Sony PCG-FH150, PCG-FH190, PCG-FH170, PCG-FH140, PCG-FX120 Service Manual

...

Confidential

PCG-FX120/FX140/FX150/FX170/FX190

US Model

Canadian Model

SERVICE MANUAL

NOTEBOOK COMPUTER

9-872-179-11

Illust : PCG-FX170

S400

— 2 —

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Information in this document is subject to change without notice.

Sony and VAIO are trademarks of Sony. Intel logo and Intel Inside

logo are registered trademarks of Intel Corporation. Pentium MMX

is a trademark of Intel Corporation. Microsoft, MS-DOS, Windo ws,

the W indows 95 and W indows 98 log o are trademarks of Microsoft

Corporation.

All other trademarks are trademarks or registered trademarks of

their respective owners. Other tr ademarks and trade names may be

used in this document to refer to the entitles claiming the marks and

names or their produces. Sony Corporation disclaims any proprietary

interest in trademarks and trade names other than its own.

Service and Inspection Precautions

1. Obey precautionary markings and instructions

Labels and stamps on the cabinet, chassis, and components identify areas

requiring special precautions. Be sure to observe these precautions, as well

as all precautions listed in the operating manual and other associated

documents.

2. Use designated parts only

The set’s components possess important safety characteristics, such as

noncombustibility and the ability to tolerate large voltages. Be sure that

replacement parts possess the same safety characteristics as the originals.

Also remember that the 0 mark, which appears in circuit diagrams and

parts lists, denotes components that have particularly important safety

functions; be extra sure to use only the designated components.

3. Always follow the original design when mounting

parts and routing wires

The original layout includes various safety features, such as inclusion of

insulating materials (tubes and tape) and the mounting of parts above the

printer board. In addition, internal wiring has been routed and clamped so

as to keep it away from hot or high-voltage parts. When mounting parts or

routing wires, therefore, be sure to duplicate the original layout.

4. Inspect after completing service

After servicing, inspect to make sure that all screws, components, and wiring

have been returned to their original condition. Also check the area around

the repair location to ensure that repair work has caused no damage, and

confirm safety.

5. When replacing chip components...

Never reuse components. Also remember that the negati ve side of tantalum

capacitors is easily damaged by heat.

6. When handling flexible print boards...

•The temperature of the soldering-iron tip should be about 270C.

•Do not apply the tip more than three times to the same pattern.

•Handle patterns with care; never apply force.

Caution: Remember that hard disk drives are easily damaged by

vibration. Always handle with care.

Caution Markings for Lithium/Ion Battery - The following or similar

texts shall be provided on battery pack of equipment or in both the

operating and the service instructions.

CAUTION: Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer. Discard used batteries according to the

manufacturer’s instructions.

CAUTION: The battery pack used in this de vice may present a fire

or chemical burn hazard if mistreated. Do not disassemble, heat

above 100°C (212°F) or incinerate.

Dispose of used battery promptly.

Keep away from children.

CAUTION: Changing the back up battery.

• Overcharging, short circuiting, reverse charging, multilation or

incineration of the cells must be avoided to prevent one or mor e of

the following occurrences; release of toxic materials, release of

hydrogen and/or oxygen gas, rise in surface temperature.

• If a cell has leaked or vented, it should be replaced immediately

while avoiding to touch it without any protection.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Confidential

— 3 —

TABLE OF CONTENTS

CHAPTER 1. REMOVAL

1-1. Flowchart ......................................................................... 1-1

1-2. Main Electrical Parts Location Diagram ......................... 1-1

1-3. Removal........................................................................... 1-2

1. Hinge Cover ..................................................................... 1-2

2. Keyboard Unit, Palm Rest Assy, Hood Keyboard Assy,

Touch Pad, CNX-125 Board ............................................ 1-2

3. Display Assy, DVD-ROM Drive, Combination Drive Bay

(CD-RW/DVD-ROM)......................................................1-3

4. HDD Assy, DC Fan..........................................................1-3

5. Latch Detector, PWS-13 Board ....................................... 1-4

6. PC Card Connector, Modem card, MBX-49 Board

Lithium Battery................................................................ 1-4

7. Speaker Unit, SWX-73 Board ......................................... 1-5

8. SO-DIMM........................................................................ 1-5

9. Modem Card .................................................................... 1-6

10. LCD Section (FX190 Model) – Made by SA – ............... 1-7

1.Bezel Housing Assy, LCD Unit (15 inch) .................... 1-7

2.Inverter Assy, LCD Harness, FPC,

Display Housing Assy .................................................. 1-8

11. LCD Section (FX150/FX170 Model) – Made by SA – ... 1-9

1.Bezel Housing Assy, LCD Unit (15 inch) .................... 1-9

2.Inverter Assy, LCD Harness, FPC,

Display Housing Assy ................................................ 1-10

12. LCD Section (FX140 Model) – Made by SA– ..............1-11

1.Bezel Housing Assy.................................................... 1-11

2.Bracket LCD Left, Bracket LCD Right,

LCD Unit (14 inch) .................................................... 1-12

3.FPC, Inverter Assy, Display Housing Assy, ......................

LCD Harness .............................................................. 1-12

13. LCD Section (FX120 Model) – Made by AC–.............. 1-13

1.Bezel Housing Assy.................................................... 1-13

2.Bracket LCD Left, Bracket LCD Right,

LCD Unit (13 inch) .................................................... 1-14

3.FPC, Inverter Assy, Display Housing Assy, ......................

LCD Harness .............................................................. 1-14

1-4. Replacing the CPU ........................................................ 1-15

1. Removing the CPU ........................................................ 1-15

2. Installing the CPU.......................................................... 1-15

1-5. DIP Switch Setting of the MBX-49 Board .................... 1-16

(to 1-17)

Section Title Page

• Abbreviations

UC : US model / Canadian model

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

Section Title Page

CHAPTER 2. SELF DIAGNOSTICS

2-1. Required Tools and Peripheral Devices ........................... 2-1

2-2. Tools and Peripheral Device Connection.........................2-3

2-3. Starting up the Service Diagnostics ................................. 2-4

2-4. Outline of Service Diagnostics Functions ....................... 2-4

2-5. Inspecting W indows.........................................................2-7

2-6. Self diagnostics Change History...................................... 2-8

(to 2-8)

CHAPTER 3. BLOCK DIAGRAM............................... 3-1

(to 3-2)

CHAPTER 4. FRAME HARNESS DIAGRAM........ 4-1

(to 4-2)

CHAPTER 5. EXPLODED VIEWS AND

PARTS LIST............................................5-1

5-1. Main Section .................................................................... 5-2

5-2. LCD Section (FX190 Model) – Made by SA –............... 5-5

5-3. LCD Section (FX150/FX170 Model) – Made by SA –... 5-7

5-4. LCD Section (FX140 Model) – Made by SA –............... 5-9

5-5. LCD Section (FX120 Model) – Made by AC –............. 5-11

(to 5-12)

1-1

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

CHAPTER 1.

REMOVAL

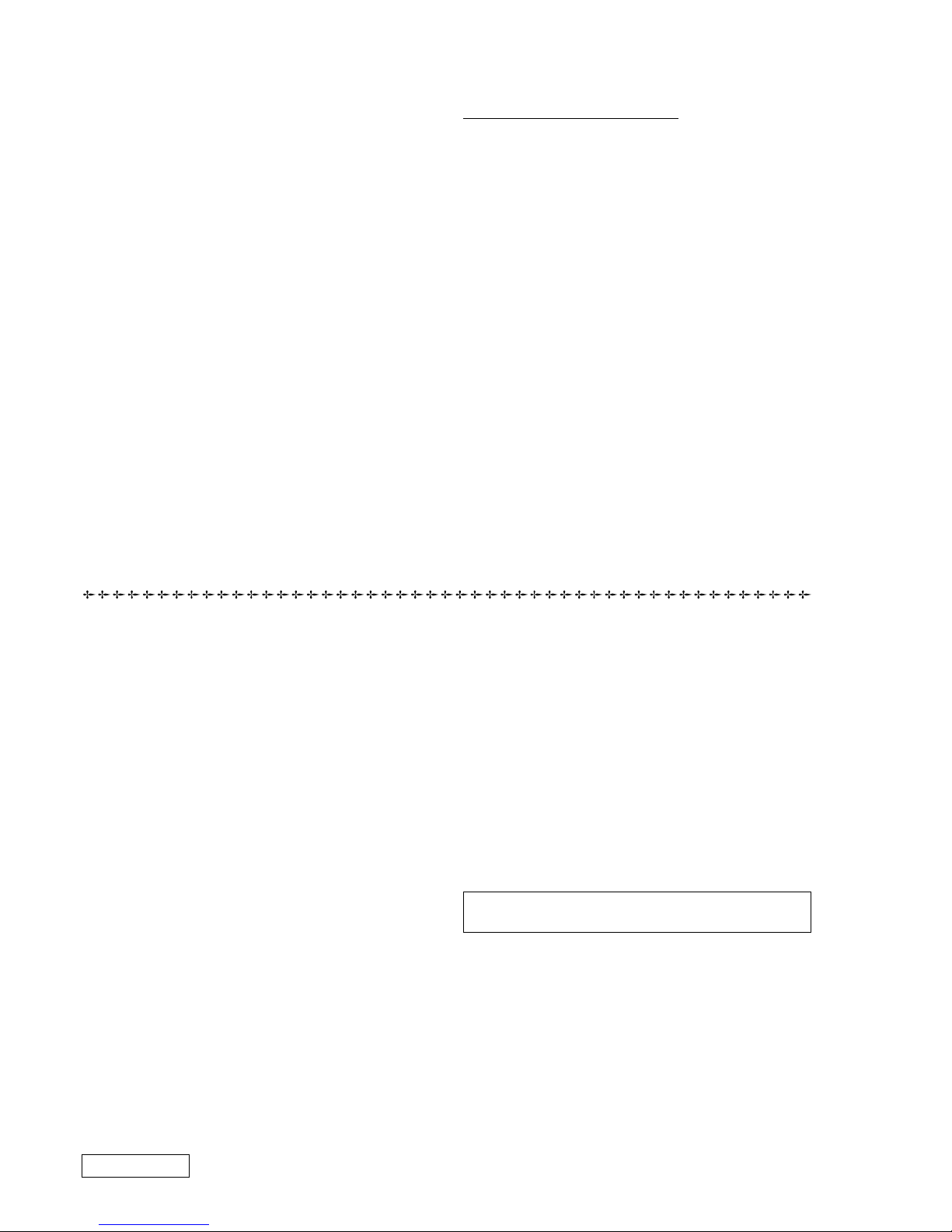

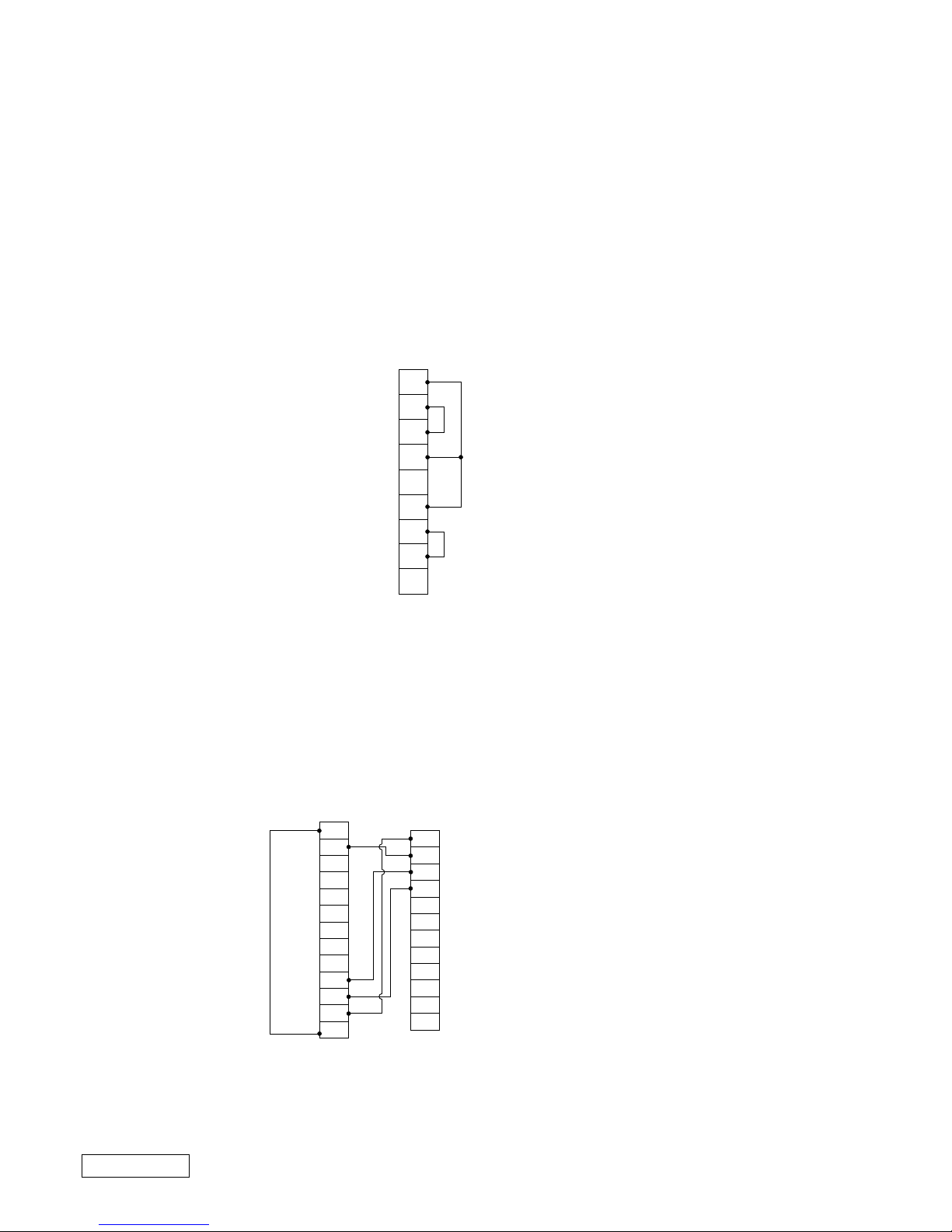

1-1. Flowchart

• P XX means pages that appears in this manual.

• Remember that hard disk drives are easily damaged by vibration. Always handle with care.

1-2. Main Electrical Parts Location Diagram

POWER

OFF

HOOD

KEYBOARD

ASSY

SO-DIMM

BATTERY

PACK

HINGE

COVER

MODEM

CARD

KEYBOARD

UNIT

P 1-2P 1-2

P 1-5P 1-5

P 1-5

P 1-2

P 1-6

P 1-2 P 1-3

P 1-4

3 through 7

P 1-4

P 1-4

P ALM REST

ASSY

P 1-3

DC

FAN

PC CARD

CONNECTOR

FDD

SPEAKER

UNIT

SWX-73

BOARD

P 1-3

DISPLAY

ASSY

P 1-4

FPC

INVERTER

ASSY

BRACKET

LCD LEFT

BRACKET

LCD RIGHT

DISPLAY

HOUSING

ASSY

BEZEL

HOUSING

ASSY

DVD-ROM

COMBINATION

DRIVE

LCD

UNIT

PWS-13

BOARD

P 1-4

P 1-3

HDD

∗P 1-7

(P 1-9)

〈P 1-11〉

[

P 1-13]

∗P 1-7

(P 1-9)

〈P 1-12〉

[

P 1-14]

∗P 1-8

(P 1-10)

〈P 1-12〉

[

P 1-14]

∗P 1-8

(P 1-10)

〈P 1-12〉

[

P 1-14]

∗P 1-8

(P 1-10)

〈P 1-12〉

[

P 1-14]

∗:FX190 Model

( ):FX150/FX170 Model

〈 〉:FX140 Model

[ ]:FX120 Model

〈P 1-12〉

[

P 1-14]

〈

P 1-12〉

[

P 1-14]

∗P 1-8

(P 1-10)

〈P 1-12〉

[

P 1-14]

LCD

HARNESS

P 1-2

PARM REST

PLATE

P 1-2

BRACKET

PAT

P 1-2

TOUCH

PAD

CNX-125

BOARD

P 1-2

MODEM

CARD

LATCH

DETECTOR

I/O

BRACKET

MBX-49

BOARD

P 1-4

LITHIUM

BATTERY

P 1-4

LCD Unit

Inverter Assy

Speaker Unit

DVD-ROM Drive

Combination Drive

(CD-RW/DVD-ROM)

PWS-13 Board

FD Drive

CNX-125 Board

MBX-49 Board

Speaker Unit

DC Fan

HDD

SWX-73 Board

Touch Pad

Modem Card

1-2

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

1-3.Removal

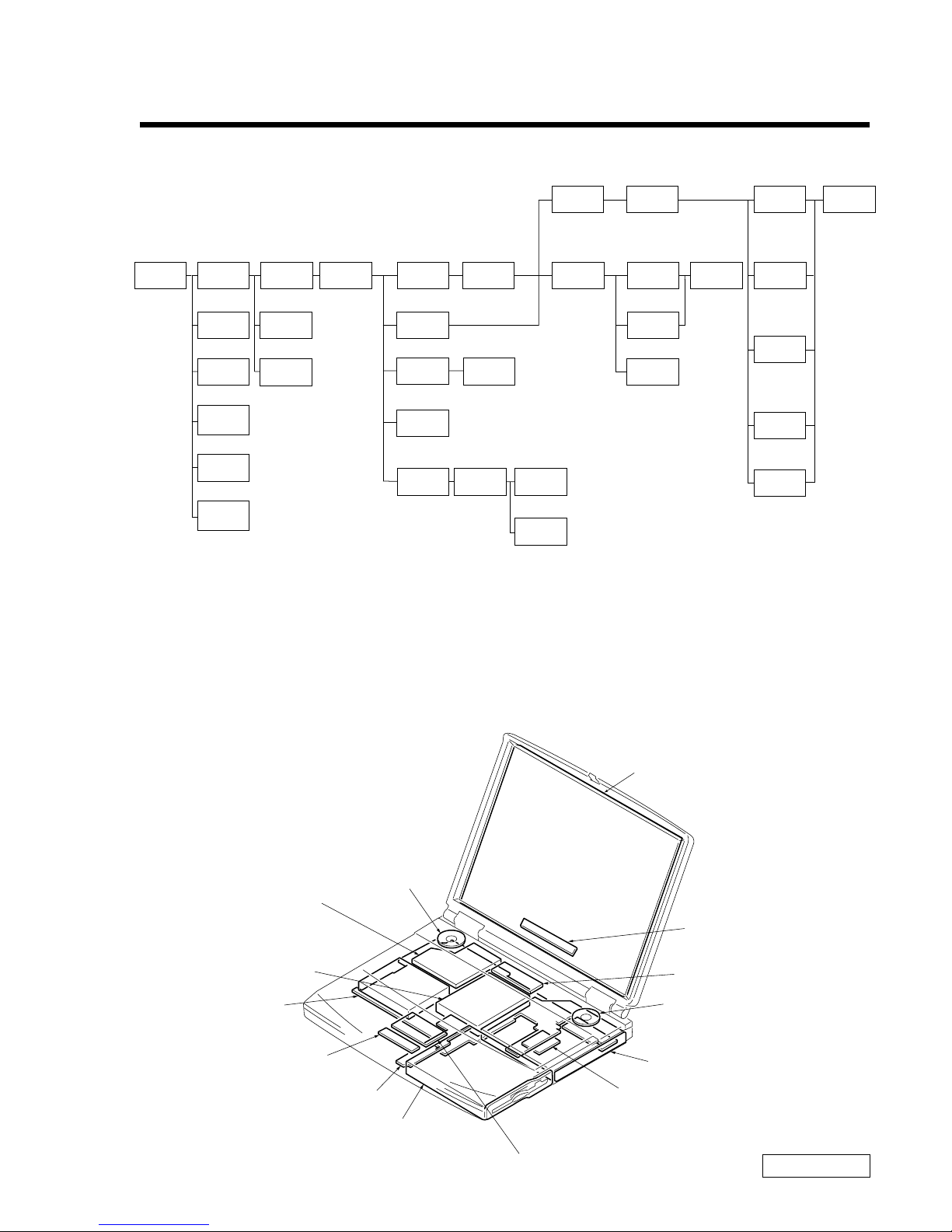

1. Hinge Cover

2. Keyboard Unit, Palm Rest Assy, Hood Keyboard Assy, Touch Pad, CNX-125 Board

2Hinge Cover

1Door I/O

3

4

2Hinge Cover

3Hood Keyboard Assy

6Keyboard Unit

0Palm Rest Assy

5

8M2X4

Special Head

(Black)

7Screw (M2),

0 Number P3 Kind (X4) (Black)

PWS-13 Board

CN4004

MBX-49 Board

CN2004

MBX-49 Board

CN1902

1M2X4 Special Head (Black)

4M2X4 Special Head (Black)

qsM2X4 Special Head (x4) (Black)

qhBracket Pat

qjTouch pad

qfPalm Rest

Plate

qkCNX-125

Board

2Pull it up sliding it

to the right.

9Pull it to the front slightly

and raise to remove it.

qdRemove by

pulling slightly

to the front

qgRemove by

pressing to

the rear

qa

1-3

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

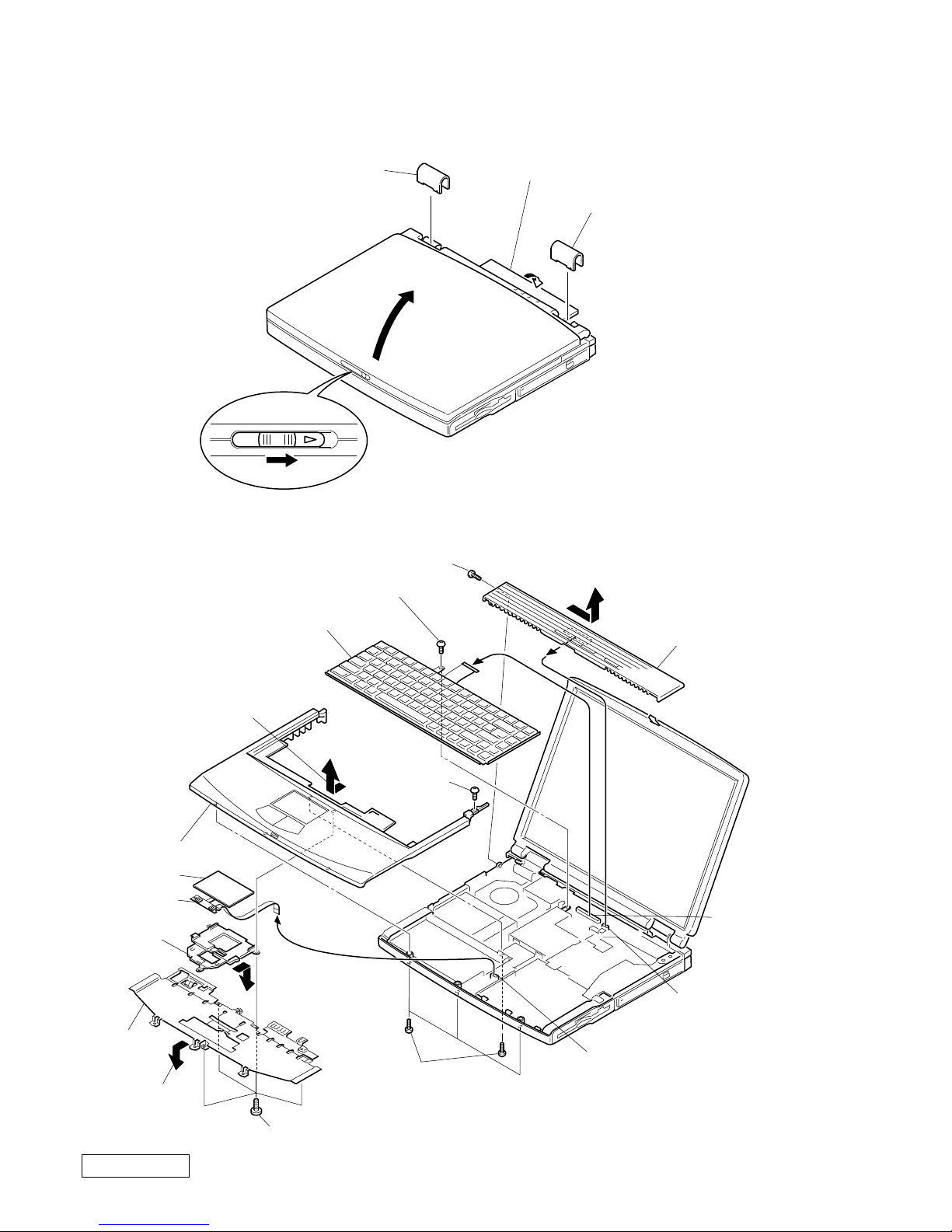

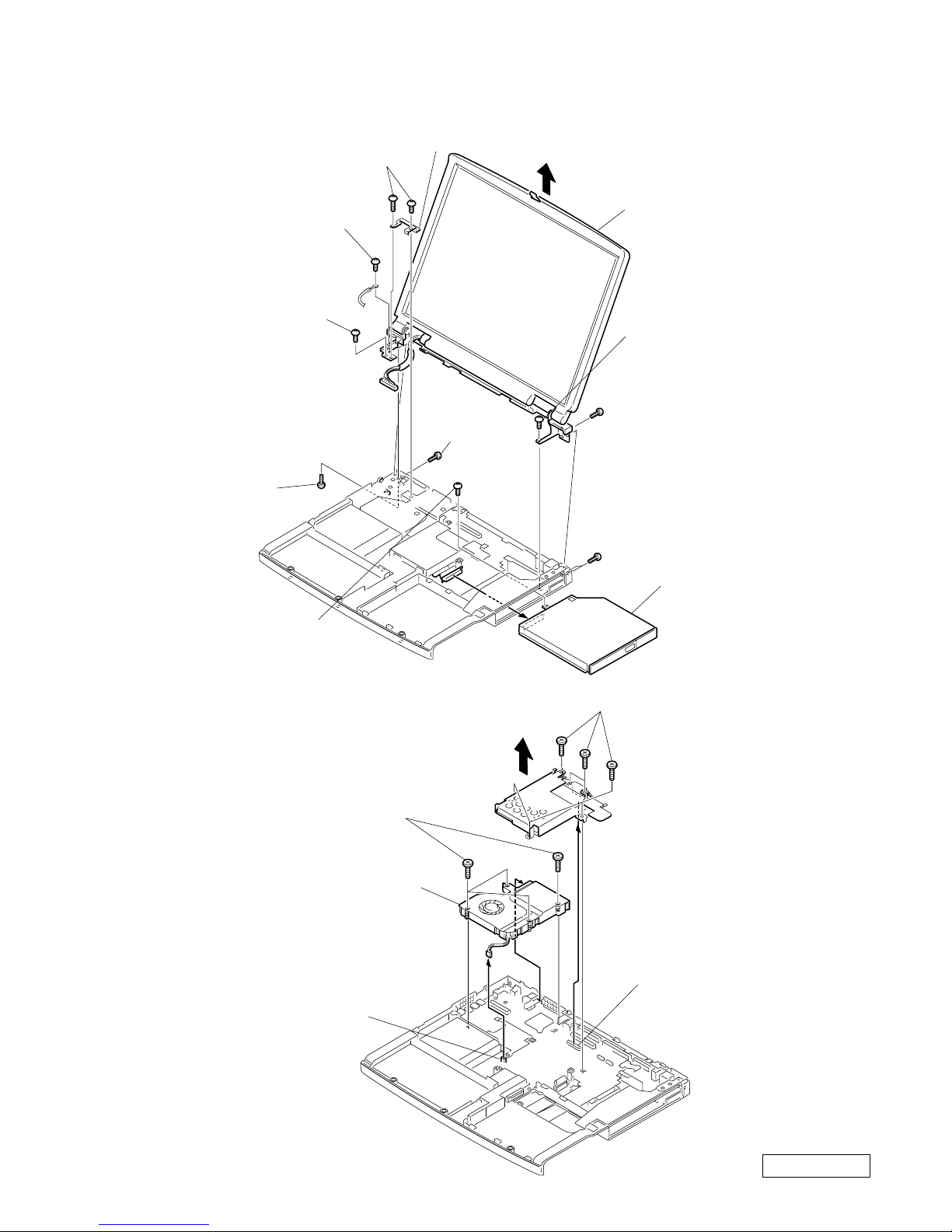

3. Display Assy, DVD-ROM Drive, Combination Drive (CD-R W/DVD-ROM)

4. HDD Assy, DC Fan

Display Assy

3

8M2X6 Special Head (Black)

9

1Screw (M2),

0 Number P3 Kind

(Black)

7M2X6

Special Head (Gold)

2M2X6 Special Head

(Gold)

6M2.6 Cross

(Hole) Bind

(Black)

6M2.6 Cross (Hole) Bind (X2) (Black)

6M2.6 Cross (Hole) Bind (Black)

4+B 2X12 (Black)

4+B M2 (X2) (Gold)

5Plate Ground

DVD-ROM Drive

Combination Drive

(CD-RW/DVD-ROM)

6DC Fan

5

MBX-49 Board

CN102

3HDD Assy

2FPC 50 Pin (for HDD)

1M2X6 Special Head (X6) (Gold)

4Screw (M2) 0 Number

P3 Kind (X4) (Black)

MBX-49 Board

CN2201

1-4

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

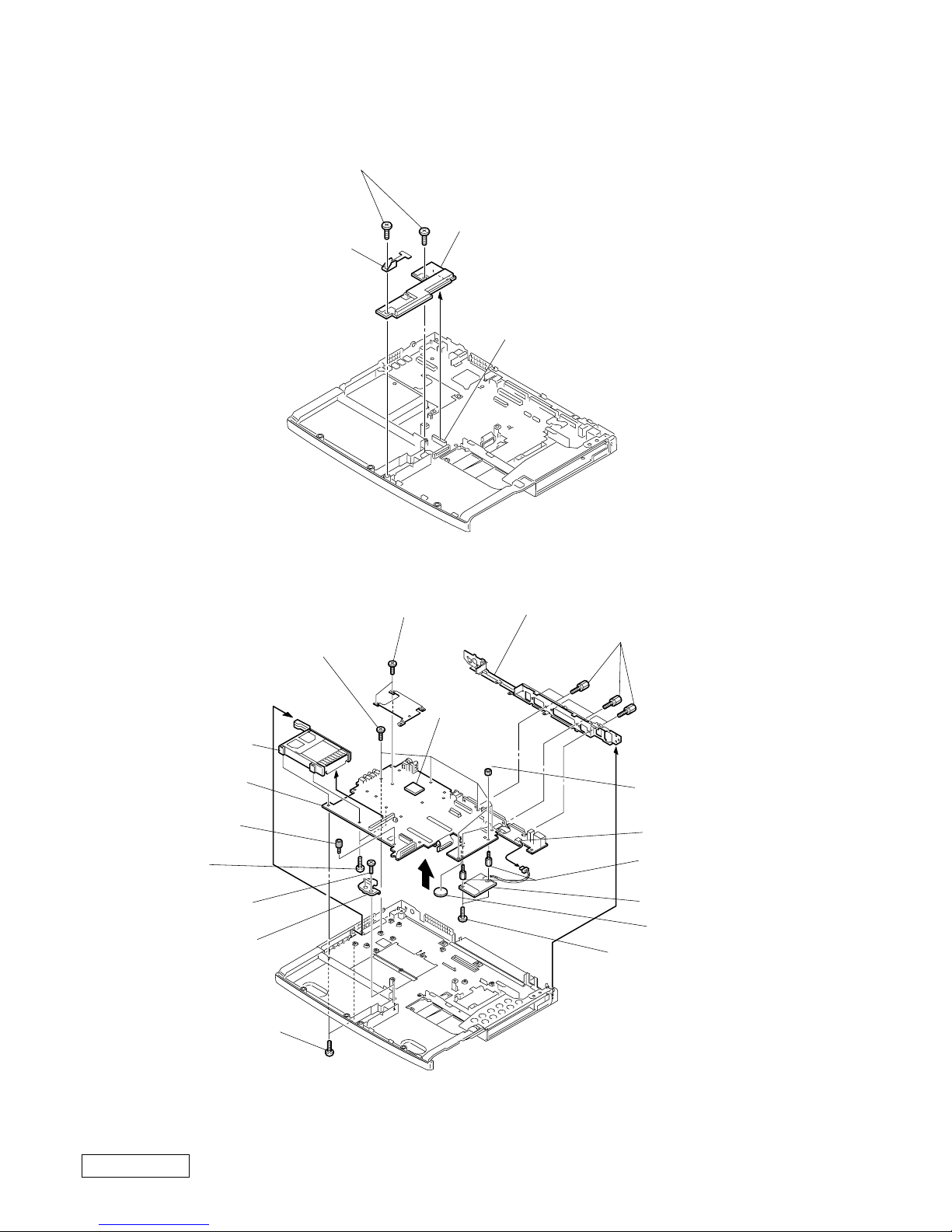

5. Latch Detector, PWS-13 Board

6. PC Card Connector, Modem Card, MBX-49 Board, Lithium Battery

∗1 When removing the CPU, refer to “ 1-4. Replacing the CPU ”.

∗2 Modem card can be removed from the bottom.

Refer to the subsequent paragraph “ 9. Modem card ” for more details.

4PWS-13 Board

3

2Latch Detector

1M2X4 Special Head (X2) (Black)

MBX-49 Board CN2701

qkMBX-49 Board

9PC Card Connector

qdM2 Grip (X2) (Black)

8+B 2X14 (X2)

(Silver)

3Screw (MBX)

(Silver)

qjI/O Bracket

qhScrew (HEX) (X6) (Silevr)

7

qs

5Bracket Bay Connector

4M2X4 Special Head

(X2) (Black)

CN151

Modem Card

*

2

qsNUT M2 TYPE2 (X2)

CPU

*

1

1M2X4 Special Head

(X2) (Black)

2M2X4 Special Head

(X5) (Black)

6Screw (M2) 0 Number

P3 Kind (X2) (Black)

0Lithium Battery

qgSpacer (MBX)

(X2)

1-5

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

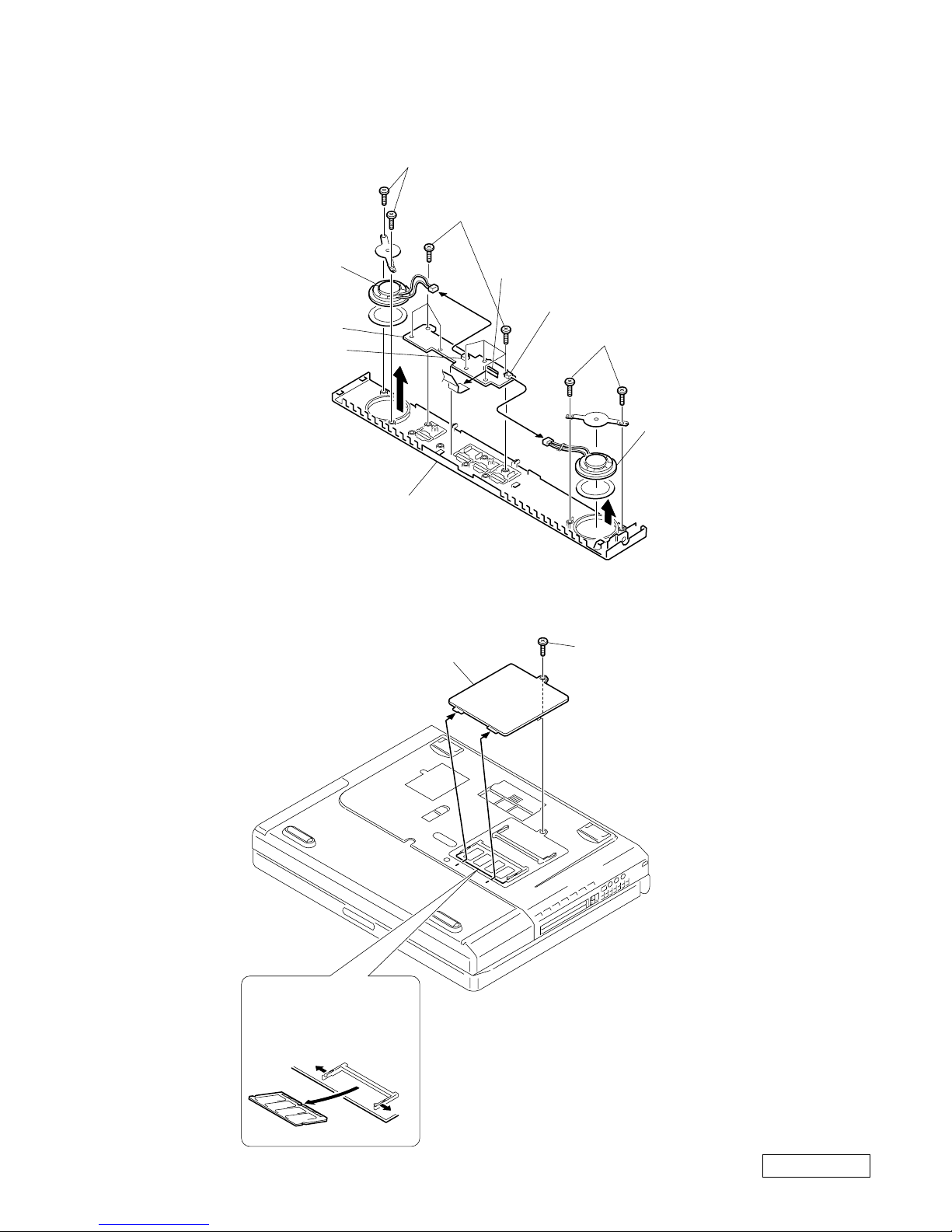

7. Speaker Unit, SWX-73 Board

8. SO-DIMM

4Speaker Unit

6Hood Keyboard

5SWX-73 Board

4Speaker Unit

2M2X4 (X7) (Black)

1

1

1

3M2X4 (X2) (Black)

3M2X4 (X2) (Black)

SWX-73 Board

CN303

SWX-73 Board

CN301

SWX-73 Board

CN302

2DIMM Door

1M2X4 Special Head (Black)

b

a

a

Removal of SO-DIMM

a → b

1-6

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

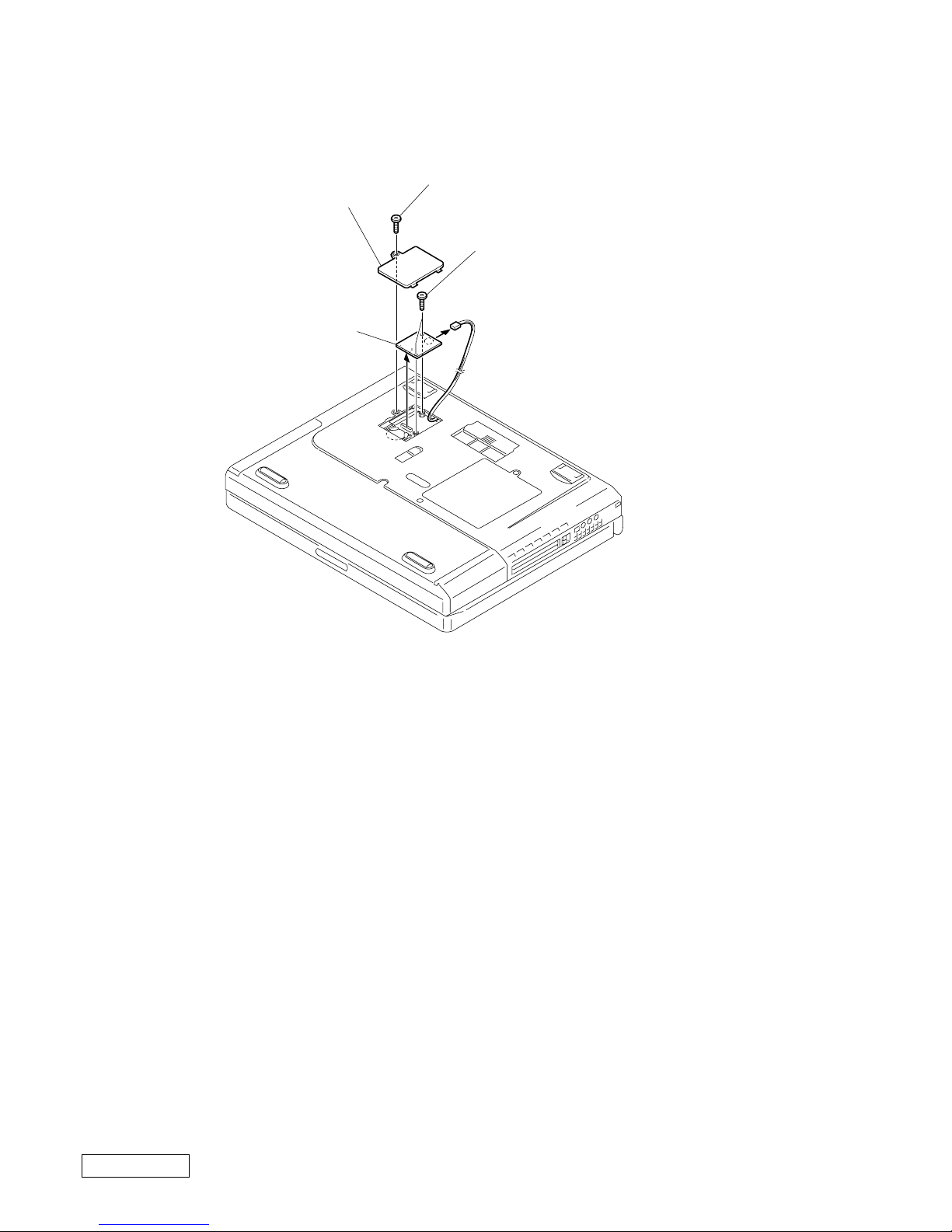

9. Modem Card

2Modem Door

4Modem Card

1M2X4 Special Head (Black)

3M2 Grip (X2) (Black)

5

1-7

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

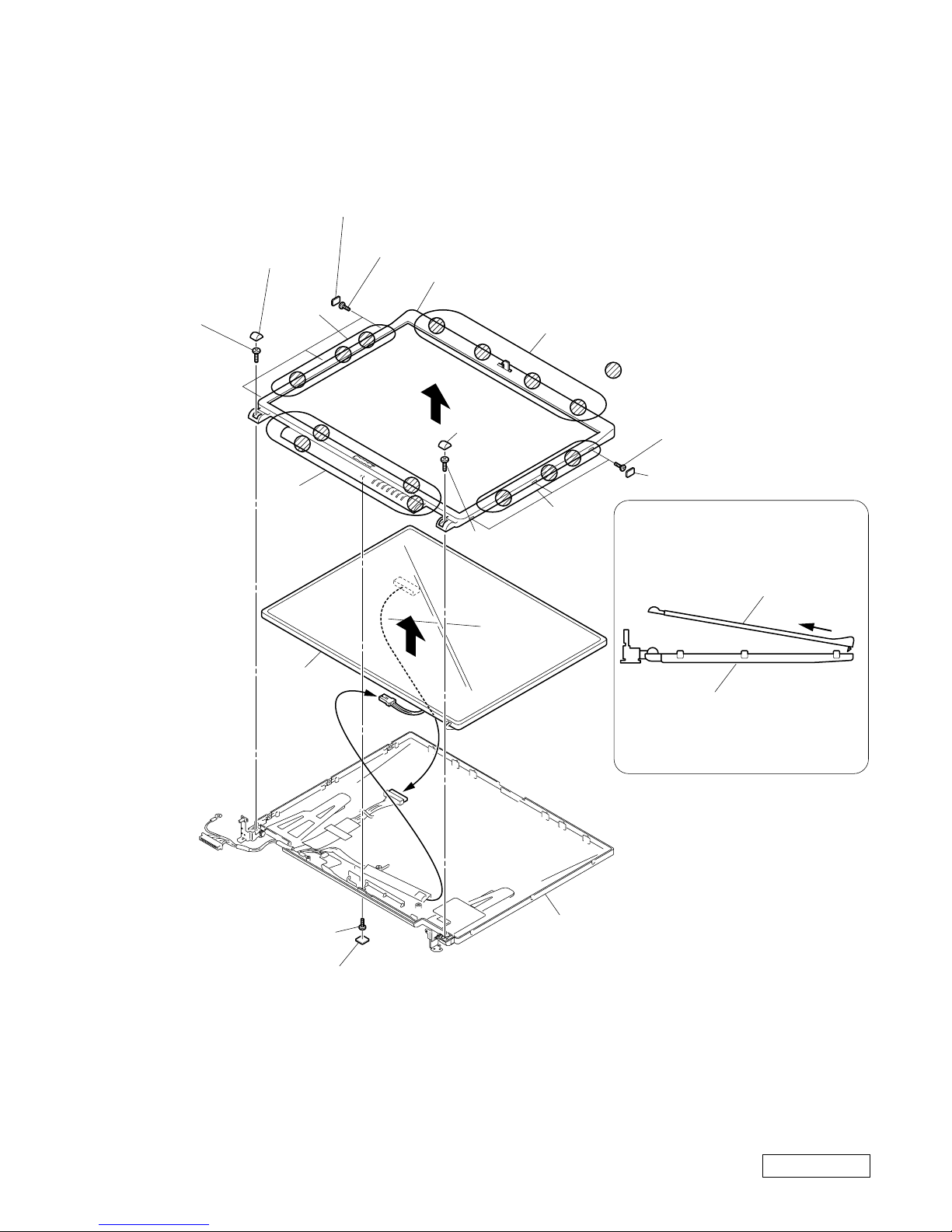

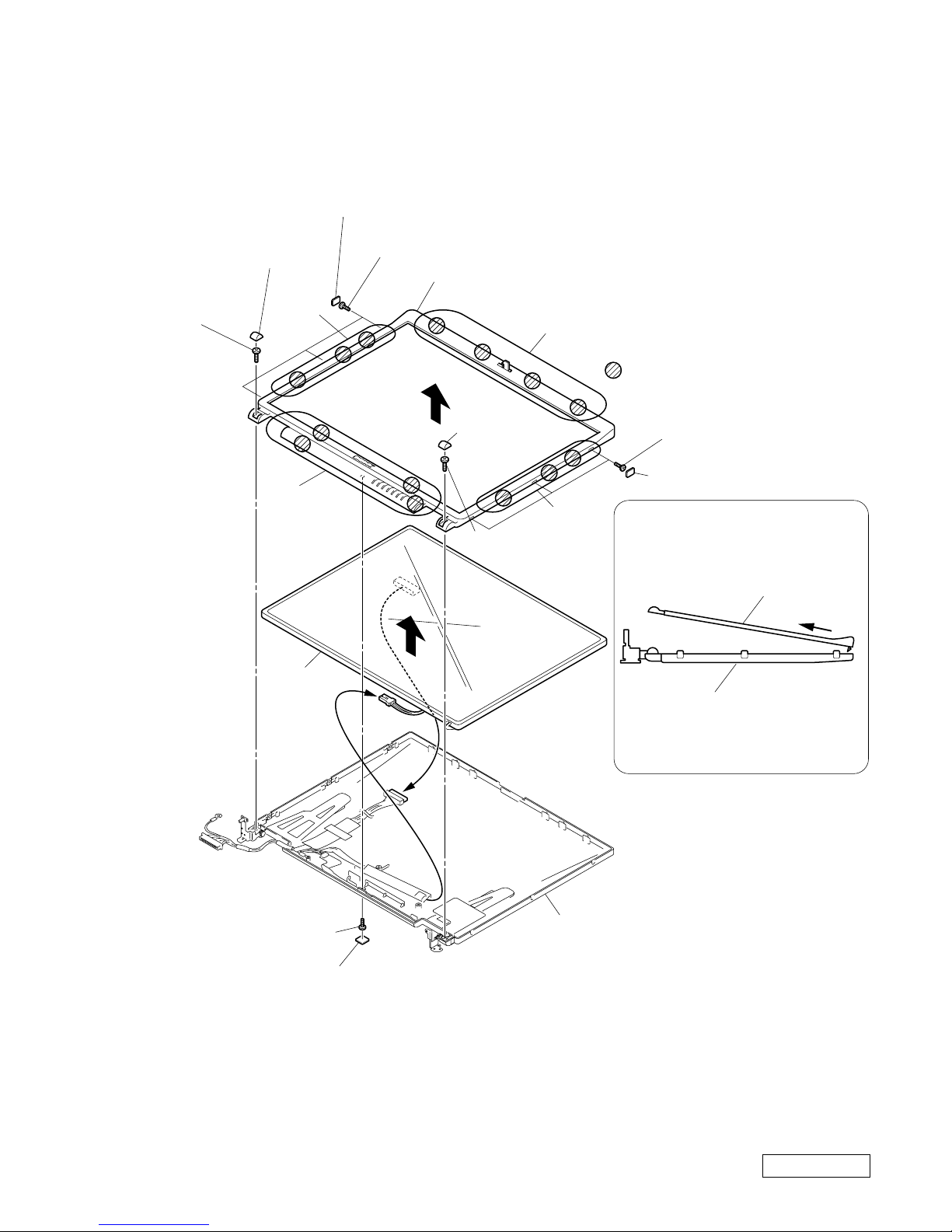

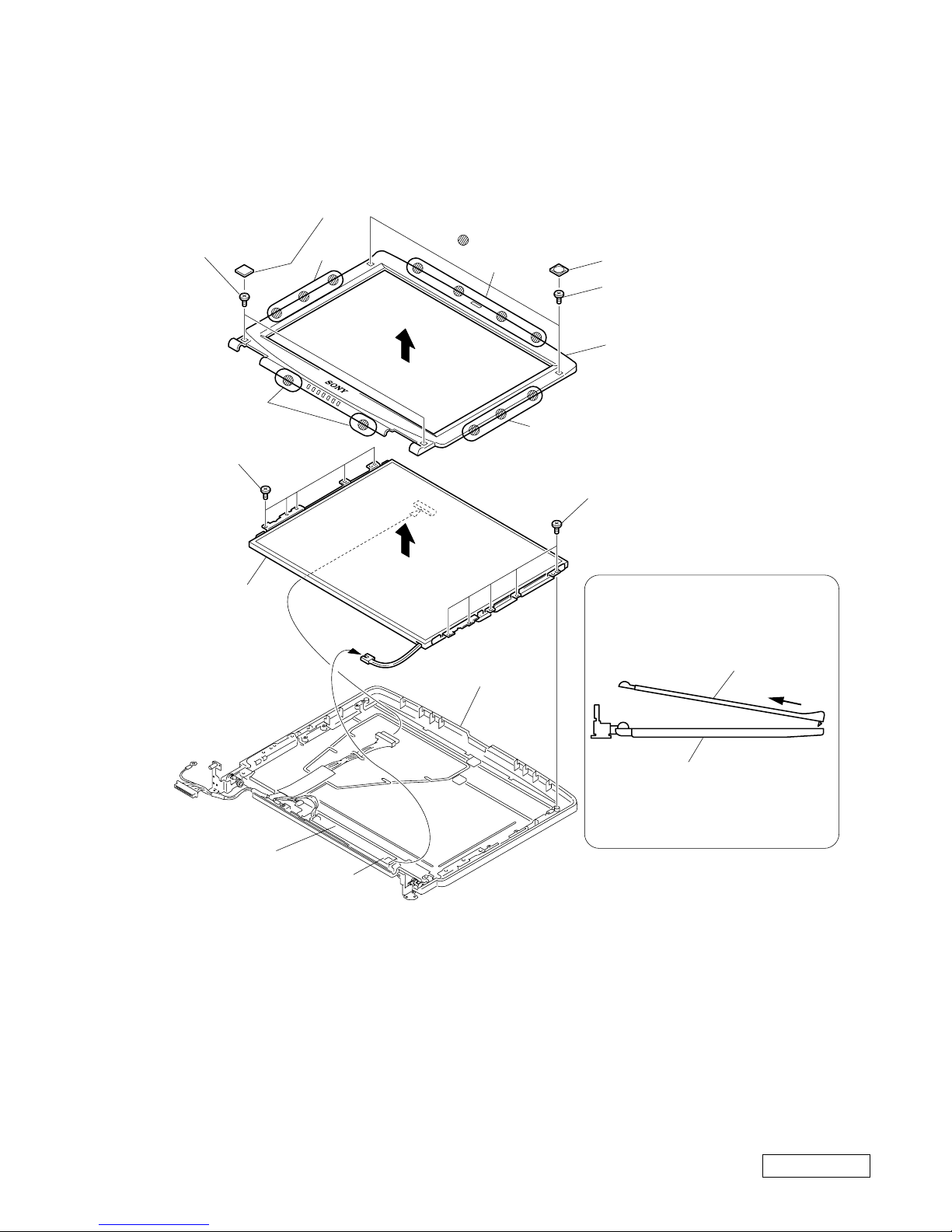

10. LCD Section (FX190 Model) – Made by SA –

1. Bezel Housing Assy, LCD Unit (15 inch)

How to release the claw A.

Pull the Bezel Housing Assy

as shown to release the claw A.

Bezel Housing Assy

Display Housing Assy

A

Order of releasing the claws C → B → A

Order of locking the claws A → B → C

Display Housing Assy

: claw part

1Side (15) Screw Cover (X3) (Gold)

5Lower Screw Cover

3Cover Screw

Shaft

3Cover Screw

Shaft

4+P 2.6X6

Lock Precision

Type3 (Black)

4+P 2.6X6 Lock

Precision Type3

(Black)

6M2X4 Special Head

(Black)

1Side (15) Screw Cover (X3)

2+P M2X3 (X3) (Gold)

2+P M2X3 (X3)

A

B

7

0

8

9

B

C

Bezel Housing Assy

LCD unit

1-8

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

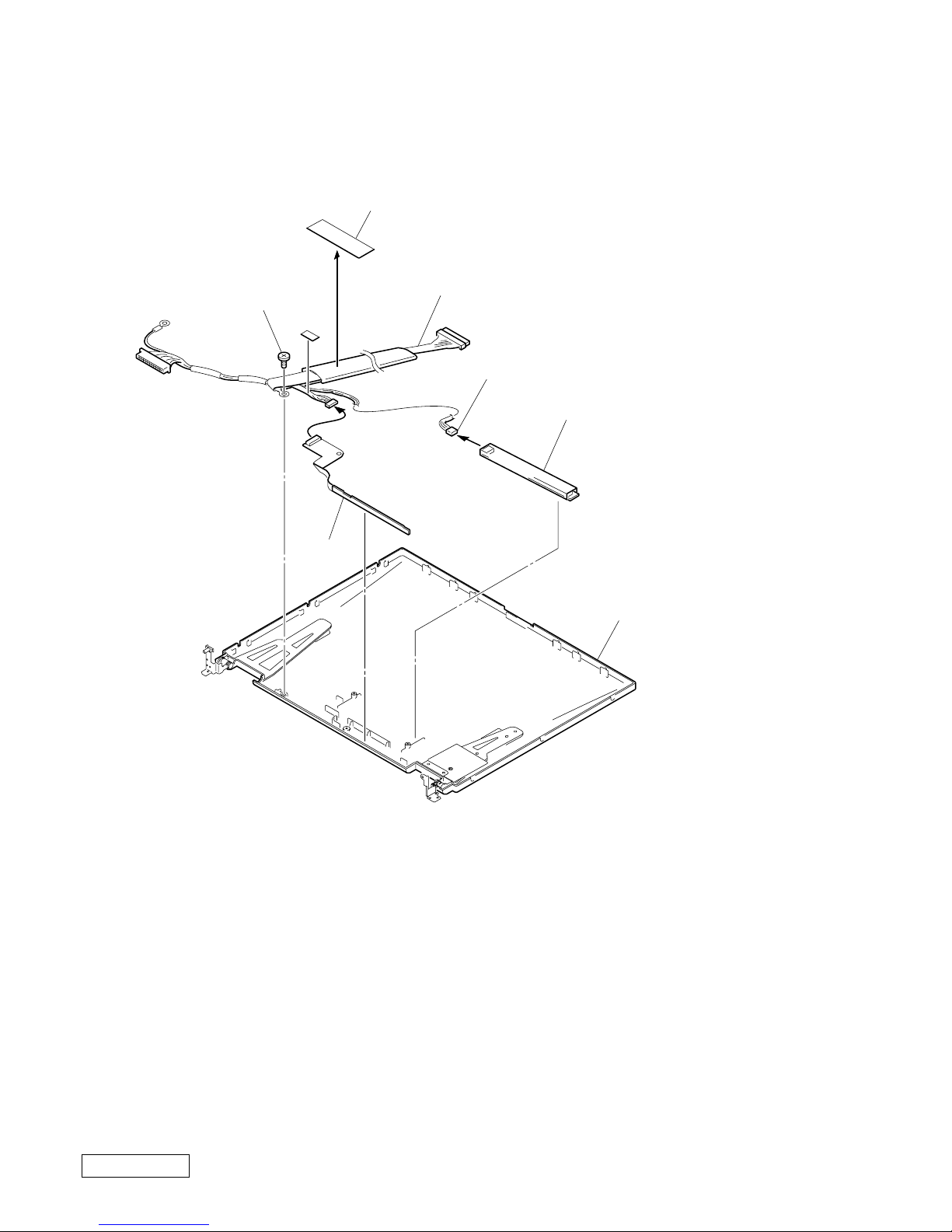

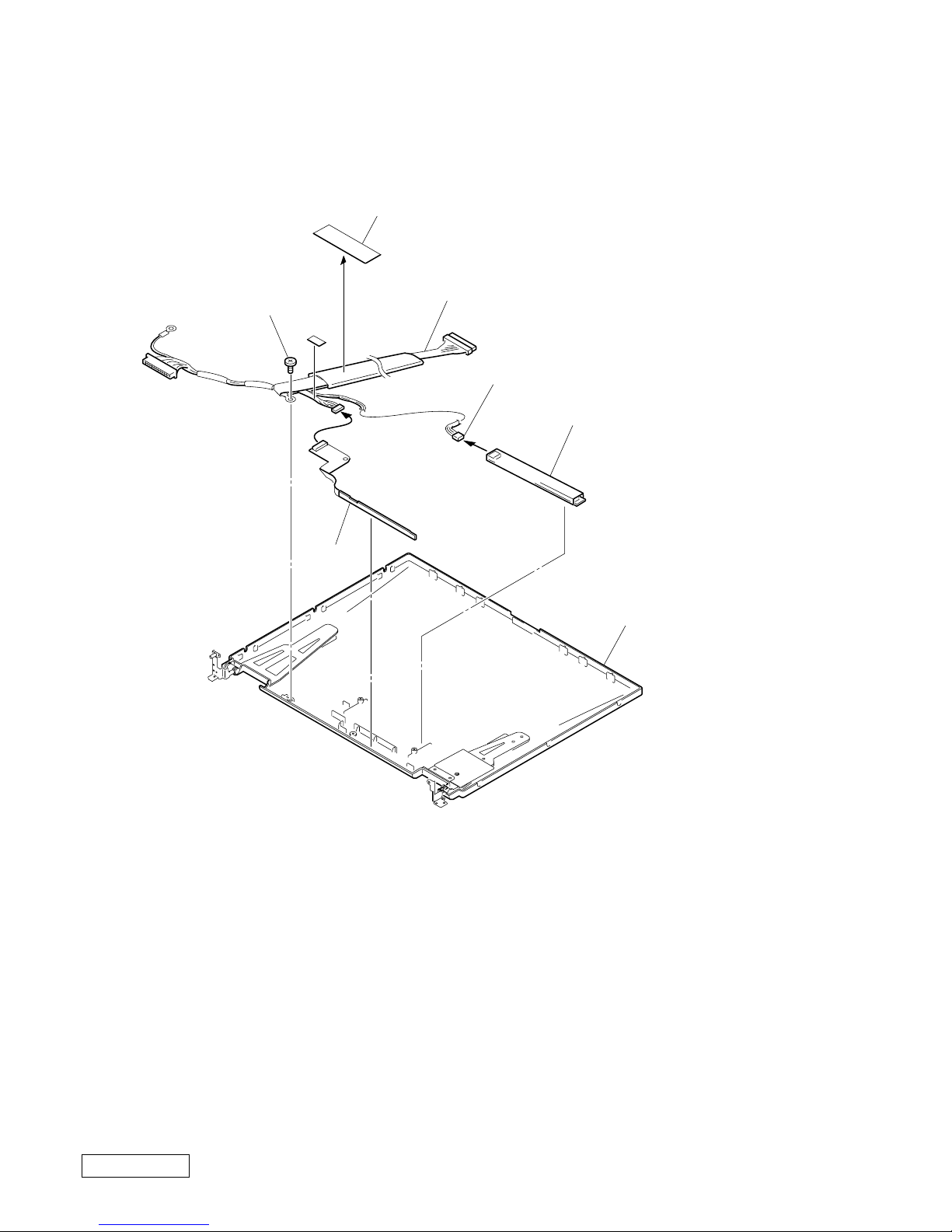

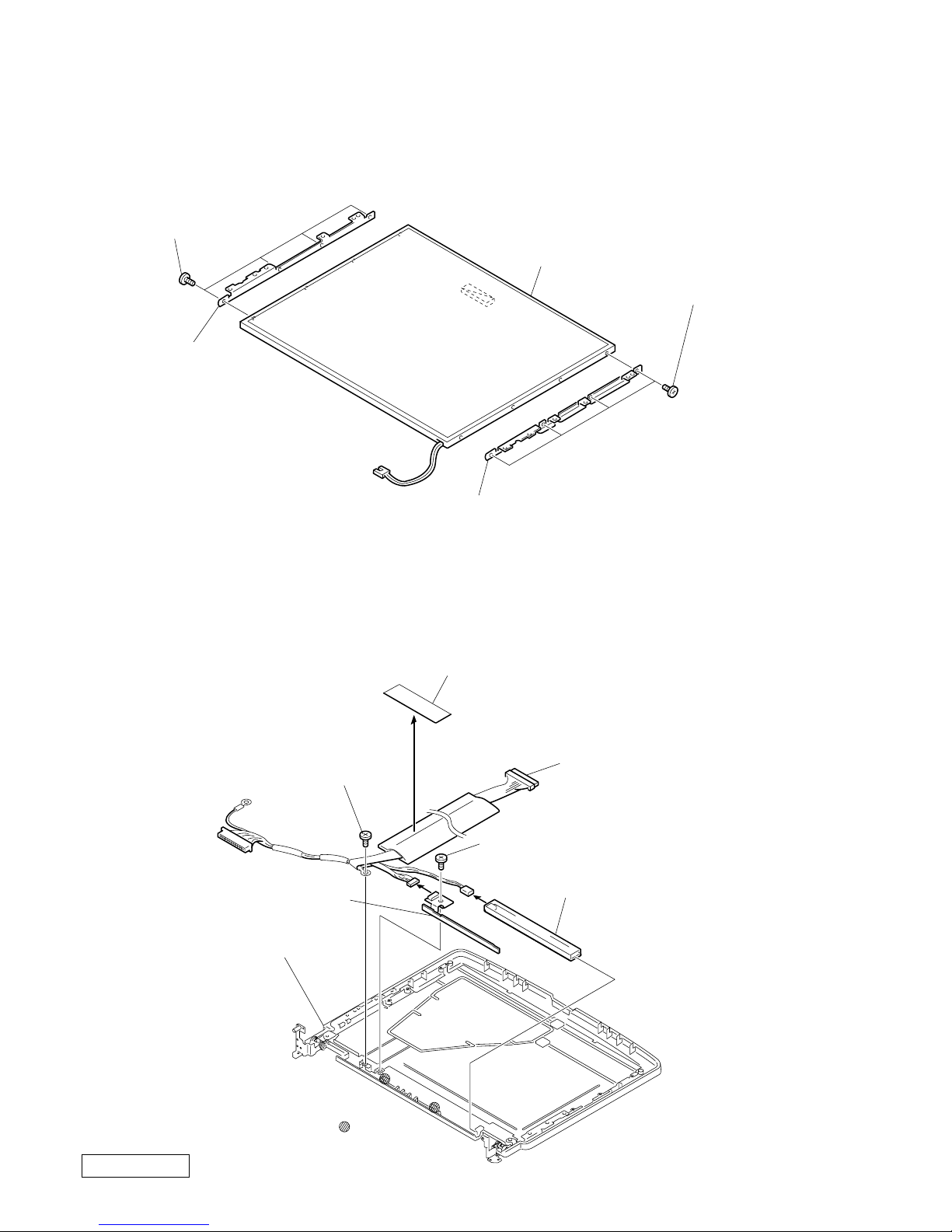

2. Inverter Assy, LCD Harness, FPC, Display Housing Assy

1

3

2Inverter Assy

9Display Housing Assy

Inverter Assy

CN2

4FPC

7M2X4 Special Head

(Black)

8LCD Harness

5

6Shield Tape (SK)

1-9

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

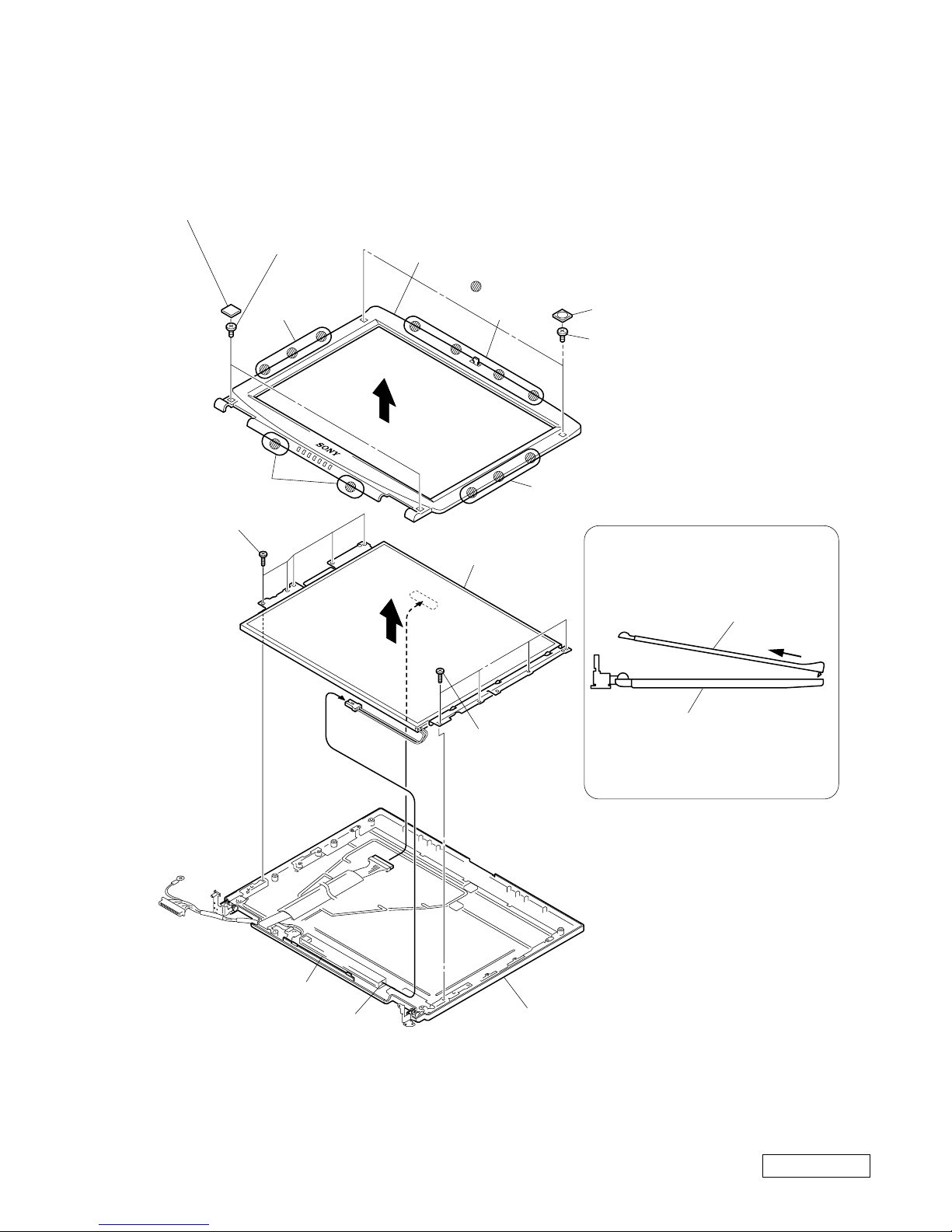

11. LCD Section (FX150/FX170 Model) – Made by SA –

1. Bezel Housing Assy, LCD Unit (15 inch)

How to release the claw A.

Pull the Bezel Housing Assy

as shown to release the claw A.

Bezel Housing Assy

Display Housing Assy

A

Order of releasing the claws C → B → A

Order of locking the claws A → B → C

Display Housing Assy

: claw part

1Side (15) Screw Cover (X3) (Gold)

5Lower Screw Cover

3Cover Screw

Shaft

3Cover Screw

Shaft

4+P 2.6X6

Lock Precision

Type3 (Black)

4+P 2.6X6 Lock

Precision Type3

(Black)

6M2X4 Special Head

(Black)

1Side (15) Screw Cover (X3)

2+P M2X3 (X3) (Gold)

2+P M2X3 (X3)

A

B

7

0

8

9

B

C

Bezel Housing Assy

LCD unit

1-10

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

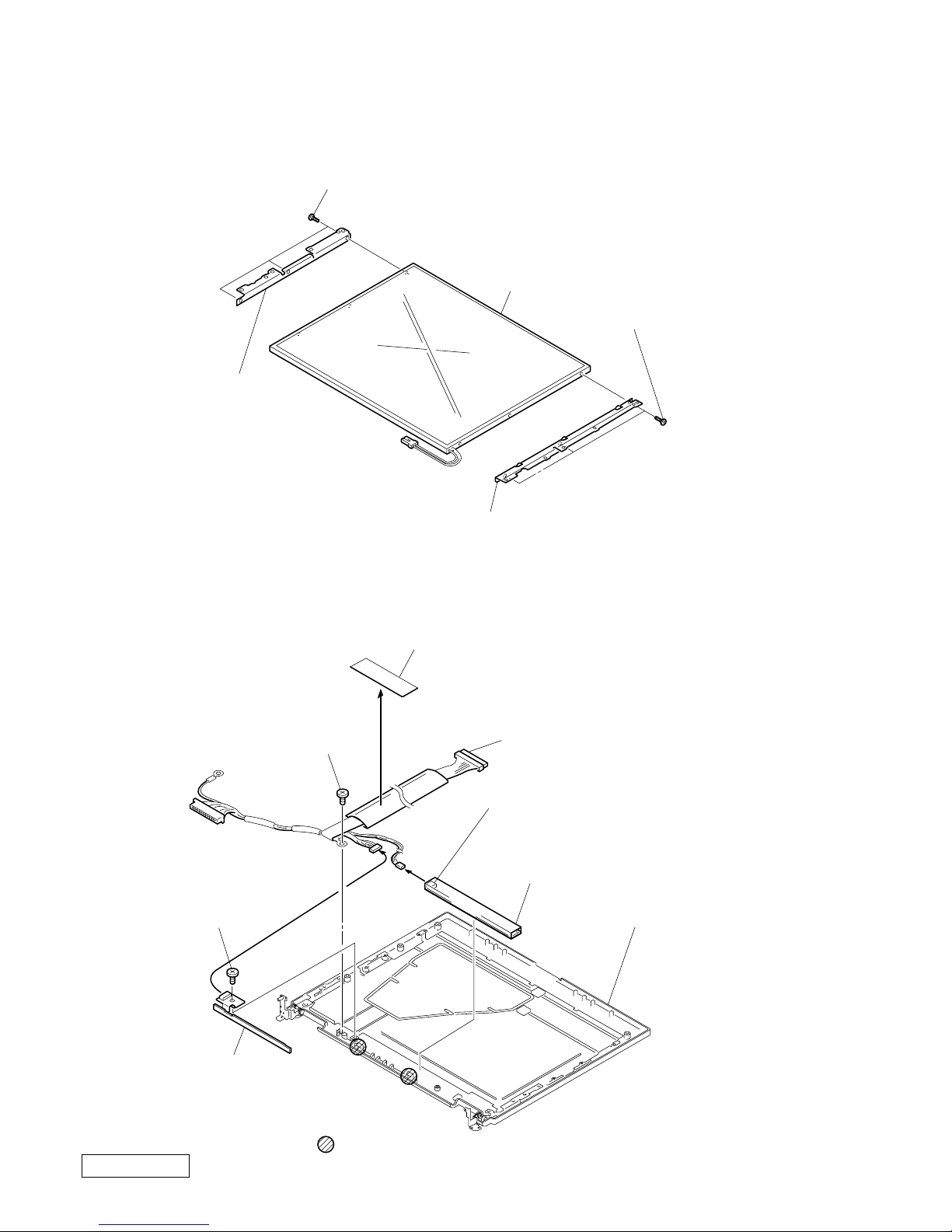

2. Inverter Assy, FPC, Display Housing Assy

1

3

2Inverter Assy

9Display Housing Assy

Inverter Assy

CN2

4FPC

7M2X4 Special Head

(Black)

8LCD Harness

5

6Shield Tape (SK)

1-11

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

12. LCD Section (FX140 Model) – Made by SA–

1. Bezel Housing Assy

Order of releasing the claws c → b → a

Order of locking the claws a → b → c

How to release the claw a

5

a

Pull the Bezel Housing

Assy as shown to release

the claw a.

: claw part

a

b

c

b

1Cover Screw Lower

1Cover Screw Upper

2M2X4 Special

Head (X2) (Black)

2M2X4 Special Head (X2)

(Black)

4M2X4 Special Head (X5) (Black)

4M2X4 Special

Head (X5) (Black)

6

7

3

Display Housing Assy

Inverter Assy

Inverter Assy

CN2

Bezel Housing Assy

Display Housing Assy

Bezel Housing Assy

LCD Unit

1-12

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

2. Bracket LCD Left, Bracket LCD Right, LCD Unit (14 inch)

3. FPC, Inverter Assy, Display Housing Assy, LCD Harness

5LCD Unit

2Bracket LCD Right

4Bracket LCD Left

1+P M2x3 Lock (X4)

(Black)

3+P M2x3 Lock (X4)

(Black)

: claw part

5M2X4 Special Head (Black)

6M2X4 Special Head

(Black)

9Display Housing Assy

4FPC

2Inverter Assy

3

1

7

8Shield Tape (SK)

0LCD Harness

1-13

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

13. LCD Section (FX120 Model) – Made by AC–

1. Bezel Housing Assy

Bezel Housing Assy

Display Housing Assy

A

7

4M2X4

Special

Head (X5) (Black)

6

5

LCD Unit

How to release the claw A.

Pull the Bezel Housing Assy

as shown to release the claw A.

: claw part

B

B

3

1Upper Screw Cover (x2)

2M2X4

Special

Head (X2) (Black)

2M2X4

Special

Head (X2)

(Black)

1Lower Screw Cover (x2)

A

C

Bezel Housing Assy

Display Housing Assy

Inverter Assy

CN2

Inverter Assy

4M2X4

Special

Head (X4)

(Black)

Order of releasing the claws C → B → A

Order of locking the claws A → B → C

1-14

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

2. Bracket LCD Left, Bracket LCD Right, LCD Unit (13 inch)

3. FPC, Inverter Assy, Display Housing Assy, LCD Harness,

5LCD Unit

1+PS M2x3 (X3) (Black)

1+PS M2X3 (X3) (Black)

4Bracket LCD Left

2Bracket LCD Right

: claw part

9M2X4

Special Head (Black)

4M2X4

Special Head

(Black)

Inverter Assy

CN1

2Inverter Assy

qaDisplay Housing Assy

7

8Shield Tape (SK)

5FPC

3

1

0LCD Harness

1-15

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

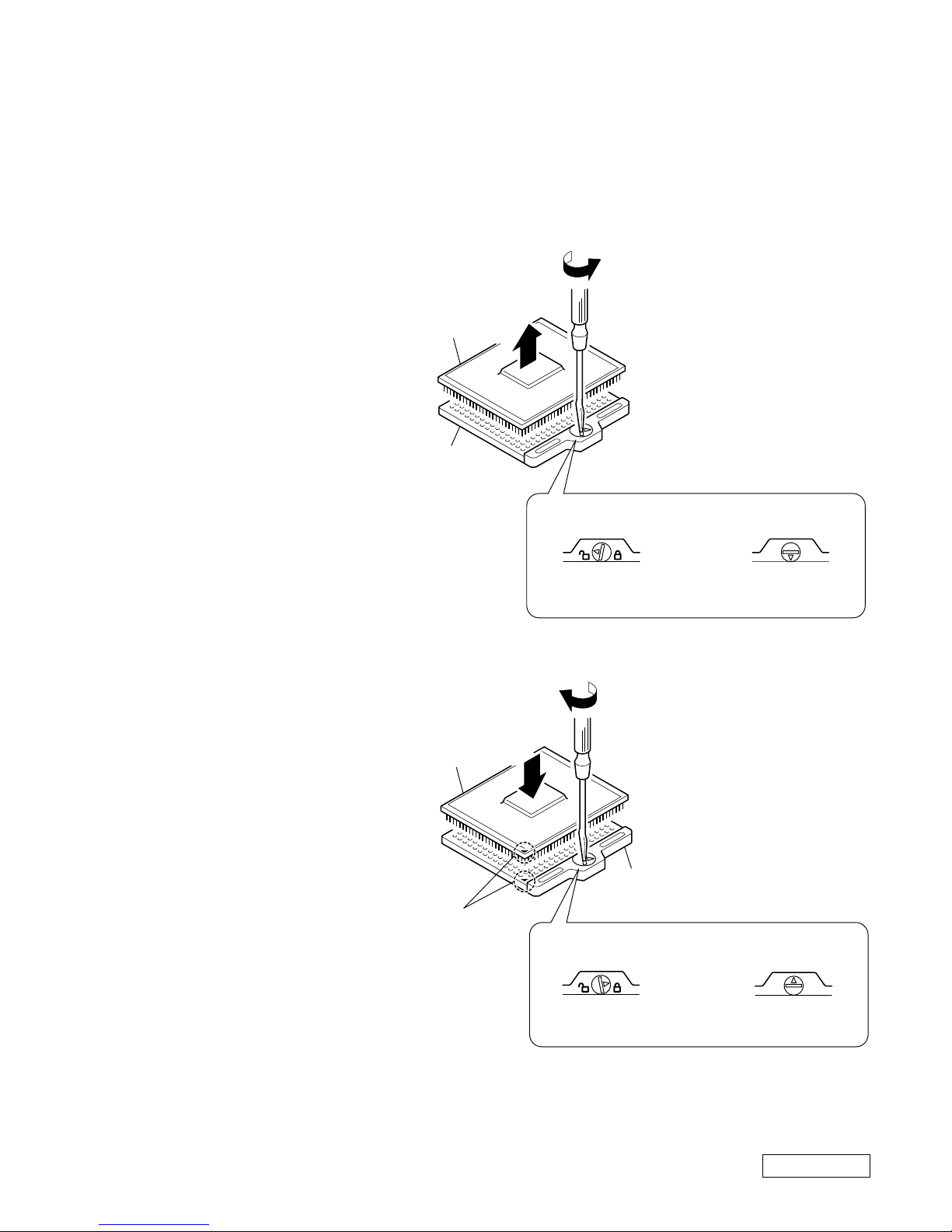

1-4.Replacing the CPU

NOTE:

This computer uses either one of the two types of CPU socket.

The CPU locking position and the lock-release position are different depending on the types of the CPU socket.

1. Removing the CPU

2. Installing the CPU

1 Align the triangle reference mark of

the CPU with that of the CPU socket

and insert all the pins of the CPU to

the corresponding holes of the CPU

socket.

2 Insert a flat-blade screwdri ver into the

notch as shown in the illustration and

rotate it so that the protrusion comes

to the lock position.

1 Insert a flat-blade screwdriv er into the

notch as shown in the illustration and

rotate it so that the protrusion comes

to the lock release position.

2 Pull the CPU gently upward to lift it

out of the CPU socket.

NOTE:

Rotate a flat-blade screwdriver to the lock position securely. If not, the operation of the CPU may become unstable.

1

2

FX120/FX140 Model FX150/FX170/

FX190 Model

2

1

FX120/FX140 Model FX150/FX170/

FX190 Model

CPU socket

CPU

Lock release position

(made by HIROSE)

Lock release position

CPU socket

CPU

Lock position

(made by HIROSE)

Lock position

Reference

marks

1-16

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

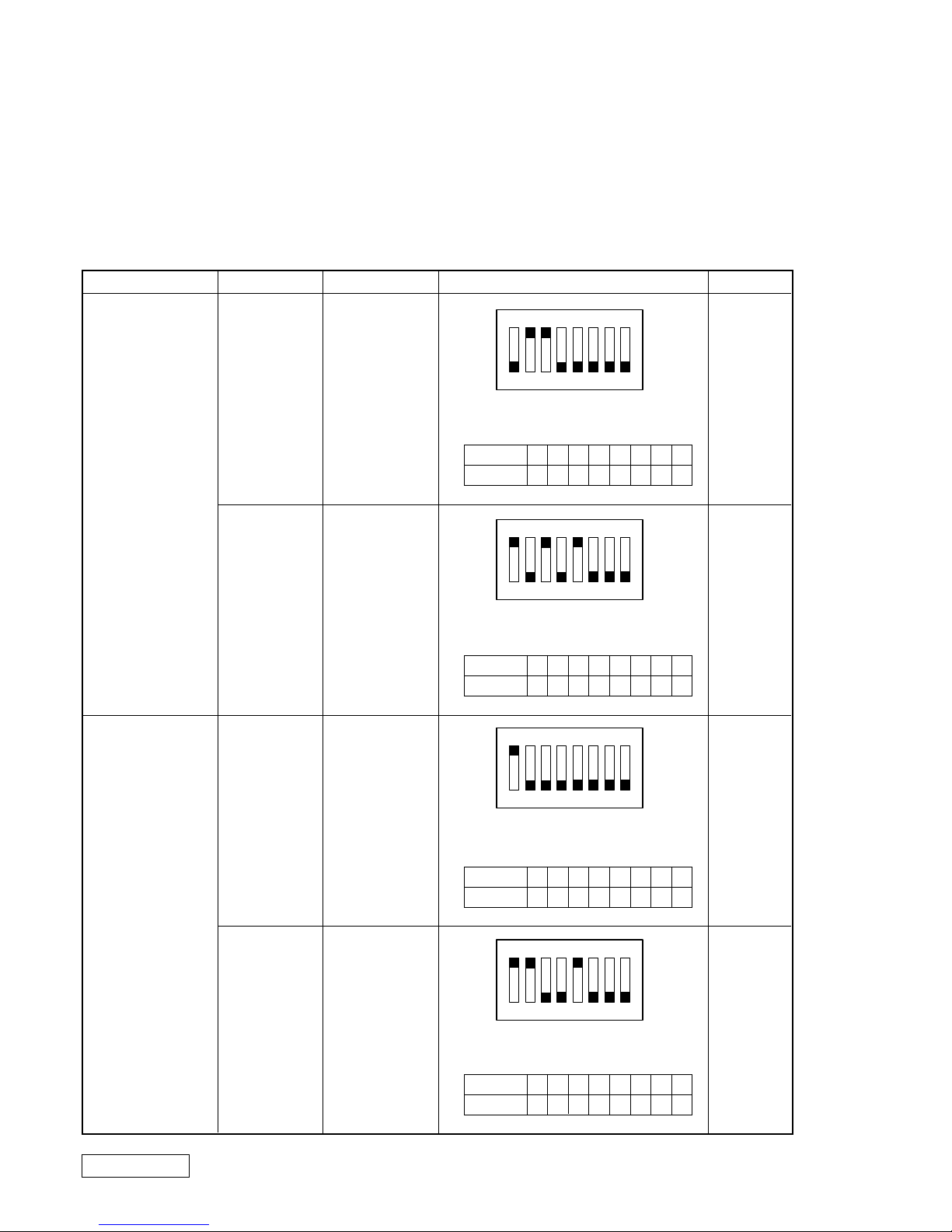

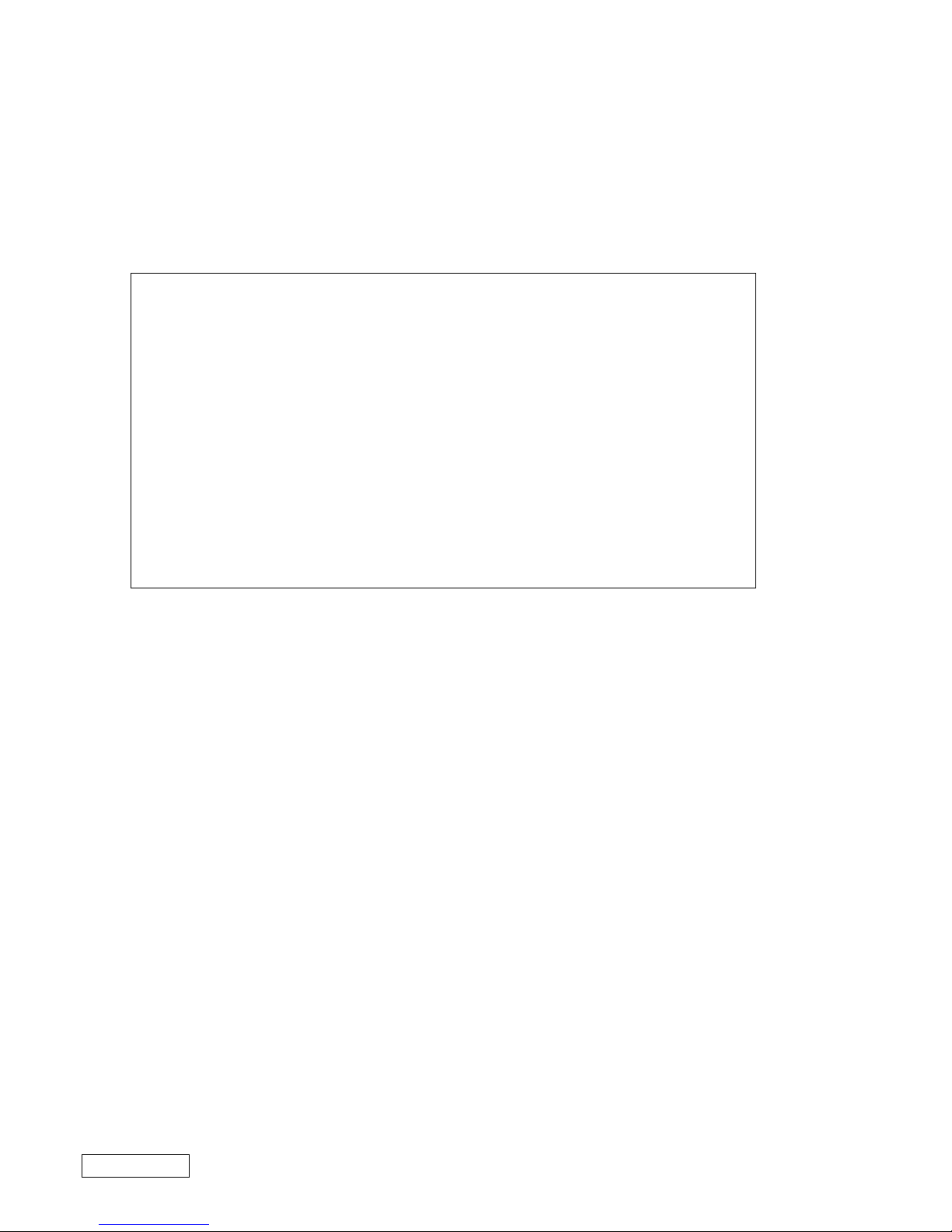

1-5. DIP Switch Setting of the MBX-49 Board

The DIP switch on the MBX-49 board (main board) is set to match with the LCD that is used in this computer,

because several types of LCD are used as shown in the following table and the DIP switch setting differs depending

on the LCD type.

NOTE:

The main LCD is used in most cases but there are also cases that the sub LCD is used.

MODEL

FX190

FX150/FX170

Name of LCD

SA

HI

SA

HI

Part No.

1-476-576-11

A-8048-250-A

1-418-574-41

A-8066-124-A

DIP switch setting

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

12345678

10011111

0 : ON 1: OFF

No.

ON/OFF

12345678

01010111

0 : ON 1: OFF

No.

ON/OFF

12345678

01111111

0 : ON 1: OFF

No.

ON/OFF

12345678

00110111

0 : ON 1: OFF

No.

ON/OFF

Note

Main

Sub

Main

Sub

1234567

8

O

N

1234567

8

O

N

1234567

8

O

N

1234567

8

O

N

1-17

Confidential

PCG-FX120/FX140/FX150/FX170/FX190 (UC)

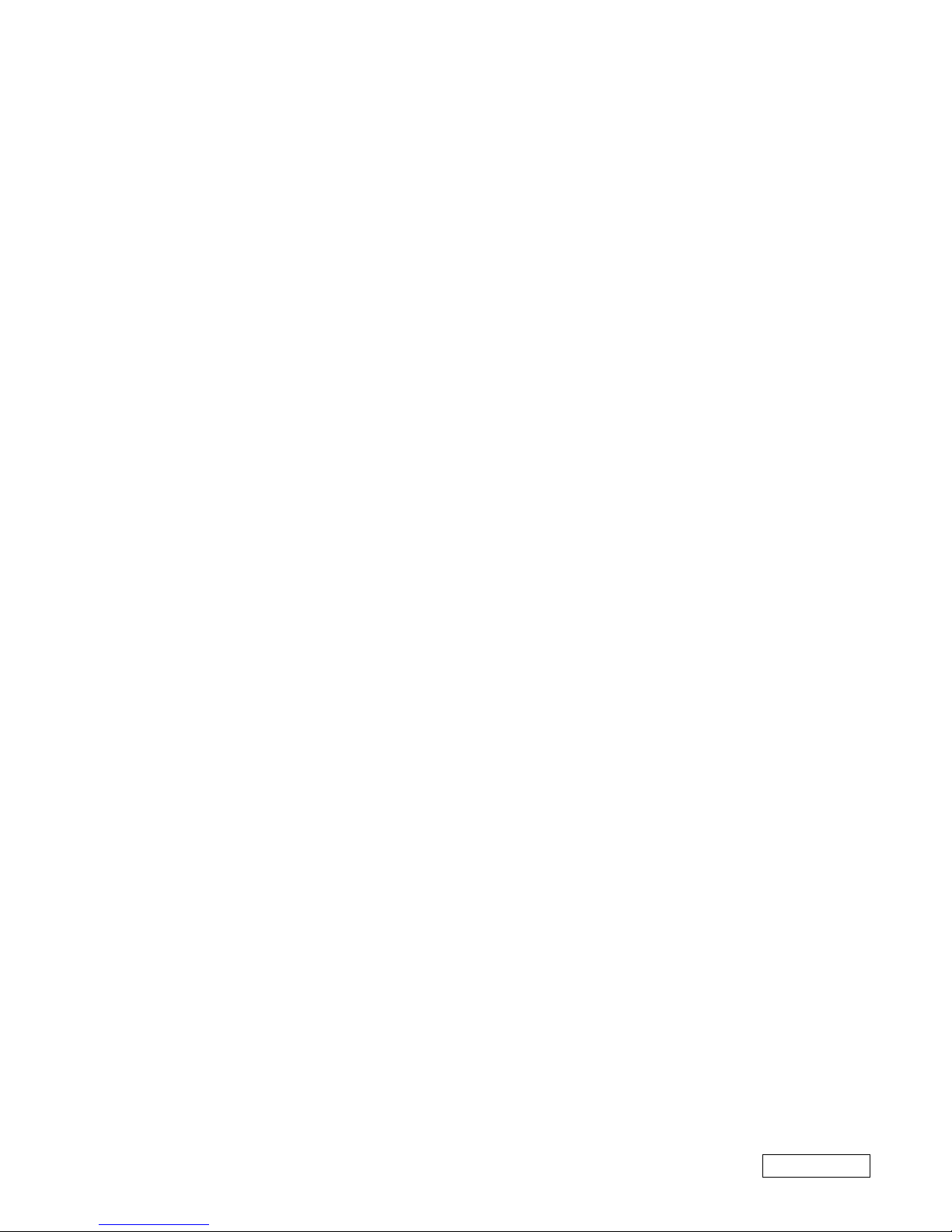

(END)

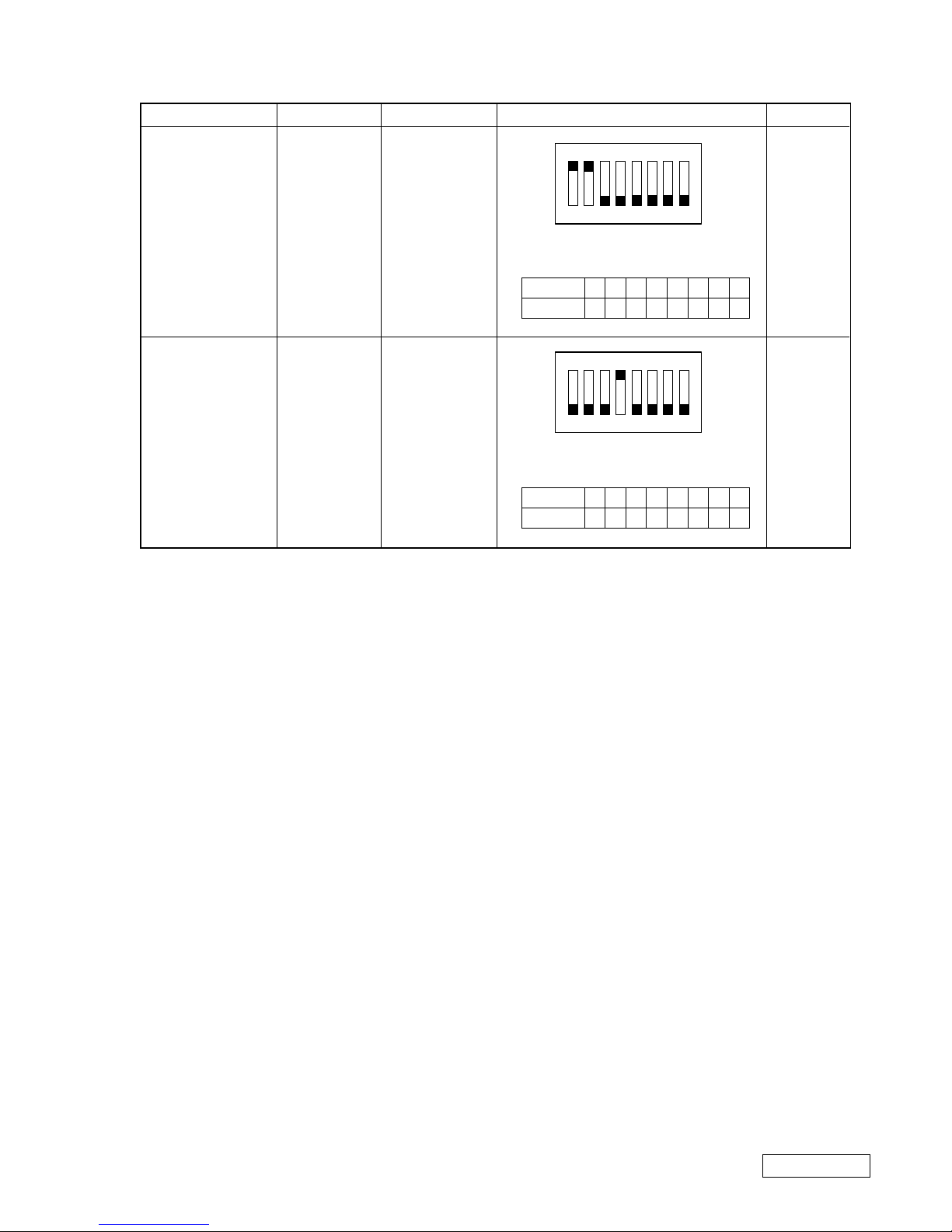

MODEL

FX140

FX120

Name of LCD

SA

AC

Part No.

1-418-716-21

1-418-882-11

DIP switch setting

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

The upper position where ON indication is

shown is the ON position .

The lower position is the OFF position.

Note

Main

Main

12345678

00111111

0 : ON 1: OFF

No.

ON/OFF

12345678

11101111

0 : ON 1: OFF

No.

ON/OFF

1234567

8

O

N

1234567

8

O

N

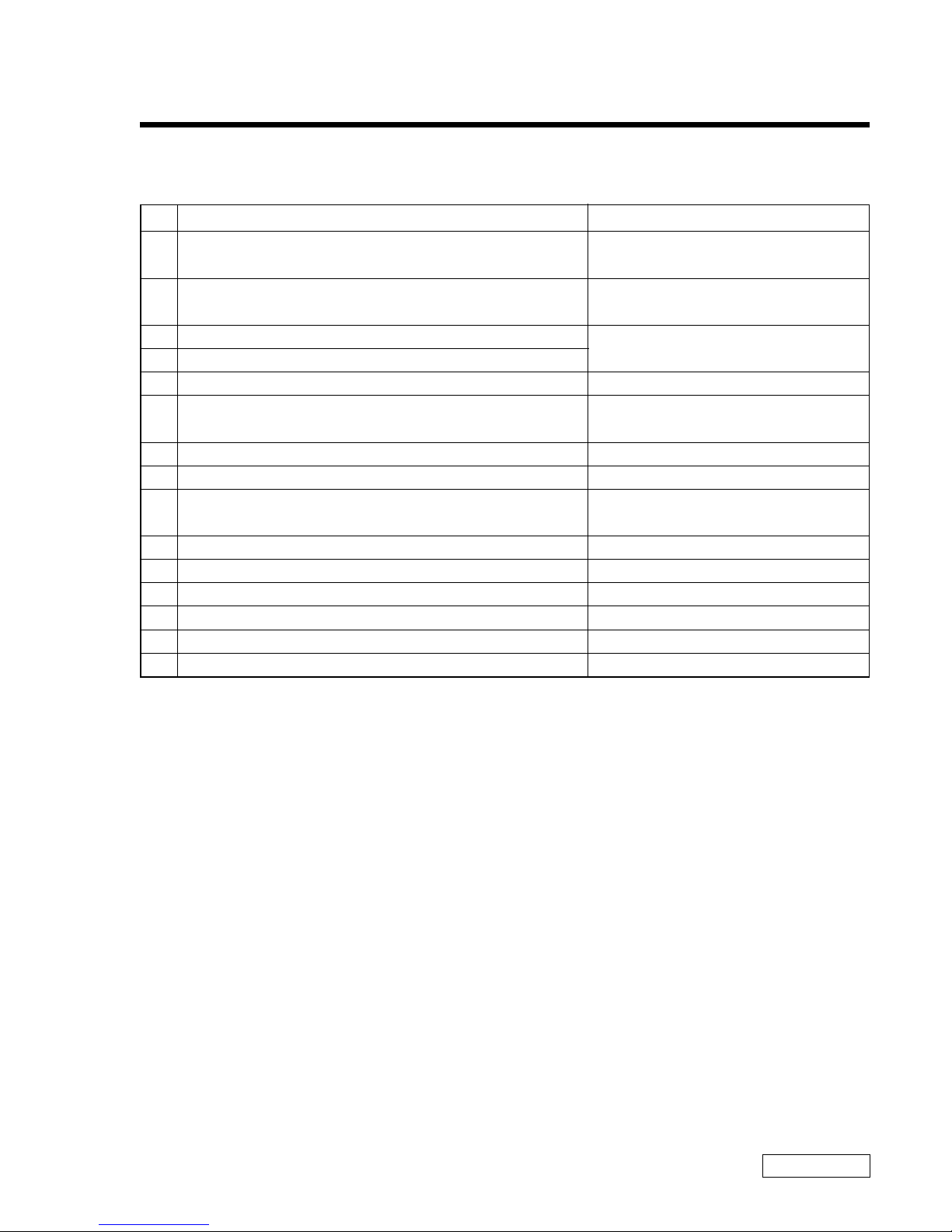

2-1 PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

CHAPTER 2.

SELF DIAGNOSTICS

2-1. Required Tools and Peripheral Devices

Test Items

Serial Port (COM) test

Parallel Port (printer) test

Audio related tests

Modem test

PC Card test

IEEE1394 test

Test of Serial/Parallel

DVD-ROM Drive and Combination

Drive (CD-RW/DVD-ROM) tests

FDD test

(Diagnostics starting software)

(Diagnostics software)

Battery related tests

(Power supply for diagnostics)

HDD related tests

Tools and Peripheral Devices

1 Serial Loopback Tool

Specified Loopback Tool (Refer to next page.)

2 Parallel Loopback Tool

Specified Loopback Tool (Refer to next page)

3 Stereo microphone

4 Headphone

5 56K Modem and Line Simulator

6 PC Card Tester

PCCtest 450 Made by Sycard Corp.

7 VAIO for IEEE1394 Test

8 Port Replicator PCGA-PRFX1 for Serial/Parallel tests

9 DVD-ROM and Combination Drive

(CD-RW/DVD-ROM) supplied

10 External FDD

11 Diagnostics FD Media

12 Diagnostics CD-ROM Media

13 Battery supplied

14 AC Adaptor supplied

15 HDD

2-2PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

• The serial loopback tool and the parallel loopback tool are necessary for diagnostics of the serial communication line and

the parallel communication line. Fabricate the serial loopback tool and the parallel loopback tool locally referring to the

connection diagrams shown below.

[Reference] On Serial/Parallel Loopback Tool

Serial Loopback Tool : For diagnostics of serial port

Parallel Loopback Tool : For diagnostics of parallel port

NOTE: The black round mark "z" indicates soldering.

NOTE: The black round mark "z" indicates soldering.

1

2

3

4

5

6

7

8

9

DB9S

DCD

RX

TX

DTR

GND

DSR

RTS

CTS

RI

• Connector Types DB9S (Female)

• Interface Standard RS-232C

• Loopback Data & Handshake

SERIAL LOOPBACK CONNECTOR CONNECTION DIAGRAM

• Connector Types DB25P(Male)

• Interface Standard Centronics

• Loopback Status to Commands

PARALLEL LOOPBACK CONNECTOR CONNECTION DIAGRAM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

D0

D1

D2

D3

D4

D5

D6

D7

-ACK

BUSY

PE

SLCT

-STROBE

-AUTO FD

-ERROR

-INT

-SLCT IN

GND

GND

GND

GND

GND

GND

GND

GND

DB25P

2-3 PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

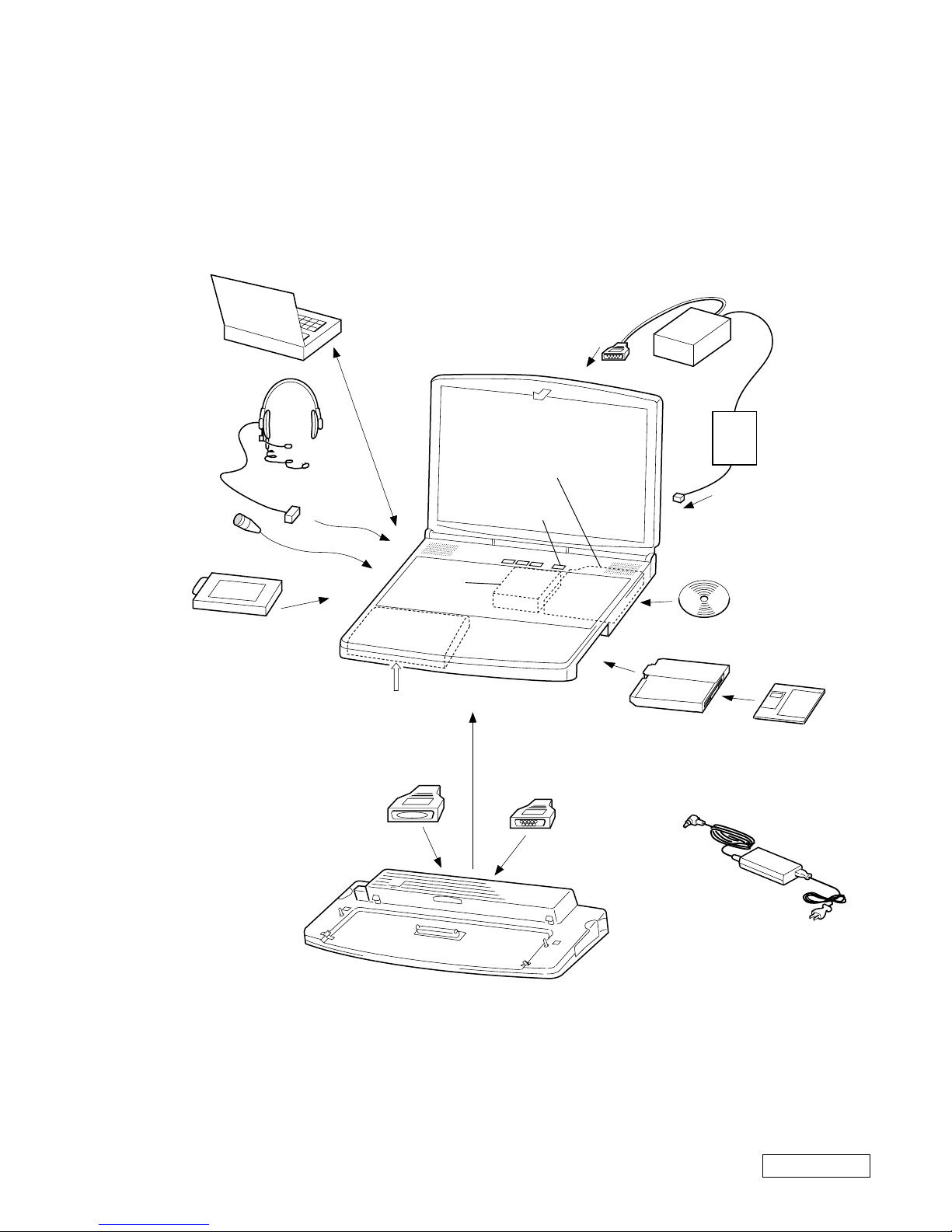

2-2. Tools and Peripheral Device Connection

System Connection Diagram

2Parallel

loopback tool

Modem

qdBattery

1Serial

loopback tool

Port Replicator

Serial I/F

9Combination Drive

(CD-RW/DVD-ROM)

DVD-ROM

Power SW

5Transmission

line simulator

6PC card tester

qsDiagnostics

CD-ROM media

qfAC adaptor

8Port Replicator PCGA-PRFX1

7VAIO for IEEE1394 test

jack

Phone

Serial

output

Parallel

output

0FDD

qaDiagnostics

FD media

qgHDD

3Stereo microphone

MIC IN

4Headphones

Headphones

connector

2-4PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

2-3. Starting up the Service Diagnostics

1. The service diagnostics floppy disk and CD disc are prepared for the respective models separately. Insert the service

diagnostics floppy disk and CD disc of the desired model, then turn on the main power of the personal computer.

Reads automatically the model information stored in the CD-ROM and displays the test menu. If the CD does not

supported the model, an error message is displayed.

2. The driver software is installed from the CD disc, the necessary ROM information is automatically read and the initial

settings are made, then the following self-diagnostics menu appears.

*************** Main Menu ****************

1:Check ROM Information... d:Parallel Loopback test...

2:Battery test... e:PC Card Slot test...

3:CD/DVD Drive test... f:Video test...

4:FDD test... g:PPK test...

5:HDD test... h:GUID (IEEE1394) test...

6:Keyboard test... i:IEEE1394 Interface test...

7:LED test... j:IrDA test...

8:Main memory test... k:Jog dial test...

9:Main system test... l:Short aging test...

a:FAN test... m:Long aging test...

b:Touch pad test... n:Aging test including the HDD test...

c:Serial Loopback test... o:Exit from Diagnostics MENU

3. When the service diagnostics ends with success, the message “Pass” appears. When it ends with failure detecting an error,

the message “Fail” appears. Press the “Esc” key to abort the self diagnostics.

2-4. Outline of Service Diagnostics Functions

• Check ROM Information...

Displays the model information, serial number, BIOS and other information saved in the BIOS ROM.

Does not test whether or not the personal computer is normal.

• Battery test...

T ests the battery as to whether the battery is attached or removed, the main po wer is supplied from an A C po wer adapter or

not, and the battery is charged or discharged. The test procedure appears on display. Perform the battery test following the

messages on display.

Remove and attach the battery → Check (Removal and attachment of battery)

Disconnect and connect the AC power → Check (Disconnection and connection of AC power)

Remove and attach the battery → Check (Discharge and charge of battery)

• CD/DVD Drive test...

Tests the CD, CD-R, Combination drive ( CD-RW/ DVD-ROM) , CD-RW and DVD drives.

• FDD test...

Tests the floppy disk drive.

2-5 PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

• HDD test...

T ests whether the HDD returns a response when communication is established with the hard disk drive. The HDD can be

tested without damaging the HDD data (without formatting the HDD) in this test since the HDD data is tentatively stored

in memory during the test.

If the main power is turned off by mistak e while the test is under way, the HDD data can be damaged. Tests the following

test automatically.

1. HDD interface test (Tests whether or not the HDD is recognized)

2. HDD seek test

3. HDD read test

4. HDD write test

5. HDD random read test and random write test (It takes about 2 hours for the 18 GB HDD. This time is a guideline and

changes depending on the model.)

6. Returns to the main menu.

• Keyboard test...

Tests the keyboard. When the “Auto select” menu is selected, the keyboard type in use is recognized from the model

information that is written in ROM when shipped from the factory and the test is executed accordingly. When a specific

keyboard type is selected such as US, UK, or JP, then the keyboard of the selected type is tested. If the model of your

computer is JP and the keyboard type is replaced by either the US type or UK type keyboard, select the k eyboard type after

it is replaced.

NOTE: The “Fn” key can be checked by pressing the “Fn” and “→” keys at the same time. Other keys can be

checked by pressing the respective keys.

• LED test...

T ests the LED. This test tur ns on one LED after another. The person conducting the test must visually check whether each

LED is normal or not.

• Main Memory test...

T ests the main memory. The Main Memory test contains the follo wing three test menus. Select the desired menu that suits

your need. The test is exited automatically when the respective test items end normally.

⋅ Fast: Tests once. (Taking one and half minutes to two minutes)

⋅ Medium: Test ten times.

⋅ Heavy: Test twenty times.

Press the “Esc” key to abort the test.

• Main System test...

Tests the fundamental functions of the CPU, etc. The test is exited automatically when all test items end normally.

• FAN test...

Tests the fan. Tests whether the fan rotates and stops. Listen to the rotating sound or feel the wind of the fan to judge

whether the fan rotates and stops. The test procedure appears on display. Perform the F AN test f ollo wing the messages on

display. Press “Y” to resume rotation when the f an comes to stop. Press “Y” when the fan starts rotating indicating that the

test ends in success.

2-6PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

• Touch pad test...

Tests the touch pad. Tests whether the cursor moves, and whether right-clicking and left-clicking function properly.

The dialog box appears three times. Move the cursor to the box that appears. The tests are performed in the follo wing order .

(1) Touch pad

(2) Left-click button

(3) Right-click button (Two times)

• Serial loopback test...

Performs the loopback test of the serial port. Connect the port replicator and the loopback tool to the serial port.

• Parallel loopback test...

Performs the loopback test of the parallel port. Connect the port replicator and loopback tool to the parallel port.

• PC card Slot test...

Tests the PC card slot. Implements the 16-bit/card-bus test for the two slots of the main unit.

• Video test...

The video test cannot be performed on the MS-DOS prompt.

Go to Video inspection of Chapter “2-5. Inspecting Windows” for the video test.

• PPK test...

T ests the PPK. If the test is not completed within the specified time, an error is triggered due to the time-out set for this test.

When two or more PPKs are set, follow the instructions that appear on the screen.

• GUID test...

This test is not required normally. Displays the GUID (i.Link ID value), and judges whether the value on the display is

appropriate.

• IEEE 1394 Interface test...

Performs the 1394 communication test. Another personal computer to communicate with is necessary for this test. The

models released from the year 2000 have already been confirmed that they do not cause any problems regarding the

IEEE1394 interface. Even models released before 2000 will cause no problem if the same type of IEEE1394 interface IC

chip (the IC chip used in the iLink block connected to the PCI bus) is used in both personal computers that are connected.

In other combinations, the IEEE1394 interface test is not confirmed. (Use of the models released from the year 2000 is

recommended.)

1. Connect the iLink cable.

2. Start up the personal computer at the other end of the IEEE1394 interface test connection using the tool floppy disk

that must be created beforehand by copying programs from the service diagnostics CD disc. (Prepare a floppy disk

that is formatted to contain the DOS system. Create a tool floppy disk by copying the entire TOOL folder of the CD

disc to a floppy disk.)

3. Select the 1394 test from the menu at the connected computer to enter the reception state.

4. After the connected personal computer has entered the reception state, select the 1394 test at the personal computer to

be tested. The IEEE1394 interface test then starts. Send and receive of the random data are repeated five times

(i.e., this test is repeated five times.)

2-7 PCG-FX120/FX140/FX150/FX170/FX190 (UC)

Confidential

• IrDA test...

The computer cannot perform this test.

• Jog dial test...

The computer cannot perform this test.

• Short aging test.../Long aging test...

Performs the aging test. The short aging test ends when all test items have been performed once. The long aging test checks

the machine for about 10 hours by repeating the test items.

• Aging test including the HDD...

NOTE:Note that this test destroys the entire contents of the user’s hard disk drive.

Perform this test only when destructive testing of HDD is desired.

The aging test is performed first, then read and write tests of the hard disk are implemented following the aging test.

There are two tests; SHORT and LONG. However, the contents of the SHORT aging test are the same as those of the

LONG aging test. The test starts immediately when the menu item is selected.

• Exit from Diagnostics MENU...

Quits the service diagnostics program and the DOS prompt appears. If you exit the service diagnostics program by

mistake, start up the program again.

2-5. Inspecting Windows

The Windows inspection contains the following three types of inspection.

Audio

Modem

Video

Before starting inspections, create a floppy disk from the service diag CD to be serviced.

The files to be used for inspection are stored in the following sub directory inside the CD. Cop y all the files in the folder t o the

floppy disk.

Audio \windiag\wave

Modem \windiag\modem

Video \windiag\video

• Audio

A microphone and headphones are required for this inspection.

Double-click “t_auw01” icon (MS-DOS icon) in the floppy disk that is created in adv ance. The display of the DOS prompt

opens and the inspection starts. Once inspection starts, follow the instructions on the display to inspect the audio.

• Modem

A modem and a line simulator are required for this inspection.

Double-click “modem” icon (MS-DOS icon) in the floppy disk that is created in advance.

The display of the DOS prompt opens and the inspection starts.

Loading...

Loading...