Sony MVC-FD200 Service Manual

MVC-FD200

SERVICE MANUAL

Level 1

Ver 1.0 2002. 01

SPECIFICATIONS

System

Image device

6.64 mm(1/2.7 type)

Color CCD

Effective pixels number

of camera

Approx. 1 976 000 pixels

Lens

3× zoomlens

f =6.4 –19.2 mm (9/32 –

25/32 inches)

(41 –123 mm

(1 5/8– 4 7/8 inches) when

convertedinto a 35 mm still

camera)

F=3.8–3.9

Exposure control

Automatic exposure

White balance

Automatic, Indoor, Outdoor,

Hold

Data system

Movie: MPEG

Still: JPEG, GIF (in TEXT

mode, Clip Motion), TIFF

MPEG

Recording medium

Floppy disk:

3.5-inch 2HDMS-DOS

format (1.44 MB)

“Memory Stick”

Flash

Recommended recording

distance (ISO set to AUTO):

0.5 mto 2.0 m (1 2/3 feet to

6 2/3 feet)

Input and Output

connector

VIDEO OUT

Minijack

Video: 1 Vp-p, 75 Ω,

unbalanced, sync negative

USB jack

mini-B

LCD screen

LCD panel

6.2 cm(2.5 type)

TFT (Thin Film Transistor

active matrix) drive

Total number of dots

123 200 (560×220) dots

General

Application

Sony battery packNP-F330

(supplied)/F550 (Optional)

Power requirements

7.2 V

Power consumption

(During shooting and

LCD backlight is on)

3.6 W

Operating temperature

0°Cto40°C(32°F to 104°F)

Storage temperature

–20°Cto+60°C (–4°Fto

+140°F)

Dimensions (Approx.)

142 × 104 × 77 mm (5 1/2 ×

4 ×3 inches) (w/h/d)

Mass (Approx.)

645 g (1 lb 7 oz)

(including NP-F330 battery

pack, floppy disk and lens

cap, etc.)

AC-L10A/L10B

AC power adaptor

Power requirements

100 to240 VAC, 50/60 Hz

Rated output voltage

DC 8.4 V, 1.5A in operating

mode

Operating temperature

0°Cto40°C(32°F to 104°F)

Storage temperature

−20°C to+60°C(−4°Fto

+140°F)

Dimensions (Approx.)

125×39×62 mm (5×1 9/16×

2 1/2 inches) (w/h/d)

Mass (Approx.)

280 g (10 oz)

NP-F330 battery

pack

Battery type

Lithium ion

Maximum output

voltage

DC 8.4 V

Mean output voltage

DC 7.2 V

AEP Model

UK Model

Capacity

5.0Wh(700mAh)

Operating temperature

0°Cto40°C(32°Fto104°F)

Dimensions (Approx.)

38.4×20.6×70.8 mm

(1 9/16×13/16×2 7/8 inches)

(w/h/d)

Mass (Approx.)

70 g (2 oz)

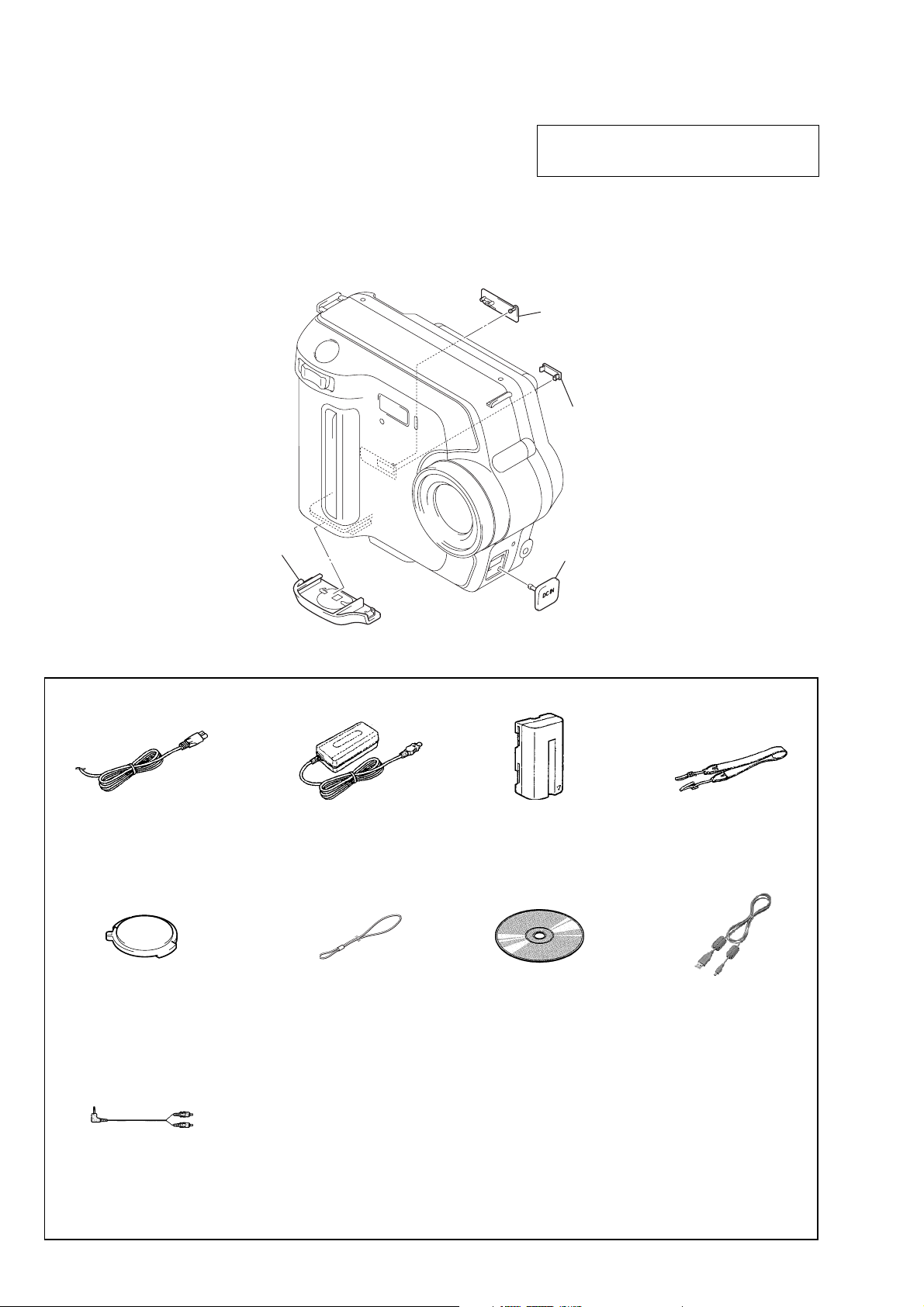

Accessories

AC-L10A/L10B

AC power adaptor (1)

Power cord (mains lead) (1)

USB cable(1)

NP-F330 battery pack (1)

VIDEO connecting cable (1)

Shoulder strap (1)

Lens cap (1)

Lens cap strap (1)

CD-ROM (SPVD-008 USB

Driver)(1)

Operating instructions (1)

Design and specifications

are subject to change

without notice.

DIGITAL STILL CAMERA

MVC-FD200

• Floppy disk that can be used by the MVC-FD200

• Size : 3.5-inch

• T ype : 2 HD

• Capacity : 1.44 MB

• Format : MS-DOS format

(512 bytes × 18 sector)

(FD can be formatted by the MVC-FD200)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when sol-

dering or unsoldering.

– 2 –

TABLE OF CONTENTS

Section Title Page

SERVICE NOTE ................................................................... 4

Self-diagnosis Display................................................... 5

1. MAIN PARTS

1. Ornamental Parts .......................................................... 6

2. DISASSEMBLY

2-1. Cabinet (Rear) Block Assembly .................................... 7

2-2. USB Connector Block ................................................... 8

2-3. FC-89 Board .................................................................. 8

2-4. FDD ............................................................................... 9

2-5. FDD Block Assembly..................................................... 9

2-6. Lens Block Assembly .................................................... 10

2-7. PK-61 Board .................................................................. 10

2-8. LCD Module................................................................... 11

3. REPAIR PARTS LIST

3-1. Exploded Views ............................................................. 12

3-1-1. Cabinet (Front) Section............................................ 12

3-1-2. Cabinet (Front) Assembly ........................................ 13

3-1-3. FDD Block Section ................................................... 14

3-1-4. Cabinet (Rear) Section ............................................ 15

3-1-5. Cabinet (Rear) Assembly......................................... 16

3-1-6. Lens Block Section................................................... 17

MVC-FD200

4. GENERAL

Introduction .............................................................................. 18

Identifying the Parts................................................................. 19

Preparing the Power Supply.................................................... 19

Setting the Date and Time....................................................... 20

Inserting a Floppy Disk............................................................ 21

Inserting a “Memory Stick” ...................................................... 21

Recording Still Images ............................................................ 21

Recording Moving Images....................................................... 23

Playing Back Still Images ........................................................ 23

Playing Back Moving Images .................................................. 23

Viewing Images Using a Computer......................................... 24

Image File Storage Destinations and Image File Names....... 26

Viewing Images Using “ImageMixer”....................................... 27

Before Performing Advanced Operations ............................... 29

Various Recording ................................................................... 31

Various Playback ..................................................................... 34

Editing ..................................................................................... 35

As an External Drive................................................................ 37

Additional Information.............................................................. 38

Troubleshooting ....................................................................... 39

Warning and Notice Messages ............................................... 40

Self-diagnosis Display ............................................................. 41

LCD Screen Indicators ............................................................ 41

– 3 –

MVC-FD200

SERVICE NOTE

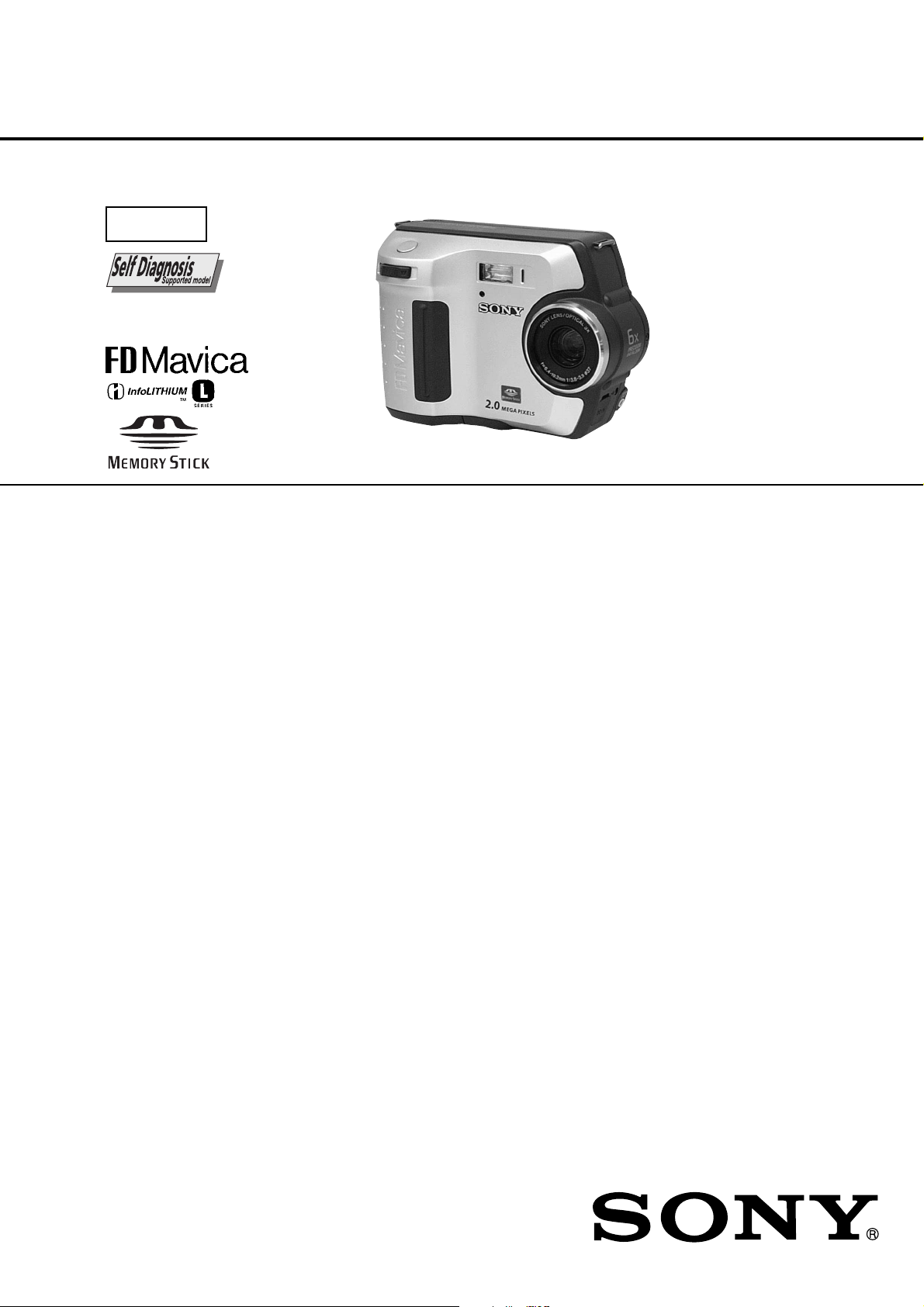

• NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some pieces of

gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

battery is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging w hen the main

power of the MVC-FD200 is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

T o preparing the short jig. a small clip is attached to eac h end of a

resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to prevent electrical shock.

Discharging the Capacitor

1 kΩ/1 W

Wrap insulating tape.

Short-circuit between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

R: 1 kΩ/1 W

(Part code:

1-215-869-11)

Capacitor

– 4 –

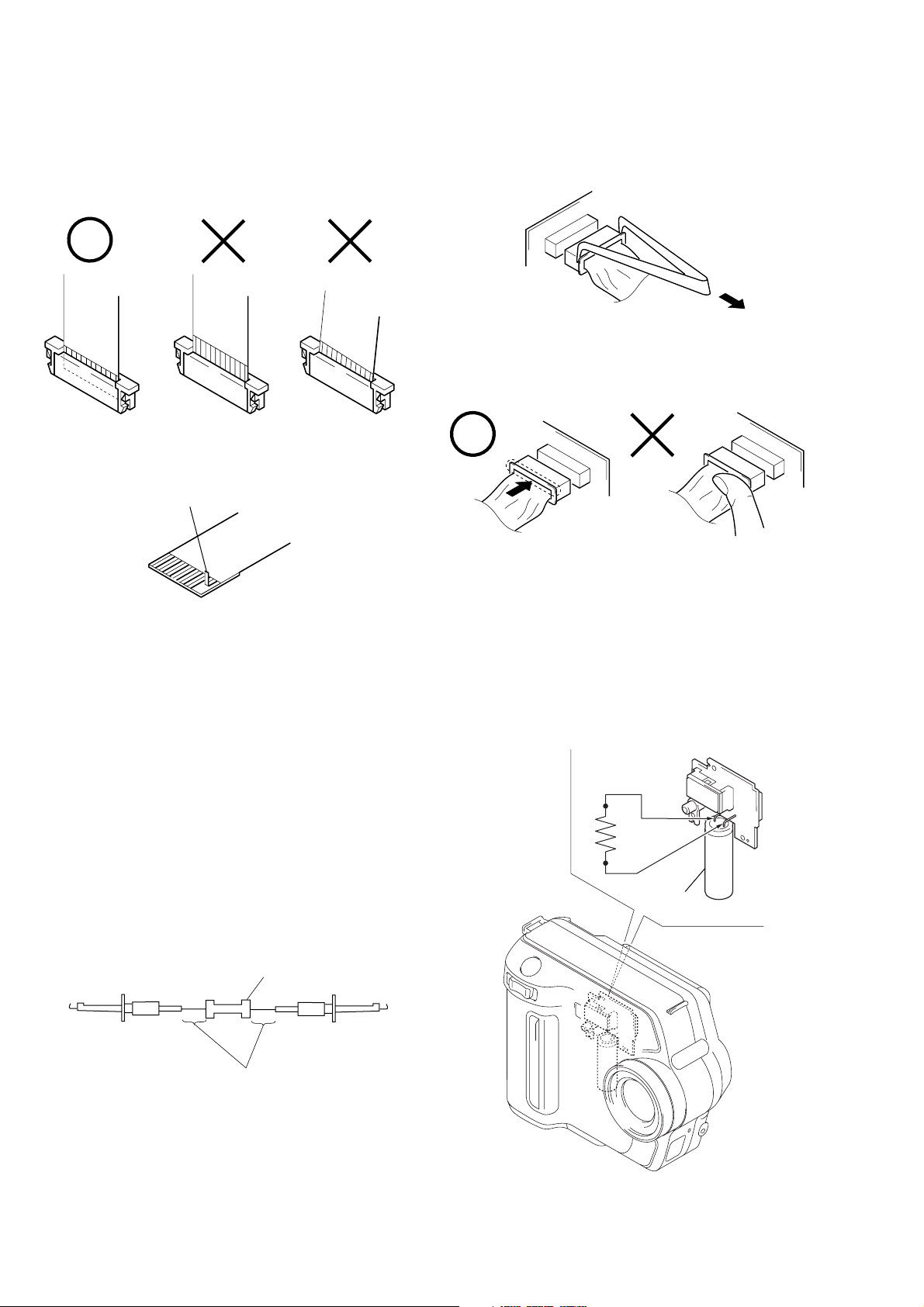

[Description on Self-diagnosis Display]

MVC-FD200

Note : The “Self-diagnosis” data is backed up by the coin lithiumbattery.

The data will be lost and initialized when the coin lithium battery

is removed.

Display Code

C:32:01

C:13:01

E:91:01

E:61:00

E61:10

Note : The error code is cleared if the battery is removed, except defective flash, unit.

*1: When the flash charging failed, Page: D, Address: 67, Data: 04 are written.

After repair, be sure to write Page: D, Address: 67, Data: 00.

[Power supplying Method]

Use the AC power adaptor (AC-L10A) when supplying the power to this set.

Change the disk and turn off the main

power then back on.

Replace the floppy disk or “Memory

Stick”.

Format the floppy disk or “Memory

Stick” with the MVC-FD200.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Countermeasure

Cause

Defective floppy disk.

• The type of floppy disk that cannot be

used by this machine, is inserted.

(Such as 2DD)

• Data is damaged.

• Unformatted disk or “Memory Stick”

is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Caution Display During Error

DRIVE ERROR

DISK ERROR

MEMORY STICK ERROR

Flash LED

*1

Flash display

Flashing at 3.2 Hz

—

– 5 –

MVC-FD200

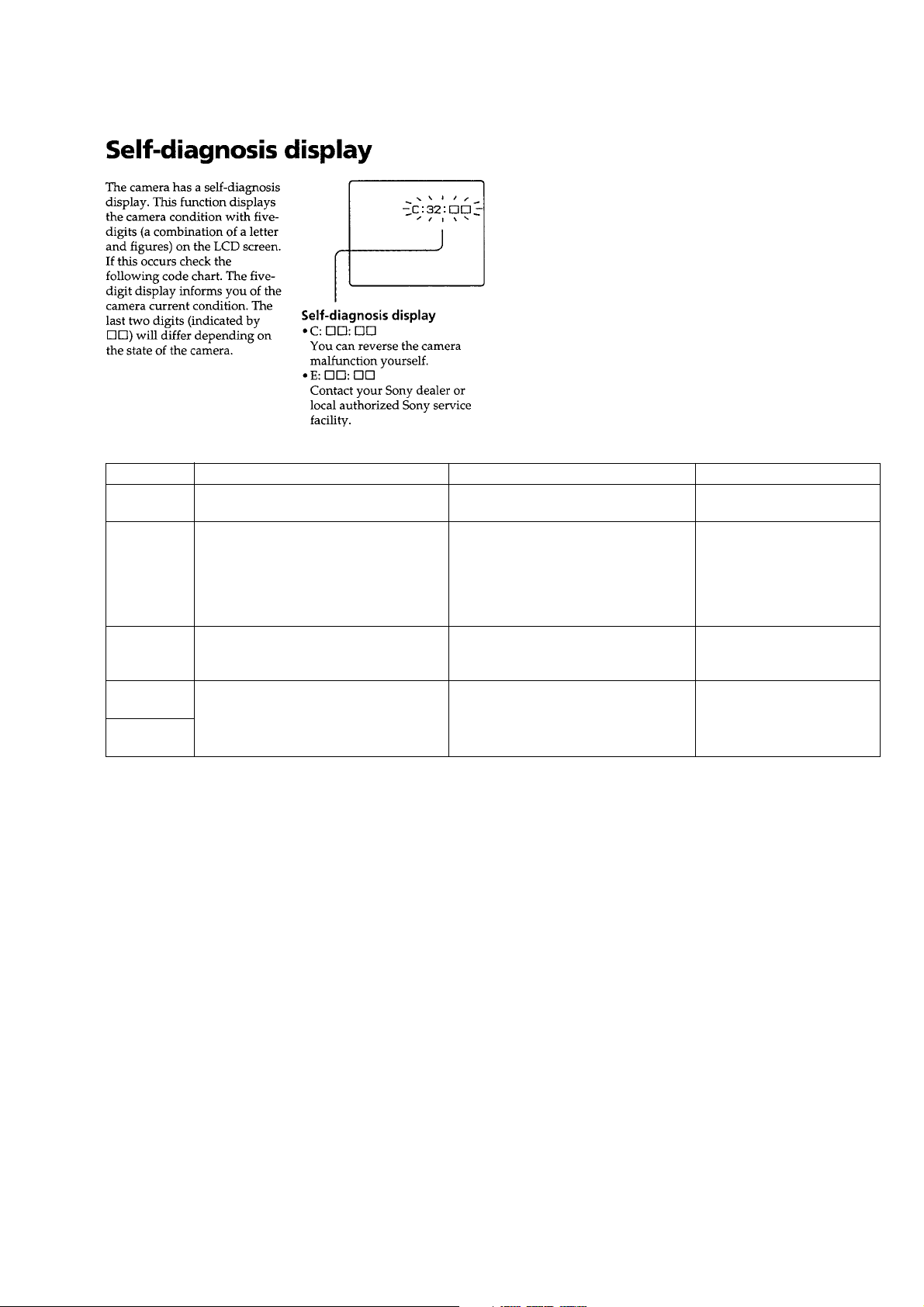

1. MAIN PARTS

Note:

• Items marked “*” are not stocked since they are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

1. ORNAMENTAL PARTS

Note: When change it, need to dismantle the set.

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

USB jack cover

3-066-802-21

(Note)

CPC lid

3-066-805-31

Battery lid

3-073-006-11

Checking supplied accessories.

Power cord (1)

0 1-769-608-11 (AEP)

0 1-783-374-11 (UK)

AC power adaptor

AC-L10A (1)

0 1-475-599-11

DC cover

3-072-999-11

(Note)

Battery pack

NP-F330 (1)

0 A-7094-141-A

Shoulder strap (1)

3-987-015-01

Lens cap (1)

X-3950-660-1

A/V connecting cable (1)

1-792-955-11

Lens cap strap (1)

3-067-797-01

– 6 –

CD-ROM

(SPVD-008 USB driver) (1)

3-072-414-01

Other accessories

3-073-074-11 MANUAL, INSTRUCTION (ENGLISH)

3-073-074-21 MANUAL, INSTRUCTION

(FRENCH, GERMAN) (AEP)

3-073-074-31 MANUAL, INSTRUCTION

(SPANISH, PORTUGUESE) (AEP)

3-073-074-41 MANUAL, INSTRUCTION

(ITALIAN, DUTCH) (AEP)

3-073-074-61 MANUAL, INSTRUCTION

(SWEDISH, RUSSIAN) (AEP)

USB cable (1)

1-823-931-11

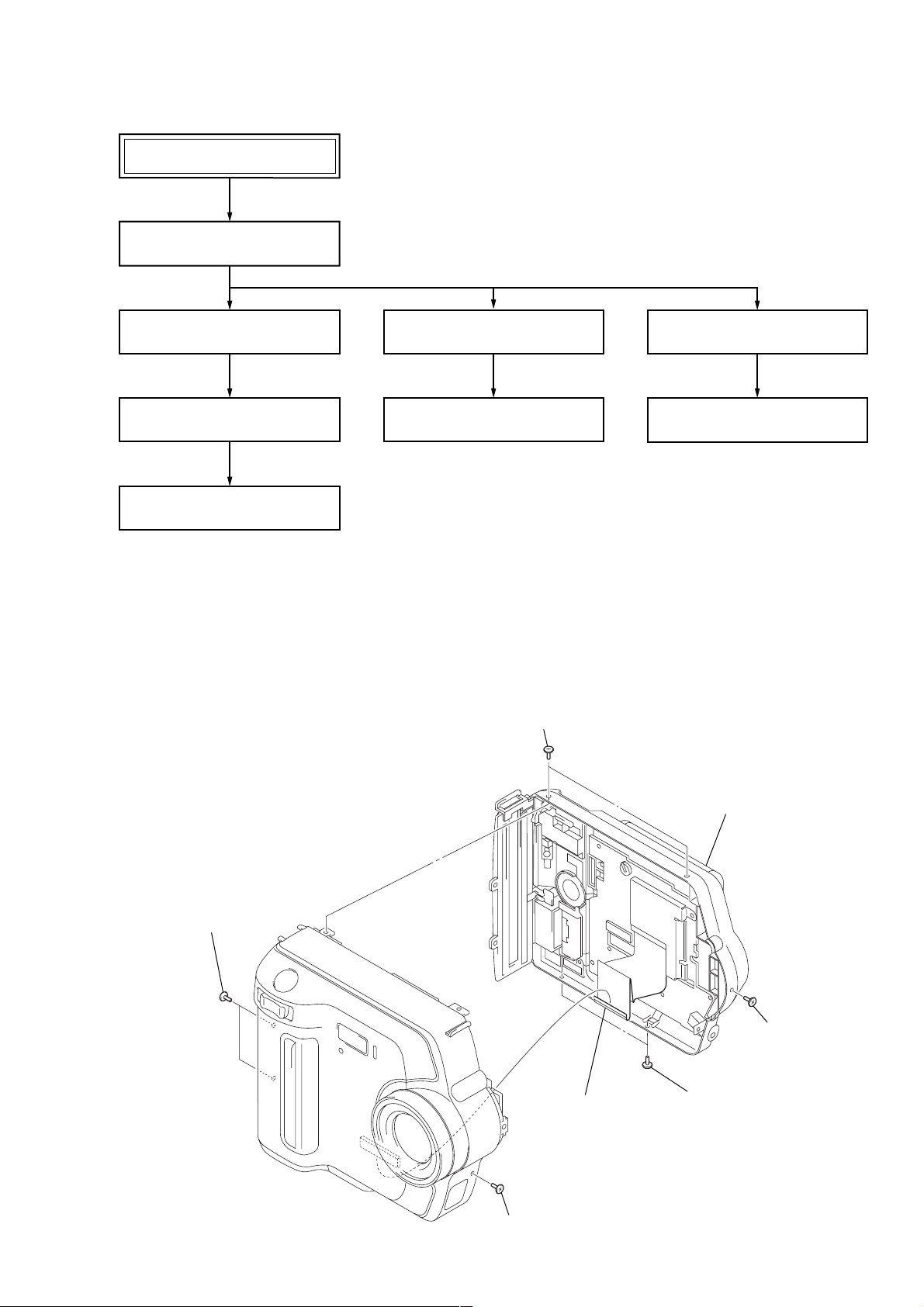

2. DISASSEMBLY

2-1. CABINET (REAR) BLOCK

ASSEMBLY (Page 7)

2-2. USB CONNECTOR BLOCK

(Page 8)

2-5. FDD BLOCK ASSEMBLY

(Page 9)

2-3. FC-89 BOARD

(Page 8)

2-4. FDD

(Page 9)

2-6. LENS BLOCK ASSEMBLY

(Page 10)

MVC-FD100/FD200

2-7. PK-61 BOARD

(Page 10)

2-8. LCD MODULE

(Page 11)

• This set can be disassembled in the order shown below.

MVC-FD200

Note: Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR) BLOCK ASSEMBLY

5 Two screws (M2)

1 Two screws (M2)

7 Flexible board

(CN801)

6 Cabinet (rear) block assembly

2 Screw (M2)

3 Two screws (M2)

4 Screw (M2)

– 7 –

MVC-FD200

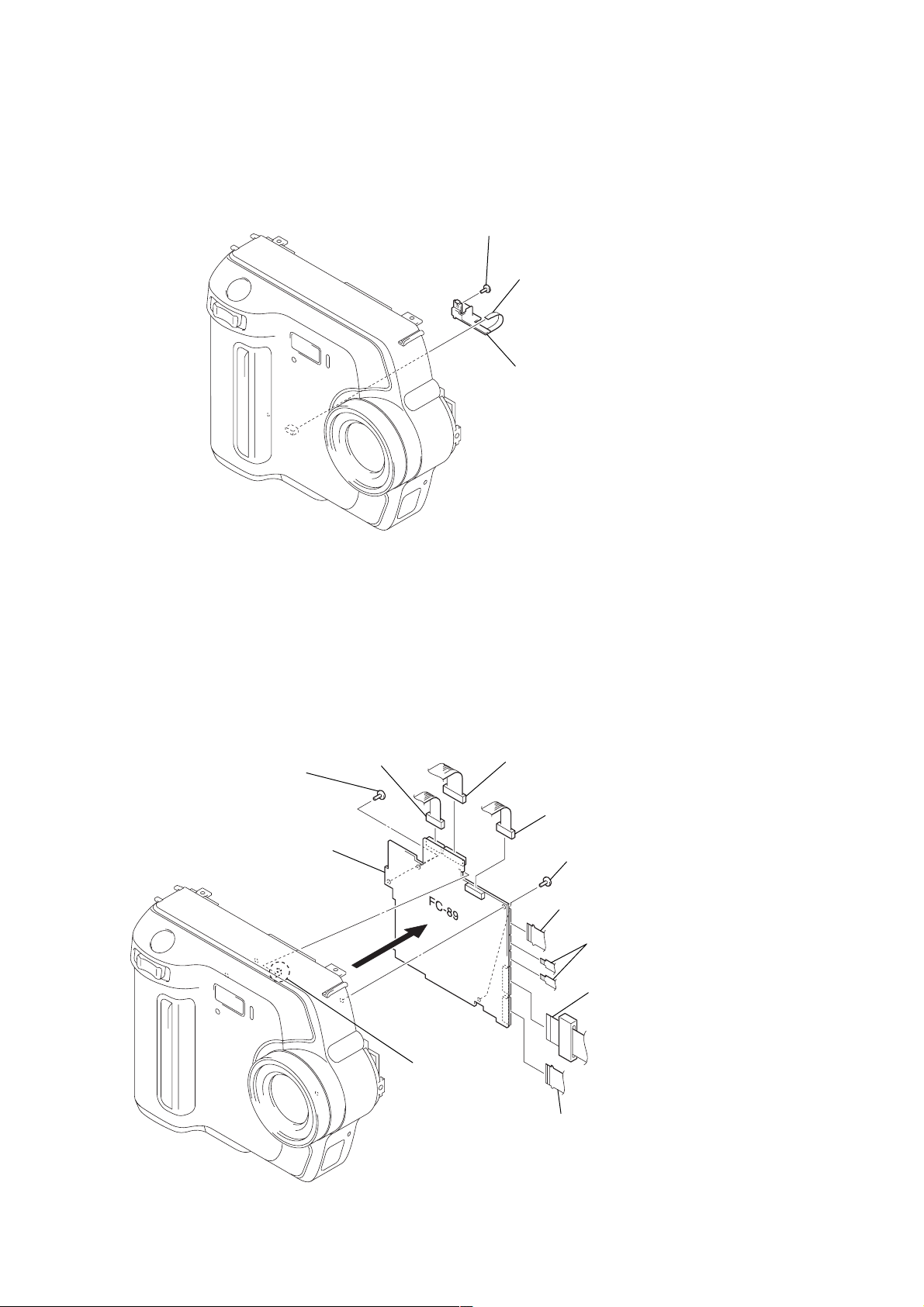

2-2. USB CONNECTOR BLOCK

1 Screw (M2)

2 Flexible board (CN682)

3 USB connector block

2-3. FC-89 BOARD

9 Two screws (M2)

qa FC-89 board

7 Connector

(CN002)

6 Connector

(CN001)

5 Connector

(CN301)

8 Two screws (M2)

1 Flexible board

(CN701)

2 Two flexible board

(CN702, 703)

3 FP-465 flexible board

(CN101)

0 Claw

4 FP-464 flexible board

(CN184)

– 8 –

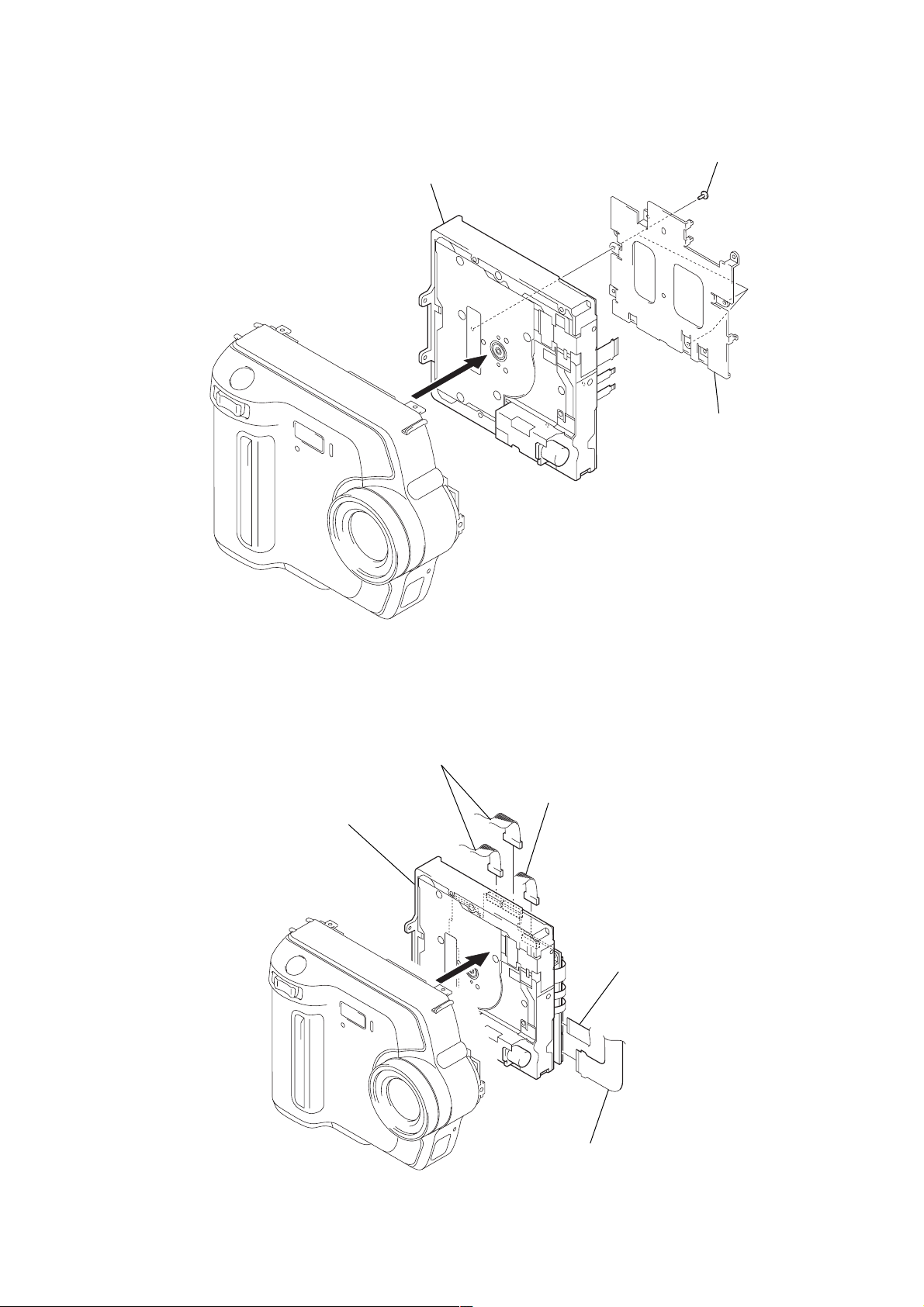

2-4. FDD

MVC-FD200

1 Three screws (M2)

3 FDD

2 FC bracket

2-5. FDD BLOCK ASSEMBLY

5 FDD block assembly

4 T wo connectors

(CN001, 002)

3 Connector

(CN301)

1 FP-465 flexible board

(CN101)

2 FP-464 flexible board (CN184)

– 9 –

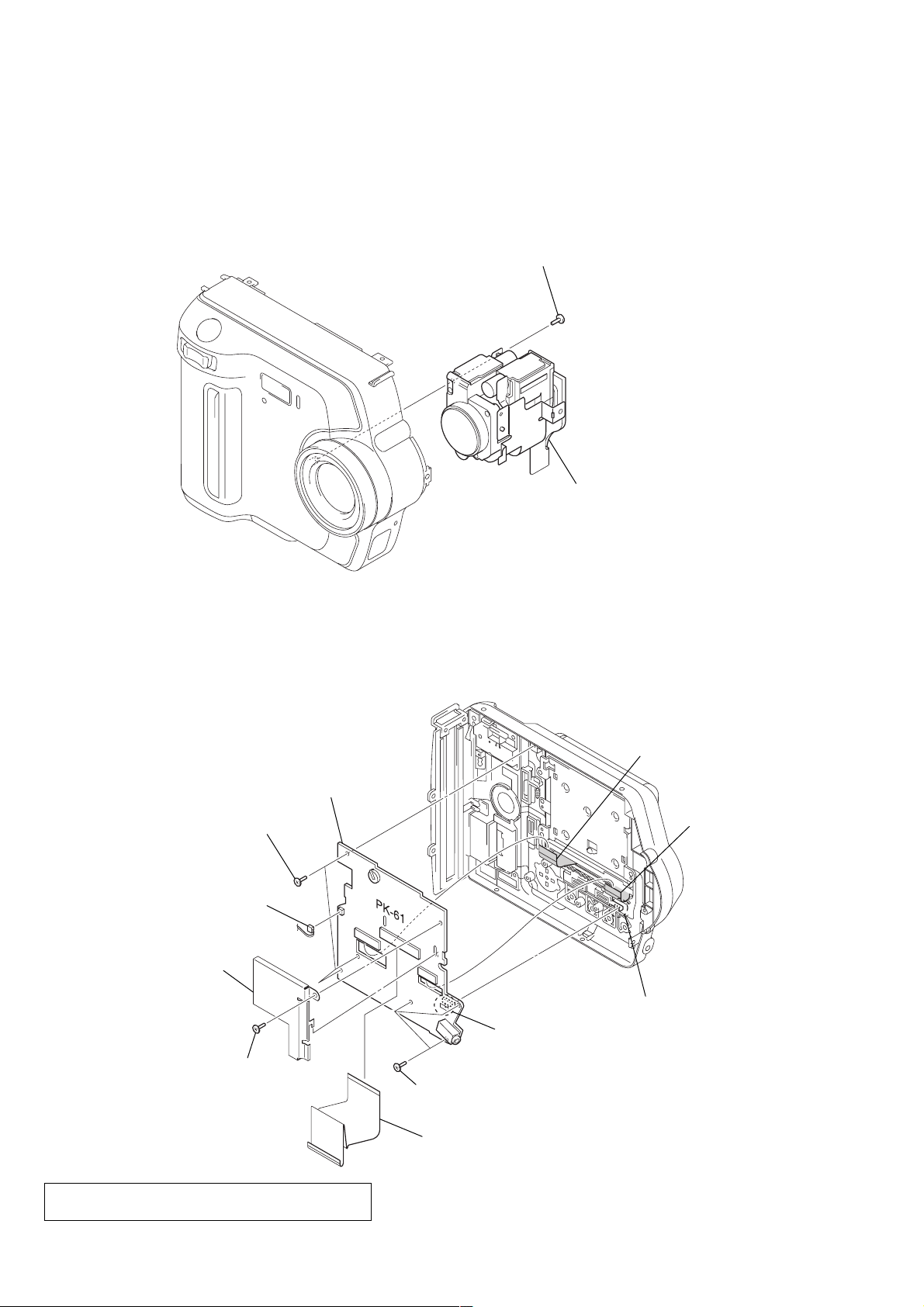

MVC-FD200

2-6. LENS BLOCK ASSEMBLY

1 Tapping screw

2-7. PK-61 BOARD

7 Three tapping screws

2 Lens block assembly

4 Flexible board

(CN902)

9 PK-61 board

5 Flexible board

(CN851)

3 Connector

(CN702)

2 PK shield case assembly

1 Tapping screw

Note: When installing PK-61 board, connect S709 with

LCD knob retainer.

LCD knob retainer

S709

8 Three tapping screws

6 FP466 flexible board

(CN701)

– 10 –

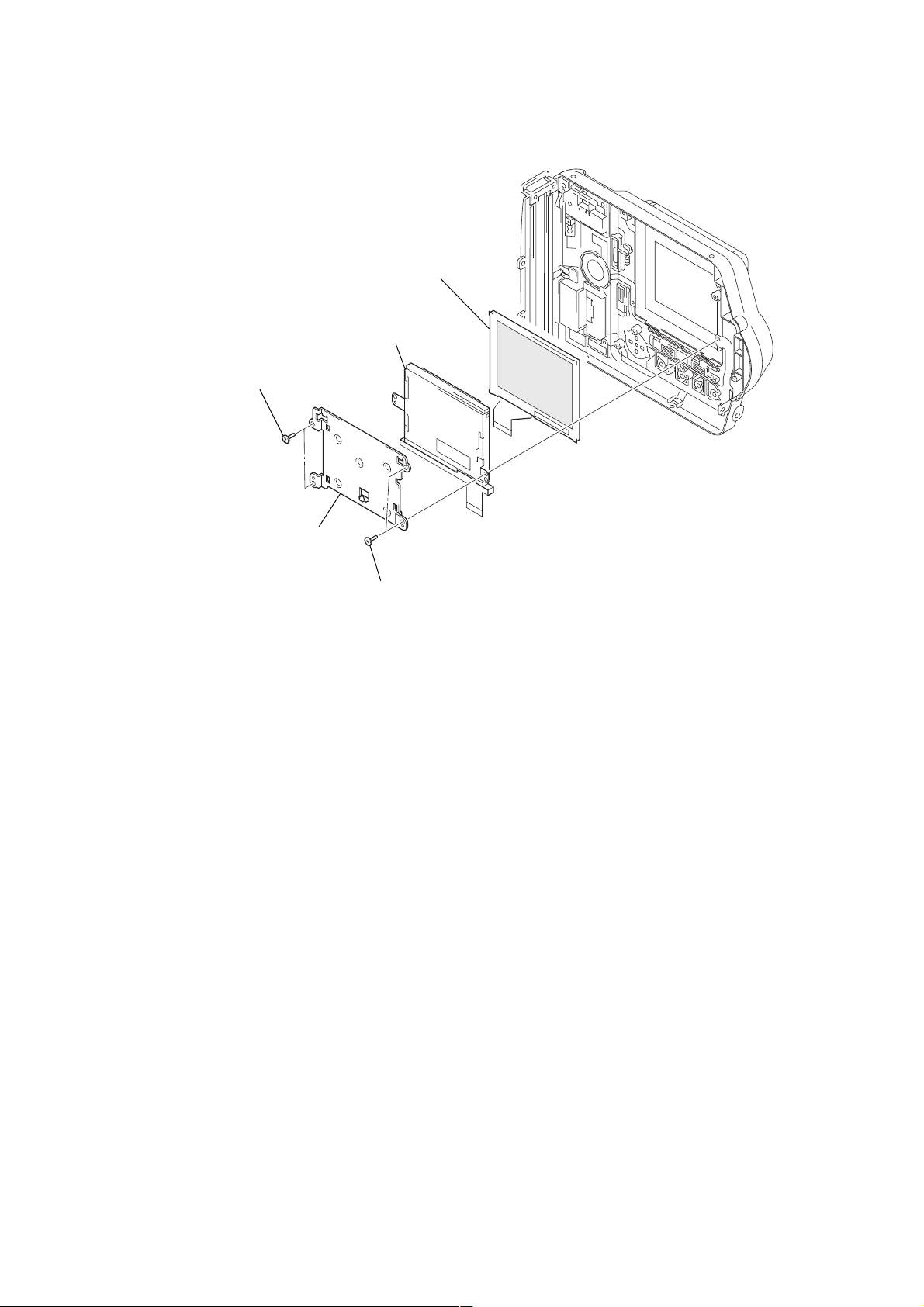

2-8. LCD MODULE

1 Two tapping screws

MVC-FD200

5 LCD module

4 Cold cathode

fluorescent tube

3 BL retainer

2 Two tapping screws

– 11 –

MVC-FD200

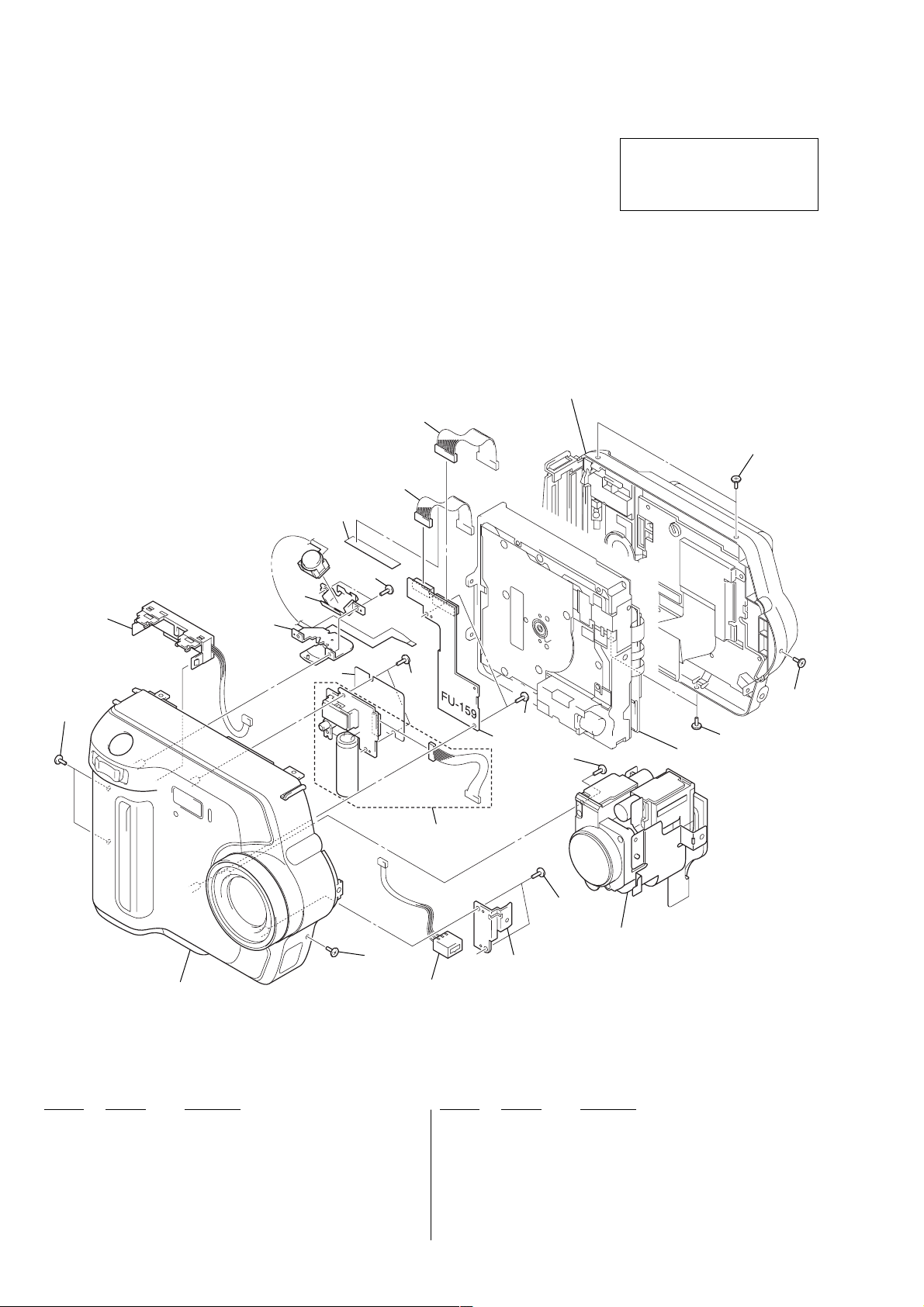

3-1. EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

3-1-1. CABINET (FRONT) SECTION

3. REPAIR PARTS LIST

• The mechanical parts with no reference number in

the exploded views are not supplied.

Cabinet (rear) section

(See page 15.)

8

9

The components identified by mark

0 or dotted line with mark 0 are

critical for safety.

Replace only with part number specified.

10

BT901

10

Cabinet (front) assembly

(See page 13.)

11

2

7

6

4

2

10

2

5

2

10

FDD block section

(See page 14.)

3

2

Lens block section

10

J001

(See page 17.)

1

Ref. No. Part No. Description Ref. No. Part No. Description

1 3-073-018-01 RETAINER, DC

2 3-948-339-61 TAPPING

0 3 not supplied FLASH UNIT

* 4 3-058-801-01 SHEET, ST INSULATING

5 not supplied FU-159 BOARD, COMPLETE

6 1-418-894-11 SWITCH BLOCK, CONTROL

7 3-073-019-01 HOLDER, SW

8 1-961-478-11 HARNESS (FU-055)

9 1-961-479-11 HARNESS (FU-056)

10 3-968-729-31 SCREW (M2), LOCK ACE, P2

* 11 3-061-228-01 RETAINER, HARNESS

BT901 1-694-297-21 TERMINAL BOARD, BATTERY

J001 1-794-045-21 CONNECTOR, DC-IN

– 12 –

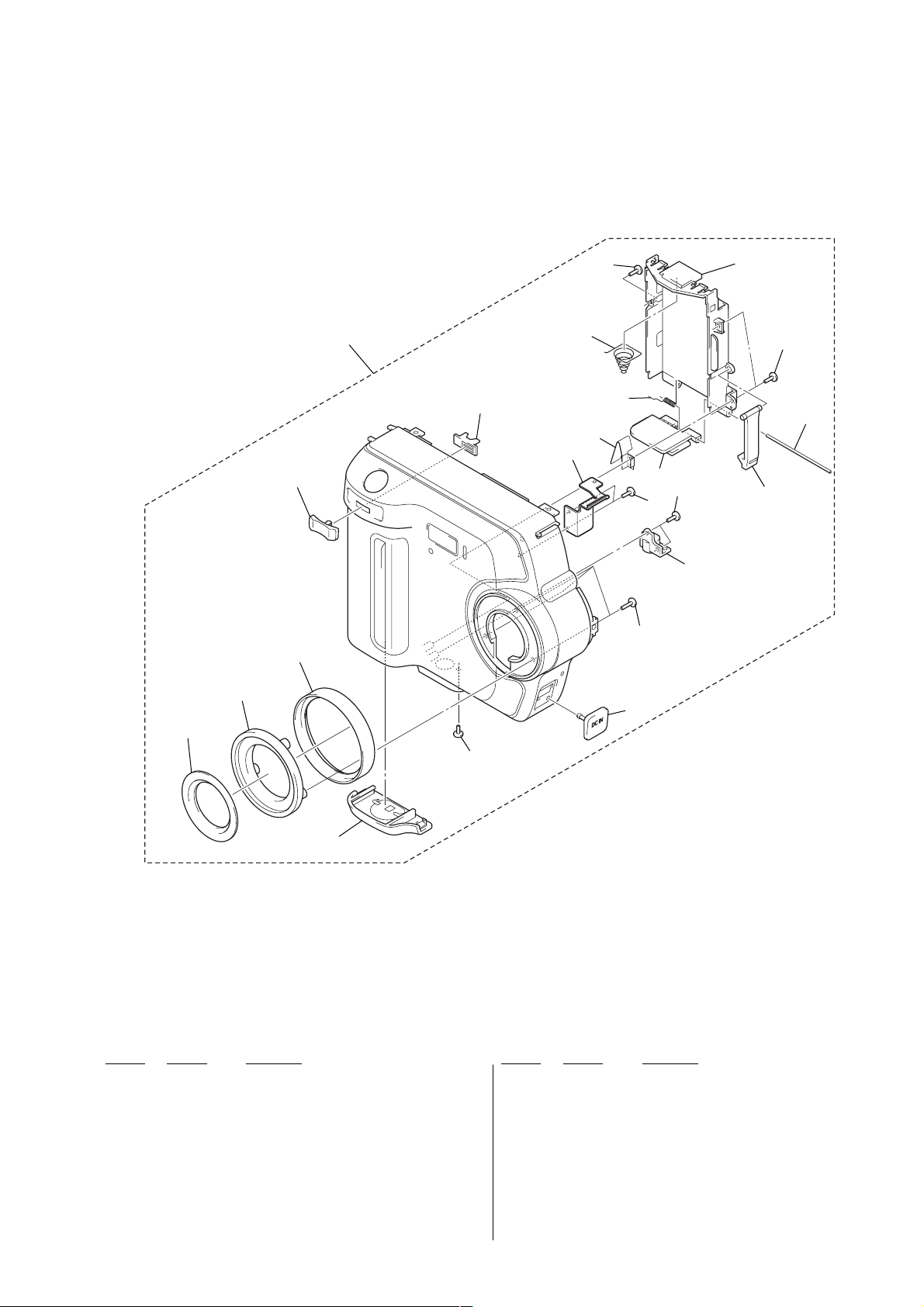

3-1-2. CABINET (FRONT) ASSEMBLY

MVC-FD200

52

53

69

54

51

70

58

63

59

64

61

57

68

60

64

64

62

64

65

66

67

56

55

Ref. No. Part No. Description Ref. No. Part No. Description

51 X-3952-212-1 CABINET (FRONT) ASSY

52 X-3952-207-1 LABEL ASSY, LENS

53 3-073-008-01 SCREW, FILTER

54 3-073-005-01 RING, ORNAMENTAL

55 3-073-006-11 LID, BATTERY

56 3-719-381-01 SCREW (M2X4)

57 3-072-999-11 COVER, DC

58 3-073-013-01 SHEET METAL (L), STRAP

59 3-066-775-01 SPRING, BT PLATE

60 3-066-772-01 PLATE, HINGE

61 3-066-778-01 SPRING, BT TORSION

62 3-066-773-01 HOLDER, BATTERY

63 3-969-380-01 SPRING, BATTERY

64 3-948-339-01 SCREW, TAPPING

65 3-066-774-01 SHAFT, HINGE

66 3-052-574-01 CLAW, BT LOCK

67 3-058-755-01 SCREW, TRIPOD

68 3-713-791-41 SCREW (M1.7X5), TAPPING, P2

69 3-073-010-11 KNOB, ZOOM

70 3-073-011-01 SLIDER, ZOOM

– 13 –

Loading...

Loading...