Page 1

MVC-CD200/CD300

SERVICE MANUAL

Level 1

Ver 1.0 2001. 05

Photo : MVC-CD300

SPECIFICATIONS

System

Image device

MVC-CD200: 6.64 mm

(1/2.7 type) color CCD

MVC-CD300: 8.93 mm

(1/1.8 type) color CCD

Lens

3× zoom lens

MVC-CD200: f = 6.1 –

18.3 mm (1/4 – 3/4 inches)

(39 – 117 mm (1 9/16 –

4 5/8 inches) when

converted into a 35 mm still

camera)

MVC-CD300: f = 7 –21 mm

(9/32 – 27/32 inches) (34 –

102 mm (1 3/8 –

4 1/8 inches) when

converted into a 35 mm still

camera)

MVC-CD200: F = 2.8 – 2.9

MVC-CD300: F = 2.0 – 2.5

Exposure c ontrol

Automatic exposure, Shutter

speed priority, Aperture

priority, Manual exposure

White balance

Automatic, Indoor, Outdoor,

One-push

Data system

Movie:MPEG1

Still: JPEG, GIF (in TEXT

mode, Clip Motion), TIFF

Audio with still image:

MPEG1 (Monaural)

Recording medium

8 cm CD-R/CD-RW

Recommended flash

recordingdistance (ISO

is set to AUTO):

MVC-CD200:0.3mto

2.5 m (11 7/8 inches to

8 1/3 feet)

MVC-CD300:0.3mto

3 m (11 7/8 inches to 9 feet

10 1/8 inches)

Drive

Read: Maximum ×8

Write: ×4

Readout

Noncontact optical readout

(using semiconductor laser)

Laser

Wavelength: 777 to 787 nm

NA: 0.5

Maximum output: 23 mW

Emission duration: 600 ns

Input and Output

connector

A/V OUT (MONO)

(Monaural)

Minijack Video:

1 Vp-p, 75 Ω, unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ

load)

Output impedance: 2.2 kΩ

ACC jack

Mini-minijack (Ø 2.5 mm)

USB jack

mini-B

LCD screen

LCD panel

TFT (Thin Film Transistor

activematrix) drive

LCD size

2.5 type

Total numberof dots

123 200 (560×220) dots

General

Application

Sonybattery pack NP-FM50

(supplied)

Power requirements

7.2 V

Power consumption

(During shooting with

the LCD backlight

turned on)

MVC-CD200: 3.0 W

MVC-CD300: 3.5 W

Operating temperature

0°Cto40°C(32°Fto104°F)

Storage temperature

–20°Cto+60°C(–4°Fto

+140°F)

Dimensions (Approx.)

MVC-CD200: 143×92×

89 mm (5 3/4×35/8×

3 5/8 inches) (w/h/d)

MVC-CD300: 143×92×

94 mm (5 3/4×35/8×

3 3/4 inches) (w/h/d)

Mass (Approx.)

MVC-CD200: 610 g

(1lb6oz)

MVC-CD300: 650 g

(1 lb 7 oz) (including NPFM50 battery pack, disc and

lens cap, etc.)

Built-in microphone

Electret condenser

microphone

Built-in speaker

Dynamic speaker

AEP Model

UK Model

AC-L10A/L10B/L10C

AC power adaptor

Power requirements

100 to 240 V AC, 50/60 Hz

Rated output voltage

DC 8.4 V,1.5 A in operating

mode

Operating temperature

0°Cto40°C(32°F to 104°F)

Storage temperature

–20°Cto+60°C(–4°Fto

+140°F)

Dimensions (Approx.)

125×39×62 mm (5×19/16×

2 1/2 inches) (w/h/d)

Mass (Approx.)

280g(10oz)

NP-FM50 battery pack

Battery type

Lithium ion

Maximum output

voltage

DC 8.4 V

Mean output voltage

DC 7.2 V

Capacity

8.5 Wh (1180 mAh)

Operating temperature

0°Cto40°C(32°F to 104°F)

Dimensions (Approx.)

38.2×20.5×55.6 mm

(1 9/16×13/16×2 1/4 inches)

(w/h/d)

Mass (Approx.)

76 g (3 oz)

Accessories

AC-L10A/L10B/L10C

AC power adaptor (1)

Power cord (mains lead) (1)

FerriteCore(1)

USB cable(1)

NP-FM50 battery pack (1)

A/V connecting cable (1)

8 cm CD adaptor (1)

Mavica disc (2) (CD-R (1),

CD-RW (1))

Shoulderstrap (1)

Lens cap (1)

Lens cap strap (1)

CD-ROM (2)

Operating instructions (2)

Design and specifications

are subject to change

without notice.

DIGITAL STILL CAMERA

Page 2

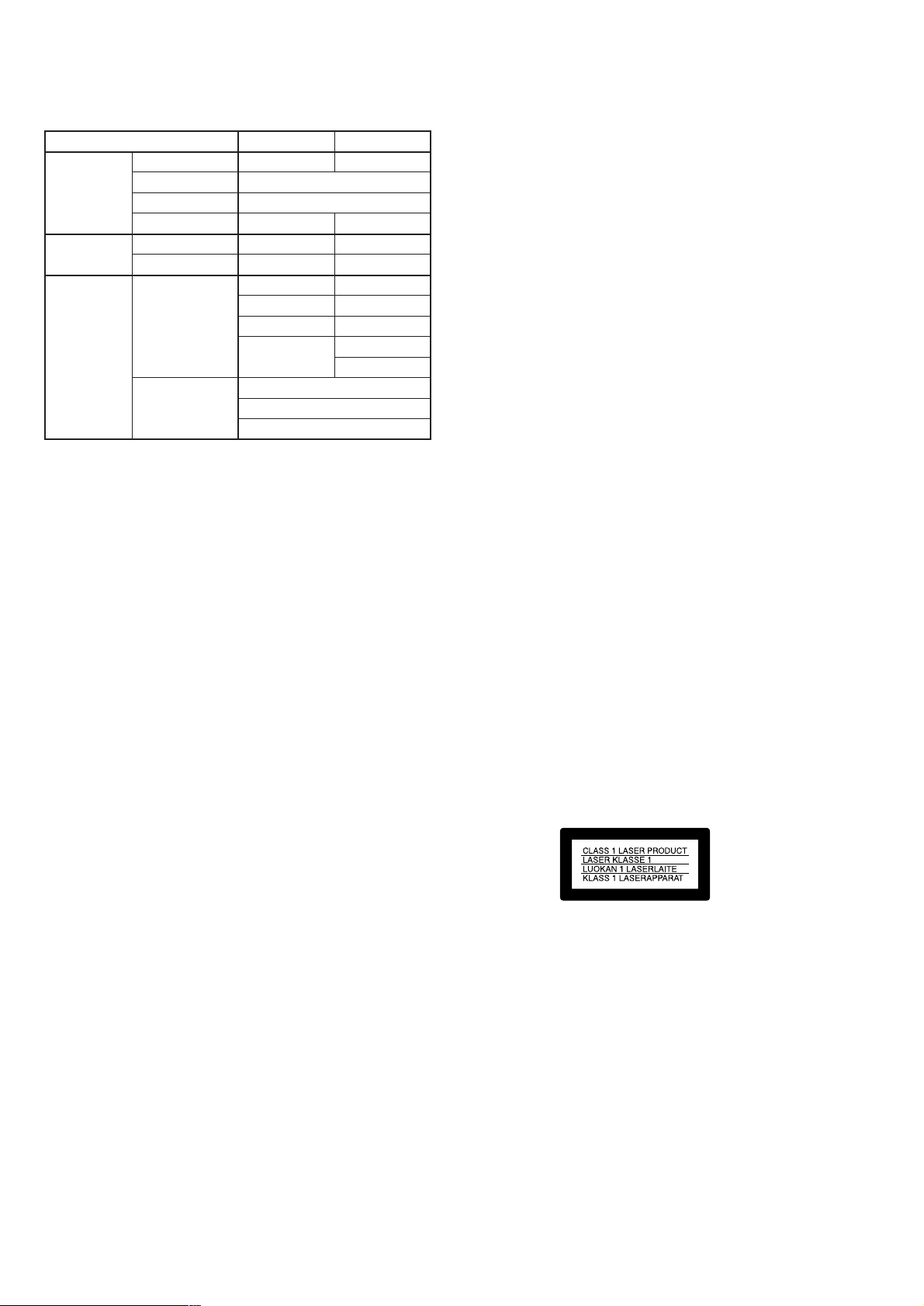

Table for difference of functions

Model

Lens Carl Zeiss lens

Optical zoom

Digital zoom

Filter diameter

CCD imager Size

Pixels

Image size Still

Movie

MVC-CD200

✕

37mm

1/2.7 type

2.1mega

1600×1200

1600 (3:2)

1024×768

640×480

320 (HQ)

320×240

640×480

MVC-CD300

a

3×

6×

52mm

1/1.8 type

3.3mega

2048×1536

2048 (3:2)

1600×1200

1280×960

640×480

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

TABLE OF CONTENTS

SERVICE NOTE ····································································· 5

1. MAIN PARTS

1. ORNAMENTAL PARTS ···················································· 7

2. DISASSEMBLY ································································· 8

2-1. LCD SECTION (PK-58 BOARD) ····································· 9

2-2. CABINET (FRONT) SECTION ······································ 10

2-3. CABINET (FRONT) ASSEMBLY (TK-61 BOARD),

CONTROL SWITCH BLOCK (RL-503) ························ 11

2-4. BATTERY HOLDER (JK-208 BOARD) ························· 12

2-5. SY-67 BOARD ································································· 12

2-6. STROBOSCOPE SECTION (FLASH UNIT) ················· 13

2-7. BASE UNIT (DDX-G2100 COMPLETE ASSEMBLY) · 13

2-8. LID CD SECTION ··························································· 14

2-9. FUNCTION BUTTON (FS-83 BOARD) ························ 14

2-10. SOLENOID PLUNGER (DOOR LOCK/STROBO-

SCOPE), CD LOCK SLIDER·········································· 15

2-11. CONTROL SWITCH BLOCK (ZK-503),

STRAP SHAFT ································································ 16

2-12. MODE KNOB, POWER SPRING ··································· 17

3. REPAIR PARTS LIST ······················································ 18

3-1. EXPLODED VIEWS ······················································· 18

3-1-1.OVERALL SECTION······················································ 18

3-1-2.CABINET (FRONT) SECTION, LENS CABINET

SECTION (CD200) ·························································· 19

3-1-3.CABINET (FRONT) SECTION, LENS CABINET

SECTION (CD300) ·························································· 20

3-1-4.LENS SECTION ······························································ 21

3-1-5.CABINET (REAR) SECTION-1 ····································· 22

3-1-6.CABINET (REAR) SECTION-2 ····································· 23

3-1-7.LID CD SECTION ··························································· 24

2. GENERAL

Introduction ············································································25

Getting started

Identifying the parts ································································ 25

Preparing the power supply ···················································· 25

Setting the date and time························································· 27

Inserting a disc ········································································ 27

Basic operations

B Recording

Initializing a disc (INITIALIZE) ············································ 28

Recording still images ···························································· 28

Recording moving images ······················································ 30

B Playback

Playing back still images ························································ 30

Playing back moving images ·················································· 30

Preparation for viewing images using a computer·················· 31

Viewing images using a computer ·········································· 32

Image file storage destinations and image file names ············ 34

Advanced operations

Before performing advanced operations

How to use the mode dial ······················································· 34

How to use the control button················································· 35

How to use the jog dial ···························································35

Menu settings·········································································· 35

Setting the image size (IMAGE SIZE) ··································· 36

B V arious recording

Recording with the exposure fixed (AE LOCK) ····················37

Recording with the manual adjustments································· 37

Recording images according to shooting conditions

(SCENE SELECTION) ·························································· 38

Recording three images continuously (BURST)

(only for MVC-CD300) ·························································· 38

Recording still images for e-mail (E-MAIL)·························· 38

Adding audio files to still images (VOICE) ··························· 38

Recording text documents (TEXT) ········································ 38

Recording still images as uncompressed files (TIFF) ············ 39

Recording three images with the exposure shifted

(only for MVC-CD300) (EXP BRKTG) ································ 39

Creating Clip Motion Files ····················································· 39

Setting the distance to the subject··········································· 40

Recording images in macro ···················································· 40

Adjusting the exposure (EXPOSURE) ··································· 40

Adjusting the white balance (WHITE BALANCE) ···············40

Enjoying picture effects (P. EFFECT) ···································· 40

Recording the date and time on the still image

(DATE/TIME)········································································· 41

Using the Spot light-metering function ·································· 41

B V arious playback

Playing back three or nine images at once······························ 41

Enlarging a part of the still image (Zoom and trimming)······· 41

Playing back the still images in order (SLIDE)······················ 42

Rotating a still image (ROTATE)············································ 42

Viewing images on a TV screen ············································· 42

B Editing

Deleting images (DELETE) ··················································· 42

Preventing accidental erasure (PROTECT) ····························43

Changing the recorded still image size (RESIZE)·················· 43

Selecting still images to print (PRINT) ·································· 43

Formatting a CD-RW······························································44

Changing the setup settings (SET UP) ··································· 44

Additional information

Precautions·············································································· 45

On discs ·················································································· 45

Using your camera abroad ······················································ 46

About “InfoLITHIUM” battery pack····································· 46

Troubleshooting ······································································ 46

Warning and notice messages ················································· 48

Self-diagnosis display ····························································· 49

LCD screen indicators ···························································· 49

— 3 —

Page 4

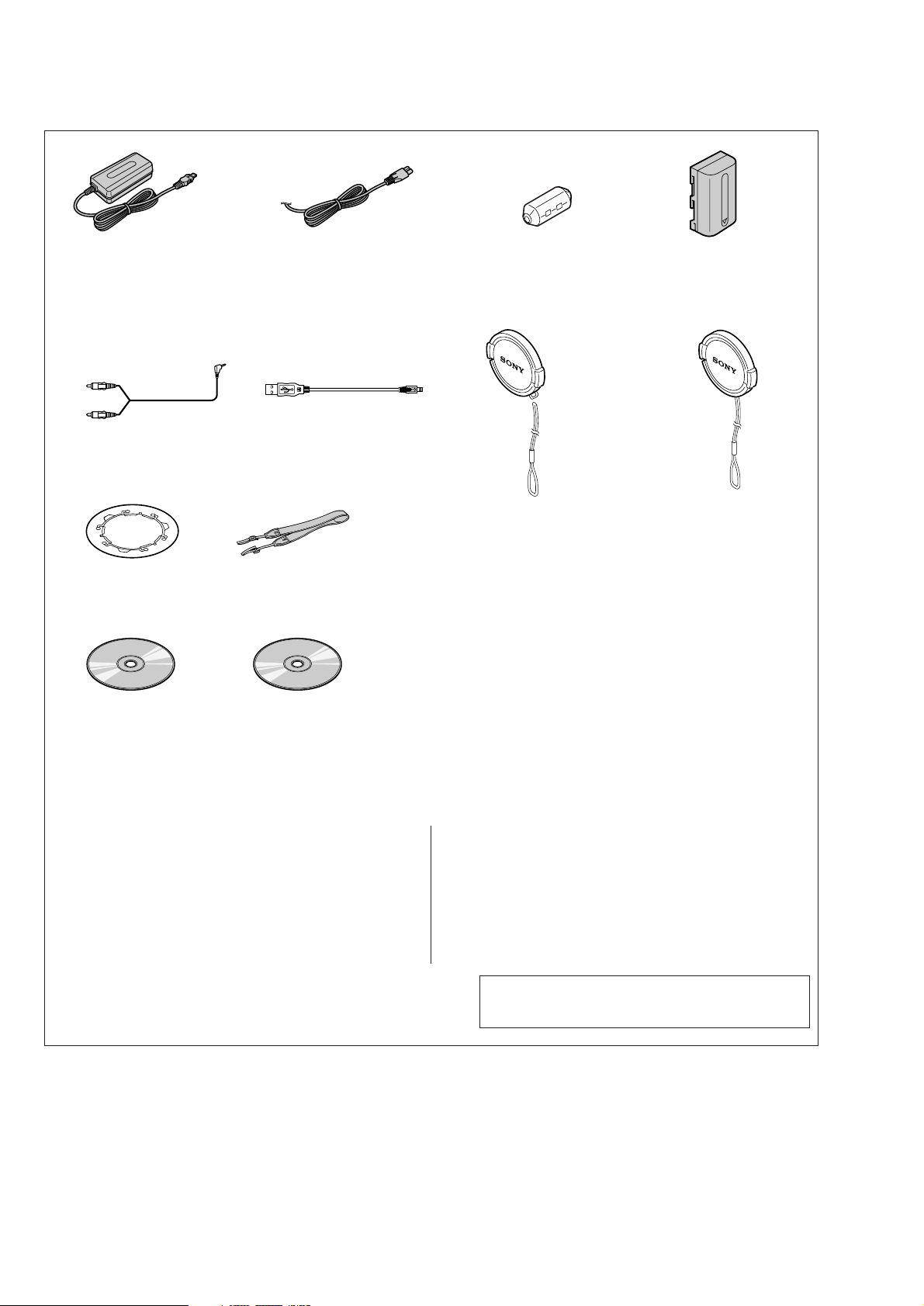

Checking supplied accessories

AC-L10A AC power adaptor (1)

0

1-475-599-11

A/V connecting cable (1.5m)(1)

1-783-738-31

8cm CD adaptor (1)

3-063-085-01

Power cord (main lead)(1) (AEP model)

0

1-769-608-11

Power cord (main lead)(with filter)(1)

(UK model)

0

1-783-374-11

USB cable (5P)(1)

1-757-293-31

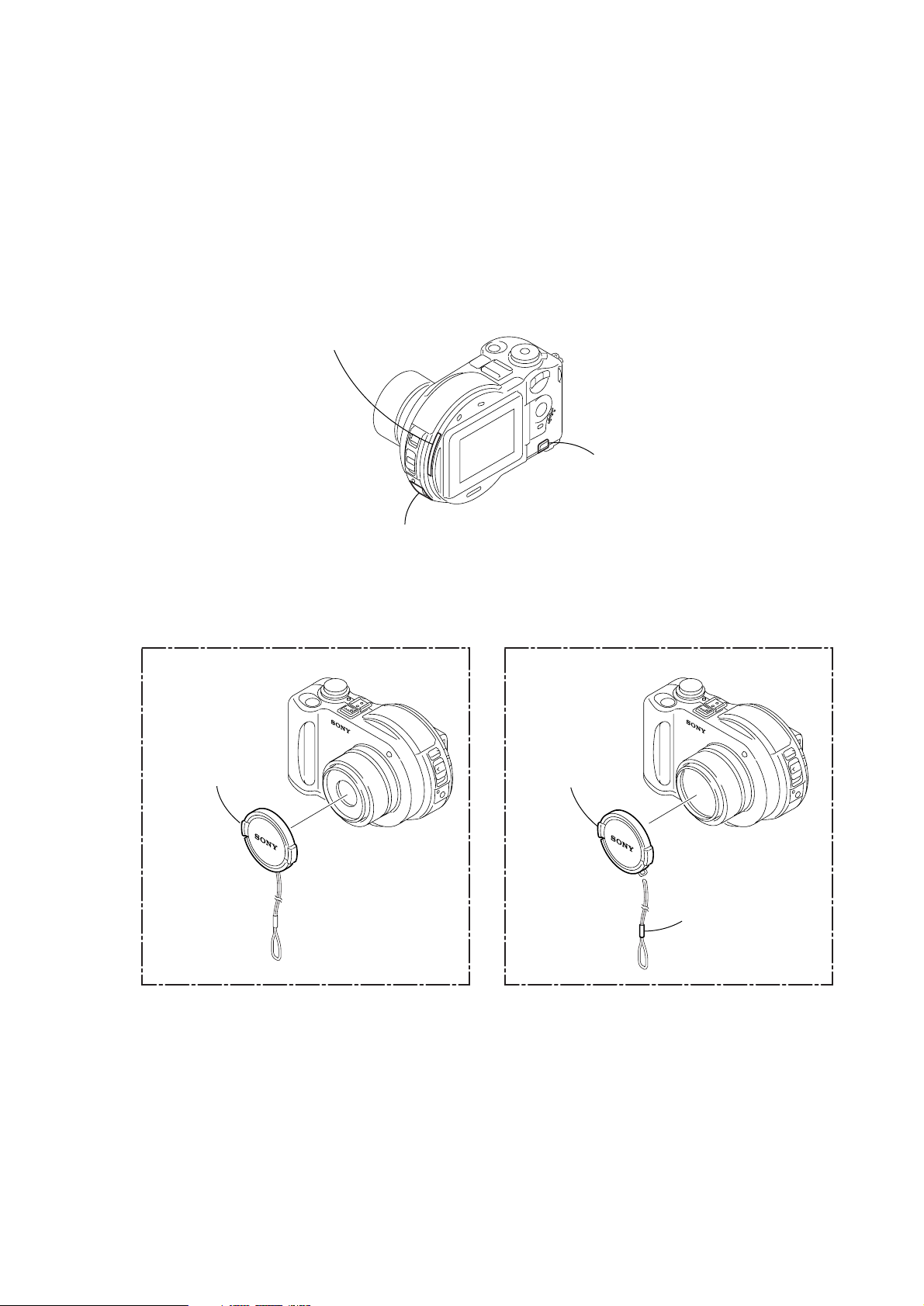

(Fig. A) Lens cap (1)(MVC-CD300)

(Fig. B) Lens cap strap (1)(MVC-CD300)

Shoulder belt (S) (1)

3-987-015-01

Mavica disc (2)(CD-R,CD-RW)

Not supplied

Clamp filter (ferrite core) (1)

1-543-798-11

(Fig. A)

(Fig. B)

X-3951-672-1

3-067-797-01

NP-FM50 battery pack (1)

Not supplied

Lens cap (1)(MVC-CD200)

X-3951-763-1

Application software:

Direct CD SPVD-006

(CD ROM) (1)

3-069-219-01

Application software:

USB driver SPVD-004 (P)

(CD-ROM)(1)

3-066-676-01

Other accessories

3-067-951-11 MANUAL,INSTRUCTION (ENGLISH)

3-067-951-21 MANUAL,INSTRUCTION (FRENCH/GERMAN)

3-067-951-31 MANUAL,INSTRUCTION (SPANISH/PORTUGEUSE)

3-067-951-41 MANUAL,INSTRUCTION (ITALIAN/DUTCH)

3-067-951-61 MANUAL,INSTRUCTION (SWEDISH)

(CD200:AEP/CD300:AEP)

(CD200:AEP/CD300:AEP)

(CD200:AEP/CD300:AEP)

(CD200:AEP/CD300:AEP)

3-067-952-11 MANUAL,INSTRUCTION (DIRECT CD)(ENGLISH)

3-067-952-21 MANUAL,INSTRUCTION (DIRECT CD)(FRENCH/GERMAN)

(CD200:AEP/CD300:AEP)

3-067-952-31 MANUAL,INSTRUCTION (DIRECT CD)

(SPANISH/PORTUGEUSE) (CD200:AEP/CD300:AEP)

3-067-952-41 MANUAL,INSTRUCTION (DIRECT CD)(ITALIAN/DUTCH)

(CD200:AEP/CD300:AEP)

3-067-952-61 MANUAL,INSTRUCTION (DIRECT CD)(SWEDISH)

(CD200:AEP/CD300:AEP)

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

— 4 —

Page 5

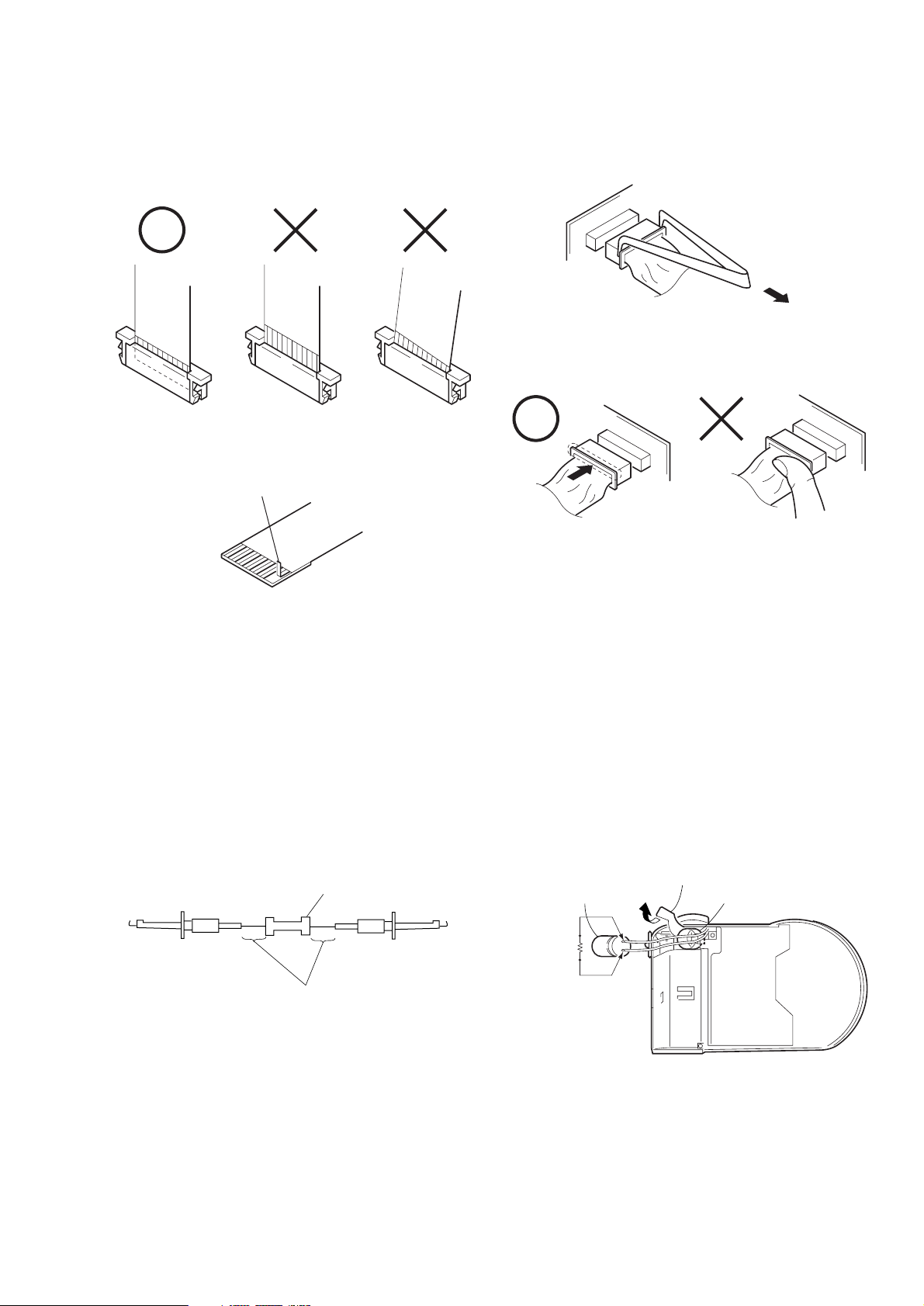

• NOTE FOR REPAIR

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the MVC-CD200/CD300 is simply turned off. Therefore,

the remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

Harness retainer

Capactior

Short jig

Capactior cap

— 5 —

Page 6

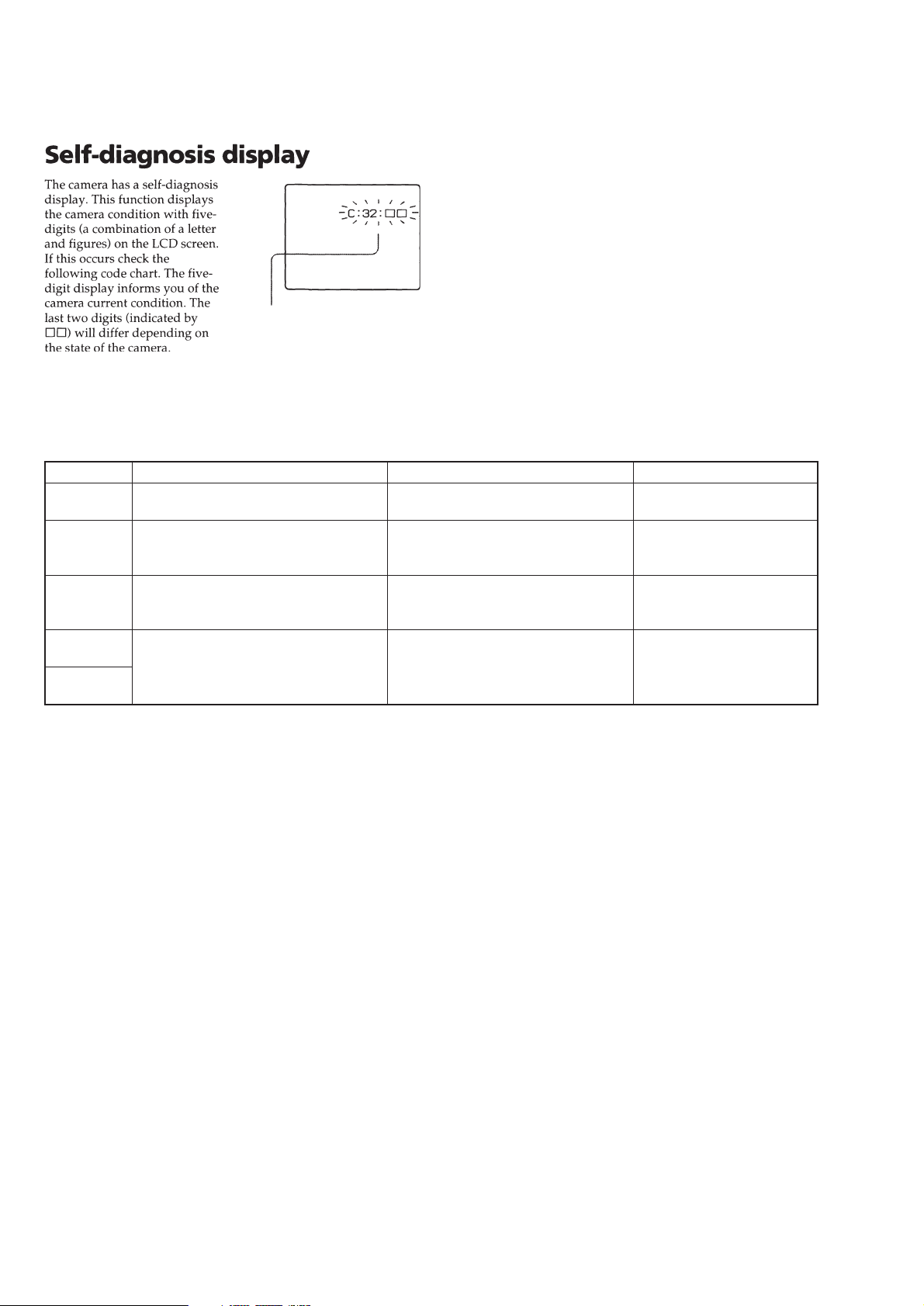

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

*1

E:61:00

*1

E:61:10

Note: The error code is cleared if the battery is removed.

*1 : The error display is given in two ways.

Change the disk and turn off the main

power then back on.

Replace the CD-R/RW disk.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Countermeasure

Cause

Defective base unit.

• The type of CD-R/RW disk that cannot

be used by this machine, is inserted.

• Data is damaged.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Caution Display During Error

DRIVE ERROR

DISK ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

— 6 —

Page 7

1. MAIN PARTS

Note:

• Follow the disassembly procedure in the numerical order given.

• Items marked “*” are not stocked since they are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

1. ORNAMENTAL PARTS

CPC lid

3-067-950-11 (CD200)

3-067-950-01 (CD300)

Note: Disassembling the main unit

is necessary to replace it.

MVC-CD200/CD300

DC cover

3-068-424-01

Note: Disassembling the main unit

is necessary to replace it.

Lens cap assembly

X-3951-763-1

JK cover

3-067-941-11 (CD200)

3-067-941-01 (CD300)

Note: Disassembling the main unit

is necessary to replace it.

(CD300)(CD200)

Lens cap assembly

X-3951-672-1

Cap string (T)

3-067-797-01

— 7 —

Page 8

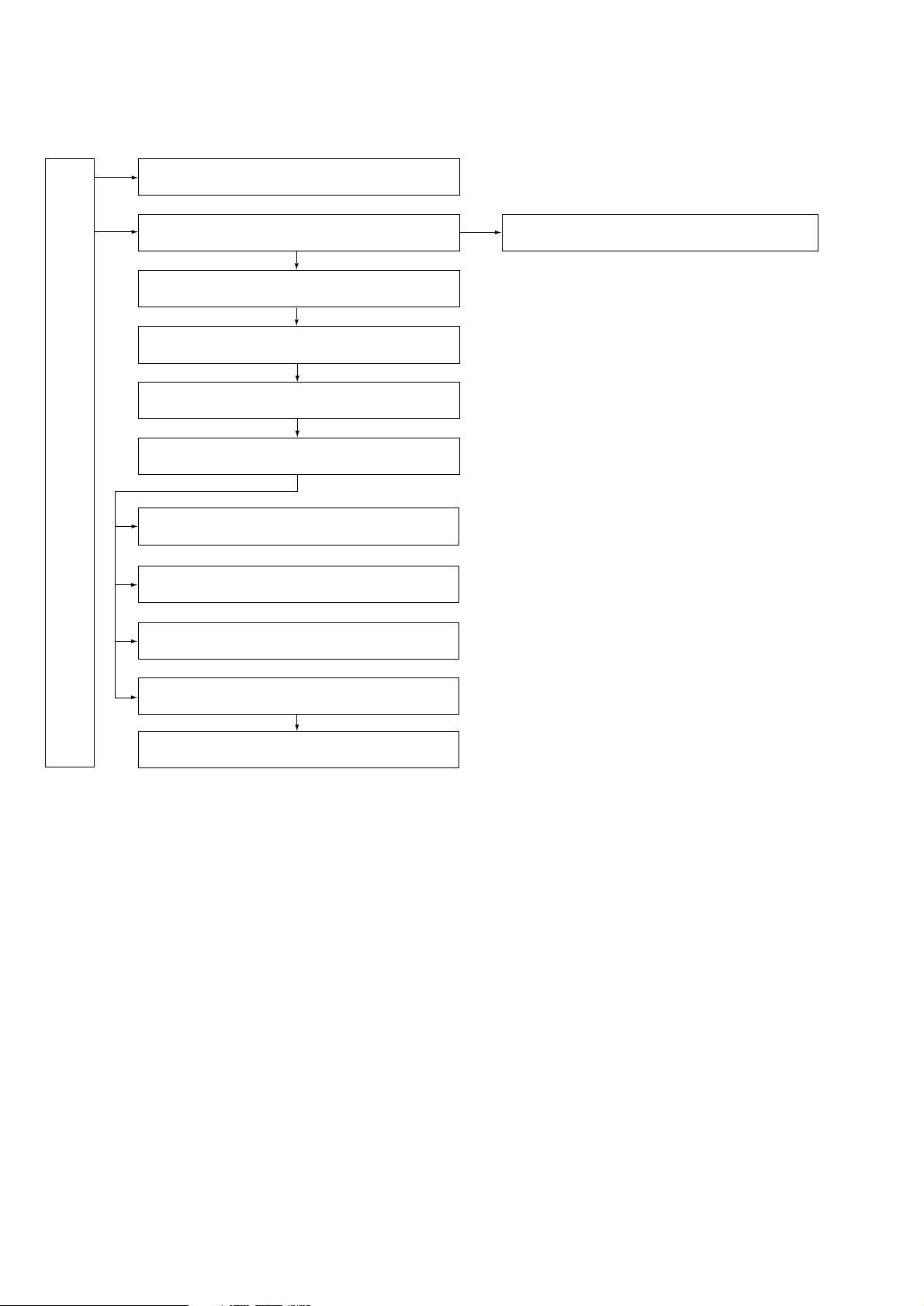

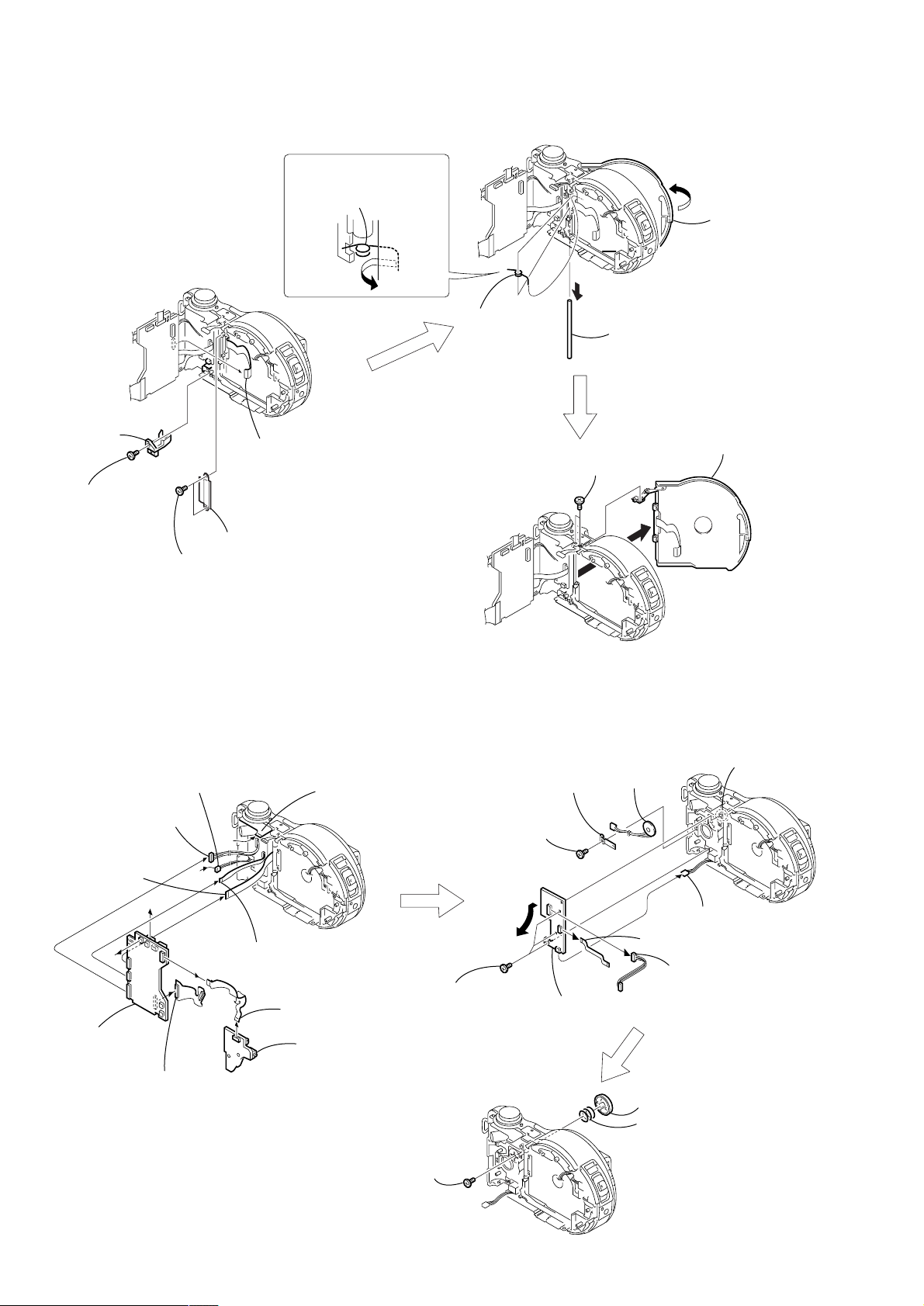

2. DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1. LCD section (PK-58 board)

2-2. Cabinet (front) section

2-4. Battery holder (JK-208 board)

2-5. SY-67 board

2-6. Stroboscope section

2-7. Base unit (DDX-G2100 complete assembly)

2-8. Lid CD section

MVC-CD200/CD300

2-9. Function button (FS-83 board)

2-10. Solenoid plunger (Door lock/Stroboscope),

CD lock slider

2-3. Cabinet (front) assembly (TK-61 board),

Control switch block (RL-503)

2-11. Control switch block (ZK-503), Strap shaft

2-12. Mode knob, Power spring

— 8 —

Page 9

NOTE: F ollo w the disassembly procedure in the numerical order given.

2-1. LCD SECTION (PK-58 BOARD)

5 PK-58

board

Remove the CD rear lid in the

direction of the arrow A.

A

3 Four precision

screws (DIA 1.7 × 4)

1 T wo precision

screws (DIA 1.7 × 4)

2 Flexible

cover (CD)

4 Precision

screw

(DIA 1.7 × 5)

3 T wo precision

screws (DIA 1.7 × 4)

Upper stay assembly

PK-58

B

4 Precision

screw (DIA 1.7 × 4)

1 Liquid crystal indicator

module (24P)

2 Back light

(10P)

1 T wo precision

screws (DIA 1.7 × 4)

Remove the PK-58

board in the direction

of the arrow B.

PK-58

PK-58

6 CD rear

lid

5 CPC lid

2 T wo precision

screws (DIA 1.7 × 4)

3 BL retainer plate

4 Back light

Cold cathode

fluorescent tube

5 Liquid crystal

indicator module

6 Solar window

— 9 —

Page 10

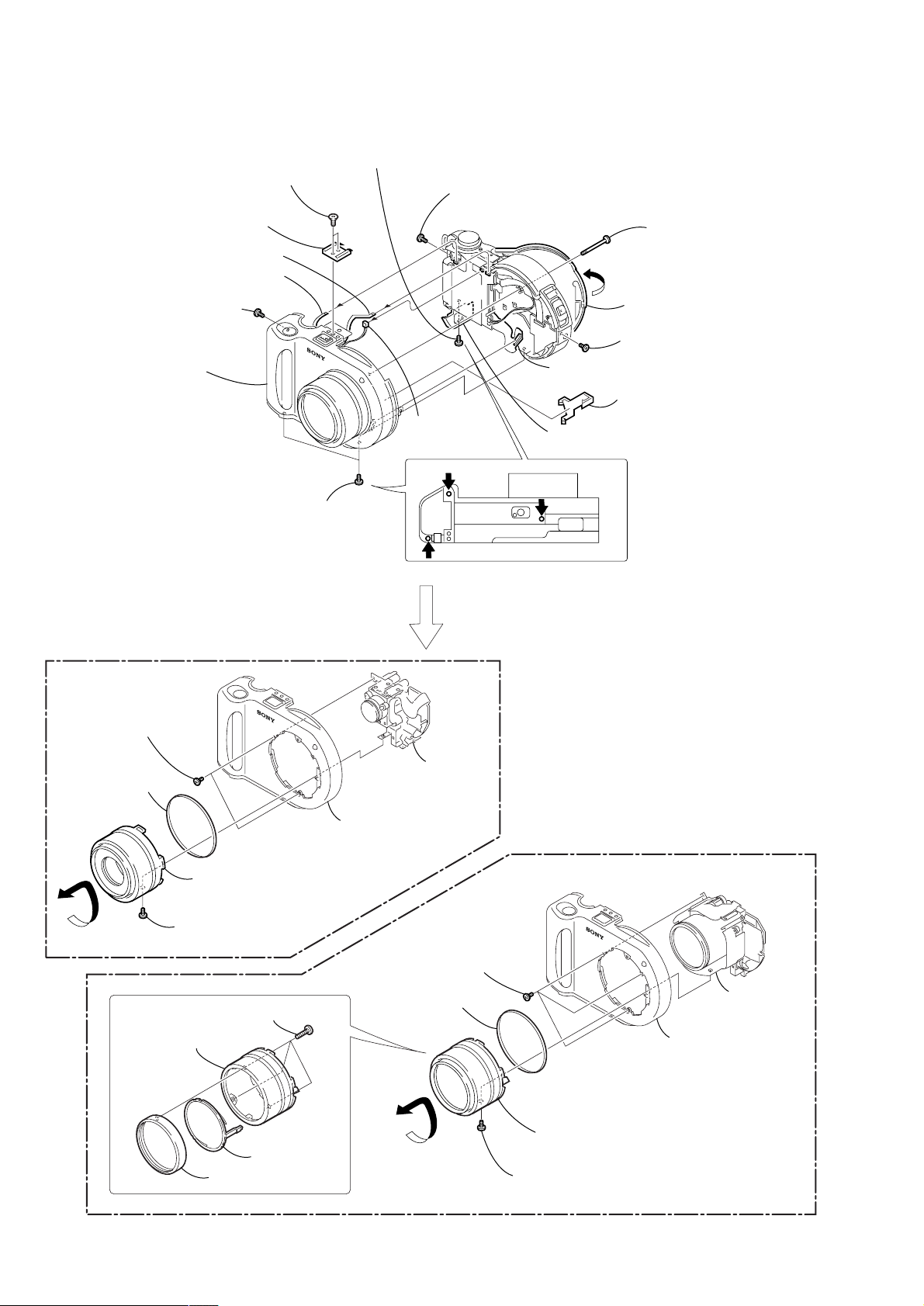

2-2. CABINET (FRONT) SECTION

3 T wo screws

(M 2 × 3.5)

4 Accessory

shoe

qf FP-369 flexible board (5P)

qg Control switch block

(RL-503) (6P)

7 Screw (M 2 × 4),

lock ace, P2

qh Cabinet (front) section,

Lens cabinet section,

Lens section

0 Two screws (M 2 × 4),

lock ace, P2

9 Screw (M 2 × 4),

lock ace, P2

6 Screw (M 2 × 4),

lock ace, P2

SY-67

qd Microphone

(2P)

JK-208

qs FP-364 flexible

board (70P)

8 Open the

BT lid

2 Special (step)

screw (M 2)

1 Open the lid

CD section

5 Screw (M 2 × 4),

lock ace, P2

qa BIB retainer

(CD200)

4 Two screws (M 2 × 4),

lock ace, P2

3 Ornamental ring

A

4 Lens cabinet (H)

6 Cabinet (front) section

2 Remove the lens cabinet assembly

in the direction of the arrow A.

1 Screw (M 2 × 4),

lock ace, P2

1 Three screws (M 1.7 × 7)

5 Lens

section

4 Three screws (M 2 × 4),

lock ace, P2

3 Ornamental ring

B

(CD300)

5 Lens

section

6 Cabinet (front) section

3 LC switch

2 Filter ring

— 10 —

2 Remove the lens cabinet assembly

in the direction of the arrow B.

1 Screw (M 2 × 4),

lock ace, P2

Page 11

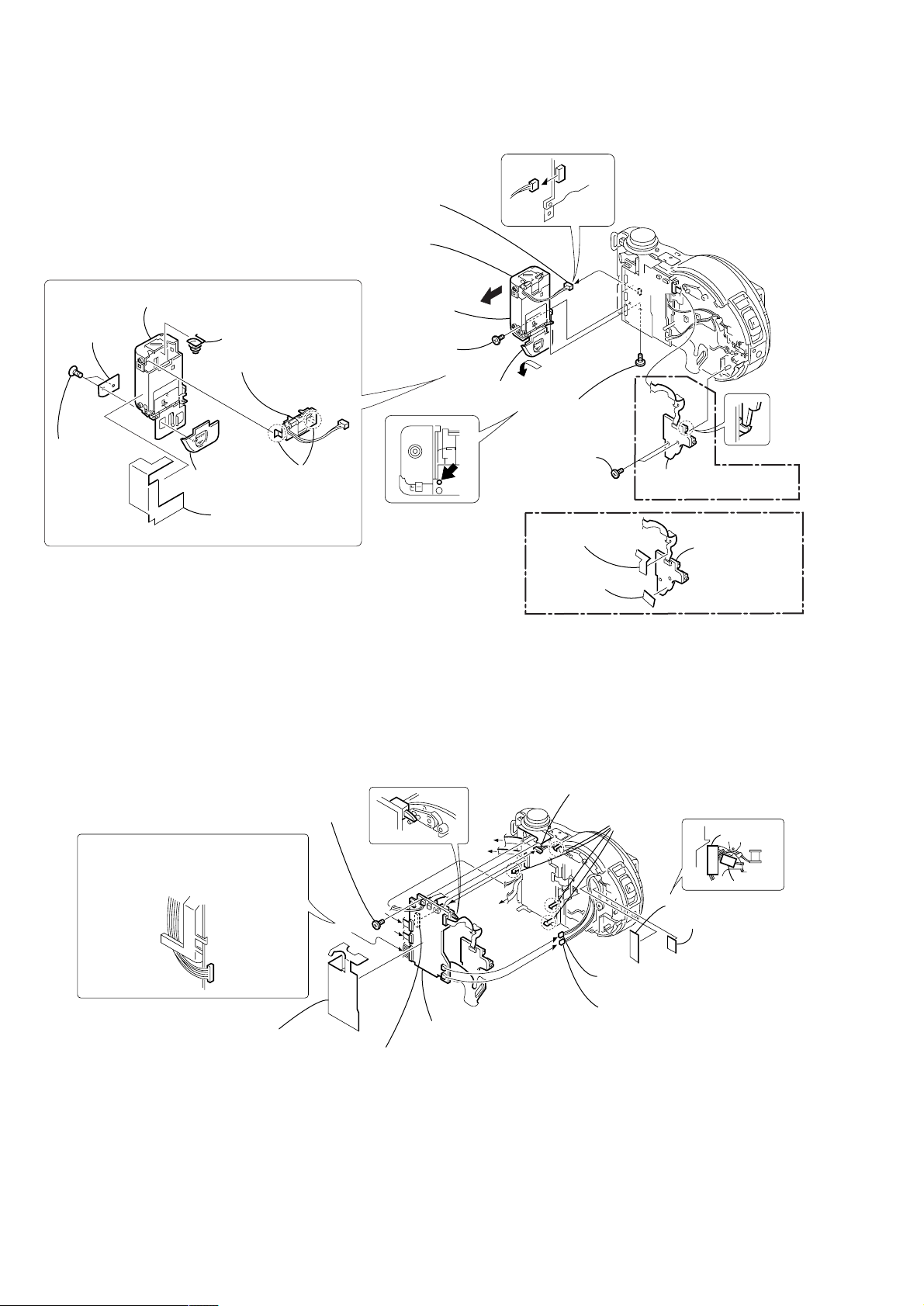

2-3. CABINET (FRONT) ASSEMBLY (TK-61 BOARD), CONTROL SWITCH BLOCK (RL-503)

1 T wo screws

(M 1.7 × 2),

lock ace, P2

6 Microphone holder

assembly

7 Microphone cushion

4 Microphone

sheet

5 T wo tapping

screws (B 1.7 × 3.5)

3 Rear sheet

metal (upper)

2 Control switch

block (RL-503)

8 Microphone

9 Retainer

sheet

metal

4 FP-370 flexible

board (5P),

LED

2 LED cap

6 TK-61 board,

FP-369 flexible

board

2 T wo claws

1 T wo precision

screws

(DIA 1.7 × 4)

5 T ape (A)

3 T wo precision

screws

(DIA 1.7 × 4)

3 Cabinet (front) assembly

1 T wo precision

screws

(DIA 1.7 × 4)

— 11 —

Page 12

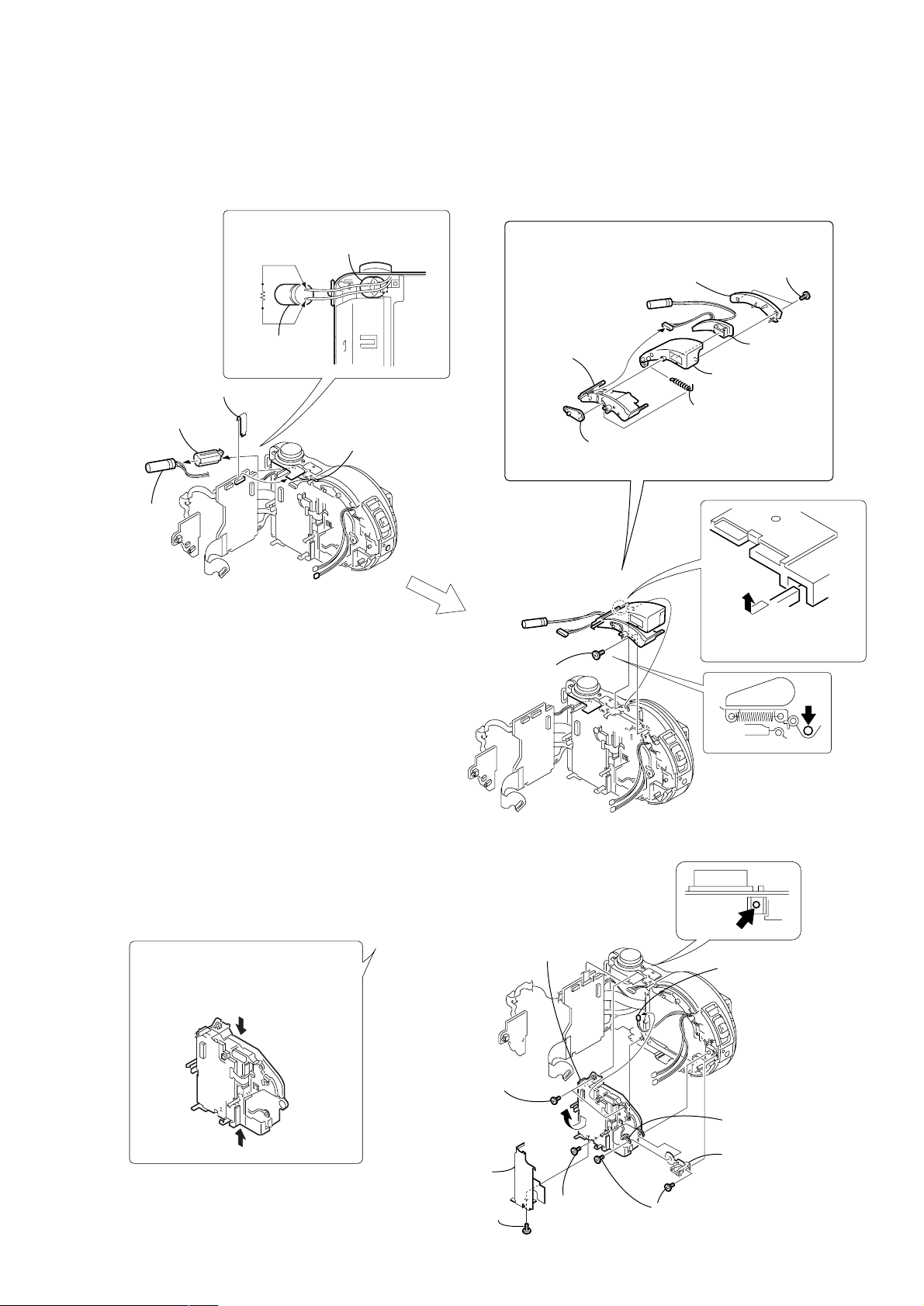

2-4. BATTERY HOLDER (JK-208 BOARD)

4 Remove the BT holder assembly

in the direction of the arrow A.

REMOVING THE BATTERY HOLDER

8 Battery holder

3 BT lid

retainer

1 T wo tapping

screws

(1.7 × 3)

7 Battery spring

6 Battery terminal

board

2 BT lid

4 BT sheet

5 Two

claws

5 Battery terminal

board (3P)

6 BT holder

assembly

3 Precision

screw

(DIA 1.7 × 4)

A

1 Open the

BT lid

7 T wo precision

screws

(DIA 1.7 × 4)

FS-83

2 Screw

(M 2 × 4),

lock ace, P2

(CD200)

8 SJ sheet

9 JK sheet

SY-67

JK

-208

(CD300)

8 JK-208 board,

FP-361 flexible board

0 JK-208 board,

FP-361 flexible

JK-208

board

2-5. SY-67 BOARD

When attaching the connector, route

the harnesses through the notch as

shown while taking care so the the

harness must not be caught or pinched.

7 Precision screw

(DIA 1.7 × 4)

1 Harness retainer

A

C

B

SY-67

0 SY-67 board, JK-208 board,

9 Remove the connector

FP-361 flexible board, FP-364 flexible board

6 Harness

(from flash unit 8P)

B

A

C

MD083

8 Four

claws

2 T ape (A)

Tape (A)

Tape (Z)

3 T ape (Z)

JK

-208

4 Harness (FS-139) (2P)

(strobe plunger)

5 Harness (FS-140) (2P)

(dew sensor)

— 12 —

Page 13

2-6. STROBOSCOPE SECTION (FLASH UNIT)

)

Note: The charging capacitor is charged to the maximum of 300V.

There is a danger of electric shock due to the high voltage when the capacitor is touched by bare hand.

Discharge the voltage remained in the capacitor, referring to the Service Note (See page 5).

1 Capacitor cap

2 Capacitor

4 Sheet (UW)

SY-

JK208

67

3 Discharging the capacitor

Short jig

Capacitor cap

Capacitor

5 Control switch block

(ZK-503) (14P)

MD083

3 Stroboscope

base

1 Precision screw

(DIA 1.7 × 4)

6 Stroboscope

cover

1 ST sensor

lever

4 T wo precision

screws

(DIA 1.7 × 4)

7 Flash unit

5 Stroboscope

case assembly

2 ST-POP-UP

spring

A

2 Remove the stroboscope

section in the direction

of the arrow A.

JK208

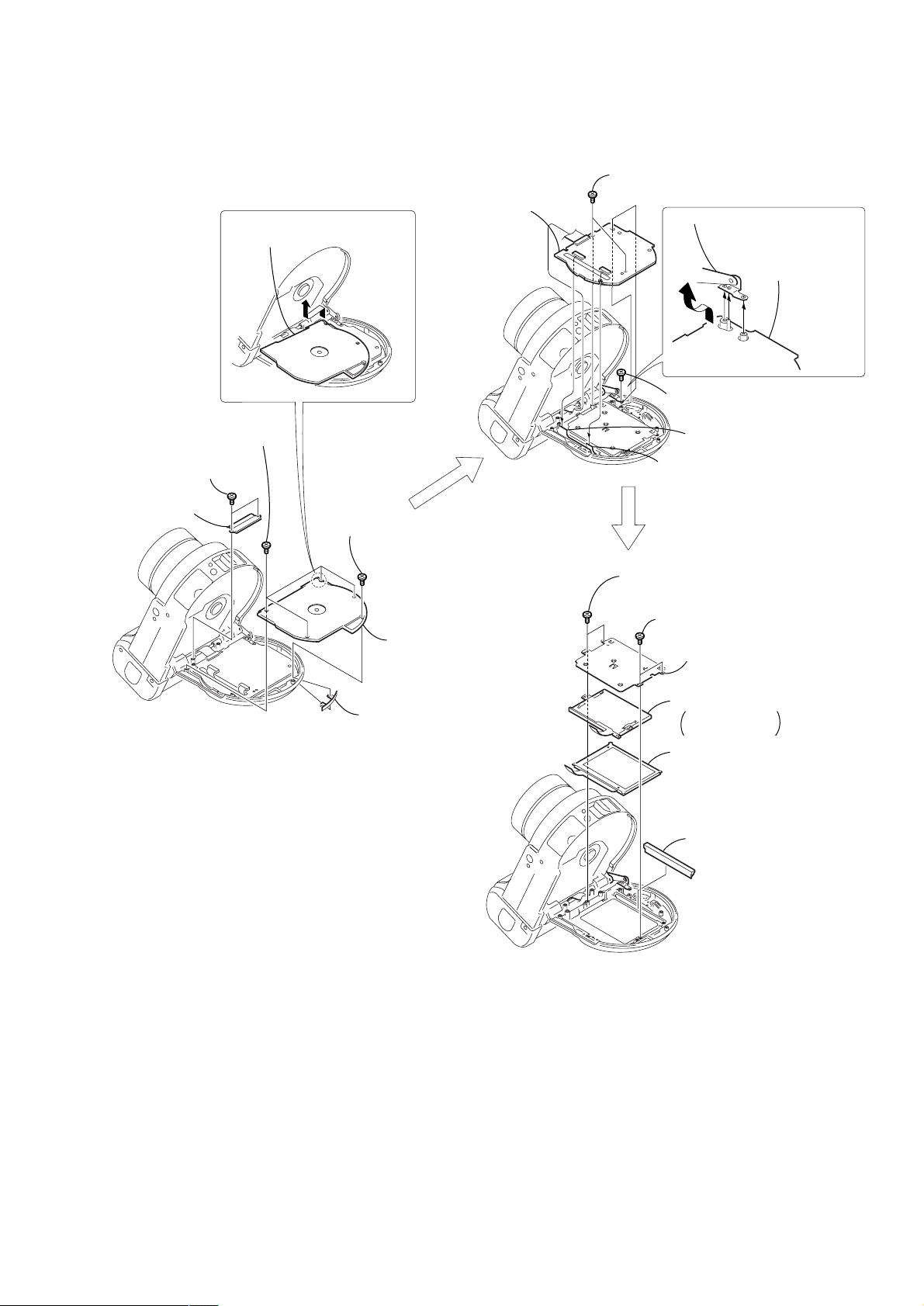

2-7. BASE UNIT (DDX-G2100 COMPLETE ASSEMBLY)

Precautions during handling

• Do not turn the side of the optical

lens downward.

• Hold the frame.

• Do not touch the optical lens surface.

MD083

7 Remove the DDX-G2100 complete

assembly in the direction of the arrow.

5 T wo precision

screws

(DIA 1.7 × 4)

9 MD heat sink,

MD sheet

8 Precision screw

(DIA 1.7 × 4)

JK208

SY67

MD083

SY67

MD083

6 Precision

screw

(DIA 1.7 × 4)

1 Harness (FS-138) (2P

(door look plunger)

3 Harness (SF-81)

4 Nut plate (side)

2 T wo precision

screws (DIA 1.7 × 4)

— 13 —

Page 14

2-8. LID CD SECTION

Remove the PRE open

spring in the direction of the

arrow C.

C

SY67

FS-83

1 Open the lid

CD section

FS-83

SY67

2 Parallel

pin cover

5 FP-363 flexible

board (33P)

1 Precision

screw

(DIA 1.7 × 4)

4 Flexible cover (CD)

3 T wo precision

screws

(DIA 1.7 × 4)

2-9. FUNCTION BUTTON (FS-83 BOARD)

3 PRE

open spring

1 T wo screws

(M 1.7 × 3), P2

SY67

A

2 Remove the Parallel pin (DIA 3)

in the direction of the arrow A.

2 Remove the lid CD section in

the direction of the arrow B.

B

FS-83

8 Harness

(FS-136) (14P)

6 FP-363 flexible

board (33P)

B

A

SY -67

9 SY-67 board

1 FP-364 flexible

board (70P)

5 Speaker (2P)

B

A

7 FP-362 flexible

board (11P)

JK

-2

08

4 Control switch block

(ZK-503) (14P)

2 FP-361 flexible

board (27P)

3 JK-208 board

1 Special head screw

(M 1.7 × 3)

7 Precision

screw

(DIA 1.7 × 4)

1 Three

precision

screws

(DIA 1.7 × 4)

8 Speaker

retainer

FS-83

9 Speaker

4 FP-362 flexible board (11P)

3 Remove the FS-83 board

in the direction of the arrow.

3 Function button

2 F button spring

2 Dowel

6 DC-IN

connector (3P)

5 Harness

(FS-136) (14P)

— 14 —

Page 15

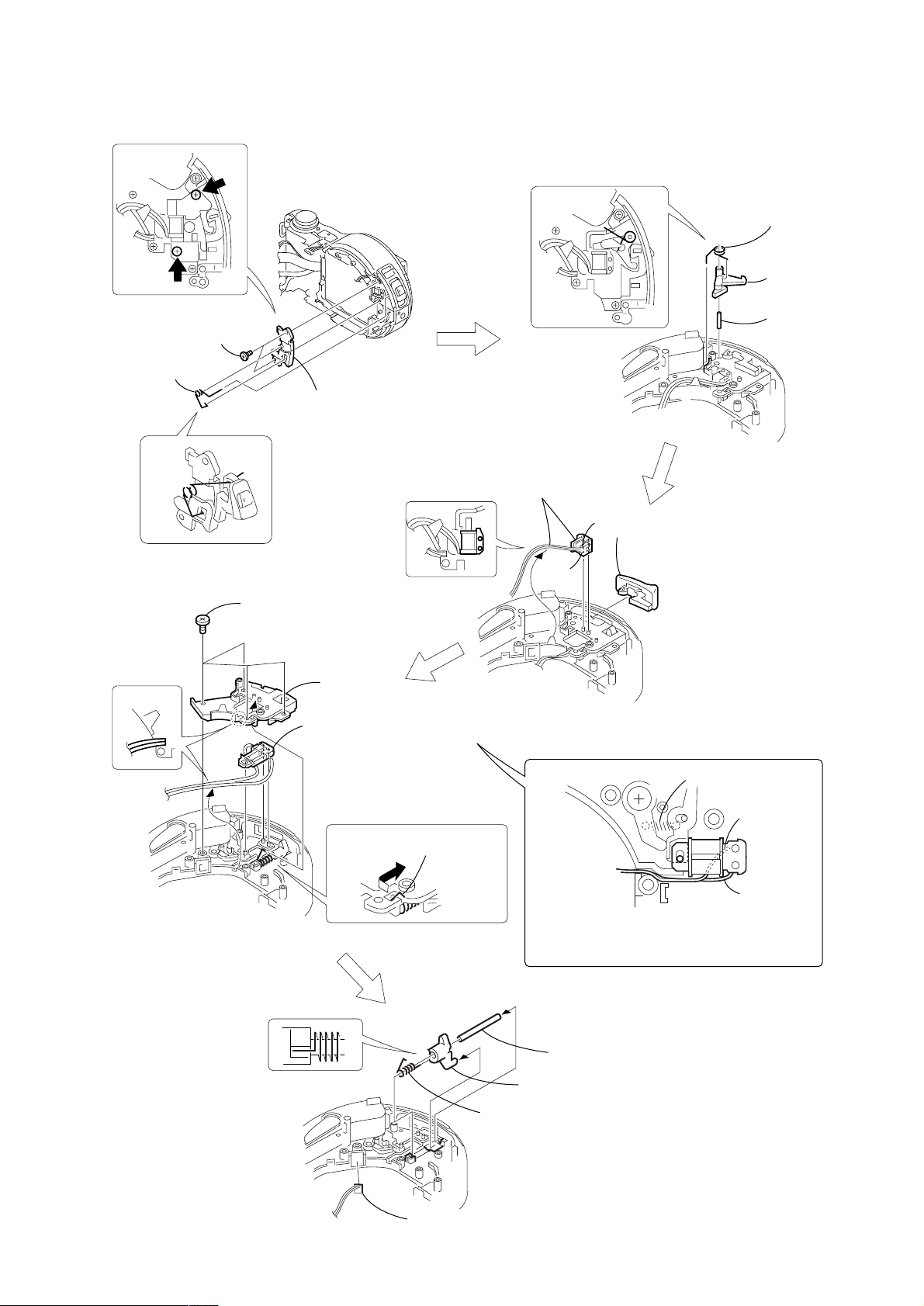

2-10. SOLENOID PLUNGER (DOOR LOCK/STROBOSCOPE), CD LOCK SLIDER

r

1 CD lock

lever spring

2 CD lock leve

2 T wo precision

screws

(DIA 1.7 × 4)

1 CD opener

spring

3 Solenoid cover

2 Four precision

screws

(DIA 1.7 × 4)

3 ST lock

cover

4 Solenoid plunger

(stroboscope), Harness (FS-139)

1 Solenoid plunger (door lock),

Harness (FS-138)

#

2 CD opener

assembly

3

3 Parallel pin

(DIA 1.6 × 6)

1 Remove the CD lock spring

in the direction of the arrow.

1 CD lock spring

4 FP-248 flexible board (dew sensor) ,

Harness (FS-140)

Spring

When attaching the solenoid plunger, route the

harnesses through the notch as shown while

taking care so that the harness must not be

caught or pinched.

2 Parallel pin

3 CD lock slider

#

3

— 15 —

Page 16

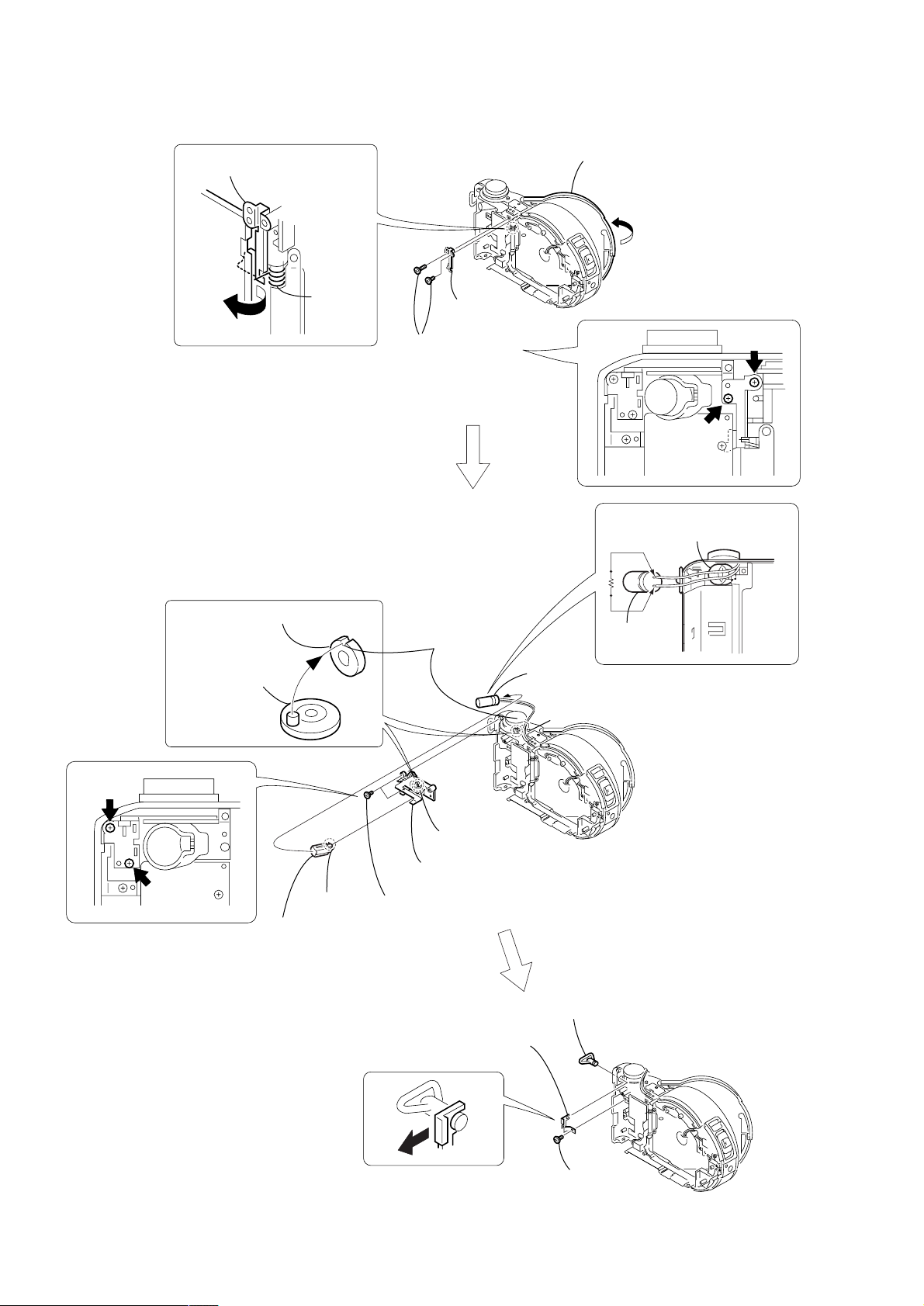

2-11. CONTROL SWITCH BLOCK (ZK-503), STRAP SHAFT

Remove the PO spring stay in

the direction of the arrow A.

FS-83

A

PRE open

spring

PRECAUTION DURING

INSTALLATION

FS-83

3 PO spring

stay

2 Two screws

(DIA 1.7 × 5.5)

1 Open the lid

CD section

Discharging the capacitor

Short jig

Capacitor cap

Mode knob

retainer

Control switch

block (ZK-503)

5 Claw

6 Capacitor

cap

"S" position

set in live A

3 Dowel

4 Control switch block

(ZK-503)

2 T wo precision

screws

(DIA 1.7 × 4)

2 Strap sheet

metal (R)

1 Capacitor

A

s

FS-83

Capacitor

3 Strap shaft

— 16 —

FS-83

1 Precision

screw

(DIA 1.7 × 4)

Page 17

2-12. MODE KNOB, POWER SPRING

"S" position set in live A

3 Mode knob

retainer

2

s

A

1 Special head screw

(M 1.7 × 3 )

7 Mode knob

6 Dial base

5 Click plate

4 Three EG grip

screws (M 1.4 × 2.5)

8 Friction spring

When attaching it, coat the

hatched portion with grease.

Click

Rear view

Note: Perform the running-in rotation of the

click plate several times.

plate

0 Power knob

Rear view

9 Slider ring

— 17 —

qa Power spring

Page 18

3. REPAIR PARTS LIST

3-1. EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

3-1-1. OVERALL SECTION

not

supplied

8

5

Cabinet (front) section,

Lens cabinet section (See page 20),

Lens section (See page 21)

(CD300)

9

J

10

BT901

6

4

3

2

• The mechanical parts with no reference number

in the exploded views are not supplied.

K

13

11

E

5

B

5

12

A

D

F

C

SY-67

7

K

15

not

supplied

G

H

I

16

(Note)

5

5

17

MD-083

18

5

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Cabinet (rear) section,

(See page 22, 23)

2

5

F

E

B

J

C

A

2

H

I

D

G

21

5

(CD200)

24

23

19

14

25

2

20

22

JK-208

5

2

1

26

not

supplied

1

2

: BT101(Lithium battery) JK-208 board on the mount position.

Note: The charging capacitor is charged to the maximum of 300V.

There is a danger of electric shock due to the high voltage when the capacitor is touched by bare hand.

Discharge the voltage remained in the capacitor, referring to the Service Note (See page 5).

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 X-3951-672-1 CAP ASSY, LENS (CD300)

1 X-3951-763-1 CAP ASSY, LENS (CD200)

2 3-968-729-71 SCREW (M2), LOCK ACE, P2

3 3-067-469-11 SHOE, ACCESSORY

4 3-069-159-21 PROCESS, (M2) INTERIOR LOCK

5 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

6 3-067-937-01 LID, BT (CD300)

6 3-067-937-11 LID, BT (CD200)

7 3-068-462-01 SPRING, ST-POP-UP

8 3-318-382-01 SCREW (1.7X3), TAPPING

13 3-068-461-01 BASE, STROBOSCOPE

14 3-067-950-01 LID, CPC (CD300)

14 3-067-950-11 LID, CPC (CD200)

15 X-3951-647-1 CASE ASSY, STROBOSCOPE (CD300)

15 X-3951-655-1 CASE ASSY, STROBOSCOPE (CD200)

0 16 not supplied FLASH UNIT

17 3-067-949-01 COVER, STROBOSCOPE (CD300)

17 3-067-949-11 COVER, STROBOSCOPE (CD200)

18 not supplied DDX-G2100 COMPLETE ASSY (SERVICE)

19 3-068-474-01 SCREW (M2), SPECIAL (STEP)

Cabinet (front) section,

Lens cabinet section

(See page 19),

Lens section

(See page 21)

9 3-969-380-01 SPRING, BATTERY

10 X-3951-639-1 HOLDER ASSY, BT (CD300)

10 X-3951-651-1 HOLDER ASSY, BT (CD200)

11 3-068-464-01 LEVER, ST SENSOR

12 not supplied SY-67 (300) BOARD, COMPLETE (SERVICE)

(CD300)

12 not supplied SY-67 (200) BOARD, COMPLETE (SERVICE)

(CD200)

20 1-681-545-11 FP-361 FLEXIBLE BOARD

21 3-068-475-01 NUT PLATE (SIDE)

22 not supplied JK-208 BOARD, COMPLETE

23 3-068-875-01 RETAINER, B2B

24 1-681-548-21 FP-364 FLEXIBLE BOARD

25 3-713-791-11 SCREW (M1.7X5), TAPPING, P2

26 3-067-797-01 STRING (T), CAP (CD300)

BT901 1-694-815-11 TERMINAL BOARD, BATTERY

— 18 —

Page 19

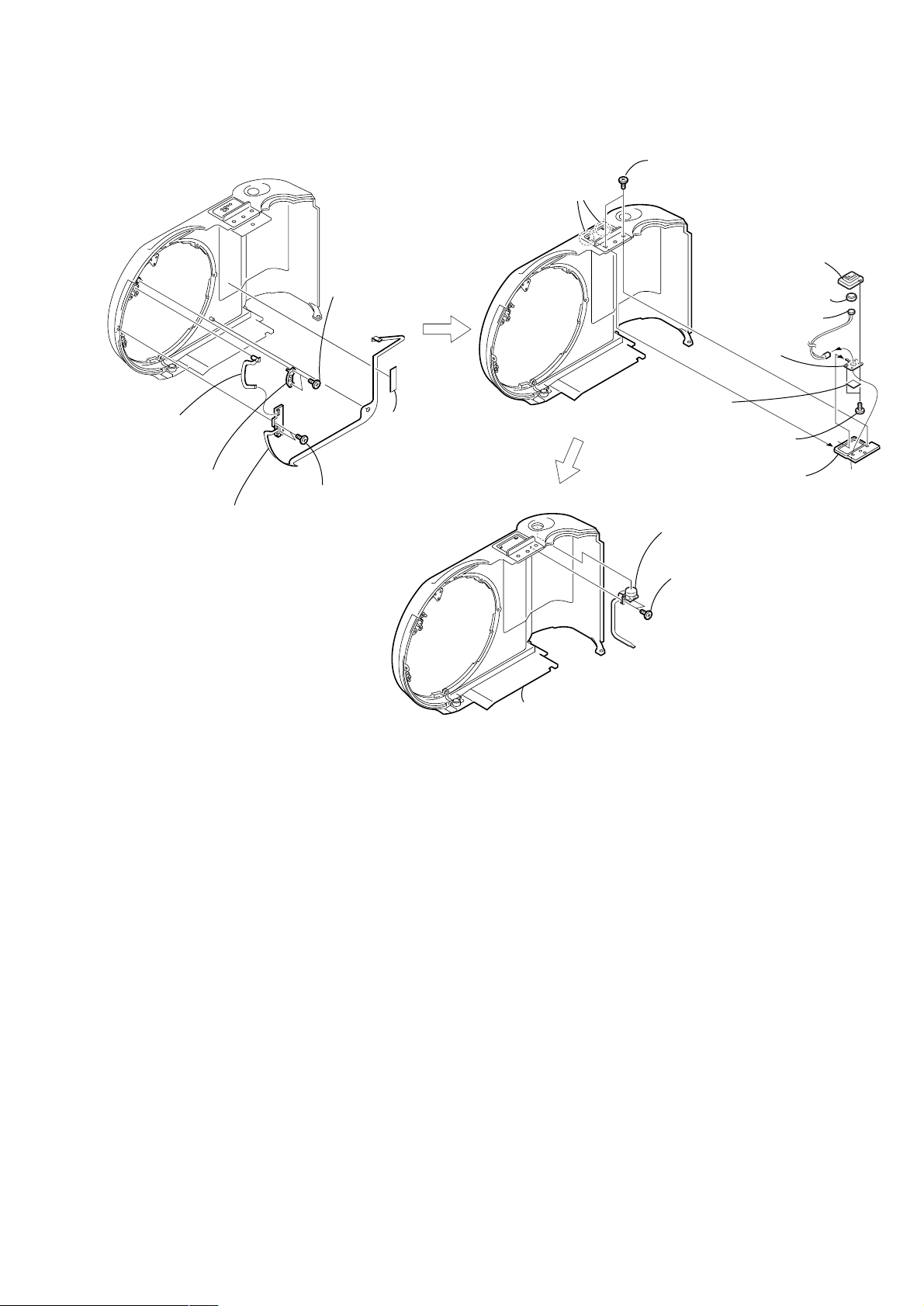

3-1-2. CABINET (FRONT) SECTION, LENS CABINET SECTION

(CD200)

52

51

A

51

55

not

supplied

51

57

B

56

53

MIC901

54

B

61

53

58

63

60

62

59

not

supplied

53

LED901

65

64

Lens section (See page 21)

53

67

66

53

A

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-968-729-71 SCREW (M2), LOCK ACE, P2

52 X-3951-650-1 CABINET ASSY, LENS

53 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

54 3-060-274-01 SCREW, TRIPOD

55 X-3951-652-1 CABINET (FRONT) ASSY

56 3-989-735-61 SCREW (M1.7), LOCK ACE, P2

57 1-476-674-11 SWITCH BLOCK, CONTROL (RL-503)

58 3-067-948-11 PLATE, SIDE ORNAMENTAL

59 3-713-791-05 SCREW (B1.7)

60 3-068-402-01 SHEET METAL, RETAINER

61 3-068-488-01 CUSHION, MICROPHONE

62 3-062-299-01 SHEET, MICROPHONE

63 X-3951-646-1 HOLDER ASSY, MICROPHONE

64 1-681-549-11 FP-369 FLEXIBLE BOARD

65 not supplied TK-61 (200) BOARD, COMPLETE

66 1-681-550-11 FP-370 FLEXIBLE BOARD

67 3-068-494-01 CAP, LED

LED901 8-719-084-32 DIODE TLOH20TP

MIC901 1-542-457-11 MICROPHONE

— 19 —

Page 20

3-1-3. CABINET (FRONT) SECTION, LENS CABINET SECTION

(CD300)

101

not

supplied

104

not

supplied

103

A

102

108

110

102

B

109

106

105

B

113

MIC901

106

107

115

112

114

111

not

supplied

117

106

LED901

116

106

118

106

119

Lens section

(See page 21)

A

102

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 3-068-411-01 RING, FILTER

102 3-968-729-71 SCREW (M2), LOCK ACE, P2

103 3-060-271-01 SCREW (M1.7X7)

104 X-3951-642-1 CABINET ASSY, LENS

105 3-060-274-01 SCREW, TRIPOD

106 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

107 3-067-948-01 PLATE, SIDE ORNAMENTAL

108 X-3951-641-1 CABINET (FRONT) ASSY

109 3-989-735-61 SCREW (M1.7), LOCK ACE, P2

110 1-476-674-11 SWITCH BLOCK, CONTROL (RL-503)

111 3-713-791-05 SCREW (B1.7)

112 3-068-402-01 SHEET METAL, RETAINER

113 3-068-488-01 CUSHION, MICROPHONE

114 3-062-299-01 SHEET, MICROPHONE

115 X-3951-646-1 HOLDER ASSY, MICROPHONE

116 1-681-549-11 FP-369 FLEXIBLE BOARD

117 not supplied TK-61 BOARD, COMPLETE

118 1-681-550-11 FP-370 FLEXIBLE BOARD

119 3-068-494-01 CAP, LED

LED901 8-719-084-32 DIODE TLOH20TP

MIC901 1-542-457-11 MICROPHONE

— 20 —

Page 21

3-1-4. LENS SECTION

(CD200)

not

supplied

(CD300)

160

M001

not

supplied

151

152

M002

154

153

154

155

156

IC101

157

not

supplied

CD-333

161

158

159

162

163

IC401

164

not

supplied

165

166

167

CD-334

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 3-831-441-11 SPACER (CD200)

152 not supplied LENS, ZOOM (VCL-6103WA) (CD200)

153 3-068-533-01 FRAME (M), LENS (CD200)

154 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION (CD200)

155 not supplied ADAPTOR (CL), CCD FITTING (CD200)

156 not supplied FILTER BLOCK, OPTICAL (CD200)

157 not supplied RUBBER (CL), SEAL (CD200)

158 not supplied CD-333 BOARD, COMPLETE (CD200)

159 not supplied TITE (2), +B TAPPING (P) (CD200)

160 not supplied FRAME (H), LENS (CD300)

161 not supplied LENS ASSY (CD300)

162 not supplied SCREW (M1.7), LOCK ACE, P2 (CD300)

163 not supplied FILTER BLOCK, OPTICAL (CD300)

164 not supplied RUBBER (N), SEAL (CD300)

165 not supplied SCREW (B1.7) (CD300)

166 not supplied CD-334 BOARD, COMPLETE (CD300)

167 not supplied SCREW (B1.7X6), TAPPING (CD300)

IC101 not supplied CCD BLOCK ASSY (CCD IMAGER) (CD200)

IC401 not supplied CCD BLOCK ASSY (CCD IMAGER) (CD300)

M001 not supplied MOTOR UNIT, FOCUS (CD200)

M002 not supplied MOTOR UNIT, ZOOM (CD200)

— 21 —

Page 22

3-1-5. CABINET (REAR) SECTION-1

Lid CD section

(See page 24)

203

205

201

206

202

205

C

218

B

FS-83

205

215

217

SP901

J901

216

207

205

205

208

214

B

204

205

209

C

213

212

A

211

A

Cabinet (rear) section-2

(See page 23)

210

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 3-069-046-01 SCREW (Y) (DIA. 1.7X5.5)

202 3-070-017-01 STAY, PO SPRING

203 3-068-479-01 CAP, CAPACITOR

204 3-070-014-01 SPRING, PRE OPEN

205 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

206 1-476-675-11 SWITCH BLOCK, CONTROL (ZK-503)

207 3-068-454-01 SHEET METAL (R), STRAP

208 3-068-457-01 SHAFT, STRAP

209 3-056-559-11 SCREW (M1.7), 0 PART-NO. P2

210 1-657-785-11 FP-248 FLEXIBLE BOARD (DEW SENSOR)

211 1-961-144-11 HARNESS (FS-140)

212 3-068-496-01 PIN (DIA. 3), PARALLEL

213 3-068-450-01 COVER (CD), FLEXIBLE

214 3-068-497-01 COVER, PARALLEL PIN

215 3-068-453-01 RETAINER, SPEAKER

216 1-961-141-11 HARNESS (FS-136)

217 1-681-546-11 FP-362 FLEXIBLE BOARD

218 not supplied FS-83 BOARD, COMPLETE

J901 1-794-045-11 CONNECTOR, DC-IN

SP901 1-544-839-11 SPEAKER (1.6 CM)

— 22 —

Page 23

3-1-6. CABINET (REAR) SECTION-2

A

A

B

B

C

252

257

258

259

251

252

253

254

277

273

255

256

260

261 272

271

256

275

280

279

277

278

not

supplied

PL902

PL901

not

supplied

270

262

264

266

268

269

267

265

263

274

C

252

276

269 3-068-536-01 KNOB (M), MODE (CD200)

* 270 3-064-250-01 SPRING, F BUTTON

271 3-067-942-01 BUTTON, FUNCTION (CD300)

271 3-067-942-11 BUTTON, FUNCTION (CD200)

272 3-068-424-01 COVER, DC

273 X-3951-648-1 OPENER ASSY, CD (CD300)

273 X-3951-656-1 OPENER ASSY, CD (CD200)

274 3-067-941-01 COVER, JK (CD300)

274 3-067-941-11 COVER, JK (CD200)

275 1-961-143-11 HARNESS (FS-139)

276 3-068-455-01 SHEET METAL (L), STRAP

277 3-065-177-01 SCREW (1.7X3)

278 3-068-421-01 RETAINER, MODE KNOB

279 3-068-401-01 HEAD (M1.7),0 PART-NO. SPECIAL

280 X-3951-643-1 CABINET (REAR) ASSY (CD300)

280 X-3951-653-1 CABINET (REAR) ASSY (CD200)

PL901 1-454-674-51 SOLENOID, PLUNGER (STOROBO PLUNGER)

PL902 1-454-988-11 SOLENOID, PLUNGER (DOOR LOCK PLUNGER)

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

251 3-068-467-01 SPRING, CD OPENER

252 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

253 3-068-470-01 COVER, SOLENOID

254 3-068-469-01 SPRING, CD LOCK LEVER

255 3-068-468-01 LEVER, CD LOCK

256 3-703-357-03 PIN, PARALLEL (DIA. 1.6X6)

257 1-961-142-11 HARNESS (FS-138)

258 3-068-481-01 COVER, ST LOCK

259 3-068-427-01 SPRING, CD LOCK

260 3-649-266-01 PIN, PARALLEL

261 3-068-428-01 SLIDER, CD LOCK

262 3-068-423-01 SPRING, POWER

263 3-068-422-01 KNOB, POWER

264 3-068-493-01 RING, SLIDER

265 3-068-625-01 SPRING, FRICTION

266 3-068-597-01 GRIP (M1.4), EG

267 3-068-623-01 PLATE, CLICK

268 3-068-619-01 BASE, DIAL

269 3-068-420-01 KNOB, MODE (CD300)

— 23 —

Page 24

3-1-7. LID CD SECTION

LCD901

304

301

302

301

301

305

303

PK-58

301

B

A

not

supplied

301

301

A

306

307

B

ND901

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

301 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

302 3-068-459-01 LID, CD REAR

303 not supplied PK-58 (SH) BOARD, COMPLETE

304 1-681-547-11 FP-363 FLEXIBLE BOARD

305 X-3951-645-1 STAY ASSY, UPPER

— 24 —

306 3-068-458-01 WINDOW, SOLAR

307 X-3951-644-1 LID ASSY, CD (CD300)

307 X-3951-654-1 LID ASSY, CD (CD200)

LCD901 not supplied INDICATOR MODULE LIQUID CRYSTAL

(LQ25A3FR30) (SERVICE)

0 ND901 not supplied TUBE, FLUORESCENT,COLD CATHODE

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 25

2. GENERAL

6

Introduction

Captures images with your computer

You can easily copy images onto your com puter through a CD-ROM drive, CD-R

drive, CD-RW drive, or the USB cable and view and modify images on your

computer using application software. When using a CD-ROM drive to view images

on your computer, the finalizat ion is required (page 32).

Flow chart for disc operations

Start

• A new disc

• The disc finalized with a computer or other equipmen t

Initialize

(page 18)

Disc preparation for

recording is complete.

The disc status

is before

finalization

Blank disc

Record

[About 1 min]

(page 32)

About 13 MB disc

space is used

Unfinalize

[About 1 min]

(page 34)

About 13 MB disc

space restores.

Format

[About 7 min]

(page 82)

The disc space is fully

available.

Finalize

Recording is complete

View on a

computer

(page 35)

Disc preparation

for viewing through

a CD-ROM drive is

complete.

: CD-R

: CD-RW

[ ] : Required

time

View on the

camera

(page 28)

View through

the USB cable

(page 38)

View through a

CD-R/CD-RW

drive

(page 41)

View through a

CD-ROM drive

(page 37)

This section is extracted from

instruction manual.

Getting started

Identifying the parts

See the pages in parenthe ses for details of operat ion.

1

2

3

4

5

Shutter button (20, 26)

A

Built-in microphone

B

Do not touch while recording.

Battery cover (bottom surface)

C

(9)

Lens

D

Tripod receptacle (bottom surface)

E

Use a tripod wi th a screw length of

less than 6.5 mm (7/32 inch). You

cannot firmly secure t he camera to

tripods having longer screws, and

may damage the camera.

Accessory shoe

F

Photocell window for flash

G

Do not block while recording with

the flash.

Flash (24)

H

Self-timer lamp/ AF illuminator

I

(24, 25)

Hook for strap and lens cap

J

Disc cover OPEN lever (16)

K

ACC (Accessory) jack

L

Connects an external flash or other

equipment.

Lens cap (supplied)

M

USB jack (38)

N

A/V OUT (MONO) jack (76)

O

Audio output is monaural.

About the Carl Zeiss lens (MVCCD300 only)

This camera is equippedwith a Carl Zeiss

lens which is capable of reproducing fine

images. The lens for this camera uses the

MTF* measurement system forcameras

developed jointly by Carl Zeiss, in

Germany, and Sony Corporation, and

offers the same quality as other Ca rl Zeiss

lenses.

∗ MTF is an abbreviation of Modulation

Transfer Function/Factor, a numeric

value indicating the amount of light from

a specific part of the subject gathered at

the corresponding position in the image.

MVC-CD200/CD300

Getting started

7

8

9

0

qa

qs

qd

qf

qg

6

1

2

3

4

5

6

7

8

9

0

qa

qs

Mode dial (45)

A

POWER switch (14)

B

(Exposure) button (67)

C

/CHG (Charge) lamp (10, 25)

D

FOCUS button (6 6)

E

Photocell window for LC D

F

screen

The LCD screen becomes brighter

when exposed to sunlight.

LCD screen

G

Disc window

H

DISPLAY/LCD BACK LIGHT ON/

I

OFF button (23)

ACCESS lamp (20)

J

Reset button (99)

K

DC IN cover/DC IN jack (10, 13)

L

A

M

S

SCN

UP

SET

8

POWER

ON/

OFF(CHG)

Attaching the

shoulder strap

Hook for strap

M

(Spot meter) button (71)

N

AE LOCK button (55)

O

Zoom W/T buttons (22)

P

Jog dial (48)

Q

POWER ON/OFF (CHG) lamp

R

(14)

Speaker

S

Control button (46)

T

MENU button (46)

U

7

qd

qf

qg

qh

qj

qk

ql

w;

wa

Preparing the power supply

Installing the battery pack

Your camera operates only with the NP-F M50 (supplied) “InfoL ITHIUM” battery

pack* (M series). See page 9 1 for more informat ion about “InfoLITH IUM” battery

pack.

1 2 3

1

2

Open the battery cover.

1

Slide the battery cover in the direction of the arrow.

Install the battery pack.

2

Insert the battery pack with the

as illustrated.

Close the battery cover.

3

mark facing toward the battery compartment

v

To remove the battery pack

Open the battery cover. Slide the battery eject lever in the arrow direction,

and remove the battery pack.

Be careful not to drop the battery pack when removing it.

Battery eject lever

*

What is “InfoLITHIUM”?

“InfoLITHIUM” is a lith ium ion battery pack which can exchange informati on such as battery

consumption with compatibl e video equipment. “InfoLITHIUM” M series battery packs have

the mark. “InfoLITHIUM” is atrademark of Sony Corporation.

2

Getting started

1

9

— 25 —

Page 26

Charging the battery pack

When the camera is turned on, you cannot charge the battery pack. Be sure to turn off

the power of the camera.

AC-L10A/L10B/L10C

AC power adaptor

Power cord

(mains lead)

3

to a wall outlet (mains)

Insert the battery pack into your camera.

1

Open the DC IN cover and connect the AC power adaptor to the DC

2

IN jack of your camera with the

Connect the power cord (mains lead) to the AC power adaptor and

3

then to a wall outlet (mains).

The /CHG lamp (orange) above the LCD screen lights up wh en charging

begins. When the /CHG lamp goes off, full charge is completed.

After charging the battery pack

Disconnect the AC power ada ptor from the DC IN jack o n your camera.

Battery remaining indicator

The LCD screen o n the camera shows the rem aining time for which y ou can still

record or play back images.

This indication may not be entirely accurate depending on the conditions of use and

the operating environment.

Charging at a room tem perature of 10°Cto30°C(50°Fto86°F) is recommended.

mark facing up.

v

2

1

Battery pack

NP-FM50 (supplied) battery pack

When you record ima ges in an extremely cold locat ion or using the LCD bac klight,

the operating time becomes short. When using the camera in an extremely cold

location, place the bat tery pack in your pocket o r other places to keep it warm, then

insert the battery pa ck into the camera just befo re recording. When u sing a pocket

heater, take care not to let the heater directly contact the battery.

Note on the /CHG lamp during charging

The /CHG lamp may flash:

• When a m alfunction occurs i n the battery pack ( page 99).

The /CHG lamp does not light up:

• When the battery pack is not installed properly.

Charging time

Battery pack Full charge (min.)

NP-FM50 (supp lied) Approx. 150

Approximate time to charge a completely discharged battery pack at a temperature of

25°C(77°F).

Battery life and number of images that can be recorded/played back

Still image recording/playback

NP-FM50 (supplied)

Battery life (min.) Number of images

Continuous recording* Approx. 75 Approx. 800

Continuous playback** Approx. 120 Approx. 1000

Approximate battery life and number of images that can be recorded/played back at a

temperature of 25°C(77°F) with a fully charged battery pack, using 640×480 image

size, standard image q uality, and NORMAL recording mode .

∗ R ecording at about 5-second intervals

∗∗Playing back single-displayed im ages continuously at about 7-second intervals

Moving image recording

NP-FM50 (supplied)

Battery life (min.)

Continuous recording Approx. 120

Approximate time that can be recorded 160×112-sized images at a temperature of

25°C(77°F) w ith a fully charged batter y pack.

Getting started

10

Notes

• The battery life and number of images willb edecreased when using at low temperature, using

the flash, turning the power on/off frequen tly, or u sing the zoom.

• The numbers of images shown on tables above are as a guide. Th e numbers may be smaller

depending on conditions.

• If sufficient battery remaining time is indicated but th e power runs out soon, fully charge the

battery so that the correct batt ery remaining time appears.

• Do not short the DC plug of the AC power adaptor with a metallic objec t, as this may cause a

malfunction.

Using the AC power adaptor

AC-L10A/L10B/L10C

AC power adaptor

Power cord

(mains lead)

2

to a wall outlet (m ains)

Open the DC IN cover and connect the AC power adaptor to the DC

1

IN jack of your camera with the

Connect the power cord (mains lead) to the AC power adaptor and

2

then to a wall outlet (mains).

Using a car battery

Use a Sony DC adaptor/ch arger.

Using your camera abroad

For details, see page 90.

When using the AC power adaptor

Be sure to use it n ear the wall outlet ( mains). If a malfun ction occurs, disco nnect the

plug from the wall outlet (mains).

mark facing up.

v

1

11

Getting started

12

13

— 26 —

Page 27

Setting the date and time

When you first use your camera, set the date and time. If these are not set, the

CLOCK SET screen app ears whenever you turn on your cam era.

1

2

POWER ON/OFF (CHG) lamp

3–6

Set the mode dial to , S, A, M, , SCN, or .

1

PushthePOWERswitchinthearrowdirectiontoturnonthe

2

power.

The POWER ON/OFF (CHG) lamp (green) lights up.

The CLOCK SET scree n appears.

When resetting the date and time once you set, set the mode dial to SET UP

(page 84), and then follow the procedure from step

Select the desired date display format with

3

on the control button, then press the

v/V

center

.

z

Select from [Y/M/D] (year/month/day), [M/D/Y]

(month/day/year), or [D/ M/Y] (day/month/yea r).

Select the year, month, day, hour or minute

4

item you want to set with

button.

The item to be set is indicated with

on the control

b/B

v/V

3

.

CLOCK SET

/:

OK

.

CLOCK SET

/:

OK

Set the numeric value withv/Von the

5

control button, then press the center

enter it.

After entering the number,

item. If you se lected [D/M/Y ] in step

time on a 24-hour cycle.

Select [OK] withBon the control button,

6

then press the center

moment to begin clock movement.

Thedateandtimeareentered.

moves to the next

v/V

at the desired

z

3

,setthe

to

z

CLOCK SET

OK

CLOCK SET

OK

Y/M/D

M/D/Y

D/M/Y

00AM12172001 /

/:

O K

CANCEL

Y/M/D

M/D/Y

D/M/Y

30PM10472001 /

/:

O K

CANCEL

Getting started

To cancel the date and time setting

Select [CANCEL] withv/V/b/Bon the control button, then press the c enterz.

Y/M/D

M/D/Y

D/M/Y

00AM12112001 /

O K

CANCEL

Y/M/D

M/D/Y

D/M/Y

00AM12112001 /

O K

CANCEL

14

Inserting a disc

Youcanuseonlythe8cmCD-Rsor8cmCD-RWsthathavethese

marks.

1 2

Disc cover

OPEN lever

Lock tab

Whileslidingthelocktabtotheleft,slidedownthedisccover

1

OPEN lever.

Open the disc cover by your hand after the cover is unlocked.

Place a disc with the printed side up.

2

Push down the center of the disc until it clicks. When installing, do not push

with too much force and do not to uch the pickup lens.

Pickup lens

Push here

Disc

15

Removing the disc

While sliding the lock tab to the left, slide down the disc cover OPEN lever, and open

the disc cover after the cover is unlocked. Then, remove the disc as illustrated below.

Notes

• Before removing the disc, be sure to check t hat the disc is not rotating.

• Do not openth edi sccover while the ACCESS lamp is lit. If you do, the recorded image may be

damaged or the disc may become unusa ble.

• When writing data on a disc or connecting with a computer using the USB connection, t hed isc

cover OPEN lever is locked.

Getting started

Close the disc cover.

3

16

17

— 27 —

Page 28

Basic operations

B

Recording

Initializing a disc (INITIALIZE)

When you use a new disc o r the disc which was finalized w ith other equipment than

this camera (page 32 ), you have to initialize the disc. Befor e initializing the dis c,

push the P OWER switch in the ar row direction to tu rn on the p ower and inse rt the

disc.

1

2

Set the mode dial to , S, A, M, SCN, or .

1

“INITIALIZE PLACE ON LEVEL SURFACE” appears on the LCD screen.

Be sure to avoid any vibration during the initialization in step

Select [OK] withvon the control button, then press the centerz.

2

Initialization starts.

2

.

What is initialization?

The initialization is required to record images on a disc.

In case that you have executed the finalization (page 32) using the camera to view

images on a CD-ROM drive, the initialization is automatically executed. You can

continuously record images. When executing the finalization using a computer or

other equipment, execute the initialization to record new images. Images recorded

before finalization will remain on the disc.

Tip

You can also execute the initialization using [ ] ( DISC TOOL) in the setup settings

(page 84).

BB

B Recording

B

INITIALIZE

AVOID ANY VIBRATION

READY TO INITIALIZE

To cancel the initialization

Select [CANCEL] withVon the control button, then press the c enterz.

INITIALIZE

AVOID ANY VIBRATION

INITIALIZE IN PROGRESS

INITIALIZE

INITIALIZE COMPLETE

To initia li z e after c a nceling t he initialization

Openandclosethedisccover.Orsetthemodedialto ,S,A,M,SCN,or ,

on the control button, then press the centerz.

press

v

18

Recording still images

Still images are recorded in JPEG format. Before recording still images, push the

POWER switch in the arrow direction to turn on the power and insert a disc.

2, 31

ACCESS lamp

Set the mode dial to , S, A, M, or SCN.

1

Press and hold the shutter button halfway down.

2

The beeps sound. However, the image has no t been recorded yet. While the

AE/AF lock indicator

exposure and focus of the captured image. When the camera finishes the

automatic adjustments, the AE/AF lock indi cator

lights up, and the camer a is ready for recording.

If you release the shu tter button, the recording w ill be canceled.

is flashing, the cam era automatically adj usts the

z

zzzz stops flashing, then

AE/AF lock indicator (green)

flashes t lights up

Press the shutter button fully down.

3

The shutter clicks. “RECORDING” appears on the LCD screen, and the ima ge

will be recorded on the disc. When “RECORDING” disappears from the LCD

screen, you can sta rt the next recording.

RECORDING

For the number of images you can record on a disc

See page 54.

Auto power-off function

If you do not operat e the camera for ab out three minutes, the cam era turns off

automatically to prevent wearing down the battery pack. To use the camera again,

push the POW ER switch in the ar row direction to tu rn on the cam era again.

Whiletheimageisbeingrecordedonadisc,theACCESSlamplights.

When this lamp is lit, do not sh ake or strike the camera. Also, do not

turn the power off, not remove the battery pack/disc, or not open the

disc cover. Otherwise, an image data breakd own may occur or the

disc may become unusable.

Notes

• When using a CD-R, even if you delete images, the dis c remaining space does not increase.

• Only when using a CD-RW, the disc remaining space increases after deleting the last-recorded

image if the is indicated on the LCD screen before delet ing. If you modify an image, or

open and close the disc cover, wi ll disappear.

• When recording bright subjects, the color of the LCD s creen may change after the AE is

locked. However, this will not affect the recorded image.

• After you change the disc, “REPAIRING DATA” appears on the LCD screen and it may take

about 10 minutes to get ready for reco rding depending on the disc c ondition.

• When you press the shutter button fully down at once, the c amera starts recording after the

automatic adjustment is complete. However, the recording cannot becarried out while the /

CHG lamp (page 8) is flashin g. (During this time, the camera is charging the flash .)

• When the AE/AF lock indicator flashes slowly, the subject may be hard to focus on because it

is too dark or no contra st, or it may be too close to the camera. Release the shutter button , and

focus on it again.

19

BB

B Recording

B

20

21

— 28 —

Page 29

Checking the last recorded image (

You can check the last recorded image by clearing the menu from the screen

(page 46) and pressing

To re turn to the normal recording mode: press the shutter button lightly, or press

) again.

b(7

To delete the image: 1. Press MENU. 2. Select [DELETE] with

.3.Select[OK]withv, then press the centerz.

z

center

) on the control button.

b(7

Quick Review

)

B

,thenpressthe

Adjusting the brightness of the LCD screen

Adjust the brightness with the [LCD BRIGHTNESS] item in the setup settings

(page 85). This ad justment does not affect t he brightness of the ima ges recorded on

the disc.

To turn off the LCD backlight

Press DISPLAY/LCD BACK LIGHT ON/OFF repeatedly to turn off the LCD

backlight (page 23). The battery life will be longer.

Using the zoom feature

The lens part moves in/out while zooming. Be careful not to touch the lens.

Zoom buttons

W: for wide-angle

(subject appears

farther away)

T: for telephoto

(subject appears

closer)

If you cannot get a sharp focus on a close subject

Press the zoom W button r epeatedly and move closer to the subj ect until the focus i s

sharp (page 66).

Minimum focal distance to the subject

W side: Approx. 50 cm (19 3/4 inches) (MVC-CD200)

Approx. 50 cm (19 3/4 inches) (MVC-CD300)

T side: Approx. 60 cm (23 5/8 inches) (MVC-CD200)

Approx. 50 cm (19 3/4 inches) (MVC-CD300)

To record even closer subjects, see page 66.

Digital zoom function

This camera has a digital zoom function.

Digital zoom enlarges t he image by digital proce ssing, and it starts t o function when

the zoom exceeds 3×.

T

W

The T-side of the bar show s the

digital zooming zone.

Using digital zoom

• The maximum zoom magnification is 6×.

• Digital zoom ing deteriorates th e picture quality. When digital zoom is not

necessary, set [DIGITAL ZOOM] to [OFF] in the setup settings (page 84).

Notes

• Digital zoom doesnot work for moving images.

• The zoom function does not work while recording a moving image. Set t he zoom position

before you start recording (MVC-CD300 only).

The indicators on the LCD screen during recording

Each time you press DISPLAY/LCD BACK LIGHT ON/OFF, the status of the LCD

screen changes as fol lows:

The LCD backlight is turned on/all the available indicators are turned on

t

The LCD backlight is t urned on/warning messag es and manual adjust ment

items which a re set using t he jog dial are tu rned on

t

The LCD backlight is turned off/warning messages and manual adjustment

items which a re set using t he jog dial are tu rned on

See page 105 for a det ailed description o f the indicators.

DISPLAY/LCD BACK

LIGHT ON/OFF

Notes

• You c annot turn off the (sel f-timer) indicator and some of the indicators used in advanced

operations.

• The indicators on the LCD screen are not recorded.

BB

B Recording

B

22

Using the self-timer

When you use the self-timer function, the subject is recorded about 10 seconds after

you press the shutter button.

Self-timer lamp

Shutter button

V ( ) on the

control button

V

Clear the menu (page 46), then press

timer) indicator appears on the LCD screen, and the subject is recorded about 10

seconds after you press the shu tter button. After you press the sh utter button, the selftimer lamp flashes until the image is recorded.

( ) on the control button. The (self-

Recording images with the flash

The initial setting is AUTO (noindication). In this mode,the flash automatically pops

up and strobes if the camera senses thatthe surroundings become dark. To change the

flash mode, clear the menu (pa ge 46), then press

repeatedly so that the flash m ode indicator on the LCD scree n changes.

Each time you press the button, the indicator changes as follows.

(No indication)

Popdowntheflashbyyourhandafterrecording.

You can change the amount of flash light with [ ±] (FLASH LEVEL) in the menu

settings (page 50).

tt t

Forced flash : The fla sh strobes regardless o f the surrounding b rightness.

No flash : The flash do es not strobe.

(No indication)

v

( ) on the control button

v ( ) on the

control button

To reduce the red-eye phenomenon

Set [RED EYE REDUCTION] to [ON] in the setup settings (page 84), the flash

strobes before recor ding to reduce the r ed-eye phenomenon. Wh en [ON] is selected ,

appears on the LCD scr een.

24

Notes

• When [ISO] is set to [AUTO] in the menu settings (page 49), the recommende ds hooting

distance is 0.3 to 2.5 m (11 7/8 inch es to 8 1/3 feet) (MVC-CD200) or 0.3 to 3.0 m (11 7/8

inches to 9 feet 101/8 inches) (MVC-CD300). When it is not set to [AUTO],the flash may be

ineffective even if the flash l evel is chang ed.

• Attaching a conversion lens (optional) may block the light from the flash a nd the recorded

image may be eclip sed.

• You c annot use the built-in flash and an external strobe (optional) at the same time.

• The RED EYE REDUCTION function may not produce the desired red-eye reduct ion effects

depending on individual differences, the distanc e to the subject, if the subject does not see the

pre-strobe, or other conditions.

• Red-eye reduction effects are also difficult to obtain if you select aslow shutter speed in shutte r

speed prioritymode.

• The flash effect is not obtained easily when you use forced f lash in a bright location.

• While charging the flash, the /CHG lamp flashes. After t he charging is complete, the lamp

goes out.

• The flash does not function when recording moving images or r ecording in EXP BRKTG or

BURST mode (MVC-CD300 only) (pages 59, 63).

Recording images with the AF illuminator

The AF illuminator is fill light to focus on a subject easily under dark conditions. Set

[AF ILLUMINATOR] to [ON] in the setup setting s, appears o n the LCD screen

and the AF illumina tor emits light when t he shutter button is pre ssed halfway under

dark situations. It keeps emitting light until the focus is locked.

AF illuminator

Notes

• If AF illuminator light does not reach the subject su fficiently or the subject has no cont rast,

focus will not be achieved. A pproximate 0.3 to 3.0 m (11 7/8 inches to 9 feet 10 1/ 8 inches)

distance is recommended.

• In TWILIGHT mode of the SCENE SELECTION function (page 58), the AF illuminator will

emit only when the fla sh mode is set to (Forced flash) .

• The AF illuminator will not emit when the LANDSCAPE mode of the SCENE SELECTION

function (page 58) is selected or [CONVERSION LENS] is set to [ON] in the setup settings

(page 85). ([CONVERSION LENS] is only for MVC-CD300.)

• Focus is achieved as long as AF illuminator light reaches the subject even if its light is slightly

out of the middle position of th e subject.

• AF illuminator lightis safe for persons. However, do not use the AF illuminator with its light

emitted directly to person eyes at poin t-blank range as its light is very strong.

23

25

BB

B Recording

B

— 29 —

Page 30

Recording moving images

1600

320

320

Moving images with aud io are recorded in M PEG format. Before r ecording moving

images, push the POWER switch in the arrow direction to turn on the power and

insert a disc.

1, 56, 7

Set the mode dial to SET UP.

1

The setup screen appea rs.

Select [ ] (CAMERA) withv/Von the

2

control button, then press

Select [MOVING IMAGE] withv/Von the

3

control button, then press

Select [MPEG MOVIE] withv/Von the

4

control button, then press the center

B

B

.

.

.

z

CAMERA

SCENE SELECTION

MOVING IMAGE

:

DATE/TIME

DIGITAL ZOOM

BRACKET STEP

RED EYE REDUCTION

AF ILLUMINATOR

SELECT

CAMERA

SCENE SELECTION

MOVING IMAGE

:

DATE/TIME

DIGITAL ZOOM

BRACKET STEP

RED EYE REDUCTION

AF ILLUMINATOR

OK

CAMERA

SCENE SELECTION

MOVING IMAGE

:

DATE/TIME

DIGITAL ZOOM

BRACKET STEP

RED EYE REDUCTION

AF ILLUMINATOR

SELECT

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

TWIRIGHT

MPEG MOVIE

OFF

ON

±0.7EV

OFF

ON

MPEG MOVIE

CLIP MOTION

TWIRIGHT

MPEG MOVIE

OFF

ON

±0.7EV

OFF

ON

Set the mode dial to .

5

The preparation for recording a moving image is complete.

Press the shutter button fully down.

6

“REC” appears on the LCD screen and the image and sound are recorded on the

disc.

Press the shutter button fully down again to stop recording.

7

The recording automatically stops in the following time even if you do not

press the shutter button again.

When selecting the 3 20 (HQ) size: Appro ximate 15 seconds

When selecting the 3 20×240 size: Approximate 1 minute

When selecting the 1 60×112 size: Approximate 4 minutes

For details on the image size, see “Setting the image size (IMAGE SIZE)” on

page 53.

Adjusting the brightness of the LCD screen, zooming or using the

self-timer

See pages 22 to 24.

The indicators on the LCD screen during recording

Press DISPLAY/LCD BACK LIGHT ON/OFF to turn on/off the indicators on the

LCD screen.

These indicators are n ot recorded. See page 105 for a deta iled description of the

indicators.

BB

B Recording

B

26

B

Playback

Playing back still images

1

2

ACCESS lamp

Set the mode dial to .

1

The ACCESS lamp lights and the last recorded image (still or moving) appear s

on the LCD screen.

Select the desired still image withb/Bon

2

the control butto n.

: To display the p receding im age.

b

: To display the next image.

B

Note

You may not be able to play back images whose image sizes are larger than the maximum image

size that can be used with this cam era for recording.

The indicators on the LCD screen during still image playback

Press DISPLAY/LCD BACK LIGHT ON/OFF to turn on/off the indicators on the

LCD screen.

See page 106 for a detailed description of the indicators.

120min

1600

1600

2001 7 4100-0028

FILE BACK/NEXT VOLUME

27/28

10:30

PM

Playing back moving images

1

2, 3

ACCESS lamp

Set the mode dial to .

1

The ACCESS lamp lights and the last recorded image (still or moving) appears

on the LCD screen.

Select the desired moving image withb/

2

on the control button.

Moving images are display ed one size smaller tha n

still images except when you shot a t the 320 (HQ)

(page 53) size.

: To display the preceding image.

b

: To display the next image.

B

Press the centerz on the control button to

3

start the playback.

The moving image and sou nd are played back.

During playback,

screen.

(playback) appears on the LCD

B

To stop the playback

Press the centerz on the control button to st op the playback.

To advance or rewind the moving image

Pressb/Bon the control button during playback. To return to the normal playback,

press the center

.

z

B

120min

320

320

21/28

00:00

10:30

2001 7 4MOV00022

FILE BACK/NEXT VOLUME

PLAY

120min

320

320

21/28

00:04

10:30

2001 7 4MOV00022

REV/CUE VOLUME

STOP

27

BB

B Playback

B

PM

PM

28

29

— 30 —

Page 31

Adjusting the volume

Pressv/Von the control button to adjust the volu me.

on the

v/V

control button

The indicators on the LCD screen during moving image playback

Press DISPLAY/LCD BACK LIGHT ON/OFF to turn on/off the indicators on the

LCD screen.

See page 107 for a detailed description of the indicators.

Preparation for viewing images

using a computer

Using the supplied 8 cm CD adaptor

When your disc drive does not conform to 8 cm CD, use the supplied 8 cm CD

adaptor.

Slide the disc into the inner groove and under two of the tabs on

1

the inner circle of adaptor in the numbered o rder.

1

2

Pull the third tab out away from the disc and the disc will slip into

2

place. Release the third tab and the disc will be held firmly in place.

Printed side of the disc (The other side is

recordable side.)

Printed side of the adaptor (SONY is printed

on this side and the other side is th e luster

side.)

BB

B Playback

B

30

Check that the disc is set correctly in the grooves of the adaptor,

3

that all the tabs are even with the surface of the adaptor, and that

the disc is not protrude from the adaptor.

If the tabs protrude, press them bac k down

into place. Otherwise, it may cause

malfunction of your disc drive.

Notes

• The supplied adaptor may not be used with your disc drive. For details, refer to th e operating

instructions of the disc drive.

• Use the adaptor at a low-speed (8-speed or lower).

• Do not place the adaptor under direct sunlight or near the h eat.

• The adaptor is only used with Mavica discs. This cannot be used with other 8 cm C D-Rs/CD-

RWs.

Preparing for viewing images on CD-ROM drives (FINALIZE)

You can play back the disc recorded wit h this camera on CD-ROM drives. You have

to execute the finalization before viewing images on a CD-ROM drive. A disc that

has not been executed th e finalization cannot be re ad with CD-ROM drives.

What is finalization?

• The finalization is required to view images on a CD-ROM drive.

• You can record new images on the finalized disc if you execute the initialization on

it again. The initialization will be automatically executed when the finalization is

executed using the camera. You have to execute the finalization to view new images

on a CD-ROM drive. Each time you execute thefinalization, approximate 13 MB of

the disc will decrease. We recommend that you execute the finalization onto

compiled data at a time.

• You can execute the finalization onto the disc later, even if you remove it from the

camera.

• The CD-ROM drive must co nform to the MultiRead type to re ad the disc that was

finalized.

Executing the finalization

SetthemodedialtoSETUP.

1

The setup screen app ears on the LCD screen.

Select [ ] (DISC TOOL) withv/Von the

2

control button, then press

Select [FINALIZE] withv/Von the control

3

button, then press

Select [OK] withvon the control button,

4

then press

“FINALIZE PLACE ON LEVEL SURFACE”

appears on the LCD screen. Be sure to avoid any

vibration during the finalization.

Select [OK] withvon the control button, then press

5

Finalization starts and the d isc remaining indicator cha nges from to , or

from to .

FINALIZE

zzzz

AVOID ANY VIBRATION

READY TO FINALIZE

.

.

BBBB

.

B

FINALIZE

AVOID ANY VIBRATION