Sony sa va100 Service Manual

SA-VA100

SERVICE MANUAL

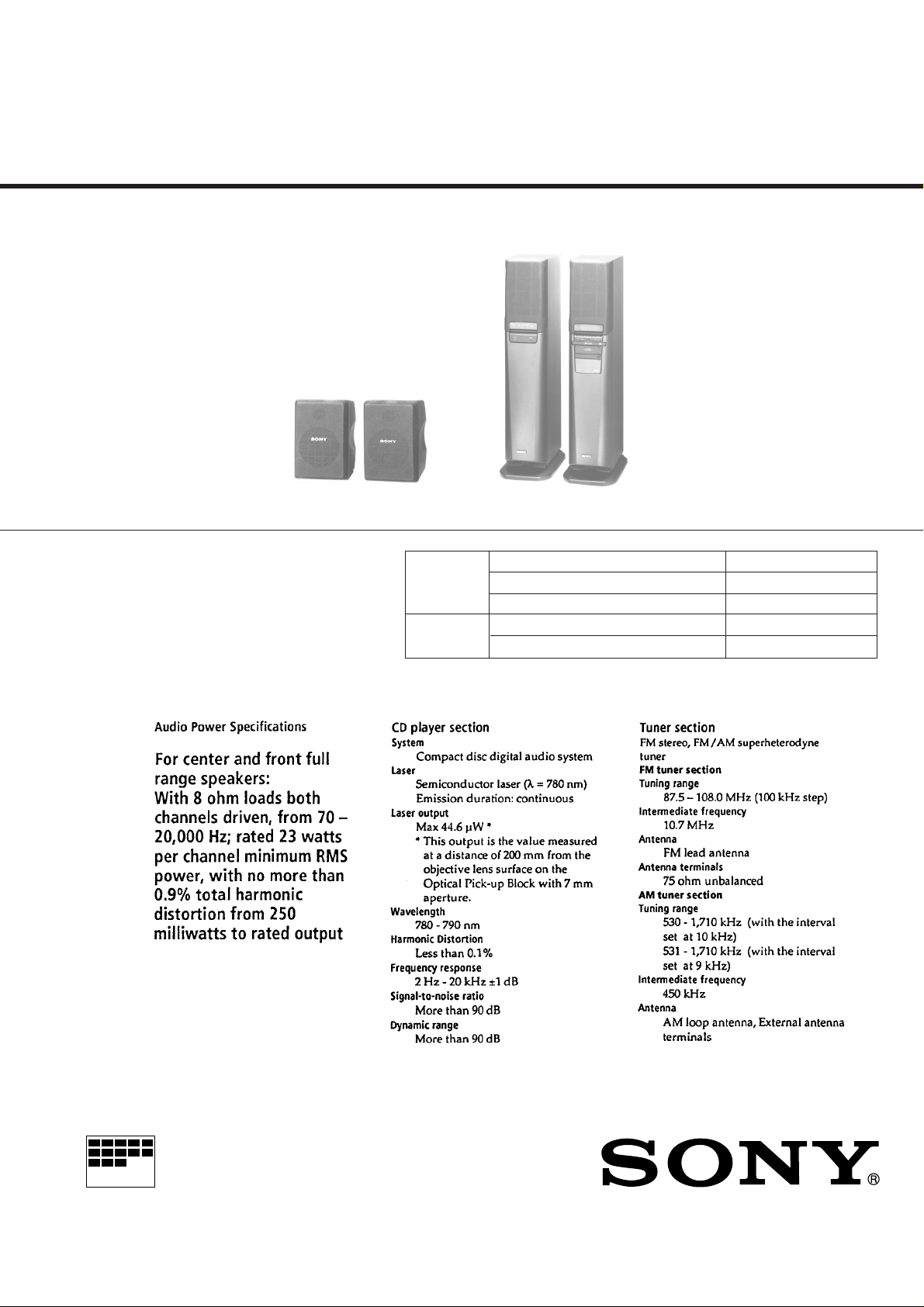

• REAR SPEAKER

CD

SECTION

T APE

SECTION

• FRONT SPEAKER SYSTEM

US Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-41

Optical Pick-up Type KSM-2101BBM (S)

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism Type TCM-190RB53C

SPECIFICA TIONS

HOME ENTERTAINMENT AUDIO SYSTEM

MICROFILM

— 1 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

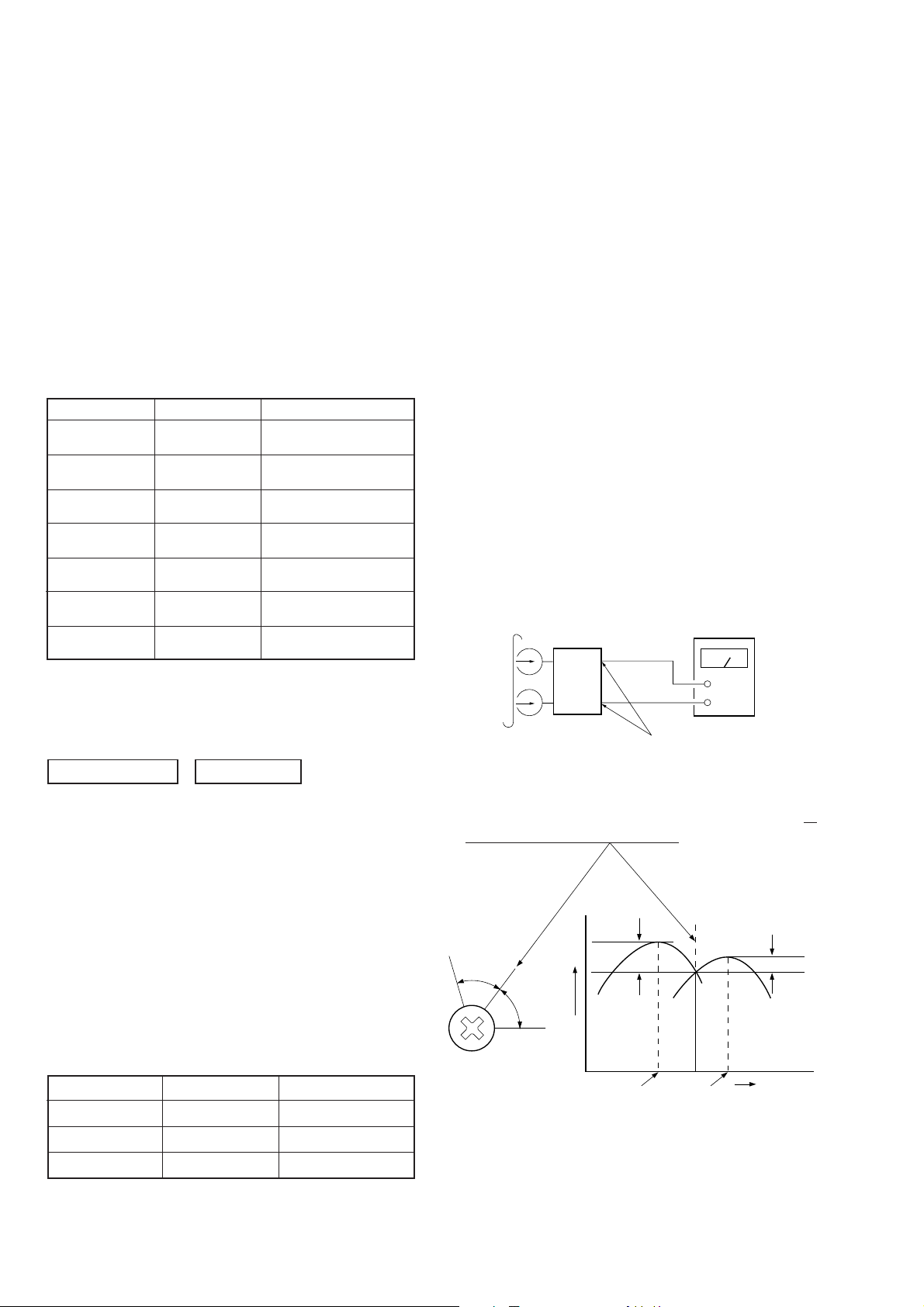

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

— 2 —

0.15

1.5k

µ

F

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

TABLE OF CONTENTS

1. SERVCING NOTE

..............................................................4

2. GENERAL .................................................................... 4

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3. DISASSEMBLY

3-1. Amplifier Block..................................................................26

3-2. Mechanism Component Block ...........................................27

3-3. CD Mechanism and TC Mechanism Block........................28

4. MECHANICAL ADJUSTMENT ................................... 30

5. ELECTRICAL ADJUSTMENT ..................................... 30

6. DIAGRAMS

6-1. Circuit Boards Location ..................................................... 38

6-2. Block Diagrams

• CD Section ....................................................................... 39

• Deck Section ....................................................................41

• OSD Section.....................................................................43

• Surround Amp Section.....................................................45

• Display Section ................................................................47

• Power Section .................................................................. 48

6-3. Printed Wiring Board — CD Section —............................50

6-4. Schematic Diagram — CD Section —...............................53

6-5. Schematic Diagram — Deck Section — ............................ 57

6-6. Printed Wiring Board — Deck Section — ......................... 61

6-7. Printed Wiring Board — OSD Section —.......................... 64

6-8. Schematic Diagram — OSD Section — ............................ 67

6-9. Schematic Diagram — Surround Amp Section —.............71

6-10. Printed Wiring Board — Surround Amp Section —..........75

6-11. Printed Wiring Board — Display Section — ..................... 79

6-12. Schematic Diagram — Display Section — ........................ 83

6-13. IC Block Diagrams ............................................................. 86

6-14. IC Pin Function

• IC106 CD System Controller

(µPD78058GC-225-3B9) ................................................ 93

• IC301 Deck System Control (HD6433522P01F) ............95

• IC401 Display Control, FL Driver

(µPD780204GF-020-3BA)..............................................97

• IC602 OSD Controller (HD6413004F) ........................... 99

• IC605 OSD (MB90095PF-G-175) ................................ 101

• IC1501 Surround System Control

(µPD78042FGF-026-3B9) ............................................ 102

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR

DOTTED LINE WITH MARK ! ON THE SCHEMATIC

DIAGRAMS AND IN THE PARTS LIST ARE CRITICAL

TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

MODEL IDENTIFICATION

— BACK PANEL —

• Abbreviation

AUS: Australian model

7. EXPLODED VIEWS

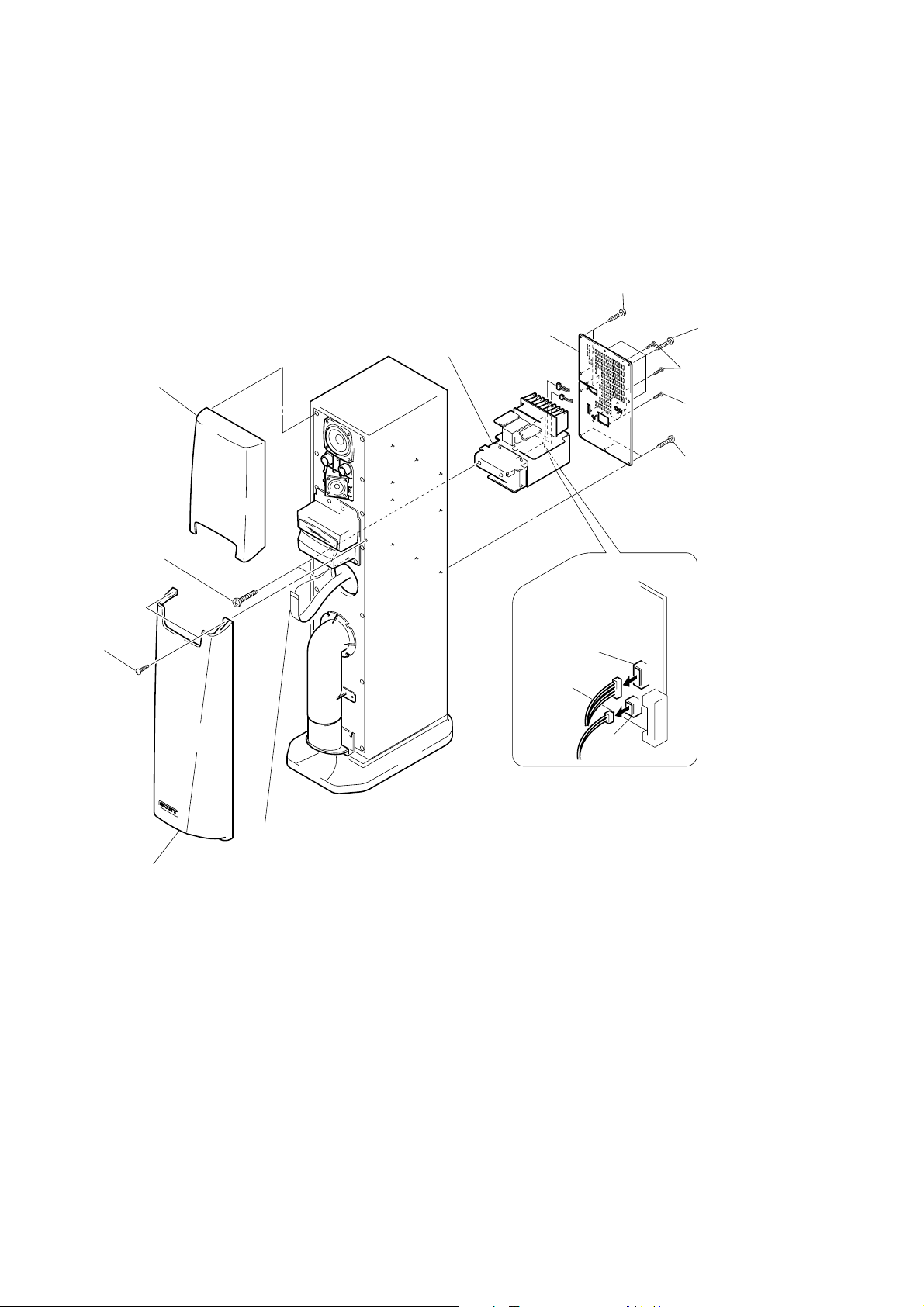

7-1. L-ch Speaker System Section...........................................104

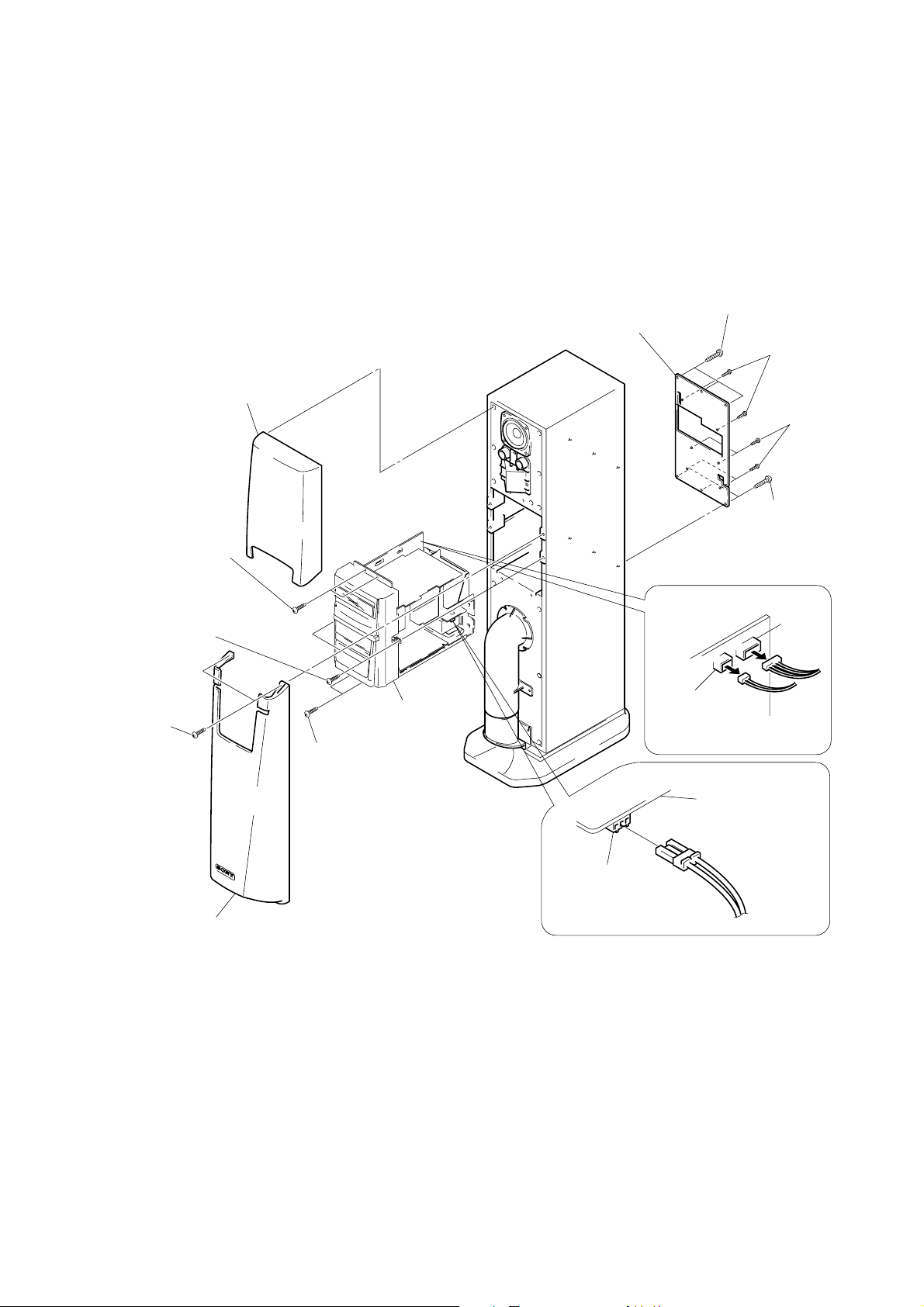

7-2. Amplifier Seciton ............................................................. 105

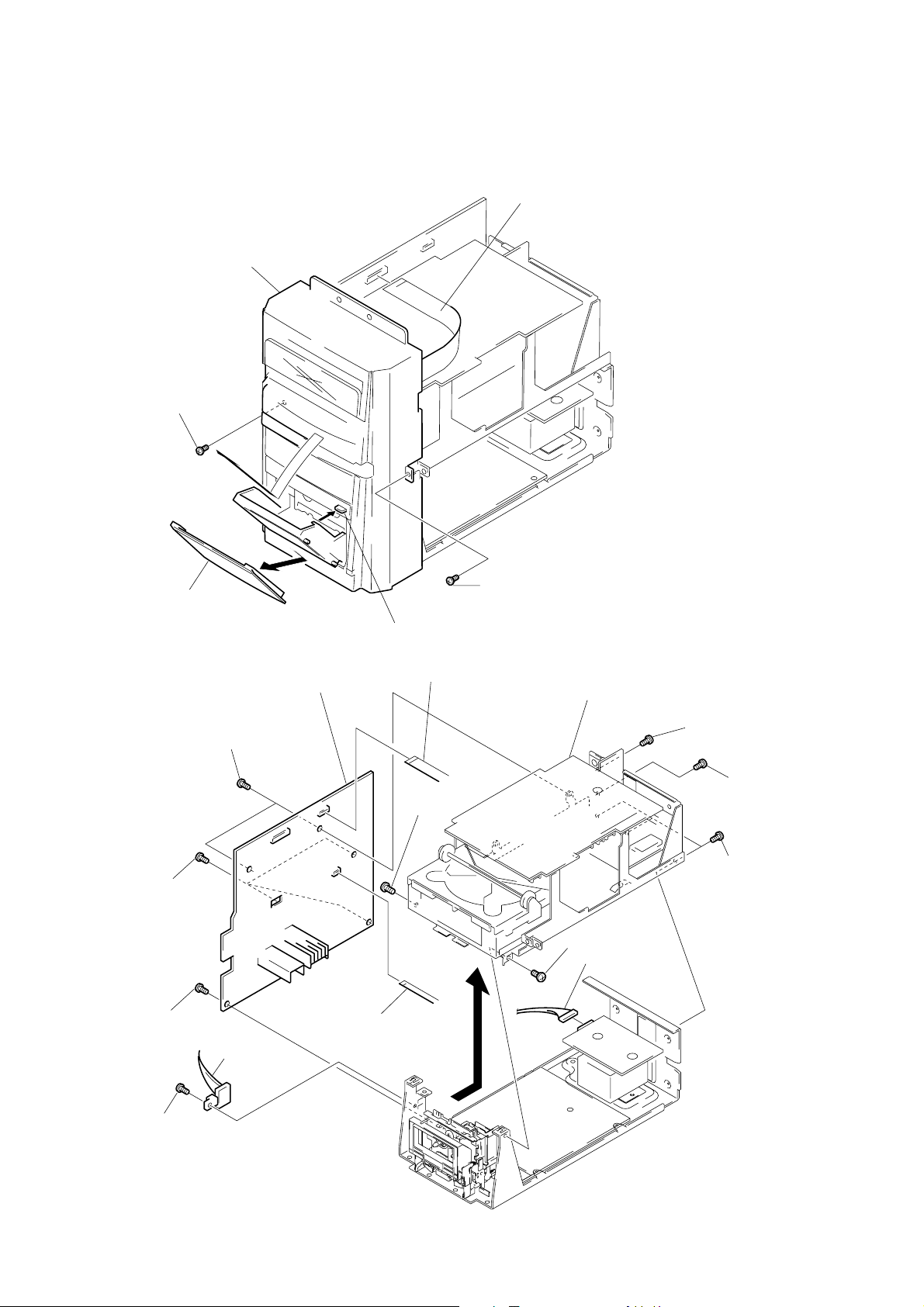

7-3. R-ch Speaker System Seciton........................................... 106

7-4. Mechanism Component Section....................................... 107

7-5. TC Mechanism Section 1 (TCM-190RB53C).................. 108

7-6. TC Mechanism Section 2 (TCM-190RB53C).................. 109

7-7. CD Mechanism Section 1 (CDM-41)............................... 110

7-8. CD Mechanism Section 2 (Tray Assembly) (CDM-41) ...111

7-9. CD Mechanism Section 3 (R Side Chassis Assembly)

(CDM-41) ......................................................................... 112

7-10. CD Mechanism Section 4 (Main Chassis Assembly)

(CDM-41) ......................................................................... 113

7-11. CD Mechanism Section 5 (Drive Unit Assembly)

(CDM-41) ......................................................................... 114

7-12. Rear Speaker System Section (SS-SR151) ...................... 115

8. ELECTRICAL PARTS LIST ........................................ 116

US model (Right)

AUS model (Right)

US model (Left)

AUS model (Left)

— 3 —

MODEL

R

L

Parts No.

PARTS No.

4-981-882-0

4-981-882-1

4-981-883-0

4-981-883-1

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objecti ve lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERA TION CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output four times.

Cold Reset

Mode which clears all the user memories of this unit and sets them to

the same state as that at shipment.

Fluorescent display tube, all LEDs lit, key-check mode

Method:

1. In the STANDBY state, press the DOLBY NR button, p button,

and DISC 6 button together . All the fluorescent display tubes and

LEDs light up.

2. Press any one button to set the key check mode.

3. When the key check mode is set, KEY TEST is displayed on the

fluorescent display tube.

4. Total pressed number of buttons are displayed below the display.

(When the ª, ·, ∏, ¬ buttons are pressed, the LEDs light up.

Each time the DISC 1 to 7 buttons are pressed, the LEDs light up

alternately in orange and green.)

Buttons already pressed once will not be counted when pressed

again.

5. When all 26 buttons are pressed, SUM OK is displayed on the

fluorescent display tube.

6. To exit the mode, disconnect the AC plug from the outlet.

OSD Color Bar Mode (OSD:On Screen Display)

To c heck the video system of this unit, check that the color bar signal

can be output.

1. In the STANDBY state, press the DOLBY NR button, p button,

and OPEN/CLOSE button together.

2. The color bar is output.

The color bar signal is output from the MONITOR OUT terminal.

3. To exit the mode, disconnect the AC plug from the outlet.

Method:

Press the DOLBY NR button, p button, and DISC 7 button together .

SHIP mode

This unit is provided with a SHIP mode to reduce damages of the

mechanism section due to shocks during transportation. Set this mode

after repairs before returning the product to the customer.

1. Press the SYSTEM POWER button, and check that all discs 1 to

7 are not in their trays.

2. Press the DOLBY NR button, p button, and DISC 7 button together, and perform cold reset.

3. Press the DIRECTION button, p button, and DISC 7 button together.

4. SHIP is displayed on the fluorescent display tube to indicate that

the SHIP mode has been set.

5. When the mechanism section stops operating, disconnect the AC

plug from the outlet.

Exiting the SHIP mode:

Insert the disconnected AC plug into the outlet again.

SECTION 2

GENERAL

This section is extracted from

instruction manual.

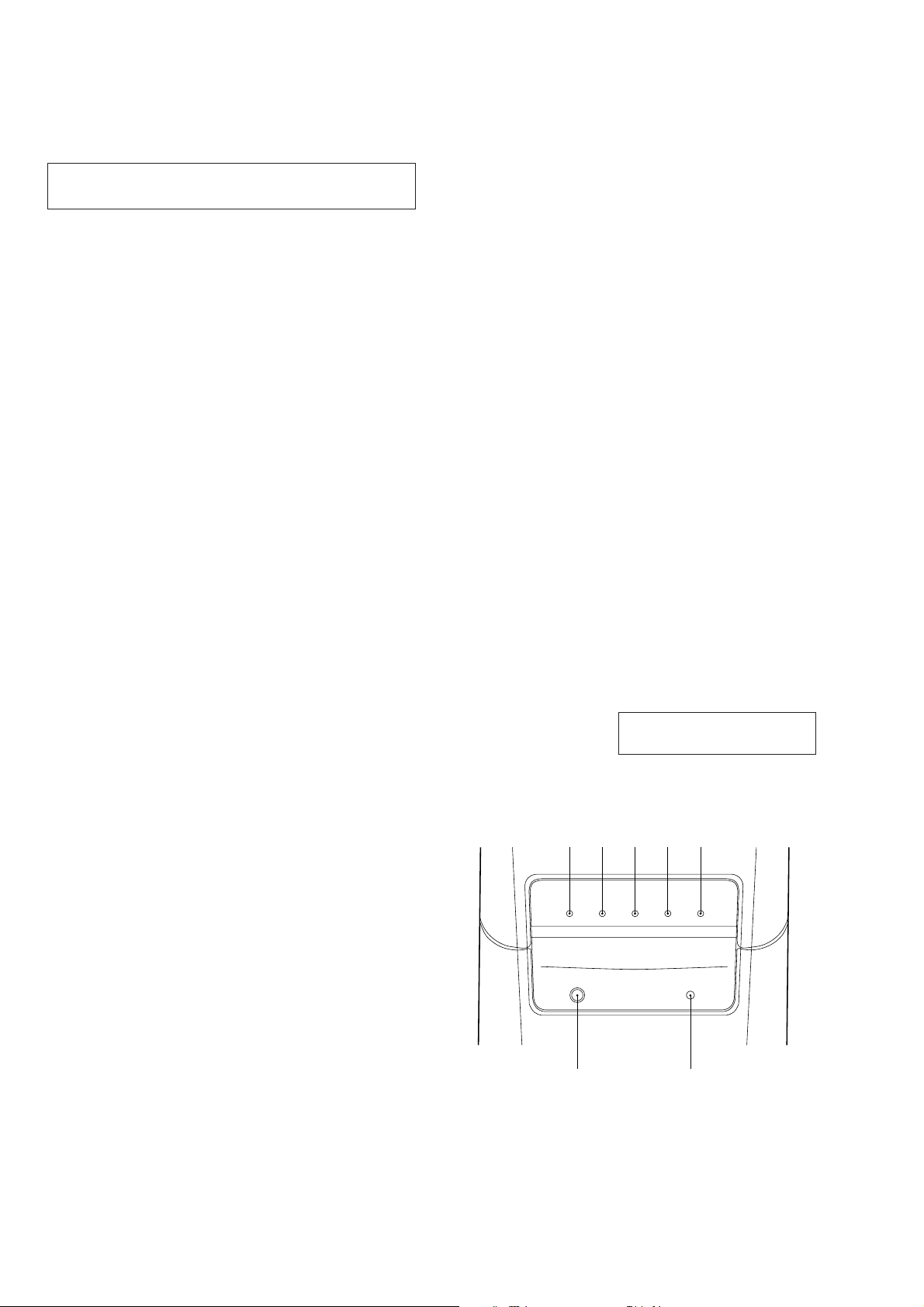

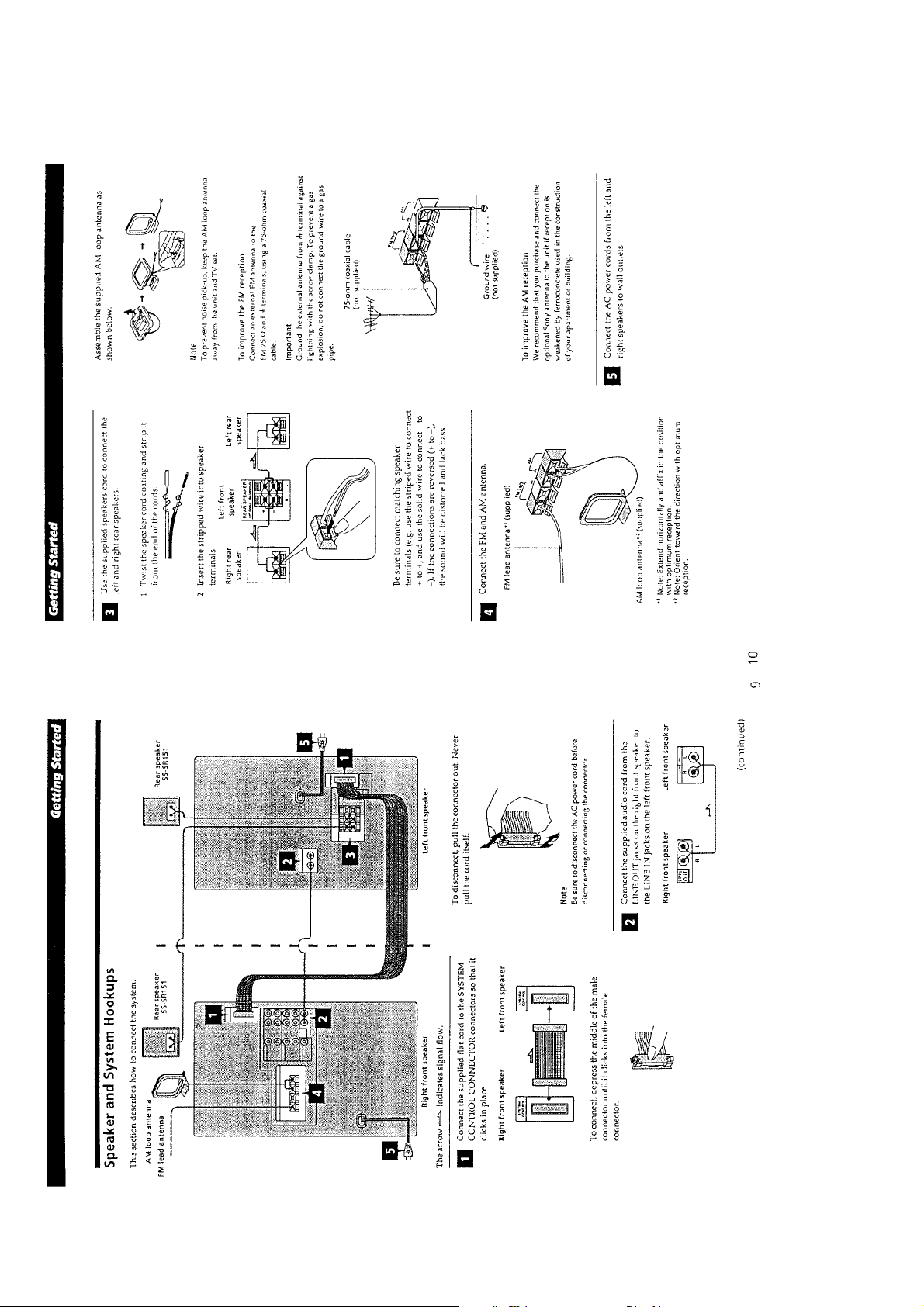

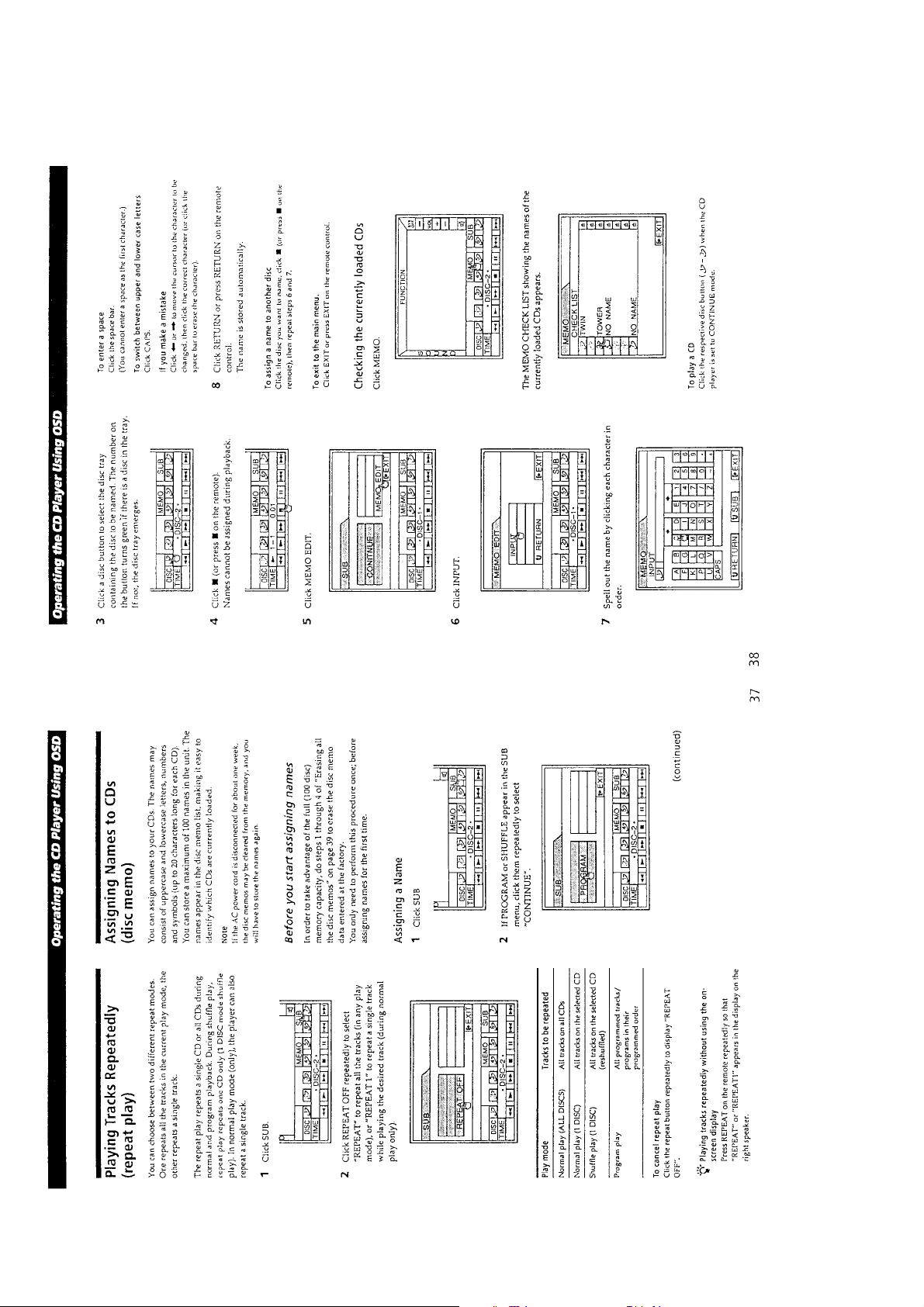

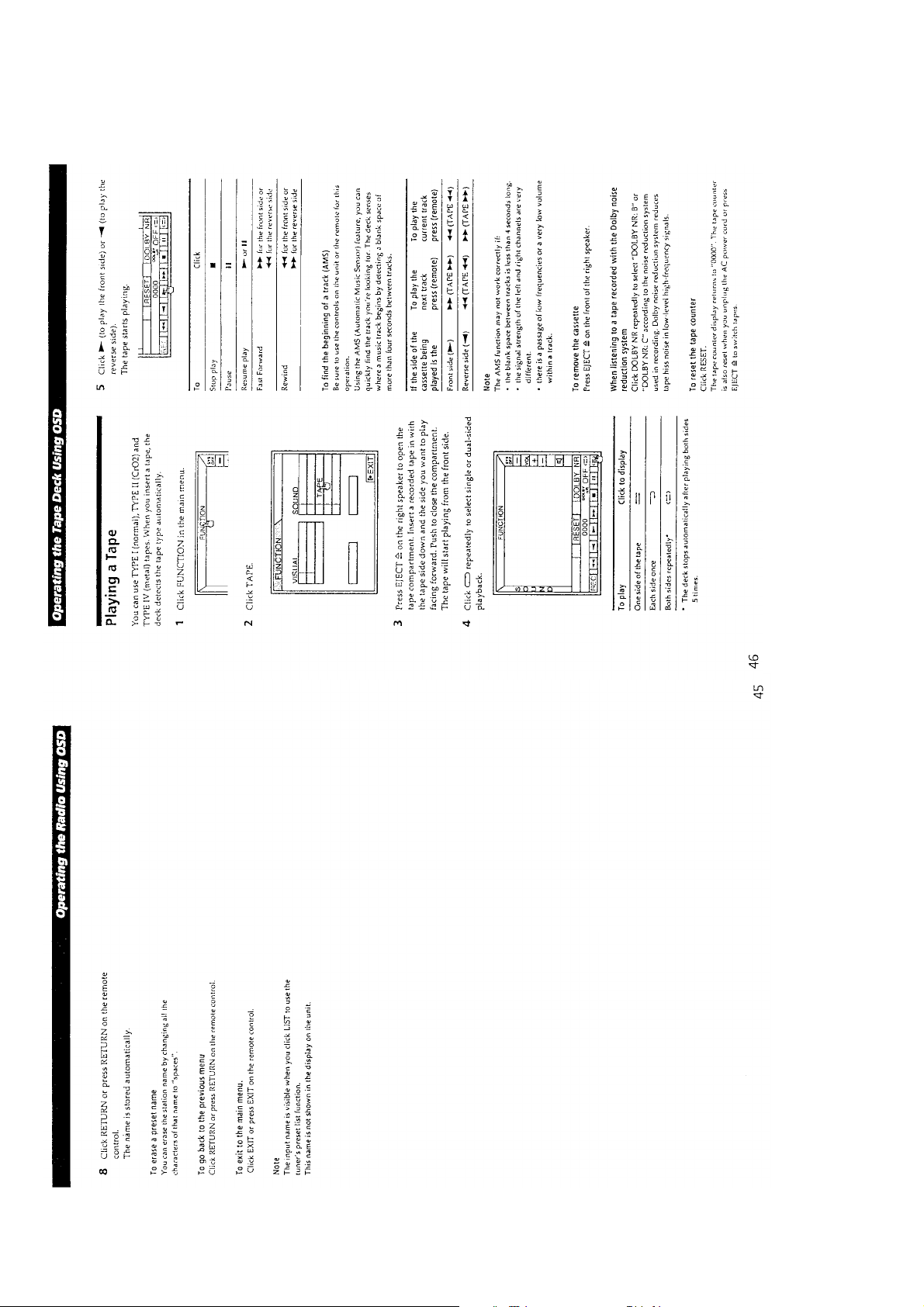

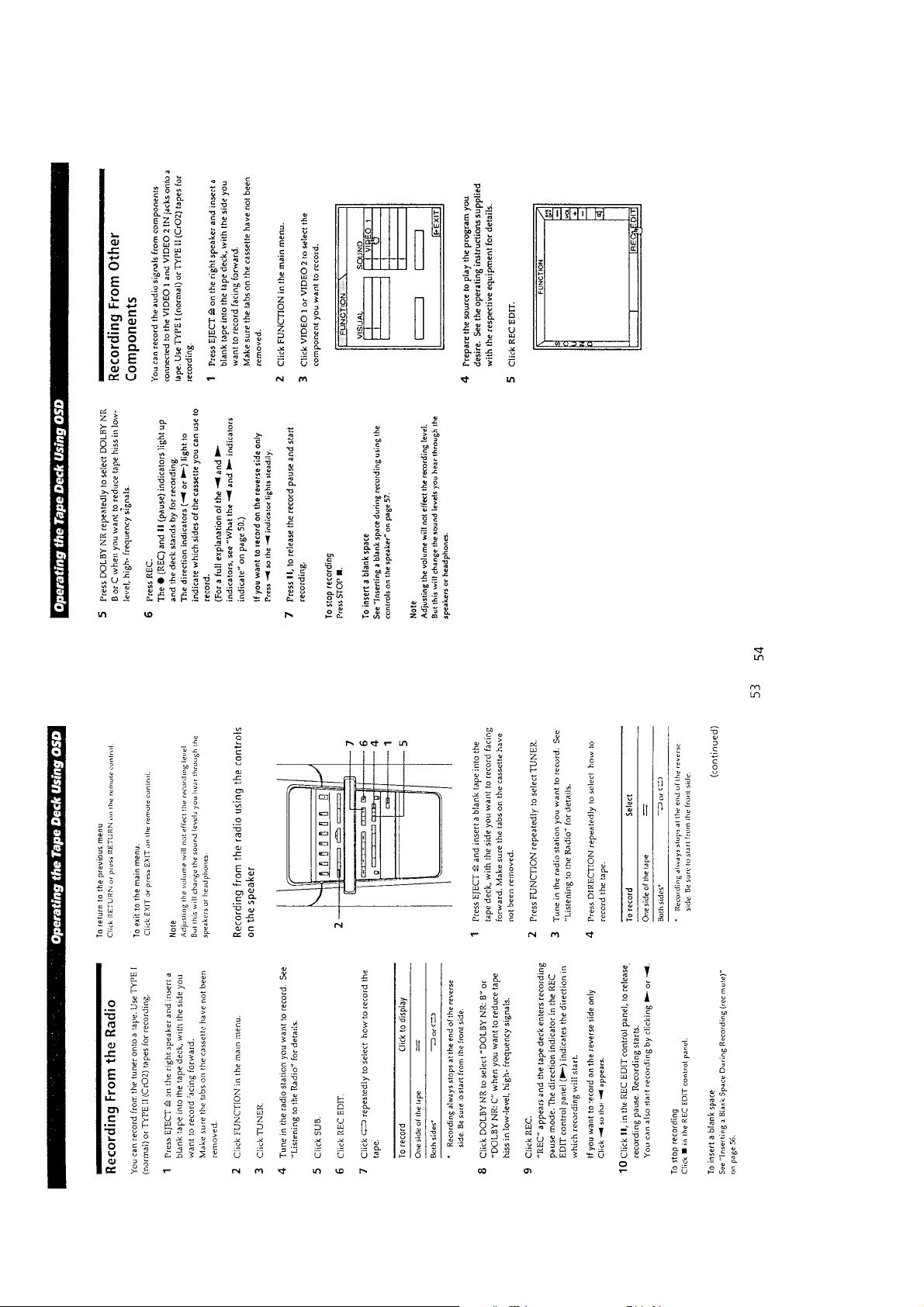

Location of Parts and Controls

Left Front Speaker -Front panel-

2

1

76

1 READY indicator

2 OPERATE indicator

3 CENTER SPEAKER EXT indicator

4 CENTER SPEAKER INT indicator

5 SPEAKERS indicator

6 SPEAKER ON/OFF button

7 HEADPHONES jack

3

45

— 4 —

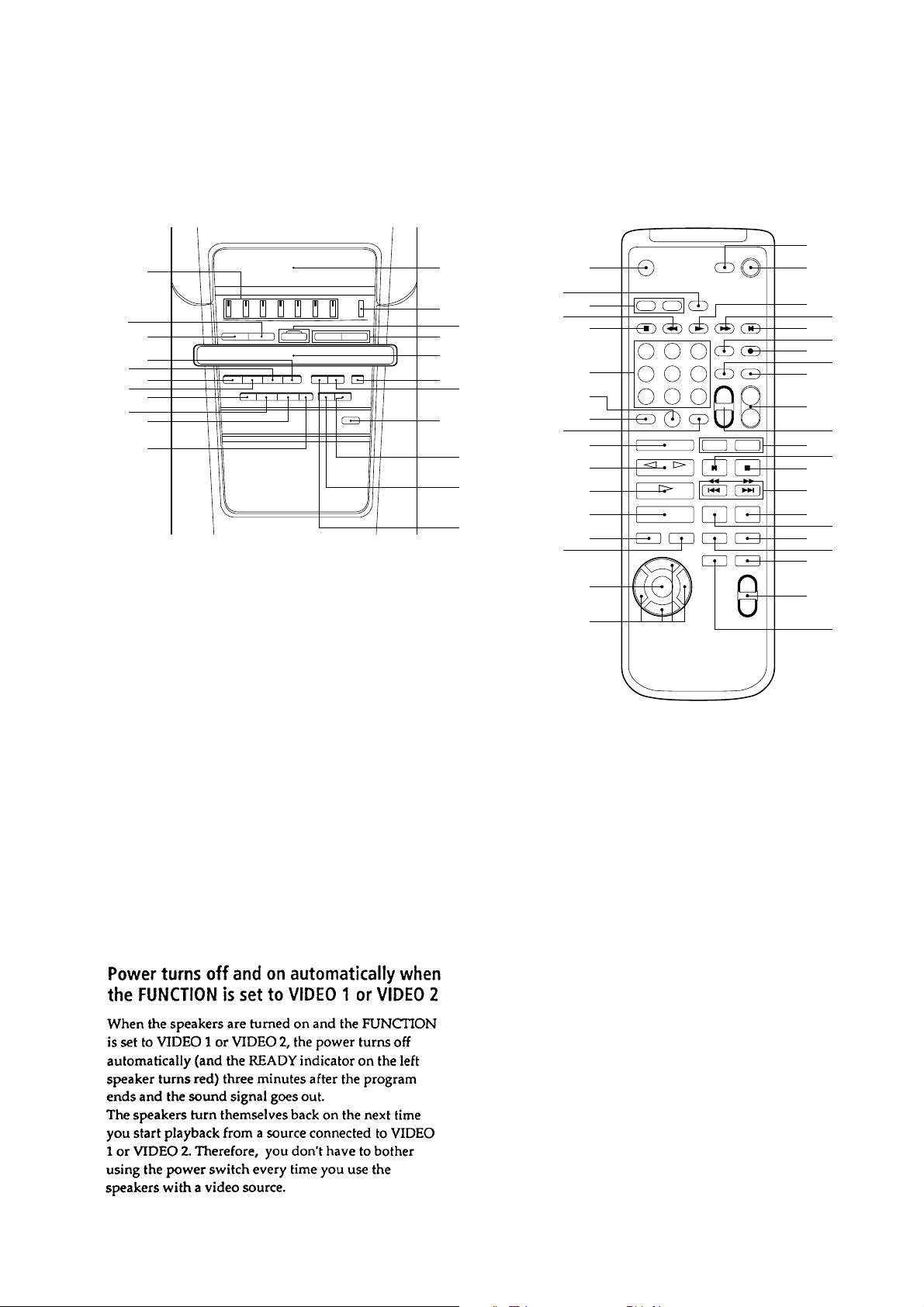

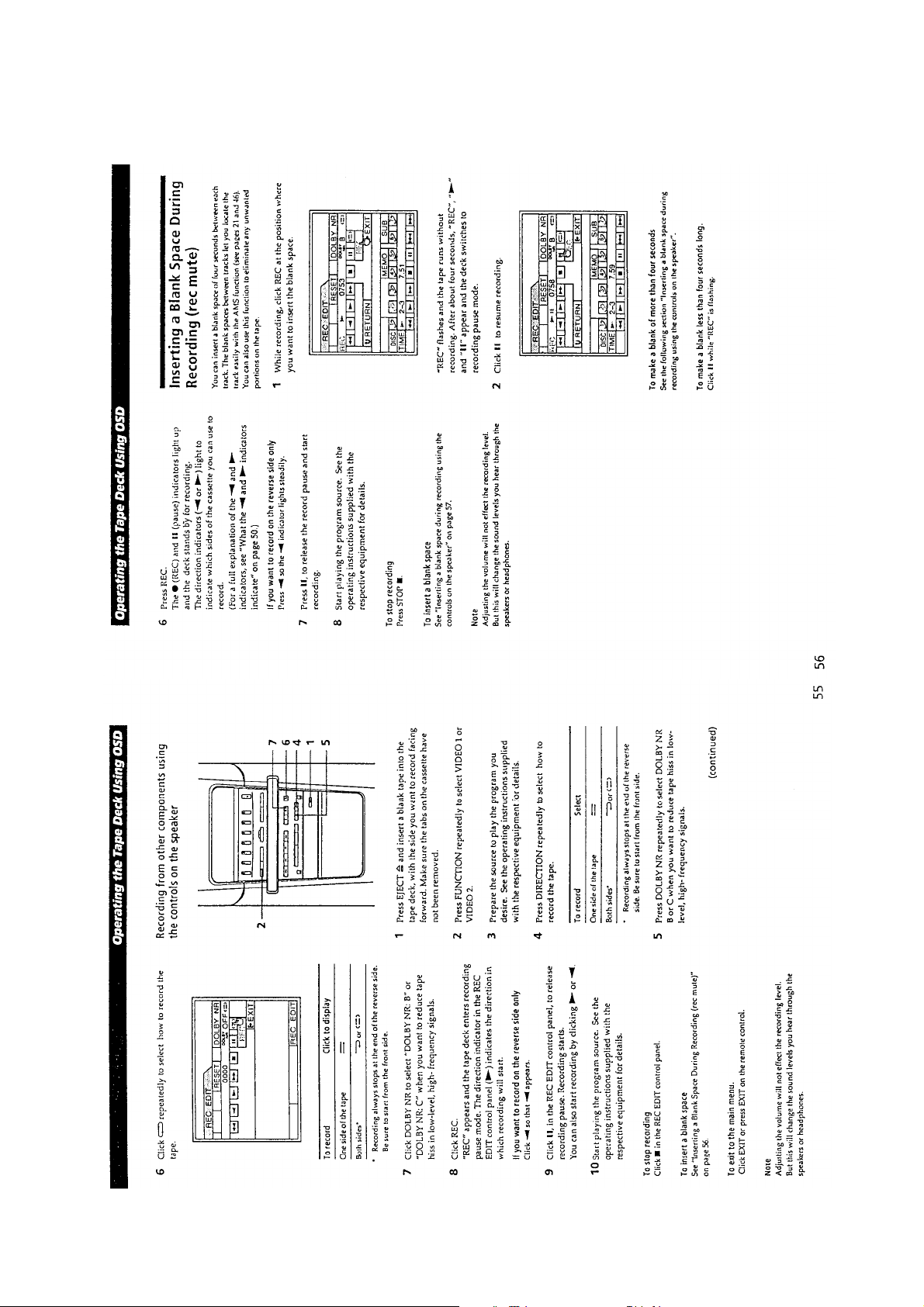

Right Front Speaker -Front panel-

1

2

3

4

5

6

7

8

9

!º

!¡

1 DISC 1 to 7 buttons

2 SURROUND button

3 FUNCTION button

4 )/± button

5 · button

6 ≠/0 button

7 ª button

8 BAND button

9 TUNING – button

!º TUNING + button

!¡ TUNING MODE button

!™ p STOP button

!£ DOLBY NR button

!¢ DIRECTION button

!∞ EJECT § button

!§ ∏ PAUSE button

!¶ ® REC button

!• Disc tray

!ª MASTER VOLUME +/– buttons

@º SYSTEM POWER button and

ON/STANDBY indicator

@¡ § OPEN/CLOSE button

@™ Display window

@™

@¡

!ª

!•

!¶

!∞

@º

!§

!¢

!£

!™

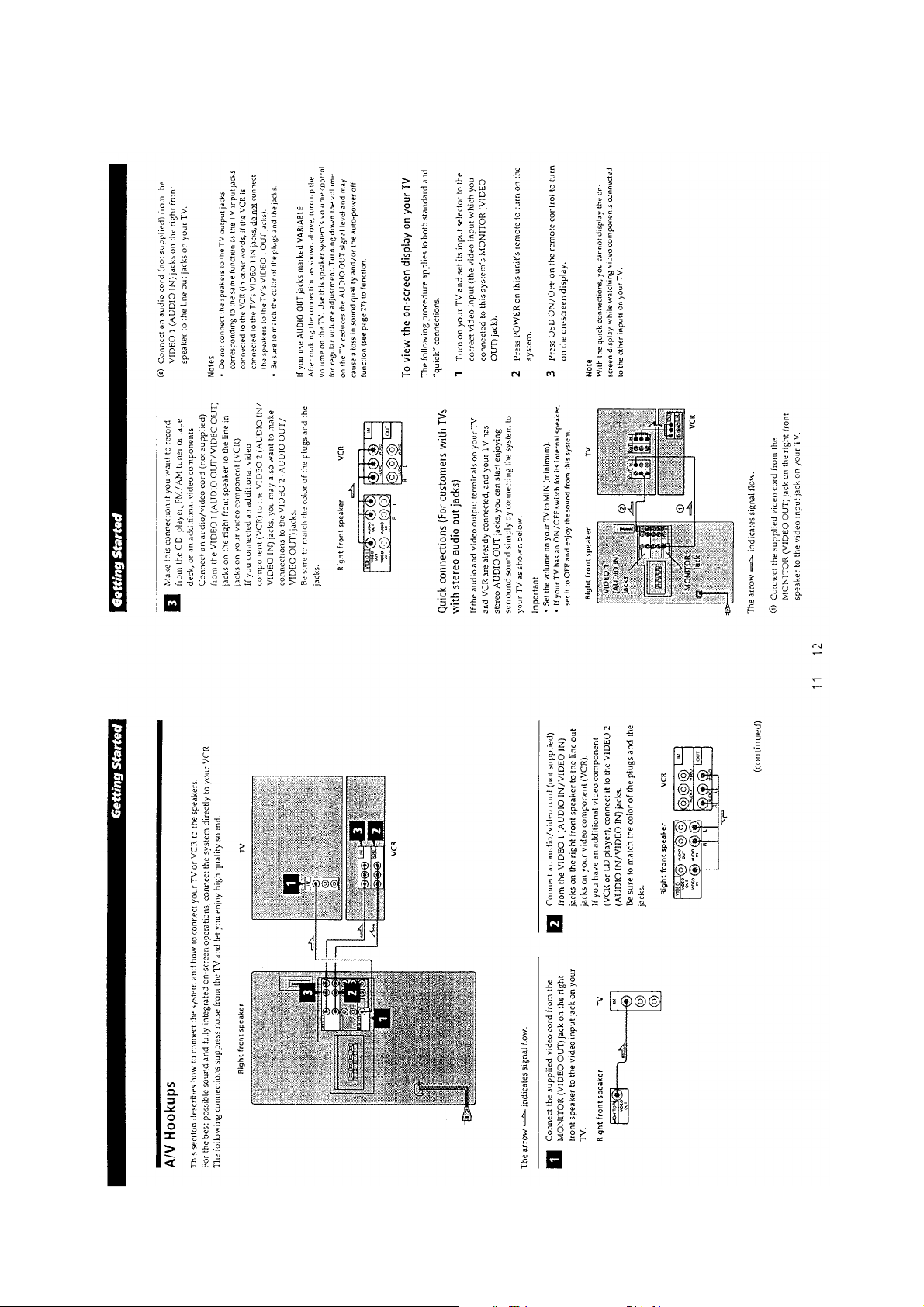

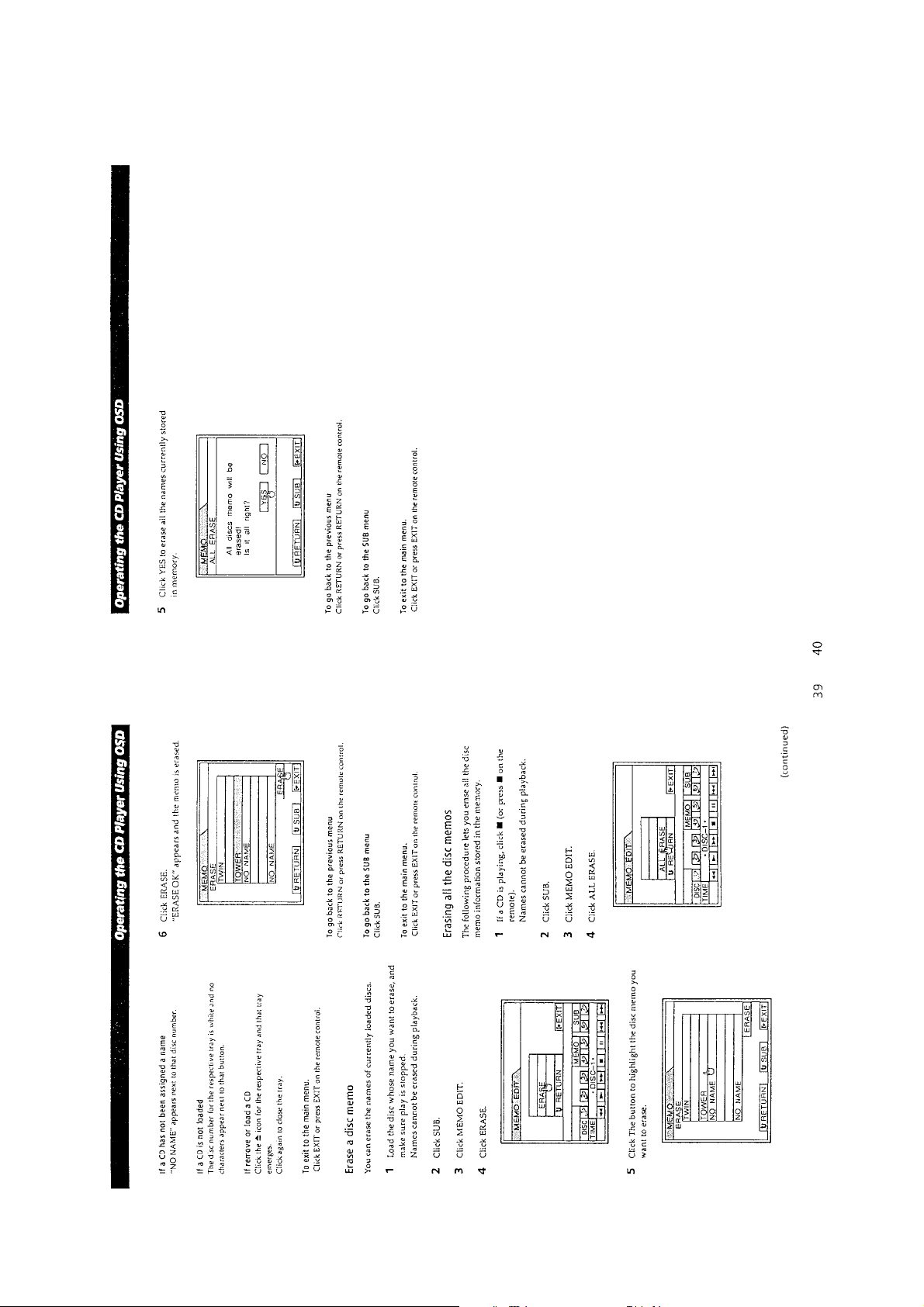

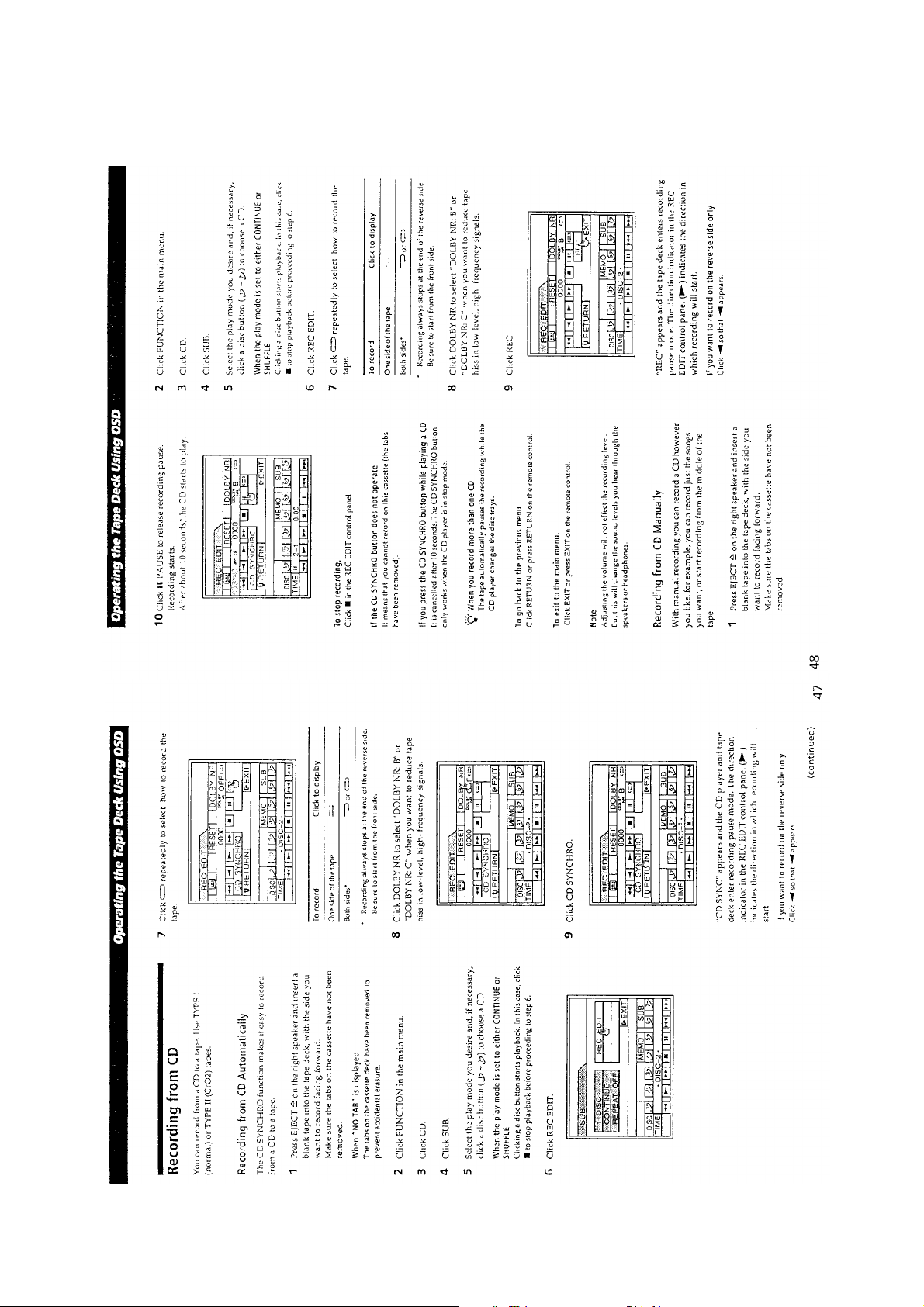

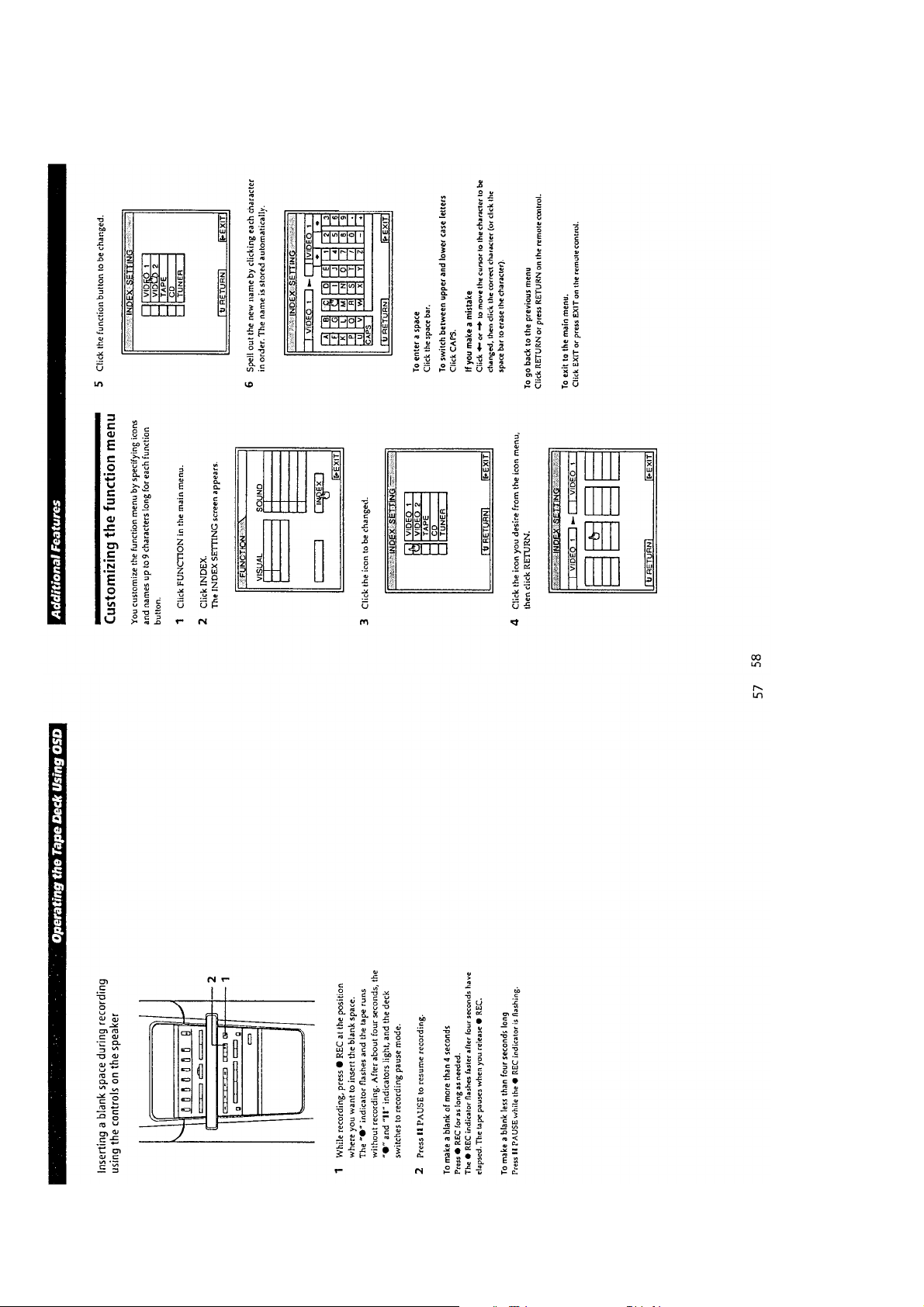

Remote commander

1

2

3

4

5

6

7

8

9

0

!¡

!™

!£

!¢

!∞

!§

!¶

1 MUTING button

2 TV CONTROL button

3 Video Source buttons

(VIDEO1, VIDEO2)

4 0 /PIP button

5 p /DISPLAY button

6 Numeric buttons

10

7

/0 button

8 >10 button

9 VISUAL ENTER button

!º TUNER BAND button

!¡ TAPE ª · button

!™ CD · button

!£ OSD ON/OFF button

!¢ RETURN button

!∞ EXIT button

!§ ENTER button

!¶ Cursor button

!• TUNER MEMORY button

!ª VOL buttons

@º SW. MODE button

#ª

#•

#¶

#§

#∞

#¢

#£

#™

#¡

#º

@ª

@•

@¶

@§

@∞

@¢

@£

@™

@¡

@º

!ª

!•

@¡ REPEAT button

@™ PLAY MODE button

@£ DISC SKIP button

@¢ I/ALL DISCS button

@∞ =/+ (CD),

0/) (TAPE) buttons

@§ p button

@¶ P button

@• TUNING –/+ buttons

@ª TV VOL buttons

#º CH buttons

#¡ SUB CH/– button

#™ TV/VIDEO button

#£ r/+ button

#¢ ANT TV VTR button

#∞ P/JUMP button

#§ )/POSITION button

#¶ (/SWAP button

#• POWER button

#ª VISUAL POWER button

— 5 —

— 6 —

— 7 —

— 8 —

— 9 —

— 10 —

— 11 —

— 12 —

— 13 —

— 14 —

— 15 —

— 16 —

— 17 —

— 18 —

— 19 —

, note that you cannot use this function

when the CD has tracks numbered 21 or higher.

— 20 —

— 21 —

— 22 —

— 23 —

— 24 —

— 25 —

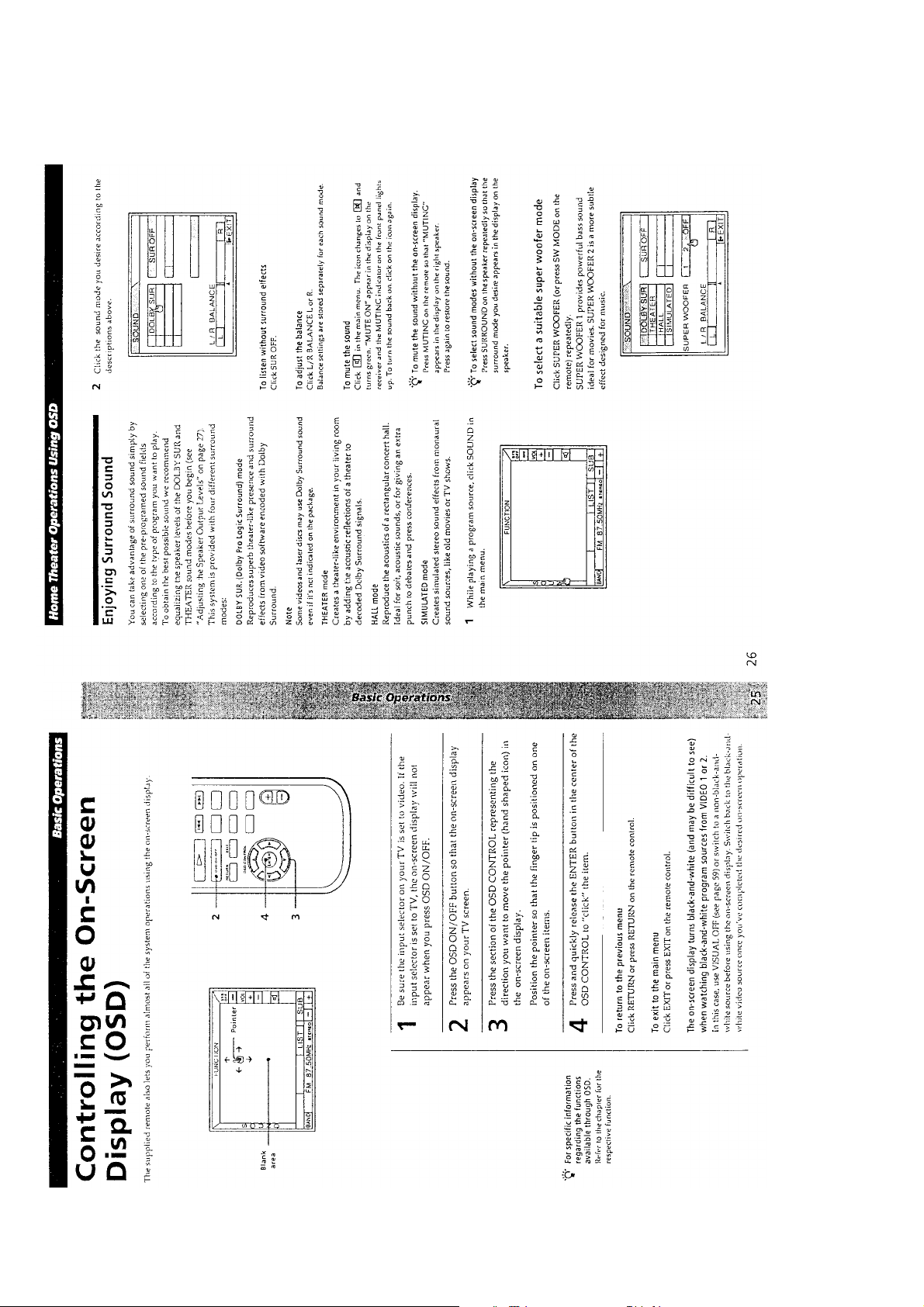

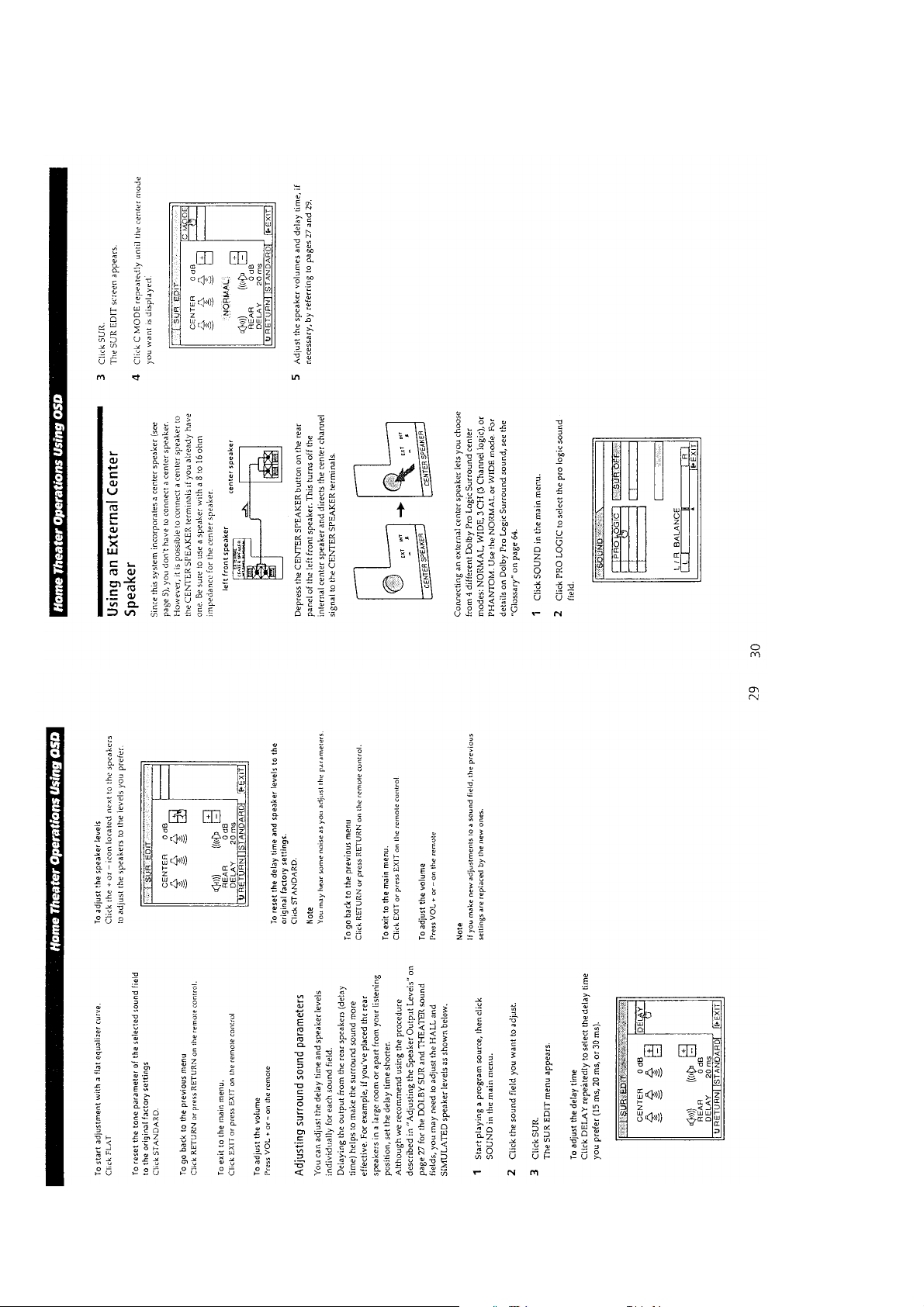

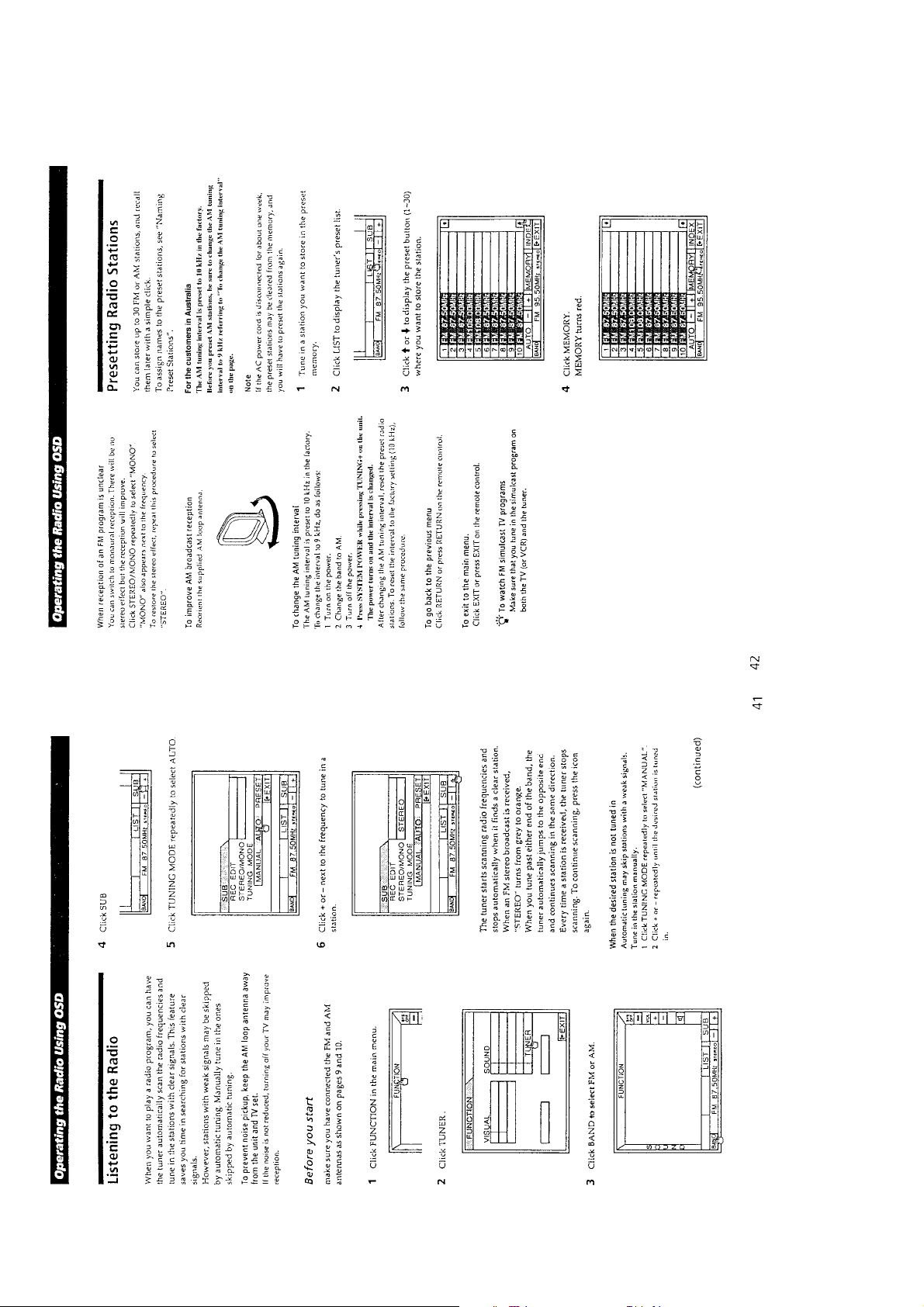

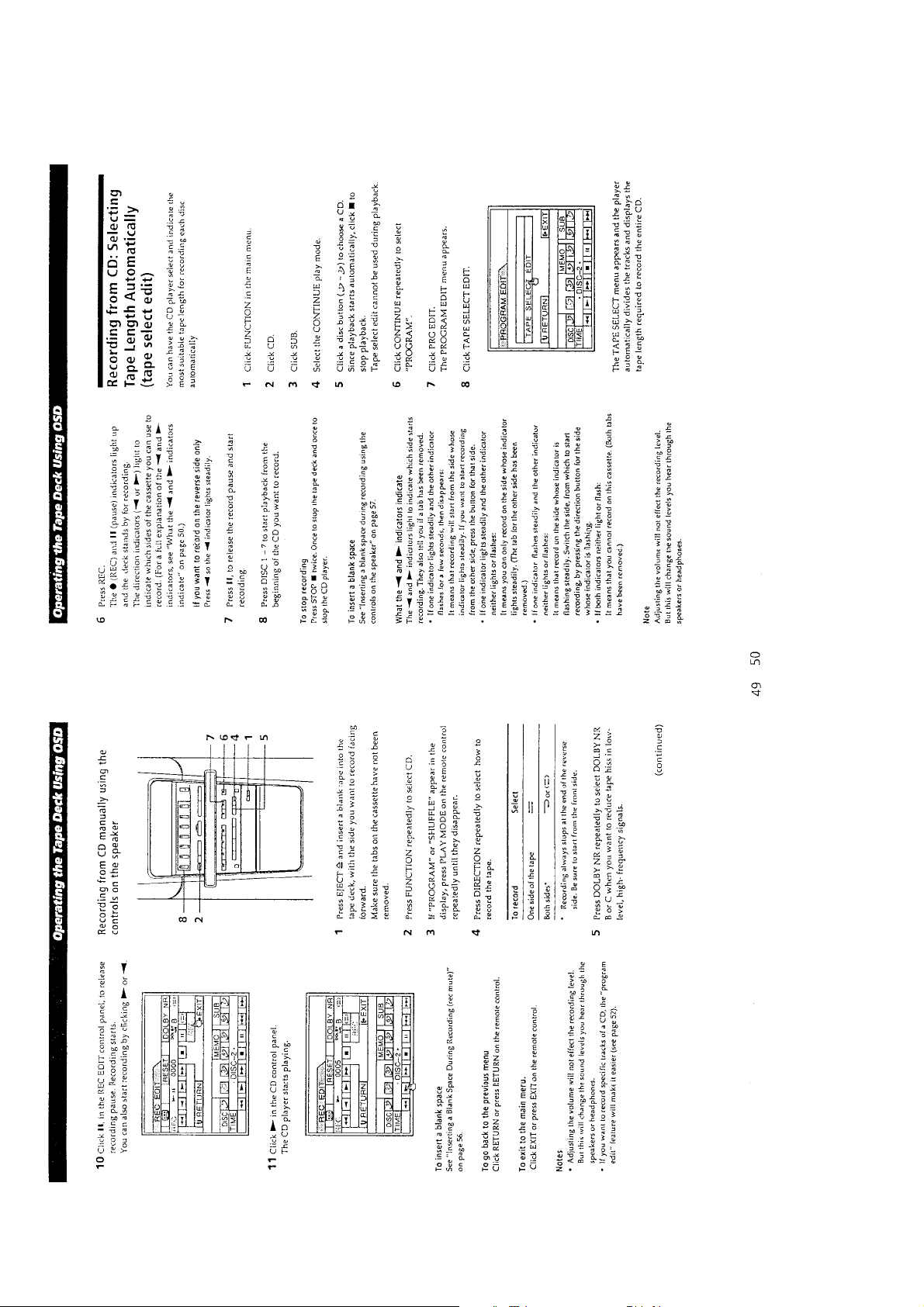

3-1. AMPLIFIER BLOCK

1

Grille frame assembly

5

Two screws

(BVTT4x25)

SECTION 3

DISASSEMBLY

0

!™

Amplifier

Back panel (L)

5

Three tapping screws

(BTP4x16)

!¡

Two connectors

6

Three tapping screws

(BTP4x16)

8

Three screws

(BVTP3x8)

9

Four screws

(BVTP3x8)

7

Three tapping screws

(BTP4x16)

2

Two screws

(P3x14)

3

Front panel (L) assembly

4

Flat type wire

(11 CORE)

PS board

CN1602

CN1603

— 26 —

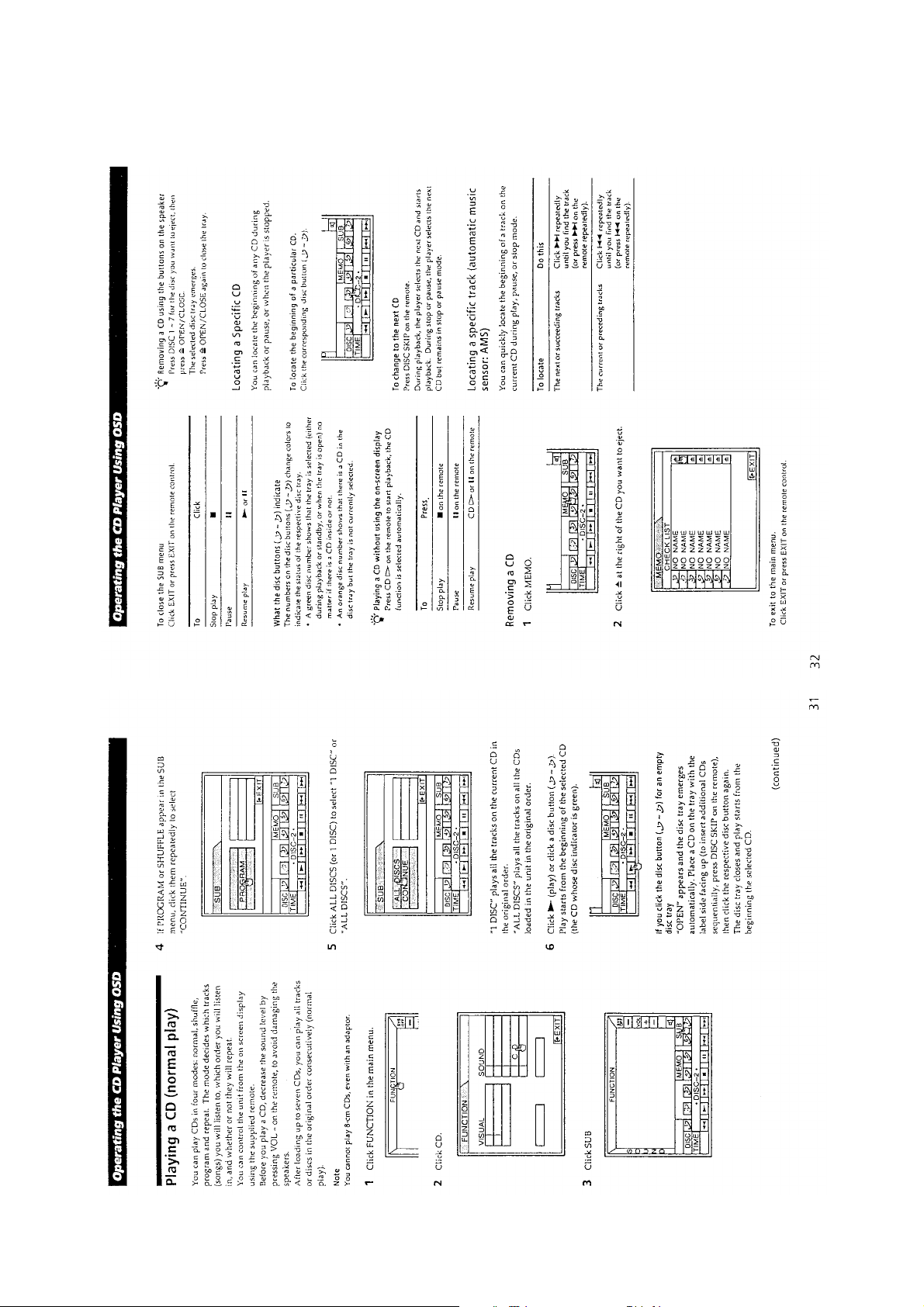

3-2. MECHANISM COMPONENT BLOCK

1

Grille frame assembly

!º

Two tapping screws

(BTP4x16)

!™

Two screws

(BVTP3x8)

8

Back panel (R)

4

9

Two connectors

Three tapping screws

(BTP4x16)

6

Two screws

(BVTP3x8)

5

Three tapping screws

(BTP4x16)

CN920

2

Two screws

(P3x14)

3

Front panel (R) assembly

!£

Mechanism component

block

!¡

Two tapping screws

(BTP4x16)

CN952

!¢

Connector

CN921

Main board

TRANS board

— 27 —

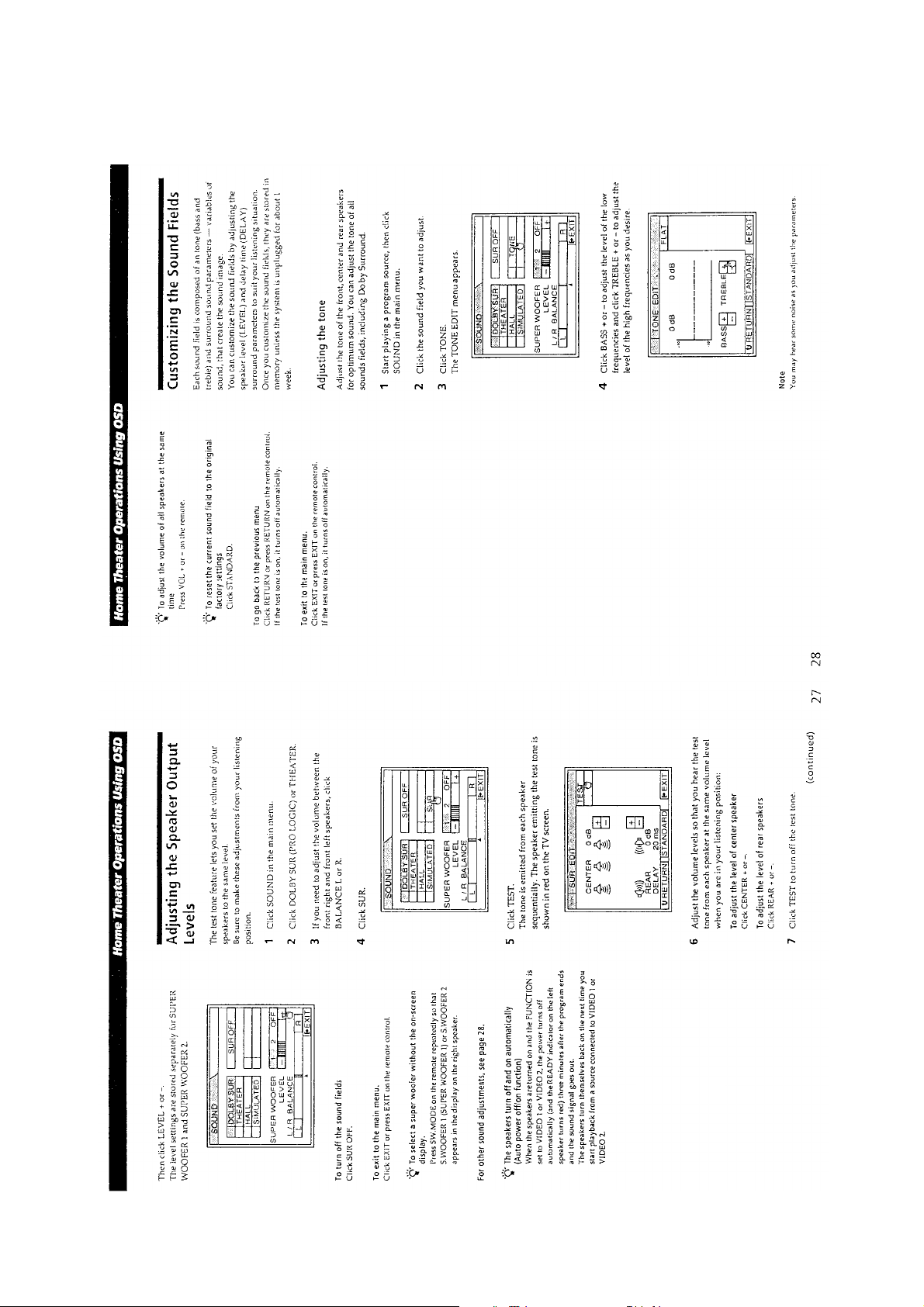

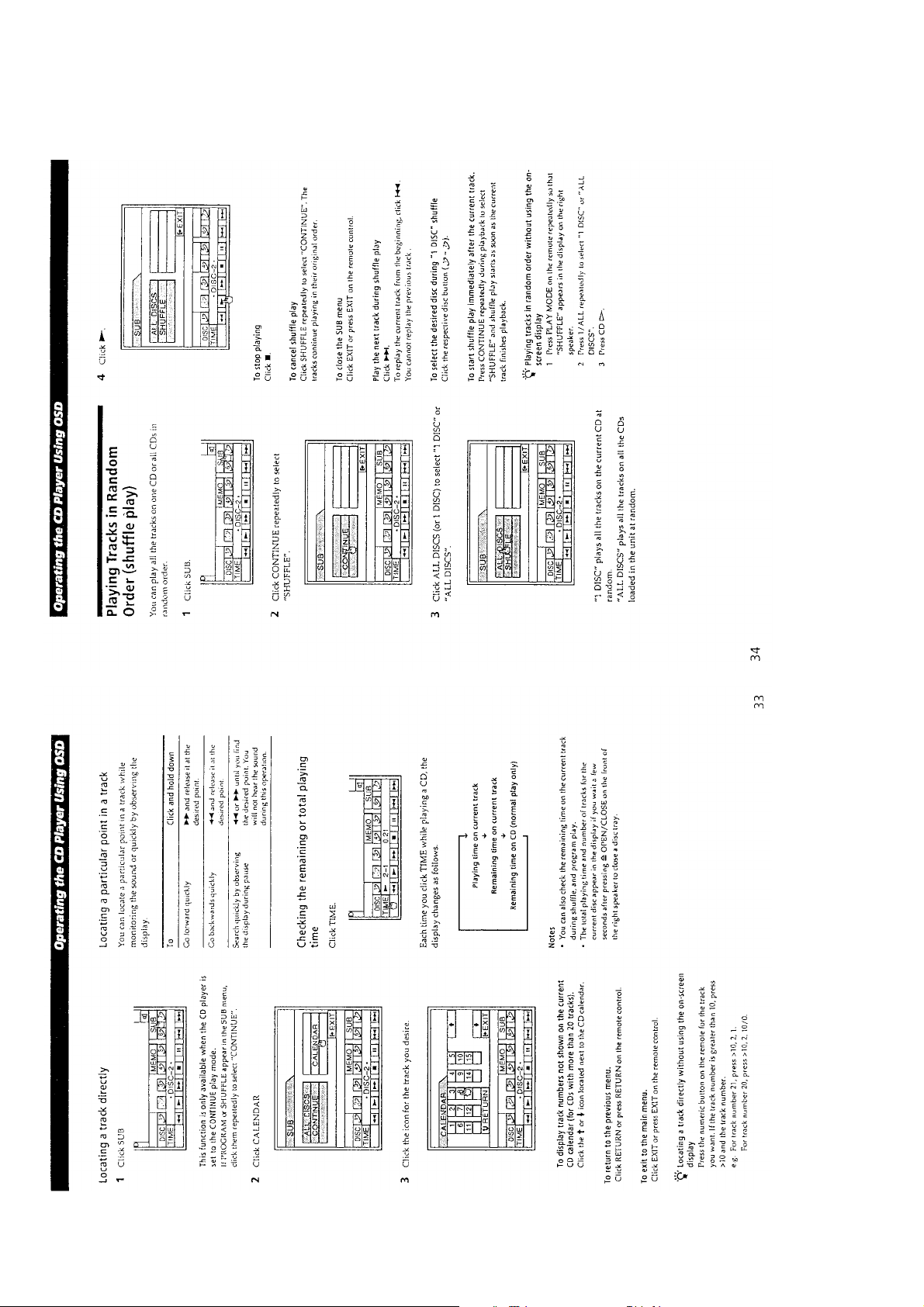

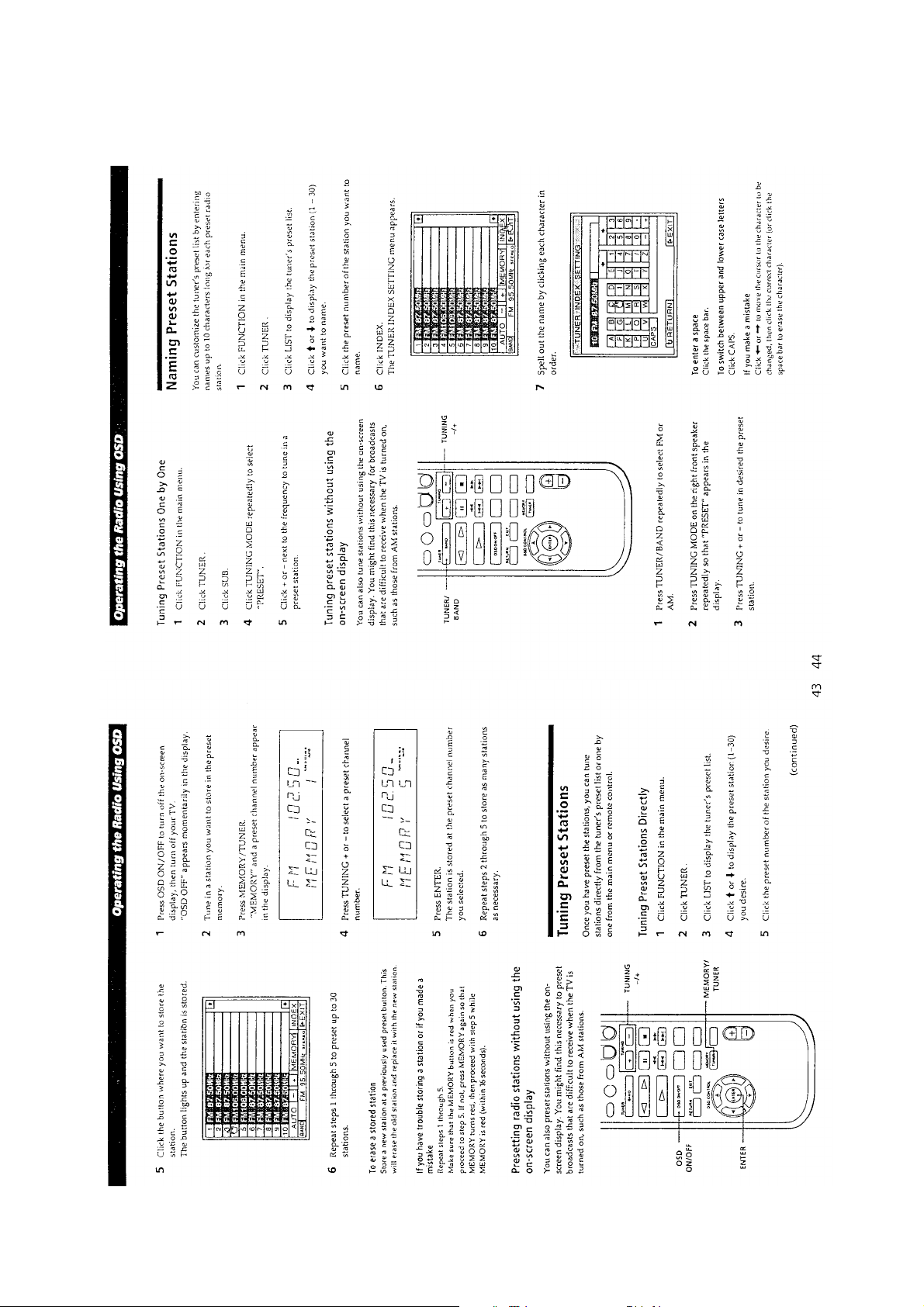

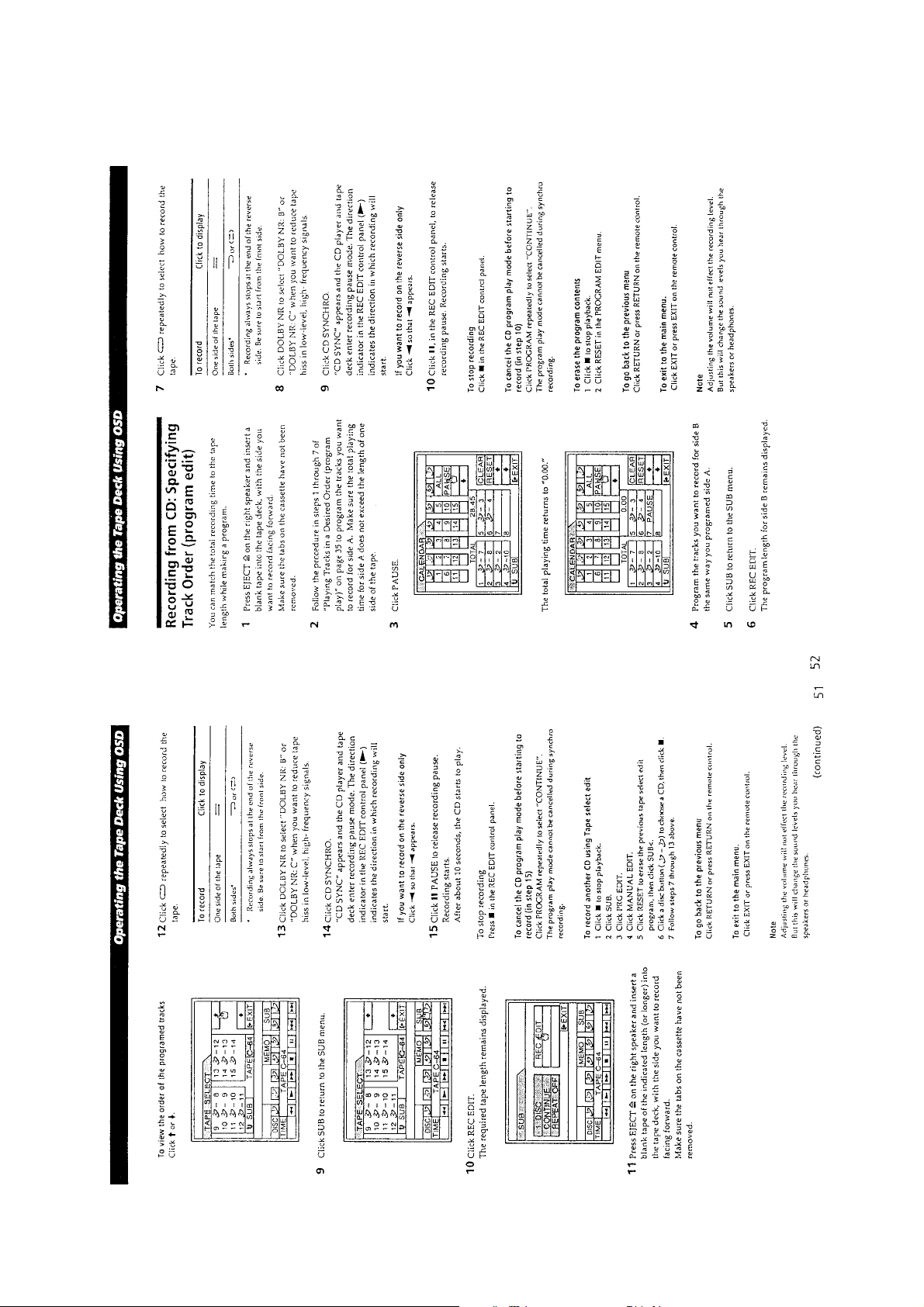

3-3. CD MECHANISM AND TC MECHANISM BLOCK

1. Lid (TC)

6

Control panel (R) assembly

4

Screw (BVTP3x8)

2

Lid (TC)

3

Flat type wire (29 CORE)

5

Screw (BVTP3x8)

2. MAIN BOARD

5

Three screws

(BVTP3x8)

6

Screw

(BVTP3x8)

4

Two screws

(BVTP3x8)

2

IC board

9

Main board

1

Push the button (EJECT).

3

Flat type wire (13 CORE)

!£

Screw

(BVTP3x8)

!º

Flat type wire

(5 CORE)

!∞

CD mechanism block

!™

Screw (BVTP3x8)

!¡

Connector (7P)

7

Screw

(BVTP3x8)

8

Tapping screw

!¢

Three screws

(BVTP3x8)

1

Screw (BVTP3x8)

— 28 —

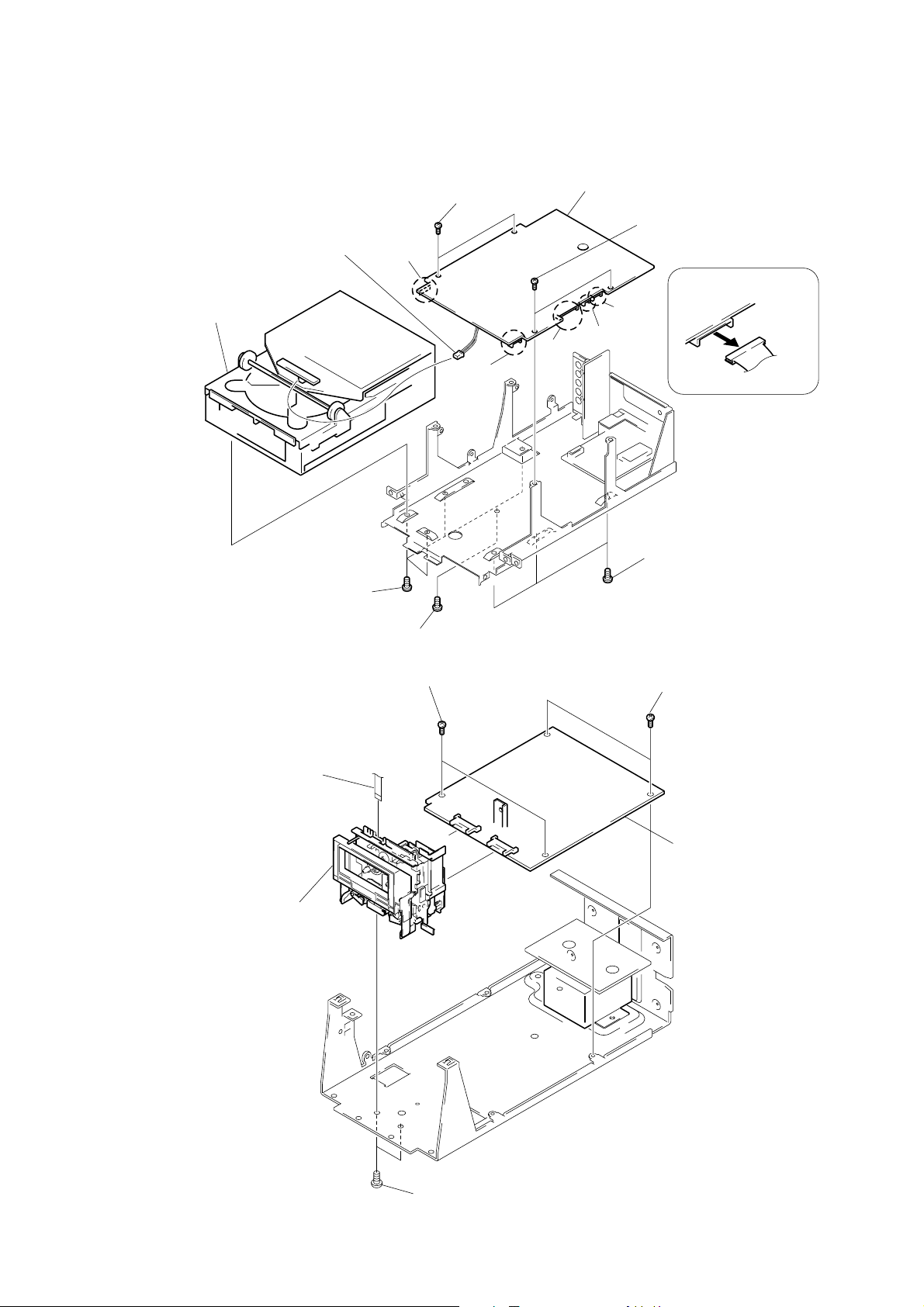

3. CD MECHANISM

9

CD mechanism deck

2

Connector (2P)

8

Four CDM screws

CN101

3

Two screws

(BVTP3x8)

CN102

CN105

5

CD board

CN103

4

Two screws

(BVTP3x8)

CN104

7

Three CDM screws

1

Five connectors

4. TC MECHANISM

6

1

Flat type wire

(7 CORE)

TC mechanism deck

6

Screw (BVTP3x8)

2

Two screws (BVTP3x8)

3

T wo screws (BVTP3x8)

4

TC board

5

Two screws

(BVTP2.6x8)

— 29 —

SECTION 4

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

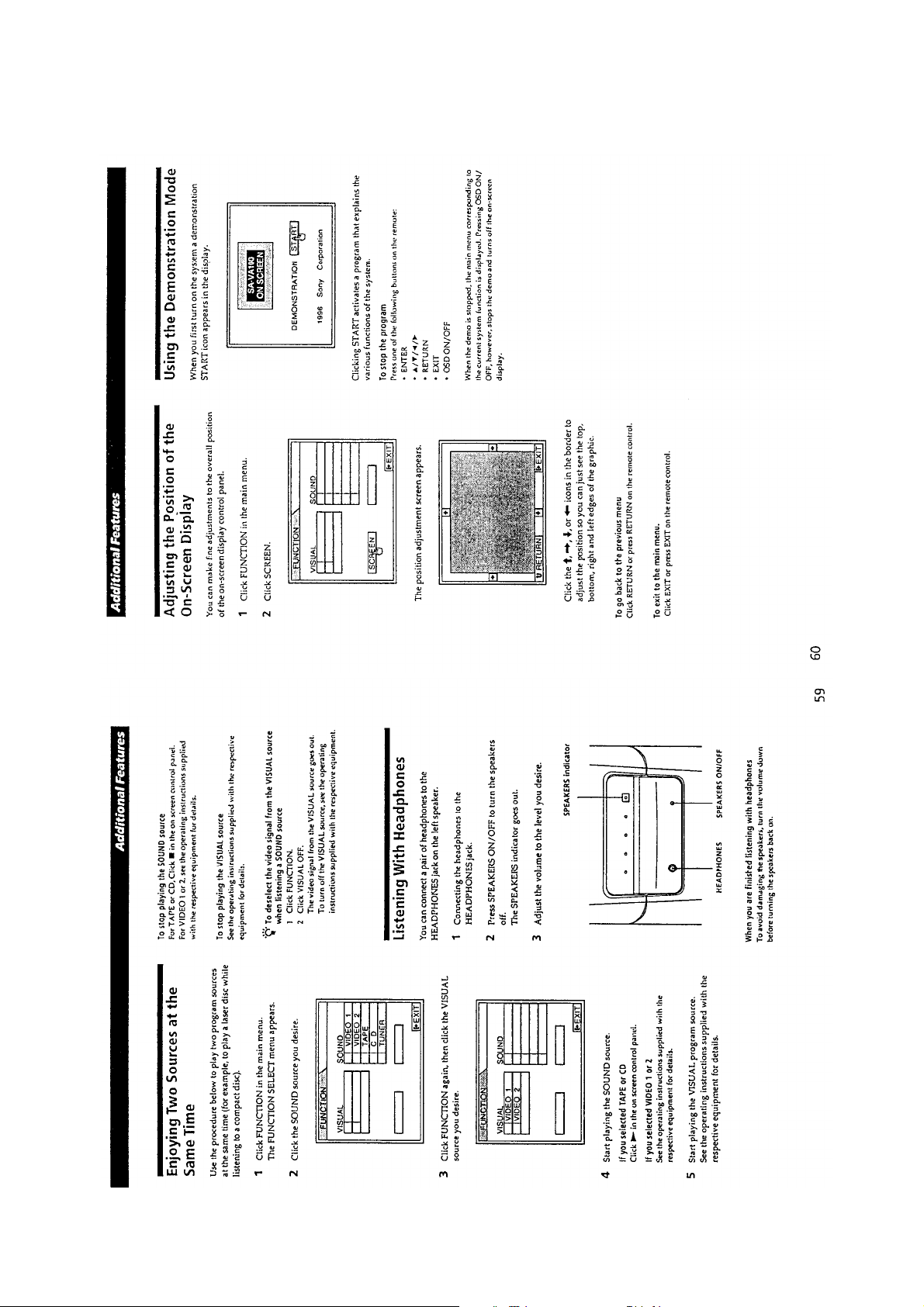

Torque Measurement

Torque

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter Meter reading

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

30 to 60 g • cm

(0.42 - 0.83 oz • inch)

1 to 5 g • cm

(0.014 - 0.069 oz • inch)

30 to 60 g • cm

(0.42 - 0.83 oz • inch)

1 to 5 g • cm

(0.014 - 0.069 oz • inch)

65 to 90 g • cm

(0.91 - 1.25 oz • inch)

110 g or more

(3.88 oz or more)

110 g or more

(3.88 oz or more)

Test Mode

Perform the tape deck adjustment after setting the test mode.

0 The sections where recording is started are memorized. When

the 0 button is pressed after recording, the tape is rewound to the

section where recording was started, and stops.

In this mode, the input source can be selected using the FUNCTION

button. To playback the recorded tape, select the TAPE using the

FUNCTION button.

To play back the tape, select TAPE using the FUNCTION button.

To exit the mode disconnect the AC plug from the outlet.

Method:

In the STANDBY state, press the DOLBY NR button,

p button, and DISC 4 button together.

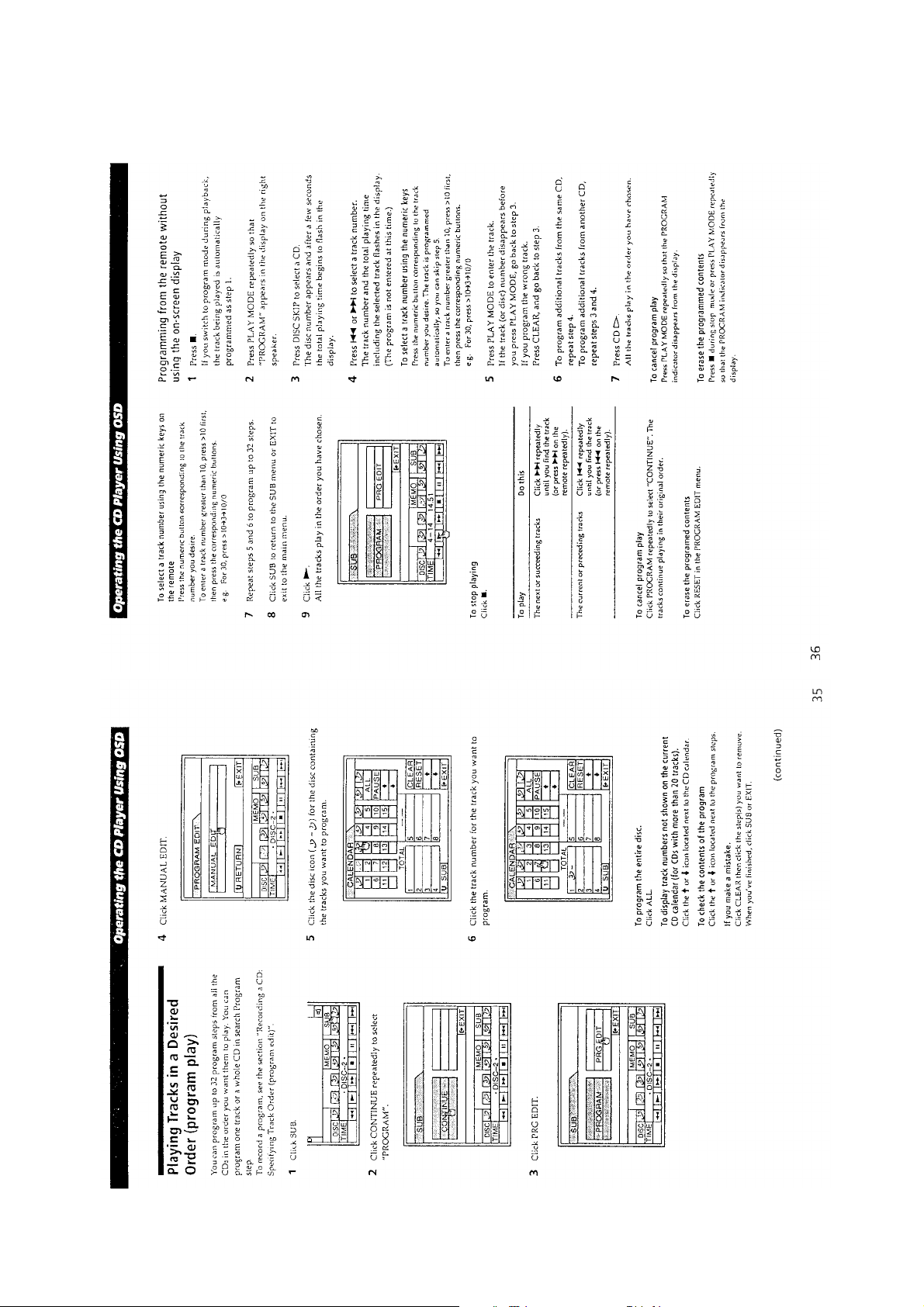

Record/Playback Head Azimuth Adjustment

Note:

Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

level meter

SECTION 5

ELECTRICAL ADJUSTMENTS

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-CH.

7. Switches and controls should be set as follows unless otherwise

specified.

DOLBY NR switch: OFF

DIRECTION switch: D

FUNCTION switch: TAPE

T ape

P-4-A100

WS-48B

P-4-L300

Signal

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

Used for

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

set

VIDEO 1 OUT

+

–

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

1dB

L-CH

peak

R-CH

peak

within 1dB

screw

position

— 30 —

Loading...

Loading...