Page 1

SERVICE MANUAL

MODEL

.............. ......... ....................

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PVM-14L5 US/CND SCC-G61K-A

PVM-20L5 US/CND SCC-G61L-A

PVM-D14L5A AUS SCC-H03D-A

PVM-D20L5A AUS SCC-H03E-A

.............. ......... ....................

REVISED-1

TRINITRON® COLOR VIDEO MONITOR

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE P ART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY . CIRCUIT ADJUSTMENTS THAT ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS MANU AL.

FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

!!

! MARK ON THE SCHEMA TIC

!!

ATTENTION!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMA TEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNAGE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT

MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS P AR SONY.

LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

PVM-14L5/20L5/D14L5A/D20L5A

!!

! SUR

!!

Page 3

Table of Contents

1. Service Informations

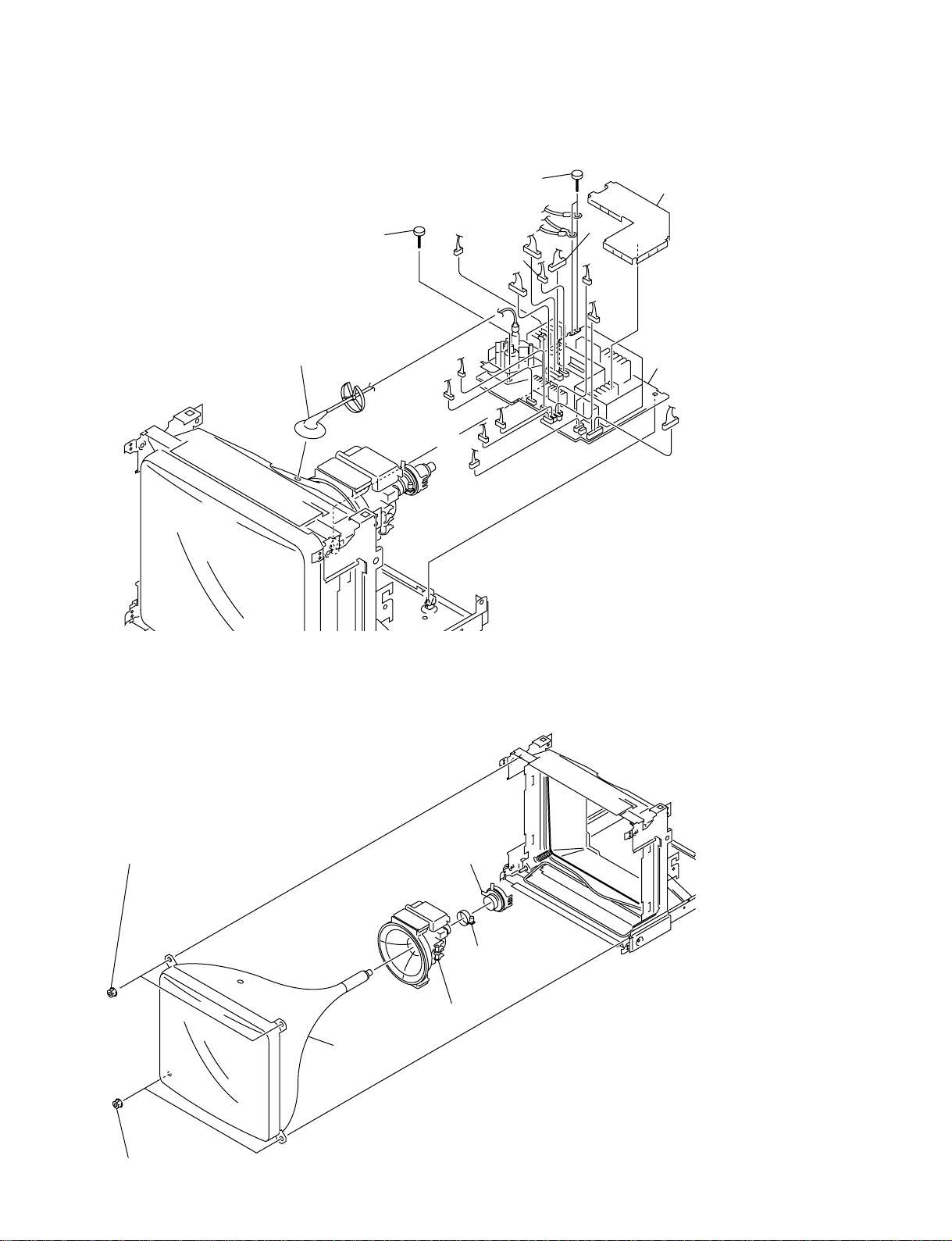

1-1. Board Layout (14 inch) ...............................................................................1-1

1-2. Disassembly (14 inch).................................................................................1-1

1-2-1. Top Cover Removal (14 inch)....................................................1-1

1-2-2. Bezel Assy Removal (14 inch)...................................................1-2

1-2-3. H1 Board Removal (14 inch) .....................................................1-2

1-2-4. H2 Board Removal (14 inch) .....................................................1-3

1-2-5. J , D1, D2 and D Boards Removal (14 inch) .............................1-3

1-2-6. C Board Removal (14 inch) .......................................................1-4

1-2-7. B Block Assy Removal (14 inch)...............................................1-4

1-2-8. K, T, B1, M and B Boards Removal (14 inch) ..........................1-5

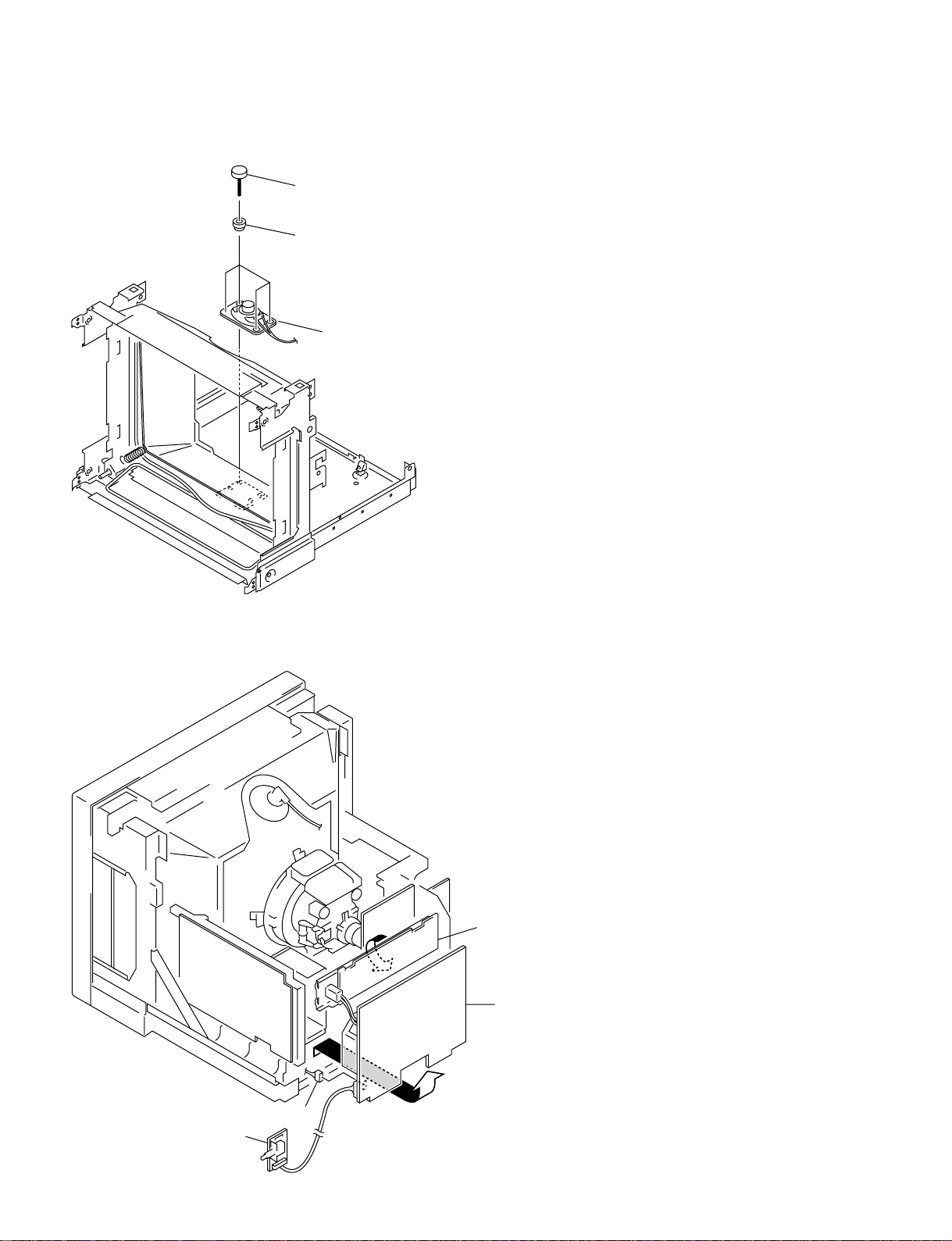

1-2-9. Q Block Assy Removal (14 inch) ..............................................1-5

1-2-10. Removal of Anode Cap .............................................................. 1-6

1-2-11. G Board Removal (14 inch) .......................................................1-6

1-2-12. Picture Tube Removal (14 inch) ................................................1-7

1-2-13. Speaker Removal (14 inch) ........................................................ 1-8

1-2-14. Service Position (14 inch) ..........................................................1-8

1-3. Board Layout (20 inch) ...............................................................................1-9

1-4. Disassembly (20 inch)...............................................................................1-10

1-4-1. Top Cover Removal (20 inch)..................................................1-10

1-4-2. Bezel Assy Removal (20 inch).................................................1-10

1-4-3. HA Board Removal (20 inch) .................................................. 1-11

1-4-4. HB Board Removal (20 inch) ..................................................1-11

1-4-5. J, D1, D2 and D Boards Removal (20 inch) ............................1-12

1-4-6. C Board Removal (20 inch) .....................................................1-12

1-4-8. K, T, B1, M and B Boards Removal (20 inch) ........................1-13

1-4-7. B Block Removal (20 inch)......................................................1-13

1-4-9. Q Block Assy Removal (20 inch) ............................................1-14

1-4-10. Removal of Anode Cap ............................................................ 1-14

1-4-11. G Board Removal (20 inch) .....................................................1-15

1-4-12. Picture Tube Removal (20 inch) ..............................................1-15

1-4-13. Speaker Removal (20 inch) ...................................................... 1-16

1-4-14. Service Position (20 inch) ........................................................1-16

2. Set-up Adjustment

2-1. Equipment Required....................................................................................2-1

2-2. Preparations (1) ...........................................................................................2-1

2-3. Preparation (2). Initialization ...................................................................2-16

2-4. Writing Model Data .................................................................................. 2-17

2-5. Picture Output ........................................................................................... 2-17

2-6. Free-run Frequency Adjustment ...............................................................2-17

PVM-14L5/20L5/D14L5A/D20L5A

1

Page 4

2-7. Landing Adjustment..................................................................................2-18

2-8. H Blanking Adjustment.............................................................................2-19

2-9. Linearity Adjustment ................................................................................2-20

2-10. Convergence Adjustment (1) .................................................................... 2-21

2-11. Deflection Yoke Neck Rotation Adjustment ............................................ 2-22

2-12. Convergence Adjustment (2) .................................................................... 2-22

2-13. G2 Adjustment ..........................................................................................2-23

2-14. White Balance Adjustment (15k)..............................................................2-23

2-15. White Balance Adjustment (33k)..............................................................2-24

2-16. SUB BRIGHT, SUB CONTRAST Adjustment (15 K) ............................ 2-24

2-17. SUB BRIGHT, SUB CONTRAST Adjustment (33 K) ............................ 2-25

2-18. White Balance Interference Correction Adjustment ................................. 2-25

2-18-1. NTSC Composite Adjustment..................................................2-25

2-18-2. PAL Composite Adjustment .................................................... 2-25

2-18-3. COMPONENT Adjustment ..................................................... 2-25

2-18-4. SDI Adjustment........................................................................2-25

2-18-5. HD and SDI Adjustments.........................................................2-26

2-19. Focus Adjustment......................................................................................2-26

3. Safety Related Adjustment

3-1. High Tension Regulator Confirmation........................................................3-2

3-2. Protection Circuit Confirmation..................................................................3-2

3-2-1. HV Protector Circuit Confirmation............................................3-2

3-2-2. 1K Protector Circuit Confirmation.............................................3-2

4. Electrical Adjustments

4-1. Equipment Required....................................................................................4-1

4-2. B Board Adjustments ..................................................................................4-2

4-2-1. Preparations ................................................................................ 4-2

4-2-2. 15k YPBPR SMPTE (601) Signal Adjustment..........................4-3

4.2-2-1. Black Level Adjustment.............................................................4-3

4-2-2-2. CHROMA Leak Adjustment......................................................4-4

4-2-2-3. MATRIX Adjustment ................................................................ 4-4

4-2-3. 15k YPBPR BETACAM SETUP 0 Signal Adjustment ............4-5

4-2-4. 15k YPBPR BETACAM SETUP 7.5 Signal Adjustment .........4-5

4-2-5. 33 k YPBPR SMPTE (709) Signal Adjustment.........................4-6

4-3. B1 Board Adjustments ................................................................................4-8

4-3-1. Preparation .................................................................................4-8

4-3-2. Y OUT Level Adjustment (BYPASS Mode) ............................. 4-9

4-3-3. Clamp Pulse Width Adjustment (NTSC) ...................................4-9

4-3-4. Burst Gate Pulse Width Adjustment (NTSC) ............................4-9

2

PVM-14L5/20L5/D14L5A/D20L5A

Page 5

4-3-5. 3.58 f0 Adjustment (NTSC) ....................................................... 4-9

4-3-6. Phase Adjustment (NTSC) .........................................................4-9

4-3-7. Level Adjustment (NTSC) .......................................................4-10

4-3-8. Burst Gate Pulse Width Adjustment (PAL) .............................4-10

4-3-9. 4.43 f0 Adjustment (PAL)........................................................4-10

4-3-10. PAL B-Y PHASE Adjustment .................................................4-10

4-3-11. PAL PHASE Adjustment (Normal) .........................................4-11

4-3-12. Level Adjustment (PAL)..........................................................4-11

4-3-13. Level Adjustment (NTSC 443) ................................................4-11

4-3-14. Clamp Pulse Width Adjustment (SECAM) ............................. 4-12

4-3-15. H. Pulse Width Adjustment (SECAM) ....................................4-12

4-3-16. Level Adjustment (SECAM)....................................................4-12

5. Theory of Operation

5-1. B Board ....................................................................................................... 5-1

5-2. BI Board ......................................................................................................5-3

5-3. C Board ....................................................................................................... 5-4

5-4. Deflection Circuit and High Tension Circuit ..............................................5-5

5-7. Power Supply Circuit ..................................................................................5-7

6. Semiconductors................................................................................. 6-1

7. Spare Parts

7-1. Notes on Repair Parts..................................................................................7-1

7-2. Exploded Views ..........................................................................................7-2

7-3. Electrical Parts List ...................................................................................7-11

8. Block Diagrams

Overall (1/2) ................................................................................................8-1

Overall (2/2) ................................................................................................8-2

Q (1/2), B (1/5), T (1/2), K..........................................................................8-3

B (2/5) ......................................................................................................... 8-4

B (3/5) ......................................................................................................... 8-5

Q (2/2), B (4/5, 5/5), M, T (2/2), H1 (14L)/HA (20L), H2 (14L)/HB (20L) ...

B1 ................................................................................................................8-7

C, D, D1, D2, DY........................................................................................8-8

G, J .............................................................................................................. 8-9

8-6

PVM-14L5/20L5/D14L5A/D20L5A

3

Page 6

9. Diagrams

9-1. Frame Schematic Diagram .......................................................................... 9-3

Frame...........................................................................................................9-3

9-2. Schematic Diagrams and Printed Wiring Boards........................................9-4

Schematic Diagrams

Q (1/2) .........................................................................................................9-5

Q (2/2) .........................................................................................................9-6

T .................................................................................................................. 9-8

B (1/5) ....................................................................................................... 9-11

B (2/5) ....................................................................................................... 9-12

B (3/5) ....................................................................................................... 9-13

B (4/5) ....................................................................................................... 9-14

B (5/5) ....................................................................................................... 9-15

B1 (1/2) .....................................................................................................9-21

B1 (2/2) .....................................................................................................9-22

M ............................................................................................................... 9-24

H1 .............................................................................................................. 9-25

H2 .............................................................................................................. 9-27

HA .............................................................................................................9-29

HB .............................................................................................................9-30

K ................................................................................................................ 9-31

C ................................................................................................................9-33

X ................................................................................................................ 9-34

J ................................................................................................................. 9-35

D ................................................................................................................ 9-37

D2 .............................................................................................................. 9-37

D1 .............................................................................................................. 9-39

G (1/2) .......................................................................................................9-42

G (2/2) .......................................................................................................9-43

Printed Wiring Boards

Q .................................................................................................................. 9-4

T .................................................................................................................. 9-7

B ................................................................................................................9-16

B1 ..............................................................................................................9-20

M ............................................................................................................... 9-23

H1 .............................................................................................................. 9-23

H2 .............................................................................................................. 9-26

HA .............................................................................................................9-28

HB .............................................................................................................9-28

K ................................................................................................................ 9-31

C ................................................................................................................9-32

X ................................................................................................................ 9-34

J ................................................................................................................. 9-35

D2 .............................................................................................................. 9-35

D ................................................................................................................ 9-36

D1 .............................................................................................................. 9-38

G ................................................................................................................ 9-40

4

PVM-14L5/20L5/D14L5A/D20L5A

Page 7

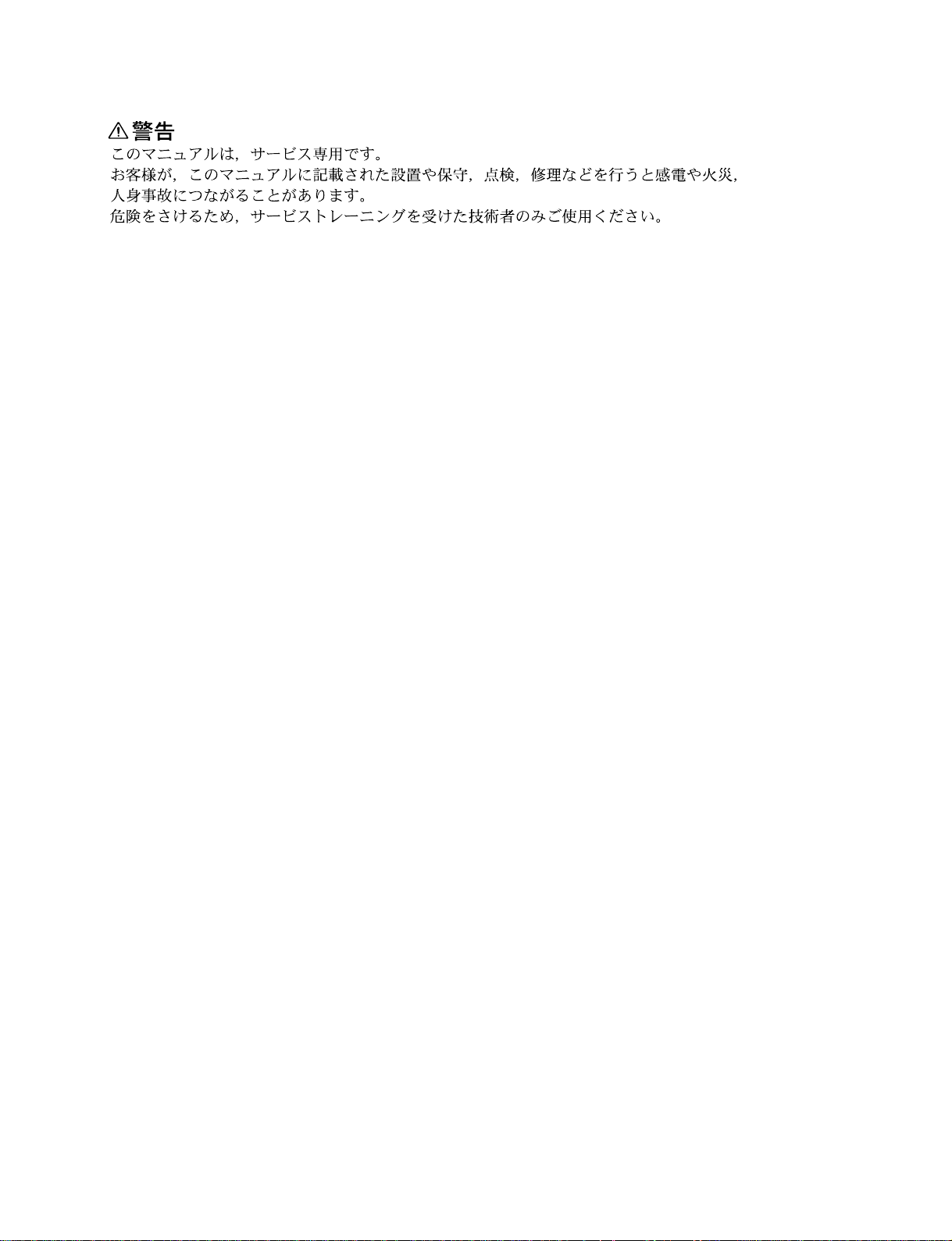

1-1. Board Layout (14 inch)

Section 1

Service Informations

X

B1

M

J

H1

B

K

G

1-2. Disassembly (14 inch)

H2

T

D2

D

Q

D1

C

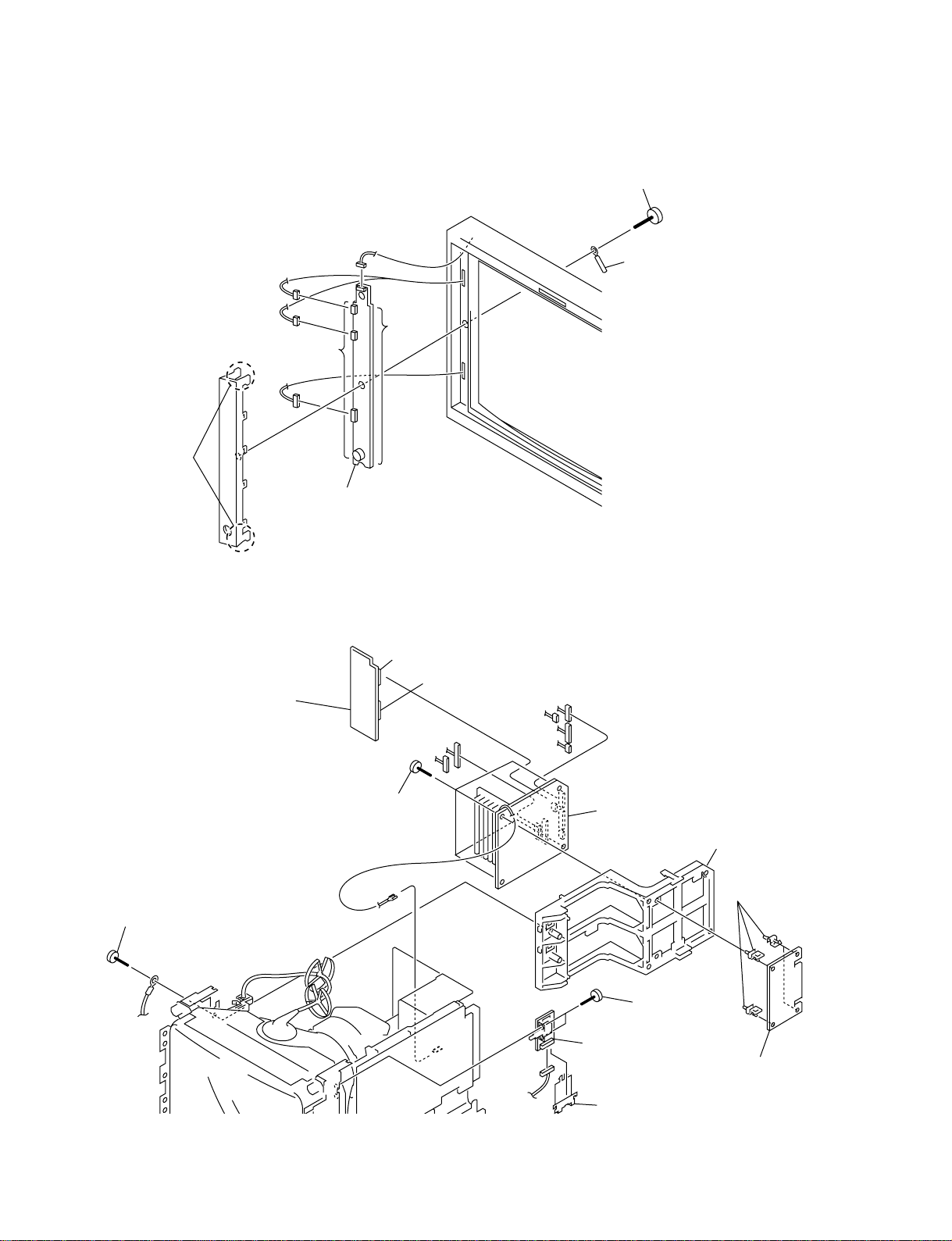

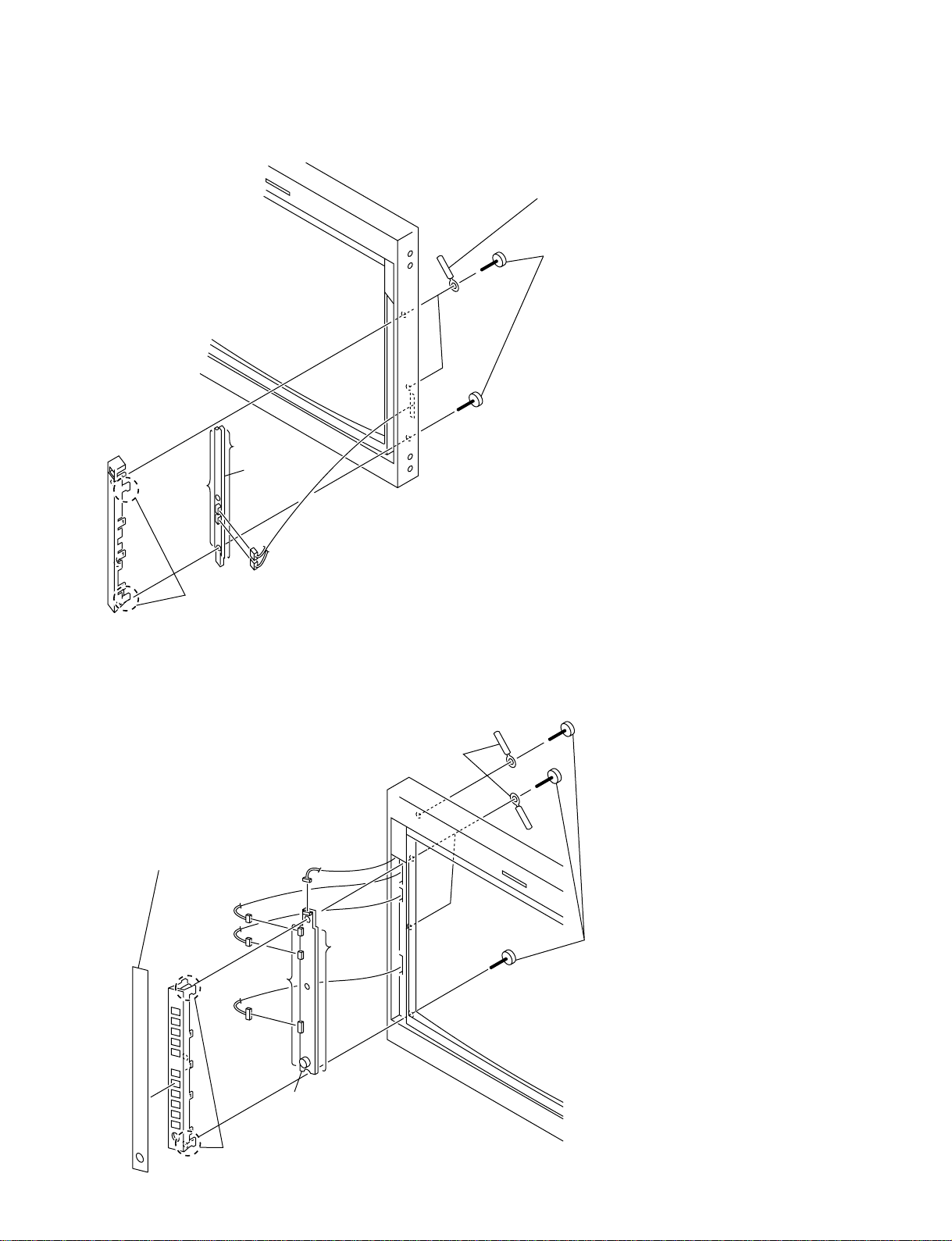

1-2-1. Top Cover Removal (14 inch)

1 Three screws

(claw case screw (OS))

4

2 Three screws

(claw case screw (OS))

Top cover

Rear cover

3 T wo screws

(+BVTT 4 x 8)

PVM-14L5/20L5/D14L5A/D20L5A

1-1

Page 8

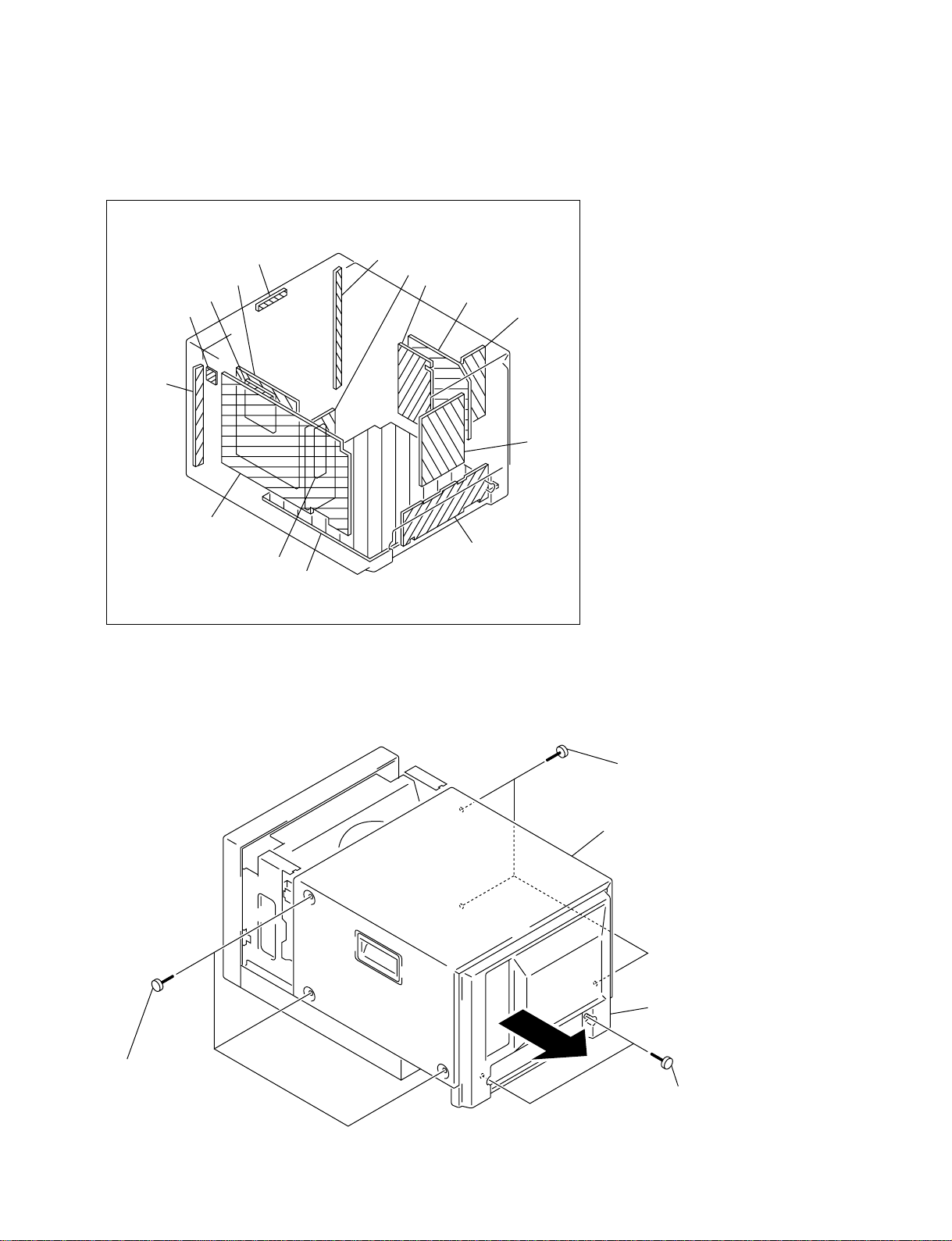

1-2-2. Bezel Assy Removal (14 inch)

Bezel assy

1 Power button

2 Two screws

(+B 3 x 8)

4

5 pin

6 Two claws

10 pin

5 Shaft switch

3 Two screws (+B 3 x 8)

7 pin

9 pin

9 pin

X board

CN900

CN105

1-2-3. H1 Board Removal (14 inch)

H1 board

4 Four claws

5 Three

claws

6 Four claws

CN2903

1 Two screws

(+BVTP 3 x 12)

2 Two wire holders

3 Screw (+BVTP 3 x 12)

CN2902

1-2

CN2901

PVM-14L5/20L5/D14L5A/D20L5A

Page 9

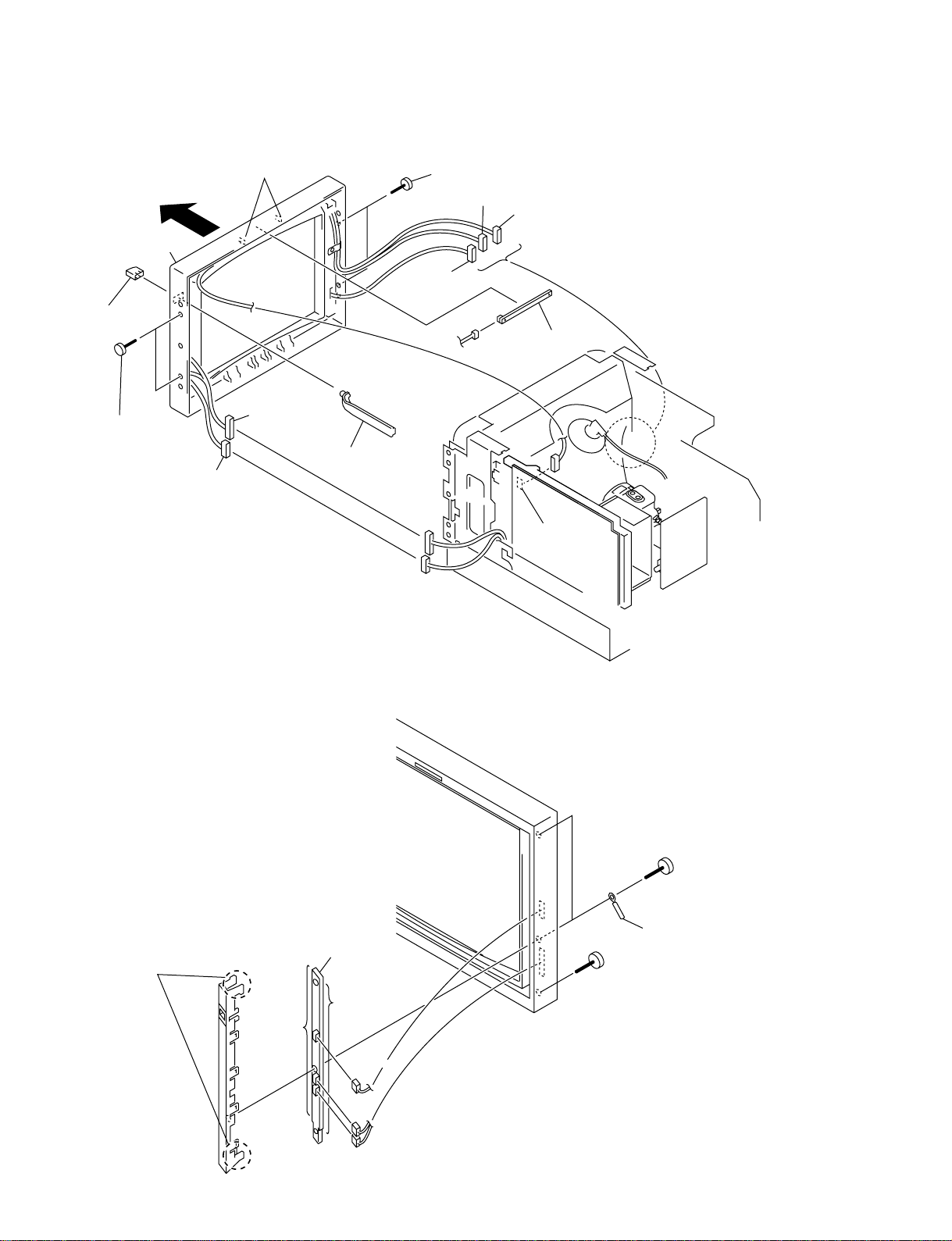

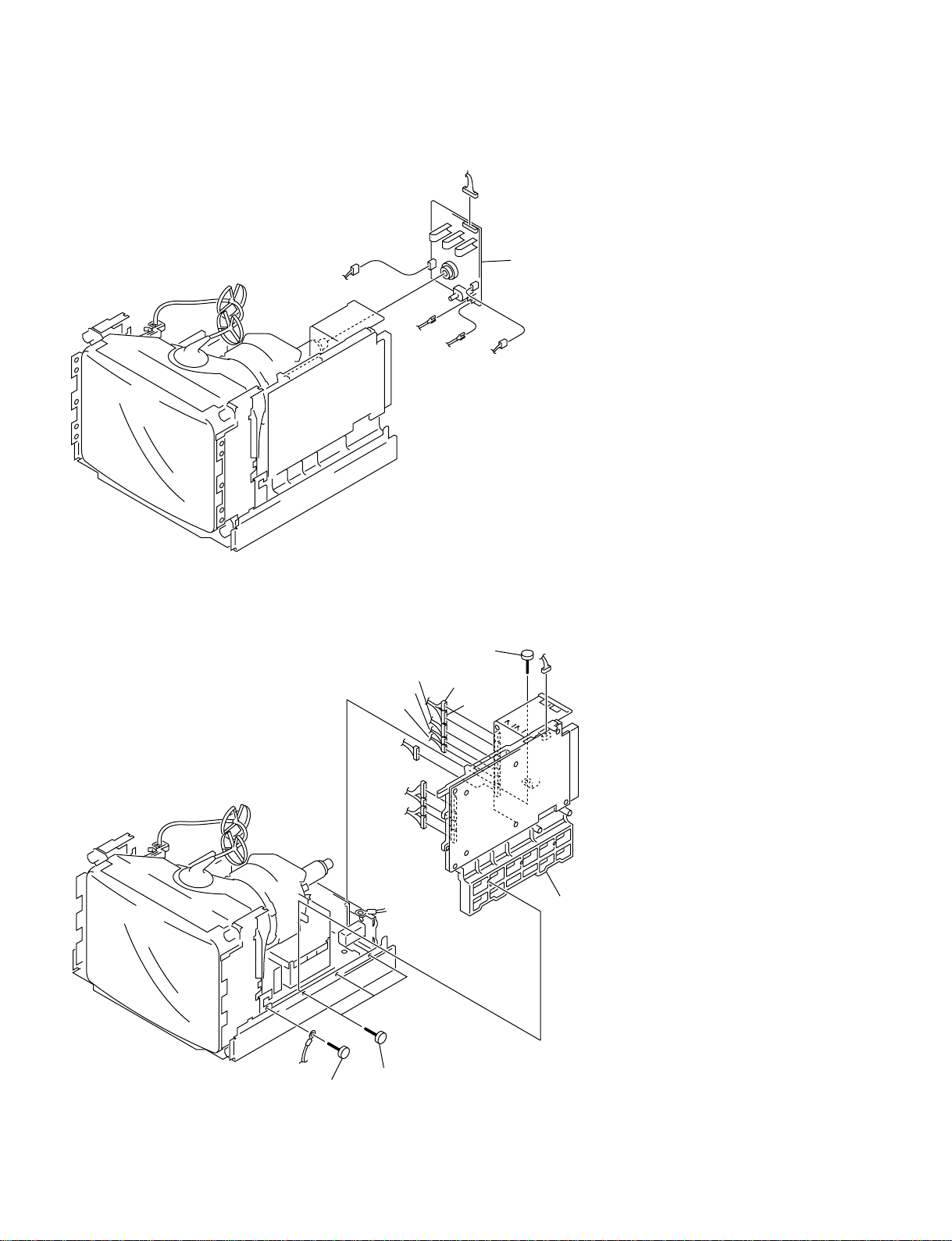

1-2-4. H2 Board Removal (14 inch)

1 Screw (+BVTP 3 x 12)

CN5005

CN5002

CN5001

4 Four claws

CN5004

3 Four claws

H2 board

5 Four

claws

1-2-5. J , D1, D2 and D Boards Removal (14 inch)

CN2502 (board to board)

CN2501 (board to board)

4 D1 board

CN1506

CN1507

CN1508

2 Wire holder

CN1501

CN1502

CN1503

5 Screw (+BVTT 4 x 8)

PVM-14L5/20L5/D14L5A/D20L5A

6 Four screws

(+BVTP 3 x 12)

CN706

CN951

D board

9 Bracket D

7 Four card edge

spacers

1 Two screws

(+PSW 3 x 8)

3 J board

8 D2 board

2 Insulator (J PWB)

1-3

Page 10

1-2-6. C Board Removal (14 inch)

CN701

CN702

1-2-7. B Block Assy Removal (14 inch)

3 Screw (+PSW 4 x 8)

CN1903

CN1907

CN703

CN1904

CN705

CN1908

CN1905

C board

CN704

CN2401

CN1906

CN102

1 Screw (+BVTP 3 x 8)

CN101

CN103

CN104

B block assy

2 Three screws (+BVTP 3 x 12)

1-4

PVM-14L5/20L5/D14L5A/D20L5A

Page 11

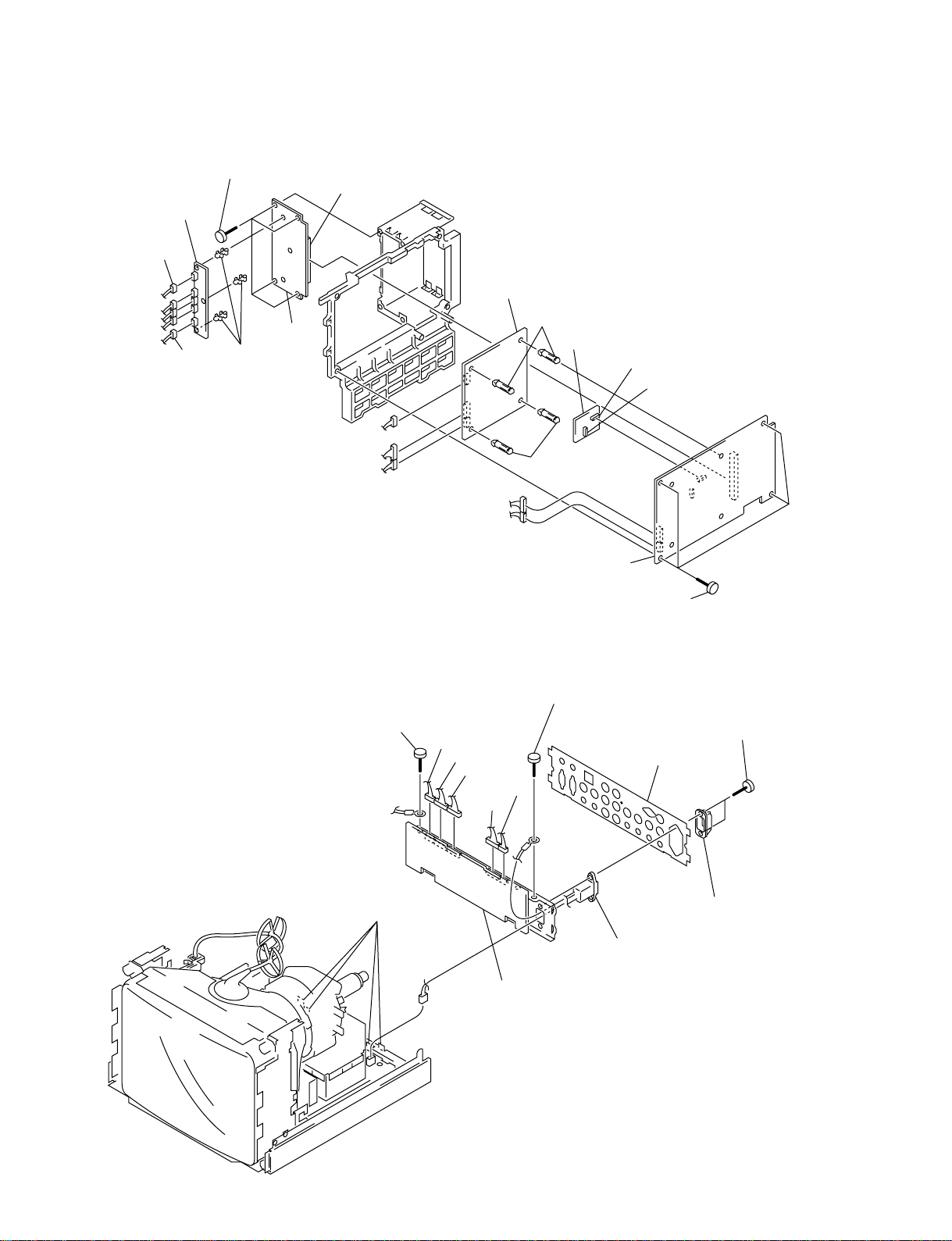

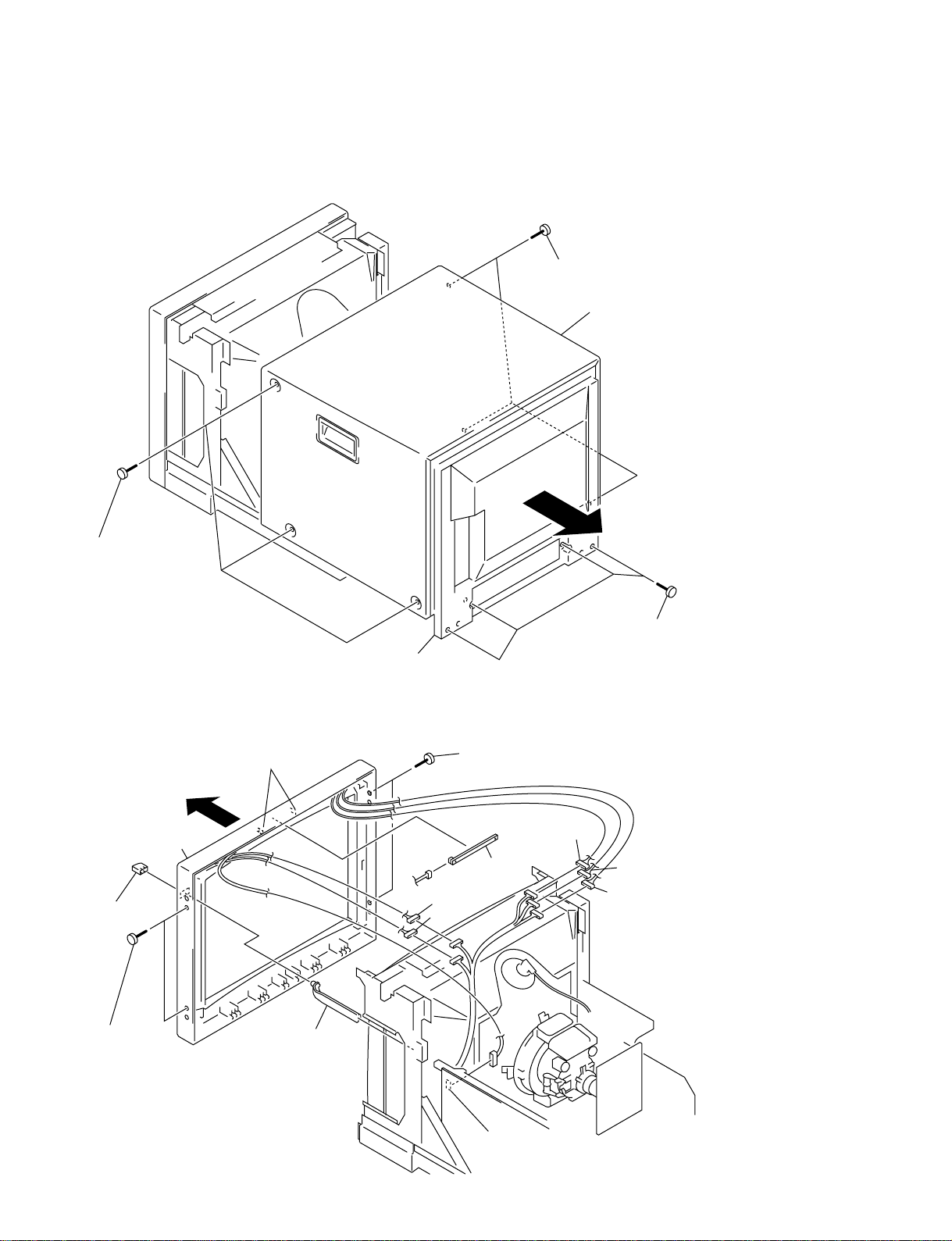

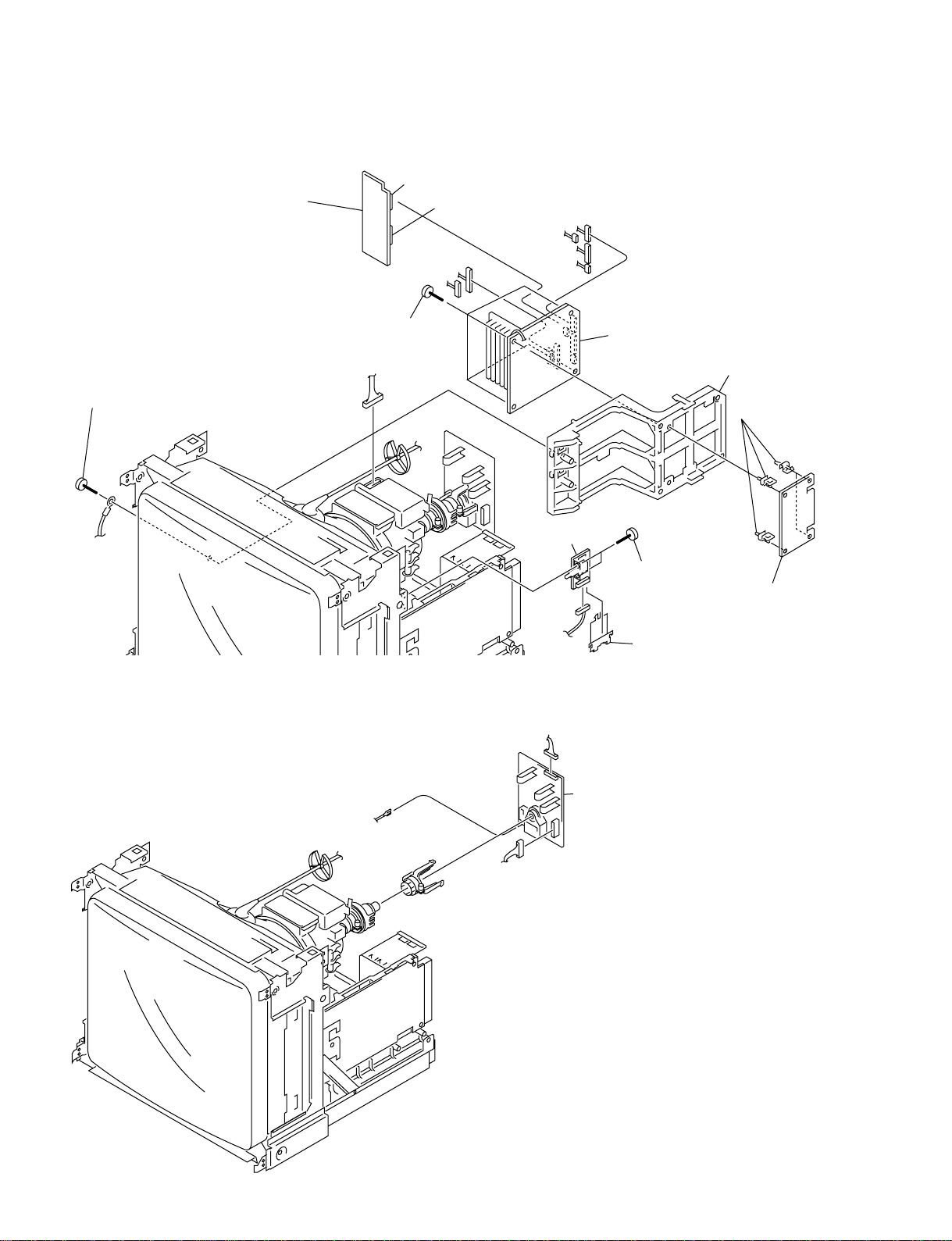

1-2-8. K, T, B1, M and B Boards Removal (14 inch)

9 Four screws (+BVTT 3 x 8)

CN1901 (board to board)

2 K board

CN3504

CN3505

CN3503

CN3502

CN3501

T board

1 Three PWB

holders

CN801

CN3802

CN3801

1-2-9. Q Block Assy Removal (14 inch)

1 Screw (+PSW 4 x 8)

CN113

CN201

CN2706

CN2707

CN2710

CN2705

5 B1 board

3 Two PWB holders

6 M board

CN107 (board to board)

CN108 (board to board)

4 Two PWB

holders

8 B board

7 Four screws

(+BVTP 3 x 12)

3 Screw (+PSW 4 x 8)

4 Two screws

(+PSW 3 x 12)

6 Connector label

CN2704

PVM-14L5/20L5/D14L5A/D20L5A

2 Four claws

CN601

5 Plug holder (A)

7 AC inlet 3p (with noise filter)

8 Q block assy

1-5

Page 12

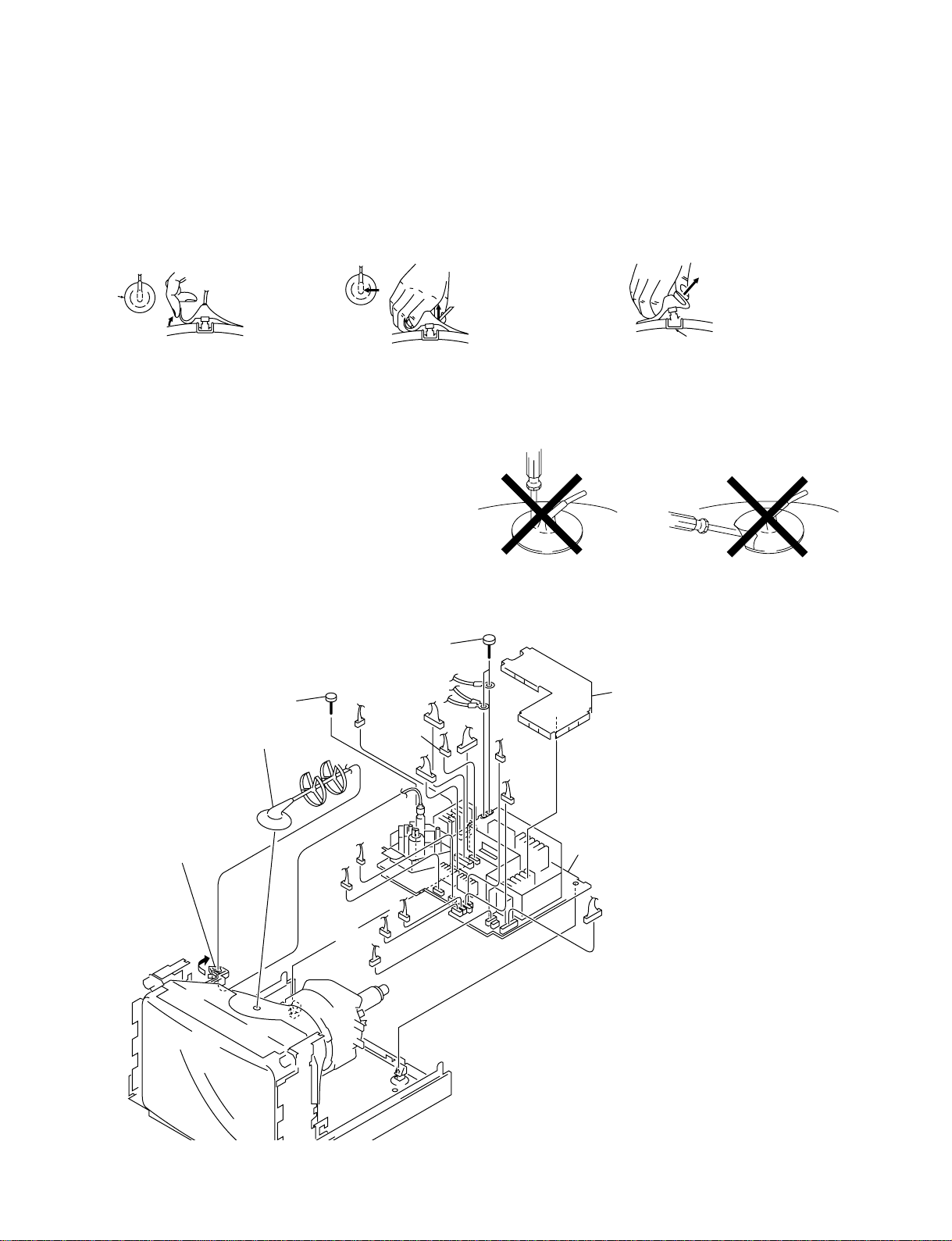

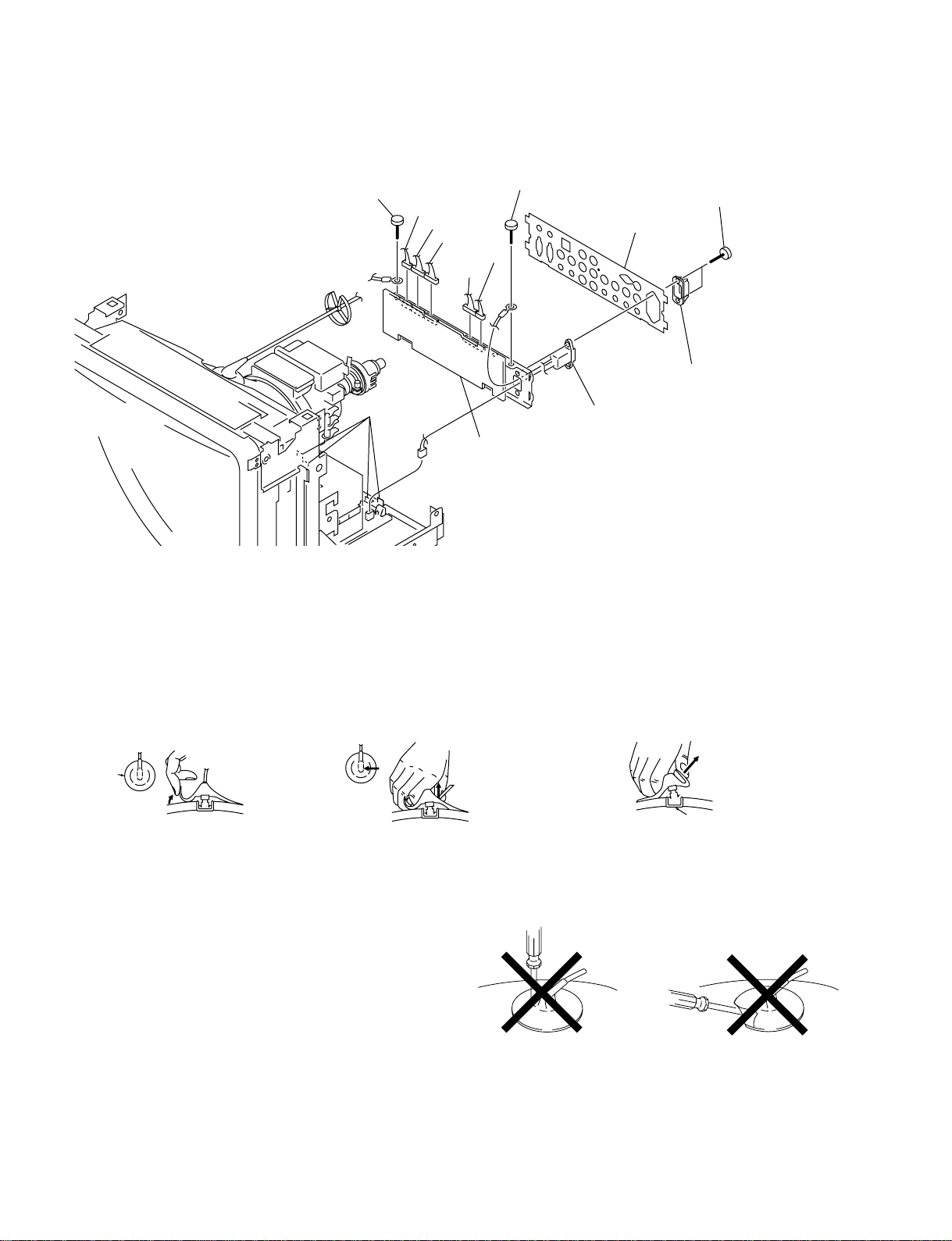

1-2-10.Removal of Anode Cap

c

Anode button

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

. Removal Procedure

..

b

a

a

b

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

..

. Handling Precautions

..

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

1-2-11.G Board Removal (14 inch)

4 Two screws (+PSW 4 x 8)

3

Screw (+BVTP 3 x 16)

1 Anode cap

CN505

CN607

CN606

CN503

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

6 G shield

CN608

CN608

CN607

2 Open the lead holder in the

direction of the arrow.

1-6

CN604

CN508

CN603

CN609

CN610

5 G board

CN602

PVM-14L5/20L5/D14L5A/D20L5A

Page 13

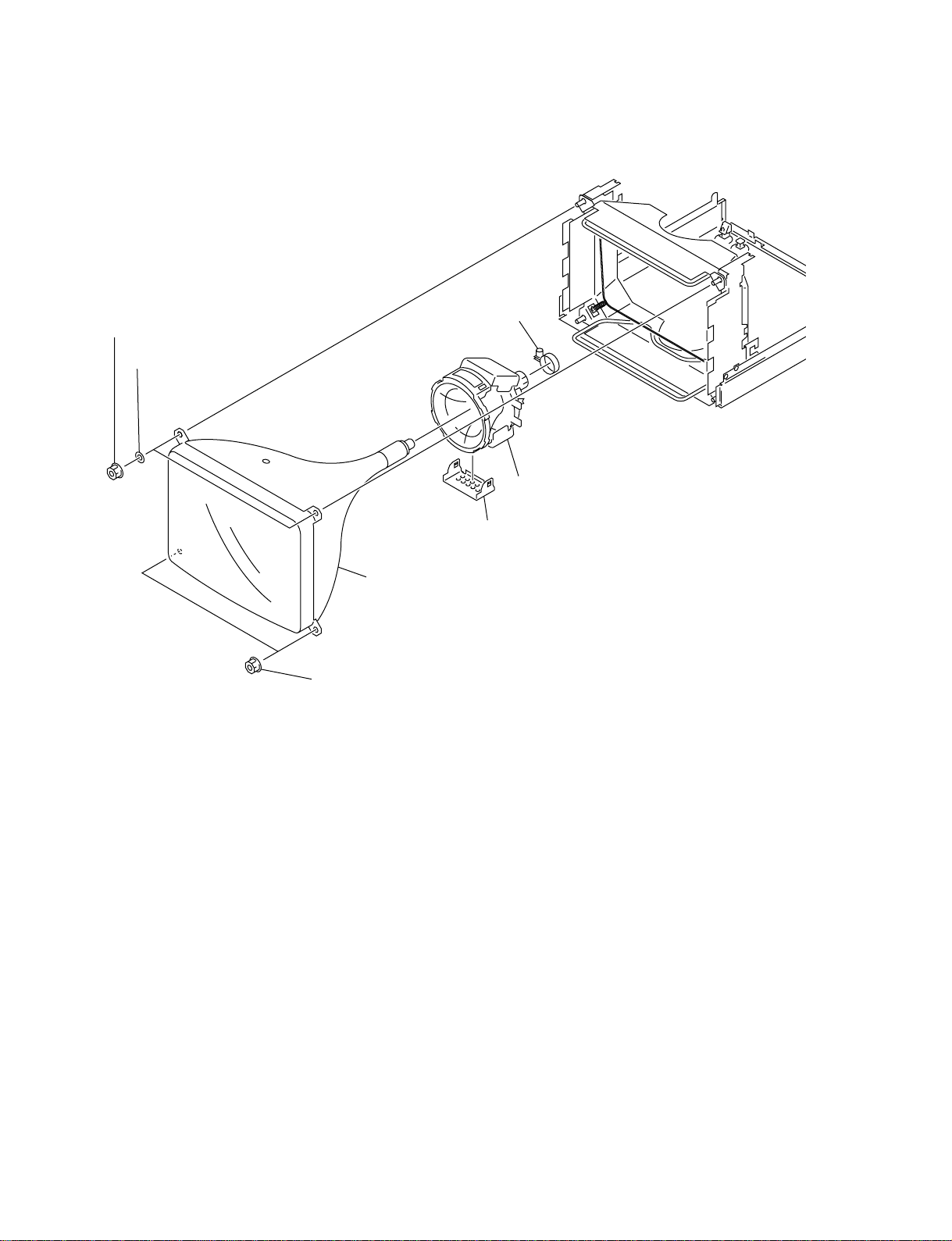

1-2-12. Picture Tube Removal (14 inch)

4 Two nuts (flange nut (B) M5)

5 Two washers

(CRT position washer)

1 Fastening band assy

3 Deflection yoke

2 DY shield

7 Picture tube

6 Two nuts (flange nut (B) M5)

PVM-14L5/20L5/D14L5A/D20L5A

1-7

Page 14

1-2-13.Speaker Removal (14 inch)

1 Four screws (step screw M3 x 4)

2 Four speaker cushions

3 Speaker

1-2-14.Service Position (14 inch)

CN603

J board

*Because there exist the portions that have the high tension voltage,

be careful that the printed boards must not touch each other

nor must not touch with the chassis.

Q board

G board

1-8

PVM-14L5/20L5/D14L5A/D20L5A

Page 15

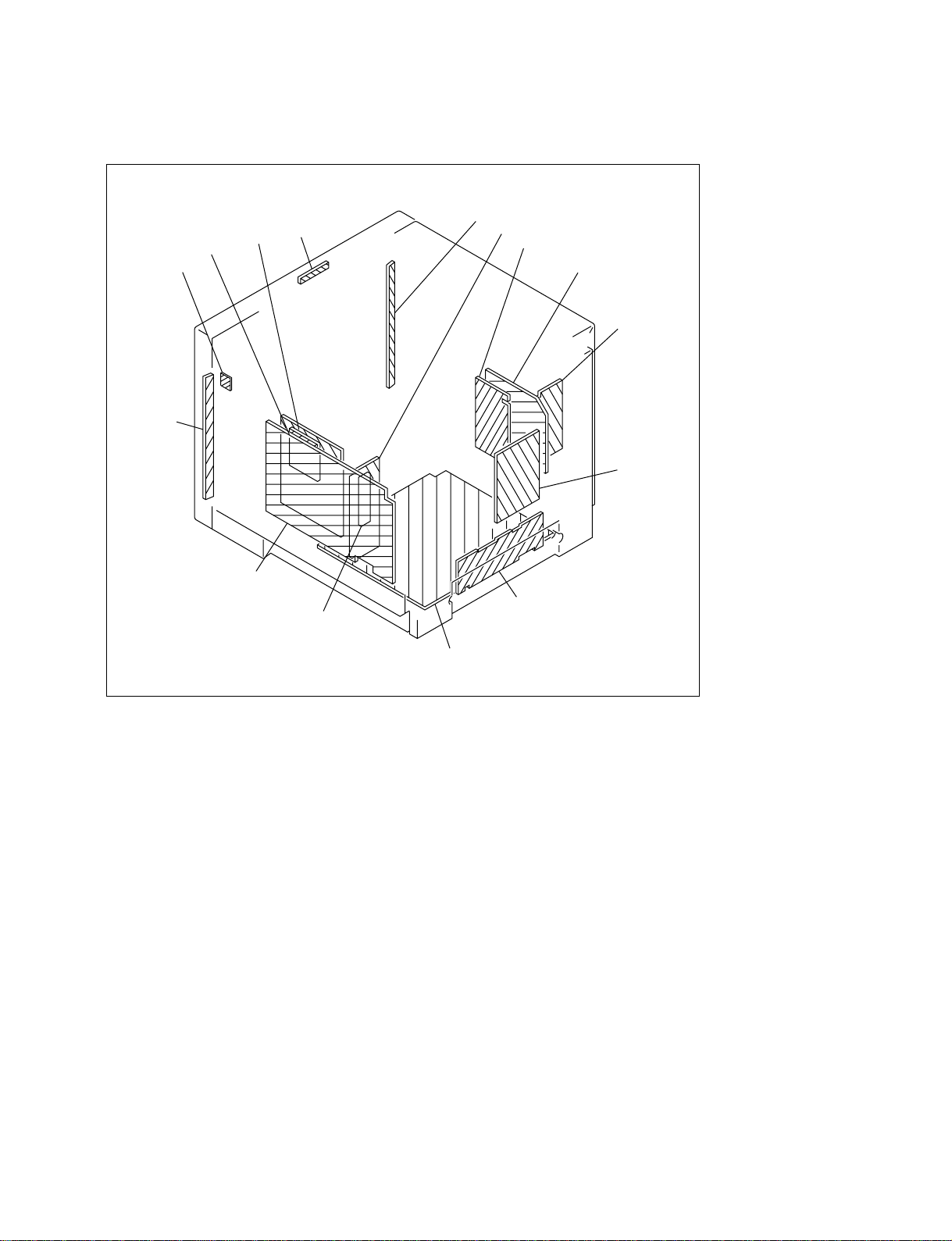

1-3. Board Layout (20 inch)

X

M

J

HA

B1

B

HB

T

D2

D

D1

C

K

G

Q

PVM-14L5/20L5/D14L5A/D20L5A

1-9

Page 16

1-4. Disassembly (20 inch)

1-4-1. Top Cover Removal (20 inch)

1 Three screws

(claw case screw (OS))

2 Three screws

(claw case screw (OS))

Top cover

4

1-4-2. Bezel Assy Removal (20 inch)

6 Two claws

4

Bezel assy

1 Power button

2 Two screws

(+B 3 x 8)

5 Shaft switch

Rear cover

3 Two screws (+B 3 x 8)

X board

CN900

10 pin

5 pin

3 Four screws

(+BVTT 4 x 8)

10 pin

9 pin

7 pin

1-10

CN105

PVM-14L5/20L5/D14L5A/D20L5A

Page 17

1-4-3. HA Board Removal (20 inch)

5 Four claws

HA board

4 Three

claws

CN2902

CN2901

3 Four claws

2 Two wire holders

1 Three screws

(+BVTP 3 x 12)

1-4-4. HB Board Removal (20 inch)

2 Three wire holders

3 Control label (L)

CN5002

CN5001

5 Four

claws

CN5004

CN5005

6 Four

claws

HB board

1 Four screws

(+BVTP 3 x 12)

4 Four claws

PVM-14L5/20L5/D14L5A/D20L5A

1-11

Page 18

1-4-5. J, D1, D2 and D Boards Removal (20 inch)

CN2502 (board to board)

4 D1 board

CN2501 (board to board)

CN1506

CN1507

CN1508

CN1502

CN1503

CN1501

6 Four screws

(+BVTP 3 x 12)

5 Screw

(+BVTT 4 x 8)

9 pin

1-4-6. C Board Removal (20 inch)

3 J board

CN951

CN701

D board

1 Two screws

(+PSW 3 x 8)

2 Insulator (J PWB)

9 Bracket D

7 Four card edge

spacers

8 D2 board

1-12

CN704

C board

CN702

PVM-14L5/20L5/D14L5A/D20L5A

Page 19

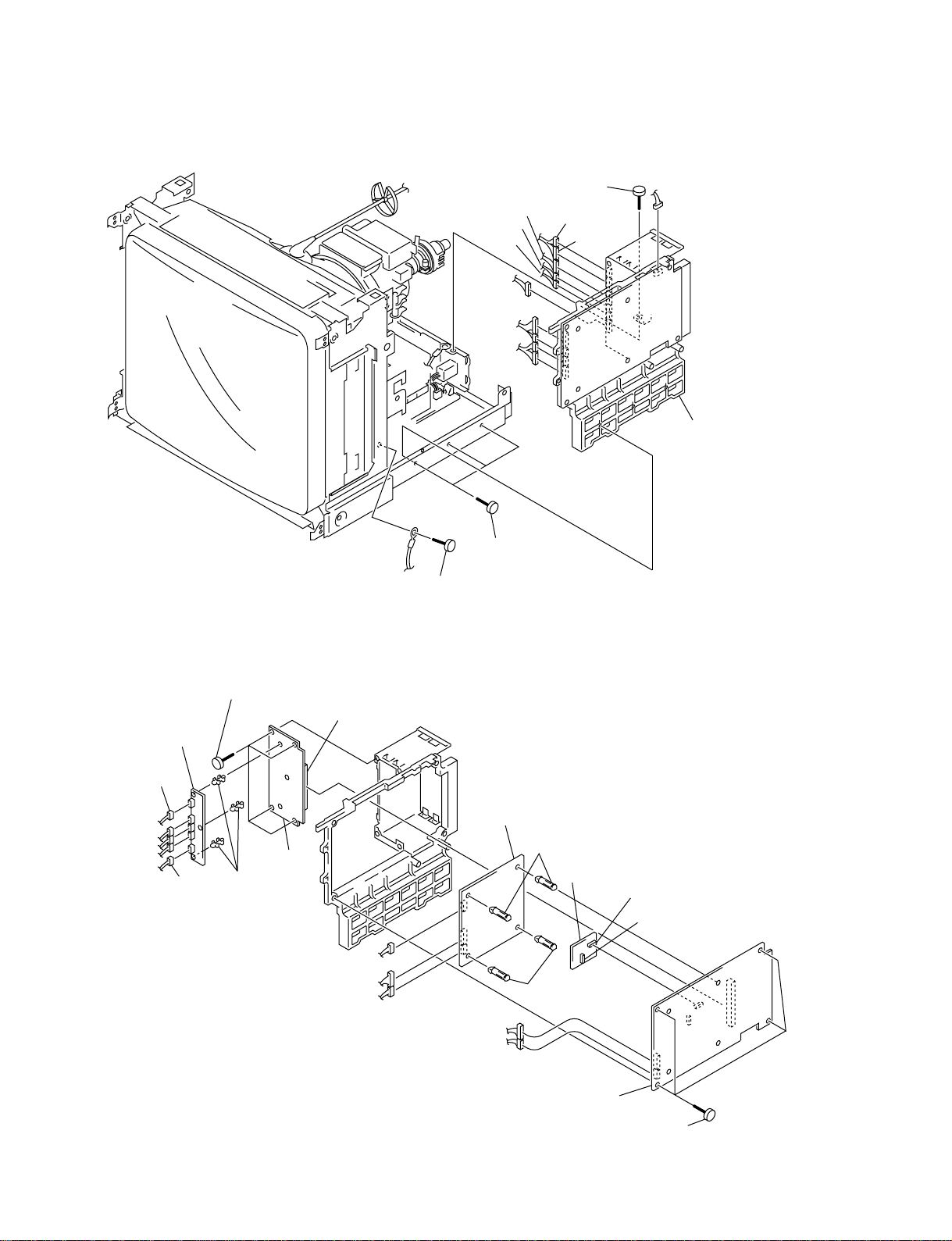

1-4-7. B Block Assy Removal (20 inch)

3 Screw (+PSW 4 x 8)

CN1904

CN1903

CN1907

CN1906

CN101

CN102

CN103

CN104

2 Three screws

(+BVTP 3 x 12)

1 Screw (+BVTT 4 x 8)

1-4-8. K, T, B1, M and B Boards Removal (20 inch)

CN1908

CN1905

CN2401

B block assy

CN3504

CN3505

CN3503

CN3502

9 Four screws (+BVTT 3 x 8)

2 K board

CN3501

T board

1 Three PWB

holders

CN1901 (board to board)

CN801

CN3802

CN3801

5 B1 board

3 Two PWB holders

6 M board

CN107 (board to board)

CN108 (board to board)

4 Two PWB

holders

CN113

CN201

8 B board

7 Four screws

(+BVTP 3 x 12)

PVM-14L5/20L5/D14L5A/D20L5A

1-13

Page 20

c

Anode button

1-4-9. Q Block Assy Removal (20 inch)

1 Screw (+PSW 4 x 8)

1-4-10.Removal of Anode Cap

CN2706

2 Four claws

CN2707

CN2710

CN2705

CN601

3 Screw (+PSW 4 x 8)

CN2704

8 Q block assy

4 Two screws

(+PSW 3 x 12)

6 Connector label

5 Plug holder (A)

7 AC inlet 3p (with noise filter)

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

. Removal Procedure

..

a

a

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

..

. Handling Precautions

..

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

b

b

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

1-14

PVM-14L5/20L5/D14L5A/D20L5A

Page 21

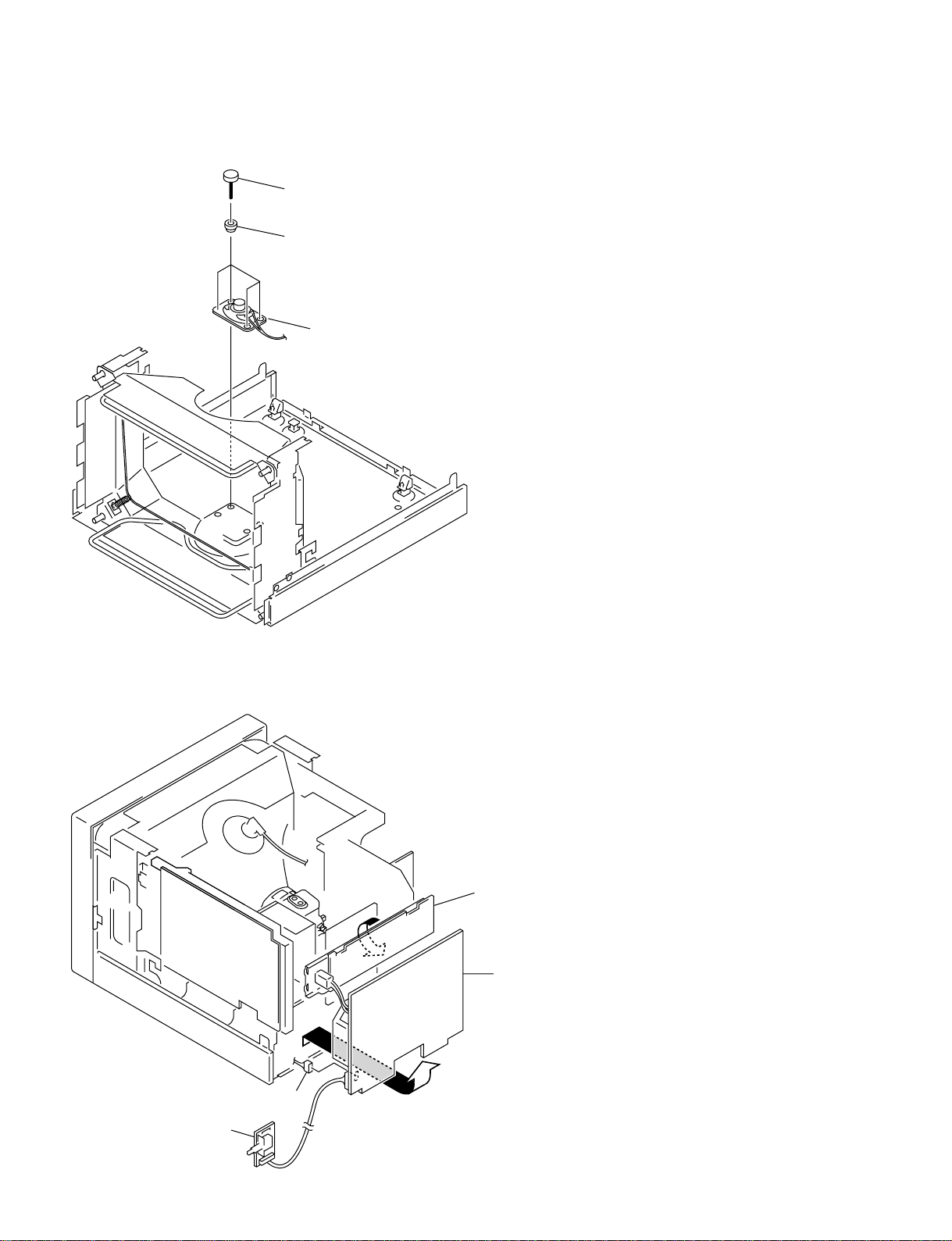

1-4-11.G Board Removal (20 inch)

2 Screw (+BVTP 3 x 16)

1 Anode cap

3 Two screws (+PSW 4 x 8)

CN505

CN607

CN606

CN503

CN604

CN508

CN609

CN610

CN603

5 G shield

CN608

CN608

CN607

4 G board

CN602

1-4-12.Picture Tube Removal (20 inch)

4 Two nuts (flange nut (B) M5)

6 Picture tube

2 Neck assy

3 Deflection yoke

1 Fastening band

assy

5 Two nuts (flange nut (B) M5)

PVM-14L5/20L5/D14L5A/D20L5A

1-15

Page 22

1-4-13.Speaker Removal (20 inch)

1 Four screws (step screw M3 x 4)

2 Four speaker cushions

3 Speaker

1-4-14.Service Position (20 inch)

*Because there exist the portions that have the high tension voltage,

be careful that the printed boards must not touch each other

nor must not touch with the chassis.

Q board

G board

1-16

CN603

J board

PVM-14L5/20L5/D14L5A/D20L5A

Page 23

Section 2

Set-up Adjustment

2-1. Equipment Required

. Oscilloscope

Sony Tektronix 2465 or equivalent (with bandwidth of

350 MHz)

. NTSC/PAL/SECAM component signal generator

Sony Tektronix TG2000 +AVG1 (option module)

+AWVG2 (option module) or equivalent

. SDI signal generator

Sony Tektronix TSG-422

. Monoscope signal generator

ShibaSoku TP22AX or equivalent

. VG (programmable video signal generator)

. VG814 or equivalent

. Frequency counter

Advantest TR5821AK or equivalent

. Digital VOM

Advantest TR6845 or equivalent

. Slide induction transformer

. High tension voltmeter

. DC power supply

. Ammeter

. Luminance meter

Minolta CA-110 or equivalent.

If the Minolta CA-110 is not available, perform the

measurement by visual inspection by comparing the

monitor that has already been adjusted earlier with the

monitor that you want to adjust.

n

Start the following adjustments after 5 minutes have

passed after the main power is turned on.

* In this chapter, [||||||] indicates the control items in the

service mode.

Example : [60|H-FREQ]

2-2. Preparations (1)

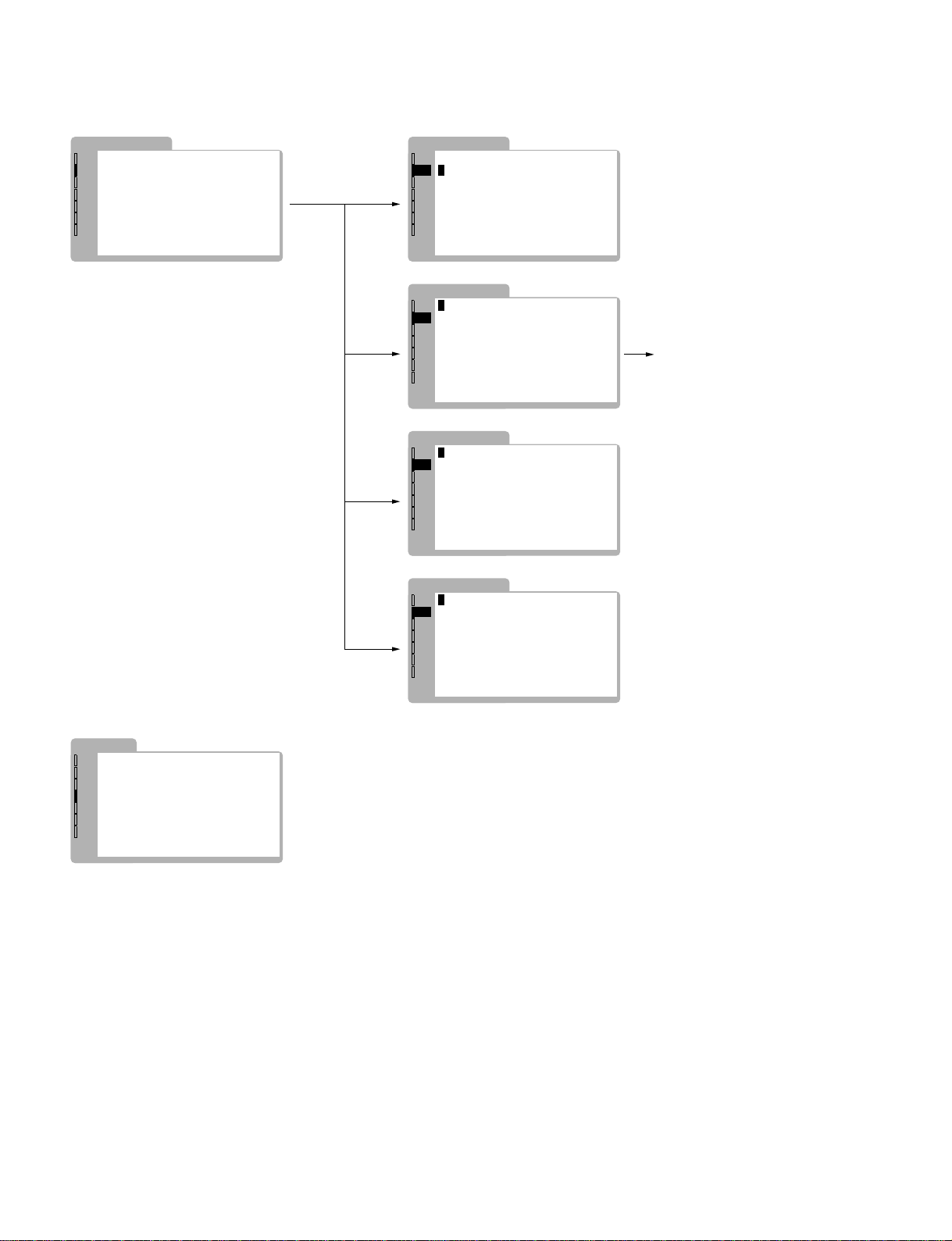

Service Mode

This set is provided with a switch for service on the front

panel that can be used to make various adjustments. The

operation method of this switch is explained in detail below.

1. Entering the service mode

Simultaneously press the [ENTER] key and the

[DEGAUSS] key shown on the display of the menu.

SIGNAL

SIG

• LEVEL-1...

DEF

• LEVEL-2...

OPT

• WHITE BALANCE...

REM

• DECODER COLOR...

SYS

• DECODER LEVEL...

STA

• DETECTION...

ENG

2. Operating the Service Mode

Select the desired service item with the [UP],

[DOWN] key and press the [ENTER] key to enter the

adjustment mode.

Press the [UP] key to increase the adjustment value.

Press the [DOWN] key to decrease the adjustment

value.

Press the [ENTER] key to save the adjustment value.

Press the [MENU] key to cancel the entry.

3. Finishing the service mode

Simultaneously press the [ENTER] key and the

[DEGAUSS] key shown on the display of the menu.

4. Easy ON/OFF of the service mode

If once entering the service mode after having turned

on the power, easy ON/OFF is possible by once more

pressing the LINE-A, LINE-B, RGB/COMP, OPT-A

or OPT-B switch on the front panel (the LED lights) as

long as the power is not turned off or as long as the

service mode is not finished.

PVM-14L5/20L5/D14L5A/D20L5A

2-1

Page 24

5. Executing FACTROY LOAD

If the adjustment data is damaged or lost by some

reasons, you can restore the default factory adjustment

data by executing FACTROY LOAD as described

below.

Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [FACTROY...] →

[LOAD...] to read the default factory data. If the

default factory data is damaged or the ROM is replaced without executing FACTORY SAVE as

described in the following paragraph, you cannot

execute FACTROY LOAD.

6. Executing FACTORY SAVE

This operation is to write the FACTROY LOAD data

into the factory data area in the memory.

Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MAINTENANCE ID]

and type 111. Then select the following submenus

from the Service Menu in the order of : [ENGINEER]

→ [FACTROY SAVE] to write the factory data in the

memory. FACTORY SAVE is protected from misoperation so that FACTORY SAVE cannot be executed unless MAINTENANCE ID is set.

5. If any IC on the B board is replaced, perform all

adjustment items of the [SIGNAL] menu and of the

[DEFLECTION] menu.

If any IC on the B1 board is replaced, perform the

adjustment items of the [SIGNAL] → [DECODER

COLOR] and of [DECODER LEVEL] menus.

6. Upon completion of adjustment, select the menus

[ENGINEER] → [FACTORY SAVE] to save the

adjustment data.

FACTORY SET

If the following circuit board is replaced or the following

NVRAM on the respective board is replaced, perform the

following settings.

B board : IC104, IC108, IC109

B1 board: IC4804

1. Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MAINTENANCE ID]

and type 111.

2. Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MODEL GRADE] →

[MODEL TYPE] and write the model data of each

model in the [MODEL TYPE] referring to table 2-4.

3. If the NVRAM on the B board is replaced, select the

following submenus from the Service Menu : [ENGINEER] → [CLEAR NVM ON B] and write data.

4. If the NVRAM on the B1 board is replaced, select the

following submenus from the Service Menu : [ENGINEER] → [CLEAR NVM ON B1] and write data.

2-2

PVM-14L5/20L5/D14L5A/D20L5A

Page 25

SIGNAL

SIG

• LEVEL-1...

• LEVEL-2...

• WHITE BALANCE...

• DECODER COLOR...

• DECODER LEVEL...

• DETECTION...

DEF

OPT

REM

SYS

STA

ENG

LEVEL-1

SIG

• Y BLACK

• PB BLACK

• PR BLACK

• CHROMA PB

• CHROMA PR

• Y LEVEL

DEF

OPT

REM

SYS

STA

ENG

LEVEL-2

SIG

• G-Y/B LEVEL

• G-Y/R LEVEL

• PB LEVEL

• PR LEVEL

DEF

OPT

REM

SYS

STA

ENG

47

84

70

74

228

182

214

140

WHITE BALANCE

SIG

• SUB CONTRAST

• SUB BRIGHT

• COLOR TEMP

• MANUAL/AUTO

DEF

OPT

REM

SYS

STA

ENG

131

35

D65

AUTO

• START...

• X 313

• Y 329

• REF VALUE D65

WHITE BALANCE

SIG

• SUB CONTRAST

• SUB BRIGHT

• COLOR TEMP

• MANUAL/AUTO

DEF

OPT

REM

SYS

STA

ENG

131

35

D65

MANUAL

• ADJUST GAIN...

• ADJUST BIAS...

• ADJUST FINE...

DECODER COLOR

SIG

• HP

• CLP

• BURST GATE PLS

• XTAL F0

DEF

OPT

REM

SYS

STA

ENG

20

216

83

81

76

• SUB PHASE

• ACC PHASE 128

• R-Y PHASE 113

DECODER LEVEL

SIG

• DEC Y LEVEL

• DEC B-Y LEVEL

• DEC R-Y LEVEL

• ACC LEVEL

DEF

OPT

REM

SYS

STA

ENG

138

171

196

128

SIGNAL/DETECTION

SIG

• MACROVISION

DEF

OPT

REM

SYS

STA

ENG

ON

54

92

• CLP P DLY 225

Service Mode screen display

PVM-14L5/20L5/D14L5A/D20L5A

2-3

Page 26

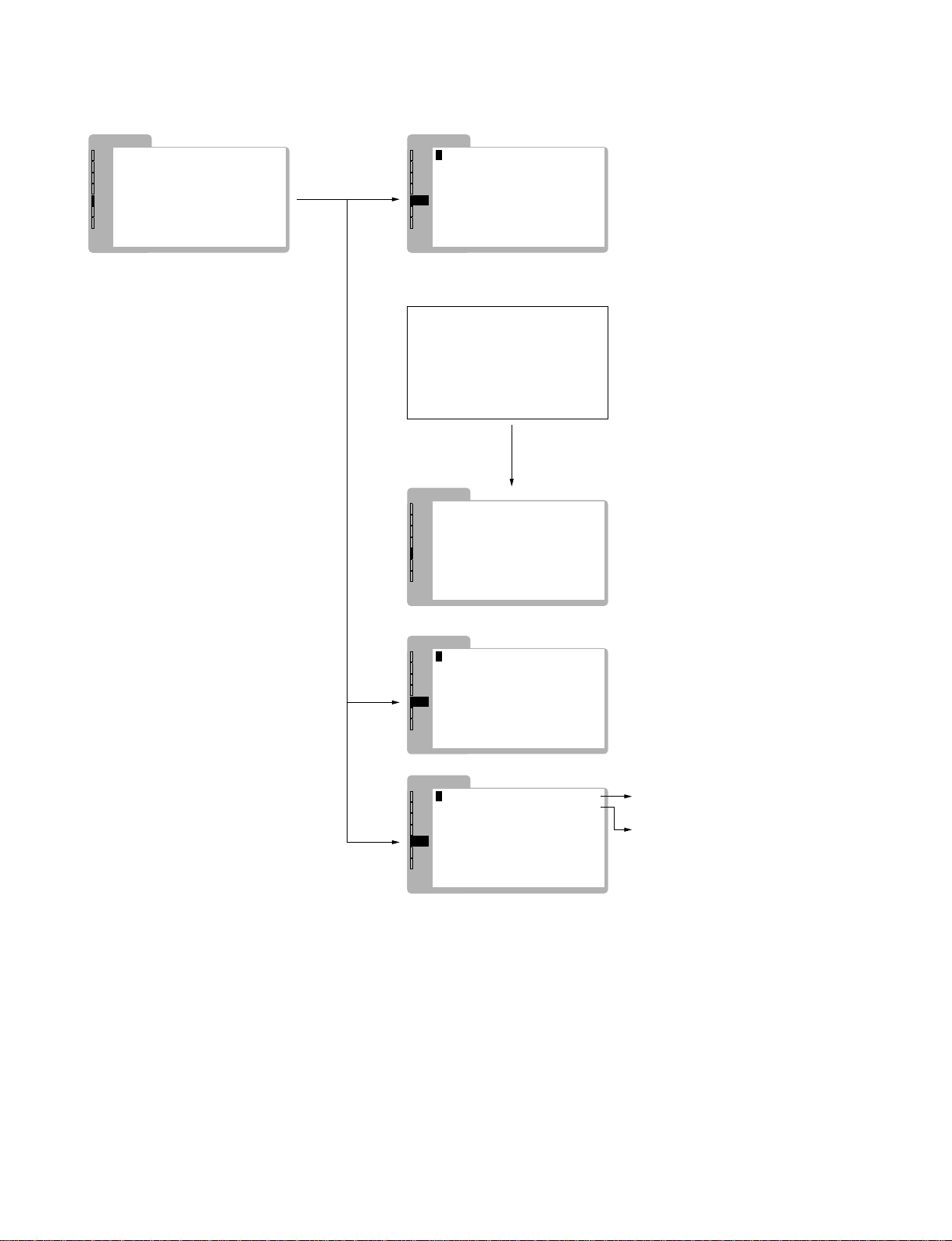

DEFLECTION

SIG

• FOCUS...

• RASTER H...

DEF

• RASTER V...

OPT

• GEOMETRY...

REM

SYS

STA

ENG

FOCUS

DEFLECTION

SIG

• H DUTY

• HFV SENSE

DEF

• HFV CONTROL

OPT

• H DF PHASE

REM

SYS

• H DF PARA

STA

• LANDING

ENG

• H PLL

RASTER H

DEFLECTION

SIG

• H SIZE

DEF

• H CENTER

OPT

• H BLK LEFT

REM

• H BLK RIGHT

SYS

• H BLK R FINE

STA

• H POSITION

ENG

• MARKER SUB L

• MARKER SUB R

RASTER V

DEFLECTION

SIG

• V SIZE

• V CENTER

DEF

• V BLK TOP

OPT

• V BLK BOTTOM

REM

• OSD TIMING

SYS

STA

ENG

GEOMETRY

DEFLECTION

SIG

• V S LIN

• V C LIN

DEF

• TRAPEZOID

OPT

• SIDE PIN

REM

• SIDE PIN W

SYS

• SIDE PIN BAL

STA

• PARA CONTROL

ENG

• SIDE PIN S

250

128

LOCK

107

215

128

121

142

82

196

28

25

62

34

18

85

11

84

59

84

0

13

24

36

32

16

16

24

H BLK R FINE is adjustable only

in 1080/60I and 1035/60I.

It is the fixed value in other modes.

REMOTE

SIG

DEF

OPT

REM

SYS

STA

ENG

2-4

SERIAL

• BAUDRATE

• STOPBIT

• PARITY

38400

2BIT

EVEN

PVM-14L5/20L5/D14L5A/D20L5A

Page 27

SYSTEM

SIG

VERSION

• MODEL GRADE

DEF

• MODEL TYPE

OPT

• W/B DESCRIPTION...

REM

• AGING MODE

SYS

• FACTORY...

STA

• SIGNAL...

ENG

• MAINTENANCE ID

1.3

L4/L3

E14

W/B DESCRIPTION

SYSTEM

SIG

• COL1 65

• COL2

DEF

OPT

REM

SYS

STA

0

ENG

93

AGING MODE

All white screen

To return to the original screen,

press the button of the input selector

illuminating in orange.

SYSTEM

SIG

VERSION

• MODEL GRADE

DEF

• MODEL TYPE

OPT

• W/B DESCRIPTION...

REM

• AGING MODE

SYS

• FACTORY...

STA

• SIGNAL...

ENG

• MAINTENANCE ID

1.3

L4/L3

E14

0

FACTORY

SYSTEM

• LOAD...

SIG

DEF

• STANDARD...

OPT

REM

SYS

STA

ENG

SIGNAL

SYSTEM

• 1080/48I

SIG

• 720/50P

DEF

OPT

REM

SYS

STA

ENG

LOAD cannot be selected and remains

in the blue display unless the NVM data is valid.

In such a case, clear the NVM and

make the NVM data valid first.

However, if the default factory data is damaged,

or if the FACTORY SET process is not executed

after ROM is replaced, LOAD cannot be executed.

STANDARD returns the various setups

of the user menu to the default factory setting.

OFF

OFF

When OFF, 1080/48I is identified

as NO SYNC.

When OFF, 720/50P is identified

as NO SYNC.

PVM-14L5/20L5/D14L5A/D20L5A

2-5

Page 28

STATUS

SIG

ADJUST ERROR

ABNORMAL I2C

DEF

OPT

NVM BOARD B

REM

NVM BOARD B1

SYS

STA

ENG

OK

OK

0

0

ENGINEER 1/3

SIG

• AUSP SAMPLE POS

DEF

• FACTORY SAVE...

OPT

REM

• CLEAR NVM ON B...

SYS

• CLEAR NVM ON B1...

STA

ENG

OPTION (BKM-129X)

OPTION

SIG

BKM-129X

DEF

OPT

REM

SYS

STA

ENG

OPTION (BKM-120D)

OPTION

SIG

BKM-120D (1/3)

DEF

• OE

• P SAVE

OPT

• DISPLAY

REM

• D A

SYS

• D B

STA

• H BLK1

ENG

OFF

ENGINEER 2/3

SIG

• DATA REFRESH

DEF

• SREM RAW DATA

• OSDLIMIT

OPT

• 4:3MARKER LIMIT OFF

REM

• AWB ANA VALUE

SYS

• INTERNAL SIGNAL

STA

ENG

OPTION

SIG

1

0

1

0

1

0

BKM-120D (2/3)

• CCP P

DEF

• DA FV

OPT

• DB FV

REM

• Y LEVEL

SYS

• PB LEVEL

STA

• PR LEVEL

ENG

ON

OFF

OFF

OFF

137

84

109

82

71

74

0

ENGINEER 3/3

SIG

• H SYNC COUNT

DEF

• MENU DOTCLOCK

• MENU H POS

OPT

• BLK DOTCLOCK 231

REM

• BLK H POS

SYS

• OPTION BOARD ID

STA

ENG

OPTION

SIG

BKM-120D (3/3)

• YB2

DEF

• YW0

OPT

• YW1

REM

SYS

STA

ENG

HIDE

231

255

14

8

0

0

0

OPTION (BKM-142HD)

OPTION

SIG

BKM-142HD 1/5

• 1125/60I SYS

DEF

• OE

OPT

• P SAVE

REM

• DISPLAY

SYS

• IN1

STA

• IN2

ENG

2-6

AUTO

OPTION

SIG

BKM-142HD 2/5

• YPBPR

1

0

0

0

0

DEF

• H BLK1

OPT

• H SUB

REM

• Y LEVEL

SYS

• PB LEVEL

STA

• PR LEVEL

ENG

OPTION

SIG

BKM-142HD 4/5

• STRB

DEF

• SYCS1

OPT

REM

• SYCS2

SYS

• SYIF0

STA

• SYIF1

ENG

• SYIF2

240

128

120

1

22

28

1

1

0

1

1

1

OPTION

SIG

BKM-142HD 3/5

• SYSTA0

DEF

• SYSTA1

OPT

• P0

REM

• P1

SYS

• P2

STA

• P3

ENG

OPTION

SIG

BKM-142HD 5/5

• SYIF3

DEF

• SYIF4

OPT

REM

• SYIF5

SYS

• SYIF6

STA

• SYIF7

ENG

0

1

1

1

0

1

1

0

0

0

0

PVM-14L5/20L5/D14L5A/D20L5A

Page 29

OPTION (BKM-150CP)

OPTION

SIG

BKM-150CP (1/4)

• OE

DEF

• P SAVE

OPT

• DISPLAY

REM

• D A

SYS

• D B

STA

• H BLK1

ENG

OPTION (BKM-126M)

OPTION

SIG

BKM-126M (1/4)

• OE

DEF

• V B

OPT

• V C

REM

• BYPASS SW

SYS

• COMB SW

STA

• ACC SW

ENG

OFF

ON

ON

OPTION

SIG

0

0

1

0

1

0

0

1

1

BKM-150CP (2/4)

• CCP P

DEF

• DA FV

OPT

• DB FV

REM

• Y LEVEL

SYS

• PB LEVEL

STA

• PR LEVEL

ENG

OPTION

SIG

BKM-150CP (4/4)

• AUDIO GRP 0

DEF

• AUDIO GRP 1

OPT

• AUDIO CH 0

REM

• AUDIO CH 1

SYS

• AUDIO MIX

STA

• AUDIO MONO L

ENG

• AUDIO MONO R 1

OPTION

SIG

BKM-126M (2/4)

• PAL S SW

DEF

• APT SW

OPT

• PCD SW

REM

• PAL SW

SYS

• KILLER

STA

ENG

110

85

110

105

OFF

OFF

ON

80

80

1

1

0

1

1

0

S

0

OPTION

SIG

BKM-150CP (3/4)

• SDTI SW

DEF

• TC MODE 0

OPT

• TC MODE 1

REM

• TC MODE 2

SYS

• AUDIO MUTE

STA

ENG

OPTION

SIG

BKM-126M (3/4)

• Y LEVEL

DEF

• PB LEVEL

OPT

• PR LEVEL

REM

• PHASE

SYS

• SUB PHASE

STA

ENG

• BGP W 127

• ACC LEVEL 127

127

127

127

127

127

0

0

0

0

0

OPTION

SIG

BKM-126M (4/4)

• APT LEVEL

DEF

• CLP W

OPT

• R-Y PHASE

REM

• ACC PHASE

SYS

• F0

STA

ENG

127

127

127

127

127

PVM-14L5/20L5/D14L5A/D20L5A

2-7

Page 30

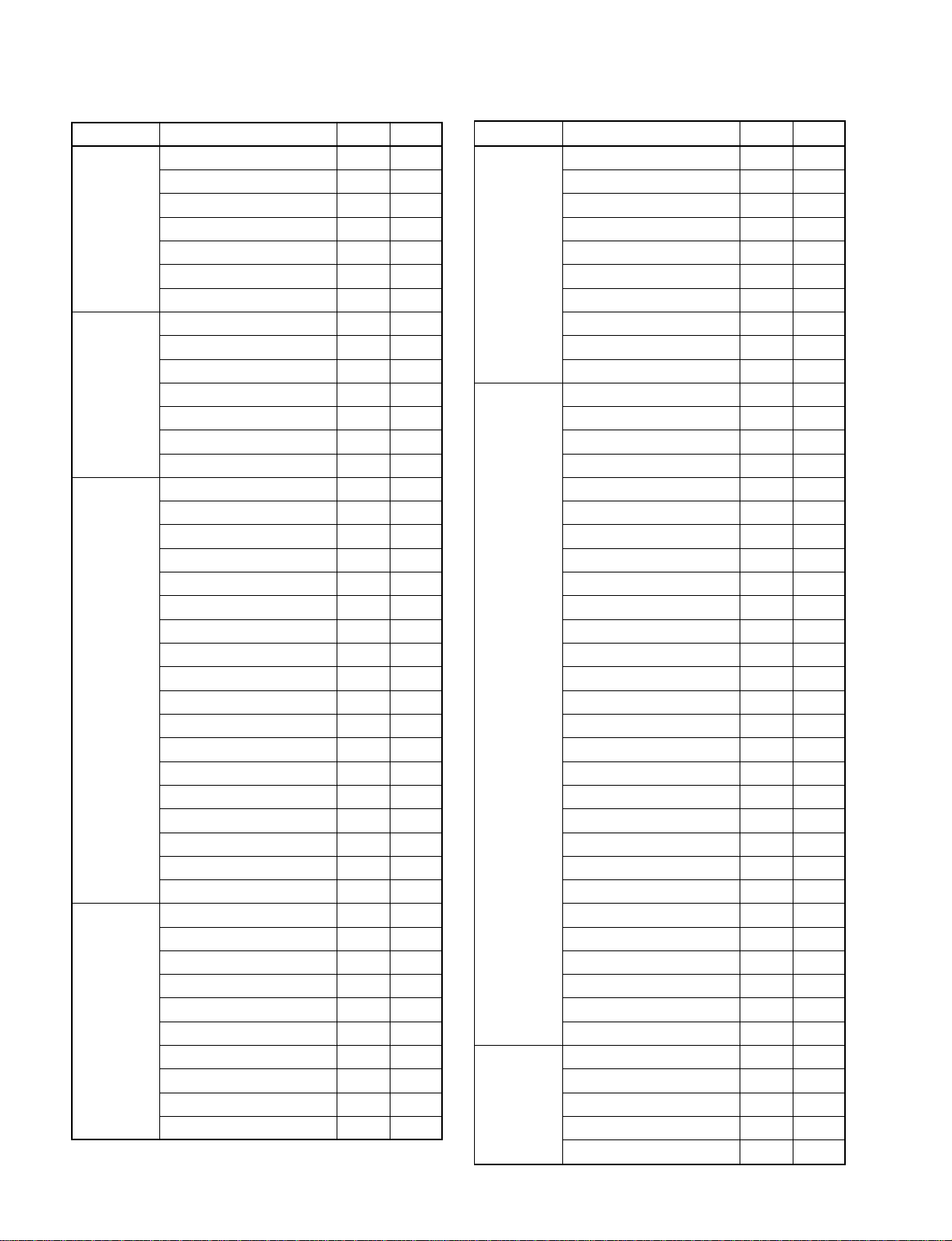

Name Description Inch20 Inch14

HFV_SENS Horizontal frequency 15K 27 42

Horizontal frequency 27K 37 25

Horizontal frequency 28K 37 25

Horizontal frequency 31K 36 33

Horizontal frequency 33K 4 26

Horizontal frequency 37K 26 16

Horizontal frequency 45K 26 17

HFV_CONTROL Horizontal frequency 15K 249 250

Horizontal frequency 27K 200 200

Horizontal frequency 28K 200 200

Horizontal frequency 31K 180 188

Horizontal frequency 33K 177 177

Horizontal frequency 37K 160 160

Horizontal frequency 45K 128 128

H_SIZE 480/60I NORMAL 74 95

480/60I UNDER 49 71

575/50I NORMAL 78 102

575/50I UNDER 56 79

1080/48I NORMAL 77 106

1080/48I UNDER 55 82

1080/50I NORMAL 77 106

1080/50I UNDER 55 82

480/60P NORMAL 46 74

480/60P UNDER 32 50

576/50P NORMAL 54 81

576/50P UNDER 34 56

1080/60I 1035/60I NORMAL 41 64

1080/60I 1035/60I UNDER 21 44

720/50P NORMAL 41 64

720/50P UNDER 21 44

720/60P NORMAL 53 75

720/60P UNDER 30 51

H_CENT 480/60I 100 107

575/50I 100 107

1080/48I 100 107

1080/50I 100 107

480/60P 100 107

576/50P 100 107

1080/60I 1035/60I NORMAL 100 107

1080/60I 1035/60I UNDER 100 107

720/50P 100 107

720/60P 100 107

Name Description Inch20 Inch14

H_POSITION 480/60I 82 85

575/50I 74 77

1080/48I 64 70

1080/50I 64 70

480/60P 83 89

576/50P 80 85

1080/60I 1035/60I NORMAL 92 101

1080/60I 1035/60I UNDER 92 101

720/50P 79 86

720/60P 79 86

SIDE_PINBAL 480/60I 4:3 NORMAL 18 19

480/60I 4:3 UNDER 18 23

480/60I 16:9 NORMAL 14 18

480/60I 16:9 UNDER 18 19

575/50I 4:3 NORMAL 14 15

575/50I 4:3 UNDER 16 15

575/50I 16:9 NORMAL 16 15

575/50I 16:9 UNDER 16 17

1080/48I NORMAL 16 17

1080/48I UNDER 16 14

1080/50I NORMAL 16 17

1080/50I UNDER 16 14

480/60P 4:3 NORMAL 15 13

480/60P 4:3 UNDER 16 16

480/60P 16:9 NORMAL 15 14

480/60P 16:9 UNDER 16 14

575/50P 4:3 NORMAL 15 16

575/50P 4:3 UNDER 15 15

575/50P 16:9 NORMAL 16 14

575/50P 16:9 UNDER 15 16

1035/60I NORMAL 14 15

1035/60I UNDER 16 14

1080/60I NORMAL 14 15

1080/60I UNDER 16 14

720/50P NORMAL 15 14

720/50P UNDER 15 15

720/60P NORMAL 15 14

720/60P UNDER 15 15

PARA_CONTROL 480/60I 4:3 NORMAL 13 14

480/60I 4:3 UNDER 14 15

480/60I 16:9 NORMAL 14 15

480/60I 16:9 UNDER 14 15

575/50I 4:3 NORMAL 11 16

2-8

PVM-14L5/20L5/D14L5A/D20L5A

Page 31

Name Description Inch20 Inch14

PARA_CONTROL 575/50I 4:3 UNDER 12 15

575/50I 16:9 NORMAL 13 17

575/50I 16:9 UNDER 14 16

1080/48I NORMAL 15 16

1080/48I UNDER 15 17

1080/50I NORMAL 15 16

1080/50I UNDER 15 17

480/60P 4:3 NORMAL 15 16

480/60P 4:3 UNDER 14 16

480/60P 16:9 NORMAL 14 15

480/60P 16:9 UNDER 14 15

575/50P 4:3 NORMAL 15 15

575/50P 4:3 UNDER 16 17

575/50P 16:9 NORMAL 16 17

575/50P 16:9 UNDER 16 16

1035/60I NORMAL 14 17

1035/60I UNDER 16 17

1080/60I NORMAL 14 17

1080/60I UNDER 16 17

720/50P NORMAL 15 16

720/50P UNDER 15 16

720/60P NORMAL 15 16

720/60P UNDER 15 16

SIDE_PIN_W 480/60I 4:3 NORMAL 31 32

480/60I 4:3 UNDER 31 31

480/60I 16:9 NORMAL 31 31

480/60I 16:9 UNDER 31 31

575/50I 4:3 NORMAL 31 31

575/50I 4:3 UNDER 31 31

575/50I 16:9 NORMAL 31 31

575/50I 16:9 UNDER 31 31

1080/48I NORMAL 31 31

1080/48I UNDER 31 31

1080/50I NORMAL 31 31

1080/50I UNDER 31 31

480/60P 4:3 NORMAL 31 31

480/60P 4:3 UNDER 31 31

480/60P 16:9 NORMAL 31 31

480/60P 16:9 UNDER 31 31

575/50P 4:3 NORMAL 31 31

575/50P 4:3 UNDER 31 31

575/50P 16:9 NORMAL 31 31

575/50P 16:9 UNDER 31 31

Name Description Inch20 Inch14

SIDE_PIN_W 1035/60I NORMAL 31 31

1035/60I UNDER 25 31

1080/60I NORMAL 31 31

1080/60I UNDER 25 31

720/50P NORMAL 31 31

720/50P UNDER 25 31

720/60P NORMAL 31 31

720/60P UNDER 25 31

SIDE_PIN 480/60I 4:3 NORMAL 15 28

480/60I 4:3 UNDER 18 31

480/60I 16:9 NORMAL 37 42

480/60I 16:9 UNDER 37 40

575/50I 4:3 NORMAL 18 31

575/50I 4:3 UNDER 19 30

575/50I 16:9 NORMAL 37 41

575/50I 16:9 UNDER 37 43

1080/48I NORMAL 34 41

1080/48I UNDER 36 42

1080/50I NORMAL 34 41

1080/50I UNDER 36 42

480/60P 4:3 NORMAL 14 27

480/60P 4:3 UNDER 17 26

480/60P 16:9 NORMAL 35 41

480/60P 16:9 UNDER 37 41

575/50P 4:3 NORMAL 17 28

575/50P 4:3 UNDER 17 29

575/50P 16:9 NORMAL 35 42

575/50P 16:9 UNDER 35 43

1035/60I NORMAL 35 41

1035/60I UNDER 38 42

1080/60I NORMAL 35 41

1080/60I UNDER 38 42

720/50P NORMAL 35 42

720/50P UNDER 38 43

720/60P NORMAL 35 42

720/60P UNDER 38 43

SIDE_PIN_S 480/60I 4:3 NORMAL 19 31

480/60I 4:3 UNDER 22 31

480/60I 16:9 NORMAL 19 31

480/60I 16:9 UNDER 25 31

575/50I 4:3 NORMAL 25 31

575/50I 4:3 UNDER 26 31

575/50I 16:9 NORMAL 27 31

PVM-14L5/20L5/D14L5A/D20L5A

2-9

Page 32

Name Description Inch20 Inch14

SIDE_PIN_S 575/50I 16:9 UNDER 29 31

1080/48I NORMAL 23 31

1080/48I UNDER 27 28

1080/50I NORMAL 23 31

1080/50I UNDER 27 28

480/60P 4:3 NORMAL 28 29

480/60P 4:3 UNDER 27 31

480/60P 16:9 NORMAL 31 29

480/60P 16:9 UNDER 31 27

575/50P 4:3 NORMAL 26 24

575/50P 4:3 UNDER 27 27

575/50P 16:9 NORMAL 31 26

575/50P 16:9 UNDER 31 27

1035/60I NORMAL 3 31

1035/60I UNDER 29 31

1080/60I NORMAL 31 31

1080/60I UNDER 29 31

720/50P NORMAL 28 31

720/50P UNDER 40 34

720/60P NORMAL 28 31

720/60P UNDER 40 34

TRAPEZOID 480/60I 4:3 NORMAL 29 27

480/60I 4:3 UNDER 31 28

480/60I 16:9 NORMAL 31 29

480/60I 16:9 UNDER 31 29

575/50I 4:3 NORMAL 31 26

575/50I 4:3 UNDER 31 26

575/50I 16:9 NORMAL 33 31

575/50I 16:9 UNDER 30 31

1080/48I NORMAL 32 29

1080/48I UNDER 33 28

1080/50I NORMAL 32 29

1080/50I UNDER 33 28

480/60P 4:3 NORMAL 26 27

480/60P 4:3 UNDER 31 28

480/60P 16:9 NORMAL 31 29

480/60P 16:9 UNDER 27 26

575/50P 4:3 NORMAL 28 26

575/50P 4:3 UNDER 32 24

575/50P 16:9 NORMAL 30 27

575/50P 16:9 UNDER 26 25

1035/60I NORMAL 24 29

1035/60I UNDER 23 26

Name Description Inch20 Inch14

TRAPEZOID 1080/60I NORMAL 28 29

1080/60I UNDER 29 26

720/50P NORMAL 30 26

720/50P UNDER 27 26

720/60P NORMAL 30 26

720/60P UNDER 27 26

V_SIZE 480/60I 4:3 NORMAL 40 93

480/60I 4:3 UNDER 0 51

480/60I 16:9 NORMAL 51 102

480/60I 16:9 UNDER 10 58

575/50I 4:3 NORMAL 51 100

575/50I 4:3 UNDER 0 51

575/50I 16:9 NORMAL 51 108

575/50I 16:9 UNDER 11 62

1080/48I NORMAL 19 83

1080/48I UNDER 0 45

1080/50I NORMAL 19 83

1080/50I UNDER 0 45

480/60P 4:3 NORMAL 51 108

480/60P 4:3 UNDER 4 63

480/60P 16:9 NORMAL 36 103

480/60P 16:9 UNDER 15 64

575/50P 4:3 NORMAL 50 96

575/50P 4:3 UNDER 3 54

575/50P 16:9 NORMAL 35 104

575/50P 16:9 UNDER 12 60

1035/60I NORMAL 23 105

1035/60I UNDER 0 60

1080/60I NORMAL 23 85

1080/60I UNDER 0 48

720/50P NORMAL 22 84

720/50P UNDER 0 48

720/60P NORMAL 22 84

720/60P UNDER 0 48

V_CENT 480/60I 128 107

575/50I 128 107

1080/48I 128 107

1080/50I 128 107

480/60P 128 107

576/50P 128 107

1035/60I 128 107

1080/60I 128 107

720/50P 128 107

2-10

PVM-14L5/20L5/D14L5A/D20L5A

Page 33

Name Description Inch20 Inch14

V_CENT 720/60P 128 107

V_S_LIN 480/60I 4:3 NORMAL 15 14

480/60I 4:3 UNDER 15 15

480/60I 16:9 NORMAL 15 15

480/60I 16:9 UNDER 16 15

575/50I 4:3 NORMAL 15 15

575/50I 4:3 UNDER 22 15

575/50I 16:9 NORMAL 24 15

575/50I 16:9 UNDER 25 15

1080/48I NORMAL 29 22

1080/48I UNDER 26 15

1080/50I NORMAL 29 22

1080/50I UNDER 26 15

480/60P 4:3 NORMAL 15 15

480/60P 4:3 UNDER 31 15

480/60P 16:9 NORMAL 24 15

480/60P 16:9 UNDER 27 15

575/50P 4:3 NORMAL 15 15

575/50P 4:3 UNDER 15 15

575/50P 16:9 NORMAL 24 15

575/50P 16:9 UNDER 26 15

1035/60I NORMAL 27 20

1035/60I UNDER 20 15

1080/60I NORMAL 27 20

1080/60I UNDER 20 15

720/50P NORMAL 21 19

720/50P UNDER 22 15

720/60P NORMAL 21 19

720/60P UNDER 22 15

V_C_LIN 480/60I 4:3 NORMAL 15 18

480/60I 4:3 UNDER 15 15

480/60I 16:9 NORMAL 15 15

480/60I 16:9 UNDER 20 15

575/50I 4:3 NORMAL 15 15

575/50I 4:3 UNDER 12 15

575/50I 16:9 NORMAL 20 15

575/50I 16:9 UNDER 15 15

1080/48I NORMAL 17 19

1080/48I UNDER 21 15

1080/50I NORMAL 17 19

1080/50I UNDER 21 15

480/60P 4:3 NORMAL 15 15

480/60P 4:3 UNDER 15 15

Name Description Inch20 Inch14

V_C_LIN 480/60P 16:9 NORMAL 21 15

480/60P 16:9 UNDER 17 15

575/50P 4:3 NORMAL 15 15

575/50P 4:3 UNDER 15 15

575/50P 16:9 NORMAL 22 15

575/50P 16:9 UNDER 19 15

1035/60I NORMAL 17 20

1035/60I UNDER 19 15

1080/60I NORMAL 17 20

1080/60I UNDER 19 15

720/50P NORMAL 21 17

720/50P UNDER 13 15

720/60P NORMAL 21 17

720/60P UNDER 13 15

H_BLK_L 480/60I 222 222

575/50I 227 227

1080/48I 225 225

1080/50I 218 218

480/60P 164 164

576/50P 181 181

1080/60I 1035/60I NORMAL 162 162

1080/60I 1035/60I UNDER 179 179

720/50P 162 162

720/60P 162 162

H_BLK_R 480/60I 133 133

575/50I 133 133

1080/48I 133 133

1080/50I 133 133

480/60P 133 133

576/50P 133 133

1080/60I 1035/60I NORMAL 133 133

1080/60I 1035/60I UNDER 133 133

720/50P 133 133

720/60P 133 133

H_BLK_R_FINE 1080/60I 1035/60I NORMAL 12 12

1080/60I 1035/60I UNDER 12 12

V_BLK_T 480/60I 107 106

575/50I 148 148

1080/48I 213 227

1080/50I 225 223

480/60P 134 132

576/50P 160 165

1035/60I 171 182

PVM-14L5/20L5/D14L5A/D20L5A

2-11

Page 34

Name Description Inch20 Inch14

V_BLK_T 1080/60I 171 182

720/50P 220 230

720/60P 190 190

V_BLK_B 480/60I 223 203

Not used 255 255

575/50I 175 157

Not used 255 255

1080/48I 122 85

1080/50I 121 85

480/60P 176 137

Not used 255 255

576/50P 64 27

Not used 255 255

1035/60I 75 38

1080/60I 75 38

720/50P 211 179

720/60P 186 154

LCC LCC 128 128

H_DF_ Horizontal frequency 15K 15 15

PHASE

Horizontal frequency 27K 15 15

Horizontal frequency 28K 15 15

Horizontal frequency 31K 15 15

Horizontal frequency 33K 15 15

Horizontal frequency 37K 15 15

Horizontal frequency 45K 15 15

H_DF_ Horizontal frequency 15K 15 15

PARA

Horizontal frequency 27K 15 15

Horizontal frequency 28K 15 15

Horizontal frequency 31K 15 15

Horizontal frequency 33K 15 15

Horizontal frequency 37K 15 15

Horizontal frequency 45K 15 15

CLP_P_ Horizontal frequency 15K 225 225

DLY

Horizontal frequency 31K 200 200

Horizontal frequency 27K/28K/33K 80 80

Horizontal frequency 45K 30 30

Horizontal frequency 15K (/31K DUMMY) SDI 180 180

Horizontal frequency 27K/28K/33K SDI 100 100

Horizontal frequency 37K/45K SDI 150 150

Y_LEVEL SETUP-0 systemn 100 100

NTSC-0/BETA-0/SMPTE/SDI

SETUP-7.5 systemn 110 110

NTSC-7.5/BETA-7.5

CHROMA_ CHROMA PR 80 80

PR

2-12

Name Description Inch20 Inch14

CHROMA_PB CHROMA PB 80 80

Y_BLACK SETUP-0 system 60 60

NTSC-0/BETA-0/SMPTE/SDI

SETUP-7.5 systemn 120 120

NTSC-7.5/BETA-7.5

PB_BLACK RGB/COMP Horizontal frequency 15K 80 80

Other than RGB/COMP 80 80

Horizontal frequency 15K

NTSC/NTSC4.43/NOCOLOR60 80 80

PAL/NOCOLOR50 80 80

SECAM 80 80

SDI Horizontal frequency 15K 80 80

Other than SDI Horizontal frequency 15K 80 80

PR_BLACK RGB/COMP Horizontal frequency 15K 80 80

Other than RGB/COMP

Horizontal frequency 15K 80 80

NTSC/NTSC4.43/NOCOLOR60 80 80

PAL/NOCOLOR50 80 80

SECAM 80 80

SDI Horizontal frequency 15K 80 80

Other than SDI Horizontal frequency 15K 80 80

GY_R_LEVEL SMPTE(709) HD-SDI 90 90

SMPTE(601) D1-SDI/SDTI-CP/DV 200 200

BETACAM SETUP 0(601) 100 100

BETACAM SETUP 7.5(601) 120 120

V_BLK_B_ 480/60I 190 190

NOSYNC

575/50I 120 120

1080/48I 120 120

1080/50I 120 120

480/60P 190 190

576/50P 120 120

1035/60I 190 190

1080/60I 190 190

720/50P 120 120

720/60P 190 190

GY_B_LEVEL SMPTE(709) HD-SDI 90 90

SMPTE(601) D1-SDI/SDTI-CP/DV 210 210

BETACAM SETUP 0 (601) 130 130

BETACAM SETUP 7.5 (601) 150 150

OSD_TIMING Don' t Care

OSD_FIELD Inch 14 and Inch 20

J, U/C Don' t Care

AEP REVERSE 2000001 2000001 2000001

|||

2000587 2000326 2000248

NORMAL 2000588 2000327 2000249

|||

14L4 20L4 14L3

PVM-14L5/20L5/D14L5A/D20L5A

Page 35

Name Description Inch20 Inch14

PR_LEVEL AUTOSETUP-OFF 170 170

15kHz SMPTE(709)

Other than AUTOSETUP-OFF 180 180

15kHz SMPTE(709)

AUTOSETUP-OFF 140 140

15kHz SMPTE(601)

Other than AUTOSETUP-OFF 140 140

15kHz SMPTE(601)

AUTOSETUP-OFF 50 50

BETACAM SETUP 0(601)

AUTOSETUP-OFF 60 60

BETACAM SETUP 7.5(601)

AUTOSETUP-OFF 150 150

NTSC SETUP0

AUTOSETUP-OFF 150 150

(S)-NTSC SETUP0

AUTOSETUP-OFF 150 150

NTSC SETUP7.5

AUTOSETUP-OFF 150 150

(S)-NTSC SETUP7.5

AUTOSETUP-OFF PAL 100 100

AUTOSETUP-OFF (S)-PAL 100 100

AUTOSETUP-OFF SECAM 100 100

AUTOSETUP-OFF NTSC 443 100 100

AUTOSETUP-OFF (S)-NTSC 443 150 150

AUTOSETUP-OFF D1-SDI 150 150

AUTOSETUP-OFF HD-SDI 140 140

AUTOSETUP-OFF SDTI-CP 140 140

AUTOSETUP-OFF DV 140 140

AUTOSETUP-OFF BKM-PALM 140 140

AUTOSETUP-ON 170 170

15kHz SMPTE(709)

Other than AUTOSETUP-ON 180 180

15kHz SMPTE(709)

AUTOSETUP-ON 140 140

15kHz SMPTE(601)

Other than AUTOSETUP-ON 140 140

15kHz SMPTE(601)

AUTOSETUP-ON 50 50

BETACAM SETUP 0(601)

AUTOSETUP-ON 60 60

BETACAM SETUP 7.5(601)

AUTOSETUP-ON 150 150

NTSC SETUP0

AUTOSETUP-ON 150 150

(S)-NTSC SETUP0

Name Description Inch20 Inch14

PR_LEVEL AUTOSETUP-ON NTSC SETUP7.5 150 150

AUTOSETUP-ON

(S)-NTSC SETUP7.5 150 150

AUTOSETUP-ON PAL 100 100

AUTOSETUP-ON (S)-PAL 100 100

AUTOSETUP-ON SECAM 100 100

AUTOSETUP-ON NTSC 443 100 100

AUTOSETUP-ON (S)-NTSC 443 150 150

AUTOSETUP-ON D1-SDI 150 150

AUTOSETUP-ON HD-SDI 140 140

AUTOSETUP-ON SDTI-CP 140 140

AUTOSETUP-ON DV 140 140

AUTOSETUP-ON BKM-PALM 140 140

PB_LEVEL AUTOSETUP-OFF 240 240

15kHz SMPTE(709)

Other than AUTOSETUP-OFF 240 240

15kHz SMPTE(709)

AUTOSETUP-OFF 200 200

15kHz SMPTE(601)

Other than AUTOSETUP-OFF 200 200

15kHz SMPTE(601)

AUTOSETUP-OFF 100 100

BETACAM SETUP 0(601)

AUTOSETUP-OFF 120 120

BETACAM SETUP 7.5(601)

AUTOSETUP-OFF 200 200

NTSC SETUP0

AUTOSETUP-OFF 200 200

(S)-NTSC SETUP0

AUTOSETUP-OFF 200 200

NTSC SETUP7.5

AUTOSETUP-OFF 200 200

(S)-NTSC SETUP7.5

AUTOSETUP-OFF PAL 200 200

AUTOSETUP-OFF (S)-PAL 200 200

AUTOSETUP-OFF SECAM 200 200

AUTOSETUP-OFF NTSC 443 200 200

AUTOSETUP-OFF 200 200

(S)-NTSC 443

AUTOSETUP-OFF D1-SDI 200 200

AUTOSETUP-OFF HD-SDI 200 200

AUTOSETUP-OFF SDTI-CP 200 200

AUTOSETUP-OFF DV 200 200

AUTOSETUP-OFF BKM-PALM 200 200

AUTOSETUP-ON 240 240

15kHz SMPTE(709)

Other than AUTOSETUP-ON 240 240

15kHz SMPTE(709)

PVM-14L5/20L5/D14L5A/D20L5A

2-13

Page 36

Name Description Inch20 Inch14

PB_LEVEL AUTOSETUP-ON 200 200

15kHz SMPTE(601)

Other than AUTOSETUP-ON 200 200

15kHz SMPTE(601)

AUTOSETUP-ON 100 100

BETACAM SETUP 0(601)

AUTOSETUP-ON 120 120

BETACAM SETUP 7.5(601)

AUTOSETUP-ON 200 200

NTSC SETUP0

AUTOSETUP-ON 200 200

(S)-NTSC SETUP0

AUTOSETUP-ON 200 200

NTSC SETUP7.5

AUTOSETUP-ON 200 200

(S)-NTSC SETUP7.5

AUTOSETUP-ON PAL 200 200

AUTOSETUP-ON (S)-PAL 200 200

AUTOSETUP-ON SECAM 200 200

AUTOSETUP-ON NTSC 443 200 200

AUTOSETUP-ON (S)-NTSC 443 200 200

AUTOSETUP-ON D1-SDI 200 200

AUTOSETUP-ON HD-SDI 200 200

AUTOSETUP-ON SDTI-CP 200 200

AUTOSETUP-ON DV 200 200

AUTOSETUP-ON BKM-PALM 200 200

SUB_CONT 480/60I 575/50I 4:3 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

1080/48I 16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

1080/50I 16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

480/60P 576/50P 4:3 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

1080/60I 1035/60I 16:9 NORMAL

78 78

UNDER SACN 50 50

Name Description Inch20 Inch14

SUB_CONT H/V DELAY 78 78

720/50P 16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

720/60P 16:9 NORMAL 78 78

UNDER SACN 50 50

H/V DELAY 78 78

SUB_BRIGHT Horizontal frequency 15K 78 78

Horizontal frequency 27K 78 78

Horizontal frequency 28K 78 78

Horizontal frequency 31K 78 78

Horizontal frequency 33K 78 78

Horizontal frequency 37K 78 78

Horizontal frequency 45K 78 78

R_GAIN COL1 15K 700 700

Other than COL1 15K 700 700

COL2 15K 700 700

Other than COL2 15K 700 700

USER 15K 700 700

Other than USER 15K 700 700

R_BIAS COL1 15K 400 400

Other than COL1 15K 400 400

COL2 15K 400 400

Other than COL2 15K 400 400

USER 15K 400 400

Other than USER 15K 400 400

G_GAIN COL1 15K 700 700

Other than COL1 15K 700 700

COL2 15K 700 700

Other than COL2 15K 700 700

USER 15K 700 700

Other than USER 15K 700 700

G_BIAS COL1 15K 400 400

Other than COL1 15K 400 400

COL2 15K 400 400

Other than COL2 15K 400 400

USER 15K 400 400

Other than USER 15K 400 400

2-14

PVM-14L5/20L5/D14L5A/D20L5A

Page 37

Name Description Inch20 Inch14

B_GAIN COL1 15K 700 700

Other than COL1 15K 700 700

COL2 15K 700 700

Other than COL2 15K 700 700

USER 15K 700 700

Other than USER 15K 700 700

B_BIAS COL1 15K 400 400

Other than COL1 15K 400 400

COL2 15K 400 400

Other than COL2 15K 400 400

USER 15K 400 400

Other than USER 15K 400 400

43MARKER_ 480/60I 50 50

SUB_L

575/50I 50 50

1080/48I 50 50

1080/50I 50 50

480/60P 50 50

576/50P 50 50

1080/60I 1035/60I NORMAL 50 50

1080/60I 1035/60I UNDER 50 50

720/50P 50 50

720/60P 50 50

43MARKER_ 480/60I 50 50

SUB_R

575/50I 50 50

1080/48I 50 50

1080/50I 50 50

480/60P 50 50

576/50P 50 50

1080/60I 1035/60I NORMAL 50 50

1080/60I 1035/60I UNDER 50 50

720/50P 50 50

720/60P 50 50

43MARKER_ 480/60I 10 10

PHASE

575/50I 10 10

1080/48I 10 10

1080/50I 10 10

480/60P 10 10

576/50P 10 10

1080/60I 1035/60I NORMAL 10 10

1080/60I 1035/60I UNDER 10 10

720/50P 10 10

720/60P 10 10

Name Description Inch20 Inch14

43MARKER_ 480/60I 10 10

WIDTH

575/50I 10 10

1080/48I 10 10

1080/50I 10 10

480/60P 10 10

576/50P 10 10

1080/60I 1035/60I NORMAL 10 10

1080/60I 1035/60I UNDER 10 10

720/50P 10 10

720/60P 10 10

WB_COL1_DISP COL1 DISPLAY 65 65

WB_COL2_DISP COL2 DISPLAY 93 93

SUBCON_ LINE-A (COMPOSITE) 50 50

CONTRAST LINE-A (S) 50 50

LINE-B (COMPOSITE) 50 50

RGB 50 50

COMPONENT 50 50

OPTION-A (Other than 129X) 50 50

OPTION-B (Other than 129X) 50 50

OPTION-RGB (129X) 50 50

OPTION-COMPONENT(129X) 50 50

SUBCON_ LINE-A (COMPOSITE) 50 50

BRIGHT

LINE-A (S) 50 50

LINE-B (COMPOSITE) 50 50

RGB 50 50

SUBCON_ COMPONENT 50 50

BRIGHT OPTION-A (Other than 129X) 50 50

OPTION-B (Other than 129X) 50 50

OPTION-RGB (129X) 50 50

OPTION-COMPONENT(129X) 50 50

SUBCON_ LINE-A (COMPOSITE) 50 50

CHROMA LINE-A (S) 50 50

LINE-B (COMPOSITE) 50 50

RGB 50 50

COMPONENT 50 50

OPTION-A (Other than 129X) 50 50

OPTION-B (Other than 129X) 50 50

OPTION-RGB(129X) 50 50

OPTION-COMPONENT(129X) 50 50

PVM-14L5/20L5/D14L5A/D20L5A

2-15

Page 38

Name Description Inch20 Inch14

SUBCON_ LINE-A (COMPOSITE) 50 50

PHASE LINE-A (S) 50 50

LINE-B (COMPOSITE) 50 50

RGB 50 50

COMPONENT 50 50

OPTION-A (Other than 129X) 50 50

OPTION-B (Other than 129X) 50 50

OPTION-RGB (129X) 50 50

OPTION-COMPONENT(129X) 50 50

SUBCON_ LINE-A (COMPOSITE) 0 0

APERTURE LINE-A (S) 0 0

LINE-B (COMPOSITE) 0 0

RGB 0 0

COMPONENT 0 0

OPTION-A (Other than 129X) 0 0

OPTION-B (Other than 129X) 0 0

OPTION-RGB (129X) 0 0

OPTION-COMPONENT (129X)

MACRO VISION

1080/48I A : 1080/48 flag ON ON

720/50P B : 720/50P flag OFF OFF

1125/60I SYS BKM-142HD AUTO DETECT AUTO AUTO

SREM_

SREM_

GROUP

BAUD RATE Serial remote 38400 38400

PARITY P : PARITY EVEN EVEN

STOP BITS S : STOP BITS 2 BIT 2 BIT

M : Supporting MacroVision ON ON

(0 : MANUAL 1 : AUTO)

SINGLE

Serial remote 0 0

Single address

Serial remote 0 0

Group address

Communication coditions

B : BAUD RATE

00

2-3. Preparation (2). Initialization

* Supply composite video or component signals as shown

in Table 2-2.

Signal Details of signal Standard

level

P-W

Composite 358NT 100 % white 0.714 V

video 443NT 75 % white 0.536 V

PALM 100 % white 0.7 V

PAL 75 % white 0.525 V

SECAM

Component BETA0 100 % white Y 0.7143 V

75 % white Y 0.536 V

75 % color 0.757 V

B-Y, R-Y

(P-P for

this item only)

BETA 7.5 100 % white Y 0.7143 V

75 % white Y 0.536 V

75 % color 0.7 V

B-Y, R-Y

(P-P for

this item only)

SMPTE 100 % white Y 0.7 V

75 % white Y 0.525 V

75%color 0.525 V

B-Y, R-Y

(P-P for

this item only)

Voice/sound _5dBs 0.436Vrms

Table 2-2

2-16

PVM-14L5/20L5/D14L5A/D20L5A

Page 39

2-4. Writing Model Data

2-5. Picture Output

1. Select the following submenus from the Service Menu

in the order of : [SYSTEM] → [MODEL GRADE] →

[MODEL TYPE] and write the model data of each

model in the [MODEL TYPE] referring to table 2-4.

Model name Model ytpe Model grade

PVM-D14L5J J14 L5

PVM-D20L5J J20 L5

PVM-14L5 U14 L5

PVM-20L5 U20 L5

PVM-14L3 E14 L3

PVM-14L4 E14 L4

PVM-20L4 E20 L4

PVM-D14L5A A14 L5

PVM-D20L5A A20 L5

Table. 2-4

2. Select the following submenus from the Service Menu

in the order of : [SIGNAL] → [WHITE|BALANCE]

and type the following data in [COLOR TEMP].

U/C, AEP 65

J 93

* Standard inspection state

Unless otherwise specified in this manual, make adjustment under the following conditions :

1. AC input voltage setting

1. Input VIDEO signals and AUDIO signals to respective

terminals on the connector panel.

2. Set the sliduck AC voltage as shown in Table 2-5.

Model name Voltage

PVM-14L5 AC 120 V ±10 %

PVM-20L5

PVM-D14L5J AC 100 V ±10 %

PVM-D20L5J

PVM-14L3 AC 240 V ±10 %

PVM-14L4

PVM-20L4

PVM-D14L5A

PVM-D20L5A

Table. 2-5

2-6. Free-run Frequency Adjustment

Find the following adjustment menu in the layer under the

DEFLECTION menu of the service mode.

FOCUS

H PLL

HFV SENCE

HFV CONTROL

APERTURE OFF (USER CONTROL menu)

BRIGHT 0

CHROMA 50

PHASE 0

CONTRAST 80

VOLUME 50

PVM-14L5/20L5/D14L5A/D20L5A

1. Connect the 480/60I cross hatch signal to the Y/G

terminal of RGB/COMPONENT IN connector.

2. Enter the service mode.

3. Switch H PLL of the menu from LOCK to FREERUN.

4. Adjust HFV SENSE and HFV CONTROL of the

menu until number of screens losing sync is minimal.

5. Switch H PLL of the menu from FREERUN to LOCK.

Confirm that the screen is locked.

6. Switch the input signal frequency as shown below and

repeat steps 3 to 5.

2-17

Page 40

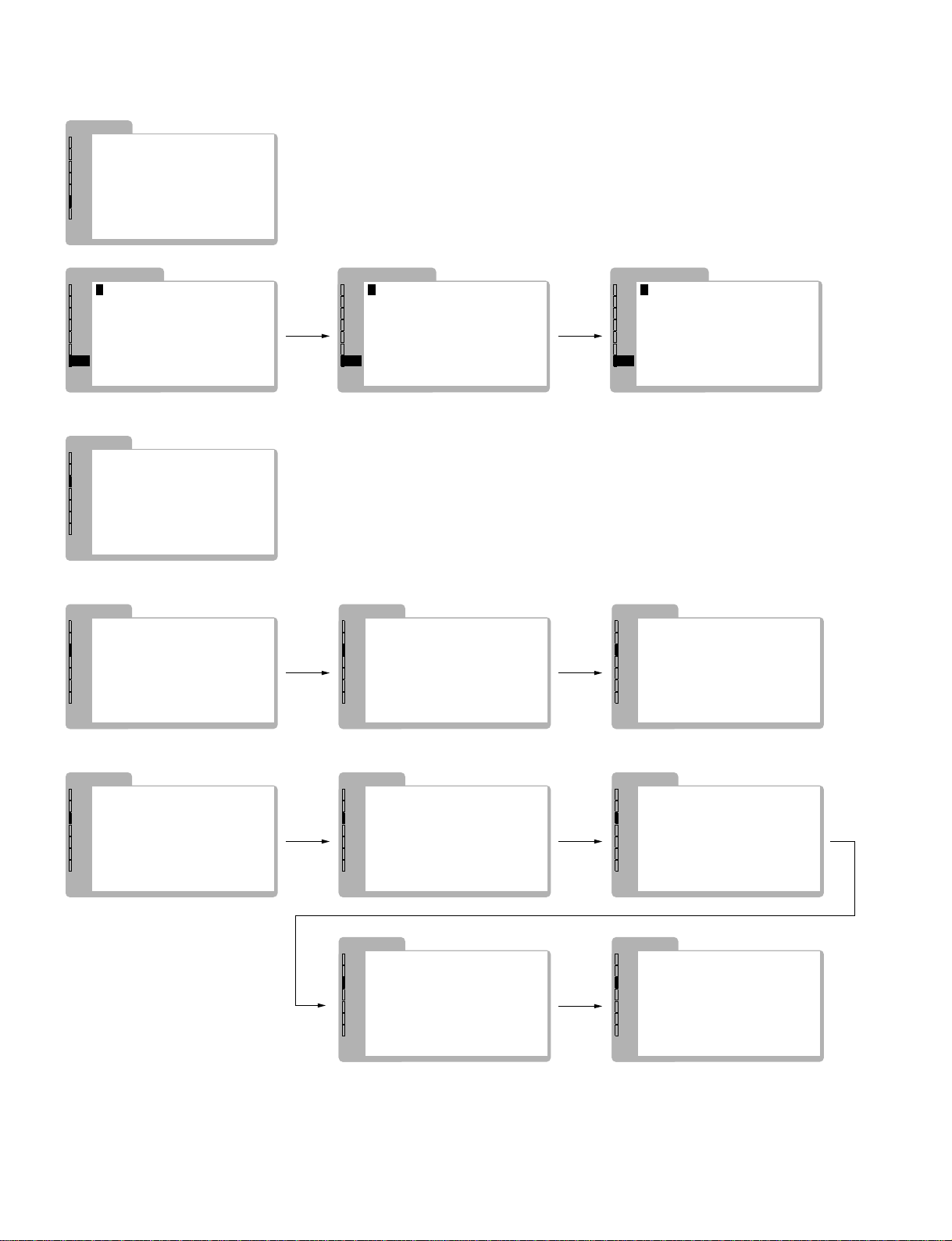

2-7. Landing Adjustment

1. CONT ... MAX

BRT ... Conspicuous position

2. Roughly adjust the white balance, G2, and convergence.

3. Switch the rotary SW of the single color switch to

change the color into green only.

4. Adjust the purity knob so that the green will come to

the center of the screen. Make R and B almost

identical. (Fig. 2-1)

5. Switch to B only, R only, and G only and verify each.

(Figs.2-1, 2-2, and 2-3)

6. Bring the deflection yoke gradually forward and adjust

the deflection yoke so that R and B on both sides of

the screen will be green. (Fig.2-2 n Fig. 2-3)

7. If the deflection yoke comes forward too much, the

pattern shown in Fig.2-4 will appear. If so, move the

deflection yoke backward. (Fig.2-4 n Fig.2-3)

8. Switch the single color switch to B and verify the

single color. (Fig.2-6)

9. Switch the single color switch to R and verify the

single color. (Fig.2-9)

10. When two colors are mixed, set the mixed color as the

standard, and repeat operations 6 and 7.

11. Switch to an all-white signal and check the uniformity.

12. When the deflection yoke position is determined,

fasten it with the fixture.

Fig. 2-1

GB

R

A’ = A

14 inch

Fig. 2-11

Purity control

Purity

Deflection yoke

Fig. 2-12

A

Fig. 2-2 Fig. 2-3 Fig. 2-4

BRG

Fig. 2-5 Fig. 2-6 Fig. 2-7

RGB

Fig. 2-8 Fig. 2-9 Fig. 2-10

A’

GGBR

B

R

2-18

GRB

BGR

RBG

PVM-14L5/20L5/D14L5A/D20L5A

Page 41

20 inch

Fig. 2-11

Purity control

Purity

Deflection yoke

Fig. 2-12

n

Attach the magnets inside the NTC for the model PVM20L4 referring to Fig. 2-13.

25mm

6-pole magnet

(Move it to the top-most position)

Install it so that the magnet

comes to the top-most position.

Fig. 2-13

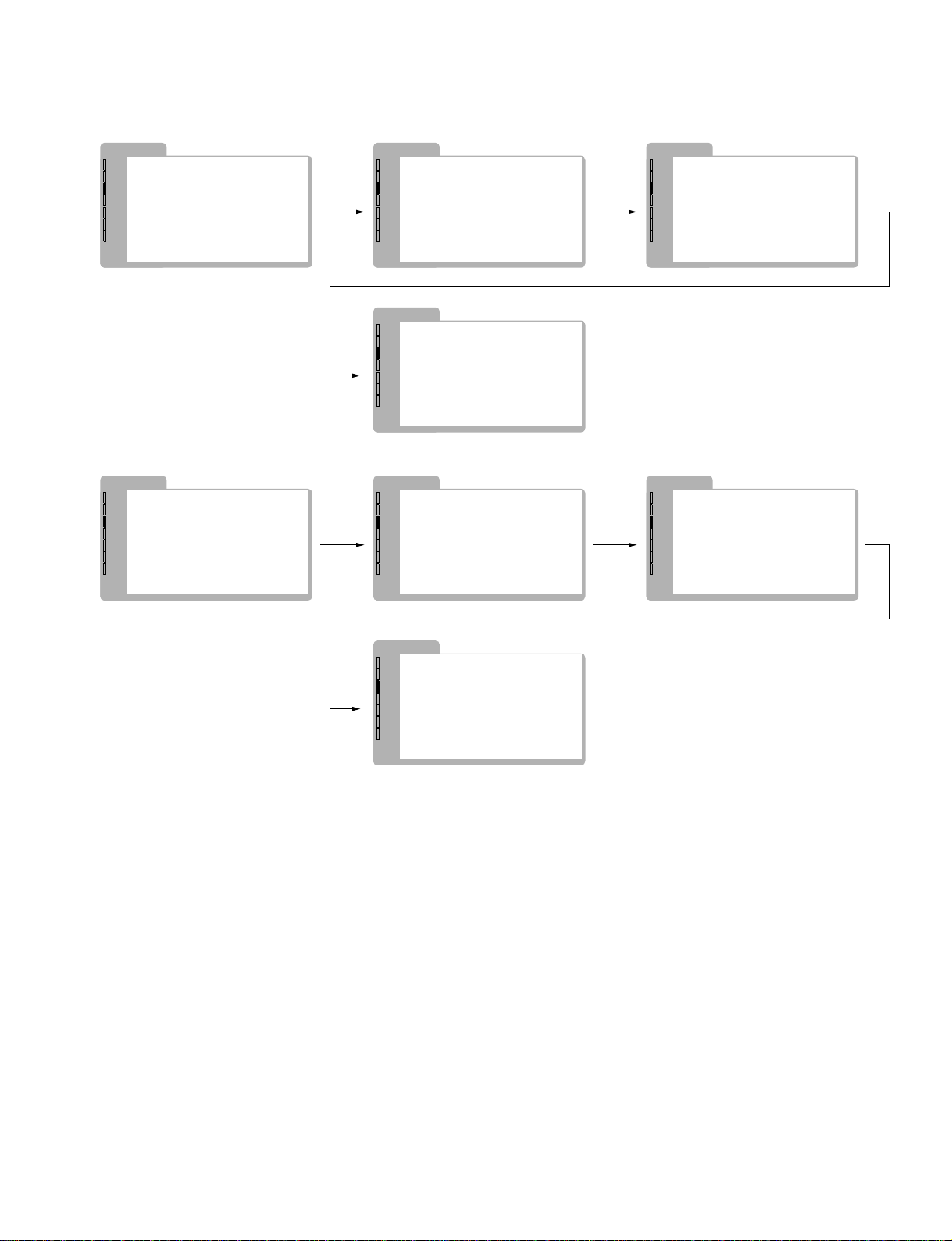

2-8. H Blanking Adjustment

RASTER H

H SIZE

H CENTER

H POSITION

H BLK LEFT

H BLK RIGHT

1. Connect the 480/60I cross hatch signal to the Y/G

terminal of RGB/COMPONENT IN connector.

2. Press the UNDER SCAN button to enter the under

scanned mode. (The UNDER SCAN button lights in

orange.)

3. Press the (+) plus button of BRIGHT to set the

brightness to MAX.

4. Enter the service mode.

5. Adjust [H|SIZE] of the menu until the entire raster

becomes visible on screen.

6. Adjust [H|BLK|RIGHT] of the menu so that the leftmost end of raster is just before starting to fold back

on screen.

7. Adjust [H|POSITION] of the menu so that the rightmost end of the raster matches with the right-most end

of the video display on screen.

8. Adjust [H|BLK|LEFT] of the menu so that the leftmost end of the raster matches with the left-most end

of the video display on screen.

9. Adjust [H|CENTER] of the menu so that the amount

of over-scanned raster is unity in the right and left of

the effective area of CRT.

10. Press the UNDER SCAN button to exit the under

scanned mode. (The UNDER SCAN button lights in

green.)

11. Adjust [H|SIZE] of the menu until the entire raster

becomes visible on screen.

12. Adjust [H|BLK|RIGHT] of the menu so that the leftmost end of raster is just before starting to fold back

on screen.

13. Adjust [H|BLK|LEFT] of the menu so that the rightmost end of raster is just before starting to fold back

on screen.

14. Adjust [H|POSITION] of the menu so that center of

the effective screen matches with the center of the

video display on screen.

15. Change the input signal frequency arbitrarily and

change the [H|CENTER] value that is adjusted in

step 9.

16. Select the various signal frequencies and repeat

adjustment from steps 5 to 8 in the same way as

described above.

PVM-14L5/20L5/D14L5A/D20L5A

2-19

Page 42

2-9. Linearity Adjustment

Find the following adjustment menu in the layer under the

DEFLECTION menu of the service mode.

RASTER H GEOMETRY

H SIZE V S LIN

H CENTER V C LIN

H POSISION TRAPEZOID

MARKER SUB L SIDE PIN

MARKER SUB R SIDE PIN W

SIDE PIN BAL

RASTER V PARA CONTROL

V SIZE SIDE PIN S

V CENTER

V BLK TOP

V BLK BOTTOM

OSD TIMING

1. Connect the 480/60I cross hatch signal to the Y/G

terminal of RGB/COMPONENT IN connector.

2. Enter the service mode.

3. Select the 4:3 normal scan mode and check the

followings. (The 16:9 button and UNDER SCAN

button light in green.)

DY Inclination Distortion check

Top and bottom V PIN Distortion Check

If the specifications cannot be met, perform the DY

Neck Rotation Adjustment.

4. Perform the horizontal trapezoid distortion adjustment

using the TLY volume control of DY. If the horizontal

trapezoid distortion is difficult to see, select Green

Only mode. If the horizontal trapezoid distortion is

adjusted significantly, the top and bottom vertical

convergence will become out of adjustments.

5. Connect the 480/60I monoscope signal to the Y/G

terminal of RGB/COMPONENT IN connector.

6. Adjust [V|CENTER] of the menu until picture comes