Sony PVM-20M2U, PVM-20M4U, PVM-20M2E, PVM-20M4E, PVM-20M4A Service Manual

SONY-

SP0402

SERVICE

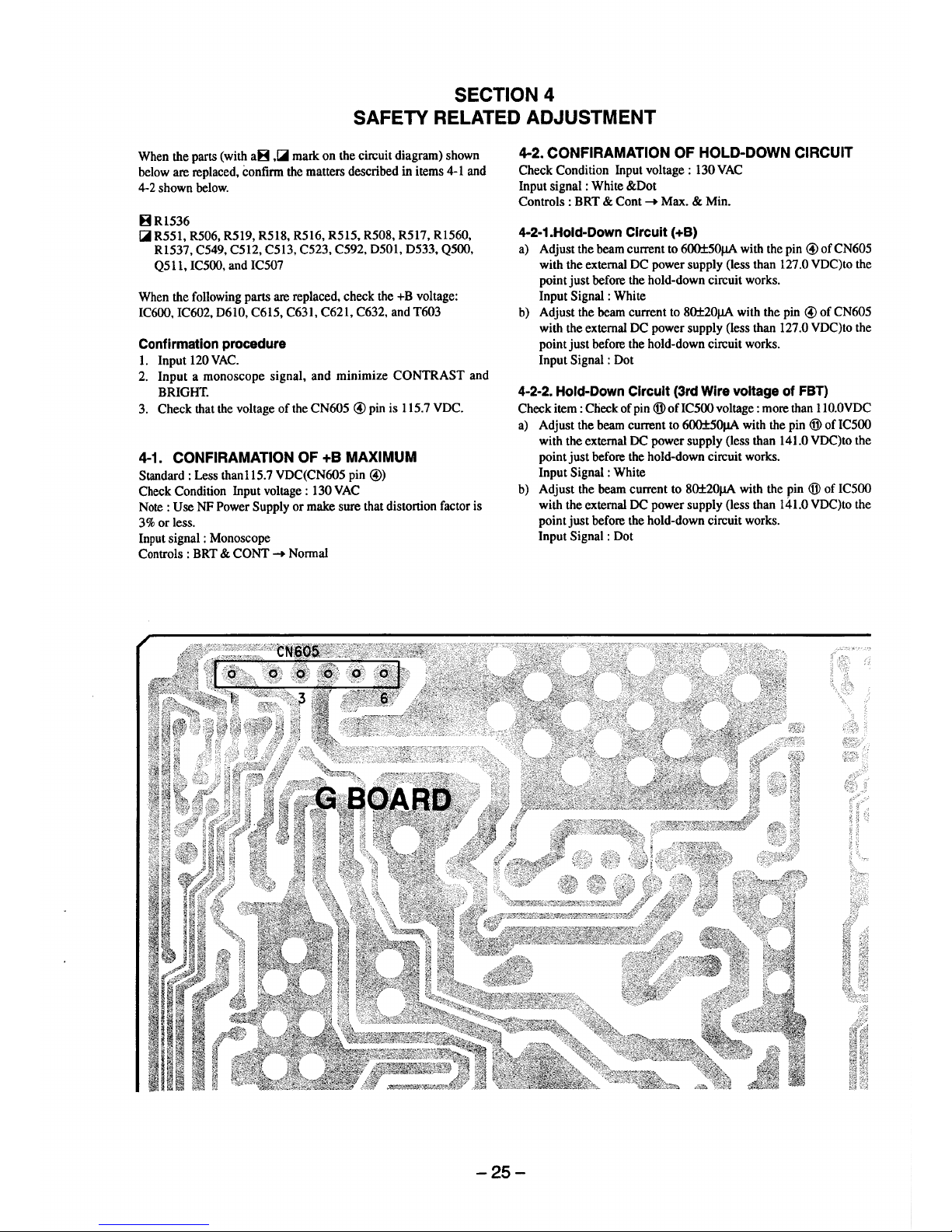

MANUAL

M.QQgl::

PVM-20M2U

PVM-20M4U

PVM-20M2E

!?.~~!:

£1:'.~~~~~-~~

M.QP.g~::

us

PVM-20M4E Canadian

SCC-G61H-A

us

PVM-20M4A

Canadian

SCC-G61F-A

AEP

SCC-G62GA

0

0

@J

lllnllllll::m

Trinitron

PVM-20M4U/20M4E

AEP

SCC-G62E-A

Australian SCC-N17C·A

Trinitron

PVM-20M2U/20M2E

TRINITRON®

COLOR

VIDEO

MONITOR

SONY.

SPECIFICATIONS

Video signal

For PVM-14M4U/14M4E/20M4U/20M4E:

Color system

Resolution

Aperture correction

Frequency response

LINE

RGB

NTSC, PAL, SECAM,

NTSC4.43

800TV

lines

OdBto+6dB

10 MHz ± 3 dB (Y signal)

10MHz±3

dB

Synchronization AFC time constant

1.0 msec.

For PVM-14M2U/14M2E/20M2U/20M2E:

Color system

Resolution

Aperture correction

Frequency response

LINE

RGB

Synchronization

NTSC, PAL, SECAM,

NTSC4.43

600TV

lines

OdBto+6dB

10 MHz ± 3 dB (Y signal)

lOMHz± 3 dB

AFC time constant 1.0 msec.

Picture performance

For PVM-14M4U/14M4E/14M2U/14M2E:

Normal scan

Under scan

H.

linearity

V. linearity

Convergence

7 % over scan

of

CRT effective screen

area

5 % underscan

of

CRT effective screen

area

Less than

4.0 % (typical)

Less than

4.0 % (typical)

Central

area:

0.4 mm (typical)

Peripheral area: 0.5 mm (typical)

Raster size stability

H:

1.0%, V: 1.5%

High voltage regulation

3.5%

Color temperature 065/D93, selectable

USER (3,200K-10,000K, factory

setting is

065)

For PVM-20M4U/20M4E:

Normal scan

Under scan

H.

linearity

V. linearity

Convergence

7 % over scan

of

CRT effective screen

area

5 % underscan

of

CRT effective screen

area

Less than

5.0 % (typical)

Less than

5.0%

(typical)

Central

area:

0.5 mm (typical)

Peripheral area: 0.7 mm (typical)

Raster size stability

H:

1.0%, V: 1.5%

High voltage regulation

4.0%

Color temperature 065/D93, selectable

USER (3,200K-10,000K, factory

setting is

065)

For

PVM-20M2U/20M2E

Normal scan

Under scan

H. linearity

V. linearity

Convergence

7 % over scan

of

CRT effective screen

area

5 % underscan

of

CRT effective screen

area

Less than

5.0 % (typical)

Less than

5.0 % (typical)

Central area:

0.6 mm (typical)

Peripheral area: 1.0 mm (typical)

Raster size stability

H:

1.0%, V: 1.5%

High voltage regulation

4.0%

Color temperature 065/D93, selectable

Inputs

USER (3,200K-10,000K, factory

setting is

065)

For PVM-14M4U/14M4E/20M4U/20M4E:

LINE AlB

VIDEO IN BNC connector (x2}, 1 Vp-p ±6 dB,

sync negative

AUDIO IN

Automatic

75

ohms termination

Phono jack (x2),

-5

dBu

3

>,

more than

47 kilo-ohms

LINEC

Y/C IN 4-pin mini-DIN

(xl)

See the pin assignment on page 19.

AUDIO IN Phono jack (XI},

-5

dBu

3

>,

more than

47 kilo-ohms

ROB/COMPONENT

RIR-

Y,G/Y,B/B-

YIN:

BNC connector (x3)

R, G, B channels:

0.7 Vp-p, ±6

dB

Sync on green: 0.3 Vp-p, negative

R-

Y,

B-Y channels:

0.

7 Vp-p, ±6

dB

Y channel: 0.7 Vp-p, ±6

dB

(Standard color bar signal

of

75%

chrominance)

Automatic 75 ohms termination

AUDIO IN Phono

jack

(xl),

-5

dBua>,

more than

47 kilo-ohms

EXT

SYNC IN

REMOTE

BNC connector

(xl)

4 Vp-p, ±6 dB, sync negative

20-pin connector

(xl)

See the pin assignment on page

19.

a) 0 dBu = 0.775 Vr.m.s.

-2-

For

PVM-14M2U/14M2E/20M2U/20M2E:

LINE

AlB

VIDEO IN

AUDIO IN

LINEC

BNC connector (X2), 1 Vp-p

± 6dB, sync negative

Automatic

75

ohms termination

Phono

jack

(x2),

-5

dBua>,

more than

47 kilo-ohms

Y/C

IN

4-pin mini-DIN (x1)

See the pin assignment

on

page 19.

AUDIO IN

Phono

jack

(xl),

-5

dBua>,

more than

4 7 kilo-ohms

ROB/COMPONENT

R/R-Y,G/Y,B/B-Y IN: BNC connector (x3)

R, G, B channels: 0.7

Vp-p ± 6dB

Sync on green: 0.3 Vp-p negative

R-Y, B-Y channel: 0.7 Vp-p

± 6dB

Y channel: 0.7

Vp-p ± 6dB

(Standard color bar signal

of

75%

chrominance)

Automatic 75 ohms termination

AUDIO IN Phono

jack

(x1),

-5

dBua>,

more than

47 kilo-ohms

EXT

SYNC IN

REMOTE

BNC connector (x1)

4 Vp-p, ±6 dB, sync negative

20-pin connector (x1)

See the pin assignment

on

page 19.

a)

0 dBu = 0.775 Vr.m.s.

Outputs (common

to

all models)

LINE AlB

VIDEO OUT

AUDIO OUT

LINEC

Y/COUT

BNC connector (x2) loop-through,

Automatic 75 ohms termination

Phono

jack

(x2) loop-through

4-pin mini-DIN (x1) loop-through,

Automatic 75 ohms termination

AUDIO

OUT Phono

jack

(xl)

loop-through

ROB/COMPONENT

R/R-Y,G/Y,B/B-Y OUT: BNC connector (x3)

loop-through

Automatic 75 ohms termination

AUDIO

OUT Phono

jack

(x1) loop-through

EXT

SYNC OUT BNC connector (x1)

Automatic 75 ohms termination

Speaker output Output level: 0.8 W

General

For

PVM-14M4U:

CRT

SMPTE-C phosphor

Power consumption

90

Wh

(with SDI: 99 Wh)

Power requirements 120 V AC, 50/60Hz

Operating temperature

0 to +35°C (32 to 95°F)

Storage temperature

-10

to +40°C (14 to104°F)

Operating humidity 35 to 85% (no condensation)

Storage humidity

0 to 90%

Dimensions (w/h/d) Approx. 346 x 340 x 431

mm

(13%x

13Y2 x 17

inches)

not incl. projecting parts and controls

Mass Approx. 16.7kg

(36lb

13

oz)

Accessory supplied AC power cord

(1)

AC plug holder (1)

Tally label (1)

Cable with a 20-pin connector

(1)

For

PVM-14M4E:

CRT EBU phosphor

Power consumption

90

Wh

(with SDI: 99 Wh)

Power requirements 100 to 240 V AC, 50/60Hz

Operating temperature

0 to +35°C (32 to 95°F)

Storage temperature

-10

to +40°C (14 to104°F)

Operating humidity 35 to 85% (no condensation)

Storage humidity

0 to 90%

Dimensions (w/h/d) Approx. 346 x 340 x 431 mm

(13%x

13\12 x 17

inches)

not incl. projecting parts and controls

Mass Approx. 16.7kg

(36lb

13

oz)

Accessory supplied AC power cord (1)

AC plug holder (1)

Tally label (1)

Cable with a 20-pin connector

(l)

For

PVM-14M2U:

CRT

P-22 phosphor

Power consumption

90

Wh

(with SDI: 99 Wh)

Power requirements 120 V AC, 50/60Hz

Operating temperature

0 to +35°C (32 to 95°F)

Storage temperature

-10

to +40°C (14 to104°F)

Operating humidity 35 to 85% (no condensation)

Storage humidity

0 to 90%

Dimensions (w/h/d) Approx. 346 x 340 x 431

mm

(13%x

13\12 x 17

inches)

not incl. projecting parts and controls

Mass Approx. 16.7kg

(36lb

13

oz)

Accessory supplied AC power cord (1)

AC plug holder (1)

Tally label

(1)

Cable with a 20-pin connector (1)

-3-

For

PVM-14M2E:

CRT P-22 phosphor

Power consumption 90 Wh (with SDI: 99 Wh)

Power requirements 100 to 240 V AC, 50/60Hz

Operating temperature

0 to +35°C (32 to 95°F)

Storage

temperature

-10

to

+40°C (14 to 1 04 °F)

Operating humidity 35

to

85% (no condensation)

Storage humidity 0 to 90%

Dimensions (w/h/d) Approx. 346 x 340 x

431

mm

(l35Jsx

13Yz x 17

inches)

not incl. projecting parts and controls

Mass Approx. 16.7kg

(36lb

l3

oz)

Accessory supplied AC power cord (1)

AC plug holder (1)

Tally label (1)

Cable with a

20-pin connector (1)

For

PVM-20M4U:

CRT SMPTE-C phosphor

Power consumption

125

Wh (with SDI:

135

Wh)

Power requirements 120 V AC, 50/60Hz

Operating temperature

0

to

+35°C (32 to 95°F)

Storage

temperature

-lO

to

+40°C (

14

to 104 °F)

Operating humidity 35 to 85% (no condensation)

Storage humidity 0 to 90%

Dimensions (w/h/d) Approx. 450 x 458 x 503 mm

(17% x

181A! x 197As

inches)

not incl. projecting parts and controls

Mass Approx.

30.0 kg (66 lb 2 oz)

Accessory supplied

AC

power cord

(1)

AC

plug holder (1)

Tally label (1)

Cable with a

20-pin connector

(l)

For

PVM-20M4E:

CRT EBU phosphor

Power consumption 130

Wh

(with SDI: 140 Wh)

Power requirements 100 to 240 V AC, 50/60Hz

Operating temperature

0

to

+35°C (32 to 95°F)

Storage

temperature

-lO

to

+40°C (14 to104°F)

Operating

humidity

35

to 85% (no condensation)

Storage humidity 0 to 90%

Dimensions (w/h/d) Approx. 450 x 458 x 503 mm

(17% x

18Ys x 197As

inches)

not incl. projecting parts and controls

Mass Approx.

30.0

kg

(66 lb 2 oz)

Accessory supplied

AC

power cord

(1)

AC

plug holder (

1)

Tally label (1)

Cable with a

20-pin connector (1)

-4-

For

PVM-20M2U:

CRT P-22 phosphor

Power consumption

115

Wh (with SDI:

125

Wh)

Power requirements 120 V AC, 50/60Hz

Operating temperature

0

to

+35°C (32 to 95°F)

Storage

temperature

-lO

to +40°C (14 to104°F)

Operating humidity 35 to

85%

(no condensation)

Storage humidity 0

to

90%

Dimensions (w/h/d) Approx. 450 x 458 x 503 mm

(17%x181A!x

197Asinches)

not incl. projecting parts and controls

Mass Approx.

30.0

kg

(66 lb 2 oz)

Accessory supplied

AC

power cord (

1)

AC

plug holder (1)

Tally label (1)

Cable with a 20-pin connector (1)

For

PVM-20M2E:

CRT P-22 phosphor

Power consumption 120

Wh

(with SDI: 130 Wh)

Power requirements 100

to

240 V AC, 50/60Hz

Operating temperature

0

to

+35°C (32 to 95°F)

Storage

temperature

-10

to

+40°C (14 tol04°F)

Operating humidity 35

to

85% (no condensation)

Storage humidity 0 to 90%

Dimensions (w/h/d) Approx. 450 x 458 x 503 mm

(17% x181As x 197A!

inches)

not incl. projecting parts and controls

Mass Approx.

30.0

kg

(66 lb 2 oz)

Accessory supplied

AC

power cord

(I)

AC plug holder (1)

Tally label (1)

Cable with a

20-pin connector (1)

Design and specifications are subject to change

without notice.

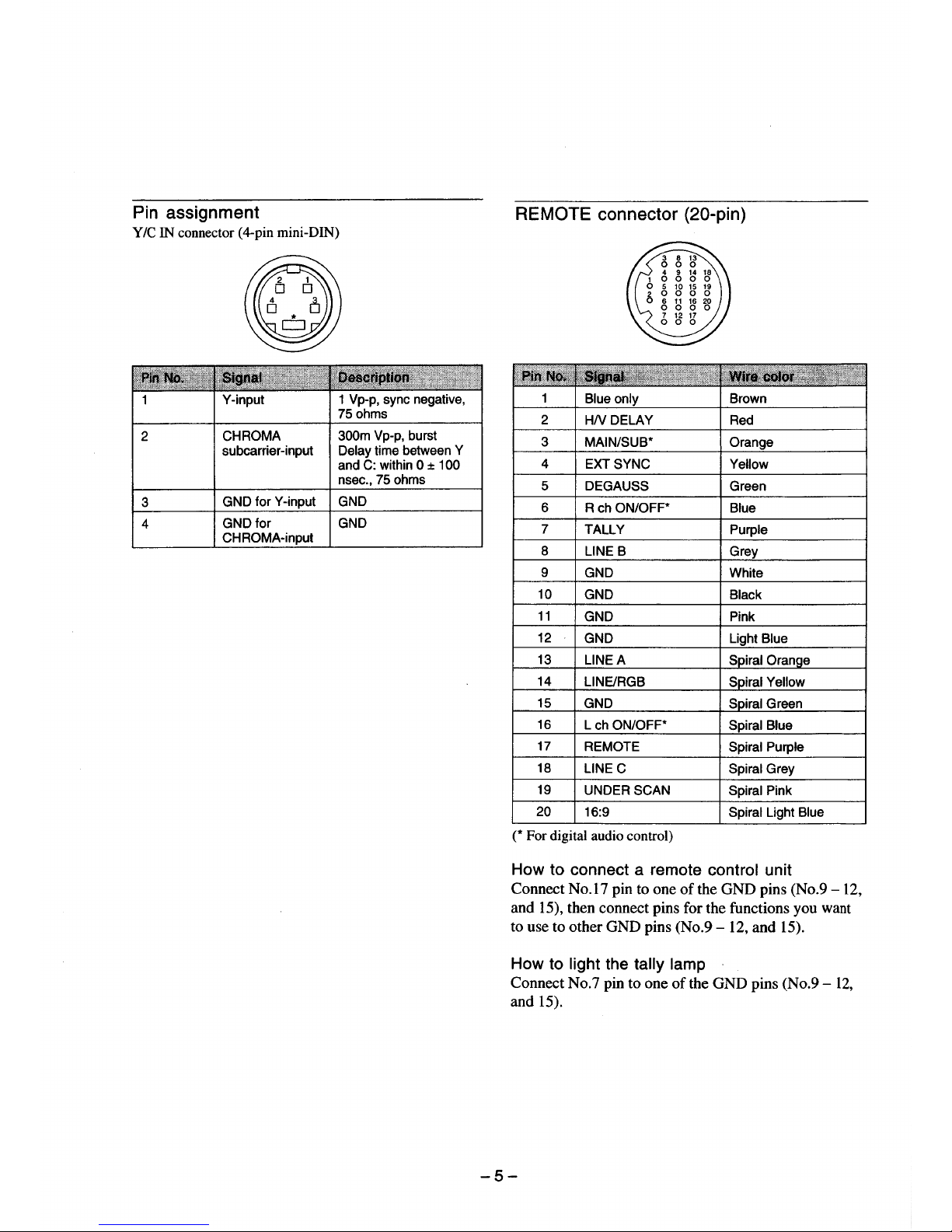

Pin assignment

Y/C IN connector (4-pin mini-DIN)

Y-input

1

Vp-p, sync negative,

75 ohms

2

CHROMA

300m Vp-p,

burst

subcarrier-input

Delay time between Y

and C: within

0 ± 1 00

nsec., 75 ohms

GND for GND

4

GNDfor

GND

CHROMA-input

REMOTE connector (20-pin)

4

EXT SYNC Yellow

5

DEGAUSS

Green

6 R

chON/OFF*

Blue

7

TALLY Purple

10

11

GND

12

GND

Spiral Grey

Spiral Pink

20

16:9 Spiral Light Blue

(*

For digital audio control)

How to connect a remote control unit

Connect No.17 pin to one

of

the GND pins

(No.9-

12.

and 15), then connect pins for the functions you want

to use to other GND pins

(No.9-

12, and 15).

How to light the tally lamp

Connect No.7 pin to one

of

the GND pins (No.9

-12,

and 15).

-5-

SAFETY CHECK-OUT

(US Model only)

After

correcting

the

original

service

problem,

perform the following safety checks before releasing

the set to the customer:

l.

Check the area of your repair for unsoldered or

poorly-soldered connections.

Check

the entire

board surface

for

solder splashes and bridges.

2.

Check the interboard wiring to ensure that no

wires

are

"pinched"

or

contact

high-wattage

resistors.

3.

Check that all

control

knobs, shields, covers,

ground

straps,

and

mounting

hardware

have

been replaced. Be absolutely

certain

that you

have replaced

all

the

insulators.

4.

Look for unauthorized replacement parts, particularly transistors. that were installed during

a previous repair.

Point

them

out

to the

cus-

tomer

and

recommend their replacement.

5.

Look for parts which, though functioning, show

obvious signs of deterioration. Point them

out

to the customer and recommend their replacement.

6.

Check the line cords for cracks and abrasion.

Recommend the replacement

of

any such line

cord

to

the customer.

7.

Check the B+ and

HV

to see

if

they are at the

values specified. Make sure

your

instruments

are

accurate;

be

suspicious of your

HV

meter

if

sets

always

have

low

HV.

8.

Check

the metal

trim,

metallized

knobs,

screws,

and all

other

exposed

metal

parts

for

AC

leakage.

Check leakage

as

described below.

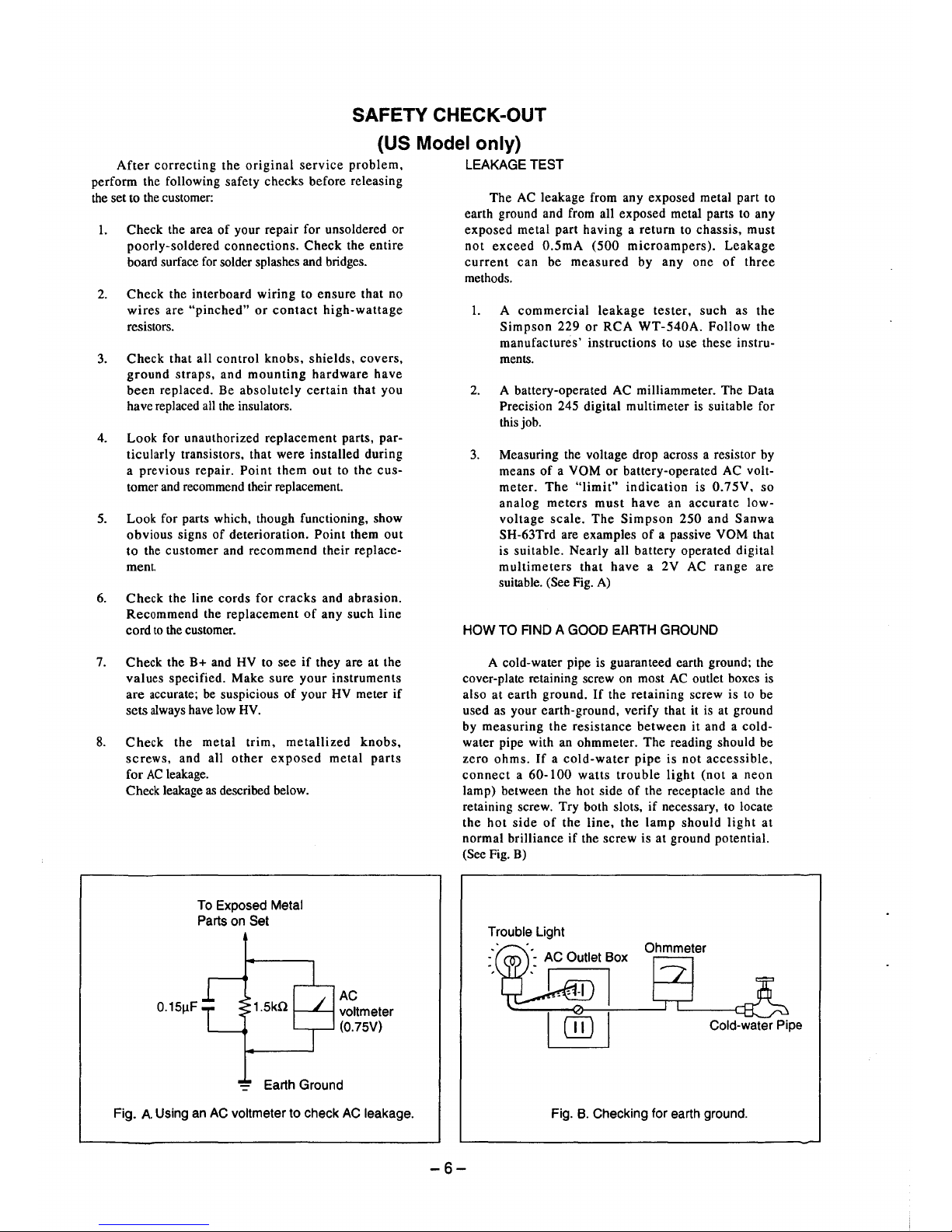

To Exposed Metal

Parts on

Set

AC

voltmeter

(0.75V)

-=

Earth Ground

Fig.

A.

Using

an

AC voltmeter to check

AC

leakage.

LEAKAGE

TEST

The

AC

leakage from any exposed metal part to

earth ground and from all exposed metal parts to any

exposed metal part having a return to chassis, must

not

exceed

0.5mA

(500

microampers).

Leakage

current

can be

measured

by any one

of

three

methods.

l.

A

commercial

leakage

tester.

such as the

Simpson

229

or

RCA WT-540A.

Follow

the

manufactures' instructions

to

use these instru-

ments.

2.

A battery-operated

AC

milliammeter. The Data

Precision 245 digital multimeter is suitable for

this job.

3.

Measuring the voltage drop across a resistor by

means

of

a VOM or battery-operated

AC

volt-

meter.

The

"limit"

indication

is

0.75V.

so

analog

meters

must

have

an

accurate

low-

voltage

scale.

The

Simpson

250 and

Sanwa

SH-63Trd are examples

of

a passive VOM that

is suitable. Nearly all battery operated digital

multimeters

that

have

a 2V

AC

range are

suitable. (See Fig.

A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground; the

cover-plate retaining screw

on

most

AC

outlet boxes

is

also at earth ground.

If

the retaining screw is

to

be

used as your earth-ground, verify that it is at ground

by measuring the resistance between it and a coldwater pipe with

an

ohmmeter. The reading should be

zero ohms.

If a cold-water

pipe

is not

accessible,

connect a 60-100

watts

trouble

light

(not

a neon

lamp) between the hot side

of

the receptacle and the

retaining screw. Try both slots,

if

necessary,

to

locate

the

hot

side

of

the line. the

lamp

should

light

at

normal brilliance

if

the screw is at ground potential.

(Sec Fig.

B)

Trouble Light

Cold-water Pipe

Fig.

B.

Checking for earth ground.

-6-

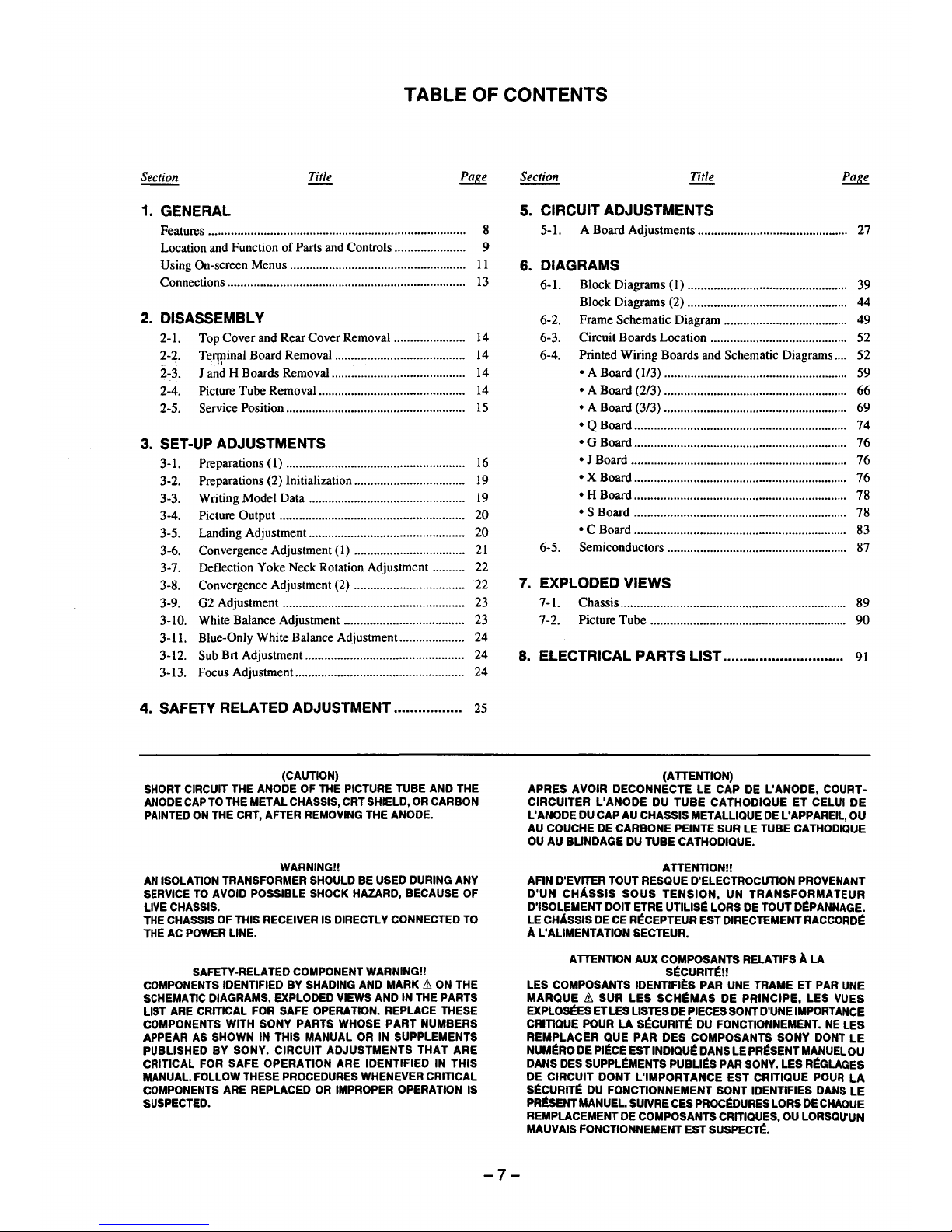

TABLE OF CONTENTS

Section

Title

1.

GENERAL

Features............................................................................... 8

Location

and

Function of Parts

and

Controls...................... 9

Using On-screen Menus ......................................................

11

Connections.........................................................................

13

2.

DISASSEMBLY

2-l.

Top

Cover

and

Rear Cover Removal ......................

14

2-2.

TeTP,Jinal

Board Removal ........................................

14

2-3. J

and

H Boards Removal.........................................

14

2-4. Picture Tube Removal.............................................

14

2-5. Service Position.......................................................

15

3. SET-UP ADJUSTMENTS

3-l. Preparations (1) ...................... ............ ............

..

.......

16

3-2. Preparations (2) Initialization..................................

19

3-3. Writing Model Data ................................................

19

3-4. Picture Output ......................................................... 20

3-5.

Landing Adjustment................................................ 20

3-6. Convergence Adjustment

(1)

..................................

21

3-7. Deflection Yoke Neck Rotation Adjustment ..........

22

3-8.

Convergence Adjustment

(2)

..................................

22

3-9.

02

Adjustment ........................................................

23

3-10.

White Balance Adjustment .....................................

23

3-11. Blue-Only White Balance Adjustment....................

24

3-12.

Sub

Brt Adjustment .................................................

24

3-13. Focus Adjustment....................................................

24

4. SAFETY RELATED ADJUSTMENT .................

25

(CAUTION)

SHORT

CIRCUIT THE ANODE OF

THE

PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR

CARBON

PAINTED

ON

THE

CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN

ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE

TO

AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF

LIVE CHASSIS.

THE

CHASSIS OF THIS RECEIVER

IS

DIRECTLY CONNECTED TO

THE

AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED

BY SHADING AND MARK &

ON

THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS

LIST

ARE CRITICAL FOR SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE

PART

NUMBERS

APPEAR AS SHOWN

IN

THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED

BY

SONY. CIRCUIT ADJUSTMENTS

THAT

ARE

CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL

COMPONENTS

ARE REPLACED

OR

IMPROPER OPERATION IS

SUSPECTED.

Section

Title

5. CIRCUIT ADJUSTMENTS

5-l.

A Board Adjustments ..............................................

27

6. DIAGRAMS

6-1. Block Diagrams (1) ................................................. 39

Block Diagrams

(2)

................................................. 44

6-2. Frame Schematic Diagram ...................................... 49

6-3. Circuit Boards Location.......................................... 52

6-4. Printed Wiring Boards

and

Schematic Diagrams.... 52

• A Board

(113)

........................................................ 59

• A Board

(213)

........................................................ 66

• A Board (3/3) ........................................................ 69

• Q Board ................................................................. 74

•G

Board ................................................................. 76

• J Board .................................................................. 76

•XBoard

................................................................. 76

• H Board .................................................................

78

• S Board .................................................................

78

• C Board .................................................................

83

6-5. Semiconductors .......................................................

87

7. EXPLODED VIEWS

7-1. Chassis ..................................................................... 89

7-2. Picture Tube ............................................................

90

8.

ELECTRICAL PARTS LIST..............................

91

(ATTENTION)

APRES AVOIR

DECONNECTE

LE

CAP DE L'ANODE, COURT-

CIRCUITER

L'ANODE

DU

TUBE

CATHODIQUE

ET

CELUI

DE

L'ANODE DU CAP AU CHASSIS METALLIQUE

DE

L'APPAREIL,

OU

AU COUCHE

DE

CARBONE PEINTE SUR LE TUBE CATHODIQUE

OU

AU BLINDAGE DU TUBE CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT

D'UN

CHASSIS

SOUS

TENSION,

UN

TRANSFORMATEUR

D'ISOLEMENT DOlT ETRE

UTILIS~

LORS DE TOUT

D~PANNAGE.

LE CHASSIS DE CE

R~CEPTEUR

EST DIRECTEMENT RACCORDE

A L'ALIMENTATION SECTEUR.

ATTENTION

AUX COMPOSANTS RELATIFS A LA

S~CURIT~!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE

MARQUE

& SUR

LES

SCH~MAS

DE

PRINCIPE,

LES VUES

EXPLOS~ES

ET LES LISTES DE PIECES SONT D'UNE IMPORTANCE

CRITIQUE POUR

LA

SECURIT~

DU

FONCTIONNEMENT.

NE

LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT

LE

NUM~RO

DE

PI~CE

EST

INDIQU~

DANS LE

PR~SENT

MANUEL OU

DANS DES

SUPPL~MENTS

PUBLI~S

PAR SONY. LES

R~GLAGES

DE CIRCUIT

DONT

L'IMPORTANCE

EST

CRITIQUE POUR

LA

S~CURIT~

DU FONCTIONNEMENT SONT IDENTIFIES

DANS

LE

PR~SENT

MANUEL

SUIVRE CES

PROC~DURES

LORS

DE

CHAQUE

REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU'UN

MAUVAIS FONCTIONNEMENT EST

SUSPECT~.

-7-

I

(X)

I

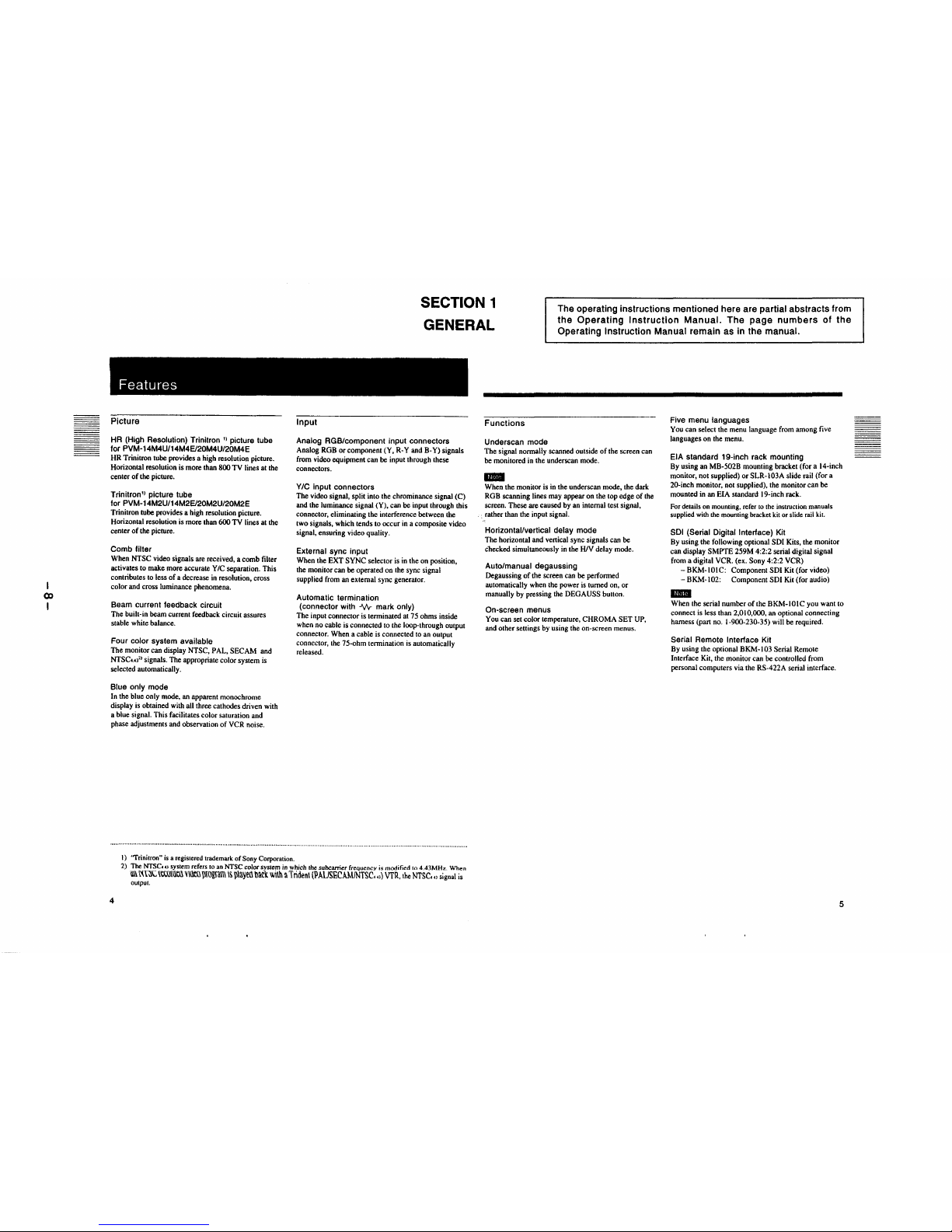

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from

the

Operating

Instruction

Manual.

The page

numbers

of

the

Operating Instruction Manual remain as in the manual.

Features

Picture

HR (High

Resolution)

Trinitron

•1

picture

tube

for

PVM-14M4U/14M4E/20M4U/20M4E

HR Trinitron tube provides a high resolution picture.

Horizontal resolution is more than

800 TV lines at the

center

of

the picture.

Trinitron'l

picture

tube

for

PVM-14M2U/14M2E/20M2U/20M2E

Trinitron tube provides a high resolution picture.

Horizontal resolution is more than

600

TV

lines at the

center

of

the picture.

Comb

filter

When

NTSC video signals are received, a comb filter

activates to make more accurate

Y /C separation. This

contributes to less

of

a decrease

in

resolution, cross

color and cross luminance phenomena.

Beam

current

feedback

circuit

The built-in beam current feedback circuit assures

stable white balance.

Four

color

system

available

The monitor can display NTSC, PAL, SECAM and

NTSCw

21

signals. The appropriate color system is

selected automatically.

Blue

only

mode

In the blue only mode, an apparent monochrome

display

is

obtained with all three cathodes driven with

a blue signal. This facilitates color saturation and

phase adjustments and observation

of

VCR noise.

I) "Trinilron"

is a regisrered

crademark

of

Sony

Corporalion.

Input

Analog

RGB!component

input

connectors

Analog RGB

or

component (Y, R-Y and B-Y) signals

from video equipment can

be

input through lhese

connectors.

Y/C

input

connectors

The video signal, split into lhe chrominance signal

(C)

and the luminance signal (Y). can be input through this

connector, eliminating the interference between the

two signals, which tends to occur in a composite video

signal, ensuring video quality.

External

sync

input

When the EXT SYNC selector is in the on position,

the monitor can be operated on lhe sync signal

supplied from an external sync generalor.

Automatic

termination

(connector

with

.A./Ir

mark

only)

The input conneclor is terminaced at 75 ohms inside

when no cable is connected

10

rhe

loop-through output

connector. When a cable is connected to an output

connector, the 75-ohm termination

is

automatically

released.

2) The

NTSCuJ

system refers 10 an NTSC color system in which rhe subcarrier freQuency

is

modified

to

4.43MHz. When

\\\

\'\'D~

\t\.\l\1\t.\\

~1\\t\l

\}l\l%!0ID

1~

\}\ayen

\lack

with a Trident

(PAUSECAMINTSC..,)

VTR.

the

NTSC..,

signal

is

output.

4

Functions

Underscan

mode

The signal normally scanned outside

of

the screen can

be monitored in the underscan mode.

..

When the monitor is in the underscan mode, the dark

RGB scanning lines may appear on the top edge

of

lhe

screen. These are caused by an internal test signal,

: rather than the input signal.

Horizontal/vertical

delay

mode

The horizontal and venical sync signals can be

checked simultaneously in the

HIV delay mode.

Auto/manual

degaussing

Degaussing

of

the screen can be performed

automatically when the power is turned on,

or

manually by pressing the DEGAUSS button.

On-screen

menus

You can set color temperature, CHROMA SET UP,

and

ocher settings by using the on-screen menus.

Five

menu

languages

You can select the menu language from among five

languages on the menu.

EIA

standard

19-inch

rack

mounting

By

using an MB-502B mounting bracket (for a 14-inch

monitor, not supplied)

or

SLR-103A slide rail (for a

20-inch monitor, not supplied), the monitor can be

mounted in an EIA standard 19-inch rack.

For details on mounting, refer

to

the instruction manuals

supplied

wilh

lhe

mounling

brackel

kil

or slide

rail

kil.

SDI

(Serial

Digital

Interface)

Kit

By using the following optional SDI Kits, the monitor

can display

SMPTE 259M 4:2:2 serial digiral signal

from a digital

VCR. (ex. Sony 4:2:2 VCR)

- BKM-IOlC: Component

SDI Kit (for video)

-

BKM-102: Component SDI Kit (for audio)

...

When the serial number

of

the BKM-IOlC you want to

connect is less than

2,010,000, an optional connecting

harness

(pan

no. 1-900-230-35) will be required.

Serial

Remote

Interface

Kit

By using the oplional

BKM-103 Serial Remote

Interface Kit, the monitor can be controlled from

personal computers via the

RS-422A serial interface.

5

<0

I

Location

and

Function

of Parts and

Controls

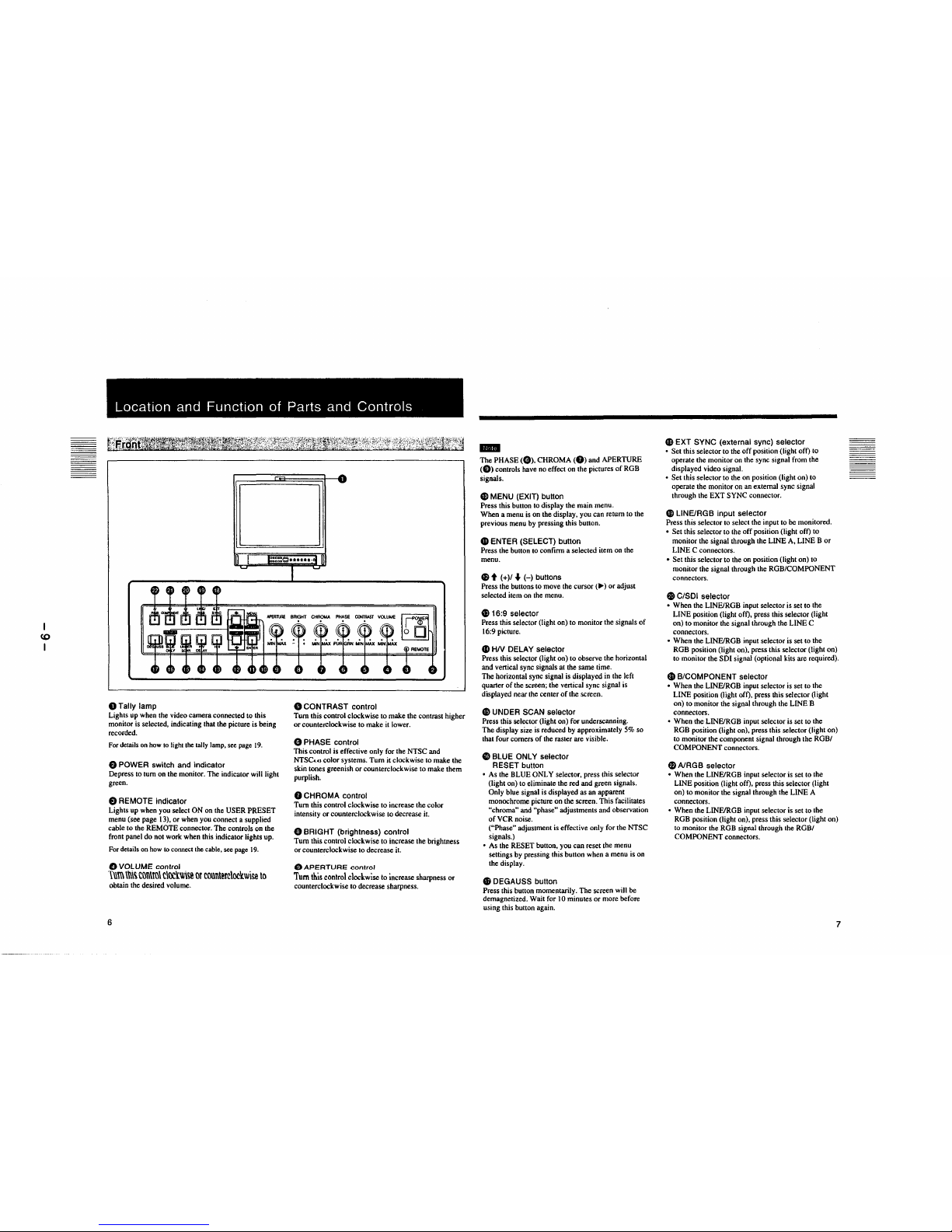

OTally

lamp

Lights

up

when the video camera connected to this

monitor is selected, indicating that the picture is being

recorded.

For details

on

how

to light

the

tally lamp, see page

19.

8 POWER switch and indicator

Depress to tum

on

the monitor. The indicator will light

green.

8 REMOTE indicator

Lights

up

when you select

ON

on the

USER

PRESET

menu (see page 13),

or

when you connect a supplied

cable to the REMOTE connector.

The

controls on the

front panel

do

not work when this indicator lights up.

For details on

how

to

connect the cable, see page 19.

0

VOLUME

control

1\\m

\\\\~

t()l\\m\

c\oc'lwi~

or

counterclockwise

to

obtain the desired volume.

6

8 CONTRAST control

Tum

this control clockwise

to

make the contrast higher

or

counterclockwise to make it lower.

0 PHASE control

This

control is effective only for the NTSC and

NTSC

•.

o color systems.

Tum

it clockwise

to

make the

skin tones greenish or counterclockwise to make them

purplish.

0 CHROMA control

Tum

this control clockwise

to

increase the color

intensity or counterclockwise to decrease it.

8 BRIGHT (brightness) control

Tum

this control clockwise to increase the brightness

or

counterclockwise to decrease it.

G)

APERTURE

control

Tum

this control clockwise to increase sharpness

or

counterclockwise

to

decrease sharpness.

IIIII

The

PHASE

(0).

CHROMA

(f))

and

APERTURE

(Ci))

controls have no effect on the pictures

of

RGB

signals.

G)

MENU (EXIT) button

Press this button to display the main menu.

When a menu

is

on the display, you can return to the

previous menu by pressing this button.

G)

ENTER (SELECT) button

Press the button to confirm a selected item on the

menu.

48

t (+)/

..

(-)

buttons

Press the buttons to move the

cursor(.,.)

or

adjust

selected item on the menu.

C816:9 selector

Press this selector (light on)

to

monitor the signals

of

16:9 picture.

4D

HN

DELAY selector

Press this selector (light on)

to

observe the horizontal

and vertical sync signals at the same time.

The

horizontal sync signal is displayed in the left

quarter

of

the screen; the vertical sync signal is

displayed near the center

of

the screen.

49

UNDER SCAN selector

Press this selector (light on) for underscanning.

The

display size is reduced by approximately 5% so

that four comers

of

the raster are visible.

4D

BLUE ONLY selector

RESET button

• As the

BLUE

ONLY selector, press this selector

(light on) to eliminate the red and green signals.

Only blue signal is displayed as an apparent

monochrome picture on the screen.

This

facilitates

"chroma" and "phase" adjustments and observation

of

VCR noise.

("Phase" adjustment is effective only for the NTSC

signals.)

• As the RESET button, you can reset the menu

settings by pressing this button when a menu is on

the display.

G)

DEGAUSS button

Press this button momentarily.

The

screen will be

demagnetized. Wait for I

0 minutes or more before

using this button again.

CD

EXT SYNC (external sync) selector

• Set this selector to the

off

position (light off) to

operate the monitor on the sync signal from the

displayed video signal.

•

Set

this selector

to

the on position (light on) to

operate the monitor on an external sync signal

through the

EXT

SYNC connector.

G>

LINEIRGB input selector

Press this selector to select the input

to

be monitored.

•

Set

this selector

to

the

off

position (light off)

to

monitor the signal through the LINE A, LINE B

or

LINE

C connectors.

•

Set

this selector

to

the on position (light on) to

monitor the signal through the

ROB/COMPONENT

connectors.

G)

C/SDI selector

• When the LINE/ROB input selector is set to the

LINE

position (light off), press this selector (light

on)

to

monitor the signal through the

LINE

C

connectors.

• When the LINE/ROB input selector is set to the

RGB position (light on), press this selector (light on)

to monitor the

SOl

signal (optional kits are required).

Gl

B/COMPONENT selector

• When the LINE/ROB input selector is set to the

LINE

position (light off), press this selector (light

on)

to

monitor the signal through the LINE B

connectors.

• When the LINEIRGB input selector is set

to

the

ROB position (light on). press this selector (light on)

to monitor the component signal through the

ROB/

COMPONENT

connectors.

$ A/RGB selector

• When the LINEIRGB input selector is set to the

LINE position (light off), press this selector (light

on)

to

monitor the signal through the LINE A

connectors.

•

When

the LINEIRGB input selector is set to the

RGB position (light on), press this selector (light on)

to monitor the

ROB signal through the ROB/

COMPONENT

connectors.

7

.....

0

I

Location

and

Function

of

Parts

and

Controls

t;·Rear·F'iih~J

;£~):,;;~~';,~:';,;;':,>i?'"cij',lii,)'L:~;~

':.\

1

;~~~('

'~~~~

·'

..

,:'~;,:::

..

'~

liNE

A

VIDEO

IN

OUT

liNE

8

VIDEO

IN

OUT

~~~~~

0

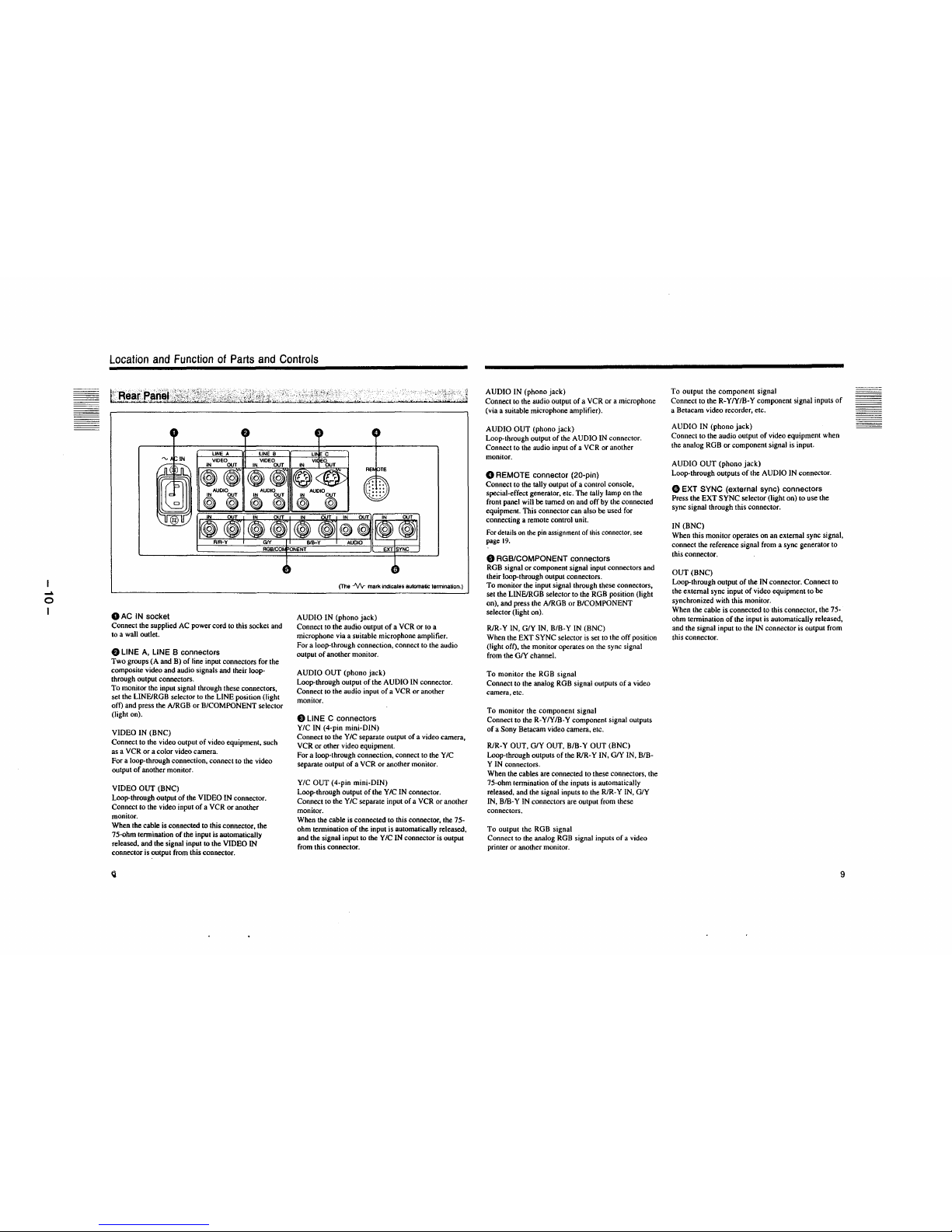

AC

IN

socket

Connect the supplied

AC

power

cord

to this

socket

and

to a

wall outlet.

8 LINE

A,

LINE B connectors

Two

groups

(A

and

B)

of

line input connectors for the

composite

video

and

audio signals and their loop-

through

output

connectors.

To

monitor

the input signal through these connectors,

set the

LINEIRGB selector

to

the

LINE

position (light

oft)

and

press the A/RGB

or

B/COMPONENT

selector

(light on).

VIDEO

IN

(BNC)

Connect

to the video

output

of

video

equipment,

such

as a VCR

or a color

video camera.

For

a loop-through connection,

connect

to

the video

output

of

another

monitor.

VIDEO

OUT

(BNC)

Loop-through

output

of

the

VIDEO

IN

connector.

Connect to the video input

of a VCR

or

another

monitor.

When

the cable is connected to this connector, the

75-ohm

tennination

of

the input is automatically

released,

and

the signal input to the

VIDEO

IN

connector

is

output

from this connector.

Q

(The

-'\1\r

mark indicates automalic termination.)

AUDIO

IN

(phono

jack)

Connect to the

audio

output

of a VCR

or

to a

microphone

via a suitable

microphone

amplifier.

For

a loop-through connection, connect to the audio

output

of

another

monitor.

AUDIO

OUT

(phono

jack)

Loop-through

output

of

the

AUDIO

IN connector.

Connect

to the audio input

of a VCR

or

another

monitor.

E) LINE C connectors

Y/C

IN

(4-pin

mini-DIN)

Connect

to the Y

/C

separate

output

of

a video

camera,

VCR

or

other

video equipment.

For

a loop-through connection, connect to the Y

/C

separate

output

of a VCR

or

another

monitor.

Y/C

OUT

(4-pin

mini-DIN)

Loop-through

output

of

the Y

/C

IN connector.

Connect

to the

Y/C

separate input

of a VCR

or

another

monitor.

When

the cable is

connected

to this connector, the

75-

ohm

tennination

of

the input is automatically released,

and

the signal input

to

the Y IC IN

connector

is

output

from

this connector.

AUDIO

IN

(phono

jack)

Connect

to the audio

output

of a VCR

or a microphone

(via a suitable microphone amplifier).

AUDIO

OUT

(phono

jack)

Loop-through

output

of

the

AUDIO

IN

connector.

Connect

to

the audio input

of a VCR

or

another

monitor.

0 REMOTE connector (20-pin)

Connect

to the tally output

of

a control

console,

special-effect generator, etc.

The

tally lamp on the

front panel

will

be

turned

on

and

off

by

the connected

equipment.

This

connector

can

also

be

used for

connecting a remote control unit.

For details on the pin assignment

of

this connector, see

page

19.

8 RGB/COMPONENT connectors

RGB

signal

or

component

signal input

connectors

and

their loop-through output connectors.

To

monitor

the input signal through these connectors,

set the

LINEIRGB

selector

to

the

RGB

position (light

on),

and

press

the AIRGB

or

B/COMPONENT

selector (light on).

RIR-Y IN,

G/Y

IN,

B/B-Y

IN

(BNC)

When

the

EXT

SYNC

selector is set

to

the

off

position

(light off), the

monitor

operates

on

the sync signal

from the

G/Y

channel.

To

monitor

the

RGB

signal

Connect

to the analog RGB signal outputs

of

a video

camera,

etc.

To

monitor

the

component

signal

Connect

to the R-Y/YIB-Y

component

signal outputs

of

a Sony

Betacam

video

camera,

etc.

RIR-Y

OUT,

G/Y

OUT,

BIB-

Y

OUT

(BNC)

Loop-through outputs

of

the RIR-Y IN,

G/Y

IN, B/B-

y IN connectors.

When

the

cables

are connected to these connectors, the

75-ohm

tennination

of

the inputs is automatically

released,

and

the signal inputs to the RIR- Y IN,

G/Y

IN,

BIB-

Y IN connectors are

output

from these

connectors.

To

output

the

RGB

signal

Connect

to the analog RGB signal inputs

of

a video

printer

or

another

monitor.

To

output

the

component

signal

Connect

to the R-Y/Y/B-Y

component

signal inputs

of

a

Betacam

video recorder, etc.

AUDIO

IN

(phono

jack)

Connect

to

the

audio

output

of

video

equipment

when

the

analog

RGB

or

component

signal is input.

AUDIO

OUT

(phono

jack)

Loop-through

outputs

of

the

AUDIO

IN connector.

0 EXT SYNC (external sync) connectors

Press the

EXT

SYNC

selector (light

on)

to

use

the

sync signal through this connector.

IN(BNC)

When

this

monitor

operates

on

an

external

sync

signal,

connect

the reference signal from a sync

generator

to

this

connector.

OUT(BNC)

Loop-through

output

of

the

IN

connector.

Connect

to

the

external

sync input

of

video

equipment

to

be

synchronized

with this monitor.

When

the cable is

connected

to this

connector,

the

75-

ohm

tennination

of

the input is automatically released,

and

the signal input

to

the IN

connector

is

output

from

this connector.

9

.....

.....

Using

On-Screen

Menus

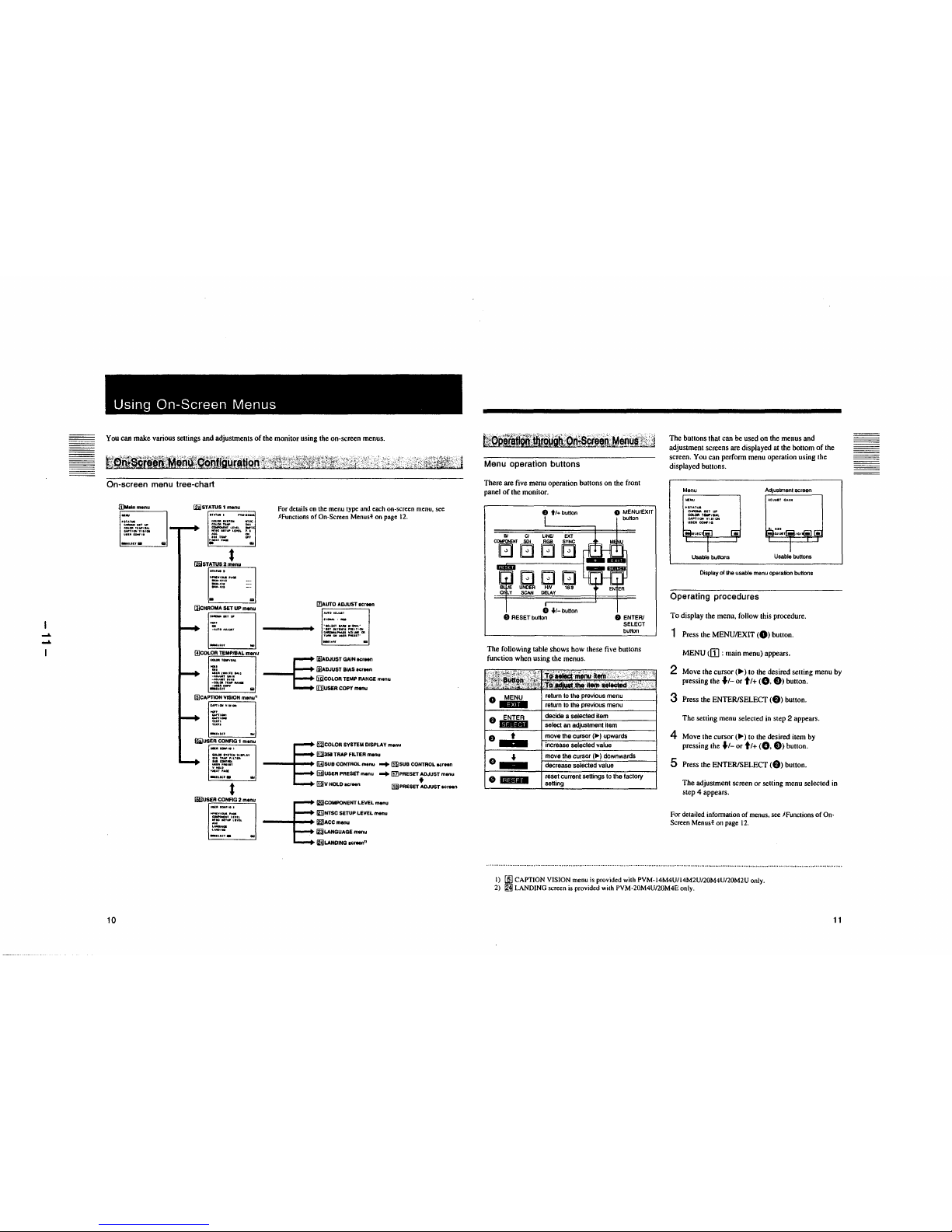

You can make various settings and adjustments

of

the monitor using the on-screen menus.

On-screen menu tree-chart

10

(]]U.In

menu

~

~

~

.

..

fii]STATUS 1 menu

COI.Illlll,.

DU

-lrf'-l~l'-

-·

llfiCUTI

..

LIWIL

ll

'"

~

1111-

Ol'f

..........

.

t

!2iilSTEJATUS2menu

-

.

.

.

..

laicHRDoMAsETuPmenu

'

..

@COLOR

TEMPIBAL

menu

..

~~~~:

[5]CAPT1EJON

VISION

menu"

'

-

.

w

l§iiUSER

CONFIG

1 menu

-••••u•o•P•••

lllf-PIUIII

~--

UQIIP

..

IIT

·-·

.,..,,

....

t

mbJUSER

CONFIG

2

menu

"'•v•-•-

-•IUVU

Jfi'ICMI

..

LUn

'"

,_

1-

...

---

"'I

For details on the menu type and each on-screen menu, see

JFuncrions

of

On-Screen Menus

-I:

on page

12.

!ZIAUTO ADJUST

ICrten

·•n•~-··-·

'NIIIUIIPII'GftTIGII

~--01-

...

(111

,,_

GIUM.II

N"ll'

---§

ia]ADJUSTGAINoc<een

li}ADJUST

BIAS

tcr"n

ffil!COLOR

TEMP

RANGE

mnu

[l]USER

COPY

menu

~

!i21COLOR

SYSTEM

DISPLAY menu

IU1351

TRAP

FILTER

menu

lBJSUB

CONTROL

menu

-+

ll3JSUB

CONTROL

sc:reen

ffiiiUSER PRESET menu

-+

ffiiPRESET

.OJUST

menu

!HV

HOLD screen (IE PRESET ADJUST acreen

~

IZli]COMPONENTLEVEL

monu

~NTSC

SETUP

LEVEL

menu

~ACCmenu

~LANGUAGE

menu

12j!LANDING acreen

11

"''~;::~,,,.~.f~~,,;":JJi

':-~:;2

'~S~.

re~~:Menu~ti·'~!

~D

ltJUQ

,.

"=LJM"

~~~

Menu operation buttons

There are five menu operation buttons on the front

panel

of

the monitor.

e

tl+bultOn

0 MENU/EXIT

button

0

+!-button

8 RESET button

8 ENTER/

SELECT

button

The

following table shows how these five buttons

function when using the menus.

MENU

0-

ENTER

f)

l!iD'il

.....

•

0-

.....

return

to

the previous

menu

return

to

the

previous

menu

decide a selected

item

select an adjustment

item

move

the cursor("') upwards

increase

selected

value

move

the cursor("') downwards

decrease

selected

value

reset current settings to

the

factory

setting

The

buttons that can he used on the menus

and

adjustment screens are displayed at the bottom

of

the

screen.

You can perform menu operation using the

displayed buttons.

Menu

•ITATu&

CHI'ICIWollilUI"

cot.Ofll

TIEWIIA~

CAJOTICN VIIICII\I

UIIEA

CONFIQ

Usable buttons

Adjustment screen

Usable buttons

Display ol

the

usable

menu

operation buttons

Operating procedures

To

display the menu, follow this procedure.

1 Press the MENU/EXIT

(0)

button.

MENU

<III

: main menu) appears.

2

Move

the cursor

((lo>)

to the desired setting menu by

pressing the

fl-

or tl+ (8.

8)

button.

3 Press the ENTER/SELECT

(8)

button.

The

setting menu selected in step 2 appears.

4 Move the cursor

((lo>)

to the desired item by

pressing the

fi-

or

tl+

(8,

8>

button.

5 Press the ENTER/SELECT

(8)

button.

The

adjustment screen or setting menu selected

in

step 4 appears.

For detailed infonnation

of

menus, see )functions

of

On·

Screen Menust

on

page

12.

I) [§)CAPTION VISION

menu

is

provided

with

PVM-14M4U/14M2U/20M4U/20M2U only.

2)

~LANDING

screen

is

provided

with

PVM·20M4U/20M4E only.

11

......

1\)

I

Using

On-Screen

Menus

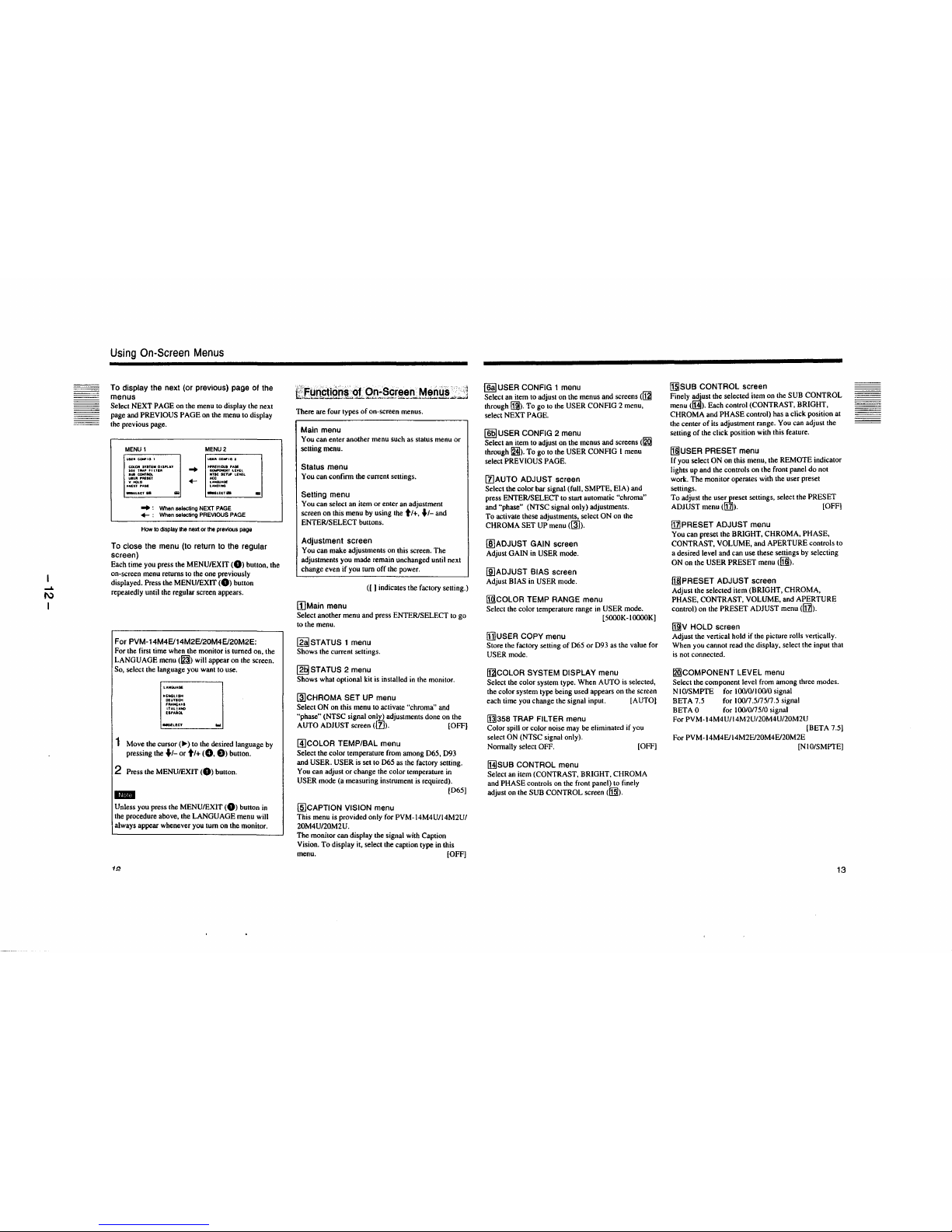

To

display

the

next

(or

previous)

page

of

the

menus

Select NEXT PAGE on the menu to display the next

page and

PREVIOUS PAGE on the menu to display

the previous page.

MENU I

(;OC.OfiiYITEIIIIOII'UY

Ul

TM,FHTEII

~U:~~C::~

..

~:'"~AU

...

UECTHI

...

+-

MENU2

•PIIEVICUIPAQIE

~T~EWIL

f~;n.uvu

-IUCTIII

-+ : When selecting NEXT PAGE

+-

: When selecting PREVIOUS PAGE

How

to

display

the

next

or

the

previous

page

To

close

the

menu

(to

return

to

the

regular

screen)

Each time you press the MENU/EXIT

<OJ

button, the

on-screen menu returns to the one previously

displayed.

Press the MENU/EXIT

(0)

button

repeatedly until the regular screen appears.

For

PVM-14M4E/14M2E/20M4E/20M2E:

For the first time when the monitor is turned on, the

LANGUAGE

menu(~)

will appear on the screen.

So, select the language you want to use.

•EifGLIIH

DEUTSCH

'""""'"''

ITALIANO

ESPAIIOi.

1 Move the

cursor(~)

to the desired language by

pressing

the..,,_

or

tl+

(0,

E))

button.

2 Press the MENU/EXIT

(0)

button.

..

Unless you press the MENU/EXIT

(0)

button

in

the procedure above, the LANGUAGE menu will

always appear whenever you tum on the monitor.

1!2

f.f{!!l,p_!Lon§.~Qf

Q~l}:~.9!!~n·.

~',EL!S

..,_j

There are four types

of

on-screen menus.

Main

menu

You

can

enter

another

menu

such

as

status

menu

or

setting menu.

Status

menu

You can confirm the current settings.

Setting

menu

You can select an item

or

enter an adjustment

screen on this menu

by

using the

tl+,

..,,_and

ENTER/SELECT buttons.

Adjustment

screen

You can make adjustments on this screen. The

adjustments you made remain unchanged until next

change even

if

you tum off the power.

([I

indicates the factory setting.)

[I]Main

menu

Select another menu and press ENTER/SELECT

to

go

to the menu.

~STATUS

1

menu

Shows the current settings.

~STATUS

2

menu

Shows what optional kit

is

installed in the monitor.

~CHROMA

SET

UP

menu

Select ON on this menu to activate "chroma" and

"phase" (NTSC signal

on!ll

adjustments done on the

AUTO ADJUST screen

([lj).

[OFF]

@]COLOR

TEMP/BAL

menu

Select the color temperature from among D65, D93

and

USER. USER is set to D65 as the factory setting.

You can adjust or change the color temperature in

USER mode (a measuring instrument is required).

[D65)

[§)CAPTION

VISION

menu

This menu is provided only for PVM-14M4U/14M2U/

20M4U/20M2U.

The monitor can display the signal with Caption

Vision. To display it, select the caption type in this

menu.

[OFF]

~USER

CONFIG 1 menu

Select an item to adjust on the menus and screens

(1J11

through~).

To go

to

the USER CONFIG 2 menu,

select

NEXT PAGE.

~USER

CONFIG 2 menu

Select an item to adjust on the menus and screens

(~

through

~).

To go

to

the USER CONFIG I menu

select

PREVIOUS PAGE.

[l]AUTO

ADJUST

screen

Select the color bar signal (full, SMPTE, EIA) and

press ENTER/SELECT to start automatic

"chroma"

and "phase" (NTSC signal only) adjustments.

To activate these adjustments, select

ON on the

CHROMA SET UP menu

(~).

(IDADJUST GAIN

screen

Adjust GAIN in USER mode.

[IDADJUST BIAS

screen

Adjust BIAS in USER mode.

llli!COLOR

TEMP

RANGE

menu

Select the color temperature range

in

USER mode.

[5000K-IOOOOK]

!!]USER

COPY

menu

Store the factory setting

of

D65

or

D93 as the value for

USER mode.

IJ1ICOLOR

SYSTEM

DISPLAY

menu

Select the color system type. When AUTO is selected,

the color system type being used appears on the screen

each time you change the signal input.

[AUTO]

~358

TRAP

FIL

TEA

menu

Color spill or color noise may be eliminated if you

select

ON

(NTSC signal only).

Normally select

OFF. [OFF]

IH]SUB

CONTROL

menu

Select an item (CONTRAST, BRIGHT, CHROMA

and PHASE controls on the front panel) to finely

adjust on the

SUB CONTROL screen (11]) .

[§]SUB

CONTROL

screen

Finely adjust the selected item on the SUB CONTROL

menu (IH]). Each control (CONTRAST, BRIGHT,

CHROMA and PHASE control) has a click position at

the center

of

its adjustment range. You can adjust the

setting

of

the click position with this feature.

[§]USER

PRESET

menu

If you select ON on this menu, the REMOTE indicator

lights up and the controls on the front panel do not

work. The monitor operates with the user preset

settings.

To adjust the

use!:_P.reset

settings, select the PRESET

ADJUST

menu

(111J).

[OFF]

111!PRESET

ADJUST

menu

You can preset the BRIGHT, CHROMA, PHASE,

CONTRAST, VOLUME,

and APERTURE controls to

a desired level and can use these settings by selecting

ON on the USER PRESET menu ([§]).

imPRESET

ADJUST

screen

Adjust the selected item (BRIGHT, CHROMA,

PHASE, CONTRAST, VOLUME,

and APERTURE

control) on the PRESET ADJUST menu

(111!).

~V

HOLD

screen

Adjust the vertical hold if the picture rolls vertically.

When you cannot read the display, select the input that

is

not

connected.

~COMPONENT

LEVEL

menu

Select the component level from among three modes.

N

I 0/SMPTE for I 00/01100/0 signal

BETA 7.5 for

IOOn.5n5n.5 signal

BETA

0 for IOO/On5/0 signal

For

PVM-14M4U/14M2U/20M4U/20M2U

[BETA 7.5)

For

PVM-14M4E/14M2E/20M4E/20M2E

[NIO/SMPTE)

13

.....

(..)

I

Using On-Screen Menus

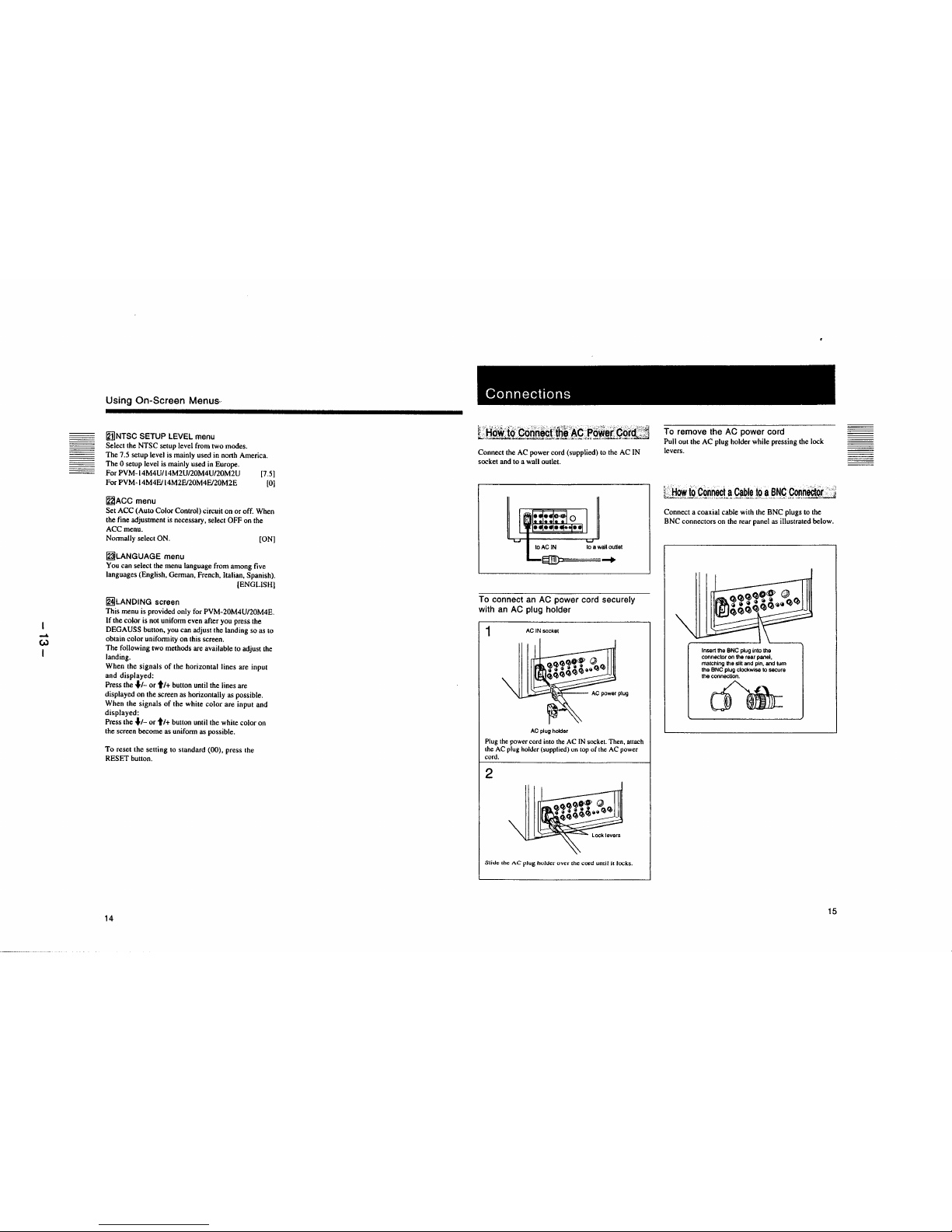

[gj]NTSC

SETUP

LEVEL

menu

Select the NTSC setup level from two modes.

The 7.5 setup level

is

mainly used

in

nonh America.

The

0 setup level

is

mainly used

in

Europe.

For

PVM-14M4U/ 14M2U/20M4U/20M2U

[7

.5]

For PVM-14M4E/14M2E/20M4E/20M2E [0]

~ACC

menu

Set ACC (Auto Color Control) circuit on or off. When

the fine adjustment

is

necessary, select OFF on the

ACCmenu.

Normally select

ON. [ON]

~LANGUAGE

menu

You can select the menu language from among five

languages (English, German, French, Italian, Spanish).

[ENGLISH]

~LANDING

screen

This menu

is

provided only for PVM-20M4U/20M4E.

If

the color

is

not uniform even after you press the

DEGAUSS button, you can adjust the landing so as to

obtain color uniformity on this screen.

The following two methods are available to adjust

the

landing.

When the signals

of

the horizontal lines are input

and displayed:

Press

the·/-

or

tl+

button until the lines are

displayed on the screen as horizontally

as

possible.

When the signals

of

the white color are input and

displayed:

Press the

·/-or

tl+

button until the white color on

the screen become as uniform as possible.

To

reset the setting to standard (00), press the

RESET button.

14

Connections

~,.-.·:·.~·"······.··

..

:'"''·~.•

......

v~'.:·,,

.... · ..

'"&

..

'?.

·>

:.·'-·:~

tJ:tew:.t<t£61irJ!2f.11!!_br:JJ:~2Yi,!ltJ:fgi'5(;£.;:J

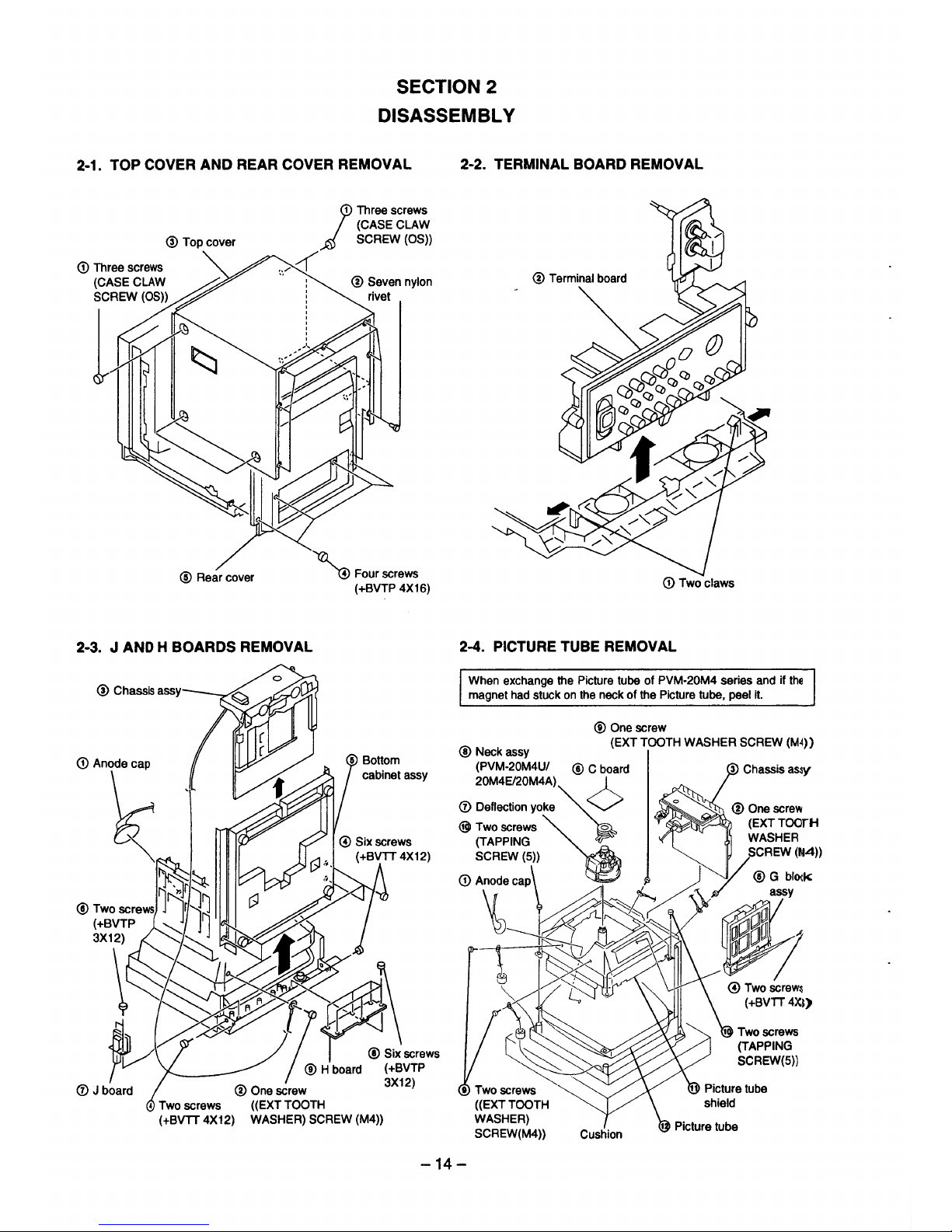

Connect the

AC

power cord (supplied) to the

AC

IN

socket and to a wall outlet.

To connect an

AC

power cord securely

with an

AC plug holder

1

AC

IN

socket

AC

plug

holder

Plug the power cord into the AC IN socket. Then, auach

the AC plug holder (supplied) un top

of

the AC power

cord.

2

Slide

the

A.C

plug

holder

over

the cord until it locks.

To remove the

AC

power cord

Pull out the

AC

plug holder while pressing the lock

levers.

81R.wi9.~~n~L~Y1bJ~!Q~-~~g

.9o_~~l2J

Connect a coaxial cable with the BNC plugs to the

BNC connectors on the rear panel as illustrated below.

Insert

the

BNC

plug

into

the

connector

on

the

rear

panel,

matching

the

slit

and

pin,

and

tum

the

BNC

plug

clockwise

to

secure

the

connection.

~

15

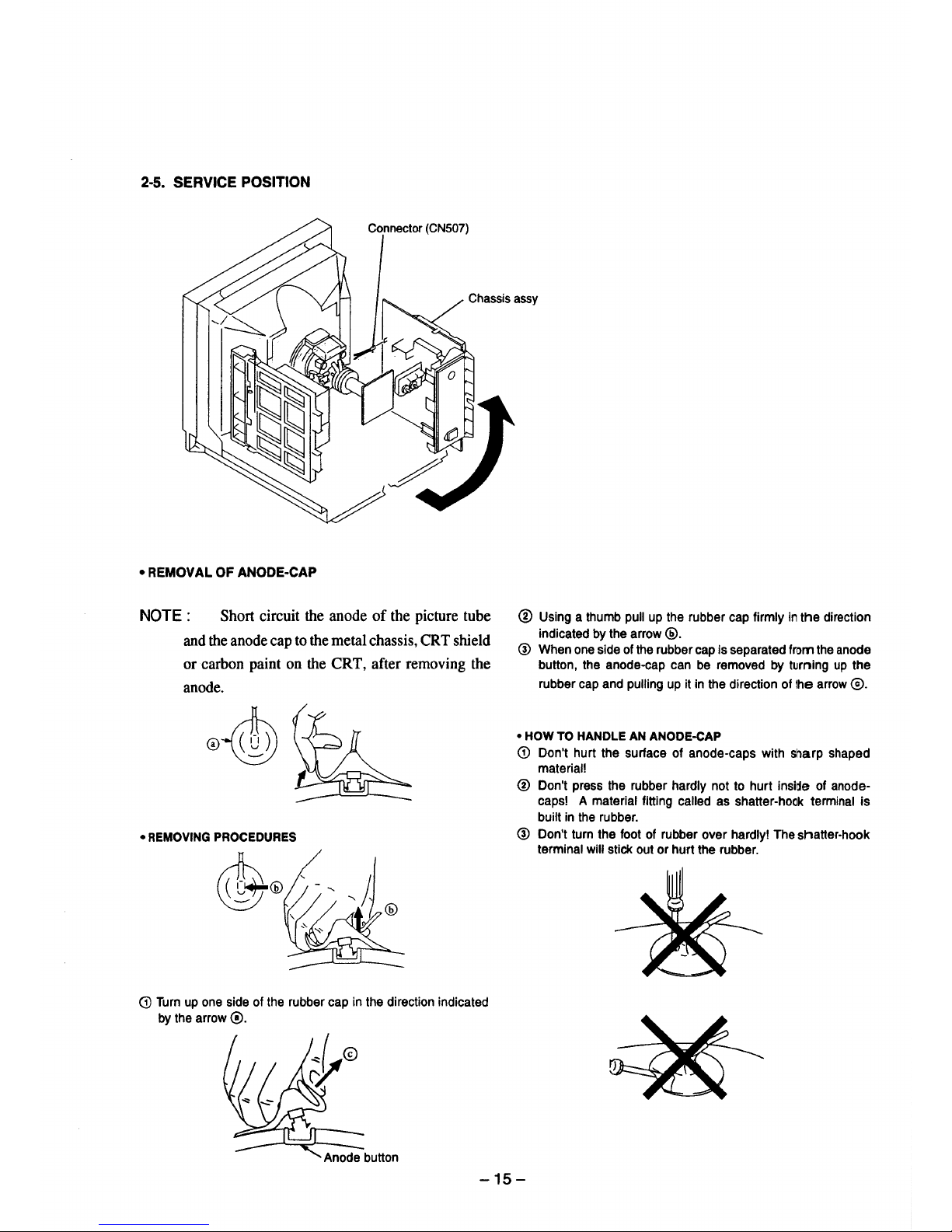

SECTION 2

DISASSEMBLY

2-1.

TOP

COVER AND REAR COVER REMOVAL

2-2. TERMINAL BOARD REMOVAL

@Top

cover

<D

Three screws

(CASE CLAW

SCREW (OS))

l

~

@Rear

cover

~\/~

1

Three screws

(CASE CLAW

SCREW(OS))

® Seven

nylon

rivet

~

Four screws

(+BVTP 4X16)

2-3. J AND H BOARDS REMOVAL

cabinet assy

<D

Two claws

2-4. PICTURE TUBE REMOVAL

When exchange the Picture tube of PVM-20M4 series and if

thE

magnet had stuck

on

the neck of the Picture tube, peel it.

®One

screw

(EXT

TOOTH WASHER SCREW

(M~))

®One

screw

(EXTTOOrH

WASHER

-14-

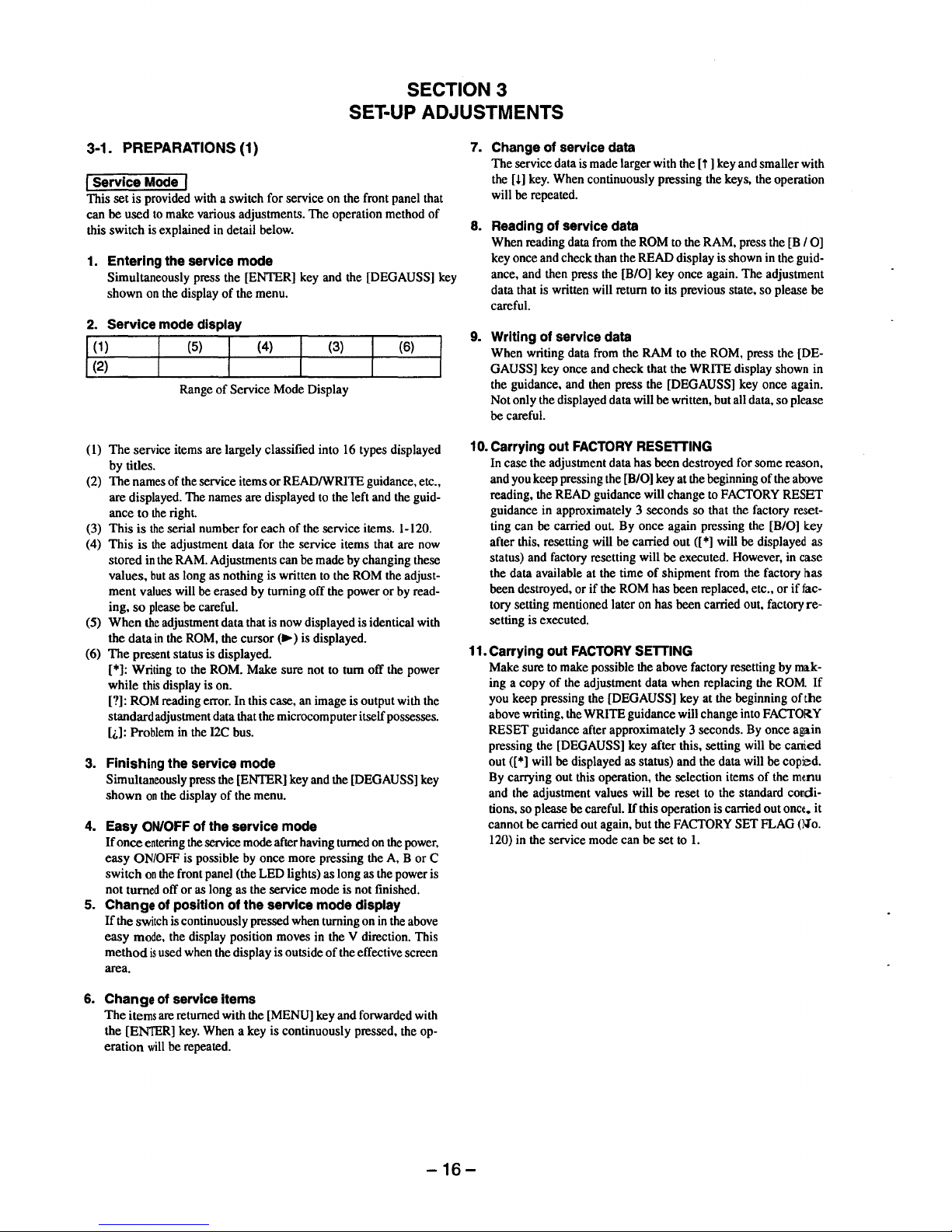

2-5. SERVICE POSITION

Chassis

assy

• REMOVAL

OF

ANODE-CAP

NOTE:

Short circuit the anode

of

the picture tube

and the anode cap to the metal chassis, CRT shield

or carbon paint on the CRT, after removing the

anode.

• REMOVING PROCEDURES

CD

Turn

up

one side of the rubber cap in the direction indicated

by

the

arrow®.

® Using a thumb pull up the rubber cap firmly

in

the

direction

indicated by the

arrow®.

@ When one side of the rubber cap is separated from the anode

button, the anode-cap can

be

removed by turning

up

the

rubber cap and

pulling

up

it in the direction of the arrow

@.

•

HOW

TO

HANDLE AN ANODE.CAP

CD

Don't hurt the surface of anode-caps with sharp shaped

material!

® Don't press the rubber hardly not to hurt insilie of anode-

caps! A

material fitting called as shatter-hook terminal

is

built

in

the rubber.

@ Don't turn the foot of rubber over hardly! The shatter-hook

terminal will stick out or hurt the rubber.

-15-

SECTION 3

SET-UP

ADJUSTMENTS

3-1. PREPARATIONS (1)

I Service Mode I

This set is provided with a switch for service

on

the front panel that

can

be used

to

make various adjustments. The operation method

of

this switch is explained in detail below.

1. Entering the service mode

Simultaneously press the [EN1ER] key and the [DEGAUSS] key

shown on the display

of

the menu.

2. Service mode display

I

~~~

I

(S)

I

(4)

(3) (6)

Range

of

Service Mode Display

(1)

The

service items are largely classified into

16

types displayed

by titles.

(2)

The

names

of

the service items

or

READ/WRITE guidance, etc.,

are displayed. The names are displayed to the left and the guidance

to

the

right.

(3) This

is

the

serial number for each

of

the service items. 1-120.

(4)

This

is

the

adjustment data for the service items that are now

stored

in

the RAM. Adjustments can be made by changing these

values,

but

as long as nothing is written to the ROM the adjust-

ment

values will be erased by turning

off

the power

or

by read-

ing,

so

please be careful.

(5)

When

the

adjustment data that is now displayed is identical with

the

data

in

the ROM, the cursor (..,.) is displayed.

(6)

The

present status is displayed.

[*]:Writing to the

ROM. Make sure not to tum

off

the power

while this display is on.

[?]: ROM reading error. In this case, an image is output with the

standard adjustment data that the microcomputer itself possesses.

[i,]: Problem

in

the

12C

bus.

3. Finishing the service mode

Simultaneously press the [EN1ER] key and the [DEGAUSS] key

shown

on

the display

of

the menu.

4. Easy ON/OFF of the service mode

If

once

entering the service mode after having turned on the power,

easy

ON/OFF is possible by once more pressing the A, B or C

switch

on

the front panel (the LED lights) as long as the power is

not turned off

or

as long as the service mode is not finished.

5. Change of position of the service mode display

If

the switch is continuously pressed when turning on

in

the above

easy mode, the display position moves in the

V direction. This

method

is

used when the display is outside

of

the effective screen

area.

6. Change

of

service items

The

items are returned with the [MENU] key and forwarded with

the [ENTER] key. When a key is continuously pressed, the operation

will

be repeated.

7. Change of service data

The

service data

is

made larger with the [ t ] key and smaller with

the

[!]

key. When continuously pressing the keys, the operation

will be repeated.

8. Reading of service data

When reading data from the ROM to the RAM, press the

[B I 0]

key once and check than the READ display is shown in the guidance, and then press the

[B/0]

key once again. The adjustment

data that is written will return to its previous state, so please be

careful.

9. Writing of service data

When writing data from the RAM to the ROM, press the [DEGAUSS] key once and check that the WRITE display shown in

the guidance, and then press the

[DEGAUSS] key once again.

Not only the displayed data will be written, but all data, so please

be careful.

10. Carrying out FACTORY RESETTING

In case the adjustment data has been destroyed for some reason,

and you keep pressing the

[B/0]

key at the beginning

of

the above

reading, the READ guidance will change to

FACTORY RESET

guidance in approximately 3 seconds so that the factory resetting can be carried out. By once again pressing the

[B/0]

k::ey

after this, resetting will be carried out ([*] will be displayed as

status) and factory resetting will

be

executed. However, in case

the data available at the time

of

shipment from the factory !las

been destroyed, or if the ROM has been replaced, etc.,

or

if

fac-

tory setting mentioned later on has been carried out, factory

re-

setting is executed.

11. Carrying out FACTORY SETTING

Make sure to make possible the above factory resetting by milking a copy

of

the adjustment data when replacing the

ROM.

If

you keep pressing the [DEGAUSS] key at the beginning

oftbe

above writing, the WRITE guidance will change into FACTORY

RESET

guidance after approximately 3 seconds. By once

ag11.in

pressing the [DEGAUSS] key after this, setting will be

canied

out([*]

will be displayed as status) and the data will be copied.

By carrying out this operation, the selection items

of

the menu

and the adjustment values will

be

reset to the standard condi-

tions, so please be careful.

If

this operation is carried out once. it

cannot be carried out again, but the

FACTORY SET FLAG

(ll

o.

120) in the service mode can be set to

I.

-16-

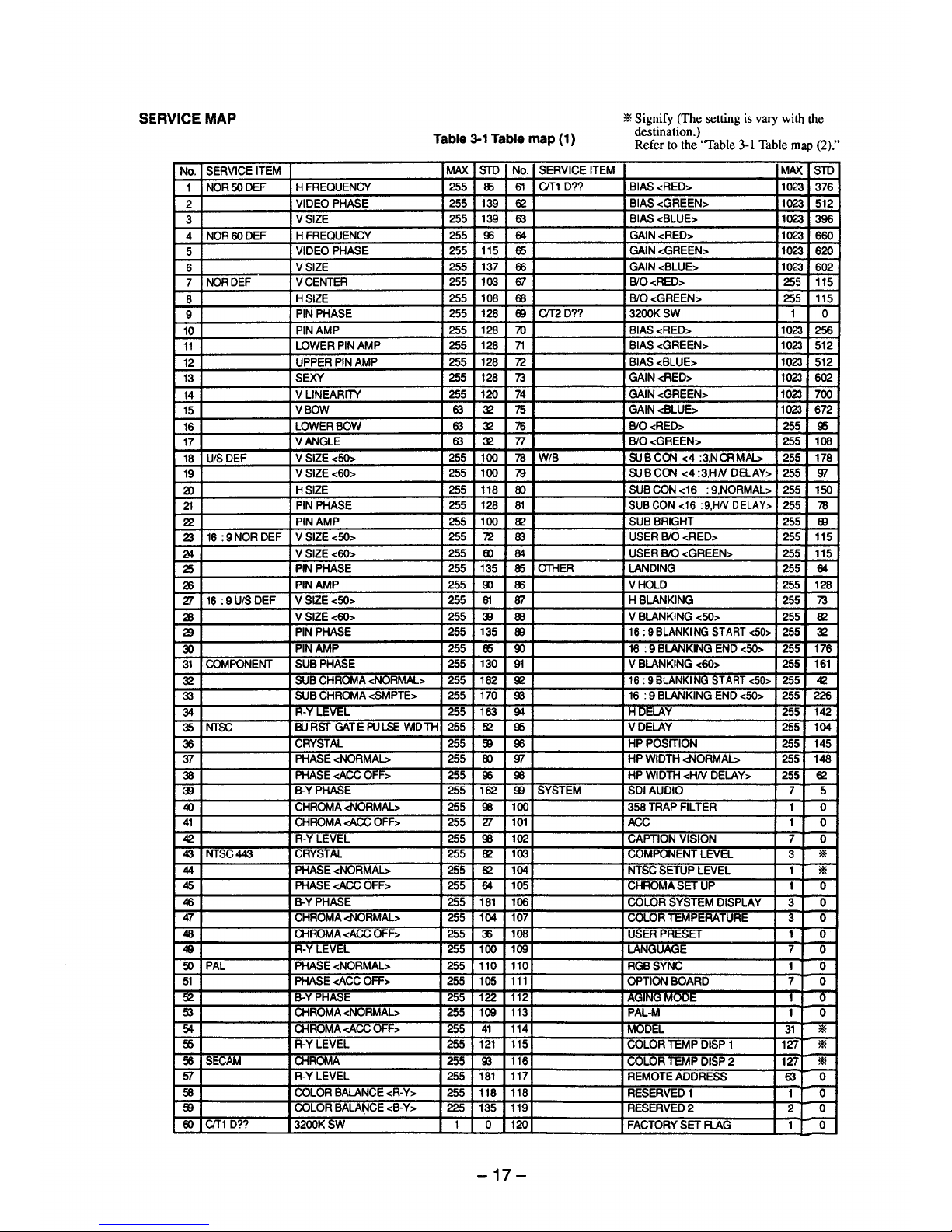

SERVICE MAP

Table

3-1

Table map (1)

No.

SERVICE

ITEM

MAX

STD

No.

SERVICE

ITEM

1

NOR50DEF

HFREQUENCY 255

ffi

61

C'T1

D??

2

VIDEO

PHASE 255

139

62

3

VSIZE

255

139

63

4

NOR60DEF

HFREQUENCY 255

96

64

5

VIDEO

PHASE

255

115

65

6

VSIZE

255

137

66

7

NORDEF

VCENTER

255

103

57

8

HSIZE

255

108

68

9

PIN

PHASE

255

128

00

C'T2

D??

10

PIN

AMP

255

128

70

11

LOWER

PIN

AMP

255

128

71

12

UPPER

PIN

AMP

255

128

72

13

SEXY

255

128

73

14

VLINEARITY

255

120

74

15

VBOW

63

32

75

16

LOWER

BOW

63

32

76

17

VANGLE

63

32

77

18

U/SDEF VSIZE<50>

255

100

78

W/B

19

VSIZE<60>

255

100

79

aJ

HSIZE

255

118

00

21

PIN

PHASE

255

128

81

22

PIN

AMP

255

100

82

Z3

16

:9NORDEF

VSIZE<50>

255

72

In

24

VSIZE<60>

255

6)

84

25

PIN

PHASE

255

135

ffi

OTHER

26

PIN

AMP

255

00

86

Zl

16

:9

U/S

DEF VSIZE<50> 255

61

~

28

V SIZE<60>

255

:!! 88

29

PIN

PHASE

255

135

le

~

PIN

AMP

255

65

00

31

COMPONENT

SUB

PHASE

255

130

91

32

SUB

CHROMA

<NORMAL>

255

182

92

33

SUB

CHROMA

<SMPTE>

255 170

m

34

R-Y

LEVEL 255

163

94

35

NTSC

B.J

RST

GATE

PULSE

WIDTH

255

S!

95

36

CRYSTAL

255

9:1

96

:rT

PHASE

<NORMAL>

255

00

IJl

38

PHASE

<ACC

OFF>

255

96

98

:!!

B-Y

PHASE

255

162

9:1

SYSTEM

40

CHROMA

<NORMAL>

255

98

100

41

CHROMA

<ACC

OFF>

255

Zl

101

42 R-YLEVEL

255

98

102

43

NTSC443

CRYSTAL

255

82

103

44

PHASE

<NORMAL>

255

62

104

45

PHASE

<ACC

OFF>

255

64

105

46

B-Y

PHASE

255

181

106

47

CHROMA

<NORMAL>

255

104

107

48

CHROMA

<ACC

OFF>

255

36

108

49

R-Y

LEVEL

255

100

109

50

PAL

PHASE

<NORMAL>

255 110

110

51

PHASE

<ACC

OFF>

255 105

111

S!

B-Y

PHASE

255

122

112

53

CHROMA

<NORMAL>

255

109

113

54

CHROMA

<ACC

OFF>

255

41

114

55

R-YLEVEL

255

121

115

56

SEC

AM

CHROMA

255 m

116

'Sl

R-YLEVEL

255

181

117

58

COLOR

BALANCE

<R·Y>

255

118

118

00

COLOR

BALA~CE

<B·Y>

225

135

119

6)

C'T1

D??

3200KSW 1

0

120

-17-

* Signify (The setting

is

vary with the

destination.)

Refer to the

"Table

3-1

Table map (2)."

MAX

STD

BIAS<RED>

1023

376

BIAS <GREEN>

1023

512

BIAS<BLUE>

1023

396

GAIN<RED>

1023

660

GAIN

<GREEN>

1023

620

GAIN<BLUE>

1023

602

BIO<RED>

255

115

BIO<GREEN>

255

115

3200KSW

1

0

BIAS<RED>

1023

256

BIAS <GREEN>

1023

512

BIAS<BLUE>

1023

512

GAIN<RED>

1023

602

GAIN

<GREEN>

1023

700

GAIN<BLUE>

1023

672

BIO<RED>

255

95

BIO<GREEN>

255

108

9JBCCJII

<4

:3,NrnMAL>

255

178

9J

B COli

<4

:3,HN

DELAY>

255

IJl

SUB

CON

<16

: 9,NORMAL>

255

150

SUB

CON

<16

:9,HN

DELAY>

255

78

SUB

BRIGHT

255

00

USER

B/0 <RED>

255

115

USER

BIO

<GREEN>

255

115

LANDING

255

64

VHOLD

255

128

HBLANKING

255

73

V BLANKING <50>

255

82

16

:9BLANKING

START

<50>

255

32

16

: 9 BLANKING

END

<50>

255

176

V BLANKING <60>

255

161

16

: 9

BLANKING

START

<50>

255

42

16

: 9 BLANKING

END

<50>

255

226

HDELAY

255

142

VDELAY

255

104

HPPOSITION

255

145

HP

WIDTH

<NORMAL>

255

148

HP

WIDTH

<HN

DELAY>

255

62

SDIAUDIO 7 5

358

TRAP

FILTER 1

0

/ICC

1

0

CAPTION VISION

7

0

COMPONENT

LEVEL

3

*

NTSC

SETUP

LEVEL

1

*

CHROMA

SET

UP

1

0

COLOR SYSTEM

DISPLAY

3 0

COLOR

TEMPERATURE 3 0

USER

PRESET 1 0

LANGUAGE

7 0

RGBSYNC

1

0

OPTION

BOARD 7 0

AGING

MODE 1 0

PAL-M

1 0

MOD

a

31

*

COLOR

TEMP

DISP

1 127

*

COLOR

TEMP

DISP

2 127

*

REMOTE

ADDRESS

63

0

RESERVED1

1

0

RESERVED2

2

0

FACTORY

SET

FLAG

1

0

Table

3-1

Table

map

(2)

I

Model Name Component level

NTSC Set-up level

Model Color

temp disp 1

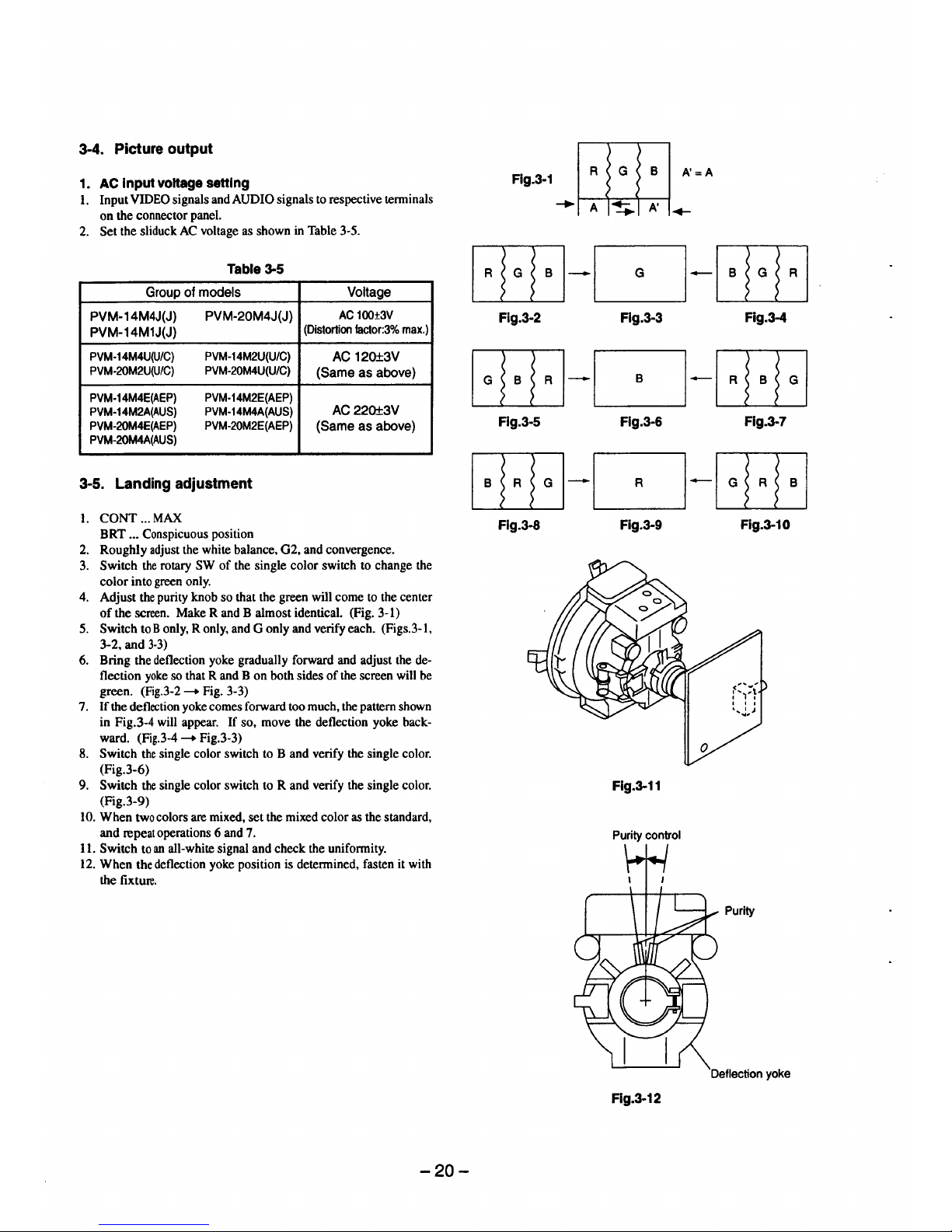

Color temp disp 2

PVM-20M4U 1

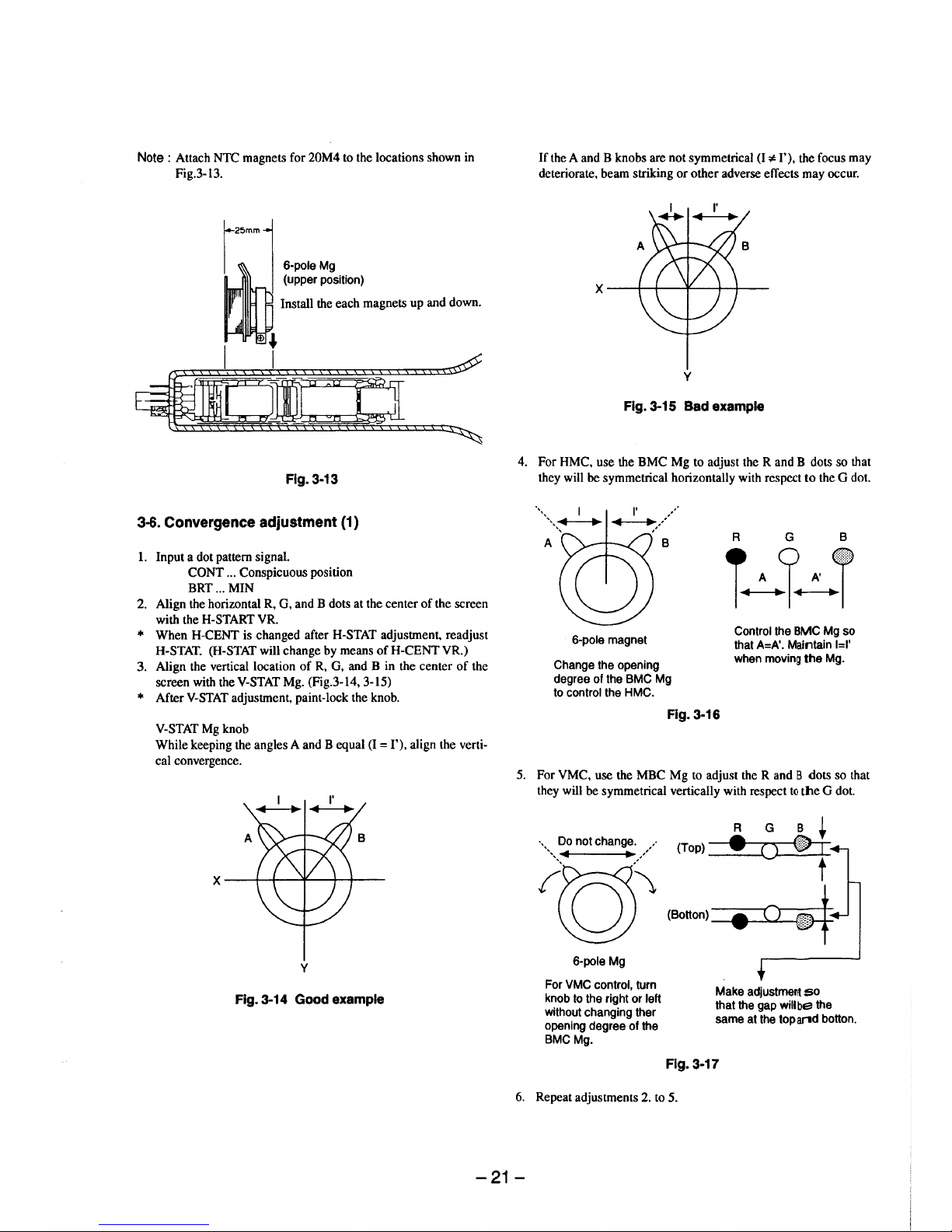

1

0 65 93

PVM-20M2U

1

1

1

65 93

PVM-20M4J 2

0

2

93

65

PVM-20M4E 2

0

3 65

93

PVM-20M2E 2

0 4

65

93

PVM-14M4U 1

1

5

65 93

PVM-14M2U 1

1

6

65

93

PVM-14M4J 2

0 7

93 65

PVM-14M1J

2

0

8 93 65

PVM-14M4E 2

0

9 65 93

PVM-14M2E

2

0 10

65 93

PVM-20M4A 2

0

11

65

93

PVM-14M4A

2

0 12

65

93

PVM-14M2A

2

0 13

65 93

PVM-14M4B 1

1

14

65 93

BVM-14M4DJ 2

0

15

93

65

BVM-14M4DE

2

0 16

65 93

PVM-20M4T 2

0

17

93

65

PVM-14M4T 1

0 18

93

65

-18-

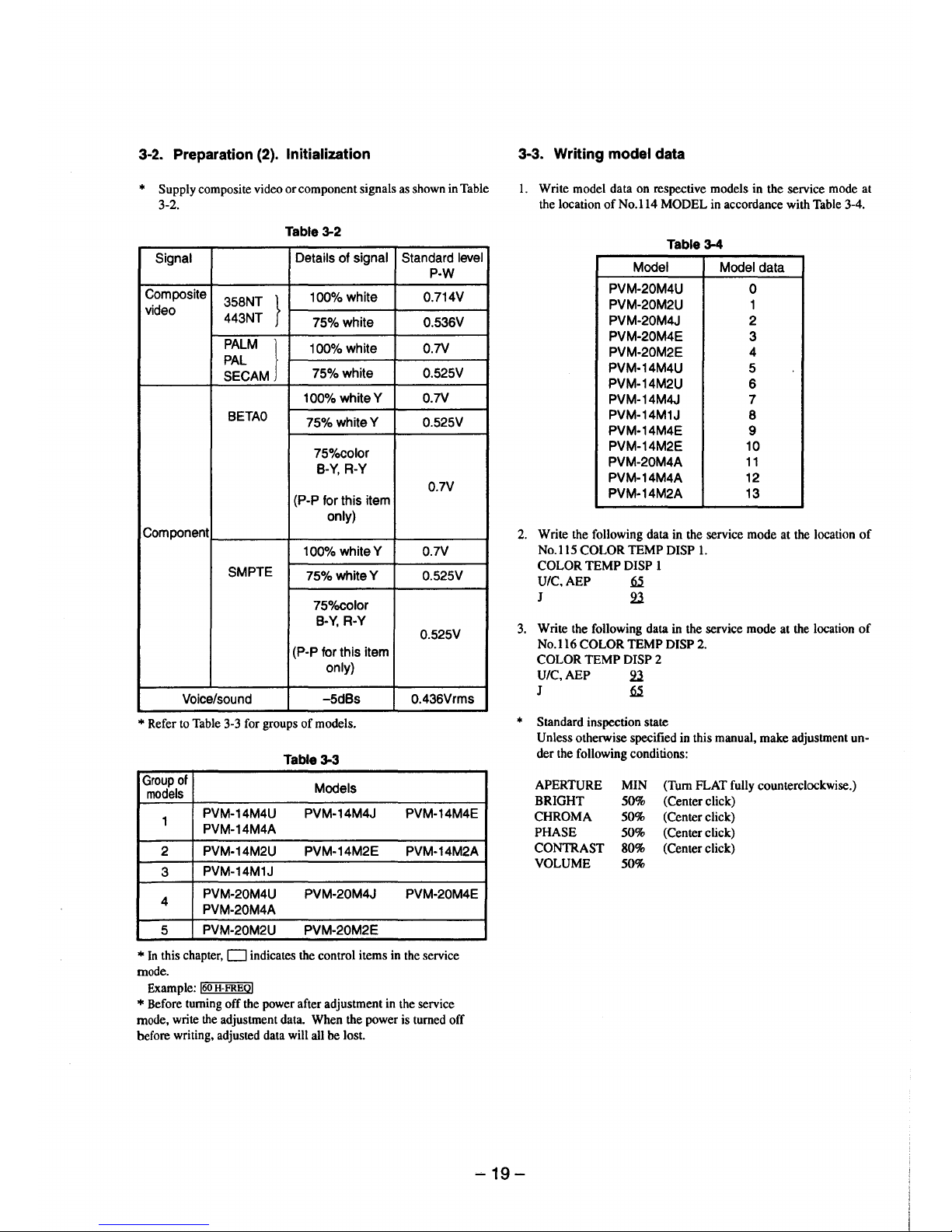

3-2. Preparation (2). Initialization

• Supply composite video

or

component

signals as shown in Table

3-2.

Table 3-2

Signal

Details

of signal Standard level

P-W

Composite

358NT

}

100% white

0.714V

video

443NT

75%white

0.536V

PALM

)

100% white 0.7V

PAL

SECAM

75%white

0.525V

100%

whiteY

0.7V

8ETAO

75%whiteY

0.525V

75%color

8-Y, R-Y

0.7V

(P-P for this item

only)

Component

100%

whiteY

0.7V

SMPTE

75%whiteY

0.525V

75%color

8-Y, R-Y

0.525V

(P-P for this item

only)

Voice/sound

-5dBs

0.436Vrms

• Refer to Table

3-3

for groups

of

models.

Table 3-3

Group

of

Models

models

1

PVM-14M4U

PVM-14M4J PVM-14M4E

PVM-14M4A

2 PVM-14M2U PVM-14M2E PVM-14M2A

3

PVM-14M1J

4

PVM-20M4U PVM-20M4J PVM-20M4E

PVM-20M4A

5 PVM-20M2U PVM-20M2E

*

In

this chapter, D indicates the control items in the service

mode.

Example:

160

H-I'REOI

* Before turning

off

the power after adjustment in the service

mode, write the adjustment data.

When

the power is turned off

before writing, adjusted data will all be lost.

3-3. Writing model data

I.

Write model data on respective models in the service mode at

the location

of

No.ll4

MODEL

in accordance with Table

3-4.

Table 3-4

Model Model data

PVM-20M4U

0

PVM-20M2U 1

PVM-20M4J 2

PVM-20M4E

3

PVM-20M2E

4

PVM-14M4U

5

PVM-14M2U

6

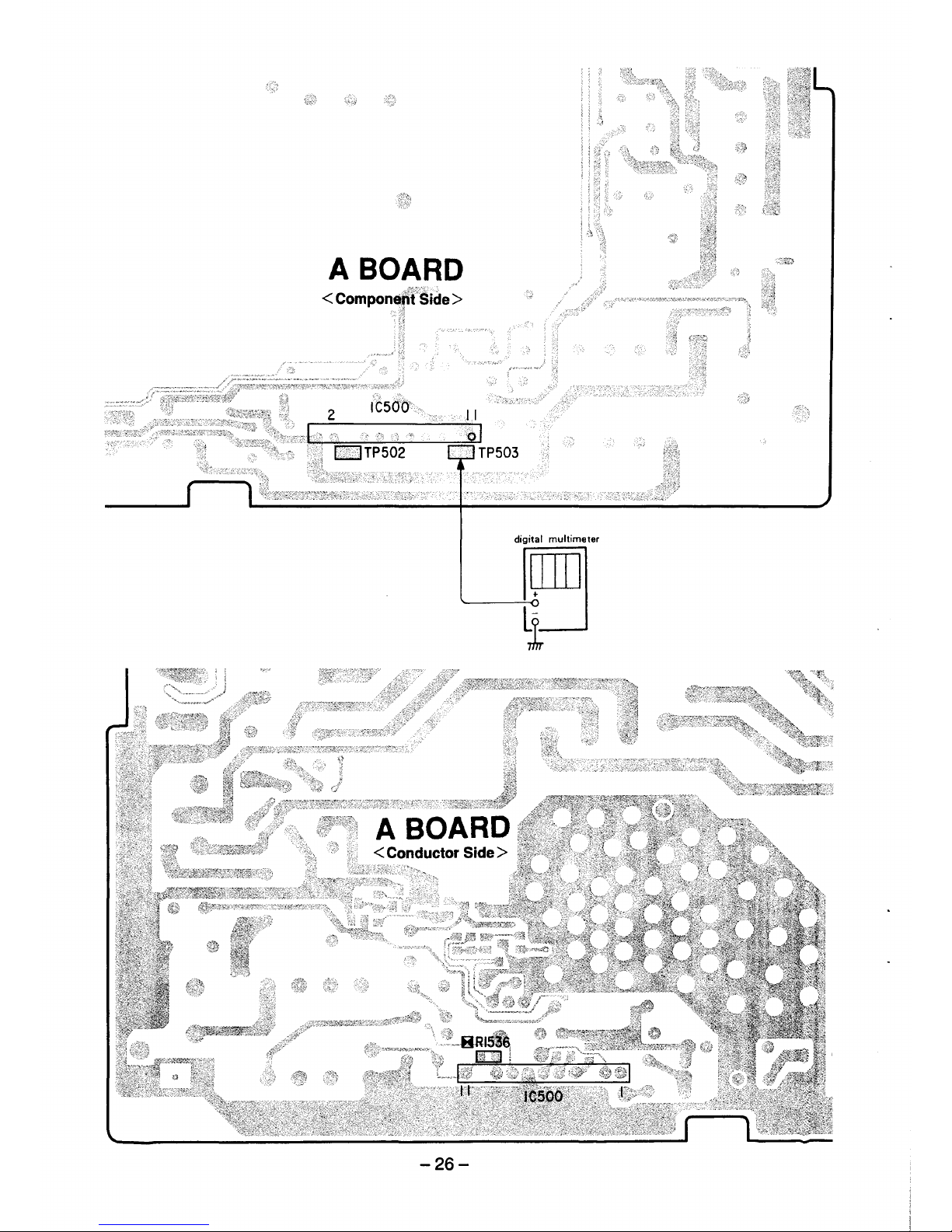

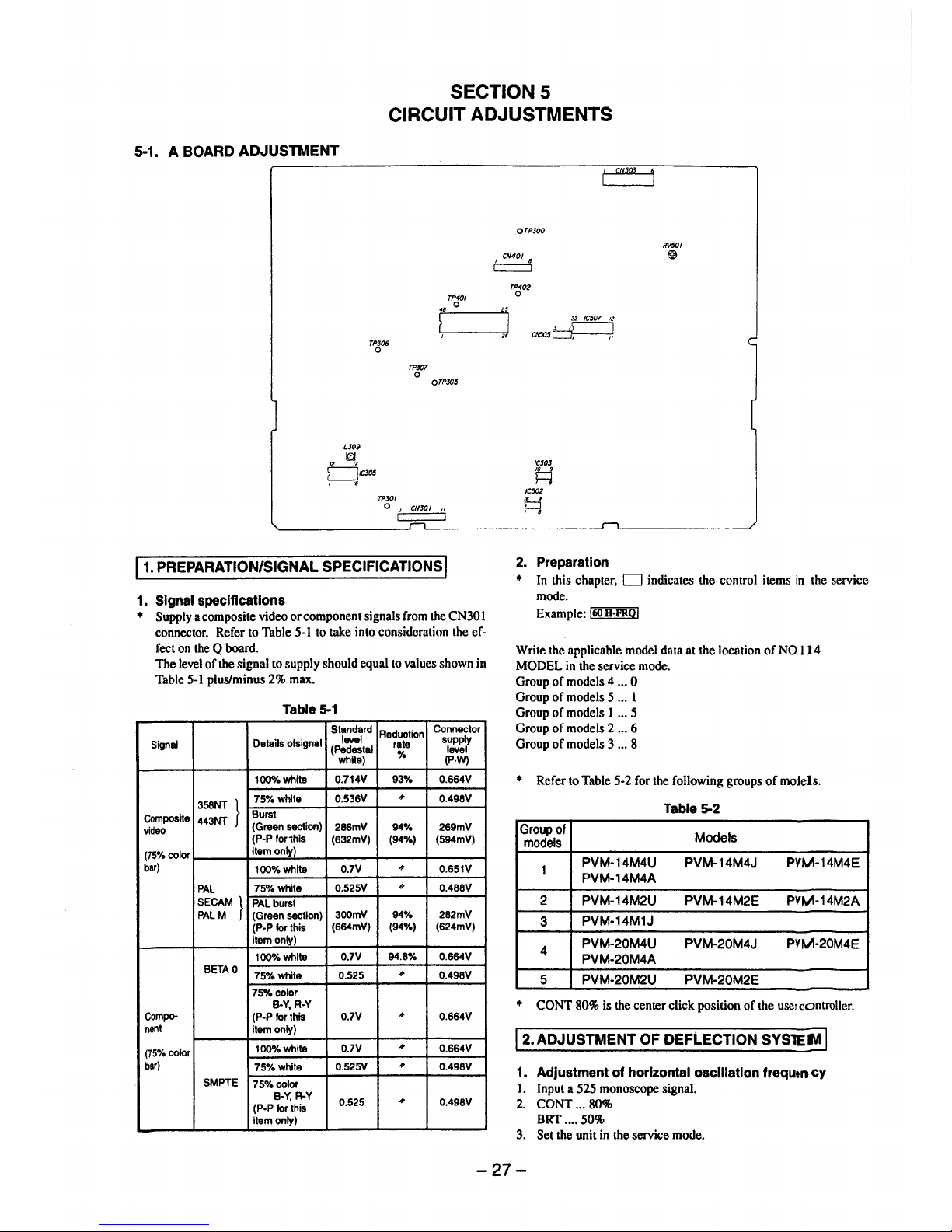

PVM-14M4J 7