Sony OA-D32V, OA-D32W Service Manual

MICRO FLOPPYDISK DRIVE

OA-D32W OA-D32V

SONY

SERVICE MANUAL

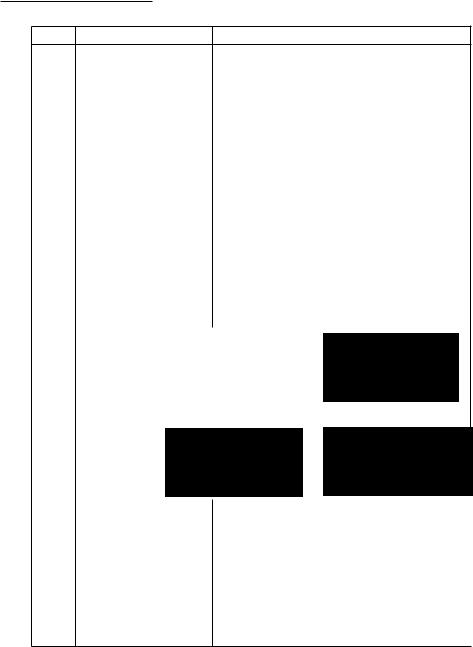

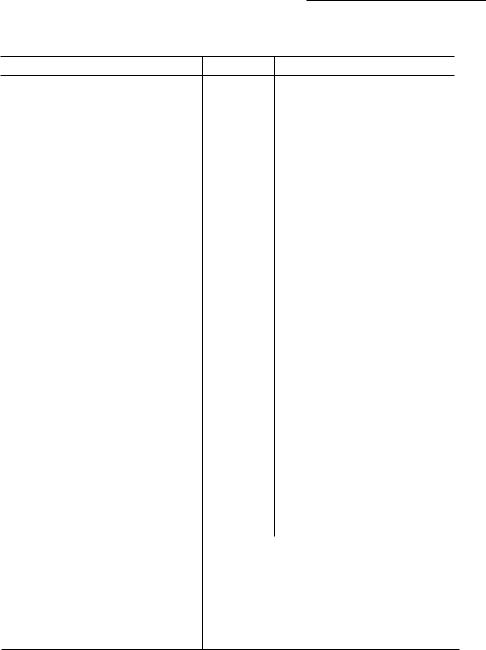

Specifications

|

OA·D32W |

OA·D32V |

|||

|

SI NG LE |

J DOUBLE |

SINGLE |

I |

DOUBLE |

|

DENSITY |

DENSITY |

DENSITY |

|

DENSITY |

|

|

|

|

|

|

Capacity |

|

|

|

|

|

Unformatted Per Disk |

500 Kbytes |

/1.0 Mbytes |

250 Kbytes |

/500 Kbytes |

|

Unformatted Per Track |

3.125 Kbytes |

6.25 Kbytes |

3.125 Kbytes |

|

6.25 Kbytes |

Bu~tTRANSFER RATE |

250 Kbits/sec |

500 Kbits/sec |

250 Kbiu/sec |

|

500 Kbits/sec |

AcctItITlme |

|

|

|

|

|

Track to Track |

12 msec. |

12 msec. |

|||

Average- |

350 msec. |

350 msec. |

|||

Settling Time |

30 msec. |

30msec. |

|||

Head Load Time |

SO msec. |

SOmsec. |

|||

Average Latency |

50 msec. |

50 msec. |

|||

Functiona' |

|

|

|

|

|

Rotational Speed |

SOO RPM |

SOO RPM |

|||

Recording Density (inside track) |

4359 bpi |

I 8717 bpi |

4094 bpi |

I |

8187 bpi |

Track density |

approx. 135 TPI |

approx.135 TPI |

|||

Cylinders |

80 |

80 |

|

||

Tracks |

160 |

80 |

|

||

R/W Heads |

|

2 |

|

1 |

|

Encoding Method |

FM, MFM |

FM, MFM |

|||

Heat Dissipation |

|

|

|

|

|

Operating Mode (Head Load) |

6.0W |

S.OW |

|||

Standby mode (Head Unload) |

3.9W |

3.9W |

|||

Media Requirements |

SONY OM·D4440 |

SONY OM·D3440 |

|||

3.5" x 3.7" (90 mm x 94 mm) |

|

|

|

|

|

|

|

|

|

|

|

- Average access time a 1/3 X {Track Nos.l x (Track to track time) + (Settling Time)

Environmental Consideration. |

|

|

||||

ReliabilitY and Maintainability |

|

|

||||

Preventive Maintenance (PM) |

|

|

Not required |

|||

Meantime Between Failures (MTBF) |

8000 POH (Power On Hourtime) |

|||||

Meantime to Repair (MTTR) |

|

|

30 min. |

|||

Component Life |

|

|

|

|

5 years or 15,000 POH |

|

Media Life |

|

|

|

|

|

3.0 x 10" passes/traek |

Disk Interchange |

|

|

|

|

20,000 times |

|

Soft Read Error |

|

|

|

|

1 per 10' bits read |

|

Hard Read Error |

|

|

|

|

1 per 10" bits read |

|

Seek Error |

|

|

|

|

|

1 per 10" seeks |

Envlronmenta' Limits |

|

|

|

|

||

Temperature (Operating) |

|

|

40· F to 115°F (5°C to 45°C) |

|||

Humidity |

(Operating) |

|

|

20 % to 80 % relative humidity, with a wet bulb temperature of85°F |

||

Vibration |

(Opel'8ting) |

|

|

(29°C) and no condensation. |

||

|

|

The unit shall |

perform all read/write operations (no seek) according |

|||

|

|

|

|

|

||

|

|

|

|

|

to specifications, with continuous vibration of less than 0.5 G (±10 %) |

|

|

|

|

|

|

from 5 Hz to 100 Hz (along the x, y, z plane). |

|

Dimensional Data |

|

|

|

|

|

|

Height |

2.0 In. |

(51 mm) |

|

|||

Width |

4.0 in. |

(102 mm) |

|

|||

Depth |

5.1 in. |

(130 mm) |

|

|||

Weight |

1.51bs |

(S50 g) |

|

|||

DC Power Requirements |

|

|

|

|

||

Reading |

+12.0 V |

±5 % |

0.30 A (typical) |

|

||

(Operating) |

+5.0 V |

±5 % |

0.48 A (typical) |

|

||

RECORD OF REVISIONS

REVISION |

|

NOTES |

|

|

|

1 |

ORIGINAL ISSUE |

November, 1983 |

|

|

|

|

|

|

-2-

TABLE OF CONTENTS

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SECTION 1. |

INTRODUCTION .••••.•• |

.. • \' .......... |

|

|

• .. |

|

• .. |

• .. |

• .. |

•• .. |

• . |

|

|||||

SECTION 2. |

TOOLS AND |

MEASURING |

INSTRUMENT.S |

. . • . • • • . • |

. . |

• • . • . . |

. •. |

8 |

|||||||||

|

2-1. |

GENERAL AND SPECIAL TOOL UST • . • . • • • |

. . |

. . |

. . . • |

. .. |

8 |

||||||||||

|

|

a. |

General Tools |

.. •• . • .......... |

|

|

•• .. |

• ... |

|

• . • . •• .. |

• . |

8 |

|||||

|

|

b. |

Special Tools |

. . • • . • • . • . |

. • |

. . • • . • |

. |

. • . • . • . • . |

. • . . |

• .. |

8 |

||||||

|

|

c. |

Measuririg Equipment |

•. '.. |

•.. |

• " |

. . . |

• • • • • . |

. • |

. . |

. . . • |

. .• |

8 |

||||

|

|

d. Disks. • . •• . • . ••• . • .. |

• .... |

|

• ..... |

|

• ............ |

|

|

|

|

• . |

|

||||

|

|

e. |

Expendable and Chemical Supplies |

.. • ... |

•• . •• |

.. •• .... |

• |

8 |

|||||||||

|

2-2. |

SPECIAL TOOLS |

.. • .. |

• ............. |

|

|

|

|

•• ..... |

|

|

• .. |

' ..... |

|

9 |

||

|

|

2-2-1. |

MFD Checker .II |

. . . . |

. . . |

. . |

. . . |

. |

. . . |

. . |

. . |

. . |

. . . . |

. .. |

9 |

||

|

|

2-2-2. |

Configuration of SMC-70 Drive Test System." . • |

. . |

. • • . |

. .. |

13 |

||||||||||

|

|

2-2-3. |

Disks • . •• .. |

|

|

|

|

|

••• |

....... |

|

• .. |

• |

14 |

|||

SECTION 3. |

TROUBLESHOOTING .. |

• .... ......... |

• |

|

|

•• . • .. • .. • ... |

|

• . • |

... |

IS |

|||||||

|

3-1. |

BEFORE TROUBLESHOOTING .....• |

•• |

... |

• ... |

|

• .. |

• ..... |

|

IS |

|||||||

|

3-2. TYPES OF ERROR ON A SYSTEM LEVEL .... |

|

• . • . •• .... |

|

IS |

||||||||||||

|

|

3-2-1. |

Soft Error ... ..... ......... |

|

• |

|

|

|

• . • ............ |

|

|

|

|

IS |

|||

|

|

3-2-2. |

Write Error • ................ |

|

|

|

|

• . : •... |

•.. |

••• : .. |

IS |

||||||

|

|

3-2-3. |

Seek Error. • . . . . . . . . . . . . . . . |

|

|

• |

• |

|

• . |

. .. |

. |

• . |

. . . . |

• •. |

IS |

||

|

|

3-2-4. |

Interchange Error .............• |

|

|

|

••• . • .. |

•• . • .... |

|

IS |

|||||||

|

3-3. |

FAULT DIAGNOSIS BY MFD CHECKER II ............... |

|

|

|

|

|

IS |

|||||||||

|

|

3-3-1. |

Normal Operation. . . . . . . . . . . |

• |

• • |

|

|

• • |

. . |

. . |

. . |

. . • • |

. .. |

IS |

|||

|

|

3-3-2. |

Check Points to Abnormal Operation ••• . • .. |

• .. |

• .. |

• .. |

20 |

||||||||||

|

3-4. |

FINAL |

CHECK . ~ . • . . . . . . . . . . . . . |

|

• |

• |

|

• . • • |

. . |

. . |

. . |

. • . . |

. •. |

23 |

|||

|

|

3-4-1. |

Setting ofSMC .......-70 |

.. • |

|

• . • . • |

.. |

• ..... |

|

. ... |

23 |

||||||

|

|

3-4-2. |

Set the Check . . . . . . . .Area |

• |

• |

• |

• . • • |

. . |

• . |

. • |

. . • . |

. •. |

23 |

||||

|

|

3-4-3. |

Check the Drive . . . . . . . .Unit |

• • . • |

|

|

. . |

• . |

. • |

. . |

• . • . • .. |

25 |

|||||

|

|

3-4-4. |

Error Message ... ... ......... |

• |

• |

|

|

|

• .... |

|

• ....... |

|

;. |

27 |

|||

SECTION 4. |

PART |

REPLACEMENT |

., . . . . . . . . . . . . . .. . • |

|

• |

|

|

|

• • . • |

. . |

• . |

. • . . |

. .. |

29 |

|||

|

4-1. |

FC-9/FC-14 MOUNTED BOARD REPLACEMENT ....... |

|

|

• .. |

• . |

29 |

||||||||||

|

|

4-1-1. Removal ................. |

.. |

|

|

|

• |

|

• . • .. |

• |

........ |

|

• |

29 |

|||

|

|

4-1-2. |

Installation and .. ..Adjustment |

• . • |

• ............. |

|

|

|

|

• |

29 |

||||||

|

4-2. |

FRONT PANEL ASS'Y ....REPLACEMENT |

|

• |

.. |

• ........ |

|

|

• . |

29 |

|||||||

|

|

4-2-1. |

Removal . • .. ... .......... |

• . • |

|

|

|

• ...... |

|

|

• ...... |

|

29 |

||||

|

|

4-2-2. Installation................................. |

|

|

|

|

|

|

|

|

|

|

29 |

||||

|

4-3. |

BLIND PANEL REPLACEMENT ...... |

..... • . • |

|

•• |

.... • .. |

30 |

||||||||||

|

|

4-3-1. |

Removal • .. .. ............. |

• |

|

|

|

|

•• .. |

• .... |

|

••• . • . |

30 |

||||

|

|

4-3-2. |

Installation................................. |

|

|

|

|

|

|

|

|

|

|

30 |

|||

- 3 -

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-4. |

LED MOUNTED BOARD ASS'Y REPLACEMENT. • • |

. . |

• . • |

. .• |

30 |

||||||||

|

|

4-4-1. Removal ................................... |

|

|

|

|

|

|

|

|

|

30 |

||

|

|

4-4-2. Installation................................. |

|

|

|

|

|

|

|

|

|

30 |

||

|

4-5. |

MAIN COVER REPLACEMENT ••••.••.•.•••••••••.•••• |

31 |

|||||||||||

|

|

3-5·1. |

Removal ........ |

• ..... |

|

• . •• . • . •••• . •• . •• . • . • |

31 |

|||||||

|

|

3-5·2. |

Installation................................. |

|

|

|

|

|

|

|

|

|

31 |

|

_ |

4-6. |

PAD ASS'Y REPLACEMENT •.•••.•.•... |

•••••.•.. |

••.•• |

31 |

|||||||||

|

|

4-6-1. Removal ................................... |

|

|

|

|

|

|

|

|

|

31 |

||

em 4-7. |

4-6-2. |

Installation and Adjustment .•.••.••••.. |

••.•.. |

•.•• |

31 |

|||||||||

D.AMPER REPLACEMENT. . • |

. . • . • • • . • . |

. |

• . . |

• . . |

• . • • . . |

.• |

31 |

|||||||

|

|

4-7·1. |

Removal •.• ; .••.•.. |

•.••.•••.••.... |

••.•.... |

• |

31 |

|||||||

|

|

4-7·2. |

Installation .. |

•• . • .. |

• .. |

• .. |

'••.••••.. |

• .. |

• |

..•... |

|

32 |

||

|

4-8. |

HEAD LOAD ASS'Y REPLACEMENT |

•.•.. |

|

••.••.•.. |

••.•. |

32 |

|||||||

|

|

4-8·1. |

Removal •••... |

•••.•.. |

••••••• |

..•.. |

•.... |

|

•••.. |

32 |

||||

|

|

4-8·2. |

Installation and Adjustment |

. . |

• . • . . |

. |

• . . |

. • • |

. . |

• . • • •. |

32 |

|||

|

4-9. |

CASSETTE·UP ASS'Y |

REPLACEMENT. • • • . • . . |

. • . • . . |

. • . • . |

33 |

||||||||

|

|

4-9·1. |

Removal •••••••••••.•••.•.. |

•.. |

•.•••.•.. |

•.•• |

33 |

|||||||

|

|

4-9·2. |

Installation and Adjustment |

. . |

• • • . . |

• |

. . • . |

. • . |

. • . • • •• |

33 |

||||

|

4-10. |

WP ARM I D-DETECTION ARM I COMPRESSION SPRING |

|

|

||||||||||

|

|

(3-659·609·00) REPLACEMENT • . • ... |

• ...... |

• . • . • ... |

|

34 |

||||||||

|

|

4-1 ()'1. Removal ................................... |

|

|

|

|

|

|

|

|

|

34 |

||

|

|

4-1()'2. |

Installation and Adjustment |

.•••.•.•••... |

••.••.••. |

34 |

||||||||

|

4-11. |

DC DISK DRIVE MOTOR (BHC·2101A) REPLACEMENT |

... |

•• |

34 |

|||||||||

|

|

4-11·1. |

Removal •... |

•.•.•••.••.•••••... |

•••.•.. |

••.•. |

34 |

|||||||

|

|

4-11·2. |

Installation and Adjustment |

.... |

• ... |

• . •• . •• . •• . • .. |

35 |

|||||||

|

4-12. |

SENSOR MOUNTED BOARD REPLACEMENT' .•••••.••.... |

|

35 |

||||||||||

|

|

4-12·1. Removal ................................... |

|

|

|

|

|

|

|

|

|

35 |

||

|

|

4-12·2. |

Installation and Adjustment •.•.••.. |

|

•.•••.••••.. |

•• |

35 |

|||||||

|

4-13. |

LEAD SCREW ASS'Y (STEPPING MOTOR I LEAD SCREW I |

|

|

||||||||||

|

|

COUPUNG ASS'Y I COMPRESSION SPRING |

|

|

|

|

|

|||||||

|

|

(4-601·083-00» REPLACEMENT |

•••.... |

|

••.. |

••••.•••. |

36 |

|||||||

|

|

4-13-1. |

Removal .•••.•••.•••.••.••.•..•..••••.••••. |

36 |

||||||||||

|

|

4-13-2. |

Installation and Adjustment |

.••.• : •.••.•..••.. |

•••• |

36 |

||||||||

|

4-14. (32V) HEAD ARM ASS'Y REPLACEMENT, |

|

|

|

|

|

|

|

||||||

|

|

(32W) HEAD CARRIAGE ASS'Y REPLACEMENT. |

. • • • • . • • •. |

37 |

||||||||||

|

|

4-14-1. Removal ................................... |

|

|

|

|

|

|

|

|

|

37 |

||

|

|

4-14-2. |

Installation and Adjustment |

.•.••.•..... |

|

•••.•.•••• |

38 |

|||||||

- 4 -

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SECTION 5. |

CHECK AND ADJUSTMENT |

. . |

. |

. . . . . . . |

. . |

. . |

. . |

. . . |

|

. . . . |

. |

. . . . |

. .. |

39 |

|||

|

5-1. |

LEAD SCREW ECCENTRICITY •• |

..•••••••.. |

|

•• ... |

|

•••••• |

39 |

|||||||||

|

|

5-1-1. |

Tools and Measuring Equipment |

•••••••••• |

..••.•• " |

39 |

|||||||||||

|

|

5-1-2. |

Measurement •••• |

..•••' •.. |

•.. |

•••••••.. |

•.. |

•.••• |

39 |

||||||||

|

|

5-1-3. |

Adjustment ••••••.•••••.• |

..••••••••.••.••••• |

39 |

||||||||||||

_ |

5-2. |

PAD PRESSURE. • . • • . |

. |

• . • • • • • • • • . |

. • • . • • . • . |

. |

• • • • • •• |

39 |

|||||||||

|

|

5-2-1. |

Tools and Measuring Equipment |

.••.••.•.•••••.•••• |

39 |

||||||||||||

|

|

5-2-2. |

Measurement. |

. . |

• . |

. • • . • . |

. . |

. • • • • • . |

|

. • • . • • . • . |

. •• |

39 |

|||||

|

|

5-2-3. |

Adjustment •... |

|

••••••• .•.•... |

•••.•.•.. |

••.. |

•• |

40 |

||||||||

|

5-3. |

HEAD COMPUANCE |

•••••••••.•••.• |

..• |

... •.... |

•.••. |

40 |

||||||||||

|

|

5-3-1. |

Tools and Measuring Equipment |

_ .•.. |

••.••.• : •••.•• |

40 |

|||||||||||

|

|

5-3-2. |

Measurement .•••.••••..•.... |

|

•.• ~ |

• . • • • . • • • • •• |

40 |

||||||||||

|

|

5-3-3. |

Adjustment |

............. |

|

• . • • . . |

• • • . • • . . |

• . . |

• .. |

41 |

|||||||

|

5-4. RADIAL AUGNMENT AND TRK 00 SENSOR |

|

. ••.. |

,. . • . . |

•. |

42 |

|||||||||||

|

|

5-4-1. |

Tools and Measuring Equipment •••.••••.. |

•.... |

•••. |

42 |

|||||||||||

|

|

5-4-2. |

Measurement. • • . . |

• • . • • • • . |

. . |

• . • • . . .• . |

. . |

. . . |

• •• |

42 |

|||||||

|

|

5-4-3. |

Adjustment .•.••.•••••.•..•.••.••••••.... |

••• |

42 |

||||||||||||

|

|

5-4-4. |

Set Up Command . . |

, • • • • |

• • • • . • . • • • . . |

• • . . |

. • • . |

.• |

42 |

||||||||

|

|

5-4-5. |

Measurement Command. • • • • • • . • . . |

• . |

. . |

• |

. . . |

. . • . |

.• |

43 |

|||||||

|

|

5-4-6. |

Adjustment Command •• . • . ••• . • .. |

• ... |

• ....... |

|

" |

44 |

|||||||||

|

|

5-4-7. |

Error Message |

.•••.•.•••.••.••• .......• |

|

•••.. |

46 |

||||||||||

_ |

5-5. |

STEPPING MOTOR LOAD TORQUE . • . . |

. |

• • . .• • |

. . . |

. • . • .. |

46 |

||||||||||

|

|

5-5-1. |

Tools and Measurement Equipment . |

. |

• • . |

. . |

• • • . |

. • • . •• |

46 |

||||||||

|

|

5-5-2. |

Measurement...... |

|

• • . • • • • • . . |

. . . |

• . . |

• |

. . . |

• . • • .• |

46 |

||||||

|

|

5-5-3. |

Adjustment .•.. |

•• . • . •• . •••••. : • • . • • |

. . . |

. • . . |

•. |

46 |

|||||||||

|

5-6. |

INDEX |

PHASE • • • • • • . • • • • • • . • • • • . . |

• • • • • • • |

. . |

• • • . . |

.• |

47 |

|||||||||

|

|

5-6-1. |

Tools and Measuring Equipment |

•.. |

•.•••••.. |

•.... |

•• |

47 |

|||||||||

|

|

5-6-2. |

Measurement •.. |

•• . •••••••.. |

•..... |

|

|

••.•... |

•.• . |

47 |

|||||||

|

|

5-6-3. |

Adjustment .. |

• ... .. |

|

•• . • |

• .. |

• .. |

• .. |

• . •• ... |

• ',' .. |

47 |

|||||

|

5-7. READ AMPUFIER GAIN AND READ AMPUFIER |

|

|

|

|

||||||||||||

|

|

OFF SET |

.. •••• .. |

• . •• . •• .•• .. |

•. ••.. |

• .•• ..... |

• . |

47 |

|||||||||

|

|

5-7-1. |

Tools and Measuring Equipment |

• .... |

|

•• . •• . • .. |

• .. |

• . |

47 |

||||||||

|

|

5-7-2. |

Measurement •.. |

•••• . •• . •• .•.. |

•• .••••........ |

|

|

47 |

|||||||||

|

|

5-7-3. |

Adjustment •.. |

••••• ...• |

•.. |

•.. |

••.•••••.••.•.. |

48 |

|||||||||

|

5-8. |

DISK DRIVE |

DC' MOTOR SPEED . • . • . . |

• .• . |

|

• • • • • • • • • • •• |

48 |

||||||||||

|

|

5-8-1. |

Tools and Measuring Equipment |

. . . |

. . . |

. |

. . . |

|

. . . |

. . . . |

.. |

48 |

|||||

|

|

5-8-2. |

Measurement........... |

|

• • • . • . .• . |

. |

• • . • • . . • • •. |

48 |

|||||||||

|

|

5-8-3. |

Adjustment •... |

|

• . ••••• .••.•.. |

•• '. • • • • • . • . . . |

•. |

49 |

|||||||||

-5-

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ED 5·9. |

HL ARM HEIGHT •.••••.•••.•.. |

••.••••.•••.••••..• |

53 |

||||||||||||||

|

|

5.9.1. |

Tools and Measuring Equipment |

•..••.•..••.••.••.• |

53 |

||||||||||||

|

|

5.9·2. |

Measurement... |

|

• . • . . |

. . . |

• . • • • • • . • . |

. . • • . • • • • •• |

53 |

||||||||

|

|

5·9·3. |

Adjustment......................... |

|

|

|

|

|

|

|

• . • • • • •• |

53 |

|||||

|

5·10. |

HEAD CLEARANCE •.•.•.•.. |

•.••••••.• |

.. |

•• " .•••.• , |

53 |

|||||||||||

|

|

5·10-1. |

Tools and Measuring Equipment |

...••••.••.••.•••.• |

53 |

||||||||||||

|

|

5·10-2. |

Measurement................................ |

|

|

|

|

|

|

|

|

|

|

53 |

|||

|

|

5·10-3. |

Adjustment................................. |

|

|

|

|

|

|

|

|

|

|

|

53 |

||

|

5·11. |

HEAD CLEANING .................................. |

|

|

|

|

|

|

|

|

|

|

|

|

|

54 |

|

ED |

|

5·11·1. |

Tools and Measuring Equipment |

.................. |

|

|

|

|

|

|

" |

54 |

|||||

|

5·11·2. |

Cleaning with Applicator |

• • . |

. . |

• . . |

. . • • . • . . |

• . • • • • .. |

|

54 |

||||||||

|

|

5·11·3. |

Cleaning with Cleaning Disk |

..•••••.•.••.•.. |

••.. |

• |

54 |

||||||||||

SECTION 6. |

PARTS |

LOCATION AND LIST (OA·D32W) .••.••.•.. |

•••••.•.. |

• |

|

55 |

|||||||||||

|

6·1. |

PARTS ASS'Y LOCATION |

•.•.•.. |

•••.. |

••.. |

|

••.••.••••• |

55 |

|||||||||

|

6·2. |

MECHANICAL PARTS |

LIST |

.••.. |

•.•••.•.•••. • |

..•.. |

•• , |

57 |

|||||||||

|

6·3. |

OVER ALL DIAGRAM |

..... |

|

•.•• |

... |

•.•••••••••••••. " |

59 |

|||||||||

|

|

6-3·1. |

Interconnection Diagram •..... |

|

••••.. |

••.••.. |

••••. |

59 |

|||||||||

|

6-4. |

CIRCUIT DIAGRAM . • • • • |

. . |

• . . |

• . . |

• • • • • • .• |

. • • . • . • • • .• |

61 |

|||||||||

|

|

6-4·1. |

Circuit Diagram on FC·9 Mounted Board .. |

• |

•••••.•.•• |

61 |

|||||||||||

|

|

6-4-2. |

Parts Layout on FC·9 Mounted Board |

•••.. |

•.. |

••••.•• |

65 |

||||||||||

|

|

6-4-3. |

Disk: Motor Circuit Diagram. |

. |

• • . • • • • • . • • . • • • • • . •• |

67 |

|||||||||||

|

|

6-4-4. |

Parts Layout on Disk Motor Circuit Board. . |

. • • • • • • • • .• |

69 |

||||||||||||

|

6·5. |

ELECTRIC PARTS ... |

• .. |

• .. |

• ; |

. . |

. . • • • • • . • . • • • • • • . • •. |

70 |

|||||||||

|

|

6-5·1. |

ChipParts Replacement Procedure. • • • • • . • • • • . • • . • •• |

70 |

|||||||||||||

|

|

6-5·2. |

Electric Parts List • . • ..... |

|

• .. |

•••• ... |

|

• . •••• .. |

• .. |

|

71 |

||||||

SECTION 7. |

PARTS LOCATION AND LIST (OA·D32V) |

••••••••.••••••••.. |

|

• |

|

75 |

|||||||||||

|

7·1. |

PARTS ASS'Y LOCATION |

...... |

|

• .. |

•••• ..... |

|

•• . • .. |

• .. |

|

75 |

||||||

|

7·2. |

MECHANICAL PARTS |

LIST |

.• , .••.••.•••••.••••••••.• |

77 |

||||||||||||

|

7·3. |

OVER ALL DIAGRAM |

................... |

|

|

|

|

|

|

; . • • • • • • |

. . |

•. |

79 |

||||

|

|

7·3·1. |

Interconnection Diagram ... |

• .. |

• .. |

• .. |

•• . •••• .. |

|

• ... |

|

79 |

||||||

|

7·4. |

CIRCUIT DIAGRAM • . • |

. . |

• . |

. • . |

. • |

. . • . |

. • . . |

• • . • • . • • . • •. |

81 |

|||||||

|

|

7-4-1. |

Circuit Diagram on FC·14 Mounted Board .•••••••.•.. |

• |

81 |

||||||||||||

|

|

7·4-2. |

Parts Layout on FC·14 Mounted Board •••.. |

•.••.••.•• |

85 |

||||||||||||

|

|

7·4-3. |

Disk: Motor Circuit Diagram |

.••.•• |

..•• . • • • • • • . • . •. |

87 |

|||||||||||

|

|

7-4-4. |

Parts Layout on Disk Motor Circuit Board. • . • • • • • . • . |

.• |

89 |

||||||||||||

|

7·S. |

ELECTRIC PARTS •.•.••.•... |

•.•.•.••••.•.••••••.•• |

90 |

|||||||||||||

|

|

7·5·1. |

Chip Parts Replacement Procedure •••• ; .• |

. • . • • • • • • .• |

90 |

||||||||||||

|

|

7·5·2. |

Electric Parts List |

• • . • . |

. • |

. . |

. . • • • . • • . • . • • • • • . • •. |

91 |

|||||||||

SECTION 8. TRANSISTORS I DIODES IICS |

PIN ARRANGEMENT |

•• |

. • • . • • • . • .• |

94 |

|||||||||||||

-6-

Introduction

SECTION 1

INTRODUCTION

This manual is a maintenance guide forOA·D32W (Double sided) and OA·D32V (Single sided).

SECTION 2 describes disks and tools necessary for maintenance.

SECTION 3 provides fault diagnostic procedures that may require spare parts or some adjustments.

The overall check after removals and adjustments will be included in this section.

SECTION 4 and 5 cover parts replacements and adjustments, respectively.

SECTION 6 and 7 consist of circuit diagrams, ass'y drawin~s, and parts lists.

The cassette dummy (4-603-929-00) should be inserted in the OA·D32W when it is transported. Otherwise, its heads may be damaged.

Perform maintenance in accordance with the procedure specified in this manual as follows:

(Example)

|

e. |

Fasten the guide shaft with the two screws (PSW2.6 x 6). |

|

Em f. |

Fasten the head board to the chassis on the bottom surface, and apply nut lock |

||

|

|

paint to the screw. |

|

Em g. Connect the head board to |

the head harness (by four points) with a soldering |

||

|

|

iron. (Refer to Fig. 4-14 (c) ) |

|

_ |

h. Connect the head board to |

the head harness (by six points) with a soldering |

|

|

|

iron. (Refer to Fig. 4-14 (d» |

|

_ |

i. |

Fasten head board and terminal shield plate with a screw (PSW2.6 x 8) on the |

|

E!D j. |

chassis bottm, and then apply nut lock paint onto it. |

||

Perform the stepping motor load torque adjustment. (Refer to 5-5) |

|||

|

k. |

Install the cassette·up ass'y in place. (Refer to 4-9) |

|

Steps e, h, i, and k should be carried out in sequence for the OA·D32W. Steps e, f, g, j and k should be carried out in sequence for the OA·D32V.

- 7 -

General and Special Tool List

SECTION 2

TOOLS AND MEASURING INSTRUMENTS

2-1. GENERAL AND SPECIAL TOOL LIST

The tools, and measuring instruments for performing maintenance on the OA-D32W/OA-D32V are listed below.

a. General Tools

TOTSU Screw Driver (M2.6)

@ Driver 2 mm e Driver 2 mm e Driver 4 mm

Tweezers

Round Nose Plier

Adj Rod

Cutter

Soldering Iron (20W)

Desoldering Metal Braid

DC Power Supplier (+5 V DC i5 %, O.S A max.,

+12 V DC i5 %, 1.5 A max.) |

|

Tester |

|

b. Special Tools |

|

MFD Checker D |

(J-609-IS2-0A) |

SMC-70 System |

|

SMI-70lll SMI-70llA I SMI-70121 SMI-70l2A

SMC-70 |

|

KX-13Gl |

|

'AID Converter |

(J-623-002-OA) |

25P/26P Conversion Cable |

(J-623-90l-0A) |

Radial Alignment System Disk |

|

(OR-DS6VA) |

(8-960-009-74) |

Error Check.system Disk (OR-D87VA)(8-960-009-75) |

|

Rotatory Knob (fOt Stepping Motor) |

(J-609-01l-0A) |

Lead Screw Eccentricity Inspection Tool (J-609-l36-OA) |

|

Standard Disk Dummy |

|

(for Cassette-Up Ass'y Installation) |

(J-609-l20-0A) |

Geared Driver |

(J-609-0 l7-0A) |

Pad Weight |

(J-609-124-0A) |

Hexagon Wrench Torque Driver |

(J-609-125-0A) |

Power Cable |

(J-609-l30-0A) |

Interface Cable |

(J-609-200-0A) |

c.Measuring Equipment Oscilloscope Dual Trace 20 MHz

Universal Counter Resolution 0.1 msec.

Tension Gauge |

(Max. 200 g) |

(J-604-163-OA) |

Tension Gauge |

(Max. 20 g) |

(7-732-050-fO) |

d.Disks·

Level Disk

lSI |

OR-D46VA |

(8-960-009-31) |

_ |

OR-D46WA |

(8-960-009-40) |

Alignment Disk |

|

|

lSI OR-D47VA |

(8-960-009-32) |

|

_ |

OR-D47WA |

(8-960-009-41) |

Dynamic Inspection Disk +30 |

|

|

lSI OR-DSIVA |

(8-960-009-35) |

|

_ |

OR-DSIWA |

(8-960-009-44) |

Dynamic Inspection Disk - 30 |

|

|

lSI OR-D52VA |

(8-960-009-36) |

|

_ |

OR-DS2WA |

(8-960-009-45) |

Cleaning Disk |

|

|

lSI |

OR-D29VA |

(8-960-009-15) |

_ |

OR-D29WA |

(8-960-009-39) |

e. Expendable and Chemical Supplies |

|

|

Nut Lock Paint |

|

|

Alcohol |

|

|

SonyOU |

(7-611-0.18-01) |

|

Sony Grease |

(7-622-001-52) |

|

Bamboo Stick |

|

|

Applicator |

|

|

-8-

2-2. SPECIAL TOOLS

2-2-1. MFD Checker D

(1) MFD Checker D configuration Main Checker Board

I/F Cable |

(26pin and 34pin) |

Power Cable |

(2 pieces) |

Conversion Board |

(26pins-to-34pins) |

NOTE: The Conversion Board and 34pin IIF Cable are required for the OA-D33W/OA-D33V.

(2)Micro Floppydisk Drive Connection (Refer to

Fig. 2-,1)

(3)MFD Checker n function switches

STEP IN • ....... Steps the head inwards. STEP OUT ....... Steps the head outwards.

The head continously moves if the switch is kept pressed.

SIDE SELECT •... Selects one of two heads (side 0 or side 1) for a double sided. (This switch is invalid for single sided versions.)

WRITE ... • .... • . Records, data specified by the OSC SEL switch, onto one track.

OSC SEL ........ Selects such write data as "2F", "IF", "WCP" (worst case pattern), or EXT.

Special Tools

WCP W1M .. • .... • Selects upper and lower patterns when the OSC SEL switch is set to WCP. (Refer to Fig. 3-3 (c), (d»

HD LOAD • ...... This is used to set the plunger solenoid active.

M,OTOR ON ... • .. This is used to operate the

|

Disk Motor. |

|

|

|

|

DRIVE SELECf |

... Selects |

the disk drive. |

|||

|

The DRIVE SELECf switch on the disk drive |

||||

|

relates to the DRIVE SELECf switch on the |

||||

|

checker as follows: |

|

|

||

|

|

|

|

|

|

|

Drive |

|

|

Checker |

|

|

IS101) |

|

1 |

|

2 |

|

1 |

|

OFF |

|

OFF |

|

2 |

|

ON |

|

OFF |

|

3 |

|

OFF |

|

ON |

|

4 |

|

ON |

|

ON |

CHGRST ........ Resets the DSKCHG signal.

600/300 SELECf (Located in the middle of the board) .......... Set the 600/300 SELECf switch at "600" for the OA-D32WIOA-D32V. SO/70 SELECf (Located in the middle of the board) .. • ..... •• Set the SO/70 SELECf switch to "SO" for the OA-D32W/OA-D32V.

Power Cable

Fig. 2-1 Drawing of Connection Between Disk Drive and MFD Checker II

-9-

Special Tools

(4) INDICATOR

OSC SEL (Four LEDs in the left of the board)

. . . . . . . . . . • . . . '. They indicate the selected position on the OSC SEL switch.

IfF signals (Five LEDs in the middle of the board) .......... They indicate at the states of TRK 00, WRTPRT, RDY, DSKCHG, and

INDEX, respectively.

The TRK 00, WRTPRT, ROY, and DSKCHG indicators are lit when the respective IfF signals are low (true). The INDEX indicator blinks when the INDEX signal is applied to the board.

TRACK POSITION (Seven segment LED indicator in the right of the board) •.. ~ .... • . ••

Indicates the current track position.

(5)Test Points

TP-I; "M;:::O';;:T:AO-;:::R-'O""N~

TP-2; WRT GATE TP-3; RD DATA TP-5; INDEX

TP-6; STEP

TP-7; ;';H-;:::D:-L~O="A-:-D;::'

The GND terminal: is marked by "GND".

MFD Checker II Block Diagram

-10-"

MFD Checker II Circuit Diagram MFD Checker II Circuit Diagram

R3B

4.7K

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R33 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SELECT! |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~DIP |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(SELECT) |

l |

I |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IIC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

lC4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DKC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

(CHORST) { RZB |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

(sIDE SE/.) 1: |

|

|

|

|

d/gdast JII< |

||||||||

|

|

|

|

|

|

|

|

|

|

...---- T"9~/c |

|

!esidt9) |

(--c:----H-GR-ST--.,~ |

||||||||||||

|

|

|

|

|

|

|

|

|

|

(SIDE SEL 'FJeSide/) |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R3S |

( |

RDDATA~:jl |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

II< |

|

|

|

TPB |

|

TP3 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF TP9 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R31 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T.P.G |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

MOTOR ON |

|

2 |

|

SELECT & |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

DKCHG |

|

|

4 |

|

SELECT I |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

CHGRST |

|

|

6 |

|

|

DIRTN |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

GND |

|

|

8 |

|

|

|

STEP |

|

||

|

I |

+5 V |

I-- |

- |

|

|

|

|

|

|

9 |

|

GND |

|

|

10 |

|

|

WRTDATA |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

2 |

|

GND |

r- |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

/I |

|

GND |

|

|

12 |

|

|

WRTGATE |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

3 |

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

GND |

t-- |

- I - |

|

|

|

|

|

13 |

|

GND |

|

|

14 |

|

|

HD |

LOAD |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

4 |

|

+IZV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

CI CZ |

|

IS |

|

GND |

|

|

16 |

|

SIDE |

SEL |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

RlWEROIJT |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

I |

|

+SV |

|

|

|

|

|

|

'~ 0.021 |

|

17 |

|

GND |

|

|

18 |

|

|

INDEX |

|

||||

|

|

|

|

|

|

|

~~ |

|

|

19 |

|

GND |

|

|

10 |

|

|

TRK |

(HI |

|

|||||

|

Z |

|

OND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

21 |

|

GND |

|

|

22 |

|

|

WRTPRT |

|

||||||

|

3 |

|

aND |

f --- |

|

|

|

|

TP4 |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

"23 |

|

GND |

|

|

24 |

|

|

RD DATA |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|

|||||||

|

4 |

|

+lZV |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

"2S |

|

GND |

|

|

|

26 |

|

|

|

READY |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

EXT WCP IF ZF

MFD Checker II Circuit Diagram

-11- |

-12- |

Configuration of SMC-70 Drive Test System Disks

2·2·2. Configuration of SMC·70 Drive Test System

System configuration for Radial Alignment and TRK 00 Sencer measurement, adjustment, and error check with SMC·70 System is shown in Fig. 2·2 (a),

(b).

2·2·3. Disks |

|

|

|

|

|

|

||

(a) |

Level disk |

|

_ |

OR·D46VA |

|

|

||

|

|

|

|

ED OR-D46WA |

|

|

||

|

These disks are used to check and adjust the read |

|

|

|||||

|

amplifier gain and off set, |

The self-read/write |

|

|

||||

|

operation can be checked with both of these |

|

|

|||||

|

disks and the SMC-70 System. |

|

|

|||||

(b) |

|

Alignment disk |

_ |

OR-D47VA |

|

|

||

|

|

|

|

ED OR-D47WA |

|

|

||

|

These disks have prerecorded data such as Cat's |

|

|

|||||

|

eye pattern and INDEX signal to check and |

|

|

|||||

|

adjust the off-tracking and index position. |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OR·D47VA |

OR·D47WA |

||

|

|

|

|

SIGNAL |

TRACK |

SIGNAL |

TRACK |

|

|

|

|

|

|

|

|

|

|

|

|

SIDE |

CAT'S |

EYE |

00, 20, 25, 30, 35, |

CAT'S EYE |

00,20,25,30,35, |

|

|

|

PATTERN |

40,45,50,55,79 |

PATTERN |

40,45,50,55,79 |

|||

|

|

0 |

||||||

|

|

|

|

|

|

|

|

|

|

|

INDEX |

|

40 |

INDEX |

40 |

||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

SIDE |

|

|

|

|

CAT'S EYE |

40 |

|

|

|

|

not applicable |

PATTERN |

|||

|

|

I |

|

|

|

|||

|

|

|

|

|

|

INDEX |

40 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

fa} Error Check

(c) DYNAMIC INSPECTION D'ISK +30 1m OR-D5IVA ED OR-D5IWA

DYNAMIC INSPECTION DISK -30 _ OR-D52VA

|

Dynamic Inspection Disk/Level Disk |

ED OR-D52WA |

|

These disks can be used in the final check for a |

|

|

|

|

To Monitor |

|

drive with the SMC-70 System. |

|

|

|

|

|

NOTE: (+) indicates that data has been recorded in the |

|

|

inner side oftracks. |

|

|

(-) indicates that data has been recorded in the |

|

|

outer side of tracks. |

|

|

Contents |

(d) CLEANING DISK

1m OR-D29VA

ED OR-D29WA

This type of disk can be used for cleaning the head.

|

OR·D51VA |

OR·D52VA |

OR·D51WA |

OR-D52WA |

|

|

|

|

|

|

|

SIDE |

Offset of +30 tJ.m for |

Offset of -30 tJ.m for |

Offset of +30 tJ.m for |

Offset of -30 tJ.m for |

|

0 |

all formatted tracks |

all formatted tracks |

all formatted tracks |

all formatted tracks |

|

|

|

|

|

|

|

SIDE |

not applicable |

not applicable |

Offset of +30 tJ.m for |

Offset of -30 tJ.m for |

|

I |

all formatted tracks |

all formatted tracks |

|||

|

|

||||

|

|

|

|

|

fb} Radial AlignmentlTRK 00 Senser

Fig. 2·2

-13- |

-14- |

Before Troubleshooting

SECTION 3

TROUBLESHOOTING

SECTION 3 describes the methods of troubleshooting. 3-2 refers to several errors specfied in a system level. 3-3 describes normal operations and the check points for abnormal operations. These descriptions define the Error Spot under operating conditions.

3-1. BEFORE TROUBLE SHOOTING

The following procedures are recommended to see if the drive is really faulty or not:

1)Incorrect operational procedure

2)program error of host system

3)Poor connection with host system (esp. GNDrelated connection, frame GND, etc.)

4)Defective disk. Check that same trouble occurs with other disks.

5)Environmental conditions (where electrical noise easily jumps into signal)

6)Influence of strong magnetic field

7)Wrong supply voltage

3·2. TYPES OF ERROR ON A SYSTEM LEVEL

3·2·1. Soft Error

Soft error are caused by;

1)Dirty head

2)Electrical noise

3)Tracking error

4)Poor connection with system (GND-related connection)

5)Incorrect motor speed

6)Incorrect head compliance

Clean the head first. Check for index pulse interval and head compliance and then read error spot more than several times. If not readable, move the head to the adjacent track in the same direction as before, then return to the desired track, and read. If readable this time, check radial alignment. (Refer to 5-4) If not readable yet, the error is not recoverable.

3·2·2. Write Error

To determine whether the disk or the drive is failing. the disk should be replaced by other disks and check that there still exists write error. If write error does not exist any more, remove the old one. If write error exists with use of any rlisk, drive might cause write error.

3·2·3. Seek Error

Seek error comes from:

1)Head movement is incorrect because ellectrical noise jumps into signal.

2)Head driving system might be at fault. If it is not re-readable after re-calibration, drive might be at fault.

3·2-4. Interchange Error

If data written on one drive is readable correctly on another drive, but not by other drives, interchange error exists.

Interchange errors are caused by;

I)Head is not properly positioned.

2)Motor speed is not correct.

3)Optimum head output level and offset and head compliance are not obtained.

4)Chucking mechanism does not work.

3·3. FAULT DIAGNOSIS BY MFD CHECKER II

3-3-1 describes check method for normal operations in accordance with the predetermined procedUres.

3-3-2 describes check points for abnormal operations which come out in accordance with the above procedures.

3·3·1. Normal Operation

Pre-setting:

1)Refering to Fig. 2-1 (Micro Floppydisk Drive Connection), connect the drive to MFD Checker

II.

2)Set the slide switch (SI01) on the disk drive to

"}".

3)Set all switches in the MFD Checker II to "OFF".

-15-

Normal· Operation

Procedure |

Step |

|

|

Operation |

||

|

|

|

|

|

|

|

1 |

Power On |

1. The head |

automatically returns to TRK 00 and stops |

|||

|

|

|

there. |

|

|

|

|

|

2. The disk motor remains stopped. |

||||

|

|

|

|

|

|

|

2 |

Drive Select Check after checked, |

1. The TRK 00, WP, |

and DSKCHG indicators light only |

|||

|

the disk drive is to be kept |

|

when the DRIVE SELECT switch on the MFD Checker |

|||

|

selected. |

|

D and the slide switch (S 10 1) on the disk drive are set as |

|||

|

|

|

follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

MFD Checker n |

Disk drive |

|

|

|

|

|

1 |

2 |

IS101) |

|

|

|

|

OFF |

OFF |

1 |

|

|

|

|

ON |

OFF |

2 |

|

|

|

|

OFF |

ON |

3 |

|

|

|

|

ON |

ON |

4 |

|

|

|

|

C?therwise, these indicators go out. |

|||

3 |

Operation during CASSETTE IN |

1. When the cassette is inserted, the motor is rotating and |

||||

|

(Alignment disk is to be inserted.) |

|

the plunger is pulled out. The head is loaded and un- |

|||

|

|

|

loaded in sequence. The motor then stops operation. |

|||

|

|

|

||||

4 |

MOTOR ON switch on |

1. The motor rotates. (The INDEX indicator on the MFD |

||||

|

|

|

Checker II blinks.) |

|

|

|

|

|

2. The TRK 00, WRTPRT, RDY, and DSKCHG indicators |

||||

|

|

|

light. (The RDY indicator, however, lights in about 1.5 |

|||

|

|

|

seconds after the disk is inserted.) |

|||

|

|

|

||||

5 |

CHGRST switch on |

1. The DSK CHG. indicator goes out at the moment when |

||||

|

|

|

the CHG RST switch is pressed. |

|||

|

|

|

||||

6 |

HD LOAD switch on |

mJ 1. The plunger Solenoid is set on, and the pad lifts down. |

||||

|

|

IE 2. The plunger Solenoid is set active and the head lifts |

||||

|

|

|

down. |

|

|

|

|

|

3. The clearance between the HL arm and pad arm is set as |

||||

|

|

|

shown in Fig. 5-9. |

|

|

|

|

|

|

||||

7 |

Stepping |

1. When the STEP IN switch is pressed, the head is con- |

||||

|

|

|

tinuously stepped in until it arrives at TRK 79. |

|||

|

|

|

When the STEP OUT switch is pressed, the head is |

|||

|

|

|

continuously stepped out until it arrives at TRK 00. |

|||

|

|

2. When the head is set to any track other than TRK 00, |

||||

|

|

|

the TRK 00 indicator does not ligh( |

|||

|

|

|

||||

8 |

Track positioning |

1. Such a Cat's eye pattern signal as slivwn in Fig. 3-1 (a) |

||||

|

|

|

can be obtained at CNI07-1 on the disk drive when the |

|||

|

|

|

head accesses TRK 20, TRK 30 or TRK 50. The oscil- |

|||

|

|

|

loscope is triggered by the signal at TP-5 of the MFD |

|||

|

|

|

Checker II. |

|

|

|

|

|

Note: Such a signal as shown in Fig. 3-1 (b) can be obtained when the |

||||

|

|

|

head accesses TRK 40. |

|

|

|

|

|

Em 2. SIDE SELECT switch to side 1. such a Cat's eye pattern |

||||

|

|

|

signal as shown Fig. 3-1 (b) can be obtained at CN 107-1 |

|||

|

|

|||||

|

|

|

on the disk drive. When the head accesses TRK 40. |

|||

|

|

3. Set amplitude L in Fig. 3-1 (a) to 5 divisions, and then |

||||

|

|

|

read amplitude R in Fig. 3-1 (a). |

|||

|

|

|

Calculate the OFF TRACK value, refering to Table 3-1 |

|||

|

|

|

||||

-16-

Normal Operation

Procedure |

Step |

|

Operation |

|

|

|

|

|

|

|

|

(c) and (d), in accordance with R in Fig. 3·1 (a). |

|

|

|

|

Then, obtain the humidity-compensated OFF |

TRACK |

|

|

|

value from the following expression: |

|

|

|

|

The compensated OFF TRACK value = OFF |

TRACK |

|

|

|

value + 0.2 (50 - |

H)(39.5 - 0.1875N - 1.5S)/33.5 ...(1) |

|

|

|

Where; |

|

|

H:Relative humidity (%)

N:Track number

S:Side ID number

Side 0: 0 |

Side 1: 1 |

The compensated OFF TRACK value should meet the following formula. . '

-20 ~ Compensated OFF TRACK value ~ +20 ... (2)

[EX] For R = 4.5 in the OA-D32V, the apparent OFF TRACK value is as shown in table 3·1 (d).

Assuming =4.5,

H = 60 %, N = 40, 'al1d S = I, we can obtain the compensated OFF TRACK value as 2.6 from expression (1). This satisfy the formula.

(a)

|

|

Fig. 3·1 Cat's Eye Pattern Signal |

|

|

(b) |

|

|

|

|

||||||||

|

|

|

|

|

|

0.0 |

0.1 |

0.2 |

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

|

|

|

|

|

2: |

|

34.5 |

32.9 |

31.3 |

29.S |

28.3 |

26.S |

25.4 |

24.0 |

22.7 |

21.4 |

|

|

|

|

|

|

3: |

|

20.1 |

IS.9 |

17.7 |

16.5 |

15.3 |

14.2 |

13.1 |

12.0 |

11.0 |

9.9 |

|

|

|

|

|

|

4: |

|

S.9 |

8.0 |

7.0 |

6.1 |

S.I |

4.2 |

3.4 |

2.5 |

1.6 |

0.8 |

|

|

|

|

|

|

5: |

|

0.0 |

-O.S |

-1.6 |

-2.3 |

-3.1 |

-3.S |

-4.6 |

-5.3 |

-6.0 |

-6.6 |

|

|

|

|

|

|

6: |

|

-7.3 |

-S.O |

-S.6 |

-9.3 |

-9.9 |

-10.5 |

-11.1 |

-11.7 |

-12.3 |

-12.9 |

|

|

|

|

|

|

|

7: |

-13.4 -14.0 |

-14.5 |

-15.1 |

-15.6 |

-16.1 |

-16.6 |

-17.1 |

-17.6 |

-IS.I |

||||

|

|

|

|

S: |

-IS.6 |

-19.0 |

-19.5 |

-20.0 |

-20.4 |

-20.9 |

-21.3 |

-21.7 |

-22.2 |

-22.6 |

|

|

|

|

|

|

9: |

|

-23.0 |

-23.4 |

-23.8 |

-24.2 |

-24.6 |

-25.0 |

-25.4 |

-25.7 |

-26.1 |

-26.5 |

|

|

|

|

|

|

|

|

|

|

|

|

(e) OA·D32W |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0 |

0.1 |

0.2 |

0.3 |

0.4 |

Q,1 |

0.6 |

0.7 |

0.8 |

0.9 |

|

|

|

|

|

|

|

2: |

36.9 |

35.1 |

33.4 |

31.S |

30.2 |

2S.7 |

27.2 |

25.7 |

24.3 |

22.9 |

|

|

|

|

|

|

|

3: |

21.5 |

20.2 |

18.9 |

17.6 |

16.4 |

15.2 |

14.0 |

12.9 |

11.7 |

10.6 |

|

|

|

|

|

|

|

~: |

9.6 |

S.S |

7.5 |

6.5 |

5.5 |

~ |

3.6 |

2.7 |

1.8 |

0.9 |

|

|

|

|

|

|

|

5: |

0.0 |

-0.9 |

-1.7 |

-2.5 |

-3.3 |

-4.1 |

-4.9 |

-5.6 |

-6.4 |

-7.1 |

|

|

|

|

|

|

|

6: |

-7.8 |

-S.S |

-9.2 |

-9.9 |

-10.6 |

-11.2 |

-11.9 |

-12.5 |

-13.1 |

-13.7 |

|

|

|

|

|

|

|

7: |

-14.3 |

-14.9 |

-15.5 |

-16.1 |

-16.6 |

-17.2 |

-17.7 |

-18.3 |

-IS.8 |

-19.3 |

|

|

|

|

|

|

|

S: |

-19.8 -20.4 |

-20.8 |

-21.3 |

-21.S |

-22.3 |

-22.S |

-23.2 |

-23.7 |

-24.1 |

|

|

||

|

|

|

|

9: |

-24.6 |

-25.0 |

-25.4 |

-25.9 |

-26.3 |

-26.7 |

-27.1 |

-27.5 |

-27.9 |

-2S.3 |

|||

|

|

|

|

|

|

|

|

|

(d) OA·D32V |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Table 3·1. Apparent off Track |

|

|

|

|

|||||

9 |

Motor speed |

|

|

|

1. The Motor speed can be |

measured at TRK35, in TP·5 on |

|||||||||||

|

|

|

|

|

|

MFD Checker II with an universal counter. |

|

|

|

|

|||||||

|

|

|

|

|

|

It should be 100 msec ± 1.5 msec. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-17-

NormalOperation

Procedure |

Step |

Operation |

10 |

Index position |

|

1. The following waveform can be obtained on TRK 40. |

|||||||

|

|

Index |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

signal |

|

|

|

|

|

|

|

|

|

|

(TP-5) |

|

|

|

|

I |

|||

|

|

|

|

|

|

|

||||

|

|

Output |

|

|

|

il |

||||

|

|

signal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(CNt07-1) |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

-100 J,lsec_::::; T::::; +100 J,lsec. |

||

|

|

|

|

|

|

|

Fig_ 3-2 Index Phase Specification |

|||

|

|

|

|

|

||||||

11 |

TRK 00 sensor level |

|

1. |

Move the head until it arrives at TRK 01. (Do not move |

||||||

|

|

|

|

|

|

the head passing TRK 01. If the head arrives at TRK 00, |

||||

|

|

|

|

|

|

through the Cat's eye pattern signal is to be rechecked |

||||

|

|

|

|

|

|

and then the head is to be set on the TRK 01.) |

||||

|

|

|

|

|

The output signal level of CN I 07-5 is 3 V or more. |

|||||

|

|

|

2. |

Move the head until it arrives at TRK 00. |

||||||

|

|

|

|

|

The output signal level of CNI07-5 is 0.7 V or less. |

|||||

|

|

|

|

|

||||||

12 |

Cassette out (When the alignment |

|

|

1. The DSKCHG indicator lights. |

||||||

|

disk is ejected.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

13 |

Write (When the level |

|

1. When the WRITE switch is pressed and "2F", "IF", or |

|||||||

|

disk is inserted) |

|

|

|

"WCP (MfW)" are written, the corresponding waveform |

|||||

|

|

|

|

|

can be obtained at CN 107-1. (Refer to Fig. 3-3) |

|||||

I (a)2F |

(b) 1F |

(c)WCP(M) |

|

(d) WCP(W) |

Fig_ 3-3 2F, IF and WCP Waveforms |

||

Em 2. Set the SIDE |

SELECT switch |

to side 1, and "2F", |

"IF", or "WCP (M/W)" are written, the corresponding |

||

waveform can |

be obtained at |

CNI07-1. (Refer to |

Fig. 3-3) |

|

|

-18-

Normal Operation'

Procedure |

Step |

|

|

|

Operation |

|

|

|

|

|

|

|

|

|

|||

14 |

Output level |

|

1. |

Move the head until it arrives at TRK 79, and then write |

||||

|

|

|

|

"2F". |

|

|

|

|

|

|

|

|

The output signal level of CNl07-l |

is 0.4 |

to 0.8 Vp·p |

||

|

|

|

|

(e |

0.2 to 0.5 Vp·p). |

|

|

|

|

|

|

|

The following read data can be obtained at TP-3 on the |

||||

|

|

|

|

checker. (Refer to Fig. 3-4 (a) (b) ) |

|

|

|

|

|

|

|

Em 2. Set the SIDE SELECT switch to side 1. |

|

|

|||

|

|

|

|

Move the head until it arrives at TRK 79, and then write |

||||

|

|

|

|

"2F". |

|

|

|

|

|

|

|

|

The output signal level of CNl07-l is 0.2 to 0.5 Vp-p. |

||||

|

|

|

|

The following read data can be obtained at TP-3 on the |

||||

|

|

|

|

checker. (Refer to Fig. 3-4 (a) ) |

|

|

|

|

|

0.2V |

|

Output |

|

|

|

||

|

-0.5 V |

|

Signal |

|

|

|

||

|

|

|

|

RDData |

|

|

|

|

|

(a)e |

|

|

(b) EE1!I |

|

|

|

|

|

Fig. 3·4 Output Signal and RD Data Waveforms |

|

|

|

||||

|

|

|

|

|

|

|

|

|

15 |

Peak Shift |

|

1. |

Write "WCP(W/M)" ontoTRK 79. |

|

|

|

|

|

|

|

|

Such waveforms as shown in Fig. 3-5 (a) (b) can be |

||||

|

|

|

|

obtained at eNl07-l and TP-3, respectively. |

|

|

||

|

|

|

|

The waveform in Fig. 3-5 (a) (b) shows the read data at |

||||

|

|

|

|

~1 |

|

|

. |

|

|

|

|

|

|

Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Signal |

|

|

|

|

|

|

|

|

(CNtOl·t) |

|

|

|

|

|

|

|

|

RDData |

|

|

|

|

|

|

|

|

(Tp·3) |

|

|

|

|

(a) |

|

|

L-J |

(b) |

|

|

|

|

Less than 2.43 IlSec. (with OA·D46VA) |

Less than 2.43 Ilsec. (with OA·046VA) |

||||||

|

Less than 2.43 jlSec. (with OA·D46WA) |

Less than 2.43 jlSec. (with OA·D46WA) |

||||||

|

|

|

Fig. 3·5 Waveforms of Output Signal and RD Data |

|||||

|

|

|

|

at TRK 79 |

|

|

|

|

|

|

Em 2. Set the SIDE SELECT switch to side 1. |

Write "WCP |

|||||

|

|

|

|

(W/M)" onto TRK 79. |

|

|

|

|

|

|

|

|

Such waveforms as shown in Fig. 3-5 (a) (b) can be |

||||

|

|

|

|

obtained at CN 107-1 and TP-3, respectively. |

|

|

||

|

|

|

|

The waveform in Fig. 3-5 (a) (b) shows the read data at |

||||

|

|

|

|

TP-3. |

|

|

|

|

|

|

|

|

|

|

|

|

|

-19-

Check Points to Abnormal Operation

3-3-2. Check Points to Abnormal Operation

|

Step |

Abnormal Operation |

|

CheckPoint |

|

Remarks |

|

|

|

|

for Each Step |

|

(defective place) |

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Power On |

I. The head ~oves tow!ll'd |

I. TRK 00 sensing circuit. |

Thcl signal of CN 103-2 is Low level |

|

|

|||

|

|

the center of the Drive. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. The head is stepped out, |

1. |

TRK 00 sensing circuit. |

The signal of CN 103-2 is High level |

|

|

||

|

|

but it is idling around |

2. Check if the TRK 00 Sensor |

|

|

|

|

|

|

|

|

the outmost track. |

|

|

|

|

|

||

|

|

|

Mounted Board is installed a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

little bit outside. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. The head moves |

1. |

Stepping motor drive system. |

A voltage of+12 V appears at |

|

|

||

|

|

uncertainly. (The head |

NOTE: If no TRK 00 is detected in |

CN I 05-2 during normal operation. |

|

|

|||

|

|

movement is not |

|

several seconds after power |

Voltages at 3 pin through 6 pin of |

|

|

||

|

|

constant.) |

|

is turned on, the CPU auto- |

of CNI05 are switched in |

|

|

|

|

|

|

|

matically stops the stepping |

|

|

|

|||

|

|

|

|

10 ± 0.1 msec intervals. |

|

|

|

||

|

|

|

|

motor and thereafter accepts |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

no instructioh. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. The disk motor rotates. |

1. |

Disk motor drive system. |

The signal CNIOI-5 and CNIOI-? |

|

|

||

|

|

|

|

|

are Low level |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive Select Check |

1. The I/F indicators are |

1. |

Drive select circuit system. |

The signal ofICIOS-3 for the |

|

|

|

|

|

after checked, the |

put out for the selected |

|

|

selected combination is High level |

|

|

||

|

disk drive is to be |

combination, or they |

|

|

during normal operation. The |

|

|

||

|

kept selected. |