Page 1

MVC-CD200/CD300

SERVICE MANUAL

Level 3

Ver 1.1 2001. 07

Photo : MVC-CD300

The information that is not described in this

Service Manual is described in the LEVEL 2

Service Manual.

When repairing, use this man ual together with

LEVEL 2 Service Manual.

US Model

Canadian Model

AEP Model

UK Model

E Model

Hong Kong Model

Australian Model

Chinese Model

Tourist Model

Korea Model

Japanese Model

This service manual contains information

for japanese model as well.

Contents of LEVEL 2 Service Manual

SERVICE NOTE

1. GENERAL

2. DISASSEMBLY

3. BLOCK DIAGRAMS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

5. ADJUSTMENTS

6. REPAIR PARTS LIST

OVERALL

MODE CONTROL

LCD

POWER

CD-333 BOARD

CD-334 BOARD

TK-61 BOARD

CONTROL SWITCH BLOCK (ZK-503)

FS-83 BOARD

JK-208 BOARD

PK-58 BOARD

EXPLODED VIEWS

ELECTRICAL PARTS LIST

DIGITAL STILL CAMERA

Page 2

TABLE OF CONTENTS

2. DISASSEMBLY

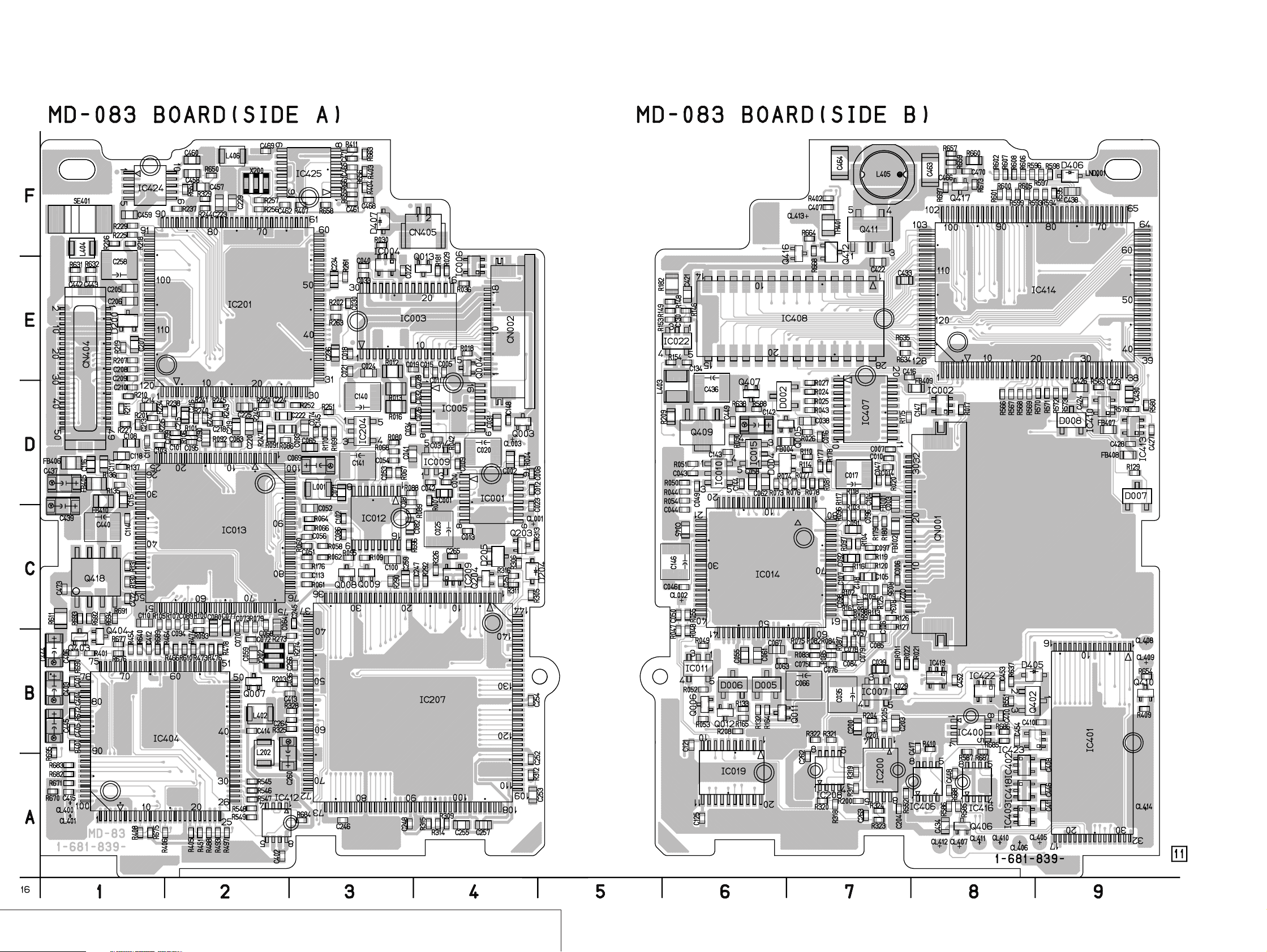

2-16. MD-083 BOARD ··························································2-15

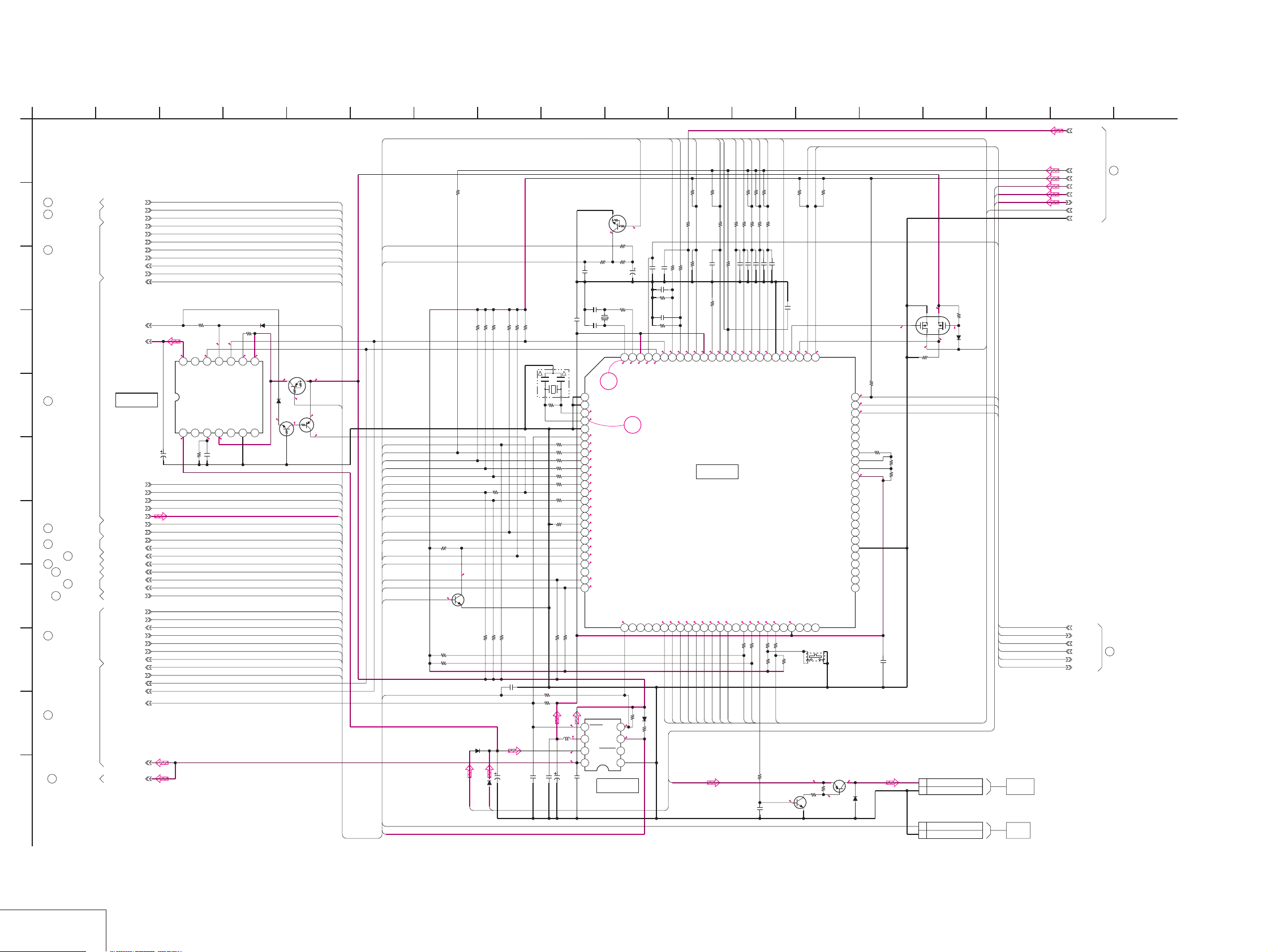

3. BLOCK DIAGRAMS

3-8.

CAMERA BLOCK DIAGRAM (1/2) (MVC-CD200)

3-9.

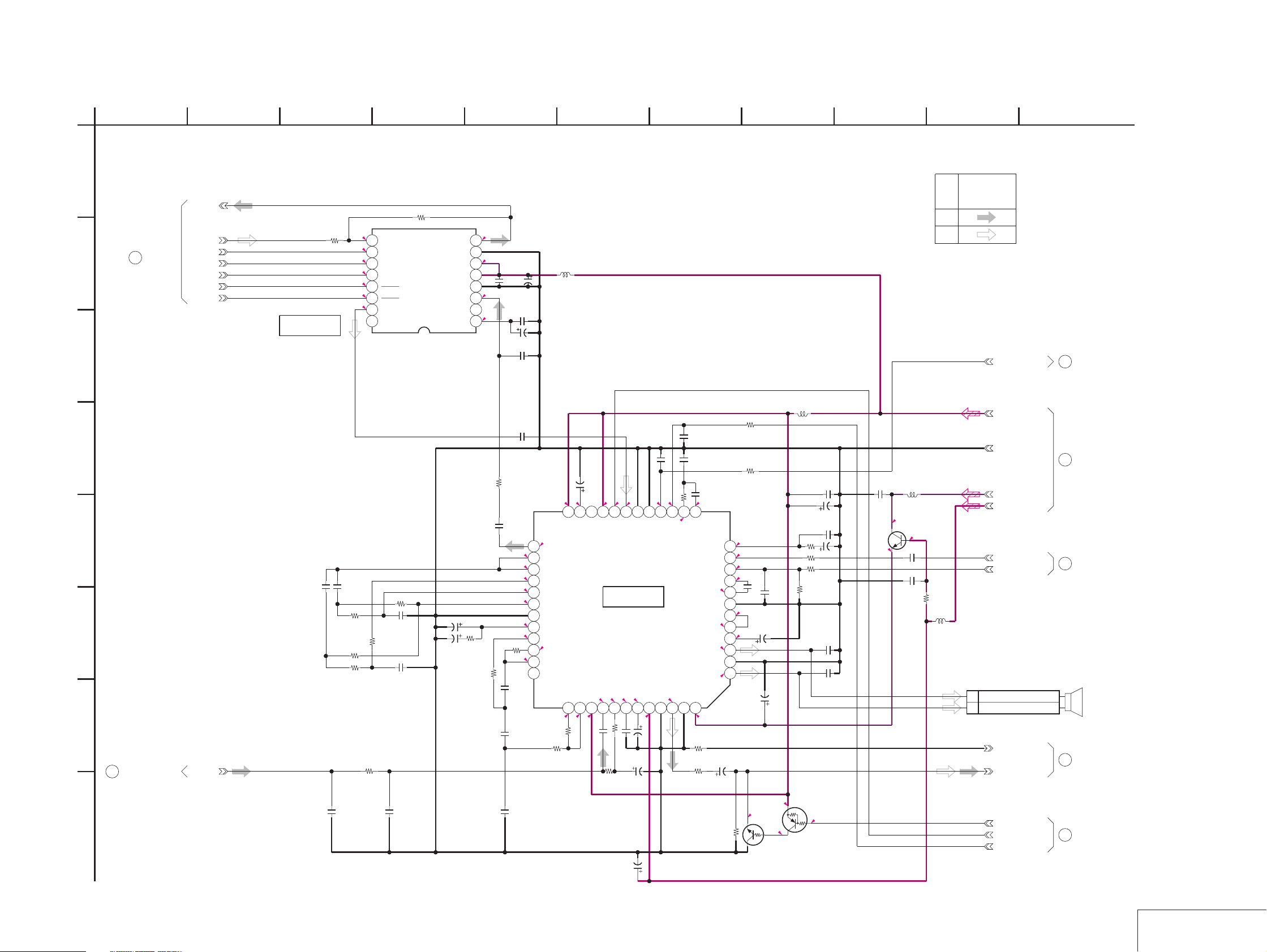

CAMERA BLOCK DIAGRAM (1/2) (MVC-CD300)

··3-15

··3-17

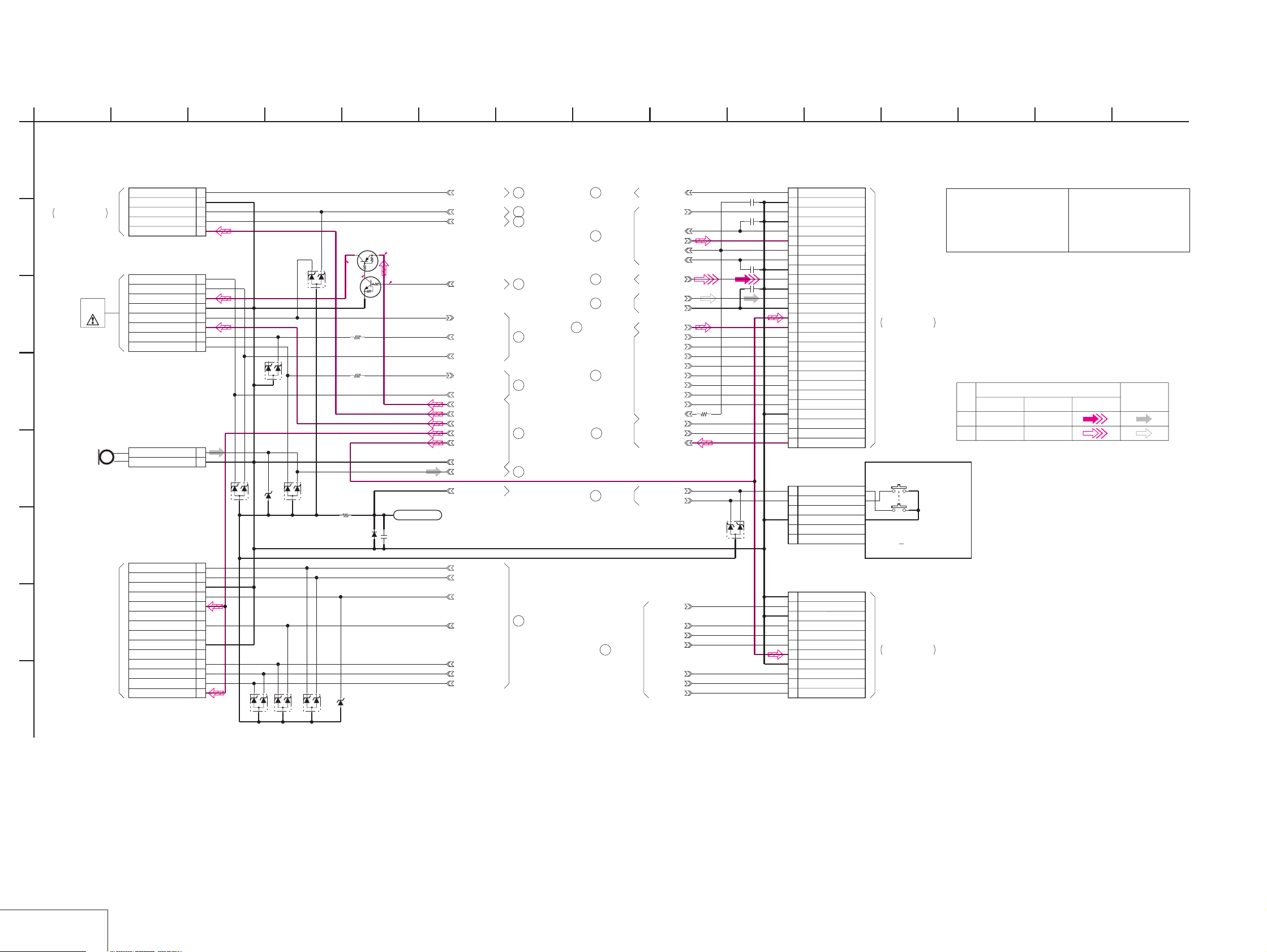

3-10. CAMERA BLOCK DIAGRAM (2/2)···························3-19

3-11. MD BLOCK DIAGRAM (1/3) ·····································3-21

3-12. MD BLOCK DIAGRAM (2/3) ·····································3-23

3-13. MD BLOCK DIAGRAM (3/3) ·····································3-25

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ··········································4-19

• SY-67 (LD, PEARL, VIDEO OUT, SH, 16M FLASH

MEMORY, 64M SDRAM, CLK GEN., CW, HI

CONTROL, AUDIO PROCESS, CONNECTOR,

DC/DC CONVERTER)

PRINTED WIRING BOARD ·······················4-19

• SY-67 (LD)(1/10)

SCHEMATIC DIAGRAM ····························4-23

• SY-67 (PEARL)(2/10)

SCHEMATIC DIAGRAM ····························4-25

• SY-67 (VIDEO OUT)(3/10)

SCHEMATIC DIAGRAM ····························4-27

• SY-67 (SH)(4/10)

SCHEMATIC DIAGRAM ····························4-29

• SY-67 (16M FLASH MEMORY, 64M SDRAM,

CLK GEN.)(5/10)

SCHEMATIC DIAGRAM ····························4-31

• SY-67 (CW)(6/10)

SCHEMATIC DIAGRAM ····························4-33

• SY-67 (HI CONTROL)(7/10)

SCHEMATIC DIAGRAM ····························4-35

• SY-67 (AUDIO PROCESS)(8/10)

SCHEMATIC DIAGRAM ····························4-37

• SY-67 (CONNECTOR)(9/10)

SCHEMATIC DIAGRAM ····························4-39

• SY-67 (DC/DC CONVERTER)(10/10)

SCHEMATIC DIAGRAM ····························4-41

• MD-083 (CD-RF PROCESS, SERVO, CD, DSP,

CD-R/RW GA, MD SYSTEM CONTROL,

EFM/ENC CONTROL)

PRINTED WIRING BOARD ·······················4-43

• MD-083 (CD-RF PROCESS)(1/5)

SCHEMATIC DIAGRAM ····························4-45

• MD-083 (SERVO)(2/5)

SCHEMATIC DIAGRAM ····························4-47

• MD-083 (CD DSP, CD-R/RW GA)(3/5)

SCHEMATIC DIAGRAM ····························4-49

• MD-083 (MD SYSTEM CONTROL)(4/5)

SCHEMATIC DIAGRAM ····························4-51

• MD-083 (EFM/ENC CONTROL)(5/5)

SCHEMATIC DIAGRAM ····························4-53

4-3. WAVEFORMS ······························································4-75

4-4. MOUNTED PARTS LOCATION ·································4-76

6. REPAIR PARTS LIST

6-1. EXPLODED VIEWS ······················································ 6-8

6-1-8.DDX-G2100 COMPLETE ASSEMBLY ························6-8

6-2. ELECTRICAL PARTS LIST ········································6-14

CAUTION

Use of controls or adjustments or performance

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

SECTION 2

DISASSEMBLY

The following flow chart shows the disassembly procedure.

Refer to level 2

2-7. SY-67 board

2-8. Base unit (DDX-G2100 complete assembly)

NOTE: F ollo w the disassembly procedure in the numerical order given.

2-16.MD-083 BOARD

After performing “Disassembly” Section 2-7

SY-67 board of MVC-CD200/CD300

Service Manual Level 2 (page 2-7),

do the following.

2-16. MD-083 board

MD-083 board service position

MVC-CD200/CD300

1 Harness (FS-138) (2P)

(door lock plunger)

JK208

6 MD

heat sink

3 Precision

screw

(DIA 1.7 × 4)

2 Flexible board

(from spindle motor 18P)

SY67

M

083

D-

4 Dowel

5 Remove the MD heat sink

in the direction of the arrow A.

A

7

SY67

1 Precision

screw

(DIA 1.7 × 4)

JK208

3

8

-0

D

M

3 MD-083 board

B

M

D

-083

C

2 Remove the MD-083 board in the direction

of the arrow BC.

4

JK208

4 MD-083 board

2 Flexible board

(from optical device)

(32P)

SY67

3

8

-0

D

M

2-15

3 Ferrite core

1 Flexible

retainer

5

Page 4

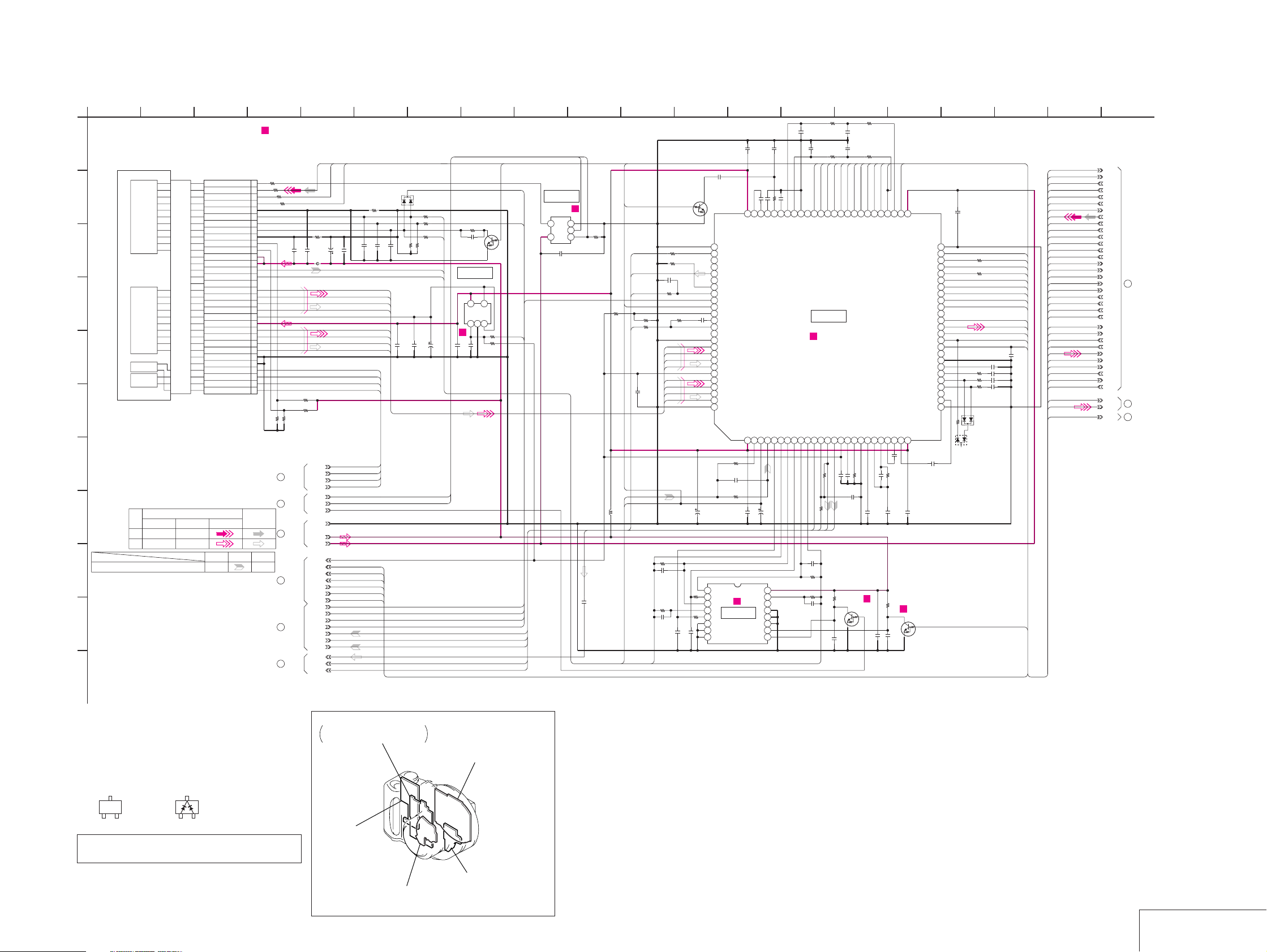

[MD-083 BOARD SERVICE POSITION]

When using the CD-R/RW

drive unit. press S101 and S103.

(CD300)

CD-334 board

C

334

Lens block assembly

(CD200)

CD-333 board

D

C

333

Lens block assembly

Control switch block

(RL-503) (6P)

SY-67 board

Extension cable

(J-6082-487-A) (50P)

JK-208 board,

FP-361 flexible

-

D

-

board

FP-364 flexible

board (70P)

JK208

SY-67

-

D

M

083

MD-083 board

Flexible board

(from spindle motor 18P)

AC power

adaptor

1

18

AC IN

CPC-9 jig

(J-6082-393-C)

Adjustment remote

commander (RM-95)

Extension cable

(J-6082-374-A) (18P)

When using the CD-R/RW drive unit.

the dew sensor must be connected.

Harness (FS-140)

(2P) (dew sensor)

2-16E

Page 5

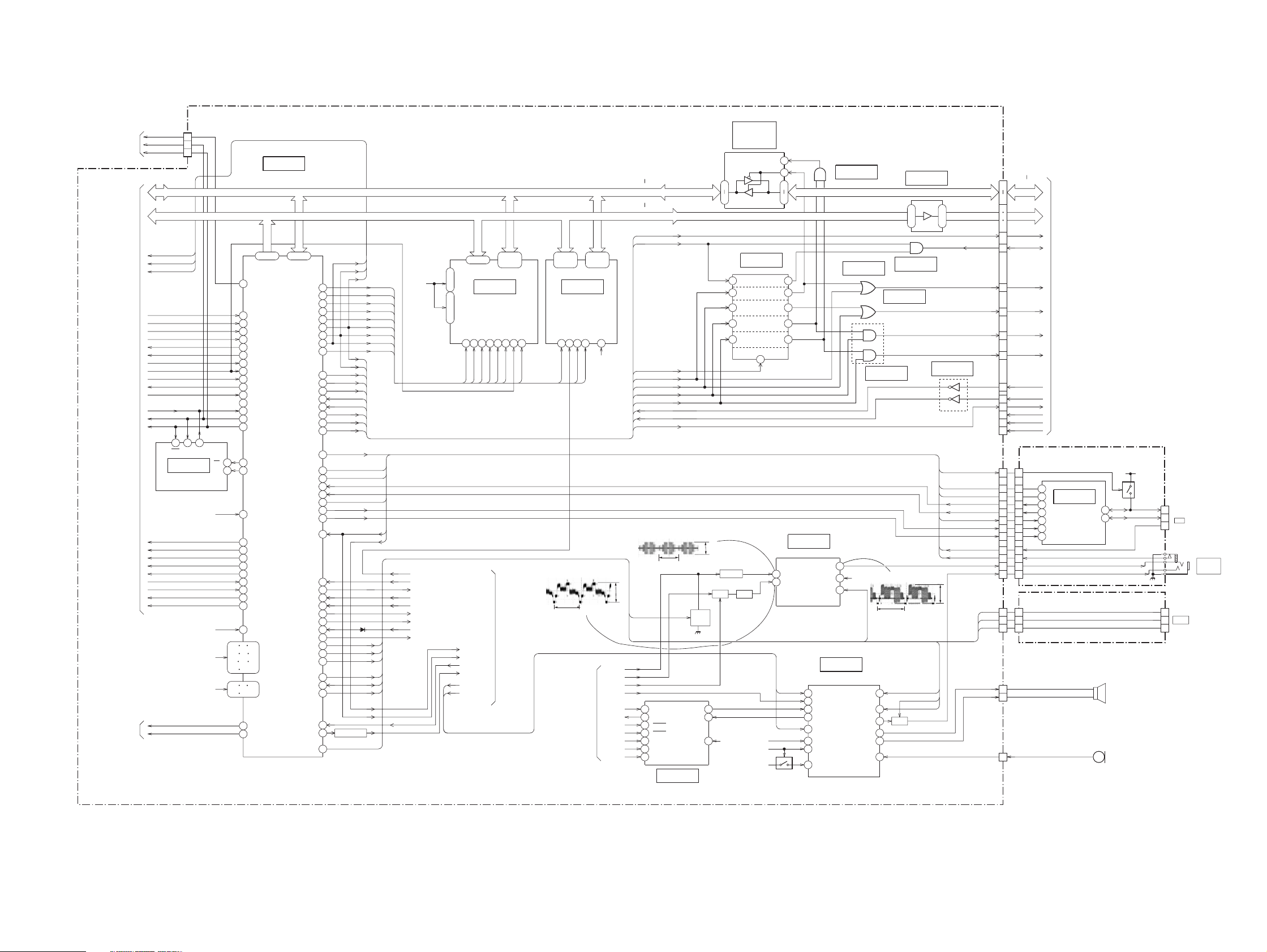

SECTION 3

BLOCK DIAGRAMS

MVC-CD200/CD300

3-8. CAMERA BLOCK DIAGRAM (1/2) (MVC-CD200)

IC101 8

33.3msec

IC101 5

33.3msec

IC101 4,6

3.475µsec

IC101 2

33.3msec

IC101 1,3

IC101 qf

3.475µsec

100µsec

54nsec

100µsec

1.0Vp-p

24.0Vp-p

7.5Vp-p

24.0Vp-p

7.5Vp-p

3.7Vp-p

CD-333 BOARD

(4-15)

IC101

CCD IMAGER

V OUT

V1A

V1B

V3A

V3B

H1

H2

RG

VSHT

CSUB

VDD

LENS UNIT

16

8

5

6

4

V2

2

3

1

V4

15

16

14

11

12

9

13

VL

IC101 qg,qh

54nsec

IRIS

METER

M

H

M001

FOCUS

MOTOR

M

M002

ZOOM

MOTOR

M

FOCUS

RESET

SENSOR

ZOOM

RESET

SENSOR

TEMP

Q102

BUFFER

Q101

SWITCH

3.6Vp-p

DRIVE-

DRIVE+

FOCUS A

FOCUS B

FOCUS B

FOCUS A

ZOOM A

ZOOM B

ZOOM B

ZOOM A

F SENS RST

F SENS VCC

Z SENS RST

Z SENS VCC

TEMP OUT

BIAS+

HALL+

HALL-

CCD OUT

V1A

V1B

V2

V3A

V3B

V4

H1

H2

RG

VSHT

VSUB CONT

CAM 15V

CAM -7.5V

CAM 15V

CAM -7.5V

CAM 3.1V

CAM 15V

CAM -7.5V

XCAM RST

XTG CS

(4-11)

IC303

Q301

CN301

13

12

DRIVE

IRIS

(1/2)

2

1

3

(4-12)

1

(4-12)

IC304

7

(2/4)

3

2

5

6

(1/4)

IC304

11

10

8

BIAS-

9

Q303

(4-11)

IC301

SHUTTER

23

DRIVE

2

IC302

ZOOM

MOTOR

DRIVE

(4-11)

5

7

FOCUS

17

MOTOR

DRIVE

19

24

1820

24

IN1,2

EN1,2

IN3,4

EN3,4

4

3

2

1

D 3.4V

CAP P 5V

1820

D 3.4V

42

75

1917

2321

17

16

15

14

6

7

20

19

Q302

21

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

DVDD1

DVDD0

CLPDM

XSHD

XSHP

CLPOB

ADCLK

RST

SEN

24 27 33 40

S/H

36.818182MHz

36.5625MHz

29

31

34

10

12

77

5

6

8

19

21

22

24

25

23

16

17

15

14

27

CN704CN203

••

X202

XTAL OSC

X201

XTAL OSC

(4-14)

IC202

A/D CONVERTER

•

AGC

A/D

CONV.

D11

D0

SCLK

SDATA

Q201

XCAM SCK

CAM SO

MCK12

TG CLK

CN203 CN704

12 66

|

12

1

48

47

PAL/XNTSC

VSUB CNT

IC101

IRIS CONT1

18

IRIS CONT2

19

HALL REF

2

HALL GAIN

3

HALL OFFSET

4

PRELAMP AF ON

7

CNT C

9

SP VOL

8

PE DAC LEVEL1

12

PE DAC LEVEL2

13

DAC STBY

66

|

|

54

54

4242

32

32

38

38

30

30

45

45

46

46

35

35

33

33

AU CLK EN

(4-24)

VCC

11

VDD

10

DI

17

CLK

16

LD

15

39

40

41

43

44

46

47

9

12

13

42

45

14

2

33

IC304

IC303

IC304

119

1210

1513

1614

V2

V4

V1A

V1B

V3A

V3B

VSHT

RG

H1

H2

VH

VL

VDD3

RST

SEN

(4-12)

14

(4-11)

7

(4-12)

10

9

EN1

EN2

EN3

EN4

IC202 e;

IC201

TIMING

GENERATOR

9

IN1

10

IN2

11

12

13

IN3

14

15

IN4

16

124µsec

CLPOB

CLPDM

ADCLK

(4/4)

12

13

(2/2)

6

5

(3/4)

XSHP

XSHD

VDD1

VDD2

VDD4

VDD5

VDD3

MCK0

8

CAM 3.1V

1.0Vp-p

(4-14)

16

17

22

20

23

7

8

15

29

14

30

CKI

26

HDI

35

VDI

34

SCK

32

SSI

31

TH301

CAM 3.1V

CA HD

CA FD

XCAM SCK

CAM SO

XCAM RST

XEAGLE/

XGCAM CS

XCAM RST

XEAGLE/ XGCAM CS

XTG CS

IRIS CONT1

IRIS CONT2

HALL REF

HALL AD

HALL OFFSET

HALL GAIN

MSHUT ON

PE DIR0A

PE DIR0B

PE DIR1A

PE DIR1B

CCD TEMP

XFC RST SENS

XZM RST LED

XLENS RST LED

LENS TEMP AD

IRIS EN

DIR0B

PE EN0

PE EN1

17

13

30

23

22

21

20

16

43

46

29

31

34

10

12

5

6

8

19

21

22

24

25

23

16

17

15

28 28

26 26

18 18

14

27

SY-67 BOARD(1/3)

IC901 2

5.5Vp-p

IC901

CLOCK

GENERATOR

(4-32)

76

MODE CONTROL

(SEE PAGE

of LEVEL 2)

48MHz

CAM 3.1V

CAM SO

XCAM SCK

21nsec

X901

XTAL

OSC

IC901 qh

21nsec

IC901 9

USB CLK

16

MC CLK

11

92

AU CLK

TG CLK

4

61nsec

5.5Vp-p

4.5Vp-p

IC901 4

D 1.8V VCC2

4.3Vp-p

26.8nsec

(4-26)

IC302

64Mbit SDRAM

PRE LAMP AF ON

XRST SYS

PAL/XNTSC

EXT STRB ON

SYS V

CAM 3.1V

1

1427VCC

3

9

43

49

VCCQ

DQML

DQMH

20A0

14|

|

35

A13

2

DQ0

|

13

16 |

42

|

DQ15

53

15

39

16

WE-

17

CAS-

18

RAS-

19

CS-

38

CLK

3-6

STRB ON

STRB PHOTO ON

PHOTO TR OUT

Q311

IC301

CAMERA DSP,MEMORY CONTROL,

VIDEO ENCODER,OPD,OSD,HOST IF,

RES CONTROL,SG,JPEG,L-MODE,

AUDIO I/F,SHUTTER CONTROL,

STROB CONTROL

8

AD IN 11

|

12

|

20

AD IN 00

9

47

83

101

VCC3CAM 3.1V

117

130

141

192

30

71

106

145

196

223

48

MCK12

5

CA HD

6

CA FD

202

VSUB CONT

114

AQ00

|

|

96

AQ13

144

DQ00

|

126

DQ15

125

QDML

124

QDMH

122

XWE

121

XCAS

120

XRAS

118

XCSO

94

QCLK

187

XFC RST SENS

148

XZM RST SENS

149

XFC RST SENS

150

XLENS RST LED

147

IRIS EN

188

PE EN0

189

PE DIR0A

190

PE DIR0B

193

PE EN1

194

PE DIR1A

195

PE DIR1B

198

M SHUT ON

59

XRST SYS

161

PE DAC LEVEL1

172

PE DAC LEVEL2

179

PAL/XNTSC

200

EXT STRB ON

199

STRB ON

158

STRB PHOTO ON

203

STRB AD

162

PY0

168

CR0

165

CB0

(4-25)

NT VD0

IRQ IMG

IRQ JPG

IRQ AUDIO

MC XCS2

MC XCS6

MC HCLK

PEARL FLD

MC DRAK0

MC DREQ0

XPWAD

XPWDA

LCD VD

WRLX

WRHX

9375D00

|

|

16

D15

38

A01

|

|

14

23

A14

184

64

63

66

41

40

72

183

69

67

39

RDX

42

43

AUCLK

218

ACLK

(IC901)

207

SIA

208

SOA

209

LRCK

210

SCLK

211

ADCK

212

213

185

182

HD

173

YO

176

CO

SYS V

IRQIMG

IRQJPG

IRQAUDIO

MC XCS2

MC XCS6

AU LRCK

MC HCLK

PEARLFLD

MC DRAK0

MC DREQ0

MC XRD

MC XWE0

MC XWE1

CAM SO

XCAM SCK

XCAM RST

XTG CS

XEAGLE/XGCAM CS

HALL AD

LENS TEMP AD

AU CLK EN

DAC STBY

CCD TEMP

AU SDTO

AU SDTI

AU LRCK

AU SCLK

AU MCLK

AU XPWAD

AU XPWDA

Y OUT

C OUT

CNT C

SP VOL

CAMERA(2)

(SEE PAGE

3-19)

CAMERA(2)

(SEE PAGE

3-19)

Q305 B

Q305

BUFFER

BUFFER

Q306

0.5Vp-p

H

Q307

BUFFER

CN707

PANEL V

5

HD0

4

PANEL Y

9

PANEL R-Y

8

PANEL B-Y

7

LCD

(PK-58)

(SEE PAGE 3-7

of LEVEL 2)

3-15 3-16

Q306 B

0.2Vp-p

H

Page 6

MVC-CD200/CD300

3-9. CAMERA BLOCK DIAGRAM (1/2) (MVC-CD300)

IC401 q;

124µsec

IC401 5

33.3msec

IC401 4,6

124µsec

2µsec

IC401 2

33.3msec

IC401 1,3

2µsec

124µsec

IC401 qs

54nsec

1.0Vp-p

22.0Vp-p

7.5Vp-p

22.0Vp-p

7.5Vp-p

3.7Vp-p

CD-334 BOARD

(4-16)

IC401

CCD IMAGER

V OUT

V1A

V1B

V3A

V3B

RG

VSHT

CSUB

VDD

IC401 qd,qf

LENS UNIT

16

V2

V4

H1

H2

VL

54nsec

IRIS

METER

M

M001

FOCUS

MOTOR

M

M002

ZOOM

MOTOR

M

FOCUS

RESET

SENSOR

ZOOM

RESET

SENSOR

Q402

10

BUFFER

5

6

4

2

3

1

14

13

12

16

Q401

17

SWITCH

11

18

CCD OUT

V1A

V1B

V2

V3A

V3B

V4

H1

H2

RG

VSHT

VSUB CONT

CAM 15V

CAM -7.5V

CAM 15V

CAM -7.5V

CAM 5V

CAM 15V

CAM -7.5V

XCAM RST

XTG CS

4.7Vp-p

IC202 qh

54nsec

CN302

IRIS B

3

IRIS B

5

IRIS A

4

IRIS A

2

FOCUS A

6

FOCUS B

7

FOCUS B

5

FOCUS A

8

D 3.4V

CAP P 5V

ZOOM A

10

ZOOM B

9

ZOOM B

12

ZOOM A

11

F SENS RST

15

F SENS VCC

14

Z SENS RST

3

Z SENS VCC

2

Q302

TEMP OUT

TEMP

CN303

D 3.4V

42

75

1917

2321

1820

IC302

(4-11)

ZOOM

MOTOR

DRIVE

21

IC301

4

33

IRIS

MOTOR

2

DRIVE

5

7

FOCUS

MOTOR

17

DRIVE

19

24

1820

24

IN1,2

EN1,2

IN3,4

EN3,4

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

A/D

CONV.

Q201

CN203 rs

D11

D0

SCLK

SDATA

12

XCAM SCK

CAM SO

MCK12

PAL/XNTSC

TG CLK

VSUB CNT

3.2Vp-p

CN203 CN704

54nsec

12 66

|

1

48

47

IC101

PRELAMP AF ON

7

CNT C

9

SP VOL

8

PE DAC LEVEL1

12

PE DAC LEVEL2

13

DAC STBY

IC103

12

IRIS

MOTOR

13

PRE-

DRIVE

(4-24)

1

VD

VCC

VDD

CLK

(4-24)

DI

LD

66

|

|

54

54

4242

32

32

38

38

30

30

45

45

46

46

35

35

33

33

AU CLK EN

11

10

17

16

15

CAM SI

6

CAM SO

5

XCAM SCK

4

XTG CS

3

XBEAR RST

9

8

DVDD1

DVDD0

CLPDM

XSHD

XSHP

CLPOB

ADCLK

RST

SEN

24 27 33 40

S/H

36.818182MHz

XTAL OSC

36.5625MHz

XTAL OSC

CN704CN203

29

31

34

IC202

A/D CONVERTER

••

X202

X201

(4-14)

•

AGC

IC202 e;

CAM 3.1V

XSHP

VDD3

MCK0

1.0Vp-p

(4-14)

16

XSHD

17

22

20

23

VDD1

7

VDD2

8

15

VDD4

29

VDD5

14

30

CKI

26

HDI

35

VDI

34

SCK

32

SSI

31

CAM 3.1V

CA HD

CA FD

XCAM SCK

CAM SO

XCAM RST

XEAGLE/

XGCAM CS

XCAM RST

XEAGLE/ XGCAM CS

XTG CS

17

13

30

23

22

21

20

16

43

46

29

31

34

124µsec

IC201

TIMING

GENERATOR

V2

39

V4

40

41

43

44

46

47

9

12

13

42

45

14

2

33

CLPOB

V1A

V1B

CLPDM

ADCLK

V3A

V3B

VSHT

RG

H1

H2

VH

VL

VDD3

RST

SEN

3.4Vp-p

9

IN1

10

EN1

IN2

11

EN2

12

13

IN3

14

EN3

15

IN4

16

EN4

MSHUT ON

PE DIR0A

PE DIR0B

IRIS EN

DIR0B

PE EN0

19

19

21

21

22

22

24

24

25

25

23

23

IC102

119

1210

1513

1614

TH301

PE DIR1A

PE DIR1B

CCD TEMP

XFC RST SENS

XZM RST LED

XLENS RST LED

LENS TEMP AD

PE EN1

16

17

15

28 28

26 26

18 18

14

27

16

17

15

14

27

CN704CN203

IC104

IC105

VD PULSE

GENERATOR

(4-24)

SYS V

M SHUT ON

SY-67 BOARD(1/3)

IC901 2

5.5Vp-p

IC901

CLOCK

GENERATOR

(4-32)

76

(SEE PAGE

of LEVEL 2)

PLL 12

(IC301)

48MHz

CAM 3.1V

CAM SO

XCAM SCK

21nsec

X901

XTAL

OSC

MODE CONTROL

3-6

IC901 qh

21nsec

IC901 9

USB CLK

16

MC CLK

11

92

AU CLK

TG CLK

4

61nsec

5.5Vp-p

4.5Vp-p

IC901 4

D 1.8V VCC2

4.3Vp-p

26.8nsec

(IC103)

(4-26)

IC302

64Mbit SDRAM

DQML

DQMH

20A0

14|

|

35

A13

2

DQ0

|

13

16 |

42

|

DQ15

53

15

39

16

WE-

17

CAS-

18

RAS-

19

CS-

38

CLK

PRE LAMP AF ON

XRST SYS

PAL/XNTSC

EXT STRB ON

STRB ON

STRB PHOTO ON

PHOTO TR OUT

SYS V

CAM 3.1V

1

1427VCC

3

9

43

49

Q311

VCCQ

IC301

CAMERA DSP,MEMORY CONTROL,

VIDEO ENCODER,OPD,OSD,HOST IF,

RES CONTROL,SG,JPEG,L-MODE,

AUDIO I/F,SHUTTER CONTROL,

STROB CONTROL

8

AD IN 11

|

12

|

20

AD IN 00

9

47

83

101

VCC3CAM 3.1V

117

130

141

192

30

71

106

145

196

223

48

MCK12

74

PLL12PLL12

5

CA HD

6

CA FD

202

VSUB CONT

114

AQ00

|

|

96

AQ13

DQ00

144

|

DQ15

126

125

QDML

124

QDMH

122

XWE

121

XCAS

120

XRAS

118

XCSO

94

QCLK

187

XFC RST SENS

148

XZM RST SENS

149

XFC RST SENS

150

XLENS RST LED

147

IRIS EN

188

PE EN0

189

PE DIR0A

190

PE DIR0B

193

PE EN1

194

PE DIR1A

195

PE DIR1B

198

M SHUT ON

59

XRST SYS

161

PE DAC LEVEL1

172

PE DAC LEVEL2

179

PAL/XNTSC

200

EXT STRB ON

199

STRB ON

158

STRB PHOTO ON

203

STRB AD

162

PY0

168

CR0

165

CB0

(4-25)

NT VD0

IRQ IMG

IRQ JPG

IRQ AUDIO

MC XCS2

MC XCS6

MC HCLK

PEARL FLD

MC DRAK0

MC DREQ0

XPWAD

XPWDA

LCD VD

WRHX

WRLX

9375D00

16

|

|

D15

38

A01

14

|

|

23

A14

184

64

63

66

41

40

72

183

69

67

39

RDX

42

43

AUCLK

218

ACLK

(IC901)

207

SIA

208

SOA

209

LRCK

210

SCLK

211

ADCK

212

213

185

182

HD

173

YO

176

CO

SYS V

IRQIMG

IRQJPG

IRQAUDIO

MC XCS2

MC XCS6

AU LRCK

MC HCLK

PEARLFLD

MC DRAK0

MC DREQ0

MC XRD

MC XWE0

MC XWE1

CAM SI

CAM SO

CAM SCK

XCAM RST

XTG CS

XEAGLE CS

HALL AD

LENS TEMP AD

AU CLK EN

DAC STBY

CCD TEMP

XBEAR RST

AU SDTO

AU SDTI

AU LRCK

AU SCLK

AU MCLK

AU XPWAD

AU XPWDA

Y OUT

C OUT

CNT C

SP VOL

CAMERA(2)

(SEE PAGE

3-19)

CAMERA(2)

(SEE PAGE

3-19)

Q305 B

0.5Vp-p

H

Q305

BUFFER

BUFFER

BUFFER

Q306

Q307

CN707

PANEL V

5

HD0

4

PANEL Y

9

PANEL R-Y

8

PANEL B-Y

7

LCD

(PK-58)

(SEE PAGE 3-7

of LEVEL 2)

3-17 3-18

Q306 B

0.2Vp-p

H

Page 7

MVC-CD200/CD300

3-10.CAMERA BLOCK DIAGRAM (2/2)

SY-67 BOARD(2/3)

94

9

10

11

12

101

105

166

169

185

196

198

199

179

173

174

(4-32)

1

117

CS

6

27

RST

134

90

31

33

115

112

206

207

26

29

161

7462 100

170116 190

201

88

8430

182

159

18

21

IC501

20

57-80

A1-A20 D0-D15

XCS LCD DAC

SYS V

IRQ IMG

IRQ JPG

IRQ AUDIO

MC XCS2

MC XCS6

AU LRCK

MC HCLK

PEAL FLD

MC DRAK0

MC DREQ0

MC DREQ1

CAM SI

CAM SO

XCAM SCK

XEEPROM CS

XEEPROM RESET

UCLK

XCAM RESET

XTG CS

XCAM RESET

XTG CS

XEAGLE/XGCAM CS

HALL AD

LENS TEMP AD

DAC ENB

DAC STBY

EXTAL

483622

VCCQ

139

VCC

(4-29)

MC CAM

SH DSP

16

35-53

MC RDXWR

MC XCS3

MC CKE

MC XRAS

MC XCAS

MC XRD

MC XWE0

MC XWE1

MC XCS0

DRAGON RST

MC DACK1

XMD POWER SAVE

MC DREQ

IRQ FDC/CW

MC XCS4

MC XCS5

MC XCLK

USB D+PULLUP

USB TXENL

USB XVDATA

USB D+ IN

USB D– IN

USB SUSPND

USB D– OUT

USB D+ OUT

USB VBUS

HI SO

HI SI

XHI SCK

XMC CS

NMI XMC NMI

XMC HELP

XRESETP

SELF TIMER SELF TIMER

AU HGL SEL

XAU SP MUTE

XAU LINE MUTE

MS BS

MS DIO

MS SCLK

PAL/XNTSC

ACCESS LED

V OUT ON

3-7

(SEE PAGE

of LEVEL 2)

CAMERA(1)

(SEE PAGE

3-16(MVC-CD200),

3-18(MVC-CD300))

16

(PK-58)

LCD

POWER

XCS PANEL D/A

CAM SO

XCAM SCK

16

14

MC XRD

MC XWE0

MC XWE1

SYS V

IRQIMG

IRQJPG

IRQAUDIO

MC XCS2

MC XCS6

AU LRCK

MC HCLK

PEARLFLD

MC DRAK0

MC DREQ0

CAM SI

CAM SO

XCAM SCK

CN707

17

18

19

234

SCK DI DO

IC505

EEPROM

(16KBIT)

USB CLK

(IC901)

AU CLK EN

XBEAR RST

XCAM RST

XTG CS

XEAGLE CS

HALL AD

LENS TEMP AD

CCD TEMP

DAC STBY

MC CLK

(IC901)

CAM 3.1V

D 1.8V

CAM DD ON

LCD DD ON

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

MC D00

VCC

CAM 3.1V

0.5Vp-p

Y OUT

C OUT

CNT C

SP VOL

AU SDTI

AU SDTO

AU LRCK

AU SCLK

MC D15

MC A01

MC A03

DRAGON RST

MC HCLK

MC XRD

MC XWE0

MC XCS4

MC XCS5

MC DREQ1

IRQ FDC/CW

XMD POWER SAVE

IC201 8

8

13

14

11

10

12

DATA BUS

ADDRESS BUS

16

14

16

2-13

20-35

1

14

96

102

110

111

113

91

92

93

99

23

120

32

199

13

103

104

169

14

187

186

146

145

191

147

148

189

178

171

172

177

106

200

121

122

124

123

193

194

192

210

USB DET

AV JACK IN

8

MS BS

MS DIO

MS SCLK

15

LED DRIVE

Q501

25

CAM 3.1V

XRST FLASH

HI SO

HI SI

XHI SCK

XMC CS

XMC HELP

XRST SYS

VCC

27

3

9

VCCQ

49

43

DQML

15 16 17 18 19 37 38 39

MC XWEO

AV JACK IN

USB JUCK IN

PAL/XNTSC

ACCESS LED

BEEP ON

BEEP

42-53

A0-A13 DQ0-DQ15

IC504

SDRAM

64MBIT

WE-

CAS-

RAS-

CS-

MC RDXWR

MC XCAS

MC XRAS

MC XCS3

MC CKE

MODE

(SEE PAGE 3-6

of LEVEL 2)

CKE

CLK

MC HCLK

CONTROL

DQMU

MC XWE1

20

1-9,

16-25,

48

IC503

(4-31)(4-31)

FLASH ROM

RESET-OECE

WE-

11

12 26 28 37

MC XWE1

XRST FLASH

MC XCSO

IC201 1

H

CAMERA(1)

(SEE PAGE

3-16(MVC-CD200),

3-18(MVC-CD300))

16MBIT

DQ0-DQ15A1-A20

MC XRD

29-36

38-45

AU XPWAD

AU XPWDA

AU MCLK

MC DACK1

H

SDTI

SDTO

PW AD

PW DA

MCLK

LRCK

SCLK

IC251

AUDIO AD/DA CONV.

A OUT L

A IN L

MCA1-MCA3

0.4Vp-p

Q301

TRAP

FREQ.

SW

VDD

(4-37)

159

3

5

16

3

(4-33)

Q309,310

IC154

IC155

9

2

14

D6

3

D1

6

D2

12

D3

11

D4

Q303

BUFFER

Q304,308

ATT

EVR

IC158

DELAY

CK

9

(4-33)

19

X OE

1

11

18

15

Q6

2

Q1

7

Q2

12

Q3

10

Q4

IC201

VIDEO AMP

8

Y IN

1

C IN

POWER SAVE

21

V OUT

(4-33)

4

IC156

(4-33)

IC153

214

2

4

1

2

7

1

6

3

5

IC157

(4-28)

3

5

VCC

6

V OUT ON

A 3.4V

IC201 3

IC152

(4-33)

(4-33)

H

IC158

5

9

12

2

1

IC160

(4-34)

(4-33)

4

2.1Vp-p

6

8

11

IC151

53

71

DRAGON RST

USB D+PULLUP

USB TXENL

USB XVDATA

USB D+ IN

USB D– IN

USB SUSPND

USB D– OUT

USB D+ OUT

USB DET

AV JACK IN

MC DACK1

(4-33)

CN701

16

3

CN709

CN707

46

31

HA0-HA2

19

22

18

HRESET

30

DACK

23

IOR

24

IOW

26

16

17

DREQ

29

HINT

21

XMD POWER SAVE

20

MPXO IF

5

DECEFM

2

FM DT

1

16

12

19

9

20

8

21

7

22

6

23

5

17

10

18

11

7

21

8

20

10

18

12

16

26

27

25

26

24

25

HDB0

MDB15

16

HCS1

HCS0

CN101

CN301

3

MD BLOCK

(MD-083)

(SEE PAGE

JK-208 BOARD(1/2)

2

3

IC101

4

5

6

12

(4-61)

13

(SEE PAGE

4-67)

3-21)

D 3.4V

Q103

MS SCLK

MS BS

MS DIO

D+

11

D-

10

V OUT

A OUT

USB

I/F

PK-58 BOARD(1/3)

D+

3

D-

CN102

2

USB

VCC

1

J102

A/V OUT

(MONO)

14

CN301

15

CPC

FOR CHECK

16

(4-38)

IC252

A 3.4V

A 3.4V

A 4.9V

CAM P 5V

BEEP

BEEP ON

Q253

11

16

19

25

10

21

44

48

LINE/SPEAKER AMP

BEEP IN

VOL CTL

PB IN

REC OUT

XBEEP MUTE

VCC

VCCH

SP VCC

LPF SEL

XAUDIO MUTE

LINE OUT

SP OUT+

SP OUT-

MIC IN

SP +

MIC SIG

1

SP -

2

CN706

1

CN711

20

15

46

40

AU HGL SEL

XAU LINE MUTE

XAU SP MUTE

Q251,252

MUTE

1

3

SP+

SP901

SP-

SPEAKER

MIC901

MIC UNIT

3-19 3-20

Page 8

MVC-CD200/CD300

3-11.MD BLOCK DIAGRAM (1/3)

MD-083 BOARD(1/3)

31

46

19

22

18

29

21

17

16

23

24

26

30

2

1

5

CN404

HDREQ

HINTRQ

XHCS0

XHCS1

XHDAK

XHIOR

XHIOW

IC419

DECEFM

FMDT

BACKUP VCC

(CN404 48 )

XCDR RSTO

41

DATA

ADDRESS

(IC414)

(IC207,404,420)

(4-53)

(IC013)

(SEE PAGE 3-23)

D405

(4-52)

8

XCE1

CE2

X0E

RX/W

CAMERA(2)

(SY-67)

(SEE PAGE

3-20)

HDB0-HDB15

16

HA0-HA2

3

DREQ

HINT

HCS0

HCS1

DACK

IOR

IOW

HRESET

DECEFM

FMDT

MPXO IF

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

IC401

SRAM

30

6

32

5

14

10 20

31

21

29

XCSSRAM

SRAM CE

XRD

XWR

8

(IC207)

(SEE PAGE 3-23)

(IC404)

A0-A16

17

D8-D15

(4-53)

IC408

4MBYTE

BUFFER

DRAW

(CN404)

(IC404)

84HD0-HD15

102

72HA0-HA2

74

71

82

76

70

69

77

80

81

75

28

5

4

26

25

128

2

127

3

114

126

103

111

15

(4-54)

IC414

ATAPI

CD-R

ENC/DEC

EFM ENC

CONTROL

8

24

88

11

16

3

HDREQ

HINTRQ

XHCS0

XHCS1

XHDAK

XHIOR

XHIOW

XCLRST

XRD

XWR

XCLDINT

XCLHINT

4.6V

XCAS

23

XMOE

22

XRAS

7

XWE

6

BA0-BA11

8

12

21

2

BD0-BD7

5

8

24

27

IC407

BUS

SW

9

8

17

19

2

D8-D15

42

54

47

40

41

33

45

29

61

58

65

57

60

59

55

56

64

62

63

6

(4-53)

ENCEFM

ATSY

CLVM

ENSY

SOCK

WLDON

IC413

IC410

C2PO

EXCK

GRSCOR

SBSO

SQSY

WFCK

FMCK

FMDT

MDATA

LRCK

BCLK

XCSCL

19

1

(4-53)

42

(4-53)

XRD

(IC207)

(SEE PAGE 3-23)

24

(IC201)

(SEE PAGE 3-25)

(IC404)

C34MV

C17MV

(IC207)

(IC207)

(IC013)

(SEE PAGE

3-24)

(SEE PAGE 3-23)

TE

3

IC200 IC208

TSHOCK

DETECT

(4-49)

TSNSCMP(IC019)

(SEE PAGE 3-24)

(IC207)

(SEE PAGE 3-23)

(IC414)

1

7

3

NMI

TSHOOK

FSHOOK

IC406

EEPROM

(4-52)

XCLDINT

XCLHINT

IC423

IC400

(CN404)

(IC401)

OR,

LAICH

(4-51)

(Q407)

(IC414)

ENCEFM

MD BLOCK(2/3)

(SEE PAGE

3-23)

(4-51)

100

3

67

1

92

55

2

54

21

96

95

56

19

6

73

12

71

72

LDEN

SLFG

SP ON

XRFRST

WAPCFUP

SENS

SNSCLK

XMRST

C2PO

XGAINT

XSQINT

XRD

XWR

DOOR LOCK

ADDRESS

IC403

4

1

IC418

2

4

IC402

4

2

ASTY

C17MV

(4-51)

TZC

(4-51)

LMT

(CN001)

(IC207)

(IC003)

(IC013)

(IC012)

(IC201)

(SEE PAGE

3-25)

(IC207)

(SEE PAGE

3-23)

(IC207,401,

(SEE PAGE

3-23)

(IC414)

(IC207)

(SEE PAGE

3-23)

(IC013)

(SEE PAGE

(SEE PAGE

3-24)

3-23)

(SEE PAGE 3-26)

(SEE PAGE

3-24)

407,414)

EJECT

XCDR RSTO

SRAM CE

XPD

E2DI

E2DO

3

E2RST

6

XE2CK

2

XE2CS

1

XCLRST

6

5

XCLR

76

62

89

63

16

974

10

99

14

74

75

91

94

A0-A19

(4-51)

IC404

SYSTEM

CONTROL

(MD)

5

8

30

32

53

23

820

D8-D15

MODE CONTROL

(SEE PAGE

3-6

of LEVEL 2)

(SY-67)

XMD POWER SAVE

TH OUT

XLID OPEN

DATA

FM CK

CN405

FM DT

MDATA

LRCK

BCLK

FSHOCK

LMT

1

CW 3.4V (CN404 15 )

D 3.4V (CN404 9 10 )

D 4.6V (CN404 11 12 )

20

CW UNREG

(CN404 13 14 )

TH401

3

IC422

47

14

EJECT

Q403,404,418

(4-53)

(IC404,CN001)

Q407,409

FB410

FB405

DC/DC

CONVERTER

IC425

Q411,417

XPD(IC404)

DSP 3.4V

3.4V

4.6V

4.6V-2

POWER 5V

(4-53)

Q412,416

3.4V

MD BLOCK(2/3)

(SEE PAGE

3-23)

MD BLOCK(3/3)

(SEE PAGE

3-25)

PL902

VCC

DOOR LOCK

PLUNGER

16

3-21 3-22

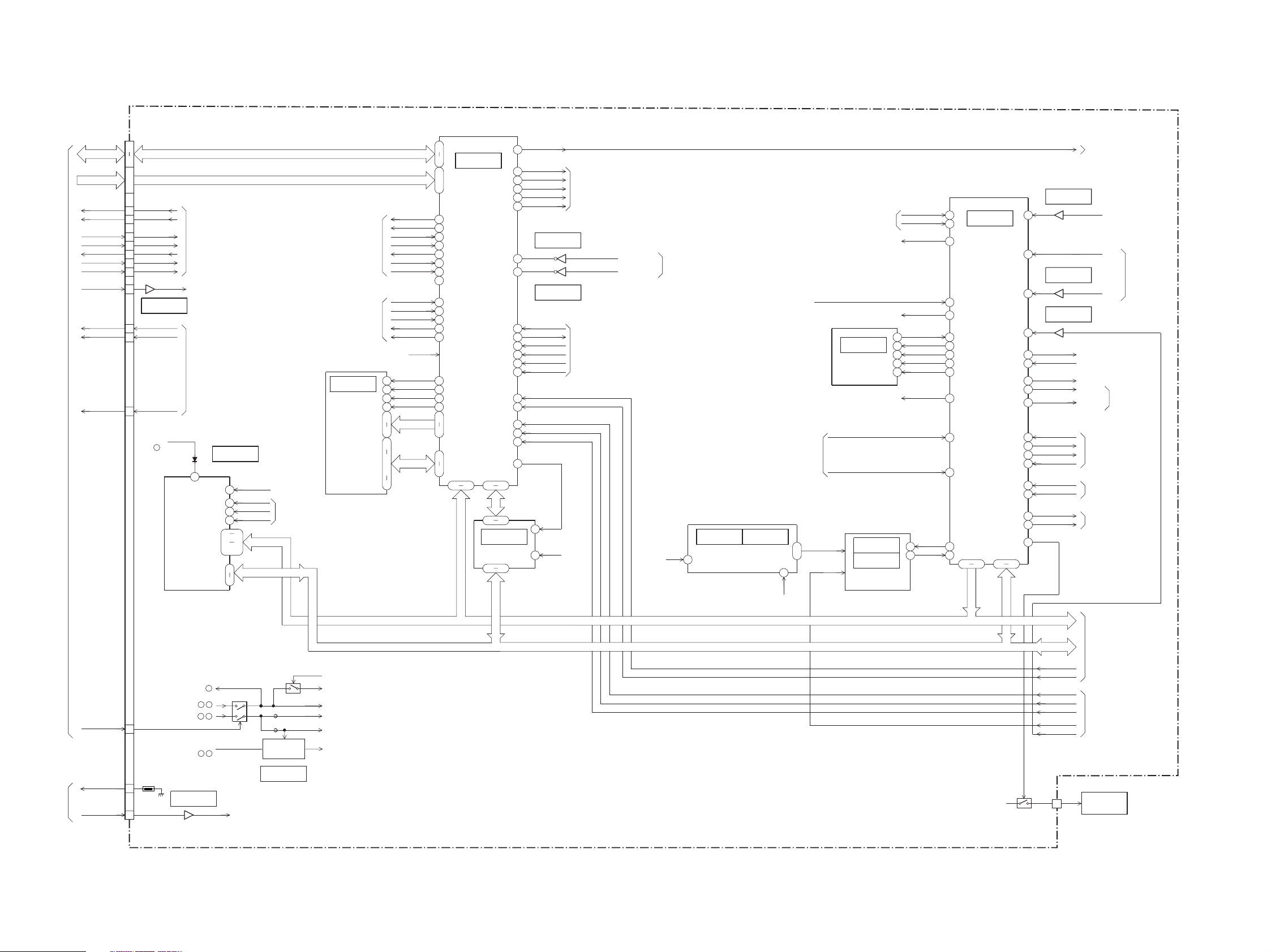

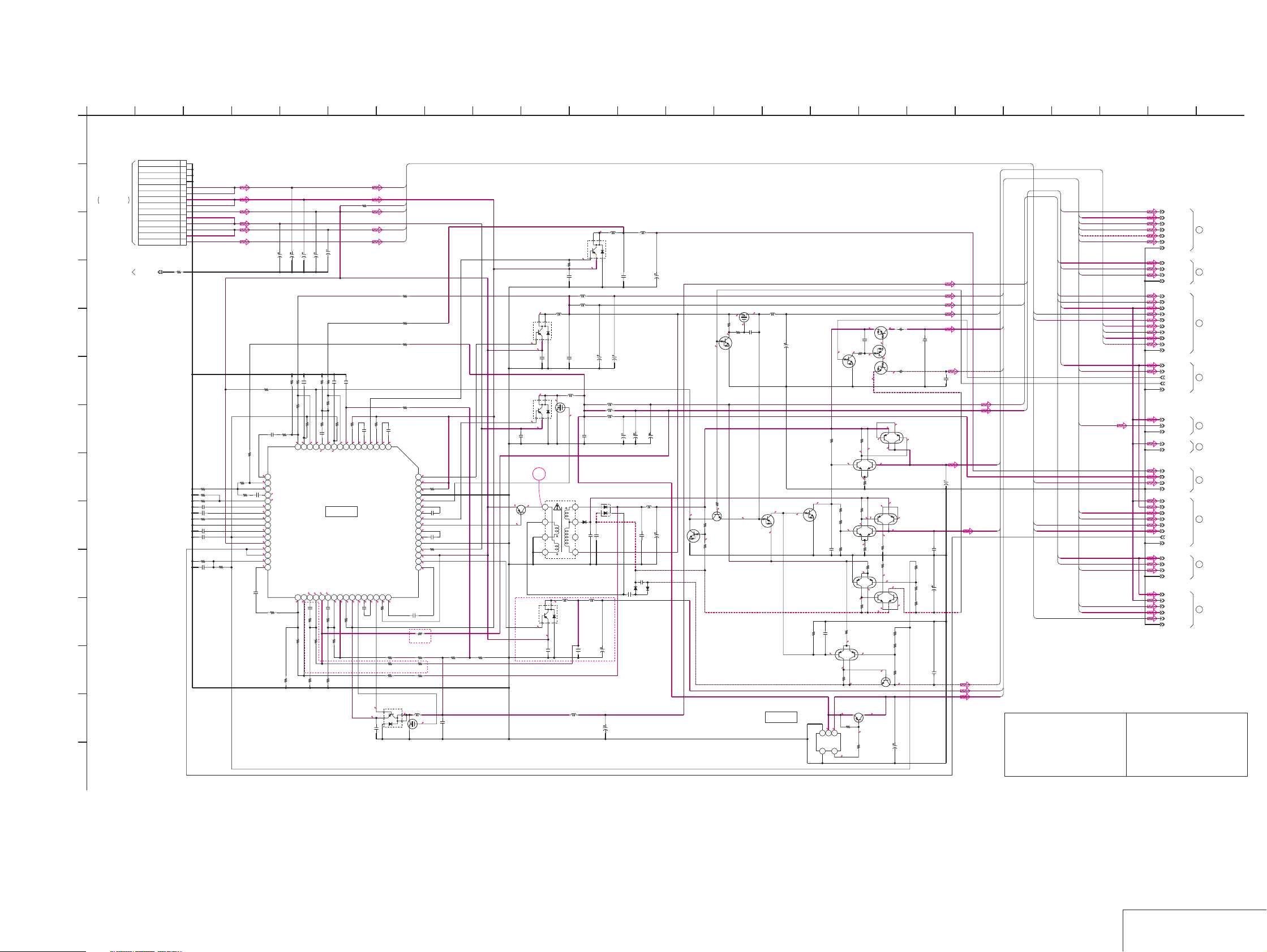

Page 9

MVC-CD200/CD300

3-12.MD BLOCK DIAGRAM (2/3)

MD-083 BOARD(2/3)

ENCEFM

49

(4-50)

IC207

ATSY

CLVM

ENSY

SOCK

WLDON

X202

34.574MHz

C34MV

C17MV

LOCKCD

MIRRO

MNTO

MNT1

MNT2

MNT3

SQCK

SQSO

SQSY

XTSL

XCSSRAM

XCDR RSTO

XGAINT

XRD

XSQINT

XWR

NMI

C33M

3.4V

FM CK

FM DT

(1/3)

ADDRESS

DATA

CD-R/RW

53

GA

52

50

51

48

42

41

43

46

128

125

121

122

123

124

118

119

120

131

69

116

133

87

134

88

132

44

74

86 101

20 8

A0-A9 D8-D15

16

MD BLOCK

(SEE PAGE

3-22)

(SEE PAGE

3-22)

(SEE PAGE 3-21)

(SEE PAGE3-22)

(SEE PAGE 3-22)

(SEE PAGE 3-25)

(SEE PAGE

(1/3)

(IC414)

(SEE PAGE

3-21)

(IC013,414)

(IC414,404)

(IC201)

(SEE PAGE

3-25)

(IC401)

(IC404)

(IC404)

(IC404)

(IC201)

MD BLOCK

3-22)

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

EQEFM

33

ODPLS

34

OSCON

36

WAPCRW

32

SPBRK

2

SPREV

57

ACTEN

63

XRW

3

ASMP

26

AGCON

22

ATFG

10

MIRR

15

MPXO

113

MSMP

24

RAPC

31

RC

16

RECD1

21

RECD2

20

RFGUP

23

RSMP

27

RZC

14

SSMP

25

TZC

13

142

WAPC

29

WAMP

28

DFCT

130

XTOK

17

FOK

129

FMCK

11

FMDT

12

Q203

144

MDPGA

60

MDSGA

61

SOFF

59

SPLHLD

143

VREF-

111

VREF+

115

XSDLTRF

5

SDLTDA

6

XSDLTDSP

4

SWDT

8

SDCK

7

SLFG

58

SPFG

56

94

XDFCT2

DFCT

DFCT2

(SEE PAGE 3-25)

(SEE PAGE 3-25)

(CN001)

(IC012)

(IC003)

(Q004)

(IC013)

(IC013,204)

(SEE PAGE

3-25)

(IC014)

(SEE PAGE

3-25,26)

(IC013,014)

(IC019)

(IC201)

(IC404)

(SEE PAGE

3-22)

(SEE PAGE 3-26)

(SEE PAGE 3-21)

(4-50)

IC209

1

2

Q204

(SEE PAGE 3-25)

(SEE PAGE 3-22)

(SEE PAGE 3-26)

(SEE PAGE 3-25)

(SEE PAGE

(SEE PAGE

4

3-25)

3-21)

(SEE PAGE

(SEE PAGE

(CN404)

(IC207)

(IC207)

(IC204,207)

(IC207,404)

(IC207,014)

(IC201,207)

(IC201,207)

(CN404)

(IC201)

3-25)

(IC207,014)

3-25)

(IC404)

(SEE PAGE

3-22)

FM DT

C34MV

ASMP

AGCON

ATFG

MIRR

MPXO

MSMP

RAPC

RC

RECD1

RFGUP

RSMP

RZC

SSMP

WAPC

WAMP

DFCT2

TZC

RECD2

DFCT

FMCK

FMDT

FOK

DECEFM

EQRF

MPP

RRF

XSDLTRF

SWDT

SDCK

XRFRST

VWDC

(4-46)

IC013

49

CD-R/RW

57

RF PROCESS

36

39

47

85

55

61

45

44

35

58

52

56

60

59

46

42

43

46

37

38

48

54

80

11

77

66

65

64

63

6

VRDC

10

8

9

7

5

PD-A

91

PD-H

99

FPDIN

4

TE

TE

13

FE

14

TEO

83

VC

15

VREF+

3

XTOK

41

DIAG

84 13

TE,FE

SLMOVE

SL FG

SP FG

SDCK

SWDT

RFAC

4.6V

4.6V-2

IC012

SW

(4-46)

(IC200)

(IC014)

(SEE PAGE

3-25,26)

(IC014,201,207)

(SEE PAGE

3-25,26)

MD BLOCK(3/3)

(SEE PAGE

3-25)

WAPCRW

WAPCFUP

(SEE PAGE3-22)

(IC207)

(IC404)

(SEE PAGE

(SEE PAGE 3-26)

(SEE PAGE 3-25)

(SEE PAGE 3-22)

3-22)

(IC014)

(IC207)

(IC014)

(IC208)

(SEE PAGE

3-22)

HAVCOS

LDLMT

VWDC2

DIAG

SLVOS

SDLTDA

SEOS

SNSCMP

TSNSCMP

SLMOVE

(IC404)

(IC207)

(IC014)

DSP3.4V

BASE UNIT(1/2)

20

21

31

32

30

29

27

26

25

18

7

10

13

16

11

12

19

(DDX-G2100)

LD

DRIVE

PD

IC

FRONT

MONITOR

OPTICAL

DEVICE

LASER

DIODE

CN001

LDD5V

4.6V

W/XR

IC002

2

EJECT

LDEN

1

ODPLS

OSCON

VWDC

VWDC2

VRDC

LDLMT

VREF+

D002

SW

IC007

4.6V

OFFSET

IC019

D/A

CONV.

(EVR)

(4-48)

AMP

HAVCOS

4.6V

12

2

19

6

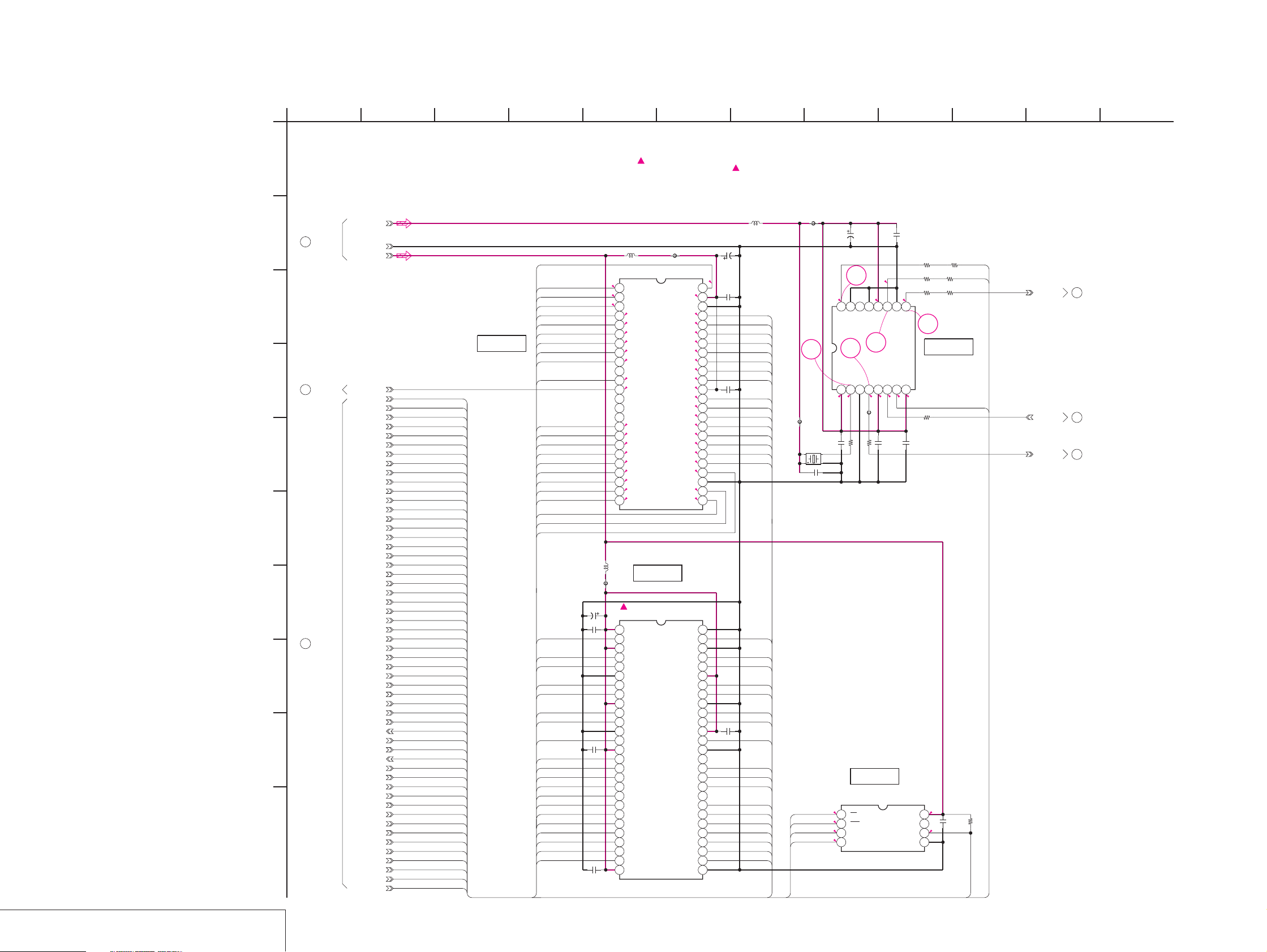

17

16

15

5

8

7

9

(4-45)

ENBL(IC404)

4

ODON

VWDC1

VWDC2

VRDC

A-H

(4-45)

VCC

VC

FPDON

3-23 3-24

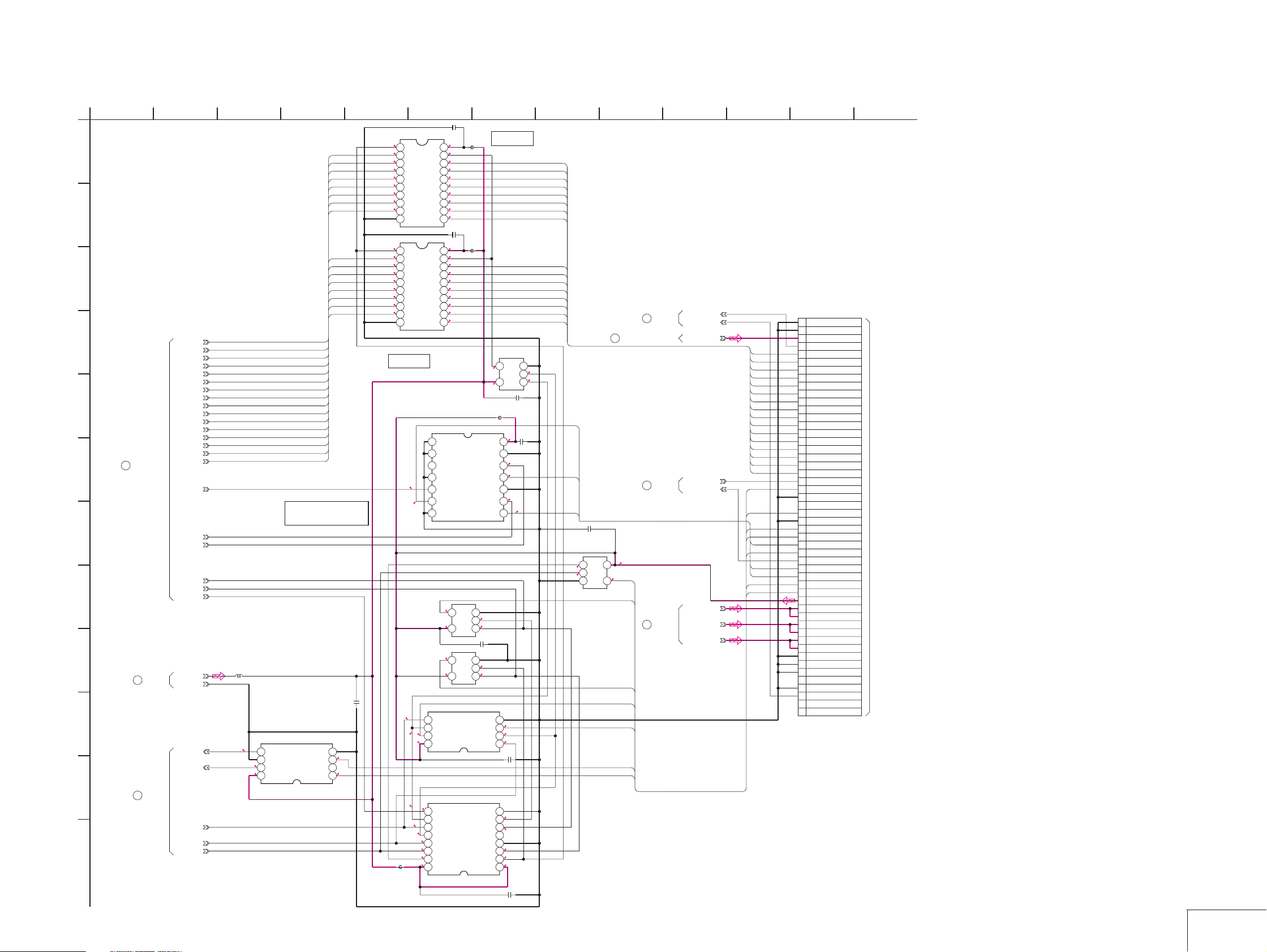

Page 10

MVC-CD200/CD300

3-13.MD BLOCK DIAGRAM (3/3)

MD-083 BOARD(3/3)

(4-49)

MD BLOCK

(1/3)

(SEE PAGE

3-22)

(SEE PAGE

(SEE PAGE

(SEE PAGE

(SEE PAGE

MD BLOCK

(1/3)

(SEE PAGE

3-22)

(IC207)

3-23)

(IC

3-21)

3-22)

3-21)

(IC404,

(SEE PAGE

3-21,22)

(IC404)

(IC414)

414)

MDATA

LRCK

BCLK

DSP3.4V

LOCKCD

MIRRO

MNTO

MNT1

MNT2

MNT3

SQCK

SQSO

XTSL

414)

SQSY

SENS

SNSCLK

XMRST

EXCK

GRSCOR

SBSO

WFCK

C2PO

LMT

FSHOCK

24

IC201

22

CD DSP

26

AUDIO DAC

100

86

42

41

40

39

58

57

44

54

78

79

60

56

90

55

53

37

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

TE,FE

SLMOVE

(SEE PAGE

(IC207)

(IC013)

(SEE PAGE

(IC014)

(IC207)

(SEE PAGE

SL FG

SP FG

RFAC

SDCK

SWDT

XDFCT2

(4-49)

3-23)

3-23)

3-23)

(IC207)

(SEE PAGE

3-23)

(IC207)

(SEE PAGE

3-23)

(SEE PAGE

3-23)

SOFF

(SEE PAGE

(SEE PAGE

SAO

SOFF

(IC207)

IC015

(4-48)

(IC207)

(SEE PAGE

3-23)

(IC013)

(IC019)

SW

3-23)

3-24)

Q006

IC011

FAO

TAO

FEIN

TEO

SLVOS

SLMOVE

(4-47)

SWDT

SDCK

XSDLTRF

DFCT2

MDPGA

MDSGA

SPLHLD

FSHOCK

FORCUS

11

SERVO

TRACKING

9

SERVO

73

FE AMP

TEIN

75

TE AMP

71

SLED

39

SERVO

78

7

72

70

SAMO

40

(4-48)

IC014

43

44

42

8

3

SE

SLED

4

POSITION

AMP

5

RECD2

69

XTOK

74

VC

53

VREF+

52

VREF-

51

SEOS

6

68

67

SPINDLE

63

SERVO

SHOCK

SENSOR

16

EC

55

SENS

15

SNSCMP

14

MD BLOCK(2/3)

(SEE PAGE

3-23)

RFAC

12

FAO

94

TAO

93

FEIN

2

TEIN

120

SWDT

81

SDCK

83

XSDLTDSP

82

SAO

92

14

15

87

88

119

118

80

1

3

98

70

71

45

IC204

SW

DFCT

FOK

MPP

RRF

XTOK

SE (IC207,013)

VC

MDPCD

X200

33.868MHz

C33M

FE

TE

DSP3.4V

4.6V

IC010

(SEE PAGE

(IC013)

VC

(IC201)

VREF+

VREF-

(IC019)

(SEE PAGE

(4-47)

AMP

(IC019)

3-24)

(SEE PAGE

3-23,24)

(IC207)

(SEE PAGE

3-23)

3-24)

(SEE PAGE 3-22)

(IC207)

(SEE PAGE

3-23)

FE

(IC404)

(IC013)

(SEE PAGE

POWER5V

4.6V-2

SP FG

SP ON

SP REV

SPBRK

(SEE PAGE

IC001

POWER5V

(4-47)

FCSDRV

2

TRKDRV

15

VC VC

IC009

(4-47)

POWER5V

9

(4-47)

SLFG TKCIN

(4-48)

ACTEN

(IC207)

3-23)

(4-47)

IC003

27

VC

SPINDLE

MOTOR

DRIVE

17

FG

19

S/S

16

RS

Q013

3-24)

BRAKE

VC SW

IC005

IC022

RATORCOMPA

2

1

29

9

14

18

SLED

DRIVE

Q004

LED

DRIVE

FOCUS

DRIVE

TRACKING

DRIVE

U

V

W

VHUIN1,2

VIN1,2

WIN1,2

41

4

6

13

11

12

14

14

IC004

Q003

CN001

FCS+

FCS-

TRK+

TRK-

SD+

SD-

TKC

LED

VCC 5

VH+

INV

(4-47)

LMT

CN002

4

2

3

1

3

2

1

4

16

17

18

7

12

13

14

BASE UNIT

(DDX-G2100)

OPTICAL

DEVICE

(2/2)

FOCUS

COIL

TRACKING

COIL

M902

SLED MOTOR

M

SLED

FG

M

SPINDLE

MOTOR

(2/2)

M901

16

3-25 3-26E

Page 11

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

MVC-CD200/CD300

Page 12

MVC-CD200/CD300

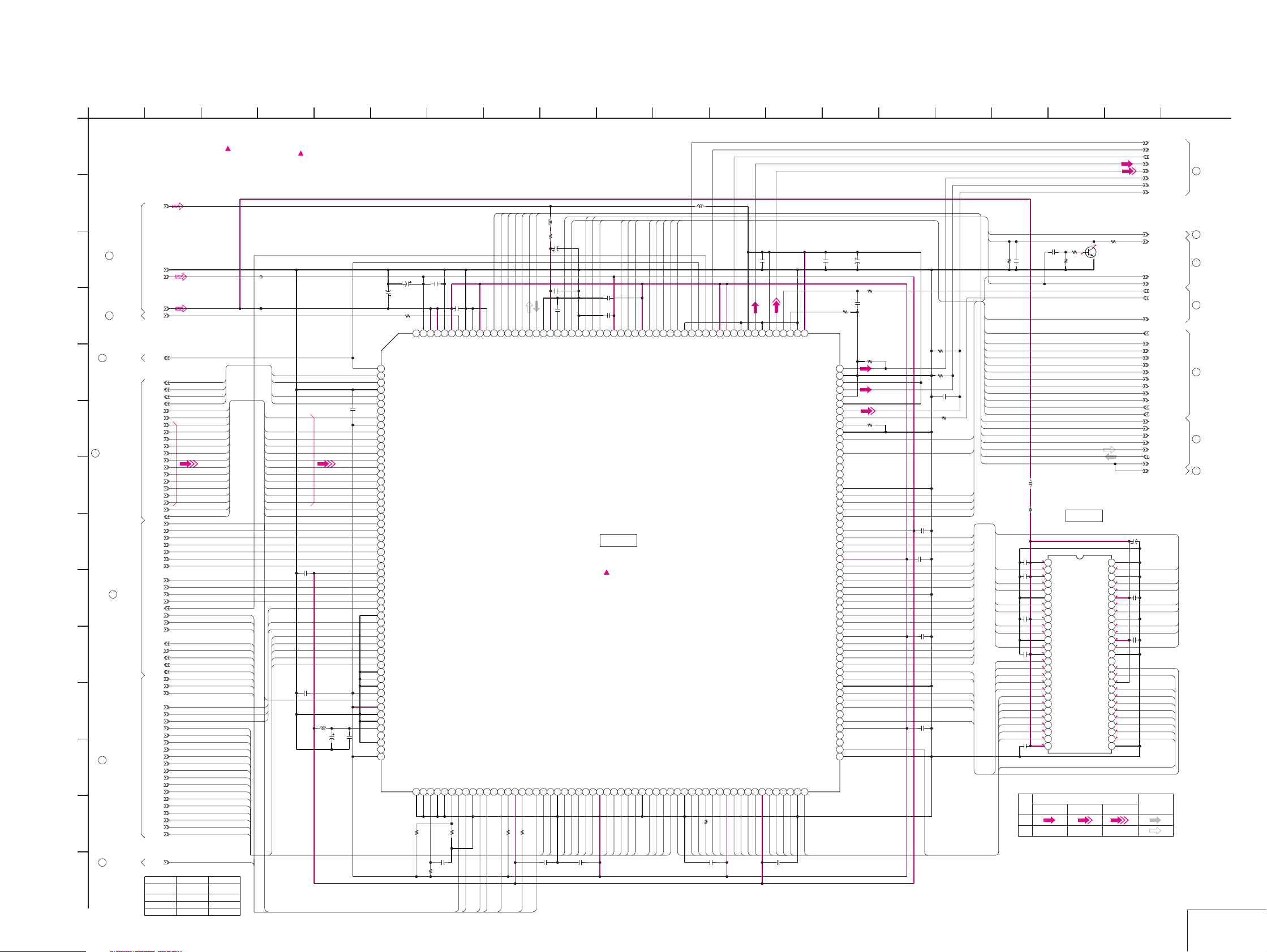

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

SY-67 (LD, PEARL, VIDEO OUT, SH, 16M FLASH MEMORY, 64M SDRAM, CLK GEN., CW, HI CONTROL,

AUDIO PROCESS, CONNECTOR, DC/DC CONVERTER)

PRINTED WIRING BO ARD

— Ref. No. SY-67 Board; 5,000 Series —

For printed wiring board

• Refer to page 4-76 for parts location.

• SY-67 board consists of m ultiple lay ers. How ev er , only

the sides (layers) A and B are shown.

• Chip parts

Transistor Diode

C

BE

5

64

2

13

3

21

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

• Replacement of CSP (Chip Size Package) IC used in

this set require a tool.

CSP IC:IC301, 501, 504

CSP (chip size package)Conventional

SY-67

LD, PEARL, VIDEO OUT, SH, 16M FLASH MEMORY,

64M SDRAM, CLK GEN, CW, HI CONTROL,

AUDIO PROCESS, DC/DC CONVERTER,

FLASH UNIT

TK-61

(LENS CAP DETECT)

CD-334 (CD300)

(LENS DRIVE, CAMERA PROCESS, CCD IMAGER)

LD, PEARL, VIDEO OUT, SH, 16M FLASH MEMORY, 64M SDRAM, CLK GEN, CW, HI CONTROL, AUDIO PROCESS, DC/DC CONVERTER

SY-67

4-20

Page 13

MVC-CD200/CD300

4-21

LD, PEARL, VIDEO OUT, SH, 16M FLASH MEMORY, 64M SDRAM, CLK GEN, CW, HI CONTROL, AUDIO PROCESS, DC/DC CONVERTER

SY-67

Page 14

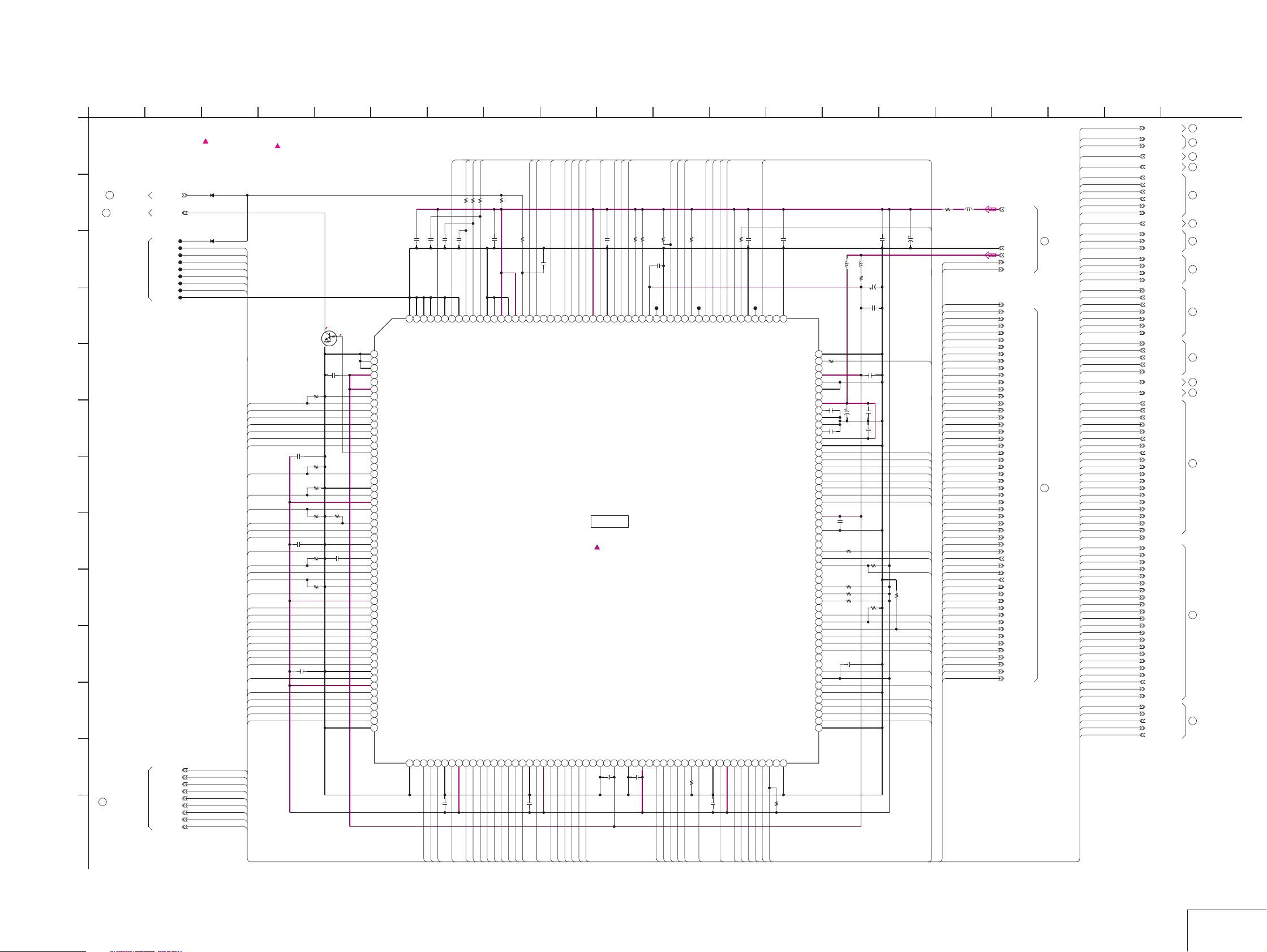

MVC-CD200/CD300

For Schematic Diagram

• Refer to page 4-19 for printed wiring board.

1

SY-67 BOARD(1/10)

LD(LD BLOCK)

A

-REF.NO.:5000 SERIESXX MARK:NO MOUNT

NO MARK:STILL/PB MODE

S :STILL MODE

P :PB MODE

B

1

TO(2/10)

C

2

TO(4/10)

D

3

TO(10/10)

E

4

TO(2/10)

F

G

H

LENS_TEMP_AD

XCAM_RESET

XEAGLE/XGCAM_CS

2589

PE_EN0

PE_DIR1B

PE_EN1

IRIS_EN

PE_DIR0B

HALL_AD

CCD_TEMP

REG_GND

CAM_P_5V

D_3.4V

CAM_3.1V

CAM_-7.5V

CAM_15V

CAM_5V

CAMTEST0

CAMTEST1

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_HD

SIGNAL PATH

CHROMA Y/CHROMA

REC

PB

VIDEO SIGNAL

Y

CAM_SO

XCAM_SCK

TO CD-333/334 BOARD(2/3) CN203

(THROUGH THE FP-364 FLEXIBLE)

(SEE PAGE 4-13)

MT_GND

1

MT_GND

3

HALL_AD

5

HALL_REF

7

LD_GND

9

LD_GND

11

D_3.4V

13

PE_DIR1B

15

PE_EN1

17

MSHUT_ON

19

IRIS_EN

21

PE_DIR0B

23

PE_EN0

25

LENS_TEMP_AD

27

XCAM_RESET

29

XEAGLE/XGCAM_CS

31

XCAM_SO

33

XCAM_SCK

35

CD_GND

37

CD_GND

39

CD_GND

41

CD_GND

43

CA_HD

45

CAM_-7.5V

47

CAM_15V

49

CAM_5V

51

CAMTEST0

53

CAMTEST1

55

CA_AD00

57

CA_AD01

59

CA_AD02

61

CA_AD03

63

CA_AD04

65

REG_GND

67

REG_GND

69

70PCN704

CAM_P_5V

CAM_P_5V

HALL_OFFSET

HALL_GAIN

IRIS_CONT1

IRIS_CONT2

XLENS_RST_LED

PE_DIR1A

XZM_RST_SENS

XZM_RST_SENS1

PE_DIR0A

XFC_RST_SENS

CCD_TEMP

VSUB_CNT

PAL/XNTSC

XTG_CS

CD_GND

TG_CLK

CD_GND

MCK12

CD_GND

CA_FD

CAM_3.1V

CAM_3.1V

CAM_3.1V

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CLPOB

DIR0B

PBLK

7

IC101

EVR(D/A CONV.)

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

70

IRIS_CONT1

IRIS_CONT2

XLENS_RST_LED

PE_DIR1A

XZM_RST_SENS

XZM_RST_SENS1

PE_DIR0A

XFC_RST_SENS

VSUB_CNT

PAL/XNTSC

TG_CLK

MCK12

CA_FD

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

PBLK

CLPOB

PLL12

1

5

6

4

TO(2/10)

TO(3/10,4/10,

5/10,7/10)

TO(5/10)

TO(2/10)

TO(9/10

(CN703))

TO(8/10)

TO(3/10)

PRELAMP_AF_ON

SP_VOL

CNT_C

7

8

9

IC103

IRIS MOTOR PRE-DRIVE

FB101

R108

*

*

C103

*

R109

*

1005

0

R101

*

C101

*

910111213141516

3.3

1

NC

2

AD3

1.5 0

3

AD4

1.8 0.4

4

AD5

5

AD6

6

AD7

0

7

AD8

S1.0

P2.2

8

AD9

S0.6

P0.7

9

AD10

3.1

VDD

10

C102

0.1u

B

1005

11

3.3

3.3

VDD

A

123

0

0

B

12

13

14

15

16

17

18

19

20

0

IC102

45

TEST0

DIR0A

DIR0B

EN0

DIR1A

DIR1B

EN1

SENS1

SENS0

VDD

YGND

*

S1.7/P0

S0.8/P0

CLK

4Q

4D 3D

5Q

5D

6D

6Q

VCC

IC101

BH2221FV-E2

IC103

*

CKOUT

TEST1

IC104

*

104 11 136

GND

20

00.9

AD2

19

AD1

18

DI

17

3.1

CLK

16

0

LD

15

NC

14

1.0

AD12

13

1.1

AD11

12

3.1

VCC

11

VSS

10

S3.1/P0

XCLR

9

1.5

CKIN

8

7

3.1

SOUT

6

0.4

SIN

5

3.1

SCK

4

3.1

CS

3

2

3.2

VDIN

1

3.3

VDD

A

123

0

GND

0

3Q

0

0

2Q

0

2D

0

1D

0

1Q

3.3

12345678

CLR

R102

*

3.2

45

Y

B

GND

3.0

IRIS_CONT2

IRIS_CONT1

C104

0.1u

B

1005

IC104

IC105

VD PULSE GENERATOR

IC105

*

IC102

VD PULSE GENERATOR

R105

R103

Q102

12

CAM_SO

XCAM_SCK

CAM_SO

XCAM_SCK

PE_DAC_LEVEL2

PE_DAC_LEVEL1

C101

C103

FB101

IC102

IC103

IC104

IC105

R101

R102

R108

R109

MSHUT_ON

DAC_STBY

DAC_ENB

CAM_SO

XTG_CS

XCAM_SCK

XBEAR_RESET

CAM_SI

SYS_V

MVC-CD200 MVC-CD300

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

0

R104

L101

10uH

C105

10u

XX

6.3V

TA

A

MARKED:MOUNT TABLE

*

Q101

0

XX

XX

XX

143

10

TO(3/10(CN707))

11

TO(2/10)

12

TO(4/10)

TO(2/10,4/10,

13

7/10)

1u

1u

0uH

TC74VHC174FT

CXD2430N-T

TC7S86FU(TE85R)

TC7S86FU(TE85R)

0

0

0

XX

16

LD

SY-67 (1/10)

4-23 4-24

Page 15

For Schematic Diagram

• Refer to page 4-19 for printed wiring board.

1

SY-67 BOARD(2/10)

PEARL(PEARL BLOCK)

-REF.NO.:5000 SERIES-

A

XX MARK:NO MOUNT

B

14

C

39

D

TO(1/10,4/10,

13

7/10)

E

F

4

TO(1/10(CN704))

G

H

15

I

J

K

16

TO(4/10,6/10)

L

M

17

TO(4/10,7/10)

N

16

TO(10/10)

TO(5/10)

TO(4/10)

A_3.4V

REG_GND

D_1.8V

CAM_3.1V

AU_CLK

SYS_V

CLPOB

PBLK

CA_HD

CA_FD

CAMTEST0

CAMTEST1

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

MCK12

PLL12

MC_A14

MC_A13

MC_A12

MC_A11

MC_A10

MC_A09

MC_A08

MC_A07

MC_A06

MC_A05

MC_A04

PEARLFLD

MC_XCS6

MC_XCS2

MC_XWE1

MC_DREQ0

MC_DRAK0

IRQJPG

IRQIMG

IRQAUDIO

MC_XRD

MC_XWE0

MC_HCLK

MC_A03

MC_A02

MC_A01

MC_D15

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

MC_D09

MC_D08

MC_D07

MC_D06

MC_D05

MC_D04

MC_D03

MC_D02

MC_D01

MC_D00

XRST_SYS

MARKED:MOUNT TABLE

*

IC302

R306

R311

R337

MVC-CD200 MVC-CD300

HV57V64162 K4S561632BOHGT-PTRPV TC1HT00

0

XX

XX

39 177

NO MARK:STILL/PB MODE

:Voltage measurment of the CPS IC

and the Transistors with mark is

not possible.

CLPOB

PBLK

CA_HD

CA_FD

CAMTEST0

CAMTEST1

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

MCK12

PLL12

MC_XCS6

MC_XCS2

MC_XWE1

MC_DREQ0

MC_DRAK0

IRQJPG

IRQIMG

IRQAUDIO

MC_XRD

MC_XWE0

MC_HCLK

MC_A03

MC_A02

MC_A01

MC_D15

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

MC_D09

MC_D08

MC_D07

MC_D06

MC_D05

MC_D04

MC_D03

MC_D02

MC_D01

MC_D00

XRST_SYS

XX

0

0

MVC-CD200/CD300

14

EXT_STRB_ON

STROBAD

C343

C342

47u

0.01u

6.3V

B

QCLKE1

QCLKE0

VAVS1

VAVD1

VAVS0

VAVD0

VREF1

DGND

PIO00

PIO01

PIO02

PIO03

PIO04

PIO05

PIO06

DGND

PIO07

PIO08

PIO09

PIO10

PIO11

DGND

QDML

QDMH

DGND

DGND

B

TA

R315

C321

47k

0.1u

B

R314

2700

±0.5%

R318

150

R316

68

1005

±0.5%

CRO

CBO

PYO

VRO1

VCC2

145146 147 148149 150 151152 153 154155 156 157158 159 160161 162 163164 165 166167 168

DQ00

DQ01

DQ02

VCC3

DQ03

DQ04

DQ05

DQ06

DQ07

DQ08

DQ09

DQ10

DQ11

VCC3

DQ12

DQ13

DQ14

DQ15

XWE

XCAS

XRAS

XCS1

XCS0

VCC3

AQ00

113114 115 116117 118 119120 121 122123 124 125126 127 128129 130 131132 133 134135 136 137138 139 140141 142 143144

R319

2700

1005

±0.5%

1005

±0.5%

R317

1005

120

±0.5%

C326

0.1u

B

R320

47k

STRB_PHOTO_ON

XZM_RST_SENS1

XLENS_RST_LED

XFC_RST_SENS

XZM_RST_SENS

IRIS_EN

C322

0.1u

B

PE_DQ00

PE_DQ01

PE_DQ02

C323

0.1u

PE_DQ03

B

PE_DQ04

PE_DQ05

PE_DQ06

PE_DQ07

PE_DQ08

PE_DQ09

PE_DQ10

PE_DQ11

C324

0.1u

PE_DQ12

B

PE_DQ13

PE_DQ14

PE_DQ15

PE_QDML

PE_QDMH

PE_XWE

PE_XCAS

PE_XRAS

PE_XCS0

C325

0.1u

B

R344

470

STRB_PHOTO_ON

STRB_ON

MSHUT_ON

XZM_RST_SENS1

VSUB_CNT

PE_DIR1B

PE_DIR1A

PE_EN1

PE_EN0

PE_DIR0B

PE_DIR0A

XLENS_RST_LED

IRIS_EN

XFC_RST_SENS

XZM_RST_SENS

AU_XPWDA

AU_XPWAD

AU_MCLK

AU_SCLK

AU_SDTI

AU_SDTO

AU_LRCK

PE_DQ00

PE_DQ01

PE_DQ02

PE_DQ03

PE_DQ04

PE_DQ05

PE_DQ06

PE_DQ07

PE_QDML

PE_XWE

PE_XCAS

PE_XRAS

PE_XCS0

PE_AQ13

PE_AQ12

PE_AQ10

PE_AQ00

PE_AQ01

PE_AQ02

PE_AQ03

C328

0.1u

B

C329

0.1u

B

C330

0.1u

B

C331

0.1u

B

C332

0.1u

B

C344

R342

0.001u

1k

C345

XX

L305

10uH

±10%

FB303

0uH

3.1

0.4

3.1

0.3

0.3

0.3

0.3

3.1

0.3

0.3

0.5

3.1

0

3.0

2.9

2.9

0

0

0

0.1

0

0

0

0

3.1

0

R343

3300

IC302

64M SDRAM

IC302

VCC

DQ0

VCCQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VCCQ

DQ5

DQ6

VSSQ

DQ7

VCC

DQML

WE~

CAS~

RAS~

CS~

A13

A12

A10/AP

A0

A1

A2

A3

VCC

*

DQMU

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

0

R302

270

2SD2216J-QR(K8).SO

STRB SWITCH

VSS

DQ15

VSSQ

DQ14

DQ13

VCCQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VCCQ

DQ8

VSS

NC

CLK

CKE

NC

A11

A9

A8

A7

A6

A5

A4

VSS

1915

PANEL_V

HDO

PAL/XNTSC

CO

YO

CRO

CBO

PYO

EXT_STRB_ON

STRB_AIN

Q311

STRB_PHOTO_ON

STRB_ON

PE_DAC_LEVEL2

PE_DAC_LEVEL1

MSHUT_ON

XZM_RST_SENS1

VSUB_CNT

PE_DIR1B

PE_DIR1A

PE_EN1

PE_EN0

PE_DIR0B

PE_DIR0A

XLENS_RST_LED

IRIS_EN

XFC_RST_SENS

XZM_RST_SENS

AU_XPWDA

AU_XPWAD

AU_MCLK

AU_SCLK

AU_SDTI

AU_SDTO

AU_LRCK

AU_LRCK

C335

10u

6.3V

TA

A

54

0.2

53

52

0.3

51

0.1

50

3.1

49

0.2

48

0.3

47

46

0.4

45

0.4

44

3.1

43

0.4

42

41

40

0

39

1.3

38

3.1

37

0

36

0

35

0.1

34

0.1

33

0.1

32

0.1

31

0.1

30

0.1

29

28

PE_DQ15

PE_DQ14

PE_DQ13

C337

0.1u

B

PE_DQ12

PE_DQ11

PE_DQ10

PE_DQ09

C338

0.1u

B

PE_DQ08

PE_QDMH

PE_QCLK

PE_AQ11

PE_AQ09

PE_AQ08

PE_AQ07

PE_AQ06

PE_AQ05

PE_AQ04

PE_AQ

18

21

22

11

1

19

20

TO(3/10)

TO(9/10(CN709))

TO(9/10(CN702))

TO(1/10)

TO(1/10(CN704))

TO(8/10)

TO(4/10)

SIGNAL PATH

PE_AQ00

VIDEO SIGNAL

CHROMA Y/CHROMA

REC

PB

Y

AUDIO

SIGNAL

PEARL

SY-67 (2/10)

STRB_ON

MSHUT_ON

C317

0.1u

B

C316

0.1u

B

IRISOUT

STROBE2

STROBE1

SHUTTER

IC301

CAMERA DSP

MEMORY CONTROL

VIDEO ENCODER

OPD,OSD,RES CONT

MB87J1691L GA-G-ER

(CSP(Chip Size Package))

D09

D10

D08

VCC3

MC_D08

MC_D09

MC_D07

10 11 136

L303

47uH

±10%

PE_EN1

PE_DIR1B

PE_DIR1A

VCC2

DIR1B

DIR1A

IC301

D06

D07

D05

MC_D06

MC_D05

MC_D04

EN1

D04

PE_DIR0B

XZM_RST_SENS

VCC3

SENS1

DGND

D03

MC_D03

MC_D02

DIR0B

D02

PE_DIR0A

DIR0A

D01

MC_D01

PE_EN0

EN0

D00

MC_D00

XFC_RST_SENS

DGND

SENS0

QCLK

DGND

PE_QCLK

LCDVD

BA1

PE_AQ13

NTVD0

BA0

PE_AQ12

C319

0.1u

B

169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208209210211212213214215216217218219220221222223224

HD

VRI

HRI

FLD

AQ12

*

R311

PE_AQ

C318

0.1u

B

AQ11

PE_AQ11

AQ10

PE_AQ10

VAVS4

EXTPAL

AQ09

AQ08

VCC3

PE_AQ08

PE_AQ09

VAVD4COVAVD3

AQ07

AQ06

PE_AQ06

PE_AQ07

VAVS3

VCC2

AQ05

PE_AQ05

C320

YO

VREF2

(STRB_PHOTO_ON)

(XZM_RST_SENS1)

(XLENS_RST_LED)

(XFC_RST_SENS)

(XZM_RST_SENS)

AQ04

AQ03

PE_AQ03

PE_AQ04

0.1u

B

VRO2

AQ02

PE_AQ02

VAVS2

(IRIS_EN)

DGND

PE_AQ01

VAVD2

AQ01

4

FB301

0uH

FB302

0uH

CLPOB

PBLK

CA_HD

CA_FD

CA_AD11

CA_AD10

CA_AD09

CA_AD08

CA_AD07

CA_AD06

CA_AD05

CA_AD04

CA_AD03

CA_AD02

CA_AD01

CA_AD00

CAMTEST1

CAMTEST0

C305

0.1u

B

MC_A03

MC_A02

MC_A01

MC_XRD

MC_XCS6

MC_XCS2

MC_XWE0

MC_XWE1

C306

0.1u

B

MCK12

PLL12

5 12

C303

C308

0.1u

10u

6.3V

B

1k

VCC2

DACMD0

SCAN1

RSTX

0.022u

SCAN2

VPD

R306

C309

*

B

SCAN3

SONYTEST

C310

0.1u

B

VCC3

PLLXMSK

IRQJPG

ACLK

IRQJPG

IRQIMG

DGND

IRQIMG

SCAN4

DGND

TA

R341

0

XACLK

DACMD1

57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100101 102 103104 105 106107 108 109110 111 112

R337

*

R305

±10%

C304

10u

6.3V

TA

12345678910111213141516171819202122232425262728293031323334353653545556

NTVDI

OPBO

SIGCCD

DGND

CCDHD

CCDFD

C307

0.1u

OPTEST0

B

ADIN11

VCC3

ADIN10

ADIN09

ADIN08

ADIN07

ADIN06

ADIN05

ADIN04

ADIN03

ADIN02

ADIN01

ADIN00

CAMTEST1

CAMTEST0

A14

A13

A12

A11

A10

A09

A08

VCC2

A07

A06

A05

A04

A03

DGND

A02

A01

RDX

CSX

CSX2

WRLX

WRHX

MD0

4452 4351 4250 4149 4048 3947 3846 3745

DGND

CLKI

VCC3

CLKTG

MD1

L301

10uH

C301

C302

0.1u

22u

B

6.3V

TA

MD2

PLLGND

PLLVCC

CLK0

MD3

PLLBYP

DACMD2

82 201816

L302

10uH

SCAN5

IRQAU

IRQAUDIO

SCAN6

DRQ1

MC_DREQ0

AU_XPWAD

AU_XPWDA

XPWDA

DRQ2

MC_DRAK0

XPWAD

DRAK1

100k

R308

AU_MCLK

ADCK

DRAK2

AU_SCLK

SCLK

VCC2

AU_LRCK

LRCK

CPUCK

R309

MC_HCLK

AU_SDTI

0

SOA

PLL24

AU_SDTO

SIA

PLL12

PLL12

R310

C314

0.1u

C311

0.1u

0

B

MC_D15

B

STROBAD

C312

10u

6.3V

VSUB_CNT

TA

EXT_STRB_ON

B

0.1u

C313

VR

AVS

AVDD

DGND

STRBAD

SUBCNTL

D15

D14

D12

D13

D11

DGND

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

C315

0.1u

B

4-25 4-26

Page 16

MVC-CD200/CD300

For Schematic Diagram

• Refer to page 4-19 for printed wiring board.

• Refer to page 4-75 for waveforms.

1

SY-67 BOARD(3/10)

VIDEO OUT(VI BLOCK)

-REF.NO.:5000 SERIES-

A

XX MARK:NO MOUNT

TO(1/10(CN704),

5

4/10,5/10,7/10)

9

TO(1/10)

B

18

TO(2/10)

C

D

E

F

G

H

PAL/XNTSC

CNT_C

CO

YO

PAL/XNTSC

CRO

CBO

PYO

HDO

PANEL_V

TO

PK-58 BOARD(1/3)

CN301

THROUGH THE

FP-363 FLEXIBLE

(SEE PAGE 4-67)

2SB1462J-QR(K8).SO

397

NO MARK:STILL/PB MODE

R333

1200

± 0.5%

0.7

33P

XCS_PANEL_D/A

PANEL_-15.3V

1.3

R334

± 0.5%

± 0.5%

CHARGE_LED

KEY_AD2

HI_UNREG

LANC_IN

LANC_OUT

REG_GND

MS_SCLK

MS_BS

MS_DIO

BL_UNREG

BL_UNREG

BL_GND

BL_GND

XCAM_SCK

CAM_SO

PANEL_13.2V

PANEL_4.9V

PANEL_6.5V

PANEL_3.4V

D_3.4V

REG_GND

PANEL_Y

PANEL_R-Y

PANEL_B-Y

REG_GND

PANEL_V

RESET

ACCESS_LED

820

R312

Q309

SWITCH

CN707

R332

4700

± 0.5%

220

VDD

HDO

N.C.

TRANSISTORHN1C01FE-Y/GR(TPLR3)

0.7

R313

150

± 0.5%

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

R721

3

1k

2

1

45 1282

R335

100

± 0.5%

Q310

SWITCH

R338

150

± 0.5%

0.2

0.10.1

R336

100

± 0.5%

0

R322

22k

RN1904FE(TPLR3)

2.4

0

VDD

RESET

XCHARGE/STB_LED

KEY_AD2

LANC_IN

LANC_OUT

MS_SCLK

MS_BS

MS_DIO

XCS_LCD_DAC

XCAM_SCK

CAM_SO

ACCESS_LED

Q301

SWITCH

C327

2.4

10 11 136

L202

Q202

XX

4

C202

XX

6.3V

TA

A

C203

0.01u

B

IC201

NJM2274R(TE2)

C201

1u

B

1.5

R205

1M

10uH

2520

1.4

3.3

5

VCC

PowerSave

C206

0.1u

C207

6.3V

TA

F

R204

1k

47u

B

VOUT_ON

C204

0.1u

F

2.9

6

7

8

C-IN

C-MUTE

32

Vsag

GND

Y-IN

V-OUT

C208

1

2

3

1.2

22u

4

6.3V

TA

C205

100u

TA B

A

R206

68

4V

V_OUT

1.2

Q201

XX

R201

R202

R330

820

1.6