( )

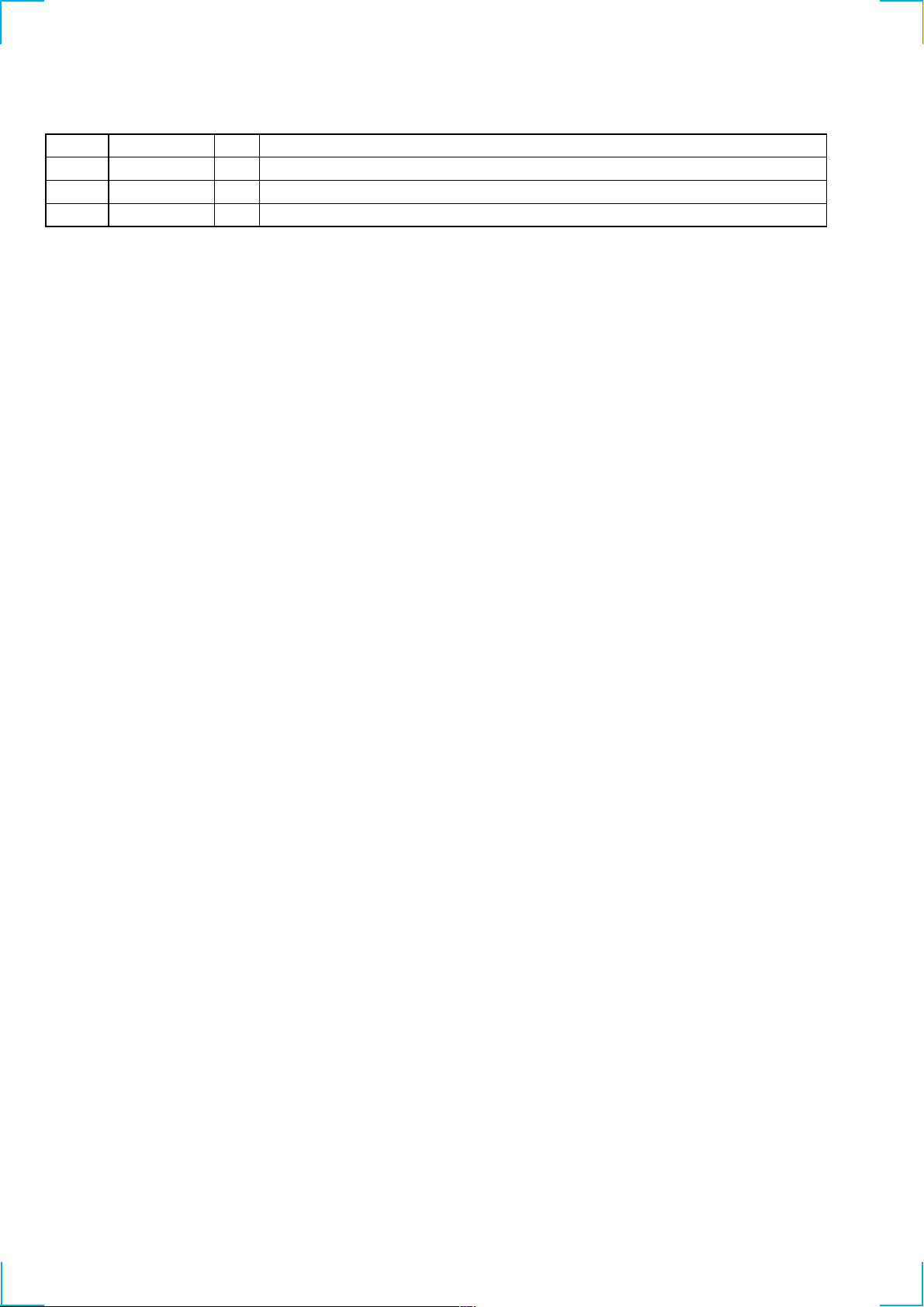

When a super audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 50 kHz (–3 dB)

Dynamic range 105 dB or more

Total harmonic distortion rate

0.0012 % or less

Wow and flutter Value of measurable limit (±0.001 %

W. PEAK) or less

When a CD is played

Frequency response 2 Hz to 20 kHz

Dynamic range 100 dB or more

Total harmonic distortion rate

0.0017 % or less

Wow and flutter Value of measurable limit (±0.001 %

W. PEAK) or less

Output connector

*Output only the audio signals of the CD

General

Laser radiant power: 5.47 uW at 650 nm

*These output is the value measured at a distance of about

200mm from the objective lens surface on the optical pick-up.

Power requirements 230 V AC, 50/60 Hz

Power consumption 26 W

Dimensions (w/h/d) 430 × 130 × 380 mm incl. projecting

parts

Mass (approx.) 14.5 kg

Supplied accessories

Design and specifications are subject to change without notice.

Load impedance

ANALOG OUT

DIGITAL (CD)

OUT OPTICAL*

DIGITAL (CD)

OUT COAXIAL*

Phono

jacks

Jack type

2 Vrms

(at 50 kilohms)

Square

optical

output

connector

–18 dBm

0.5 Vp-p

Over 10 kilohms

Light emitting

wave length:

660 nm

Output level

75 ohms

Coaxial

output

connector

PHONES

Stereo

phone jack

32 ohms

20 mW

•Audio connecting cord

(phono jack × 2 y phono jack × 2) (1)

•Mains lead (1)

•Remote commander (remote) RM-SX90 (1)

•R06 (size-AA) batteries (2)

SCD-555ES

SERVICE MANUAL

Photo: Gold type

SPECIFICATIONS

AEP Model

Model Name Using Similar Mechanism CDP-D500

CD Mechanism Type CDM19HN-DVBU4

Base Unit Name DVBU4

Optical Pick-up Name KHM-230AAA/J1NP

SUPER AUDIO CD PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES (1) ........................................ 3

2. GENERAL ................................................................... 6

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3. DISASSEMBLY ......................................................... 9

4. DIAGRAMS

4-1. Notes for Printed Wiring Boards and

Schematic Diagrams ....................................................... 15

4-2. Printed Wiring Boards

– RF/SWITCH/LOADING MOTOR Boards – .............. 16

4-3. Schematic Diagram

– RF/SWITCH/LOADING MOTOR Boards – .............. 17

4-4. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 18

4-5. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 19

4-6. Schematic Diagram – MAIN Board (1/6) – .................. 20

4-7. Schematic Diagram – MAIN Board (2/6) – .................. 21

4-8. Schematic Diagram – MAIN Board (3/6) – .................. 22

4-9. Schematic Diagram – MAIN Board (4/6) – .................. 23

4-10. Schematic Diagram – MAIN Board (5/6) – .................. 24

4-11. Schematic Diagram – MAIN Board (6/6) – .................. 25

4-12. Printed Wiring Board

– AUDIO Board (Component Side) – ............................ 26

4-13. Printed Wiring Boards – AUDIO (Conductor Side)/

LINE OUT/HEADPHONE Boards – ............................. 27

4-14. Schematic Diagram – AUDIO Board (1/2) – ................ 28

4-15. Schematic Diagram – AUDIO (2/2)/LINE OUT/

HEADPHONE Boards – ................................................. 29

4-16. Printed Wiring Board – DIGITAL OUT Board –.......... 30

4-17. Schematic Diagram – DIGITAL OUT Board – ............ 31

4-18. Printed Wiring Board – DISPLAY Board – .................. 32

4-19. Schematic Diagram – DISPLAY Board – ..................... 33

4-20. Printed Wiring Boards

– JOG/KEY/R. CNTL Boards – ..................................... 34

4-21. Schematic Diagram – JOG/KEY/R. CNTL Boards – ... 34

4-22. Schematic Diagram

– POWER/AC/POWER SWITCH Boards – .................. 35

4-23. Printed Wiring Board

– POWER Board (Component Side) – ........................... 36

4-24. Printed Wiring Boards – POWER (Conductor Side)/

AC/POWER SWITCH Boards – .................................... 37

4-25. IC Pin Function Description ........................................... 47

This appliance is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT

MARKING is located on the rear exterior.

The following caution label is located

inside the unit.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

5. SERVICING NOTES (2) ........................................ 59

6. TEST MODE ............................................................... 60

7. EXPLODED VIEWS................................................ 74

8. ELECTRICAL PARTS LIST ............................... 80

2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SECTION 1

e

SERVICING NOTES (1)

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

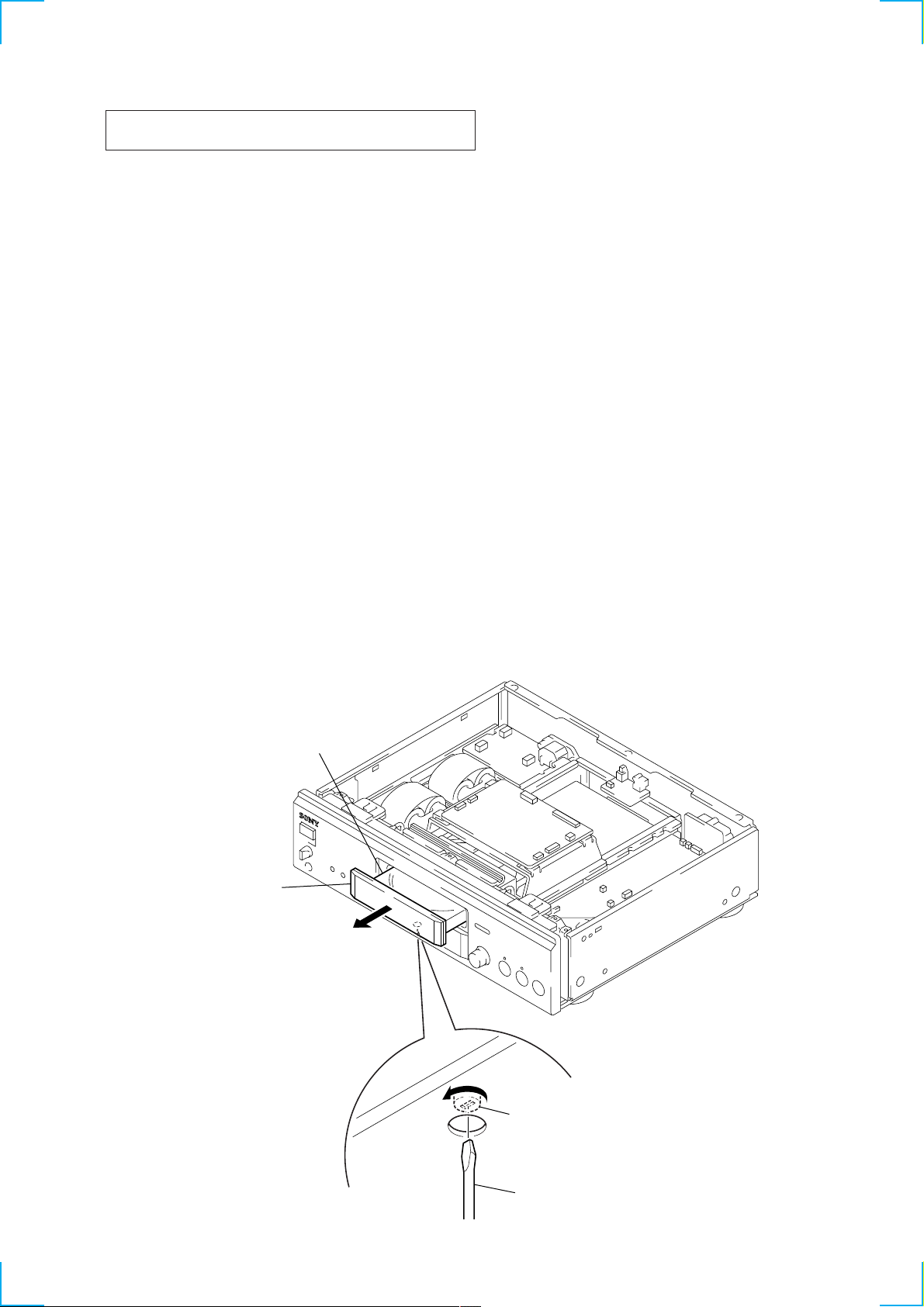

HOW TO OPEN THE DISC TABLE WHEN POWER SWITCH TURNS OFF

disc table

loading panel ass’y

B

2

Draw out the loading panel ass’y

in the direction of arrow

B

.

A

cover (CAM)

tapering driver

1

Insert a tapering driver in the hol

at the bottom of the unit,

turn the cover (CAM) fully in the

direction of arrow A.

3

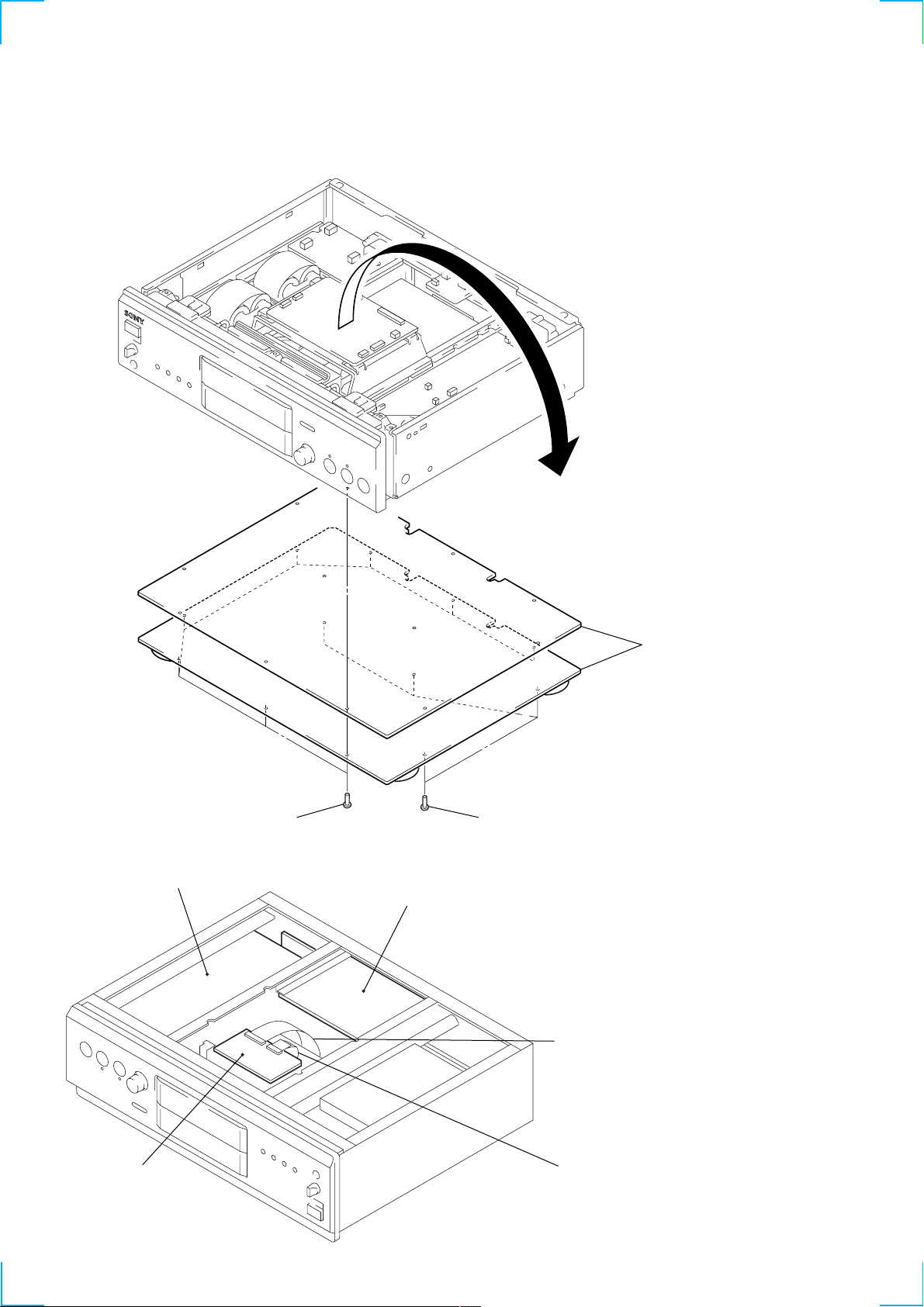

Note: Follow the disassembly procedure in the numerical order given.

s

AUDIO/POWER BOARDS AND RF BOARD SERVICE POSITION

1

Remove the case.

2

Turn over the set.

– BOTTOM VIEW –

AUDIO board

3

eight screws (3 × 8)

POWER board

4

two bottom plate

3

four screws (3 × 8)

INSTALLATION TWO WIRES (FLAT TYPE) (25/35 CORE)

Note: When the wire (flat type) (35 core) is disconnected

from the RF board, then it is again connected,

disconnect the wire (flat type) (25 core) once,

and reconnect the wire (flat type) (35 core) first.

wire (flat type) (35 core)

RF board

wire (flat type) (25 core)

4

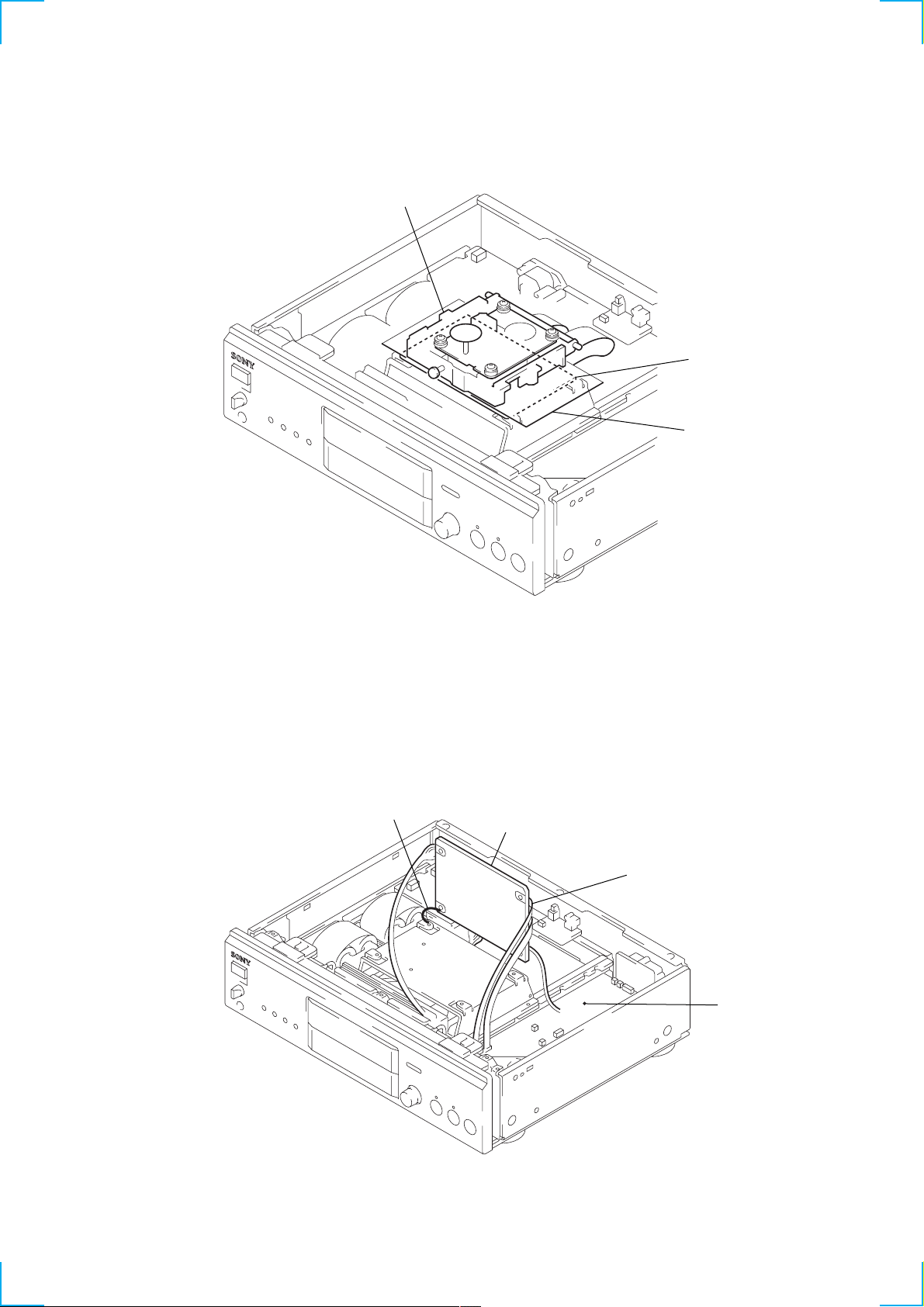

OPTICAL PICK-UP SERVICE POSITION

d

Place the insulator on the MAIN board, then install the base unit (DVBU4) on it as shown in the figure.

base unit

(DVBU4)

MAIN boar

insulator

MAIN BOARD SERVICE POSITION

In checking the MAIN board, prepare jig (extension cable J-2501-155-A: 1.00 mm Pitch, 9 cores, Length 300 mm).

Note: Be sure to ground the MAIN board with a lead wire when checking it.

lead wire

MAIN board

connect jig (extension cable

J-2501-155-A) to the MAIN

board (CN902) and AUDIO

board (CN308).

AUDIO board

5

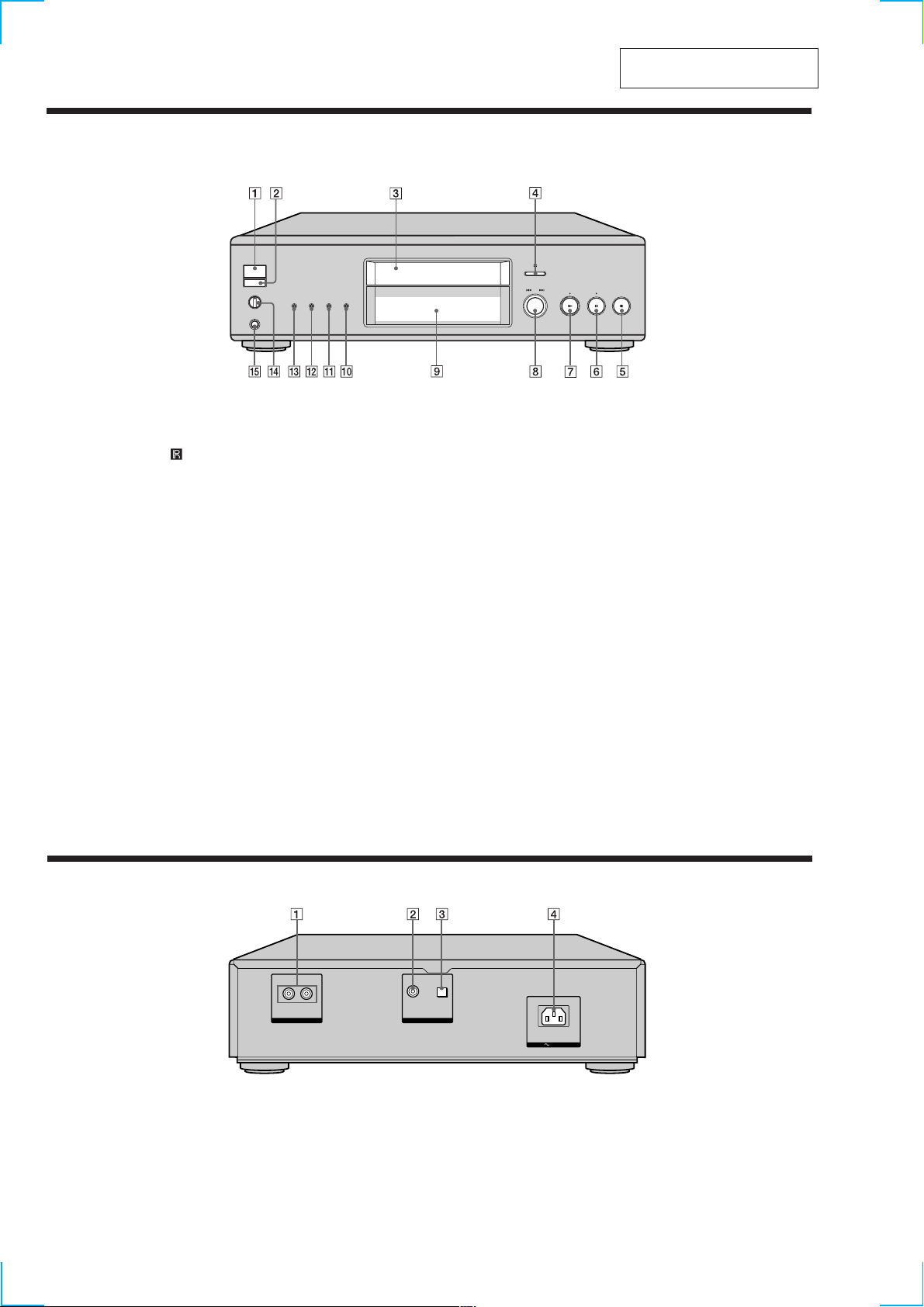

Front Panel Parts

Descriptions

SECTION 2

GENERAL

This section is extracted from

instruction manual.

1 POWER switch (11)

Press to turn on/off the player.

2 Remote sensor

(4)

3 Disc tray (11)

Press A OPEN/CLOSE to open/

close the disc tray.

4 A OPEN/CLOSE button (11)

Press to open/close the disc tray.

5 x button (12)

Press to stop play.

6 X button (12)

Press to pause play.

X indicator

Lights up during pause.

7 N button (11)

Press to start play.

N indicator

Lights up during playback.

POWER

PHONE LEVEL

MIN MAX

PHONES

TIME/TEXT SACD/CD

DIGITAL OUTFILTER

8 lAMSL dial (AMS:

Automatic Music Senser) (11)

When you turn the lAMSL

dial counterclockwise by one click,

you go back to the preceding track;

when you turn the lAMSL

dial clockwise by one click, you go

to the succeeding track.

9 Display window (12)

Shows various information.

0 SACD/CD button (with an LED)

(11)

Each time you press the button

while the Hybrid disc (page 11) is

loaded, the layer changes between

the HD layer (the LED turns on) and

CD layer (the LED turns off).

qa DIGITAL OUT button (with an LED)

(5)

Press when a component is

connected to the DIGITAL (CD)

OUT connectors. Each time you

OPEN/CLOSE

AMS

PUSH ENTER

press the button, the DIGITAL OUT

mode changes between ON (the

digital signals can be output/the

LED turns on) and OFF (the digital

signals cannot be output/the LED

turns off). The digital signal can be

output only when you play a CD.

qs FILTER button (18)

Press to select a digital filter type

when playing a CD.

qd TIME/TEXT button (12)

Each time you press the button, the

playing time of the track, the total

remaining time on the disc, or TEXT

information appears in the display.

qf PHONE LEVEL

Adjust the headphones volume.

qg PHONES

Connect the headphones.

Rear Panel Parts Descriptions

R

L

OUT

ANALOG

1 ANALOG OUT jacks (5)

Connect to an audio component using the audio

connecting cord.

2 DIGITAL (CD) OUT COAXIAL connector (5)

Connect to an audio component using the coaxial

digital cable.

3 DIGITAL (CD) OUT OPTICAL connector (5)

Connect to an audio component using an optical

digital cable.

6

COAXIAL

OPTICAL

OUT

DIGITAL (CD)

AC IN

4 AC IN terminal (5)

Connect the mains lead.

Note

Only the audio signals of the CD can be output from the

DIGITAL (CD) OUT connectors shown in 2 and 3 . Those of

the Super Audio CD cannot be output through DIGITAL (CD)

OUT connectors.

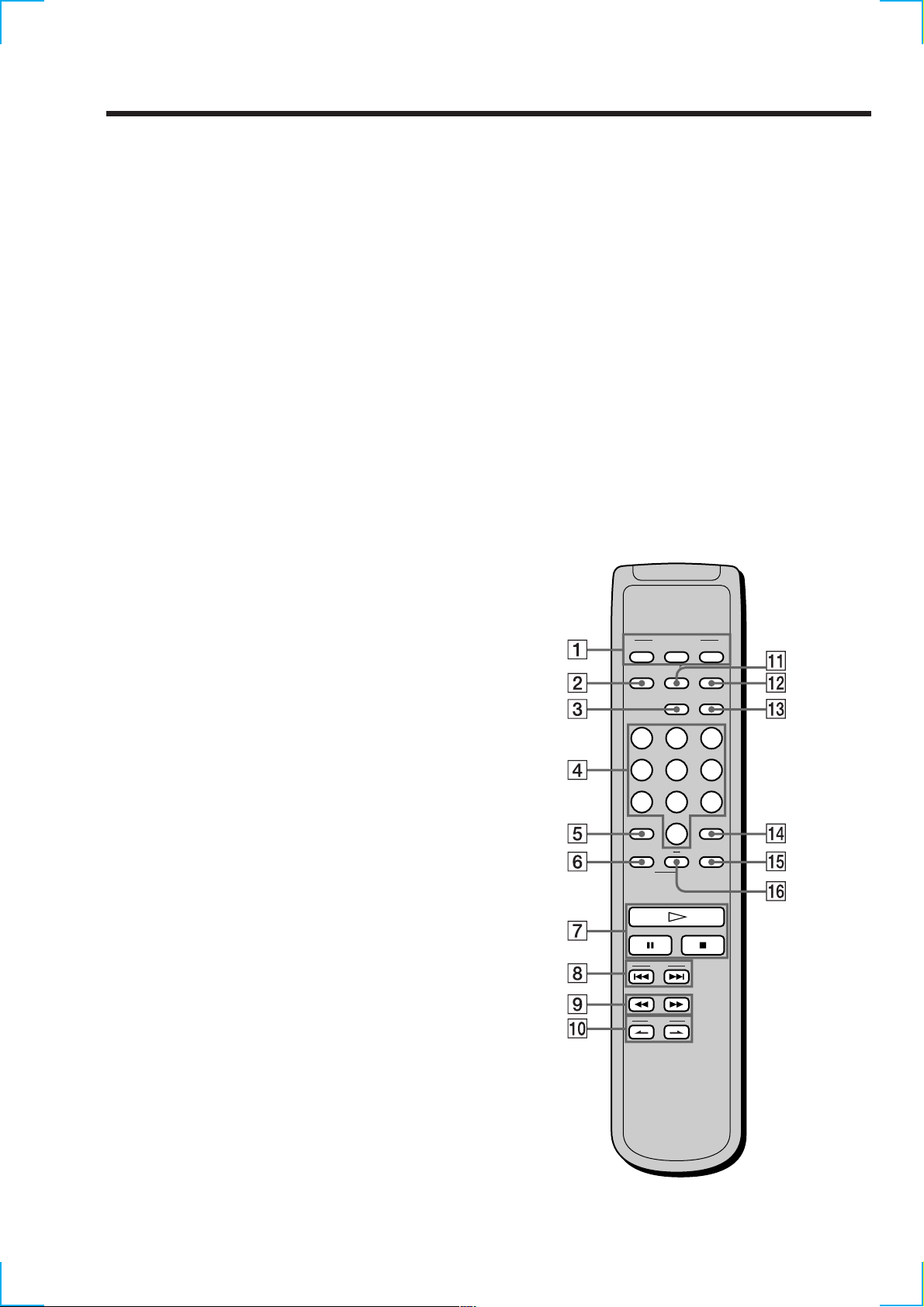

Remote Parts Descriptions

1 CONTINUE button (17)

Press to resume normal play from Shuffle Play or

Programme Play.

SHUFFLE button (17)

Press to select Shuffle Play.

PROGRAM button (17)

Press to select Programme Play.

2 SACD/CD button (11)

Each time you press the button while the Hybrid disc

(page 11) is loaded, the layer changes between an HD

layer (the SACD/CD LED turns on) and CD layer (the

SACD/CD LED turns off).

3 DISPLAY MODE button (13)

Press to turn off the information.

4 Number buttons (14)

Press to enter the track numbers.

5

i

10 button (14)

Press to locate a track numbered over 10.

6 REPEAT button (16)

Press repeatedly to play all tracks or only one track on

the disc.

7 H button (11)

Press to start play.

X button (12)

Press to pause play.

x button (12)

Press to stop play.

8 AMS ./> (AMS: Automatic Music Sensor)

buttons (14)

Press to locate a specific track.

9 m/M buttons (15)

Press to locate a portion you want to play within a

track.

qa TIME/TEXT button (12)

Each time you press the button, the playing time of the

track, the total remaining time on the disc, or TEXT

information appears in the display.

qs LANGUAGE button (14)

Press to change the displayed language if the TEXT

disc has several languages.

qd DIGITAL FILTER button (18)

Press to select a digital filter type when playing a CD.

qf CLEAR button (17)

Press to delete a programmed track number.

qg CHECK button (18)

Press to check the programmed order.

qh AyB button (16)

Press to select Repeat A-B Play.

PLAY MODE

CONTINUE SHUFFLE

SACD/CD

PROGRAM

TIME/

TEXT

LANGUAGE

DISPLAY/ DIGITAL/

MODE

FILTER

123

456

78

>10 CLEAR

REPEAT

CLEAR

9

10/0

BA CHECK

0 INDEX >/. buttons (15)

Press to locate a specific point marked with an index

signal when you play a disc that has index signals.

AMS

INDEX

7

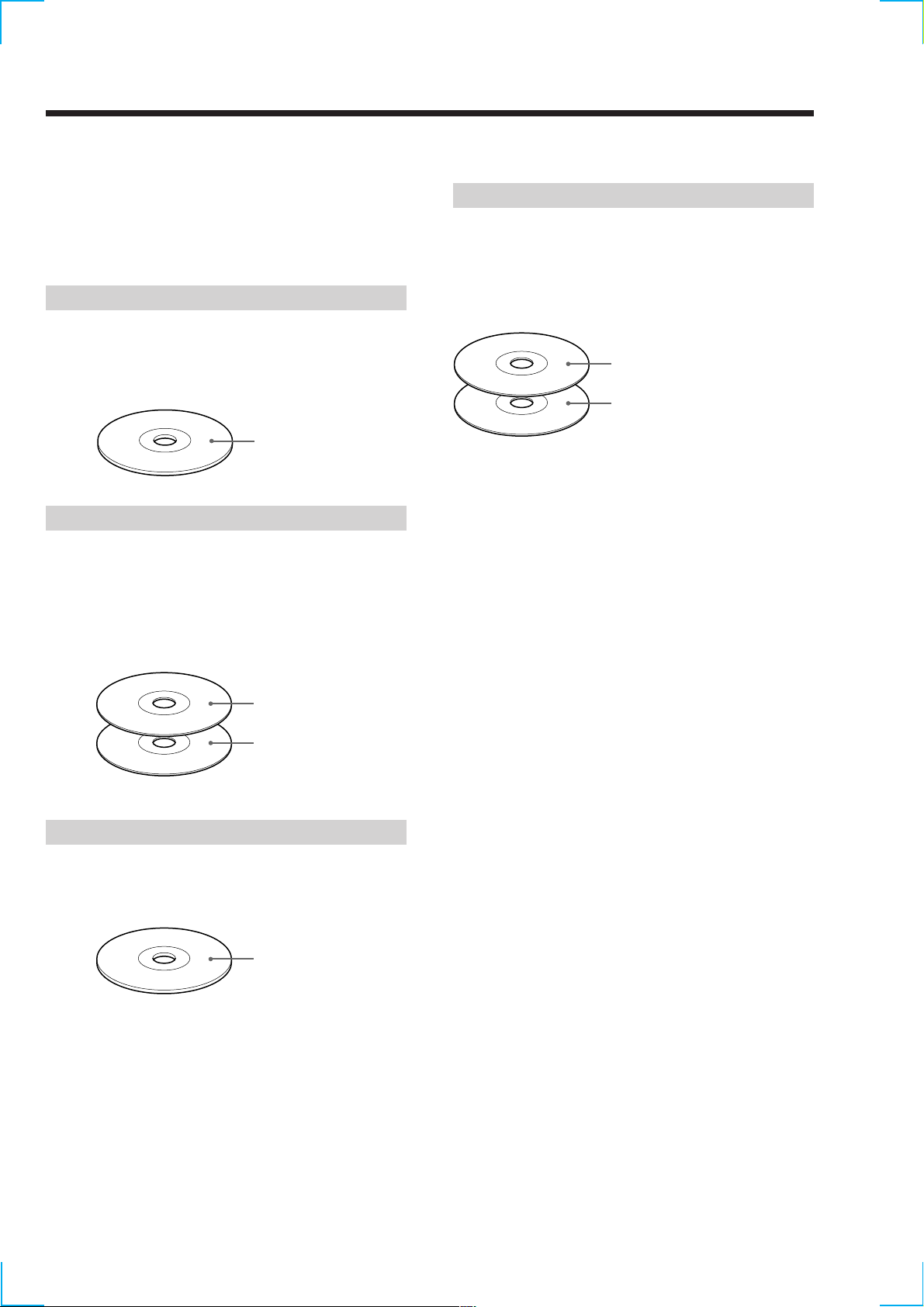

Compatible Disc Types

You can play the following discs with this player.

Depending on the type of disc to be played, select the

appropriate indicator by pressing SACD/CD on the front

panel of the player or on the remote (pages 11).

Super Audio CD (single layer disc)

This disc consists of a single HD layer*.

Press SACD/CD repeatedly so that “SUPER AUDIO CD”

appears in the display (the SACD/CD LED turns on).

*High density signal layer for the Super Audio CD

HD (high density) layer

Super Audio CD (dual layer disc)

This disc consists of dual HD layers and is capable of

extended play over long periods.

Press SACD/CD repeatedly so that “SUPER AUDIO CD”

appears in the display (the SACD/CD LED turns on).

Also, as the dual layer disc consists of dual HD layers on

one side only, it is not necessary to turn the disc over.

Super Audio CD + CD (Hybrid disc)

This disc consists of an HD layer and a CD layer. Press

SACD/CD to select the layer you want to listen to. Also,

as the dual layers are on one side, it is not necessary to

turn the disc over. You can play the CD layer using a

conventional CD player.

CD layer

HD layer

Incompatible Discs

This player cannot play the following discs. If you try to

play them, the error message “TOC Error” or “NO DISC”

will appear or there will be no sound.

• CD-ROM

• DVD, etc.

HD layer

HD layer

Conventional CD

This disc is the standard format.

Press SACD/CD repeatedly so that “CD” appears in the

display (the SACD/CD LED turns off).

CD layer

8

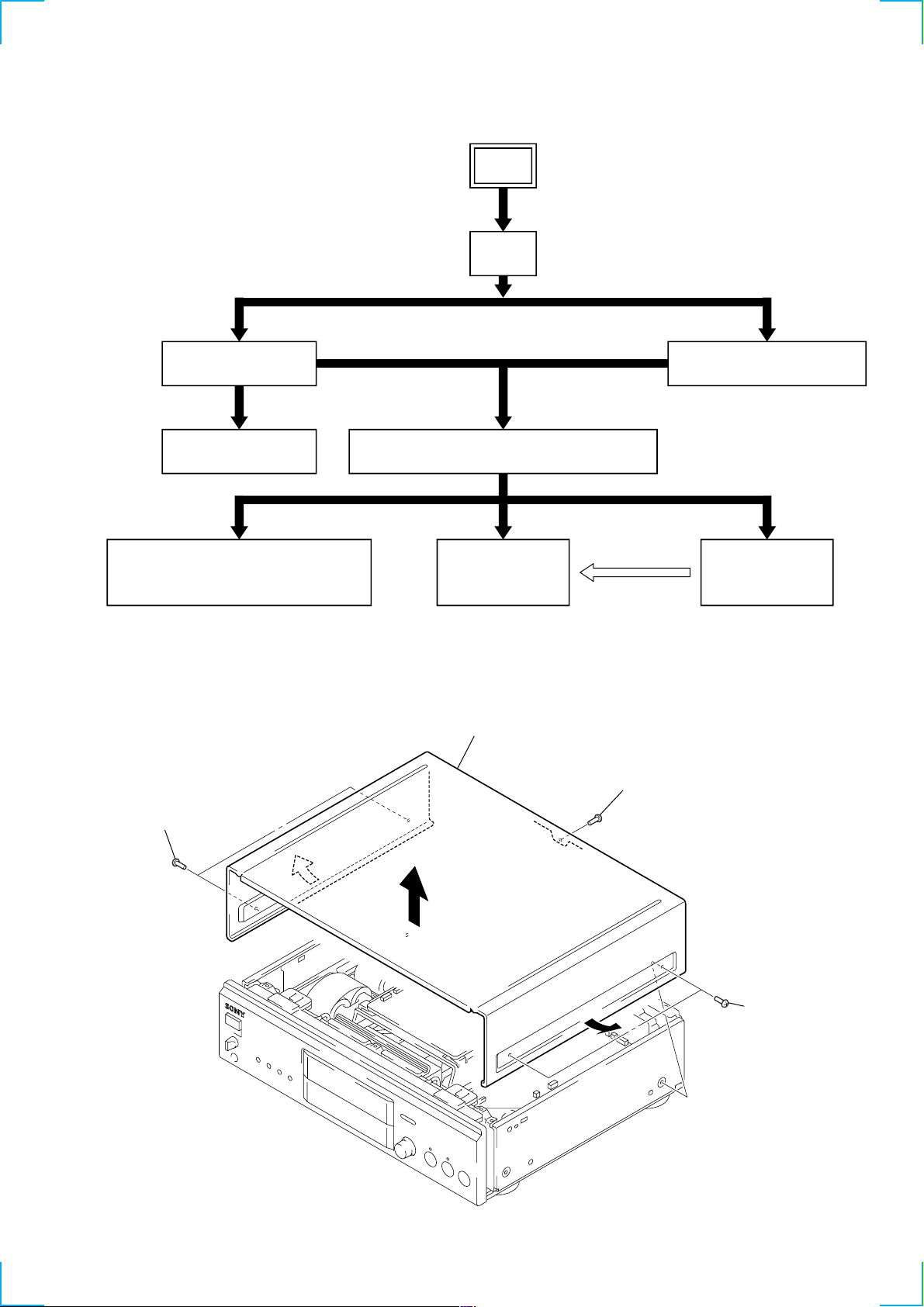

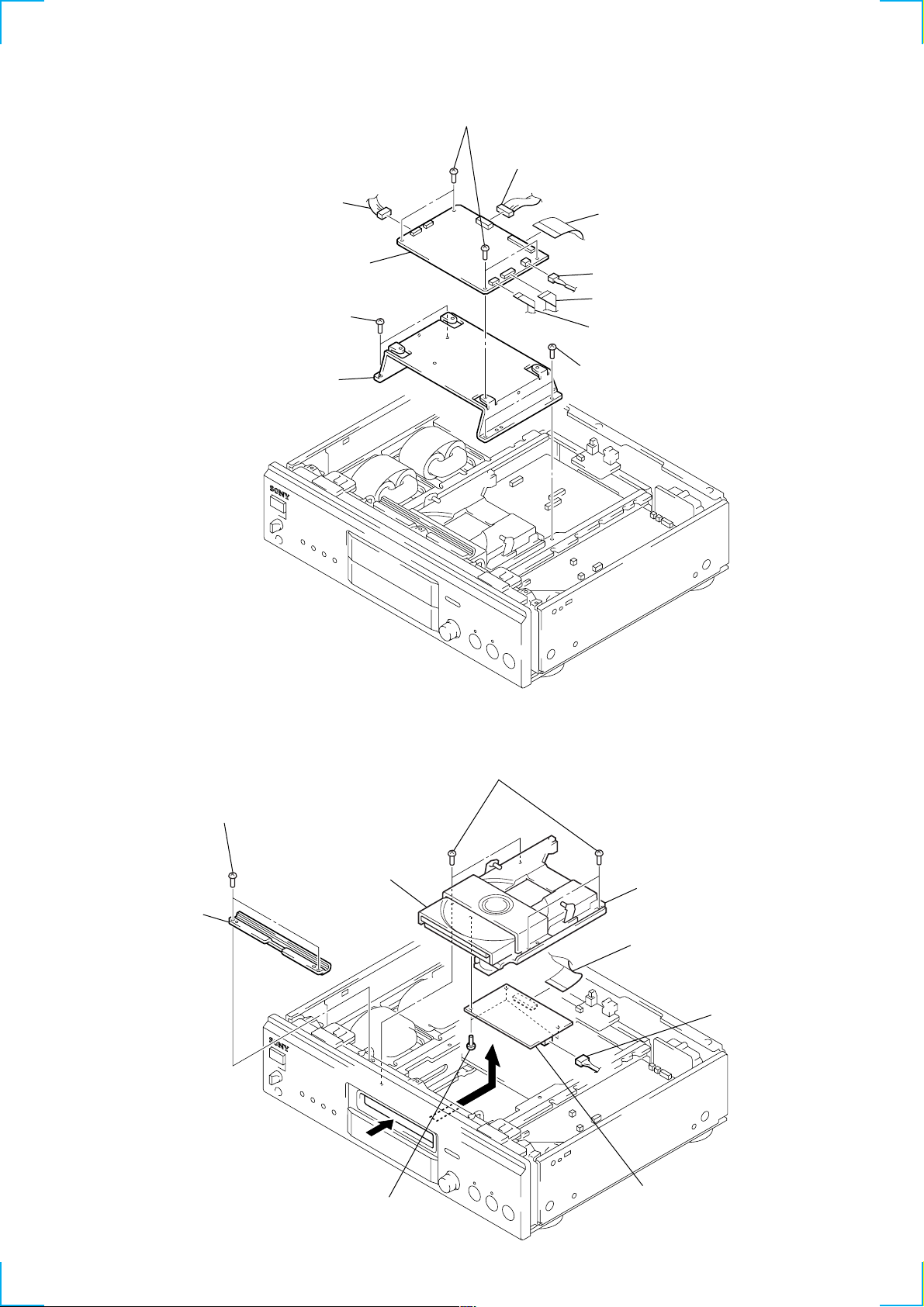

• This set can be disassembled in the order shown below.

1

flat head screw (TP)

4

case

1

two flat head screws (TP)

1

two flat head screws

(TP)

2

2

3

SECTION 3

DISASSEMBLY

SET

CASE

(Page 9)

LOADING PANEL ASS’Y

(Page 10)

FRONT PANEL SECTION

(Page 10)

DISC TABLE, BELT, LOADING MOTOR (M1)

(Page 12)

Note: Follow the disassembly procedure in the numerical order given.

MECHANISM DECK (CDM19HN-DVBU4), RF BOARD

OPTICAL PICK-UP

(KHM-230AAA/J1NP)

After removing the base unit (DVBU4), the optical pick-up (KHM-230AAA/J1NP)

can be removed.

CASE

(Page 11)

(Page 12)

MAIN BOARD, BRACKET (MAIN)

(Page 11)

BASE UNIT (DVBU4)

(Page 13)

9

LOADING PANEL ASSY

5

loading panel ass’y

4

bracket (loading panel)

3

two screws

(P3 × 10)

2

A

cover (CAM)

1

Insert a tapering driver in the hole

at the bottom of the unit,

turn the cover (CAM) fully in the

direction of arrow A.

FRONT PANEL SECTION

3

screw (3 × 8)

2

three connectors

(CN371, 372, 481)

5

front panel section

4

bracket (F)

4

3

screw (3 × 8)

bracket (F)

2

two connectors

(CN408, 903)

tapering driver

10

1

six screws

(3

×

8)

MAIN BOARD, BRACKET (MAIN)

)

2

two screws

(3

×

8)

3

bracket

(guide wire)

1

Push the disc table in the

direction of arrow

A

.

9

three screws

(BVTP2.6

×

8)

0

RF board

8

connector

(CN002)

7

wire (flat type) (25 core)

(CN003)

6

mechanism deck (CDM19HN-DVBU4)

4

four screws (3 × 8)

disc table

A

5

2

connector

(CN903)

4

MAIN board

5

two screws

(3

×

8)

6

bracket (main)

3

four screws (3 × 8)

2

connector

(CN701)

1

wire (flat type) (35 core

(CN503)

2

connector (CN904)

1

wire (flat type) (16 core)

(CN901)

1

wire (flat type) (9 core)

(CN902)

5

two screws

×

8)

(3

MECHANISM DECK (CDM19HN-DVBU4), RF BOARD

11

)

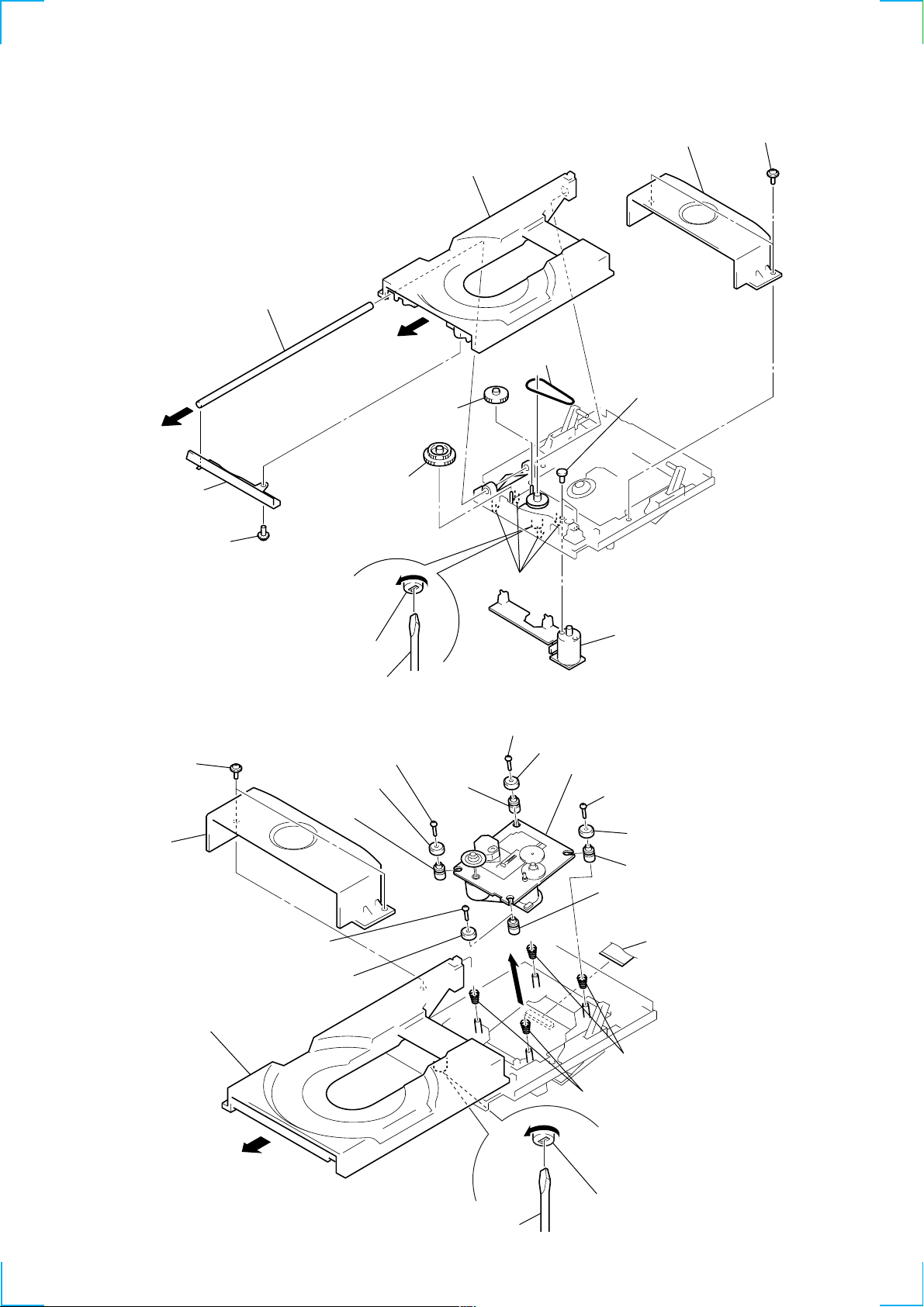

DISC TABLE, BELT, LOADING MOTOR (M1)

8

guide bar (main)

9

disc table

2

holder (A. P.) ass’y

1

two screws

(BVTT M3 S

7

6

bracket (disc table)

5

tapping screw

3

Insert a tapering driver in the

hole of the cover (CAM) and

turn fully in the direction of

arrow

A

.

cover (CAM)

OPTICAL PICK-UP (KHM-230AAA/J1NP)

1

2

holder (A. P.) ass’y

two screws

(BVTT M3 S)

6

7

9

insulator

4

qa

0

gear (P)

A

taper driver

screw

(BVTP2.6

stopper

gear (C)

×

8)

9

qf

6

screw

(BVTP2.6

insulator

qs

belt

four claws

×

8)

7

qd

two screws

(P3

×

3)

qg

loading motor (M1)

stopper

0

optical pick-up (KHM-230AAA/J1NP)

6

screw

(BVTP2.6

7

stopper

9

insulator

9

insulator

×

8)

12

6

screw

(BVTP2.6

4

Draw out the disc table fully

in the arrow

B

B

direction.

×

8)

7

stopper

8

A

taper driver

5

wire (flat type) (25 core)

(CN003)

two cone type coil spring (230)

qa

qa

two cone type coil spring (230)

3

Insert a tapering driver in the

hole of the cover (CAM) and

turn fully in the direction of

A

arrow

.

cover (CAM)

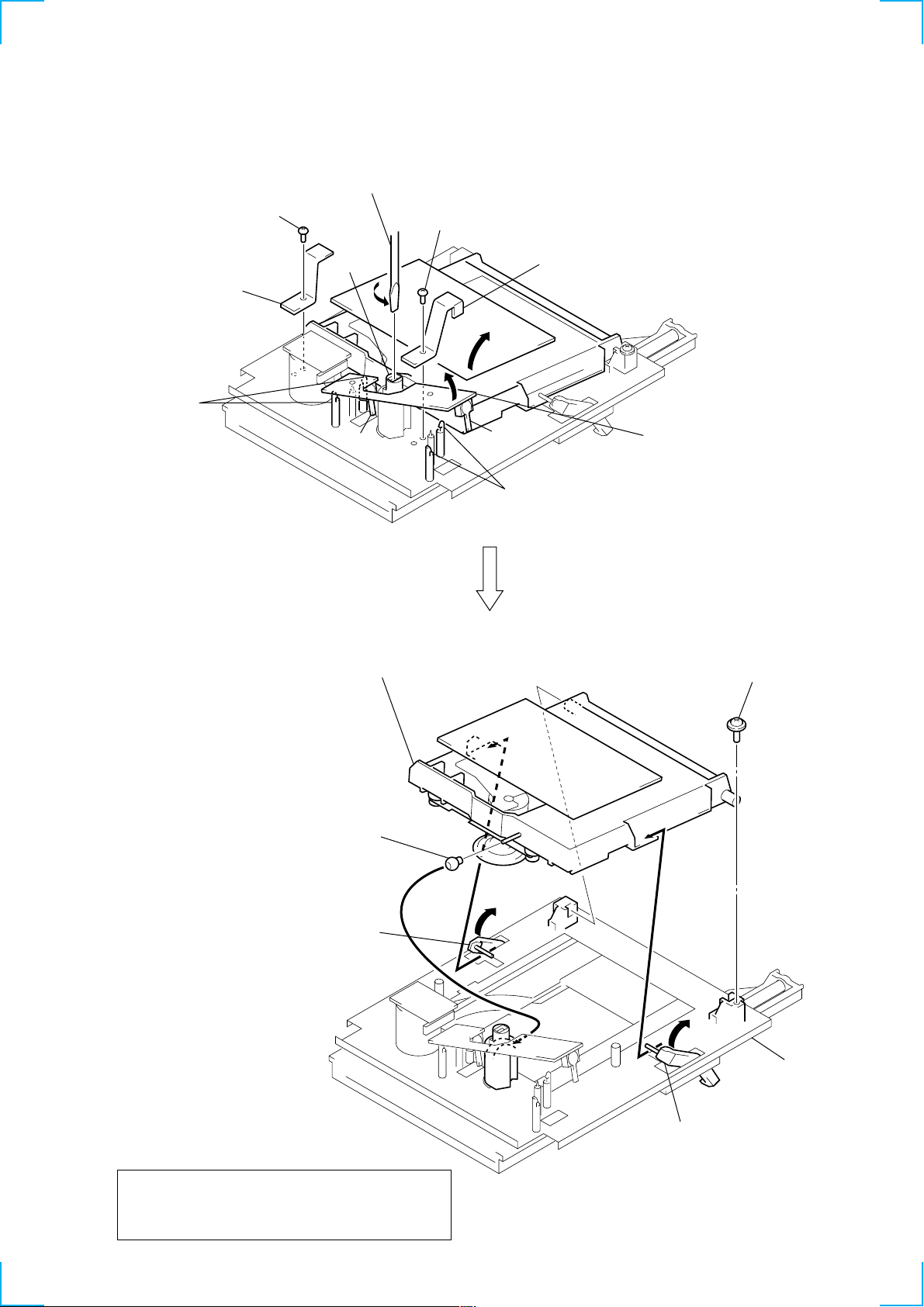

BASE UNIT (DVBU4)

5

screw

(BVTT3

6

limiter (R)

1

two claws

7

Insert a taper driver into the cover (CAM),

and rotate in the arrow

the base unit (DVBU4) in the arrow

(Chuck release state)

×

6)

cover (CAM)

B

B

direction to raise

3

screw

(BVTT3

A

C

×

C

direction.

6)

4

limiter (L)

S001

9

Raising the stable lock (L/R) Ass’y simultaneously

in the arrow D direction, remove the base unit (DVBU4)

from the chassis (outseat).

Note: The stable lock (L/R) Ass’y will attempt to

return in the reverse direction of arrow

by a spring force. Therefore, take care not

to break the shaft of stable lock (L/R) Ass’y

when removing the stable lock (L/R) Ass’y

from the base unit (DVBU4).

0

D

roller (L)

S002

1

two claws

2

Up the SWITCH board in the

direction of arrow

Note: Take care not to break the shaft of

the switch (S001, S002) when raising

the SWITCH board.

8

A

.

screw (PTPWH3 × 8)

stable lock (R) ass’y

In removing the optical pick-up (KHM-230AAA/J1NP)

after removing the base unit (DVBU4),

perform the optical pick-up (KHM-230AAA/J1NP) removal

procedure after step 5 on page 12.

D

D

chassis (outseat)

stable lock (L) ass’y

13

MEMO

14

4-25. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC509 CXD3008Q

(DIGITAL SIGNAL PROCESSOR, DIGITAL SERVO PROCESSOR, DIGITAL FILTER, D/A CONVERTER)

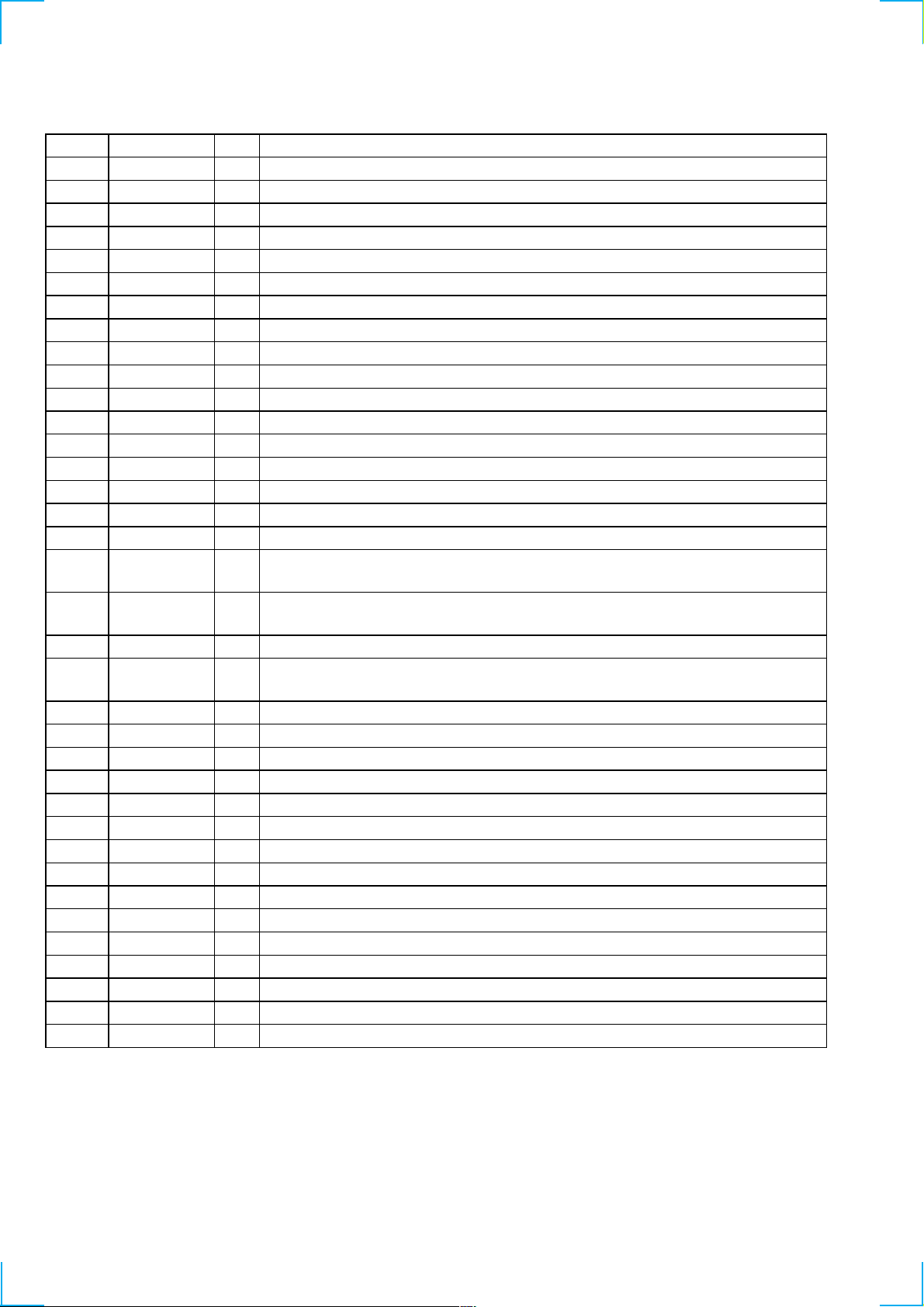

Pin No. Pin Name I/O Description

1 DVDD0 —

2 XRST I

3 MUTE I

4 DATA I

5 XLAT I

6 CLOK I

7 SENS O

8 SCLK I

9 ATSK I

10 WFCK O

11 XUGF O

12 XPCK O

13 GFS O

14 C2PO O

15 SCOR O

16 C4M O

17 WDCK O

18 DVSS0 —

19 COUT O

20 MIRR O

21 DFCT O

22 FOK O

23 PWMI I

24 LOCK O

25 MDP O

26 SSTP I

27 FSTO O

28 DVDD1 —

29 SFDR O

30 SRDR O

31 TFDR O

32 TRDR O

33 FFDR O

34 FRDR O

35 DVSS1 —

36 TEST I

37 TES1 I

38 VC I

39 FE I

40 SE I

41 TE I

42 CE I

43 RFDC I

44 ADIO O

Power supply terminal (+5V) (digital system)

Reset signal input from the expander (IC902) “L”: reset

Muting control signal input from the CPU (IC901) “H”: muting

Serial data input from the CPU (IC901)

Latch signal input from the CPU (IC901)

Clock signal input from the CPU (IC901)

Internal status (SENSE) signal output to the CPU (IC901)

Serial data transfer clock input from the CPU (IC901)

Input pin for anti-shock (fixed at “L”)

Write frame clock signal output to the SACD decoder (IC701)

XUGF signal output terminal Not used (open)

XPCK signal output terminal Not used (open)

Guard frame sync signal output to the CPU (IC901)

C2 pointer signal output to the SACD decoder (IC701)

Subcode sync OR signal output to the SACD decoder (IC701) and the CPU (IC901)

4.2336 MHz clock signal output terminal Not used (open)

Guard subcode sync OR signal output to the SACD decoder (IC701)

Ground terminal (digital system)

Numbers of track counted signal output to the CPU (IC901)

Mirror signal output to the CPU (IC901)

Defect signal output terminal Not used (pull up)

Focus OK signal output to the CPU (IC901)

Not used (fixed at “L”)

GFS is sampled by 460 Hz “H” output when GFS is “H”

Spindle motor (M3) servo drive signal output to the SACD decoder (IC701)

Detection signal input from limit switch (S1) The optical pick-up is inner position when “H”

2/3 divider output terminal Not used (open)

Power supply terminal (+5V) (digital system)

Sled servo drive PWM signal (+) output to the BA5938FP (IC502)

Sled servo drive PWM signal (–) output to the BA5938FP (IC502)

Tracking servo drive PWM signal (+) output to the BA5938FP (IC502)

Tracking servo drive PWM signal (–) output to the BA5938FP (IC502)

Focus servo drive PWM signal (+) output to the BA5938FP (IC502)

Focus servo drive PWM signal (–) output to the BA5938FP (IC502)

Ground terminal (digital system)

Input terminal for the test (fixed at “L”)

Input terminal for the test (fixed at “L”)

Middle point voltage (+1.65V) input from the NJM3403AV (IC009)

Focus error signal input from the CXD1881R (IC001)

Sled error signal input from the CXD1881R (IC001)

Tracking error signal input from the CXD1881R (IC001)

Chip enable signal input from the CXD1881R (IC001)

RF signal (DC level) input from the CXD1881R (IC001)

Output terminal for the A/D converter Not used (open)

47

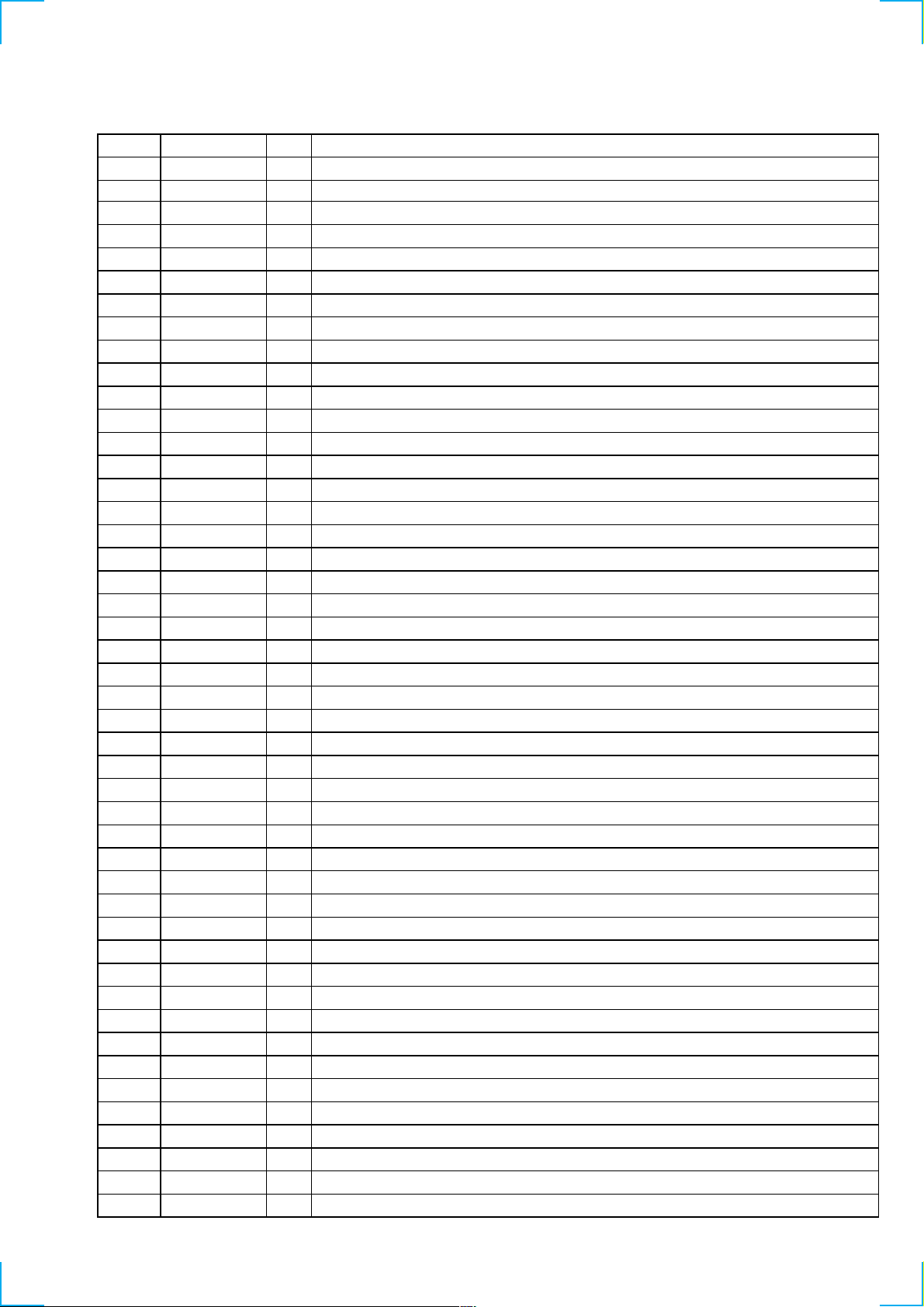

Pin No. Pin Name I/O Description

45 AVSS0 —

46 IGEN I

47 AVDD0 —

48 ASYO O

49 ASYI I

50 RFAC I

51 AVSS1 —

52 CLTV I

53 FILO O

54 FILI I

55 PCO O

56 AVDD1 —

57 BIAS I

58 VCTL I

59 V16M O

60 VPCO O

61 DVDD2 —

62 ASYE I

63 MD2 I

64 DOUT O

65 LRCK O

66 PCMD O

67 BCLK O

68 EMPH O

69 XTSL I

70 DVSS2 —

71 XTAI I

72 XTAO O

73 SOUT O

74 SOCK O

75 XOLT I

76 SQSO O

77 SQCK I

78 SCOR O

79 SBSO O

80 EXCK I

Ground terminal (analog system)

Stabilized current input for operational amplifiers

Power supply terminal (+5V) (analog system)

Playback EFM full-swing output terminal

Playback EFM asymmetry comparator voltage input terminal

EFM RF signal (AC level) input from the CXD1881R (IC001)

Ground terminal (analog system)

Internal VCO control voltage input of the EFM playback master PLL

Filter output for master clock of the playback EFM master PLL

Filter input for master clock of the playback EFM master PLL

Phase comparison output for master clock of the playback EFM master PLL

Power supply terminal (+5V) (analog system)

Playback EFM asymmetry circuit constant current input terminal

Control voltage input terminal for the variable pitch Not used (fixed at “L”)

16.9344 MHz clock signal output Not used (open)

PLL charge pump output terminal for the variable pitch Not used (fixed at “L”)

Power supply terminal (+5V) (digital system)

Playback EFM asymmetry circuit on/off selection signal input terminal

Not used (fixed at “H”)

Digital out on/off control signal input from the CPU (IC901)

“L”: digital out on, “H”: digital out off

Digital audio signal output to the DIGITAL (CD) OUT OPTICAL (IC392)

L/R sampling clock signal (44.1 kHz) output to the digital filter (IC301) and SACD decoder

(IC701)

Serial data output to the digital filter (IC301) and SACD decoder (IC701)

Bit clock signal (2.8224 MHz) output to the digital filter (IC301) and SACD decoder (IC701)

Playback disc output terminal in emphasis mode Not used (open)

Input terminal for the system clock frequency setting Fixed at “H” in this set

Ground terminal (digital system)

System clock input terminal (33.86688 MHz)

System clock output terminal (33.86688 MHz) Not used (open)

Not used (open)

Not used (open)

Not used (open)

Subcode Q data output to the CPU (IC901)

Subcode Q data reading clock signal input from the CPU (IC901)

Not used (open)

Subcode serial data output to the SACD decoder (IC701)

Subcode serial data reading clock signal input to the SACD decoder (IC701)

48

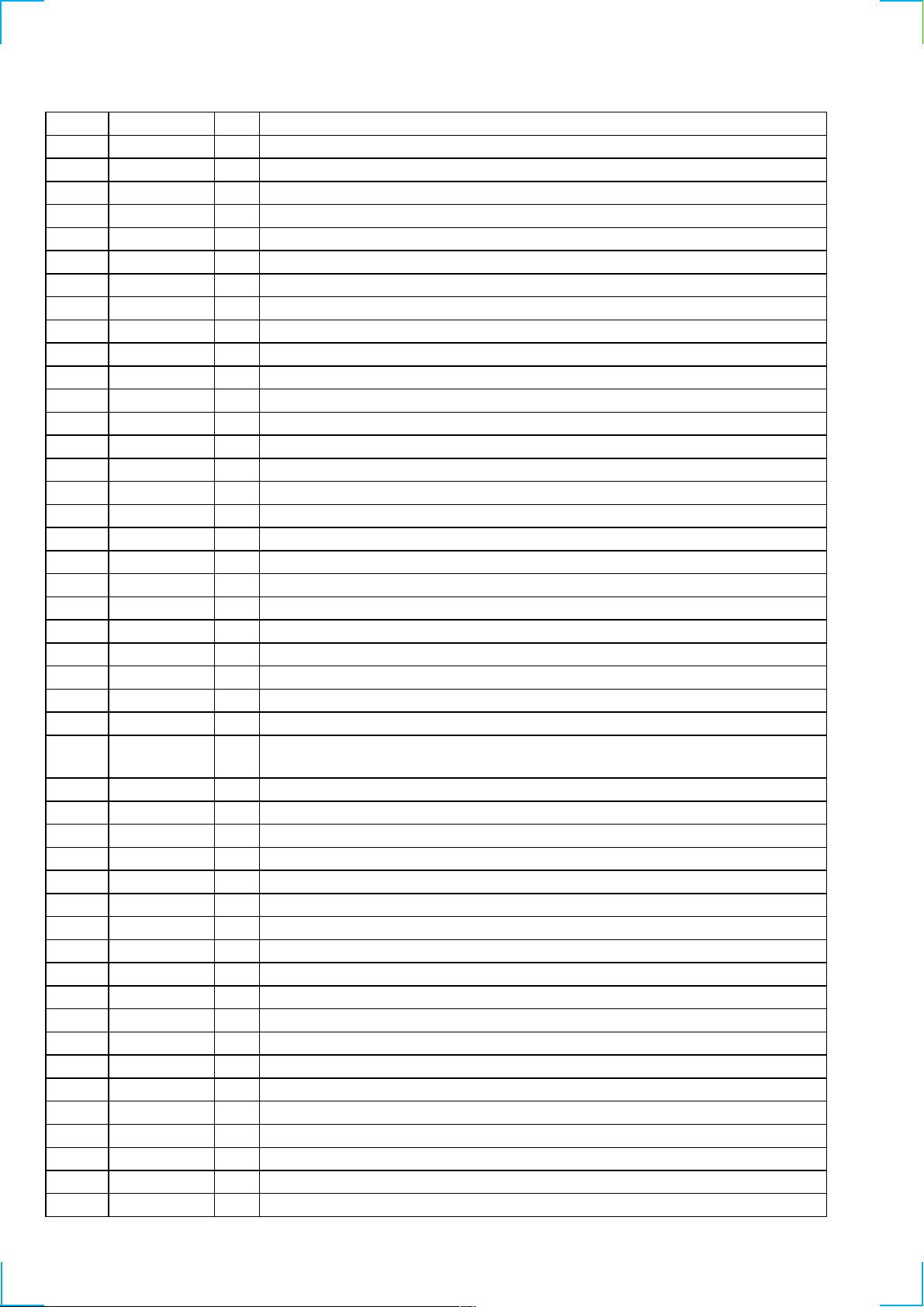

• MAIN BOARD IC701 CXD1882R (SACD DECODER)

Pin No. Pin Name I/O Description

1, 2 D5, D6 I/O

3 VSS —

4 D7 I/O

5A0I

6 VDD —

7A1I

8 VDD5V —

9 to 14 A2 to A7 I

15 VSS —

16 XWAIT O

17 XRD I

18 XWR I

19 XCS I

20, 21 XINT0, XINT1 O

22 VDD —

23 XHRS I

24 HDB7 O

25 VSS —

26 HDB8 O

27 HDB6 O

28 VDDS —

29 HDB9 O

30 HDB5 O

31 HDBA O

32 HDB4 O

33 VSS —

34 HDBB O

35 HDB3 O

36 VDD —

37 HDBC O

38 VDDS —

39 HDB2 O

40 HDBD O

41 HDB1 O

42 VSS —

43 HDBE O

44 HDB0 O

45 HDBF O

46 XACK O

47 VDDS —

48 DCK O

49 XSHDR0 O

50 VDD —

51 REDY O

52 VSS —

53 REQUEST I

Two-way data bus with the CPU (IC901) and expander (IC902)

Ground terminal (digital system)

Two-way data bus with the CPU (IC901) and expander (IC902)

Address signal input from the CPU (IC901)

Power supply terminal (+3.3V) (digital system)

Address signal input from the CPU (IC901)

Power supply terminal (+5V)

Address signal input from the CPU (IC901)

Ground terminal (digital system)

Wait signal output terminal Not used (open)

Read strobe signal input from the CPU (IC901)

Write strobe signal input from the CPU (IC901)

Chip select signal input from the CPU (IC901)

Interrupt signal output to the CPU (IC901)

Power supply terminal (+3.3V) (digital system)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Ground terminal (digital system)

Error flag signal output to the DSD decoder (IC801)

Stream data signal output to the DSD decoder (IC801)

Power supply terminal (+5V) (digital system)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Ground terminal (digital system)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Power supply terminal (+3.3V) (digital system)

Not used (open)

Power supply terminal (+5V) (digital system)

Stream data signal output to the DSD decoder (IC801)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Ground terminal (digital system)

Not used (open)

Stream data signal output to the DSD decoder (IC801)

Not used (open)

Serial data transfer acknowledge signal output to the DSD decoder (IC801)

Power supply terminal (+5V) (digital system)

Serial data transfer clock signal output to the DSD decoder (IC801)

Header flag signal output to the DSD decoder (IC801)

Power supply terminal (+3.3V) (digital system)

Not used (pull up)

Ground terminal (digital system)

Serial data transfer request signal input from the DSD decoder (IC801)

49

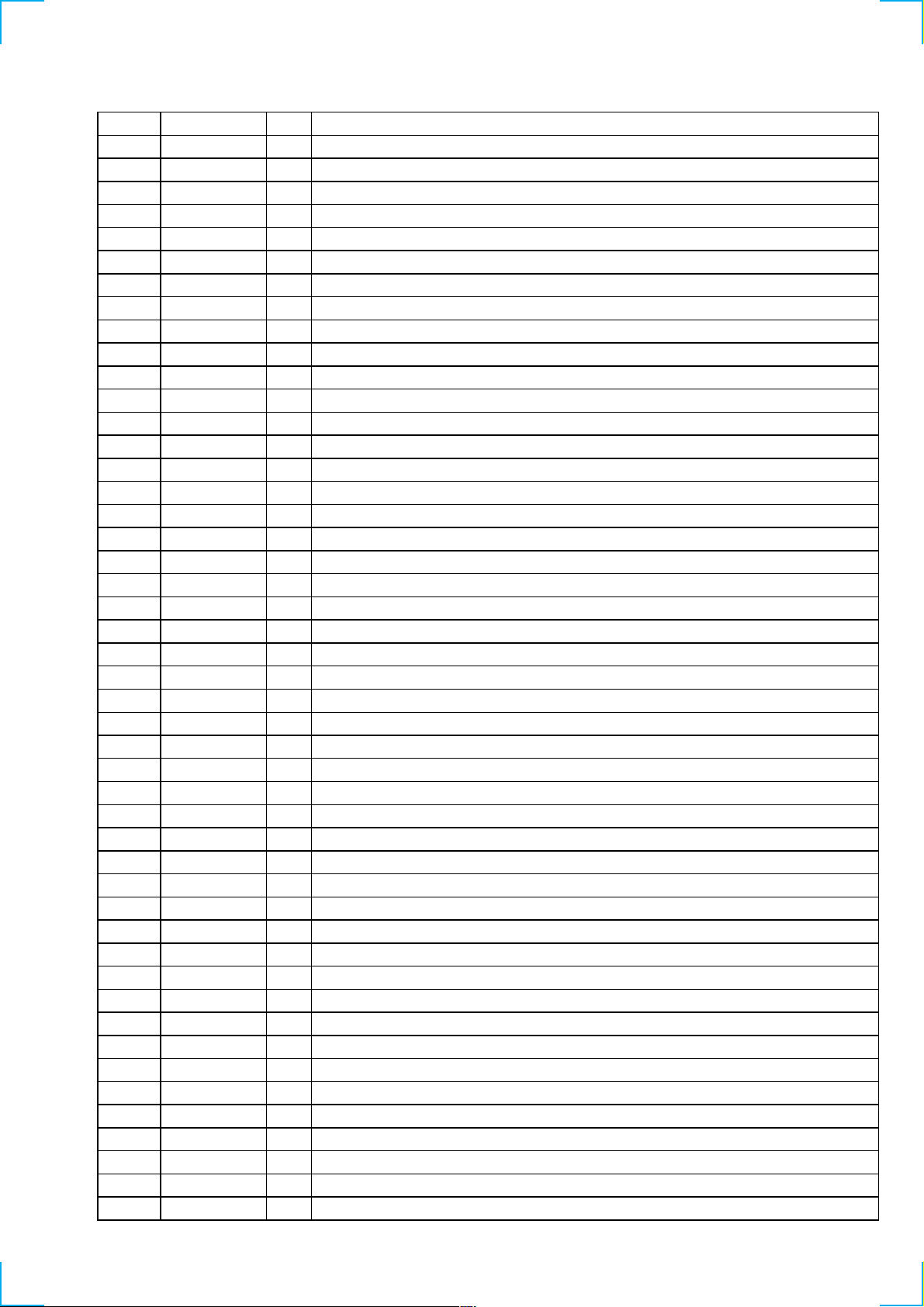

Pin No. Pin Name I/O Description

6

54 HINT O

55 XS16 O

56 HA1 I

57 XPDI I/O

58 VDDS —

59, 60 HA0, HA2 I

61 VSS —

62, 63 HCS0, HCS1 I

64 VDD —

65 DASP I/O

66 to 69 MDB0 to MDB3 I/O

70 VSS —

71 MDB4 I/O

72 VDD5V —

73 to 75 MDB5 to MDB7 I/O

76 XMWR O

77 VDD —

78 XRAS O

79, 80 MA0, MA1 O

81 VSS —

82 to 87 MA2 to MA7 O

88 VDD —

89 MA8 O

90 VSS —

91 MA9/MNT0 O

92 MA10/MNT1 O

93 MA11/MNT2 O

94 XMOE O

95 XCAS O

96, 97 MDB8, MDB9 I/O

98 VSS —

99 MDBA I/O

100 VDD —

101, 102 MDBB, MDBC I/O

103 VDD5V —

104 to 10

113, 114 ASF1, AFS2 —

MDBD to MDBF I/O

107 GFS O

108 VSS —

109 APEO O

110 VDD —

111 DASYO O

112 GNDA5 —

115 DASYI I

116 RFDCC I

117 RF IN I

Not used (pull up)

Not used (pull up)

Not used (fixed at “H” )

Not used (pull up)

Power supply terminal (+5V) (digital system)

Not used (fixed at “H” )

Ground terminal (digital system)

Not used (open)

Power supply terminal (+3.3V) (digital system)

Not used (pull up)

Two-way data bus with the D-RAM (IC706)

Ground terminal (digital system)

Two-way data bus with the D-RAM (IC706)

Power supply terminal (+5V)

Two-way data bus with the D-RAM (IC706)

Write enable signal output to the D-RAM (IC706)

Power supply terminal (+3.3V) (digital system)

Row address strobe signal output to the D-RAM (IC706)

Address signal output to the D-RAM (IC706)

Ground terminal (digital system)

Address signal output to the D-RAM (IC706)

Power supply terminal (+3.3V) (digital system)

Address signal output to the D-RAM (IC706)

Ground terminal (digital system)

Address signal output to the D-RAM (IC706)

RF data signal output terminal for disc mark detection

Clock signal output terminal for disc mark detection

Monitor signal output to the CPU (IC901)

Output enable signal output to the D-RAM (IC706)

Column address strobe signal output to the D-RAM (IC706)

Two-way data bus with the D-RAM (IC706)

Ground terminal (digital system)

Two-way data bus with the D-RAM (IC706)

Power supply terminal (+3.3V) (digital system)

Two-way data bus with the D-RAM (IC706)

Power supply terminal (+5V)

Two-way data bus with the D-RAM (IC706)

Guard frame sync signal output to the CPU (IC901)

Ground terminal (digital system)

Absolute phase error signal output

Power supply terminal (+3.3V) (digital system)

RF binary signal output

Ground terminal (analog system)

Filter connected terminal for selection the constant asymmetry compensation

Analog signal input after integrated from the RF binary signal

Input terminal for adjusting DC cut high-pass filter for RF signal

RF signal input from the CXD1881R (IC001)

50

Pin No. Pin Name I/O Description

118, 119 VCCA5, VCCA4 —

120 VCOR1 —

121 VCOIN I

122, 123 GNDA4, GNDA3 —

124 LPF5 O

125 VC1 I

126, 127 LPF2, LPF1 I

128, 129 VCCA3, VCCA2 —

130 PDO O

131 PDHVCC I

132 FDO O

133, 134 GNDA2, GNDA1 —

135 SPO O

136 VC2 I

137 MDIN2 I

138 MDIN1 I

139 VCCA1 —

140 CLVS O

141 VSS —

142 MDSOUT O

143 VDD —

144 MDPOUT O

145 DEFECT I

146 GSCOR I

147 EXCK O

148 SBIN I

149 VSS —

150 SCOR I

151 WFCK I

152 VDD5V —

153 XRCI I

154 VDDS —

155 C2PO I

156 VDD —

157 DBCK O

158 BCLK I

159 DDAT O

160 MDAT I

161 VSS —

162 DLRC O

163 LRCK I

164 XRST I

165 IFS0 I

166 IFS1 I

167 XTAL I

168 VSS —

169 XTA2 O

Power supply terminal (+3.3V) (analog system)

VCO oscillating range setting resistor connected terminal

VCO input terminal

Ground terminal (analog system)

Signal output from the operation amplifier from PLL loop filter

Middle point voltage (+1.65V) input terminal

Inverted signal input to the operation amplifier from PLL loop filter

Power supply terminal (+3.3V) (analog system)

Signal output from the charge pump for phase comparator

Middle point voltage input terminal for RF PLL

Signal output from the charge pump for frequency comparator

Ground terminal (analog system)

Spindle motor (M3) control signal output to the BA5912AFP (IC512)

Middle point voltage (+1.65V) input terminal

Spindle motor (M3) control signal input from the CXD3008Q (IC509)

MDP input terminal

Power supply terminal (+3.3V) (analog system)

Control signal output for selection the spindle control filter at CLVS

Ground terminal (digital system)

Frequency error output terminal of internal CLV circuit

Power supply terminal (+3.3V) (digital system)

Phase error output terminal of internal CLV circuit

Defect signal input terminal Not used (fixed at “L” )

Guard subcode sync OR signal input from the CXD3008Q (IC509)

Subcode serial data reading clock signal output to the CXD3008Q (IC509)

Subcode serial data input from the CXD3008Q (IC509)

Ground terminal (digital system)

Subcode sync OR signal input from the CXD3008Q (IC509)

Write frame clock signal input from the CXD3008Q (IC509)

Power supply terminal (+5V)

RAM overflow signal input terminal Not used (fixed at “L” )

Power supply terminal (+5V) (digital system)

C2 pointer signal input from the CXD3008Q (IC509)

Power supply terminal (+3.3V) (digital system)

Bit clock signal (2.8224 MHz) output terminal Not used (open)

Bit clock signal (2.8224 MHz) input from the CXD3008Q (IC509)

PCM data output terminal Not used (open)

Serial data input from the CXD3008Q (IC509)

Ground terminal (digital system)

L/R sampling clock signal (44.1 kHz) output terminal Not used (open)

L/R sampling clock signal (44.1 kHz) input from the CXD3008Q (IC509)

Reset signal input from the expander (IC902) “L”: reset

Interface select signal input terminal Fixed at “L” in this set

Interface select signal input terminal Fixed at “H” in this set

33.86688 MHz clock signal input terminal

Ground terminal (digital system)

System clock output terminal (33.86688 MHz)

51

Pin No. Pin Name I/O Description

6

170 XTA1 I

171 VDD —

172 to 17

D0 to D4 I/O

System clock input terminal (33.86688 MHz)

Power supply terminal (+3.3V) (digital system)

Two-way data bus with the CPU (IC901) and expander (IC902)

52

• MAIN BOARD IC801 CXD2751Q (DSD DECODER)

Pin No. Pin Name I/O Description

1 XSRQ O

2 XSHD I

3VDD—

4VSS—

5 SDCK I

6 SMUTE I

7 XMSLAT I

8 MSCK I

9 MSDATI I

10 MSDATO O

11 MSREDY I

12 XMSDOE O

13 XRST I

14 MCKI I

15 VSS —

16 CK75S I

17 EXCKO1 O

18 EXCKO2 O

19 LRCK I/O

20 UBIT —

21 MNT2 O

22 TRST I

23 TCK I

24 TDI I

25 TENA1 I

26 TDO O

27 VST —

28 VDD —

29 VSS —

30 MNT1 O

31 MNT0 O

32 XBIT O

33 F75HZ O

34 SUPDAT O

35 SUPAK O

36 SUPEN O

37 TEST1 I

38 VSS —

39 TEST2 I

40, 41 VSS —

42 BCKD I

43 DSDL —

44 DSDR —

45 MUDAT —

46 BCKA I

47 DSAL O

Serial data transfer request signal output to the SACD decoder (IC701)

Header flag signal input from the SACD decoder (IC701)

Power supply terminal (+3.3V) (digital system)

Ground terminal (digital system)

Serial data transfer clock signal input from the SACD decoder (IC701)

Muting signal input from the CPU (IC901) “L”: muting

Latch signal input from the CPU (IC901)

Serial data transfer clock signal input from the CPU (IC901)

Serial data input from the CPU (IC901)

Serial data output to the CPU (IC901)

Ready signal input from the CPU (IC901) “L”: ready

Data enable signal output terminal Not used (open)

Reset signal input from the expander (IC902) “L”: reset

Master clock signal input terminal

Ground terminal (digital system)

Master clock selection signal input terminal “L”: 512fs, “H”: 768fs (fixed at “H” in this set)

External clock 1 signal output terminal

External clock 2 signal output terminal Not used (open)

L/R sampling clock signal (44.1kHz) input/output terminal Not used (open)

Not used (open)

Monitor 2 signal output terminal Not used (open)

Reset signal input terminal “L”: reset Not used (fixed at “L”)

Clock signal input terminal for test (normally: fixed at “L”)

Serial data input terminal for test (normally: open)

Enable signal input terminal for test (normally: open)

Serial data output terminal for test (normally: open)

Ground terminal for test (digital system)

Power supply terminal (+3.3V) (digital system)

Ground terminal (digital system)

Monitor 1 signal output terminal Not used (open)

Monitor 0 signal output terminal Not used (open)

Bit clock signal (2.8224 MHz) output terminal Not used (open)

Clock signal (75 Hz) output terminal Not used (open)

Serial data output terminal Not used (open)

Acknowledge signal output terminal Not used (open)

Enable signal output terminal Not used (open)

Test 1 signal input terminal for test (normally: fixed at “L”)

Ground terminal (digital system)

Test 2 signal input terminal for test (normally: fixed at “L”)

Ground terminal (digital system)

Shift clock signal input from the digital filter (IC301)

Not used (open)

Not used (open)

Not used (open)

Shift clock signal input from the digital filter (IC301)

DSD data (Lch) output to the digital filter (IC301)

53

Pin No. Pin Name I/O Description

48 DSAR O

49 ZDFLGL O

50 ZDFLGR O

51, 52 A0, A1 O

53 VDD —

54 VSS —

55 to 63 A2 to A10 O

64 NC —

65 VSS —

66 XWE O

67 XCAS O

68 XRAS O

69 XOE O

70 to 77 DQ0 to DQ7 I/O

78 VDD —

79 VSS —

80 WCK I

81 WRFD I

82 to 89 WAD0 to WAD7 I

90 VSS —

91 to 98 SD7 to SD0 I

99 SDEF I

100 XSAK I

DSD data (Rch) output to the digital filter (IC301)

Data (Lch) flag detection signal output terminal Not used (open)

Data (Rch) flag detection signal output terminal Not used (open)

Address signal output to the D-RAM (IC808)

Power supply terminal (+3.3V) (digital system)

Ground terminal (digital system)

Address signal output to the D-RAM (IC808)

Not used (open)

Ground terminal (digital system)

Write enable signal output to the D-RAM (IC808)

Column address strobe signal output to the D-RAM (IC808)

Row address strobe signal output to the D-RAM (IC808)

Output enable signal output to the D-RAM (IC808)

Two-way data bus with the D-RAM (IC808)

Power supply terminal (+3.3V) (digital system)

Ground terminal (digital system)

Clock signal input terminal for disc mark detection

RF data signal input terminal for disc mark detection

A/D data signal input from the A/D converter (IC804) for disc mark detection

Ground terminal (digital system)

Stream data signal input from the SACD decoder (IC701)

Error flag signal input from the SACD decoder (IC701)

Serial data transfer acknowledge signal input from the SACD decoder (IC701)

54

• MAIN BOARD IC901 CXP973F064R-1 (CPU)

Pin No. Pin Name I/O Description

1 MODE DF O

2 AMUTE O

3 DOCTRL O

4 LAT DAC O

5 DATA DAC O

6 CLK DAC O

7 FCS JMP 1 O

8 FCS JMP 2 O

9 SENS CD I

10 XCS DRAM O

11 XCS IO O

12 XCS DVD O

13 VSS —

14 to 21 D0 to D7 I/O

22 INT0 DVD I

23 INT1 DVD I

24 T SENS I

25 MON DVD I

26 DATA CD O

27 XLAT CD O

28 A1IN I

29 CONT CD I

30 IN SW I

31 OUT SW I

32 MIRR RF I

33 SUBQ CD I

34 SCOR CD I

35 SQCLK CD O

36 ——

37 CLOK CD O

38 XRST I

39 VSS —

40 XTAL I

41 EXTAL O

42 VDD —

43 LDON RF O

44 XDIS IO O

45 MUTE DSD O

46 XLAT DSD O

47 READY DSD O

48 SDIN DSD I

49 SOUT DSD O

SACD/CD mode selection signal output to the digital filter (IC301) and D/A converter (IC302)

“L”: CD mode, “H”: SACD mode

Muting signal output to the analog line circuit “H”: muting

Digital out on/off control signal output to the CXD3008Q (IC509)

“L”: digital out off, “H”: digital out on

Latch signal output to the D/A converter (IC904)

Serial data output to the D/A converter (IC904)

Clock signal output to the D/A converter (IC904)

Focus jump 1 signal output to the BA5983FP (IC502)

Focus jump 2 signal output to the BA5983FP (IC502)

Internal status (SENSE) signal input from the CXD3008Q (IC509)

Chip select signal output terminal Not used (pull up)

Chip select signal output to the expander (IC902)

Chip select signal output to the SACD decoder (IC701)

Ground terminal (digital system)

Two-way data bus with the SACD decoder (IC701) and expander (IC902)

Interrupt signal input from the SACD decoder (IC701)

Interrupt signal input from the SACD decoder (IC701)

Disc tray status detection signal input terminal Not used (open)

Monitor signal input from the SACD decoder (IC701)

Serial data output to the CXD3008Q (IC509)

Latch signal output to the CXD3008Q (IC509)

Control A1 signal input terminal Not used (fixed at “H”)

Numbers of track counted signal input from the CXD3008Q (IC509)

Loading in switch (S001) input terminal “L”: loading in

Loading out switch (S002) input terminal “L”: loading out

Mirror signal input from the CXD3008Q (IC509)

Subcode Q data input from the CXD3008Q (IC509)

Subcode sync OR signal input from the CXD3008Q (IC509)

Subcode Q data reading clock signal output to the CXD3008Q (IC509)

Not used (open)

Clock signal output to the CXD3008Q (IC509)

System reset signal input from the reset signal generator (IC905) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Ground terminal (digital system)

System clock input terminal (20 MHz)

System clock output terminal (20 MHz)

Power supply terminal (+3.3V) (digital system)

Laser diode on/off control signal output to the CXD1881R (IC001)

“L”: laser diode off, “H”: laser diode on

Reset signal output to the expander (IC902) “L”: reset

Muting signal output to the DSD decoder (IC801) “L”: muting

Latch signal output to the DSD decoder (IC801)

Ready signal output to the DSD decoder (IC801) “L”: ready

Serial data input from the DSD decoder (IC801)

Serial data output to the DSD decoder (IC801)

55

Pin No. Pin Name I/O Description

50 SCK DSD O

51 BUSY DP I

52 SIN DP I

53 SOUT DP O

54 SCLK DP O

55 VSS —

56 REQ DP O

57 FCS BST O

58 GFS DVD I

59 MUTE CD O

60 MUTE 2D O

61 MUTE LOAD O

62 FG I

63 MUTE SP O

64 JITTER I

65 TE I

66 MON RF I

67 FE I

68 AVSS —

69 AVREF I

70 AVDD —

71 GFS CD I

72 SCLK CD O

73 DFCT CD I

74 FOK CD I

75 LOCK CD I

76 XRF AD CE O

77 DFCT SW O

78 EEPSIO I/O

79 EEPSCL O

80 SIN PC I

81 SOUT PC O

82 SCLK RF I

83 SDATA RF I/O

84 XWR O

85 XRD O

86 NC —

87 VDD —

88 VSS —

89 to 91 A0 to A2 O

92 to 96 A3 to A7 O

97 INIT DF O

98 LATCH DF O

99 SHIFT DF O

100 SCDATA DF O

Serial data transfer clock signal output to the DSD decoder (IC801)

Busy signal input from the CXP84120 (IC1001)

Serial data input from the CXP84120 (IC1001)

Serial data output to the CXP84120 (IC1001)

Serial data transfer clock signal output to the CXP84120 (IC1001)

Ground terminal (digital system)

Request signal output to the CXP84120 (IC1001)

Focus boost signal output terminal Not used (open)

Guard frame sync signal input from the SACD decoder (IC701)

Muting signal output to the CXD3008Q (IC509) “H”: muting

Muting signal output to the BA5938FP (IC502)

Muting signal output to the BA5912AFP (IC512)

FG signal input terminal Not used (open)

Muting signal output to the BA5912AFP (IC512)

Jitter signal input terminal

Tracking error signal input from the CXD1881R (IC001)

Monitor signal input from the CXD1881R (IC001)

Focus error signal input from the CXD1881R (IC001)

Ground terminal (for A/D converter)

Reference voltage input terminal (for A/D converter)

Power supply terminal (+3.3V) (for A/D converter)

Guard frame sync signal input from the CXD3008Q (IC509)

Serial data transfer clock signal output to the CXD3008Q (IC509)

Defect signal input terminal Not used (open)

Focus OK signal input from the CXD3008Q (IC509)

GFS sampled by 460 Hz “H” input when GFS is “H”

Chip enable signal output to the A/D converter (IC804)

Defect selection signal output terminal

Two-way data bus with the EEPROM (IC903)

Clock signal output to the EEPROM (IC903)

Serial data input from the RS-232C (for check)

Serial data output to the RS-232C (for check)

Clock signal input from the CXD1881R (IC001)

Two-way data bus with the CXD1881R (IC001)

Write strobe signal output to the SACD decoder (IC701) and expander (IC902)

Read strobe signal output to the SACD decoder (IC701) and expander (IC902)

Not used (fixed at “H” )

Power supply terminal (+3.3V) (digital system)

Ground terminal (digital system)

Address signal output to the SACD decoder (IC701) and expander (IC902)

Address signal output to the SACD decoder (IC701)

Initial signal output to the digital filter (IC301)

Latch signal output to the digital filter (IC301)

Shift signal output to the digital filter (IC301)

Serial data output to the digital filter (IC301)

56

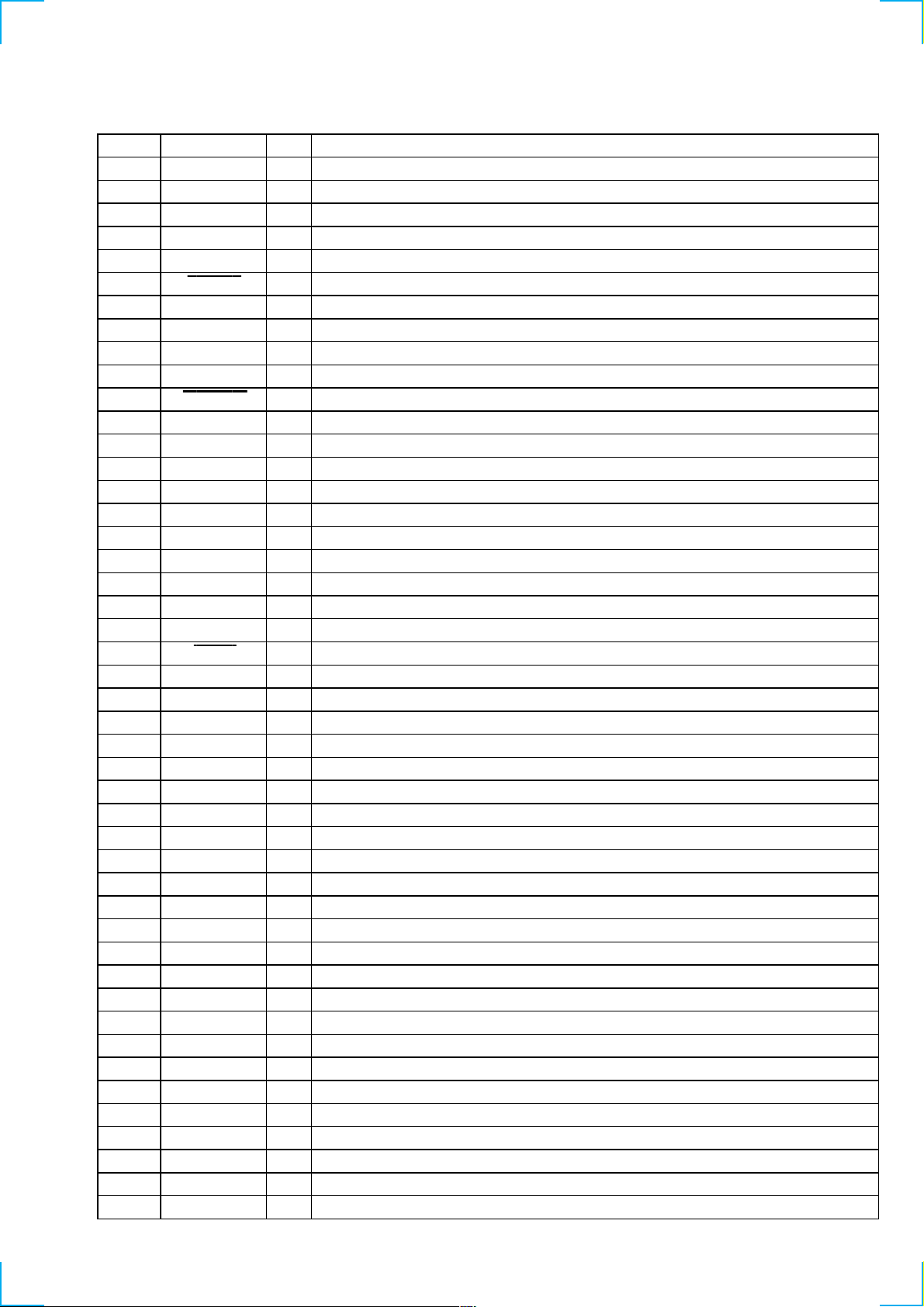

• MAIN BOARD IC902 CXD1095BR (EXPANDER)

Pin No.

1

2

3

4, 5

6

7

8

9

10

11, 12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 to 30

31, 32

33 to 37

38

39

40

41

42

43

44 to 46

47, 48

49

50

51

52

53

54

55

56

Pin Name

LIM SW

(WISE)

F COMPL

SPCNTL1,

SPTNCL0

TBLL

TBLR

VSS

REMCODE

D SENS

S1, S2

LOAD OUT

SDCNTL

LOAD IN

A1OUT

NC

RST DSD

RST DP

RST DVD

RST CD

VMOD

VSS

VDD

MULTI

SDEN

ISBTEST

D0 to D2

NC

D3 to D7

XCLR

XDIS

VSS

XWR

XRD

XCS

A0 to A2

PE0, PE1

NC

TRKFIL

PE3

12V ON

PA1

CD SACD

VSS

VDD

I/O Description

I

Detection signal input terminal from limit switch Not used (open)

I

Not used (open)

I

Focus jump low level signal input terminal Not used (open)

O

Spindle motor control signal output terminal Not used (open)

O

Table motor drive signal (counterclockwise direction) output terminal Not used (open)

O

Table motor drive signal (clockwise direction) output terminal Not used (open)

—

Ground terminal (digital system)

I

Remote category signal output terminal Not used (open)

I

Disc status detection signal input terminal Not used (open)

I

Disc tray position detection signal input terminal Not used (open)

O

Loading motor drive signal (loading out direction) output terminal Not used (open)

O

Sled motor control signal output terminal Not used (open)

O

Loading motor drive signal (loading in direction) output terminal Not used (open)

O

Control A1 signal output terminal Not used (open)

—

Not used (open)

O

Reset signal output to the DSD decoder (IC801) “L”: reset

O

Reset signal output to the CXP84120 (IC1001) “L”: reset

O

Reset signal output to the SACD decoder (IC701) “L”: reset

O

Reset signal output to the CXD30008Q (IC509) “L”: reset

Power on/off control signal output for modulation circuit on optical pick-up block

O

“L”: power off, “H”: power on

—

Ground terminal (digital system)

—

Power supply terminal (+3.3V)

O

Multi/2ch selection signal output terminal “L”: 2ch, “H”: multi Not used (open)

O

Serial enable signal output to CXD1881R (IC001)

O

Output terminal for disc inspection mode Not used (open)

I/O

Two-way data bus with the SACD decoder (IC701) and the CPU (IC901)

—

Not used (open)

I/O

Two-way data bus with the SACD decoder (IC701) and the CPU (IC901)

I

Clear signal input terminal Not used (fixed at “H”)

I

Reset signal input from the CPU (IC901) “L”: reset

—

Ground terminal (digital system)

I

Write strobe signal input from the CPU (IC901)

I

Read strobe signal input from the CPU (IC901)

I

Chip select signal input from the CPU (IC901)

I

Address signal input from the CPU (IC901)

—

Not used (open)

—

Not used (open)

O

Tracking filter signal output terminal Not used (open)

—

Not used (open)

O

Control signal output terminal for low-energy mode Not used (fixed at “H”)

—

Not used (open)

O

SACD/CD mode selection signal output terminal Not used (open)

—

Ground terminal (digital system)

—

Power supply terminal (+3.3V) (digital system)

57

Pin No.

57

58

59

60, 61

62

63, 64

Pin Name

AGING ERR

PA4

OUT SW

PA6, PA7

F COMPH

NC

I/O Description

O

Debug flag signal output terminal Not used (open)

—

Not used (open)

I

Disc tray out detection signal input terminal Not used (open)

—

Not used (open)

I

Focus jump high level signal input terminal Not used (open)

—

Not used (open)

58

SECTION 5

SERVICING NOTES (2)

Cleaning of Optical Pick-up Lens

In cleaning the lens of optical pick-up, use the air blower.

Never use a cotton swab for cleaning the lens of optical pick-up, which otherwise causes a trouble.

Resetting Operation at Power ON

If the power is turned on with a disc loaded in the set, a sequence of operation as shown below will be performed.

(The operation varies depending on the type of disc) Condition: continue mode

(1) CD

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for CD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Auto play (track No.1)

(2) SACD (single layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment

12. Tracking & sled servo on

13. Focus bias auto adjustment

14. Focus servo gain auto adjustment

15. Tracking servo gain auto adjustment

16. Jump to lead-in area

17. Read TOC

18. Auto play (track No.1)

(3) SACD (dual layer)

1. Sled reverse move (sled in)

2. Disc detect

3. IC setting for SACD

4. Servo error signal offset auto adjustment

5. Spindle kick for LD on

6. LD on

7. Focus search

8. Focus servo on (layer 0)

9. Spindle kick

10. Spindle servo on

11. E-F balance auto adjustment (layer 0)

12. Tracking & sled servo on (layer 0)

13. Focus bias auto adjustment (layer 0)

14. Focus servo gain auto adjustment (layer 0)

15. Tracking servo gain auto adjustment (layer 0)

16. Jump to lead-in area

17. Read TOC

18. Focus jump (layer 0tlayer 1)

19. E-F balance auto adjustment (layer 1)

20. Tracking & sled servo on (layer 1)

21. Focus bias auto adjustment (layer 1)

22. Focus servo gain auto adjustment (layer 1)

23. Tracking servo gain auto adjustment (layer 1)

24. Focus Jump (layer 1tlayer 0)

25. Auto play (track No.1)

59

SECTION 6

TEST MODE

This set automatically executes self-diagnosis and various checks

by entering the test mode.

Note: This set automatically makes various adjustments according to the

type of disc, thereby not requiring adjustment of the set when parts

were replaced. However, be sure to execute 6-1. IC AND FLUORESCENT DISPLAY TUBE CHECK, 6-2. AUTO CHECK and 6-

7. WAVEFORMS CHECK.

Setting Method of Test Mode

Turn the [POWER] switch on while pressing the [ AMS ]

dial and the [TIME/TEXT] button. Release the [TIME/TEXT] button

and the

[ AMS ] dial in this order when “TEST MODE

lL

Menu” is displayed on the fluorescent display tube. (If the

[ AMS ] dial is released first, the test mode becomes active

lL

but “TEST MODE Menu” is not displayed)

Disc for Test Mode

Various checks of this set require the following discs.

Model Type *1 Category Application

SATD-04 12 cm disc Adjusted value check,

(J-2501-184-A) SL Reference disc Operation check,

Optical waveform check

Not specified DL 12 cm disc Operation check

PATD-012 Adjusted value check,

(4-225-203-01) CD 12 cm disc Operation check,

YEDS-18 Reference disc Optical waveform check

(3-702-101-01)

Not specified HYBRID 12 cm disc Operation check

*1 SL: Single Layer

Releasing Method of Test Mode

To release the test mode, turn the [POWER] switch off.

Selection/Entry of Test Mode

T o select and enter the “TEST MODE Menu”, operate as follows.

1. Rotate the [ AMS ] dial to select the menu, and press

the [ AMS ] dial to enter.

lL

lL

2. The test is switched on or off alternately each time the

[ AMS ] dial is pressed.

lL

3. To return to the previous step, rotate the [ AMS ] dial

to select the desired item, and press the [ AMS ] dial

to enter.

DL: Dual Layer

Test Mode Command List

The contents of test mode are as follows.

Note: Wrong operation in the test mode causes a trouble, thus requiring extreme care.

LINE command (1X): Use mainly for a manufacturing line.

No. Name Description Remarks

05 DSP MON1 XUGF, XPCK, C2PO outputted from IC509 (CD DSP) Not used for the servicing

06 DSP MON2 MNT0, MNT1, MNT2, MNT3 outputted from IC509 (CD DSP) Not used for the servicing

07 DSP MON3 RFCK, XPCK, XROF, GTOP outputted from IC509 (CD DSP) Electrical measurement,

CD CLV jitter measurement

l

L

lL

lL

STANDARD command (1X): Use when the servo is applied by manual operation.

No. Name Description Remarks

12 LD ON/OFF The laser diode is turned on or off On or off are switched alternately

13 SPIN ON/OFF The spindle motor is rotated with the regulated voltage On or off are switched alternately

14 FSRV ON/OFF The focus servo is turned on or off On or off are switched alternately

15 TSRV ON/OFF The tracking servo is turned on or off On or off are switched alternately

16 CLV ON/OFF The spindle SLV servo is turned on or off On or off are switched alternately

17 SSRV ON/OFF The sled servo is turned on or off On or off are switched alternately

18 ALL SRV ON All servos are turned on

19 ALL SRV OFF All servos are turned off Stop command in the test mode

Focus and tracking servos must be already turned on

Focus, tracking and spindle servos must be already turned on

FOCUS command (2X): Focus related. (All servos must be already turned on (except command 21))

No. Name Description Remarks

21 FSRCH ON/OFF The continuous vertical motion of the optical pick-up lens is turned on or Avoid a long-time use

22 F-BIAS UP Increase focus bias Focus bias value

23 F-BIAS DOWN Decrease focus bias Focus bias value

24 ADJ FCSBIAS The focus bias is adjusted automatically

25 FGAIN UP/DW The focus servo gain is switched between normal and down Normal or down are switched alternately

26 FJMP UP/DWN Focus jump is executed Valid only for DL

27 FOCUS AGC The focus servo gain is adjusted automatically

28 DISP FBdata The focus bias adjusted value is displayed Hexadecimal display 9 bit data

Note: On or off and up or down are switched alternately

off

Both + and - directions are searched to search for best jitter point

UP: layer 0t1, DOWN: layer 1t0

60

OFFSET (PI, FE, TE) command (3X): Adjusts the offset of PI, FE and TE signals.

No. Name Description Remarks

31 PI/FE OFSET Adjusts the offset of PI, FE and TE signals TE offset adjustment is executed for the CD

This adjustment must be executed after 61 DISC DETECT only

TRACKING command (4X): Tracking servo related.

No. Name Description Remarks

41 TGAIN NM/UP The tracking servo gain is switched between normal and up Normal or up are switched alternately

44 ADJ TRK DSP The traverse AGC and E-F balance adjustment is performed

45 TRACKING AGC The tracking servo gain is adjusted automatically

SEARCH command (5X): Track search related.(Not used for the servicing)

No. Name Description Remarks

51 1-TRCK JUMP One-track jump is performed

52 M-TRCK MOVE M-track movement is performed

53 FINE SEARCH Fine search is performed

DISC DETECT command (6X): Disc type check related.

No. Name Description Remarks

61 DISC DETECT Disc type check is executed Refer to how to apply servo by manual

62 SET DISC CD Enter disc type CD setting CD forced setting

63 SET DISC SL Enter disc type SL setting SL forced setting

64 SET DISC DD Enter disc type DD setting DD forced setting

65 SET DISC HH Enter disc type HYBRID HD setting HD forced setting

66 SET DISC HC Enter disc type HYBRID CD setting CD forced setting

Display after judgment operation (62 page)

DSKMOD CD: Judged as CD

DSKMOD SL: Judged as SACD (SL)

DSKMOD DL: Judged as SACD (DL)

DSKMOD HLHD: Judged as HYBRID HD

DSKMOD CDRW: Judged as CD-RW

TOOLS command (8X): Performs aging, reads adjusting parameters, etc.

No. Name Description Remarks

81 VERSION Firmware version is displayed Example: Ver 1.00

83 TRAY AGING Tray open-close aging is performed Number of times and eccentricity

84 JITTER Jitter measurement Not used for the servicing

85 ERROR RATE Error rate measurement Error rate

86 ALL SRV ON Apply all servos Use when applying the servo by

87 DISP ADJ DT Automatic adjusting parameters are displayed Refer to auto check items (65 page)

88 (DISP ADJ DT) Automatic adjusting parameters are displayed Refer to auto check items (65 page)

89 (DISP ADJ DT) Automatic adjusting parameters are displayed Refer to auto check items (65 page)

8d Set Up Init Set to factory shipping mode Set when repair completed

8F 49 TRCK JIT Used for jitter measurement of 49th music on SACD-S4 For manufacturing line

Not used for the servicing measurement

CD: C1, C2 Not used for the servicing

SACD: PO, PI1, PI2

Full automatic measurement including PI, FE and TE offset adjustment is manual operation

performed Refer to STANDARD command (60 page)

The offset adjusted values are scroll-displayed in order of RF, VC, FE and

TE Refer to auto check items (65 page)

The set values of adjusting registers are scroll-displayed in order of PIOR,

CCR and TRCR

The adjusted values are scroll-displayed in order of FGAIN, TGAIN,

FBIAS and TRVSC

PLAY, REPEAT, DIGIFIL, etc. are initialized Refer to 6-6. SHIPPING MODE (69 page)

Not used for the servicing

61

QA command (9X)

No. Name Description Remarks

92 SET CHECK The set is checked Refer to 6-2 AUTO CHECK (65 page)

94 SET AGING The set aging is performed Refer to 6-5 AGING MODE (69 page)

95 DISPLAY ERROR The content of error recorded to the set is read and displayed

96 D-OUT OnOff Digital out of CD is turned on or off

98 APDO JITTER Not used for the servicing

9C BU DENCHO The content of error recorded to the set is read, and then the S curve Refer to 6-7WAVEFORMS CHECK

9D P-ON HOUR Approximate cumulative power supplying time is displayed In unit of 1 hour

9E RFD OUT RFD output is turned on or off Not used for the servicing

Repeat by the specified number of times or until an error occurred

(Error recording) Only one item is recorded

waveform, traverse waveform, and RF waveform can be checked (71 page)

successively

(Initialized by 8d command)

SACD jitter measuring mode

How to Apply Servo by Manual Operation

In analyzing failures of the set, the servo may be applied by manual operation. To apply servo in the test mode, use the following method.

1. After setting the test mode, rotate the [ AMS ] dial to select a command, and press the [ AMS ] dial to enter.

lL

lL

2. “61 DISC DETECT” (Disc type check)t“86 ALL SRV ON” (All servos on + auto adjustment)

3. If applying servo while checking the condition one by one, “61 DISC DETECT” (Disc type check)t“31 PI/FE OFSET” (Offset

automatic adjustment)t“14 FSRV ON/OFF” (Focus servo on) t“16 CLV ON/OFF” (CLV servo on)t“44 ADJ TRK DSP ” (E-F

balance adjustment)t“15 TSRV ON/OFF” (Tr acking servo on)t“17 SSR V ON/OFF” (Sled serv o on)t“24 ADJ FCSBIAS” (Focus

bias adjustment)t“27 FOCUS AGC” (Focus auto gain adjustment)t“45 TRACKING AGC” (Tracking auto gain adjustment).

Note: 1. On and off are alternately switched in the same command.

2. For a stop, select “19 ALL SRV OFF” and press the [ AMS ] dial.

lL

Set Check

92. SET CHECK SET TEST START 10. TOTAL CHECK 120. MANUAL CHK

0. IC&FL CHECK ? 11. AUTO CHECK ? 121. LOAD IN ?

1. TOTAL CHECK ? 12. MANUAL CHK ? 122. SPIN UP ?

2. F.JUMP CHECK ?

3.HYB CHECK ? TOTAL CHK END ? 124. READ TOC&PSP ?

4. DISP ERROR ? 125. 1/3 SEEK ?

END ?? 126. 1-M SEEK ?

13. DISP RSLT ? 123. PARAMETER ?

127. ERROR RATE ?

128. HENSHIN ?

129. SPIN DOWN ?

12A. LOAD OUT ?

MAN. CHK END?

Press the [ AMS ] dial when No.sssss sssss*1 is displayed, and a checking for that display will start or the lower layer

will be selected. For the selection on the same layer, rotate the [ AMS ] dial. It is looped on the same layer, and when “END?” is

displayed, press the [ AMS ] dial to return to the upper layer.

lL

lL

lL

*1 s denotes a displayed character.

62

Manual Check Method

In the “12. MANUAL CHK”, individual checks (121. LOAD IN to 12A. LOAD OUT) are possible.

Example: If 124. READ TOC of 12. MANUAL CHECK is to be checked.

Setting Method:

1. After setting the test mode, rotate the [ AMS ] dial to select “92. SET CHECK” and press the [ AMS ] dial to enter.

2. When “SET TEST START” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “1. TOTAL CHECK?”

and press the [ AMS ] dial to enter.

3. When “10. TOTAL CHECK” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “12. MANUAL CHK?" and

press the [ AMS ] dial to enter.

4. When “120. MANUAL CHK” is displayed, rotate the [ AMS ] dial clockwise by 4 clicks to select “124. READ TOC&PSP?”

and press the [ AMS ] dial to enter.

5. A checking will start automatically.

Note: In making a check, the disc must be loaded. Immediately when a check started, the tray is drawn into the set. Also, the tray can be opened/closed

even during the set check mode.

lL

lL

lL

lL

lL

lL

lL

lL

63

6-1. IC AND FLUORESCENT DISPLAY TUBE CHECK

(SELF-DIAGNOSIS)

The communication between microcomputer and main ICs (selfdiagnosis) and the fluorescent display tube all lit are checked.

Checking Method:

1. After setting the test mode, rotate the [ AMS ] dial to

select “92. SET CHECK” and press the [ AMS ] dial

lL

lL

to enter.

2. When “SET TEST START” is displayed, rotate the

[ AMS ] dial clockwise by 1 click to select “0. IC&FL

lL

CHECK?” and press the [ AMS ] dial to enter.

lL

3. A checking will start automatically, and “0. IC&FL CHECK”

will be displayed. (Checking time is about 3 seconds)

4. After IC communication check, all segments of fluorescent

display tube will be lit. At this time, check visually for a skipped

character.

5. At successful completion of check, “0. IC CHECK OK” is

displayed. In this case, no error exists in the IC interface. Proceed to 6-2. AUTO CHECK.

Note: The check mentioned above tests the communication from micro-

computer to main ICs. Even if the check successfully finished, the

IC to be checked is not always normal. Consider it for reference

only.

6. In case of an IC communication error, the following display

will be given during the checking. Possible causes of error are

as listed below.

Error display Causes (typical example)

DVD DEC. ERROR 1. IC701 (SACD decoder) is faulty

DVD DRAM ERR 1. IC706 (D-RAM) is faulty

CD DSP ERROR 1. IC509 (CD DSP) is faulty

D/A ERROR 1. IC904 (D/A converter) is faulty

EEPROM ERROR 1. IC903 (EEPROM) is faulty

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin rf (XDIS) does not go “H”

• IC902 (expander) is faulty

3. 768fs (33.86688 MHz) is not present to

IC701 pin <znm (XTAL)

• IC811 (3-multiplying circuit) is faulty

• Clock signal 256fs is not sent from

AUDIO board (CN901 pin qg)

• CN901 pin qh (DFGND) and pin qf

(DF3V) are open or shorted

• CN901 pin qh (DFGND) and pin qf

(DF3V) are open or shorted

• CN901 and FFC connection is loose,

or FFC is disconnected

2. IC701 pin <znv (XRST) does not go “H”

• IC901 pin rf (XDIS) does not go “H”

• IC902 (expander) is faulty

3. Faulty communication line between

IC701 and IC706

• Data line, address line, WE, etc.

4. D903 (1SS367) is faulty

2. 768fs (33.86688 MHz) is not present to

IC509 pin ua (XTAL)

Same as cause 3 of DVD DEC. ERROR

3. IC509 pin 2 (XRST) does not go “H”

• IC901 pin rf (XDIS) does not go “H”

• IC902 (expander) is faulty

2. Faulty IC703 (jitter amplifier) peripheral

circuits

3. IC901 pin yf (JIT) is faulty

Error display Causes (typical example)

PRAWN DRAM ERR 1. IC808 (D-RAM) is faulty

*1 2. IC801 (DSD decoder) is faulty

RF AMP ERROR 1. IC001 (RF AMP) is faulty

3. 768fs (33.86688 MHz) is not present to

IC801 pin qf (MCKI)

Same as cause 3 of DVD DEC. ERROR

4. IC801 pin qd (XRST) does not go “H”

• IC901 pin rf (XDIS) does not go “H”

• IC902 (expander) is faulty

5. Faulty communication line between

IC801 and IC808

• Data line, address line, WE, etc.

6. D903 (1SS367) is faulty

D+3.3V is not present to IC808

2. Loose connection between CN503 on

MAIN board and CN001 on RF board,

or FFC disconnection

CN503 pin ql (CLK RF), pin w; (DATA

RF) and pin wa (SDEN) must be checked

*1 DSD decoder is also checked.

Causes Common to Each IC:

1. Faulty communication line between microcomputer and each

IC.

Disconnected patterns, floating series resistors, bridge, etc.

2. Faulty IC supply voltage.

Particularly, check D+3.3V voltage. (D+5V for display

microcomputer)

3. Faulty microcomputer communication port to each IC

Note: In case of more than two errors, the error display is switched over

one after another, thus making the reading difficult.

In such a case, press again the [ AMS ] dial to make a

recheck for error reading.

lL

64

6-2. AUTO CHECK (AUTOMATIC VARIOUS MEASUREMENTS)

The auto check is performed to check if the set operates stably . Though a checking is made automatically, whether the measured data are

within the specification is evaluated by the service person. The auto check results in NG immediately, if the check itself causes an error.

Setting Method of Auto Check Mode:

1. After setting the test mode, rotate the [ AMS ] dial to select “92. SET CHECK” and press the [ AMS ] dial to enter.

2. When “SET TEST START” is displayed, rotate the [ AMS ] dial clockwise by 2 clicks to select “1. TOTAL CHECK?”

and press the [ AMS ] dial to enter.

lL

3. When “10. TOTAL CHECK” is displayed, rotate the [ AMS ] dial clockwise by 1 click to select “11. AUTO CHECK”

and press the [ AMS ] dial to enter.

lL

lL

lL

lL

lL

CD and SACD (SL) Disc Operation Check

Checking method:

1. Press the [OPEN/CLOSE] button to open the tray and place the test disc *1.

2. Press the [ AMS ] dial, and the following check will be performed automatically.

lL

3. Finally, the test disc will be ejected and the auto check will finish.

4. “AUTO CHECK OK” will be displayed at successful completion of auto check.

5. Recheck is enabled if the [ AMS ] dial is pressed in step 4. (Also, use this operation when exchanging the test disc)

lL

6. In case of an error during the checking, the check is interrupted automatically and the error is displayed. (Error display example:

“LOAD IN ERROR”) After error display, “CONT?STOP (J/S)” is displayed. In this case, if the [ AMS ] dial is pressed, the

check where the error occurred is skipped and you can proceed to the next check. Also, if [ ] button is pressed, the check finishes and

lL

x

“AUTO CHECK NG” is displayed when even one NG item exists.

*1 Use PATD-012 or YEDS-18 for CD, and SATD-S4 for SACD (SL). Using another disc will result in a checking failure.

Check Items:

Items Description Remarks

LOAD IN TIME (msec) Time until a disc is chucked from the state where loading tray is out Loading in switch HtL

SPIN UP TIME (msec) Time from spindle kick to PLL lock Lock signal LtH

RF/VC/FE/TE (ORG) Offset values before RF (PI), VC, FE, TE signal offset adjustment At offset 0

RF/VC/FE/TE (ADJ) Offset values after RF (PI), VC, FE, TE signal offset adjustment VC offset is not adjusted

PI/TRVS PP (ORG/ADJ) PI (ORG): PI value at disc type check (decimal data) PI level conversion

PIOR/CCR/TRCR PIOR: Set value of PI offset coarse adjusting register Registers in RF amplifier

FOCUS/TRK GAIN Auto gain adjusted values of focus and tracking servos Reference: 30h

FBIAS/TRVSC/TRCR2/CFR FBIAS: Focus bias set value (9 bit data in hex notation) TRCR2 adjusts the E-F gain

MIN JITTER AT F.BIAS Minimum jitter value in focus bias adjustment (CD only) Correlative with RF jitter

READ TOC TIME (msec) Time required for TOC reading

PSP AMPLITUDE SACD only

1/3 SEEK TIME Seek time between 1/3LBA and 2/3LBA of the disc LBA: Absolute address

F) A VE/MIN/MAX (msec): 1/3LBAt2/3LBA avera ge/minimum/maximum

R) AVE/MIN/MAX (msec): 2/3LBAt1/3LBA average/minimum/maximum

1/MAX SEEK TIME Seek time between most inward track (0LBA) and most outward track max

F) A VE/MIN/MAX (msec): most inwardtmost outward average/minimum/maximum

R) A VE/MIN/MAX (msec): most outwartmost inward average/minimum/maximum

ERROR RATE Error rate measurement Measure for 10 sec at track No.5

RF (8 bit data in hex notation) RF: A0h

VC, FE, TE (9 bit data in hex notation) VC, FE, TE: 00h

(Less than ORG value if offset correction is normal) (Measurement only)

RF (8 bit data in hex notation) Also, for SACD, the TE offset is

VC, FE, TE (9 bit data in hex notation) not measured and adjusted

PI (ADJ): PI value after PI offset adjustment Read value × 12.9mV

(read value at microcomputer A/D) (decimal data)

TRVS PP (ORG):Traverse level before level correction (AGC) Traverse level conversion

(decimal data) Read value × 12.9mV

TRVS PP (ADJ):Traverse level after level correction (AGC)

(decimal data) 12.9mV=3.3V ÷ 256 (8 bit)

CCR: Set value of FE offset coarse adjusting register

TRCR: Set value of TE offset coarse adjusting register

(8 bit data in hex notation)

TRVSC: Traverse center value (9 bit data in hex notation) balance and used for CD only

TRCR2: Set value of E-F balance coarse adjusting register (Fixed to 06 for SACD)

CFR: Set value of traverse level adjusting register TRCR2 and CFR are registers in

RF amplifier

LBA

For CD: Average value/Maximum value of C1 and C2 For the SACD, 160 block data

For SACD: Average value/Maximum value of PO, PI1 and PI2 except the data under tracking jump

65

Items Description Remarks

HENSIN Eccentricity measurement For the CD only are measured

SPIN DOWN TIME (msec) Time from spindle brake application to rotation stop For CD: Over 64 monitoring

LOAD OUT TIME (msec) Time until loading table comes out from the state where a disc is in chuck Loading out switch HtL

Eccentricity (actual eccentric amount) of disc, disc pulley total • Read by dividing by 10

• 0 may be displayed if eccentricity

is small (10um or less) (Due to

measurement reason)

For SACD: VCO1D monitoring

Measured Data Reading Method:

To judge the check result, the measured data must be read.