Page 1

DIGIT AL AUDIO MIXING CONSOLE

OXF-R3

OPERA TION MANUAL

1st Edition (Revised 3)

Software Version 3.0 and Later

[English]

Page 2

CAUTION

Installation has to be done by a SONY authorized

technician.

WARNING

To prevent fire or shock hazard, do not expose the unit to

rain or moisture.

To avoid electrical shock, do not open the cabinet. Refer

servicing to qualified personnel only.

VORSICHT

Um Feuergefahr und die Gefahr eines elektrischen Schlages

zu vermeiden, darf das Gerät weder Regen noch

Feuchtigkeit ausgesetzt werden.

Um einen elektrischen Schlag zu vermeiden, darf das

Gehäuse nicht geöffnet werden. Überlassen Sie

Wartungsarbeiten stets nur einem Fachmann.

For customers in the U.S.A

WARNING

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your authority

to operate this equipment.

For customers in Europe

This product with CE marking complies with both the EMC

Directive (89/336/EEC) and the Low Voltage Directive

(73/23/EEC) issued by the Commission of the European

Community.

Compliance with these directives implies conformity to the

following European standards:

• EN60950 : Product Safety

• EN55103-1: Electromagnetic Interference (Emission)

• EN55103-2: Electromagnetic Susceptibility (Imunity)

This product is intended for use in the following

Electromagnetic Environment(s)

E4 (controlled EMC environment, ex. TV studio)

Pour les clients européens

Ce produit portant la marque CE est conforme à la fois à la

Directive sur la compatibilité électromagnétique (EMC)

(89/336/CEE) et à la Directive sur les basses tensions

(73/23/CEE) émises par la Commission de la Communauté

européenne.

La conformité à cas directives implique la conformtié aux

normes eropéennes suivantes:

• EN60950 : Sécurité des produits

• EN55103-1 : Interférence électromagnétiques (émission)

• EN55103-2 : Sensibilité électromagnétique (immunité)

Ce produit est prévu pour étre utilisé dans les environments

électromagnétiques suivants:

E4 (environment EMC contrôlé ex. studio de télévision).

Für Kunden in Europa

Dieses Product besitzt die CE-Kennzeichnung und erfüllt

sowahl die EMV-Directive (89/336/EEC) als auch die

Directive Niederspannung (73/23/CEE) der EGKommission.

The shielded interface cable recommended in this manual

must be used with this equipment in order to comply with

the limits for a digital device pursuant to Subpart B of Part

15 of FCC rules.

!

This symbol is intended to alert the user to the

presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

Die Erfüllung dieser Directiven bedeutet Konformität für die

folgenden Europäischen Normen:

• EN60950 : Produktsicherheit

• EN55103-1 : Electromagnetische Interferenz (Emission)

• EN55103-2 : Electromagnetische Empfindlichkeit

(Immunität)

Dies Produkt ist für den Einsatz unter folgenden

electromagnetischen Bedingungen ausgelegt:

E4 (kontrollierter EMV-Bereich, z.B. Fernsehstudio)

Page 3

Peak Inrush Current

OXF-CP3048PS

(1) Power ON, current probe method:

50A (100V)

110A (240V)

(2) Hot switching inrush current, measured in

accordance with European standard EN55103-1:

40A (230V)

OXF-IO3000

(1) Mise sous tension (ON), méthode de sondage du

courant:

20A (100)

70A (240V)

(2) Mesuré conformément

EN55103-1:

à la norme européenne

30A (230V)

OXF-SP3000

(1) Power ON, current probe method:

40A (100V)

80A (240V)

(2) Hot switching inrush current, measured in

accordance with European standard EN55103-1:

80A (230V)

OXF-IO3000

(1) Power ON, current probe method:

20A (100V)

70A (240V)

(2) Hot switching inrush current, measured in

accordance with European standard EN55103-1:

30A (230V)

Appel de Courant de Crête

OXF-CP3048PS

(1) Mise sous tension (ON), méthode de sondage du

courant:

50A (100V)

110A (240V)

(2) Mesuré conformément

EN55103-1:

40A (230V)

à la norme européenne

Spitzenstrom

OXF-CP3048PS

(1) Einschaltstrom, Stromsonde:

50A (100V)

110A (240V)

(2) Gemessen in EN55103-1:

40A (230V)

OXF-SP3000

(1) Einschaltstrom, Stromsonde:

40A (100V)

80A (240V)

(2) Gemessen in EN55103-1:

80A (230V)

OXF-IO3000

(1) Einschaltstrom, Stromsonde:

20A (100V)

70A (240V)

(2) Gemessen in EN55103-1:

30A (230V)

OXF-SP3000

(1) Mise sous tension (ON), méthode de sondage du

courant:

40A (100V)

80A (240V)

(2) Mesuré conformément

EN55103-1:

à la norme européenne

80A (230V)

i

Page 4

OXF-CP3048PS only

WARNING

This unit has no power switch.

When installing the unit, incorporate a readily

accessible disconnect device in the fixed wiring, or

connect the power cord to a socket-outlet which must

be provided near the unit and easily accessible.

If a fault should occur during operation of the unit,

operate the disconnect device to switch the power

supply off, or disconnect the power cord.

WARNUNG

Dieses Gerät hat keinen Netzschalter.

Beim Einbau des Geräts ist daher im Festkabel ein

leicht zugänglicher Unterbrecher einzufügen, oder das

Netzkabel muß mit einer in der Nähe des Geräts

befindlichen, leicht zugänglichen Wandsteckdose

verbunden werden.

Wenn während des Betriebs eine Funktionsstörung

auftritt, ist der Unterbrecher zu betätigen bzw, das

Netzkabel abzuziehen, damit die Stromversorgung

zum Gerät unterbrochen wird.

WARNING: THIS WARNING IS APPLICABLE FOR

USA ONLY.

If used in USA, use the UL LISTED power cord

specified below.

DO NOT USE ANY OTHER POWER CORD.

Plug Cap Parallel blade with ground pin

(NEMA 5-15P Configuration)

Cord Type SJT, three 16 or 18 AWG wires

Length Less than 2.5 m (8 ft 3 in)

Rating Minimum 10 A, 125 V

Using this unit at a voltage other than 120V may

require the use of a different line cord or attachment

plug, or both.

To reduce the risk of fire or electric shock, refer

servicing to qualified service personnel.

ii

Page 5

Table of Contents

About This Manual....................................................................................5

Chapter 1

Overview

Chapter 2

Powering The OXF-R3

Chapter 3

Getting Started

1-1 Overview......................................................................................... 1-2

1-2 Data Flow........................................................................................ 1-4

1-3 Signal Flow...................................................................................... 1-6

2-1 OXF-R3 Start-Up........................................................................... 2-2

2-1-1 Start-Up Procedure............................................................. 2-2

2-2 OXF-R3 Shutdown......................................................................... 2-4

2-2-1 Shutdown Procedure .......................................................... 2-4

3-1 The Control Surface...................................................................... 3-2

3-2 Fader Paging.......................................................................... 3 - 8

3-3 Assignable Channel Processing................................. 3 - 9

3-4 Input Channel, Equaliser and Filters.............. 3-10

3-5 Free Assign Area and Dynamics............................... 3-11

3-6 Multitrack, Routing for Multitrack,

Super Send Groups and Multi-Format.................... 3-12

3-7Sends......................................................................................... 3-13

3-8 Select To Faders.............................................................. 3-14

3-9 Select To Pans................................................................... 3-17

3-10 Basic Console Operations........................................3-18

3-10-1 To Route a Mic or Line Input to the Main Output Bus ... 3-19

3-10-2 To Set Up a Super Send Group from Channel Inputs...... 3-20

3-10-3 To Send Signals to Tracks on Tape ................................. 3-21

3-10-4 To Monitor Signals to and from Tape.............................. 3-22

3-10-5 To Set Up a Stereo Headphone Mix for Foldback 1 O/P 3-23

3-10-6 To Equalise Signal Feeding the Multitrack ..................... 3-24

3-10-7 To Equalise Monitor Signal Post Multitrack ................... 3-25

3-10-8 To Insert Dynamics Pre Multitrack Send......................... 3-26

3-10-9 To Insert Dynamics Post Multitrack Return .................... 3-27

3-10-10To Bounce Tracks ............................................................ 3-28

3-10-11To Set Up Super Send Groups from Multitrack .............. 3-29

3-10-12To Set Up a De-Esser Using Dynamics Side-Chain EQ.. 3-30

3-10-13To Link Compressor Side-Chains in a Group ................. 3-31

3-10-14To Link Compressor Side-Chains so that One Channel

Controls a Second Channel.............................................. 3-32

Table of Contents 1

Page 6

Table of Contents

Chapter 4

Signal Paths

4-1 The Basic (Default) Signal Path................................................... 4-2

4-2 Stereo Mix-Down Signal Path with Processing Inserted........... 4-4

4-3 Mix-Down with Post Channel Fader Insert................................ 4-6

4-4 Recording to a Multitrack............................................................ 4-7

4-5 In-Line Channel Multitrack Recording Set-up.......................... 4-8

4-6 In-Line Channel with Insert Post Channel Fader

(Monitor Function)........................................................................ 4-9

4-7 SEND 1 Pre Fader Headphones Feed........................................ 4-10

4-8 SEND 1 Post Fader Headphones Feed...................................... 4-11

4-9 Broadcast Mode........................................................................... 4-12

4-10 Channel Metering........................................................................ 4-15

4-10-1 Channel Meter Default..................................................... 4-15

4-10-2 Channel Meters to Input .................................................. 4-15

4-10-3 Send Monitor ................................................................... 4-16

4-10-4 Return Monitor ................................................................ 4-16

4-10-5 MULTI in Channel Path .................................................. 4-17

4-11 Dynamics Side-Chain Linking................................................... 4-18

4-11-1 Dynamics Side-Chain Link Right .................................... 4-18

4-11-2 Dynamics Side-Chain Busses 1-4 .................................... 4-20

4-12Mixing to the Main Output Bus.............................. 4-22

4-12-1 Main Output Bus Set-up .................................................. 4-24

4-12-2 Channel Signal to the Main Output ................................. 4-26

4-13 Multi-Stem Set-up........................................................ 4-29

4-13-1 Multi-Stem Set-up Procedure .......................................... 4-32

4-13-2 Multi-Stem Monitor Path ................................................. 4-36

4-13-3 Multi-Stem Source Channels ........................................... 4-40

4-13-4 STEM Monitor Switching ............................................... 4-48

4-13-5 STEM Monitor Switching GUI Set-up ............................ 4-50

4-13-6 Fold-Down Matrix GUIs ................................................. 4-52

Chapter 5

Control Screens

Chapter 6

Technical Descriptions

5-1 The Master Control Screens.......................................................... 5-2

5- 2Channel Screens.................................................................... 5 - 5

5-2-1 Routing GUI........................................................................... 5-8

5-2-2 I/O GUI ................................................................................ 5-11

5-2-3 Equaliser & Filters GUI ....................................................... 5-28

5-2-4 Dynamics GUI ..................................................................... 5-29

5-2-5 Preferences GUI ................................................................... 5-30

5-2-6 Master GUI (Includes Main Bus Outputs) ........................... 5-39

6- 1OXF-R3 System Description............................................ 6 - 2

6-1-1 Control Surface Configurations ........................................... 6-3

6-2 Channels Section Panels................................................................ 6-6

6-2-1 Fader Panel........................................................................... 6-6

6-2-2 Select to Faders Panel .......................................................... 6-9

6-2-3 Pans Panel .......................................................................... 6-13

6-2-4 Select to Pans Panel ........................................................... 6-15

6-2-5 Input and Equaliser Panel .................................................. 6-17

6-2-6 Free Assign Area & Dynamics Panel ................................ 6-20

6-2-7 Multitrack Panel................................................................. 6-25

2 Table of Contents

Page 7

Chapter 6

Technical Descriptions

6-2-8 Routing Panel..................................................................... 6-28

6-2-9 LCD Channel Screen Panel ............................................... 6-31

6-2-10 Sends 1-24 Panel ................................................................ 6-32

6- 3Central Section Panels................................................. 6-38

6-3-1 Master Fader Panel ............................................................ 6-38

6-3-2 Monitor Panel..................................................................... 6-39

6-3-3 Control Keyboard Panel..................................................... 6-62

6-3-4 Super Send Groups, Send Outputs and

Multi-Format Panel ............................................................ 6-76

6-3-5 Central Section Faders ....................................................... 6-86

6-3-6 Control LCD Screen Panel................................................. 6-87

6-3-7 QWERTY Keyboard.......................................................... 6-88

6-3-8 Trackerballs........................................................................ 6-89

6- 4Meter Bridge......................................................................... 6-90

6-4-1 Mono Channel Meters........................................................ 6-90

6-4-2 Stereo Centre Section Meters............................................. 6-92

6-4-3 Other Meter Bridge Indicators ........................................... 6-95

6- 5Signal Processing Rack................................................. 6-96

6-5-1 SP Rack Modules ............................................................... 6-96

6- 6I/O Racks................................................................................6-97

6-6-1 I/O Rack Modules .............................................................. 6-97

Chapter 7

Session Management™

(Continued)

7- 1The Basics................................................................................ 7 - 2

7- 2Files Hierarchy and Automatable Controls........ 7 - 3

7-2-1 Files Hierarchy..................................................................... 7-3

7-2-2 Automatable Controls .......................................................... 7-6

7- 3File Data Storage............................................................... 7 - 7

7- 4Programme Material............................................................. 7 - 8

7- 5Mixing Overview.................................................................... 7 - 9

7-5-1 Getting Started ..................................................................... 7-9

7-5-2 Name the Artist/Project and Title ...................................... 7-10

7-5-3 To Set Cue Points............................................................... 7-11

7-5-4 To Automate Cuts .............................................................. 7-13

7-5-5 To Save a Mix .................................................................... 7-19

7-5-6 To Automate Fader Moves ................................................ 7-20

7-5-7 Dropping Out of Write on Subsequent Mix Passes ........... 7-21

7-5-8 To Record Absolute Moves for a Number of Faders........ 7-22

7-5-9 To Trim Fader Moves ........................................................ 7-22

7-5-10 To Trim Moves for a Number of Faders ............................ 7-22

7-5-11 To Automate a Pan Move (or any other Knob) ................. 7-23

7-5-12 To Assemble a Mix ............................................................ 7-24

Table of Contents 3

Page 8

Table of Contents

Chapter 7

Session Management™

7-6 The Session Management™ Screen Pages ................................. 7-27

7-6-1 The Start-up Logo Screen .................................................. 7-27

7-6-2 The System Screen............................................................. 7-28

7-6-3 The Machines Screen ......................................................... 7-30

7-6-4 Artists/Projects & Titles Screen......................................... 7-32

7-6-5 Mixes & Cues Screen......................................................... 7-35

7-6-6 Merge/Assemble Screen .................................................... 7-40

7-6-7 Track Lists Screen.............................................................. 7-46

7-6-8 Snapshots, Copy & Link Screen ........................................ 7-49

7-6-9 Copy Channel Fader Balance to M/T Faders and M/T to

Channels............................................................................. 7-60

7-6-10 Copy Monitor and M/T Send Fader Balance to Cues ........ 7-60

7-6-11 Quick Copy EQ A to B and B to A.................................... 7-60

7-6-12 Machine Remotes Screen................................................... 7-61

7- 7Dynamic Automation Moves ............................................ 7-64

7-7-1 Motorised Fader Controls .................................................. 7-64

7-7-2 Automating Faders............................................................. 7-65

7-7-3 To Automate Cuts .............................................................. 7-70

7-7-4 To Automate Other Switches............................................. 7-76

7-7-5 To Automate a Pan Move (or any other knob) .................. 7-77

7-7-6 Dropping Out of Write on Subsequent Mix Passes

for Knobs........................................................................... 7-78

7-7-7 To Trim Pan Moves (or any other knob) ........................... 7-78

7-7-8 Automation Off and Selective Automation Isolate............ 7-79

7-7-9 Film Mode.......................................................................... 7-80

7-7-10 Global Ready Enable ......................................................... 7-81

7- 8Offline Automation...........................................................7-84

7 - 9MIDI............................................................................................ 7-89

7-9-1 MIDI Control Pages ........................................................... 7-89

7-9-2 Setting MIDI parameters.................................................... 7-90

7-9-3 MIDI Bars & Beats ............................................................ 7-93

7-10 Backups................................................................................ 7-95

7-11 Preferences.....................................................................7-101

Appendixes

4 Table of Contents

Software Installation/Upgrades........................................................... A-2

Multi-Format LS Calibration.............................................................. A-3

Specifications......................................................................................... A-6

OXF-R3 Diagnostics........................................................................... A-17

Index........................................................................................................I-1

Page 9

About This Manual

Purpose and intended readers

This is the operation manual for the OXF-R3 digital

audio mixing console. It explains how to use the

OXF-R3 to record, mix and output digital audio

signals.

This manual is aimed at professionals such as

operators and engineers working in high-end recording

studios, production companies and broadcasting

stations. It is assumed that the reader has prior

experience of using professional audio equipment.

Use this manual as a reference, by referring to the

chapters as summarised below. If however you have

limited experience of using this kind of equipment, we

recommend that you read through the entire manual.

The block diagrams contained in this manual are

intended to help you understand the signal flow and

operation of the OXF-R3.

Model numbers covered by this manual

This manual refers in general terms to the OXF-R3.

The illustrations show the 24-C-24 version, which is

the current model.

Chapter 6 Technical Descriptions

Provides the descriptions of all the modules of the

OXF-R3, including the names, locations and functions

of the controls. This chapter also includes descriptions

of the associated SP Rack and I/O Rack system.

Chapter 7 Session Management™ System

Describes the sophisticated and flexible Session

Management™ system available to OXF-R3 users,

including automation of functions - a key feature of the

Session Management™ system. Both static and

dynamic automation is possible using the OXF-R3.

Appendixes

Provide the information for the following:

•Software installation/upgrades

•Multi-format LS calibration

•Specifications

•Diagnostic facilities (There are no user operable

diagnostic facilities provided in this version of the

OXF-R3).

Organisation

This manual is divided into the following seven

chapters and four appendixes:

Chapter 1 Overview

Introduces the features of the OXF-R3 and how it may

be used to configure a complete system.

Chapter 2 Powering the OXF-R3

Includes the system power-up procedure and the

boot-up sequence for the host computer.

Chapter 3 Getting Started

Gives an overview of the OXF-R3 control surface

describing the principles of operation. The panels are

described in enough detail to allow the experienced

operator to start using the OXF-R3.

Chapter 4 Signal Paths

Explains the general principles of building signal paths

and gives examples of types of signal paths that may

be built from the basic default signal path existing at

‘fire-up’.

Chapter 5 Control Screens

Lists all the control screens available in the OXF-R3.

The screens related to the channels and mixer

functions are described in detail.

About This Manual 5

Page 10

About This Manual

Conventions used in this manual

This manual uses the following conventions:

Chapter 3, Section 10

Subsection 5

within Section 10

•

•

Operation

Step number

Cross-reference within

the manual

Important note

6 About This Manual

•

•

Page 11

Related manuals

In addition to this operation manual, the following

manuals are available for the OXF-R3:

•Installation Manual

•Service Manual

About This Manual 7

Page 12

About This Manual

Glossary of Terms

ABS Absolute

ADC Analogue to Digital Converter

AES Audio Engineering Society

AFL After Fader Listen

ATR Audio Tape Recorder

AUX Auxiliary

CAL Calibrated or Calibration

CH Channel

CMRR Common Mode Rejection Ratio

CR Control Room

DAC Digital to Analogue Converter

DAT Digital Audio Tape

DIV Divergence

DYN Dynamics

EBU European Broadcasting Union

EDL Edit Decision List

EQ Equaliser or Equalisation

EXT External

FILT Filter

FS Sampling Frequency

GDC Global Delay Compensation

GPI General Purpose Interface

GUI Graphical User Interface

O/B Outside Broadcast

O/L Overload

PAN Panoramic

PCB Printed Circuit Board

PCM Pulse Code Modulation

PFL Pre Fader Listen

PSU Power Supply Unit

RET Return

RSL Remote Studio Link

S-C Side Chain

SDDS Sony Dynamic Digital Sound

SDIF Sony Digital Interface Format

SEL Select

SIG Signal

SM Session Management

SMPTE Society of Motion Picture & Television

Engineers

SMS Session Management System

SP Signal Processing

SPL Sound Pressure Level

SRC Sample Rate Converter

SSG Super Send Group

STER Stereo

SUR Surround

S/W Software

HF High Frequency

HMF Higher Mid Frequency

H/W Hardware

I/O Input/Output

LCD Liquid Crystal Display

LED Light Emitting Diode

LF Low Frequency

LMF Lower Mid Frequency

L/R Left/Right

LS Loudspeaker

MADI Multi-Channel Audio Digital Interface

MF Mid Frequency

MIC Microphone

MIDI Musical Instrument Digital Interface

M.O. Magneto-Optical (disk)

MON Monitor

M/T Multitrack

MTR Meter

T/B Talkback

TC Time Code

TCF Time Code Frame

TFT Thin Film Transistor

T/LIST Track List

TRM Trim

VCA Voltage Controlled Amplifier

VDU Video Display Unit

VGA Video Graphics Array

8 Glossary of Terms

Page 13

Chapter 1 – Overview

This chapter introduces the OXF-R3 digital audio mixing console and

describes the main features. An example system configuration and a

signal flow diagram are included.

Chapter 1 Contents

1-1 Overview ......................................................................................... 1-2

1-2 Data Flow ........................................................................................ 1-4

1-3 Signal Flow...................................................................................... 1-6

Chapter 1 Overview

Chapter 1 Overview 1-1

Page 14

1-1 Overview

1-1 Overview

Chapter 1 Overview

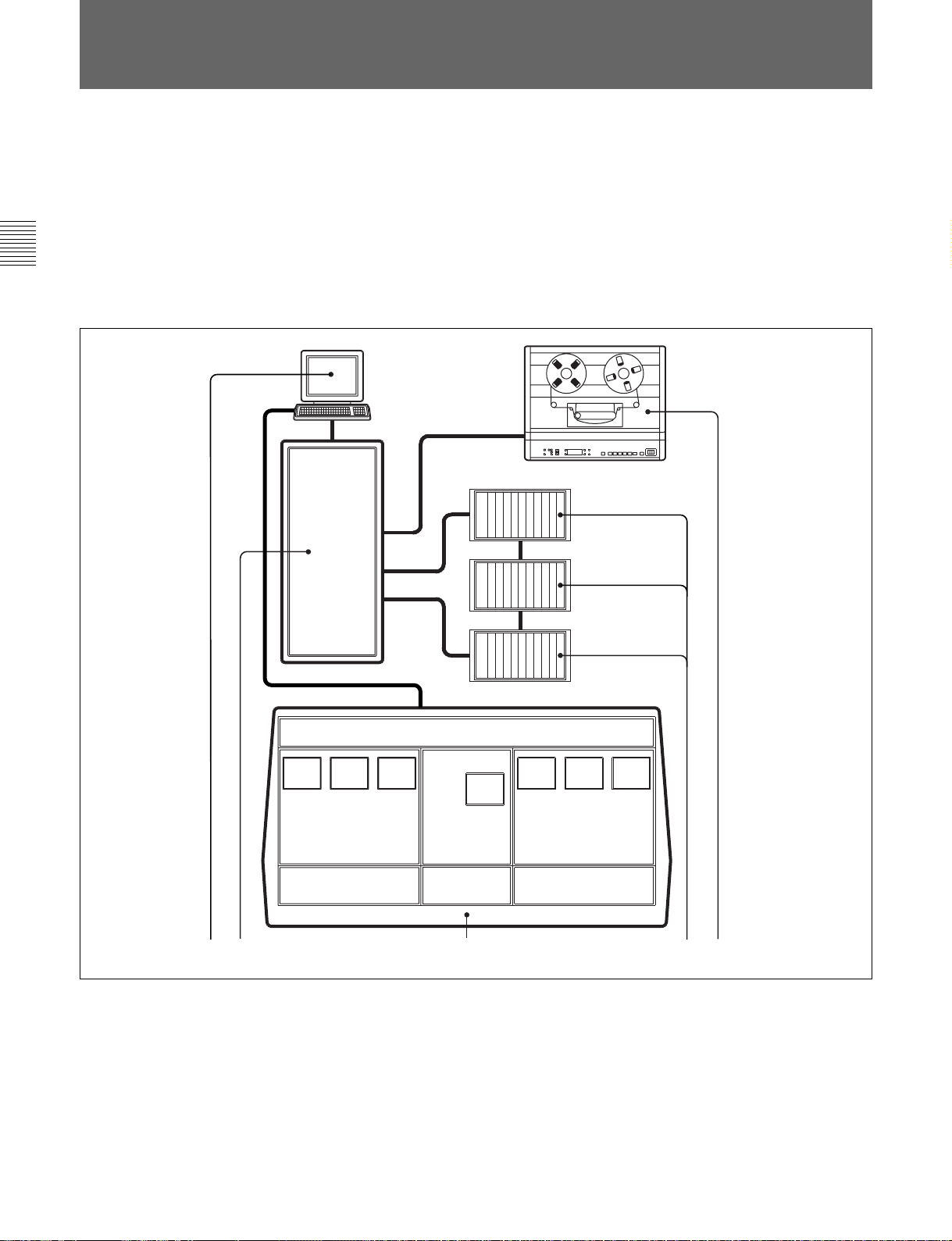

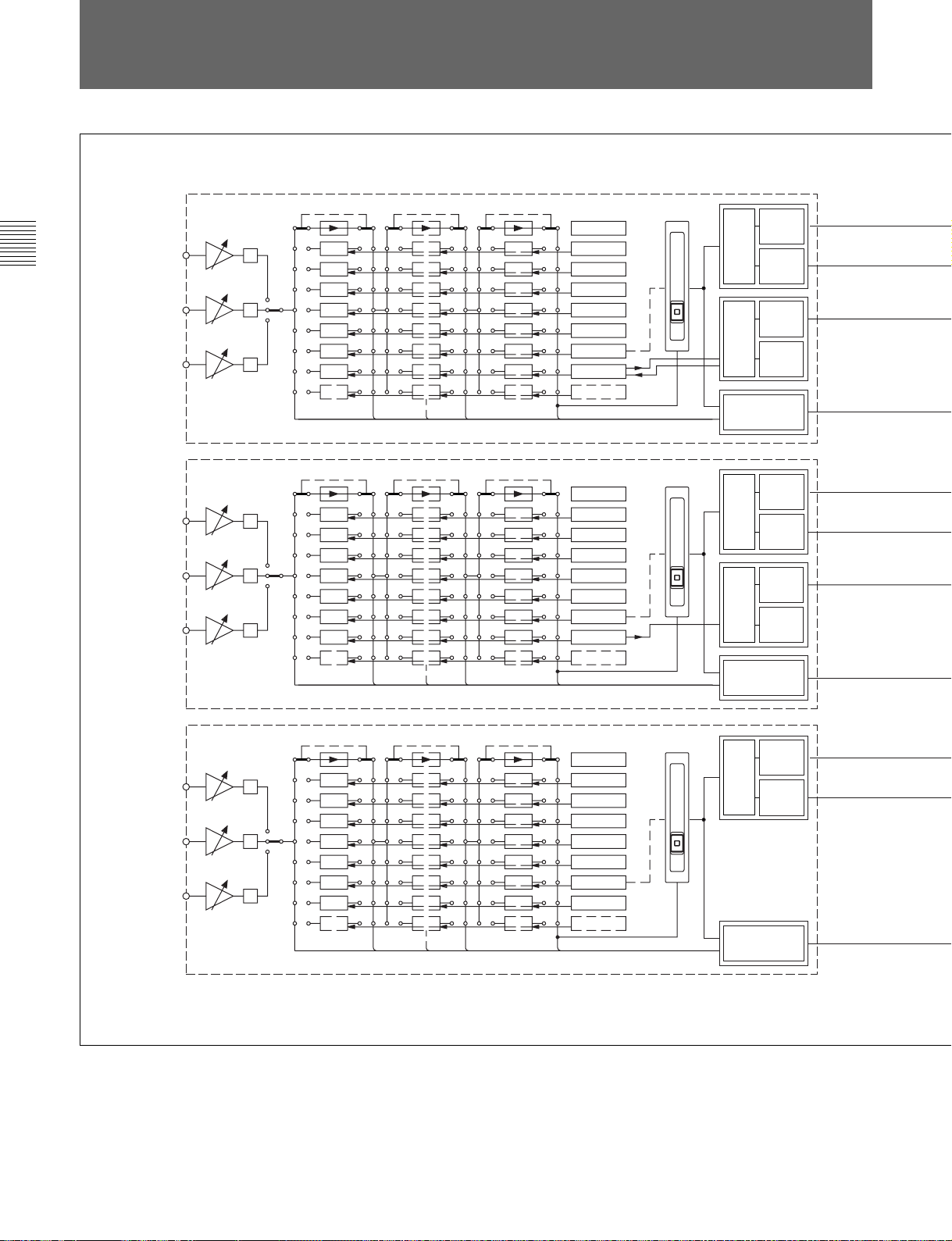

The OXF-R3 is a ‘high end’ digital audio mixing console system. It

comprises four main components:

• Control Console with Modular Control Surface

• Host Computer

• Signal Processing (SP) Rack

• Digital and Analogue I/O Racks

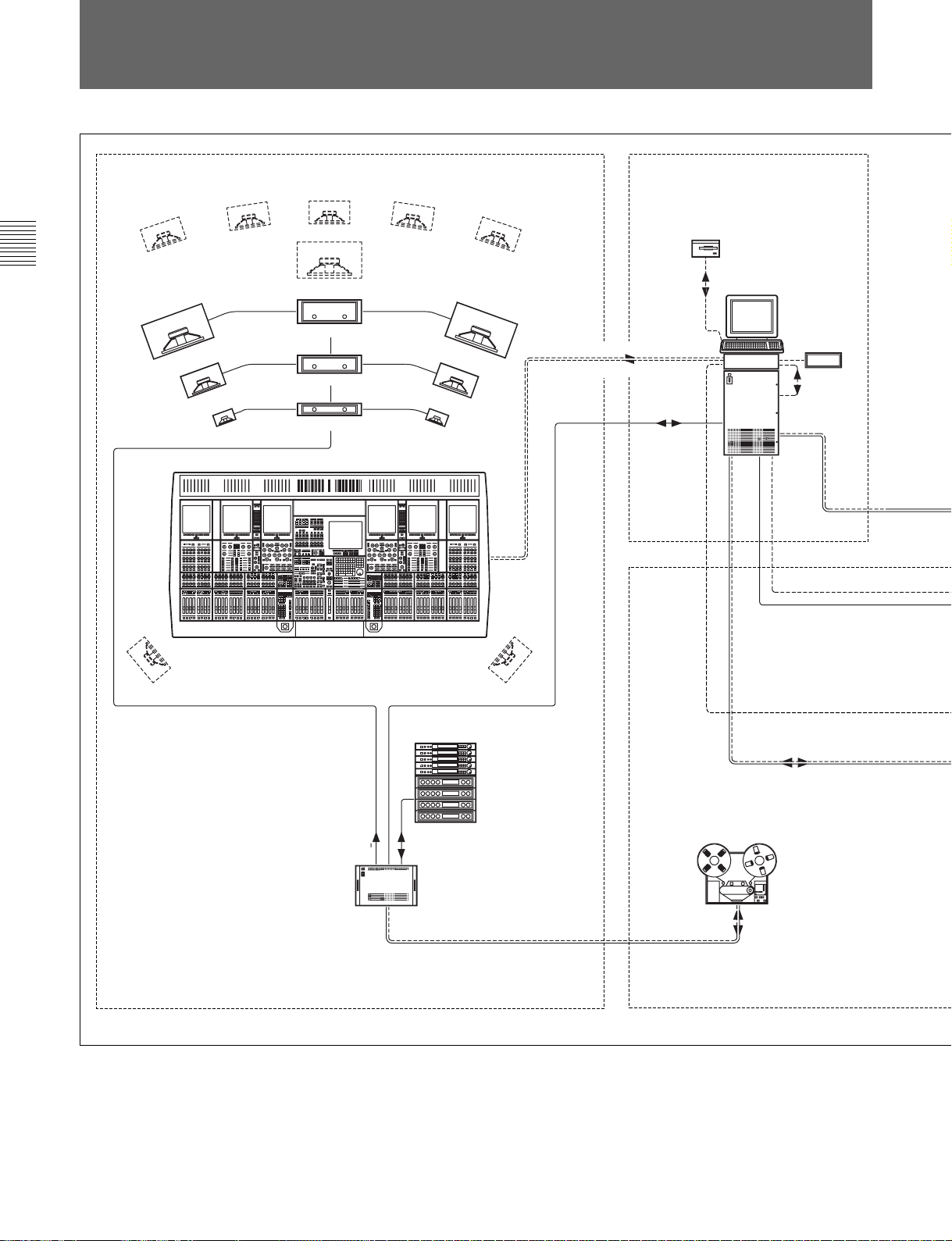

The following illustration shows a basic system concept diagram.

21

1 SP Rack

2 Host Computer

3 Multitrack Tape Recorder(s)

1-2 Chapter 1 Overview

5

System Concept diagram

4 Digital and Analogue I/O Racks

5 Control Console

4

3

Page 15

Control Console

Compared with traditional console designs, the OXF-R3 offers greater

flexibility within more compact dimensions by using an assignable control

surface.

Modular Control Surface

The control surface of the OXF-R3 makes extensive use of assignable

panels to provide a console of manageable size for either one or two

operators, whilst giving greatly increased functionality. The current

system is capable of controlling up to 96 full channels and 12 stereo return

channels. The modular system divides functionally into the master

section, located in the centre, and the channel sections located either side

of the master section.

Signal Processing (SP) Rack

The SP rack is designed to use the minimum number of signal processing

cards depending on the system size. A high level Software Design Tools

System is used to generate automatically the low level software microcode

which runs the SP system. Data links to and from the control console are

via Ethernet connections, whilst a MADI interface is used between the SP

rack and the I/O racks. Additional bandwidth, available within the MADI

signal, is used to pass data for purposes such as remote control of analogue

amplifier gain.

Chapter 1 Overview

Digital and Analogue I/O Racks

The I/O racks are designed to be located close to the equipment with which

they interface. Each I/O rack can contain a mix of up to 56 high quality

analogue inputs and/or outputs on 10 analogue I/O cards. Each analogue

card handles 4 or 8 inputs and 4 or 8 outputs according to its type. A mix

of input and output cards in the same I/O rack may, for example, allow cue

outputs for headphones to be local to appropriate microphone sources.

The digital and analogue I/O are housed in a single rack type. Digital I/O

has the same capability as the analogue, of up to 56 inputs and 56 outputs

per rack via AES/EBU and SDIF-2 (24) modules. The digital I/O system

also includes modules for Timecode, 9-Pin, GPI and MIDI. MADI

connections may be made directly to the SP rack.

Machine Control

Machine control for the OXF-R3 is accomplished via Sony 9-Pin control

and third party devices such as the “motionworker”, supplied by

Motionworks Ltd.

Note:

Refer to the Appendixes in this manual for further details of OXF-R3 capabilities.

Chapter 1 Overview 1-3

Page 16

1-1 Overview

1-2 Data Flow

1

Chapter 1 Overview

2

(LC)

L

C

SUB

CR MONITORS 1

CR MONITORS 2

CR MONITORS 3

(RC)

R

CONTROL FOR SP AUDIO PROCESSING & MACHINES

SYSTEM STATUS & DISPLAY DATA

MADI

AUTOMATION

MEDIA

HOST COMPUTER

MODEM

SP RACK

4

SURROUND L SURROUND R

AUDIO AUDIO

I/O RACK

Sample installation illustrating Audio & Control Data flow

FX RACK

1 Control Room

2 TRACK ANALOGUE

GPI

AUDIO

MADI

1-4 Chapter 1 Overview

2 Rack Room

Page 17

3

GPI

RECORD REHEARSE CUE

LISTEN

STUDIO

L/S

Chapter 1 Overview

GAIN

MADI

FS

MADI

I/O

RACK

AES/EBU

I/O RACK

MOTIONWORKER PROTOCOL

MASTER TC

TRANSPORT 9P

TC

TRANSPORT 9P

PCM-7050

DAT

AES/EBU

AUDIO

TC

PCM-7050

DAT

AES/EBU

AUDIO

AUDIO

TC

SYNCHRONISER

TC

MOTIONWORKER

TC

TRANSPORT 9P

FOLDBACK

GPI

RECORD REMOTES & TALLIES

TRANSPORT 9P

TC

PCM-7050

DAT

AES/EBU

PCM-3348 48 TRACK

PCM-9000

MASTERDISC

FS OUT

3 Studio

4 Machine Room

TIME CODE CONTROL DATA AUDIO DATA

Chapter 1 Overview 1-5

Page 18

1-1 Overview

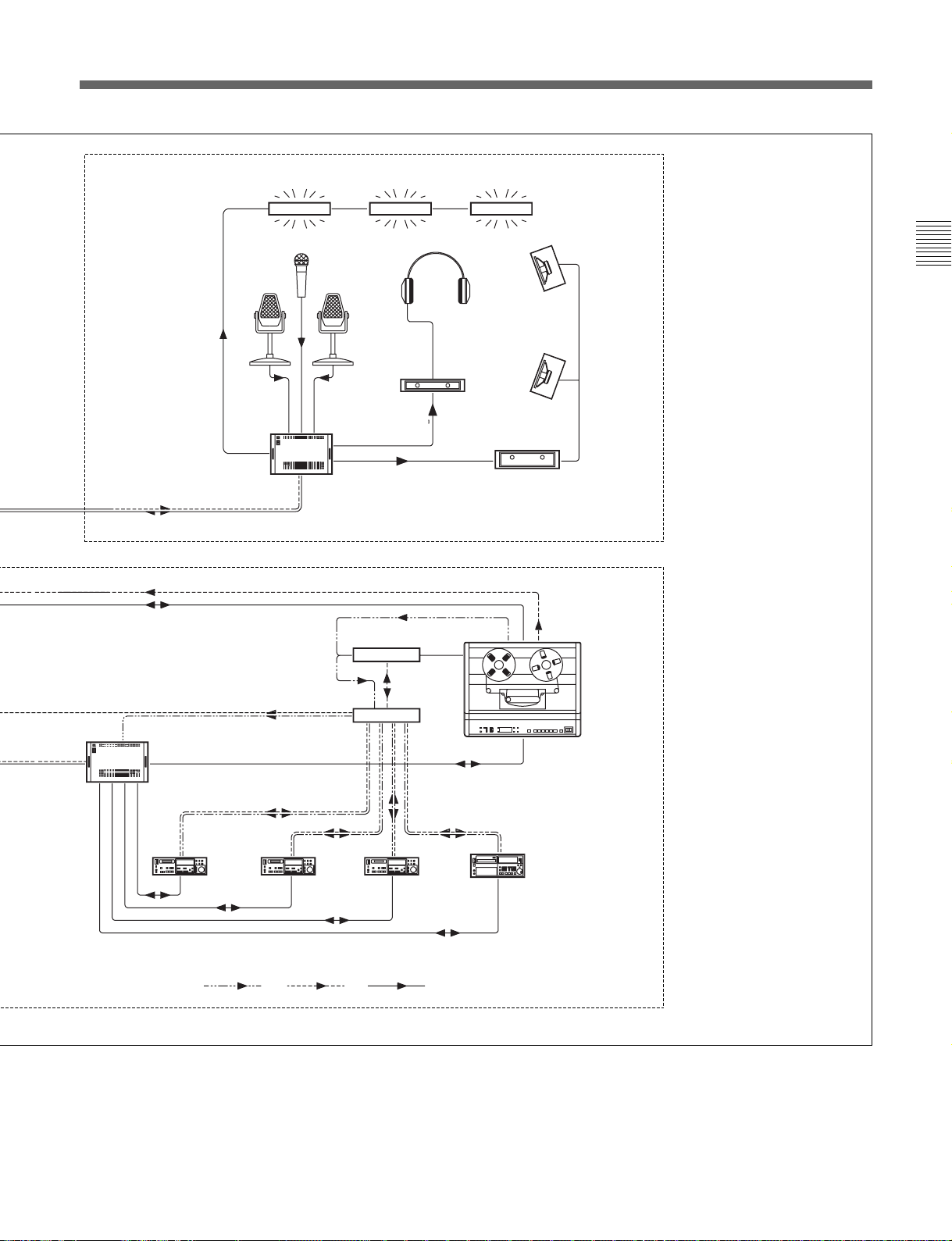

1-3 Signal Flow

Chapter 1 Overview

MIC

M/T

LINE

MIC

M/T

LINE

Ø

Ø

Ø

CHs 1-48

Ø

Ø

Ø

CHs 49-96

SELECTOR 1 SELECTORS 2-7 SELECTOR 8

SELECTOR 1 SELECTORS 2-7 SELECTOR 8

BYPASS

FILTERS

5 BAND EQ

DYNAMICS

INSERT

DELAY FX

FADER

MULTITRACK

FUTURE SP

BYPASS

FILTERS

5 BAND EQ

DYNAMICS

INSERT

DELAY FX

FADER

MULTITRACK

FUTURE SP

ST.

LCRS

5.1

7.1

ST

LCRS

5.1

7.1

UP

TO 8

STEMS

AUXILIARY

SENDS 1-24

ST.

LCRS

5.1

7.1

ST

LCRS

5.1

7.1

UP

TO 8

STEMS

AUXILIARY

SENDS 1-24

MAIN

OUTPUT

BUS

SUPER

SEND GPs

1-16

BUSSES

1-48

48 M/T

SENDS &

RETURNS

CUE &

MAIN

OUTPUT

BUS

SUPER

SEND GPs

1-16

BUSSES

1-48

48 M/T

DIRECT

OUTPUTS

CUE &

M/T

M/T

MIC

M/T

LINE

OXF-R3 signal flow

SELECTOR 1 SELECTORS 2-7 SELECTOR 8

Ø

Ø

Ø

RETURN CHs 97-120

BYPASS

2 BAND EQ

INSERT

DELAY FX

FADER

FUTURE SP

ST.

LCRS

5.1

7.1

CUE &

AUXILIARY

SENDS 1-24

MAIN

OUTPUT

BUS

SUPER

SEND GPs

1-16

1-6 Chapter 1 Overview

Page 19

MAIN OUTPUT BUS - STEREO, LCRS, 5.1 or 7.1

16 SUPER SEND GROUPS - MONO, STEREO, LCR, LCRS, 5.0, 5.1, 7.0 & 7.1

48 MULTITRACK BUSSES - Up to 8 MULTI-CHANNEL STEMS

CUE & AUXILIARY SENDS 1-24

Chapter 1 Overview 1-7

LISTEN MIC 1

TALKBACK

MONITOR SECTION

FOLDBACK 1

FOLDBACK 2

FOLDBACK 3

FOLDBACK 4

TALKBACK 1

STUDIO LS 2

AFL

PFL

STUDIO LS 1

SOLO

LS 3

MONITOR LS

MONITOR INPUTS

SURROUND

4 X 8 WIDE

LS 2

CONTROL ROOM

MONITOR LS

EXTERNAL SOURCES 9-12

MONITOR LS

EXTERNAL SOURCES 1-8

8 X STEREO MONITOR

INPUTS

LS 1

MAIN

CONTROL ROOM

Chapter 1 Overview

Page 20

Page 21

Chapter 2 – Powering The OXF-R3

This chapter provides step-by-step procedures for starting up the OXF-R3,

including the power-up sequence and the booting of the Host Computer. It

also includes the procedure for controlled shutdown of the OXF-R3.

Chapter 2 Contents

2-1 OXF-R3 Start-Up ........................................................................... 2-2

2-1-1 Start-up Procedure ............................................................... 2-2

2-2 OXF-R3 Shutdown ......................................................................... 2-4

2-2-1 Shutdown Procedure ............................................................ 2-4

Chapter 2 Powering The OXF-R3

Chapter 2 Powering the OXF-R3 2-1

Page 22

2-1 OXF-R3 Start-Up Procedure

2-1 OXF-R3 Start-Up

CAUTIONS:

1. Before starting-up the OXF-R3, check that all Monitor

Loudspeaker Power Amps are turned off or muted.

2. Switch on equipment in the sequence given here, to ensure troublefree start-up.

Chapter 2 Powering The OXF-R3

2-1-1 Start-Up Procedure

1. Check that the motionworker and Lynx Time Code Module are already

switched on and running normally.

2. Switch on the power to the SP Rack.

3. Switch on the power to the Host Computer.

4. Switch on the power to the I/O Racks.

Note:

It is important that the I/O racks are switched on in the sequence of the Sync

Clock wiring loop connected to the clock inputs of the I/O Racks.

5. The Host Computer performs its start-up and self-test routines. At the

end of these routines, a triple chevron prompt >>> should be displayed

on the monitor.

6. Type b then press {RETURN} to start the boot-up process for the

OXF-R3 system.

2-2 Chapter 2 Powering the OXF-R3

Note:

If your Host Computer has been configured for Auto-boot (an option at set-up),

the triple chevron prompt will not be displayed and boot-up will proceed

automatically.

7. At the end of the boot-up procedure, the Login field will be displayed

on the monitor.

8. Now switch on the power to the control panel. All 7 LCD screens will

show activity as programs are downloaded from the Host Computer to

the computers within the console. When downloading is completed,

an ‘X’ is displayed in the centre of each screen.

Page 23

9. Log in at the Host Computer. Note that the user name and password

below are the system defaults.

Type sm (case-sensitive) then press {RETURN}.

Type in the password: oxf-r3 (case-sensitive), then press {RETURN}.

Notes:

1 oxf-r3 is the default password. This may be changed but its modification must

be carried out with help from Sony personnel.

2 Login can be initiated while programs are still being downloaded from the Host

Computer. It is not necessary to wait until all the console LCD screens are

displaying ‘X’ in their centres.

10. Once logged-in, a window is displayed on the monitor of the Host

Computer. Use the mouse to move the cursor into this window entitled

STIF. Note that the window surround changes colour from green to

red, to indicate that this is now the active window.

11. Check that the console LCD screens are all displaying ‘X’ before

proceeding, then:

Type: run_r3 (case-sensitive) then press {RETURN}.

Chapter 2 Powering The OXF-R3

12. Observe that the centre LCD screen in the console displays a summary

of the processes being executed by the Host Computer which are

displayed in greater detail on the monitor.

13. When the loading of the Netlist is complete, the centre screen of the

console displays the OXF-R3 logo.

14. Switch-on is now complete, but wait until all controls on the control

panel are initialised (indicated by their lighting up) before operating

the system.

Chapter 2 Powering the OXF-R3 2-3

Page 24

2-2 OXF-R3 Shutdown Procedure

2-2 OXF-R3 Shutdown

CAUTION:

Turn off or mute all monitor amplifiers connected to the OXF-R3.

Unless the OXF-R3 is to remain switched off for a prolonged period, it

will be more convenient to leave the Clock Synchronisation source

running.

Chapter 2 Powering the OXF-R3

2-2-1 Shutdown Procedure

1. At the centre LCD screen on the OXF-R3 control surface, use the

appropriate softkey to select SYSTEM.

Note:

If necessary, retrace a number of steps through the screens hierarchy to reach this

point. Refer to the Screens Structure diagram in Chapter 5 for detailed

information on the screen page hierarchy.

2. On the SYSTEM screen page, click on SYSTEM SHUTDOWN on the

right side of the screen if it is displayed.

3. If SHUTDOWN is not displayed click on the ‘User field’ for a pop-up

and click on ADMIN. Enter the admin password (default is admin in

lower case) and click on OK. The field which includes SYSTEM

SHUTDOWN will then appear in the right side of the screen. Click on

it. A dialogue box will appear on the screen to request confirmation of

Shutdown and ask if current work should be saved. Press {ENTER} on

the Control Keyboard or click on OK.

4. The console now shuts down and power to the control surface can be

turned off but the STIF and UNIX windows on the Host Computer

monitor remain.

2-4 Chapter 2 Powering the OXF-R3

5. On the Host Computer, place the mouse cursor in the STIF window

and

Type: exit (case-sensitive) then press {RETURN}.

Note:

It is important to switch off the power to the control surface for a minimum of 10

seconds before attempting a re-start.

6. For a re-boot, turn on the power to the control surface again and follow

the Start-Up Procedure, in the previous section, from step 11. For a

complete power-down, continue with step 7 in this section.

Page 25

7. To shut down the Host Computer, place the cursor in the UNIX

window, and

Type: su (case-sensitive) which stands for ‘superuser’, then press

{RETURN}.

8. At the ‘password’ prompt:

Type the superuser password, oxf-r3 (case sensitive) is the default,

then press {RETURN}.

9. At the prompt which follows:

Type: shutdown -h now (case sensitive), then press {RETURN}.

10. Wait for the >>> prompt to appear before powering down the Host

Computer, SP and I/O Racks.

Chapter 2 Powering the OXF-R3

Chapter 2 Powering the OXF-R3 2-5

Page 26

Page 27

Chapter 3 – Getting Started

This chapter gives an overview of the control surface layout and

functionality. It also provides easy to follow, step-by-step procedures for

basic operations of the console. These are designed to help the

experienced operator become familiar with the OXF-R3 within a short

period of time.

Chapter 3 Contents

3-1 The Control Surface...................................................................... 3-2

3-2 Fader Paging.................................................................................... 3-8

3-3 Assignable Channel Processing ...................................................... 3-9

3-4 Input Channel, Equaliser and Filters ............................................. 3-10

3-5 Free Assign Area and Dynamics ................................................... 3-11

3-6 Multitrack, Routing for Multitrack, Super Send Groups and

Multi-Format ............................................................................... 3-12

3-7 Sends ............................................................................................. 3-13

3-8 Select To Faders .......................................................................... 3-14

3-9 Select To Pans .............................................................................. 3-17

3-10 Basic Console Operations ........................................................... 3-18

3-10-1 To Route a Mic or Line Input to the Main Output Bus ... 3-19

3-10-2 To Set Up a Super Send Group from Channel Inputs...... 3-20

3-10-3 To Send Signals to Tracks on Tape ................................. 3-21

3-10-4 To Monitor Signals to and from Tape.............................. 3-22

3-10-5 To Set Up a Stereo Headphone Mix for Foldback 1 O/P 3-23

3-10-6 To Equalise Signal Feeding the Multitrack ..................... 3-24

3-10-7 To Equalise Monitor Signal Post Multitrack ................... 3-25

3-10-8 To Insert Dynamics Pre Multitrack Send......................... 3-26

3-10-9 To Insert Dynamics Post Multitrack Return .................... 3-27

3-10-10 To Bounce Tracks ............................................................ 3-28

3-10-11 To Set Up Super Send Groups from Multitrack .............. 3-29

3-10-12 To Set Up a De-Esser Using Dynamics Side-Chain EQ.. 3-30

3-10-13 To Link Compressor Side-Chains in a Group.................. 3-31

3-10-14 To Link Compressor Side-Chains so that One Channel

Controls a Second Channel.............................................. 3-32

Chapter 3 Getting Started

Chapter 3 Getting Started 3-1

Page 28

3-1 The Control Surface

3-1 The Control Surface

The OXF-R3 comes in two configurations known as the 24-C-24 and the

24-C-0. The basic elements are illustrated below.

Chapter 3 Getting Started

1

2 3

24-C-24 Control Surface Configuration

4

1

24-C-0 Control Surface Configuration

4

2

3-2 Chapter 3 Getting Started

Page 29

Control Surface Elements

11

1 Left hand 24 Fader Channels Section

11

22

2 Central Master Section

22

33

3 Right hand 24 Fader Channels Section

33

44

4 Meter Bridge

44

The Control Surface in general

A key feature of the OXF-R3 is its Assignable Panels, which divide further

into four basic areas:

• INPUT CHANNEL, EQUALISER and FILTERS

• FREE ASSIGN AREA & DYNAMICS

• MULTITRACK, ROUTING for MULTITRACK, SUPER SEND

GROUPS and MULTI-FORMAT

• SENDS (For Foldback and Effects feeds)

The channel section panel areas are mirrored so that every function can be

operated from either side of the console, allowing two operators to work

on the same channels simultaneously. The ability to have 48 channel

faders and their related functions on view at all times is an advantage but

everything can be operated from just one 24 fader channel bank and the

centre section, as in the more compact 24-C-0 design.

Use the following two diagrams for reference to identify each area as it is

explained whilst reading through this manual.

Chapter 3 Getting Started

Operation of the control surface can be split into 5 main areas:

1. USE OF FADER PAGING

2. USING ASSIGNABLE SIGNAL PROCESSING

3. SELECT TO FADERS FUNCTIONS

4. SELECT TO PANS FUNCTIONS

5. BUILDING SIGNAL PATHS

(Described in detail in Chapter 4)

Chapter 3 Getting Started 3-3

Page 30

3-1 The Control Surface

1

OXF-R3 Assignable Channel Areas

3-4 Chapter 3 Getting Started

1 Left hand assignable channel controls

2 Right hand assignable channel controls

Page 31

2

Chapter 3 Getting Started

Chapter 3 Getting Started 3-5

Page 32

3-1 The Control Surface

1

Chapter 3 Getting Started

3

9

!º

3

4

!¡

3

5

6

7

8

2

!•

OXF-R3 panel locations

3-6 Chapter 3 Getting Started

!£

!¢

!™

!ª

@™

!∞

@º

!§

@¡

@£

@º

!¶

Page 33

1 Meter Bridge – Mono Meters

3

!¡

4

3

!º

9

3

1

2 Meter Bridge – Stereo Meters

3 Channel Screens (6)

4 Routing Panels

5 Multi-Channel Set-up Panel

6 Super Send Group Masters

7 Sends Masters

Chapter 3 Getting Started

8 Central Control Screen

9 Sends Panels

0 Free Assign Area/Dynamics

Panels

!¡Input & Equaliser Panels

!™ Multitrack Panels

!£Track Monitoring Controls

!¢Assignable Pan Knobs

!∞

@™

!ª

!™

!£

!¢

!∞ Select to Pans Panels

!§Monitor & Foldback Panel

!¶Control Keyboard & Automation

Controls

!•Assignable Channel Faders

!ªSelect to Faders Panels

@º Multi-Purpose Faders

@¡ Main Output Fader

@™ Trackerballs

@£ QWERTY Keyboard (beneath

sliding cover)

!•

Chapter 3 Getting Started 3-7

Page 34

3-2 Fader Paging

3-2 Fader Paging

Chapter 3 Getting Started

The OXF-R3 has 48 (or 24 on a 24-C-0) channel faders on its control

surface but Fader Paging enables control of a much greater number of

channels. Fader Paging allows banks of 24 channels to be selected on

either side of the centre section at any time. The diagram illustrates how

Fader Paging relates to a standard in-line console. Use the SELECT TO

FADERS panel to select the fader bank required. Within that panel, there

are a number of buttons marked CHS 1-24, CHS 25-48 and so on. There is

a SELECT TO FADERS panel for each set of 24 channel faders, left and

right of the centre section.

96 CHANNEL IN-LINE CONSOLE

1-24 25-48 49-72

CENTRAL

MASTER

SECTION

73-96

SELECT TO FADERS

PANEL

SELECT TO FADERS

SEND1SEND2SEND3SEND4SEND5SEND6SEND7SEND

SEND9SEND10SEND11SEND12SEND13SEND

SEND18SEND19SEND20SEND21SEND22SEND23SEND

SEND

17

SHOW

SUB

SUPER

VALUE

LEVEL

SGs 1-16

INPUT

GROUP

M/T

GAIN

TRIM

SEND

M/T

CHANs

MON

CHS

CHS

CHS

1-24

25-48

49-72

CHS

CHS

73-96

97-120

ABS & TRM

SELECT L

TO CUTS

MASTERS

ABS & TRM

SELECT R

TO FADs

MASTERS

Paging of Faders for the left side of the control surface

8

SEND15SEND

16

14

24

SEL

SENDS

1-8

SENDS

9-16

SENDS

17-24

SUPER

SGs 1-8

SUPER

SGs 9-16

GROUPs

1-8

GROUPs

9-16

GROUPs

17-24

GROUPs

25-32

CHS

1-24

CHS

73-96

ABS &TRM

TO FADs

ABS &TRM

TO CUTS

CHS

25-48

CHS

97-120

CHS

49-72

SELECT L

MASTERS

SELECT R

MASTERS

3-8 Chapter 3 Getting Started

Page 35

3-3 Assignable Channel Processing

Once the appropriate bank of 24 channel faders is selected, individual

channel controls can be adjusted. To do this, press the ACCESS button

below the fader for the channel required. Then all the ASSIGNABLE

PANELS belong to the channel, displaying its settings. Adjust as

necessary.

As can be seen from the diagram, the functions on an in-line vertical

channel strip become horizontal on the OXF-R3. In other words, the

whole panel is equivalent to an exceptionally comprehensive channel strip.

This is assigned to each channel individually, simply by pressing the

appropriate channel ACCESS button.

MULTI-FORMAT

ROUTING

Chapter 3 Getting Started

ROUTING

SENDS 1-24

FREE ASSIGN AREA DYNAMICS

MULTITRACK

EQUALISER & FILTERS

INPUT CHANNEL & INSERTS

DYNAMICS

EQ &

FILTERS

AUX SENDS

MULTITRACK

ACCESS

Assignable panels

Chapter 3 Getting Started 3-9

Page 36

3-3 Assignable Channel Processing

3-4 Input Channel, Equaliser and Filters

Chapter 3 Getting Started

SLOPE

The Input Channel section is much more flexible than a conventional inline analogue channel strip in that it allows processing elements to be

configured in almost any order. The eight boxes towards the bottom of the

panel enable up to eight functions to be placed in each channel path with

individual IN switches. The order of the processes can be totally different

on every channel, as desired.

The 5 Band Equaliser and High & Low Filters sections are independent

and can be assigned separately within the channel signal path. To view

parameters and curves whenever EQ and Filters are in use, access the EQ

page available on the channel screens.

Various EQ options are available which are selected using the {IN} and

{+} / {-} buttons situated in the upper middle section of the panel.

EQUALISER & FILTERS

LMF

FREQ

LF

Q

XXXXXXXX

IN

HMF

QFREQ

SLOPE

HF

FREQ

FREQ

IN

Q

LF

IN

AB

FREQ

MF

IN

Q

IN

INPUT CHANNEL & INSERTS

XXXXXXXX XXXXXXXX XXXXXXXX XXXXXXXX

O

MIC

M/T

LINE

GAIN

IN

IN

IN

XXXXXXXXXXXXXXXX XXXXXXXX XXXXXXXX

IN

FREQ

FREQ

IN

Q

HF

XXXXXXXX

IN

IN

IN

IN

3-10 Chapter 3 Getting Started

Input Channel & Inserts, Equaliser and Filters panel

Page 37

3-5 Free Assign Area and Dynamics

3-5 Free Assign Area and Dynamics

FREE ASSIGN AREA & DYNAMICS

THRESHLD

ATTACK

DYNAMICS

GATE EXP

80

60

40

35

30

25

20

15

10

5

COMP LIMIT

20

18

16

14

12

10

8

6

4

2

HOLD

RELEASE

RANGE

ACCESS

ACCESS

ACCESS

ACCESS

ACCESS

ACCESS

LOCAL

LOCAL

GATE

EXPANDER

COMPRESS

LIMITER

S–C EQ

The Dynamics function area (lower left) contains:

SIG EQ

S–C EQ

IN

IN

IN

IN

IN

IN

O/L

0

4

8

12

16

20

26

32

40

50

METERS

HOLD

INPUT

OUTPUT

IN

IN

IN

IN

IN

IN

Free Assign Area & Dynamics panel

DELAY

Chapter 3 Getting Started

ACCESS

ACCESS

ACCESS

ACCESS

ACCESS

ACCESS

• GATE

• EXPANDER

• COMPRESSOR (there are a number of Compressor options)

• LIMITER

• SIDE-CHAIN EQUALISER (S-C EQ).

Each section of the Dynamics has its own side-chain and allows very

comprehensive control, equivalent to that of high specification units. All

four side-chains operate on a single gain control element. The Side-Chain

EQ is a fully parametric 2-band element which may be inserted in three

ways:

• in the Dynamics Side-Chain only

• in the Signal Path only as a second EQ

• in the Signal Path and the Side-Chain.

The current Free Assign Area (lower right) contains:

• DELAY Effect

This area includes space for additional effects as and when software

upgrades are introduced in the future.

Chapter 3 Getting Started 3-11

Page 38

3-6 Multitrack, Routing for Multitrack, Super Send

3-6 Multitrack, Routing for Multitrack, Sub-Groups and Multi-Format

Chapter 3 Getting Started

Groups and Multi-Format

MULTI-FORMAT Buttons

These routing buttons have a layout matching a set of

MULTI-FORMAT

L

L

ROUTE TO TRACKS

13 14 15 16

17 18 19 20

21 22 23 24

25 26 27 28

29 30 31 32

33 34 35 36

37 38 39 40

41 42 43 44

45 46 47 48

SSGs 1-8

R

CR

C

C

SUB

L-S R-S

MONO

ROUTING

1234

5678

9 101112

1

SSGs 9-16

3112101

4125

9

14

A

E

8167156

STEMS

BFCGD

BOUNCE

2MULTITRACK

13

H

7.1 surround LS. Their function depends on what is

selected to the faders at the SELECT TO FADERS

panel. In other words, they set the destinations for the

signals currently passing through the faders.

ROUTING Buttons 1-48,

Two sets of buttons on each side of the console allow

channel sources to be assigned to Multitrack Group

Busses 1-48 ({GRP} - default) or Direct Outputs

({DIR} ). The routing for 48 channels can be displayed

simultaneously by showing 8 channels on each of the

associated six channel screens, three per side. The

screens display further channels automatically,

consistent with fader paging.

SSGs 1-8 & SSGs 9-16

These buttons allow post channel fader and pan feeds

to Super Send Groups 1-16. They are paged and

legends lit depending on whether {SUPERSGs1-8} or

{SUPERSGs9-16} is selected in the centre section.

STEM Selectors

These buttons are operational in Multi-Format Mode

to assign channel outputs to stems set up on the

multitrack busses.

{A}{A}

{A} -

{A}{A}

{H}{H}

{H}

{H}{H}

{GRP}{GRP}

{GRP} &

{GRP}{GRP}

{DIR}{DIR}

{DIR}

{DIR}{DIR}

MULTITRACK

GROUP

TRIM

AFL

SOURCE

INSERT

IN

ACCESS

DIV

SUR.

L/R

PAN

LR

LEVEL

AFL CUT

IN

0

+10

Routing for Multitrack, Super Send Groups & Multi-Format

and Multitrack panels

{BOUNCE}{BOUNCE}

{BOUNCE} Push-Button

{BOUNCE}{BOUNCE}

Redirects the output of a channel from the Main

Output Bus to the multitrack routing buttons in the

MULTITRACK section for bounce-down purposes.

One of the stems A-H must be selected to bounce down a

surround source or a signal with surround panning.

MULTITRACK

This panel contains controls related to the multitrack

except individual track remotes and monitor switching.

These are above the pan controls in line with their

equivalent number channel faders. All level controls

can be assigned to faders. Surround panning is

available at this panel in parallel with the joysticks and

individual pans above the faders. These pan controls

are operational on what is selected to the faders at the

SELECT TO FADERS panel.

The OXF-R3 allows the multitrack to be used ‘in-line’

for normal record/remix work or ‘on-the-side’ where a

live mix requires a multitrack backup. A separate

stereo monitor bus is included specifically for monitoring

the multitrack when used in parallel with a live mix.

3-12 Chapter 3 Getting Started

Page 39

3-7 Sends

3-7 Sends

There are currently 24 mono Sends that can be linked as odd/even pairs,

set up at the SEND OUTPUTS 1-24 panel in the centre section, to provide

up to 12 stereos. The levels to the busses can be set via the individual

dedicated controls on the channels SENDS 1-24 panels for each channel

individually. Alternatively Sends can be assigned, one bus at a time, to the

faders or assignable knobs (PANs). This allows a mix to an effect or

foldback to be set up using the faders or a row of knobs on a console-wide

basis. The source points for each Send can be set individually on each

channel or on a console-wide basis.

Chapter 3 Getting Started

SENDS 1-24

SOURCE

SELECT

∞∞∞∞ ∞∞∞∞

∞∞∞∞ ∞∞∞∞

ONON ONON ONON ONON

∞∞∞∞ ∞∞∞∞

SELECT SOURCE FOR

ONONONONONONONON

ONONONONONONONON

Sends 1-24 panel

Chapter 3 Getting Started 3-13

Page 40

3-8 Select T o Faders

3-8 Select To Faders

Chapter 3 Getting Started

The main purpose of faders on a mixing console is to control the levels of

the signals through the channels. Once a balance is achieved, the fader

positions give an extremely useful graphical representation.

It is common with in-line analogue console channel strips to split the

signal flow into channel and monitor paths with a fader for each. The

OXF-R3 takes this concept a stage further, allowing all level and gain

control to be accomplished using the faders. This is achieved by assigning

the faders to all gain and level functions via the SELECT TO FADERS

panel.

INPUT GAIN

Select to Faders

SENDS

GROUP TRIM

M/T SEND

CHANNEL FADER

3-14 Chapter 3 Getting Started

Page 41

As an example, on the SELECT TO FADERS panels, adjacent to the

channel faders on either side of the centre section, there are buttons

marked:

11

{CHANS}{CHANS}

1

{CHANS}

11

{CHANS}{CHANS}

22

{M/TSEND}{M/TSEND}

2

{M/TSEND}

22

{M/TSEND}{M/TSEND}

The default is {CHANS} , which assigns the faders to the channel outputs

when they control the level to the Main Output Bus. Selecting M/T SEND

is equivalent to selecting the ‘small fader’ function to the OXF-R3 faders.

The combined use of Fader Paging and the Select to Faders functionality

allows control of all channel level functions, using the 48 conveniently

placed, high quality faders in the left and right channels sections.

Chapter 3 Getting Started

1

2

Select To Faders panel layout

Chapter 3 Getting Started 3-15

Page 42

3-8 Select T o Faders

Chapter 3 Getting Started

Exploiting this approach even further, the faders can also be assigned to

control Input Gain, Group Trim and all Send Bus levels.

The Select to Faders diagram at the beginning of this section is a visual

guide showing how the OXF-R3 accommodates conventional in-line

channel strip level controls on its faders. Note that all level controls are

still available in parallel within the assignable panels in a more

conventional manner.

This approach is very convenient for checking foldback or effects send

balances. The faders and their selector system are very close at hand,

allowing any balance to be quickly checked at a glance and adjusted.

A copy function allows the user to take the balance set-up as the monitor

mix and transfer it to any of the Send Bus mixes. The fader balance copy

function applies to M/T Send Faders to Channel Faders and vice versa.

This is described in detail in Chapter 6.

The 16 centre section master faders are also assignable in two groups of 8

faders. They are assigned via the SEL area on the SELECT TO FADERS

panel and may control:

• SENDs (Send Master levels)

• SUPER SGs (Super Send Group master levels)

• GROUPs (VCA style control group masters)

3-16 Chapter 3 Getting Started

Page 43

3-9 Select To Pans

3-9 Select To Pans

The Pan Knobs above the faders are assignable in a similar manner to the

faders. Although their primary job is panning, they can also be used to

perform all channel level adjustments, such as input gain settings and Send

Bus levels. They are really Definable Knobs rather than just Pans.

As can be seen in the diagram below, the SELECT TO PANS panel

performs a function for the Pans similar to that of the SELECT TO

FADERS panel for the faders. All equivalent level and gain control

functions, on an in-line channel strip, may be assigned to the row of

Definable Knobs whose default setting is channel Pan.

A typical set-up could have Mic Gain controlled by the knobs, whilst the

faders control the M/T Send. With this set-up, all levels are easily adjusted

during tracking. Remember that dedicated knobs are always available on

the assignable panel areas in parallel for all level controls.

INPUT GAIN

Chapter 3 Getting Started

Select to Pans

SENDS

GROUP TRIM

M/T SEND

PAN

Chapter 3 Getting Started 3-17

Page 44

3-10 Basic Console Operations3-10 Basic Console Operations

3-10 Basic Console Operations

Chapter 3 Getting Started

General

The following series of illustrations and brief step by step procedures are

designed to allow new OXF-R3 operators to begin using the console in a

very short space of time, without having detailed knowledge of the system.

System Set-up

The examples shown assume that signal sources, such as microphones, line

level signals and multitrack or hard disc recorder, are already connected

and routed to appropriate inputs, with machine control in place. They also

assume that the control room monitor LS are hooked up to the OXF-R3

system.

Main Bus Set-up

The Main Output Bus can be set for the following ‘widths’: Stereo, LCRS,

5.1 and 7.1. For the purposes of the examples, the fire-up default of Stereo

will be assumed.

3-18 Chapter 3 Getting Started

Page 45

3-10-1 To Route a Mic or Line Input to the Main Output Bus

Chapter 3 Getting Started

134562

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, press either

{MIC} or {LINE} as required, and set the input GAIN

knob to a suitable setting.

3 Make sure {CHANS} is selected on the Select To

Faders panel (fire-up default).

4 At the Routing panel, select {L} and {R} (fire-up

default) if not already lit.

5 Adjust the level to the Main Output Bus with the

Channel Fader.

6 Open the Main Fader and turn up the CR Monitor

level.

Chapter 3 Getting Started 3-19

Page 46

3-10 Basic Console Operations

3-10-2 To Set Up a Super Send Group from Channel Inputs

Chapter 3 Getting Started

124,8 63 75

1 Press {ACCESS} for the first Channel to be routed

to a Super Send Group (SSG).

2 Make sure {CHANS} is selected on the Select To

Faders panel (fire-up default).

3 Make sure {SUPERSGs1-8} is selected in the SSG

masters section.

4 At the Routing panel, de-select {L} and {R} .

5 At the same panel, select the SSGs required,

{1/9} and {2/10} in this case.

3-20 Chapter 3 Getting Started

6 At the Select To Faders panel (SEL section), select

{SUPERSGs1-8} , then adjust the Fader to 0dB in

the Central Faders panel.

7 Above the SSG 1 level knob select {MAIN} and its

{ACCESS} .

8 At the top of the Routing panel select {L} .

9 Repeat steps 7 and 8 for SSG 2 but select {R} at

the Routing panel.

10 Repeat steps 1 to 5 for further channels.

Page 47

3-10-3 To Send Signals to Tracks on Tape

Chapter 3 Getting Started

1346527

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, press either

{MIC} or {LINE} as required, and set the input GAIN

knob to a suitable setting.

3 At the same panel, select ‘MULTI’ in one of the

eight windows. Do this using the {+} and {–}

buttons, and then press the large {IN} button.

4 At the Routing panel, select the tracks required in

the ROUTE TO TRACKS section. The Pan

works across odd and even numbers in Stereo.

5 To pan between tracks, press {CUT} , if it is lit

which sets the pan into operation, and adjust the

Pan Knob accordingly.

6 On the Select To Faders panel, press {M/TSEND} .

7 Adjust the level to tape using the Fader. Check the

meter level for the track to which the signal is

routed.

Chapter 3 Getting Started 3-21

Page 48

3-10 Basic Console Operations

3-10-4 To Monitor Signals To and From Tape

Chapter 3 Getting Started

1247 65 3

1 Press {ACCESS} for the desired Channel.

2 Select {CHANS} on the Select To Faders panel

(fire-up default).

3 At the Input Channel & Inserts panel, select

‘MULTI’ in window number 4 using the {+} and

{–} buttons either side. Select its large {IN}

button to insert the multitrack into the signal path.

4 At the Pans panel, press {SEND} to select the signal

being fed to tape

3-22 Chapter 3 Getting Started

5 Or press {SEND} to select the signal from tape.

6 Open the Main Fader and turn up the CR Monitor

level.

7 Use the Channel Fader to adjust monitor level via

the Main Output Bus.

Page 49

3-10-5 To Set Up a Stereo Headphone Mix for Foldback 1 O/P

Chapter 3 Getting Started

1 At the Send Outputs 1-24 panel in the console

centre section, select {17-24} and then select

{STEREO} between Send Masters 17 and 18.

Sends 17 and 18 are a dedicated assignment to

Stereo Foldback 1. Select {AFL} to audition the

balance.

Note:

Send Masters 19 and 20 are assigned to Stereo Foldback

O/P 2; 21 and 22 to Foldback 3; 23 and 24 to Foldback 4.

2 At the Select To Faders panel, select {SEND17} or

{SEND18} . Pressing either will light both.

1243 5

3 Turn off the {CUT} buttons and set up the balance

and pan positions using the Faders and their Pans.

Turn off the Pan {CUT} if necessary.

4 At the Foldback Groups 1-4 section, located in the

central Monitor panel, adjust the LEVEL pot for a

suitable level in the headphones. (Make sure

{CUT} is not lit) Use the {T/BF/Back1} button to

talk to the artist(s).

5 The bus level itself, which defaults to unity gain,

can be adjusted using the central faders. On the

Select To Faders panel, SEL section, select

{SENDs17-24} and adjust Fader 17 or 18.

Chapter 3 Getting Started 3-23

Page 50

3-10 Basic Console Operations

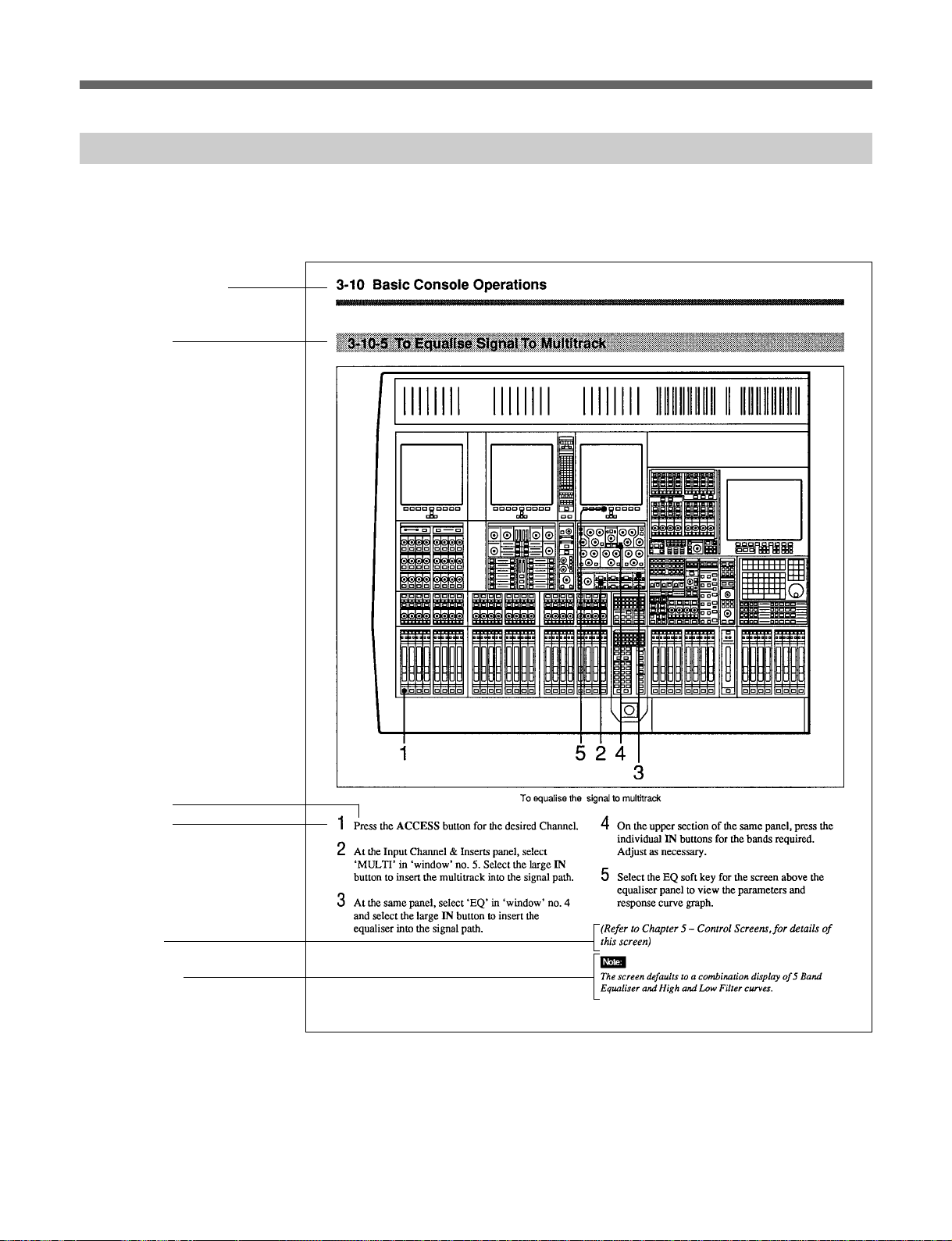

3-10-6 To Equalise Signal Feeding the Multitrack

Chapter 3 Getting Started

13452

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, select

‘MULTI’ in window number 4 using the {+} and

{–} buttons either side. Select its large {IN}

button to insert the multitrack into the signal path.

3 At the same panel, select ‘EQ’ in a window before

window 4, window 1 for example, and select the

large {IN} button to insert the equaliser into the

signal path before the multitrack.

3-24 Chapter 3 Getting Started

4 On the upper section of the same panel, select the

individual {IN} buttons for the bands required and

adjust as necessary.

5 Select the EQ softkey for the screen above the

equaliser panel to view the parameters and

response curve graph.

Page 51

3-10-7 To Equalise Monitor Signal Post Multitrack

Chapter 3 Getting Started

12453

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, select

‘MULTI’ in window number 5 using the {+} and

{–} buttons either side. Select its large {IN}

button to insert the multitrack into the signal path.

3 At the same panel, select ‘EQ’ in a window after

window 5, window 8 for example, and select the

large {IN} button to insert the equaliser into the

signal path after the multitrack.

4 On the upper section of the same panel, select the

individual {IN} buttons for the bands required and

adjust as necessary.

5 Select the EQ softkey for the screen above the

equaliser panel to view the parameters and

response curve graph.

Chapter 3 Getting Started 3-25

Page 52

3-10 Basic Console Operations

3-10-8 To Insert Dynamics Pre Multitrack Send

Chapter 3 Getting Started

1245 36

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, select

‘MULTI’ in window number 5 using the {+} and

{–} buttons either side. Select its large {IN}

button to insert the multitrack into the signal path.

3 At the same panel, select ‘DYN’ in a window

before window 5, window 4 for example, and

select the large {IN} button to insert the dynamics

processor into the signal path before the multitrack.

4 In the Dynamics section, located in the Free

Assign Area, select {IN} buttons for the processing

3-26 Chapter 3 Getting Started

required: Gate, Compressor, etc., indicated by 8

character dot displays.

5 On the LCD screen above the dynamics controls,

press the Dynamics softkey to view the parameters

and transfer curve graph.

6 The dynamics processing is set and displayed via

definable knobs and switches. Set their functions

via the local {ACCESS} keys according to the

processes in use. Adjust whilst viewing the

settings on the LCD screen. The settings for all

functions are displayed simultaneously.

Page 53

3-10-9 To Insert Dynamics Post Multitrack Return

Chapter 3 Getting Started

1245 36

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, select

‘MULTI’ in window number 5 using the {+} and

{–} buttons either side. Select its large {IN}

button to insert the multitrack into the signal path.

3 At the same panel, select ‘DYN’ in a window after

window 5, window 8 for example, and select the

large {IN} button to insert the dynamics processor

into the signal path before the multitrack.

4 In the Dynamics section, located in the Free

Assign Area, select {IN} buttons for the processing

required: Gate, Compressor, etc., indicated by 8

character dot displays.

5 On the LCD screen above the dynamics controls,

press the Dynamics softkey to see the parameters

and transfer curve graph.

6 The dynamics processing is set and displayed via

definable knobs and switches. Set their functions

via the local {ACCESS} keys according to the

processes in use. Adjust whilst viewing the

settings on the LCD screen. The settings for all

functions are displayed simultaneously.

Chapter 3 Getting Started 3-27

Page 54

3-10 Basic Console Operations

3-10-10 To Bounce Tracks

Chapter 3 Getting Started

12356487

1 Press {ACCESS} for the desired Channel.

2 Make sure {CHANS} is selected on the Select To

Faders panel (fire-up default).

3 At the Routing panel, select {CHANS} . The {L}

and {R} buttons will be de-selected automatically

so that the channel output is no longer routed to the

Main Output Bus.

4 At the same panel select the destination tracks

required for the bounce, in the ROUTE TO

TRACKS section. Fader and Pan settings will be

retained (L to odd-numbered tracks, R to even).

3-28 Chapter 3 Getting Started

5 Select {ACCESS} for the first of the new tracks.

6 On the Input Channel & Inserts panel, select

‘MULTI’ and its large {IN} button in one of the

eight windows. Repeat for other bounce tracks.

7 Select the {SEND} on the channels to which the

bounce is routed, for a monitor signal for those

tracks.

8 Set the monitor level for the new track(s).

9 The original balance will be bounced down to the

selected multitrack tracks. Repeat steps 1 to 4 for

other tracks to be bounced down.

Page 55

3-10-11 To Set Up Super Send Groups from Multitrack

Chapter 3 Getting Started

124,8 63 75

1 Press {ACCESS} for the first Channel to be routed

to a Super Send Group (SSG).

2 Make sure {CHANS} is selected on the Select To

Faders panel (fire-up default).

3 Make sure {SUPERSGs1-8} is selected in the SSG

masters section.

4 At the Routing panel, de-select {L} and {R} .

5 At the same panel, select the SSGs required,

{1/9} and {2/10} in this case.

6 At the Select To Faders panel (SEL section), select

{SUPERSGs1-8} , then adjust the Fader to 0dB in

the Central Faders panel.

7 Above the SSG 1 level knob select {MAIN} and its

{ACCESS} .

8 At the top of the Routing panel select {L} .

9 Repeat steps 7 and 8 for SSG 2 but select {R} at

the Routing panel.

10 Repeat steps 1 to 5 for further channels.

Chapter 3 Getting Started 3-29

Page 56

3-10 Basic Console Operations

3-10-12 To Set Up a De-Esser Using Dynamics Side-Chain EQ

Chapter 3 Getting Started

13 72456

1 Press {ACCESS} for the desired Channel.

2 At the Input Channel & Inserts panel, select

‘DYN’ in one of the eight windows. Do this using

the {+} and {–} buttons, and then press the large

{IN} button.

3 At the Free Assign Area & Dynamics panel, select

SC EQ IN; its {ACCESS} button will light

automatically.

4 At the same panel, press the button adjacent to the

SIG EQ display and adjust the HF controls to

boost the frequency band to be attenuated.

3-30 Chapter 3 Getting Started

5 Now de-select SIG EQ and select S-C EQ to

affect just the side-chain signal.

6 At the same panel, select COMPRESS {IN} . The

Compressor {ACCESS} will be selected

automatically, allowing the compressor to be set.

7 Select the Dynamics softkey to view compressor

parameters and transfer curve graph on the LCD

screen.

Page 57

3-10-13 To Link Compressor Side-Chains in a Group

Chapter 3 Getting Started

13 4265

1 Press {ACCESS} for the first Channel to have a

dynamics side-chain link.

2 At the Input Channel & Inserts panel, select

‘DYN’ in one of the eight windows. Do this using

the {+} and {–} buttons, and then press the large

{IN} button.

3 At the Free Assign Area & Dynamics section,

select the COMPRESS {IN} . Its {ACCESS} will

be selected automatically, assigning the