Sony SCD-333-A Service manual

s

r

SCD-333A

NOTES ON CLEANING THE OBJECTIVE LENS

SERVICE MANUAL

SERVICE NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

Laser Diode Properties

• Material: GaAlAs

• Wavelength: 780 nm

• Emission Duration: continuous

• Laser Output Power: less than 44.6 µW*

* This output is the v alue measured at a distance of 200 mm from

the objective lens surfase on the Optical Pick-up Block.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

cotton swabs

optical pick-up

slide base

Apply CD lens cleaner B-4 (Part No.:J-2501-000-A) to cotton swabs

(narrow type) (Part No.:J-2501-023-A) to be lightly wet. Use a force

(about 5 g (0.18 oz)) to make the objective lens in contact with the

bottom lightly, and clean the lens by spirals as following below.

Replace the cotton swab and repeat this cleaning two or three times.

surface of objective len

Notes:

Do not force to push the objective lens. Otherwise, the plate spring

supporting the objective lens will be bent, causing a deteriorated

RF waveform.

Never touch anything other than the objective lens. Otherwise, a

significant deterioration occurs in the RF waveform.

objective lens

2-axis actuato

2-axis cover

COMPACT DISC MECHANISM

SCD-333A

SECTION 1

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

for printed wiring boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

z

•

: Through hole.

• b : Pattern from the side which enables seeing.

(The other layer’s patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

for schematic diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• % : indicates tolerance.

f

•

: internal component.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• Signal path.

J : CD

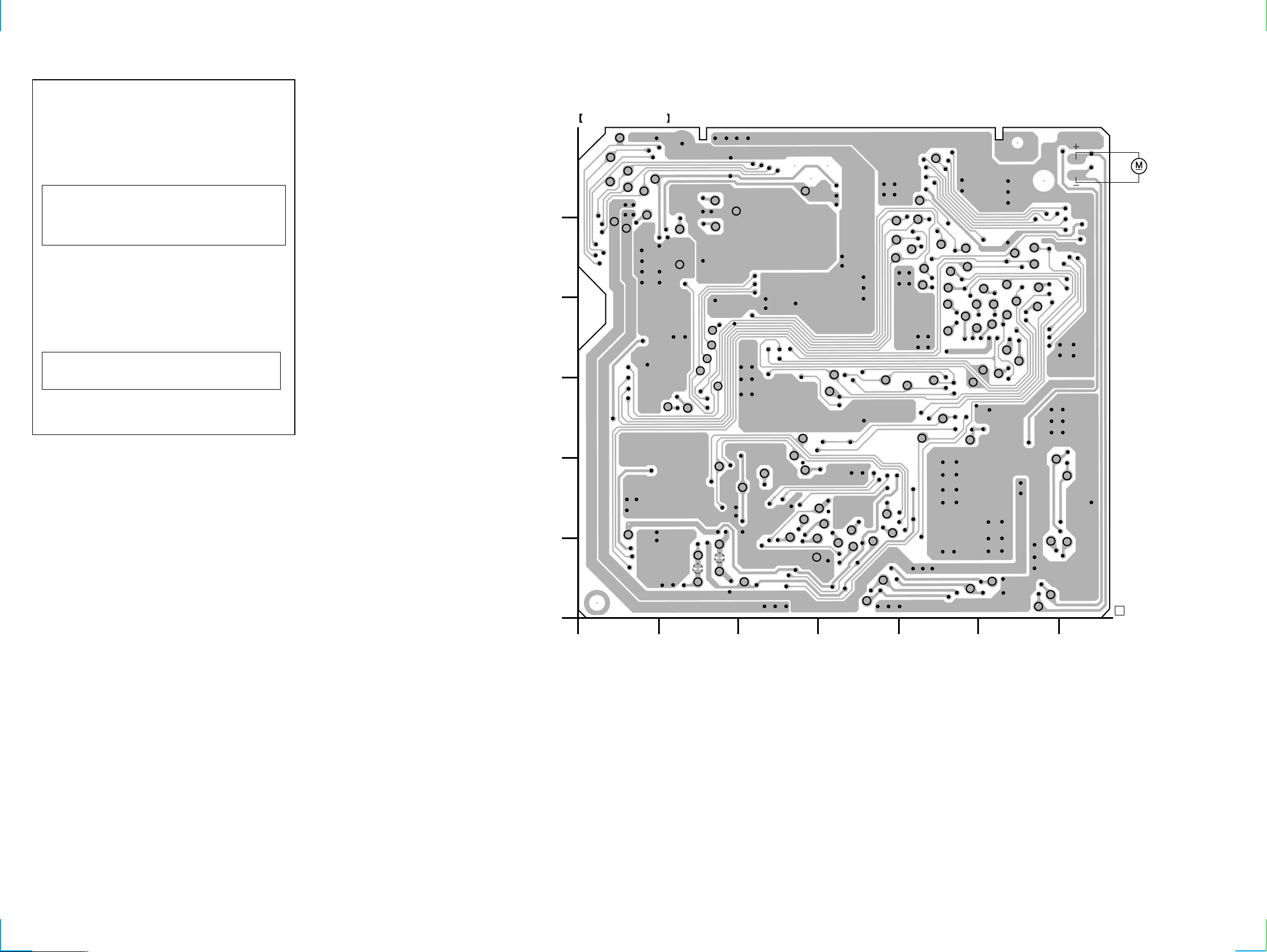

1-1. PRINTED WIRING BOARDS

MD-MAIN BOARD (SIDE A)

TP001

TP002

TP005

TP006

TP010

TP019

TP007

TP009

TP038 TP034

TP013

TP011

TP037

TP016

TP014

TP032

TP033

TP036

TP023

A

B

C

TP004

TP012

D

TP043

TP015

TP039

TP040

TP008

TP042

TP041

TP026

M70

M61

TP017

TP022

TP028

M24

M23

TP027

M25

M26

M16

M17

M02

TP003

TP025

M22

M06

M69

M15

M11

M07

M19

M39

M76

M75

TP029

M80

M29

M27

M63

M74

M67

M71

M21

M10

M28

M52

M35

M66

M41

M51

M58

M38

TP061

TP062

RED

WHT

M903

(LOADING)

TP066

TP069

TP068

TP065

TP073

TP067

TP070

TP050

TP071

TP055

TP049

TP072

TP054

TP051

TP056

TP057

TP063

TP059

TP064

TP058

1-660-771-

21

E

TP052

TP044

BR001

F

TP045

04

1

TP046

BR002

TP053

TP047

23 7456

2 2

SCD-333A

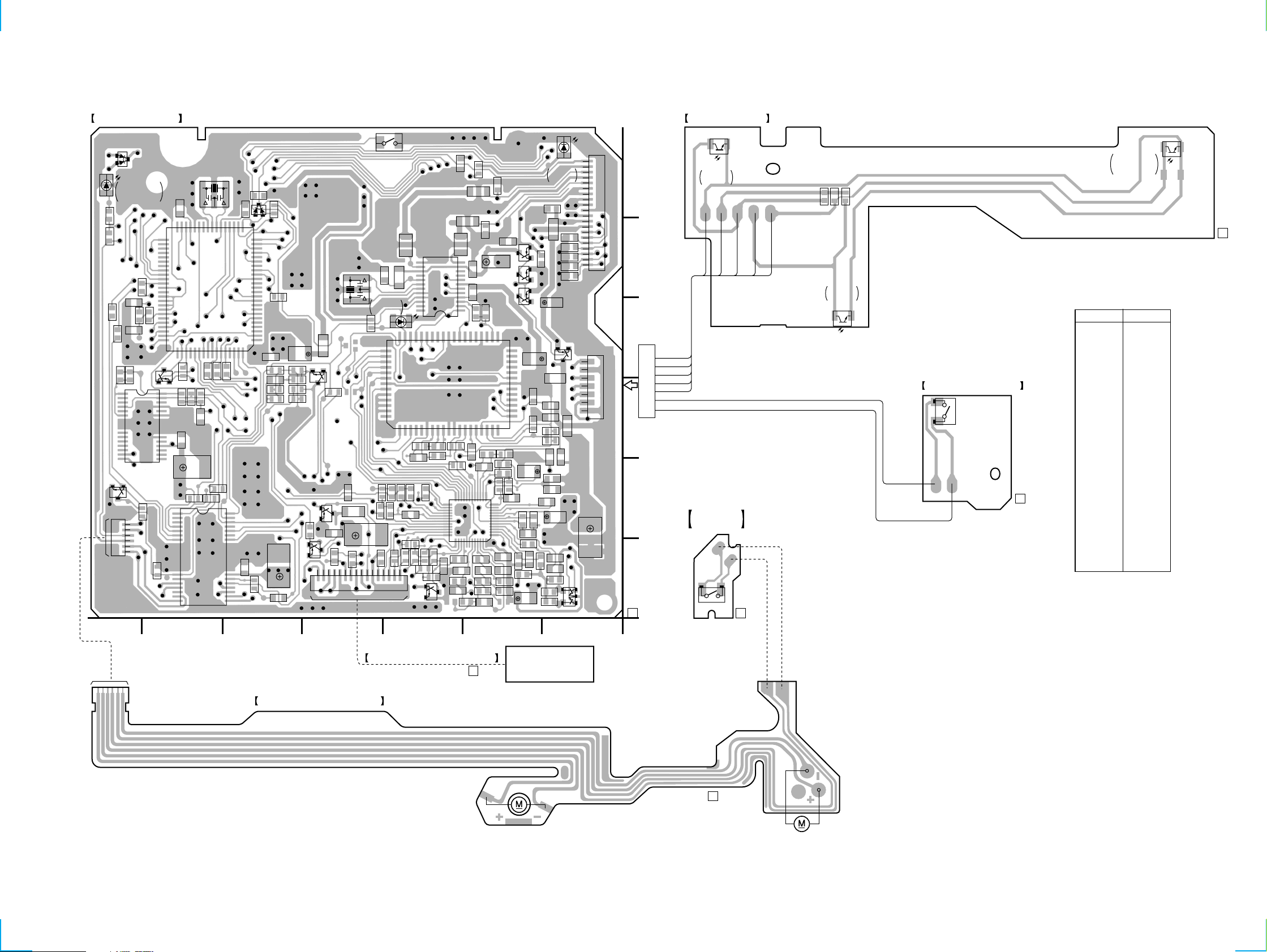

MD-MAIN BOARD (SIDE B)

D401

D632

LOADING

COMPLETION

DETECT

R632

R603

C621

R604

C620

R605

C403

125

IC402

13 14

Q401

CN104

1

6

R404

41 24

R607

R620

R621

64

65

Q603

R408

R406

X601

C630

IC601

R610

R612

R407C405

R405

R403

C404

C411

R590

R606R402

1

IC401

14 15

R609

28

2540

80

R611

R602

C627

D601

1

C402

C602

R401

R608

R550

C591

C590

R593

C401

R601

C410

SW602

(CHAKING DET)

C210

X301

C610

R591

R592

R594

R595

L601

Q590

R548

C532

Q502

L503

R511

R512

R546

Q501

116

C554

R502

C303

L301

D631

DISC IN

DETECT

R631

52

64

119

R536

C524

C507

C505

C504

R510

C506

R508

R509

R503

R507

R504

R501

R506

R544

CN103

13 12

IC301

24 1

IC502

R535

R537

C503

25

36

R505

R547

C530

Q504

C525

R534

R543

C508

R545

R513

C509

R514C512

C601

L101

C110

IC501

L201

C302C304

C526

C523

R518

C510

R541

R515

R630

R301

R533

1324

4837

C101

C310

C305

3351

12

1

C201

C301

Q302

Q602

32

20

R532

R530

R531

R529

C513

C511

R517

R542

237456

R528

C521

Q301

C556

C518

R524

C514

R520

C553

C501

R525

R539

R540

C519

R526

C515

C628

C629

C611

L501

C528

C529

C527

R538

R527

C520

C516

R523

C517

R519

R522

R521

D630

DISC IN

DETECT

L602

C626

C625

C624

C623

C622

Q601

C522

C502

C555

L502

Q503

1-660-771-

1

CN101

20

10

1

CN102

7

1

C552

A

B

C

D

E

F

SENSOR BOARD

Q623

LOADING

Q620

DISC IN

DETECT

R620

R622

R621

BLK/WHT

ORG/WHT

BLU/WHT

WHT

PNK/WHT

Q621

7

PNK/WHT

WHT

BLU/WHT

ORG/WHT

BLK/WHT

RED

BLK

1

DISC IN

DETECT

DISC IN SW BOARD

SW621

(DISC IN)

1-660-773-

13

• Semiconductor

LIMIT SW

BOARD

SW620

(LIMIT)

21

1-660-772-

13

COMPLETION

DETECT

Location

Ref. No. Location

D401 A-7

D601 A-5

D630 A-1

D631 C-3

D632 A-7

IC301 B-3

IC401 F-6

IC402 D-7

IC501 E-2

IC502 D-3

IC601 B-6

Q301 B-2

Q302 B-2

Q401 E-7

Q501 F-4

Q502 E-4

Q503 F-1

Q504 F-3

Q590 C-4

Q601 C-1

Q602 B-2

Q603 C-6

1-660-775-

13

61

04

MOTOR FLEXIBLE BOARD

PICK-UP FLEXIBLE BOARD

1-660-769-

11

M902

(SLED)

OPTICAL

PICK-UP

KSS-520A

1-660-770-

11

33

M901

(SPINDLE)

Loading...

Loading...