Page 1

MZ-R37

SERVICE MANUAL

Ver 1.1 1999. 04

US and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

SPECIFICATIONS

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: continuous

Laser output: less than 44.6 µW

(This output is the value measured at a

distance of 200 mm from the lens surface on

the optical pick-up block with 7 mm

aperture.)

Recording and playback time

Maximum 74 minutes (MDW-74, stereo

recording)

Maximum 148 minutes (MDW-74, monaural

recording)

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon

Code (ACIRC)

Sampling frequency

44.1 kHz

Sampling rate converter

Input: 32 kHz / 44.1 kHz / 48 kHz

Coding

Adaptive TRansform Acoustic Coding (ATRAC)

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism MZ-R55

MiniDisc Mechanism Type MT-MZR37-161

Optical Pick-up Type KMS-280A

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limit

Inputs

MIC (PLUG IN POWER): stereo mini-jack,

0.35–1.38 mV

(OPTICAL) LINE IN: stereo mini-jack with

optical (digital) in

• Line in: 69–194 mV

• Optical (digital) in: wave length 660 nm

Outputs

PHONES/REMOTE: stereo mini-jack,

maximum output level 5 mW + 5 mW, load

impedance 16 ohm

LINE OUT: stereo mini-jack, 194 mV, load

impedance 10 kilohm or greater

General

Power requirements

Sony AC Power Adaptor (supplied)

connected at the DC IN 4.5 V jack:

120 V AC, 60 Hz (US, Canadian model)

220–230 V AC, 50/60 Hz (AEP model)

230–240 V AC, 50 Hz (UK model)

240 V AC, 50 Hz (Australian and New Zealand model)

Two nickel-cadmium rechargeable batteries

NC-AA (supplied)

Two LR6 (size AA) alkaline batteries (not supplied)

– Continued on next page –

MICROFILM

PORTABLE MINIDISC RECORDER

– 1 –

Page 2

Battery operation time

Batteries Recording

Two NC-AA Approx. Approx.

nickel-cadmium

rechargeable batteries

Two LR6 (size AA) ––––

Sony alkaline dry batteries 13 hours

1)

The battery life may be shorter due to

operating conditions and the temperature

of the location.

2)

When you record, use fully charged

rechargeable batteries.

3)

Recording time may differ according to the

alkaline batteries.

Dimensions

Approx. 116.8 × 18.5 × 86.1 mm (w/h/d)

(4 5/8 × 3/4 × 3 1/2 in.)

Mass

Approx. 160 g (5.6 oz) the recorder only

Approx. 220 g (7.8 oz) incl. a recordable MD,

and two NC-AA nickel-cadmium

rechargeable batteries

Supplied accessories

Optical cable (1) (MC-918)

AC power adaptor (1) (AC-MZR37)

Headphones with a remote control (1) (SZR-S17)

NC-AA nickel-cadmium rechargeable batteries (2)

Rechargeable battery carrying case (1)

Design and specifications are subject to change without notice.

1)

3 hours 5 hours

3)

2)

Playback

Approx.

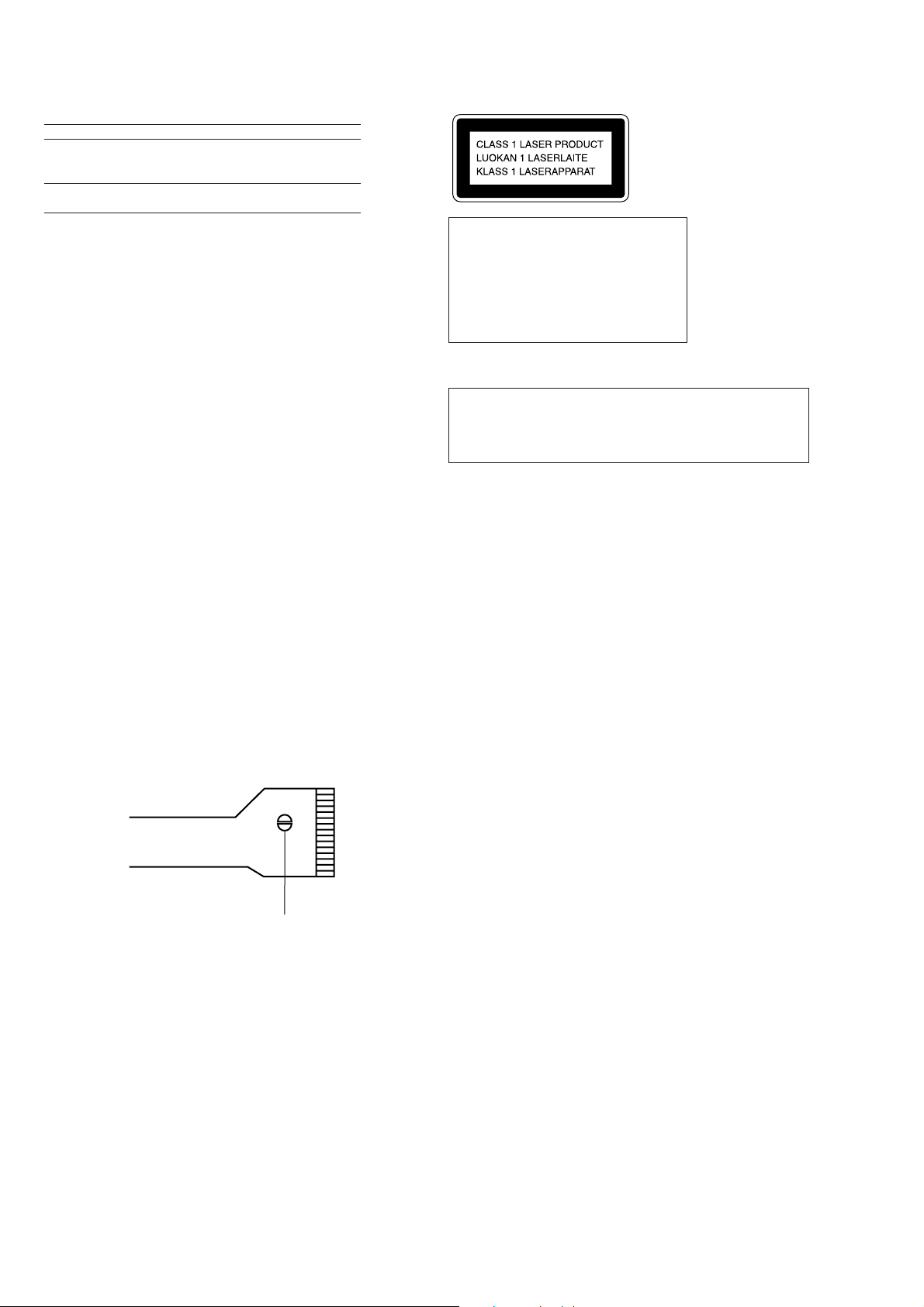

Precautions for Laser Diode Emission Check

When checking the emission of the laser diode during adjustments, never view directly downwards as this may lead to

blindness.

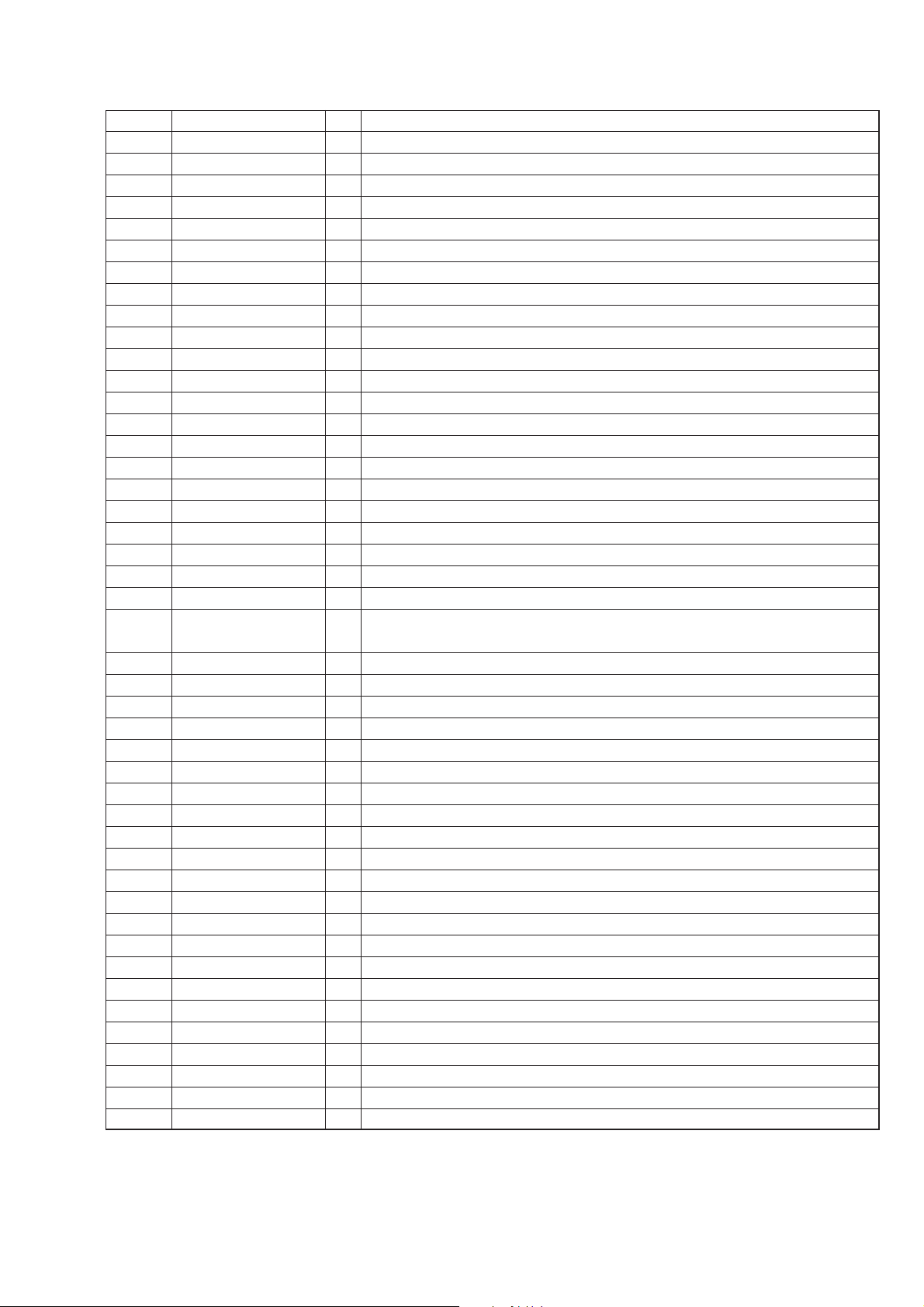

Precautions for Using Optical Pick-up (KMS-280A)

As the laser diode inside the optical pick-up damages by static

electricity easily, solder the laser tap of the Optical pick-up

flexible board when handling. Also take the necessary measures

to prevent damages by static electricity. Handle the Optical pickup flexible board with care as it breaks easily.

This MiniDisc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on

the bottom exterior.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Laser tap

Optical Pick-up flexible board

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

TABLE OF CONTENTS

r

1. GENERAL

Looking at the controls ...................................................... 4

2. SELF-DIAGNOSTIC

2-1. General ............................................................................... 5

2-2. Test Mode Setting .............................................................. 5

2-3. Operation in Test Mode Setting ......................................... 5

2-4. Releasing the Test Mode .................................................... 5

2-5. Self-Diagnostic Mode ........................................................ 5

2-6. Clearing the Error Indication Code

and Total Recording Time.................................................. 6

3. DISASSEMBLY

3-1. Panel, Bottom..................................................................... 7

3-2. Panel (SV) Assy, Front ....................................................... 7

3-3. LCD Module ...................................................................... 8

3-4. Connector ........................................................................... 8

3-5. Main Board ........................................................................ 9

3-6. Panel (SV) Assy, Upper ..................................................... 9

3-7. Cabinet (SV) Assy ........................................................... 10

3-8. OP Block Assy ................................................................. 10

3-9. Holder Assy...................................................................... 11

4. TEST MODE

4-1. General ............................................................................. 12

4-2. Test Mode Setting ............................................................ 12

4-3. Test Mode Structure......................................................... 12

4-4. Manual Mode ................................................................... 12

4-5. Overall Adjustment Mode (Assy Mode).......................... 15

4-6. Hybrid Mode, Key Check Mode...................................... 16

5. ELECTRICAL ADJUSTMENTS........................... 17

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 20

6-2. Block Diagram – Servo Section –.................................... 25

6-3. Block Diagram – Audio Section – ................................... 27

6-4. Block Diagram – System Control Section – .................... 29

6-5. Printed Wiring Board ....................................................... 31

6-6. Schematic Diagram – Main Section (1/3) –..................... 35

6-7. Schematic Diagram – Main Section (2/3) –..................... 38

6-8. Schematic Diagram – Main Section (3/3) –..................... 41

7. EXPLODED VIEWS

7-1. Panel Section.................................................................... 49

7-2. Cabinet (SV) Assy Section .............................................. 50

7-3. Mechanism Deck Section ................................................ 51

8. ELECTRICAL PARTS LIST................................... 52

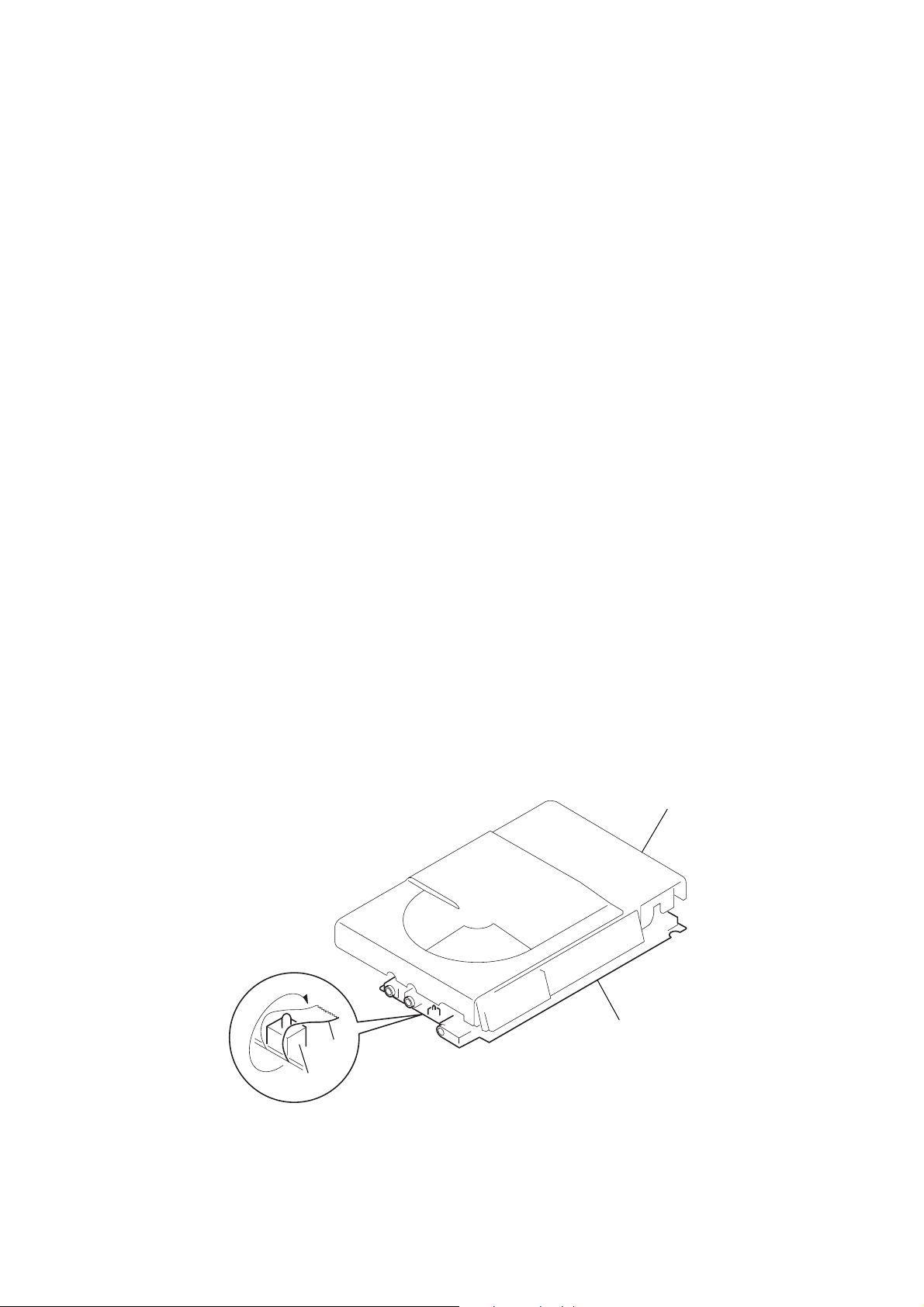

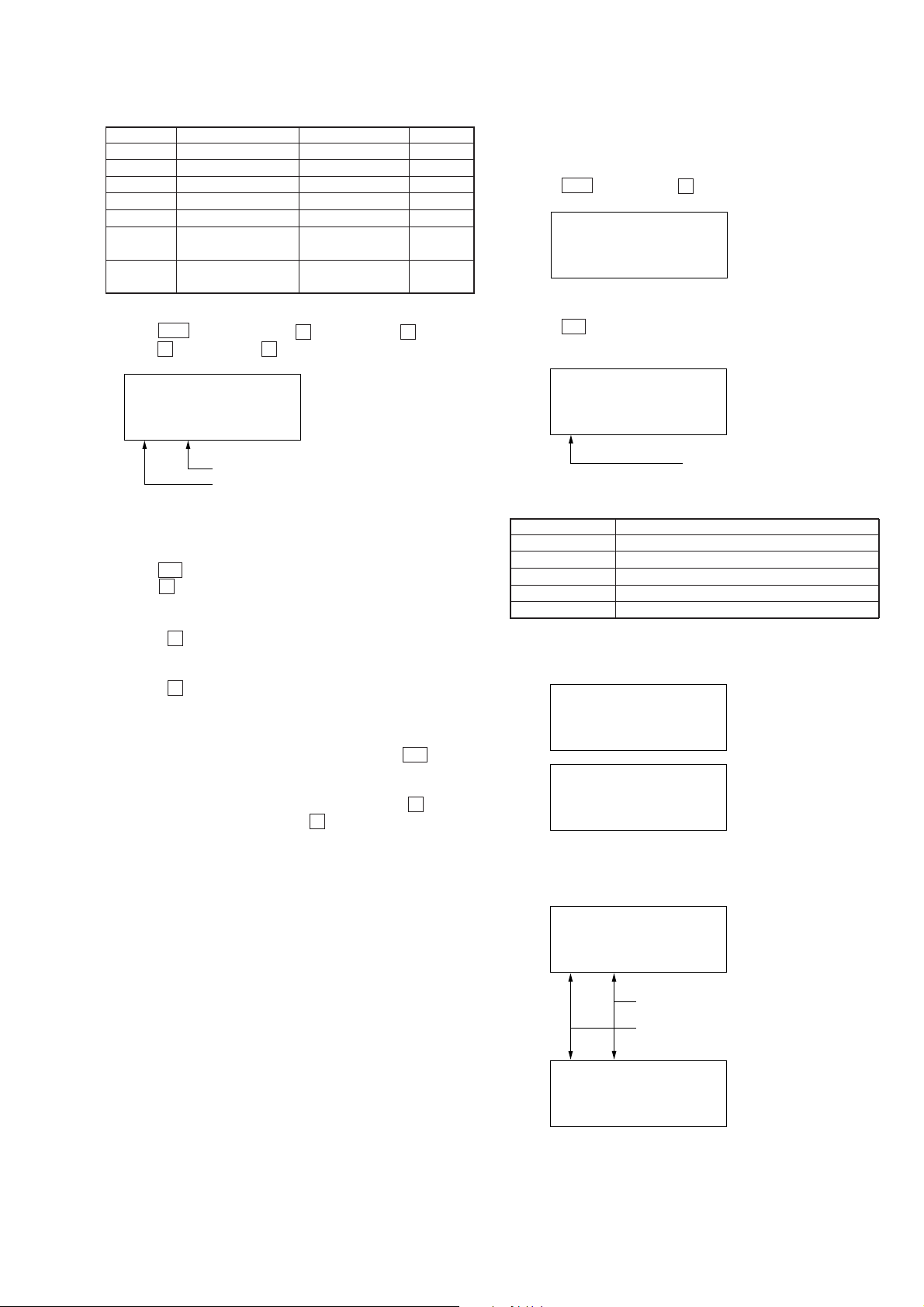

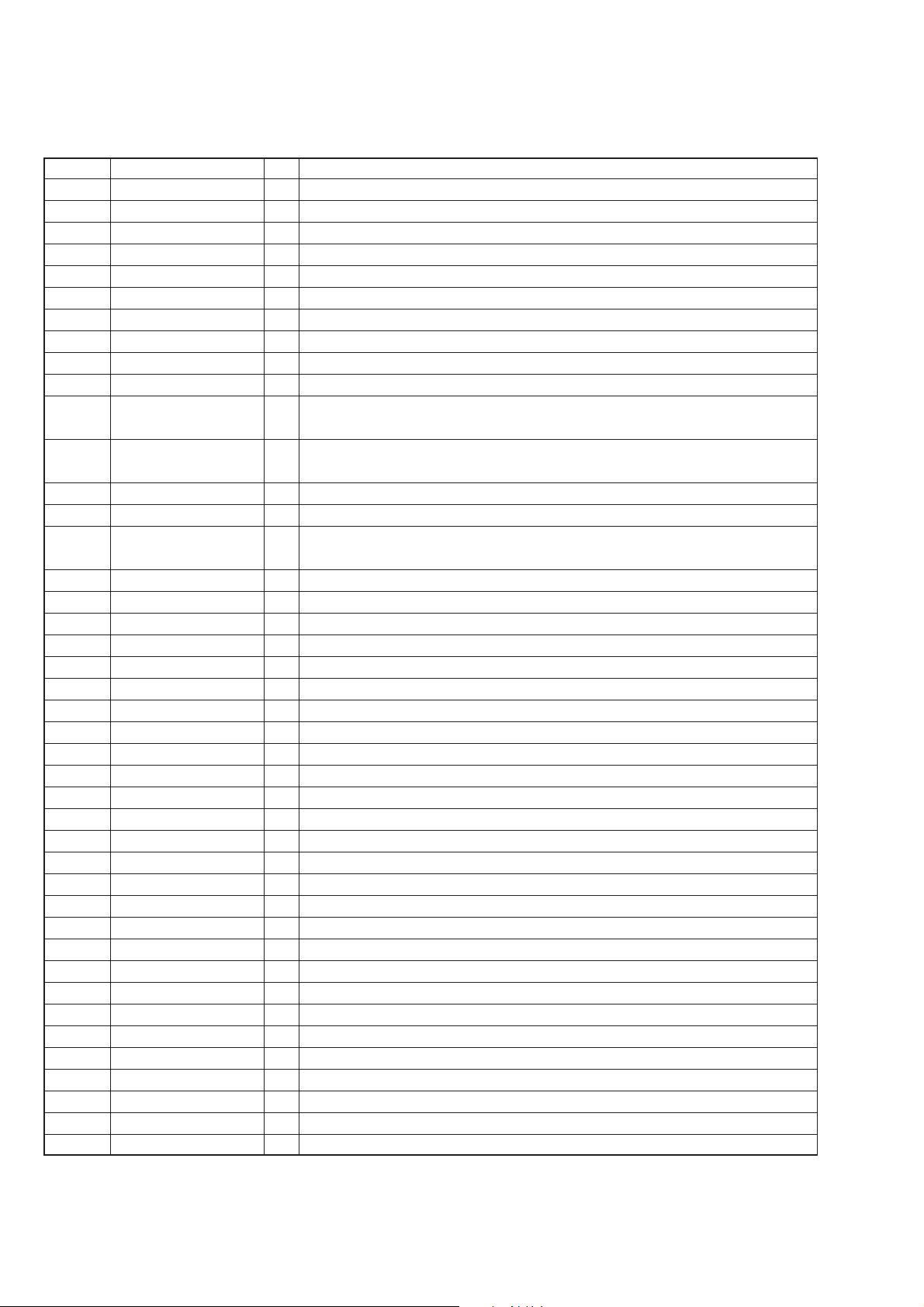

SERVICING NOTE

1) When repairing this device with the power on, if you remove

the main board or open the upper panel assy, this device stops

working.

In this case, you can work without the device stopping by

fastening the hook of the OPEN1 switch (S801) with tape.

tape

S801

panel assy, uppe

MAIN board

2) This set is designed to perform automatic adjustment for each

adjustment and write its value to EEPROM. Therefore, when

EEPROM (IC803) has been replaced in service, be sure to perform automatic adjustment and write resultant values to the new

EEPROM.

Refer to page 12 for details.

– 3 –

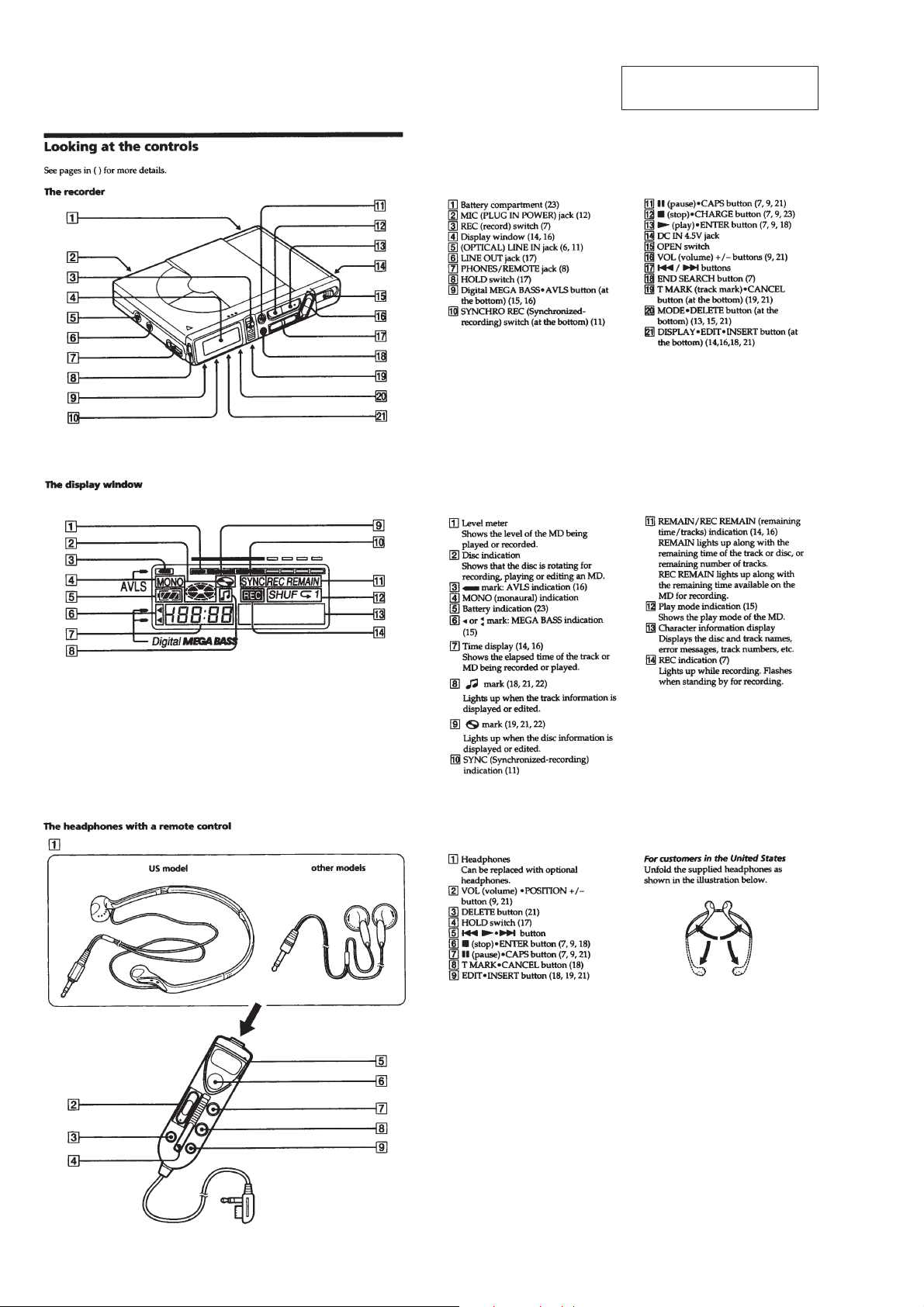

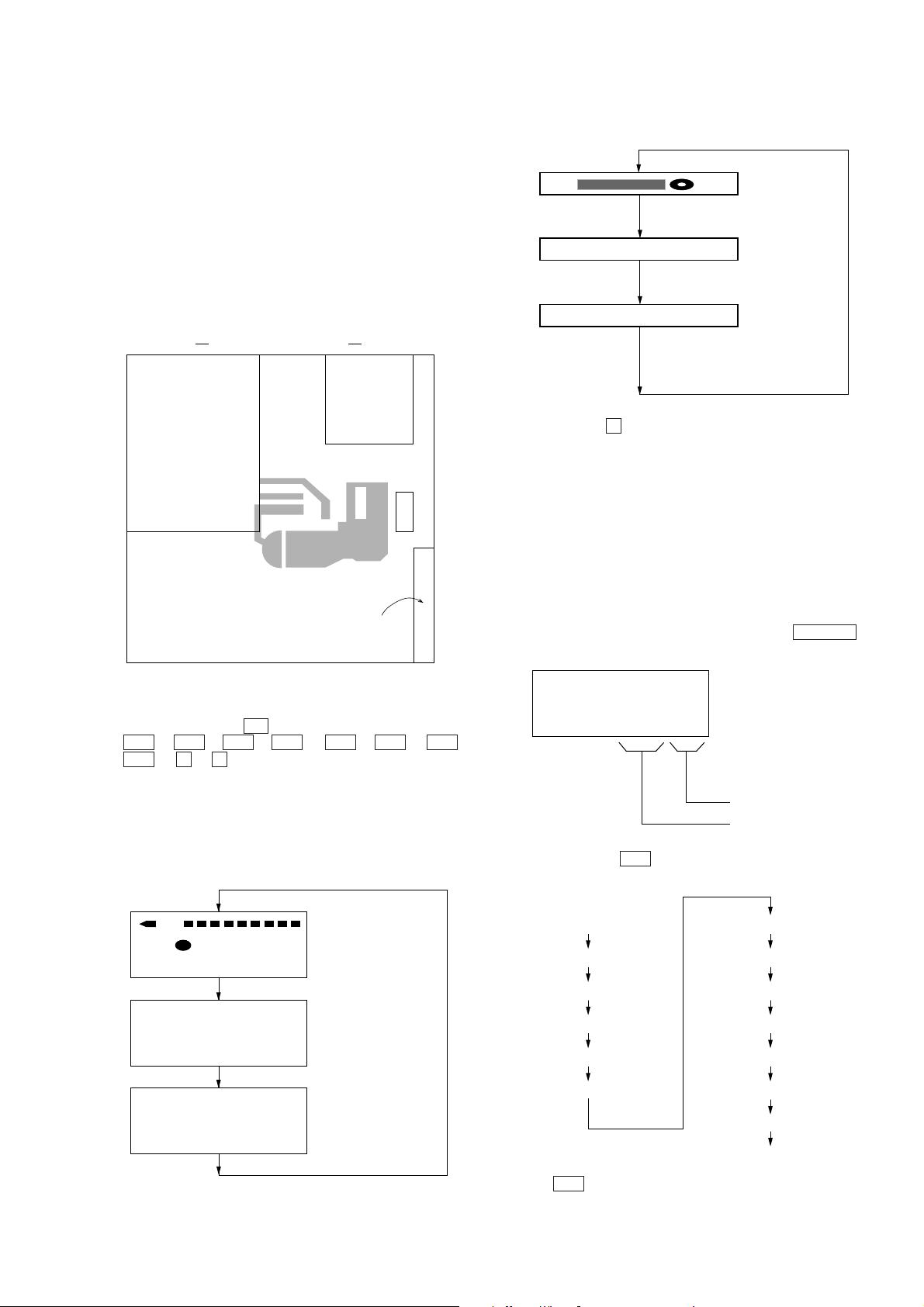

Page 4

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 4 –

Page 5

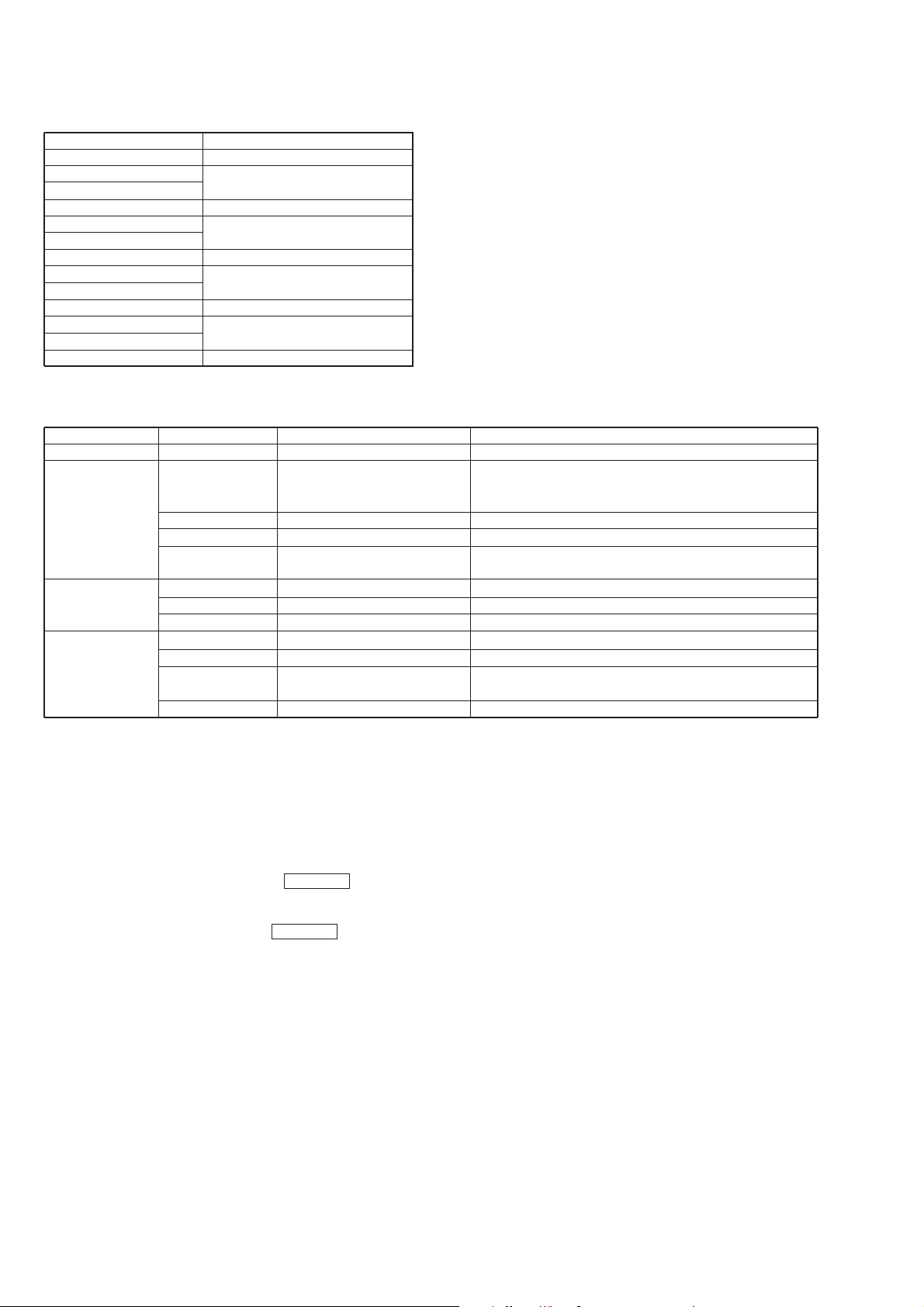

SECTION 2

888

ı

Vr. 1.‚‚

All ON

All OFF

Microprocessor

version

display

Error indication code

History code

1st0 00

SELF-DIAGNOSTIC

2-1. GENERAL

This set uses the self-diagnostic system in which if an error occurs

in playback/recording mode, the error is detected by the model

control and power control blocks of the microprocessor and information on the cause is stored as history in EEPROM.

By viewing this history in test mode, it helps you to analyze a fault

and determine its location.

2-2. TEST MODE SETTING

There are two different methods to set the test mode:

1 Short BP801 (TEST) on the main board with a solder bridge

(connect pin @§ of IC801 to the ground). Then, turn on the

power.

MAIN BOARD (SIDE B)

X801

IC801

25

26

BP801

(TEST)

C401

IC301

2) Remote controller LCD

• Holding down P allows the current display to be maintained

while it being depressed.

2-4. RELEASING THE TEST MODE

For test mode set with the method 1:

Turn off the power and open the solder bridge on BP801 on the

main board.

For test mode set with the method 2:

Turn off the power.

2-5. SELF-DIAGNOSTIC MODE

1. Go into the test mode.

2. With the unit LCD indicators all flashing, press DISPLAY key

to go into the self-diagnostic mode.

2 In the normal mode, use the keys on the unit to perform the

following operations:

Press and hold down ( and press the keys below in this turn:

+ n + n =n = n + n = n + n

= n P n P

2-3. OPERATION IN TEST MODE SETTING

When the test mode is set, the LCD shows repeated cycles of the

following display:

1) Unit LCD

ı

188:88 pppppp

Vr. 1.00

All ON

All OFF

Microprocessor

version

display

3. Then, eac h time ) ke y is pressed, the reference information

display changes as given below.

1st ‚ XX

1st 1 ‚‚

1st 2 ‚‚

N ‚ XX

N 1 ‚‚

N 2 ‚‚

N-1 ‚ XX

N-1 1 ‚‚

N-1 2 ‚‚

N-2 ‚ XX

N-2 1 ‚‚

N-2 2 ‚‚

R XXXX

1st ‚ XX

• Press = key to go back to the previous display.

(return)

– 5 –

Page 6

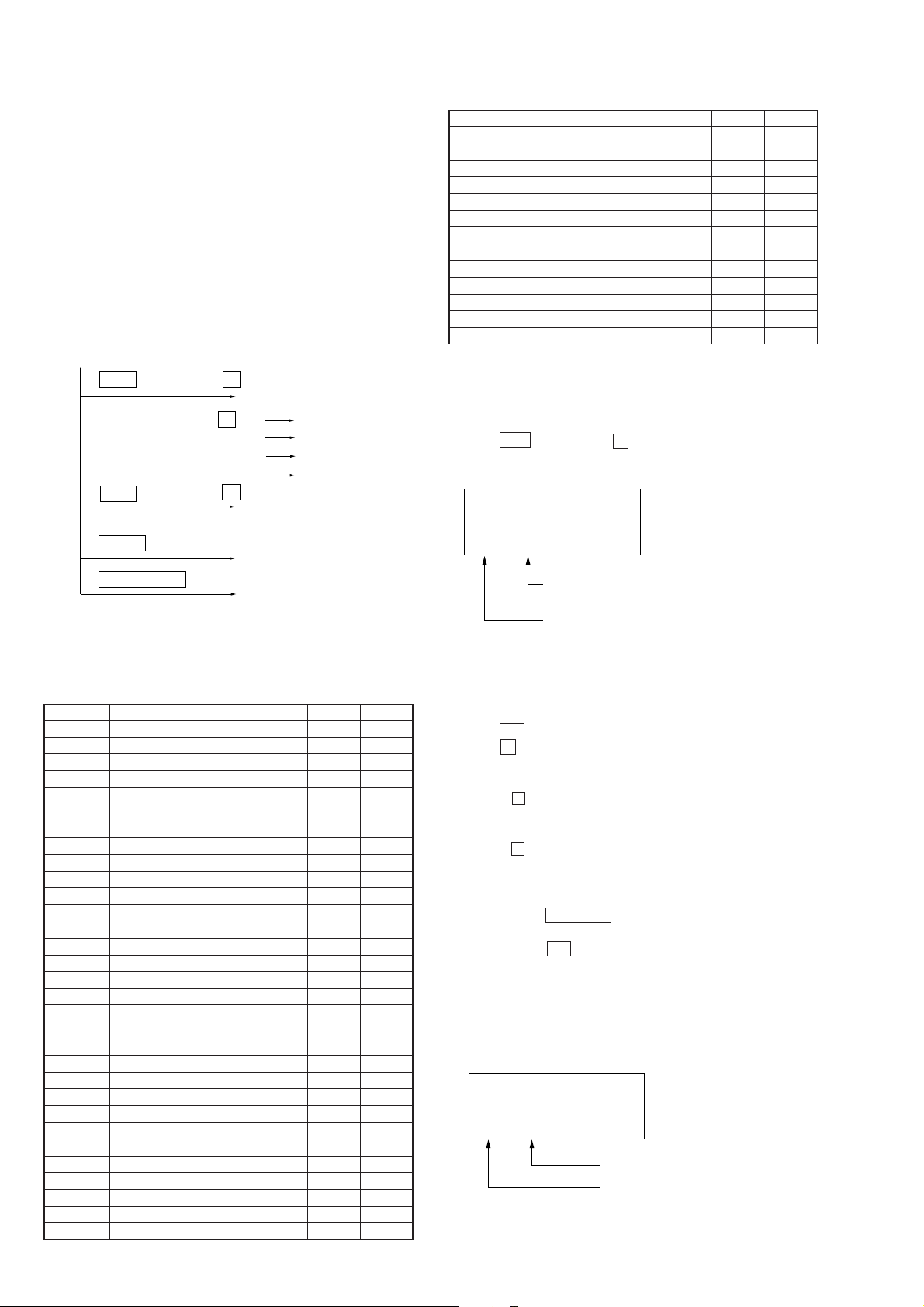

• Description of History Codes

History code number Description

1st 0 The first error

1st 1

1st 2

N 0 The last error

N1

N2

N-1 0 One error before the last.

N-1 1

N-1 2

N-2 0 Two errors before the last.

N-2 1

N-2 2

R Total recording time *1)

• Description of Error Indication Codes

Problem Indication code Meaning of code Description

No error 00

Abnormal stop

during recording

Abnormal stop

during playback

Abnormal stop of

recording/playback

caused by power

system

00 indicated

00 indicated

00 indicated

00 indicated

01 Servo error Focus out of alignment.

02 ADIP read error Unable to read the ADIP address.

03 Shock detected during write Jumped by 1.5 tracks or more due to shock during write.

04

11 No focus applied Focus could not be applied.

12 CRC error Unable to read the address.

15 FG error Abnormal rotation of disc.

21 Lower voltage due to overload Power voltage reduced due to overload.

22 Momentary interruption Momentary interruption detected.

23

24 Low power voltage in DSP

Shock detected during

laser down

Lower power voltage in motor Power voltage for motor continuously reduced to less than

system 1V.

*1) Total recording time

Total recording time is recorded in minutes as an index for load to

the OP. It is recorded in hexadecimal format and up to 65,535 min.

(about 886 discs of 74-minute disc) can be counted. It returns to

“0000h” when recorder goes beyond this limit.

Example :REC 000A n Approx. 10 min.

REC 00A0 n Approx. 160 min.

REC 0A00 n Approx. 2,560 min.

Abnormal disc RPM.

Attempt to access an abnormal address.

Shock detected when laser was moving down.

2-6. CLEARING THE ERROR INDICATION CODE

AND TO TAL RECORDING TIME

After repair, reset the error indication code.

Reset the total recording time when you have replaced the OP.

1. Go into the self-diagnostic mode. (See page 5.)

2. To reset the error indication code, slide REC c key when

the code is displayed.

(All data including 1st, N , N-1 and N-2 are reset.)

3. T o reset the total recording time, slide REC c key when the

time is displayed.

– 6 –

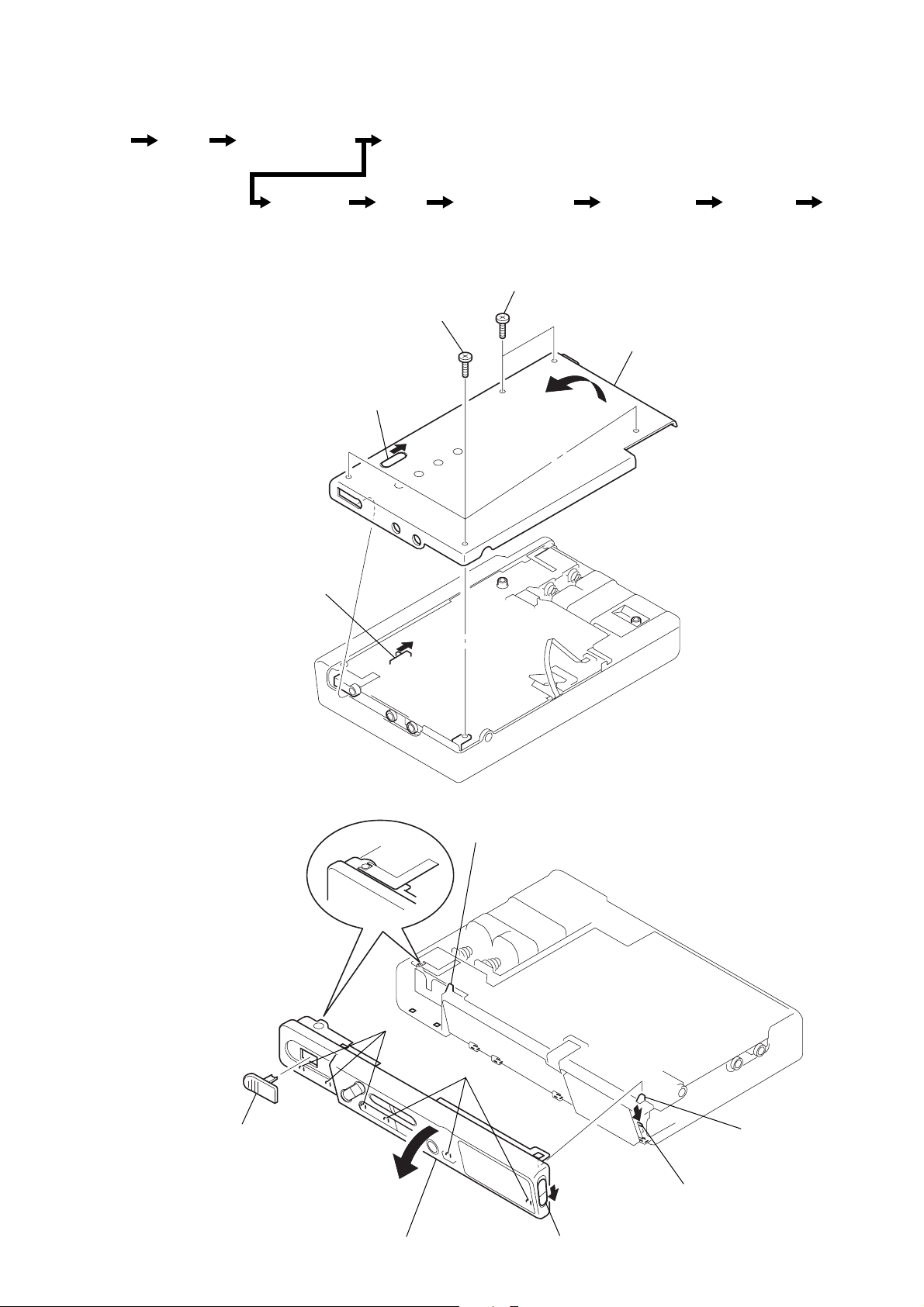

Page 7

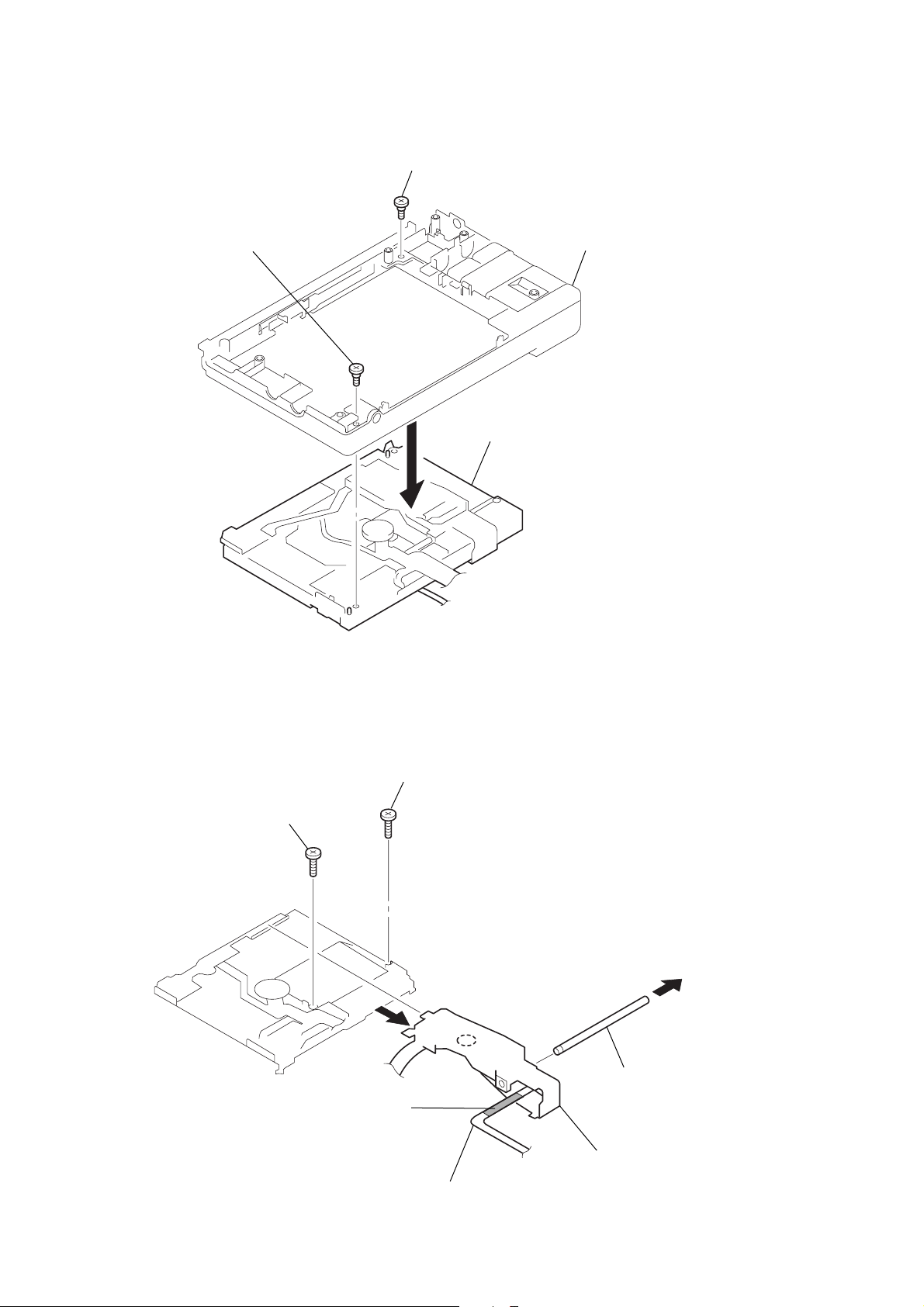

SECTION 3

y

y

y

1

1.7x4.5, tapping

2

1.7x4.5, tapping

3

panel, bottom

knob

switch

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

Set Panel,

Bottom

Panel (SV) Assy,

Front

LCD Module

Connector Main

Board

Panel (SV) Assy,

Upper

Note : Follow the disassembly procedure in the n umerical order given.

3-1. PANEL, BOTTOM

Cabinet (SV)

Ass

OP Block

Ass

Holder

Ass

3-2. PANEL (SV) ASSY, FRONT

1

knob (OPEN)

claws

4

2

claw

claws

5

panel (SV) assy, front

knob

switch

3

claw

– 7 –

Page 8

3-3. LCD MODULE

2

3

3-4. CONNECTOR

4

5

LCD module

1

CN601

1

2

CN702

CN801

– 8 –

3

CN701

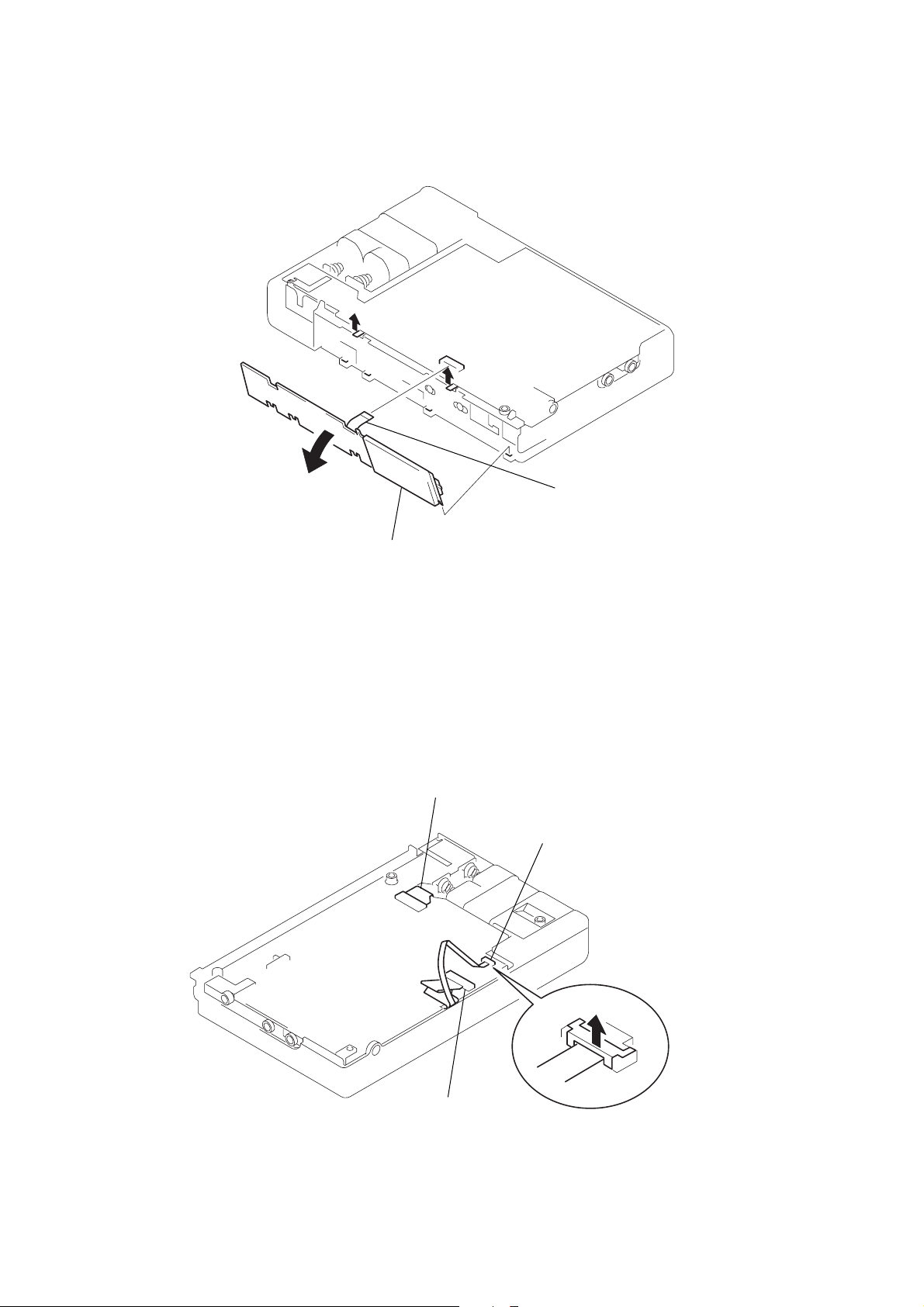

Page 9

3-5. MAIN BOARD

)

2

1.7x4.5, tapping

1

1.7x4.5, tapping

4

MAIN board

3

claws

3-6. PANEL (SV) ASSY, UPPER

1

M1.4, precision

4

claw

8

panel (SV) assy, upper

7

3

bearing (stopper

6

boss

2

– 9 –

5

claw

Page 10

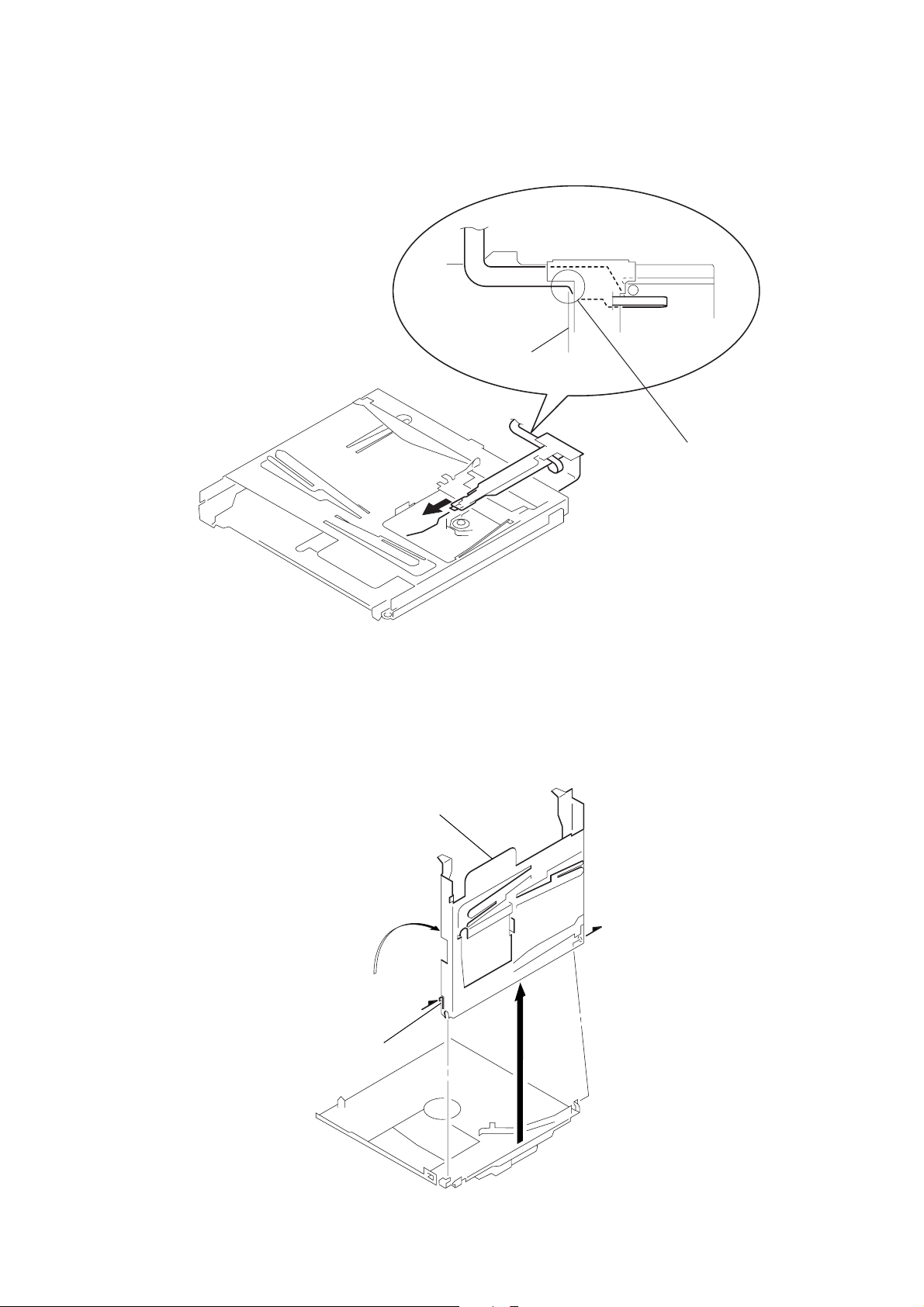

3-7. CABINET (SV) ASSY

y

n

2

MD, step

1

MD, step

4

3

mechanism block assy

cabinet (SV) ass

3-8. OP BLOCK ASSY

2

M1.4x3.0

adhesive sheet

1

M1.4x3.0 locking

4

flexible board

3

shaft, mai

OP block assy

– 10 –

Page 11

• Notes for Installation of the OP Block Assy

• Be careful to avoid contact

of the lens with the chassis

when installing the OP block

assy.

• Location of the Flexible Board

marked line

Align this portion of the

flexible board with the

marked line on the holder.

3-9. HOLDER ASSY

1

claw

2

4

holder assy

3

– 11 –

Page 12

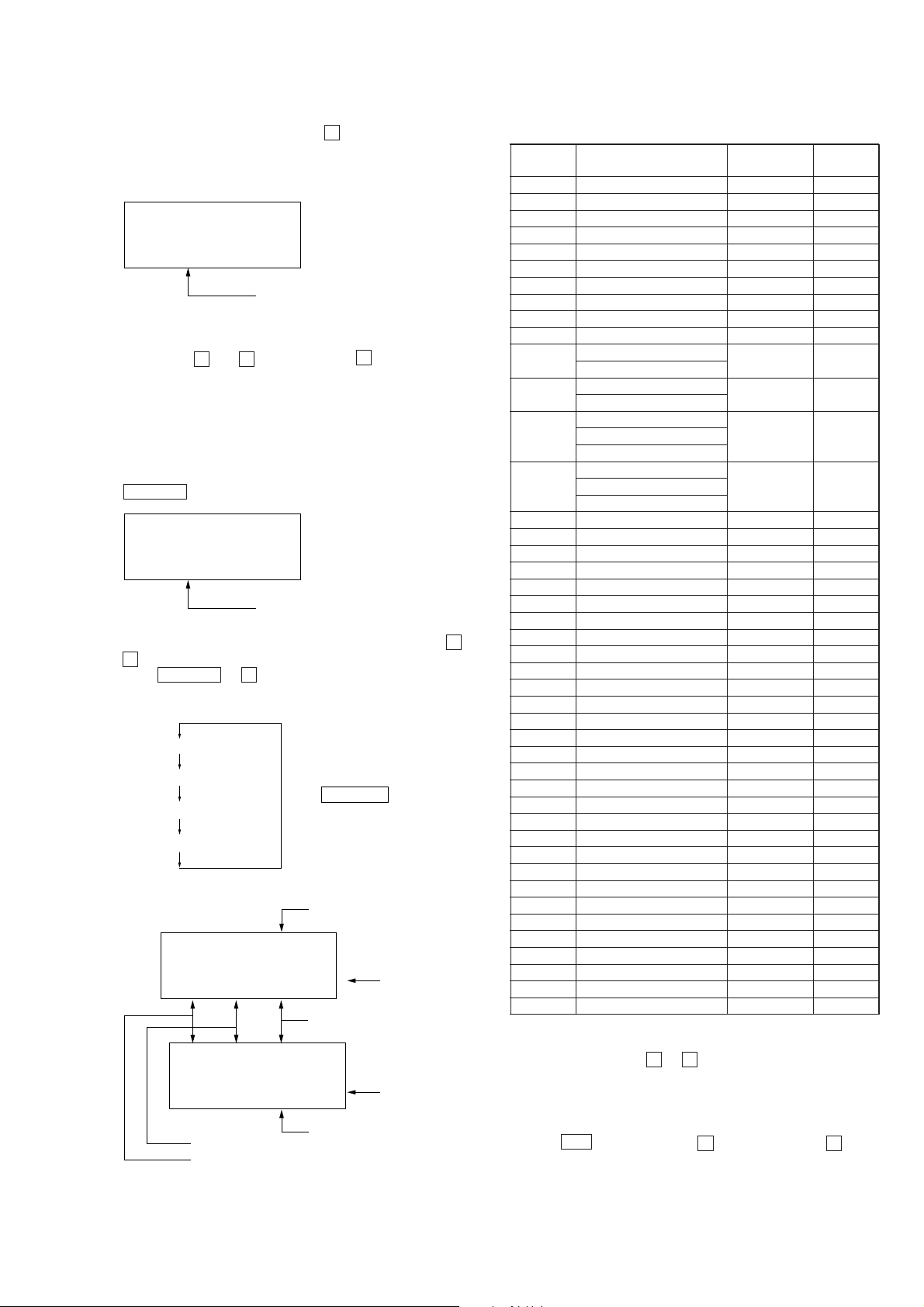

SECTION 4

)

)

)

TEST MODE

4-1. GENERAL

This set provides the Overall adjustment mode (Assy mode) that

allows CD and MO disk to be automatically adjusted when in the

test mode. In this Assy mode, the system discriminates between

CD and MO disk and then automatically perform adjustments for

them in sequence. If a fault is found, the system displays its location. Also, the Serv o mode allows each indi vidual adjustment to be

automatically adjusted.

4-2. TEST MODE SETTING

See page 5.

4-3. TEST MODE STRUCTURE

Test mode

or VOLUME key

+

+

Manual Mode

VOLUME key

+

Servo Mode

Audio Mode

Mechanism Mode

Power Mode

or VOLUME key

=

–

Overall Adjustment Mode

(Assy Mode)

MODE key

Hybrid Mode (ALL Mode)

EDIT/ENTER key

Key Check Mode

4-4. MANUAL MODE

(1) Servo Mode

• How to Transfer in the Servo Mode:

Mode No. Test Description Check Write

000 Servo mode

010 Offset correction value indication

011 VC offset correction

012 Focus bias correction

013 FE offset correction

014 ABCD offset correction

015 All servo ON

016 Temperature indication

020 Laser power adjustment

021 Laser CD/MO read adjustment ® (08)

022 Laser MO write adjustment ® (4C)

023 Sled normal ® (45)

024 Sled intermittent ® (65)

025 Sled access ® (30)

030 MO test adjustment

031 MO focus search adjustment

032 MO read EF balance adjustment ® (0F)

033 MO read ABCD level ® (07)

034 MO write EF balance adjustment ® (10)

035 MO write ABCD level ® (18)

036 Laser MO read adjustment ® (08)

037 MO focus gain ® (30)

038 MO tracking gain ® (30)

039 MO focus bias ®® (0B)

040 Low reflection CD test adjustment

041

Low reflection CD focus search adjustment

042

Low reflection CD EF balance adjustment

043 Low reflection CD ABCD level ® (06)

044 Laser low reflection CD read ® (08)

045 Low reflection CD focus gain ® (30)

046 Low reflection CD tracking gain ® (30)

® (10)

Mode No. Test Description Check Write

047 Low reflection CD focus bias ®® (00)

050 CD test adjustment

051 CD focus search adjustment

052 CD EF balance adjustment ® (10)

053 CD ABCD level adjustment ® (15)

054 Laser CD read ® (08)

055 CD focus gain ® (30)

056 CD tracking gain ® (30)

057 CD focus bias ®® (00)

060 Recording test

061 32 cluster full recording

062 Recording shock

063 32 cluster full playback

Check : Mode to display error rate and cluster.

Write : Mode to permit adjustment (Default value given in paren

theses).

1. Go into the test mode.

2. Press + or VOLUME + key to set the servo mode.

Unit LCD display

XX XX SERVO

Adjustment value

(The data can be changed/written when flashing.

Mode No.

(The lower two digits are indicated.

Three digits are indicated on the

remote controller LCD.)

3. Press the keys below to change the mode No.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + :Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

Note) Press the REC c key is the mode “33” to shift to the

mode “34”.

Press the ( key is the mode “34” to shift to the mode

“35”.

• How to Adjust in Servo Mode:

1. When the servo mode is set to the appropriate mode for each

adjustment, the lower two digits of the mode No. and the value

stored in EEPROM are displayed and flashing.

XX XX SERVO

Adjustment value (flashing

Mode No. (lower two digits

– 12 –

Page 13

2. To perform automatic adjustment for an adjustment item with

)

)

the mode number 030 to 047, press P key.

If the result of adjustment is OK, the adjustment value changes

from flashing to steady on and it is automatically written to

EEPROM.

32 OF SERVO

Adjustment value

(flashing to steady on

3. To perform manual adjustment, change the adjustment v alue with

VOLUME + or – key, and press P key to write it to

EEPROM.

Note) Normally, automatic adjustment should be performed. Do

not execute manual adjustment.

• System Gain Mode

1. This mode allows the system gain to be freely adjusted. Press

DISPLAY key to enter this mode.

32 OF S-GAIN

Adjustment value (flashing

2. Increase or decrease the adjustment value with V OLUME + or

– key.

3. Press DISPLAY or p key to return to the normal mode.

4. For the error rate display enabled:

Normal Mode

AT error rate

Press DISPLAY key

Block error rate

System gain Mode

Indicate of AT error rate

39 OA 000a4F

Cluster value

39 OA 000b4F

ATT error value

Block error value

(2) Audio Mode

• How to Transfer in the Audio Mode

Mode No. Test Description Write

100 Audio mode

110 Audio playback

111 L/R=1 kHz 0 dB Playback VOL HP output

112 L=1 kHz 0 dB Playback VOL HP output

113 R=1 kHz 0 dB Playback VOL HP output

114 L/R – ∞ dB Playback VOL HP output

115

116

117 INFI ZERO & BEEP Playback VOL HP output

120 Audio recording test

121 LINE manual recording

122

123 LINE automatic recording

124

130 DIGITAL A GC ADJ1

131 MIC UP SR ® (30)

132 MIC DOWN SR ® (FA)

133 MIC THD0 ® (D0)

134 MIC GAIN ® (00)

135 MIC A TT A CK ® (A0)

136 MIC RECOVER ® (F8)

137 MIC THD2 ® (F0)

138 MIC GAIN2 ® (D0)

139 MIC RTIME ® (01)

140 DIGITAL A GC ADJ2

141 LINE UP SR ® (17)

142 LINE DOWN SR ® (FF)

143 LINE THD0 ® (D0)

144 LINE GAIN ® (0C)

145 LINE A TTACK ® (33)

146 LINE RECOVER ® (FB)

147 LINE THD2 ® (E4)

148 LINE GAIN2 ® (5F)

149 LINE RTIME ® (04)

150 DIGITAL A GC ADJ3

151 MAN UP SR ® (C0)

152 MAN DOWN SR ® (40)

153 AUTO THD3 ® (51)

154 AUTO LMT UP SR ® (FF)

155 AUTO LMT DOWN SR ® (E0)

156 MAN THD3 ® (51)

157 MANU LMT UP SR ® (FF)

158 MANU LMT DOWN SR ® (A0)

159 THD1 ® (1A)

L/R=1 kHz 0 dB & EVR max

L/R=1 kHz 0 dB & AVLS on

*1) MIC manual recording

DEMP LINE manual recording

*1) DEMP MIC manual recording

*1) OPT automatic recording HP VOL HP output

MIC automatic recording

DEMP LINE automatic recording

*1)

DEMP OPT automatic recording

DEMP MIC automatic recording

Playback VOL HP output

Playback VOL HP output

Recording VOL HP output

Recording VOL HP output

HP VOL HP output

Change

Description

*1) The port is detected and the input is automatically selected.

Contents changed : Contents to be changed when VOLUME

+ or – key is pressed.

Write : Mode to permit adjustment

(Default value given in parentheses)

Adjustment value (flashing)

Mode No. (lower two digits)

Indicate of block error rate

Note) In normal service, do not adjust the system gain mode.

1. Go into the test mode.

2. Press + key or VOLUME + key and VOLUME + key in

this turn to set the audio mode.

– 13 –

Page 14

Unit LCD display (3) Mechanism Mode

)

)

• How to Transfer the Mode in the Mechanism Mode:

Mode No. Test Description Operation

200 FUNCTION Stepper control

XX XX AUDIO

Adjustment value

(The data can be changed/written when flashing.

Mode No.

(Lower two digits are displayed.)

3. Press the keys below to change the mode number.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place

is 0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place is

non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

• How to Adjust in the Audio Mode

1. When the audio mode is set to the appropriate mode for each

adjustment, the lower tow digits of the mode No. and the value

stored in EEPROM are displayed and flashing.

2. Change the adjustment value with VOLUME + or – key and

press P key to write the new value to EEPROM.

• How to Check in the Audio Mode

The audio mode allows the checks below to be performed:

1. For the mode numbers of 111 to 113, 115 and 116, pressing P

key will activ ate a beep. But for the mode number of 117, pressing P key will not activate a beep. (No beep sounds when

c HOLD switch is put on.)

2. For the mode numbers of 121 to 124, pressing Digital MEGA

BASS key will display the DBB mode for the adjustment v alue.

1 : Mode 1

2 : Mode 2

13 : OFF

(This will not be accepted when the LINE OUT jack is plugged.

The display will be 13 : OFF when LINE OUT jack is plugged

in Modes 1 and 2.)

210 MECHA test Initial position return

211 HEAD adjustment Operation variation changing (19)

212 REC position Recording head descent

220 RESUME Resume

221 RESUME CLEAR Resume clear/initialization

1. Go into the test mode.

2. Press + or V OLUME + and V OLUME + and V OLUME

+ in this turn to set the mechanism mode.

Unit LCD display

XX XX MECHA

3. Press the keys below to change the mode No.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

• How to Check in the Mechanism Mode

The mechanism mode allows the checks below to be performed:

1. For the mode numbers of 200, 210 to 212, 220 and 221, pressing

= key will move the optical pickup to the inner radius.

Pressing + key will move the pickup to the outer radius.

2. For the mode numbers of 211 and 212, pressing P key will

start aging. Pressing p key will stop aging.

• Mode No. 211 ... Sled aging with stepper at playback position.

• Mode No. 212 ... Sled aging with stepper at recording position.

3. With the mode number 210 selected, pr essing P k ey will start

aging with steeper at between home and recording positions.

p key will stop aging.

( ) : Default value

Adjustment value

Mode No.

(Lower two digits are displayed.

– 14 –

Page 15

)

)

(4) Power Mode

Mode No. Test Description Indication value Remark

300 POWER test

310 POWER SUPPLY

311 DC IN +B voltage value

320 CHG TEST

321 Charging start

322 BA TT under CHGMNT

voltage value

323 BATT under +B CHGMNT

voltage value

4-5. O VERALL ADJUSTMENT MODE (ASSY MODE)

• How to Adjust in Assy Mode

1. Go into the test mode.

2. Press = or VOLUME – key.

XX ASSY-M

1. Go into the test mode.

2. Press + key or VOLUME + and VOLUME + and VOLUME + and VOLUME + in this turn to set the power mode.

XX XX POWER

Adjustment value

Mode No.

(Lower two digits are displayed.

3. Press the keys below to change the mode No.

( :Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

Note) With the mode number 310 selected, pressing ( key will

transfer to the mode number (311) for the currently operating power.

With the mode number 300 selected, pressing P key will

set the sleep mode. Pressing p key will release it.

3. Insert the test CD (TDYS-1) or an available SONY CD.

4. Press ( key . The system discr iminates between CD and MO

and performs automatic adjustment for CD.

51 CD-RUN

Mode No. under adjustment.

• CD Automatic Adjustment

Mode No. Adjustment Description

052 CD EF balance adjustment

053 CD ABCD level adjustment

055 CD focus gain

056 CD tracking gain

057 CD focus bias

5. If the result of automatic adjustment is OK, the following display appears:

CD-OK

MD-OK

(CD)

(MD)

• How to Check in the Power Mode

1. For the mode numbers of 311, the voltage of the currently

operating power is displayed.

6. If the result of automatic adjustment is NG, the following display appears:

XX XX CD-NG

Result of adjustment

NG mode No. (lower two digits

XX XX MD-OK

– 15 –

Page 16

* For the mode numbers of 039 and 057, if the focus bias value is

)

00

)

NG, the following display is repeated:

55 30

Focus bias value

Mode No.

While P key is being depressed

10. If the result of automatic adjustment is OK, the following display appears:

11. If the result of automatic adjustment is NG, the following display appears:

82 00

77 01

Error code (01 to 04)

Meaning of focus bias

* For the mode numbers of 039 and 061, if the At error rate is NG,

the following display is repeated:

39 03

At error value

Mode No. (lower two digits

7. If NG, set the servo mode. Perform automatic adjustment for

the items not accepted (see the servo mode).

8. Insert a MO disk.

9. Press ( key . The system discr iminates between CD and MO

and performs automatic adjustment for the MO disk.

Result of adjustment

NG Mode No. (lower two digits

12. If NG, set the servo mode. Perform automatic adjustment for

the items not accepted (see the servo mode).

4-6. HYBRID MODE, KEY CHECK MODE

These modes are not used in normal service.

61

• MO Automatic Adjustment

Mode No. Adjustment Description

032 MO read EF balance adjustment

033 MO read ABCD level

034 MO write EF balance adjustment

035 MO write ABCD level

037 MO focus gain

038 MO tracking gain

061 32 cluster full recording

062 Recording shock

063 32 cluster full playback

039 MO focus bias

042 Low refrection CD EF balance adjustment

043 Low refrection CD ABCD level

044 Laser low reflection CD read

046 Low refrection CD tracking gain

Mode No. (lower two digits)

– 16 –

Page 17

SECTION 5

r

e

ELECTRICAL ADJUSTMENTS

PRECAUTIONS FOR ADJUSTMENT

1) Perform all adjustments in the order given in the test mode.

After adjusting, exit the test mode.

2) Use the following tools and measuring instruments.

• Test CD TDYS-1

(Part No. : 4-963-646-01)

• Recorded MO disk PTDM-1

(Part No. : J-2501-054-A)

• Laser power meter LPM-8001

(Part No. : J-2501-046-A)

• Oscilloscope (Frequency band above 40 MHz. Perform the

calibration of probe first before measuring.)

• Digital voltmeter

3) Unless specified othewise, supply DC 4.5V from the DC IN 4.5V

jack.

4) Swtich, knob positions

HOLD switch .............. OFF

AVLS switch ................ NORM

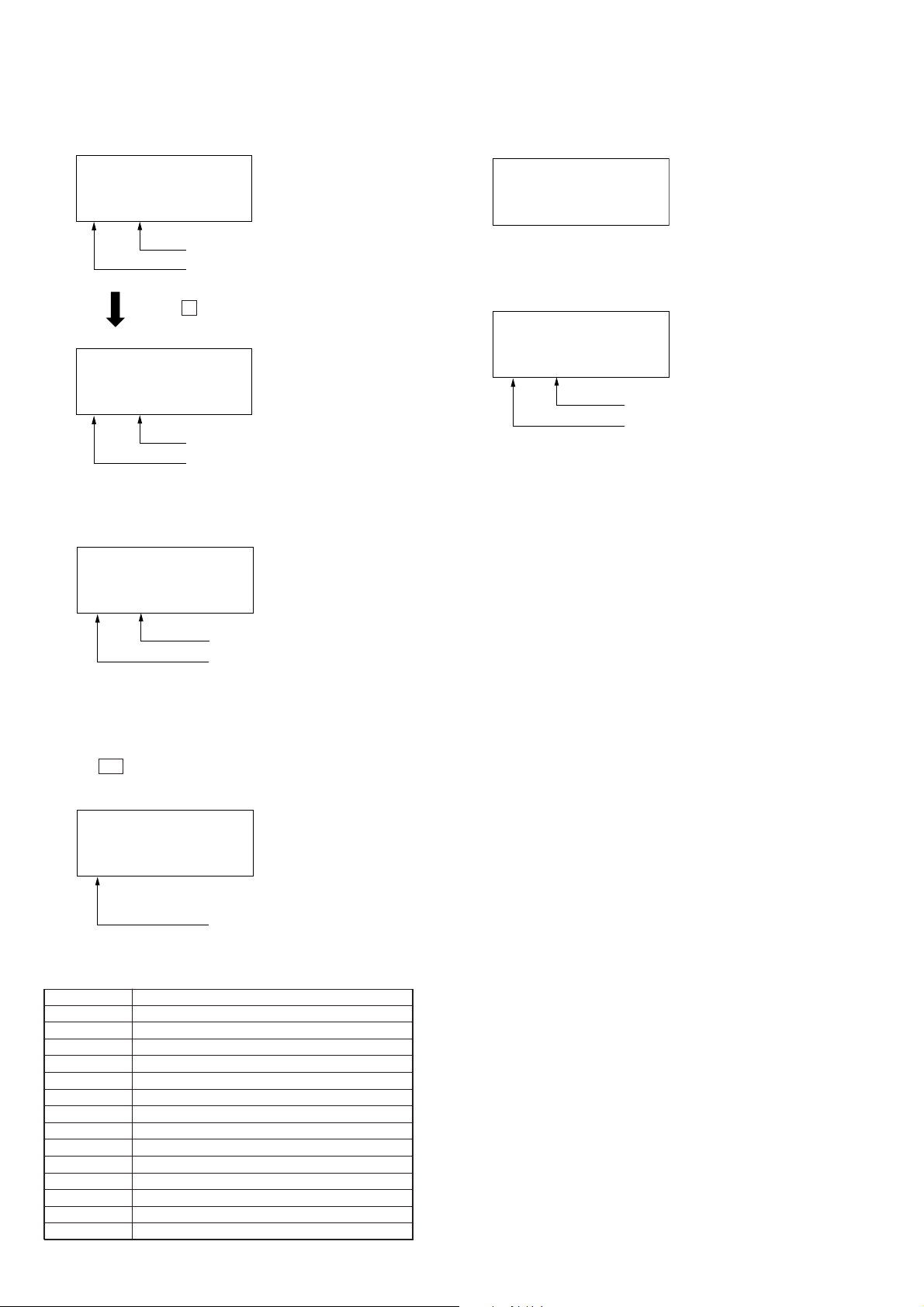

LASER POWER CHECK

Connection :

laser

power meter

Optical pick-up

objective lens

MO TRA VERSE ADJUSTMENT

Connection :

oscilloscop

MAIN board

SP526 (TE)

AP503 (VC)

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key , and set the MO test adjustment mode (Mode

: 030) using the VOLUME + or – key.

3. Press the = or + key and move the optical pick-up to

the center circumference.

4. Insert any MO disk available on the market.

5. When the ( key is pressed, the MO read EF balance adjustment mode (Mode : 032) will be set after MO focus search

adjustment mode (Mode : 031).

6. Press the P key to perform automatic adjustment, and check

that the traverse wav eform is symmetrical at the top and bottom.

7. Slide the REC key and set the MO write EF balance adjust

ment mode (Mode : 034).

8. Press the P key to perform automatic adjustment, and check

that the traverse wav eform is symmetrical at the top and bottom.

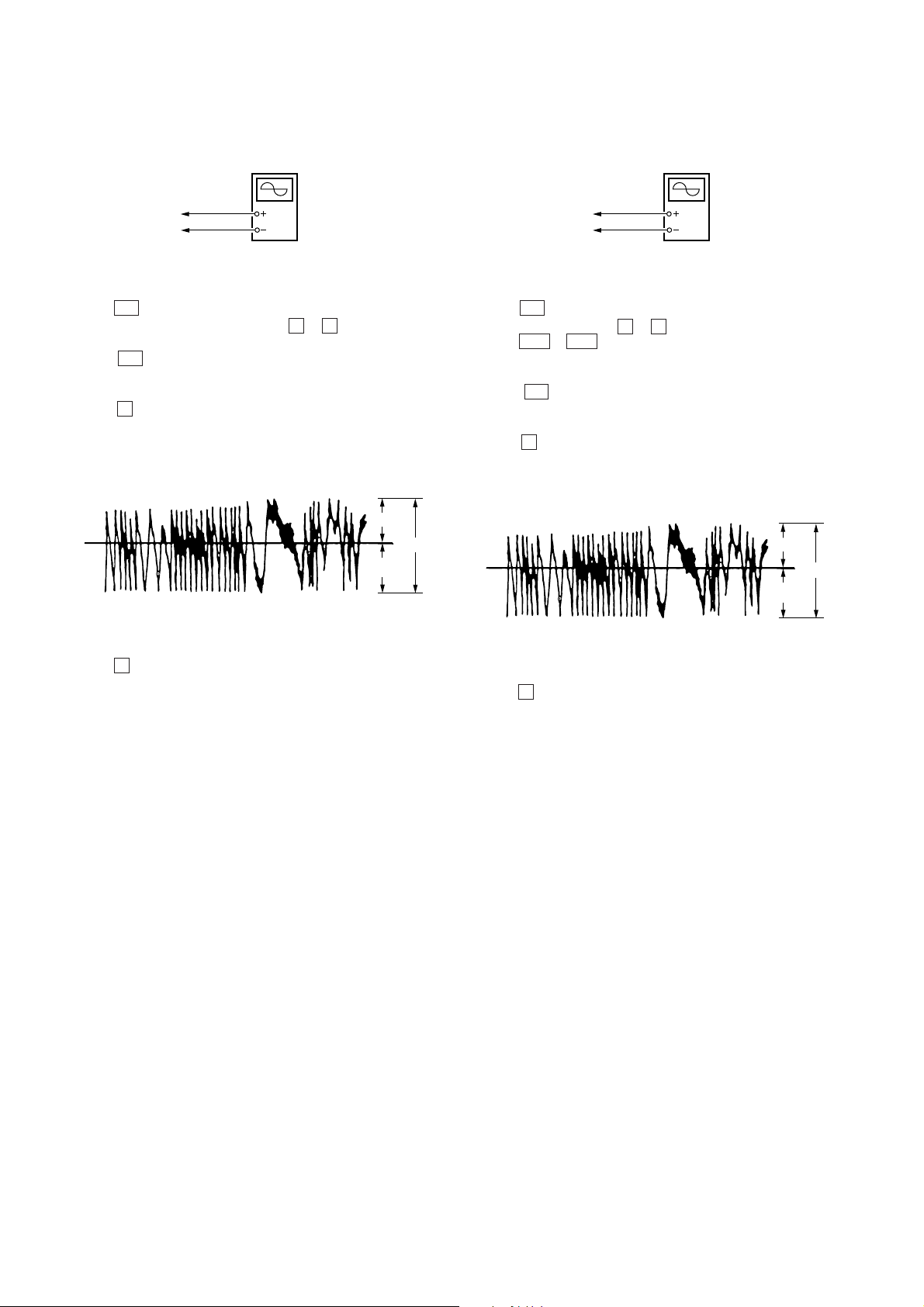

(Traverse waveform)

digital voltmete

MAIN board

AP5117 (VCC)

AP574 (LDI0)

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key, and set the laser power adjustment mode

(Mode : 020) using the VOLUME + or – key.

3. Press the = key and move the optical pick-up to the inner

most circumference.

4. Open the cover and set the laser power meter on the objective

lens of the optical pick-up.

5. Press the ( key, and set the laser CD/MO read adjustment

mode (Mode : 021).

6. Check that the laser power meter reading is 0.85 ± 0.085 mW.

7. Check that the voltage between AP5117 (VCC) and AP574

(LDI0) at this time is below 40 mV.

8. Press the ( key, and set the laser MO write adjustment

mode (Mode : 022).

9. Check that the laser power meter reading is 6.8 ± 0.68 mW.

10. Press the P key to finalize the adjustment data.

11. Check that the voltage between AP5117 (VCC) and AP574

(LDI0) at this time is below 80 mV.

12. Press the p key.

13. Exit the test mode.

A

0 V

B

Specification : A = B, C 1.0 Vp-p

>

=

9. Check that the traverse level at this time is above 1.0 Vp-p.

10. Press the p key.

11. Exit the test mode.

Note) Using a recorded disk in this adjustment will erase the data.

Adjustment Location : See page 19.

C

Adjustment Location : See page 19.

– 17 –

Page 18

LOW REFLECTION CD TRAVERSE ADJUSTMENT

e

e

Connection :

CD TRA VERSE ADJUSTMENT

Connection :

oscilloscop

MAIN board

SP526 (TE)

AP503 (VC)

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key , and set the low reflection CD test adjustment

mode (Mode : 040) using the VOLUME + or – key.

3. Insert any MO disk available on the market.

4. When the ( key is pressed, the low reflection CD EF balance

adjustment mode (Mode : 042) will be set after low reflection

CD focus search adjustment mode (Mode : 041).

5. Press the P key to perform automatic adjustment, and check

that the traverse wa veform is symmetrical at the top and bottom.

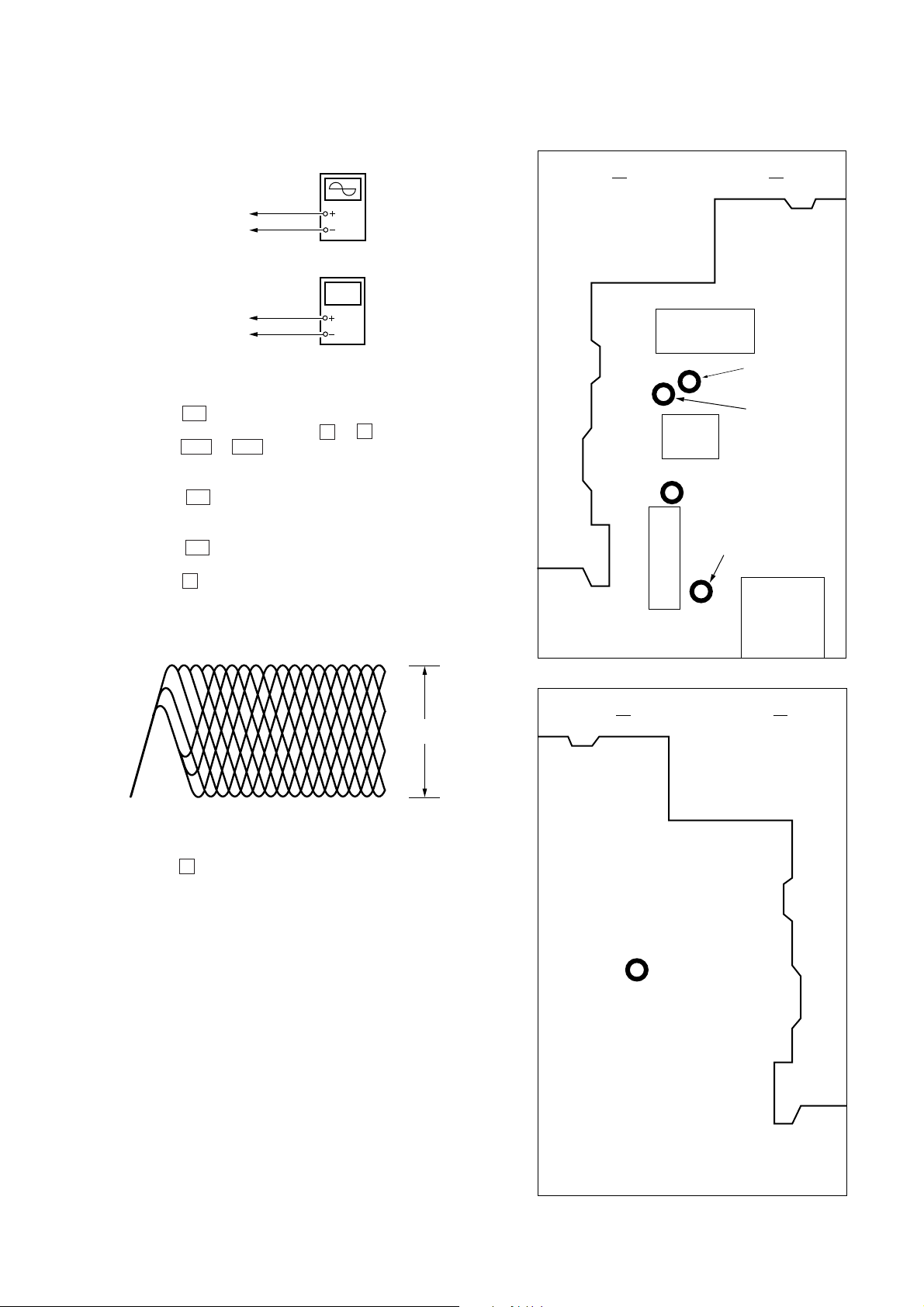

(Traverse waveform)

A

0 V

B

Specification : A = B, C 0.9 Vp-p

>

=

6. Check that the traverse level at this time is above 0.9 Vp-p.

7. Press the p key.

8. Exit the test mode.

Adjustment Location : See page 19.

oscilloscop

MAIN board

SP526 (TE)

AP503 (VC)

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key, and set the CD test adjustment mode (Mode

: 050) using the VOLUME + or – key.

3. Press the = or + key and move the optical pick-up to the

center circumference.

4. Insert a test CD (TDYS-1).

5. When the ( key is pressed, the CD EF balance adjustment

mode (Mode : 052) will be set after CD focus search adjustment

mode (Mode : 051).

6. Press the P key to perform automatic adjustment, and check

that the traverse wav eform is symmetrical at the top and bottom.

(Traverse waveform)

C

0 V

Specification : A = B, C 1.0 Vp-p

>

=

7. Check that the traverse level at this time is above 1.0 Vp-p.

8. Press the p key.

9. Exit the test mode.

A

C

B

Adjustment Location : See page 19.

– 18 –

Page 19

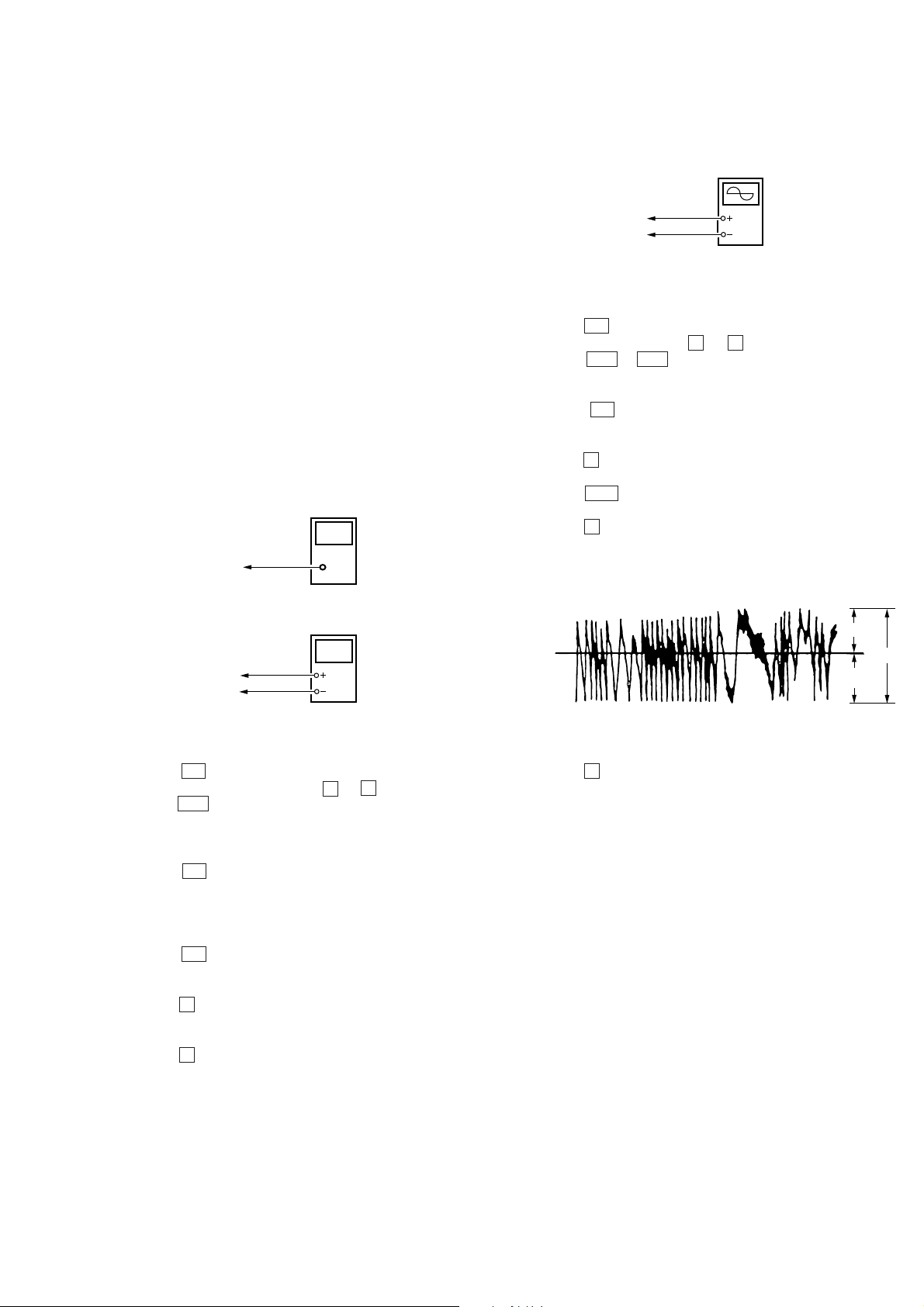

CD RF LEVEL CHECK

r

AP538 (RF)

IC701

CN501

IC501

IC901

AP574 (LDIO)

AP503 (VC)

AP5117 (VCC)

MAIN BOARD (SIDE B)

MAIN BOARD (SIDE A)

SP526 (TE)

Connection :

oscilloscope

MAIN board

AP538 (RF)

AP503 (VC)

digital voltmete

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key, and set the CD test adjustment mode

(Mode : 050) using the VOLUME + or – key.

3. Press the = or + key and move the optical pick-up to

the center circumference.

4. Insert a test CD (TDYS-1).

5. When the ( key is pressed, the CD EF balance adjustment

mode (Mode : 052) will be set after CD focus search adjustment mode (Mode : 051).

6. When the ( key is pressed, the CD ABCD level adjustment

mode (Mode : 053) is set.

7. Press the P key to perform automatic adjustment, and check

that the RF level is 1.1 ± 0.33 Vp-p.

MAIN board

AP5117 (VCC)

AP574 (LDIO)

Adjustment Location :

(RF waveform)

8. Check that the voltage between AP5117 (VCC) and AP574

(LDIO) and at this time is below 40 mV.

9. Press the p key.

10. Exit the test mode.

1.1 ± 0.33 Vp-p

– 19 –

Page 20

SECTION 6

DIAGRAMS

6-1. IC PIN DESCRIPTIONS

• IC601 CXD2652AR (DIGITAL SERVO, ENC/DEC & ATRAC MEMORY CONTROLLER)

Pin No. Pin name I/O Pin Description

1 MNT 0 O Traverse count signal output.

2 MNT 1 O Track jump detect output.

3 MNT 2 — Not used (Open).

4 MNT 3 O Focus OK signal output.

5 SWDT I Inputs write data signal from system control (IC801).

6 SCLK I Inputs serial clock signal from system control (IC801).

7 XLAT I Inputs serial latch signal from system control (IC801).

8 SRDT O Outputs write data signal to system control (IC801).

9 SENS O Outputs internal status (SENS) to system control (IC801).

10 XRST I Inputs reset signal from system control (IC801). L : Reset

11 SQSY O

12 DQSY O

13 WRPWR I Inputs laser power switching signal from system control (IC801).

14 NC — Not used (Open).

15 TX I

16 OSC1 O Clock output (22.5 MHz).

17 OSC0 I Clock input (22.5 MHz).

18 XTSL — Not used (Fixed at “L”)

19 NC — Not used (Connect to ground).

20 RVSS — Connect to ground.

21 DIN I Digital audio signal input pin (For optical input).

22 NC — Not used (Open).

23 ADDT I Audio data input from A/D converter (IC301).

24 DATA O Monitor/decode audio data output to A/D converter (IC301).

25 ALRCK O L/R clock output to D/A converter (IC301).

26 ABCK O Bit clock signal output to A/D, D/A converter (IC301).

27 FS256 O 11.2896 MHz clock output (MCLK).

28 DVDD — Power supply (+2.8 V) for digital.

29 – 39 A00 – A08, A10, A11 O Address signal output to DRAM (IC602).

40 DVSS — Ground terminal.

41 XOE O Output enable contol signal output to DRAM (IC602).

42 XCAS O Column address strobe singal output to DRAM (IC602).

43 A09 O Address signal output to DRAM (IC602).

44 XRAS O Row address strobe signal output to DRAM (IC602).

45 XWE O Read/write control signal output to DRAM (IC602).

46 – 49 D0 – D3 I Data signal input from DRAM (IC602).

50 MVCI — Not used (Connect to ground).

51 ASYO O Playback EFM full-swing output (L : VSS, H : VDD).

52 ASYI I Playback EFM asymmetry comparate voltage input.

53 AVDD — Power supply (+2.8 V) for analog.

54 BIAS I Playback EFM asymmetry circuit constant current input.

55 RFI I Inputs playback EFM RF signal from RF amplifier (IC501).

Output subcode Q sync (SCOR) to system control (IC801).

Outputs “L” every 13.3 msec. Outputs “H” at all most mostly.

Outputs digital-in U-bit CD format subcode Q sync (SCOR) to system control (IC801).

Outputs “L” every 13.3 msec. Outputs “H” at all most mostly.

Input of write data taransmission timing from system control (IC801).

Also used as magnetic field head ON/OFF output.

– 20 –

Page 21

Pin No. Pin name I/O Pin Description

56 AVSS — Ground terminal.

57 PDO — Not used (Open).

58 PCO O Decoder PLL master clock PLL phase comparison output.

59 FILI I Decoder PLL master clock PLL filter input.

60 FILO O Decoder PLL master clock PLL filter output.

61 CLTV I Decoder PLL master clock PLL VCO control voltage input.

62 PEAK I Inputs peak hold signal for light amount signal from RF amplifier (IC501).

63 BOTM I Inputs bottom hold signal for light amount signal from RF amplifier (IC501).

64 ABCD I Light amount signal from RF amplifier (IC501).

65 FE I Input focus error signal from RF amplifier (IC501).

66 AUX1 I Input of auxiliary signal from RF amplifier (IC501).

67 VC I Input of middle point voltage (+1.4 V) from RF amplifier (IC501).

68 ADIO — Not used (Open).

69 AVDD — Power supply (+2.8 V) for analog.

70 ADRT — Not used (Connect to +2.8 V).

71 ADRB — Not used (Connect to ground).

72 AVSS — Ground terminal.

73 SE I Input of sled error signal from RF amplifier (IC501).

74 TE I Input of tracking error signal from RF amplifier (IC501).

75 AUX2 — Not used (Connect to +2.8 V).

76 DCHG — Not used (Connect to +2.8 V).

77 APC — Not used (Connect to +2.8 V).

78 ADFG I

79 FO CONT O Focus control output to RF amplifier (IC501).

80 XLRF I Latch signal input from RF amplifier (IC501).

81 CKRF O RFCK clock (7.35 kHz) signal output.

82 DTRF I Serial data input from RF amplifier (IC501).

83 APCREF I Laser power setting signal input.

84 LDDR — Not used (Open).

85 TRDR O Tracking servo drive signal output (–).

86 TFDR O Tracking servo drive signal output (+).

87 DVDD — Power supply (+2.8 V) for digital.

88 FFDR O Focus servo drive signal output (+).

89 FRDR O Focus servo drive signal output (–).

90 FS4 O 176.4 kHz clock signal output (MCLK).

91 SRDR O Sled servo drive signal output (–).

92 SFDR O Sled servo drive signal output (+).

93 SPRD O Spindle servo drive signal output (–).

94 SPFD O Spindle servo drive signal output (+).

95 FGIN I FG signal input from spindle motor driver (IC761).

96 TEST1 — Not used (Connect to ground).

97 TEST2 — Not used (Connect to ground).

98 TEST3 — Not used (Connect to ground).

99 DVSS — Ground terminal.

100 EFMO O EFM recording signal output.

Input of ADIP dual FM signal from RF amplifier (IC501) (22.05 kHz ± 1 kHz).

(TTL Schmit input)

– 21 –

Page 22

• IC801 CXP740010 (SYSTEM CONTROL)

Pin No. Pin name I/O Pin Description

1 CLKCS O Not used (Chip select output to real time clock).

2 XRST O Reset output. L : Reset

3 WRPWR O Laser power switching signal output.

4 TX O Write data transfer timing output.

5 SDI2 I Serial data input.

6 SDO2 O Serial data output.

7 SCK2 O Serial clock output.

8 RFSW O Power control output.

9 SSB I/O SSB data signal input and output.

10 SSB SCK I/O SSB clock signal input and output. (Not used (Open).)

11 DTCK I/O Remote control data signal input/output.

12 SPCK — Not used (Open).

13 WP I Wake-up signal input from remote control key and this unit key.

14 OPEN I Detecting switch for opening and closing of the upper cover. L : Close

15 CLOCK I Not used (CLOCK SET switch input).

16 NI MH CHG O NI MH charge control output.

17 SLEEP O Sleep signal output.

18 T.MARK I T.MARK (Track mark) switch input.

19 REC I Not used (REC switch input).

20 PROTECT I Disc write protect switch. H : Protect

21 HOLD I HOLD switch input (This unit). L : HOLD

22 SYNC REC I SYNCHRO REC switch input.

23 D. B. B I DIGITAL MEGA BASS slide switch input.

24 XLINEDET I LINE IN (OPTICAL) detection input. L : LINE IN

25 INMU1 O INMU signal output.

26 XTEST I Test mode terminal. L : Test mode

27 XDCIN I Not used (Open). (DC input detect. L : DC IN)

28 KANA SE L — Not used (Open).

29 XPHOTO SW O ON/OFF control signal output of PHOTO circuit.

30 XP CONT — Not used (Open). (Power control output. L : ON)

31 X2VCONT —

32 XREC LED — Not used (Open). (REC LED control. L : ON)

33 MODE2 O

34 MODE1 O

35 XNIMH CHG — Not used (Open). (Battery charger control signal output. L : Charge)

36 XLCD ON O LCD ON/OFF control. L : ON

37 INMU0 O INMU signal output.

38 MRST I Microprocessor reset input.

39 VSS — Ground.

40 XTAL — System clock (12 MHz).

41 EXTAL — System clock (12 MHz).

42 LCD DS O LCD communication strobe signal output to LCD driver.

43 LCD XC D O Com/data select signal output.

44 LCD DATA O LCD data output.

45 LCD SCK O Serial clock output.

46 CHG MNT I Battery charge voltage minitor input.

47 INLS I Detecting switch for internal circuit of sleding. L : Internal circuit

48 HIDC MNT I Voltage monitor DC input.

49 KEY R I Remote control key input.

Not used (Open). (Outputs H while operating with a lithium battery. 2V power control

signal output. L : ON)

REC drive (IC901) control signal output.

– 22 –

Page 23

Pin No. Pin name I/O Pin Description

50 AVSS — Ground terminal for A/D converter.

51 AVREF I A/D converter reference voltage input.

52 AVDD — A/D converter power supply terminal.

53 VLG2-MNT I DSP power monitor signal.

54 TEMP I Temp meter (IC802) input.

55 KEY3 I Key input.

56 KEY2 I Key input.

57 KEY1 I Key input.

58 XINT REC SW I Recording head position detect input.

59 UNREG MNT I 2.8 V voltage monitor input.

60 BAT VC I Battery detect signal input.

61 FG IN I FG input from motor driver (IC503).

62 NC — Not used (Open).

63 FOK PORT I Focus OK signal input.

64 –––– — Not used (Open).

65 LCD RESET O LCD reset signal output.

66 XJACKDET I LINE IN (OPTICAL) jack detection input.

67 OPT DET I LINE IN (OPTICAL) optical detection input.

68 XMIC DET I MIC (PLUG IN) jack detection.

69 (NC) — Not used (Open).

70 FSI (NC) — Not used (Open).

71 SPOFF O

72 RSI O

73 RH PWM O RH constant current control signal output.

74 (NC) — Not used (Open).

75 DQSY I Subcode Q sync (SCOR) of digital in U-bit CD format from IC601.

76 T COUNT I Traverse count signal input.

77 SDI1 I Serial data input.

78 SDO1 O Serial data output.

79 SCK1 O Serial clock output.

80 SQSY I SUB-Q/ADIP SYNC input.

81 BEEP O BEEP sound output control.

82 XLAT O Latch output.

83 NC — Not used (Open).

84 TEX — Not used (Fixed at “L”).

85 TX — Not used (Fixed at “L”).

86 VSS — Ground.

87 VDD — Power supply pin (+2.8V).

88 NC — Not used (Fixed at “H”).

89 XCS ADA O A/D, D/A converter chip select output.

90 XPD ADA O A/D, D/A converter power down signal output. H : Power down

91 KEY ON O SLEEP : L, action : H.

92 XNIMH DET (NC) — Not used (Open). (Battery detect switch input.)

93 A MUTE O Analog mute control. H : Mute

94 XOPT CTL O Power supply control output for an optical input.

95 FFCLR O Flip flop clear signal output.

96 XCE NV O EEPROM chip select output.

97 SENS I SENS input.

98 LDON O “H” : APC circuit ON, “L” : APC circuit OFF

99 XSHOCK I Track jump detection input from IC601.

100 CLV STB O CLV drive control signal output.

REC head motor control signal output.

– 23 – – 24 –

Page 24

MZ-R37

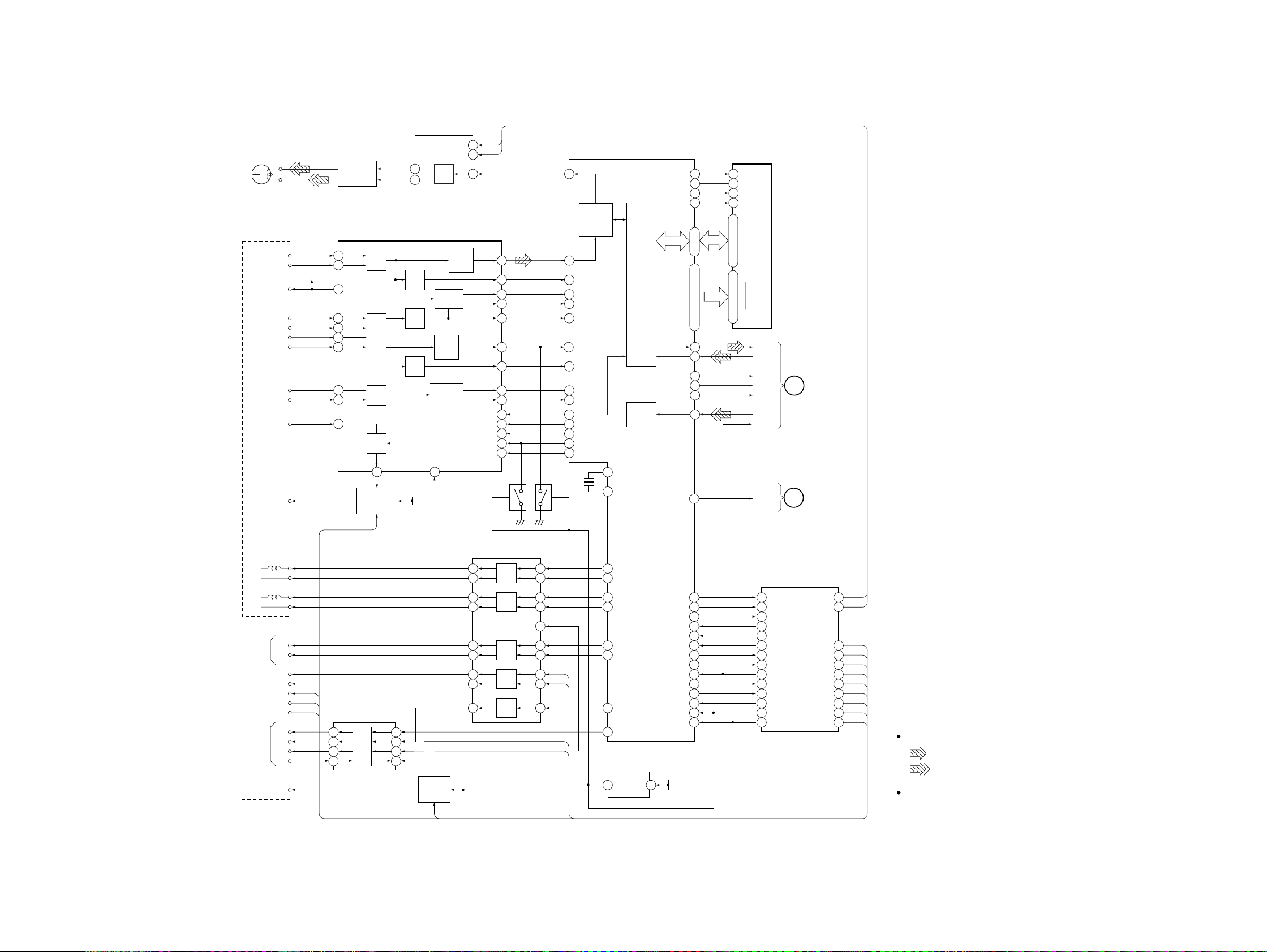

6-2. BLOCK DIAGRAM — SERVO SECTION —

04

OVER

WRITE

HEAD

MOTOR

SPINDLE

MOTOR

MD MECHANISM

OPTICAL

PICK-UP

PD

VCC

TRACKING

COIL

FOCUS COIL

SLED

SD+

SD–

AOUT

AOUTB

PROTECT

XINTREC SW

INLS

COM

2.8V

REC DRIVE

IC901 (1/2)

8

MODE1

9

MODE2

12

17

14

11

63

62

RF AMP

IC501

AUX

SW

ABCD

AMP

AI

AMP

2.8V

HA

HB

TRACKING

XSTBY

POWER

SWITCH

Q761

EFM

LOGIC

AGC/

PEAK/

BOTTOM

FOCUS

ERROR

AMP

ERROR

AMP

XPHOTO SW

EFM

64

RF

RF

EQ

38

AUX

33

PEAK

37

BOTM

36

ABCD

354

FE

34

ADFG

32

TE

26

SE

28

SWDT

16

SCLK

17

XLAT

18

APCREF

12

FO CONT

20

Q581

(1/2)

FOCUS/TRACKING COIL

SLED/SPINDLE MOTOR DRIVE

IC701

29

DRIVE

27

8

DRIVE

10

12

DRIVE

14

4

DRIVE

6

DRIVE

25

2.8V

100

65

Q581

(2/2)

20

21

16

17

34

PSB

18

19

SPOFF

35

RSI

3

22 94

CLV STB

XRFSW

OVER WRITE

HEAD DRIVE

Q741,742

I

J

A

B

C

D

E

F

+

–

+

–

W

V

U

1

2

VC

3

5

6

7

8

9

10

SPINDLE MOTOR DRIVE

6

19

20

1

VCVC

AUTO POWER

CONTROL

LDON

IC761

DRIVE

RF

AMP

I-V

CONV.

I-V

CONV.

APC

Q571

11 19

VM

STBY

FG

DIGITAL SERVO ENC/DEC

ATRAC MEMORY CONTROLER

EFMO

EFM/

ACIRC

ENCODER/

DECODER

RFI

55

AUX1

66

PEAK

62

BOTM

63

ABCD

64

FE

ADFG

78

TE

74

SE

73

DTRF

82

CDRF

81

XLRF

80

APCREF

83

FO CONT

79

16

17

X601

22.5MHz

86

85

88

89

92

91

93

3 4

IC601

MEMORY

CONTROL

OSCI

OSCO

TFDR

TRDR

FFDR

FRDR

SFDR

SRDR

SPFD

SPRD

HIGH

VCC DET

IC581

&

SHOCK

PROOF

DIGITAL

AUDIO

IN

XWE

XRAS

XCAS

XOE

D0-D3

A00

A09

DADT

ADDT

ALRCK

ABCK

FS256

FS4

MNT 0

MNT 1

MNT 3

SWDT

SCLK

XLAT

SRDT

SENS

XRST

SQSY

DQSY

WRPWR

FGIN

2.8V

DIN

DRAM

IC602

45

44

42

41

46

|

49

29

|

32

•

|

34

|

38

•

43

24

23

25

26

27

3

4

17

16

1

•

2

•

18

•

19

5

|

9

•

11

|

15

XWE

XRAS

XCAS

XOE

DQ1-DQ4

A0

A9

SDTI

SDTO

LRCK

BCK

MCLK

A

AUDIO

SECTION

(Page 27)

21

DIN

XRST

SYSTEM

90

FS4

C

CONTROL

SECTION

(Page 30)

SYSTEM CONTROL

IC801 (1/3)

1

2

4

5

6

7

8

9

10

11

12

15

TX

13

95

76

T COUNT MODE 1

99

XSHOCK

63

FOK PORT

78

SDO 1

79

SCK 1

82

XLAT

77

SDI 1

97

SENSE

2

XRST

80

SQSY

DQSY

TX

WRPWR

FGIN

XPHOTOSW

XINTRECSW

75

4

3

61

MODE 2

CLV STB

RF SW

RSI

SPOFF

INLS

PROTECT

LDON

34

33

100

8

72

71

29

47

58

20

98

Signal path

: PLAY(DIGITAL)

: REC(DIGITAL)

R-ch : same as L-ch.

– 25 – – 26 –

Page 25

MZ-R37

6-3. BLOCK DIAGRAM — AUDIO SECTION —

DIN

SERVO

SECTION

(Page 26)

04

SDTO

A

LRCK

BCK

SDTI

MCLK

XRST

4

2

3

5

1

46

EEPROM

IC803

DO

SCK

AUDIO

CONTROL

CS

DI

I/F

1

3

4

2

Signal path

ADC

DAC

CDTI

CDTO

CCLK

15 14 13 12 47

KCS

PD

: PLAY(DIGITAL)

: REC(DIGITAL)

: PLAY(ANALOG)

: REC(ANALOG)

R-ch : same as L-ch.

RCH

RCH

90

89

7

5

6

96

A/D, D/A

CONVERTER

IC301

SYSTEM CONTROL

IC801 (2/3)

XPD ADA

XCS ADA

SCK 2

SDI2

SDO2

XCSNV

OPT CONT

XJACK DET

XMIC DET

XLINE DET

KEY RMC

SYSTEM

CONTROL

SECTION

(Page 29)

BEEP

AMUTE

OPT DET

DTCK

6-4. BLOCK DIAGRAM — SYSTEM CONTROL SECTION —

2.8V

41

44

25

26

29

81

93

94

66

67

68

24

11

49

KEYRMC

B

7 5

MIC AMP

IC302

8

MIC 2.5V

17

LINE/HP AMP

IC303

16

21

23

MUTE VCOM

9

4

6

OPT

CONTROL

Q302

REG

IC304

5

MIC2.5V 2.8V

XCE

3

INOUT

J301

LINE IN

(OPTICAL)

R-CH

2

R-CH

R-CH

RVCC

DTCK

KEY R

(+2.8V)

J303

MIC

(PLUG IN POWER)

J302

LINE OUT

J304

/REMOTE

AUDIO

SECTION

(Page 27)

KEYRMC

B

SYSTEM CONTROL

IC801 (3/3)

WP

LCD

MODULE

WITH

SWITCH

MEGA BASS

TEMP

METER

IC802

UNIT

S805

Digital

S803

T. MARK

41

VDD

(+2.9V)

X801

12MHz

S802

(OPEN 2)

S881

DISPLAY

S882

MODE

Q801(1/2)

S804

SYNCHRO

REC

OFF

ON

VCC

(+2.8V)

S801

(OPEN 1)

Q821

POWER

SWITCH

VCC

(+2.8V)

04

65

LCD RESET

45

LCD SCK

44

LCD DATA

43

LCD XC D

42 91

LCD STB KEY ON

57

KEY 1

56

KEY 2

21

HOLD

36

XLCD

41

EXTAL

40

XTAL

22

SYNC REC

23

DBB

18

T.MARK

54

TEMP

14

OPEN

55

KEY3

D801

MRST

SLEEP

INMU0

INMU1

NI MH CHG

FFCLR

WP

CHG MNT

BAT VC

HIDC MNT

38

17

Q902

WP

Q801

(2/2)

Q901

IC951

4 1

Q851

37

25

16

95

13

46

60

48

POWER CONTROL

IC901

FS4

25 67

REMKEY VC

24

KEY ON

6

72

23

10

70

69

71

52

51

XRST

SLEEP

INMU

CHG

FFCLR

WAKEO

WAKE

RS

CHG SW

VLG2

VLG20

VLG20

VB

VB

VL

VL1

VB

VB

L4

VDD

INM4

RF4

DC IN

68

14

47

48

32

33

37

38

39

40

49

61

54

55

57

FS4

VDD

(+2.9V)

+2.8V

+2.8V

D905

IC971

DC-DC CONVERTER

2 1

VOUT VIN

VCE VOUT

EXT

5

SERVO

C

SECTION

(Page 26)

Q971

IC972

REG

1 3

Q903

D902

Q906

D906

D901

T901

UNREG

RECHARGEABLE

BATTERY

(NC-AA)

700mAh 2.4V

J901

DC IN 4.5V

¥

(CHASSIS)(CHASSIS)

– 27 – – 28 – – 29 –

– 30 –

Page 26

MZ-R37

• Semiconductor

Location

Ref. No. Location

D401 E-4

D402 H-4

D403 G-3

D404 H-25

D406 C-3

D407 D-26

D408 F-26

D741 B-20

D742 C-20

D801 G-22

D901 H-17

D902 H-16

D903 H-19

D904 G-17

D905 H-19

D906 G-11

D907 H-16

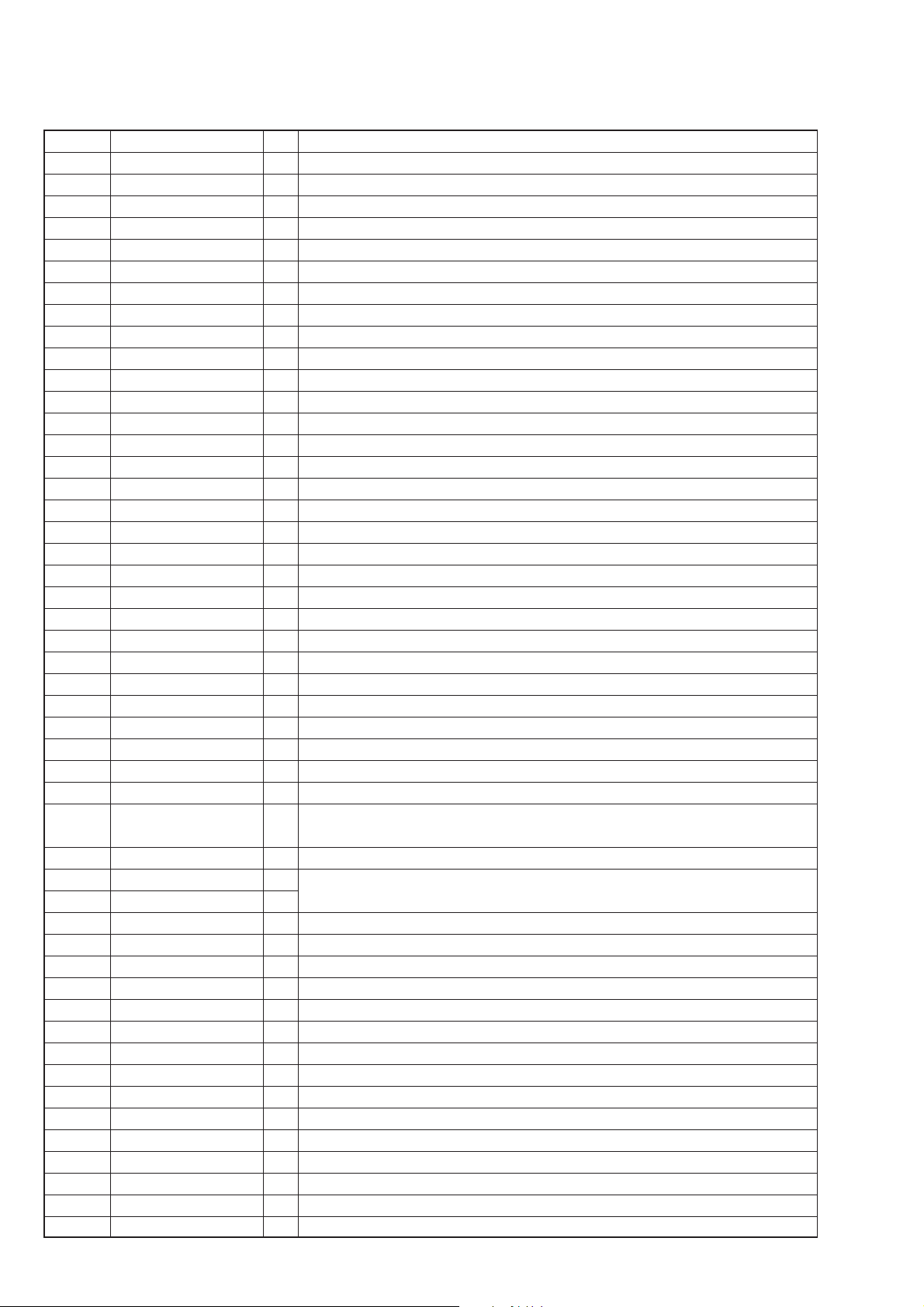

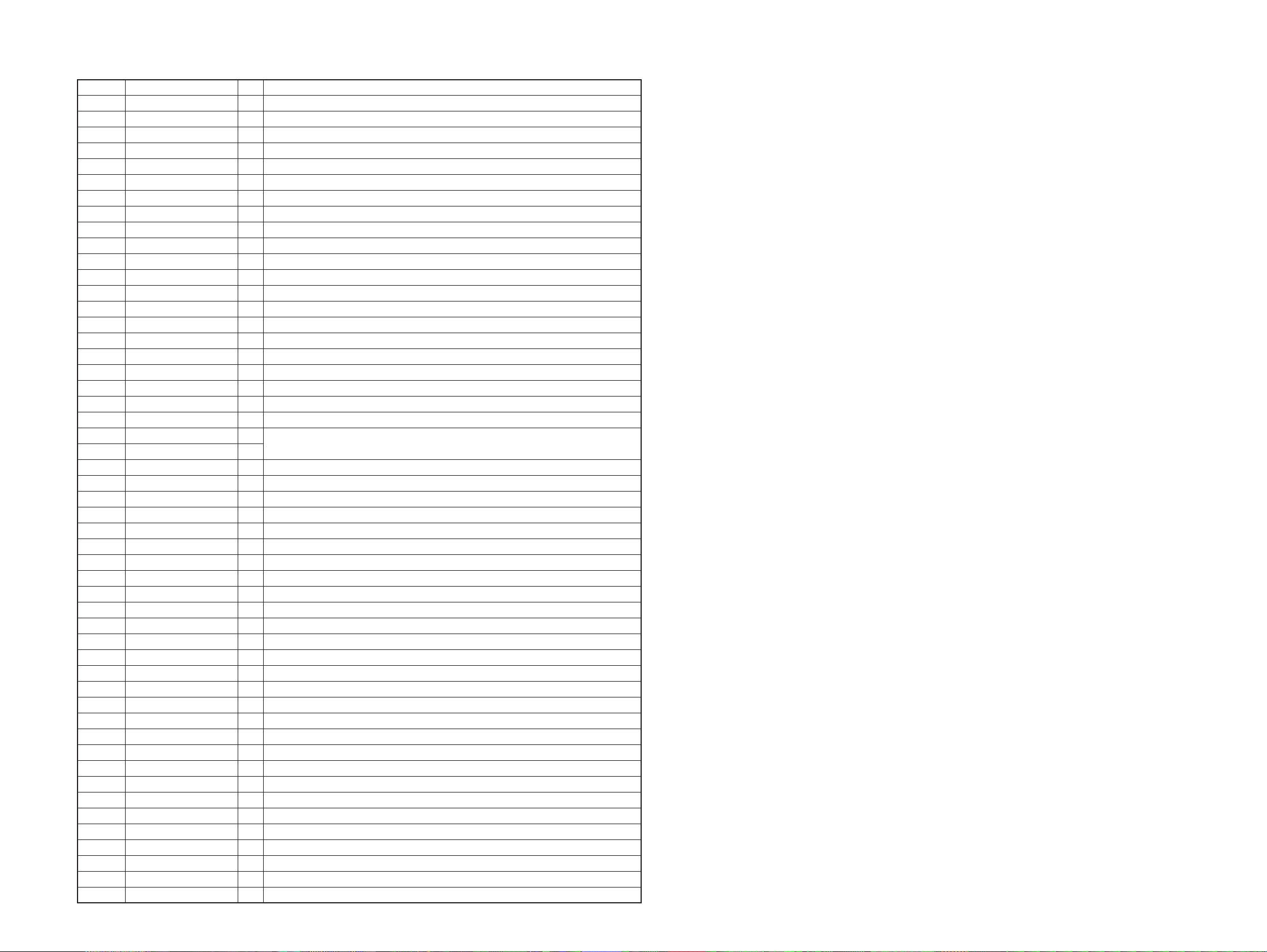

6-5. PRINTED WIRING BOARD

IC301 D-24

IC302 C-25

IC303 F-24

IC304 A-23

IC501 E-19

IC601 E-21

IC602 F-23

IC701 C-19

IC761 C-21

IC801 C-22

IC802 D-4

IC803 E-5

IC901 G-20

IC951 B-22

IC971 H-17

IC972 H-11

J301 D-3

Q302 D-4

Q571 D-18

Q741 B-20

Q742 D-20

Q761 D-21

Q801 G-22

Q821 H-5

Q851 C-21

Q901 H-22

Q902 H-17

Q903 G-16

Q906 H-18

Q971 H-17

Note:

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

(The other layer’s patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

– 31 – – 32 – – 33 – – 34 –

Page 27

MZ-R37

6-6. SCHEMATIC DIAGRAM — MAIN SECTION (1/3) — • Refer to page 44 for IC Block Diagrams.

• Wavef orms

VOLT/DIV : 0.5V AC

1

TIME/DIV : 1µsec

IC501

VOLT/DIV : 0.1V AC

2

TIME/DIV : 0.1msec

Approx. 0.5Vp-p

IC501 @ª

VOLT/DIV : 1V AC

3

TIME/DIV : 5msec

13.4msec

IC601

VOLT/DIV : 1V AC

4

TIME/DIV : 20nsec

1.0±0.3Vp-p

#•

2.8Vp-p

!¡

(Page 42)

(Page 38)

(Page 38)

(Page 43)

(Page 42)

(Page 38)

(Page 38)

(Page 38)

2.6Vp-p

22.5MHz

IC601

!¶

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• A : B+ Line.

• P ower voltage is dc 4.5 V and fed with regulated dc pow er

supply from external power voltage jack.

• Voltage and waveforms are dc with respect to ground

under no-signal conditions.

no mark : PB

( ) : REC

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : PB (digital)

c : REC (digital)

: Impossible to measure

∗

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

– 35 – – 36 – – 37 –

Page 28

MZ-R37

• Wavef orm

5

VOLT/DIV : 1V AC

TIME/DIV : 20nsec

12kHz

IC801

$º

2.2Vp-p

6-7. SCHEMATIC DIAGRAM — MAIN SECTION (2/3) — • Refer to page 44 for IC Block Diagrams.

(Page 43)

(Page 42)

(Page 37)

(Page 37)

(Page 37)

(Page 37)

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

• C : panel designation.

• A : B+ Line.

• P ower voltage is dc 4.5 V and fed with regulated dc pow er

• Voltage and waveforms are dc with respect to ground

• V oltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

supply from external power voltage jack.

under no-signal conditions.

no mark : PB

( ) : REC

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

c : REC (digital)

: Impossible to measure

∗

4

W or less unless otherwise

(Page 43)

(Page 37)

(Page 37)

– 38 – – 39 – – 40 –

Page 29

6-8. SCHEMATIC DIAGRAM — MAIN SECTION (3/3) — • Refer to page 44 for IC Block Diagrams.

MZ-R37

(Page 37)

(Page 37)

(Page 38)

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

• C : panel designation.

• A : B+ Line.

4

W or less unless otherwise

(Page 38)

• P ower voltage is dc 4.5 V and fed with regulated dc pow er

supply from external power voltage jack.

• Voltage is dc with respect to ground under no-signal

condition.

no mark : PB

( ) : REC

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

(Page 38) (Page 37)

– 41 – – 42 – – 43 –

• Signal path.

F : PB (analog)

L : REC (analog)

J : PB (digital)

c : REC (digital)

Page 30

• IC Block Diagrams

MCLK

LRCK

BCLK

SDTO

SDTI

DIFO

DIFI

TST3

DCODE0

DCODE1

DCODE2

CS(SCK)

IC301 AK4517-VQ-L

CMODE

PD

RST

SSB

LIN1

RIN1

TST1

LIN2

RIN2

TST2

LIN3

DZF

3839404142434445 3747 46

DACDBBDPGA

ROUT1

OPGAR

RIN3

10

11

12

1

2

3

4

5

6

7

8

9

48

CLOCK

DIVIDER

AUDIO

I/F

CONTROLLER

CONTROL

REGISTER

I/F

151413 16 24232217 18 19 20 21

CDTO

DGND

CCLK(SSI)

CDTI(SSO)

VB

VA

VD

AGND

VCOM

IC303 AN7535SA-E1

MUTE TC

MUTE

VREF

BEEP IN

GAIN CONTROL

PRE GND

LINE NF1

LINE IN1

24 23

MUTE

VCC

1 7 10 122 3 54 6 8 9 11

VCC 1

22 21 20 19 18 17 16 15 14 13

VREF

RIPPLE

RIPPLE

VCC

DET.

VCC

BEEP

OUT 1

NC

VREF

GND

CENTER OUT

IN1

VREF

OUT 2

LINE OUT1

IN2

HPF

LINE VCC

ADO

LINE IN2

LINE NF2

NC

LINE OUT2

IC501 CXA2523AR

MORFO47MORFI46RFO45OPN

48

–

+

RFA1

+

IPGAL

36

1I

ADCL

35

VCMC

34

VCMR

33

ADCR

32

IPGAR

31

VRAD

30

LOUT2

29

ROUT2

28

VRDA

27

OPGAL

26

LOUT1

25

2J

CVB

3VC

4A

IVR

5B

IVR

6C

IVR

7D

IVR

8E

IVR

9F

IVR

GSW

10PD

11APC

12APCREF

+

–

–

RFA2

–

–

–

–

–

GND

AA

BB

CC

DD

+

14

–

–

EE

FF

TEMPI

+

–

+

–

+

–

+

–

+

–

+

–

+

–

IV

13

1

2

1

2

GRVA

EBAL

–

HLPT

OFST

GRV

+

–

+

–

FBAL

OPO43ADDC42COMPP41COMPO40AGCI39RF AGC38RF37PEAK

44

USROP

EE'

–

–

–

–

+

+

–

–

–

–

+

+

15

–1

–2

–2

–1

ESW

FF'

AUXSW

TEMPR

+

–

–

+

–

+

COMMAND

DECODE

17

SCLK

SWDT

BPF3T

BPF22

WBL

WBL

18

XLAT

RFA3

PTGR

PBSW

ABCDA

FEA

ATA

EFB TESW

SCRI - PARA

16

RF AGC EQ

USRC

PEAK

BOTTOM

WBL

ADIP

PTGR

19

XSTBY

PEAK3T

P-P

AGC

WBL

3T

EQ

BGR

VREF

20

F0CNT

3T

3T WBL

PBH

EQ

DET

AUX

SW

TEMP

36

BOTM

35

ABCD

34

FE

33

TG

TG

24

VCC

AUX

32 ADFG

31 ADAGC

30 ADIN

29 ADFM

28 SE

27 CSLED

26 TE

25 WBLADJ

IC701 MPC17A58DTBEL

BPFC

DET

–1

–2

SEA

–1

–2

TEA

VI CONV

23

22

21

VREF

3TADJ

EQADJ

IC602 MN41X4400TT-10TIL

DQ0

1

DQ1

2

WE

3

VG

VG

STEP

MOTOR

DRIVER

CLOCK

GENERATOR

ADDRESS

BUFFER

SPOFF

PSB

35 3436

PRE-DRIVER

LGND

CBR REFRESH

COUNTER

DECODERS

B OUT

B OUT B

RAS

VDD

4

A9

5

A0

6

A1

7

A2

8

A3

9

10

ROW

PGND35

WORDS

DRIVERS

PRE-DRIVER

F03

DECODERS

VM3

R03

MEMORY

CELLS

SENSE

AMPS

COLUMN

PGND34

26 25272829 21 2024 23 192233 32 31 30

FM0

PRE-DRIVER

I/O

SELECTION

HALF

BLIDGE

DRIVER

WRITE

CLOCK

GENERATOR

DATA

INPUT

BUFFER

DATA

OUTPUT

BUFFER

VM4VCFM1

VC

RI3

FI3

PRE-DRIVER

20

VSS

19

DQ3

18

DQ2

17

CAS

16

OE

15

A8

14

A7

13

A6

12

A5

A4

11

RI2

CONTROLCONTROLCONTROLCONTROLCONTROL

PRE-DRIVER

PRE-DRIVER

IC304 RN5RZ25AA-TR

1

GND

CURRENT LIMIT

2

VDD

3

VOUT

VREF

VOUT

VSS

IC972 XC61AN1102MRIC971 XC6383D331MR

VIN

3

1

321 4 5 6 7 8 9 10 11 12 13 15 161718

2

VREF

FS1

PGND5

RS1

A OUT

VM5

AOUT B

PGND15

IC802 S-8110ANP-DSB-T2

5

CE

TEMPERATURE

SENSOR

4

NC

VDD

1

VOUT

2

NC

3

4

VSS

CE

VOUT

NC

1

2

3

CHIP ENABLE

VDD

VREF

BUFFER

2STEP PFM

CONTROL

OSC 100/180kHz

5

EXT

4

VSS

– 44 – – 45 – – 46 –

H BLIDGE

DRIVER

CH3

F01

VM1

R01

PGND12

F02

VM2

14

H BLIDGE

R02

DRIVER

CH2

PGND2

FI1

H BLIDGE

DRIVER

CH1

FI2

RI1

Page 31

IC761 BA6966FV-E2

VOUT WOUT N.C VM

1 2 3 4 5 6 7 8 9 10

UOUT RF UIN VIN WIN COM CST CSL1 CSL2 GND

1920 18 17 1516 14 13 11

PREDRIVE

UP-DOWN

DISTRIBUTION

DRIVING SIGNAL

COMPOSITION LOGIC

TIMING SELECTOR

VCC RIB FGBRK+ BRK-STBY

STAND-BY

TSD

EX-OR

START

CONTROL

LOGIC

PHASE

CONTROL

12

COMPOSITION

SLOBE

WAVE

IC803 AK6420AM-E

INSTRUCTION

REGISTER

CS

1

SK

2

3

DI

4

DO

INSTRUCTION

DECODE,

CONTROL

AND

CLOCK

GENERATION

DATA

REGISTER

ADD

BUFFER

16 16

R/W AMPS

AND

AUTO ERASE

DECODER

VPP SW

VREF

VPP

GENERATOR

EEPROM

2048bit

128x16

8

VCC

RDY/BUSY

7

RESET

6

GND

5

– 47 –

Page 32

IC901 MPC18A35FTA

RF4

55

56

DGND

DCIN

57

DC IN

VG1

C1H

C1L

VDD

EFM

PGND3

58

59

60

61

62

HB

HA

63

64

65

L3

66

67

VC

CHARGE

PUMP

EFM

DC/DC

INM4

VLIM

RS

525354

REGULATORSETUP

DCIN

CHGSW

VG2

GENERATOR

VR2

L4

48495051

L2L

L2L

PGND2

PGND2

L2H

PRE-DRIVER

DRIVE

CONTROL

L2H

VLG2

VLG20

VLG20

47 46 45 44 43 4142 40 39 38 37

VBVBVLI

POWER SW

PRE-DRIVER

VLG1

PRE-DRIVER

VLI

36

35

34

33

32

31

30

29

28

27

26

25

24

PSL1

PSAM

VAM3

VB

VB

L1

L1

L1

PGND

PGND

REMGND

REMKEY

KEYON

SYNC

WAKEO

FFCLR

WAKE

SLEEP

OSC

68

69

70

71

72

REFERENCE

DCDTB

REF

SELECT

BANDGAP

VREF

SYSTEM

CONTROL

AGND

SUB

REFERENCE

LOW VC

DETECT

RSTAD

54321

CRST

XRST

LICHG

MODE1

MODE2

SAW TOOTH

11109876 12 1513 14 16 17 18

CHG

RF2

INM2

INP2

VLG2

RF1

INM1

INP1S

INP1

23

INMU

22

DTC2

21

DTC1

20

VBSEL

19

VLG1

– 48 –

Page 33

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• Abbreviation

CND : Canadian model

FR : French model

7-1. PANEL SECTION

SECTION 7

EXPLODED VIEWS

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

Parts Color Cabinet’s Color

• Accessories and packing materials are

given in the last of this parts list.

2

N

N

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

12

11

3

14

not supplied

1

4

13

9

10

5

8

Ref. No. Part No. Description Remark

1 X-4951-492-1 PANEL (S) ASSY, UPPER (SILVER)

1 X-4951-493-1 PANEL (L) ASSY, UPPER (BLUE)

(EXCEPT US,CND)

2 4-216-591-01 PLATE, ORNAMENTAL

3 4-963-883-41 SCREW (M1.4), PRECISION PAN

4 X-4950-928-1 LID (S) ASSY, BATTERY CASE (SILVER)

4 X-4950-929-1 LID (L) ASSY, BATTERY CASE (BLUE)

(EXCEPT US,CND)

5 4-217-749-01 BEARING (STOPPER)

6 4-216-610-01 PANEL, BOTTOM (SILVER)

6 4-216-610-11 PANEL, BOTTOM (BLUE) (EXCEPT US,CND)

7 3-318-382-11 SCREW (1.7X4.5), TAPPING

6

7

Ref. No. Part No. Description Remark

8 4-216-597-01 KNOB (SYNCHRO)

9 4-216-611-01 BUTTON

10 4-216-607-01 KNOB (OPEN) (SILVER)

10 4-216-607-11 KNOB (OPEN) (BLUE) (EXCEPT US,CND)

11 4-216-600-01 WINDOW (LCD)

12 4-216-606-01 KNOB (HOLD) (SILVER)

12 4-216-606-11 KNOB (HOLD) (BLUE) (EXCEPT US,CND)

13 X-4951-494-1 PANEL (S) ASSY, FRONT (SILVER)

13 X-4951-495-1 PANEL (L) ASSY, FRONT (BLUE)

(EXCEPT US,CND)

14 4-219-748-01 SPACER (HOLDER)

– 49 –

Page 34

7-2. CABINET (SV) ASSY SECTION

MT-MZR37-161

LCD1

62

66

64

69

52

62

65

63

69

53

51

54

55

56

57

67

58

59

60

65

70

71

68

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 X-4951-496-1 CABINET (S) ASSY (SILVER)

51 X-4951-497-1 CABINET (L) ASSY (BLUE) (EXCEPT US,CND)

52 4-963-883-41 SCREW (M1.4), PRECISION PAN

53 X-4950-927-1 PLATE ASSY, FULCRUM

54 4-216-593-01 SPRING (LOCK), TENSION

55 4-216-584-01 LEVER (LOCK)

56 4-216-594-01 SPRING (OPEN), COMPRESSION

57 4-216-583-01 LEVER (OPEN)

58 A-3323-122-A MAIN BOARD, COMPLETE (FR)

58 A-3323-123-A MAIN BOARD, COMPLETE (US,CND)

58 A-3323-124-A MAIN BOARD, COMPLETE (EXCEPT US,CND,FR)

59 4-216-592-01 TERMINAL (A), BATTERY DETECTION

60 3-318-382-11 SCREW (1.7X4.5), TAPPING

61 4-216-598-01 SPRING, BATTERY COIL

62 4-212-820-01 DAMPER

63 4-982-382-11 SCREW (MD), STEP

64 4-216-585-01 SCREW, STEP

65 4-220-363-01 SPACER (POWER)

66 4-219-746-01 SPACER (MD)

67 4-216-582-11 SPACER

68 4-219-414-01 PLATE, RADIATION

69 4-220-364-01 SPACER (MIC A)

70 4-219-747-01 SPACER (MAIN)

71 4-220-442-01 SPRING (A), BATTERY COIL

LCD1 1-803-367-11 LCD MODULE

60

61

– 50 –

Page 35

7-3. MECHANISM DECK SECTION

(MT-MZR37-161)

101

107

106

M1

104

105

108

103

119

110

110

108

117

112

114

118

115

111

M2

109

124

113

107

107

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 X-4950-391-1 HOLDER ASSY

102 3-704-197-31 SCREW (M1.4X3.0), LOCKING

103 4-212-312-01 SHAFT, MAIN

104 X-4950-390-1 CHASSIS ASSY

105 4-995-585-11 SPRING (LIMITER), TORSION

116

123

M3

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

115 1-671-605-11 MD FLEXIBLE BOARD