SONY MVC-FD85, FD90 Service Manual

MVC-FD85/FD90

SERVICE MANUAL

Level 1

Ver 1.0 2000. 03

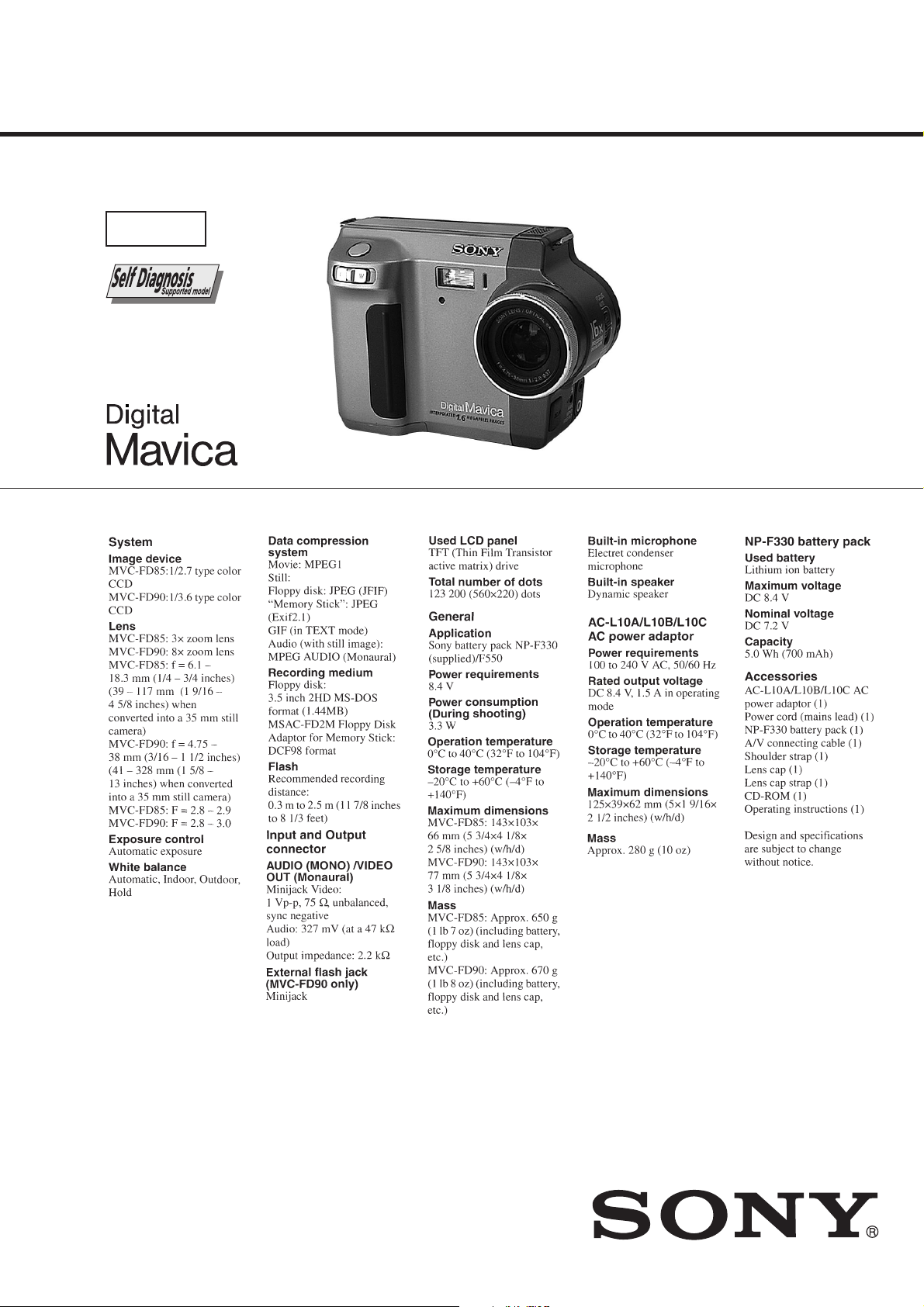

Photo: MVC-FD90

SPECIFICA TIONS

AEP Model

UK Model

DIGITAL STILL CAMERA

TABLE OF CONTENTS

SERVICE NOTE ····································································· 3

1. MAIN PARTS

1. ORNAMENTAL PARTS ···················································· 5

2. DISASSEMBLY ································································· 6

2-1. CABINET (REAR) BLOCK ASSEMBLY ························ 6

2-2. FC-72 BOARD, FLOPPY DISK DRIVE ·························· 7

2-3. LENS BLOCK ASSEMBLY··············································8

2-4. FLASH UNIT, FU-140/146 BOARD································· 8

2-5. DC-IN CONNECTOR, MICROPHONE UNIT················· 9

2-6. HINGE ASSEMBL Y,

BATTERY TERMIN AL BOARD······································ 9

2-7. LCD, PK-50/52 BOARD·················································· 10

2-8. EJECT BUTTON SECTION ··········································· 11

2. REPAIR PARTS LIST

2-1. EXPLODED VIEWS ······················································· 12

2-1-1.CABINET (FRONT) BLOCK SECTION-1 ···················· 12

2-1-2.CABINET (FRONT) BLOCK SECTION-2 ···················· 13

2-1-3.CABINET (REAR) BLOCK SECTION ·························· 14

2-1-4.LENS BLOCK SECTION················································ 15

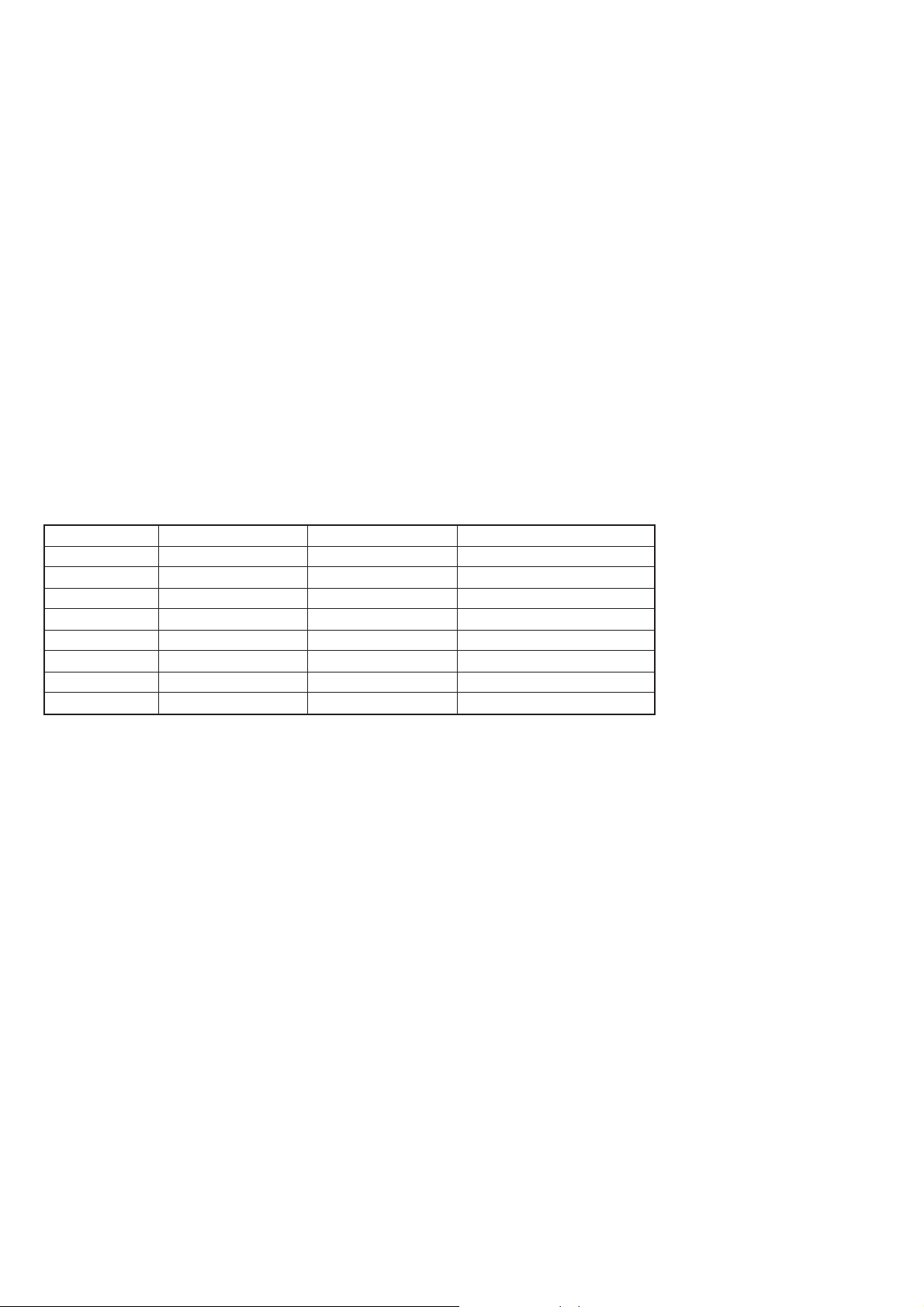

Table for differences of function

Model

CCD imager size

Lens Optical

Manual foucs

LANC jack

CD board

FC board

PD board

FU board

MVC-FD85

1/2.7 inch

3 ×

CD-248

FC-72

PD-52

FU-146

MVC-FD90

1/3.6 inch

8 ×

a

a

CD-246

FC-72

PD-50

FU-140

3. GENERAL

Getting started

Identifying the parts ································································ 16

Preparing the power supply ···················································· 17

Setting the date and time························································· 18

Inserting a floppy disk ···························································· 18

Basic operations

Recording still images ···························································· 18

Recording moving images ······················································ 19

Playing back still images ························································ 20

Playing back moving images ·················································· 20

Viewing images using a personal computer ··························· 20

Image file storage destinations and image file names ············ 21

Advanced operations

Before performing advanced operations································· 21

Additional information

Precautions·············································································· 28

Using your camera abroad ······················································ 28

Troubleshooting ······································································ 28

Warning and notice messages ················································· 29

Self-diagnosis display ····························································· 29

LCD screen indicators ···························································· 30

Remark

a: with CN401 of FC-72 board.

a: with J782 of PK-50 board.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

• NOT FOR REPAIR

Capacitor

Short jig

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the MVC-FD85/FD90 is simply turned off. Therefore,

the remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

— 3 —

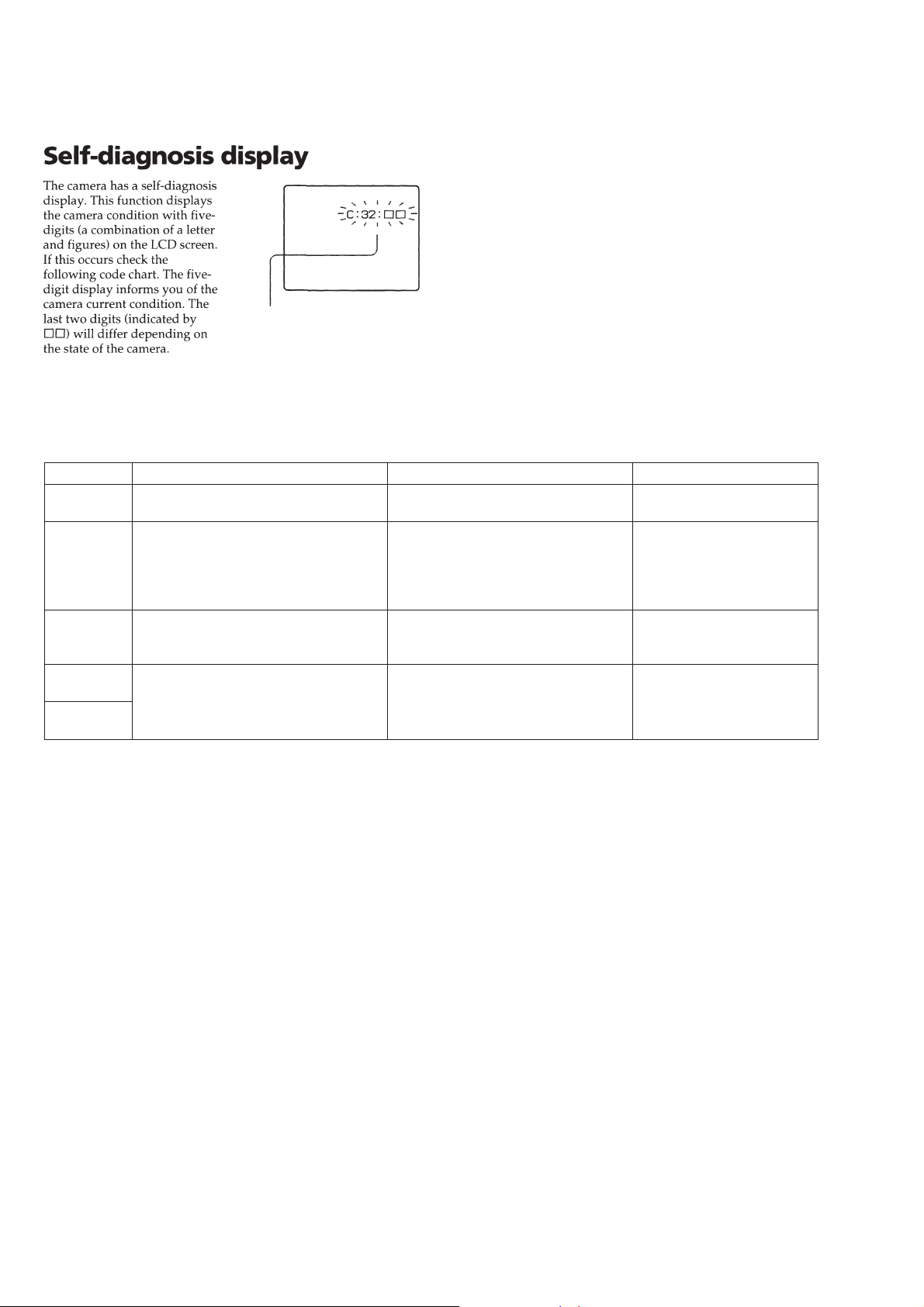

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

Note : The “Self-diagnosis” data is backed up by the coin lithium

battery.The data will be lost and initialized when the coin lithium

battery is removed.

Display Code

C:32:01

C:13:01

E:91:01

E:61:00

E:61:10

Countermeasure

Change the disk and turn off the main

power then back on.

Replace the floppy disk.

Format the floppy disk with the MVCFD85/FD90.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Cause

Defective floppy disk.

• The type of floppy disk that cannot be

used by this machine, is inserted.

(Such as 2DD)

• Data is damaged.

• Unformatted disk is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Caution Display During Error

DRIVE ERROR

DISK ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

— 4 —

1. MAIN PARTS

)

Note:

• Follow the disassembly procedure in the numerical order given.

• Items marked “*” are not stocked since they are seldom required for routine service. Some delay should

be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

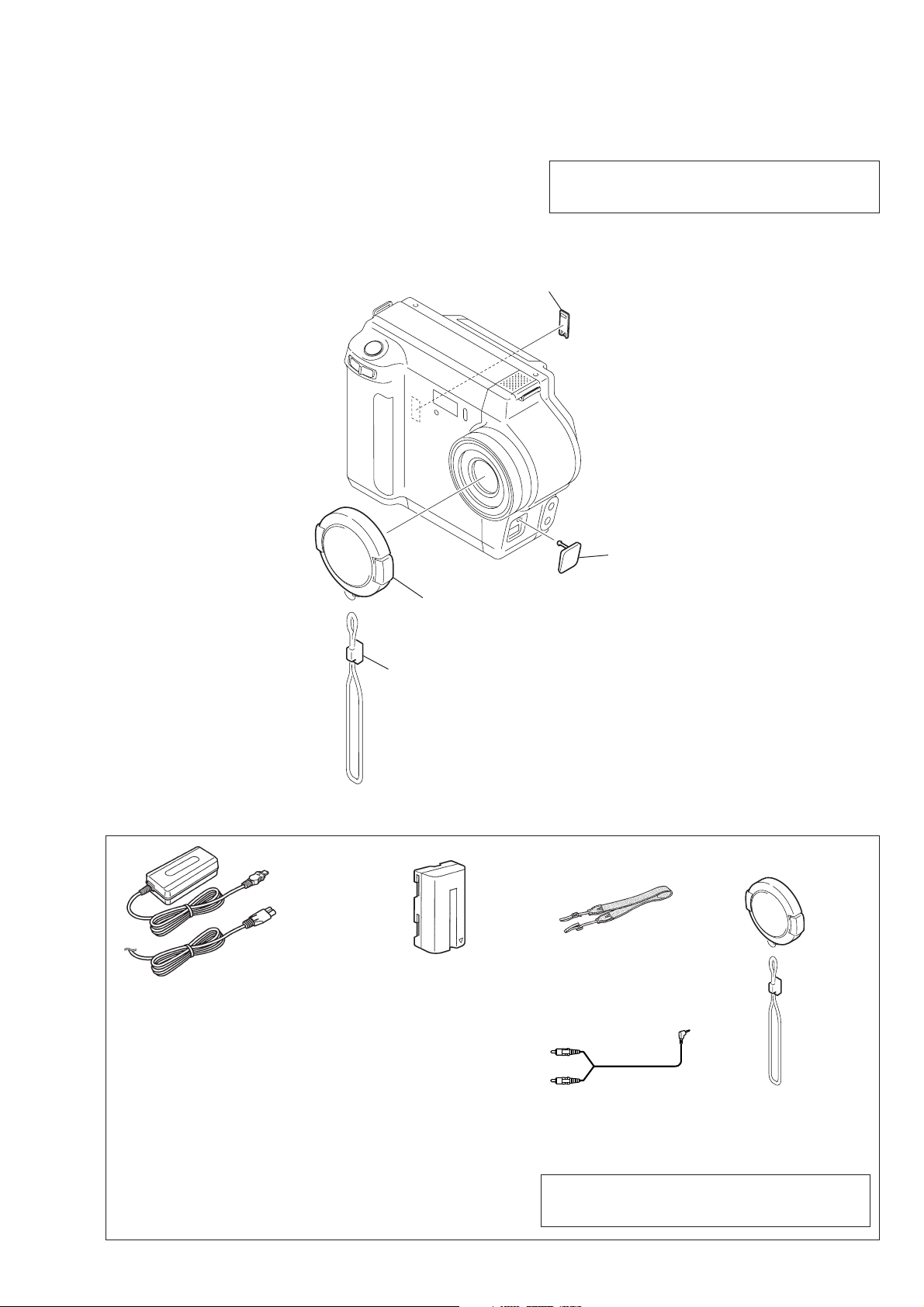

1. ORNAMENTAL PARTS

CPC Lid

3-058-792-01

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

MVC-FD85/FD90

Checking supplied accessories

AC-VF10 power adaptor (1)

0

1-475-599-11

Power cord set (1) (AEP model)

0

1-769-608-11

Power cord (with filter) (1) (UK model)

0

1-783-374-11

Lens cap assembly

X-3950-660-1

Cap string

3-724-594-01

NP-F330 battery pack (1)

(MVC-FD90: AEP, UK model)

A-7094-141-A

DC cover

3-058-767-01

Shoulder belt (S) (1)

3-987-015-01

(Fig. A

(Fig. B)

Other accessories

3-060-831-11 MANUAL, INSTRUCTION (ENGLISH)(AEP,UK MODEL)

3-060-831-21 MANUAL, INSTRUCTION (FRENCH/GERMAN)(AEP MODEL)

3-060-831-31 MANUAL, INSTRUCTION (SPANISH/PORTUGUESE)(AEP MODEL)

3-060-831-41 MANUAL, INSTRUCTION (ITALIAN/DUTCH)(AEP MODEL)

3-060-831-61 MANUAL, INSTRUCTION (SWEDISH/RUSSIAN)(AEP MODEL)

— 5 —

Cord connector (A/V) (1)

1-783-738-11

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

(Fig. A) Lens cap assy (1)

X-3950-660-1

(Fig. B) Cap string (1)

3-724-594-01

2. DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1 . Cabinet (Rear) block assembly

2-7. LCD, PK-50/52 board, Speaker

2-8. Eject button section

2-2. FC-72 board, Floppy disk drive

MVC-FD85/FD90

2-3. Lens block assembly

2-4. Flash unit, FU-146 board

2-5. DC-IN connector, Microphone UNIT,

Control switch block (MF 330)(MVC-FD90)

2-6. Hinge assembly, Battery terminal board,

Control switch block

NOTE: F ollo w the disassembly procedure in the numerical order given.

2-1. CABINET (REAR) BLOCK ASSEMBLY

7

Cabinet (front) block assembly

5

Two screws (M2 × 4),

lock ace, p2

3

Two screws (M2 × 4), lock ace, p2

FC-72

Board

a

4

Screw (M2 × 4),

lock ace, p2

a

2

Screw (M2 × 4),

lock ace, p2

6

Cabinet (rear) block assembly

1

Two screws (M2 × 4),

lock ace, p2

— 6 —

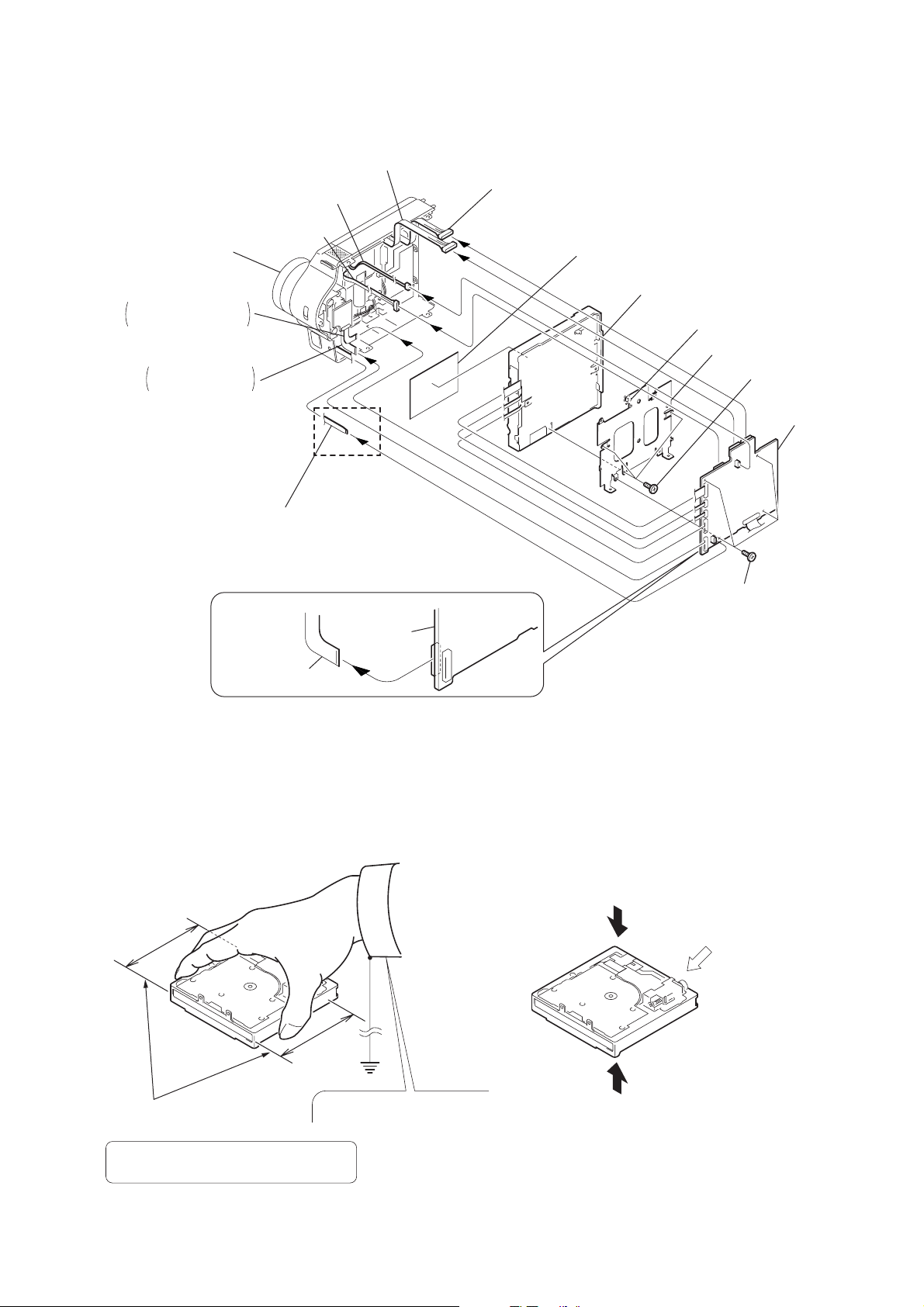

2-2. FC-72 BOARD, FLOPPY DISK DRIVE

9

FU-51 harness (12p)

1

Microphone unit (2p)

q;

qa

Cabinet (front)

block assembly

2

Flexible board (18P)

MVC-FD85 FP-231

MVC-FD90 FP-167

3

Lens block assembly

MVC-FD85 (26P)

MVC-FD90 (24P)

Flash unit (10p)

4

Control switch block(MF330)(6p)

(MVC-FD90)

8

FU-52 harness (9p)

qf

Blind sheet

qg

Floppy disk drive (4 × )

6

Claw

qd

FC Bracket

FC-72

Board

qs

Three screws

(M2 × 2.5)

7

FC-72 board

MVC-FD90

Lens block

assembly (26P)

Cautions When Handling FDD

1. Correct Way of Holding an FDD

FC-72

board

5

Four screws (M2 × 2.5)

2. Prohibited Items

Do not apply any physical stress to the center of the top plate.

Do not apply any physical

stress to the spindle motor.

Range of holding FDD

If the FDD is not held correctly,

the components of the FDD may be bent.

Wear an earthed wrist strap.

Do not hold an FDD by sandwiching

the upper and lower surfaces.

— 7 —

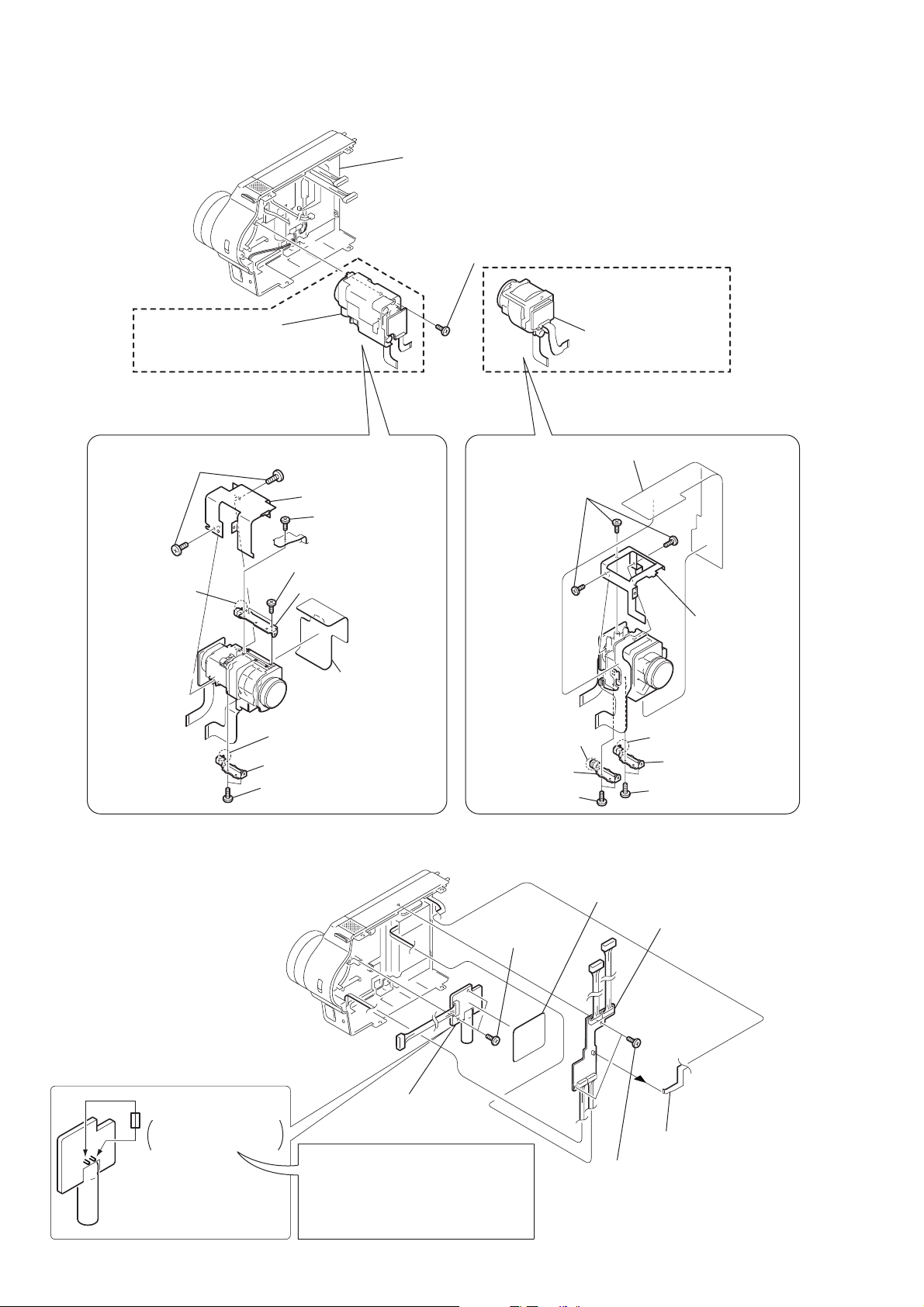

2-3. LENS BLOCK ASSEMBLY

2

Lens block assembly

(MVC-FD90)

3

Cabinet (front) assembly

1

Tapping screw (M2 × 5)

2

Lens block assembly

(MVC-FD85)

REMOVING THE FOCUS STEPPING

MOTOR, ZOOM STEPPING MOTOR

1

Two screws (M2 × 5)

2

Lens frame

4

screw

5

T wo screws

7

6

Remove

soldering

Zoom stepping motor

9

Remove soldering

q;

Focus stepping motor

8

Two screws

3

Lens sheet

1

Two screws

(M2

5

Remove soldering

6

Focus

motor unit

4

Two screws

REMOVING THE FOCUS MOTOR

UNIT, ZOOM MOTOR UNIT

3

Lens sheet (L)

×

5)

2

Lens frame

8

Remove soldering

9

Zoom

motor unit

7

Two screws

2-4. FLASH UNIT, FU-140/146 BOARD

Short jig (see page 3)

1k

Ω

. 1W

parts.No.1-215-869-11

When handling the flash unit, be sure to

discharge the chargingcapacitor before

handling it.

For discharge short jig to the positive (+)

and negetive (–) terminals of the charging

capacitor for about ten seconds.

3

Flash unit

— 8 —

2

T wo tapping

screws (M2

1

ST inslating sheet

6

FU-140 board (MVC-FD90)

×

5)

FU-146 board (MVC-FD85)

4

Control switch

block (6p)

5

T wo tapping

screws (M2

×

5)

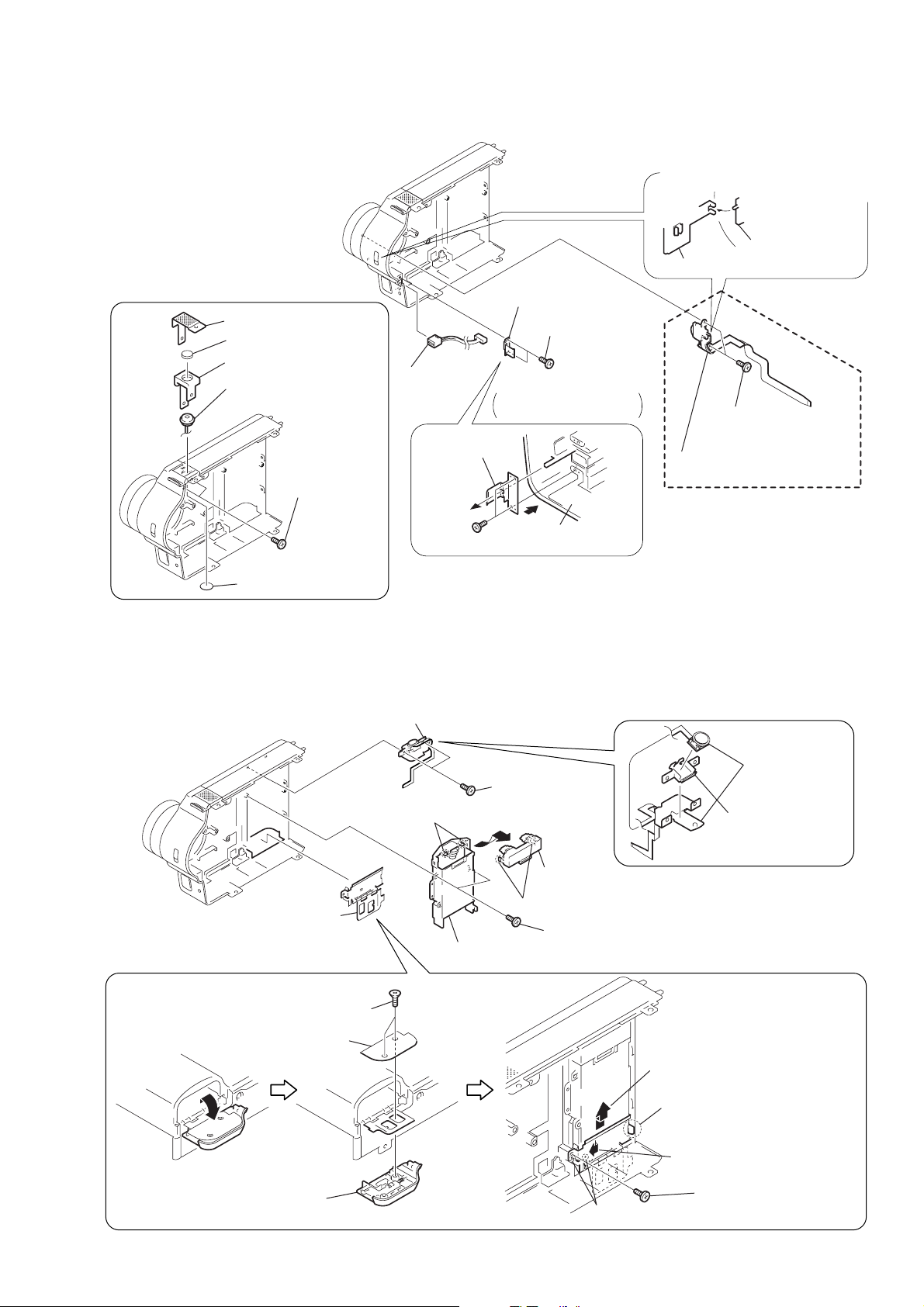

2-5. DC-IN CONNECTOR, MICROPHONE UNIT

)

2

T wo tapping

screws (M2

×

4)

4

Battery lid

8

Claw

6

Two claws

A

B

4

Two claws

3

Battery holder

6

Battery

terminal board (Remove it in the direction of the arrow

C

.)

5

Two claws

3

Hinge retainer

7

Remove the hinge assembly

in the direction of the arrow

A

.

9

Remove the hinge assembly

in the direction of the arrow

B

.

1

5

T apping

screw (M2

×

5)

2

T wo tapping

screws (M2

×

5)

7

T wo tapping

screws (M2

×

5)

8

1

Hinge assembly

2

Control switch

block

1

SW holder

REMOVING THE HINGE ASSEMBLY

REMOVING THE CONTROL

SWITCH BLOCK (zoom and shutter)

C

REMOVING THE

MICROPHONE UNIT

2

Microphone cover

4

Microphone cushion

3

Microphone holder

6

Microphone unit

1

T wo tapping

screws (M2

×

5)

3

DC-IN

connector

DC retainer

2

DC retainer

1

T wo tapping

screws (M2

PRECAUTION DURING

INSTALLATION

Cabinet (front)

assembly

(PRECAUTION DURING INSTALLATION

Align the switch position as shown.

Control switch block

(MF 330)

1

T wo tapping

screws (M2

×

5)

×

5)

Focus slider

2

Control switch block (MF 330)

(MVC-FD90)

5

Microphone sheet

2-6. HINGE ASSEMBLY, BATTERY TERMINAL BOARD

— 9 —

Loading...

Loading...