Sony MVC-CD500 Service Manual

MVC-CD500

SERVICE MANUAL

Ver 1.0 2003. 04

Revision History

Revision History

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987621641.pdf).

• Reference No. search on printed wiring boards is available.

On the CD-439, SY-086 board and the DDX-G3000 COMPLETE ASSEMBLY

This service manual provides the information on the premised of the circuit board replacement service and not intended

repair inside the CD-439 and SY-086 board in case of trouble. It is also premised that the mechanism deck DDX-G3000

COMPLETE ASSEMBLY shall be exchanged as an assembly in case of trouble.

Therefore, disassembling procedure and e xploded view of the DDX-G3000 COMPLETE ASSEMBLY are not shown. The block

diagram, printed wiring board, schematic diagram and electrical parts list of the CD-439 and SY-086 board are also not shown.

Note that the following pages are lacking intentionally.

The following pages are not shown.

CD-439 and SY-086 board

Schematic diagram .............................Pages 4-15 to 4-42

Printed wiring board............................Pages 4-55 to 4-60

Waveforms ...........................................

Mounted parts location ........................

Electrical parts list...............................Pages 5-14 to 5-21

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

DDX-G3000 COMPLETE ASSEMBLY

Disassembly........................................Pages 2-14 to 2-17

Exploded view.....................................Pages 5-9 to 5-10

Pages 4-62 to 4-63

Pages 4-65 to 4-66

REPAIR PARTS LIST

REPAIR PARTS LIST

DIGITAL STILL CAMERA

MVC-CD500

COVER

COVER

x Camera

[System]

Image device

Total pixels number of camera

Effective pixels number of camera

Lens 3 zoom lens

Exposure control

White balance

File format (DCF compliant)

Recording media

Flash Recommended distance (ISO set to

[Drive]

Readout Non-contact optical readout (using

Laser Wavelength: 779 to 789 nm

9.04 mm (1/1.8 type) color CCD

Primary color filter

Approx. 5 255 000 pixels

Approx. 5 090 000 pixels

f = 7.0 – 21.0 mm (9/32 – 27/32

inches) (34 – 102 mm (1 3/8 – 4 1/8

inches) when converted to a 35 mm

still camera)

F2.0 – 2.5

Automatic exposure, Shutter speed

priority, Aperture priority, Manual

exposure, Scene selection (6 modes)

Automatic, Daylight, Cloudy,

Fluorescent, Incandescent, Flash,

One-push

Still images: Exif Ver. 2.2 JPEG

compliant, GIF (for Clip Motion),

TIFF, DPOF compatible

Audio with still image: MPEG1

compliant (Monaural)

Movies: MPEG1 compliant

(Monaural)

8 cm CD-R/CD-RW

Auto): 0.5 m to 5.0 m (19 3/4 inches

to 196 7/8 inches)

semiconductor laser)

Maximum output: 23 mW

SPECIFICATIONS

[Input and Output connectors]

A/V OUT (MONO) (Monaural)

ACC jack Mini-minijack (ø 2.5 mm)

USB jack mini-B

[LCD screen]

LCD panel

Total number of dots

[General]

Used battery pack

Power requirements

Power co nsumption (d uring shooti ng with

LCD backlight on)

Operating temperature

Storage temperature

Dimensions

Mass Approx. 606 g (1 lb 5 oz) (including

Built-in microphone

Built-in speaker

Exif Print Compatible

PRINT Image Matching II Compatible

Minijack

Video: 1 Vp-p, 75 Ω, unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ load)

Output impedance 2.2 kΩ

6.2 cm (2.5 type) TFT drive

123 200 (560 × 220) dots

NP-FM50

7.2 V

3.0 W

0°C to 40°C (32°F to 104°F)

–20°C to +60°C (4°F to +140°F)

138.5 × 95.7 × 103.1 mm

(5 1/23 × 7/84 × 1/8 inches)

(W/H/D, excluding maximum

protrusions)

battery pack NP-FM50, disc, and lens

cap)

Electret condenser microphone

Dynamic speaker

x AC-L15A/L15B AC Adaptor

Power re quirements

Current consumption

Power consumption

Output voltage

Operating temperature

Storage temperature

Dimensions (approx.)

Mass (approx.)

100 – 240 V AC, 50/60 Hz

0.35 – 0.18 A

18 W

8.4 V DC, 1.5 A

0°C to 40°C (32°F to 104°F)

–20°C to +60°C (–4°F to +140°F)

56 × 31 × 100 mm

(2 1/4 × 1 1/4 × 4 inches) (w/h/d )

excluding projecting parts

190 g (6.7 oz) excluding power cord

(mains lead)

x NP-FM50 battery pack

Used battery

Maximum voltage

Nominal voltage

Capacity 8.5 Wh (1 180 mAh)

Lithium-ion battery

DC 8.4 V

DC 7.2 V

x Accessories

AC Adaptor (1)

Power cord (mains lead) (1)

USB cable (1)

NP-FM50 battery pack (1)

A/V connecting cable (1)

8 cm CD adaptor (1)

Mavica disc (2) (CD-R (1), CD-RW (1))

Shoulder strap (1)

Lens cap (1)

Lens cap strap (1)

CD-ROM (SPVD-010) (1)

Operating instructions (1)

Design and specifications are subject to change

without notice.

— 2 —

MVC-CD500

CAUTION

Use of controls or adjustments or performance

procedures other than those specified herein may

result in hazardous radiation exposure.

WARNING!!

WHEN SERVICING, DO NOT APPROA CH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSER VE FROM A DISTANCE OF MORE

THAN 30 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

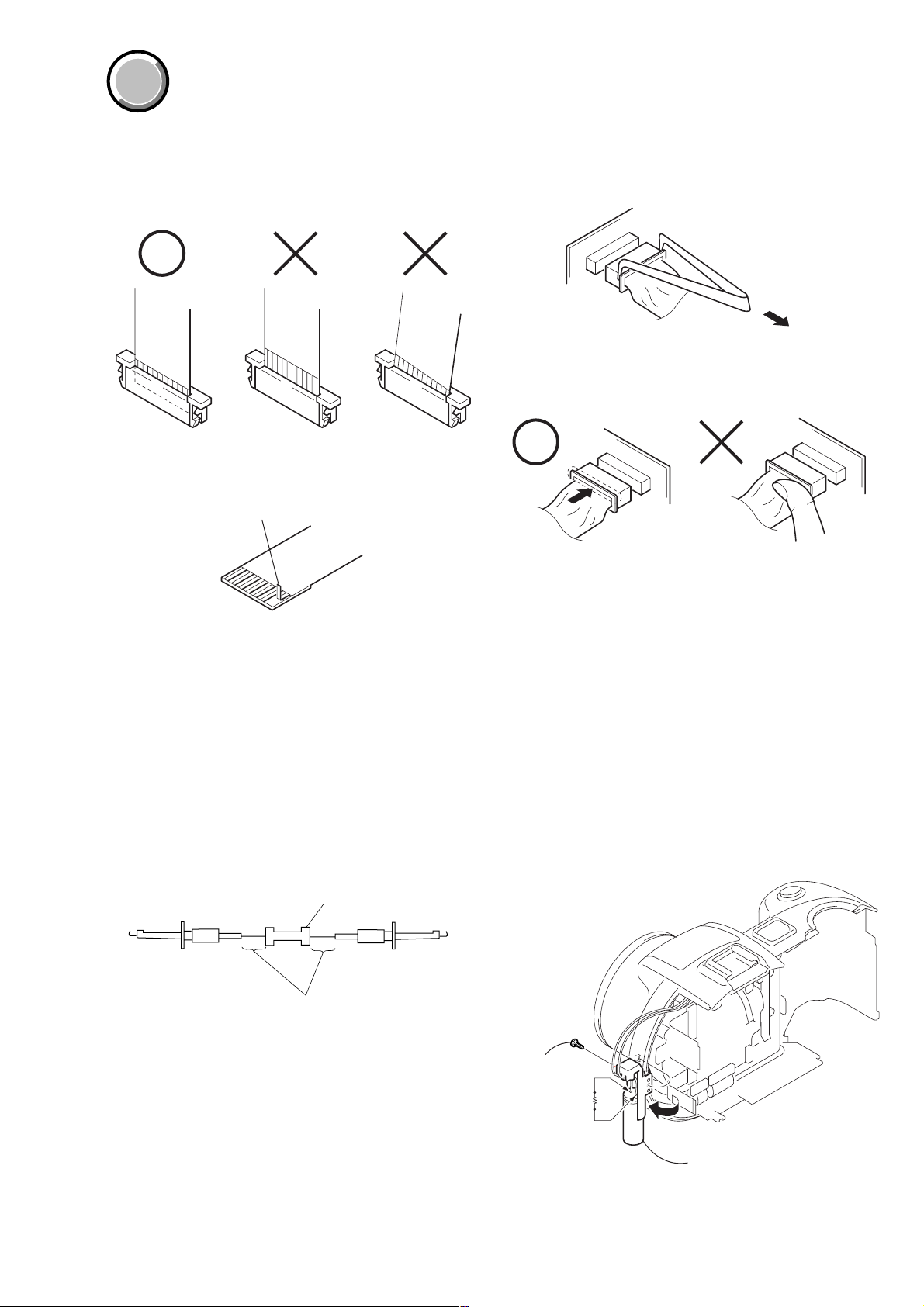

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

MVC-CD500

COVER

COVER

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. NOTE FOR REPAIR ·······················································1-1

1-2. Discharging of the FLASH unit’s charging capacitor ·····1-1

1. Preparing the Short Jig ···················································· 1-1

2. Discharging the Capacitor ···············································1-1

1-3. NOTES ON HANDLING THE LASER DIODE············ 1-2

1. Precaution for Checking Emission of Laser ···················· 1-2

2. Soldering Conditions of Laser Unit·································1-2

1-4. Description on Self-diagnosis Display ····························1-3

2. DISASSEMBLY

2-1. PK-068 BOARD······························································2-2

2-2. LCD SECTION ·······························································2-2

2-3. SIDE CABINET SECTION ············································ 2-3

2-4. JK-253 BOARD ······························································2-4

2-5. SIDE CABINET ASSEMBLY ········································2-4

2-6. CABINET (REAR) SECTION ·······································2-5

2-7. DISCHARGING THE CAPA CIT OR······························2-5

2-8. LENS SECTION ·····························································2-6

2-9. CD-439 BOARD, LENS ASSEMBLY ··························· 2-9

2-10. MICROPHONE·····························································2-10

2-11. STROBOSCOPE SECTION ·········································2-10

2-12. FLASH UNIT ································································2-11

2-13. BT HOLDER SECTION ···············································2-11

2-14. DDX-G3000 COMPLETE SECTION ··························2-12

2-15. CIRCUIT BOARDS LOCATION ·································2-12

2-16. FLEXIBLE BOARDS LOCATION ······························2-13

Disassembling procedure of DDX-G3000 COMPLETE

ASSEMBLY are not shown. Pages from 2-14 to 2-17

are not shown.

HELP (List of caution points is shown here.)

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/2) ···························3-3

3-3. POWER BLOCK DIAGRAM (1/2) ································ 3-5

3-4. POWER BLOCK DIAGRAM (2/2) ································ 3-7

4-3. PRINTED WIRING BOARDS

• JK-253 (AV/USB/LANC JACK)

PRINTED WIRING BOARD ·······················4-47

• LS-064 (SW)

PRINTED WIRING BOARD ·······················4-47

• PK-069 (LCD DRIVER, TIMING GENERATOR, BACK

LIGHT)

PRINTED WIRING BOARD ·······················4-49

• FS-086 (DC IN, CHARGER)

PRINTED WIRING BOARD ·······················4-53

Printed wiring board of the CD-439 board and SY-086

board are not shown.

Pages from 4-55 to 4-60 are not shown.

4-4. WAVEFORMS ······························································4-61

Waveforms of the CD-439 board and SY-086 board

are not shown.

Pages from 4-62 to 4-63 are not shown.

4-5. MOUNTED PARTS LOCATION ·································4-64

Mounted parts location of the CD-439 board and

SY-086 boards is not shown.

Pages from 4-65 to 4-66 are not shown.

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-1

5-1-1.OVERALL SECTION ····················································· 5-3

5-1-2.CABINET (FRONT) SECTION ·····································5-4

5-1-3.LENS SECTION ·····························································5-5

5-1-4.STROBOSCOPE SECTION···········································5-6

5-1-5.SIDE CABINET SECTION············································5-7

5-1-6.CABINET (REAR) SECTION ·······································5-8

Exploded view and parts list of DDX-G3000 COMPLETE ASSEMBLY are not shown.

Page 5-9 and 5-10 are not shown.

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2) ······················· 4-1

FRAME SCHEMATIC DIAGRAM (2/2) ·······················4-3

4-2. SCHEMATIC DIAGRAMS

• PK-068 (1/2)(LCD DRIVER, TIMING GENERATOR)

SCHEMATIC DIAGRAM ······························4-7

• PK-068 (2/2)(BACK LIGHT)

SCHEMATIC DIAGRAM ······························4-9

• JK-253 (AV/USB/LANC JACK)

SCHEMATIC DIAGRAM ····························4-11

• FS-086 (DC IN, CHARGER)

SCHEMATIC DIAGRAM ····························4-13

Shematic diagram of the CD-439 board and SY-086

board are not shown.

Pages from 4-15 to 4-42 are not shown.

• LS-064 (SW)

SCHEMATIC DIAGRAM ····························4-43

• CONTROL SWITCH BLOCK (RS-340)

SCHEMATIC DIAGRAM ····························4-43

• FP-764 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-43

• FLASH UNIT

SCHEMATIC DIAGRAM ····························4-43

5-2. ELECTRICAL PARTS LIST ········································5-11

Parts list of the CD-439 board and SY-086 board

are not shown.

Pages from 5-14 to 5-21 are not shown.

— 4 —

MVC-CD500

CD-439

Capacitor

Tapping screw

(M1.7

×

5)

Short jig

COVER

COVER

SECTION 1

SERVICE NOTE

1-1. NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

1-2. DISCHARGING OF THE FLASH UNIT’S CHARGING CAPACITOR

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the MVC-CD500 is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

1. Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

2. Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

1-1

MVC-CD500

1-3. NOTES ON HANDLING THE LASER DIODE

[LASER UNIT AND BASE UNIT (DDX-G3000)]

The laser diode may suffer electrostatic breakdown because of the

potential difference generated by the charged electrostatic load, etc.

on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

1. Precaution for Checking Emission of Laser

Diode [Base Unit (DDX-G3000)]

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface of

the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Optical pick-up

(Laser diode)

2. Soldering Conditions of Laser Unit

Temperature of Less than 350 °C

the Soldering Iron

Time to Solder 3 seconds

Interval to Solder Next terminal is soldered after waiting

for 1 second

Note: Adjustment is needed when laser unit is replaced.

Refer to “19. AF Laser Output Adjustment” and “20. AF Laser Axis

Check” of SERVICE MANUAL, ADJ (987621651.pdf).

Laser unit

(LED901)

1-2

1-4. DESCRIPTION ON SELF-DIAGNOSIS DISPLAY

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

MVC-CD500

Display Code

C:32:01

C:13:01

E:91:01

*1

E:61:00

*1

E:61:10

Note: The error code is cleared if the battery is removed.

*1 : The error display is given in two ways.

Change the disk and turn off the main

power then back on.

Replace the CD-R/RW disk.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Countermeasure

Cause

Defective base unit.

• The type of CD-R/RW disk that cannot

be used by this machine, is inserted.

• Data is damaged.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Caution Display During Error

DRIVE ERROR

DISK ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

1-3E

MVC-CD500

COVER

COVER

SECTION 2

DISASSEMBLY

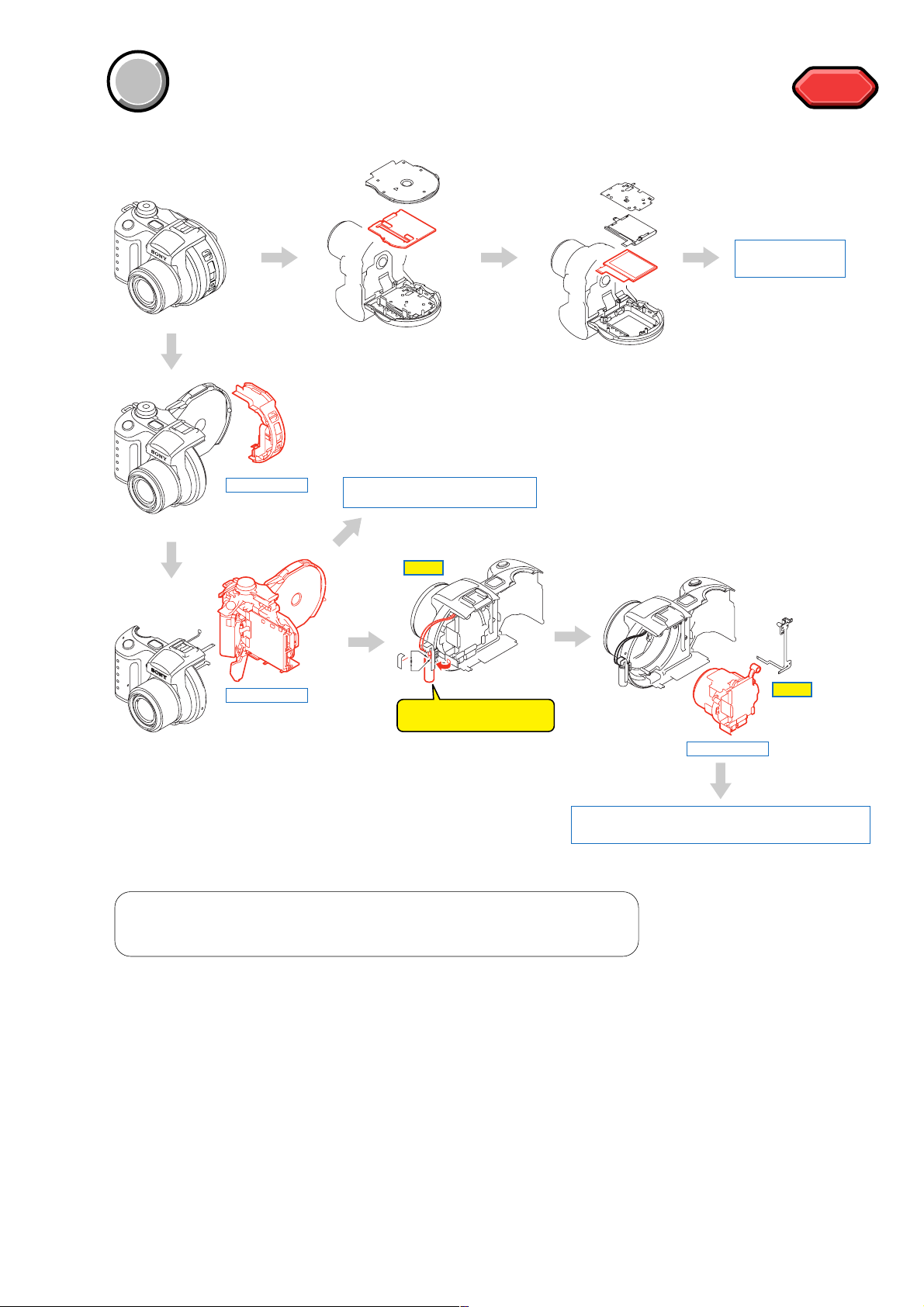

The following flow chart shows the disassembly procedure.

DISASSEMBLY

Refer to level 3

Disassembling procedure

of DDX-G3000 complete section.

HELP

HELP

PK-068 board

service position

HELP

DISASSEMBLY

Discharging the Capacitor

(CD-439, JK-253, SY-086 BOARDS AND

CAMERA SECTION CHECK SERVICE POSITION )

PROCEDURE OF REMOVING THE LENS SECTION. (CD-439, JK-253, SY-086 BOARDS AND CAMERA SECTION CHECK SERVICE POSITION )

1 2-1. PK-068 BOARD ............................................

2 2-2. LCD SECTION................................................

3 2-3. SIDE CABINET SECTION...............................

4 2-6. CABINET (REAR) SECTION ..........................

5 2-7. DISCHARGING THE CAPACITOR..................

6 2-8. LENS SECTION...............................................

(page 2-2)

(page 2-2)

(page 2-3)

(page 2-5)

(page 2-5)

(page 2-6)

HELP

DISASSEMBLY

2-1

MVC-CD500

e

NOTE: F ollo w the disassembly procedure in the numerical order given.

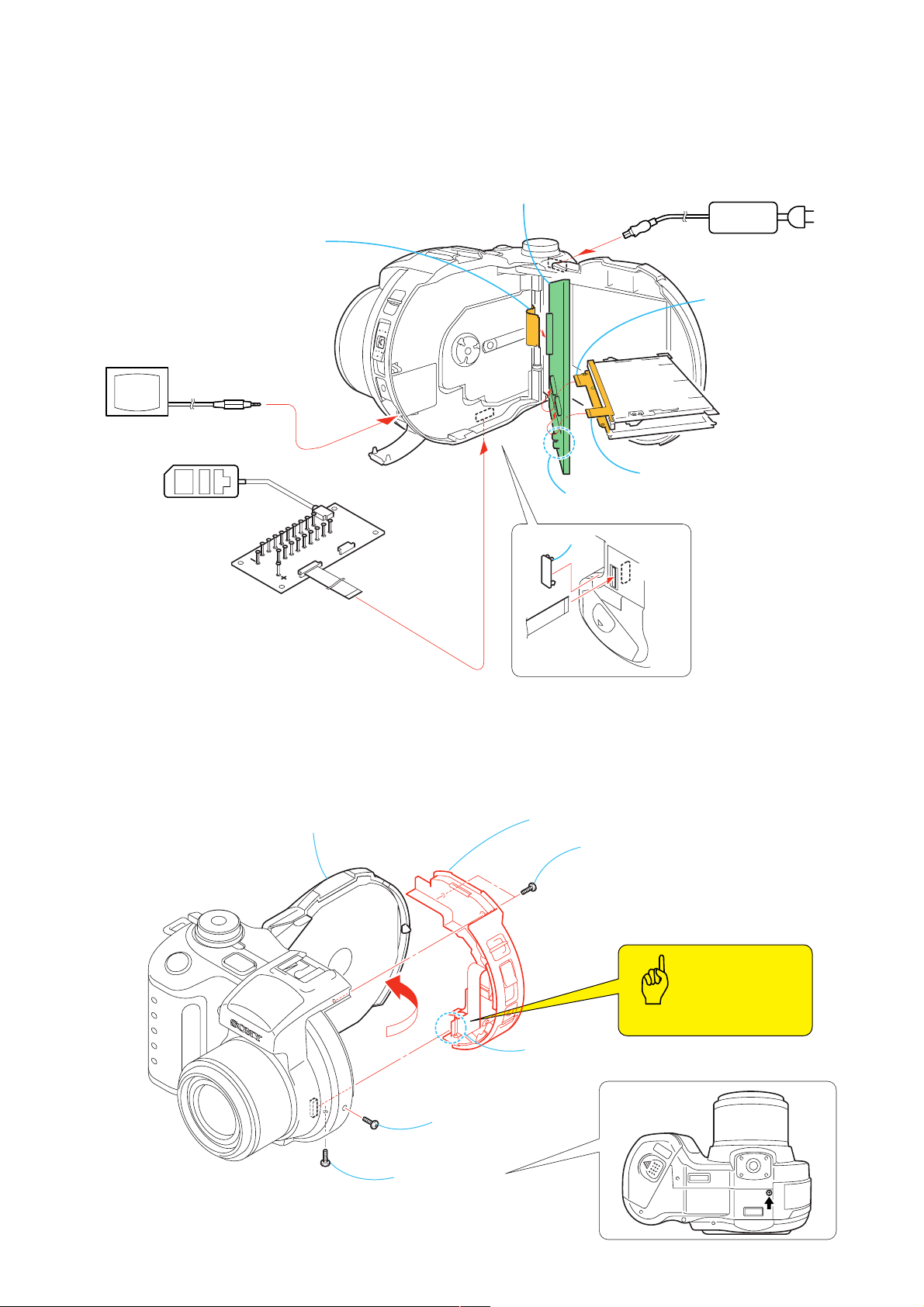

2-1. PK-068 BOARD

4

CD cabinet lid assembly

8

FP-766 flexible board

(32P)

2

Five tapping screws

(M1.7 × 5) (black)

7

Two tapping screws

(M1.7 × 4) (silver)

5

Flexible board

(from the LCD module) (24P)

6

Flexible board

(from the back light) (10P)

2-2. LCD SECTION

2

Five tapping screws

(M1.7 × 4) (silver)

PK-068

1

Tapping screw

(M1.7

×

5) (black)

9

PK-068 board

1

Open the CD cabinet.

3

Claw

2-2

3

BL retainer

4

Back light

5

Liquid crystal indicator modul

MVC-CD500

Back light (10P) (CN201)

FP-766 flexible board

(32P) (CN303)

Liquid crystal indicator module

(24P) (CN302)

PK-068 board

CPC-9 jig

(J-6082-393-C)

1

18

Adjustment remote

commander (RM-95)

1

18

CN714

AC IN

AC power

adaptor

Monitor TV

1

18

CN714

CPC lid

Note : Must be pressed lid open/close detect switch (S307, S308 on PK-068 board) when using the CD-R/RW drive unit.

S307, S308

Lid open/close detect switch (Note)

AV OUT

DC IN

LANC

[PK-068 BOARD SERVICE POSITION]

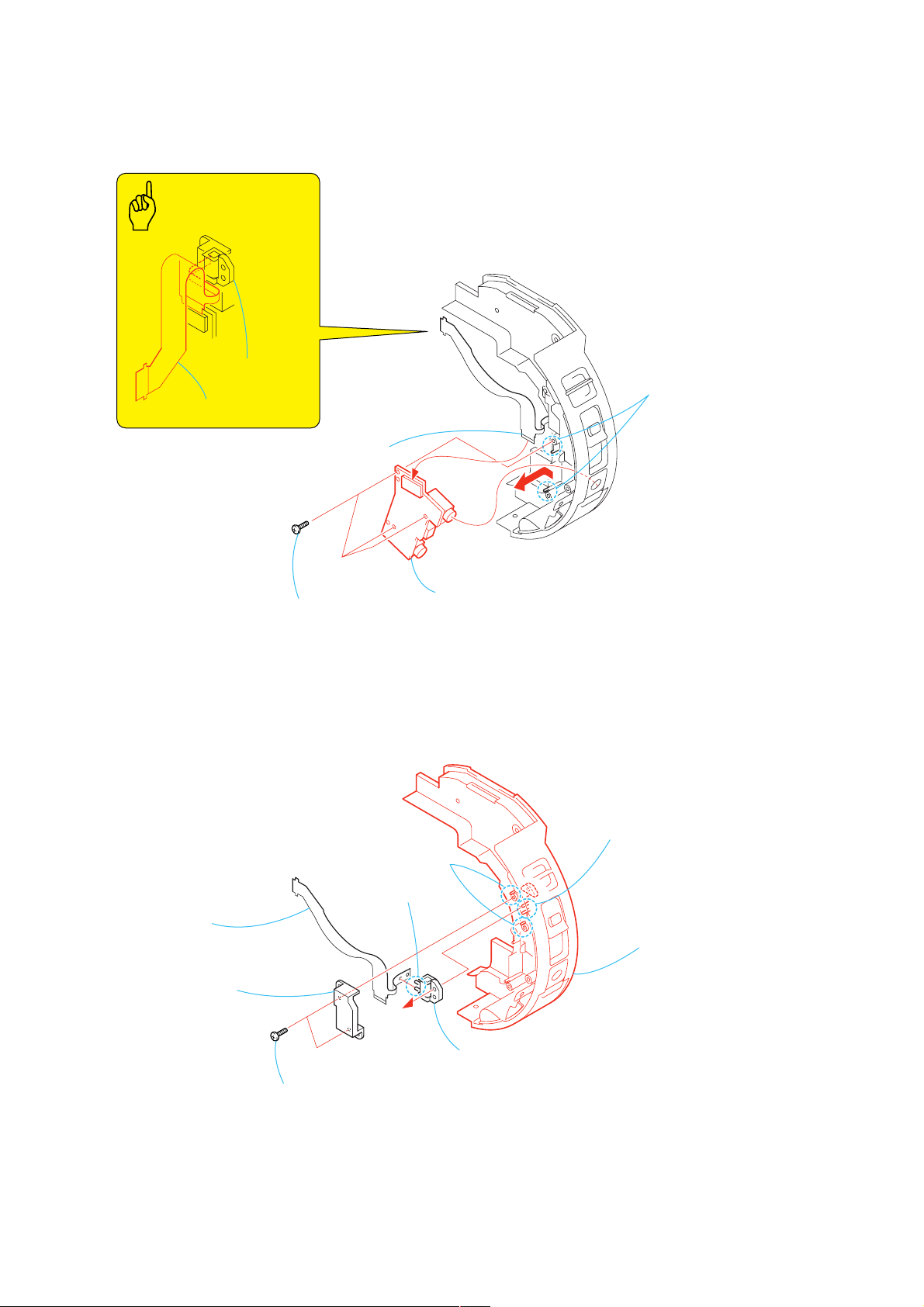

2-3. SIDE CABINET SECTION

3

Open the CD cabinet.

2

(M2

1

ES lock screw

×

(M2

ES lock screw

×

4)

4)

5

Side cabinet section

6

(20P)

4

(M2

FP-767 flexible board

Two ES lock screws

×

4)

Caution

Note: Be careful not to

break the flexible board.

2-3

MVC-CD500

s

y

2-4. JK-253 BO ARD

FP-767 flexible board

Caution

Plunger solenoid

(Door open sensor)

2

FP-767 flexible

board (21P)

3

T wo dowel

1

Three tapping screws

(M1.7

2-5. SIDE CABINET ASSEMBLY

7

FP-767 flexible

board

JK-253

4

×

4)

2

T wo dowels

6

Remove soldering

from the two points

in the direction of the arrow.

Remove the JK-253 board

4

T wo dowels

8

Side cabinet assembl

3

CD solenoid cover

1

T wo tapping

screws (M1.7 × 4)

5

Plunger solenoid

(Door open sensor)

2-4

2-6. CABINET (REAR) SECTION

CD-439

4

Discharging the capacitor

Capacitor

2

Turn over the capacitor retainer

in the direction of the arrow.

1

Tapping screw

(M1.7

×

5)

3

T ape (A)

Caution

Tape (A)

Capacitor

Caution

Note: The power supply capacitor of the flash unit is charged to the high tension

voltage as high as 300 V at a maximum. You will get electrical shock when

you touch the terminal of the charged capacitor . The charged potential

remains even after the main power of the machine is turned off. Discharge

the remaining power in the capacitor referring to Service Note

(See page 1-1). High-voltage cautions. Short jig (R: 1k

Ω

/1W)

9

Harness (2P)

(from the microphone)

3

Two ES lock screws

×

(M2

4)

6

Remove the cabinet (rear)

section in the direction of the arrow.

8

Hot shoe (10P)

B

A

B

A

SY-086

5

Open the battery lid.

7

Harness SS-089 (8P)

(from the flash unit)

MVC-CD500

0

Cabinet (rear)

section

4

(M2

2-7. DISCHARGING THE CAP ACIT OR

ES lock screw

×

4)

2

FP-763 flexible board (51P)

(from the CD-439 board)

1

FP-685 flexible board (18P)

(from the CD-439 board)

2-5

MVC-CD500

s

2-8. LENS SECTION

4

Dowel

5

FP-764 flexible board,

Assist light retainer, Laser unit

3

Two tapping screws

(M1.7 × 5)

Caution

Tape (Z)

Caution

Note: High-voltage cautions.

(See page 1-1)

CD-439

1

T ape (Z)

2

FP-764 flexible board

(6P)

LS-064 board

CD-439

FP-764 flexible board

Routing of the FP-764 flexible

board

8

FP-764 flexible board (6P),

Assist light retainer, Laser unit

LS-064 board

7

Lens section

2-6

CD-439

6

Three tapping screw

(M1.7 × 5)

MVC-CD500

)

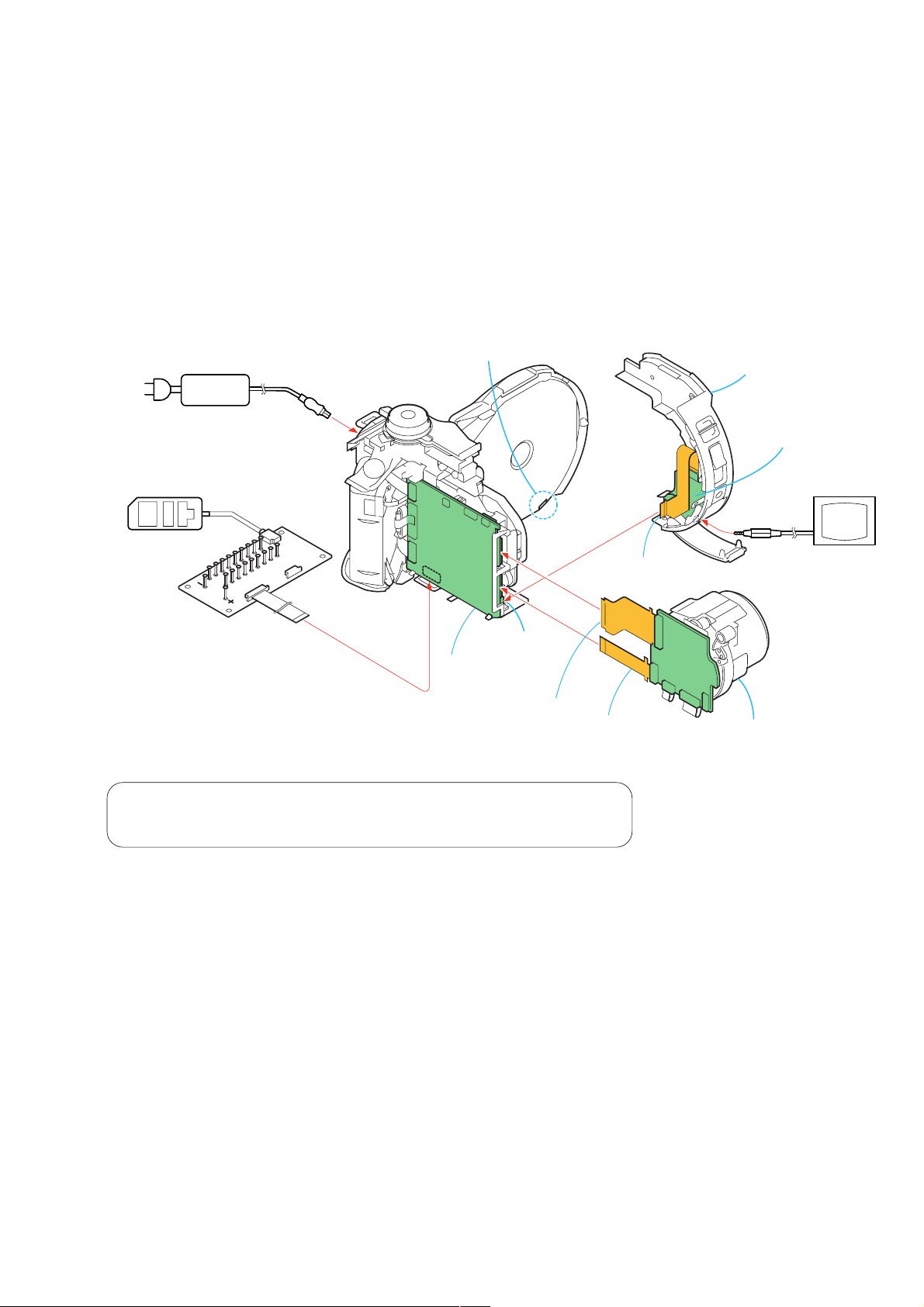

[CD-439, JK-253, SY-086 BOARDS AND CAMERA SECTION CHECK SERVICE POSITION

Note: Refer to SERVICE MANUAL level 3 for SY-086 board.

Must be pressed lid open/close detect switch (S307, S308 on PK-068 board) when using the CD-R/RW drive unit.

Setting the "Forced Power ON" mode

[Forced STILL Power ON]

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set

data: 00, and press the PAUSE button.

3) Select page: D, address: 21, set

data: 07, and press the PAUSE button.

AC IN

Adjustment remote

commander (RM-95)

AC power

adaptor

DC IN

[Forced PLAY Power ON" mode]

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set

data: 00, and press the PAUSE button.

3) Select page: D, address: 21, set

data: 08, and press the PAUSE button.

S307, S308

Lid open/close detect switch (Note)

Exiting the "Forced Power ON" mode

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set

data: E0, and press the PAUSE button.

3) Select page: D, address: 21, set

data: 00, and press the PAUSE button.

4) Select page: 0, address: 01, and set

data: 00.

Side cabinet section

JK-253 board

Monitor TV

LANC

CN724

SY-086

18

1

CN651

CN718

SY-086 board

(Note)

FP-763 flexible

board (51P)

CPC-9 jig

(J-6082-393-C)

18

1

CN714

PROCEDURE OF REMOVING THE LENS SECTION.

(CD-439, JK-253, SY-086 BOARDS AND CAMERA SECTION CHECK

SERVICE POSITION )

1 2-1. PK-068 BOARD ............................................

2 2-2. LCD SECTION................................................

3 2-3. SIDE CABINET SECTION...............................

4 2-6. CABINET (REAR) SECTION ..........................

5 2-7. DISCHARGING THE CAPACITOR..................

6 2-8. LENS SECTION...............................................

(page 2-2)

(page 2-2)

(page 2-3)

(page 2-5)

(page 2-5)

(page 2-6)

FP-767 flexible

board (20P)

CD-439

FP-685 flexible

board (18P)

AV OUT

Lens section

2-7

MVC-CD500

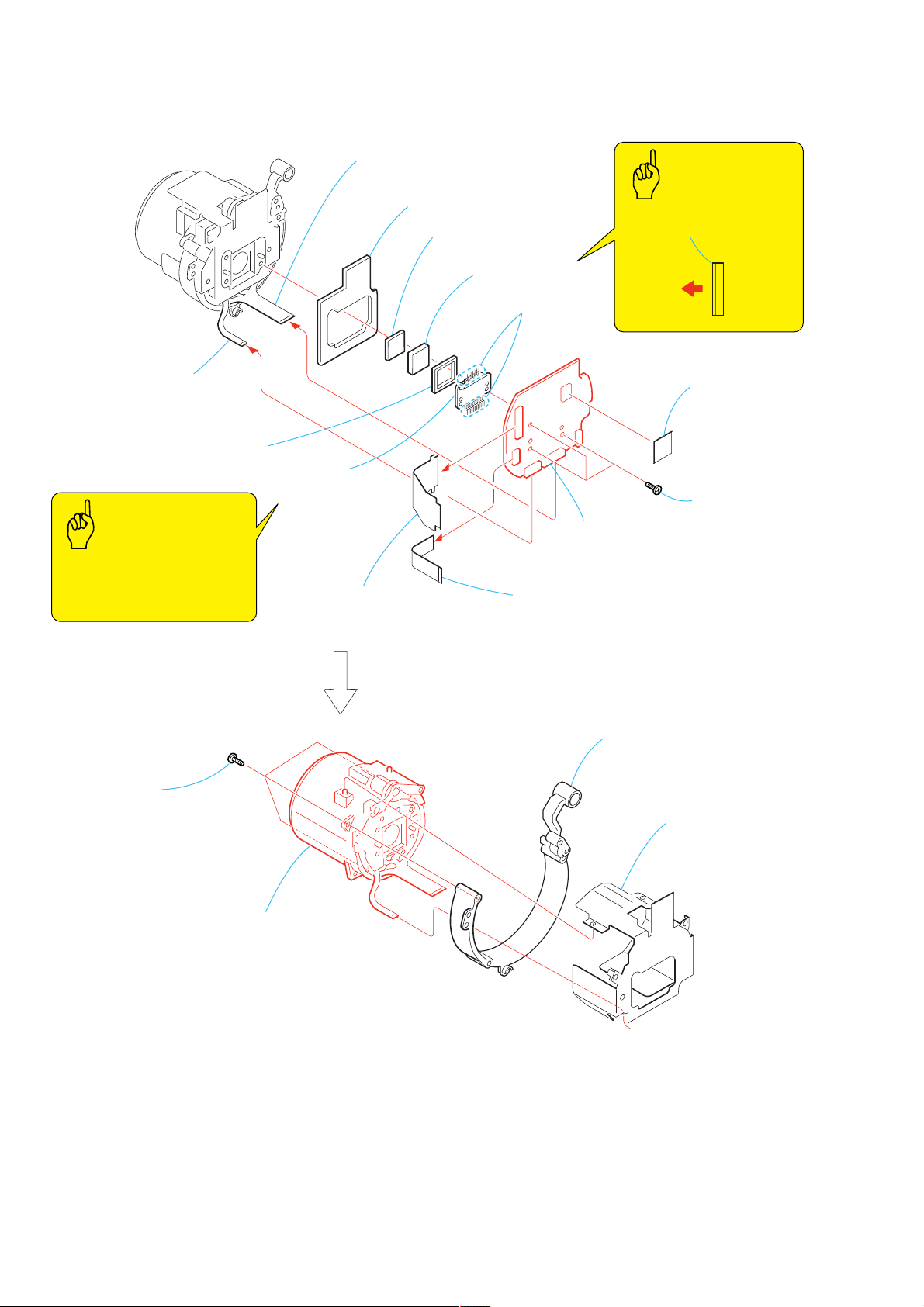

2-9. CD-439 BOARD, LENS ASSEMBLY

4

Flexible board (6P)

(from the lens assembly)

5

Flexible board (16P)

(from the lens assembly)

7

Radiation sheet (A)

8

Light interception plate

9

Optical filter block

qa

Remove the

solderings

Caution

Note: Direction of installation of

optical filter block.

CCD

1

Sheet (S)

0

Seal rubber

Caution

Note: Never remove the lens from

the CD board except when it is

required in such a case as CCD

imager check.

qg

Three tapping

screws (M1.7

×

5)

qs

CCD block

assembly

2

FP-763 flexible board

(51P)

CD-439

qd

CD-439 board

3

FP-685 flexible board

(18P)

qh

Lens holder

qf

6

Three tapping

screws (M1.7

CCD heat sink

×

6)

qj

Lens assembly

2-8

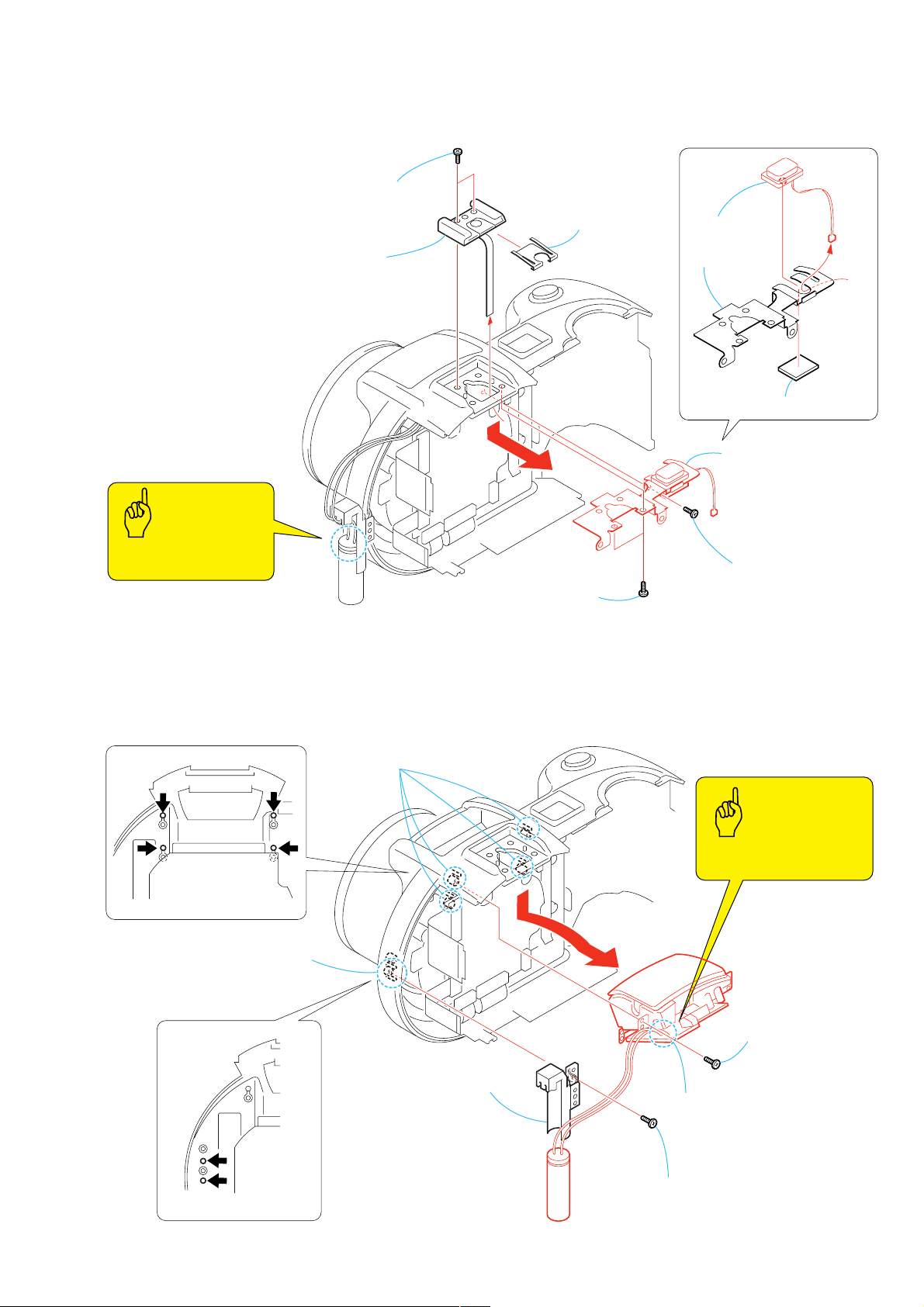

2-10.MICROPHONE

CD-439

1

Tapping screw

(M1.7

×

5) (black)

4

Tapping screw

(M1.7

×

5) (black)

3

Capacitor retainer

5

Four dowels

2

Two dowels

6

Remove the stroboscope section

in the direction of the arrow.

Caution

Note: High-voltage cautions.

(See page 1-1)

CD-439

CD-439

Caution

2

Two screws (M1.7 × 4),

lock ace, p2 (silver)

4

Shoe connector

CD-439

1

Shoe spring

MVC-CD500

9

Microphone

8

Shoe

stiffener

7

Sound absorption sheet

6

Shoe stiffener,

Microphone,

Sound absorption sheet

Note: High-voltage cautions.

(See page 1-1)

2-11.STROBOSCOPE SECTION

3

Two screws (M1.7 × 4),

lock ace, p2 (silver)

5

(M1.7

Tapping screw

×

5) (black)

2-9

MVC-CD500

2-12.FLASH UNIT

2

ST roof cover

8

ST electrostatic

sheet

1

Two tapping screws

(M1.7

×

4) (silver)

Caution

Note: High-voltage cautions.

(See page 1-1)

7

Two dowels

6

Stroboscope

case assembly

4

ST solenoid cover

3

Five screws

(M1.7

×

4) (silver)

Caution

5

Harness cover

9

Flash unit

ST electrostatic

sheet

Flash unit

2-13.BT HOLDER SECTION

3

BT holder section

FS-086

board

CN003

2

Battery terminal board (3P)

1

Open the battery lid.

SY-086

2-10

2-14.DDX-G3000 COMPLETE SECTION

Route it under the projected

portion.

Caution

Control switch block

RS-340

SY-086

2

FP-765 flexible board (12P)

(from the FS-086 board)

SY-086

MVC-CD500

1

Control switch block RS-340

(14P)

FP-766 flexible

board

5

Two tapping screws

(M1.7

×

5)

FP-765 flexible

board

9

Sheet (P)

4

Harness FS-145 (14P)

(from the FS-086 board)

7

Dowel

SY-086

3

FP-766 flexible board (32P)

(from the PK-086 board)

SY-086

8

DDX-G3000

complete section,

SY-086 board

6

ES lock screw

×

(M2

4)

Caution

Precautions during handling

• Do not turn the side of the optical lens downward.

• Hold the frame.

• Do not touch the optical lens surface.

Refer to level 3

Disassembling procedure of

DDX-G3000 complete section.

2-11

SY-086

Loading...

Loading...