURR

L

L

R

R

CENTER

SUB

WOOFER

FRONT

OUT

ANALOG DIGITAL(CD) IR REMOTE

IR

IN

5

SCD-C2000ES

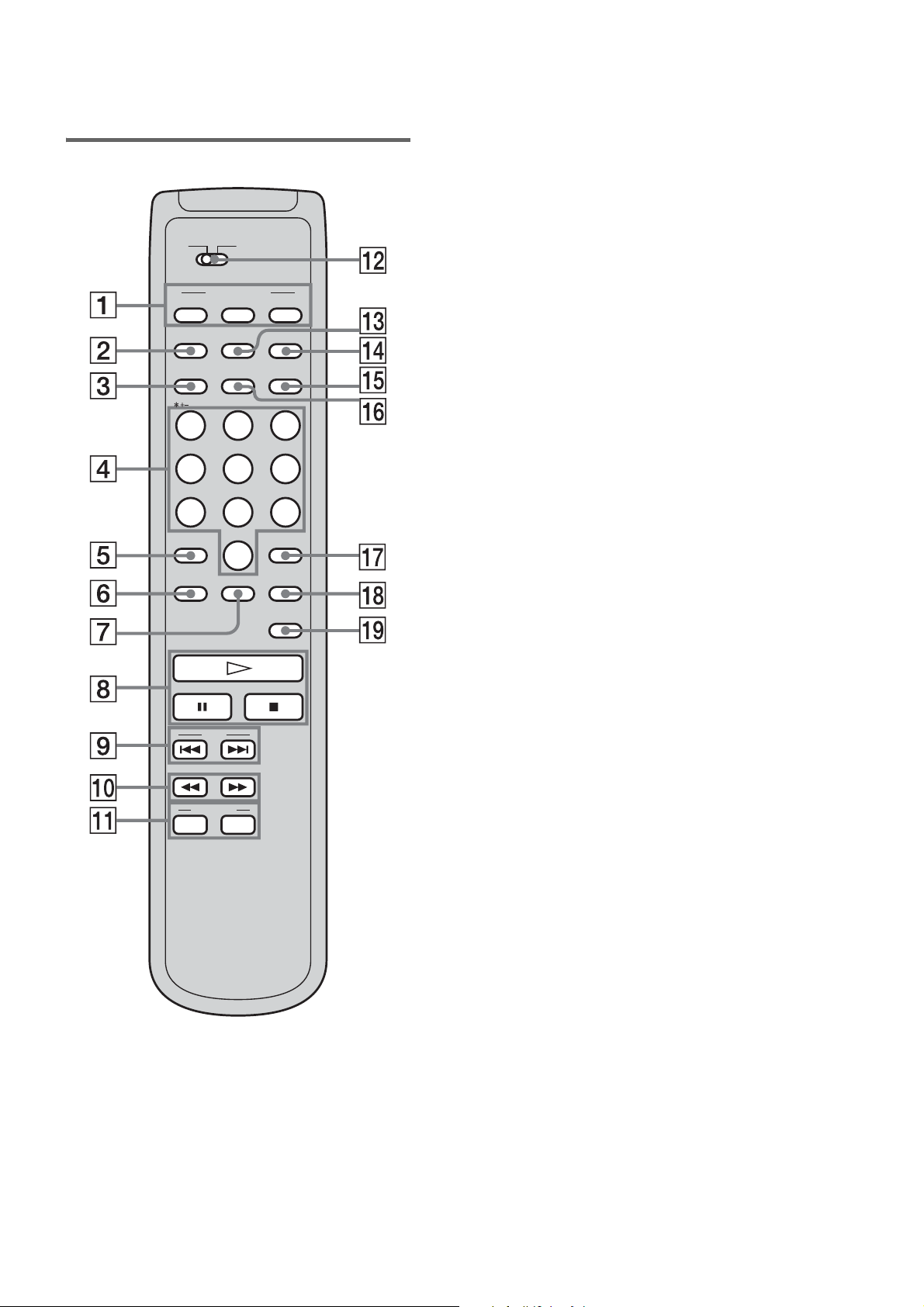

Remote

CD2

CD1

PLAY MODE

CONTINUE SHUFFLE

NAME

INPUT

TIME/TEXT

DISC

CAPS

PROGRAM

DISPLAY

SA-CD/CD

MODE

MULTI/2CH

SPACE

ABC DEF

123

JKL MNOGHI

456

TUV WXYZPQRS

78

>10 ENTER

10/0

REPEAT CHECK

AMS

DISC SKIP

–+

9

CLEAR

LEVEL

ADJ

A CONTINUE button (9, 15, 16)

Press to resume Continuous Play from Shuffle Play

or Program Play.

SHUFFLE button (15)

PROGRAM button (15)

B NAME INPUT button (21)

Press to enter the nam e in put mode.

C DISC button (10, 15)

Press to select the disc .

CAPS button (21)

Press to switch be tween capital lett ers (ABC) and

numbers (123) in name input mode.

D Numeric buttons (10, 15, 21 )

E >10 button (10, 15)

F REPEAT button (14)

G CHECK button (16)

Press to check the programed order.

H H button (10, 14, 15)

X button (10)

x button (10, 16, 22)

I AMS ./> buttons

(AMS: Automatic Music Sensor) (9, 10, 13,

14, 15, 17, 18, 20, 21)

J m/M buttons (14, 21)

K DISC SKIP +/– buttons (9, 13)

Press to select the disc .

L CD1/2 (command mode) switch (9)

Select the command mod e .

M DISPLAY MODE button (13)

Press to turn the displa y information o ff or o n.

N SA-CD/CD button (5, 10)

Each time you press the button while playing back

a hybrid disc, the layer to be played back switches

between the SA-CD la ye r and the CD layer.

O MULTI/2CH button (5, 10)

Press to select the playback area when a disc with

the 2 channel area and the multi-c ha nnel area is

lo aded.

P TIME/TEXT button (12)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appears in the display.

SPACE button (21)

Press to insert a space in name input mode.

Q ENTER button (9, 10, 13, 15, 17, 19, 2 0, 22)

R CLEAR button (15, 16, 22)

Press to delete a programe d tr a c k n umber.

S LEVEL ADJ button (18)

Press to adjust the output level balance for the

Multi-channel management function.

6

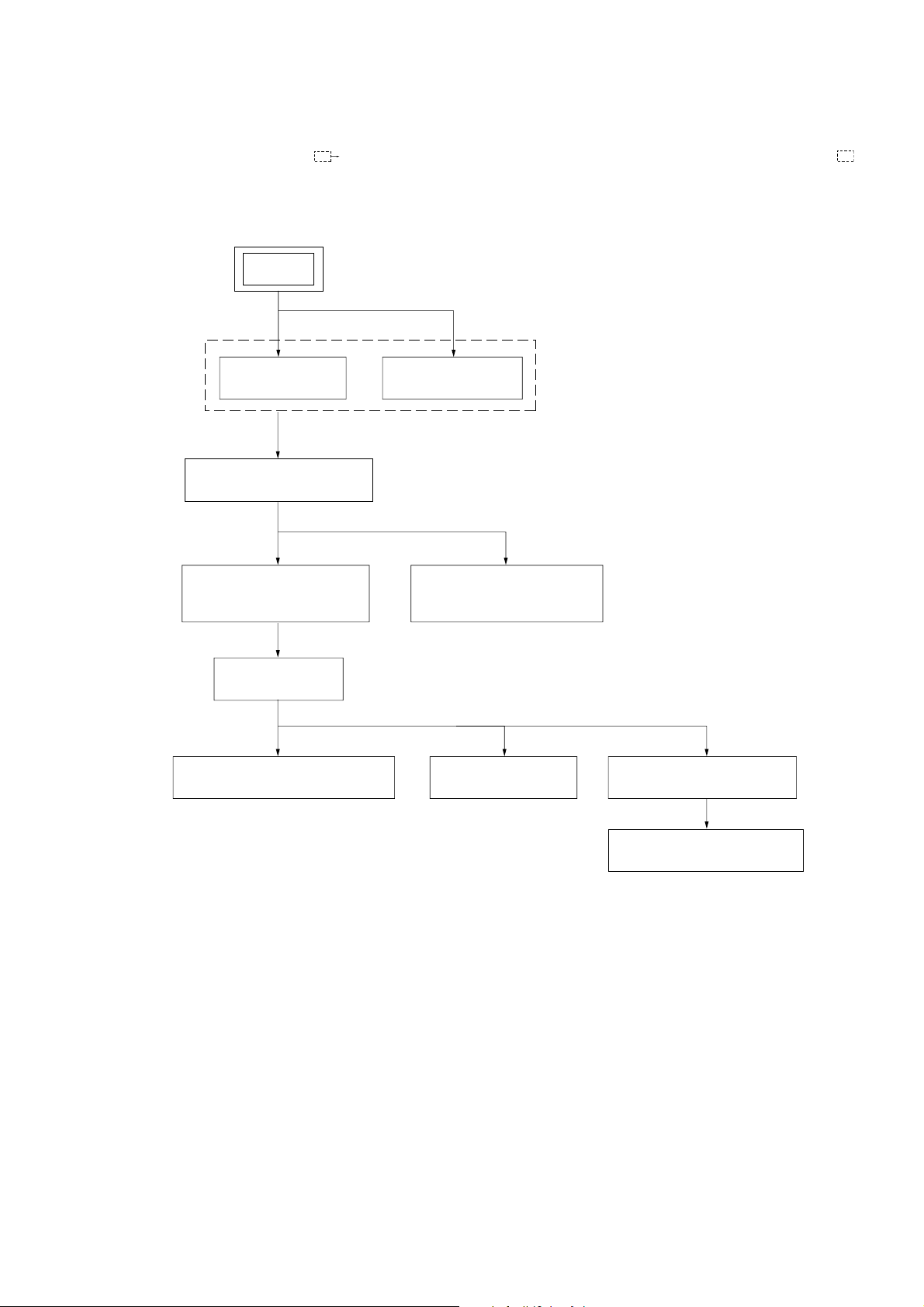

•This set can be disassembled in the order shown below.

•The dotted square with arrow (

) prompts you to move to the next job when all of the works within the dotted square ( ) are

completed.

3-1. DISASSEMBLY FLOW

SET

SCD-C2000ES

SECTION 3

DISASSEMBLY

3-2. UPPER CASE

(Page 8)

3-4.FRONT PANEL SECTION

(Page 9)

3-5.CD MECHANISM DECK

(CDM79C-DVBU51)

(Page 9)

3-7.TABLE ASSY

(Page 10)

3-8.SE-130 BOARD, TD UNIT ASSY

(Page 11)

3-3. LOADING PANEL

(Page 8)

3-6.KEY BOARD, LED BOARD,

DISPLAY BOARD

(Page 10)

3-9.DC MOTOR (M901)

(Page 11)

3-10.PICK-UP UNIT SECTION

(Page 12)

3-11.RF BOARD, PICK-UP UNIT

(Page 12)

7

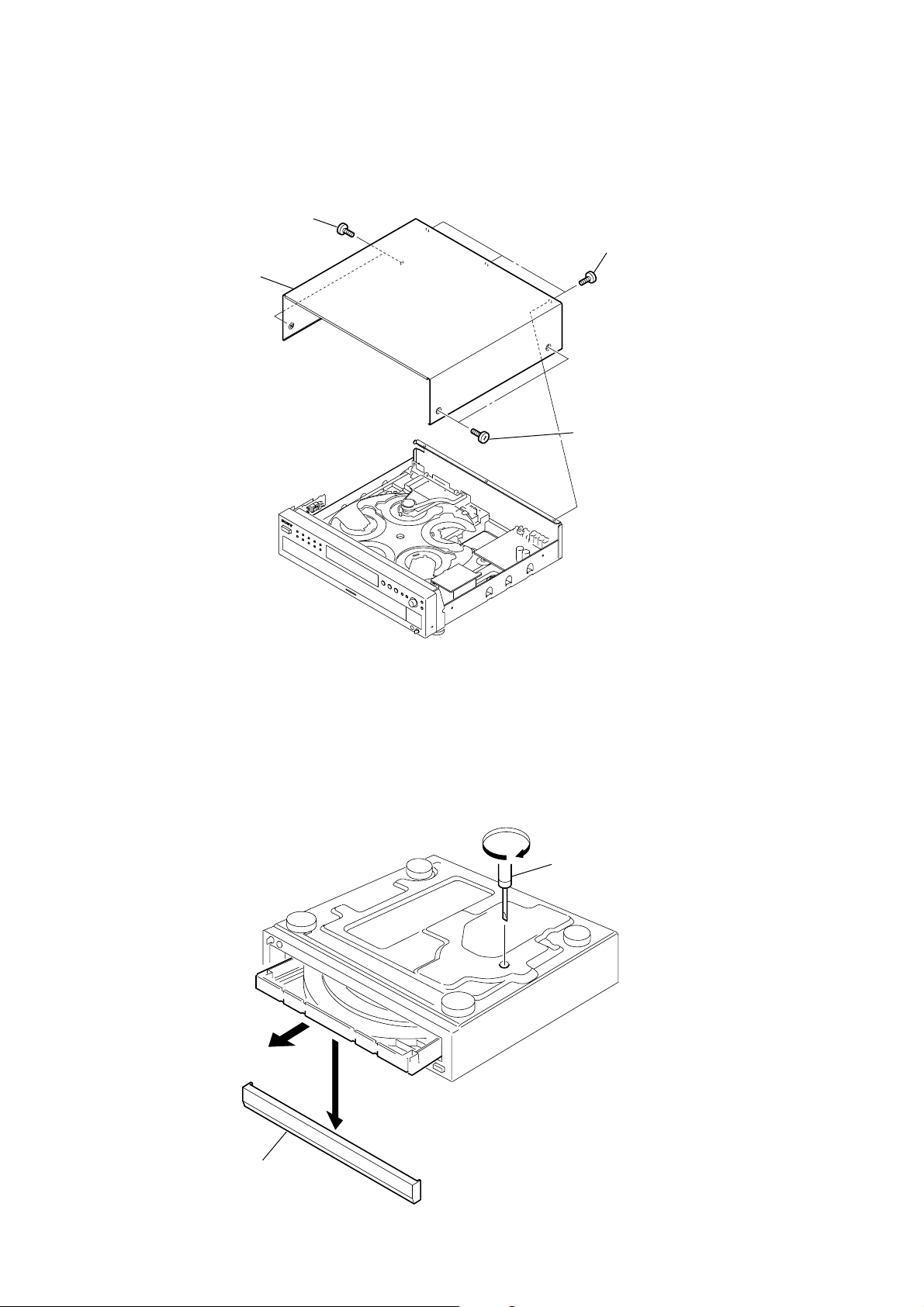

SCD-C2000ES

s

r

Note: Follow the disassembly procedure in the numerical order given.

3-2. UPPER CASE

1

two screws

(BV/RING)

4

upper case

2

3

two screws

(BV/RING)

three screw

(BV/RING)

3-3. LOADING PANEL

2

loading panel

3

1

tapering drive

8

)

3-4. FRONT PANEL SECTION

)

4

connector

(2p) (CN891)

8

three screws

(+BVTP 3

9

front panel section

×

7

four screws

(+BVTP 3

8)

1

×

5

screw

(+BVTP 2.6

connector

(2p) (CN101)

8)

SCD-C2000ES

×

8)

3

wire (flat type)

(13 core) (CN703

6

screw

2

connector

(3p) (CN881)

(+BVTP 2.6

×

8)

3-5. CD MECHANISM DECK

(CDM79C-DVBU51)

8

9

CD mechanism deck

(CDM79C-DVBU51)

two screws

(+BVTP 3

gear (shaft)

4

7

×

8)

two screws

(+BVTP 3

5

wire (flat type)

(31 core) (CN702

6

connector

(11p) (CN001)

×

8)

2

sub shassis

1

3

Turn the gear (shaft) in the

direction of the arrow.

three screws

(+BVTP 3

×

8)

9

SCD-C2000ES

)

3-6. KEY BOARD, LED BOARD, DISPLAY BOARD

q;

claw

qa

DISPLAY board

9

connector

(2p) (CN804)

5

connector

(2p) (CN814)

8

6

LED board

connector

(3p) (CN805)

2

connector

(3p) (CN813)

7

3

nine screws

(+BVTP 2.6

4

two screws

(+BVTP 2.6

KEY board

×

8)

×

8)

1

four screws

(+BVTP 2.6

×

8

3-7. TABLE ASSY

4

6

plate (guide)

screw

(+BTP 2.6

5

claw

×

8)

3

7

screw

(+BTP 2.6

qa

table assy

1

floating screw

(+PTPWH M2.6)

2

tray

0

flat type wire

(6 core) (CN002)

×

8)

10

plate (guide)

9

8

claw

3-8. SE-130 BOARD, TD UNIT ASSY

4

two screws

(+BTP 2.6 × 8)

6

SE-130 board

1

connector

(CN102)

5

flat type wire

(6 core) (CN101)

0

8

two screws

(+P 3

table assy

qa

TD belt

×

3)

TD unit assy

SCD-C2000ES

7

two screws

(+BTP 2.6 × 8)

9

TD motor assy

3-9. DC MOTOR (M901)

5

connector

(CN004)

2

claw

3

claw

6

DC motor (M901)

4

two screws

(+P 2.6

3

belt (loading)

2

gear (loading A)

×

4)

1

screw

(+PTPWH M2.6)

11

SCD-C2000ES

y

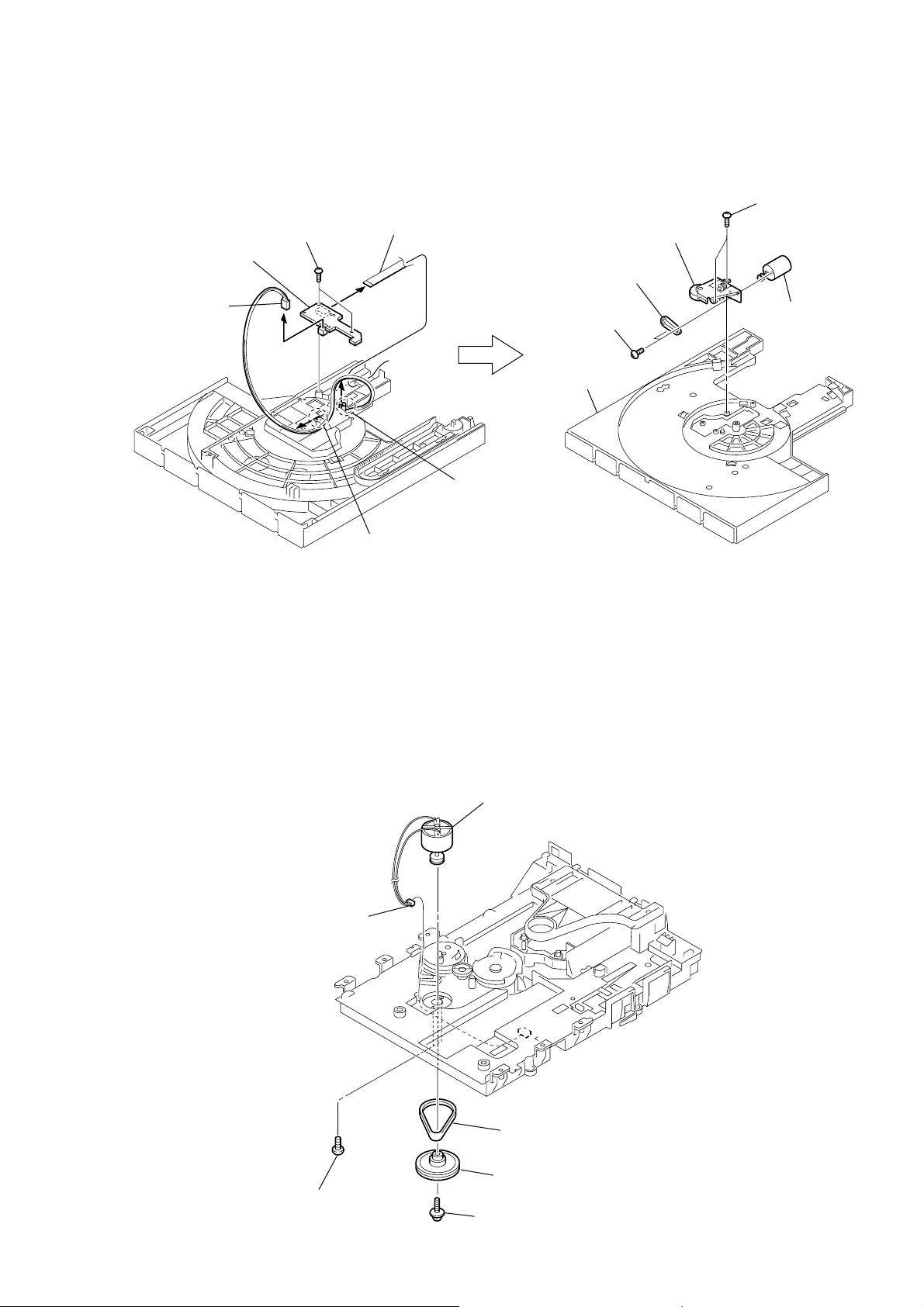

3-10. PICK-UP UNIT SECTION

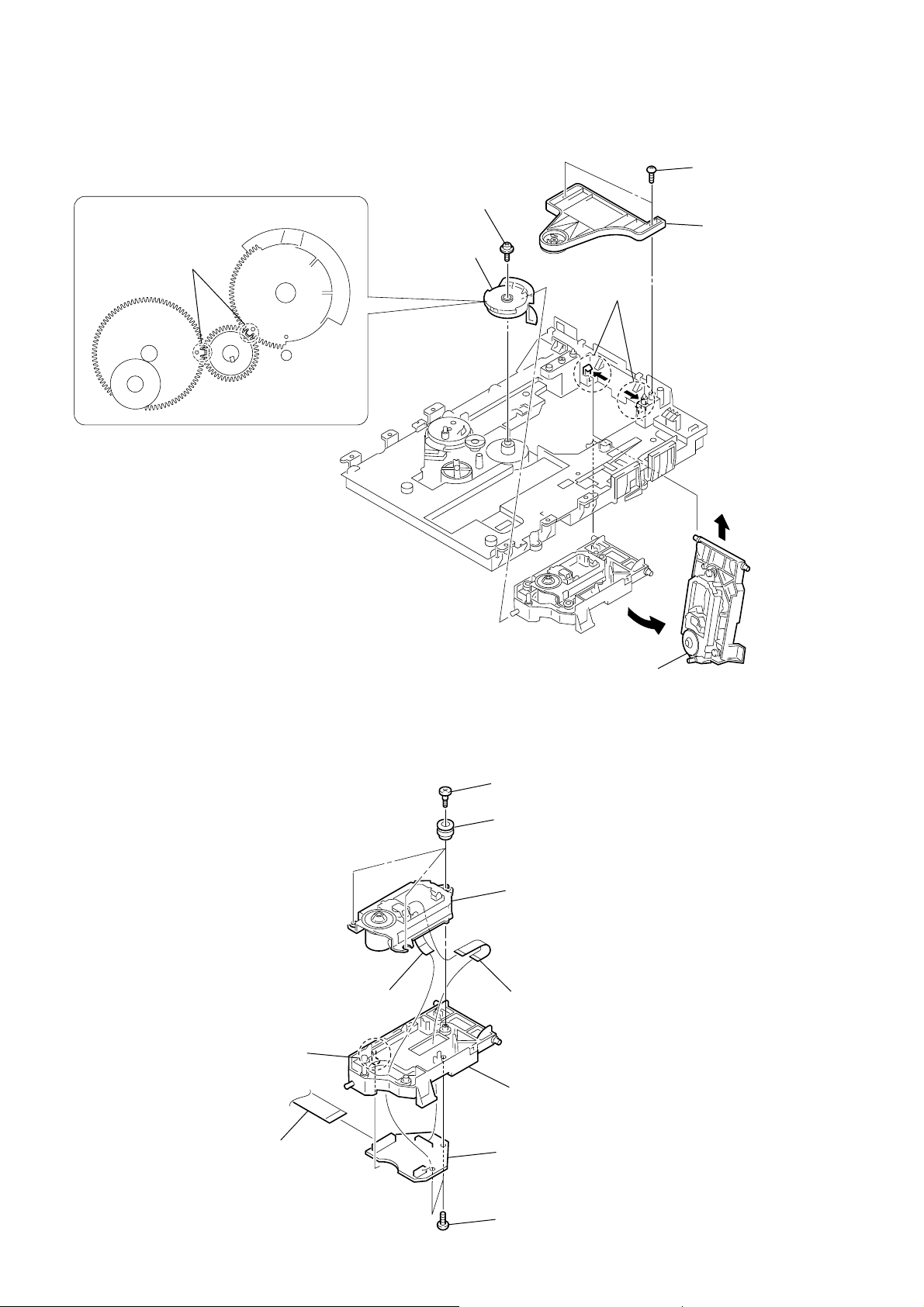

PRECAUTION DURING GEAR (CHUC)

adjust phases

gear (chuck)

3

screw

(+PTPWH M2.6)

4

gear (chuck)

1

two screws

(+BV B3)

2

chuck ass

gear (loading B)

gear (idoler)

6

two claws

8

pick-up unit section

7

5

3-11. RF BOARD, PICK-UP UNIT

4

(CN003)

2

5

flexible flat cable (31 core)

(CN002)

flexible flat cable (9 core)

claw

7

three step screws (M)

8

three insulators

9

pick-up unit

3

flexible flat cable (24 core)

(CN001)

9

holder (BU) assy

6

RF board

12

1

two screws

(+BTP 2.6

×

10)

SECTION 4

DIAGRAMS

SCD-C2000ES

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

• f : internal component.

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

These are omitted.

Note Schematic Diagrams.

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note:

The components identified by mark 0 or dotted line with mark 0 are

critical for safety.

Replace only with part

number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark: SACD PLAY

( ) : CD PLAY

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage v ariations ma y be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage v ariations ma y be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : CD DIGITAL OUT (OPTICAL)

4

W or less unless otherwise

Note:

Les composants identifiés

par une marque 0 sont critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

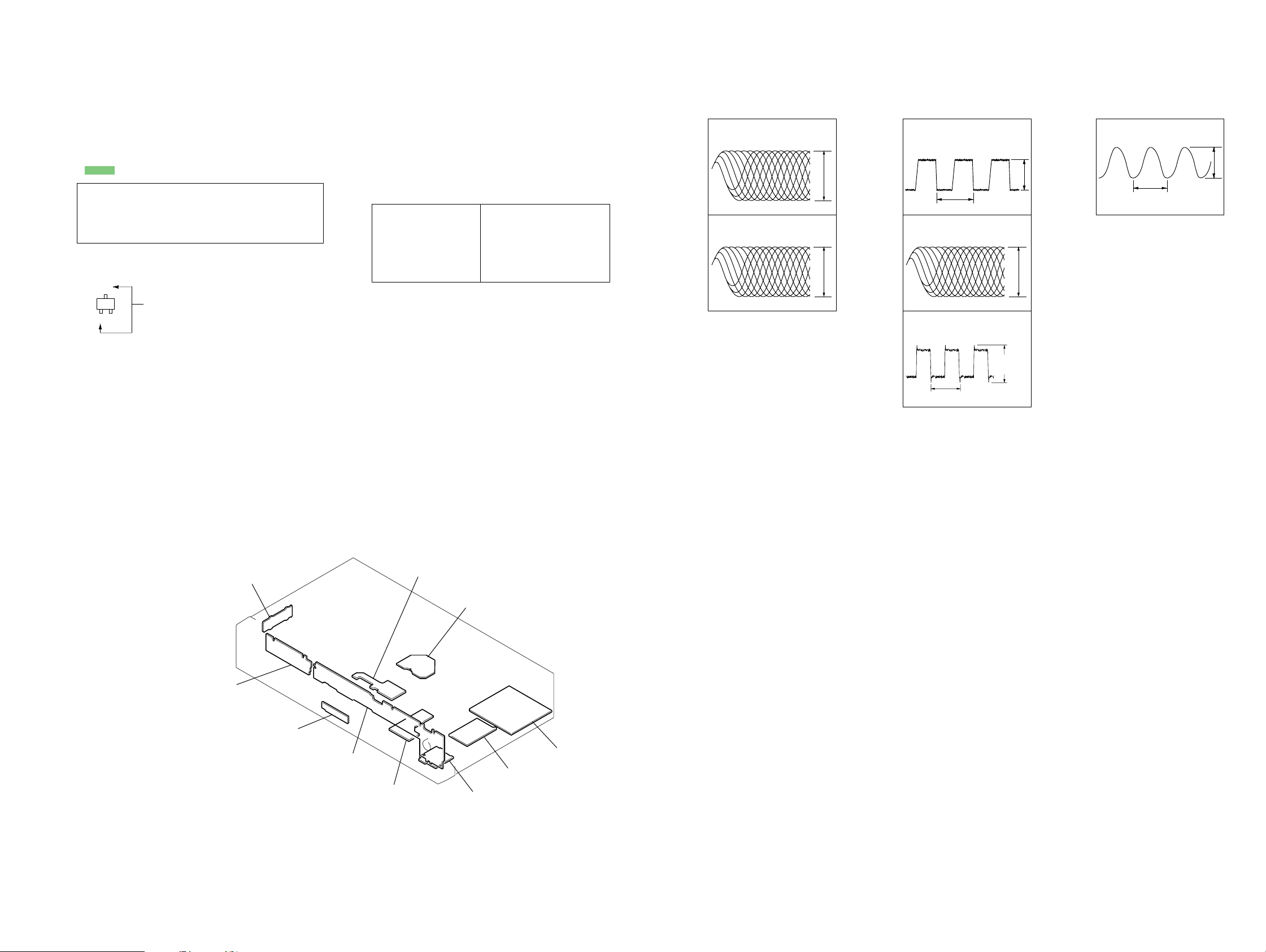

•Waveforms

– RF Board – – MAIN Board – – DISPLAY Board –

5

1

IC001 tl SIGO (CD)

200 ns/DIV

1

IC001 tl SIGO (SACD)

40 ns/DIV

1.4 Vp-p

1.4 Vp-p

2

IC706 uk DSPHREFO

354 ns

3

4

<z./

IC706

40 ns/DIV

RF IN (SACD)

1.4 Vp-p

IC320 2,4,6,q;,qs

88.6 ns

3.3 to 3.5

Vp-p

3.3 to 3.5

Vp-p

IC801 3 X1

200 ns

3.1 Vp-p

1 V/DIV, 200 ns/DIV

• Circuit Boards Location

KEY board

POWER SW board

LED board

DISPLAY board

MD-94 board

SE-130 board

RF board

MAIN board

PT board

HP board

SCD-C2000ES

1313

SCD-C2000ES

4-1. BLOCK DIAGRAM

TURN TABLE

MOTOR

PH101

PH102

IC309(1/2)

HEADPHONE AMP

611

BUFFER

Q341

+3.3V

IC950

+5V REG

IC985

AU+ REG

D OUT

MUTE

OPTICAL PICK-UP BLOCK

IC001

19

VC

1

RFIP

14

A

13

B

12

C

11

D

15

E

16

F

25

DVDLD

26

CDLD

24

LDSELO

2

PD

MOTOR/COIL DRIVER

37

DO1+

36

DO1-

35

DO2+

34

DO2-

32

DO3+

31

DO3-

30

DO4+

29

DO4-

28

DO5+

27

DO5-

46

OPIN1-

47

OPIN1+

25

DO6+

24

DO6-

Q822-Q825

FLDRIVER

Q823

Q822

RF AMP

41TE

42FE

PI

36

33MIRR

TZC

37

DFT

38

45SRD 245

46SWD 246

47SCLK 247

48SDEN 244

LDON

27

VCI

39

IC712

IN1+

48

IN1-

1

IN2+

3

4

IN2-

5

OUT2

IN3+

6

IN3-

7 SLDB

9

IN4+

IN4-

10 SLDA

12

IN5+

IN5-

13

45

OPOUT1

1716REV

FWD

PS

39

MUTE12

19

MUTE34

20

MUTE5

21

Q825

Q824

+3.3V

FLDRIVER

Q821

LIMIT

IN

SWITCH

D509

S841-845,

S851-853,855,

S875-871

IC802

SIRCS

VCC

VC

RF

A

B

C

D

E

F

DVDLD

CDLD

SW

PD

VR

GND

FCS+

FCS-

TR+

TR-

M

M

M

SPM+

LOADP

M

LOADN

INDICATION TUBE

FL801

SLB+

SLB-

SLA+

SLA-

SPM-

A5V

Q001

LD

DRIVE

Q002

LD

DRIVE

5

6

7

8

9-20,32-48

49

6,14

5

3

8

9

2

1

7

10

17

19

15

12

4

FOCUS

COIL

TRACKING

COIL

SLED B

MOTOR

SLED A

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

M

4

3

2

1

2

3

4

TM-

TM+

DSENS

SENSOR

TSENS

1

1

LED

IC706

DIGITAL SERVO,

DIGITAL SIGNAL PROCESSOR

DOUT958

19059SIGO

RFAC

PCMD1

200

201

202

231

230

229

234 INLIM

215

216

213

214

203

220

219

206

221

222

204

235

RM

CDBCK

TEI

CDLRCK

FEI

DSAL

PI

DSAR

DSALS

MIRR

DSARS

TZC

DSAC

DFCTI

DSASW

DSPHREFO

SSI

MCKI

SSO

29

+3.3V

SCK

SCS

FDOP

FDON

TDOP

TDON

SEI

VCO

MDS0

MDP0

SP RV

FGMODE

1

21-29 13,15-22A0-8 CA0-8

11-18 4-11D0-7 CD0-7

XINT

XCS

XWAIT

XWR

XRD

XRST

JIT

SMUTE

MA0-10,BA A0-10,BA

MD0-15 DQ0-15

XRAS,

XCAS,

XMWR,

MCKE,

MMCK,

LDQM,

UDQM

X801

5MHz

KEY

100

226

96

95

94

83

84

85

86

89

90

78

3

32

33

34

35

36

37

61

4

12

16

7

DISPLAY CONTROLLER

3X1

4X2

17 SIRCS

22-19

ANI0-3

80 FIP0

79 FIP1

78 FIP2

77 FIP3

76-61,58-46

45 FIP33

IC701

RESET

IC702

EEPROM

IC708

16M SDRAM

RAS,

CAS,

WE,

CKE,

CLK,

LDQM,

UDQM

IC801

FIP4-32

IC705

Q826

MASTER CONTROL

92

XINT0

87

XCS

73

XWAIT

71

XWR

70

XRD

72

XWRST

59

XRST

EPR/B,

XEPCS,

XEWC,

EEPSO,

EEPSI,

EEPSCK

52

JIT

74

SMUTE

38

XLDON

TRAY OUT33

TRAY IN

30

DRV ON

35

36

SP ON

849 IFSISO1

838 IFSOSI1

9112 XIFINTACK

857 IFSCSCK1

9615 XIFCSINTP0

3SLATR DAC

2SCLK DAC

1SDATA DAC

94MZR

95MZL

L MUTE

98

97R MUTE

100M/2

S001 (TRY POSITION DETECT SWITCH)

25LOAD S0

27LOAD S1

26LOAD S2

39TRMP

40TRMM 2OUT2

29DSENS

30TSENS TSENS

EXTAL

65

ROTARY

ENCODER

IC710

TURN TABULE MOTOR DRIVER

9

RIN

7

FIN

INVERTER

Q701

+1.8V

4OUT1

TM-

TM+

DSENS

SENSOR

LED

3.3V

X321

11.2896MHz

56

34

11 10

13 12

9812

IC320

INVERTER

IC703

+1.8V REG

3 1

+5V

AU+

1

3 1

3 1

9

8

D511

6

OUT

6RESET

D801

LED DRIVER

11P23

J341

IC330

OPTICAL OUT

1

IC920

+3.3V REG

3 1

MUTE REG

Q961

COAXIAL

OPTICAL

D961,965

+12V

RECT

DIGITAL

OUT

(CD)

IC200

DAC

4

PDATA

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

14 ZEROR

13 ZEROL

IC230

DAC

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

IC260

DAC

3 PBCK

5 PLRCK

1 DSDL

2 DSDR

20 DBCK

19 DSCK

18 PSCK

17 MS

16 MC

15 MD

VFL

D921-924

D931-934

RECT

D936,981,983,984

VOUTL

VOUTR

VOUTL 9

VOUTR

VOUTL

VOUTR

VFL REG

Q971

RECT

RECT

9

10

SL

SR

10

CENTER

9

SW

10

VF2

VF1

IC309(2/2)

HEADPHONE AMP

IC400(1/2)

IC400(2/2)

IC430(1/2)

IC430(2/2)

IC460(1/2)

IC460(2/2)

POWER TRANSFORMER

SUB POWER TRANSFORMER

21

AMP

67

Q401,402

AMP

21

Q501,502

AMP

67

Q431,432

AMP

21

Q531,532

AMP

67

Q462,463

AMP

21

Q562,563

T101

D971

T102

HP MUTE

HP MUTE

MUTE

MUTE

L MUTE

Q303

R MUTE

Q305

MUTE

Q301

MUTE

MUTE

MUTE

MUTE

Q403

Q503

RV881

LEVEL

S891

POWER

J352

J351(1/3)

J351(2/3)

J351(3/3)

L

R

L

R

SL

SR

CENTER

SW

J881

PHONES

2CH OUT

• Signal Path

: CD

: CD DIGITAL OUT (OPTICAL)

SCD-C2000ES

IR CONTROL

1

COM

7

CH0

IC803

6CH1

MUTE

Q806

J701

IR IN

1414

Loading...

Loading...