Sony MVS -8000X, MVS-7000X Quick Setup Manual

MVS -8000X/MVS-7000X

QUICK SETUP GUIDE

Revision 1.3

Copyright © 2012 Sony Electronics Inc. All rights Reserved.

All features, specifications and procedures subject to change without notice.

pg. 1

Table of Contents

Section 1: Overview ..................................................................................................................................... 5

What is the MVS System? ........................................................................................................................ 5

After your Installation… ........................................................................................................................... 8

Installation Check-Out........................................................................................................................... 8

Operator Training .................................................................................................................................. 9

Section 2: Engineering Quick Start (Hardware) ......................................................................................... 10

Where to turn for help ........................................................................................................................... 10

What are all these boxes? ...................................................................................................................... 10

Unpacking the boxes .............................................................................................................................. 11

Rack Mounting ....................................................................................................................................... 12

Power Requirements & Environmental ................................................................................................. 12

Where do the components go? .............................................................................................................. 12

Group and Unit ID settings ..................................................................................................................... 13

Wiring ..................................................................................................................................................... 14

LANs .................................................................................................................................................... 14

SWITCHER CHASSIS (MVS-7000X only) .................................................................................................. 16

Video Inputs ........................................................................................................................................ 17

Video Outputs ..................................................................................................................................... 17

Reference ............................................................................................................................................ 17

Format Converter ................................................................................................................................ 18

Multi-Viewer ....................................................................................................................................... 18

DME Inputs and Outputs..................................................................................................................... 18

SWITCHER CHASSIS (MVS-8000X only) .................................................................................................. 20

Video Inputs ........................................................................................................................................ 21

Video Outputs ..................................................................................................................................... 21

MVS-8000X Dedicated M/E Outputs .................................................................................................. 22

Reference ............................................................................................................................................ 22

Format Converters .............................................................................................................................. 22

Multi-Viewer ....................................................................................................................................... 23

DME Inputs and Outputs..................................................................................................................... 23

Control Panel .......................................................................................................................................... 25

Panel Type ........................................................................................................................................... 25

Connecting the Panel .......................................................................................................................... 27

pg. 2

External Adapters ................................................................................................................................ 27

USB/Memory Stick .............................................................................................................................. 28

Other Control Panel connections ........................................................................................................ 28

DME Chassis ............................................................................................................................................ 29

Device Control Unit (DCU) ...................................................................................................................... 29

Parallel Tally ........................................................................................................................................ 30

Serial Tally ........................................................................................................................................... 30

Aux Bus Remotes .................................................................................................................................... 31

After the Install ....................................................................................................................................... 32

Routine Maintenance ......................................................................................................................... 32

Other tips to keep your new switcher working well….. ...................................................................... 32

Start-up ................................................................................................................................................... 33

Section 3: Engineering Quick Start (Software) .......................................................................................... 34

Menu Overview ...................................................................................................................................... 34

Menu Page Numbers .......................................................................................................................... 36

Network Config ....................................................................................................................................... 37

LAN Diagnostics ...................................................................................................................................... 40

Errors ....................................................................................................................................................... 40

System Config ......................................................................................................................................... 42

Signal Format ......................................................................................................................................... 44

Format Converters .................................................................................................................................. 48

Software Versions .................................................................................................................................. 49

MVS-7000X FlexConfig ........................................................................................................................... 50

A Note on using 8 Keyers .................................................................................................................... 53

Outputs ................................................................................................................................................... 54

Inputs ...................................................................................................................................................... 56

Naming Inputs ..................................................................................................................................... 57

VIDEO/KEY and Table Assignments ..................................................................................................... 58

Key Signals ........................................................................................................................................... 59

Sub-Tables ........................................................................................................................................... 61

Table Copy ........................................................................................................................................... 62

Table Button Assign ............................................................................................................................ 64

A Word of Caution! ............................................................................................................................. 64

Let’s Try This Out! ............................................................................................................................... 65

pg. 3

Using the Multi-Viewer .......................................................................................................................... 66

Using the internal Format Converters ................................................................................................... 68

Format Converters for MVS-8000X ..................................................................................................... 68

Format Converters for MVS-7000X ..................................................................................................... 68

Format Converter Parameters ............................................................................................................ 70

Format Converter Outputs .................................................................................................................. 70

Saving Our Work .................................................................................................................................... 72

Start-Up Mode .................................................................................................................................... 72

Setup Define ........................................................................................................................................ 73

Saving To Disk ..................................................................................................................................... 74

That’s It! ...................................................................................................................................................... 79

pg. 4

Section 1: Overview

Welcome to Sony’s MVS line of television production switchers. The MVS Series represents more than

ten years of evolutionary growth of an amazing production switcher platform.

The original MVS-8000 switcher was brought to market in 2001. The MVS series is unique in that

instead of creating a switcher system with a finite market life, the MVS series was designed as an

evolutionary and modular product line – one designed to change and adapt over time. This approach

allows Sony to replace individual components in the MVS system when technology changes. The

advantage is the system software and overall operation of the MVS switcher does not change. This

allows an operator to seamlessly transition from, say, an original MVS-8000, manufactured in 2001, to a

current state of the art MVS-8000X or MVS-7000X.

This Quick Setup Guide is primarily for engineers responsible for the planning and installation of a new

MVS X-Series production switcher. This document will help you to understand what will be arriving in

boxes, and when. It will also give you a general understanding of what goes where and how to connect

everything together. The end goal, after completing this document, is to successfully have everything

powered-up, communicating and have at least one input video source and one output monitor for

Program. This document does not cover more advanced items like setting up and programming tallies,

multiple control panels, etc. Each item mentioned comes with its own detailed installation manual

which will likely answer all your questions not covered in this document.

What is the MVS System?

A typical MVS switcher system consists of the following major items:

1. MVS switcher frame

2. Control Panel

3. DME Frame

4. Device Control Unit

The MVS switcher frame, or Switcher, is the main processing unit where all your inputs and outputs will

be connected. The Mix/Effects circuitry is also in this unit. This chassis is typically mounted in the

Engineering/Terminal Gear area.

The Control Panel is where all user interaction with the switcher takes place. The control panel really

isn’t a single item. The main surface is made up of individual modules, each with a specific task. The

advantage to a modular control surface is that changes can be made, by the end user, at any time.

Depending on the model of control panel, there may be several parts. For instance, the CCP-8000A

series panel has a main section, a menu display, a System Control Unit (the CPU and Power Supplies for

the panel), and maybe an external Aux row or even external modules. As the panel is completely

customizable at order time, it is important to consult with your Sony account manager and Sales

Support Engineer as to the exact panel assembly you purchased before cutting console openings. They

can tell you the “assembly number” of your unique panel. That assembly number can be matched to a

dimension grid in the control panel installation guide.

pg. 5

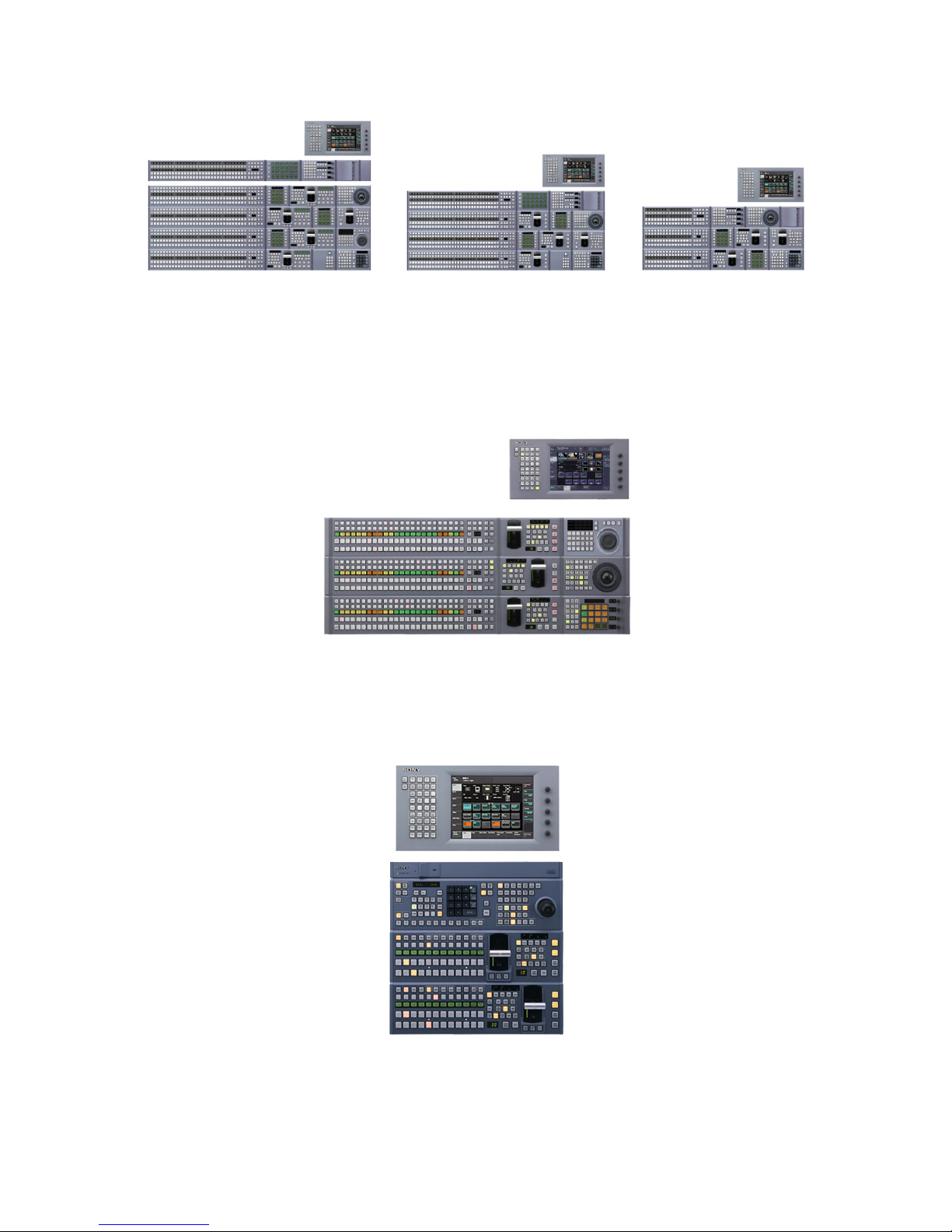

As an example, below, these are just a few of the different combinations of modules and sizes of CCP8000A control panels.

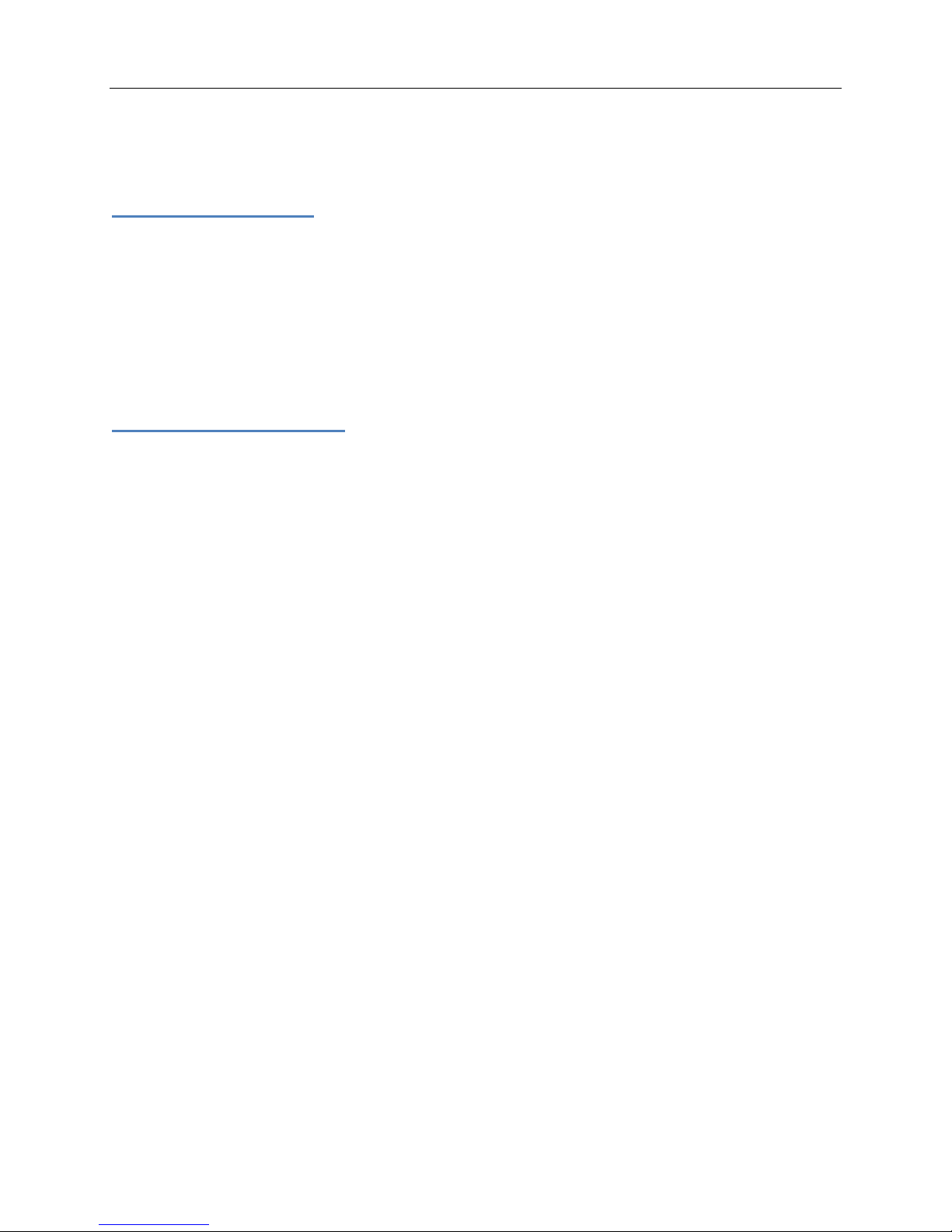

The CCP-6000 series control panel is smaller than the CCP-8000A panel. Instead of being configured

module by module, as the CCP-8000A series is, the CCP-6000 series comes as a standard unit. An

optional menu display and other modules may be added by the end user at purchase time. A System

Control Unit is also required. The CCP-6000 panel, below, is shown with an optional MKS-8036A Device

Control Module.

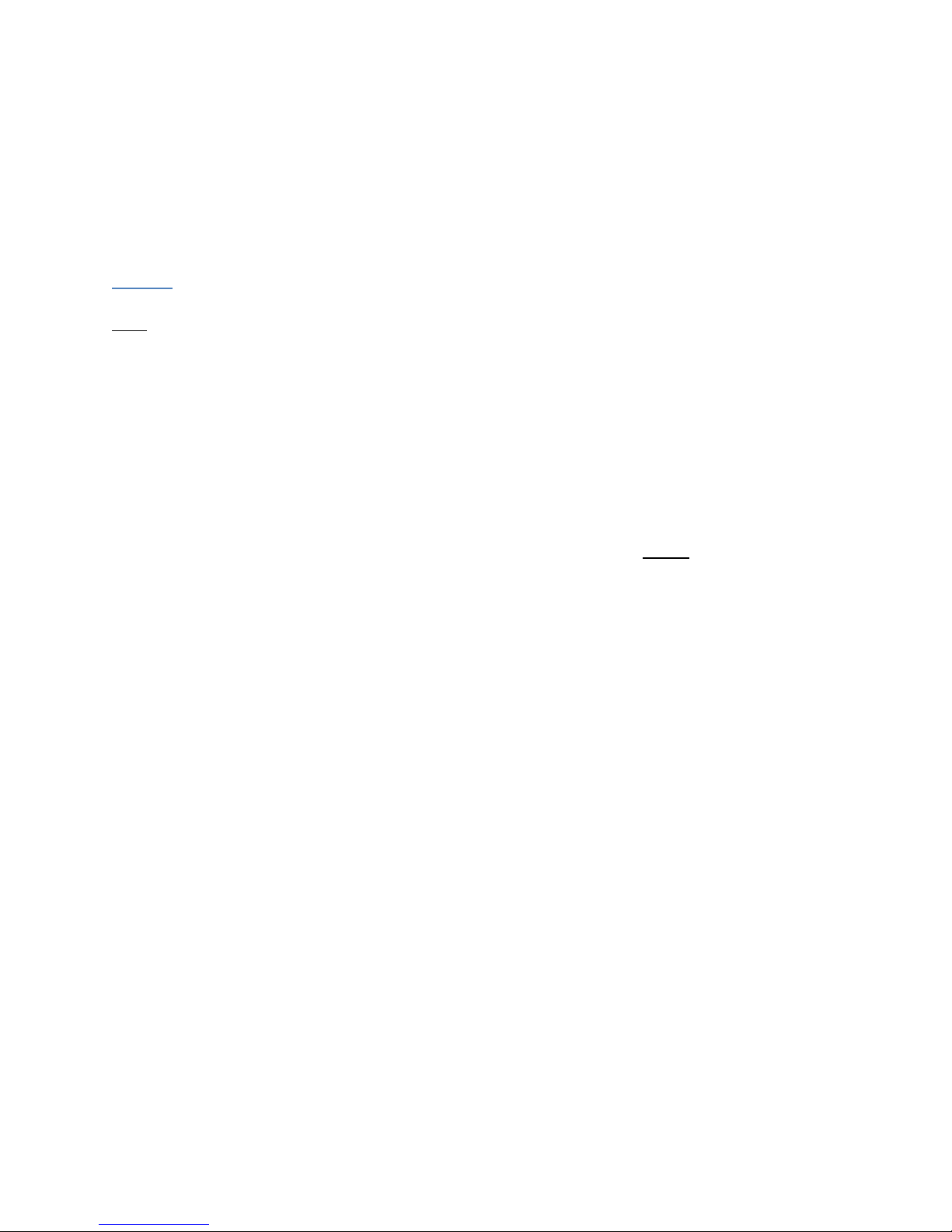

The CCP-9000 series control panels are ultra-compact, 19” wide panels. Unlike the CCP-8000A and CCP6000 series panels, the CCP-9000 series have the System Control Unit built-in. A menu display is

required and there may also be optional external modules.

pg. 6

The MKS-8010B is a 1RU System Control Unit (SCU) for both the CCP-8000A and CCP-6000 control

panels. The SCU can be a maximum of 10 meters away from the control panel surface. The SCU is

connected to the control surface with either SWC-5005 cables (5m) or SWC-5010 (10m) 50-pin D-Sub

cables for power and data. These cable length choices were made at the time of ordering. Typically, the

SCU is mounted in the monitor wall or under the tabletop of the switcher control panel.. The power

buttons are recessed to prevent accidental operation by knees or feet when mounted under the

console.

Depending on the model of switcher, the DME (Digital Effects) system may be either internal option

boards or a separate chassis frame. With the 8000X system, DMEs are always in a separate frame. The

MVE-8000A is a 2RU frame that houses up to 4 channels of effects. The MVE-9000 is a 4RU frame that

also houses up to 4 channels. A total of 8 channels of DME can be installed in a single switcher system.

If more than 4 channels are purchased, an additional DME frame is required.

The MVS-7000X has two internal slots for plug-in DME boards. Each board has 2-channel capability. If

more than 4 channels of DME are required for a MVS-7000X system, then one external DME frame

(either MVE-8000A or MVE-9000) can also be installed.

The DME channels described here are in addition to the 2.5D Resizers that are standard on every keyer

on the 8000X and 7000X.

In keeping with the modular design of the MVS series, the Tally and Device Control Unit (DCU) is also a

separate frame from the switcher. There are two different models of DCU. The 3RU MKS-8700, which

allows for 5 option boards, provides the ultimate in flexibility for RS-422 ports and GPI/GPO and Parallel

Tally. The 1RU MKS-2700 has a fixed configuration of 6 RS-422 ports and 32 GPI/GPO/Parallel Tally. The

MKS-8700 has two serial tally ports whereas the MKS-2700 has none. If you require serial tally when

using a MKS-2700 please use the port marked EDITOR on the MKS-8010B System Control Unit (15-pin to

9-pin adapter is required).

Because the MVS system is so configurable, the descriptions above are not exhaustive. If you have any

questions regarding your unique system configuration, please contact your Sony Account Manager or

Sales Support Engineer.

pg. 7

After your Installation…

Installation Check-Out

Standard to the MVS series is an on-site Installation Check-Out (ICO) by a Sony Field Service Engineer.

The amount of on-site time varies, depending on which switcher was purchased and the complexity of

the install (for example, was a router interface also purchased?). The typical on-site time is two days.

ICO scheduling is done through your Sony Account Manager, who will need the exact models of each

chassis and their respective serial numbers. Sony requires at least two weeks’ notice to schedule the

ICO. It is also important that the switcher be completely installed before the Service Engineer arrives.

The ICO does not cover mounting equipment, running/connecting cables or any System Design. If

these services are required, please contact your Sony account manager.

As a general rule the following items should be complete before the ICO date:

1. Complete installation of all switcher components, including cabling.

2. At least 4 video and 1 key source run to the inputs.

3. At least 2 monitors (PGM/PVW) are wired and operating

The ICO Field Service Engineer will ensure that:

1. The installation was done correctly and that all individual components are operating, as

designed, and communicating with each other.

2. All Inputs and Outputs are working

3. That all Mix/Effects boards and Keyers are operating

4. That all DME channels are operating

5. Assist in programing Tally and GPI

6. Assist in establishing communication between the MVS and external devices (i.e. DDRs, etc.)

Please note that while the ICO engineer can assist in making devices “talk” to the switcher, they are not

responsible for programming third-party devices. You may need to contact the manufacturer of the

third-party device for assistance.

The ICO also covers basic engineering menu system setup and basic troubleshooting and maintenance.

If a more thorough maintenance course is required, please contact your Sony Account Manager.

The ICO must occur before operator training. It is also strongly recommend that the ICO and operator

training are not back-to-back. If an error or defect is discovered during the ICO, it could impact your

ability to train operators.

pg. 8

Operator Training

As an option, Sony can supply operator training for your MVS switcher. This training is listed as a lineitem option in the switcher quote and, typically, is a 3-day course; however, additional days can be

purchased.

Sony has a very experienced pool of certified contract trainers who use MVS switchers daily. There are

some important guidelines when determining your training schedule:

1. Sony requires at least 30 days’ notice to set up training. Many variables can affect our ability

to provide a trainer on your requested dates. In addition to your primary training dates, we

strongly recommend you have at least two alternate dates in case we are not able to

accommodate your first choice. Also note that our trainers’ personal schedules are booked

months in advance. Once booked, we will do our best to accommodate any changes to your

training schedule, but we cannot guarantee availability. Changing your training dates after

booking can affect your on-air date!

2. Training is limited to no more than a total of 10 hours per day. Adding additional time to a day

may result in additional charges for training.

3. Regardless of how much training has been purchased, if the customer requests a trainer to

make two or more separate visits, additional costs will apply.

4. Unless previously arranged, it is entirely at the trainer’s discretion to accept working a split shift

(for example, 5 hours in the 8a-1p time and another 5 hours in the 7p-12a time).

5. It is recommended that no more than 5 people attend each training class.

6. It is recommended that students with similar experience and skills be grouped together.

Printed operator manuals are not supplied; however a PDF version of the manual will be available and

may be distributed and printed freely.

Please contact your Sony Account Manager to arrange your operator training. Remember, a minimum

of 30 days advance notice is required.

pg. 9

Section 2: Engineering Quick Start (Hardware)

This section covers the physical installation of your new switcher. Many items will be covered including

unpacking the boxes, identification of parts, wiring and basic setup.

Where to turn for help

Unpacking an installing a production switcher can be a daunting task, at best. While the installation

manuals for each component, and also this document, will provide you with all the information you will

need, sometimes a little extra help would be nice. Please contact your Sony Account Manager for

assistance. Your Sony Account Manager can assist you on missing items, if any, and has the ability to

bring in other resources, like Sales Support Engineers or Service Engineers, to make your installation go

as smoothly as possible.

What are all these boxes?

As described above, an MVS system consists of several, individual, components. Many of these will be

shipped separately. Different items come from different warehouses, so all your ordered items may not

arrive on the same day. For instance, most of the switcher components are shipped directly from the

factory in Japan, where other items like Ethernet switches, the menu arm and rack rails are shipped

from our domestic warehouses. Also, any items purchased as B-Stock (refurbished) will not be included

in configured product. For example, if your switcher is supposed to have the Frame Memory option, but

you had the opportunity to purchase that option as B-Stock, it will come packaged separately and will

not be installed in your switcher frame when it arrives.

It is important to note that this guide is not a replacement for the individual installation and operation

manuals that come with each component. Installation guidelines and procedures, as well as

specifications, can change without notice. Only the individual installation guides that are shipped with

your products are guaranteed to have the latest and most accurate information. This guide also does

not cover installing option boards or power supplies, including which slot they must be installed in.

Please refer to the individual installation guides that come with the product for detailed component

installation instructions.

Below describes the typical boxes you will receive, depending on which model switcher you purchased.

1. Switcher Chassis (10RU for 8000X, 8RU for 7000X)

2. MVE Digital Effects Chassis (2RU or 4RU, depending on model and number of channels)

• MVS-7000X has built-in DMEs that do not require their own chassis. If you have more

than 4 channels you will have an external MVE Chassis.

• MVS-8000X: If you have more than 4 channels you will receive two MVE chassis boxes

3. Device Control Unit Chassis (1 or 3RU, depending on model)

4. System Control Unit Chassis (1RU)

5. Control Panel (varies in size)

• CCP-8000A Series modular panels are pre-assembled and configured-to-order at the

factory. In the box you will find the main panel and the separate aux panel (if so

configured)

• CCP-6000 Series panels are pre-assembled at the factory but are not configured-to-

order as the CCP-8000A series panels are. If you ordered additional modules, such as a

pg. 10

Shotbox™ or a Device Control Module, they will be shipped separately and must be

installed by the end user.

• CCP-9000 Series panels come as pre-fabricated units in their own boxes.

6. Menu Panel (if purchased)

7. SWC-50xx cables (interconnects between SCU and panel)

8. External module adapters for the control panel (MKS-8075A or MKS-8076)

9. Ethernet Switch Kit (if purchased)

• The MVS system requires three discreet, private, LANs to operate. Typically a kit

consisting of two rack-mount Ethernet switches and Ethernet cables, is purchased with

the system. The third LAN simply uses a crossover cable and doesn’t require a

dedicated switch.

10. MVS Menu Arm (if purchased)

11. Rack Rails

12. Power Cords

13. Aux Buss Remotes (if purchased)

14. Router Interface Items

• If you purchased a third-party router interface, you will receive four additional boxes

including a HKSP-R80 (controller), PFV-SP3100 or PFV-SP3300 (card cages for controller),

HK-PSU01 (backup PSU) and RMM-10 (rack rails).

Unpacking the boxes

Be careful to follow any directions and warnings on the exterior of the individual boxes to avoid damage

to your product. Also, please do not discard anything from the boxes until the ICO and training have

been completed.

Boxes that typically have extra items:

1. Control Panel

a. The roller-ball for the trackball module is not shipped installed as it can damage the

module. It will need to be installed by unscrewing the outside Z-Ring and dropping the

ball into the hole. Please tighten the Z-Ring when finished.

b. Button Puller. This item is required to remove the buttons from the control panel.

Attempting to remove the buttons without using this tool (i.e. using pliers) can result in

damage to the button which is NOT covered under warranty.

c. Additional Button labels. There are many sheets of additional button labels in a plastic

package. These will be needed during your ICO and operator training. DO NOT

DISCARD!

d. Terminating resistor for the reference loop connector.

e. Trackball overlay for device control.

i. This is only needed if a jog/shuttle module has not been installed in the control

panel. If this overlay is needed, it is simply set on top/around the buttons of the

trackball module.

2. Ethernet Switch Kit (if purchased)

a. TWO Ethernet Switches (one for Control LAN, one for DATA LAN – the PERIPHERAL LAN

use a crossover cable and does not require a dedicated switch)

b. 3x 100 feet length of Ethernet Cable

c. Crossover adapter and short cable for PERIPHERAL LAN

3. Switcher, DME, SCU and DCU Chassis

a. Terminating resistor for the reference loop connector

pg. 11

Rack Mounting

Proper support is required when rack-mounting all components. Failure to provide proper support can

result in damage to the external chassis and internal boards which are not covered under warranty.

You do not need to put space between components when rack-mounting. All MVS components are

designed to be installed directly on top of each other.

Each rack-mountable item in an MVS system will have a rack mount kit specified at the time of ordering.

Typically, these are all RMM-10 kits. The single exception is the MVS-8000X chassis. The 8000X chassis

comes with its own mounting bracket. Please refer to the RMM-10 rack kits for assembly instructions

and the individual components’ installation manuals for mounting procedures.

Power Requirements & Environmental

Each chassis varies on its power requirements, depending on the model and the number of option

boards installed.

Please see each component’s installation manual for specifications on power consumption and

environmental considerations.

Where do the components go?

Typically, the switcher chassis, the DME chassis (if needed) and the DCU Chassis all are mounted

together in the Engineering/Terminal Gear racks. The connecting cables back to the control room are

three Ethernet cables. Even though the specification of the maximum distance for a single Ethernet run

is 384ft, Sony recommends your single cable-run is no longer than 305 feet. If you need runs longer

than that, you may have to convert Ethernet to fiber optic or explore other methods such as repeaters

or additional Ethernet switches.

As mentioned above, the SCU (MKS-8010B) does not get installed with the main switcher components.

The SCU is the power supply and CPU for the control panel. It must be within 10m of the control panel

surface (your cable lengths were determined at the time of purchase). The SCU is typically installed in

the monitor wall or in the console under the control surface. The power buttons are recessed to

prevent accidental shutdown by feet or knees.

Even though the DCU (MKS-2700 or MKS-8700) is typically racked with the switcher and DME chassis, it

is not required. If you have many external devices that use RS422 you may find it is more convenient to

shorten the RS422 cable runs by mounting the DCU closer to the third-party devices. The DCU uses a

single cross-over LAN cable that goes to the SCU (MKS-8010B). The same recommended 305ft Ethernet

limitation applies.

pg. 12

Group and Unit ID settings

The MVS family uses fixed IP address, based upon the type of chassis. There are two settings that can be

changed by the end user. These are, primarily, to accommodate customers who have multiple switchers

on the same LAN or multiple individual chassis as part of the same system (for example 8 channels of

MVE-8000A DME will require two DME chassis, which will require different IP addresses.)

The two settings are Unit ID and Group ID. Both are set with DIP switches on the CPU card in each

chassis. Unit ID is the setting that tells the system there are multiple of the same chassis on the same

switcher system. For example, you have two DME chassis for 8 channels, each chassis holding 4

channels, one DME chassis would be set to Unit ID 1, the other to Unit ID 2. Another example is when

you have two control panels attached to the same switcher chassis. The first control panel would be set

to Unit ID 1, the second to Unit ID 2.

In the engineering Setup Menu, you will see a list of all switcher items that are discovered. You will see

items like SWR1, PNL1, DME1, DME2 (depending on your configuration). By the way, DME1 and DME2

are examples of two chassis being on a system, one being Unit ID 1 and the other being Unit ID 2.

If you have two completely separate control rooms, but they are both on the same switcher LAN, this is

where you set different Group IDs. Using a separate Group ID allows each control room to have

“proper” Unit ID’s without having to remember things like “DME4 is really DME2 in control Room 2”.

Typically a new switcher system delivered from the factory will have both the Group ID and Unit ID set

to 1 on all components. However, it is important to note that if you ordered more than one of the same

item (i.e. two DME chassis or multiple control panels), you must set the Unit ID’s before turning the

system on. We all know how computers love to have IP address conflicts. MVS is no different.

If you have purchased two complete switcher systems for two control rooms, you will need to plan out

which system will be Group 1 and which will be Group 2 and set the Group ID for the components

assigned to each room. Don’t forget the Unit ID settings also apply, as mentioned above.

Please refer to the installation manual on each chassis to determine how to set the Group and Unit IDs.

However, for a quick reference:

MVS-8000X is set on the CPU-82 board. Group ID is SW902 and Unit ID is SW903. Both can be accessed

from the front of the board. Typically they should both be set to 1.

MVS-7000X is set on the CPU-82A board. Group ID is SW902 and Unit ID is SW903. Both can be

accessed from the front of the board. Typically they should both be set to 1.

MVE-8000A is set on the

accessed from the front of the board. Typically they should both be set to 1 unless you have two units.

If you have two units that will be used for the same switcher, set SW103 on one chassis to 1 and the

other chassis to 2. In the next section, Wiring, make sure to physically wire the DME chassis set to Unit

ID1 as DME1 (channels 1-4) and the DME chassis set to Unit ID2 unit to DME2 (channels 5-8).

MKS-8010B (SCU) is set on the CA76 board. Group ID is SW9107 and Unit ID is SW9106. Both can be

accessed from the front of the board. Typically they should both be set to 1. However, if you have

multiple control panels that will be used with the same switcher chassis, the unit ID must be changed to

be unique for each MKS-8010B.

CA-54CFC board. Group ID is SW102 and Unit ID is SW103. Both can be

pg. 13

MKS-2700 (Compact Device Control Unit) is set on the IF963 Board. Group ID is SW402 and Unit ID is

SW403. Both can be accessed from the front of the board. Typically they should both be set to 1.

MKS-8700 (Standard Device Control Unit) is set on the CA47 board. Group ID is SW754 and Unit ID is

SW755. Both can be accessed from the front of the board. Typically they should both be set to 1.

If you have any kind of a non-standard configuration or would just like a little help, please feel free to

contact your Sony Account Manager. They can connect you with the right people to help.

Wiring

LANs

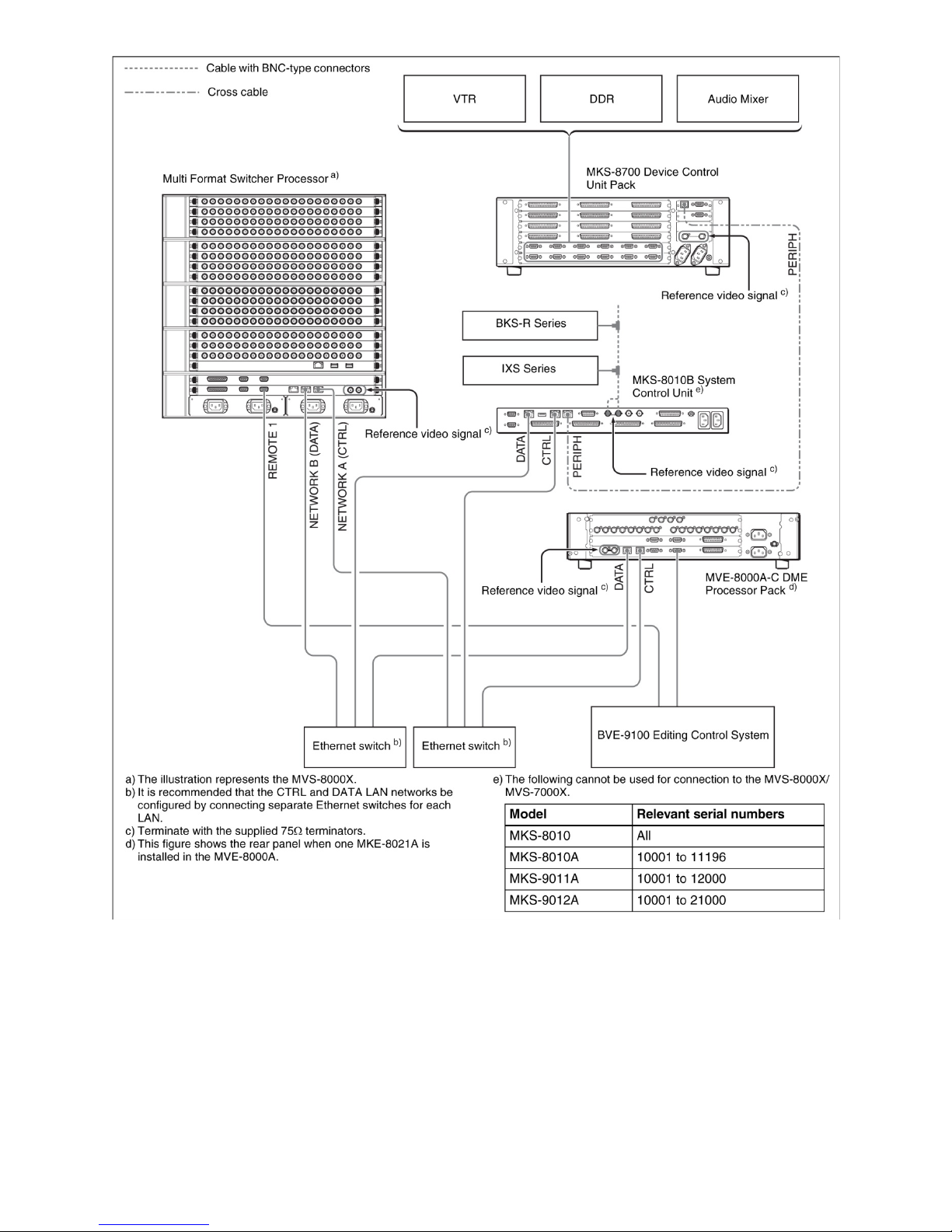

The MVS System uses three private LANs for communication. The CONTROL LAN handles real-time

communication between the control panel and the individual chassis. The DATA LAN handles packetized

communication, such as file loading/saving, Frame Memory transfers, etc. between the individual

chassis and the control panel. Finally the PERIPHERAL LAN handles communication from the control

panel to the DCU for Tally, GPI/GPO and RS422. These networks are discreet, by design, and keep only

related network traffic isolated to the proper LAN. Please do not attach any cables that would connect

one LAN to another. However, in an emergency (such as a switch failing) you can combine LANs

together to stay “on the air”, but it is not recommended to operate for long periods of time this way.

Unless specifically directed by Sony personnel or a Sony equipment manual, do not connect your

“house” or any other network into the Ethernet switches for your MVS switcher.

After rack mounting the two Ethernet switches, please mark one of them as CONTROL LAN and the

other as DATA LAN. This will help ensure all future connections go to the correct switch.

First, let’s connect the CONTROL LAN cables. You will find CTRL RJ-45 connectors on the Switcher

chassis (toward the bottom), the SCU and the DME chassis (if you have one). If you have 2 DME chassis,

then it will be necessary to connect both DME chassis’ CTRL LANs to the CONTROL LAN Ethernet switch.

Next, repeat the above procedure, except this time, connect all the DATA RJ-45 connectors on each

device into the DATA LAN Ethernet switch.

To connect the DCU to the SCU, a dedicated Ethernet switch is not required since only the two devices

“talk” to each other. Simply use a crossover cable or crossover adapter to connect the SCU and DCU

“PERIPH” RJ-45 connectors together. If you purchased the Ethernet Switch kit from Sony, you will find a

long Ethernet cable, a crossover adapter and a short jumper cable for this purpose.

If you have the Frame Memory option in your MVS switcher, please attach a cat5e cable (not provided)

between the DATA LAN Ethernet switch and the FM LAN port on the back of the switcher chassis. This

speeds up communication between the Frame Memory system and the control panel.

pg. 14

In the above diagram, you can see that the Switcher, DME (if needed) and Panel (really the SCU) all have

CNTL and DATA Ethernet cables going to their respective switches. You can also see that the DCU has a

crossover cable going to the SCU.

pg. 15

SWITCHER CHASSIS (MVS-7000X only)

pg. 16

Video Inputs

The MVS-7000X has up to 80 non-looping inputs, each in blocks of 20. These can be seen in the above

photo on slots 5-8. All inputs are “mappable” from the control panel menu to any crosspoint button so

there is no need to match the physical input to where the operator would like to select it. Also, there is

no differentiation between video and key inputs. Wire key inputs to any of the input connectors.

Video/Key matching is done later in the setup menu.

Video Outputs

An MVS-7000X can have either 24 or 48 outputs. If only 24 outputs are configured, then there will be a

blank in slot #10. Please notice that Slot #9 has outputs 1-20 and in the middle of slot #11 you will find

outputs 21-24. If you have 48 outputs, then you will find Outputs 25-44 on Slot #10 and Outputs 45-48

on the right-side of slot #11. Outputs 23-24 and 47-48 have dual outputs. If there is a blank in slot 10

(switcher only has 24 outputs), then the BNC connectors for Outputs 45-48 are not functional.

Just like inputs, all outputs on the 7000X are mappable from the Setup Menu. However, the default

factory setting is:

Out 1 M/E 1 OUT 1 (M/E 1PGM)

Out 2 M/E 1 OUT 2 (M/E 1 PVW)

Out 3 M/E 2 OUT 1 (M/E 2 PGM)

Out 4 M/E 2 OUT 2 (M/E 2 PVW)

Out 5 M/E 3 OUT 1 (M/E 3 PGM)

Out 6 M/E 3 OUT 2 (M/E 3 PVW)

Out 7 P/P OUT 1 (P/P PGM)

Out 8 P/P OUT 2 (P/P PVW)

Out 9 EDIT PVW

When you are wiring outputs, please note that the EDIT PVW output is the correct output for “Preview.”

This enables the preview switcher (which is normally set to P/P PVW) to also show other M/E previews

and other important signals like “Show Key.”

Reference

The MVS-7000X requires house “black” reference to operate. If you are not looping black, please

connect a 75-ohm terminating resistor to the loop connector. Both “black” and tri-level sync are

permitted, however tri-level sync is only required for special applications, like 24P production. It is also

very important to note that BLACK reference is required when using the internal format converters. The

internal format converters will not work with tri-level sync.

pg. 17

Format Converter

If you purchased the optional format converter card, you have 8 format converter input channels and

either 2 or 4 format converted outputs (depending on how many output cards are in the frame).

Any of the 80 primary inputs can be internally routed to a format converter input channel. This is done

in the setup menu. On slot #11, you will see four connectors marked as FC 1-4. These are the Format

Converter outputs. If your switcher has only 24 outputs, then FC3-4 are not functional.

Multi-Viewer

The MVS-7000X has up to two Multi-Viewer Outputs as a standard feature. If your switcher is

configured with 24 outputs, then the MSD1 connector on Slot 11 will be active. If you have 48 outputs,

then both MSD1 and MSD2 will be active.

The Multi-viewer is a basic system that allows multiple outputs to be shown simultaneously on a single

monitor. There are two options for the type of display: 4 (quad split) and 10 (two large and 8 small).

On-Air tally is provided. Multi-Viewer settings are made in the Engineering Setup menu.

The Multi-Viewer is not designed to replace the large monitor-wall systems that are typically found in

today’s production environments. However, it is a handy standard feature of the MVS-X series to,

perhaps, removes items the whole control room doesn’t need to see, like M/E outputs and put them on

a separate monitor just for the switcher operator. For planning your output assignments, it is important

to remember two things:

• For a signal to appear on the Multi-Viewer, it must be assigned to a physical output

• Each Multi-viewer’s window assignments are exclusive to its physical output card. This means

that Multi-Viewer #1 can only “see” signals that are assigned to Out 1-24. Multi-Viewer #2 can

only “see” signals that are assigned to Out 25-48. For example, it is not possible assign a signal

that is mapped to output 51 to Multi-Viewer #1, as Multi-Viewer #1 can only access outputs 1-

24.

DME Inputs and Outputs

The 7000X has the ability to use up to 4 channels of plug-In, internal, DME channels. However the MVS

system, as a whole, can accommodate 8 channels. If you ordered your 7000X with more than 4 channels

of DME, you will have an external DME chassis that needs to be hooked up to the switcher. If you have

more than 4 channels, you will have also purchased dedicated DME input and Output backplane boards.

If, for some reason, you are not using the internal DMEs on the 7000X, up to 8 channels (2 external

chassis) of MVE-8000A or MVE-9000 DME can also be connected to the 7000X switcher via these

dedicated connectors.

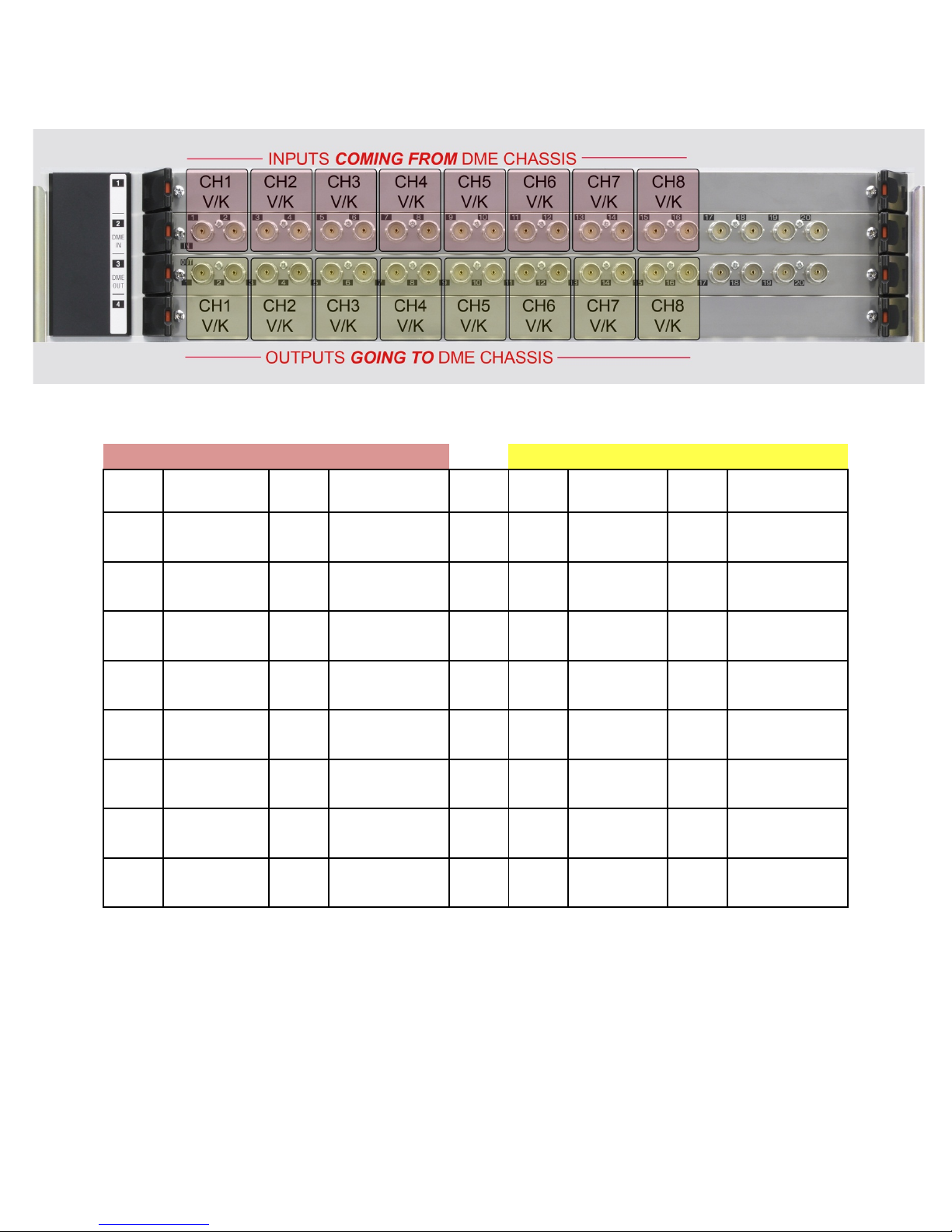

MVS-7000X backplane Slots 2 & 3 are Input and Output connectors when using an external DME chassis

(typically for more than 4 channels). Slot # 2 is for video coming FROM the DME (connected to the

OUTPUT connectors on the DME Chassis). Slot #3 is for video GOING TO the DME (connected to the

INPUT connectors on the DME Chassis). Using these dedicated connectors saves primary inputs and

outputs, while still allowing the external DME chassis to function as a fully integrated device. In very

specific production requirements, it may be desirable to wire the DME chassis as a true external device,

meaning using primary inputs and outputs. Since this type of wiring is rare, please contact your Sony

account manager or Sales Support Engineer if you need assistance.

pg. 18

SLOT 2 (FROM DME)

SLOT 3 (TO DME)

SIGNAL

(DME1)

SIGNAL

(DME1)

The following shows the backplane of the MVS-7000X’s DME I/O:

BNC

BNC SIGNAL(DME2) BNC

BNC SIGNAL(DME2)

1 CH1 V Out 9 CH5 V Out 1 CH1 V In 9 CH5 V In

2 CH1 K Out 10 CH5 K Out 2 CH1 K In 10 CH5 K In

3 CH2 V Out 11 CH6 V Out 3 CH2 V In 11 CH6 V In

4 CH2 K Out 12 CH6 K Out 4 CH2 K In 12 CH6 K In

5 CH3 V Out 13 CH7 V Out 5 CH3 V In 13 CH7 V In

6 CH3 K Out 14 CH7 K Out 6 CH3 K In 14 CH7 K In

7 CH4 V Out 15 CH8 V Out 7 CH4 V In 15 CH8 V In

8 CH4 K Out 16 CH8 K Out 8 CH4 K In 16 CH8 K In

Notes:

1. If an internal DME is installed it will always be DME1 (Unit ID 1) and BNC connectors 1-8 for both

input and output are not used.

2. If a chassis of MVE-8000A or MVE-9000 is installed in addition to the internal DME, connect the

external chassis to BNC connectors 9-16 (CH5-8).

3. If no internal DME is installed then BNC Connectors 1-8 (CH1-4) are for the first external chassis and

9-16 (CH5-8) are for the second external chassis.

pg. 19

SWITCHER CHASSIS (MVS-8000X only)

pg. 20

Video Inputs

The MVS-8000X has up to 164 non-looping inputs, each in blocks of 20 with a couple of exceptions. Each

of the backplane input cards has 20 BNC connectors. The 8000X comes standard with 24 inputs. The

first 20 of those inputs are found on slot #5. The extra 4 inputs are actually inputs 141-144 and can be

found on slot #12. Regardless of how many extra inputs are purchased, inputs 141-144 are always

available. For example, if you purchased an 8000X with 64 inputs, you would find inputs 1-20 on slot #5,

inputs 21-40 on slot 6, inputs 41-60 on slot #7 and inputs 141-144 (the extra 4) on slot #12.

So far we’ve accounted for 144 of the possible 164 inputs. The MVS-8000X may also have an additional

20 inputs in slot #3 called “Premium Inputs.” Premium Inputs are special inputs that are available on the

switcher when the second matrix board is installed. The second Matrix board is automatically installed

when either the inputs exceed 64 or when the 8000X is configured as a 5 M/E system. Premium Inputs

can be used as regular, primary inputs. However, for your wiring design, it is very important to note that

if you have M/E 4 (you have a 5 M/E switcher) that the keyers on M/E 4 can only get their key signals

from these Premium Inputs. Standard inputs cannot be used as key signals for the keyers on M/E 4.

However, Premium Inputs can appear everywhere on the switcher. A good rule of thumb is…. If you

have M/E 4 (i.e. a 5 M/E 8000X) then put all your key signals on the premium input card in slot #3.

In addition, if you purchased any internal format converters, the inputs for the format converter

channels will also be on slot #12. They are in blocks of eight, as each format converter card is an 8channel option.

Video Outputs

A MVS-8000X can have either 24 or 48 primary outputs. If only 24 outputs are configured, then there

will be a blank in slot #14. Please notice that Slot #13 has outputs 1-20 and in the middle of slot #15 you

will find outputs 21-24. If you have 48 outputs, then you will find Outputs 25-44 on Slot #14 and

Outputs 45-48 on the right-side of slot #15. Note that output 23-24 and 47-48 have dual outputs. If

there is a blank in slot #14 (switcher only has 24 outputs), then the BNC connectors for Outputs 45-48

are not functional.

Just like inputs, all outputs on the 8000X are mappable from the Setup Menu. However, the default

factory setting is:

Out 1 M/E 1 OUT 1 (M/E 1PGM)

Out 2 M/E 1 OUT 2 (M/E 1 PVW)

Out 3 M/E 2 OUT 1 (M/E 2 PGM)

Out 4 M/E 2 OUT 2 (M/E 2 PVW)

Out 5 M/E 3 OUT 1 (M/E 3 PGM)

Out 6 M/E 3 OUT 2 (M/E 3 PVW)

Out 7 P/P OUT 1 (P/P PGM)

Out 8 P/P OUT 2 (P/P PVW)

Out 9 EDIT PVW

When you are wiring outputs, please note that the EDIT PVW output is the correct output for “Preview.”

This enables the preview switcher (which is normally set to P/P PVW) to also show other M/E previews

and other important signals like “Show Key.”

pg. 21

MVS-8000X Dedicated M/E Outputs

In addition to the primary outputs, the MVS-8000X also has, on slot 4, dedicated outputs for each M/E.

There are four for each M/E and Program/Preset. These output signals correspond to the first 4

“internal” outputs of each M/E, and are set in the Engineering Setup Menu. By default they are:

1. PGM

2. PVW

3. CLEAN

4. KEY PVW 1

However, please keep in mind that the majority of switcher operators run the M/Es in a mode called

“Multi-Program 2” which changes the output settings of the M/E bank (for instance, each M/E’s “sub”

output is fixed at M/E Output 6 – which does not have a physical, dedicated output connector and must

be routed through a standard output. It is recommended you consult with your operators before

deciding to use these M/E outputs.

Reference

The MVS-8000X requires house “black” reference to operate. If you are not looping black, please

connect a 75-ohm terminating resistor to the loop connector. Both “black” and tri-level sync are

permitted, however tri-level sync is only required for special applications, like 24P production. It is also

very important to note that BLACK reference is required when using the internal format converters. The

internal format converters will not work with tri-level sync.

Format Converters

If you purchased either one or two of the optional format converter cards, you can have either 8 or 16

format converted inputs (depending on whether you purchased one or two boards) and either 2 or 4

format converted outputs (depending on how many output boards are in the switcher chassis).

On slot #15, you will see four connectors marked as FC 1-4. These are the format converter outputs. If

your switcher has only 24 outputs, then FC3-4 are not functional.

Format converters on the 8000X have dedicated inputs on slot #12. If you have a single source that

sometimes outputs SD and sometimes outputs your “normal” house production format (i.e. 1080i) then

you will need to send the signal to both a format converter input and a standard primary input.

pg. 22

Multi-Viewer

The MVS-8000X has up to two Multi-Viewer Outputs as a standard feature. If your switcher is

configured with 24 outputs, then the MSD1 connector on Slot 15 will be active. If you have 48 outputs,

then both MSD1 and MSD2 will be active.

The Multi-viewer is a basic system that allows multiple outputs to be shown simultaneously on a single

monitor. There are two options for the type of display: 4 (quad split) and 10 (two large and 8 small).

On-Air tally is provided. Multi-Viewer settings are made in the Engineering Setup menu.

The Multi-Viewer is not designed to replace the large monitor-wall systems that are typically found in

today’s production environments. However, it is a handy standard feature of the MVS-X series to,

perhaps, removes items the whole control room doesn’t need to see, like M/E outputs and put them on

a separate monitor just for the switcher operator. For planning your output assignments, it is important

to remember two things:

• For a signal to appear on the Multi-Viewer, it must be assigned to a physical output

• Each Multi-viewer’s window assignments are exclusive to its physical output card. This means

that Multi-Viewer #1 can only “see” signals that are assigned to Out 1-24. Multi-Viewer #2 can

only “see” signals that are assigned to Out 25-48. For example, it is not possible assign a signal

that is mapped to output 51 to Multi-Viewer #1, as Multi-Viewer #1 can only access outputs 1-

24.

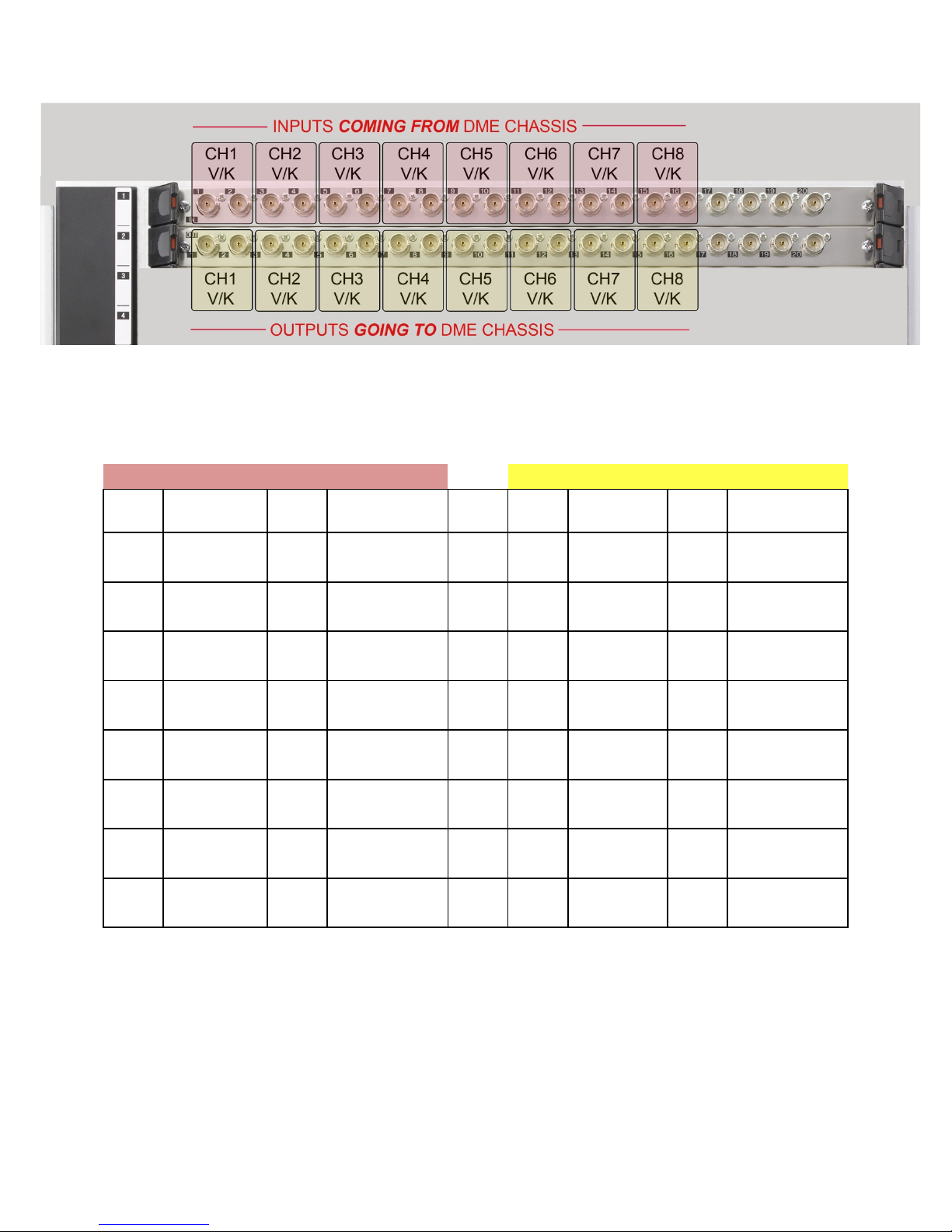

DME Inputs and Outputs

The 8000X has the ability to use up to 8 channels of DME. Each group of 4 channels will be housed in an

external chassis – a MVE-8000A, a MVE-9000 or a combination of both. If you ordered your 8000X with

any DME channels, then you will have also purchased dedicated DME input and Output backplane

boards.

Slots 1 & 2 are Input and Output connectors when using an external DME chassis. Slot # 1 is for video

coming FROM the DME (connected to the OUTPUT connectors on the DME Chassis). Slot #2 is for video

GOING TO the DME (connected to the INPUT connectors on the DME Chassis). Using these dedicated

connectors saves primary inputs and outputs, while still allowing the external DME chassis to function as

a fully integrated device. In very specific production requirements, it may be desirable to wire the DME

chassis as a true external device, meaning using primary inputs and outputs. Since this type of wiring is

rare, please contact your Sony account manager or Sales Support Engineer if you need assistance.

pg. 23

The following shows the backplane of the MVS-8000X’s DME I/O:

SLOT 1 (FROM DME)

SLOT 2 (TO DME)

SIGNAL

(DME1)

SIGNAL

(DME1)

BNC

BNC SIGNAL(DME2) BNC

BNC SIGNAL(DME2)

1 CH1 V Out 9 CH5 V Out 1 CH1 V In 9 CH5 V In

2 CH1 K Out 10 CH5 K Out 2 CH1 K In 10 CH5 K In

3 CH2 V Out 11 CH6 V Out 3 CH2 V In 11 CH6 V In

4 CH2 K Out 12 CH6 K Out 4 CH2 K In 12 CH6 K In

5 CH3 V Out 13 CH7 V Out 5 CH3 V In 13 CH7 V In

6 CH3 K Out 14 CH7 K Out 6 CH3 K In 14 CH7 K In

7 CH4 V Out 15 CH8 V Out 7 CH4 V In 15 CH8 V In

8 CH4 K Out 16 CH8 K Out 8 CH4 K In 16 CH8 K In

Notes:

Connectors 1-8 (CH1-4) are for the first external chassis and 9-16 (CH5-8) are for the second external

chassis.

pg. 24

Loading...

Loading...