Page 1

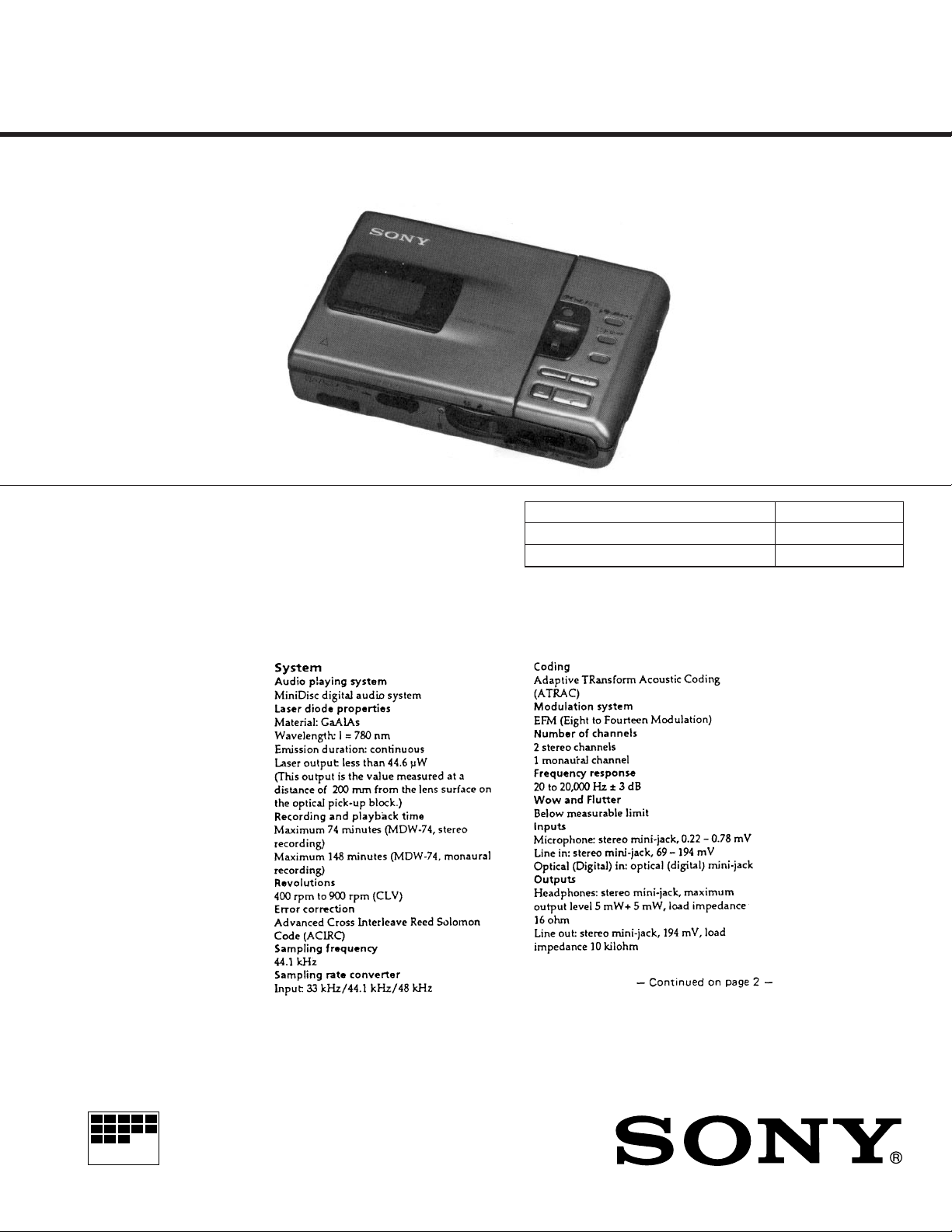

MZ-R30

SERVICE MANUAL

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Austr alian Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZR30-124

Optical Pick-up Type KMS-250A/J2N

MICROFILM

PORTABLE MINIDISC RECORDER

Page 2

TABLE OF CONTENTS

Specifications ............................................................................... 1

1. SERVICE NOTE .................................................................. 3

2. GENERAL ............................................................................ 4

3. DISASSEMBLY

3-1. Upper Panel Assy, Bottom Panel Assy Removal.......... 20

3-2. Main Board Removal ................................................... 20

3-3. Mechanism Deck Removal........................................... 21

3-4. Optical Pick-up Assy, Control Board,

REC Board Removal .................................................... 21

3-5. Battery Case Assy Removal ......................................... 22

3-6. Switch board, Power Board Removal........................... 22

4. TEST MODE ...................................................................... 23

5. ELECTRICAL ADJUSTMENTS ..................................... 29

6. EXPLANATION OF IC TERMINALS ............................. 33

For customers in Europe

This MiniDisc Recorder is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT label is

located on the buttom exterior.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

CAUTION

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

7. DIAGRAMS

7-1. Block Diagram.............................................................. 37

7-2. Cricuit Boards Location ............................................... 41

7-3. Printed Wiring Boards – Main Section –...................... 42

7-4. Schematic Diagram – Main (1/3) Section – ................. 47

7-5. Schematic Diagram – Main (2/3) Section – ................. 51

7-6. Schematic Diagram – Main (3/3) Section – ................. 55

7-7. Schematic Diagram – Power Section – ....................... 57

7-8. Printed Wiring Boards – Control Section –.................. 60

7-9. Schematic Diagram – Control Section – ..................... 63

8. EXPLODED VIEWS

8-1. Upper Panel, Bottom Panel Section ............................. 69

8-2. Chassis Section ............................................................. 70

8-3. Mechanism Deck Section-1.......................................... 71

8-4. Mechanism Deck Section-2.......................................... 72

9. ELECTRICAL PARTS LIST ............................................ 73

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY

– 2 –

Page 3

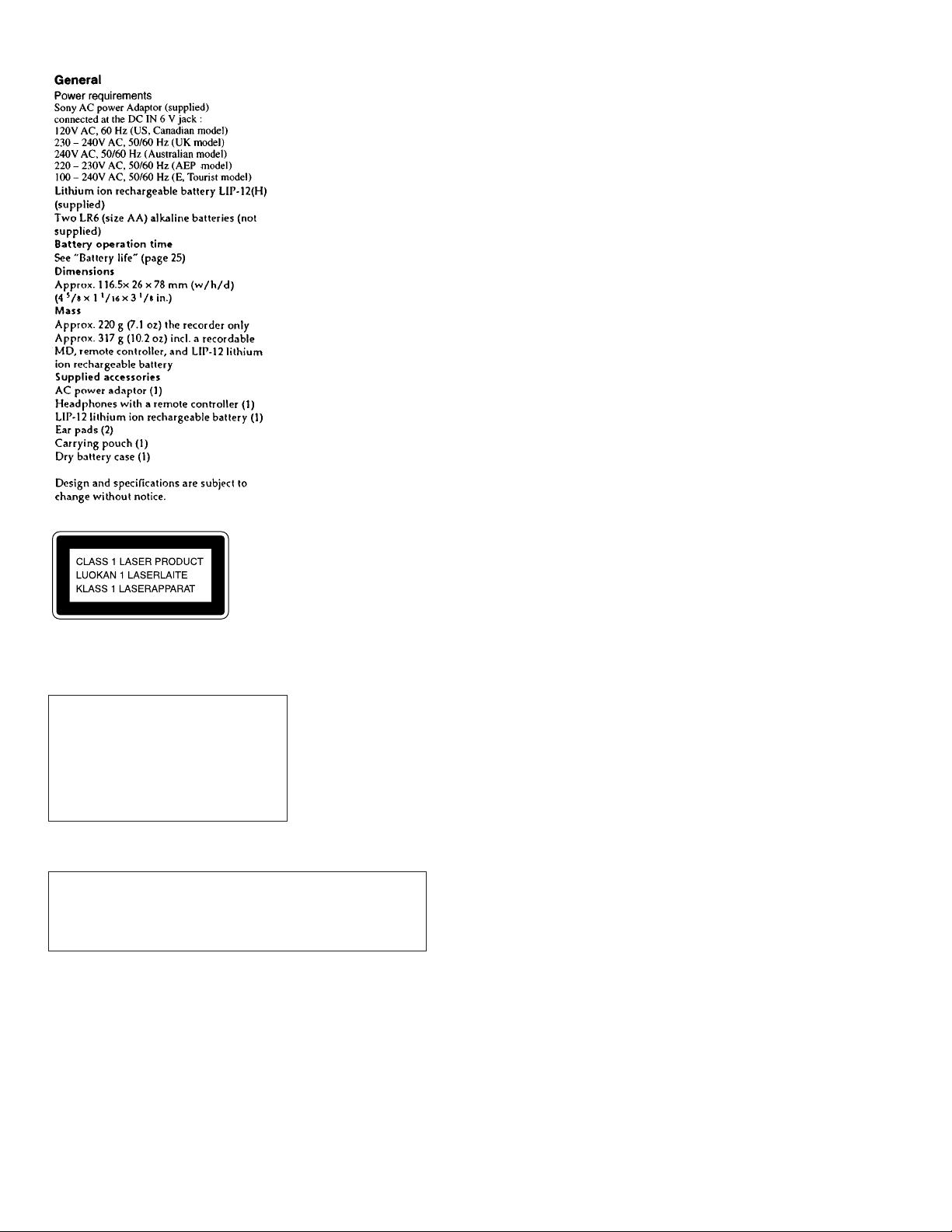

SECTION 1

SERVICING NOTE

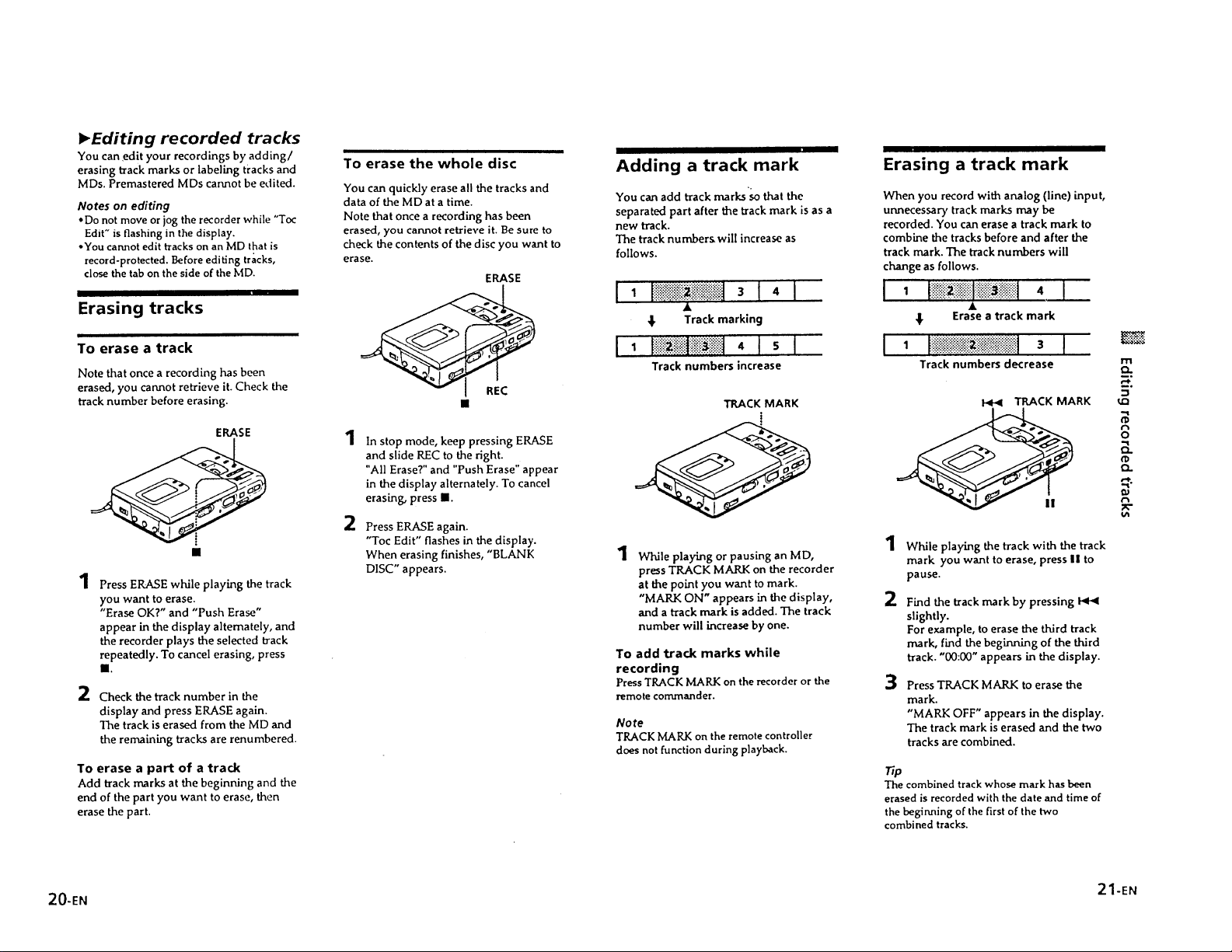

When repairing this device with the power on, if you remove the main board or open the upper panel assembly, this device stops working.

In this case, you can work without the device stopping by fastening the hook of the Open/Close detection switch (S817) with tape.

Tape

Door open/close

switch (S817)

Main board

– 3 –

Page 4

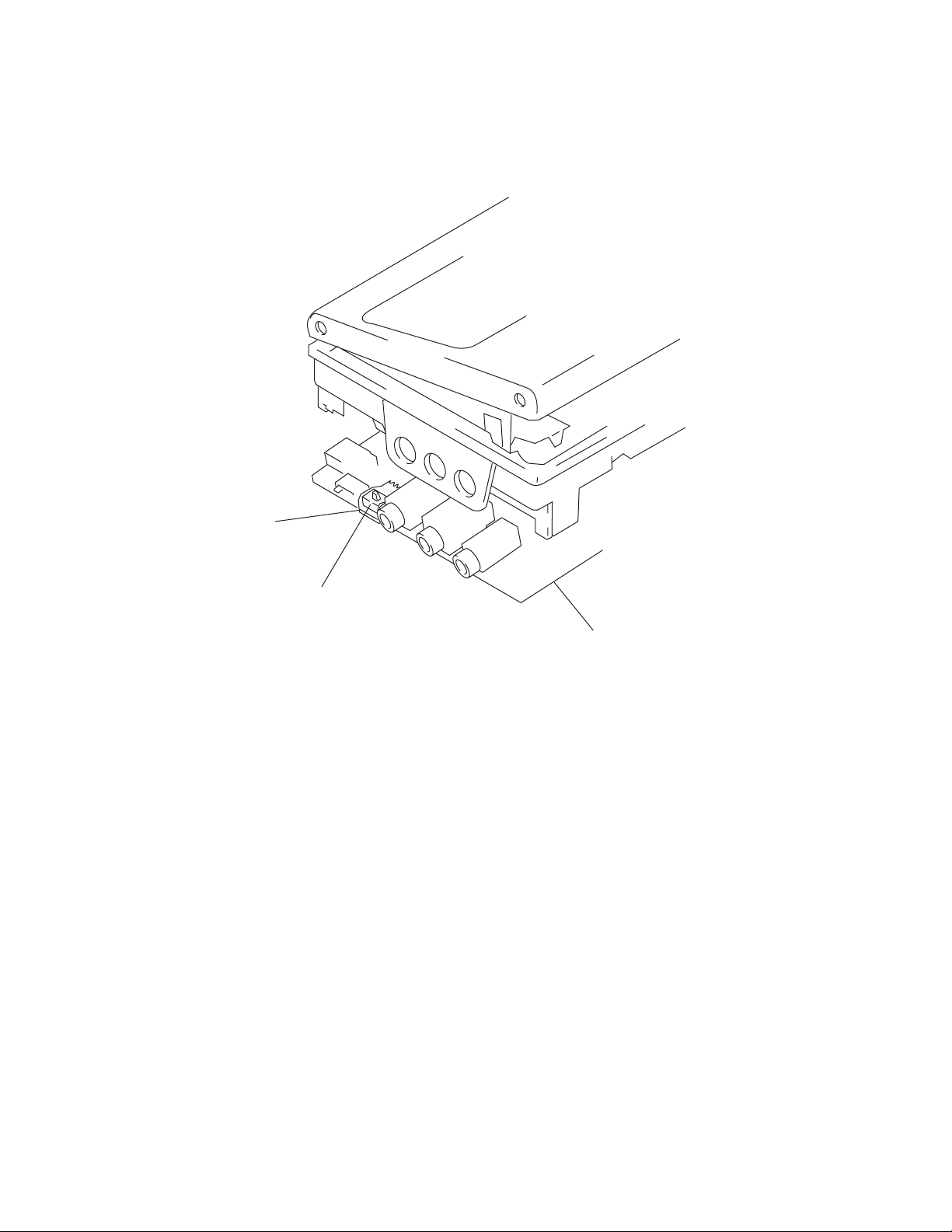

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

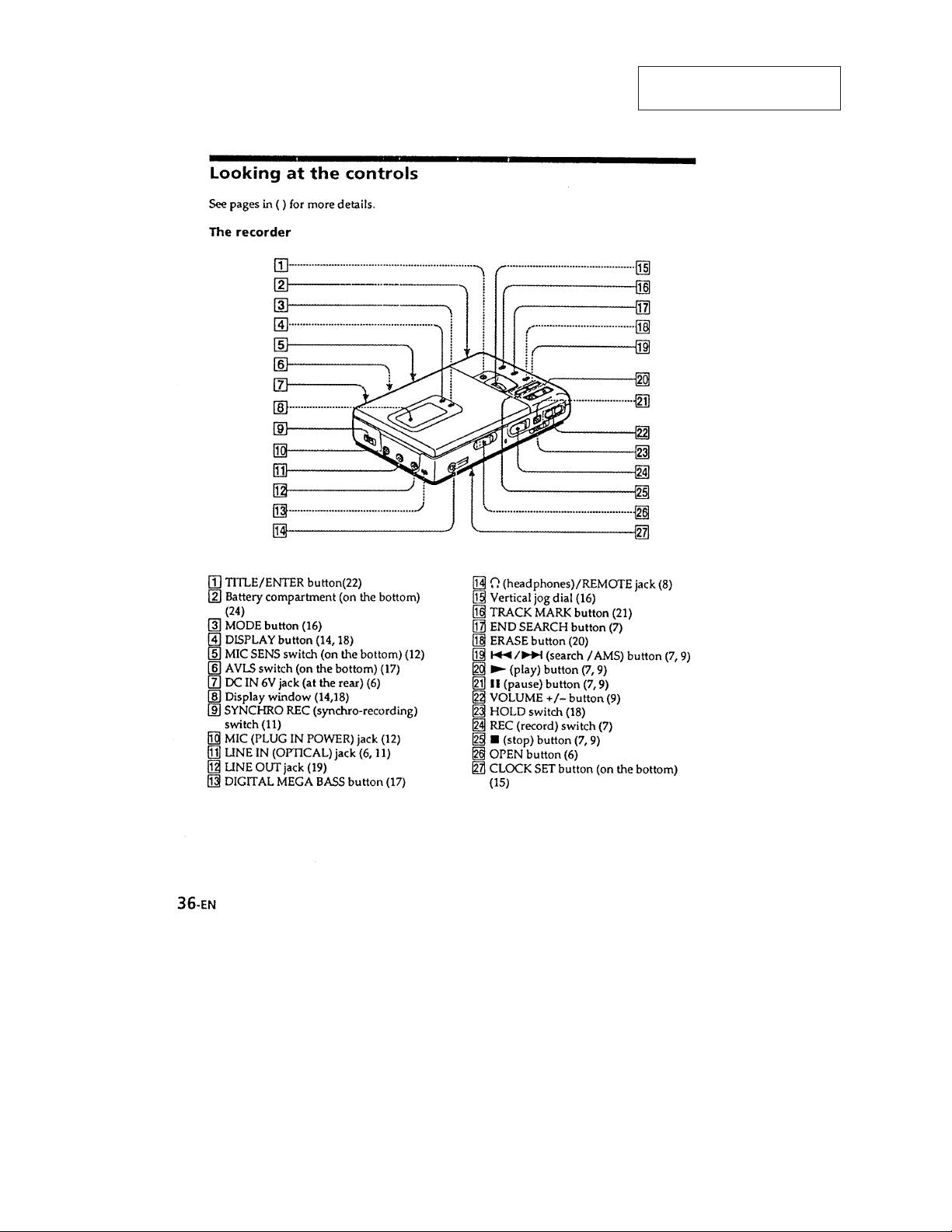

Page 5

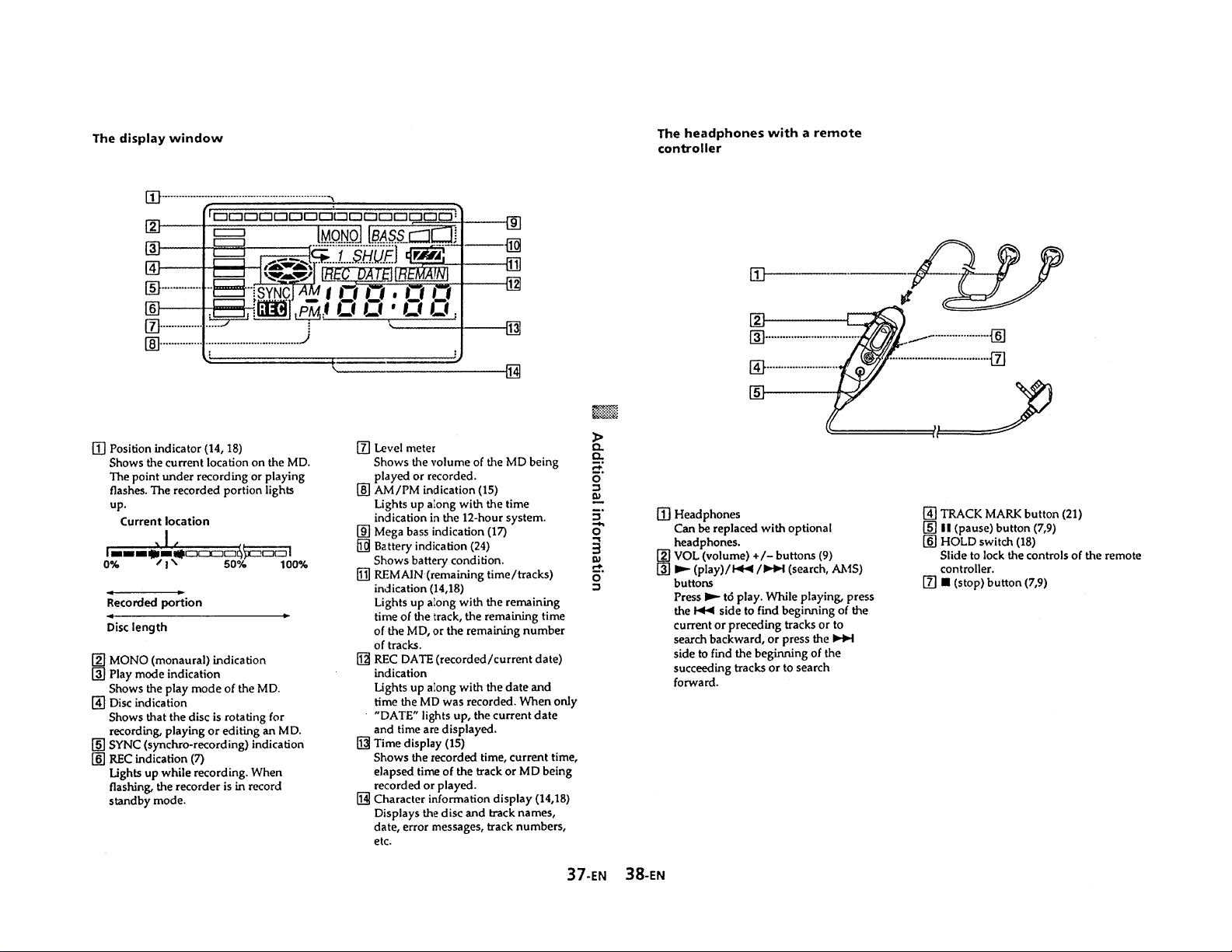

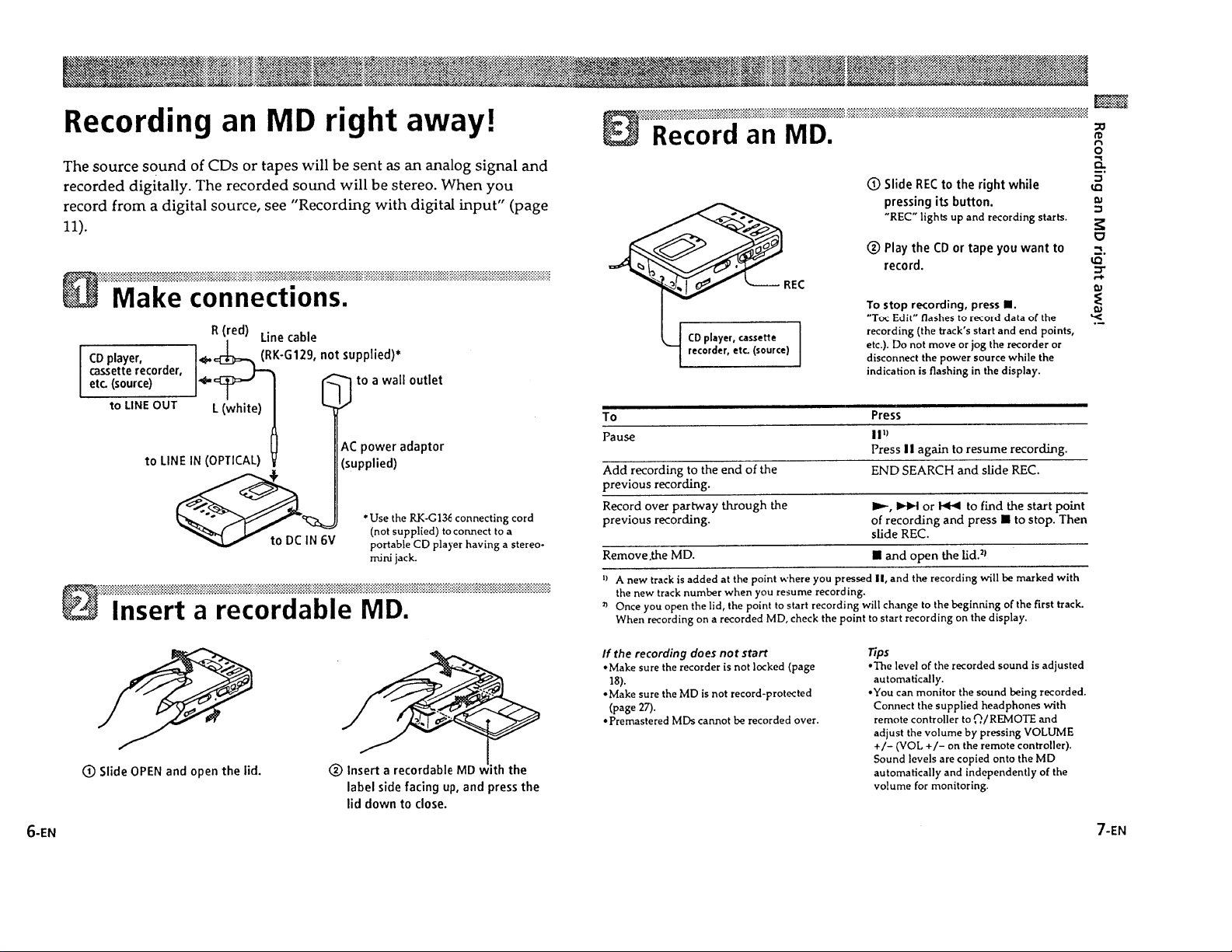

– 5 –

Page 6

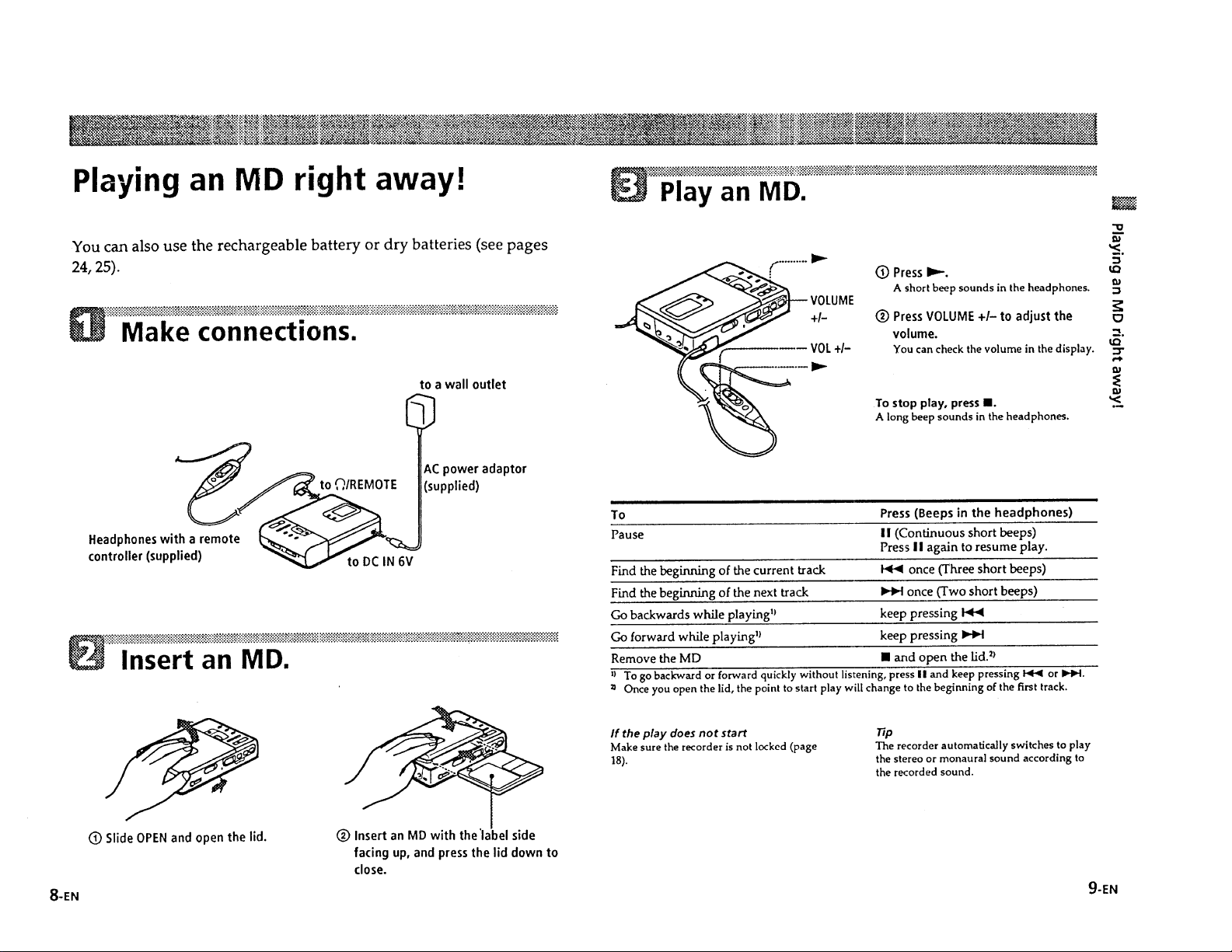

– 6 –

Page 7

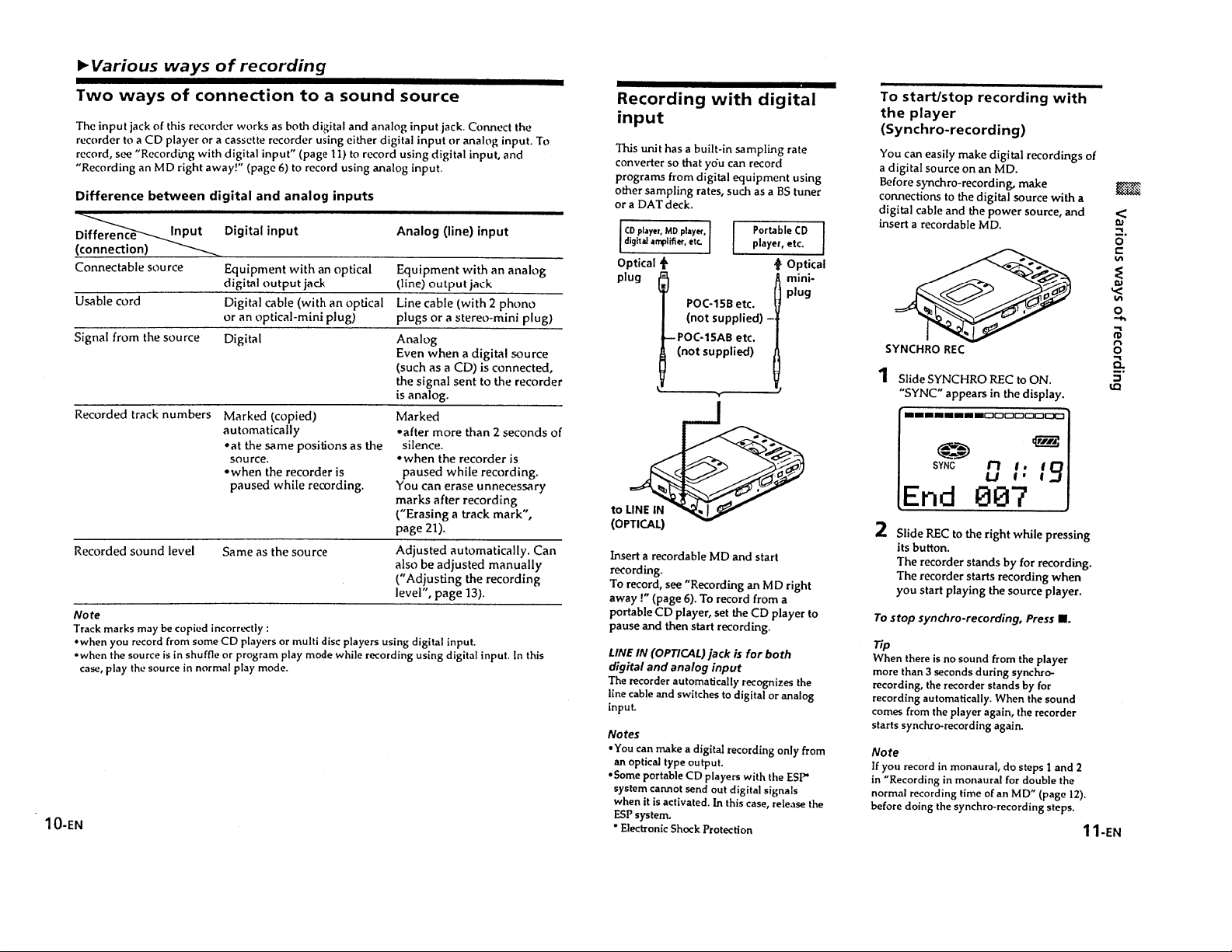

– 7 –

Page 8

– 8 –

Page 9

– 9 –

Page 10

– 10 –

Page 11

– 11 –

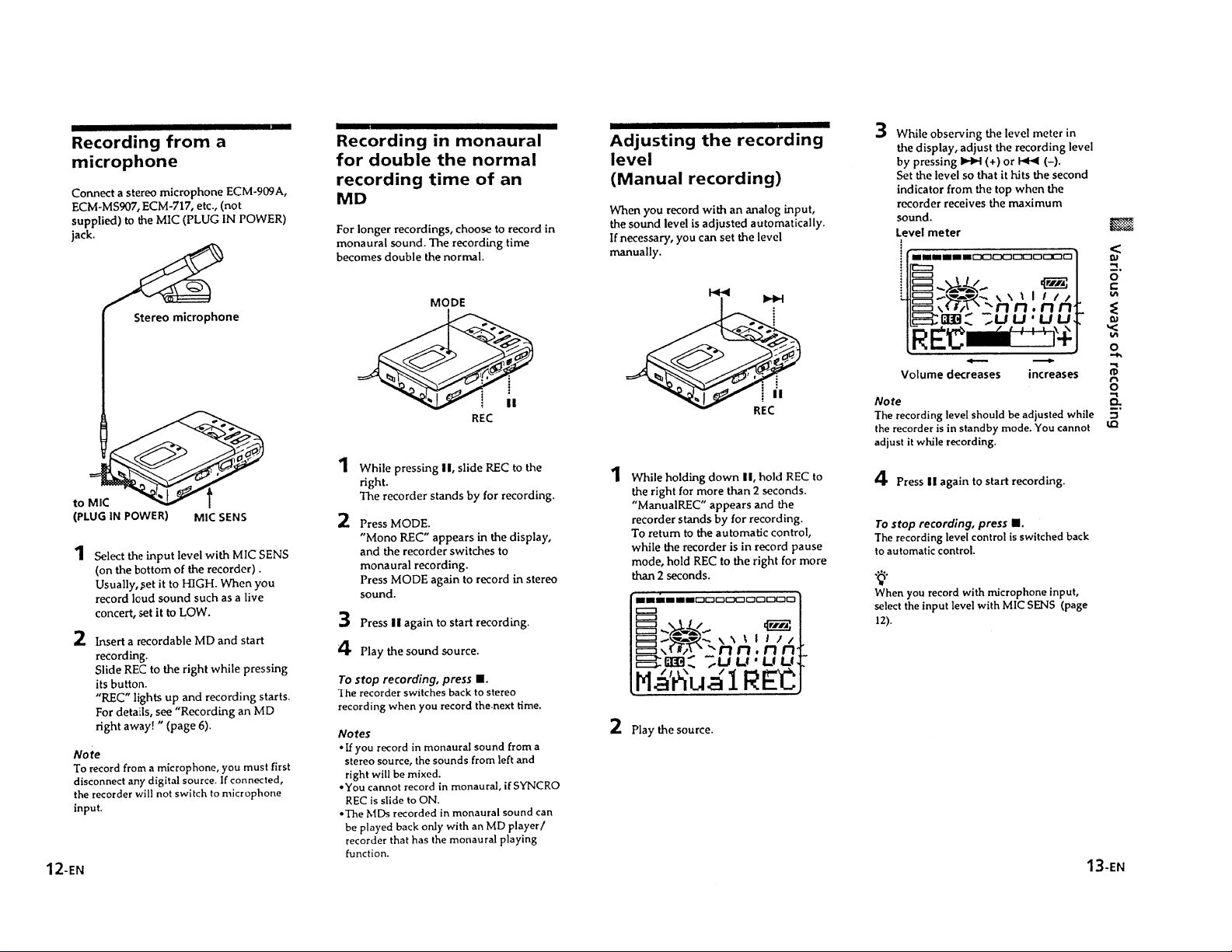

Page 12

– 12 –

Page 13

– 13 –

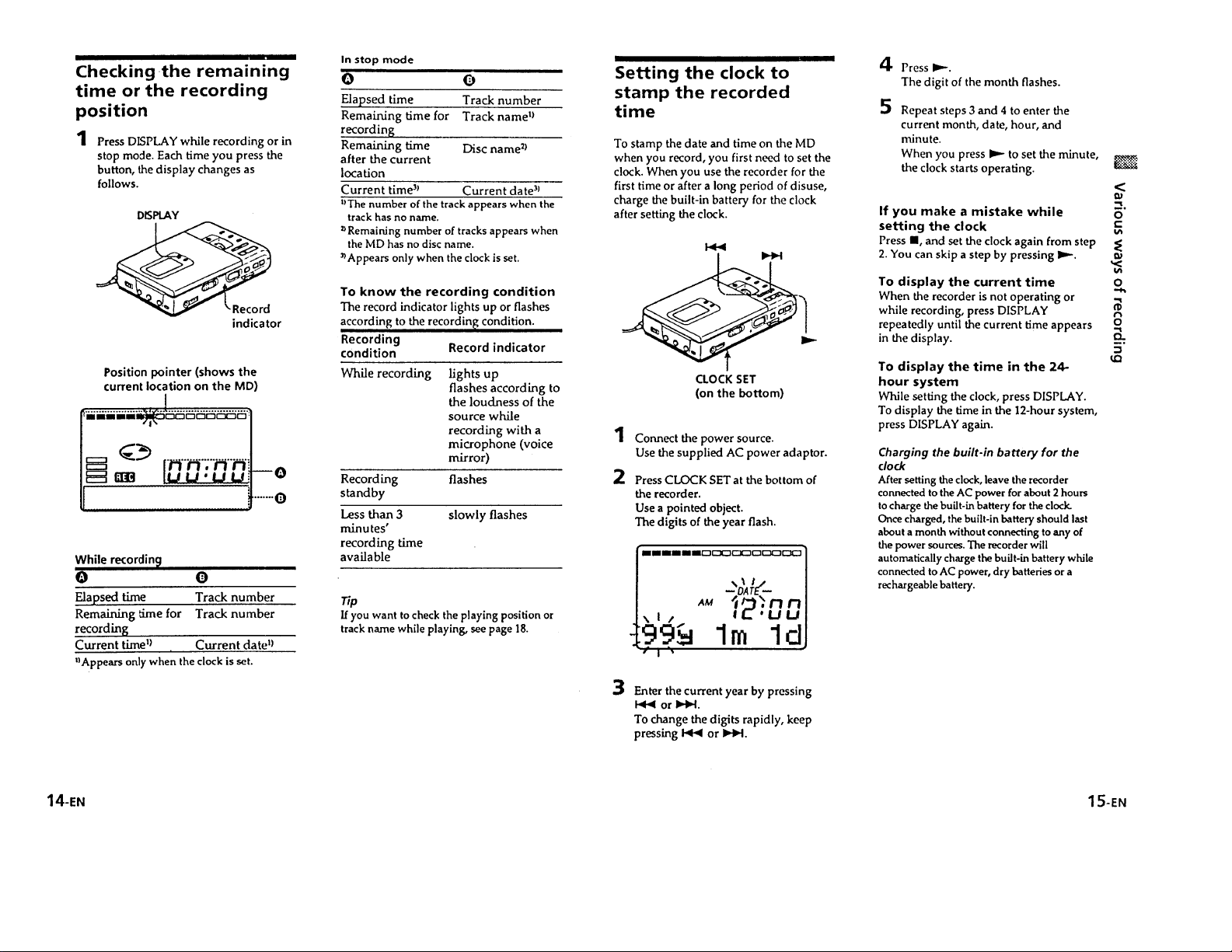

Page 14

– 14 –

Page 15

– 15 –

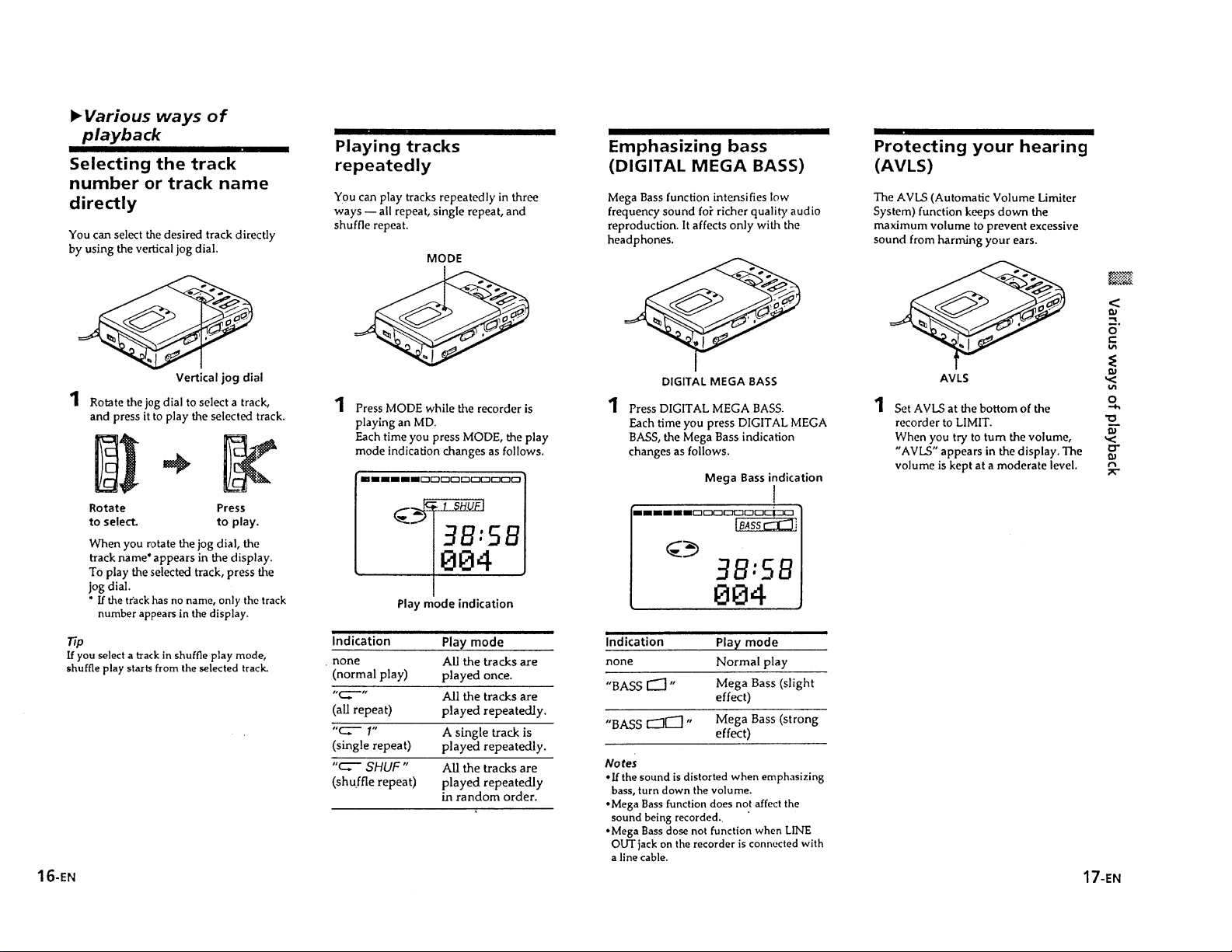

Page 16

– 16 –

Page 17

– 17 –

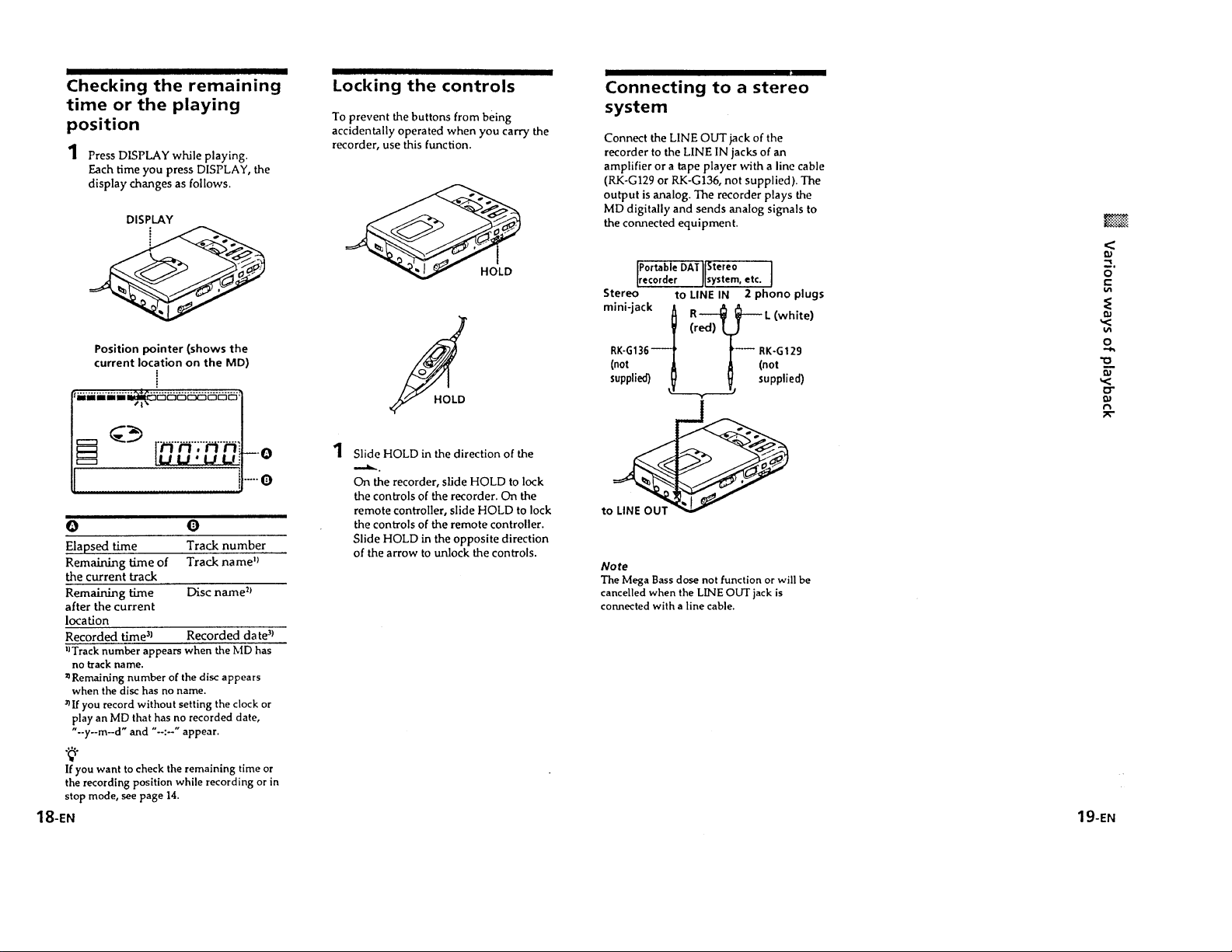

Page 18

– 18 –

Page 19

– 19 –

Page 20

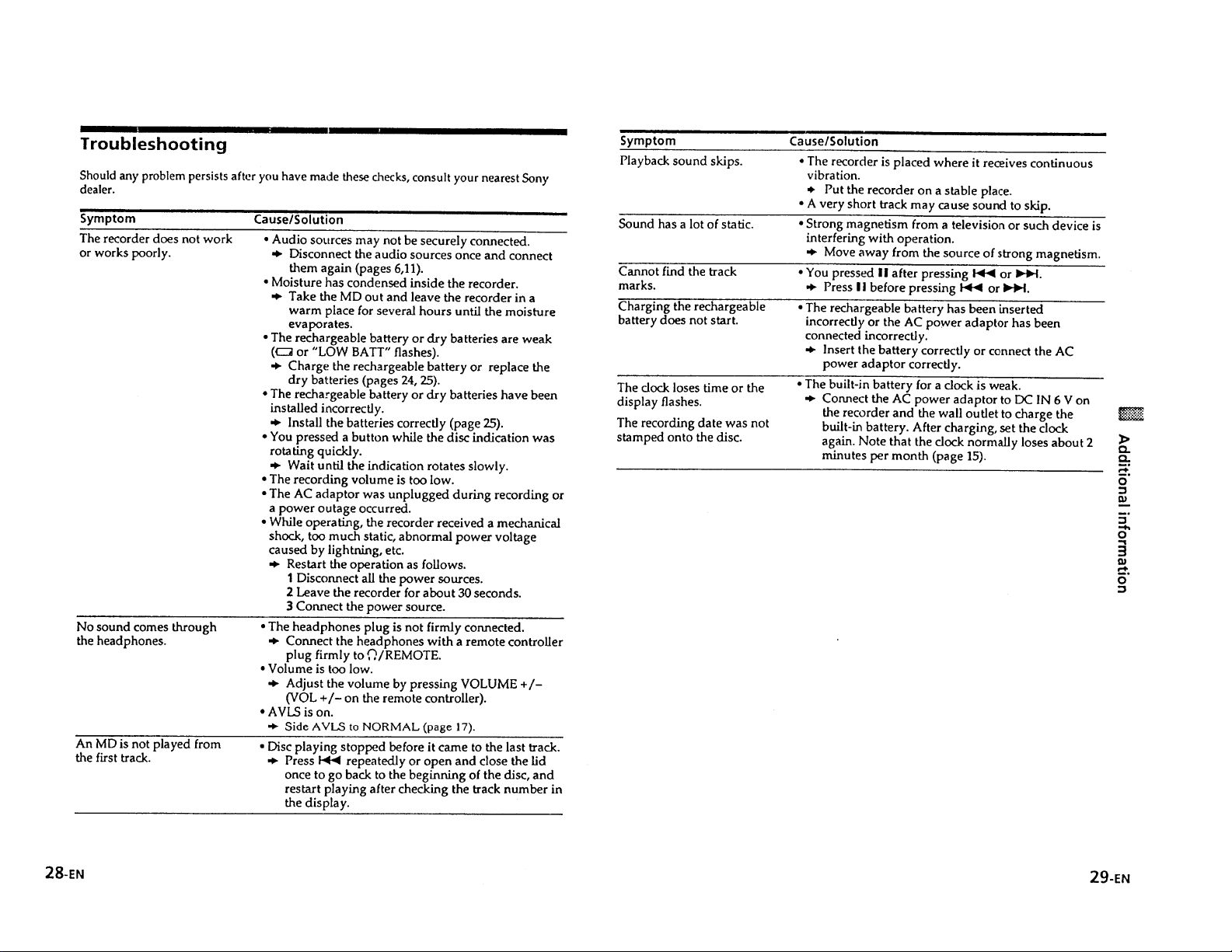

SECTION 3

DISASSENBLY

r

The equipment can be removed using the following procedure.

Set

Panel (upper, bottom) assy

Note : Follow the disassembly procedure in the numerical order given.

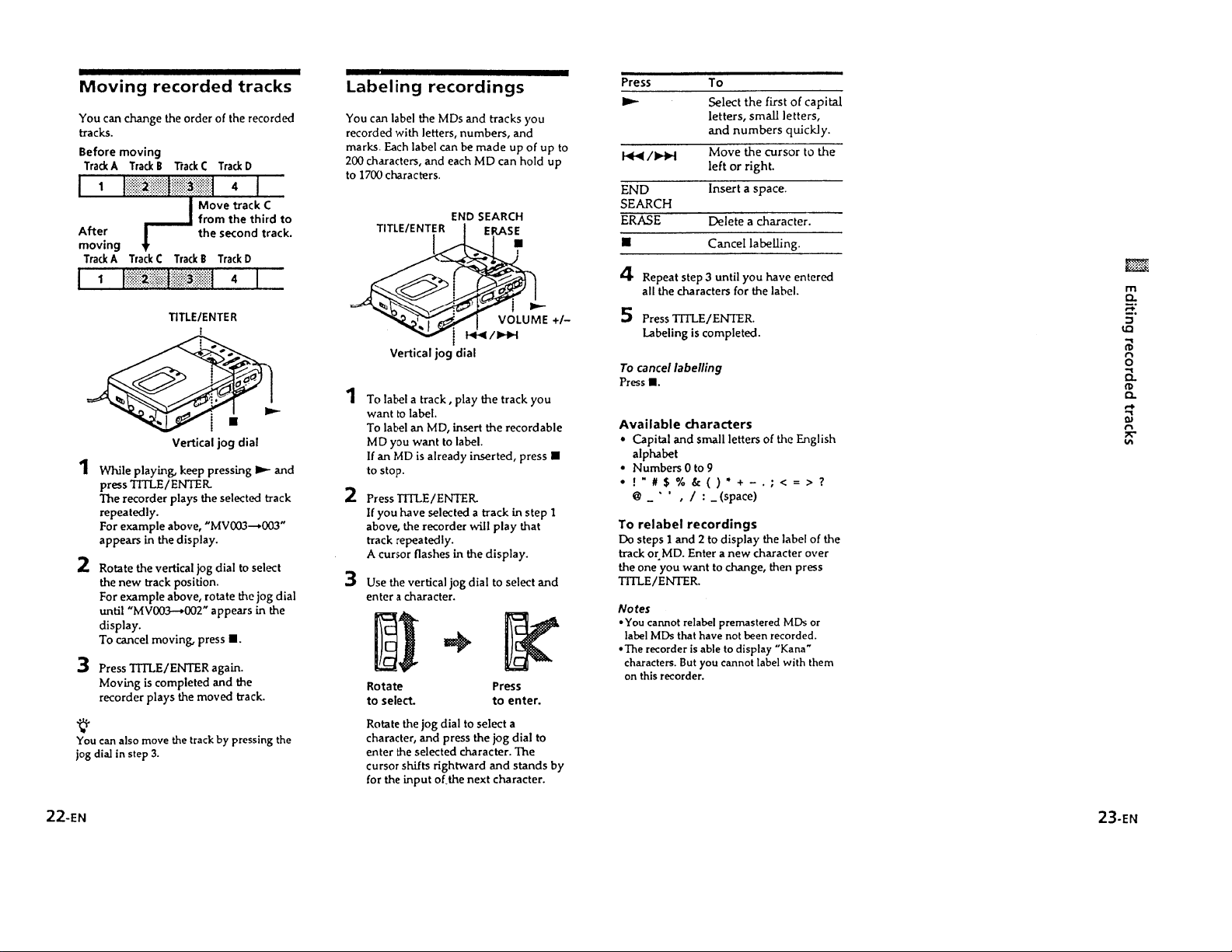

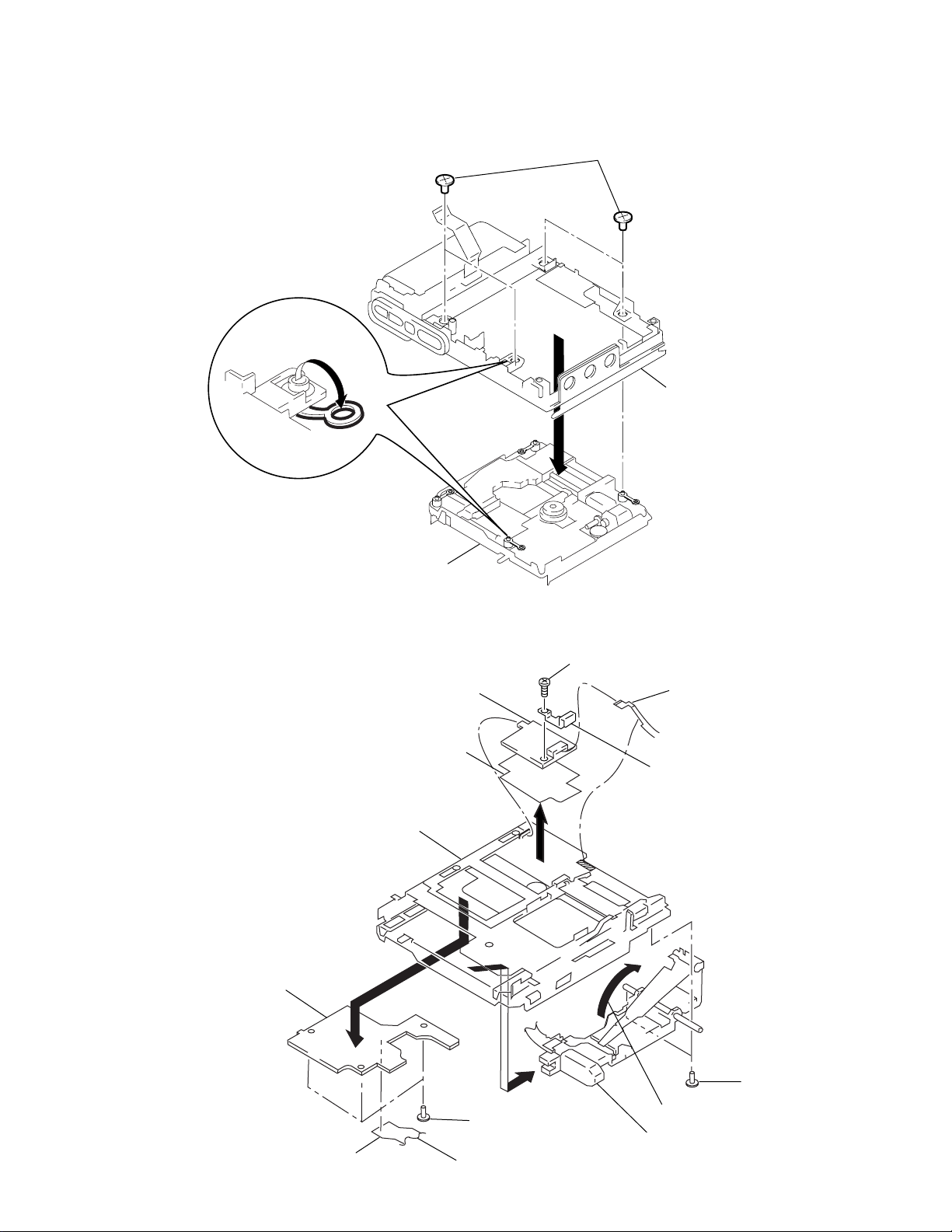

3-1. UPPER PANEL ASSY, BOTTOM PANEL ASSY REMOVAL

Main board Mechanism deck

Battery case assy

Switch board

Power board

Battery case

2

Optical pick-up assy

Control board

Rec board

LCD flexible board (Main board, CN905)

1

Screws

(M1.4 precision pan)

Upper panel assy

4

(M1.4 precision pan)

3-2. MAIN BOARD REMOVAL

* Note for installation

Install the main board pressing the OPEN

button on door open side.

Sometime the open/close detection switch

(S817) will be broken.

5

Flat cable

(24 core)

Screws

5

(1.7x2.5 tapping)

3

Screw

2

6

Screw

(M1.4 precision pan)

Screw (M1.7x2.5)

7

1

Screws

(M1.4 toothed lock)

Main board

Main assy

6

Screws

(M1.4 precision pan)

Bottom panel assy

6

Screws

(M1.4 precision pan)

6

OP flexible board

(Main board CN501)

Ornamental belt assy

Note for installation

*

After installing the main board, make the flexible board ride on the molding. If you hold

the flexible board and main board with a pair of tweezers, the board will ride correctly.

7

3

JOG unit flexible board

(Main board CN904)

– 20 –

4

MD frexible board

(Main board CN502)

* Note for installation

After installing the main

board, push the flexible

board to the outside with a

pair of tweezers. Otherwise,

it may be caught between

the optical pickup section and

the molding.

Page 21

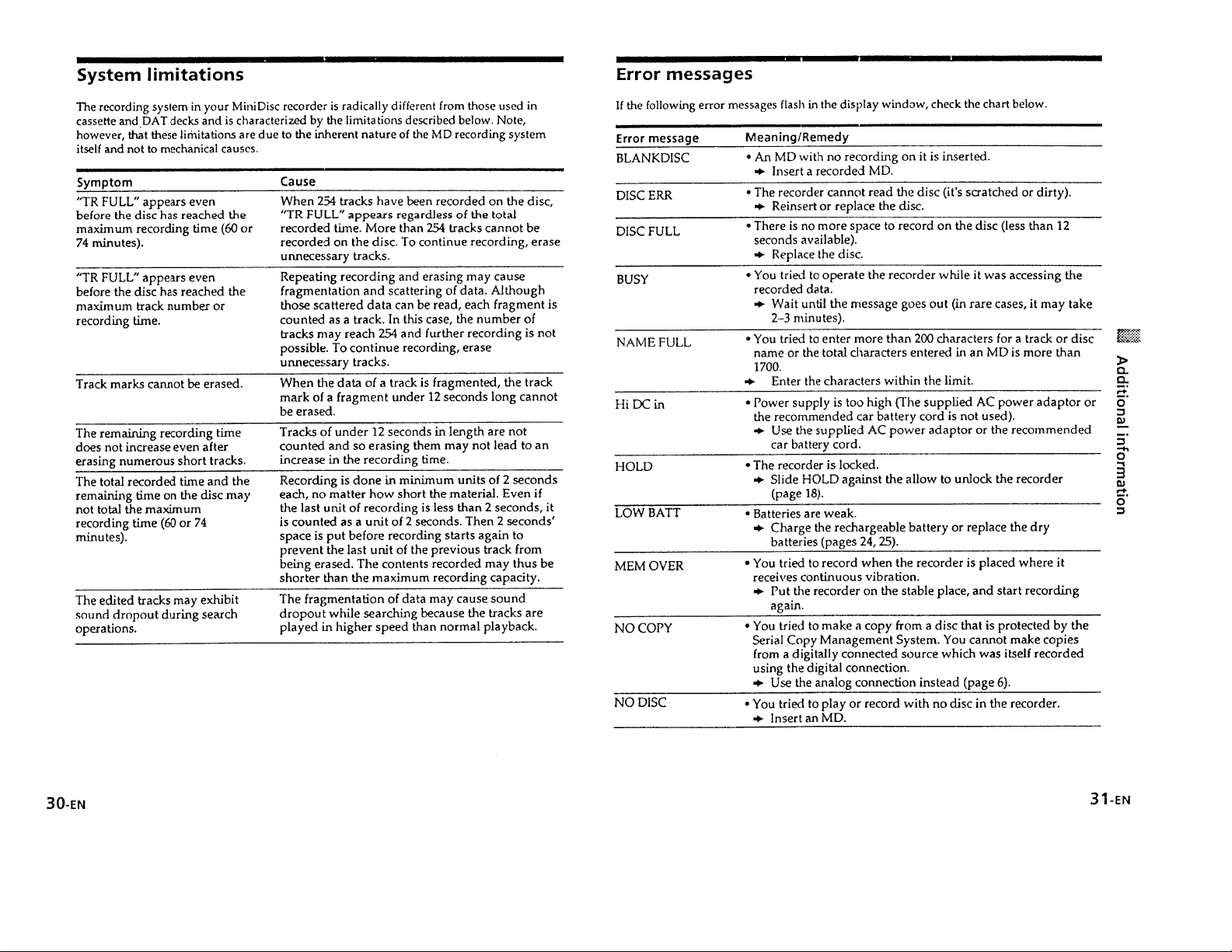

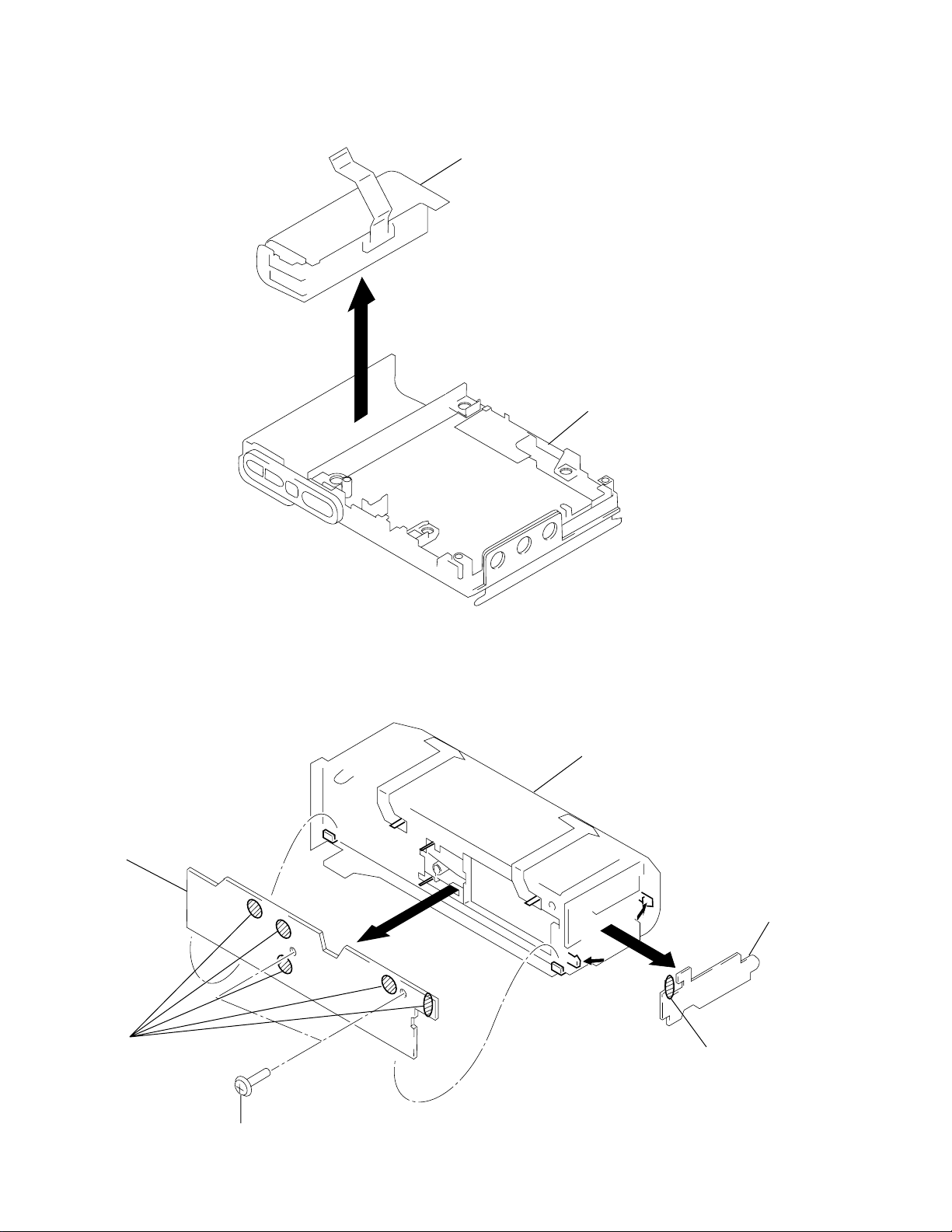

3-3. MECHANISM DECK (MT-MZR30-124) REMOVAL

y

)

2

Remove the damper

fastening ring section.

Mechanism deck

1

Screws (Damper)

3

Ornamental belt ass

3-4. OPTICAL PICK-UP ASSY, CONTROL BOARD, REC BOARD REMOVAL

8

Screw

REC board

Insulating sheet

Control board

5

Remove solder

Mechanism deck

7

4

6

Screws (M1.4)

CLV flexible board

9

1

Head flexible board

(REC board, CN402)

Lever stopper

2

(M1.4x3, locking

3

Over wirte head

Optical pick-up assy

Screws

– 21 –

Page 22

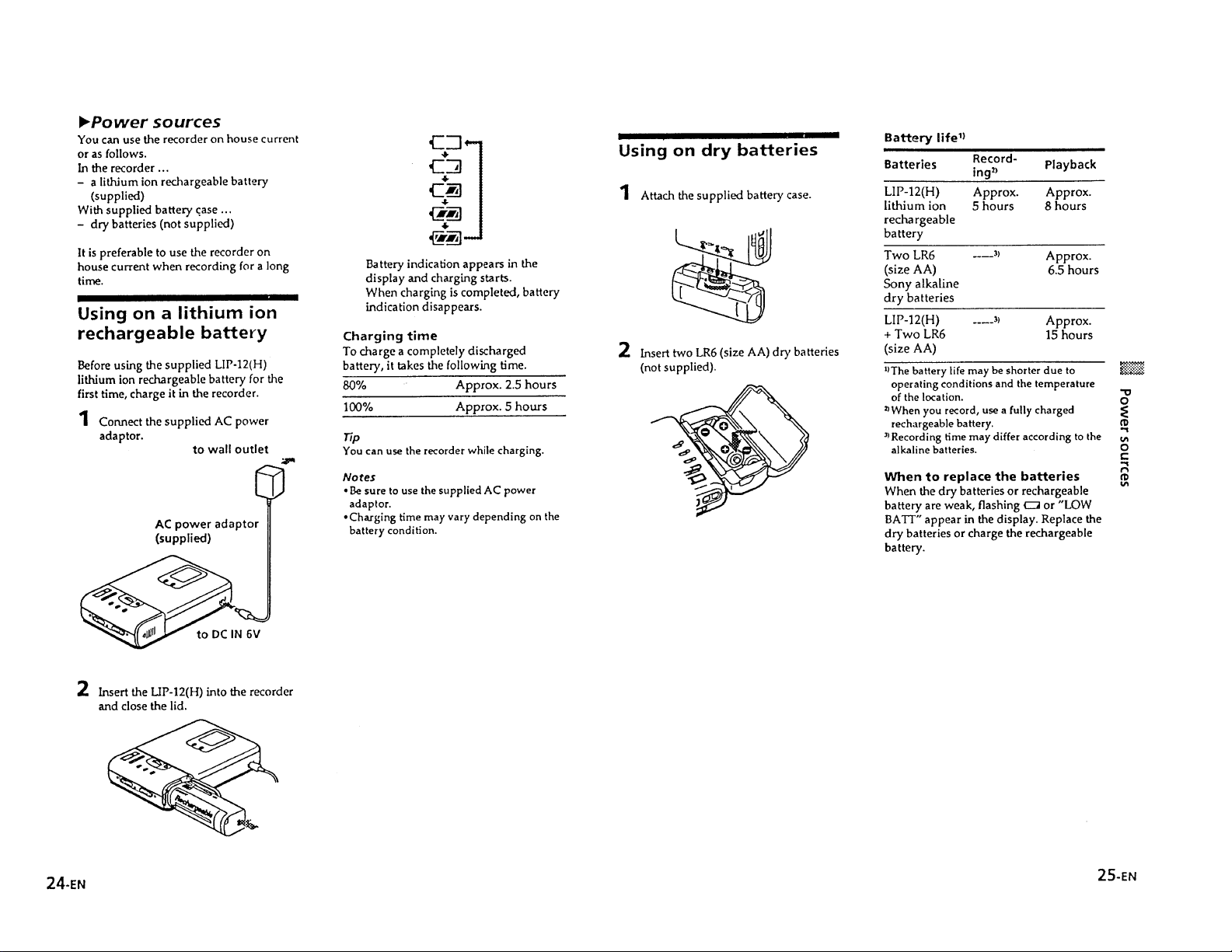

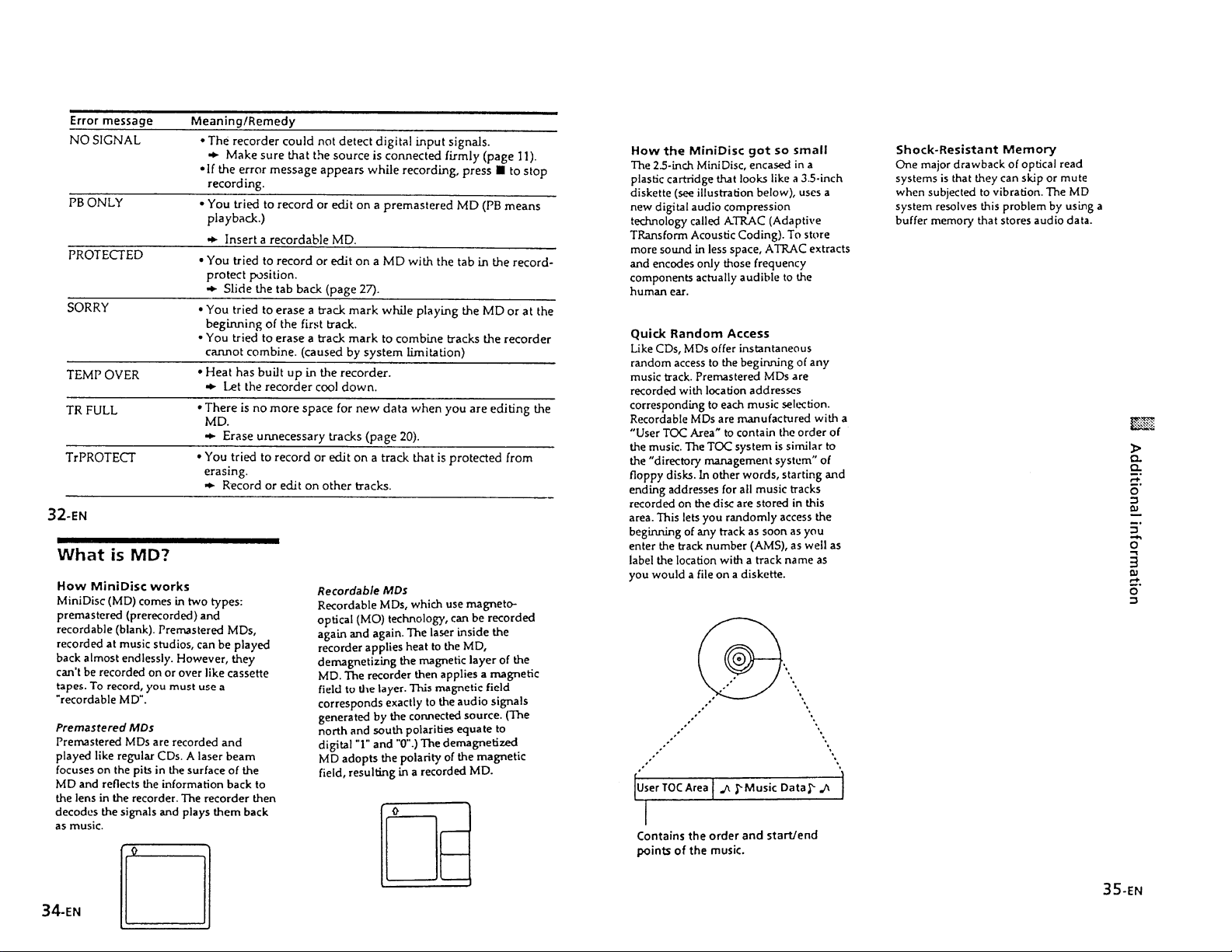

3-5. BATTERY CASE ASSY REMOVAL

t

d

Battery case assy

1

Ornamental bel

3-6. SWITCH BOARD, POWER BOARD REMOVAL

Power board

4

Remove solder

6

Battery case

2

3

2

1

Remove solder

Switch boar

5

Screws (M1.4)

– 22 –

Page 23

SECTION 4

p key

+ key

VOLUME +key or – key

Display when Test Mode is Set

= key

Servo Mode

Segment Section : 00

Dot Section : SERVO

Audio Mode

Segment Section : 00

Dot Section : AUDIO

Power Mode

Segment Section : 00

Dot Section : POWER

General Adjustment Mode

Segment Section : 4000

Dot Section : Assy MODE

Mecha Mode

Segment Section : 00 00

Dot Section : MECHA

Select dial number (blinks)

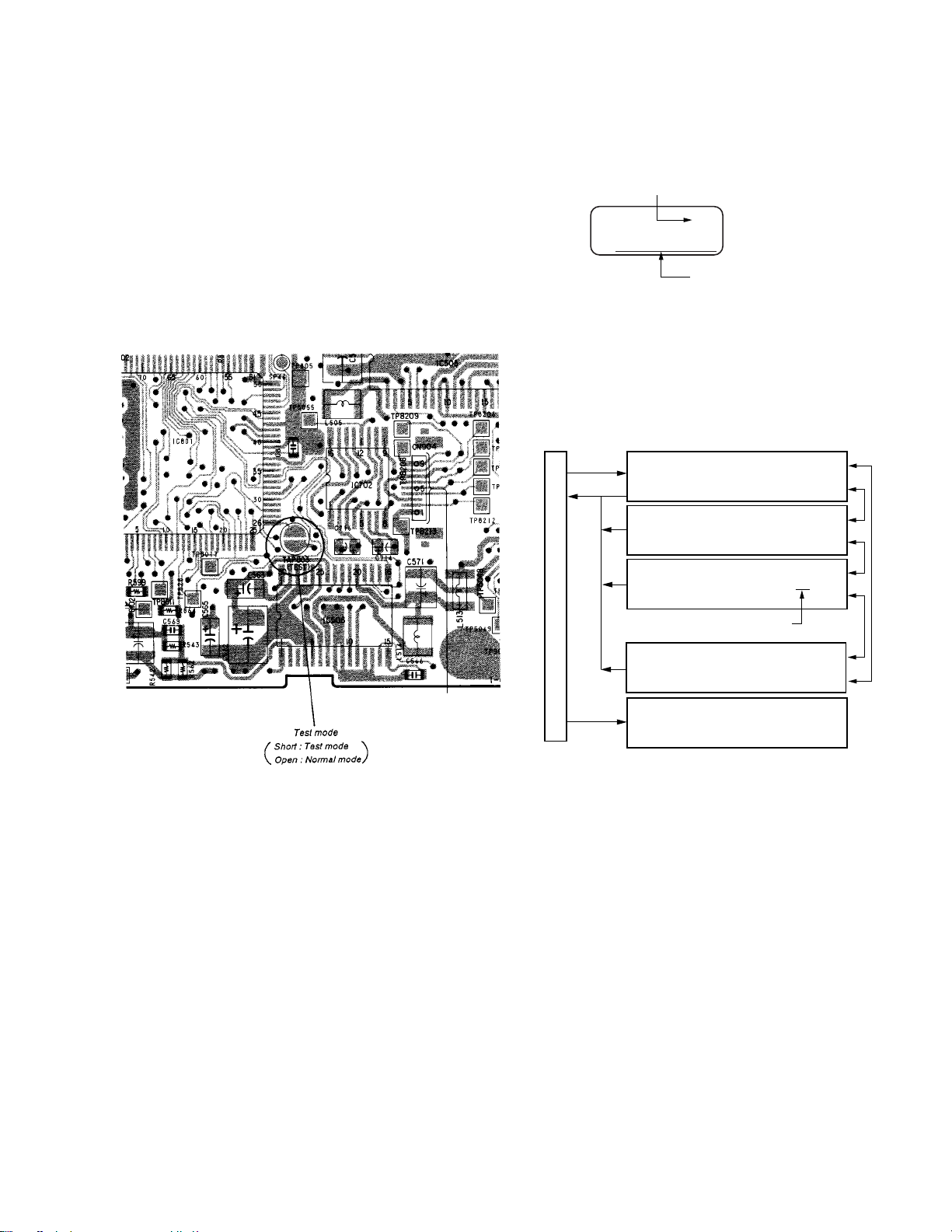

TEST MODE

[Outline]

• The general adjustment mode of this unit performs CD and MO

adjustments automatically when set. In this mode, the disc is determined if CD or MO and adjustments are automatically performed

in order. If errors are detected , the faulty locations are displayed.

The servo mode performs each adjustment automatically.

[Setting the Test Mode]

Short-circuit the soldering bridge of TAP803 (TEST) on the main

board (connect Pin @§ of IC801 to the GND) and turn on the power

supply.

[MAIN BOARD] (SIDE A)

[Operations When Test Mode is Set]

When the test mode is set, the LCD will display as follows.

Self-diagnostic display

(displayed while the DISPLAY key is pressed)

Segment section

00

Ver 00.75

Dot section

ROM version displayed

• The LCD performs the following repeatedly.

ROM version displayed / all lit / all off

• The display can be held and checked by pressing P key.

• The self-diagnostic display appears while the DISPLAY key is

pressed.

[Structure of Test Mode]

The test mode of this unit consists of the following five modes.

[Exiting the Test Mode]

Turn off the power supply and open the soldering bridge of TAP803

(TEST) on the main board.

• In modes other than the general adjustment mode, the last two digits of the mode number will be displayed at the 00 section.

– 23 –

Page 24

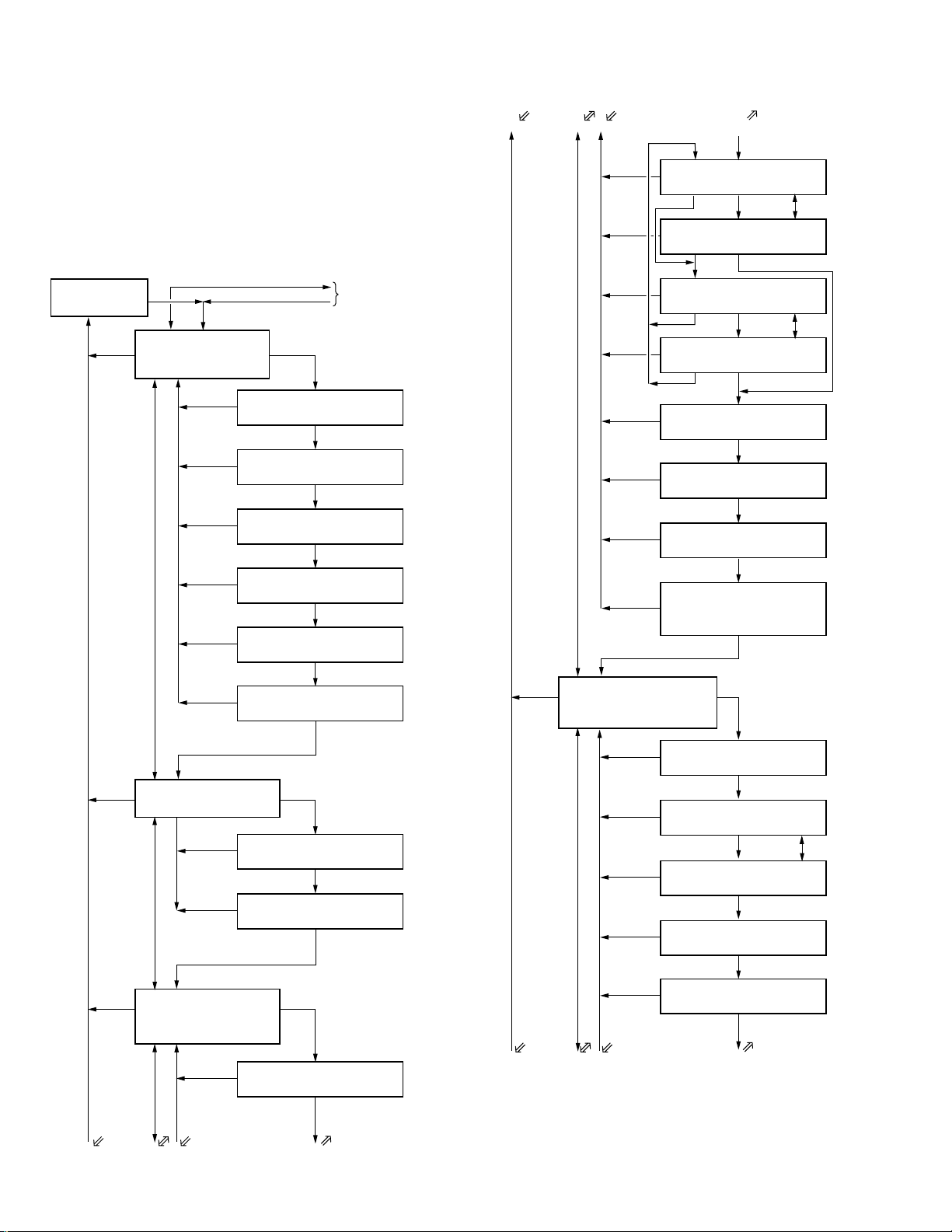

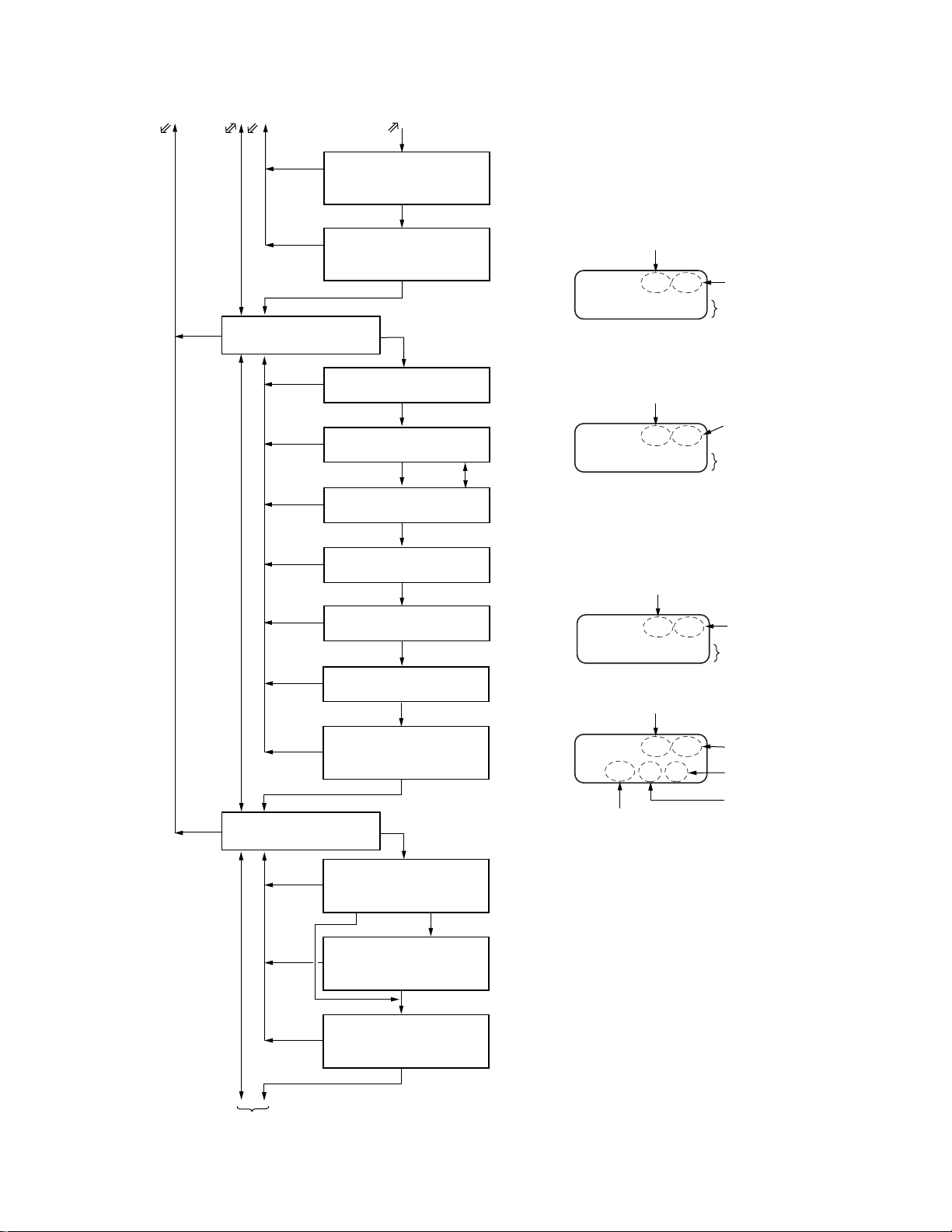

[Servo Mode]

• Set the test mode, press the + key, and set the servo mode using

the VOLUME + and – keys.

• When the servo mode is set, the optical pickup will move to the

outer circumference or inner circumference if the + key or =

key is pressed.

• To set other modes, refer to “ Structure of Test Mode ”.

• Structure of Servo Mode

Mode : 000

Servo mode

p key

p key

p key

VOLUME +key or –key

” key

Mode : 010

M

Offset compensation

value displyed

p key

VC offset compensation

p key

FE offset compensation

p key

APC offset compensation

p key

VOLUME +key or – key

p key

p key

Mode : 020

M

Laser power adjustment

p key

p key

VOLUME +key or – key

Mode : 030

M

MO playback recording

adjustment

ABCD offset compensation

Laser MO read adjustment

Laser MO write adjustment

1

(To page 25)

” key

Mode : 011

M

” key

Mode : 012

M

” key

Mode : 013

M

” key

Mode : 014

M

” key

Mode : 015

All servo ON

M

” key

Mode : 016

Temperature display

M

” key

” key

Mode : 021

M

” key

Mode : 022

M

” key

” key

2 3 4 5

*1:+ key

:= key

*2:REC key

VOLUME +key or – key

p key

Low reflection CD playback

VOLUME +key or – key

p key

p key

p key

p key

p key

p key

p key

p key

Mode : 040

M

adjustment

p key

p key

p key

p key

p key

MO tracking gain adjustment

Low reflection CD EF balance adjustment

Low reflection CD ABCD level adjustment

Laser Low reflection CD read adjustment

Low reflection CD focus gain adjustment

Mode : 032

MO playback EF balance adjustment

*2

Mode : 033

MO playback ABCD level adjustment

*2

Mode : 034

MO recording EF balance adjustment

*2

Mode : 035

MO recording ABCD level adjustment

*2

Mode : 036

Laser MO read adjustment

Mode : 037

MO focus gain adjustment

Mode : 038

Mode : 039

MO focus bias variable

(Cluster Display)

Mode : 041

Low reflection CD focus serch ON

Mode : 042

Mode : 043

Mode : 044

Mode : 045

M

M

M

M

M

M

M

M

” key

M

” key

” key

” key

” key

” key

” key

” key

” key

” key

” key

” key

” key

” key

*1

*1

*1

p key

or – key

VOLUME +key

2 3 4 5

Mode : 031

MO focus search ON

M

6 7 8 9

(To page 25) (To page 25) (To page 25)

” key

– 24 –

Page 25

6 7 8 9

VOLUME +key or – key

p key

CD playback adjustment

*1:+ key

:= key

VOLUME +key or – keyVOLUME +key or – key

p key

p key

p key

Mode : 050

M

p key

p key

p key

p key

p key

p key

p key

Mode : 060

Full REC

CD tracking gain adjustment

Mode : 046

Low reflection CD tracking

gain adjustment

Mode : 047

Low reflection CD focus bias variable

(Cluster Display)

Mode : 051

CD focus search ON

Mode : 052

CD EF balance adjustment

Mode : 053

CD ABC level adjustment

Mode : 054

Laser CD read adjustment

Mode : 055

CD focus gain adjustment

Mode : 056

Mode : 057

CD focus bias adjustment

(Cluster Display)

M

” key

M

” key

” key

” key

” key

” key

” key

” key

” key

” key

” key

• Adjusting Method

Note : There is basically no display for individual adjustment items.

1. When the adjustment modes are set according to “Structure of

Servo Mode”, the last two digits of the mode number and the adjustment value written in the EEPROM will be displayed blinking.

2. When the P key is pressed, the following will be displayed and

adjustments will be performed automatically.

*1

Note : The adjustment value can be changed as desired using the

3. After the adjustments are completed, the item is displayed again

and the adjustment value that was blinking lights up.

• Cluster Display

• Nothing is performed at mode numbers 070 to 073.

Only such upper position titles as SER VO, AUDIO, etc.

(100s position) are displayed.

Mode No. (Last 2 digits)

52 09

Mode No. (Last 2 digits)

52 09

AUTO_ADJ

Adjustment value

(Blinks)

Display of item

Adjustment value

(Blinks)

Automatic adjustment

being performed

VOLUME + and – keys, but try to avoid this as much as

possible.

Mode No. (Last 2 digits)

52 08

Mode No. (Last 2 digits)

52 09

026 4B 01

Cluster value

Adjustment value

(Lights)

Display of item

Adjustment value

(Blinks)

BLOCK error rate

AT error rate

*2:REC key

1

(To page 24)

p key

p key

p key

Mode : 061

32 cluster full REC

(Cluster Display)

” key

Mode : 062

REC shock

(Cluster Display)

” key

Mode : 063

32 cluster PLAY

(Cluster Display)

” key

*2

– 25 –

Page 26

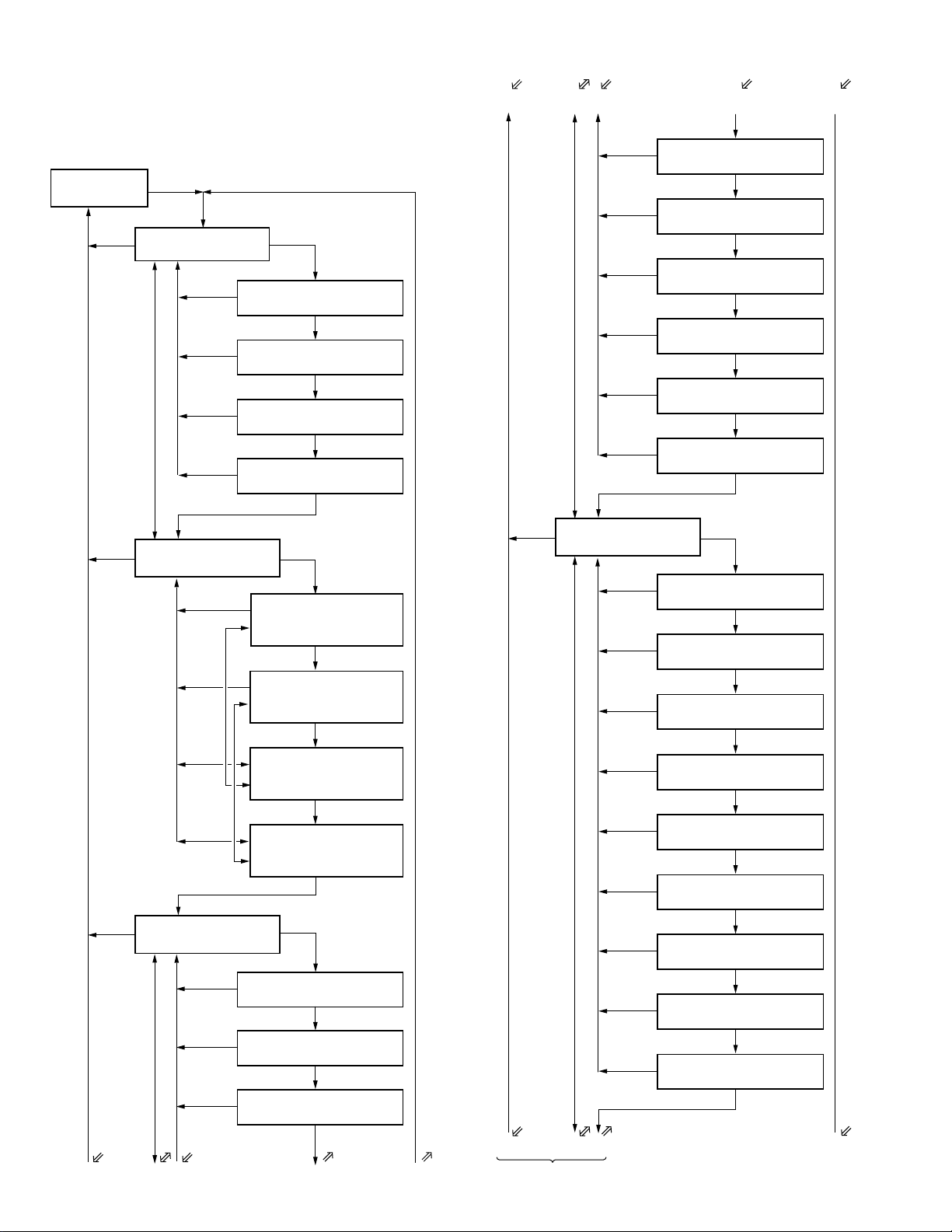

[Audio Mode]

1

23

4

5

VOLUME +key or – keyVOLUME +key or – key

p key

” key

M

Mode : 140

Digital AGC Adjustment 2

p key

M

Mode : 134

MIC GAIN

” key

p key

M

Mode : 135

MIC ATTACK

” key

p key

M

Mode : 136

MIC RECOVER

” key

p key

M

Mode : 137

MIC THD2

” key

p key

M

Mode : 138

MIC GAIN 2

” key

p key

Mode : 141

LINE UP SR

” key

p key

Mode : 142

LINE DOWN SR

” key

p key

Mode : 143

LINE THD0

” key

p key

Mode : 144

LINE GAIN

” key

p key

Mode : 145

LINE ATTACK

” key

p key

Mode : 146

LINE RECOVER

” key

p key

Mode : 147

LINE THD2

” key

p key

Mode : 148

LINE GAIN2

” key

p key

Mode : 149

LINE RTIME

” key

p key

M

Mode : 139

MIC RTIME

” key

1 2 3 4 5

6 7 8 9

(To page 27) (To page 27)

• Set the test mode, press the + key, and set the audio mode using

the VOLUME + and – keys.

• To set other modes, refer to “Structure of Test Mode”.

• Structuer of Audio Mode

Mode : 100

Audio mode

p key

VOLUME +key or – key

p key

p key

VOLUME +key or – key

” key

Mode : 110

M

Audio playback test

p key

p key

p key

p key

Mode : 120

M

Audio recording test

p key

p key

p key

VOLUME +key or – key

p key

Mode : 130

M

Digital AGC adjustment 1

p key

p key

p key

DEMP Manual recording

REC key REC key

DEMP AGC recording

” key

Mode : 111

L&R 1kHz 0dB

M

” key

Mode : 112

L 1kHz 0dB R-

M

” key

Mode : 113

L-

∞

R 1kHz 0dB

M

” key

Mode : 114

L&R-

∞

M

” key

” key

Mode : 121

Manual recording

(LINE, MIC)

” key

Mode : 122

(LINE, MIC)

” key

Mode : 123

AGC recording

(LINE, OPT, MIC)

” key

Mode : 124

(LINE, OPT, MIC)

” key

” key

Mode : 131

MIC UP SR

M

” key

Mode : 132

MIC DOWN SR

M

” key

Mode : 133

MIC THDO

M

” key

∞

– 26 –

Page 27

6 7 8 9

” key

p key

p key

” key

Mode : 200

Mecha Mode

M

Mode : 210

Mechanism check

M

Mode : 211

EJECT prohibited

p key

” key

M

Mode : 212

Magnetic head ON

” key

[Mecha Mode]

• Set the test mode, press the + key, and set the mecha mode

using the VOLUME + and – keys.

• To set other modes, refer to “Structure of Test Mode”.

p key

Mode : 150

M

Digital AGC Adjustment 3

p key

p key

p key

p key

AUTO LMT UP SR

p key

AUTO LMT DOWN SR

p key

p key

MANU LMT UP SR

p key

MANU LMT DOWN SR

p key

” key

Mode : 151

MAN UP SR

” key

Mode : 152

MAN DOWN SR

” key

Mode : 153

AUT O THD3

” key

Mode : 154

” key

Mode : 155

” key

Mode : 156

MAN THD3

” key

Mode : 157

” key

Mode : 158

” key

Mode : 159

THD1

” key

• When the P key is pressed at mode numbers 100, 110 to 114, the

buzzer will sound.

• When the VOLUME keys + and – are pressed at mode numbers

111 to 113, 123, 124, the volume of the headphone output will

increase/decrease.

When the = key or + key is pressed, the volume of the head-

phone output will become maximum/minimum.

• When the VOLUME keys + and – are pressed at mode numbers

121 or 122, the recording level will increase/decrease.

When the = key or + key is pressed, the recording level will

become maximum/minimum.

• At mode numbers 121 to 124, the recording LED will light up.

• At mode numbers 121 to 124, the microprocessor will detect the

port and automatically determine the input.

• Structure of Mecha Mode

• At mode numbers 200, 210 to 212, the optical pick up can be moved

to the outer circumference or inner circumference using the =

or + key.

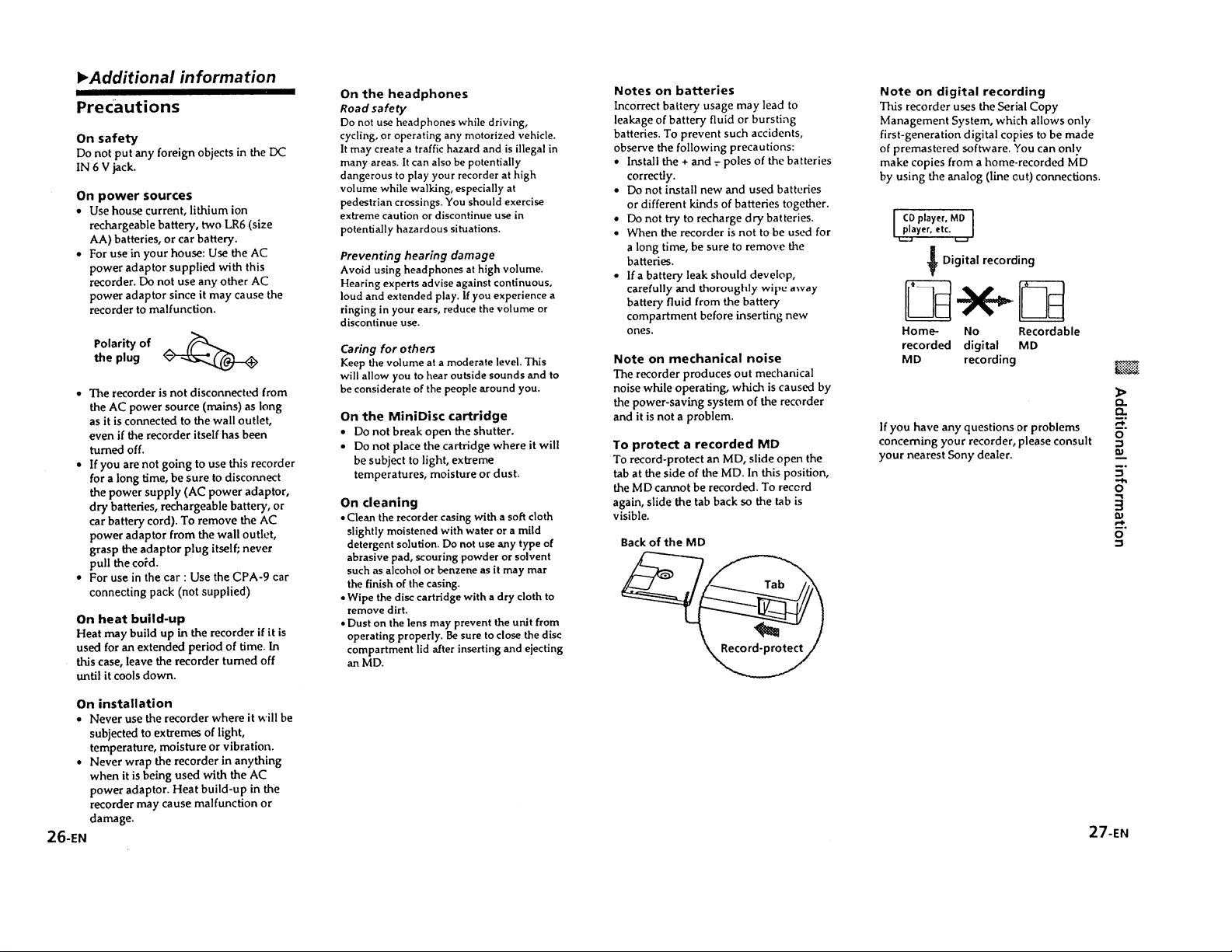

[Power supply Mode]

• Set the test mode, press the + key, and set the power supply

mode using the VOLUME + and – keys.

• To set other modes, refer to “Structure of Test Mode”.

• Structure of Power Supply Mode

Mode : 300

Power supply mode

p key

” key

Mode : 310

M

Power supply

discrimination test

” key

(Automatic discrimination)

p key

p key

VOLUME +key or – key

p key

p key

Mode : 311

Ni MH

Mode : 312

AM3 ✕ 2

Mode : 313

DC IN

Mode : 314

EXT BATT

” key

” key

” key

” key

– 27 –

p key

Mode : 320

Charge test

” key

Mode : 321

Main Charge

p key

Page 28

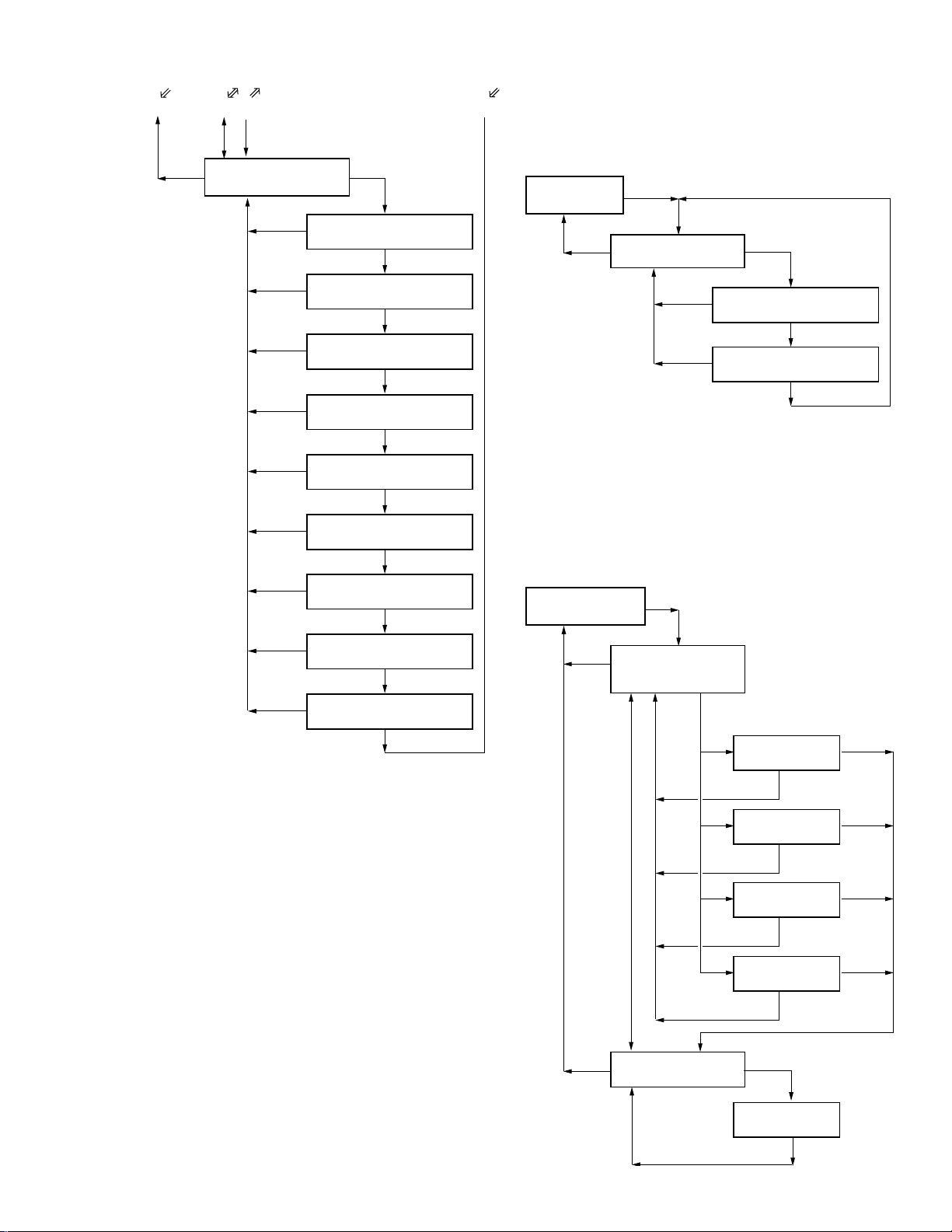

[General Adjustment Mode]

• Set the test mode, press the = key, and set the general adjust-

ment mode.

• To set other modes, cut of f the power once and power on again.

• When the general adjustment mode is set, the LCD display will be

as follows.

4000

Assy MODE

• Structure of General Adjustment Mode

General

adjustment mode

” key (CD, MO discrimination)

CD automatic

adjustment

p key

OK

NG

” key

p key

• MO Automatic Adjustment

No. Mode No. Adjustment

1 032 MO playback EF balance adjustment

2 033 MO playback ABCD level adjustment

3 034 MO recording EF balance adjustment

4 035 MO recording ABCD level adjustment

5 037 MO focus gain adjustment

6 038 MO tracking gain adjustment

7 061 32 cluster full REC

8 062 REC shock

9 063 32 cluster PLAY

10 039 MO focus bias adjustment

11 042 Low reflection CD EF balance adjustment

12 043 Low reflection CD ABCD level adjustment

13 045 Laser low reflection CD read adjustment

14 046 Low reflection CD tracking gain adjustment

MO automatic

adjustment

p key

Reset

OK

NG

” key

p key

Adjusting Method :

1. Set the test mode, press the = key to set the general adjustment

mode.

2. Load the CD test disc (TDYS-1) or SONY MO disc available on

the market.

3. When the ” key is pressed, the disc is determined if CD or MO,

the automatic adjustment modes are set, and adjustments are performed automatically in the following order.

• CD Automatic Adjustment

No. Mode No. Adjustment

1 052 CD EF balance adjustment

2 053 CD ABCD level adjustment

3 055 CD focus gain adjustment

4 056 CD tracking gain adjustment

5 057 CD focus bias adjustment

* Display during MO automatic adjustment

37

Mode No.

during adjustment

MO RUN

4. If the automatic adjustment results are OK, the following will be

displayed.

00

CD mode OK

5. If the automatic adjustment results are NG, the following will be

displayed.

NG mode No. (Last 2 digits)

55 7F

Adjustment results

CD mode NG

* When the mode number is 039, 057 and the focus bias value is

NG, the following will be displayed.

Mode No. (Last 2 digits)

57 30

Focus bias value

CD mode NG

77 : focus bias

Displayed while the P key is

pressed

* Display during CD automatic adjustment

51

Mode No.

during adjustment

CD RUN

– 28 –

77 01

CD mode NG

Error code

(01 to 04)

Page 29

SECTION 5

ELECTRICAL ADJUSTMENTS

* When the mode number is 039, 061 and the AT error rate is NG,

the following will be displayed.

Mode No. (Last 2 digits)

39 03

AT error value

CD mode NG

* When NG, set the servo mode and perform the automatic adjust-

ment of the NG item. (Refer to “Servo Mode”)

5-1. Precautions for Laser Diode Emission Check

When checking the emission of the laser diode during adjustments,

never view directly downwards as this may lead to blindness.

5-2. Precautions for Using Optical Pickup

(KMS–250A/J2N)

As the laser diode inside the optical pickup damages by static electricity easily, solder the laser tap of the flexible board when handling.

Also take the necessary measures to prevent damages by static electricity. Handle the flexible board with care as it breaks easily

Laser tap

Optical Pickup flexible board

5-3. Precautions for Adjustment

1) Perform all adjustments in the order given in the test mode.

After adjusting, exit the test mode.

2) Use the following tools and measuring instruments.

• CD test disc TDYS-1

(Parts Code : 4-963-646-01)

• Recorded MO disc PTDM-1

(Parts Code : J-2501-054-A)

• Laser power meter LPM-1

(Parts Code : J-2501-046-A)

• Oscilloscope (Frequency band above 40MHz. Perform the cali-

bration of probe first before measuring.)

• Digital voltmeter

3) Unless specified othewise, supply DC 6V from the DC IN 6V

jack.

4) Swtich, knob positions

Hold switch...................... OFF

AVLS switch.................... OFF

– 29 –

Page 30

5-4. Laser Power Check

r

e

Connection :

Optical pickup

objective lens

Laser

power meter

5-5. MO Traverse Adjustment

Connection :

Oscilloscop

MAIN board

TP5980 (TE)

AP5430 (VC)

Digital voltmete

MAIN board

AP5022 (VCC)

AP574 (LDIO)

Adjusting Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ” key, and set the laser power adjustment mode (Mode

: 020) using the volume + and – keys.

3. Press the = key and move the optical pickup to the inner most

circumference.

4. Open the cover and set the laser power meter on the objective lens

of the optical pickup.

5. Press the ” key, and set the laser MO read adjustment mode (Mode

: 021).

6. Check that the laser power meter reading is 0.85 ±0.085mW.

7. Check that the voltage between AP5022 (VCC) and AP574

(LDIO) at this time is below 44mV.

8. Press the ”key, and set the laser MO write adjustment mode (Mode

: 022).

9. Check that the laser power meter reading is 6.8 ±0.68mW.

10.Press the P key to finalize the adjustment data.

11.Check that the voltage between AP5022 (VCC) and AP574

(LDIO) at this time is below 88mV.

12.Press the p key.

13.Exit the test mode.

Adjusting Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ” key, and set the MO playback adjustment mode (Mode

: 030) using the volume + and – keys.

3. Press the = and + keys and move the optical pickup to the

center circumference.

4. Load any MO disc available on the market.

5. When the ” key is pressed, the MO playback EF balance adjust-

ment mode (Mode : 032) will be set after focus search ON (Mode

: 031).

6. Press the P key to perform automatic adjustment, and check that

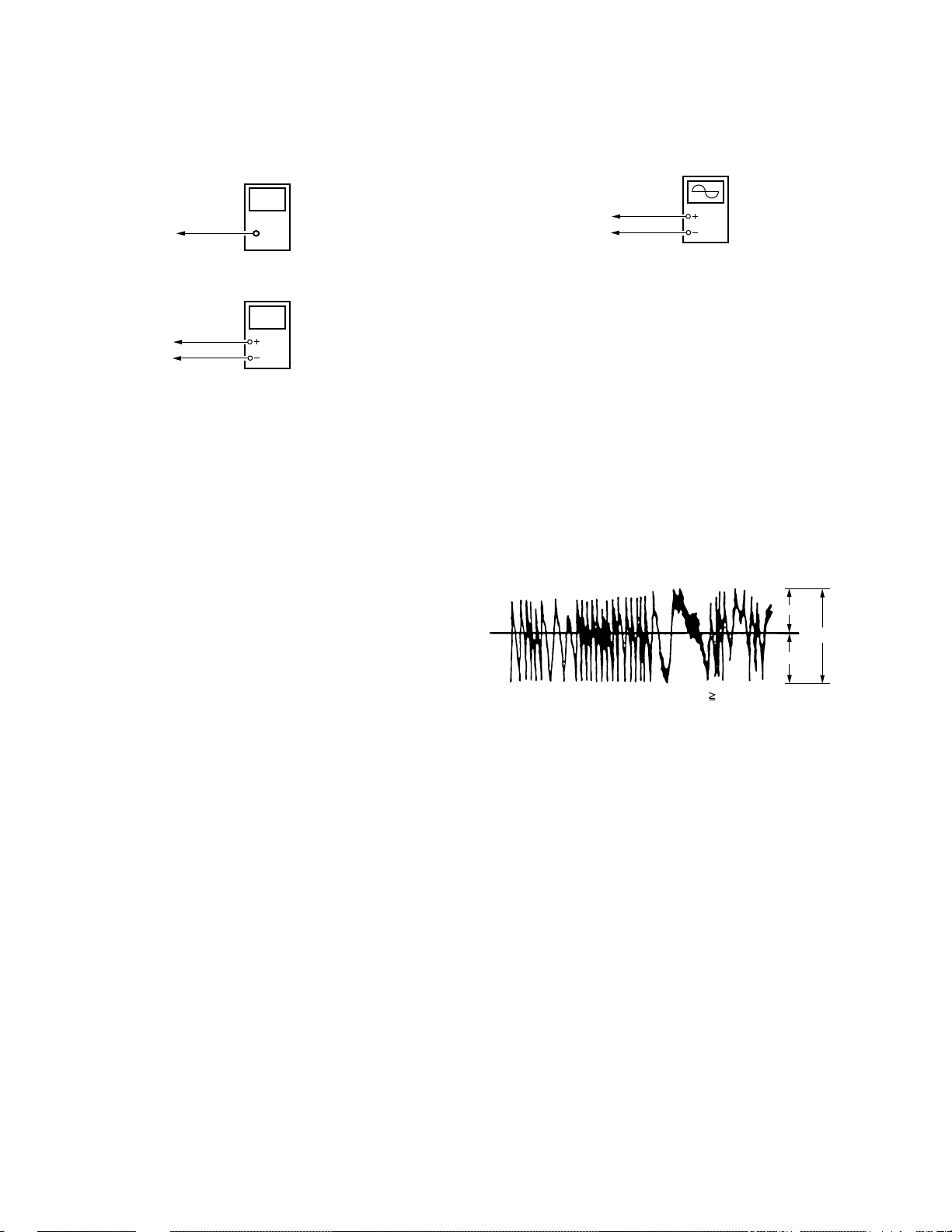

the traverse waveform is symmetrical at the top and bottom.

7. Slide the recording key and set the MO recording EF balance adjustment mode (Mode : 034).

8. Press the P key to perform automatic adjustment, and check that

the traverse waveform is symmetrical at the top and bottom.

(Traverse Waveform)

A

0V

Specification : A = B, C 1.0 Vp-p

C

B

9. Check that the traverse level at this time is above 1.0Vp-p.

10.Press the p key.

11.Exit the test mode.

Note : Using a recorded disc in this adjustment will erase the data.

– 30 –

Page 31

5-6. Low Reflection CD Traverse Adjustment

e

e

Connection :

Oscilloscop

MAIN board

TP5980 (TE)

AP5430 (VC)

5-7. CD Traverse Adjustment

Connection :

Oscilloscop

MAIN board

TP5980 (TE)

AP5430 (VC)

Adjusting Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ” key, and set the low reflection CD playback adjust-

ment mode (Mode : 040) using the volume + and – keys.

3. Load any MO disc available on the market.

4. When the ” key is pressed, the low reflection CD playback EF

balance adjustment mode (Mode : 042) will be set after low reflection CD focus search ON (Mode : 041).

5. Press the P key to perform automatic adjustment, and check that

the traverse waveform is symmetrical at the top and bottom.

(Traverse Waveform)

A

0V

Specification : A = B, C 0.9 Vp-p

C

B

6. Check that the traverse level at this time is above 0.9Vp-p.

7. Press the p key.

8. Exit the test mode.

Adjusting Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ” key, and set the CD playback adjustment mode (Mode

: 050) using the volume + and – keys.

3. Press the = and + keys and move the optical pickup to the

center circumference.

4. Load a CD test disc (TDYS-1).

5. When the ” key is pressed, the CD playback EF balance adjust-

ment mode (Mode : 052) will be set after CD focus search ON

(Mode : 051).

6. Press the P key to perform automatic adjustment, and check that

the traverse waveform is symmetrical at the top and bottom.

(Traverse Waveform)

A

0V

B

Specification : A = B, C 1.0 Vp-p

7. Check that the traverse level at this time is above 1.0Vp-p.

8. Press the p key.

9. Exit the test mode.

C

– 31 –

Page 32

5-8. CD RF Level Check

r

Connection :

Oscilloscope

MAIN board

AP5500 (RF)

AP5430 (VC)

Digital voltmete

MAIN board

AP5022 (VCC)

AP574 (LDIO)

Adjusting Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ” key, and set the CD playback adjustment mode (Mode

: 050) using the volume + and -keys.

3. Press the = and + keys and move the optical pickup to the

center circumference.

4. Load a CD test disc (TDYS-1).

5. When the ” key is pressed, the CD EF balance adjustment mode

(Mode : 052) will be set after CD focus search ON (Mode : 051).

6. When the ” key is pressed, the ABCD level adjustment mode

(Mode : 053) is set.

7. Press the P key to perform automatic adjustment, and check that

the RF level is 1.0 ±0.3Vp-p.

Adjustment Location :

(RF waveform)

1.0 ± 0.3 Vp-p

8. Check that the voltage between AP5022 (VCC) and AP574

(LDIO) at this time is below 44mV.

9. Press the p key.

10.Exit the test mode.

– 32 –

Page 33

SECTION 6

EXPLANATION OF IC TERMINALS

IC503 DIGITAL SERVO, ATRAC (CXD2652R)

Pin No. Pin name I/O Description

1 MNT 0 O Traverse count signal output.

2 MNT 1 O Track jump detect output.

3 MNT 2 – Not used (Open).

4 MNT 3 – Not used (Open).

5 SWDT I Inputs write data signal from system controller (IC801).

6 SCLK I Inputs serial clock signal from system controller (IC801).

7 XLAT I Inputs serial latch signal from system controller (IC801).

8 SRDT O Outputs write data signal to system controller (IC801).

9 SENS O Outputs internal status (SENSE) to system controller (IC801).

10 XRST I Inputs reset signal from system controller (IC801). Reset : L

11 SQSY O

12 DQSY O

13 WRPWR I Inputs laser power switching signal from system controller (IC801).

14 NC – Not used (Open).

15 TX I

16 OSC1 O Clock output (45MHz).

17 OSC0 I Clock input (45MHz).

18 XTSL – Not used (Fixed at “L”)

19 RVDD – Not used (Open).

20 RVSS – Connect to ground.

21 DIN I Digital audio signal input pin (For optical input).

22 NC – Not used (Open).

23 ADDT I Audio data input from A/D converter (IC303).

24 DATA O Monitor/decode audio data output to A/D converter (IC303).

25 ALRCK O L/R clock output to D/A converter (IC303).

26 ABCK O Bit clock signal output to A/D, D/A converter (IC303).

27 FS256 O 11.2896MHz clock output (MCLK).

28 DVDD – Power supply (+2.8V) for digital.

29 – 32 A03 – A00 O Address signal output to RAM (IC509).

33 NC – Not used (Open).

34 – 38 A04 – A08 O Address signal output to RAM (IC509).

39 NC – Not used (Open).

40 DVSS – Ground terminal.

41 XOE O Output enable contol signal output to RAM (IC509).

42 XCAS O Column address strobe singal output to RAM (IC509).

43 A09 O Address signal output to RAM (IC509).

44 XRAS O Row address strobe signal output to RAM (IC509).

45 XWE O Read/write control signal output to RAM (IC509).

46 – 49 D1 – D3 I Data signal input from RAM (IC509).

50 MVCI – Not used (Connect to ground).

51 ASYO O Playback EFM full-swing output (L : VSS, H : VDD).

52 ASYI I Playback EFM asymmetry comparate voltage input.

Output subcode Q sync (SCOR) to system controller (IC801).

Outputs “L” every 13.3msec. Outputs “H” at all most mostly.

Outputs digital-in U-bit CD format subcode Q sync (SCOR) to system controller (IC801).

Outputs “L” every 13.3msec. Outputs “H” at all most mostly.

Input of write data taransmission timing from system controller (IC801).

Also used as magnetic field head ON/OFF output.

– 33 –

Page 34

Pin No. Pin name I/O Description

53 AVDD – Power supply (+2.8V) for analog.

54 BIAS I Playback EFM asymmetry circuit constant current input.

55 RFI I Inputs playback EFM RF signal from RF amplifier (IC501).

56 AVSS – Ground terminal.

57 PDO – Not used (Open).

58 PCO O Decoder PLL master clock PLL phase comparison output.

59 FILI I Decoder PLL master clock PLL filter input.

60 FILO O Decoder PLL master clock PLL filter output.

61 CLTV I Decoder PLL master clock PLL VCO control voltage input.

62 PEAK I Inputs peak hold signal for light amount signal from RF amplifier (IC501).

63 BOTM I Inputs bottom hold signal for light amount signal from RF amplifier (IC501).

64 ABCD I Light amount signal from RF amplifier (IC501).

65 FE I Input focus error signal from RF amplifier (IC501).

66 AUX1 I Input of auxiliary signal from RF amplifier (IC501).

67 VC I Input of middle point voltage (+1.4V) from RF amplifier (IC501).

68 ADIO – Not used (Open).

69 AVDD – Power supply (+2.8V) for analog.

70 ADRT – Not used (Connect to +2.8V).

71 ADRB – Not used (Open).

72 AVSS – Ground terminal.

73 SE I Input of sled error signal from RF amplifier (IC501).

74 TE I Input of tracking error signal from RF amplifier (IC501).

75 AUX2 – Not used (Open).

76 DCHG – Not used (Connect to +2.8V).

77 APC – Not used (Connect to +2.8V).

78 ADFG I

79 FO CONT O Focus control output to RF amplifier (IC501).

80 XLRF I Latch signal input from RF amplifier (IC501).

81 CKRF O RFCK clock (7.35kHz) signal output.

82 DTRF I Serial data input from system controller (IC801).

83 APCREF I Laser power setting signal input.

84 LDDR – Not used (Open).

85 TRDR O Tracking servo drive signal output (–).

86 TFDR O Tracking servo drive signal output (+).

87 DVDD – Power supply (+2.8V) for digital.

88 FFDR O Focus servo drive signal output (+).

89 FRDR O Focus servo drive signal output (–).

90 FS4 O 176.4kHz clock signal output (MCLK).

91 SRDR O Sled servo drive signal output (–).

92 SFDR O Sled servo drive signal output (+).

93 SPRD O Spindle servo drive signal output (–).

94 SPFD O Spindle servo drive signal output (+).

95 FGIN I FG signal input from spindle motor driver (IC701).

96 TEST1 – Not used (Connect to +2.8V).

97 TEST2 – Not used (Connect to +2.8V).

98 TEST3 – Not used (Connect to +2.8V).

99 DVSS – Ground terminal.

100 EFMO O EFM recording signal ouput.

Input of ADIP dual FM signal from RF amplifier (IC501) (22.05kHz±1kHz).

(TTL Schmidt input)

– 34 –

Page 35

IC801 SYSTEM CONTROL (CXP81960M-632R)

Pin No. Pin name I/O Description

1 CLCS O Chip select output to real time clock (IC804).

2 XRST O Reset output. L : Reset

3 WRPWR – Laser power switching signal output.

4 TX O Write data transfer timing output.

5 SENSE I Internal status (SENSE) input.

6 LDON O Laser ON signal. H : ON

7 XSHOCK I Track jump detection input.

8 PIT/GRV I COMP signal input from RF amplifier (IC501).

9 INLS I Detecting switch for internal circuit of sleding. Internal circuit : L

10 PROTECT I Disc write protect switch. H : Protect

11 DATA O Data output to remote control.

12 HOLD I Hold switch input (This unit). L : Hold

13 WP I Wake-up signal input from remote control key and this unit key.

14 OPEN I Detecting switch for opening and closing of the upper cover. Close : L

15 CLOCK I CLOCK SET switch input.

16 CLSDIO I Serial clock input.

17 SDIO2 I/O Serial data input/output.

18 PUSH JOG I Push JOG switch input.

19 LCD STB O LCD standby ouput.

20 CLSCK O Serial clock output for real time clock (IC804).

21 SDI2 I Serial data input.

22 SYNC. REC I SYNCHRO REC switch input.

23 D. B. B I DIGITAL MEGA BASS switch input.

24 LINEDET I Line input detect. L : Line

––––––––––––––––––––

25 AVLS I AVLS switch input. L : ON

26 TEST I Test mode terminal. L : Test mode

27 DCIN I DC input detect. L : DC IN

––––––––––––

28 KANASE L – Not used (Connect toground).

29 –––– – Not used (Open).

30 PCONT O Power control output. L : ON

31 BATTON O Outputs L while operating with a battery.

–––––––––––––––

––––––––––––––––––

32 RECLED O REC LED control. L : ON

33 MODE2 O

34 MODE1 O

Head drive (IC506) control signal output.

35 RFSW O Power control output to RF amplifier (IC501).

36 LCD ON O LCD ON/OFF control. L : ON

–––––––––––––––––

37 MP – Microprocessor mode input (Fixed at “L”).

38 MRST I Microprocessor reset input.

–––––––––––––

39 VSS – Ground.

40 XTAL – System clock (12MHz).

41 EXTAL – System clock (12MHz).

42 CS – Chip Select input (Connected to +2.8V).

43 –––– – Not used (Fixed at “L”).

44 LCDDATA O LCD data output.

45 LCDSCK O Serial clock output.

46 LI-MNT I Voltage monitor for lithium battery.

47 FDMON I Focus coil position monitor input.

48 HIDCMNT I Voltage monitor DC input.

49 KEY2 I Remote control key input.

50 AVSS – A/D converter ground terminal.

– 35 –

Page 36

Pin No. Pin name I/O Description

51 AVREF I A/D converter reference voltage input.

52 AVDD – A/D converter power supply terminal.

53 AM3 I AC adaptor or EXT battery detection input. L : EXT battery

54 TEMP I Temp meter (IC803) input.

55 KEY3 I PLAY Key input.

56 KEY4 I Key input.

57 KEY0 I Key input.

58 KEY1 I Key input.

59 UNMNT (LI+MNT) I UNREG voltage monitor.

60 LIMIT (LI+MNT) I Voltage monitor for lithium battery.

61 FGIN I FG input from motor driver (IC701).

62 SLA I

63 SLB I

JOG dial signal input.

64 INTSW I INITIAL switch input.

65 P ACK IN I MEDIA switch input.

66 JACKDET I Input jack detection input.

––––––––––––––––––––

67 OPT DET I Detecting input an optical input.

68 MICDET I MIC jack detection.

69 XLAT O Latch output.

70 KEYON O TRACK MARK jack input.

71 ST1SOU O

72 ST2SOU O

Stepping motor signal output.

73 XAMON O Charge current control.

74 –––– – Not used (Open).

75 DQSY I Subcode Q sync (SCOR) of digital in U-bit CD format from IC503.

76 TCOUNT I Traverse count signal input.

77 SDI1 I Serial data input.

78 SDO1 O Serial data output.

79 SCK1 O Serial clock output.

80 SQSY I SUB-Q/ADIP SYNC input.

81 BEEP O BEEP sound output control. H : BEEP sound output

82 –––– – Not used (Open).

83 REFLCT I CD/MO discrimination switch.

84 TEX – Not used (Fixed at “L”)

85 XT – Not used (Open).

86 VSS – Ground.

87 VDD – Power supply pin (+2.8V).

88 NC – Not used (Fixed at “H”)

89 CS I Chip select input.

90 PD O D/A converter power down detect during recording. H : Power down

––––––––

––––––––

91 –––– – Not used (Open).

92 –––– – Not used (Open).

93 AMUTE O Analog mute control. L : Mute

94 OPTCONT O Power supply control output for an optical input.

95 CSHP O

96 CSNV O

Chip select output.

97 SCK2 O Serial clock output.

98 XMODON O HF module control output.

99 SDO2 O Serial data output.

100 LI–CHG O Charge control. H : Charge

– 36 –

Page 37

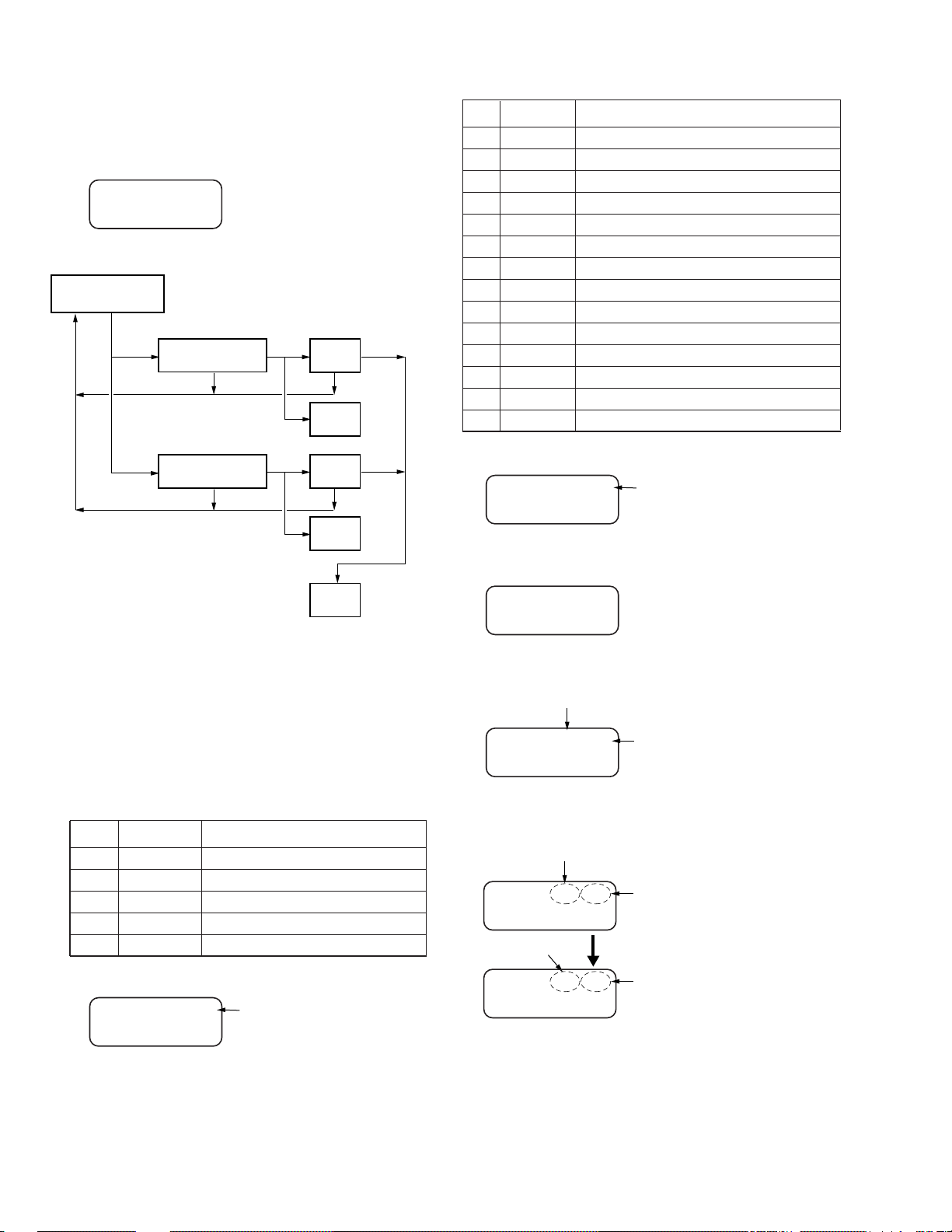

7-1. BLOCK DIAGRAM

d

SECTION 7

MZ-R30

DIAGRAMS

7-2. CIRCUIT BOARDS LOCATION

REC board

CONTROL board

MAIN board

SWITCH board

POWER boar

• Signal path.

: PB

: REC

: MIC

– 37 – – 38 – – 39 – – 40 – – 41 –

Page 38

MZ-R30

r

SEMICONDUCTOR LOCATION

Ref. No. Location

D101 B-3

D201 B-3

D301 E-17

D303 C-4

D304 B-4

D305 C-4

D307 B-3

D308 C-17

D310 C-3

D501 F-14

D502 H-15

D503 D-9

D504 D-8

D801 C-23

D802 C-23

D803 B-15

D804 E-16

D805 I-17

D806 H-18

D807 B-6

D808 H-17

D809 H-17

D810 F-26

D812 F-25

D902 G-2

D903 G-19

D905 F-18

D906 H-17

D907 G-19

D3001 C-17

IC301 E-4

IC302 E-2

IC303 E-4

IC304 D-5

IC306 C-5

IC352 C-4

IC501 C-8

IC502 B-6

IC503 D-14

IC504 B-13

IC505 F-8

IC506 H-7

IC508 E-12

IC509 D-16

IC510 B-15

IC702 G-8

IC801 G-6

IC802 G-18

IC803 E-7

IC804 H-18

Ref. No. Location

IC805 B-4

IC806 B-23

IC807 G-17

IC808 E-23

IC809 D-23

IC810 B-23

IC909 G-19

Q101 E-4

Q102 C-18

Q201 E-4

Q202 D-19

Q301 D-18

Q302 D-6

Q305 D-18

Q309 C-18

Q311 B-17

Q312 C-17

Q313 B-16

Q314 B-17

Q318 C-18

Q320 B-16

Q502 D-13

Q503 B-16

Q504 E-15

Q505 H-15

Q506 C-13

Q701 G-14

Q702 G-14

Q801 H-18

Q802 B-23

Q803 B-26

Q804 G-26

Q805 F-26

Q806 C-6

Q807 D-23

Q808 C-26

Q810 C-6

Q811 H-13

Q812 H-13

Q813 C-27

Q814 B-27

Q815 C-26

Q901 G-19

Q902 G-4

Q903 G-2

Q904 G-4

Q907 H-5

Q910 F-3

7-3. PRINTED WIRING BOARDS – MAIN SECTION –

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

A

[MAIN BOARD] (SIDE A)

US,CND MODEL

B

C

D

E

F

G

H

I

J

S810

DIGITAL MEGA BASS

J303

LINE OUT

J301

MIC

PLUG IN POWER

TP3228

1

4

TP3225

TP3012

US,CND

MODEL

TP3227TP3224

TP3014

THP901

D201

8

5

TP3013

DC IN 6V

TP3222

J901

TP3223

US,CND

MODEL

S301

MIC SENS

LOW

HIGH

S811

OFF

ON

AP3002

AP3003

D303

AVLS

C910

D304 D305

C911

TP8007

16

20 1116

1

36

37

40

45

48

510

1

6

1

TP8006

TP8005

13 10 5 1

89

1

5

10

1

4

3035

25

24

20

15

13

12

4

3

TP8013

TP8004

LCD MODULE

132

8

5

C121 C221

TP8001TP8012

TP8015

TP8016

5052

76

85

TP

75

95

S809

CLOCK SET

5

TP8011

TP8102

TP8168

R838

J302

2 / REMOTE

[SWITCH BOARD]

[MAIN BOARD] (SIDE B)

S818

8

1

HOLD

45

5

4

23

1

5

4

S808

REC

123

76

80

85

90

95

100

70

75

15

60

65

10

15

AP5022

(VCC)

45

3

1

2

SP543

TP5980

(TE)

SP569

SP548

C506

1

3

2

51

5565

45

16

12

35

5

1

26

2515

TAP803

(TEST)

20

25

30

24

20

25

30

36

AP5500

(RF)

TP500

15 10

9

8

16

45

37

40

253036

9

5

1

1315

12

10

5

(VC)

1

48

SP567

19

15

18

22

20

15

10

5

1

TP5020

TP5019

22

TP5018

20

TP5017

TP5016

15

10

5

1

TP

5014

TP

5013

TP

5011

TP

5010

(LDI1)

AP574

(LDIO)

1

5

10

15

20

24

TP8303

TP5031

MINI DISC

OPTICAL

PICK-UP

BLOCK

(KMS-250A/J2N)

CLV BOARD

(CN701)

REC BOARD

B

(CN401)

(Page 62)

D803

REC

55

51

50

45

40

35

30

26

25

20

S823

OPEN

[POWER BOARD]

(SIDE A)

3

44

2

3

1

1

5

6

10

8

5

1

4

20

16

15

11

8

5

1

4

8

5

4

1

4

1

4

5

8

1

5

8

1

8

US,CND

MODEL

(DOOR OPEN/CLOSE)

SYNCHRO REC

S816

ON

OFF

S817

J304

LINE IN

(OPTICAL)

2

1

5

C840

1 4

8

1 4

5

58

5

1

8

RECHARGEABLE

(IEC DESIGNATION R6)

BATTERY

(NI – MH)

OR

DRY BATTERY

SIZE “AA”

2PCS,3V

123

RECHARGEABLE

BATTERY

(LITHIUM ION)

LIP-12

3.6V

[POWER BOARD]

(SIDE B)

123

1

5

10

15

20

24

TP891

13

4

51

15

10

5

1-663-388-

13

(13)

1-663-388-

(13)

13

1-663-387-

13

1-663-387-

(13)

(SIDE A)

13

1-663-389-

Note:

• : parts extracted from the component side.

•

•

(13)

: Through hole.

: Pattern from the side which enables seeing.

Caution :

[SWITCH BOARD]

(SIDE B)

S806

R845

R844

S804

VOLUME

S805

13

1-663-389-

(The other layers’ patterns are not indicated)

(13)

(13)

Pattern face side : Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

SWITCH UNIT WITH JOG DIAL

Parts face side : Parts on the parts face side seen from the

(Component side) parts face are indicated.

• Abbreviation

CND : Canadian

JE : Tourist

– 42 – – 43 – – 44 – – 45 – – 46 –

Page 39

7-4. SCHEMATIC DIAGRAM – MAIN (1/3) SECTION –

r

Refer to page 65 for IC Block Diagrams.

r

WAVEFORMS

3

IC501 #•

4

Approx. 0.5 Vp-p

IC501 @ª

1.0

±

0.3 Vp-p

MZ-R30

5

2.7 Vp-p

13.1 msec

IC503 !¡

6

2.9 Vp-p

45.158 MHz

IC503 !¶

(Page 64)

(Page 51)

(Page 56)

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

specified.

•

: B+ Line

B +

• Power voltage is dc 6V and fed with regulated dc power supply

from external power voltage jack (J901).

• Voltage and waveforms are dc with respect to ground under

no-signal conditions.

no mark : PB

( ) : REC

• Voltages are taken with a VOM ( Input impedance 10MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Wavef orms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

: PB

: REC

• Abbreviation

CND : Canadian

JE : Tourist

1

/4 W or less unless otherwise

– 47 – – 48 – – 49 – – 50 –

Page 40

MZ-R30

r

WAVEFORMS

1

2

1.2 MHz

IC801 $º

2.1 Vp-p

0.7 Vp-p

7-5. SCHEMATIC DIAGRAM – MAIN (2/3) SECTION –

r

Refer to page 67 for IC Block Diagrams.

32.768 kHz

IC804 2

(Page 57)

(Page 49)

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

specified.

• ¢ : internal component.

: B+ Line

•

B +

• Power voltage is dc 6V and fed with regulated dc power supply

from external power voltage jack (J901).

• Voltage and waveforms are dc with respect to ground under

no-signal conditions.

no mark : PB

( ) : REC

: CHARGE

• Voltages are taken with a VOM ( Input impedance 10MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Wavef orms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

1

/4 W or less unless otherwise

(Page 56)

– 51 – – 52 – – 53 – – 54 –

Page 41

7-6. SCHEMATIC DIAGRAM – MAIN (3/3) SECTION –

r

Refer to page 68 for IC Block Diagrams.

7-7. SCHEMATIC DIAGRAM – POWER SECTION –

MZ-R30

(Page 49)

(Page 51)

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

specified.

•

: B+ Line

B +

• Power voltage is dc 6V and fed with regulated dc power supply

from external power voltage jack (J901).

• Voltage and waveforms are dc with respect to ground under

no-signal conditions.

no mark : PB

( ) : REC

• Voltages are taken with a VOM ( Input impedance 10MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Signal path.

: PB

: REC

: MIC

• Abbreviation

CND : Canadian

1

/4 W or less unless otherwise

(Page 54)

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

specified.

•

: B+ Line

B +

•

: adjustment for repair.

• Power voltage is dc 6V and fed with regulated dc power supply

from external power voltage jack (J901).

• Voltage and waveforms are dc with respect to ground under

no-signal conditions.

• Voltages are taken with a VOM ( Input impedance 10MΩ).

Voltage variations may be noted due to normal production

tolerances.

1

/4 W or less unless otherwise

– 55 – – 56 – – 57 – – 58 – – 59–

Page 42

MZ-R30

(Page 47)

7-8. PRINTED WIRING BOARDS – CONTROL SECTION –

1 2 3 4 5 6 7 8 9 10 11 12

7-8. PRINTED WIRING BOARDS – CONTROL SECTION –

r

SEMICONDUCTOR

LOCATION

Ref. No. Location

D401 A-11

D402 B-12

IC701 B-7

Q401 B-11

Q402 A-11

Q403 B-12

Q404 A-12

Q703 B-2

[ CONTROL BOARD ] (SIDE B)

A

S702 (PROTECT)

(REFLECT)

B

(INITIAL)

[ CONTROL BOARD ] (SIDE A)

CN701

HR901

OVER WRITE

HEAD

15

20

10

5

C702

B

MAIN BOARD

CN502

(Page 44)

[ REC BOARD ] (SIDE A)

C

[ REC BOARD ] (SIDE B)

D

M901

SPINDLE

MOTOR

Note:

• : parts extracted from the component side.

•

: Through hole.

•

: Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated)

Caution :

Pattern face side : Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side : Parts on the parts face side seen from the

(Component side) parts face are indicated.

4

M902

SLED MOTOR

E

M903

STEPING

MOTOR

1-663-391-

(INLIMIT)

Note :

• All capacitors are in µF unless otherwise noted. pF: µµF

50WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

specified.

•

: B+ Line

B +

• Power voltage is dc 6V and fed with regulated dc power supply

from external power voltage jack (J901).

• Voltage and waveforms are dc with respect to ground under

no-signal conditions.

no mark : PB

( ) : REC

• Voltages are taken with a VOM ( Input impedance 10MΩ).

Voltage variations may be noted due to normal production

tolerances.

1

/4 W or less unless otherwise

– 60 – – 61 – – 62 – – 63 – – 64 –

Page 43

r

1 2 3 4 5 6 7 8

16

15 14 13 12 11 10

9

CONTROL

LOGIC

H

BRIDGE 2

H

BRIDGE 1

LVDET

PGND2

OUT2A

IN2A

IN2B

VG

VM2

OUT2B

PGND1

OUT1A

VM1

IN1A

IN1B

VC

OEB

LGND

OUT1B

LEVEL

SHIFT

DRIVER

VC

VC

VC

VC

VC

VC

VC

VC

36 7

VG

VD12VD16VD8FO111RO19PGND10PGND15FO2

13

RO214PGND21VD25VD30VD29FO326RO327PGND28PGND22FO4

24

RO423PGND

2

VC

3

CLK

34

PS

6

FI1

5

RI1

33

OE

17

FI2

18

RI2

31

FI3

32

RI3

20

19

PI4

4

35

GND

1

LG

VC

VC

CLOCK

DC/DC

CONVERTER

CLK

DETECTOR

DRIVER

PRE-DRIVER

CONTROL

DRIVER

PRE-DRIVER

CONTROL

DRIVER

PRE-DRIVER

CONTROL

DRIVER

PRE-DRIVER

CONTROL

21

22

23

24

25

26

2728

29

30

16

17

18

19

20

2

3

5

4

6

7

8

9

10

1

11

12

13

14

15

CONTROL

LOGIC

CHARGE PUMP

SAW

SAW

CLK

OSC

EFM

LOGIC

BIAS

VREF

PRE

DRIVER

VREF

COMP

COMP

+

PRE DRIVER

SAW

EN ENB

OP

RF

SS

DTC

NC

PGNDLG

VB

VIN

VIH

VGH

CIL

VCC

CK

COSC

MODE 1

MODE 2

INM

ERRID

ERRIV

GND

VSET

VG

VGL

PGNDB

HA

HB

PGNDA

GND

EFM

VERF

IC BLOCK DIAGRAM – MAIN (1/3) SECTION –

IC501 CXA2523R

MORF O

MORF I

RFO

OPN

46 45 44 43 42 41 40 39 38 37

47

48

RFA I

I

1

J

2

CVB

3

VC

4

A

I VR

B

5

I VR

C

6

I VR

7

D

I VR

E

8

I VR

9

F

I VR

GSW 1V

10

PD

RF A2

1

HLPT

2

CFST

1

2

GRV

GRVA

AA

BB

CC

DD

EE

FF

EE °

FBAL

USROP

EFB

FF °

AUXSW

OPO

1

2

PTGR

1

2

ABCDA

FEA

ATA

COMMAND

ADDC

BPF 22

WBL

WBL

TESW

COMPP

BPF3T

3T

3T

USRC

PEAK

BOTTOM

WBL

ADIP

AGC

PTGR

BGR

COMPO

WBL

3T

EQ

EQ

AGC I

PEAK3T

P-P

WBL

PBH

RF AGCRFPEAK

EQRF AGC

DET

EQ

TEMP

BPFC

DET

1

2

SEA

1

2

TEA

VI CONV

36

35

34

33

32

31

30

29

28

27

26

25

IC505 MPC17A38VMEL

BOTM

ABCD

FE

AUX

ADFG

ADAGC

ADIN

IC506 MPC18A20VMEL

ADFM

SE

CSLED

TE

WBLAD

APC

11

APCREF

12

IC702 MPC17A33SVMEL

XLAT

VREF

19

VREF

FOCNT

XSTBY

– 65 – – 66 –

3TADJ

EQADJ

24 23222120181716151413

VCC

SCRI - PARA

DECODE

SWDT

SCLK

GND

TEMPI

TEMPR

Page 44

r

2

COUT

1

GND

65-TO-1

MULTIPLEXER

65-TO-1

MULTIPLEXER

POS64

POS0

POS0

POS64

16-BIT

I/O SHIFT

REGISTER

b15a0

3

CLK

4

DIN

5

CS

6

ZCEN

7

MODE

8

WO

9

LO

10

HO

19

VU (UCI)

20

VCC

18

VD (DCI)

17

BO (UCO)

16

BI (DCO)

15

MUTE

14

AGND

13

HI

12

LI

11

WI

COMMAND/CONTROL

UNIT

IC BLOCK DIAGRAM – MAIN (2/3) SECTION –

IC802 RS5RJ29261-T1

VSS

1

OSC

VLX LIMITER

VFM

r

IC BLOCK DIAGRAM – MAIN (3/3) SECTION –

IC909 MM1332DFBE

VCC

8

LX

8

EXT

CEL

7

6

C5

5

IC352 DC1802E-TE2

CE

2

–

7

EXT

+

SOFT START

VREF 1

VD OUT

3

+

–

VREF 2

6

VDD

–

VD IN

+

4

5

V OUT

1

SW1

2

SW2

3

LV GND

4

IC807 AK93C45LV-L

GND

4

DO

DATA

REGISTER

VTEF

3

DI

2

SK

1

CS

INSTRUCTION

REGISTER

INSTRUCTION

CONTROL

GENERATION

DECODE

&

CLOCK

ADD

BUFFERS

– 67 – – 68 –

R/W AMPS

&

AUTO ERASE

VPP

GENERATOR

VPP SW

DECODER

EEPROM

1024BIT

64X16

5

NC

6

NC

7

VCC

8

IC303 AK4515-VQ

44

LIN1

41

LIN2

LIN3

38

RIN1

43

RIN2

40

RIN3

37

22

VCOM

26

LOUT

25

ROUT

27

VRDA

20

VA

19

VB

AGND

21

CONTROL REGISTER

10

AGND

13

PGAL

––

CS

PGAR

VCML

ADCL

ADCR

VCMR

31 32 3334 3536

18

VD

17

DGND

46

XRST

–––

PD

ADC

Audio I/F

Controller

DBBDAC

I/F

15

14

16

CDTI

CCLK

CDTO

DPGA

CLOCK

DRIVER

1

45

SSB

MCLK

48

CMODE

47

LRCK

2

3

BCLK

SDTO

4

5

SDTI

6

DIF0

7

DIF1

24

DZF

42

TST1

39

TST2

8

TST3

9

TST4

Page 45

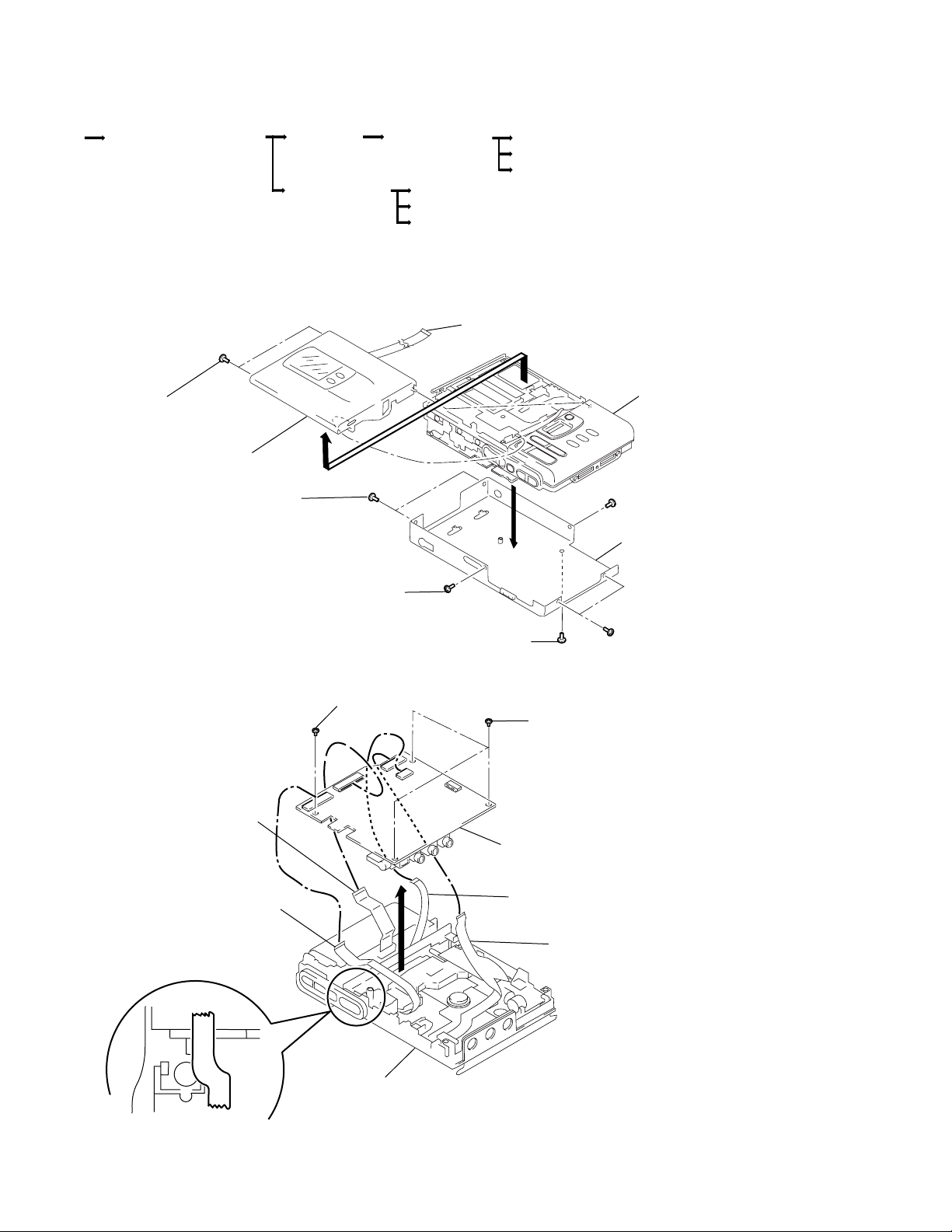

SECTION 8

EXPLODED VIEWS

NOTE :

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• Color indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ••• (RED)

↑ ↑

Parts color Cabinet's color

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference num-

ber in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

• Abbreviation

CND : Canadian

AUS : Australian

8-1.UPPER PANEL, BOTTOM PANEL SECTION

17

23

15

16

25

14

19

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

Les composants identifiés par une

marque !sont critiques pour la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

22

24

18

not supplied

19

13

10

20

not supplied

8

6

10

21

7

12

11

3

9

5

4

1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 X-4947-770-1 PANEL ASSY, BOTTOM

2 4-986-207-01 KNOB (TUN)

3 4-983-999-01 KNOB (OPEN)

4 4-972-492-11 KNOB (AVLS)

5 4-963-851-11 KNOB (AVLS)

6 4-986-204-01 BUTTON (DBB)

7 4-986-205-01 SHEET (DBB), ADHESIVE

8 4-984-000-01 KNOB (DBB)

9 4-984-017-11 SCREW (1.7X2.5), TAPPING

10 4-963-883-41 SCREW (M1.4), PRECISION PAN

11 4-963-883-21 SCREW (M1.4), PRECISION PAN

12 4-986-190-01 HOLDER (LCD)

13 1-801-522-11 LCD MODULE

14 4-986-189-01 BUTTON (DISP)

15 X-4947-769-1 PANEL ASSY, UPPER

16 4-986-185-01 SHEET (LCD WINDOW), ADHESIVE

17 4-986-184-11 WINDOW (LCD)

18 A-3293-312-A MAIN BOARD, COMPLETE (E, Tourist)

18 A-3293-360-A MAIN BOARD, COMPLETE (AEP, UK, AUS)

18 A-3293-361-A MAIN BOARD, COMPLETE (US, CND)

19 3-335-797-91 SCREW (M1.4), TOOTHED LOCK

20 3-375-114-21 SCREW (M1.7X2.5)

* 21 4-988-279-01 CUSHION (LCD)

* 22 4-988-280-01 CUSHION

23 4-963-883-21 SPACER (M1.4), PRECISION PAN…(SILVER)

23 4-963-883-31 SPACER (M1.4), PRECISION PAN…(BLUE)

24 3-831-441-11 CUSHION (A)

* 25 4-988-105-01 CUSHION (HEAD)

2

10

10

– 69 –

Page 46

8-2. CHASSIS SECTION

Mechanism deck

62

55

57

63

56

64

54

59

58

59

62

54

53

60

64

65

59

61

67

66

74

52

68

51

72

71

not supplied

73

not

supplied

75

not

supplied

69

76

62

not

supplied

70

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 1-473-895-11 SWITCH UNIT (WITH JOG DIAL)

52 4-984-017-11 SCREW (1.7X2.5), TAPPING

53 4-986-186-01 RETAINER (DIAL)

54 4-963-924-01 SCREW (DAMPER)

55 X-4947-771-1 BELT ASSY, ORNAMENTAL

56 4-983-998-01 KNOB (REC)

57 4-984-006-01 SCREW, STEP

58 4-983-995-01 LEVER (REC)

59 4-984-004-01 SPRING (LOCK), COMPRESSION

60 4-983-993-01 LEVER (OPEN)

61 4-983-994-01 ARM, LOCK

62 4-963-883-21 SCREW (M1.4), PRECISION PAN…(SILVER)

62 4-963-883-31 SCREW (M1.4), PRECISION PAN…(BLUE)

63 X-4947-717-1 PLATE ASSY, FULCRUM

64 4-983-311-01 DAMPER

65 4-986-188-01 REINFORCEMENT

66 3-335-797-91 SCREW (M1.4), TOOTHED LOCK

67 A-3306-147-A SWITCH BOARD, COMPLETE

68 A-3293-253-A POWER BOARD, COMPLETE

69 4-986-183-01 LID, BATTERY CASE

70 X-4947-720-1 PLATE (BATTERY)ASSY,ORNAMENTAL

70 X-4947-842-1 PLATE (BATTERY)ASSY, (L)…(BLUE)

71 X-4947-772-1 CASE ASSY, BATTERY

72 4-984-016-01 SPRING (POP UP), COIL

73 4-988-114-01 TERMINAL, BATTERY

74 1-777-761-11 WIRE (FLAT TYPE) (24 CORE)

75 4-984-019-01 SHAFT (BATTERY CASE LID)

76 4-984-018-01 PLATE, FULCRUM

…

(SILVER)

– 70 –

Page 47

8-3. MECHANISM DECK SECTION-1

(MT-MZR30-124)

112

113

114

111

not supplied

104

not supplied

110

103

not

supplied

106

115

105

117

116

103

119

120

107

118

121

not supplied

107

102

107

101

Les composants identifiés par une

marque !sont critiques pour la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

not supplied

107

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 A-3303-501-A SCREW BLOCK ASSY, LEAD

102 4-972-548-01 GEAR (BH)

103 3-366-890-11 SCREW (M1.4)

104 X-4947-429-1 CHASSIS ASSY

105 4-964-537-01 SCREW (M1.4X4.5), TAPPING

106 1-651-018-11 SLED FLEXIBLE BOARD

107 3-704-197-33 SCREW (M1.4X3.0), LOCKING

110 4-964-538-01 SCREW (M1.4X2)

111 X-4947-887-1 HOLDER ASSY

112 4-955-841-01 SCREW

105

not

supplied

103

M902

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

113 4-988-174-01 STOPPER, LEVER

* 114 1-663-390-11 REC BOARD

115 4-984-032-01 SHEET, INSULATING

116 3-348-160-01 SCREW (M1.4X1.3),PRECISION PAN

117 4-983-357-01 CLAW, LOCK RELEASE

* 118 4-983-356-01 GUIDE, HOLDER

119 4-963-914-02 RACK (INSERTER)

120 4-983-358-01 SPRING, TENSION

! 121 X-4948-260-1 OPTICAL PICK-UP ASSY

M902 A-3303-502-A MOTOR BLOCK ASSY (SLED)

– 71 –

Page 48

8-4. MECHANISM DECK SECTION-2

(MT-MZR30-124)

not supplied

M903

161

157

157

M901

154

160

155

156

158

154

159

157

157

152

151

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 A-3293-256-A CONTROL PC BOARD ASSY,

152 3-366-890-11 SCREW (M1.4)

153 1-663-392-11 MD FLEXIBLE BOARD

154 3-338-645-31 WASHER (0.8-2.5)

155 4-963-901-01 GEAR, WORM

158 4-963-898-01 GEAR (WORM WHEEL)

159 X-4944-449-1 CHASSIS ASSY, GEAR

160 4-964-564-01 SCREW (M1.2X1.6)

161 1-651-017-11 CLV FLEXIBLE BOARD

M901 1-698-542-11 MOTOR (SPINDLE)

153

156 4-972-546-01 SPRING (WORM GEAR),COMPRESSION

157 4-955-841-01 SCREW

M903 A-3303-499-A STEPPER BLOCK ASSY (STEPPING)

– 72 –

Page 49

SECTION 9

ELECTRICAL PARTS LIST

CONTROL

MAIN

NOTE :

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used on

the set.

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• RESISTORS

All resistors are in ohms

METAL : Metal-film resistor

METAL OXIDE :Metal oxide-film resistor

F : nonflammable

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3293-256-A CONTROL BOARD, COMPLETE

*************************

1-651-017-11 CLV FLEXIBLE BOARD

< CAPACITOR >

C701 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C702 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C703 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C704 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C705 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C706 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C707 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C709 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C710 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C711 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

< CONNECTOR >

CN701 1-691-356-21 CONNECTOR, FFC/FPC (ZIF) 18P

CN702 1-691-370-11 CONNECTOR, FFC/FPC 6P

< IC >

IC701 8-759-335-44 IC CXA8048N

< TRANSISTOR >

Q703 8-729-427-83 TRANSISTOR XP6501

< RESISTOR >

R701 1-218-871-11 METAL CHIP 10K 0.50% 1/16W

R702 1-218-871-11 METAL CHIP 10K 0.50% 1/16W

R703 1-216-815-11 METAL CHIP 330 5% 1/16W

R704 1-217-671-11 METAL CHIP 1 5% 1/10W

R705 1-217-671-11 METAL CHIP 1 5% 1/10W

R706 1-216-833-11 METAL CHIP 10K 5% 1/16W

R711 1-216-864-11 METAL CHIP 0 5% 1/16W

• SEMICONDUCTORS

In each case, u : µ , for example :

uA.... : µ A.... , uPA.... : µ PA....

uPB.... : µ PB.... , uPC.... : µ PC....

uPD.... : µ PD....

• CAPACITORS

uF : µ F

• COILS

uH : µ H

• Abbreviation

CND : Canadian

AUS : Australian

E13 : 220-230V AC area

E33 : 100-240V AC area

S701 1-692-849-21 SWITCH, PUSH (1 KEY) (MEDIR)

S702 1-692-847-21 SWITCH, PUSH (1 KEY) (PROTECT)

S703 1-692-377-31 SWITCH, PUSH (1 KEY) (REFLECT)

S704 1-572-467-41 SWITCH, PUSH (1 KEY) (INITIAL)

S705 1-572-467-41 SWITCH, PUSH (1 KEY) (INLIMIT)

************************************************************

A-3293-312-A MAIN BOARD, COMPLETE (E, Tourist)

A-3293-360-A MAIN BOARD, COMPLETE (AEP, UK, AUS)

A-3293-361-A MAIN BOARD, COMPLETE (US, CND)

C101 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C102 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C103 1-135-337-11 TANTAL. CHIP 1uF 20% 6.3V

C104 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C105 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C106 1-110-975-11 TANTAL. CHIP 47uF 20% 6.3V

C107 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C108 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C109 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C110 1-135-337-11 TANTAL. CHIP 1uF 20% 6.3V

C117 1-135-181-21 TANTALUM CHIP 4.7uF 20% 6.3V

C118 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C120 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C121 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C122 1-162-960-11 CERAMIC CHIP 220PF 10% 50V

C123 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C124 1-165-128-11 CERAMIC CHIP 0.22uF 16V

C125 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C131 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C140 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C161 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

C168 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C201 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

Les composants identifiés par une

marque !sont critiques pour la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

< SWITCH >

*********************

< CAPACITOR >

– 73 –

Page 50

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C202 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C203 1-135-337-11 TANTAL. CHIP 1uF 20% 6.3V

C204 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C205 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C206 1-110-975-11 TANTAL. CHIP 47uF 20% 6.3V

C207 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C208 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C209 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C210 1-135-337-11 TANTAL. CHIP 1uF 20% 6.3V

C217 1-135-181-21 TANTALUM CHIP 4.7uF 20% 6.3V

C218 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C220 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C368 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C369 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C391 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

(US,CND)

C392 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C393 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

(US,CND)

C394 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

(US,CND)

C399 1-107-816-11 TANTAL. CHIP 0.68uF 20% 10V

C501 1-115-169-11 TANTALUM 10uF 20% 6.3V

C504 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C505 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C221 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C222 1-162-960-11 CERAMIC CHIP 220PF 10% 50V

C223 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C224 1-165-128-11 CERAMIC CHIP 0.22uF 16V

C225 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C231 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C240 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C261 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

C268 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C292 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C293 1-104-912-11 TANTALUM CHIP 3.3uF 20% 6.3V

C294 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

C295 1-135-181-21 TANTALUM CHIP 4.7uF 20% 6.3V

C296 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C301 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C302 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C303 1-107-813-11 TANTAL. CHIP 10uF 20% 6.3V

C304 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C305 1-110-975-11 TANTAL. CHIP 47uF 20% 6.3V

C307 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C308 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C310 1-164-361-11 CERAMIC CHIP 0.047uF 16V

C311 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C312 1-110-975-11 TANTAL. CHIP 47uF 20% 6.3V

C314 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C506 1-162-965-11 CERAMIC CHIP 0.0015uF 10% 50V

C507 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C508 1-162-969-11 CERAMIC CHIP 0.0068uF 10% 25V

C509 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C510 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C511 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C512 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C513 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C515 1-104-752-11 TANTAL. CHIP 33uF 20% 6.3V

C517 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C518 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C519 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C521 1-164-677-11 CERAMIC CHIP 0.033uF 10% 16V

C522 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C523 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C524 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C525 1-104-929-11 TANTAL. CHIP 22uF 20% 6.3V

C526 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C528 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C529 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C530 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C531 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C532 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C533 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C534 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C315 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C318 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C319 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C320 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C321 1-104-929-11 TANTAL. CHIP 22uF 20% 6.3V

C322 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C327 1-104-929-11 TANTAL. CHIP 22uF 20% 6.3V

C338 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C345 1-104-929-11 TANTAL. CHIP 22uF 20% 6.3V

C346 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C351 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C359 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V