Page 1

Page 2

Information in this document is subject to change without notice.

Sony and VAIO are trademarks of Sony. Microsoft, MS-DOS,

Windows, the Windows 95, Windows 98, Windows 2000 and

Windows ME logo are trademarks of Microsoft Corporation.

All other trademarks are trademarks or registered trademarks of

their respective owners. Other trademar ks and trade names may be

used in this document to refer to the entitles claiming the marks and

names or their produces. Sony Corporation disclaims any proprietary

interest in trademarks and trade names other than its own.

Caution Markings for Lithium/Ion Battery - The following or similar

texts shall be provided on battery pack of equipment or in both the

operating and the service instructions.

CAUTION: Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer. Discard used batteries according to the

manufacturer’s instructions.

CAUTION: The battery pack used in this de vice may present a fire

or chemical burn hazard if mistreated. Do not disassemble, heat

above 100°C (212°F) or incinerate.

Dispose of used battery promptly.

Keep away from children.

CAUTION: Changing the back up battery.

• Overcharging, short circuiting, reverse charging, multilation

or incineration of the cells must bi avoided to prevent one or

more of the following occurrences; release of toxic materials,

release of hydrogen and/or oxygen gas, rise in surface

temperature.

• If a cell has leaked or vented, it should be replaced

immediately while avoiding to touch it without any protection.

Service and Inspection Precautions

1. Obey precautionary markings and instructions

Labels and stamps on the cabinet, chassis, and components identify areas

requiring special precautions. Be sure to observe these precautions, as

well as all precautions listed in the operating manual and other associated

documents.

2. Use designated parts only

The set’s components possess important safety characteristics, such as

noncombustibility and the ability to tolerate large voltages. Be sure that

replacement parts possess the same safety characteristics as the originals.

Also remember that the 0 mark, which appears in circuit diagrams and

parts lists, denotes components that have particularly important safety

functions; be extra sure to use only the designated components.

3. Always follow the original design when

mounting parts and routing wires

The original layout includes various safety features, such as inclusion of

insulating materials (tubes and tape) and the mounting of parts above the

printer board. In addition, internal wiring has been routed and clamped so

as to keep it away from hot or high-voltage parts. When mounting parts or

routing wires, therefore, be sure to duplicate the original layout.

4. Inspect after completing service

After servicing, inspect to make sure that all screws, components, and wiring

have been returned to their original condition. Also check the area around

the repair location to ensure that repair work has caused no damage, and

confirm safety.

5. When replacing chip components...

Never reuse components. Also remember that the negati ve side of tantalum

capacitors is easily damaged by heat.

6. When handling flexible print boards...

•The temperature of the soldering-iron tip should be about 270C.

•Do not apply the tip more than three times to the same pattern.

•Handle patterns with care; never apply force.

Caution: Remember that hard disk drives are easily damaged by

vibration. Always handle with care.

Confidential

– 2 –PCG-C1VN (UC)

Page 3

TABLE OF CONTENTS

Section Title Page

CHAPTER 1. REMOVAL

1-1. Flowchart ......................................................................... 1-1

1-2. Main Electrical Parts Location Diagram ......................... 1-1

1-3. Removal ...........................................................................1-2

1. Key Board Unit ................................................................ 1-2

2. Cursor Sensor Module ..................................................... 1-2

3. Parm Rest Sub Assy......................................................... 1-3

4. SWX-62 Board ................................................................ 1-3

5. SWX-63 Board ................................................................ 1-4

6. Speaker (30X15 With Harness) ....................................... 1-4

7. IFX-128 Board ................................................................. 1-5

8. Nickel Hydrogen Battery ................................................. 1-5

9. Assy HDD 12.0 GB ......................................................... 1-6

10. MBX-45 Board ................................................................ 1-6

11. Fan With Heatsink ........................................................... 1-7

12. PC Card Connector (Ejector) ........................................... 1-7

13. LCD Housing Assy .......................................................... 1-8

14. CNX-108 Board ............................................................... 1-8

15. Bezel Assy .......................................................................1-9

16. LCD 1210 Assy................................................................1-9

17. CCD SD22 Assy, Inverter Unit ...................................... 1-10

(to 1-10)

CHAPTER 2. SELF DIAGNOSTICS

2-1. Note.................................................................................. 2-1

2-2. Necessary Equipment ...................................................... 2-1

2-3. Starting the Diagnostics ...................................................2-1

2-4. Diagnosis with Diagnostic Program ................................ 2-1

2-5. Test Items......................................................................... 2-2

2-6. Windows Test................................................................... 2-5

2-7. Other Test not Supported ................................................. 2-5

(to 2-5)

CHAPTER 3. BLOCK DIAGRAM ............................... 3-1

(to 3-2)

CHAPTER 4. FRAME HARNESS DIAGRAM ........ 4-1

(to 4-2)

CHAPTER 5. EXPLODED VIEWS AND

PARTS LIST

5-1. Main Section ....................................................................5-1

5-2. LCD Section .................................................................... 5-3

5-3. Accessories ...................................................................... 5-5

(to 5-5)

• Abbreviations

UC : US model / Canadian model

– 3 –

Confidential

PCG-C1VN (UC)

Page 4

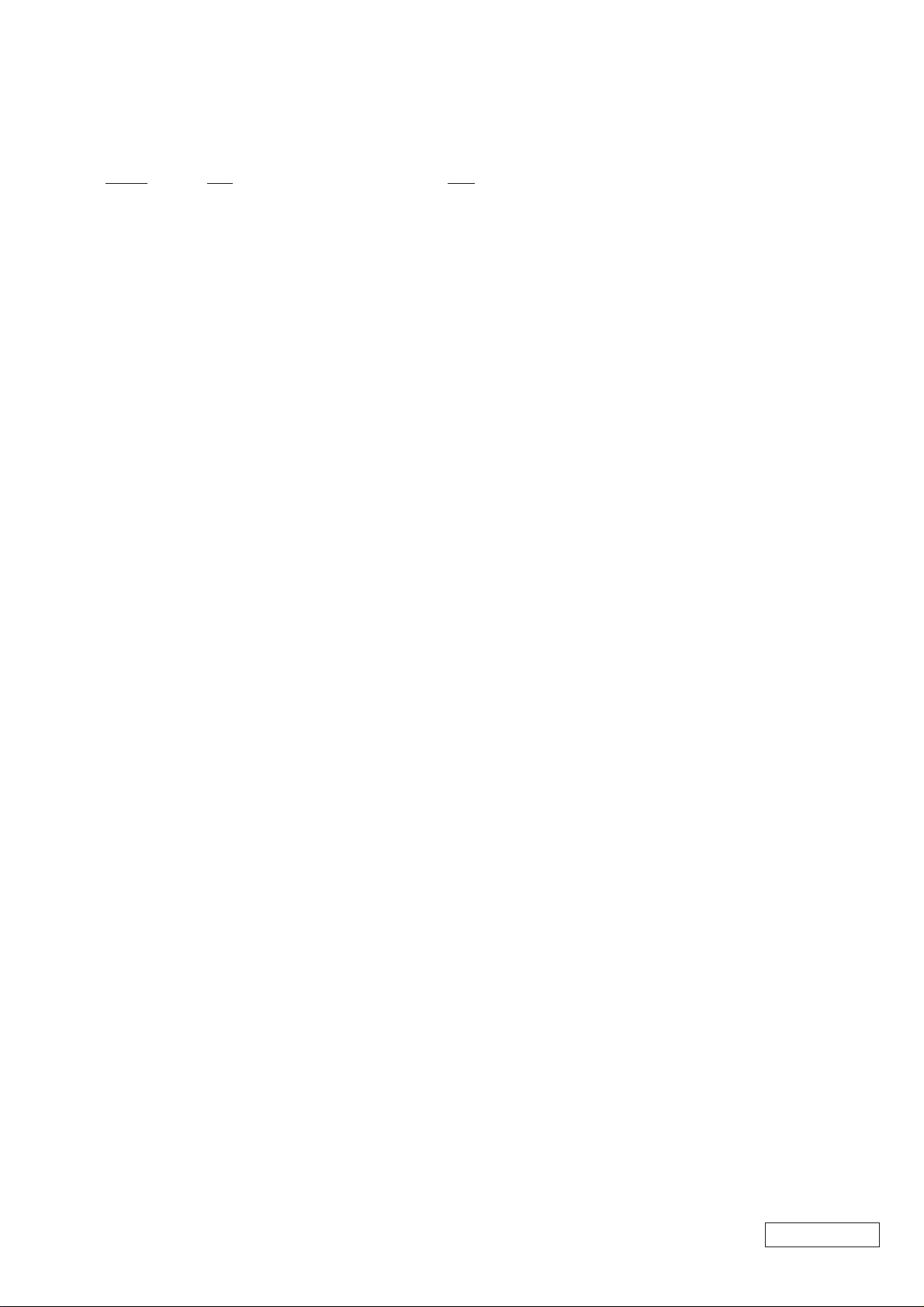

1-1. Flowchart

CHAPTER 1.

REMOVAL

POWER

OFF

KEY BOARD

UNIT

P 1-2

PARM REST

SUB ASSY

P 1-3

CURSOR

SENSOR

MODULE

P 1-2

ASSY HDD

12.0 GB

P 1-6

SWX-62

BOARD

P 1-3

SWX-63

BOARD

P 1-4

SPEAKER

(30X15 WITH

HARNESS)

P 1-4

IFX-128

BOARD

P 1-5

NICKEL

HYDROGEN

BATTERY

P 1-5

LCD

HOUSING

ASSY

P 1-8 P 1-9

MBX-45

BOARD

P 1-6

CNX-108

BOARD

P 1-8

BEZEL

ASSY

FAN WITH

HEATSINK

P 1-7

PC CARD

CONNECTOR

(EJECTOR)

P 1-7

LCD 1210

ASSY

P 1-9

• P XX means pages that appears in this manual.

• Remember that hard disk drives are easily damaged by vibration. Always handle with care.

CCD SD22

ASSY

P 1-10

INVERTER

UNIT

P 1-10

1-2. Main Electrical Parts Location Diagram

LCD 1210 Assy

CCD SD22 Assy

Cursor Sensor

Module

MBX-45 Board

PC Card Connector

(Ejector)

Speaker

(30X15 With Harness)

Fan With Heatsink

SWX-63 Board

Nickel Hydrogen

Battery

Speaker

(30X15 With Harness)

IFX-128 Board

Inverter Unit

SWX-62 Board

Assy HDD 12.0 GB

CNX-108 Board

Confidential

1-1 PCG-C1VN (UC)

Page 5

1-3. Removal

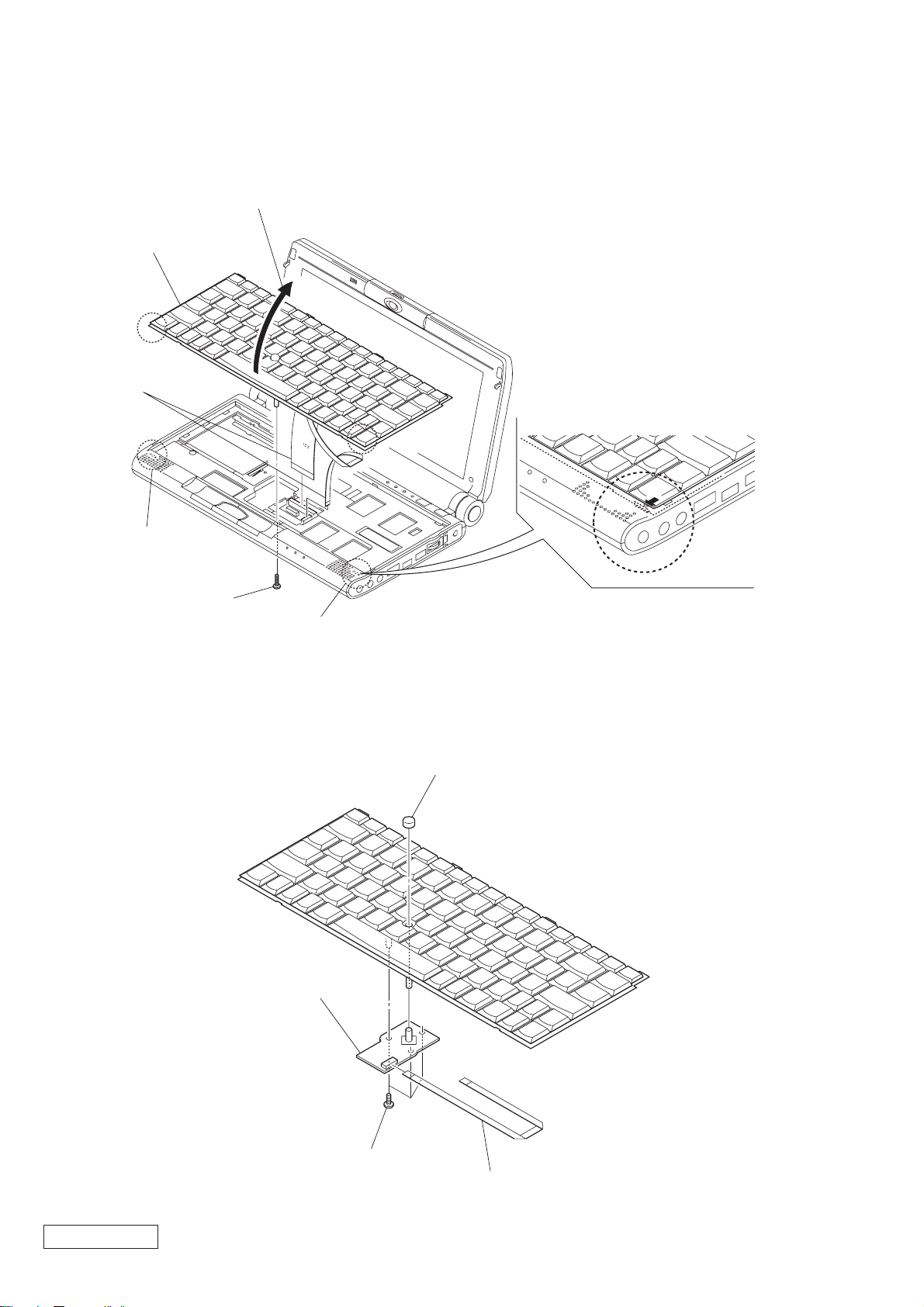

1. Key Board Unit

Key Board Unit

4 Harness

2 Claw

3 Open in the direction of arrow.

1 M2X8

2. Cursor Sensor Module

Cursor Sensor Module

2 Claw

1 Cap Sensor

Confidential

2 M2X3 Grip

3 FFC (MBX-TP1)

1-2PCG-C1VN (UC)

Page 6

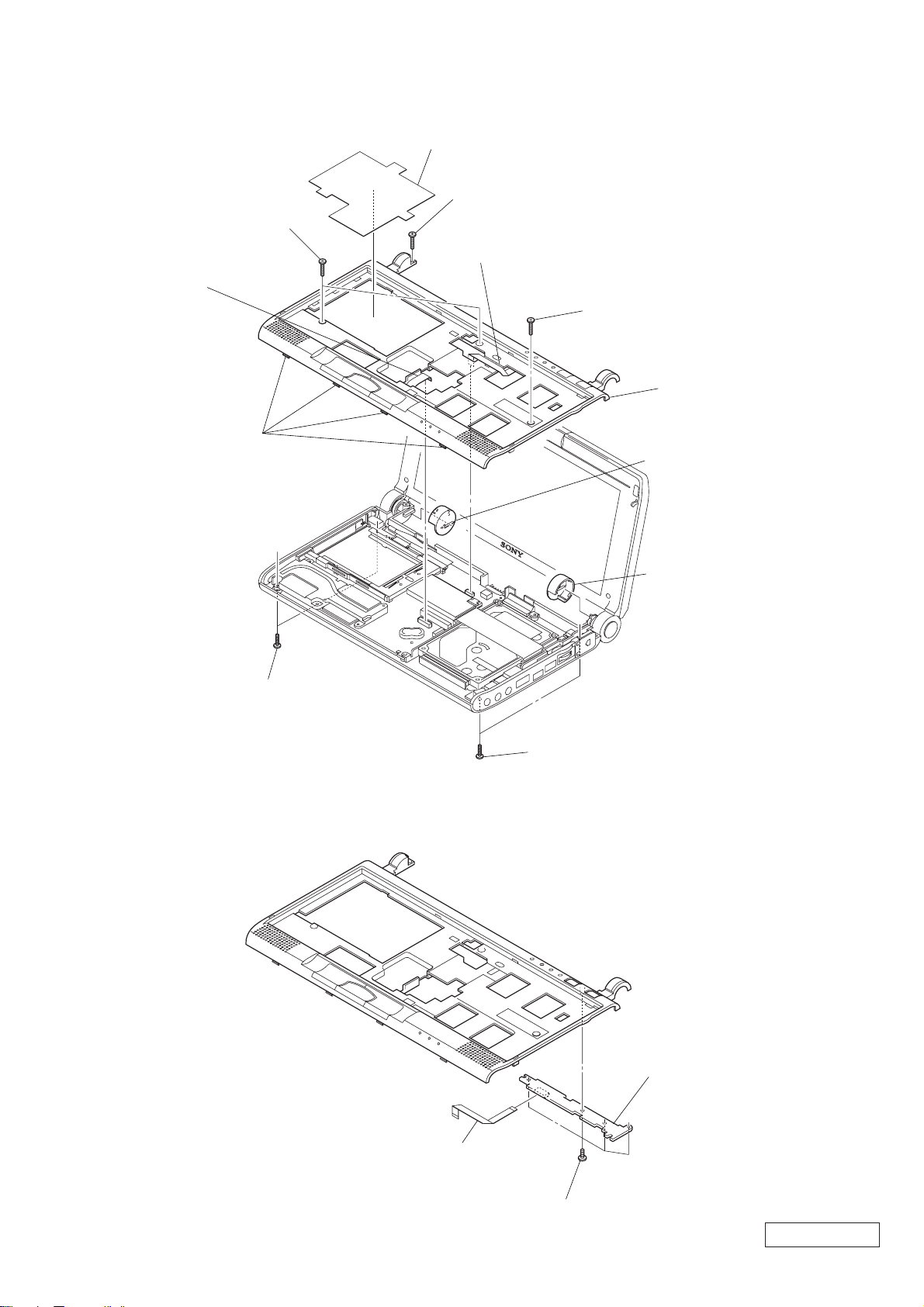

3. Parm Rest Sub Assy

1 Heatsink (Card Slot)

4 M2X6

8 FFC

(MBX-SWX63)

5 M2X6

9 Claw

7 FFC

(MBX45-SWX62)

5 M2X6

Parm Rest Sub Assy

2 Undo three claws and

remove the main cover (L).

3 Undo three claws and

remove the main cover (R).

4. SWX-62 Board

6 M2X8

6 M2X8

SWX-62 Board

2 FFC

(MBX45-SWX62)

1-3 PCG-C1VN (UC)

1 M2X4

Confidential

Page 7

5. SWX-63 Board

SWX-63 Board

3 FFC (MBX-SWX2)

2 Harness

6. Speaker (30X15 With Harness)

Speaker

(30X15 With Harness)

3 Speaker

Retainer

1 M2X4

1 M2X4

4 Harness

2 Claw

2 Harness

Speaker

(30X15 With Harness)

Confidential

4 Harness

3 Speaker

Retainer

2 Claw

1 M2X4

1-4PCG-C1VN (UC)

Page 8

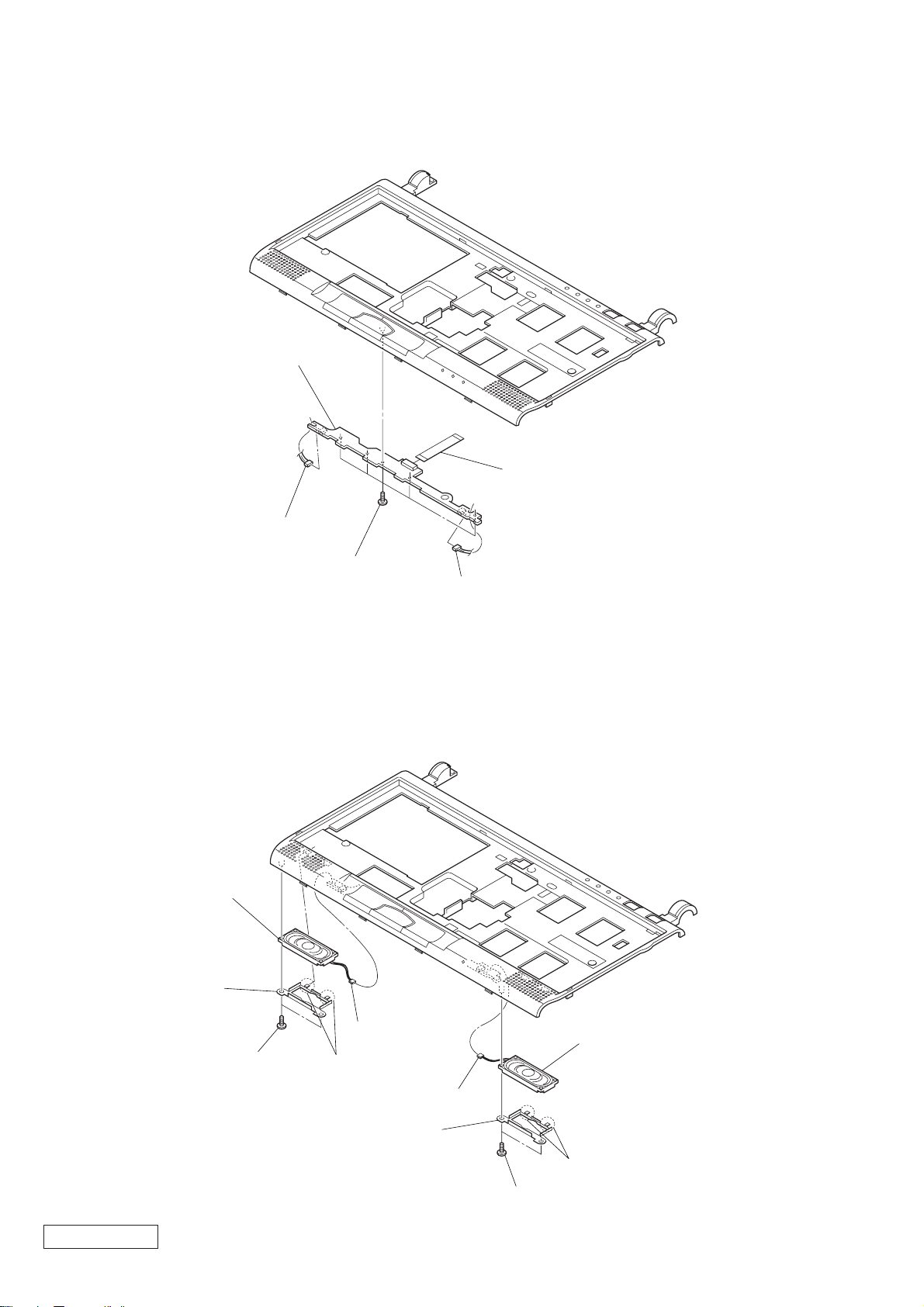

7. IFX-128 Board

1 Harness

IFX-128 Board

8. Nickel Hydrogen Battery

2 Nickel Hydrogen Battery

1 Harness

Confidential

1-5 PCG-C1VN (UC)

Page 9

9. Assy HDD 12.0 GB

1 FFC (MBX-45-CNX108)

2 M2X5

2 M2X5

Assy HDD 12.0 GB

10. MBX-45 Board

6 Escutcheon (L)

Sub Assy

MBX-45 Board

3 Print PWB Simple

Substance

4 M2X5

5 Hole Blind

1 LCD Harness

3 Harness With

Connector (DC)

2 Harness

Confidential

1-6PCG-C1VN (UC)

Page 10

11. Fan With Heatsink

Thermal Sheet (T)

Fan With Heatsink

The fan with heatsink must be installed

*

with the thermal sheet (T) in soft state to

protect the CPU from the stress.

For this purpose, with the thermal sheet

(T) pasted, warm the fan with heatsink to

about 70 °C, and when the thermal sheet

(T) has become soft, install the fan with

heatsink on the main board.

12. PC Card Connector (Ejector)

1 Harness

2 M2X4

1 +PS 2X8

PC Card Connector (Ejector)

Confidential

1-7 PCG-C1VN (UC)

Page 11

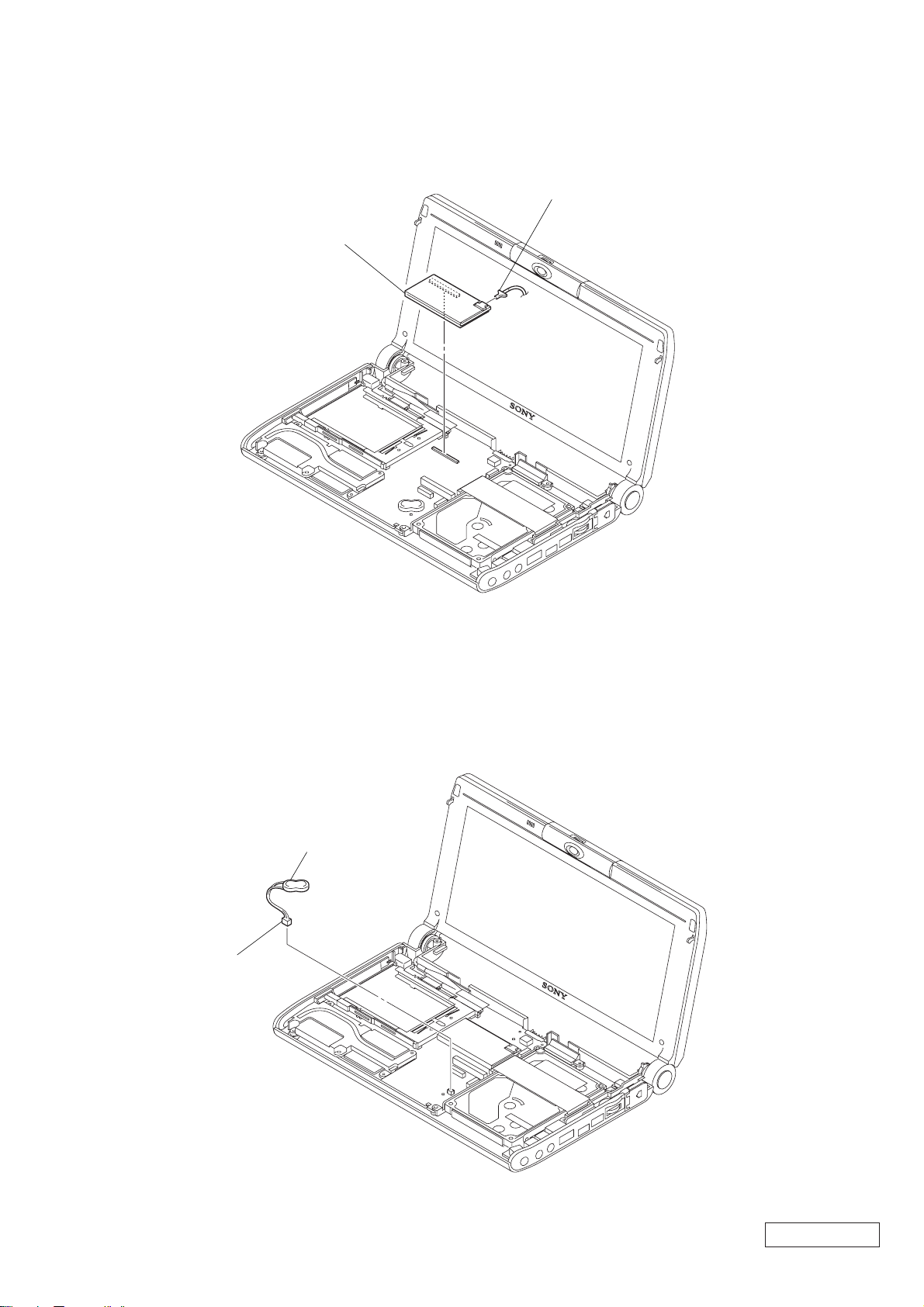

13. LCD Housing Assy

LCD Housing Assy

1 LCD Harness

14. CNX-108 Board

2 M2X5

3 M2X3 Grip

1 Harness With

Connector (DC)

2 M2X6

Confidential

CNX-108 Board

3 Modular Harness

4 Escutcheon R

1-8PCG-C1VN (UC)

Page 12

15. Bezel Assy

6 Blind Rubber

(Left)

1 Undo three claws

and remove the hinge

cover assy.

8 Undo ten claws and

remove the bezel assy.

7 M2X5

3 M2X6

16. LCD 1210 Assy

2 Blind Rubber

(Lower)

LCD 1210 Assy

2 Blind Rubber

(Lower)

5 M2X5

4 Blind Rubber (Right)

1 Undo three claws and

remove the hinge cover assy.

3 M2X6

2 LCD Harness

1 M2X4

3 Harness

Confidential

1-9 PCG-C1VN (UC)

Page 13

17. CCD SD22 Assy, Inverter Unit

6 Microphone Assy,

3 LCD Harness

5 Spring Bolt

(M2.6)

CCD SD22 Assy

4 M2X4

1 Flexible Print PWB

2 Inverter Unit

0 Spring Bolt

9 Microphone

Cover Assy

7 Blind Plate

qa Microphone

Holder

(M2.6)

8 M2X3

(Microphone)

qd Tapping Screw

qs Ring (F)

When mounting the ring (F),

*

Align markings of camera

(side of gear) and groove of

ring (F).

If disintegrated, do not turn

*

ring (F).

Focus adjustment is off.

(1.7X3)

qf Bearing (C)

CCD SD22 Assy

Do not dismantle

*

the CCD SD22 Assy.

For example, removing

the connector.

Groove

Marking

Confidential

1-10PCG-C1VN (UC)

(END)

Page 14

CHAPTER 2.

SELF DIAGNOSTICS

2-1. Note

This diagnostics document covers the checking items and the selftest that can be conducted on the set and the FDD & CDROM drive.

2-2. Necessary Equipment

• PCG-C1VN set

• Floppy disk drive

• CD-ROM drive

• Battery

• AC adapter

• CD-ROM for Diagnostics

• FD for Diagnostics (DOS system should be loaded)

• Other jigs and tools necessary for the test

(All may not be required, but if not missing, some items cannot be tested.)

• PCG-C1VN series (IEEE 1394 Interface, etc.)

2-3. Starting the Diagnostics

Connect the FDD, CD-ROM drive, battery, and AC adapter to the PCG-C1VN set (simply called the set).

Insert the FD for Diagnostics in the FDD, and CD-ROM for Diagnostics in the CD-ROM drive.

2-4. Diagnosis with Diagnostic Program

With the FD for Diagnostics inserted in the FDD and the CD-R OM for Diagnostics in the CD-ROM dri ve, turning on the po wer

switch on the set allows the diagnostic program to start from the CD, then the following screen to appear.

• Diagnostics Menu

************ Main Menu ************

1:Check ROM Information... c:GUID (IEEE1394) test...

2:Battery test... d:IEEE1394 Interface test...

3:HDD test... e:IrDA test...

4:Keyboard test... f:Jog dial test...

5:LED test... g:Camera test...

6:Main memory test... h:Shutter Button test...

7:Main system test... i:Short aging test...

8:Fan test... j:Long aging test...

9:Touch pad test... k:Aging test including the HDD test...

a:Video test... l:Exit from Diagnostics MENU

b:PPK test...

Confidential

2-1 PCG-C1VN (UC)

Page 15

Select one menu item, and that item will be tested automatically.

As some items will prompt you to press a key or hear a sound, perform operation following the instructions.

• For the contents of menu items, refer to 2-5. Test Items. (Contents may change a little.)

If the test successfully completed,

******

PASS

******

or, if the test failed

******

FAIL

******

is displayed.

To abort the test, press the [Esc] key.

2-5. T est Items

• Check ROM Information...

Model information, serial number, BIOS, etc. written to the BIOS ROM are displayed.

Whether the information is correct is not tested.

• Battery test...

The battery test is conducted. Battery mounting/demounting, AC power supply/shut-of f, and battery char ging/discharg ing

are checked.

As the test procedure is displayed, conduct the test following the displayed procedure.

Battery mount/demount → Check (Mount/demount the battery)

AC power connect/disconnect → Check (Supply/shut off the AC power)

Battery mount/dismount → Check (Charge/discharge the battery)

• HDD test...

Communication is made to the HDD to check if a response is returned.

In this test, the data in HDD are temporarily transferred to the memory, and therefore no data are destroyed (HDD formatting is not executed).

The HDD data may be destroyed if the power is interrupted during the test.

In this test, the following items are executed automatically.

1. HDD interface test (whether HDD is recognized is checked)

2. HDD seek test

3. HDD read test

4. HDD write test

5. HDD random read/random write test

(It takes about 2 hours to test 18 GB HDD. The time will vary depending on the model.)

6. Return to Main Menu

Confidential

2-2PCG-C1VN (UC)

Page 16

• Keyboard test...

The keyboard is tested. Choose “Auto select”, and the test will be ex ecuted by judging the type of k e yboard follo wing the

specifications at the shipment from the model information written to the ROM. Choosing JP, US, or UK allows each type

of keyboard to be tested.

When the keyboard was replaced with US or UK type ev en if the type of the set is JP, select US or UK type used at present.

Note: To check the [Fn] key in the test, press the [Fn] + [→] keys. In checking the other keys, press each key.

• LED test...

The LED is tested. Each LED is lit sequentially. An inspector checks visually whether LED is normal or not.

First, check LEDs on the front side (left → right), and then check LEDs in the center (left → right).

Note: The memory stick access test cannot be executed on the MS-DOS. Execute it on the Windows.

• Main Memory test...

The memory is tested. The test consists of three test menus, and therefore select the desired menu.

Respective tests quit automatically when they successfully completed.

Fast : 1 time (1 minute 30 seconds to 2 minutes)

Medium: 10 times

Heavy : 20 times

To abort the test, press the [Esc] key.

• Main System test...

Fundamental functions of the CPU are tested. The test quits automatically when the test of all items successfully completed.

• FAN test...

The fan is tested. The fan rotation and stop are checked.

Check the fan operating condition from the sound or airflow. Execute the test following the message. First press the [Y]

key if the fan stops. Then, press the [Y] key when the fan rotates.

• Touch pad test...

The touch pad is tested.

The cursor movement and the left/right clicking are checked. As the dialog box is displayed three times, move the cursor

into the dialog box.

Conduct the test in the following order.

1. Left click button

2. Right click button

3. Touch pad*

(* If you operate with the touch pad before this test starts up, the test fails in starting up.)

• Video test...

The video is tested. Each time the key is pressed, sev eral patterns are displayed. The inspector checks visually whether the

patterns are normal or not. If normal, press the [Y] key.

Note: Conduct this test after making sure which patterns are normal.

• PPK test...

This test cannot be executed for this set.

Confidential

2-3 PCG-C1VN (UC)

Page 17

• GUID (IEEE1394) test...

Normally, this is not used. GUID (i.LINK ID) value is displayed. Whether this value is correct is not checked.

• IEEE1394 Interface test...

The communication test of 1394 is executed. Another PC is required as a communication counterpart. The models released

after year 2000 will operate normally. F or the models released earlier than year 2000, the model having same 1394 chip as

that of PC to be tested will operate normally. (Accordingly, it is recommended to use the models released after year 2000

as a communication counterpart.)

Connect the i.LINK cable, and start the communication counterpart PC using the TOOL FD created from the CD in

advance. (To create the TOOL FD, copy the contents of TOOL folder in the CD to the FD that stores the DOS system.)

From the MENU in the communication counterpart PC, select the 1394 test to place the PC in the receive state. After

confirming that the communication counterpart PC is in the receive state, select the 1394 test on the machine to be tested ,

and the test will start. Random data transmission and receiving are repeated 10 times. (This test is repeated 10 times.)

• IrDA test...

This test is not executed for this set.

• Camera test...

The built-in camera is tested. Whether an image captured in the camera is displayed correctly and the camera rotation

switch functions normally can be checked. Perform operation sequentially following the instructions given on the screen.

• Shutter Button test...

The Shutter button on the camera is tested. The time-out has been set, and if the button is not operated for the specified

time, an error occurs.

• Jog dial test...

The jog dial turning and clicking are tested. The < > mark will be displayed, then turn the jog dial downward to meet with

(^_^) mark and click the jog dial. Next, turn the jog dial upward to meet with (^_^) mark displayed upward and click the

jog dial.

• Short aging test.../Long aging test...

The aging test is executed. The short test quits when the test of all items is e xecuted once. In the long test, respecti ve item s

are tested repeatedly over a total of about 10 hours.

• Aging test including the HDD test...

Execute this test when destructive test is applied to the HDD. The HDD read/write test is executed after the aging test.

Though two test menus, short and long, are available, the contents of a ging test are same as Short aging test.../Long aging

test... The test will start immediately if the menu is selected.

Note: Executing this test will destroy the contents of user’s HDD, thus requiring extreme care.

• Exit from Diagnostics MENU

The diagnostic test quits and the DOS prompt is displayed. If you exited from diagnostic test by mistake, restart the

diagnostic program.

Confidential

2-4PCG-C1VN (UC)

Page 18

2-6. Windows T est

There are two kinds of menus in the Windows test, as follows:

Audio

Modem

Before the test, create the FD from the CD for service diagnostics of the model concerned.

The files used for each test are saved in the following directories in the CD. Copy all files in the folder.

Audio ¥windiag¥wave

Modem ¥windiag¥modem

• Audio

This test requires the microphone and headphone.

Double-click the t_auw01 icon (MS-DOS icon) in the FD created in advance.

The DOS prompt screen will open and the test will start. After that, execute the test following the instructions on the

screen.

• Modem

This test requires the modem and circuit simulator.

Double-click the Modem icon (MS-DOS icon) in the FD created in advance.

The DOS prompt screen will open and the test will start.

2-7. Other Test not Supported

• PCMCIA test

The 16 bit PC-CARD test is substituted by using the CD-ROM.

The CardBUS and ZV cannot be tested because special tools are necessary.

Confidential

2-5 PCG-C1VN (UC)

(END)

Page 19

CHAPTER 3.

CN

Exp. Memory

EM-33

S DRAM

VCC 3.3V (+3 VSUS)

Memory

SDR

128MB

VCC 3.3V (+3 VSUS)

BLOCK DIAGRAM

MIC

CAM

/ BCX-SD22 1 A

1/6" 760H + INT/PG CONV

LCD

1024 x 480

Wide X G A

TFT

CPU

TM56 00

CPU CORE & N or th Br idg e

L1(64k) & L2(128k) Cache

Memory Contro l l e r

+VCPUCORE(1.3- 1. 6V )

+3 VRUN

+2.5VRUN

HC

LK0

29.4989M

CN

4

TV OUT

Hz

CN

Graphics

ATI

Mobility-M1

8MB SGRAM

+3VSUS

+2.5VSUS

+2.5VVID

VGA

3

PCI (3.3V)

Inver ter

MJPEG

Kawatetsu

M-CHip

+3VRUN

SM Bus 1

CN

5 6

Frame

Buffer

33MHz

CN MODEM CARD

CardBus

Ricoh

R5C457II

+3VRUN

+2.5VSUS

CN

i.LINK

i.LINK

TI

TSB43L V 2 2

+3VRUN

24.576MHz

BusMaste r

--------- ----- ----- ----REQ0/GNT0 PCLK0 AD19 PIRQD i.LINK (Sony)

REQ1/GNT1 PCLK1 AD20 PIRQC Audio (YAMAHA)

REQ2/GNT2 PCLK5 AD23 PIRQB CardBus (Richo)

REQ3/GNT3 PCLK6 AD16 PIRQA Video (ATI)

REQ4/GNT4 PCLK4 AD21 PIRQB Modem

REQ5/GNT5 PCLK2 AD22 PIRQB M-Chip (Kawatetsu)

PCLK0/3 TM5400

(TRANSEMETA)

1

2

3

PCLK IDSEL INTA

PCLKF AD18 PIIX4E (Intel)

CN X-108

I/O C onnector

CN

CN

DC IN

CN

USB

CN

VGA

CN

HDD

5V(+5VPIDE)

PCGA-BP51 system

BATT

11.1V/1800 mAh

PORT80

Ext BIOS

H8 Crisis

(Serial)

Clock G

enerator

South Bridge

FW8237MB

CN

SD,Control

PIIX 4 E

+3VA L W

+3VRUN

2USB0

14.31818MHz

32.768kHz

IMIC9716CTB-D

HCLK0 (66MHz)

PCLK* (33MHz)

REF1 (14.31818MHz)

48MHz (48MHz)

+3VRUN

+2.5VRUN

24.576MHz

6

Audio

YMF754-R

+2.5VSUS

+2.5VRUN

4

YAMAHA

N IN/OUT

LI

Mic in

HeadPhone

Out

CN

CN

MIC

IN

HeadPhone

OUT

AV Jack

8bit X-Bus (3.3V)

CN

BIOS

2MB Flas h R OM

1

DC

CN

PS & Charger

VCC 5V (ALW, SUS, RUN)

VCC 3V (ALW, SUS, RUN)

VCC 2.5V (SUS, RUN)

+VCPUCORE (1.20 - 1. 65V)

+3VRUN

I/O Exp ander1

(ADR=0111 101x )

+3VA L W

5

ATF0 - CPU

ADM1030

(ADR=100110x)

+3VA L W

SM Bus 0

M Bus 1

S

I/O Expander0

(ADR=0111 100x)

+3VA L W

10.000MHz

EC+KBC

H8S/2147A

100QFP (16x16 )

+3VA L W

+5VA L W

+3VREF

MS

TI

F731791P BK

MS_+VSUMIRE

+3VRUN

Flash Memor y

Magic

Gate

JOG

SWX-63

CN

(TP & SP connection)

CN

STBY/PWR/BAT / I NFO/BT LED

Track Point S W

MBX-45 (Main

SONY PROPRIETARY

3-1 3-2

System Board)

INFORMATION

CN CN

eyboad

K

Track

Point

Sensor+ Cn t l

JOG G/A

"SOMETARO"

+3VRUN

S

LOT

Memory S t i c k

(END)

SWX-62

PWR&Shutter SW

CN

Power S W Shutt e r S W

CN

MS/IDE/NUM/CAPS / SCRL LED

BT SW

Confidential

PCG-C1VN (UC)

Page 20

CHAPTER 4.

FRAME HARNESS DIAGRAM

LCD HOUSING ASSY

LCD HARNESS

Side L

CN1401

i.LINK

PC

CARD

CONNECTOR

MEMORY

STICK

CN3202

1

2

SPEAKER

Lch

MIC

LCD

UNIT

CN1300

1

PC

CARD

CN2301

10

1

125

CN900

KEY BOARD

UNIT

SWX-63 BOARD

SIDE A

CCD SD22 ASSY

FROM board connector (direct connection)

Harness (connector at both end)

Harness (soldered at one end)

LITHIUM ION

BATTERY PACK

CN1900

61

Rear

POWER

BUTTON

CAPTURE

BUTTON

INVERTER UNIT

NICKEL HYDROGEN

CN101

BATTERY

IFX-128

CN1700

CN3700CN1200

1120 40

35

21

199

2

2

1

BOARD

SIDE A

100

100

CN1000

99

MBX-45 BOARD

6834

SIDE A

16 1

CN3200

FFC (MBX-SWX2)

CN3201

12

216

115

CURSOR

SENSOR

MODULE

CN1

1

2

CN1901

CN903

21

10 1

CN902

CN2000

CN901

40 1

CN1001

18

PRINT PWB SIMPLE

FFC (MBX-TP1)

SUBSTANCE

HDD

(12.0GB)

150

FFC (MBX-SWX1)

12

CN1800

140 2

EXTENSION

SWX-62 BOARD

SIDE A

10 1

1139

CN600

CN3100

MODULAR HARNESS

HARNESS WITH CONNECTOR (DC)

MBX-45 BOARD

SIDE B

M

DC FAN

(WITH HEATSINK)

FFC (MBX45-CNX108)

1

CN3002

2

CN3202

39 1

40 2

CNX-108 BOARD

SIDE A

Side R

MODULAR

JACK

JOG

DIAL

14

CN3001

1

21

CN3003

DC IN

CN3004

USB

14

J3000

MIC IN

J3001

HEADPHONE OUT

J3002

VIDEO OUT & LINE OUT

VGA CABLE

ASSY

FDD ASSY or

CD-ROM

DRIVE

MEMORY MODULE

PCGA-MM164

BUTTON

SPEAKER

Rch

4-1 4-2

Confidential

PCG-C1VN (UC)

(END)

Page 21

CHAPTER 5.

EXPLODED VIEWS AND PARTS LIST

NOTE:

• The mechanical par ts with no reference number in the

exploded views are not supplied.

• Items mar ked “ * ” are not stocked since they are seldom

required for routine service. Some delay should be

anticipated when ordering these items.

• When the same reference numbers are written down in the

list, please use the one listed in the first place as the main

part.

5-1. Main Section

207

54

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

52

B5

22

B11

23

24

B5

25

B11

26

Ref.No. Part No. Description

1 A-8066-204-A SWX-62 MOUNT

2 1-794-957-11 FFC (MBX45-SWX62)

3 4-643-063-01 BUTTON, POWER

4 4-648-579-01 LED (KEY BOARD)

* 5 4-648-584-02 RETAINER, SPEAKER

6 1-529-886-11 SPEAKER (30X15 WITH HARNESS)

7 4-648-697-01 SHEET (SPEAKER), ADHESIVE

8 1-791-607-12 FFC (MBX-SW2)

9 4-648-580-01 LED (POWER)

10 A-8066-206-A SWX-63 MOUNT

12 X-4622-964-1 REST SUB ASSY, PALM

13 1-772-335-21 SENSOR MODULE, CURSOR

14 1-791-606-11 FFC (MBX-TP1)

15 1-418-674-23 KEY BOARD UNIT

17 1-763-589-11 FAN WITH HEATSINK

18 1-793-637-11 CONNECTOR, PC CARD (EJECTOR)

* 19 4-648-856-01 SHEET (T), INSULATING

22 1-791-650-11 SUBSTANCE, PRINT PWB SIMPLE

* 23 4-643-048-12 BRACKET (L), HDD

24 1-794-958-11 FFC (MBX45-CNX108)

25 A-8066-145-A ASSY HDD 12.0GB (S)

* 26 4-643-049-12 BRACKET (R), HDD

27 1-959-997-21 HARNESS, MODULAR

28 1-791-608-11 CONNECTOR, HARNESS WITH (DC)

29 4-648-550-01 ESCUTCHEON (R)

31 A-8066-200-A CNX-108 COMPLE

32 4-643-040-01 COVER (L), MAIN

34 4-643-041-01 COVER (R), MAIN

35 4-636-934-01 SPACER (SPRING)

36 4-635-956-01 SPRING (B), COMPRESSION COIL

12

B1

66

B2

38 X-4623-005-2 CABINET SUB ASSY, BOTTOM

39 4-635-946-11 FOOT

40 4-643-028-11 LID, MEMORY

41 A-8047-772-A MBX-45 J/UC ASSY (S)

42 A-8066-571-A IFX-128 COMPLE

43 4-643-811-03 SHEET (IFX), INSULATING

44 1-756-038-21 BATTERY, NICKEL HYDROGEN

45 4-643-046-01 BLIND, HOLE

46 4-648-575-02 SHEET (T), THERMAL

47 4-648-586-01 SHEET (M), BLIND

48 X-4623-006-1 ESCUTCHEON (L) SUB ASSY

50 4-643-050-02 SPRING, TORSION

52 4-648-548-21 LABEL, ID

* 54 4-646-035-01 HEATSINK (CARD SLOT)

58 4-645-941-01 GASKET (RING)

62 4-648-546-01 WINDOW (M)

63 4-651-288-01 SHEET (BOARD), BLIND

64 4-651-484-01 SHEET, EMI

65 4-651-287-01 SPACER (CARD)

66 4-640-515-21 GASKET

B1 4-639-112-01 SCREW M2X4

B2 4-644-002-21 SCREW M2 (SB) (2X6)

B4 4-644-002-01 SCREW M2 (SB) (2X4)

B5 4-635-301-01 SCREW M3X4

B6 4-644-637-11 GRIP, M2 EG (2X8)

B7 7-628-253-35 SCREW +PS 2X8

B10 4-645-214-01 GRIP, M2 (2X3)

B11 4-644-002-31 SCREW M2 (SB) (2X5)

To paste the thermal sheet (T) (46) to the fan with

*

heatsink, warm the thermal sheet (T) adequately until it

becomes soft.

For further information, refer to the removal (page 1-7).

B6

50

19

62

43

58

40

B6

A

32

B10

39

B6

28

38

B11

45

34

29

31

B10

B2

27

35

36

B11

13

C

B10

B2

C

7

6

10

5

B1

9

8

B

14

2

15

18

17

B2

47

45

46

4

3

1

B1

65

64

63

B4

B7

B

A

48

B11

44

41

42

Confidential

5-1 5-2

PCG-C1VN (UC)

Page 22

5-2. LCD Section

B11

104

101

B2

102

105

106

B4

130

108

B8

B10

107

109

110

A

B8

111

129

B

131

112

124

113

A

B9

121

B4

B4

114

123

115

B

127

122

116

116

125

119

120

126

B4

117

118

Ref.No. Part No. Description

101 X-4623-091-1 COVER ASSY, HINGE

102 4-648-046-01 RUBBER (LOWER), BLIND

103 4-643-076-01 RUBBER (RIGHT), BLIND

104 4-643-077-01 RUBBER (LEFT), BLIND

105 X-4622-406-3 BEZEL ASSY

106 4-644-102-01 INSULATOR (UPPER), MICROPHONE

107 A-8046-178-A LCD 1210 ASSY (S)

108 X-4622-314-1 COVER ASSY, MICROPHONE

109 4-643-033-02 HOLDER, MICROPHONE

110 4-643-080-01 RING (F)

111 4-643-066-03 HINGE (C)

112 4-643-067-11 CABINET, MICROPHONE

113 4-643-034-01 NUT (MIC), PLATE

114 4-643-079-02 BEARING (C)

115 4-643-035-01 LATCH (L)

116 4-643-051-01 SPRING, COMPRESSION

117 X-4623-099-1 HOUSING ASSY

118 4-643-081-11 HINGE (LCD)

119 1-476-365-11 INVERTER UNIT

120 4-643-064-02 INSULATING SHEET (INVERTER)

121 1-960-040-12 HARNESS, LCD

122 A-8047-774-A CCD SD22 ASSY (S)

123 4-644-103-01 INSULATOR (UNDER), MICROPHONE

* 124 4-645-340-01 GUARD, CABLE

125 4-643-029-01 LATCH (R)

126 4-643-072-02 LEVER, SWITCH

127 4-643-038-01 CLAMP

129 4-643-812-11 PLATE (MICROPHONE), BLIND

130 4-646-976-02 CUSHION (LATCH)

131 4-651-914-02 TAPE (MICROPHONE)

B2 4-644-002-21 SCREW M2 (SB) (2X6)

B4 4-644-002-01 SCREW M2 (SB) (2X4)

* B8 4-640-695-11 BOLT (M2.6), SPRING

B9 3-318-382-21 SCREW (1.7X3), TAPPING

B10 4-645-214-01 GRIP, M2 (2X3)

B11 4-644-002-31 SCREW M2 (SB) (2X5)

Do not dismantle the CCD SD22 assy (122).

*

For example, removing the connector.

When mounting the ring (F) (110), align markings of camera

*

(side of gear) and groove of ring (F).

If disintegrated, do not turn ring (F) (110).

*

Focus adjustment is off.

Confidential

PCG-C1VN (UC)

B11

103

B2

102

101

5-3 5-4

Page 23

5-3. Accessories

202

Display Adaptor (1)

Ref.No. Part No. Description

ACCESSORIES

***********

202 1-757-026-11 CABLE, VGA

0 203 1-418-518-21 ADAPTOR, A.C.

204 1-756-074-21 BATTERY PACK, LITHIUM ION

0 206 1-782-614-31 CORD, POWER

207 4-643-958-01 CAP (IN BAG), SENSOR

209 1-765-080-31 CORD, CONNECTION

210 A-8056-432-A EM-33 MOUNTED PWB

203

AC Adaptor

204

Battery Pack (1)

206

Power Cord (1)

4-650-622-11 WELCOME MAT, C1

4-650-626-11 USER GUIDE, C1

4-650-629-11 QUICK START, C1

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

207

Spare Cap

(for Stick) (2)

209

AV Connecting Cable

210

EM-33 Mounted PWB

Confidential

5-5 PCG-C1VN (UC)

(END)

Page 24

PCG-C1VN (UC)

PCG-C1VN (UC)

9-872-126-11

Sony Corporation

XXX

– 34 –

9-872-126-11

2000J0500-1

This manual and the constituent data may not be

replicated, copied nor reprinted in whole or in part

without prior written authorization of Sony Corporation.

English

2000J0500-1

Printed in XXX

© 2000 Sony Corporation

Loading...

Loading...