Page 1

MVC-CD1000

SERVICE MANUAL

US Model

Canadian Model

Level 2

Ver 1.0 2000. 07

Australian Model

Japanese Model

This service manual contains information for japanese model as well.

On the SY-060 board and the DDX-G2000 COMPLETE ASSEMBLY (Including the MD-082 Board)

This service manual provides the information on the premised of the circuit board replacement service and not intended

repair inside the SY-062 board in case of trouble. It is also premised that the mechanism deck DDX-G2000 COMPLETE

ASSEMBLY (including the MD-082 board) shall be exchanged as an assembly in case of trouble .

Therefore, disassembling procedure and exploded view of the DDX-G2000 COMPLETE ASSEMBLY are not shown. The

block diagram, schematic diagram, printed wiring board and electrical parts list of the SY-062 board are also not shown.

Note that the following pages are lacking intentionally.

SY-062 board

Block diagram............................... Page 3-19 to 3-22

Schematic diagram....................... Page 4-15 to 4-22

Printed wiring board ..................... Page 4-11 to 4-14

Electrical parts list ........................ Page 6-16 to 6-18

DDX-G2000 COMPLETE ASSEMBLY

Disassembly ................................. Page 2-12 to 2-13

Exploded view .............................. Page 6-8

MD-082 board

Block diagram ............................ Page 3-23 to 3-28

Schematic diagram .................... Page 4-27 to 4-36

Printed wiring board ................... Page 4-23 to 4-26

Electrical parts list ...................... Page 6-11 to 6-16

AEP Model

UK Model

E Model

The above-described information is shown in service manual Level 3.

SPECIFICATIONS

System

Image device

1/2.7 type color CCD

Lens

10× zoom lens

f = 1/4 – 2 3/8 in (6.0 –

60.0 mm) (1 9/16 – 15 3/8 in

(39 – 390 mm) when

converted into a 35 mm still

camera)

F = 2.8

Exposure control

Automatic exposure

White balan c e

Automatic, Indoor, Outdoor,

One-push

Data compression

system

Movie: MPEG1

Still:

JPEG, TIFF, GIF (in TEXT

mode)

Audio (with still im age):

MPEG AUDIO (Monaural)

Recording medium

8 cm CD-R

Flash

Recommended recording

distance:

23 5/8 in to 8 1/3 feet (0.6 m

to 2.5 m)

Drive

Read: Maximum ×8

Write: × 4

Readout

Noncontact optical readout

(using semiconductor laser)

Laser

Wa velength: 777 to 787 nm

NA: 0.5

Maximum output: 23 mW

Emission duration: 600 ns

Input and O utput

connector

A/V OUT (MONO) jack

(Monaural)

Minijack Video:

1 Vp-p, 75Ω , unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ

load)

Output impedance: 2.2 k

DIGITAL I/O jack

4-pin connector

External flash jack

Minijack

LCD screen

LCD panel

TFT (Thin Film Transistor

active matrix) drive

LCD size

2.5 type

T otal number of dots

123 200 (560×220) dots

Viewfinder

Ω

LCD panel

TFT (Thin Film Transistor

active matrix) drive

T otal number of dots

180 000 (800×225) dots

— Continued on next page —

DIGITAL STILL CAMERA

Page 2

General

Application

Sony battery pack NP-F550

Power requirements

8.4 V

Power consumption

(During shooting)

4.9 W (When using the LCD

screen)

4.5 W (When u sing the

viewfinder)

Operation temperature

32 °F to 104 °F (0 °C t o

40 °C)

Storage te m p erature

–4 °F to +140 °F (–20 °C to

+60 °C)

Maximum dimensions

5 1/2×5 1/4×8 3/8 in

(137×131×212 mm) (w/ h/d)

Mass

Approx. 35 oz (990 g)

(including battery, disc and

lens cap, etc.)

Built-in microphone

Electret condenser

microphone

Built-in speaker

Dynamic speaker

AC-L10A/L10B/L10C

AC power adaptor

Power requirements

100 V to 240 V AC,

50/60 Hz

Rated output voltage

DC 8.4 V, 1.5 A in operating

mode

Operation temperature

32 °F to 104 °F (0 °C to

40°C)

Storage temperature

–4 °F to +140 °F (–20 °C to

+60 °C)

Maximum dimensions

5×1 9/16×2 1/2 in

(125×39×62 mm) (w/h/d)

Mass

Approx. 10 oz (280 g)

NP-F550 battery pack

Used battery

Lithium ion battery

Maximum vo ltage

DC 8.4 V

Nominal voltage

DC 7.2 V

Capacity

10.8 Wh (1 500 mAh)

Accessories

AC-L10A/L10B/L10C

AC power adaptor (1)

Power cord (mains lead) (1)

NP-F550 battery pack (1)

A/V connecting cable (1)

USB cable (1 )

8 cm CD adaptor (1)

Mavica disc (5)

Shoulder strap (1)

Lens cap (1)

Lens cap strap (1)

CD-ROM (3)

Operating instructions (3)

Design and specifications

are subject to change

without notice.

CAUTION

Use of controls or adjustments or performance

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

TABLE OF CONTENTS

SERVICE NOTE ····································································· 6

1. GENERAL

Getting started

Identifying the parts ·······························································1-1

Preparing the power supply ···················································1-1

Setting the date and time························································1-2

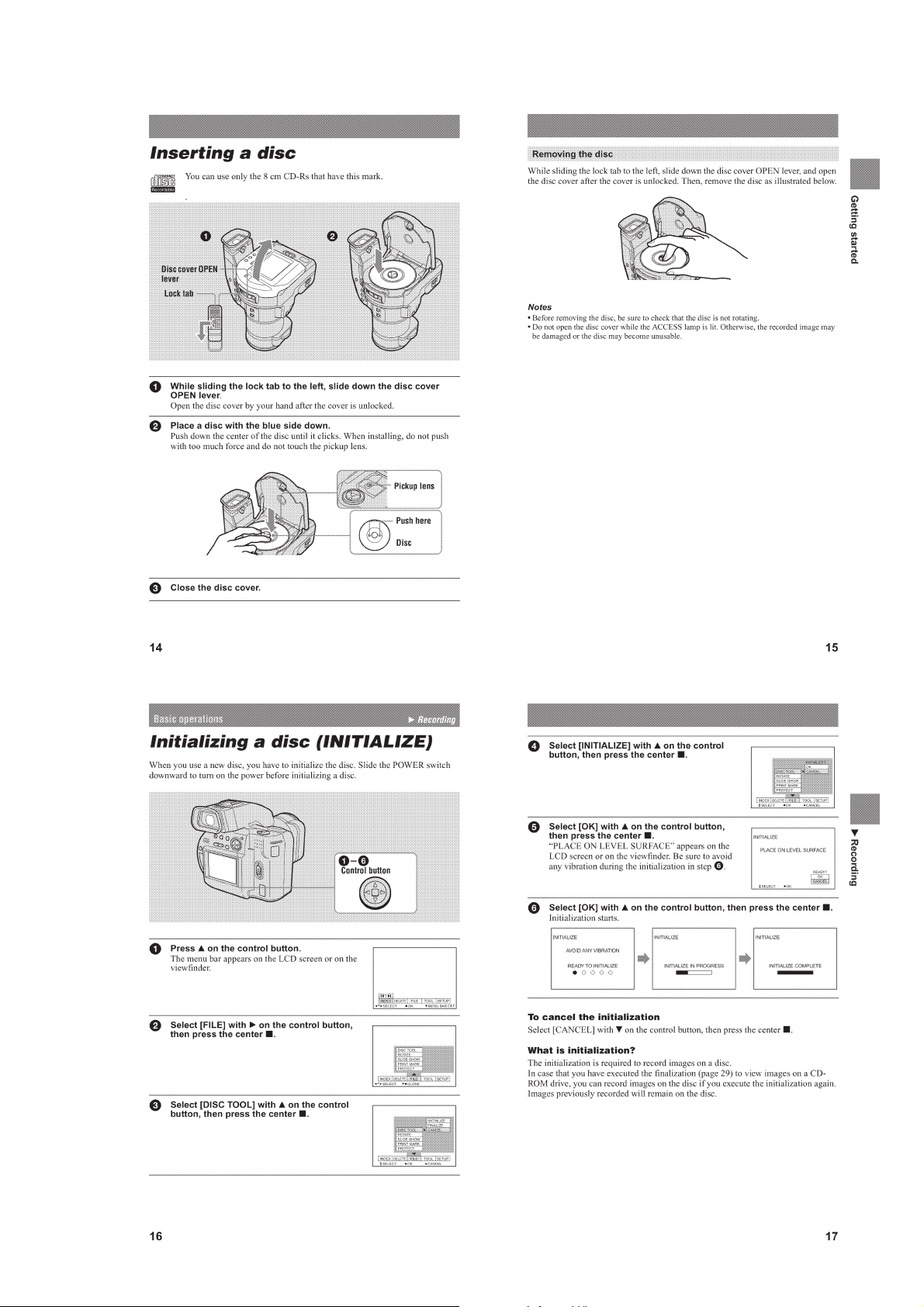

Inserting a disc ·······································································1-3

Basic operations

B Recording

Initializing a disc (INITIALIZE) ···········································1-3

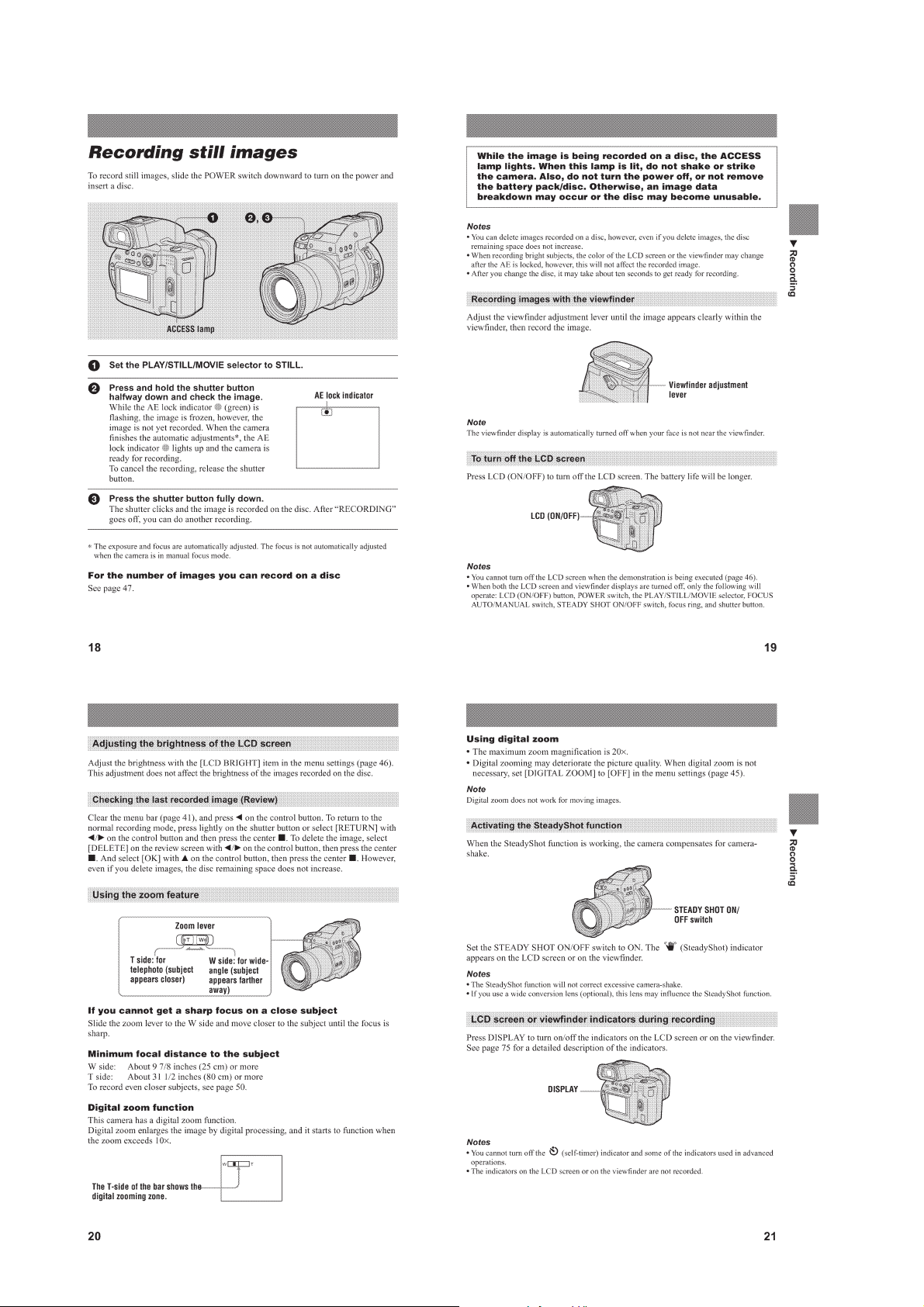

Recording still images ···························································1-4

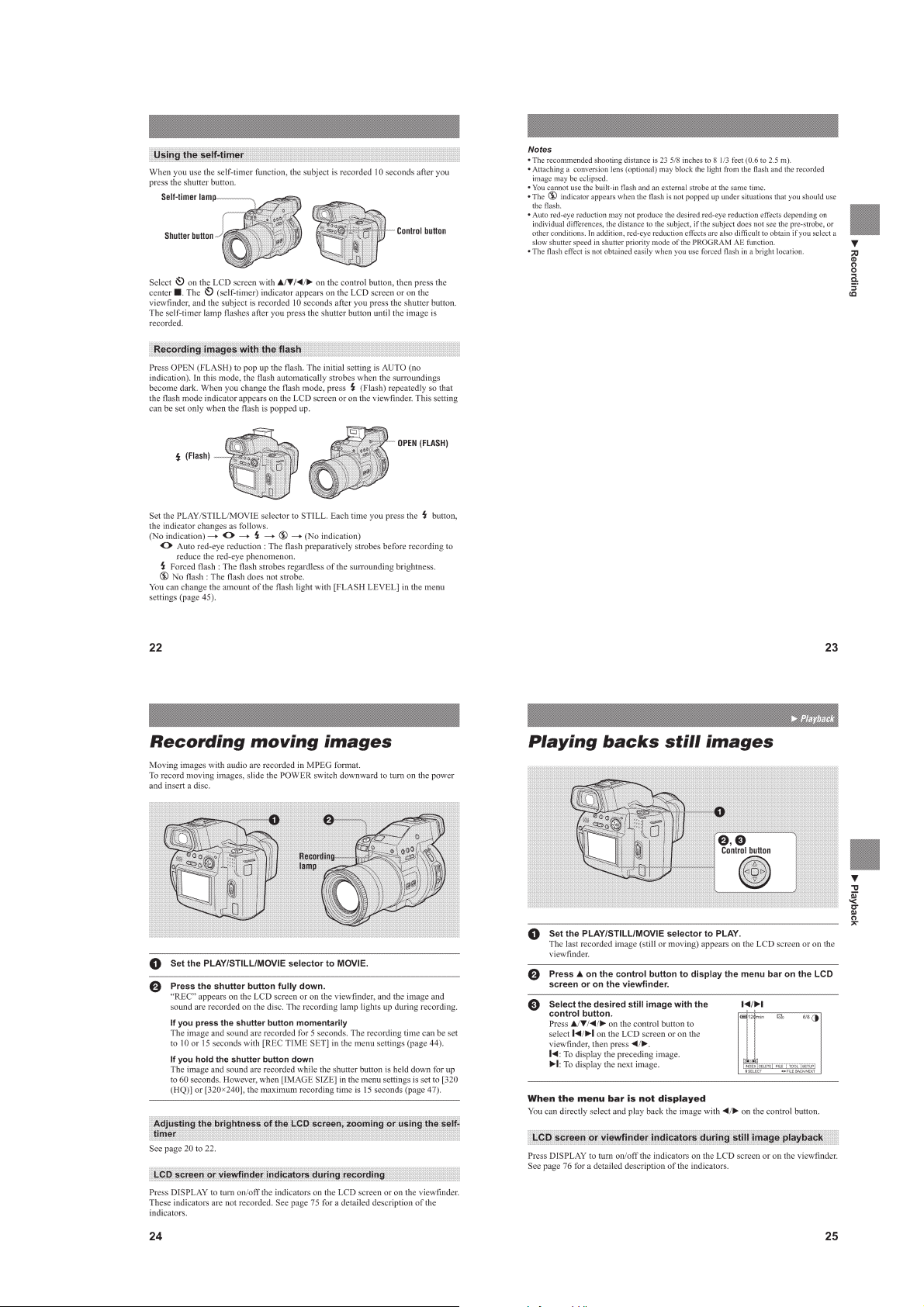

Recording moving images ·····················································1-5

B Playback

Playing back still images ·······················································1-5

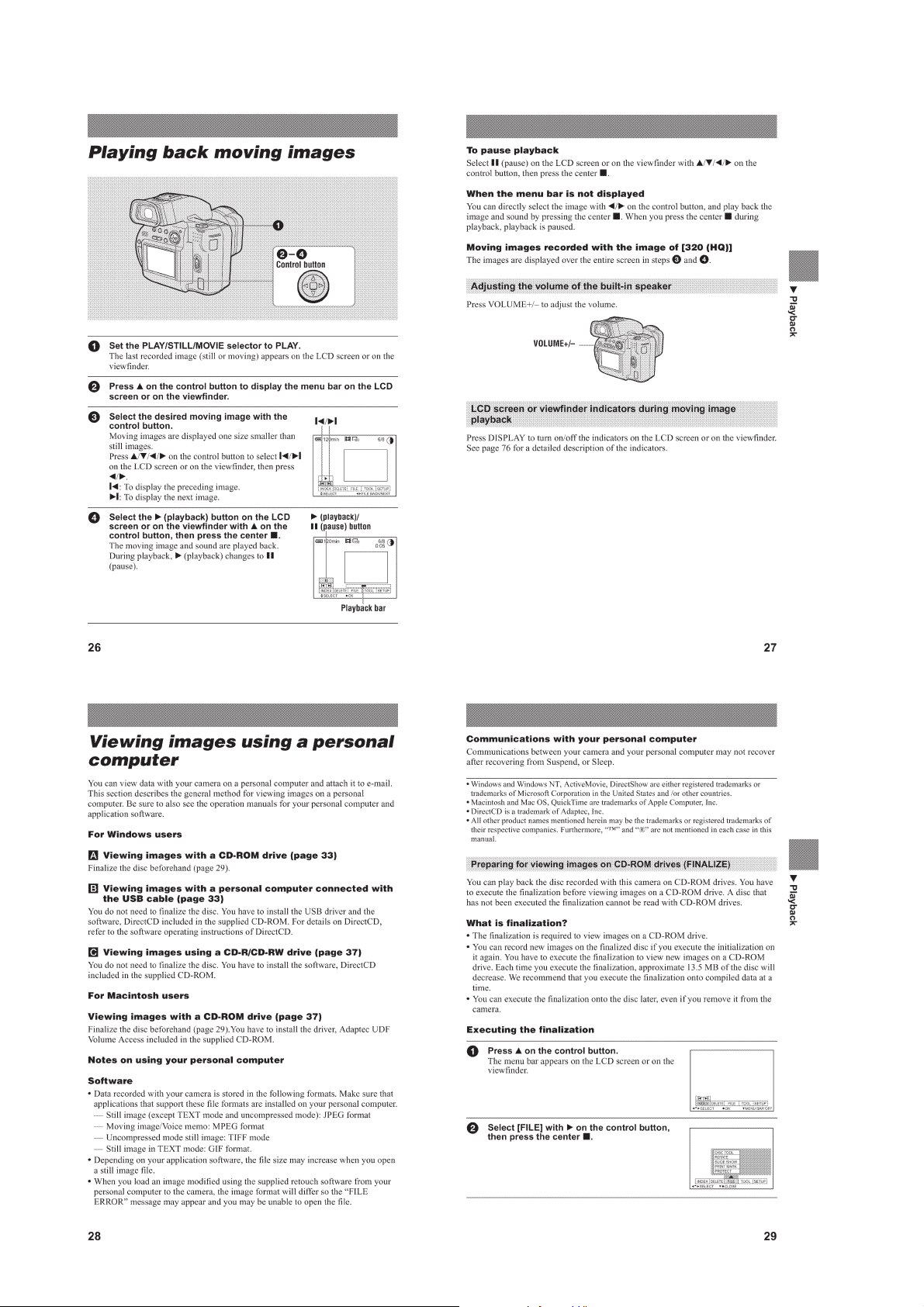

Playing back moving images ·················································1-6

Viewing images using a personal computer ··························1-6

Image file storage destinations and image file names ···········1-9

Advanced operations

Before performing advanced operations

How to use the PLAY/STILL/MOVIE selector·····················1-9

How to use the control button················································1-9

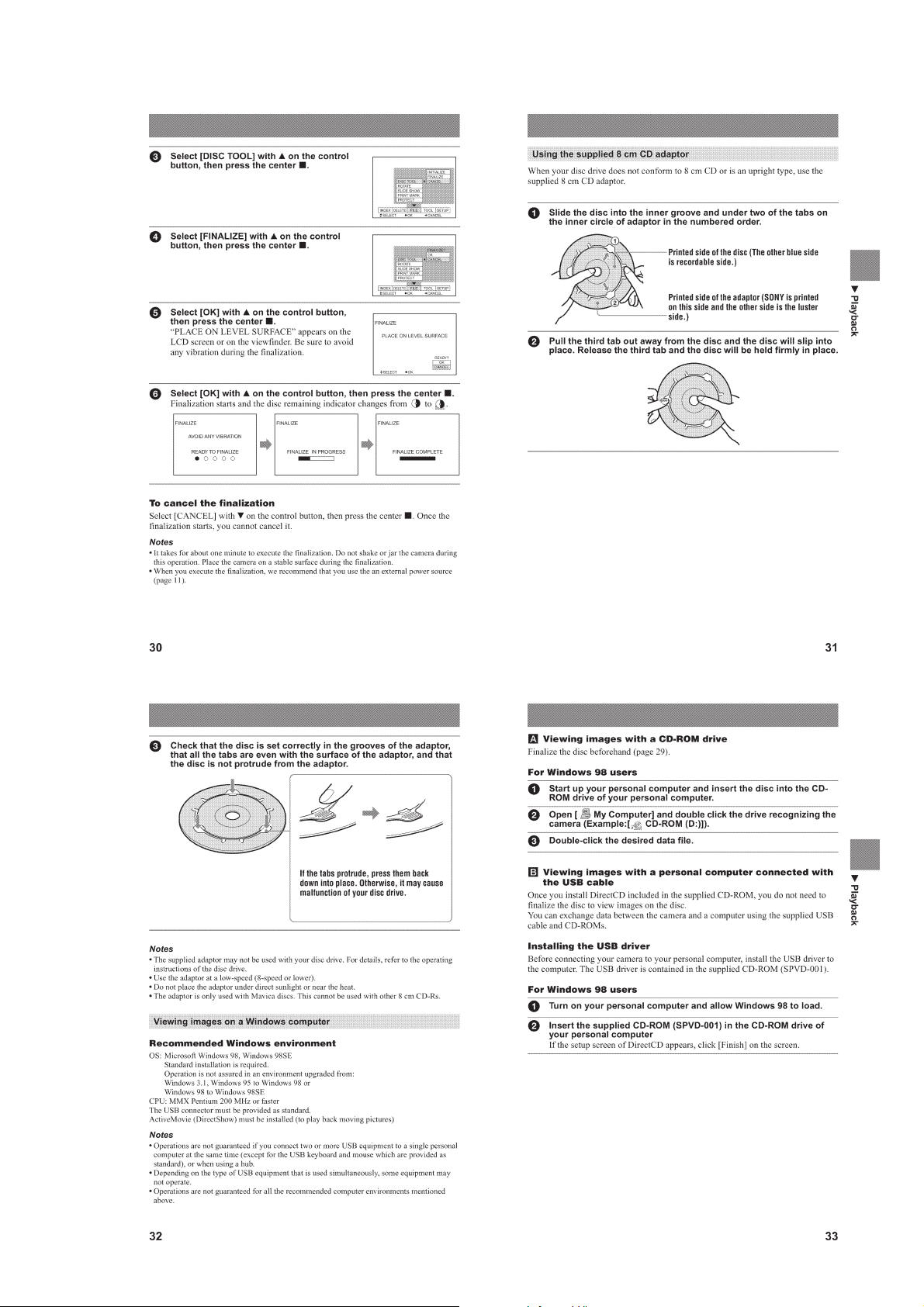

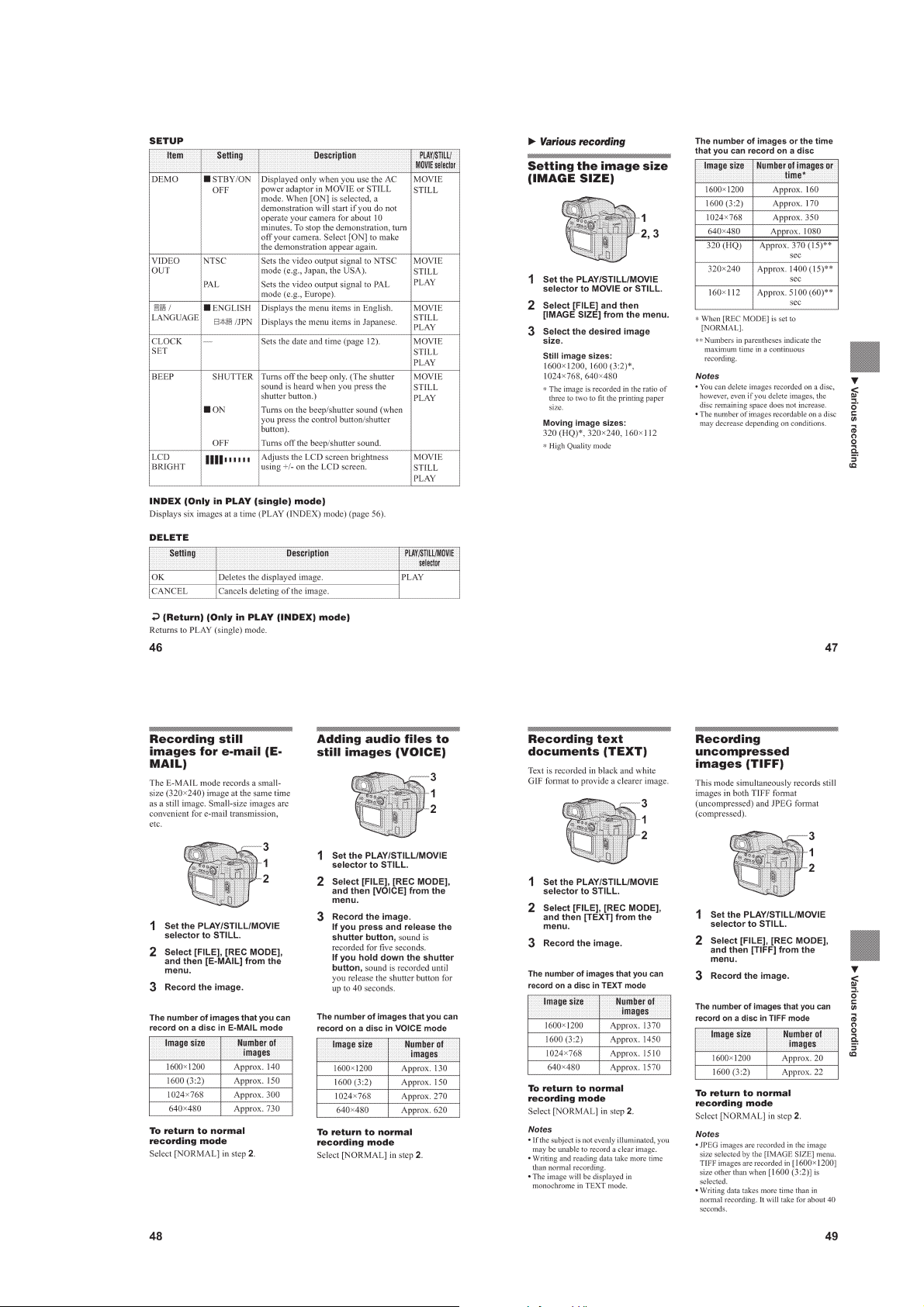

How to change the menu settings ········································1-10

B V arious recording

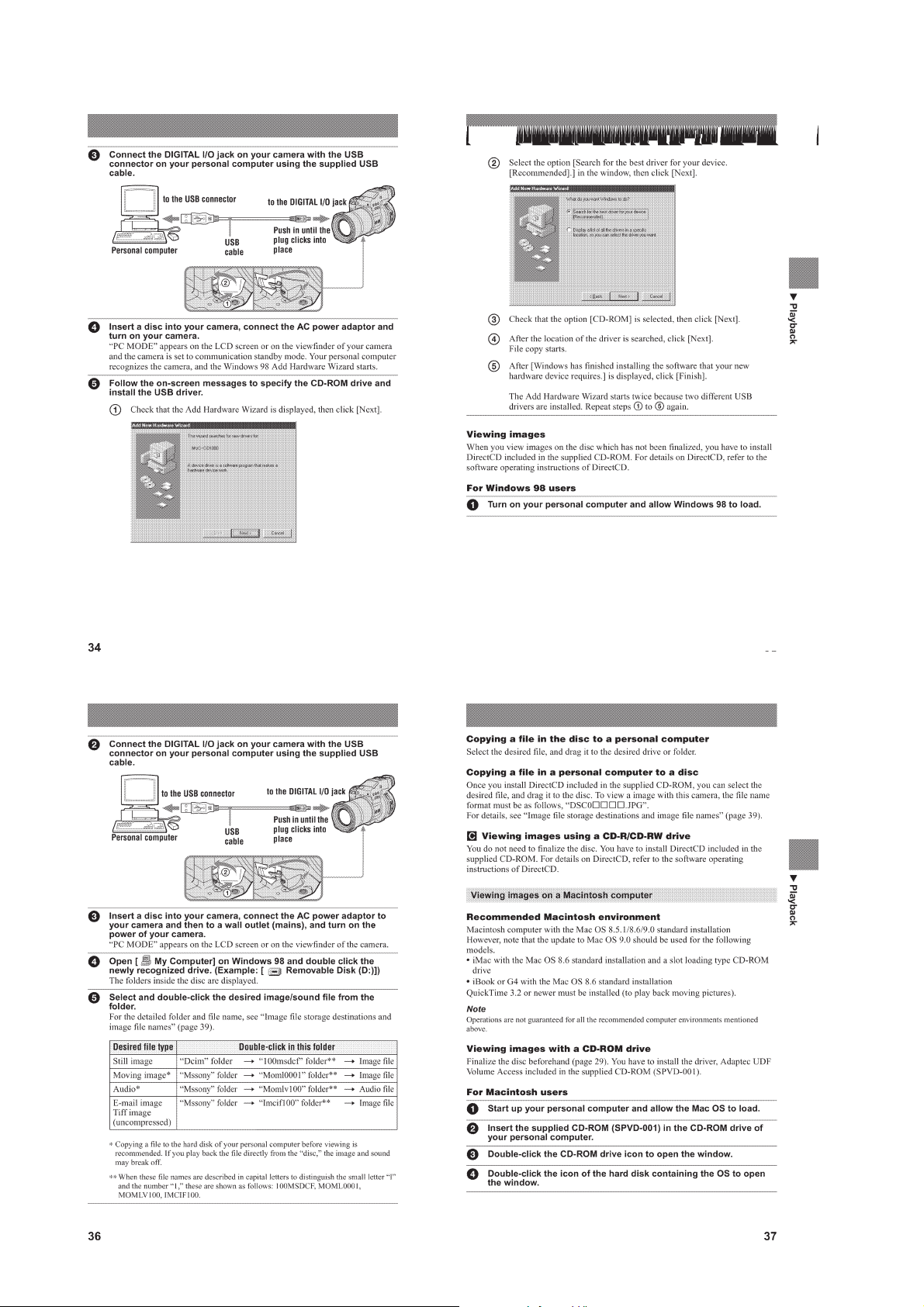

Setting the image size (IMAGE SIZE) ································1-11

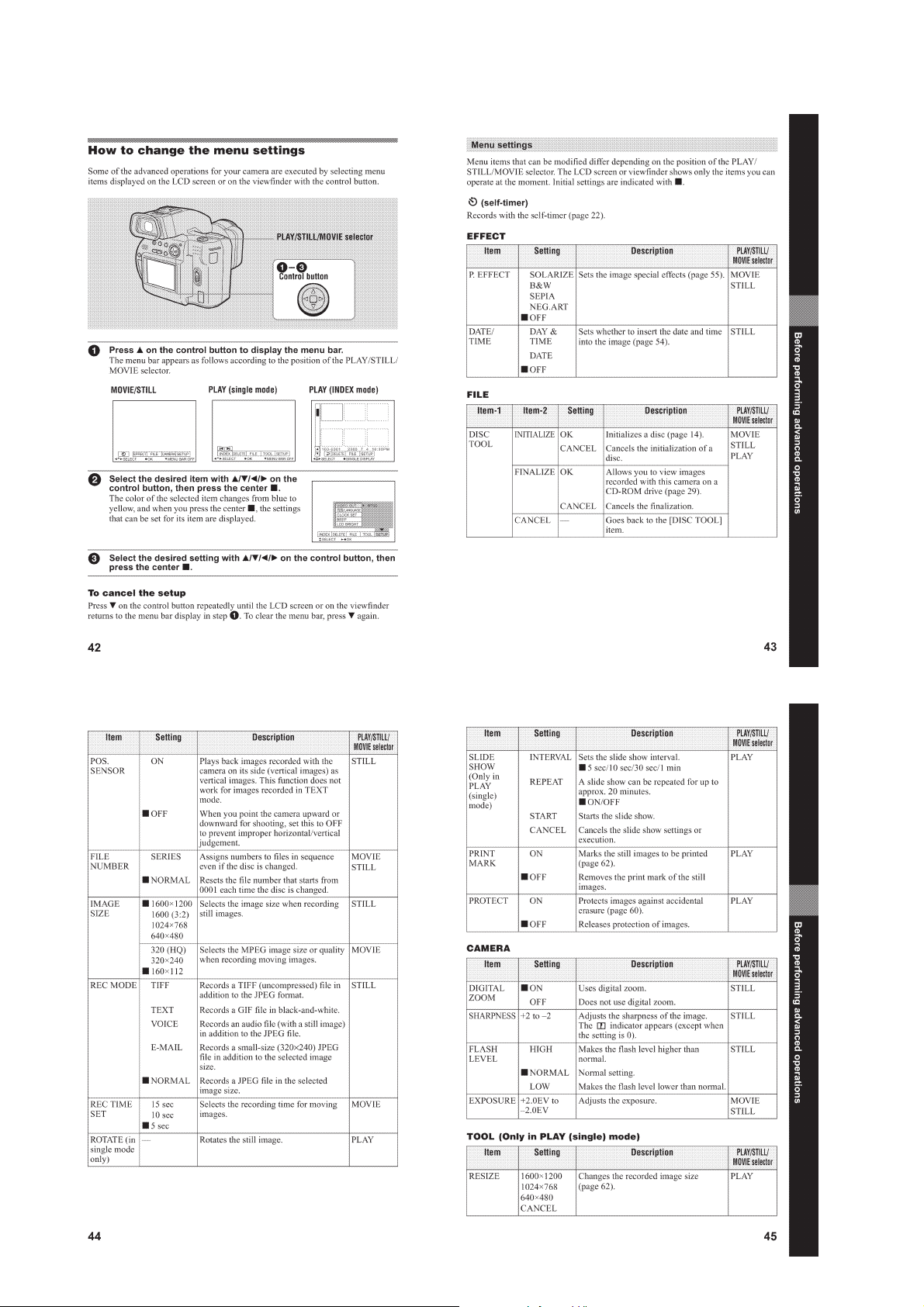

Recording still images for e-mail (E-MAIL)·······················1-11

Adding audio files to still images (VOICE) ························1-11

Recording text documents (TEXT) ·····································1-11

Recording uncompressed images (TIFF)·····························1-11

Recording images in macro ·················································1-12

Focusing manually·······························································1-12

Using the PROGRAM AE function ·····································1-12

Using the Spot light–metering function······························· 1-12

Adjusting the exposure (EXPOSURE) ································1-12

Adjusting the white balance (WHITE BALANCE) ············1-12

Recording the date and time on the still image (DATE/TIME) ·

Enjoying picture effects (PICTURE EFFECT) ···················1-13

B V arious playback

Playing back six images at once (INDEX) ··························1-13

Enlarging a part of the still image (Zoom and trimming)···· 1-13

Rotating a still image (ROTATE) ·········································1-14

Playing back the still images in order (SLIDE SHOW) ······1-14

Viewing images on a TV screen ··········································1-14

B Editing

Preventing accidental erasure (PROTECT) ·························1-14

Deleting images (DELETE) ················································1-14

Changing the recorded still image size (RESIZE)··············· 1-15

Selecting still images to print (PRINT MARK) ··················1-15

Additional information

Precautions··········································································· 1-15

On discs ···············································································1-16

Using your camera abroad ···················································1-16

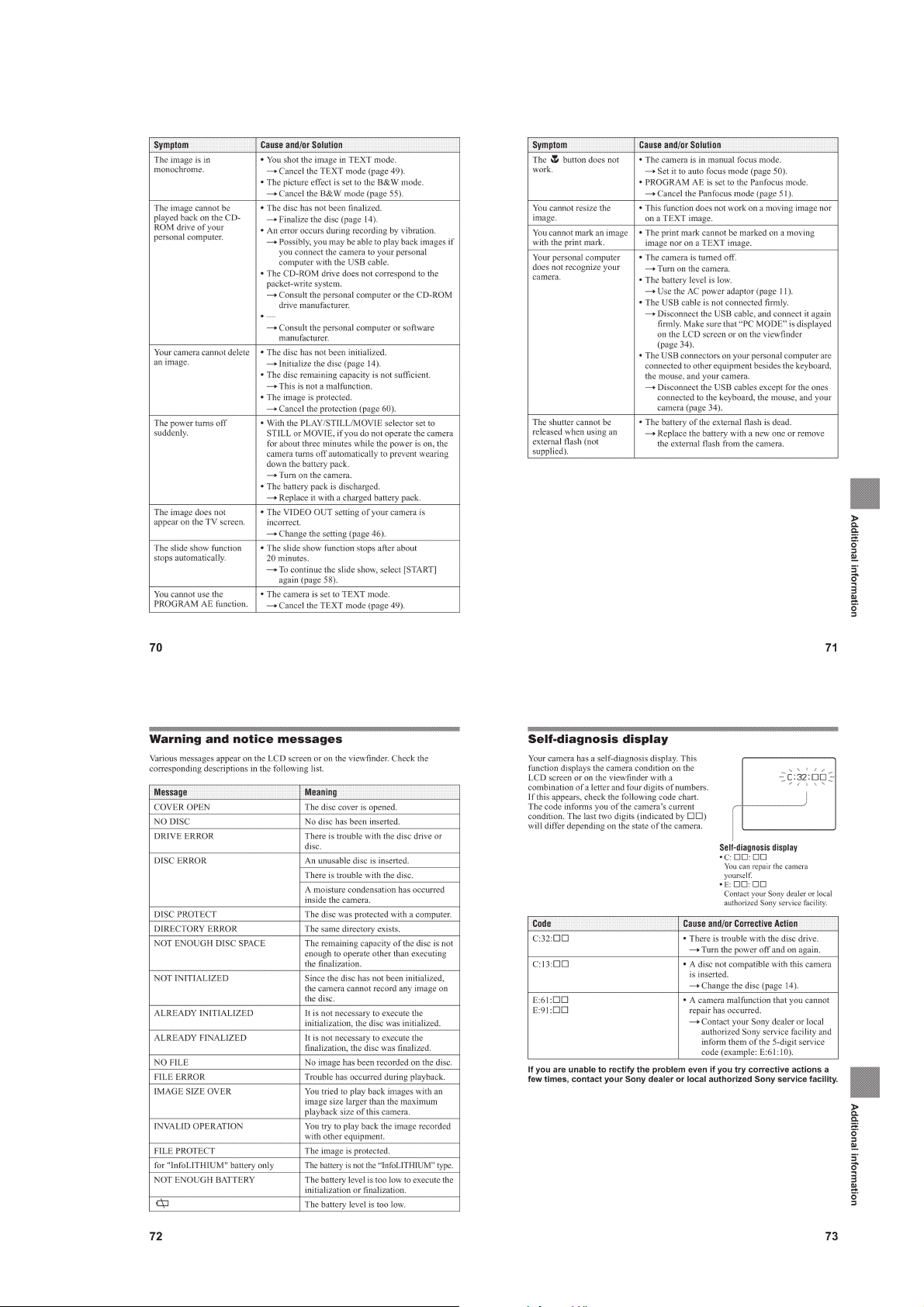

Troubleshooting ···································································1-16

Warning and notice messages ··············································1-17

Self-diagnosis display ··························································1-17

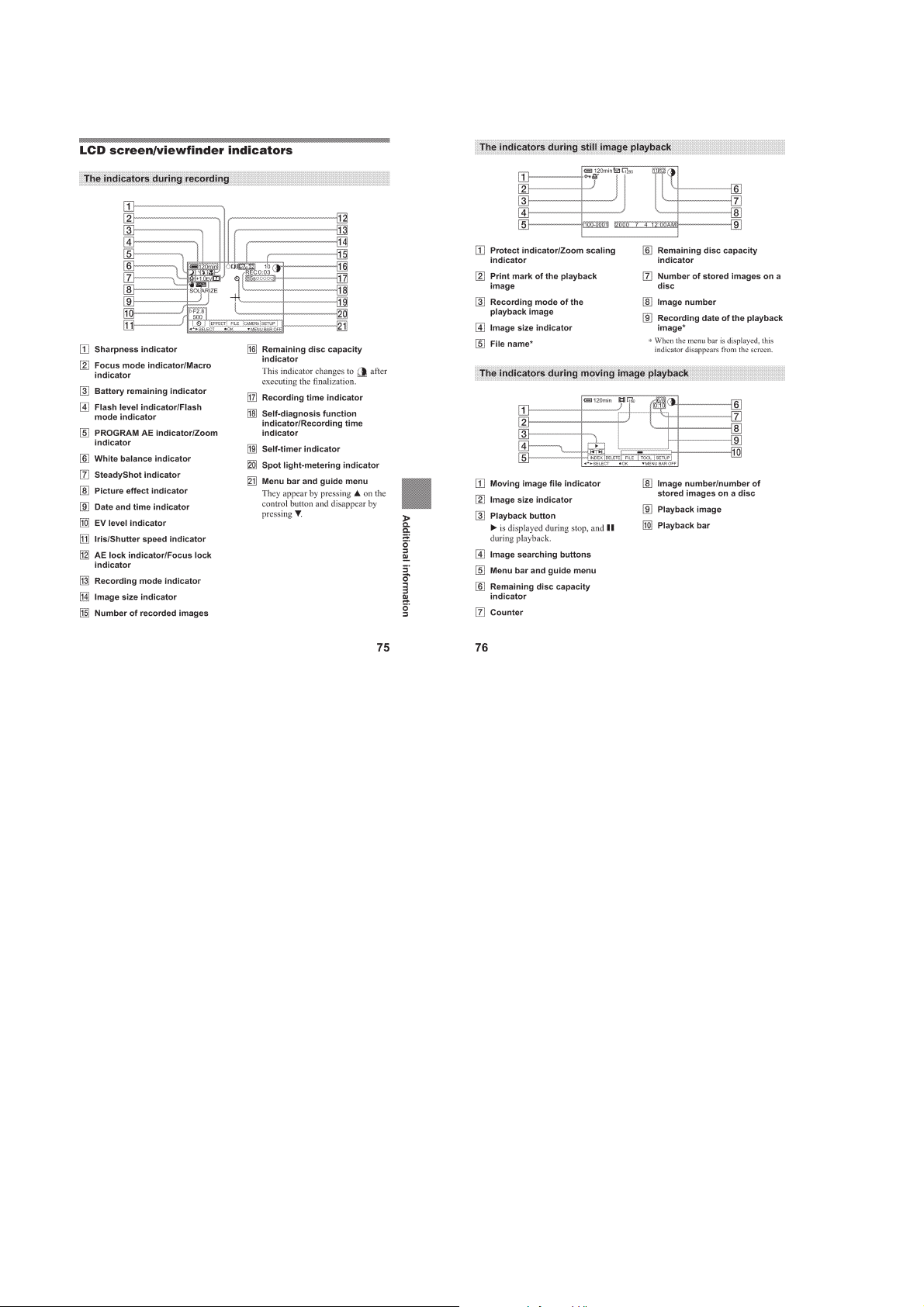

LCD screen/viewfinder indicators ·······································1-18

1-13

2. DISASSEMBLY

2-1. LCD SECTION (PK-051 BOARD) ································2-2

2-2. CABINET (UPPER) SECTION······································2-3

2-3. FLASH UNIT··································································2-3

2-4. EVF SECTION································································2-4

2-5. CABINET (F) SECTION,

CABINET (CENTER) SECTION···································2-5

2-6. LENS BLOCK ASSEMBLY,

CONTROL SWITCH BLOCK (FS52K),

CONTROL SWITCH BLOCK (JK52K) ························2-5

2-7. CONTROL SWITCH BLOCK (ZM52K)······················· 2-6

2-8. VP-051, SE-115 BOARDS ·············································2-6

2-9. SY -060, VC-246 BOARDS ·············································2-7

2-10. MECHANISM DECK (DDX-G2000 COMPLETE

ASSEMBLY),

2-11. LID CABINET SECTION,

CONTROL SWITCH BLOCK (MP52K) ·······················2-9

2-12.

CD-272 BOARD, LENS ASSEMBLY, VAP ASSEMBLY··

2-13. CIRCUIT BOARDS LOCATION ·································2-10

2-14. FLEXIBLE BOARDS LOCATION ······························ 2-11

Disassembling procedure of Mechanism deck (DDXG2000 COMPLETE ASSEMBLY) are not shown.

Pages 2-12 and 2-13 are not shown.

CONTROL SWITCH BLOCK (AJ52K) ··

2-8

2-9

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM-1 ·································3-1

OVERALL BLOCK DIAGRAM-2 ·································3-3

3-2. STEADY SHOT BLOCK DIAGRAM····························3-5

3-3. MODE CONTROL BLOCK DIAGRAM ·······················3-7

3-4. LCD BLOCK DIAGRAM ··············································3-9

3-5. EVF BLOCK DIAGRAM·············································3-11

3-6. POWER BLOCK DIAGRAM-1 ···································3-13

POWER BLOCK DIAGRAM-2 ···································3-15

POWER BLOCK DIAGRAM-3 ···································3-17

Founctional block diagrams are not shown.

Pages from 3-19 to 3-28 are not shown.

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2) ·······················4-1

FRAME SCHEMATIC DIAGRAM (2/2) ·······················4-3

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································4-5

• CD-272 (CCD IMAGER)

PRINTED WIRING BOARD ·························4-7

• CD-272 (CCD IMAGER)

SCHEMATIC DIAGRAM ······························4-9

• CONTROL SWITCH BLOCK (JK52K, FS52K)

SCHEMATIC DIAGRAM ····························4-10

Schematic diagram and printed wiring board of the SY062 and MD-082 boards are not shown.

Pages from 4-11 to 4-36 are not shown.

• MK-015 (EYE SENSOR)

PRINTED WIRING BOARD ·······················4-37

• MK-015 (EYE SENSOR)

SCHEMATIC DIAGRAM ····························4-38

• VC-246 (LENS DRIVE, VIDEO AMP, BUS SWITCH,

LINE/SPEAKER AMP, HI CONTROL,

DC/DC CONVERTER-1,2)

PRINTED WIRING BOARD ·······················4-39

• VC-246 (LENS DRIVE)(1/8)

SCHEMATIC DIAGRAM ····························4-43

• VC-246 (VIDEO AMP)(2/8)

SCHEMATIC DIAGRAM ····························4-45

• VC-246 (CAMERA/MD INTERFACE)(3/8)

SCHEMATIC DIAGRAM ····························4-47

• VC-246 (LINE/SPEAKER AMP)(4/8)

SCHEMATIC DIAGRAM ····························4-49

• VC-246 (HI CONTROL)(5/8)

SCHEMATIC DIAGRAM ····························4-51

• VC-246 (DC/DC CONVERTER-1)(6/8)

SCHEMATIC DIAGRAM ····························4-53

• VC-246 (DC/DC CONVERTER-2)(7/8)

SCHEMATIC DIAGRAM ····························4-55

— 3 —

Page 4

• VC-246 (CONNECTOR)(8/8)

SCHEMATIC DIAGRAM ····························4-57

• VP-051 (STEADY SHOT, LENS MOTOR DRIVE)

PRINTED WIRING BOARD ·······················4-59

• VP-051 (STEADY SHOT, LENS MOTOR DRIVE)

SCHEMATIC DIAGRAM ····························4-61

• SE-115 (PITCH/YAW SENSOR)

PRINTED WIRING BOARD ·······················4-63

• SE-115 (PITCH/YAW SENSOR)

SCHEMATIC DIAGRAM ····························4-65

• SW-342 (USER CONTROL)

PRINTED WIRING BOARD ·······················4-67

• SW-342 (USER CONTROL),

CONTROL SWITCH BLOCK (LC52K)

SCHEMATIC DIAGRAMS··························4-69

• PK-051 (LCD DRIVE, BACK-LIGHT,

TIMING GENERATOR)

PRINTED WIRING BOARD ·······················4-71

• PK-051 (LCD DRIVE, BACK-LIGHT)(1/2)

SCHEMATIC DIAGRAM ····························4-75

• PK-051 (TIMING GENERATOR)(2/2)

SCHEMATIC DIAGRAM ····························4-77

• LB-066 (BACK-LIGHT)

PRINTED WIRING BOARD ·······················4-79

• LB-066 (BACK-LIGHT)

SCHEMATIC DIAGRAM ····························4-80

• VF-144 (LCD DRIVE, TIMING GENERATOR)

PRINTED WIRING BOARD ·······················4-81

• VF-144 (LCD DRIVE)(1/2)

SCHEMATIC DIAGRAM ····························4-83

• VF-144 (TIMING GENERATOR)(2/2)

SCHEMATIC DIAGRAM ····························4-85

• CONTROL SWITCH BLOCK

(AE52K, ZM52K, AJ52K, MP52K)

SCHEMATIC DIAGRAM ····························4-87

4-3. WAVEFORMS ······························································4-89

4-4. MOUNTED PARTS LOCATION ·································4-94

5. ADJUSTMENTS

1. Before Starting Adjustment·············································5-1

1-1. Adjusting items when replacing main parts and boards··5-2

5-1. ADJUSTMENT·······························································5-3

1-1. PREPARATIONS BEFORE ADJUSTMENT ·················5-3

1-1-1.List of Service Tools························································5-3

1-1-2.Preparations ·····································································5-4

1-1-3.Discharging of the Flashlight Power Supply···················5-5

1-1-4.Precaution ········································································5-7

1. Setting the Switch···························································· 5-7

2. Order of Adjustments ······················································5-7

3. Subjects ···········································································5-7

1-2. INITIALIZATION OF B, D, E, F, 7 PAGE DATA ·········5-8

1-2-1.INITIALIZATION OF D PAGE DATA ·························· 5-8

1. Initializing the D Page Data ············································5-8

2. Modification of D Page Data···········································5-8

3. D Page Table ····································································5-8

1-2-2.Initializing the B, E, F, 7 Page Data ································5-9

1. Initializing the B, E, F, 7 Page Data ································5-9

2. Modification of B, E, F, 7 Page Data······························· 5-9

3. F Page Table ··································································5-10

4. 7 Page Table···································································5-11

5. E Page Table ··································································5-12

6. B Page Table ··································································5-12

1-3. VIDEO SYSTEM ADJUSTMENTS·····························5-13

1. Video Output Level Adjustment (VC-246 board) ········· 5-13

1-4. CAMERA SYSTEM ADJUSTMENTS························5-14

1. Zoom Key Center Adjustment ·······································5-14

2. HALL Adjustment ·························································5-14

3. Flange Back Adjustment (Using Minipattern Box)·······5-15

4. Flange Back Adjustment

(Using Flange Back Adjustment Chart) ························5-16

4-1. Flange Back Adjustment (1)··········································5-16

4-2. Flange Back Adjustment (2)··········································5-16

5. Flange Back Check························································5-17

6. F No. Standard Data Input············································· 5-17

7. Mechanical Shutter Adjustment ····································5-17

8. Picture Frame Setting ····················································5-18

9. Light Level Adjustment and ND Shutter Check ············5-19

10. Mixed Color Cancel Adjustment···································5-19

11. Auto White Balance Standard Data Input ·····················5-20

12. White Balance ND Filter Compensation·······················5-20

13. Auto White Balance Adjustment ···································5-21

14. Color Reproduction Adjustment (ND Filter OFF) ········5-21

15. Color Reproduction Adjustment (ND Filter ON)··········5-22

16. Color Reproduction Check ············································5-23

17. White Balance Check ····················································5-24

18. Strobe White Balance Adjustment·································5-25

19. Strobe Light Level and White Balance Check ··············5-25

20. CCD Black Defect Compensation································· 5-26

21. CCD White Defect Compensation ································5-26

22. Steady shot adjustment ··················································5-27

22-1. Steady Shot Adjustment (1)···········································5-27

22-2. Steady Shot Adjustment (2)···········································5-28

1-5. LCD SYSTEM ADJUSTMENT ···································5-29

1. LCD Initial Data Input ··················································5-29

2. VCO Adjustment (PK-051 board)································· 5-30

3. D Range Adjustment (PK-051 board) ···························5-30

4. Bright Adjustment (PK-051 board) ·······························5-31

5. Contrast Adjustment (PK-051 board)····························5-31

6. Color Adjustment (PK-051 board) ································5-32

7. V-COM Level Adjustment (PK-051 board) ··················5-32

8. V-COM Adjustment (PK-051 board) ····························5-33

9. White Balance Adjustment (PK-051 board)··················5-33

1-6. COLOR ELECTRONIC VIEWFINDER SYSTEM

ADJUSTMENT·····························································5-34

1. Initial Data Input ···························································5-34

2. VCO Adjustment (VF-144 board)································· 5-35

3. Bright Adjustment (VF-144 board) ·······························5-35

4. Contrast Adjustment (VF-144 board)····························5-36

5. Backlight Consumption Current Adjustment

(VF-144 board)······························································5-36

6. White Balance Adjustment (VF-144 board)··················5-37

7. Eye Sensor Adjustment (VF-144 board) ·······················5-37

1-7. SYSTEM CONTROL SYSTEM ADJUSTMENT ········5-38

1. Battery End Adjustment (VC-246 board)······················5-38

2. Serial No. Input ·····························································5-39

5-2. SERVICE MODE··························································5-40

2-1. ADJUSTMENT REMOTE COMMANDER ················5-40

1. Using the Adjustment Remote Commander·················· 5-40

2. Precautions Upon Using the Adjustment Remote

Commander ···································································5-40

2-2. DATA PROCESS···························································5-41

2-3. SERVICE MODE··························································5-42

1. Setting the Test Mode ····················································5-42

2. Bit Value Discrimination ···············································5-42

3. Emergency Memory Address of Flash Unit ··················5-42

4. Record of Use check······················································5-43

5. Self Diagnosis Log check··············································5-43

6. Switch check (1) ····························································5-44

7. Switch check (2) ····························································5-44

8. LED check ·····································································5-44

9. Position sensor check (VP-051 board PH201) ··············5-45

10. VAP (Active prism actuator) lock check ·······················5-45

— 4 —

Page 5

6. REPAIR PARTS LIST

6-1. EXPLODED VIEWS ······················································6-1

6-1-1.OVERALL SECTION·····················································6-1

6-1-2.CABINET (UPPER) SECTION······································6-2

6-1-3.EVF SECTION································································6-3

6-1-4.CABINET (F) SECTION ················································6-4

6-1-5.LENS SECTION ·····························································6-5

6-1-6.CABINET (CENTER) SECTION··································· 6-6

6-1-7.LID CABINET SECTION ··············································6-7

Exploded view and parts list of DDX-G2000 COMPLETE

ASSEMBLY are not shown.

Page 6-8 is not shown.

6-2. ELECTRICAL PARTS LIST ··········································6-9

Electrical parts list of the SY-062 and MD-082 boards

are not shown.

Pages from 6-11 to 6-18 are not shown.

* Color reproduction frame is shown on page 199.

— 5 —

Page 6

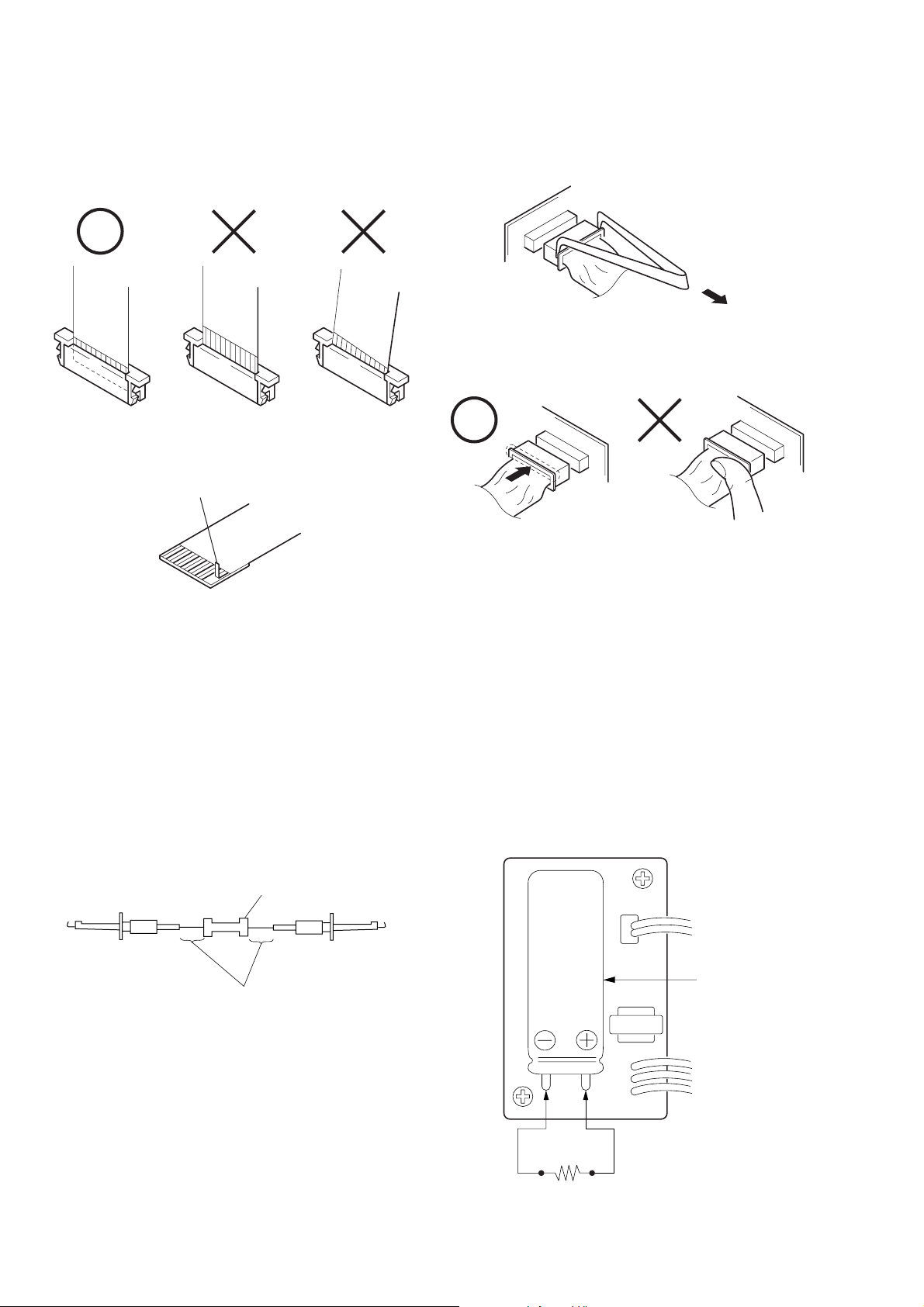

• NOTE FOR REPAIR

r

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the MVC-CD1000 is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

Capacito

Short jig

— 6 —

Page 7

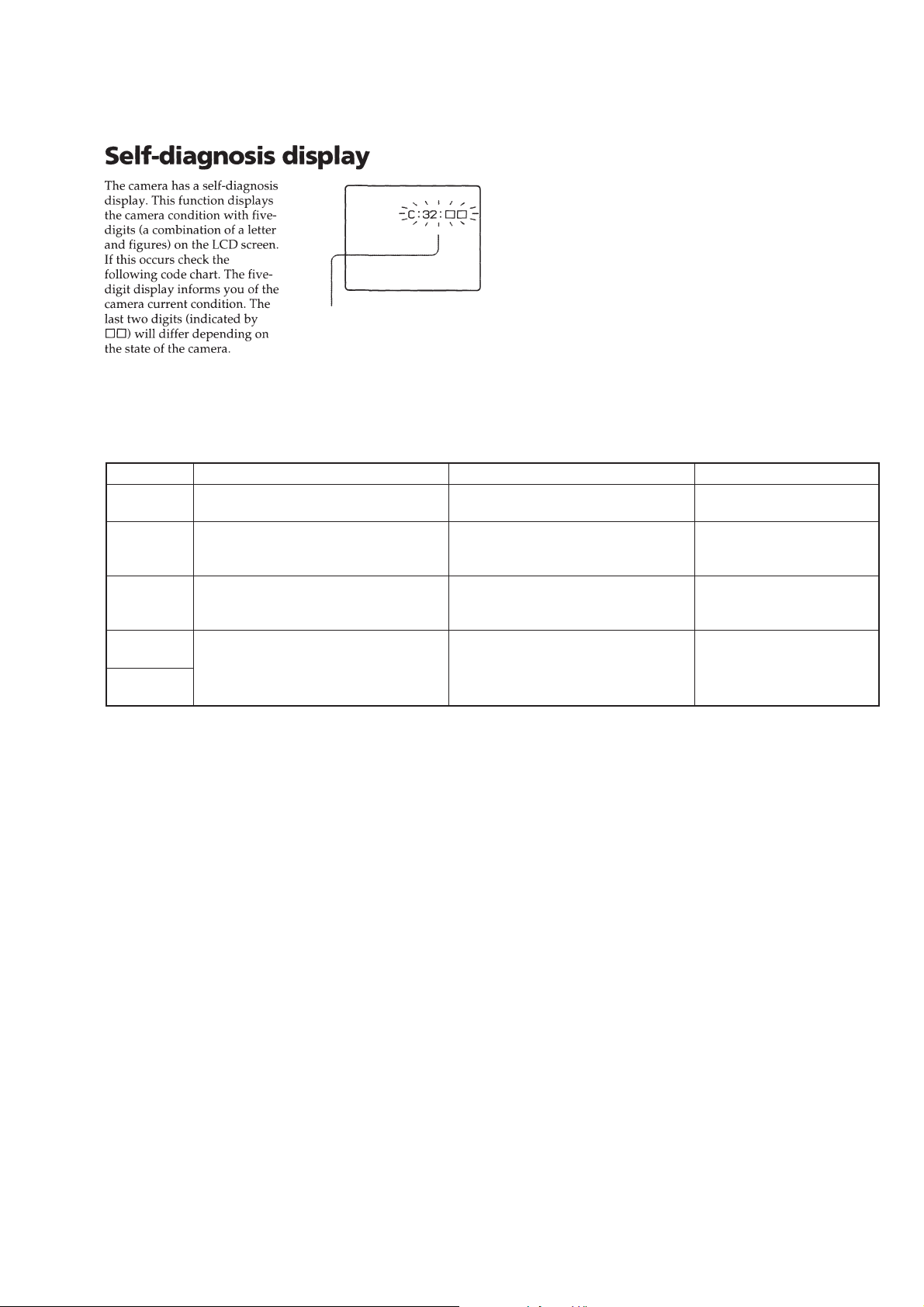

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

*1

E:61:00

*1

E:61:10

Note: The error code is cleared if rthe battery is removed, except

defective flash, unit.

*1 : The error display is given in two ways.

*2 : When the flash charging failed, Page:D, Address:67, Data:04

are written.

After repair, be sure to write Page:D, Address:67, Data:00.

Change the disk and turn off the main

power then back on.

Replace the CD-R disk.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Countermeasure

Defective base unit.

• The type of CD-R disk that cannot be

• Data is damaged.

*2

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

used by this machine, is inserted.

Caution Display During Error

DRIVE ERROR

DISK ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

— 7 —

Page 8

SECTION 1

GENERAL

MVC-CD1000

This section is extracted from

instruction manual.

1-1

Page 9

1-2

Page 10

1-3

Page 11

1-4

Page 12

1-5

Page 13

1-6

Page 14

1-7

Page 15

1-8

Page 16

1-9

Page 17

1-10

Page 18

1-11

Page 19

1-12

Page 20

1-13

Page 21

1-14

Page 22

1-15

Page 23

1-16

Page 24

1-17

Page 25

1-18E

Page 26

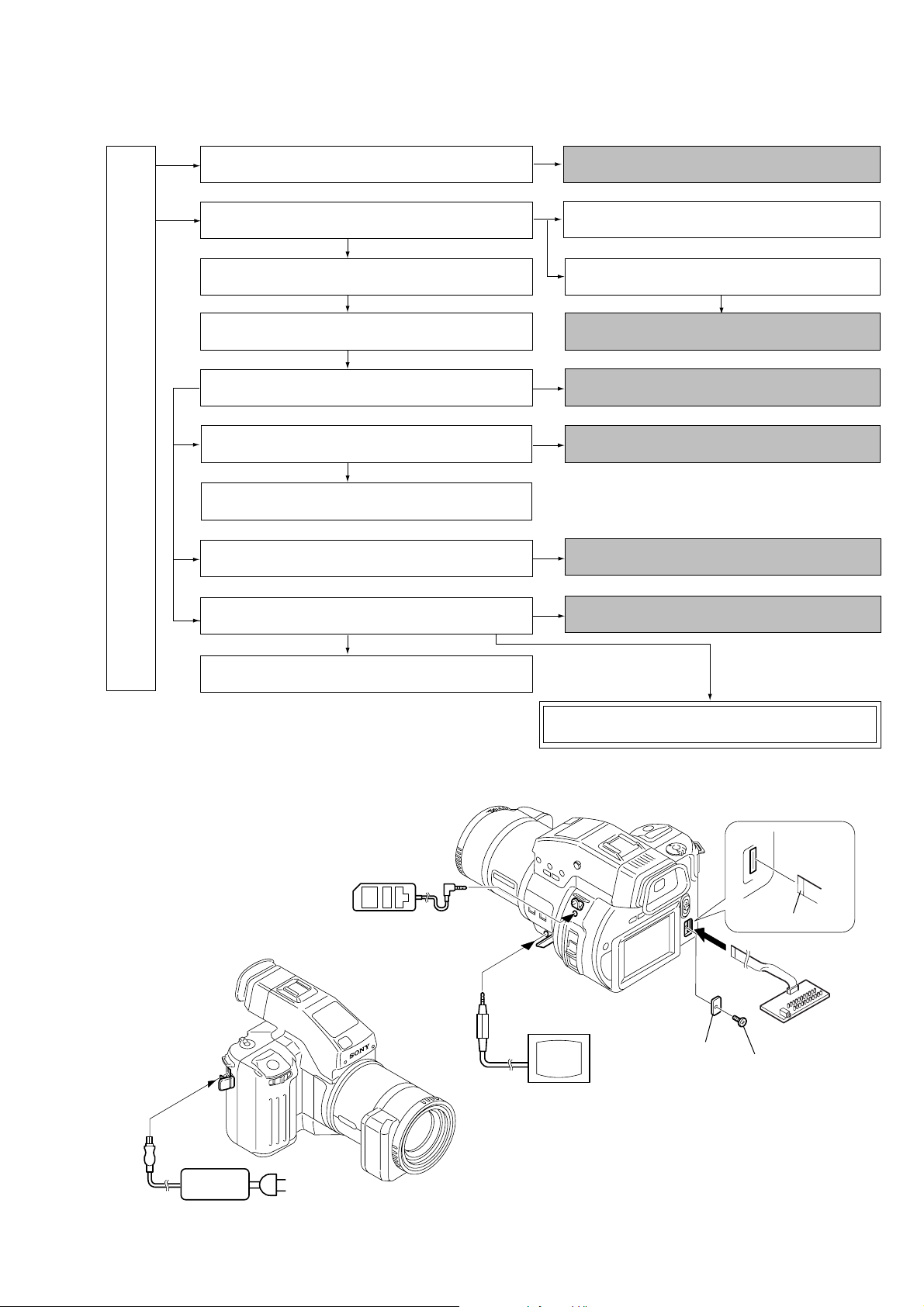

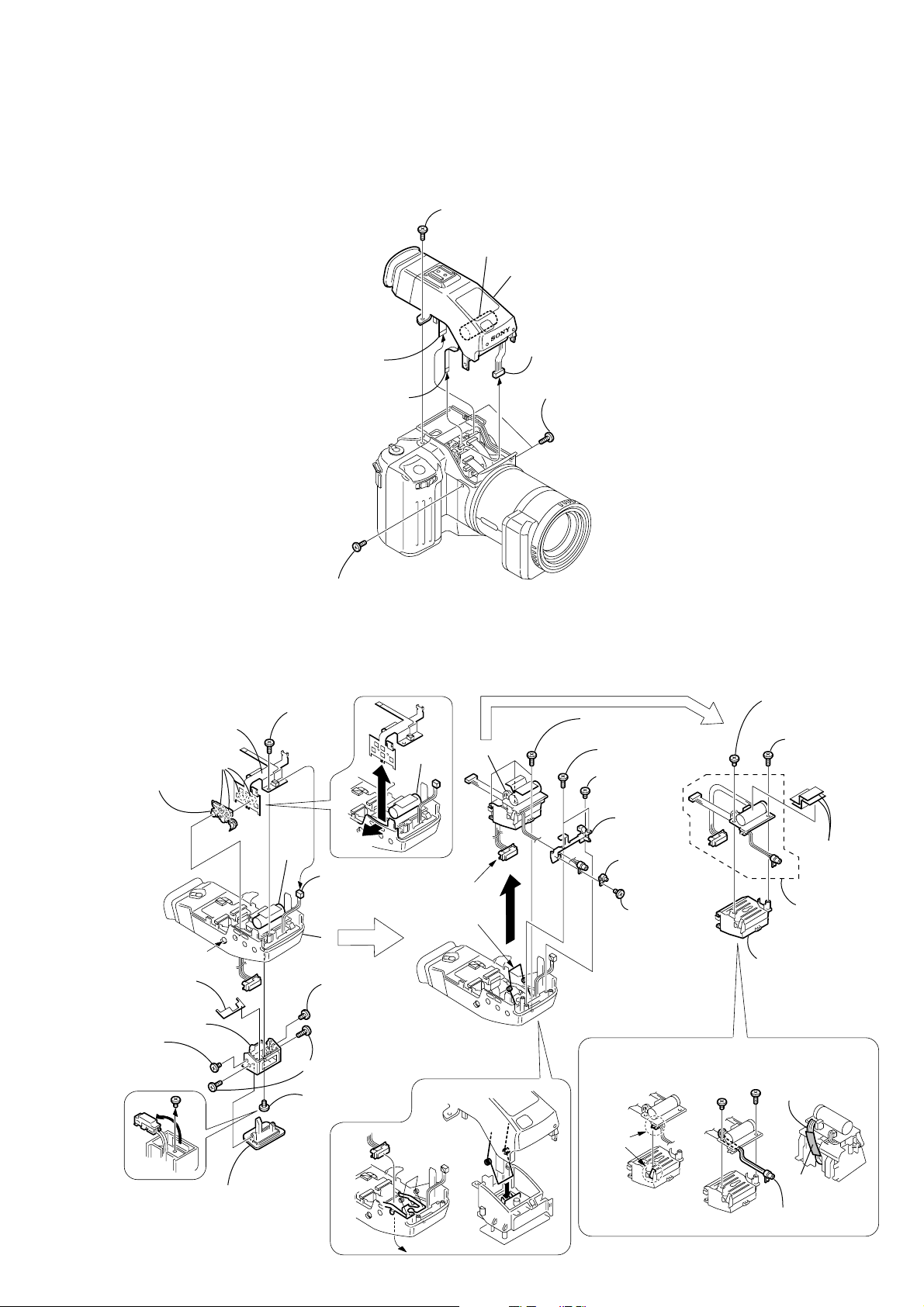

SECTION 2

MVC-CD1000

2-2. Cabinet (upper) section

2-6. Lens block assembly, Control switch block (FS52K),

Control switch block (JK52K)

2-7. Control switch block (ZM52K)

MK-015, VF-144, LB-066 boards service position

VP-051, CD-272, SE-115 boards service position

CD-272, SE-115 boards service position

2-1. LCD section (PK-051 board)

2-5. Cabinet (F) section, Cabinet (center) section

2-8. VP-051, SE-115 boards

2-12. CD-272 board, Lens assembly, VAP assembly

PK-051 board service position

2-3. Flash unit

2-4. EVF section

Tapping

screw (B2

×

5)

CPC jack lid

CPC-12 jig

(J-6082-436-A)

1

1

22

22

Conductor side

1

22

Adjustment remote

commander (RM-95)

AC IN

AC power

adaptor

Monitor TV

2-9. SY-060, VC-246 boards

VC-246, SY-060, CD-272, SE-115 boards and

Camera section check service position

2-10. Mechanism deck (DDX-G2000 complete assembly),

Control switch block (AJ52K)

Mechanism deck (DDX-G2000 complete assembly)

check service position

2-11. Lid cabinet section,

Control switch block (MP52K)

[CONNECTION OF THE EQUIPMENT]

Disassembling procedure of Mechanism deck

(DDX-G2000 COMPLETE ASSEMBLY) are not shown.

DISASSEMBLY

The following flow chart shows the disassembly procedure.

MVC-CD1000

2-1

Page 27

NOTE: F ollo w the disassembly procedure in the numerical order given.

e

2-1. LCD SECTION (PK-051 BOARD)

Remove the lid rear lid

in the direction of the arrow.

×

5)

2

Hinge shaft

stopper

1

T wo tapping

screws (B2 × 5)

3

Six tapping

screws (B2

6

Lid rear lid

B

6

T wo screws

(M2

PK-051

Board

×

3), lock ace, p2

8

PK-051 board

5

Four tapping

screws (B2

7

BL support

assembly

×

5)

A

A

7

Lock plate

8

Peep window

5

Tilt up the upper

hinge assembly

in the direction

of the arrow.

[PK-051 BOARD SERVICE POSITION]

Monitor TV

4

Screw (M2 × 3),

lock ace, p2

2

(B2

1

Control switch block

(LC52K) (4P)

3

(LC52K)

Adjustment remote

commander (RM-95)

Lid rear lid

q;

Back light

Cold cathode

fluorescent tube

9

Liquid crystal

indicator module

4

FP-046 flexibl

board (24P)

T apping screw

×

5)

Control switch block

B

Setup before LCD section check

To facilitate the checks, set the “Internal color bar signal” mode

using the adjustment remote control before LCD section check.

Setting the “Internal color bar signal” mode.

1) Set the PLAY/STILL/MOVIE switch to “PLAY”.

2) Select page: 5, address: F1, and set data: 04.

FP-046 flexible board (24P)

Insulation sheet

1

22

Liquid crystal

indicator module

SW

-342

PK-051

Board

22

Back light

Cold cathode

fluorescent tube

Exiting the “Internal color bar signal” mode.

1) Select page: 5, address: F1, and set data: 00.

SW-342 board

PK-051 board

AC power

adaptor

1

1

22

CPC-12 jig

(J-6082-436-A)

AC IN

2-2

Page 28

2-2. CABINET (UPPER) SECTION

d

Note: The built-in charging capacitor inside the FLASH unit is charged to the maximum of 300V.

There is a danger of electric shock due to the high voltage when the capacitor is tached by bare hand.

Discharge the voltage remained in the capacitor, referring to the Service Note (See page 6).

6

FP-041 flexible

board (25P)

4

Control switch block

(AE52K) (6P)

1

Screw (M2 × 5),

lock ace, p2

Note

7

(upper) section

Cabinet

5

Flash unit

(10P)

3

T wo screws

(M2 × 5),

lock ace, p2

2

Screw (M2 × 5),

lock ace, p2

2-3. FLASH UNIT

Note: The built-in charging capacitor inside the FLASH unit is charged to the maximum of 300V.

There is a danger of electric shock due to the high voltage when the capacitor is tached by bare hand.

Discharge the voltage remained in the capacitor, referring to the Service Note (See page 6).

2

4

Control switch

block (AE52K)

3

Two

dowels

5

AE button

6

Push the

button to open

the flash unit

9

Stroboscope

blind plate

qd

Stroboscope

luminous case

qa

Screw

(M2 × 3),

lock ace, p2

T apping

screw

(B2 × 5)

Note

1

Microphone

(2P)

qf

qs

Screw

(M2 × 3),

lock ace, p2

7

T wo tapping

screws (B2 × 5)

q;

Screw (M2 × 3),

lock ace, p2

Pull

Note

Be careful that

the flash must

not be caught.

PRECAUTION

DURING

INSTALLATION

8

7

Three tapping

6

screws (B2 × 5)

1

T wo tapping

screws (B2 × 5)

2

Screw

(M2 × 3),

lock ace, p2

4

5

Hard steel

light guide

cap

3

Screw

(M2 × 3),

lock ace, p2

PRECAUTION DURING

INSTALLATION

Switch

position

2

Screw

(M2 × 3),

lock ace, p2

1

T apping

screw

(B2 × 5)

4

Two S shiel

plates

5

Flash unit

3

Stroboscope

base assembly

Attaching harnesses of the

Flash unit

Harness (Flash)

8

Stroboscope lid

Tape

Ray catcher

element

2-3

Page 29

2-4. EVF SECTION

1

Screw

(M2 × 5),

lock ace, p2

2

T apping

screw

(B2 × 5)

4

EVF section

3

T wo tapping

screws (B2 × 5)

qa

assembly (453)

9

claws

qs

Cover the cushion and

diffusion plate with a piece

of paper or adhesive tape

or the like so that the parts

must not be scattered.

5

MK-015 board

2

VF cabinet (rear) assembly

4

VF lens

Three

VF-144

6

Three claws

VF cabinet (upper)

3

Two claws

q;

LB-066 board

8

VF cabinet (lower)

assembly

1

T wo tapping

screws (M1.7 × 4)

7

VF-144 board

[MK-015, VF-144, LB-066 BOARDS SERVICE POSITION]

LB-066 board

VF lens assembly (453)

AC IN

CPC-12 jig

(J-6082-436-A)

1

1

22

AC power

adaptor

MK-015 board

VF-144

VF-144 board

22

1

22

Setup before EVF section check

To facilitate the checks, set the “Internal color bar signal” mode

using the adjustment remote control before EVF section check.

Setting the “Internal color bar signal” mode.

1) Set the PLAY/STILL/MOVIE switch to “PLAY”.

2) Select page: 5, address: F1, and set data: 04.

FP-041 flexible board (25P)

Adjustment remote

commander (RM-95)

Monitor TV

Exiting the “Internal color bar signal” mode.

1) Select page: 5, address: F1, and set data: 00.

2-4

Page 30

2-5. CABINET (F) SECTION, CABINET (CENTER) SECTION

9

qf

Cabinet (center)

section

Two screws (M2 × 5),

lock ace, p2

SY 060

qa

T wo screws

(M2 × 5),

lock ace, p2

6

FP-040 flexible board (22P)

3

Flexible board (from lens assembly)(26P)

4

Ferrite core and F adhesive sheet

qs

Screw (M2 × 5), lock ace, p2

7

Battery terminal board (4P)

8

Control switch block (ZM52K) (6P)

2

q;

Two screws (M2 × 5),

lock ace, p2

Control switch block (FS52K) (4P)

1

Control switch block (JK52K) (8P)

5

FP-044 flexible board (18P)

qd

Cabinet (F) section

2-6. LENS BLOCK ASSEMBLY, CONTROL SWITCH BLOCK (FS52K),

CONTROL SWITCH BLOCK (JK52K)

6

2

Lens block assembly

4

T ape

5

Control switch

block (FS52K)

3

Lens ring

T wo screws

(M2 × 3),

lock ace, p2

7

Control switch

block (JK52K)

1

Four screws

(+PS 2 × 8)

2-5

Page 31

2-7. CONTROL SWITCH BLOCK (ZM52K)

PRECAUTION

DURING INSTALLATION

2

T wo tapping

1

screws K1 (B2

3

Hinge retainer

4

Battery lid

×

5)

[CD-272, SE-115 BOARDS SERVICE POSITION]

Control switch block (JK52K) (8P)

Control switch block (ZM52K) (6P)

CPC-12 jig

(J-6082-436-A)

1

22

1

When installing it,

align the switch position

as shown.

Control switch

block (ZM52K),

Switch holder

qa

T apping

screw

(B2 × 5)

7

BT lock claw

6

Adjustment remote

commander (RM-95)

Monitor TV

Control switch

qs

block (ZM52K)

q;

Ground plate (ZM)

9

T apping

screw (B2

8

Battery terminal board,

×

5)

Battery holder,

Hinge holder assembly,

etc

5

Three tapping

screws (B2

×

5)

22

AC IN

AC power

adaptor

FP-040 flexible board (22P)

Flexible board

(from lens assembly)(26P)

2-8. VP-051, SE-115 BOARDS

7

Lens cabinet

(upper) assembly

4

FP-043 flexible

board (8P)

1

Screw (M2 × 5),

lock ace, p2

5

Lens cabinet (VP)

assembly and

MF block

A

3

Remove the two claws

(Remove it while taking

care as the FP-043 flexible

board is connected.)

9

Lens cabinet

(lower) assembly

1

22

CD-272 board

SE-115 board

A

B

CD272

SY 060

B

6

Four claws

The claws can be released easily

by pressing portion

8

Three tapping

screws (B2

2

screw (B2

q;

T apping

×

5)

4

5

×

5)

Two claws

VP-051 board

FP-044 flexible board (18P)

Lens block assembly

B

at the same time.

CD272

VP-051

3

(M2

lock ace, p2

Screw

×

2

SE-115 board

1

Three screws

×

(M2

3),

lock ace, p2

3),

2-6

Page 32

S

Y

-

0

6

0

1

1

22

22

1

22

VP-051

VP-051 board

Lens assembly

SE-115 board

AC IN

AC power

adaptor

Adjustment remote

commander (RM-95)

Monitor TV

Control switch block (JK52K) (8P)

Control switch block (ZM52K) (6P)

Flexible board

(from lens assembly)(26P)

FP-040 flexible board (22P)

FP-044 flexible board (18P)

CPC-12 jig

(J-6082-436-A)

CD-272 board

[VP-051, CD-272, SE-115 BOARDS SERVICE POSITION]

2-9. SY-060, VC-246 BOARDS

VC246

MD082

SY 060

SY 060

VC246

MD082

SY 060

C

D

-

272

1

Three screws

(M2

×

3),

lock ace, p2

5

T wo screws

(M2

×

3), lock ace, p2

7

T wo screws

(M2 × 3),

lock ace, p2

6

SY frame (A)

8

SY frame (B)

2

Board to board

connector (80P)

9

Board to board

connector (50P)

q;

Claw

3

SY-060 board

qa

VC-246 board

4

Control switch block

(AJ52K) (8P)

CPC-12 jig

(J-6082-436-A)

1

1

22

22

1

22

Control switch block (ZM52K) (6P)

Adjustment remote

commander (RM-95)

Monitor TV

Control switch block (JK52K) (8P)

Extension cable

(J-6082-444-A) (80P)

Extension cable

(J-6082-487-A) (50P)

Flexible board

(from lens assembly)(26P)

FP-040 flexible board (22P)

FP-044 flexible board (18P)

AC IN

AC power

adaptor

Lens block assembly

CD-272 board

SE-115 board

SY-060 board

VC-246 board

[VC-246, SY-060, CD-272, SE-115 BOARDS AND CAMERA SECTION CHECK SERVICE POSITION]

2-7

Page 33

2-10.MECHANISM DECK (DDX-G2000 COMPLETE ASSEMBLY), CONTROL SWITCH

)

BLOCK (AJ52K)

1

M

082

Control switch block

(AJ52K) (8P)

3

Board to board

connector (50P)

D-

5

SY-060, VC-246 boards

Precautions during handling

• Do not turn the side of the optical lens downward.

• Hold the frame.

• Do not touch the optical lens surface.

1

4

Claw

2

Screw

(M2 × 5),

lock ace, p2

5

(M2

lock ace, p2

Screw

SY 060

2

T wo screws

×

(M2

lock ace, p2

6

3),

Mechanism deck

DDX-G2000

MD-082

Board

7

Control switch block

(AJ52K)

6

Strap plate (L)

complete assembly

Note

5

T wo tapping

MD-082

Board

3

Screw

(M2 × 5),

lock ace, p2

2

4

T wo tapping

screws (B2 × 5)

×

5),

1

T wo tapping

screws (B2 × 5)

3

Open leaf spring

screws (B2 × 5

4

Screw

(M2 × 5),

lock ace, p2

Note: Disassembling procedure of Mechanism deck

(DDX-G2000 COMPLETE ASSEMBLY) are not shown.

[MECHANISM DECK (DDX-G2000 COMPLETE ASSEMBLY) CHECK SERVICE POSITION]

CPC-12 jig

(J-6082-436-A)

Cabinet (center) section

Adjustment remote

commander (RM-95)

AC IN

AC power

adaptor

1

1

22

22

SY-060

1

22

VC-246

VC-246 board

SY-060 board

Control switch block

(AJ52K) (8P)

Mechanism deck

(DDX-G2000 complete assembly)

Extension cable

(J-6082-487-A) (50P)

2-8

Page 34

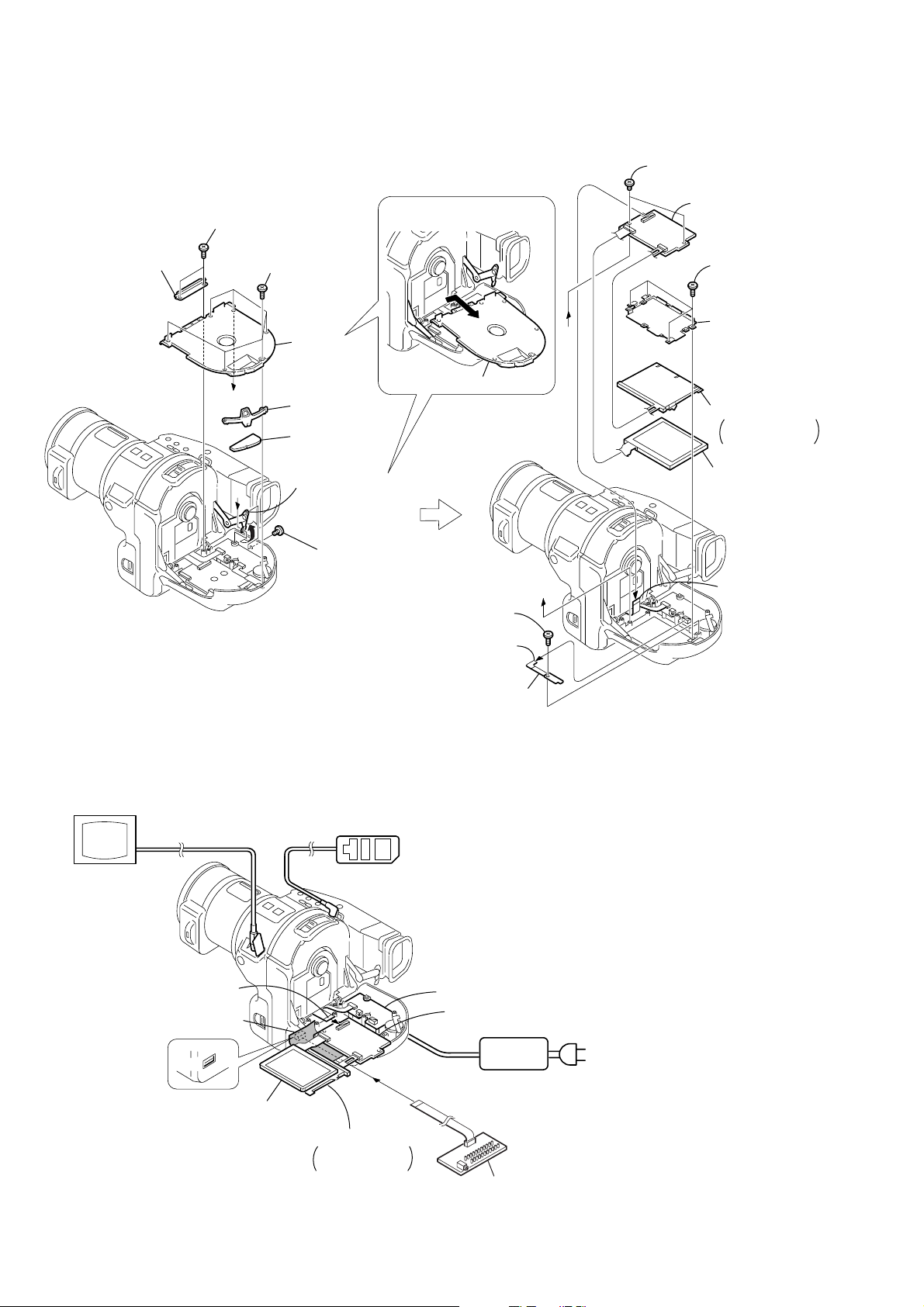

2-11.LID CABINET SECTION, CONTROL SWITCH BLOCK (MP52K)

A

A

A

B

1

T apping

screw (B2

×

5)

8

Four

claws

7

Zoom lens

(VCL-6010WA)

9

CCD fitting

adaptor (CL)

q;

Optical filter block

qa

Seal rubber (CL)

qs

Remove

the solderings

qd

CD-272

board

6

Two tapping

screws

(B1.9

×

7.5)

1

T apping

screw (M1.7

×

6)

3

VAP assembly

5

Lens frame

3

Three

dowels

4

2

T apping

screw

(B2

×

5)

qf

CD heat sink

qg

CCD block

assembly

2

Lens assembly

Rotate it in the direction of

the arrow

A

and remove it

in the direction of the arrow

B

.

8

2

Two

claws

3

Flexible guide

7

6

Hinge shaft stopper

4

5

Two claws

1

T wo tapping

screws (B2 × 5)

screws (B2 × 5)

PRECAUTION

DURING INSTALLATION

When installing it,

align the switch position

as shown.

Two hinge shafts

T wo tapping

qa

Lid cabinet section

9

Screw (M2 × 3),

lock ace, p2

q;

Screw (M2 × 3),

lock ace, p2

5

Strap plate (R)

1

Extension coil

spring (lid)

3

Spring plate

6

DC-IN

connector

q;

Control switch block

(MP52K)

2-12.CD-272 BOARD, LENS ASSEMBLY, VAP ASSEMBLY

2-9

9

T apping

screw (B2 × 5)

8

Damper holder

2

T apping

screw (B2 × 5)

4

T wo tapping

screws (B2 × 5)

7

T apping

screw (B2 × 5)

Page 35

2-13.CIRCUIT BOARDS LOCATION

The circuit boards contained in the zoom lens are not shown.

SW-342 (USER CONTROL)

LB-066 (BACK-LIGHT)

FLASH UNIT

CD-272 (CCD IMAGER)

PK-051

LCD DRIVE, BACK-LIGHT

TIMING GENERATOR

MD-082

CD-RF PROCESS, SERVO, CD DSP,

CD-R/RW GA, MD SYSTEM CONTROL,

EFM/ENC CONTROL

MK-015 (EYE SENSOR)

SE-115 (PITCH/YAW SENSOR)

VP-051

(STEADY SHOT, LENS MOTOR DRIVE)

VC-246

LENS DRIVE, VIDEO AMP, BUS SWITCH,

LINE/SPEAKER AMP, HI CONTROL,

DC/DC CONVERTER, CONNECTOR

SY-060

CAMERA PROCESSOR, CAMERA CONT,

MC CAM/SH DSP, IN/OUT

VF-144

LCD DRIVE, TIMING

GENERATOR

2-10

Page 36

2-14.FLEXIBLE BOARDS LOCATION

K

The flexible boards contained in the mechanism deck and that in the zoom lens are not shown.

FP-041

FP-042

FP-045

CONTROL SWITCH BLOCK

(JK52K)

CONTROL SWITCH BLOCK

(LC52K)

CONTROL SWITCH BLOCK

(FS52K)

CONTROL SWITCH BLOCK

(MP52K)

CONTROL SWITCH BLOCK

(AE52K)

FP-046

CONTROL SWITCH BLOCK

(AJ52K)

CC-102

FP-039

FP-043

FP-044

CONTROL SWITCH BLOC

(ZM52K)

FP-040

FP-038

Disassembling procedure of Mechanism

deck (DDX-G2000 COMPLETE ASSEMBLY)

are not shown.

Pages 2-12 and 2-13 are not shown.

2-11E

Page 37

SECTION 3

BLOCK DIAGRAMS

MVC-CD1000

3-1. OVERALL BLOCK DIAGRAM-1

ZOOM

ACTIVE

PRISM

ACTUATOR

P DRIVE Y DRIVE

IC201-207

ACTIVE PRISM

ACTUATOR

DRIVE

(4-61,62)

VP-051

BOARD

IC209

STEADY

SHOT

CONTROL

IC208

A/D CONV.

IC301

PITCH/YAW

SENSOR AMP

SE303 SE304

PITCH

SENSOR

YAW

SENSOR

SE-115 BOARD

LENS

(4-62)

(4-62)

(4-65)

ND FILTER

MOTOR

IC201

ND FILTER

M

ND FILTER

DRIVE

(4-43)

ND ON

SY-060

BOARD(2/3)

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

FOCUS

MOTOR

ZOOM

MOTOR

MM

FOCUS

RESET

SENSOR

FOCUS

MOTOR

DRIVE

ZOOM

MOTOR

DRIVE

IC203

(4-43)

ENO,EN1

ENOA,B

EN1A,B

ZOOM

RESET

SENSOR

IRIS

METER

HALL

H

XZM RST SENS

XFC RST SENS

IC202

IRIS

(SHUTTRE)

M

HALL (+)

SHUTTER DRIVE

CD-272 BOARD

IC204

IC205

IRIS DRIVE

HALL AMP

(4-43)

(4-43)

(4-9)

IC101

CCD IMAGER

IRIS CONT 1,2

CAM SO,CAM SI,XCAM SCK

FOCUS A,B

V1A,V1B,V2,

V3A,V3B,V4,

RG,VSHT

H1,H2

HALL AD

MSHUT ON

CCD OUT

SY-060 BOARD

VC-246

BOARD(1/2)

FOCUS

RING

MF UNIT

BT901

BATT

J901

DC IN

TERMINAL

S

Q002,003

F001

F002

F003

F004

F005

F006

16

FAST CHARGE ON

IC001

DC/DC

CONVERTER

BATT SIG

BATT/XEXT

SYS DD ON

LCD DD ON

EVF DD ON

(4-53)

D 4.6V

D 3.4V

CAM 15V

CAM P5V

CW P 4.6V

A 4.9V

CAM -7.5V

CAM 3.2V

D 3.2V

A 3.2V

D 1.8V

PANEL -15.3V

PANEL 13.2V

PANEL 6.5V

PANEL 4.9V

EVF 3.1V

EVF 12V

EVF BL 4.75V

VAP P 5V

HI UNREG

ACV UNREG

BL UNREG

ST UNREG

BATT UNREG

(4-15)

IC602

(4-15)

IC601

S/H,AGC,

A/D CONV.

TIMING

GENERATOR

CAM SO,XCAM,SCK

(4-44)

IC206

EVR

FLASH

UNIT

FLASH

UNIT

MK-015

BOARD

IC032

MCK12

MCK24

EYE

SENSOR

(4-38)

AD DATA

ST UNREG

STB CHARGE

(4-18)

IC702

SDRAM

64Mbit

EVF SENS

EVF BL 4.75V

MCK12

MCK24

ADDRESS

14

DATA

16

XZM RST SENS

XFC RST SENS

MSHUT ON

ENO,EN1

ENO A,B

EN1 A,B

ND ON

STB ON

VD,HD

Y

R-Y

B-Y

(4-17)

1212

IC701

CAMERA DSP

MEMORY CONTROL

VIDEO ENCODER

OPD,OSD,HOST IF

RES CONTROL

SG,JPEG,L-MODE

AUDIO I/F

SHUTTER CONTROL

STROBO CONTROL

CAM SO,CAM SI,XCAM SCK

VF-144 BOARD

16

14

MC XCS2

MC XCS6

AU SDTO

AU SDTI

Y

C

Y

R-Y

B-Y

VD,HD

EXT STRB ON

(4-45)

Y

IC501

C

VIDEO AMP

IC503

EVR

IC603

TIMING

GENERATOR

(4-84) (4-86)

IC502

LCD

DRIVE

IC601

BACK LIGHT

DRIVE

DATA BUS

ADDRESS BUS

HI SO,XHI SCK

(4-83)

(4-85)

R

G

B

EXT STRB ON

VIDEO OUT

AUSTD

DD ON

Y,R-Y,B-Y,VD,HD

LCD902

LCD

PANEL

ND011

BACK LIGHT

LB-066

BOARD

CONTINUED ON

(SEE PAGE

3-3)

3-1 3-2

Page 38

MVC-CD1000

OVERALL BLOCK DIAGRAM-2

SY-060 BOARD(3/3)

CONTINUED ON

PAGE 3-2

DATA BUS

ADDRESS BUS

(4-20)

IC807

EEPROM

CAM SO,CAM SI,XCAM SCK

EXT STRB ON

HI S0,XHI SCK

VIDEO OUT

AUSTD

DD ON

Y,R-Y,B-Y,VD,HD

MC XCS2

MC XCS6

AU SDTO

AU SDTI

IC801

IC302

24

MC CAM

SH DSP

(4-19)

(4-49)

AUDIO

AD/DA

CONV.

16

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-47,48)

IC154

MD-082 BOARD

IC414

IC155

ATAP1

CD-R

ENC/DEC

EFM ENC

CONTROL

(4-35) (4-35)

88

XCAM/PB SW

MOVIE/XSTILL SW

HI CONTROL

XPWR SW

CHARGE LED

POWER LED

32KHZ

USB D+/D- OUT

USB D+/D- IN

16

12

IC806

SDRAM

16Mbit

(4-20) (4-20)

MC XCS3

IC802

USB

I/F

BATT UNREG

ACV UNREG

VIDEO OUT

AUDIO OUT

HI SO,HI SI,XHI SCK

IC805

MC XCS0

(4-20)

17

FLASH ROM

8Mbit

D+,D-

(4-51)

IC401

3.2V REG

16

16

BUS

SWITCH

3

VDD

IC403

RESET

16

3

HCS0,1

IC404

RESET

(4-51)

(4-52)

IC406

AU OUT

AU IN

MIC SIG

(4-49)

IC303

LINE/

SPEAKER

AMP

MIC AMP

AUDIO OUT

SP+,SP-

EEPROM

BEEP

HALL AD

FOCUS A,B

EVF SENS

EVF DD ON

BATT SIG

FAST CHARGE ON

BATT/XEXT

SYS DD ON

LCD DD ON

STB CHARGE

(4-51,52)

LANC IN

LANC OUT

XLID OPEN

KEY AD0,1

KEY_AD2,3,4

XSHTR SW

XSHTR LOCK SW

ZOOM SW AD

ENCEFM

FMDT,FMCK

MDATA,BCLK,LRCK

DATA

8

IC408

BUFFER

DATA BUS

ADDRESS BUS

SRAM

(4-52)

IC405

TIMER

CLOCK

IC402

LANC

I/O

DRAM

VDD

BATT

(4-51)

17

IC405

FLASH

ROM

12

ADDRESS

17 1616

IC401

(4-34) (4-34) (4-33) (4-35) (4-31)

IC207

(4-31,32)

20 8

20

IC404

SYSTEM

CONTROL(MD)

S001

PLAY/STILL/MOVIE SW

S201

POWER SW

D404,405

POWER,CHARGE,LED

BT401

LITHIUM VANADIUM

BATTERY

CD-R/RW

GA

16

CONTROL

SWITCH

BLOCK

(MP52K)

LANC SIG

EXT STRB ON

S101 S102

OPEN/CLOSE

CONTROL SWITCH BLOCK

(AJ52K)

EQ EFM

(4-30)

FMDT,FMCK

SWDT,SDCK

IC406

EEPROM

(SEE PAGE 4-88)

IC019

EVR

(D/A CONV)

SW-342 BOARD

S401-407

FUNCTION SW

AU SP+,SP-

IC201

CD

DSP

AUDIO

OAC

RF AC

J101

LANC/

EXT FLASH

SP901

SPEAKER

IC013

CD-R/RW

RF

PROCESS

(4-28)

IC014

FOCUS

SERVO

TRACKING

SERVO

SLED

SERVO

SPINDLE

SERVO

(4-29)

FE,TE

A-H

IC001

IC005

IC003

D+,D-

VIDEO OUT

AUDIO OUT

CONTROL SWITCH

BLOCK(JK52)

(SEE PAGE 4-22)

S301

DISPLAY SW

CONTROL SWITCH

BLOCK(LC52K)

(SEE PAGE 4-69)

FOCUS/

TRACKING

DRIVE

(4-29)

SLED

DRIVE

(4-29)

SPINDLE

DRIVE

(4-29)

BASE UNIT

LD

DRIVE

PD

IC

FRONT

MONITOR

CN002

DIGITAL I/O

(USB)

J001

AV OUT

(MONO)

LASER

DIODE

PH901

M901

SPINDLE

MOTOR

FOCUS

COIL

TRACKING

COIL

M

M902

SLED

MOTOR

M

OPTICAL

DEVICE

CONTROL SWITCH BLOCK

(FS52K)

STEADY SHOT SW

FOCUS SW

(SEE PAGE 4-21)

KEY AD3,4

VC-246

BOARD

16

ZOOM SW AD

RV001 S001

ZOOM VR SHUTTER

CONTROL

SWITCH BLOCK

(ZM52K)

XSHTR SW

XSHTR LOCK SW

SW

HI SO,XHI SCK

KEY AD2

S401-405

FUNCTION

SW

CONTROL SWITCH BLOCK

(AE52K)

(SEE PAGE 4-87)(SEE PAGE 4-87)

BL UNREG

MIC901

MIC

IC801

EVR

(4-75)

VD,HD

Y

R-Y

B-Y

PK-051 BOARD

(4-77)

IC901

TIMING

GENERATOR

IC802

LCD

DRIVE

(4-76)

IC851,852

BACK LIGHT DRIVE

(4-75,76)

BL HIGH

R

G

B

3-3 3-4

LCD901

2.5INCH

LCD

PANEL

ND901

BACK LIGHT

Page 39

MVC-CD1000

3-2. STEADY SHOT BLOCK DIAGRAM

ACTIVE

PRISM

ACTUATOR

OUT1

CRST

OUT2

M

SENS

2

19

18

20

VCC

FOCUS

RING

SE-115 BOARD

16

SE303

PITCH

SENSOR

SE304

YAW

SENSOR

M906

VAP-LOCK

MOTOR

(4-65)

IC301

PITCH/YAW SENSOR AMP

LPF

4

2

1

4

2

1

8

LIA1

4

VREF1

LPF

LIA2

12

16

VREF2

MF UNIT

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

VP-051 BOARD

(4-61)

(4-61)

IC204

BUFFER

1

IC201

(4-61)

IC204

BUFFER

1

2

2

(4-61)

(1/2)

(4-62)

IC208

A/D CONV.

PS

YS

LOCK+

LOCK-

SENS OUT

FOCUS A

FOCUS B

P DRIVE

CN201

P DRIVE A

1

P DRIVE B

2

P DAMP A

3

Y DRIVE A

13

Y DRIVE B

12

Y DAMP A

11

P OUT

9

Y OUT

6

5

A +4.9V

1

2

7

(4-61)

1

2

7

(4-61)

IC202

Y DRIVE

+

3

-

+

5

6

+

3

-

+

5

6

8

7

8

9

14

13

(4-61)

IC205

AMP

(1/2)

+

10

9

+

5

6

+

10

-

+

12

-

IC203

VAP LOCK MOTOR DRIVE

OUT1 IN23

S +3.2V

2

OUT2

VS

5

PROTECT

Q201,202

2

5

CN203

CN202CN301

PITCH

6

6

C RESET

4

4

YAW

2

2

3

3

•

•

5

5

4

6

CN204

VAP P5V

104

IN1

9

VCC

1

+

-

14

13

1

2

(1/2)

3

IC205

AMP

CLK

HSTX

DO

CI

TC LKX

CSX

VCC

A VRH

A +4.9V

+

-

+

-

10

16

12

15

9

14

13

19

•

20

D +3.2V

(IC208,209)

A +4.9V

(IC208)

(4-62)

S +3.2V

IC209

(1/2)

(4-61)

STEADY SHOT

CONTROL

A 4.9V

(IC204-207)

IC206

LPF

12

LPF

IC207

3

42

(4-61)

24

44

P PWM

43

Y PWM

VAP P 5V

(IC203)

VAP P 5V

(IC201,202)

Q205,206

Q209,210

Q203,204

Q208,211

CN205

14

D 3.2V

7

A 4.9V

POWER

(SY-060)

(SEE PAGE

3-17)

5

VAP P 5V

IC209 wg

(4-62)

X201

12MHz

3.0Vp-p

EXTAL

25

ETAL

24

83.3nsec (12MHz)

IC210

4

Q207

IC208 0

83.3nsec (12MHz)

D +3.2V

A +4.9V

2

C RESET

5

VDD

57

AV REF

33

A VDD

34

3.9Vp-p

VAP HSTX

730

VAP SIN

8

VAP SOUT

9

VAP SCK

10

VAP CS

11

VAP SI

VAP SO

VAP SCK

VAP CS

VAP RESET

SYS V

29

31

28

27

46

PH201

POSITION

SENSOR

D +3.2V

11

CAM SO

10

CAM SI

12

XCAM SCK

9

XVAP CS

8

XVAP RESET

3

SYS V

15

VAP LOCK ON

16

VAP LOCK SENS

2

XLEFT DOWN

1

XRIGHT DOWN

6

CAM DD ON

17

FOCUS A

18

FOCUS B

CAMERA(2)

(SY-060)

(SEE PAGE

3-21

of LEVEL 3)

CAMERA(1)

(SY-060)

(SEE PAGE

3-20

of LEVEL 3)

MODE

CONTROL

(SY-060)

(SEE PAGE

3-7)

3-5 3-6

Page 40

MVC-CD1000

3-3. MODE CONTROL BLOCK DIAGRAM

XRIGHT DOWN

STEADY

SHOT

(VP-051)

(SEE PAGE 3-6)

XLEFT DOWN

CAM DD ON

FOCUS A

FOCUS B

CONTROL SWITCH

BLOCK(LC52K)

S301

DISPLAY

(SEE PAGE 4-70)

CONTROL SWITCH BLOCK(AE52K)

(SEE PAGE 4-78)

S404S405

-

CONTROL

SWITCH

BLOCK

(FS52K)

PROGRAM AE

+

MANUAL

STEADY

PROGRAM AE

(SEE PAGE 4-21)

SY-060 BOARD

(SEE PAGE 4-21,22)

17

18

13

2

1

CN904

FOCUS

AUTO

SHOT

S403

ONE PUSH

WHITE

BALANCE

ON

OFF

2

3

S406

(FLASH)

S407

VOLUME

-

WHITE

BALANCE

CN903

SW-342 BOARD

21

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

VC-246 BOARD

S404

(MACRO)

S405 S403

VOLUME

+

J101

LANC/EXT

FLASH

FOR CHECK

KEY AD2

S401S402

PROGRAM

AE

(SELF TIMER)

FLASH

UNIT

(SEE PAGE 4-69,70)

S402

SPOT METER

S401

MENU

LCD

(ON/OFF)

CONTROL SWITCH BLOCK(AJ52K)

VDD

CONTROL SWITCH BLOCK(MP52K)

XCPC IN

5

LANC IN

11

CN201

CPC

LANC OUT

12

VDD

18

UNREG

10

VDD

CONTROL

SWITCH

BLOCK

(ZM52K)

(SEE PAGE 4-87)

FLASH

UNIT

3

7

4

8

1

10

2

6

9

1

UP

2

LEFT

54

DOWN

S101,102

OPEN/CLOSE

S001

STILL MOVIEPLAY

S201

POWER

ON/OFF

S001

(SHUTTER)

POP UP ON

TALLY

STB CHARGE

XSTB FULL

STRB PHOTO ON

PHOTO TR OUT

STRB ON

(SEE PAGE 3-20

of LEVEL 3)

7

SET

6

RIGHT

COMMON

3

D402

(FLASH LED)

D403

(ACCESS LED)

(SEE PAGE 4-88)

LANC JACK IN

(SEE PAGE 4-88)

MOVIE/XSTILL SW

D405

(CHARGE LED)

D404

(POWER LED)

RV001

ZOOM

WT

3

7

4

8

1

10

CAMERA(1)

(SY-060)

KEY AD 0

KEY AD 1

232C SENS

LANC DC

LANC SIG

LID OPEN

XCAM/PB SW

XPWR SW

A4.9V

UNREG

KEY AD3

KEY AD4

CN401CN402

9

8

74

65

CN906CN901

CN905

CN906 CN552

121112

8

9

40

42

60

58

17

48 48

50

CN556

2

3

7

6

8

5

3

CN559

15

18

29

26

8

1

2

7

5

4

CN555

6

2

5

1

CN557

11

8

9

CN551

40

42

60

58

17

50

KEY AD 0

KEY AD 1

STB LED

ACCESS LED

LANC JACK IN

XCPC IN

LANC IN

LANC OUT

MOVIE/XSTILL SW

XCAM/PB SW

XPWR SW

CHARGE LED

POWER LED

XSHTR LOCK SW

XSHTR SW

ZOOM SW AD

CN558

KEY AD2

POP UP ON

TALLY

STB CHG

XSTB FULL

CN552

KEY AD3

KEY AD4

XLEFT DOWN

XRIGHT DOWN

CAM DD ON

FOCUS A

FOCUS B

Q401,402,404

LANC DC

LANC SIG

LID OPEN

32.768KHz

EXT STRB

DRIVE

X402

VDD

UNREG

Q413

LED DRIVE

BT401

LITHIUM VANADIUM BATTERY

8

VDD CLK OUT

X IN

2

X OUT

3

ACV UNREG

1

14

11

Q409

LED DRIVE

Q411

LED DRIVE

IC404 r;

50 nsec (20MHz)

(4-52)

IC405

TIMER CLOCK

(4-51)

IC402

LANC I/O

EXT STRB ON

ACCESS LED

XLID OPEN

D405

Q412

LED DRIVE

0.8Vp-p

D410

2

(4-52)

IC406

EEPROM

VCC

(4-51)

IC401

3

8

2

D 3.2V

D404

D403

CN551

17

21

10

CN552

CN554

19 HI SO

20

18

2

1

3

25

23

47

CN560

ACV UNREG

BATT UNREG

POWER

CHARGE INH

LCD DD ON

SYS DD ON

BATT/XEXT

INIT CHARGE

FAST CHARGE

D 3.2V

EVF DD ON

CAM DD ON

SYS V

6

PAL/XNTSC

EXT STRB ON

USB DET

ACCESS LED

PAL/XNTSC

XRST SYS

MC XFL RST

XMC HELP

BEEP ON

BEEPMOD

AV JACK IN

XMC CS

HI SO

HI SI

XHI SCK

XHI SCK

XCS PANEL D/A

CN553

HI SO

XHI SCK

XCS EVF D/A

EVF SENS

EVF LED ON

XLID DET

(SEE PAGE

3-15)

CAMERA(1)

(SY-060)

(SEE PAGE

3-20

of LEVEL 3)

CAMERA(2)

(SEE PAGE

3-21

of LEVEL 3)

LCD

(PK-051)

(SEE PAGE 3-9)

EVF

(VF-144)

(SEE PAGE 3-11)

MD BLOCK

(MD-082)

(SEE PAGE

3-23

of LEVEL 3)

3.2V

REG

1

52

CS

5

XSCK

6

SIO

7

32KHz

24

CS RTS

7

RTS SCK

8

RTS SIO

78

KEY AD 0

KEY AD 1

79

(4-51,52)

IC404

HI CONTROL

56

STB LED

31

LANC JACK IN

VDD

Q406

4

8

10

12

X401

20MHz

10

XLANC ON

1

LANC IN

2

LANC OUT

19

XLANC PWR ON

18

XLID OPEN

69

XCPC IN

21

MOVIE/XSTILL SW

15

XCAM/PB SW

14

XPWR SW

94

CHARGE LED

60

POWER LED

17

XSHTR LOCK SW

16

XSHTR SW

89

ZOOM SW

80

KEY AD2

83

KEY AD5

58

SELF TIMER

93

STB CHG

32

XSTB FUL

40

20MHz OUT

41

20MHz IN

81

KEY AD3

82

KEY AD4

6

XLEFT DOWN

5

XRIGHT DOWN

XMC DEAD DET

BACKUP VCC

XRESET

ACV SENS

BATT SENS

DC PACK SW

BATT SO

BATT SI

LCD DD ON

BATT/XEXT

INIT CAHRGE

FAST CHARGE

DD CON SENS

EVF DD ON

CAM DD ON

USB DET

XRST SYS

XRST FLASH

BEEP ON

MELODY

MELODY ENV

AV JACK IN

XCS MC

XHI SCK

XCS LCD D/A

XCS EEPROM

XEEPROM WE

XCS EVF D/A

EVF SENS

EVF LED ON

FOCUS A

FOCUS B

SYS V

HI SO

42

51

75

76

77

86

87

38

72

71

65

49

48

47

29SYS DD ON

20

27

100

92

99

25

64

3

PAL

68

9

98

67

97

36

59

30

50

45

44

HI SI

46

26

95

12

28

91

96

70

73

VDD

(4-51)

IC403

RESET

1

Q414

IF BLOCK BATT SIG

Q408

3

DI

4

DO

2

SCK

1

CS

6

RST

3-7 3-8

Page 41

MVC-CD1000

3-4. LCD BLOCK DIAGRAM

PK-051 BOARD(3/3)

MODE

CAMERA(1)

(SEE PAGE

3-20 of

LEVEL 3)

(SEE PAGE

3-16)

CN201

FOR

CHECK

(SY-060)

POWER

(VC-246)

CPC

16

CONTROL

(VC-246)

(SEE PAGE

3-8)

VG

9

PANEL COM

8

HSY

7

MAKER RECOG

13

REG GND

4

CONTROL

SWITCH

BLOCK

(MP52K)

(SEE PAGE 4-88)

(SEE PAGE 4-58)

VC-246

BOARD

PANEL Y

PANEL R-Y

PANEL B-Y

PANEL V

BL UNREG

PANEL 4.9V

PANEL 13.2V

D 3.2V

PANEL -15.3V

PANEL 6.5V

PANEL 3.2V

(SEE PAGE 4-58)

VC-246

BOARD

HDO

XCS PANEL D/A

XHI SCK

54

50

48

38

CN551

CN555

17

9

16

19

HI SO

CN554

CN554

7

5

6

D 3.2V

PANEL 3.2V

PANEL Y

15

10

PANEL R-Y

16

9

PANEL B-Y

8

17

PANEL V

2352

2

HDO

24

1

3

BL UNREG

4

12

PANEL 4.9V

10

PANEL 13.2V

D 3.2V

14

PANEL -15.3V

9

PANEL 6.5V

11

13

PANEL 3.2V

CN801

CN801

20

5

4

3

17

PANEL COM

21

22

8

R977

NO MOUNT

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

COMTST

BRIGHT

COLOR

BRT TST

CONTRAST

V COM

RGB AMP

COM ADJ

BL LEVEL

P MUTE

V REV

H REV

BRT.R

BRT.B

NTSC

(4-75)

16

15

18

1

2

11

3

4

5

8

VCO

9

6

7

10

17

12

Y

8

R-Y

9

B-Y

10

IC801

I/O EXP (EVR)

22

XEN

CLK

19

SI

20

VCC

14

VDD

13

VDDA

23

IC802 8

H

0.5Vp-p

IC802 9

0.22Vp-p

H

IC802 q;

0.22Vp-p

H

VG

COLOR

6

COLOR

44

VCC1

25

PANEL 3.2V

IC802 ws

VSH

VCC2

26

PANEL 6.5V

PANEL 4.9V

CONTRAST

40

CONTRAST

IC802

2H

(4-76)

LCD DRIVE

14

BRT TST

38

BRT TST

EXT BGP

1

RGB AMP

30

RGB AMP

48

4

3.4Vp-p

BLACK IN

2

BRT B

BRT R

31

32

SUB BRT B

SUB BRT R

(4-76)

IC803

OR GATE

WIDOV

BRIGHT

39

BRIGHT

IC802 wf

COM ADJ

35

COM ADJ

29

FRPV

IC802 w;

FRP

COM FRP

28

2H

COM OUT

R OUT

G OUT

B OUT

2H

BL LEVEL

V-COM

VCO

V REV

H REV

COMTST

NTSC

HDO

PANEL V

P XHD

HSY

3.4Vp-p

41

20

22

24

IC902

3.4Vp-p

(4-77)

FILTER

VCO

BL_UNREG

PANEL

4.9V

10

2

3

22

20

21

24

23

19

10

3

1

9

5

18

6

17

14

7

8

13

12

16

15

2

4

BL LOW

BL HIGH

VSH

VDD

VSS

VCOM

VGL

VGH

MODE2

GRES

MODE1

GPCK

MCLK

GSRT

RESET

SRTL

SRTR

HCNT

CLT

V REF H

V REF L

VR

VG

VB

OE

BACK LIGHT UNIT

ND901

(BACK LIGHT)

LCD901

2.5INCH COLOR

LCD UNIT

Q856

SWITCHING

L852L851

2

1

4

5

3

(4-75)

IC851

HCNT

SWITCHING REG.

2

7

OUTPUT

VCC

PWM

AMP

SAW

OSC

1V

SHORT

CIRCUIT

PROTECT

(4-77)

9

11

FRPV

13

14

18

15

24

23

16

17

22

21

12

42

CLR

30

VDD

PANEL 3.2V

Q851,852

R OUT

G OUT

B OUT

COM OUT

WIDOV,FRPV

IC901

TIMING GENERATOR

(2/2)

32

PDP

27

OSCI

26

OSC0

44

V REVC

46

H REVC

47

COMTST

41

NTPC1

37

SYNI

34

P15

BGPO

3

HSY

4

GND

7

WIDOV

MODE2/CLS

GRES/SPS

MODE1/RES

GPCK/EX1

MCLK/CLD

OE/SPD

GSRT/MODE1

RESET/MODE2

SRTL/CTR

SRTR/EX3

FB

1

3

4

5

VG

PANEL COM

SWITCHING

Q853

PROTECT

SWITCH

Q854

IC902

COM AMP

(4-77)

(1/2)

Q901-904

COM

DRIVE

L853

T851

1

2

3

4

5

10

6

CN851

C866

LED

D854

(STARTER)

Q855

Q860

INVERTER

DRIVE

Q857-859

BL

LEVEL

(4-76)

IC852

3

PANEL 3.2V

D853

CN901

PANEL 4.9V

PANEL 3.2V

PANEL -15.3V

PANEL 13.2V

Q861

LED SWITCH

CURRENT

4

DETECT

3-9 3-10

Page 42

MVC-CD1000

3-5. EVF BLOCK DIA GRAM

VF-144 BOARD

CN501

EVF Y

1954

EVF R-Y

18

EVF B-Y

20

EVF XVD

17

EVF XHD

21

12

13

14

10

11

24 2

24

25

23

CN502

5

1

6

3

14

1

2

9

10

11

7

8

6

9

5

14

13

12

15

16

MODE CONTROL

(SEE PAGE 3-8)

CAMERA(1)

(SY-060)

(SEE PAGE

3-20 of

LEVEL 3)

VC-246 BOARD

(SEE PAGE 4-57,58)

(VC-246)

PANEL R-Y

PANEL B-Y

PANEL Y

PANEL V

HD0

EVF 12.0V

BL UNREG

DATA FROM HI(HI SO)

XCS EVF EVR(D/A)

CN551

50

48

52

38

EVF 3.1V

D 3.2V

XHI SCK

EVF SENS

EVF LED ON

CN553

CN553

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

(4-38)

Q032

5

SENS DET

6

CN031

Q033

LED DRIVE

D 3.2V

BL UNREG

14

1

2

9

10

11

IC032

43

EYE SENSOR LED

MK-015 BOARD

BL UNREG

D3.2V

Q031

EYE SENSOR

D031

EVF 3.1V

D 3.2V

EVF 12.0V

D_3.2V

EVF 3.1V

20

19

22

21

14

23

13

EVF Y

EVF R-Y

EVF B-Y

EVF XVD

EVF XHD

EVF VG

EVF VCO

HD OUT

INV CURRENT

(4-84)

IC503

EVR(D/A CONVERTER)

SI

XSCK

XCS

SO

VCC D

VDD A

VDD

X NTSC

COLOR

SUB BRT R

SUB BRT B

CONTRAST

BLACK LIMIT

GAMMA

INV CURRENT

LOOK LEVEL

PICTURE

AGC LEVEL

X NTSC

IC502 w;

16

ADJ

17

WIDE

15

BRT

1

2

3

4

5

6

7

VCO

VXO

8

9

10

11

12

IC502 9

0.22Vp-p

H

Y

8

R-Y

9

B-Y

10

HD

14

EXT BGP

IC502 q;

PICTURE

BRT

COLOR

AGC LEVEL

46 48 45 47 28

BRIGHT

SH B

GAMMA

(4-83)

IC502

33 27 4039 32 31615

GAMMA 1

SH R

SH A

BLACK LIMIT

RGB BLK

SH G

CONTRAST

SUB BRT R

LCD DRIVER

SUB BRT B

H

0.5Vp-p

IC502 wf

IC502 8

R OUT

G OUT

B OUT

25

VCC2

VCC1

FRP

EVF 12.0V

44

EVF 3.1V

20

22

24

LPF

15

16

29

R

G

B

COM

8.0Vp-p

CN601

IC502 ws

CN021

16

18

14

15

15

17

17

13

19

14

16

16

8.0Vp-p

2H

8.0Vp-p

2H

LCD902

R

G

B

COM

EVF LCD UNIT

EVF BL +

CONTROL

SWITCH

BLOCK

(MP52K)

(SEE PAGE

4-88)

CN555

R561,562

EVF VG

EVF VCO

23 24 22 25

EVF VG

EVF VCO

EVF BL +

21 22 19 20

CN201

CPC

FOR CHECK

EVF BL 4.75V

EVF VG

9

17

2

4

Q001

SWITCHING

T011

ND011

BACK LIGHT

8

5

D001

HD

EVF 3.1V

ADJ

WIDE

X NTSC

VXO

VCO

8

18

CN601

D.P

EVF BL

4.75V

11

22

FB

98

33

BL LOW

76

CN001

LB-066

BOARD(1/2)

(SEE PAGE 4-80)

EVF BL

4.75V

19

7

20

6

Q602,603

1

Vcc1

Q601

DISCHARGE

SW

5

SCP

TRIANGLE

OSC

34

(4-85)

IC601

DC/AC CONVERTER

SCP

COMP

SYNCCT

14

Vcc2

PWM

COMP

+

CURRENT

ERROR AMP

PROTECT DET

OUTPUT

VREF